Methane-circulating retort capable of handling 500 to 1,000 tons of oil shale daily

An oil shale and dry distillation furnace technology, which is applied in the field of oil shale gas full-circulation dry distillation furnaces with a daily processing capacity of 500 to 1000 tons, can solve the problems of difficulty, poor uniform gas distribution in the dry distillation furnace, etc. Save investment and improve the effect of automatic control level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

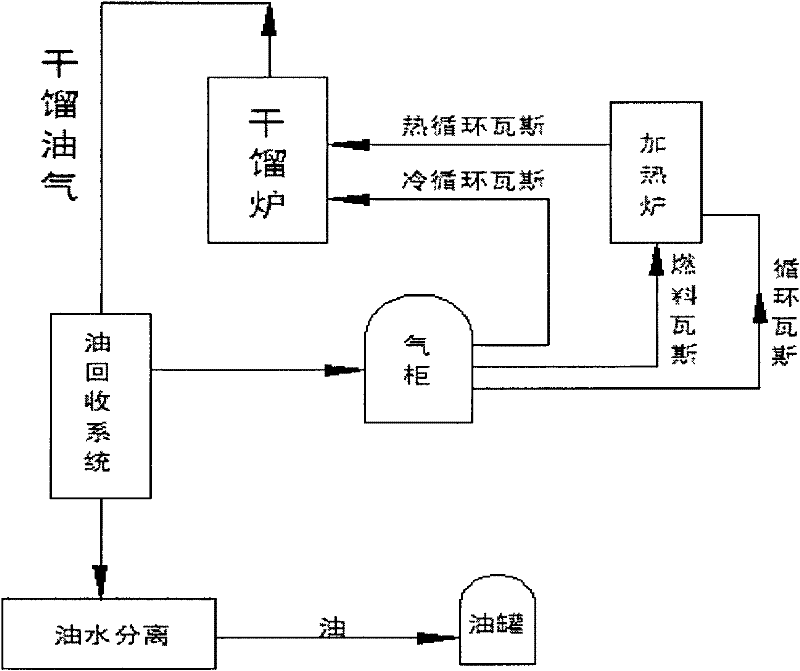

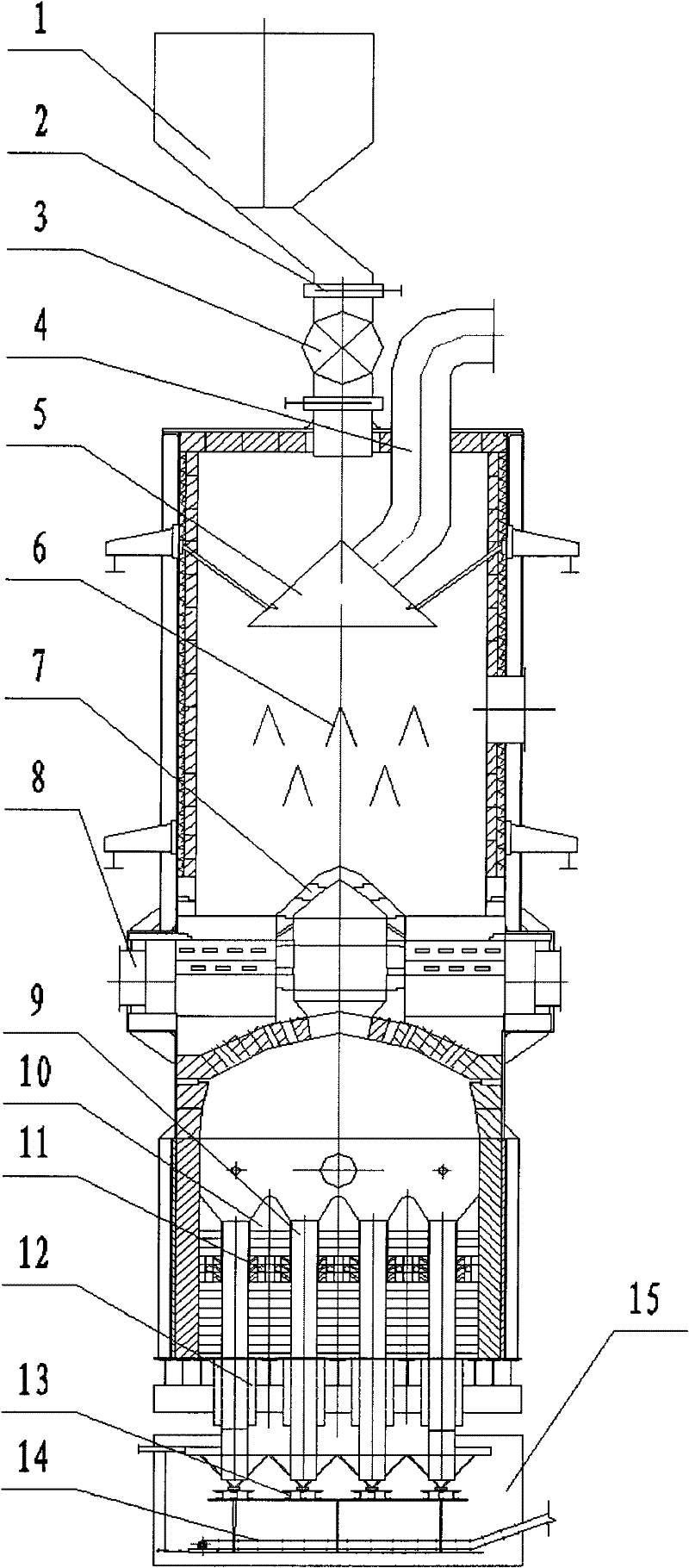

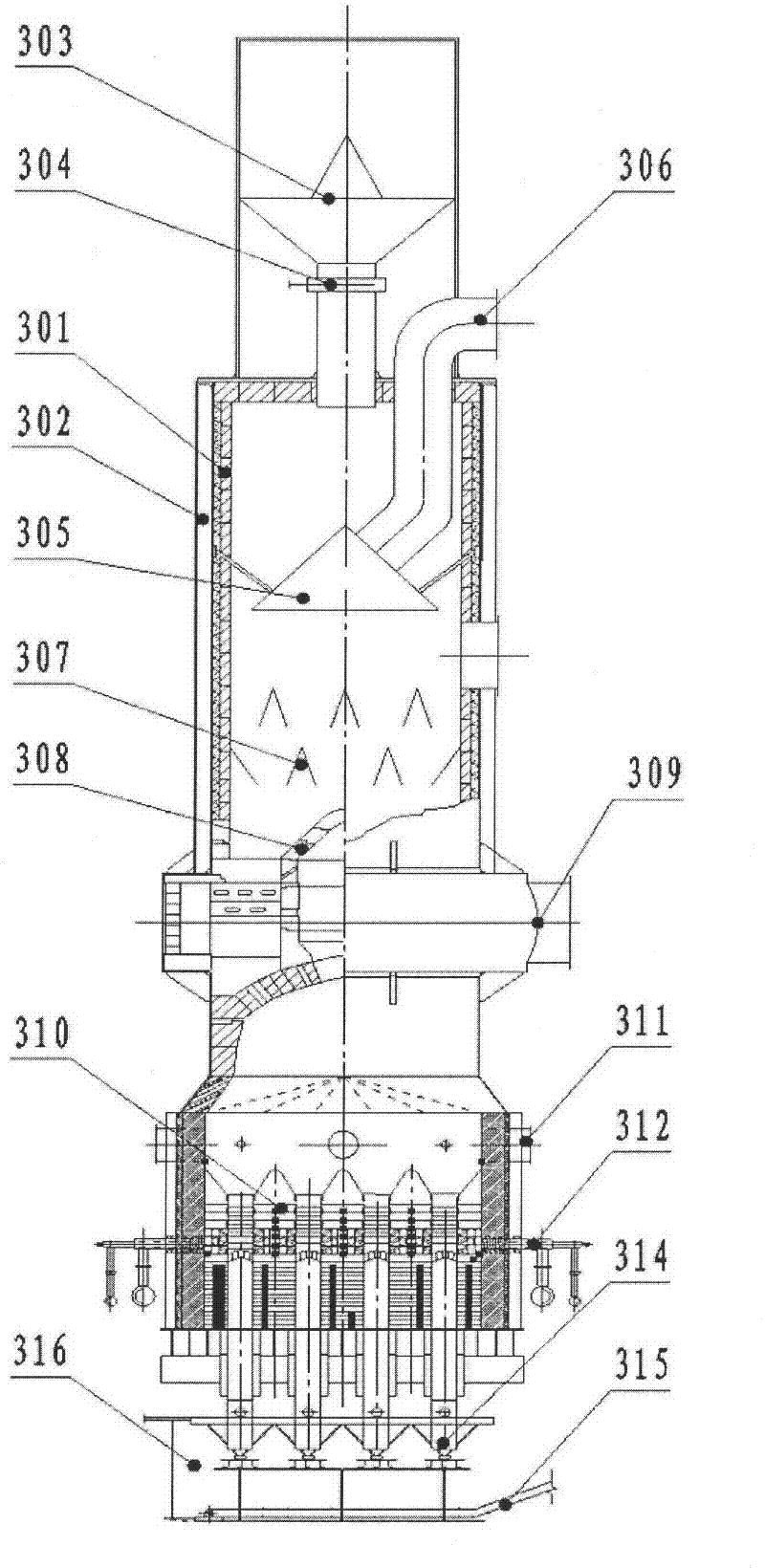

[0046] figure 1 It is the process flow of the heat carrier of the gas full cycle dry distillation process of the present invention. The figure mainly reflects the full cycle process of gas as the heat carrier of carbonization. When the oily gas produced during the carbonization process of oil shale is discharged from the top of the carbonization furnace, the temperature is about 110°C. After the shale oil is recovered by the oil recovery device, it is cooled To about 40 ℃, into the gas tank. A part is sent to the heating furnace by the gas fan as fuel; a part is sent to the heating furnace by the gas fan to be heated to over 700°C as thermal cycle gas and then sent back to the retort furnace, and the temperature exceeds 680°C when entering the retort furnace; part is used as cold cycle gas by the gas The fan is sent to the bottom of the retort furnace to recover the waste heat of semi-coke. After the temperature rises above 450°C, it is mixed with the heat circulation gas at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com