Foodstuff packaging membrane and its manufacturing method

A technology of food packaging film and manufacturing method, applied in packaging, wrapping paper, transportation and packaging, etc., to achieve high barrier properties, overcome processing difficulties, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

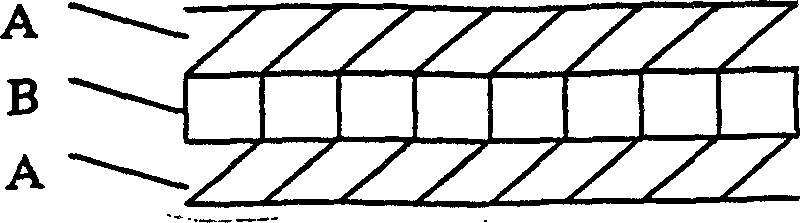

[0064] In one embodiment of the present invention, the packaging film has a three-layer structure of RF-PA / nano-polymer or EVOH / PA, wherein the nano-polymer is one of nano-PA, nano-EVOH or nano-PET.

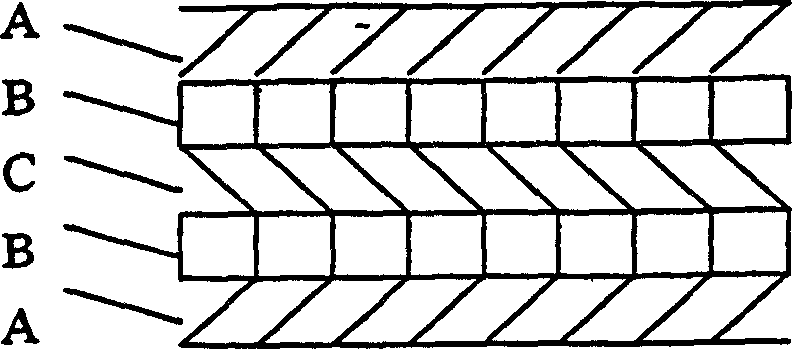

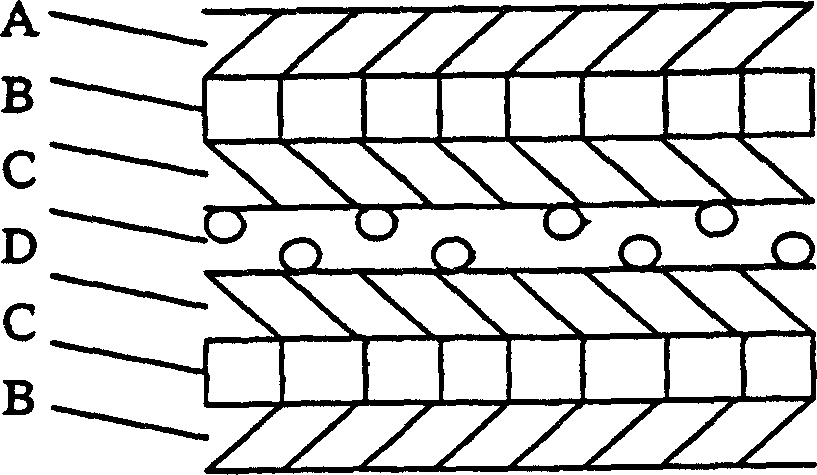

[0065] In another embodiment of the present invention, the packaging film has a five-layer structure of RF-PA / nano-PA / MXD6 or EVOH / PA / RF-PA.

[0066] The production method is as follows: select a plasticizing extruder according to the number of layers of the food packaging film bag, extrude through a co-extrusion die, and wind and water cool (up blowing or down blowing) and then draw and coil.

[0067] The production method of the heat-shrinkable stretch film is as follows: through multiple plasticizing extruders, extruding through a co-extrusion film head, down-blown water cooling, synchronous biaxial stretching, heat setting, and rolling to obtain a heat-shrinkable stretch film.

[0068] The transparency of the product of the present invention is that the total light transmitta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| barrier rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com