Automatic dust removing device for solar cell assembly

A solar cell and automatic dust removal technology, which is applied in the field of solar technology applications, can solve the problems of lower module output power, high maintenance cost, and lower light transmittance on the module surface, so as to ensure normal output, high degree of automation, and avoid hot spot effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

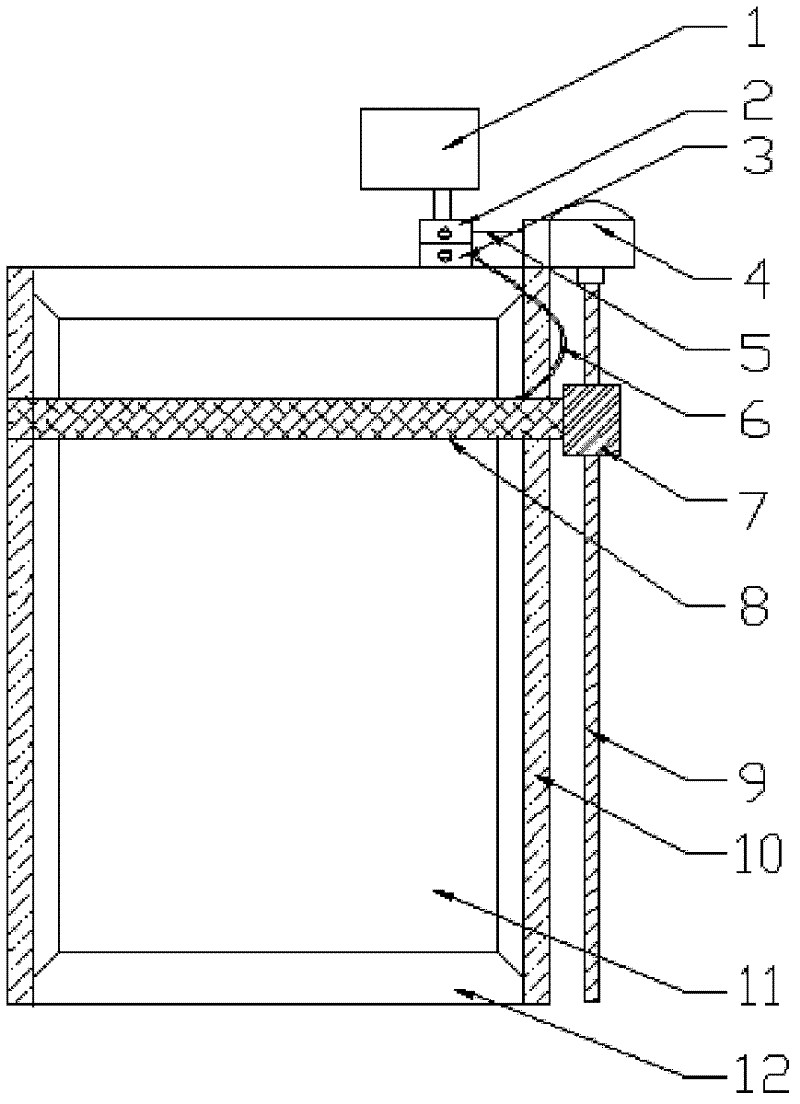

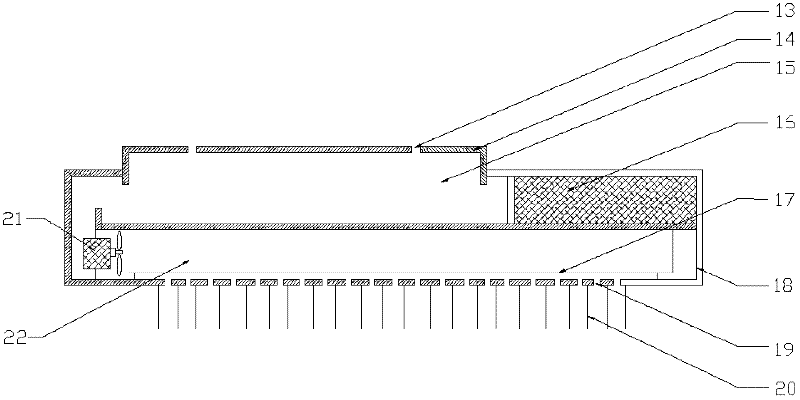

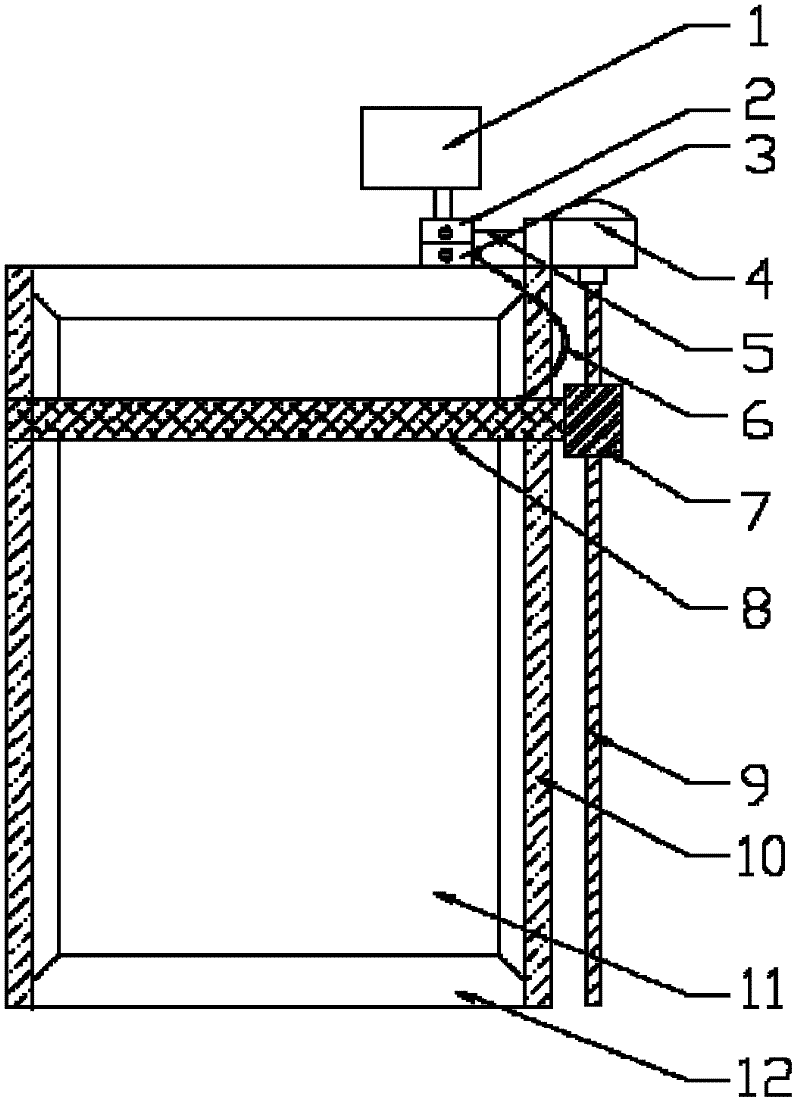

[0018] In order to further understand the technical characteristics and content of the patent of the present invention, the detailed technical description of this patent is as follows in conjunction with the accompanying drawings:

[0019] Such as figure 1 As shown, in the solar cell module automatic dust removal device of the present invention, two linear guide rails 10 are respectively fixed on a group of parallel opposite sides of the frame 12 of the solar cell module; a DC motor 4 is fixed on one end of the frame 12 and connected to a DC motor power supply The switch 2 is connected by a wire 5 . The DC motor 4 is also connected with a ball screw 9, and the ball screw 9 is parallel to the linear guide 10; Nut 7. The DC motor power switch 2 is connected to the external power supply 1. The DC motor power switch 2 controls the opening of the DC motor 4. The rotation of the DC motor 4 makes the nut 7 on the ball screw 9 move up and down, and the electrostatic brush 8 also mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com