Patents

Literature

3458results about "Flexible article cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

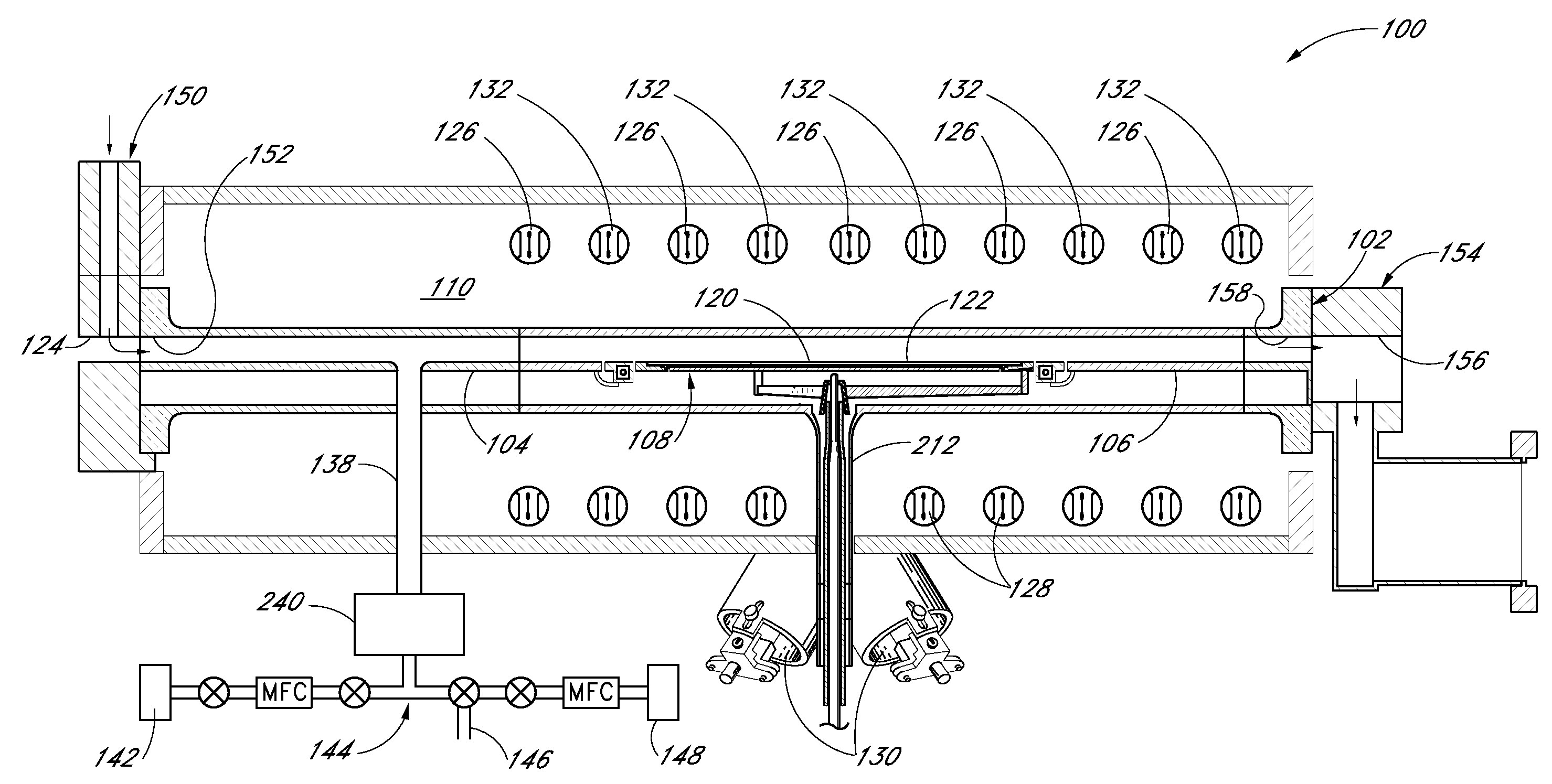

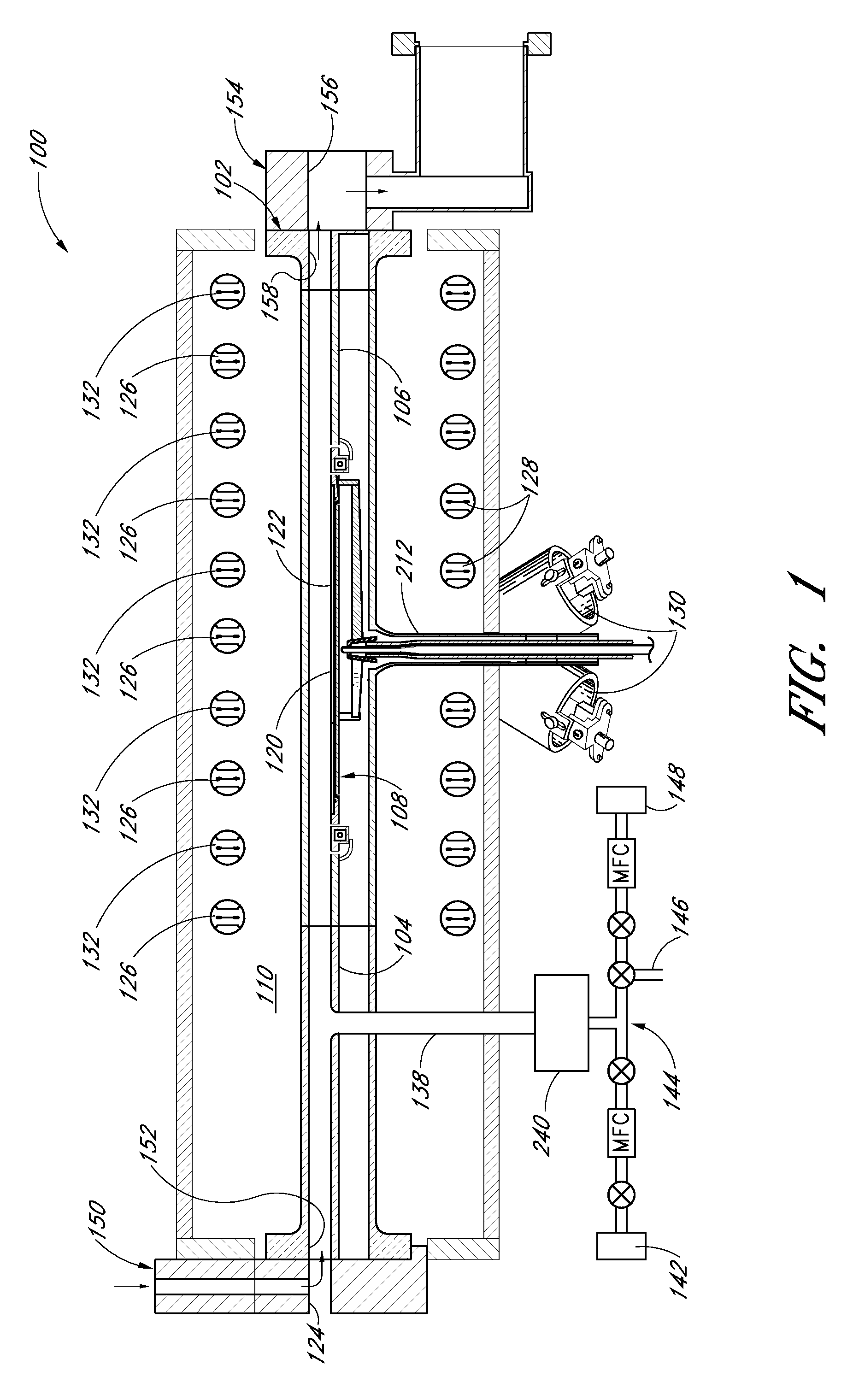

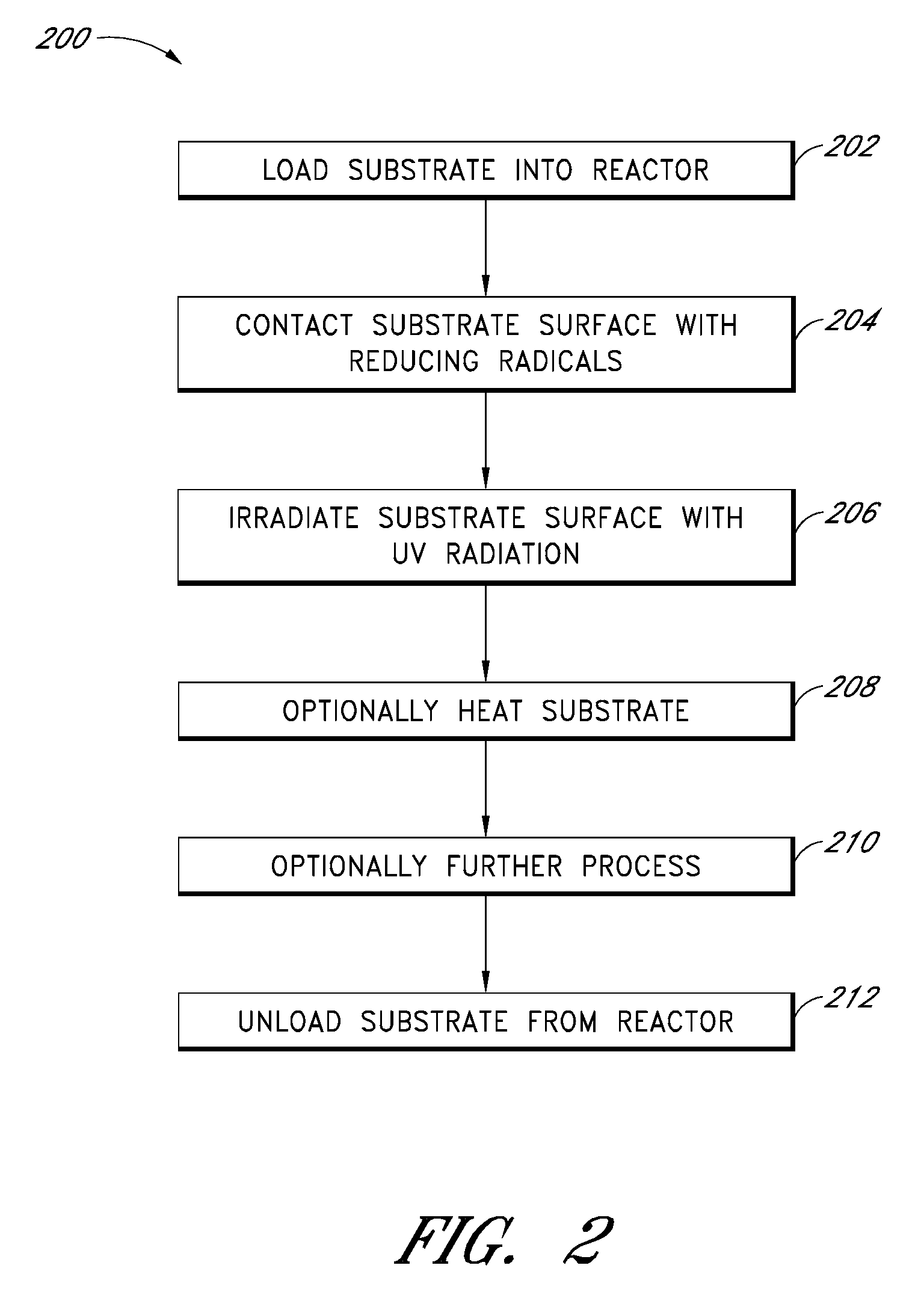

Low-temperature cleaning of native oxide

InactiveUS20080289650A1Reduce vertical sizeReduce device sizeElectrostatic cleaningSemiconductor/solid-state device manufacturingHydrogenSurface cleaning

Disclosed herein is a method of cleaning oxide from a surface in the fabrication of an integrated device using reducing radicals and UV radiation. For silicon surfaces, the cleaning may be performed at a temperature at which a hydrogen-terminated passivated surface is stable, such that the surface remains protected after loading into the chamber until the cleaning is performed. Performing the cleaning at a lower temperature also consumes a reduced portion of the thermal budget of a semiconductor device. Epitaxial deposition can then be performed over the cleaned surface.

Owner:ASM AMERICA INC

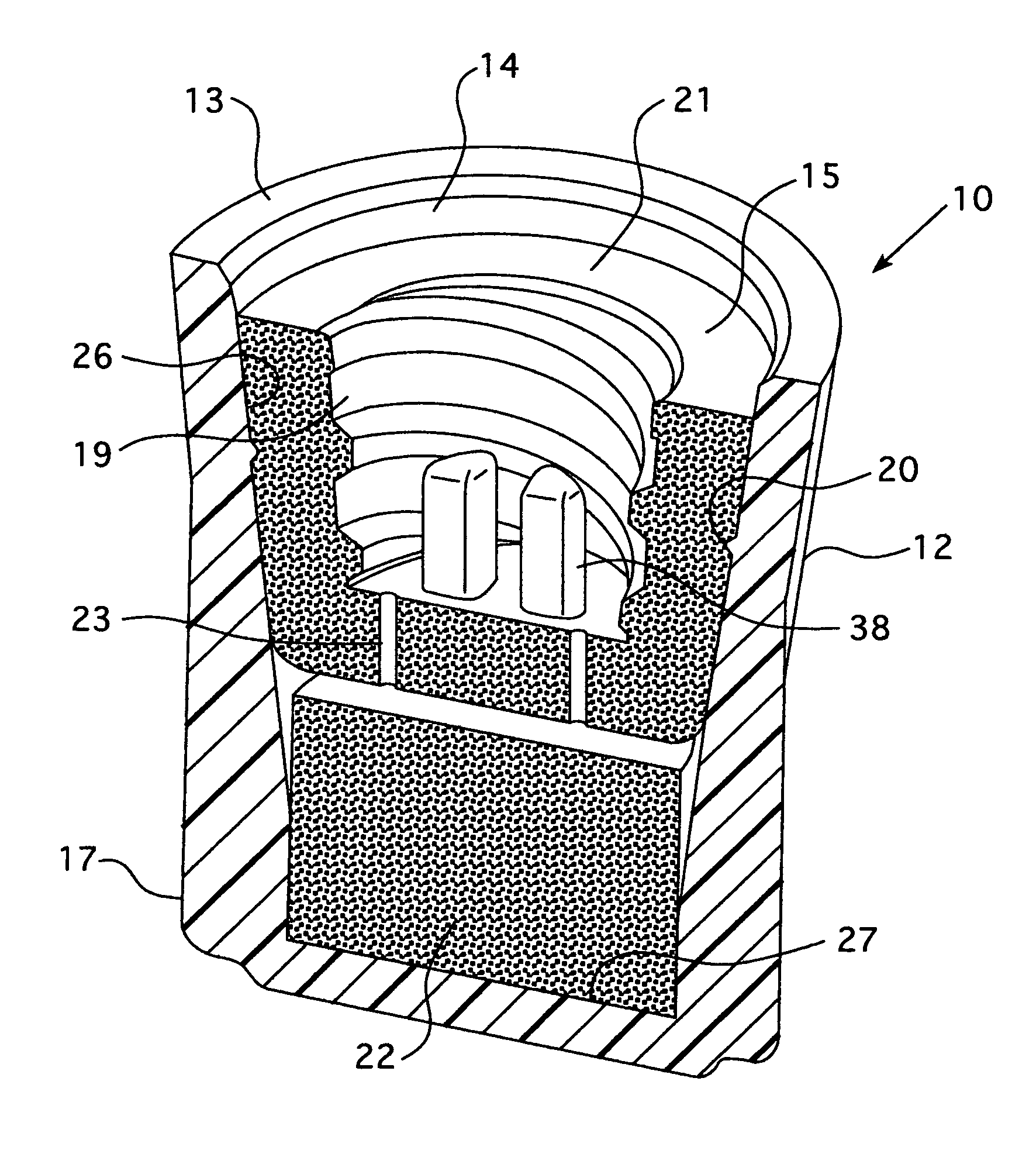

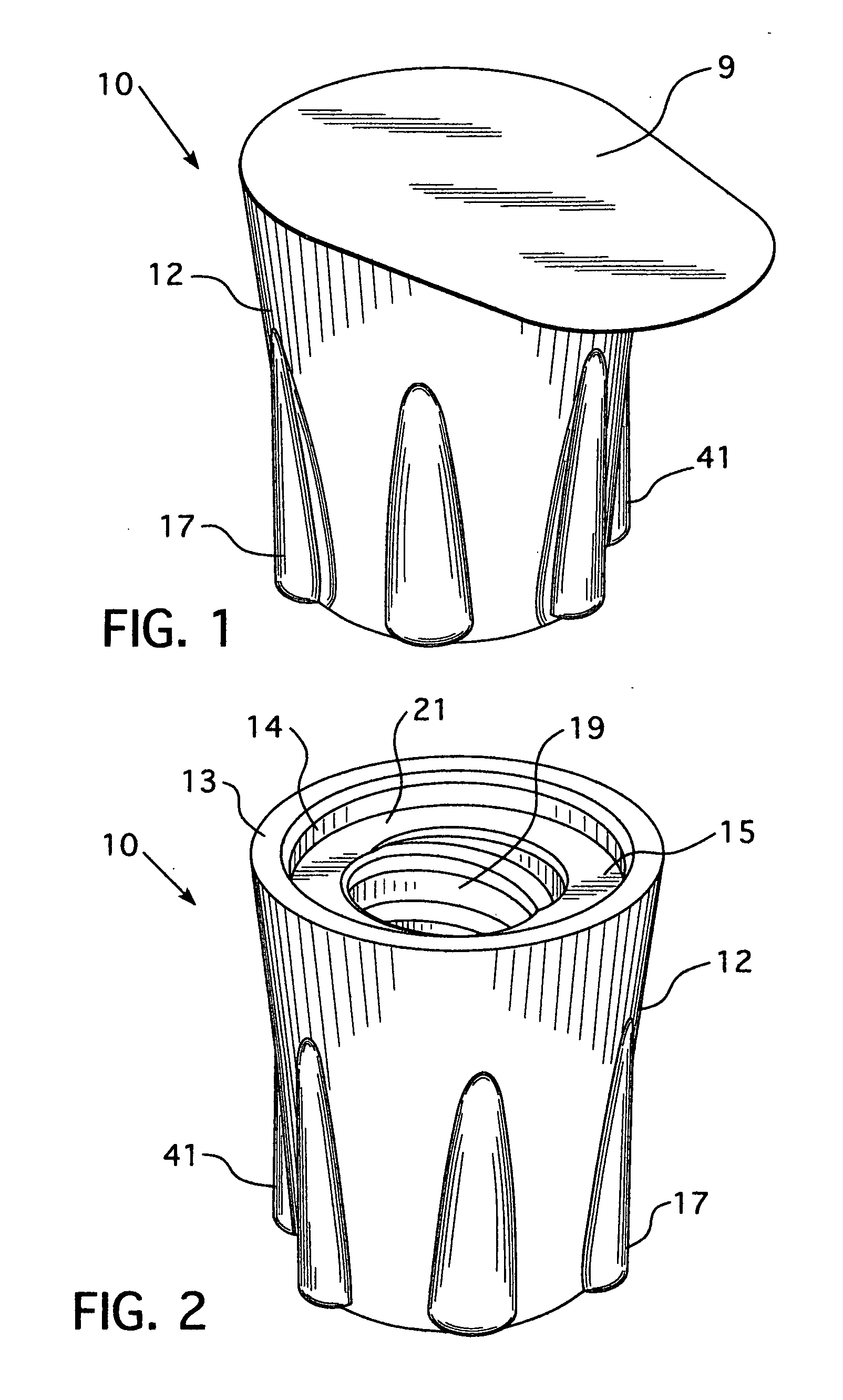

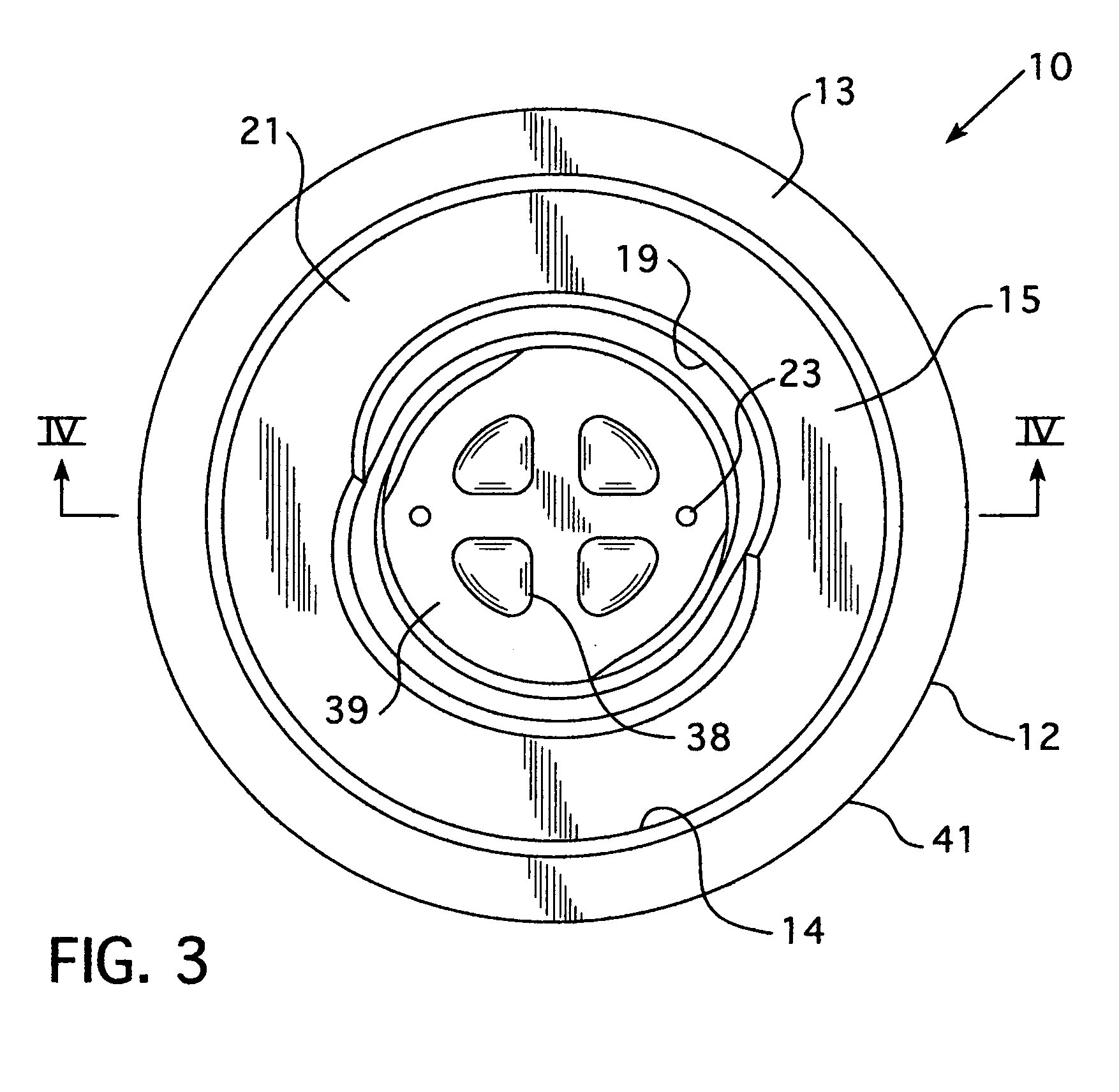

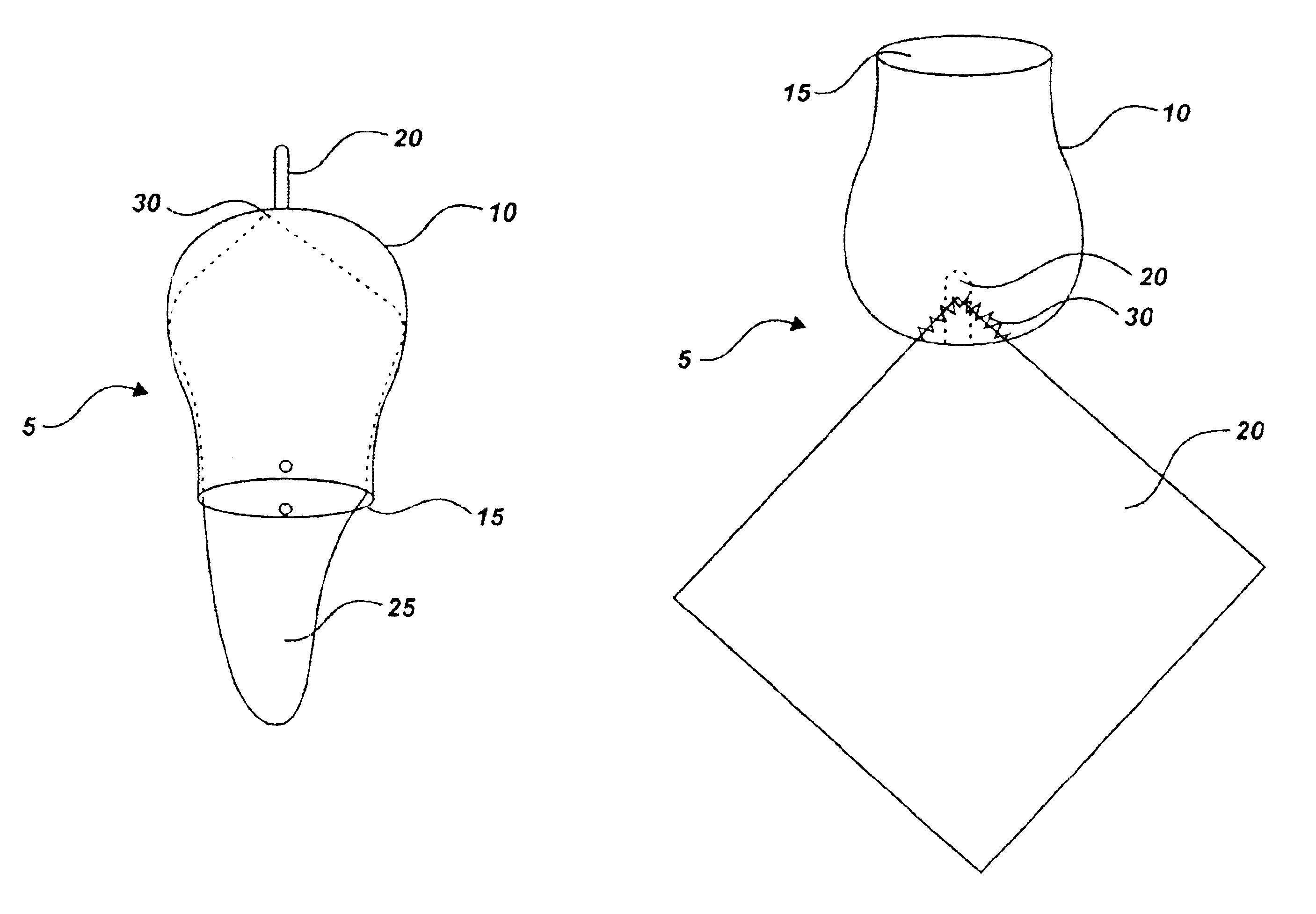

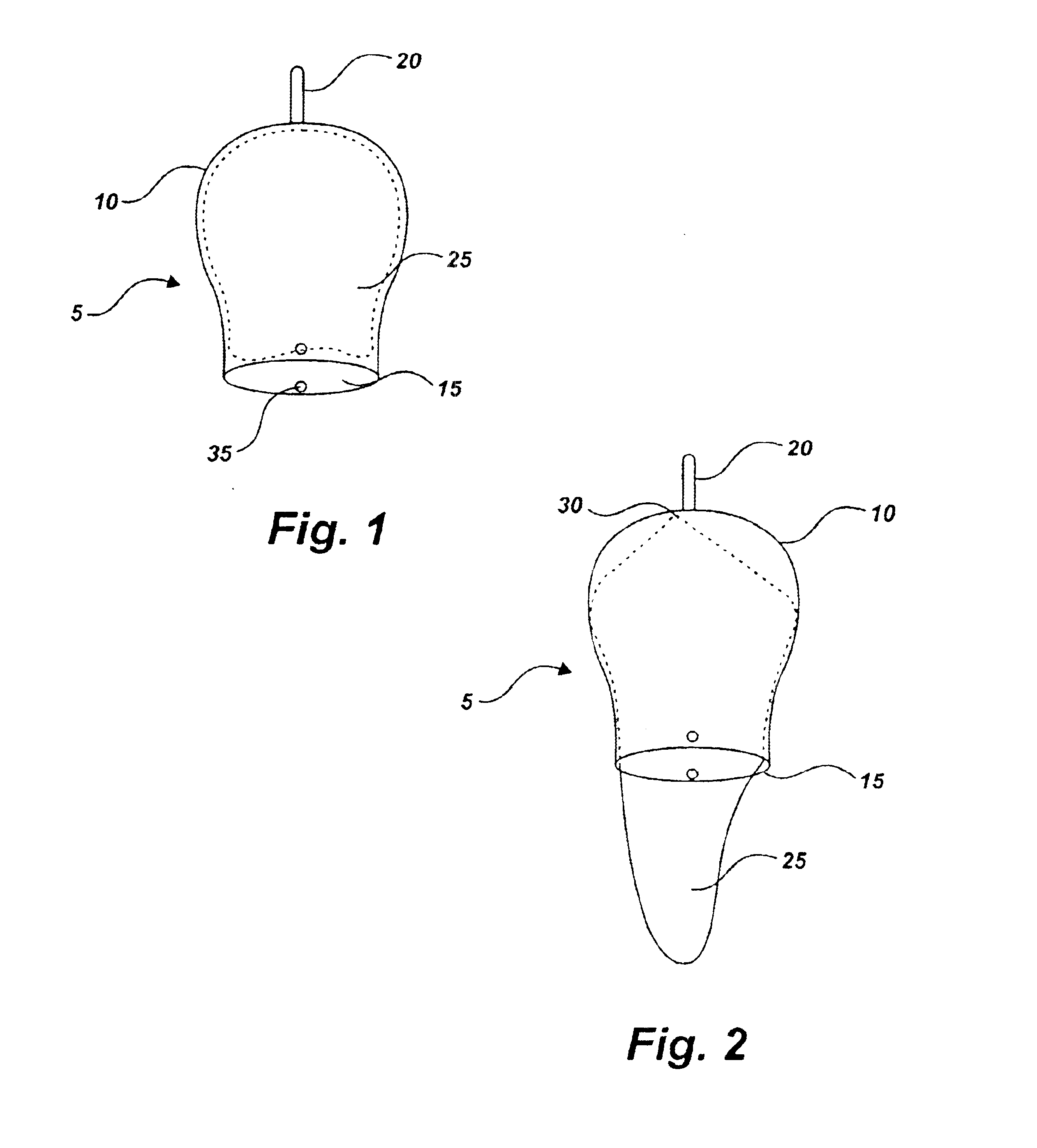

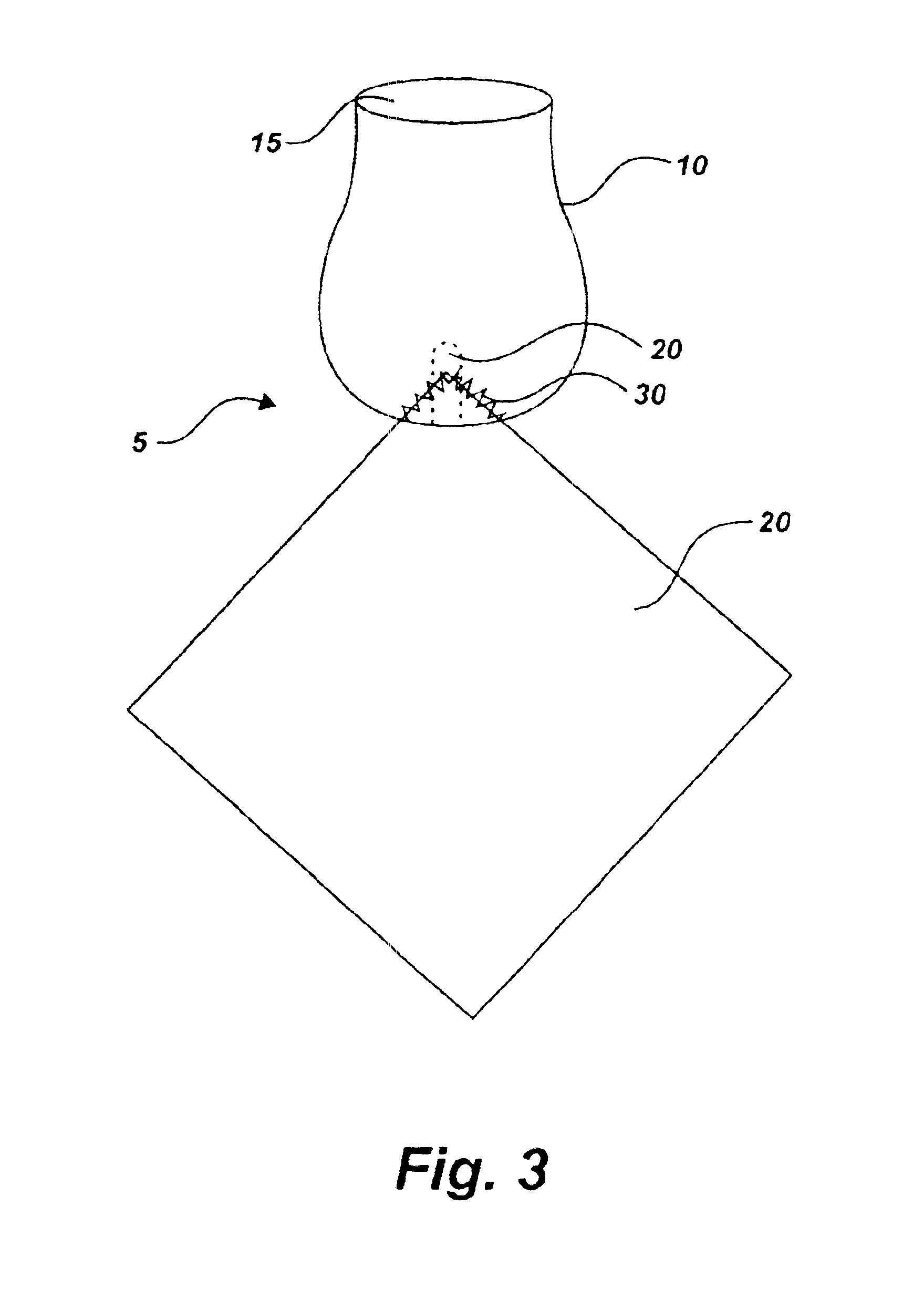

Apparatus and method for sterilizing a tubular medical line port

InactiveUS20100050351A1Avoid accessMedical devicesFlexible article cleaningBiomedical engineeringMedical treatment

An apparatus for sterilizing a tubular medical line port, having a cap with an open distal end and a cavity therein which is dimensioned to receive an outer scrubbing member and the medical line port. Outer disinfected-impregnated scrubbing member is coaxially received in the cavity and has a socket therein dimensioned for engaging exterior side surfaces of the tubular medical line port when inserted into the socket for thereby scrubbing exterior surfaces of the port with the scrubbing member by rotating the cap. The outer scrubbing member is axially displacable downwardly in the cavity by insertion of the medical line port therein from an upper position prior to use to a lower position where it is retained to thereby indicate that the apparatus has been used and should not therefore be reused. A reuse prevention insert is also provided in the cavity of the cap and is displacable with the outer scrubbing member from the upper position prior to use to the lower position during and after use. This insert is provided with inwardly protruding teeth that are biased for inward compression and thereby prevent re-access of a medical line port into the socket of the scrubbing member after removal of the medical line port.

Owner:REDEV AUTHORITY OF THE COUNTY OF ERIE +1

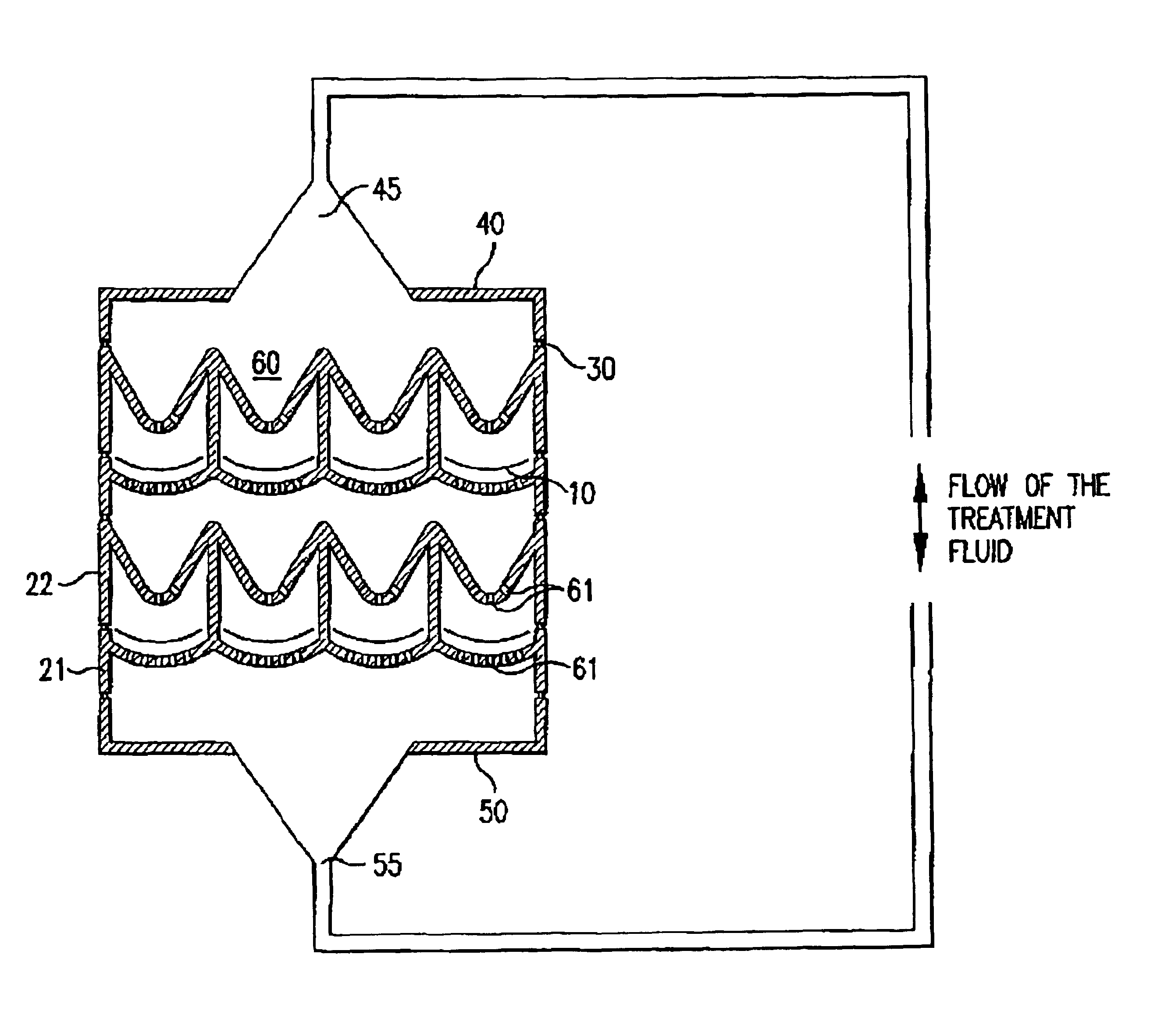

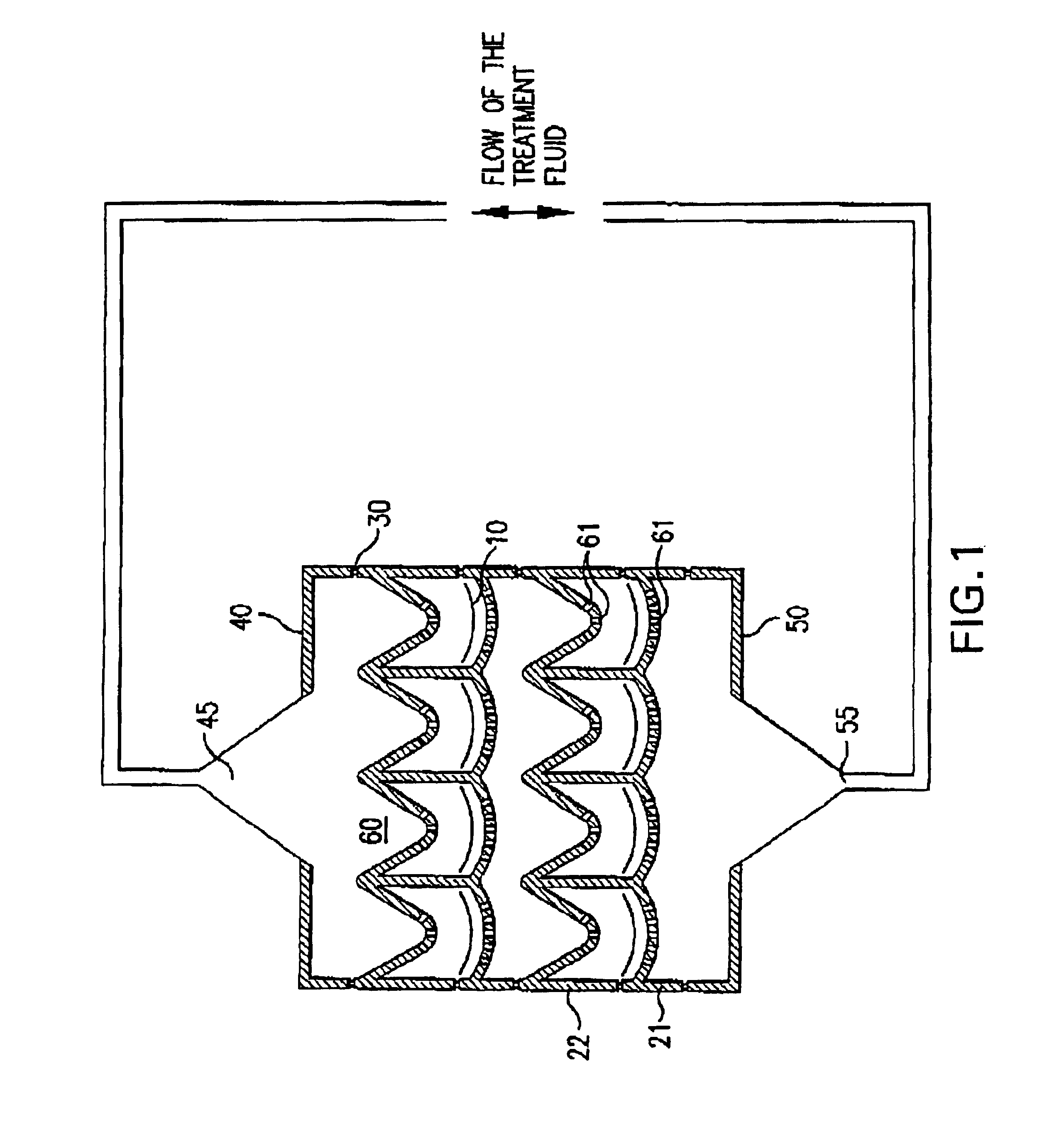

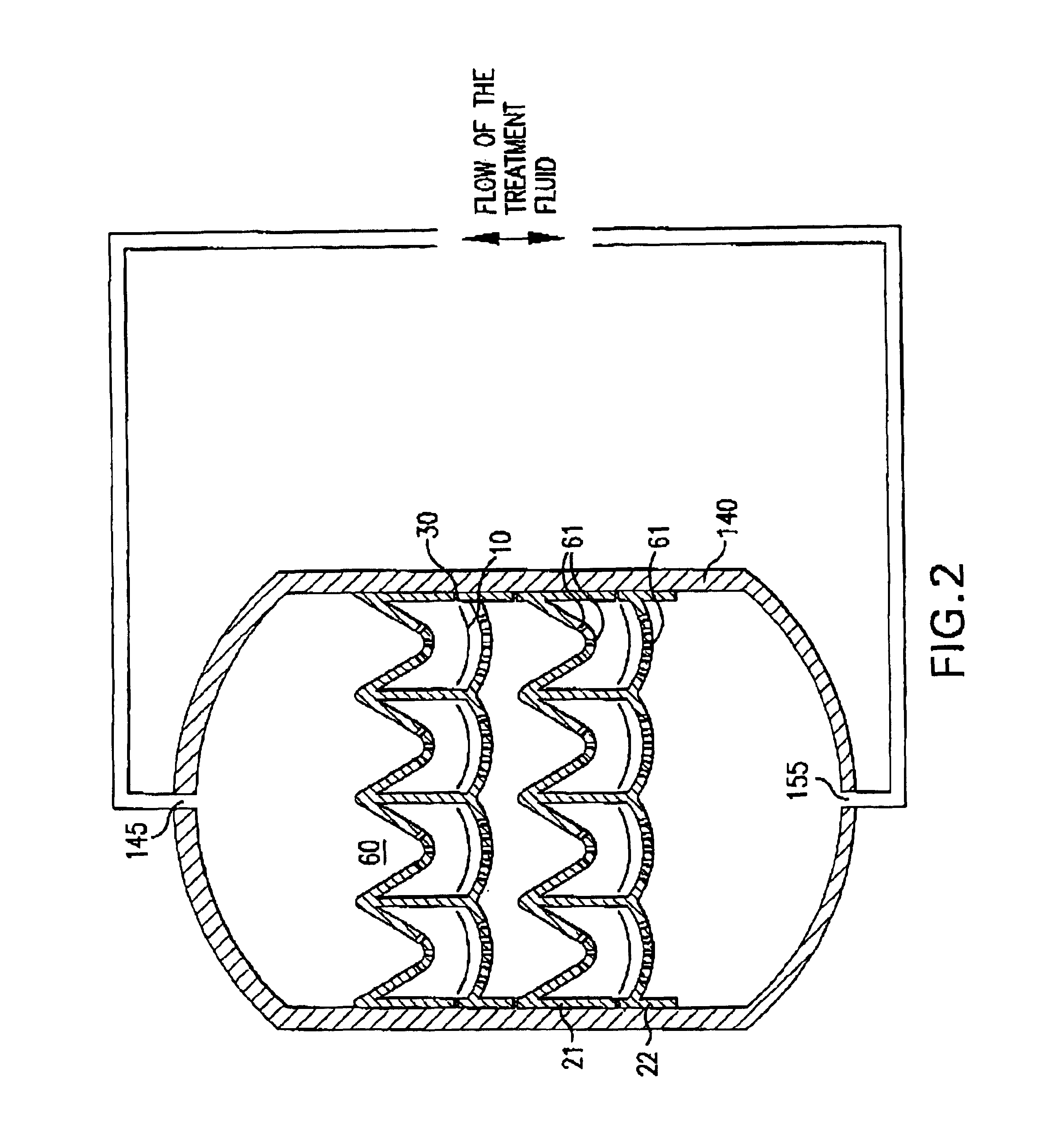

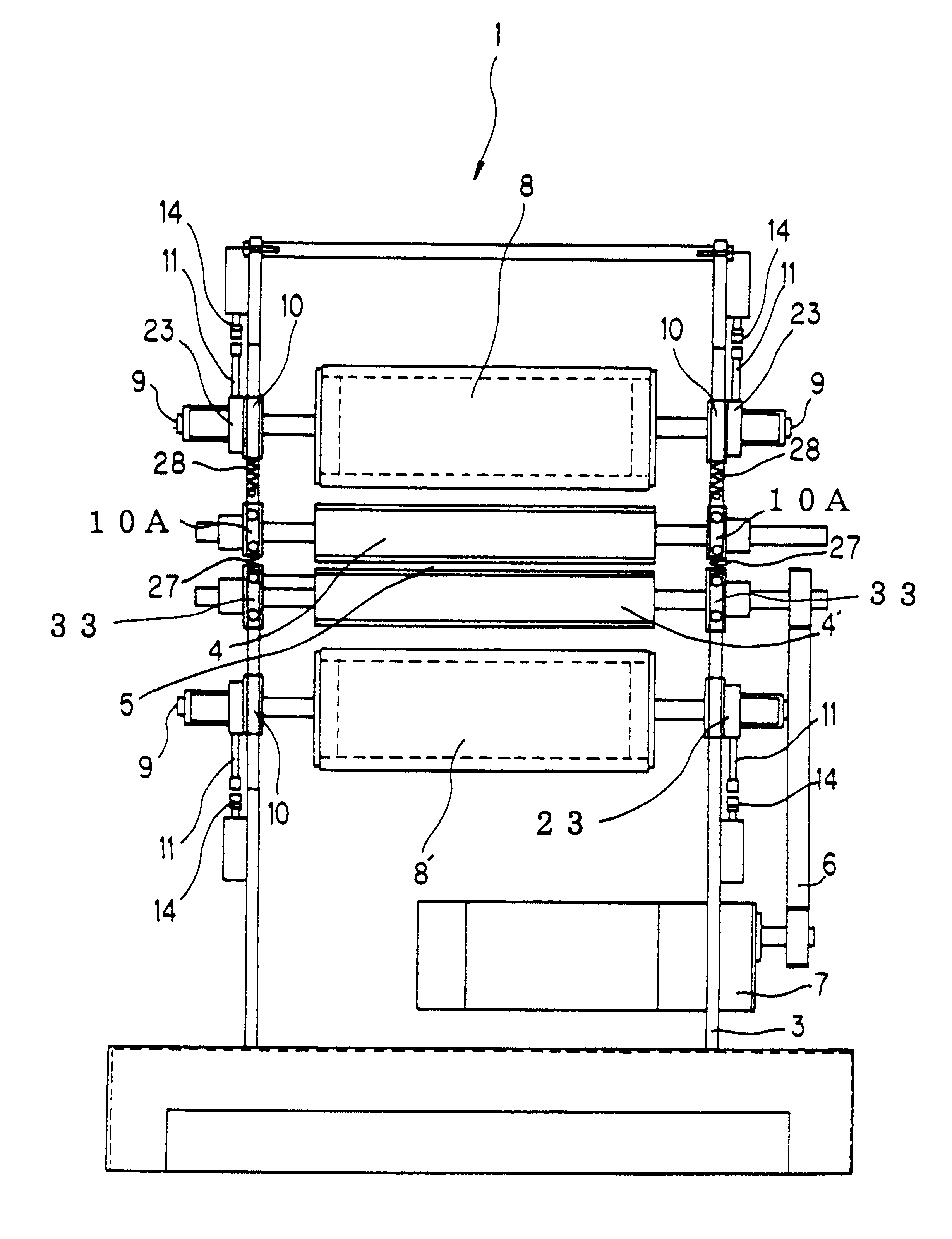

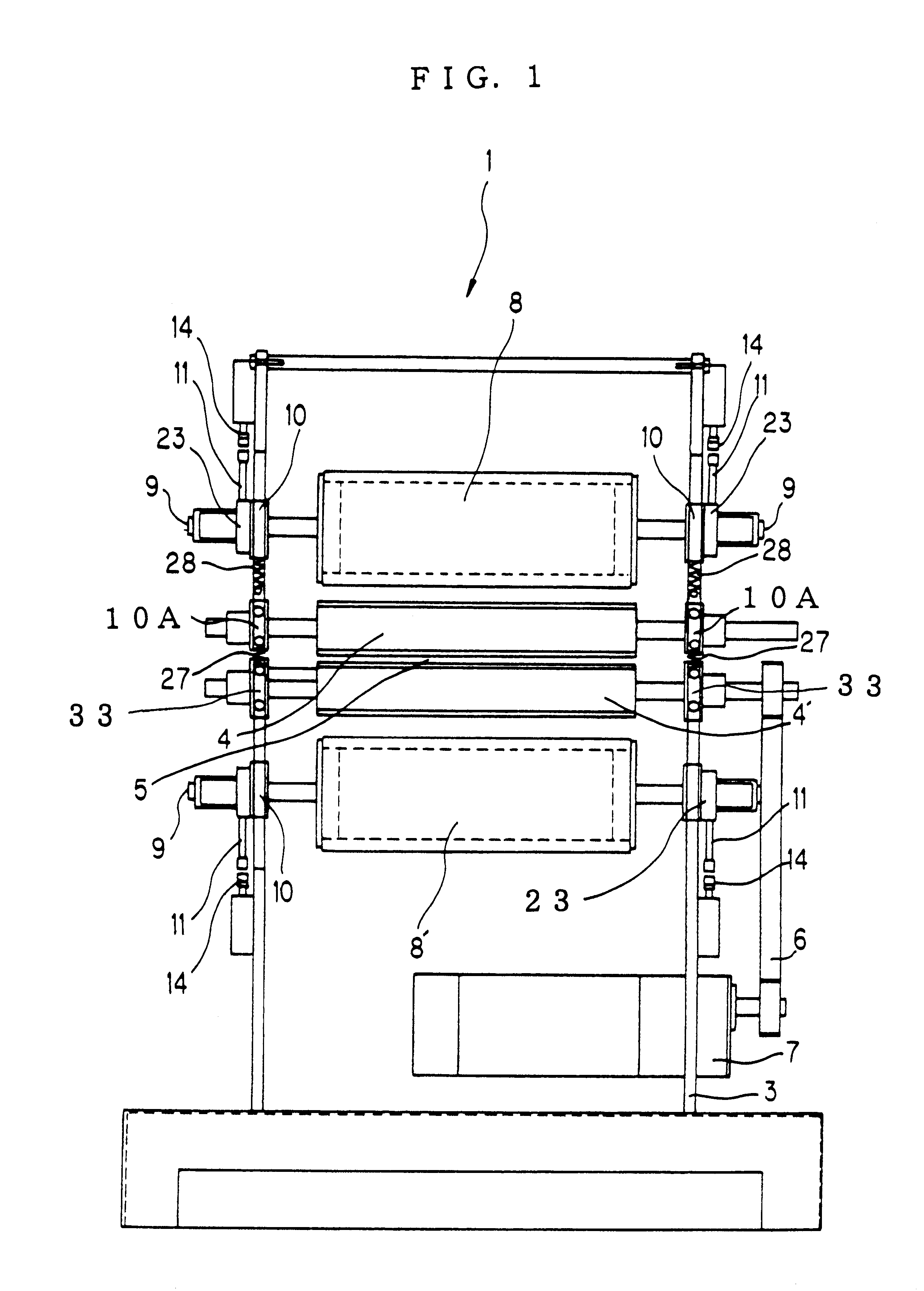

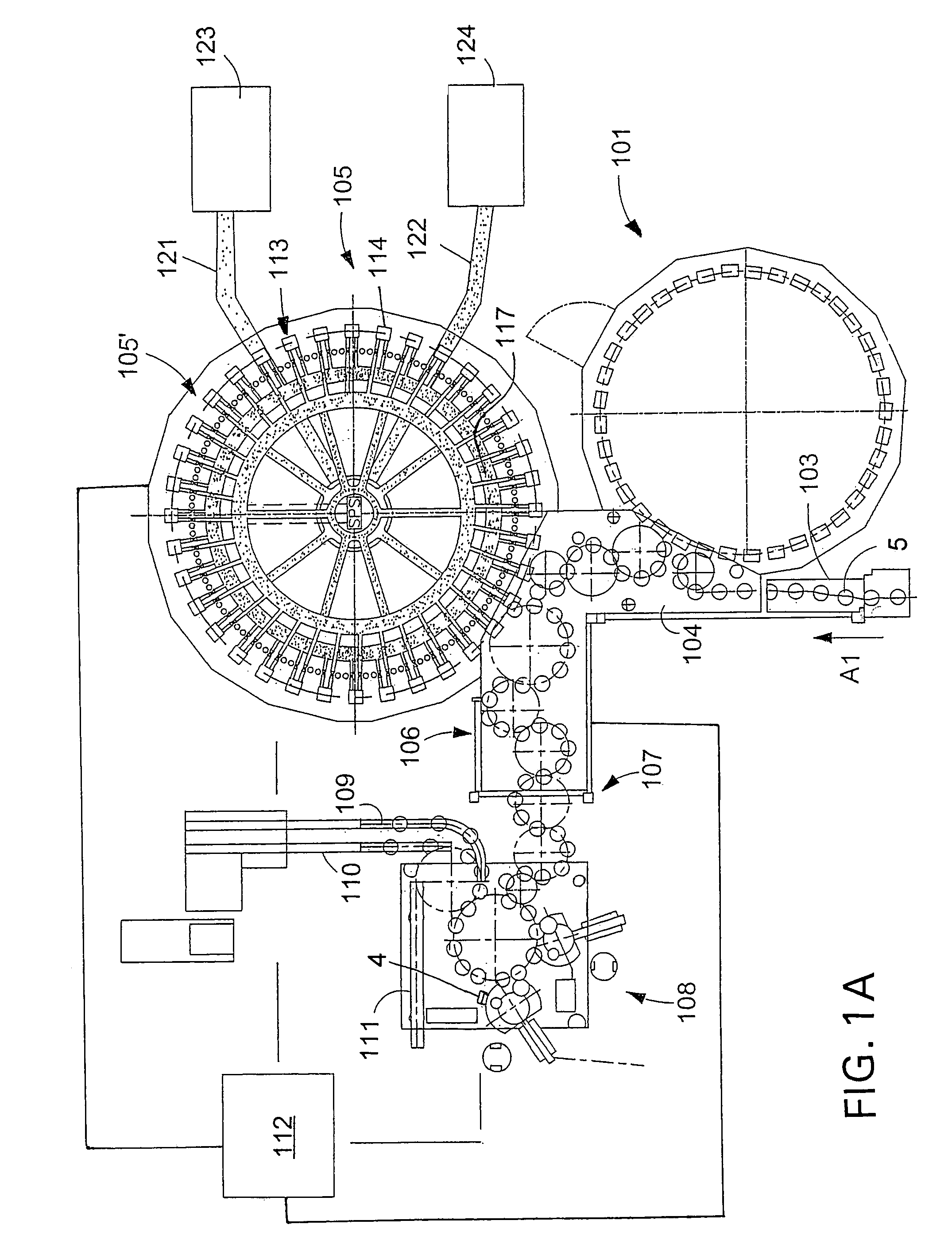

System and method for treating articles with fluids

InactiveUS6884457B2Efficiently and uniformly treatingEfficiently uniformly treatingGlovesPretreated surfacesBiomedical engineeringTreatment system

The present invention provides a method for efficiently and uniformly treating articles with two or more fluids without transferring the articles from one container to another container. The method comprises: providing the fluids, one at a time, to treat the articles in a treatment system, wherein the treatment system comprises one or more trays each of which has one or more baskets, each basket capable of holding one article, and wherein said trays are stacked to form a vessel or are stacked and placed within a preformed vessel, said vessel or preformed vessel comprising a first entrance / exit and a second entrance / exit for the fluids; and each time one of the fluids is provided to treat the articles, (a) flushing continuously the articles with the fluid in a first flow direction from the first entrance / exit to the second entrance / exit, (b) reversing the flow direction of the fluid, (c) flushing continuously the articles with the fluid in a second direction from the second entrance / exit to the first entrance / exit for a second period of time, and (d) if necessary, repeating steps (a) to (c) for a desired number of times.

Owner:ALCON INC

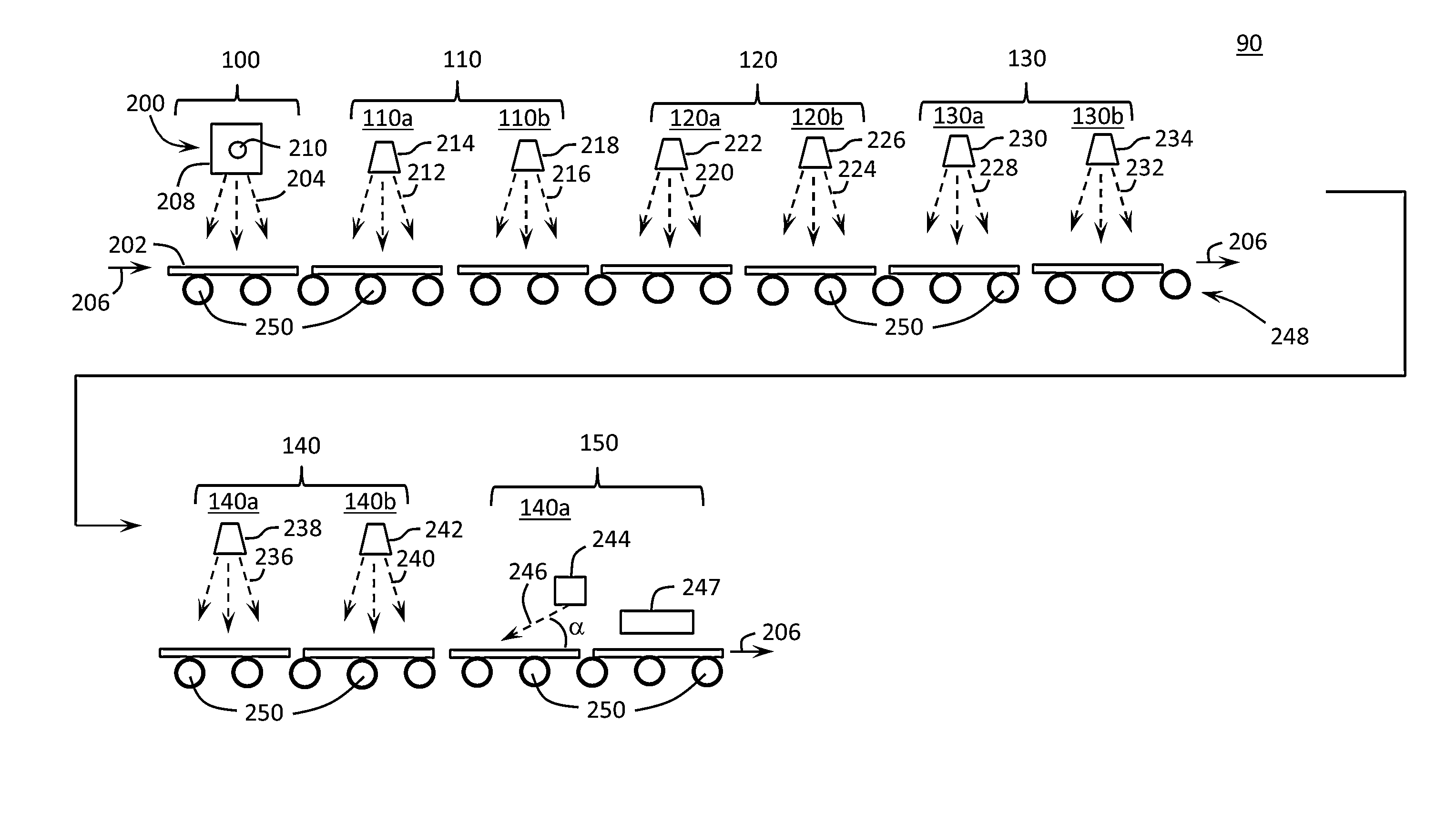

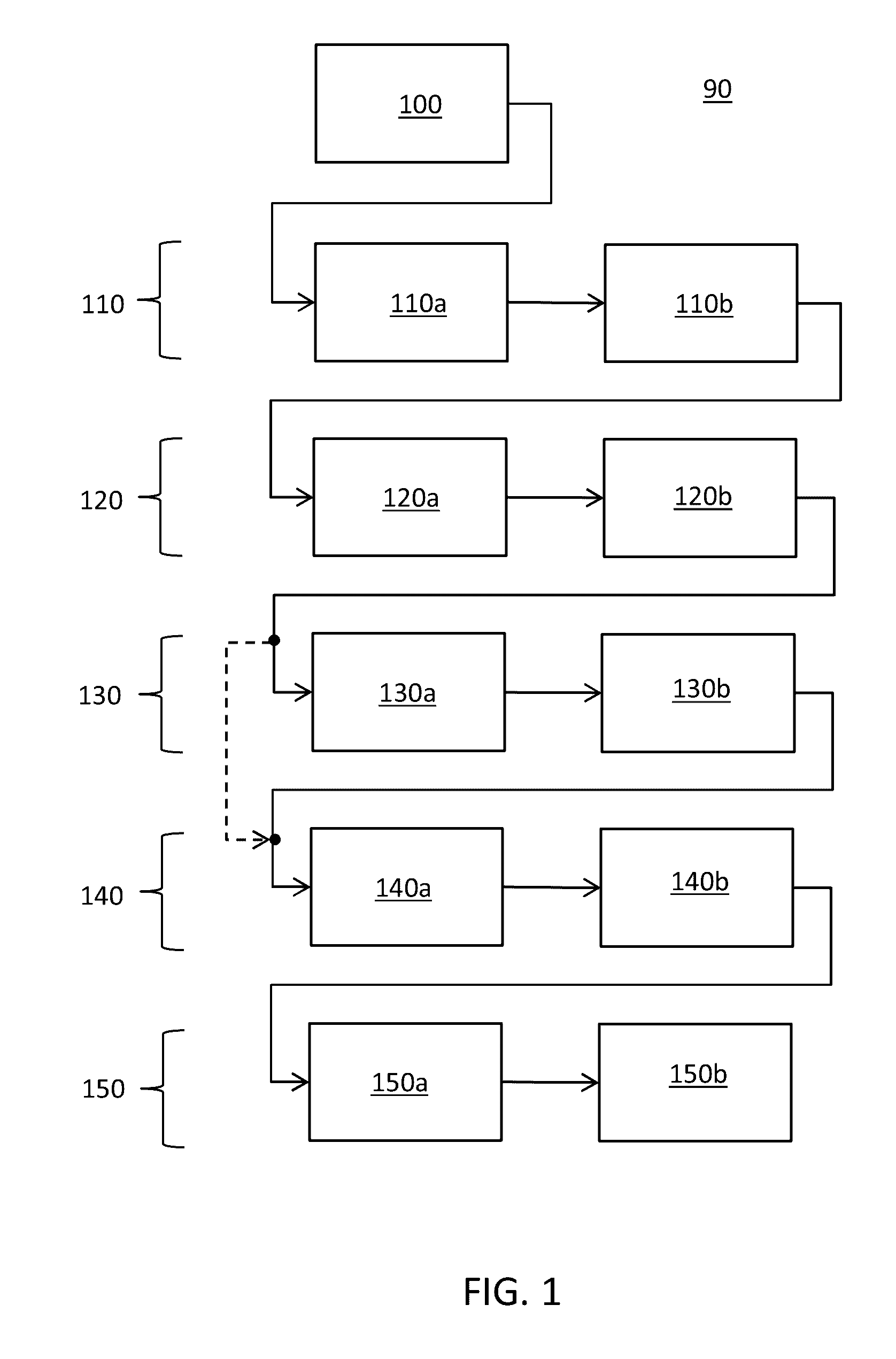

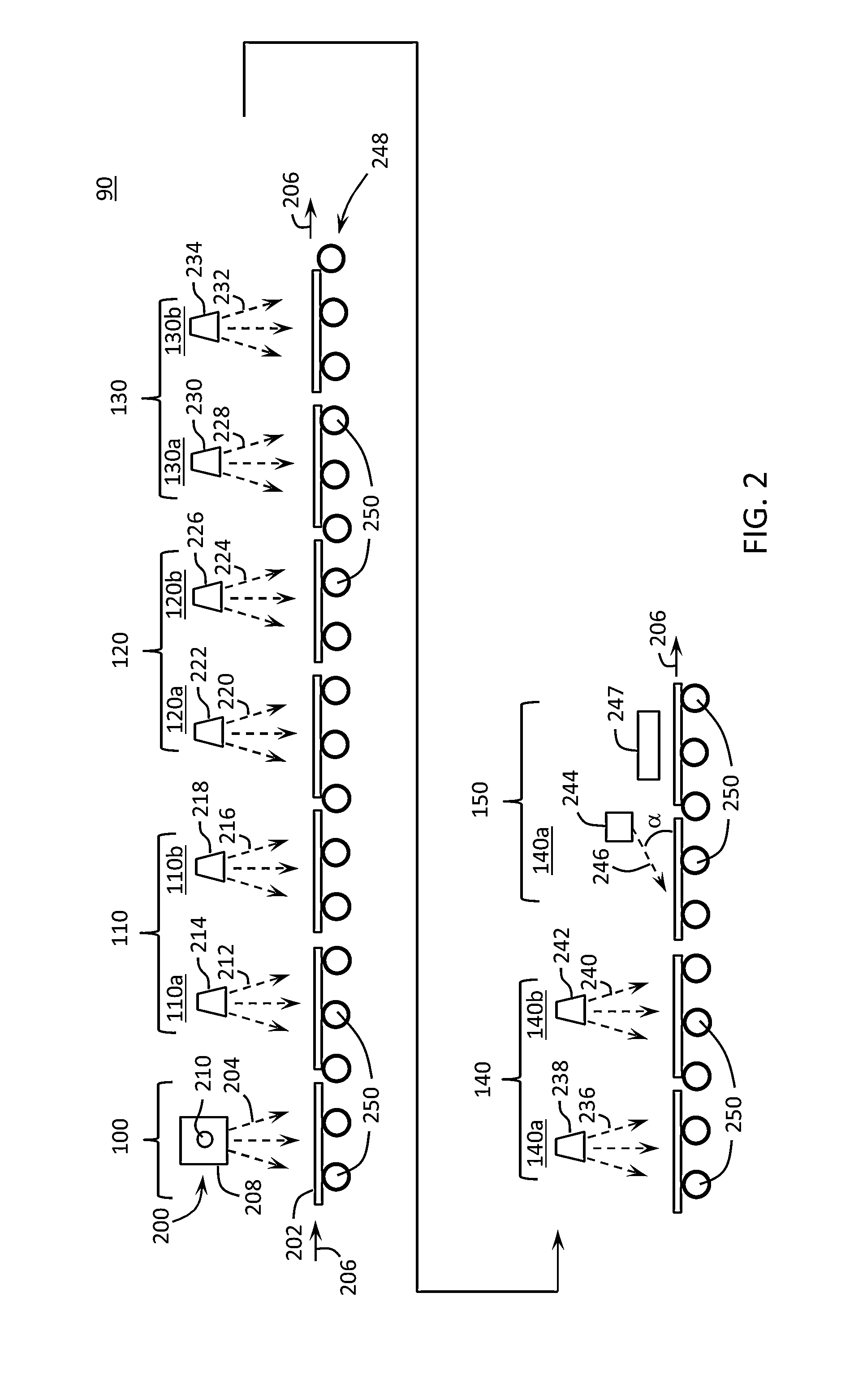

Method of cleaning glass substrates

InactiveUS9561982B2Low levelEnhance electrostatic interactionSemiconductor/solid-state device manufacturingFlexible article cleaningThin glassElectrostatic discharge

A method of cleaning thin glass substrates comprises applying a sequence of chemical washing steps as the thin glass substrate is being conveyed in a conveyance direction. In addition, surfaces of the glass substrate may be treated to enhance electrostatic discharge properties of the glass substrates.

Owner:CORNING INC

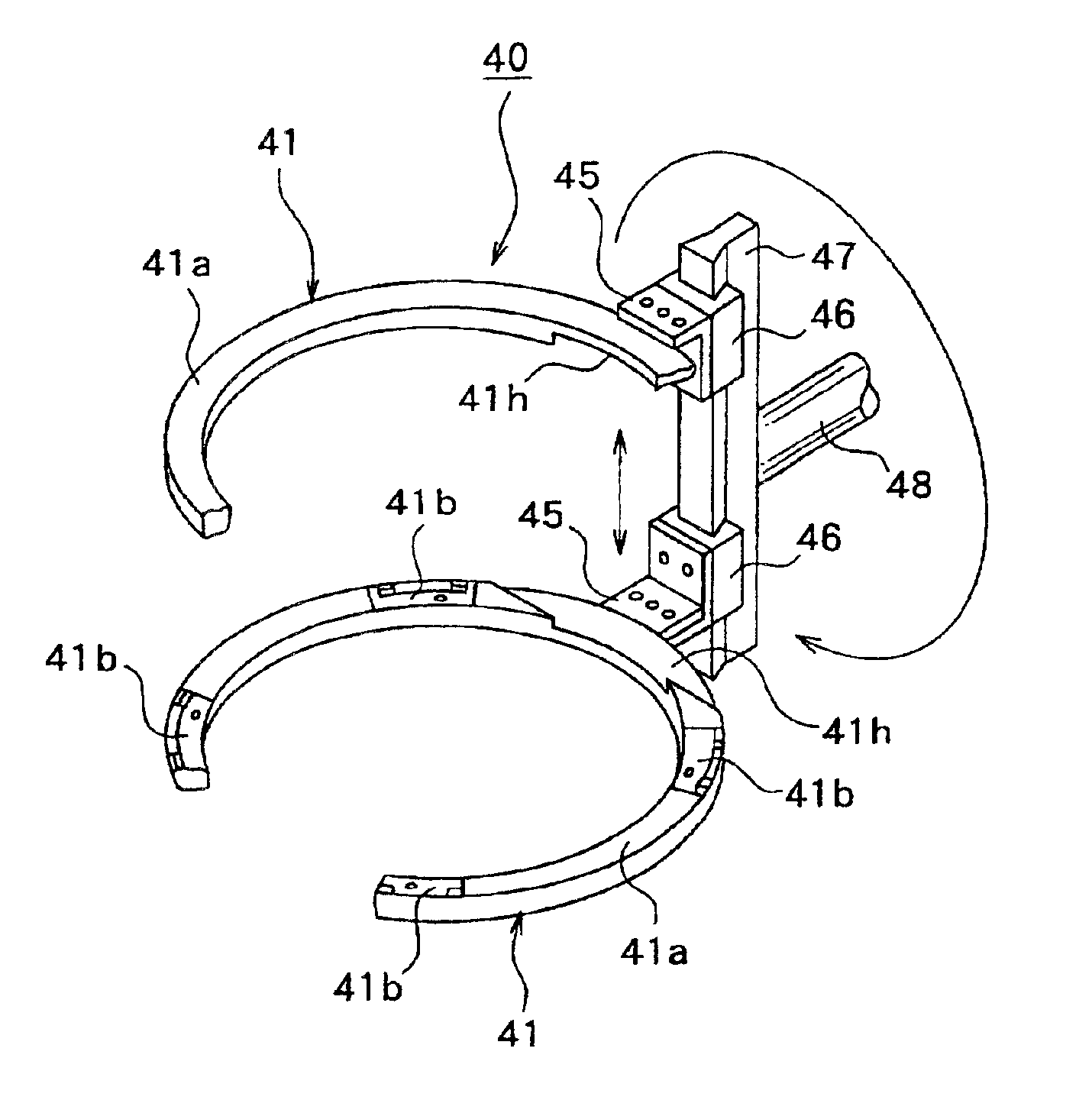

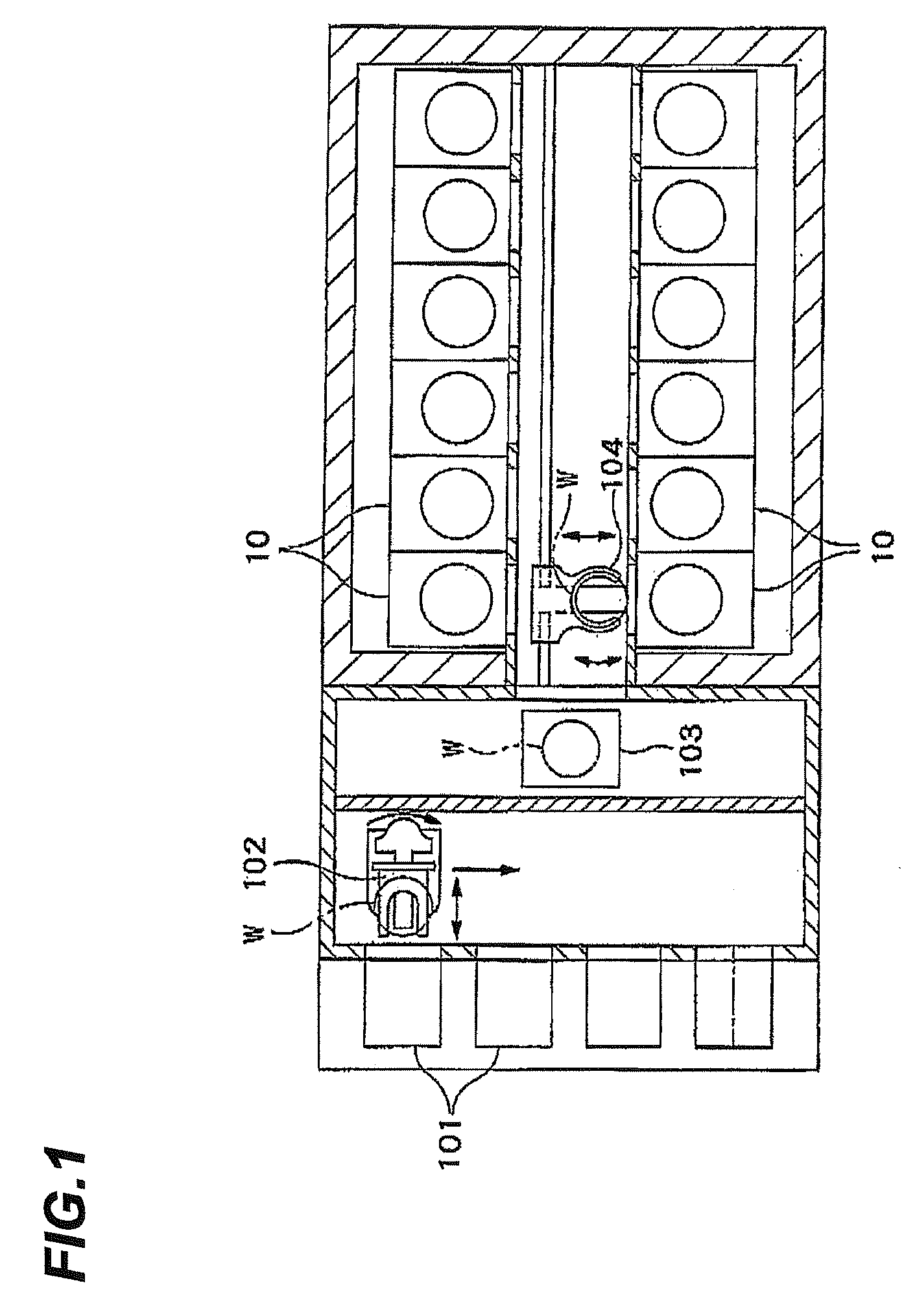

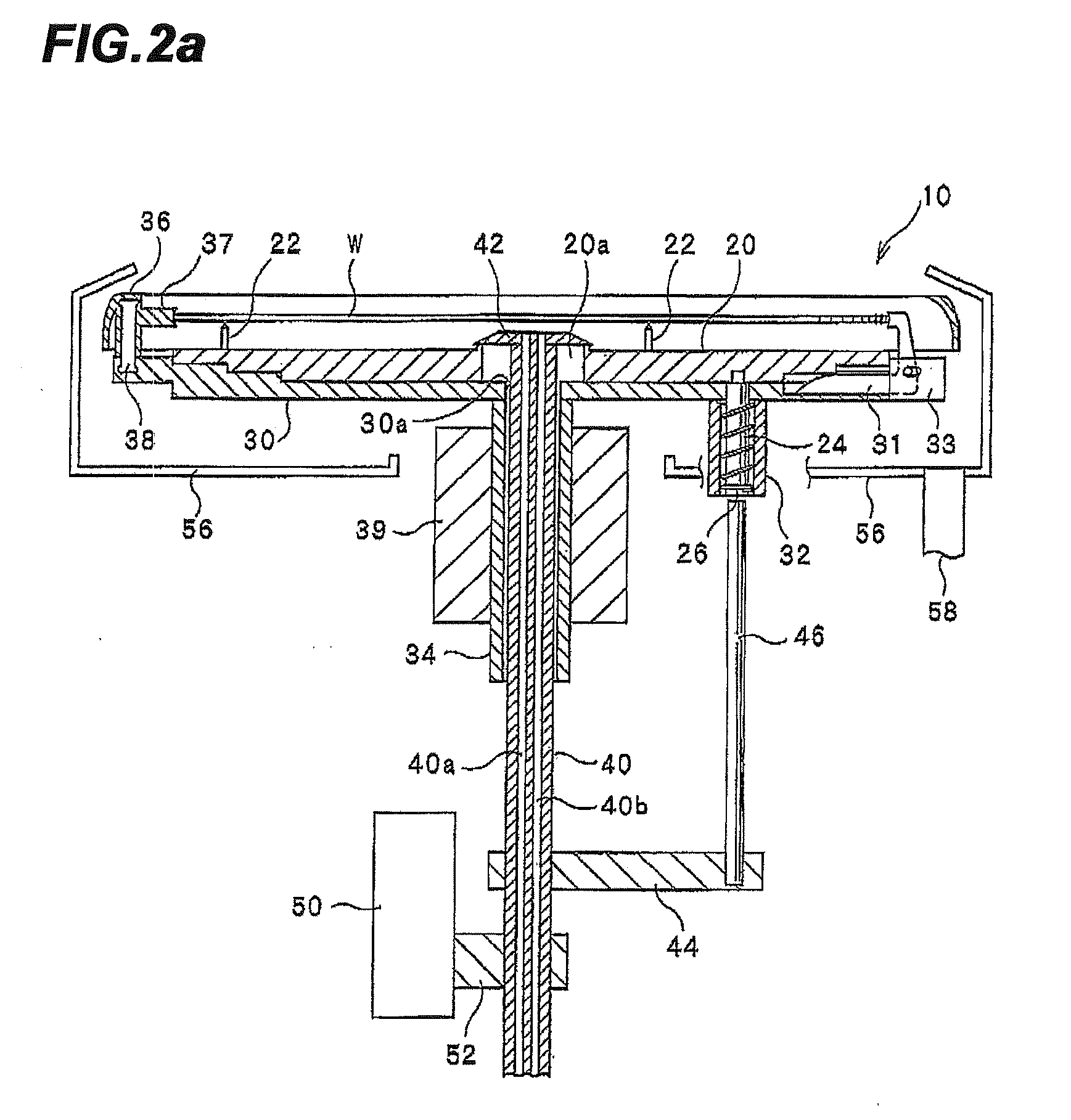

Substrate dual-side processing apparatus

InactiveUS6874515B2Accurate operationImprove throughputSemiconductor/solid-state device manufacturingFlexible article cleaningEngineeringTransfer mechanism

A substrate dual-side processing apparatus has a processor to apply a specific process to a front surface and a rear surface of a substrate, a reversing unit to reverse the substrate and a substrate-transfer mechanism to transfer the substrate between the processor and the reversing unit. The reversing unit has a holder for holding the substrate when the substrate is being transferred to and from the substrate-transfer mechanism and a rotating mechanism for rotating the substrate, thus the substrate being reversed while held by the holders. The reversing unit may have a pair of holders for holding the substrate at the front and rear surfaces, a drive mechanism for driving the pair of holders so that the holders become close to or apart from each other and a rotating mechanism for rotating the substrate, thus the substrate being reversed while held by the holders.

Owner:TOKYO ELECTRON LTD

Automatic cleaning machine

InactiveCN102698988AAvoid harmHigh degree of automationElectrostatic cleaningFlexible article cleaningAlcoholSpray nozzle

The present invention discloses a cleaning machine, especially to an automatic cleaning machine for cleaning a mobile phone screen. The cleaning machine comprises a rack which is provided with an alcohol pressure cylinder; a conveyor belt wheel which is provided with a conveyor belt; an unreeling wheel which is rotatingly connected with the rack and provided with a non-dust cloth roller; a retrieving wheel rotatingly connected with the rack, one end of a non-dust cloth discharged by the non-dust cloth roller is wound on the retrieving wheel through a stretching wheel; a rolling wheel driving motor, a rotating shaft of which is connected with the unreeling wheel or the retrieving wheel; a cleaning motor which is arranged between the unreeling wheel and the retrieving wheel, a rotating shaft of the cleaning motor is an eccentric shaft, the eccentric shaft is connected with a friction block, the alcohol pressure cylinder is connected with a nozzle through a pipeline, and the opening direction of the nozzle is toward the unreeling wheel. By adopting the cleaning machine, problems that the mobile phone screen needs to be cleaned by people, the efficiency is low, the labor intensity is large, human body can be damaged, costs are high can be solved, and certain beneficial effects can be realized.

Owner:青岛有信印刷机有限公司

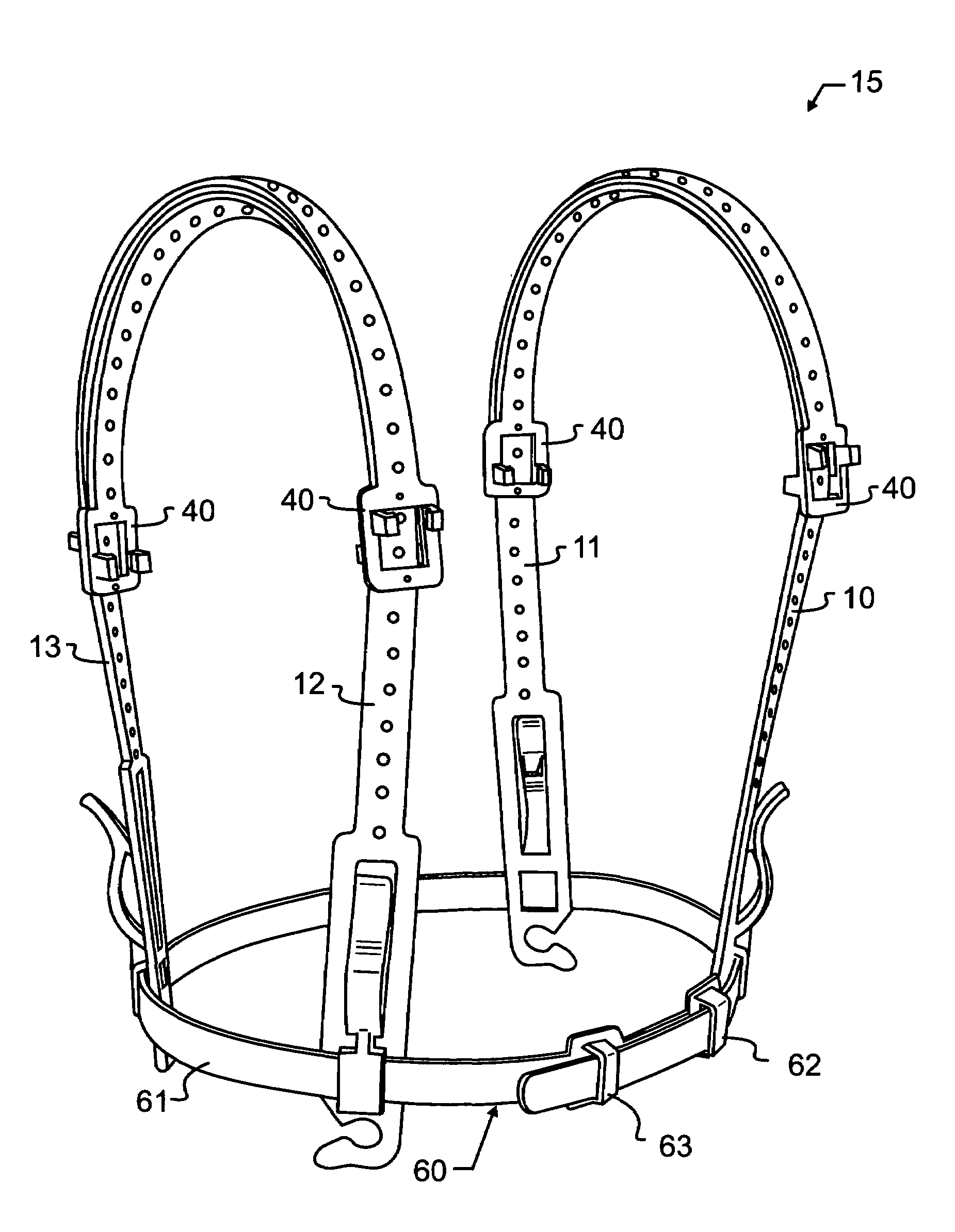

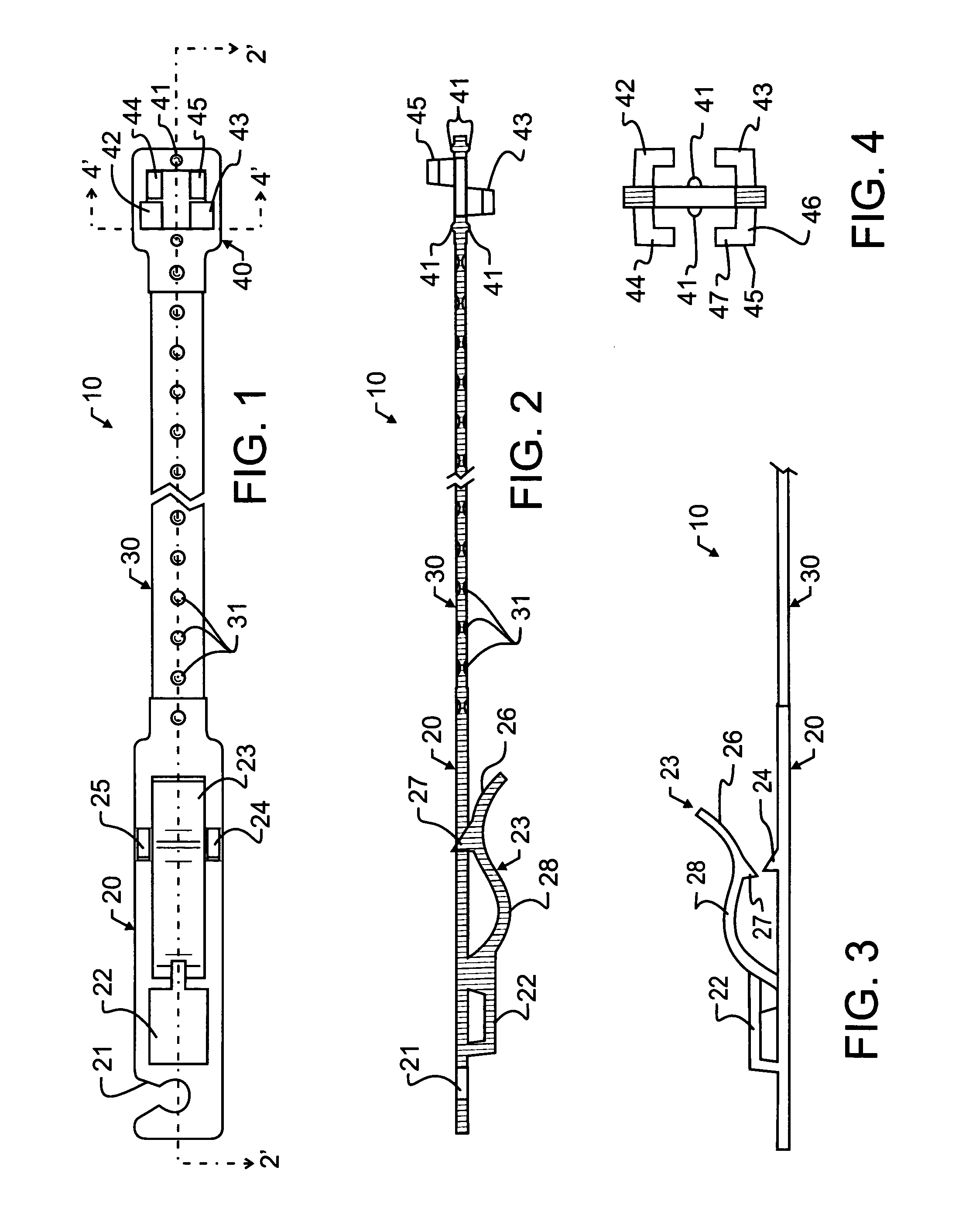

Bag washing apparatus and method

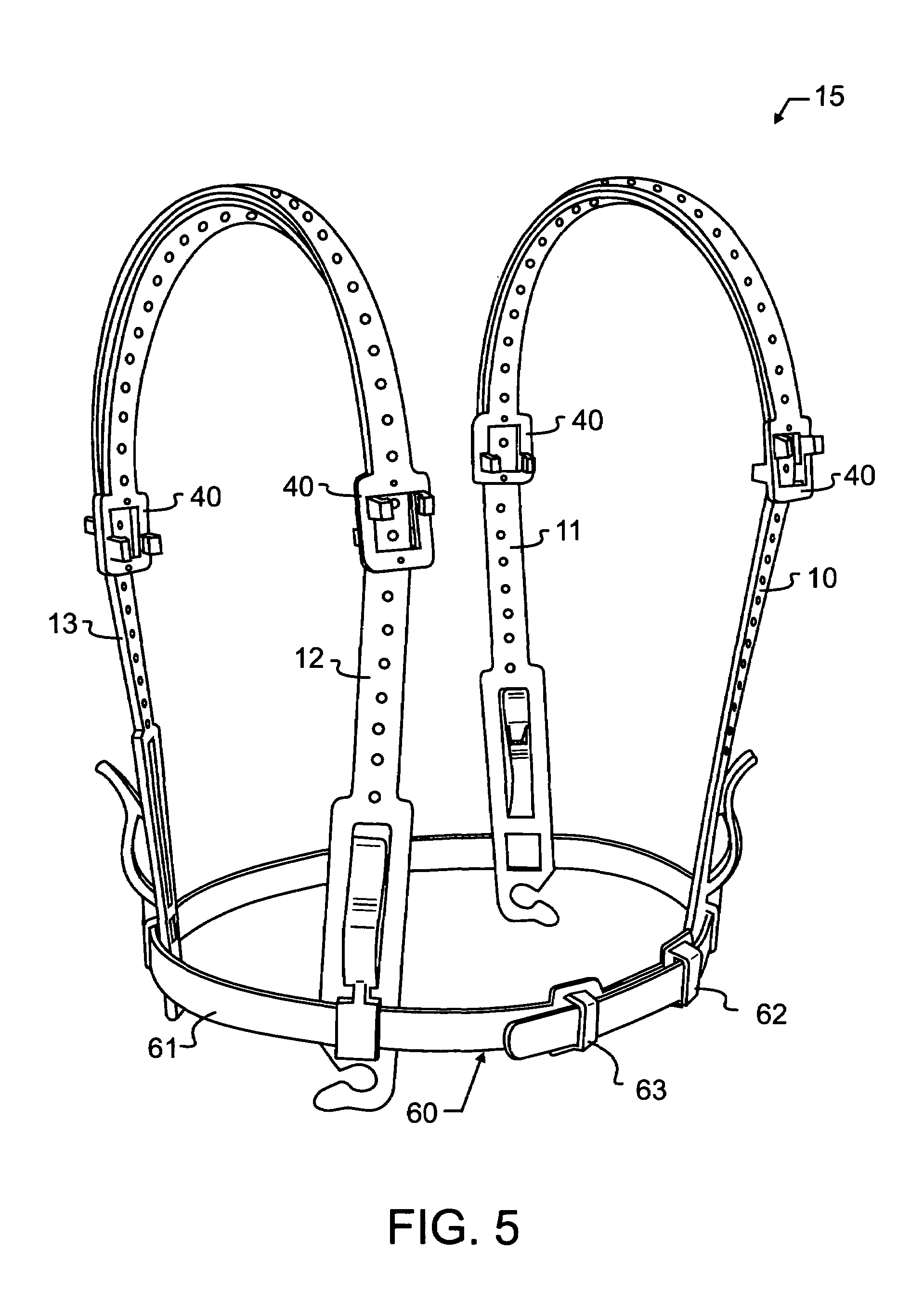

InactiveUS6983754B1Easy to adaptEasy to configureCard-filingHollow article cleaningEngineeringCHEEK DIMPLES

A support structure and method, designed to maintain a resealable plastic bag in an open position within a dishwasher through the washing and drying cycles, has at least two vertically extending support and restraining straps that may be engaged with like straps to form a resilient support framework. A plurality of mating dimples and protrusions offer controlled size adjustments, while maintaining the reliability of the structure. The structure is readily collapsible to a flat and compact structure prior to purchase and when not in use, and includes features to engage with the rack in the dishwasher to prevent the support and bag from being substantially relocated during the wash process.

Owner:ANDERSON RANDY M +1

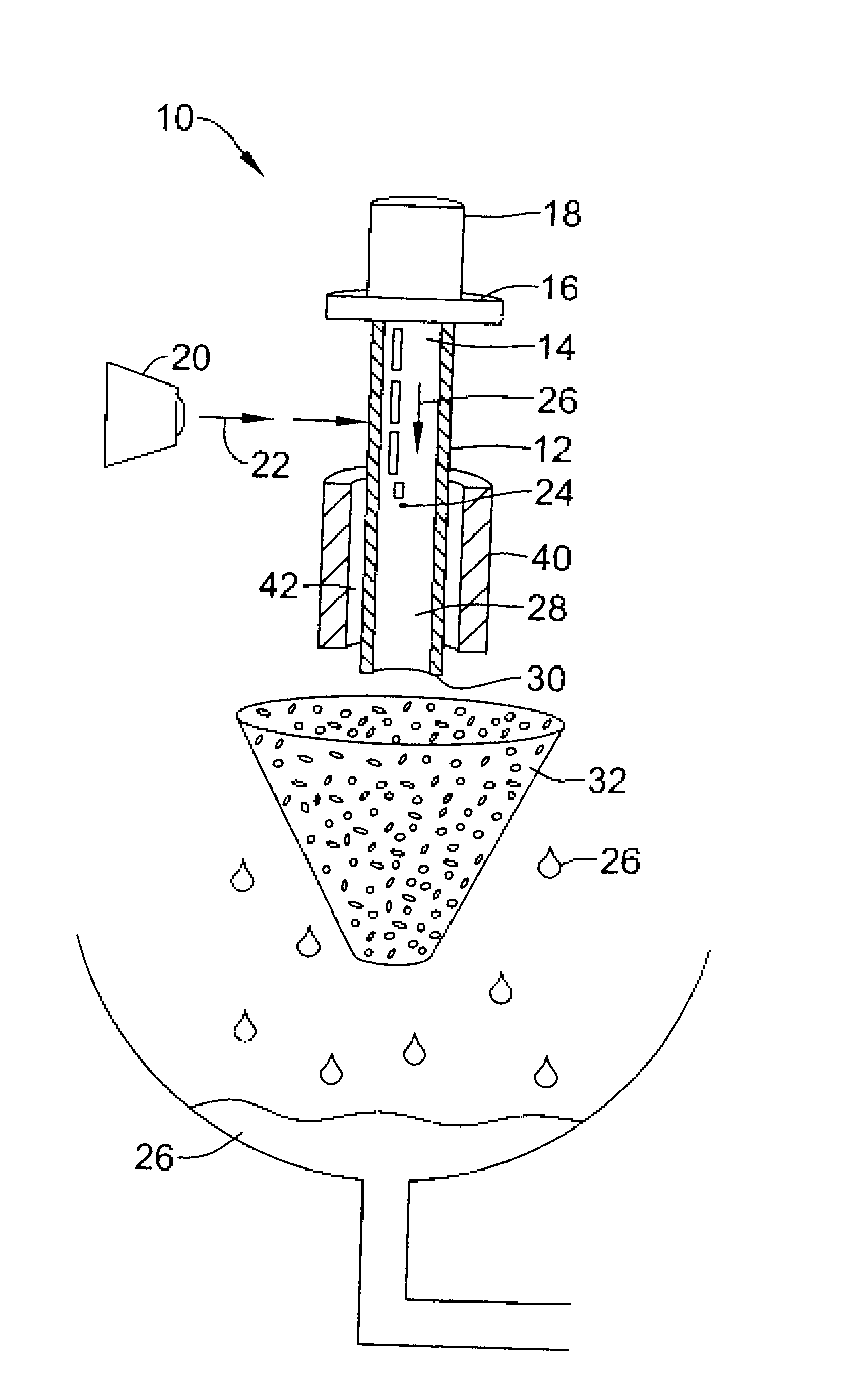

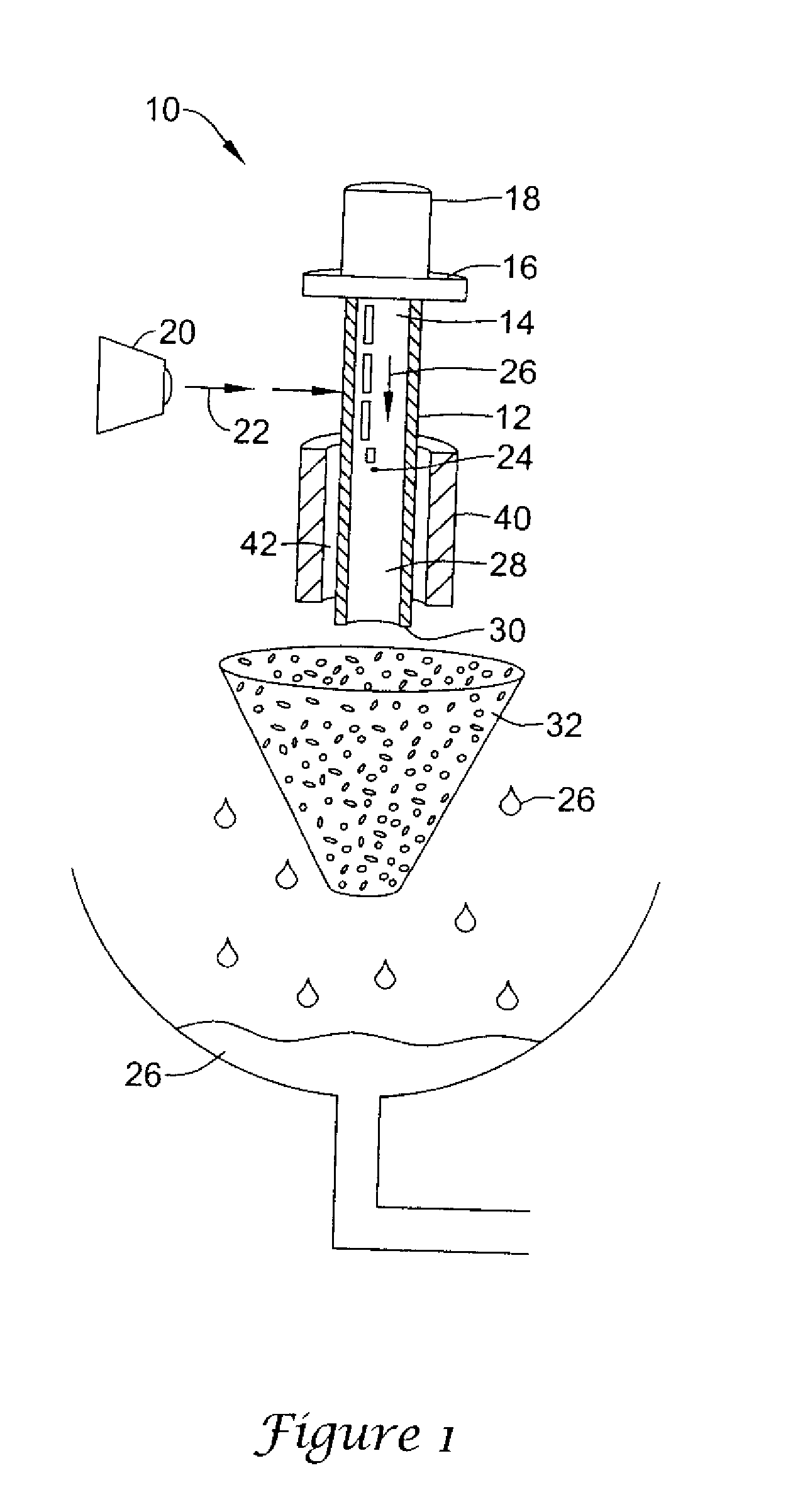

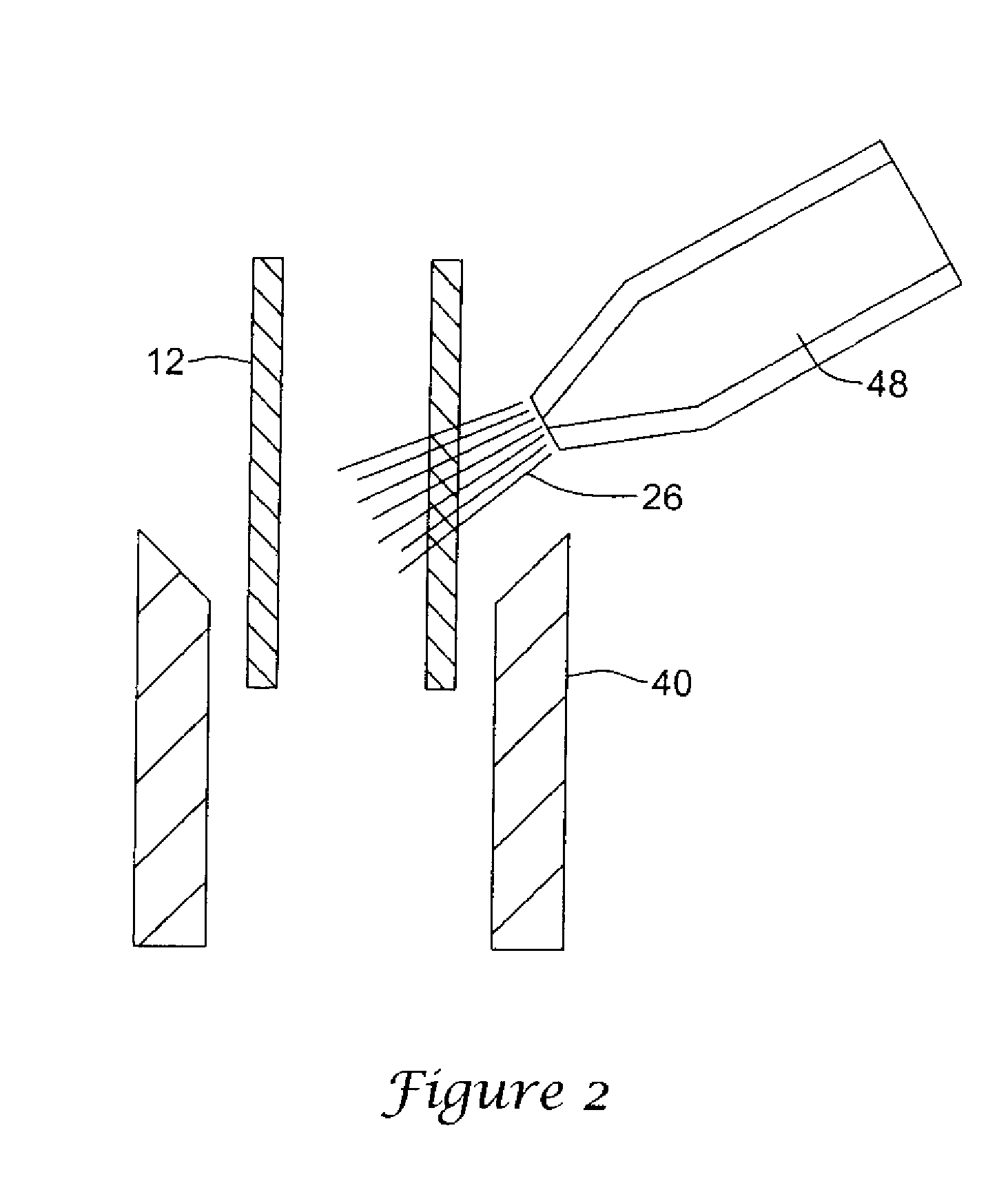

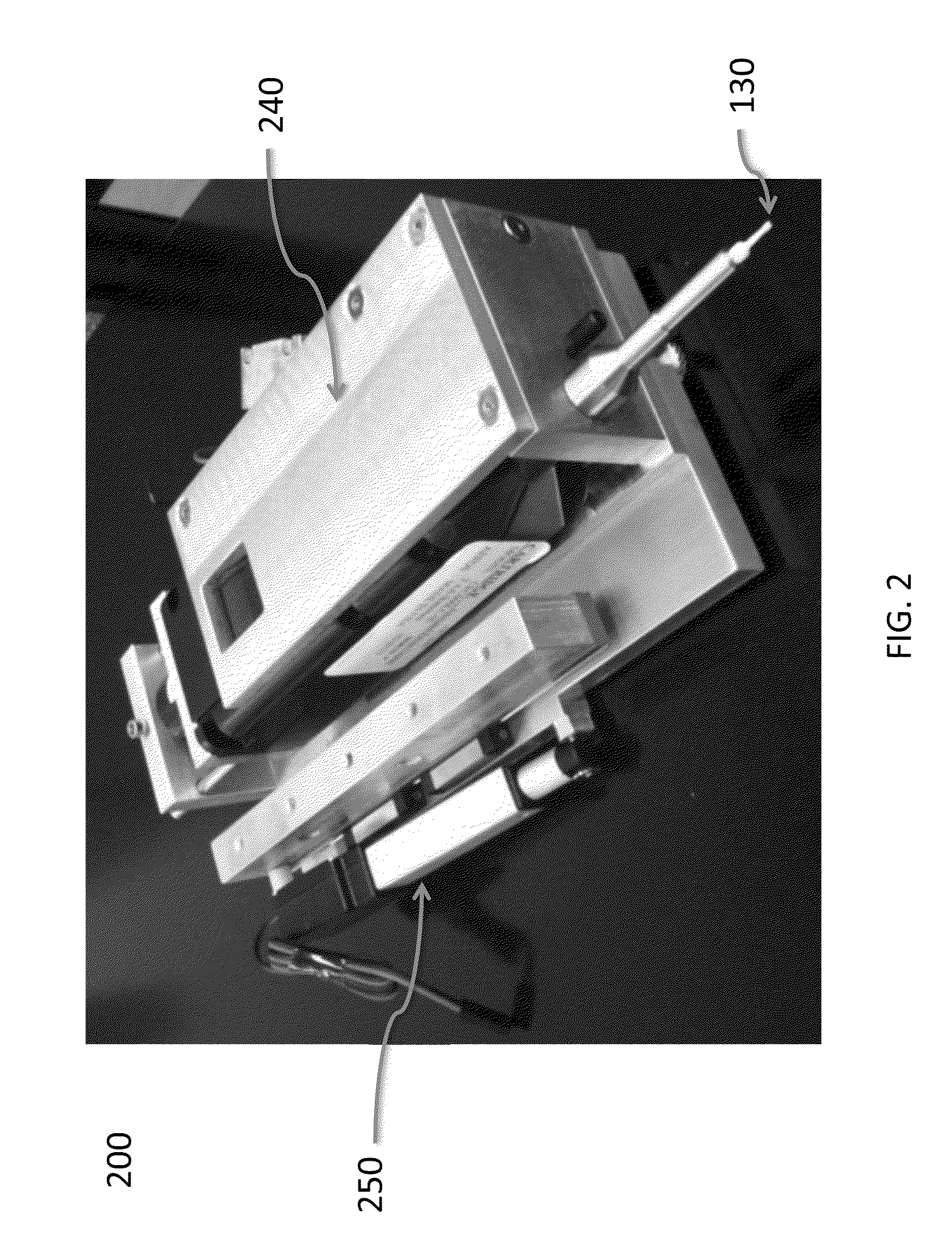

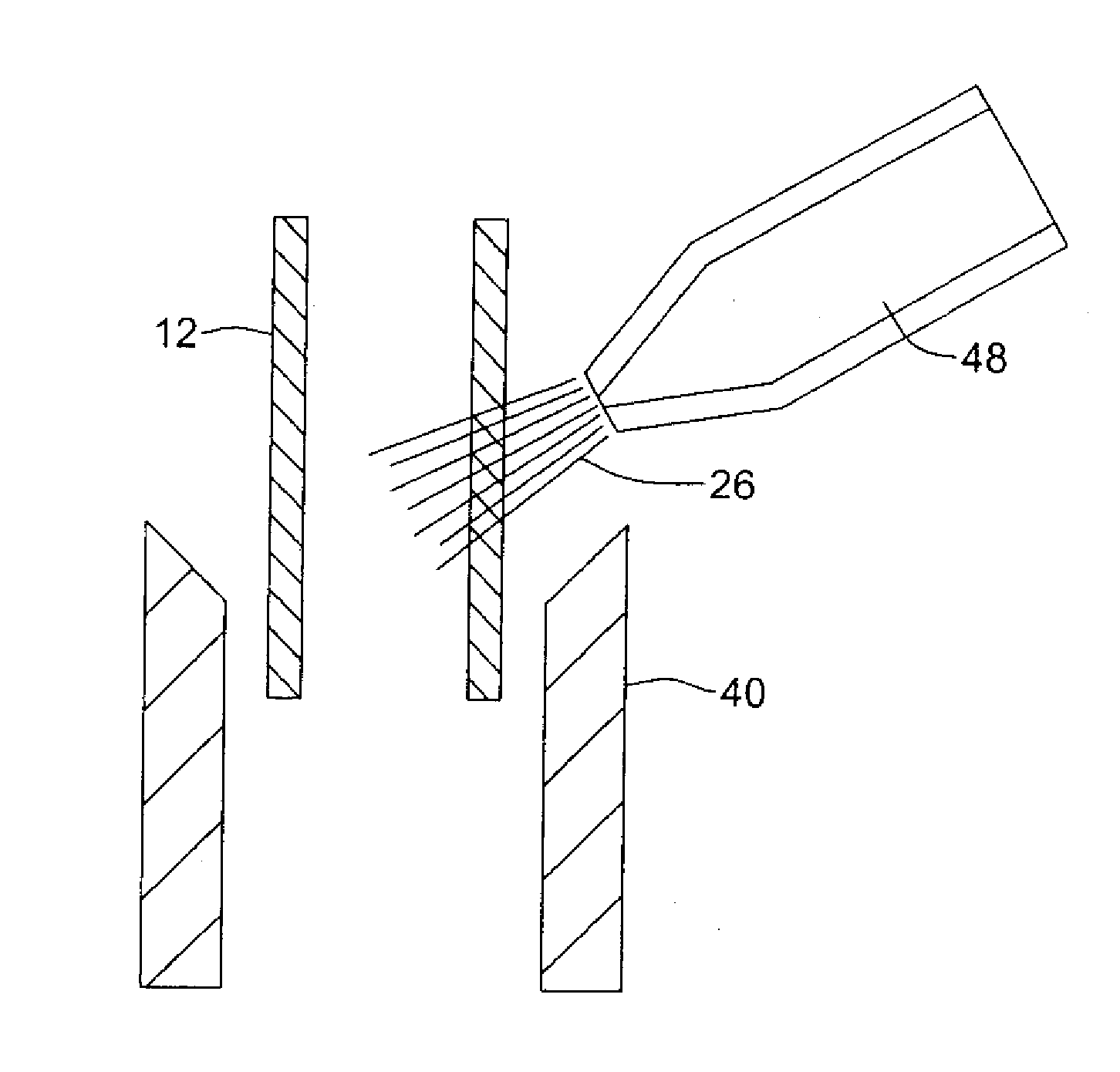

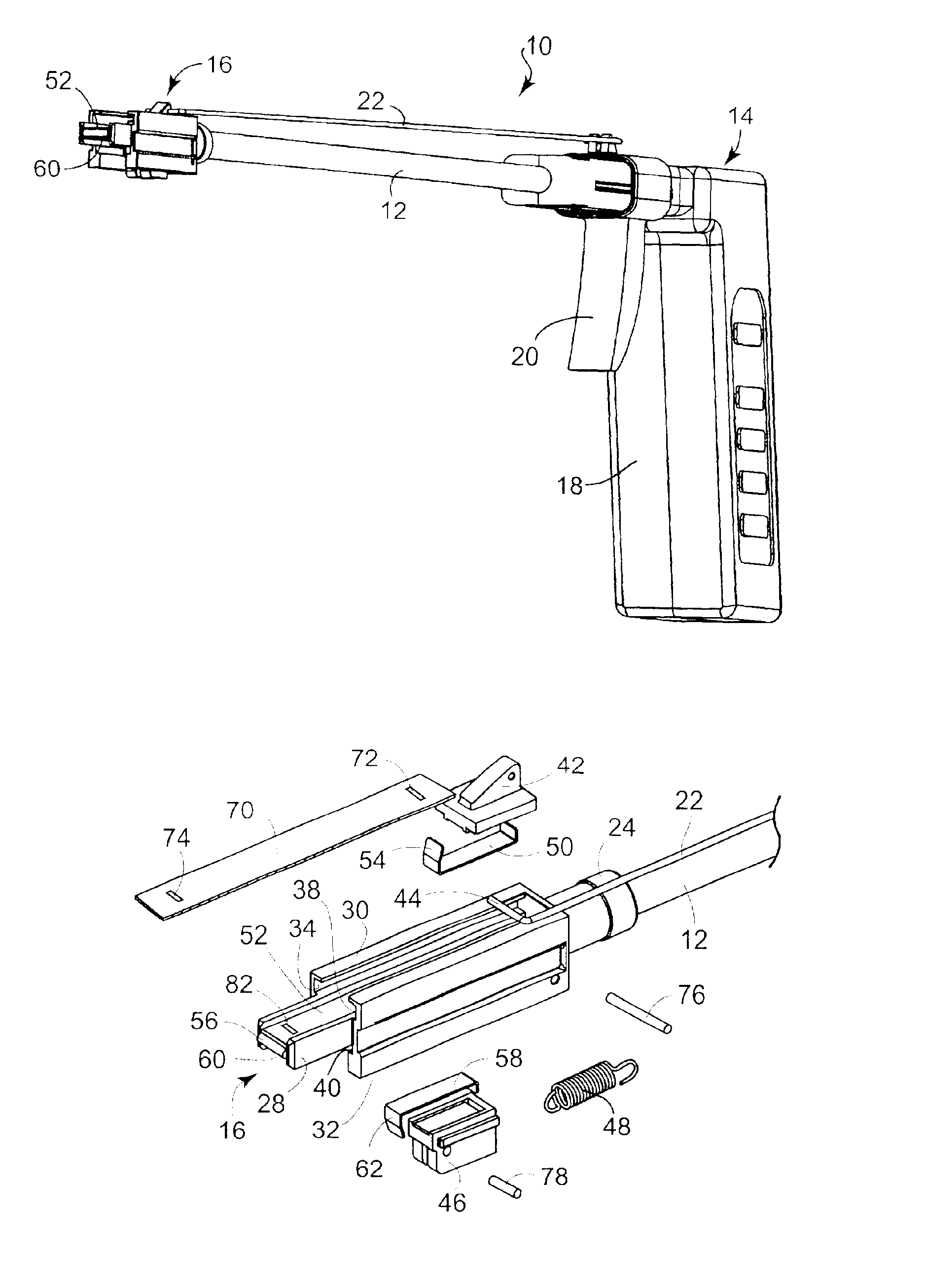

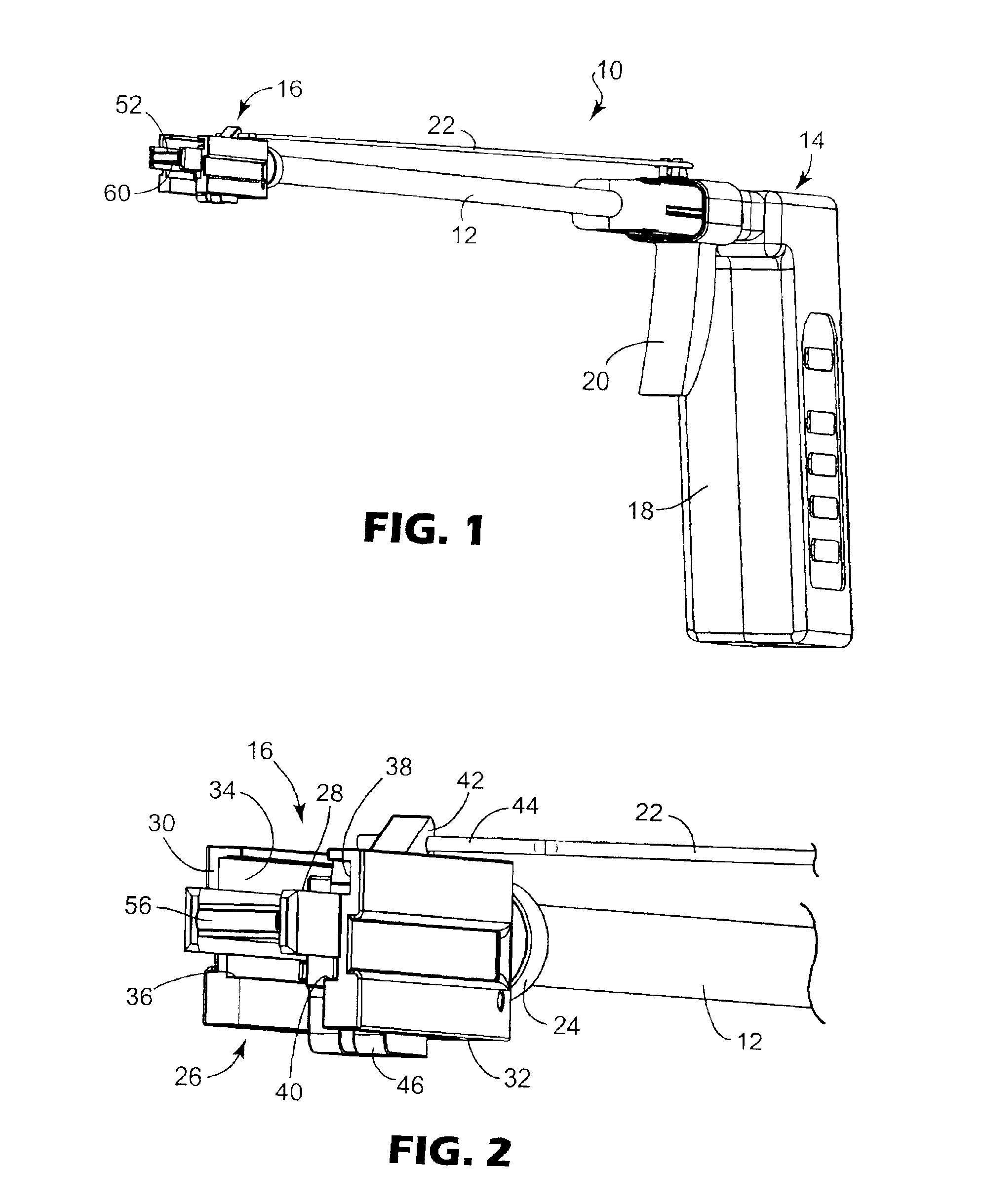

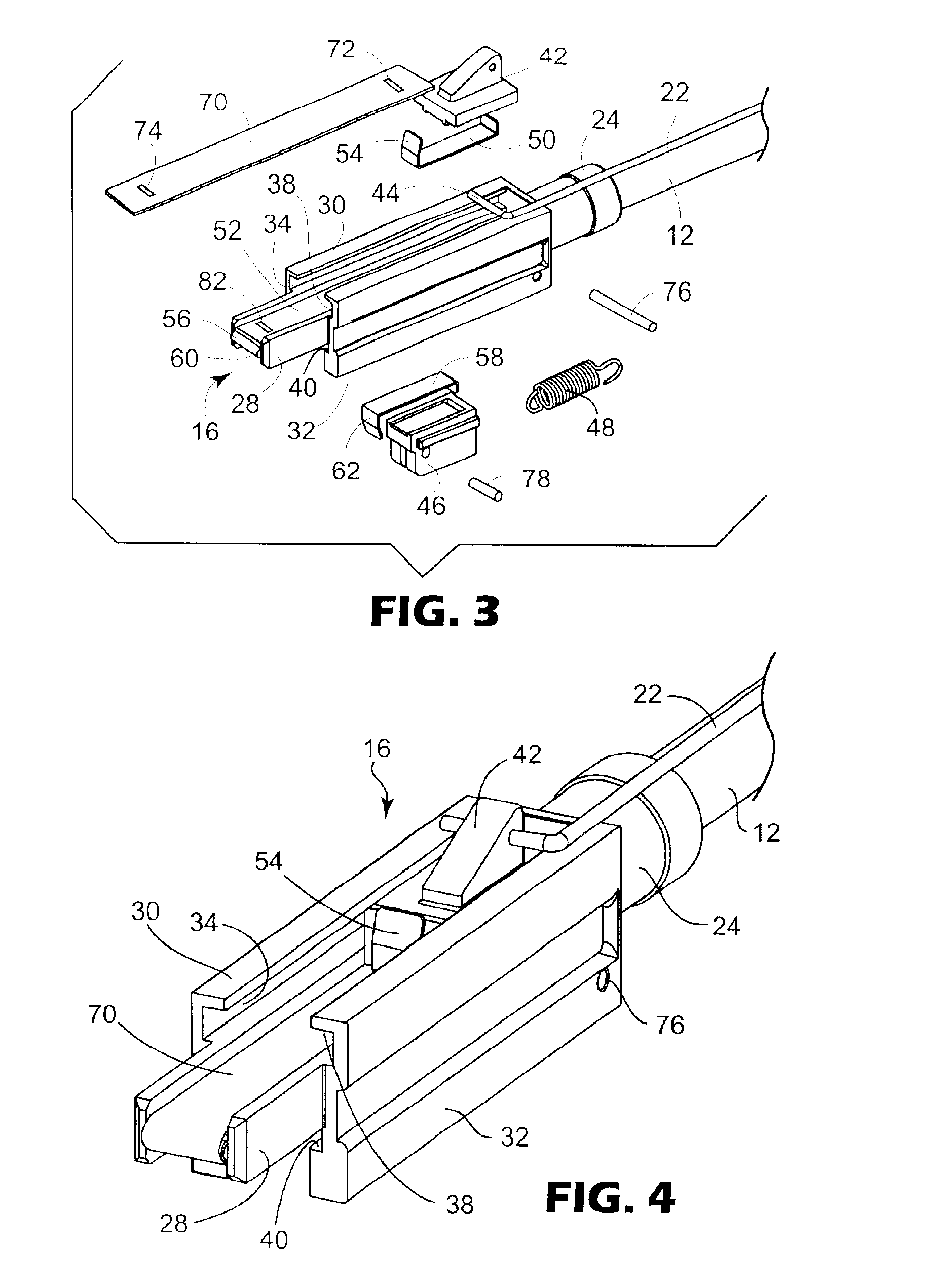

Vertical stent cutting process

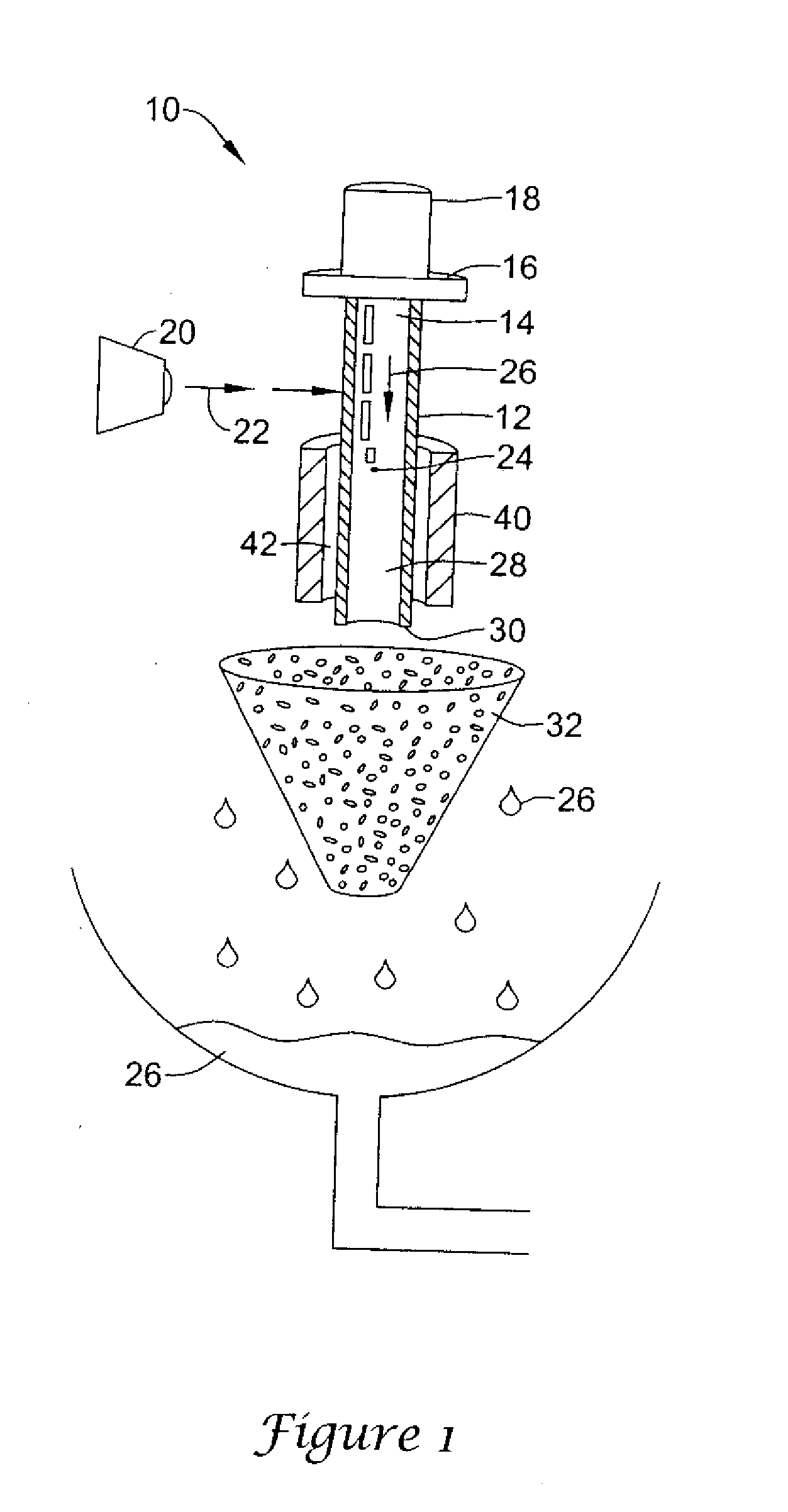

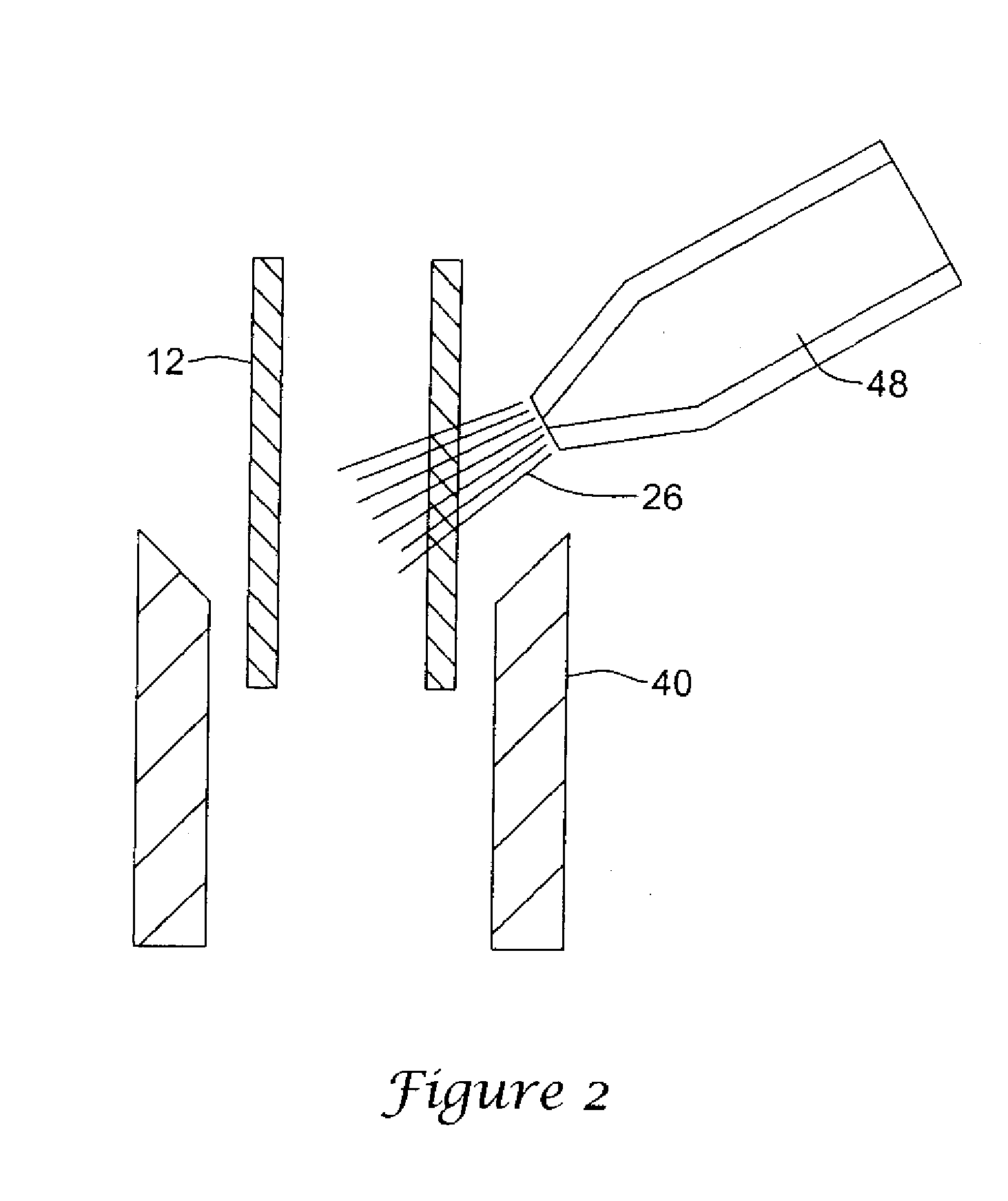

InactiveUS8044322B2Improve stabilityAssist in removingStentsFlexible article cleaningInsertion stentMedical device

A system and method for processing a tubular member for producing a medical device, wherein the tubular member is oriented in a longitudinally vertical position during processing.

Owner:BOSTON SCI SCIMED INC

Apparatus and method for sterilizing a tubular medical line port

An apparatus for sterilizing a tubular medical line port, having a cap with an open distal end and a cavity therein which is dimensioned to receive an outer scrubbing member and the medical line port. Outer disinfected-impregnated scrubbing member is coaxially received in the cavity and has a socket therein dimensioned for engaging exterior side surfaces of the tubular medical line port when inserted into the socket for thereby scrubbing exterior surfaces of the port with the scrubbing member by rotating the cap. The outer scrubbing member is axially displacable downwardly in the cavity by insertion of the medical line port therein from an upper position prior to use to a lower position where it is retained to thereby indicate that the apparatus has been used and should not therefore be reused. A reuse prevention insert is also provided in the cavity of the cap and is displacable with the outer scrubbing member from the upper position prior to use to the lower position during and after use. This insert is provided with inwardly protruding teeth that are biased for inward compression and thereby prevent re-access of a medical line port into the socket of the scrubbing member after removal of the medical line port.

Owner:REDEV AUTHORITY OF THE COUNTY OF ERIE +1

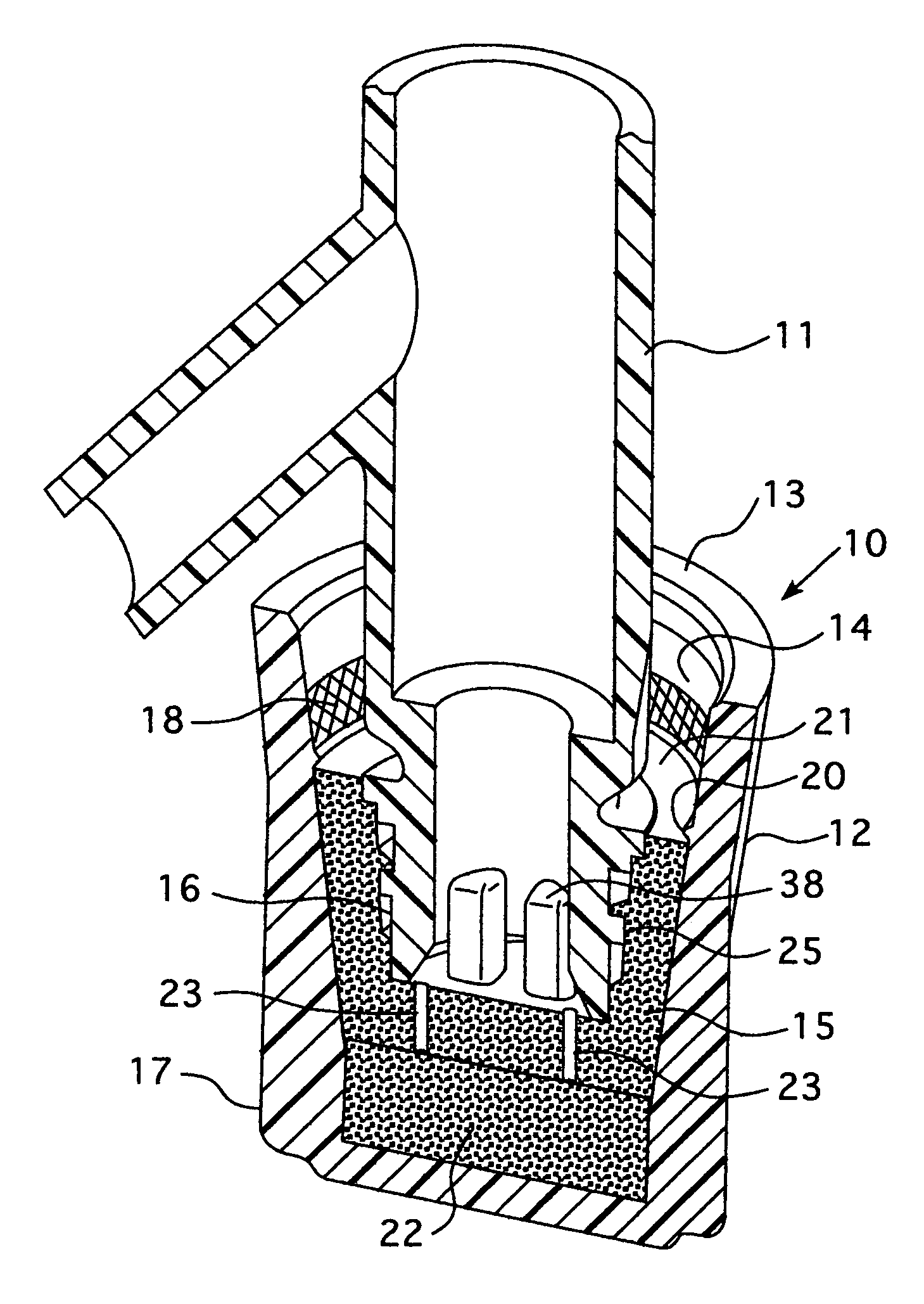

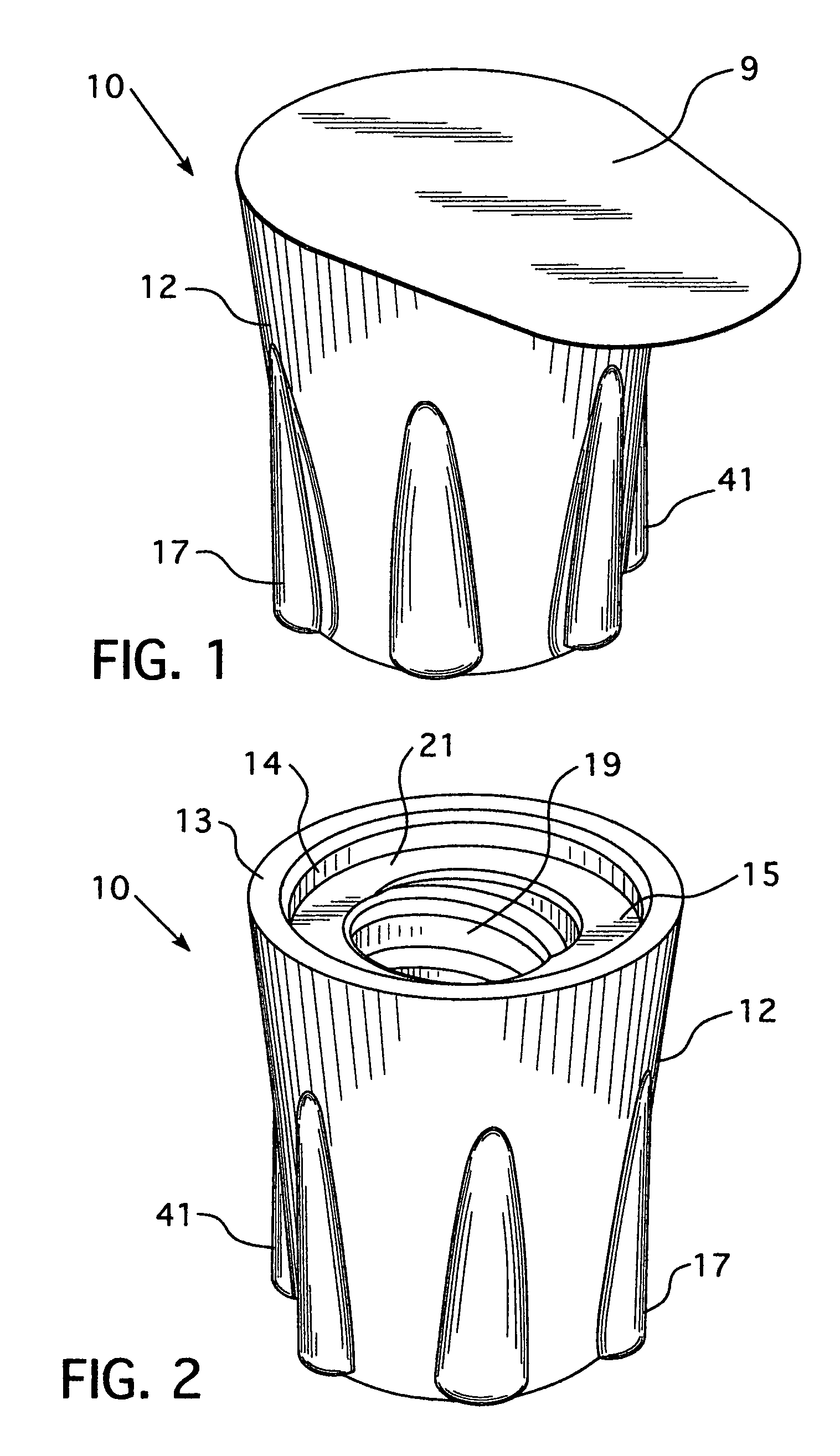

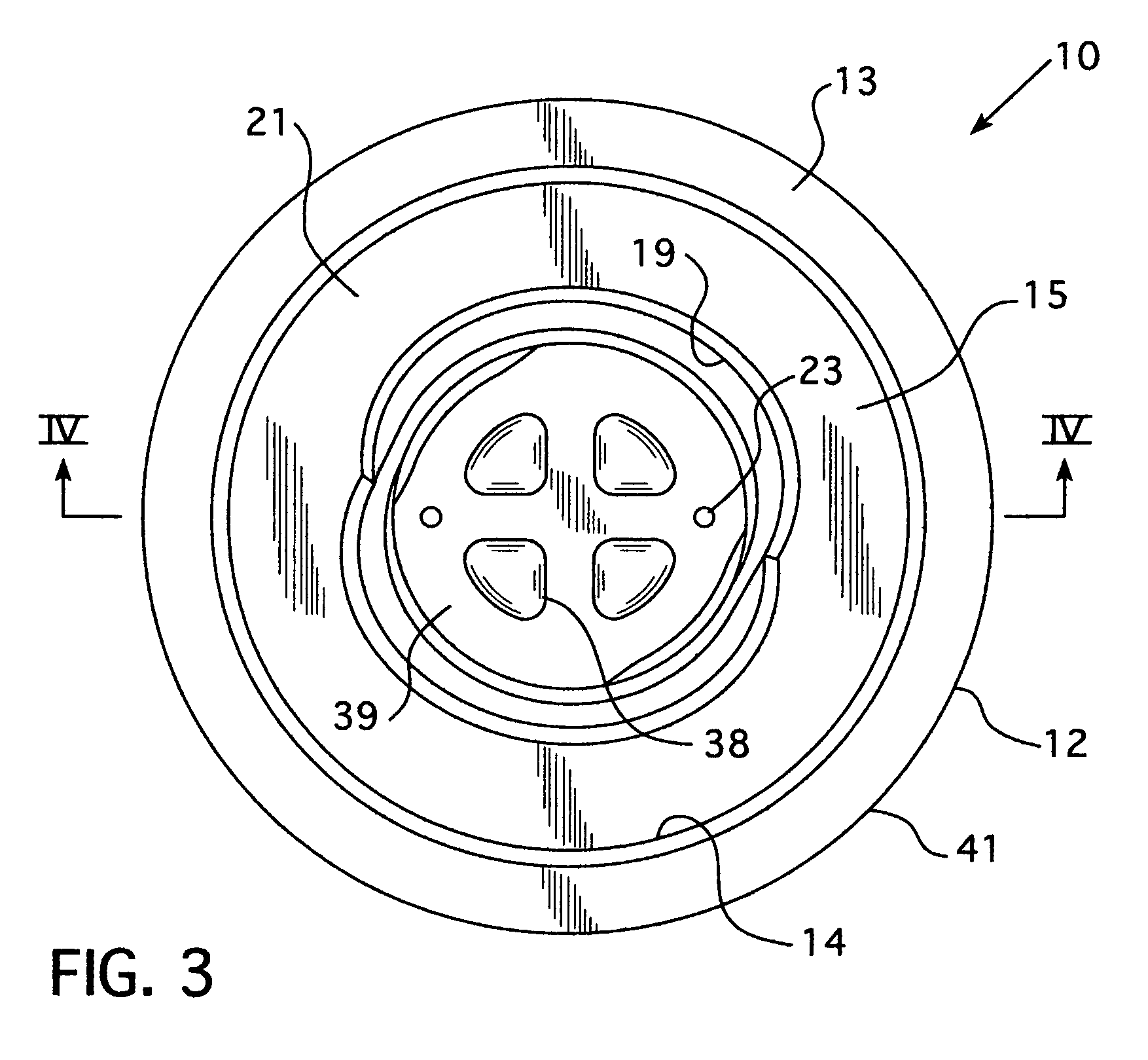

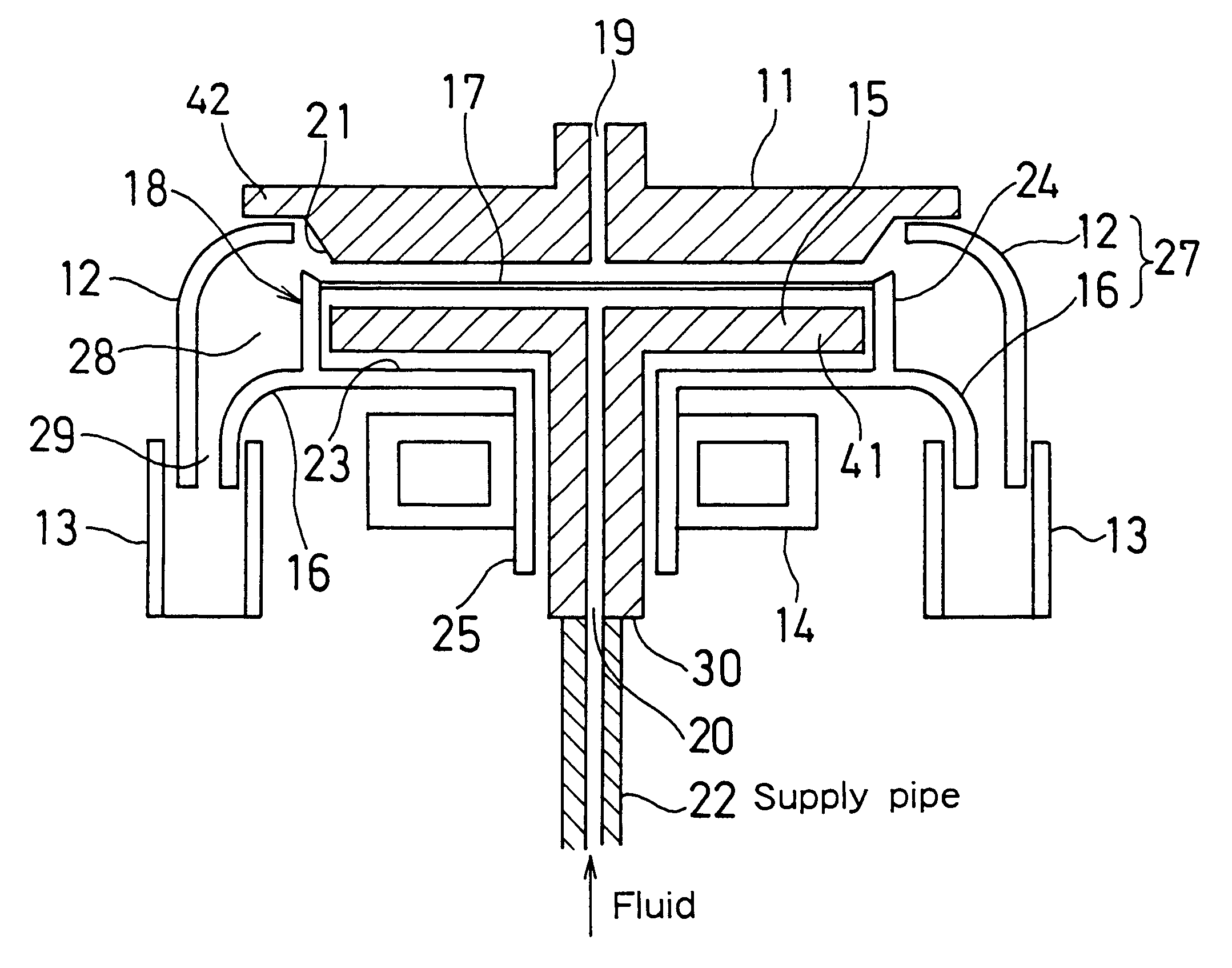

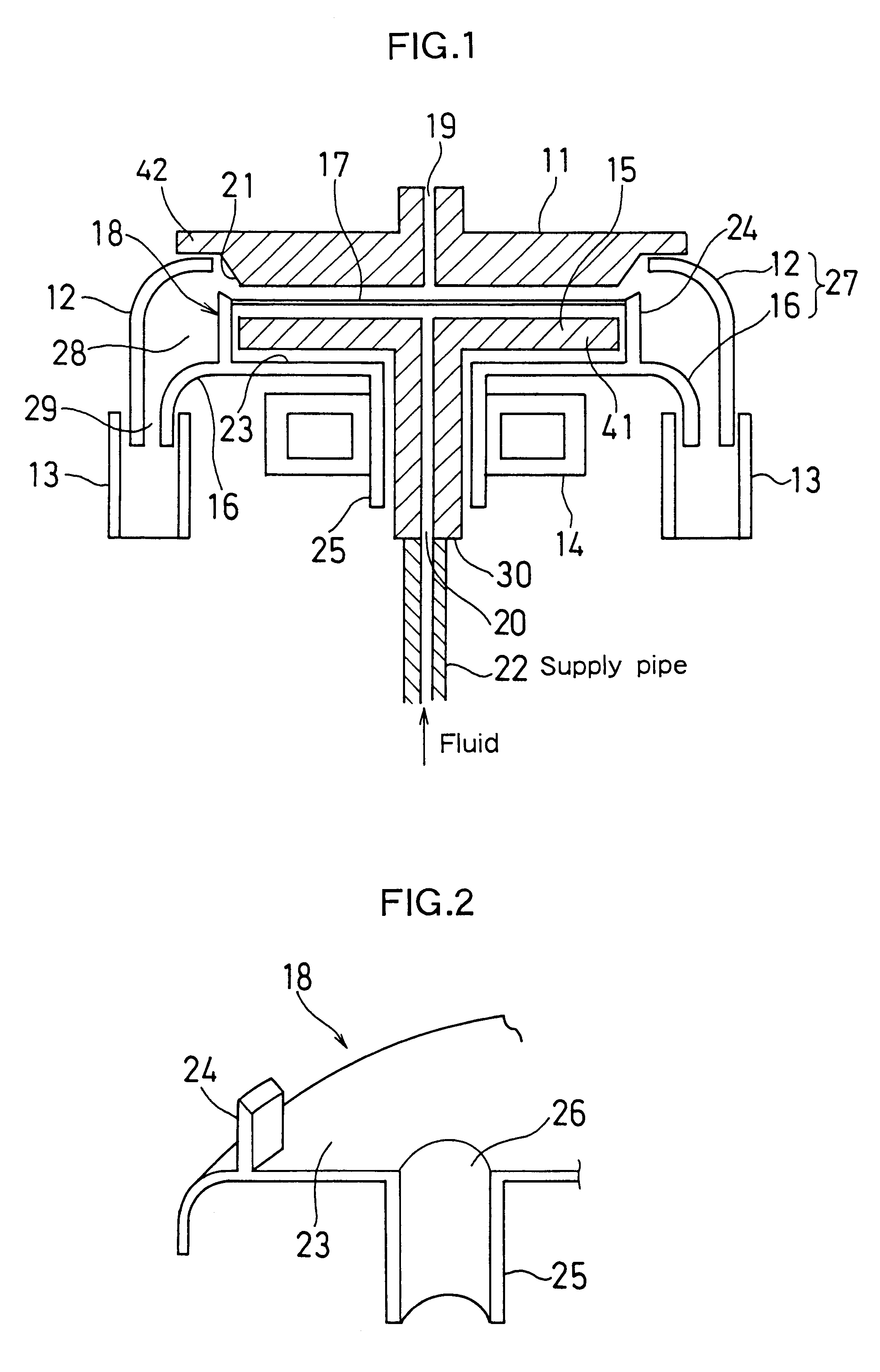

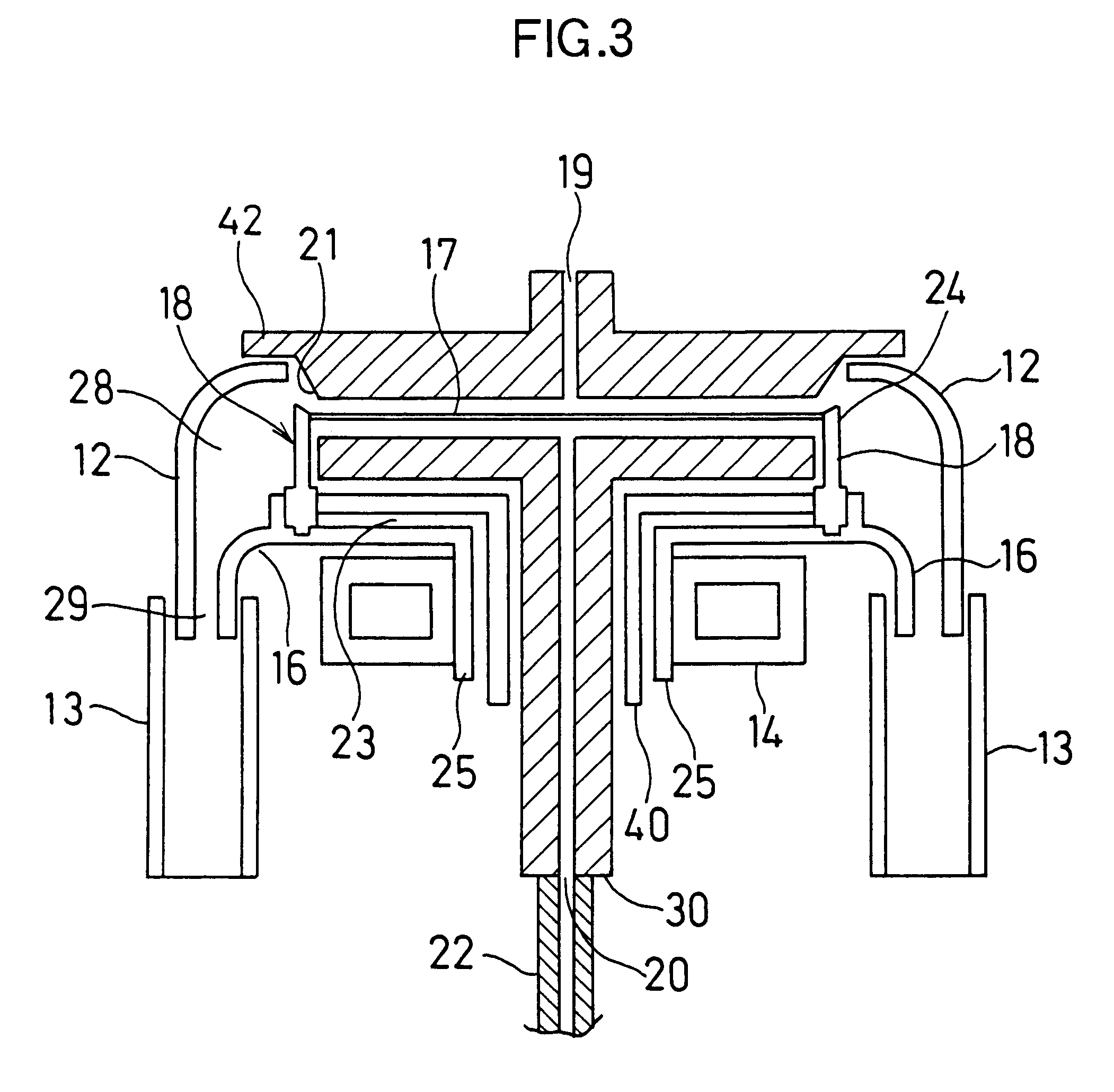

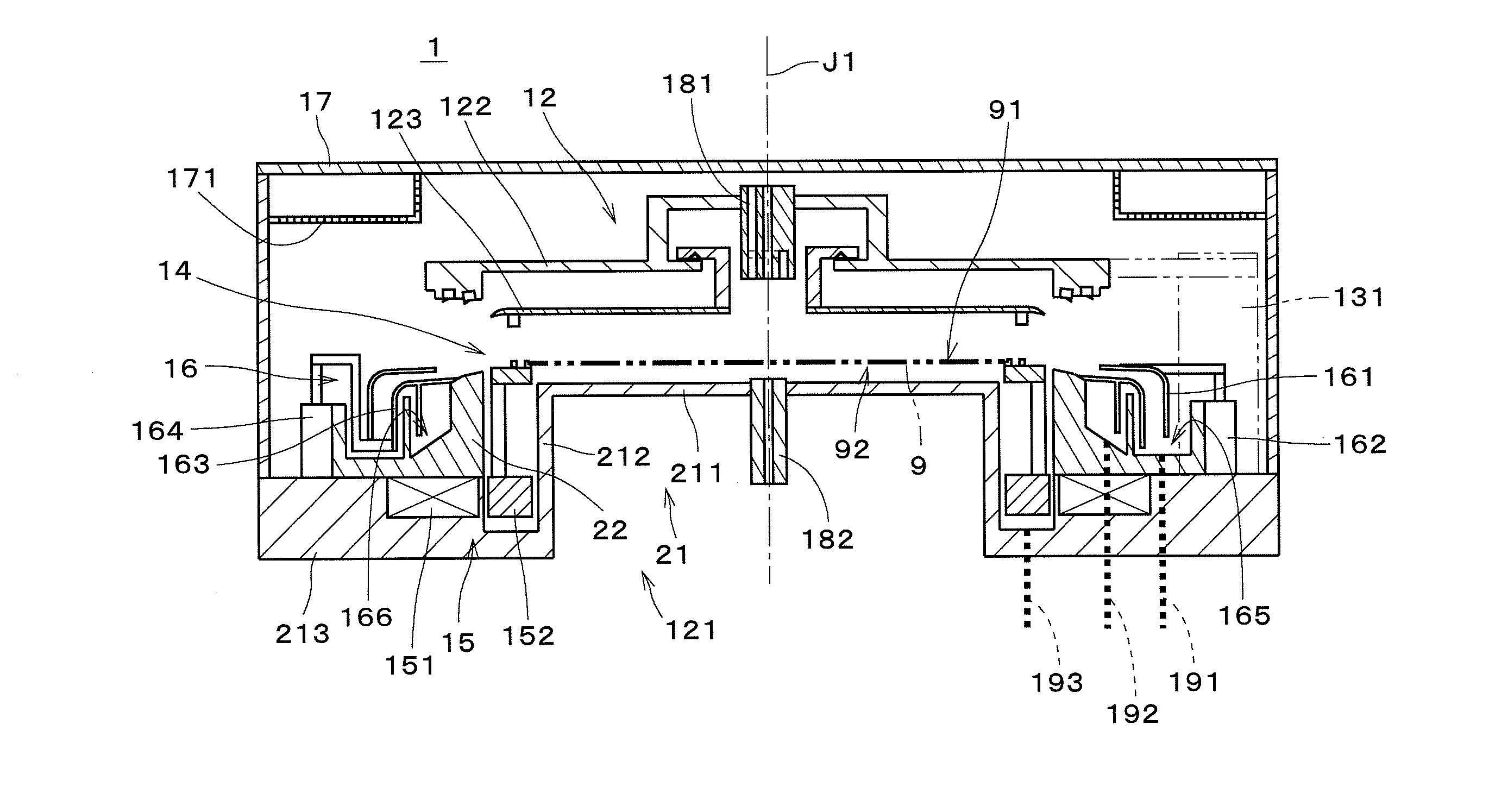

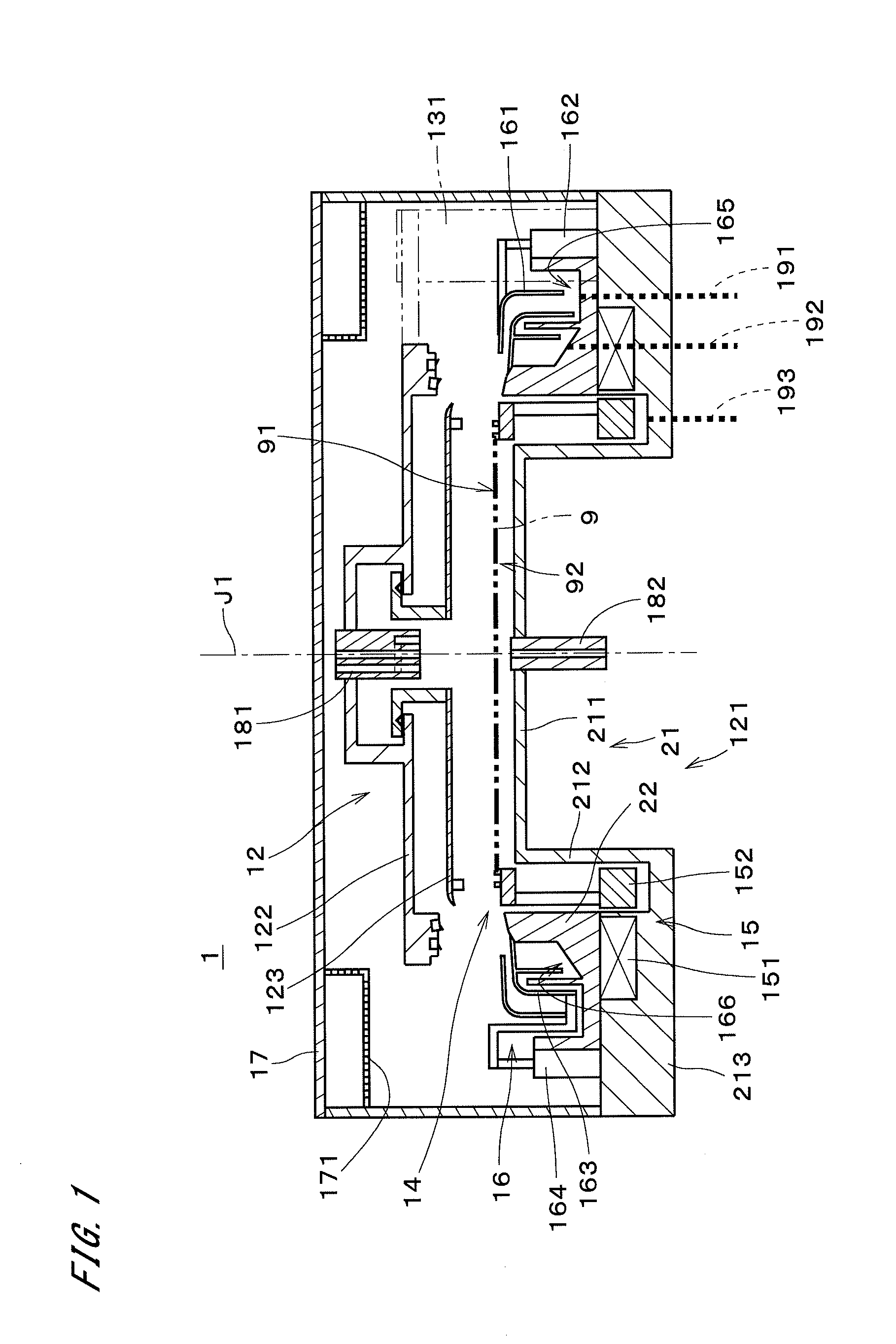

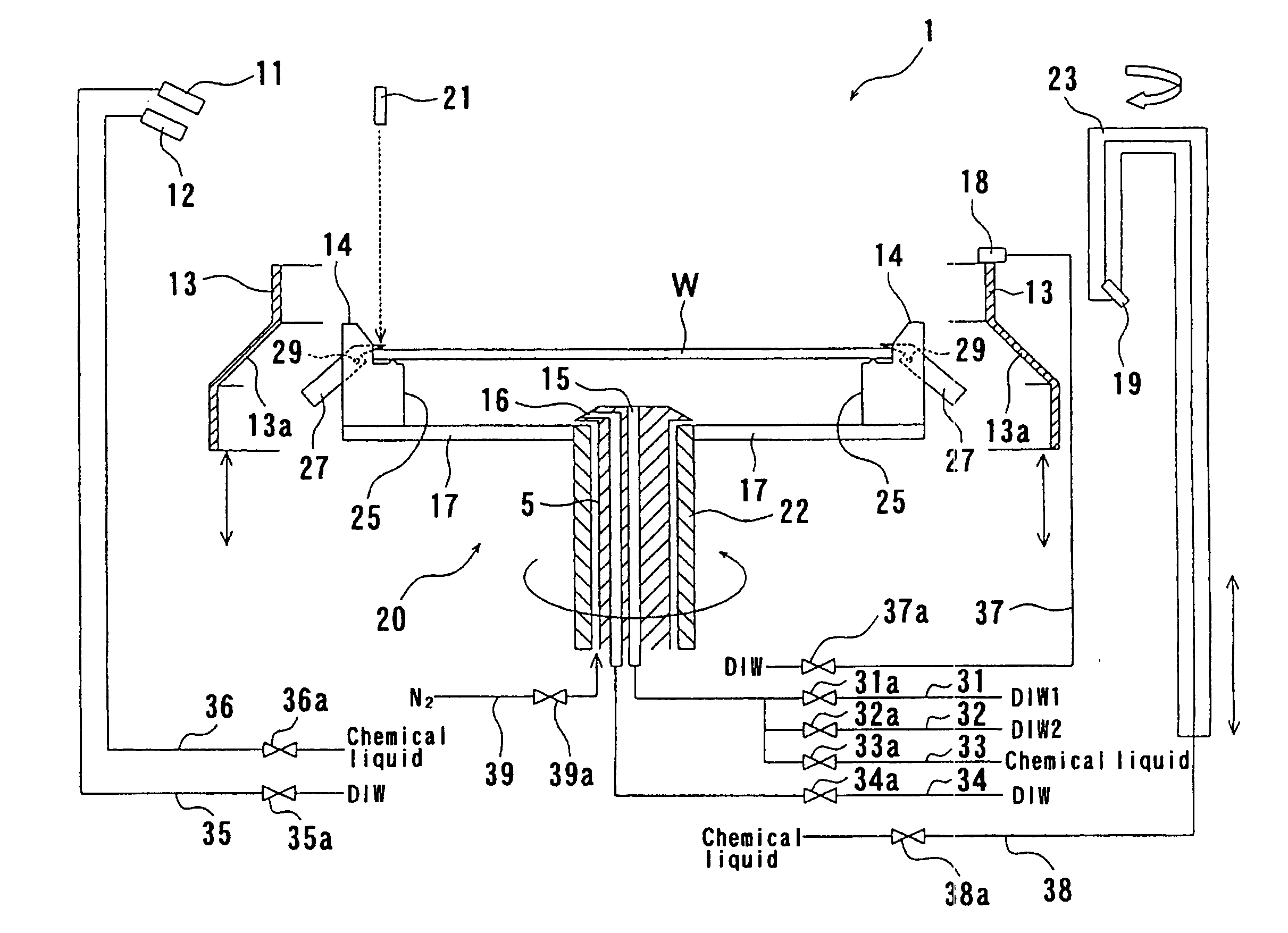

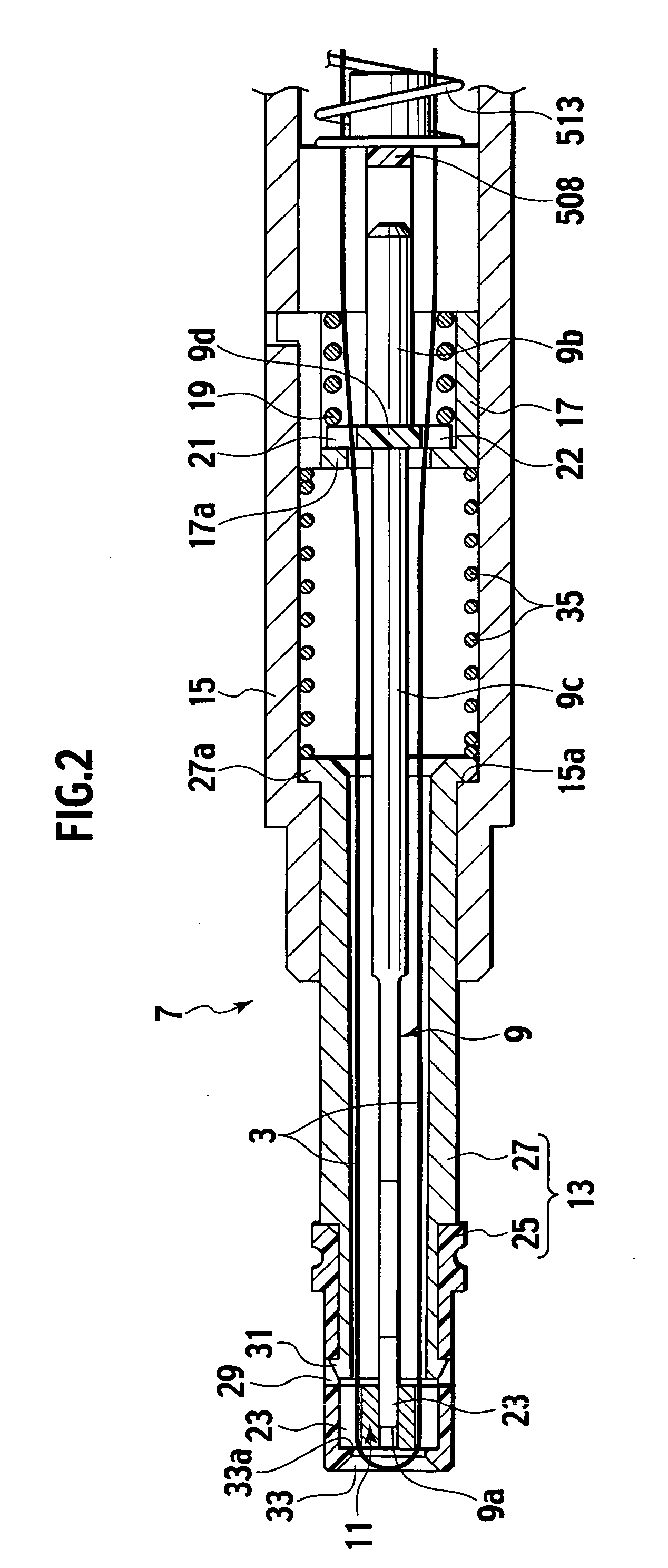

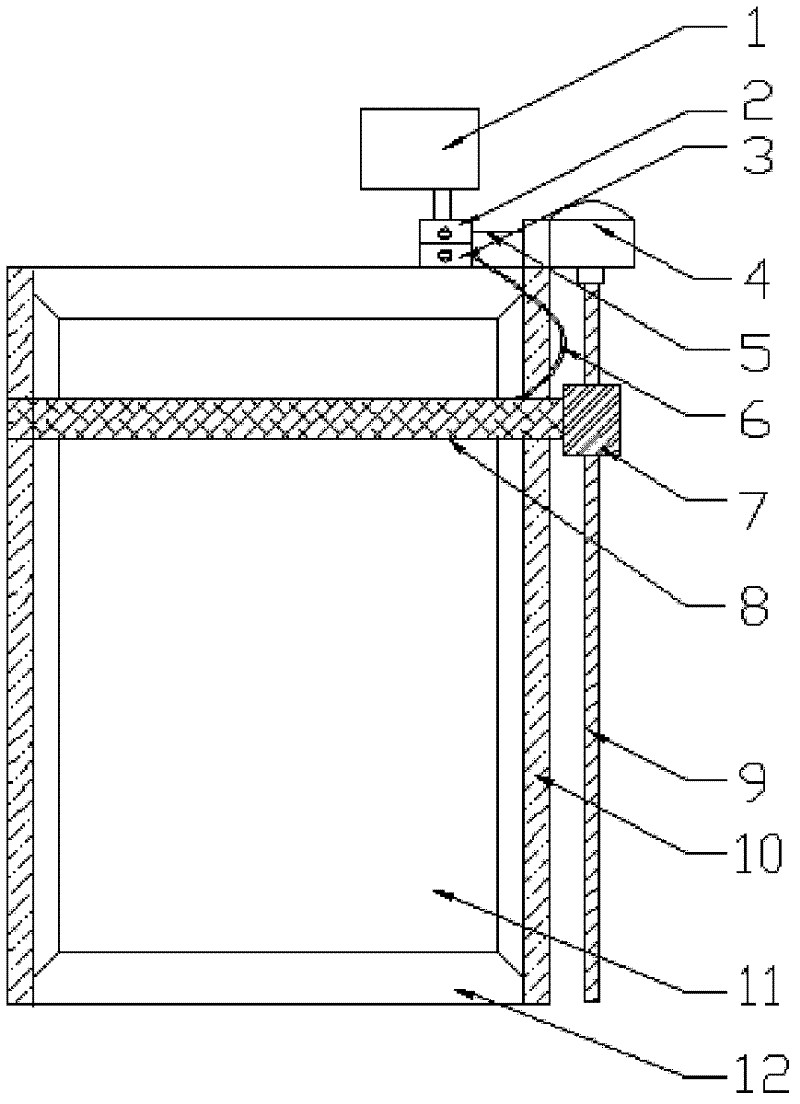

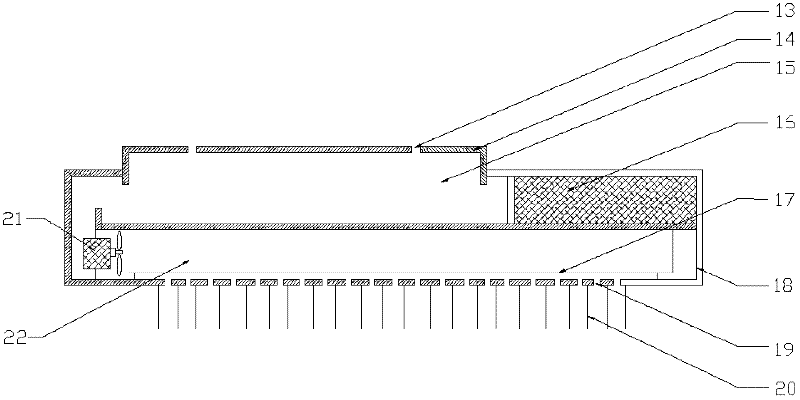

Fluid processing apparatus

InactiveUS6431190B1Electrostatic cleaningSemiconductor/solid-state device manufacturingEngineeringRubbing

To carry out very clean and low-cost fluid processing on both the front and rear surfaces of an object to be processed without generating rubbing particles and without leakage of fluid. A retention member for the object to be processed 18 that retains the object to be processed 17 and a rear shielding plate 15 that prevents the rear surface of the object to be processed from becoming contaminated by excessive fluid flow are mechanically separated. The rear shielding plate 15 is fixed in like manner to a front shielding plate 11, only the retention member for the object to be processed 18 is allowed to rotate making it possible to rigidly connect a supply pipe 22 (that supplies fluid through the rear shielding plate 15) to the rear shielding plate 15. Further, a circulation system is provided that collects fluid which underwent front surface processing in a collection tube 13, circulates that fluid and then supplies it to the rear surface of the object to be processed from a supply pipe.

Owner:KOKUSA ELECTRIC CO LTD

Substrate or sheet surface cleaning apparatus

InactiveUS6237176B1Efficient captureEfficient removalLiquid processingCarpet cleanersFixed bearingSurface cleaning

A substrate or sheet surface cleaning apparatus is provided with at least one tacky rubber roller and at least one adhesive tape roll which is brought into close contact with the tacky rubber roller. The roller and roll are rotatably supported at opposite ends of their shafts by bearings which are slidable in a vertical direction. Pressed rods are arranged integrally on the slidable bearings for the roll. By urging the pressed rods with pressing rods driven by d.c. motors via gear trains while controlling the d.c. motors by a position sensor, the pressure between the roll and the roller and the pressure between the roller and the substrate or sheet are optimized so that dirt or particles can be efficiently removed from an opposing surface of the substrate or sheet. Another substrate or sheet surface cleaning apparatus is provided two tacky rubber rollers arranged in an up-and-down parallel relationship and two adhesive tape rolls arranged above the upper roller and below the lower roller, respectively. Position adjusters with one or more springs disposed therein are arranged between slidable bearings supporting the upper roller and fixed bearings supporting the lower roller to correct tilting, if any, of the upper roller.

Owner:RAYON IND

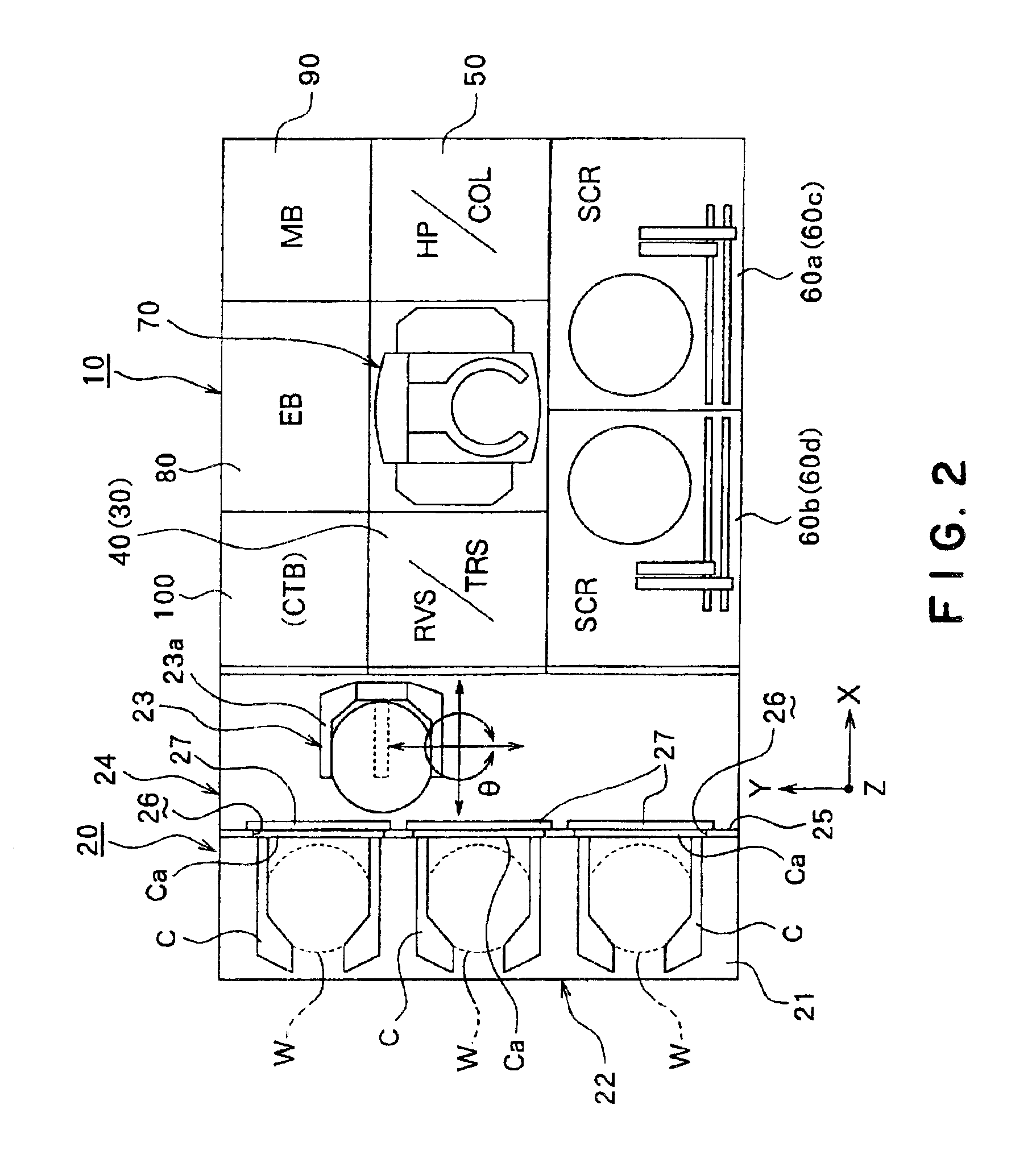

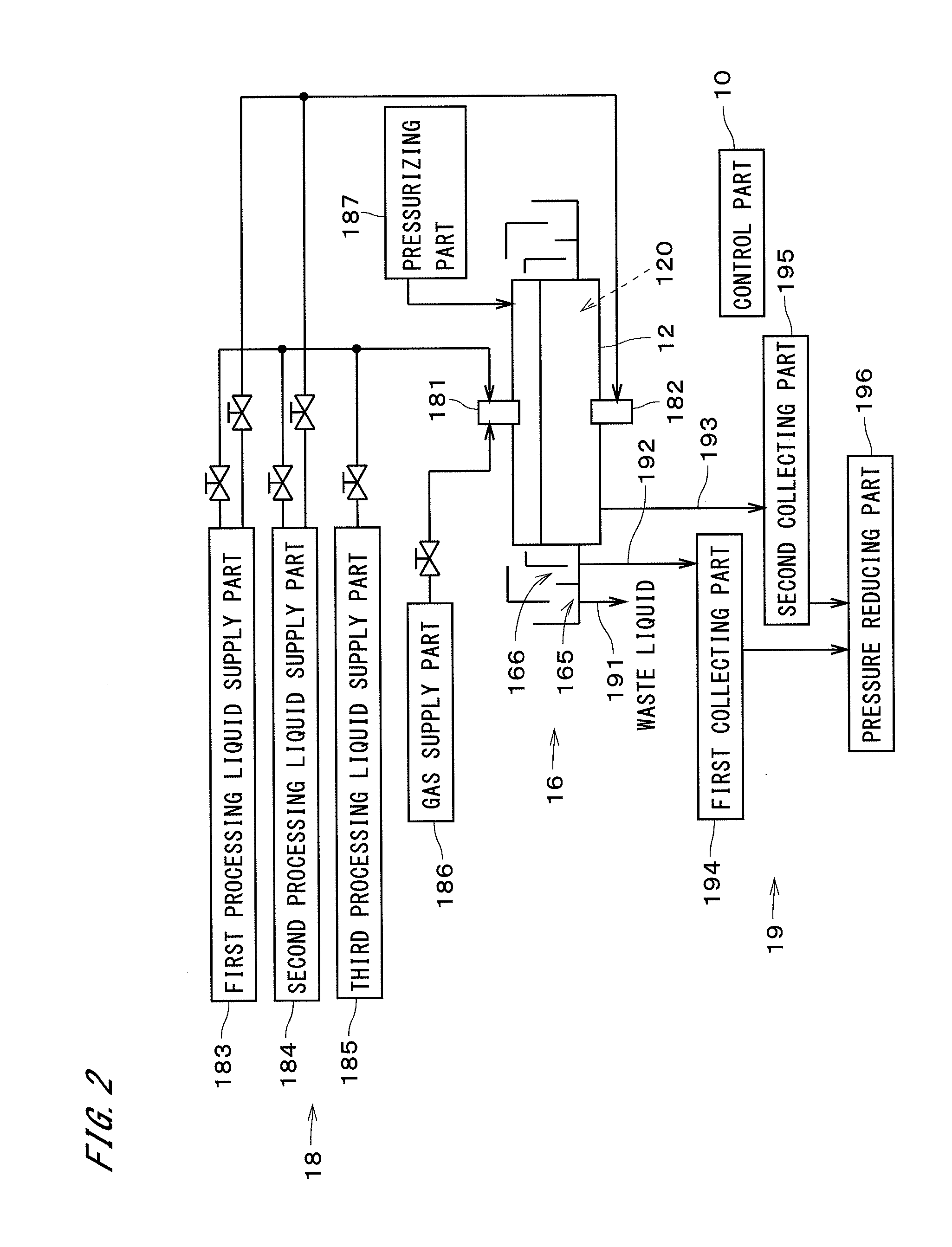

Substrate processing apparatus

ActiveUS20140060423A1Improve efficiencyProcess is performedLiquid surface applicatorsSpraying apparatusEngineeringPressure reduction

A substrate processing apparatus includes a chamber, a substrate holding part, a substrate rotating mechanism, a liquid receiving part, and an upper nozzle. The chamber includes a chamber body and a chamber cover, and the chamber cover is moved up and down. While the chamber cover is in contact with the chamber body, a small sealed space is formed and some processings involving pressure reduction or pressurization are performed. When the chamber cover is moved up, an annular opening is formed between the chamber cover and the chamber body. On an outer side relative to the annular opening, positioned are a first cup part and a second cup part. A processing liquid spattering from a substrate is received by the first cup part or the second cup part. In the substrate processing apparatus, it is possible to perform various processings in the small chamber.

Owner:DAINIPPON SCREEN MTG CO LTD

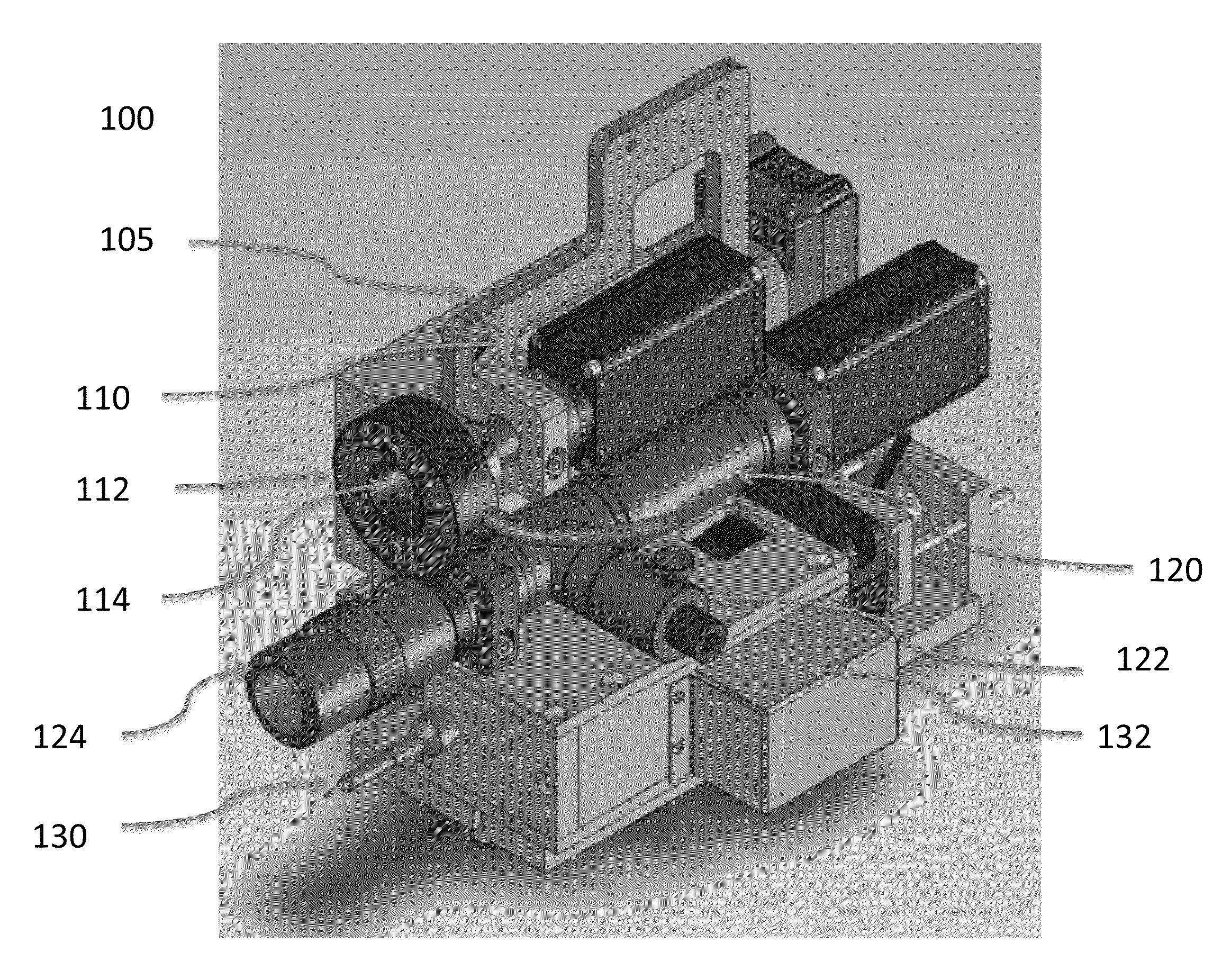

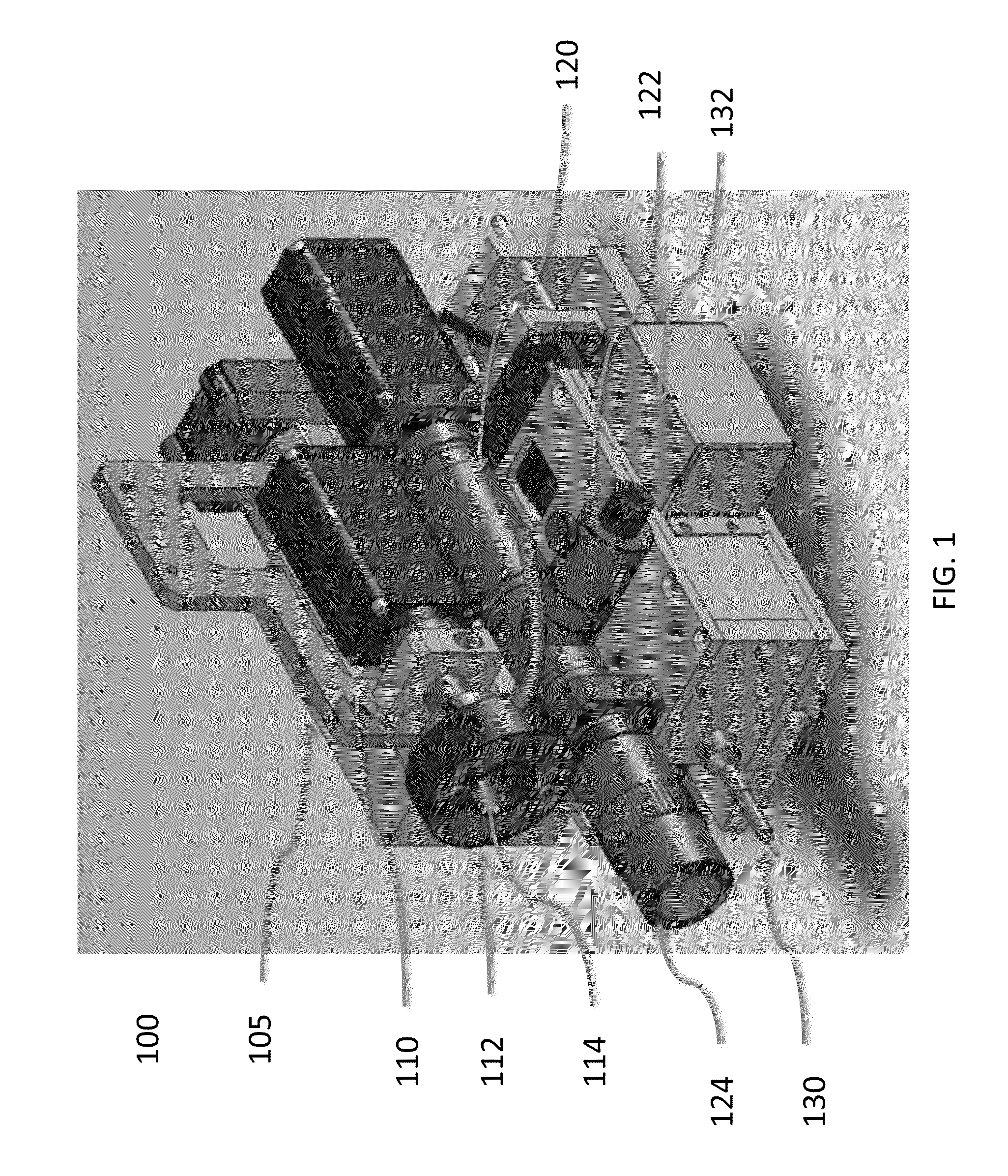

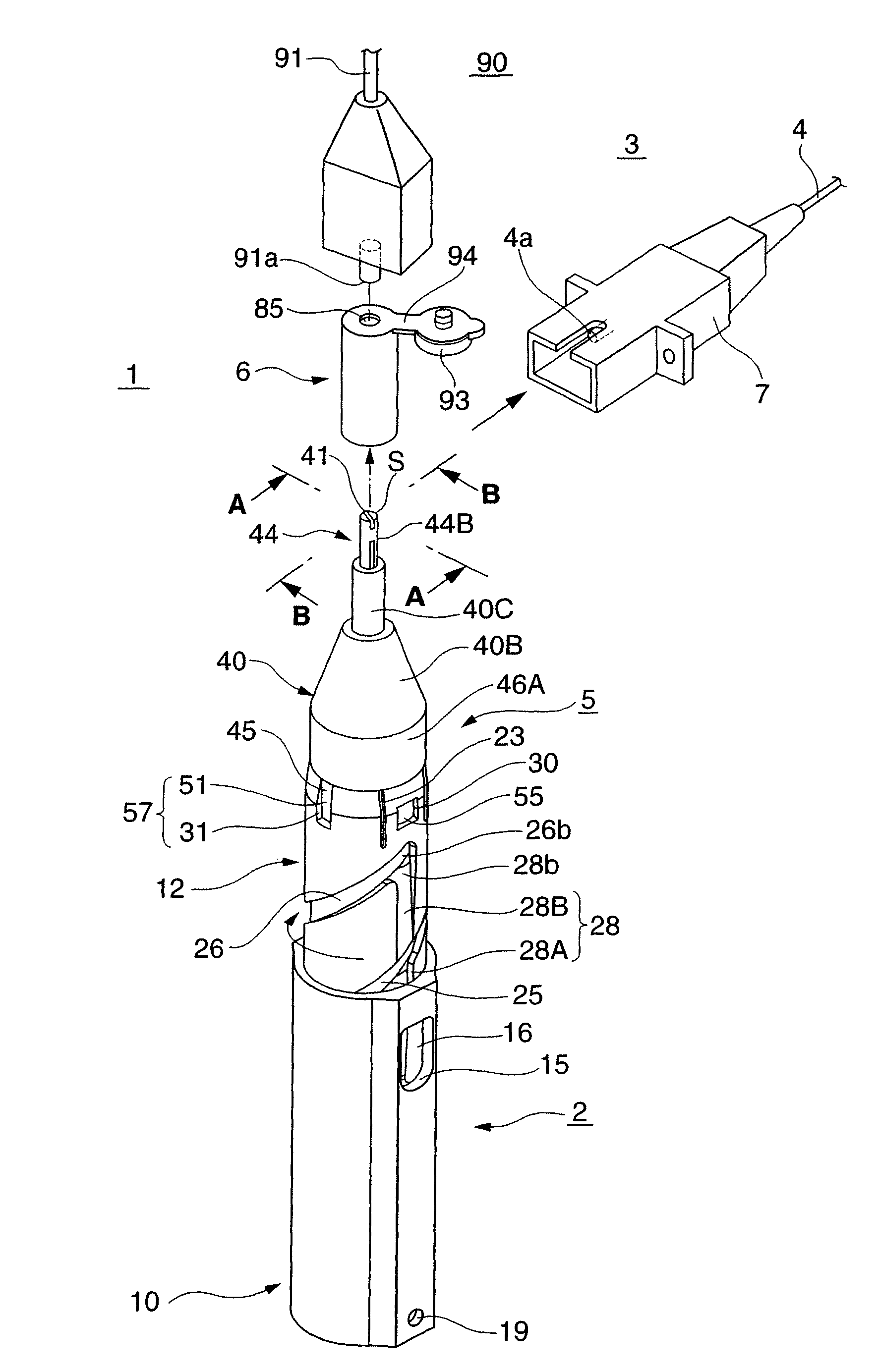

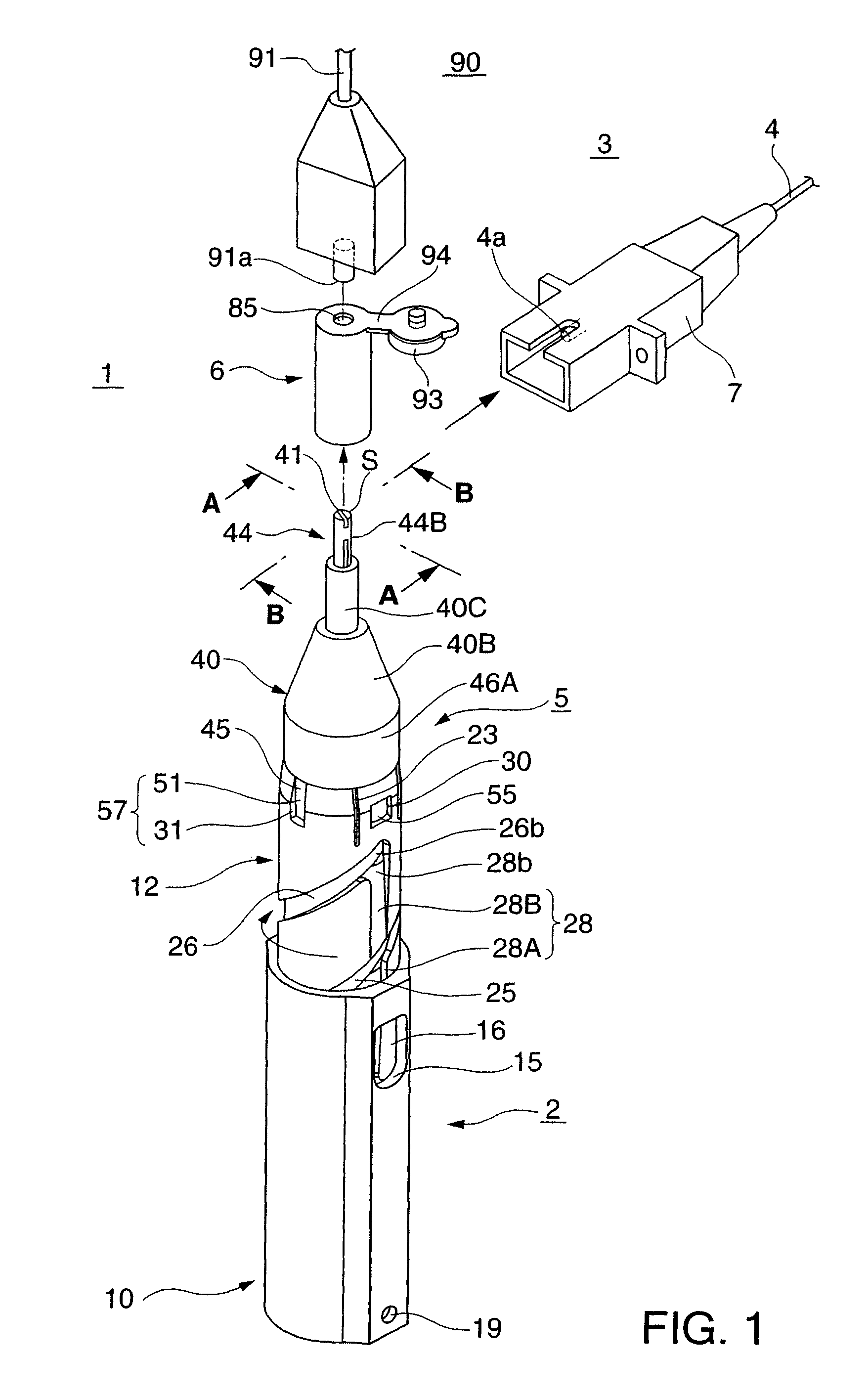

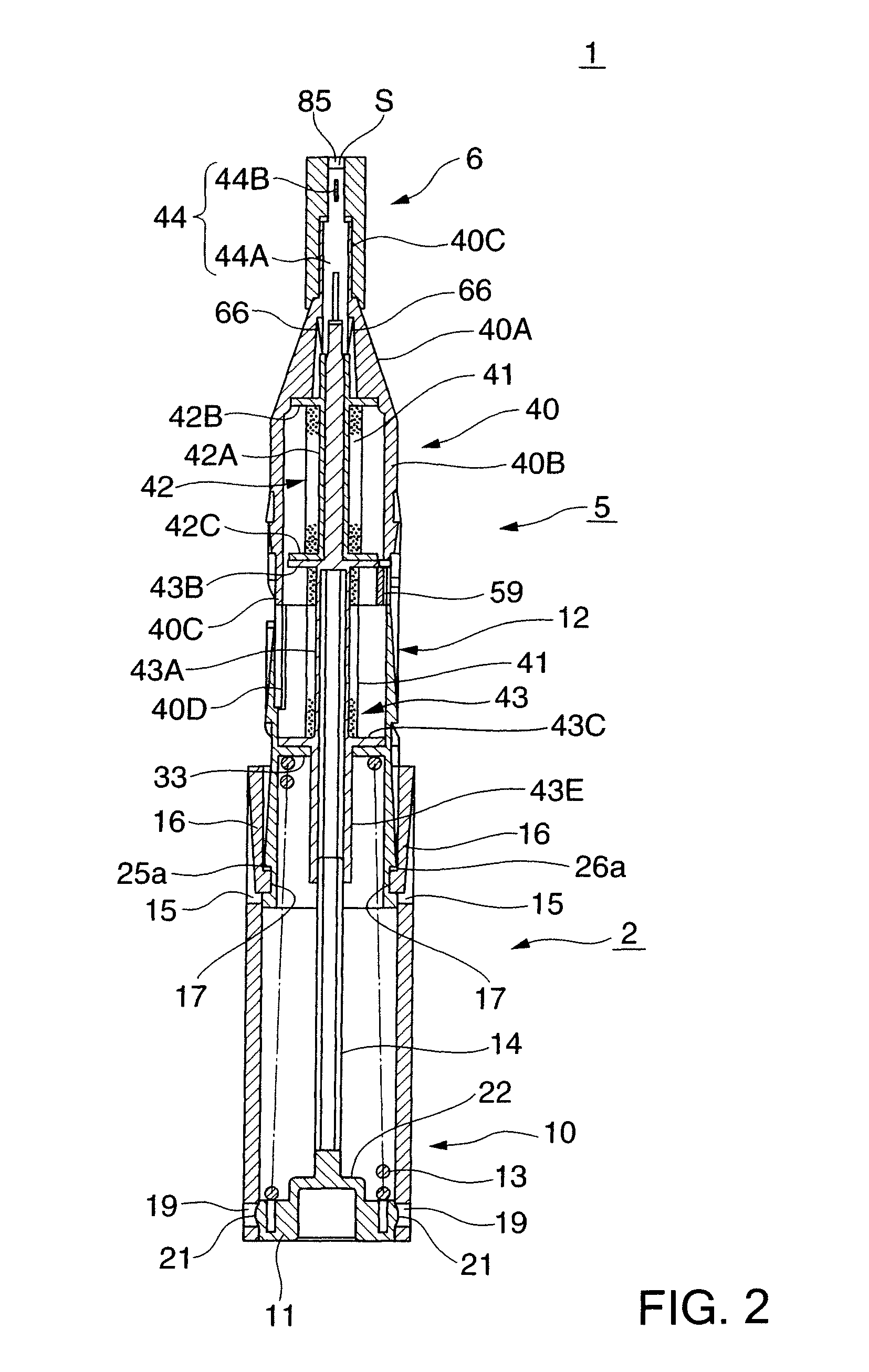

System and method of an integrated fiber optic inspection and cleaning apparatus

ActiveUS20130229650A1Rapid positioningHigh resolutionOptically investigating flaws/contaminationFlexible article cleaningFiberWide field

This disclosure concerns a cleaning and inspection system for fiber optics that is rapid, reliable and useful for various types of fiber optics. In an embodiment, the system includes a wide field of view (FOV) camera to image the ferrule and rapidly locate the fiber ends and a narrow FOV camera to provide detailed inspection of fiber ends. A cleaning module with a cleaning tip and a cleaning media that is drawn through the tip is used to clean the fiber ends. Images captured by the dual cameras are automatically enhanced and analyzed to determine the effectiveness of the cleaning process and to identify the types and quantity of defects present. In another embodiment, a single higher resolution camera is provided with a lens that can image an entire fiber array and yet enable defects to be detected by analysis of sub-images of each fiber in the fiber array.

Owner:FIBERQA

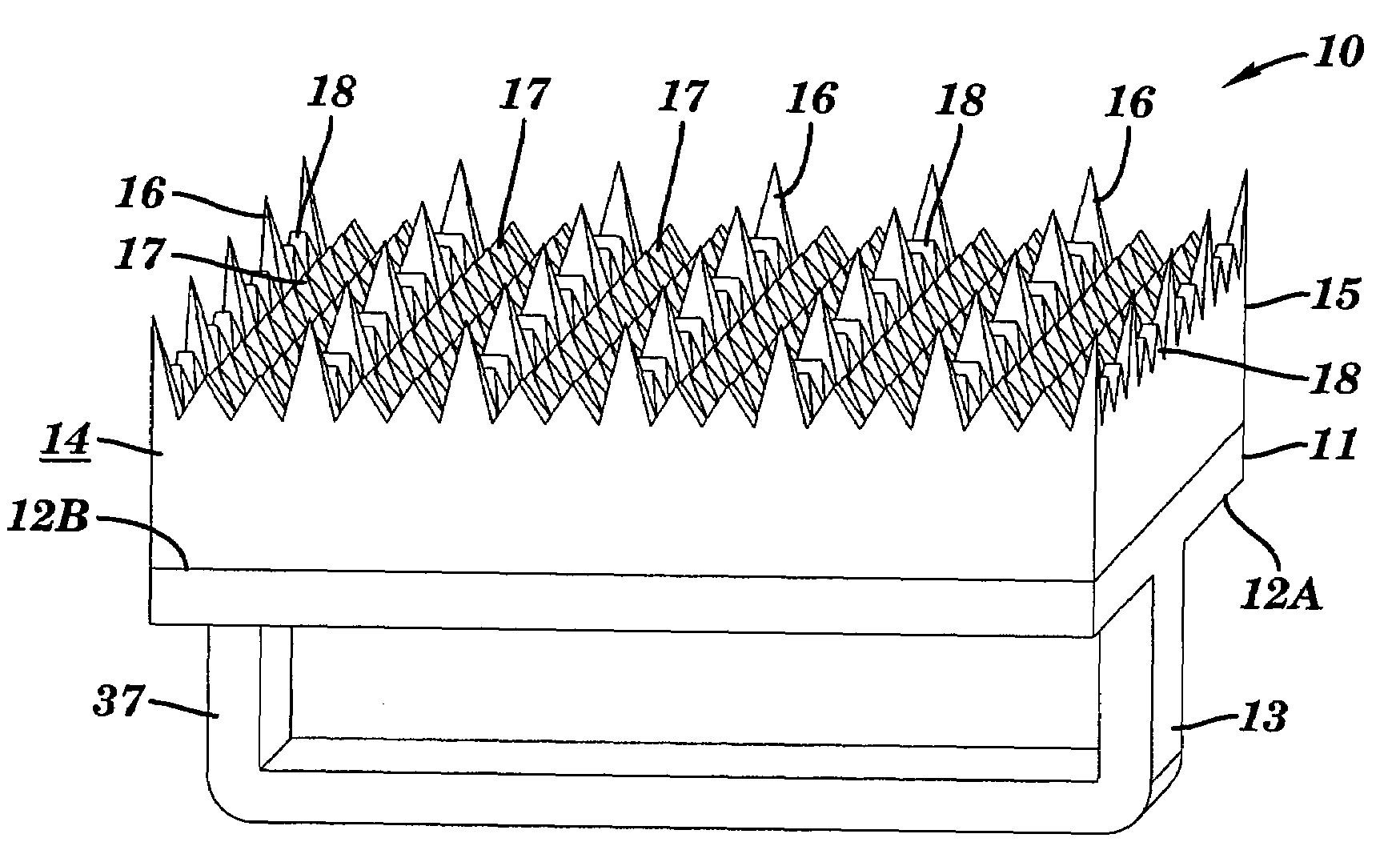

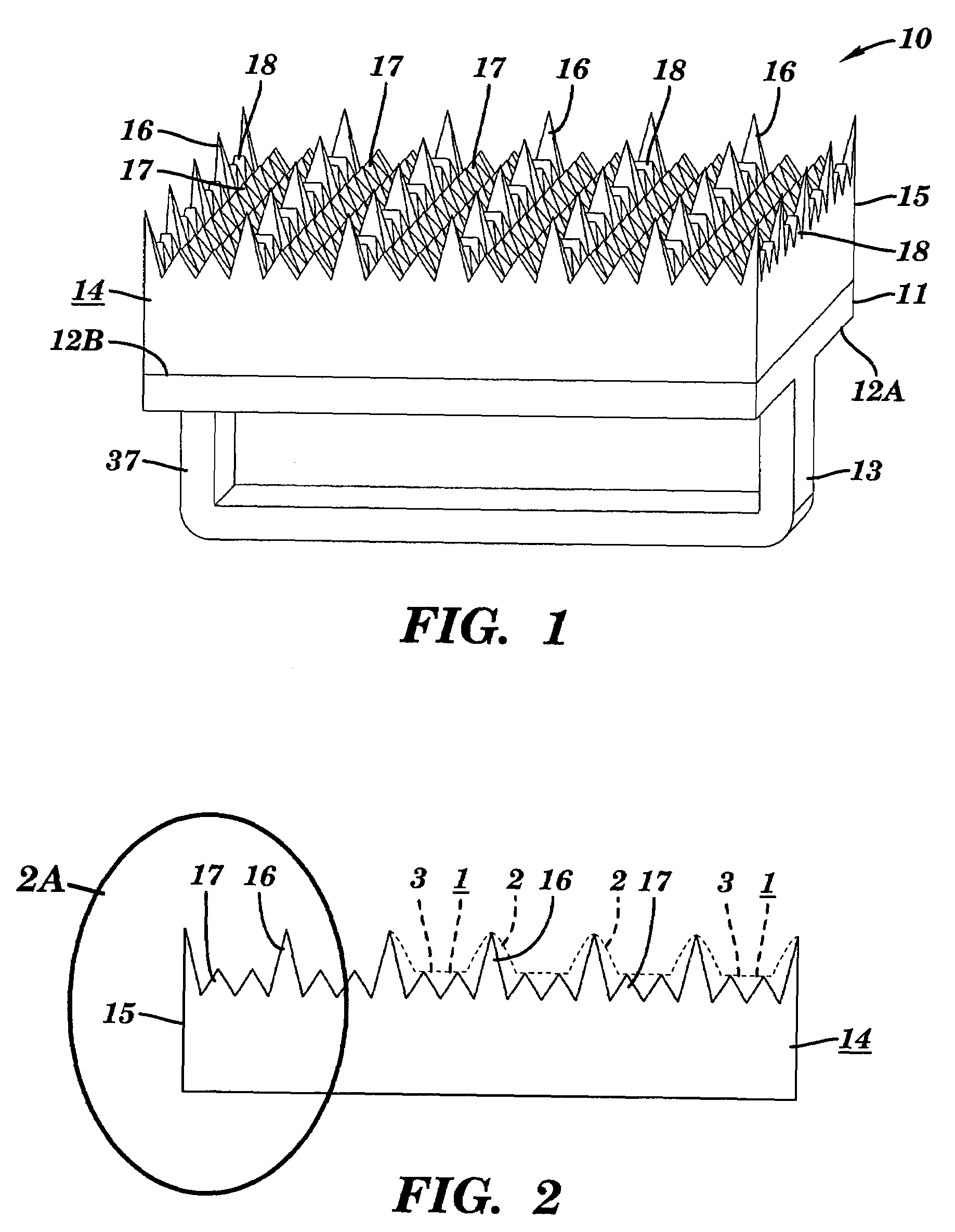

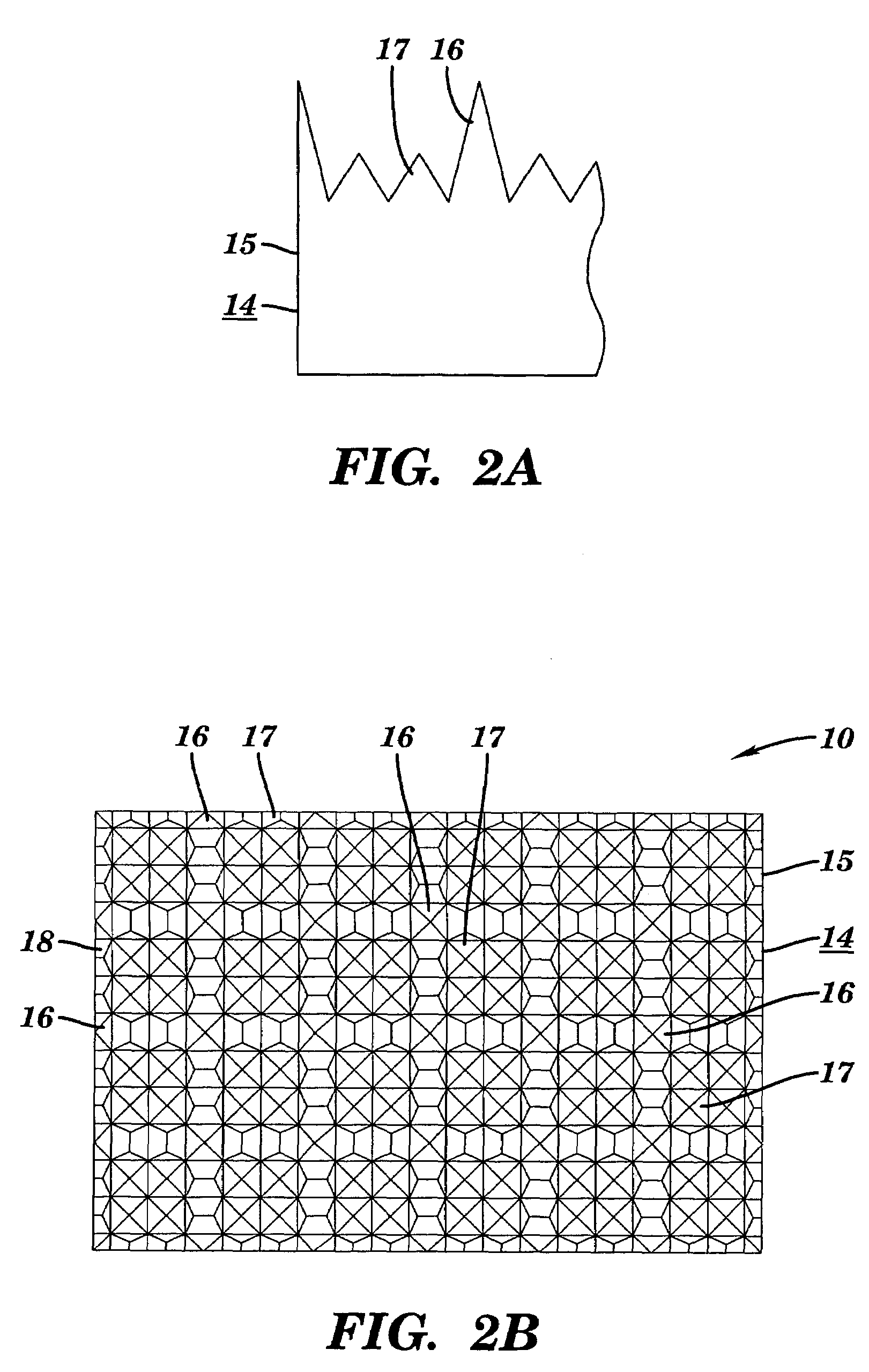

Article and method for cleaning uneven, variable geometry surfaces of electronic devices, internal electronic assemblies, or the like

InactiveUS7284293B1Fast and practicalVersatile and economical and easy to useKitchenware cleanersBrush bodiesSurface mountingEngineering

This disclosure relates to an article for cleaning uneven, variable geometry surfaces of electronic devices, internal electronic assemblies, or the like. The article comprises a housing having opposing faces with a support mounted to a first of the faces and a cleaning surface mounted to a second and opposite face of the housing. The cleaning surface includes a substantially flexible material formed in multiple, alternating patterns comprising at least one row of non-continuous, relatively tall triangular-like spikes separated by a plurality of rows of continuous, relatively short triangular-like spikes. Upon grasping of the support by a user, pressing the cleaning surface into contact with a surface to be cleaned, and moving the article along and against the surface, the relatively tall triangular-like spikes engage generally low portions of the surface, whereas the relatively short triangular-like spikes engage generally higher portions of the surface so as to remove dirt and debris from the low to the high portions of the surface, respectively.

Owner:HEWLETT PACKARD DEV CO LP

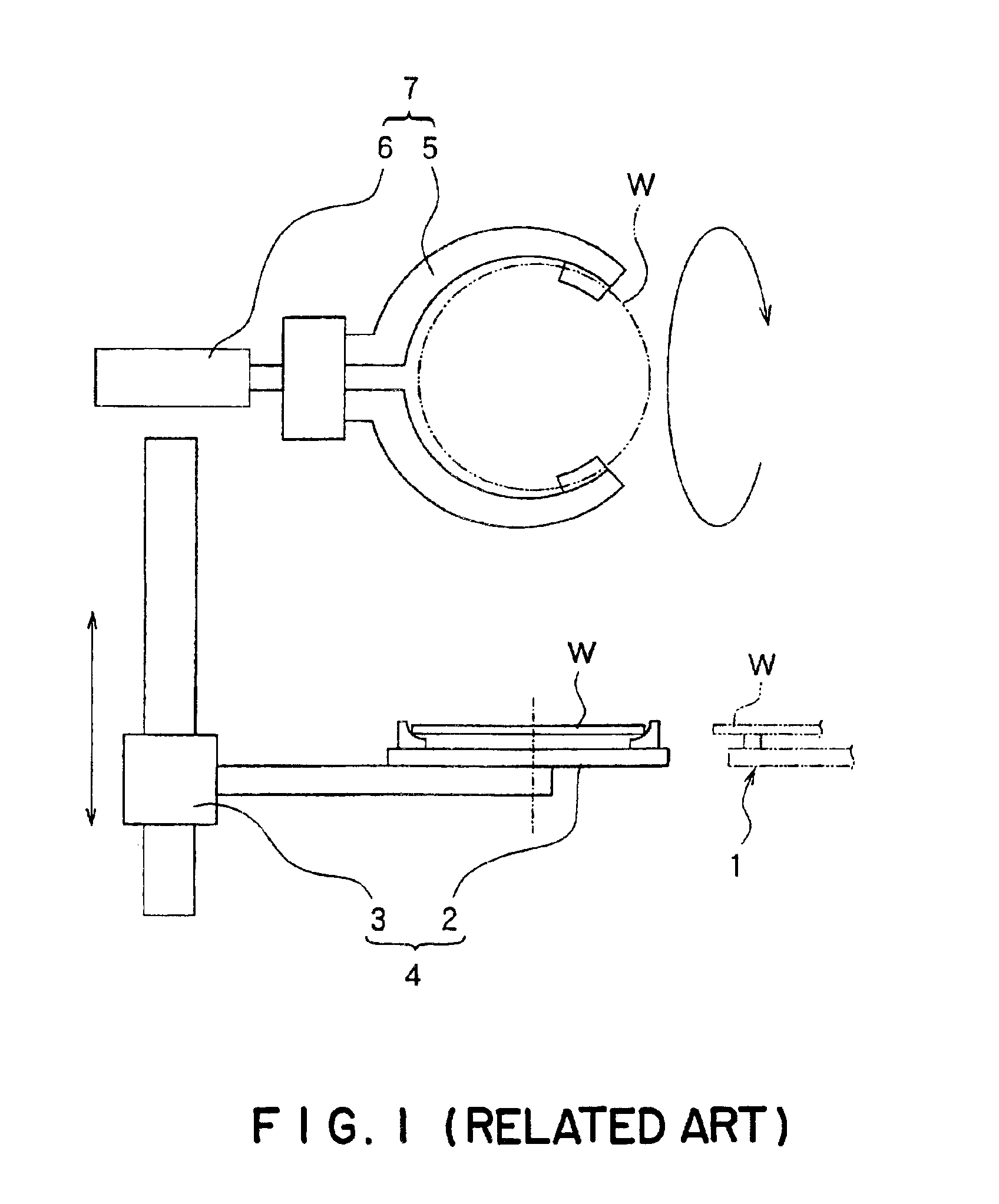

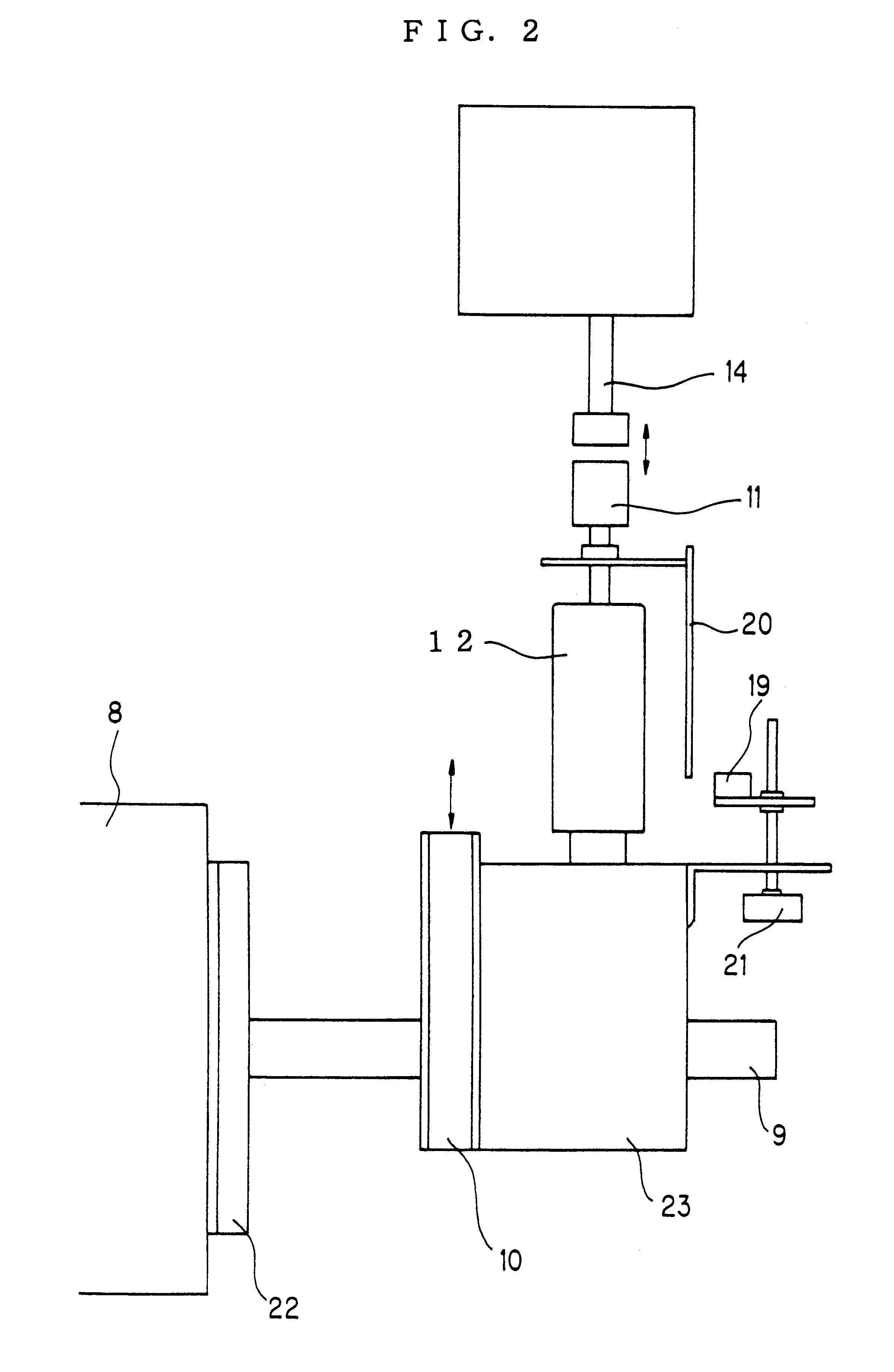

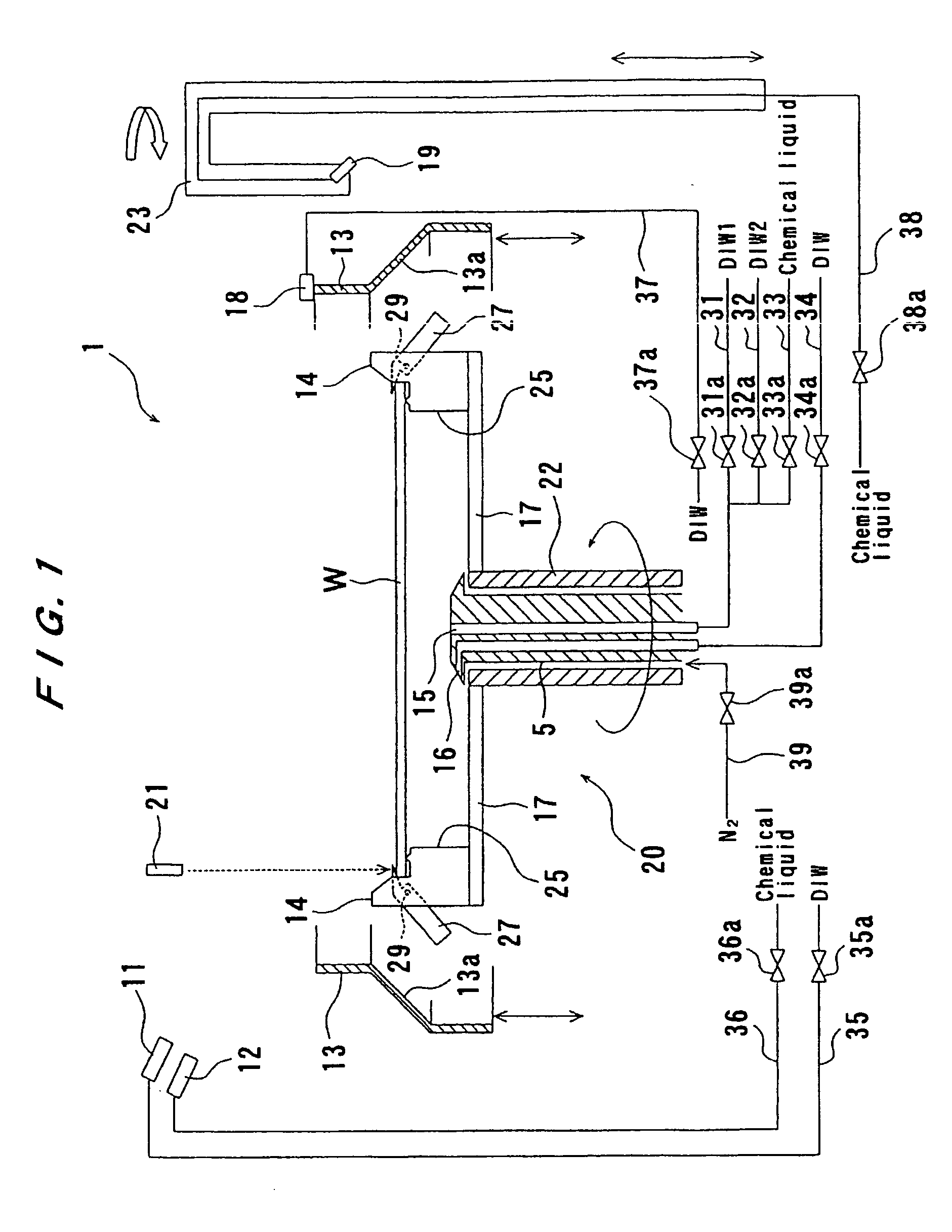

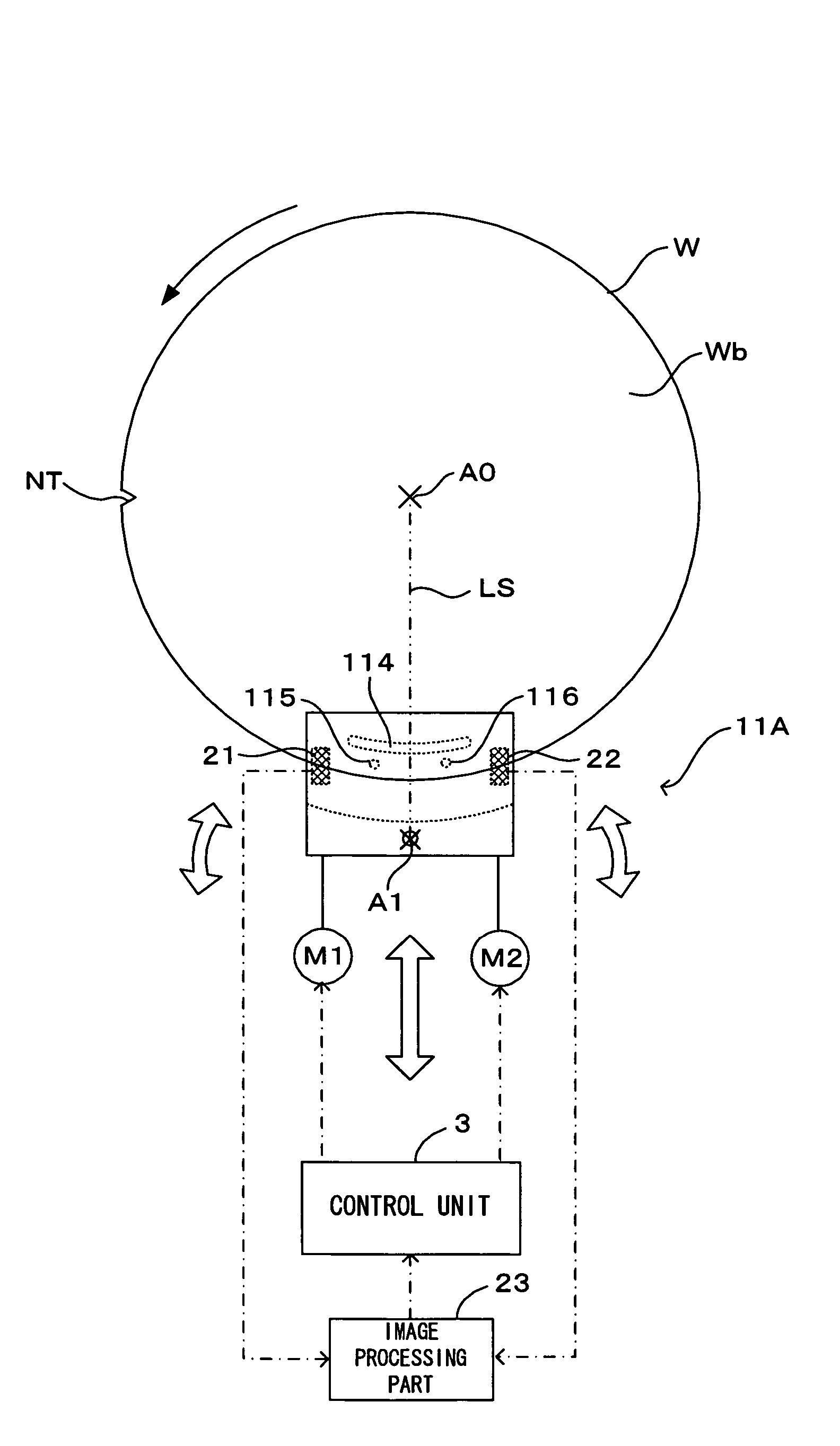

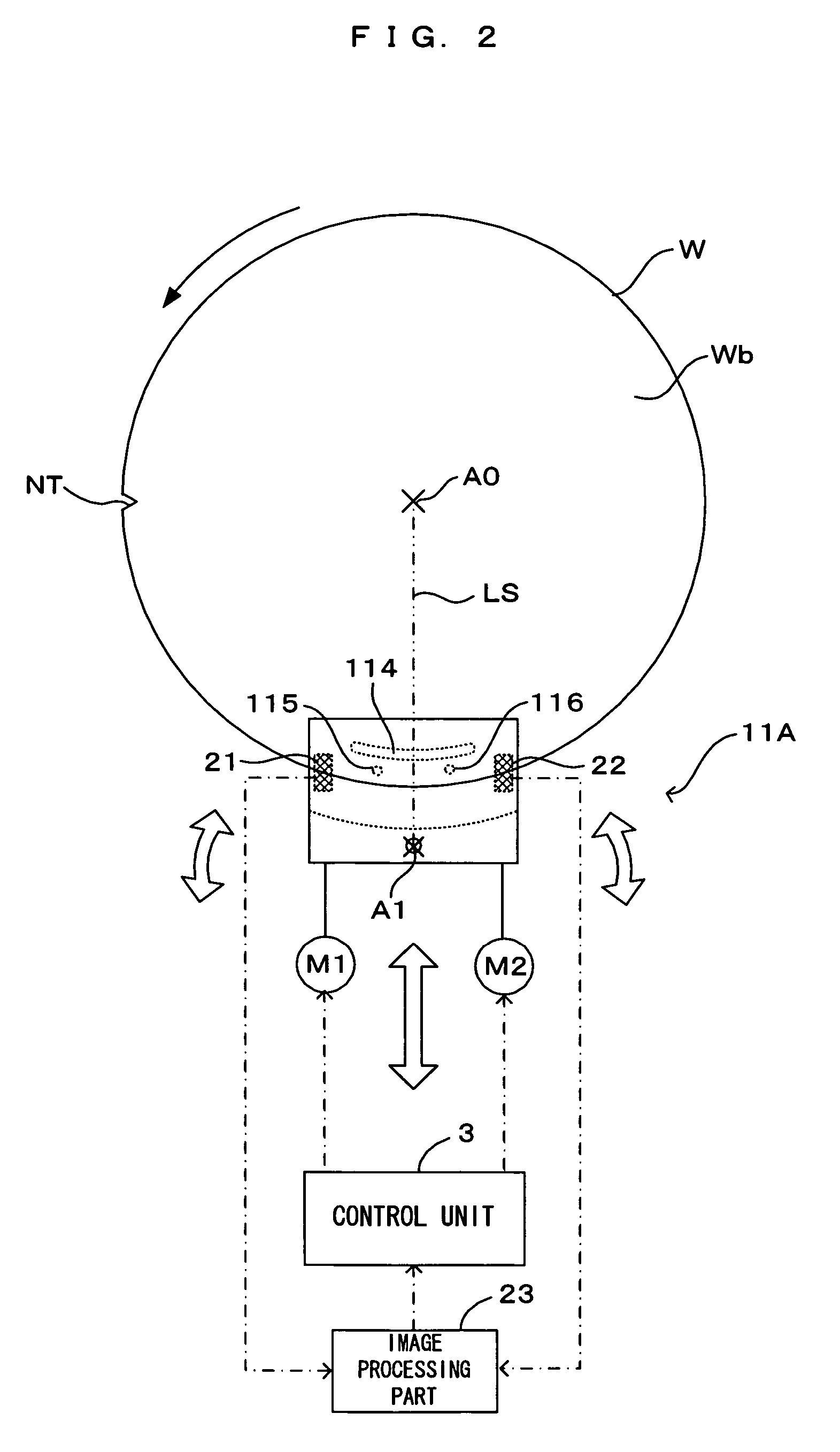

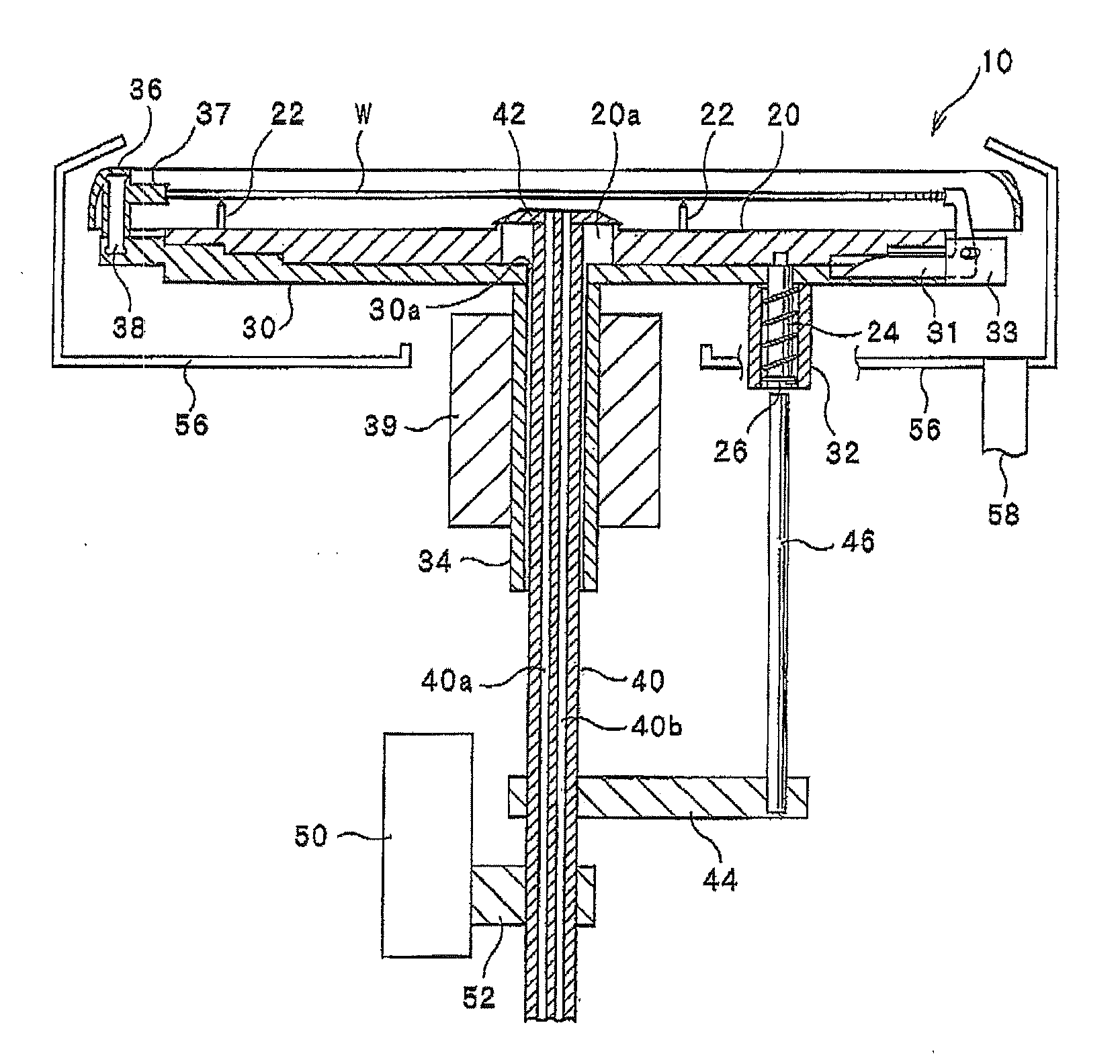

Substrate Processing Apparatus and Method

InactiveUS20080110861A1Avoid pollutionDecorative surface effectsSemiconductor/solid-state device manufacturingEngineering

The substrate processing apparatus has substrate holding mechanisms (14) for holding the substrate (W) under a holding force which is changed according to a rotational speed of the substrate holding mechanisms (14), a substrate rotation mechanism (22) for rotating the substrate holding mechanisms (14) to rotate the substrate (W) held by the substrate holding mechanisms (14), and a treatment liquid supply mechanism (12, 15, 19) for supplying a treatment liquid to a desired portion of the substrate (W) held by the substrate holding mechanisms (14).

Owner:EBARA CORP

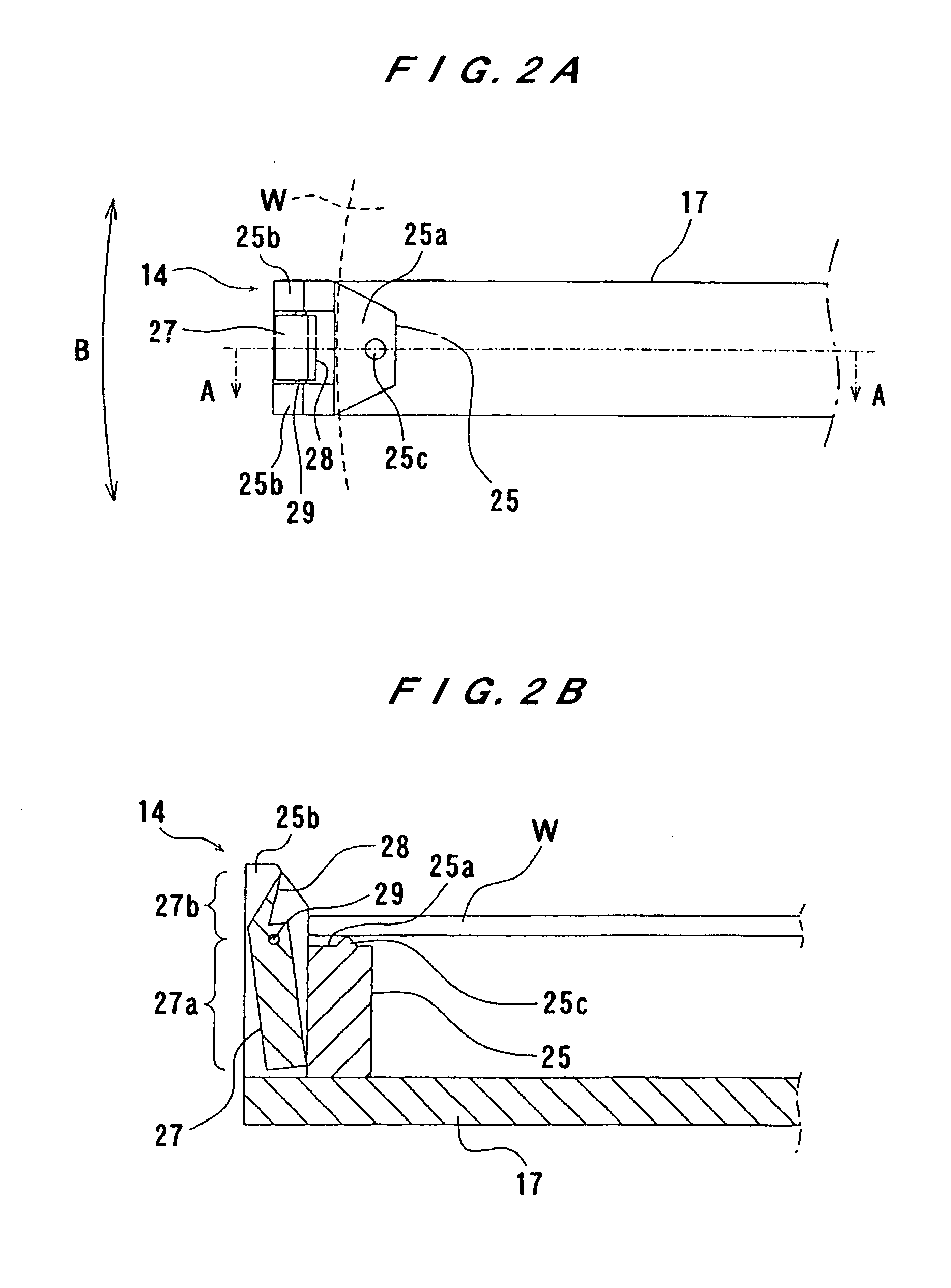

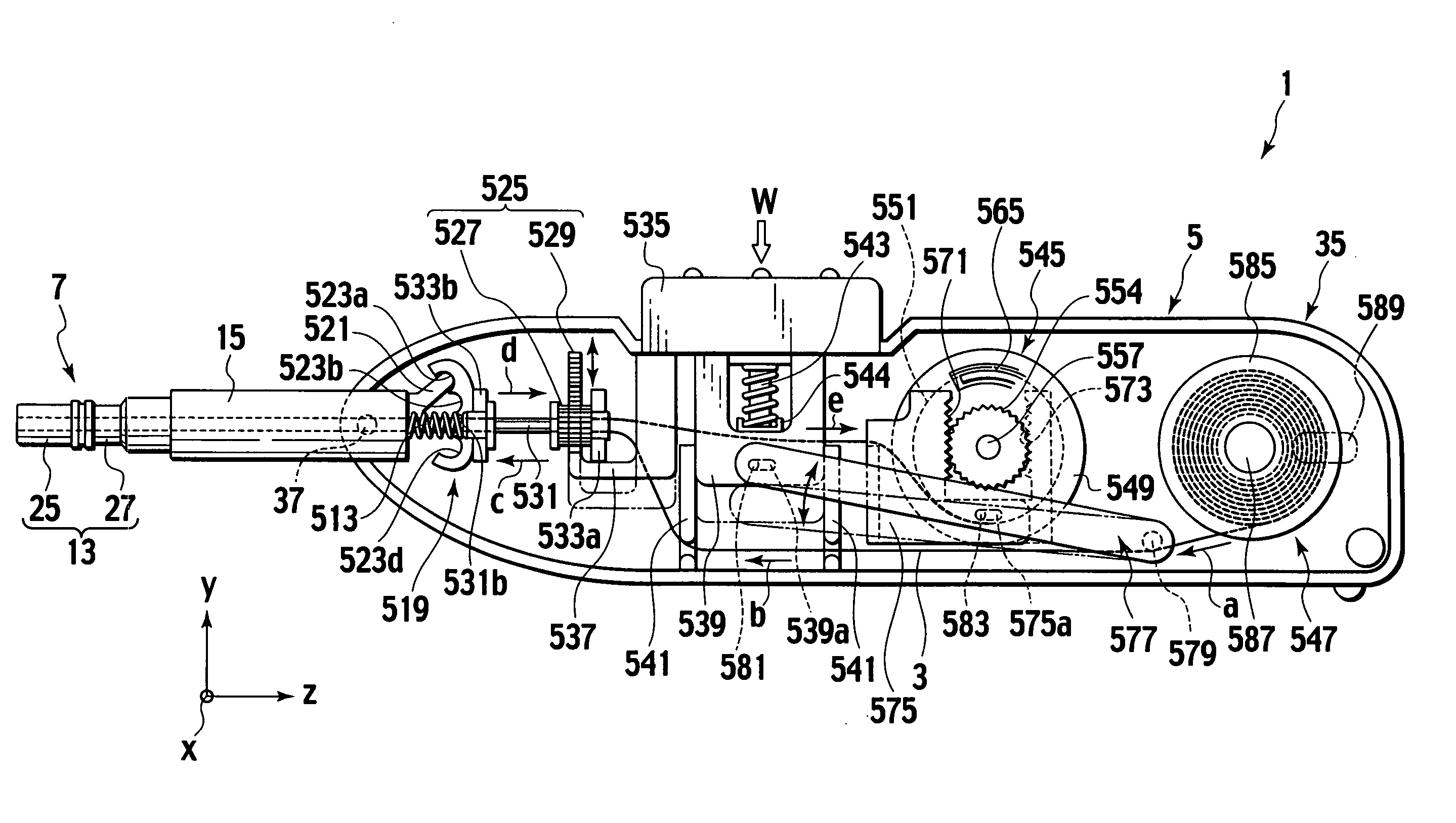

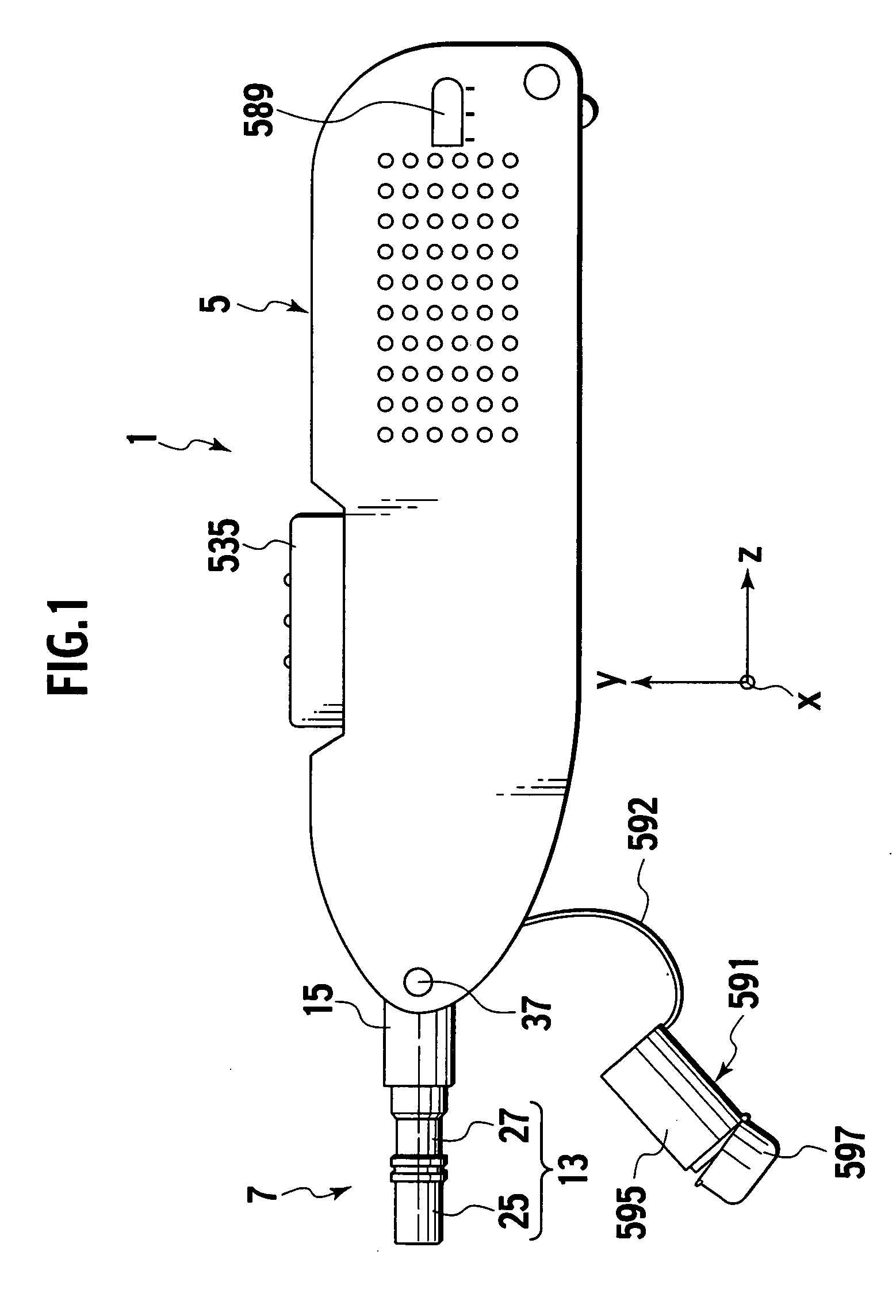

Optical connector cleaning tool

ActiveUS8402587B2Easy to carrySimple structureLiquid processingReconditioning/cleaning record carriersMechanical engineeringHelix

An optical connector cleaning tool includes a holder, cleaner, and cap. The holder includes, a cylindrical slider, a cylindrical body which is rotatable and movable in the axial direction with respect to the slider, and a slider return spring which biases the body forward to return the slider to the initial position. The slider has a pair of elastic pieces having guide projections. In the outer circumferential surface of the body, spiral grooves with which the guide projections engage are formed within the angular range of 360°. When the slider moves forward, the body rotates by the cam action of the guide projections and spiral grooves. The cleaner includes, a cleaning thread accommodated in a rotary pod, a supply reel, a take-up reel, and a cleaning pin, and is connected to the body.

Owner:NTT ADVANCED TECH

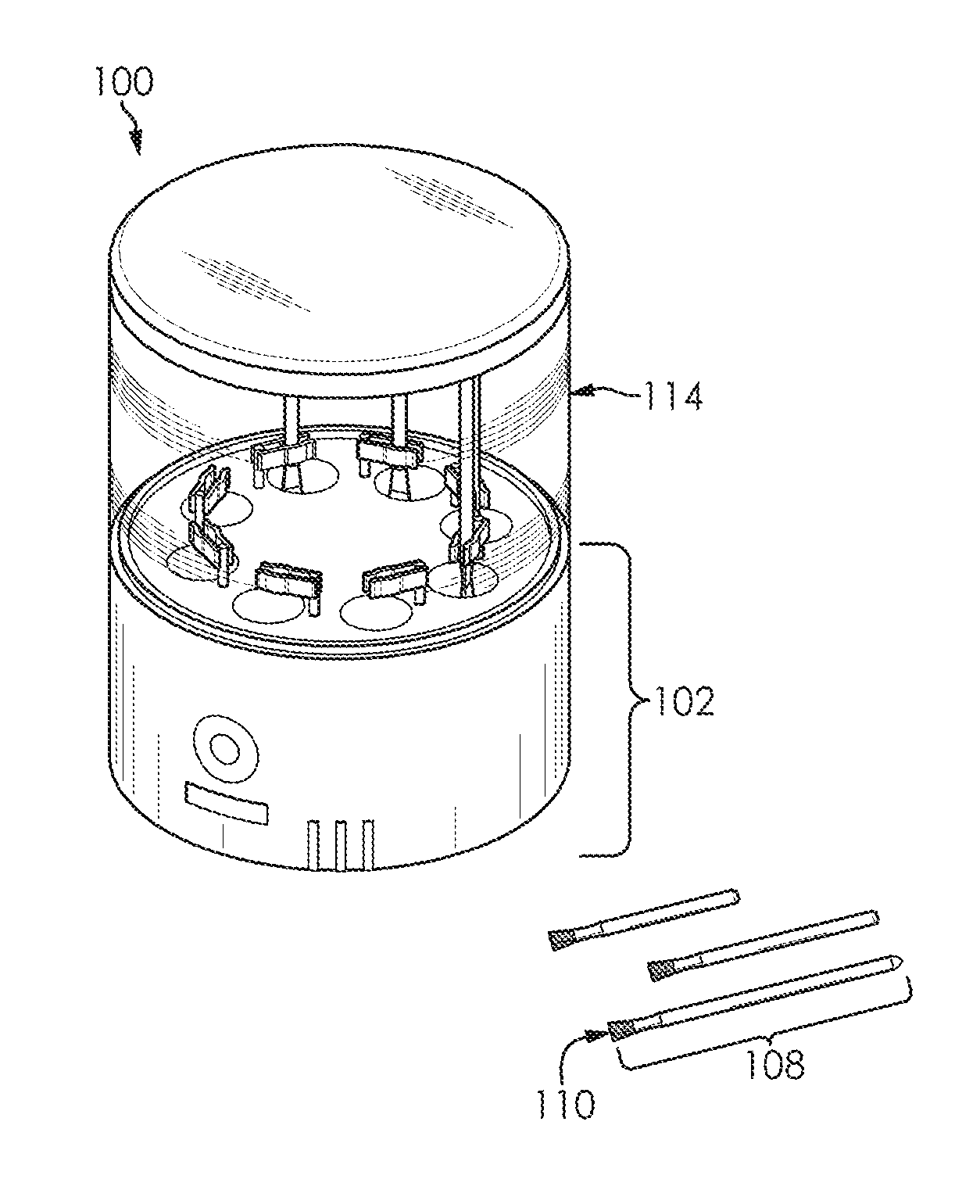

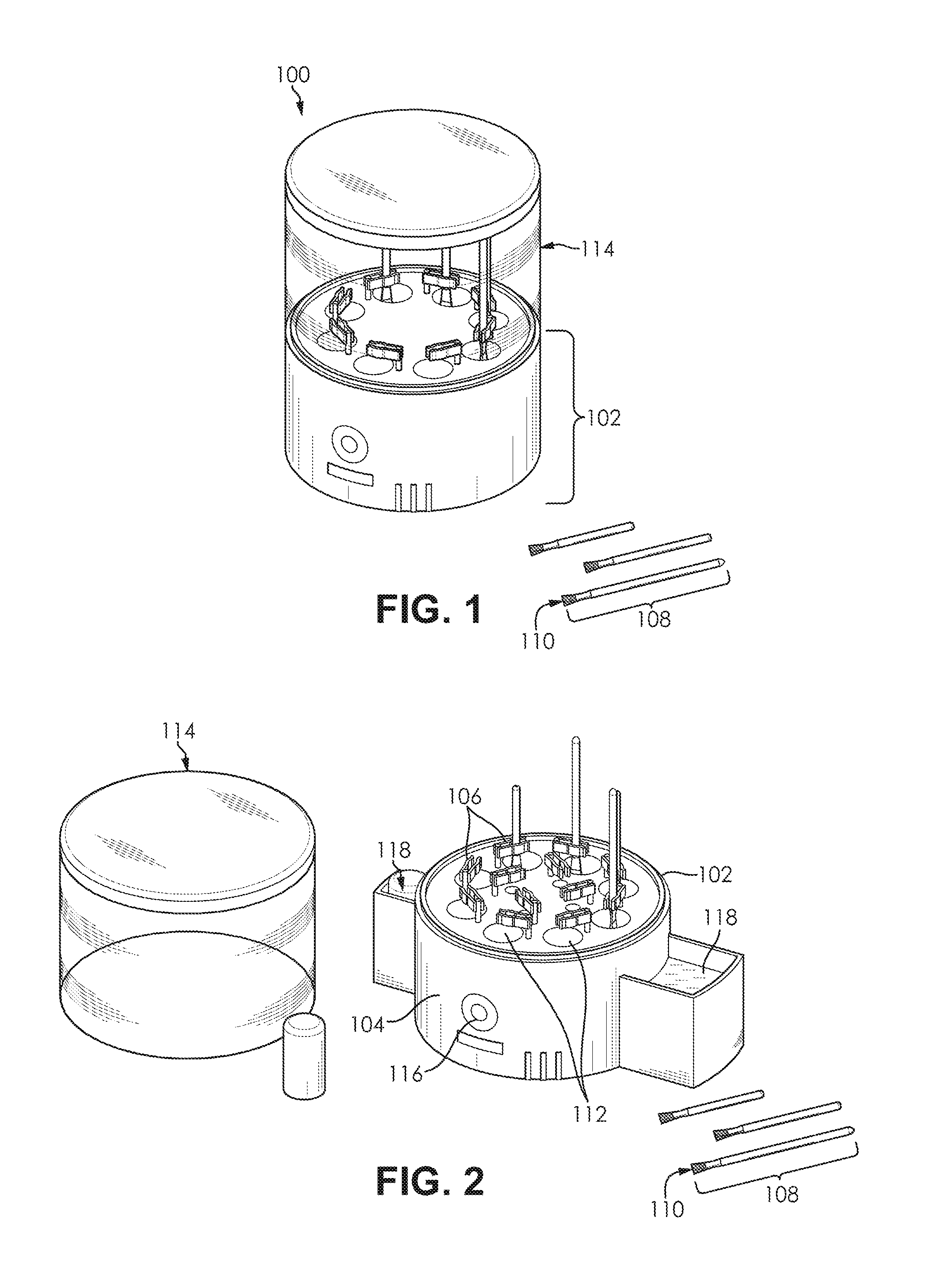

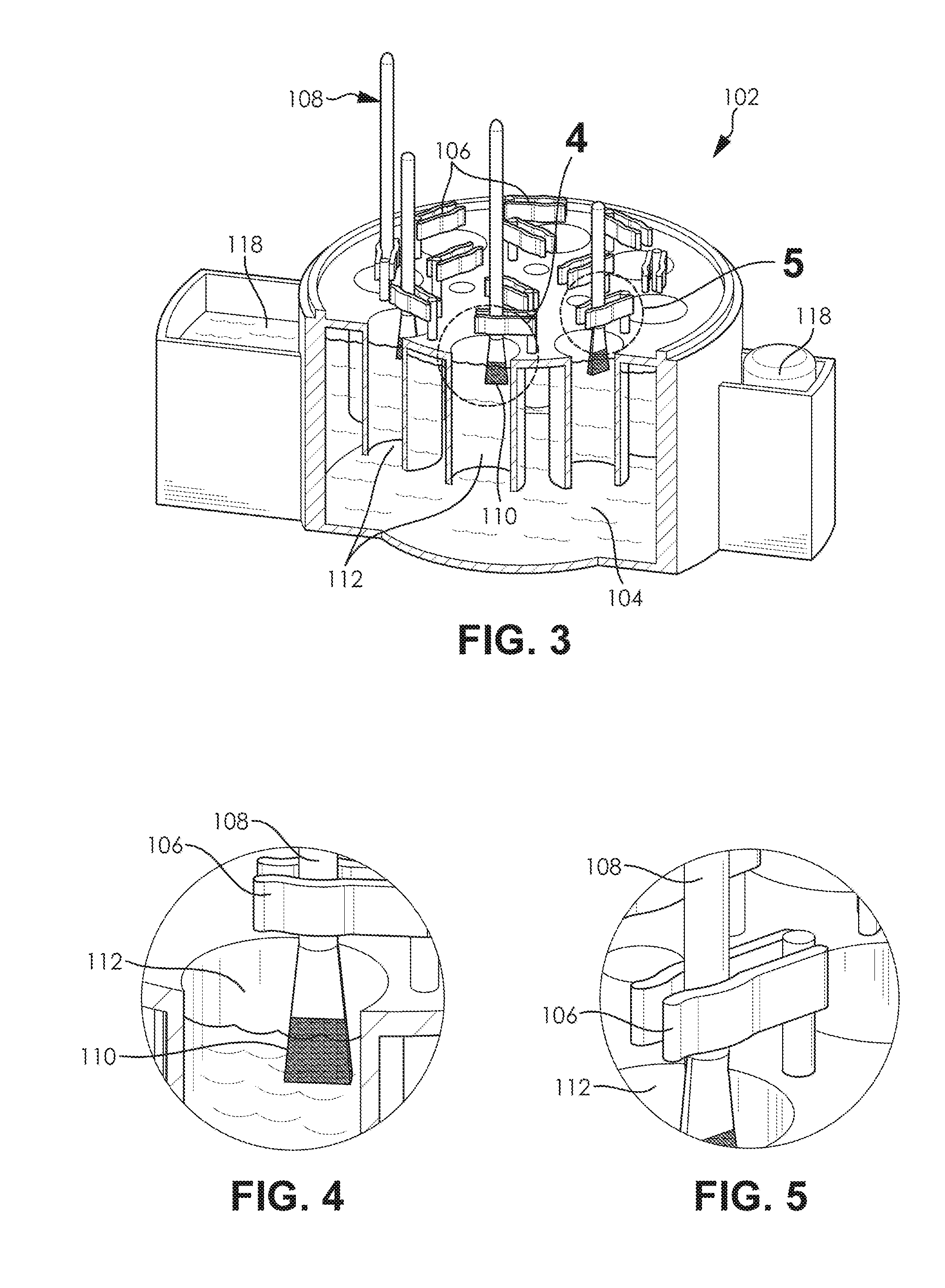

Makeup brush cleaner and sanitizer

The present invention generally relates to a makeup brush cleaner and sanitizer. Specifically, embodiments of the present invention relate to an apparatus configured to hold multiple cosmetics or other makeup type brushes in specifically designed retention means such that only the brush tips / bristles of the brushes are subject to the sanitation area of the apparatus. Certain embodiments of the present apparatus provide the sanitation area of the apparatus to clean the brush tips / bristles of the retained brushes via one or more of a cleaning solution, water, ultra-violet cleaning source, ultrasonic cleaning source, gentle agitation, or any combination thereof.

Owner:MCCORMICK MATT +1

Cleaner for an optical fiber connector

InactiveUS20060191091A1Promote recoveryLiquid processingReconditioning/cleaning record carriersEngineeringOptical fiber connector

A cleaner for an optical fiber connector which is made up of an elongated inner guide member having a base and an end tip, around which a cleaning member extends along the extension axis thereof, from the base to the end tip and returning again to the base; a sliding member supported so as to be slidable along the inner guide member and having a pair of guide parts that guide the cleaning member, which can slide between a projected position protruding beyond the end tip of the inner guide member and a retracted position retreating beyond the end tip, such that when the sliding member is in the projected position, the cleaning member is positioned extending around the sliding member instead of around the end tip of the inner guide member; and a tubular shaped external guide member that supports the sliding member and encloses the inner guide member and the cleaning member.

Owner:SEIKOH GIKEN

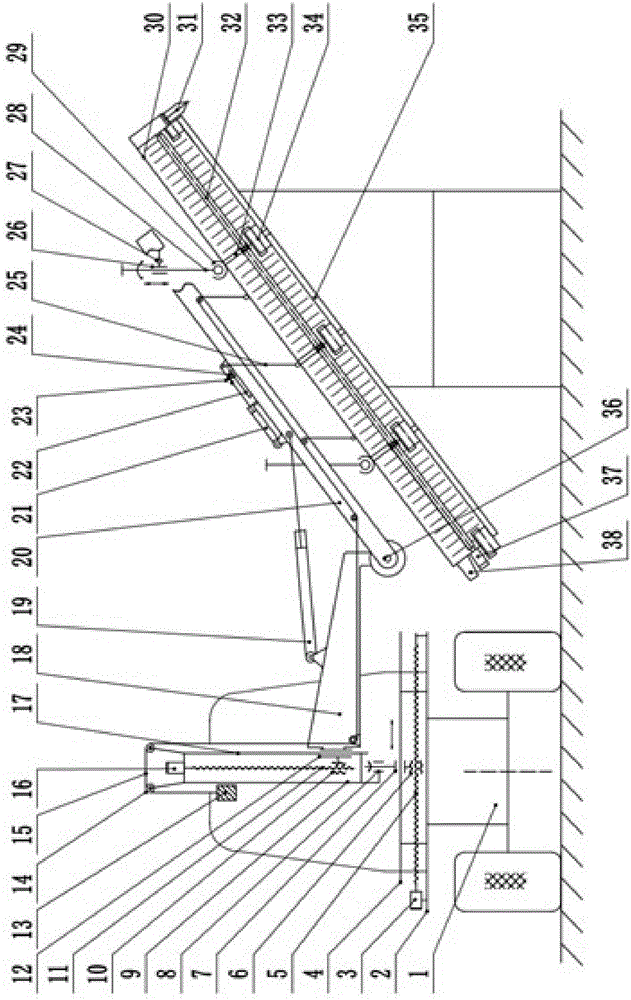

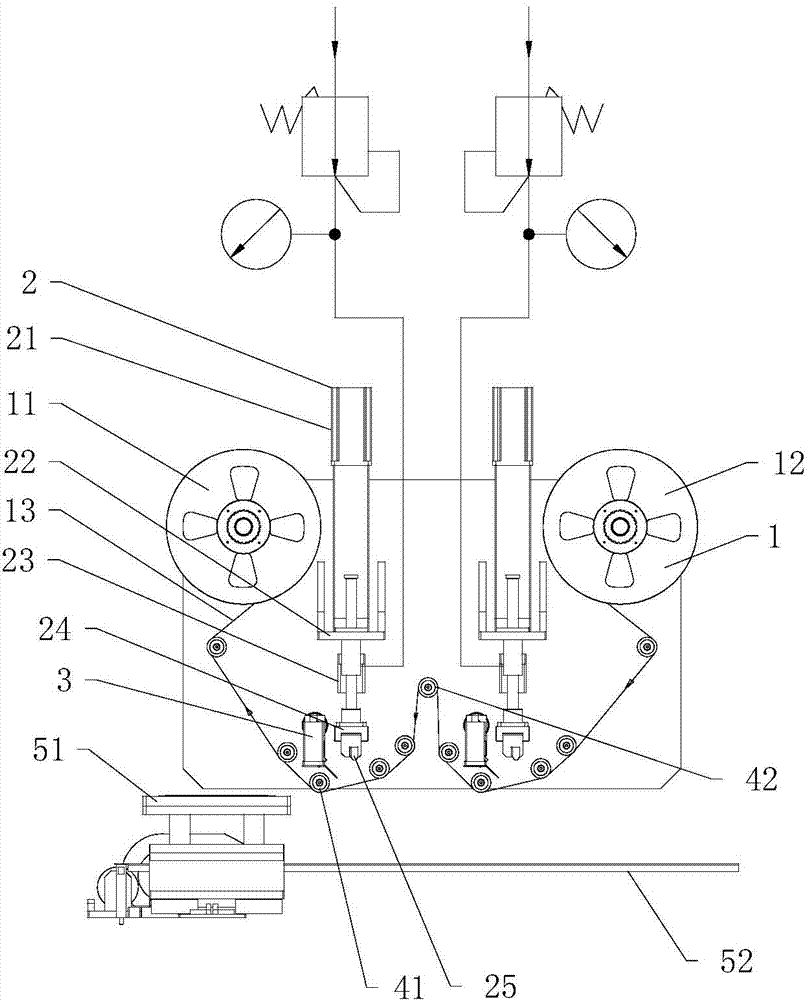

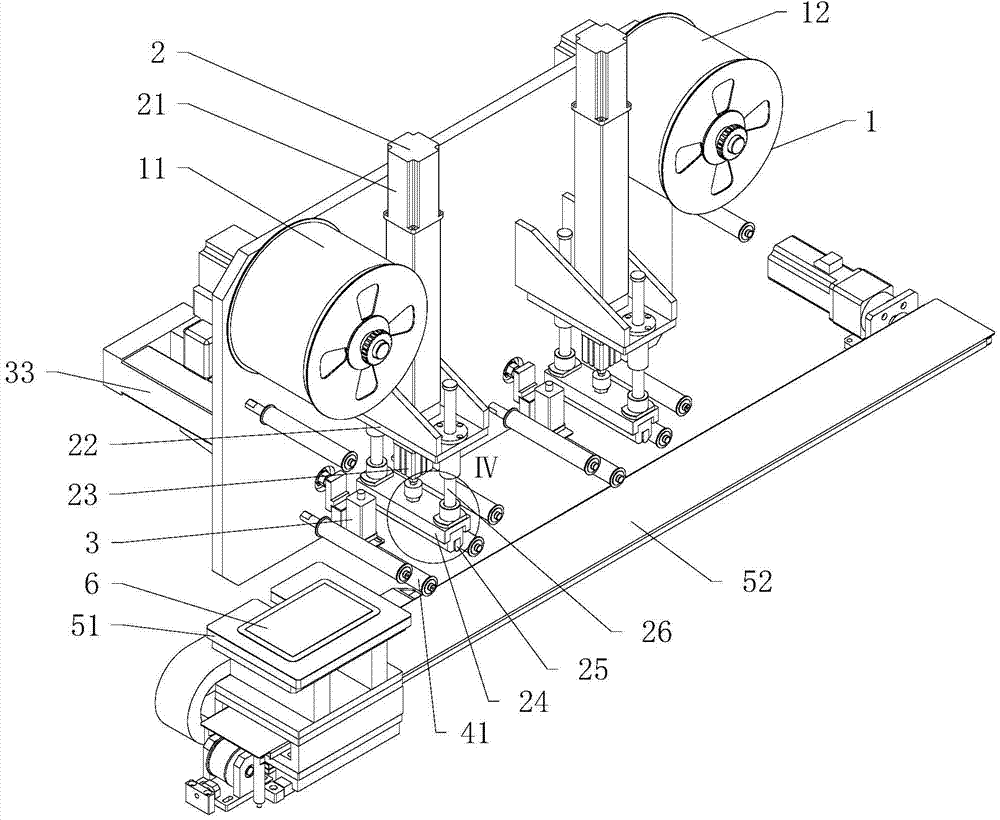

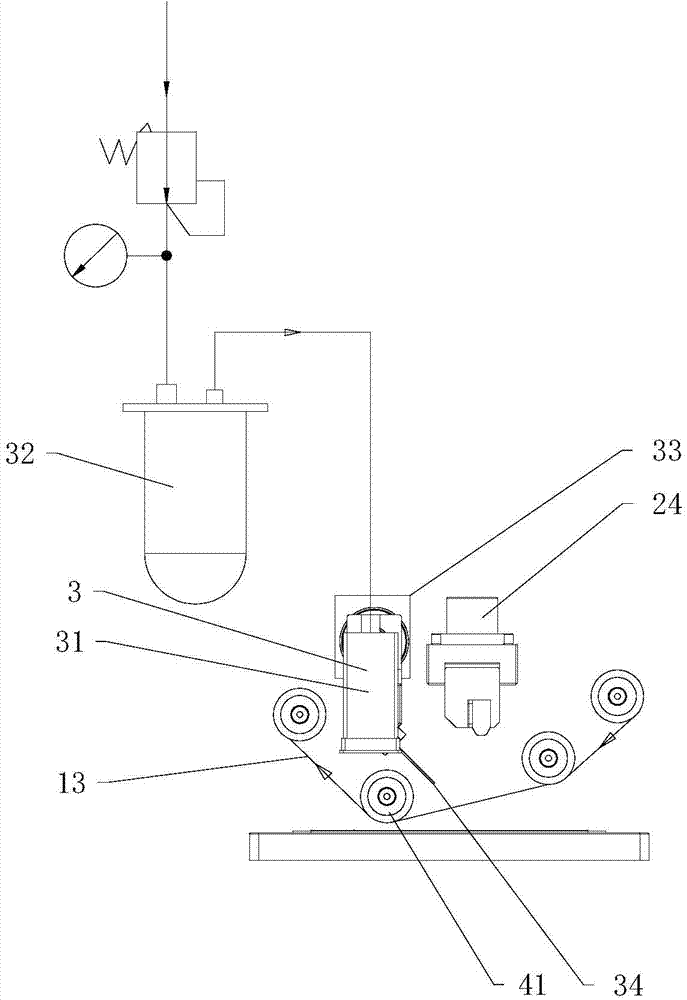

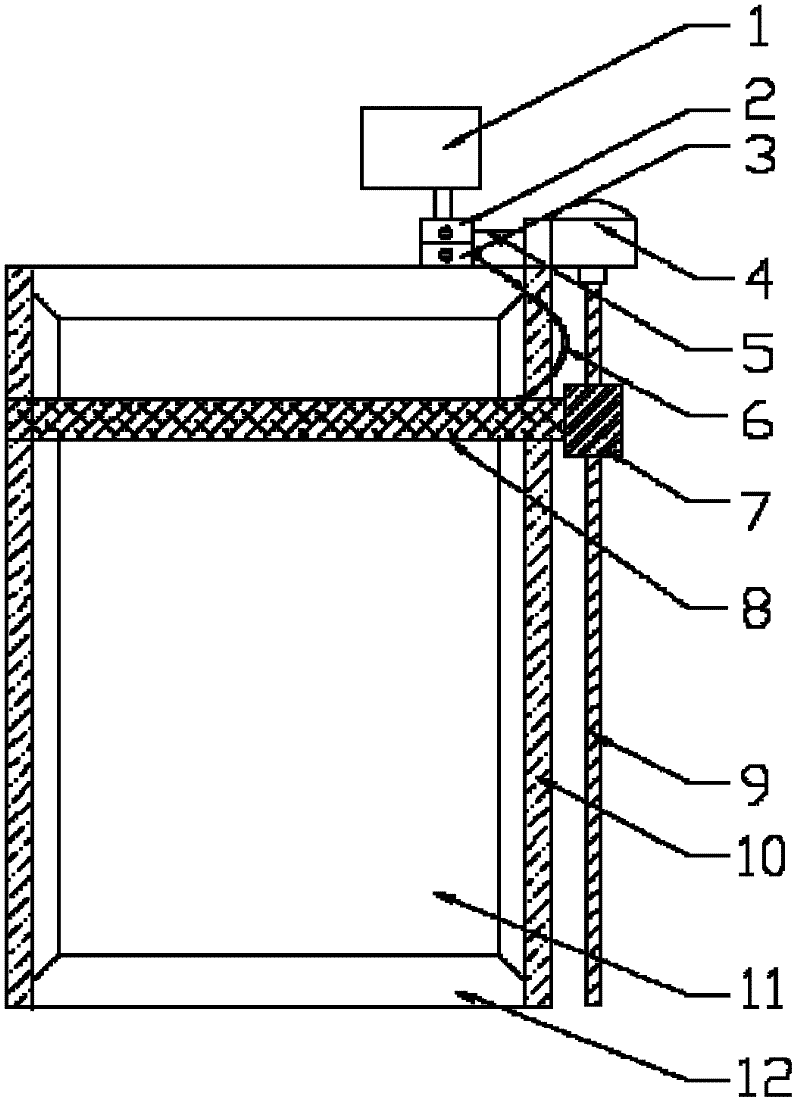

Solar photovoltaic panel cleaning equipment with cleaning brushes capable of being adjusted in self-adaptation mode

ActiveCN106040625AConstant compressionIncrease contactFlexible article cleaningCleaning using toolsDrive motorSelf adaptive

Solar photovoltaic panel cleaning equipment with cleaning brushes capable of being adjusted in a self-adaptation mode is composed of the four parts comprising a vehicle body, an automatic cleaning brush adjustment device, a cleaning brush self-adaptation adjustment device and a cleaning brush body. The vehicle body is composed of a driving vehicle (1) and a rack (2). The cleaning brush body is composed of a brush body supporting beam (30), a conical guide wheel (31), brush rollers (32), separating plates (33), supporting wheels (34), a photovoltaic panel (35), a brush driving motor (37) and an air guide pipe (38), wherein the conical guide wheel (31) is fixed to the uppermost end of the brush body supporting beam (30), the three to five separating plates (33) are evenly distributed on the brush body supporting beam (30), the lower end of each separating plate is provided with one set of supporting wheels (34), two cleaning brushes (32) are installed between every two adjacent separating plates (33) in parallel, the cleaning brushes (32) are integrally connected in series through bearings on the separating plates (33), the lowermost end of each row of cleaning brushes is connected with the brush driving motor (37), and the air guide pipe (38) is installed in a cavity of the brush body supporting beam (30).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

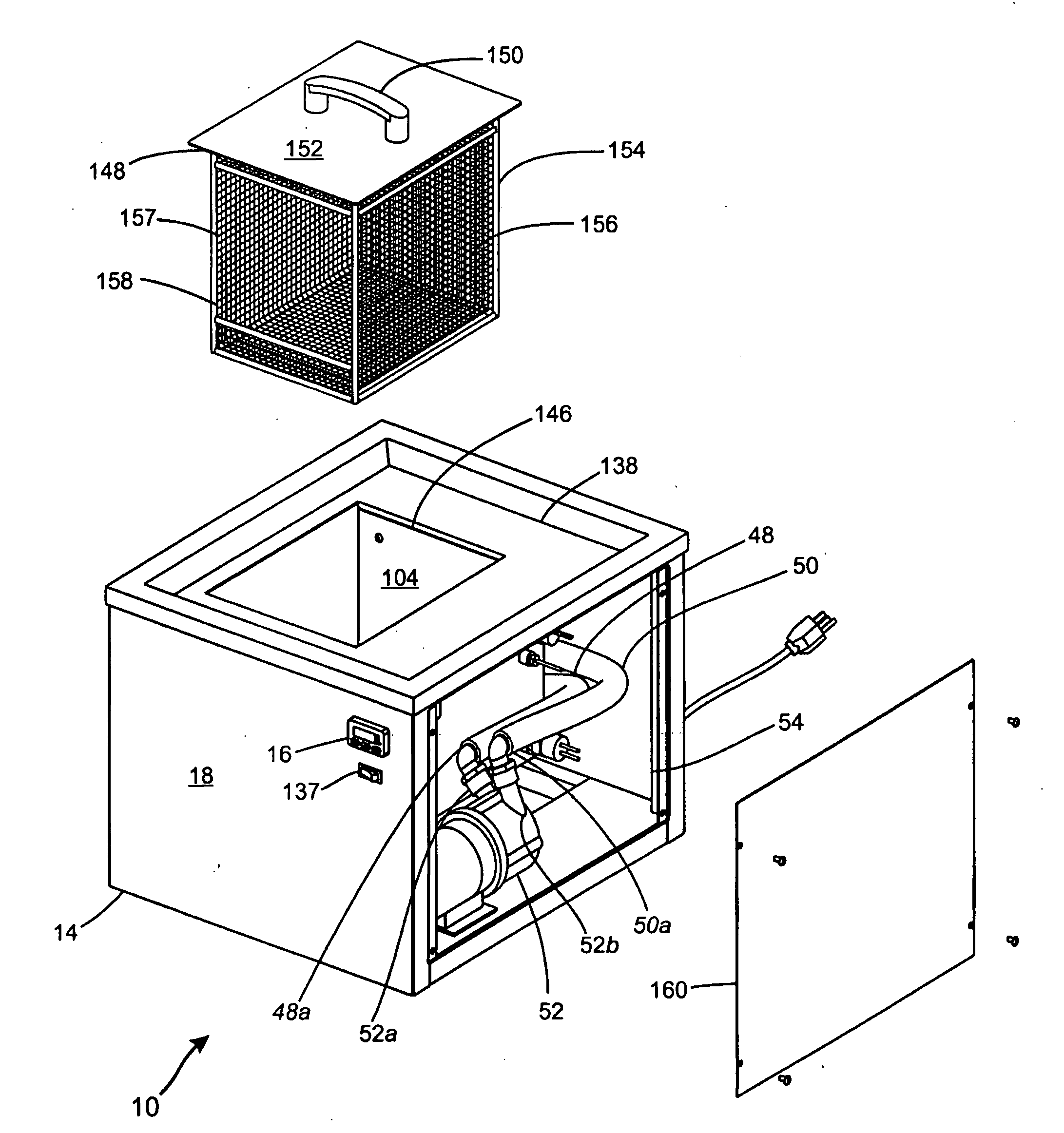

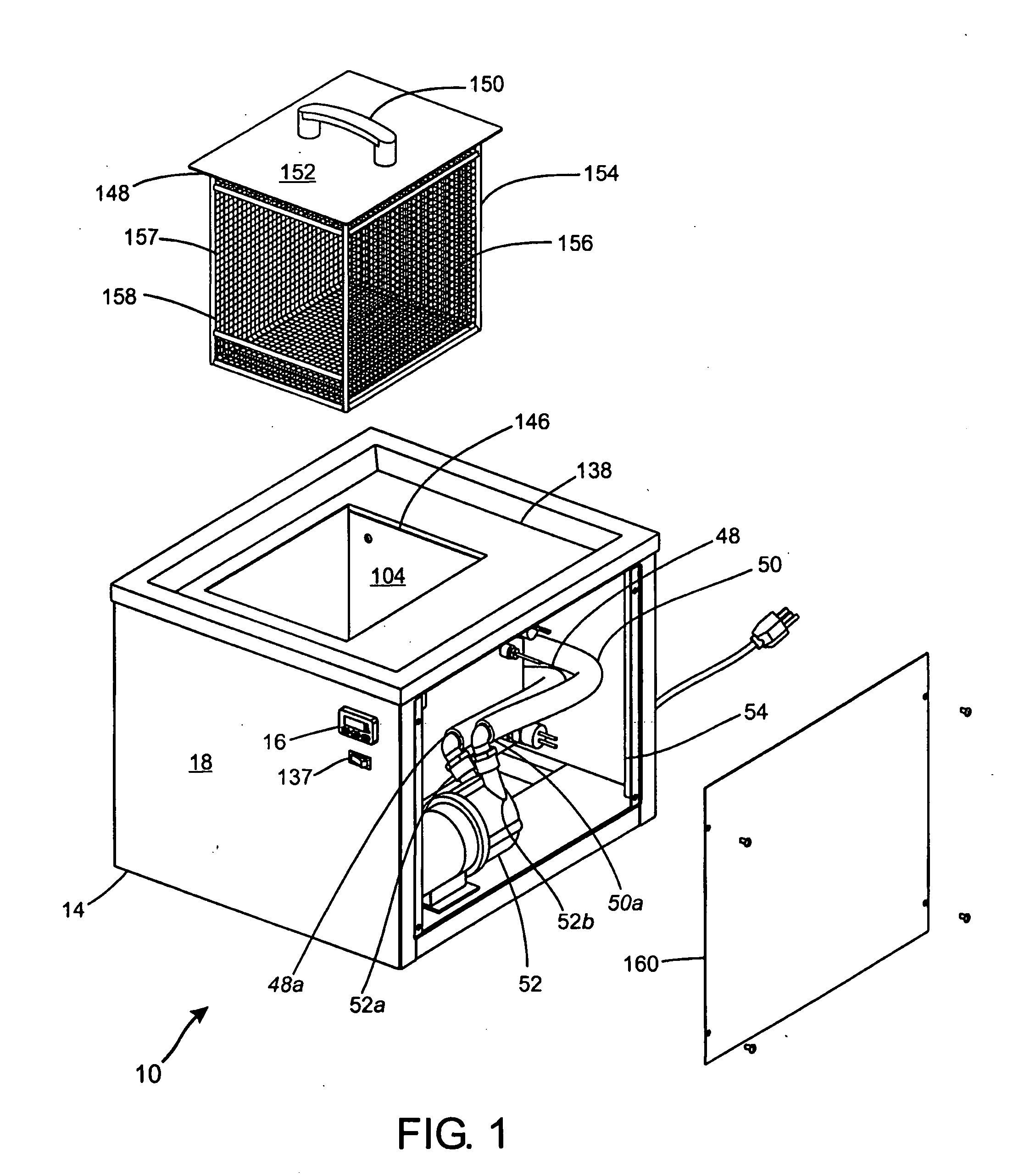

Removing Soluble Support Material From Rapid Prototype Part

ActiveUS20090241997A1Additive manufacturing apparatusHollow article cleaningFused deposition modelingBiomedical engineering

A container has been devised for use with a rapid prototype part making machine, specifically of the type having Fused Deposition Modeling (FDM) capabilities. The container includes a liner that has an exterior surface and that is expandable to define a mouth portion and a volume for receiving, via the mouth portion, a rapid prototype part having soluble support material deposited on the rapid prototype part. An inlet port is formed on the exterior surface and is in fluid communication with the volume. An outlet port is formed on the exterior surface and is in fluid communication with the volume. A sealing arrangement is configured and arranged to selectively substantially prevent egress of an aqueous cleaning solution from the mouth portion of the liner. The inlet port is configured to introduce the aqueous cleaning solution into the volume to remove the soluble support material from the rapid prototype part.

Owner:TAFOYA DAVID JONATHAN

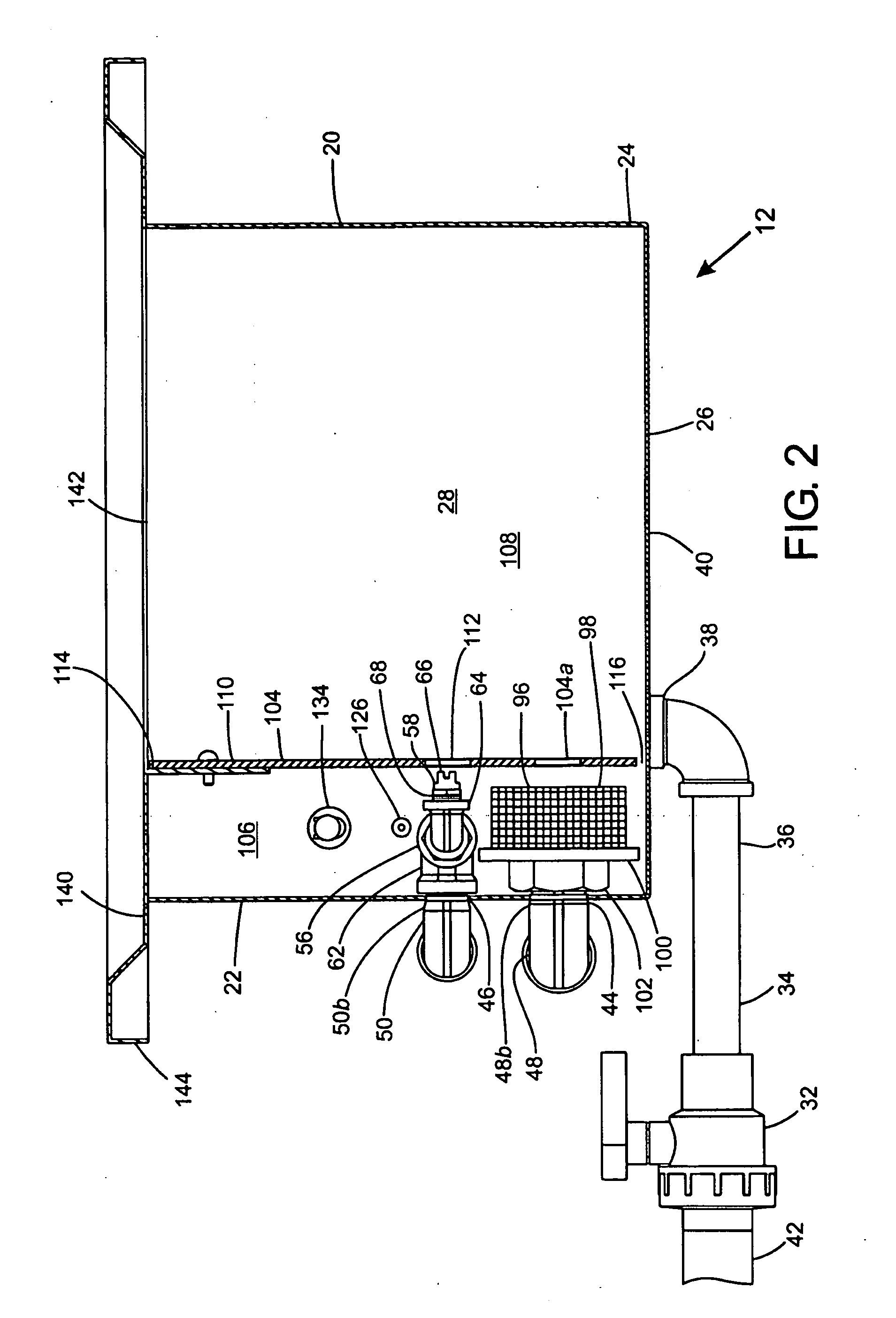

Substrate processing apparatus for treating substrate with predetermined processing by supplying processing liquid to rim portion of rotating substrate

ActiveUS7935217B2Decorative surface effectsSemiconductor/solid-state device manufacturingImaging processingEdge surface

A bevel unit comprises CCDs and processing liquid nozzles, and the CCDs take an image of a circumferential edge surface of a substrate. An image processing part detects the distances between the circumferential edge surface of the substrate and the processing liquid nozzles by image processing the signals from the CCDs. A control unit compares thus detected distances between the circumferential edge surface of the substrate and the processing liquid nozzles with set distances from the circumferential edge surface of the substrate to the processing liquid nozzles which are set in a recipe so as to be a desired rim etching width, and calculates an amount of displacement between the detected distances and the set distances. In accordance with the amount of displacement, the control unit activates motors and accordingly positions the bevel unit.

Owner:DAINIPPON SCREEN MTG CO LTD

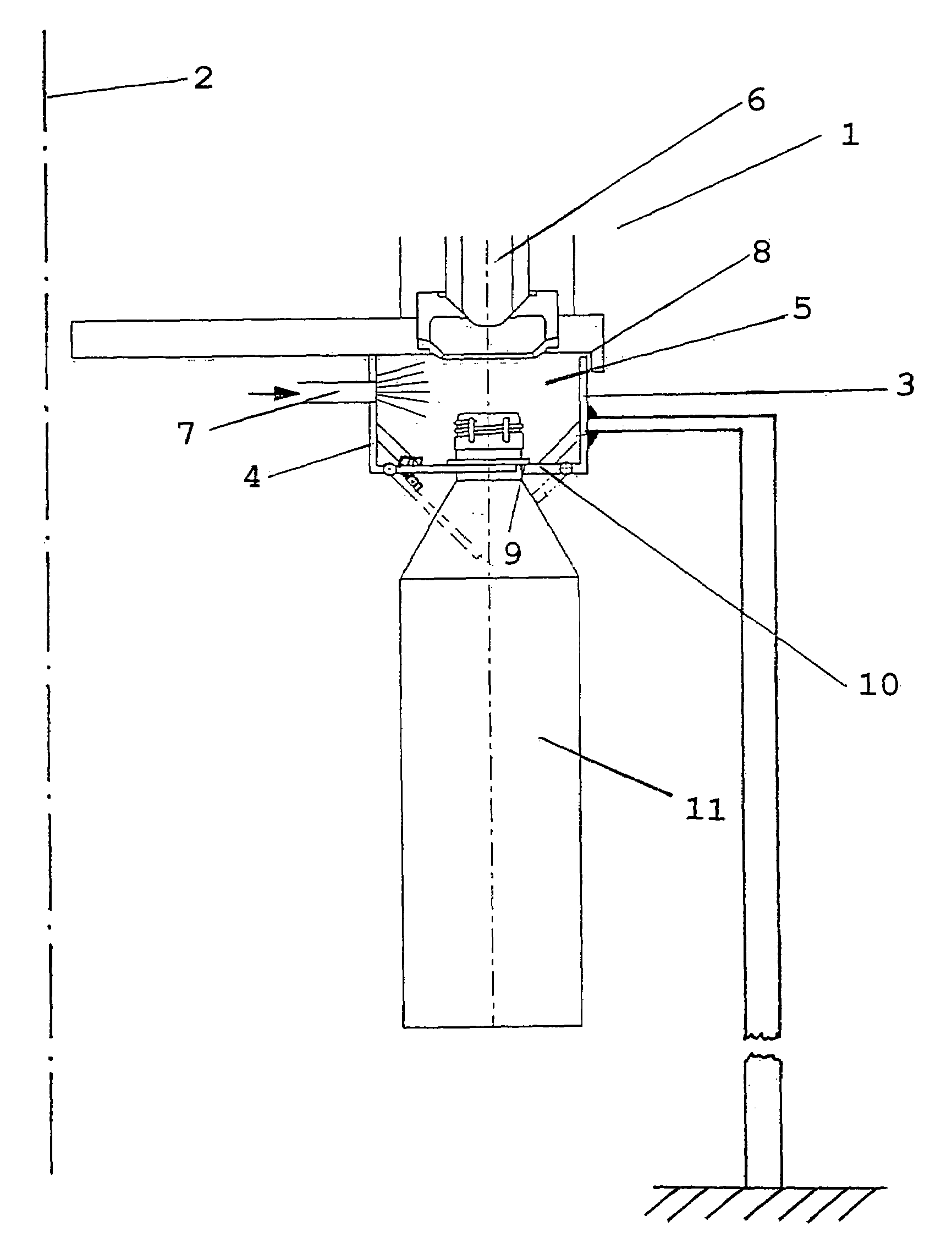

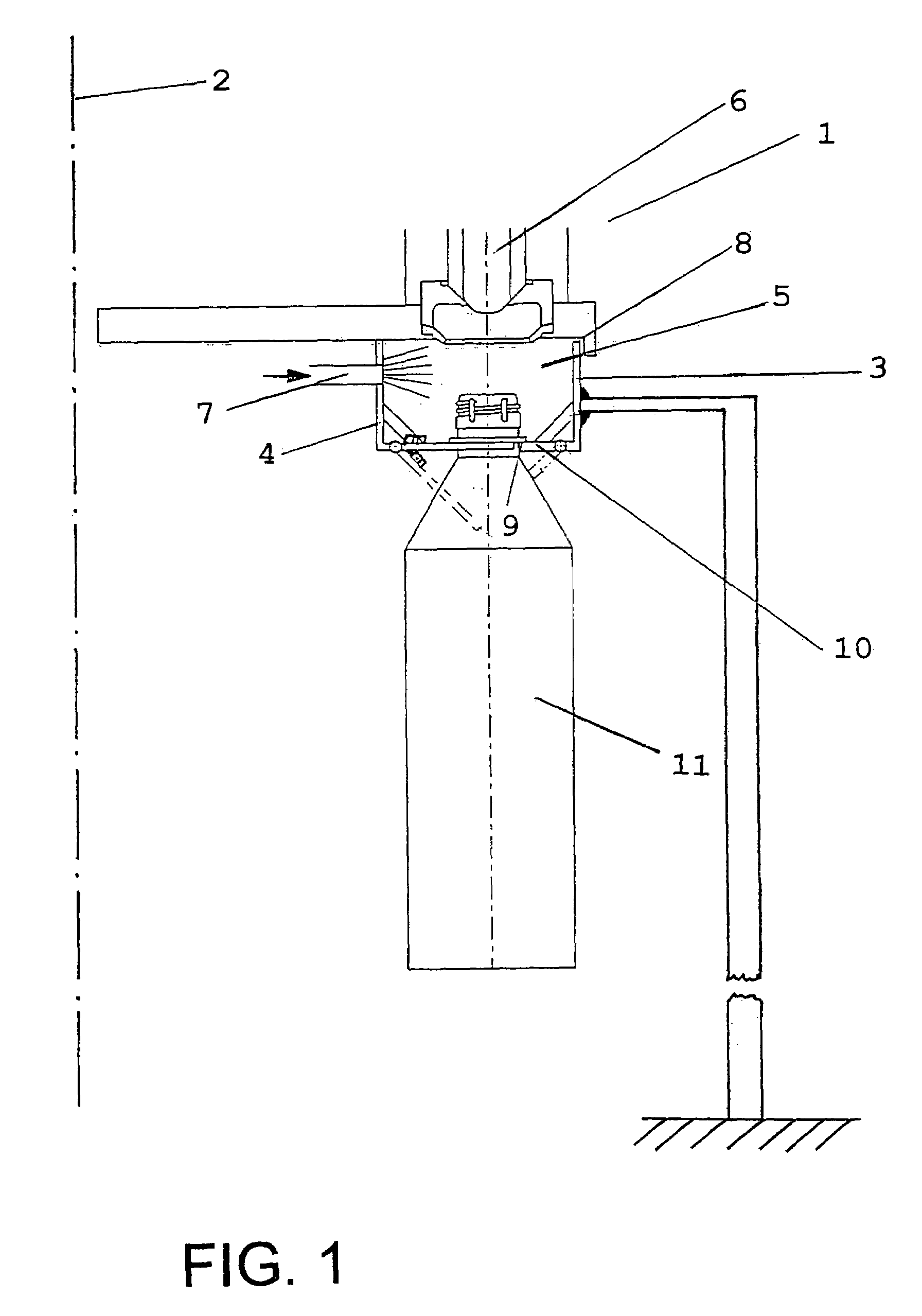

Beverage bottling plant for filling bottles with a liquid beverage filling material, having a container handling machine with interchangeable receptacles for the container mouth

ActiveUS7121062B2Reduce equipment costsFlexible article cleaningPackaging under vacuum/special atmosphereFilling materialsEngineering

A container handling machine for containers, such as bottles, with a carousel that rotates around a vertical axis, with handling stations located at appropriate intervals for the handling of the containers, whereby the handling stations are located in a space that is essentially enclosed and is pressurized with a controlled atmosphere and having rotating portions of the space and non-rotating portions that are stationary with respect to the rotating portions, with receptacles (12) for holding the containers corresponding to each handling station, whereby these receptacles (12) are interchangeable.

Owner:KHS GMBH

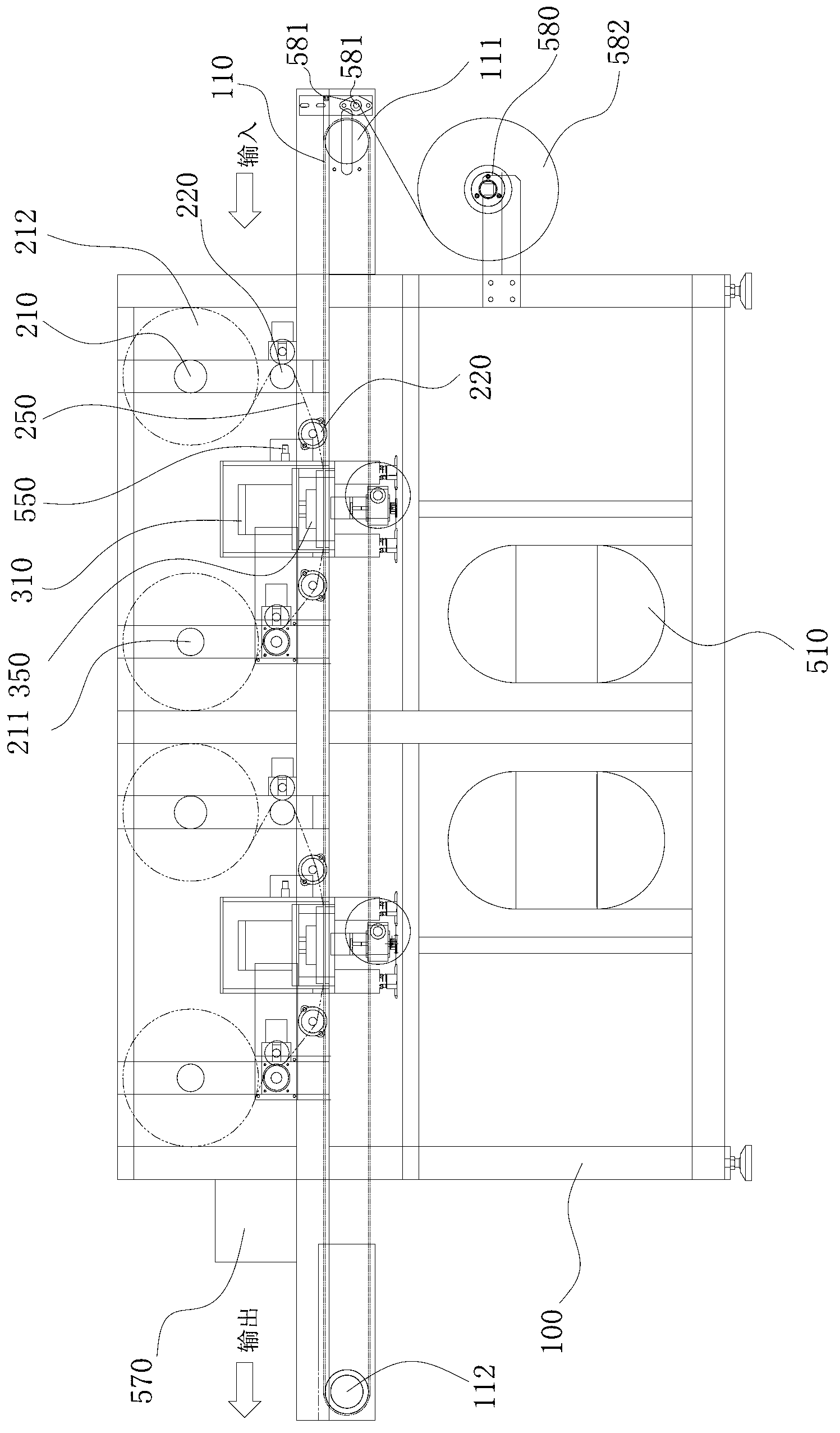

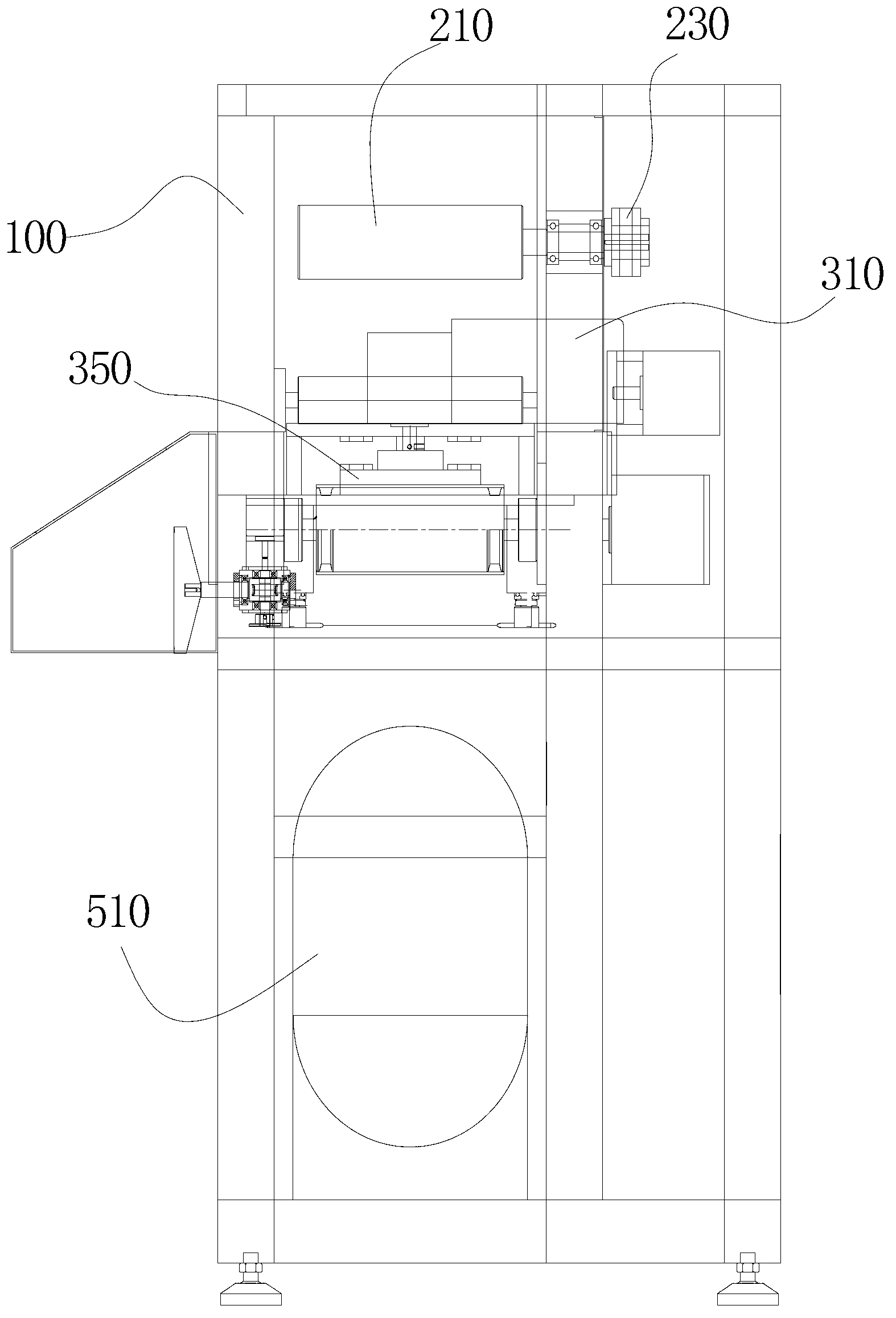

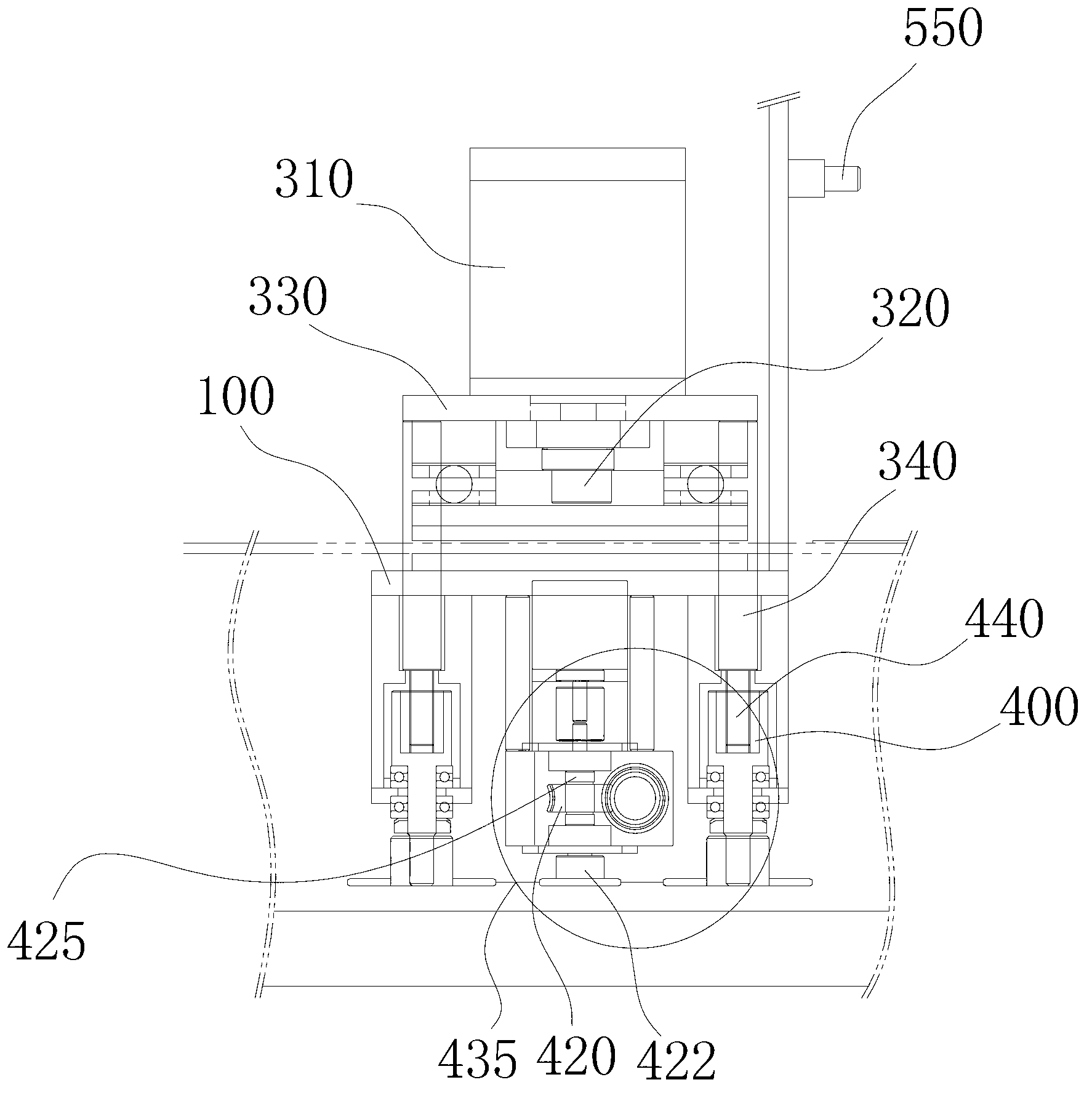

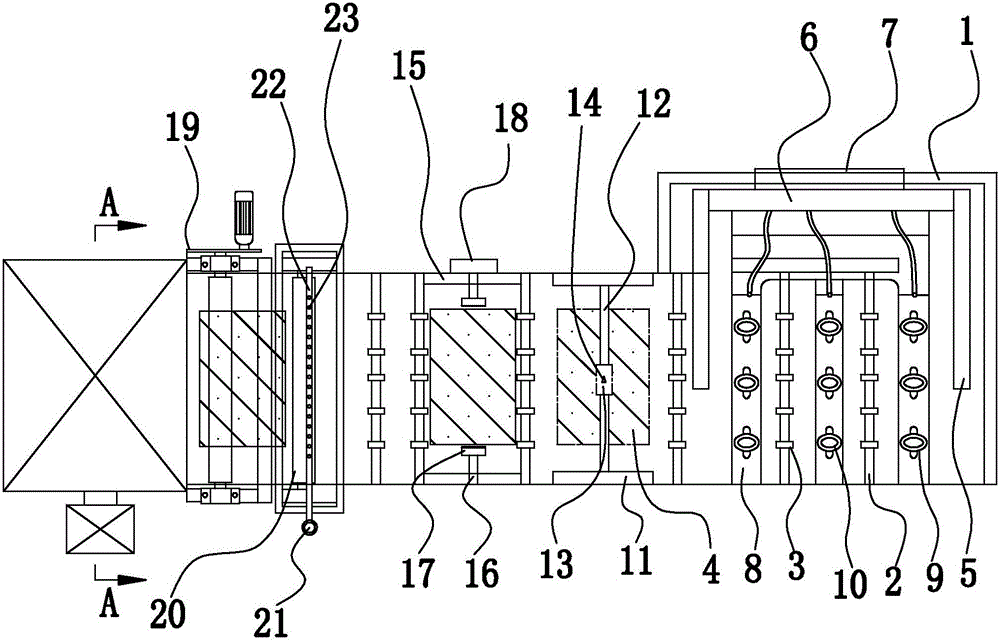

Wiping washing machine

InactiveCN104759440AGuaranteed contactGood wipe clean effectFlexible article cleaningCleaning using toolsEngineeringMechanical engineering

The invention provides a wiping washing machine. The machine comprises a moving platform, a glass element to be wiped, and an operation panel; a dustproof cloth transmission mechanism and at least two wiping mechanisms are arranged at one side of the operation panel; a liquid injection mechanism is correspondingly arranged in the front of each wiping mechanism; the dustproof cloth conveying device comprises discharging mechanisms, receiving mechanism the dustproof cloth belts, wherein the discharging mechanisms and are receiving mechanism which are respectively arranged at two sides of the two wiping mechanisms; the dustproof clothes are conveyed from the discharging mechanisms and sequentially pass through one of the sides of each liquid injection mechanism and the corresponding wiping mechanism, opposite to the operation panel; each liquid injection mechanism comprises an injection head for injecting a cleaning solution to each dustproof cloth belt. With the adoption of the machine, the glass element positioned on the moving platform can be fully washed and wiped at a plurality of times under single return stroke of circular wiping of the dustproof cloth belts, so that the wiping and cleaning effects are good.

Owner:SHENZHEN LIBURUI TECH

Vertical stent cutting process

InactiveUS20110036820A1Improve stabilityAssist in removingStentsFlexible article cleaningInsertion stentMedical device

A system and method for processing a tubular member for producing a medical device, wherein the tubular member is oriented in a longitudinally vertical position during processing.

Owner:BOSTON SCI SCIMED INC

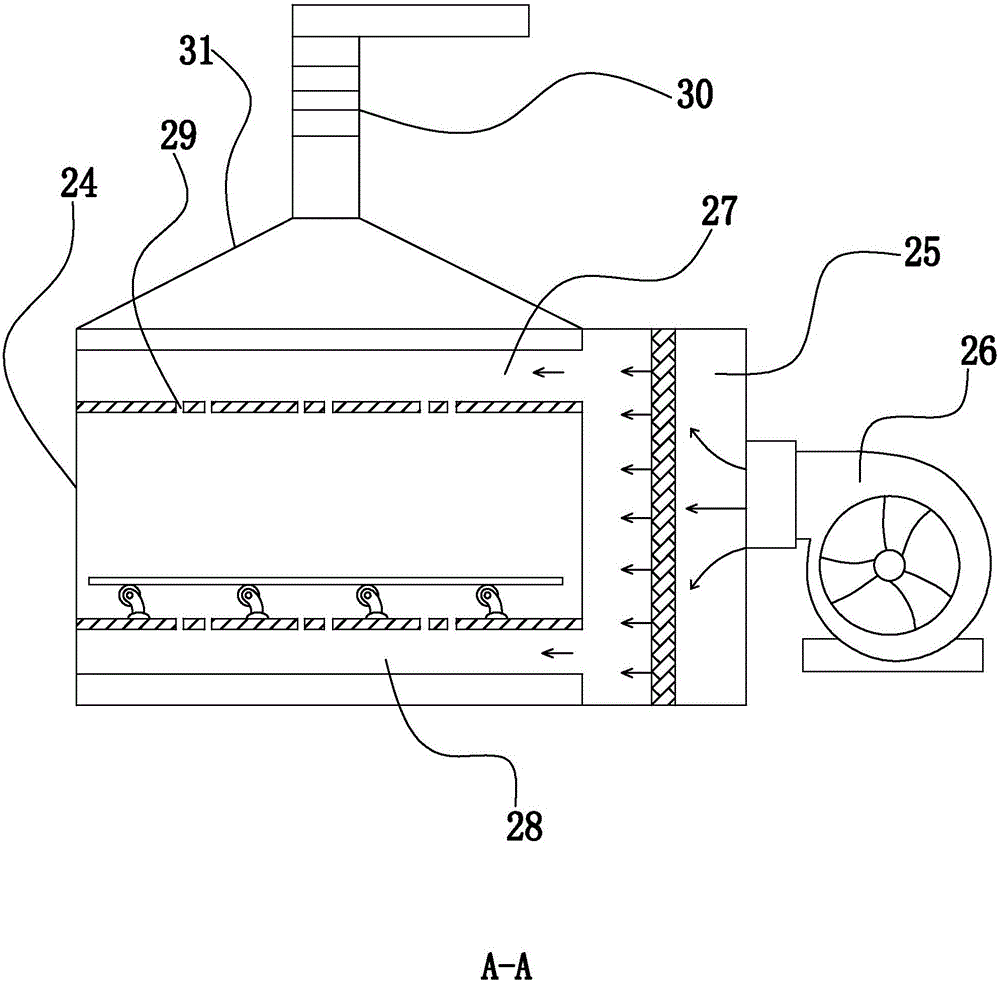

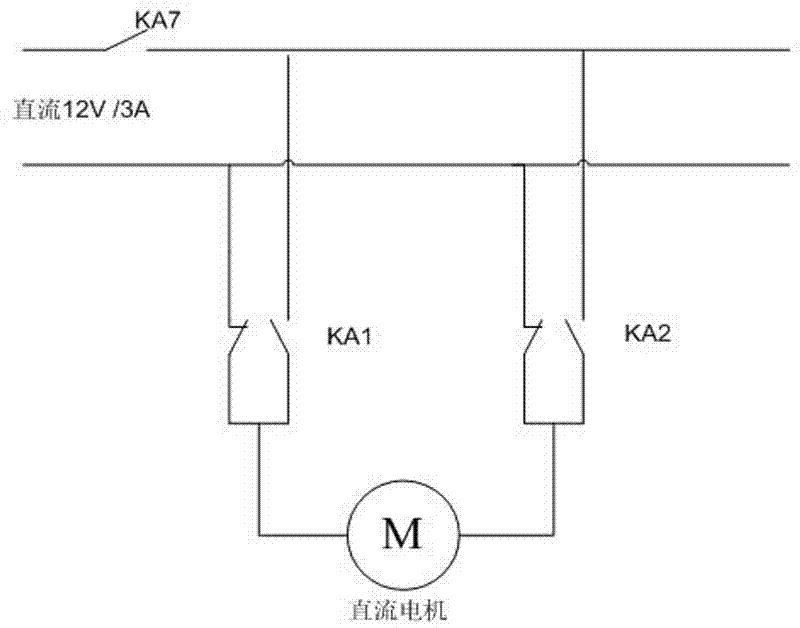

Automatic dust removing device for solar cell assembly

InactiveCN102416393AExtended service lifeAvoid hot spotsFlexible article cleaningEngineeringMaterial resources

The invention discloses an automatic dust removing device for a solar cell assembly. The dust removing device comprises a direct-current motor power supply switch, a direct-current motor, a ball screw, a linear guide rail and an electrostatic brush, wherein the electrostatic brush comprises an electrostatic generator and fan power supply switch, an electrostatic brush cover, a vent, an electrostatic generator, a fan, an electrostatic net, a dust absorption brush and a dust storage chamber; and the electrostatic brush moves up and down on the surface of the assembly during working and absorbs dust by using electrostatic effect, so that the purpose of removing the dust is fulfilled. The device has high automation degree and high work efficiency, saves a large amount of manpower and material resources, and can effectively remove the dust on the surface of the assembly so that the solar radiation intensity on the surface of the assembly is maximum and normal power output of the assembly is ensured; and through the device, hot spot effect in the assembly can be avoided, the assembly is protected, and the service life of the assembly is prolonged.

Owner:WORLDWIDE ENERGY & MFG NANTONG

Automatic glass processing device

InactiveCN106007349AImprove work efficiencyShorten production timeEdge grinding machinesDrying gas arrangementsEngineeringIdler-wheel

The invention relates to an automatic glass processing device, comprising a bracket, a withdrawal device, a transmission mechanism, a cutting device, a grinding device, a cleaning device and a drying device; On the transmission mechanism, the transmission mechanism includes several rollers for carrying glass and sliding the glass, and several rollers are uniformly arranged on the rollers; the rollers are driven by motors; the glass is driven through the cutting device and the grinding device in turn , a cleaning device and a drying device; the cutting device, the grinding device, the cleaning device and the drying device are arranged on the support; compared with the prior art, by setting the withdrawal device, the transmission mechanism, the cutting device, the grinding device, the cleaning device on the support device and drying device; glass conveying, cutting, grinding, cleaning and drying can be completed at one time, and the whole process is streamlined, which improves work efficiency, saves production time, and is conducive to popularization.

Owner:浙江飞越汉禾坊新材料有限公司

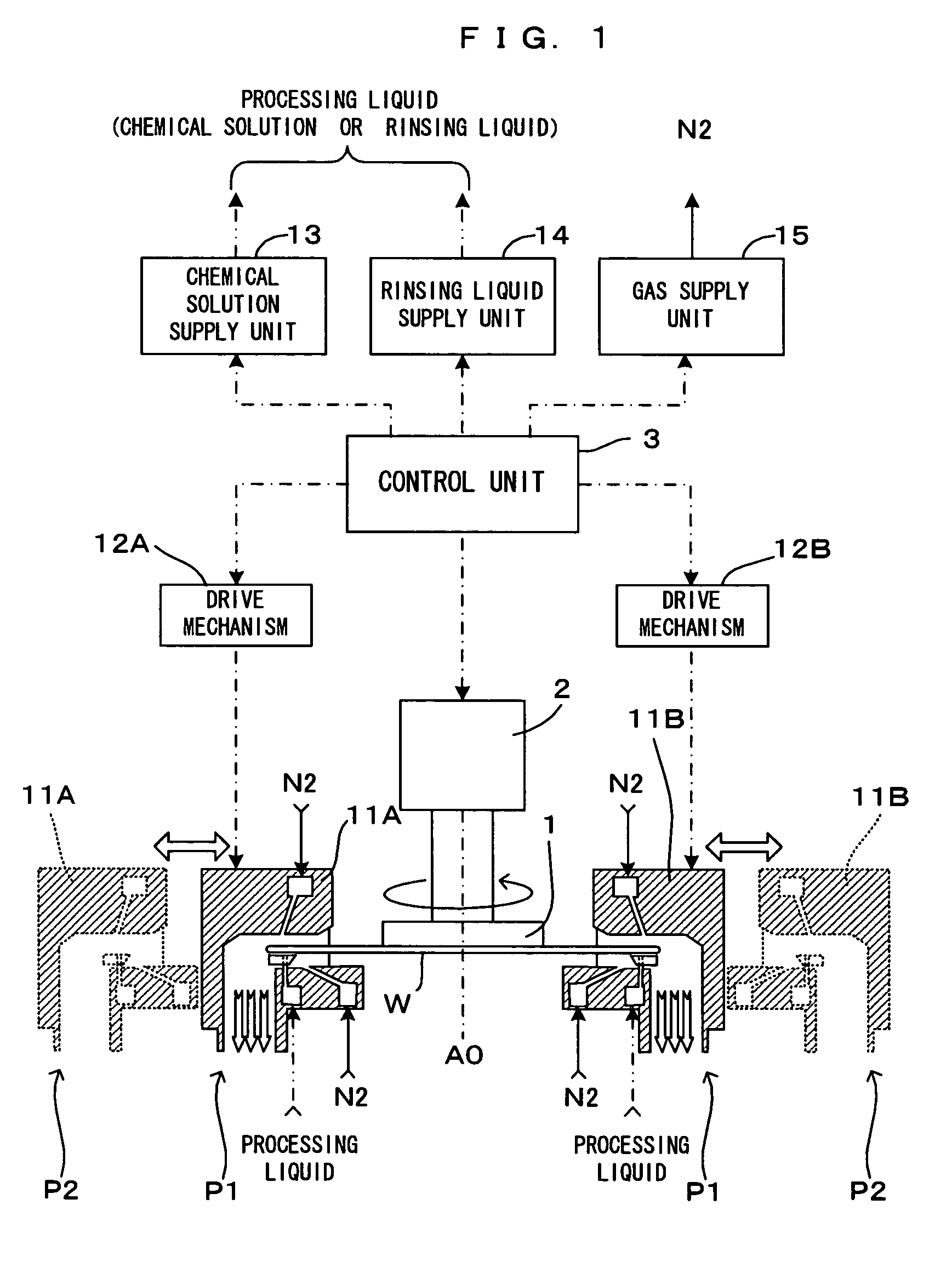

Liquid processing apparatus and liquid processing method

ActiveUS20110048469A1Semiconductor/solid-state device manufacturingFlexible article cleaningMechanical engineering

Disclosed is a liquid processing apparatus and a liquid processing method that can prevent a processing liquid from being left on a lift pin after a drying-out process of a substrate, thereby preventing the processing liquid from being attached to the back surface of the substrate after the liquid processing. The liquid processing apparatus of the present disclosure includes a holding plate that supports a substrate, a lift pin plate provided above the holding plate having a lift pin that supports the wafer from a lower side, and a processing liquid supply unit that supplies the processing liquid to the back surface of the wafer. The processing liquid supply unit is provided with a head part configured to close a penetrating hole of the lift pin plate. The processing liquid supply unit and the lift pin plate are configured to be elevated with respect to the holding plate.

Owner:TOKYO ELECTRON LTD

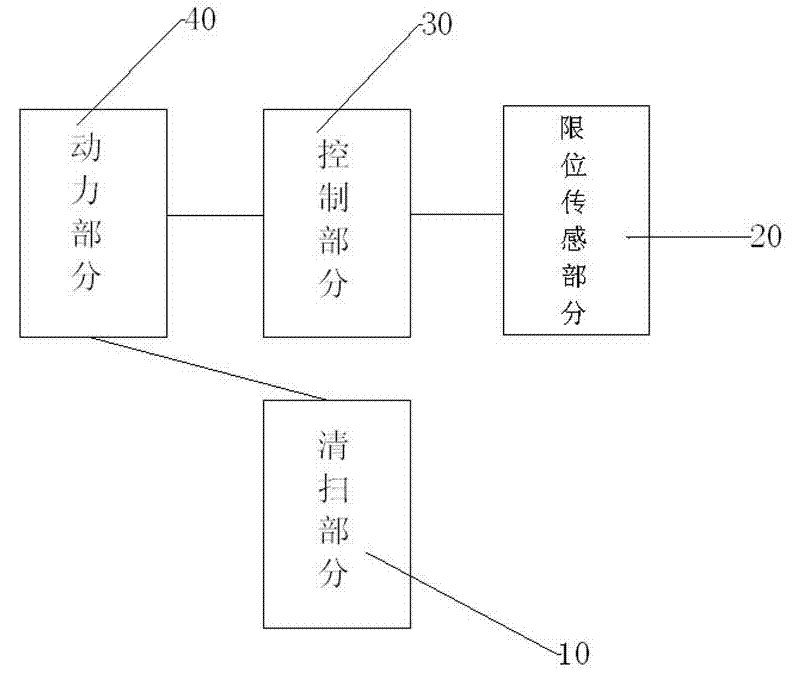

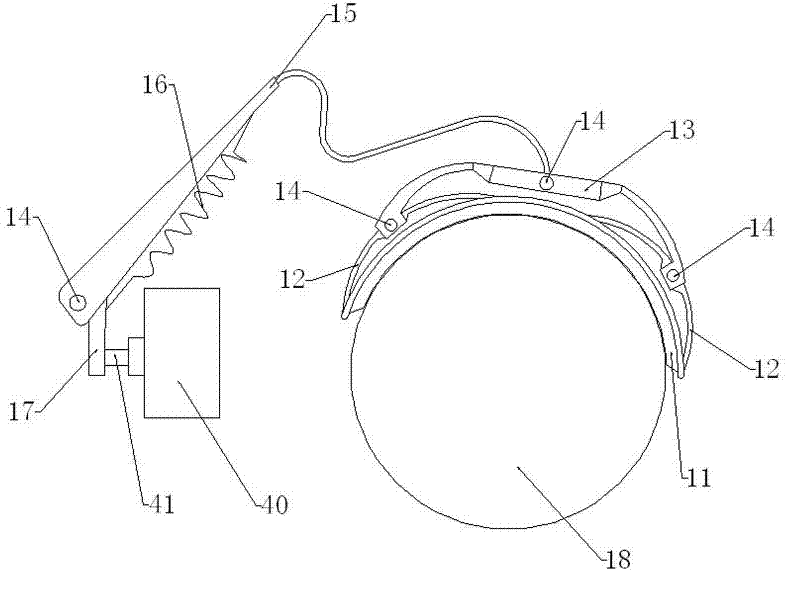

Automatic cleaning device for ball camera

The invention discloses an automatic cleaning device for a ball camera, which comprises a cleaning part, a limit sensor part, a power part and a control part, wherein the cleaning part comprises an arc wiper blade, two arc handles, a pressure arm, a rocker arm, a tension spring, a swinging arm, and the like. In the invention, a reciprocation and swinging connection rod mechanism is additionally arranged outside the ball protective cover of the camera and is driven by a direct current motor; the arc rubber wiper blade is adhered to the outside surface of the ball protective cover of the camera to repeatedly wipe the outside surface of the ball protective cover of the camera so that the purpose of cleaning the outside surface of the ball protective cover of the camera is achieved.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +1

Article and process for cleaning optical surfaces

InactiveUS6854152B2Simple cleaning systemEasy to cleanLiquid processingReconditioning/cleaning record carriersReciprocating motionEngineering

An article and process for cleaning relatively inaccessible and recessed surfaces, including a shaft having a first end opposite a second end with a cleaning head assembly, including a movable strip of buffing material, at the first end of the shaft. The article has an actuator at the second end of the shaft; and a connector coupling the cleaning head assembly to the actuator to move the movable strip during positional change of the actuator. Repeated positional change of the actuator produces reciprocatory movement in the movable strip of buffing material to produce a rubbing, cleaning action of the material against a recessed surface.

Owner:3M INNOVATIVE PROPERTIES CO

Cloth accessory

Owner:ALPINE INNOVATIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com