Molten steel quantity conversion based slab cutting optimization method and control system thereof

An optimization method and technology of molten steel quantity, applied in the optimization method of slab cutting in continuous casting production line and its control system field, can solve problems such as inability to cut into a normal slab, uncoordinated logistics organization, limited amount of remaining molten steel, etc. , to achieve the effect of improving calculation accuracy, improving calculation range and precision, and expanding calculation and cutting range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

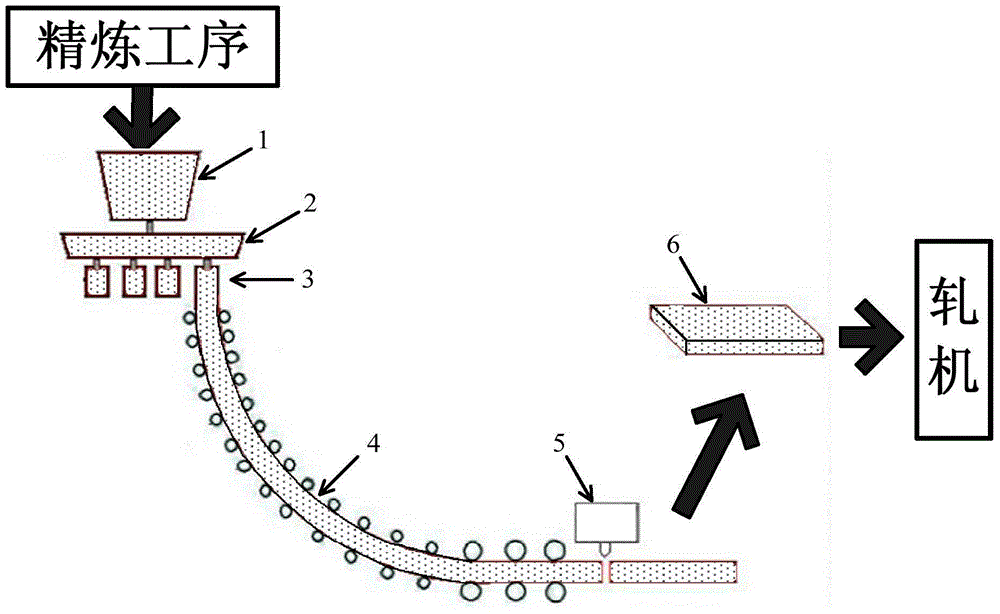

[0055] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments. The continuous casting machines used in modern iron and steel enterprises are generally one machine with multiple streams, so as to improve production efficiency under the condition of the same continuous casting machine equipment. The following embodiments all take a continuous casting machine with one machine and two strands as an example to illustrate the technical solution of the present invention, and these technical solutions are also applicable to a continuous casting machine with one machine and multiple strands.

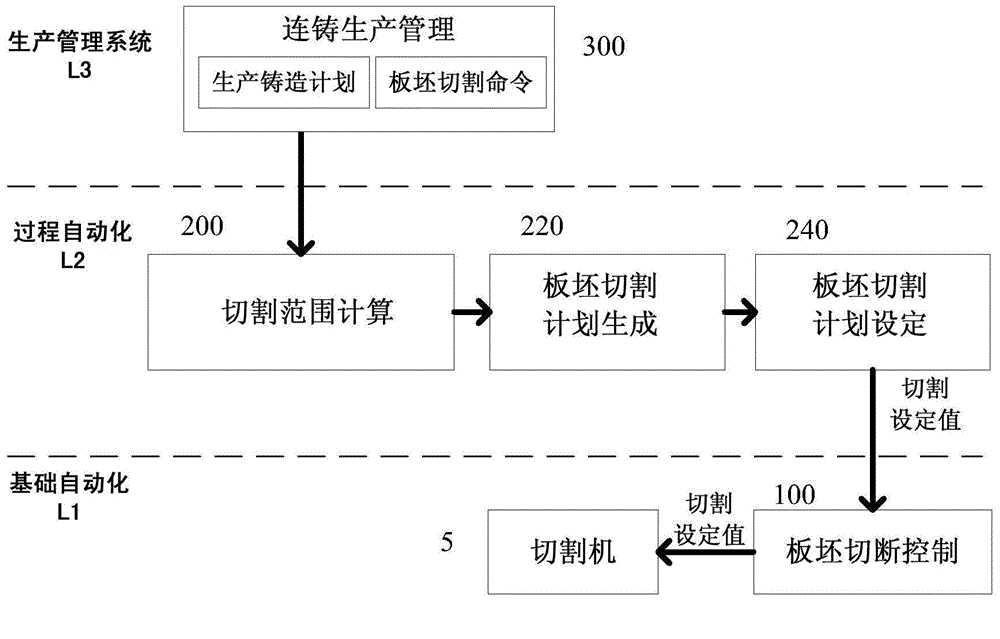

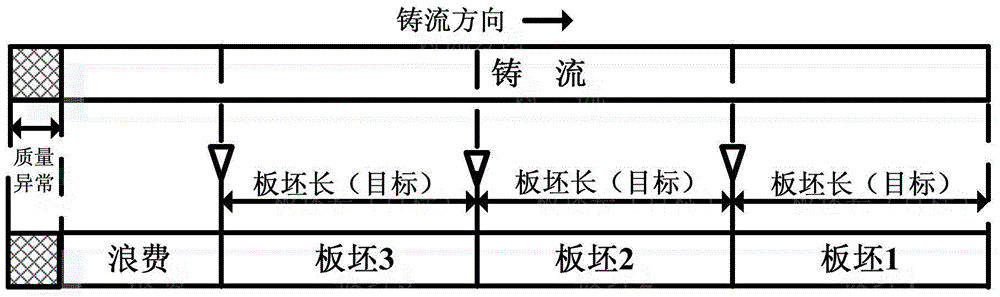

[0056] The slab cutting optimization method based on molten steel conversion of the present invention is used for the slab cutting control of the continuous casting production line. The overall framework of the slab cutting process automation system of the continuous c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com