Patents

Literature

42results about How to "High tensile and flexural strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

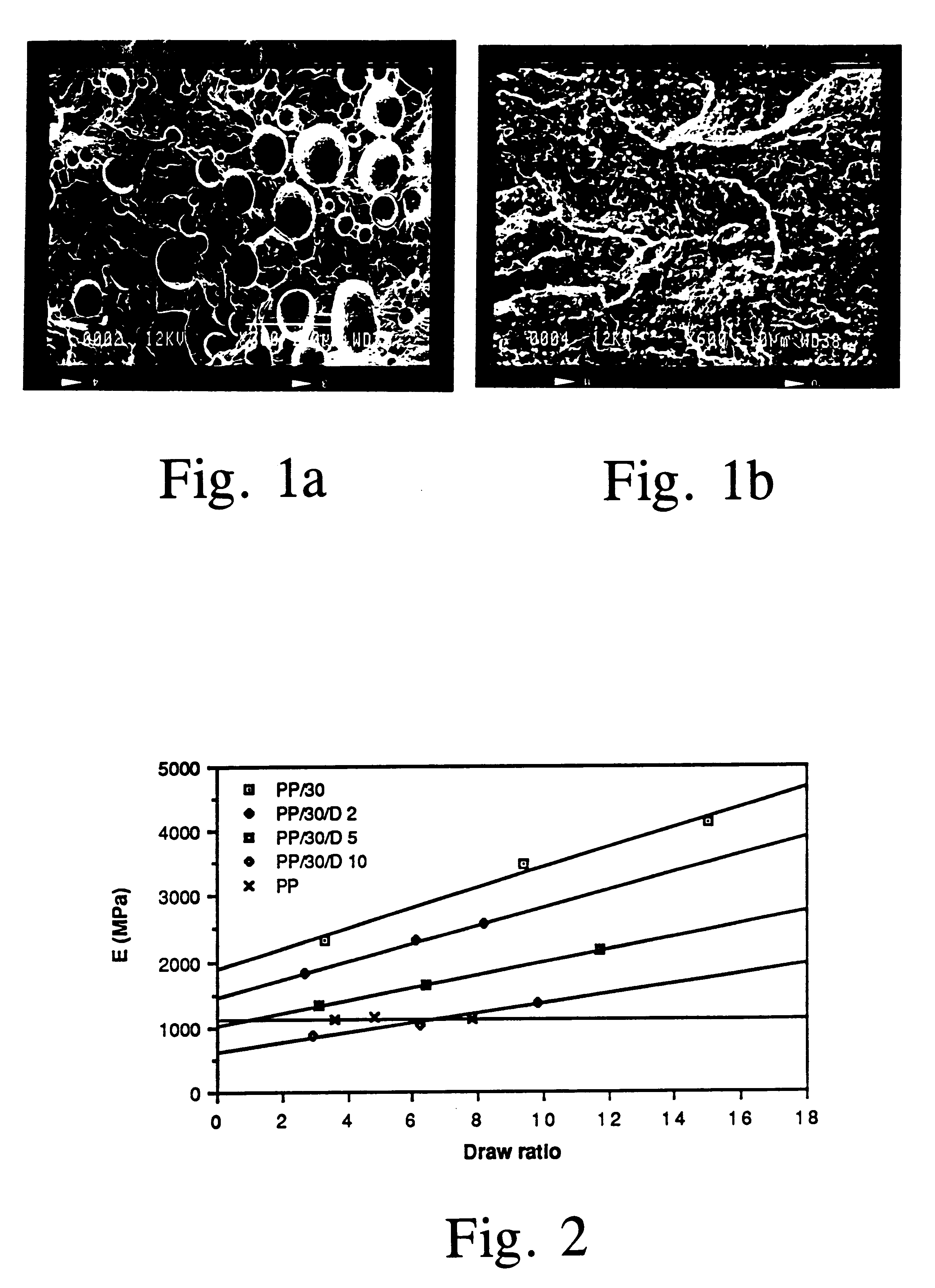

Liquid crystal polymer blends, process for the preparation thereof and products manufactured from the blends

A polymer blend, a process for the preparation thereof and products manufactured from the polymer blend. The polymer blend contains 95 to 50 parts by weight of a polyolefin- or polyester-based polymer matrix, 5 to 50 parts by weight of an aromatic main-chain liquid crystalline polymer and plastic additives, if any. Further, the blend contains, based on the total weight of the previous components, 0.1 to 30 percent by weight of a substance (a compatibilizer) which improves the compatibility of the polymer matrix and the liquid crystalline component. The compatibilizer includes a polymer containing reactive functional groups. Preferably, the compatibilizer includes an SEBS polymer functionalized with maleic anhydride or an olefin polymer functionalized with glycidyl methacrylate.

Owner:OPTATECH CORP

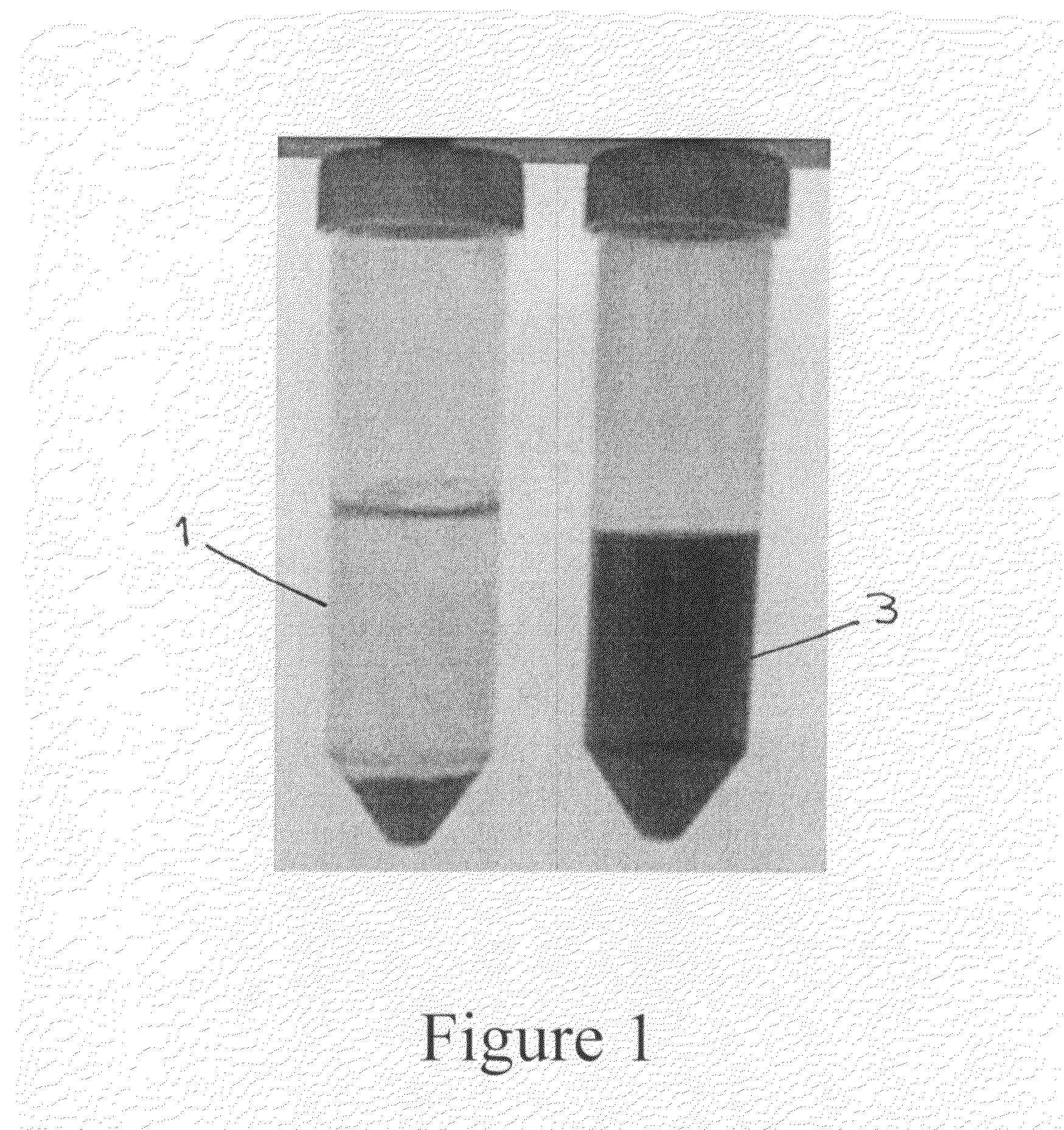

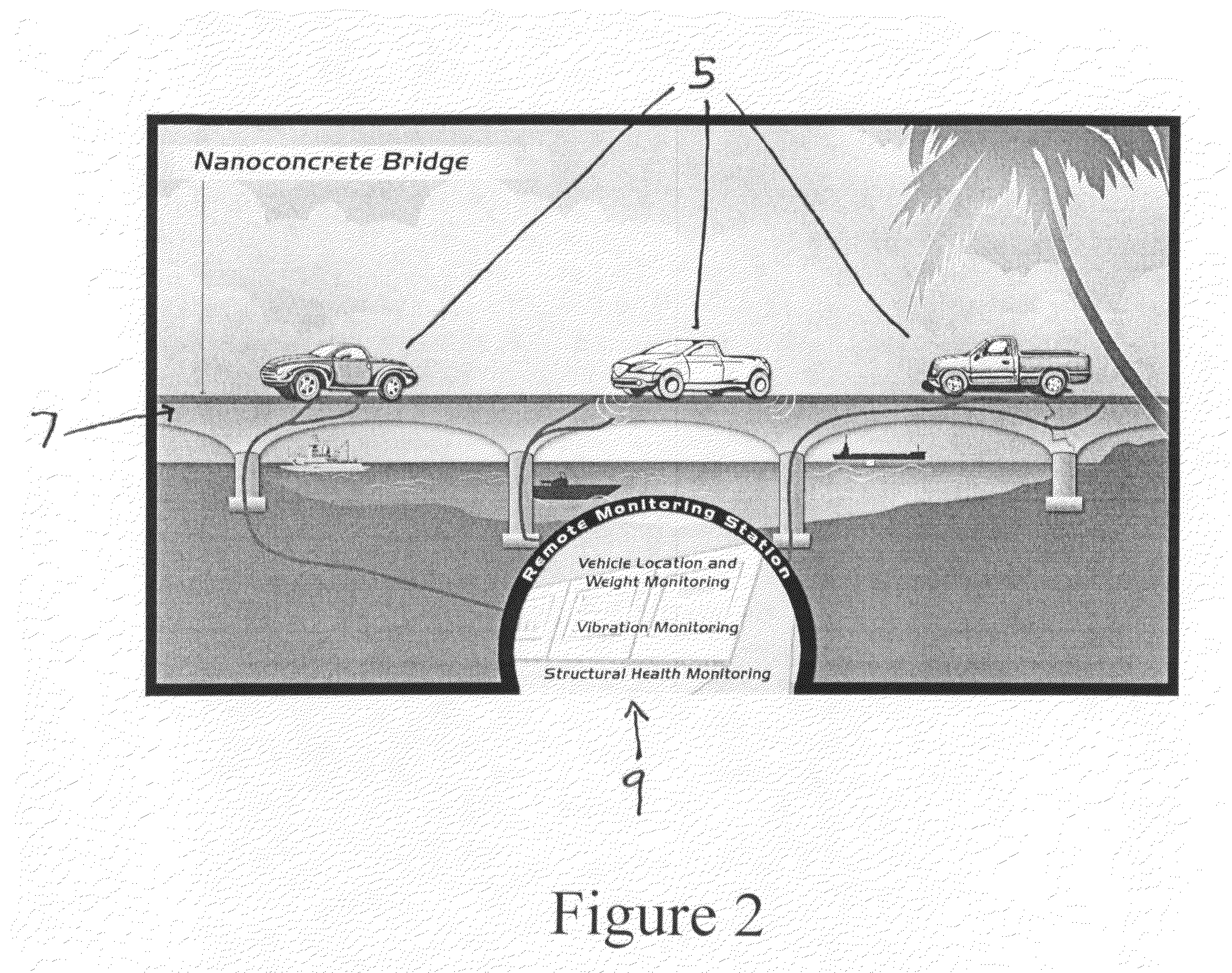

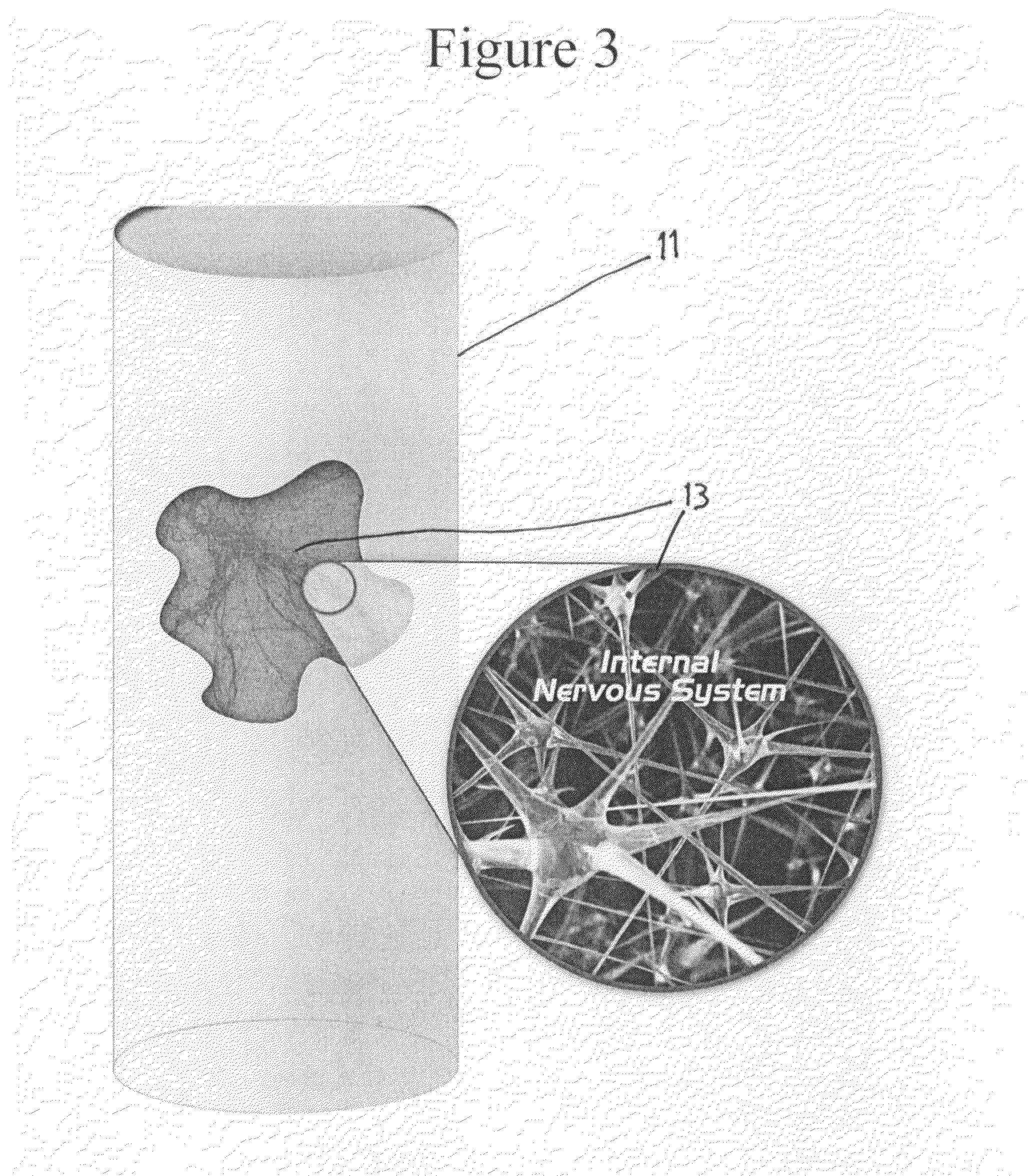

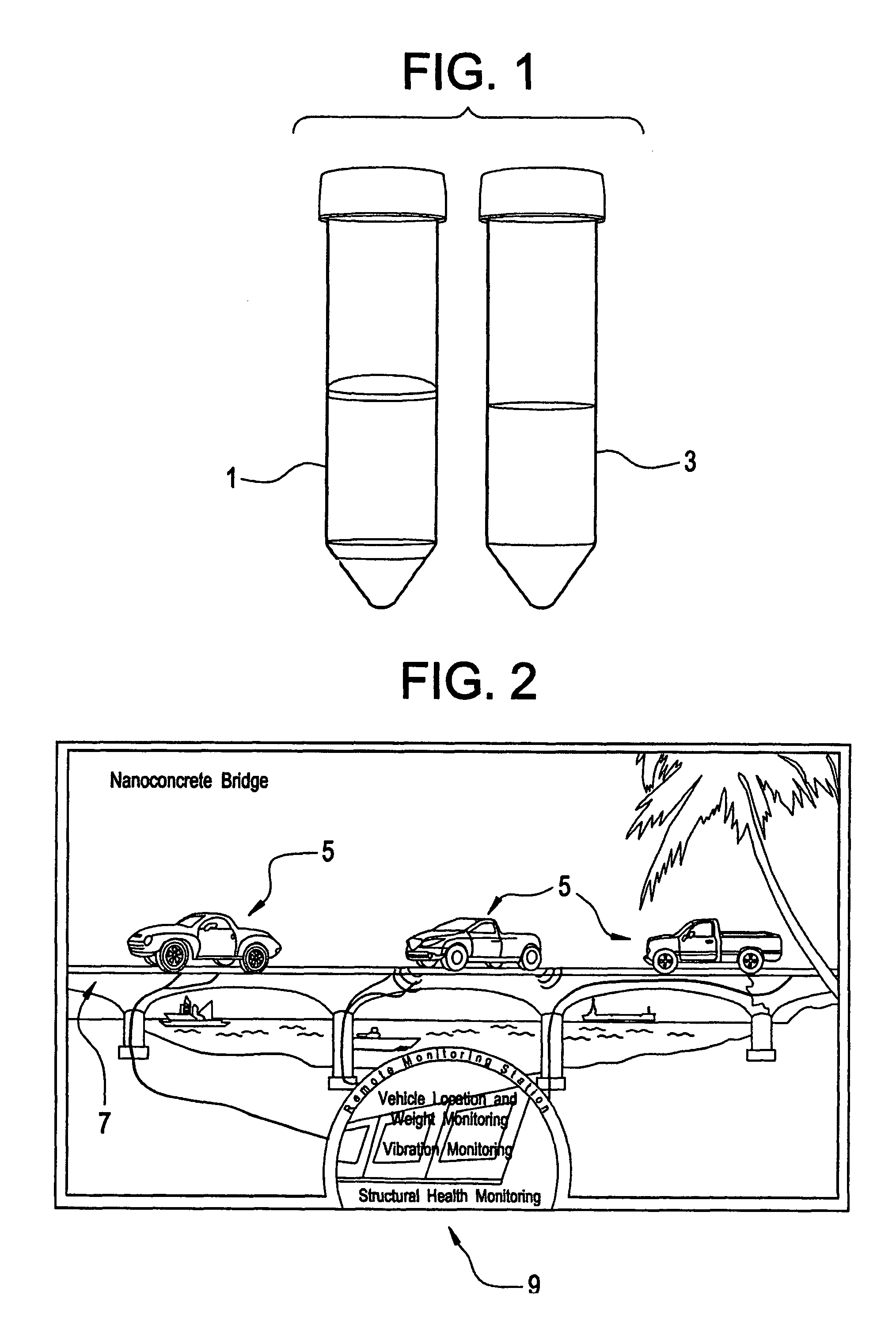

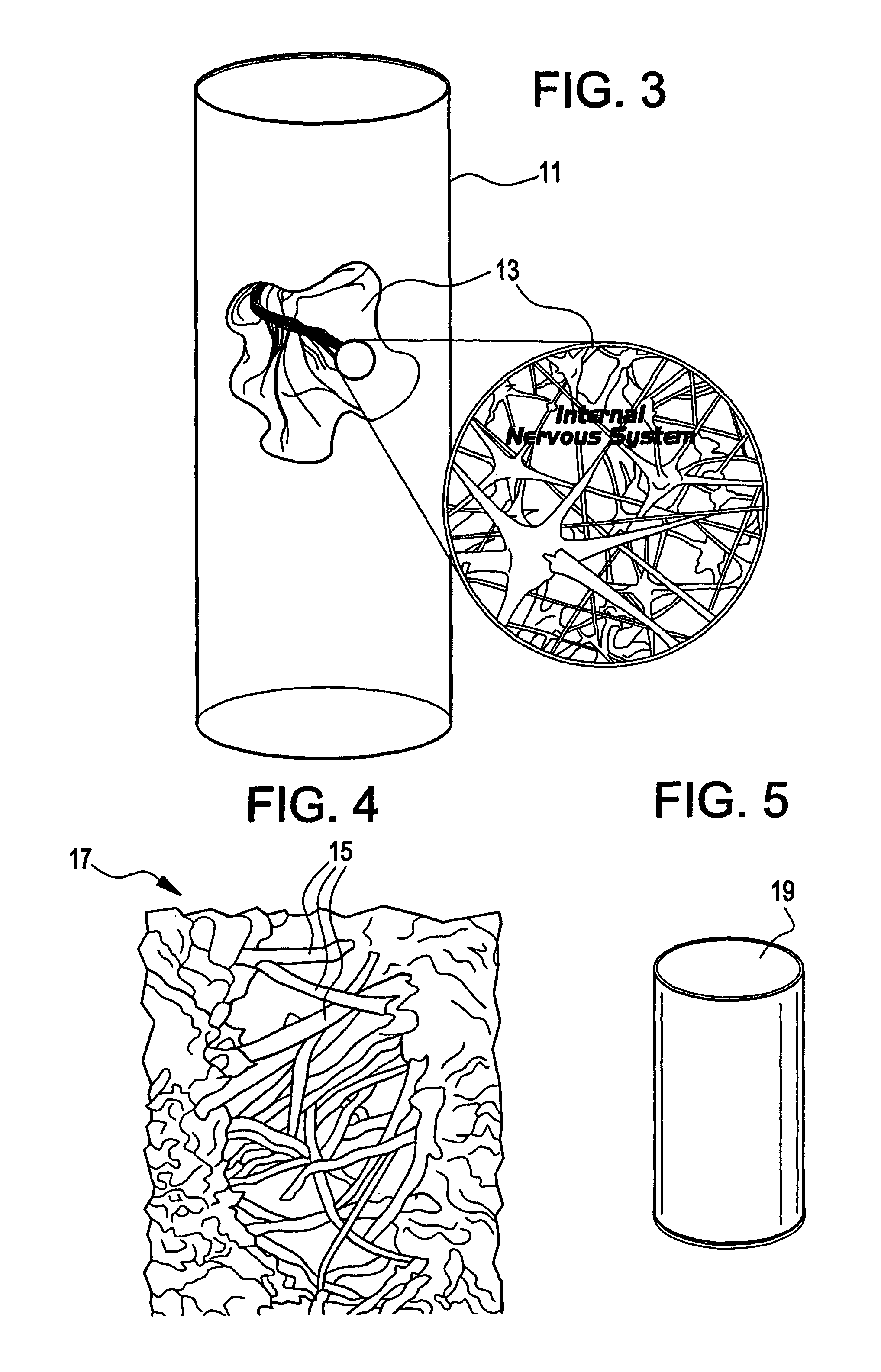

Multifunctional cementitious nanocomposite material and methods of making the same

ActiveUS7666327B1Without altering manufacturing processImprove scalabilitySolid waste managementConductive materialCelluloseWater use

A high performance multifunctional cementitious nanocomposite material is made by adding a nano admixture to the water used in a conventional cementitious material manufacturing process. The nano admixture is made by dispersing nanomaterials in a solvent and sonicating the mixture, adding a hydrophilic emulsifier, thickener, additive or cellulose derived compound to hot water, where it separates and expands, cooling the water, causing the compound to dissolve, and then adding the solvent and nanomaterial mixture to the water and mechanically mixing. The contact between the nanomaterials and the surrounding matrix changes with applied stress, affecting the volume electrical response of the finished nanocomposite material. By measuring the electrical resistance of the material, its structural health, as well as the stress applied to it, can be monitored. A bridge made with the material is monitored for structural integrity and for the weight, speed, and location of traffic over the bridge.

Owner:OCEANIT LAB

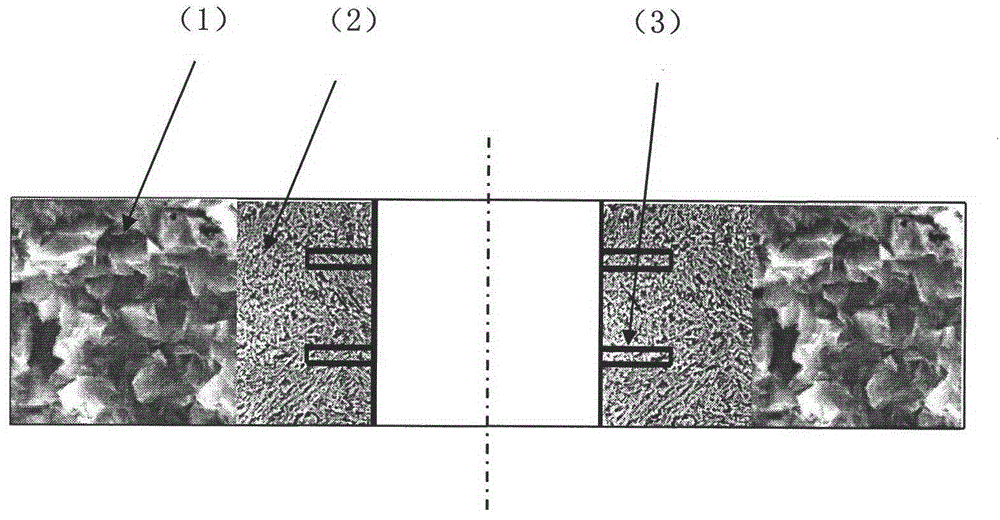

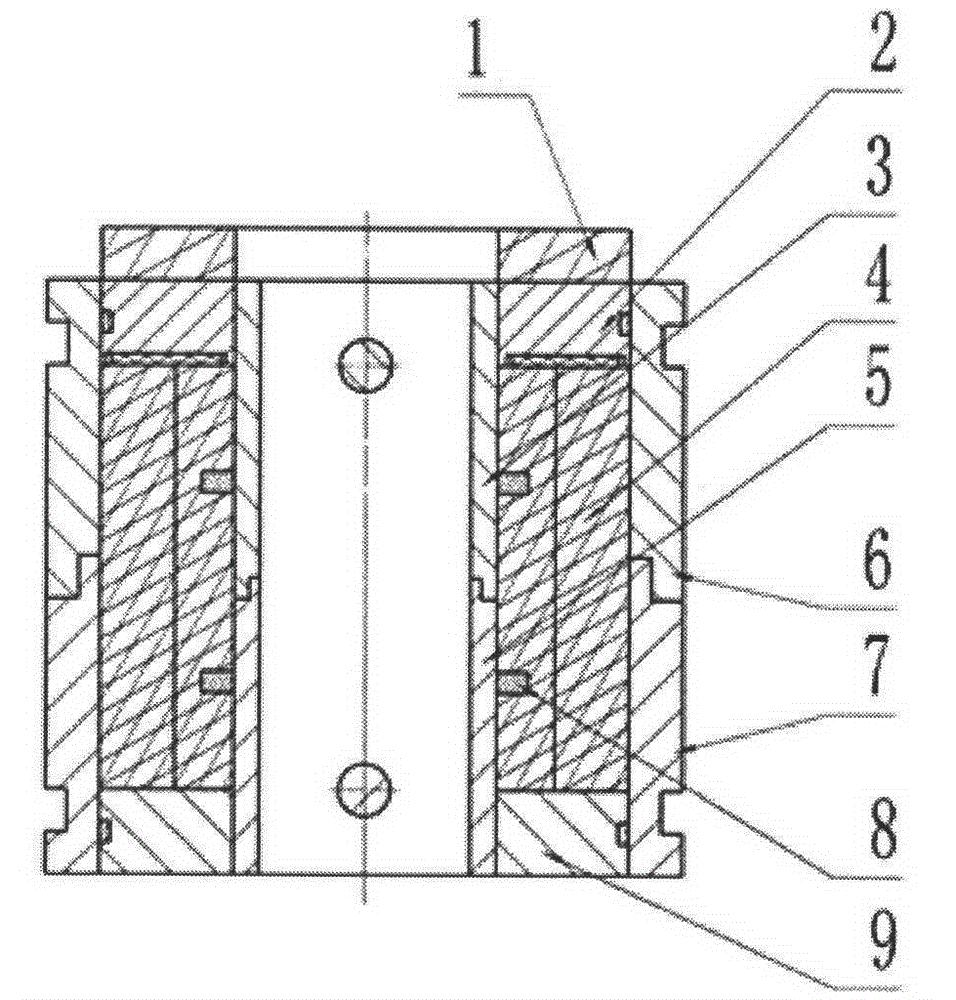

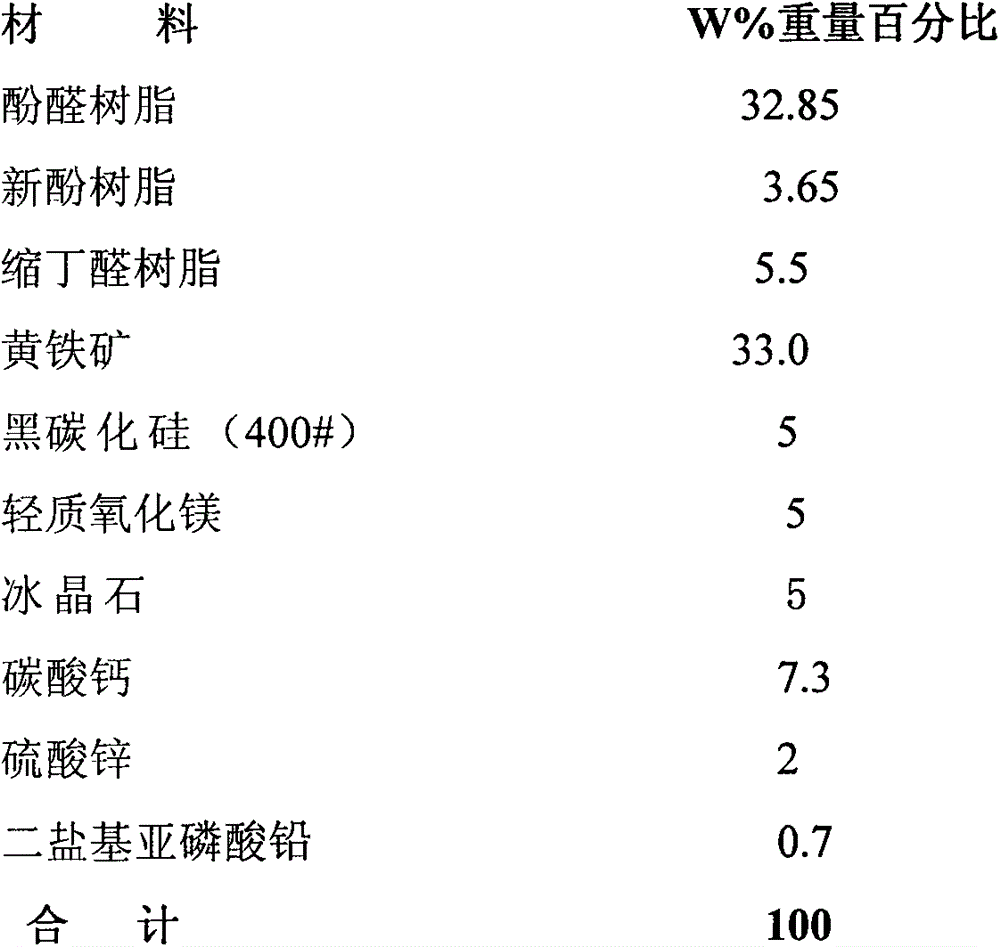

Large-standard high-speed resin heavy duty grinding wheel for grinding steel billet

ActiveCN104625978AHigh tensile and flexural strengthImprove the lubrication effectAbrasion apparatusGrinding devicesFiberMaximum diameter

The preparation method for the large-standard high-speed resin heavy duty grinding wheel for grinding a steel billet comprises the steps that a dedicated binding agent for a high-performance modified high polymer matrix phenolic resin grinding wheel is prepared by using phenolic resin, xylok resin, butyral resin, iron pyrite, cryolite, light magnesium oxide, barite, 400 # carborundum and calcium carbonate, dedicated formulas for a grinding layer and a core layer are separately designed by using grinding materials such as fused alumina zirconia, aluminium oxide sintered corundum, black silicon carbide, furfural, dibutyl ester, fibers and steel rings, and the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is prepared by adopting a dual-phase reinforced composite technology and structure. According to the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet, the linear velocity is equal or greater than 90 m / s to 120 m / s, the maximum diameter is 925 mm, the thickness is 125 mm, and the tensile and breaking strength and the grinding efficiency of the grinding wheel are greatly improved. When the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is under heavy duty, the adaptability of the condition of grinding range is wide, and the linear velocity is high. The grinding efficiency reaches a thickness of 1 cm at a time, the problems that an existing grinding wheel cannot adapt to a steel billet, and the heavy duty grinding of steel is difficult are solved well, and the increasing development requirements of the iron and steel industry are met.

Owner:江苏华东砂轮有限公司

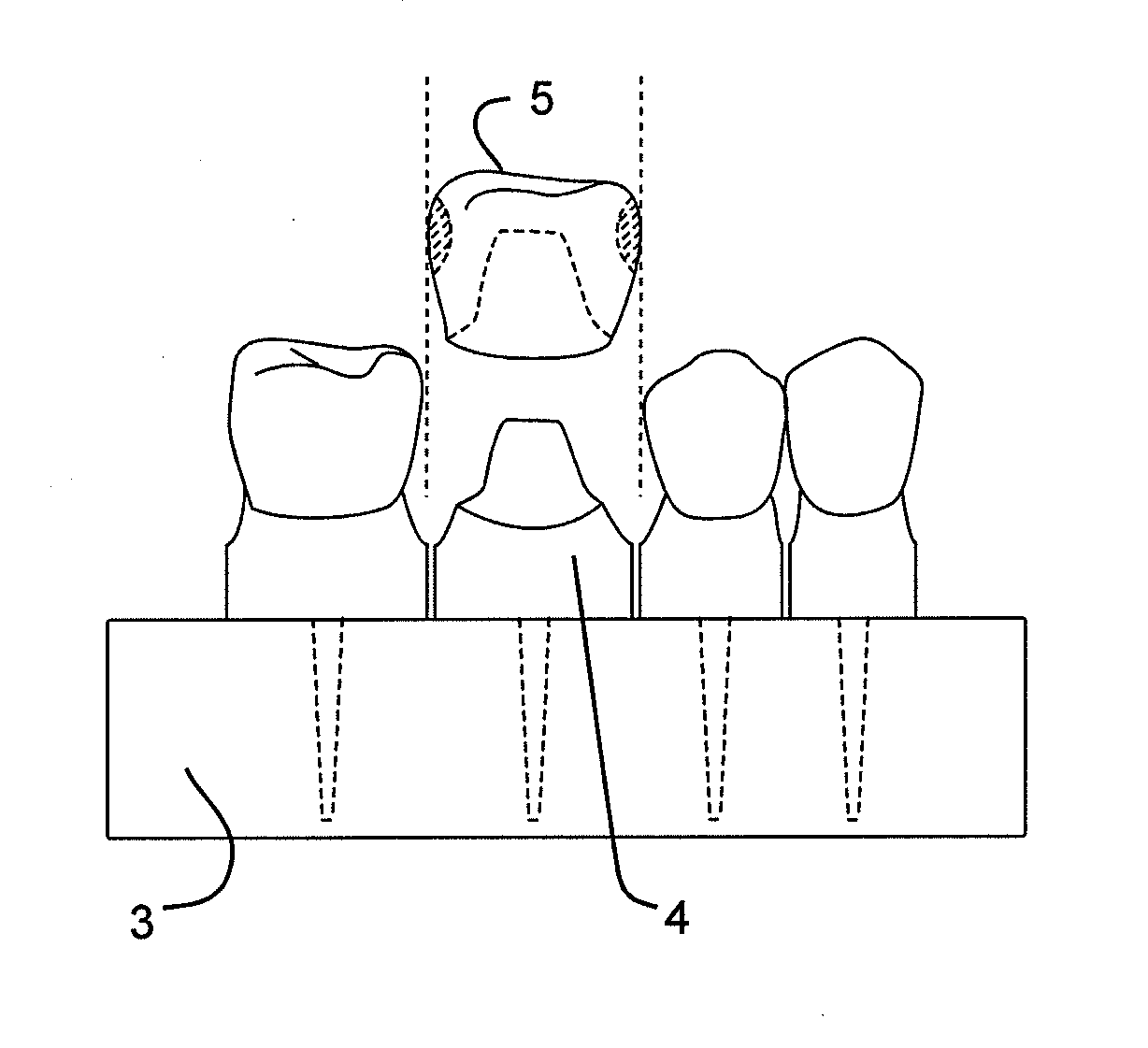

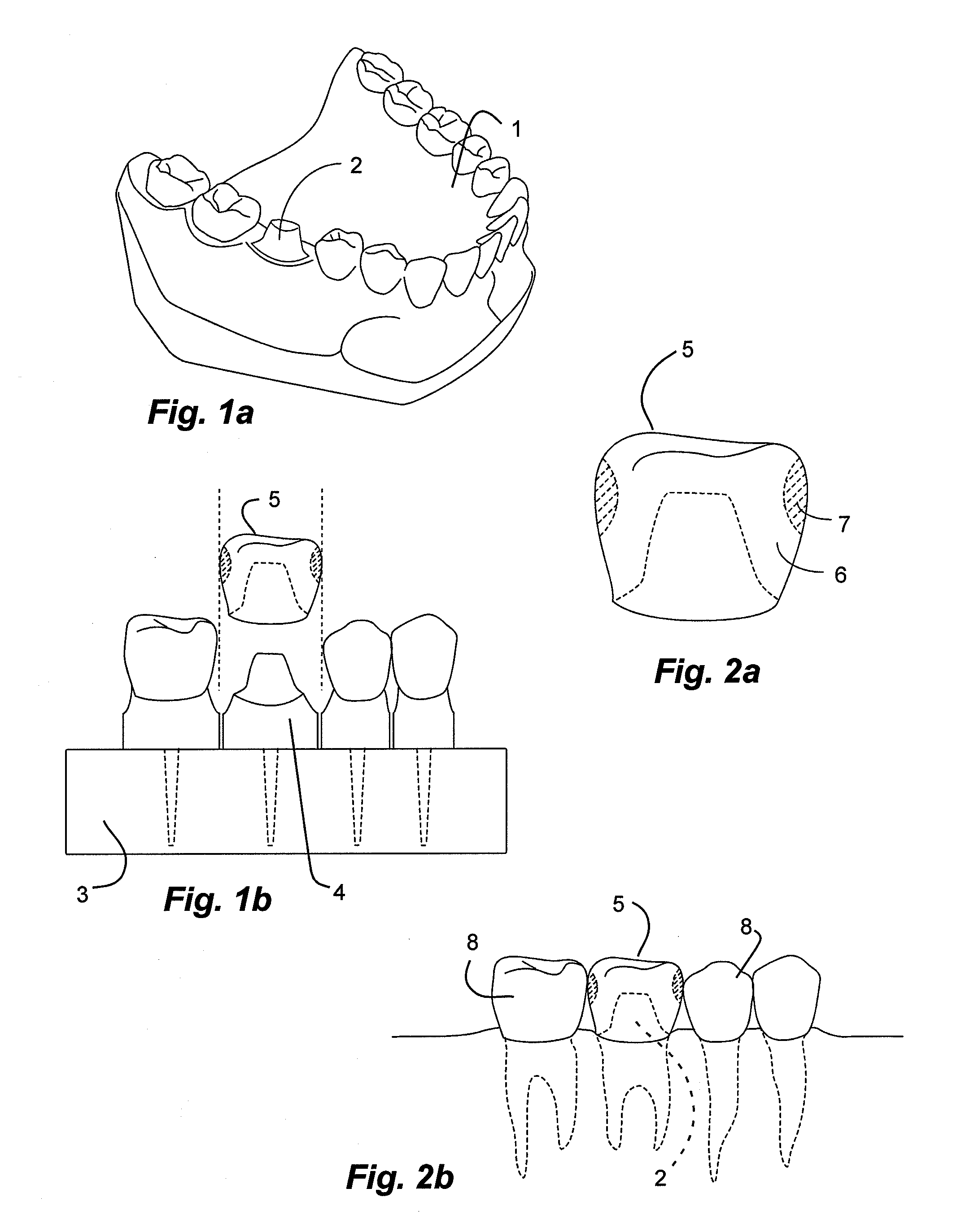

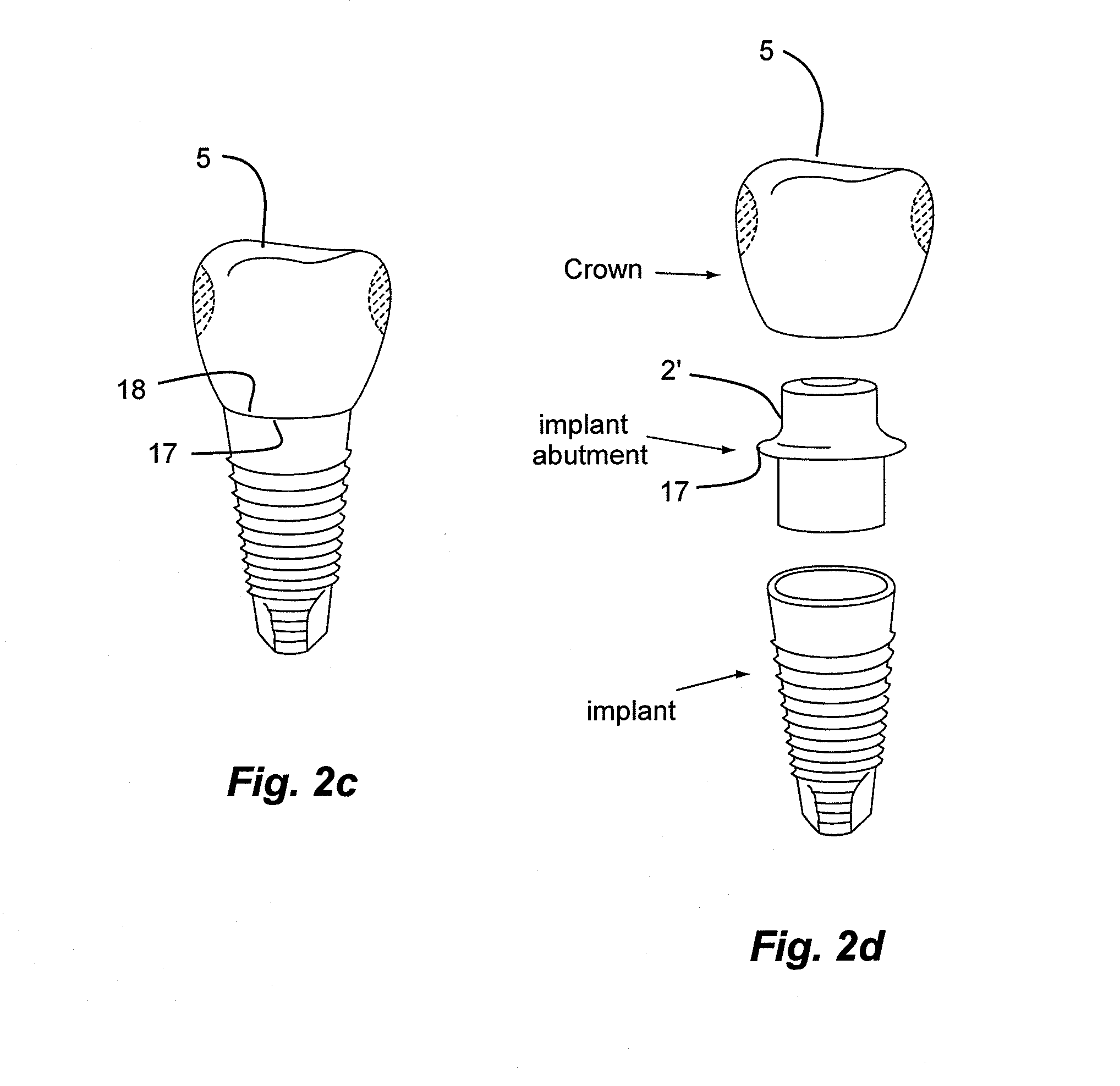

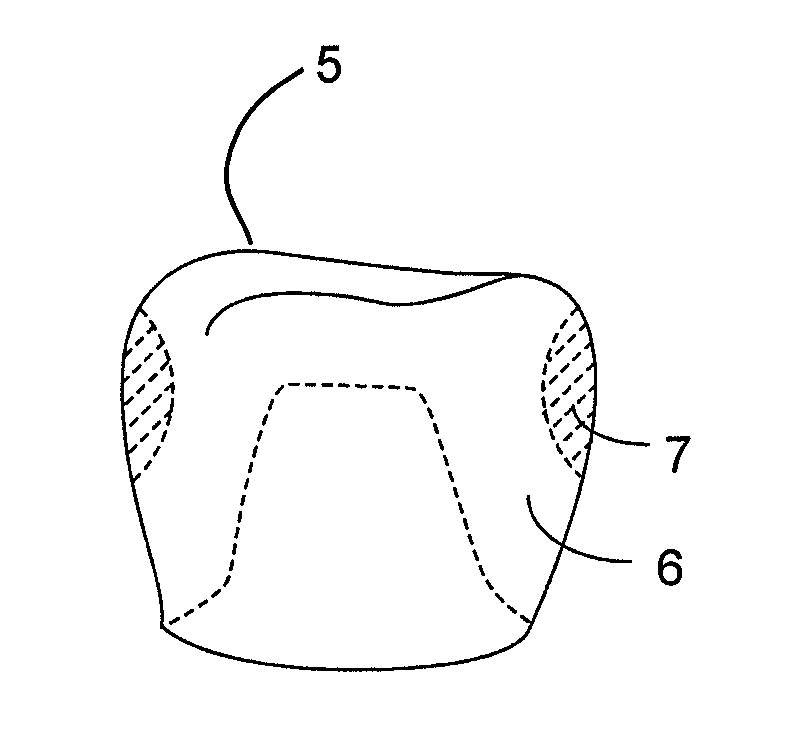

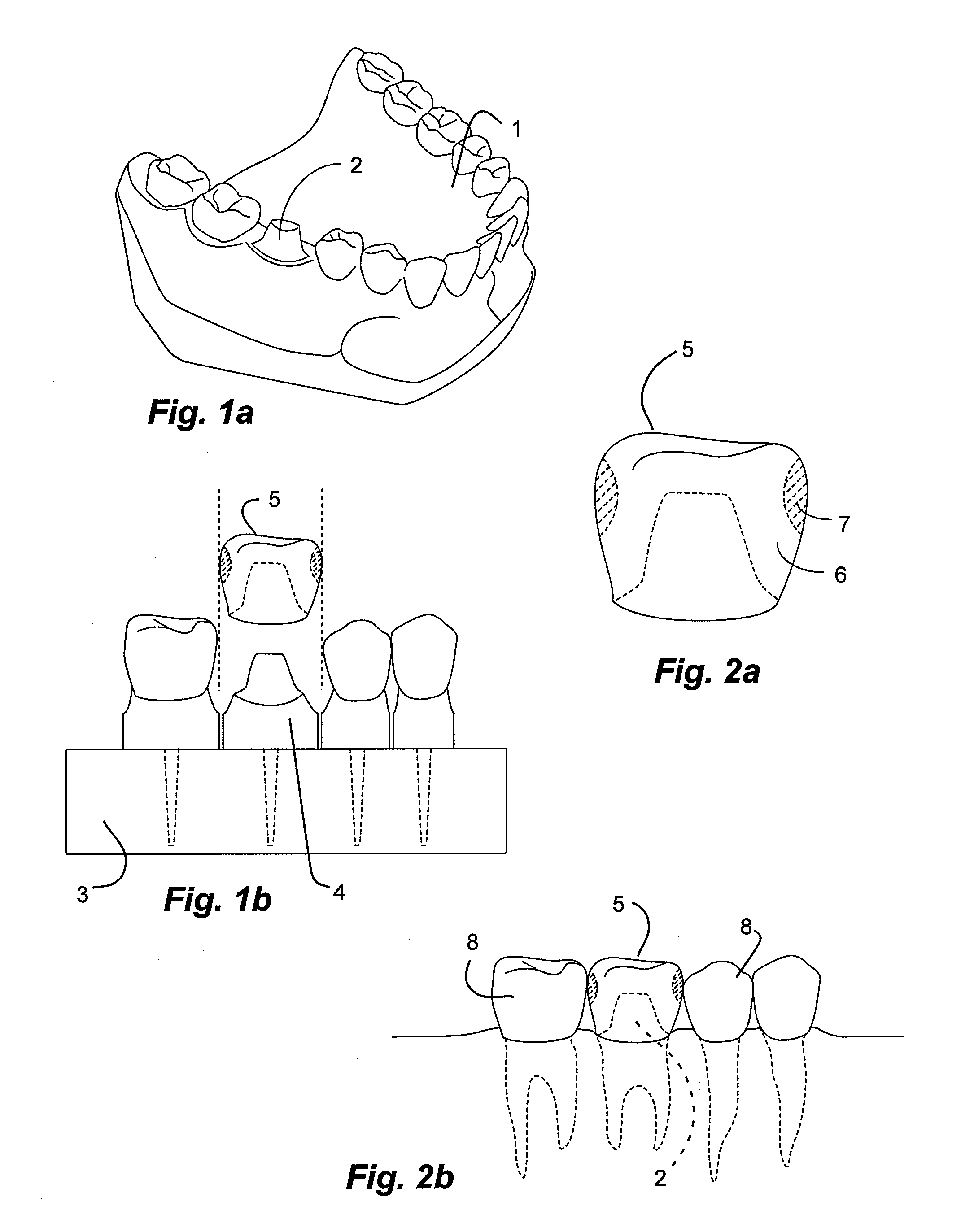

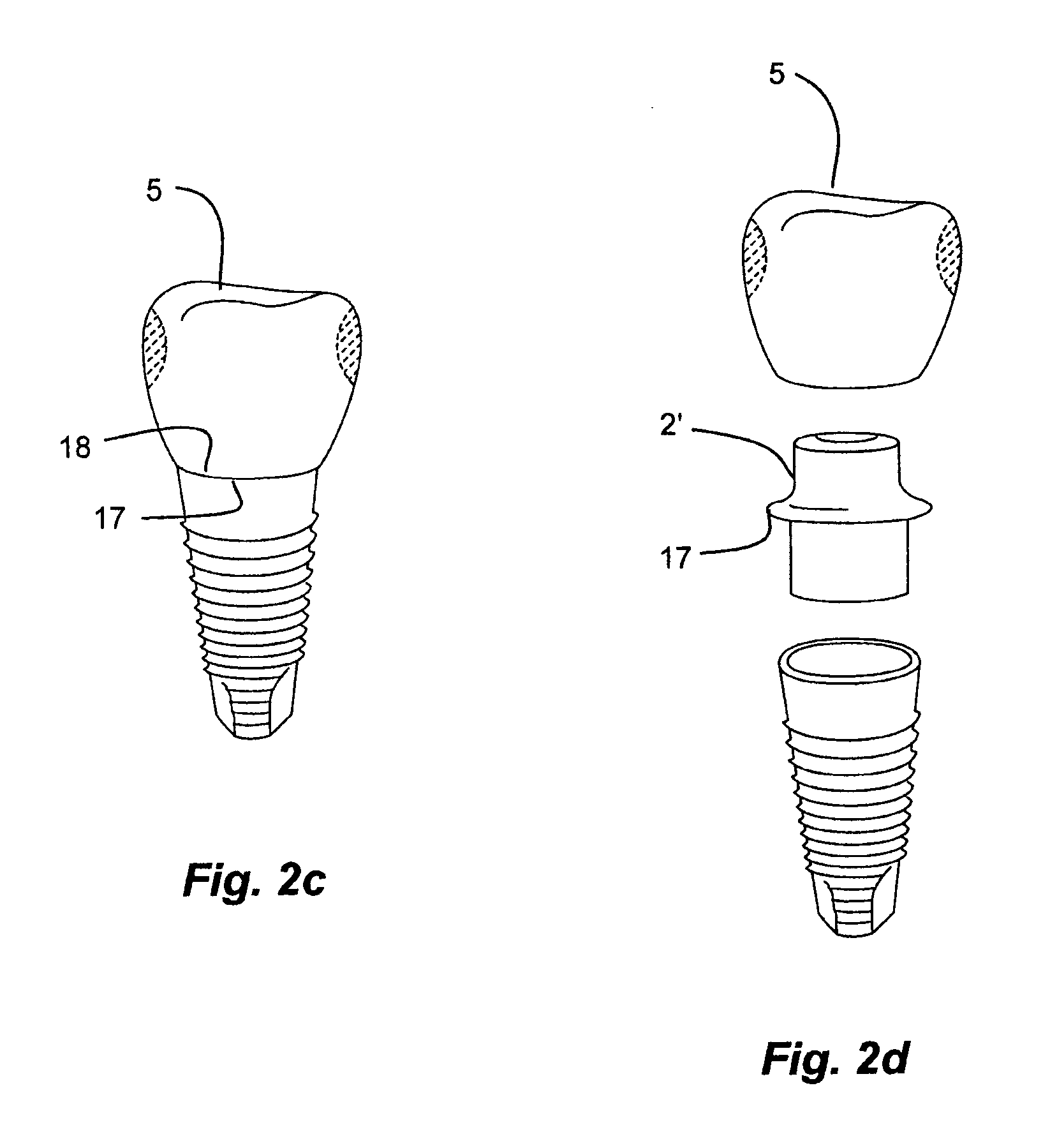

Method of making a dental prosthesis

ActiveUS20150111172A1Improve flexural strengthReduce generationImpression capsFastening prosthesisRestorative materialDentures

A method of making a dental crown or bridge restoration comprises forming a precursor crown outside of a patient's mouth with a first restorative material, with a buccal contour on the buccal wall substantially the same as a buccal contour on a final crown restoration, and an open space on or around at least one of the mesial side wall or the distal side wall; and filling and securing a second material, different from the first restorative material, inside the open space or pocket of the precursor crown while outside the patient's mouth, and with the precursor crown having a strength substantially equivalent to the final crown restoration, and with the buccal contour being substantially the same as the buccal contour on the final crown, prior to filling and securing the second material.

Owner:B & D DENTAL

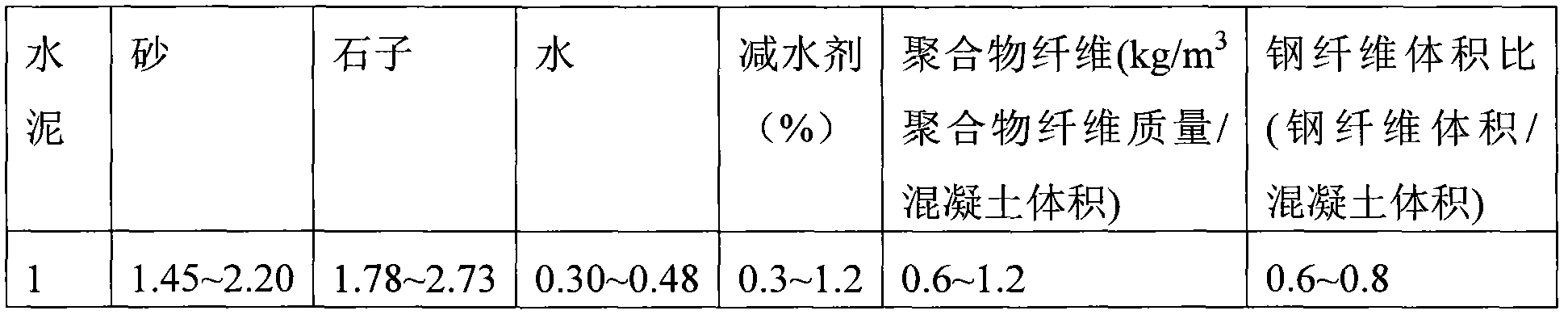

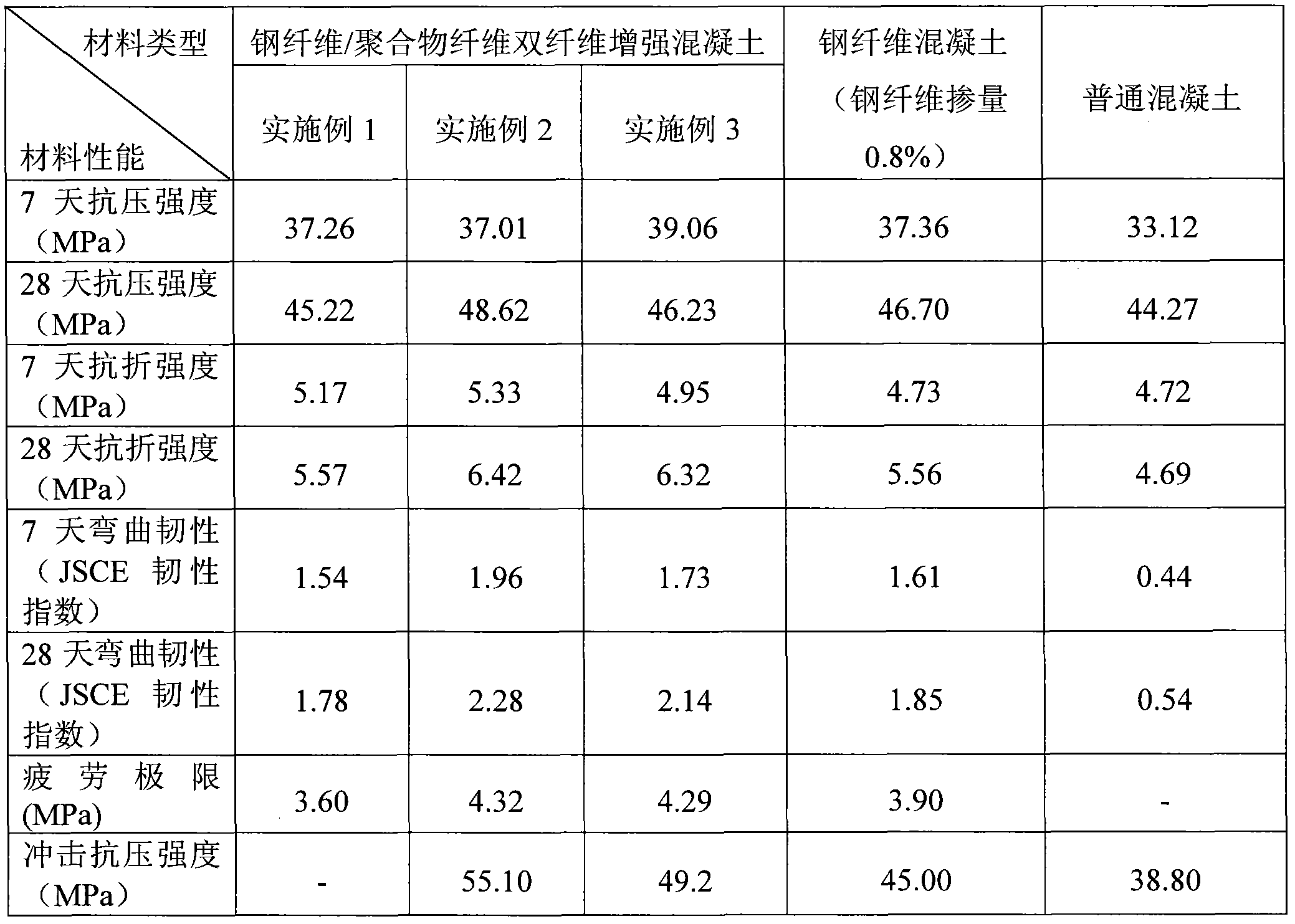

Steel fiber/polymer fiber dual-fiber reinforced concrete and preparation method thereof

InactiveCN101985393AGood combination of rigidity and softnessHigh initial crack strengthSuperplasticizerBridge deck

The invention relates to steel fiber / polymer fiber dual-fiber reinforced concrete and a preparation method thereof, and the preparation method is as follows: pouring cement, sand and stones into a mixing device according to the weight ratio of 1: 1.45-2.20: 1.78-2.73, further putting steel fiber into the mixture according to the steel fiber-concrete volume ratio of 0.6-0.8%: 1, and mixing uniformly; preparing water according to the water-cement weight ratio of 0.30-0.48:1, putting a high-efficient water reducing agent into the mixture according to the high-efficient water reducing agent-cement weight ratio of 0.3-1.2%: 1, putting into the water according to the proportion of 0.6-1.2kg polymer fiber per 1m3 concrete, stirring uniformly and obtaining the mixture; and putting the mixture into a concrete mixing device, stirring uniformly and then obtaining the steel fiber / polymer fiber dual-fiber reinforced concrete. The concrete has excellent quality and can be applied in the fields of rigid bridge deck pavement of concrete bridges and overlaying of old cement and concrete pavements.

Owner:SOUTH CHINA UNIV OF TECH +1

Concrete for high-ground stress and high-ground temperature tunnel excavation primary support

InactiveCN105272012AHigh compressive strengthHigh strengthSolid waste managementGround temperatureCrack resistance

The invention belongs to the technical field of underground engineering materials and particularly relates to concrete for high-ground stress and high-ground temperature tunnel excavation primary support. 1m<3> of concrete comprises the following raw materials in mass: 350 to 400kg of cement, 850 to 1,000kg of coarse aggregate, 450 to 550kg of sand, 200 to 220kg of water, 50 to 100kg of II-grade fly ash, 20 to 40kg of basalt fiber, 10 to 15kg of redispersible latex powder, 6 to 8kg of steel-imitating fiber, 2 to 3 kg of high-performance poly-carboxylic acid water reducing agent and 10 to 15kg of accelerated agent. The concrete has heat tolerance and the function of preventing the brittle failure, such as rock burst; comprehensive problems of rock burst and terrestrial heat damage can be solved; the concrete is easy to stir and mix and good in construction performance; after being ejected onto a wall rock, the concrete can be quickly felted with the wall rock; under the action of the accelerated agent, the concrete is hardened with relatively short time. After the concrete is hardened, the concrete is good in heat tolerance, high in compression strength, high in tensile strength, high in bending strength, good in toughness and good in crack resistance.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Method of making a dental prosthesis

ActiveUS9168114B2Improve flexural strengthReduce generationImpression capsFastening prosthesisRestorative materialDentures

A method of making a dental crown or bridge restoration includes forming a precursor crown outside of a patient's mouth with a first restorative material, with a buccal contour on the buccal wall substantially the same as a buccal contour on a final crown restoration, and an open space on or around at least one of the mesial side wall or the distal side wall; and filling and securing a second material, different from the first restorative material, inside the open space or pocket of the precursor crown while outside the patient's mouth, and with the precursor crown having a strength substantially equivalent to the final crown restoration, and with the buccal contour being substantially the same as the buccal contour on the final crown, prior to filling and securing the second material.

Owner:B & D DENTAL

Multifunctional cementitious nanocomposite material and methods of making the same

ActiveUS7875211B1Without altering manufacturing processImprove scalabilityNon-metal conductorsSolid waste managementCelluloseWater use

A high performance multifunctional cementitious nanocomposite material is made by adding a nano admixture to the water used in a conventional cementitious material manufacturing process. The nano admixture is made by dispersing nanomaterials in a solvent and sonicating the mixture, adding a hydrophilic emulsifier, thickener, additive or cellulose derived compound to hot water, where it separates and expands, cooling the water, causing the compound to dissolve, and then adding the solvent and nanomaterial mixture to the water and mechanically mixing. The contact between the nanomaterials and the surrounding matrix changes with applied stress, affecting the volume electrical response of the finished nanocomposite material. By measuring the electrical resistance of the material, its structural health, as well as the stress applied to it, can be monitored. A bridge made with the material is monitored for structural integrity and for the weight, speed, and location of traffic over the bridge.

Owner:OCEANIT LAB

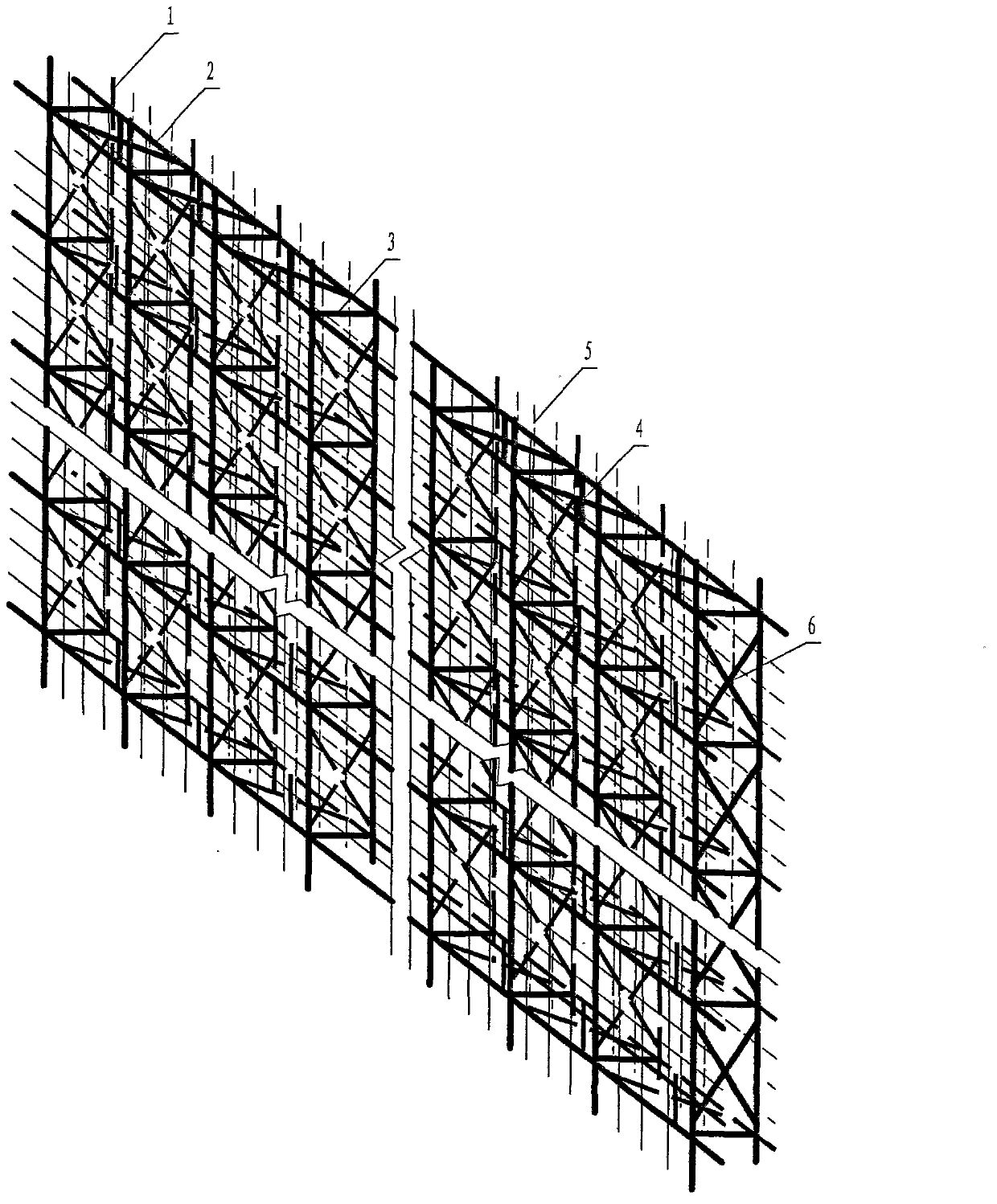

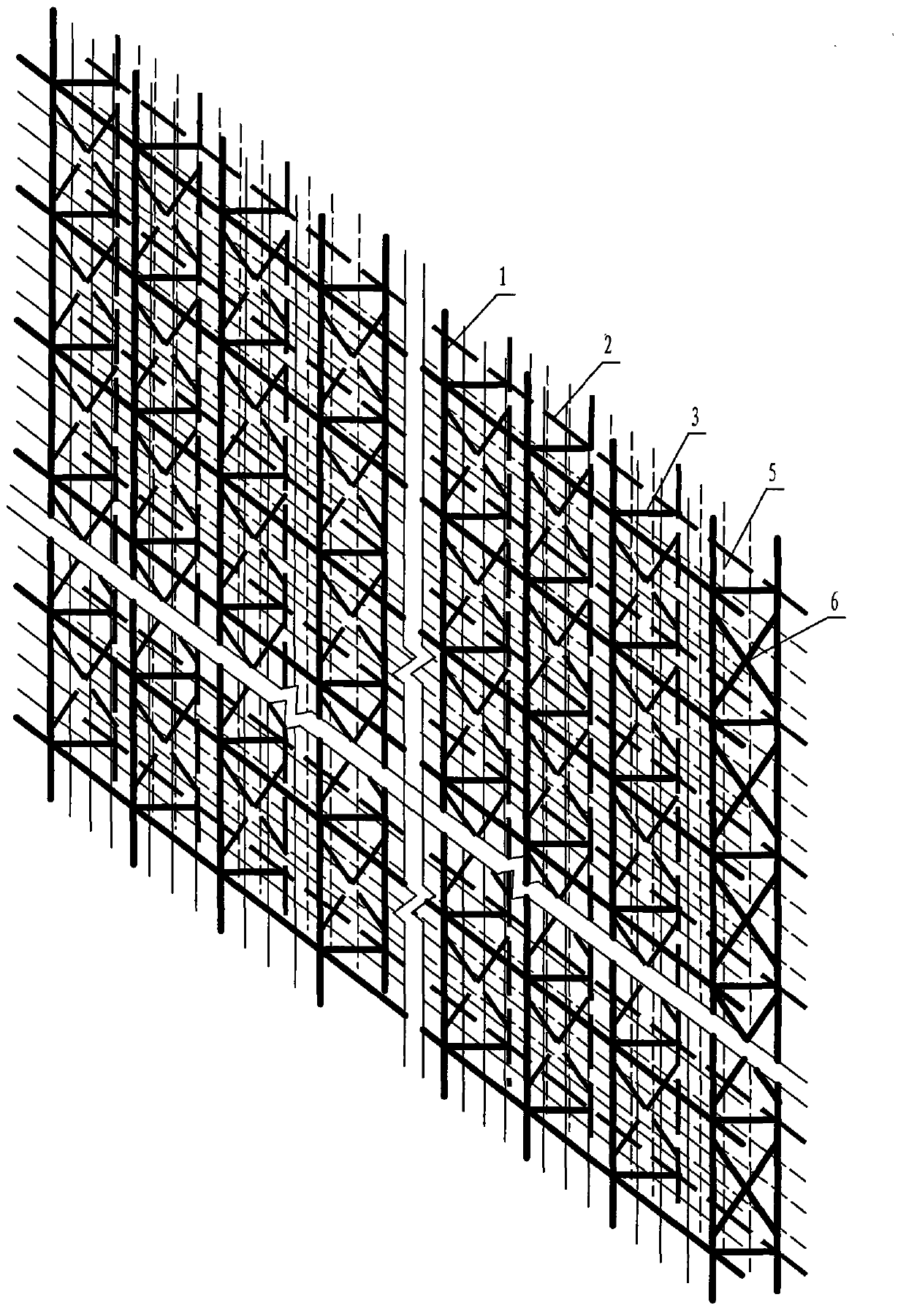

Preparation method of floor plate

InactiveCN102922600AHigh tensile and flexural strengthEven by forceCeramic shaping apparatusRebarHigh performance concrete

A preparation method of a floor plate comprises three steps of manufacturing a three-dimensional trussed type steel bar net rack, preparing concrete materials and manufacturing the floor plate. The three-dimensional trussed type zinc-coated steel wire net rack is connected with high performance concrete in a solidification mode, so that the floor plate has high bearing capacity and high durability, and is simple and easy to install, fast in construction speed, reductive in pollution on site, and saving in a great amount of steel, concrete and wood and expenses of labors, water and electricity. The floor plate can be standardized in a factory and manufactured in a scale mode, and is an innovation-type assembly type strong intensity floor plate.

Owner:闫丕

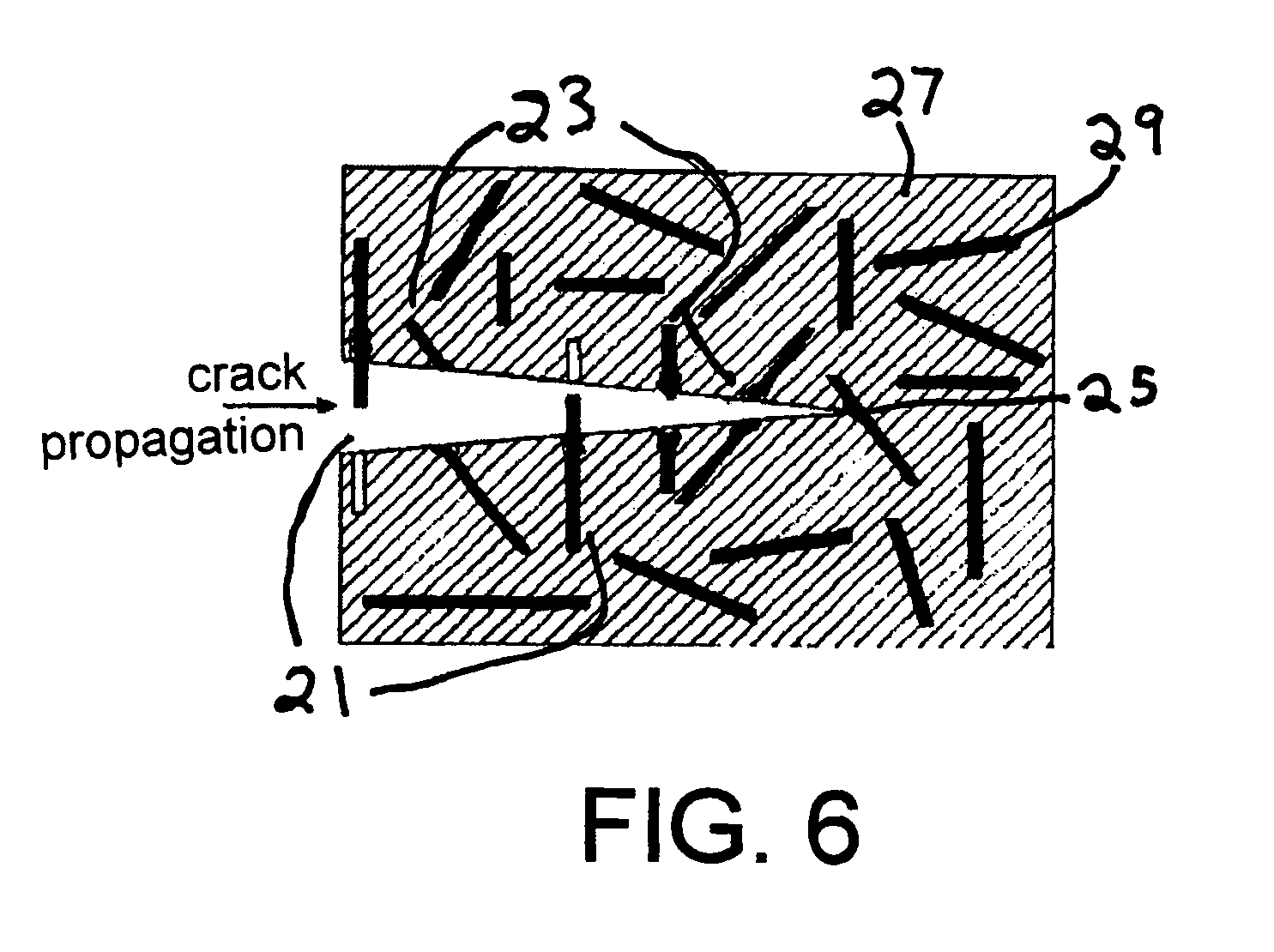

Cementitious matrix and fiber reinforced cement based mixture

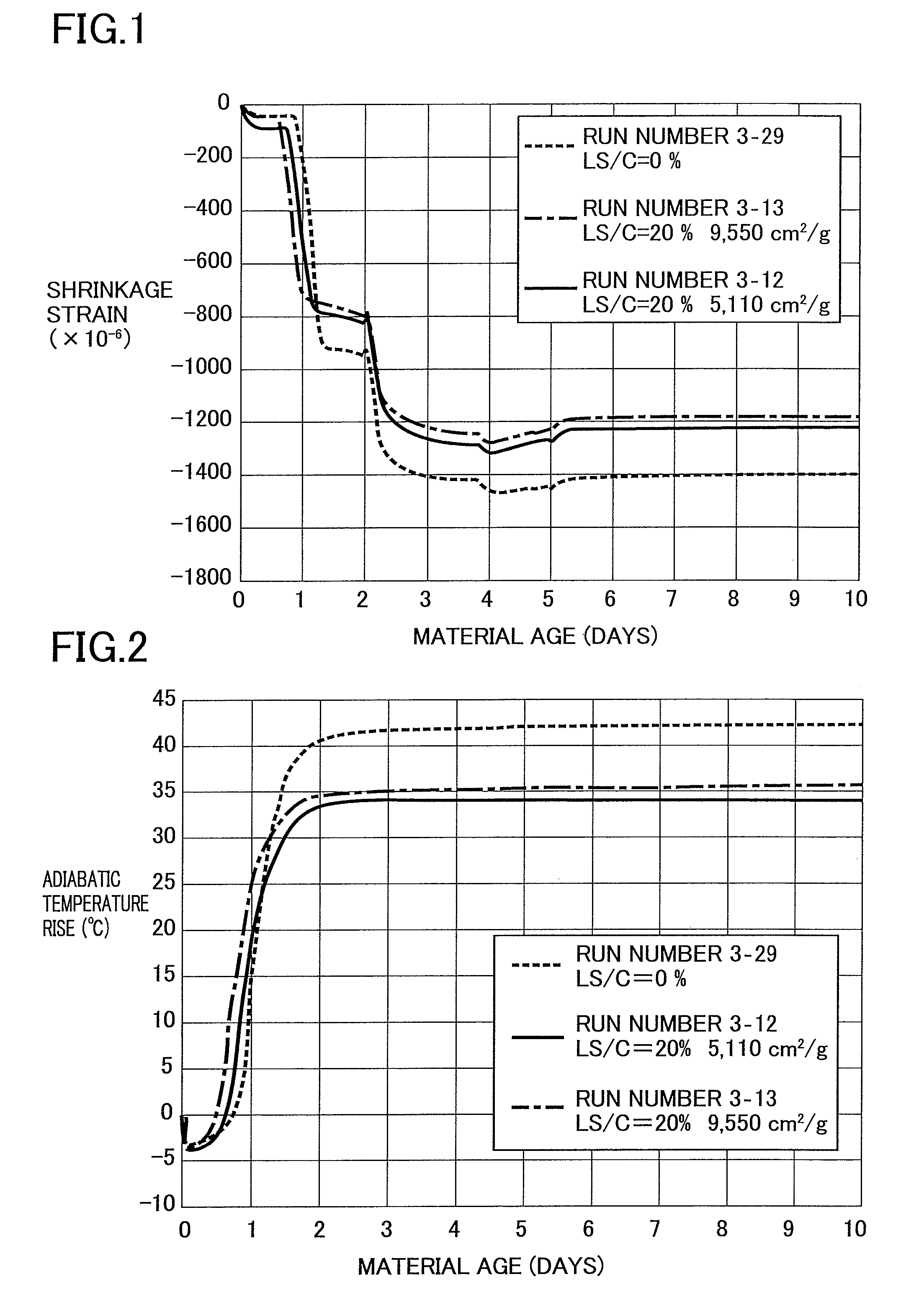

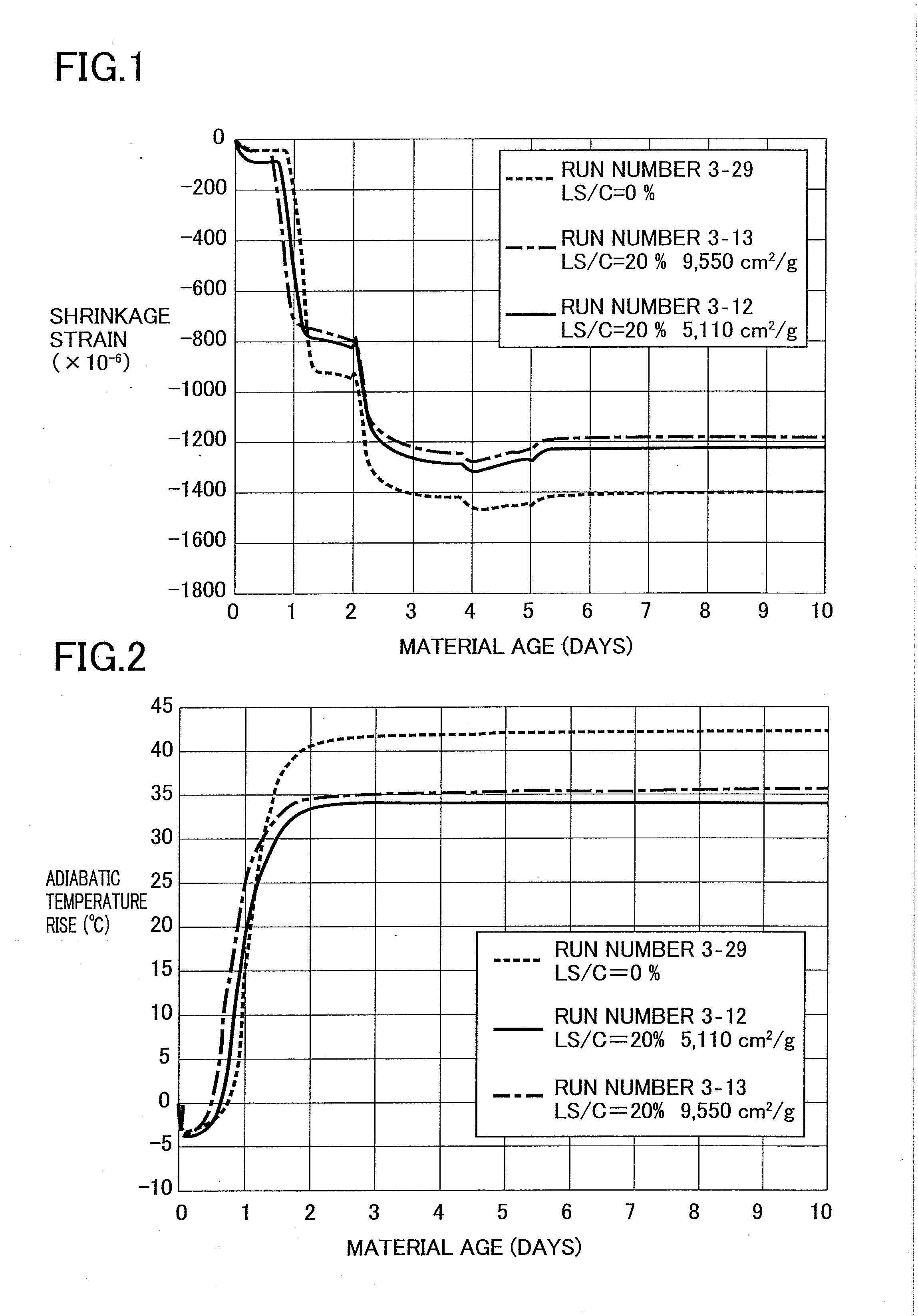

ActiveUS9115026B2Early strengthHigh tensile and flexural strengthSolid waste managementChemical admixtureSlag

Owner:TAISEI CORP

Cementitious matrix and fiber reinforced cement based mixture

ActiveUS20150166414A1Early strengthHigh tensile and flexural strengthSolid waste managementChemical admixtureSlag

A cementitious matrix in which the development of early strength is fast, the hydration heat temperature is small, and the amount of shrinkage during curing is small, while keeping the fluidity when concrete is fresh, is provided. The cementitious matrix is characterized by comprising 100 parts by weight of Portland cement, 5 to 30 parts by weight of silica fume, 5 to 25 parts by weight of limestone powder, 30 to 80 parts by weight of at least one of ground blast furnace slag or fly ash, at least one chemical admixture, water, and 70 to 150 parts by weight of aggregate having a largest aggregate diameter of 1.2 to 3.5 mm.

Owner:TAISEI CORP

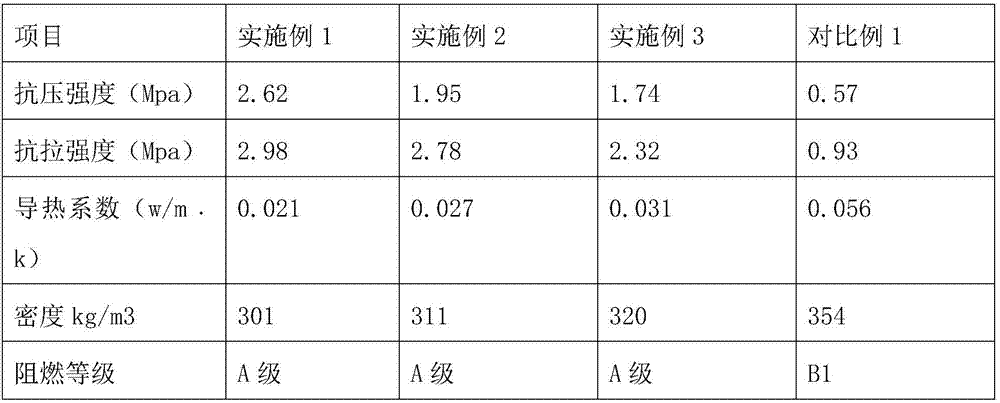

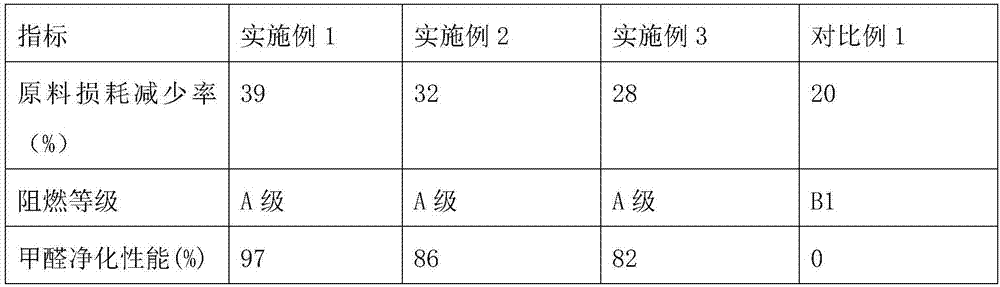

Fireproof door core filling material and preparation method thereof

The invention provides a fireproof door core filling material and a preparation method thereof, and relates to the field of fireproof materials. The fireproof door core filling material comprises the following raw materials in parts by weight: 32-40 parts of perlite, 14-18 parts of bentonite, and 10-12 parts of magnesium sulfate 16-20 parts of magnesium oxide, 10-12 parts of calcium hydroxide, 4-8 parts of boron oxide, 5-7 parts of lignin, 5-11 parts of ceramic fiber, 17-21 parts of glass wool, 13-19 parts of zirconia 8-14 parts of airgel, 6-18 parts of nano-silicon carbide, 1-3 parts of inorganic binder and 7-11 parts of water; the preparation method comprises the following steps: (1) weighing raw materials; (2) preparing mixed solution; (3) stirring. The invention solves the problem that the existing fire door core filling material is still insufficient when applied to fire doors with high requirements on compressive strength, tensile strength, thermal insulation, bulk density and fire protection.

Owner:HEFEI SHANGHAN DECORATION ENG CO LTD

Energy-saving environment-friendly wall body material and preparation method thereof

The invention provides an energy-saving environment-friendly wall body material and a preparation method thereof, and relates to the field of building materials. The energy-saving environment-friendly wall body material is prepared from the following raw materials in parts by weight: 15 to 19 parts of fine sand, 30 to 40 parts of crushed stone, 18 to 30 parts of cement, 10 to 15 parts of waste polyurethane foam plastic, 9 to 17 parts of waste extruded sheet, 15 to 20 parts of bamboo charcoal, 5 to 9 parts of ceramic fiber, 8 to 14 parts of polyamide fiber, 3 to 5 parts of attapulgite, 12 to 16 parts of phenolic foam, 11 to 17 parts of vermiculite, 0.2 to 0.4 part of bonding agent, 0.7 to 1.1 parts of thermal stabilizer, 0.3 to 0.5 part of air entraining agent, 0.2 to 0.6 part of retarder, 0.3 to 0.7 part of water reducing agent, and 3 to 7 parts of water. The preparation method comprises the following steps: (1) weighting the raw materials; (2) calcining the vermiculite; (3) smashing the mixed materials; (4) preparing a mixture; (5) preparing mixed slurry; (6) casing, demolding and curing. The energy-saving environment-friendly wall body material prepared by the method provided by the invention has the advantages of high compressive strength, high tensile strength, high heat preservation and insulation performance, energy saving and high environmental friendliness.

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

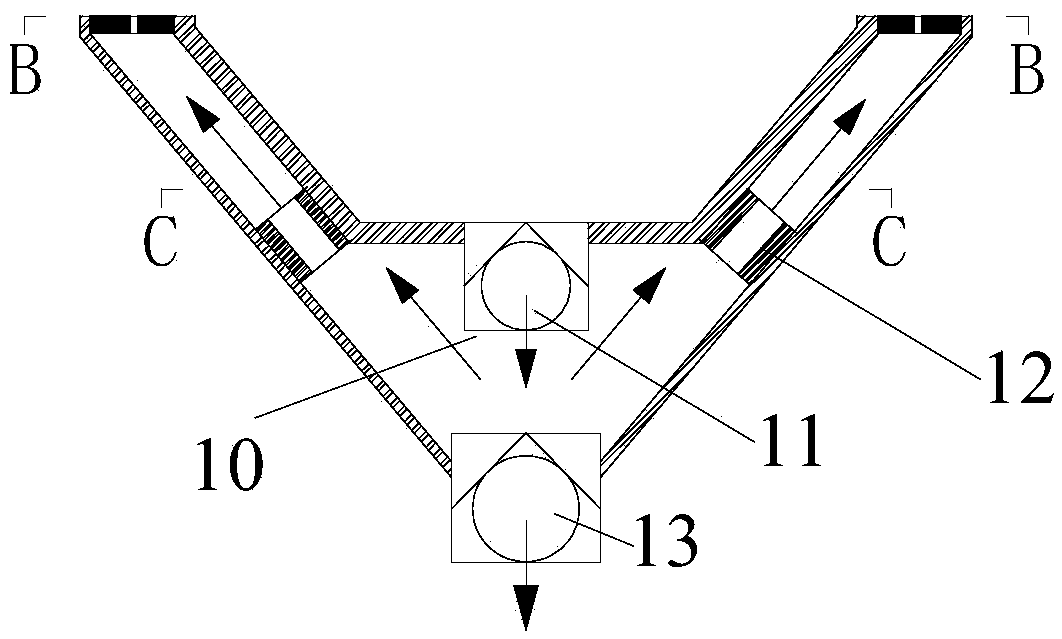

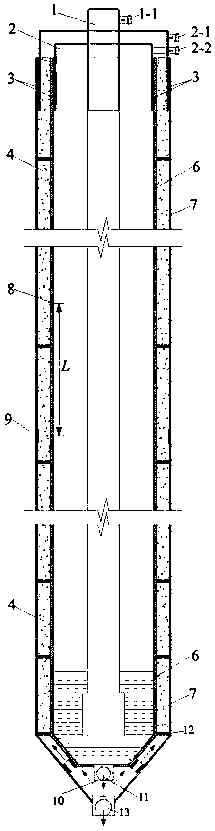

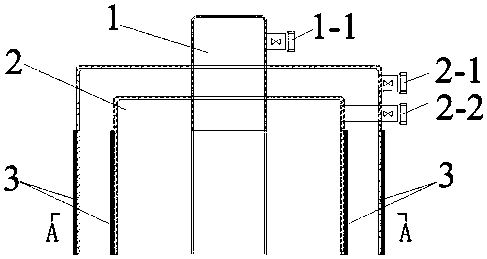

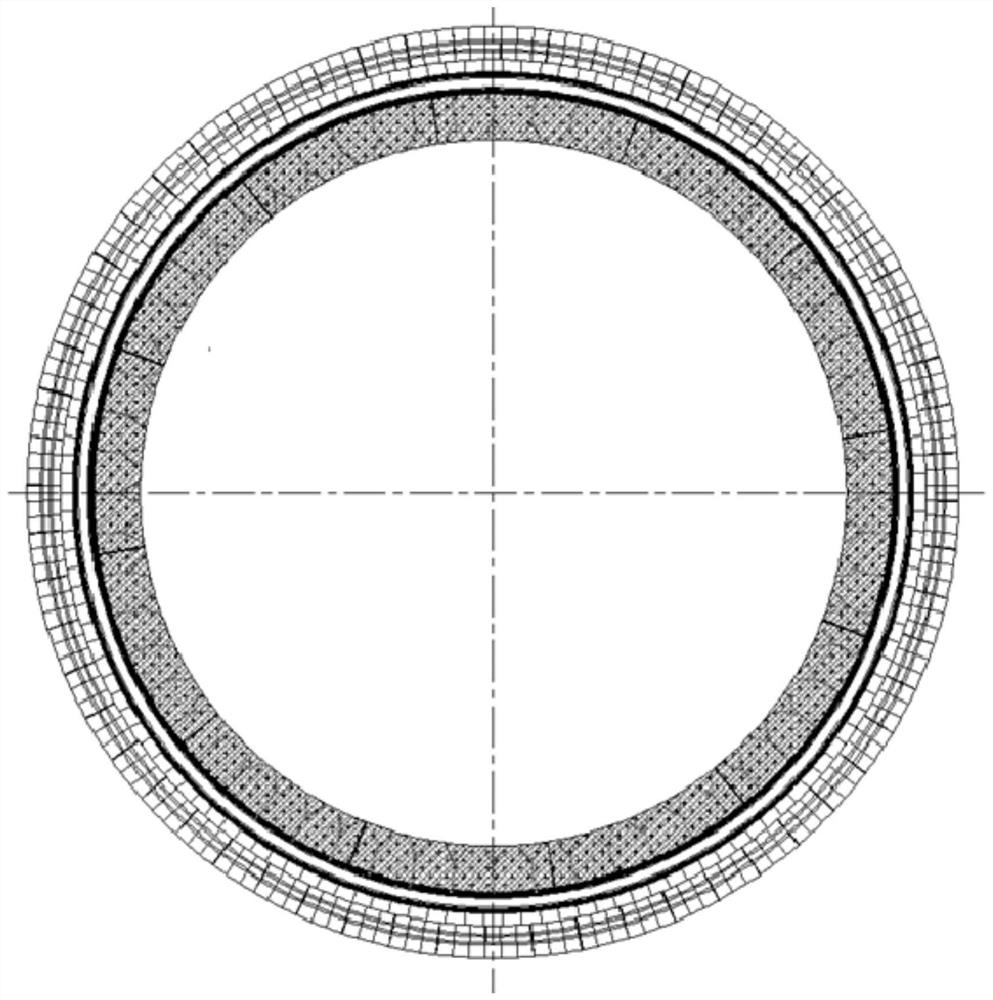

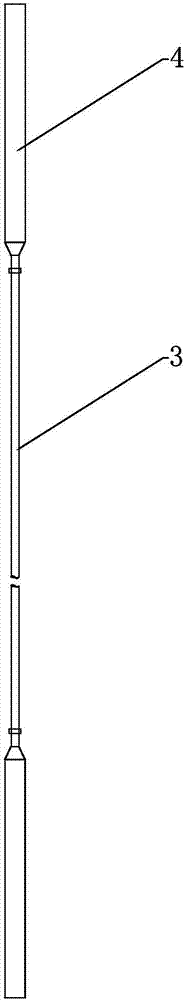

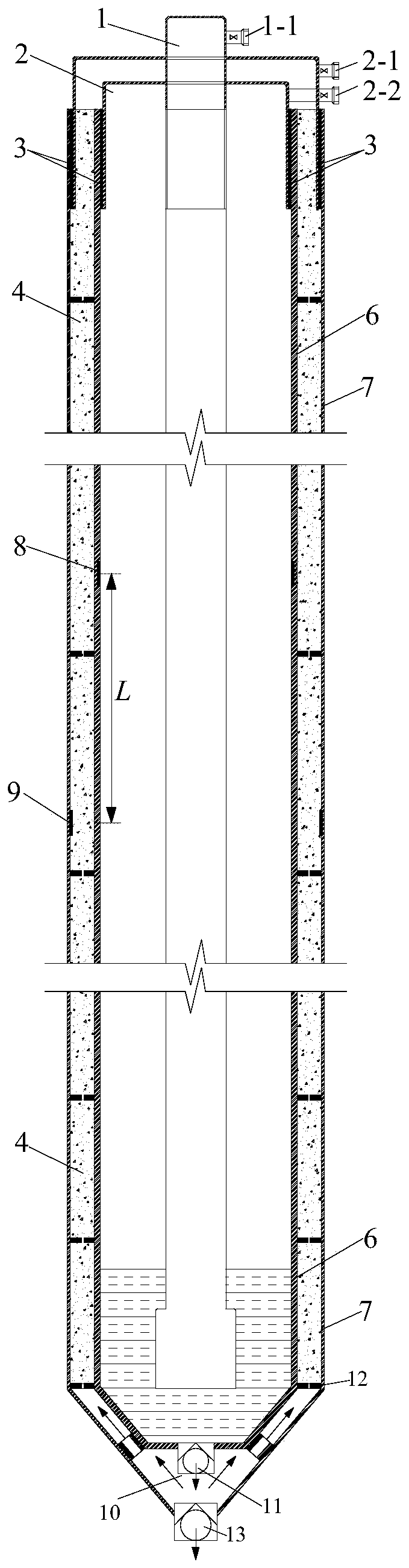

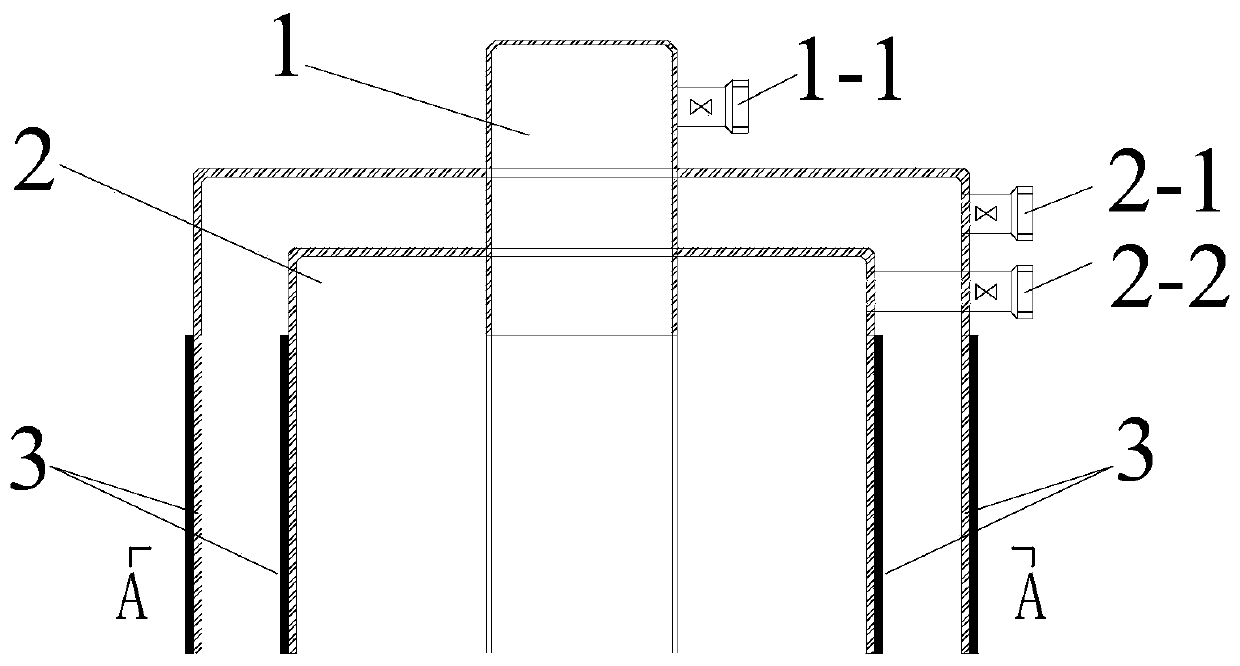

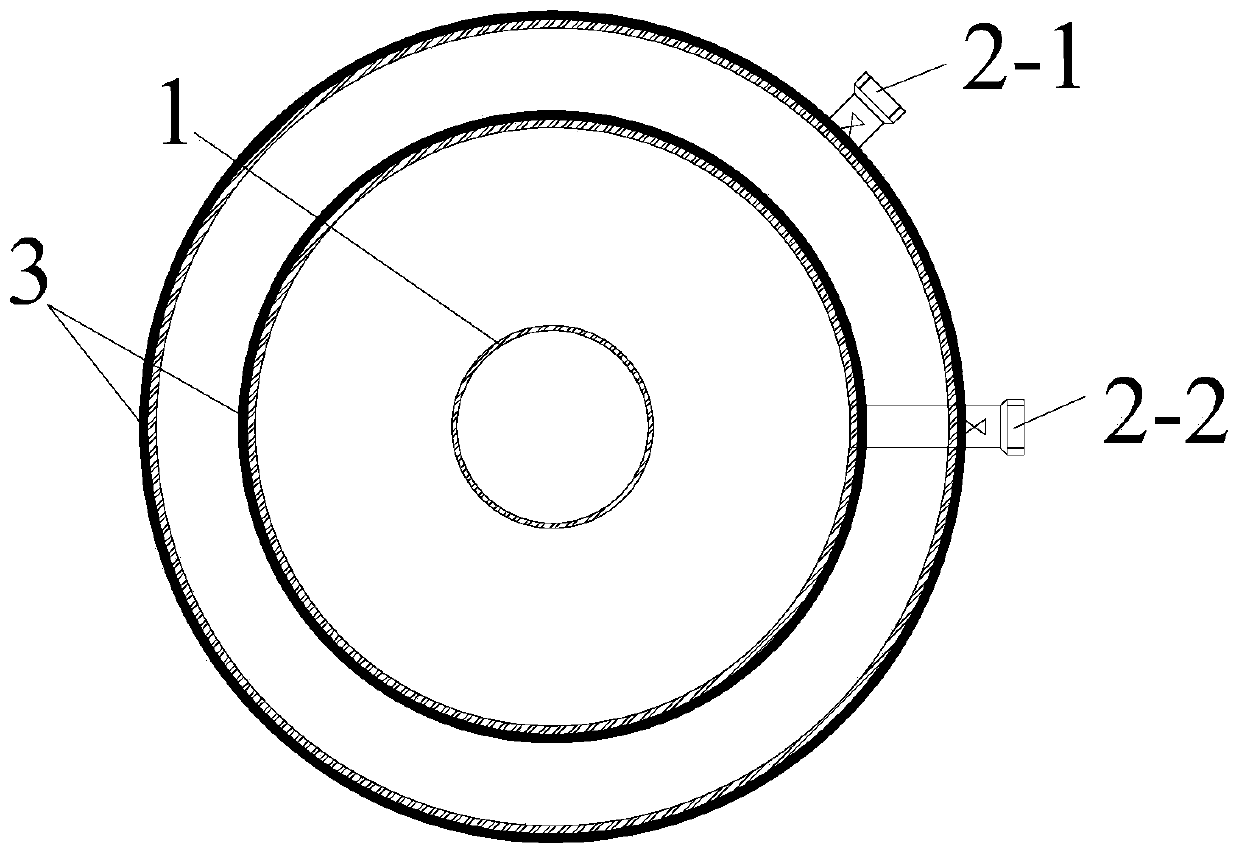

Double-layered cavity inner fiber web reinforced grouting full-length reinforced freezing pipe and construction method thereof

ActiveCN109505607AHigh tensile and flexural strengthIncrease stiffnessShaft sinkingTunnelsFiberAqueous corrosion

The invention discloses a double-layered cavity fiber web reinforced grouting full-length reinforced freezing pipe and a construction method thereof. The pipe mainly comprises a main body structure with steel pipes with large and small diameters in sleeve connection to form a cavity of inner and outer walls, a bottom taper angle device connecting the inner and outer steel pipe walls of the main body structure and an inner and outer pipe top port sealing device. The bottom taper angle device is also of a double-layered cavity structure communicated with the cavity of the main body structure, and the bottom taper angle device is internally provided with a one-way backstop pressure valve communicated with the inside of the freezing pipe and the cavity. According to the design, by means of matched operation of a liquid feeding pipe and the one-way backstop pressure valve, cement slurry is injected into the cavity of the main body structure, and a pre-placed fiber web is placed to form fiber web reinforced concrete. The stiffness, the strength and the corrosion resistance of the freezing pipe are greatly improved. The freezing pipe is suitable for the stratum freezing method construction project subjected to complex high stress and aqueous corrosion, effectively reduces the accident probability of freezing wall melting due to salt leakage caused by damage and fracture caused by thecorrosion and the high stress, and avoids inducing flooding accidents.

Owner:CHINA UNIV OF MINING & TECH

Energy-saving and environment-friendly building decoration material and preparation method thereof

InactiveCN107266006ALow long-term utilizationTo achieve the effect of energy saving and environmental protectionFiberSlag

The invention provides an energy-saving and environment-friendly building decoration material and a preparation method thereof and relates to the field of building materials. The energy-saving and environment-friendly building decoration material comprises waste plastic, slag powder, stone powder, polyvinyl chloride resin, glass fibers, bamboo fibers, nanometer silicon carbide, zirconium oxide, ceramic fibers, graphite, airgel, water glass, diatomite, attapulgite, activated carbon powder, a flame retardant and a compatibilizer according to a weight part ratio. The preparation method comprises (1) raw material weighing, (2) plastic granule preparation, (3) stirring and (4) heating and extrusion forming. The building decoration material has the advantages of good fire resistance, good energy saving and environmental protection effect and low cost.

Owner:合肥市一片叶装饰工程有限公司

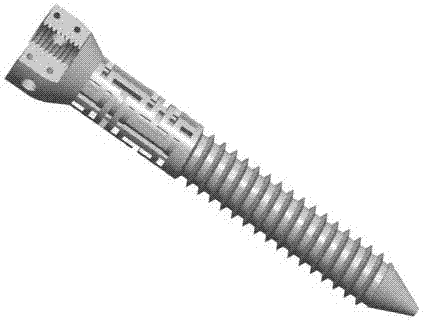

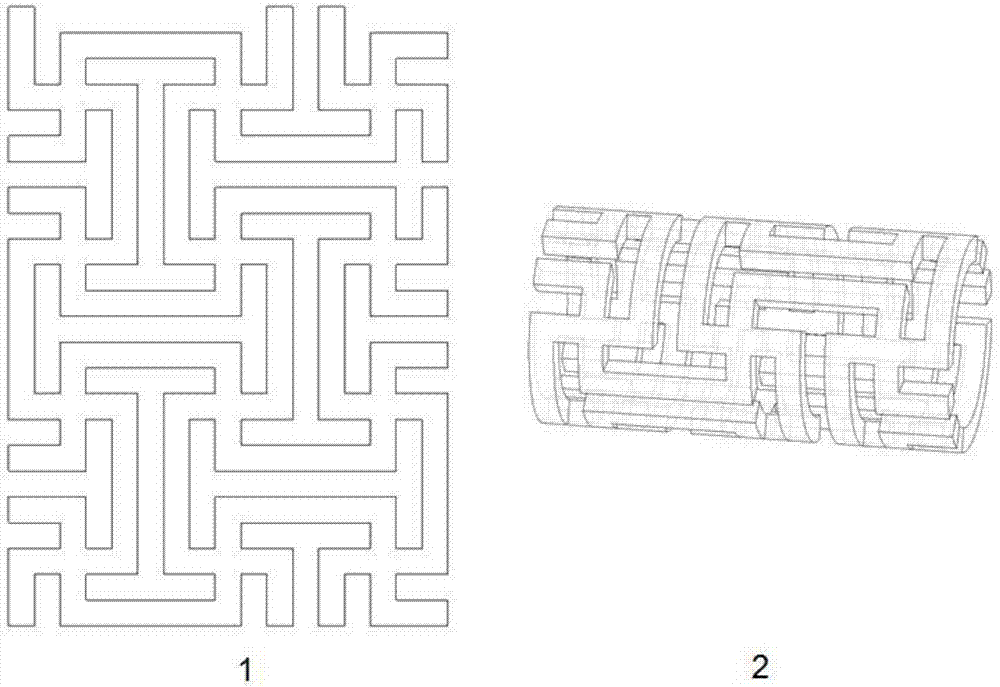

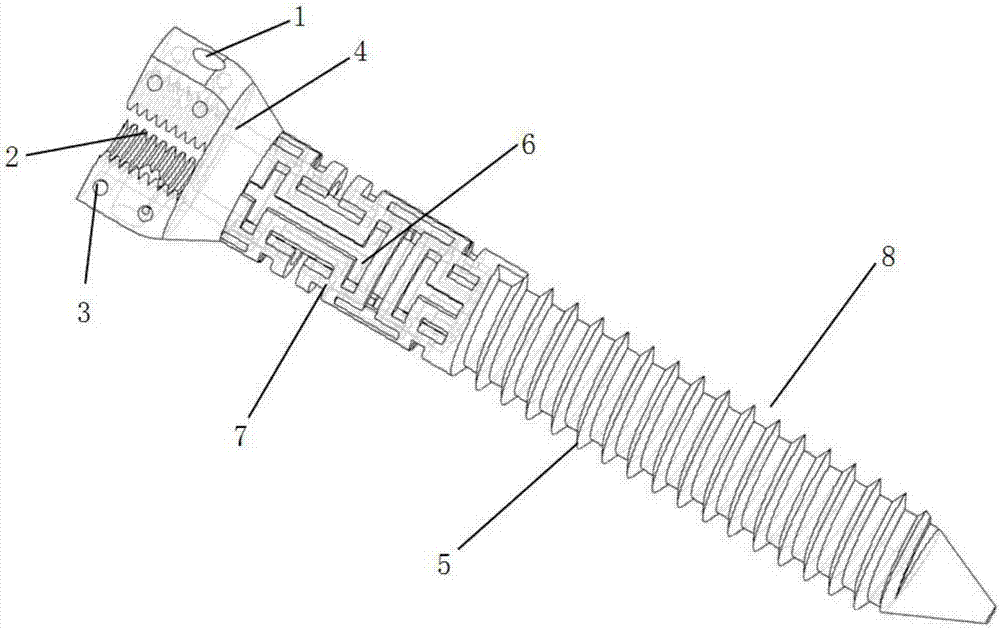

Novel anti-pullout pedicle screw based on additive manufacturing technology

ActiveCN107981926AHigh tensile and flexural strengthGood adhesionInternal osteosythesisOsseointegrationManufacturing technology

The invention discloses a novel anti-pullout pedicle screw based on the additive manufacturing technology, which is high in strength and capable of promoting osseointegration. The pedicle screw is composed of a solid nail lower end with a thread, a nail upper end with a peripheral tensile expansion structure and an internal solid cylinder, and a nail base connected with the peripheral tensile expansion structure, as is shown in Figure 1. With the tensile expansion performance of the tensile expansion structure, the pedicle screw expands when tensioned, and thus the stability of the pedicle screw and the vertebral body is improved; meanwhile, the tensile expansion structure part is of a porous structure, and osteocytes can grow into the porous structure easily to promote osseointegration and accelerate integration of the pedicle screw and the vertebral body; besides, unique structural design is adopted to overcome the defect of low strength of the tensile expansion structure, so that the mechanical strength of the pedicle screw is ensured and the internal fixation effect is improved while the anti-pullout performance of the pedicle screw is achieved. The pedicle screw can be easilyapplied to design of orthopedic medical instruments.

Owner:BEIHANG UNIV

Energy-saving and environment-friendly building material and preparation method thereof

The invention provides an energy-saving and environment-friendly building material and a preparation method thereof and relates to the field of building materials. The energy-saving and environment-friendly building material contains the following raw materials in parts by weight: 5-9 parts of nano titanium dioxide, 7-11 parts of asphalt, 11-15 parts of bauxite, 8-10 parts of tricalcium silicate, 4-8 parts of polypropylene resin, 13-21 parts of flue dust, 12-18 parts of zirconium phosphate silver-loaded powder, 13-17 parts of waste glass, 5-9 parts of waste polyethylene foam plastic, 9-13 parts of ceramic fiber, 7-11 parts of polyarmide fiber, 13-17 parts of active carbon, 13-23 parts of attapulgite, 11-21 parts of diatomite, 2-4 parts of adhesive, 0.5-0.9 part of retarder, 0.1-0.5 parts of antioxidant, 0.3-0.9 part of heat stabilizer, 0.2-0.4 part of water reducing agent and 5-7 parts of water. The preparation method comprises the following steps: (1) weighing the materials; (2) heating; (3) crushing; (4) stirring; (5) pressurizing and forming; and (6) drying. The energy-saving and environment-friendly building material and the preparation method provided by the invention have the advantage that the problem that the existing building materials have shortages when being applied to buildings with higher requirements for environmental protection, compression resistance, bending resistance and tensile strength is solved.

Owner:合肥聪亨新型建材科技有限公司

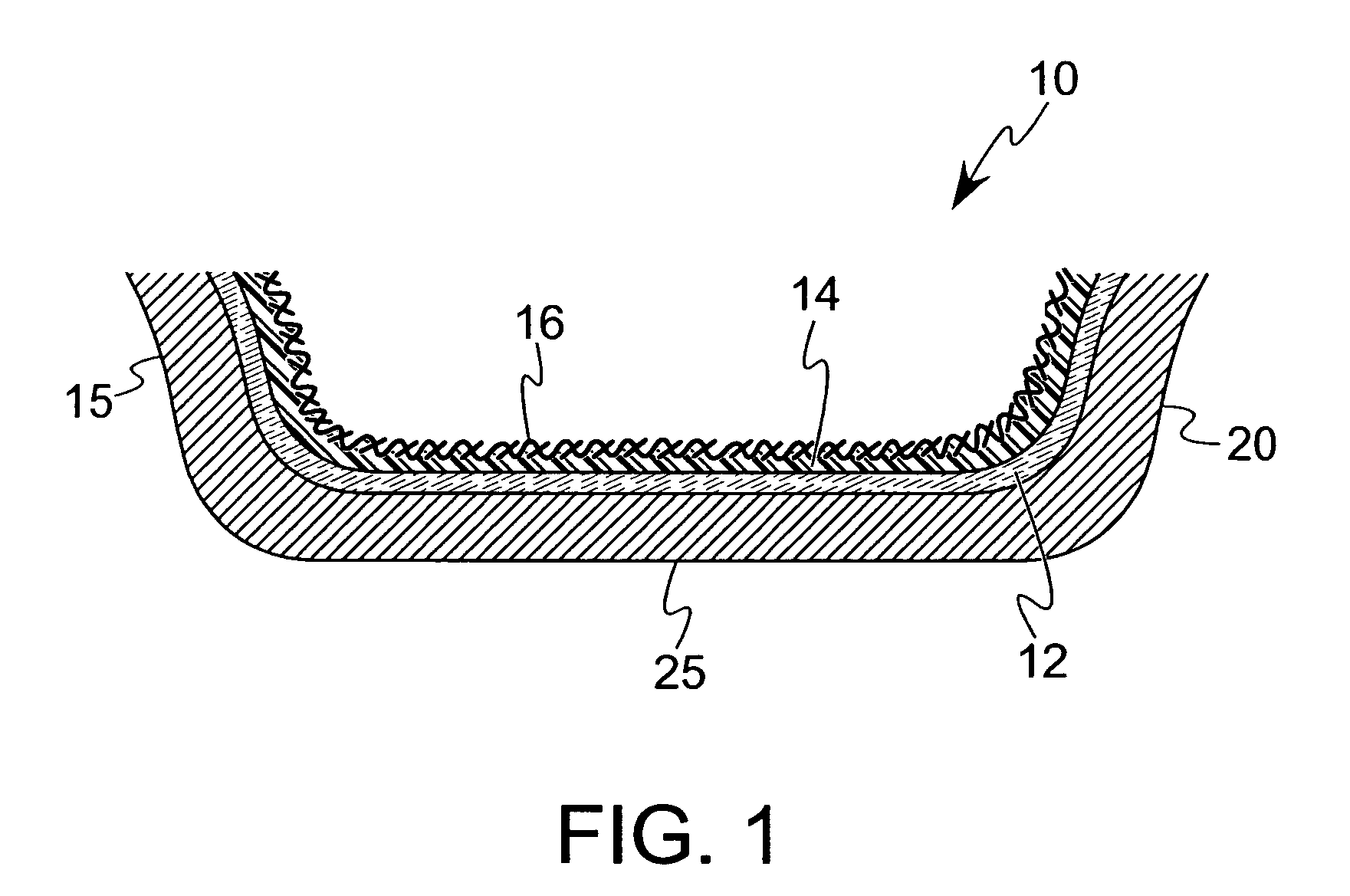

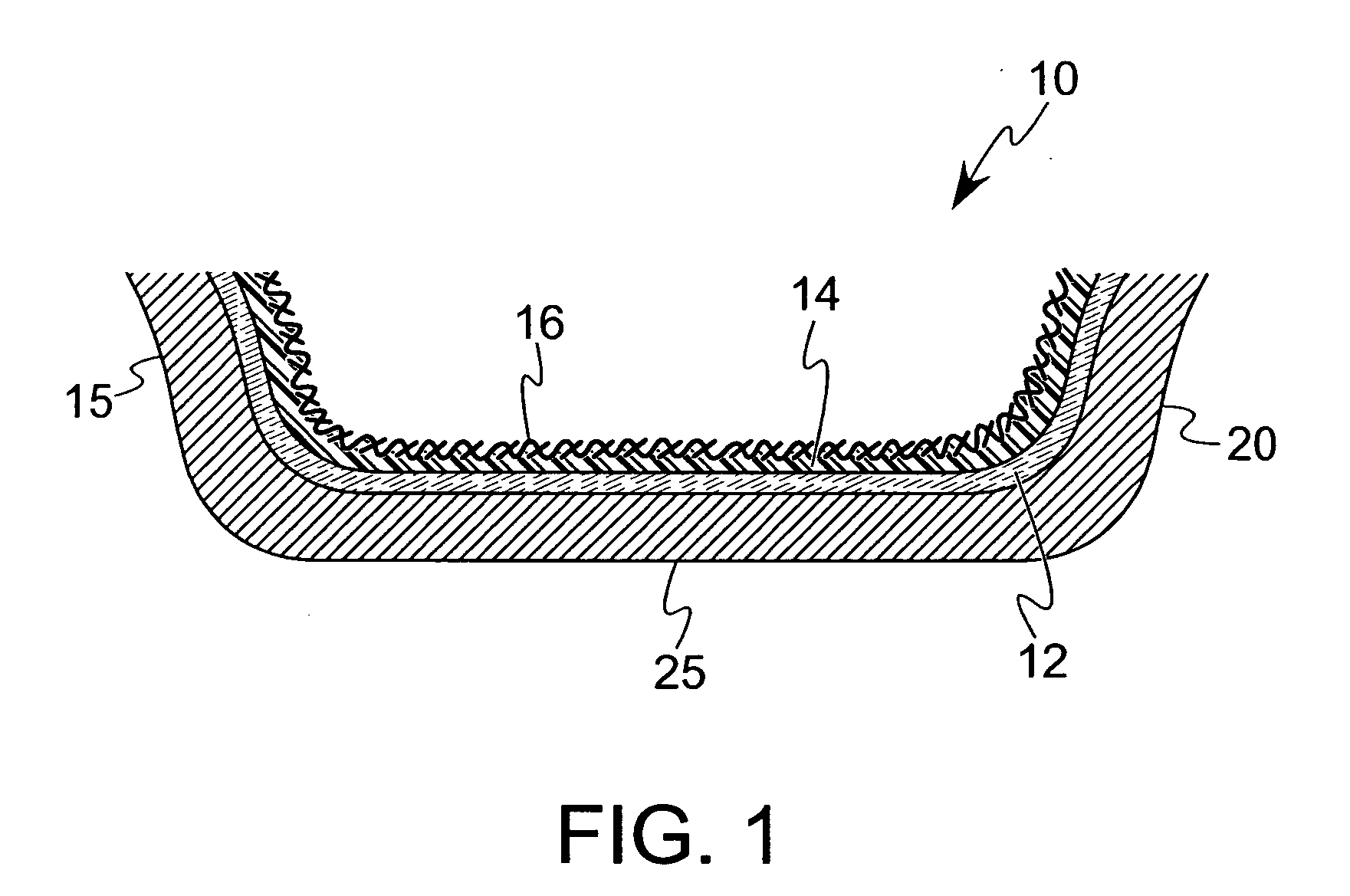

Sprayable skin composition and method of applying

InactiveUS7608655B2Sufficient reinforcementFast and cost-effective mannerMouldsAlkaline-earth metal silicatesFiberSynthetic resin

A sprayable skin composition and method of applying the skin composition is provided for use in reinforcing plastic products. The skin composition comprises a mixture of reinforcing wollastonite fibers and a synthetic resin, along with additional additives such as thixotropic agents, accelerators, stabilizers, and an air release agent. The composition is applied by spraying onto a gel coat in a mold and forms a gel within 1 to 3 minutes without the formation of air bubbles.

Owner:ILLINOIS TOOL WORKS INC

A preparation method of single-layer porous graphene reinforced carbon fiber fishing rod

The invention discloses a preparation method of a single-layer porous graphene enhanced carbon fiber fishing rod, and belongs to the technical field of high polymer materials. The preparation method is characterized by comprising the steps that expanded graphite is separated into graphene microfilm dispersible fluid at first, the graphene microfilm dispersible fluid is subjected to spray drying toform graphene microfilm powder, the powder is oxidized and subjected to microwave treatment in NMP dispersion fluid to prepare a single-layer porous graphene precursor, the precursor is activated through strong base, and single-layer porous graphene with many holes and the large hole diameter is obtained and compounded with carbon fiber to obtain a carbon fiber cloth material, and finally the material is cut and rolled to form the fishing rod. The carbon fiber can be easily wrapped by the single-layer porous graphene, an enough channel is provided for circulation of resin between the carbon fiber cloth, an organic whole with good continuity is formed between the graphene and the carbon fiber and between the carbon fiber, so that the stretching bending strength of the carbon fiber fishingrod is greatly improved, and the fishing weight of the fishing rod is remarkably improved.

Owner:陈川莲 +2

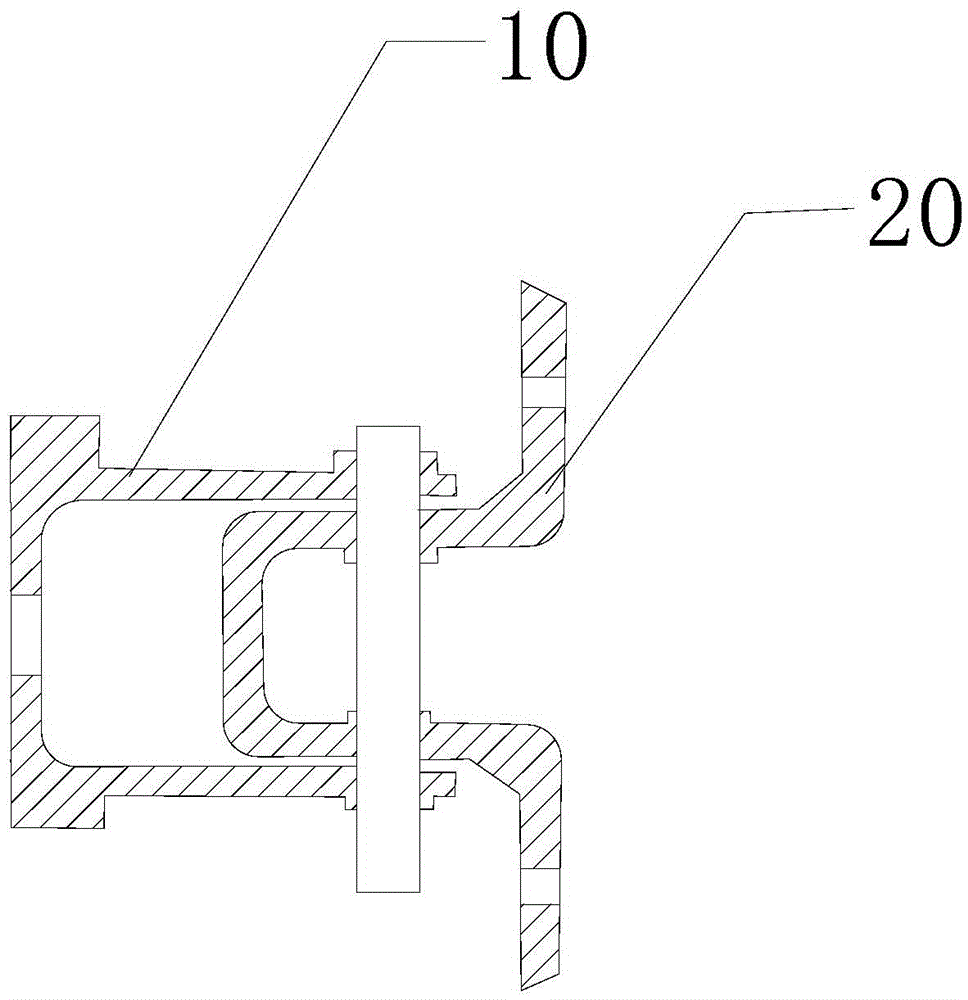

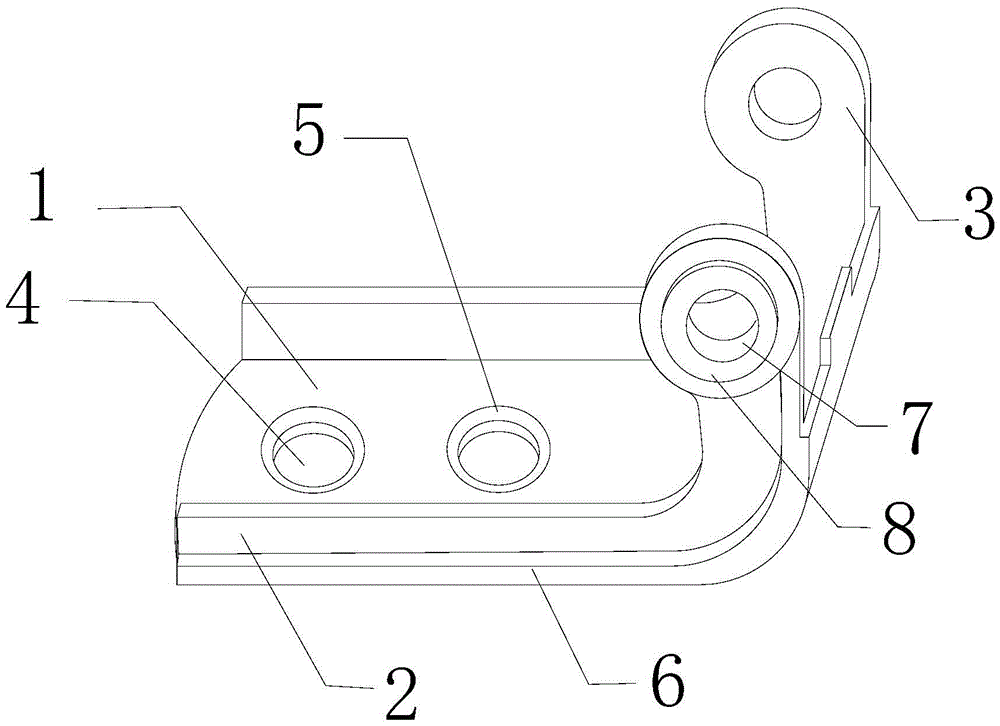

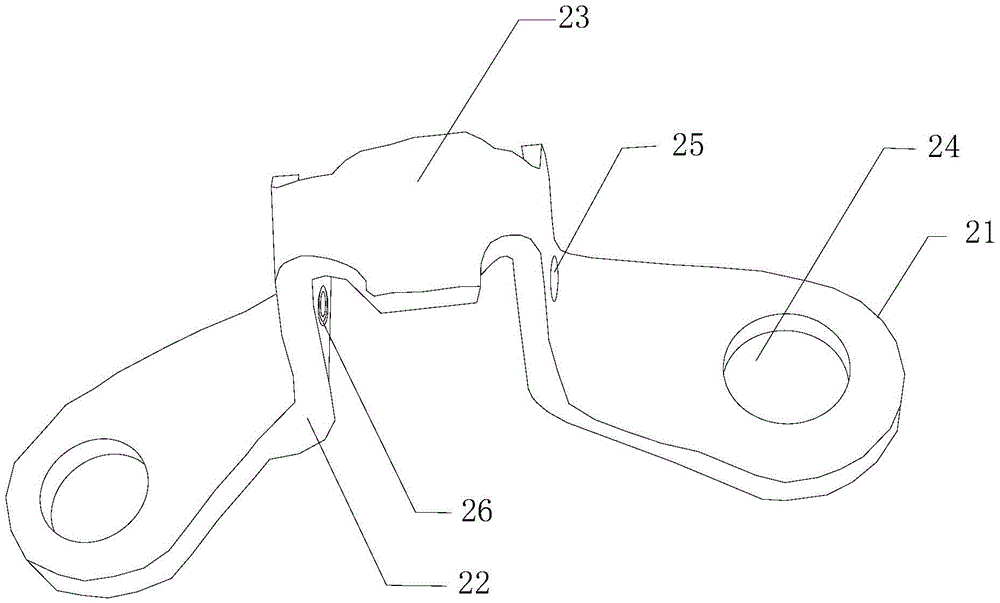

Reinforced aluminum alloy automobile door hinge

InactiveCN105604419AHigh tensile and flexural strengthFirmly connectedWing accessoriesHingesCar doorAluminium alloy

The invention discloses a reinforced aluminum alloy automobile door hinge. The reinforced aluminum alloy automobile door hinge comprises an automobile body part and an automobile door part, wherein the automobile body part comprises a fixed structure, a guide structure and a connecting shaft structure; and the automobile door part comprises a fixed small structure, a reinforced structure and a connecting shaft large structure. The reinforced aluminum alloy automobile door hinge disclosed by the invention has a relatively reasonable structure and relatively high stress intensity, and has the advantages of abrasion resistance, durability, easiness in recovery of deformation, convenience for installation and detachment, and easiness in popularization and application.

Owner:ZHEJIANG JINSHENG AUTO PART CO LTD

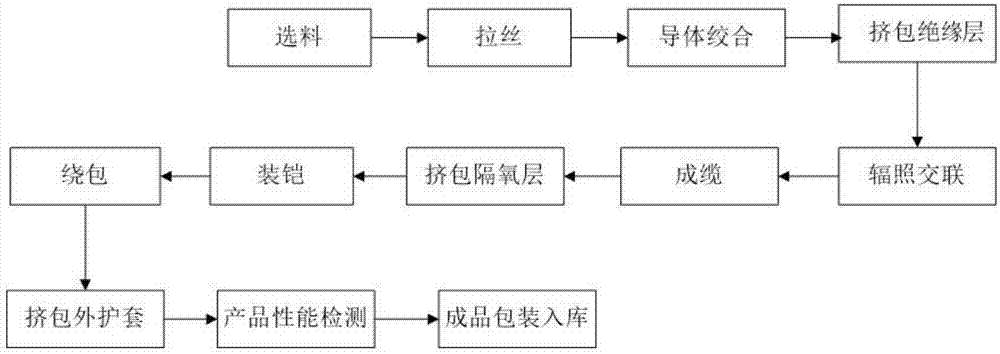

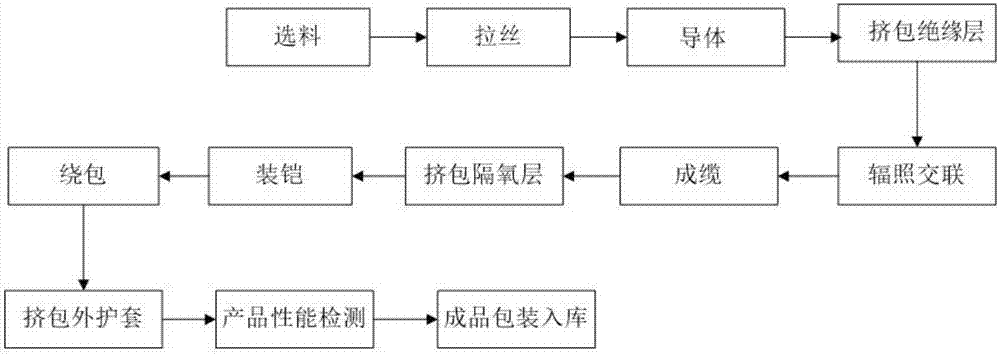

Manufacturing method of high-flame-resistant, low-emission, green and environmentally-friendly cable

InactiveCN108010629AImprove flame retardant performanceImproved ability to suppress flame spreadInsulated cablesInsulated conductorsElectrical conductorEngineering

The invention discloses a manufacturing method of a high-flame-resistant, low-emission, green and environmentally-friendly cable. The method comprises the following steps: (1) material selection; (2)wire drawing; (3) conductor or conductor twisting; (4) extruded insulation; (5) irradiation crosslinking; (6) cabling; (7) oxygen barrier extrusion; (8) armoring; (9) lapping; (10) outer sheath extrusion; (11) product performance detection; and (12) finished product packaging and storage. The cable manufactured by the invention overcomes the disadvantages that halogen-containing series flame-resistant electric wires and cables are high in smoke generation and high in toxicity, and also solves the problem that halogen-free series flame-resistant electric wires and cables cannot reach the specifications of new edition of 'civil architectural electrical design code', so that the flame resistant level of the cable can reach level A, the combustion performance reaches level B1, the smoke toxicity reaches level t0, the combustion dripping / particle level reaches level d0, the corrosion performance level also can reach level a1, and the cable can be widely used in civil architectures.

Owner:SICHUAN MINGXING CABLE

Sprayable skin composition and method of applying

InactiveUS20060036011A1Sufficient reinforcementInhibition formationMouldsAlkaline-earth metal silicatesFiberSynthetic resin

A sprayable skin composition and method of applying the skin composition is provided for use in reinforcing plastic products. The skin composition comprises a mixture of reinforcing wollastonite fibers and a synthetic resin, along with additional additives such as thixotropic agents, accelerators, stabilizers, and an air release agent. The composition is applied by spraying onto a gel coat in a mold and forms a gel within 1 to 3 minutes without the formation of air bubbles.

Owner:ILLINOIS TOOL WORKS INC

Molded parts made of carrier materials which contain foaming reactive resin

InactiveUS20150322230A1Improve mechanical propertiesImprove flexural strengthPolymer chemistryCompressive deformation

The invention provides a molding producible by a process comprising the following steps:a) introduction of a foamable reactive resin into a support material andb) compressive deformation of the support material comprising the foamable reactive resin.

Owner:BASF AG

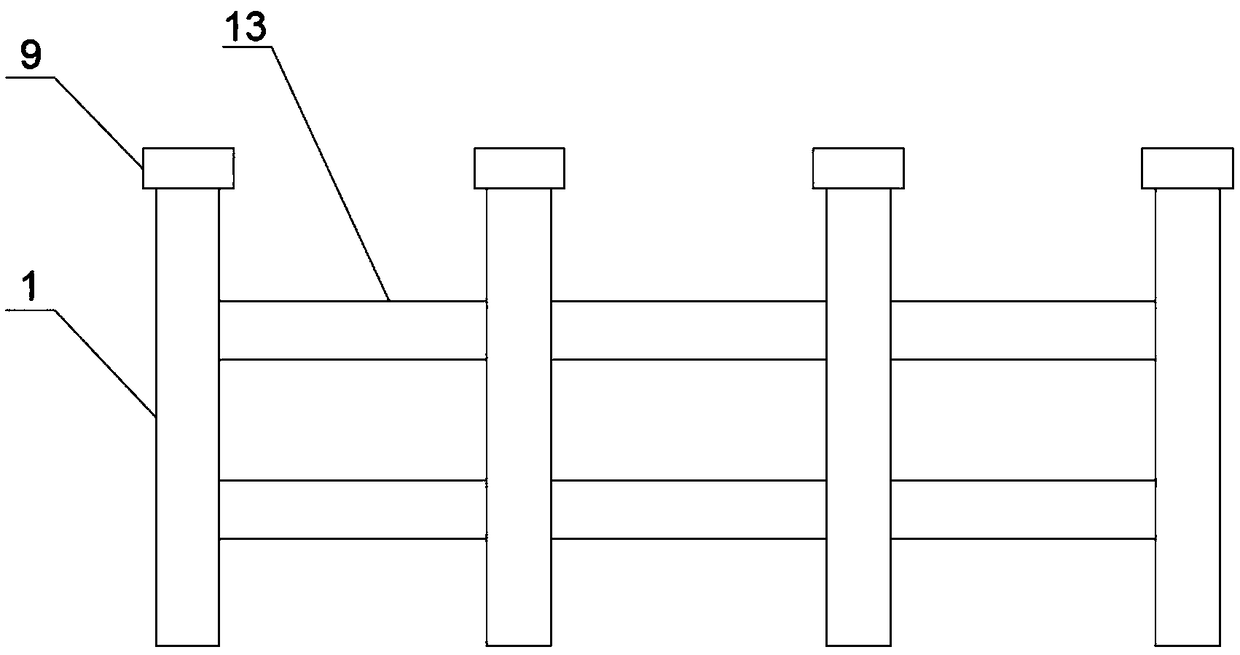

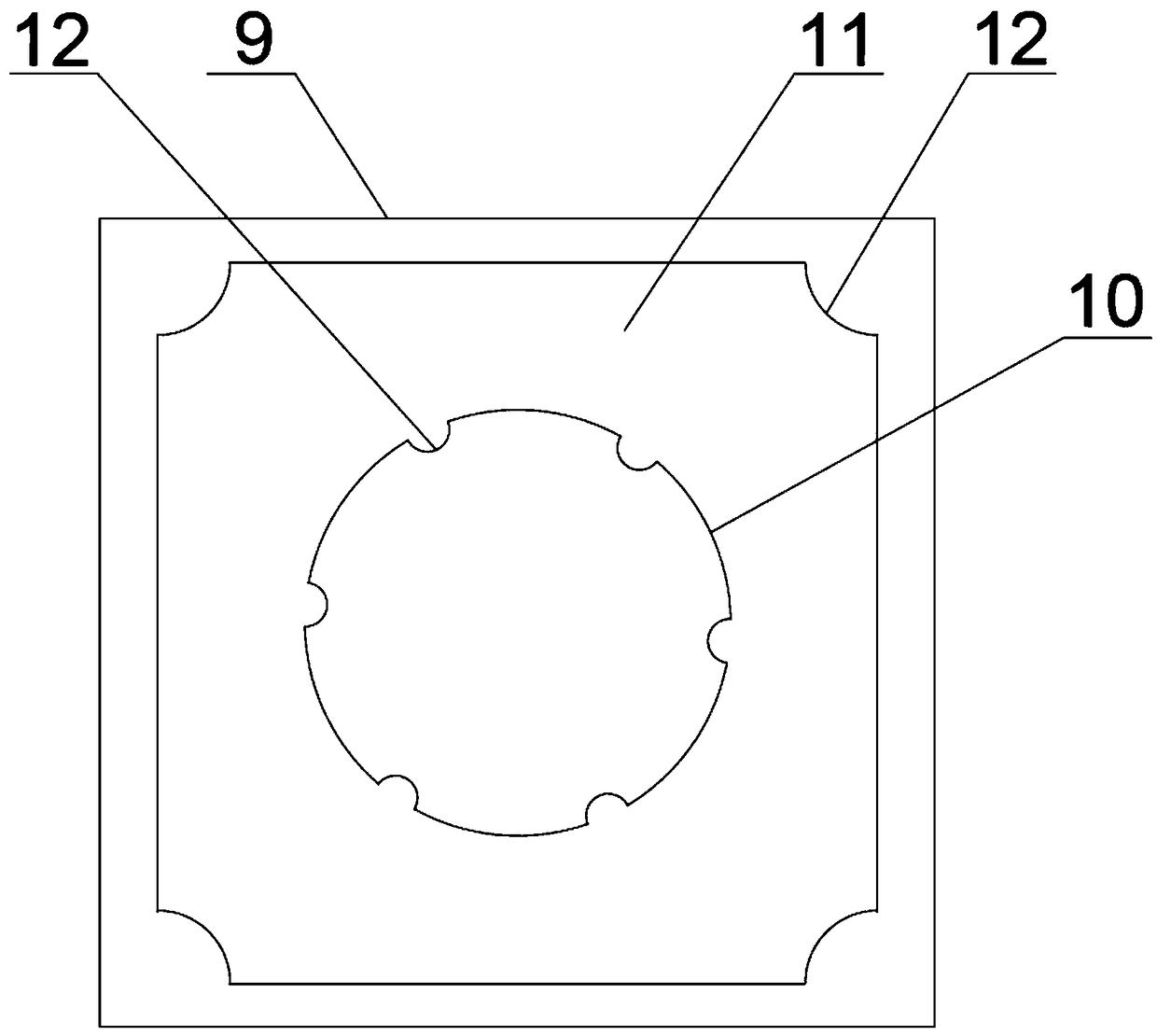

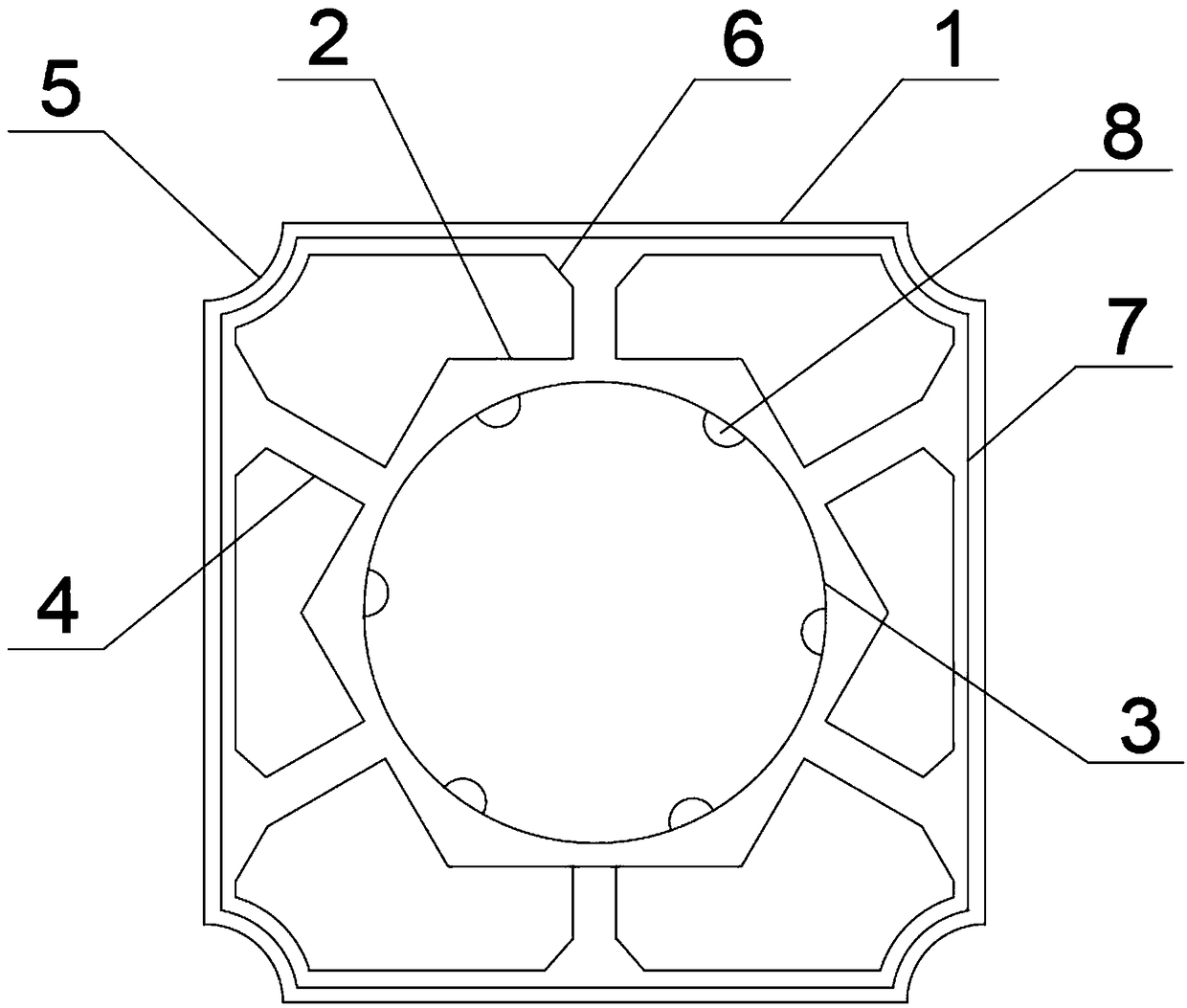

High-strength plastic-wood handrail

InactiveCN108643697AHigh strengthHigh tensile strengthStrutsFencingWire gauzeUltimate tensile strength

The invention discloses a high-strength plastic-wood handrail. The high-strength plastic-wood handrail comprises a plurality of vertical columns arranged in the lateral direction, and at least one cross bar is fixedly connected between every two vertical columns. Each vertical column comprises a cover body, an outer tube and an inner tube arranged in the outer tube, and the inner tube and the outer tube are coaxially arranged. Multiple ribs parallel to the axis of the inner tube are arranged between the outer wall of the inner tube and the inner wall of the outer tube in the circumferential direction of the inner tube. The cross section of the outer tube is rectangular, the cross section of the inner tube is polygonal, and a central circular hole coaxially arranged with the inner tube is arranged in the inner tube. An interlayer is arranged in the outer tube, steel wire gauzes are arranged on two sides of the interlayer, and a fireproof asbestos cloth is arranged in the middle of the interlayer. The cover body is provided with a groove which is recessed inward and the groove fits with the outer wall of the outer tube. A protruding column coaxially arranged with the groove is arranged in the central position in the groove, and the protruding column is slidably connected to the central circular hole in an inserting mode. The outdoor plastic-wood column has the advantages of highstrength, less material consumption and fire prevention.

Owner:ANHUI HAOSEN NEW MATERIAL TECH CO LTD

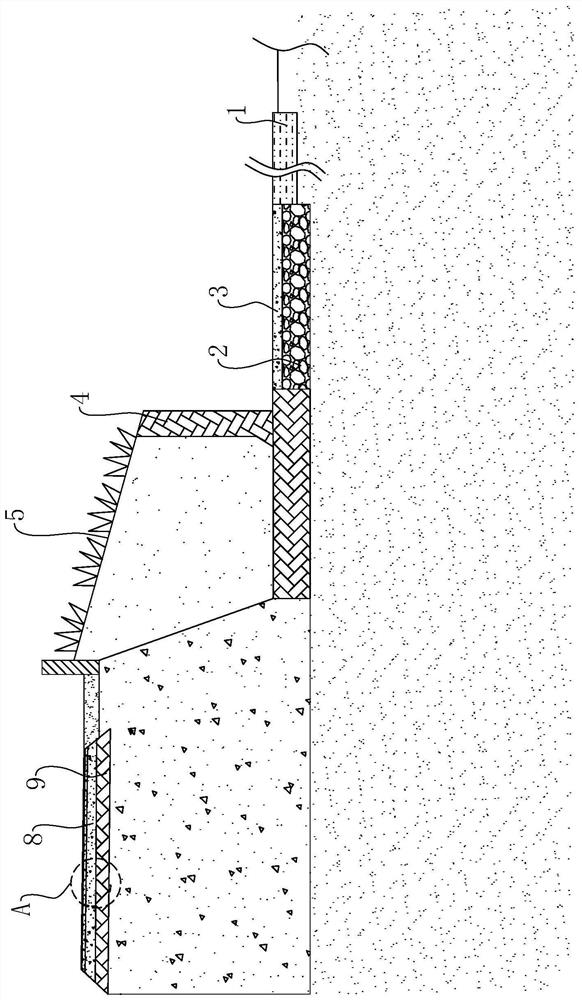

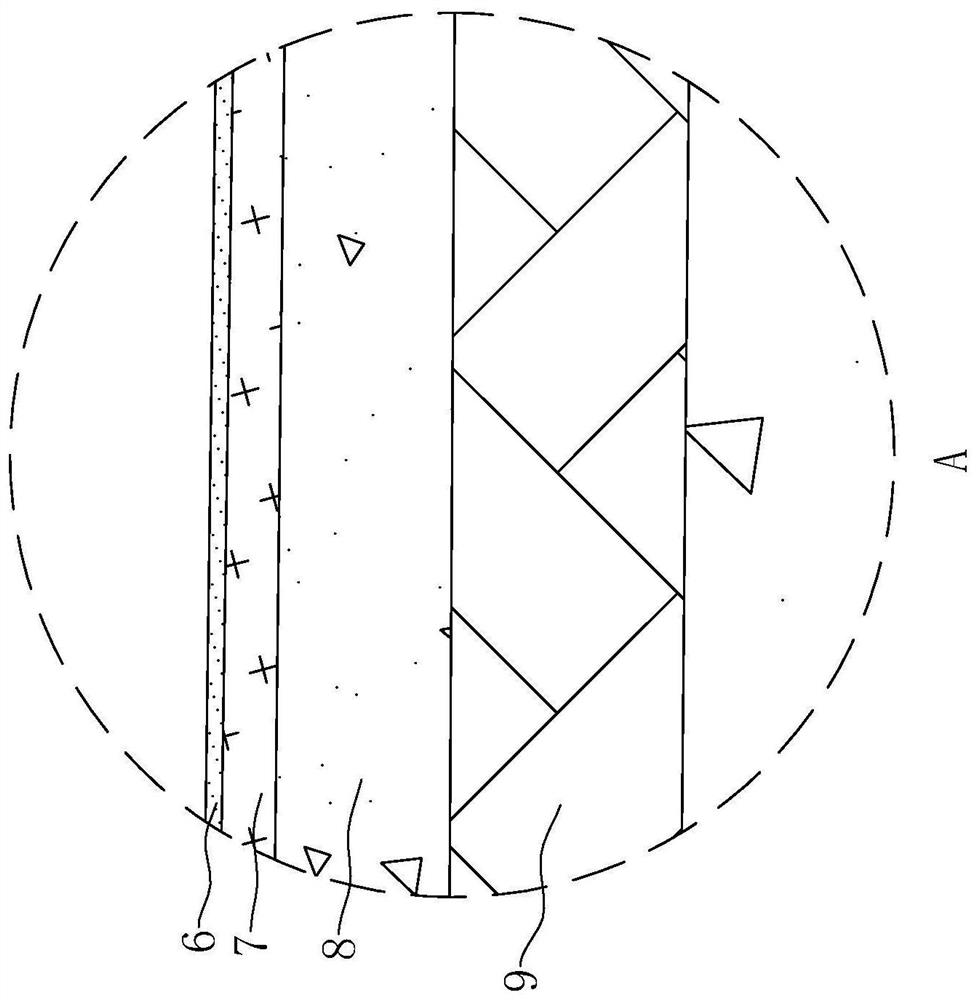

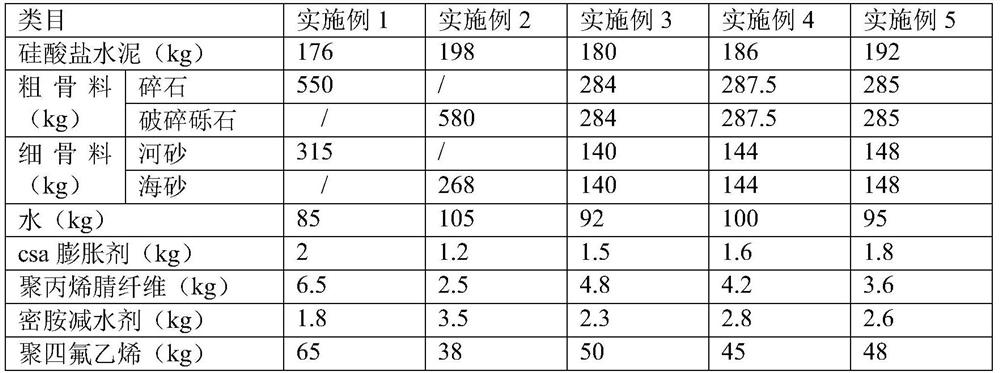

River channel revetment construction method and river channel revetment

ActiveCN113914258AImprove impermeabilityImprove pore structureBreakwatersQuaysSoil scienceRiver routing

The invention relates to the field of river bank construction, in particular to a river channel revetment construction method and a river channel revetment. The river channel revetment comprises punning layers symmetrically arranged on the two sides of a river channel, a first rock ballast cushion layer, a foot protection layer, a quay wall, a river channel inclined section, a fine asphalt layer, a coarse asphalt layer, a water stabilizing layer and a second rock ballast cushion layer. The punning layers and the first rock ballast cushion layer are laid on a foundation trench of the river channel, one side of the first rock ballast cushion layer is fixedly connected with one sides of the punning layers, and the other side of the first rock ballast cushion layer is connected with one side of the quay wall. The bottom of the foot protection layer is fixedly connected to the top of the first rock ballast cushion layer, the river channel inclined section is located above the quay wall, and turf is arranged on the river channel inclined section. The side, away from the center of the river channel, of the river channel inclined section is connected with a levee crown, and the fine asphalt layer, the coarse asphalt layer, the water stabilizing layer and the second rock ballast cushion layer are sequentially arranged at the levee crown from top to bottom. The river channel revetment construction method and the river channel revetment have the beneficial effects that the waterproof effect of the river channel revetment is improved, and the service life of the revetment is prolonged.

Owner:浙江艮威水利建设有限公司

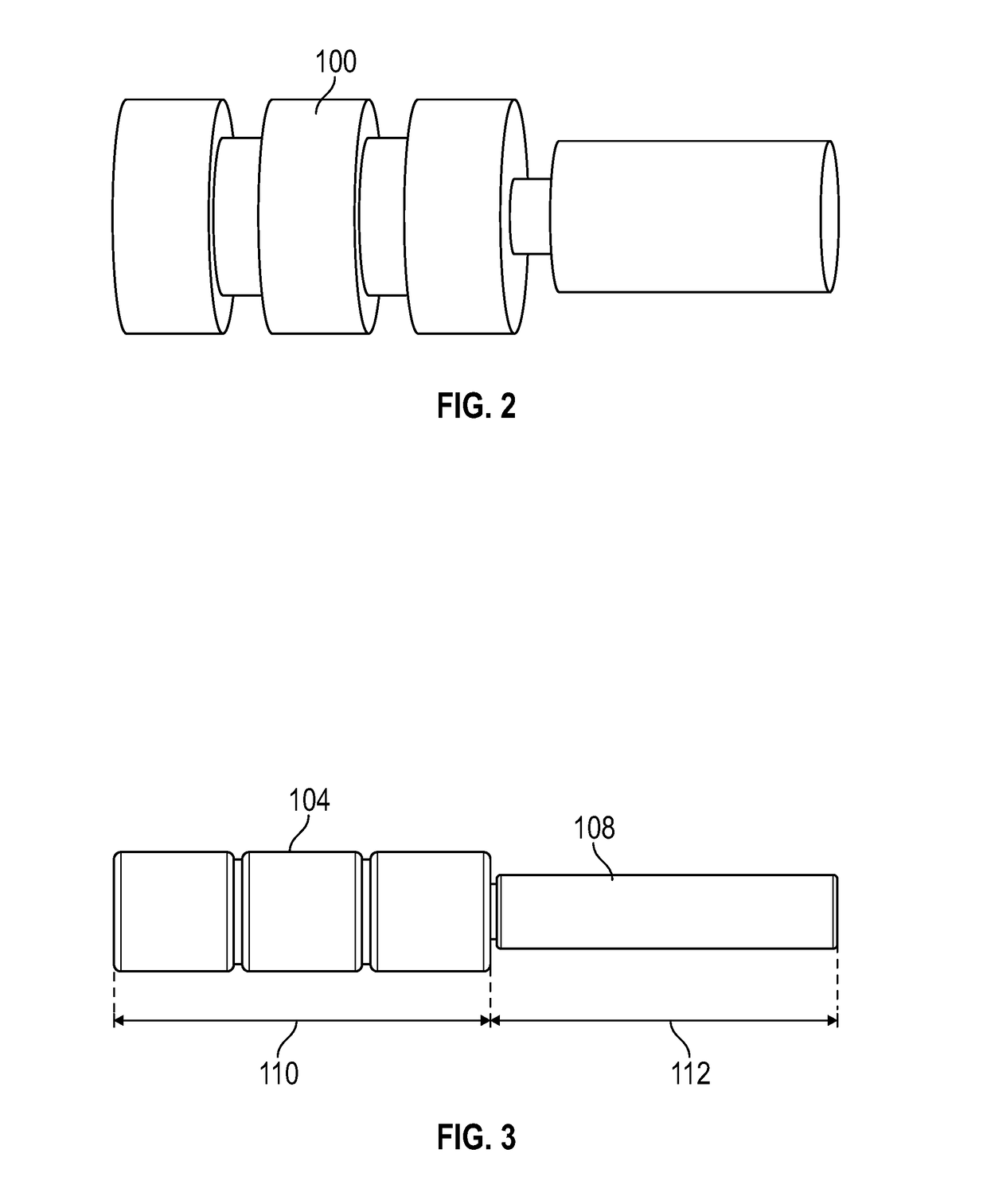

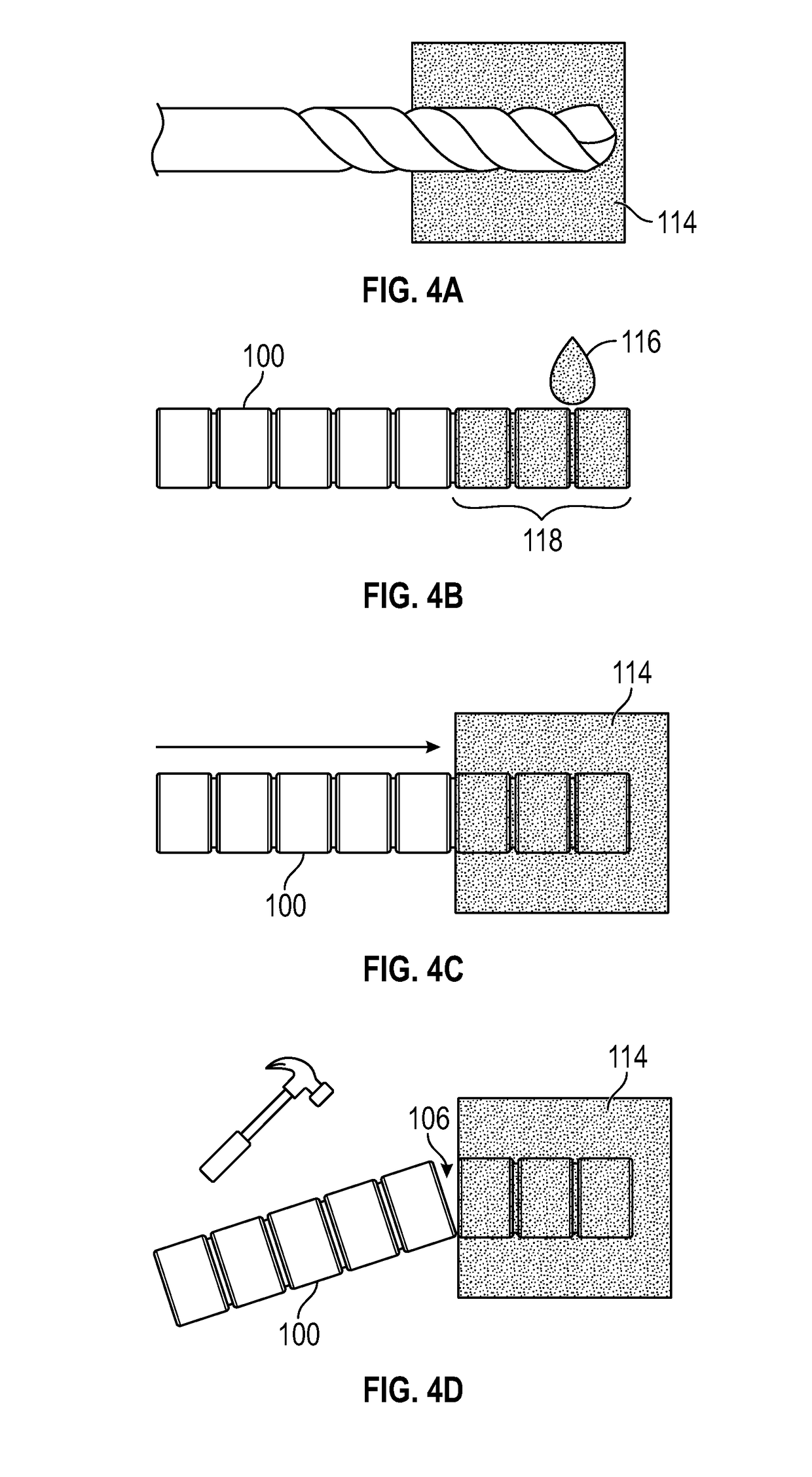

Stripped Hole Repair Device

InactiveUS20180372141A1Improve retentionFlat surfaceBuilding repairsIrregularity removal devicesMostly TrueEngineering

Current stripped hole repair devices operate by expanding to exert pressure against the inside of a hole into which the device is placed, and are by design suitable only for repairing a stripped or damaged hole in alignment with the original hole. Likewise, various methods exist that do not result in a smooth surface into which a new hole can be drilled. In most cases, these methods are non-permanent, temporary, non-weight-bearing devices that inadequately address the problem. The solution provided comprises a solid plastic insert with segments that break off at a desired length, into which a new hole may be drilled and a screw inserted. The method for installing the apparatus utilizes an adhesive that bonds to the medium into which it is installed. The disclosure describes a simplified and practical method to repair a stripped screw hole, and an apparatus that can be manufactured and made commercially available.

Owner:KING ANDREW

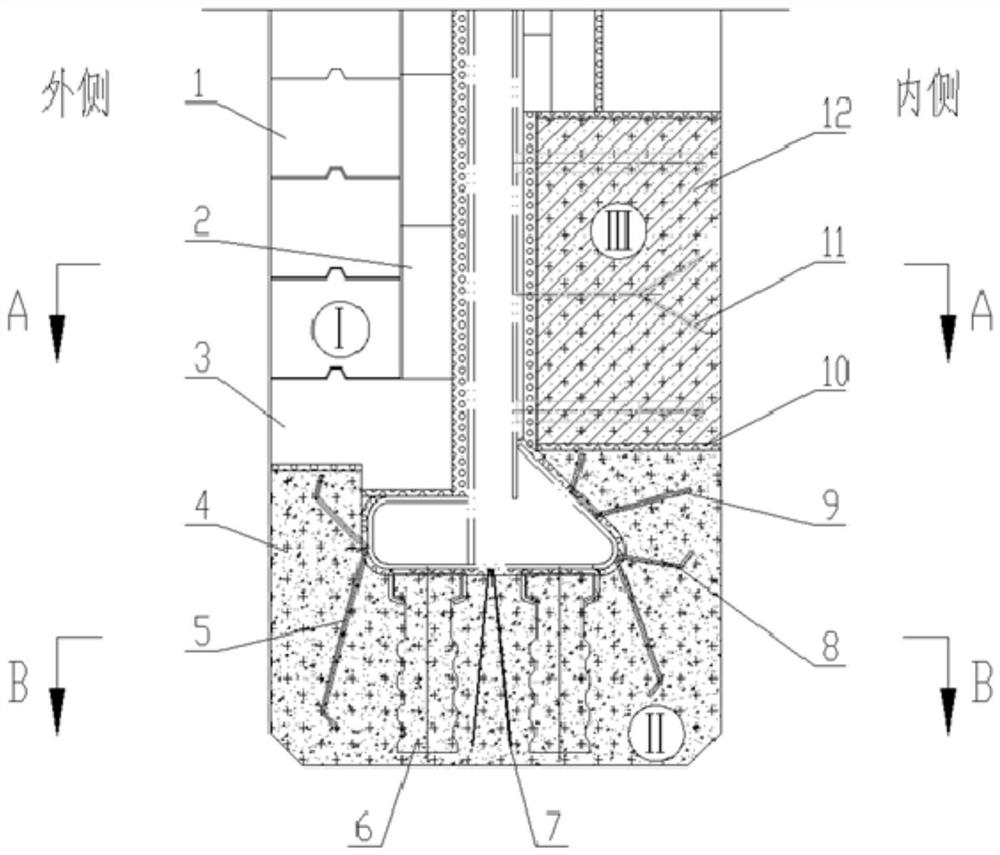

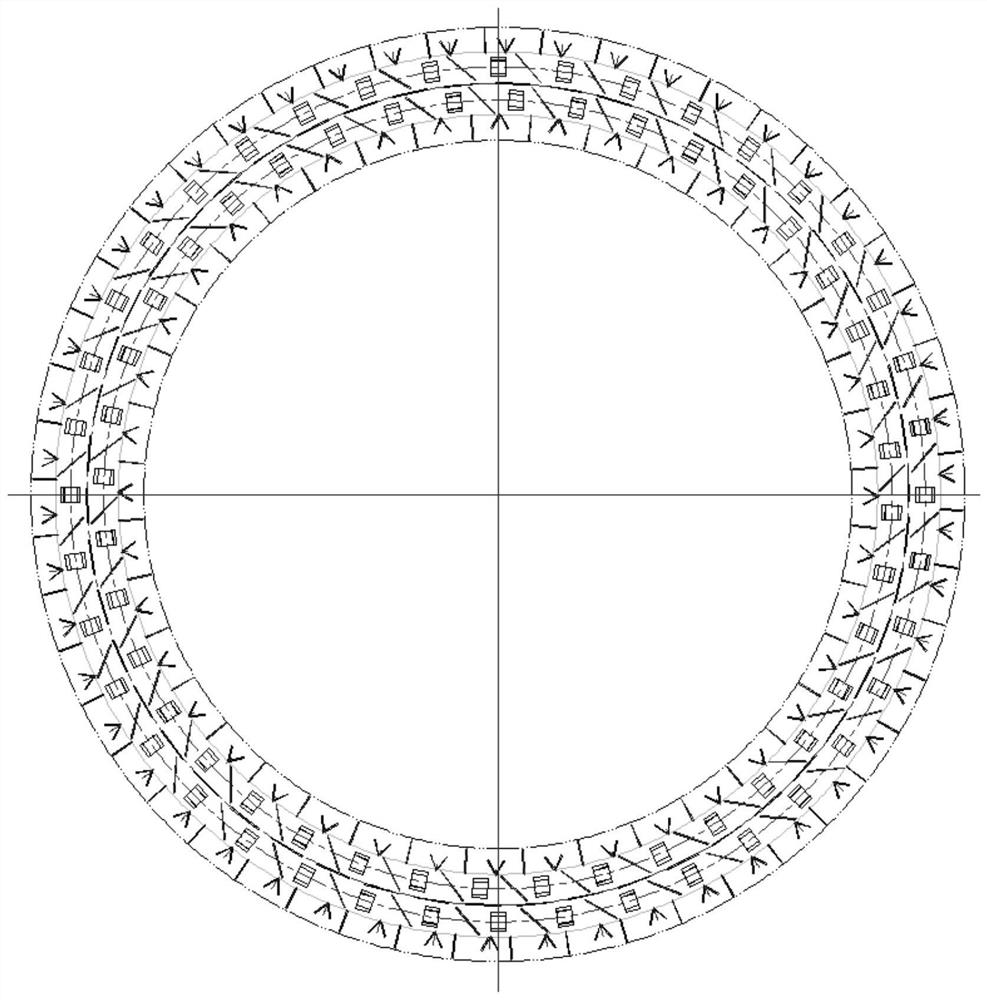

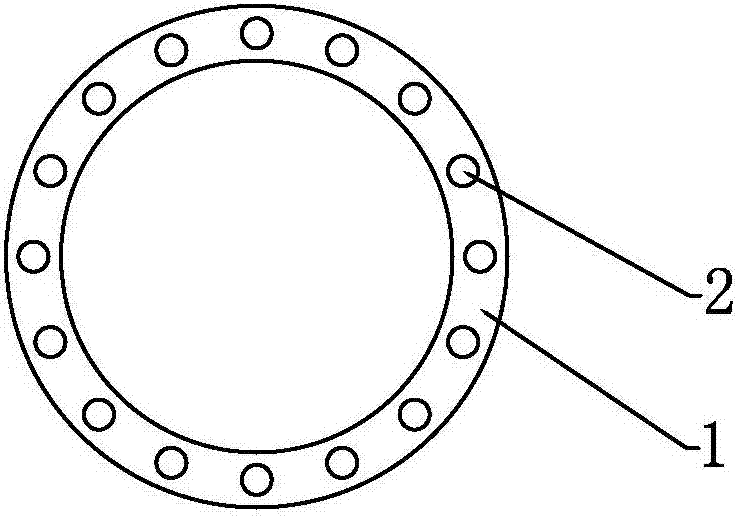

A circular suspended masonry structure for industrial furnaces with internal and external channels

ActiveCN111351361BHigh tensile and flexural strengthTelescopic structure increasesLinings repairFurnace floorsArchitectural engineeringFire brick

The invention discloses a circular suspended masonry structure for industrial furnaces with internal and external passages. The masonry structure mainly includes three parts, the first part is made of shaped refractory bricks, the second part and the third part are made of It is made of unshaped refractory bulk material and anchoring components. The circular suspended masonry structure for industrial furnaces with internal and external passages disclosed by the present invention can effectively improve the stability and strength of the circular masonry structure of industrial furnaces with internal and external passages, prolong the service period, and also provide a guarantee for later maintenance. It provides convenience, thereby helping to improve construction efficiency and industrial production efficiency.

Owner:北京嘉永会通能源科技有限公司

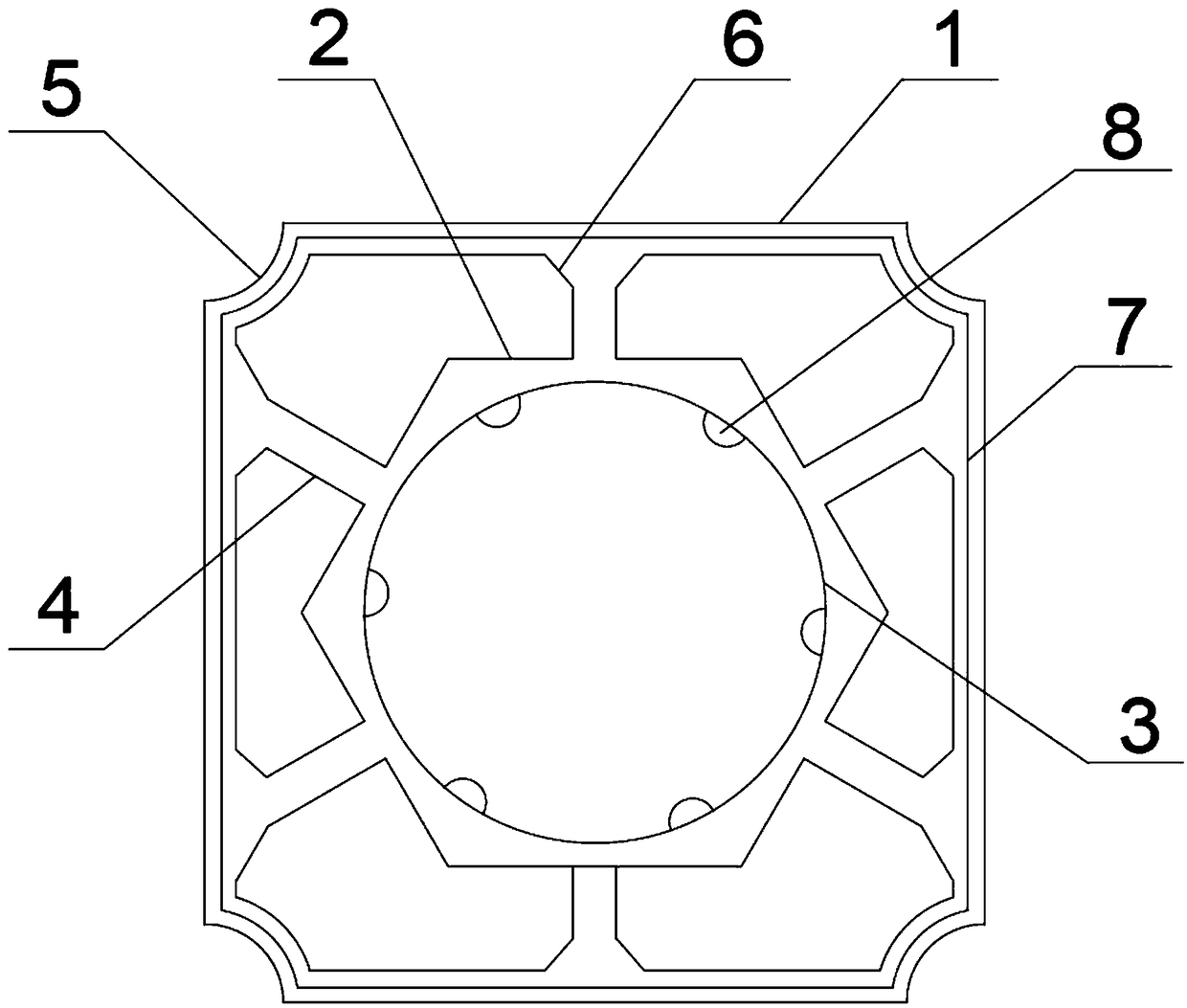

Fire-proof high-strength plastic wood stand column

InactiveCN108643707AHigh tensile strengthHigh tensile and flexural strengthStrutsFencingMaterial consumptionAsbestos

The invention discloses a fire-proof high-strength plastic wood stand column. The fire-proof high-strength plastic wood stand column comprises an outer pipe and an inner pipe coaxially arranged in theouter pipe. A plurality of ribs parallel to the axis of an inner pipe are arranged between the outer wall of the inner pipe and the inner wall of an outer pipe in the circumferential direction of theinner pipe. The cross section of the outer pipe is rectangular, the cross section of the inner pipe is polygonal, and a central circular hole which is formed coaxially with the inner pipe is arrangedin the inner pipe. An interlayer is arranged in the outer pipe, steel wire mesh are arranged on both sides of the interlayer, and a fire protection asbestos cloth is arranged in the middle of the outer pipe. The fire-proof high-strength plastic wood stand column has the advantages of high strength, less material consumption and fire protection.

Owner:ANHUI HAOSEN NEW MATERIAL TECH CO LTD

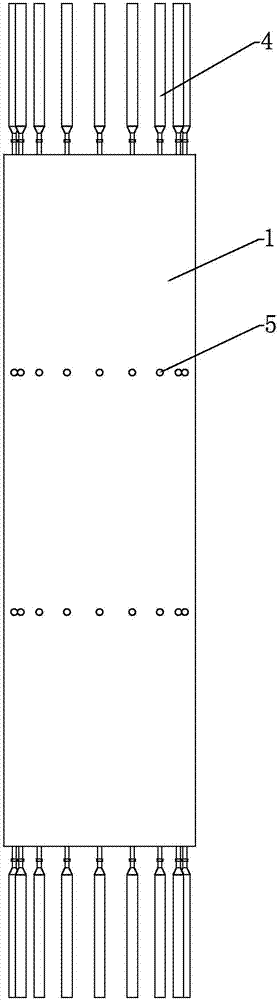

Large compound radiant heating rod and preparation method thereof

PendingCN106900094AReasonable structureHigh tensile and flexural strengthOhmic-resistance heating detailsFurnace heating elementsFilling-inEngineering

The invention discloses a large compound radiant heating rod and a preparation method thereof. The large-scale compound radiant heating rod includes a fixed sleeve of an insulating material. A plurality of mounting column holes are disposed uniformly in a penetrating manner on the tube wall of the fixed sleeve along the axis of the fixed sleeve. A heating rod is inserted in each mounting column hole. A plurality of fixing holes communicating with the mounting column holes are disposed in the outer side wall of the fixed sleeve closely adjacent to each of the mounting column holes. Ceramic consolidation agents are filled in the fixing holes and in the mounting column holes facing the fixing holes. According to the invention, the plurality of heating rods are mounted together in the fixed sleeve, the radiation area and length of the radiated heat by the heating rods to a furnace are increased, the outer layer of fixed sleeve is used as a protective layer, the tensile strength and breaking strength are high, the damage rate of the heating rods are greatly reduced, so that the heating rods can be arbitrarily arranged in the heating furnace to increase the heating capacity of the electric furnace and the processing of various large products is facilitated.

Owner:孙劲腾 +1

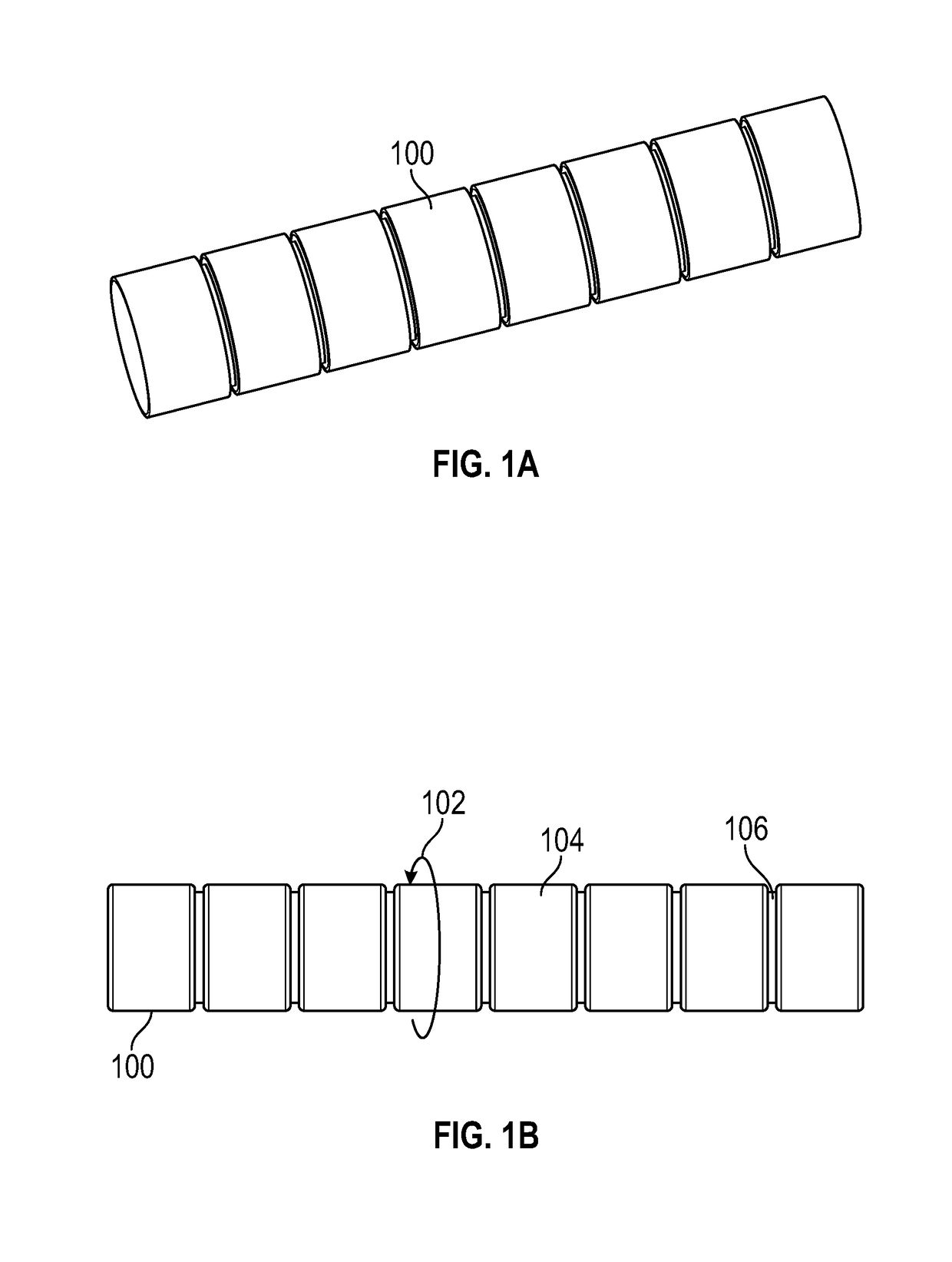

Fiber mesh reinforced grouting full-length reinforced frozen pipe in double-layer sandwich cavity and construction method

ActiveCN109505607BHigh tensile and flexural strengthIncrease stiffnessShaft sinkingTunnelsAqueous corrosionFiber

The invention discloses a double-layered cavity fiber web reinforced grouting full-length reinforced freezing pipe and a construction method thereof. The pipe mainly comprises a main body structure with steel pipes with large and small diameters in sleeve connection to form a cavity of inner and outer walls, a bottom taper angle device connecting the inner and outer steel pipe walls of the main body structure and an inner and outer pipe top port sealing device. The bottom taper angle device is also of a double-layered cavity structure communicated with the cavity of the main body structure, and the bottom taper angle device is internally provided with a one-way backstop pressure valve communicated with the inside of the freezing pipe and the cavity. According to the design, by means of matched operation of a liquid feeding pipe and the one-way backstop pressure valve, cement slurry is injected into the cavity of the main body structure, and a pre-placed fiber web is placed to form fiber web reinforced concrete. The stiffness, the strength and the corrosion resistance of the freezing pipe are greatly improved. The freezing pipe is suitable for the stratum freezing method construction project subjected to complex high stress and aqueous corrosion, effectively reduces the accident probability of freezing wall melting due to salt leakage caused by damage and fracture caused by thecorrosion and the high stress, and avoids inducing flooding accidents.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com