Patents

Literature

507 results about "General assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

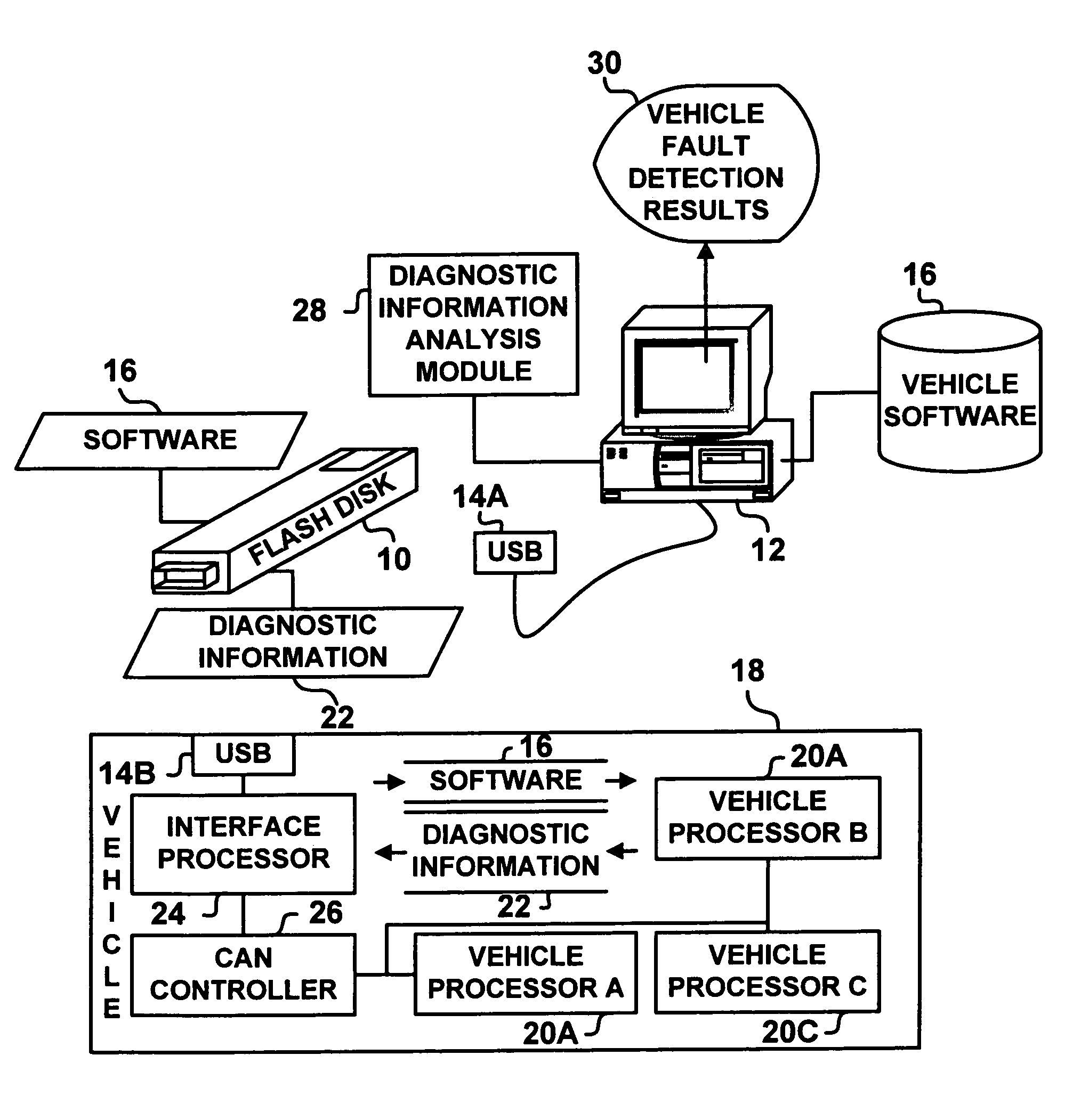

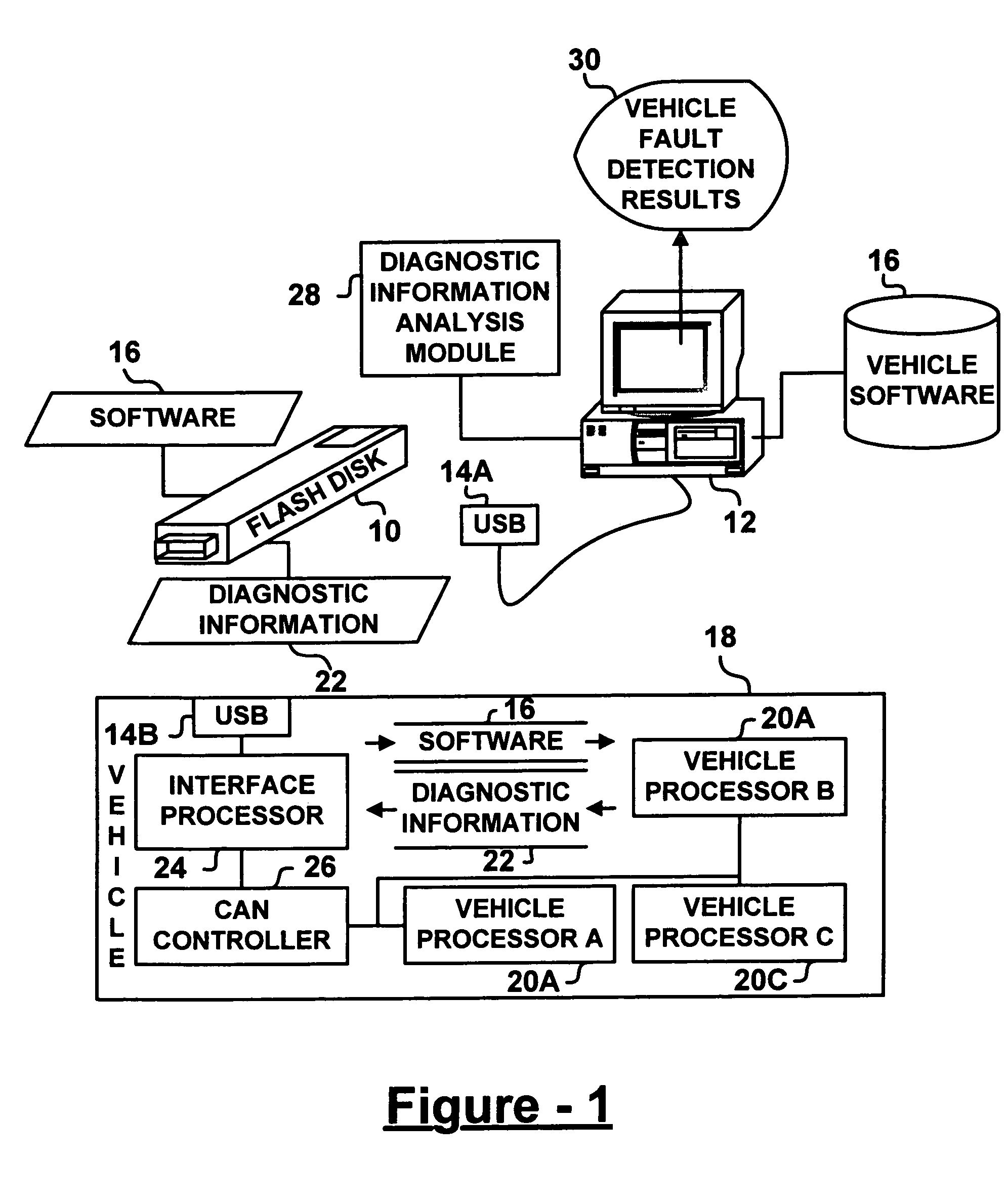

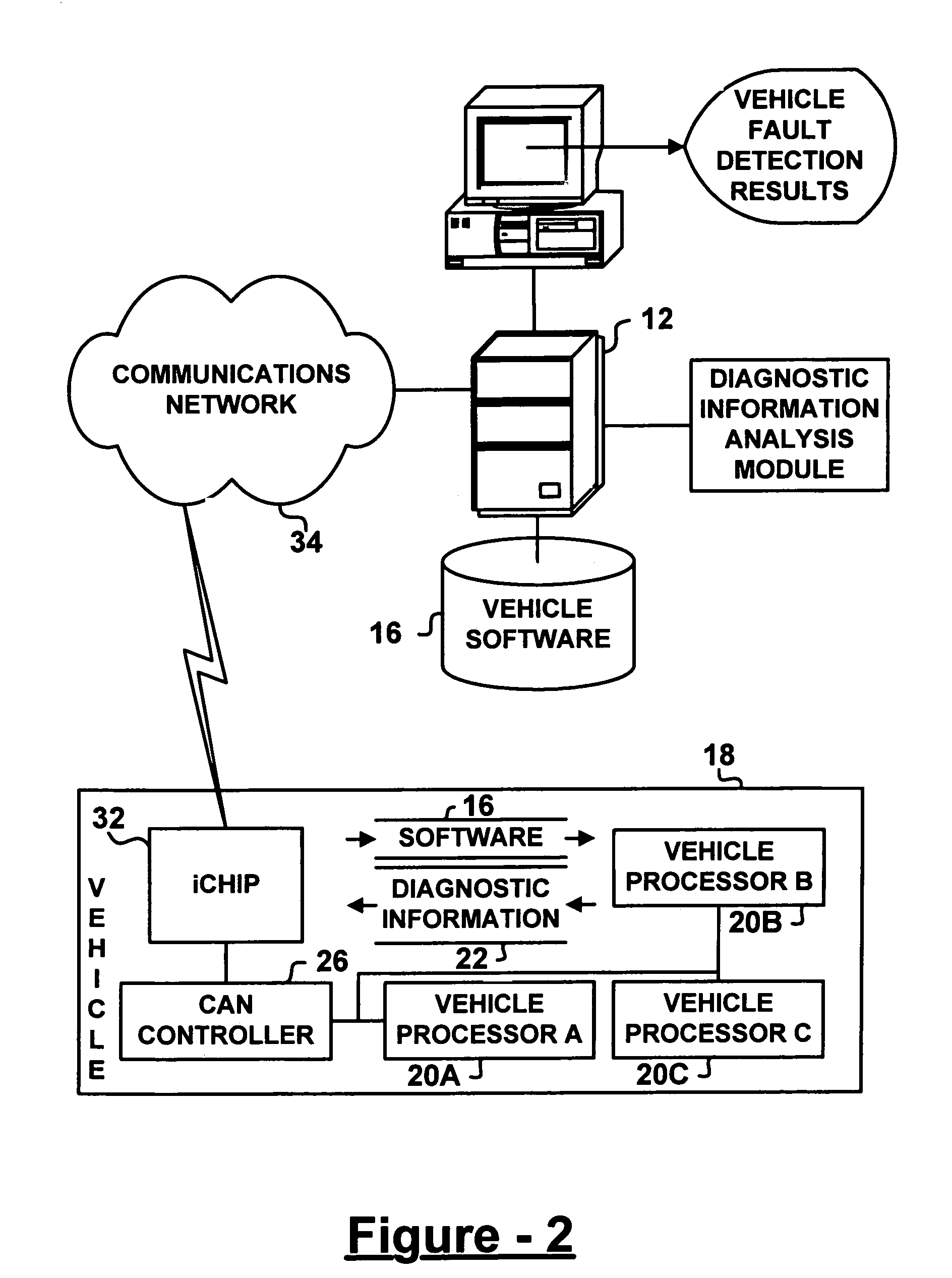

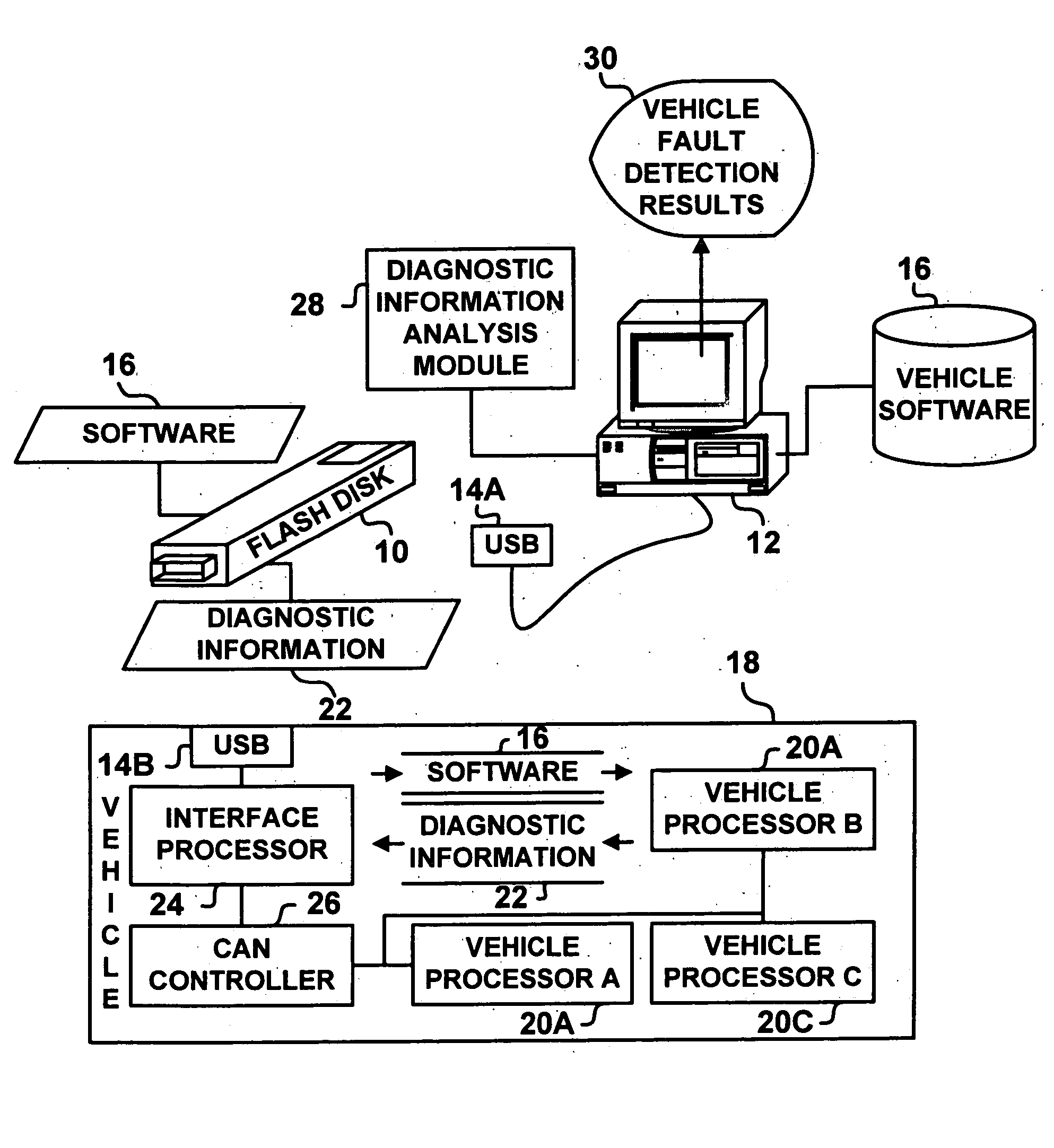

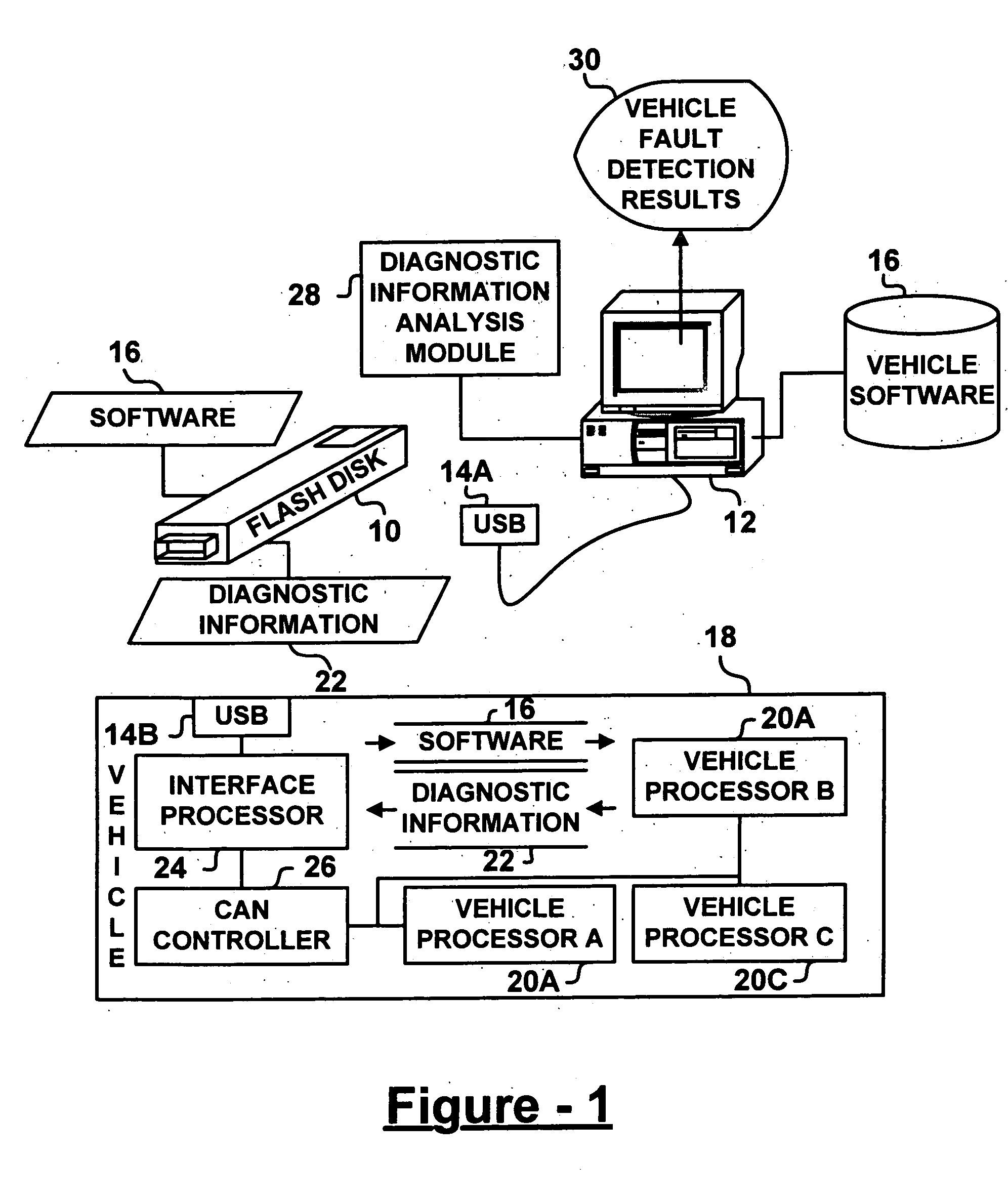

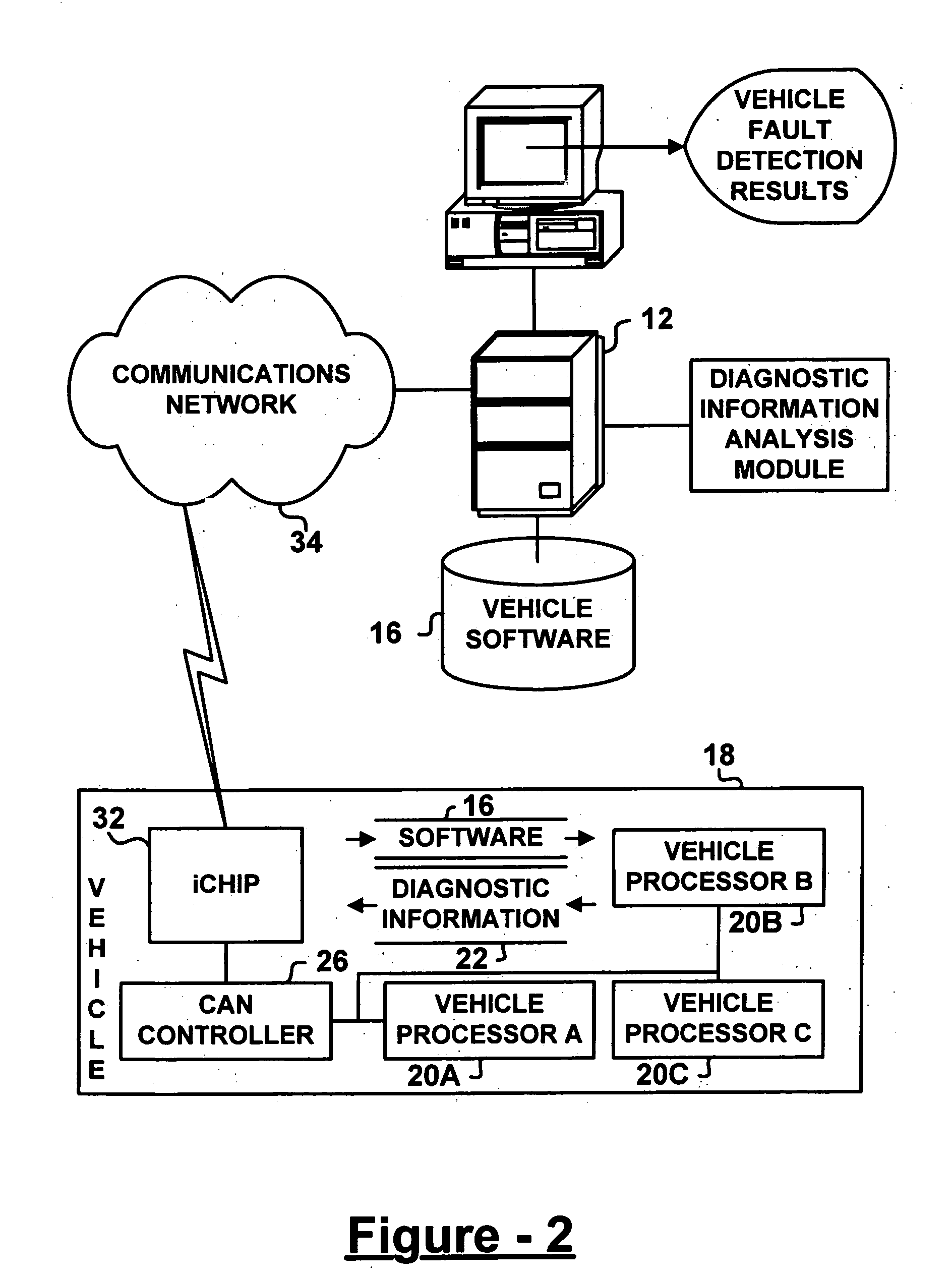

System and method to load vehicle operation software and calibration data in general assembly and service environment

ActiveUS6978198B2Vehicle testingRegistering/indicating working of vehiclesGeneral assemblyIn vehicle

A data exchange system for use in vehicle assembly includes a data exchange mechanism exchanging vehicle software and / or diagnostic information between vehicle processors and an external processor. In one aspect, the data exchange mechanism is a portable memory device, such as a USB flash disk, alternately connecting to USB ports of the external processor and the vehicle. Vehicle software is automatically loaded onto vehicle processors by an interface processor connected to a CAN controller, and the processors similarly write back diagnostic information. In another aspect, the data exchange mechanism is a wireless mechanism, such as an iCHIP, connecting the external processor and vehicle processors through a communications network and a CAN controller. Vehicle processors individually wirelessly request appropriate vehicle software and / or provide diagnostic information. The data exchange mechanism may be permanently integrated into the vehicle, or temporarily connected to the vehicle by an alternative connection mechanism, such as the ALDL.

Owner:GM GLOBAL TECH OPERATIONS LLC

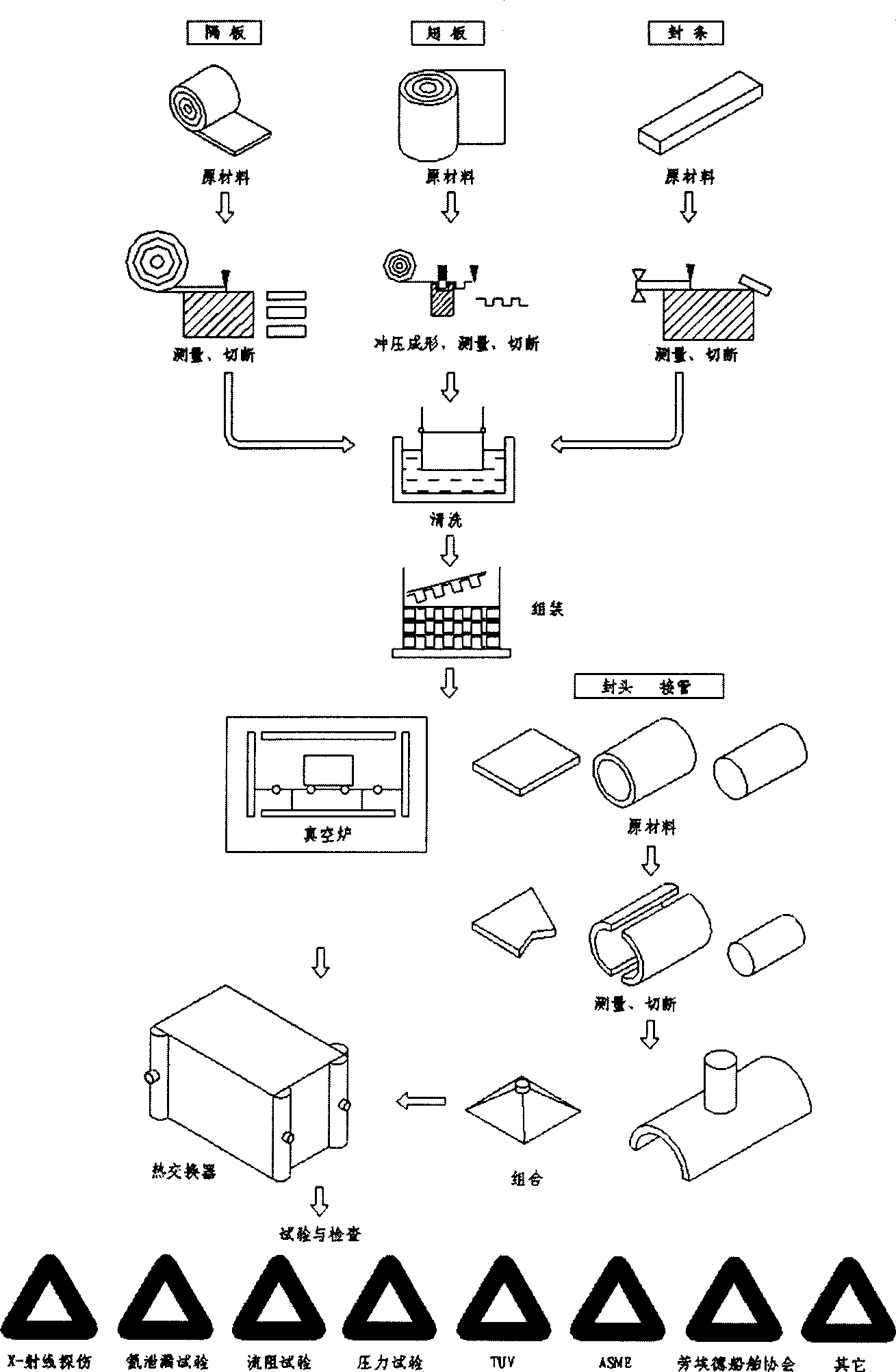

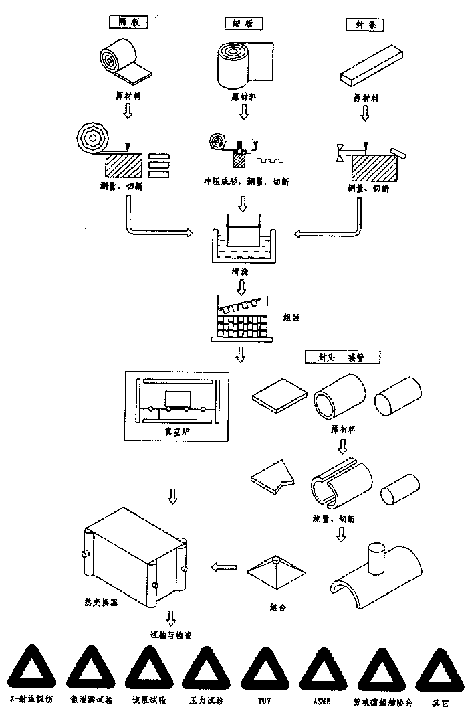

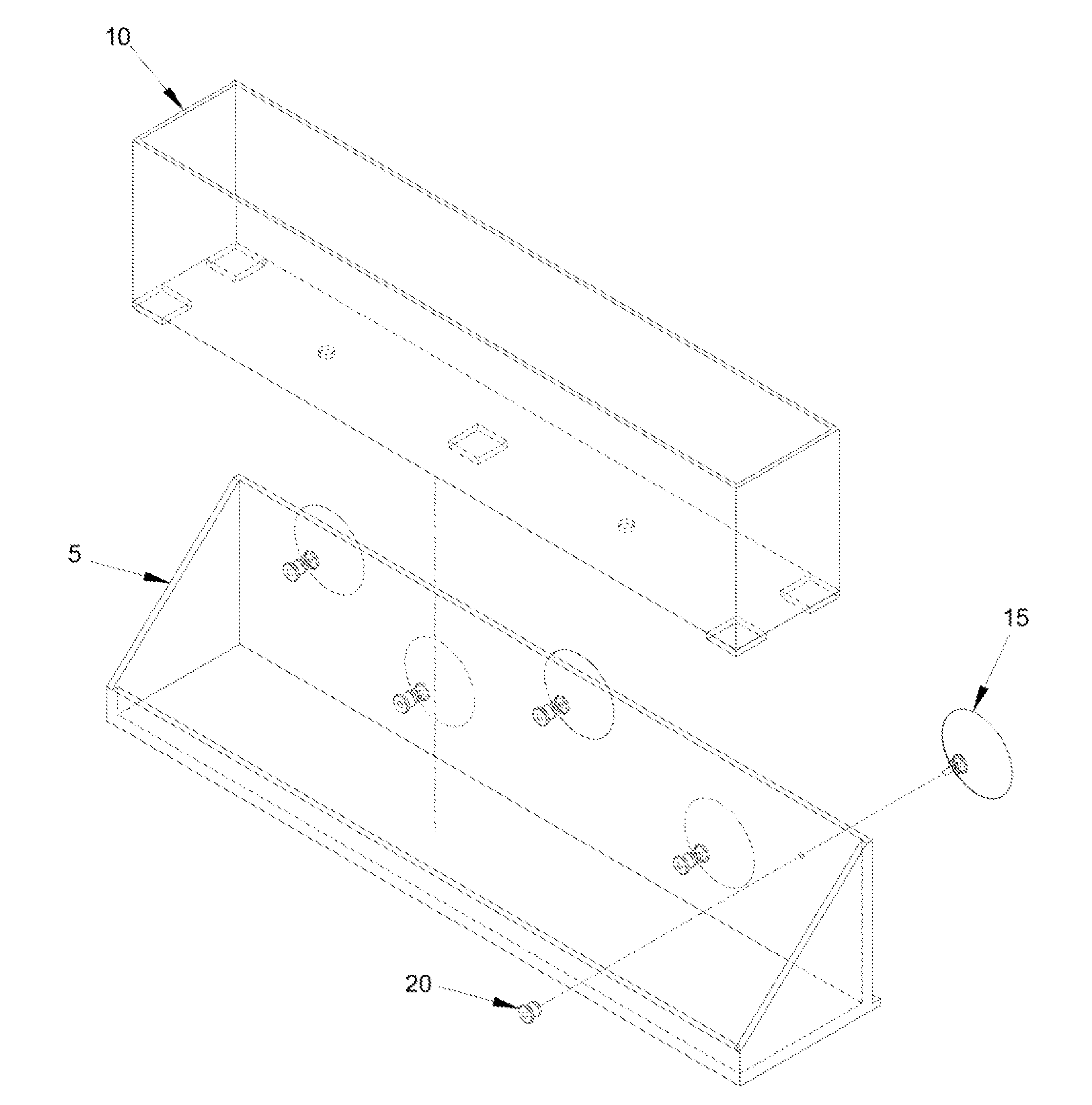

Manufacture of fine-type stainless steel plate heat exchanger

InactiveCN1375374AImprove wettabilityIngredients evenly distributedSoldering apparatusX-rayHigh pressure water

The production method of austenitic stainless steel plate fin heat exchanger includes the following steps: part preparation: partition, sealing strip, fin, sealing head and connecting pipe preparation; cleaning before welding; acid pickling to remove oil, dirt and oxide, and using high-pressure water to wash; element assembling and holding; vacuum braze welding, adopting argon arc welding to weldscaling head and connecting pipe, making general assembly; test and inspection, making x-ray inspection, helium leak detection, flow resistance test, pressure test, TUV, ASME and other test and inspection. Said invented process raise the production quality of said stainless steel plate fin heat exchanger, tensile-strength of connector and its service life.

Owner:NANJING UNIV OF TECH

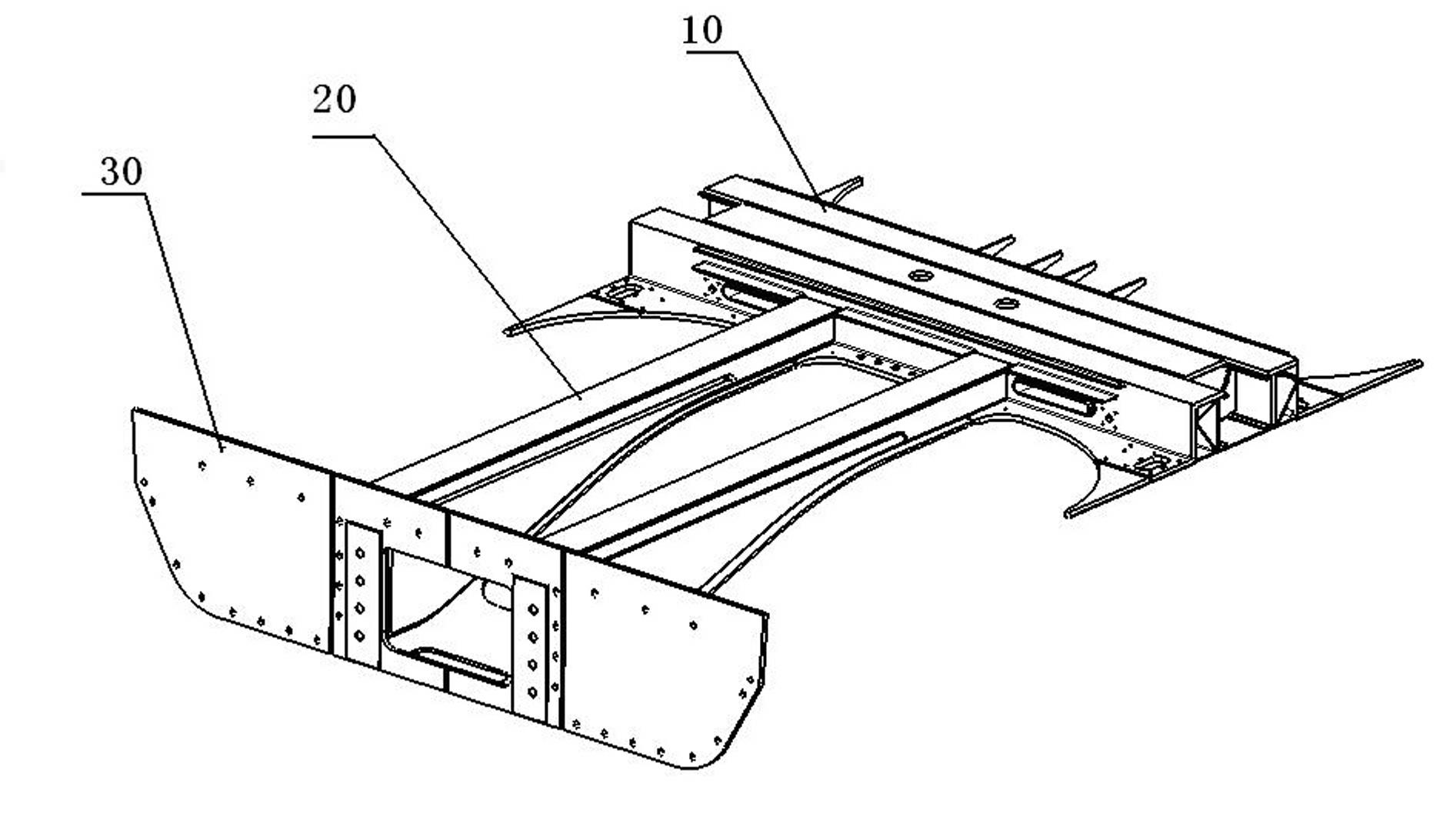

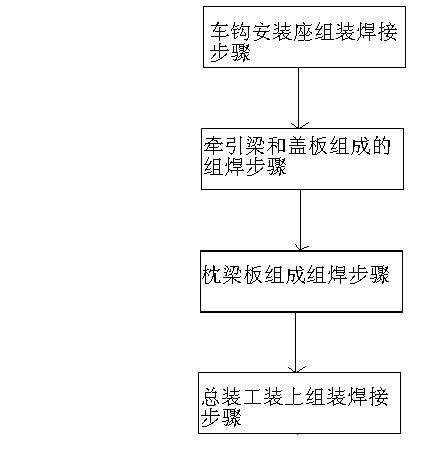

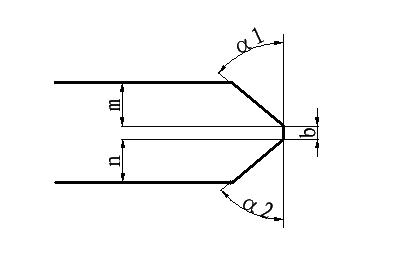

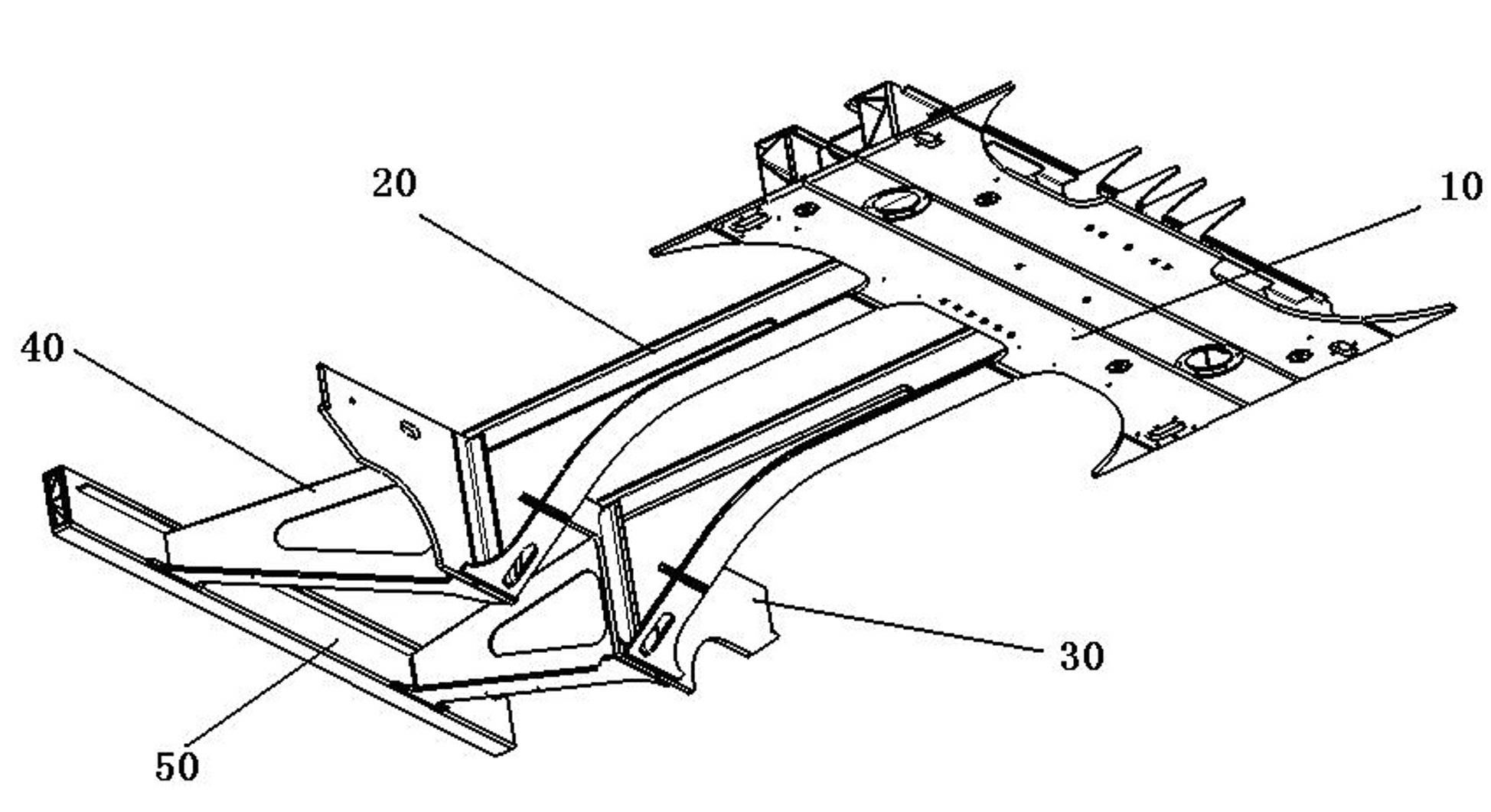

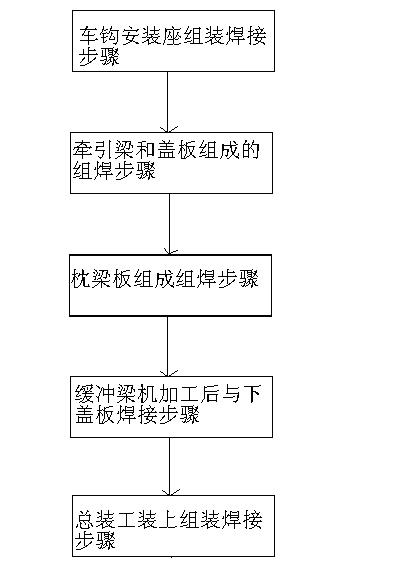

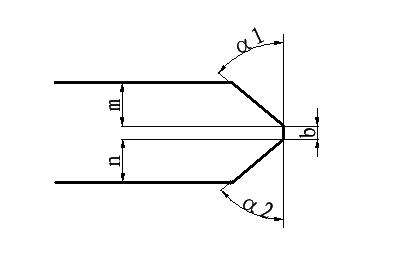

Vehicle body draft, bolster and buffer assembling and welding process

ActiveCN102107337APerfect welding welding processPrevent changes in volume sizeWelding apparatusGeneral assemblyAir spring

The invention discloses a vehicle body draft, bolster and buffer assembling and welding process. The vehicle body draft, bolster and buffer comprises a body bolster, a draft sill and a coupler mounting base which are all made of aluminium alloy materials. The process comprises the following steps: (A) assembling and welding the coupler mounting base; (B) assembling and welding the draft sill and a cover plate; (C) assembling and welding the components of a body bolster plate; and (D) carrying out assembling and welding on a general assembly equipment: assembling and welding the coupler mounting base, the draft sill and the body bolster on the general assembly equipment; dispensing with machining and ensuring the flatness to be 0.5mm after completing welding; ensuring the verticality between the coupler mounting surface and the air spring mounting surface to be not more than 1.5mm; and ensuring the deviation from the center of the coupler mounting base to the center of the air spring hole to be not more than + / -1mm. The process has the beneficial effects of solving the problem of assembling and welding of the aluminium alloy structures of high-speed trains, collecting the parameters of aluminium alloy welding through experiments, perfecting the aluminium alloy assembling and welding process, preventing deformation after welding and variation of the material displacement size, ensuring the product quality and reducing the production cost and energy waste.

Owner:南京雷尔伟新技术股份有限公司

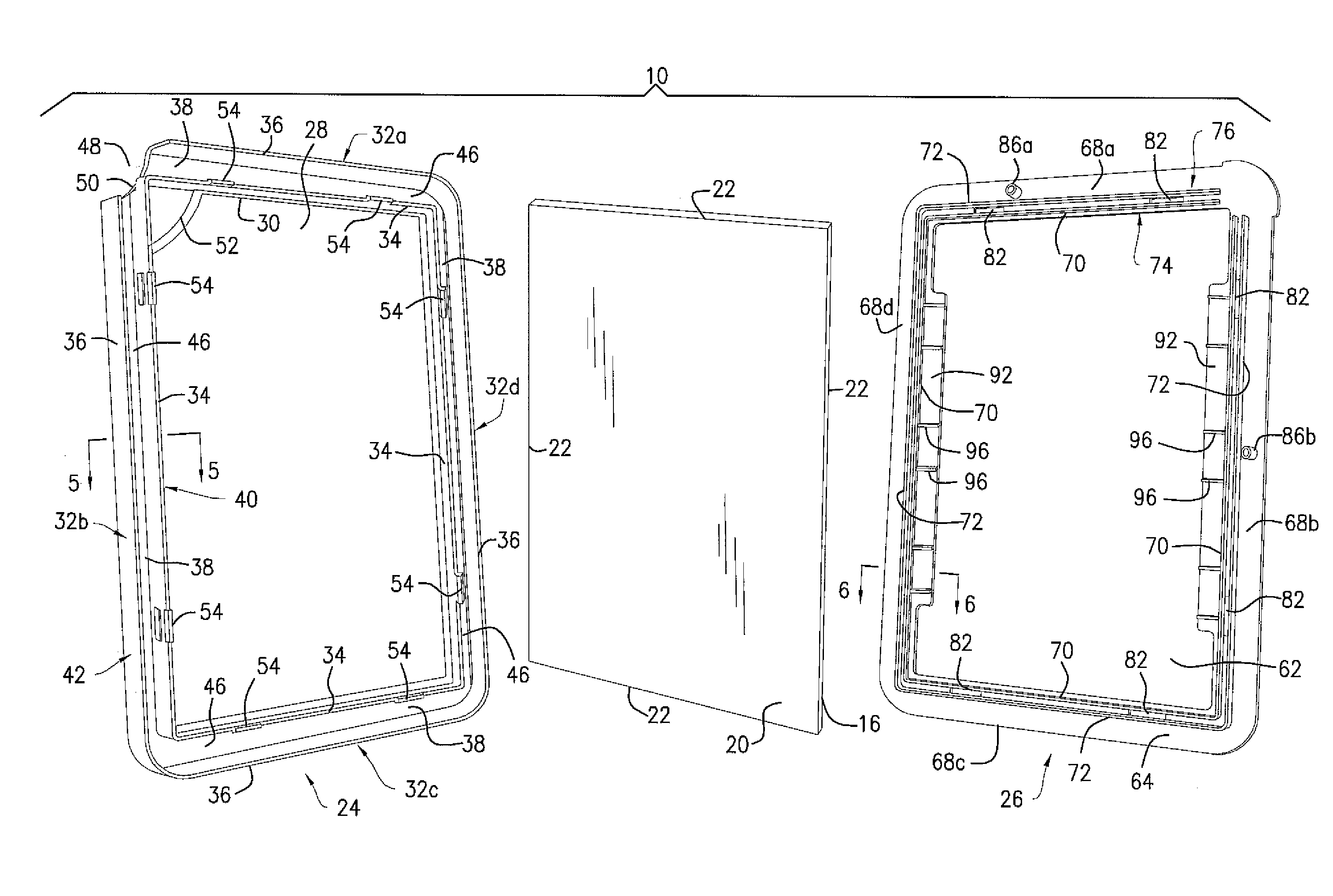

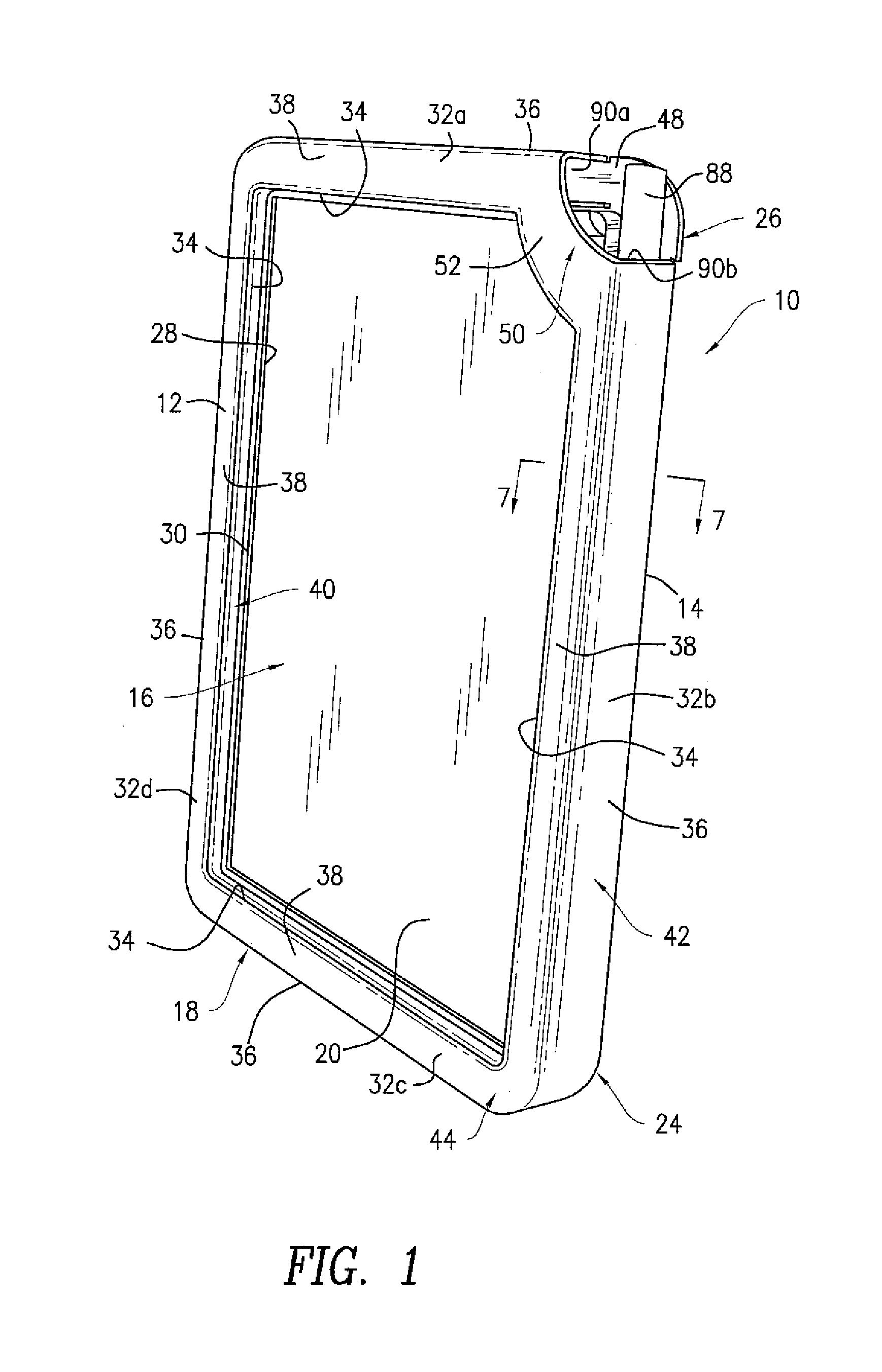

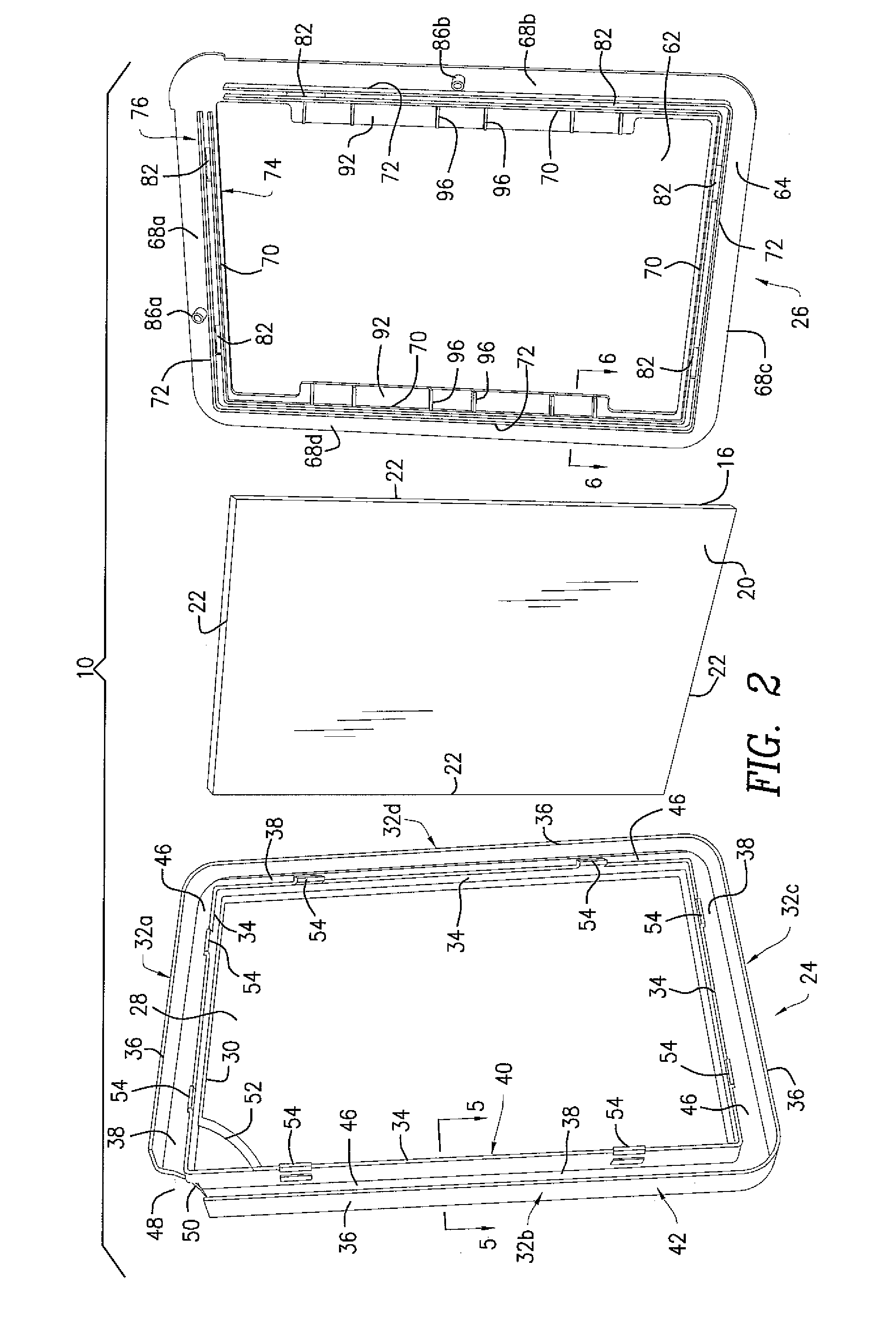

Board assembly

InactiveUS7293993B2Easy to assembleWriting boardsBuilding componentsGeneral assemblyElectrical and Electronics engineering

A board assembly includes a panel and a frame. The frame has a generally annular shape and includes first and second sections. The panel is retained between the first and second sections. The frame also includes a snap-fit device positioned on at least one of the first and second sections for attaching the second section to the first section, thereby facilitating the assembly of the panel with the frame. The frame also includes a plurality of storage pockets formed therewithin for receiving a writing instrument in different orientations.

Owner:MEGA BRANDS INT R L LUXEMBOURG ZUG BRANCH

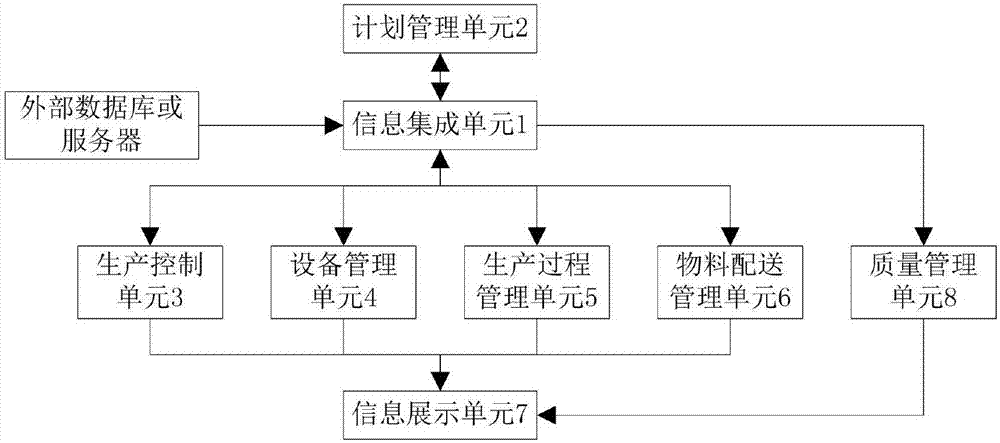

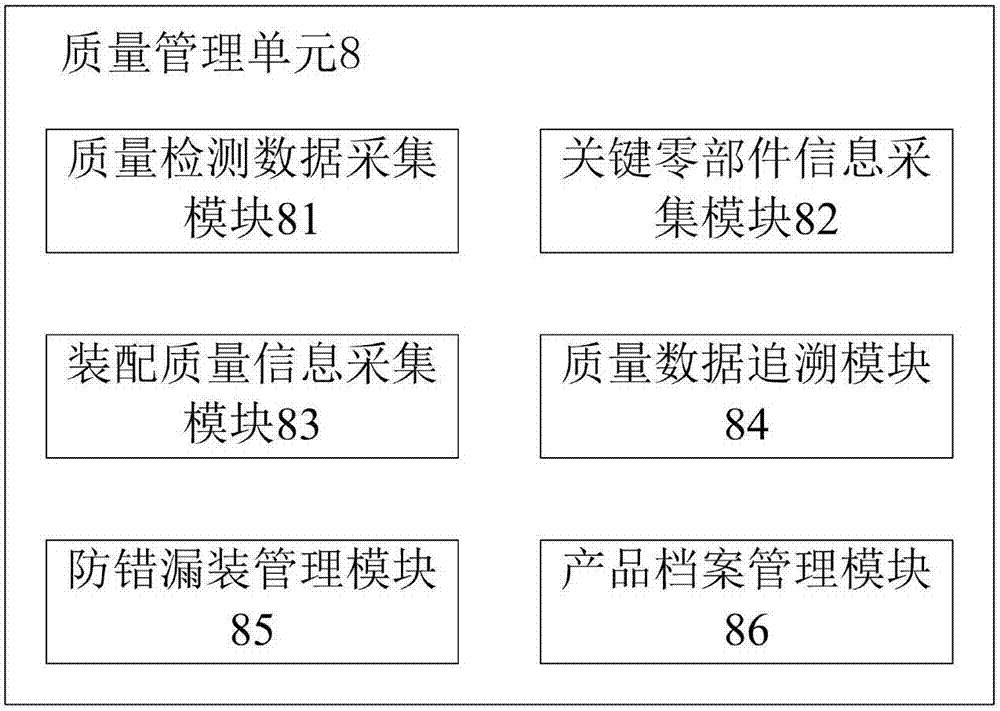

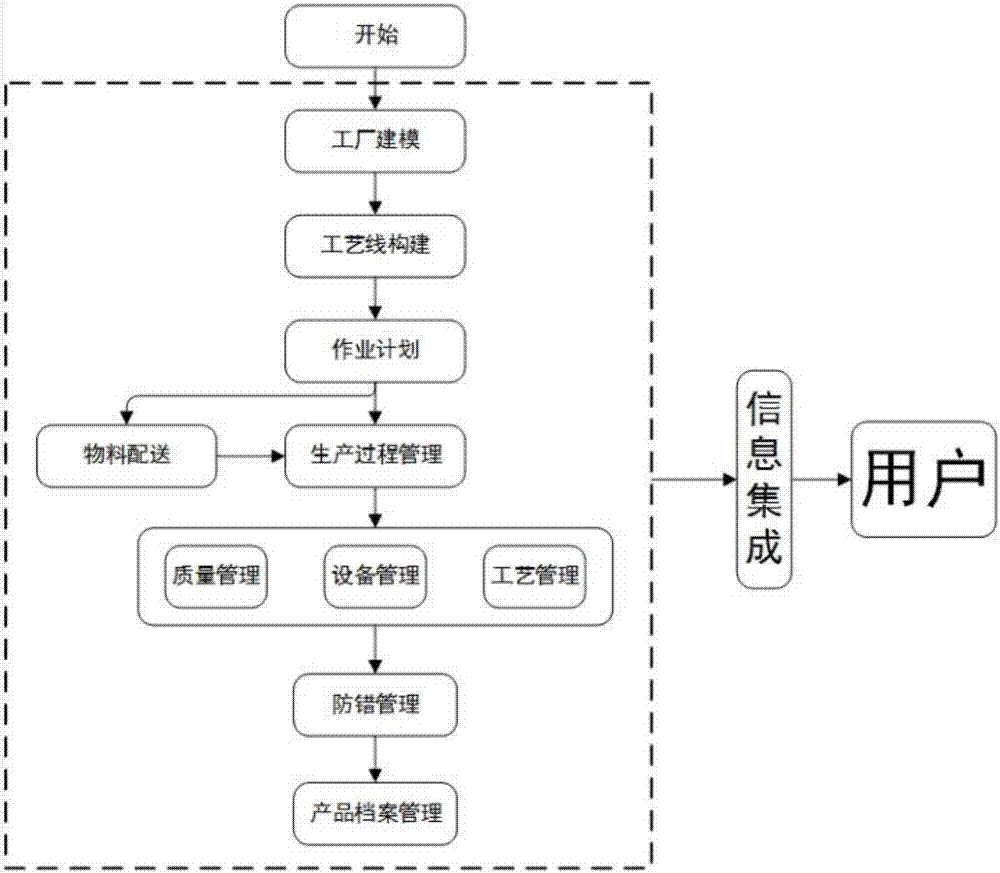

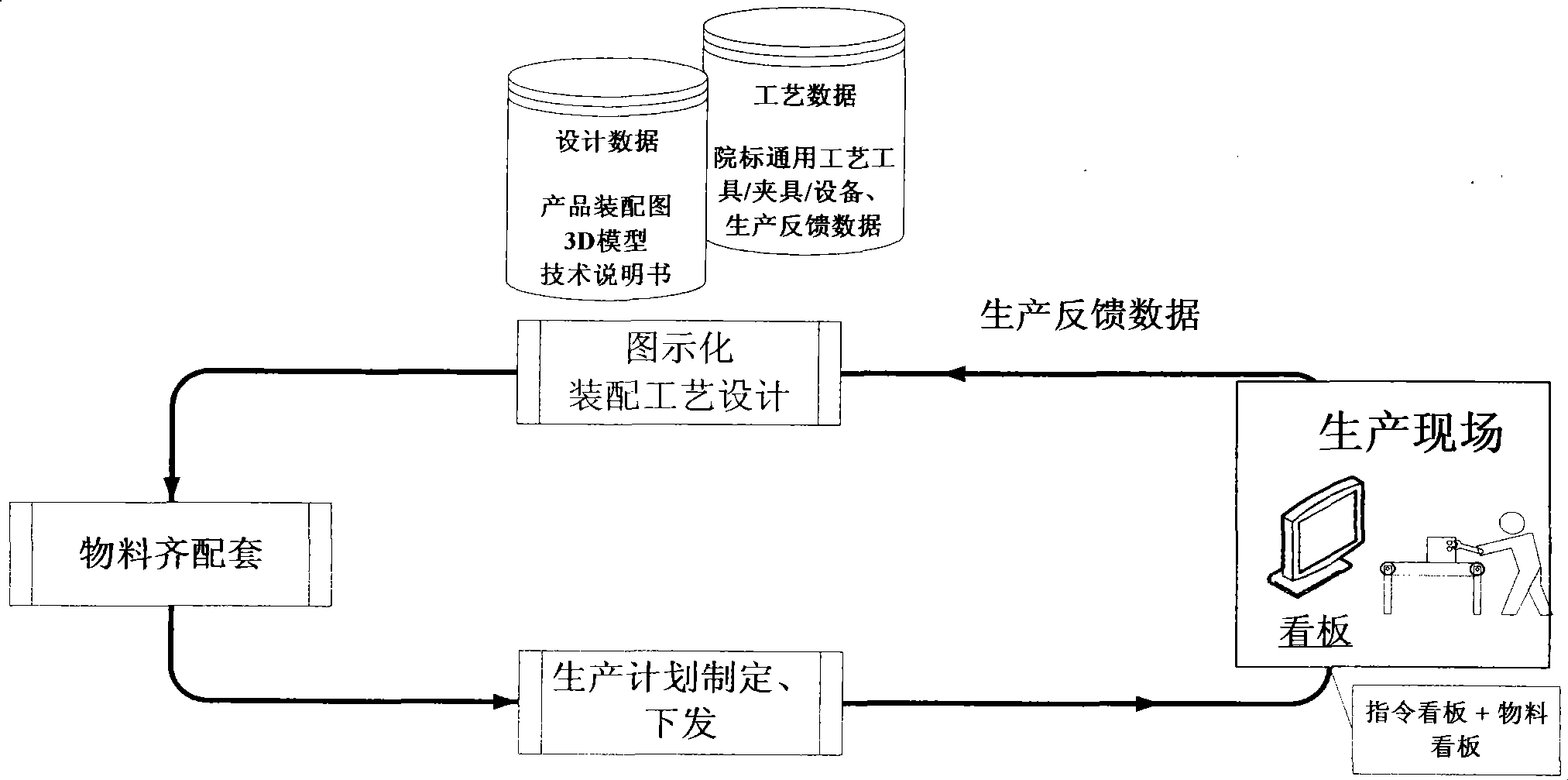

Digitalized flexible system and management method used for automobile manufacturing

ActiveCN107168258ASee clearlyProgramme total factory controlData connectionThree dimensional simulation

The invention discloses a digitalized flexible system and a management method used for automobile manufacturing. The system comprises an information integrating unit (1), a plan management unit (2), a production control unit (3), an equipment management unit (4), a production process management unit (5), a material distribution management unit (6), an information displaying unit (7) and a quality management unit (8). According to the invention, users are enabled to see all kinds of data in production quite clearly through a visualization interface; the whole production processes can be displayed to the users through a simulation mode; through interconnection of production and manufacturing onsite control data, a three-dimensional simulation model and onsite data acquisition, and data connection with an external management system, complete availability of information flows of enterprises is achieved; production and manufacturing preparation time of a general assembly shop is effectively shortened; and efficiency and quality of technology planning of the general assembly shop are improved.

Owner:大唐互联科技(武汉)有限公司

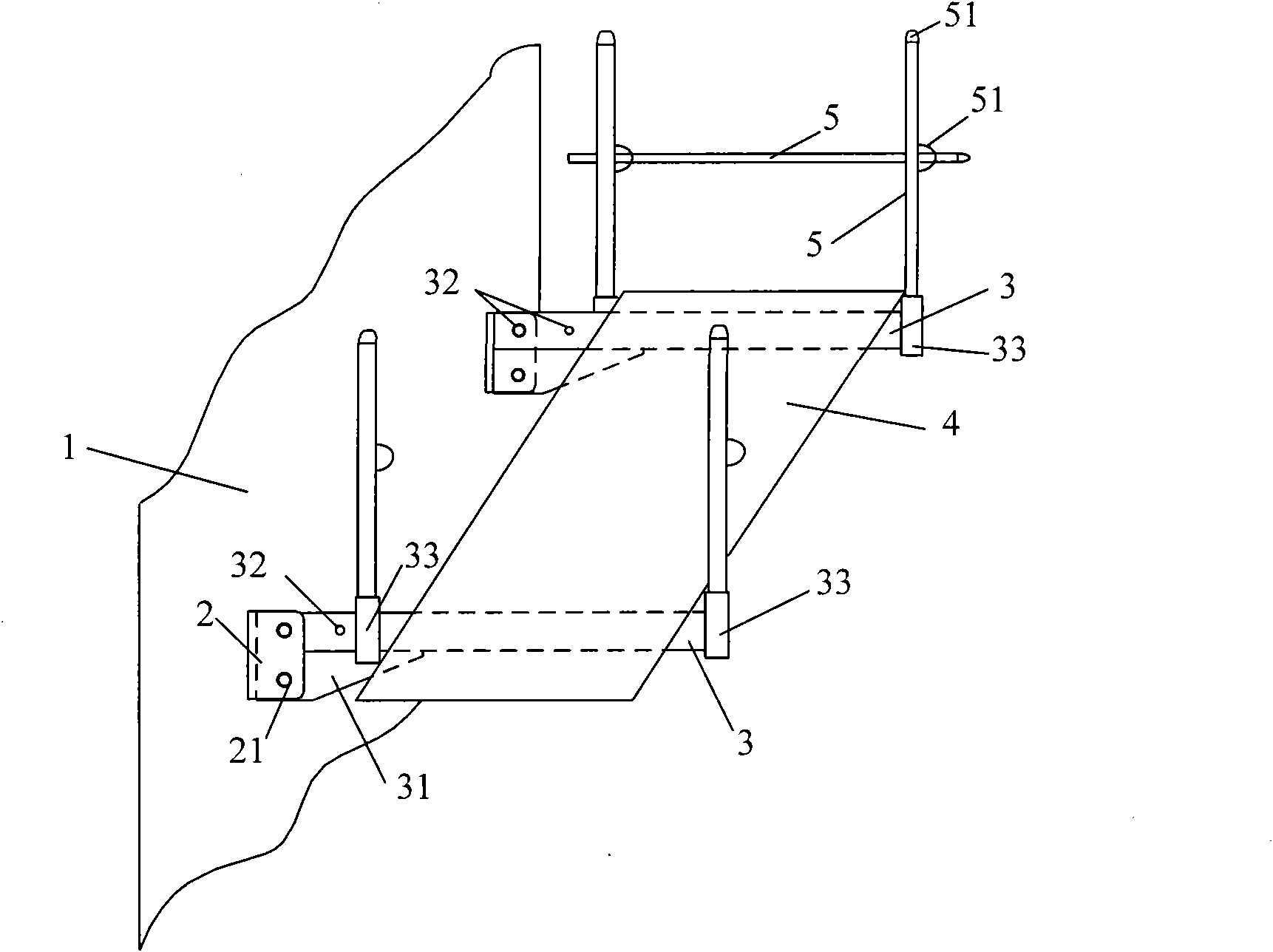

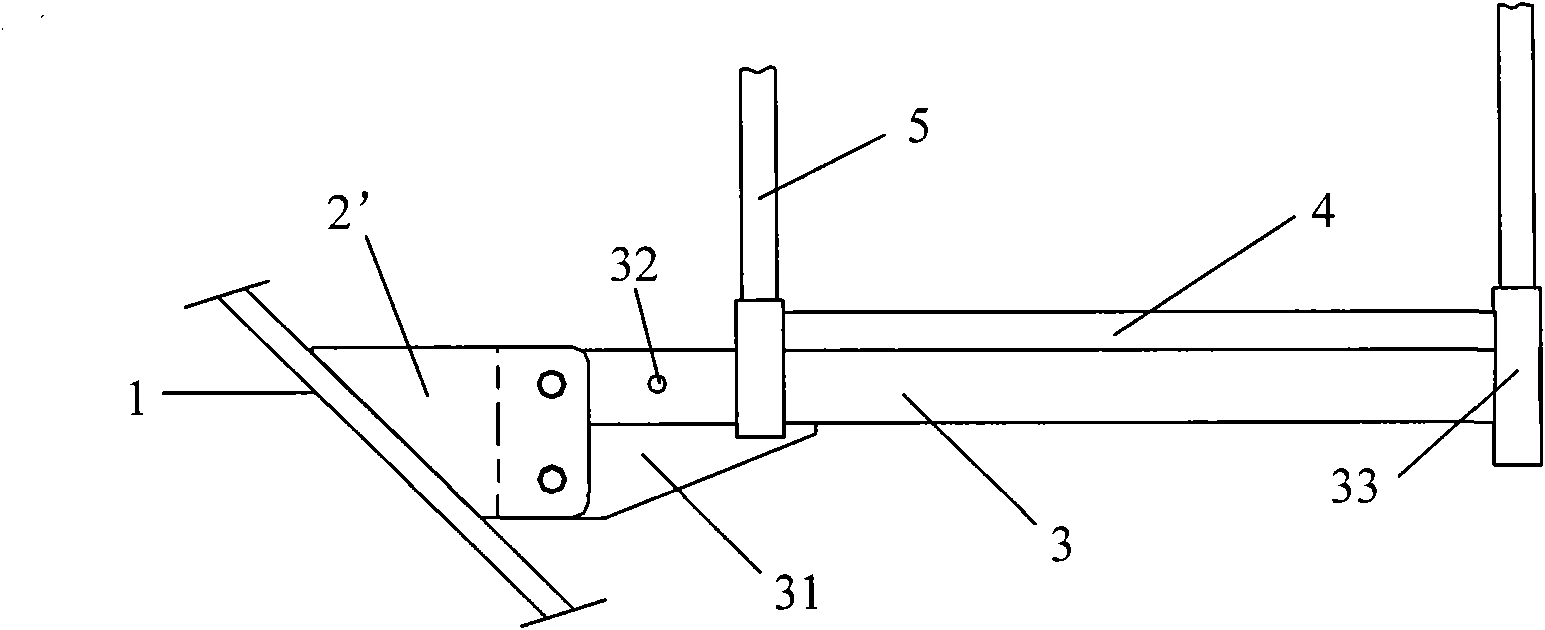

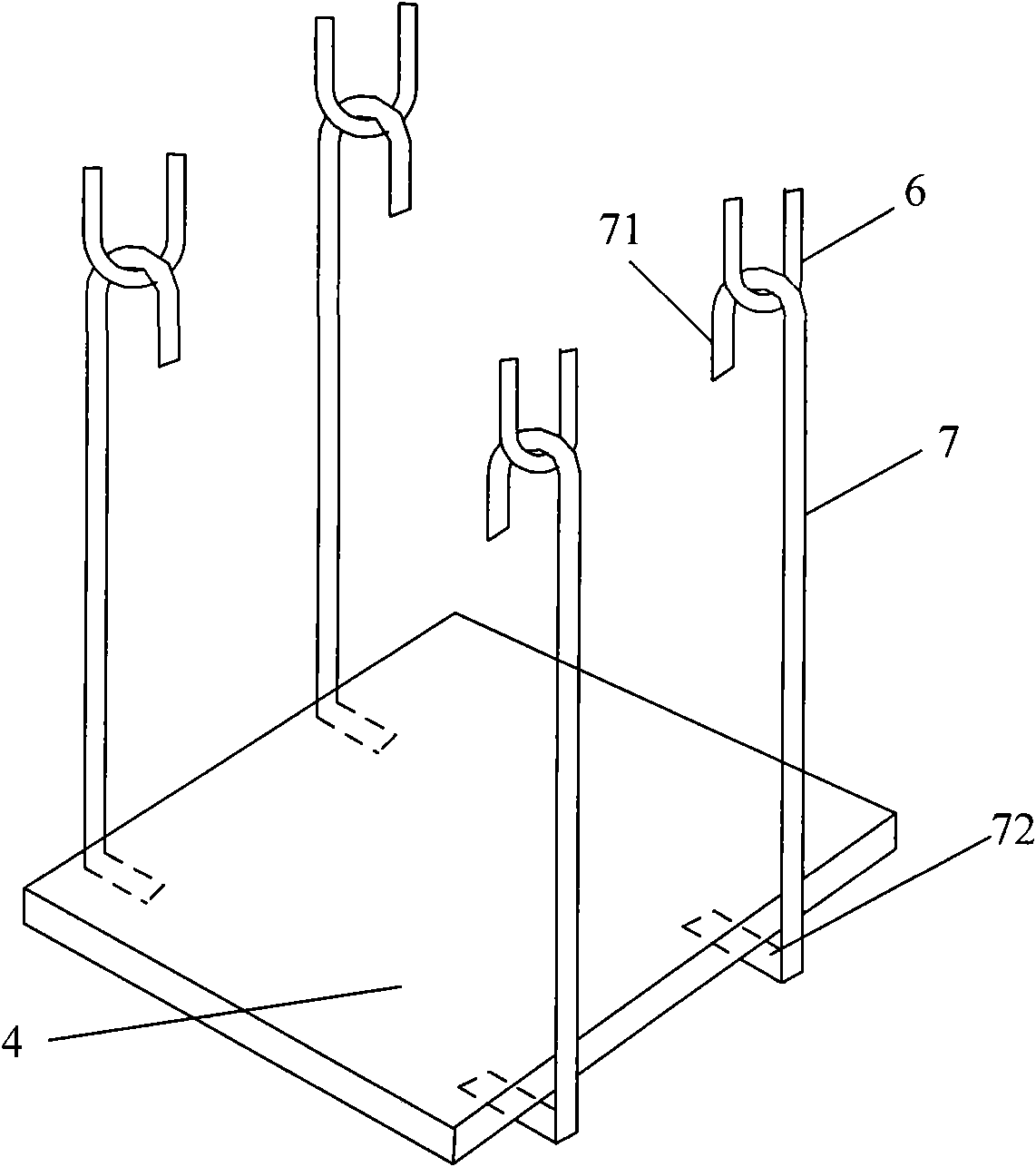

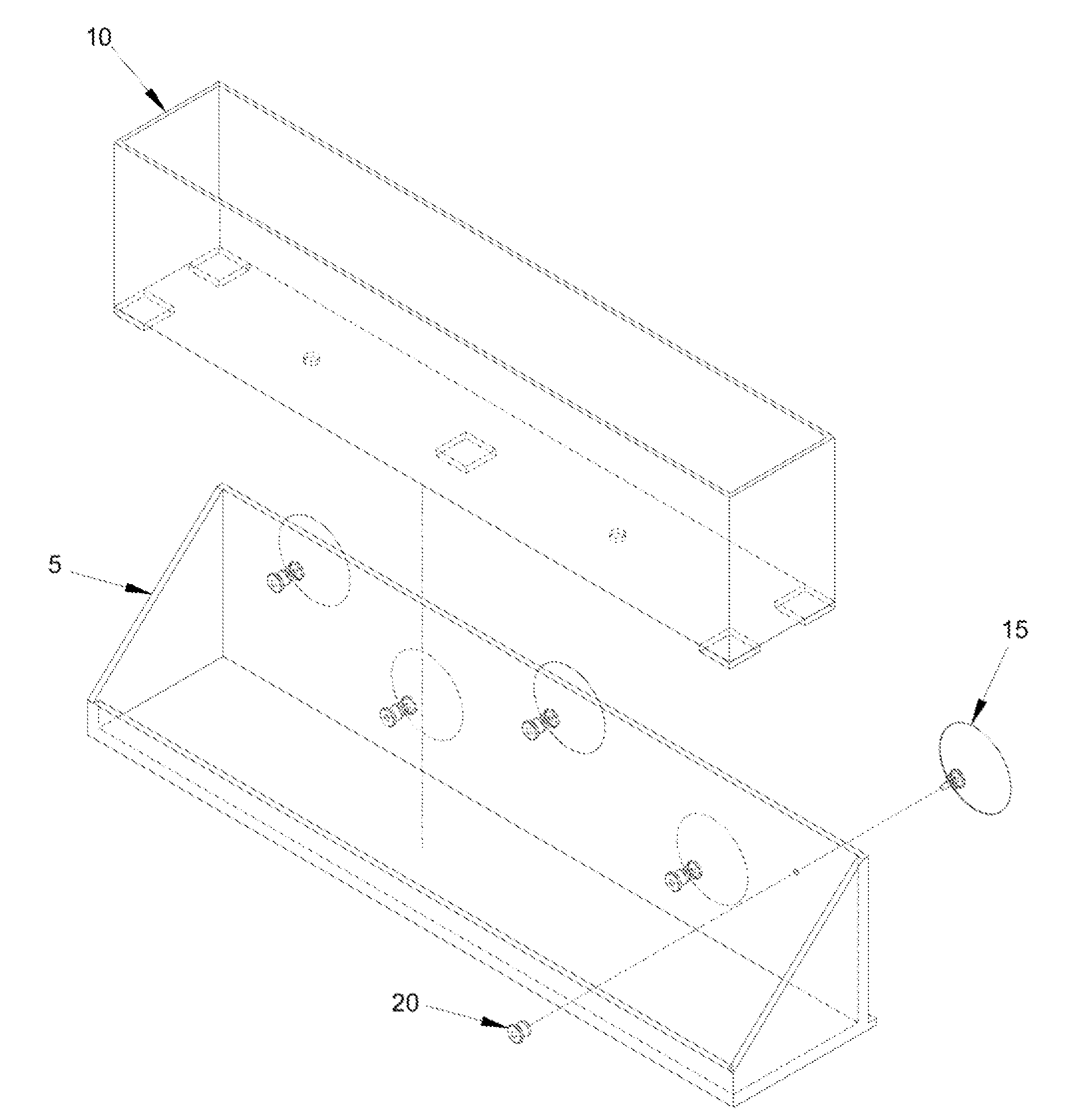

Fabricated scaffold and using method thereof

InactiveCN101844612AImprove utilizationShorten the timeDry-dockingSlipwaysWork patternGeneral assembly

The invention discloses a fabricated scaffold and a using method thereof. The fabricated scaffold comprises a plurality of fixing parts, bearing parts and a plurality of scaffold platforms, wherein the plurality of fixing parts are vertical to a mounting surface; one bearing part is arranged on each fixing part; and the plurality of scaffold platforms are paved between two or among more than two bearing parts. The using method thereof comprises the following steps of: a ship segment stage, namely vertically and fixedly arranging the plurality of fixing parts on the mounting surface at preset intervals; and a general assembly and carrying phase, namely arranging one bearing part on each fixing part and arranging one scaffold platform on the adjacent bearing part. In the invention, a conventional operating mode that a tubular scaffold is needed to be erected in a whole cabin space so as to help a worker reach a higher operation point is changed, a method for extendedly arranging the scaffold clung to the mounting surface is adopted so as to release most of the space in the cabin, shorten the construction period, improve the use ratio of a dock, and reduce the hazard index of workersbelow the scaffold; and the fabricated scaffold has very obvious effect on backing construction in the ship building.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

Vehicle body draft, bolster and buffer assembling and welding process

ActiveCN102107338APerfect welding welding processPrevent changes in volume sizeWelding apparatusGeneral assemblyAir spring

The invention discloses a vehicle body draft, bolster and buffer assembling and welding process. The vehicle body draft, bolster and buffer comprises a body bolster, a draft sill, a coupler mounting base, a buffer sill and an end sill which are all made of aluminium alloy materials. The process comprises the following steps: (A) assembling and welding the coupler mounting base; (B) assembling andwelding the composition of the draft sill and a cover plate; (C) assembling and welding the components of a body bolster plate; (D) welding the buffer sill and a lower cover plate after machining thebuffer sill; and (E) assembling and welding the end sill, the buffer sill, the coupler mounting base, the draft sill and the body bolster on general assembly equipment; ensuring the verticality between the coupler mounting surface and the air spring mounting surface to be not more than 1.5mm; ensuring the deviation from the center of the coupler mounting base to the center of the air spring hole to be not more than + / -1mm; and ensuring the maximum straightness to be 2mm after assembling the end sill. The process has the beneficial effects of solving the problem of assembling and welding of the aluminium alloy structures of high-speed trains, collecting the parameters of aluminium alloy welding through experiments, perfecting the aluminium alloy assembling and welding process, preventing deformation after welding and variation of the material displacement size, ensuring the product quality and reducing the production cost and energy waste.

Owner:南京雷尔伟新技术股份有限公司

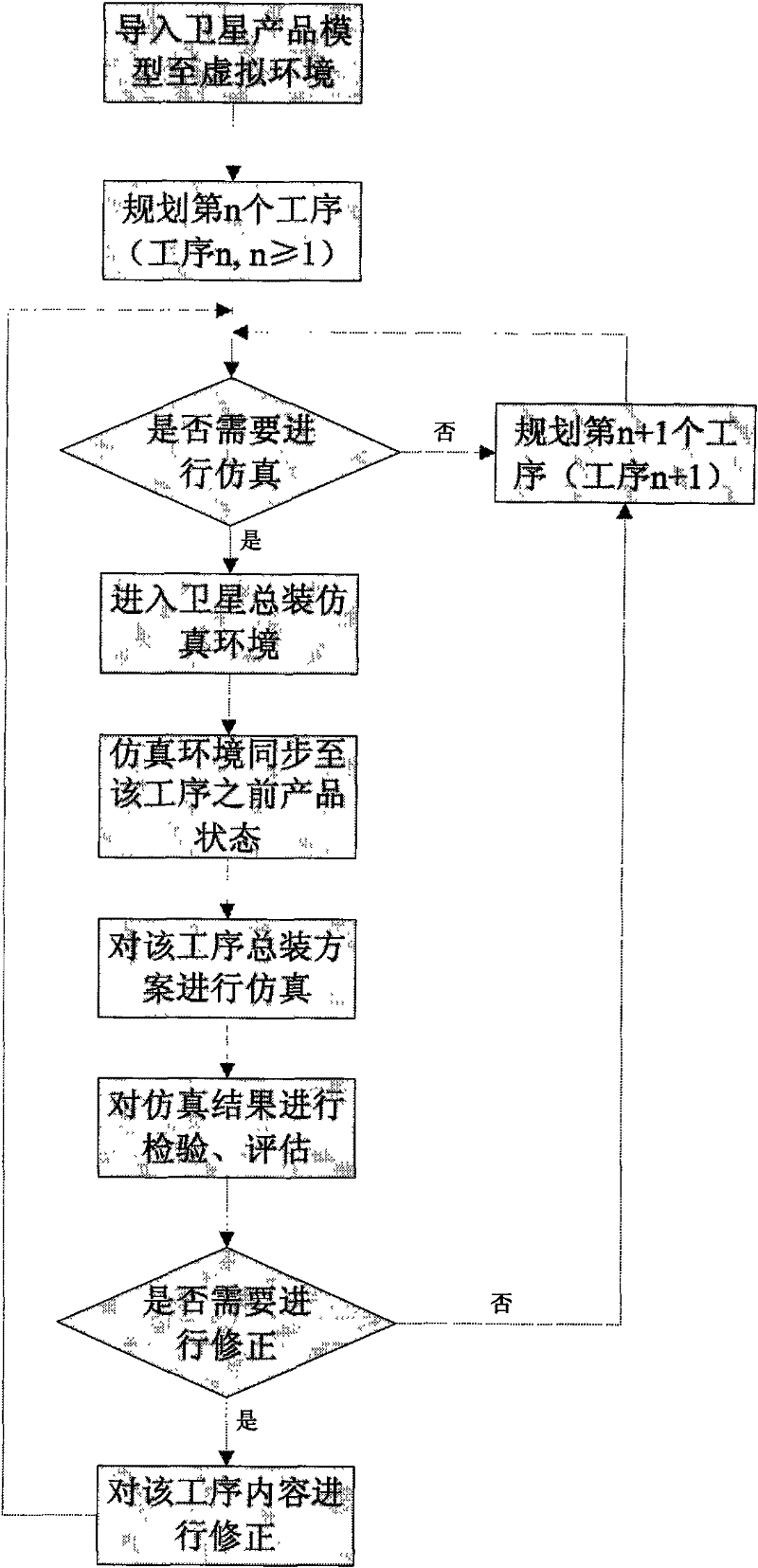

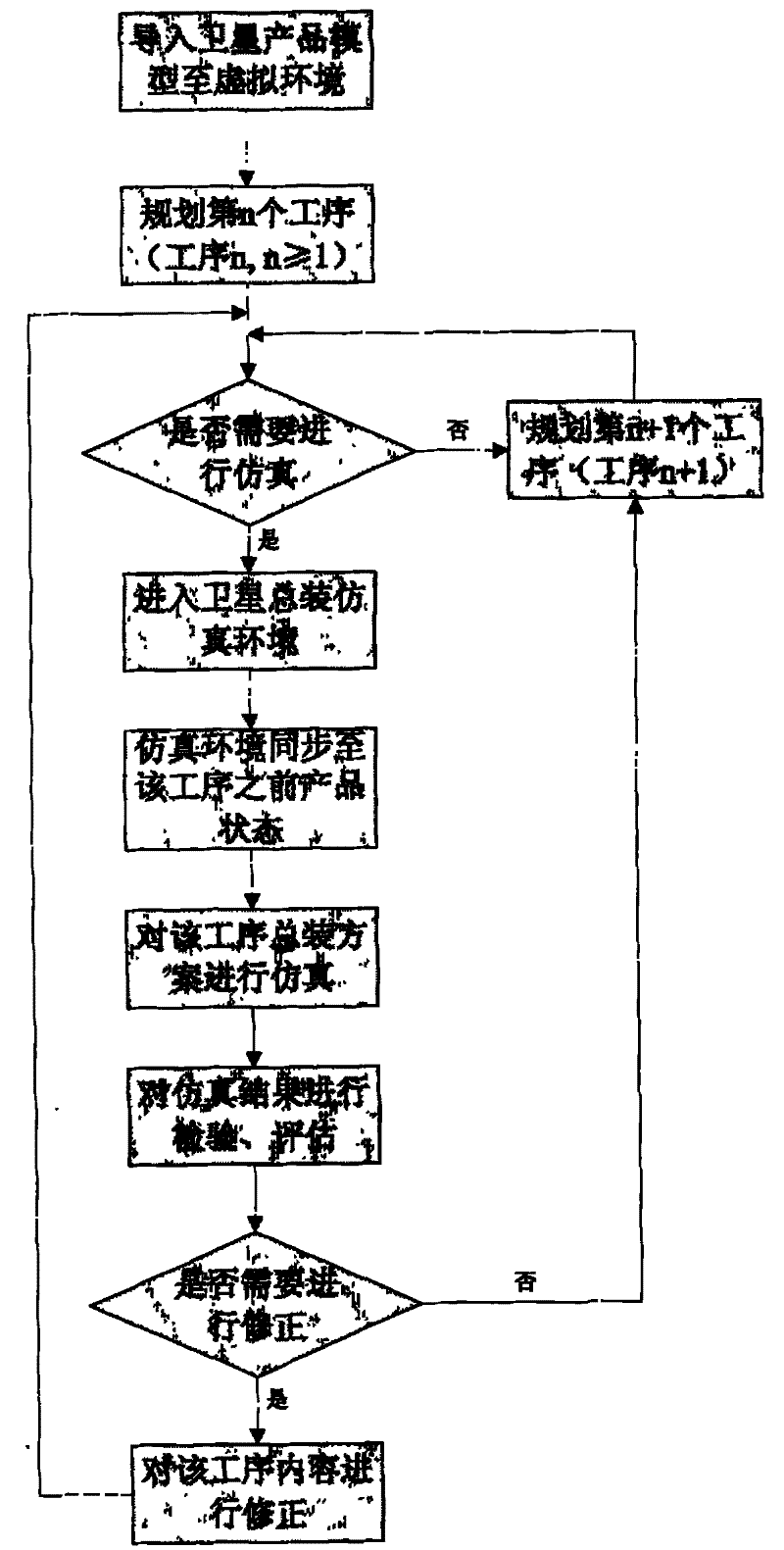

Two-dimensional three-dimensional combined satellite general assembly process planning and simulation method

InactiveCN102456082AHigh feasibilityReduce difficultySpecial data processing applicationsGeneral assemblySimulation

The invention provides a two-dimensional three-dimensional combined satellite general assembly process planning and simulation method. In the invention, based on the combination of a three-dimensional virtual reality environment and a two-dimensional general assembly process planning environment, with a two-dimensional process planning workflow as a guide and satellite general assembly process simulation as a design and testing means of the satellite general assembly process planning, an assembly scheme can be simulated at any time in a virtual reality environment to test the feasibility, safety, operational comfortableness and the like of the satellite assembly scheme while the two-dimensional process planning is performed, so that designers can design, simulate and test a general assembly process more visually and clearly, the limitation that technologists perform process planning completely based on personal experiences in the conventional design of two-dimensional satellite general assembly process is overcome, and the two-dimensional and three-dimensional process design methods are combined by means of a three-dimensional virtual assembly environment, thereby greatly improving the working efficiency of process planning, reducing the dependence of the technologists on personal experiences in a working process, and improving the optimization degree of the process design scheme.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

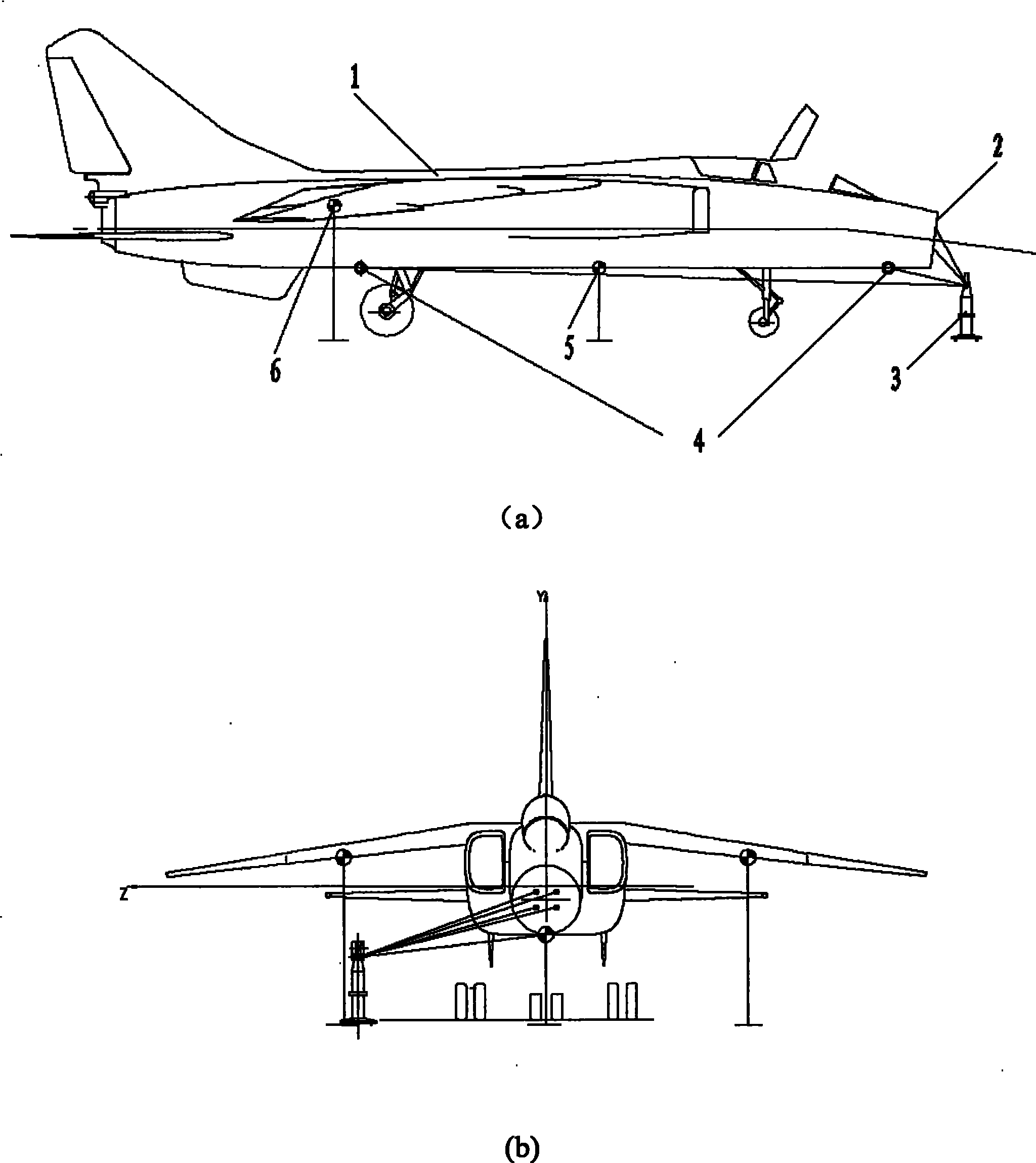

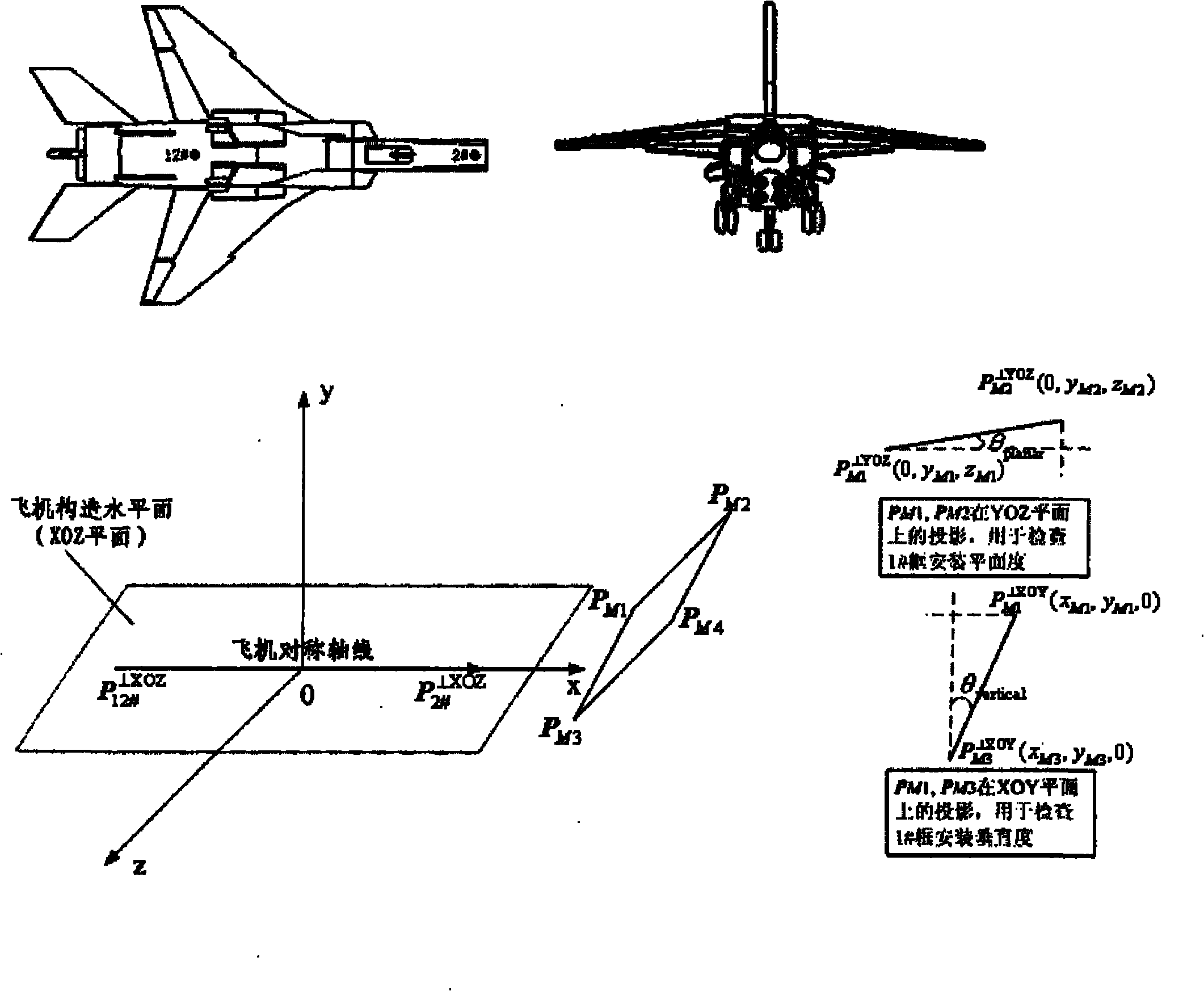

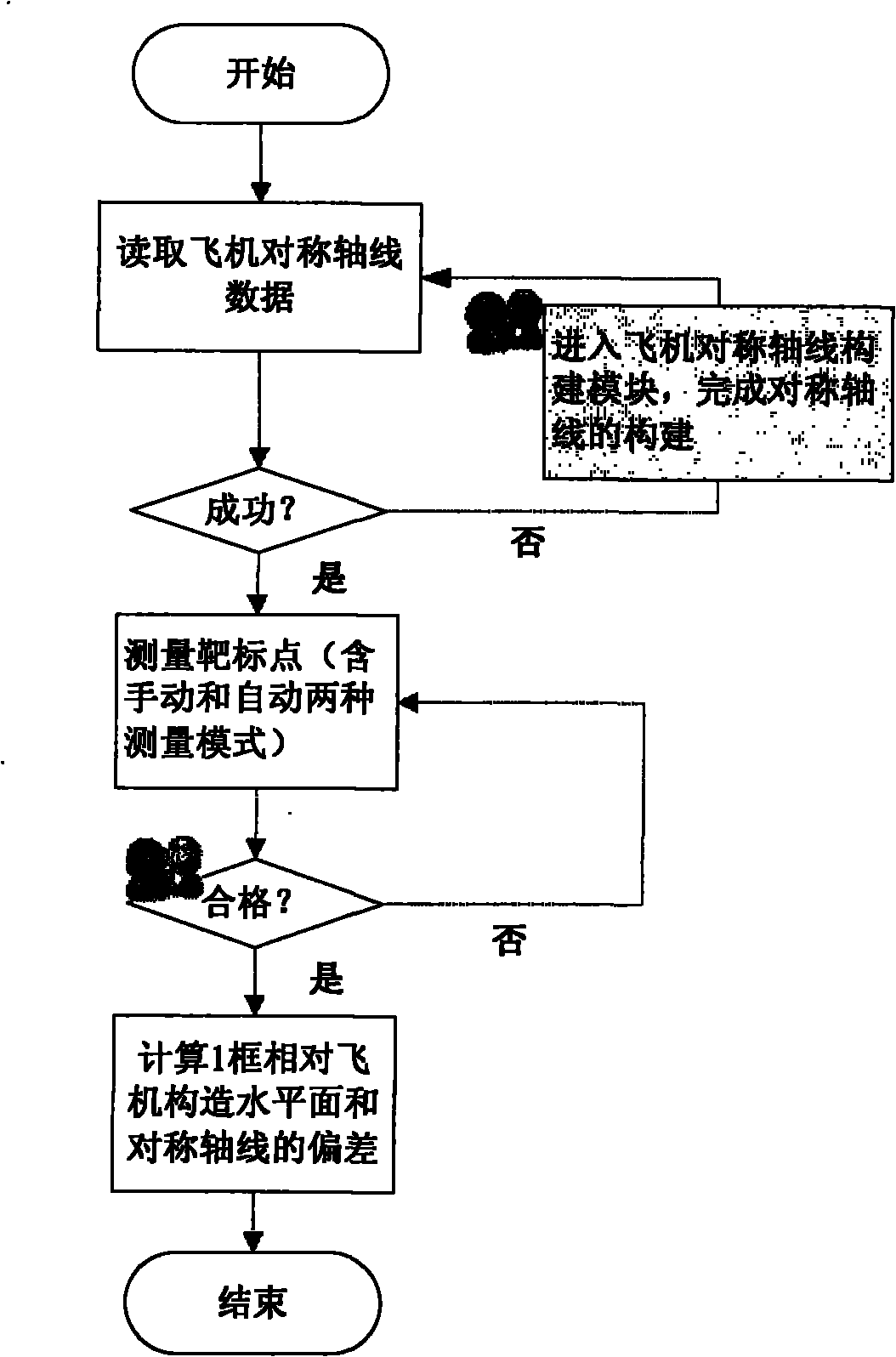

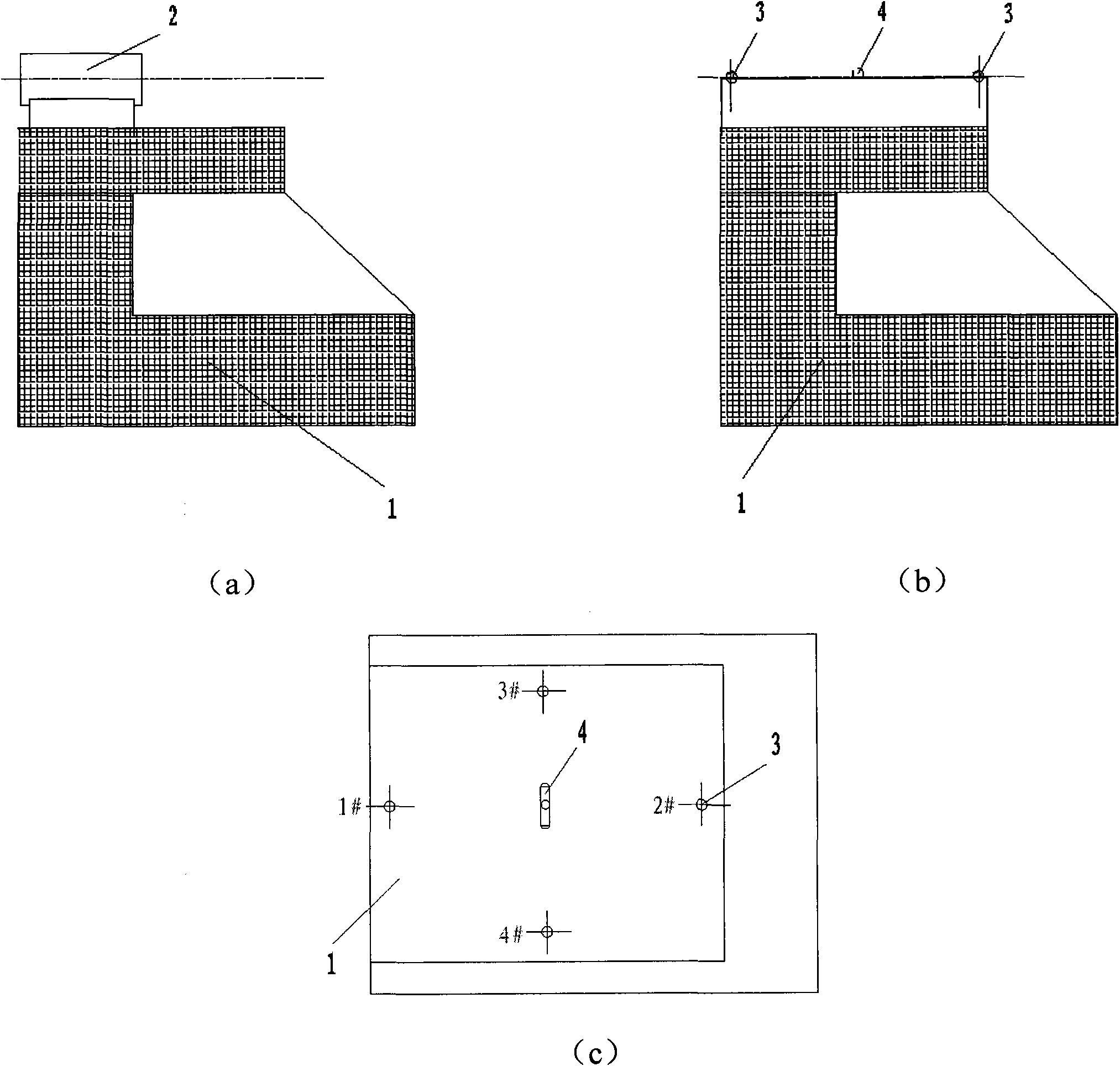

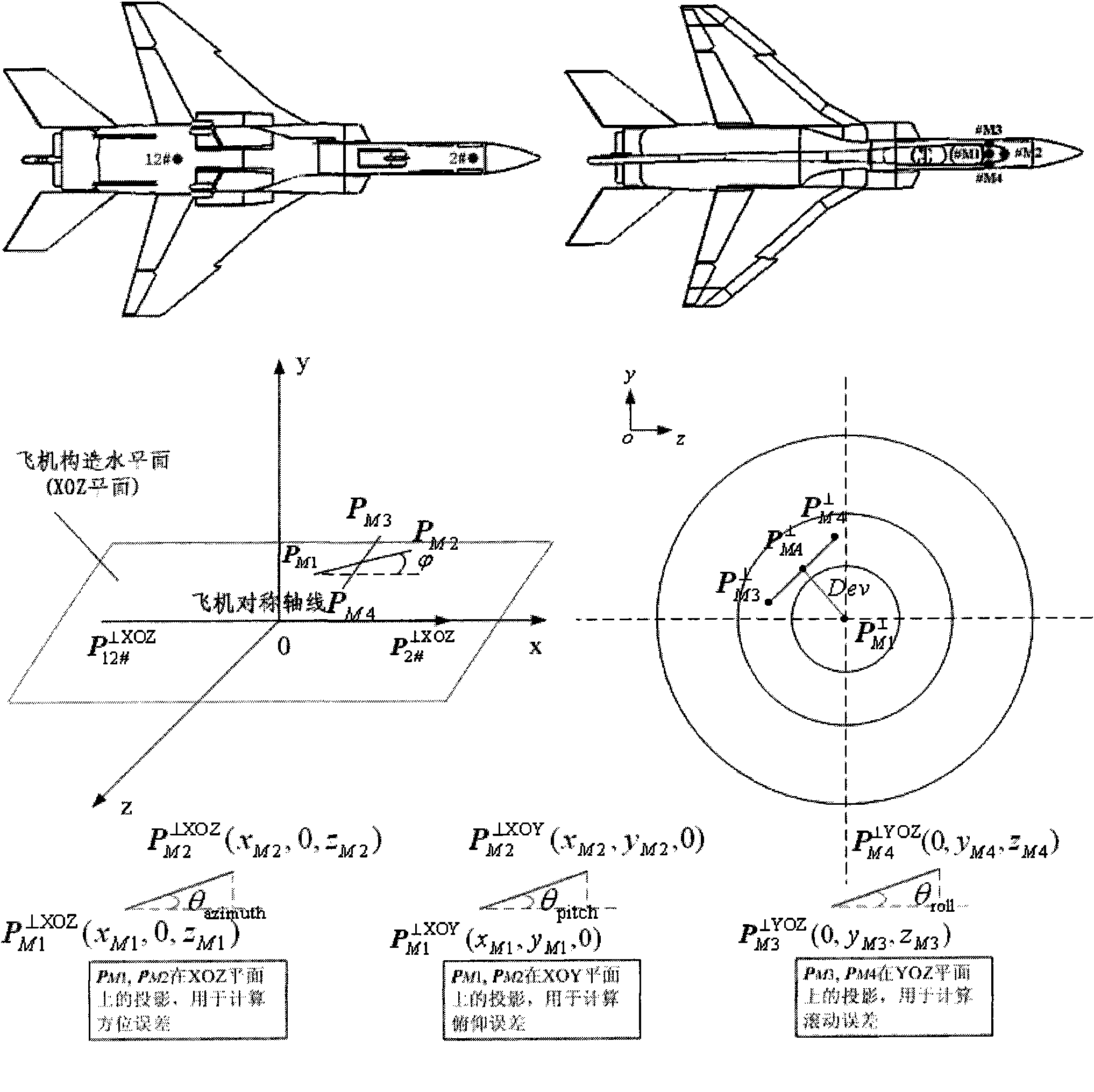

Method for measuring precision of 1# frame of plane general assembly

InactiveCN101865653AImprove automationImprove the level of integrationUsing optical meansGeneral assemblyMeasurement point

The invention discloses a method for measuring precision of a 1# frame of a plane general assembly, which comprises the following steps of: 1) levelling a plane to ensure that a measuring coordinate system of a laser tracker is unified with an assembly coordinate system of a station position of the plane general assembly; 2) measuring a 2# measuring point and a 12# measuring point by using the laser tracker, and constructing a symmetrical axial line of the plane automatically by using a computer; 3) starting a measuring program to measure four drone points on the 1# frame by adopting a manual or automatic measurement mode; and 4) calculating deviations of the 1# frame relative to a construction horizontal surface of the plane and the symmetrical axial line of the plane. The method has the following advantages that: 1) compared with a conventional optical measurement method, a digitized measurement system can effectively improve the measurement precision and greatly improve the measurement efficiency; and 2) the automation and integration levels of the plane general assembly are further improved.

Owner:XIAN AIRCRAFT IND GROUP +1

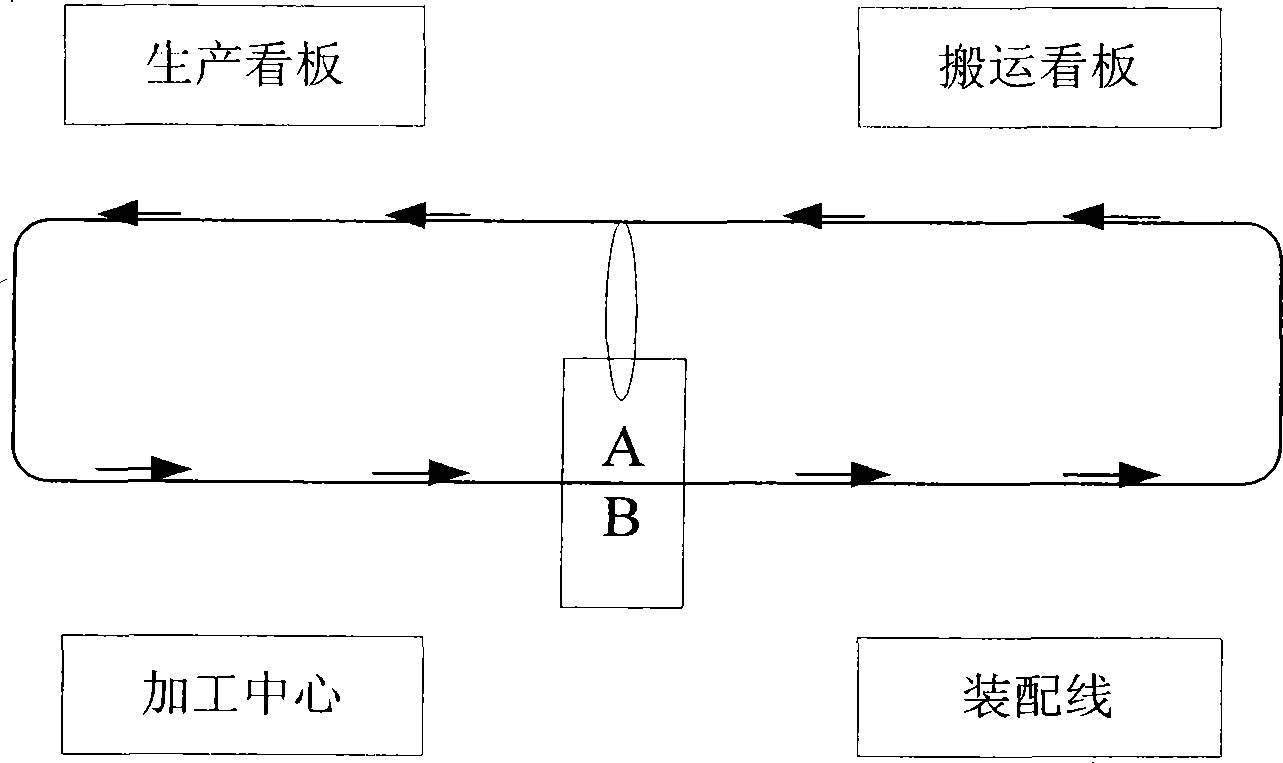

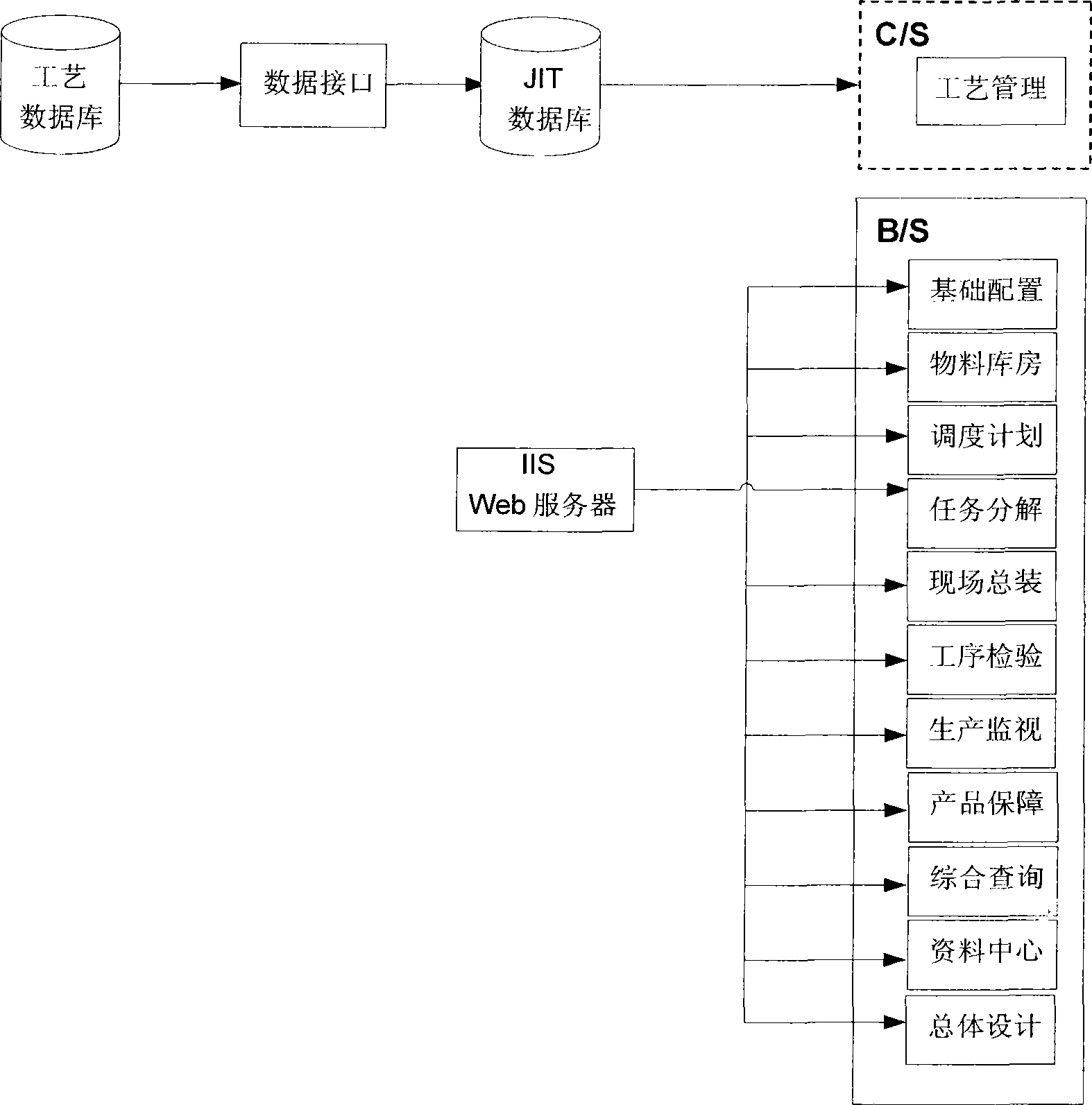

Billboard management system and method

InactiveCN101546393AImprove work efficiencyAccelerate the development progressResourcesManufacturing computing systemsDocumentation procedureDecomposition

The invention discloses a billboard management system and a billboard management method, wherein the system comprises: a basic configuration module, which establishes a data interface with the system, performs debug on process faults, inputs models, fascicules, working procedures, process steps, assorted tables and key working procedures, and maintains correlative information of a structure tree; a material warehouse module, which manages material assorted information, performs material distribution, warehousing and ex-warehouse management, and finishes allocation management of the materials between models; a process management billboard module, which is used for achieving temporary process documentation and process modification, solving on-site technical problems and compiling process rated details; a production plan management module, which is used for finishing production flow design and production route design, and establishing and adjusting or distributing a production arrangement plan; a workshop operation plan billboard module, which generates an intraday task list according to a scheduled production plan and distributes the task list to each working position billboard for instructing the intraday work; a execution billboard module, which finishes plan decomposition and appoints the starting time and ending time of the plan for each working procedure task, inspects the completed working procedures in the system at the first time when the working procedures are completed, and fills in inspection records and prints assembling process cards; and an on-site inspection module, which fills in quality control cards of the key working procedures and manages a single closed loop for soling the technical problems. The billboard management system and the billboard management method optimize the general assembly working mode and the production flow and solve various links unadaptable to a batch production mode in the process of the general assembly currently.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

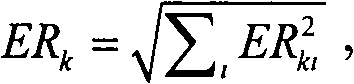

Determination method of satellite antenna pointing accuracy

A determination method of satellite antenna pointing accuracy comprises the following steps: firstly, with respect to a satellite large-scale system, determining various error sources that influence the satellite antenna pointing accuracy, wherein the error sources mainly comprise antenna characteristics, installation errors of satellite general assembly and parts, attitude control errors of a satellite system system, and satellite orbit drift; secondly, performing effect characteristic analysis of the determined various error source items, wherein the error source items are divided into constant errors, daily variable errors, short-period errors, and long-term errors; finally, calculating the rolling, pitching, yaw pointing errors of the satellite antenna on a satellite shaft, the pointing errors in the north-south and west-east directions, and the antenna pointing half cone angle errors. The method of the invention comprehensively considers various error sources and their characteristics that influence the satellite antenna pointing accuracy, can accurately provide the satellite antenna pointing accuracy, is simple in calculation, and is applicable to the engineering calculation of earth stationary orbit satellite antenna pointing accuracy.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

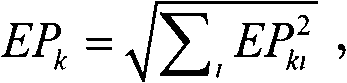

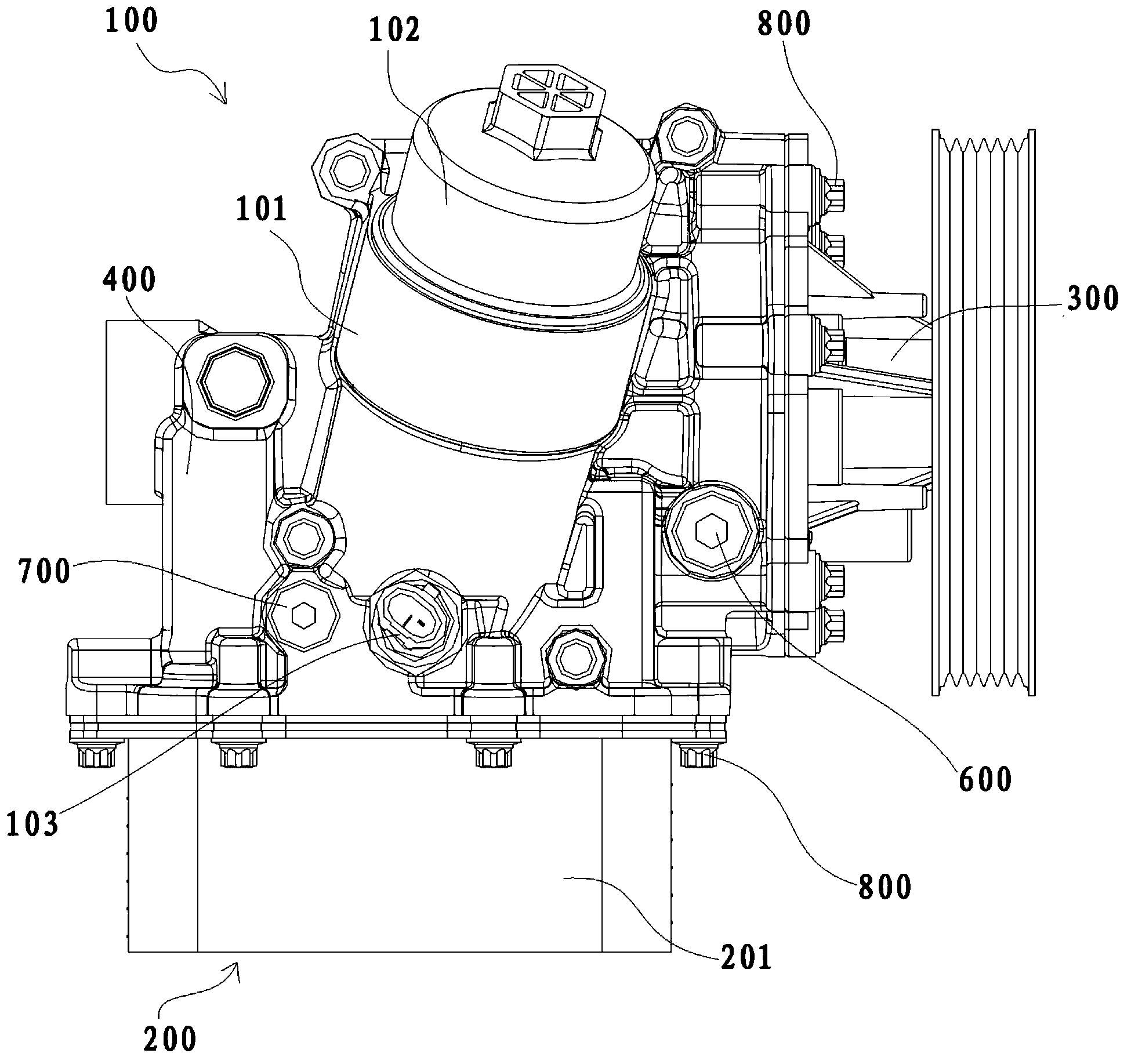

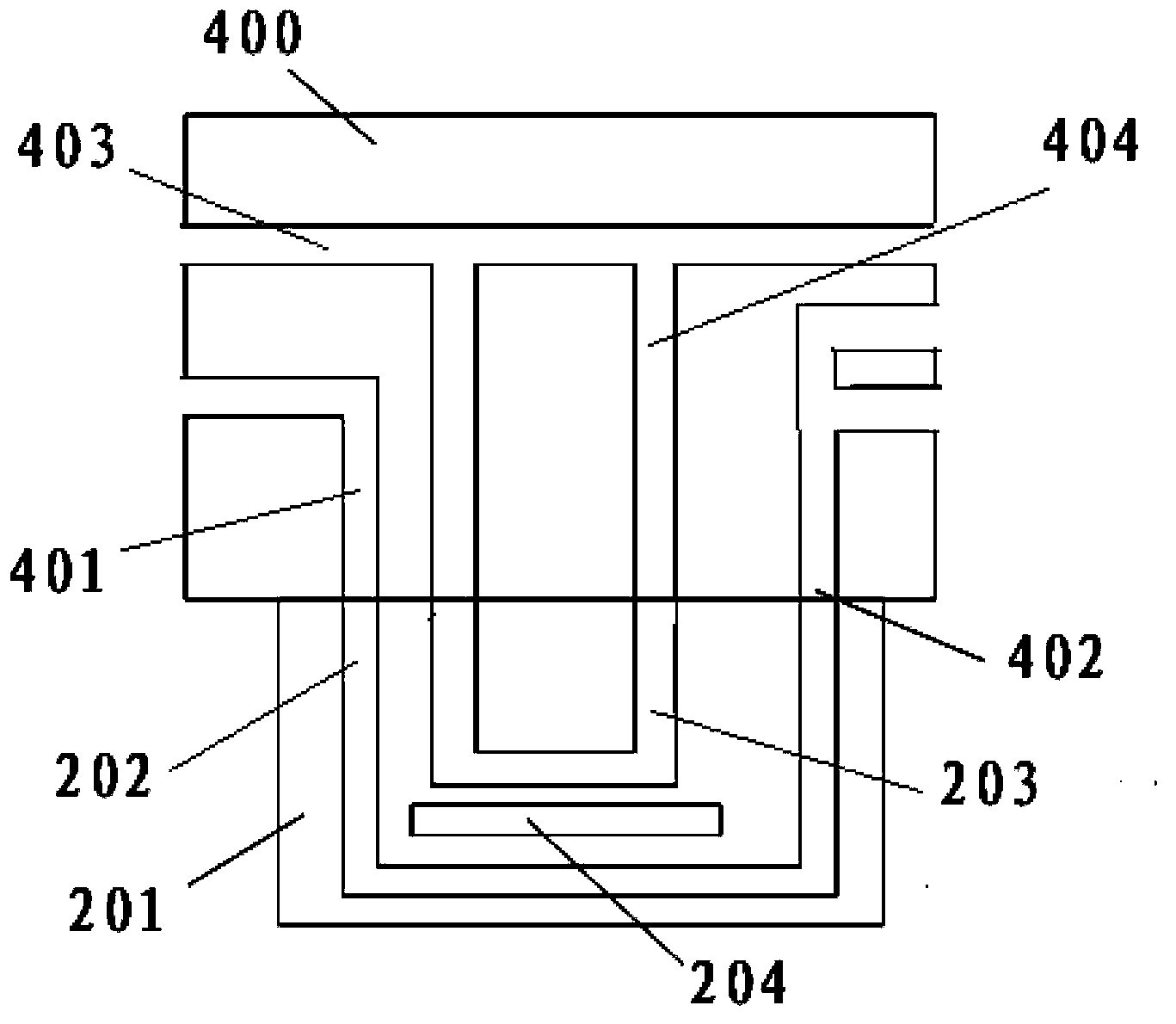

Automobile engine oil filtration and cooling integrated structure and automobile

ActiveCN103670584AImprove assembly efficiencyImprove cooling efficiencyMachines/enginesLubricant mounting/connectionGeneral assemblyFiltration

The invention provides an automobile engine oil filtration and cooling integrated structure and an automobile. The automobile engine oil filtration and cooling integrated structure comprises a mounting base, a water pump assembly, an engine oil cooler assembly and an engine oil filter assembly. The water pump assembly, the engine oil cooler assembly and the engine oil filter assembly are internally arranged on the mounting base to form the integrated structure; the mounting base is also provided with an engine oil pressure sensor which is used for acquiring the engine oil pressure of a main oil way and feeding back the pressure to an engine control unit. According to the automobile engine oil filtration and cooling integrated structure, the engine oil filter, the engine oil cooler and the water pump are integrated, so that a cooling circuit is more compact, the cooling efficiency of the system is improved, and the number of engine parts is reduced; in addition, only one assembling face is required for connection between the integrated structure and an engine cylinder, so that the space layout structure is compact, installation is convenient, and the general assembly efficiency of an engine is improved.

Owner:北京汽车动力总成有限公司

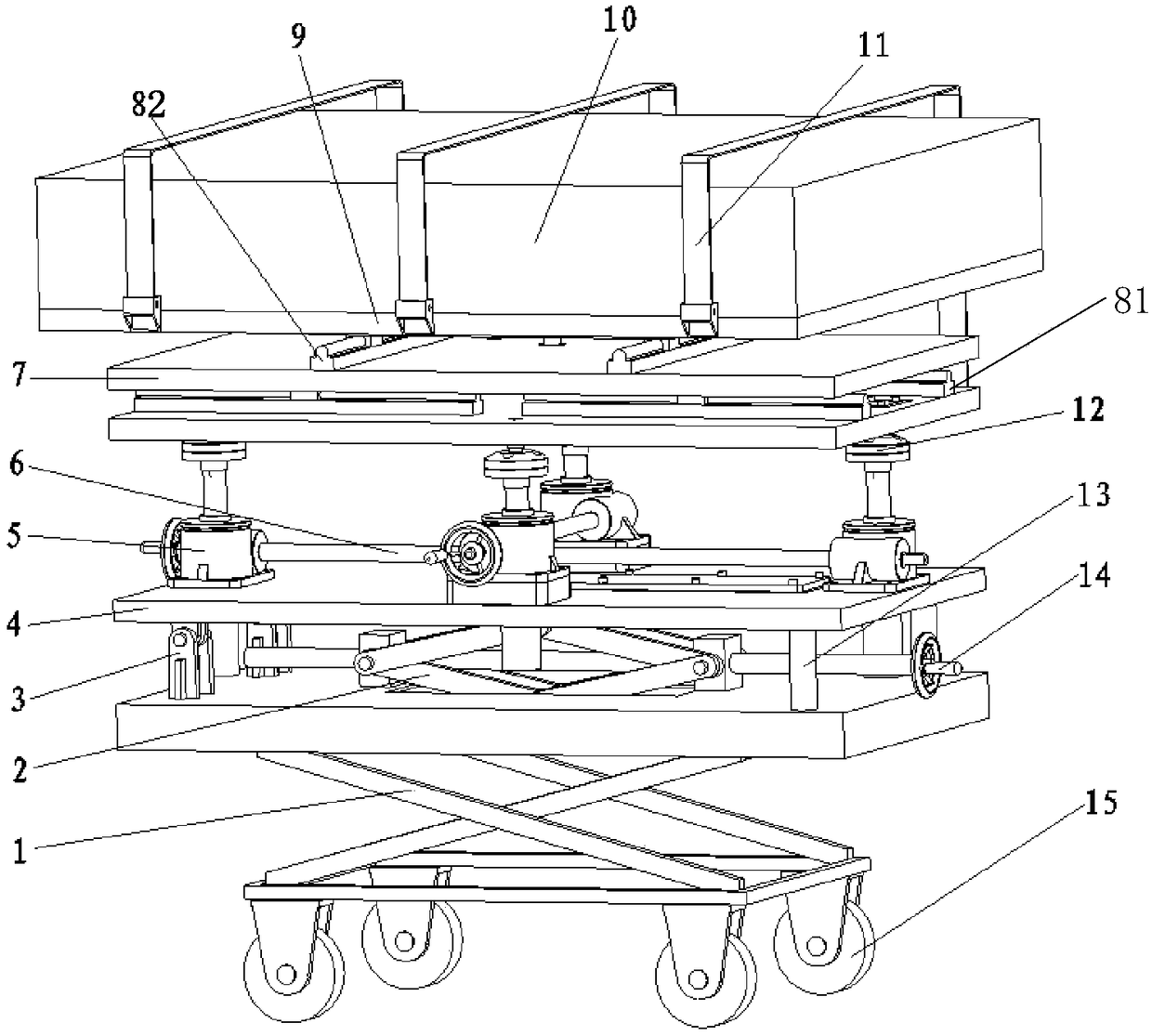

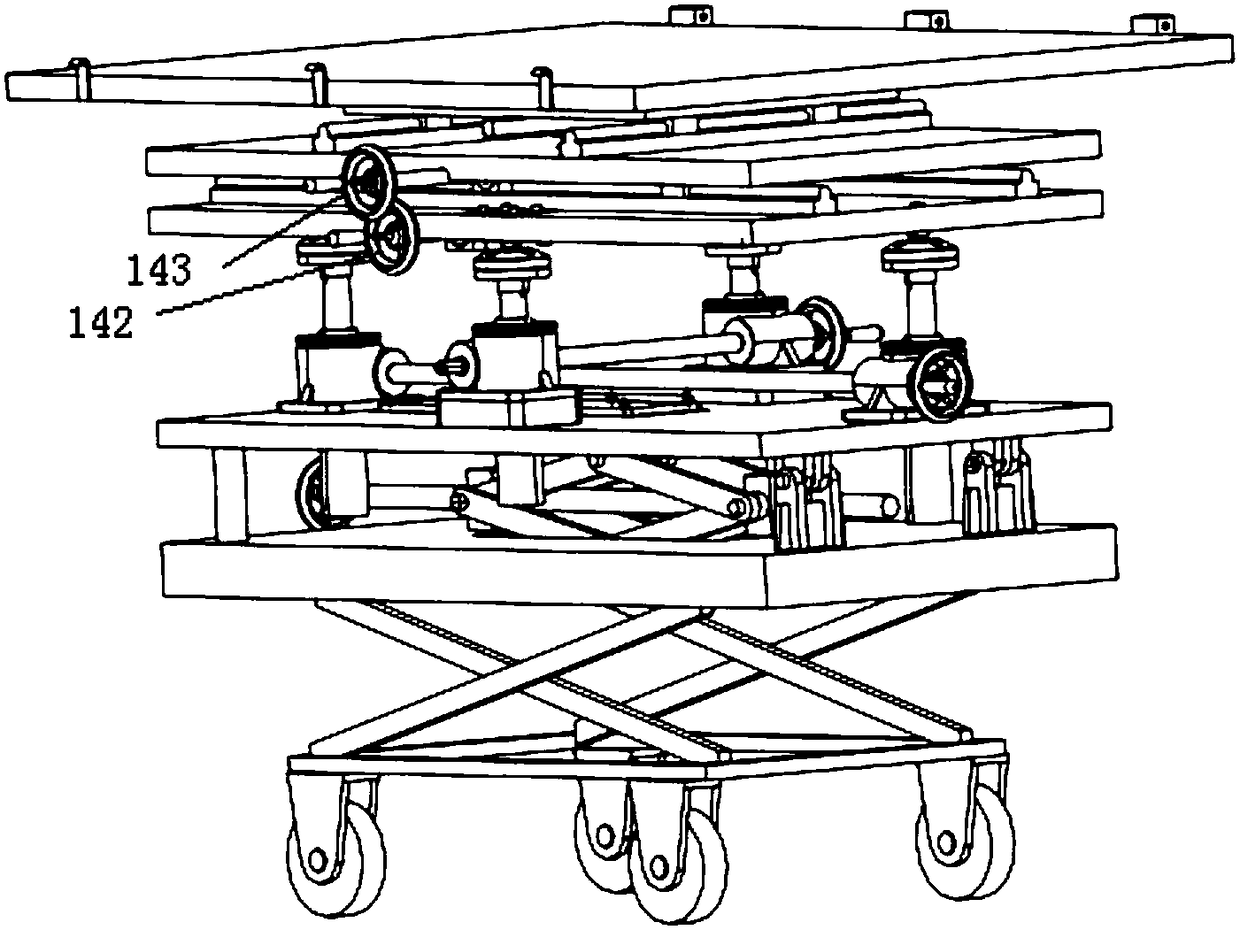

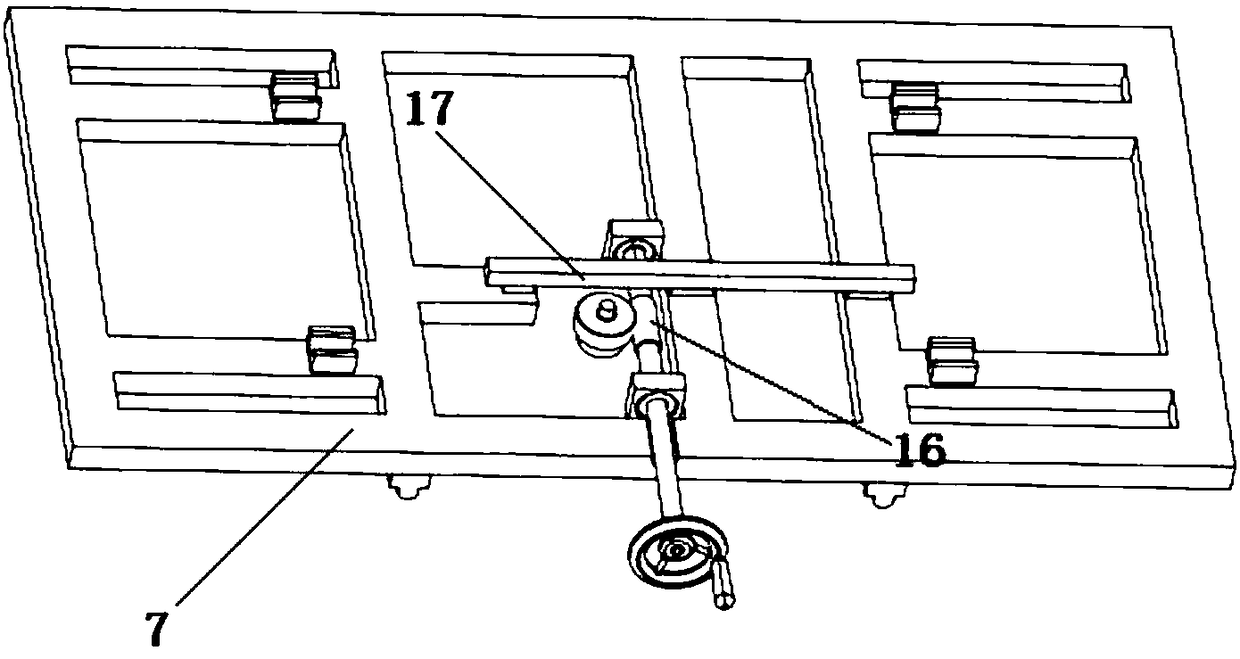

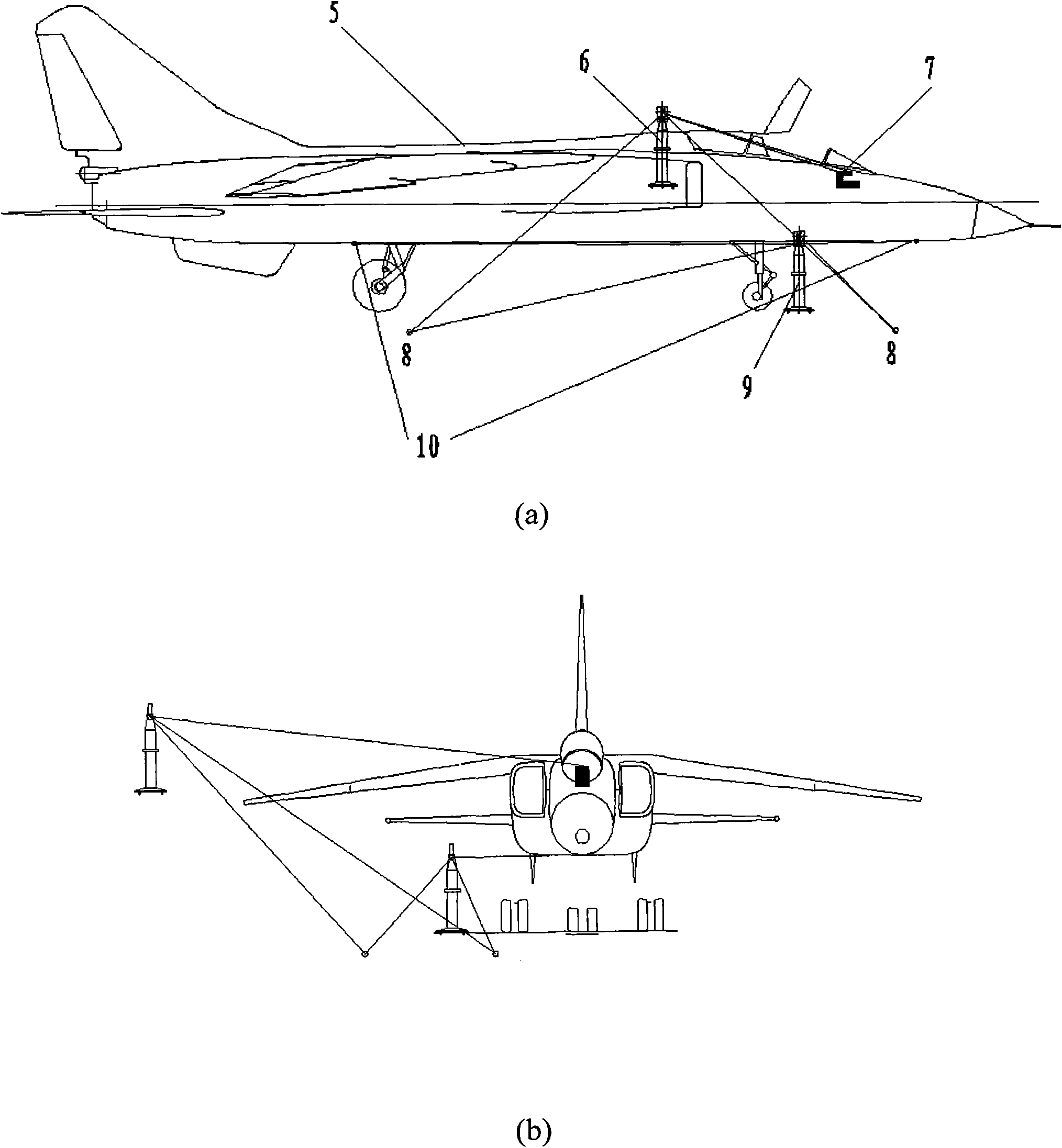

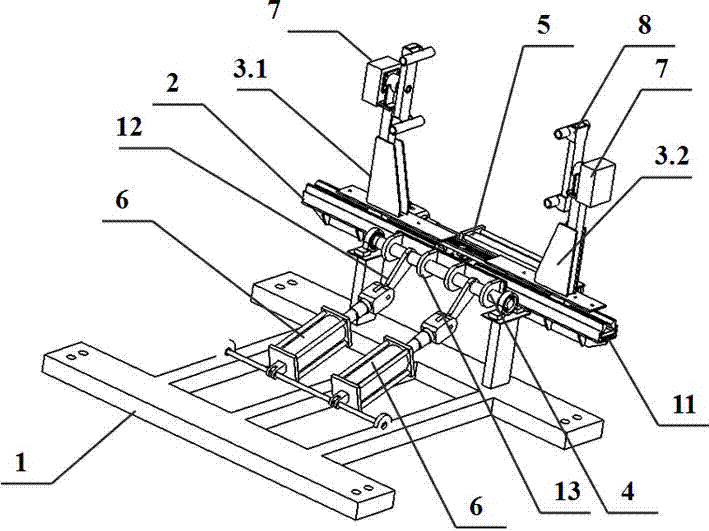

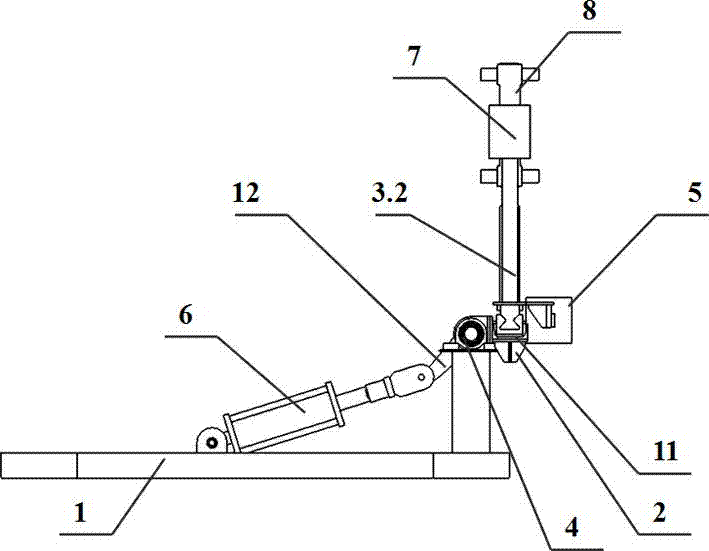

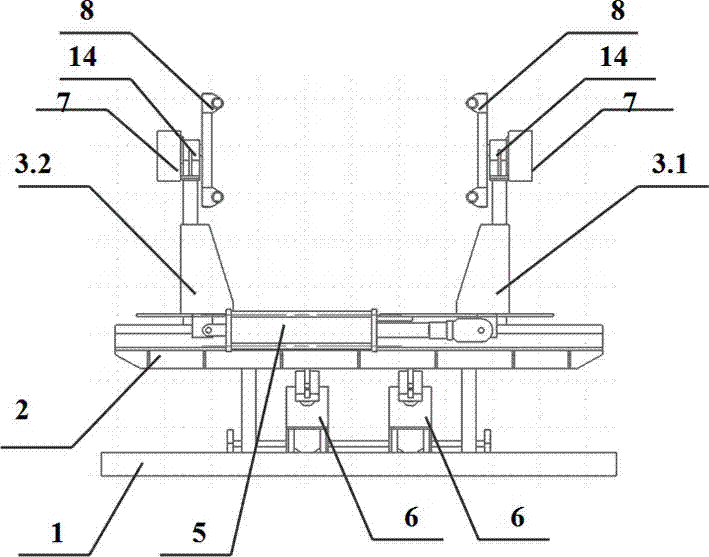

Six-DOF (degree of freedom) portable universal carrier for attitude adjustment and abutting for wings and V-shaped tailfin of unmanned aerial vehicle

The invention discloses a six-DOF (degree of freedom) portable universal carrier for attitude adjustment and abutting for wings and V-shaped tailfin of an unmanned aerial vehicle, comprising a hydraulic lift cart, a rhomboid tilting mechanism component, hinge supports, a tilting support plate, a worm-gear lifter, lifter transmission connection rods, a longitudinal-transverse carrier plate component, a wing support plate, high-density sponge, universal ball-head components, support racks, a first hand-wheel component and a plurality of universal castors. The carrier can meet the various needs of a general assembly and overall adjustment process of unmanned aerial vehicles, for fixation and supporting, attitude adjusting by lifting, and mobile carrying.

Owner:CAIHONG DRONE TECH CO LTD

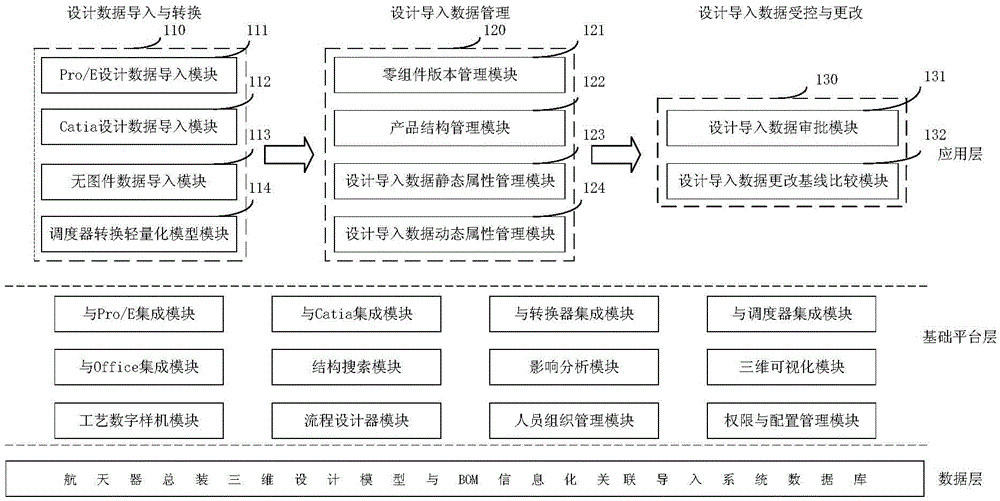

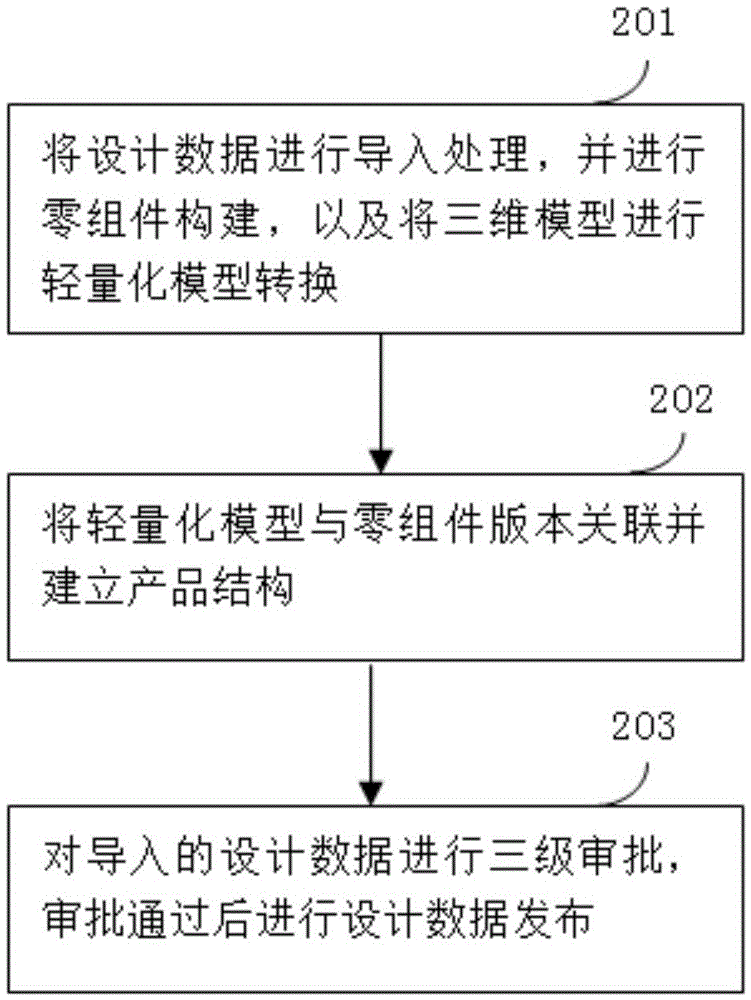

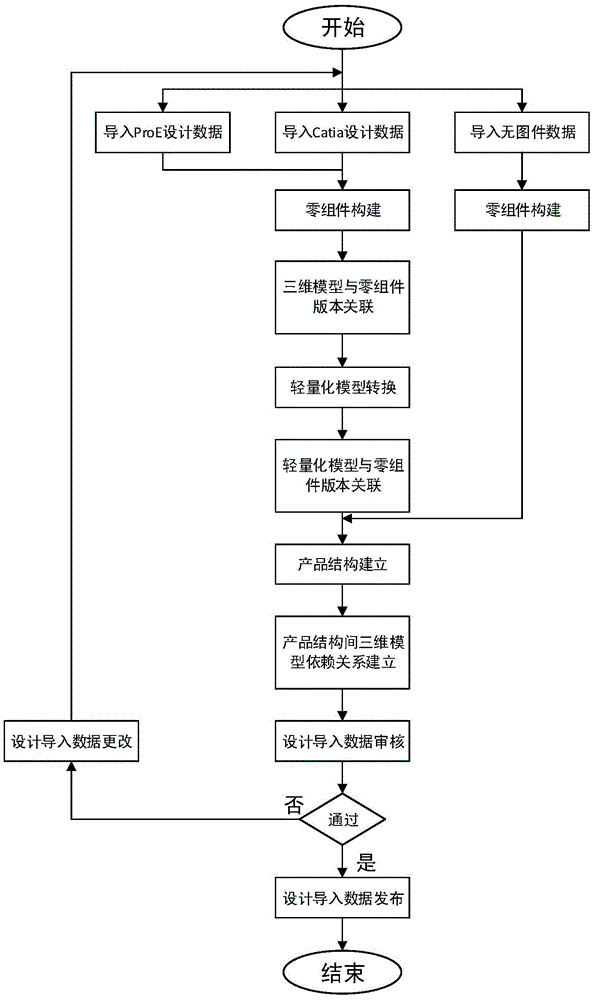

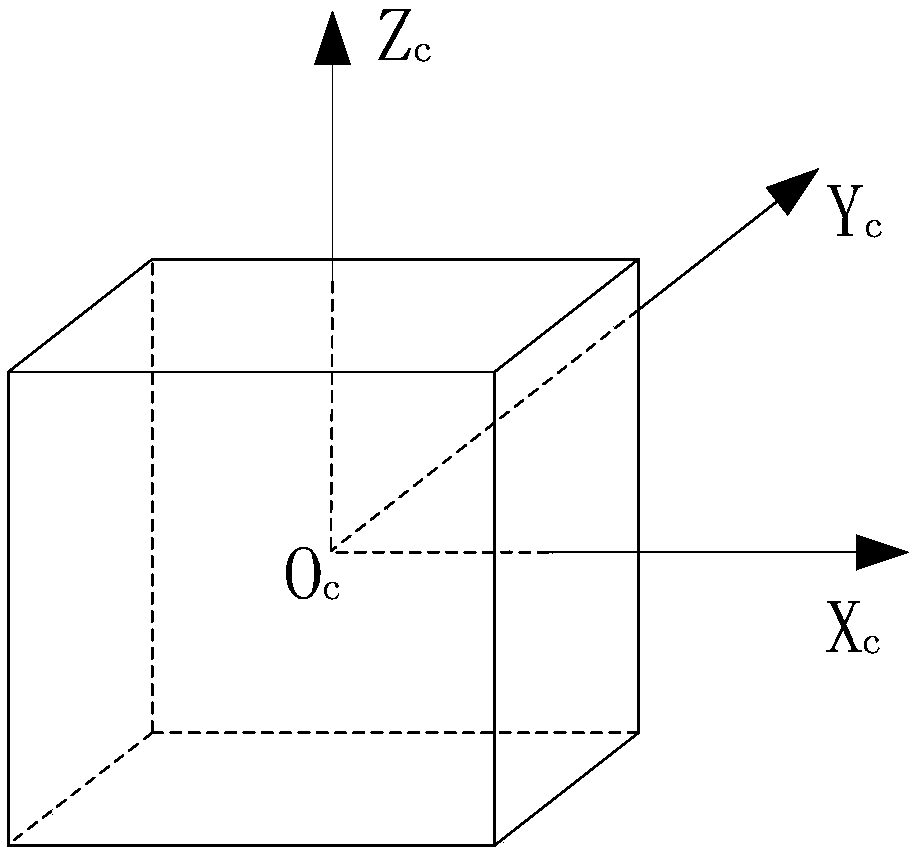

Spacecraft general assembly three-dimensional design model and BOM association import system and method

InactiveCN106682248AImprove loading speedQuality improvementSpecial data processing applications3D modellingThree levelData control

The invention discloses a spacecraft general assembly three-dimensional design model and a BOM association import system and method. The import system comprises a design data import and conversion module which is used for importing and processing design data and performing component construction so as to perform light weight model conversion on the three-dimensional design model; a design import data management module which is used for associating the version of the light weight model and the component and establishing product structure; a design import data controlled and changing module which is used for carrying out three-level approval on the imported design data and publishing the design data after the data passing through the approval. The spacecraft general assembly three-dimensional design model and the BOM association import system and method form a unified data source facing general assembly technology design, containing product structure, three-dimensional design model and structural attribute to realize association of three-dimensional design model and the BOM structure, increase the efficiency of spacecraft design information transmission and guarantee the product quality and reduce investment in human resource.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

Assembly sequence planning method

The invention relates to an assembly sequence planning method. According to the method, a general assembly body model is disassembled to sub assembly components; the sub assembly components are assembled into a general assembly body model; an optimal assembly sequence can be obtained based on the connection of the general assembly body model; the sub assembly components are disassembled into sub assembly parts; the sub assembly parts are assembled into sub assembly components; a disassembly sequence can be obtained through the sub assembly parts; algorithm optimization and evaluation are carried out through the disassembly sequence; an optimal disassembly sequence is selected through the algorithm optimization and evaluation; and the sub assembly parts can be obtained through selecting the optimal disassembly sequence.

Owner:XIAN TECHNOLOGICAL UNIV

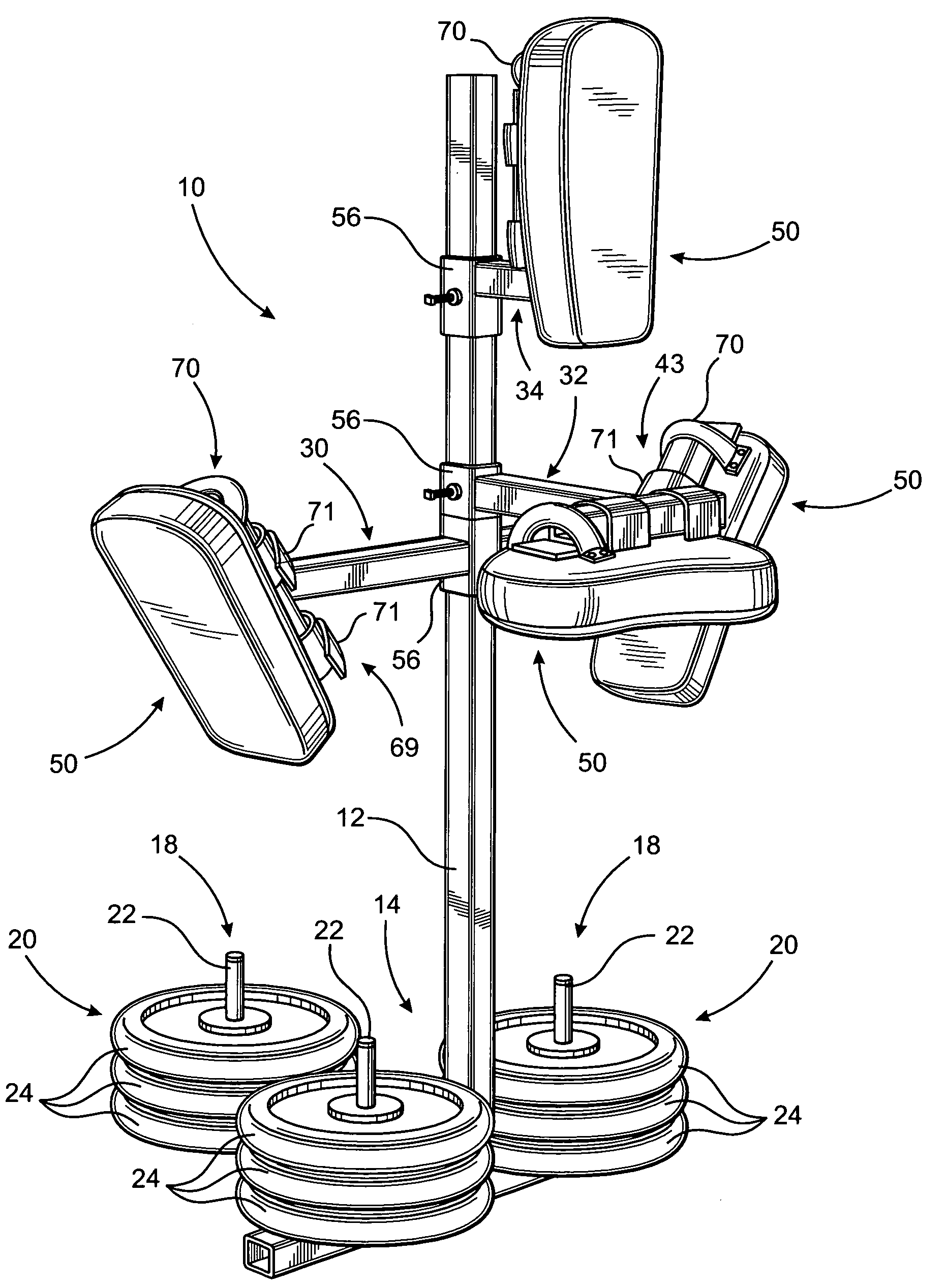

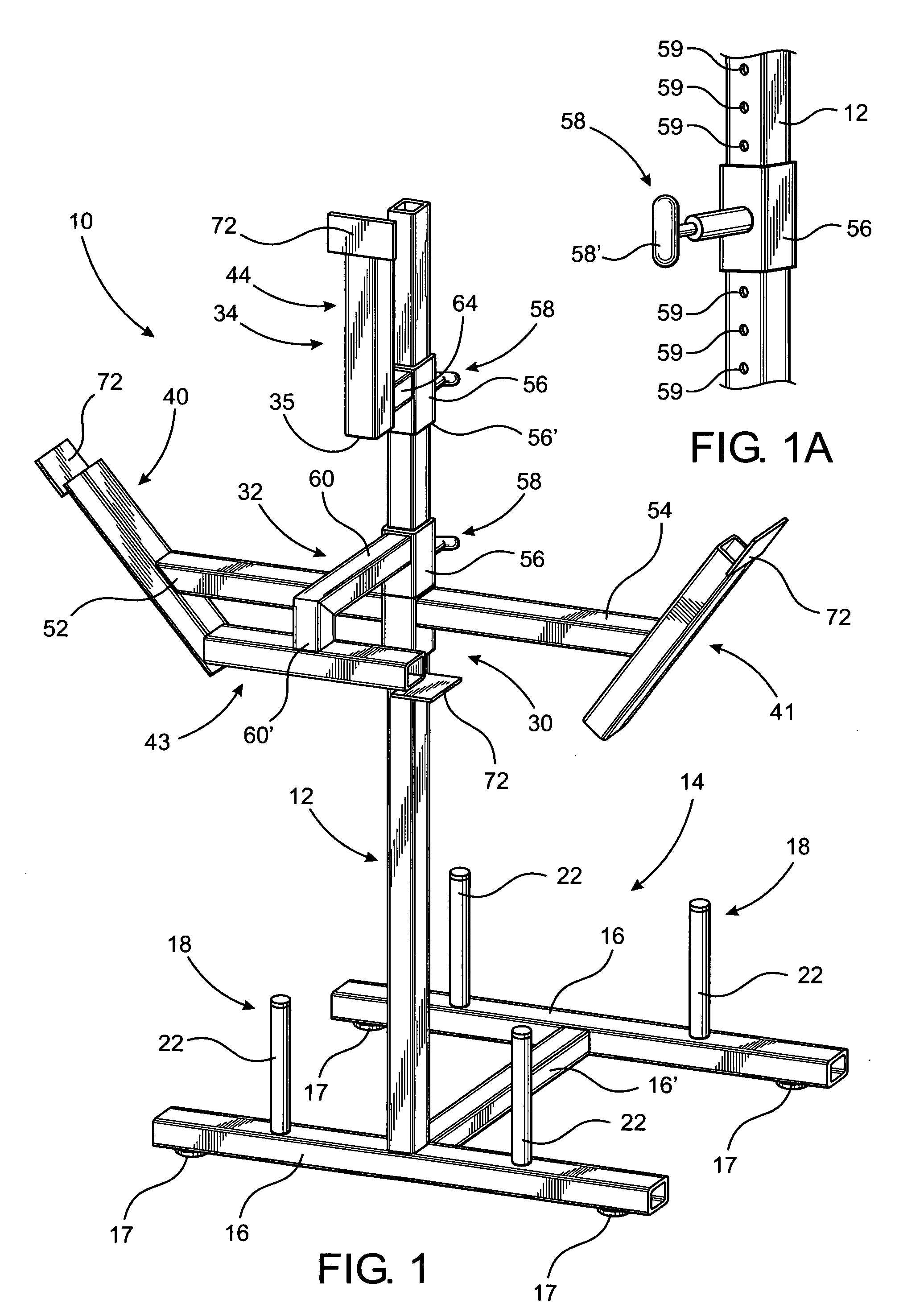

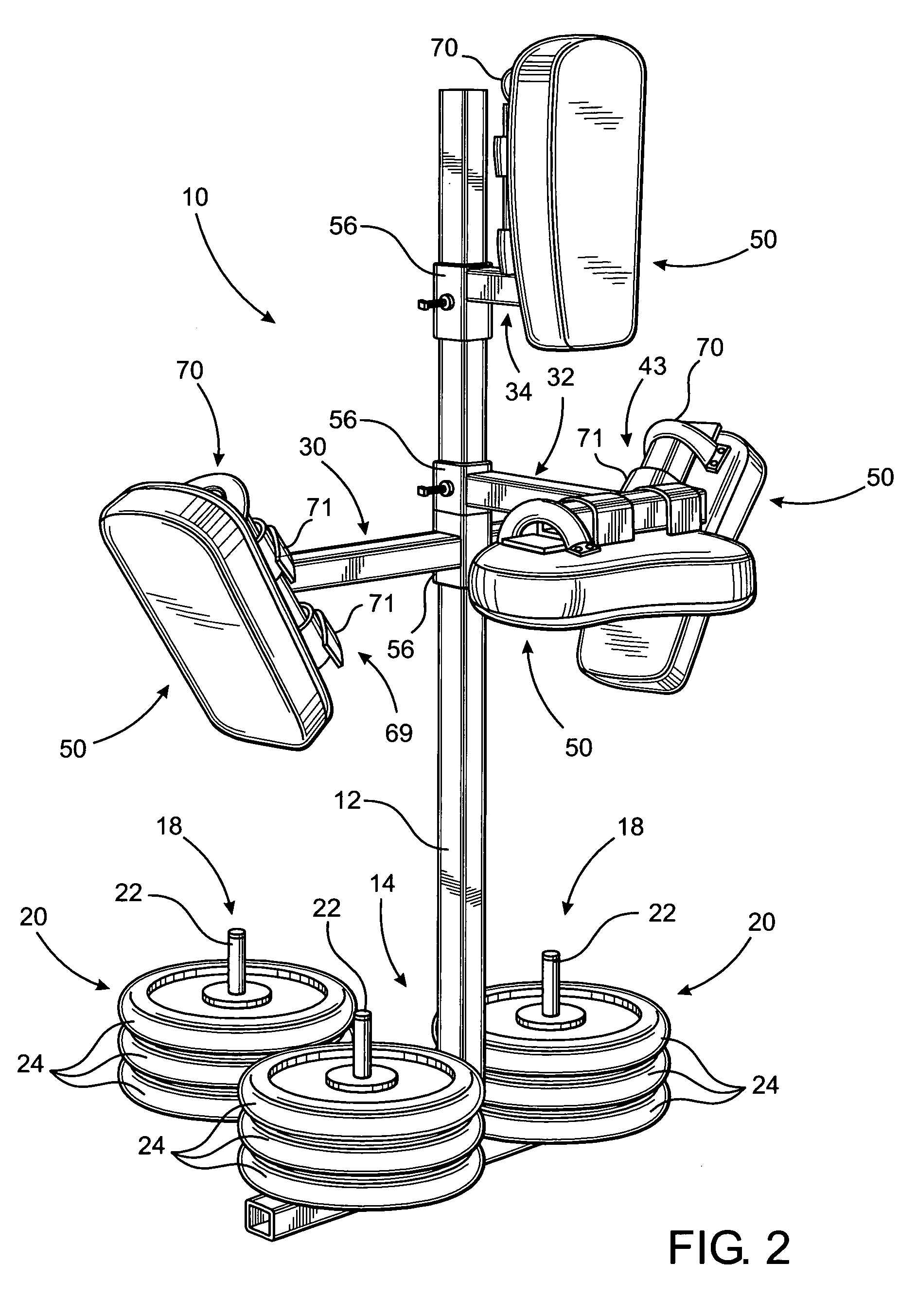

Martial arts practice assembly

An assembly structured to facilitate the practice of various martial art techniques by an individual such as kicks, punches and other physically delivered blows associated with various forms of the martial arts. At least one elongated stanchion is operatively supported by a base, preferably having a stabilizing assembly, in a substantially vertical, upright position. The stanchion comprises a plurality of support assemblies extending outwardly therefrom and being adjustable at various heights along the length thereof. Each or a predetermined number of the support assemblies include a mounting structure secured to an outer end thereof at a predetermined orientation. Each of the mounting structures is dimensioned, disposed and configured to have a striking target, such as a Thai pad, or like structure disposed in an exposed, accessible location to facilitate the delivery, by the individual, of different types of martial art blows.

Owner:GONZALEZ ANGEL

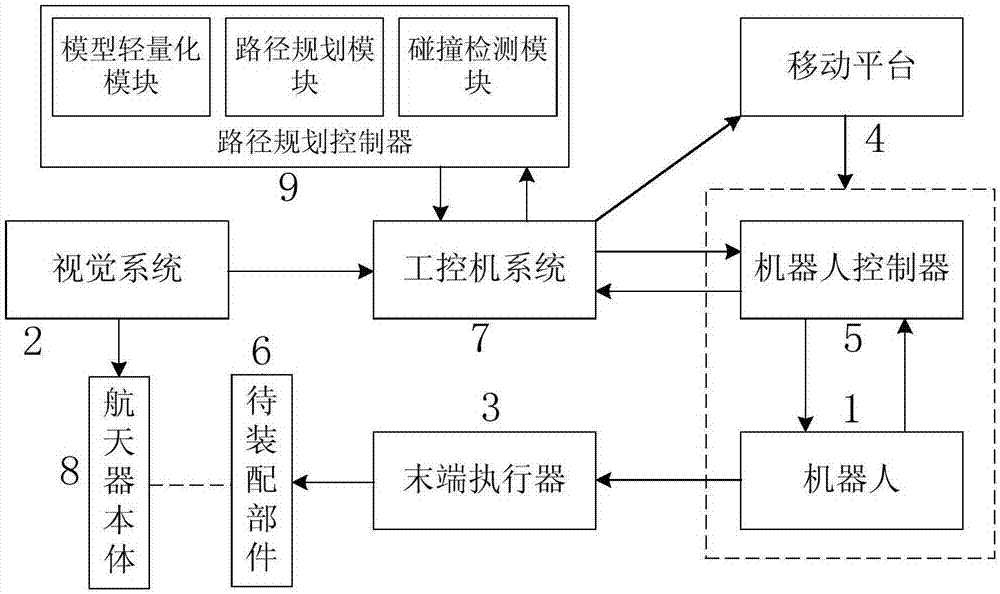

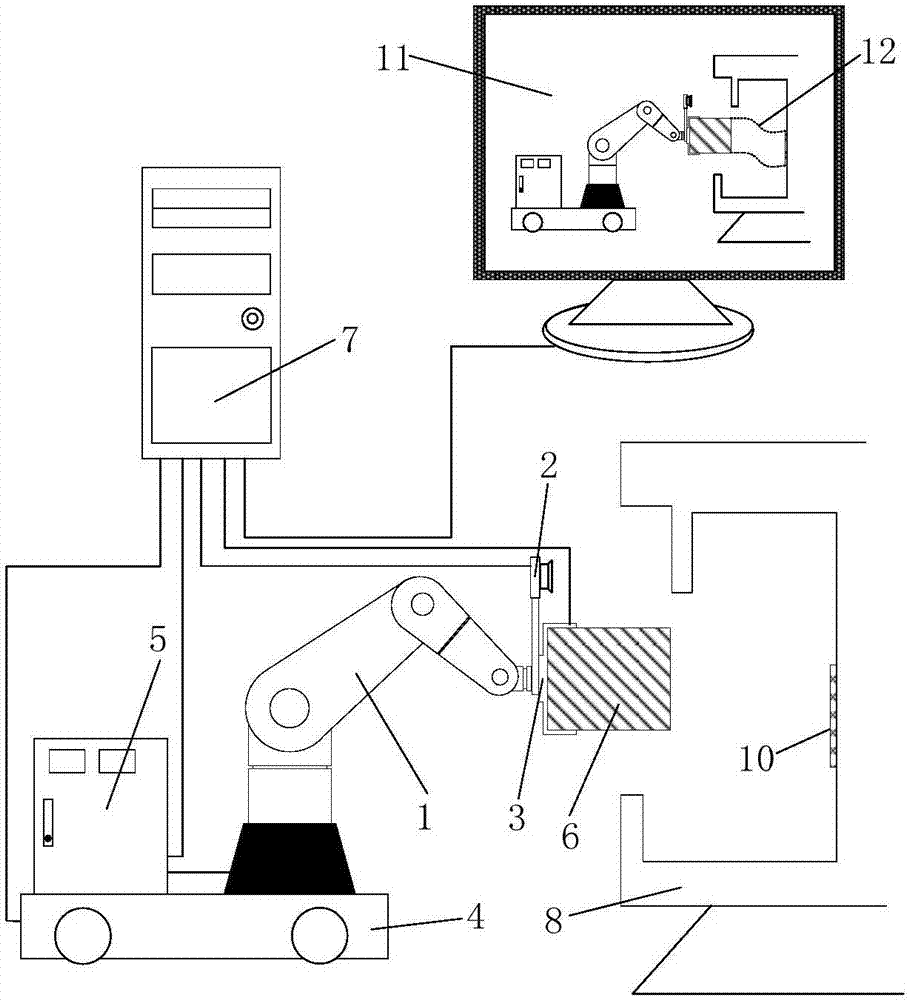

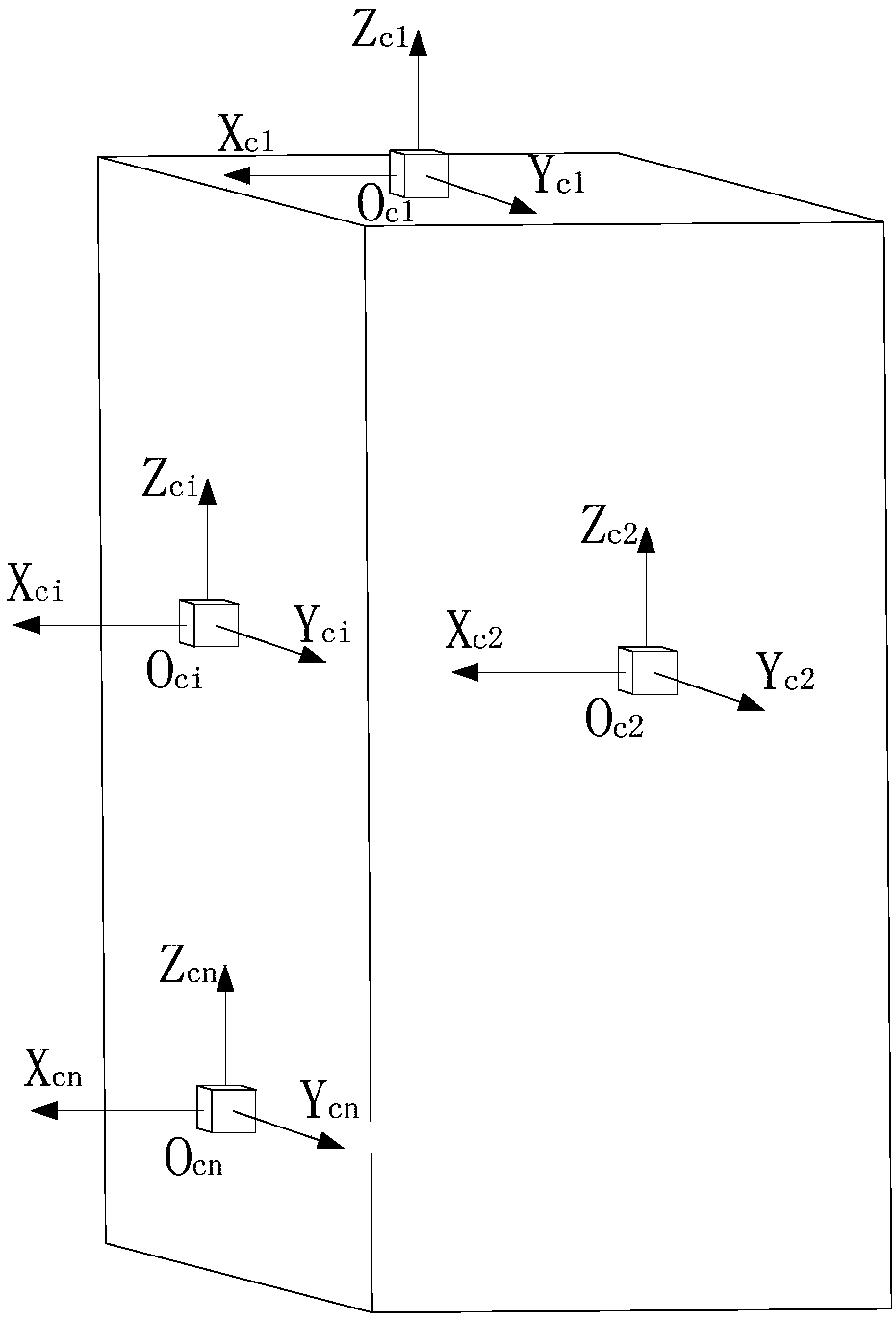

Robot automatic assembling method and system based on vision positioning

InactiveCN107538508AFlexible operationLarge working spaceSpecial data processing applicationsManipulatorGeneral assemblyPersonal computer

The invention discloses a robot automatic assembling system based on vision positioning. The robot automatic assembling system comprises an industrial personal computer, a path planning controller, amoving platform, a robot, a robot controller and the like, and the industrial personal computer is connected with the robot controller, a vision system, the moving platform and the like. The moving platform is controlled to transfer the robot to an assembly site; the collected data of the visual system are received and processed, and thus the conversion relationship between the spacecraft coordinate system and the robot base coordinate system is obtained; and then a tail-end actuator is controlled to grab to-be-assembled parts and sends a motion instruction to the robot controller according tothe assembly path given by the path planning controller to control the robot to drive the tail-end actuator to move, and thus automatic assembly of aerospace products is completed. The advantages that operation of the robot is flexible and the working space is large are utilized, the visual system is carried to identify the geometrical features of the mounting position, the detection range is large, positioning accuracy is high, operation is easy and convenient, the response speed is high, and the robot automatic assembling system can be quickly applied to different general assembly stationsof a spacecraft.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

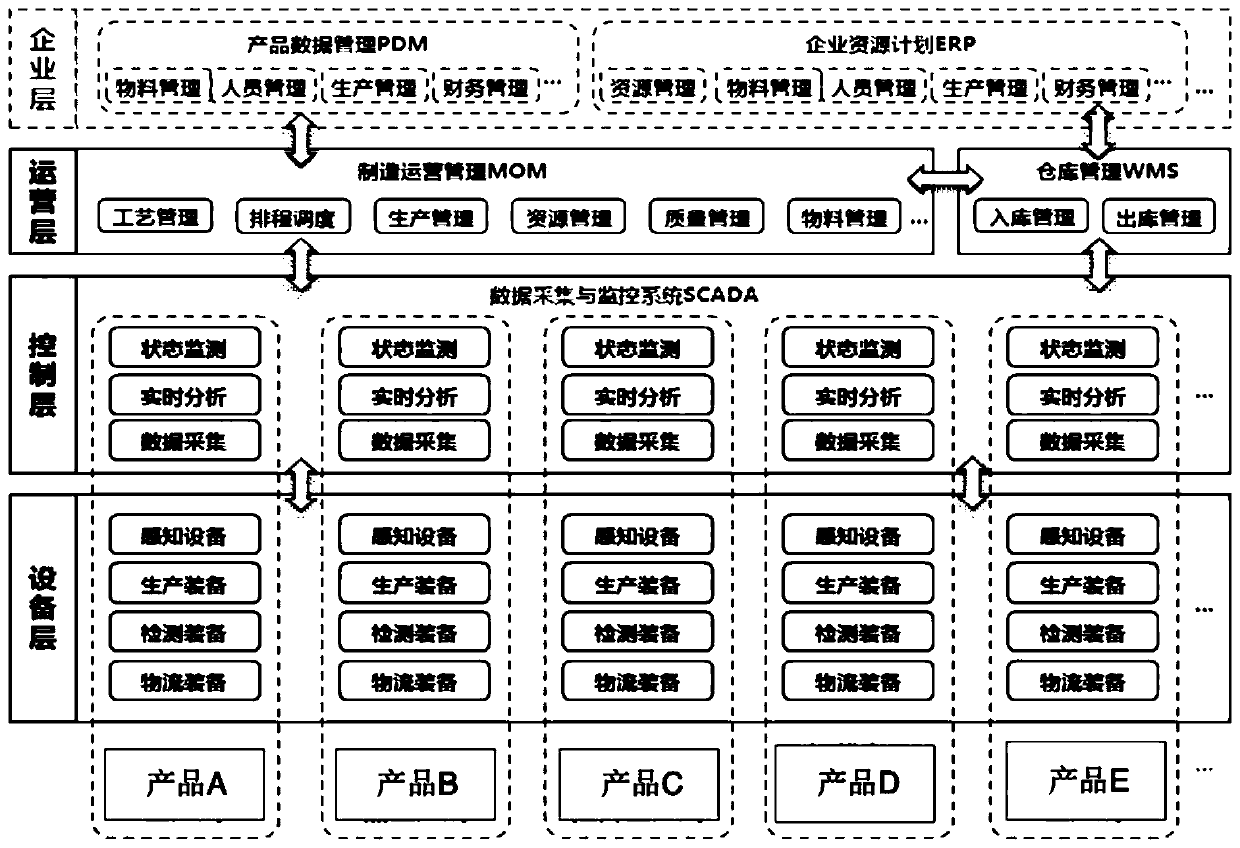

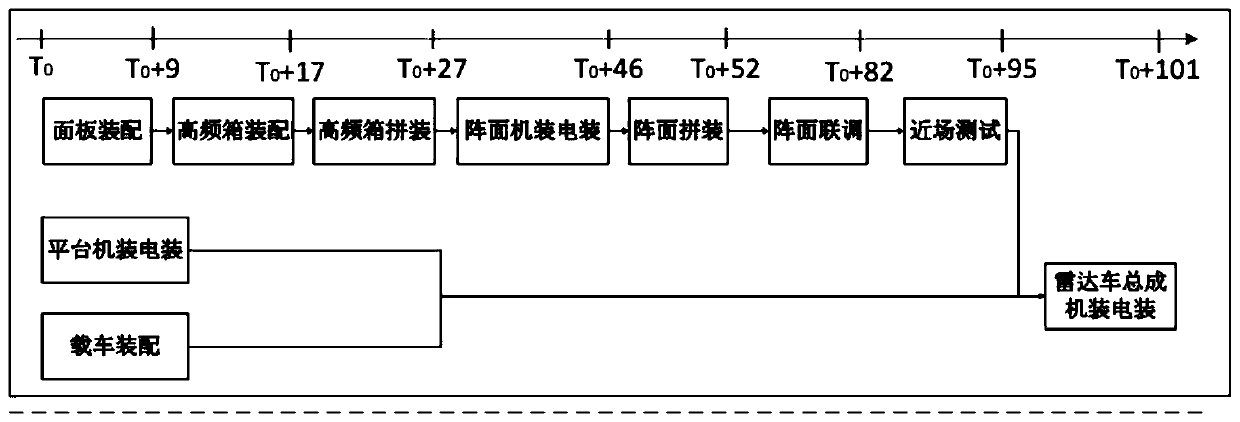

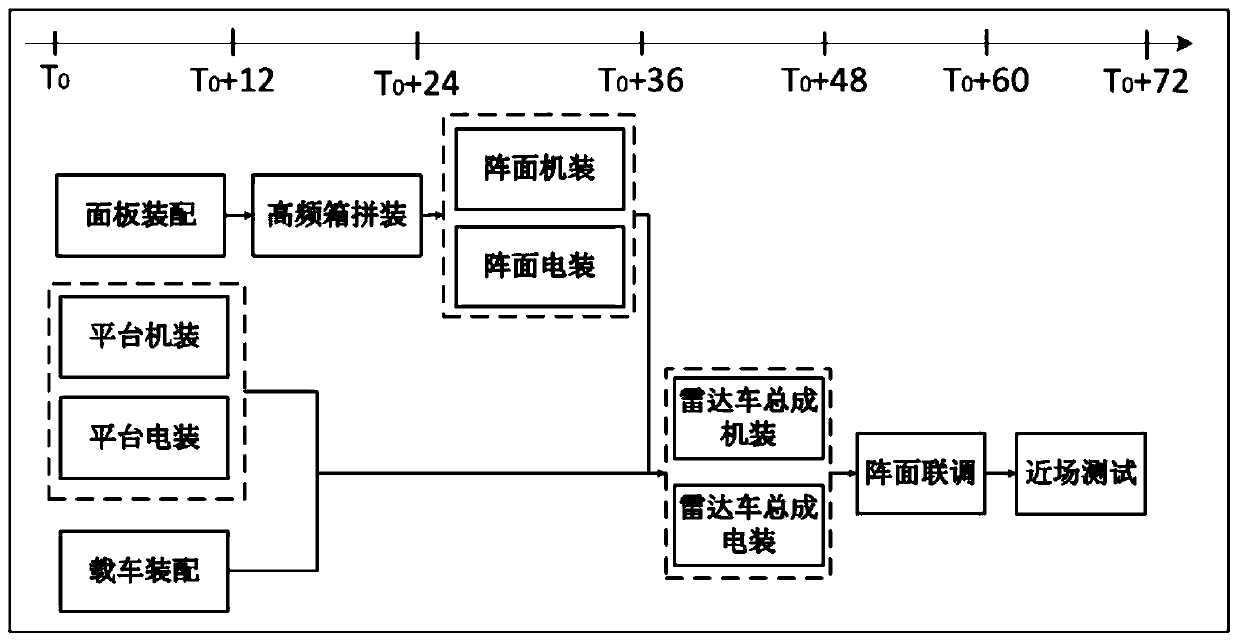

Production process simulation optimization method based on digital twinning

PendingCN111539583AReal-time display of usageDisplay usage in real timeForecastingDesign optimisation/simulationProcess equipmentProduction logistics

The invention discloses a production process simulation optimization method based on digital twinning based on the flexible production requirements of multiple varieties, small batch and variable paces. A manufacturing operation management system and a data acquisition and control system based on big data are constructed; the intelligent level of production logistics and the professional level ofgeneral assembly process equipment are improved, a general assembly intelligent workshop with a batch product pulsation production line and a developed product intelligent general assembly unit as main bodies is formed, and more optimization decisions are provided for physical entities through information fusion and data interaction between virtual models and the physical entities.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

System and method to load vehicle operation software and calibration data in general assembly and service environment

ActiveUS20050090942A1Vehicle testingRegistering/indicating working of vehiclesGeneral assemblyIn vehicle

A data exchange system for use in vehicle assembly includes a data exchange mechanism exchanging vehicle software and / or diagnostic information between vehicle processors and an external processor. In one aspect, the data exchange mechanism is a portable memory device, such as a USB flash disk, alternately connecting to USB ports of the external processor and the vehicle. Vehicle software is automatically loaded onto vehicle processors by an interface processor connected to a CAN controller, and the processors similarly write back diagnostic information. In another aspect, the data exchange mechanism is a wireless mechanism, such as an iCHIP, connecting the external processor and vehicle processors through a communications network and a CAN controller. Vehicle processors individually wirelessly request appropriate vehicle software and / or provide diagnostic information. The data exchange mechanism may be permanently integrated into the vehicle, or temporarily connected to the vehicle by an alternative connection mechanism, such as the ALDL.

Owner:GM GLOBAL TECH OPERATIONS LLC

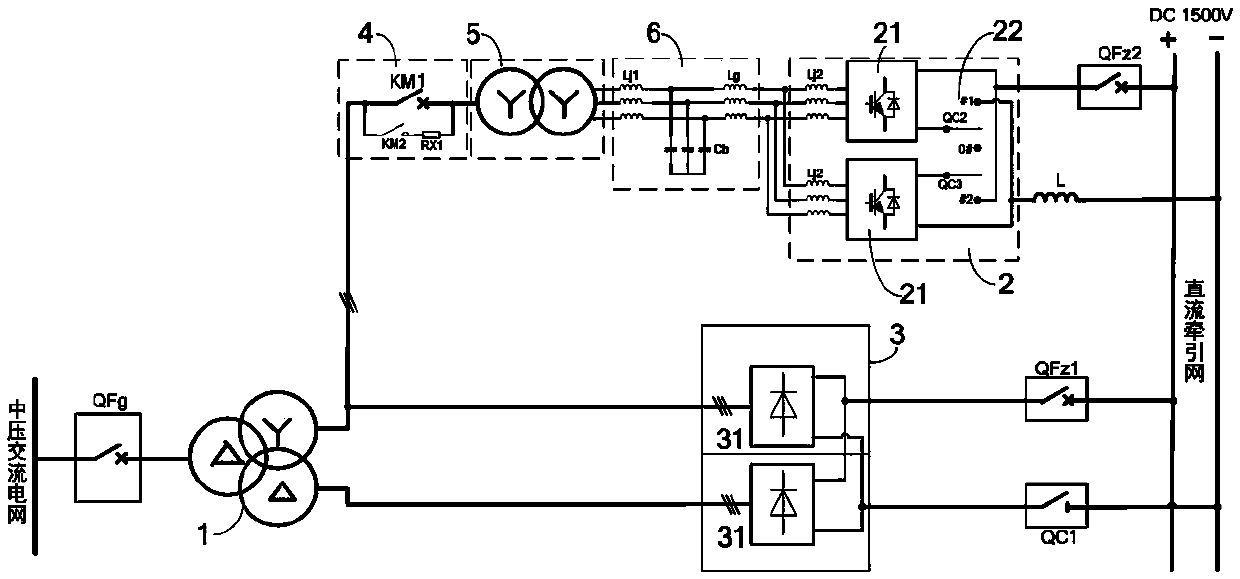

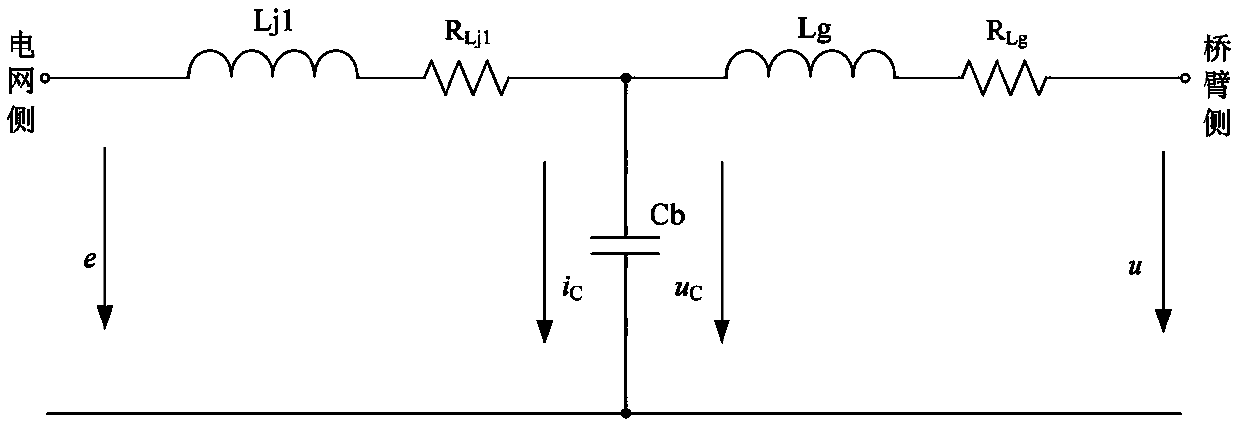

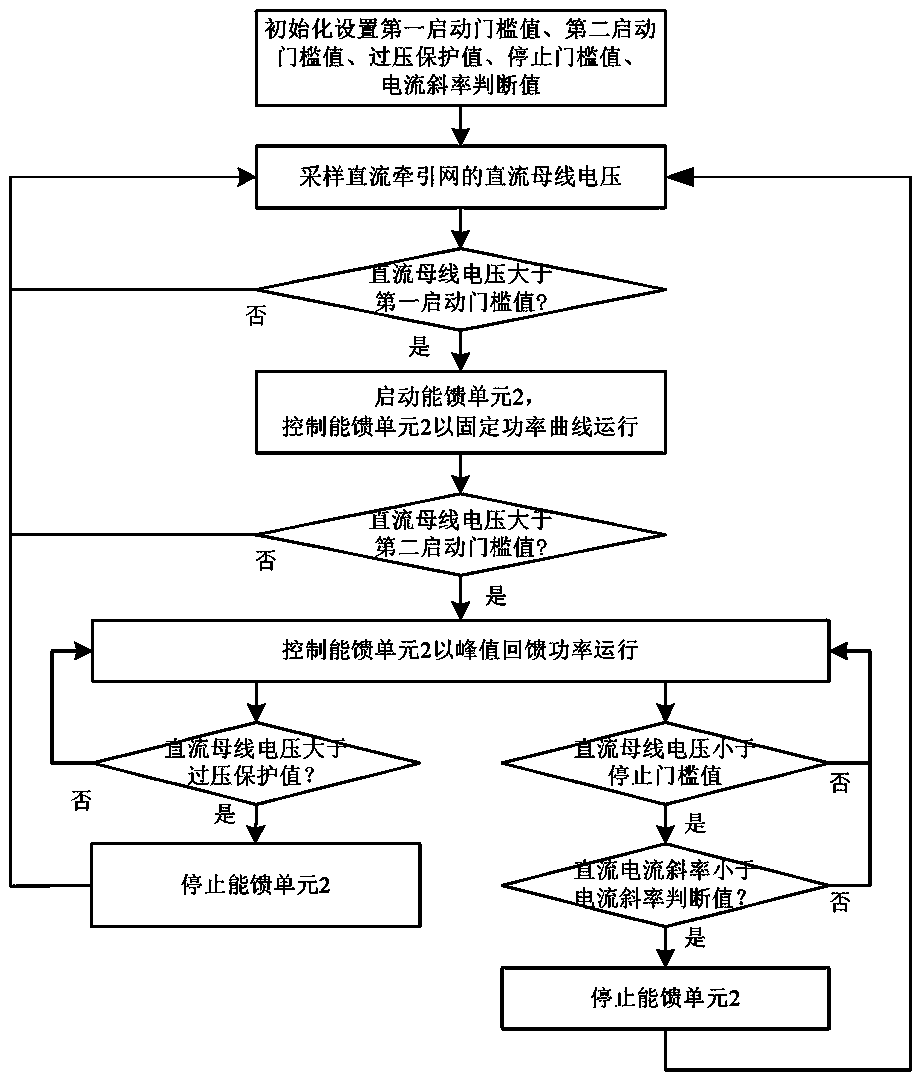

Co-rectifier transformer medium voltage type regenerative braking energy feedback device and control method thereof

InactiveCN107565826AEliminate circulationReduced footprintElectrodynamic brake systemsAc-dc conversionOvervoltageLow voltage

The invention discloses a co-rectifier transformer medium voltage type regenerative braking energy feedback device and a control method thereof; the feedback device comprises a rectifier transformer,an energy feedback unit, and a rectifier unit; a grid connected switch and an isolation transformer are respectively connected in series between the energy feedback unit and a rectifier transformer valve side winding; the energy feedback unit comprises two inverters; DC sides of the two inverters are provided with a single-knife-double-end isolation switch block; the DC sides of the two invertersare connected with a DC traction network through the single-knife-double-end isolation switch block; the feedback device control method comprises the following steps: starting, running and stopping the energy feedback unit according to a first startup threshold value, a second startup threshold value, an overvoltage protection value, a stop threshold value and a current gradient determination value. The feedback device can eliminate the circulation between the energy feedback unit and the rectifier unit, has a larger feedback capacity than a low voltage feedback device, has a simplified structure when compared with a conventional medium voltage feedback device, and uses less general assembly dimensions and land occupation areas, thus reducing cost, and providing good versatility.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

HUD (Heads-Up Display) digitized boresight method applied to plane general assembly

InactiveCN101832737AImprove automationImprove the level of integrationSighting devicesHead-up displayGeneral assembly

The invention discloses an HUD (Heads-Up Display) digitized boresight method applied to plane general assembly, comprising the following steps of: (1) leveling a plane, arranging a laser tracker on a lower station, unifying a measuring coordinate system of the laser tracker with an assembly coordinate system of the lower station and centering a water bubble on an HUD boresight device; (2) measuring a No. 2 point and a No. 12 point by utilizing the tracker and constructing a symmetric axis of the plane in a computer; (3) moving the tracker to an upper station and unifying a measuring coordinate system of the tracker with an assembly coordinate system of the upper station; (4) finishing the measurement of a target on the boresight device; (5) calculating and displaying the deviations of theboresight device relative to the construction plane and the symmetric axis of the plane through patterns and finishing HUD boresight if satisfying the requirement or else continuing the HUD boresight; and (6) manually adjusting the mounting position of the boresight device according to the prompts of the computer and repeating the steps (4) and (5) until satisfying the requirement. The invention can effectively improve the boresight precision and the efficiency, lessen the reliance of boresight operation on the size of a field space, and improve the automated and integrated level of plane general assembly.

Owner:ZHEJIANG UNIV

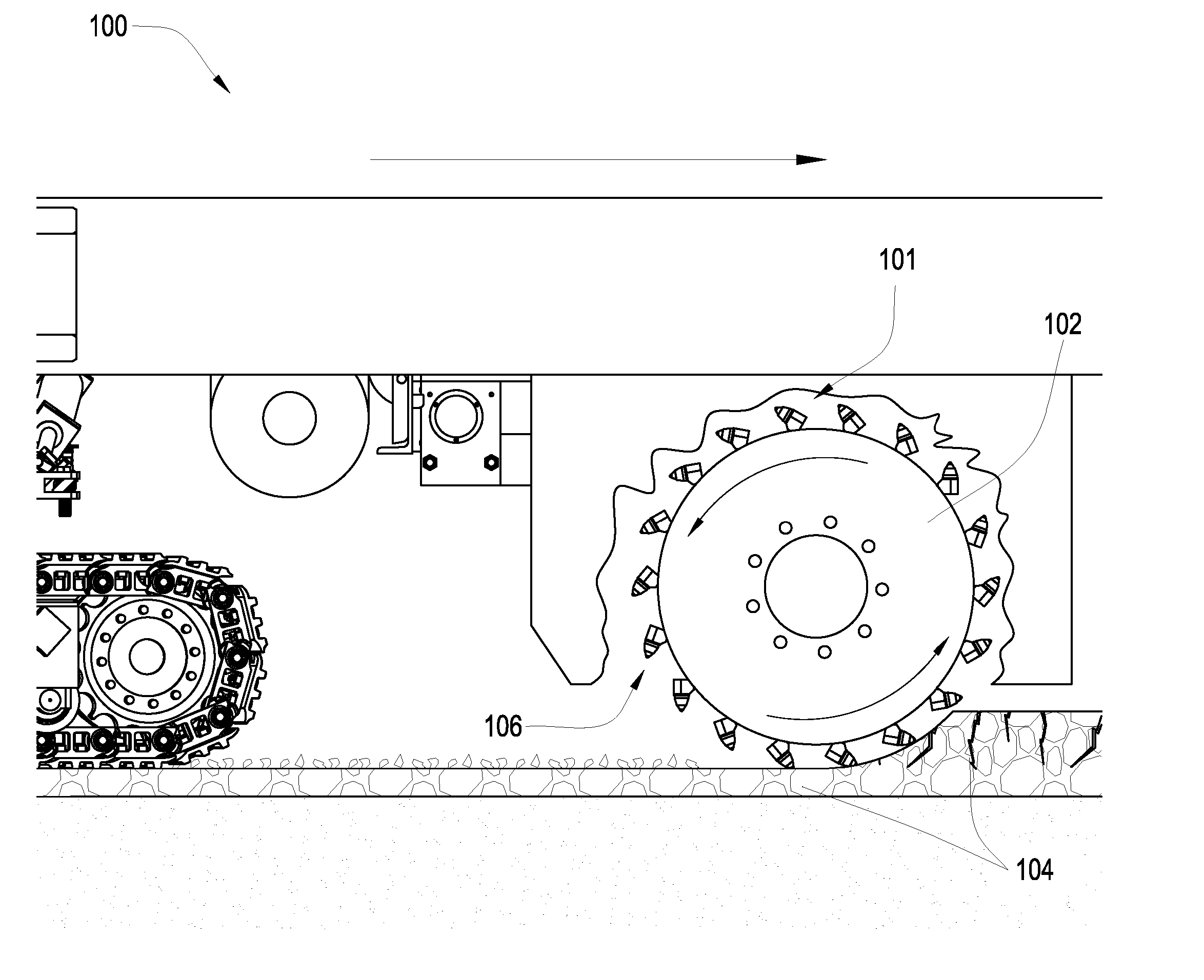

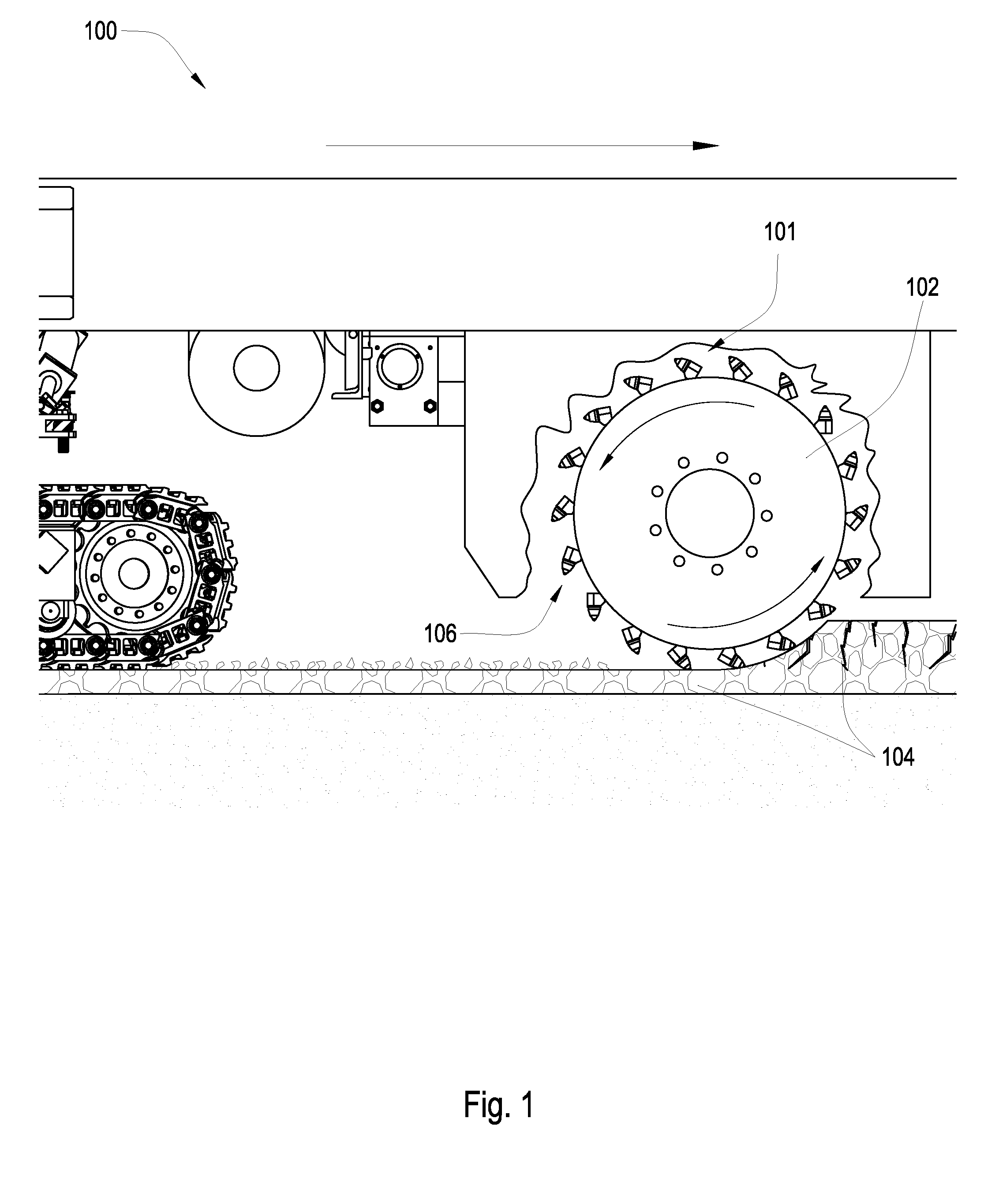

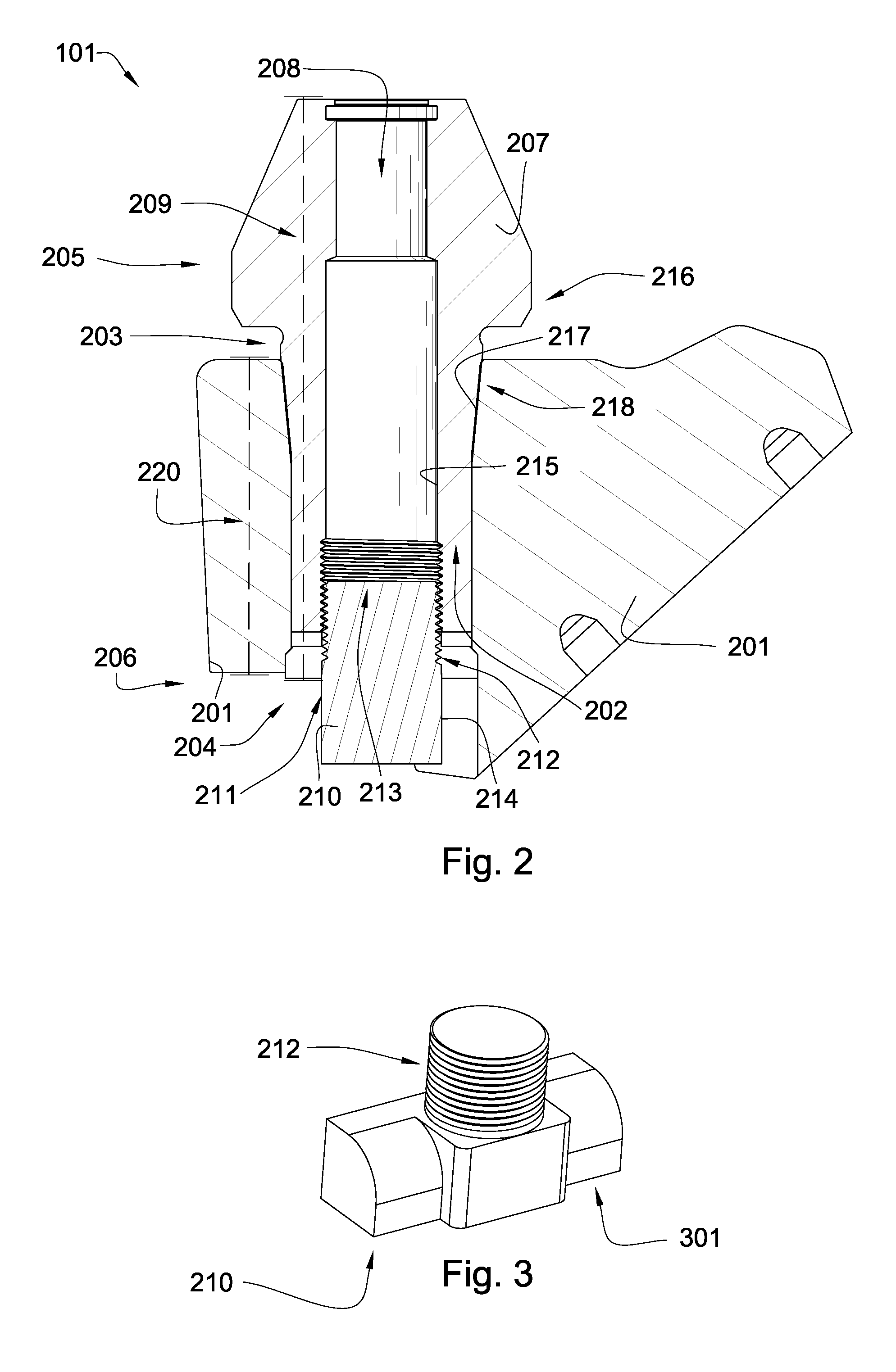

Holder Assembly

In one aspect of the invention, a holder assembly comprises a connection block having a block bore extending from a first opening proximate a first end of the assembly to a second opening proximate a second end of the assembly. The block is adapted for connection to a driving mechanism. An extension element is disposed in the block bore and protrudes from the first opening of the block bore. The extension element comprises a central extension bore having a longitudinal length. An attachment mechanism is disposed within the central extension bore of the extension element and is disposed proximate the second end of the assembly.

Owner:NOVATEK INC

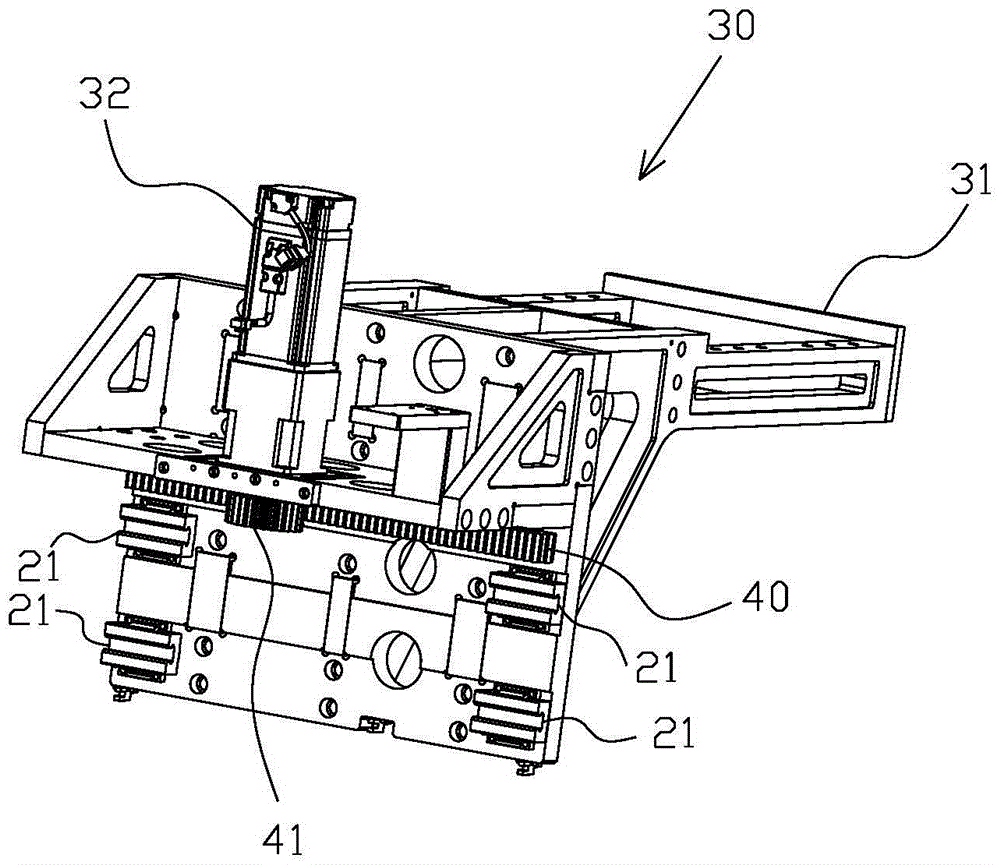

Turning device for assembling tires of heavy duty cars

ActiveCN102381383AMeet the front and back assembly requirementsMeet assembly requirementsVehiclesGeneral assemblyEngineering

The invention relates to a turning device for assembling tires of heavy duty cars, which is necessary non-standard equipment for assembling tires at a tail end station of a tire conveyor line of a general assembly shop and mainly comprises a turning framework, a turning cylinder and a turning clamping arm mechanism. The turning clamping arm mechanism mainly consists of a turning guide rail, a left clamping arm, a right clamping arm, a clamping cylinder, a rotating cylinder and a clamping claw. The turning cylinder drives a rotary shaft to rotate so that the clamping arm mechanism turns between the horizontal direction and the perpendicular direction, the cylinder rotates on the left clamping arm and the right clamping arm, and accordingly requirements on obverse and reverse assembly of tires on rear axles can be met. The clamping cylinder can meet requirements of assembling tires of different sizes, and mixed line production of various types of vehicles is realized. The turning device is reasonable in design, compact in structure, simple and safe in process actions, and applicable to a tire conveying and assembling system with high mechanical degree, labor intensity of workers is reduced, and labor efficiency is improved by 40% at least.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Method for manufacturing re-combined bamboo timber furniture

InactiveCN101879737AAbundant resourcesIncrease profitWood working apparatusSolid woodGeneral assembly

The invention relates to a method for manufacturing re-combined bamboo timber furniture, which is characterized by comprising the following steps of: 1, material proportioning or material cutting; 2, polishing or precision cutting; 3, gluing or veneering decoration; 4, edge precision cutting or irregular milling; 5, tenoning or boring or drilling; 6, molding surface machining; 7, part assembling and machining; 8, surface coating; 9, general assembly; and 10, packaging. The method has the advantages that: the re-combined bamboo timber furniture, which have various types (fixed, detachable, folding and the like) and various structures and are manufactured by using re-combined bamboo timber, replace solid wood furniture, and have the characteristics of high mechanical properties, good textures and colors, abundant material resources, high utilization rate, convenient machining and environmental protection.

Owner:NANJING FORESTRY UNIV

Suction cup surface mounted shelf and planter assembly

Suction Cup Surface Mounted Shelf and Planter Assembly, when temporarily affixed to any appropriate surface, can be used to simulate an indoor greenhouse and / or used as an outdoor window box planter. The Assembly can also be used as a support and containment system for any appropriate item. The Suction Cup Surface Mounted Shelf can be used independently from the planter and serve as a general purpose shelf to hold appropriate items. The Planter can be utilized as a freestanding planter and / or serve as a general purpose container to hold appropriate items.

Owner:REX CHRISTINA ANN

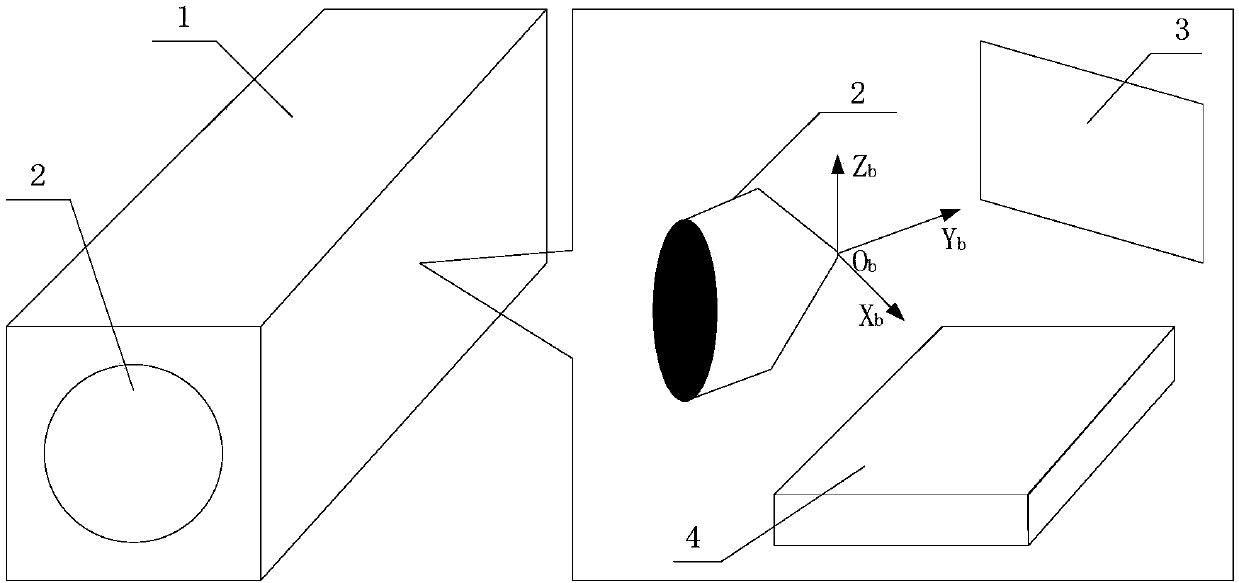

Spacecraft equipment pose information measuring method based on six-freedom-degree laser tracking target

ActiveCN107782293AReduce occupancyImprove on-site measurement efficiencySurveying instrumentsGeneral assemblyTheodolite

The invention discloses a spacecraft equipment pose information measuring method based on a six-freedom-degree laser tracking target. The method is characterized in that the six-freedom-degree laser tracking target and a laser tracker or total station are utilized, and by virtue of relative pose relation of each equipment laser tracking target coordinate system relative to the laser tracker or a total station coordinate system, the measurement of the relative pose relation among different equipment coordinate systems is realized by carrying out coordinate system transmission operation. The method disclosed by the invention can be used for solving the problems that measurement efficiency is low, measurement difficulty is big and many people are needed when multiple theodolites are utilizedfor realizing measurement through collimation and mutual alignment currently, convenience; the flexibility and measurement efficiency of spacecraft general assembly field equipment mounting accuracy measurement are greatly improved on the basis of guaranteeing relatively high angle measurement accuracy; and spacecraft development demands are effectively met.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

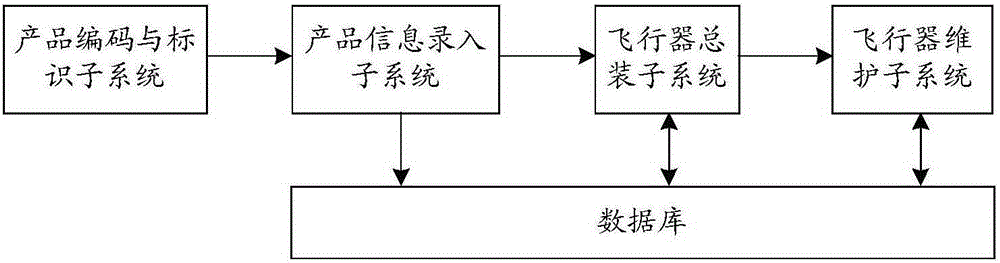

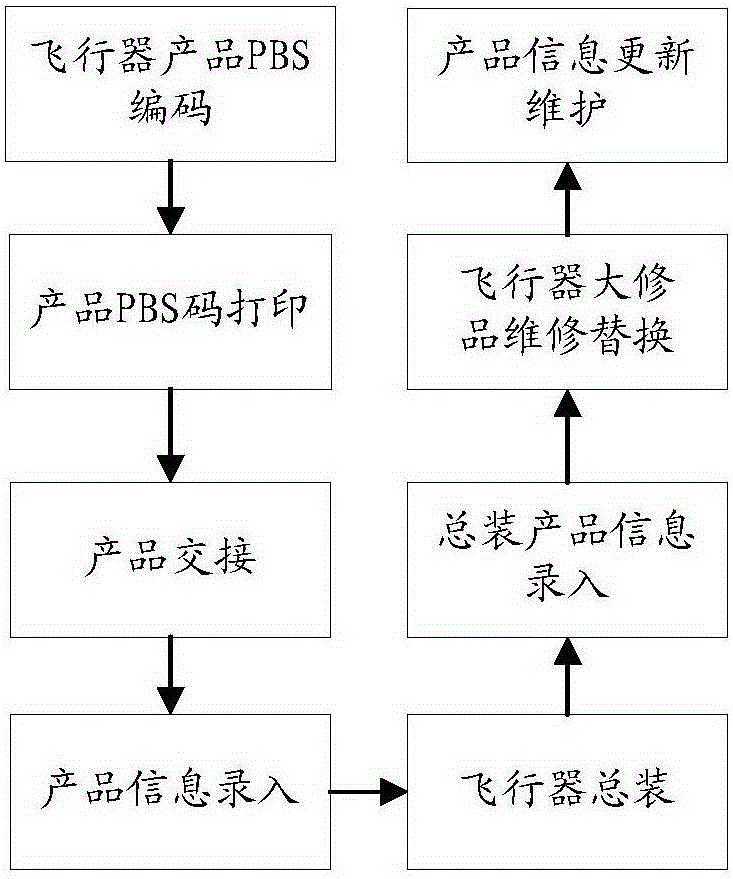

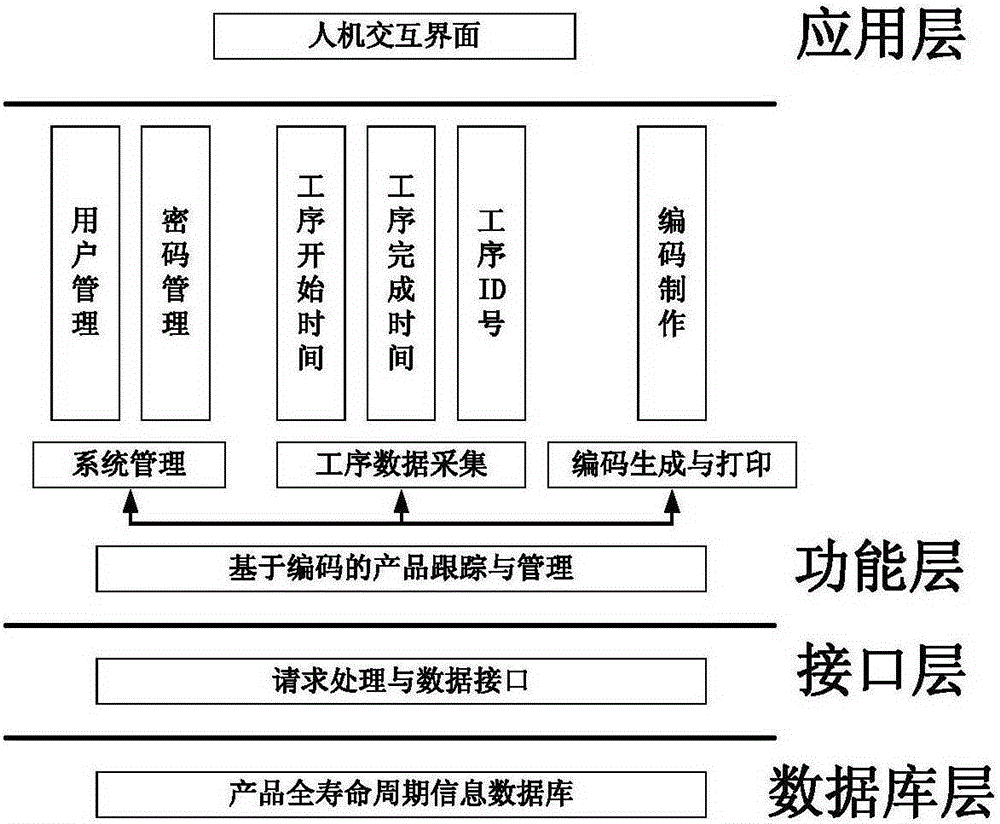

Aircraft full-life-cycle configuration management system

ActiveCN105260816AEasy to storeEasy to testResourcesManufacturing computing systemsGeneral assemblyFull life cycle

The invention provides an aircraft full-life-cycle configuration management system. The aircraft full-life-cycle configuration management system comprises a product coding and identifying subsystem, a product information entering subsystem, an aircraft general assembly subsystem, an aircraft maintenance subsystem and a database. The aircraft full-life-cycle configuration management system compiles identification codes for aircraft products, records information data of the all processes of product warehousing, aircraft generally assembling, component maintenance and product replacing, and realizes the configuration state management in the full life cycle of the aircraft. The system manages all the products by means of identification codes, so that uniform management of the aircraft in processes of product warehousing, generally assembling, maintenance and replacing is facilitated, the technical states and maintenance information of all aircraft products are recorded, and state querying and problem tracing are convenient.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

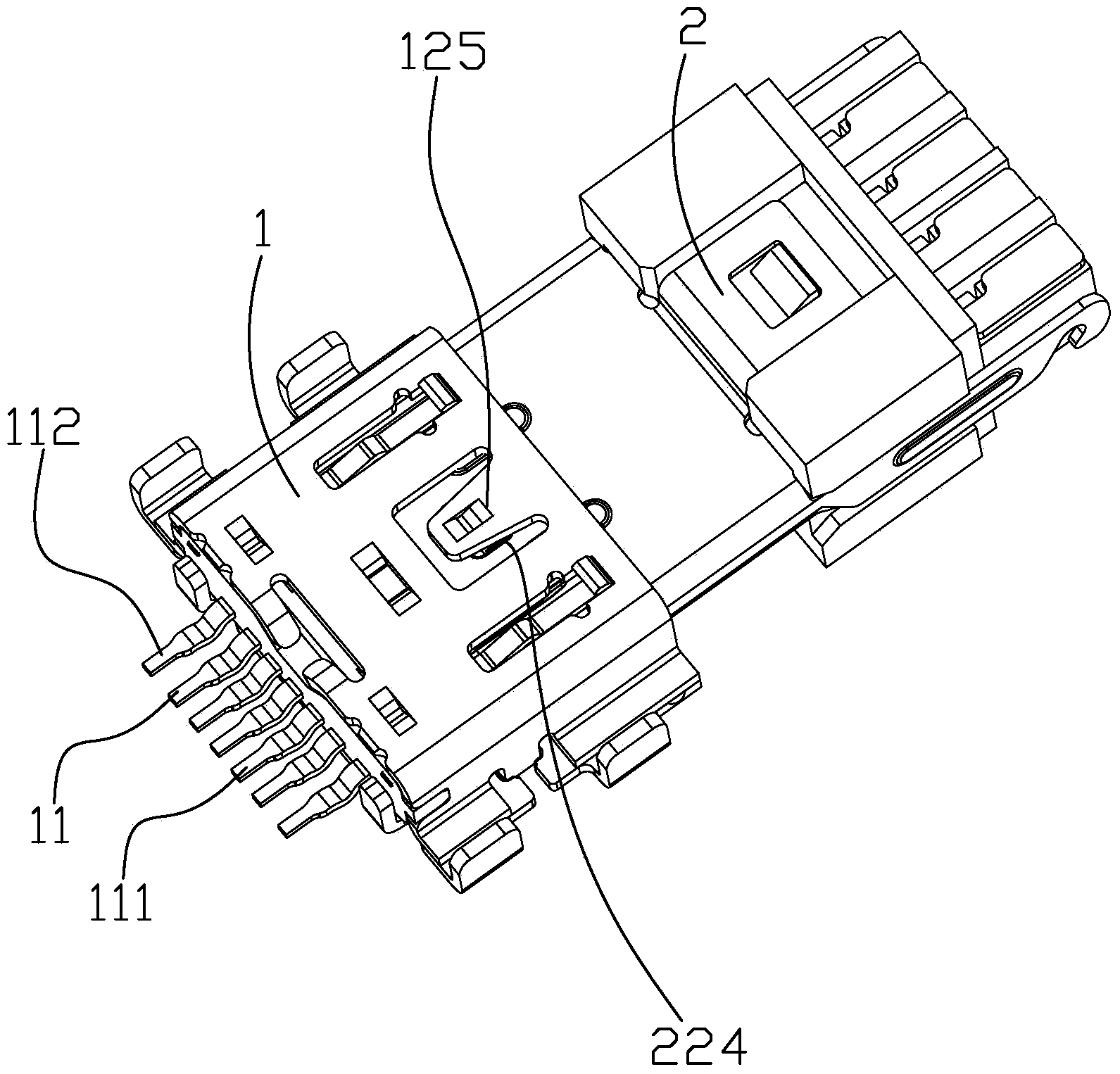

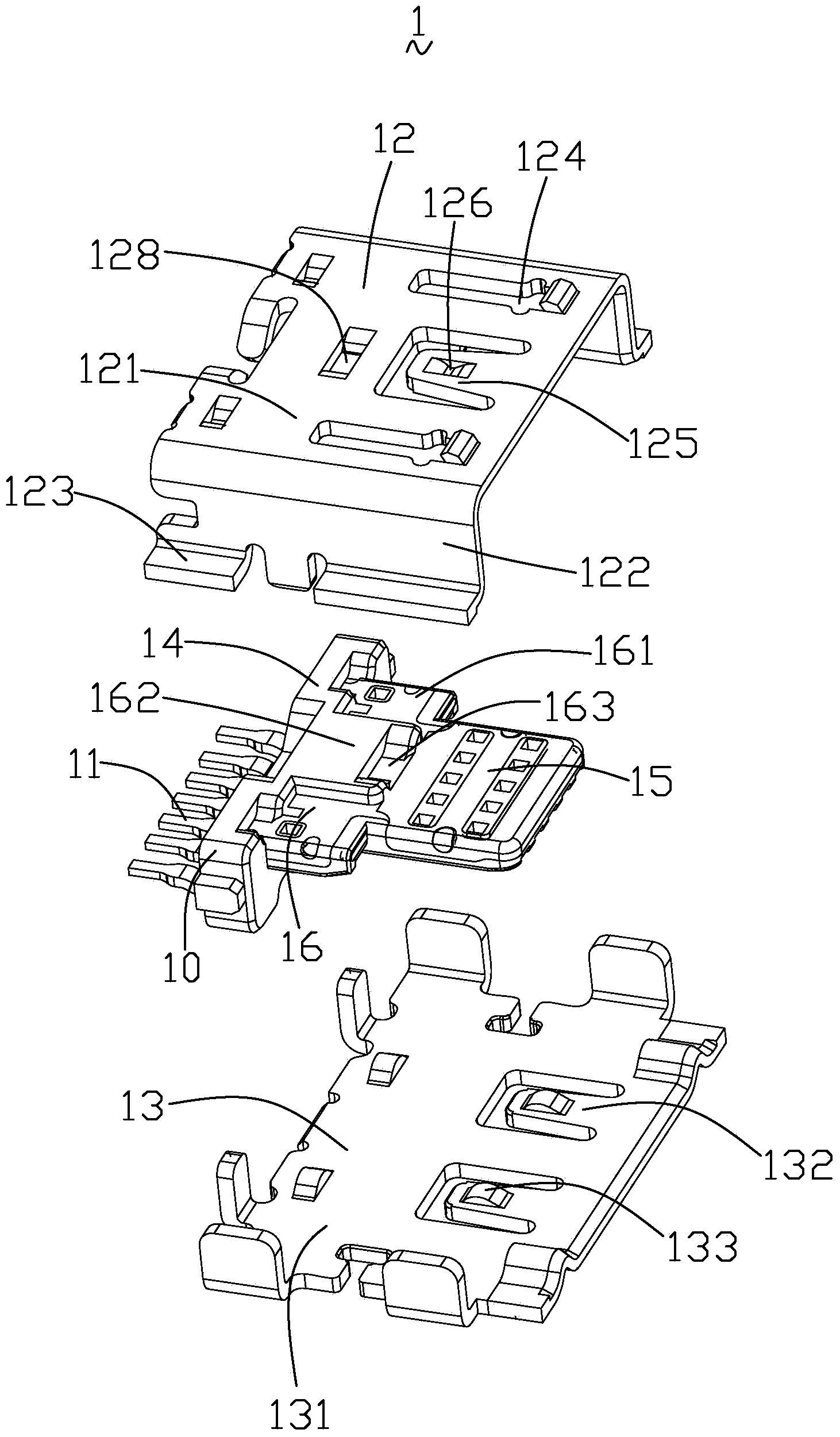

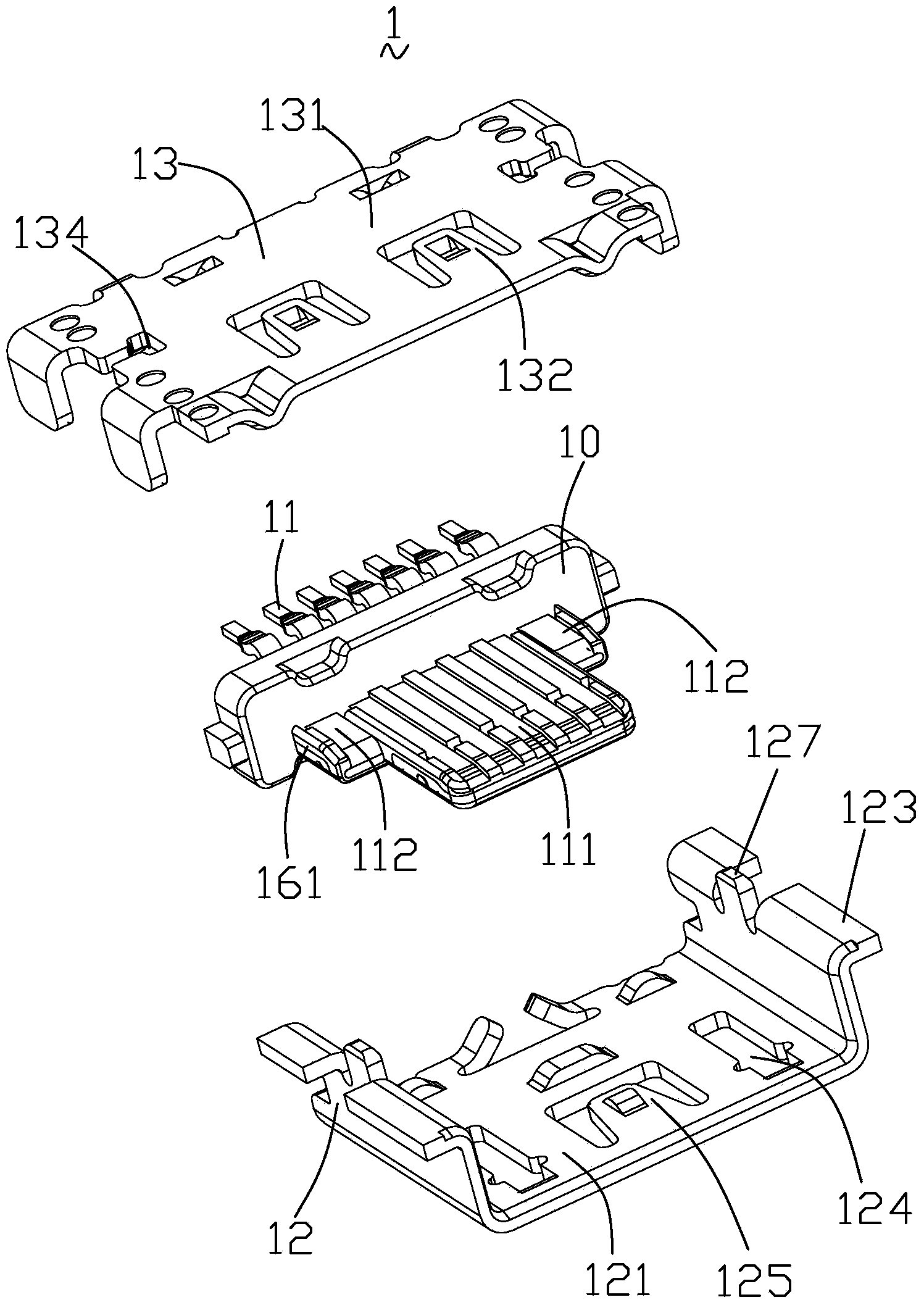

General assembly type seven-pin USB (Universal Serial Bus) socket, plug and connector assembly

ActiveCN103811889ACompatible and snap fitImprove compatibilityCoupling contact membersGeneral assemblyEngineering

A general assembly type seven-pin USB (Universal Serial Bus) socket comprises a socket body, seven socket terminals and a cover body; the seven socket terminals are integrally formed in the socket body; the cover body coats the periphery of the socket body; the socket body comprises a base portion, a first tongue plate and a second tongue plate; the first tongue plate is formed by forward extension from the base portion; the second tongue plate is formed by forward extension from the first tongue plate; the horizontal bilateral sides of the first tongue plate extend outward to form two side portions; the socket terminals comprise five conventional socket terminals and two additional socket terminals; the five conventional socket terminals penetrate the base portion and the first tongue plate to extend to the second tongue plate; the two additional socket terminals penetrate the base portion and extend to the two side portions of the first tongue plate; the seven-pin USB socket is compatible with the abutting connection type improved seven-pin USB plug and a conventional five-pin USB plug. The general assembly type seven-pin USB socket can be compatible with the different plugs.

Owner:SHENZHEN EVERWIN PRECISION TECH

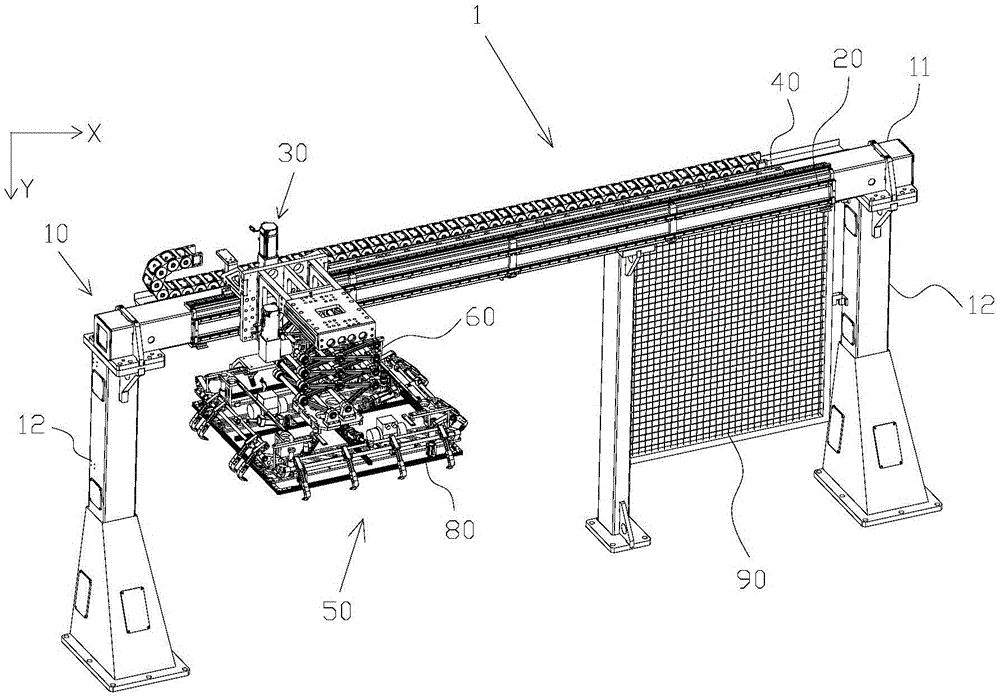

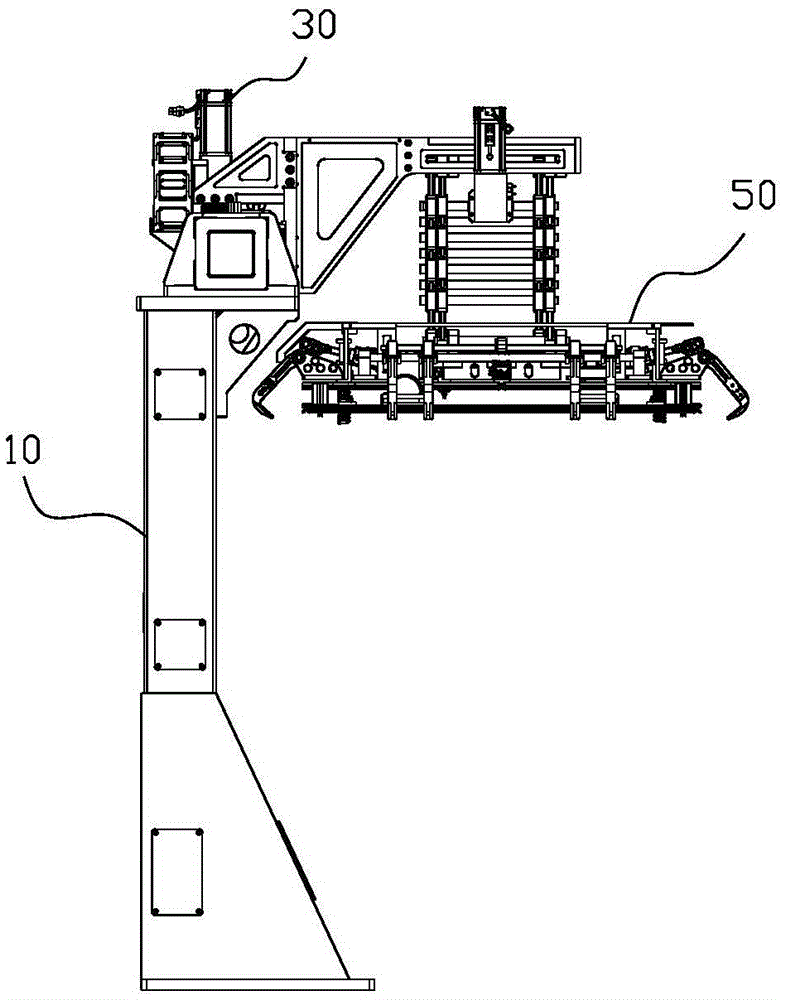

Automatic carrying device for air conditioner compressor stack separation boards and automatic compressor carrying system

ActiveCN105417181AImprove work efficiencyReduce manufacturing costConveyorsStacking articlesGeneral assemblyControl system

The invention provides an automatic carrying device for air conditioner compressor stack separation boards and an automatic compressor carrying system. The automatic carrying device for the air conditioner compressor stack separation boards comprises a supporting mechanism, a drive mechanism connected with the supporting mechanism in a sliding manner and a stack separation board carrying mechanism, wherein the stack separation board carrying mechanism comprises a lifting mechanism and a grabbing mechanism and the lifting mechanism controls the grabbing mechanism to ascend and descend. The automatic compressor carrying system comprises the automatic carrying device for the air conditioner compressor stack separation boards, an air conditioner compressor carrying robot and a control system. Firstly, the separation boards on an air conditioner stack are carried away through the automatic carrying device for the air conditioner compressor stack separation boards, a compressor on the stack is carried to a to-be-assembled position through the air conditioner compressor carrying robot, human intervention is avoided in the whole carrying process of the air conditioner compressor, all the working procedures for carrying the air conditioner compressor from the stack to an assembly line can be finished, and the air conditioner general assembly work efficiency is greatly improved.

Owner:ZHUHAI ZHIXIN AUTOMATIC TECH CO LTD

Industrial production management system based on two-dimensional code and RFID label technology

InactiveCN105956773ARecord in timeRealize real-time trackingResourcesSensing by electromagnetic radiationProduction lineManagement unit

The invention relates to the technical field of information management, in particular to an industrial production management system based on two-dimensional code and RFID tag technology. Including system management unit, PCB board production management unit, final assembly production management unit and warehouse entry and exit management unit; the system management unit, PCB board production management unit, final assembly production management unit and warehouse entry and exit management unit are all connected to the control host; according to the whole machine and The two-dimensional code and RFID label attached to the PCB can realize real-time tracking of the model, production date, production line and other information of the whole machine and main substrates, and record production information, customer information and other information in time; Monitoring and management can find bottlenecks in production, quickly count and query data, and provide basis for production scheduling and order placement; for unqualified products, it can also quickly get the source of the problem and provide support for management.

Owner:叶江鹏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com