Production process simulation optimization method based on digital twinning

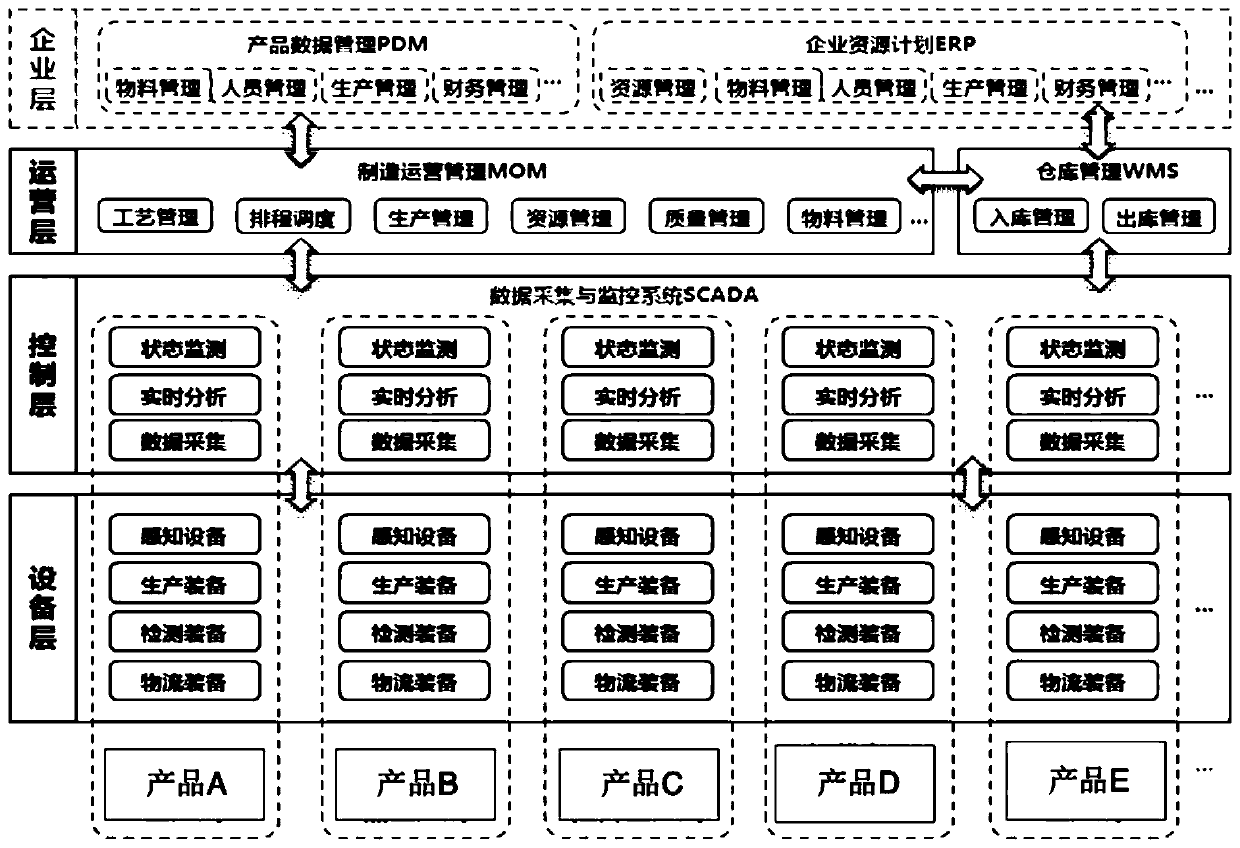

A technology of production process and optimization method, applied in the field of digital twins, can solve the problems of insufficient refinement of production planning and scheduling, weak process control and traceability, and weak dynamic response ability, etc., to achieve the promotion of specialization of final assembly process equipment The effect of improving the level of production logistics, improving the intelligent level of production logistics, and enhancing the ability of station assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

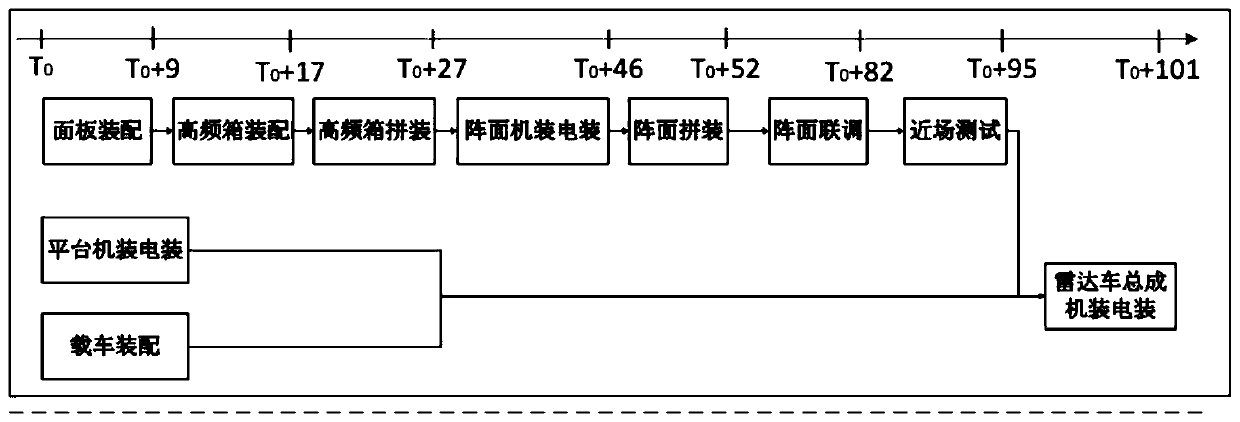

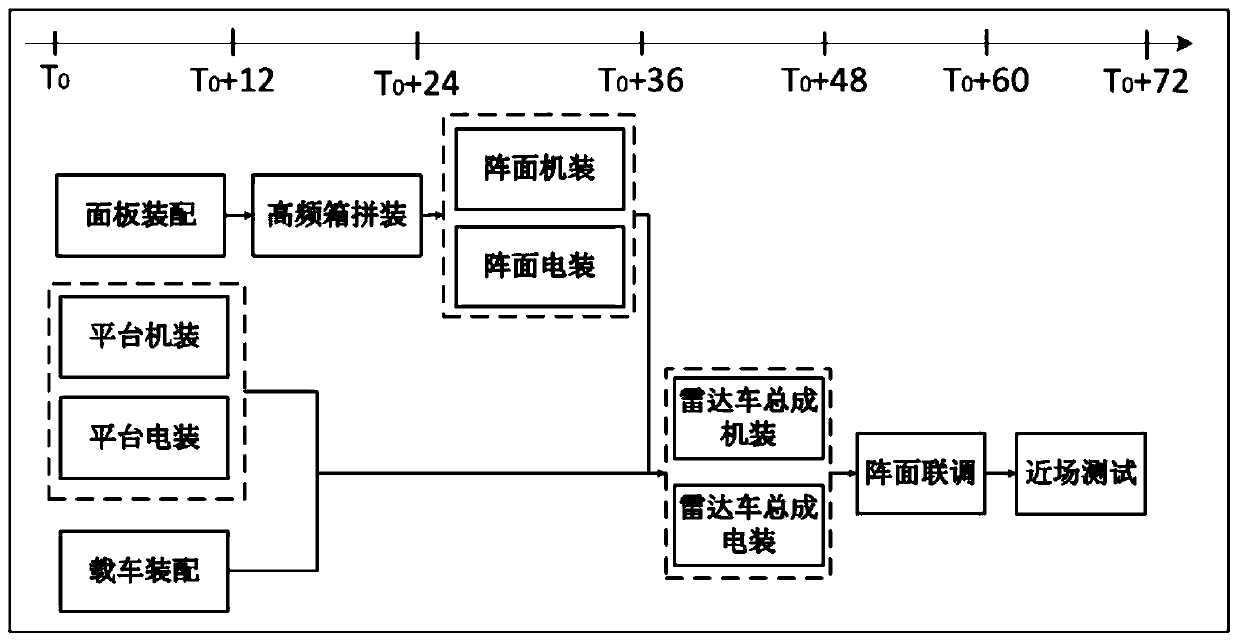

[0039] Functions such as operating status, key station operating status, assembly process monitoring, production process simulation and optimization, etc., realize effective management of the workshop operation process, comprehensively improve the management and control capabilities of the intelligent workshop, and calculate the actual assembly process through real-time simulation of the workshop operating status. According to the progress deviation of each work step, the final assembly process is adjusted according to the work step deviation, the process flow is further optimized, the station beat is balanced, and the assembly capacity of the station is improved to improve the efficiency of the final assembly.

[0040] Adjust the final assembly process according to the deviation of the working steps, further optimize the process, balance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com