Patents

Literature

115 results about "Production logistics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production Logistics. It makes sense for the industry to have full order books, since these ensure turnover growth and spur on expected profits. In general, full order books represent the acceptance of a means of production or a finished product by the market. However, they present a huge challenge in terms of production logistics.

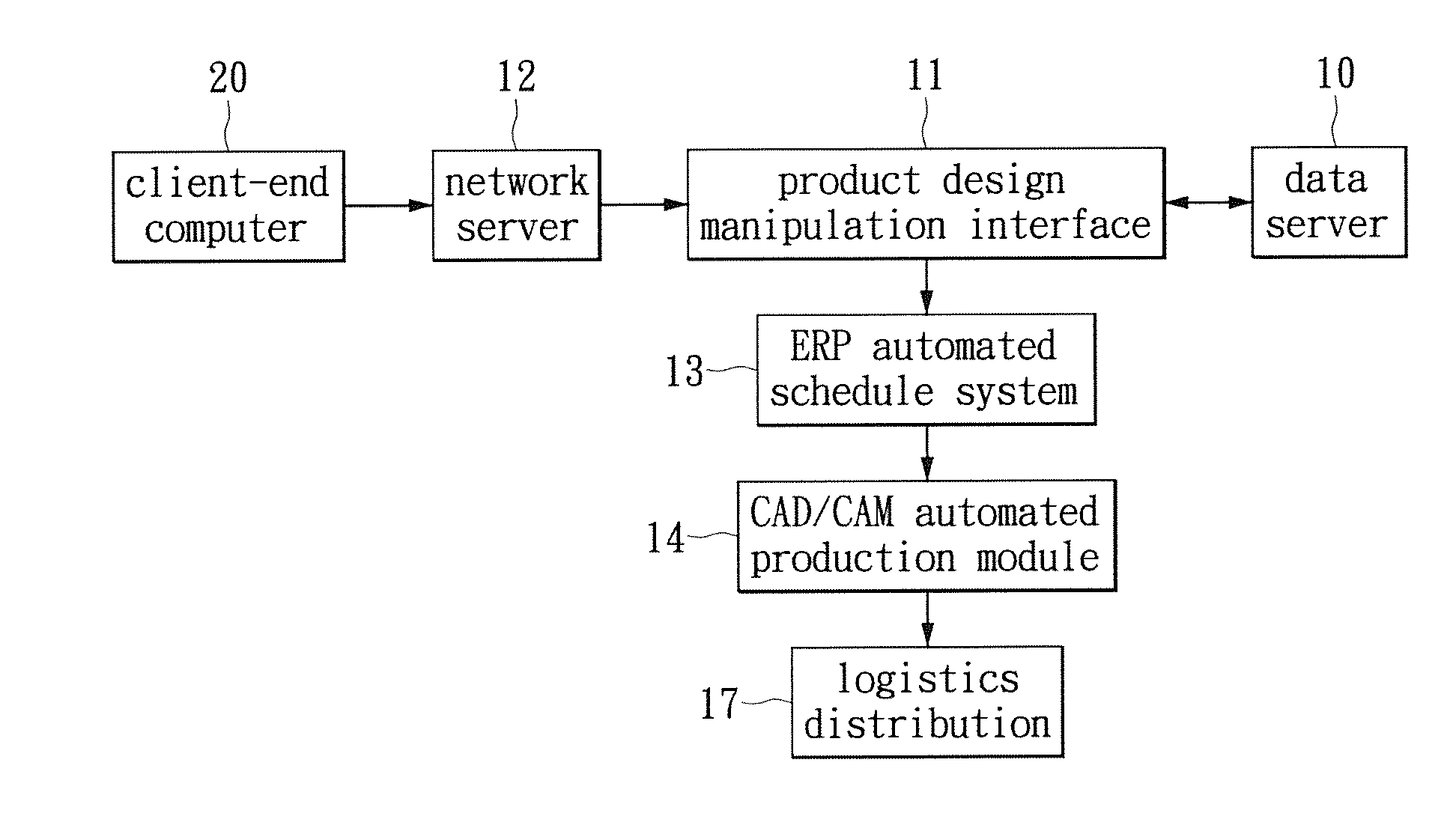

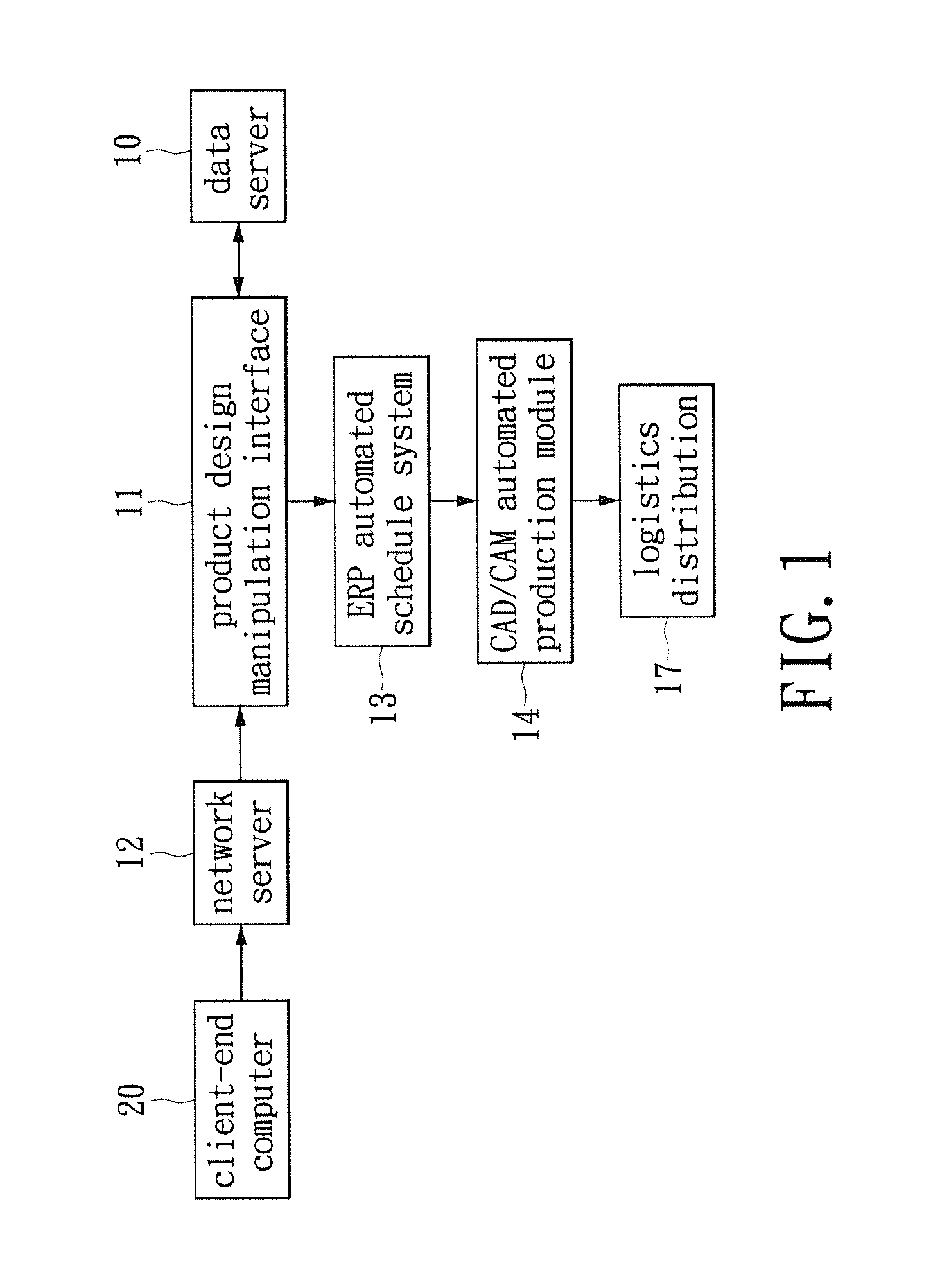

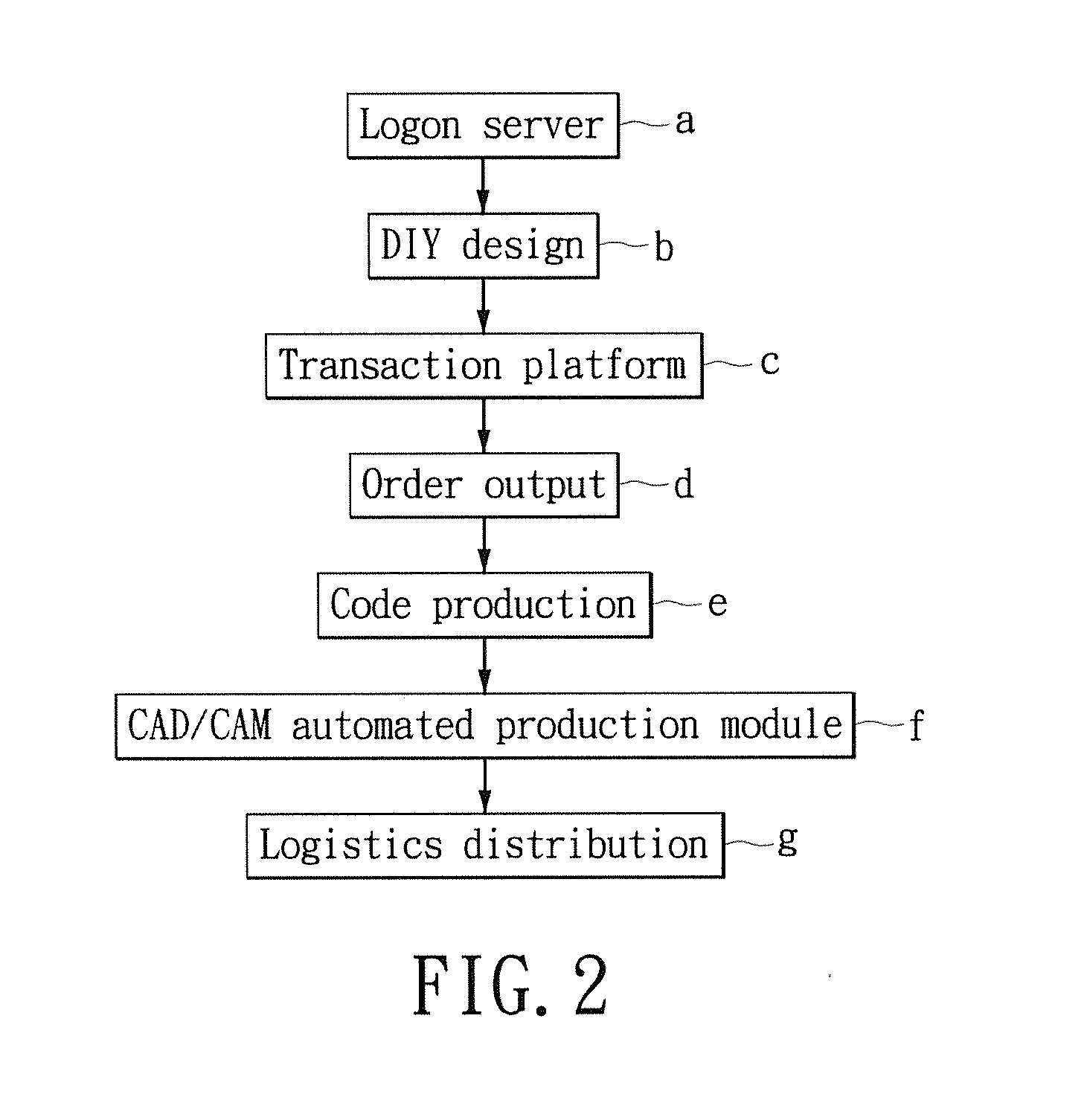

System and method for remotely customized ordering commodity's design and manufacture combined with a network

InactiveUS20130138529A1Deep and fast ordering experienceReduce riskBuying/selling/leasing transactionsLogisticsDistribution systemProgram planning

A system and method for remotely customized ordering commodity's design and manufacture combined with a network are provided by the present invention. The method includes: a client computer manipulates a product design manipulation interface to access data in a data server and performs commodity's design; a transaction platform pays directly to form an order; an ERP automated production schedule system issues the production instructions and the operation guidance automatically utilizing the order; CAD / CAM automated production modules perform production; a logistics distribution system directly delivers commodities to consumers. Through the above-mentioned method, low-cost operation is really realized, and a kind of new business model of zero inventory is achieved by make-to-order.

Owner:HOU I SHUN

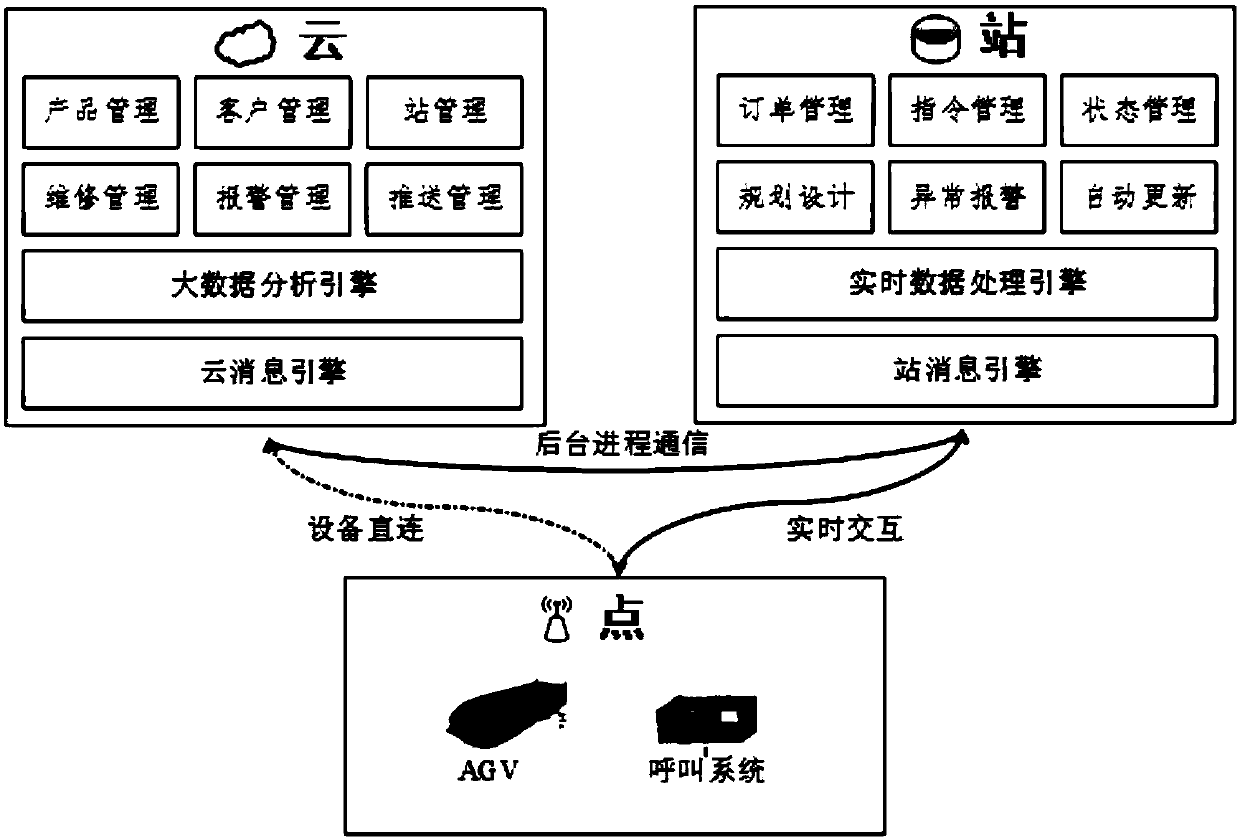

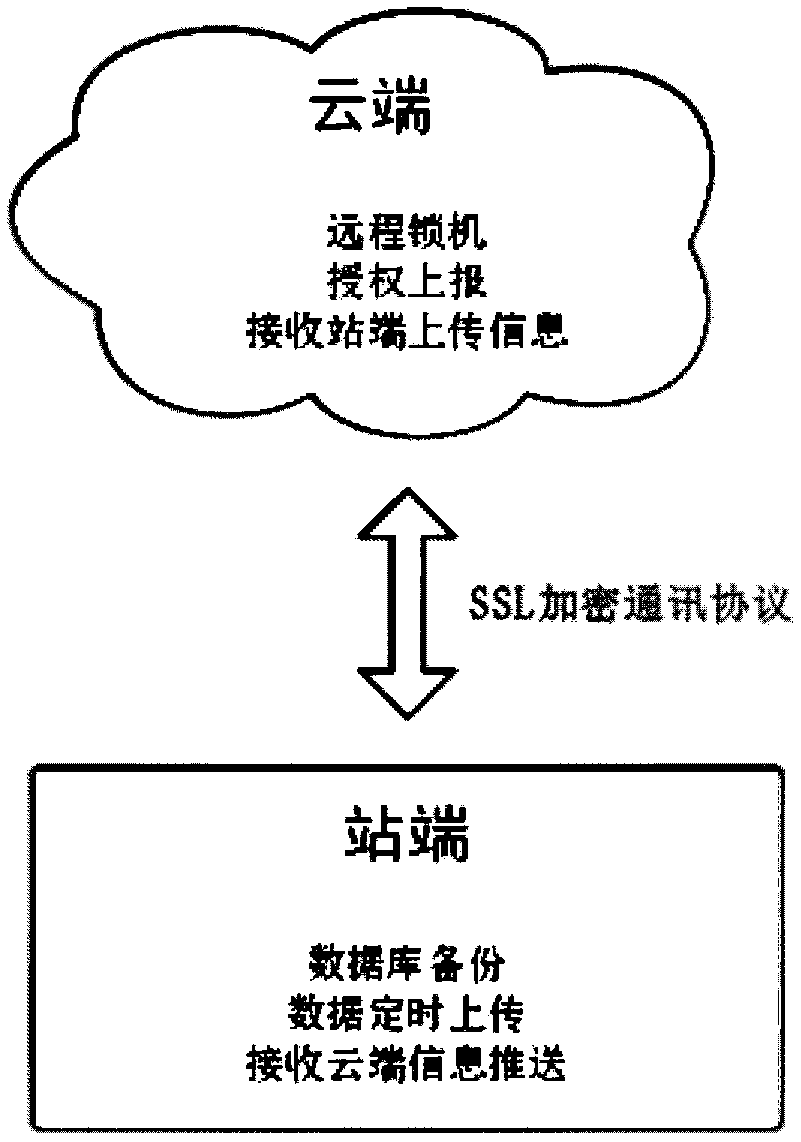

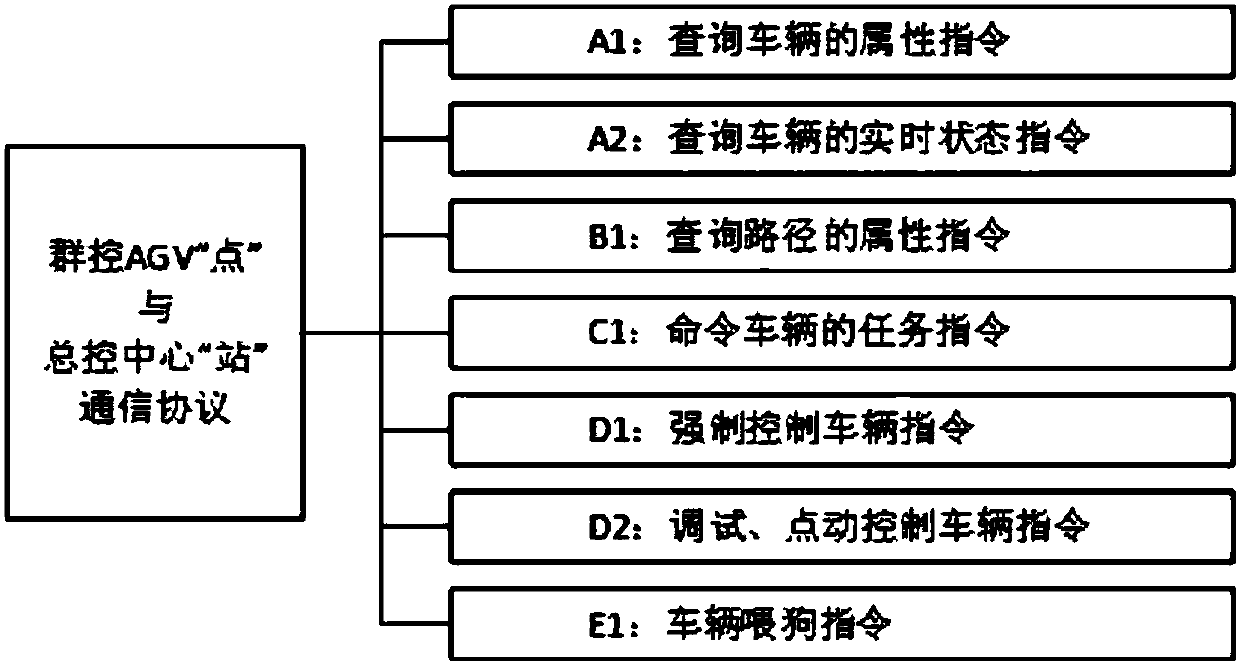

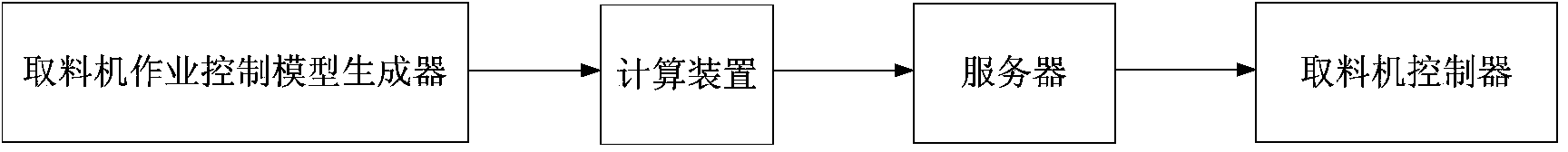

Production logistics intelligent distribution AGV system based on cloud-station-point architecture, and application thereof

PendingCN107705045ARealize distributed management and controlTo achieve the purpose of data centralizationResourcesLogisticsProduction logisticsLogistics management

The present invention relates to a production logistics intelligent distribution AGV system based on a cloud-station-point architecture, and the application thereof. The system comprises a cloud platform, a station end and a point end. The cloud platform comprises a ring network and a cloud server which is used for operating a data analysis and decision system; the station end comprises a plurality of AGV scheduling subsystems, and each AGV scheduling subsystem comprises at least one station server responsible for AGV vehicle scheduling in a corresponding plant area; and the point end comprises a plurality of AGV vehicles under a plant area corresponding to each AGV scheduling subsystem, the plurality of AGV vehicles carries out real-time signal transmission with the station end through the wireless AP and the switch, and the station end is connected with the cloud platform through the wireless communication module for data transmission. The technical scheme of the present invention achieves the purposes of distributed control and data centralization of a plurality of AGVs, achieves the unified management, scheduling, monitoring and analysis of the plurality of AGVs, and solves theproblems that the traditional system cannot implement cross-site, cross-workshop and cross-plant AGV control and data centralization, so that effective integration of data is really realized.

Owner:SHANDONG UNIV +2

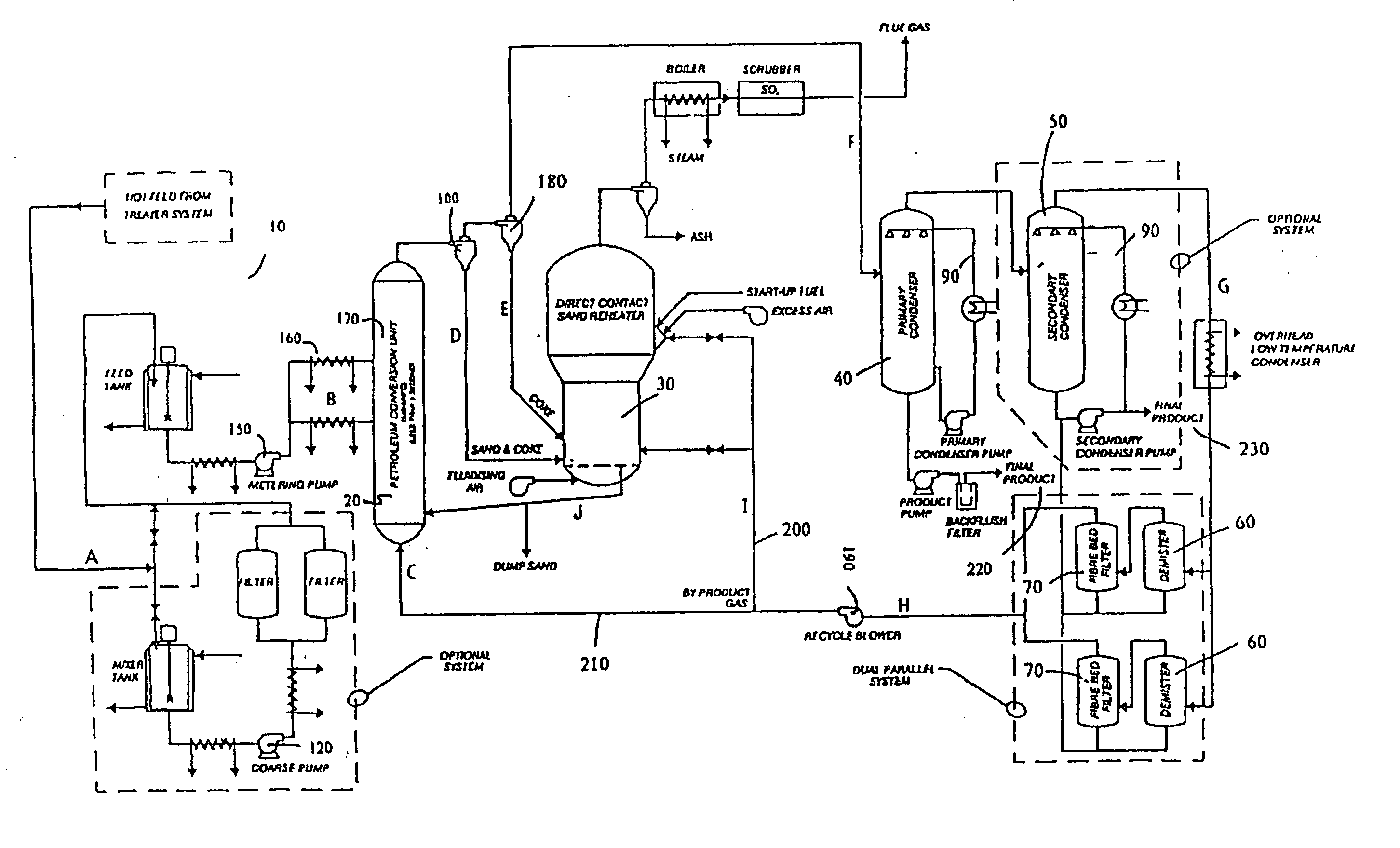

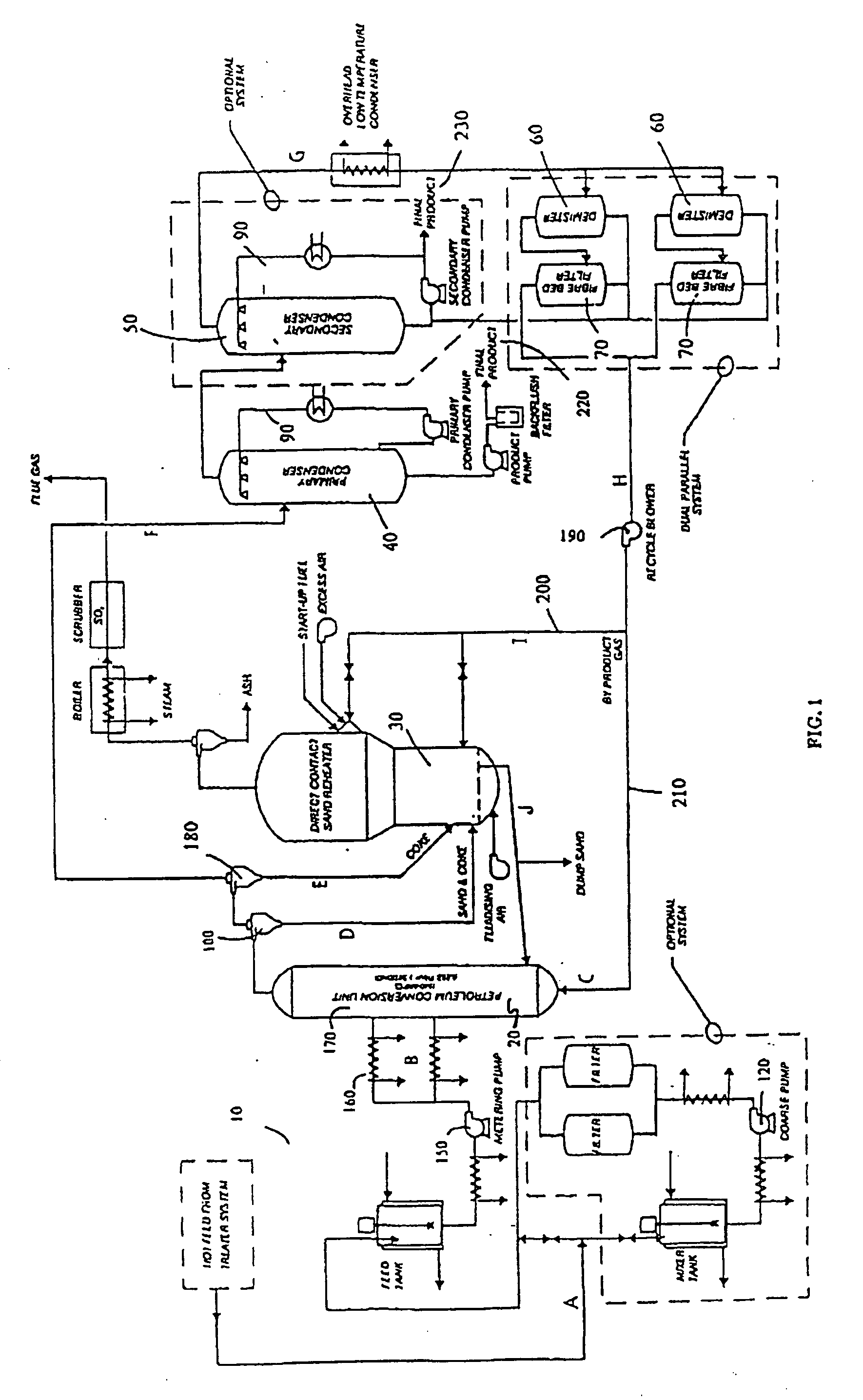

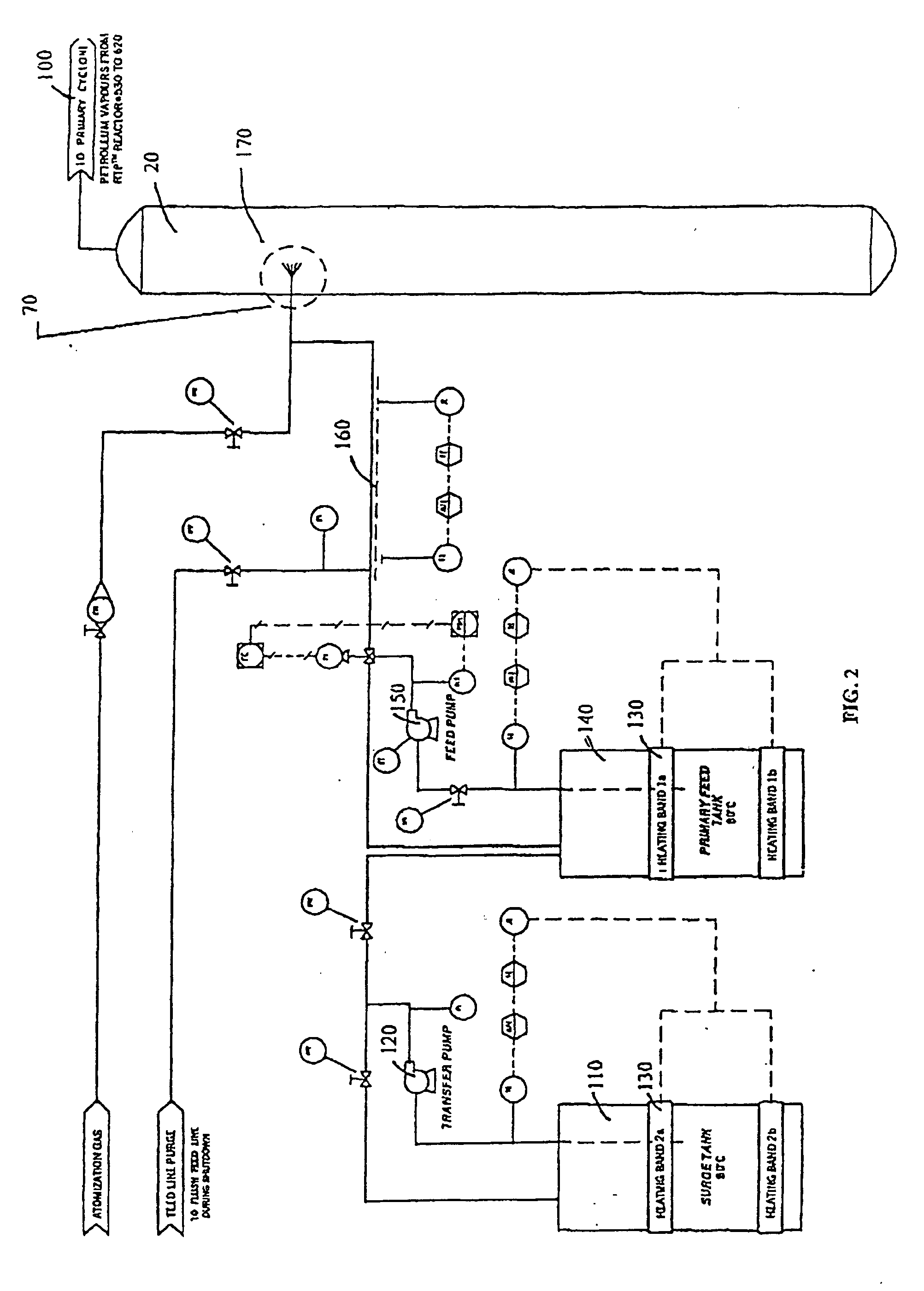

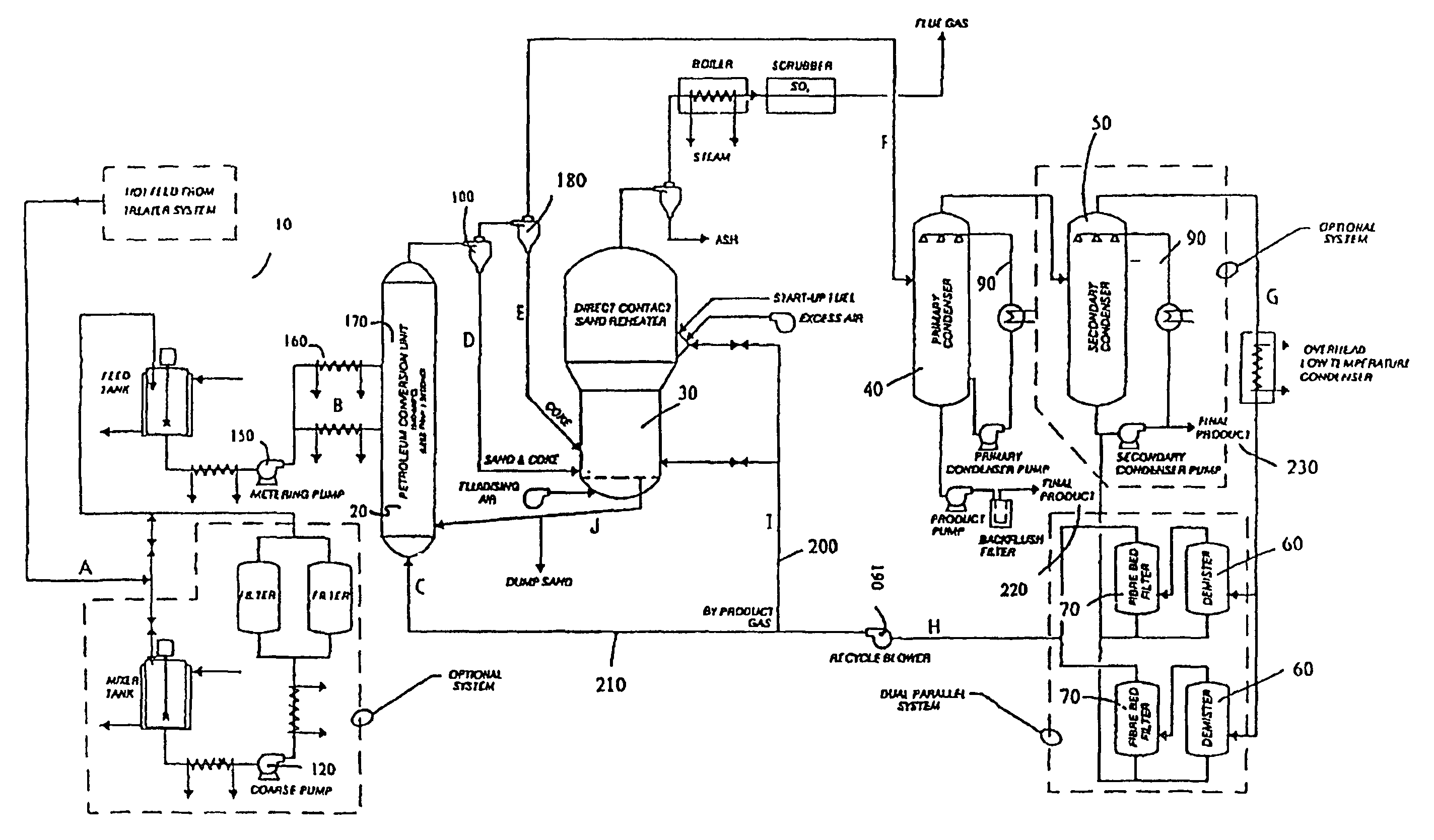

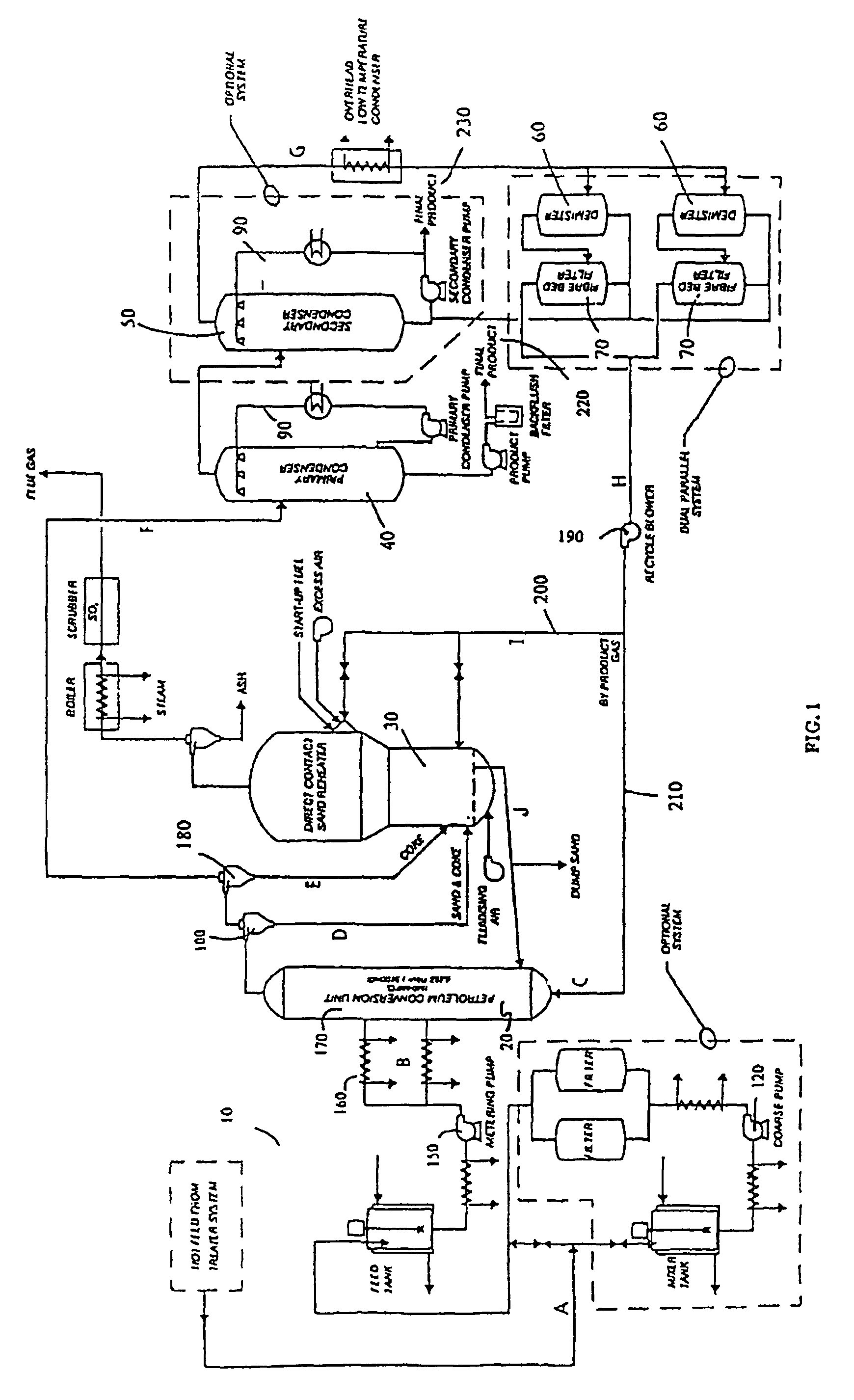

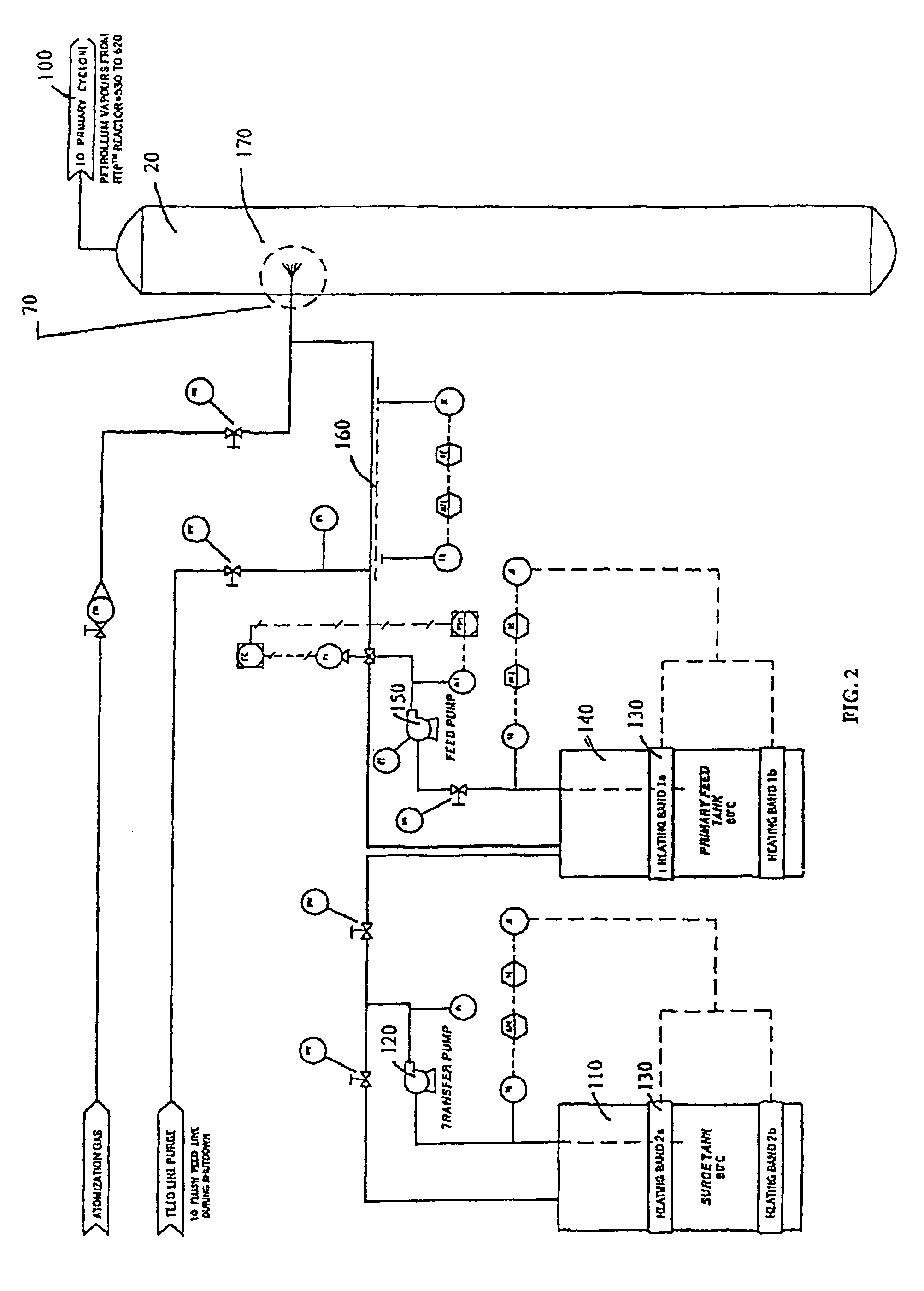

Products produced from rapid thermal processing of heavy hydrocarbon feedstocks

InactiveUS20070170095A1Upgrade and reduce viscosityRapid heat treatmentThermal non-catalytic crackingLiquid organic insulatorsParticulatesLiquid product

The present invention is directed to the upgrading of heavy hydrocarbon feedstock that utilizes a short residence pyrolytic reactor operating under conditions that cracks and chemically upgrades the feedstock. The process of the present invention provides for the preparation of a partially upgraded feedstock exhibiting reduced viscosity and increased API gravity. This process selectively removes metals, salts, water and nitrogen from the feedstock, while at the same time maximizes the yield of the liquid product, and minimizes coke and gas production. Furthermore, this process reduces the viscosity of the feedstock in order to permit pipeline transport, if desired, of the upgraded feedstock with little or no addition of diluents. The method for upgrading a heavy hydrocarbon feedstock comprises introducing a particulate heat carrier into an upflow reactor, introducing the heavy hydrocarbon feedstock into the upflow reactor at a location above that of the particulate heat carrier so that a loading ratio of the particulate heat carrier to feedstock is from about 15:1 to about 200:1, allowing the heavy hydrocarbon feedstock to interact with the heat carrier with a residence time of less than about 1 second, to produce a product stream, separating the product stream from the particulate heat carrier, regenerating the particulate heat carrier, and collecting a gaseous and liquid product from the product stream. This invention also pertains to the products produced by the method.

Owner:IVANHOE HTL GASOLINEEUM

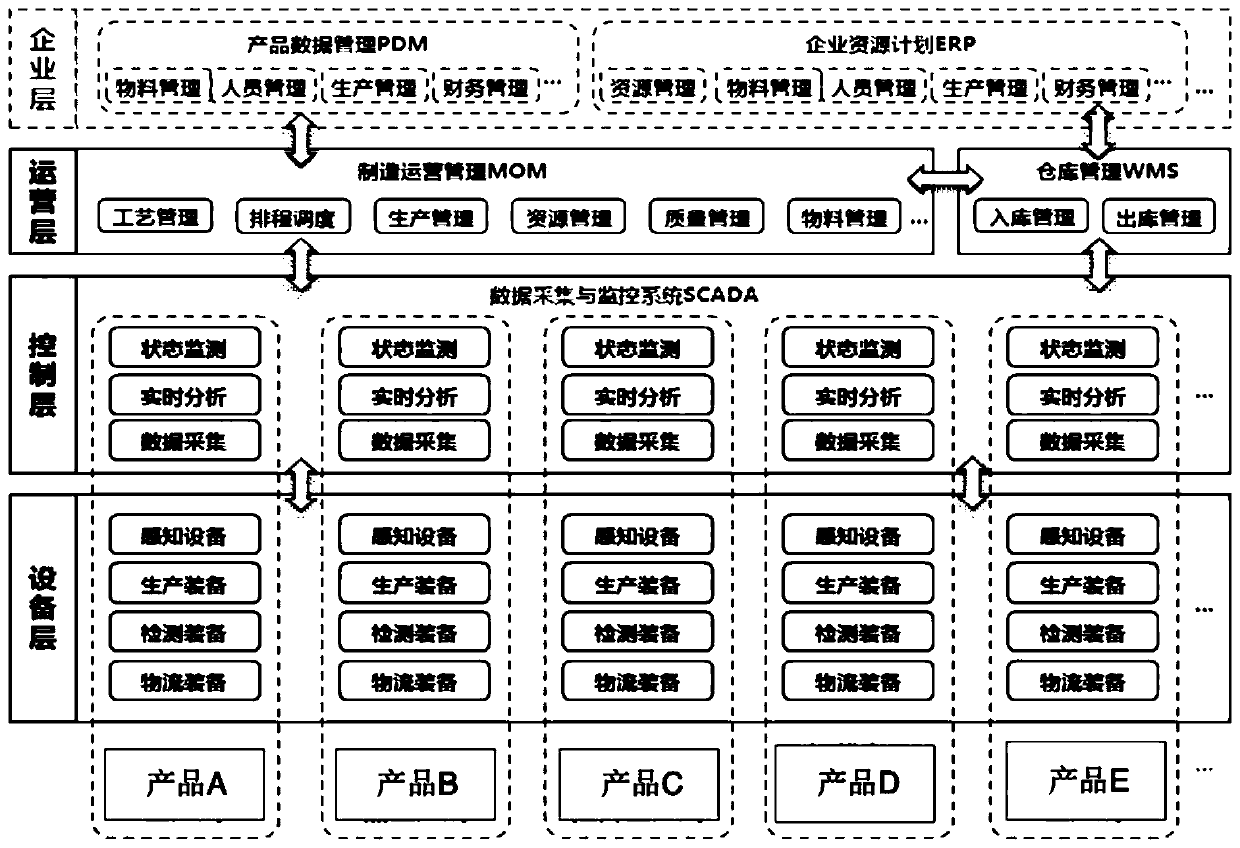

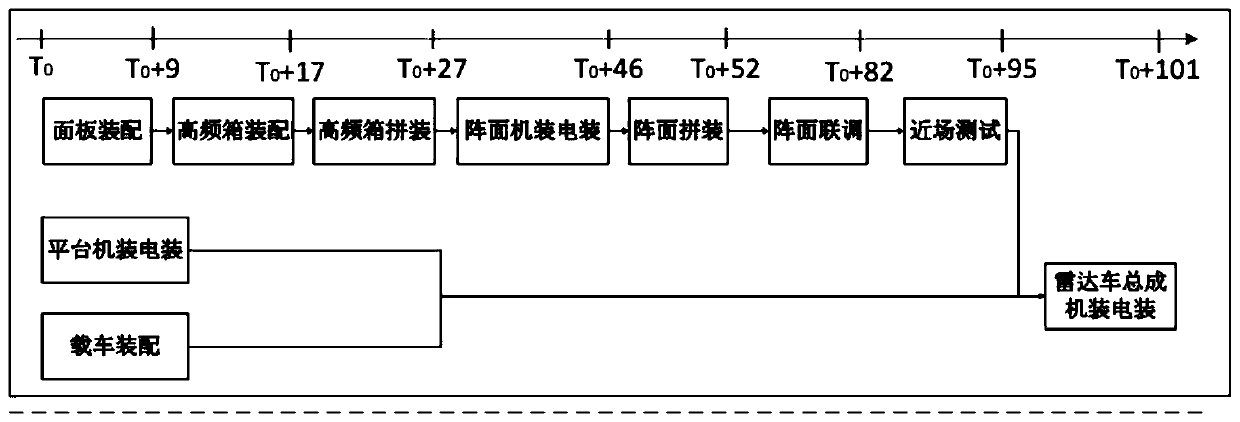

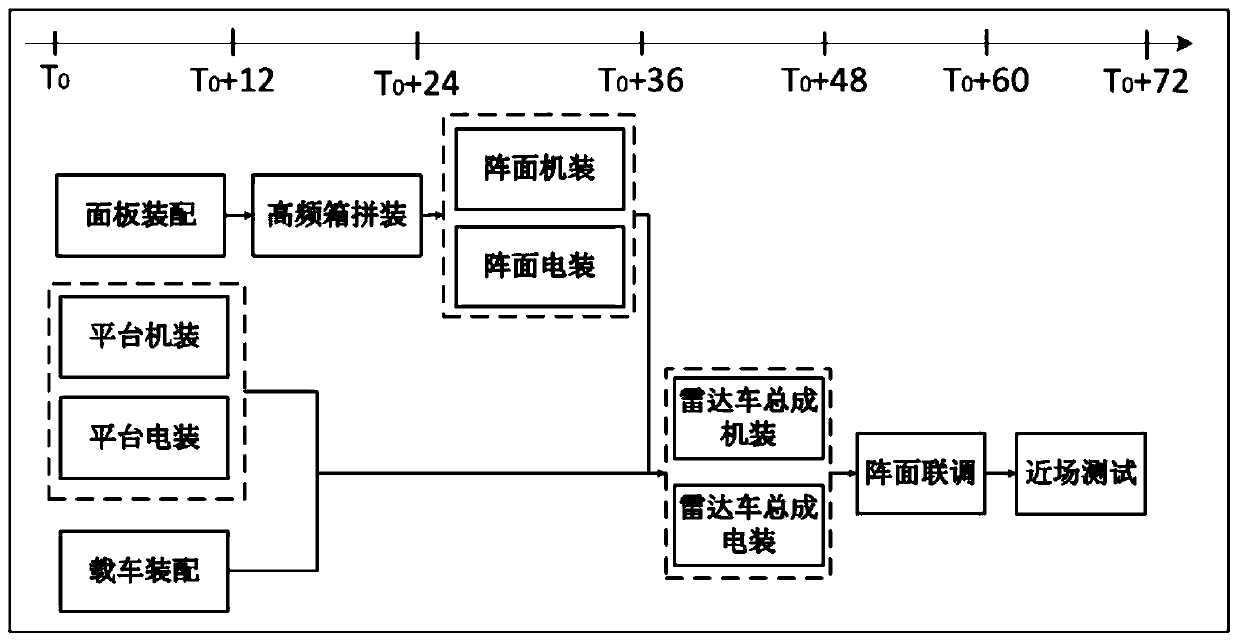

Production process simulation optimization method based on digital twinning

PendingCN111539583AReal-time display of usageDisplay usage in real timeForecastingDesign optimisation/simulationProcess equipmentProduction logistics

The invention discloses a production process simulation optimization method based on digital twinning based on the flexible production requirements of multiple varieties, small batch and variable paces. A manufacturing operation management system and a data acquisition and control system based on big data are constructed; the intelligent level of production logistics and the professional level ofgeneral assembly process equipment are improved, a general assembly intelligent workshop with a batch product pulsation production line and a developed product intelligent general assembly unit as main bodies is formed, and more optimization decisions are provided for physical entities through information fusion and data interaction between virtual models and the physical entities.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

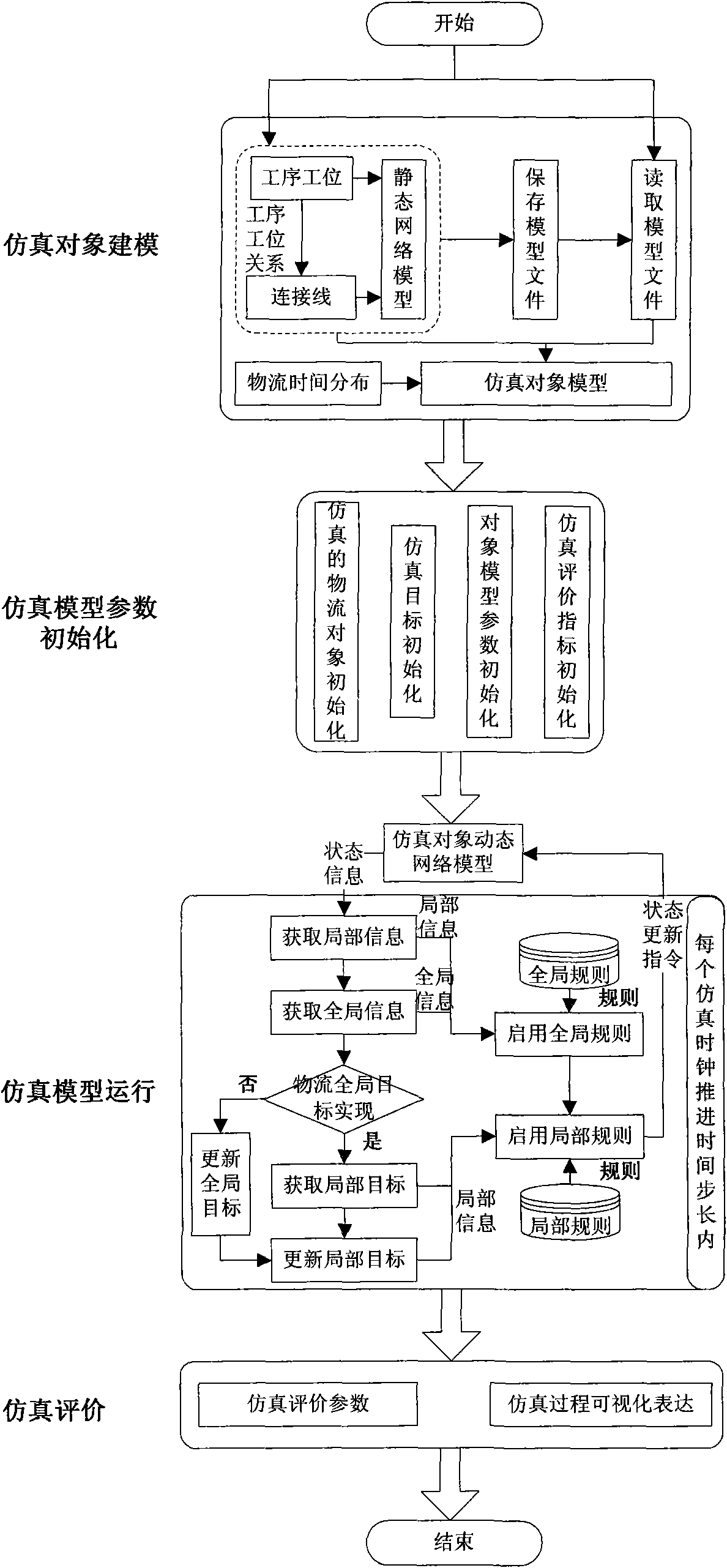

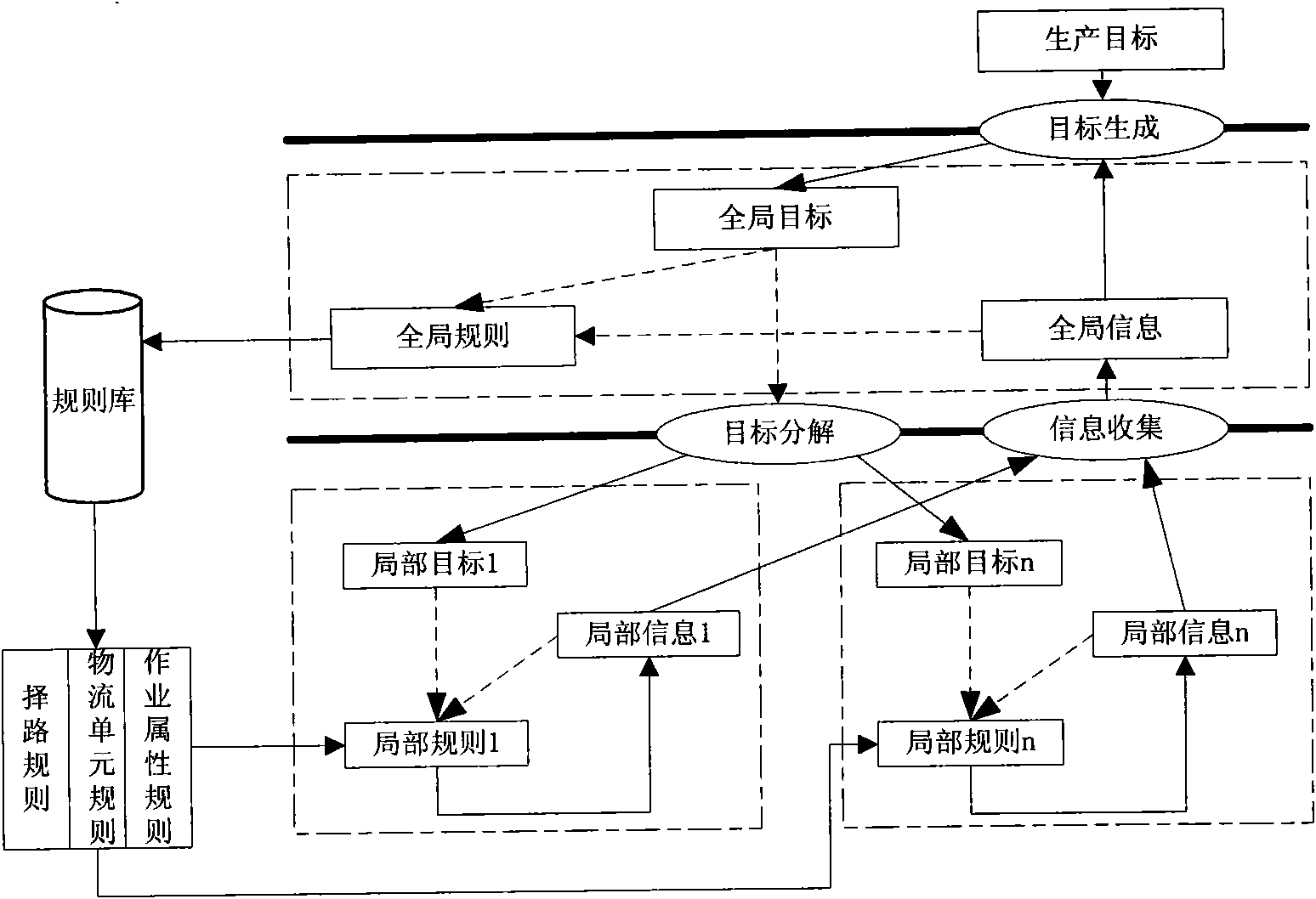

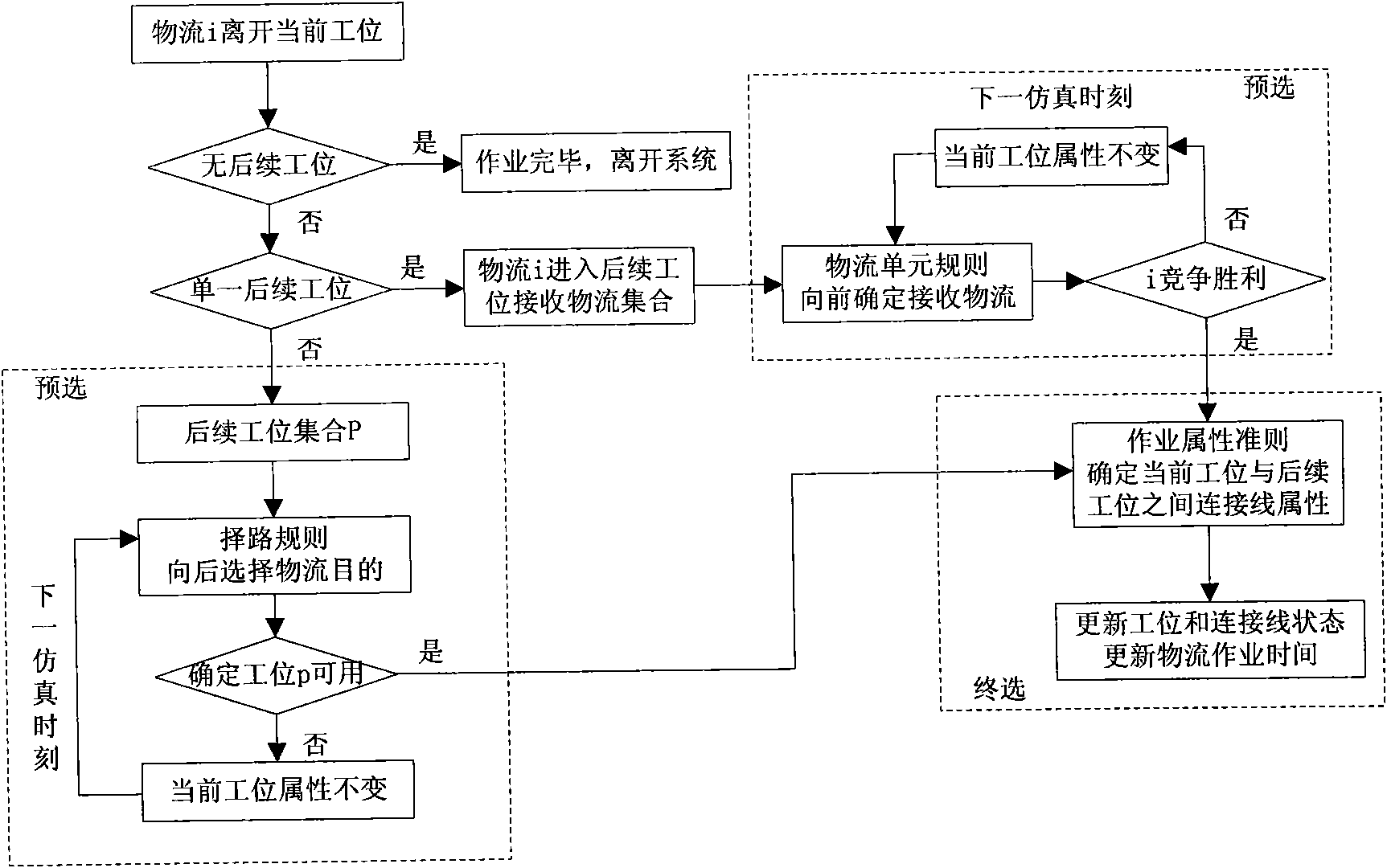

Material flow simulation optimization method in steel making-continuous casting production based on target guiding

InactiveCN101789096ARealize analysisSteelmaking-Continuous Casting Production Process OptimizationResourcesManufacturing computing systemsProduction logisticsProcess design

The invention provides a material flow simulation optimization method in steel making-continuous casting production based on target guiding. In the method, in order to meet continuous casting of a continuous casting machine, by the guiding action of the target, material flow objects are guided for simulating, evolving and operating in a production process network; with the help of the organic integration of global and local targets, rules and information, the self-organization evolution of the simulation process under traction and constraint of other organizations is realized, thereby obtaining simulation optimization results meeting actual targets and constraint conditions; and simultaneously, models can express and reflect the random characters of the operating time of each production procedure link in the production process, and evaluate the simulation results. The method can be used for optimizing production process design in steel making-continuous casting production, assisting in optimizing production operation, realizing the analysis on the rationality of the production process, establishing production planning, and assisting production scheduling.

Owner:CHONGQING UNIV

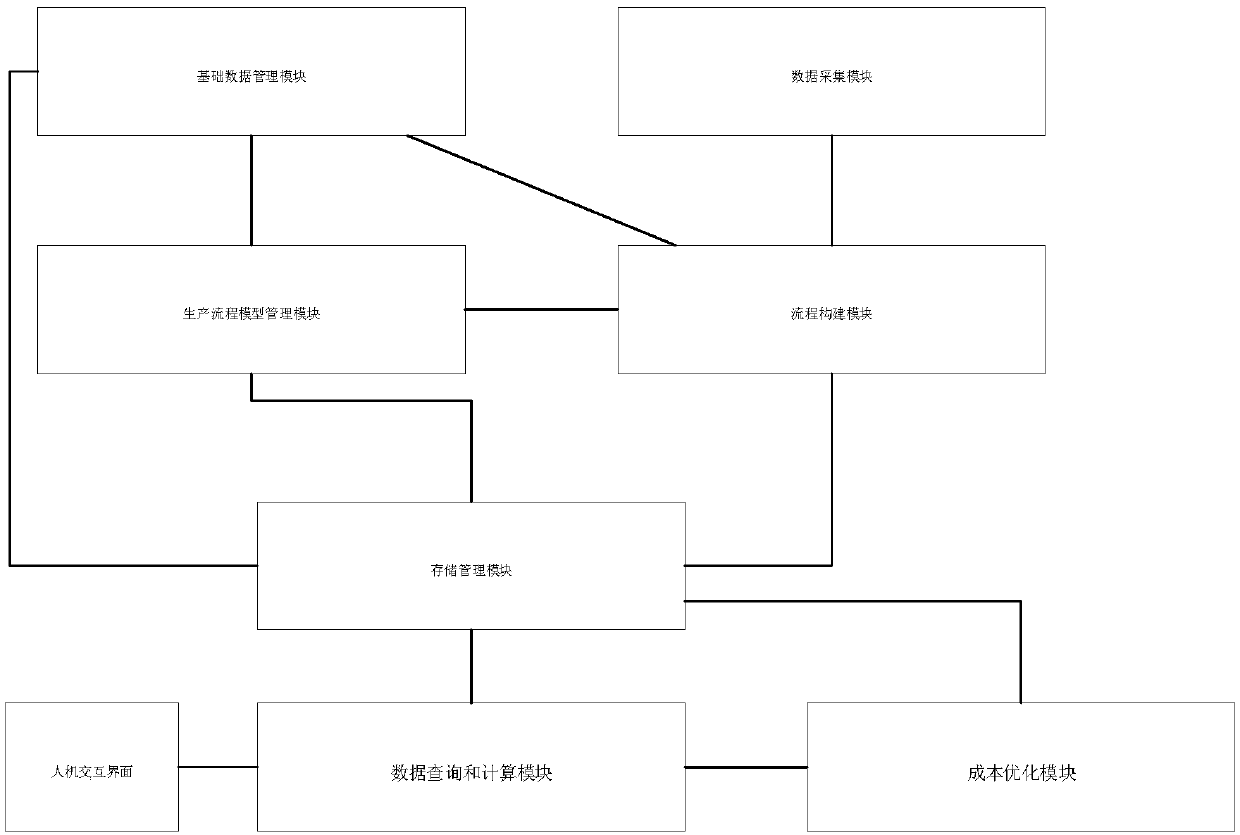

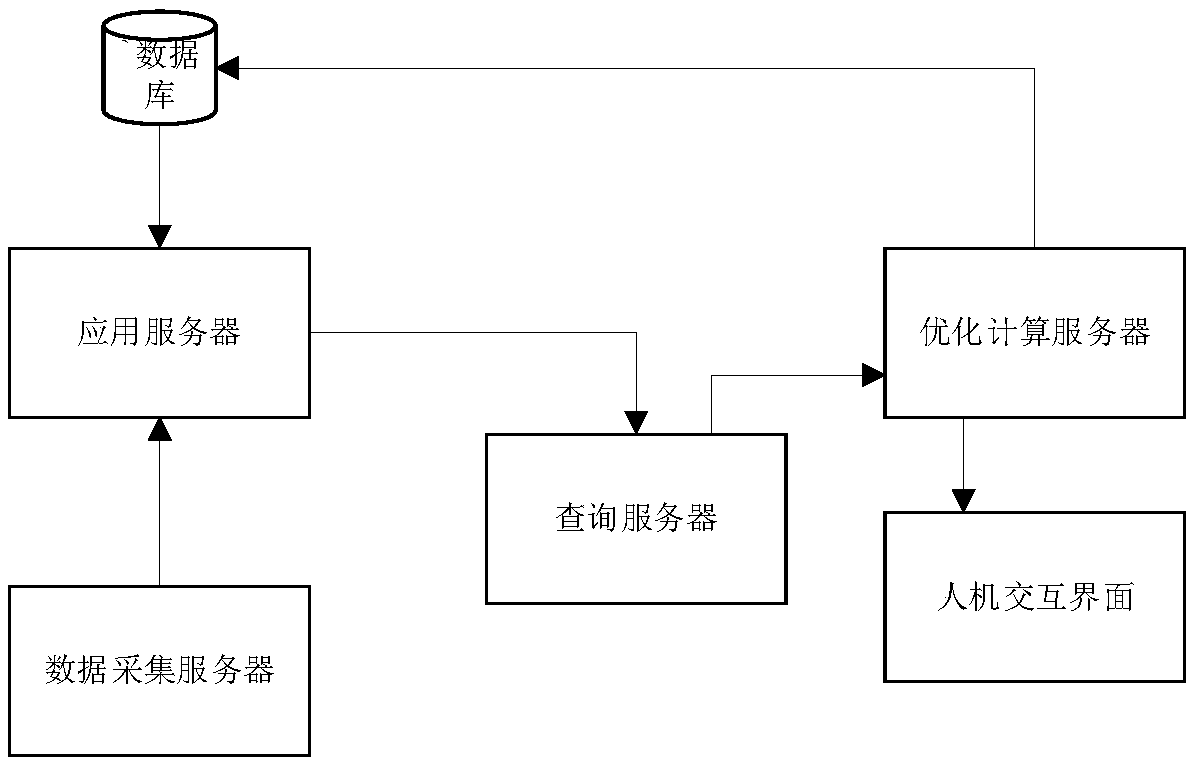

A production process modeling and product data tracking system

The invention discloses a production process modeling and product data tracking system, and belongs to the technical field of industrial automation. A method based on production flow chart structure modeling and data tracking is provided, various elements in a production flow network are connected in series, and complex logistics tracking and cost optimization of industrial enterprises are achieved. The system comprises a production flow model management module, a basic data management module, a data acquisition module, a flow management module, a data storage module, a flow construction module, a data query and calculation module, a cost optimization module and a man-machine interaction module. The modules are all deployed on a computing network node supporting TCP / IP, and communicate with each other through a network protocol supporting TCP / IP. The method has the advantages that the method is used for analyzing and optimizing the production logistics rhythm of industrial enterprisesand reducing the production operation cost of the enterprises.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

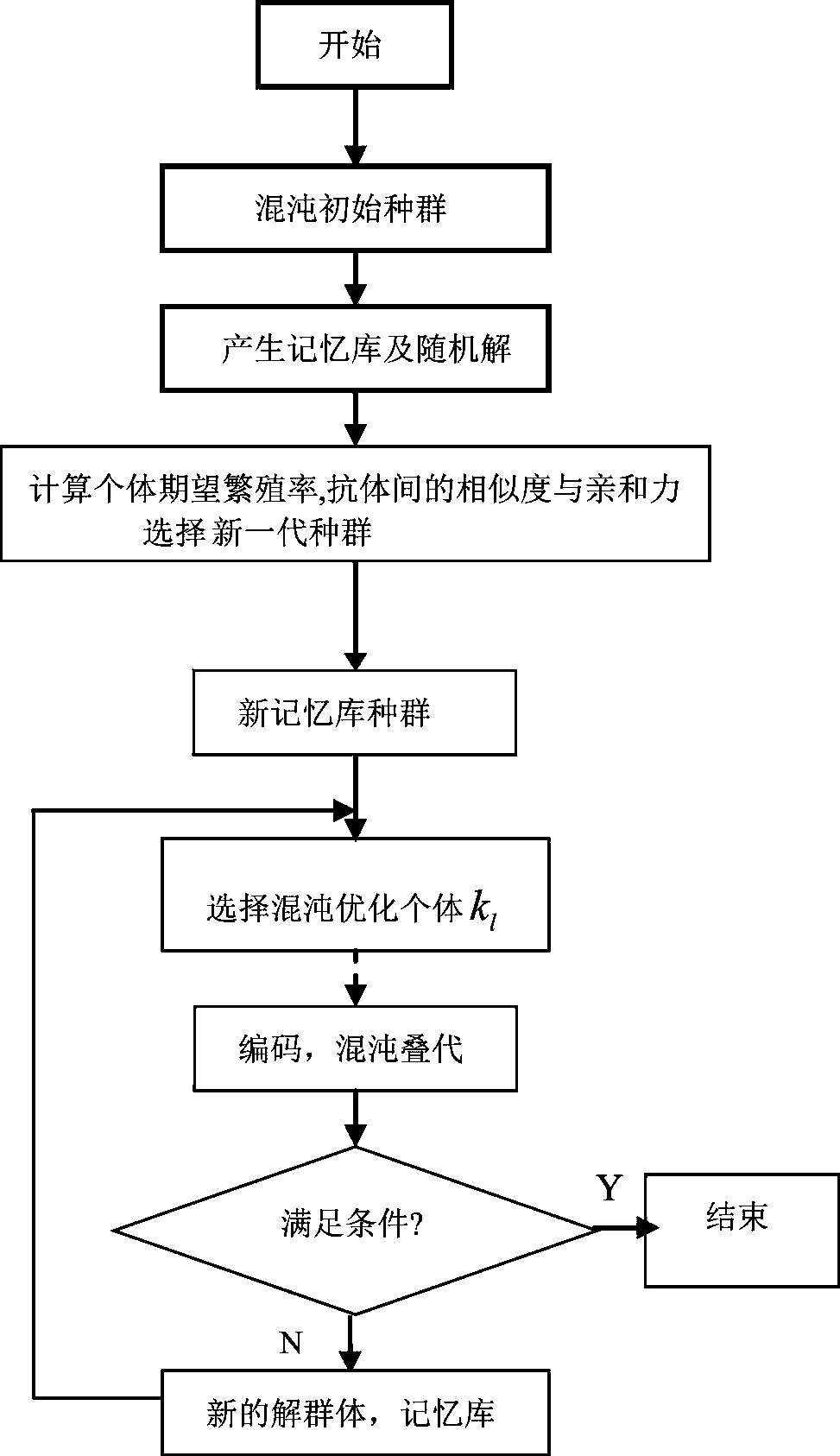

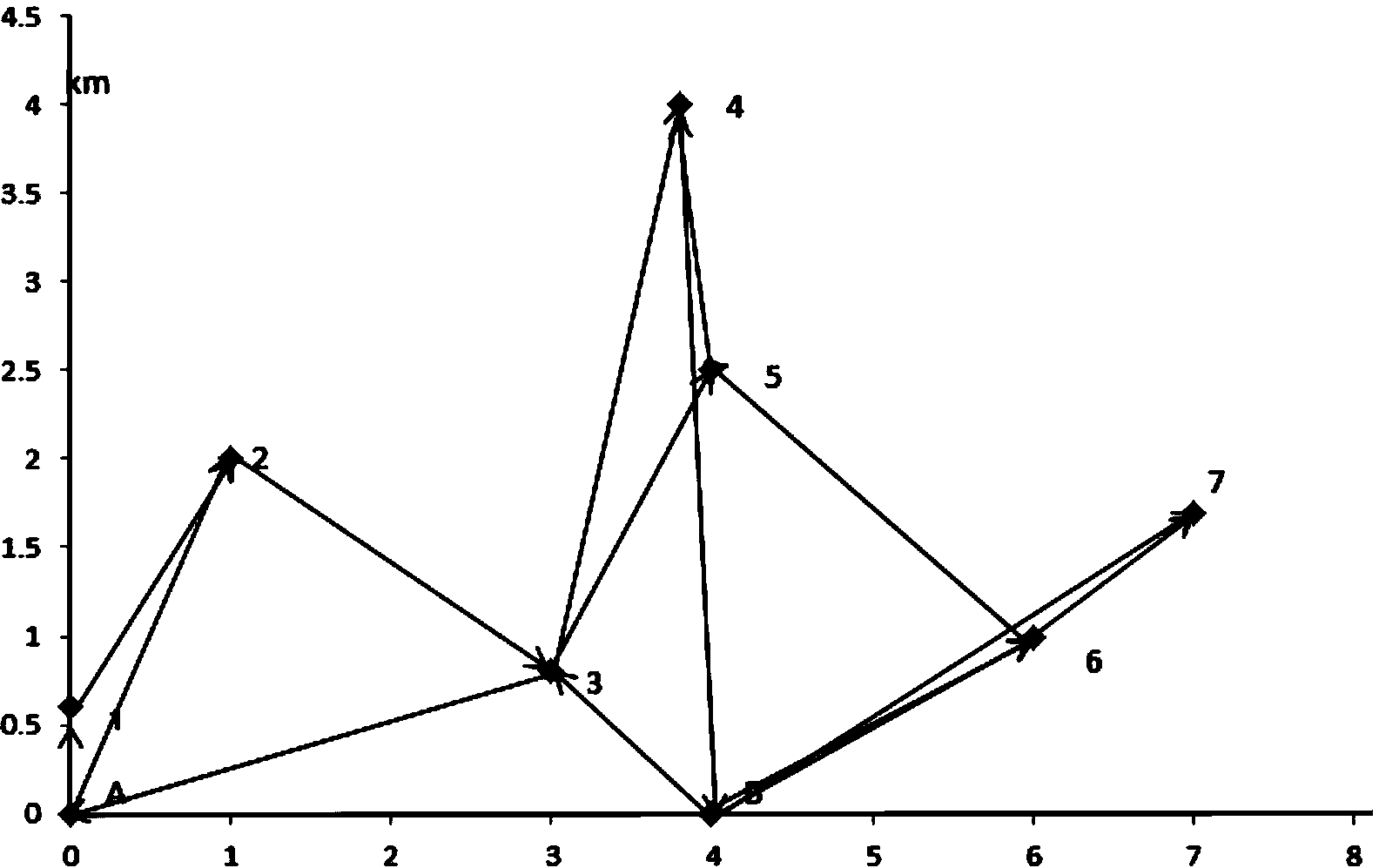

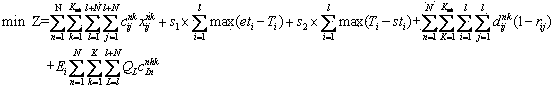

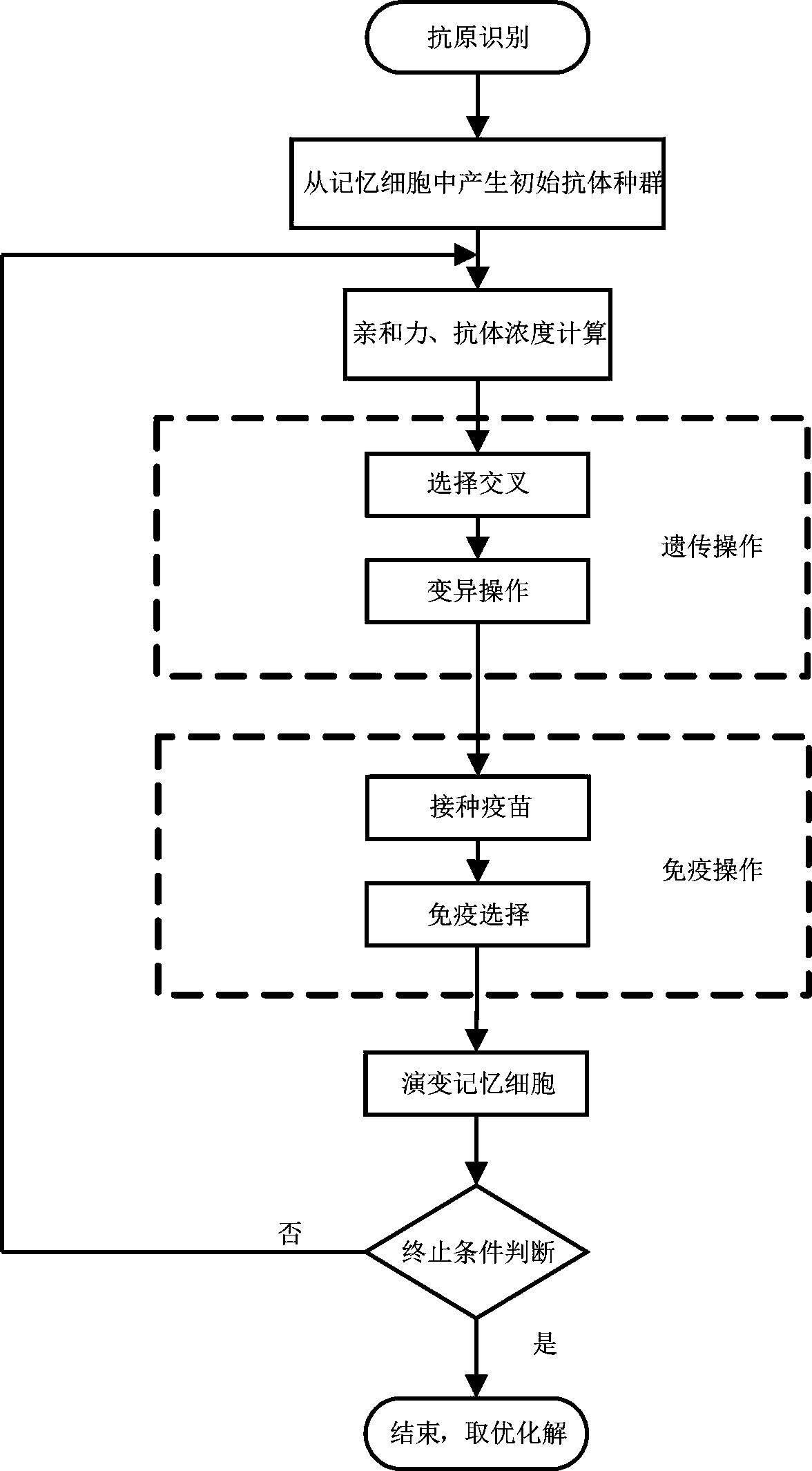

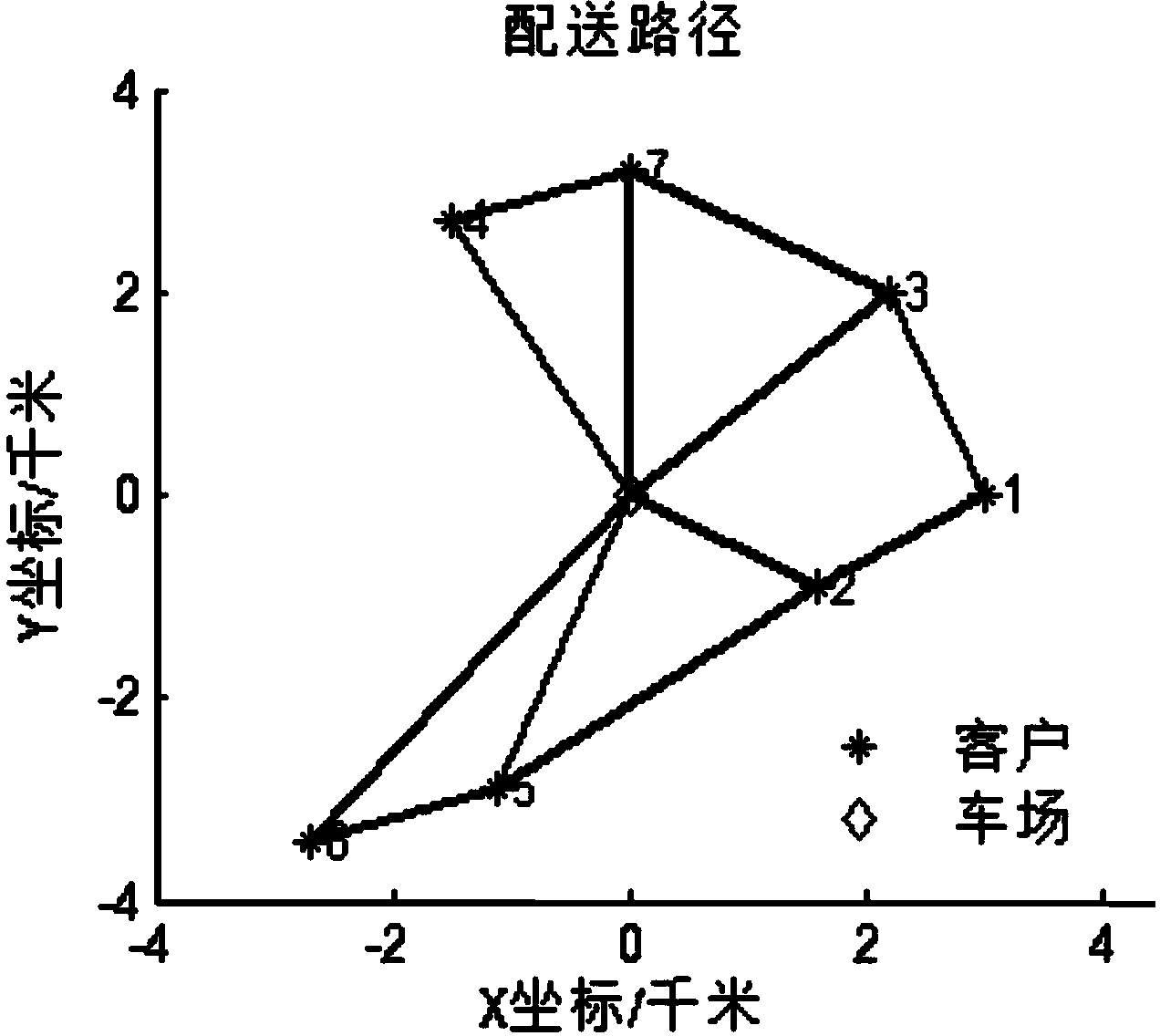

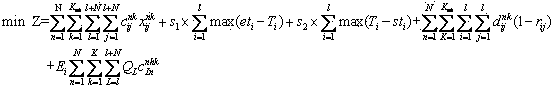

Chaos immune algorithm based multi-vehicle assembly line logistics transportation scheduling method

InactiveCN104036380AQuality improvementFast convergenceLogisticsLogistics managementProduction logistics

The invention discloses a chaos immune algorithm based multi-vehicle assembly line logistics transportation scheduling method, and aims to solve the problem about logistics transportation scheduling of multi-depot and multi-vehicle assembly line production. The method includes: firstly, according to characteristics of an assembly line production mode, determining basic factors of the logistics transportation scheduling problem, wherein the basic factors include time windows, distribution periodicity, cargo relevance, multi-type depots and the like of production logistics transportation scheduling; secondly, establishing a mathematical model including an objective function and constraint conditions; thirdly, designing a chaos immune algorithm for the proposed mathematical model; finally, utilizing the designed chaos immune algorithm to solve the mathematical model. By applying the designed algorithm, the problem about logistics transportation scheduling of assembly line production of multiple vehicles and multiple distribution centers is solved, and solution quality of the algorithm is improved to a certain degree while rate of convergence is increased to a certain degree as well.

Owner:GUANGDONG UNIV OF TECH

Process of producing logistic tray with waste plastics

InactiveCN1887952AReduce pollutionHigh strengthRigid containersProduction logisticsPolyethylene glycol

The process of producing logistic tray with waste plastics relates to utilization of waste plastics. Waste polyethylene and polypropylene plastics are produced into logistic tray through the steps of washing, drying, sorting, crushing, adding modifier and injection molding. The modifier comprises propylene dichloride resin, calcium carbonate, stearate and surfactant polyethylene glycol. The present invention produces logistic tray with waste plastic completely and is environment friendly, and the produced logistic tray has high strength, durable and with less deformation.

Owner:HUBEI TONGJITANG PHARMACY

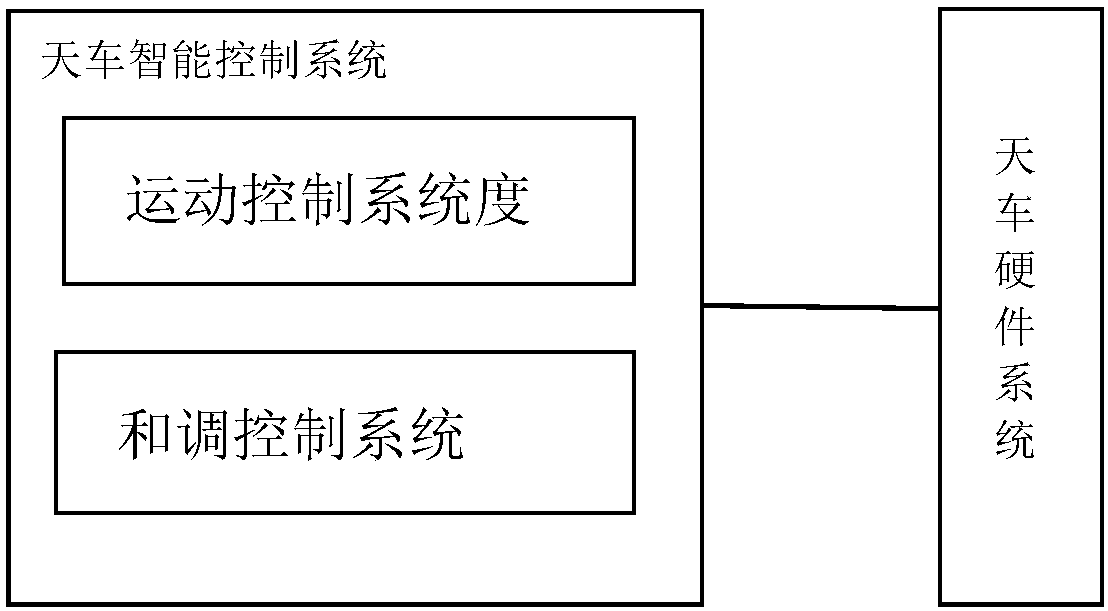

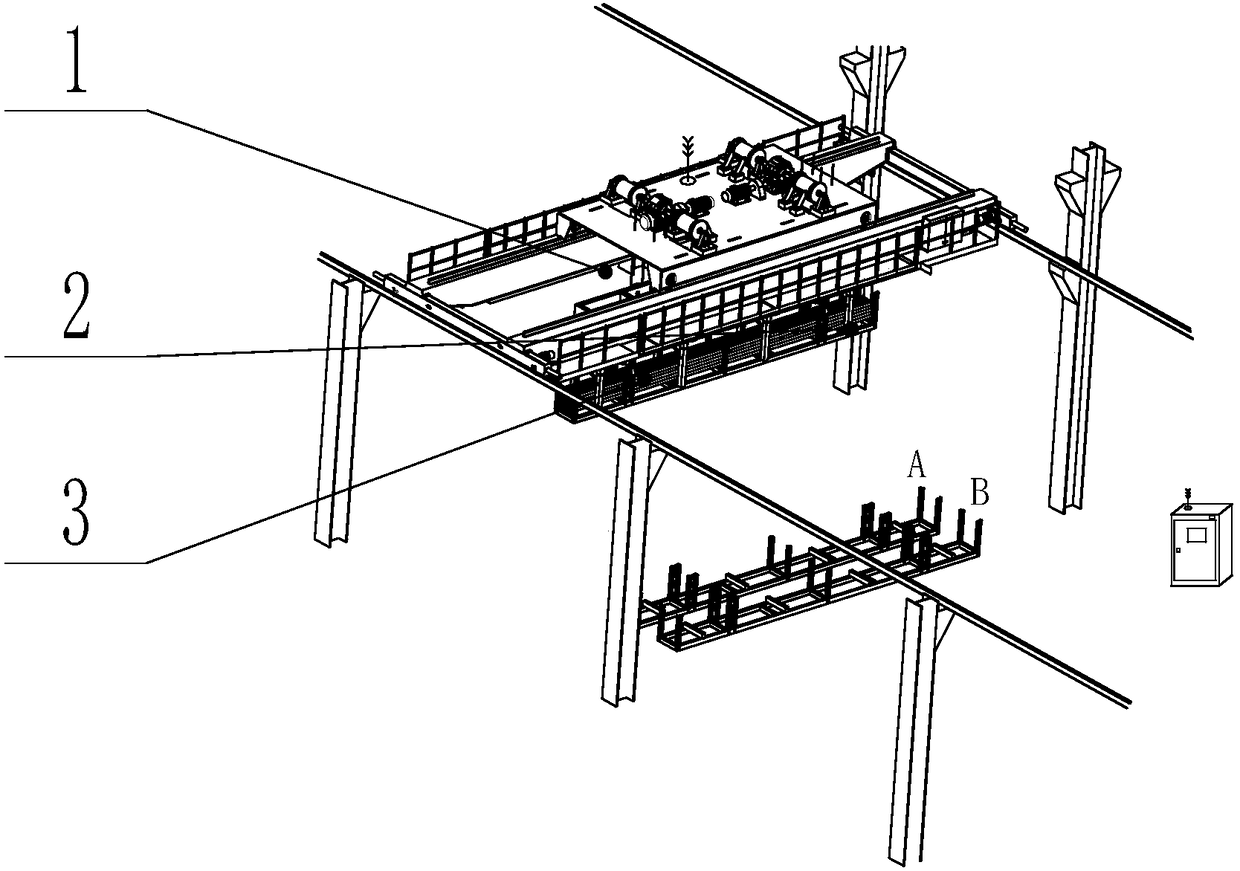

Intelligent section bar lifting overhead crane system

ActiveCN108163717AReduce in quantityImprove working environmentSafety gearProduction logisticsWorking environment

The invention provides an intelligent section bar lifting overhead crane system and relates to a full-automatic hoisting and lifting technology and belongs to the field of intelligent devices. The intelligent section bar lifting overhead crane system is composed of a crane body, an electrical system and a dispatching system and is dedicatedly designed for section bar production, machining and lifting application. The intelligent section bar lifting overhead crane system is complete and high in applicability. An intelligent overhead crane control system adopts a wireless numerical control system and a high-precision locating system. The intelligent overhead crane control system detects the three-dimensional positions of lifting tools in real time and monitors the work states of intelligentoverhead cranes, makes an online track record of the production logistic states and achieves self-dispatching, logistic state management and overhead crane work information real-time gathering of theoverhead cranes for all work stations. Operation personnel of the intelligent crane system can achieve operation of the overhead cranes on all the work stations in a dispatching and controlling chamber in a remote manner, so that the number of operation personnel can be reduced, the work environment of the operation personnel is improved, and the personal safety of the operation personnel is improved; and the intelligent section bar lifting overhead crane system is particularly suitable for application in factory automation.

Owner:合肥哈工热气球数字科技有限公司

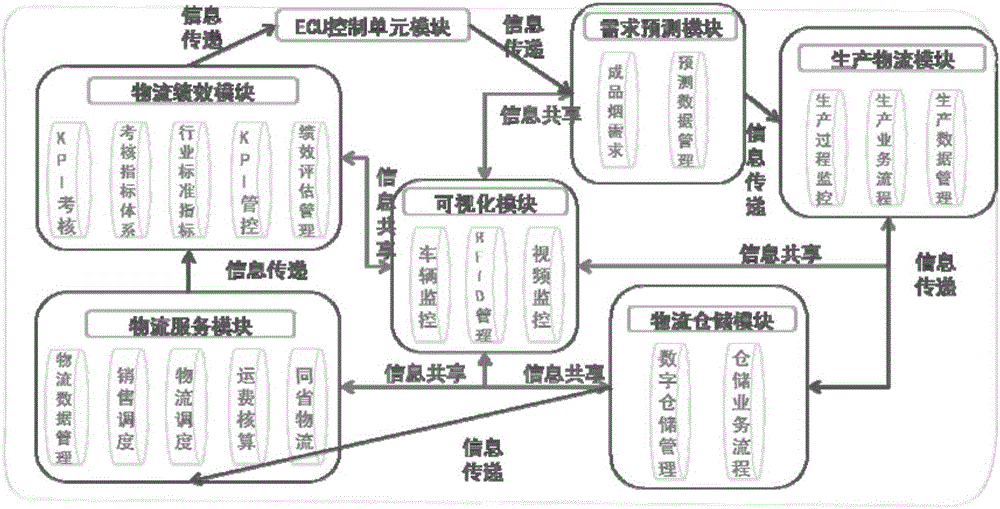

Tobacco logistics information collaborative management system based on Internet of Things

The invention discloses a tobacco logistics information collaborative management system based on the Internet of Things. Besides hardware equipment which serves as basic necessities, the tobacco logistics information collaborative management system further comprises a demand forecasting module, a production logistics management module, a logistics storage management module, a logistics service management module, a logistics performance management module and a visualized management module in the information data processing process. The technical scheme of the tobacco logistics information collaborative management system can effectively solve the technical problems of unnecessary procedure delay and increased operating cost caused by unsmooth connection of tobacco logistics operation, and avoids the problems of serious ''information isolated island'' phenomenon of tobacco raw and auxiliary materials, unsmooth information communication between raw and auxiliary material suppliers and tobacco industrial enterprises, and unbalanced production and marketing of tobacco raw and auxiliary materials.

Owner:CHINA TOBACCO ZHEJIANG IND

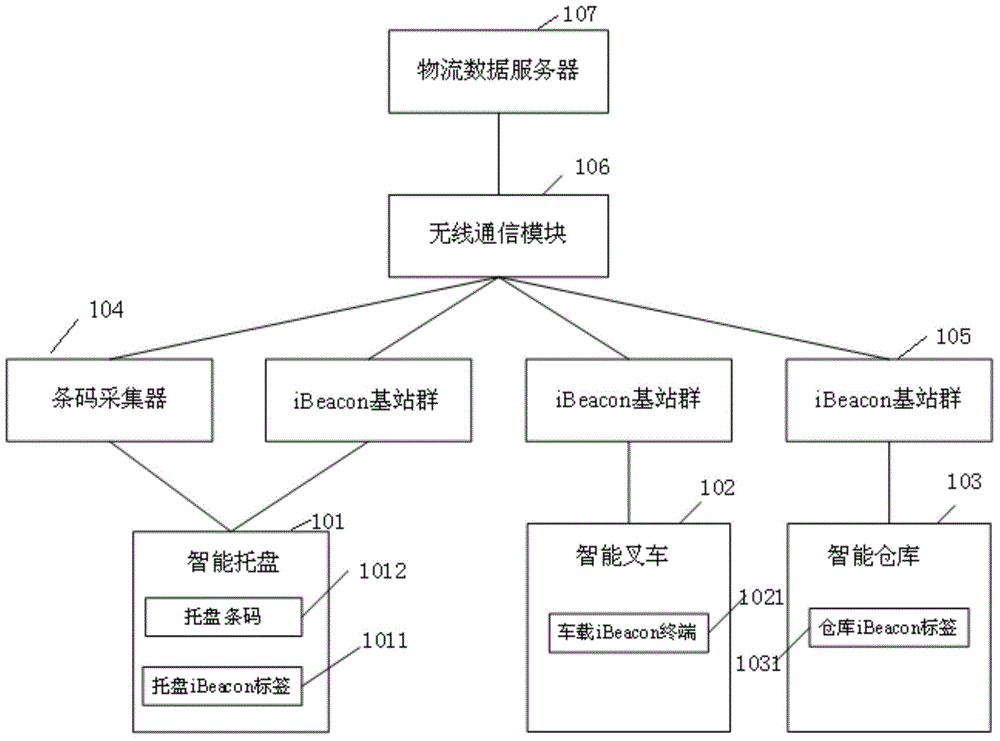

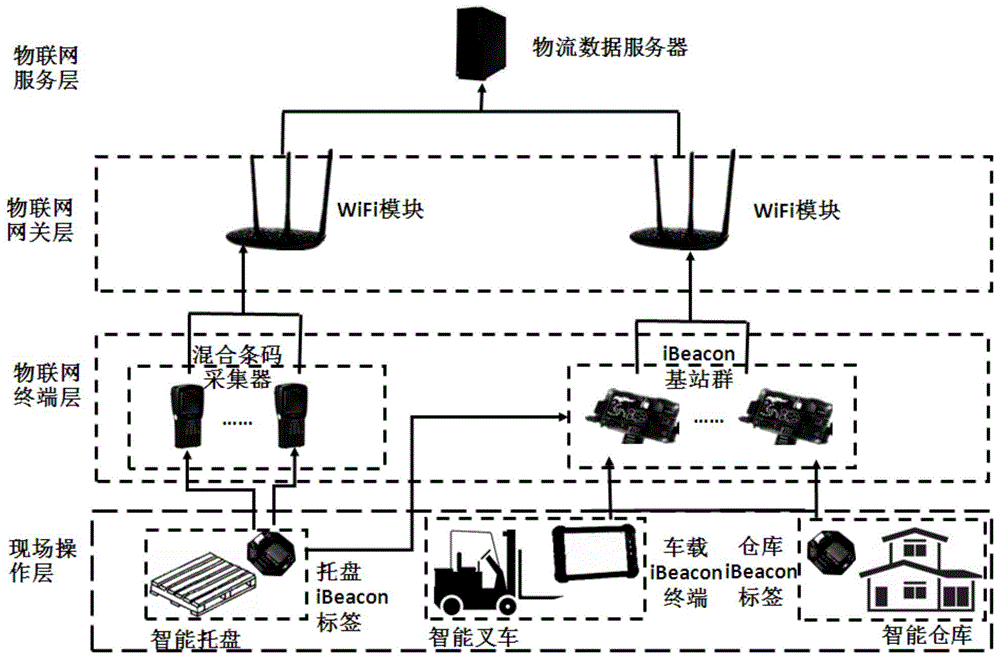

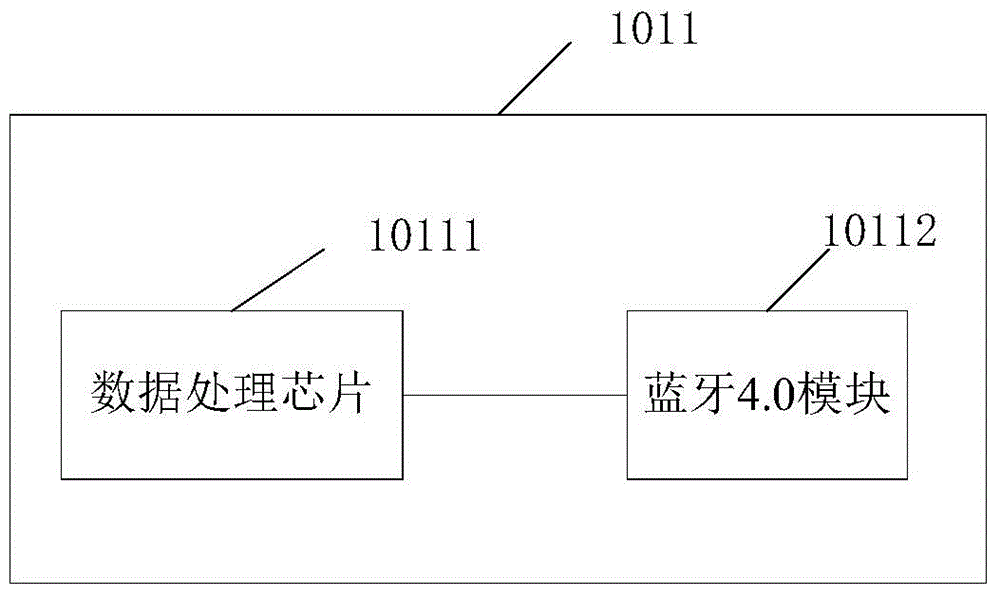

Production logistics management method and system based on iBeacon

InactiveCN104809604AClearly in chargePrecise deliveryLogisticsLogistics managementProduction logistics

The invention discloses a production logistics management system based on iBeacon. The system comprises an intelligent tray with a tray barcode and a tray iBeacon label, an intelligent warehouse with a warehouse iBeacon label arranged on an entrance guard, an intelligent forklift with a vehicle-mounted iBeancon terminal, an iBeacon base station group, a wireless communication module and a logistic data server. A production logistics management method based on iBeacon is further disclosed. The method and system improves logistics distribution efficiency and saves a large amount of manpower, materials and resources.

Owner:GUANGDONG UNIV OF TECH

Cooperative follow-up operation navigation method and cooperative follow-up operation navigation device of greenhouse mobile operation platform

ActiveCN106708061ASmooth rideRealize the navigation functionPosition/course control in two dimensionsVehiclesProduction logisticsLogistics management

The invention discloses a cooperative follow-up operation navigation method and a cooperative follow-up operation navigation device of a greenhouse mobile operation platform, belonging to the technical field of intelligent equipment of facility agriculture. According to the method and the device, the autonomous navigation for the mobile platform is realized between ridges in a greenhouse by means of a magnetic navigation sensor module, the distance between the mobile platform and an operator can be further detected by using a distance measuring sensor module, and the start and stop of the mobile platform can be controlled by a main controller, so that the cooperative follow-up operation function of the mobile platform and the operator can be realized. The method and the device can be used for loading working tools and transporting materials, fruits and the like, effectively solves the problem of production logistics transportation in the greenhouse by means of a simple structure and control method, lightens the labor intensity, increases the production efficiency and reduces the cost.

Owner:JIANGSU UNIV

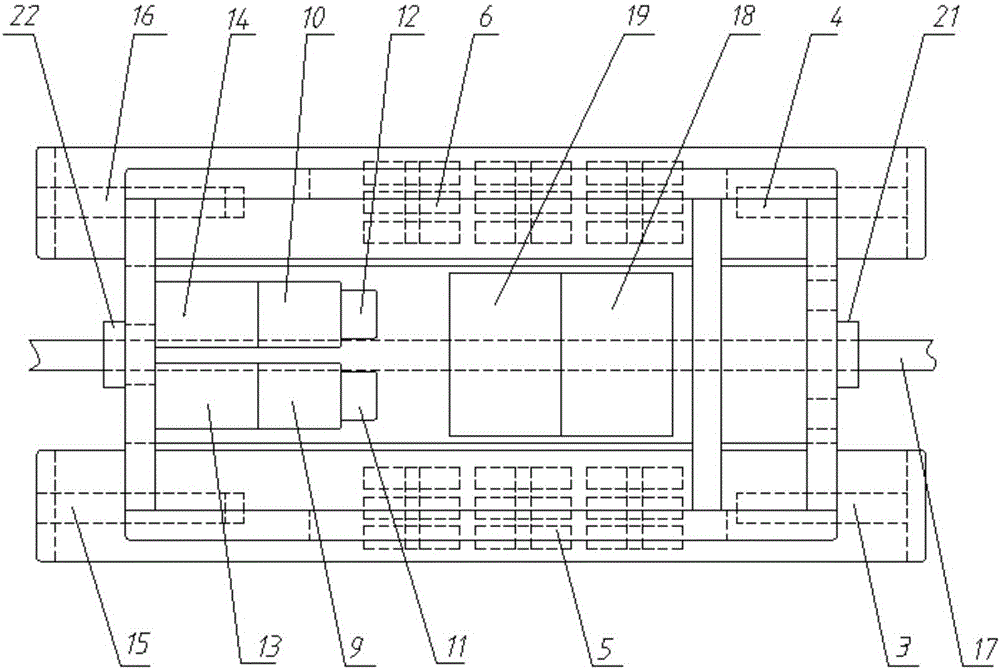

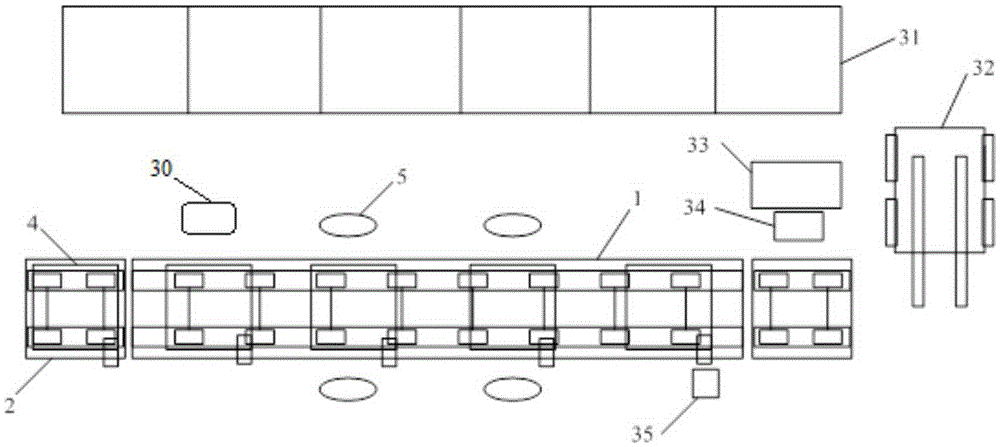

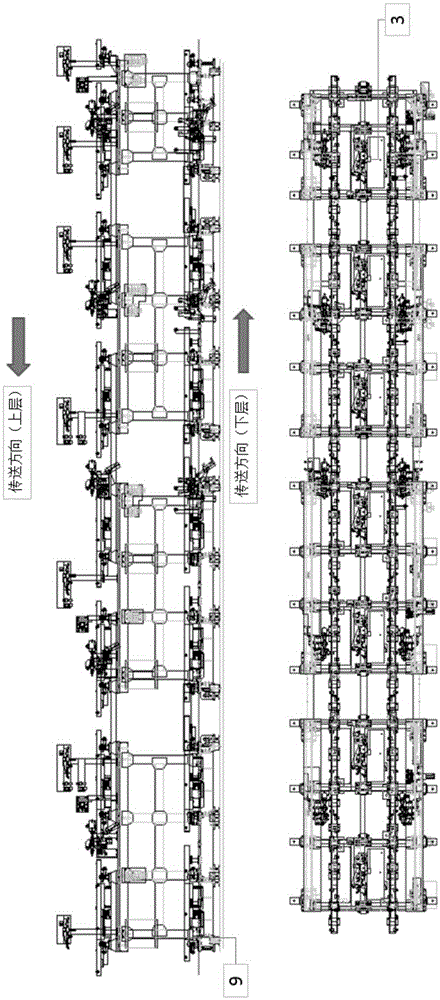

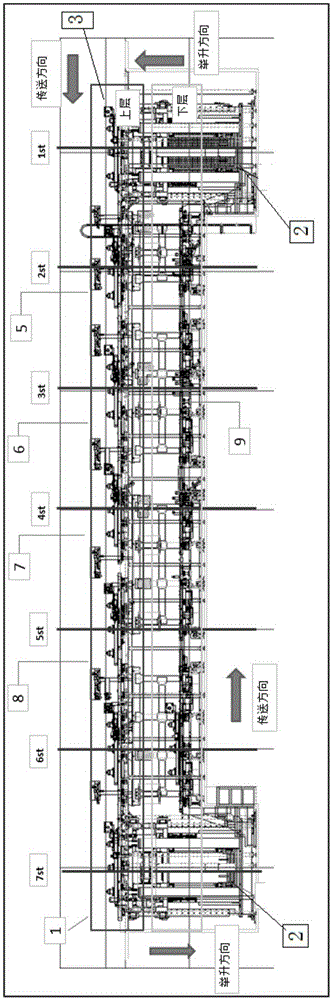

Automatic flexible welding production line oriented to multiple classes of small assemblies and control method of production line

ActiveCN105252179AAchieve productionAchieve replacementWelding/cutting auxillary devicesAuxillary welding devicesProduction lineProduction logistics

The invention discloses an automatic flexible welding production line oriented to multiple classes of small assemblies. The automatic flexible welding production line comprises a line body, lifting mechanisms, a conveying mechanism, a following platform, welding robots, a fixture base and a line body control system. During automatic welding production of parts of the small assemblies, in order to achieve production efficiency of short takt time and meet the requirements for high flexibility in welding assembling production of different parts, the system is supposed to have good welding extendibility; besides, due to the diversity of the parts of the small assemblies, concise and smooth production logistics is needed, fixtures shall be replaced rapidly and reliably, and personnel investment shall be low. In this way, automatic welding through the robots is adopted, the layout form that the double-layer line body, the following fixtures and the following platform can be separated is adopted, the fixture base and a transfer trolley are added, and therefore the high-flexibility welding performance of the automatic flexible welding production line oriented to the multiple classes of small assemblies is achieved, and moreover a high automation degree and low personnel investment can be organically integrated. The production line is an ideal automatic small-assembly welding production line and has broad application prospects.

Owner:YANGZHOU XINLIAN AUTO PARTS +1

Single-vehicle streamline logistics transportation dispatching method on basis of immune genetic algorithm

InactiveCN104036381AQuality improvementFast convergenceLogisticsImmune genetic algorithmProduction logistics

The invention discloses a single-vehicle streamline logistics transportation dispatching method on the basis of an immune genetic algorithm. Multi-yard single-vehicle streamline production logistics transportation dispatching can be implemented by the aid of the single-vehicle streamline logistics transportation dispatching method. The single-vehicle streamline logistics transportation dispatching method includes building multi-yard single-vehicle streamline logistics transportation dispatching models; determining basic factors, including production logistics transportation dispatching time windows, delivery periodicity, goods relevance, yard diversity and the like, of logistics transportation dispatching according to characteristics of streamline production modes; building mathematical models containing objective functions and constraint conditions; designing the immune genetic algorithm for the mathematical models; solving the mathematical models by the aid of the designed immune genetic algorithm. The single-vehicle streamline logistics transportation dispatching method has the advantages that streamline production logistics transportation dispatching can be effectively implemented for a multi-vehicle single delivery center by the aid of the designed algorithm, the solution quality of the algorithm can be improved to a certain extent, and the convergence rate of the algorithm can be increased to a certain extent.

Owner:GUANGDONG UNIV OF TECH

Products produced from rapid thermal processing of heavy hydrocarbon feedstocks

InactiveUS8062503B2Upgrade and reduce viscosityRapid heat treatmentThermal non-catalytic crackingLiquid organic insulatorsParticulatesLiquid product

The present invention is directed to the upgrading of heavy hydrocarbon feedstock that utilizes a short residence pyrolytic reactor operating under conditions that cracks and chemically upgrades the feedstock. The process of the present invention provides for the preparation of a partially upgraded feedstock exhibiting reduced viscosity and increased API gravity. This process selectively removes metals, salts, water and nitrogen from the feedstock, while at the same time maximizes the yield of the liquid product, and minimizes coke and gas production. Furthermore, this process reduces the viscosity of the feedstock in order to permit pipeline transport, if desired, of the upgraded feedstock with little or no addition of diluents. The method for upgrading a heavy hydrocarbon feedstock comprises introducing a particulate heat carrier into an upflow reactor, introducing the heavy hydrocarbon feedstock into the upflow reactor at a location above that of the particulate heat carrier so that a loading ratio of the particulate heat carrier to feedstock is from about 15:1 to about 200:1, allowing the heavy hydrocarbon feedstock to interact with the heat carrier with a residence time of less than about 1 second, to produce a product stream, separating the product stream from the particulate heat carrier, regenerating the particulate heat carrier, and collecting a gaseous and liquid product from the product stream. This invention also pertains to the products produced by the method.

Owner:IVANHOE HTL GASOLINEEUM

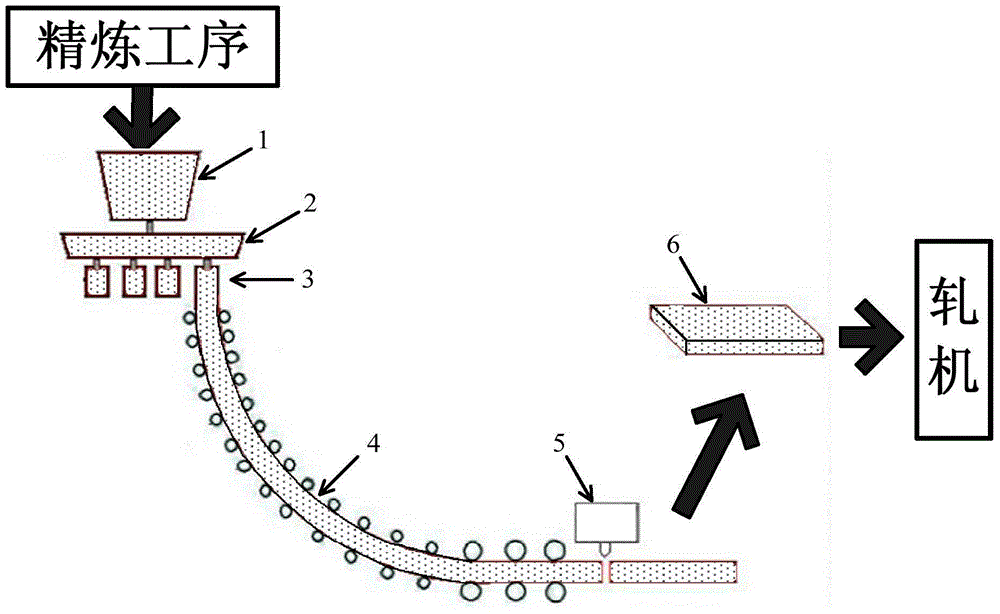

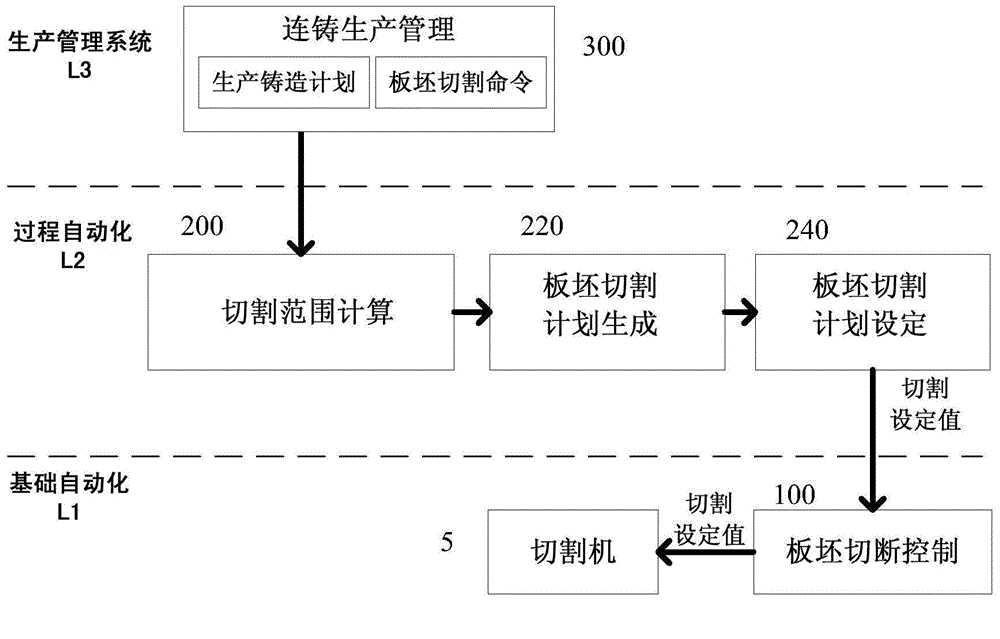

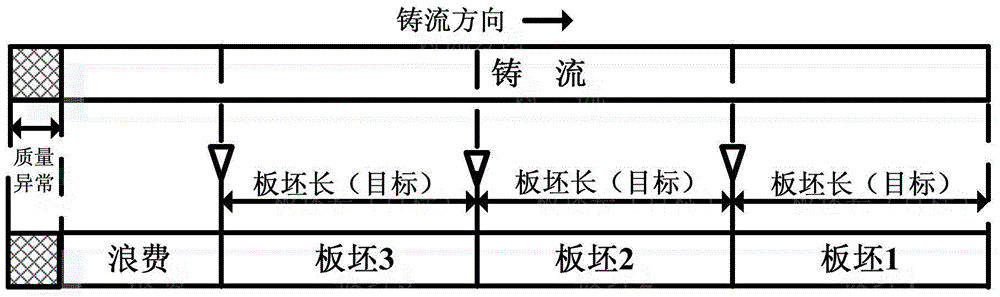

Molten steel quantity conversion based slab cutting optimization method and control system thereof

InactiveCN106270432AIncrease the number of prediction calculation blocksExpand the scope ofProduction logisticsManagement system

The invention discloses a molten steel quantity conversion based slab cutting optimization method and a control system thereof and relates to a control device or method special for metal rolling machines or other machining products, in particular to an optimization method for continuous casting production line slab cutting and a control system thereof. A production casting plan and a slab cutting instruction are received from a production and management system, basic slab cutting data is acquired, and actual cutting performance feedback is received at basic automation level; a calculation casting length is determined according to conversion casting length and strand casting length, a calculate cutting range is corrected by combining with an actual cutting performance feedback value, cutting optimization calculation is performed according to a cutting instruction length range to generate an optimal cutting scheme for cutting setting, and slab cutting is controller. Based on cutting prediction of molten steel quantities in large ladles and middle ladles, the calculated cutting range is widened, the predicted calculation block number of slab cutting is increased, the cutting calculation range and precision are improved, smooth and stable production logistics is guaranteed, and tail molten steel quantity waste is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

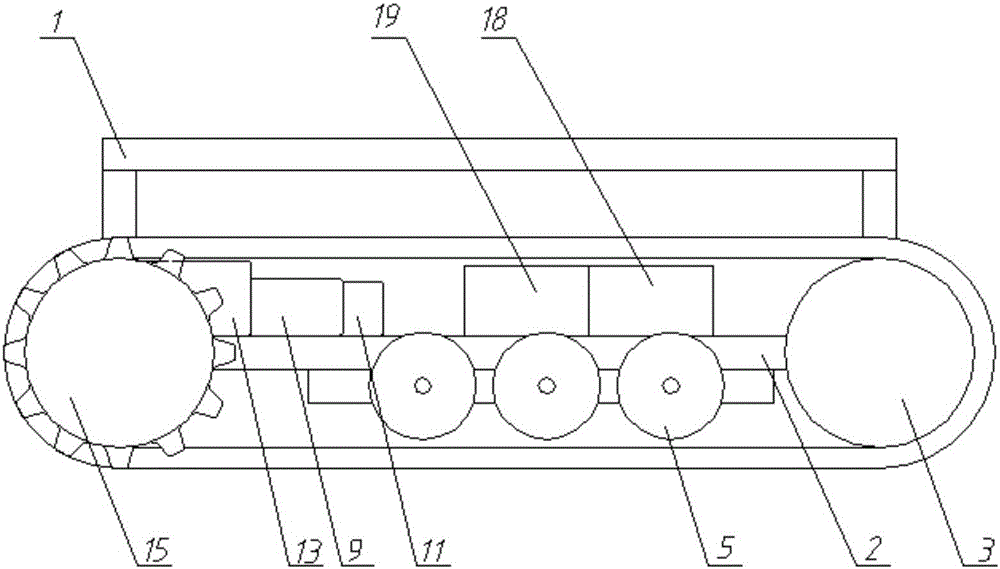

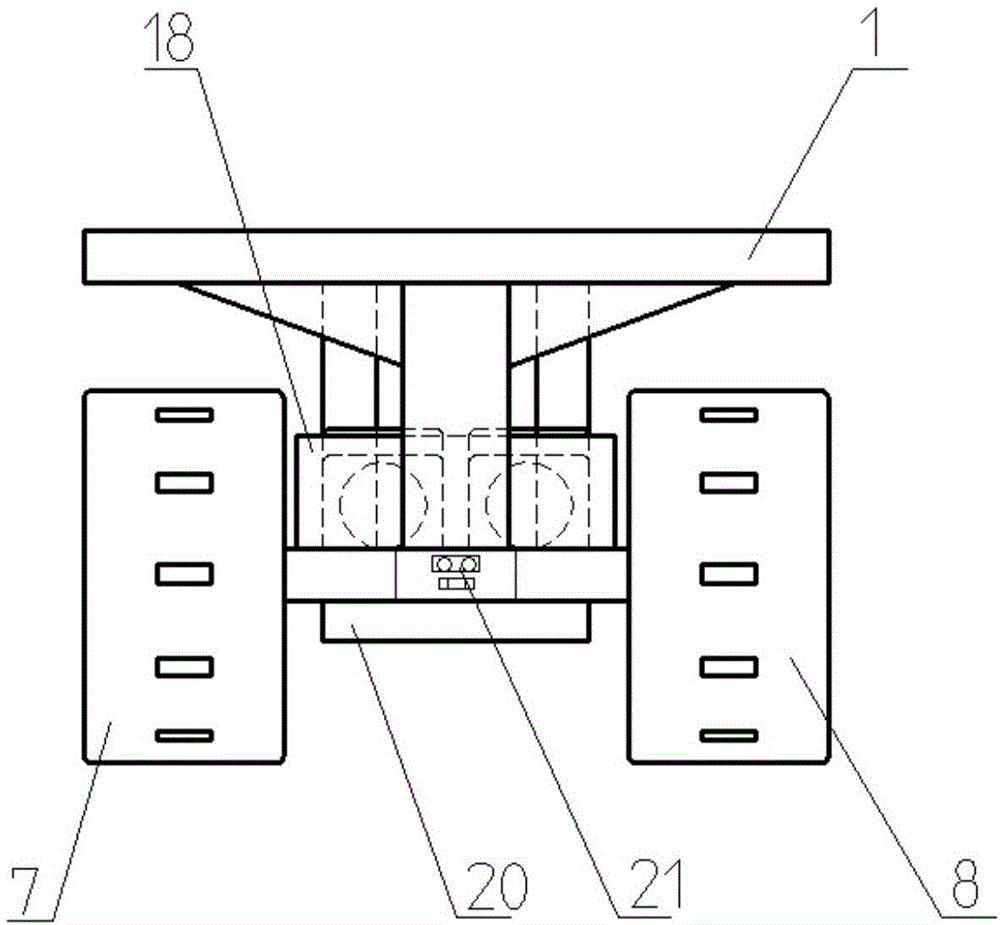

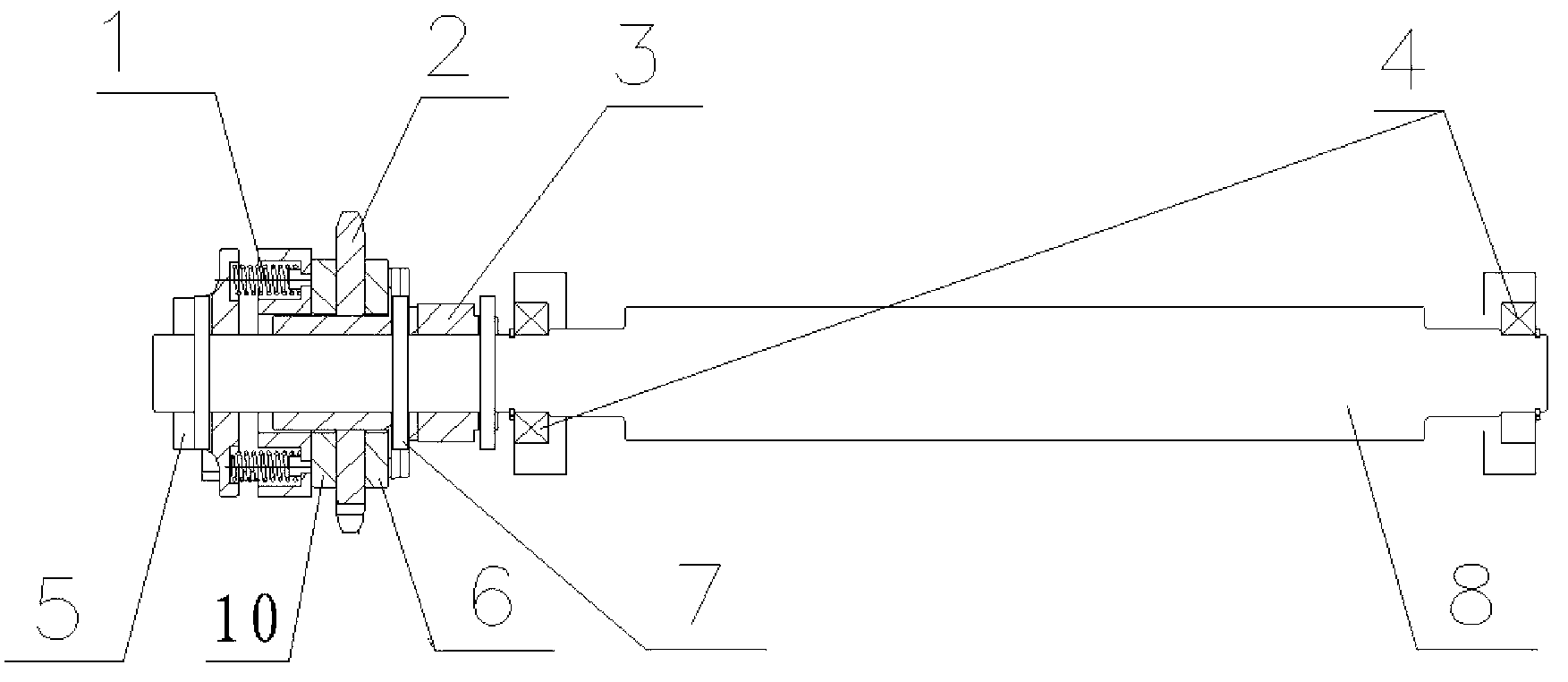

Friction adjustable power roller feeding channel

InactiveCN103231888AReduce wearRealize automatic loading and unloadingRoller-waysProduction logisticsDrive shaft

The invention relates to and provides a friction adjustable power roller feeding channel. The friction adjustable power roller feeding channel is characterized in that a roller unit comprises a transmission shaft (8) which is arranged on two bearings (4); a section of the transmission shaft (8), which is arranged on the outer side of one of the two bearings (4), is sequentially provided with a baffle (7), a first friction piece (6), a transmission chain wheel (2), a second friction piece (10), a spring (1) and an adjusting sleeve (5); the baffle (7) is fixed on the transmission shaft (8); and the first friction piece (6), the transmission chain wheel (2) and the spring (1) are matched with the transmission shaft (8) in a clearance mode. The friction adjustable power roller feeding channel has the advantages of being suitable for achievement of accurate conveying of machined parts in a production logistics automatic line of the mechanical processing industry, enabling a roller pressed by workpieces to stop rotating when the workpieces are blocked during usage and accordingly being capable of meeting the using requirements to adapt to multiple occasions.

Owner:宁夏巨能机器人股份有限公司

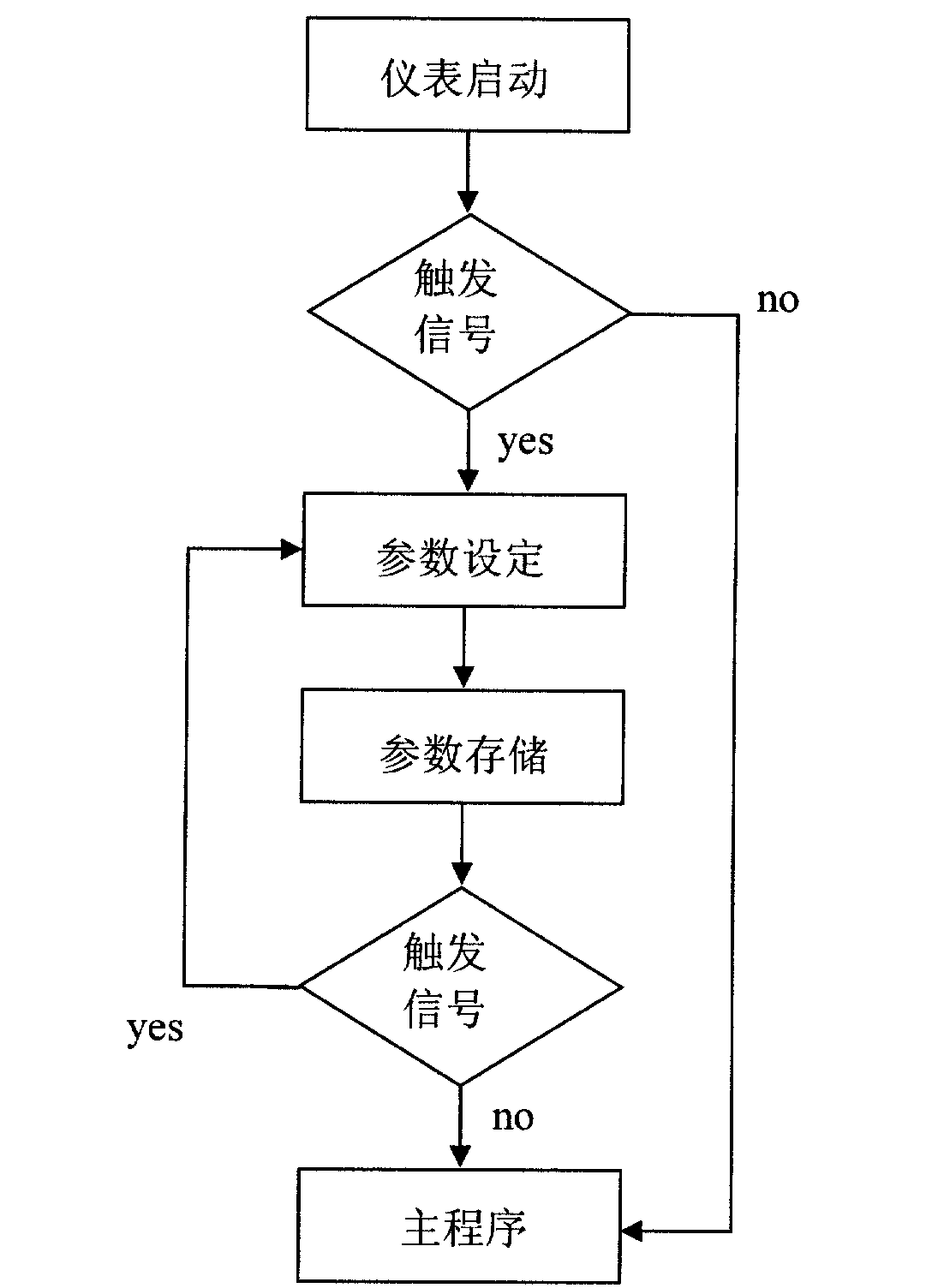

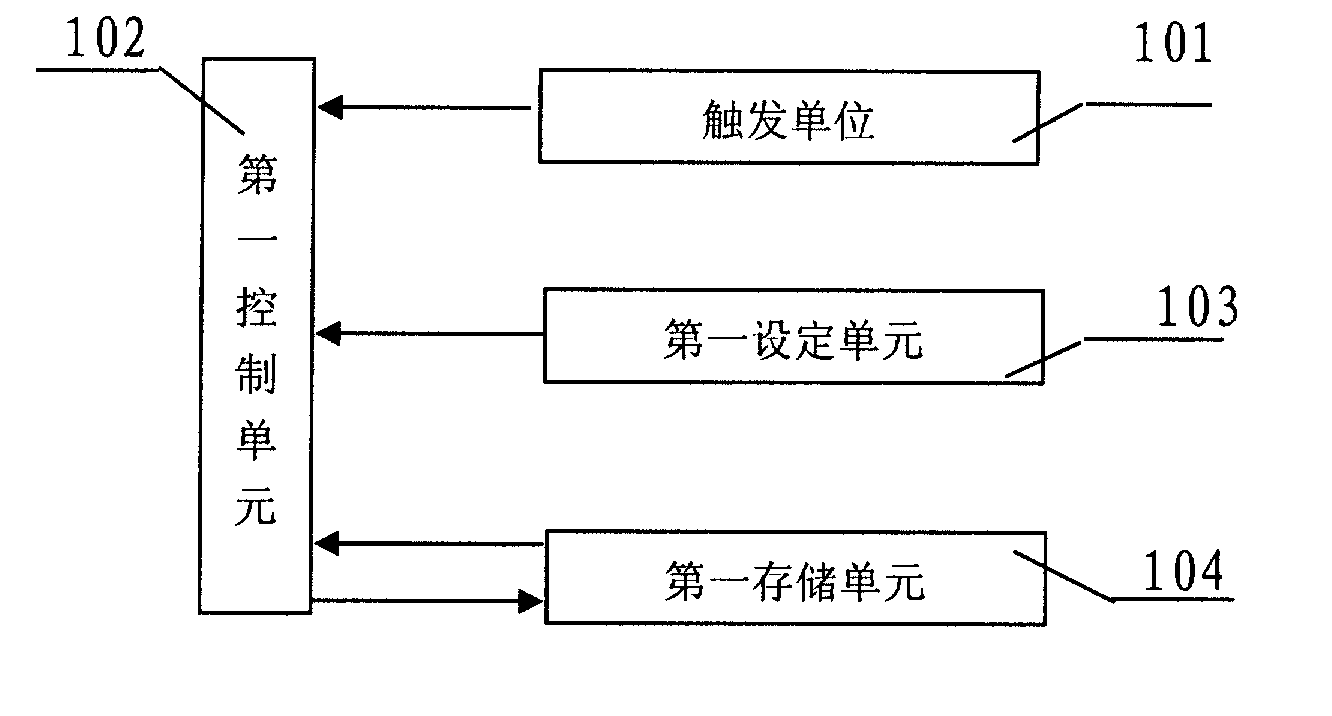

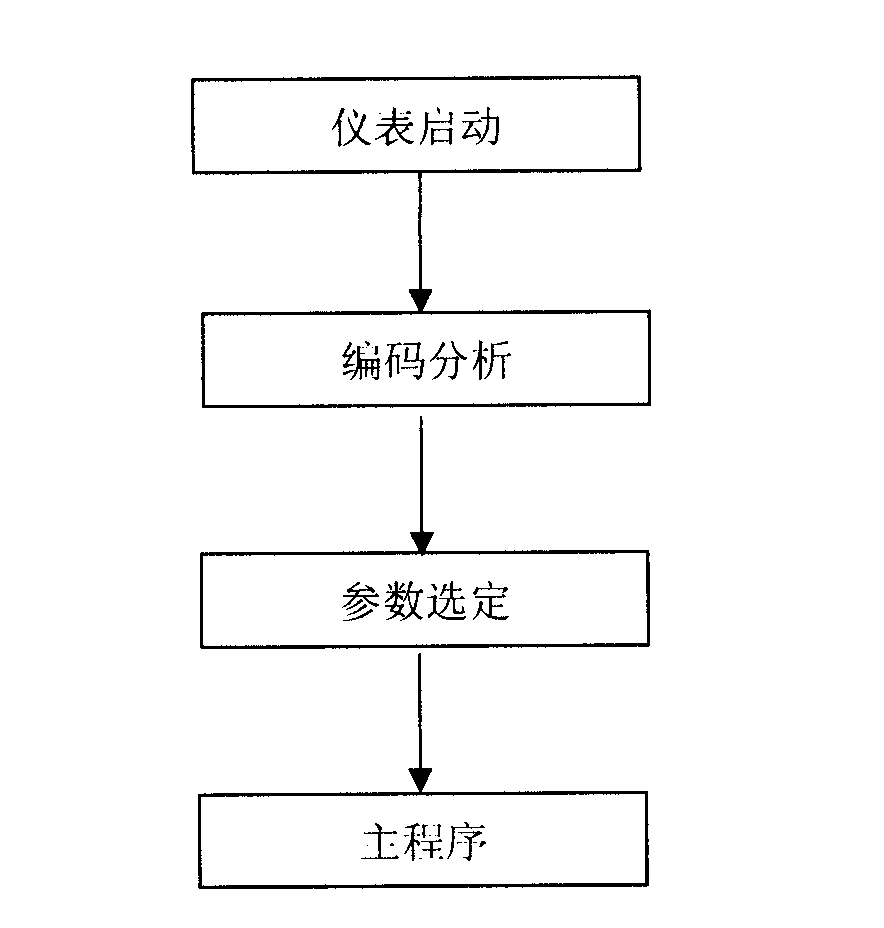

Design method and device of vehicle universal instrument capable setting parameter

The invention discloses a method for designing a vehicle universal instrument with settable parameters, which comprises the following step: when an instrument is started, if a trigger signal is determined to be searched, performing parameter setting operations and storing the parameter after setting for the convenience of invocation. The invention also provides a device for designing the vehicle universal instrument with the settable parameters corresponding to the method, which comprises the following components: a triggering unit which is used for sending the trigger signal for starting the parameter setting operations of the instrument, a first control unit which is used for sending a parameter setting command of the instrument if the trigger signal is determined to be searched when the instrument is started, a first setting unit which is used for performing the parameter setting operations of the vehicle universal instrument when the parameter setting command of the instrument is received, and a first storage unit which is used for storing the parameters after setting for the convenience of invocation. The method and the device can decrease the amount of the instrument model to further reduce the workload of an automobile factory and an instrument manufacturing plant, the control difficulty of production logistics, and the turnover pressure of production stock fund.

Owner:武汉一通电子有限公司

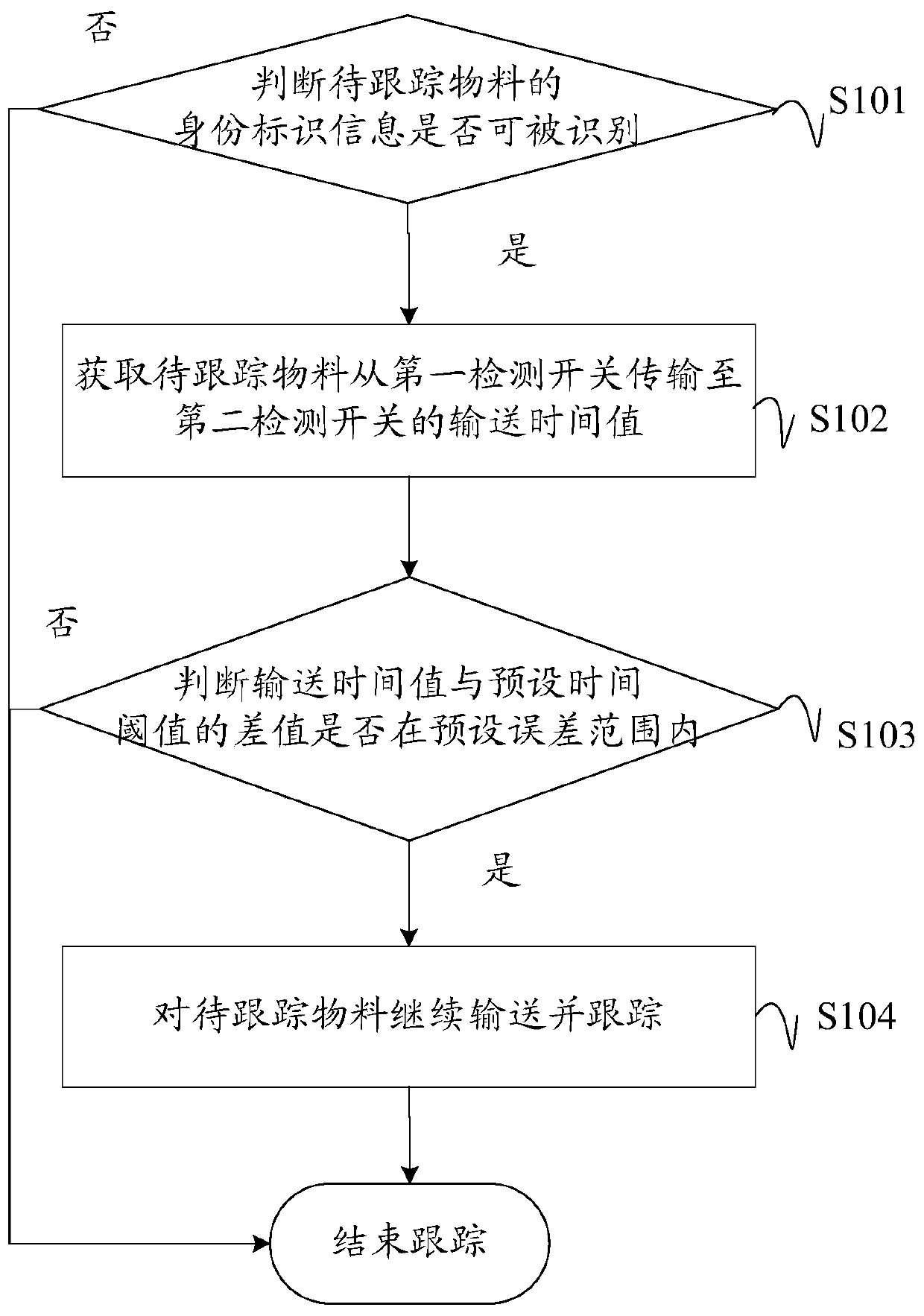

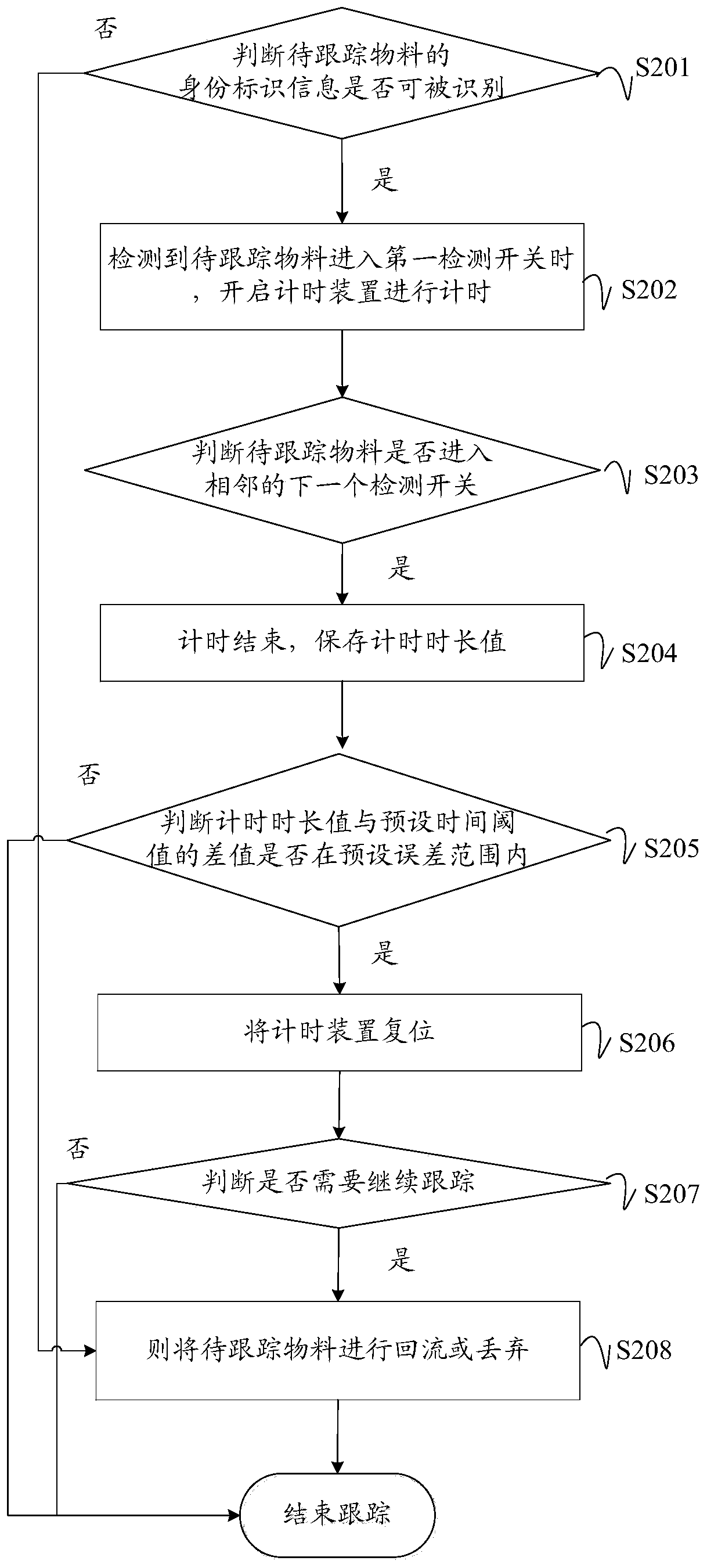

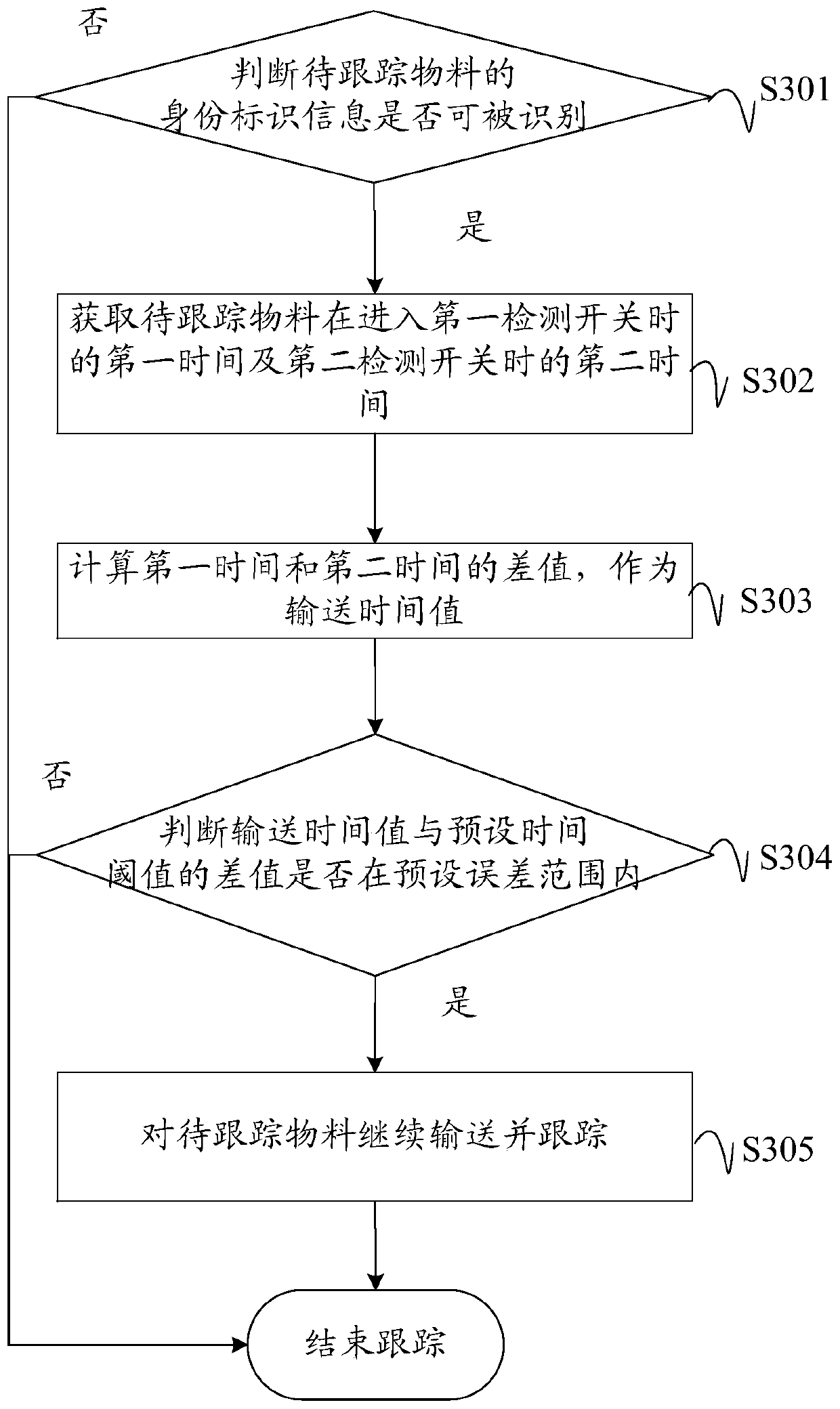

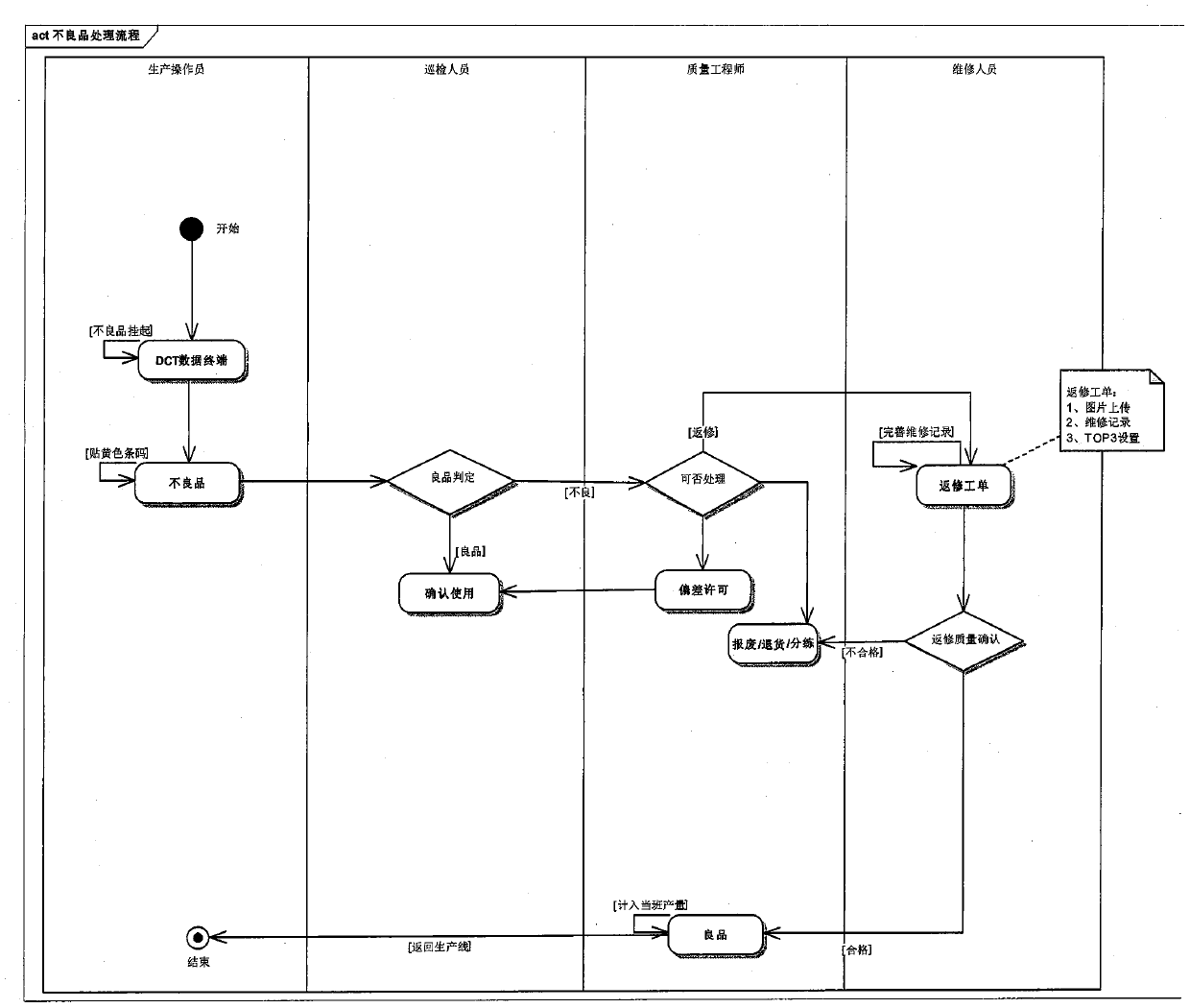

Method, device and equipment for tracking and controlling production logistics and computer readable storage medium

The embodiment of the invention discloses a method, device and equipment for tracking and controlling production logistics and a computer readable storage medium. The method for tracking and controlling the production logistics comprises the steps that when identification information of a material to be tracked is identified, actual time for transmitting the material to be tracked from a first detection switch to a second detection switch is obtained as a transmission time value; and if the difference value between the transmission time value and a preset time threshold value is within a preset error range, it is indicated that the material tracking is successful, and then the material to be tracked is continuously conveyed and tracked, specifically, the time threshold value is the standard time required for transmitting the material to be tracked on a preset distance section of a conveying line, and the distance section is the distance between the first detection switch and the seconddetection switch. According to the method, the device and the equipment, the material can be tracked more efficiently, more stable and more accurately, thereby being convenient for both stable operation of material conveying and later sorting as well as for cost reduction of the detection switches.

Owner:浙江国自智能装备有限公司

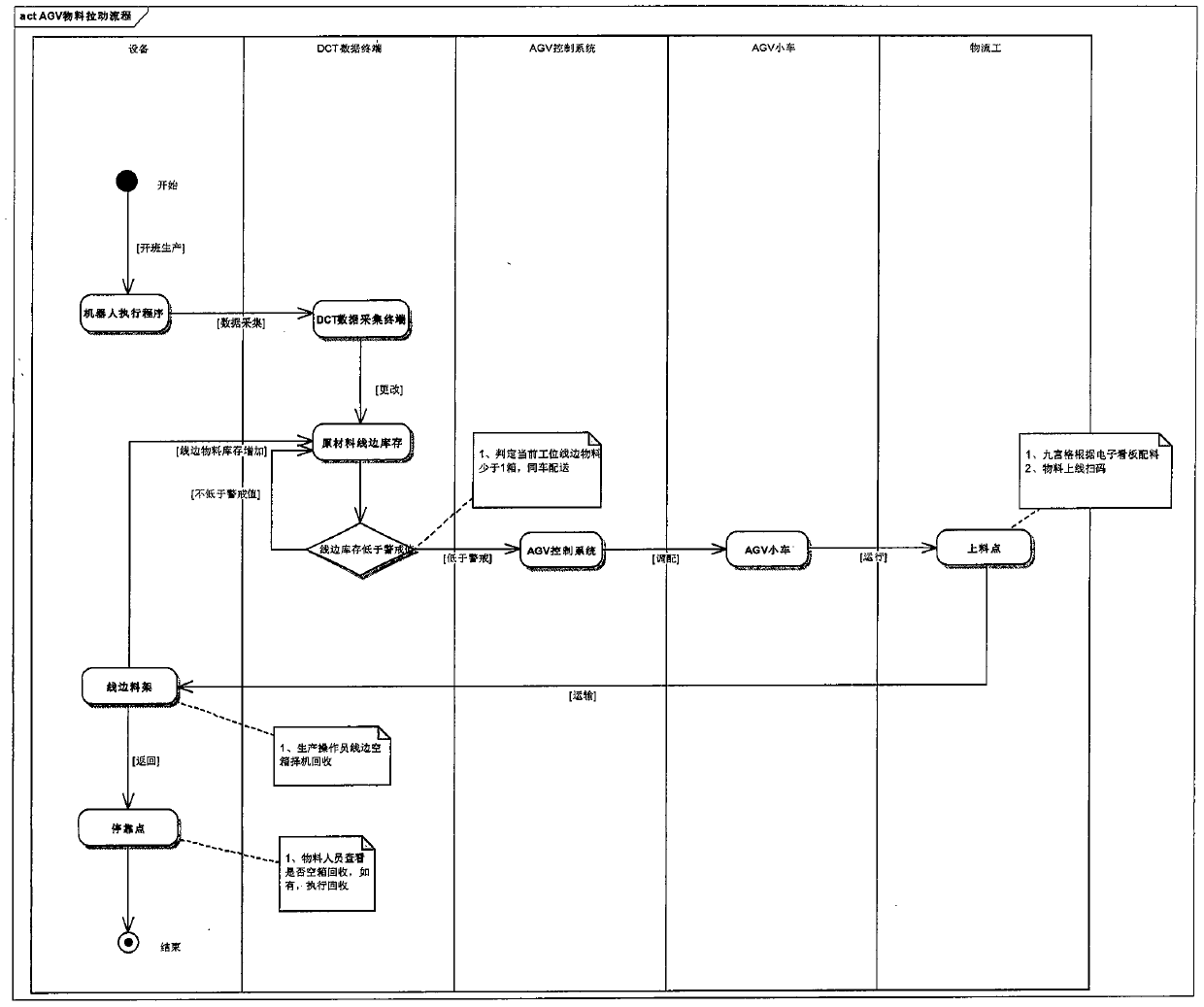

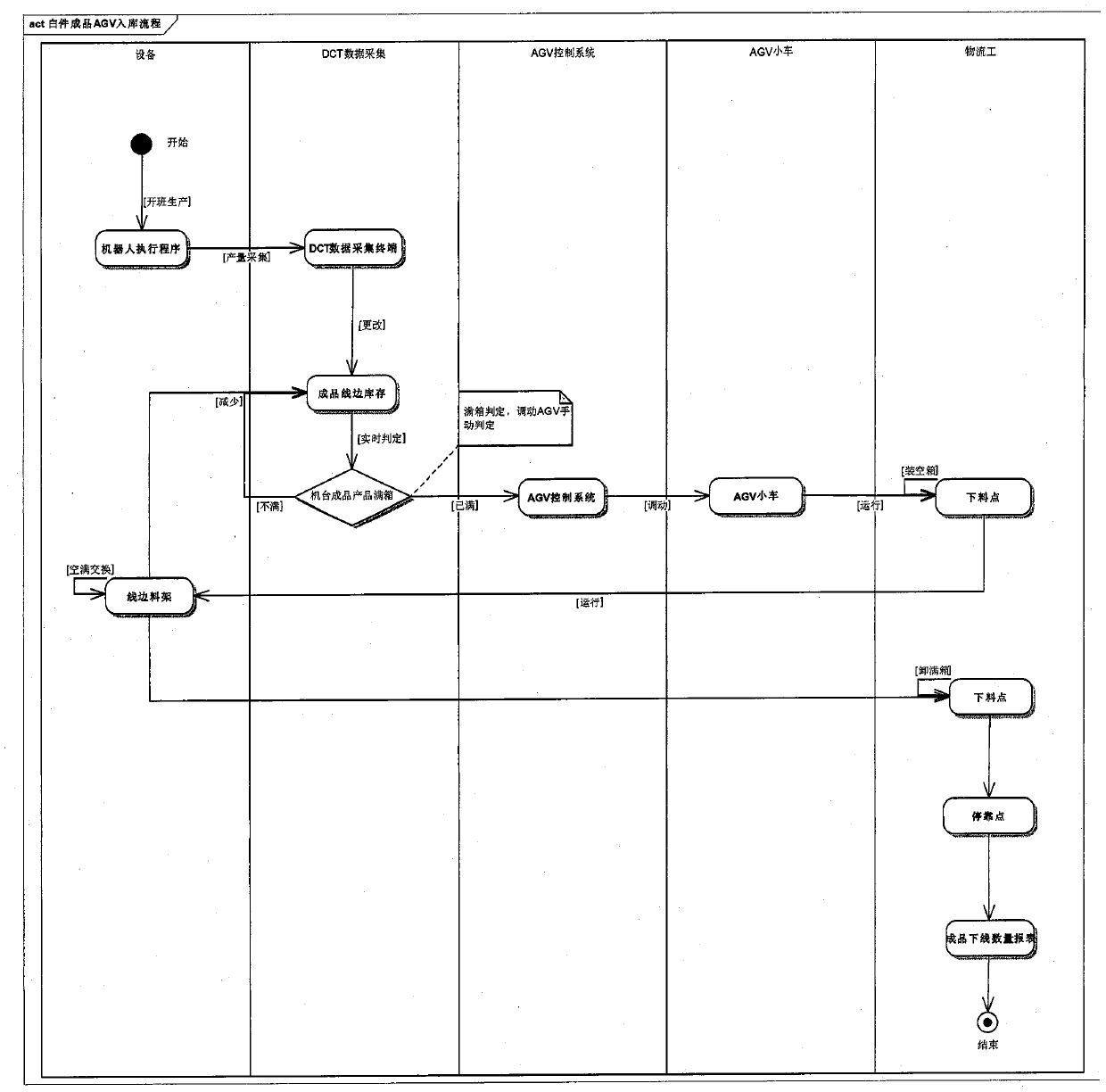

Automated Guided Vehicle control system

InactiveCN110147092ALow costReduce the number of laborPosition/course control in two dimensionsVehiclesProduction logisticsControl system

The invention provides an AGV (Automated Guided Vehicle) control system which belongs to the field of computer programs. People manage logistics of a production site of a factory through the AGV control system and visualize and informationize some data, a manager can better know about situations of the production site through the information, the system can be connected with other systems and is more complete, and by means of a new scheme, the production efficiency of the factory is improved, and the optimal benefit is acquired. By means of the AGV control system, people automatize some hardware, production personnel of the factory become standardized, the factory becomes simple and clear, unnecessary safety accidents generated by walking of the personnel in the production process of the factory are reduced, and more time and cost are saved. The system gives an optimal solution to the production logistics of the factory to the greatest extent, and the manager can better perfect the requirements for the production site by changing a new solution through the system.

Owner:SHANGHAI FENSHI INFORMATION TECH CO LTD

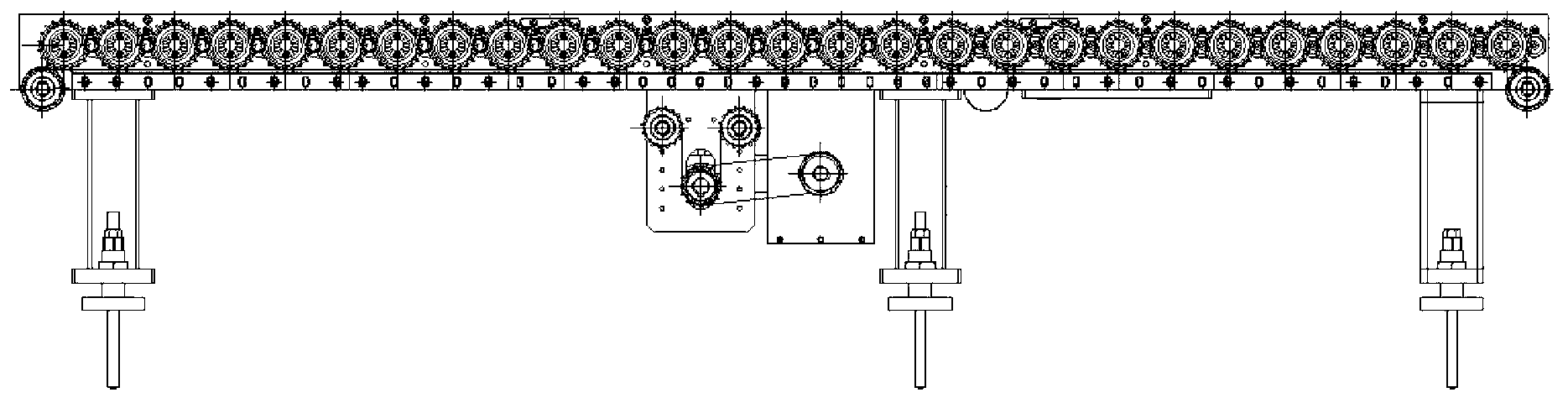

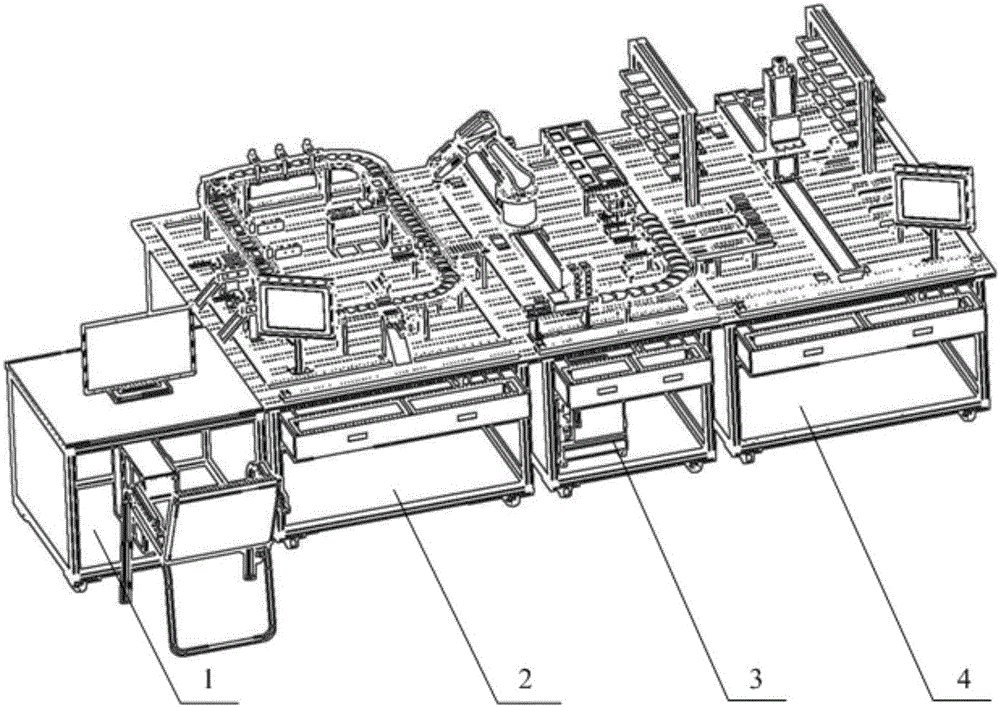

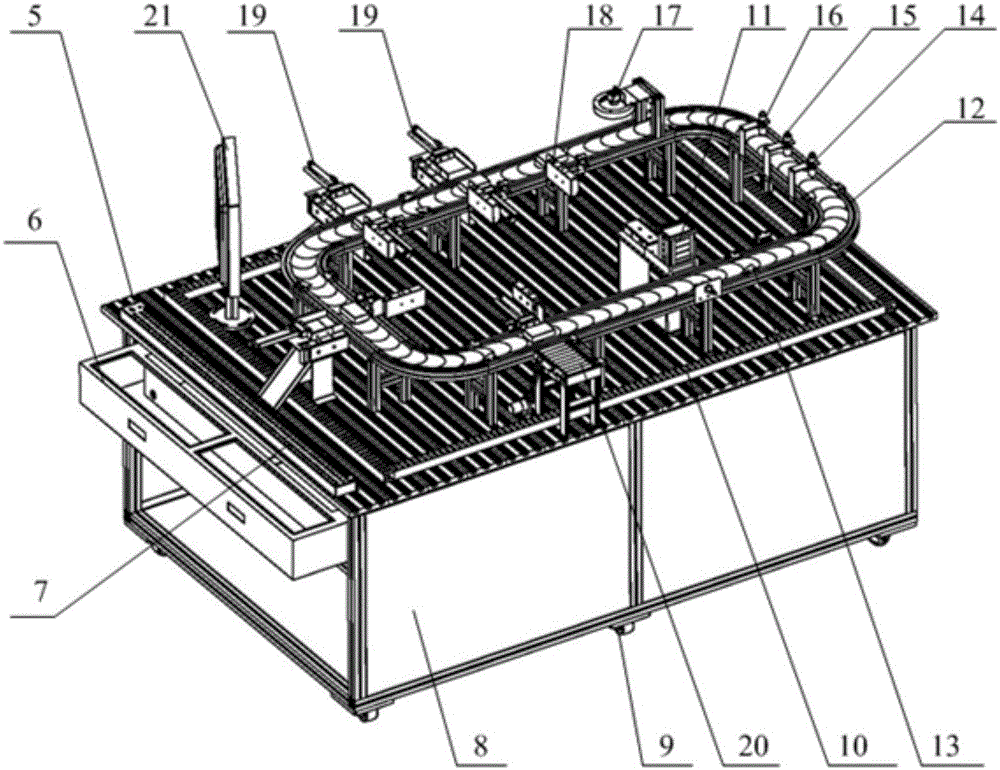

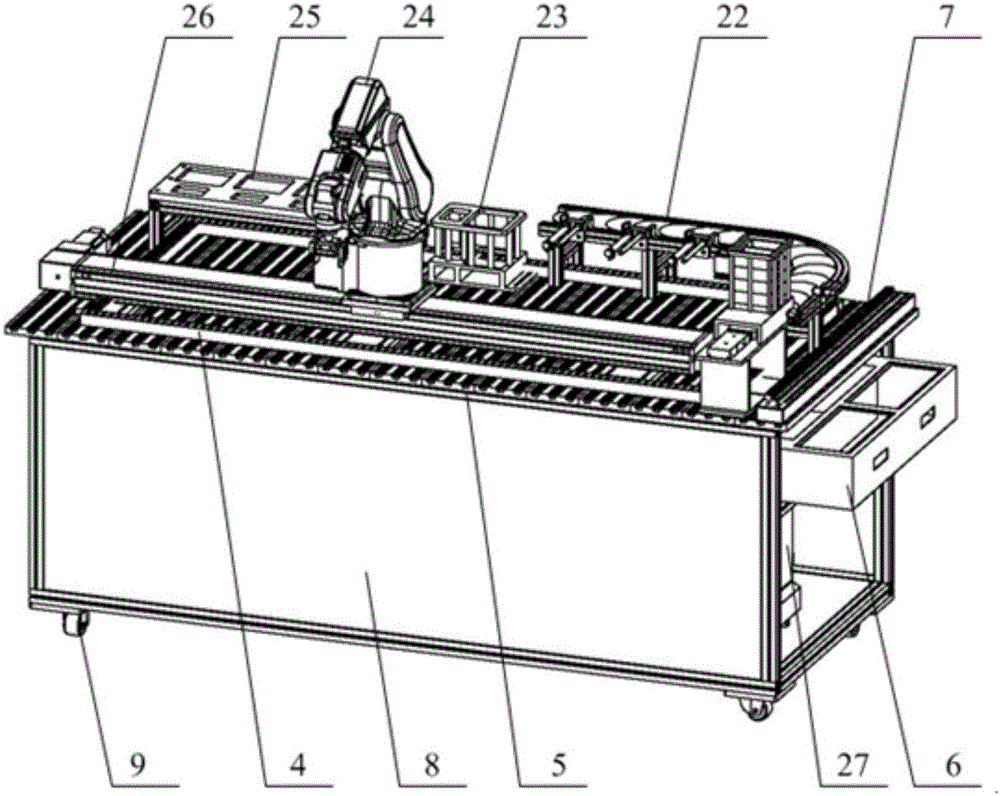

Modular tobacco logistics production line practical training device

ActiveCN105118370AMeet actual needsMeet Production TrainingEducational modelsProduction logisticsLogistics management

The invention discloses a modular tobacco logistics production line practical training device. The modular tobacco logistics production line practical training device comprises an annular convey station used for testing materials and eliminating unqualified materials, a three-dimensional elevated storehouse station used for storing the materials, a sorting and stacking station arranged between the annular convey station and the three-dimensional elevated storehouse station, and a monitoring station, wherein the annular convey station is provided with an eliminating device and a test apparatus for testing the materials, the sorting and stacking station is provided with industrial mechanical arms which are used for grabbing the materials and arranging the materials on the annular convey station or the three-dimensional elevated storehouse station, and the monitoring station is provided with a main controller and a display which is used for checking operating condition, wherein the main controller is connected with the annular convey station, the three-dimensional elevated storehouse station and the sorting and stacking station respectively. The practical training device satisfies actual requirements of tobacco production enterprises. The practical training device is designed and developed through adopting a modularization method. With the practical training device adopted, requirements of tobacco production enterprises in production training of employees can be satisfied, and excessive use of production logistics lines of the enterprises can be avoided, and economic efficiency can be improved.

Owner:CHINA TOBACCO SICHUAN IND CO LTD

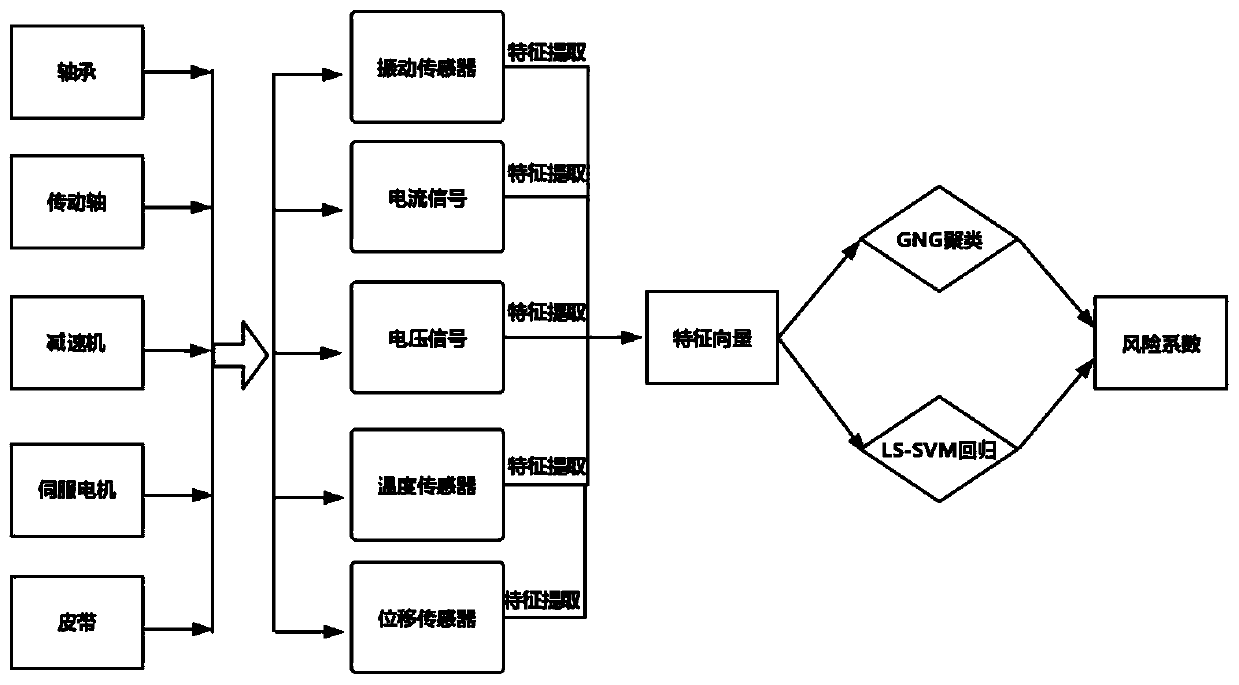

Fault early warning method for production logistics conveying equipment

ActiveCN110322048ATesting/monitoring control systemsKernel methodsProduction logisticsModel parameters

The invention discloses a fault early warning method for production logistics conveying equipment. The method comprises steps of carrying out feature extraction and dimension reduction processing on historical signal data obtained by the sensor; after the feature vector is obtained, on one hand, dividing the normal state data into multiple working conditions by using a growth-type neural gas (GNG)algorithm to obtain a plurality of clustering centers, and calculating the Euclidean distance between the feature vector obtained by the current operation data and the clustering centers to obtain asimilarity trend; on the other hand, constructing a historical memory matrix, and optimizing the LS-SVM regression on the model parameters by an improved particle swarm algorithm; calculating the residual value of the current state; finally, combining the residual value and the similarity trend to obtain a risk coefficient, evaluating the equipment state, and giving an early warning for the equipment fault. According to the method, the fault real-time early warning technology of the production logistics conveying equipment is achieved, reference is provided for timely maintenance of the equipment, and economic losses caused by shutdown due to equipment faults are avoided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

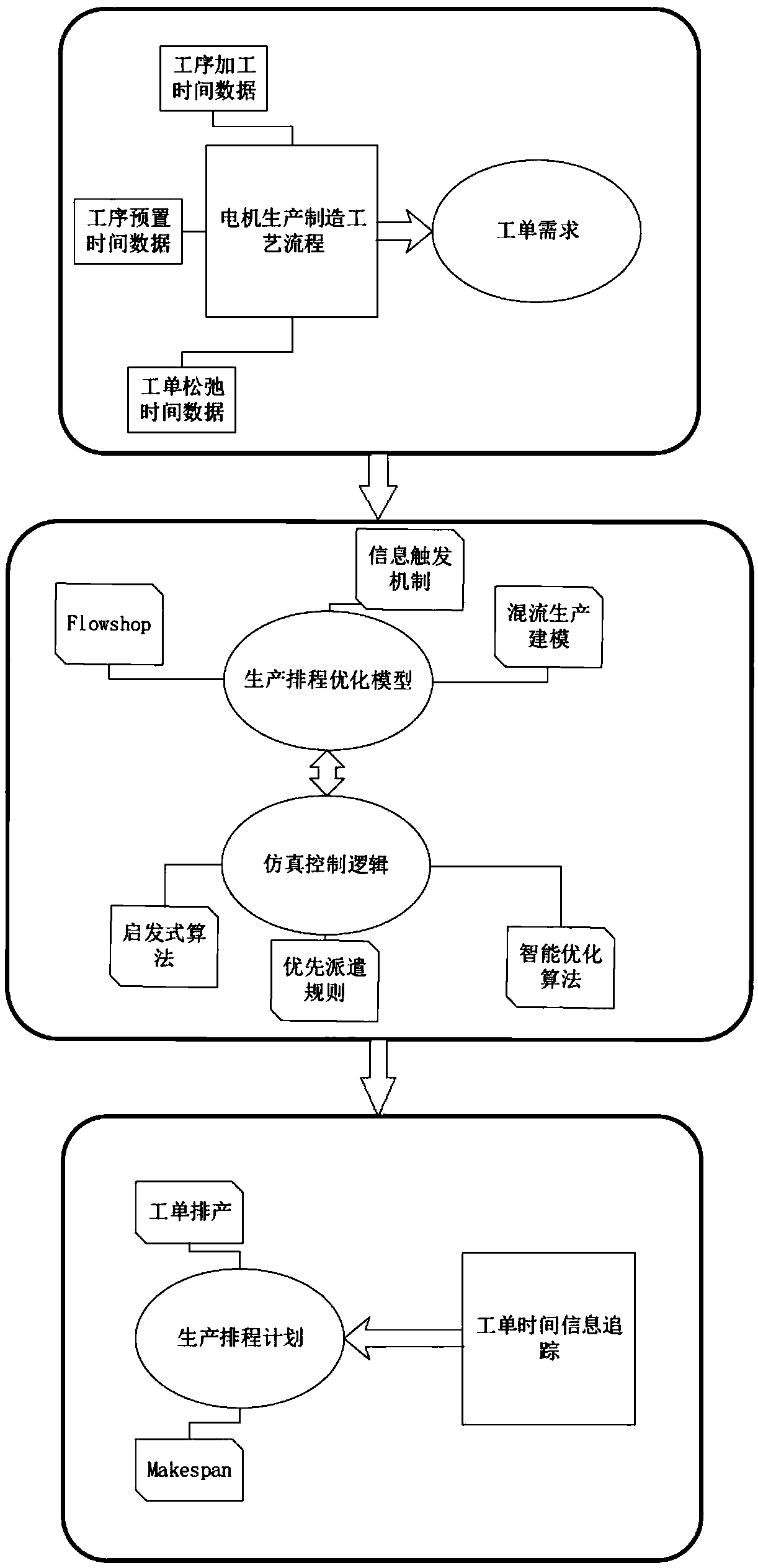

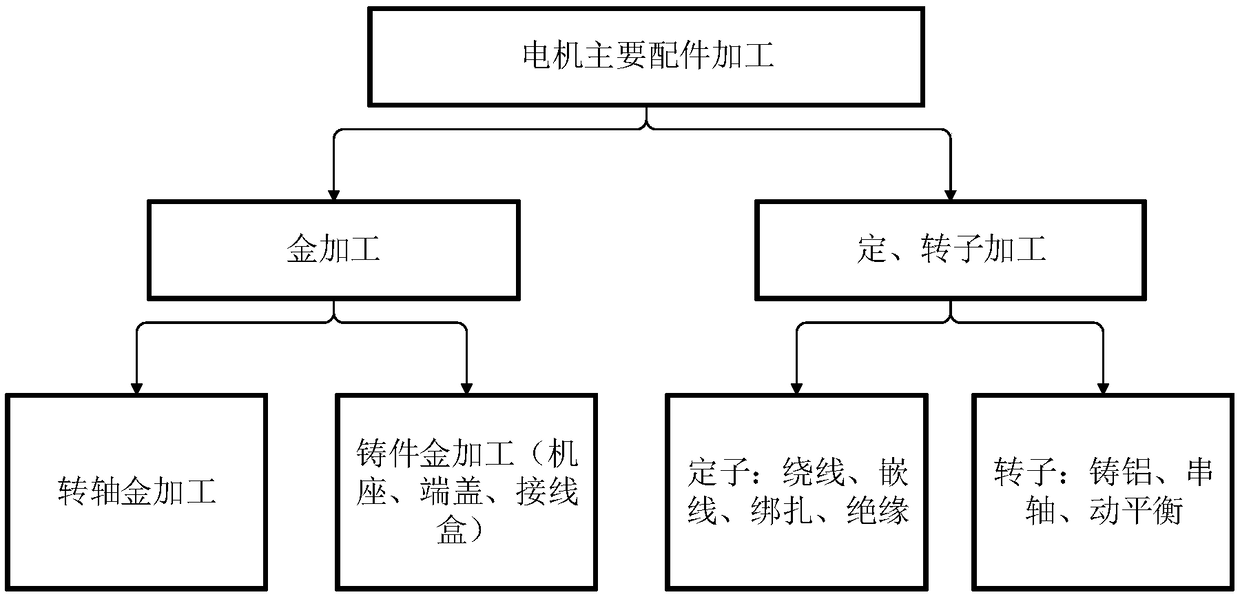

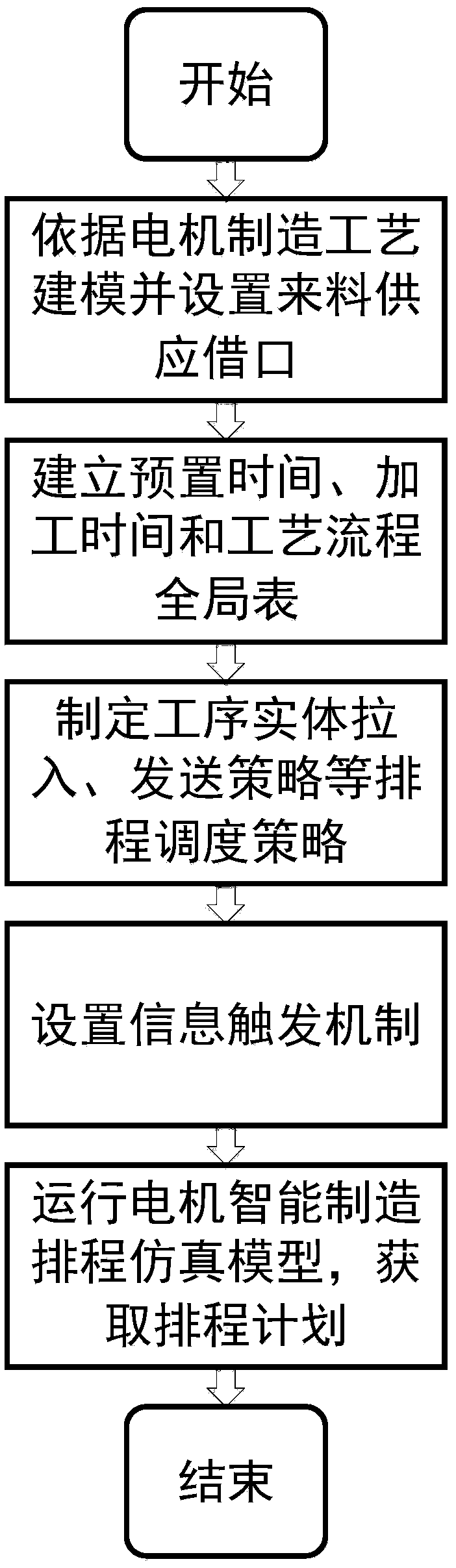

A scheduling method for intelligent manufacturing of electric machines based on logistics simulation

InactiveCN109508956ALower average wait timeReduce replacementManufacturing dynamo-electric machinesOffice automationMixed flowProduction logistics

The invention provides a scheduling method for intelligent manufacturing of electric machines based on logistics simulation, The simulation optimization technology is applied, A layerer modeling is carried out on that production logistics of the intelligent manufacturing of the actual electric motor, With the help of the information trigger mechanism of the simulation system, the comprehensive heuristic optimization algorithm and the priority dispatch rule are used to control the simulation logic. The debugging results are verified by the simulation model and the scheduling plan is given to enhance the flexibility of the intelligent manufacturing assembly line of the motor, so as to cope with the highly mixed-flow production situation of multiple varieties and small batches.

Owner:SHANGHAI JIAO TONG UNIV

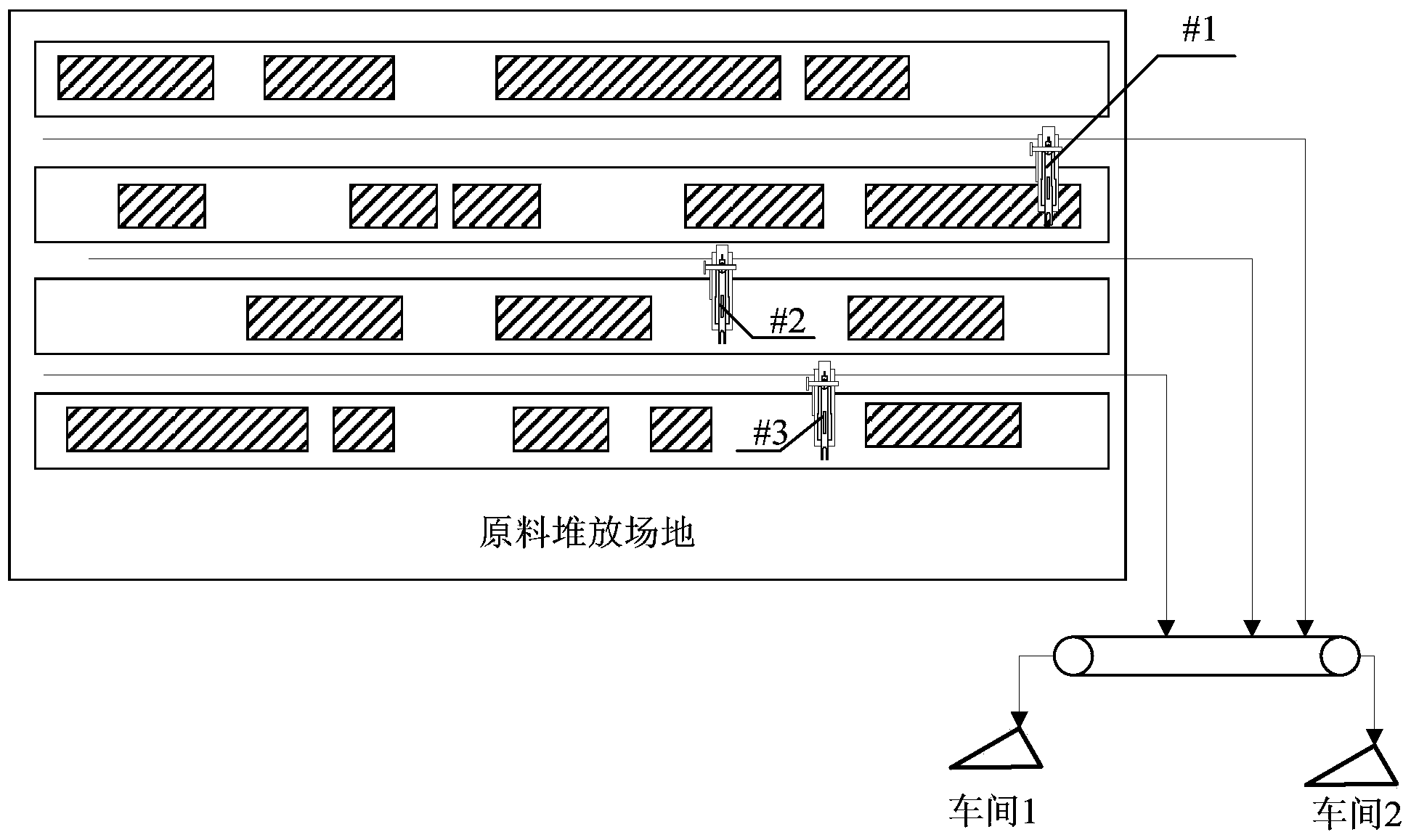

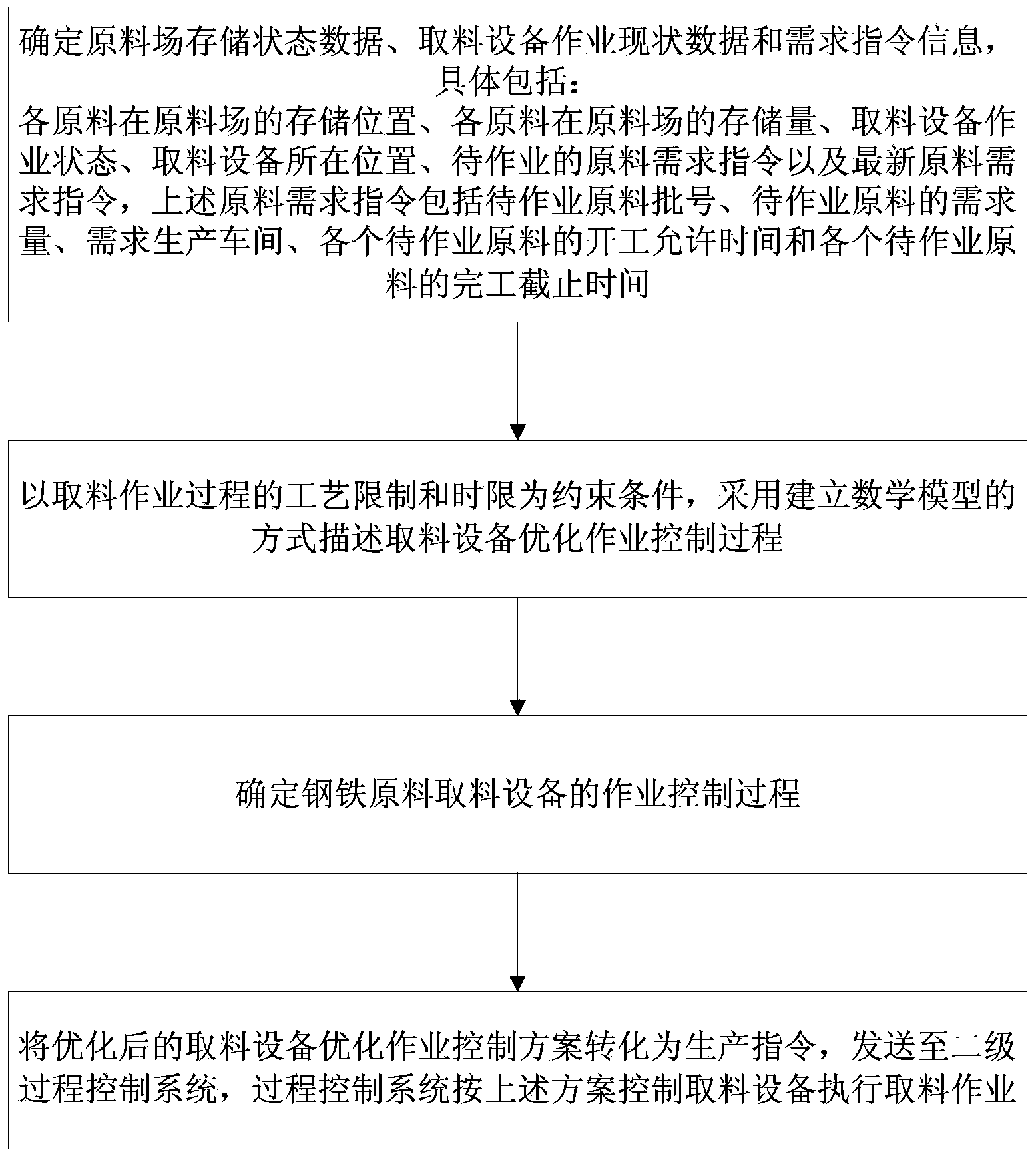

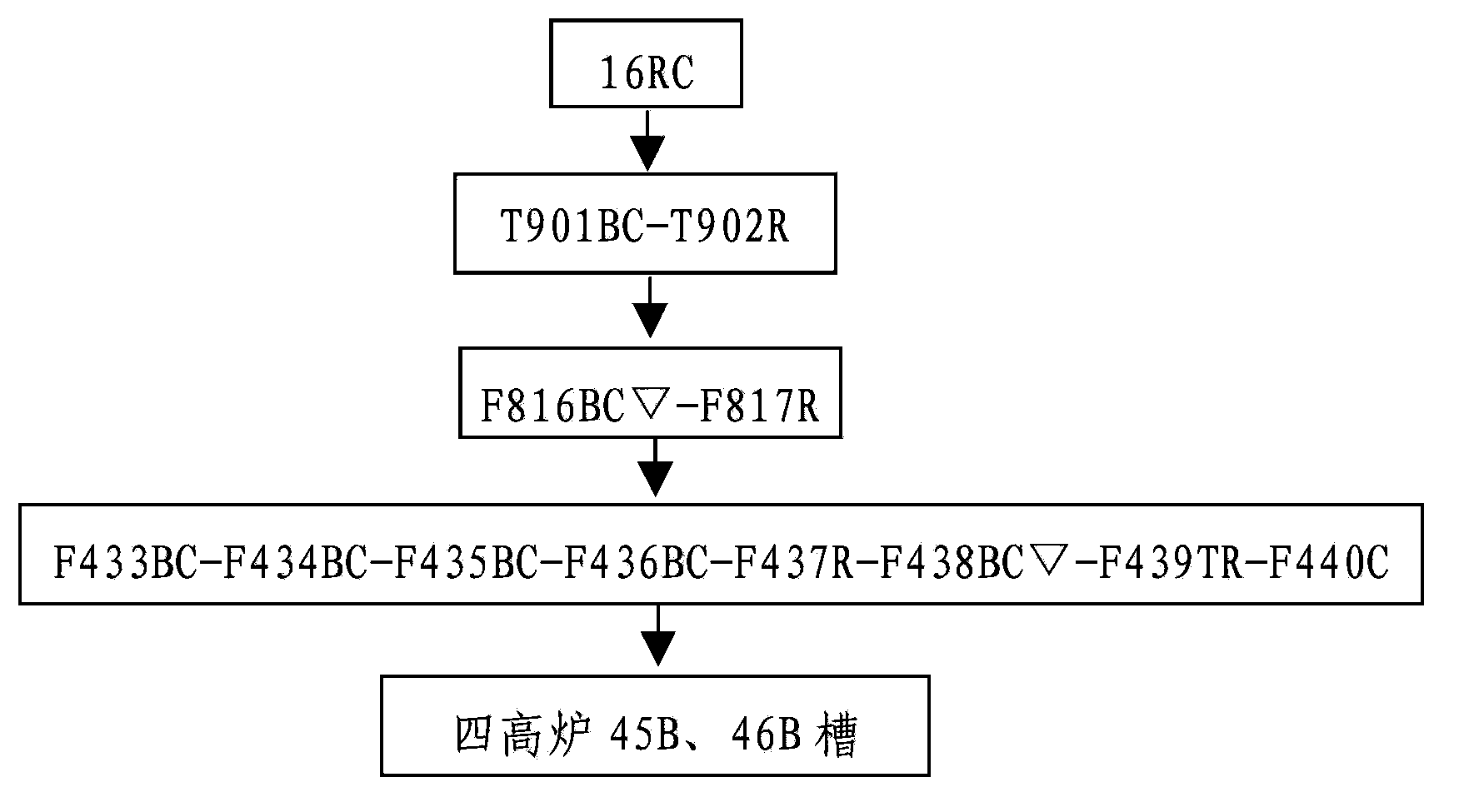

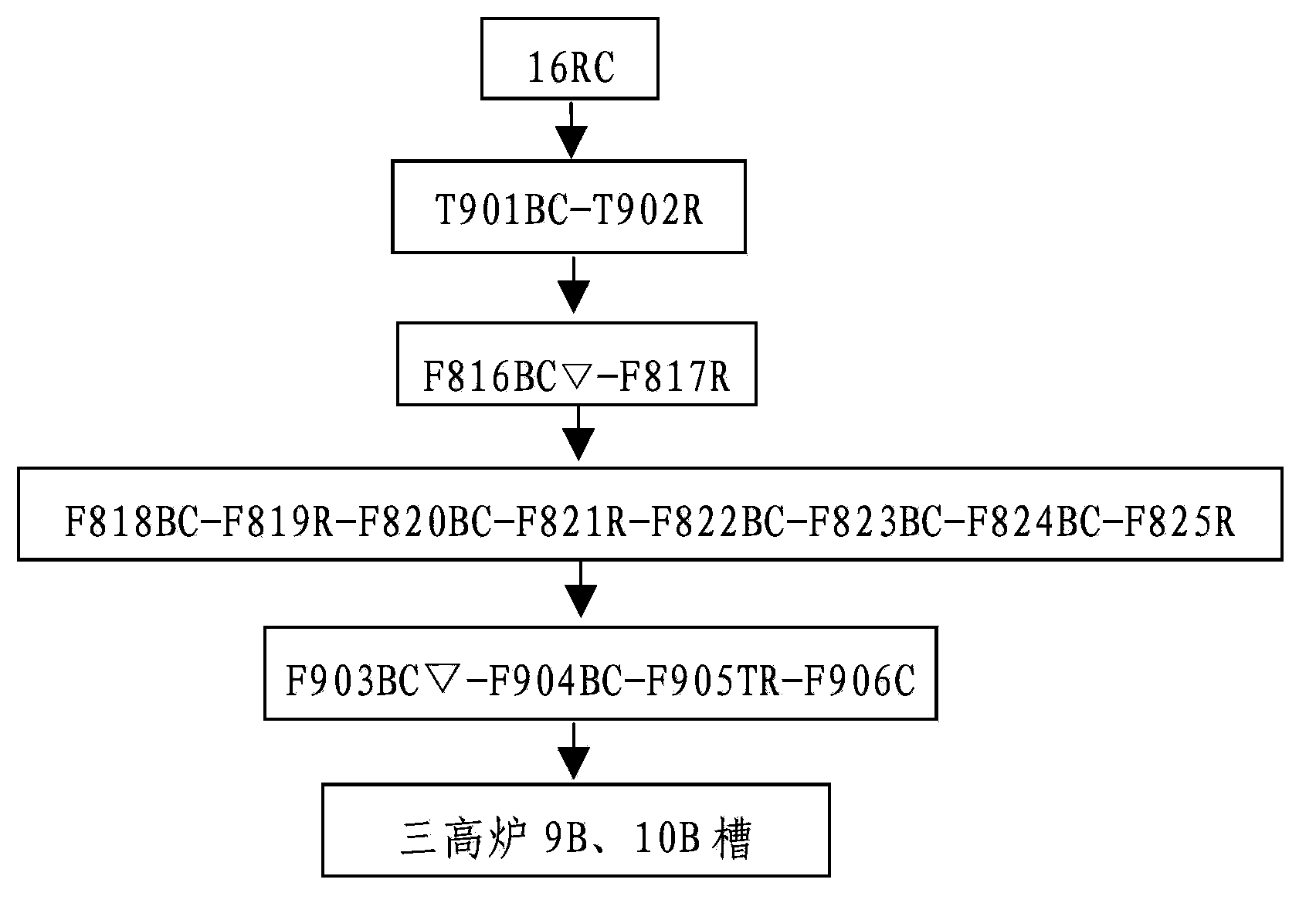

Optimized operation control method for raw material taking equipment in iron and steel enterprise

ActiveCN103529805AAvoid issues such as supply disruptionsGuaranteed uptimeTotal factory controlProgramme total factory controlProduction logisticsMathematical model

The invention relates to an optimized operation control method for raw material taking equipment in an iron and steel enterprise and belongs to the technical field of iron and steel raw material production logistics. According to the invention, process characteristics in the control process of the iron and steel raw material taking equipment are scientifically and quantitatively described by a mathematical model; on the basis of the process characteristics, the taking equipment is subjected to operation control by adopting an intelligent optimization algorithm to enable a raw material taking and transmission production system to be in the optimal working state, so that the problems of interruption of raw material supply and the like which are caused by unreasonable distribution to a great extent, the stable operation and balanced production of the equipment are guaranteed, the utilization rate of the equipment is improved, the production cycle is shortened and the production efficiency is improved.

Owner:NORTHEASTERN UNIV

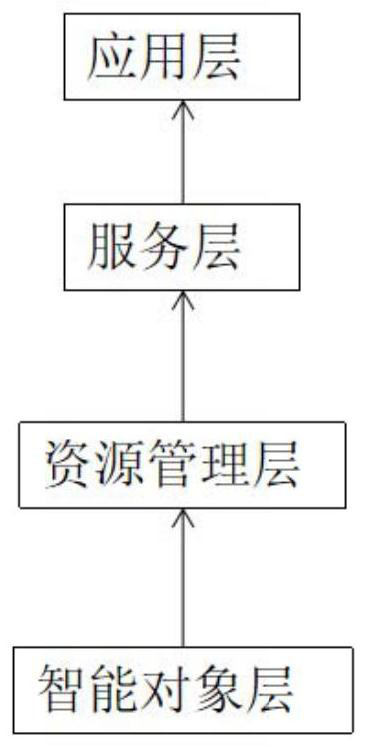

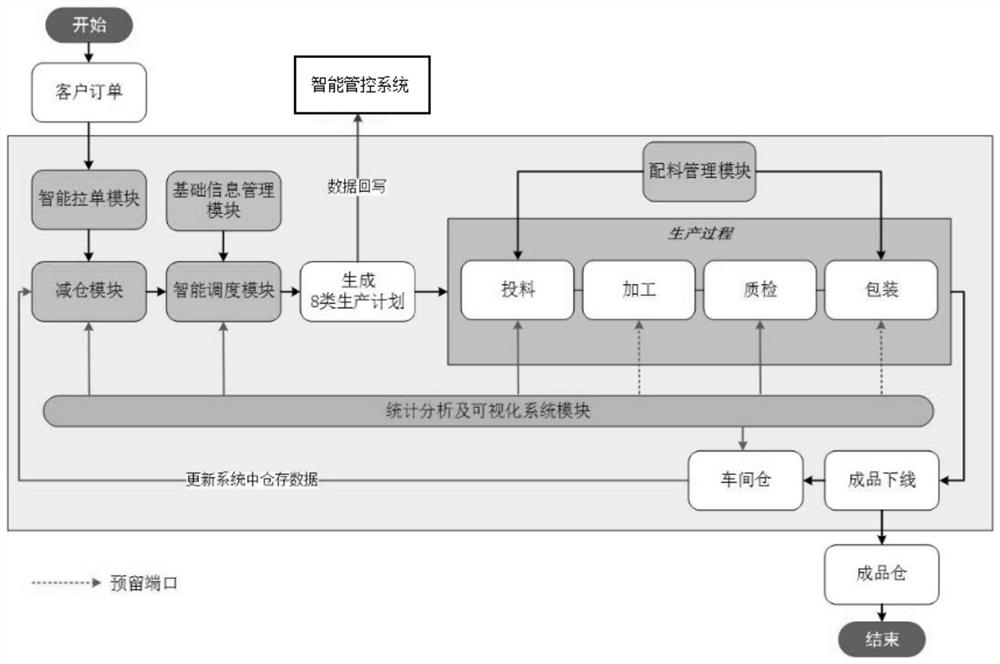

Intelligent management and control system for high-dynamic production logistics process

ActiveCN111915410ASolve the problem of information collectionWeaken Strong Coupling ConfigurationBuying/selling/leasing transactionsResourcesLogistics managementProduction logistics

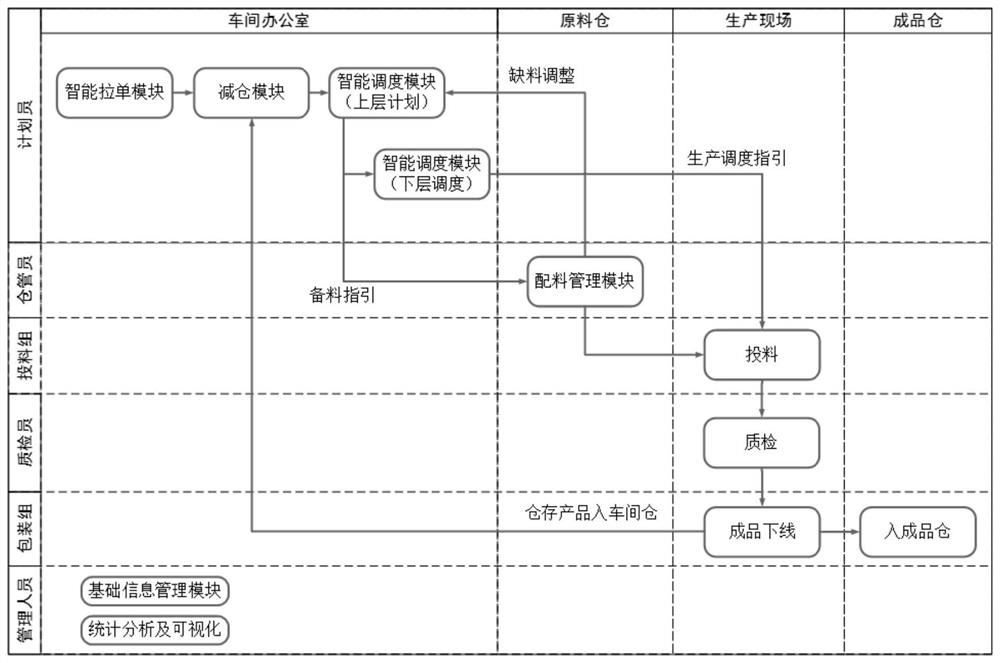

The invention provides an intelligent management and control system for a high-dynamic production logistics process, and relates to the technical field of logistics management and control, and the system comprises a production logistics management and control platform of an intelligent object, and the production logistics management and control platform of the intelligent object comprises an application layer; wherein the application layer comprises an intelligent order pulling module, a warehouse reduction module, an intelligent scheduling module, a batching management module, a statistical analysis and visualization module and a basic information management module; the intelligent order pulling module is used for pulling customer orders into the module order pools and sequentially putting the orders into the corresponding workshop order pools, the orders in each workshop order pool are sorted according to the delivery date, the orders are combined according to the productivity and related rules, and a production plan of the day is generated; according to the intelligent management and control system provided by the invention, the problems that planners cannot obtain sales order information from the global perspective for optimization decision due to an original order placing mode, and linkage orders cannot be produced and offline by each workshop at the same time are solved.

Owner:JINAN UNIVERSITY

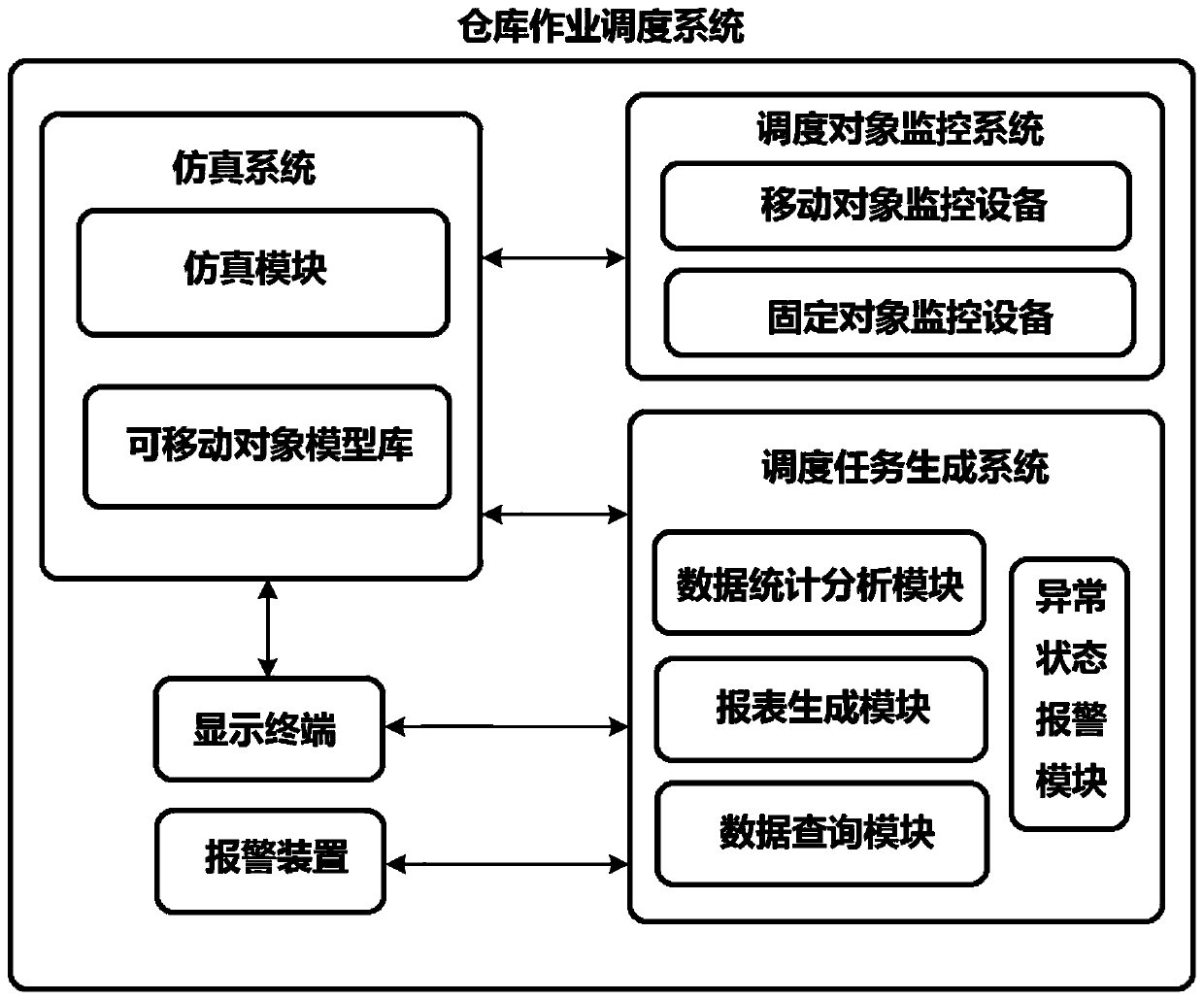

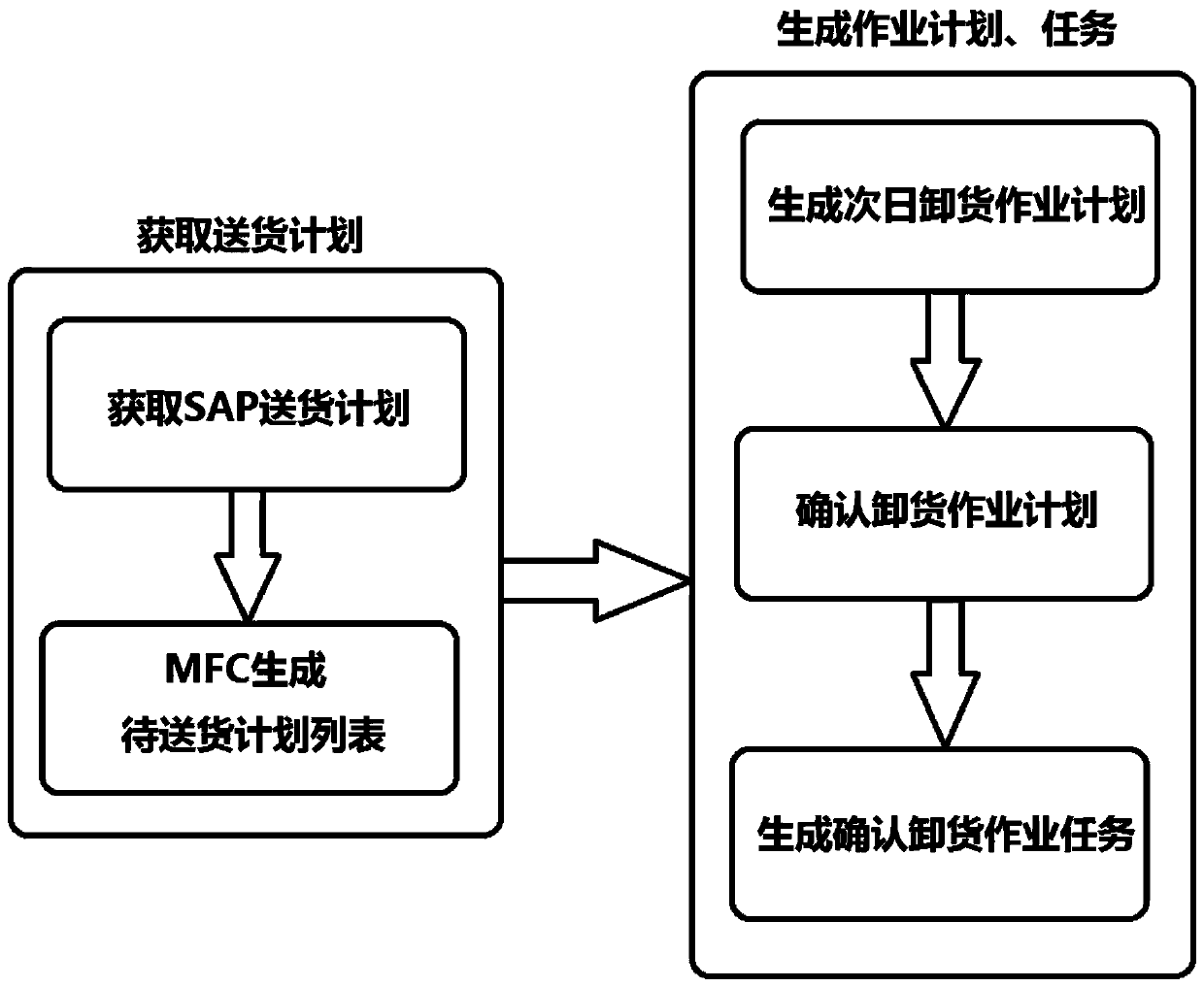

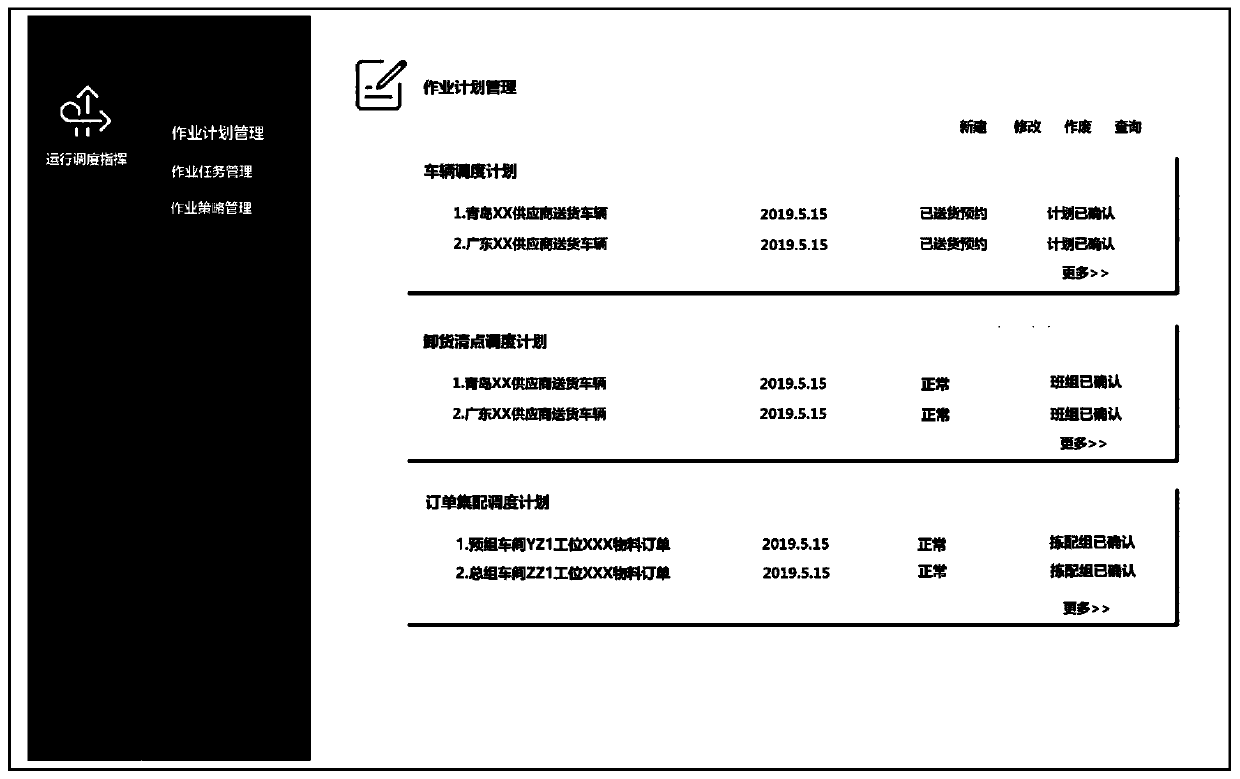

Warehouse operation scheduling system

InactiveCN110516939AEasy to controlAchieve real-time interoperabilityResourcesLogisticsOperation schedulingProduction logistics

The invention belongs to the field of intelligent management of production logistics warehouses, particularly relates to a warehouse operation scheduling system, and aims to solve the problems of lowwarehouse scheduling management accuracy and efficiency. The system comprises a scheduling object monitoring system used for collecting and sending monitoring information of a preset category and receiving a scheduling instruction issued by a scheduling task generation system; a simulation system which is used for realizing model movement according to a preset logic and updating a model state according to the monitoring information uploaded by the scheduling object monitoring system; and a scheduling task generation system which is used for acquiring monitoring information of a preset categoryfrom the scheduling object monitoring system, acquiring input operation plan information and generating a scheduling instruction according to a built-in operation plan. According to the system, eachpiece of information in warehouse operation is known at the first time through a clear simulated three-dimensional view, the whole warehouse operation process is rapidly and accurately controlled, warehouse scheduling display is more accurate, and the efficiency of cooperative work is improved.

Owner:中科富创(北京)智能系统技术有限公司 +1

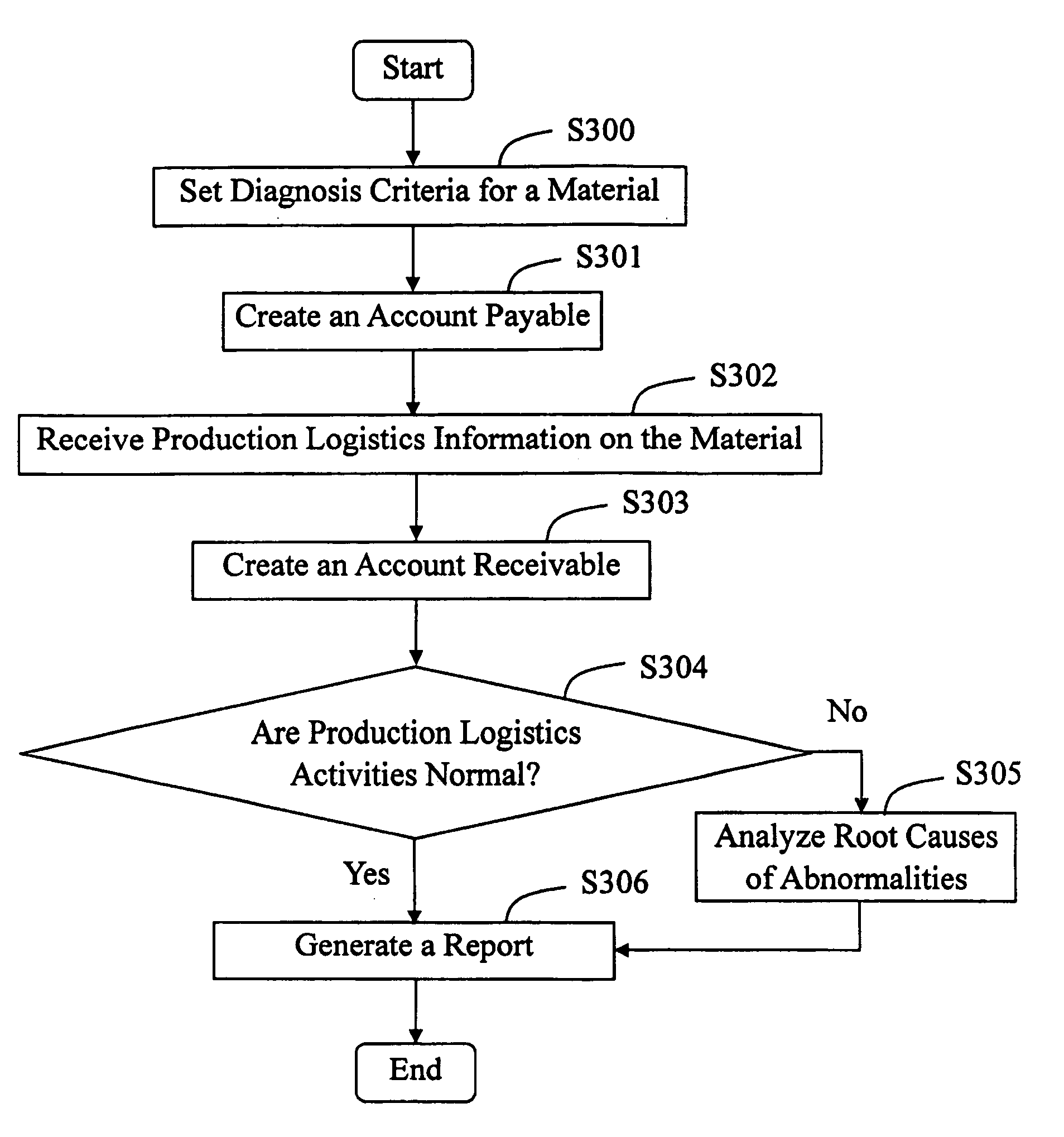

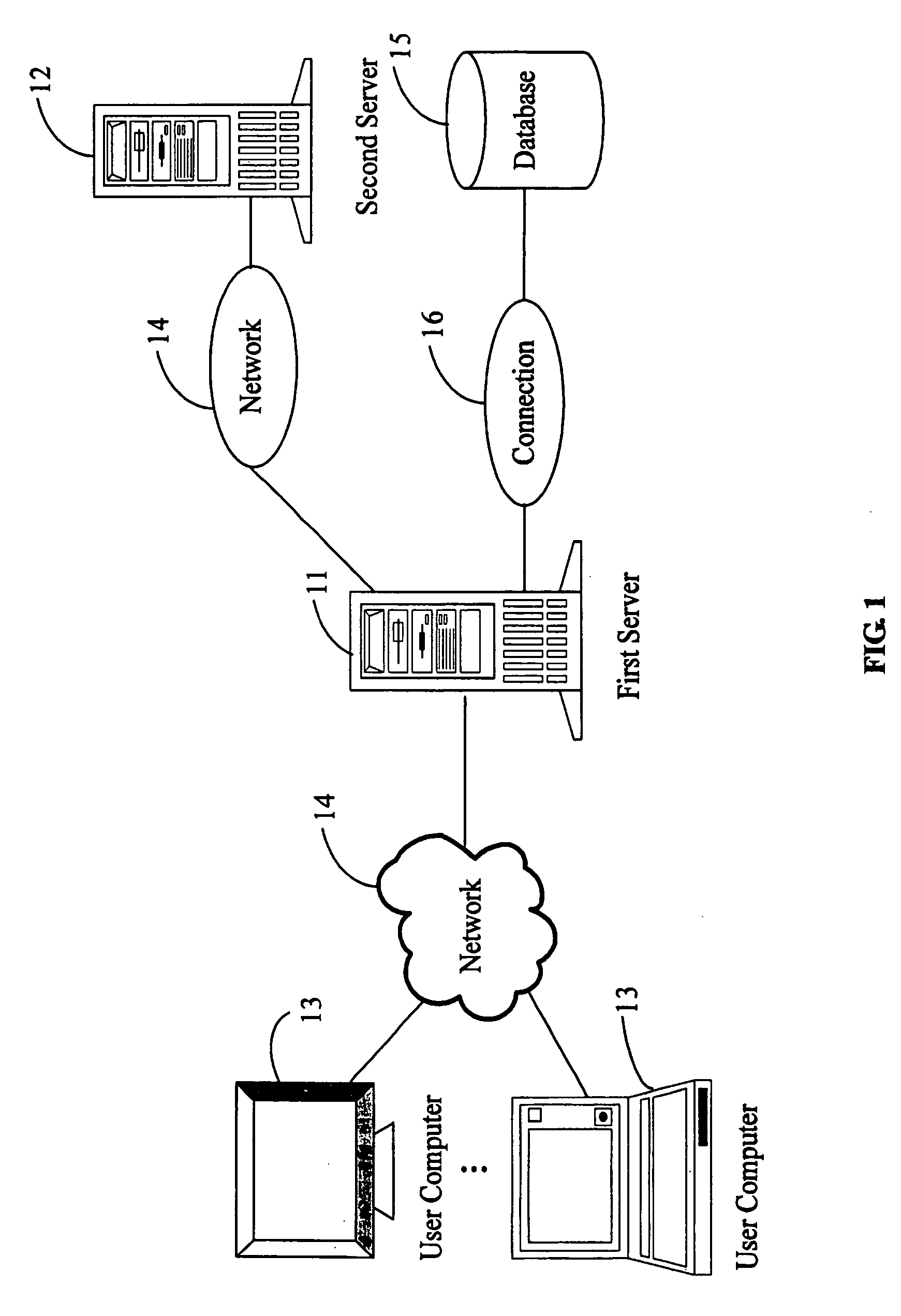

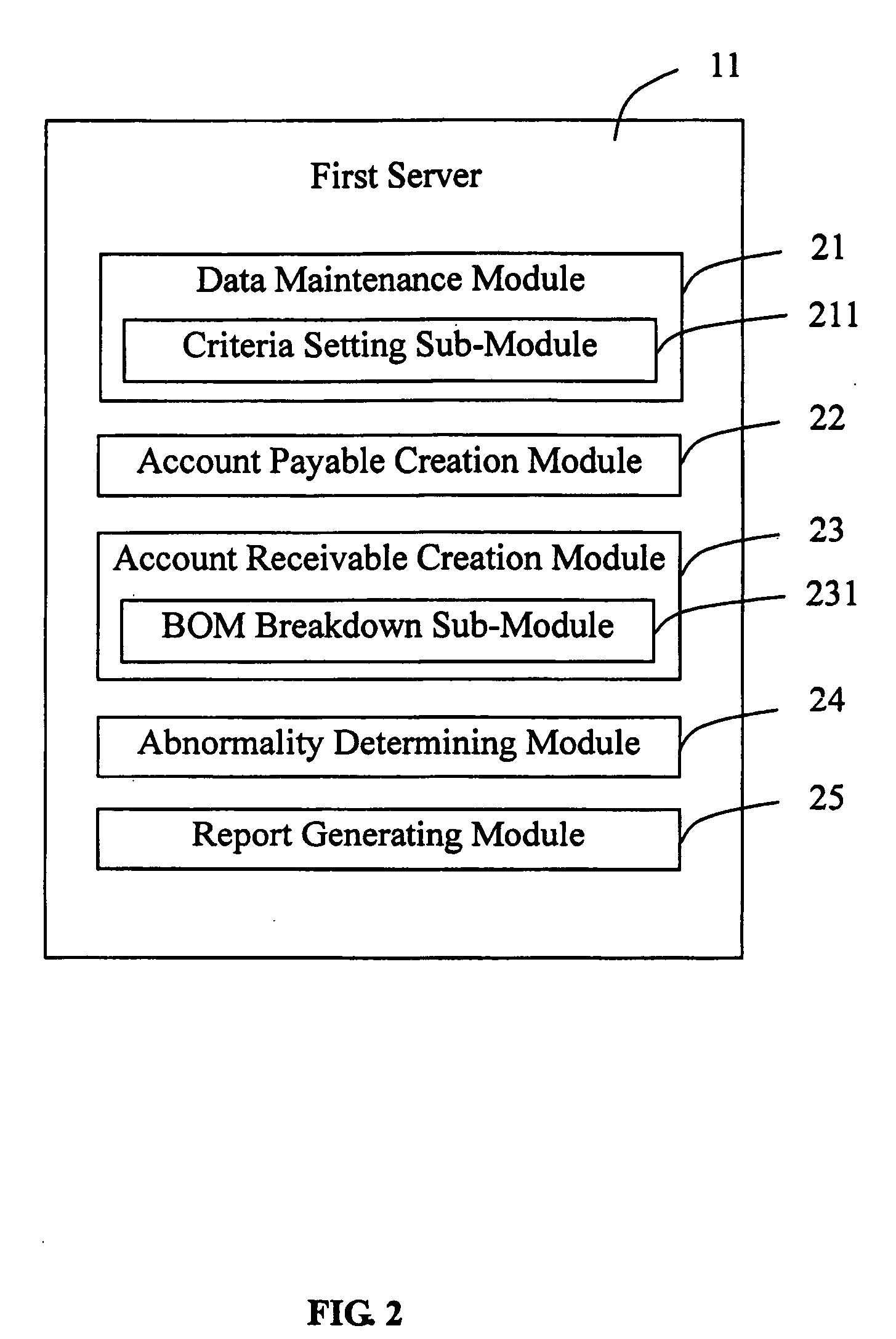

System and method for diagnosing production logistics abnormalities

InactiveUS20050108073A1Easy to identifyResourcesSpecial data processing applicationsProduction logisticsAccounts payable

A system for diagnosing production logistics abnormalities includes a first server (11) and a second server (12). The second server transmits production logistics information to the first server. The first server analyzes the received information, and determines whether production logistics activities are abnormal. The first server includes: a data maintenance module (21) including a criteria setting sub-module (211) for setting diagnosis criteria; an account payable creation module (22) for creating an account payable including an account payable creation date when a material is purchased; an account receivable creation module (23) for creating an account receivable including an account receivable creation date when a product incorporating the material is sold; and an abnormality determining module (24) for comparing a time period between the account payable creation date and the account receivable creation date and a preset time interval, to determine whether the production logistics activities of the material are abnormal.

Owner:HON HAI PRECISION IND CO LTD

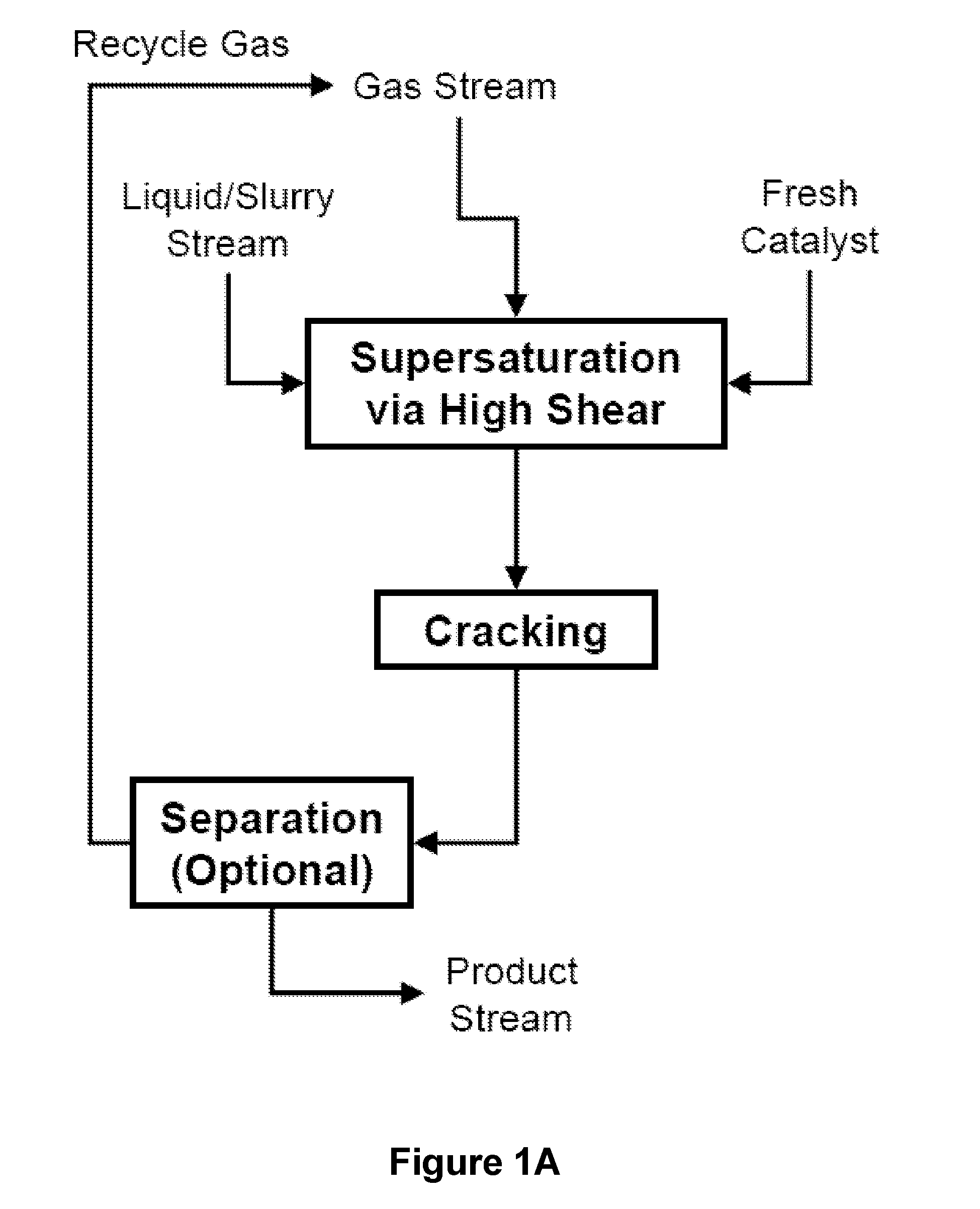

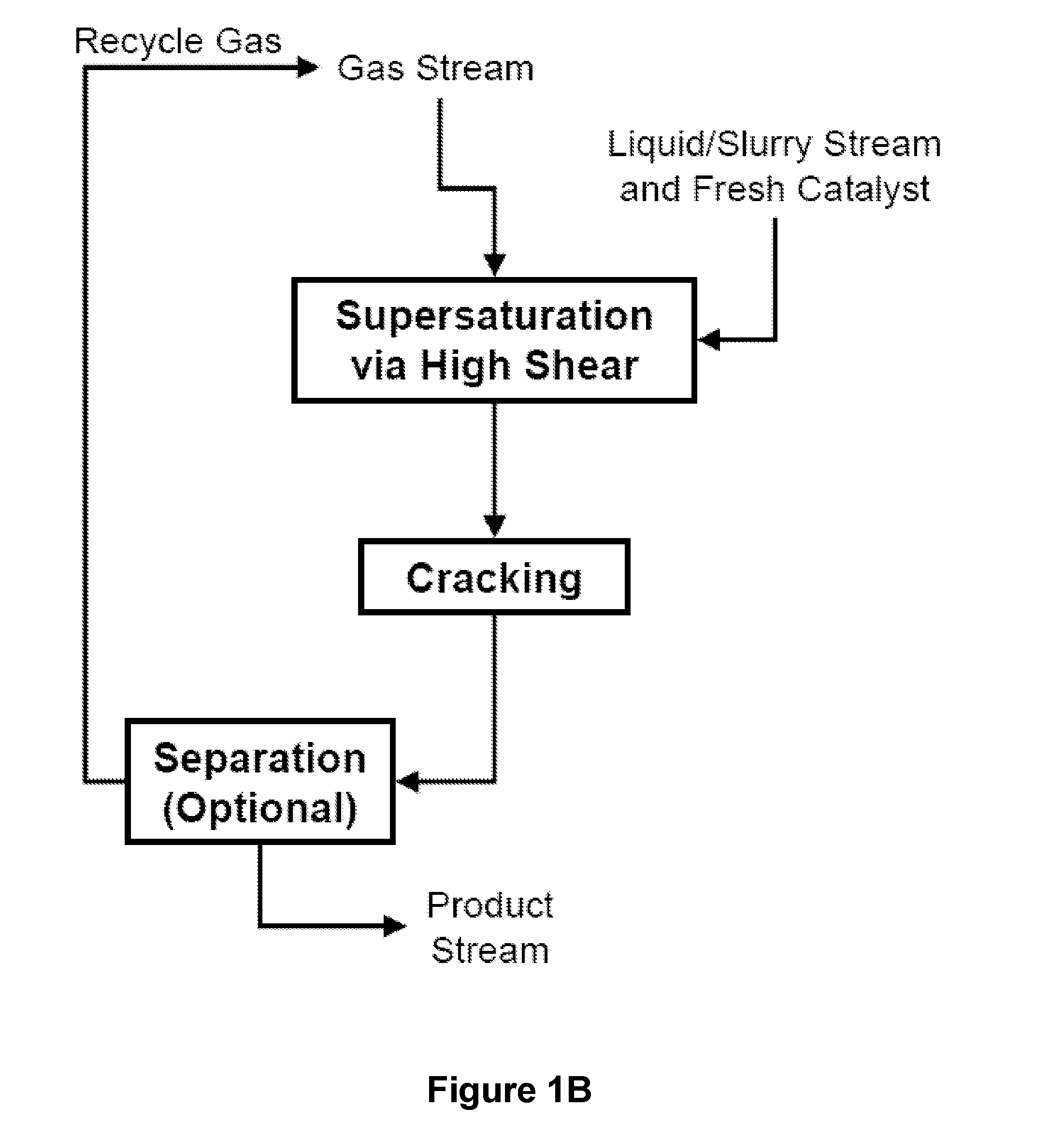

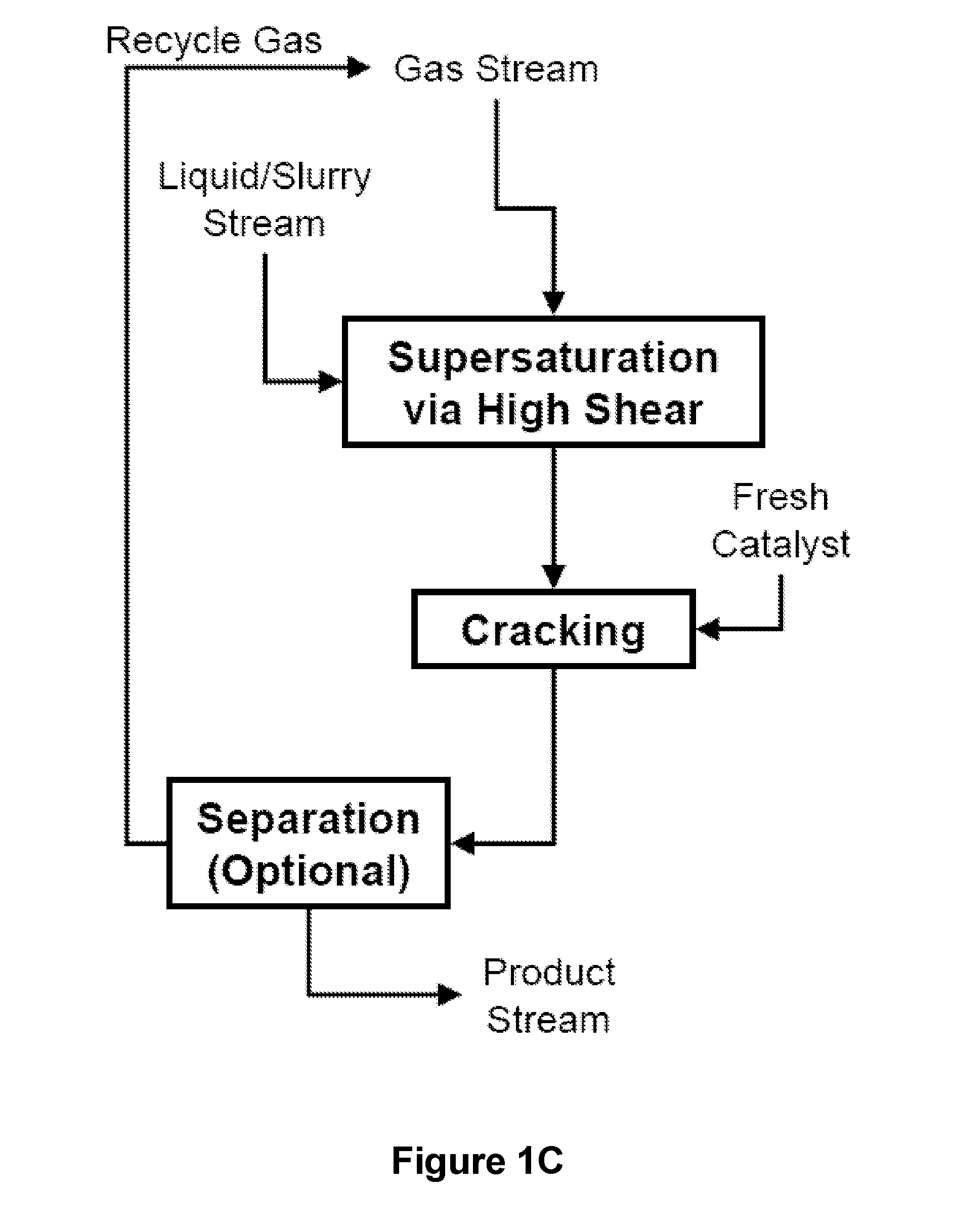

System and process for hydrocracking and hydrogenation

InactiveUS20140209509A1Promote formationPromotes formationRotary stirring mixersMixing methodsProduction logisticsHydrogen

Herein disclosed is a method for hydrogenation comprising: supersaturating a hydrocarbonaceous liquid or slurry stream in a high shear device with a gas stream comprising hydrogen and optionally one or more C1-C6 hydrocarbons to form a supersaturated dispersion; and introducing the supersaturated dispersion into a reactor in the presence of a hydrogenation catalyst to generate a product stream. In some embodiments, the catalyst is present as a slurry or a fluidized or fixed bed of catalyst. In some embodiments, the hydrogenation catalyst is mixed with the hydrocarbonaceous liquid or slurry stream and the gas stream in the high shear device. In some embodiments, the method further comprises recycling at least a portion of an off gas from the reactor, recycling at least a portion of the product stream from the reactor, or both. Also disclosed herein is a system for hydrogenation.

Owner:HRD CORP

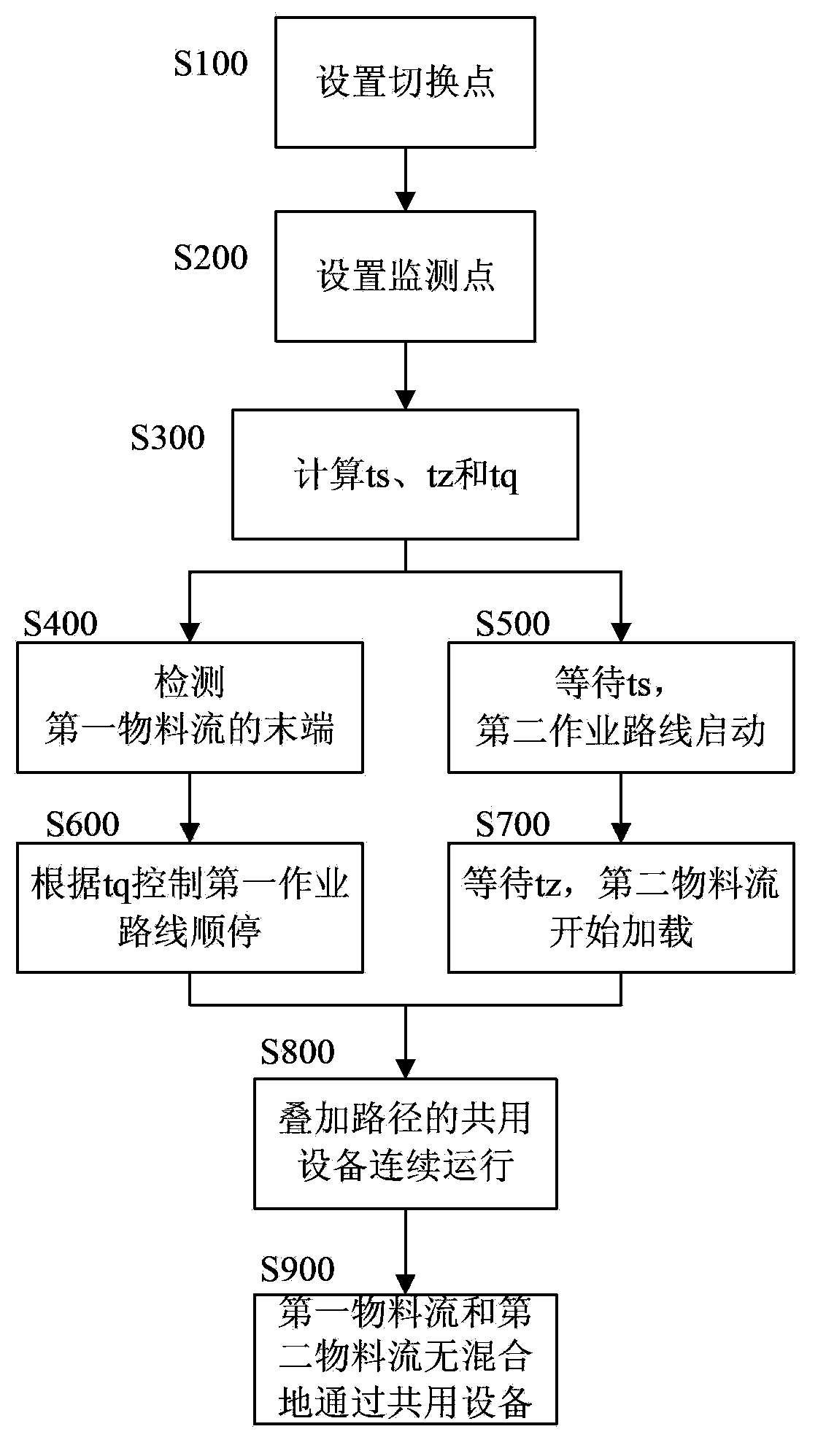

Control method of overlaying-type logistics conveying system

ActiveCN103625880ASavings startShorten the timeControl devices for conveyorsElectricityContinuous/uninterrupted

The invention relates to a control method suitable for metallurgy industry production logistics conveying, in particular to a control method of an overlaying-type logistics conveying system. The control method is especially suitable for controlling over metallurgy crude fuel conveying. The overlaying-type logistics conveying system at least comprises a first working line and a second working line. Each working line comprises a plurality of material conveying devices which are connected in sequence. At least one section of each of the two working lines comprises an overlaying line of a shared conveying device, and a material monitoring device is arranged on the overlaying line. The shared device of the overlaying line runs continuously. Material monitoring devices are arranged at monitoring points on the working lines, the fact that material flow passes through the shared device of the overlaying line in sequence without being mixed in the working lines is monitored in real time, by overlaying using of the working lines, starting and stopping time of logistics system equipment is saved, the conveying speed of materials is effectively accelerated, idle operation time of rubber belt conveying equipment is shortened, the equipment using rate is improved, and waste of electricity resources caused by idle operation of the equipment is lowered.

Owner:BAOSHAN IRON & STEEL CO LTD

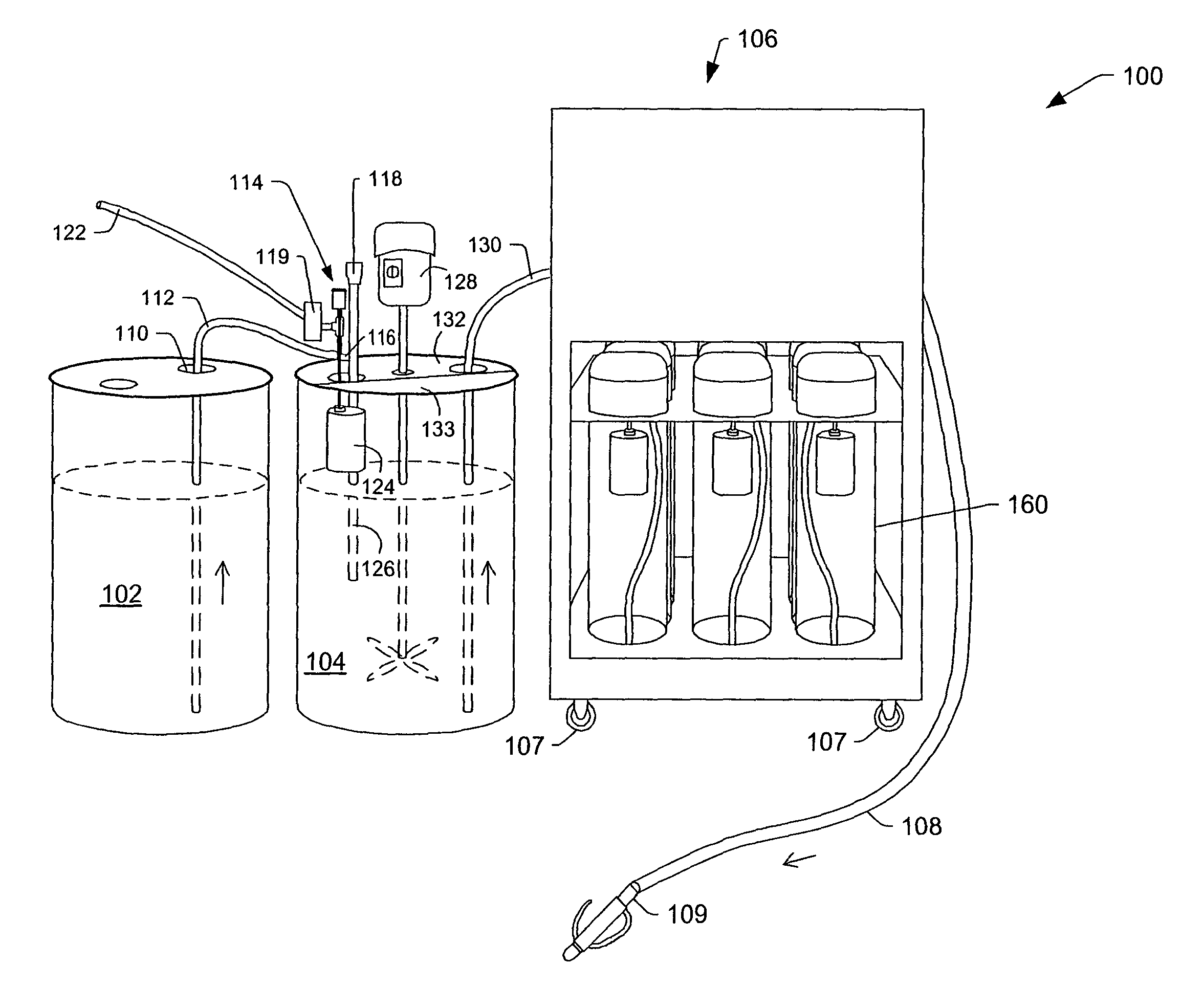

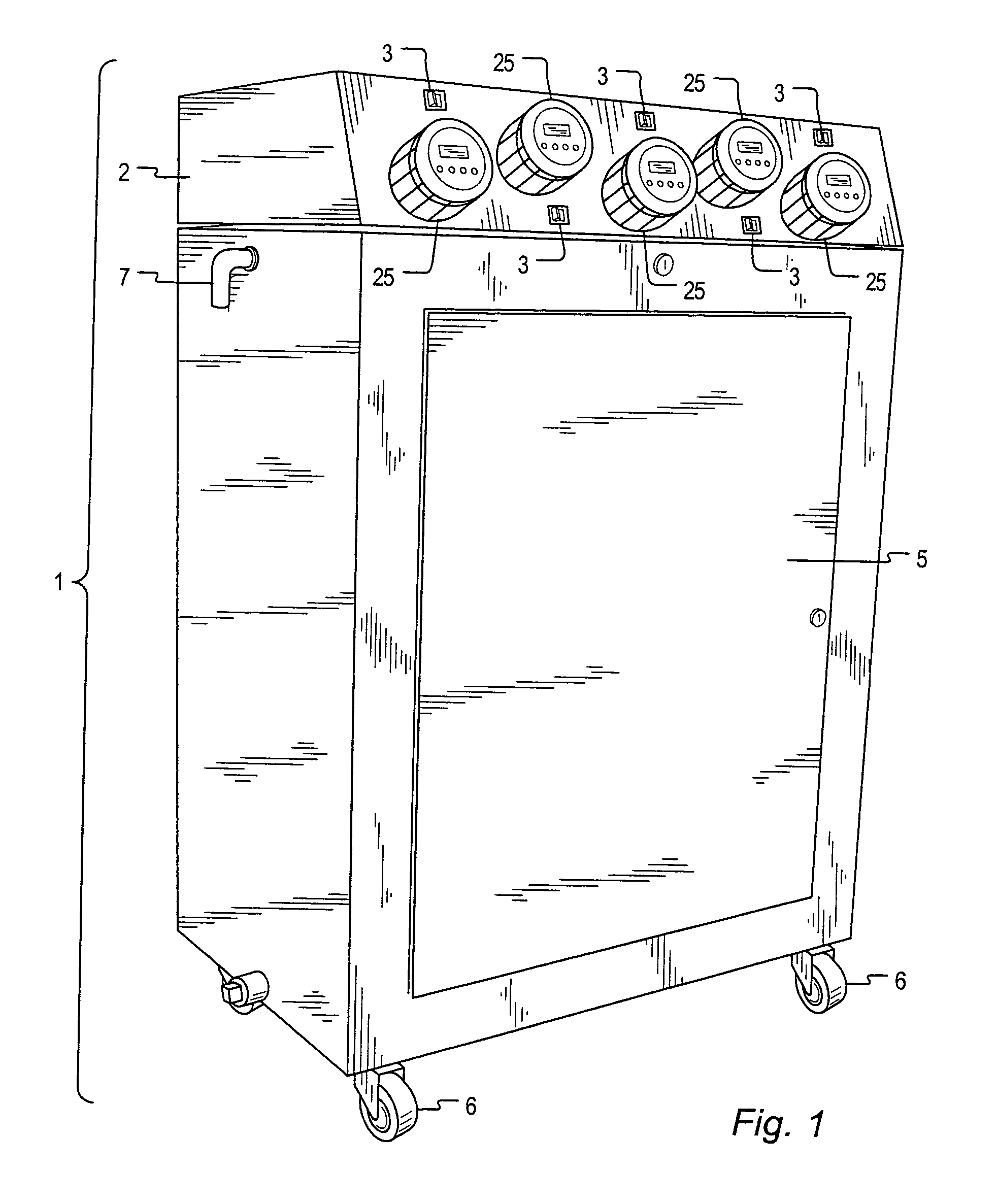

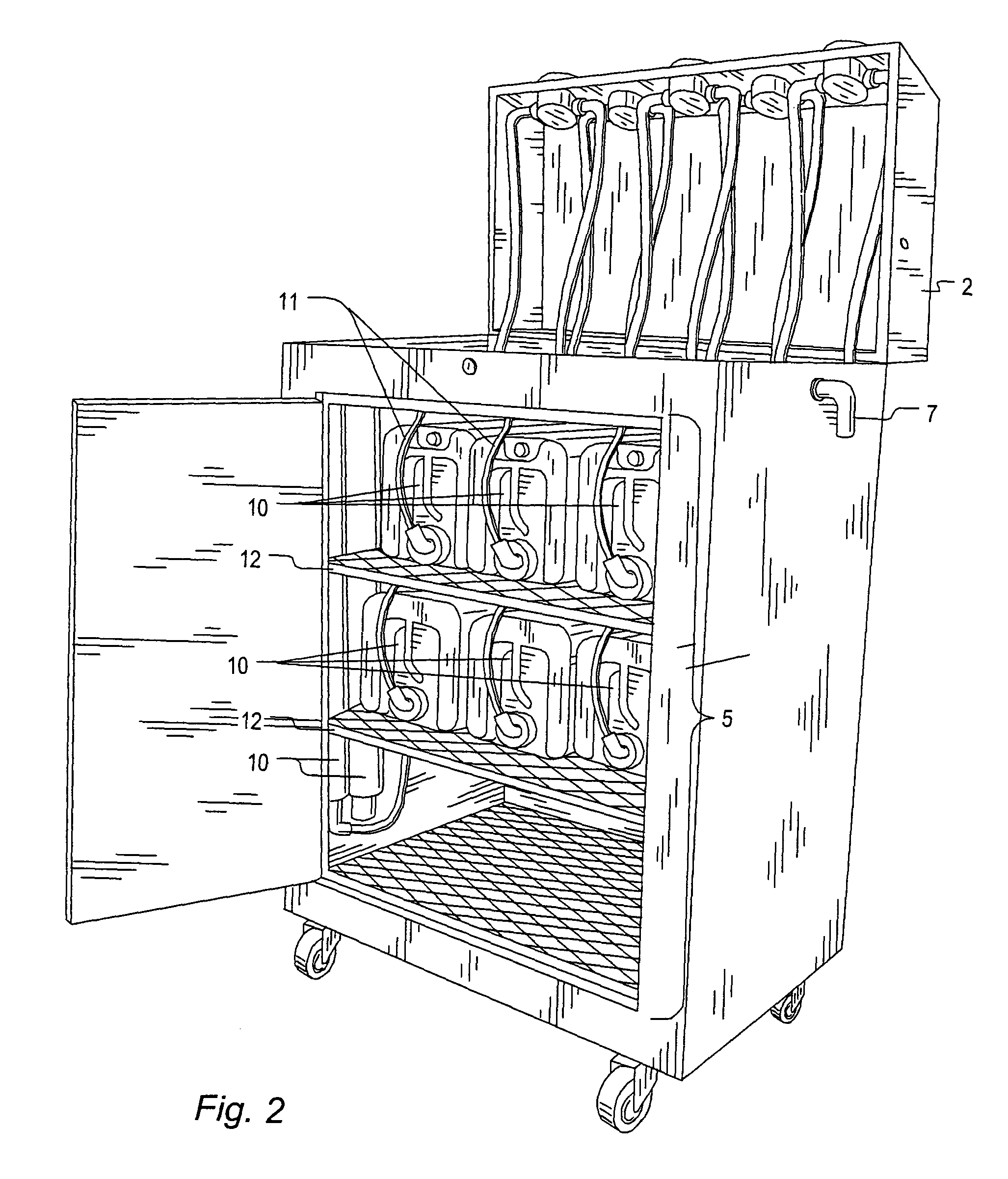

Apparatus and methods for a customer to produce and dispense automobile appearance care products

InactiveUS6988637B2Reduce in quantityReduce overusePower operated devicesFlow mixersProduction logisticsHybrid system

An apparatus may be used to dispense a plurality of automotive appearance care products. The apparatus may include a plurality of storage containers. Mixing systems may be coupled to the storage containers. The mixing systems may combine raw materials with a carrier fluid to produce product fluids. The product fluids may be stored in storage vessels. A plurality of pumps may be used to produce a flow of one or more product fluids. The product fluids may be dispensed through one or more dispensing conduits. A user may dispense the product fluids for use as automotive appearance care products. The user may receive a statement of a fee for using the apparatus based on a selected basis.

Owner:ILLINOIS TOOL WORKS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com