Printing antenna with baseplate integrated waveguide feeder

A substrate-integrated waveguide and waveguide feeding technology, applied in the field of antennas and feeding, can solve the problem that there are not many types of antennas, and achieve the effects of improving cross-polarization and bandwidth performance, simple and convenient sealing, economical, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

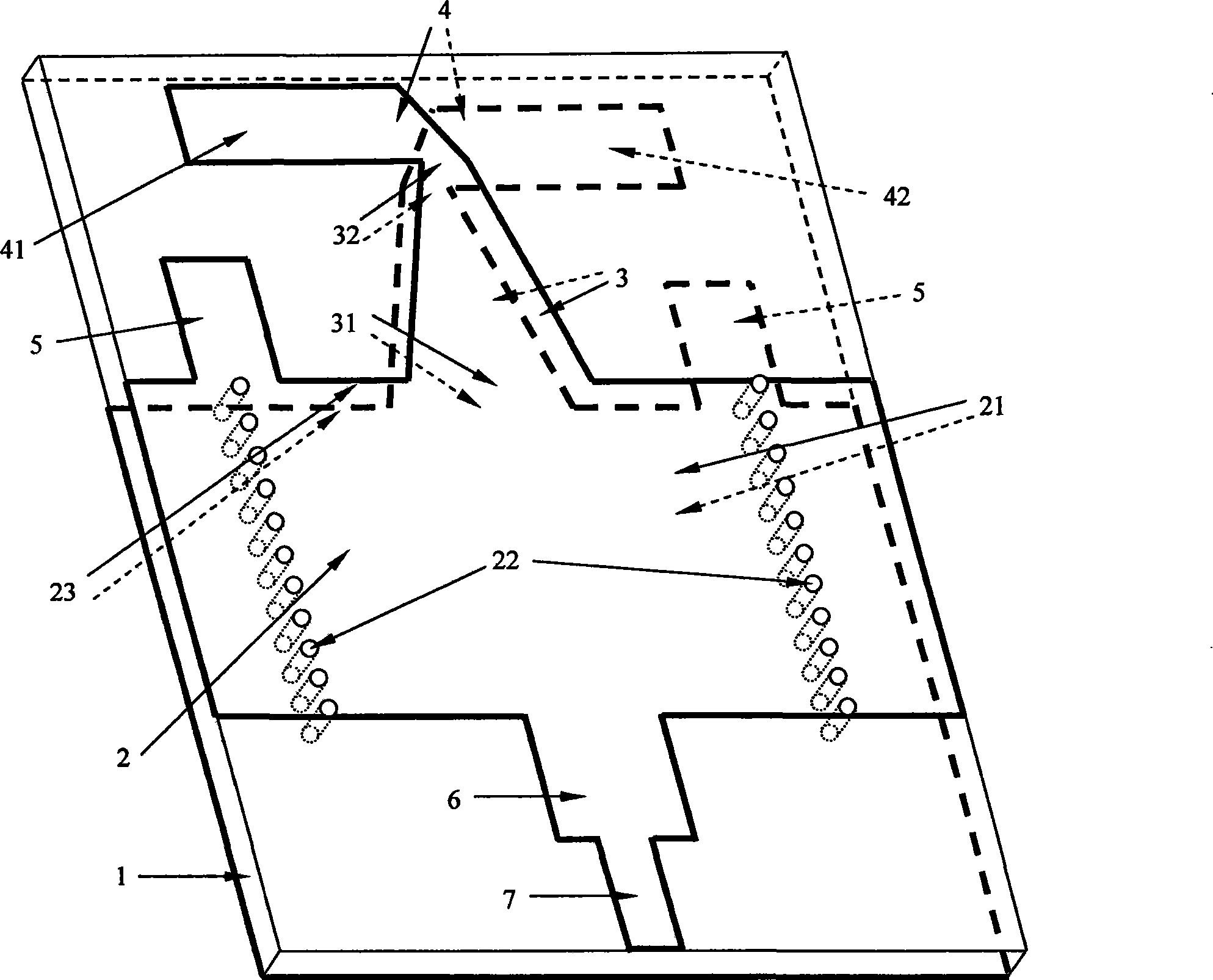

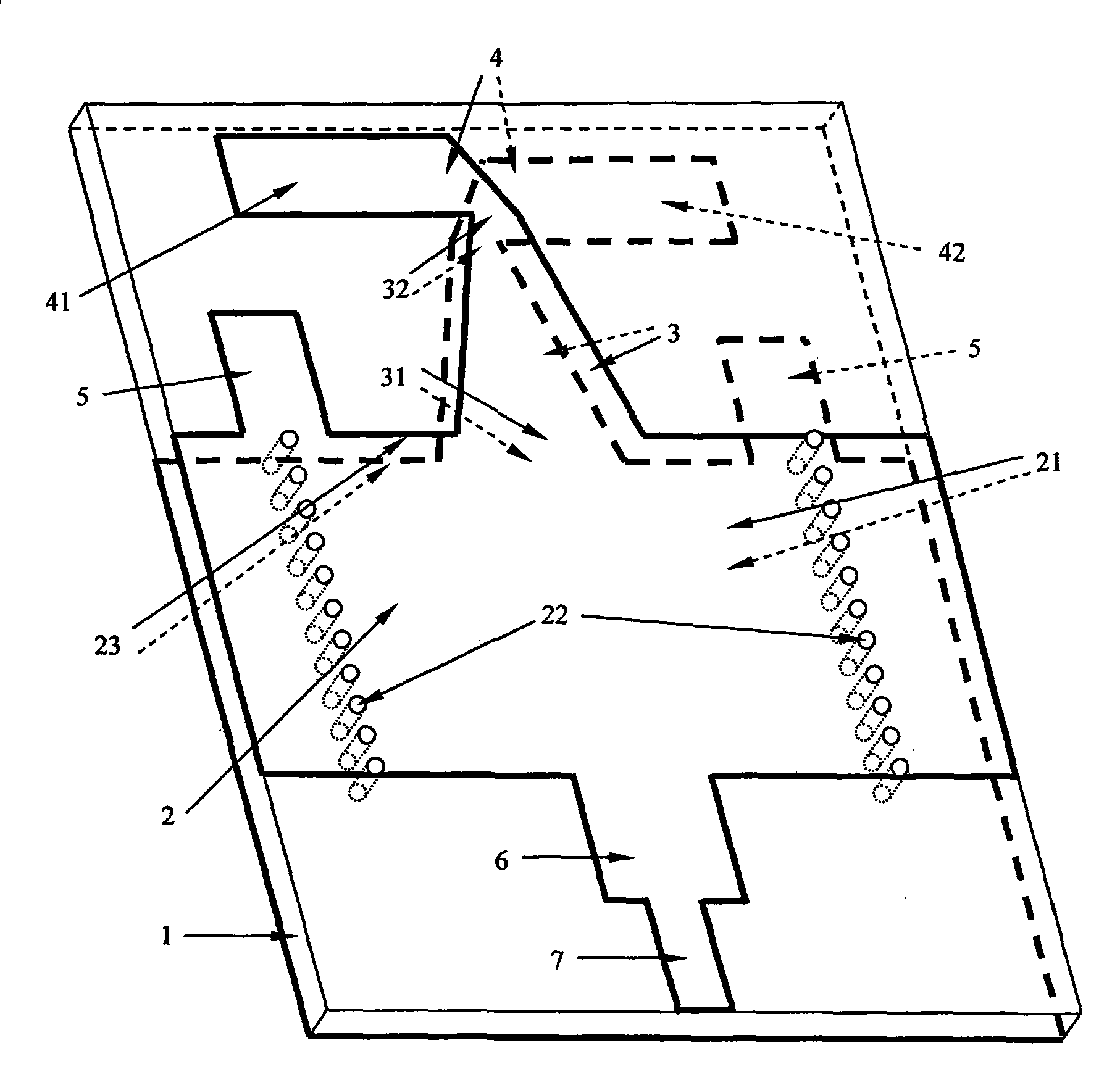

[0018] Embodiment 1 A substrate-integrated waveguide-fed printed antenna with a metal reflector.

[0019] Antenna structure such as figure 2 All dimensions shown are in mm. The size of the metal reflector is 150×150×4 (L×W×H), and a 43×1 slot is opened on the reflector to let the dielectric substrate with the substrate integrated waveguide and the printed antenna pass through. The size of the substrate in this embodiment is 43×44×1. One side of the reflector is the antenna radiating outward, and the other side is the SIW and the transition switch connected with the circuit. The gap is located at the SIW, so that the purpose of sealing and isolation can be achieved, and the short circuit of the radio frequency signal will not be caused because the gap on the metal reflector is connected to the metal on the upper and lower sides of the substrate.

Embodiment 2

[0020] Embodiment 2 A printed antenna array fed by a waveguide is integrated into a substrate that realizes sealing connection with a circuit shielding box.

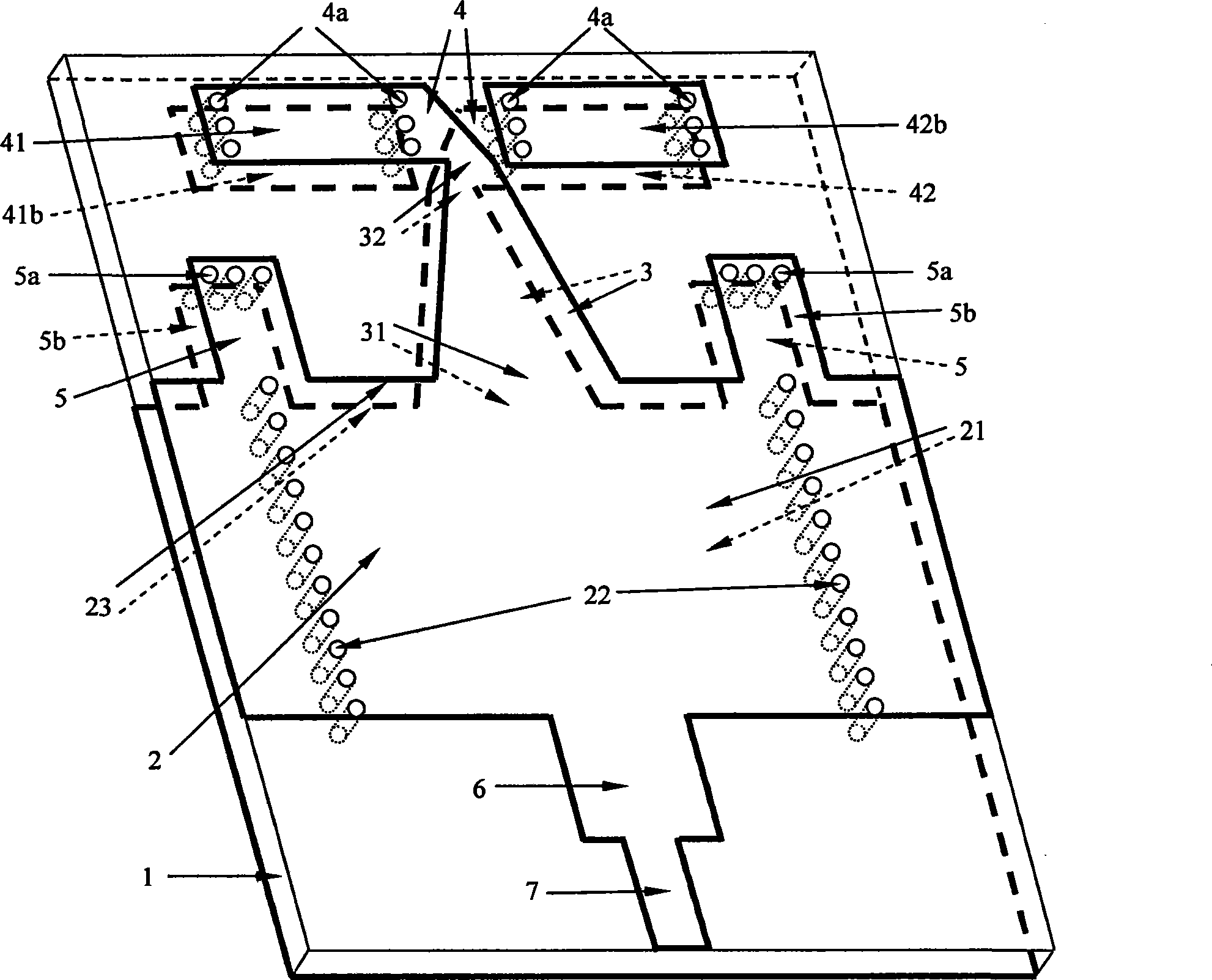

[0021] An antenna array structure in which the printed antenna fed by the substrate integrated waveguide is sealed and connected to the circuit inside the circuit shielding box through the gap on the reflector and the shielding box wall. An example is an 8×8 array, and each antenna board is processed with 8 arranged horizontally such as figure 1 or figure 2 The substrate-integrated waveguide-fed printed antenna unit with the structure shown (used in the schematic diagram for the convenience of drawing figure 1 Structure representation), each unit is connected to the corresponding circuit inside the circuit box by the SIW section through the gap on the reflector and the circuit box shell, and there are 8 layers of such circuit boxes and antenna boards arranged vertically to form an 8×8 array. Since the gap of each laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com