Energy-saving and environment-friendly building decoration material and preparation method thereof

A building decoration material, energy saving and environmental protection technology, applied in the field of building decoration materials and their preparation, can solve the problems of high cost, poor fire resistance, poor energy saving and environmental protection effect, etc., and achieve high tensile and flexural strength, good fire resistance, long-term use low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

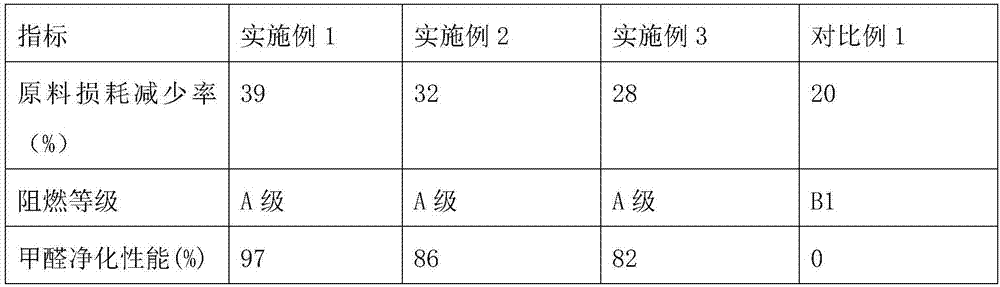

Examples

Embodiment 1

[0041] An energy-saving and environment-friendly building decoration material, comprising the following raw materials in parts by weight: 30 parts of waste plastics, 25 parts of slag powder, 18 parts of stone powder, 11 parts of polyvinyl chloride resin, 23 parts of glass fiber, 5 parts of bamboo fiber, nano-carbonized 13 parts of silicon, 11 parts of zirconia, 10 parts of ceramic fiber, 11 parts of graphite, 12 parts of airgel, 3 parts of water glass, 16 parts of diatomaceous earth, 11 parts of attapulgite, 14 parts of activated carbon, and 0.5 parts of flame retardant And compatibilizer 0.6 part.

[0042] Slag powder is added to the raw materials. As industrial waste, the long-term utilization rate of slag powder is low, and it will cause environmental pollution if it is discarded. Now it is recycled and reused to achieve the effect of energy saving and environmental protection.

[0043] Ceramic fibers are added to the raw materials. Ceramic fibers have the characteristics o...

Embodiment 2

[0061] An energy-saving and environment-friendly building decoration material, comprising the following raw materials in parts by weight: 20 parts of waste plastics, 20 parts of slag powder, 15 parts of stone powder, 5 parts of polyvinyl chloride resin, 19 parts of glass fiber, 2 parts of bamboo fiber, nano-carbonized 11 parts of silicon, 9 parts of zirconia, 8 parts of ceramic fiber, 7 parts of graphite, 8 parts of airgel, 2 parts of water glass, 11 parts of diatomaceous earth, 9 parts of attapulgite, 7 parts of activated carbon, and 0.4 parts of flame retardant And compatibilizer 0.5 part.

[0062] Slag powder is added to the raw materials. As industrial waste, the long-term utilization rate of slag powder is low, and discarding it will cause environmental pollution. Now it is recycled and reused to achieve the effect of energy saving and environmental protection.

[0063] Ceramic fibers are added to the raw materials. Ceramic fibers have the characteristics of light weight,...

Embodiment 3

[0081] An energy-saving and environment-friendly building decoration material, comprising the following raw materials in parts by weight: 40 parts of waste plastics, 30 parts of slag powder, 21 parts of stone powder, 17 parts of polyvinyl chloride resin, 27 parts of glass fiber, 8 parts of bamboo fiber, nano-carbonized 15 parts of silicon, 13 parts of zirconia, 12 parts of ceramic fiber, 15 parts of graphite, 16 parts of airgel, 4 parts of water glass, 21 parts of diatomite, 13 parts of attapulgite, 21 parts of activated carbon, and 0.6 parts of flame retardant And compatibilizer 0.7 part.

[0082] Slag powder is added to the raw materials. As industrial waste, the long-term utilization rate of slag powder is low, and discarding it will cause environmental pollution. Now it is recycled and reused to achieve the effect of energy saving and environmental protection.

[0083] Ceramic fibers are added to the raw materials. Ceramic fibers have the characteristics of light weight, h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com