Method for extruding and forming short fiber reinforced-rubber composite material in radial direction

A short fiber reinforced and composite material technology is applied in the field of radial orientation extrusion molding of short fiber reinforced rubber composite materials, which can solve the problems of complicated operation, low production efficiency, low efficiency, etc., and achieves low technical level requirements and improved product quality. , the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

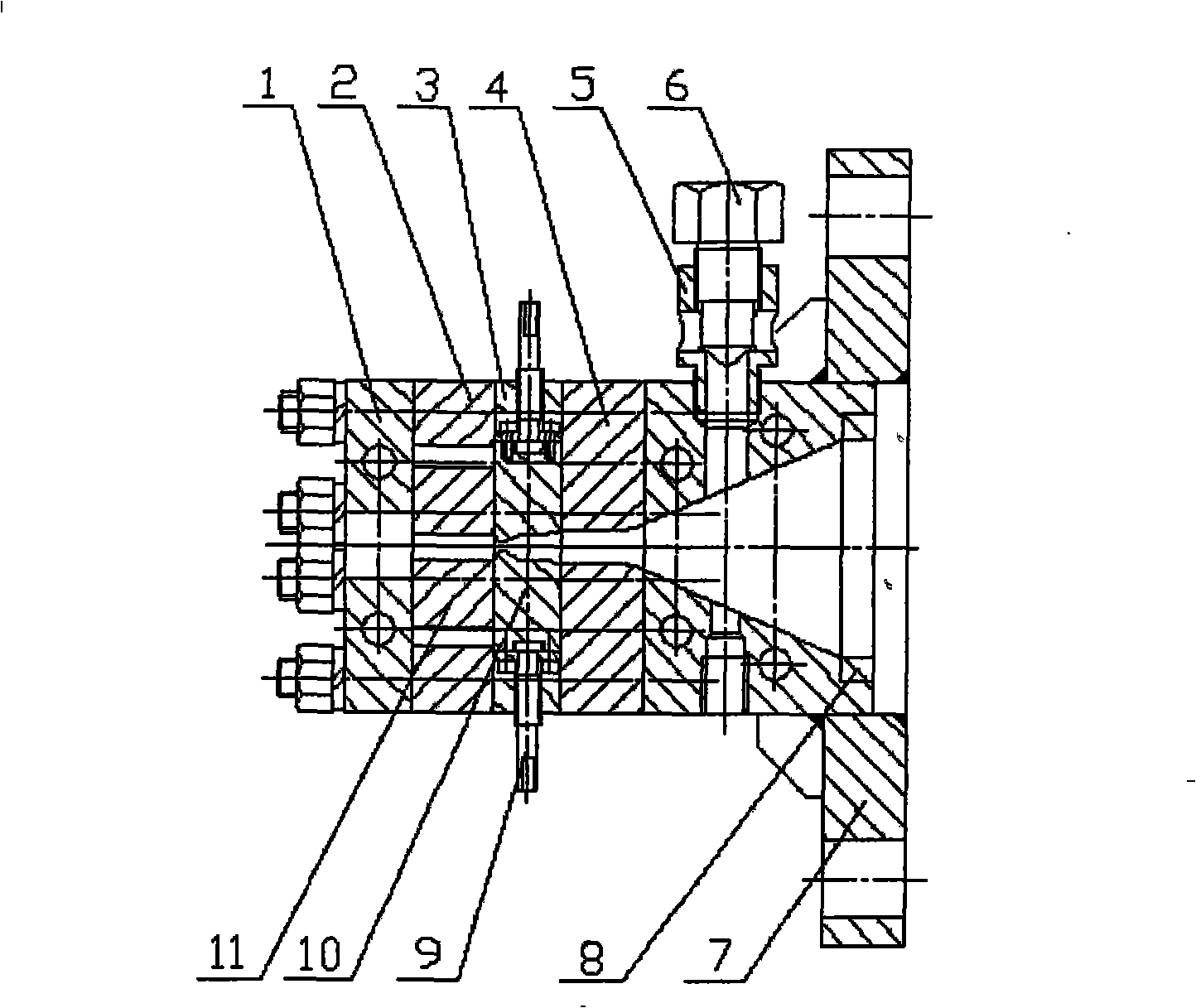

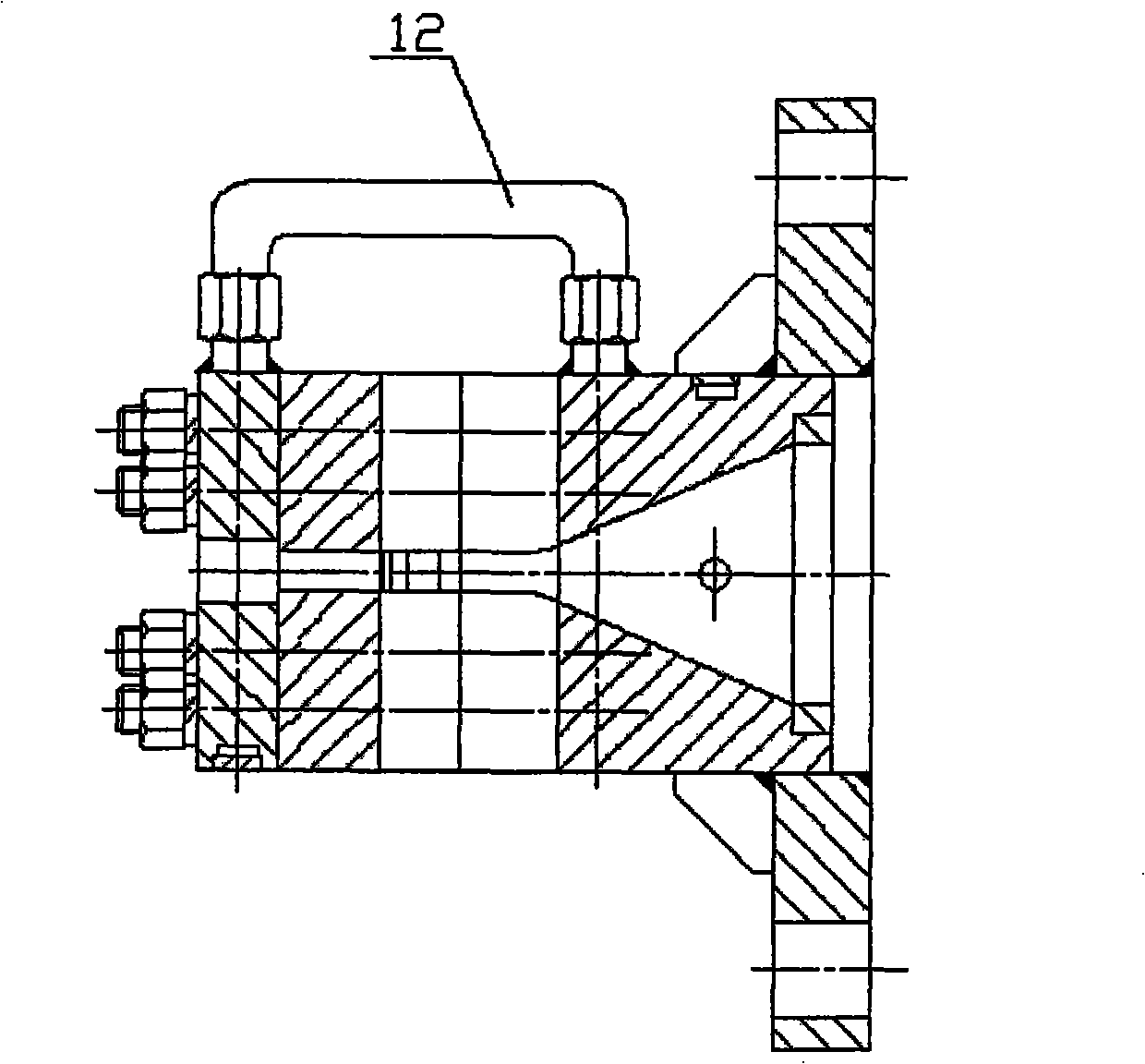

[0011] The specific steps of extrusion molding radial orientation of the present embodiment are as follows:

[0012] a) Put the mixed rubber containing short fibers into the cold-feed extruder. The extruder is selected as XJW60-200, and the screw speed is between 15-60 rpm, and the screw is rotated and sheared. Extrusion processing, suitable for the requirements of different rubber products;

[0013] b) After the rubber is conveyed and pressurized by the screw, it enters the head of the extruder, and is oriented for the first time in the axial orientation flow channel of the head. Most of the short fibers can be oriented in the axially oriented flow channel. The head pressure of this section is between 2-6Mpa, and the pressure can be adjusted by the overflow valve; the length of the flow channel can be adjusted by the disassembled flow channel plate. Between 10-50mm, suitable for the orientation of short fibers of different lengths; the height and width of the flow channel ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com