Gas-liquid separating device

A gas-liquid separation device and a technology for gas-liquid separation, which are applied to the separation device of liquid two-phase and gas field, can solve the problems of unsatisfactory requirements, difficult cleaning and maintenance, low separation efficiency, etc., and achieve reliable effect, stable structure, The effect of reducing the motion section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

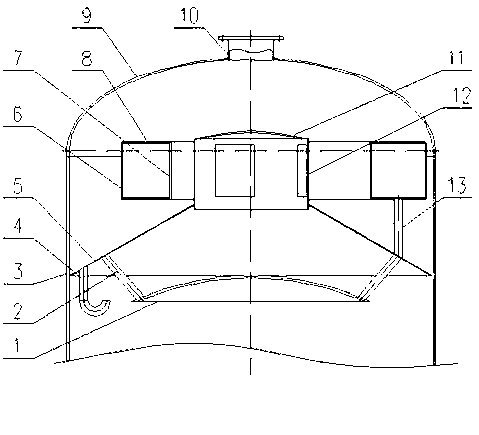

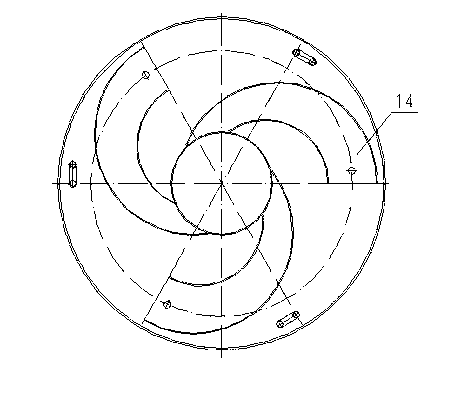

[0014] The present invention is explained below with reference to the drawings and embodiments.

[0015] In this embodiment, the number of centrifuge cylinders is set to three, which are evenly arranged in a circle.

[0016] In evaporators that are widely used, the quality requirements for secondary steam are also very high, because relatively pure secondary steam can improve equipment thermal efficiency, extend equipment service life, reduce water hammer, and obtain ideal secondary condensate. Therefore, the role of the gas and liquid separation device is very critical. The gas-liquid separation device of the present invention is generally arranged on the top of the vapor-liquid evaporation equipment (such as air conditioner, compressor, tower or evaporator) to be separated, fixed in a stepped manner, and communicated with the secondary vapor exhaust port.

[0017] In the present invention, an exhaust port 10 is provided on the upper part of the head 9. A cylindrical structure 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com