Patents

Literature

909 results about "Reinforced rubber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reinforced rubber products are one of the largest groups of composite materials, though rarely referred to as composite materials. Familiar examples are automobile tyres, hoses and conveyor belts.

Compounding silica-reinforced rubber with low volatile organic compound (VOC) emission

ActiveUS20060217473A1Enhanced rubber reinforcementEnhanced interactionSilicon organic compoundsSynthetic resin layered productsAlcoholReinforced rubber

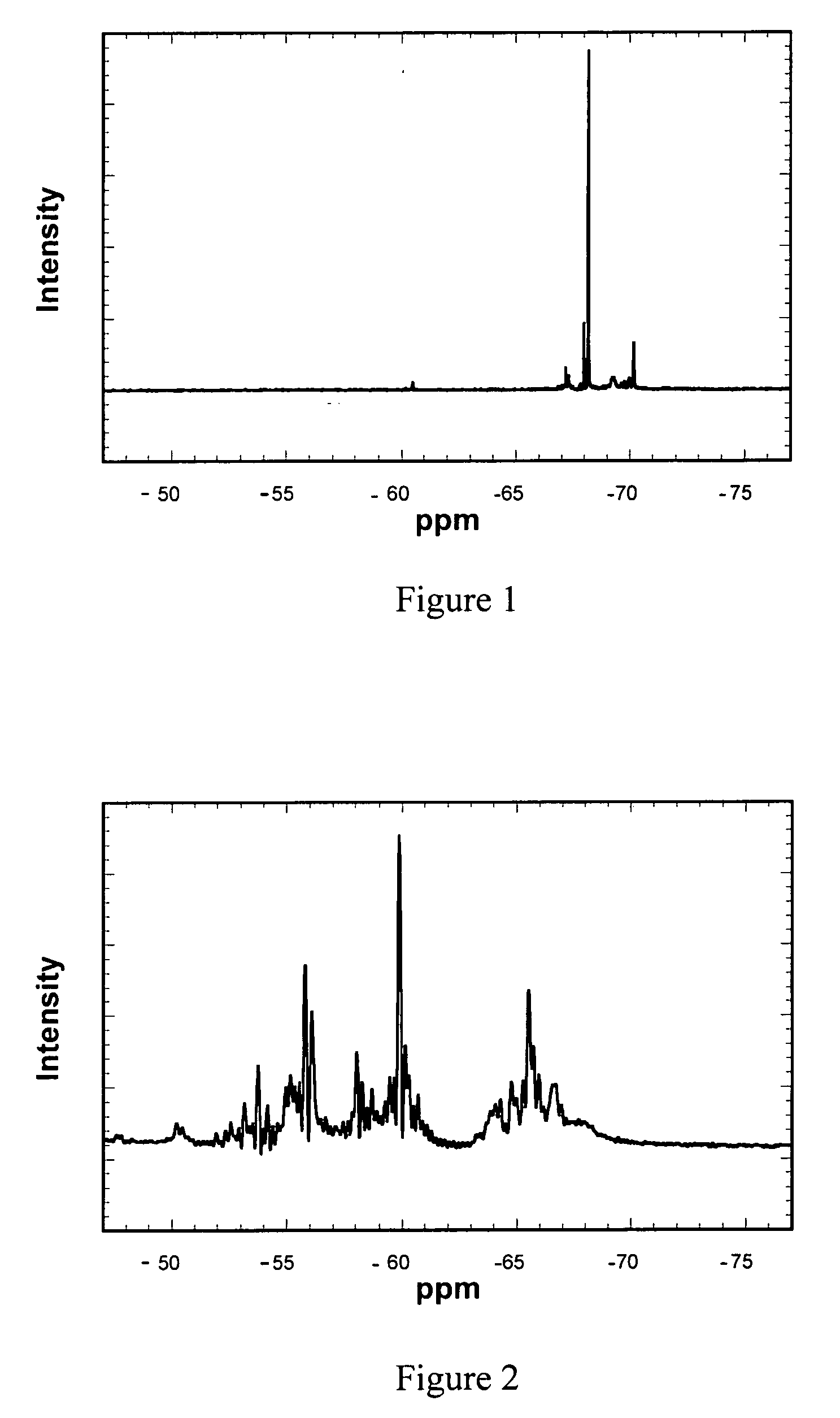

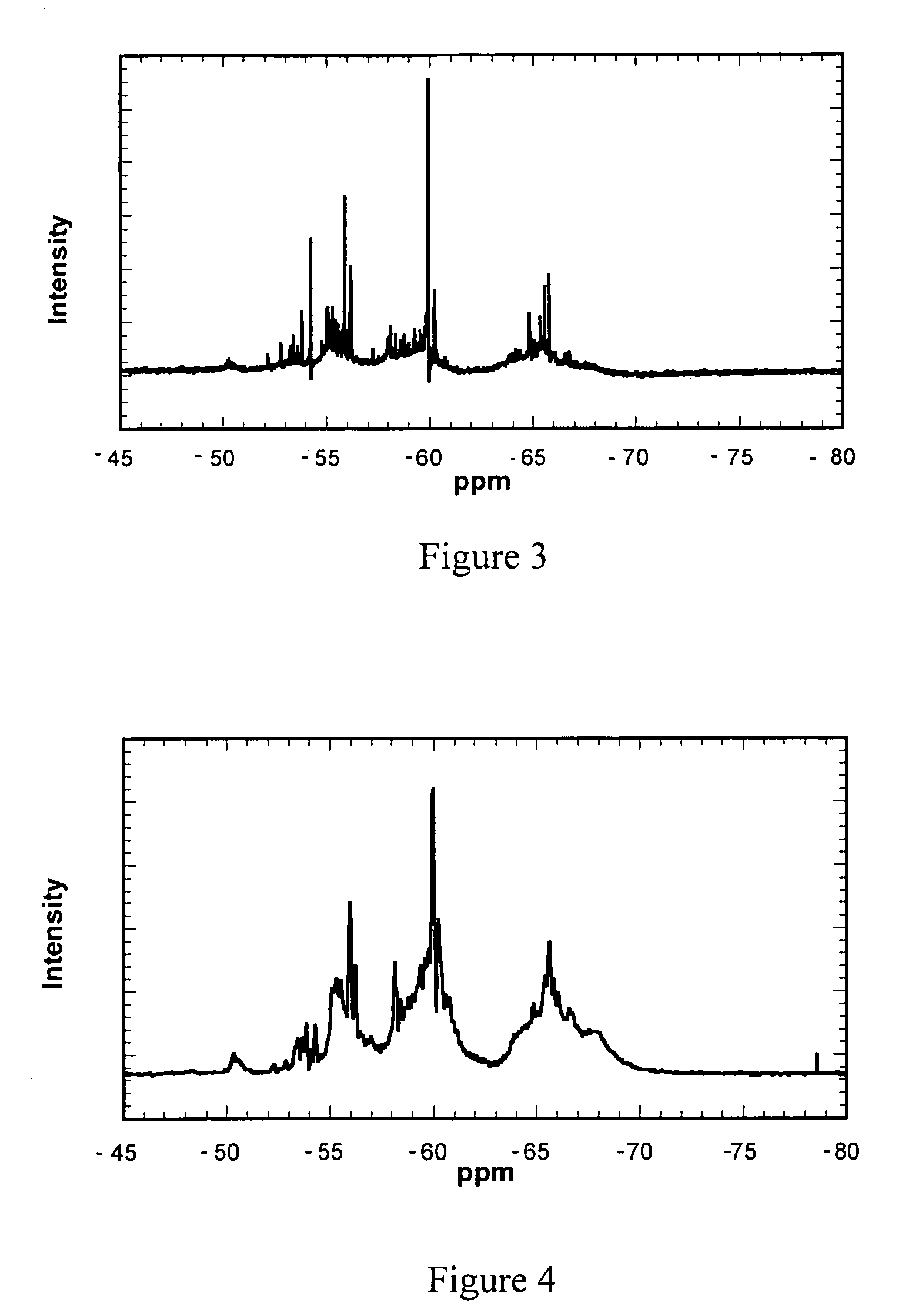

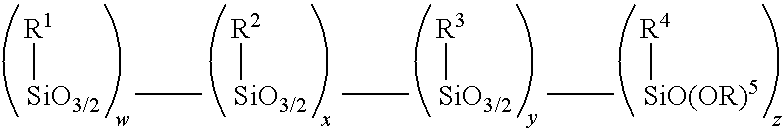

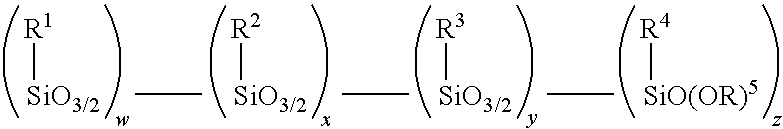

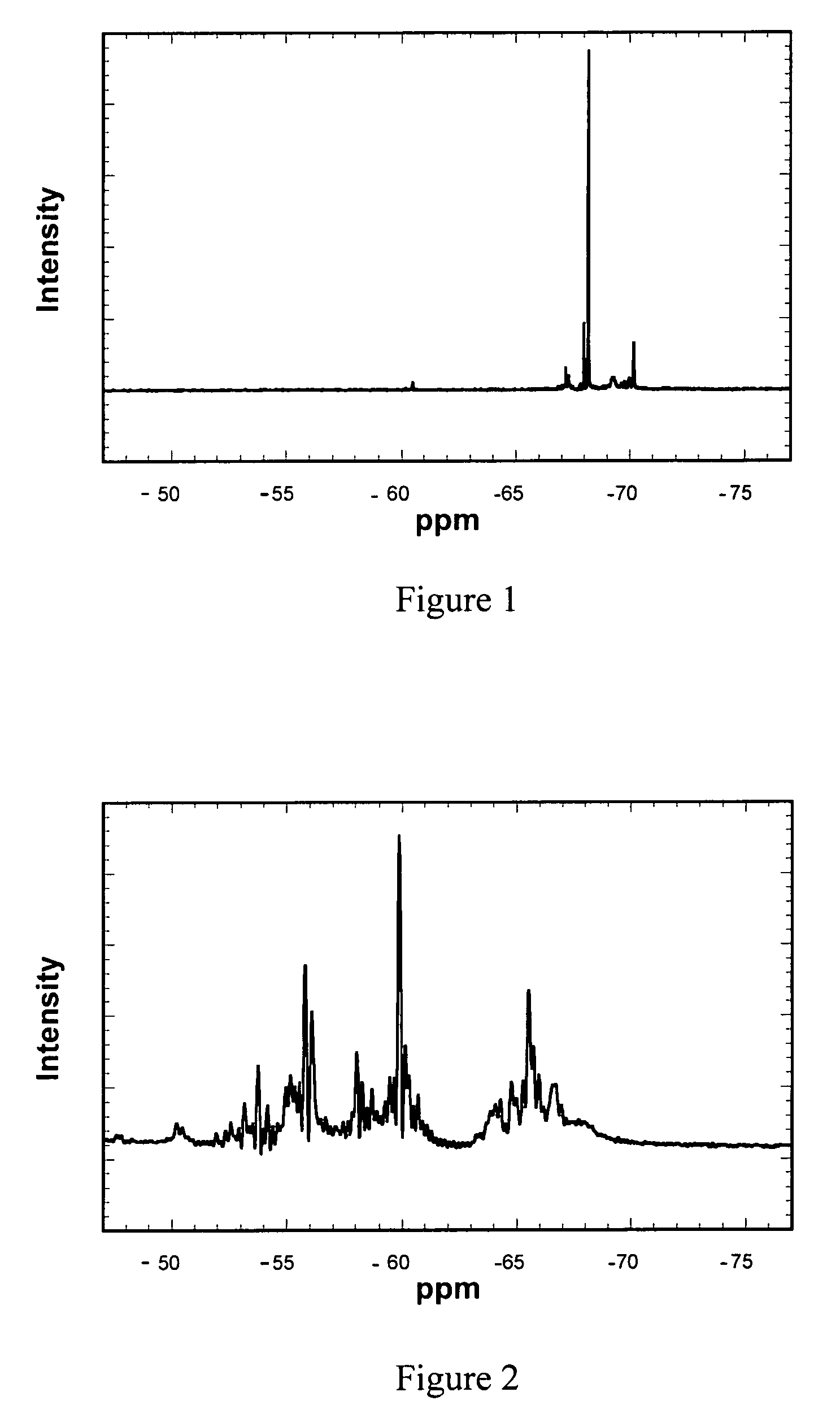

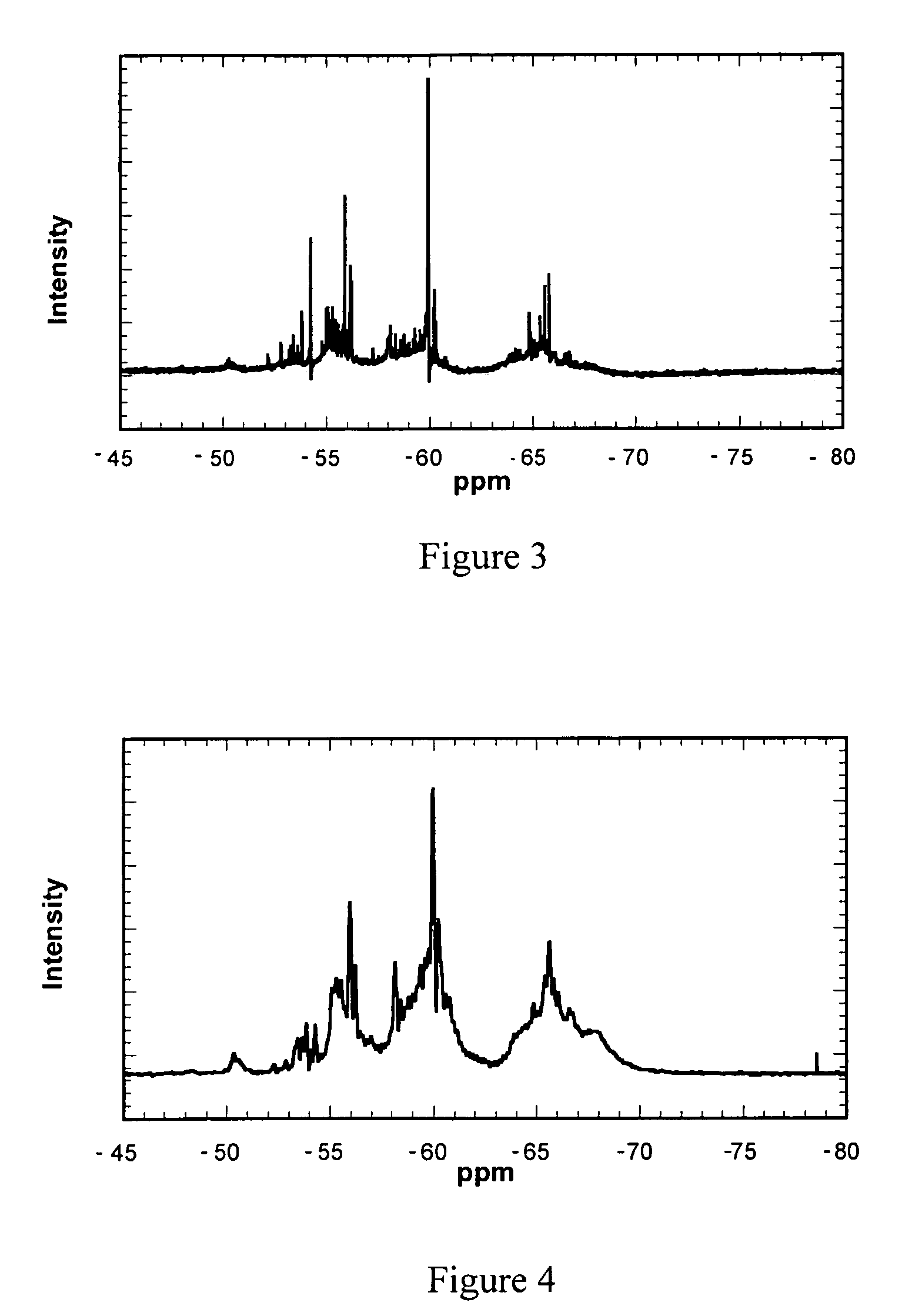

Alkoxy-modified silsesquioxane compounds are described. The alkoxy-modified silsesquioxane compounds contain an alkoxysilane group that participates in an alkoxysilane-silica reaction as a silica dispersing agent in rubber, with the release of zero to about 0.1% by weight of the rubber of volatile organic compounds (VOC), especially alcohol, during compounding and further processing. Further described are methods for making alkoxy-modified silsesquioxanes, methods for making vulcanizable rubber compounds containing alkoxy-modified silsesquioxanes, vulcanizable rubber compounds containing alkoxy-modified silsesquioxanes, and pneumatic tires comprising a component that contains alkoxy-modified silsesquioxanes.

Owner:BRIDGESTONE CORP

Rubber composition with silica reinforcement obtained with an amino acid or amino acid-containing protein based activator and use thereof in tires

InactiveUS20030135006A1Enhance various physical propertyImprove curingSpecial tyresTyre tread bands/patternsElastomerPolymer science

The invention relates to the preparation of a silica reinforced rubber composition where alkoxysilane and / or sulfur cure reactions within the elastomer host are controlled by the use of a selected amino acid, or amino acid-containing protein based, activator. The invention also relates to such composite and to a tire having at least one component of such composite

Owner:THE GOODYEAR TIRE & RUBBER CO

Silica-reinforced rubber compounded with blocked mercaptosilanes and alkyl alkoxysilanes

The invention provides a sulfur vulcanizable silica-reinforced elastomeric compound having improved tensile mechanical and dynamic viscoelastic properties. The compounds are formed by mixing an elastomer optionally having an alkoxysilane terminal group, with silica in the presence of an alkyl alkoxysilane and a blocked mercaptosilane. In particular, the mercaptosilane moiety of the blocked mercaptosilane and the alkyl alkoxysilane are present in a weight ratio of about 0.001:1 to about 0.20:1. Preferably, the blocked mercaptosilane and the alkyl alkoxysilane are compounded with the elastomer and the silica at high temperature to facilitate the silica-silane reaction. A deblocking agent is added at any desired mixing stage, optionally with the cure package, to allow binding of the mercaptosilane to the polymer.

Owner:BRIDGESTONE CORP

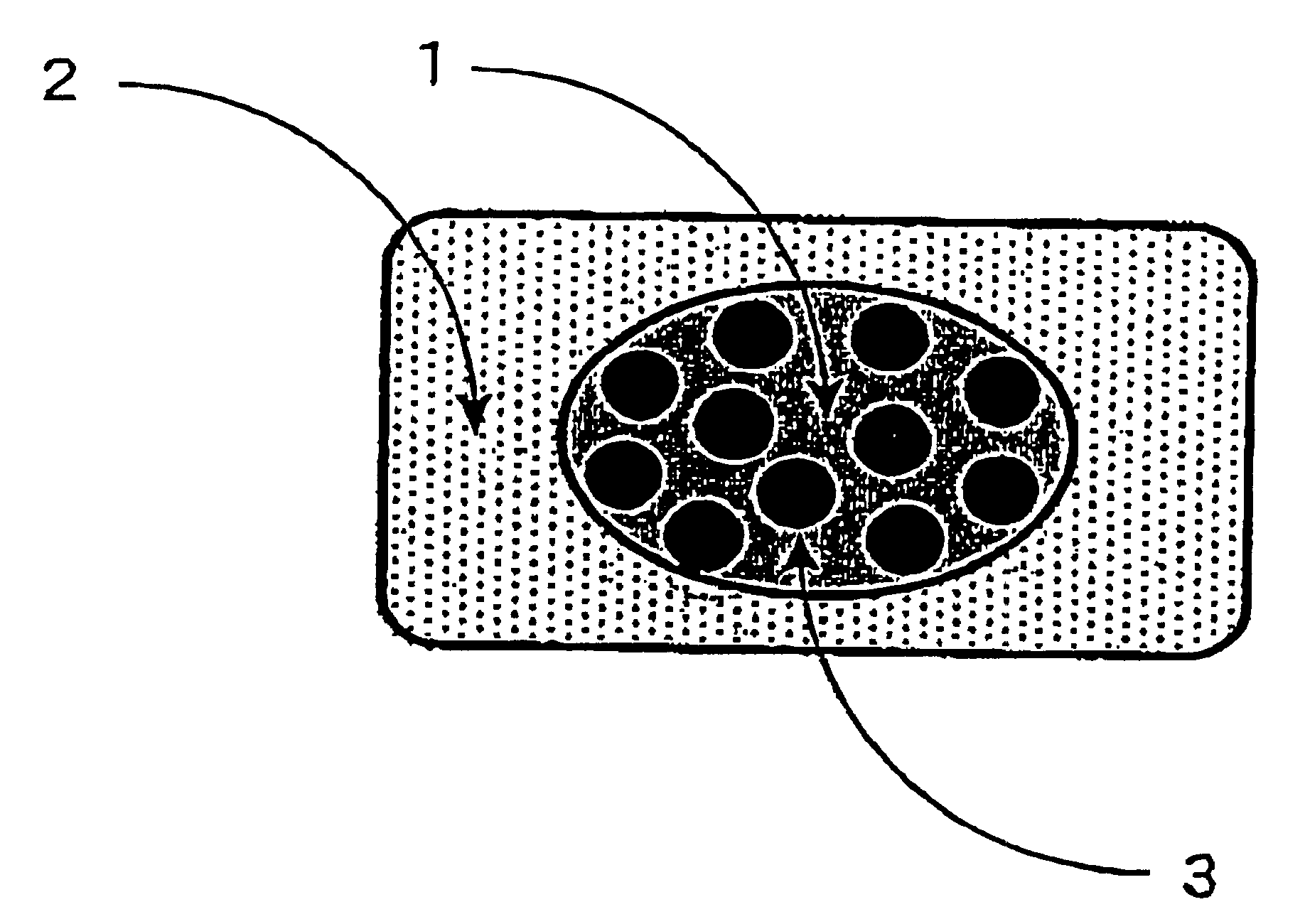

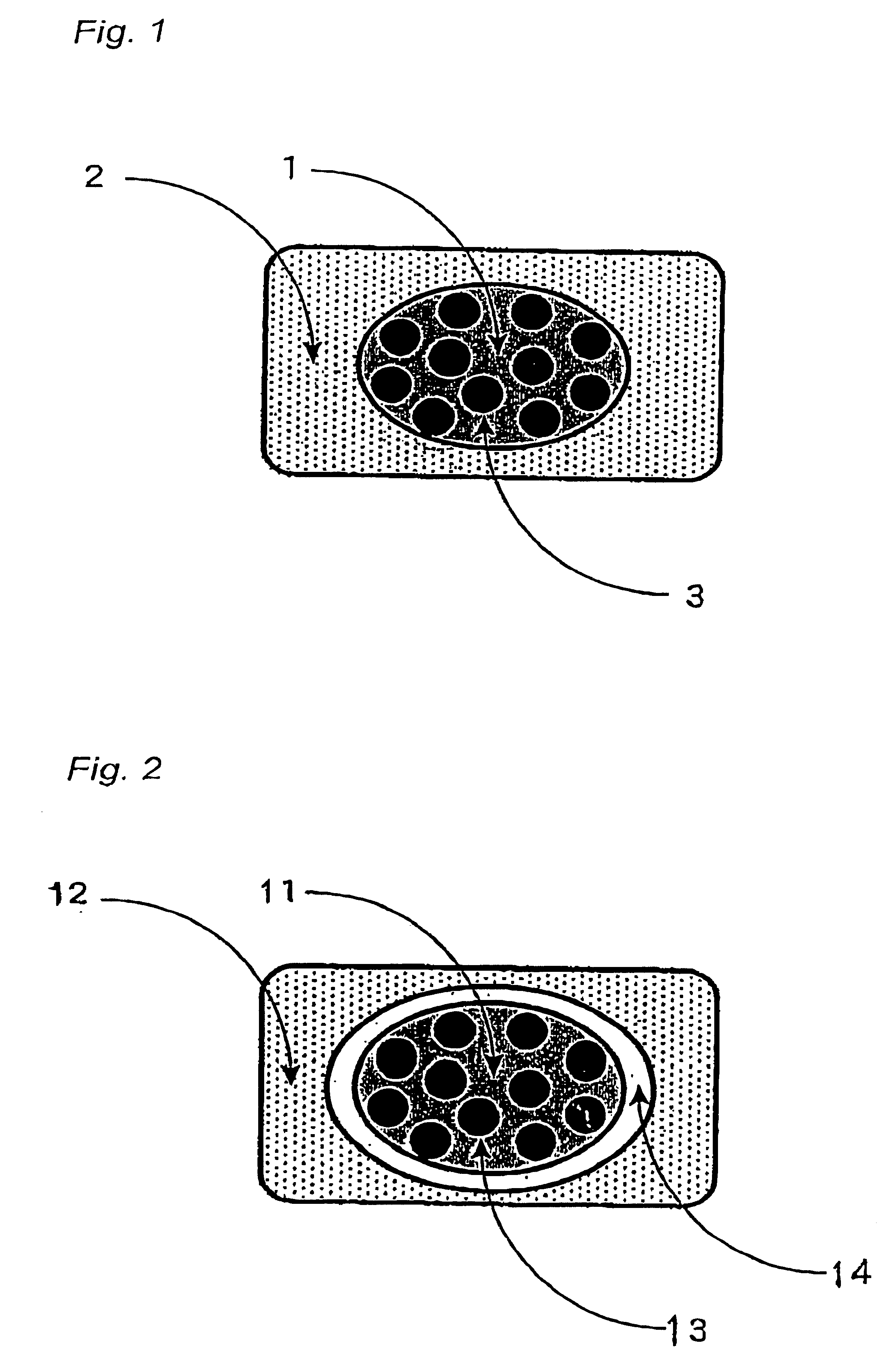

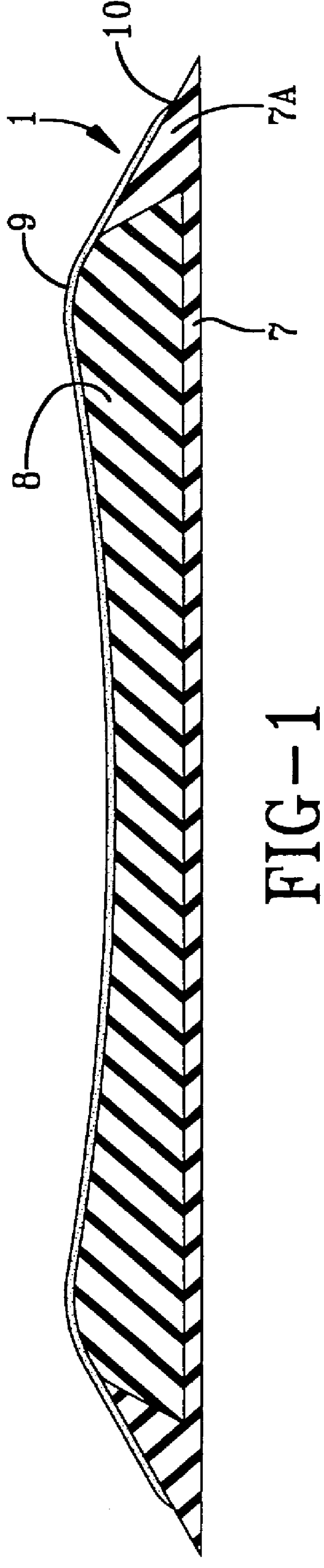

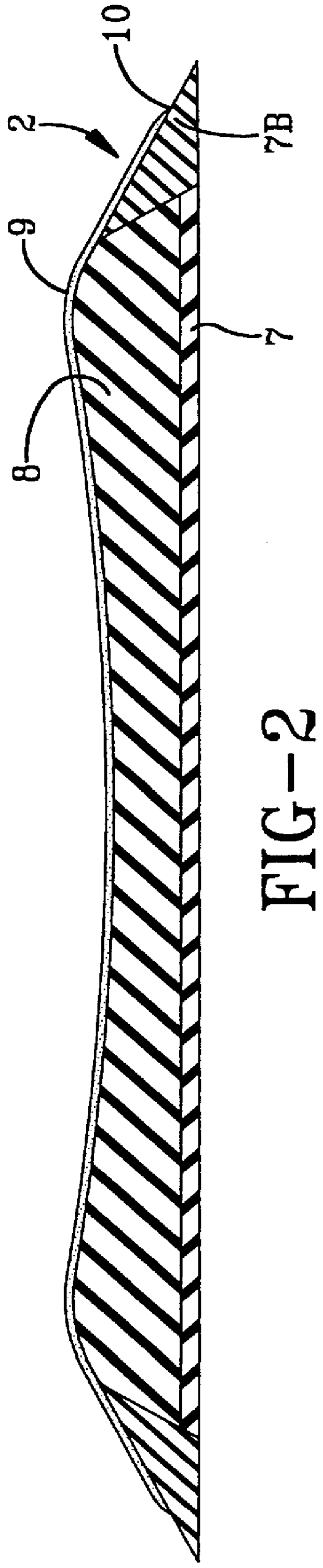

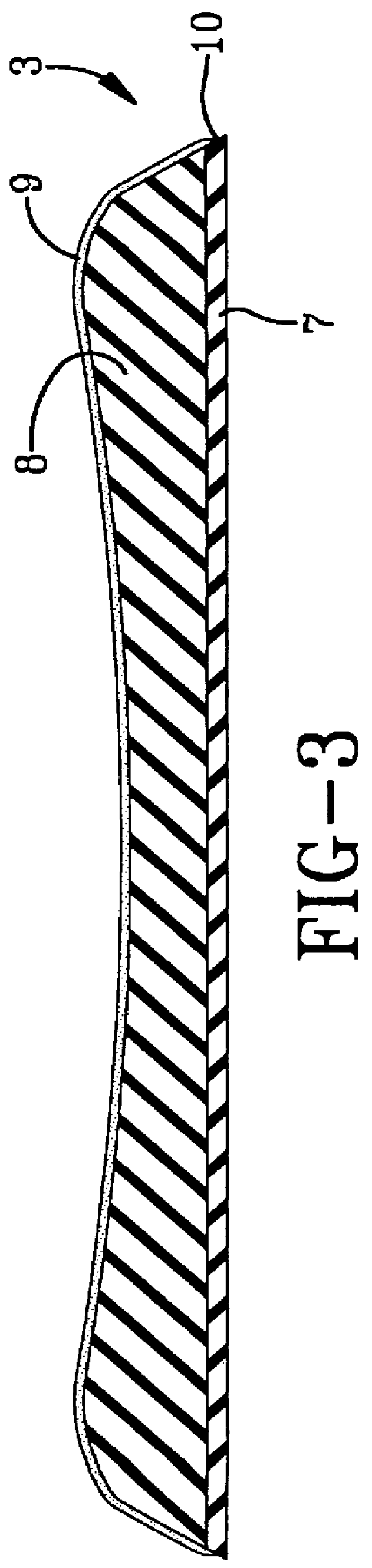

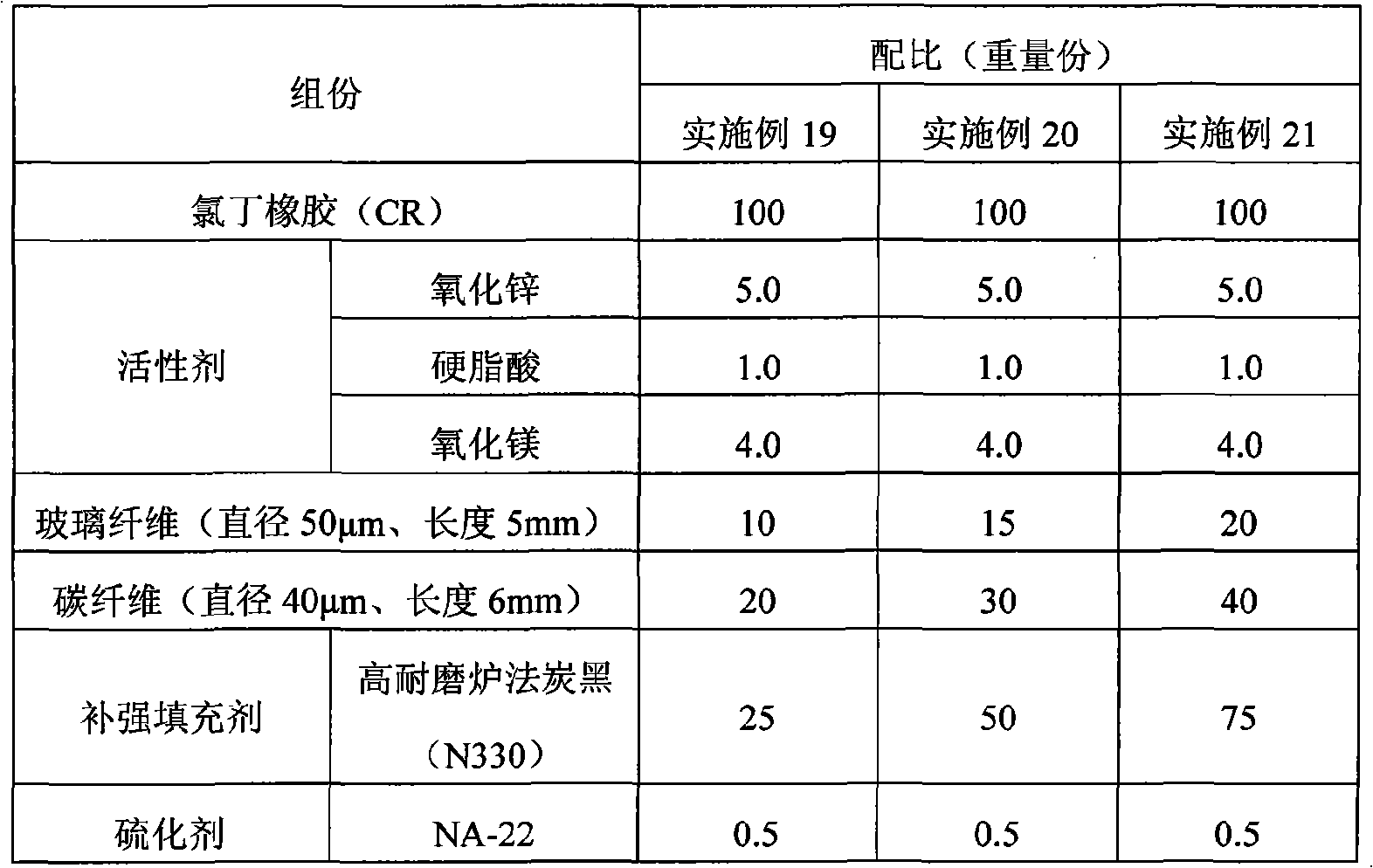

Prepreg and fiber-reinforced rubber materials

The object is to provide a carbon fiber-reinforced rubber material which is superior in heat resistance, water resistance, and dimensional stability and exhibits resistance to fatigue from flexing at a practical level. The present invention relates to a prepreg comprising a liquid rubber composition having a viscosity in a range of 0.01 Pa.s to 100 Pa.s at 70° C. and substantially containing no solvent, the liquid rubber being impregnated into a reinforcing fiber, and relates to a fiber-reinforced rubber material comprising the prepreg in which the liquid rubber is crosslinked. Also, the present invention relates to a fiber-reinforced rubber material comprising a substrate comprising a rubber component, the substrate being reinforced by a core material comprising a prepreg of a reinforcing fiber impregnated with the same rubber component.

Owner:TORAY IND INC

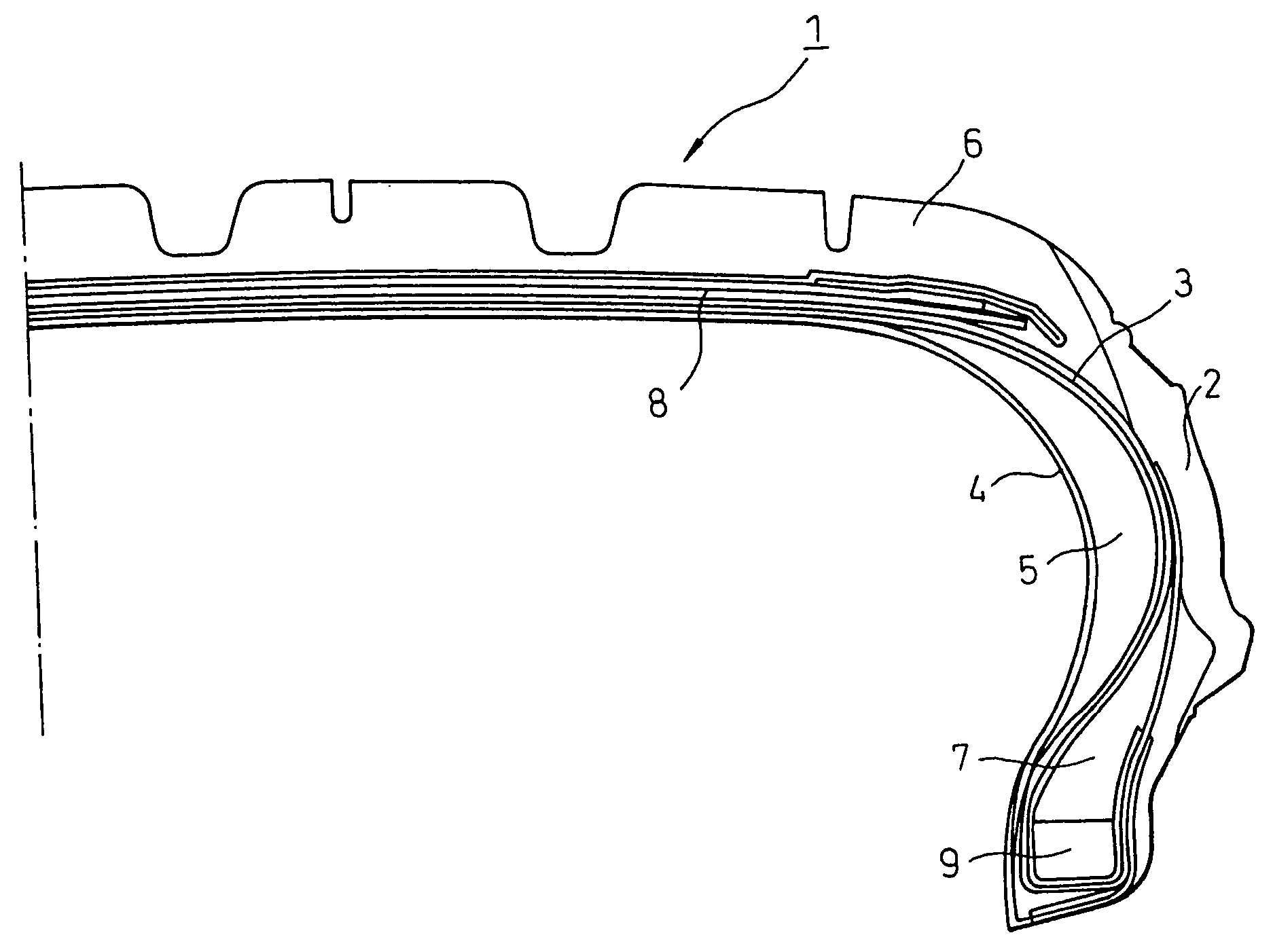

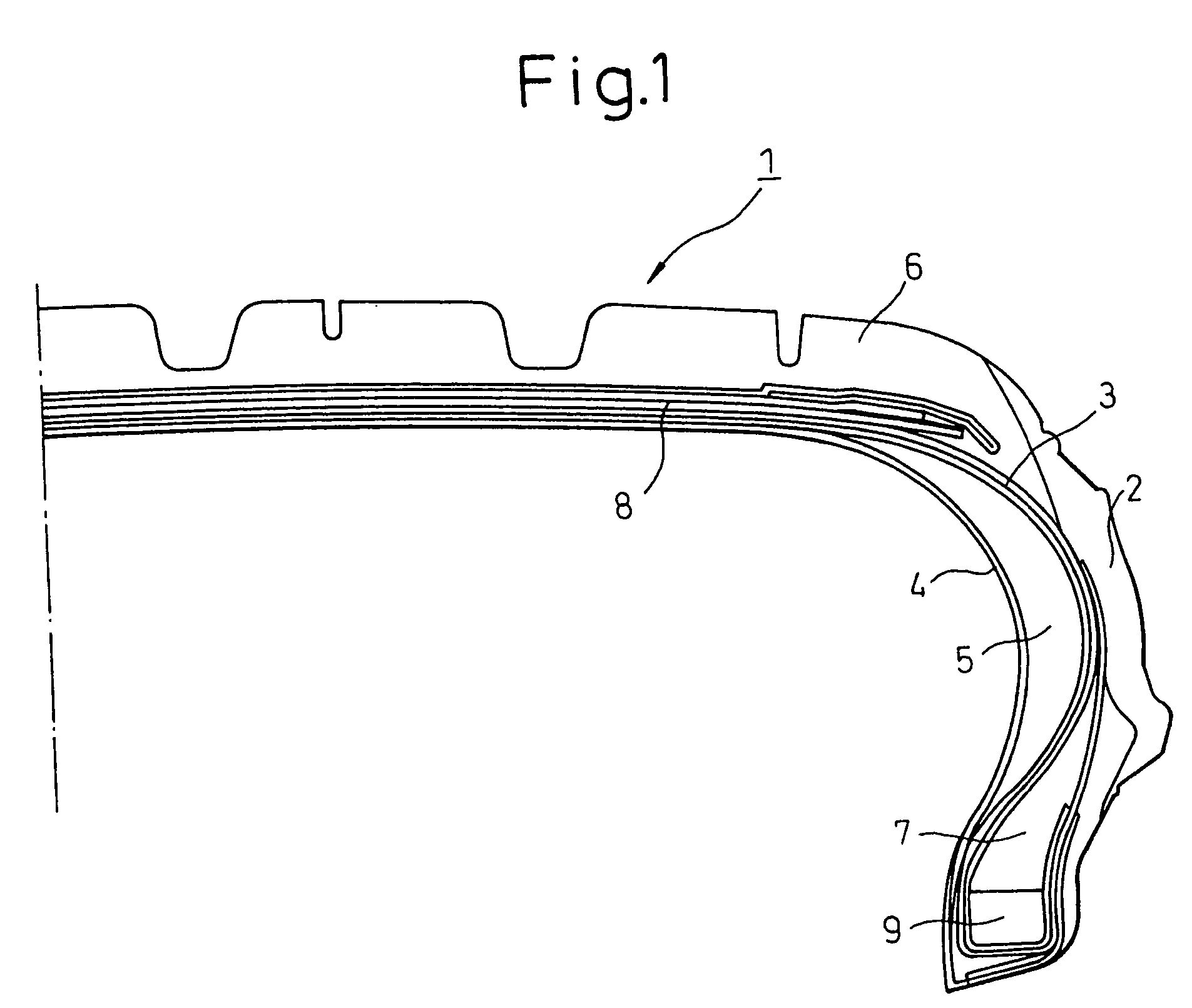

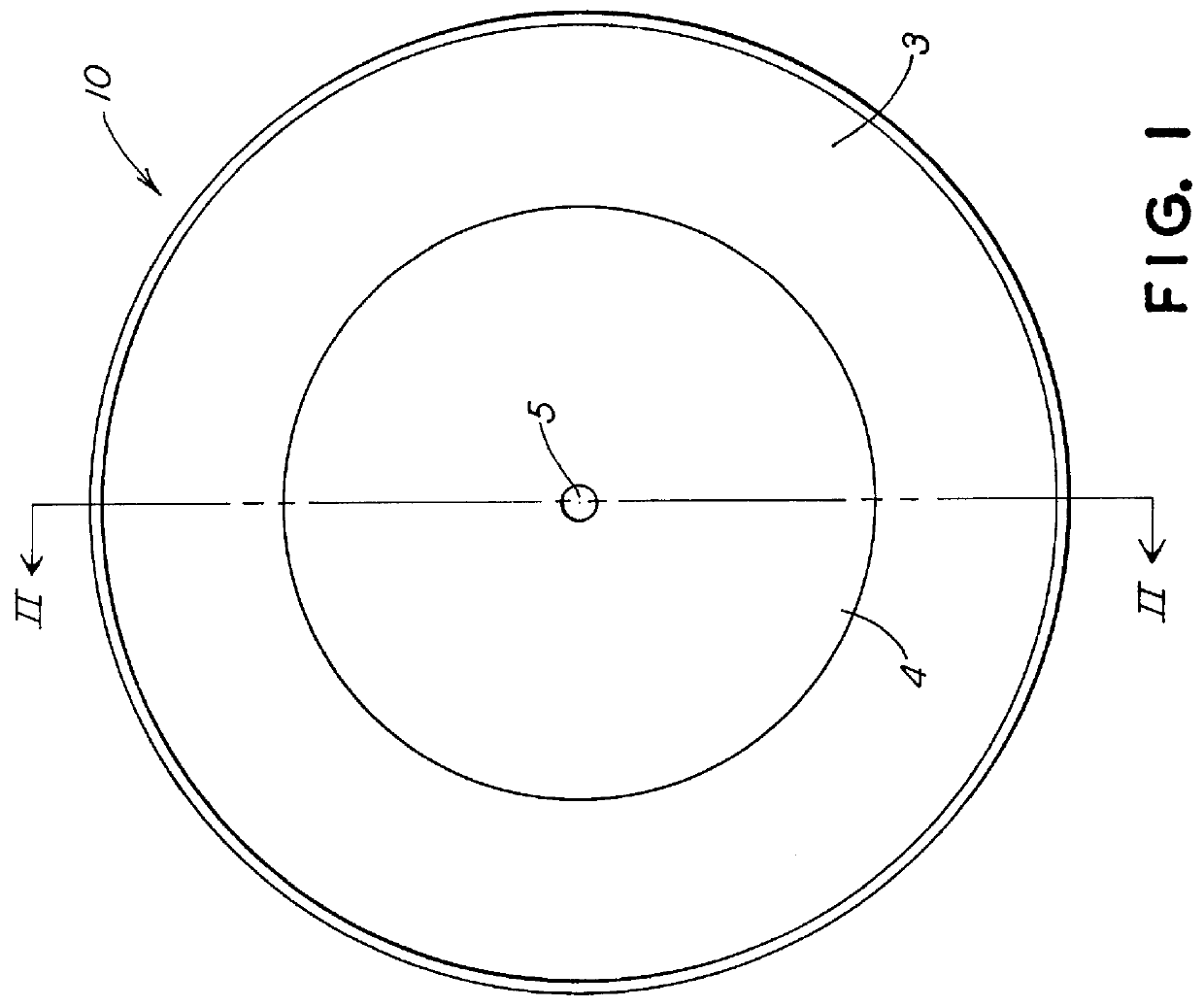

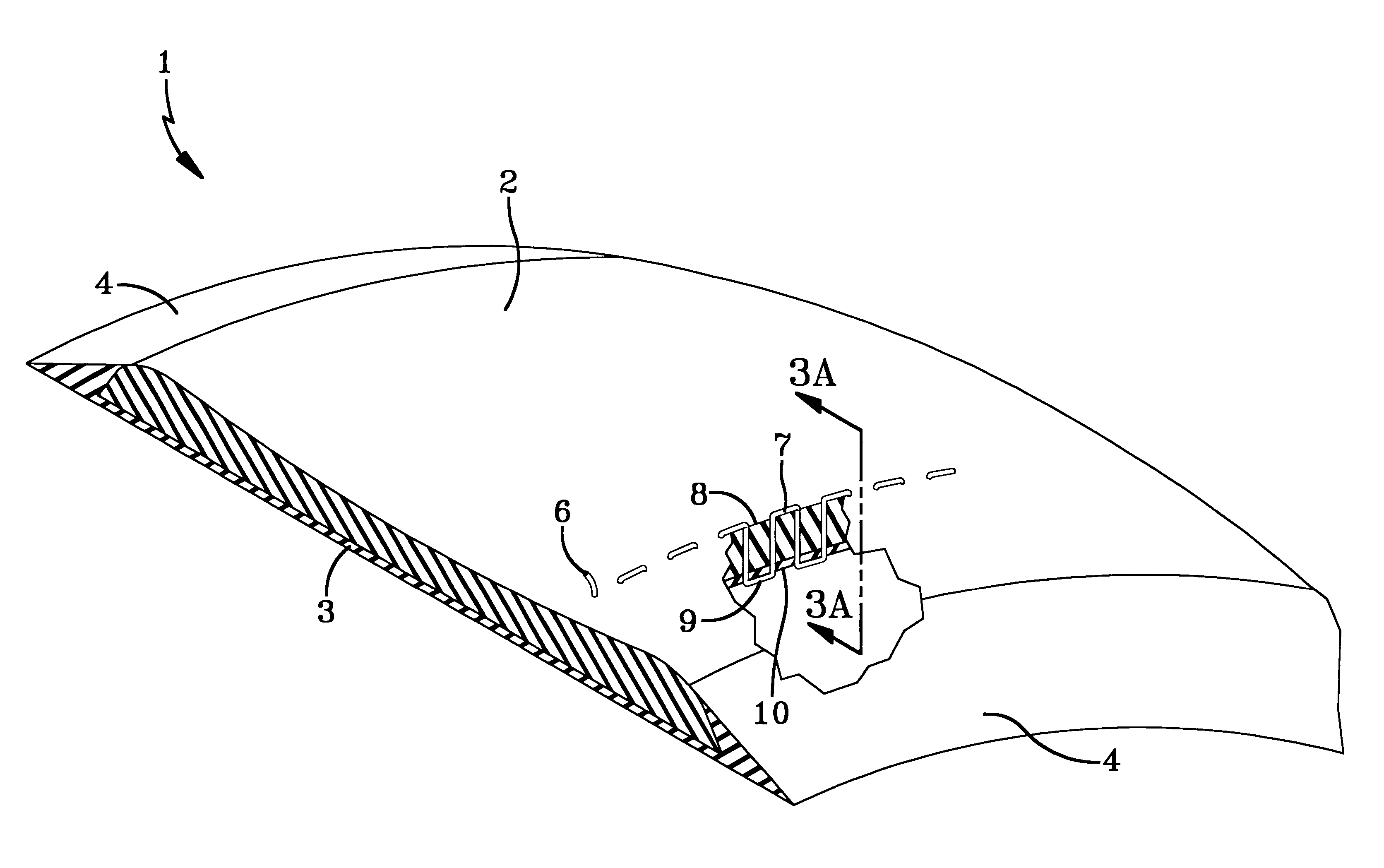

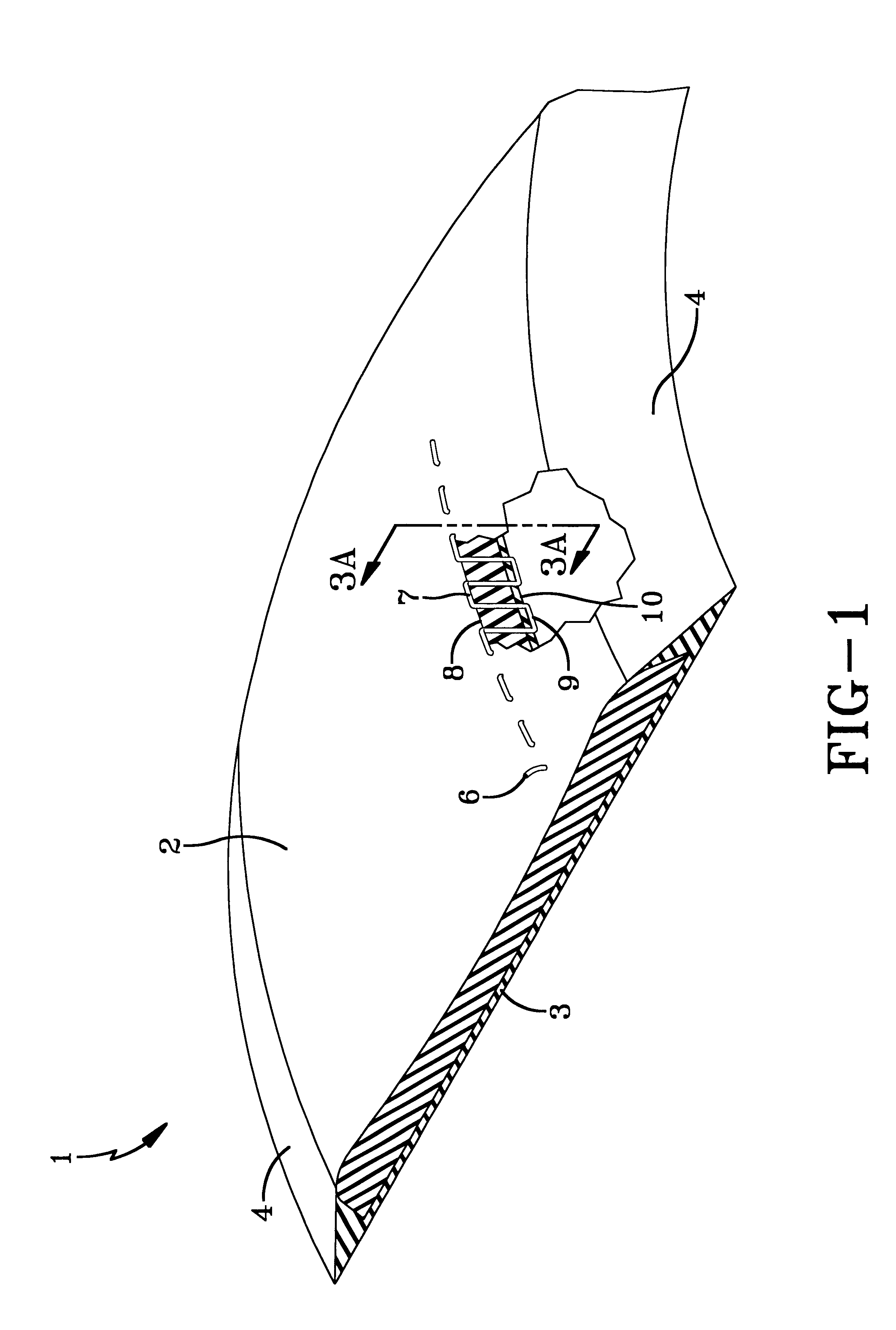

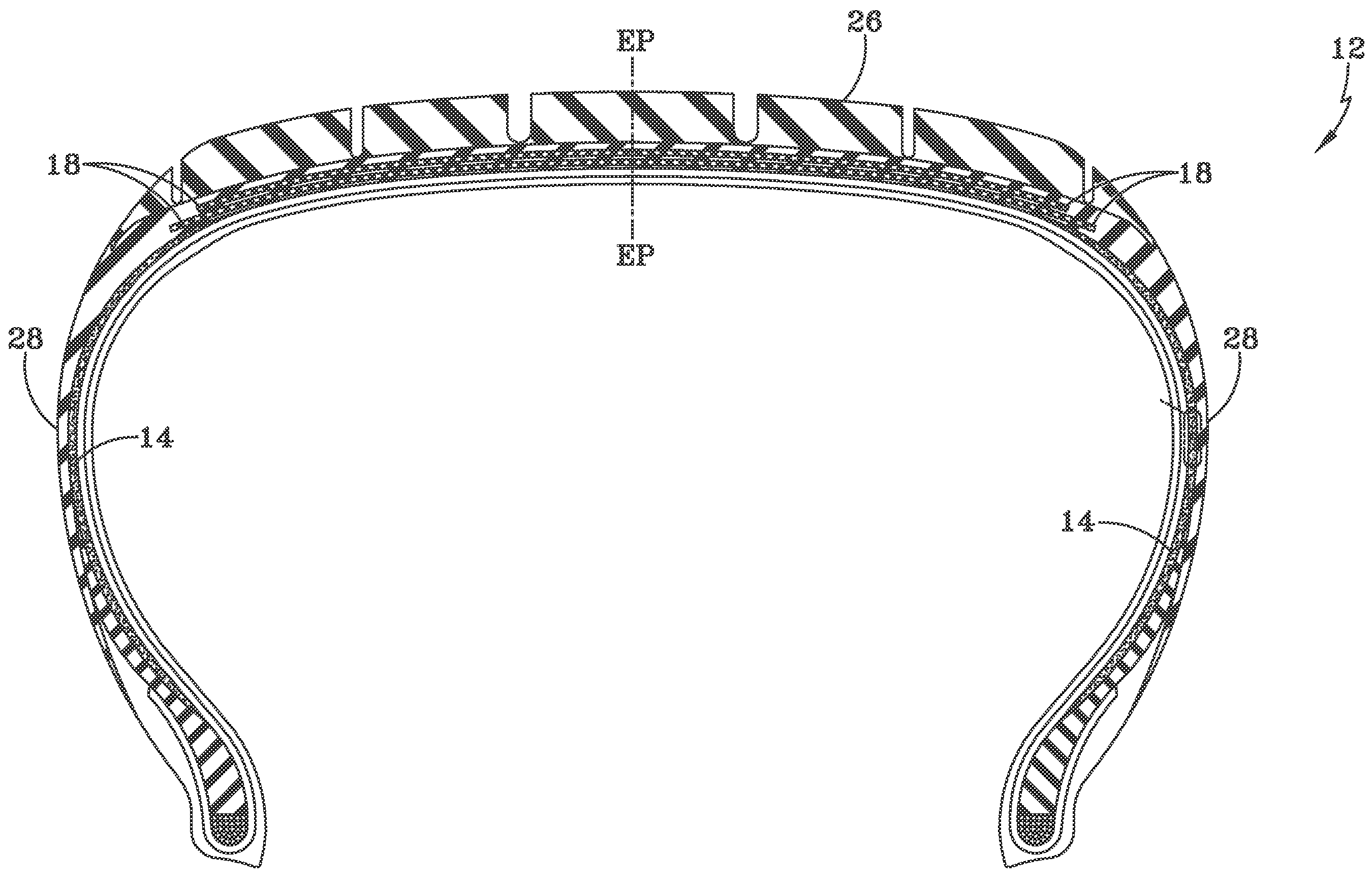

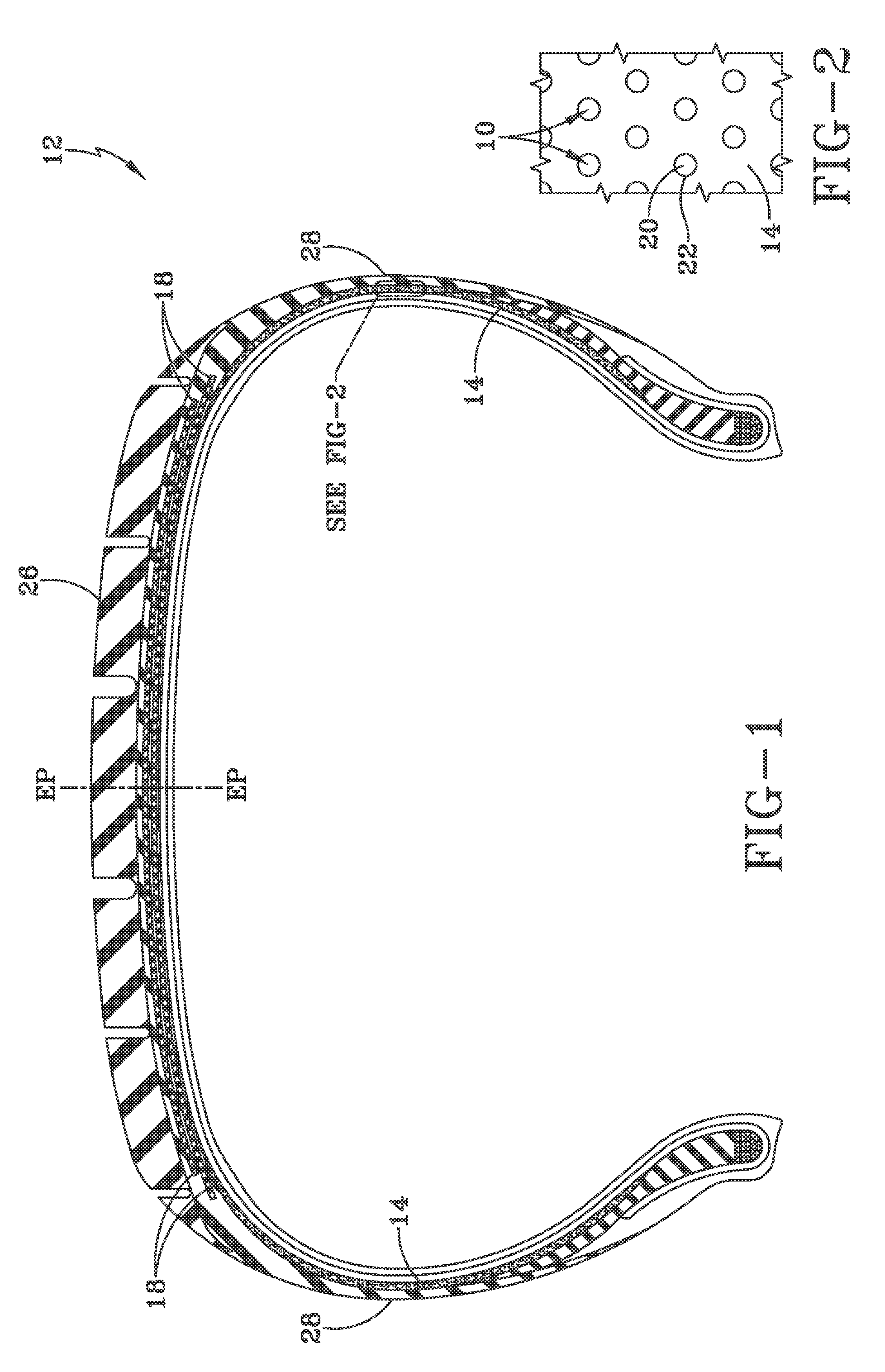

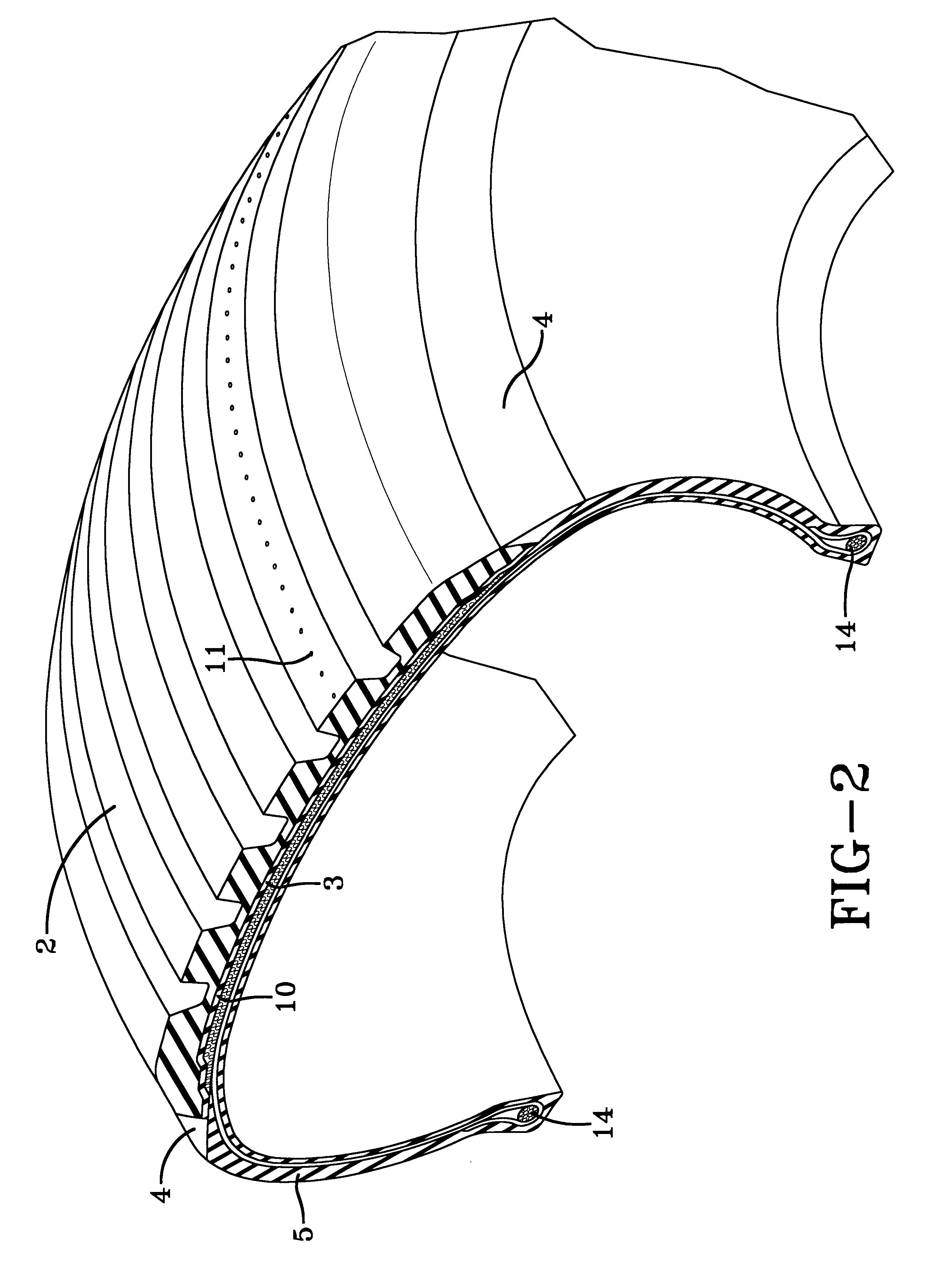

Pneumatic tire having run flat capability

InactiveUS20040031550A1Reduce tire weightSuppressing heat buildupWithout separate inflatable insertsWith separate inflatable insertsElastomerThermoplastic elastomer

A pneumatic tire having a runflat capability provided with a crescent shaped reinforcing rubber layer at the side part thereof, wherein an inner layer is composed of a thermoplastic elastomer composition containing (A) at least one thermoplastic resin having an air permeation coefficient of 100x10<-12 >cc.cm / cm<2>.sec.cmHg or less and a Young's modulus of more than 500 MPa and (B) at least one elastomer ingredient having an air permeation coefficient of 50x10<-12 >cc.cm / cm<2>.sec.cmHg or more and a Young's modulus of 500 MPa or less in amounts of at least 30% by weight based upon the total polymer ingredients and having an air permeation coefficient of 100x10<-12 >cc.cm / cm<2>.sec.cmHg or less.

Owner:YOKOHAMA RUBBER CO LTD

Tire having silica reinforced rubber tread with outer cap containing carbon black

InactiveUS6044882AImprove propertiesAdvantageously producedSpecial tyresTyresTire beadPolymer science

The invention relates to a rubber tire composed of carbon black reinforced rubber carcass and having a rubber tread which is quantitatively reinforced with silica and which, in turn, has a thin, integral, rubber outer cap on its outer surface which contains a quantitative amount of carbon black. In one aspect, said outer cap, sometimes referred to herein as an outer top cap, extends across the outer surface of the tread which is normally intended to be ground contacting and in an alternative aspect, the outer top cap extends only over the outer portion, namely the peripheral edges, of said tread surface intended to be ground contacting. The outer, carbon black reinforced, rubber tread top cap connects with at least one other carbon black reinforced rubber component of the tire in a manner to provide a path of reduced electrical resistance from said outer tread top cap to the bead portion of the tire carcass and, therefore, such a path from the vehicle to the road surface.

Owner:THE GOODYEAR TIRE & RUBBER CO

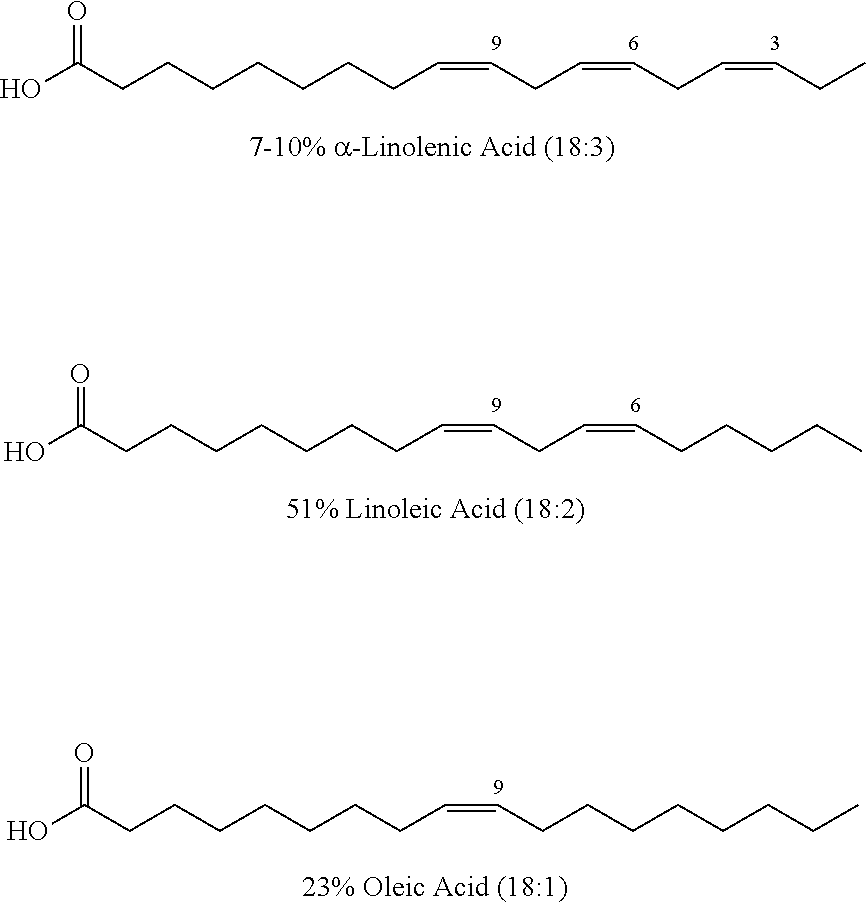

Tire with rubber tread containing combination of resin and vegetable oil, particularly soybean oil

InactiveUS20140135437A1Improve propertiesAdvantageously producedSpecial tyresInksVegetable oilReinforced rubber

This invention relates to a tire with a circumferential rubber tread composition comprised of a silica reinforced rubber composition containing diene based polymers in combination with traction resin(s) and vegetable oil, particularly soybean oil.

Owner:THE GOODYEAR TIRE & RUBBER CO

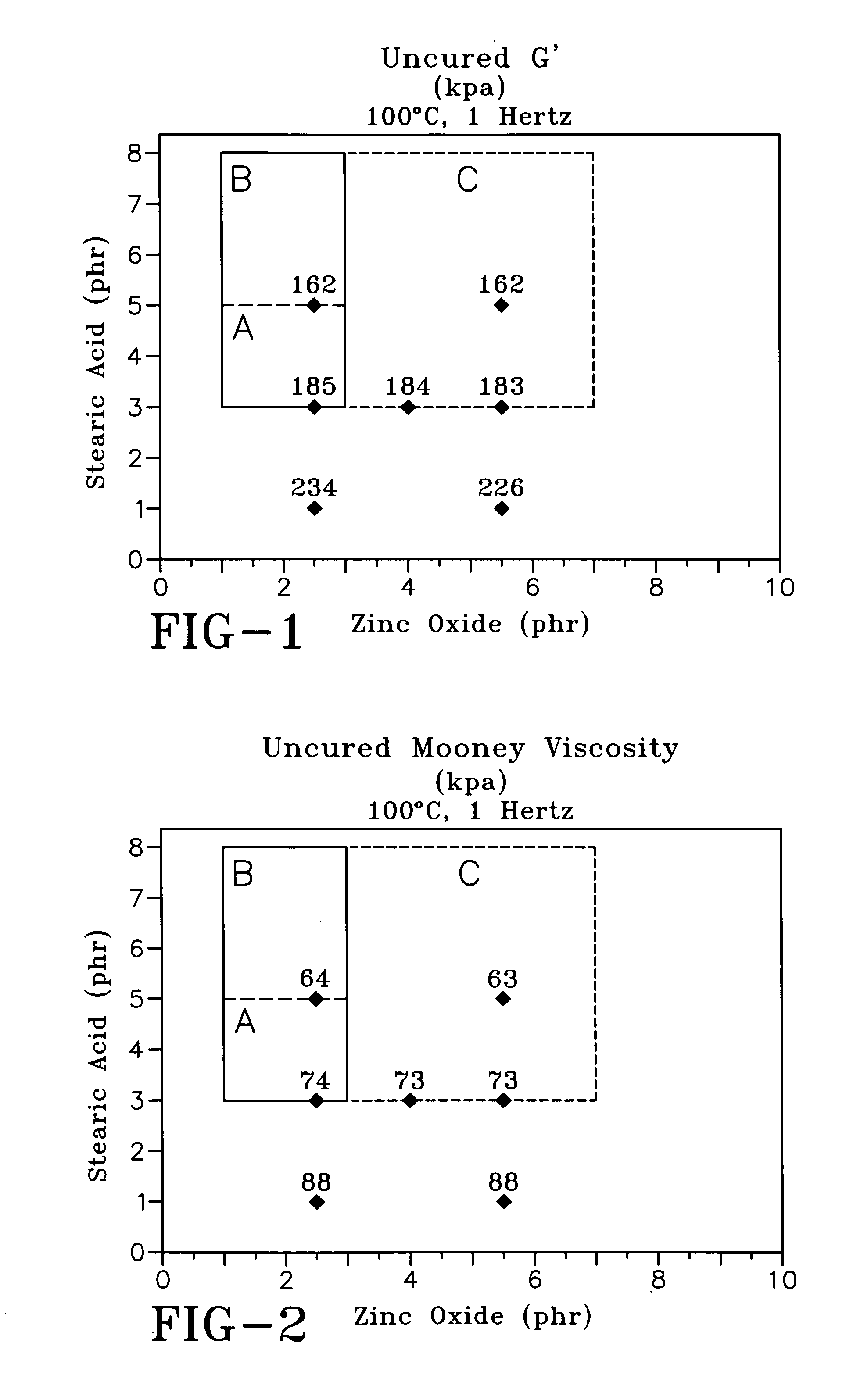

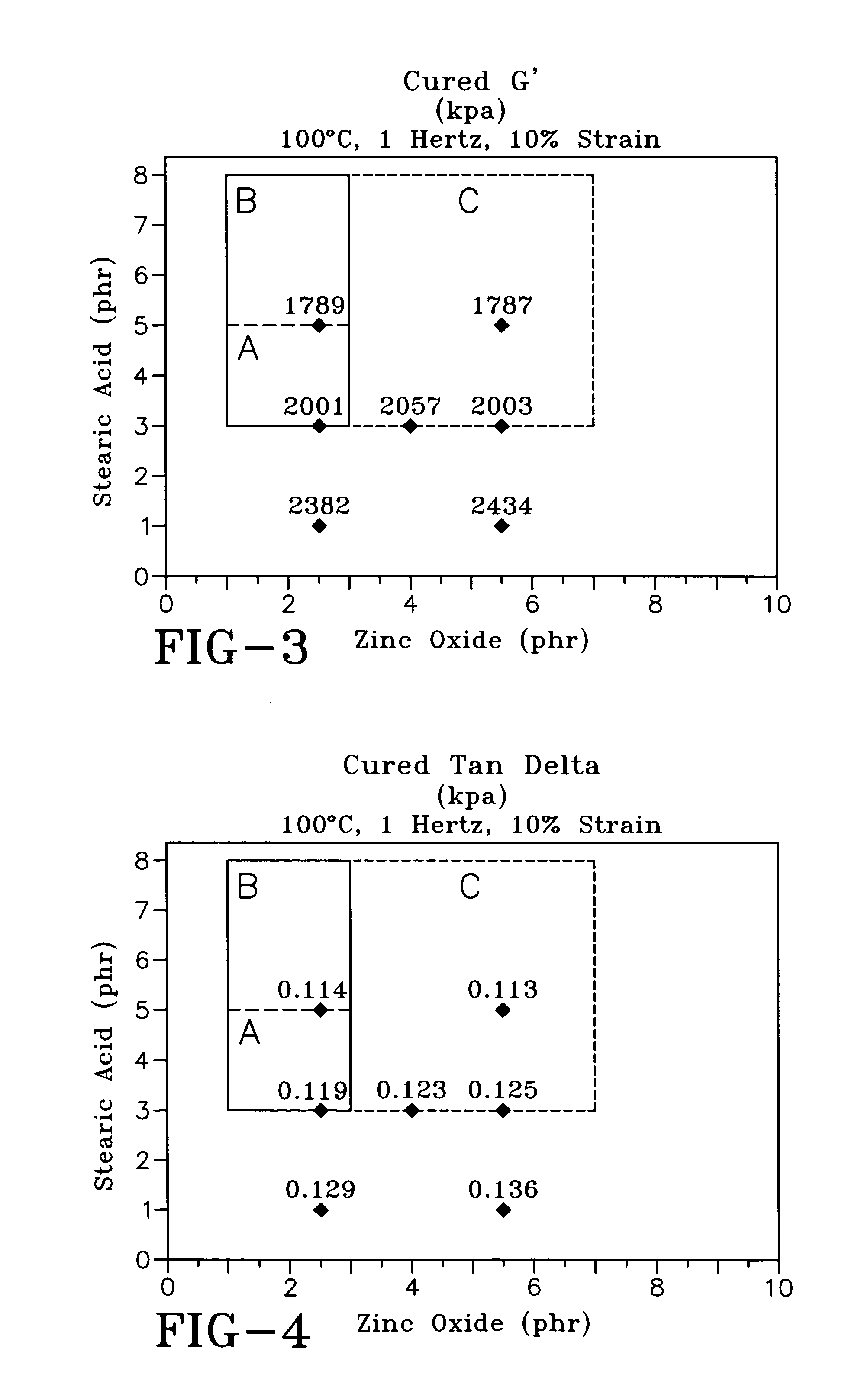

Silica reinforced rubber composition and use in tires

InactiveUS20080027162A1Promote migrationReduce hysteresisSpecial tyresSolid ballsCouplingCarboxylic acid

This invention relates to the preparation of silica-rich rubber compositions which contain silica reinforcement and silica coupler together with a specified combination of zinc oxide and long chain (fatty) carboxylic acid such as stearic acid. The silica, silica coupling agent, zinc oxide and stearic acid are combined in a manner to form a complex network. The silica is a precipitated silica in a form of silica aggregates which contain hydroxyl groups on its surface. A preferred silica coupling agent is a bis (3-trialkoxysilylalkyl) polysulfide which contains an average of from 2 to about 4, preferably from 2 to about 2.6, connecting sulfur atoms in its polysulfidic bridge. The invention further relates to tires having a component thereof such as, for example, a tread.

Owner:HUA KUO CHIH +3

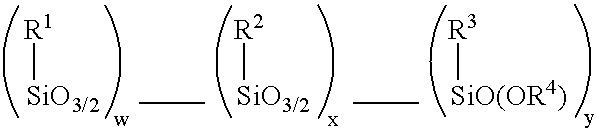

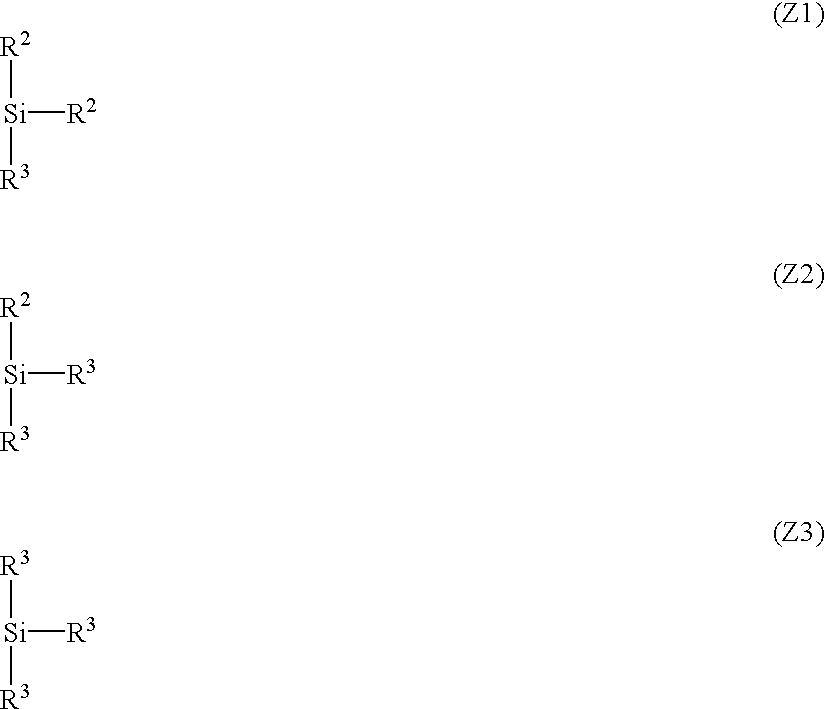

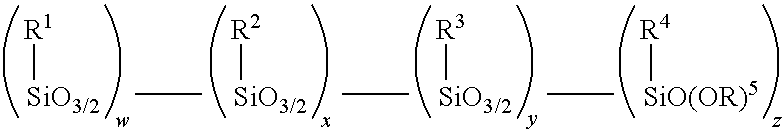

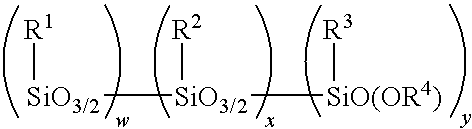

Amino alkoxy-modified silsesquioxanes and method of preparation

InactiveUS20090203929A1Low VOC emissionCoating adhesionSilicon organic compoundsCoatingsThioenolThiol

An amino alkoxy-modified silsesquioxane (AMS) comprising one or more compounds selected from the group consisting of an amino AMS, an amino / mercaptan co-AMS, an amino / blocked mercaptan co-AMS, mixtures thereof, and a weak acid-neutralized solid or aqueous solution thereof, and a method of making the amino AMS, are presented. The compounds are useful in compounding, processing, cure and storage of silica-reinforced rubbers because they contain low levels of volatile organic compounds (VOC).

Owner:BRIDGESTONE CORP

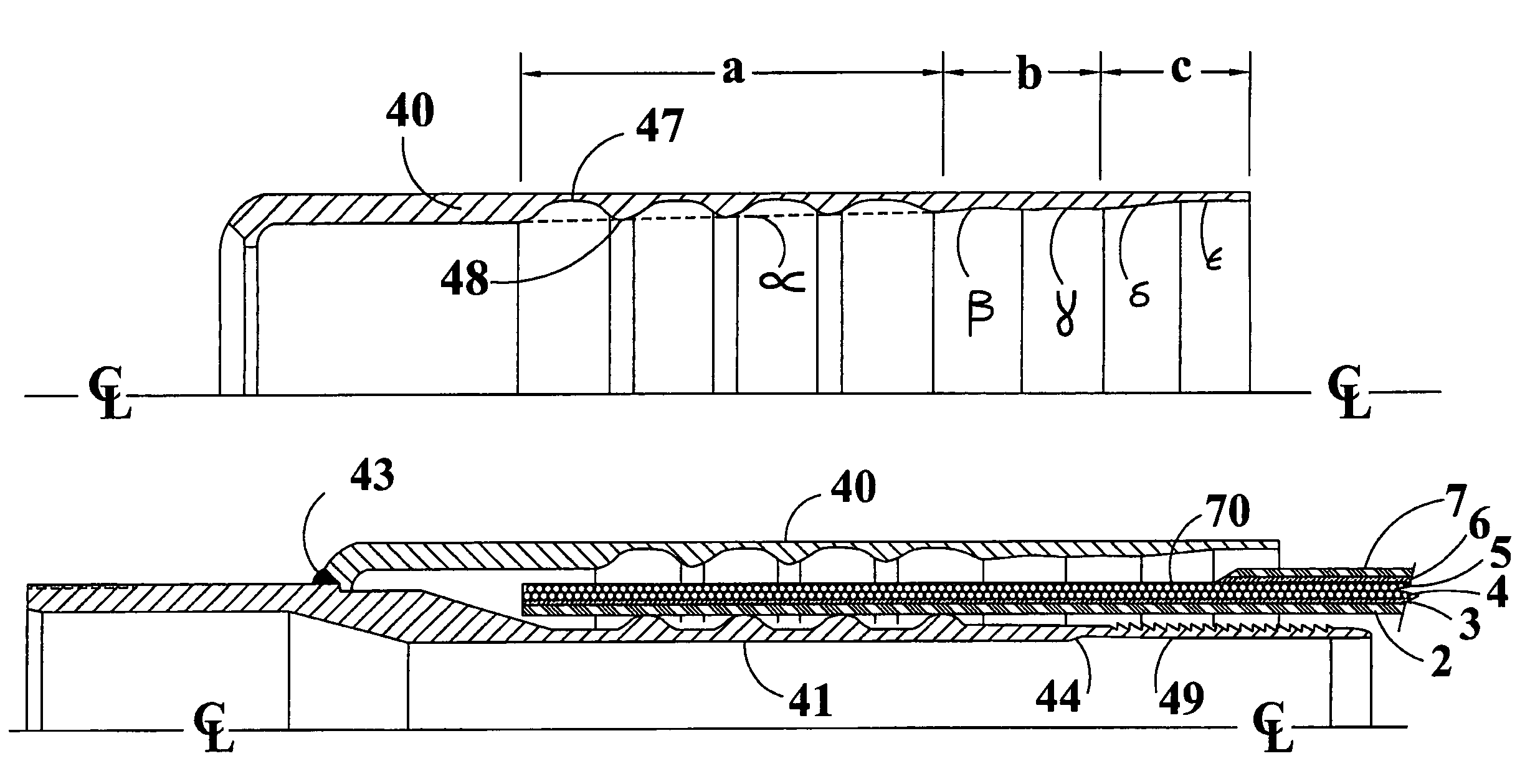

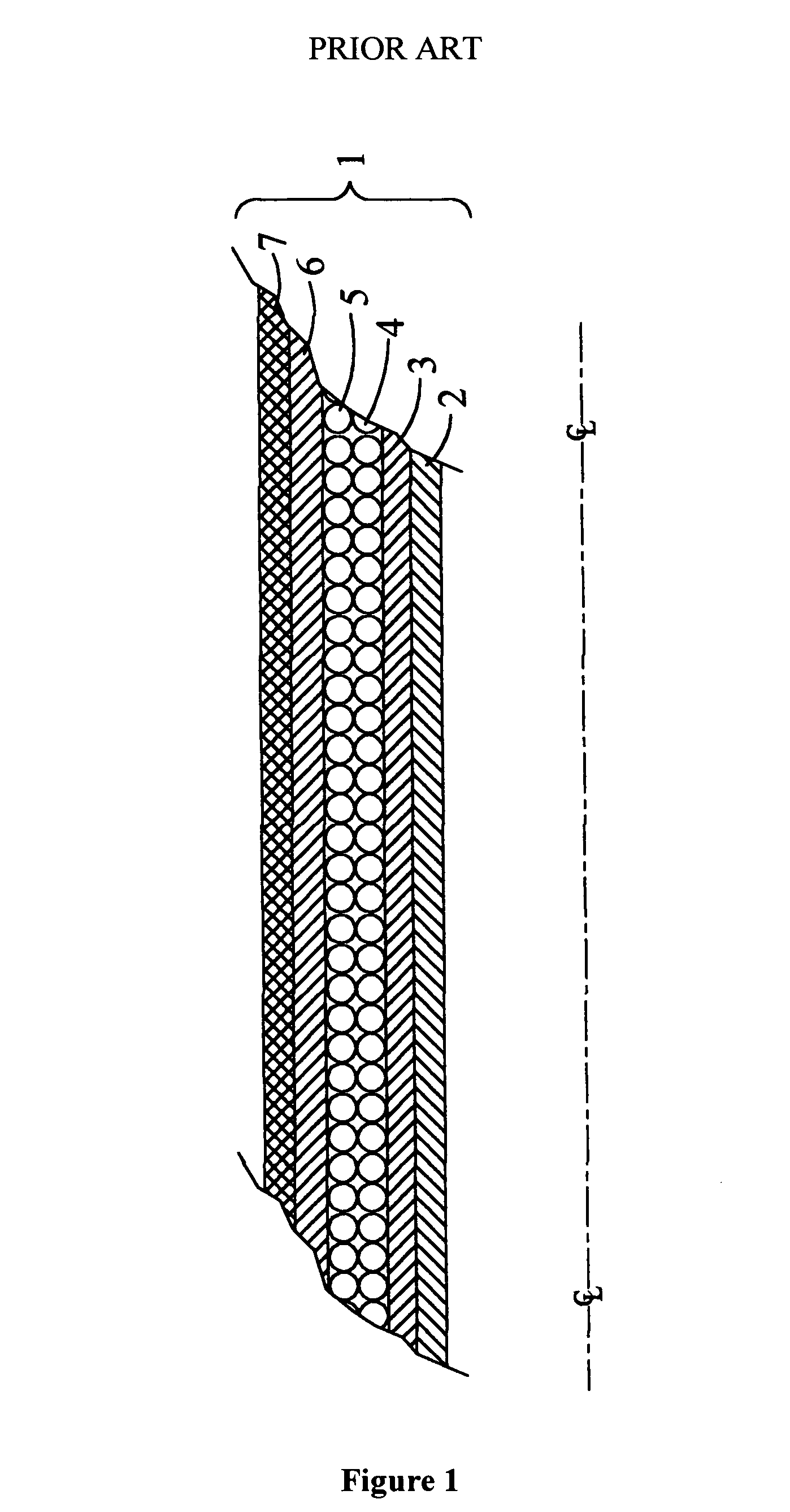

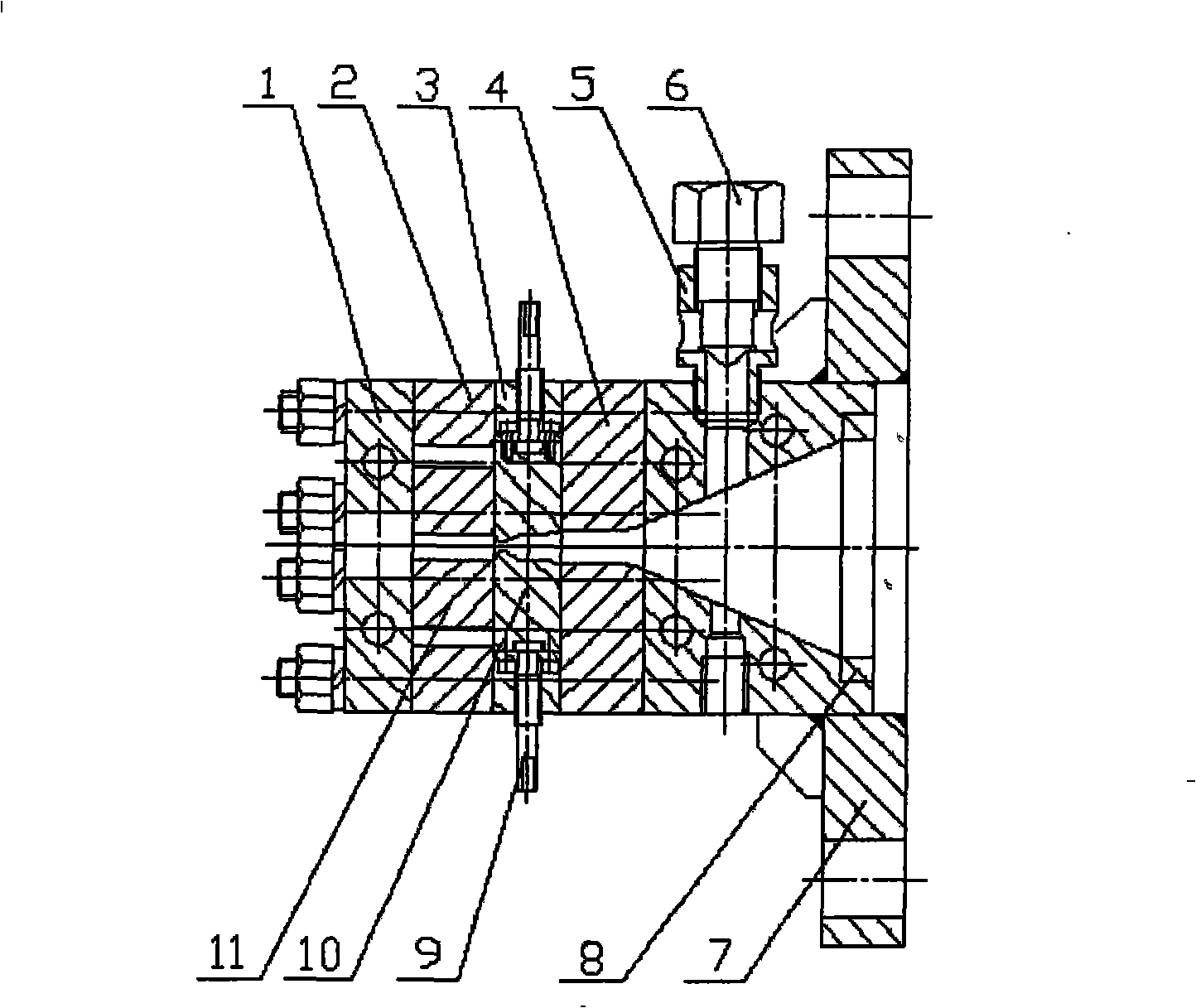

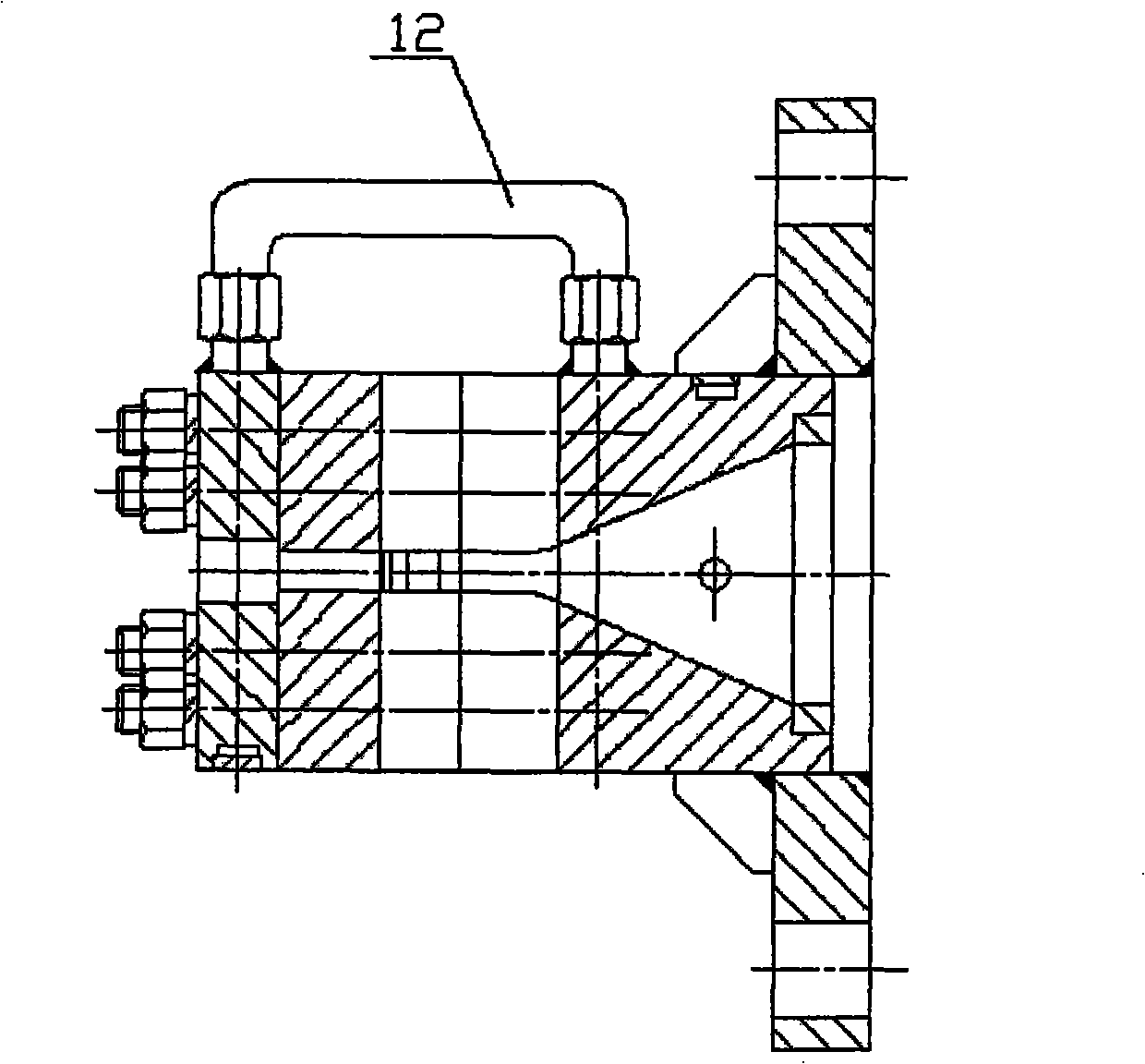

High pressure reinforced rubber hose swage or crimped coupling and method of attachment

InactiveUS7338090B2High possible lockExtended diameter rangeJoints with sealing surfacesHose connectionsTO-18Coupling

Swage end-connector for high pressure reinforced flexible hose particularly suitable in the petrochemical and drilling industries for hoses. Two connectors are disclosed one for intermediate hose pressure burst ratings up to 12,500 psi and internal diameters up to 3½ inches and higher hose pressure burst ratings up to 18,750 psi and internal diameters up to 4 inches. Both embodiment connectors will withstand the rated burst pressure of the hose to which they are connected and will withstand a pump-off force that exceeds the burst pressure of the hose. That is, the hose will fail before the connector pops off the hose.

Owner:BALDWIN & LOKE

Industrial lignin reinforcing rubber and preparation method of industrial lignin reinforcing rubber

The invention relates to industrial lignin reinforcing rubber and a preparation method of the industrial lignin reinforcing rubber. The industrial lignin reinforcing rubber is characterized in that 1, the industrial lignin reinforcing rubber comprises lignin dispersoid, rubber latex, a small number of plasticizers and operation oil or comprises multi-component lignin dispersoid, rubber latex, a small number of plasticizers and operation oil; 2, the lignin dispersoid is suspension of lignin in water, the weight part of the lignin is 5 to 30 percent, the multi-component lignin dispersoid is suspension of the lignin and inorganic fillers in water, and the weight proportion of the lignin to the water is (5-30):(95-70); and 3, in the lignin dispersoid and the multi-component lignin dispersoid, the lignin is hydroxymethylation modified dispersoid. The preparation method comprises the steps of 1. lignin preparation, 2, lignin dispersoid preparation, 3, rubber latex preparation, 4, cosedimentation and solidification and 5, industrial lignin reinforcing rubber obtaining. The industrial lignin reinforcing rubber and the preparation method have the advantages that the physical and mechanical properties of the rubber are not reduced, meanwhile, the drying processes in the lignin and rubber production process are combined, and the motive power consumption of rubber mixing is reduced.

Owner:广西合山林格高分子材料科技有限公司

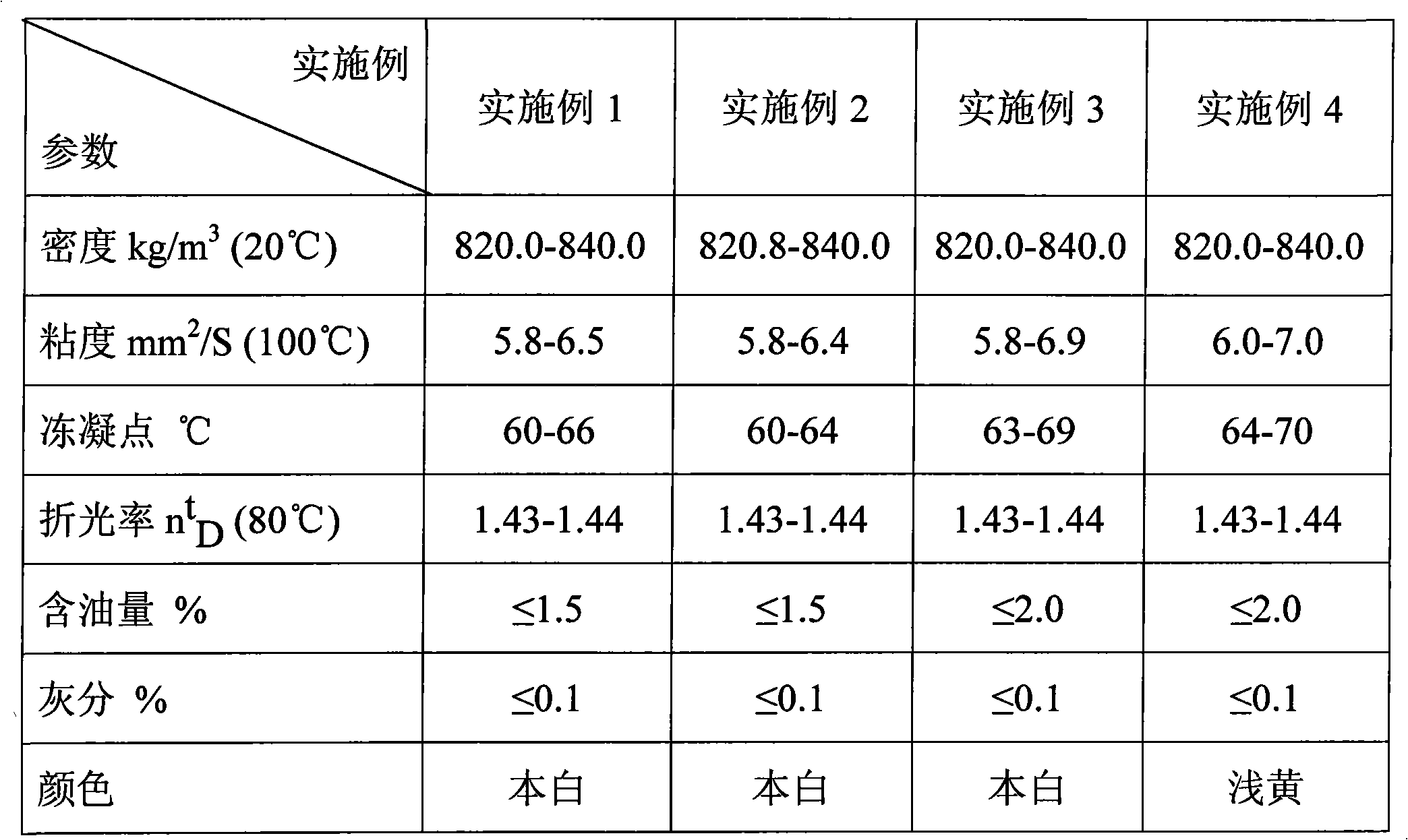

Novel rubber protective wax

The invention discloses a novel rubber protective wax which comprises the following components in percentage by weight: 14-20 percent of paraffin, 55-60 percent of mixed crystal wax, 24-30 percent ofmicrocrystalline wax and 1-2 percent of polyethylene wax. The invention has favorable seal performance and can reinforce the ozone and ageing resistance of a rubber product and prolong the service life of the rubber product.

Owner:上海绿菱特种蜡制品厂

Abrasion resistant plastic bonded to a diaphragm

InactiveUS6080685AWithout substantially affecting such diaphragm's flexibilityFlexible wall reciprocating enginesEngine diaphragmsEngineeringReinforced rubber

An improved diaphragm substantially resistant to abrasive wear for use in certain applications in which at least a portion of such diaphragm is in contact with another surface which would tend to abrade such diaphragm, such diaphragm comprising at least one layer of a flexible material selected from a group including natural rubber, synthetic rubber, fabric reinforced rubber, plastic and mixtures thereof and an abrasion resistant polymeric material having a predetermined thickness. This abrasion resistant polymeric material is adhered to such diaphragm at least in the portion that such diaphragm is in contact with another surface and is subject to abrasion. This type of abrasion generally occurs in the flange area of the diaphragm.

Owner:WESTINGHOUSE AIR BRAKE CO

Tire with rubber component

ActiveUS20120029114A1Improve hysteresis loss characteristicPlastic/resin/waxes insulatorsSpecial tyresElastomerEngineering

Pneumatic rubber tire with a component comprised of a silica reinforced rubber composition comprised of specialized polybutadiene rubber, functionalized styrene / butadiene elastomer and cis 1,4-polyisoprene rubber.

Owner:THE GOODYEAR TIRE & RUBBER CO

High-toughness nanofiber-reinforced rubber-base 3D printing material and preparation method thereof

ActiveCN104761761AHigh bonding strengthImprove toughnessAdditive manufacturing apparatusAdhesiveSolvent

The invention relates to a 3D printing material and a preparation method thereof, belonging to the field of 3D printing materials. The invention is characterized in that the high-toughness nanofiber-reinforced rubber-base 3D printing material (adhesive) is prepared from compound rubber, a thermoplastic polymer nanofiber-reinforced material and a solvent. The compound rubber, thermoplastic polymer nanofiber-reinforced material and solvent are sheared and blended in a weight ratio of (1-30):(1-20):(1-98) by a high-speed shearing machine to obtain the high-toughness nanofiber-reinforced rubber-base 3D printing material. The high-toughness nanofiber-reinforced rubber-base 3D printing material has the characteristics of high adhesive strength and favorable toughness. The powder material for 3D printers does not need pretreatment, and thus, is suitable for large-scale quick production of complex products.

Owner:WUHAN TEXTILE UNIV

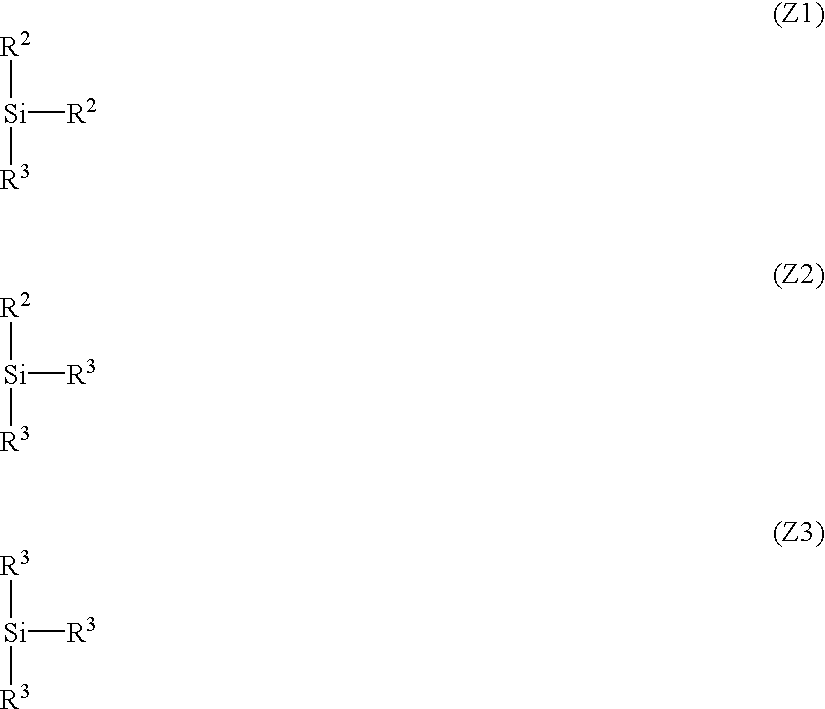

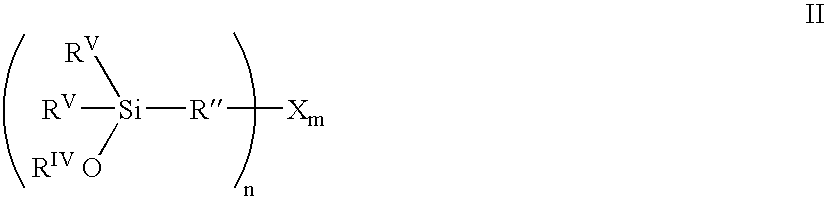

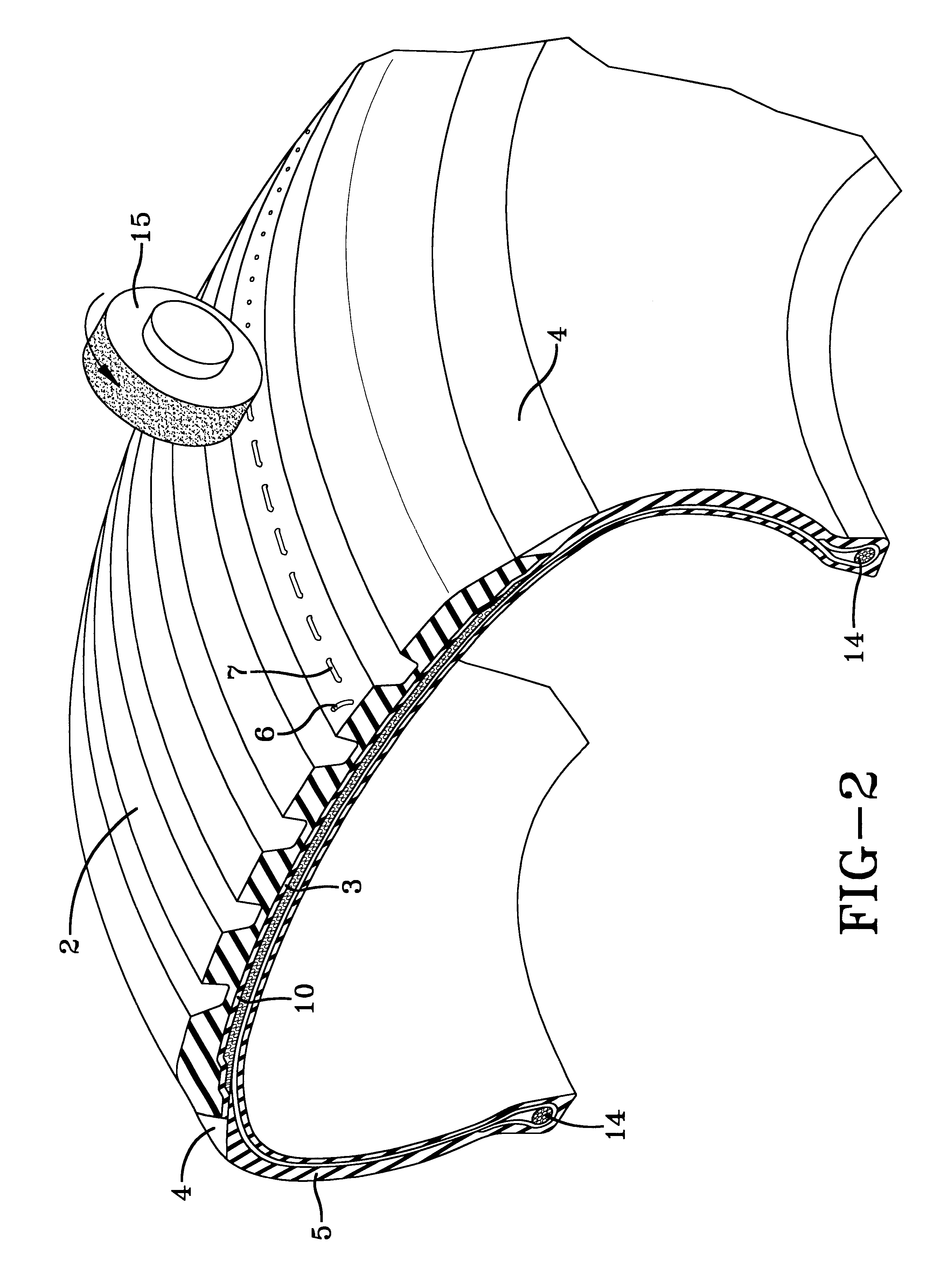

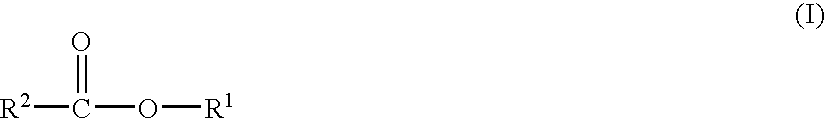

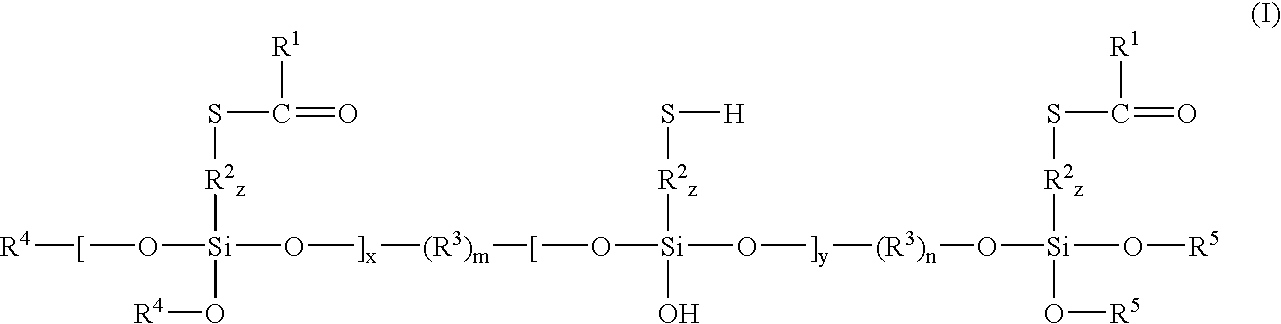

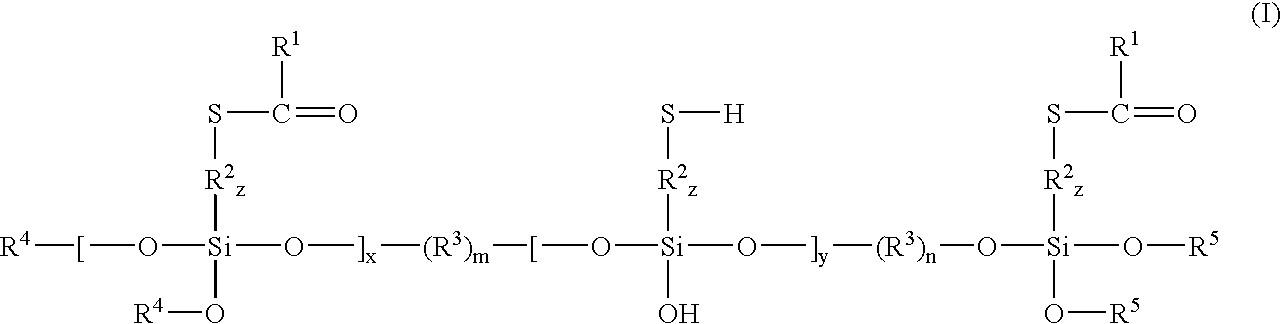

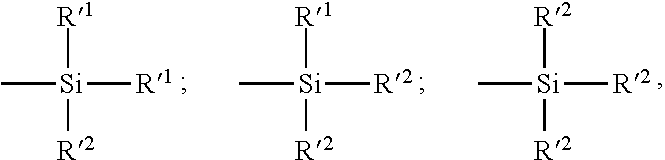

Organosilicon compounds

ActiveUS20040266968A1Less influencePrevulcanization behaviour is also improvedSilicon organic compoundsOrganic chemistry methodsAlcoholSilanes

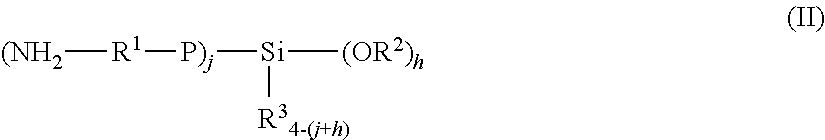

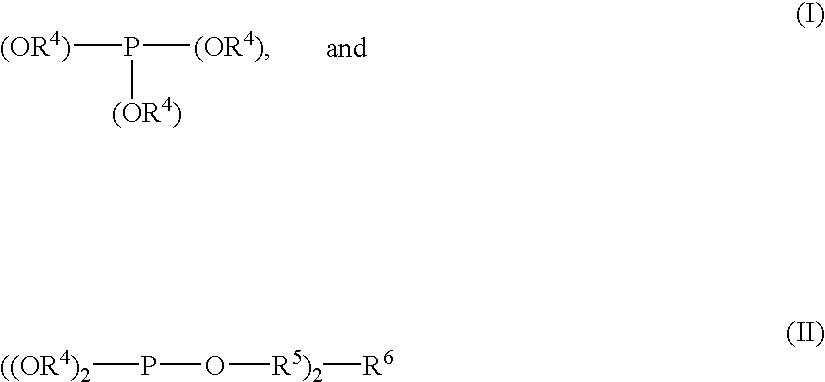

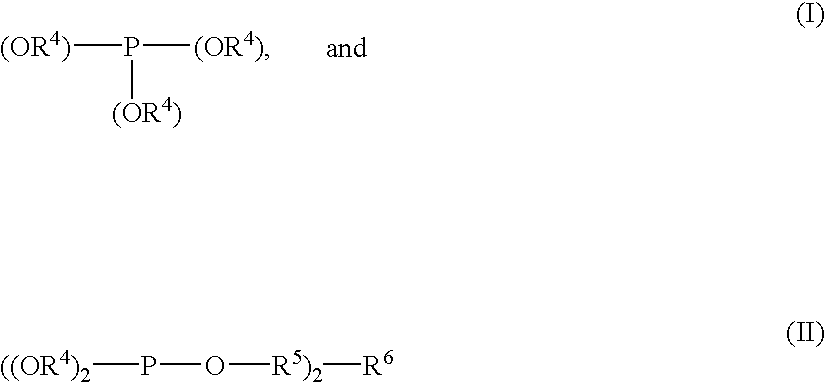

Organosilicon compounds of the general formula I are produced by catalytically reacting silanes of the general formula II with alcohols of the general formula R'-OH, with the elimination of R<IV>OH, wherein the molar ratio of R-OH to R<IV>OH- groups is at least 1 and R<IV>OH is removed continuously or discontinuously from the reaction mixture. The organosilicon compounds may be used as coupling agents in filler-reinforced rubber mixtures.

Owner:EVONIK OPERATIONS GMBH

Compounding silica-reinforced rubber with low volatile organic compound (VOC) emission

ActiveUS7799870B2Improve reinforcementGreat tractionSilicon organic compoundsSynthetic resin layered productsPolymer scienceAlkoxy group

Alkoxy-modified silsesquioxane compounds are described. The alkoxy-modified silsesquioxane compounds contain an alkoxysilane group that participates in an alkoxysilane-silica reaction as a silica dispersing agent in rubber, with the release of zero to about 0.1% by weight of the rubber of volatile organic compounds (VOC), especially alcohol, during compounding and further processing. Further described are methods for making alkoxy-modified silsesquioxanes, methods for making vulcanizable rubber compounds containing alkoxy-modified silsesquioxanes, vulcanizable rubber compounds containing alkoxy-modified silsesquioxanes, and pneumatic tires comprising a component that contains alkoxy-modified silsesquioxanes.

Owner:BRIDGESTONE CORP

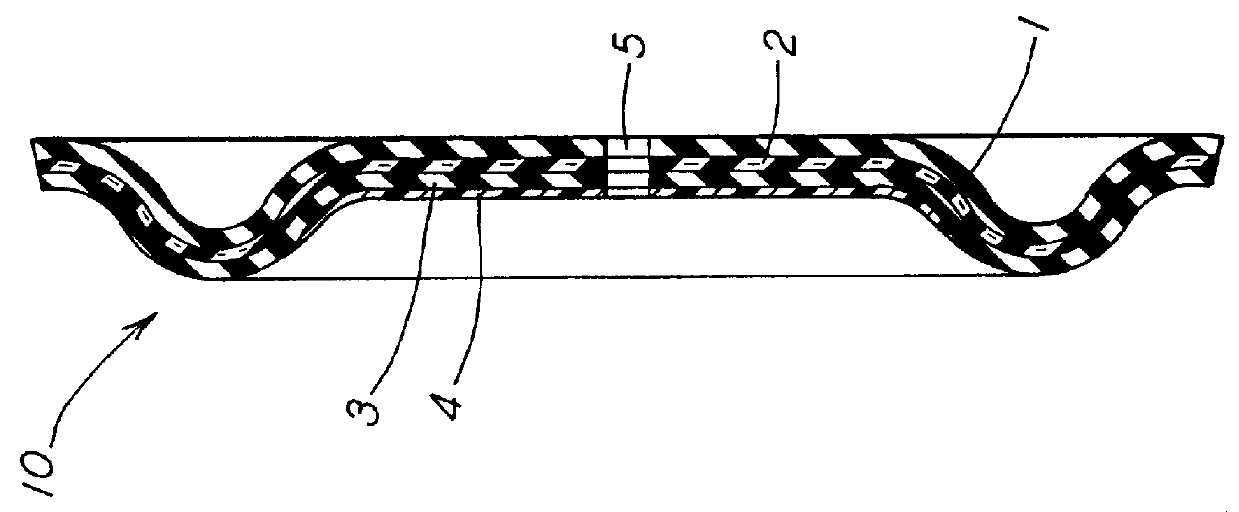

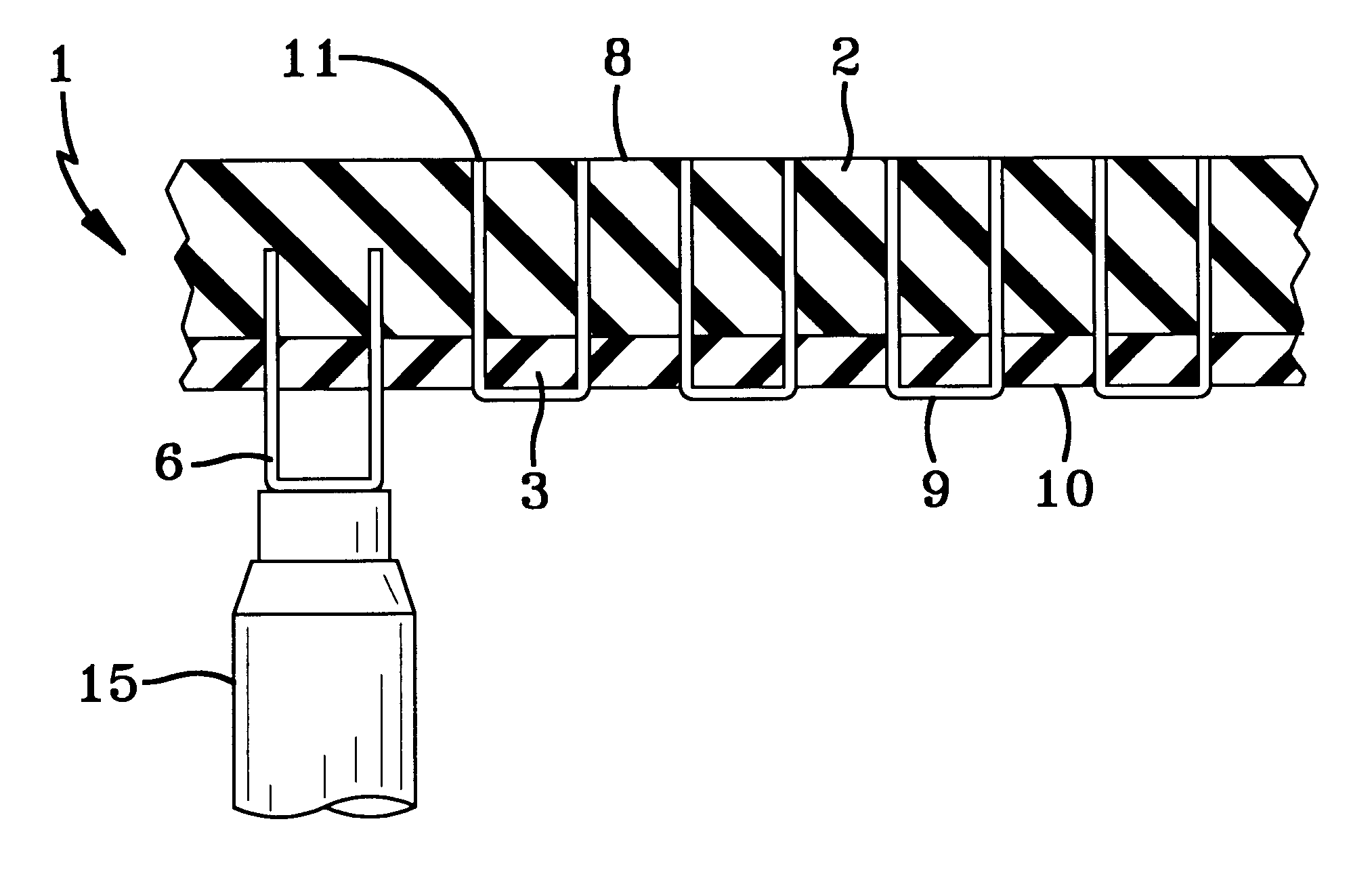

Tire with tread containing electrically conductive stitched thread

InactiveUS6289958B1Lower resistanceIncrease resistanceTyresSpecial tyresEngineeringReinforced rubber

The invention relates to a rubber tire, and its preparation, composed of carbon black reinforced rubber carcass with an outer, circumferential rubber tread construction of a rubber composition having a relatively high electrical resistivity. The tire tread construction has an electrically conductive filamentary thread stitched through the tread construction and extending between the inner surface of the tread to its outer surface. An electrically conductive path is thereby created through the tire tread.

Owner:THE GOODYEAR TIRE & RUBBER CO

Starch composite reinforced rubber composition and tire with at least one component thereof

The present invention relates to a rubber composition containing at least one diene-based elastomer, a starch / plasticizer composite and an adduct of maleic anhydride and polybutadiene, and to pneumatic tires having at least one component comprised of such rubber composition. Such tire component can be, for example, its circumferential tread or other component of the tire.

Owner:WEYDERT MARC +3

Tire having tread with colored sidewall in connection with a plurality of colored tread grooves

InactiveUS20020144761A1Improve propertiesAdditional componentSpecial tyresTyre tread bands/patternsEngineeringReinforced rubber

The present invention relates to a tire with a colored sidewall joined with a plurality of colored grooves in its tread. In particular, the present invention relates to a tire of a black-colored rubber composition having a non-black colored sidewall portion which is integral with a plurality of non-black colored grooves of a tread of lug and groove configuration. For said tread, at least a portion of the visible surface of a plurality of tread grooves, exclusive of the outer surface portion of said carbon black reinforced rubber lugs intended to be ground-contacting, is of a non-black colored, synthetic amorphous silica reinforced rubber composition exclusive of carbon black. For said colored sidewall and plurality of connecting tread groove combination, said tread groove and sidewall may be of the same or different non-black color(s). In one aspect, said non-black visible surface of said tread grooves and connecting sidewall contains an elastomeric brominated copolymer of isobutylene and p-methyl styrene in combination with an organo phosphite compound.

Owner:THE GOODYEAR TIRE & RUBBER CO

Rubber composition and pneumatic tire using the same

InactiveUS20070167555A1Reduce fuel consumptionReduce consumptionSpecial tyresTyre beadsSilicon dioxidePolybutadiene

A rubber composition containing (i) a conjugated diene-based rubber gel having a toluene swelling index of 16 to 70, (ii) a diene-based rubber such as natural rubber, polyisoprene rubber, aromatic vinyl-conjugated diene copolymer rubber and / or polybutadiene rubber, and (iii) an optional carbon black and / or silica and (a) a pneumatic tire using this composition as a high hardness reinforcing layer extending from a bead along a tire sidewalls, in which the fluidity and dimensional stability at the time of extrusion are improved, while maintaining a sufficient hardness of a high hardness reinforced rubber, (b) a pneumatic tire using this composition as two ends of a tire tread extrudate, maintaining a flex fatigue of the two ends of the tread, in which the extrudability and extrusion dimensional stability are improved and (c) a pneumatic tire using the composition as a 1.5 mm to 6 mm thick undertread, in which a high elasticity and relatively thick gauge undertread, and excellent processability and steering stability are provided.

Owner:THE YOKOHAMA RUBBER CO LTD +1

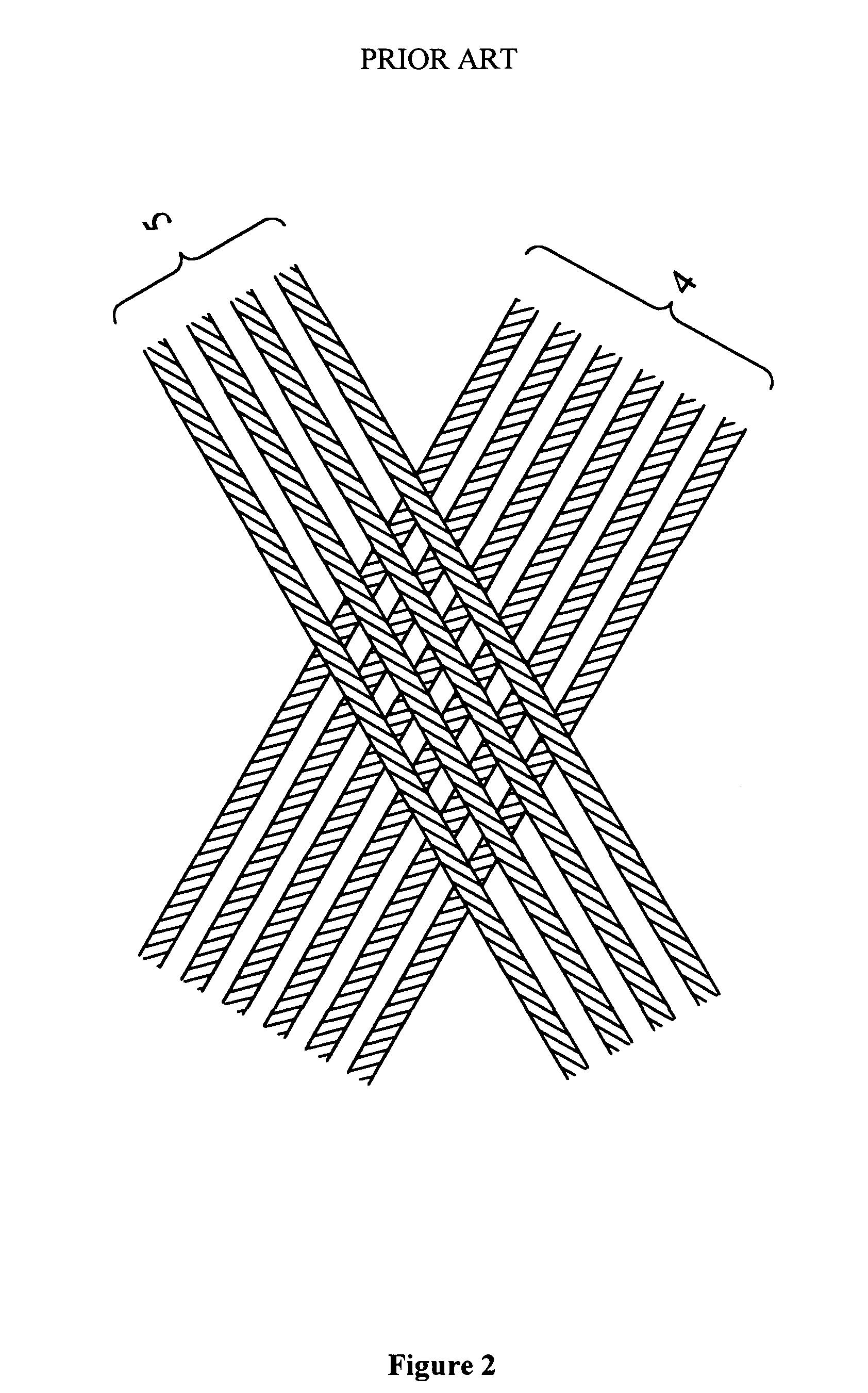

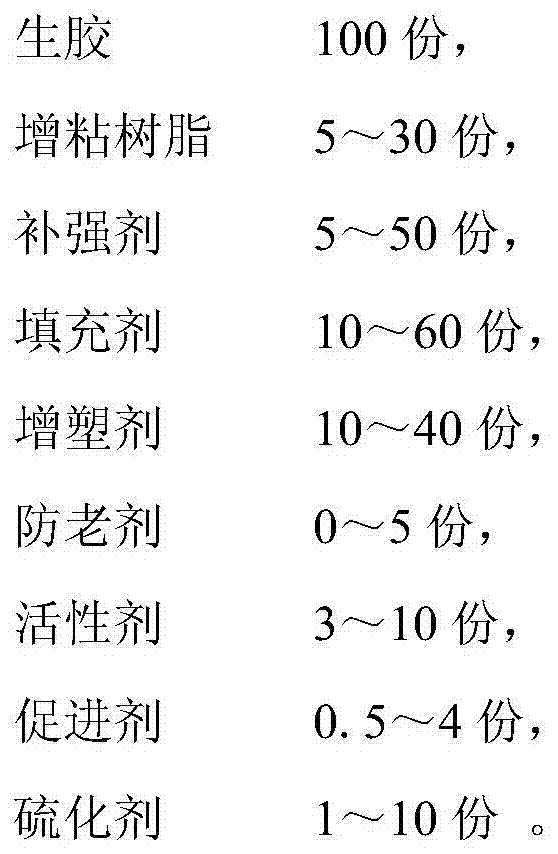

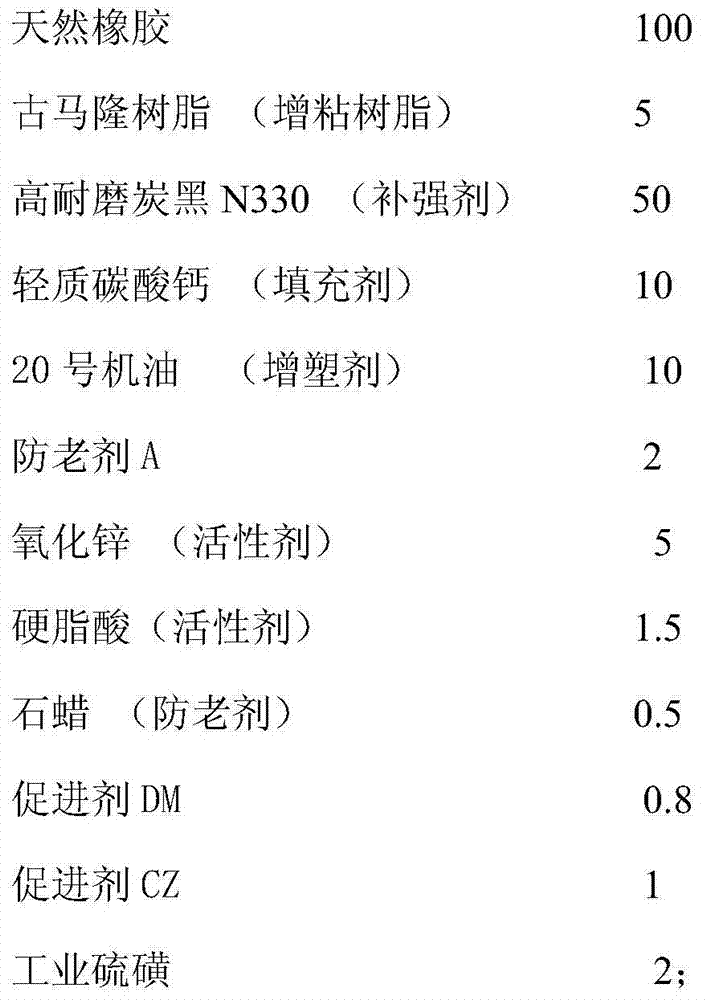

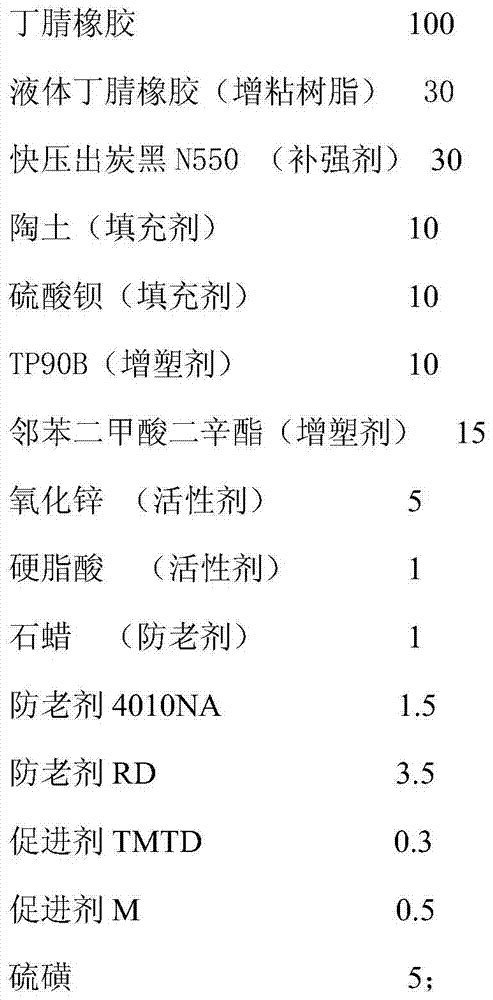

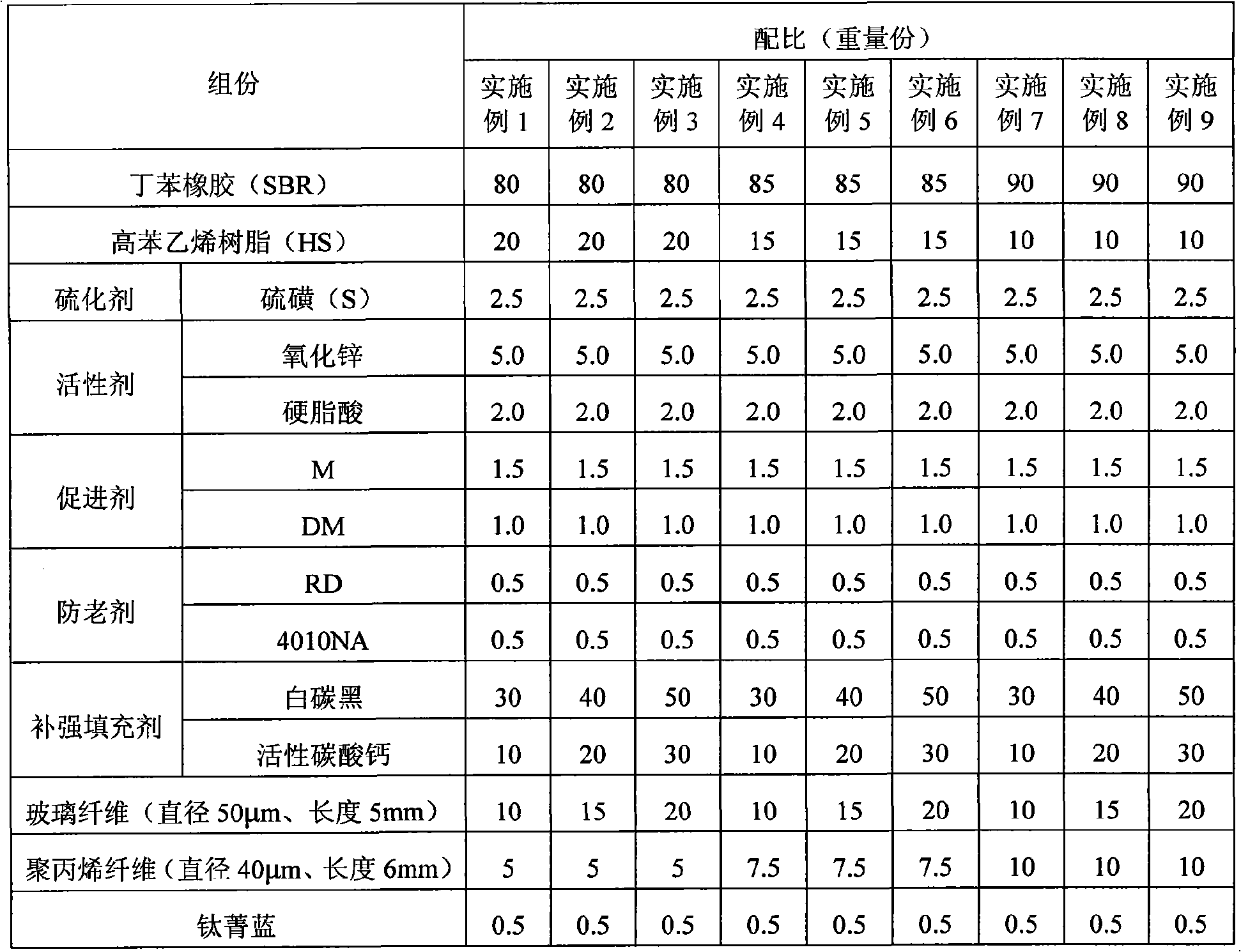

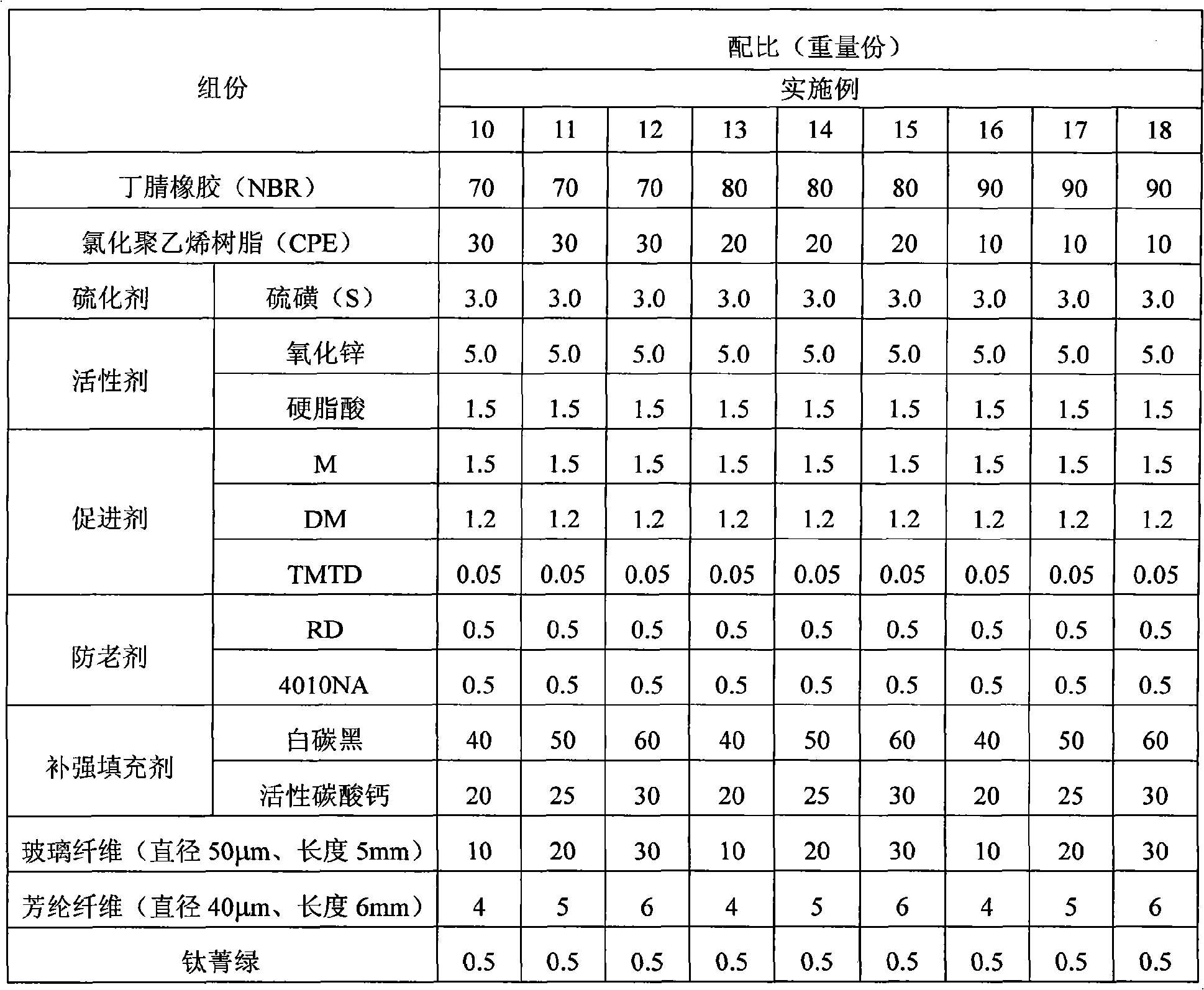

Fiber reinforced rubber

The invention relates to a fiber reinforced rubber, for which the strength can be remarkably improved, the permanent compression set can be reduced and the anti-tear performance of rubber sheet can be enhanced. A method for preparing the fiber reinforced rubber comprises the following steps: a. mastication of rubber; b. reinforcing filler, fiber and accessory ingredient are added into the rubber for mixing; wherein, the fiber and the reinforcing filler is evenly mixed to prepare pre-dispersoid, and the pre-dispersoid is added into the rubber. As a preferred proposal, the method adopts styrene-butadiene rubber, nitrile rubber and neoprene which have the good properties of wearing resistance, pressure resistance, oil and water resistance and air tightness resistance as the rubber. The rubber sheet produced by the method can work under ultra-high temperature and pressure in various media for a long time with the maximum working temperature being 300 DEG C, and maintains good elasticity, less compressive deformation and excellent physical and mechanical properties which are reduced by not more than 20% compared with those at the normal temperature.

Owner:南京固柏橡塑制品有限公司

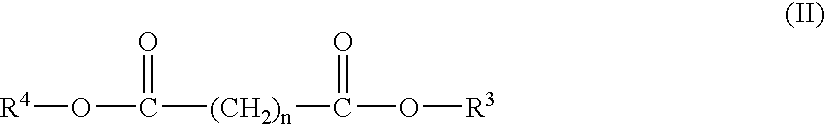

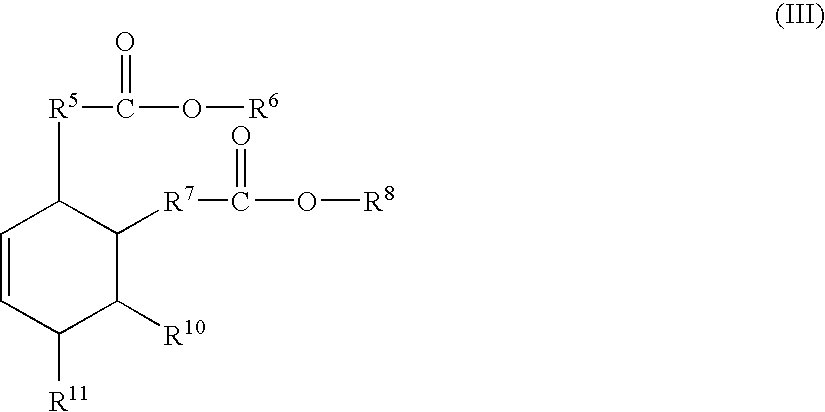

Adhesion promoter for cord-reinforced rubber and metal or polymer substrate/rubber composites

A rubber composition including a natural or synthetic rubber, and an adhesive resin capable of unexpected adhesion to metal, polymer and glass substrates, particularly cords in radical tires, hoses, conveyor belts, transmission belts, and the like by the addition of long chain esters, including mono, di- and tri-esters.

Owner:LASALLE BANK NAT ASSOC

Self-healing materials and use thereof for extending the lifespan of a tire

The present invention is directed to self-healing materials and use thereof for extending the lifespan of a tire. The self-healing material includes a rubber healing agent, e.g., sulfur, encapsulated by a coating material, e.g., polypropylene, defining a microcapsule. The self-healing materials are processed with rubbery polymers to provide a rubber compound suitable for use in a tire. The microcapsule coating material is selected to prevent release of the healing agent during the processing steps of the rubber compound, such as can occur through melting or softening of the coating material, and to release the healing agent, e.g., via melting or softening, at a desired temperature greater than a tire's running temperature. Release of the healing agent can help repair damage to local polymeric structure, such as broken cross-links, by reacting with the surrounding rubber. In this way, that area of the rubber compound can be reinforced, thereby prolonging the life of the tire.

Owner:GOBINATH THULASIRAM +3

Tire with tread containing electrically conductive staples

InactiveUS6220319B1Lower resistanceIncrease resistanceTyresSpecial tyresPolymer scienceHigh resistivity

The invention relates to a rubber tire composed of carbon black reinforced rubber carcass with an outer, circumferential rubber tread construction of a rubber composition having a relatively high electrical resistivity. The tire tread construction has electrically conductive filament stapled through the tread construction and extending between the inner surface of the tread to its outer surface. An electrically conductive path is thereby created through the tread.

Owner:THE GOODYEAR TIRE & RUBBER CO

Method for extruding and forming short fiber reinforced-rubber composite material in radial direction

The invention relates to a short fiber reinforced rubber composite material radial orientation extrusion molding method and the procedures are as follows: at first, rubber molten mass containing short fiber is carried out with the extrusion processing in an extruder; at the end of the screw rod in the extruder tube, the rubber is extruded into an axial orientation channel, the flow direction of the rubber mass is adopted for orientation, and the axial orientation of the short fiber is realized in the axial orientation channel of a machine head; the rubber mass which goes through the axial orientation passes through a resistance dam formed by contracting the thickness of the channel under the function of extrusion pressure; the rubber is characterized by extrusion swelling, so the short fiber is inclined owing to rolling over after the rubber mass passes through the resistance dam; the expanded rubber mass keeps flowing along the channel, the inclined degree of the part in middle and at edge is increased owing to velocity gradient, the radial orientation of the short fiber is increased and then the radial orientation is realized. The method of the invention has the advantages of simple and easily-controlled technique procedures, wide application range, good radial orientation quality of products, and low cost.

Owner:QINGDAO UNIV OF SCI & TECH

Composition for promoting adhesion between rubber and textiles

InactiveUS6046262ALimited shelf lifeStable aqueous dispersion/solutionAdhesive processesImpression capsSilane compoundsPolyester

A composition for the promotion of adhesion between a rubber formulation and a textile substrate is provided. The inventive composition comprises either a mixture of specific amine functional silanes and organo-functional silanes having reactive groups or groups with an affinity for rubber. The inventive method entails the use of the inventive composition or a silane compound having both an amine moiety and a reactive group having an affinity for rubber formulations, particularly an unsaturated carbon-carbon bond. The composition may be utilized to adhere any standard reinforcement-type textile, such as polyester or polyamide, to a standard rubber composition, such as SBR, NBR, or EPDM. A method for adhering textiles to rubber formulations is also provided involving a pre-dip, -spray, -coat, and the like, of the inventive composition on a reinforcement-type textile surface followed by the contacting of the rubber formulation. Optionally, and preferably, the process involves the extra utilization of resorcinol-formaldehyde latex as an effective bonding agent to improve the adhesion between the two layers. The resulting textile-reinforced rubber product may be utilized as an automobile fan or timing belt, an automobile tire component, and any other rubber article which requires long-lasting, durable textile reinforcement.

Owner:MILLIKEN & CO

Silica reinforced rubber composition and use in tires

InactiveUS20080194748A1Promote migrationReduced and retarded rubber viscosityFibre treatmentSpecial tyresElastomerPolymer science

This invention relates to the preparation of silica-containing rubber compositions which contain precipitated silica reinforcement and use of an oligomeric organomercaptosilane coupling agent containing a plurality of mercapto and silane moieties, and a minimal content, if any, of ethoxy groups and is thus substantially free of ethoxy groups. The interaction of the plurality of mercapto moieties, or groups, of such oligomeric organomercaptosilane with the diene-based elastomer can promote a significant viscosity build up of the uncured rubber composition in a preliminary non-productive mixing stage and therefore present significant rubber processing difficulties during the mixing of the rubber composition. A challenge is therefore presented for reducing such viscosity buildup for such uncured silica-containing rubber composition.

Owner:THE GOODYEAR TIRE & RUBBER CO

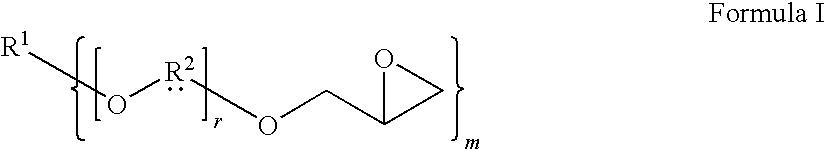

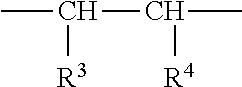

Process for preparing a diene copolymer comprising a polyether block, diene copolymer comprising a polyether block, reinforced rubber composition and tire

InactiveUS8455584B2Improve mechanical propertiesSimple preparation processFilm/foil adhesivesSpecial tyresHysteresisElastomer

A process for preparing, in one step, a diene block copolymer, of which at least one of these blocks is constituted of a polyether, the number-average molecular weight of which is approximately from 100 to 5000 g / mol, and at least one other of these blocks is constituted of a diene elastomer. The process according to the invention allows a high degree of grafting of the polyether to the polymer chains. Also disclosed is a reinforced rubber composition, especially intended for the manufacture of tires, comprising such a block copolymer which is intended to interact with the reinforcing filler. Such a rubber composition has improved hysteresis properties in the vulcanized state, while retaining satisfactory processing properties in the non-vulcanized state.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

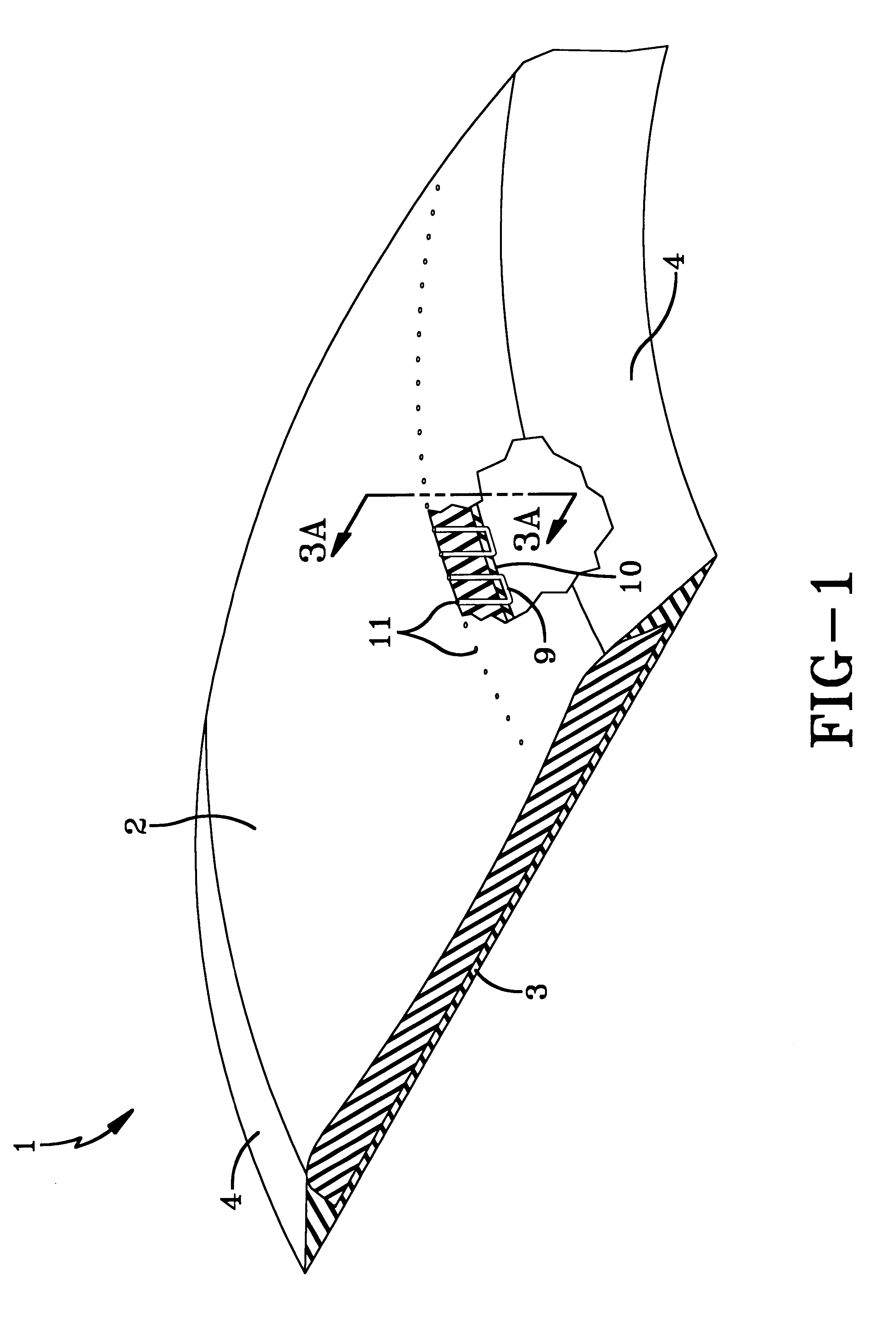

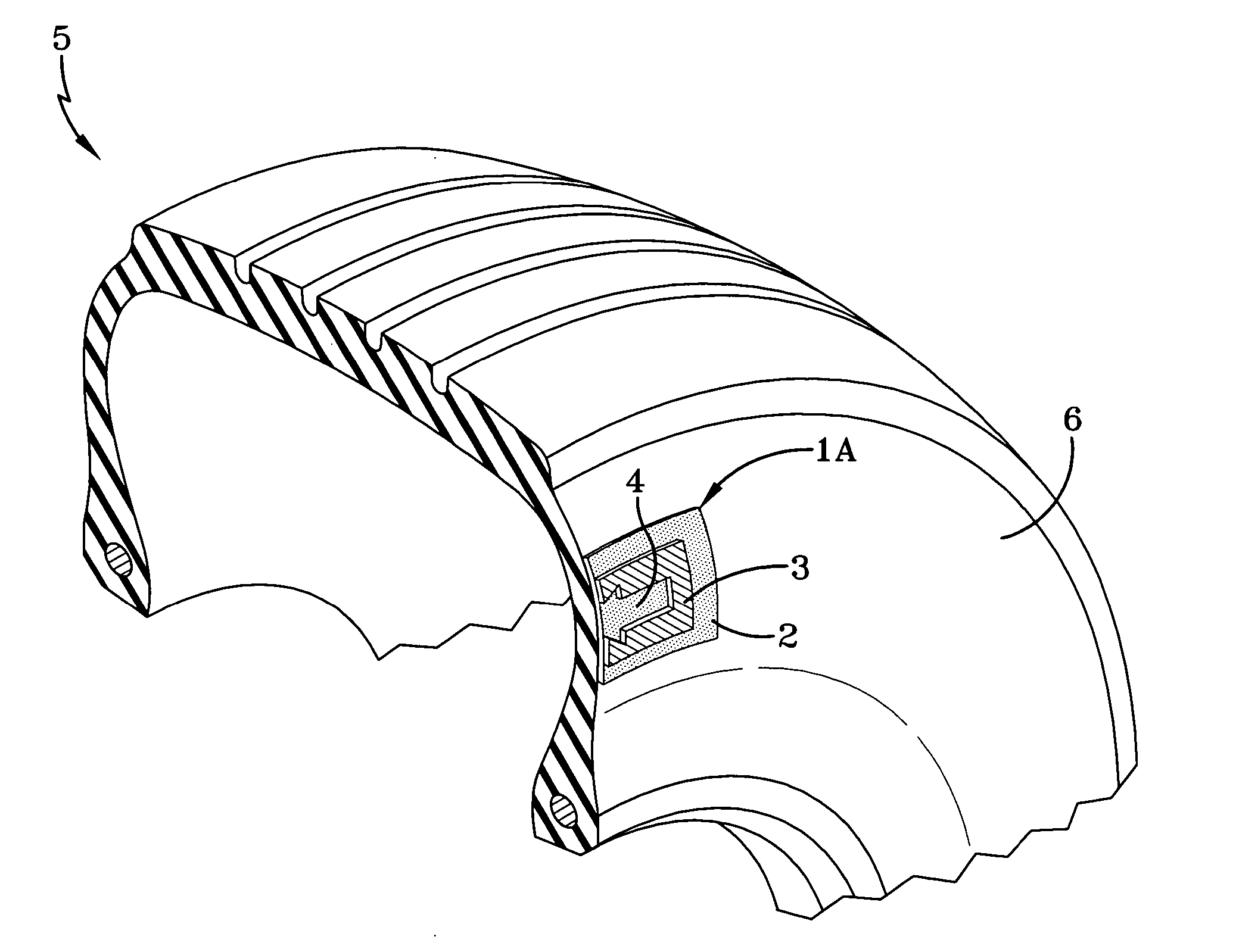

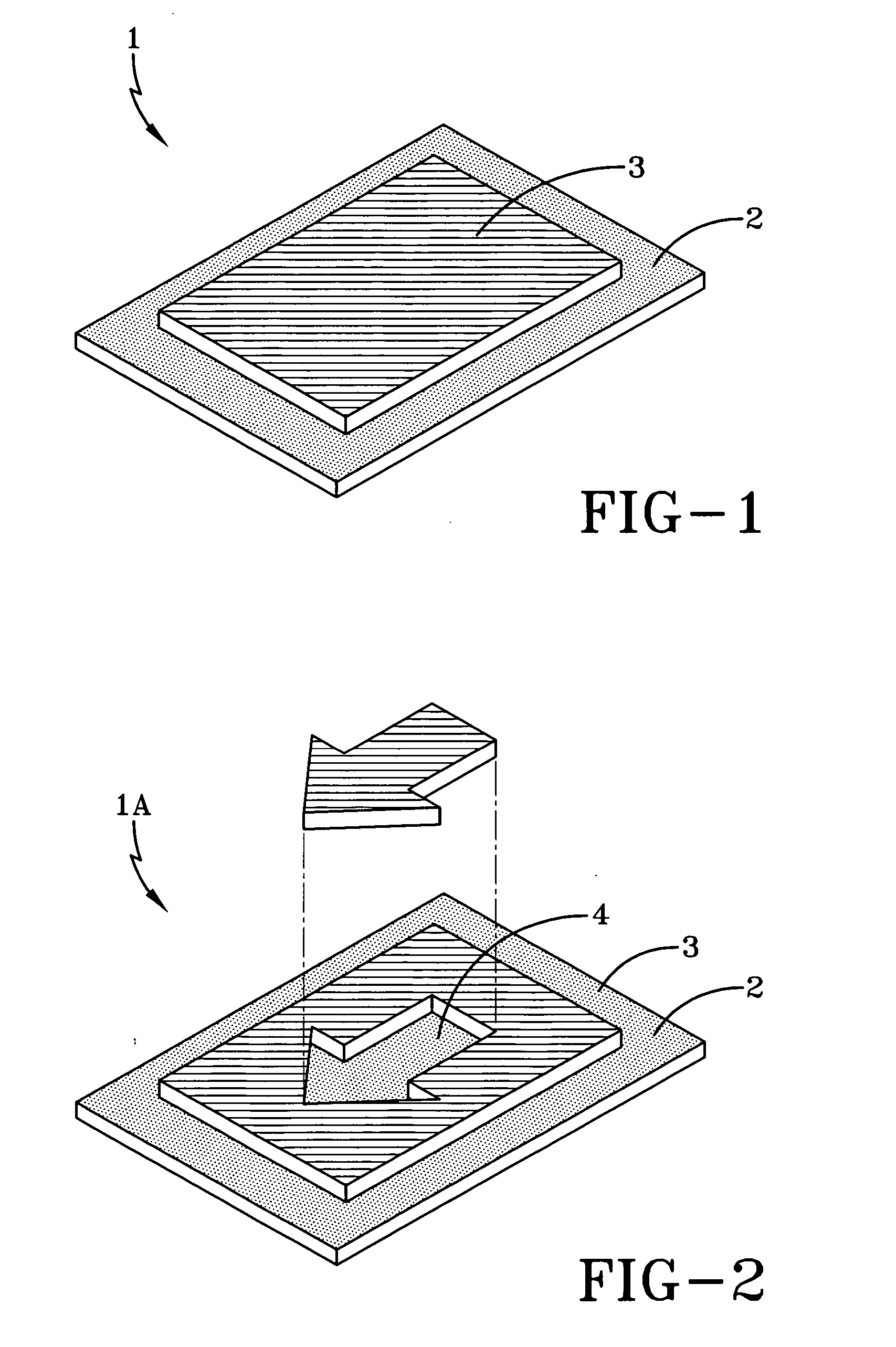

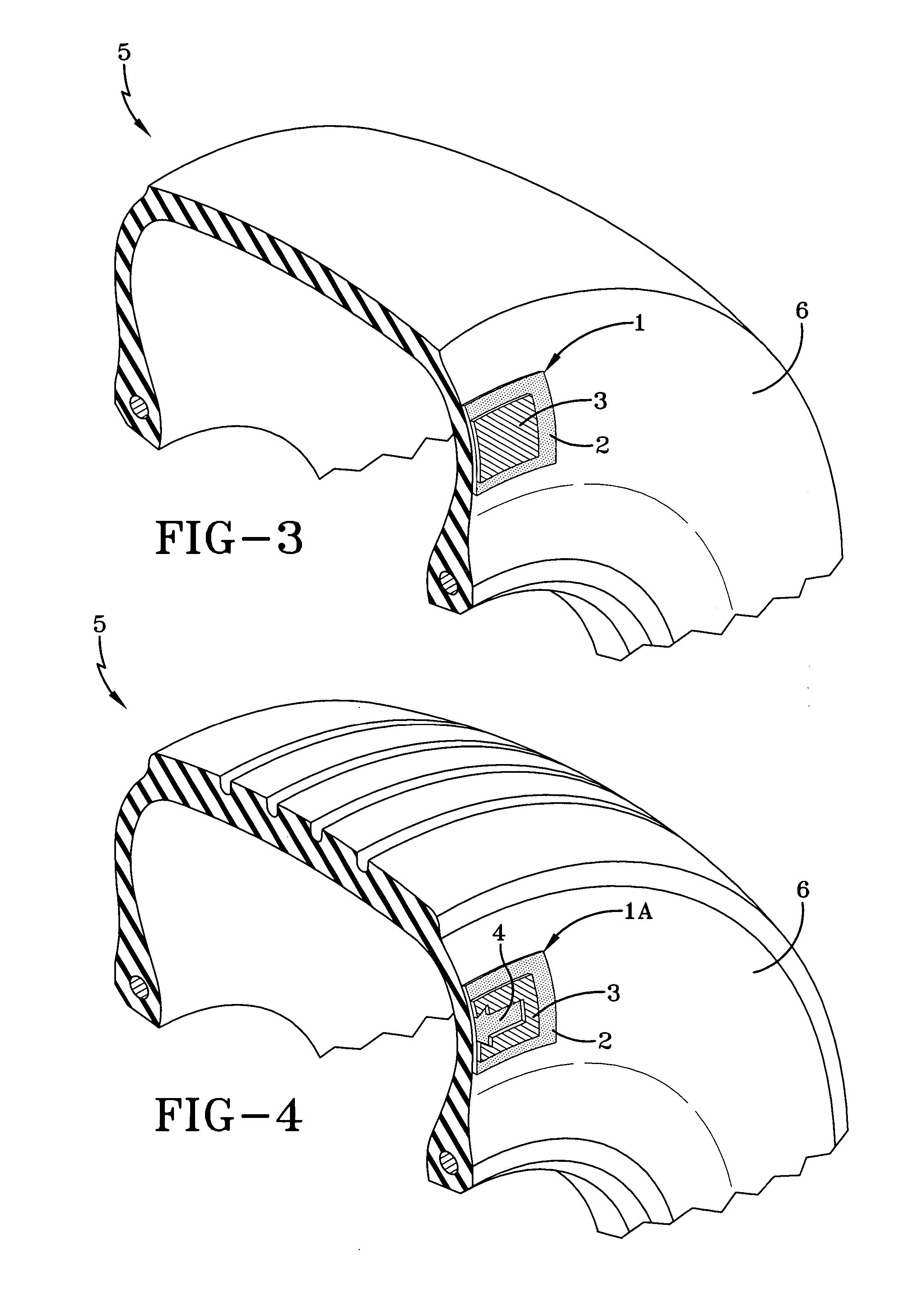

Tire having sidewall with integral colored marking composite

This invention relates to a tire with a rubber sidewall having at least one layered rubber composite integral with a portion of its outer surface as a means of visibly identifying the tire. The layered composite is an integral composite in a sense of being comprised of a base rubber layer and a contrastingly colored marking rubber layer being partially pre-cured together prior to application to the outer surface of an uncured rubber sidewall. The integrally layered composite and tire rubber sidewall are integral in a sense of being co-cured together with the surface of the base rubber layer facing the rubber sidewall surface. The base rubber layer is a black colored carbon black reinforced rubber layer. The marking rubber layer is of color which contrasts with the black color of the base rubber layer. The base layer is a protective rubber layer which extends beyond the peripheral edges of said marking layer and is protective in a sense of inhibiting, or retarding, discoloring materials from migrating through it to the contrastingly colored marking layer.

Owner:BALOGH GEORGE +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com