Glass cover plate flat plate cleaning equipment

A technology for cleaning equipment and glass cover plates, applied in lighting and heating equipment, removing smoke and dust, cleaning flexible objects, etc., can solve the problems of affecting the workshop environment, glass pollution, increasing the air knife, etc., to achieve high efficiency and avoid pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

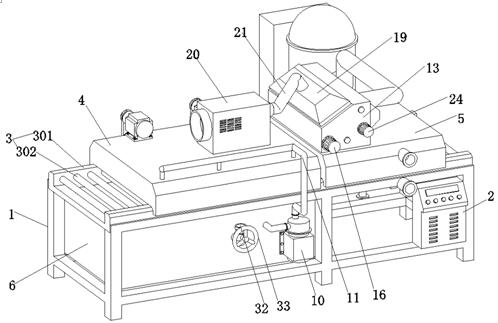

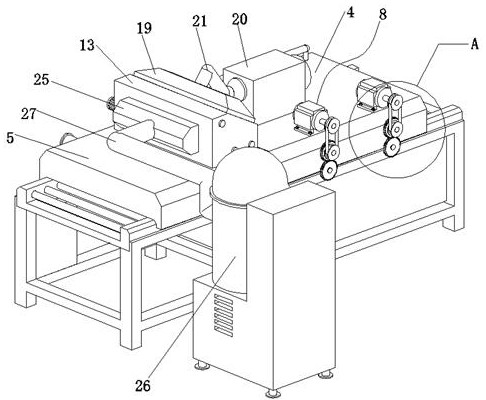

[0034] This embodiment 1 has introduced a kind of flat plate cleaning equipment for glass cover, refer to the attached figure 1 And attached figure 2 , which includes a frame 1 and a control cabinet 2, and the control cabinet 2 is arranged at the right end of the frame 1. The upper end of frame 1 is provided with roller table conveying mechanism 3, and its roller table conveying mechanism 3 is prior art, and specifically it comprises two crate boxes 301 before and after, and equidistant rotation is provided with between two crate boxes 301 There are a plurality of drive rollers 302, and the outer surface of the drive rollers 302 is covered with a rubber skin layer, and the crate 301 is provided with a power device (not shown) that drives each drive roller 302 to rotate.

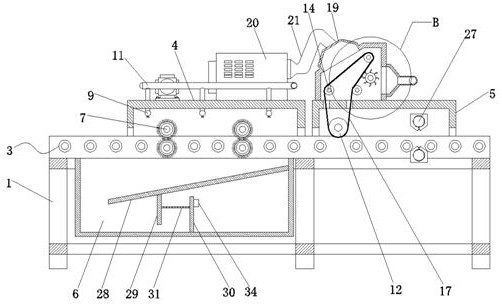

[0035] Reference attached figure 1 And attached image 3 , a cleaning box 4 is arranged on the left end of the roller conveyor mechanism 3, an air-drying box 5 is arranged on the roller conveyor mechanism...

Embodiment 2

[0040] Embodiment 2 is an improvement made to the interior of the water tank on the basis of Embodiment 1. The same parts of Embodiment 2 and Embodiment 1 will not be described again. The difference is that, refer to the attached image 3 , the upper end opening of the water tank 6 is arranged, and the upper end opening of the water tank 6 is arranged directly below the cleaning tank 4 . In this embodiment, the right side wall of the water tank 6 is provided with a water deflector 28 which is set low on the left and high on the right. Riser 29 is arranged, and a gap is also left between the riser 29 and the bottom wall of the water tank 6, and then a dividing plate 30 is connected on the water tank 6 bottom wall positioned at the right side of the rising plate 29, and the gap between the rising plate 29 and the dividing plate 30 The setting can achieve the effect similar to that of a U-shaped liquid level gauge, and then a filter cloth 31 is arranged between the vertical plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com