Calcium carbonate whisker reinforced rubber base friction material and preparation method therefor

A technology of calcium carbonate whiskers and friction materials, applied in friction linings, chemical instruments and methods, mechanical equipment, etc., can solve the problems of unstable friction coefficient, low heat resistance, and high cost, so as to overcome thermal cracks, improve Stable, cost-effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

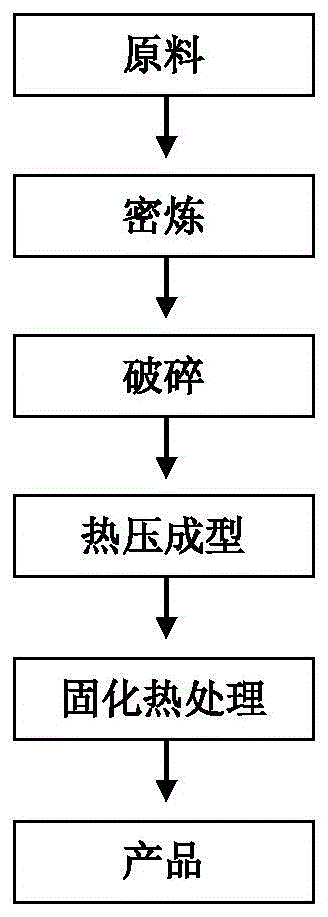

Method used

Image

Examples

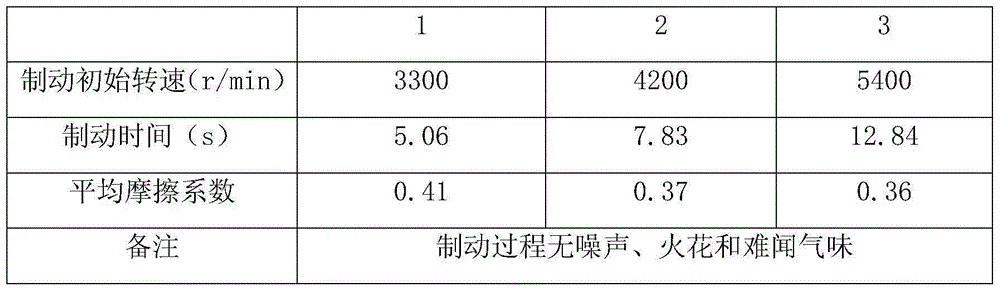

Embodiment 1

[0033] A calcium carbonate whisker reinforced rubber-based friction material, the content of each component is:

[0034] Nitrile rubber 9kg, styrene-butadiene rubber 3kg, 6224 resin 3kg, 307 resin 4kg, calcium carbonate whisker 5kg, steel fiber 10kg, sepiolite fiber 5kg, mineral fiber 8kg, aramid fiber 2kg, barium sulfate 5kg, magnesium oxide 8.5 kg, alumina 3kg, flake graphite 5kg, carbon black 3kg, petroleum coke 6kg, Cardolite cashew nut shell oil friction powder 3kg, sulfur 0.5kg and vulcanization accelerator 0.75kg.

[0035] Preparation:

[0036] (1) Ingredients: weigh various raw materials with an electronic scale in strict accordance with the above formula requirements;

[0037] (2) Internal mixing: Put the above-mentioned raw materials into a pressurized flip-type internal mixer, and mix for 15 minutes at a speed of 30r / min and a temperature of 80°C, discharge from the discharge port, and cool and dry the discharged materials at room temperature dry to obtain dry mat...

Embodiment 2

[0048] A calcium carbonate whisker reinforced rubber-based friction material, the content of each component is:

[0049] 8kg of nitrile rubber, 7kg of styrene-butadiene rubber, 2kg of 6224 resin, 3kg of 307 resin, 10kg of calcium carbonate whisker, 15kg of steel fiber, 8kg of sepiolite fiber, 1kg of mineral fiber, 6kg of barium sulfate, 5kg of magnesium oxide, 3kg of aluminum oxide, Flake graphite 8kg, carbon black 1kg, petroleum coke 8kg, Cardolite cashew nut shell oil friction powder 4kg, sulfur 0.5kg and vulcanization accelerator 1kg.

[0050] Preparation:

[0051] (1) Ingredients: weigh various raw materials with an electronic scale in strict accordance with the above formula requirements;

[0052] (2) Internal mixing: Put the above-mentioned raw materials into a pressurized flip-type internal mixer, and mix for 15 minutes at a speed of 30r / min and a temperature of 80°C, discharge from the discharge port, and cool and dry the discharged materials at room temperature dry ...

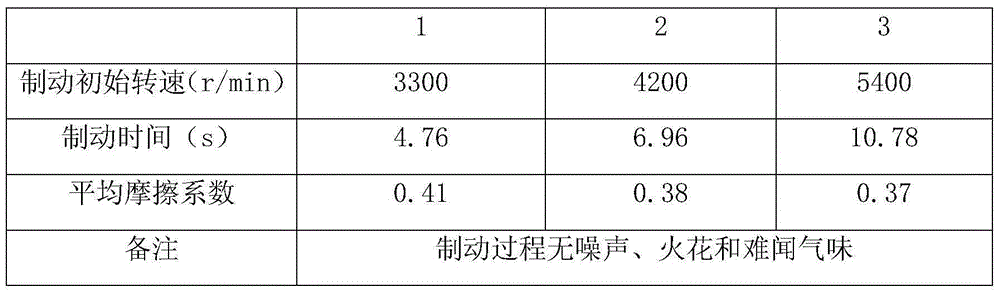

Embodiment 3

[0063] A calcium carbonate whisker reinforced rubber-based friction material, the content of each component is:

[0064] 12kg of nitrile rubber, 6kg of styrene-butadiene rubber, 4kg of 6224 resin, 4kg of 307 resin, 15kg of calcium carbonate whisker, 15kg of steel fiber, 5kg of sepiolite fiber, 6kg of barium sulfate, 10kg of magnesium oxide, 2kg of aluminum oxide, 6kg of flake graphite, Carbon black 5kg, petroleum coke 5kg, Cardolite cashew nut shell oil friction powder 3kg, sulfur 1kg and vulcanization accelerator 0.5kg.

[0065] Preparation:

[0066] (1) Ingredients: weigh various raw materials with an electronic scale in strict accordance with the above formula requirements;

[0067] (2) Internal mixing: Put the above-mentioned raw materials into a pressurized flip-type internal mixer, and mix for 15 minutes at a speed of 30r / min and a temperature of 80°C, discharge from the discharge port, and cool and dry the discharged materials at room temperature dry to obtain dry mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com