Patents

Literature

166results about How to "Avoid hot spots" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

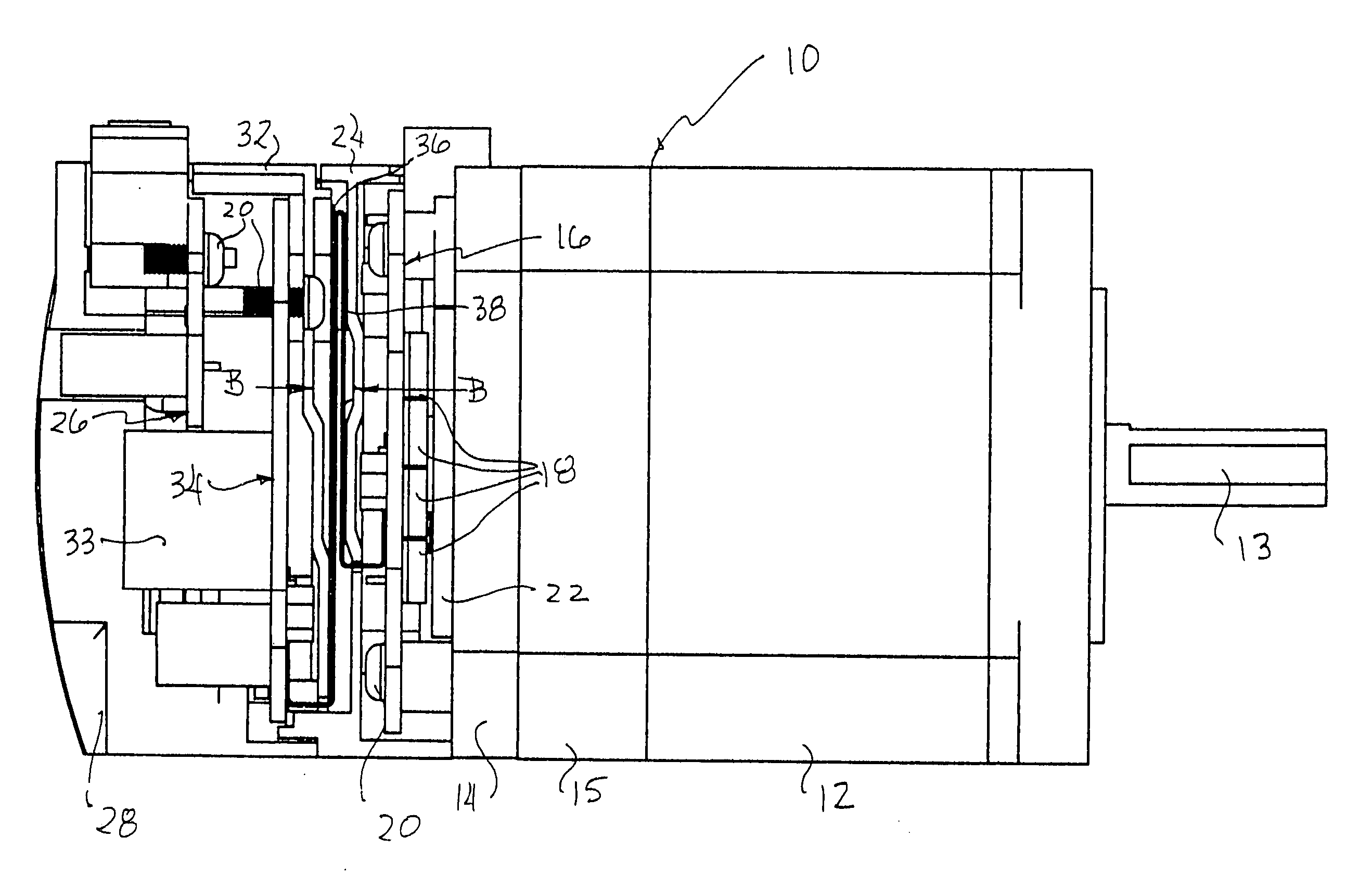

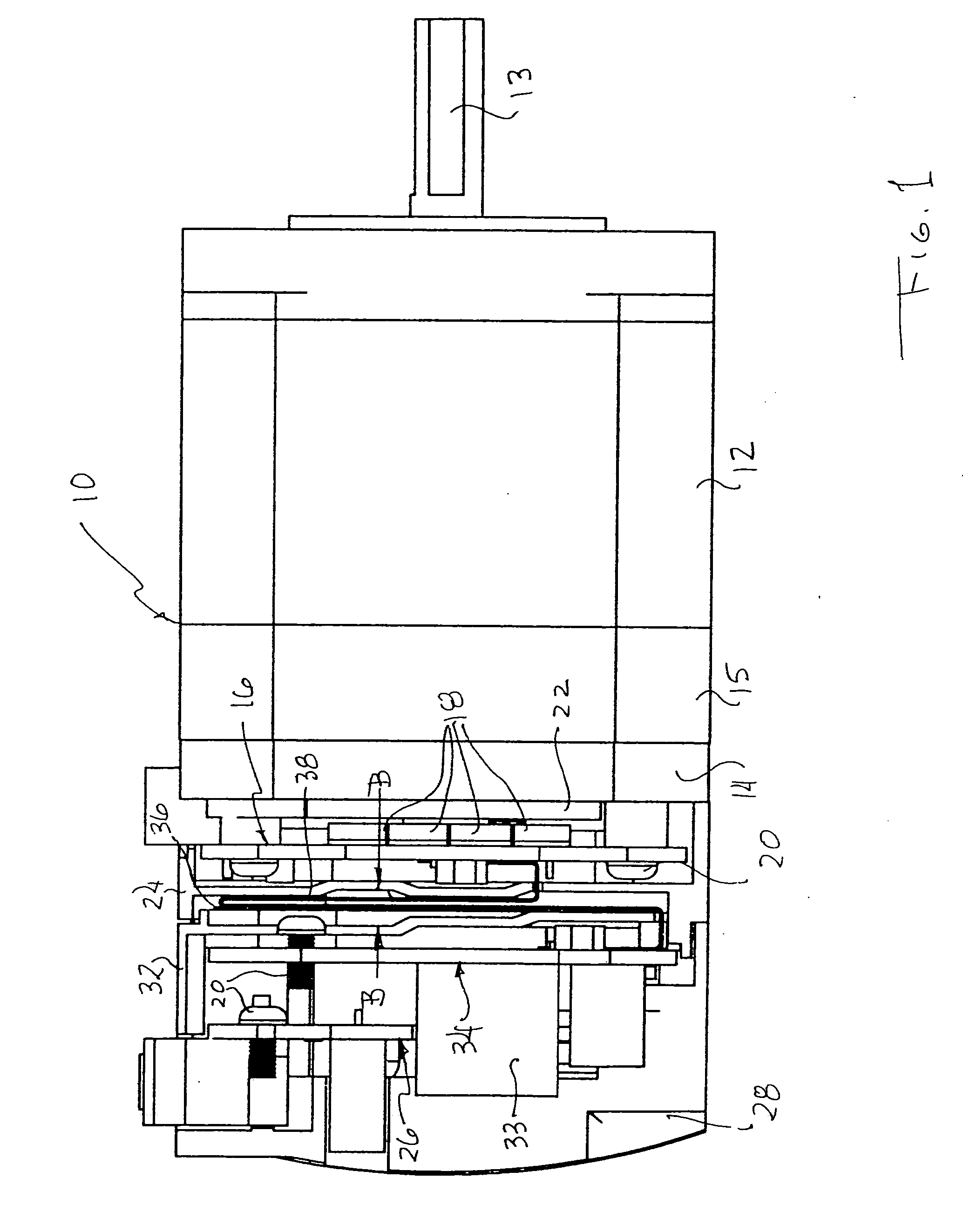

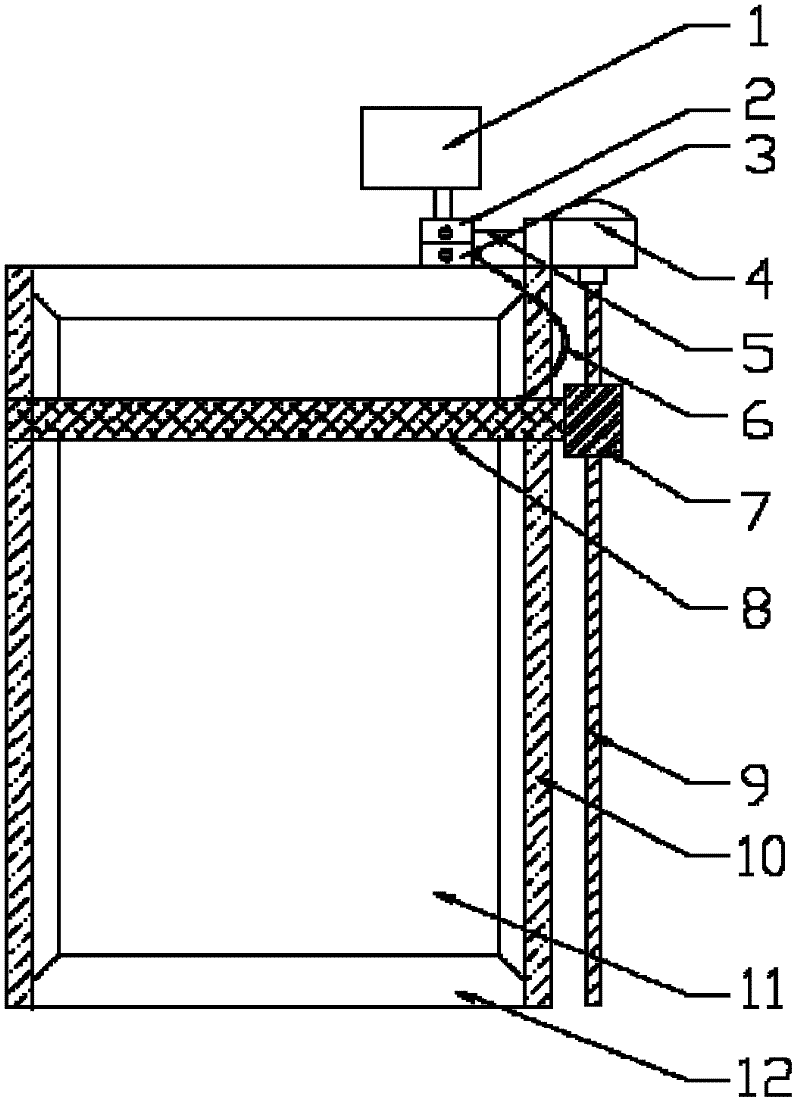

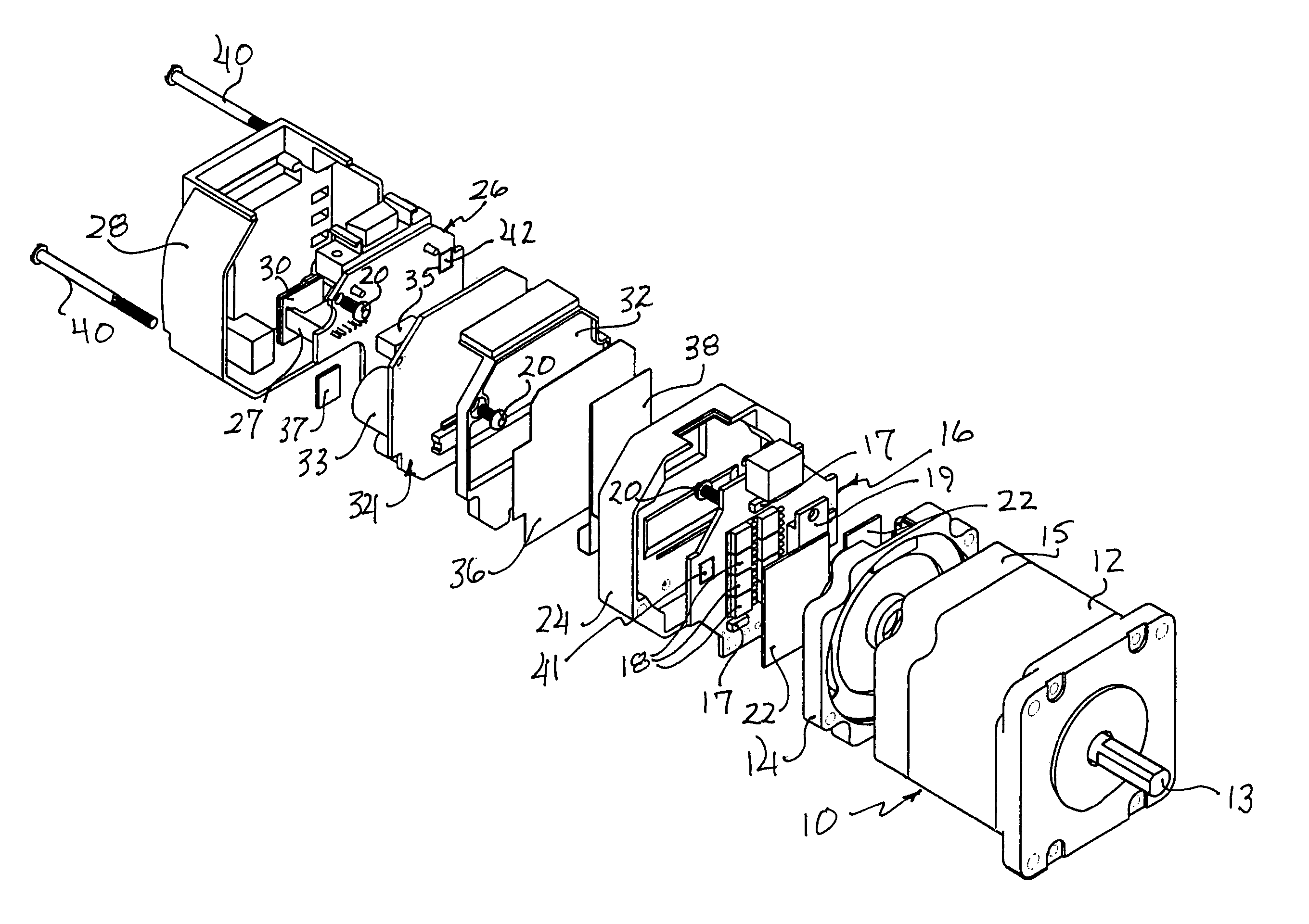

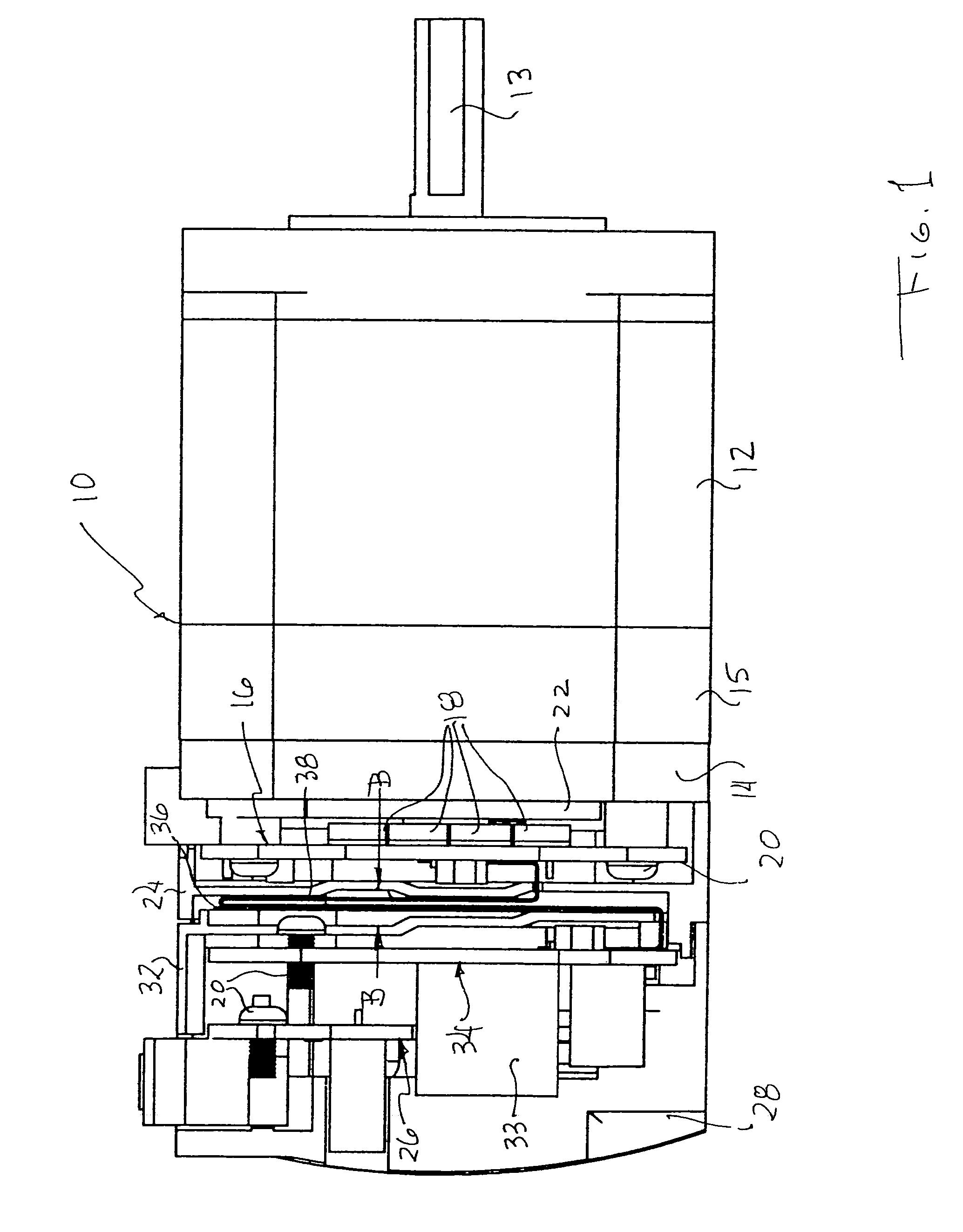

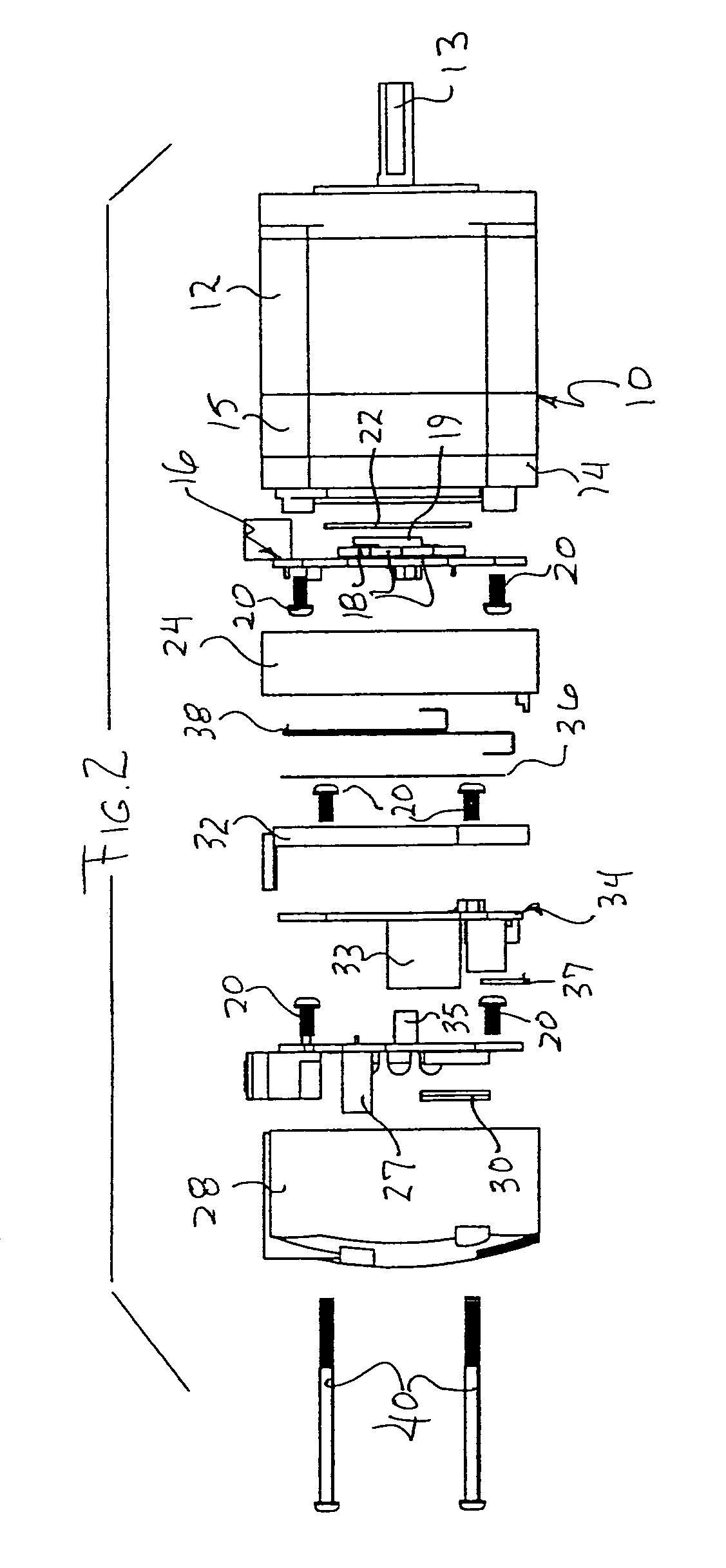

Integrated electric motor and drive, optimized for high-temperature operation

InactiveUS20060158049A1Improve performanceImprove heat transfer performanceAssociation with control/drive circuitsMagnetic circuit rotating partsHeat sensitiveControl theory

The heat-generating components of an integrated motor system are disposed proximate the motor body, for efficient heat dissipation, and the heat-sensitive components are segregated therefrom, physically and thermally.

Owner:ORIENTAL MOTOR BOSTON TECH GROUP

Heat-conducting plastic and preparation method thereof

ActiveCN102746560AImprove thermal conductivityEasy injection moldingHeat conductingDegrees of freedom

The invention discloses a heat-conducting plastic and a preparation method thereof, wherein the heat-conducting plastic comprises, by weight, 25% to 80% of matrix resins, 5% to 40% of heat-conducting fillers, 5% to 10% of coupling agents and 5% to 30% of halogen-free flame retardants. According to the heat-conducting plastic, the coefficient of heat conductivity is high, the injection molding is convenient, the cost is low, heat dissipation is even, hot spots can be avoided, local deformation of parts caused by the high temperature is reduced, the weight is light and lighter than the weight of aluminum materials by 40% to 50%, the molding processing is convenient, secondary processing is not needed, and the product design degree of freedom is high.

Owner:SHENZHEN FRD SCI & TECH

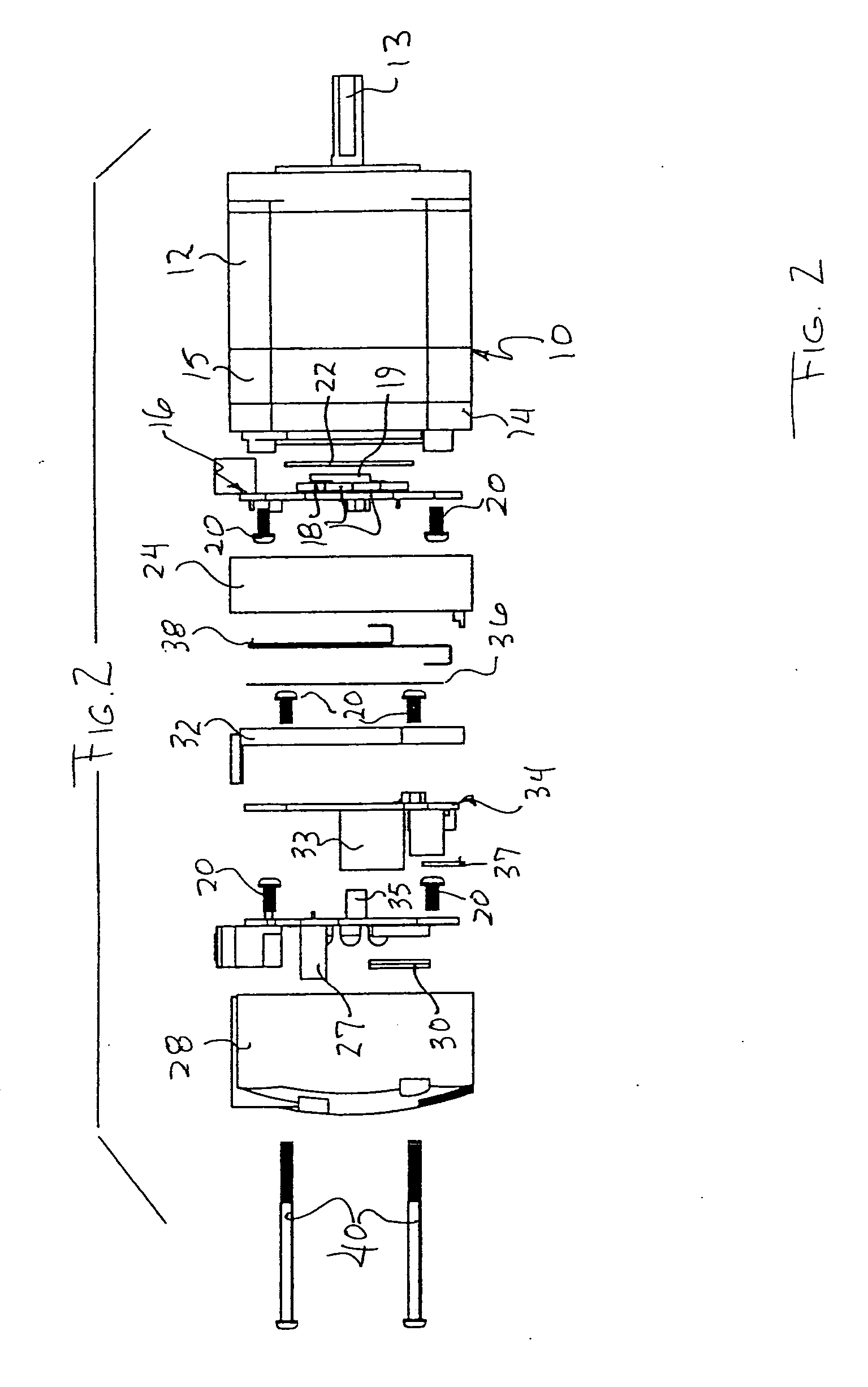

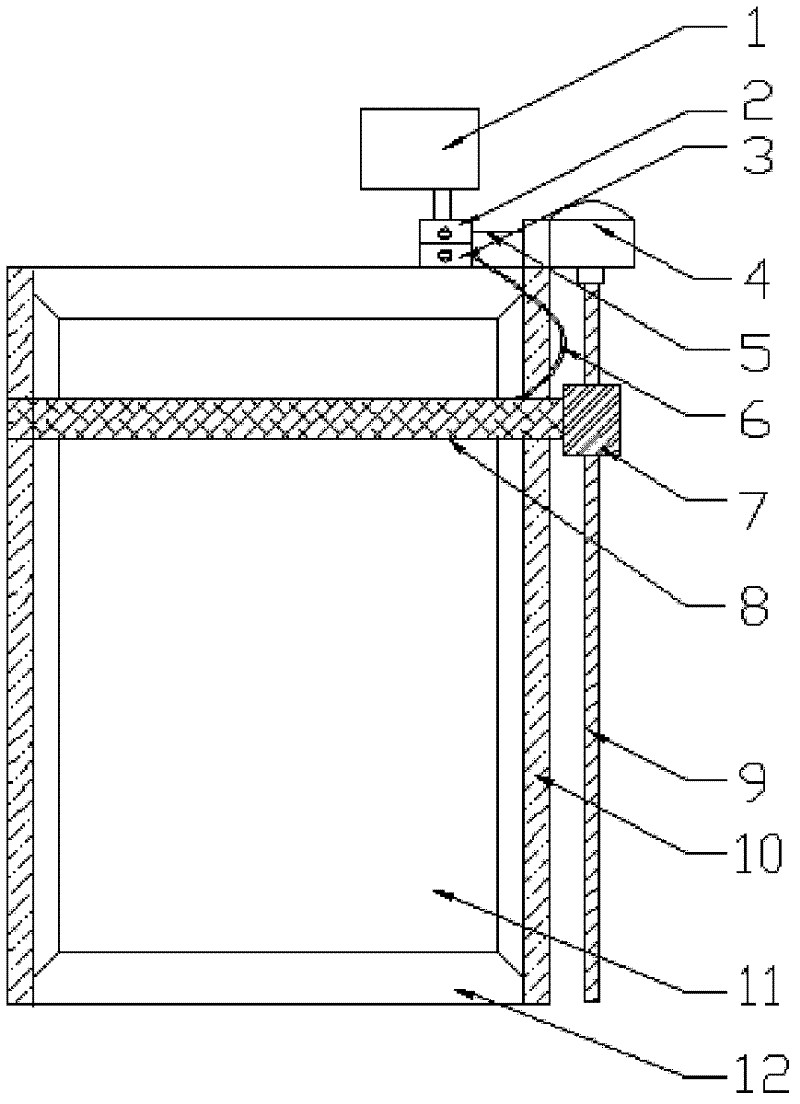

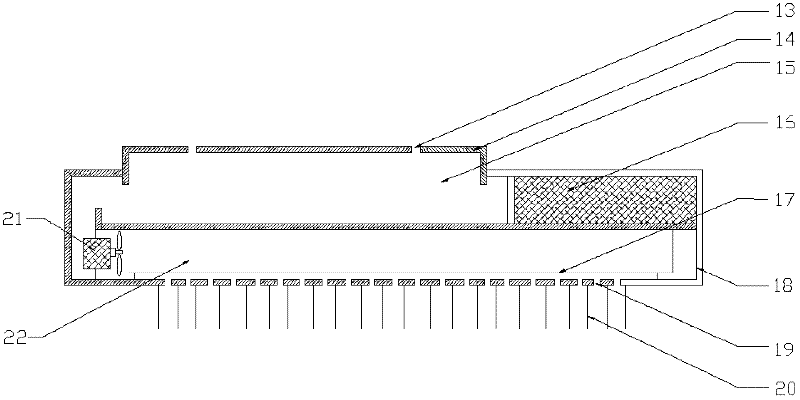

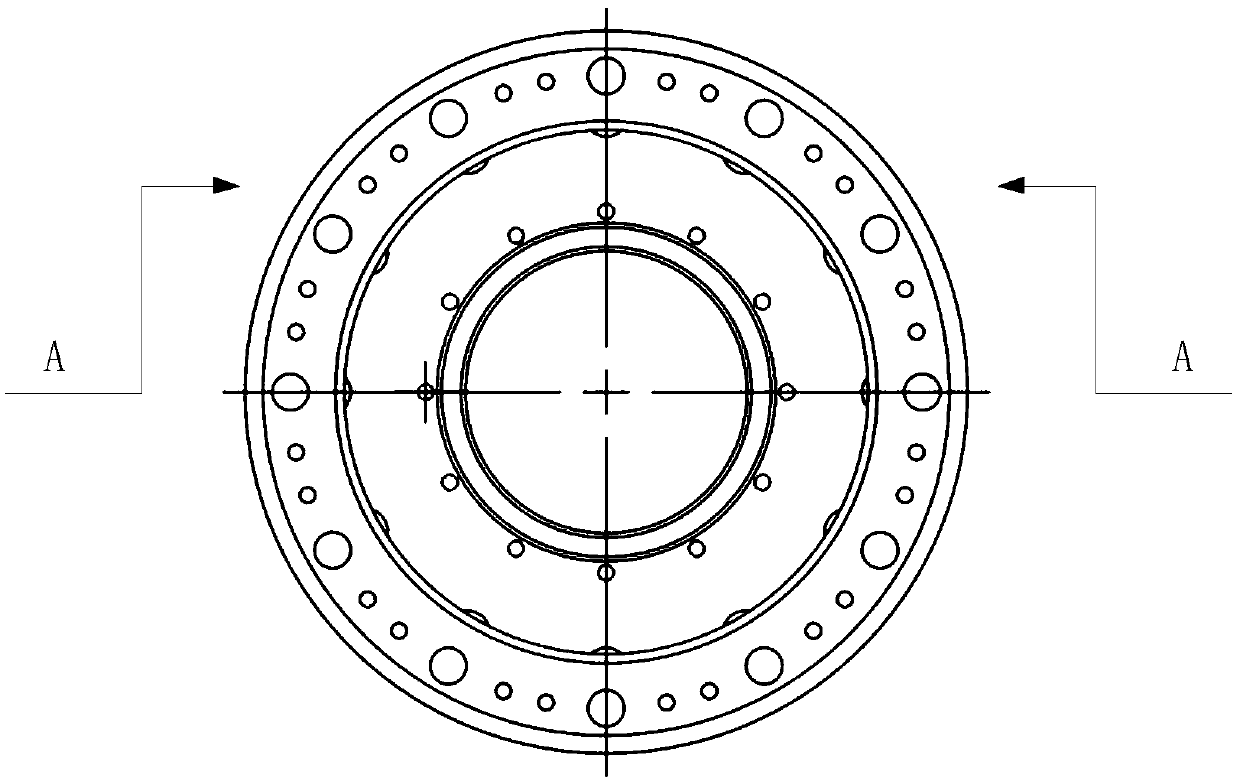

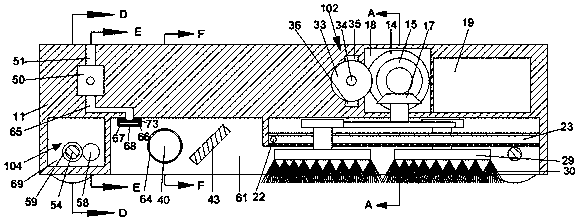

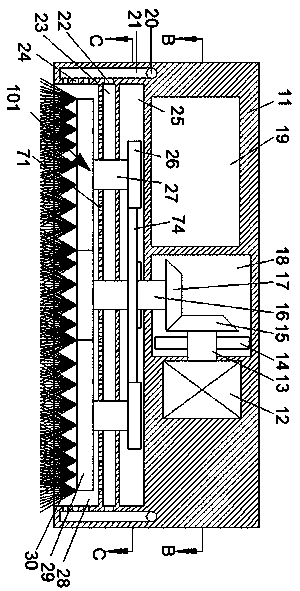

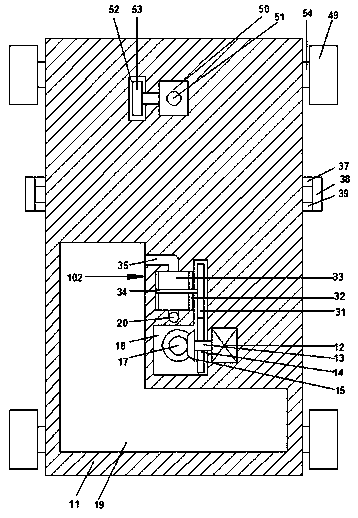

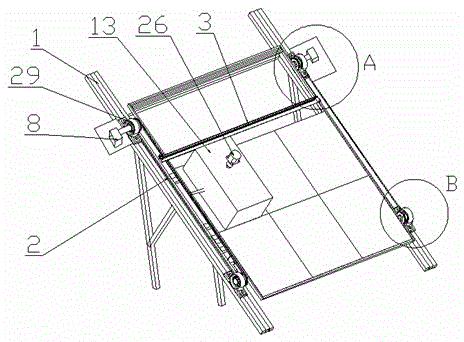

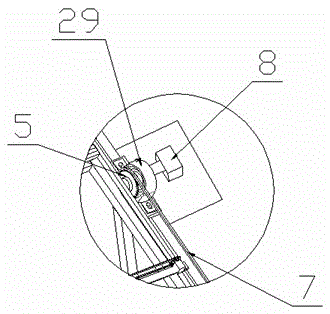

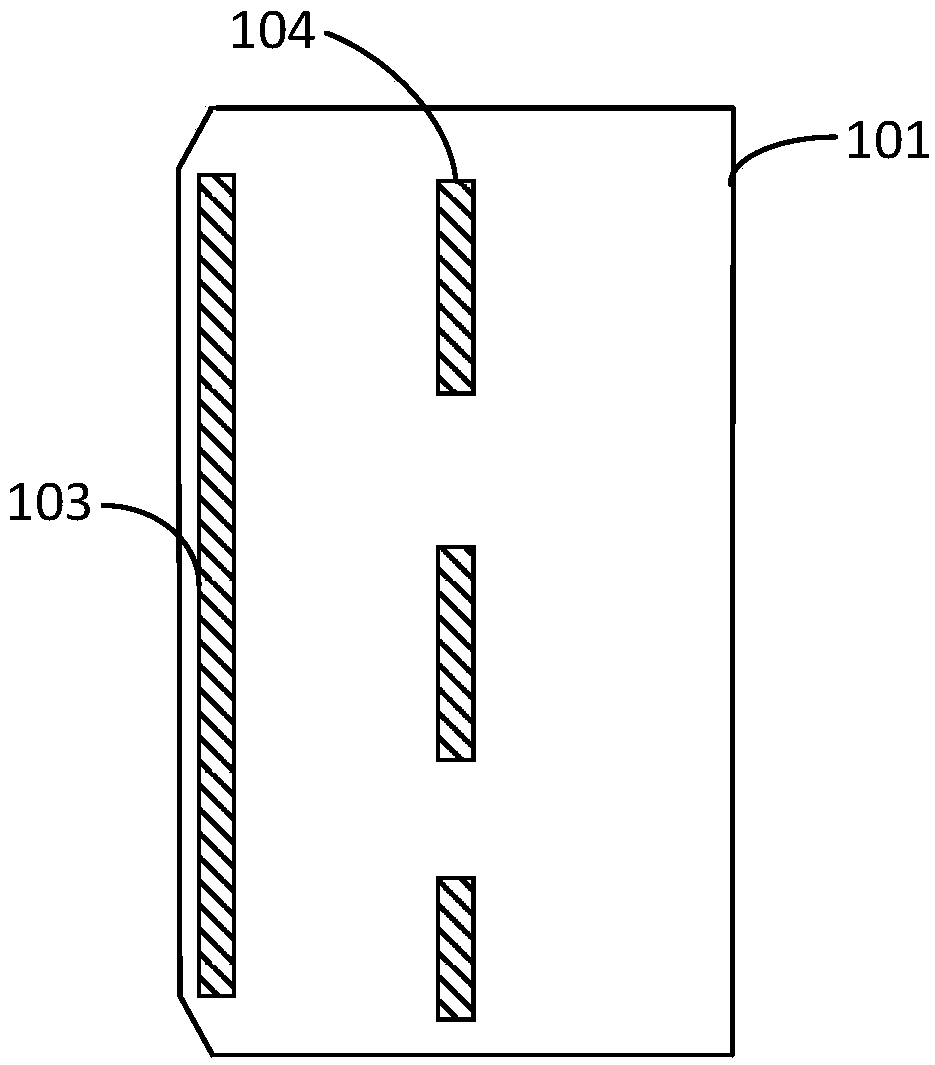

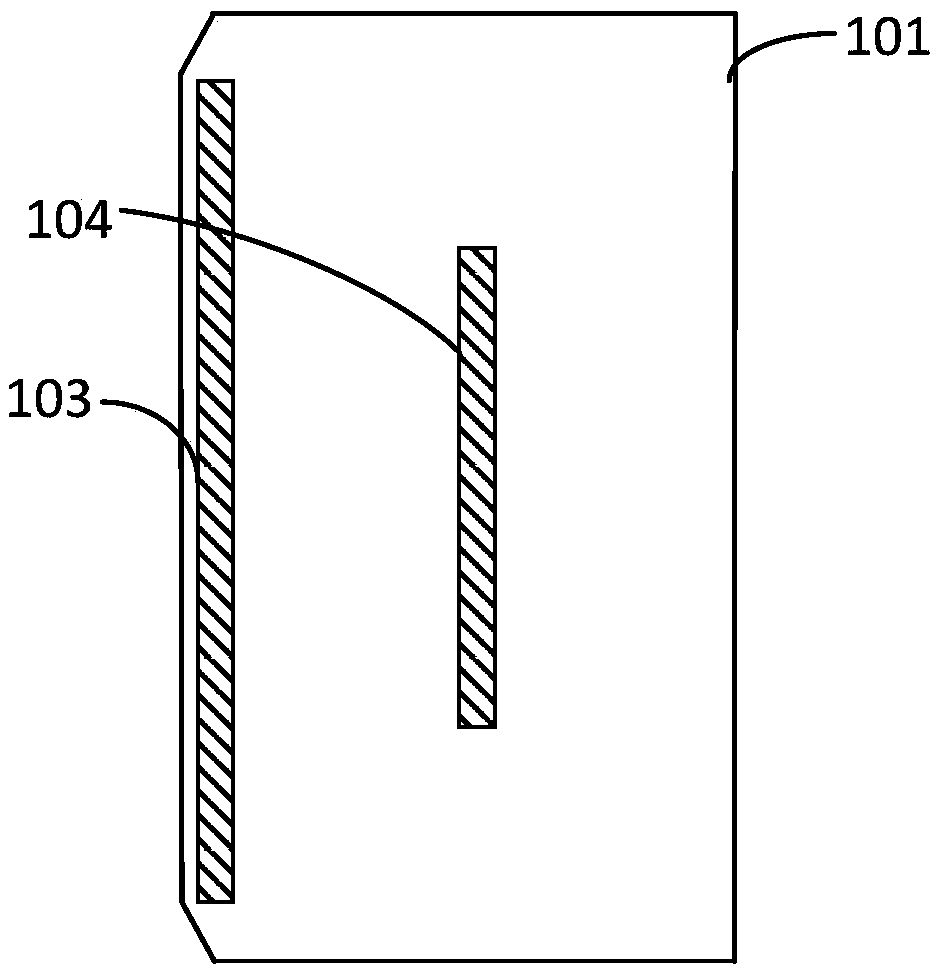

Automatic dust removing device for solar cell assembly

InactiveCN102416393AExtended service lifeAvoid hot spotsFlexible article cleaningEngineeringMaterial resources

The invention discloses an automatic dust removing device for a solar cell assembly. The dust removing device comprises a direct-current motor power supply switch, a direct-current motor, a ball screw, a linear guide rail and an electrostatic brush, wherein the electrostatic brush comprises an electrostatic generator and fan power supply switch, an electrostatic brush cover, a vent, an electrostatic generator, a fan, an electrostatic net, a dust absorption brush and a dust storage chamber; and the electrostatic brush moves up and down on the surface of the assembly during working and absorbs dust by using electrostatic effect, so that the purpose of removing the dust is fulfilled. The device has high automation degree and high work efficiency, saves a large amount of manpower and material resources, and can effectively remove the dust on the surface of the assembly so that the solar radiation intensity on the surface of the assembly is maximum and normal power output of the assembly is ensured; and through the device, hot spot effect in the assembly can be avoided, the assembly is protected, and the service life of the assembly is prolonged.

Owner:WORLDWIDE ENERGY & MFG NANTONG

Integrated electric motor and drive, optimized for high-temperature operation

InactiveUS7199496B2Improve performanceAccelerated dissipationAssociation with control/drive circuitsMagnetic circuit rotating partsHeat sensitiveControl theory

The heat-generating components of an integrated motor system are disposed proximate the motor body, for efficient heat dissipation, and the heat-sensitive components are segregated therefrom, physically and thermally.

Owner:ORIENTAL MOTOR BOSTON TECH GROUP

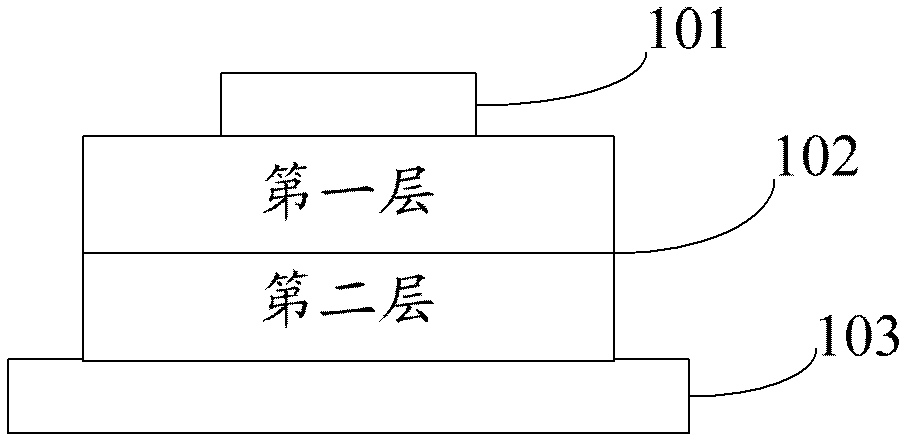

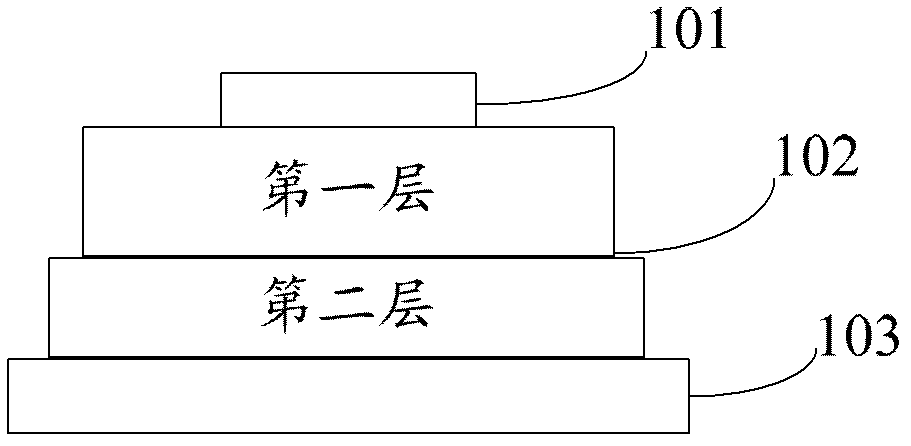

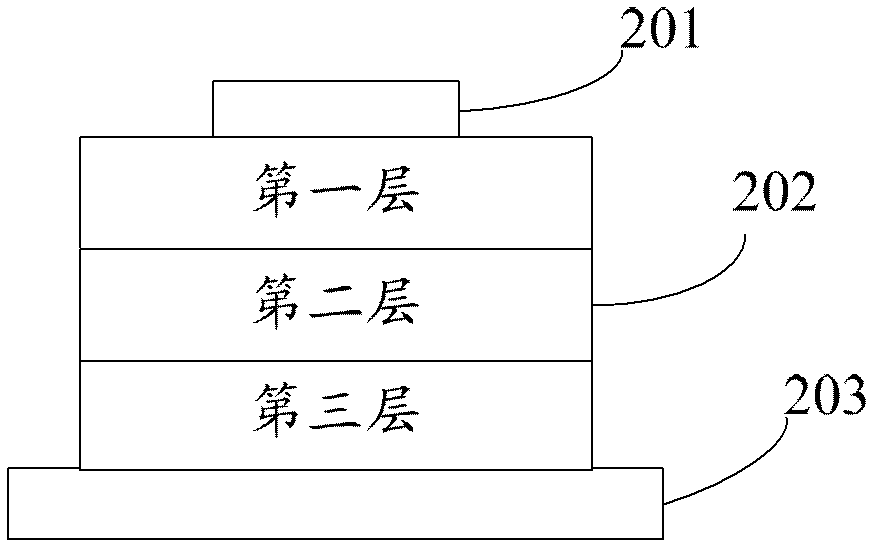

Electronic device

InactiveCN103025122AImprove comfortRapid and even conductionSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeating element

The invention provides an electronic device which comprises a heating element and an outer shell; a heat radiating device is arranged between the heating element and the outer shell; the electronic device comprises a first layer and a second layer, wherein the first layer is in contact with the heating element; and the second layer is arranged on the first layer and is in contact with the outer shell; the heat conducting capability of the first layer is higher than that of the second layer; the second layer is used for preventing heat from passing through rapidly, so that heat is diffused at the first layer; or the electronic device comprises a first layer, a third layer and a second layer, wherein the first layer is in contact with the heating element; the third layer is in contact with the outer shell; the second layer is arranged between the first layer and the third layer; the heat conducting capabilities of the first layer and the third layer are both higher than that of the second layer; the second layer is used for preventing heat from passing through rapidly, so that heat is diffused at the first layer; additionally, the outer shell of the electronic device also can act as a heat radiating device, and comprises an inner layer in contact with the heating element and an outer layer which clings to the inner layer; the heat conducting capability of the inner layer is higher than that of the outer layer; and the outer layer prevents heat from passing through rapidly, so that heat is diffused at the inner layer, a partial overheated region is prevented from being formed on the outer shell in contact with users, and the using comfort of users is improved.

Owner:LENOVO (BEIJING) CO LTD

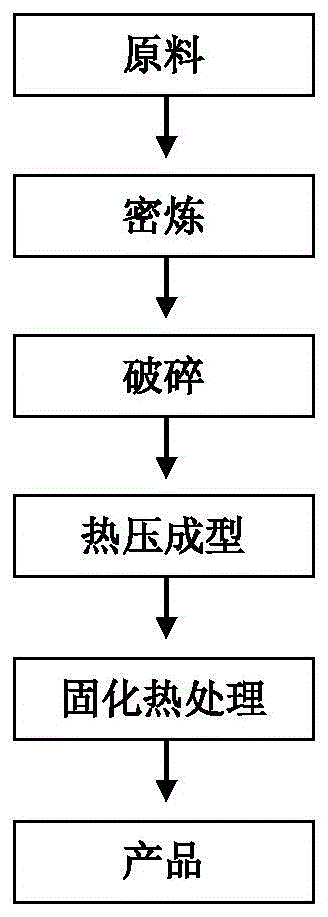

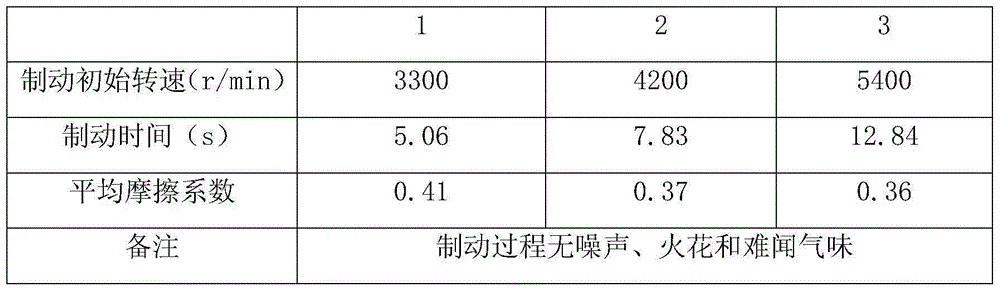

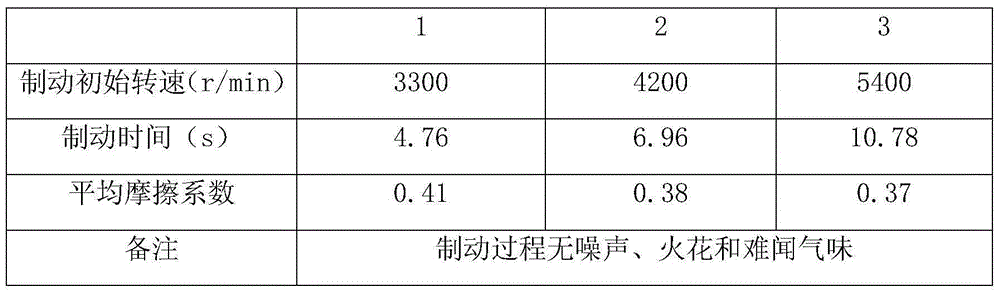

Calcium carbonate whisker reinforced rubber base friction material and preparation method therefor

InactiveCN105111532AImprove brittlenessImprove heat resistanceOther chemical processesFriction liningButadiene-styrene rubberPetroleum coke

The present invention discloses a calcium carbonate whisker reinforced rubber base friction material, and a preparation method therefor. The material comprises: 8-15 parts of nitrile rubber, 10-15 parts of styrene-butadiene rubber, 5-10 parts of phenolic resin, 5-25 parts of calcium carbonate whisker, 10-20 parts of steel fiber, 2-8 parts of sepiolite fiber, 0-8 parts of mineral fiber, 0-3 parts of aramid fiber, 5-8 parts of barium sulfate, 5-10 parts of magnesium oxide, 2-3 parts of aluminum oxide, 5-10 parts of flake graphite, 1-5 parts of carbon black, 5-10 parts of petroleum coke, 3-6 parts of Cardolite cashew nut shell oil friction powder, 0.5-1 parts of sulfur, and 0.5-1 parts of accelerator. The preparation method comprises process steps of such as material collocation, mixing, pressing molding and the like. Brake pads synthesized by the method provided by the invention have the advantages including excellent friction and wear performance, stable braking performance, high heat-resistant property, safe, environmentally-friendly, and low in cost; and is suitable for braking devices for automobiles and motive power machines, thereby achieving a very wide application prospect and applying to industrial production.

Owner:GUANGXI UNIV +2

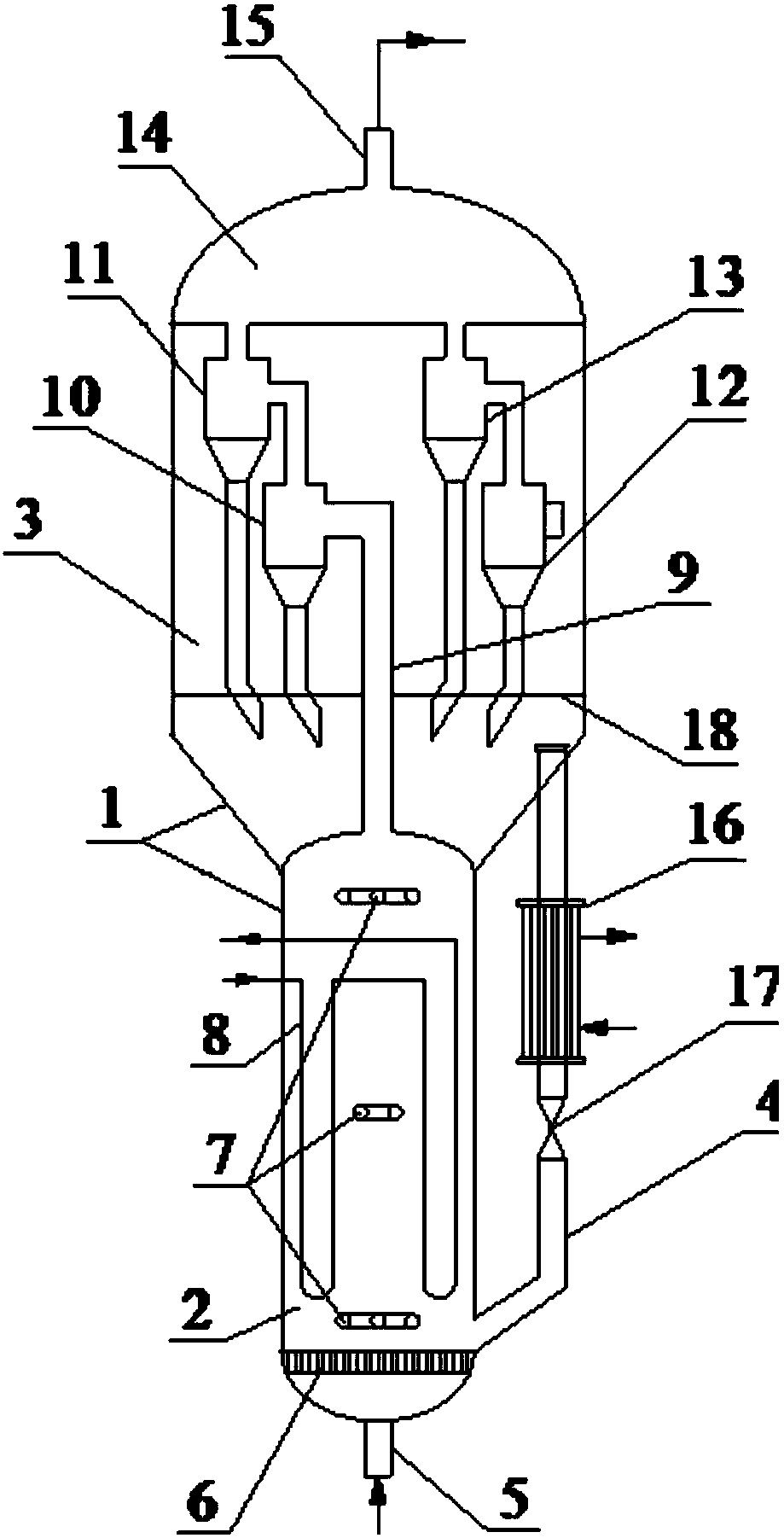

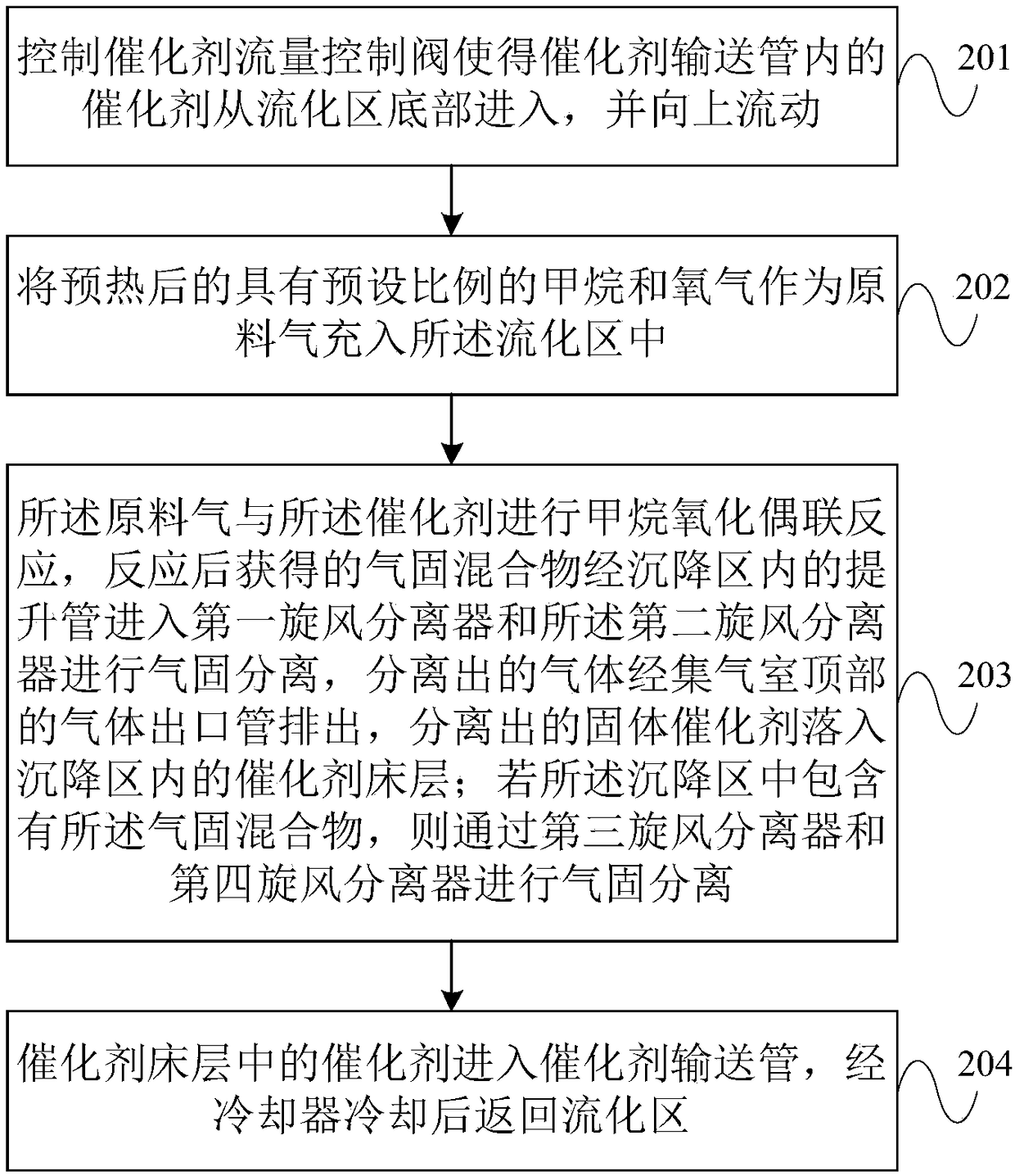

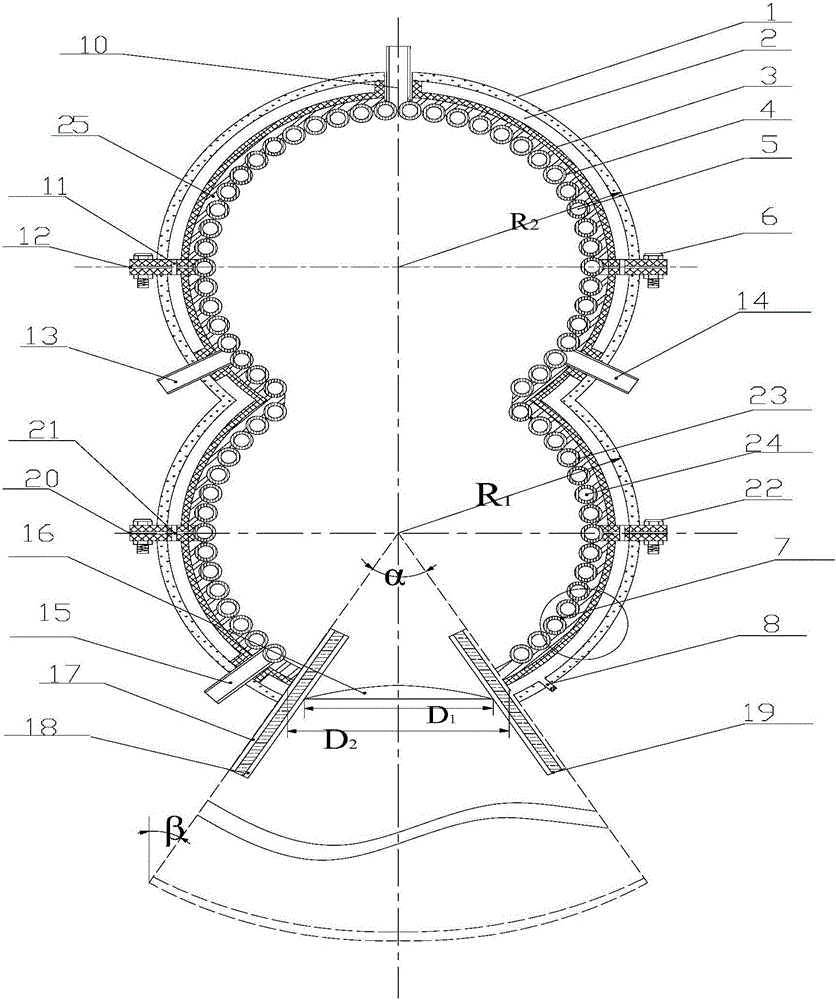

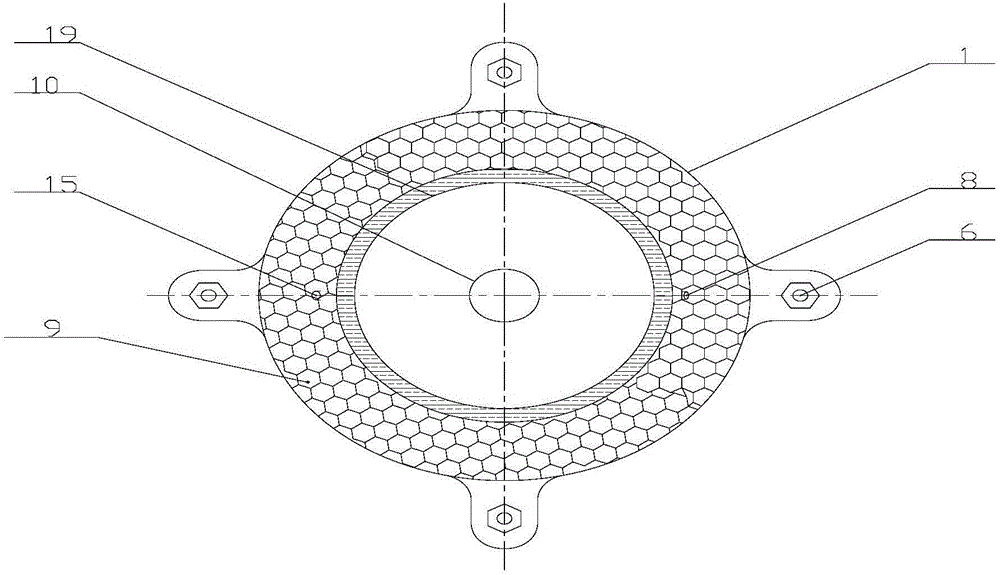

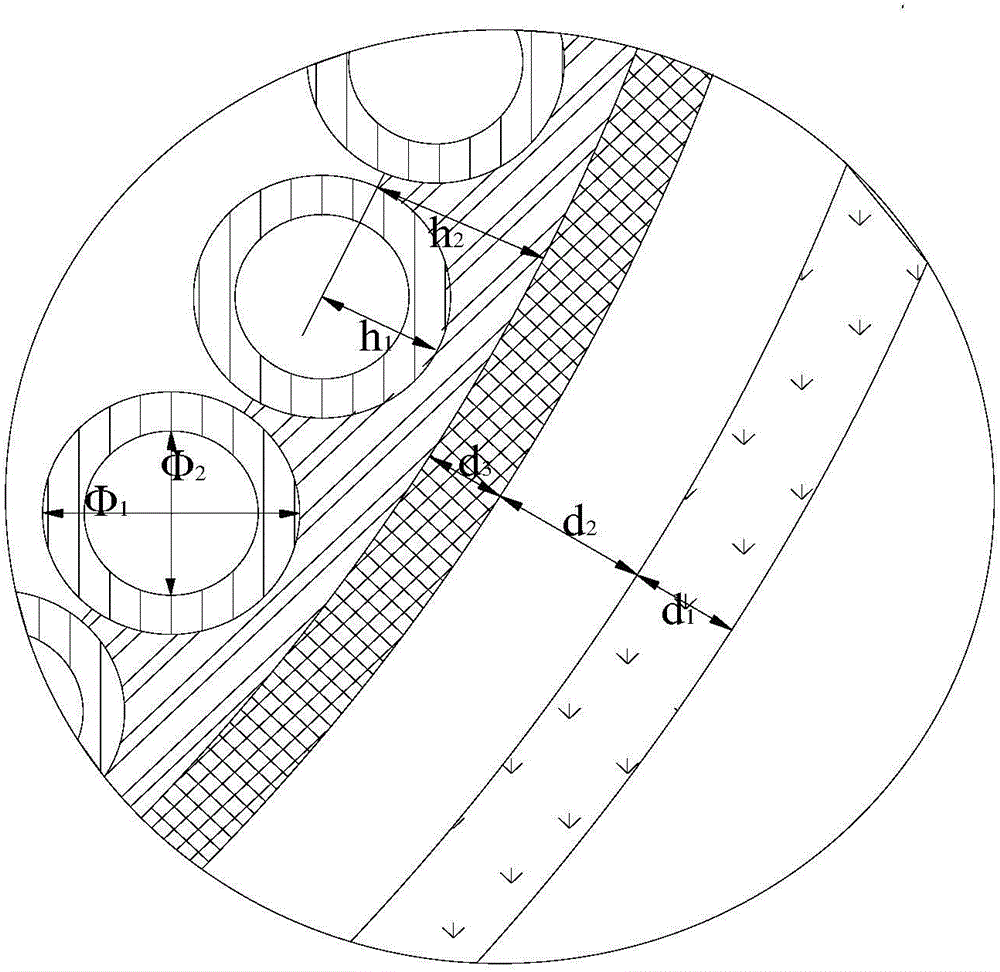

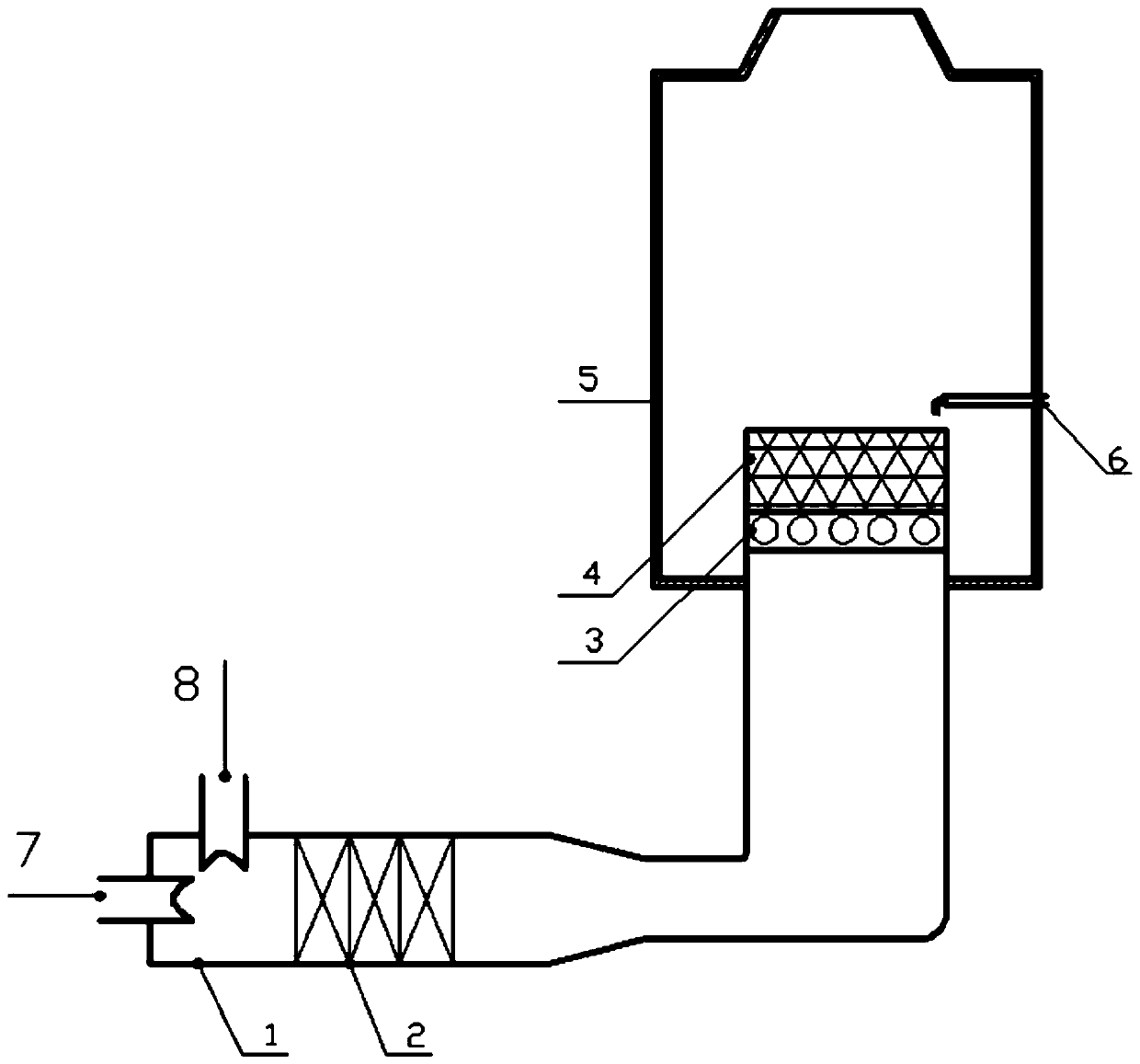

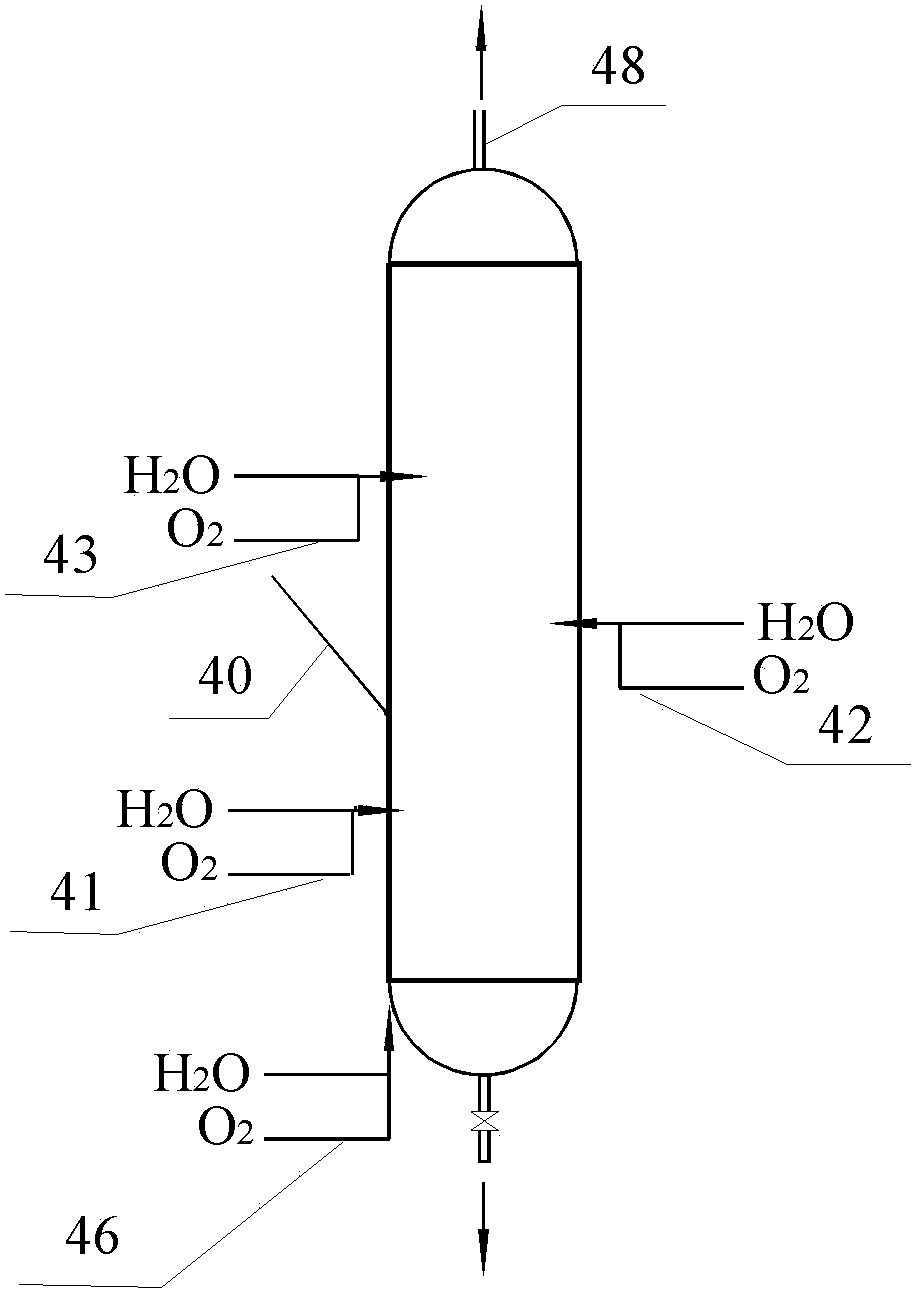

Reaction device and method for preparing ethylene by oxidative coupling of methane

ActiveCN108530248AAvoid "hot spots"Uniform temperature distributionCatalystsHydrocarbon preparation catalystsOxygenDistributor

An embodiment of the invention provides a reaction device and method for preparing ethylene by oxidative coupling of methane. The device comprises a reactor and a catalyst delivering tube, wherein thereactor comprises a fluidization region and a settling region; the settling region is positioned on the upper portion of the fluidization region, and is coaxially connected with the fluidization region, an inlet of the catalyst delivering tube is connected with the settling region, and an outlet of the catalyst delivering tube is connected with the fluidization region; a gas distributor is arranged on the lower portion of the inside of the fluidization region, an oxygen distributor and a heat exchange tube bundle are arranged in a space from the position above the gas distributor to the top of the fluidization region, and the bottom of the fluidization region is connected with one end of a raw material inlet tube; and a raising pipe, a cyclone separator and a gas collecting chamber are arranged in the settling region, the top of the settling region is connected with one end of a gas outlet tube, and one end of the raising tube is connected with the cyclone separator while the other end of the raising tube is connected with the fluidization region. According to the embodiment of the invention, catalyst particles violently move under the effect of upflow through a fluidized bed reactor, and thus, the temperature of a catalyst bed layer is distributed uniformly.

Owner:SINOPEC ENG GRP CO LTD

Semi-embedding type eight-shaped cavity type solar receiver and working method thereof

InactiveCN105841363AReduce convective heat lossEfficient heat absorptionSolar heating energySolar heat collector controllersLight reflectionHeat losses

The invention discloses a semi-embedding type eight-shaped cavity type solar receiver and a working method thereof. The solar receiver comprises a regular hexagonal convex mirror, a glass housing, a heat insulation vacuum layer, a steel inner shell, a soft heat transfer layer, a helical heat exchange coil tube, a heat conductive fluid, light reflection type wind shields and a cavity mouth convex mirror, wherein different from the traditional heat absorber, the solar receiver is in an eight shape, and independent feeding and discharge holes are formed in a low-temperature heating part and a high-temperature heating part and can be used for heating working media with different temperature requirements in a middle-high temperature solar heat utilization system and transporting the media with different temperatures respectively; the media can be secondarily heated by utilizing the focusing action of the regular hexagonal convex mirror; semi-embedding type connection between the soft heat transfer layer and the helical heat exchange coil tube makes the coil tube more uniformly heated, and thus heat spots are prevented from occurring; and through the focusing and closing actions of the cavity mouth convex mirror, the effects of efficiently absorbing heat and reducing convective heat loss can be reached.

Owner:SOUTH CHINA UNIV OF TECH

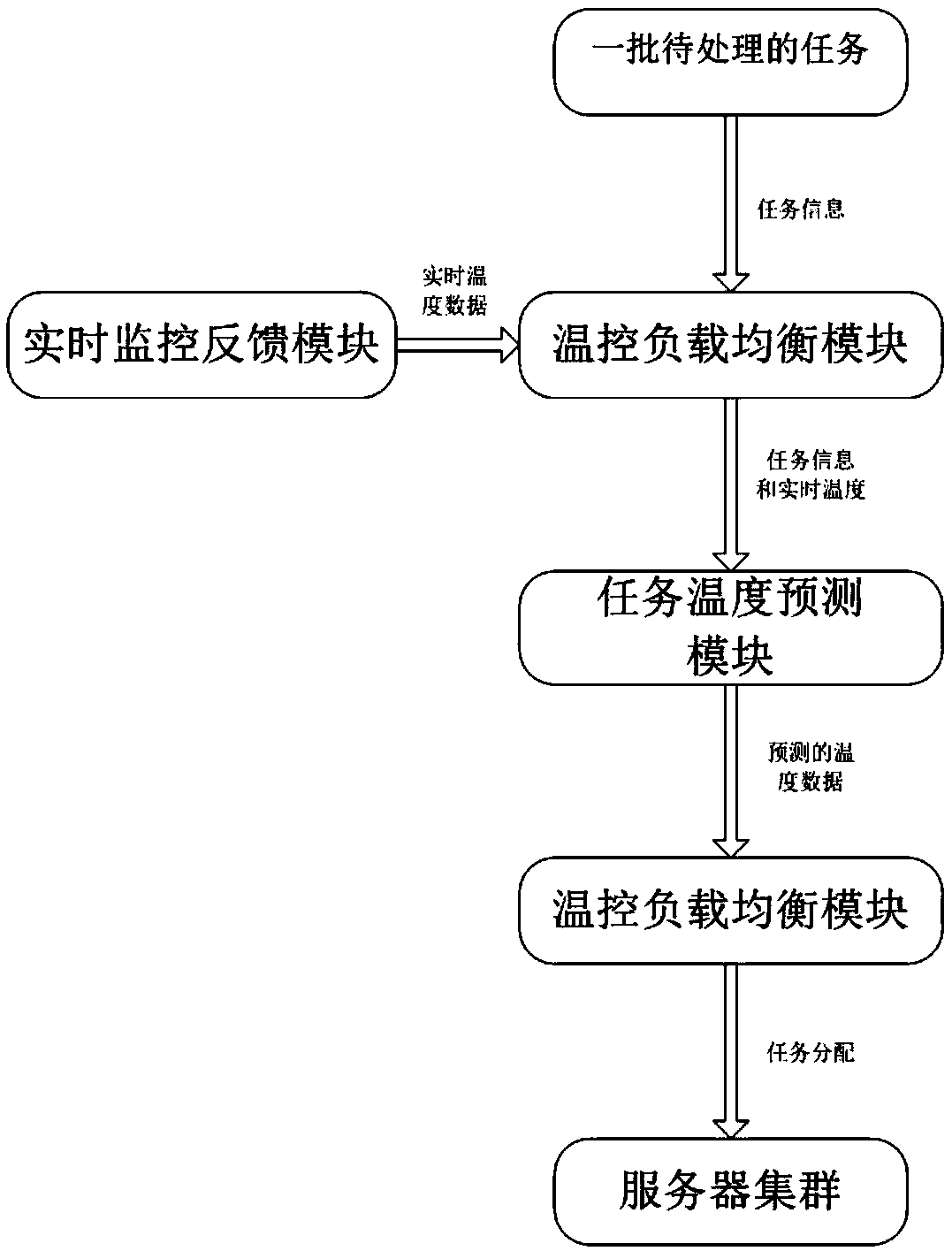

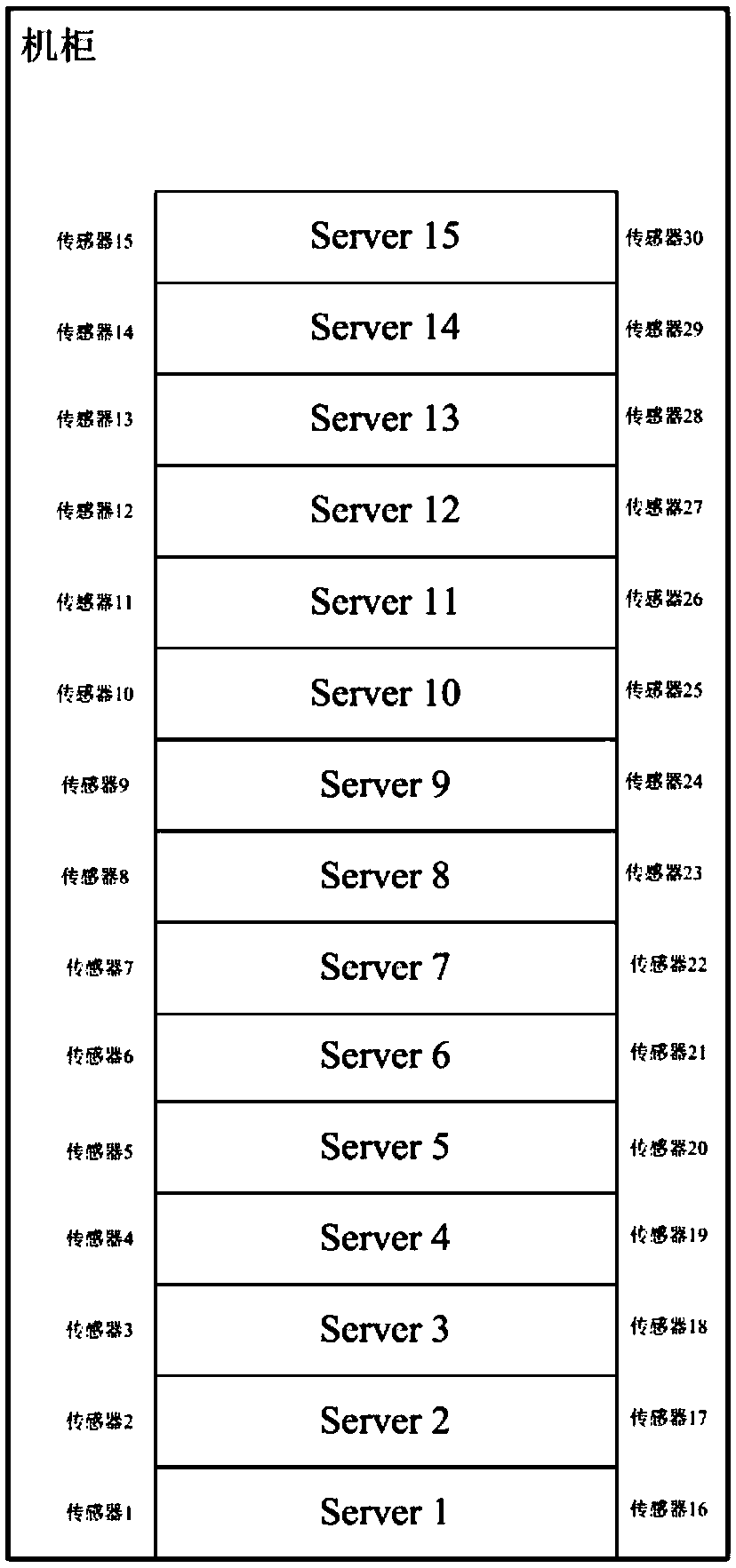

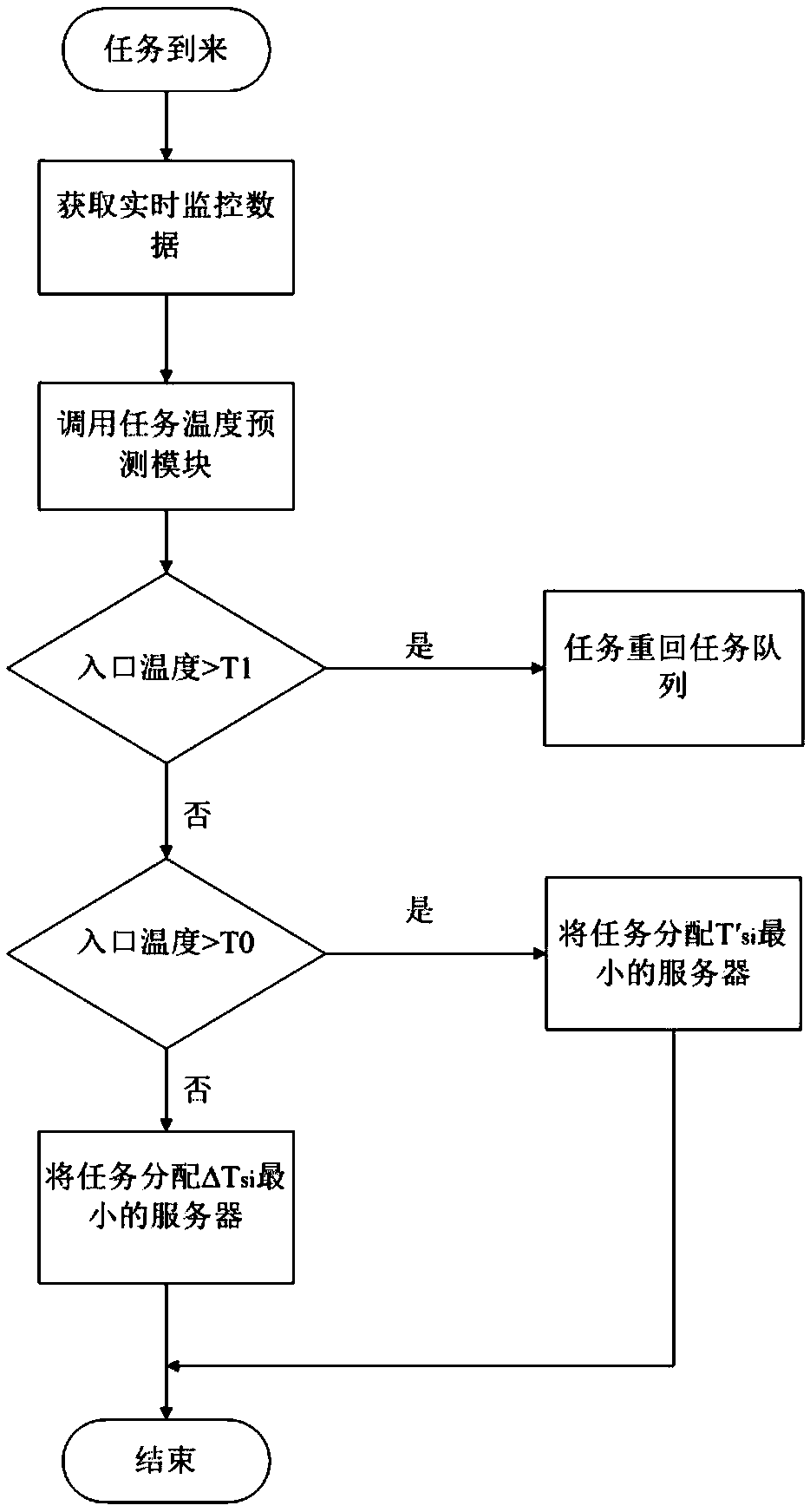

Data center task temperature prediction and scheduling method based on RBF neural network

ActiveCN109375994AReduce the temperatureReduce energy consumptionProgram initiation/switchingDigital data processing detailsTemperature controlData center

The invention discloses a data center task temperature prediction and scheduling method based on an RBF neural network, which includes adopting the RBF neural network to establish a task temperature prediction model; establishing a temperature-controlled load balancing module, determining a safe temperature and an alert temperature of the server, and judging and selecting with any server Si; the monitoring feedback module real-time monitors and feeds server operating temperature back to the temperature control load balancing module, the temperature control load balancing module is used for scheduling control. The invention carries out task scheduling through active temperature prediction, and has better flexibility than the method of determining task scheduling only based on feedback temperature. By setting two active scheduling strategies in different temperature ranges, the energy consumption can be reduced and the safe operation of the data center can be ensured.

Owner:XI AN JIAOTONG UNIV

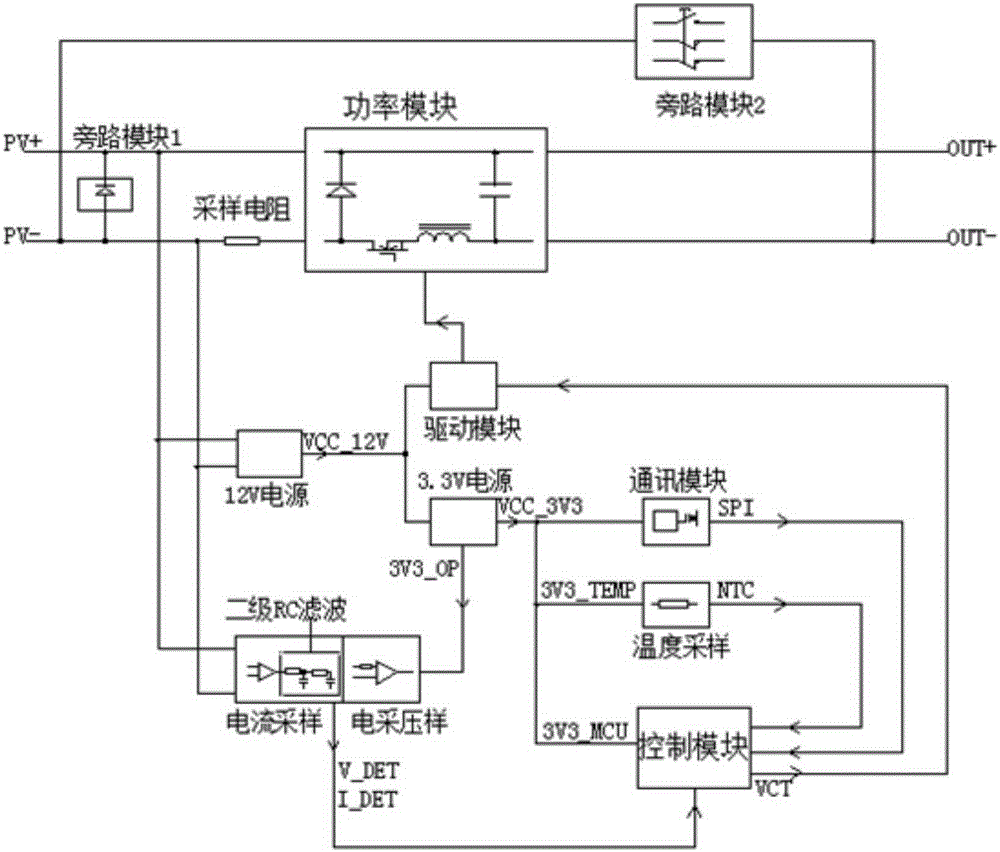

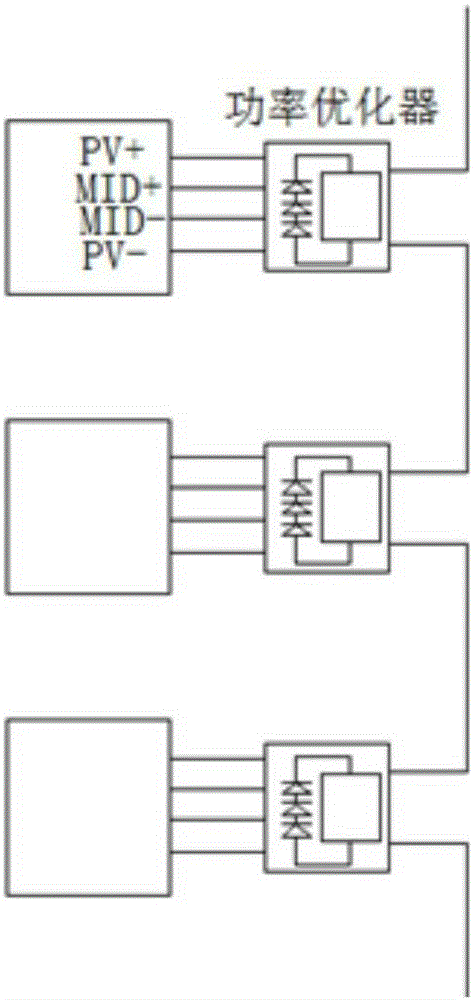

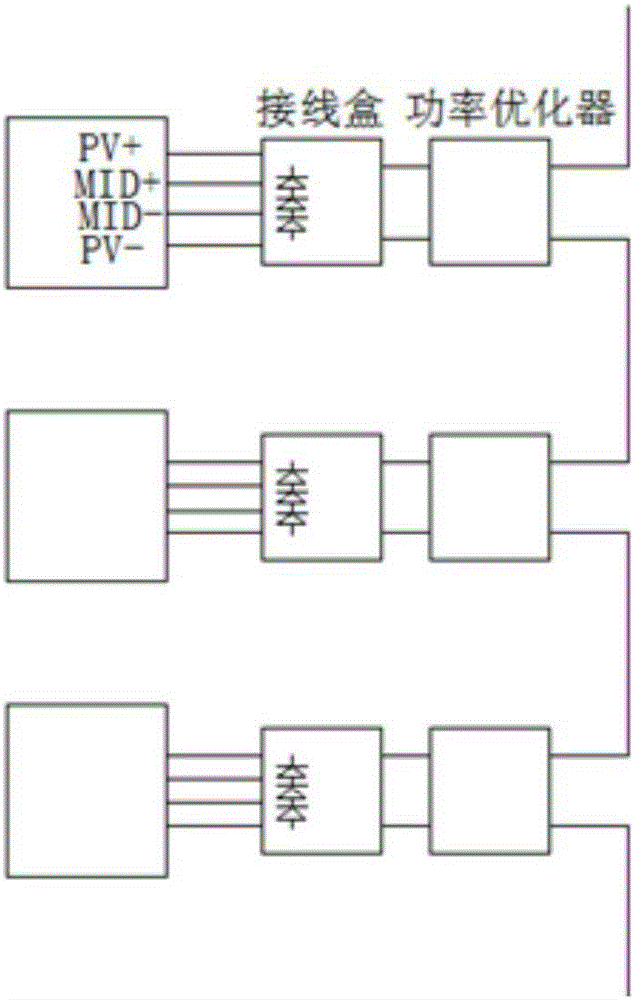

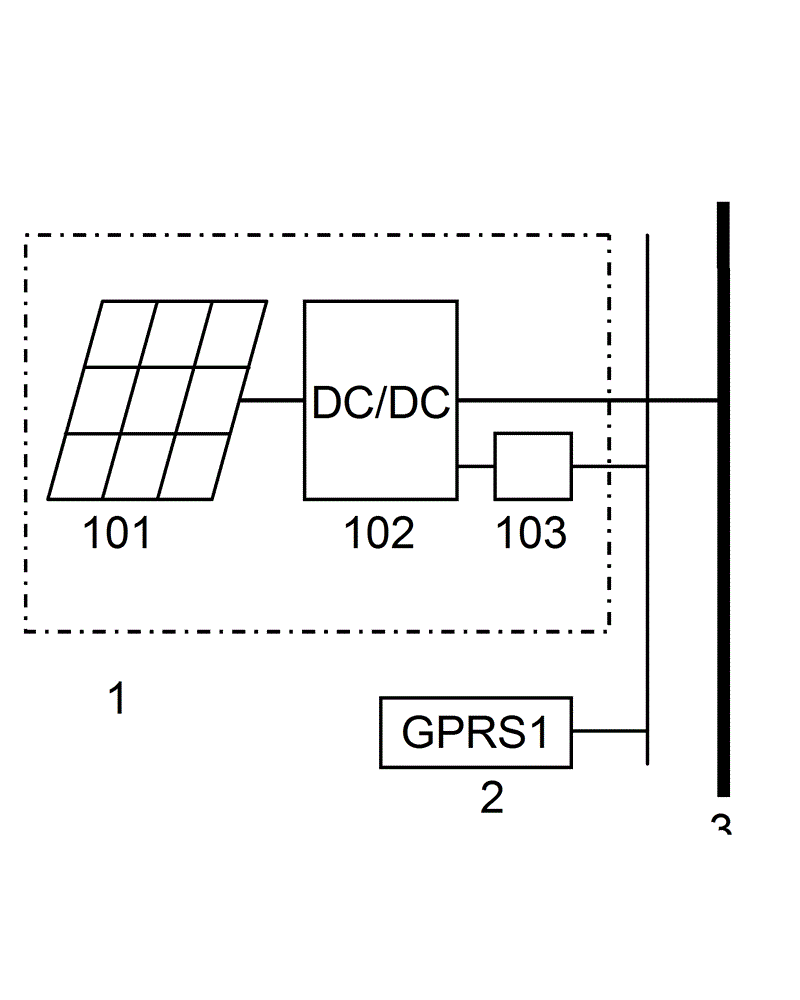

Intelligent photovoltaic power adjustor and adjusting method

InactiveCN105245104AAvoid hot spotsReduce Component MismatchesDc-dc conversionPhotovoltaic energy generationPower modulePhotovoltaics

The invention provides an intelligent photovoltaic power adjustor and an adjusting method. The intelligent photovoltaic power adjustor comprises a power module, a sampling module, a control module, a driving module, a communication module, a power module and the like; the input end of the power module is connected with the output end of a photovoltaic module; the sampling module is provided with a sampling circuit, and the output end of the sampling circuit is connected with the control module; the control module is provided with an MCU (Micro Control Unit) control circuit; the power module is provided with a switching tube, and the driving module is connected with the switching tube of the power module; and the communication module realizes bidirectional feedback of the control module and a background monitoring system. By adopting the intelligent photovoltaic power adjustor and the adjusting method, the maximum power of each module can be tracked, so that the power loss can be reduced; the power adjustor can substitute a junction box, and can also be connected to the rear end of a junction box; double bypass protection is realized, the hot spot effect is avoided through a bypass diode, and the normal operation of a whole set and even a power station is prevented from being influenced by the fault or invalidation of a single module through a bypass switch to reduce power generation loss.

Owner:成都创达自动化控制有限公司

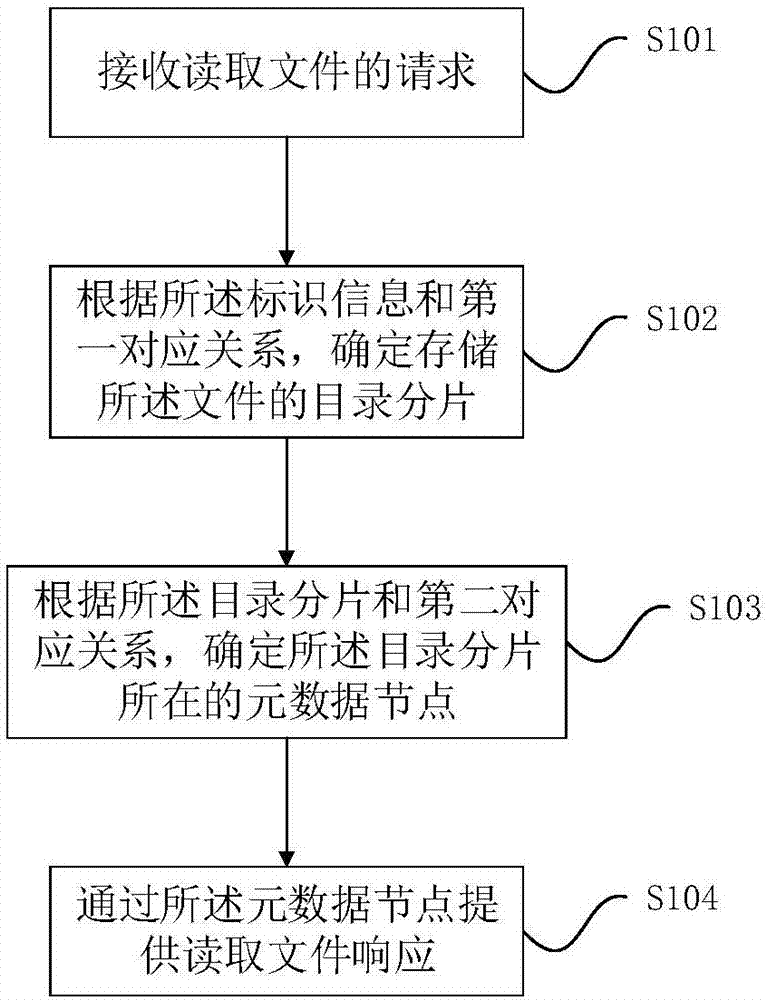

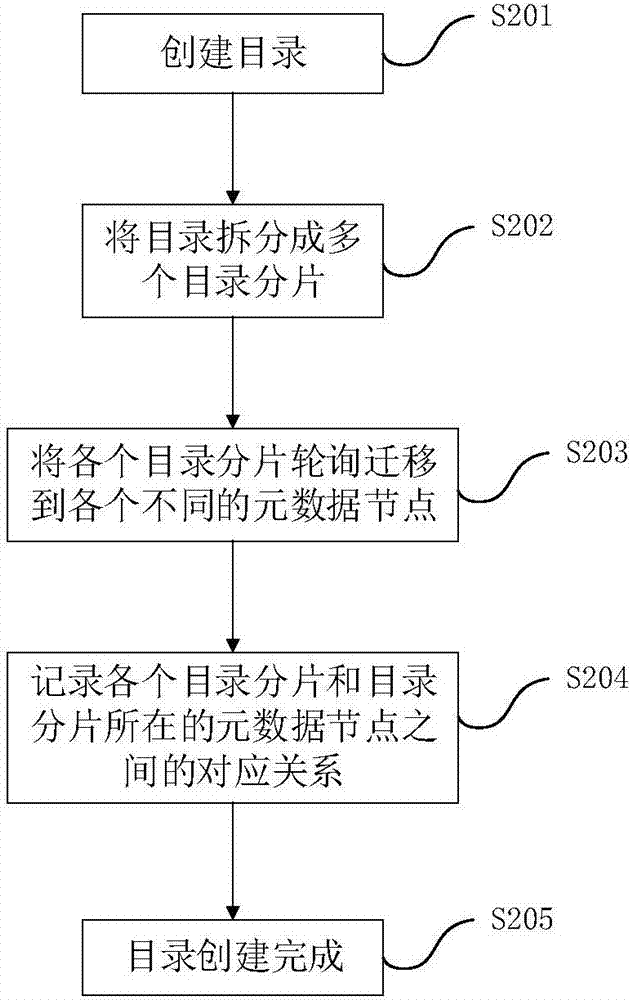

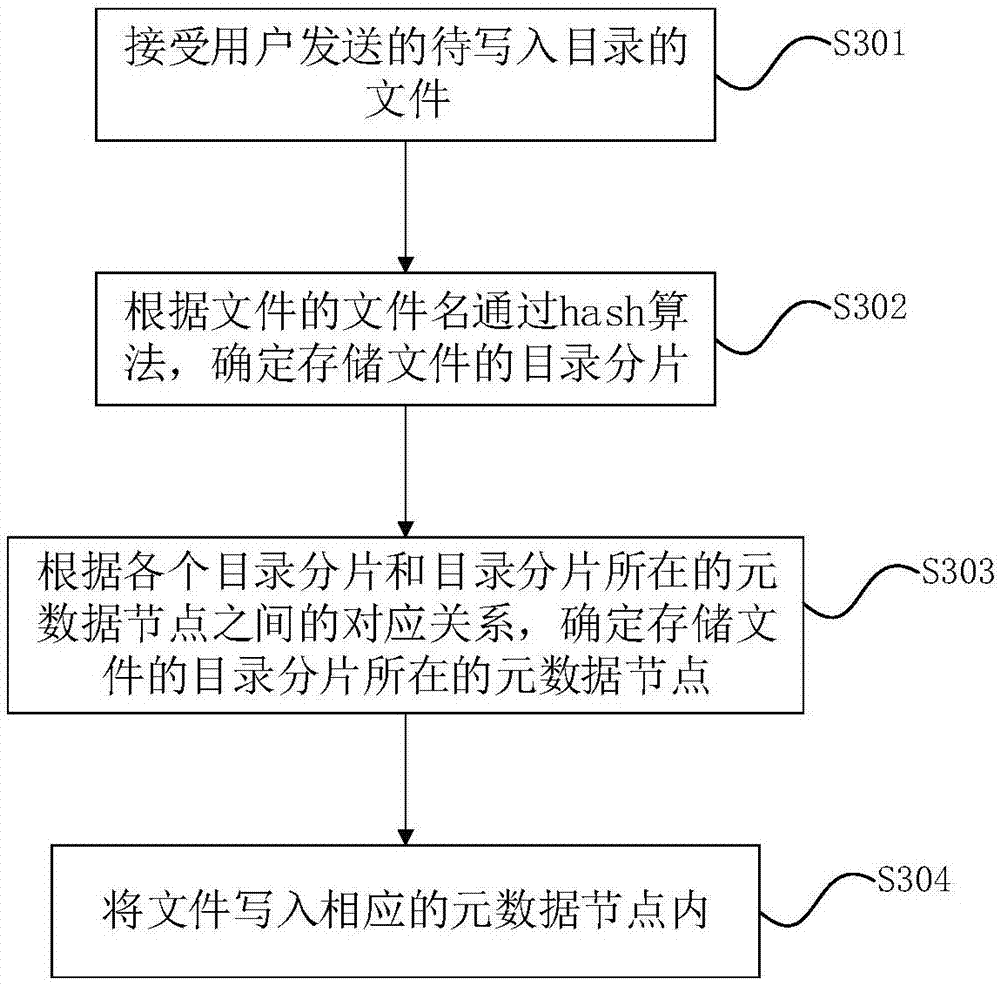

Method and device for reading distributed metadata files

InactiveCN107315547AAvoid hot spotsLower the heatInput/output to record carriersMetadata managementDatabase

The invention discloses a method for reading distributed metadata files. After a directory is created, the directory is split into multiple directory fragments, and the multiple directory fragments are migrated to multiple metadata nodes, files which need to be written into the directory are stored in all the multiple directory fragments, when the files are read, according to the corresponding relations of identification information of the files and the directory fragments, and the directory fragments and the metadata nodes, metadata nodes stored in the files are finally determined so as to read the files, the frequency of frequently accessing the metadata nodes in which hotspot directories are located is reduced to a certain degree, the degree of hotspot of the metadata nodes is lowered, the loading pressure of the metadata nodes is reduced, and the performance of a whole metadata management system is improved. The invention further discloses a device for reading the distributed metadata files, and the device has the above same advantages.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Processing method for avoiding hot spot effect of solar cell module

InactiveCN101226970AImprove appearance qualityQuality improvementFinal product manufactureSemiconductor devicesUltrasound attenuationInterconnector

The invention provides a method for processing a solar cell module, which avoids a hot spot effect. The appearance quality and the various properties of the solar cell module which is processed through the method are greatly improved, the packaging power loss and the power attenuation are effectively reduced, and the hot spot effect which is produced during a solar system is used is effectively avoided. The steps comprises battery sorting, interconnector dip coating treatment, face up bonding, series welding, toughened glass-EVA-battery plate-EVA-TPT laminated processing, intermediate inspection, lamination, trimming, the installment of aluminum alloy frame, the installment of waterproof terminal box, appearance cleaning, module testing, pressure test and visual inspection. The invention is characterized in that the methods of the interconnector dip coating treatment are that moderate interconnectors are paved in a net basket, the interconnectors are straightly put, then the net basket which is equipped with the interconnectors is socked in a flux for 5-8 minutes, the net basket is taken out from a soaking pool and is put on a shelf to filter for 2-3 minutes, and then the net basket is pumped by pumping vacuum equipment for 2-3 minutes.

Owner:张二建

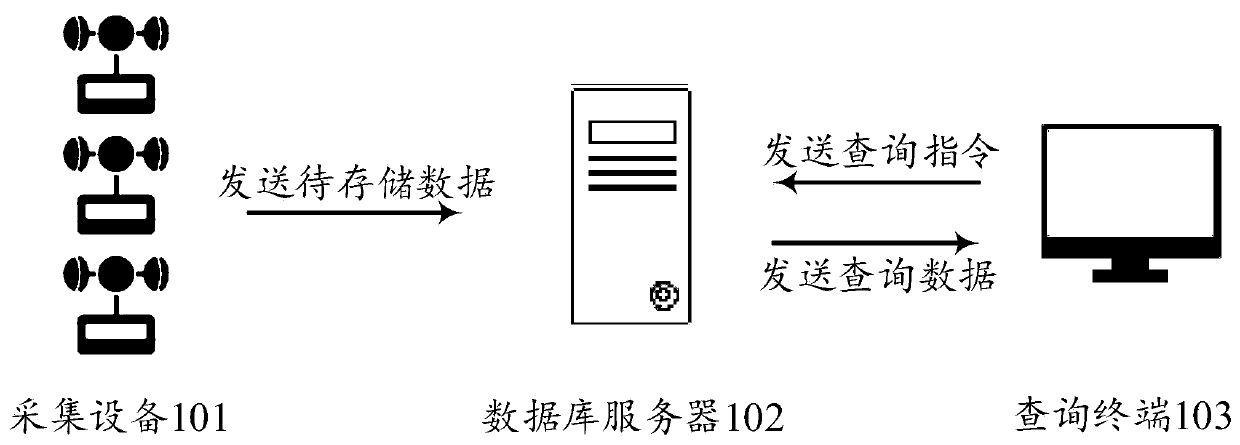

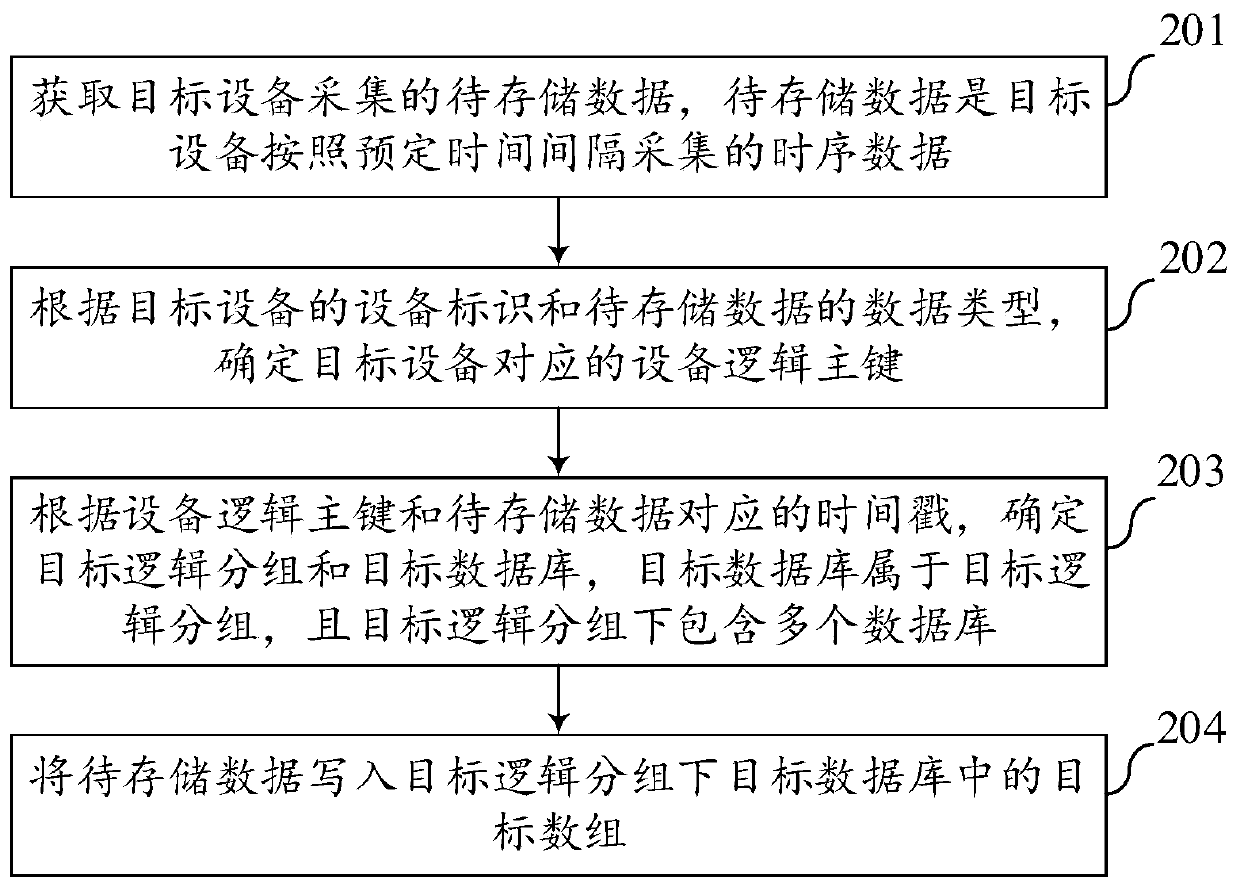

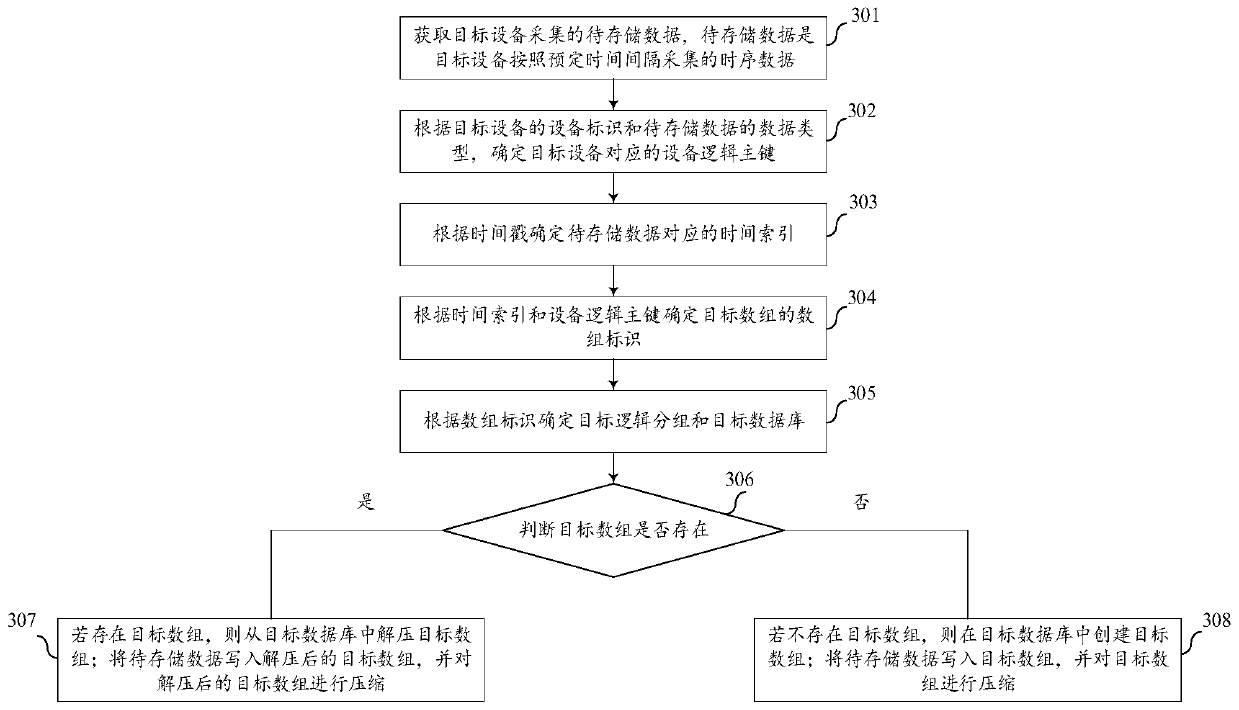

Time series data storage method and device, server and storage medium

PendingCN111125089ASimple horizontal expansion processAvoid hot spotsSpecial data processing applicationsDatabase indexingData classData mining

The embodiment of the invention discloses a time series data storage method and a device, a server and a storage medium, and belongs to the field of databases. The method comprises the steps of obtaining to-be-stored data collected by target equipment; determining an equipment logic primary key corresponding to the target equipment according to the equipment identifier of the target equipment andthe data type of the to-be-stored data; determining a target logic group and a target database according to the device logic primary key and a timestamp corresponding to the to-be-stored data, the target database belonging to the target logic group, and the target logic group including a plurality of databases; and writing the to-be-stored data into a target array in a target database under the target logic group. In the method of the invention, when the data are increased, the horizontal capacity expansion can be completed by only adding one or more logic groups, the historical data do not need to be migrated, the horizontal capacity expansion process is simple, and the data are distributed and stored in the plurality of databases under the target logic group, so that the hotspot problemcaused by centralized operation for a single database is avoided.

Owner:ENVISION DIGITAL INT PTE LTD +1

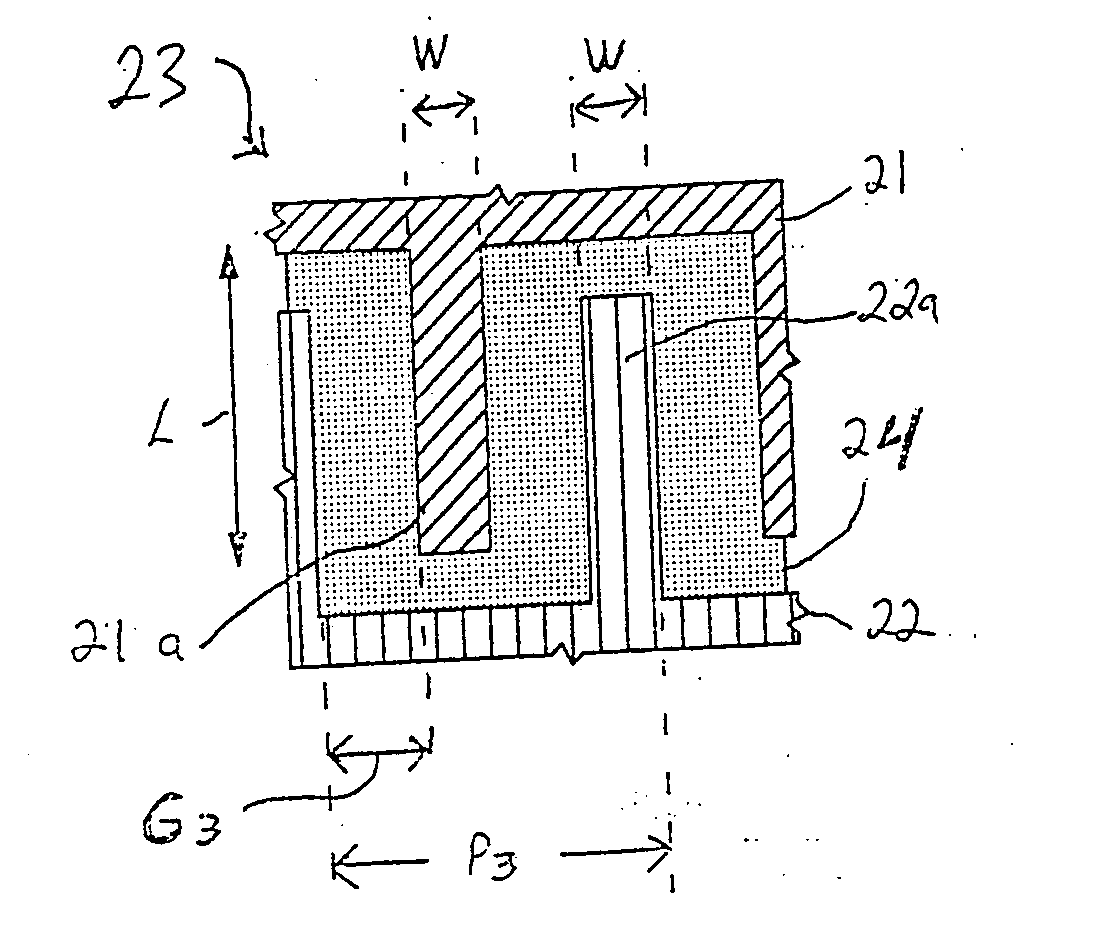

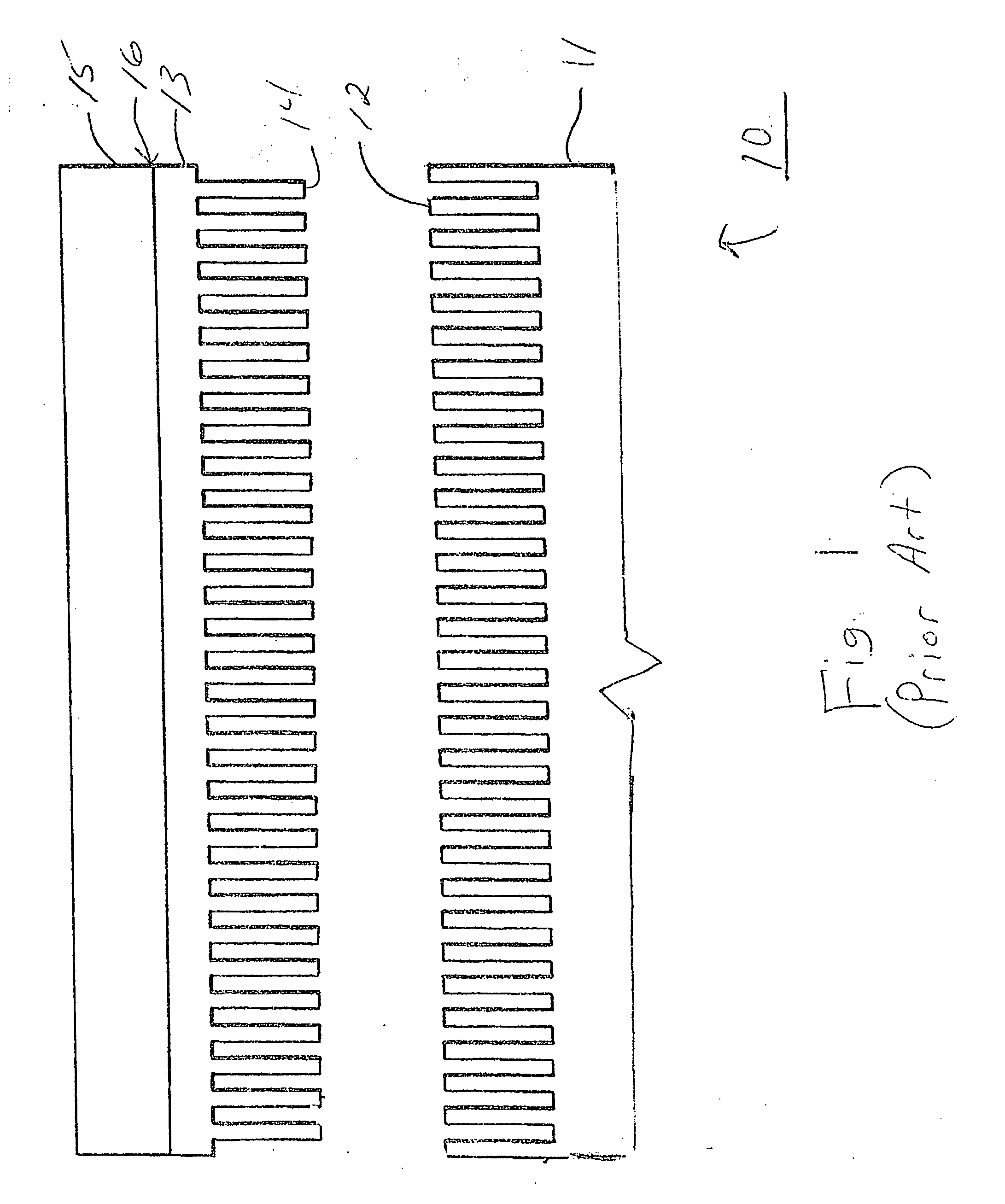

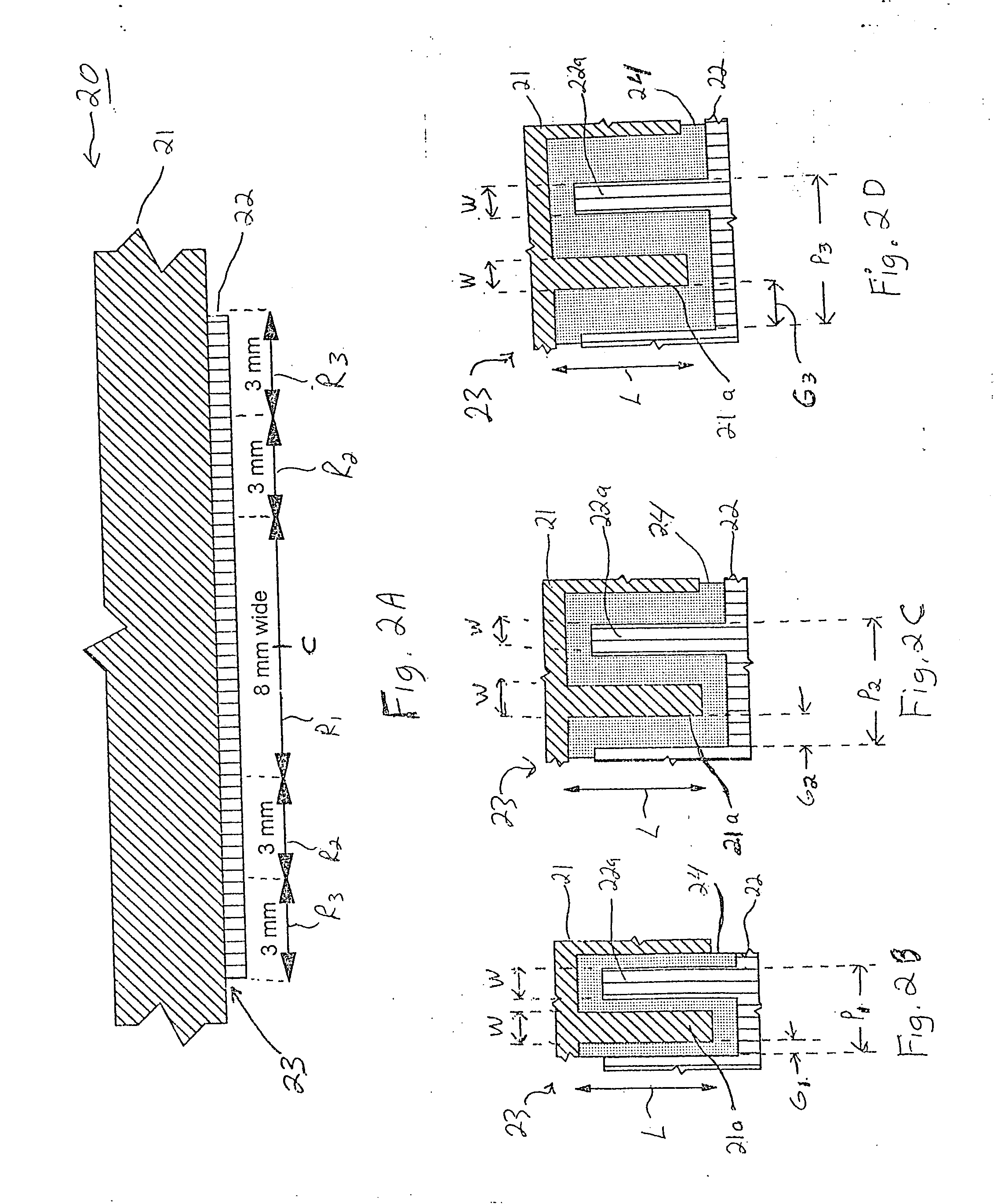

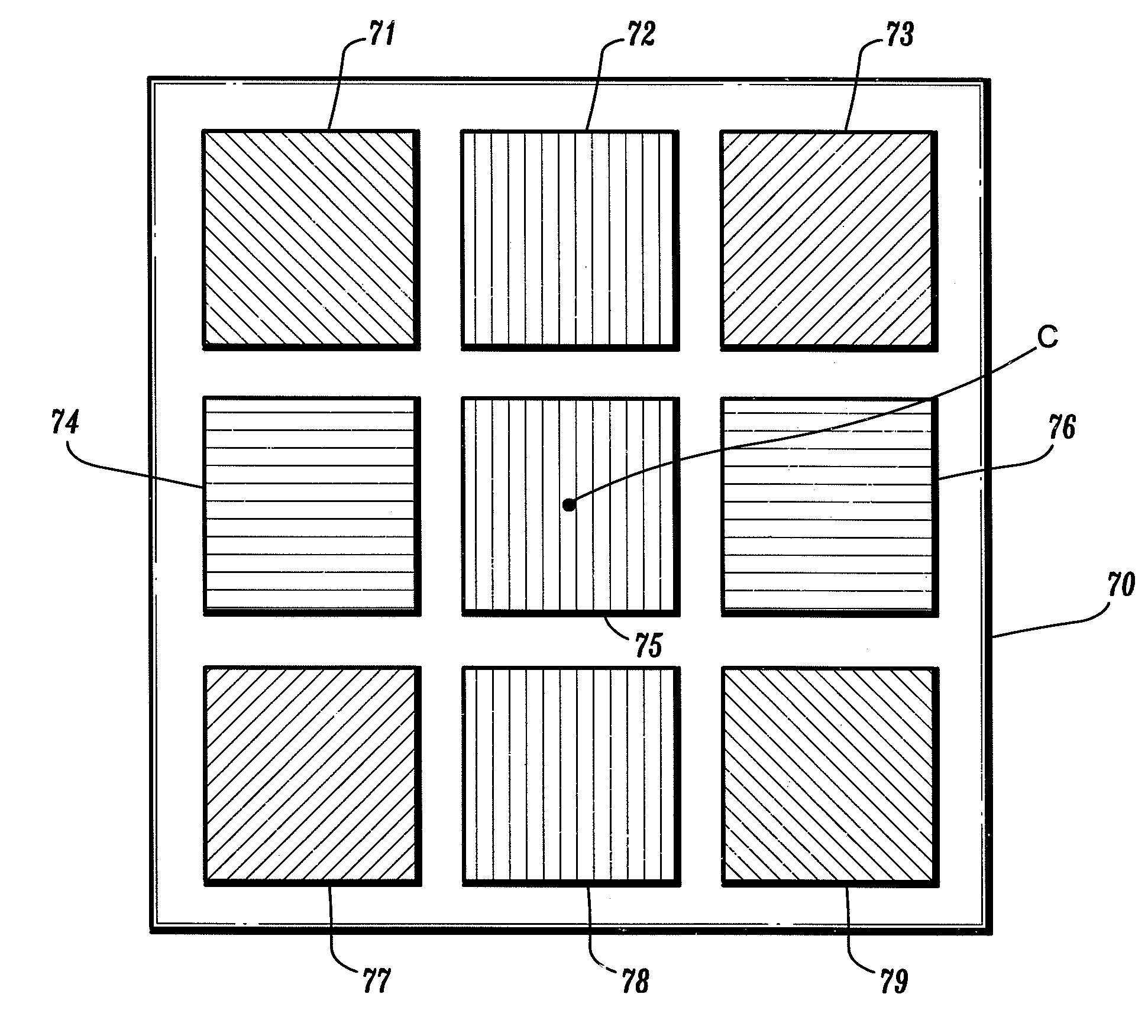

Apparatus and methods for cooling semiconductor integrated circuit package structures

InactiveUS20050189568A1Improve thermal conductivityReduce thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesRelative displacementHeat conducting

Apparatus and methods are provided for thermally coupling a semiconductor chip directly to a heat conducting device (e.g., a copper heat sink) using a thermal joint that provides increased thermal conductivity between the heat conducting device and high power density regions of the semiconductor chip, while minimizing or eliminating mechanical stress due to the relative displacement due to the difference in thermal expansion between the semiconductor chip and the heat conducting device.

Owner:IBM CORP

Apparatus and methods for cooling semiconductor integrated circuit package structures

InactiveUS7288839B2Improve thermal conductivityReduce thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesRelative displacementHeat conducting

Apparatus and methods are provided for thermally coupling a semiconductor chip directly to a heat conducting device (e.g., a copper heat sink) using a thermal joint that provides increased thermal conductivity between the heat conducting device and high power density regions of the semiconductor chip, while minimizing or eliminating mechanical stress due to the relative displacement due to the difference in thermal expansion between the semiconductor chip and the heat conducting device.

Owner:INT BUSINESS MASCH CORP

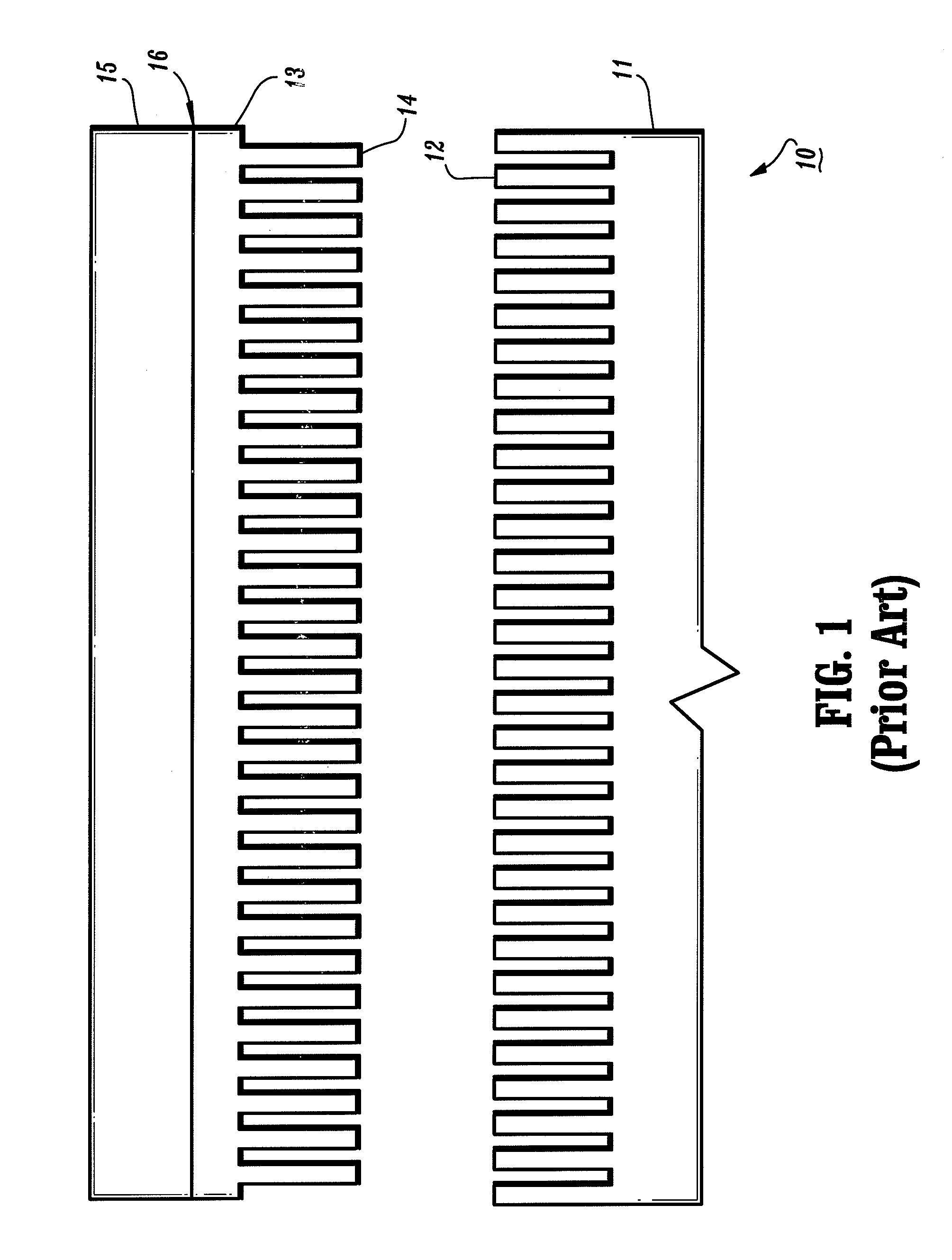

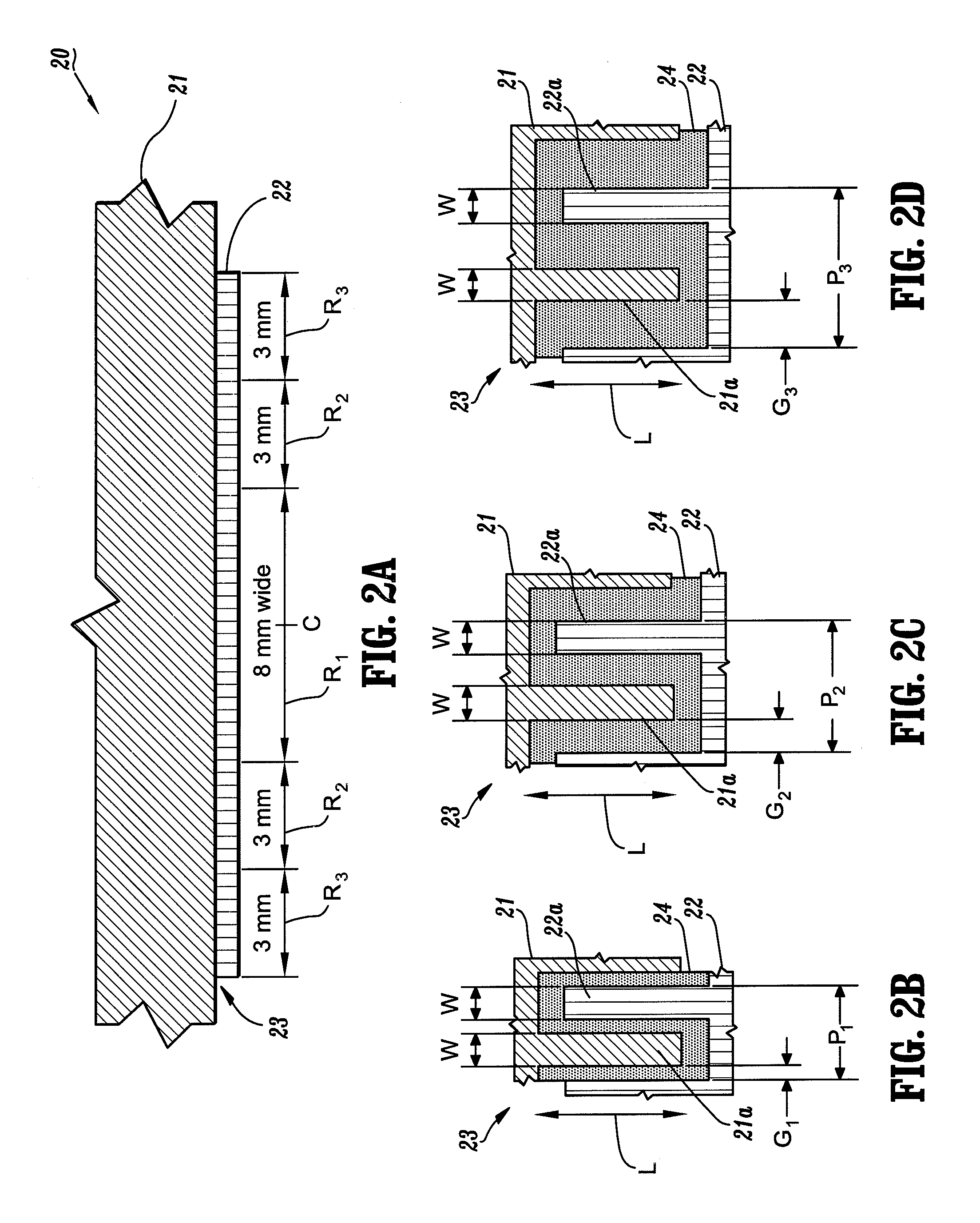

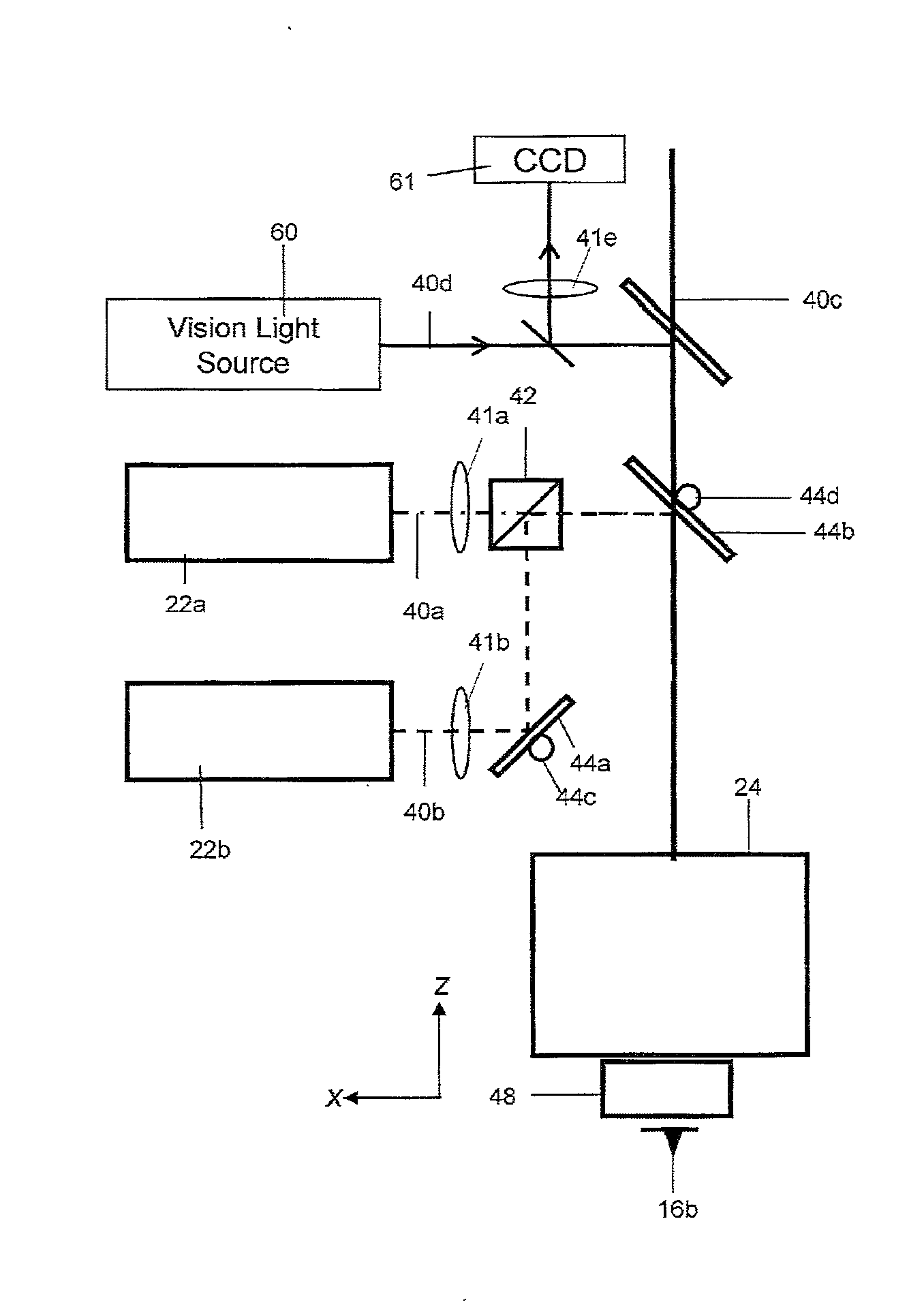

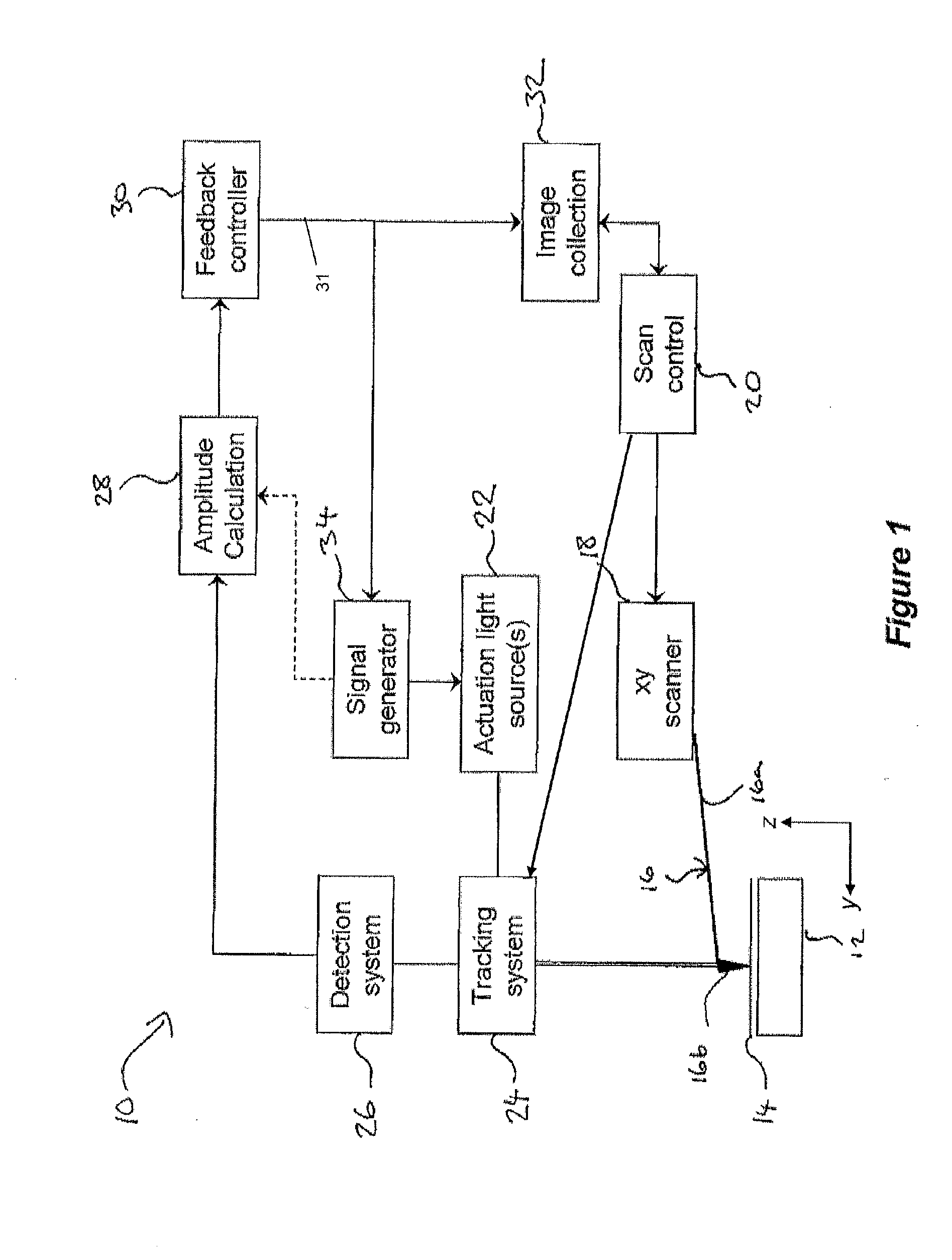

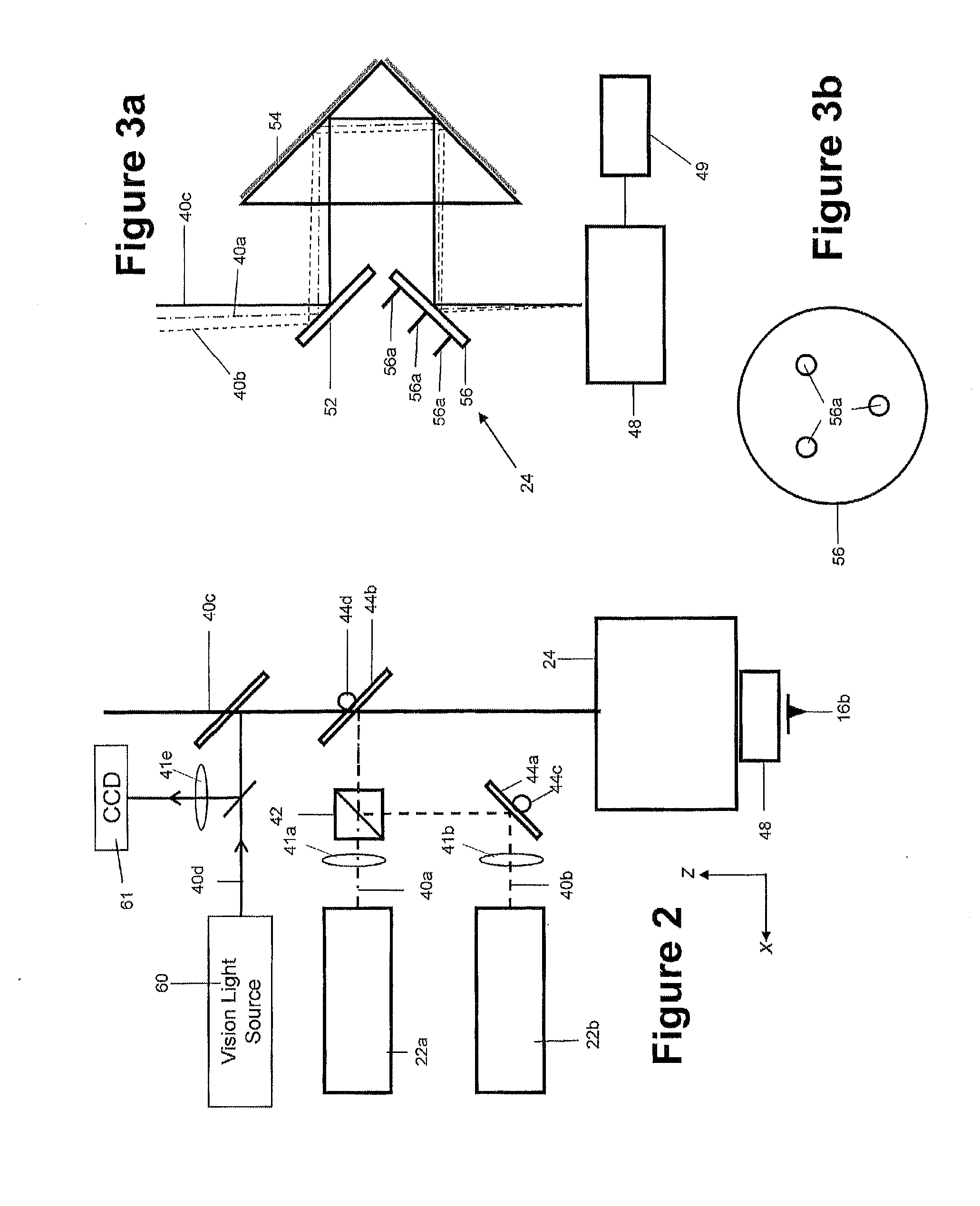

Photothermal actuation of a probe for scanning probe microscopy

ActiveUS20150219684A1Improve performanceOvercome the heatNanotechnologyScanning probe techniquesLight beamScanning probe microscopy

Various methods of driving a probe of a scanning probe microscope are disclosed. One set of methods distribute the energy of a radiation beam over a wide area of the probe by either scanning the beam or increasing its illumination area. Another method changes the intensity profile of the radiation beam with a diffractive optical element, enabling a more uniform intensity profile across the width of the illumination. Another method uses a diffractive optical element to change the circumferential shape of the radiation beam, and hence the shape of the area illuminated on the probe, in order to match the shape of the probe and hence distribute the energy over a wider area.

Owner:INFINITESIMA

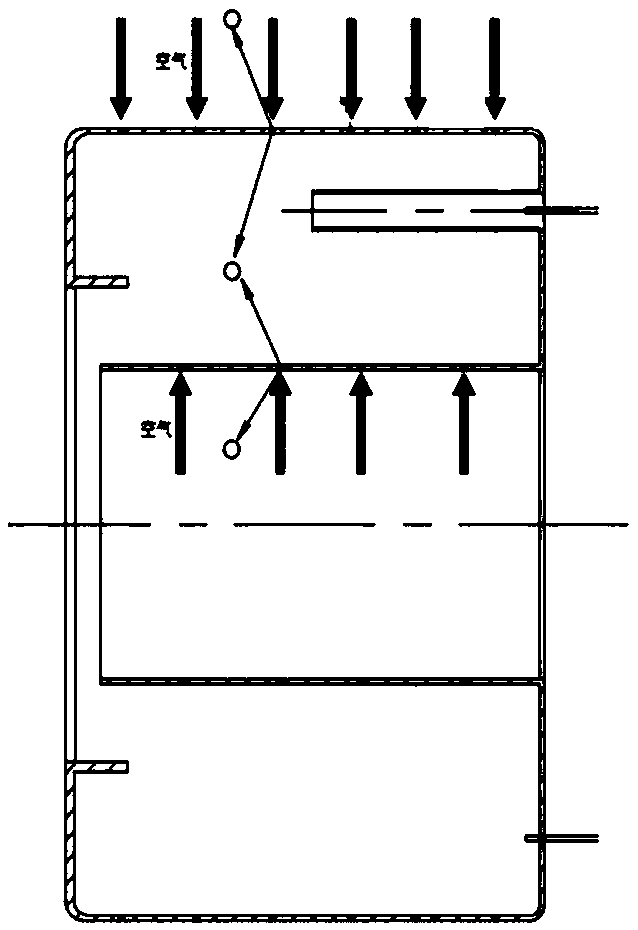

Combustor for medium-high temperature solid fuel cell and application thereof

PendingCN110360555AUniform porosityUniformityBurner ignition devicsFuel cellsCombustion chamberEngineering

The invention belongs to the field of fuel cells, and particularly discloses a combustor for a medium-high temperature solid fuel cell and an application thereof. An air inlet and a fuel inlet are arranged at an inlet end of a static mixing cavity in the combustor and are used for mixing air and fuel to obtain mixed gas; a shunting orifice plate is connected with an outlet end of the static mixingcavity to provide a buffer area for the mixed gas and shunt the mixed gas; a metal mesh structure is connected with the shunting orifice plate, so that the phenomena of tempering and flamelifting areprevented; a combustion chamber is arranged on the outer side of the static mixing cavity and provides a space for mixed gas combustion; and a pulse igniter is arranged above the metal mesh structureand used for igniting the mixed gas. According to the combustor, the shunting orifice plate is utilized to provide the buffer area for the high-flow-rate mixed gas, meanwhile, flame generated by combustion is divided into a plurality of fine flame flows by utilizing the metal mesh structure, and stable gas flow and temperature gradient are formed, so that the phenomena of the tempering and flamelifting are prevented.

Owner:HUAZHONG UNIV OF SCI & TECH

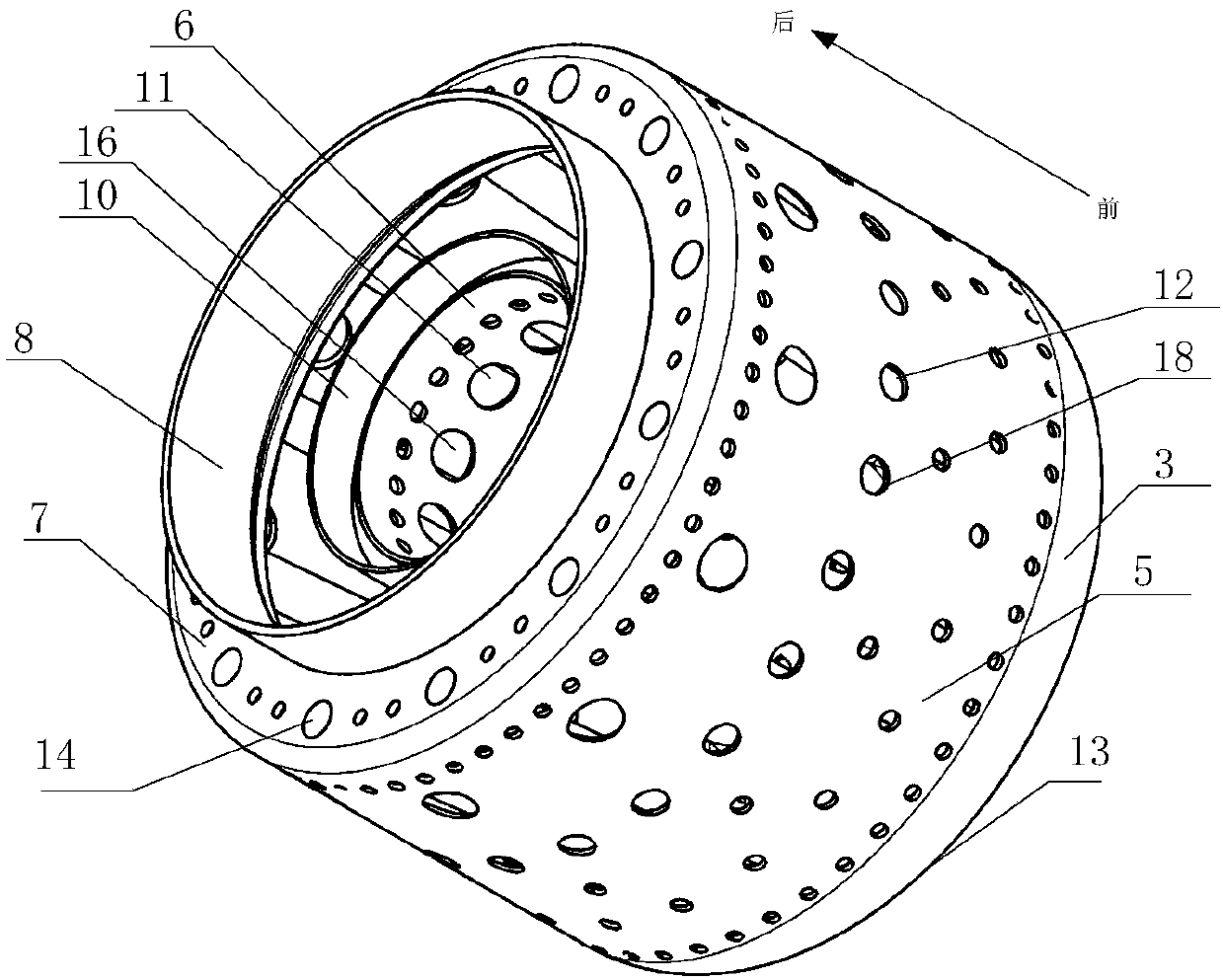

Evaporating pipe type compact combustion chamber

ActiveCN109668173ASmall sizeReduce usageContinuous combustion chamberCombustion chamberPollutant emissions

The invention discloses an evaporating pipe type compact combustion chamber. The inner wall and outer wall of the combustion chamber and an evaporating pipe are integrally formed, so that the weight is lowered, the overall dimensions are reduced and the whole performance is improved. Inner air film holes and outer air film holes are formed in the inner wall and the outer wall of the combustion chamber separately and are both divergent air film holes, namely the hole area of the inner air film holes and the outer air film holes in one side of a flame tube is greater than that of the inner air film holes and the outer air film holes in the other side of the flame tube. Accordingly, the surficial area of the inner wall surface of the flame tube is increased, wall surface heat transfer is intensified, flow field homogeneity is optimized, combustion efficiency is improved, the temperature distribution coefficient of a combustion chamber outlet is decreased and pollutant emission is reduced.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

Solar panel cleaning device

ActiveCN111570338AQuick CleanabilityQuick dryingDrying solid materials without heatDrying gas arrangementsEngineeringAtmospheric sciences

The invention discloses a solar panel cleaning device. The solar panel cleaning device comprises a housing, the right half of the housing is provided with a cleaning mechanism, the cleaning mechanismcomprises a cleaning cavity located in the lower side of the housing with a downward opening, the middle of the cleaning cavity is provided with a rotary brush plate, the lower end surface of the brush plate is fixed with a brush, and the front and rear sides of the cleaning cavity are symmetrically provided with water storage cavities. According to the solar panel cleaning device, the cleaned surface is subject to water scraping treatment through a water scraping plate, at the same time, the cleaned surface is wiped with an absorbent cloth, first drying treatment on the surface of a solar panel is completed, and then the wind of a fan is supplied and heated, hot air is blown to the surface of the solar panel for secondary drying, fast cleaning and drying to the solar panel is facilitated,at the same time, dust is prevented from falling on the surface of the wet solar panel, the hot spot effect generated by incomplete cleaning caused by part factors after cleaning is effectively prevented.

Owner:福建泰阳新能源开发有限公司

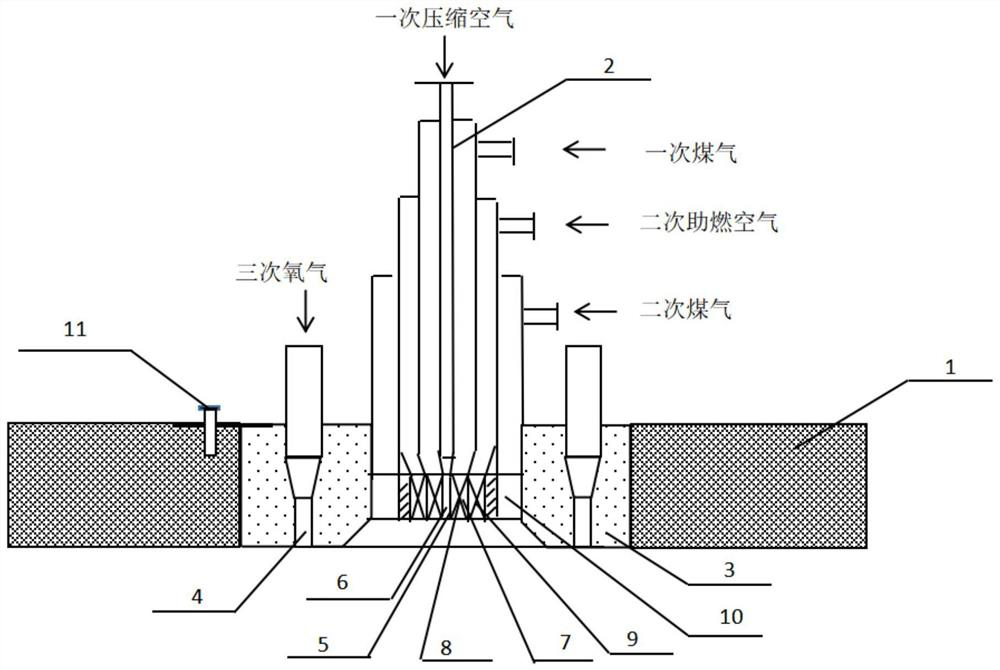

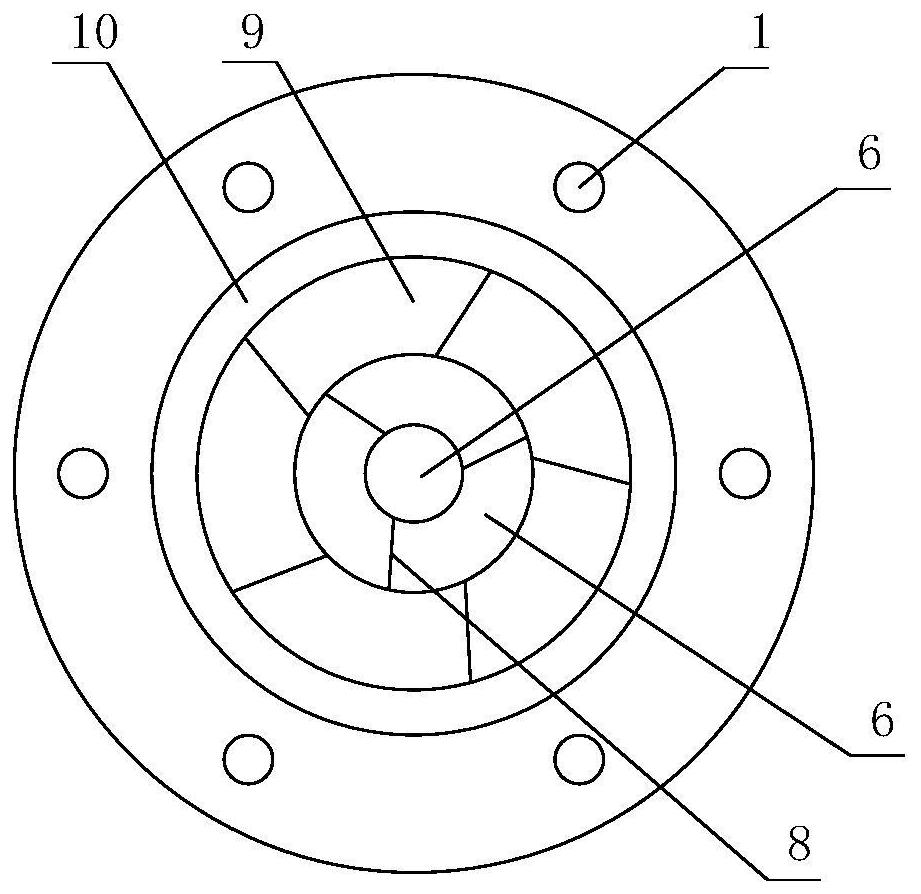

Oxygen jet multi-stage dispersion combustion roaster

PendingCN112944344AReduce the temperature difference between upper and lowerReduce productionMelt-holding vesselsIndirect carbon-dioxide mitigationThermodynamicsCombustion

The invention relates to an oxygen jet multi-stage dispersion combustion roaster which comprises a metal structure burner and a refractory burner brick; the metal structure burner is arranged in the center of a ladle cover; the metal structure burner is of a four-layer sleeve structure; a first-stage compressed air channel is arranged in the center; a first-stage gas channel, a second-stage combustion-supporting air channel and a second-stage gas channel are sequentially arranged outside the first-stage compressed air channel; a compressed air nozzle is of a contracted conical structure and is arranged at the bottom of the first-stage compressed air channel; a first-stage gas circular seam is arranged at the bottom of the first-stage gas channel; a second-stage air circular seam is arranged at the bottom of the second-stage combustion-supporting air channel; a second-stage gas circular seam is arranged at the bottom of the second-stage gas channel; an oxygen jet orifice is fixed outside the metal structure burner; and a whole burner nozzle is fixed in the burner brick. The oxygen jet multi-stage dispersion combustion roaster has the advantages that oxygen high-speed jet is utilized to strengthen steel ladle bottom heating, upper and lower temperature difference of a steel ladle is reduced, and a local high-temperature area formed by high oxygen concentration is avoided.

Owner:ANGANG STEEL CO LTD

Solar photovoltaic substrate cleaning device

ActiveCN105680791APromote absorptionReduce labor costsPhotovoltaicsPhotovoltaic energy generationWater resourcesEngineering

The invention discloses a solar photovoltaic substrate cleaning device, and belongs to the technical field of cleaning and maintaining. According to the technical scheme, the solar energy photovoltaic substrate cleaning device comprises a support, a pulling device arranged at two sides of the support, a translation device arranged on the pulling device and a cleaning device. The solar photovoltaic substrate cleaning device has the advantages that the solar photovoltaic substrate is arranged on a support in a slope shape, the solar energy can be absorbed better, the manual cleaning is not needed, the labor cost of the manual cleaning is reduced, the defects of water cleaning are avoided, the hot pot effect caused by water cleaning uncleanness is eliminated, the solar photovoltaic substrate can be cleaned in time without water in a dry and unwatered area, the water resource is saved and the power generating efficiency is improved.

Owner:徐州中伦光伏材料有限公司

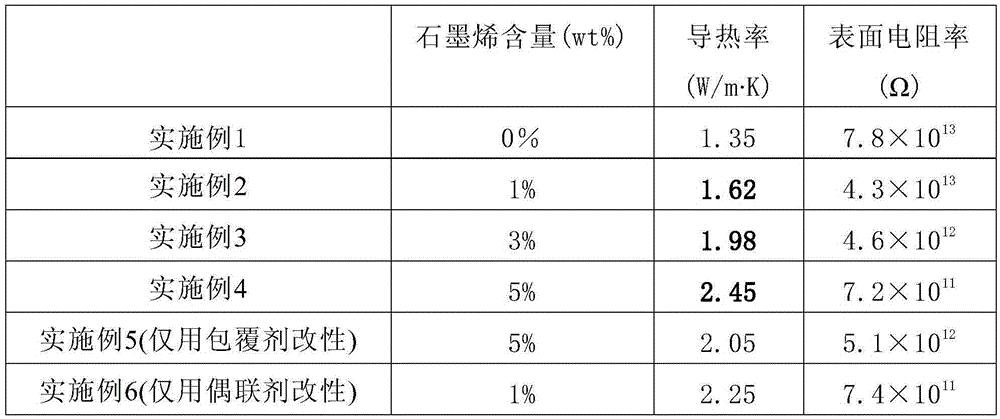

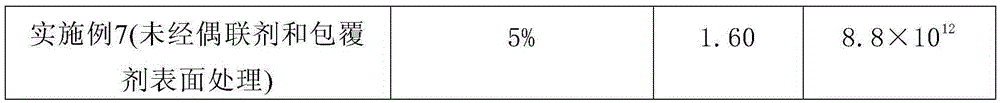

High heat conductivity and insulation plastic as well as preparation method and application thereof

The invention relates to high heat conductivity and insulation plastic as well as a preparation method and application thereof. The invention specifically discloses the high heat conductivity and insulation plastic. The high heat conductivity and insulation plastic comprises thermoplastic plastic and a compound heat conductivity filler uniformly distributed in the thermoplastic plastic, wherein the compound heat conductivity filler is prepared from graphene and an inorganic insulation type heat conductivity filler. The invention further discloses the preparation method and the application of the high heat conductivity and insulation plastic. Under a condition of keeping the mechanical property and the insulation performance of the high heat conductivity and insulation plastic, by adding of the specific compound heat conductivity filler, the heat conductivity of the high heat conductivity and insulation plastic is obviously improved, and the obvious improvement has an important significance for extending the application field of heat conductivity plastic.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Control method of direct-current photovoltaic power generating modules

ActiveCN104578171AGuaranteed uptimeAvoid hot spotsSingle network parallel feeding arrangementsPhotovoltaic energy generationComputer moduleEngineering

The invention relates to a control method of direct-current photovoltaic power generating modules, and belongs to the technical field of photovoltaic power generation. The method comprises the steps of firstly, forming a photovoltaic power generation system by adopting direct-current photovoltaic power generating modules, GPRS modules, a direct-current bus, an inverter and an alternating-current electric network; connecting all the direct-current photovoltaic power generating modules as basic units in parallel with the direct-current bus, meanwhile, dividing all the direct-current photovoltaic power generating modules into a plurality of groups, wherein each group comprises n direct-current photovoltaic power generating modules and a GPRS module, and carrying out wireless communication with an upper computer; secondly, detecting and judging the malfunction according to output voltage of a photovoltaic component and output power of direct-current photovoltaic power generating modules; and finally, determining the operation state of each direct-current photovoltaic power generating module according to the voltage of the direct-current bus. According to the invention, the structure is simple; the control is flexible and convenient; the malfunction diagnosis and positioning are rapid and accurate; the hot spot effect formed by shadows and the like can be solved completely; the maximal power generating efficiency is realized; the control method is especially suitable for distribution type photovoltaic power stations.

Owner:山东永锦电气股份有限公司

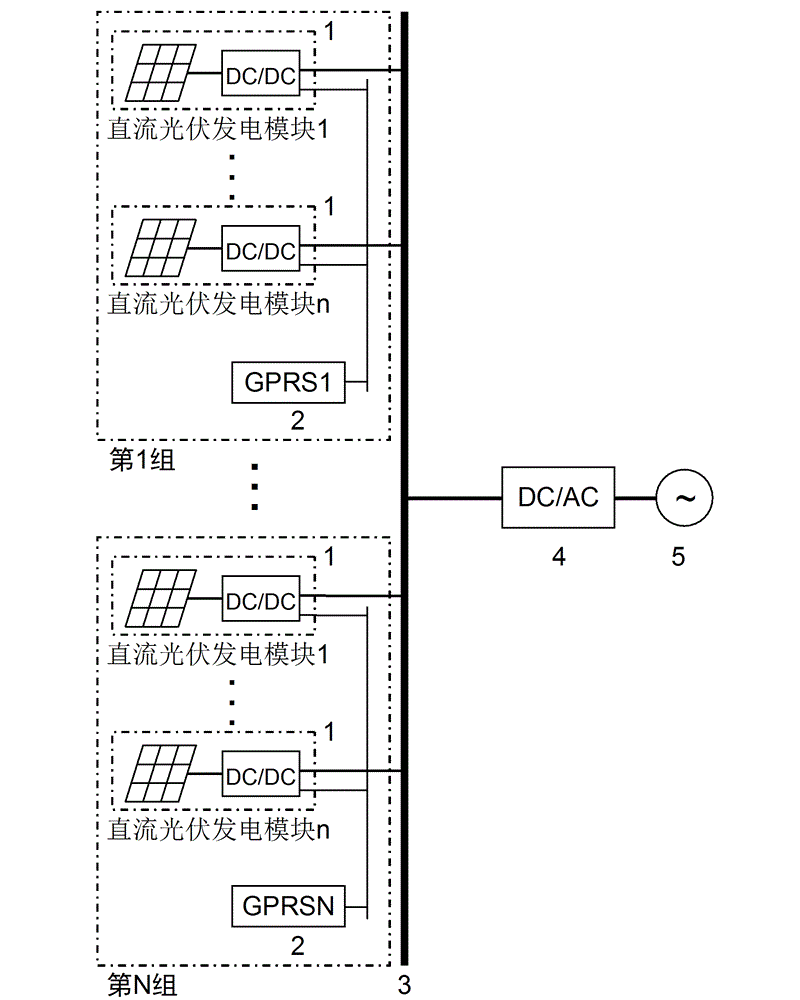

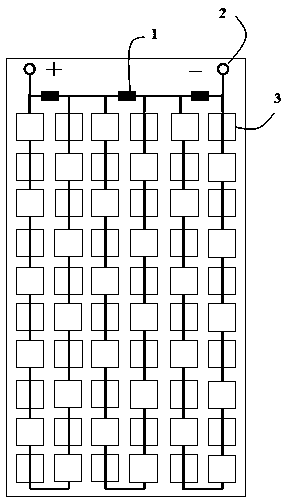

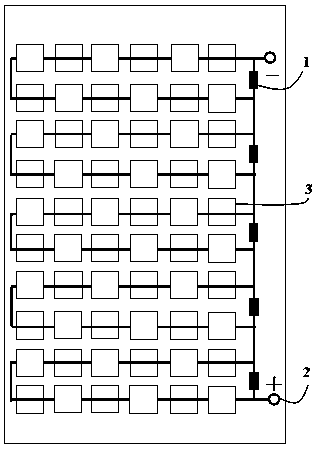

Solar cell module with integrated optimizer

InactiveCN104253171AAvoid hot spotsPower lossPhotovoltaicsPhotovoltaic energy generationEngineeringComputational physics

The invention discloses a solar cell module with an integrated optimizer. The solar cell module comprises a front face packaging glass layer, a front face EVA (Ethylene Vinyl Acetate) layer, battery pieces, a rear face EVA layer, a rear plate and the optimizer which are superposed in sequence, wherein the optimizer is connected with battery clusters in parallel; the solar cell module is composed of a plurality of battery clusters which are connected transversely and vertically in series; each battery cluster is composed of the plurality of battery pieces. When one or more battery pieces in one battery cluster of the module are shielded or damaged, the integrated optimizer can be used for adjusting current and voltage of the battery cluster so that the current of the battery cluster is the same as that of the other battery clusters; on one hand, the influences on normally-working battery clusters by the battery clusters with problems are avoided and the output power of the assembly is improved, on the other hand, the current of the battery clusters with the problems is the same as that of the other battery clusters, no current mismatch is caused and a hot spot phenomenon is effectively prevented from occurring.

Owner:ALTUSVIA ENERGY TAICANG

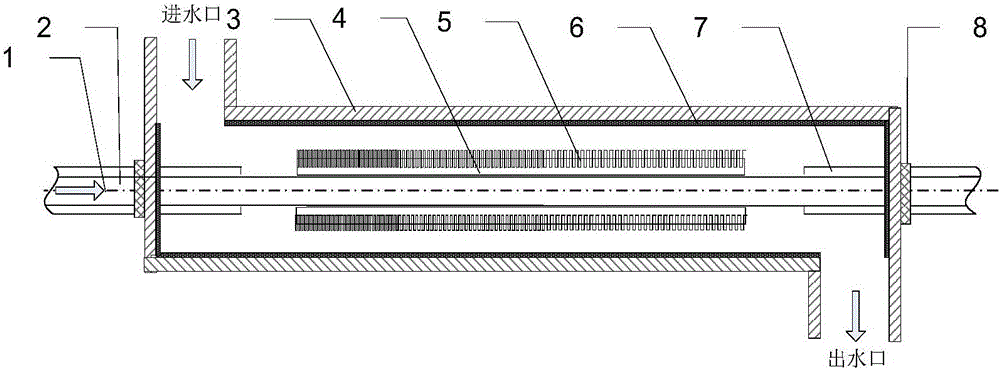

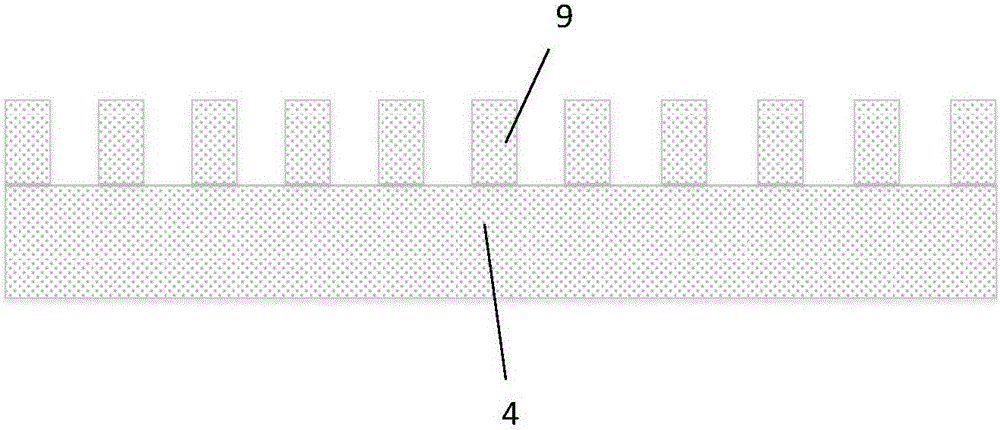

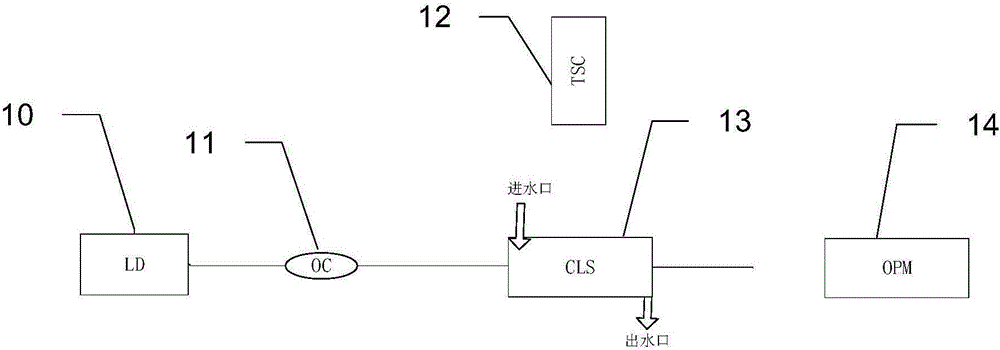

Cladding light stripper for optical fiber lasers and making method thereof

InactiveCN105826802AControl powerImprove abilitiesActive medium shape and constructionGratingRefractive index

The invention discloses a cladding light stripper for optical fiber lasers and a making method thereof. The stripper comprises a cladding optical fiber, multiple optical gratings, and a cooling tube sleeve. The making method comprises the following steps: coating the outer surface of a bare optical fiber inner cladding with ultraviolet photoresist of which the refractive index is greater than or equal to that of the inner cladding; etching multiple gratings on the ultraviolet photoresist, and stripping out the residual light in the inner cladding through diffraction of the multiple gratings; and sleeving the finished multiple gratings in a metal tube, and sealing the metal tube with a sealing sleeve, wherein the wall of the metal tube is fully covered with a heat absorption material which absorbs the light stripped from the inner cladding, and circulating cooling water is fed to take away the generated heat. The light transmittance of the cladding light is adjusted by gratings of different structures so as to achieve the purpose of efficient and uniform light stripping, avoid overheated spots of the stripper and ensure high stability of optical fibers. The stripper has the characteristics of simple structure, wide applicability, high reliability, and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Blending type LED backlight

InactiveCN101968180AIncrease profitShorten the separation distancePoint-like light sourceLighting heating/cooling arrangementsGamutEngineering

The invention discloses a blending type LED backlight comprising an LED light bar and at least one main LED, wherein the main LEDs are evenly distributed on the LED light bar, at least one secondary LED is arranged between the main LEDs, the colour gamut of the secondary LED is same with the colour gamut of the main LEDs, and at least one type of the secondary LED is provided; the power of the secondary LED is less than the power of the main LED, the secondary LEDs arranged between the main LEDs are evenly arranged along the LED light bar, and each main LED and each secondary LED are respectively provided with an independent power supply. The backlight saves energy, has high power supply utilization rate, and does not have colour bleaching, and a module can form dynamic response.

Owner:BOE OPTICAL SCI & TECH

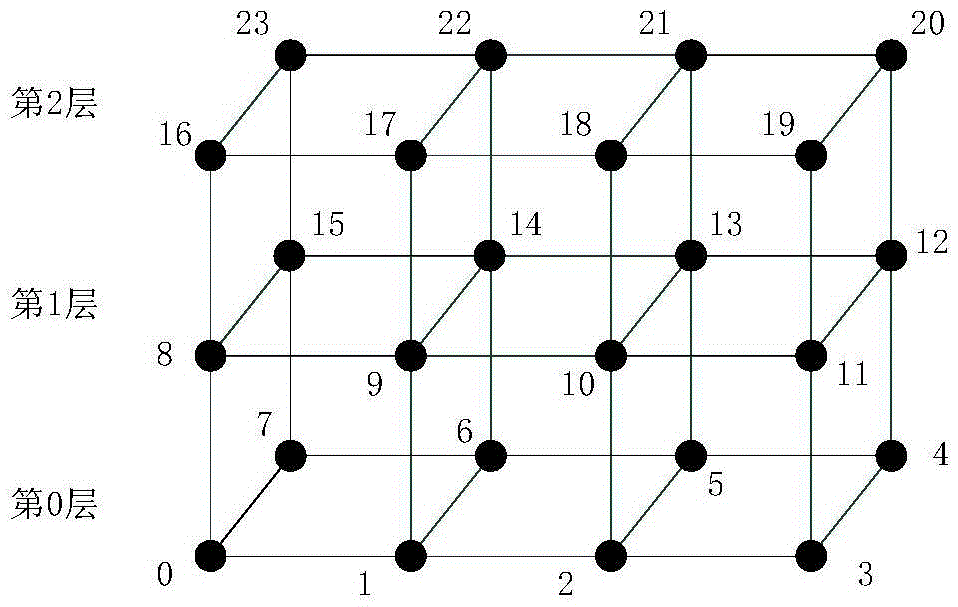

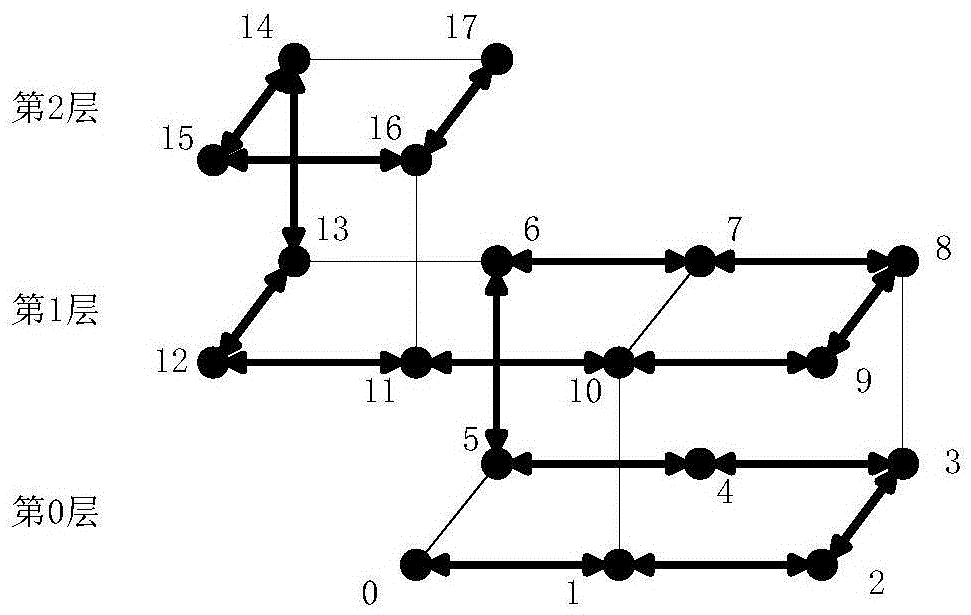

Routing method and system for non-regular three-dimensional integrated circuit network-on-chip

ActiveCN105577539AImprove communication performanceImprove throughputData switching networksTree rootNetwork packet

The invention provides a routing method and system for a non-regular three-dimensional integrated circuit network-on-chip. The method comprises the steps of according to the topological structure of the non-regular three-dimensional integrated circuit network-on-chip, determining that a Hamiltonian path based error tolerance routing algorithm route data package or a spanning tree based error tolerance routing algorithm route data package is adopted; if the Hamiltonian path based error tolerance routing algorithm route data package is adopted, determining to perform routing error tolerance by use of the sequence of monotonous ascending node number or monotonous descending node number according to positions of a source node and a destination node; and if the spanning tree based error tolerance routing algorithm route data package is adopted, selecting to generate a tree root node, and selecting a transmission path to finish transmission of the data package according to the root node and positions of the source node and the destination node.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

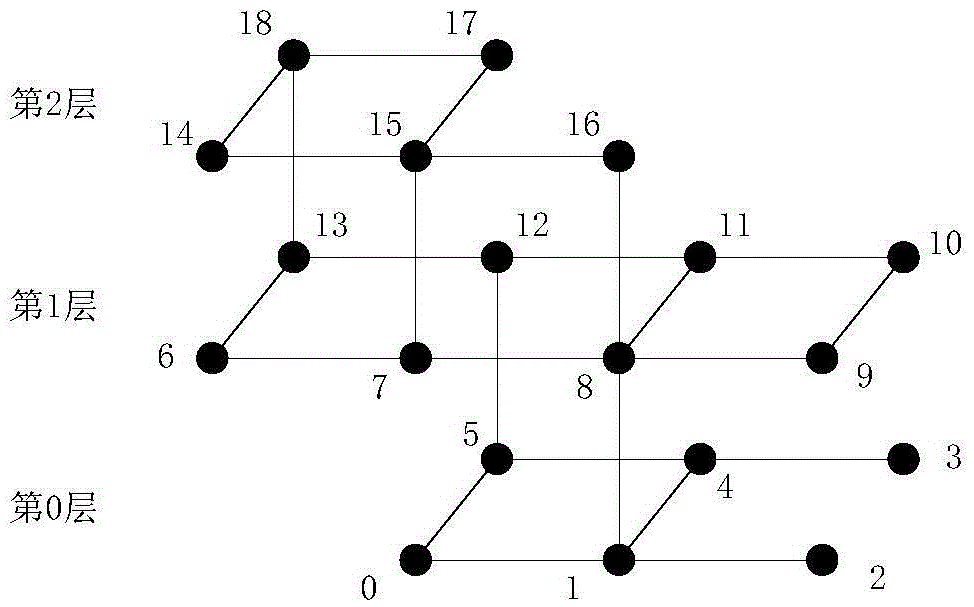

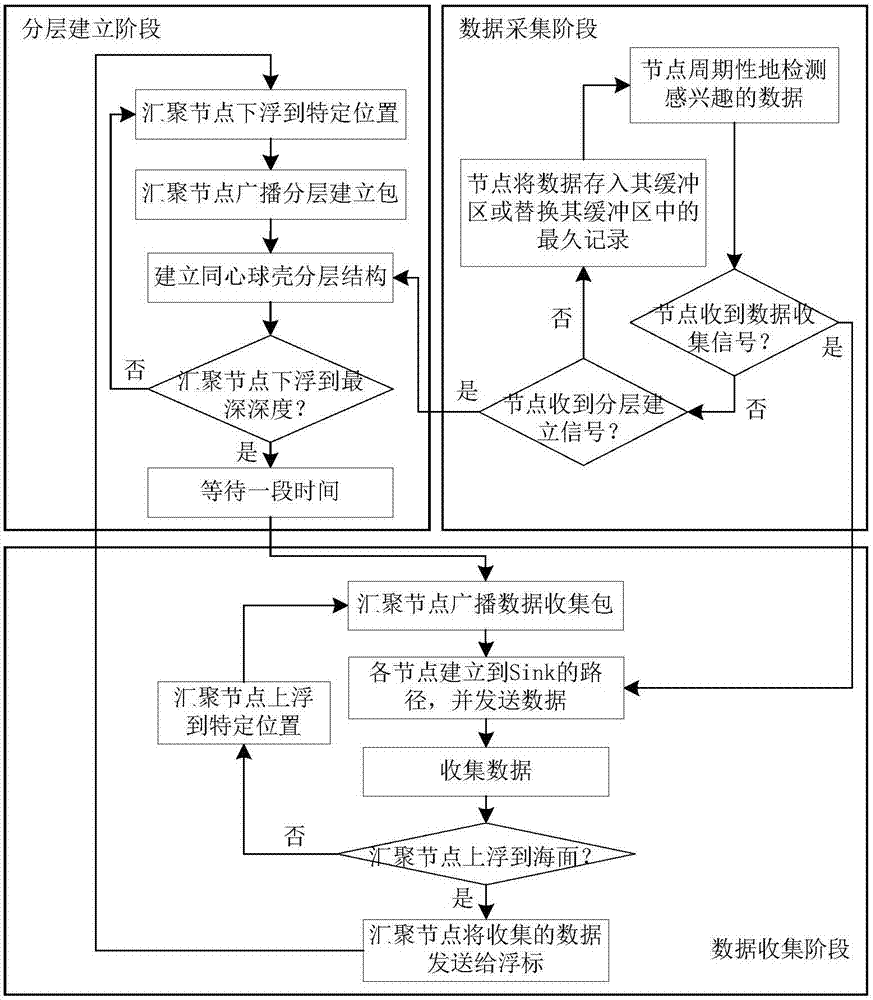

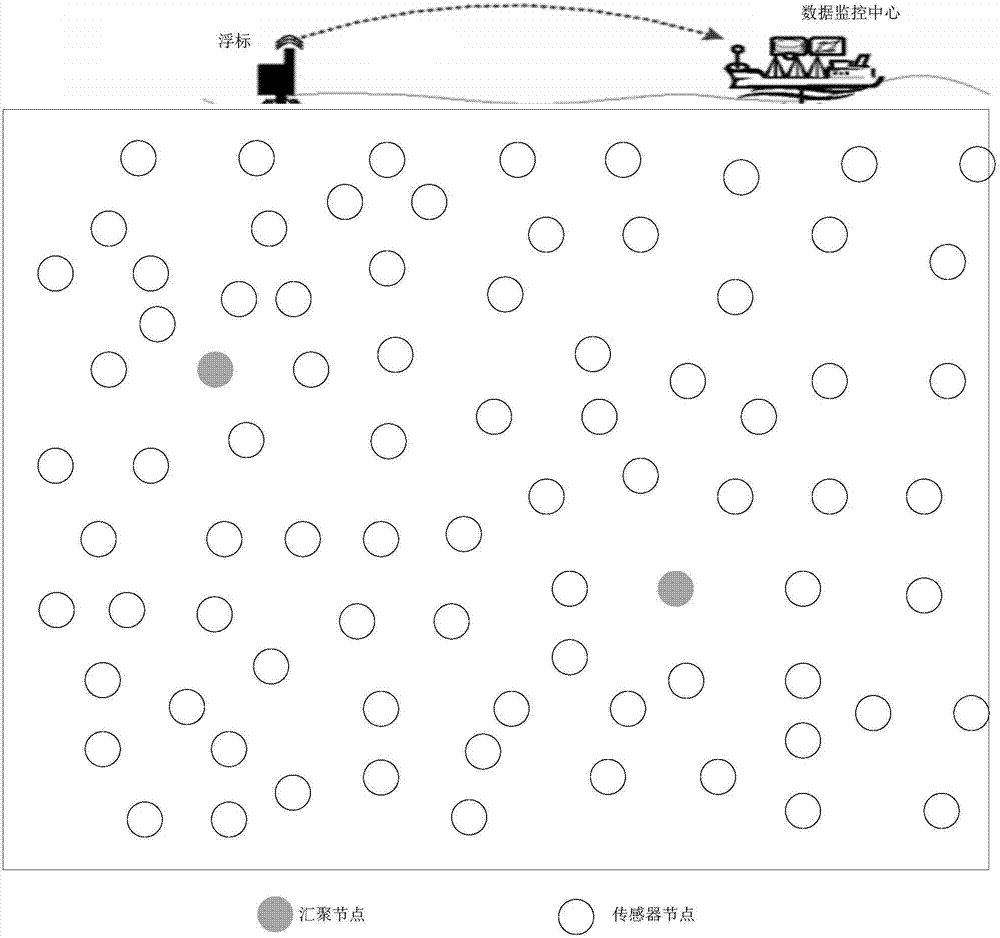

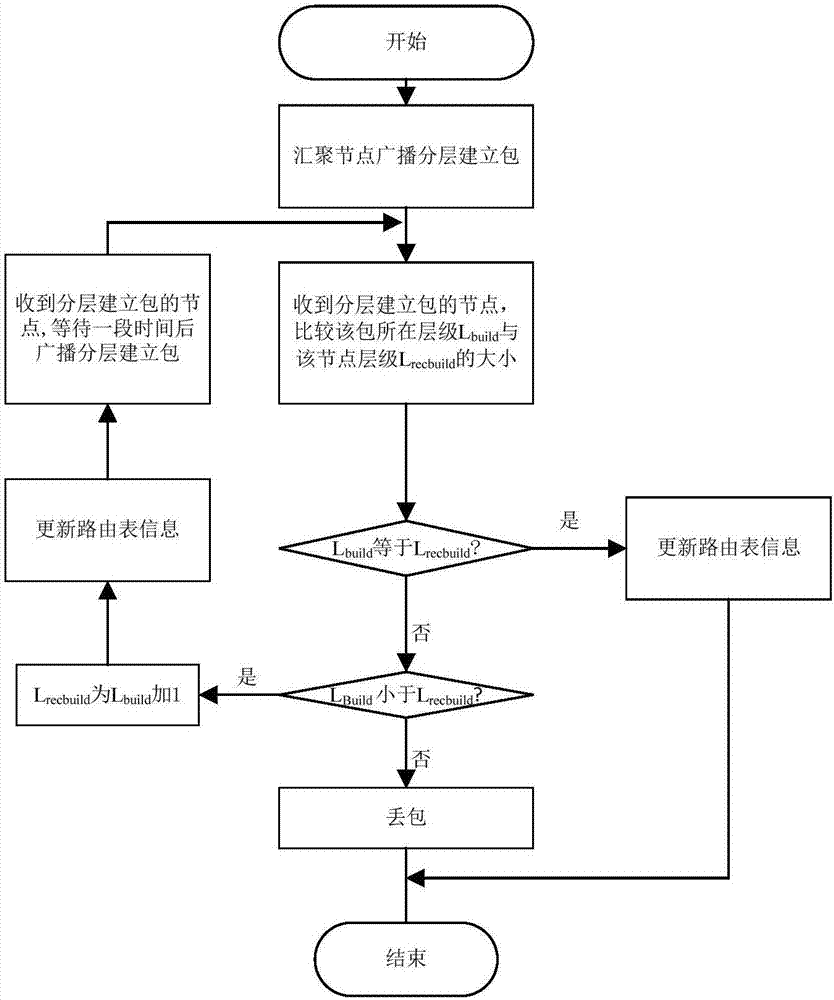

Underwater sensor network routing method for cavity sensing

ActiveCN106879044AImprove delivery rateExtend your lifeNetwork topologiesHigh level techniquesUnderwater sensor networksNetwork packet

The present invention provides an underwater sensor network routing method for cavity sensing. The method includes the following steps that: when arriving at a set position during a downward floating process, an aggregation node broadcasts a layered establishment packet and executes a layered establishment task, when the aggregation node arrives at a largest depth, the aggregation node waits for a period of time, and then broadcasts a data collection packet and executes a data collection task, after finishing data collection, the aggregation node begins to float upwards, when the aggregation node arrives at the set position, the aggregation node broadcasts a data collection packet and executes a data collection task, when the aggregation node arrives the surface of water, the aggregation node sends the collected data to a buoy node; sensor nodes periodically collect data of interest; if the sensor nodes receive layered establishment signals, the sensor nodes enter a layered establishment stage and establish a concentric spherical shell layered structure; and if the sensor nodes receive data collection signals, the sensor nodes enter a data collection stage, the sensor nodes build paths to the aggregation node and send the data. According to the underwater sensor network routing method for cavity sensing of the invention, same-layer transmission and the residual energy of the nodes are considered, the generation of same-layer cyclic transmission, hot zones and cavities can be avoided, the arrival rate of data packets can be improved, and the service life of a network can be prolonged.

Owner:HARBIN ENG UNIV

Solar cell, solar cell string and lamination tile photovoltaic module

InactiveCN108735831AWill not cause failureDoes not significantly reduce output powerPhotovoltaic energy generationSemiconductor devicesPower flowElectrical battery

The invention is applicable to the technical field of photovoltaic power generation and provides a solar cell, a solar cell string and a lamination tile photovoltaic module. The lamination tile photovoltaic module comprises a plurality of solar cells, wherein accessory grid lines are arranged on back surfaces of the solar cells, the solar cells are connected in a lamination tile shape to form sub-cell strings, a front-surface main grid line of an arbitrary solar cell is in overlap joint with a back-surface main grid line of the adjacent solar cell, a plurality of sub-cell strings arranged in parallel are connected in parallel to form the cell string by a first parallel convergence strip and a second parallel convergence strip, the corresponding accessory grid lines in the plurality of sub-cell strings arranged in parallel are connected by conductive strips, and the plurality of cell strings arranged in parallel are connected in series by series convergence strips. When a solar cell piece is shielded, a current can pass by the shielded solar cell by the accessory grid lines, and a hot spot effect is prevented.

Owner:YINGLI ENERGY CHINA

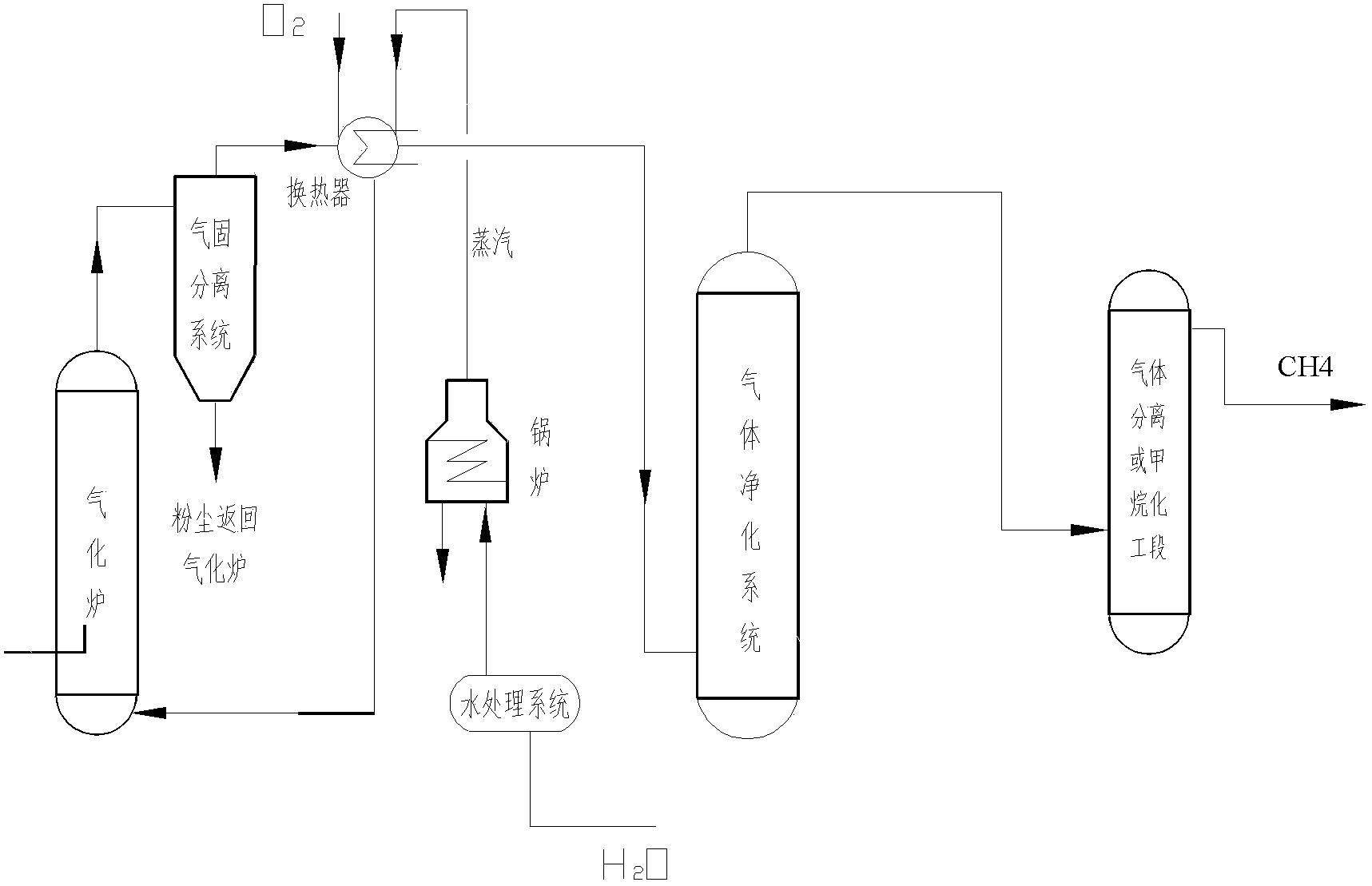

Technology for preparing natural gas through self-heating catalytic gasification of fire coal, and system thereof

The invention provides a technology for preparing natural gas through self-heating catalytic gasification of fire coal, and a system thereof. Coal, a catalyst and a gasifying agent are supplied to a gasifying apparatus, wherein the gasifying agent is supplied to the gasifying apparatus in a dispersion mode from different positions of the gasifying apparatus, and oxygen is introduced into the gasifying apparatus. The technology for preparing the natural gas through self-heating catalytic gasification of fire coal, which allows heat required by a catalytic gasifying reaction to be provided in a fire coal self-heating mode, has the characteristics of no installation of a heating device, simplicity, good economy, and realization of single-furnace heat coupling, and the system has a high efficiency; and additionally, the gasifying agent is supplied to the gasifying apparatus in a dispersion mode, so heat required by the reaction is supplied, the oxygen concentration can be controlled within the specific limits through controlling the full-bed oxygen distribution and adjusting the ratio of steam to oxygen in a distribution plate and a bed in order to avoid a local high-temperature region appearing in the bed, thereby slag bonding can be effectively avoided.

Owner:ENN SCI & TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com