Sealing ring for rotating shaft

A technology for sealing rings and rotating shafts, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of high cost of use, easy leakage, and large creep, and achieve fewer parts, less wear and tear, and lower cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

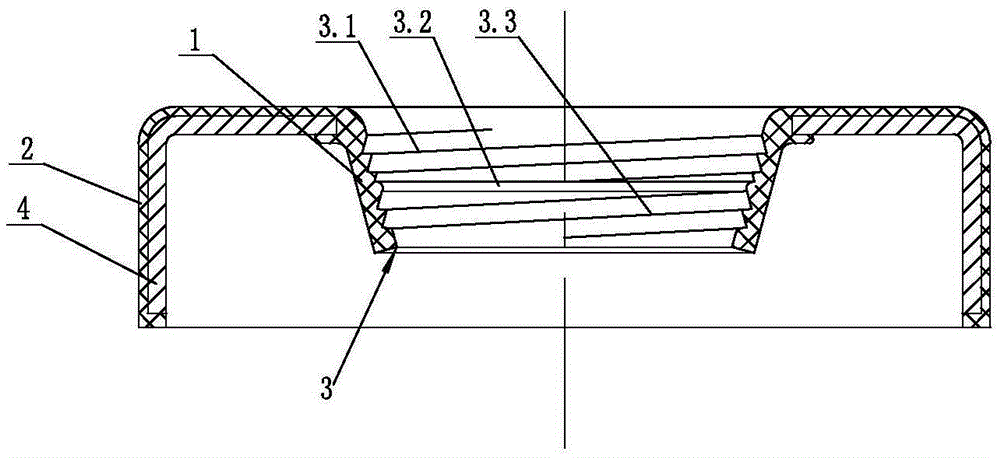

[0015] Such as figure 1 As shown, a sealing ring for a rotating shaft includes a sealing lip 1, an outer diameter sealing body 2 and a sealing rib 3 at the sealing lip 1, the sealing lip 1 is connected with the outer diameter sealing body 2, and the The sealing rib 3 is divided into a first spiral sealing rib 3.1, an annular sealing rib 3.2 and a second spiral sealing rib 3.3, and the annular sealing rib 3.2 is located between the first spiral sealing rib 3.1 and the second spiral sealing rib 3.3, so There is an interference fit between the sealing lip 1 and the rotating shaft. The helical directions of the first spiral sealing rib 3.1 and the second spiral sealing rib 3.3 are the same, so that the outer first spiral sealing rib 3.1 has a pressing effect on the annular sealing rib 3.2, so that the annular sealing rib 3.2 fits better with the rotating shaft close.

[0016] The section of the first spiral sealing rib 3.1 and the second spiral sealing rib 3.3 is triangular (als...

Embodiment 2

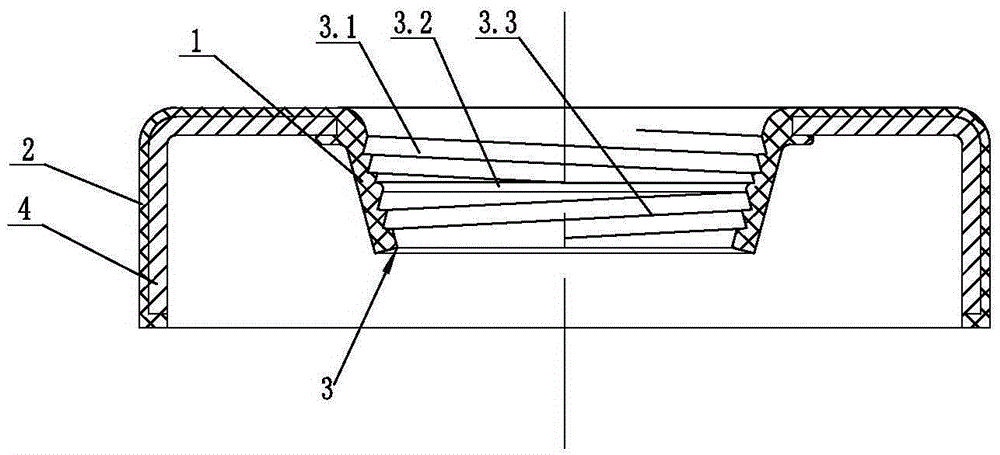

[0020] Such as figure 2 As shown, the helical direction of the first helical sealing rib 3.1 is opposite to that of the second helical sealing rib 3.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com