Patents

Literature

3203 results about "Fluorite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

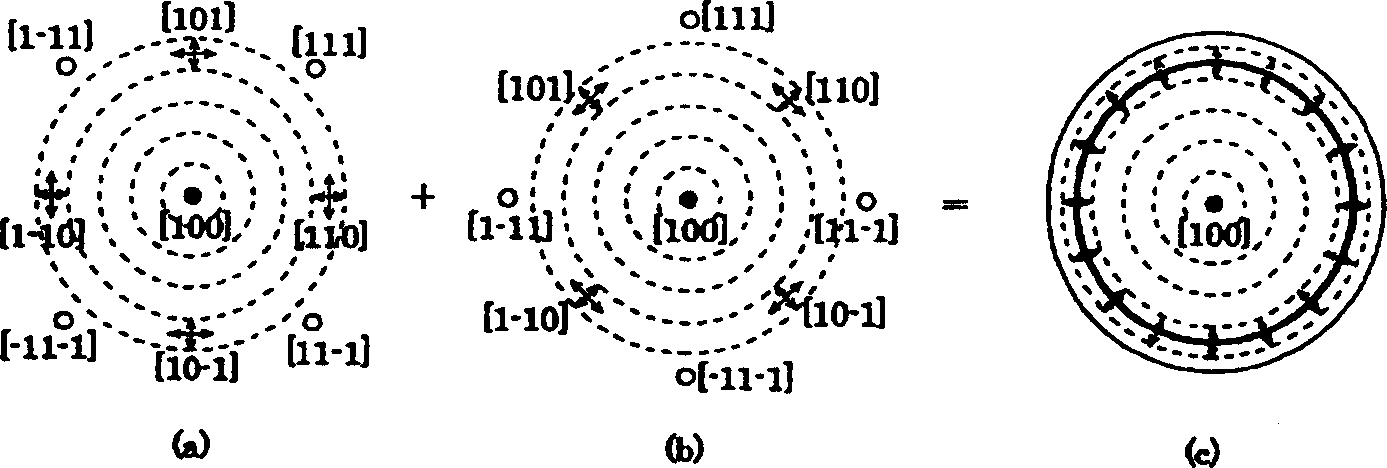

Fluorite (also called fluorspar) is the mineral form of calcium fluoride, CaF₂. It belongs to the halide minerals. It crystallizes in isometric cubic habit, although octahedral and more complex isometric forms are not uncommon.

Blast-furnace smelting method for vanadium titano-magnetite

InactiveCN101775451ARaise the gradeReduce tons of iron slagBlast furnace detailsMagnetiteBlast furnace smelting

The invention discloses a blast-furnace smelting method for vanadium titano-magnetite. The method is realized in a way that: vanadium titano-magnetite accounts for 30-60% of ferrous burden which is fed into a blast furnace, and the burden comprises 40-65% of agglomerate, 30-50% of pellet and 5-10% of lump ore; the diacidic basicities CaO / SiO2 of agglomerate, pellet and blast-furnace slag are respectively controlled at 1.6-2.5, 0.6-1.0 and 1.05-1.20; the content of MgO in blast-furnace slag is controlled at 7.5-9.0%; by adding two batches of ore and three batches of coke and using the charging operation of the development center, manganese oxide ore or sintered manganese ore powder, and fluorite are incorporated into injection coal and injected into the blast furnace along with the coal powder; and thus, the content of MnO in the slag and the content of CaF2 in the slag are respectively controlled at 1.0-4.5% and 0.50-2.0%, and the oxygen-enrichment percentage of the blast furnace is controlled at 2.0-4.0%. Compared with the smelting blast furnace using the same quality and structure of the burden, the comprehensive coke ratio of the invention is reduced by 20-50kg per ton of iron, the content of TFe in the slag is reduced by 50%, and the comprehensive cost per ton of iron is reduced by 30-50 yuan. The invention has wide prospects for popularization and application.

Owner:CENT SOUTH UNIV

Low grade fluorite and barite flotation separation method

A low grade fluorite and barite flotation separation method uses waterglass as the inhibitor for silicious mineral and calcium carbonate mineral; uses oleic acid as the collector for fluorite and barite; and uses starch, sodium sulphate, hydrochloric acid and sodium hexametaphosphate as the inhibitor for barite mineral. The invention can perform flotation separation of low grade fluorite and barite effectively; under the condition that the given fluorite grade is 33.92%-40.41%, and the barite grade is 34.67%-35.33%, by mixing, flotation and separation, can achieves the fluorite concentrate with grade of above 95% and recovery rate of 75.5%-78.5%, and the barite concentrate with grade of 92.3%-93.27% and recovery rate of 75.2%-79.73%.

Owner:GUANGXI UNIV

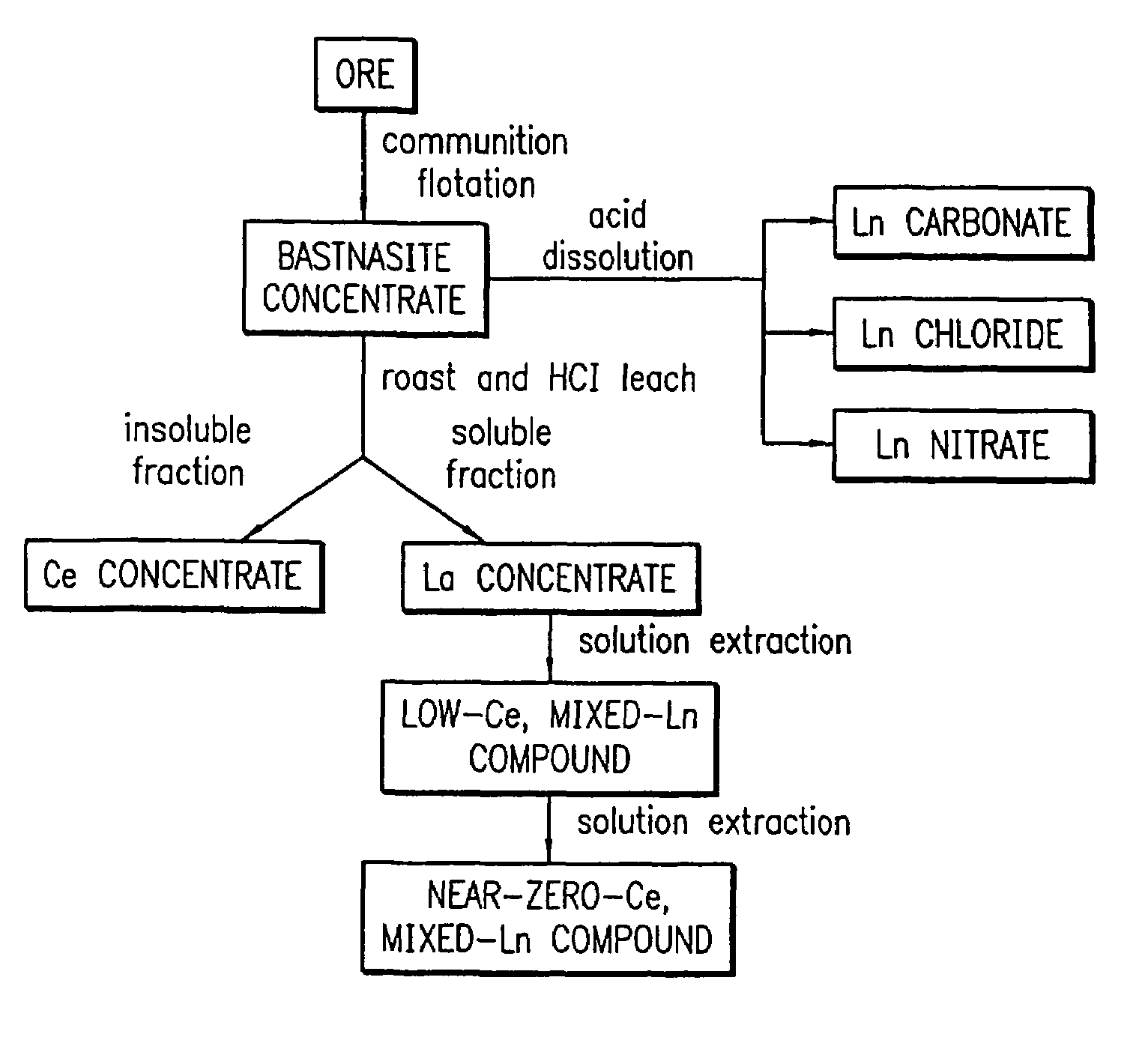

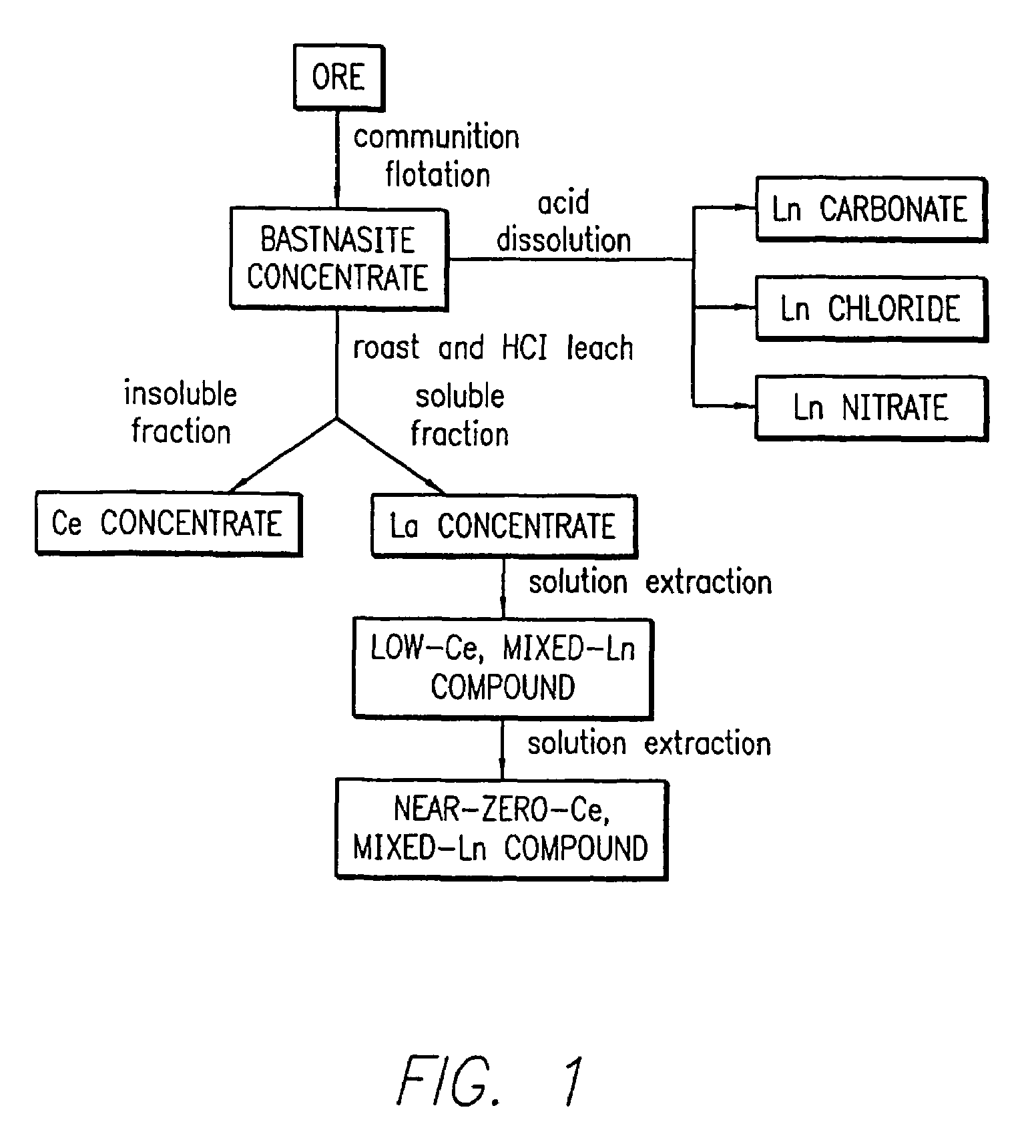

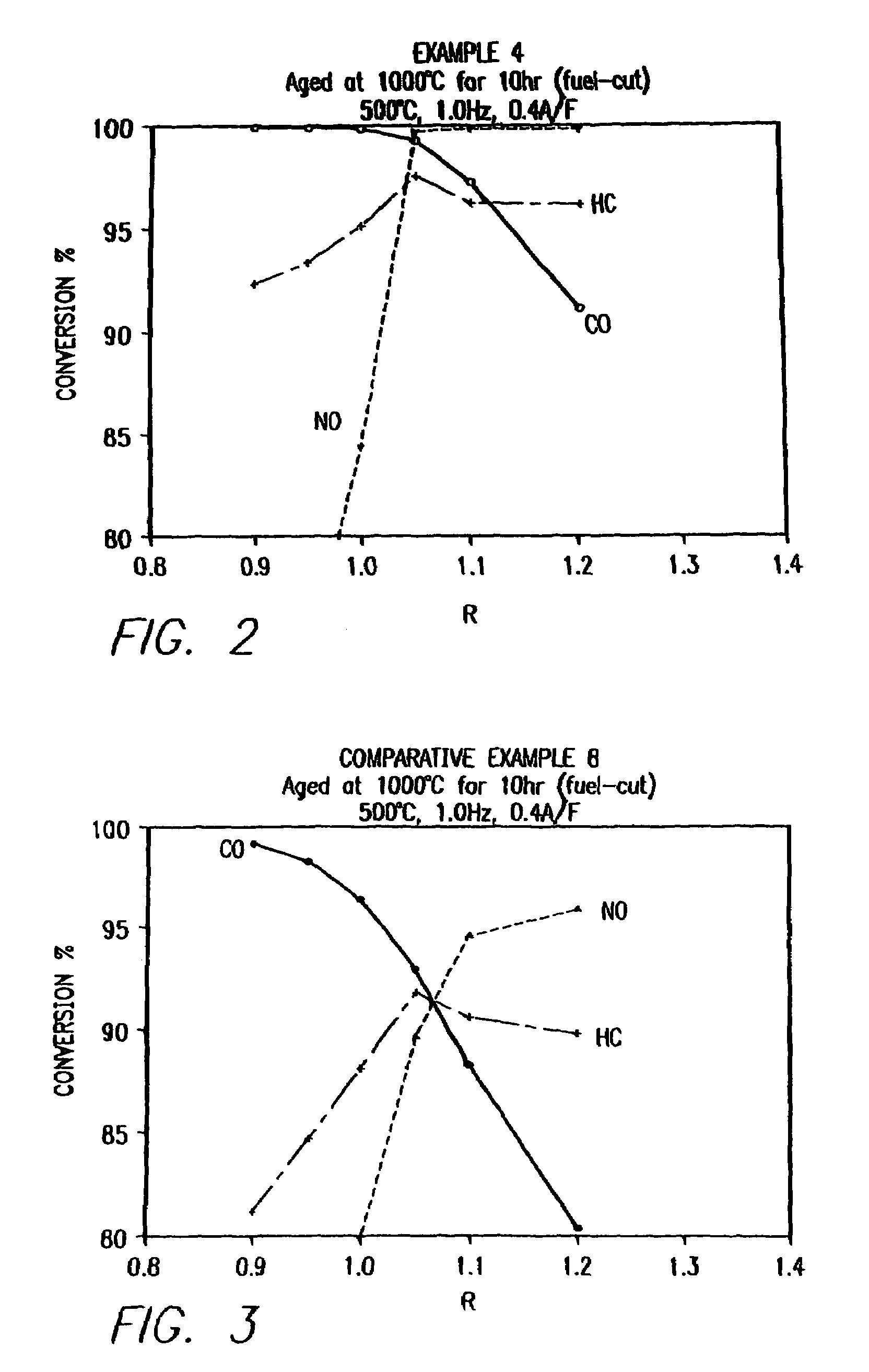

Mixed-phase ceramic oxide three-way catalyst formulations and methods for preparing the catalysts

InactiveUS7641875B1Improve efficiencyLess timeOrganic chemistryNitrogen compoundsLanthanidePt element

A multi-phase catalyst for the simultaneous conversion of oxides of nitrogen, carbon monoxide, and hydrocarbons is provided. A catalyst composition comprising the multi-phase catalyst and methods of making the catalyst composition are also provided. The multi-phase catalyst may be represented by the general formula of CeyLn1-xAx+sMOZ, wherein Ln is a mixture of elements originally in the form of single-phase mixed lanthanides collected from natural ores, a single lanthanide, or a mixture of lanthanides; A is an element selected from a group consisting of Mg, Ca, Sr, Ba, Li, Na, K, Cs, Rb, or any combination thereof; and M is an element selected from the group consisting of Fe, Mn, Cr, Ni, Co, Cu, V, Zr, Pt, Pd, Rh, Ru, Ag, Au, Al, Ga, Mo, W, Ti, or any combination thereof; x is a number defined by 0≦x<1.0; y is a number defined by 0≦y<10; s is a number defined by 0≦s<10; where s=0 only when y>0 and y=0 only when s>0. The multi-phase catalyst can have an overlayer of an oxide having the fluorite structure with a combination of platinum and / or rhodium.

Owner:CATALYTIC SOLUTIONS INC

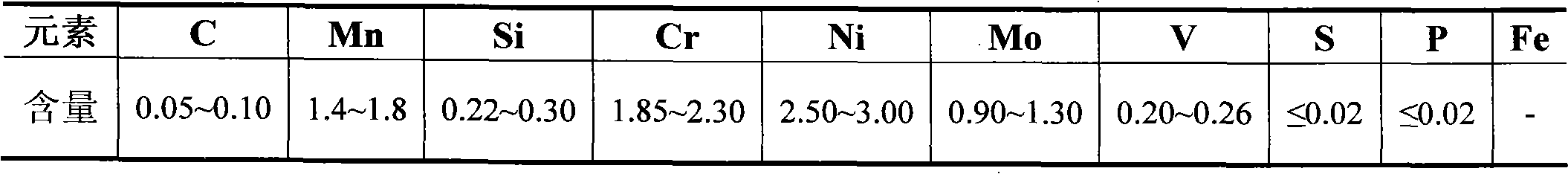

Nickel-based welding electrode for welding nickel-chromium-molybdenum alloy

ActiveCN102430876AExcellent heat crack resistanceEasy to useWelding/cutting media/materialsSoldering mediaCrack resistanceNiobium

The invention relates to a nickel-based welding electrode which comprises the following component by weight percent (wt%): 50.0-68.0% of Ni, 18.0-23.0% of Cr, 6.0-11.0% of Mo, 3.0-6.0% of Nb, 2.50-9.00% of Fe, 0.01-0.1% of C, 0.10-1.00% of Mn, 0.010-0.10% of Si, 0.015% of S or less, 0.015% of P or less, 0.01-0.10% of Cu, 0.003-0.010% of Co and the balance of impurities. The coat of the nickel-based welding electrode comprises the following components by weight percent of the welding core: 12-18% of marble, 10-15% of fluorite, 12-18% of barium carbonate, 5.0-6.4% of rutile, 3.5-5.0% of ferroniobium, 3.3-4.5 of chromium metal powder, 0.45-0.65% of sodium carbonate, 0.45-0.65% of electrolytic manganese and 1.3-1.8% of zircon sand, and the adhesion agent is 10-20% of the total weight of the power. The nickel-based welding electrode is prepared by mixing, wrapping mixture on the welding core and baking at low and high temperature. The nickel-based welding electrode disclosed by the invention is used for nickel-chromium-molybdenum alloy steel welding, ensures that the excellent mechanical properties, the excellent corrosion resistance, the excellent thermal crack resistance and the hightensile strength of the welding seam match with those of the base material, has good welding process performance, guarantees attractive molding and can be used for the welding of the steel (with 9% of Ni) working at low temperature.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Production of clean high carbon chromic bearing steel

A method for manufacturing high-cleaning and high carbon complex bearing steel includes: 1) choosing charging mixture 2) first steel making molten steel by is greater than or equal to 30ton electric furnace a. smelting furnace burden b. running out foaming slag and adding lime c. alloying when steel tapping with 92% tap and >90% level 3) refining molten steel by steel ladle furnace a. cleaning steel ladle and furnace cleaning b. through bottom blowing argon mixing with 60 min, earlier stage argon blowing intensity 0.4Mpa and later stage 0.3Mpa, material adding amount is less than or equal to 8Kg / ton steel c. precipitating and deoxidizing by two-stage aluminum feeding method, adding crystallized silicon powder, fluorite(content of calcium is greater than or equal to 98%) into slag face, and dispersing deoxidizing 4) vacuum furnace treating a. bottom blowing argon 0.3Mpa, 25min, vacuum content is less than or equal to 140Pa b. bottom blowing argon mixing 15min, 0.1Mpa without materials after treating 5) molten steel mould casting under inactive gas a. ingot moulding temperature 70deg.C, runner brick coating b. pouring speed 5.1ton steel / min of ingot body and mouth. It achieves high yield.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Series flux cord welding rod used for pile-up welding reparing and remanufacturing large type medium high carbon steel parts

InactiveCN100999041AImprove crack resistanceHigh carbon contentArc welding apparatusWelding/cutting media/materialsHigh carbonRare earth

The present invention discloses a series flux-cored wire for reparation and refabrication of large-size medium-high carbon steel components and parts. Its chemical composition includes (wt%) 5-10 of fluorite, 25-45% of high-carbon ferrochrome, 2-10% of high-carbon manganese iron, 5-8% of tantiron, 10-15% of ferro-molybdenum, 8-14% of rare earth oxide, 5-15% of metal nickel, 2-5% of ferrovanadium, 0.5-2% of graphite, 2-4% of chloride and 1-2.5% of aluminium-magnesium alloy. Its external covering adopts low-carbon steel tape.

Owner:QINHUANGDAO WEIERDE SPECIAL WELDING IND

Melted iron dephosphorization agent using vessel slag as raw material

A molten iron dephosphorization agent using furnace slag as raw material comprising the constituents of (wt%) furnace slag 20-50, calcarea lime 15-28, ferrum oxide 20-43, fluorite 0-3, soda 0-3, lime stone 0-3. The furnace slag proportion amounts 20-50%, the ferrum oxide can be sintered ore or rolled steel iron sheet, or can be revolving furnace smoke or sintered dedusting ash. The invention realizes reduced production costs, saved lime and low fusing point.

Owner:BAOSHAN IRON & STEEL CO LTD

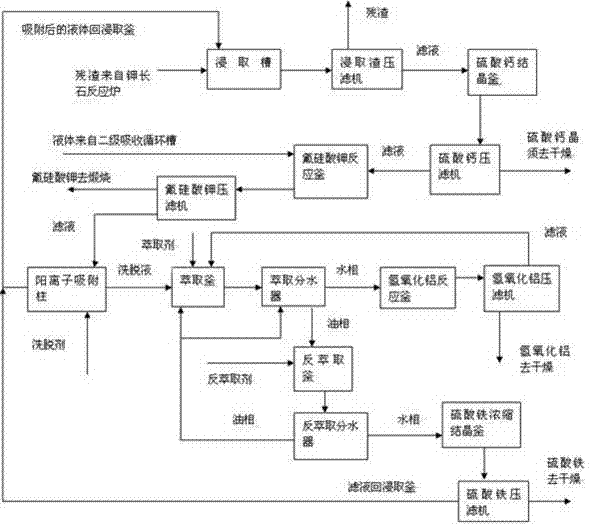

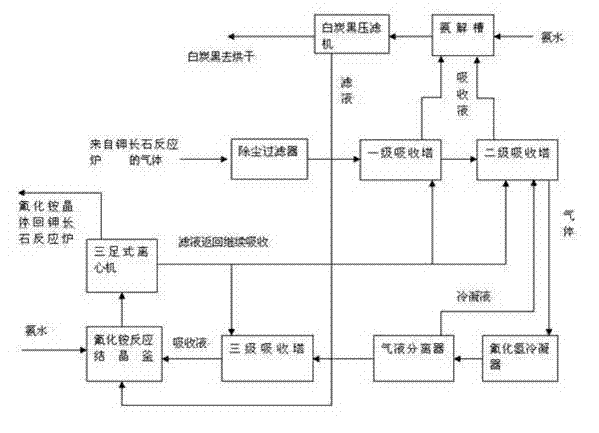

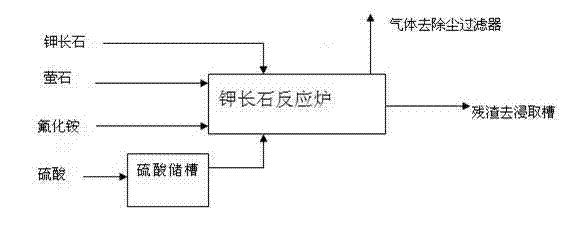

Process for decomposing potassium feldspar by adopting low-temperature semidry method for comprehensive utilization

ActiveCN103172074AAvoid wastingLower requirementSilicon halogen compoundsSilicaAluminium hydroxideDecomposition

The invention relates to potassium feldspar decomposition and comprehensive utilization technology and in particular relates to a process for decomposing potassium feldspar by adopting a low-temperature semidry method for comprehensive utilization. The process comprises the steps of fully mixing potassium feldspar, fluorite and sulfuric acid, then adding the mixture to a converter reactor to react at 180-250 DEG C, separating SiF4 and HF generated through a reaction from a system under the condition of negative pressure, carrying out absorption with ethanol and water solution to prepare white carbon black, recovering fluorine resources in the process from the solution in the forms of ammonium fluoride and other aids by adopting the method of adding ammonia water and applying the recovered fluorine sources to decomposition of potassium feldspar and carrying out a series of processes such as extraction on the solids after a reaction to obtain calcium sulfate whisker, potassium fluosilicate, aluminium hydroxide and ferric sulfate products. Compared with the method for decomposing potassium feldspar by a high temperature method, the process has the advantages that the reaction conditions are mild and the requirements for equipment are lower; the white carbon black is directly prepared through gas hydrolysis, thus avoiding the tedious course from solid phase separation; and the fluorine resources introduced to the decomposition course are recycled by adopting the mode of ammonium fluoride, thus avoiding waste of the fluorine resources.

Owner:LUOYANG FLUORIDE & POTASSIUM TECH +1

Projection optical system, exposure apparatus with the same system and exposure method

InactiveCN1453645ASemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusOptical propertyCrystalline materials

Owner:NIKON CORP

Core glaze for matte sand streak enamel glaze and production method thereof

The invention discloses a core glaze for a matte sand streak enamel glaze, belonging to the technical field of enamel glazes. The core glaze comprises, by weight, 20 to 35% of quartz sand, 20 to 30% of magnesium oxide, 18 to 28% of soda ash, 8 to 15% of potash feldspar, 2 to 5% of borax, 1 to 2% of fluorite, 1 to 3% of calcium carbonate, 2 to 5% of trisodium phosphate and 0.02 to 0.1% of cobalt oxide. Through cooperative usage of the core glaze with commercially available bright glazes, colorants and the like, matte sand streak glaze products of different colors and different texture can be conveniently and rapidly at a low temperature in a small scale.

Owner:娄底湘信新材料科技有限公司

Formulation for medicinal neutral boron silicate glass

The present invention is one kind of neutral borosilicate glass for medicine production. The neutral borosilicate glass has recipe comprising quartz sand 168-178 Kg, feldspar powder 14.7-18.7 Kg, borax pentahydrate 49-51 Kg, sodium carbonate 8-12 Kg, barium carbonate 8.6-9.4 Kg, sodium nitrate 0.4-0.6 Kg, calcite 1-2 Kg, fluorite 0-4 Kg, potassium carbonate 8.5-9.5 Kg, salt 0.8-1.6 Kg, cerium oxide 0.5-0.9 Kg and cullet 120 Kg. It has high chemical stability, high hydrolysis stability, few alkali metal volatilizations, simple production process and low cost.

Owner:东营力诺玻璃制品有限责任公司

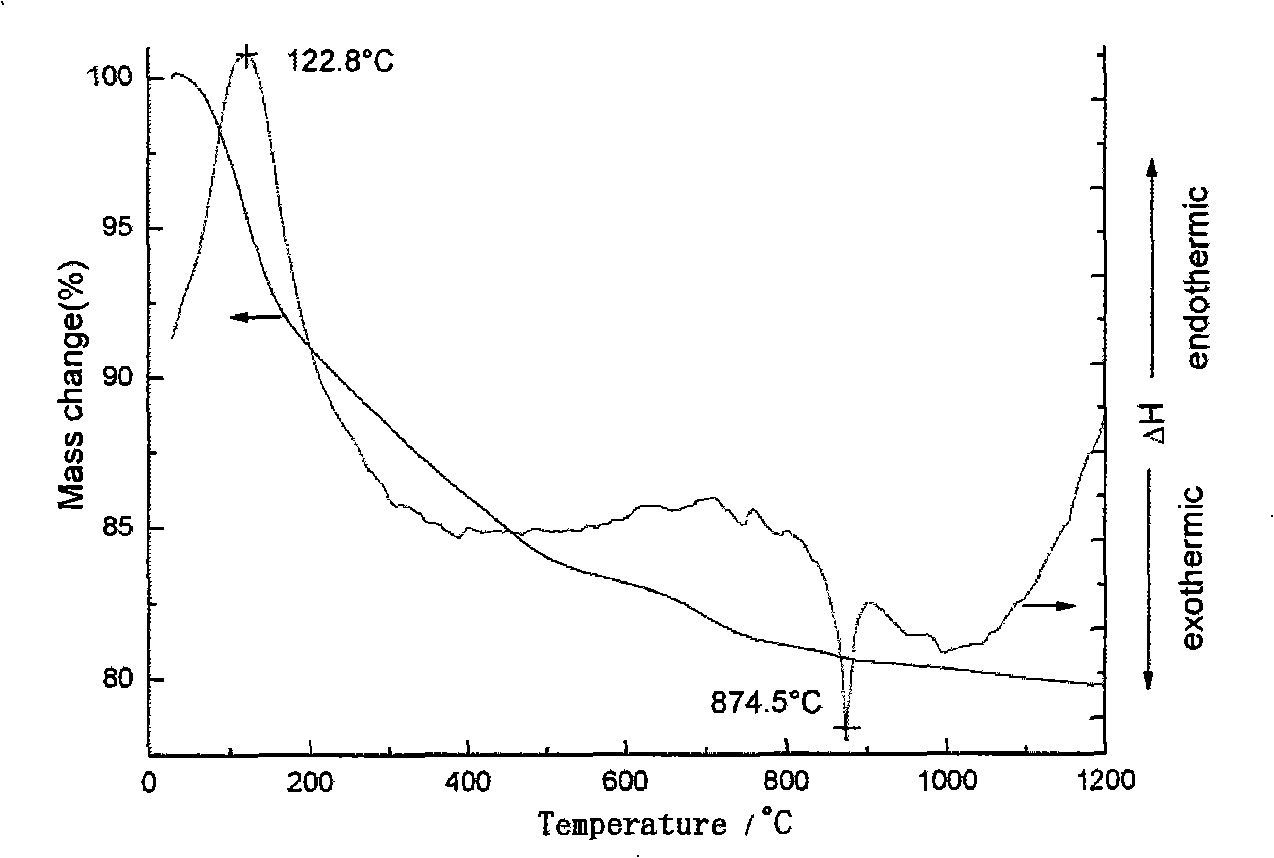

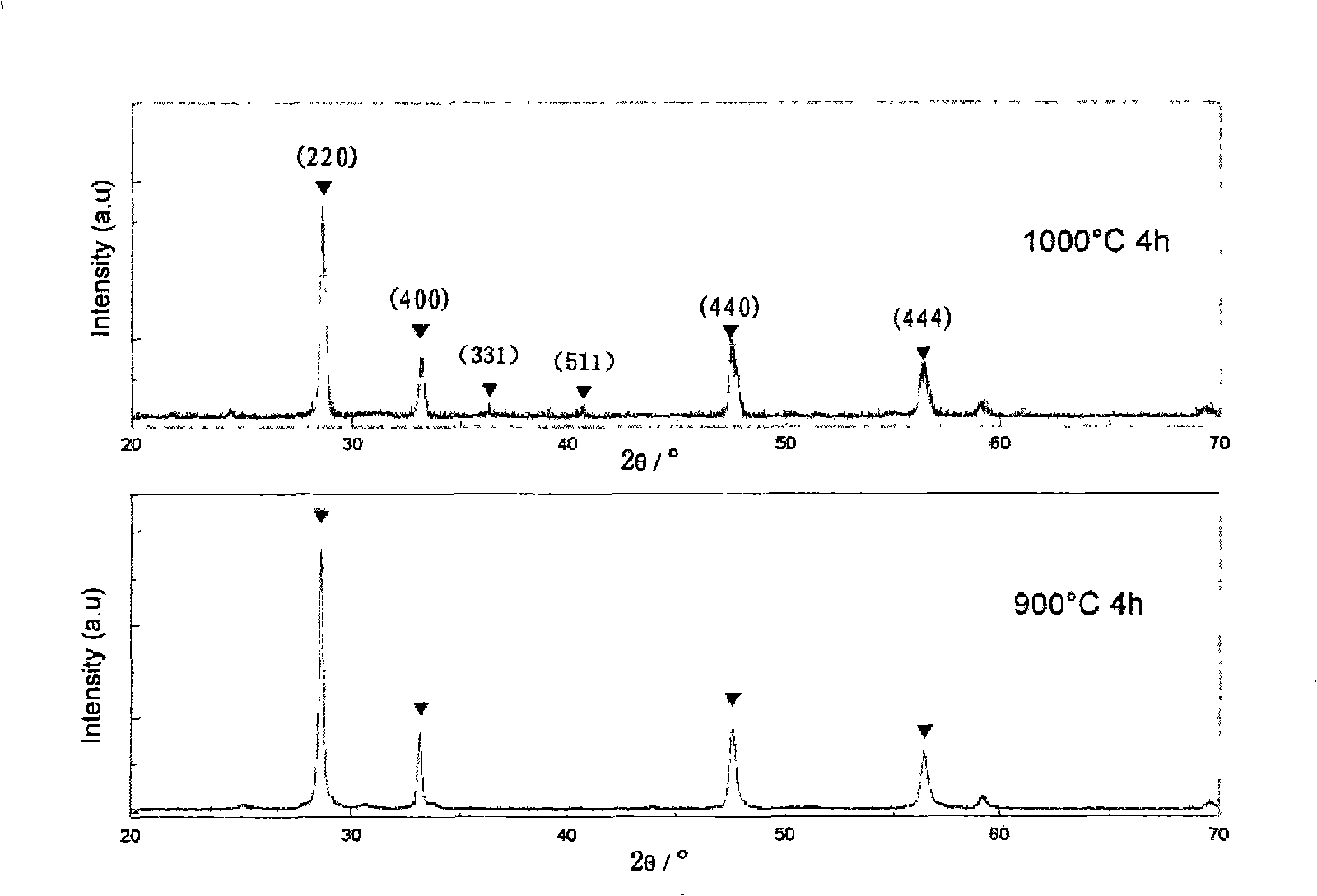

Method for preparing lanthanum zirconate powder

InactiveCN101407336ALow thermal conductivityGood heat insulationZirconium compoundsRare earth metal compoundsSolid reactionPyrochlore

The invention relates to a method for preparing a lanthanum zirconic acid powder, which belongs to the preparation field of ceramic powder used for high temperature heat barrier. The method uses lanthanum oxide or lanthanum soluble salt and zircon salt for respectively preparing the solutions containing La<3+> and Zr<4+>; the two solutions are mixed and dropped into a precipitator (or the precipitator is dropped into the mixing solutions) under continual stirring to obtain precipitate; and the precipitate are washed with a plurality of times, then dried, ground and finally calcined at certain temperature to obtain La2Zr2O7 of defect fluorite structure or pyrochlore constitution. Compared with the existing universal solid reaction process, the method lowers the synthesis temperature by 500-700 DEG C. The heat-insulating property (heat diffusivity) of the obtained power is reduced by about 50 percent compared with YSZ, and reduced by about 40 percent compared with the lanthanum zirconic acid powder obtained by the solid reaction process. The method solves the problems of overhigh heat diffusivity, severe sinter and phase change inefficiency in the existing ceramic materials used for the coating of high temperature heat barrier.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Longquan official ware celadon glaze of the Ming Dynasty and method for manufacturing Longquan official ware celadon product of the Ming Dynasty by using glaze

The invention relates to a Longquan official ware celadon glaze of the Ming Dynasty, wherein the glaze material comprises the following components in percentage by weight: 43-48% of Linggeng glaze clay, 6-9% of lime stone, 6-9% of quartz, 14-18% of Dayao violet gold clay, 15-22% of Xiyuan glaze clay and 1.2-1.6% of fluorite. The glaze material has green and tender glaze color as jades, moist color and luster, strong jade texture, wide adaptability and good thermal stability. The invention further provides a method for manufacturing a Longquan official ware celadon product of the Ming Dynasty by using the Longquan official ware celadon glaze of the Ming Dynasty. The method is scientific and reasonable, is easily implemented, and has high rate of finished products and good porcelain texture.

Owner:李邦强

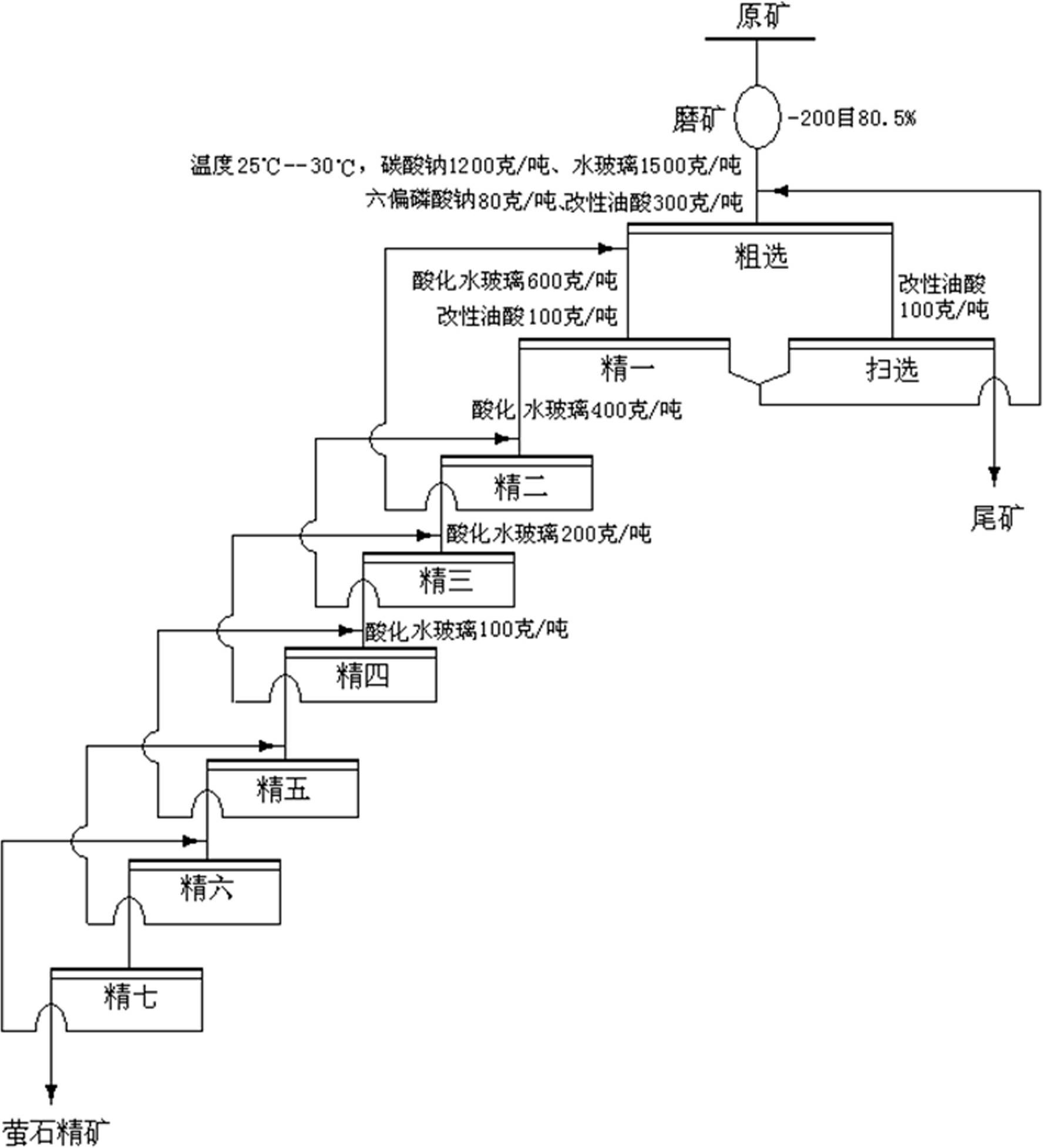

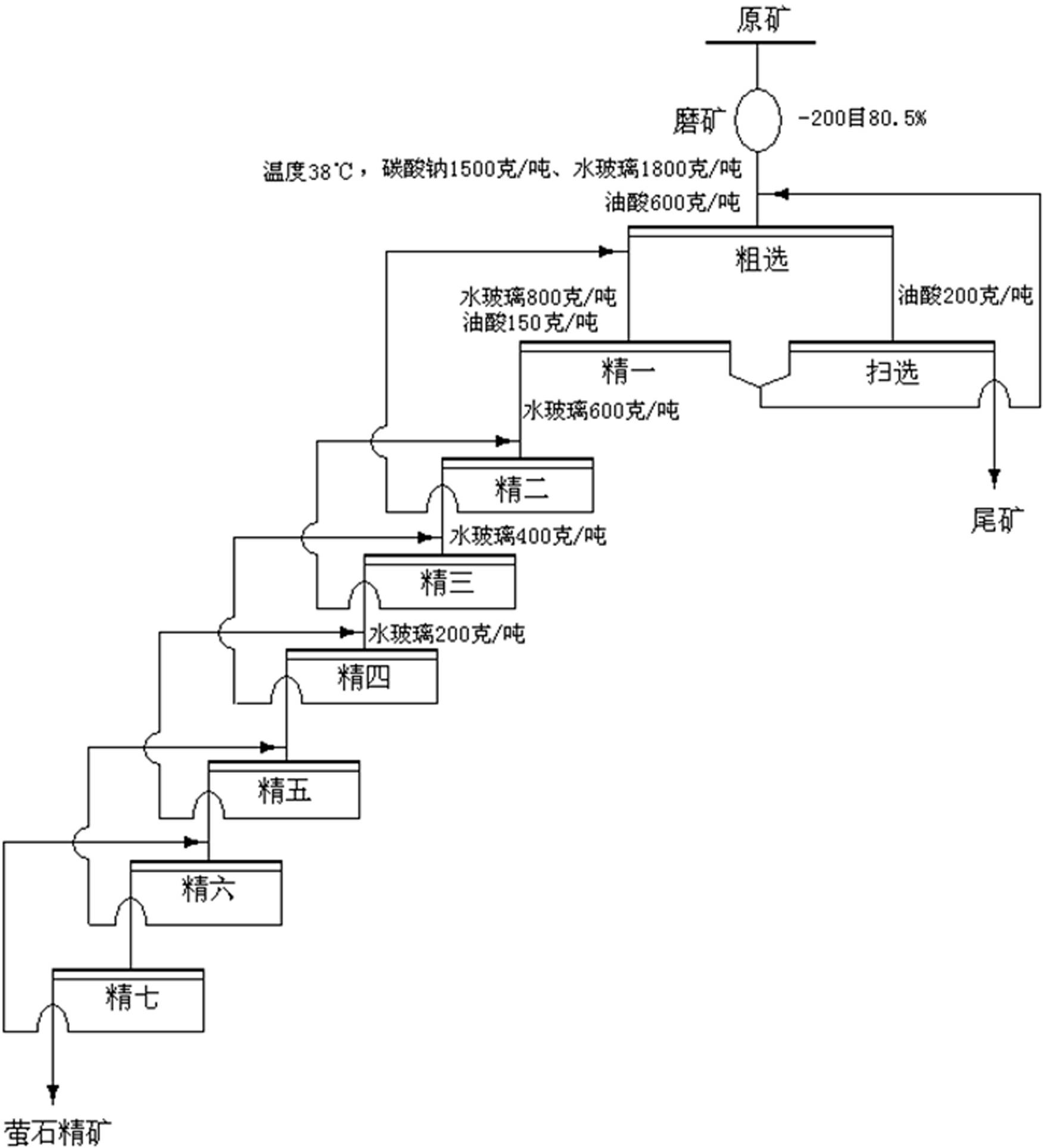

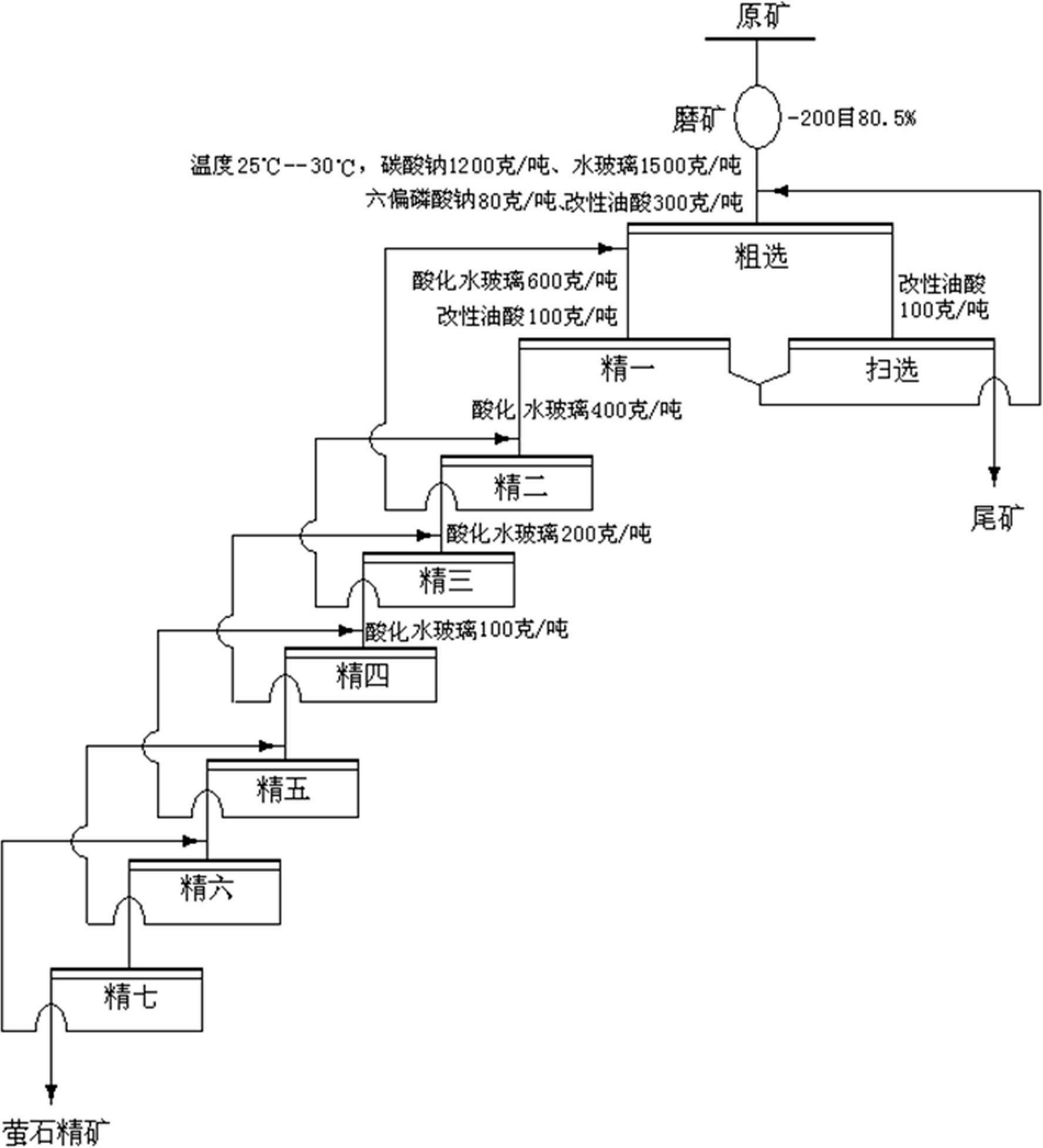

Mineral separation process of complex fluorite difficult to separate

The invention relates to a mineral separation process, in particular to a mineral separation process of complex fluorite difficult to separate. The process includes utilizing sodium hydroxide to treat oleic acid to obtain modified oleic acid, utilizing concentrated sulfuric acid to treat water glass and obtain acidized water glass, conducting ore grinding on fluorite ores according to the prior art, conducting coarse separation under the temperature of 25-30 DEG C, then conducting seven times fine separation on coarse separation foams and adding the acidized water glass into the foams in the first four times of fine separation to prepare fluorite concentrate. The process can improve separation efficiency of calcium fluoride, silica and calcite, improves quality and recycle rate of the fluorite ores, obtains high quality acid grade fluorite ores and resolves the problem of difficulty in separation of complex fluorite flotation, is remarkable in application effect in separation of the complex fluorite difficult to separate, has repeatability, simultaneously reduces requirements of fluorite mineral flotation for ore temperature, reduces energy consumption, reduces usage of collectingagent oleic acid, reduces environment pollution caused by exhaust of a large amount of waste water containing oleic acid and has better economical and social benefits.

Owner:BAIYIN NONFERROUS GROUP

Nickel-base welding rod

InactiveCN101745759AGood production technologyImprove yieldWelding/cutting media/materialsSoldering mediaSlagManganese

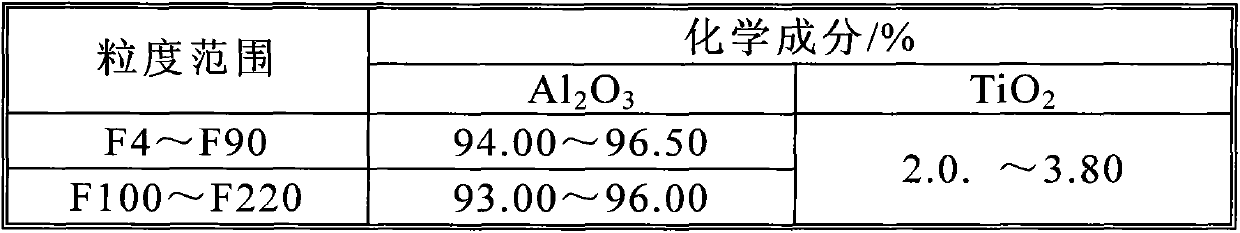

The invention relates to a welding material technology, in particular to a nickel-base welding rod. The welding rod uses a SNi6062 welding wire as a core wire. The electrode coating comprises the following solid ingredients in percentage by mass: 36-50% of rutile, 2-7% of titanium pigment, 20-30% of fluorite, 3-8% of cryolite, 2-4% of phlogopite, 2-4% of zircon sand, 0.5-1.5% of sodium carbonate, 5-10% of manganese metal, 2-4% of ferrotitanium containing 25-35% of Ti, and 2-4% of ferroniobium containing 50-60% of Nb. The nickel-base welding rod has the advantages of favorable performance of production technique, smooth welding rod surface, high yield, stable eccentricity; during welding, the nickel-base welding rod has the advantages of stable electric arc, basically no splash, favorable slag detachability and outstanding operating performance; and the appearance of the welding seam is beautiful, the height of a weld bead is moderate, the wetting angle of a welding seam is moderate, and the strength and plasticity of deposited metals are moderate.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

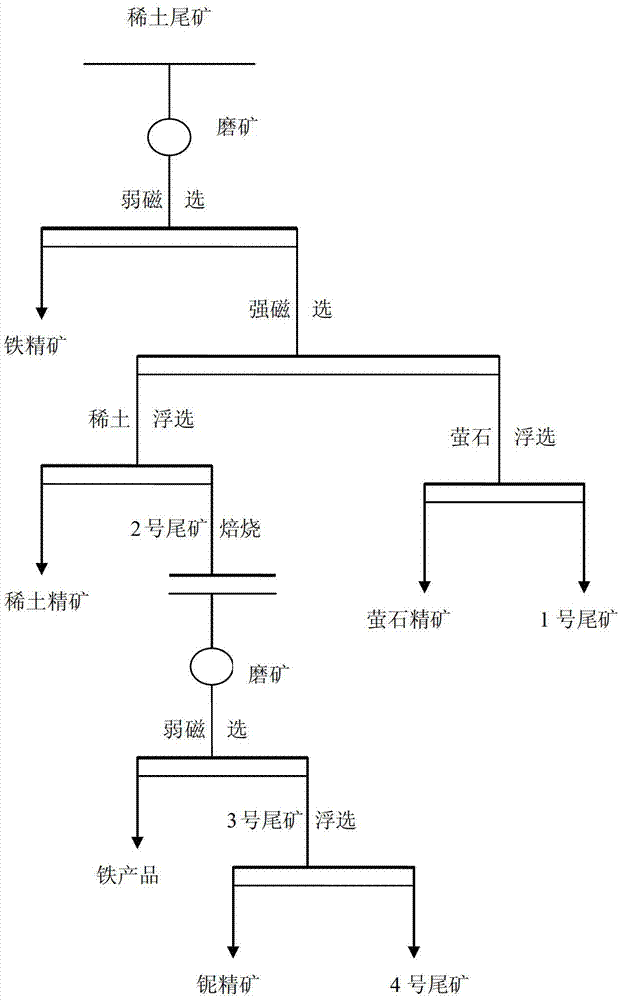

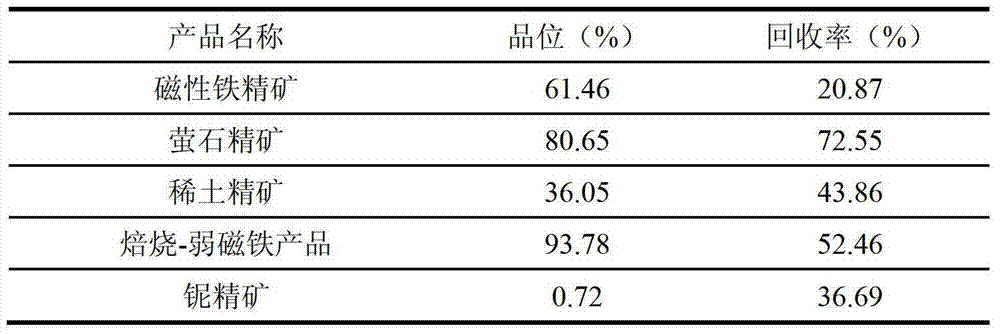

Method for comprehensively recycling valuable minerals in rare-earth tailings

InactiveCN103394408ATake advantage ofOptimized flotation collectionFlotationWet separationResource utilizationNiobium

The invention relates to a method for comprehensively recycling valuable compositions of rare earth, iron, niobium and fluorite in rare-earth tailings, and belongs to the fields of comprehensive resource utilization technologies and mineral processing engineering. The rare earth, the iron, the niobium and the fluorite in the rare-earth tailings are efficiently and comprehensively recycled by the method including 'grinding the rare-earth tailings, performing low-intensity magnetic separation, performing high-intensity magnetic separation on weak-intensity magnetic tailings, performing flotation on high-intensity magnetic tailings to obtain fluorite in the high-intensity magnetic tailings, performing flotation separation on high-intensity magnetic concentrates to obtain rare earth, iron and niobium in the high-intensity magnetic concentrates, reducing and roasting base flows, performing low-intensity magnetic separation to obtain iron and niobium in the base flows and performing flotation on low-intensity magnetic tailings to obtain niobium in the low-intensity magnetic tailings according to characteristics that the rare-earth tailings contain the various valuable compositions. Compared with a method for singly recycling one or two valuable compositions, the method has the advantages that the purpose of comprehensively recycling the valuable compositions in the rare-earth tailings can be effectively achieved, secondary resources can be sufficiently utilized, and the method has excellent economical and social benefits.

Owner:UNIV OF SCI & TECH BEIJING

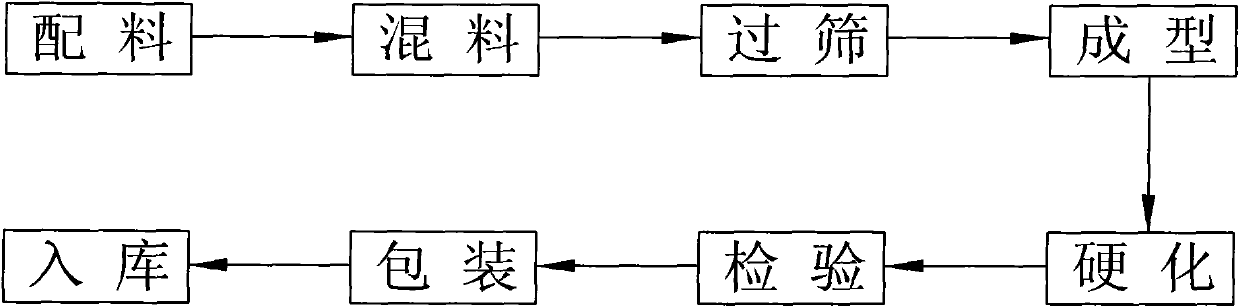

Resin rough grinding wheel and preparation method thereof

ActiveCN103465179AImprove grinding efficiencyIncrease roughnessAbrasion apparatusGrinding devicesPyriteAlumina zirconia

The invention relates to a resin rough grinding wheel and a preparation method thereof. The resin rough grinding wheel comprises a grinding body and reinforcing meshes, wherein the reinforcing meshes are arranged inside the grinding body to enhance the revolving strength of the grinding body. The grinding body is composed of 115-150 parts of grinding materials, 5-15 parts of liquid phenolic resin, 25-45 parts of phenolic resin powder and 15-35 parts of filling, wherein the grinding materials comprise 30-40 parts of microcrystal corundum, 80-100 parts of fused alumina zirconia and 5-10 parts of garnets, the filling is composed of 9-21 parts of pyrite, 1-3 parts of cryolite, 1-3 parts of ferric oxide, 1-3 parts of quick lime and 3-5 parts of fluorite. The resin rough grinding wheel is prepared through the steps of preparation, mixing, sifting, shaping, hardening, testing, packaging and storing, has high strength, good abrasive resistance and self-sharpening performance, high grinding efficiency, good roughness and low workpiece burning possibility; meanwhile, the surface of the grinding wheel is not easy to block and has good breathability, good tenacity and high security performance.

Owner:NINGBO DAHUA GRINDING WHEEL

High draw speed plate blank continuous casting low carbon steel crystallizer protective slag

The present invention relates to a high pulling rate sheet billet continuously-casting low-carbon crystallizer protective slag. Said protective slag is formed from the following ingredients: (by wt%) melting material 50-65%, lithium carbonate 1.2-3.6%, sodium carbonate 2.3-6.0%, fluorite is 3.0-6.9%, quartz sand 6.0-9.5%, satellite 7.0-10.0%, manganese ore powder 5.0-9.0%, ferrous and 1.0-3.5%, carbon blank 2.0-7.0% and bentonite 2.0-5.5%.

Owner:宝钢集团上海梅山有限公司

High-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag and preparation method thereof

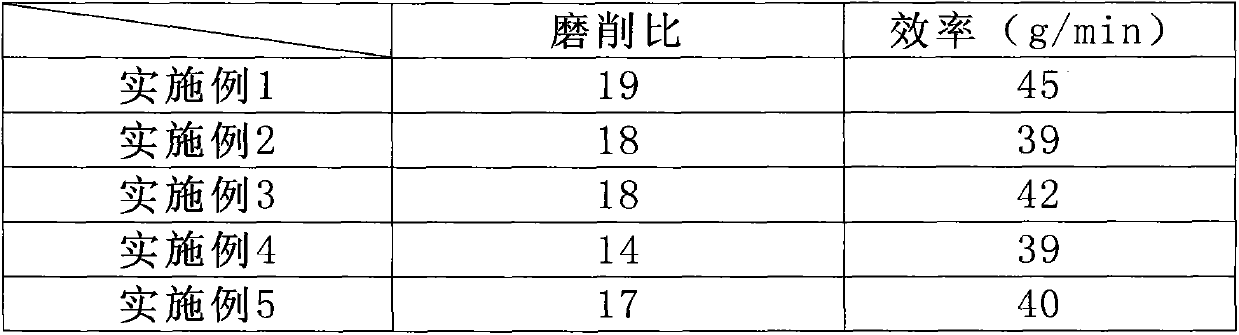

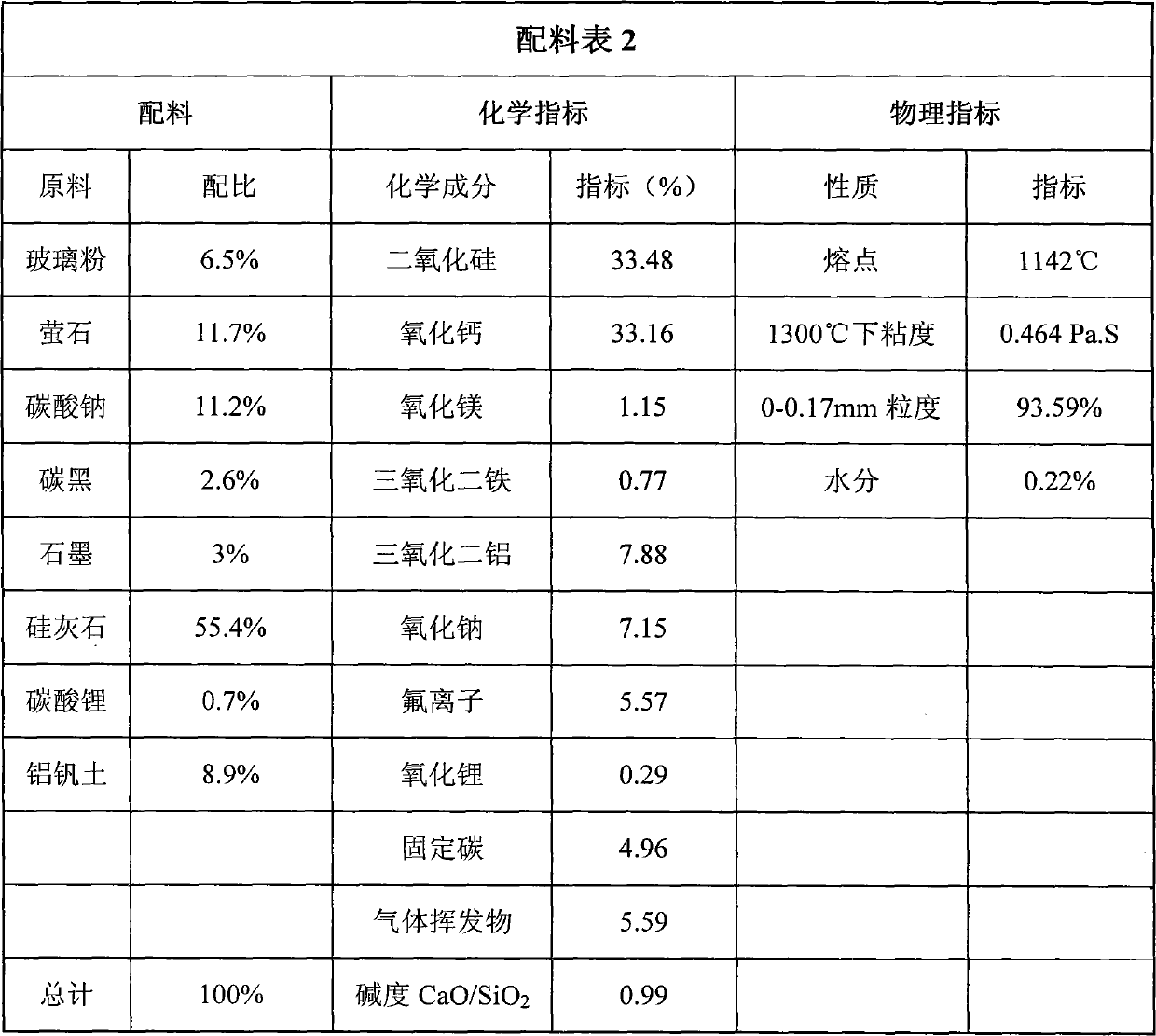

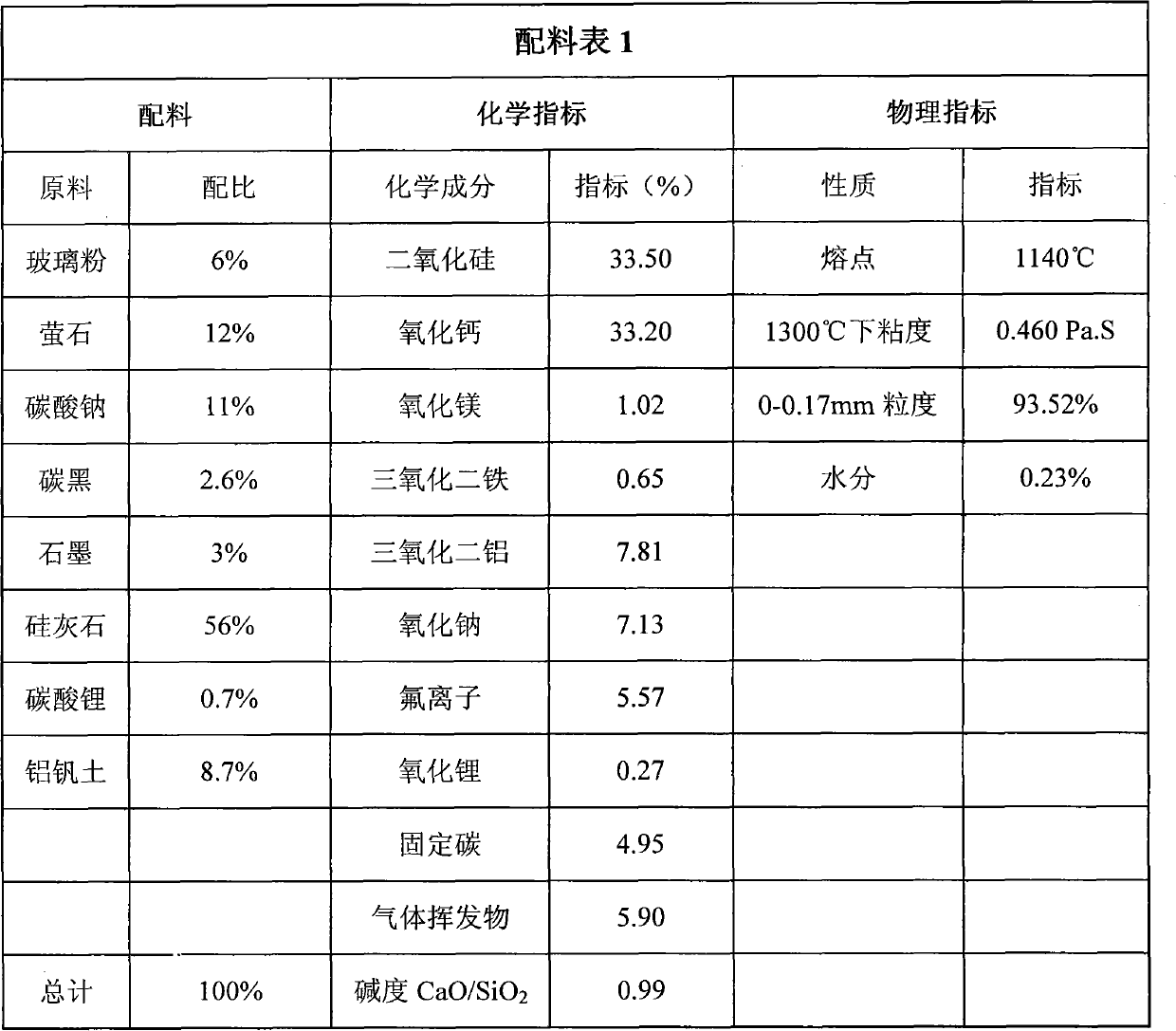

The invention discloses high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag which comprises the following components in percentage by weight: 54-57% of wollastonite, 9-13% of fluorite, 9-13% of sodium carbonate, 0-1% of lithium carbonate, 5-7% of glass dust, 8-12% of vanadine soil, 2.5-2.7% of soot carbon and 3-3.5% of graphite, and comprises the chemical components in percentage by weight: 31.9-34.9% of calcium oxide, 32.1-35.1% of silicon dioxide, 7.3-8.3% of aluminium oxide, 0.5-1.5% of magnesium oxide, 0.5-1.4% of iron sesquioxide, 4.4-6.4% of fluorion, 6.5-7.5% of sodium oxide, 0-0.39% of lithium oxide, 4.5-6.0% of fixed carbon and 4-7% of gas volatile matters. The alkalinity of the covering slag, namely the ratio of CaO to SiO2, is 0.91 to 1.00, the melting point of the covering slag is 1100 DEG C to 1160 DEG C, and the viscosity of the covering slag is 0.3 to 0.6 Pa.s at 1300 DEG C. The invention can solve the problems of easy crusting, slag entrainment, slag inclusion, slag sticking on casting blank surfaces, bubbles under skins, cracks, deep chatter mark, felting, bleed-out, and the like of the covering slag in the crystallizer during high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting, and has the advantages of uniform and stable slagging in the crystallizer, good casting blank quality, difficult felting and bleed-out, and the like.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Method for preparing full-silicide ABC dry powder fire fighting agent

InactiveCN101485927AMaintain water repellency and moisture resistanceStable moisture contentFire extinguisherPhosphateMoisture

The invention discloses a method for preparing a full siliconization ABC powder extinguishing agent, which comprises the following steps: pulverizing monoammonium phosphate and ammonium sulphate; weighing 2 to 4 percent of floridin, 1 to 3 percent of mica powder, 0.5 to 10 percent of talcum powder, 0.5 to 10 percent of ore fluorite, 2 to 4 percent of lyophobic white carbon black, 0.2 to 0.6 percent of organic silicon oil, 40 to 91 percent of pulverized monoammonium phosphate and 1.5 to 50 percent of ammonium sulphate in percentage by weight; mixing the materials evenly except the lyophobic white carbon black and the organic silicon oil; stirring the organic silicon oil, an organic solvent and water to form an emulsifying silicon oil solution in the ratio of 1:0.4:1; pressurizing the solution to between 0.4 to 0.6Mpa, and spraying the solution onto the mixed materials to be silicified for 30 to 60min; drying and stirring the silicified materials, and adding the lyophobic white carbon black to be mixed evenly, sieved and packaged. The extinguishing agent prepared by the invention has the advantages of stable water ratio, high performance of moisture prevention and agglomeration prevention and better fire-extinguishing efficiency.

Owner:NINGBO NENGLIN FIRE FIGHTING EQUIP

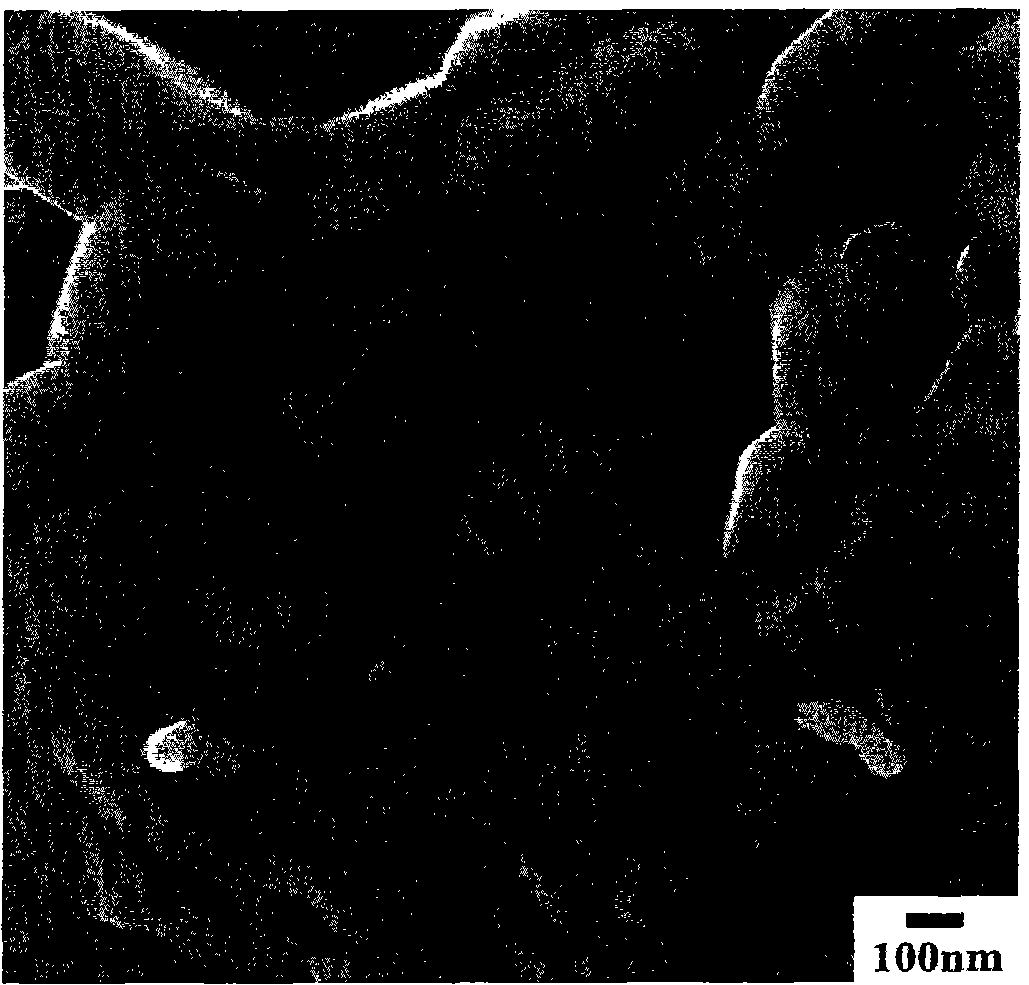

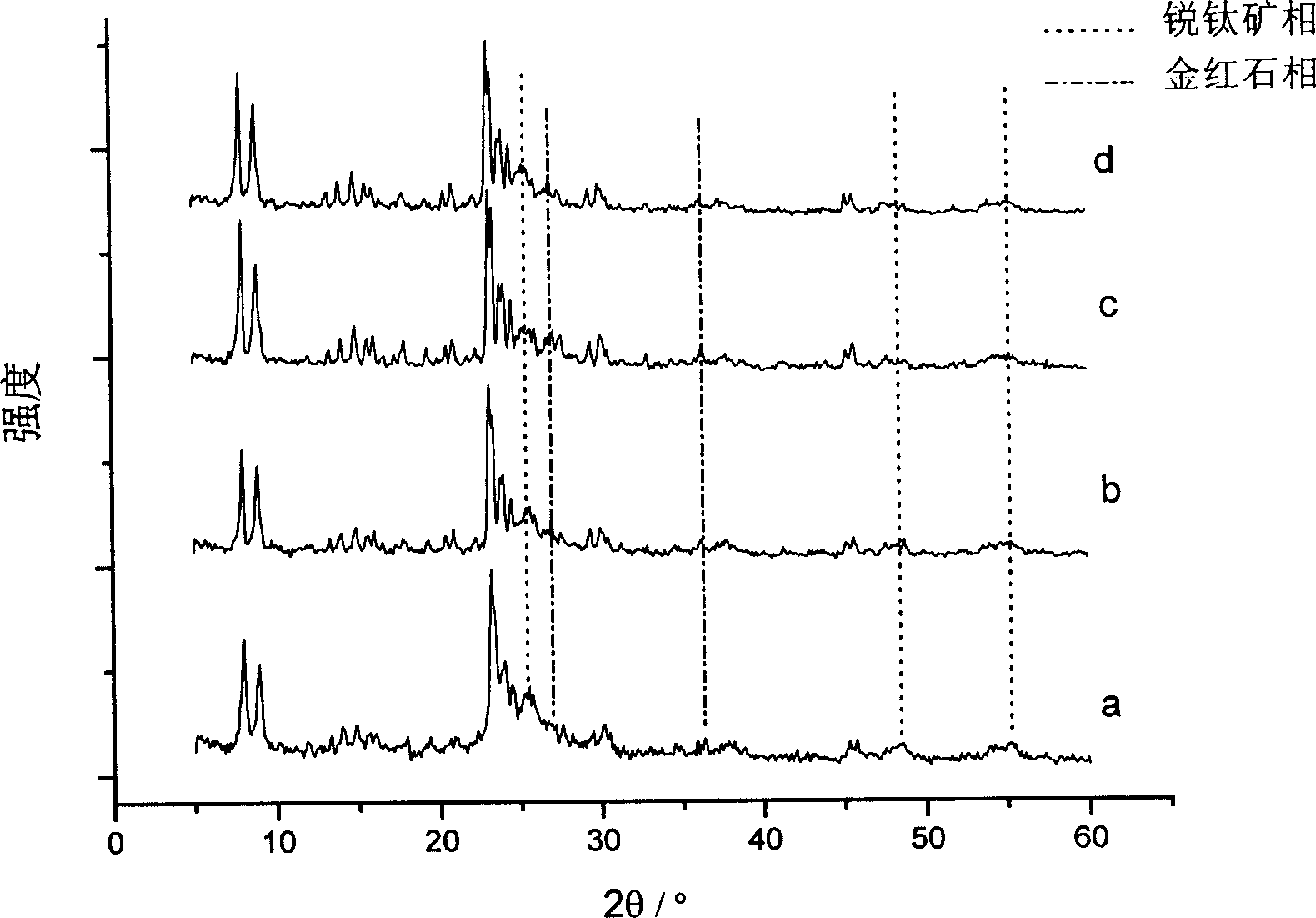

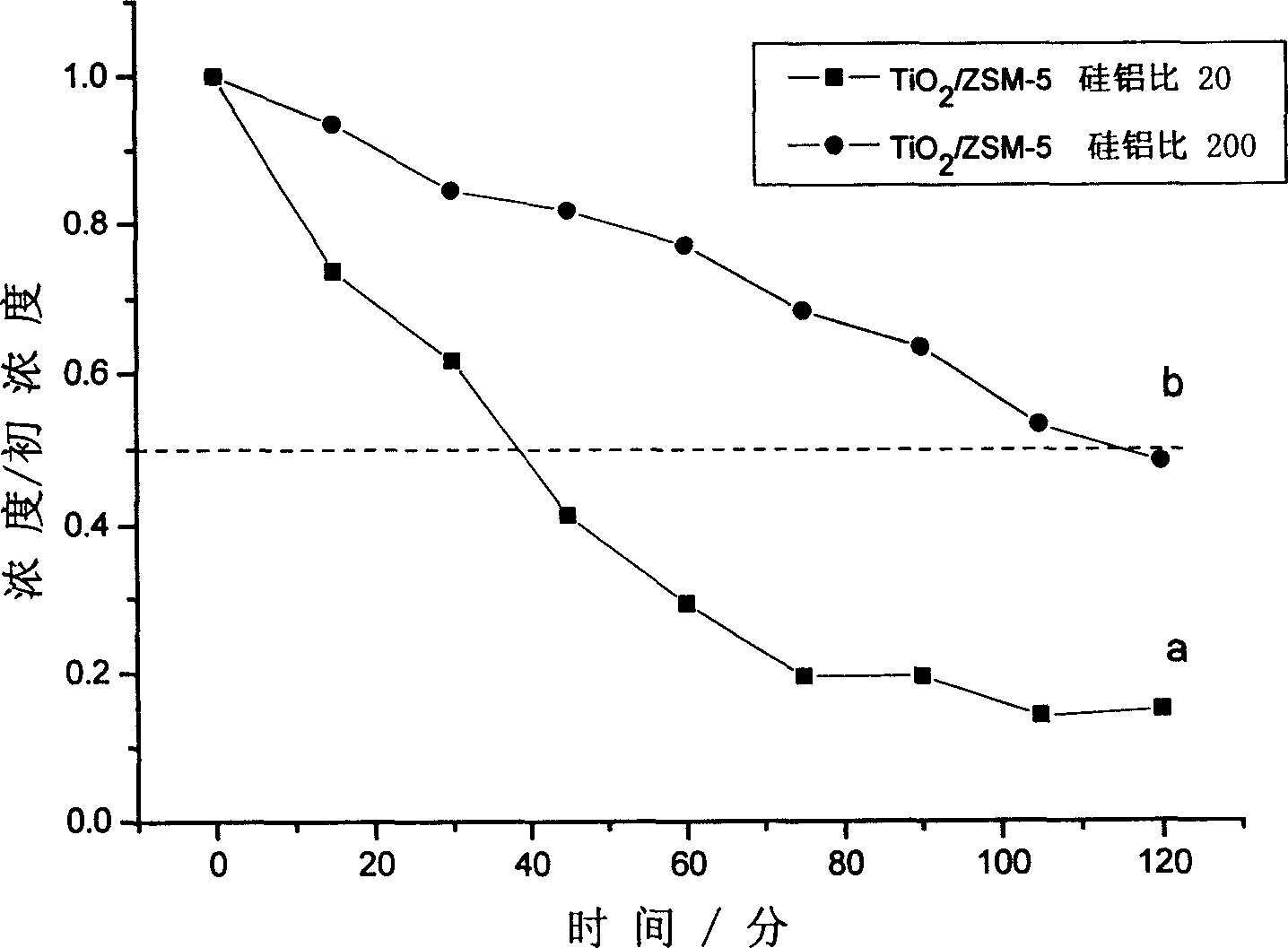

Nano Titanium dioxide/fluorite photocataly tic material and preparation process thereof

A composite nano-TiO2 / zeolite photo-catalyst is prepared from zeolite as basic material and soluble Ti salt as precursor through immersing the zeolite molecular sieve with different skeletons in the solution containing Ti ions, drying by evaporating and calcination. It has the crystal phases of anatase and rutile, and controllable high catalytic activity.

Owner:FUDAN UNIV

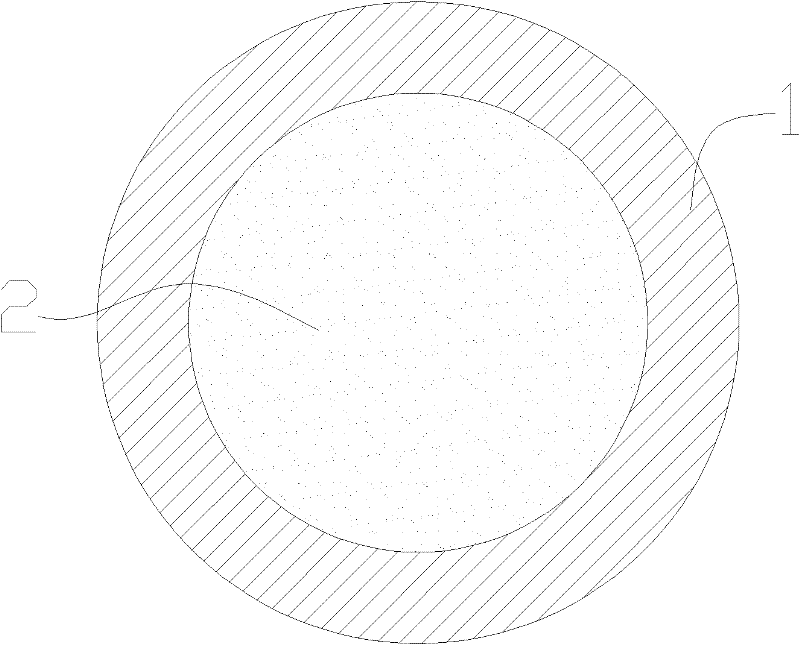

Core-spun thread and method for implementing molten steel vanadium-nitrogen alloying

The invention discloses a core-spun thread and method for implementing molten steel vanadium-nitrogen alloying, and the method can be used for feeding the core-spun thread into molten steel conveniently and preventing the thread from being jammed and broken and is beneficial to improving the recovery rate of nitrogen and vanadium. The core-spun thread comprises a core layer and skin, wherein the core layer contains vanadium nitride alloy and fluorite. The method mainly comprises the following steps: adding the fluorite to the core layer of the core-spun thread; and then feeding the core-spun thread into the molten steel. The method has the beneficial effects that the fluorite is added into the core layer, so that the melting point of steel slag is reduced and the steel slag fluidity is improved so as to facilitate the process of feeding the core-spun thread into the molten steel, thus reducing the loss of the core-spun thread in steel slag layers, being beneficial to improving the recovery rate of vanadium and nitrogen and preventing the core-spun thread from being jammed and broken during the feeding process.

Owner:PANZHIHUA IRON AND STEEL +2

6-aliphatic hydrocarbon amido hexyl hydroximic acid collecting agent and preparation and application methods thereof

ActiveCN103301952AImprove flotation recoveryAchieve high flotation separationFlotationReaction temperatureCarboxylic acid

A structural formula of a 6-aliphatic hydrocarbon amido hexyl hydroximic acid collecting agent is represented by a formula (I), wherein R represents C2-C18 aliphatic hydrocarbon group. The preparation method comprises the steps as follows: caprolactam and hydroxylamine hydrochloride or hydroxylamine sulphate are taken as raw materials, methylbenzene is taken as a solvent, the reaction temperature ranges from 80 DEG C to 110 DEG C, the reaction lasts for 1-4 hours, and 6-amino hexyl hydroximic acid is generated; 6-amino hexyl hydroximic acid reacts with C2-C18 fat carboxylic acid at the reaction temperature ranging from 100 DEG C to 160 DEG C for 1-4 hours to generate 6-aliphatic hydrocarbon amido hexyl hydroximic acid, and the product yield can be higher than 91%; and 6-aliphatic hydrocarbon amido hexyl hydroximic acid used in flotation of scheelite, wolframite, tombarthite ore, tin ore, bauxite, titanic iron ore or fluorite ore is taken as the collecting agent, so that the flotation recovery rate can be increased by 3%-10%.

Owner:CENT SOUTH UNIV

Beneficiation method for separating fluorite and tungsten through flotation

ActiveCN104084315AAvoid the problem of poor floatability and difficult flotation recoveryAvoid lostFlotationSulfidationTungsten

The invention discloses a beneficiation method for separating fluorite, white tungsten (black tungsten) and gangue minerals in complex polymetallic ore through flotation. Non-magnetic products of tailings subjected to sulphide ore flotation or tailings subjected to sulphide ore flotation and then subjected to strong magnetic separation for recycling black tungsten serve as two kinds of samples. The pH value is controlled by adding regulators, white tungsten, black tungsten, other gangue combined inhibitors and collectors are added, fluorite is subjected to differential flotation, then, tungsten minerals are subjected to flotation, and therefore fluorite and tungsten can be efficiently recycled. Loss of fluorite in tungsten flotation concentrate is avoided when tungsten minerals are subjected to differential flotation, and the defect that when tungsten flotation is performed, fluorite is difficult to recycle through flotation because the inhibitors have strong inhibition on fluorite, and beneficiation efficiency is low is avoided. Compared with a current beneficiation situation, the fluorite recycling rates of tests on the two different samples are increased by 39% to 48 % and 9% respectively, and the tungsten recycling efficiency is improved by 3%.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL +1

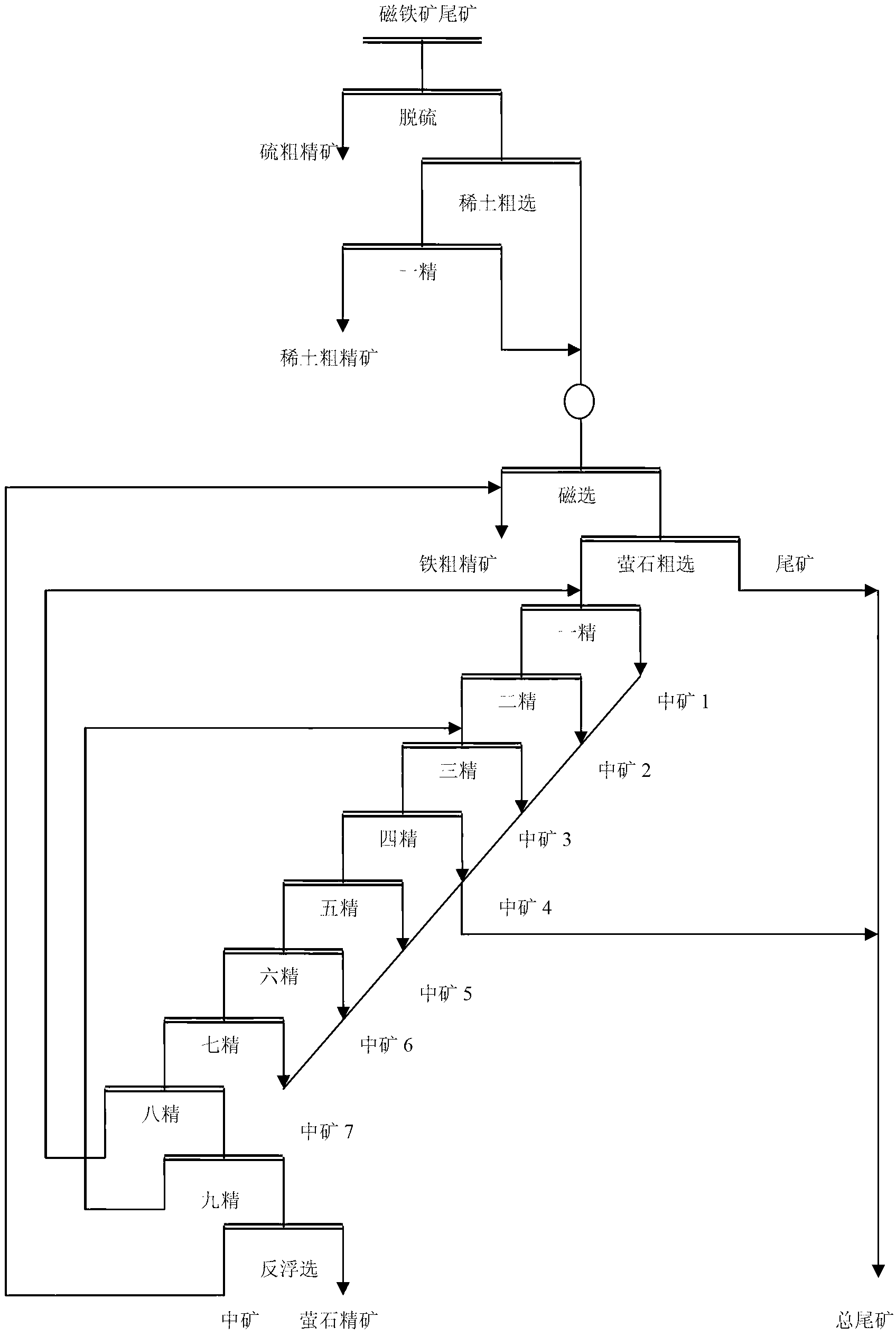

Mineral processing technology for recycling fluorite from baotite, magnetite and tailing

The invention belongs to the technical field of mineral engineering and provides a mineral processing technology for recycling fluorite from baotite, magnetite and tailing. In the tailing, mineral particle size of the fluorite is thin, iron-bearing mineral, rare-earth mineral, gangue mineral and the fluorite mineral are closely symbiotic and floatability of minerals such as rear earth, barite, apatite, calcite and dolomite is close to the fluorite mineral, so that separation of the fluorite mineral is difficult. According to the mineral processing technology for recycling the fluorite from the baotite, the magnetite and the tailing, priority desulfuration, rear earth flotation, ore grinding, iron selection through magnetic separation, fluorite selection through direct flotation and a reverse flotation sorting technology are performed on the magnetite and the tailing to enable pyrite, the rare earth, the iron-bearing mineral and the fluorite to be picked out in sections, efficient, high selective, easy-to-operate inhibitor and collecting agent combination is utilized in sorting of fluorite which is mostly performed monomer separation, so that fine fluorite of high grade and high recovery rate is obtained, a purpose of synthetically recycling valuable minerals is achieved, and effective separation of the fluorite mineral and the gangue mineral is achieved.

Owner:包钢集团矿山研究院(有限责任公司)

High-temperature-resisting easy collapse molding sand and preparation method thereof

InactiveCN103495693AImprove breathabilityImprove liquidityFoundry mouldsFoundry coresWet bondingSodium metasilicate

High-temperature-resisting easy collapse molding sand is made from, by weight, 240-280 parts of quartz sand, 50-55 parts of lightweight calcium carbonate powder, 20-30 parts of hollow ceramic microspheres, 10-15 parts of hollow glass microspheres, 40-55 parts of aluminum silicate powder, 25-30 parts of titanium dioxide, 35-40 parts of fluorite nano-powder, 30-40 parts of gypsum whisker, 60-70 parts of expanded perlite, 10-15 parts of talcum powder, 2-4 parts of sodium metasilicate, 1-2 parts of glucose powder, 1-2 parts of urea, 1-2 parts of chlorinated paraffin, and a proper amount of water. The materials such as the hollow ceramic microspheres and the hollow glass microspheres are used, so that the molding sand is fine in breathability and fluidity; meanwhile, the lightweight calcium carbonate, the glucose, the urea and the like are used, so that the molding sand is fine in high temperature collapsibility, high dry strength of sand molds, high in wet bonding power, excellent in sticking resistance and applicable to various hardening manners; drying time after CO2 hardening is shortened, and reuse rate of used sand can be increased significantly.

Owner:HEFEI CITY TENVER PRECISION CASTING

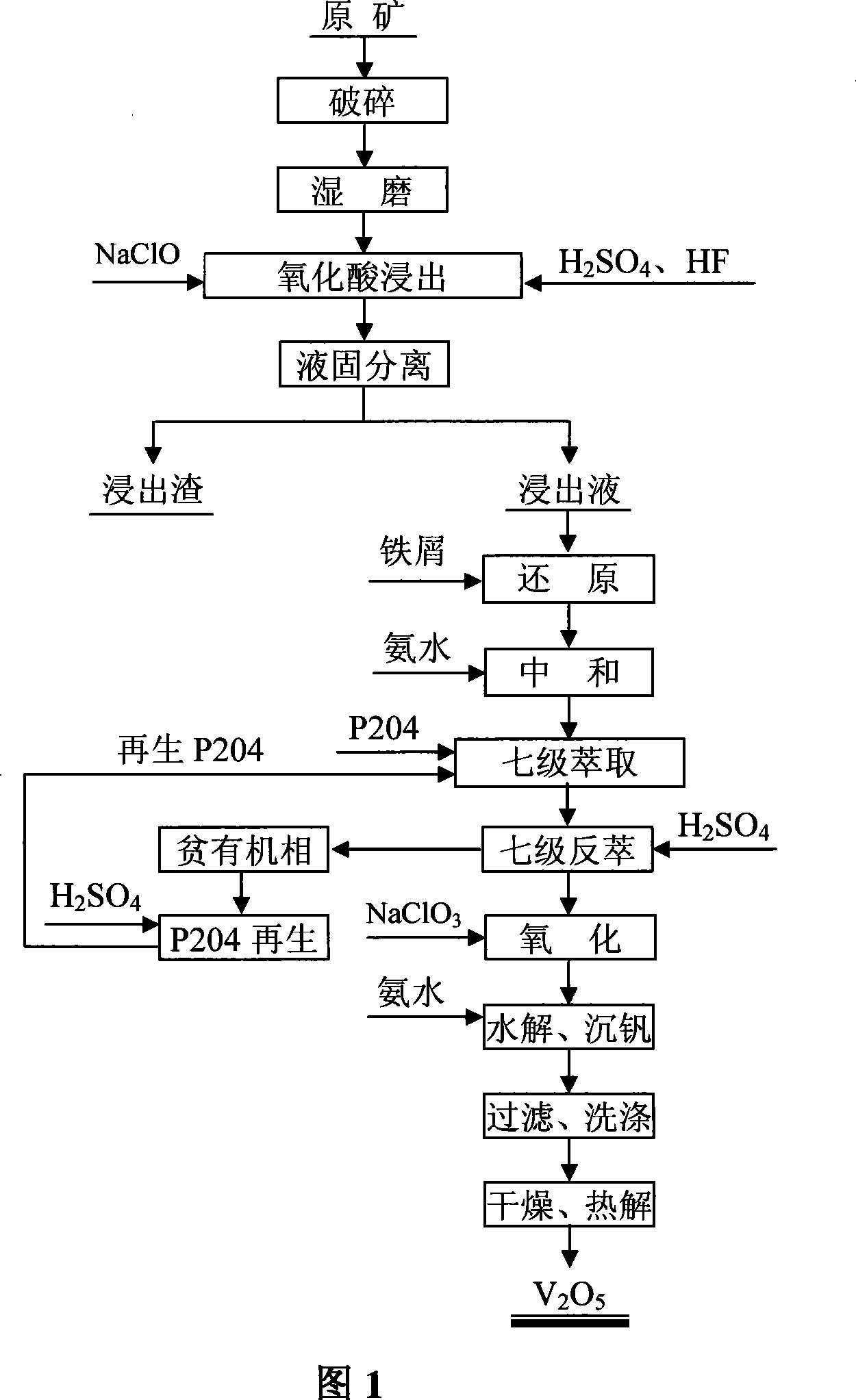

Method for coproducing vanadium pentoxide from vanadium-containing stone coal ore and fluorite

InactiveCN101239740ASolve the problem of leaching and extracting vanadiumSimplification of smelting processVanadium oxidesSulfateChemical combination

The present invention provides a preparing method of vanadic oxide by coal mine containing vanadium and fluorite. The invention belongs to vanadic hydrometallurgy technology, especially a melting technique of directly lixiviating and separating vanadium from coal mine containing vanadium. Acylvanadium sulfate is prepared by mixing coal mine containing vanadium, fluorite mine and sulphuric acid, then pumped in the reactive tank, further chemical combination and dissolving, acylvanadium sulfate enters in solution, qualified vanadic oxide is prepared. The invention adopts whole wet to process coal mine containing vanadium,recovering and utilizing vanadium, the method has a simple process, strength process, high metal recovery rate, easy to separate object metal, small consumption agent, integrated valuable metal and lower pollution.

Owner:KUNMING UNIV OF SCI & TECH

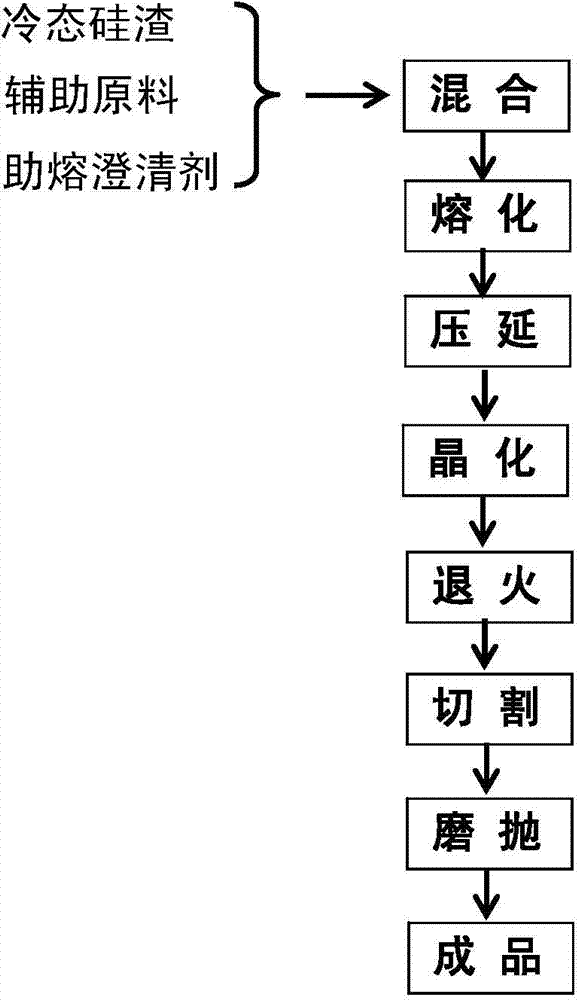

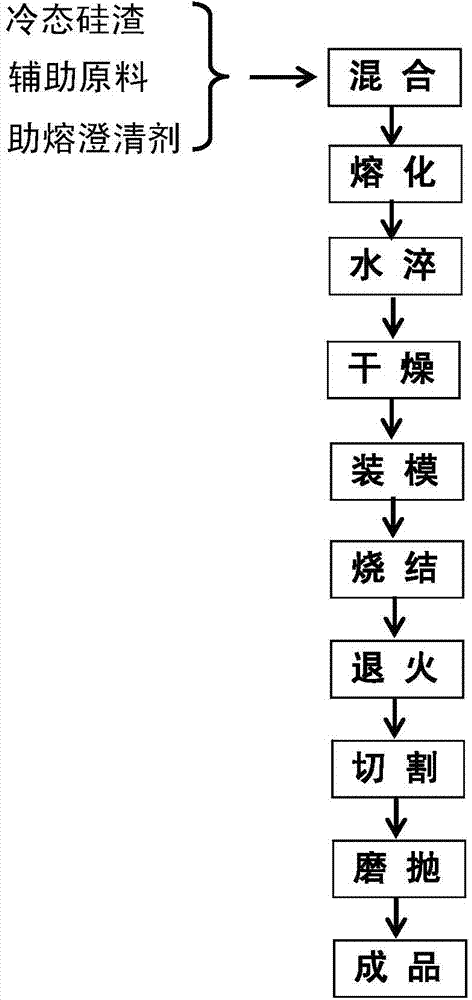

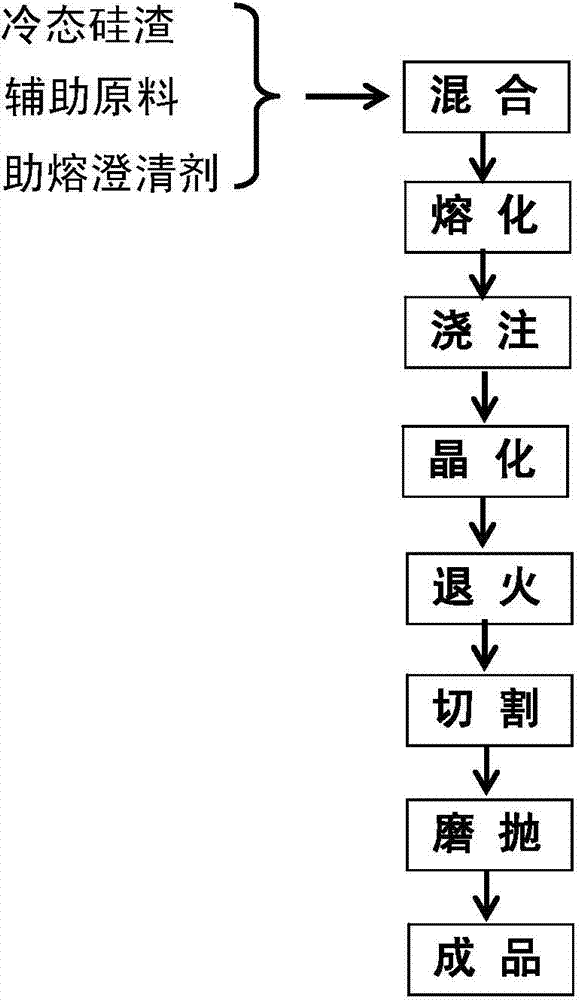

Silicon-slag microcrystalline glass and preparation method thereof

The invention relates to silicon-slag microcrystalline glass and a preparation method thereof. Silicon smelting waste slag is taken as a major raw material, and silicon dioxide or silica sand (SiO2), fluorite (CaF2), limestone or calcite (CaCO3), industrial sodium carbonate (Na2CO3), zinc oxide (ZnO) and potassium carbonate (K2CO3) are taken as auxiliary raw materials, wherein the dosage of the silicon smelting waste slag in the raw materials of the microcrystalline glass is 26.0-75.0wt%. The preparation method specifically comprises the following steps of: evenly mixing cold-state silicon slag with other auxiliary raw materials in a blender mixer to obtain a basic mixed batch, melting the basic mixed batch into qualified glass liquid in a melting furnace, and then performing calendering, casting or water quenching on the glass liquid to form a basic glass plate or granules; finally, subjecting the basic glass plate to crystallization heat treatment to obtain the microcrystalline glass. The density of the microcrystalline glass is 2.5-2.8 g / cm<3>, the rupture strength of the microcrystalline glass is 30.0-103.5 MPa, the compressive strength of the microcrystalline glass is 70.0-903.0 MPa, the Moh's hardness of the microcrystalline glass is 5-8 and the abrasive resistance of the microcrystalline glass is 0.063-0.15 g / cm<2>; the silicon-slag microcrystalline glass can be widely applied to the fields such as chemical engineering, metallurgy, architectural ornament, petroleum, mine and machinery.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Fluorite slag-containing aerated concrete block

The invention discloses a fluorite slag-containing aerated concrete block. The fluorite slag-containing aerated concrete block is prepared from the following raw materials by the conventional process for preparing the aerated concreted block: 25 to 30 weight parts of coal ash, 5 to 10 weight parts of cement, 10 to 15 weight parts of quick lime, 5 to 10 weight parts of modified nano powder, 5 to 10 weight parts of volcanic rock powder, 3 to 5 weight parts of gypsum, 0.05 to 0.1 weight part of aluminum powder, 0.02 to 0.08 weight part of peregal, 0.03 to 0.08 weight part of oxyparaffin soap, 0.3 to 0.5 weight part of soda ash, 0.5 to 0.8 weight part of bentonite, 0.3 to 0.5 weight part of zinc stearate, 0.01 to 0.03 weight part of aluminum hydroxide, 0.05 to 0.1 weight part of sodium hexametaphosphate and an appropriate amount of water. Nano mineral powder is added, so that the volume weight of the brick, and the energy consumption are reduced; the aerated brick is high in thermal insulation performance and sound insulation performance; compared with the conventional aerated concrete block, the fluorite slag-containing aerated concrete block has the advantages that the thermal insulation performance and the sound insulation performance are improved obviously; the raw materials are mixed according to an optimized formula; and the intensity and the freezing resistance of the brick are improved obviously.

Owner:沛县铸本混凝土有限公司

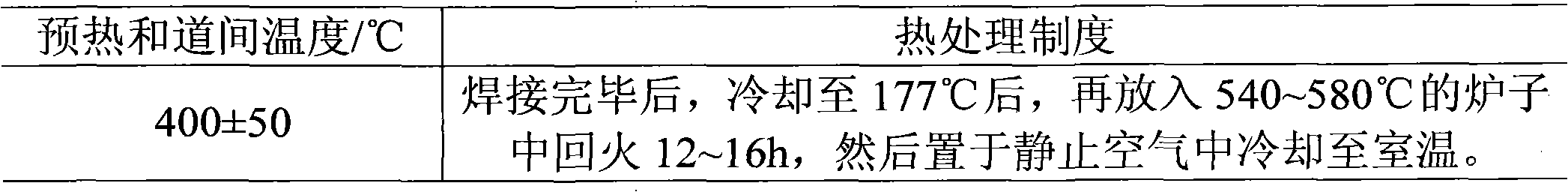

Surfacing electrode for repairing hot forged mould

InactiveCN101898284AExcellent welding performanceImprove yieldWelding/cutting media/materialsSoldering mediaSolid componentSlag

The invention discloses a surfacing electrode for repairing a hot forged mould, which uses a low-carbon steel H08A core wire conforming to the GB / T3429 requirement. The solid component quality content of coating is as follows: 30-40% of marble, 12-20% of fluorite, 1.5-3% of zircon sand, 0-2% of soda ash, 2-5% of silicon epitaxy material, 1-3% of titanium white, 0-3% of flogopite, 1-2% of rare earth fluoride, 3-7% of manganese metal, 2-5% of ferrosilicon, 4-6% of ferrotitanium, 4-8% of chromium metal, 4-8% of ferromolybdenum, 6-12% of metallic nickel and 1-2% of aluminium magnesium alloy. The invention has favorable welding rod performance, smooth welding rod surface, high yield and stable eccentricity; electric arc is easy to ignite and is stable to burn; coating is even to melt, a welding line is attractive in shape, and slag is easy to clean; and a deposition metal weld metal buildup has moderate welding state hardness which reaches the requirements of the hot forged mould, thus improving the service life cycle of the hot forged mould.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com