Tubular product hydraulic forming device capable of achieving inside and outside pressurization

A hydroforming and pipe technology, applied in the field of pipe hydroforming, can solve the problem of simultaneous loading of pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

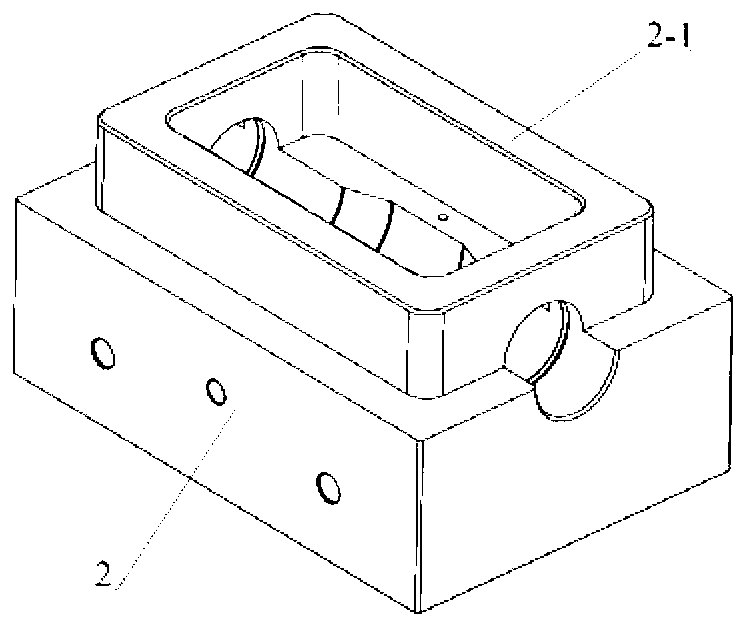

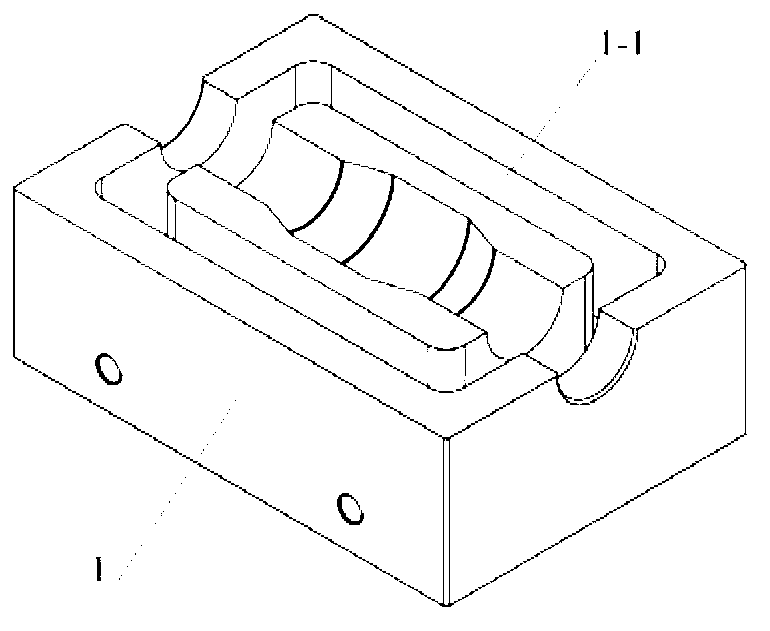

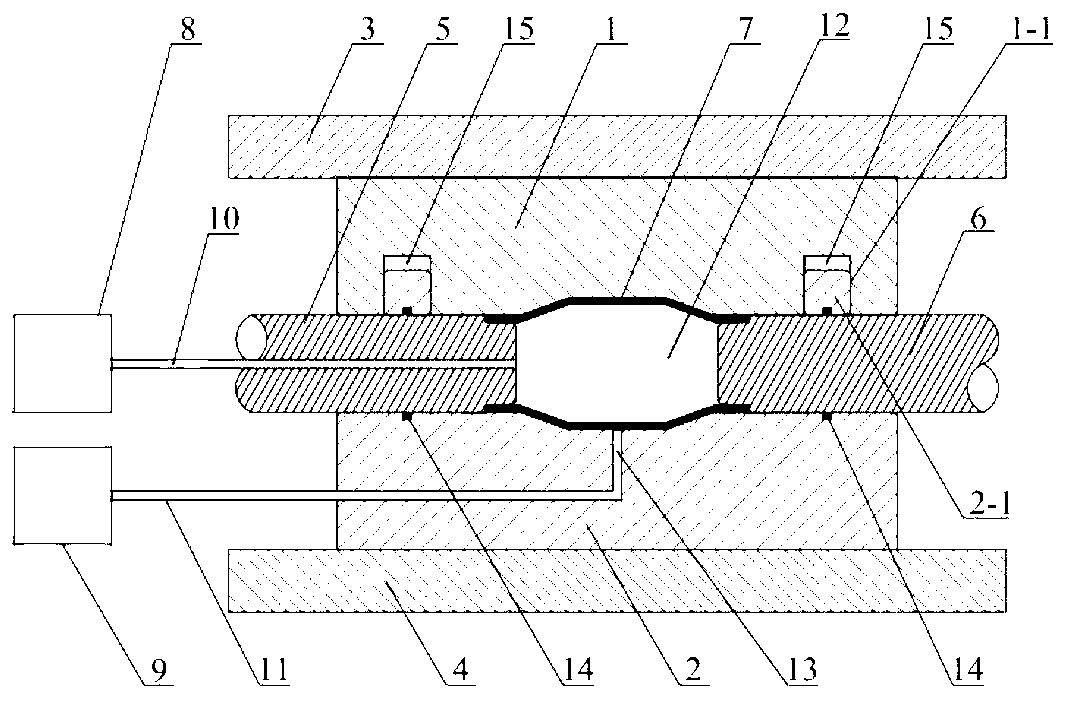

[0036] Specific implementation mode 1: Combination Figure 1 to Figure 10 To explain this embodiment, a pipe hydroforming device that can realize internal and external pressurization in this embodiment includes an upper mold 1, a lower mold 2, an upper template 3, a lower template 4, a left punch 5, and a right punch. The head 6, the upper mold 1 and the lower mold 2 are closed to form a complete mold cavity, which is located between the upper mold 3 and the lower mold 4. The upper mold 3 is connected with the mold upper mold 1, and the lower mold 4 is connected with the mold lower mold. 2Connect. The two ends of the mold cavity are respectively provided with a left punch 5 and a right punch 6; the left punch 5 is provided with a first liquid channel 10 along its axial direction, and the internal pressure booster 8 passes through the first liquid channel 10 is in communication with the inner cavity of the pipe 7, and the pressure intensifier 8 can be filled with liquid medium ...

specific Embodiment approach 2

[0039] Specific embodiment two: Combining embodiment one and Picture 11 To illustrate this embodiment, the difference between this embodiment and the first embodiment is that the first sealing ring 14 between the left punch 5, the right punch 6 and the boss 2-1 of the lower die 2 is set to be more One (at least two), so that a better sealing effect can be achieved, so that the external pressure can reach a greater value. The other components and connection modes are the same as in the first embodiment.

specific Embodiment approach 3

[0040] Specific implementation mode 3: Combining implementation mode 1 and Picture 12 To illustrate this embodiment, the difference between this embodiment and the first embodiment is that the forming device further includes a second sealing ring 16, and the pipe cavity and the left punch are formed at both ends of the upper mold 1 and the lower mold 2. One or more second sealing rings 16 are arranged between the head 5 and the right punch 6 respectively. The second sealing ring 16 is arranged on the punch, and the number of the second sealing rings on the left and right punches depends on the number of punches in the pipe forming process. Depending on the advancement distance of the head, it should be ensured that at least one second sealing ring 16 forms a sealing fit with the boss 2-1 at each moment.

[0041] When the first seal ring on the punch enters the boss 2-1, the external pressure around the punch can be sealed. With the continuous advancement of the left and right pun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com