Patents

Literature

310 results about "Alumina zirconia" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Short fiber-particle synergetically-reinforced copper-based composite material and preparation method thereof

The invention relates to a copper-based composite material, and particularly relates to a short fiber-particle synergetically-reinforced copper-based composite material which is prepared through powder metallurgy. Short fibers and particles are used as reinforced phases, the content of the short fiber is 0.1-0.1 wt%, and the content of reinforcement particles is 0.1-10 wt%. The short fibers can be carbon nanotubes, carbon nanofibers, ceramic short fibers, and the like, and the particles used as reinforced phases can be aluminum oxide, zirconium oxide, magnesium oxide, titanium dioxide, silicon carbide, titanium carbide, tungsten carbide, silicon nitride, aluminum nitride, titanium nitride, titanium diboride, Ti3SiC2, and the like. The composite material is prepared through the steps of mixing, forming, sintering and processing, and the room temperature and the high temperature strength of the composite material can be increased by more than 3 times in comparison with those of pure copper; the electrical conductivity of the composite material can reach more than 80% of that of pure copper; the thermal conductivity of the composite material can reach more than 70% of that of pure copper; the coefficient of friction of the composite material can be reduced to be below 70% of that of pure copper; and the wear rate of the composite material can be reduced to be below 50% of that of pure copper.

Owner:UNIV OF SCI & TECH BEIJING

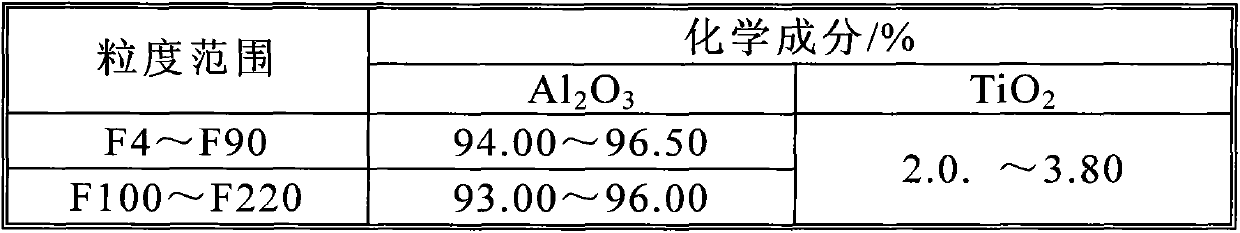

Aluminum and zirconium oxynitride abrasive grains

Corundum-zirconia abrasive grains containing more than 50 wt % of an alumina-zirconia eutectic mixture. The grains contain 0.3 to 3% nitrogen, and more than 75% of the zirconia crystals are cubic in shape. The abrasive grains are of particular use for making grinding wheels, abrasive fabrics and papers, polishing compounds and sprayed abrasives.

Owner:PEM ABRASIFS REFRACTAIRES

Metal oxide nanorod arrays on monolithic substrates

ActiveUS20140256534A1Improve thermal stabilitySulfur poisoningMolecular sieve catalystsLayered productsCerium(IV) oxideMetal particle

A metal oxide nanorod array structure according to embodiments disclosed herein includes a monolithic substrate having a surface and multiple channels, an interface layer bonded to the surface of the substrate, and a metal oxide nanorod array coupled to the substrate surface via the interface layer. The metal oxide can include ceria, zinc oxide, tin oxide, alumina, zirconia, cobalt oxide, and gallium oxide. The substrate can include a glass substrate, a plastic substrate, a silicon substrate, a ceramic monolith, and a stainless steel monolith. The ceramic can include cordierite, alumina, tin oxide, and titania. The nanorod array structure can include a perovskite shell, such as a lanthanum-based transition metal oxide, or a metal oxide shell, such as ceria, zinc oxide, tin oxide, alumina, zirconia, cobalt oxide, and gallium oxide, or a coating of metal particles, such as platinum, gold, palladium, rhodium, and ruthenium, over each metal oxide nanorod. Structures can be bonded to the surface of a substrate and resist erosion if exposed to high velocity flow rates.

Owner:UNIV OF CONNECTICUT

Metal Oxide Nanoporous Material, Coating Composition to Obtain the Same, and Methods of Manufacturing Them

ActiveUS20070215009A1Improve adhesionImprove heat resistanceInternal combustion piston enginesAlkali metal silicate coatingsAlkali metal oxideRare earth

A metal oxide nanoporous material comprises two or more kinds of first metal oxides selected from the group consisting of alumina, zirconia, titania, iron oxide, rare-earth oxides, alkali metal oxides and alkaline-earth metal oxides. The metal oxide nanoporous material has nanopores, each with a diameter of 10 nm or smaller, in which the metal oxides are dispersed homogeneously in the wall forming the nanopores.

Owner:TOYOTA CENT RES & DEV LAB INC

Diamond/cubic boron nitride saw blade for cutting metal and fabricating method therefor

ActiveCN1669708ANo harmHuman and Environmental HazardsMetal sawing toolsSawing tools dressing arrangementsBoron carbideBoron nitride

This invention relates to a saw bit belonging to mechanical working field, which comprises metal base being alloy steel or carbon steel, with Phi8-Phi10mm radiating holes equispaced on its surface; Carcass including alumina, zircite, quartz, tungsten carbide, zirconium diboride, molybdenum disilicide; common abradant including brown fused alumina, carbofrax, green silicon carbide, cubic carbofrax, boron carbide; superhard abradant including diamond and cubic boron nitride. The produce process includes mixing carcass flour, working layered material batching-mixing process, welding layered material batching-mixing process, koldflo, thermal pressing-sintering formation, arc milling, welding, dressing and making edge. The invention has improved working efficiency, lowered product cost, and is suitable for cutting metal tube, plate such as this materials.

Owner:SF DIAMOND CO LTD

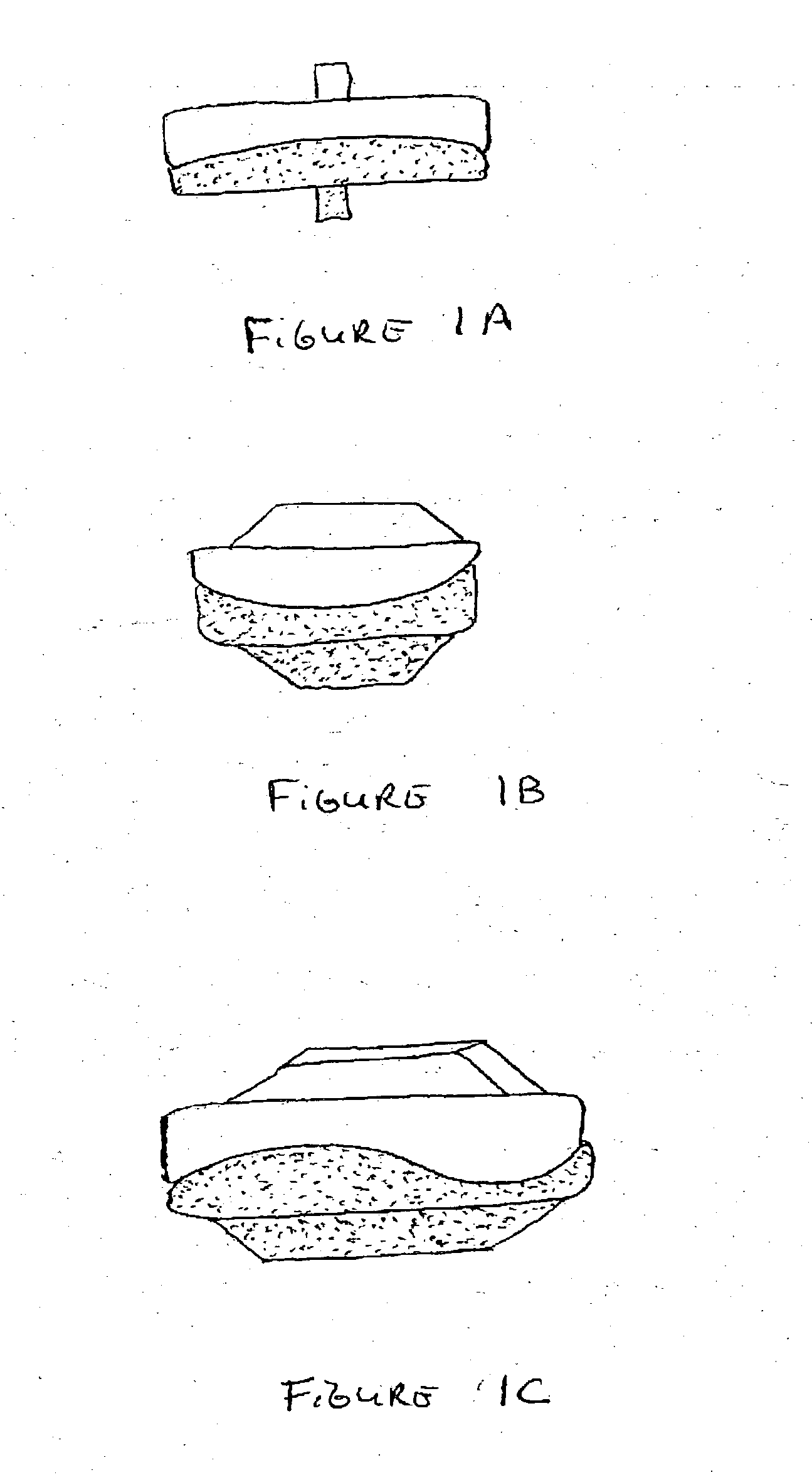

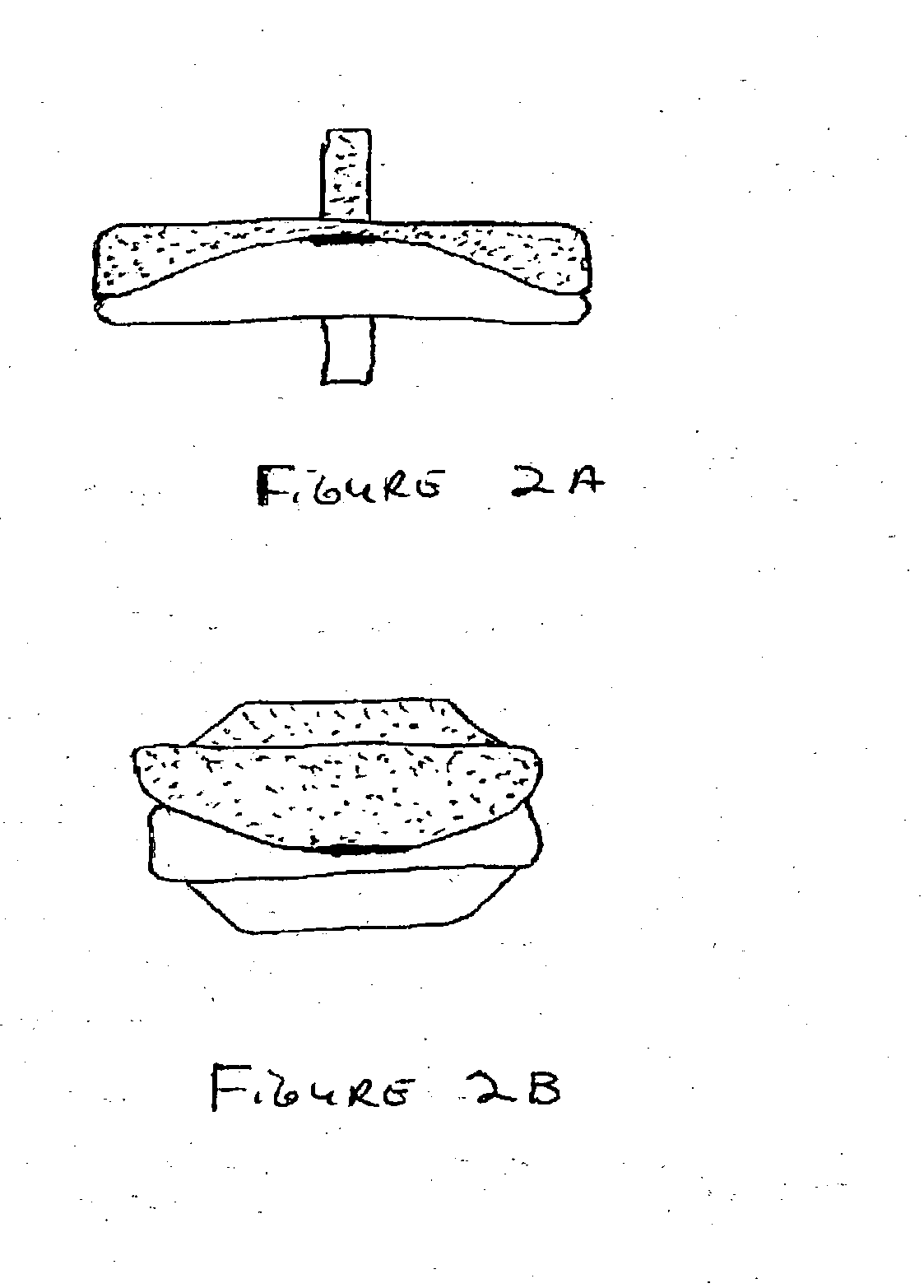

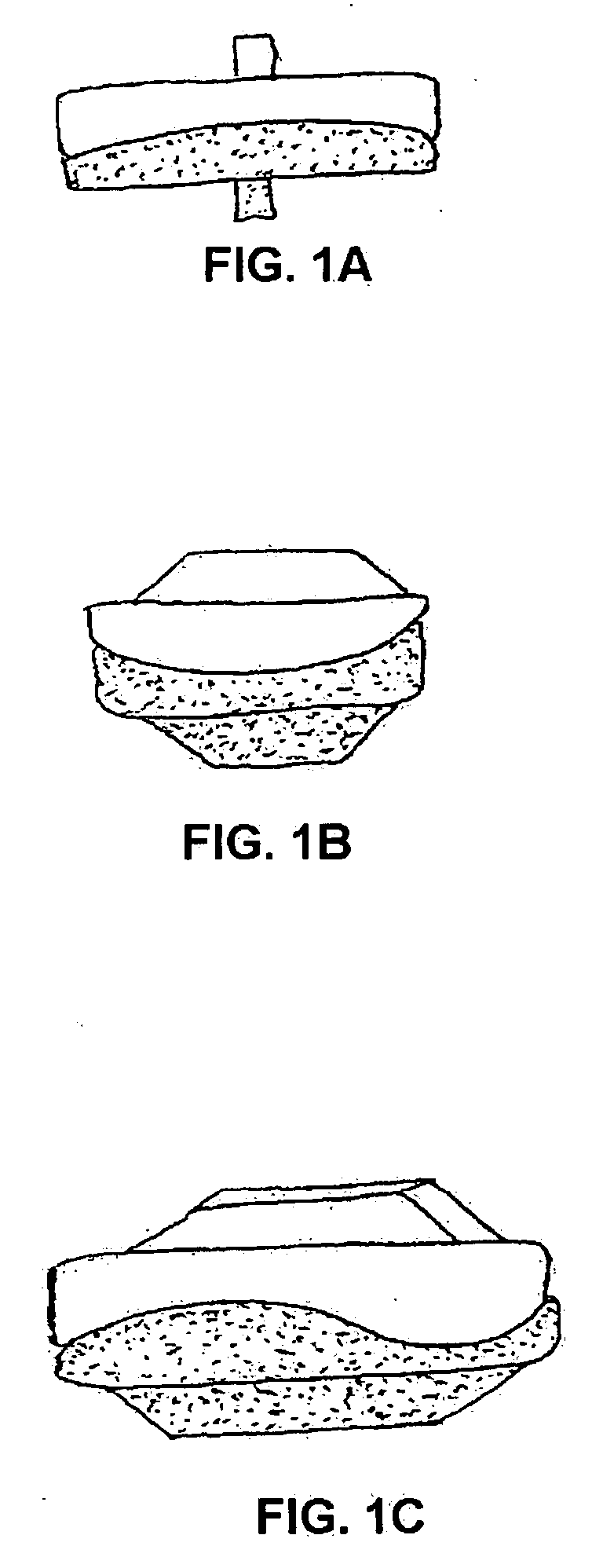

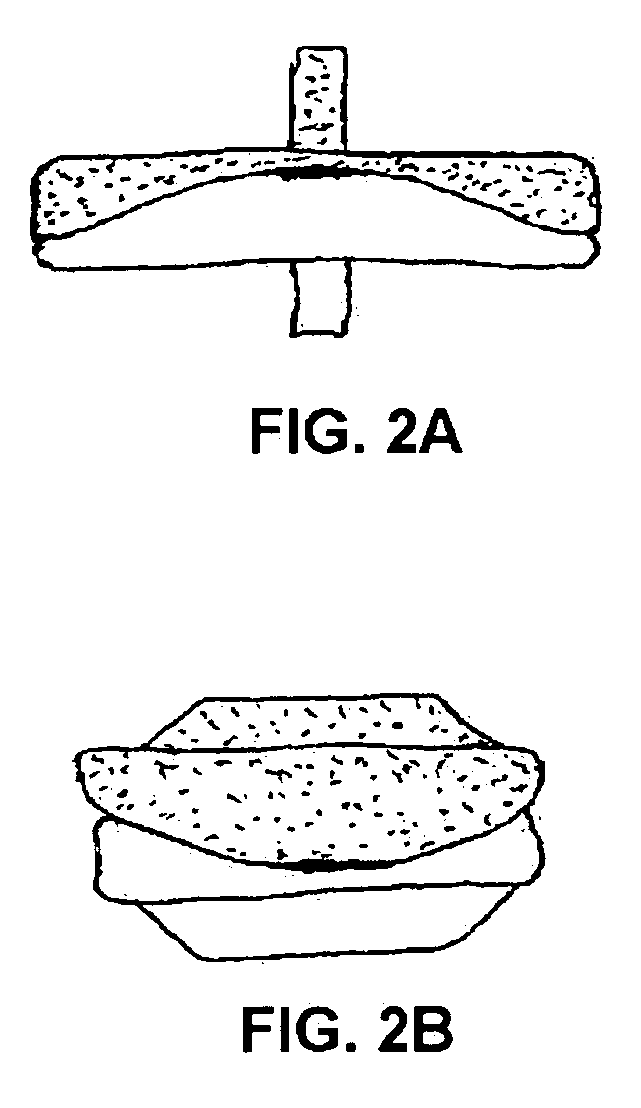

Spacerless artificial disc replacements

InactiveUS20080027548A9More wear-resistantMore flexiblyJoint implantsSpinal implantsAlloyAxial rotation

Spacerless artificial disc replacements (ADRs) are disclosed. One preferred embodiment includes two saddle-shaped components to facilitate more normal spinal flexion, extension, and lateral bending while limit axial rotation, thereby protecting the facet joints and the annulus fibrosus (AF). Either or both the superior and inferior components are made of a hard material such as chrome cobalt, titanium, or a ceramic including alumina, zirconia, or calcium phosphate. The articulating surfaces of the ADR are also preferably highly polished to reduce friction between the components. Metals, alloys or other materials with shape-memory characteristics may also prove beneficial.

Owner:HOWMEDICA OSTEONICS CORP

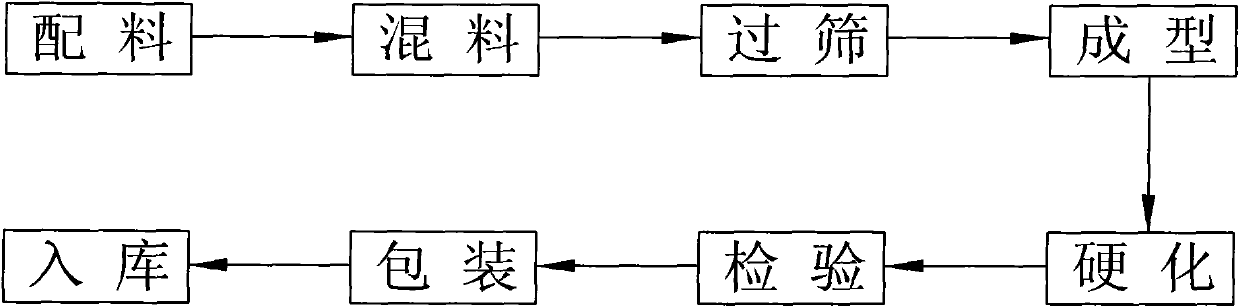

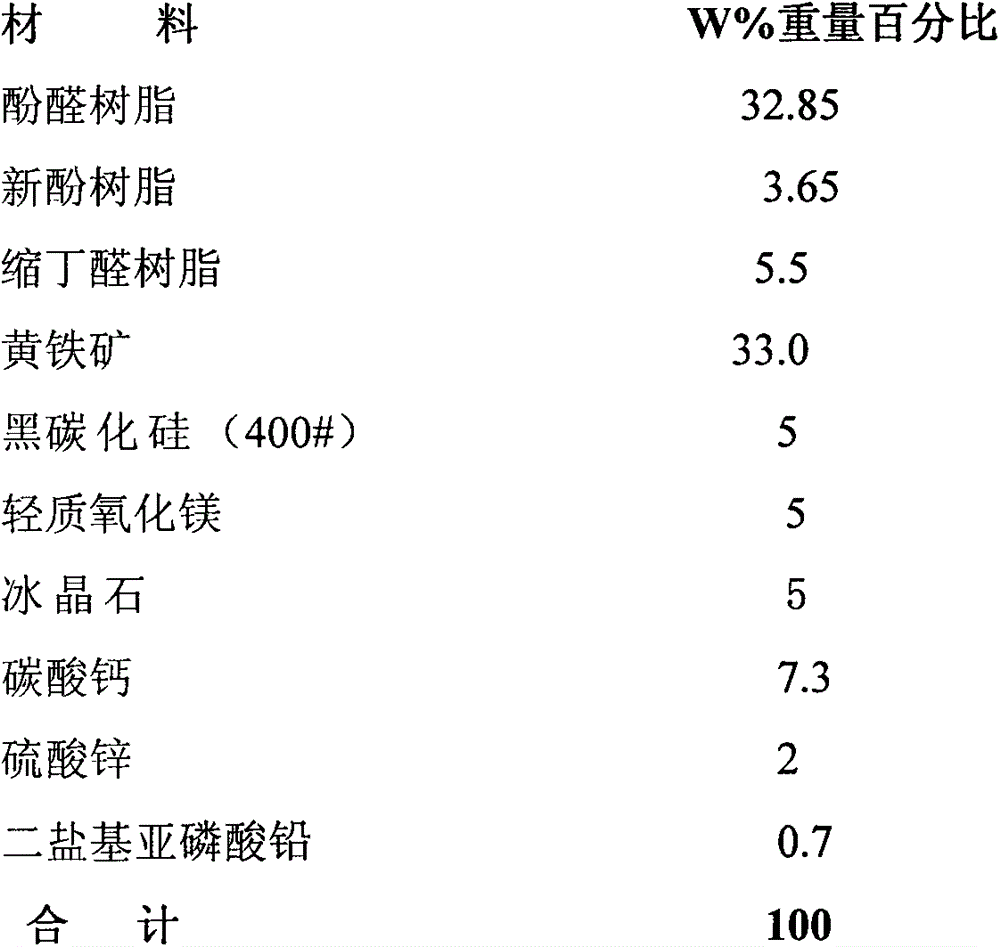

Resin rough grinding wheel and preparation method thereof

ActiveCN103465179AImprove grinding efficiencyIncrease roughnessAbrasion apparatusGrinding devicesPyriteAlumina zirconia

The invention relates to a resin rough grinding wheel and a preparation method thereof. The resin rough grinding wheel comprises a grinding body and reinforcing meshes, wherein the reinforcing meshes are arranged inside the grinding body to enhance the revolving strength of the grinding body. The grinding body is composed of 115-150 parts of grinding materials, 5-15 parts of liquid phenolic resin, 25-45 parts of phenolic resin powder and 15-35 parts of filling, wherein the grinding materials comprise 30-40 parts of microcrystal corundum, 80-100 parts of fused alumina zirconia and 5-10 parts of garnets, the filling is composed of 9-21 parts of pyrite, 1-3 parts of cryolite, 1-3 parts of ferric oxide, 1-3 parts of quick lime and 3-5 parts of fluorite. The resin rough grinding wheel is prepared through the steps of preparation, mixing, sifting, shaping, hardening, testing, packaging and storing, has high strength, good abrasive resistance and self-sharpening performance, high grinding efficiency, good roughness and low workpiece burning possibility; meanwhile, the surface of the grinding wheel is not easy to block and has good breathability, good tenacity and high security performance.

Owner:NINGBO DAHUA GRINDING WHEEL

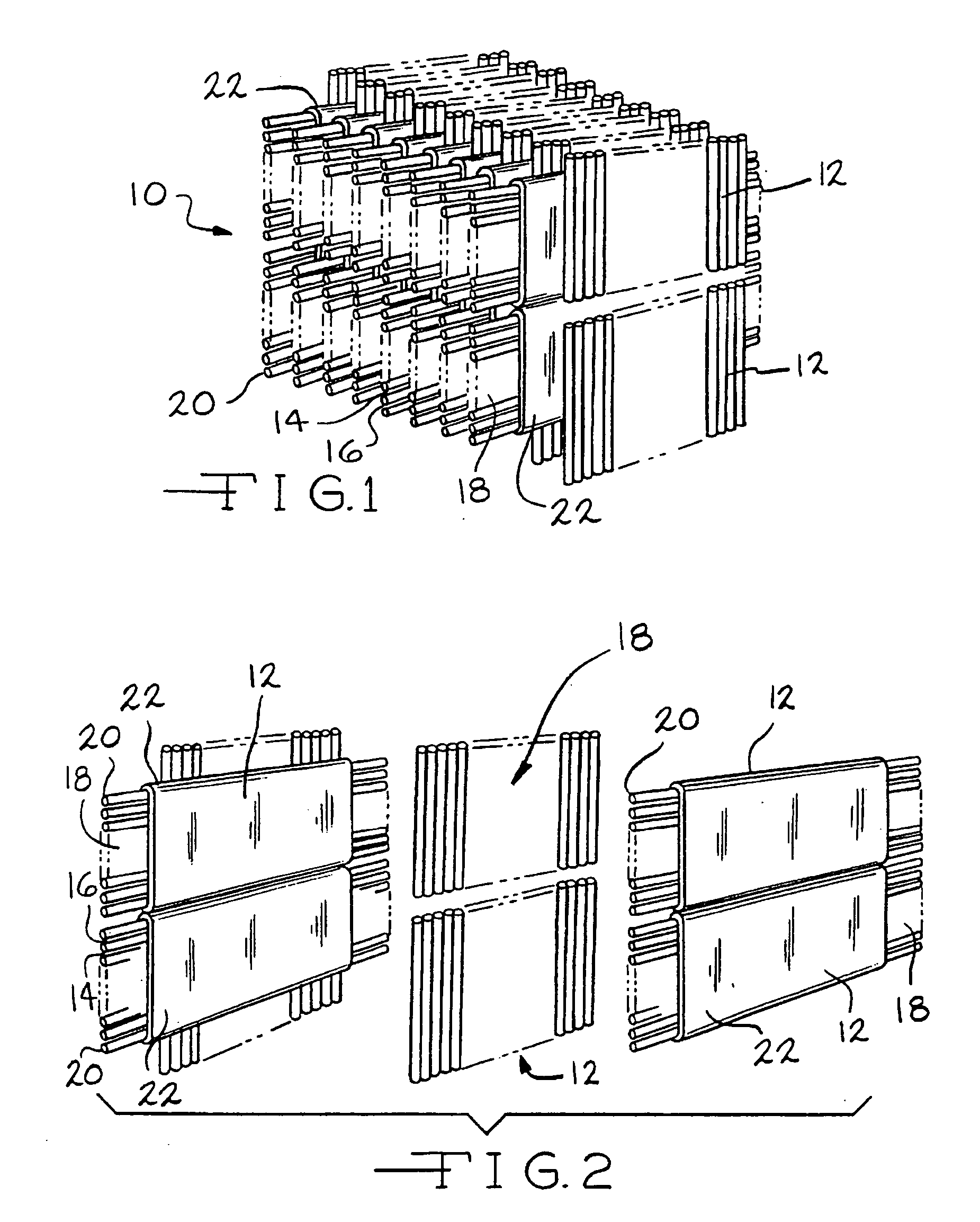

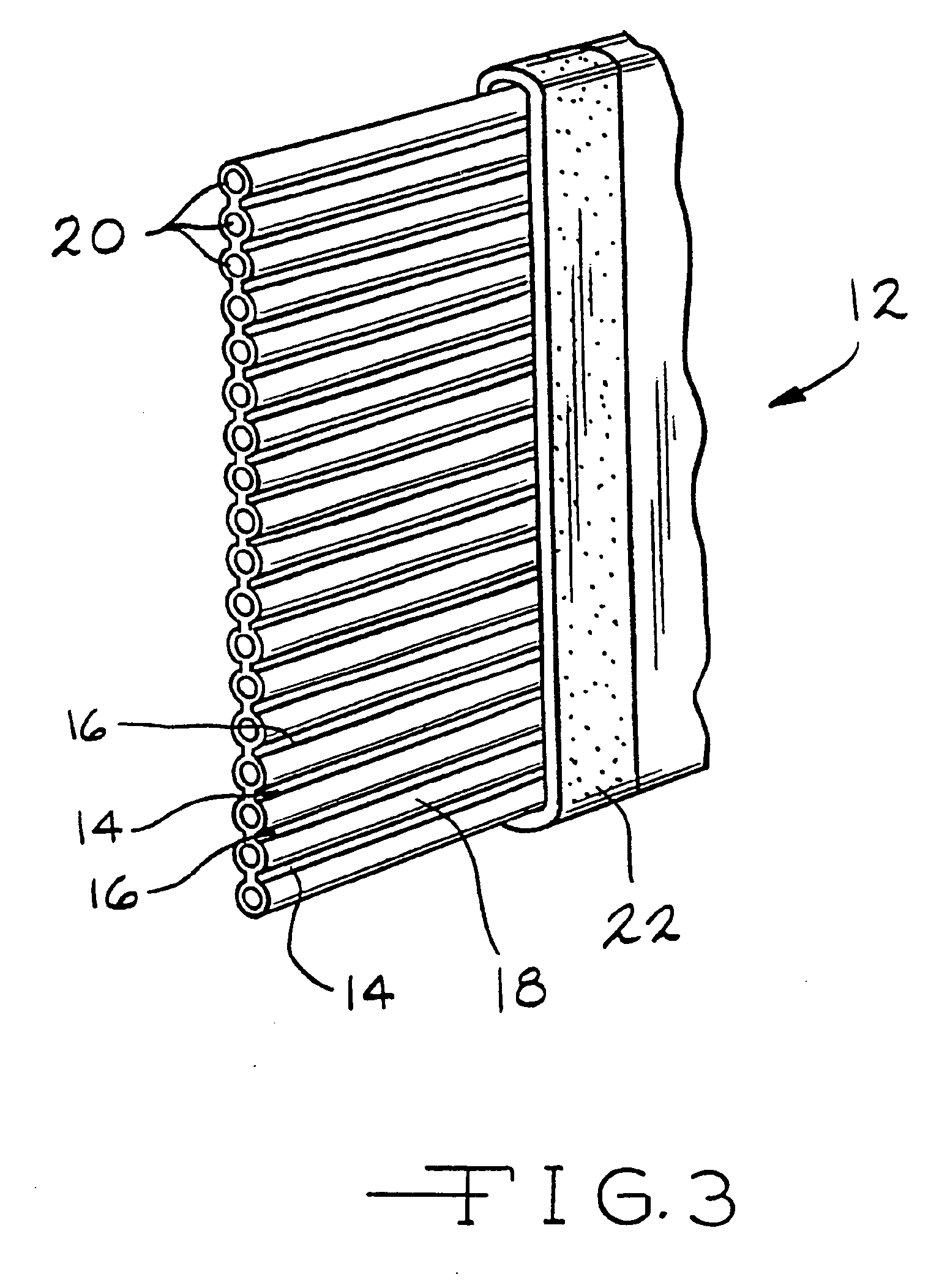

Layered composition and processes for preparing and using the composition

A layered composition which can be used in various processes has been developed. The composition comprises an inner core such as a cordierite core and an outer layer comprising a refractory inorganic oxide, a fibrous component and an inorganic binder. The refractory inorganic oxide layer can be alumina, zirconia, titania, etc. while the fibrous component can be titania fibers, silica fibers, carbon fibers, etc. The inorganic oxide binder can be alumina, silica, zirconia, etc. The layer can also contain catalytic metals such as gold and platinum plus other modifiers. The layered composition is prepared by coating the inner core with a slurry comprising the refractory inorganic oxide, fibrous component, an inorganic binder precursor and an organic binding agent such as polyvinyl alcohol. The composition can be used in various hydrocarbon conversion processes.

Owner:UOP LLC

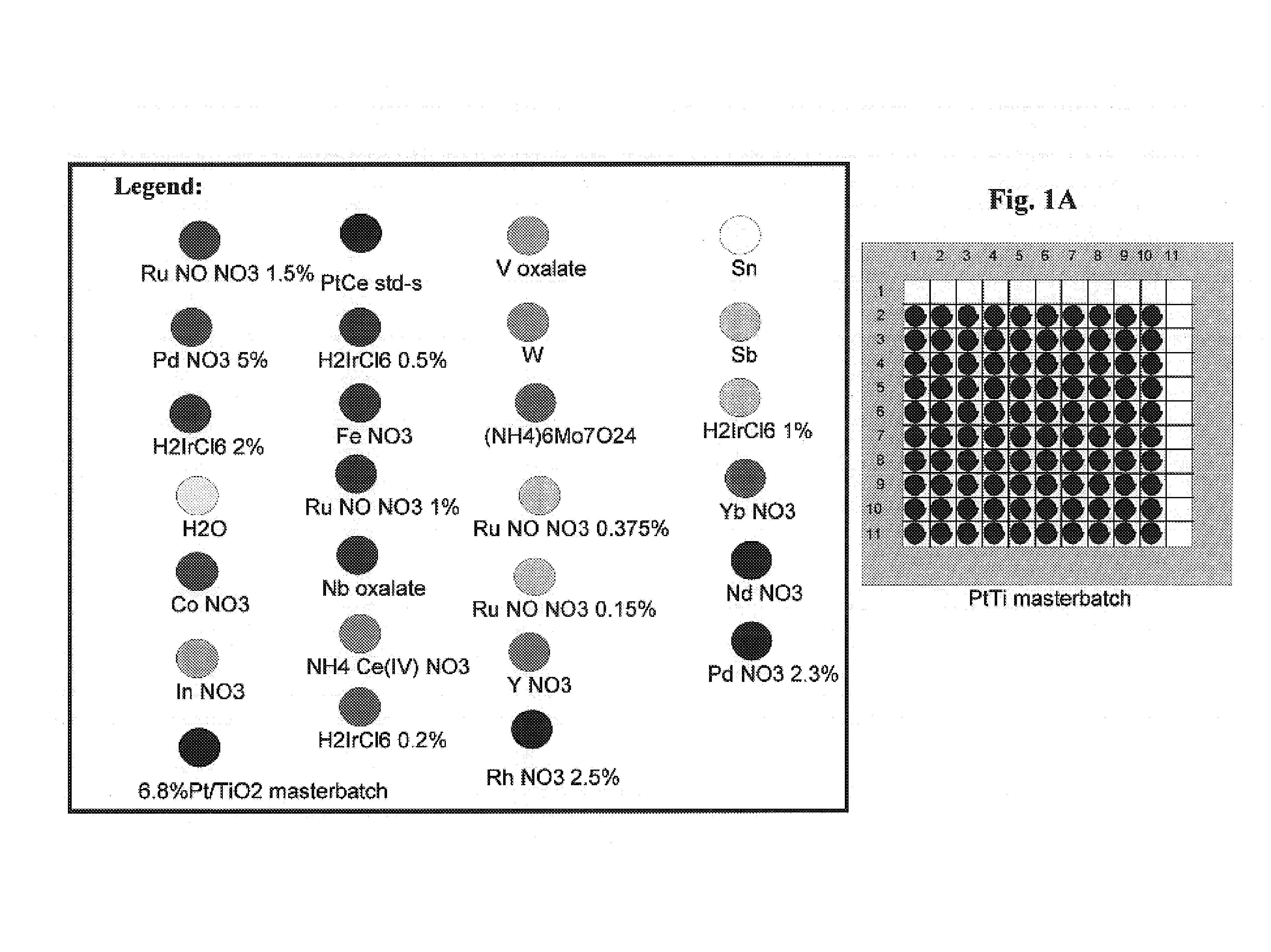

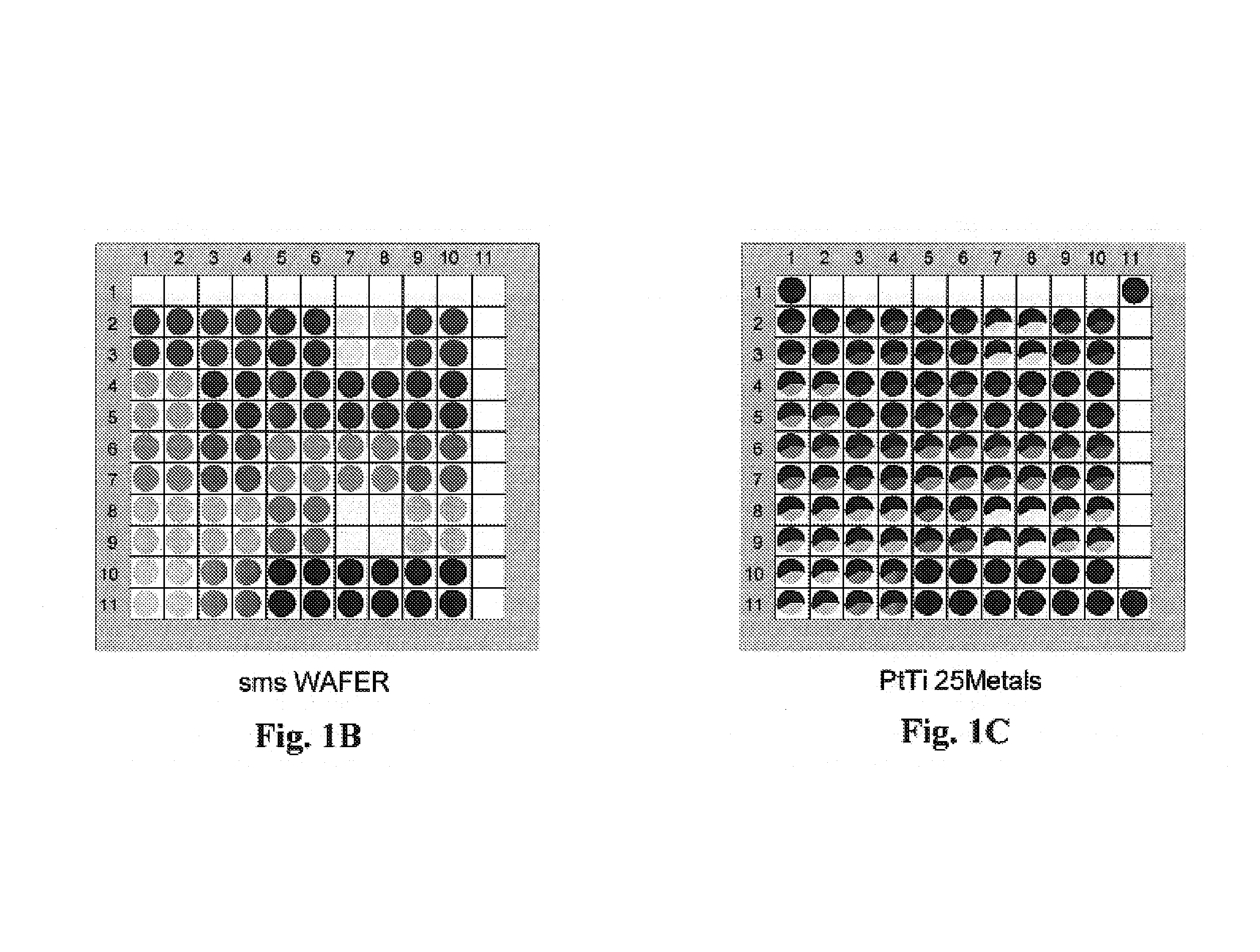

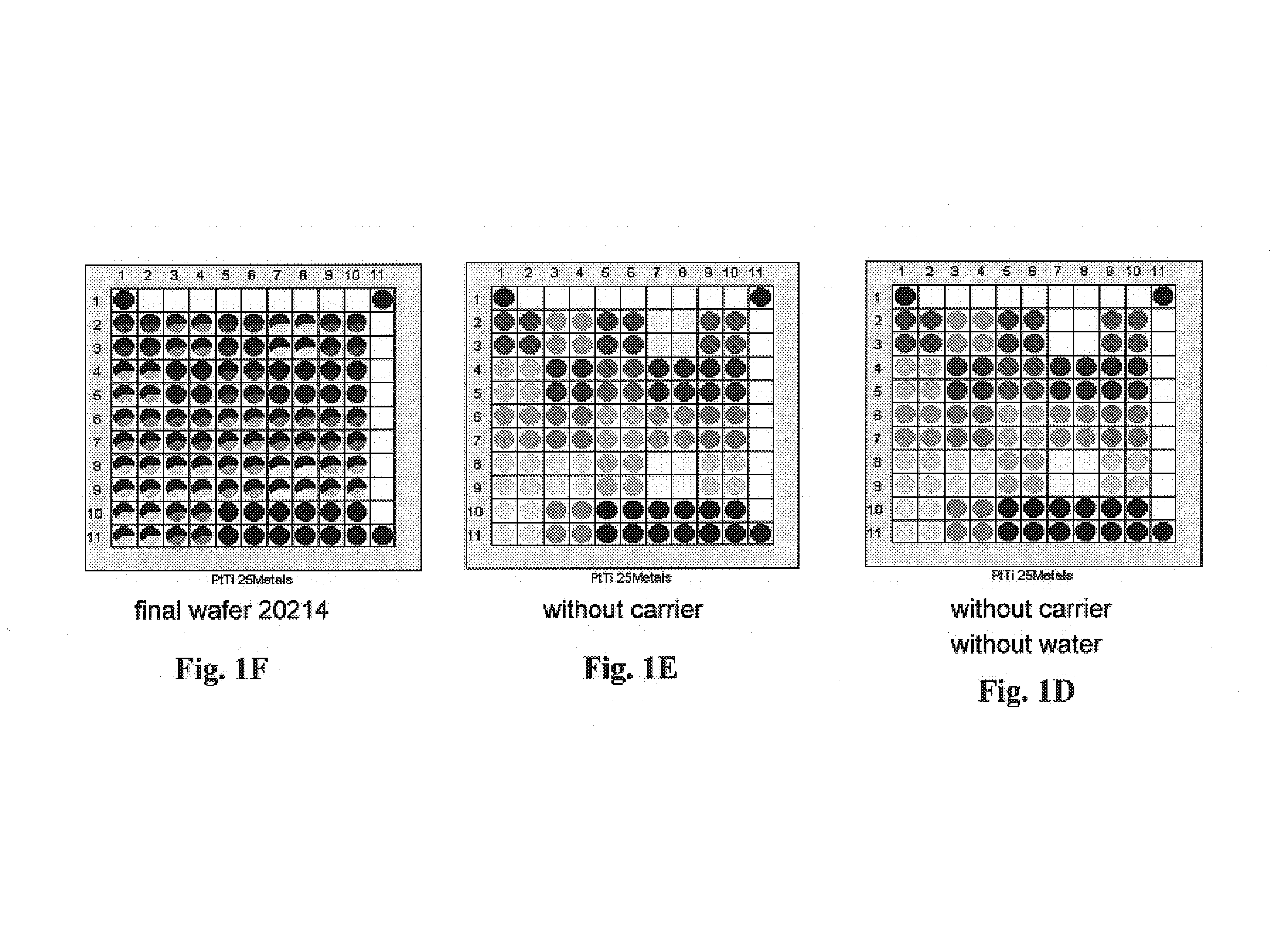

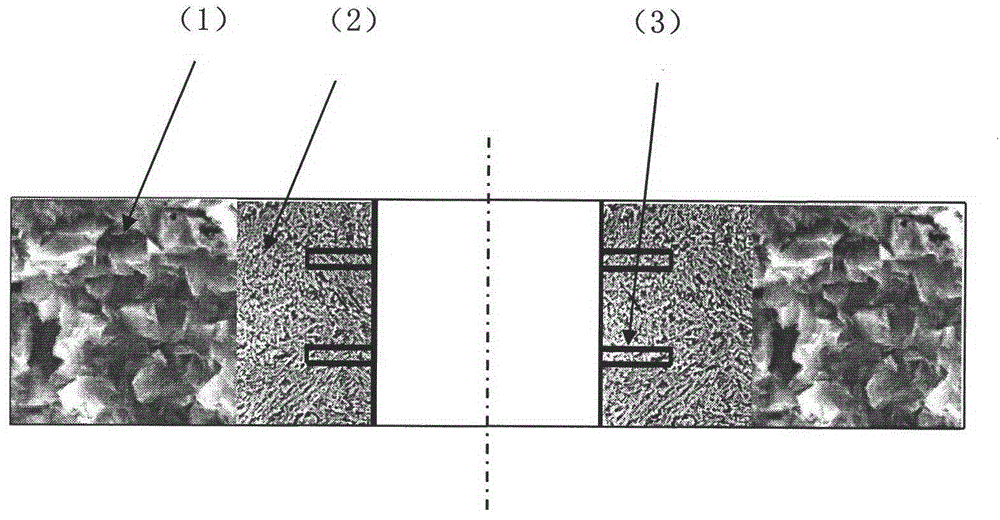

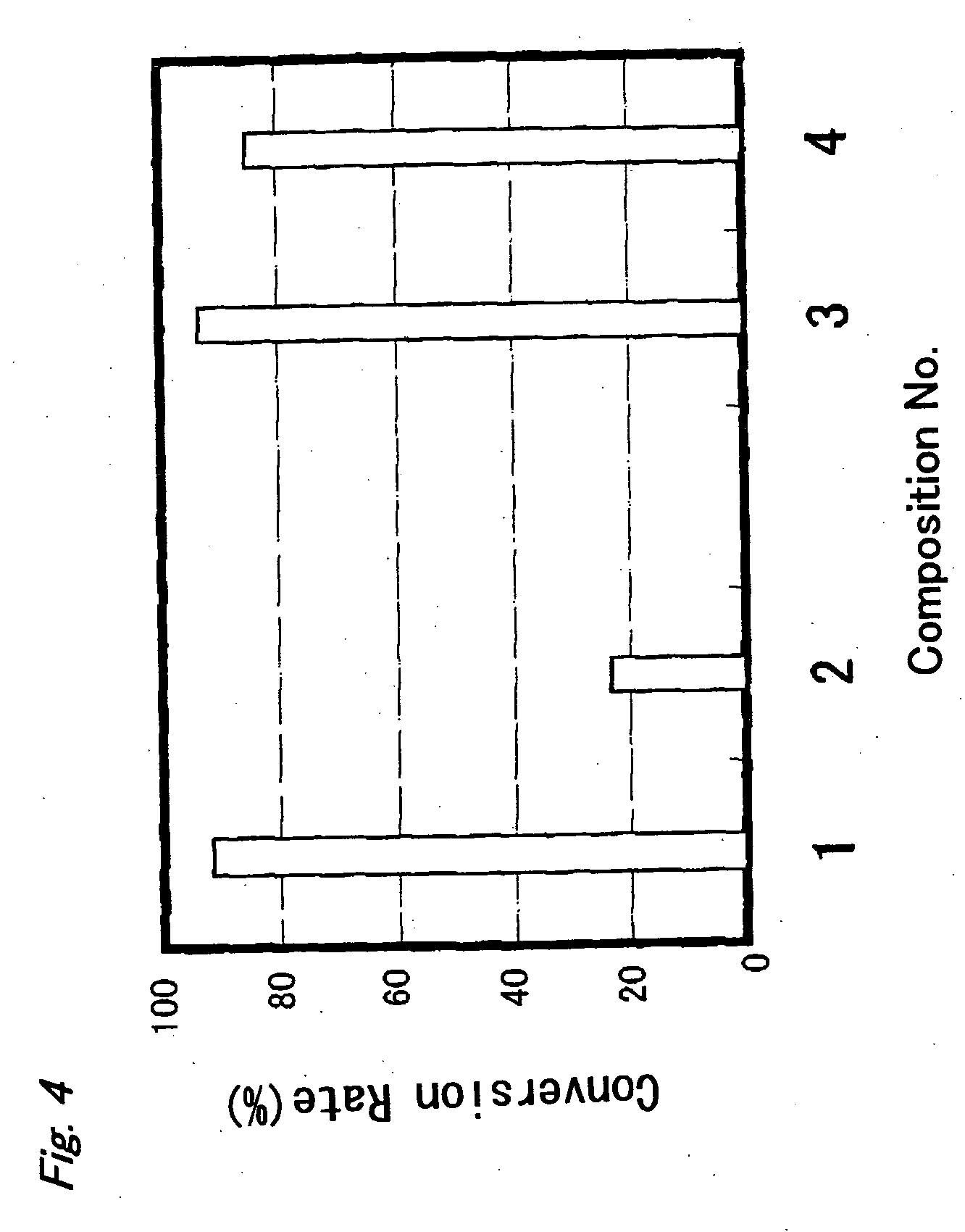

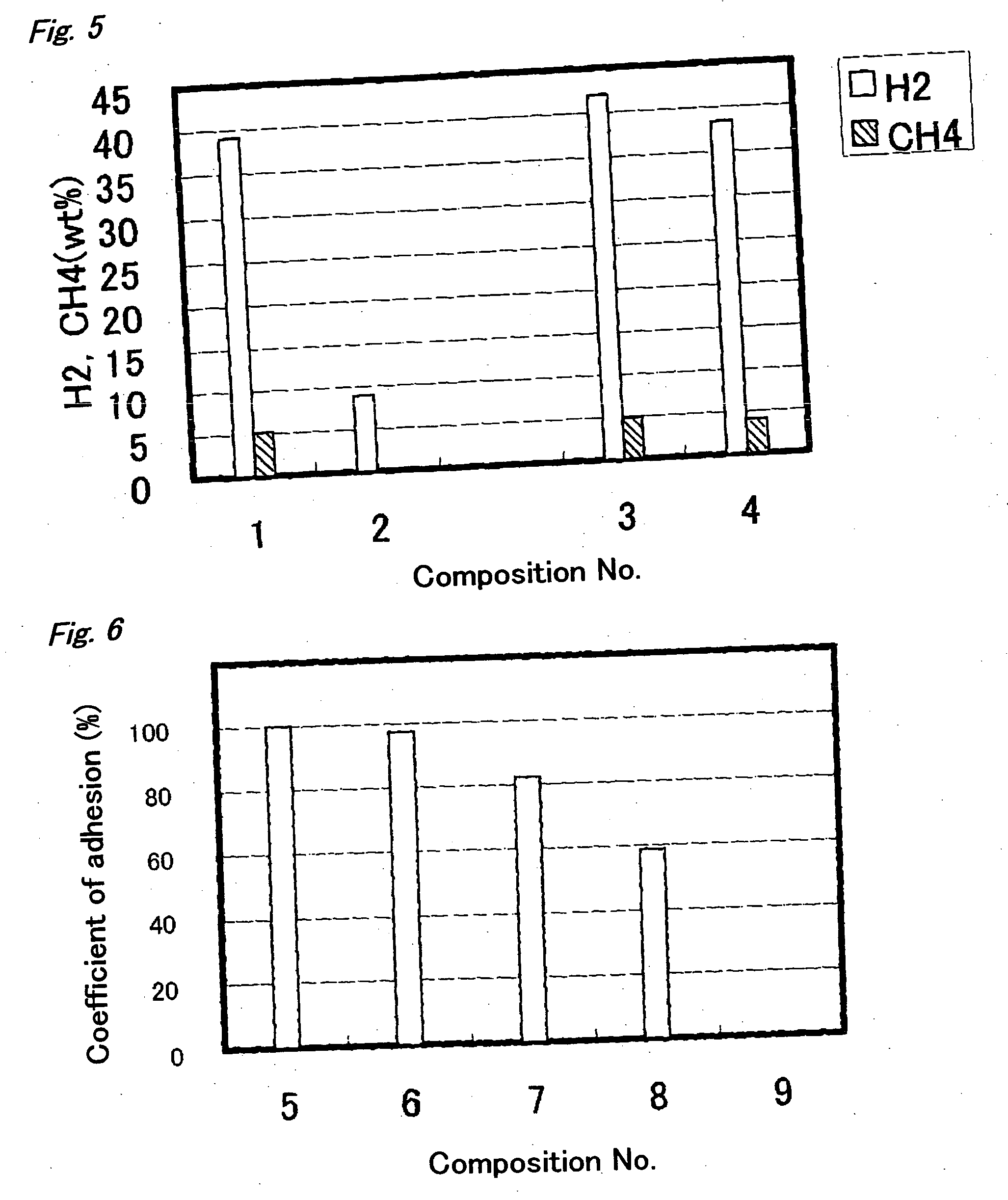

Platinum-ruthenium containing catalyst formulations for hydrogen generation

A method and catalysts for producing a hydrogen-rich syngas are disclosed. According to the method a CO-containing gas contacts a water gas shift (WGS) catalyst, optionally in the presence of water, preferably at a temperature of less than about 450° C. to produce a hydrogen-rich gas, such as a hydrogen-rich syngas. Also disclosed is a water gas shift catalyst formulated from:a) Pt, its oxides or mixtures thereof;b) Ru, its oxides or mixtures thereof; andc) at least one of Li, Na, K, Rb, Cs, Mg, Ca, Sr, Ba, Sc, Y, Ti, Zr, V, Mo, Mn, Fe, Co, Rh, Ir, Ge, Sn, Sb, La, Ce, Pr, Sm, and Eu. Another disclosed catalyst formulation comprises Pt, its oxides or mixtures thereof; Ru, its oxides or mixtures thereof; Co, its oxides or mixtures thereof; and at least one of Li, Na, K, Rb, Cs, Mg, Ca, Sr, Ba, Sc, Y, Ti, Zr, V, Mo, Mn, Fe, Rh, Ir, Ge, Sn, Sb, La, Ce, Pr, Sm, and Eu, their oxides and mixtures thereof. The WGS catalyst may be supported on a carrier, such as any one member or a combination of alumina, zirconia, titania, ceria, magnesia, lanthania, niobia, zeolite, perovskite, silica clay, yttria and iron oxide. Fuel processors containing such water gas shift catalysts are also disclosed.

Owner:FREESLATE +1

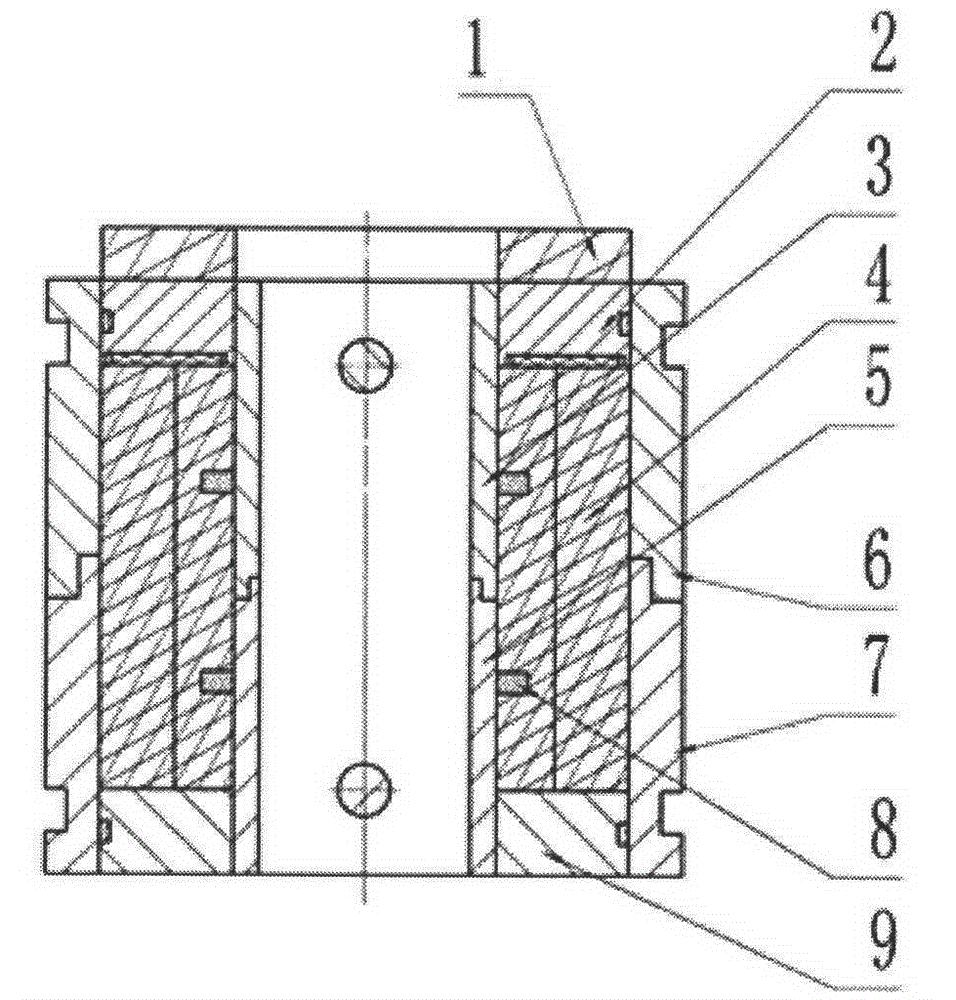

Large-standard high-speed resin heavy duty grinding wheel for grinding steel billet

ActiveCN104625978AHigh tensile and flexural strengthImprove the lubrication effectAbrasion apparatusGrinding devicesFiberMaximum diameter

The preparation method for the large-standard high-speed resin heavy duty grinding wheel for grinding a steel billet comprises the steps that a dedicated binding agent for a high-performance modified high polymer matrix phenolic resin grinding wheel is prepared by using phenolic resin, xylok resin, butyral resin, iron pyrite, cryolite, light magnesium oxide, barite, 400 # carborundum and calcium carbonate, dedicated formulas for a grinding layer and a core layer are separately designed by using grinding materials such as fused alumina zirconia, aluminium oxide sintered corundum, black silicon carbide, furfural, dibutyl ester, fibers and steel rings, and the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is prepared by adopting a dual-phase reinforced composite technology and structure. According to the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet, the linear velocity is equal or greater than 90 m / s to 120 m / s, the maximum diameter is 925 mm, the thickness is 125 mm, and the tensile and breaking strength and the grinding efficiency of the grinding wheel are greatly improved. When the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is under heavy duty, the adaptability of the condition of grinding range is wide, and the linear velocity is high. The grinding efficiency reaches a thickness of 1 cm at a time, the problems that an existing grinding wheel cannot adapt to a steel billet, and the heavy duty grinding of steel is difficult are solved well, and the increasing development requirements of the iron and steel industry are met.

Owner:江苏华东砂轮有限公司

Sealing materials and devices utilizing such materials

A solid oxide fuel cell device incorporates a sealing material resistant to hydrogen gas permeation at a sealing temperature in the intermediate temperature range of 600° C.-800° C., the seal having a CTE in the 100×10−7 / ° C. to 120×10−7 / ° C., wherein the sealing material comprises in weight %, of: (i) a 80 to 95 wt % of glass frit, the glass frit itself having a composition in mole percent of: SiO2 70-85%; Al2O3 0-5%; Na2O3 0-8%; K2O 10-25%; ZnO 0-10%; ZrO2 0-6%; MgO 0-7%; TiO2 0-2%; and (ii) and 5 wt % to 25 wt % of addition comprising at least one of: alumina, zirconia or leucite.

Owner:CORNING INC

Spacerless artificial disc replacements

InactiveUS20050267582A1More flexiblyPrevent rotationJoint implantsSpinal implantsSpinal columnAxial rotation

Spacerless artificial disc replacements (ADR) are disclosed. One preferred embodiment includes two saddle-shaped components to facilitate more normal spinal flexion, extension, and lateral bending while limit axial rotation, thereby protecting the facet joints and the annulus fibrosus (AF). Either or both of the superior and inferior components are made of a hard material such as chrome cobalt, titanium, or a ceramic including alumina, zirconia, or calcium phosphate. The articulating surfaces of the ADR are also preferably highly polished to reduce friction between the components. Metals, alloys or other materials with shape-memory characteristics may also prove beneficial.

Owner:HOWMEDICA OSTEONICS CORP

Skin radiance cosmetic compositions

A cosmetic skin care composition that can provide the consumer-desired properties of appearance of natural skin radiance, containing solid single-crystal flat platy particles having an Index of Refraction of about 1.8 to about 2.2, the composition having less than 20% Opacity, preferably less than 10% Opacity. The platy particles preferably include bismuth oxy-chloride, aluminum oxide, zirconium oxide, boron nitride, solid solutions and mixtures thereof. A method of imparting radiant skin appearance, especially in the facial area, by applying to the skin the inventive composition is also disclosed.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Surface-Coated Cutting Tool

InactiveUS20070298280A1Increase resistanceImprove toughnessPigmenting treatmentOther chemical processesAlumina zirconiaTitanium

The present invention is directed to a surface-coated cutting tool including a substrate and a coating layer formed on the substrate. The coating layer includes a first coating layer composed of titanium boronitride or titanium boron-oxynitride and a second coating layer formed from at least one selected from the group consisting of aluminum oxide, zirconium oxide, hafnium oxide and a solid solution mainly including two or more of these components. The first coating layer is located directly under the second coating layer, between the substrate and the second coating layer. The second coating layer has compressive stress at least in an area involved with cutting.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

Preparation method for alumina-zirconia ceramic fiber

The invention relates to a preparation method for alumina-zirconia ceramic fiber. The method comprises the following steps: utilizing aluminium isopropoxide, formic acid, zirconium acetate and / or additive to prepare spinnable colloidal sol precursor, adopting a centrifugal fiber forming technology to prepare gel fibre, and then calcining to obtain the alumina-zirconia ceramic fiber with the diameter of 1 to 8 micrometers. The colloidal sol prepared by the invention is stable in framework, cheap in used raw materials, mild in fiber forming condition and simple in preparation process. The calcined ceramic fiber is good in flexibility and low in heat conductivity coefficient, and can be used for high temperature thermal insulation material.

Owner:SHANDONG UNIV

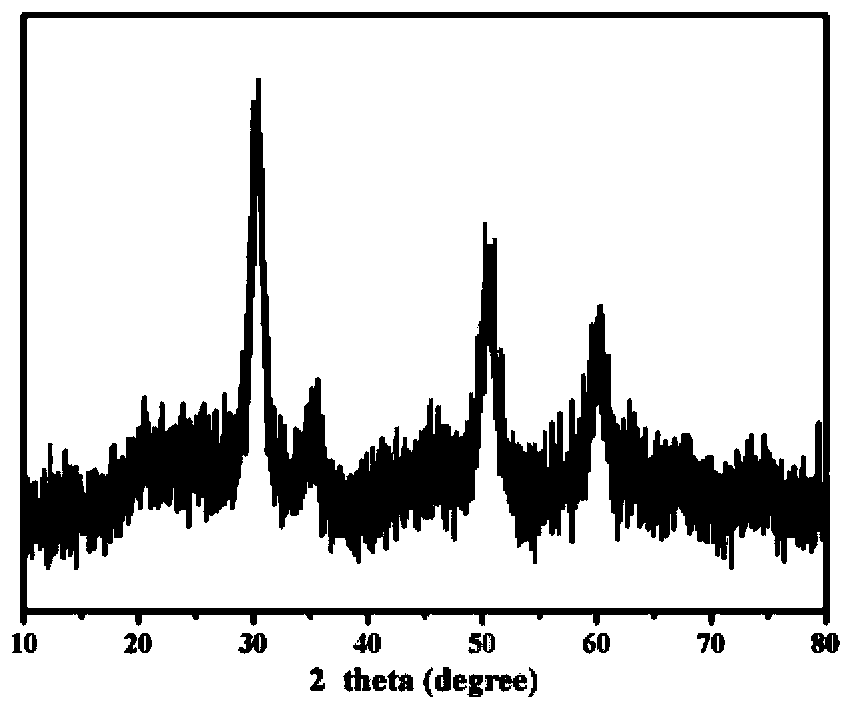

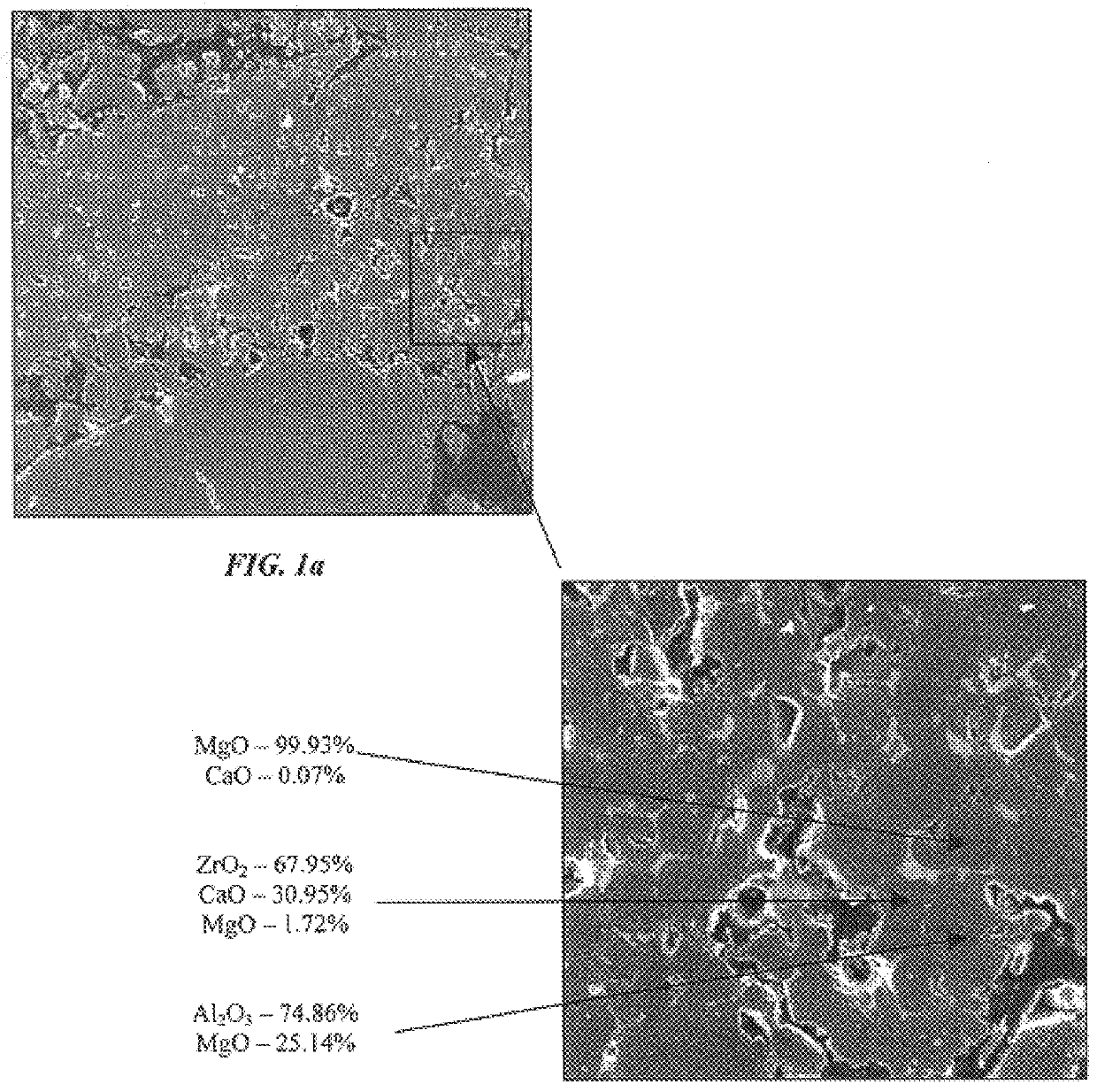

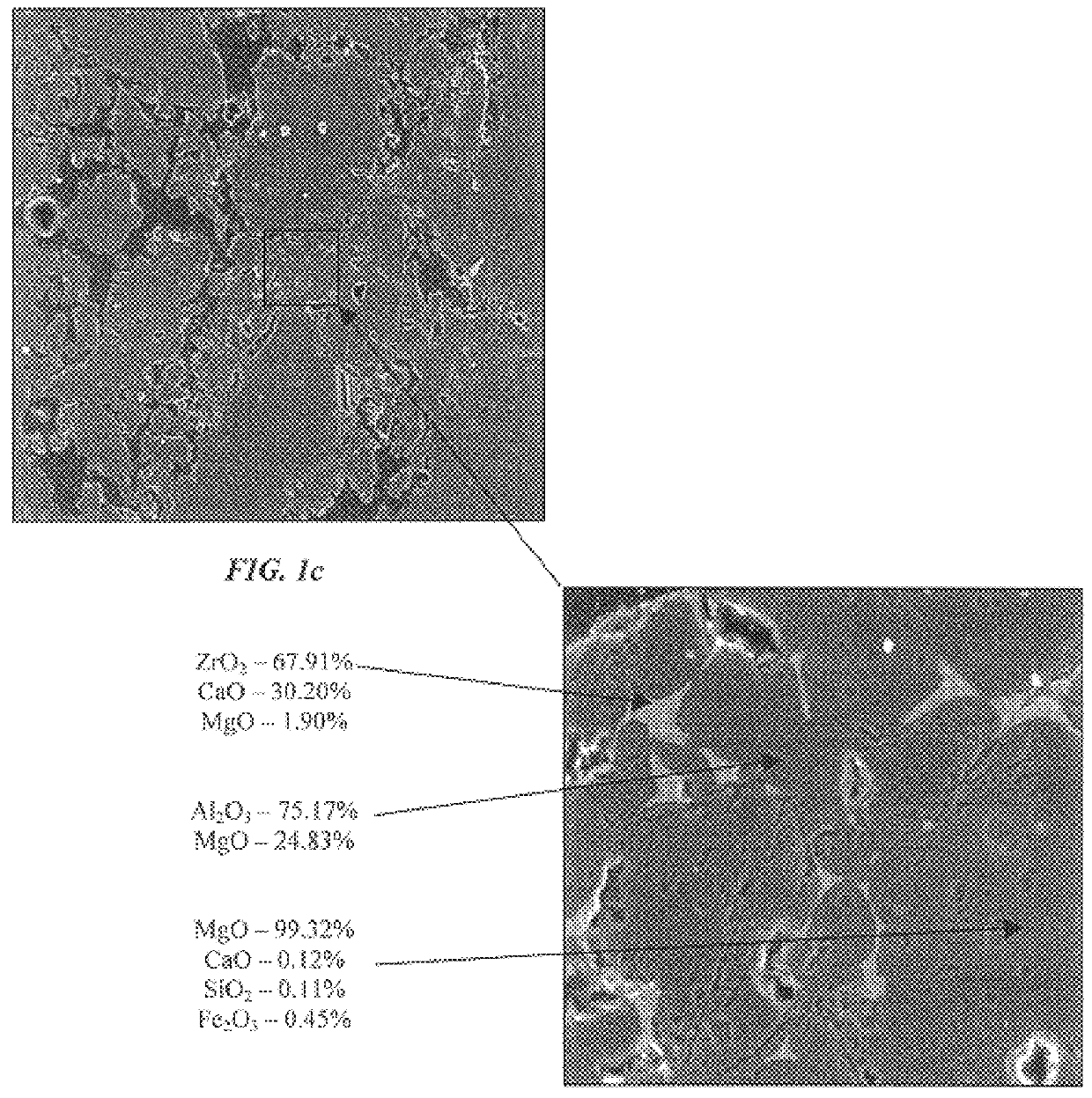

Magnesia spinel refractory brick

The present invention discloses novel magnesia-spinel refractory compositions and bricks formed thereof that exhibit longer lining life, greater hot strength and reduced tendency to spall under high thermal loading conditions. The invention is designed to slow or retard the reaction between spinel and lime through the addition of zirconia in the form of an alumina-zirconia grain to the refractory mix. Zirconia reacts more readily with the lime in the refractory composition and surrounding environment to form calcium zirconate.

Owner:BAKER REFRACTORIE

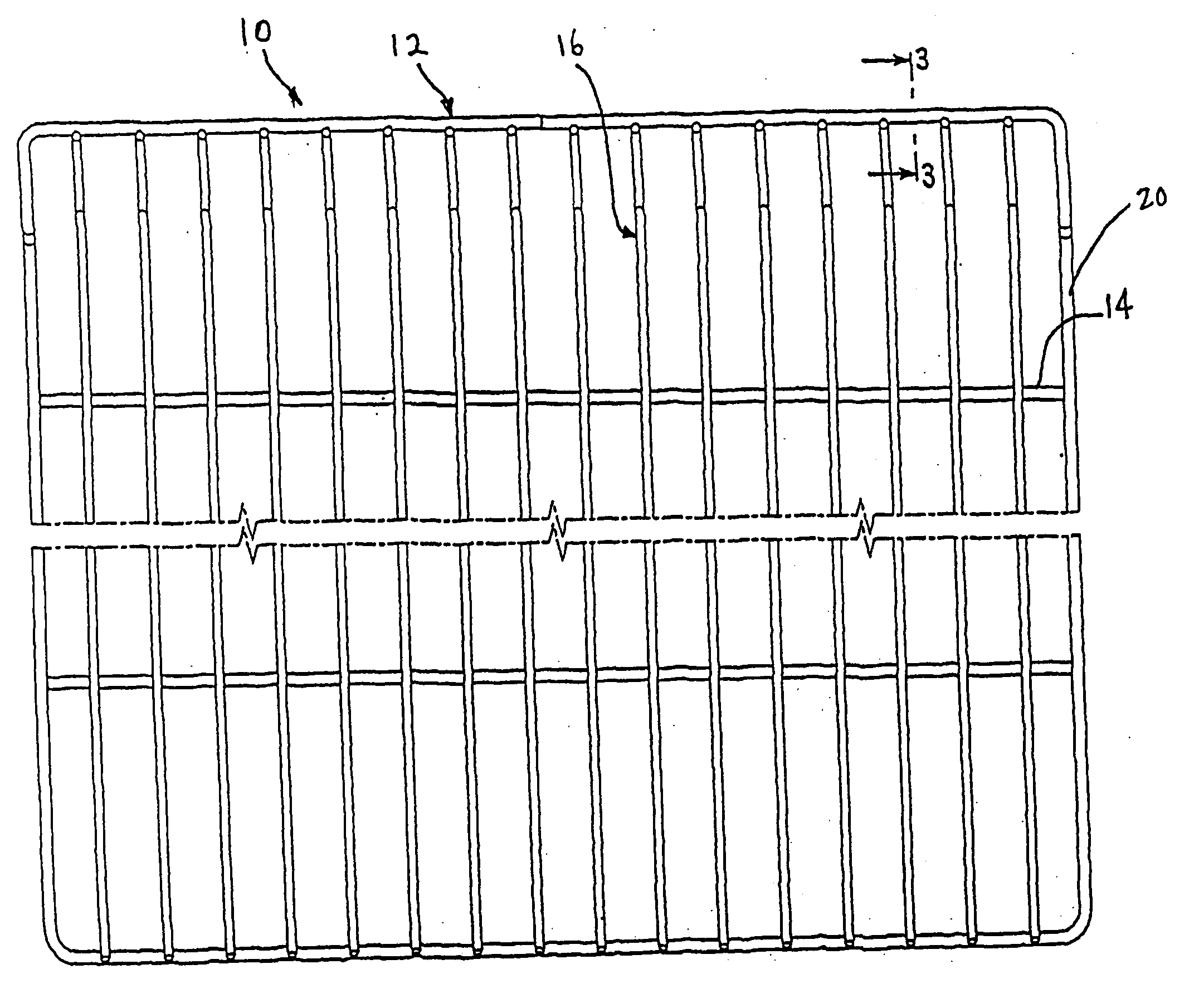

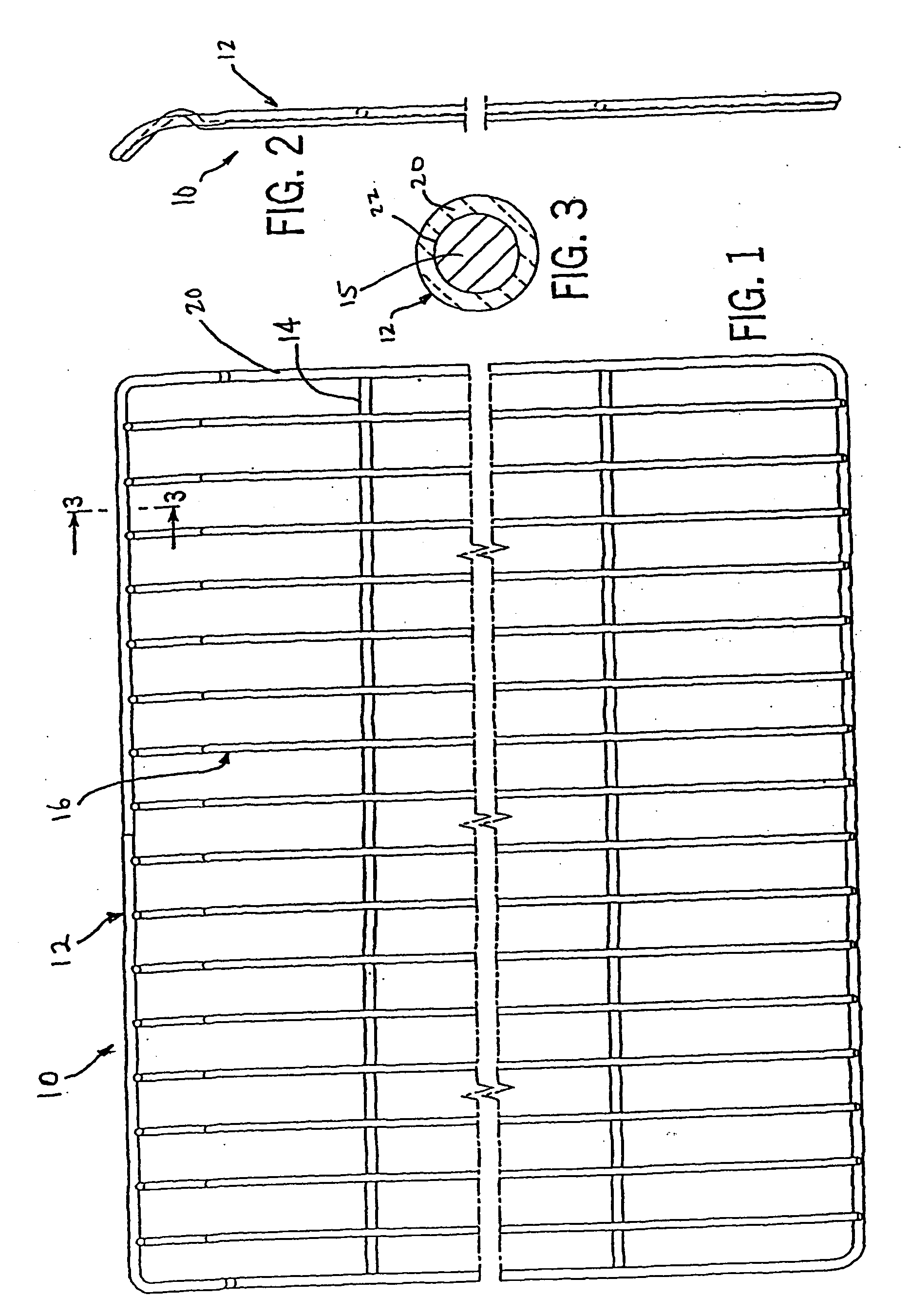

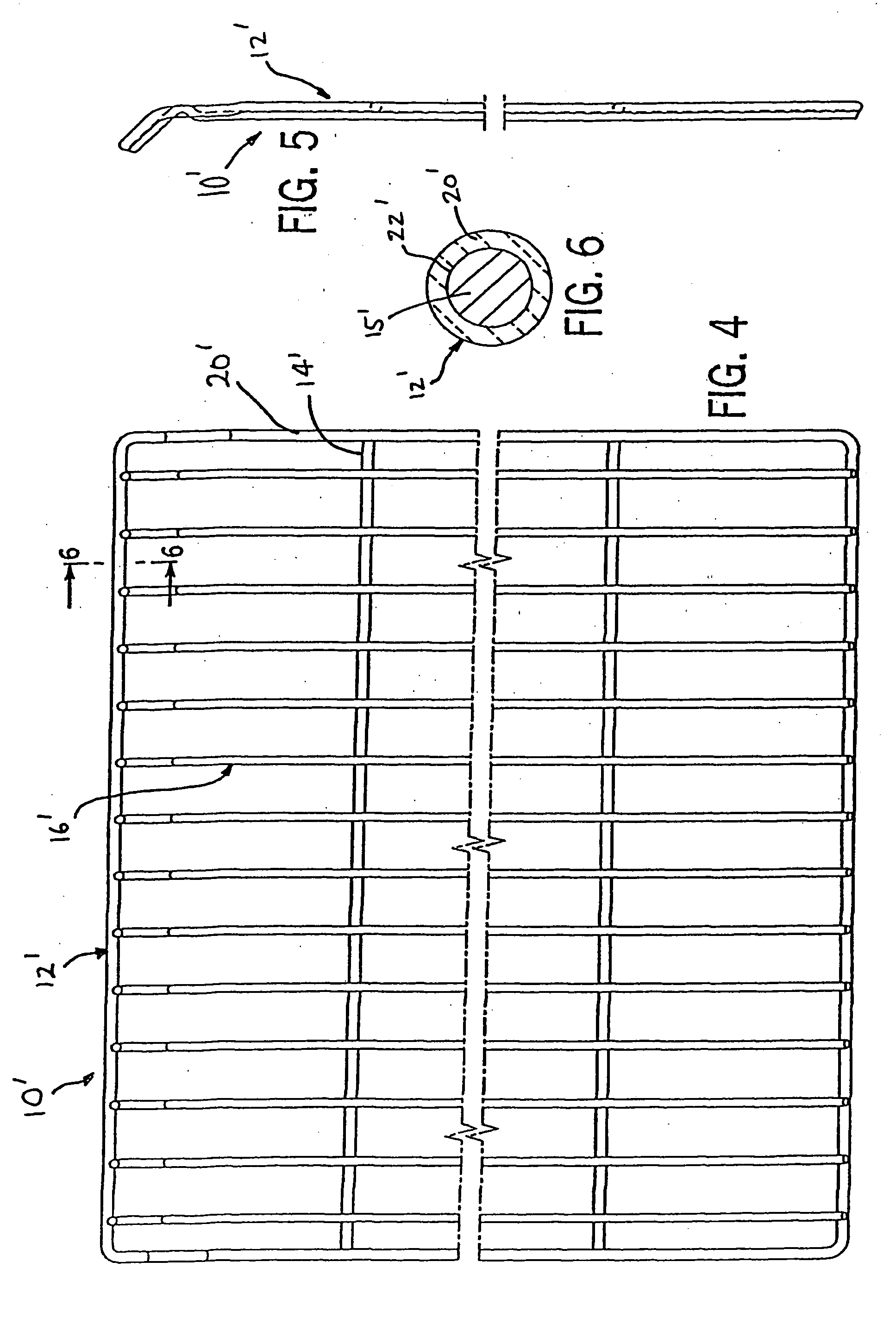

Oven rack having an integral lubricious, dry porcelain surface

InactiveUS20070272231A1Avoid chippingReduce the overall diameterDomestic stoves or rangesStoves/ranges shelves or racksDiamond-like carbonAntimony trioxide

A lubricious porcelain coated steel wire oven rack. The preferred coated steel wire oven rack includes a plurality of elongated steel wire members joined together to form an oven rack having an outer surface. The plurality of elongated steel wire members are made from a cold drawn steel rod material containing from about 80 to about 99.9% by weight of iron, up to about 0.08% by weight of carbon and from about 0.001 to about 0.2% by weight of a carbon stabilizing transition metal, preferably selected from the group consisting of Vanadium, Tantalum, Titanium and Niobium. In a preferred embodiment, the porcelain surface of the oven rack includes a dry lubricant selected from carbon; graphite; boron nitride; cubic boron nitride; molybdenum (IV) sulfide; molybdenum disulfide; molybdenum sulfide; molybdenum (IV) selenide; molybdenum selenide; tungsten (IV) sulfide; tungsten disulfide; tungsten sulfide; silicon nitride (Si3N4); TiN; TiC; TiCN; TiO2; TiAlN; CrN; SiC; diamond-like carbon; tungsten carbide (WC); zirconium oxide (ZrO2); zirconium oxide and 0.1 to 40 weight % aluminum oxide; alumina-zirconia; antimony; antimony oxide; antimony trioxide; and mixtures thereof.

Owner:SSW ADVANCED TECH LLC

High-temperature protective coating for high-carbon steel billet and application thereof

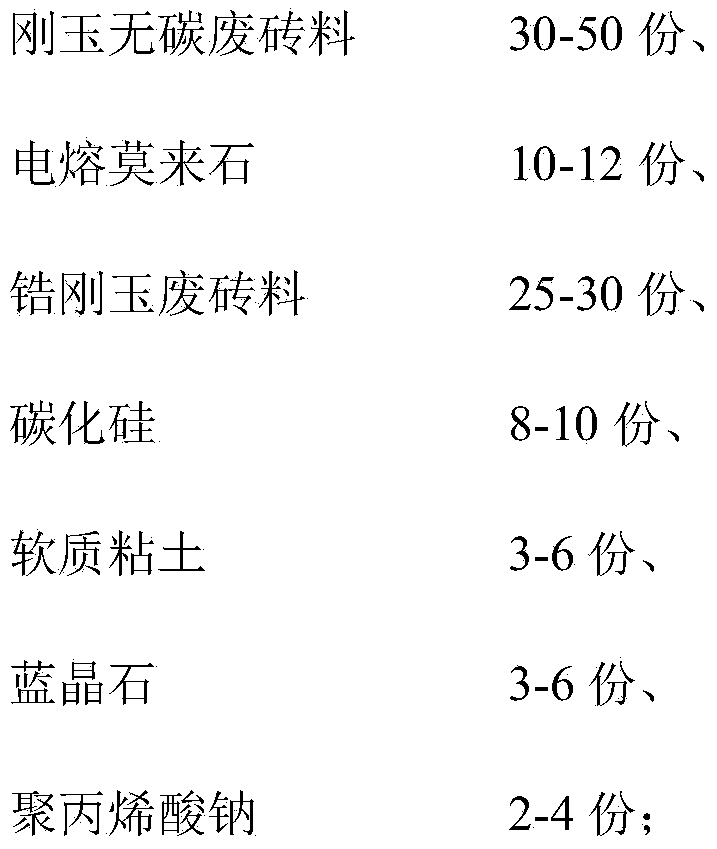

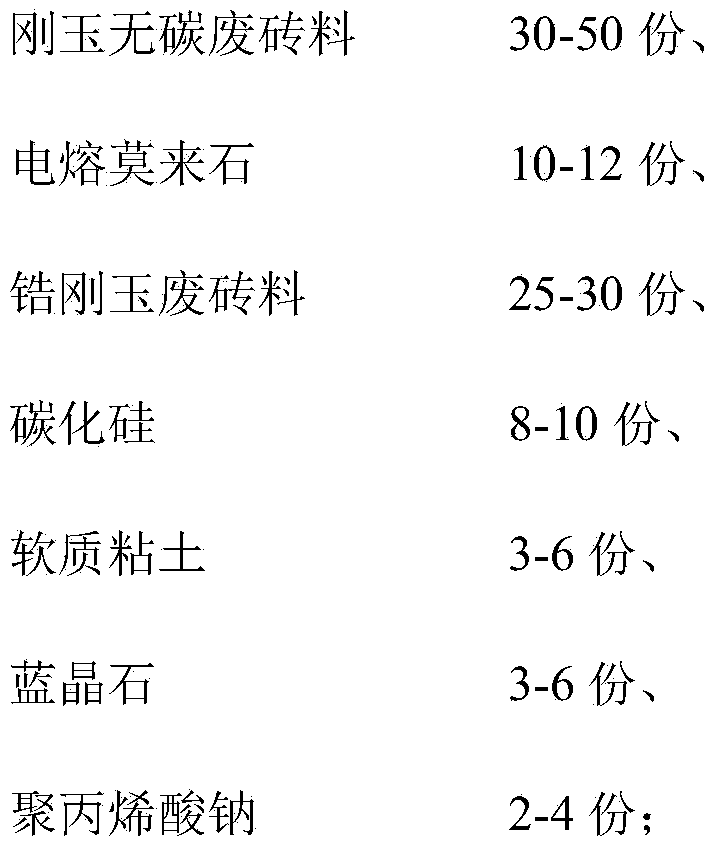

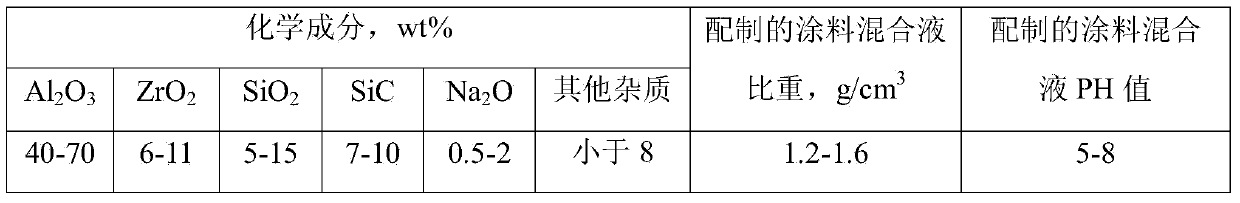

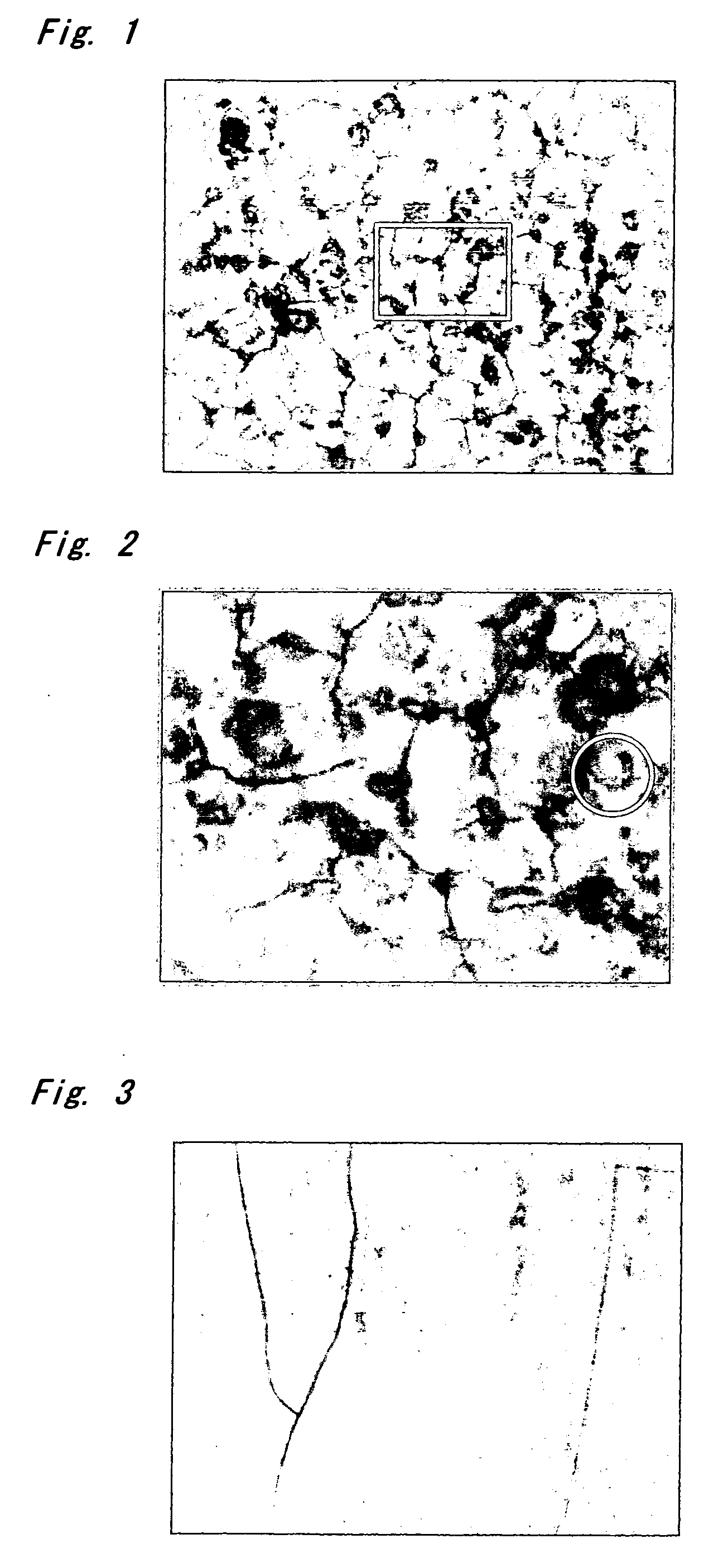

The invention discloses a high-temperature protective coating for a high-carbon steel billet. The coating comprises a dry powder material and an adhesive. The dry powder material is prepared from the following components in parts by weight: 30-50 parts of corundum carbon-free waste brick materials, 10-12 parts of electro-fused mullite, 25-30 parts of fused alumina zirconia waste brick materials, 8-10 parts of silicon carbide, 3-6 parts of soft clay, 3-6 parts of kyanite and 2-4 parts of sodium polyacrylate. The adhesive is prepared from a solid compound adhesive and a liquid compound adhesive. The dosage of the solid compound adhesive is 3-6% of the total weight of the dry powder material and the dosage of the liquid compound adhesive is 2-4% of the total weight of the dry powder material. The protective coating can be used for directly spraying the hot state billet with the surface temperature of 400-1100 DEG C, and not only has the double functions of preventing oxidization and resisting decarburization, but also has the self-repairing ability, so that the loss of iron scale and the thickness of a decarburized layer in the heating process of the high-carbon steel billet are remarkably reduced, the surface quality of the billet is improved. The production efficiency of a rolling mill is improved, and the production cost is lowered.

Owner:辽宁富城耐火材料(集团)有限公司

Catalyst used for preparing tetrachloroethylene and its preparation method and use

InactiveCN101143328AHalogenated hydrocarbon preparationMetal/metal-oxides/metal-hydroxide catalystsGas phaseCobalt

The invention relates to novel catalyst to prepare tetrachloroethylene in carbon tetrachloride gas-phase catalysis. The invention is characterized in that the catalyst carrier is prepared from soluble salt solution or mixed solution with ammonia in coprecipitation method. And then one or two of the mixtures such as the compounds of platinum, palladium and nickel, etc, together with one or a plurality of the mixtures such as the compounds of silver, cobalt, tin, zinc, copper or iron is / are loaded on the catalyst carrier in conventional equivalent impregnation method or excessive impregnation method. One or two of the composite oxides of alumina, zirconia, silica and titania is / are used as the carrier or carriers of the catalyst. One or two of platinum, palladium or nickel and one or two of silver, cobalt, tin, zinc, copper and iron are used as the active components to form multi-metal catalyst. The catalyst prepared in the method of the invention maintains high transformation rate of carbon tetrachloride, at the same time reduces the production of by-products such as methane, maintains high selectivity of tetrachloroethylene, and maintains a long service life of the catalyst.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Catalyst support and method of producing the same

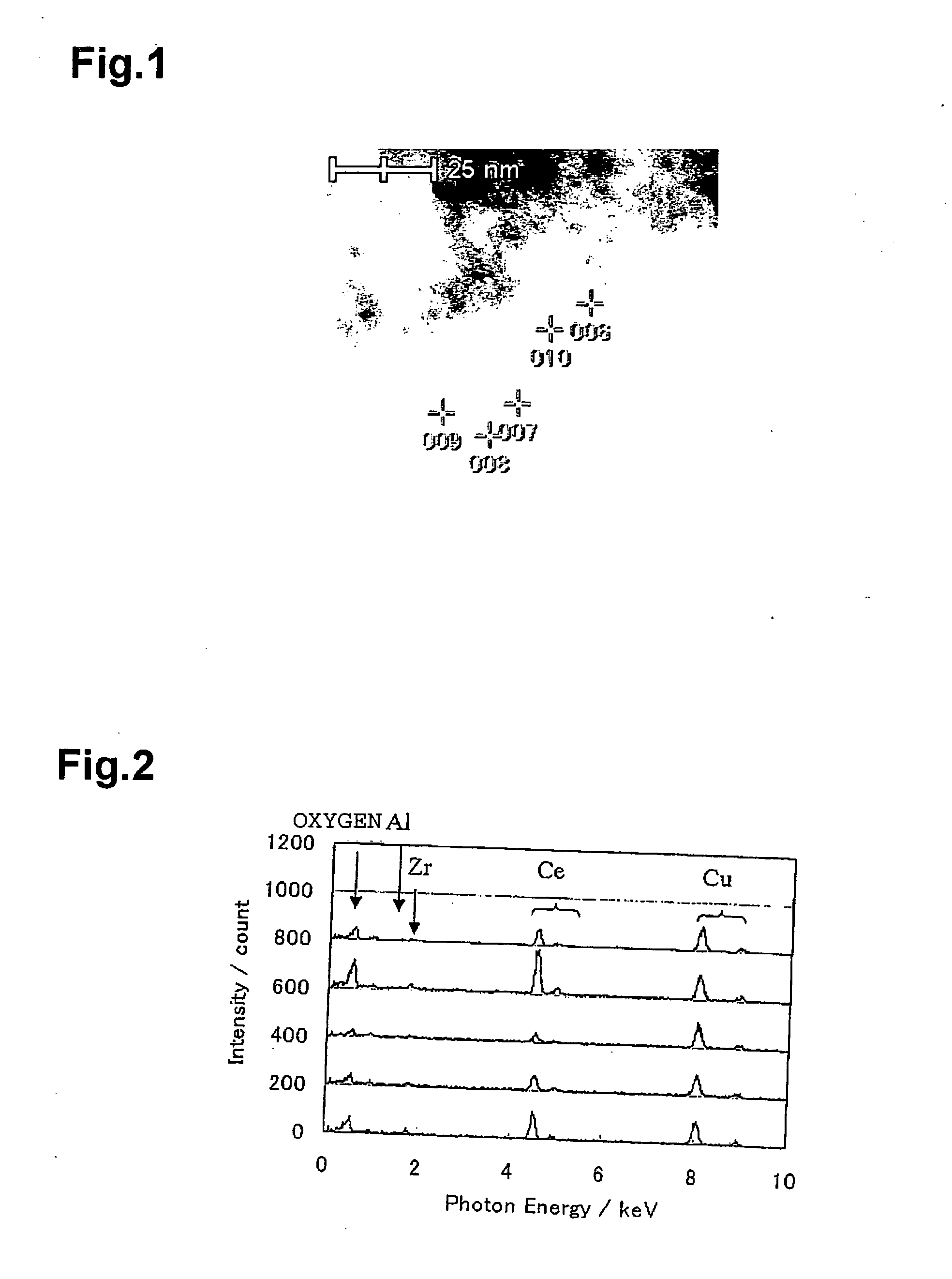

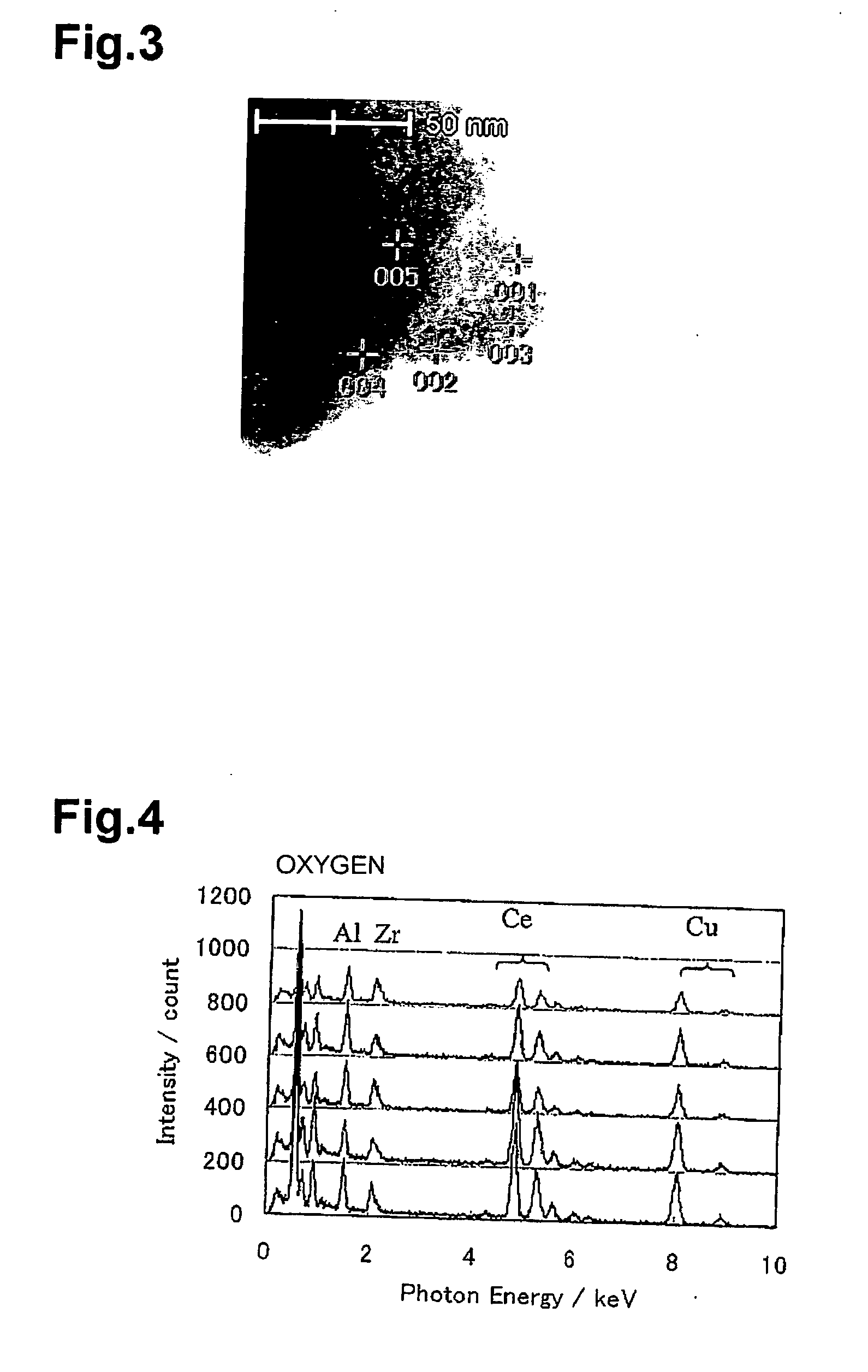

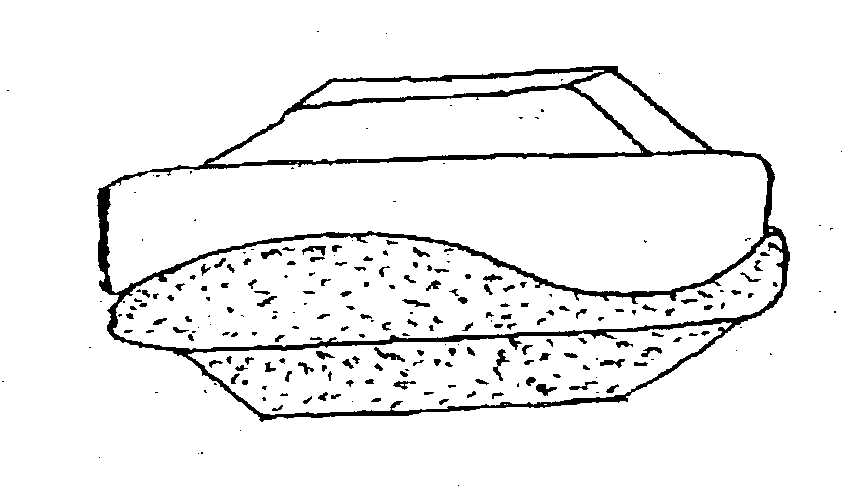

ActiveUS20060172886A1Improve adhesionImprove reforming performanceHydrogenCatalyst activation/preparationRare-earth elementAlkali metal oxide

A method of producing a catalyst support comprising a substrate, and coating formed on the surface of the substrate and including powder of a first metal oxide of at least one member selected from the group consisting of alumina, zirconia, titania, iron oxides, oxides of rare earth elements, alkali metal oxides and alkali earth metal oxides, wherein the coating is obtained by heat treating the substrate after applied with a coating composition obtained by mixing the first metal oxide powder together with a fluid raw material composition containing raw material of a second metal oxide of at least one member selected from the group consisting of alumina, zirconia, titania, iron oxides, oxides of rare earth elements, alkali metal oxides and alkali earth metal oxides, at a shear rate of 1000 sec−1 or higher.

Owner:TOYOTA CENT RES & DEV LAB INC

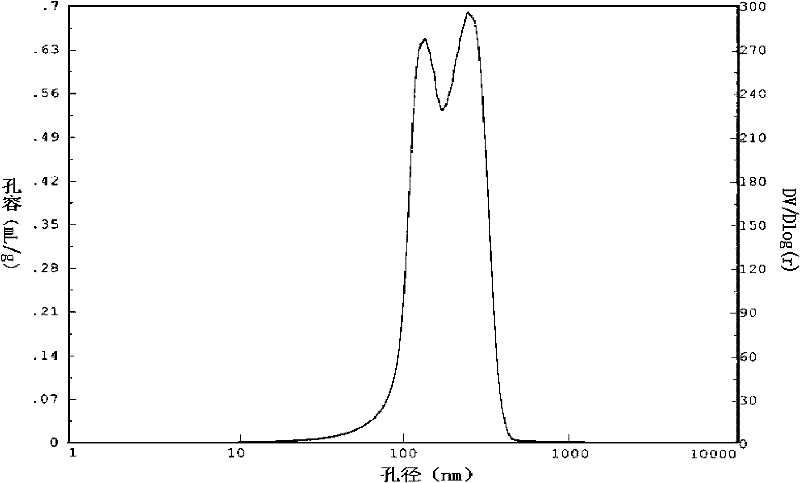

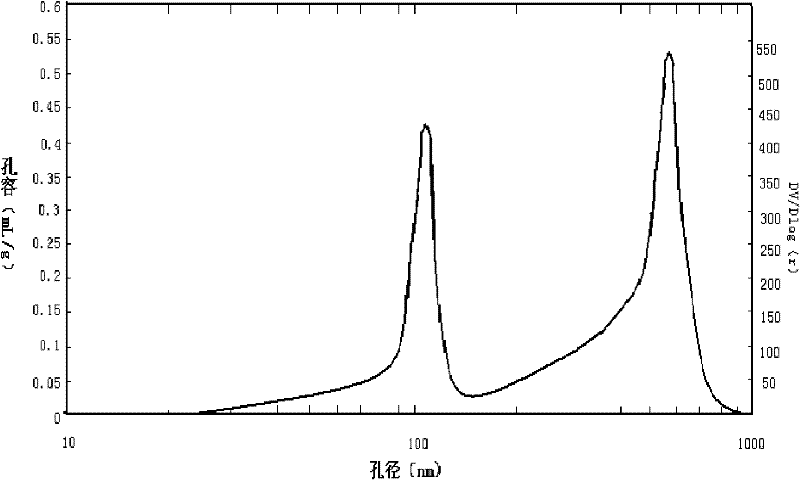

Alumina-zirconia composite carrier and preparation method thereof

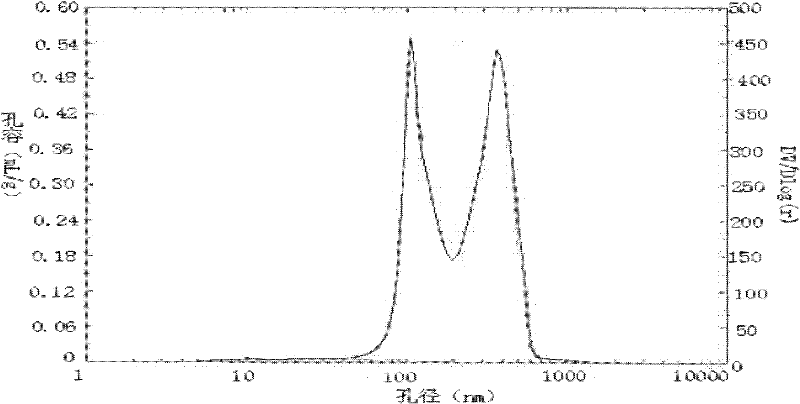

ActiveCN102247896AHigh selectivityAvoid cokingCatalyst carriersHydrocarbon purification/separationAlumina zirconiaPhysical property

The invention relates to an alumina-zirconia composite carrier and a preparation method thereof. The carrier comprises the following components in percentage by mass: 1 to 95 percent of alumina and 5 to 99 percent of zirconia; the carrier has the following physical properties that: the bulk density is 0.8 to 1.1g / ml, the pore volume is 0.3 to 0.6ml / g, the specific surface area is 5 to 60m<2> / g, and the average pore size is 80 to 350nm, 100 to 250nm preferably; and the carrier has two peaks when the pore size is 90 to 140nm and 250 to 500nm. The invention also discloses the preparation method of the carrier, and a carrier-containing hydrogenation catalyst.

Owner:PETROCHINA CO LTD

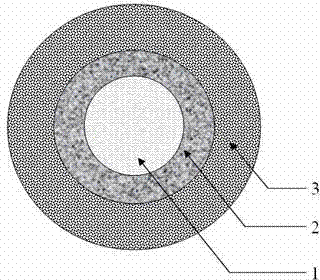

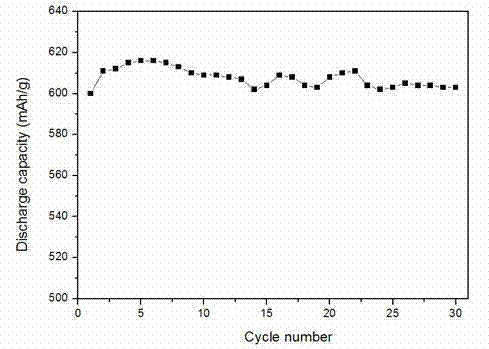

Lithium ion battery cathode material with two-shell layer structure and preparation method thereof

InactiveCN103545497ASimple preparation processWith mass productionCell electrodesElectrical batteryAlumina zirconia

The invention relates to a lithium ion battery cathode material with a two-shell layer structure, which is characterized by consisting of two shell layers, wherein the first shell layer is a metal oxide shell layer, and the second shell layer is made of an intangible carbon shell layer material; the first shell layer wraps the surface of silicon particles, and the second shell layer wraps the surface of the first shell layer; the metal oxide shell layer is one of aluminum oxide, zirconium oxide and zinc oxide; and the intangible carbon shell layer is prepared by carbonizing sucrose, glucose and polyethylene. The reaction interface of the electrolyte and silicon powder is lowered and the side reaction is reduced by use of oxide; and with the flexibility and scalability of the carbon material, the problem of chalking caused by the silicon volume expansion is reduced. Moreover, the invention also provides a preparation method of the cathode material, wherein the method realizes simple preparation and has the possibility of batch production.

Owner:CHINA FIRST AUTOMOBILE

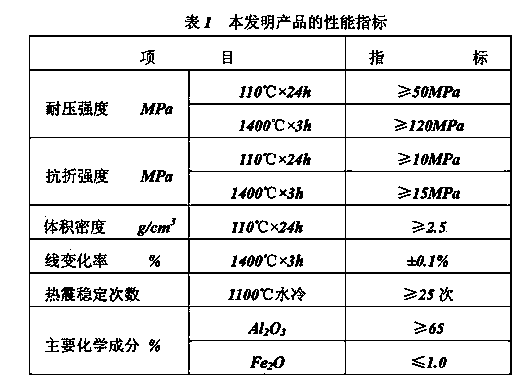

Zirconium-containing high-strength wear-resistant castable

The invention discloses a zirconium-containing high-strength wear-resistant castable, which comprises, by weight: 23-32% of brown fused alumina, 42-52% of sintered mullite, 4-8% of corundum powder, 6-10% of mullite fine powder, 3-5% of a-AI2O3, 2-5% of fused alumina zirconia fine powder, 3-5% of silica powder, 6-10% of pure calcium aluminate cement and 0.1-0.15% of a water reducing agent. The zirconium-containing high-strength wear-resistant castable is prepared by: firstly grinding and mixing the corundum powder, the mullite fine powder, the a-AI2O3 and the fused alumina zirconia powder, then adding the remaining various raw materials, and performing mixing stirring. The castable product disclosed in the invention has the characteristics of high bonding strength, strong anti-scouring performance, high compressive strength, good wear resistance, and good thermal shock resistance and stripping resistance, etc.

Owner:巩义市科恒耐火材料有限公司

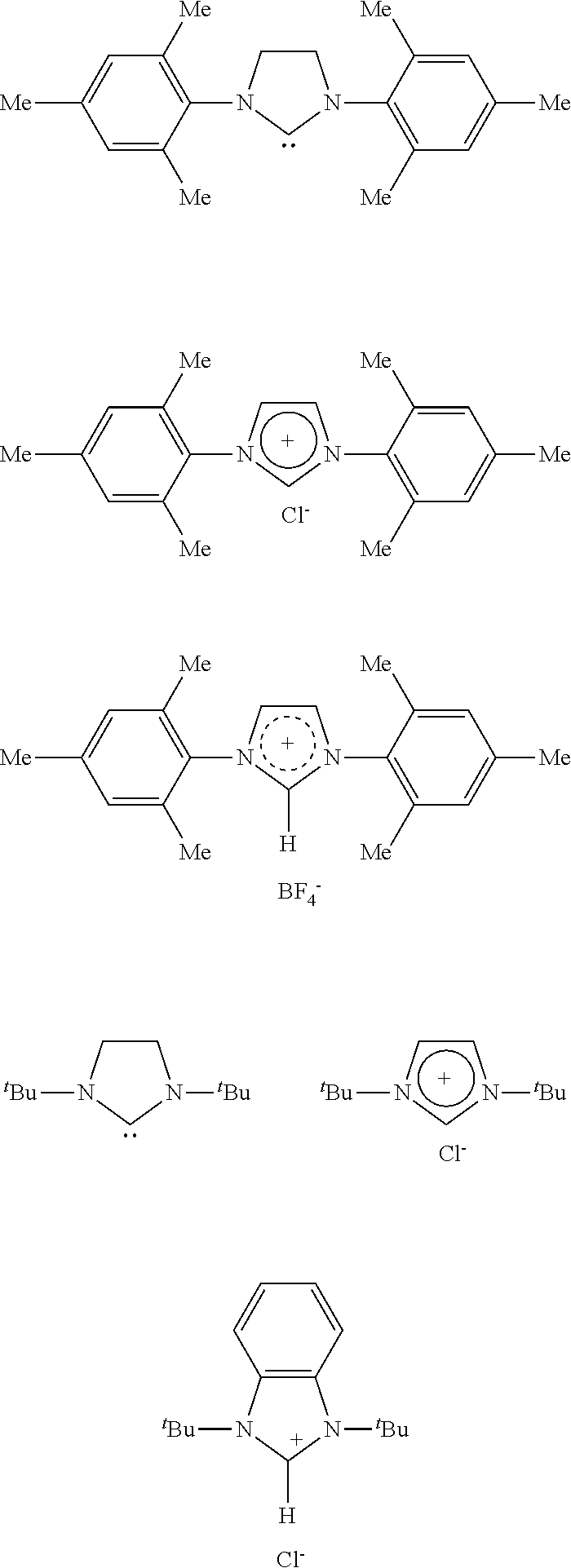

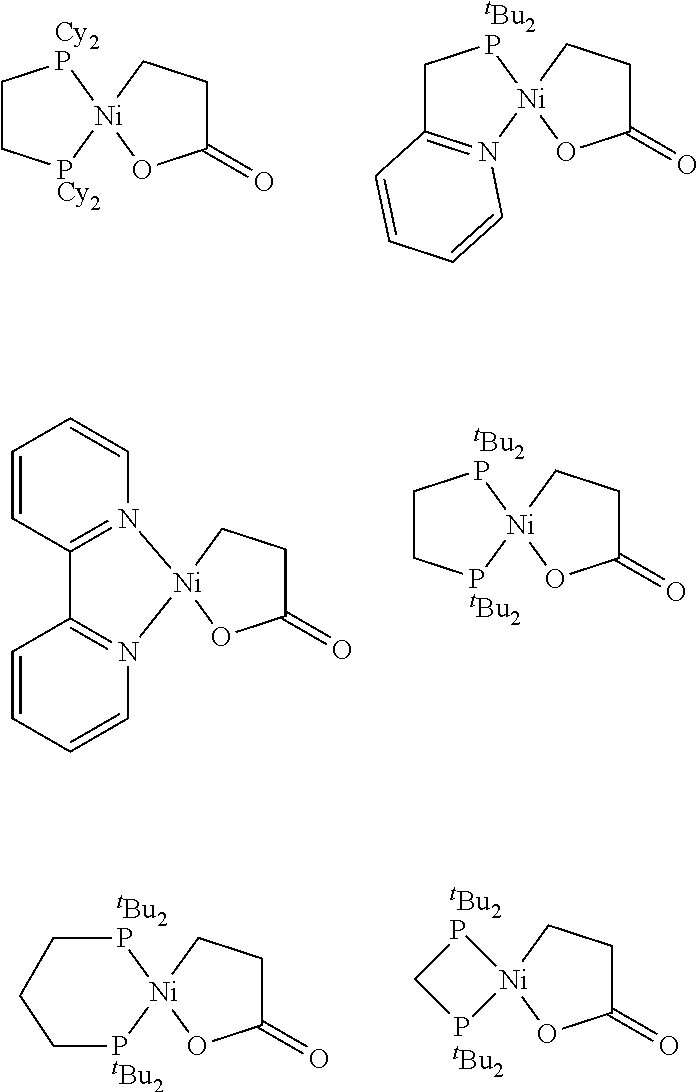

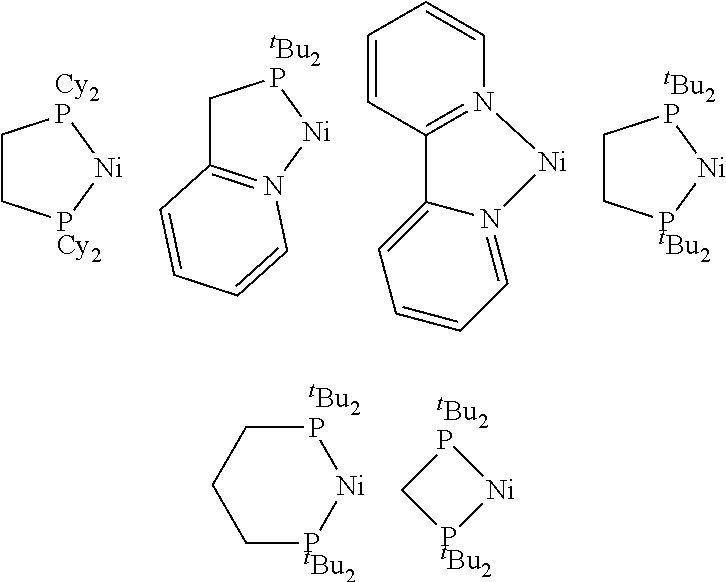

Methods for the production of α,β-unsaturated carboxylic acids and salts thereof

ActiveUS9416087B2Easy to separateProcedure is very challengingOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMixed oxideSepiolite

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

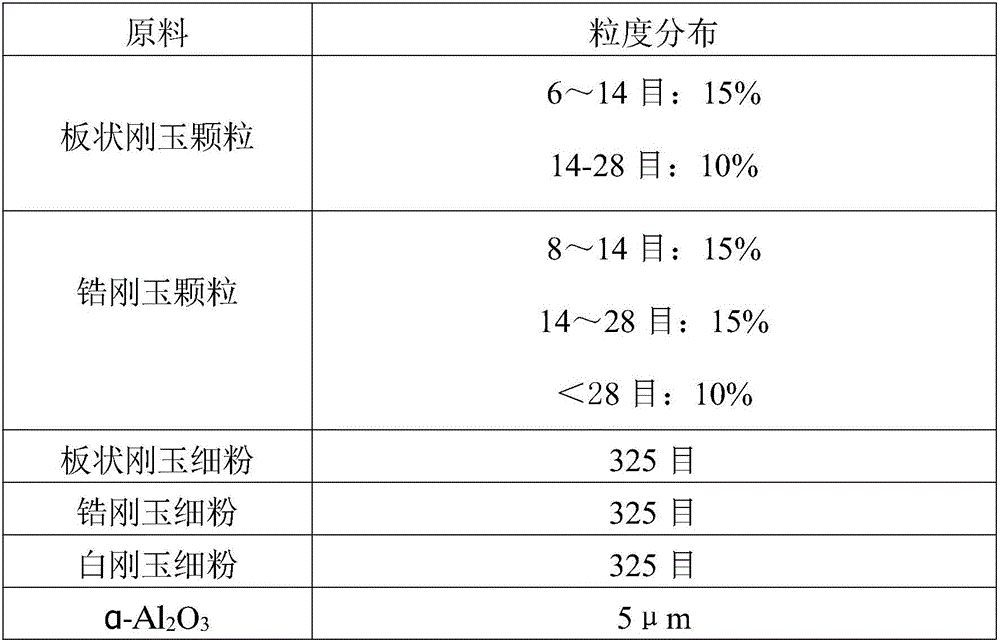

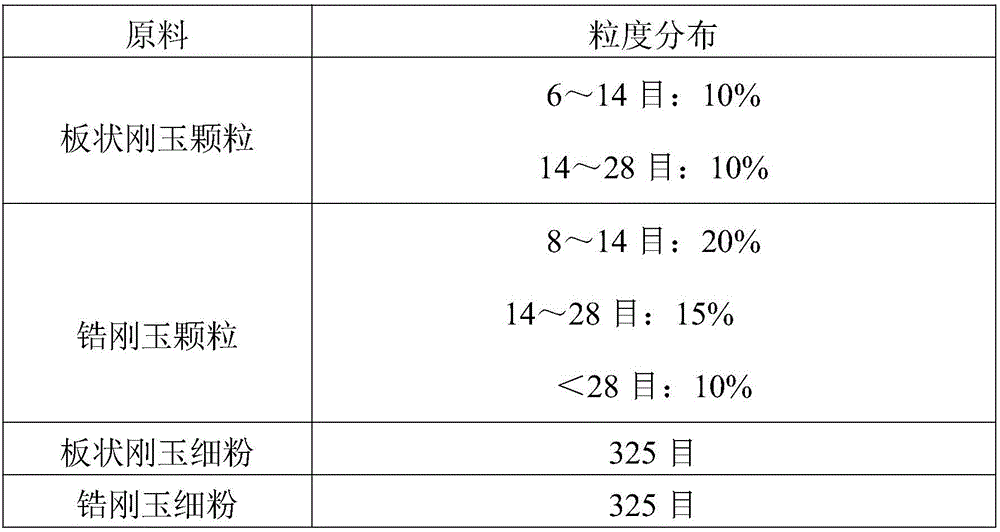

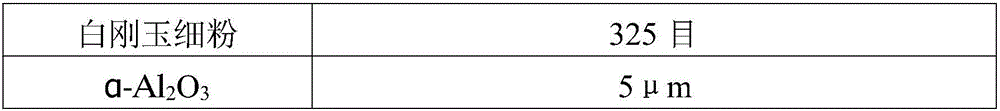

Gate valve sliding plate brick for slag retaining of converter and preparation method thereof

The invention discloses a gate valve sliding plate brick for slag retaining of a converter and a preparation method thereof. Based on the total amount of 100 percent, the brick comprises the following components in percentage by weight: 20 to 30 percent of tabular corundum particles, 30 to 45 percent of zirconia corundum particles, 5 to 10 percent of tabular corundum fine powder, 5 to 10 percent of zirconia corundum fine powder, 5 to 20 percent of white corundum fine powder, 0 to 5 percent of alpha-Al2O3, 1 to 4 percent of flake graphite, 0 to 2 percent of expanded graphite, 0 to 5 percent of aluminum metal powder, 0 to 5 percent of silicon metal powder, 0 to 3 percent of boron carbide and 4 to 6 percent of additional phenolic resin. According to the gate valve sliding plate brick and the preparation method thereof, the service life of the brick on 100-ton converters is prolonged from original 10 to 12 converters to 13 to 15 converters, and is basically equivalent to that of a zirconia plate embedded gate valve sliding plate; compared with a conventional alumina-zirconia-carbon gate valve sliding plate, a sliding plate for which the brick is used has the advantages that transverse cracking and fracturing phenomena of the sliding plate are remarkably reduced, and the thermal shock resistance is obviously improved, the surface of the plate is smooth, the erosion pore expanding rate is low, the number of continuous using times is increased, and the safety is improved.

Owner:瑞泰马钢新材料科技有限公司 +1

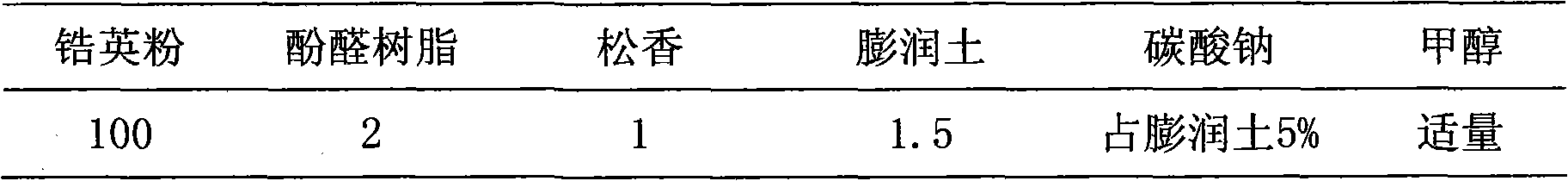

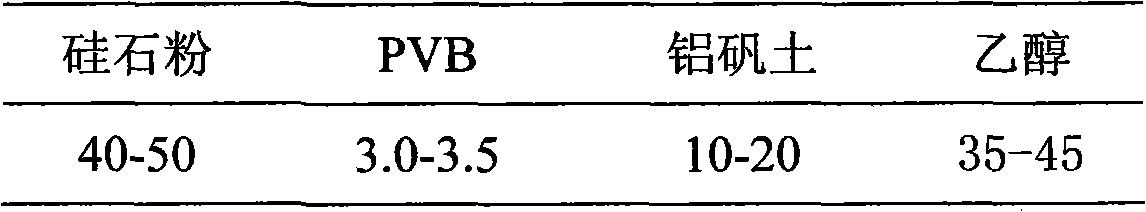

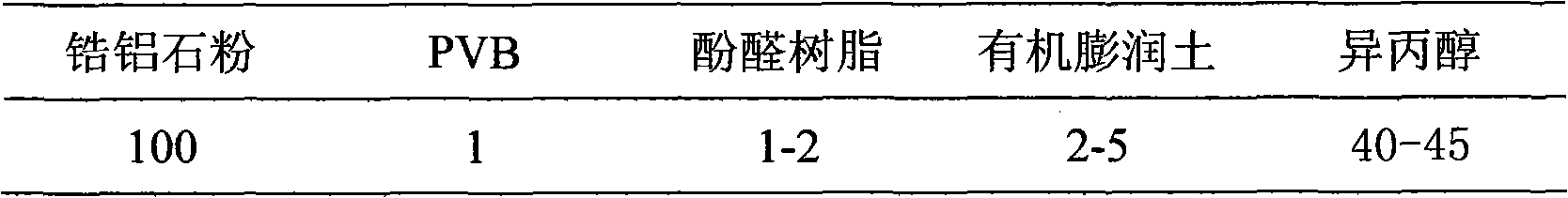

Isopropanol-based coating for lost foam casting steel and production method thereof

InactiveCN102218502AAvoid Chemical Sticky Sand DefectsLow costFoundry mouldsFoundry coresPolyvinyl butyralSodium Bentonite

The invention relates to an isopropanol-based coating for lost foam casting steel and a production method thereof. The coating uses alumina-zirconia powder as a fireproof material, uses PVB (Polyvinyl Butyral) and phenol formaldehyde resin as adhesives, uses organic bentonite as a suspending agent, and takes suitable quantity of isopropanol as a material coating carrier. The production method comprises the following steps of firstly dissolving the PVB and the phenol formaldehyde resin in an alcohol; sufficiently mixing the mixed solution to form a colloida solution; subsequently mixing the organic bentonite and the alumina-zironia powder uniformly; finally conducting sufficient ball-grinding and mixing to the mixed aggregates, adhesive solutions and isopropanol for 45-70 minutes at the speed of 1450r / min, thus preparing the isopropanol-based coating for lost foam casting steel. The coating has low manufacturing cost, simple technological process and high casting quality, and is particularly suitable for roughcast production of complex and large cast steel.

Owner:浙江宸宇重工有限公司 +1

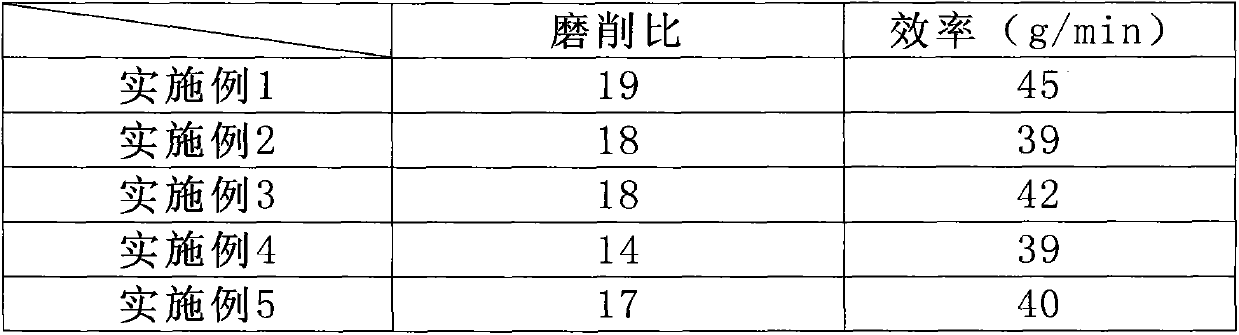

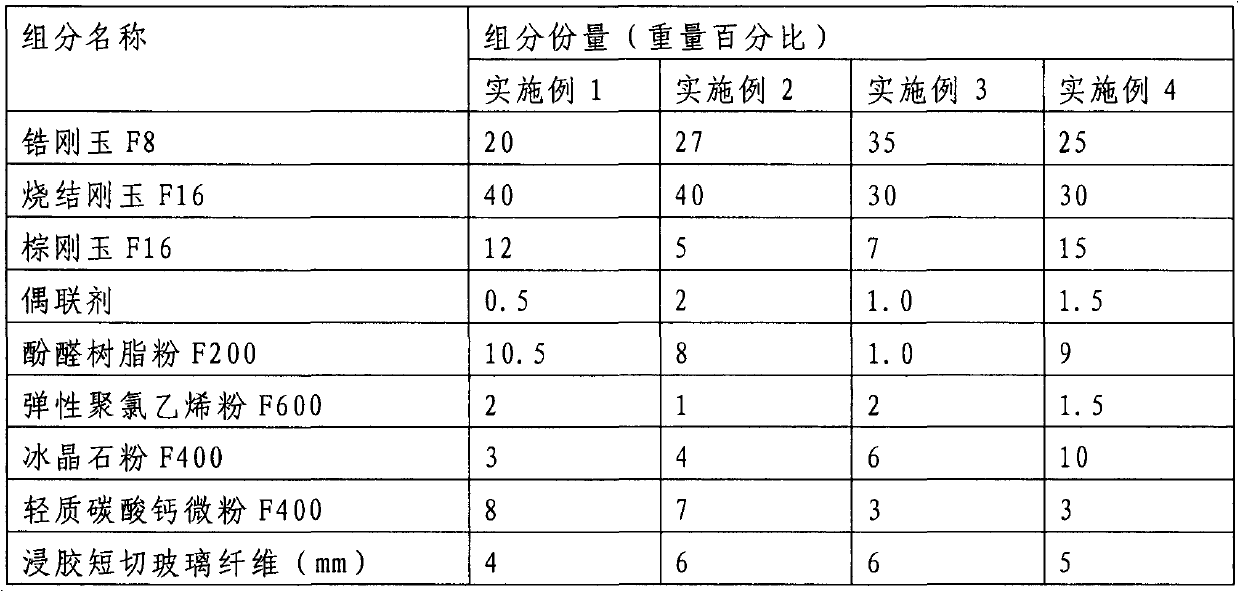

Heavy-load grinding wheel and preparation method thereof

InactiveCN103144047APlay the role of cushioning and dampingImprove flame retardant performanceAbrasion apparatusGrinding devicesPolyvinyl chlorideGrinding wheel

The invention discloses a heavy-load grinding wheel. The heavy-load grinding wheel comprises the following components in percentage by weight: sintered corundum, fused alumina zirconia, brown fused alumina, a coupler, phenol-formaldehyde resin powder, elastic polyvinyl chloride powder, cryolite powder, light calcium carbonate micro powder and impregnation chopped glass fibers and is prepared by a hot pressing molding process. The elastic polyvinyl chloride resin powder is mixed in a grinding material, so that the tenacity and the shock absorbing effect of the grinding wheel are improved, and the probability of sheet blasting is greatly reduced. On the other hand, elastic polyvinyl chloride has excellent flame resistance, so that burning of grinding heat to phenol-formaldehyde resin is reduced, the bonding ability of the phenol-formaldehyde resin to the grinding material is improved, and the grinding ratio of the grinding wheel is improved. The coupler is used for modifying the surface of the phenol-formaldehyde resin, so that the interface bonding force between the organic resin and the inorganic grinding material is stronger, and the rotation strength of the grinding wheel is improved. Furthermore, due to the adoption of the impregnation chopped glass fibers, the dissolving ability of the phenol-formaldehyde resin is favorably enhanced, and the rotation strength of the grinding wheel is further improved.

Owner:泰州苏蒙砂轮有限公司

Preparation of 3D rapid prototyping alumina-zirconia-carbon ceramic powder material

InactiveCN104725046ASmall median diameterNarrow particle size distributionAdditive manufacturing apparatusAdhesiveSilanes

The invention discloses a method for preparing a 3D rapid prototyping alumina-zirconia-carbon ceramic powder material. The method is characterized by comprising the following steps: firstly, pre-treating alumina-zirconia-carbon ceramic powder with N-(beta-aminoethyl)-gamma-amino propyl trimethoxy silane and stearic acid to obtain pre-treated alumina-zirconia-carbon ceramic powder; then, adding the following components in percentage by mass: 60-70 percent of trichloroethane and 2-5 percent of bisphenol A polycarbonate into a reactor, stirring and dissolving, and adding 26-36 percent of the pre-treated alumina-zirconia-carbon ceramic powder, uniformly stirring and mixing, intensively stirring at constant temperature of 50+ / -5 DEG C, refluxing to react for 5-7 hours, and drying by spraying to obtain the rapid prototyping alumina-zirconia-carbon ceramic powder material. The material does not need to spray adhesive, can be directly molded in a molding temperature range of 220-230 DEG C, has the advantages of simple preparation process, easily controlled condition and low production cost, and is easy for industrial production.

Owner:UNIV OF JINAN

Grinding wheel special for rail grinding train and manufacturing method of grinding wheel

The invention discloses a grinding wheel special for a rail grinding train and a manufacturing method of the grinding wheel, and relates to the technical field of manufacturing of grinding wheels. Thegrinding wheel special for the rail grinding train comprises, by weight, 25-35 parts of modified zirconia alumina, 35-55 parts of modified brown fused alumina, 9-15 parts of mixed resin, 3-5 parts ofaluminum oxide hollow balls, 1.5-8 parts of pyrite powder, 1-6 parts of cryolite powder, 0.5-5 parts of barium sulfate powder, 0.5-4 parts of calcium carbonate powder, 0.5-4 parts of graphite powder,3-6 parts of copper powder and 1-8 parts of fiber-reinforced materials, wherein the modified zirconia alumina and the modified brown fused alumina are fused alumina zirconia and brown fused alumina which are dried after being soaked in a KH550 alcohol solution with the concentration of 3-10wt%. The grinding wheel special for the rail grinding train is high in strength, good in tenacity, good in self sharpness and high in grinding capacity; blockage is unlikely to occur in the grinding process; a steel rail is unlikely to be burnt in the polishing process; and the steel rail has good surface quality after being polished by the grinding wheel.

Owner:SOUTHWEST JIAOTONG UNIV

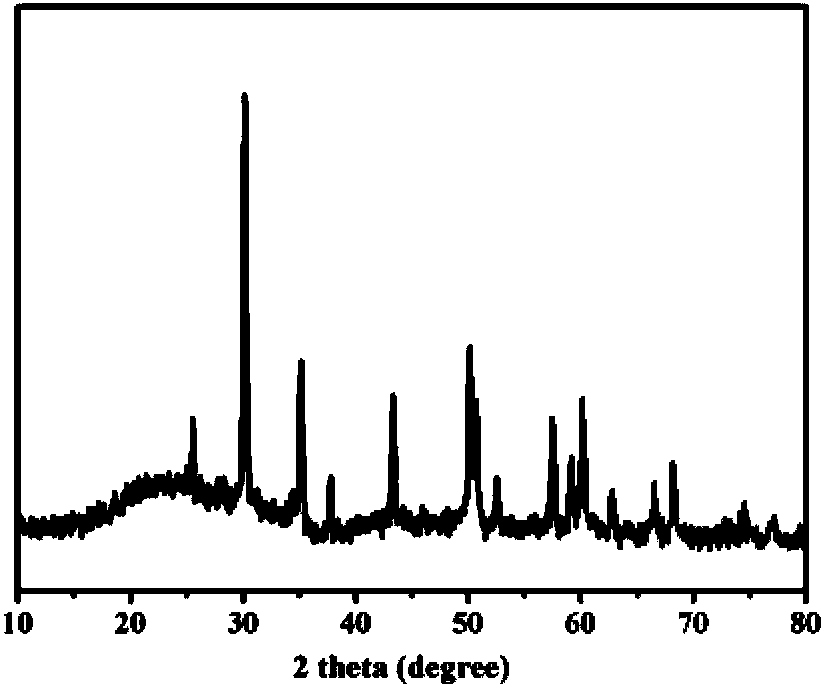

Sandwich structure bulletproof ceramic sheet and low temperature sintering preparation method

InactiveCN103382099AImprove impact resistanceImprove mechanical propertiesPersonal protection gearComposite ceramicAlumina zirconia

The invention relates to a sandwich structure bulletproof ceramic sheet. The bulletproof ceramic sheet is characterized in that its upper surface layer and lower surface layer are composed of 85-95% of Al2O3 and 5-15% of ZrO2 by mass, and a central layer consists of 75-85% of Al2O3 and 15-25% of ZrO2 by mass; the surface layers and the central layer of the sintered sandwich structure bulletproof ceramic sheet are in a thickness ratio of 1:5-15; the surface of the bulletproof ceramic sheet is in a regular hexagon or square shape, the bulletproof ceramic sheet has a sandwich layer structure in the thickness direction, for the sintered regular hexagon, the length of its diagonal lines is 40-60mm, and the thickness is 7-12mm, or for the square, the side length is 30-60mm, and the thickness is 7-12mm; and the sintered bulletproof ceramic sheet has a relative density of 98.5-99.5%, impact toughness of 1-1.4J, bending strength of 500-600MPa, and fracture toughness of 8-11 MPa.m<1 / 2>. The sandwich structure bulletproof ceramic sheet can be used as a hard bulletproof material of human body and armor. By introducing the sandwich structure to alumina-zirconia composite ceramics, certain component difference between adjacent layers is ensured, so that the ceramic sheet can have excellent impact resistance. And a three-step forming method is employed to achieve densification of the ceramic sheet in an atmospheric environment at a low temperature.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com