Low temperature co-fired ceramic-based micro-electromechanical system (MEMS) packaging method

A technology of low-temperature co-fired ceramics and packaging methods, which is applied in the fields of crafts for producing decorative surface effects, decorative arts, microstructure devices, etc., to achieve the effects of reducing risks and losses, avoiding device failure, and good airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

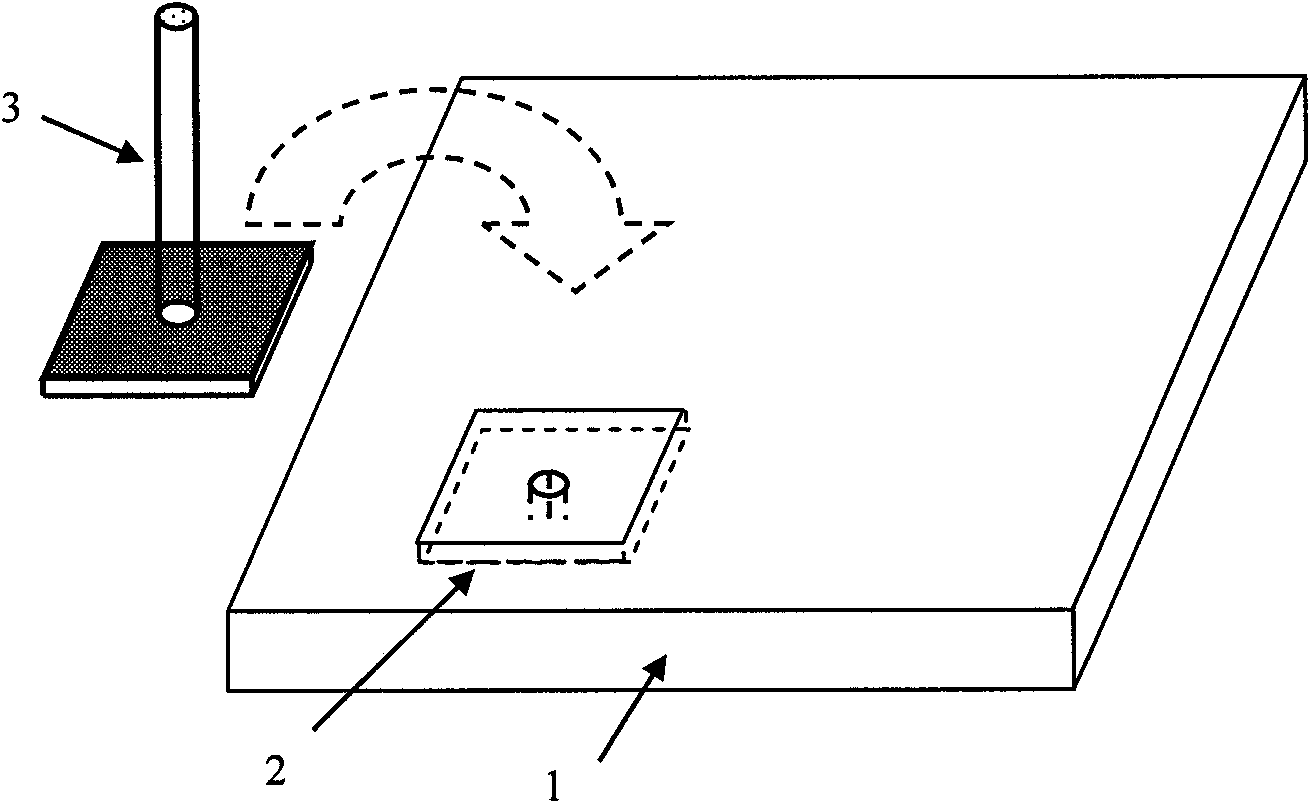

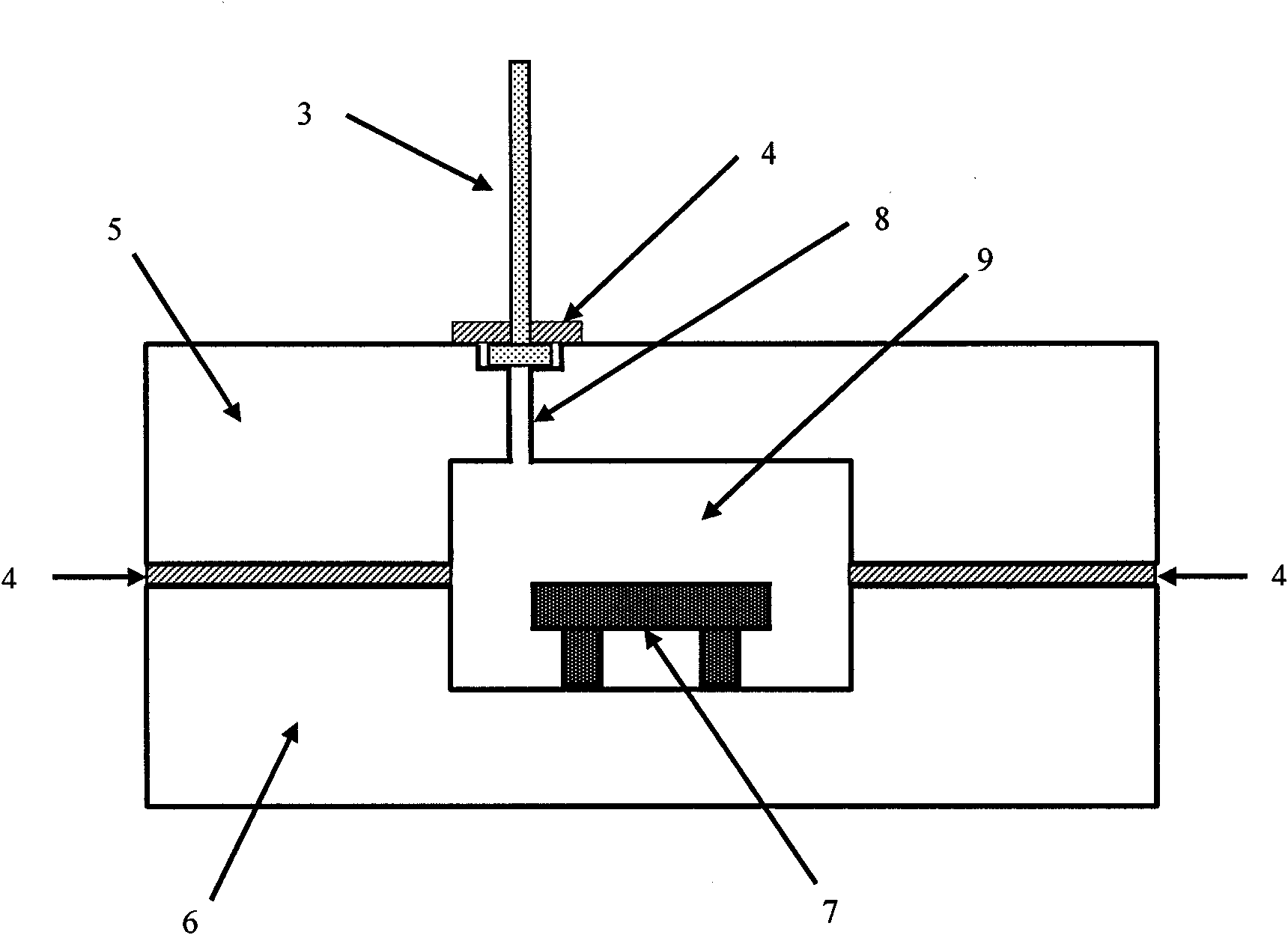

[0048] Vacuum packaging of MEMS using LTCC substrate embedded microfluidics (see figure 2 ), the steps are:

[0049] 1. The package is welded by two substrates. Process the upper substrate 5 first:

[0050] 1) According to the design, cut strip-shaped empty slots and square vertical holes on the LTCC green ceramic sheet by micro-machining methods such as micro-machining or corrosion, and then print metal paste to make metal interconnection wires and vertical interconnection via hole fillers and I / O pads;

[0051] 2) Accurately align and laminate the above-mentioned processed multi-layer green ceramic sheets, and sinter them into an integrated upper substrate 5 by using the conventional process of LTCC, and form vertical three-dimensional interconnection electrical signal lines on the substrate 5 at the same time of sintering , an embedded micro-channel 8 and an open cavity, wherein one end of the micro-channel 8 communicates with the top of the cavity, and the other end le...

Embodiment 2

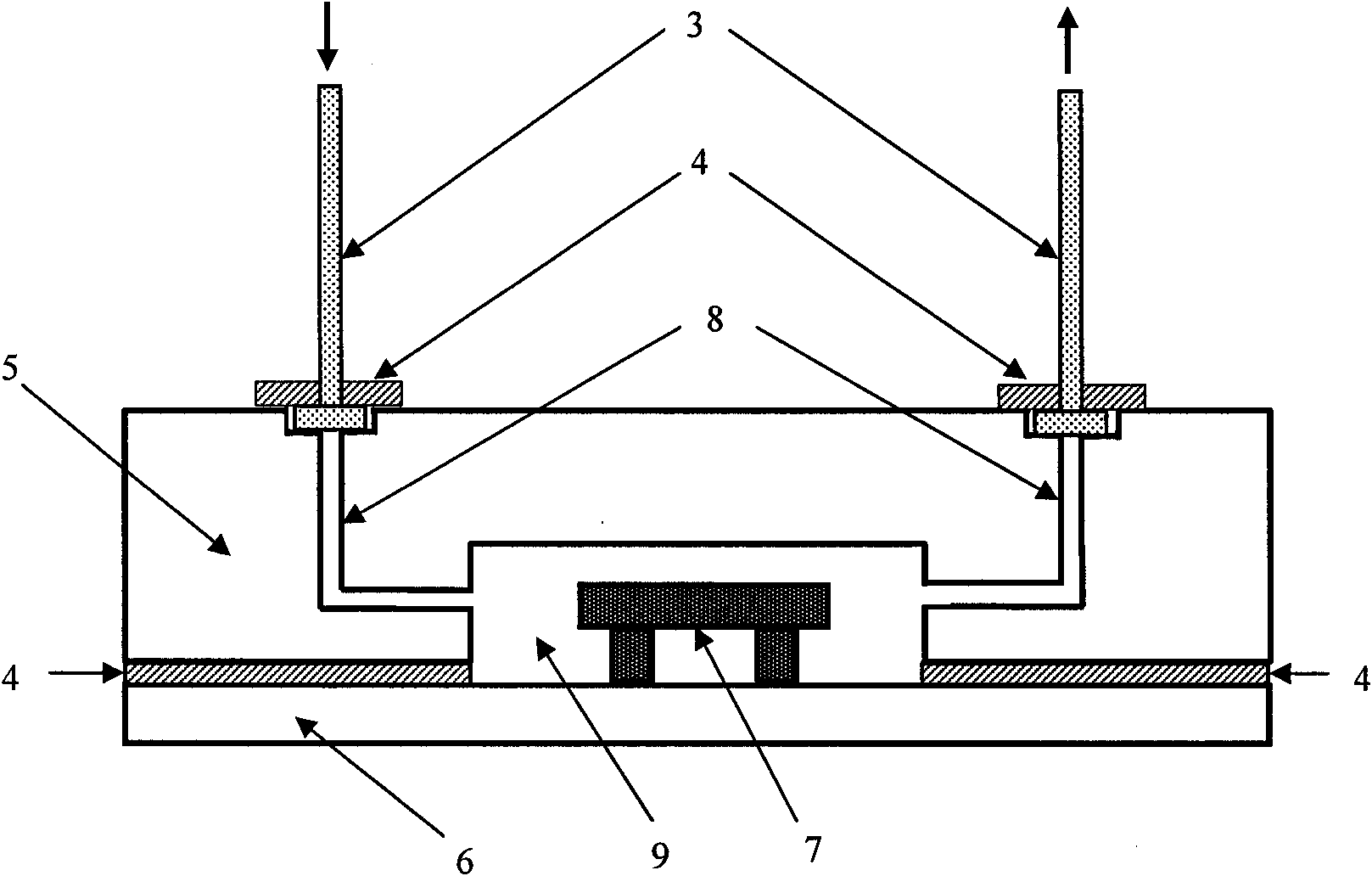

[0059] Using LTCC substrates to embed microfluidic channels for medical, biological, and chemical microfluidic transport cycles (see image 3 ), the steps are:

[0060] 1. The package is welded by two substrates, and the upper substrate 5 is processed first:

[0061] 1) Cut strip-shaped and square slots on the LTCC green ceramic sheet according to the design, and then print the metal paste on the LTCC green ceramic sheet to make metal interconnection wires, vertical interconnect via hole fillers and I / O pads;

[0062] 2) The above-mentioned processed multi-layer green ceramic sheets are precisely aligned and laminated, and sintered into an integrated substrate by using the conventional process of LTCC. The channel 8 and the open cavity 9 and the interface groove are respectively processed with an inlet micro-channel and an outlet micro-channel, and the micro-channel communicates with the side wall of the cavity;

[0063] 2. Put the metal tube 3 with the flange into the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com