Movement butt joint device for large body part of airplane general assembly

A docking device and general assembly technology, applied in aircraft assembly, aircraft parts, ground installations, etc., can solve the problems of low docking accuracy, long stagnation time of large parts, hidden safety and quality hazards, etc., to eliminate assembly stress and meet the requirements of automatic docking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

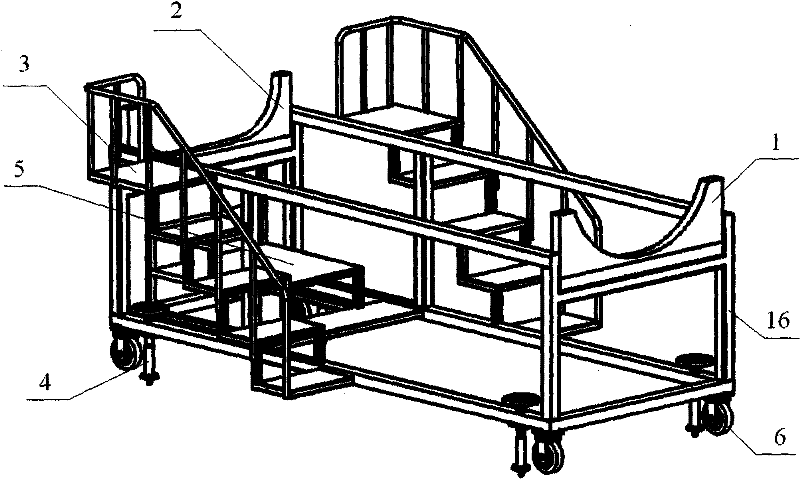

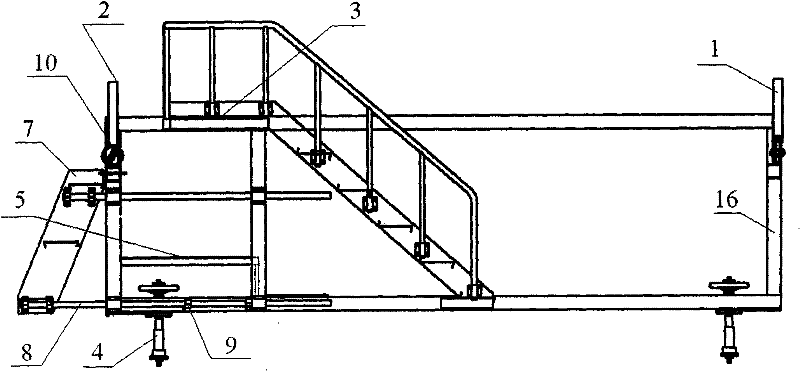

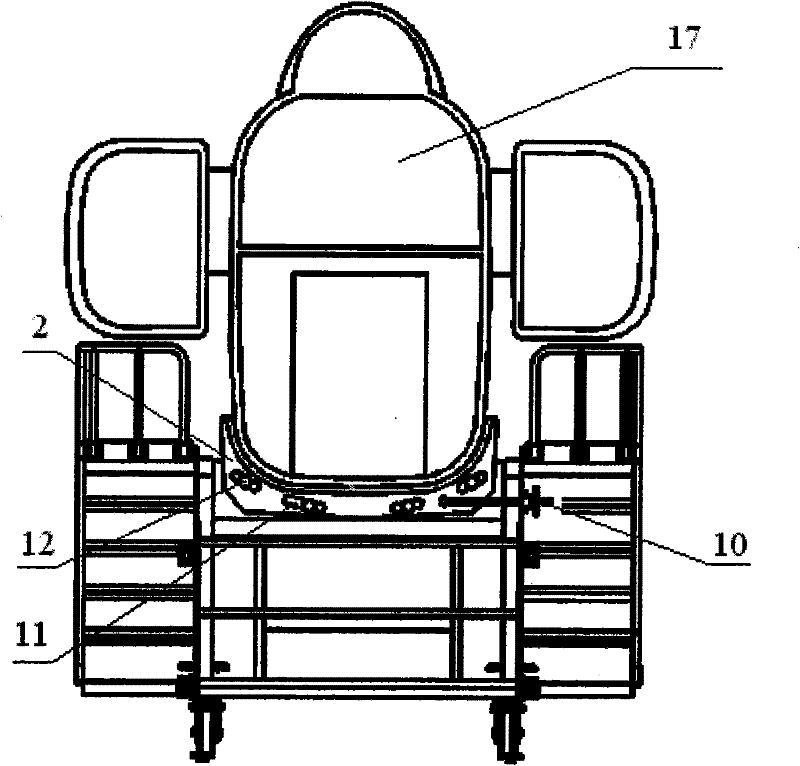

[0013] With reference to the drawings, the frame body 16 of the mobile docking device for large parts of the aircraft assembly fuselage is welded by rigid structural parts. On both sides of the frame body 16, there are two symmetrical upper docking working platforms 3, The inner side of the main body 16 is provided with a lower docking work platform 5, and a telescopic work platform 7 is also provided on the rear side of the frame body 16. The telescopic work platform 7 is connected to the rear side of the frame body 16 through a sliding rod 8 and a positioning pin 9. Operators can stand on the above-mentioned working platform to measure the posture of the docking surface of the fuselage and do the docking work; there are rollers 6 and anchor bolts 4 at the bottom of the frame body. During transportation, the anchor bolts are raised and the device and the device are connected with the rollers. The large part of the fuselage is moved to the docking platform of the aircraft, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com