Multi-axis linkage numerical control laser processing system

A CNC laser and processing system technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of small processing range of joint robot laser processing system, improve flexibility and automatic control ability, improve processing parts Size range, the effect of increasing the size range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in more detail below by means of examples, but the following examples are only illustrative, and the protection scope of the present invention is not limited by these examples.

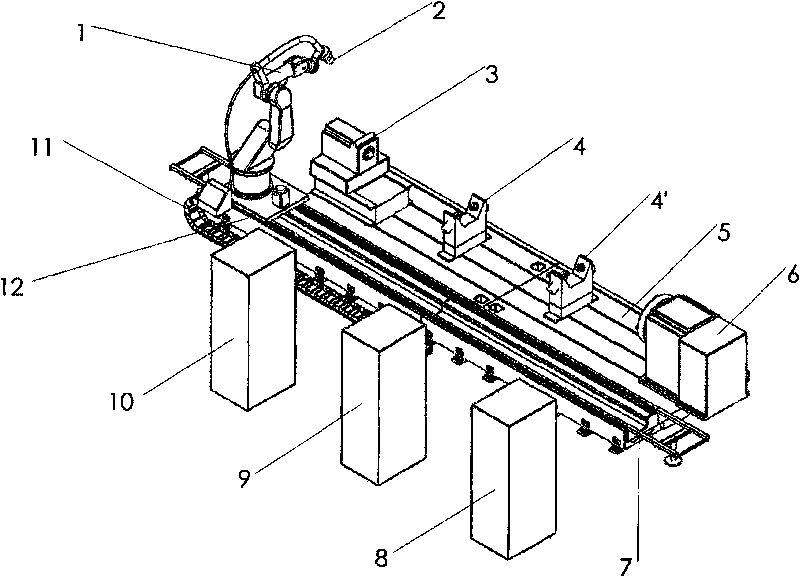

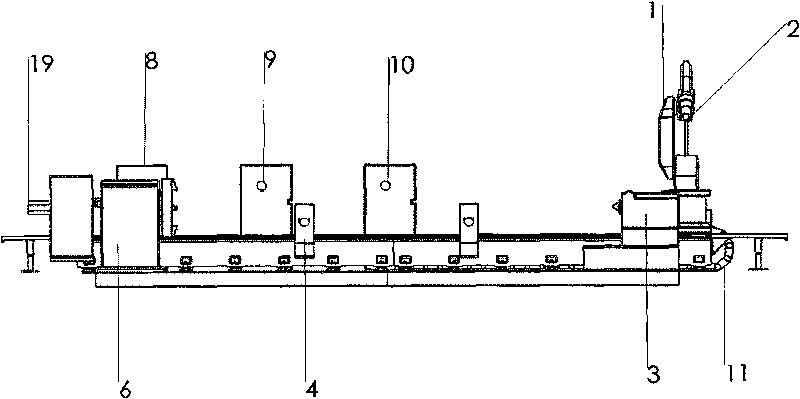

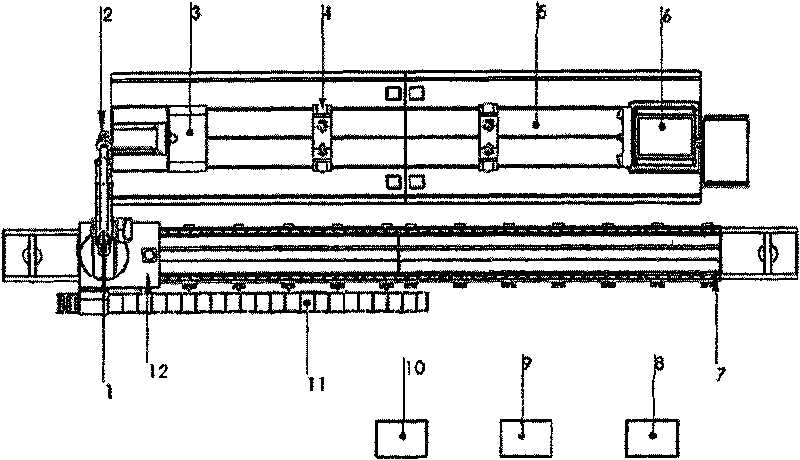

[0032] Such as Figure 1 to Figure 4 As shown, the system of the present invention includes a robot 1, a laser processing head 2, a workbench tailstock 3, first and second open center brackets 4, 4', a workbench 5, a bedside box 6, a rail platform 7, and a laser 8. Cooling machine 9, controller 10, drag chain 11, moving slide 12, optical fiber 20.

[0033] The mobile slide 12 includes a feed slide 21, a servo motor 22, a limit switch 23 and a feed component. The bottom of feed slide seat 21 is provided with the chute 25 that cooperates with first linear guide rail 28 and 28 ', can move along guide rail platform 7. The feed component is installed on the bottom of the feed slide 21, which can be selected according to different situations. If the guide rail tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com