Compressed action independent-chamber reciprocating type four-stroke engine

A four-stroke internal combustion engine, reciprocating technology, applied to engine components, combustion engines, machines/engines, etc., can solve problems such as complex structures, achieve high chamber wall temperature, reduce losses, and increase the flow cross-section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

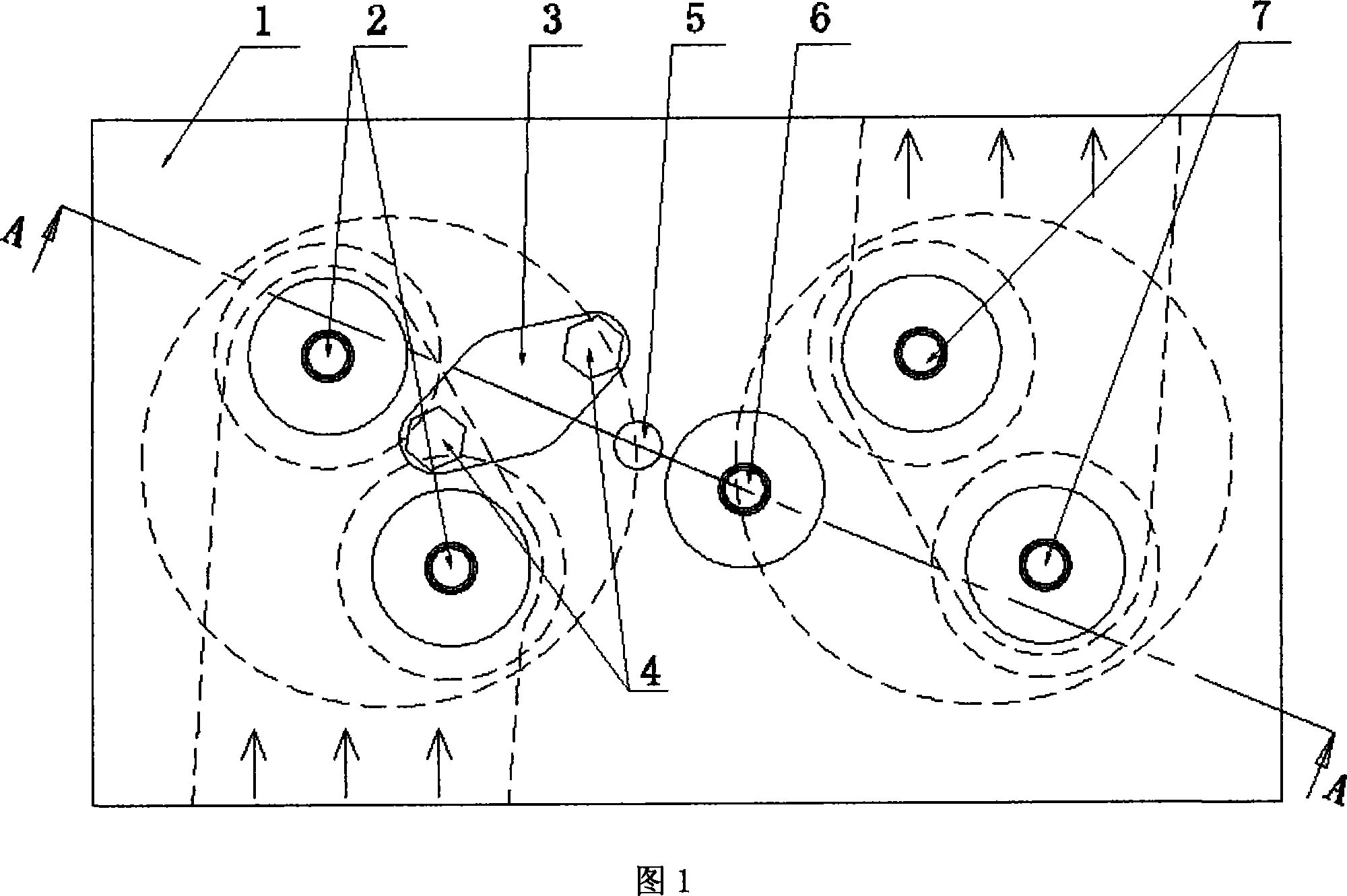

[0045] Compression work independent chamber reciprocating four-stroke engine contains at least one set of compression chamber and work chamber, and engines with more than four cylinders are composed of half sets of compression chambers and work chambers. And the engine that contains a group of compression chamber and work chamber contains two cylinders and existing reciprocating piston type four-stroke two-cylinder engine is structurally similar, just take the engine that contains a group of compression chamber and work chamber as example to illustrate embodiment below. Engines with more than four cylinders consist of the following units with half the number of cylinders.

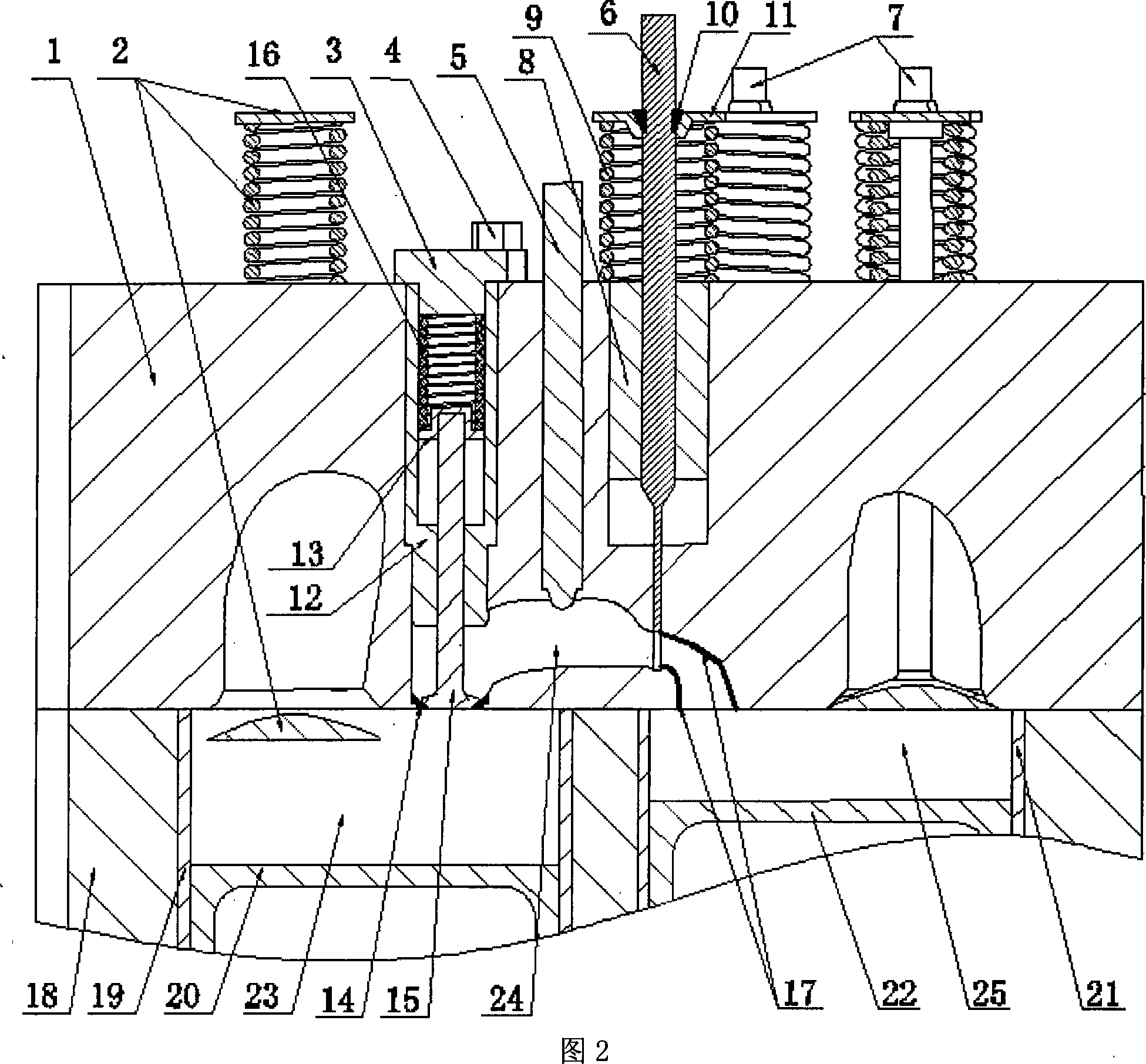

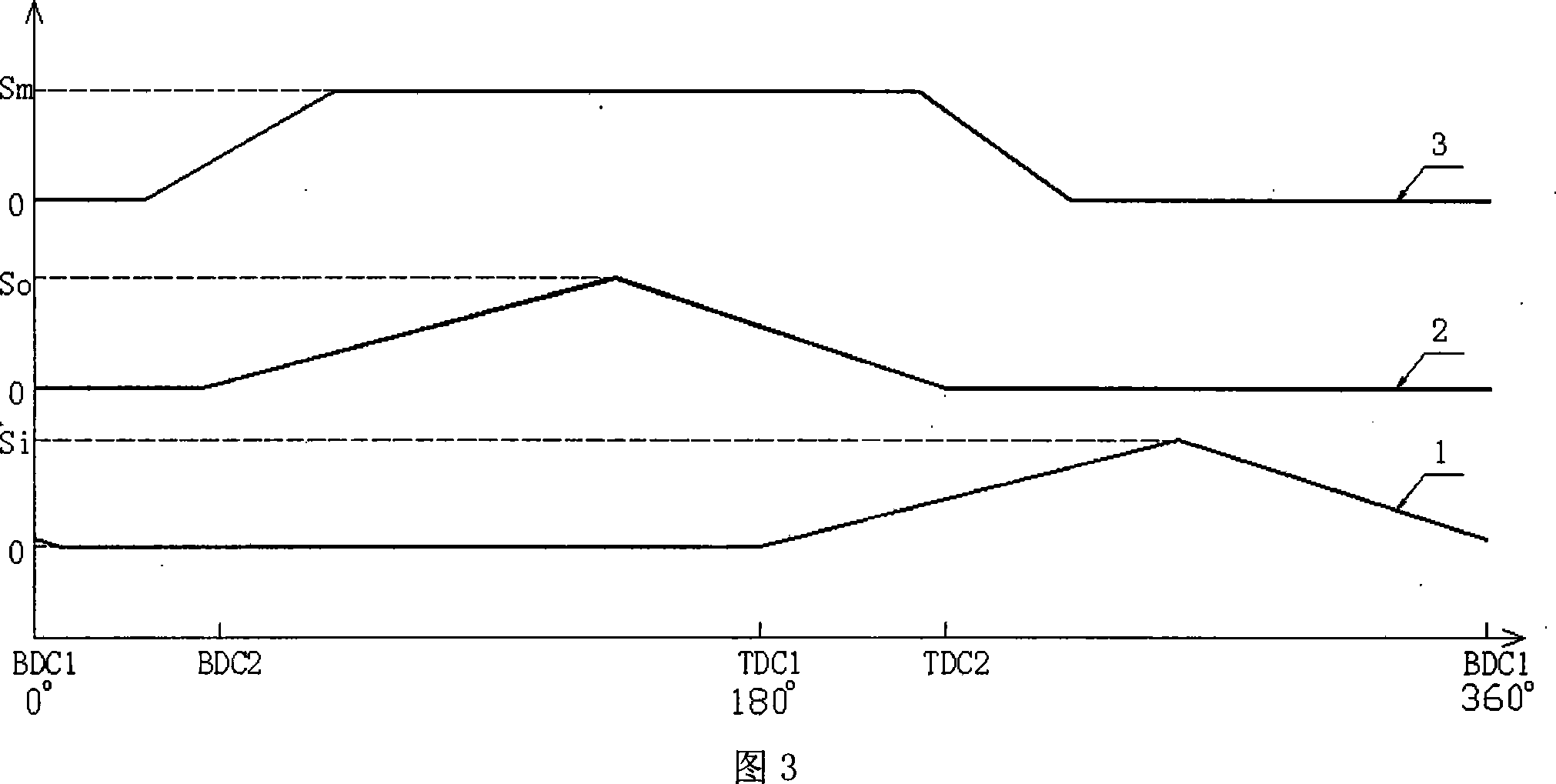

[0046] As shown in Figure 1 and Figure 2:

[0047]The left part of the cylinder head body (1) forms a compression chamber (23) with the compression cylinder liner (19) and the compression piston (20), and the right part of the cylinder head body (1) forms a compression chamber (23) with the working cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com