Patents

Literature

465 results about "Food hygiene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

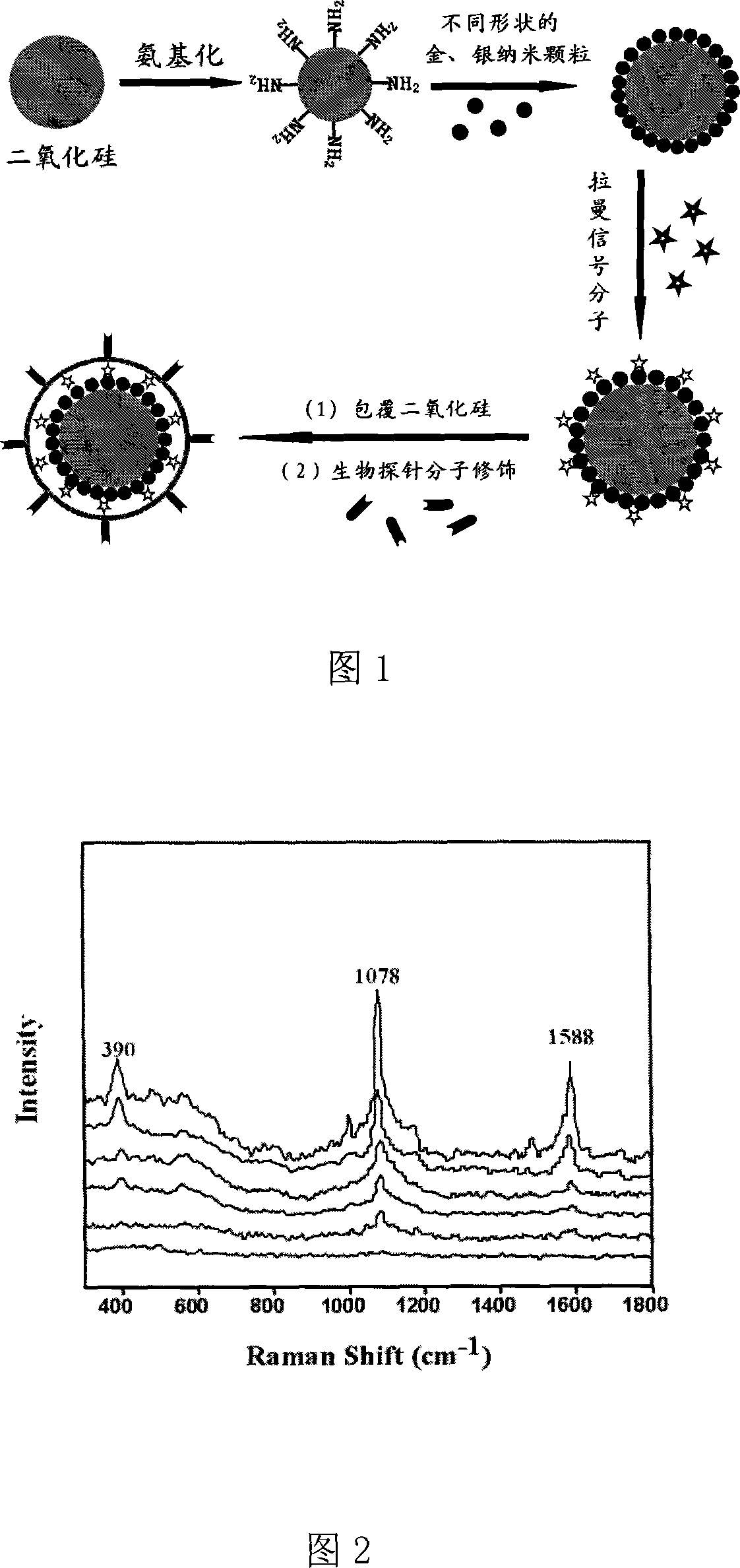

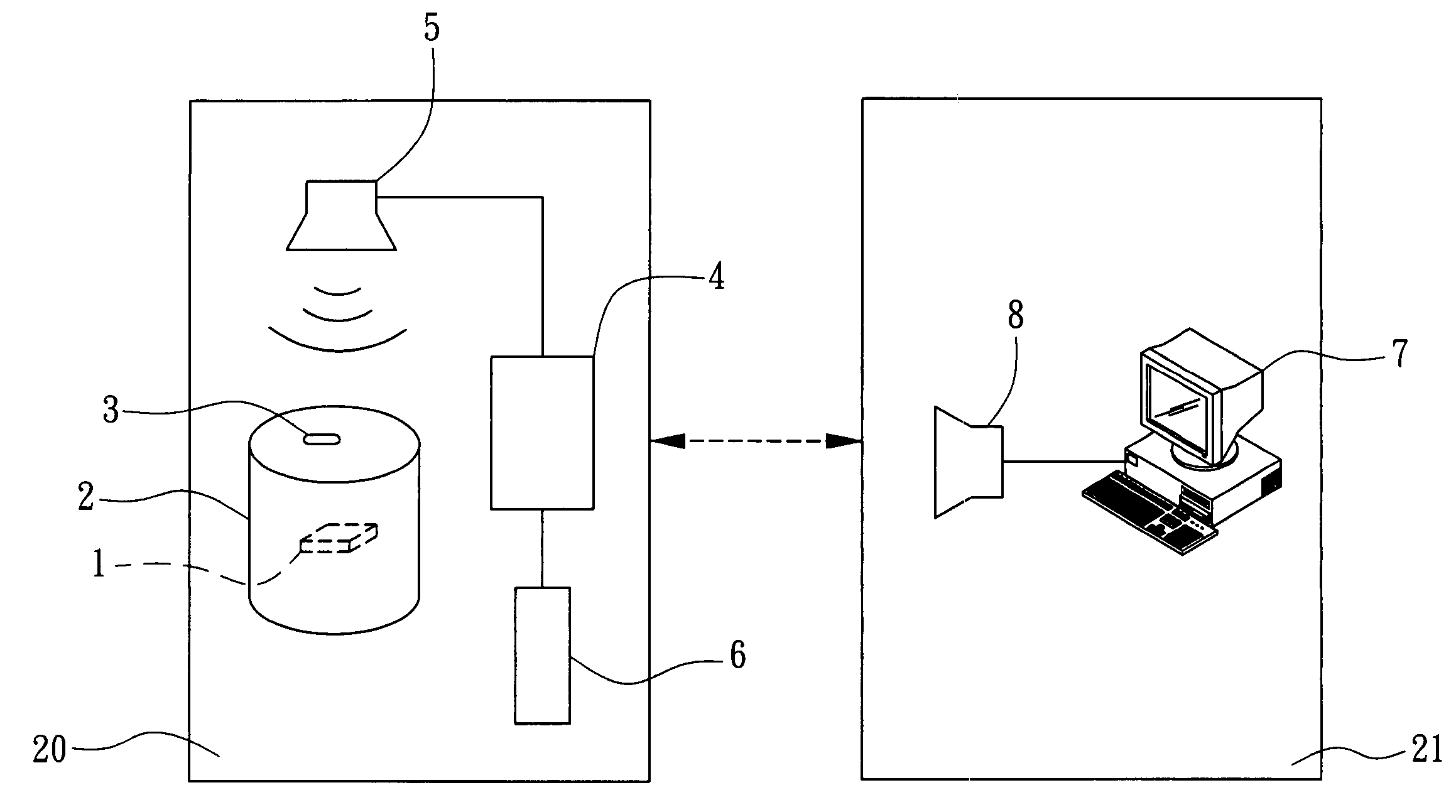

SERS biological probe and method for making same

InactiveCN101216429AStrong SERS effectSignificant SERS effectRaman scatteringBiological testingProtein moleculesSignalling molecules

The invention discloses a SERS biological probe and a preparation method thereof. The SERS biological probe provided by the invention comprises a SiO2 core and a metal nanoparticle layer on the surface of the SiO2 core, wherein a plurality of Raman signal molecules connected with the metal nanoparticle layer; a SiO2 layer is also provided outside the metal nanoparticle layer; the Raman signal molecules are positioned between the metal nanoparticle layer and the SiO2 layer; the SiO2 layer surface is modified with biological probe molecules; and the metal nanoparticle layer is Au nanoparticle layer or Ag nanoparticle layer. The SERS biological probe provided by the invention has wide generality, and has wide application prospect in identification and detection of biological molecules (DNA molecules and protein molecules), rapid disease diagnosis, biomedical imaging technology as well as in the fields of serious disease treatment, food hygiene, environmental monitoring, etc.

Owner:CAPITAL NORMAL UNIVERSITY

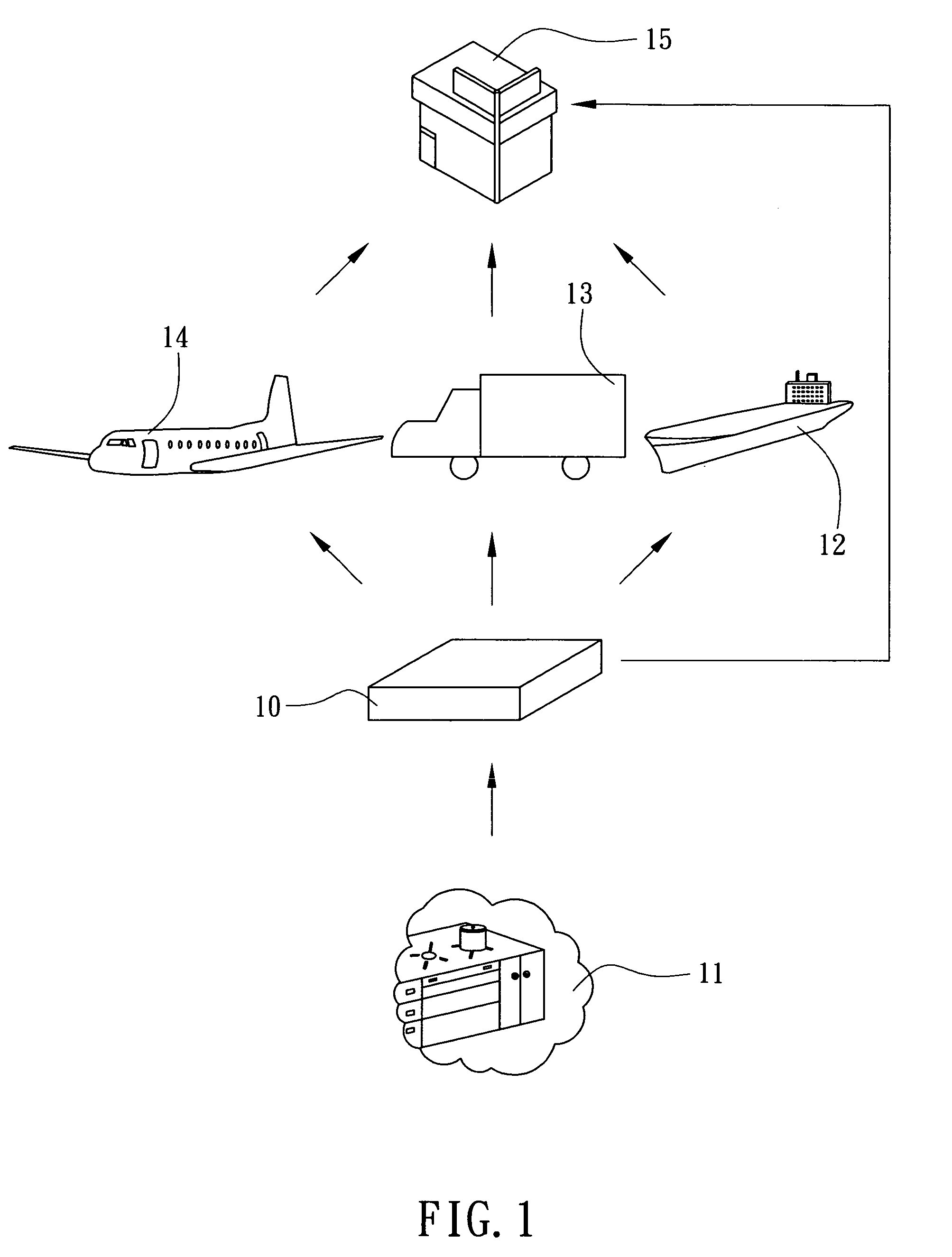

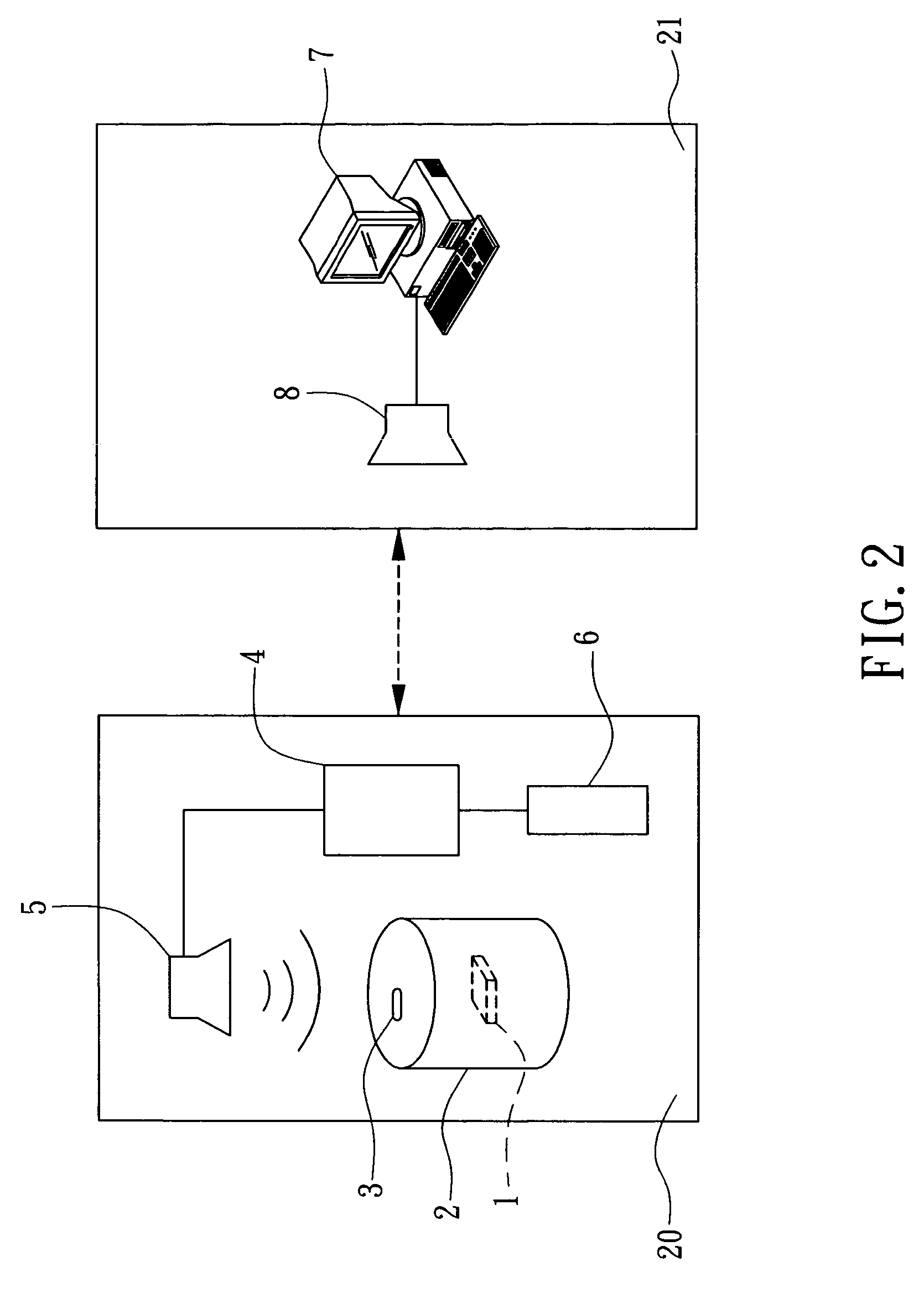

RFID system for monitoring food hygiene

ActiveUS7271719B2Data processing applicationsHealthcare resources and facilitiesElectricityDisplay device

The present invention discloses a RFID system for monitoring food hygiene, comprising: a first accommodating space; an object-under-monitor with a RFID tag attached thereon, being disposed in the first accommodating space; an environmental sensor, disposed in the first accommodating space; a processor, electrically connected to the environmental sensor; a first RFID accessing device, disposed in the first accommodating space while electrically connected to the processor; a second accommodating space; a displaying device, disposed in the second accommodating space; and a second RFID accessing device, disposed in the second accommodating space while electrically connected to the displaying device.

Owner:IND TECH RES INST

Austenitic stainless steel with excellent polishing performance and manufacturing method thereof

InactiveCN102162075AImprove grinding effectImprove surface polishing performanceTemperature control deviceFurnace typesElectrolysisAcid washing

The invention discloses an austenitic stainless steel with excellent polishing performance. The austenitic stainless steel comprises the following chemical components in percentage by weight: 16 to 20 percent of Cr, 7 to 15 percent of Ni, less than or equal to 2 percent of Mn, 0.2 to 2 percent of Cu, less than or equal to 0.05 percent of Al, less than or equal to 0.5 percent of Si, 0.03 to 0.1 percent of C, less than or equal to 0.05 percent of N, 0.01 to 0.06 percent of P, 0.003 to 0.05 percent of S, 0.05 to 0.5 percent of V, and the balance of iron and inevitable impurities. A manufacturing method for an austenitic stainless steel cold-rolled plate comprises the following steps of: heating a continuous cast plate blank to the temperature of between 1,100 and 1,300 DEG C; performing rough rolling at the temperature of between 1,000 and 1,250 DEG C; performing final rolling at the temperature of between 950 and 1,100 DEG C; performing quick cooling; coiling at the temperature of less than 700 DEG C; performing hot rolling to form a hot-rolled plate of the required specification; annealing the hot-rolled plate at the temperature of between 950 and 1,200 DEG C; removing oxide skin by adopting a continuous acid washing process of phosphorus breakage, shot blasting, electrolysis and mixed acid washing; performing cold rolling, wherein the overall reduction rate is more than 50 percent; and performing continuous annealing at the temperature of between 950 and 1,200 DEG C, or performing full-hydrogen bright annealing at the temperature of between 950 and 1,200 DEG C. The austenitic stainless steel cold-rolled plate has completely improved grinding performance and surface polishing performance, and is particularly suitable for the industries of building decoration, plastic dies, food sanitation, electronics and the like with strict polishing performance requirements.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for preparing food hygiene-level active carbon by use of bagasse

ActiveCN103803547ASolve the reuse problemHigh dry matter contentCarbon compoundsActive agentBiological waste

The invention relates to an active carbon material, and particularly relates to a method for preparing food hygiene-level active carbon by use of biological waste resource bagasse. The method comprises the steps of collecting and cleaning the residual bagasse after sugar production; sufficiently fermenting at 10-50 DEG C, drying, grinding and sieving; then performing the operation treatment such as soaking in an active agent solution, charring, activation and the like on the pretreated bagasse; washing, drying and grinding to obtain a high-performance active carbon product which can be applied to decoloration, refining and impurity removal of the sugar industry and the fields of foods and medicines such as medicinal crude drugs and the like. According to the method provided by the invention, by adopting the waste bagasse as a raw material, the comprehensive utilization of resources and environmental protection are facilitated; moreover, the price is low, the product quality is high, and the economic and social benefits are good.

Owner:JIANGSU ZHUHAI ACTIVATED CARBON CO LTD

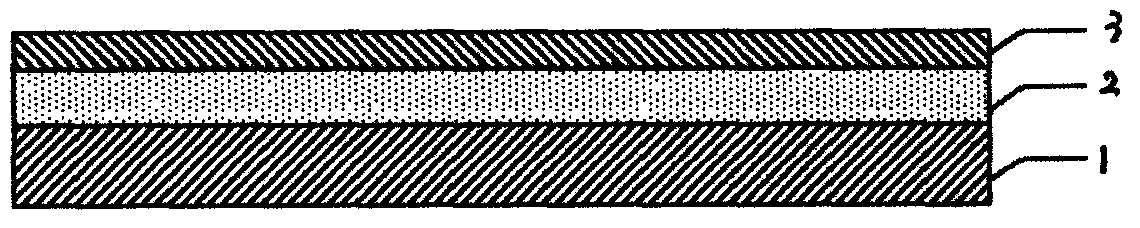

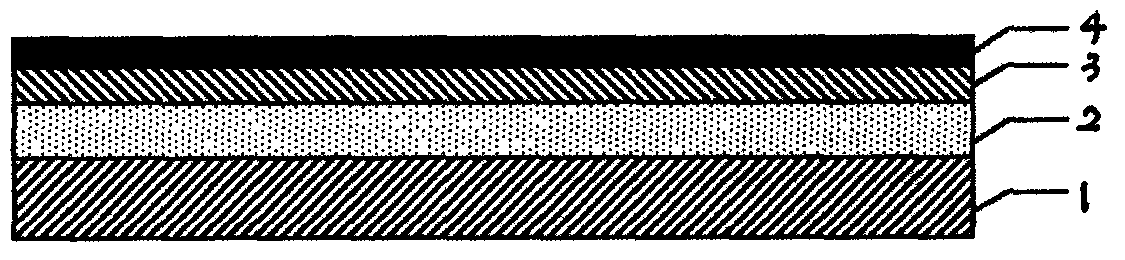

Plastic-free environment-friendly isolation paper, plastic-free environment-friendly release paper as well as preparation method of plastic-free environment-friendly isolation paper and plastic-free environment-friendly release paper

ActiveCN102817281AImprove flatnessImprove isolationLamination ancillary operationsPaper coatingLogistics managementIsolation layer

The invention belongs to the field of papermaking technology, and particularly relates to a plastic-free environment-friendly isolation paper and a plastic-free environment-friendly release paper used for the industry fields of food hygiene, pharmaceutical packaging, electronic appliances, household products, cosmetics, supermarket logistics, post express and the like and a preparation method of the plastic-free environment-friendly isolation paper and the plastic-free environment-friendly release paper. The technical scheme is as follows: the isolation paper is composed of a 30-60g / m<2> low-weight tissue paper or a 50-200g / m<2> cultural paper, and a precoating layer and an isolation layer coated in sequence on the tissue or cultural paper surface, wherein a layer of precoating is coated on the front face of the base paper firstly and then a layer of isolation layer is coated into the precoating layer; the release paper is formed by coating a solvent-free silicone oil onto the isolation paper and comprises the base paper layer, the precoating layer, the isolation layer and the silicone oil layer from top to bottom in sequence. The paper prepared by the method provided by the invention has the characteristics of low requirements for base paper performance, good isolation (release) effect, high paper smoothness, no pollution, easiness of recycling, stable properties and the like. The production process has the advantages of low manufacture cost, high production efficiency, easiness of mass production and the like.

Owner:GUANGDONG GUANHAO HIGH TECH

Rapid processing method of low-sulfur konjac powder

The invention provides a rapid processing method of low-sulfur konjac powder, and relates to the technical field of subsidiary agricultural product processing. The rapid processing method is characterized by comprising the following steps: washing, peeling and crushing konjac, and then removing juice to obtain wet konjac powder; adding sulfite, evenly mixing, and then carrying out microwave drying to obtain dry konjac powder; and finally processing the obtained dry konjac powder into fine konjac powder. The rapid processing method has the advantages of simple processing equipment, short drying time, simple and feasible color protection technology, low cost, less residual SO2 and no environmental pollution, thus meeting the related national standards and food hygiene requirements.

Owner:SHAANXI UNIV OF TECH

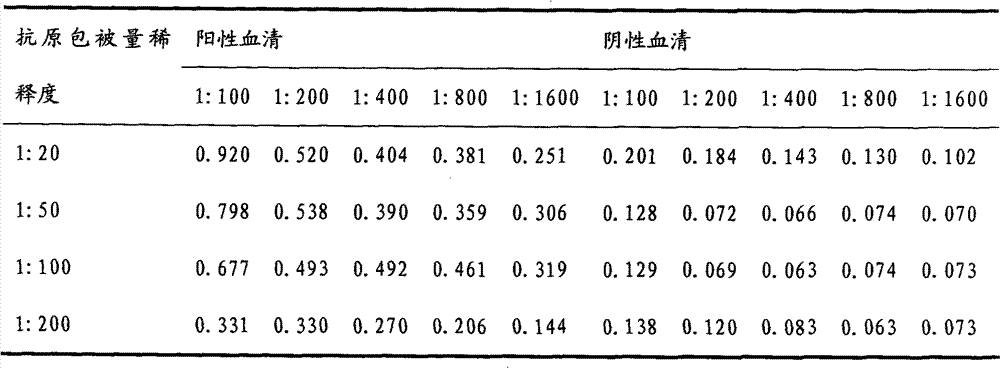

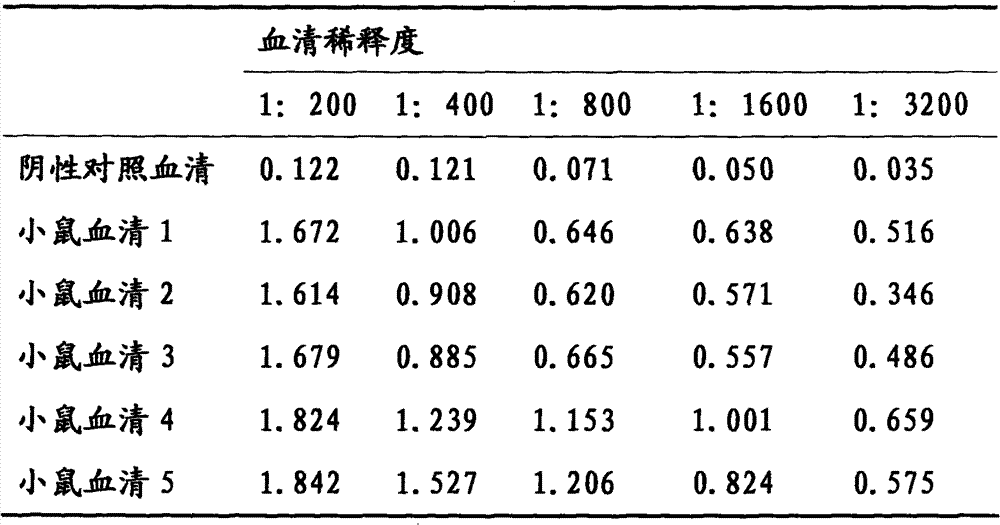

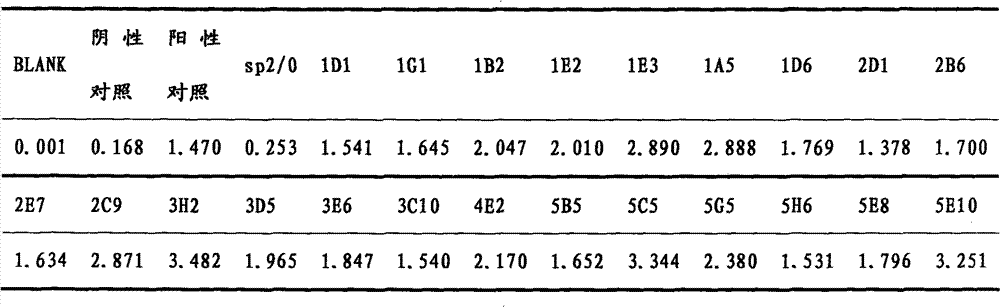

Competitive ELISA kit for peste-des-petits-ruminants antibody detection and preparation method thereof

ActiveCN102967710ANo cross reactionStrong specificityImmunoglobulins against virusesBiological testingSerum igeElisa kit

Belonging to the field of biotechnologies, the invention discloses a competitive ELISA kit for detection of a peste-des-petits-ruminants virus antibody. The kit comprises a detection system composed of a coating antigen reaction solution and a monoclonal antibody reaction solution. The kit adopts prokaryotically expressed peste-des-petits-ruminants Nigeria 75 / 1 strain N protein as the coating antigen and employs a monoclonal antibody against N protein as the competitive antibody. The antibody against a peste-des-petits-ruminants virus in sheep serum is detected according to a competitive ELISA principle. The kit provided in the invention can rapidly and specifically detect the peste-des-petits-ruminants virus antibody in serum, and simultaneously has the advantages of large-scale production of monoclonal antibodies, good reaction specificity, high sensitivity, simple operation, low cost, stable, reliable and easily observable reaction results, thus being very suitable for import and export quarantine of sheep, food hygiene and screening of large batches of samples in livestock breeding farms, and being easy for large-scale popularization and application.

Owner:LANZHOU INST OF VETERINARY SCI CHINESE ACAD OF AGRI SCI

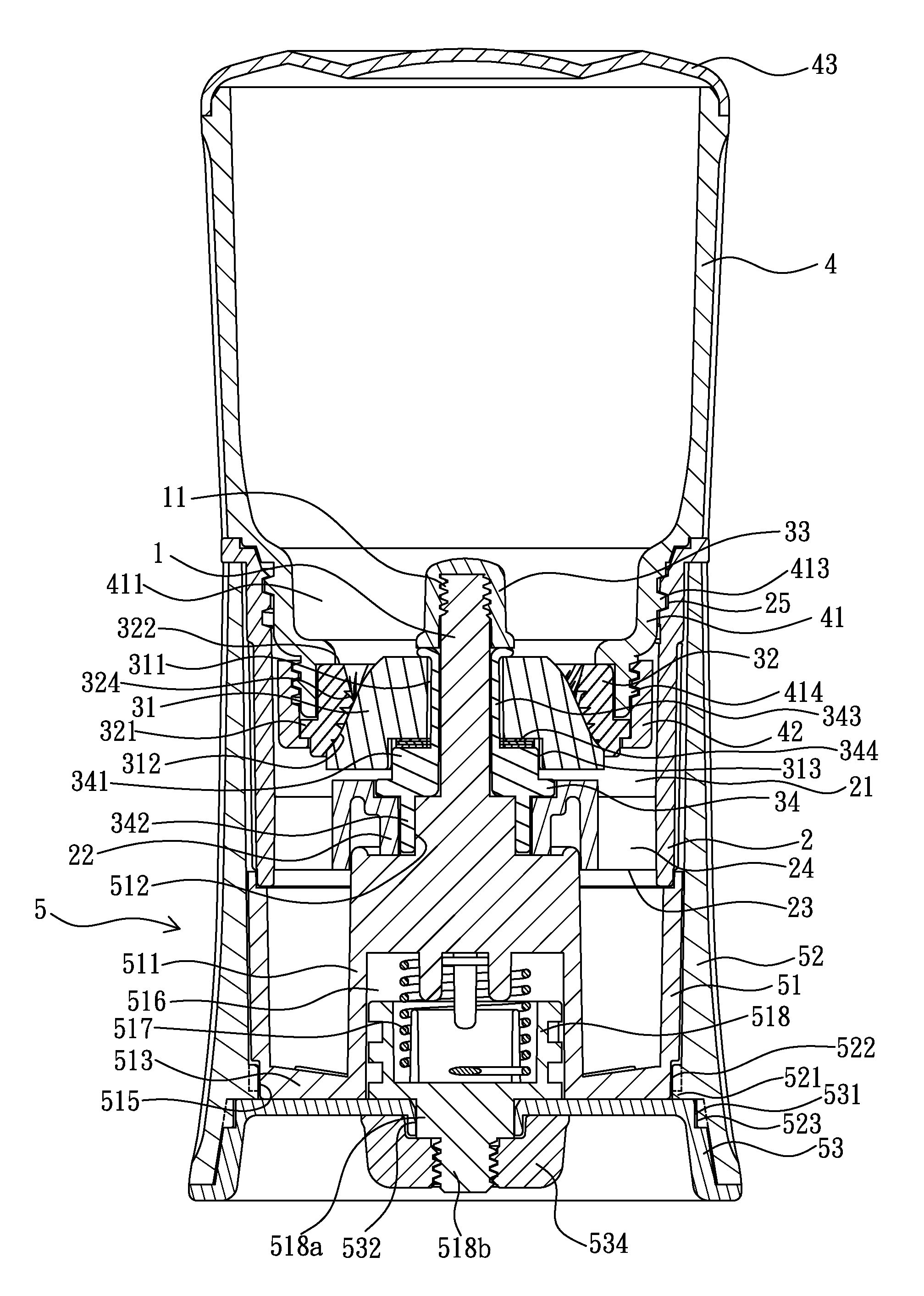

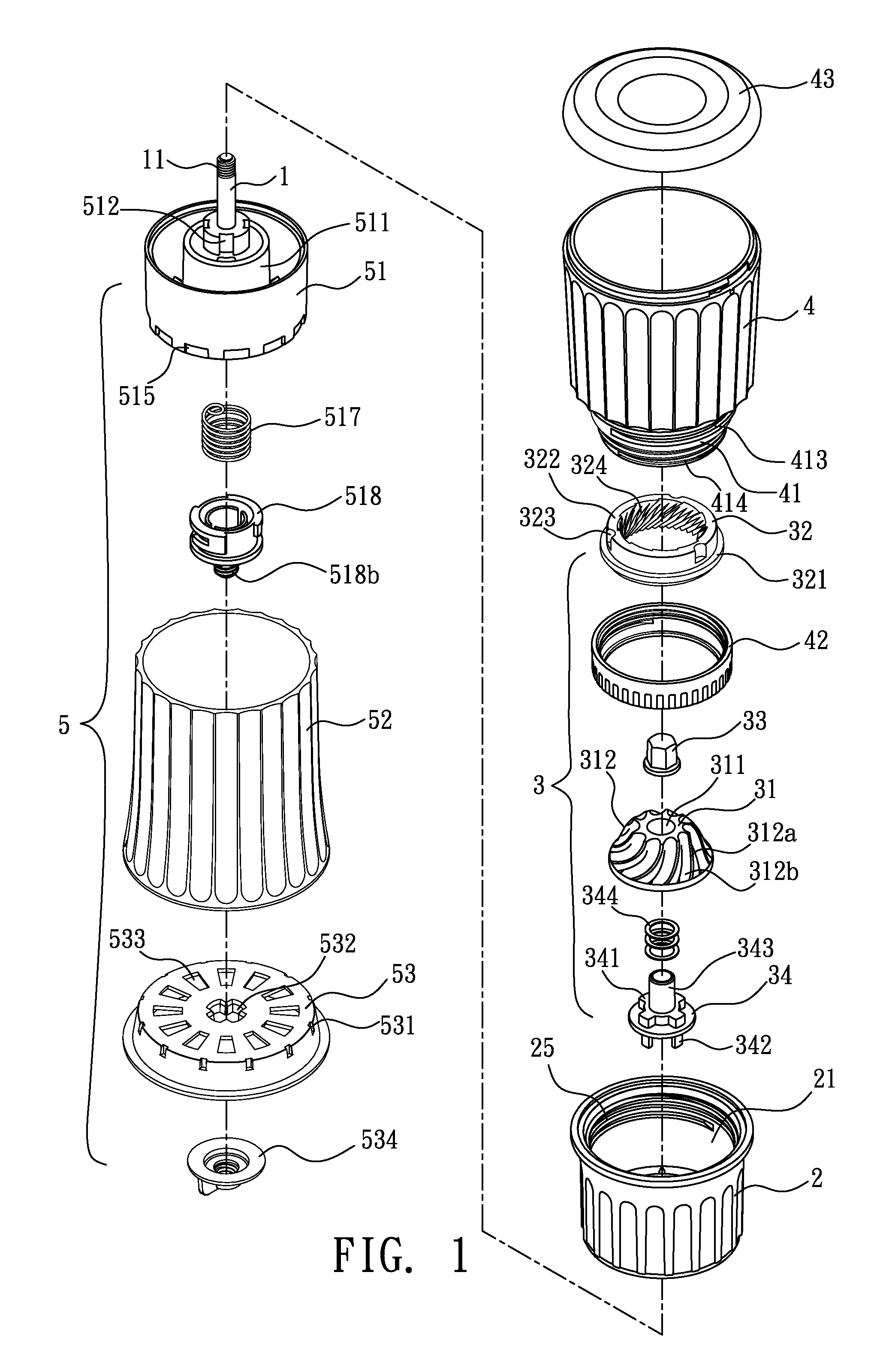

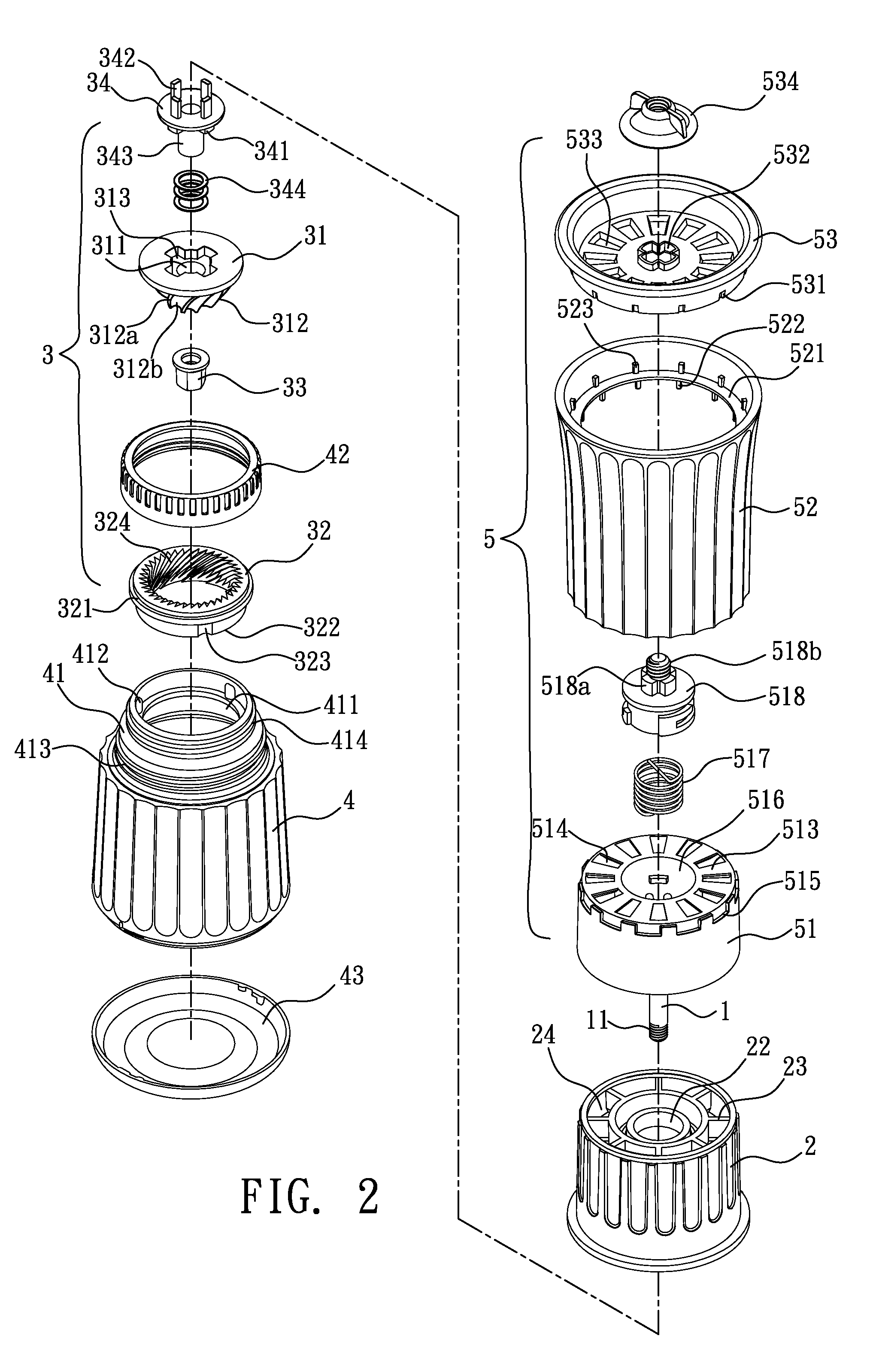

Grinder and automatic open/close control device thereof

InactiveUS20130026269A1Easy to carryCoffee millsGrinding machine componentsDrive shaftGrinding wheel

The present invention relates to a grinder, comprising a grinding unit is installed between a receptacle and a base. A grinding wheel and a grinding base of the grinding unit are detachably and respectively installed on a transmission shaft and at the bottom side of the receptacle, and a bottom cover of an automatic open / close control device utilizes an engaging button for being combined with a combination part of a fasten cover installed at the bottom side of a follower member, so the bottom cover can be detachably installed at the bottom opening of a housing. Accordingly, components which may have food powders adhered thereon, such as the grinding wheel and the grinding base of the grinding unit and the follower member, the housing and the bottom cover of the automatic open / close control device are capable of being detached for cleaning, so the food hygiene can be ensured.

Owner:PAI

Ultra-fine composite modified heavy calcium carbonate powder, preparation method and uses thereof

ActiveCN101367963AOvercoming reunion tendenciesMake up for inherent performance deficienciesPigmenting treatmentTitaniumStearic acid

The invention discloses a superfine compound modified heavy calcium carbonate powder body, a preparation method and an application thereof. The powder body comprises the following materials by the weight portion: 80-90 portions of heavy calcium carbonate (d50 is smaller than or equal to1um), 10-15 portions of talc powder (d50 is smaller than or equal to1um), 1-2 portions of titanium ester coupling agent and 1-1.2 portions of stearic acid. The heavy calcium carbonate is added in the talc powder, the temperature is raised, and then the coupling agent is added, the temperature is raised, cooled evenly, and the stearic acid is added. The powder body is applied to environment-friendly degradative compound modified resin. Compared with the prior art, the produced superfine compound modified heavy micro calcium carbonate is well compatible with other organic carriers and auxiliary materials, and the processing fluidity is sound; in addition to the functions of filling and increment, the mechanical property and the appearance of the products are not influenced; the compound resin made of the superfine compound modified heavy calcium carbonate powder body can be degraded completely and rapidly, and is nontoxic and harmless, and can well meet the requirements of food hygiene.

Owner:芜湖同达新材料科技有限公司

Modified polypropylene, process for preparing modified polypropylene, modified polyropylene composition and foamed product

A modified polypropylene has a melt flow rate of 0.1 to 10 g / 10 min, a melt tension of 3 to 20 g and a gel fraction, as determined by boiling paraxylene extraction, of 0.01 to 25% by weight. The modified polypropylene, a process for preparing the modified polypropylene, and a modified polypropylene composition containing the modified polypropylene are capable of producing a foamed product having excellent foam properties and food hygienic qualities. The foamed product obtained from the modified polypropylene or the modified polypropylene composition is lightweight, highly rigid and excellent in chemical resistance and food hygienic qualities, and hence it can be used for food packaging containers and trays, particularly containers of noodles or ice cream and trays of fish or meat, for which polystyrene has been heretofore used.

Owner:MITSUI CHEM INC

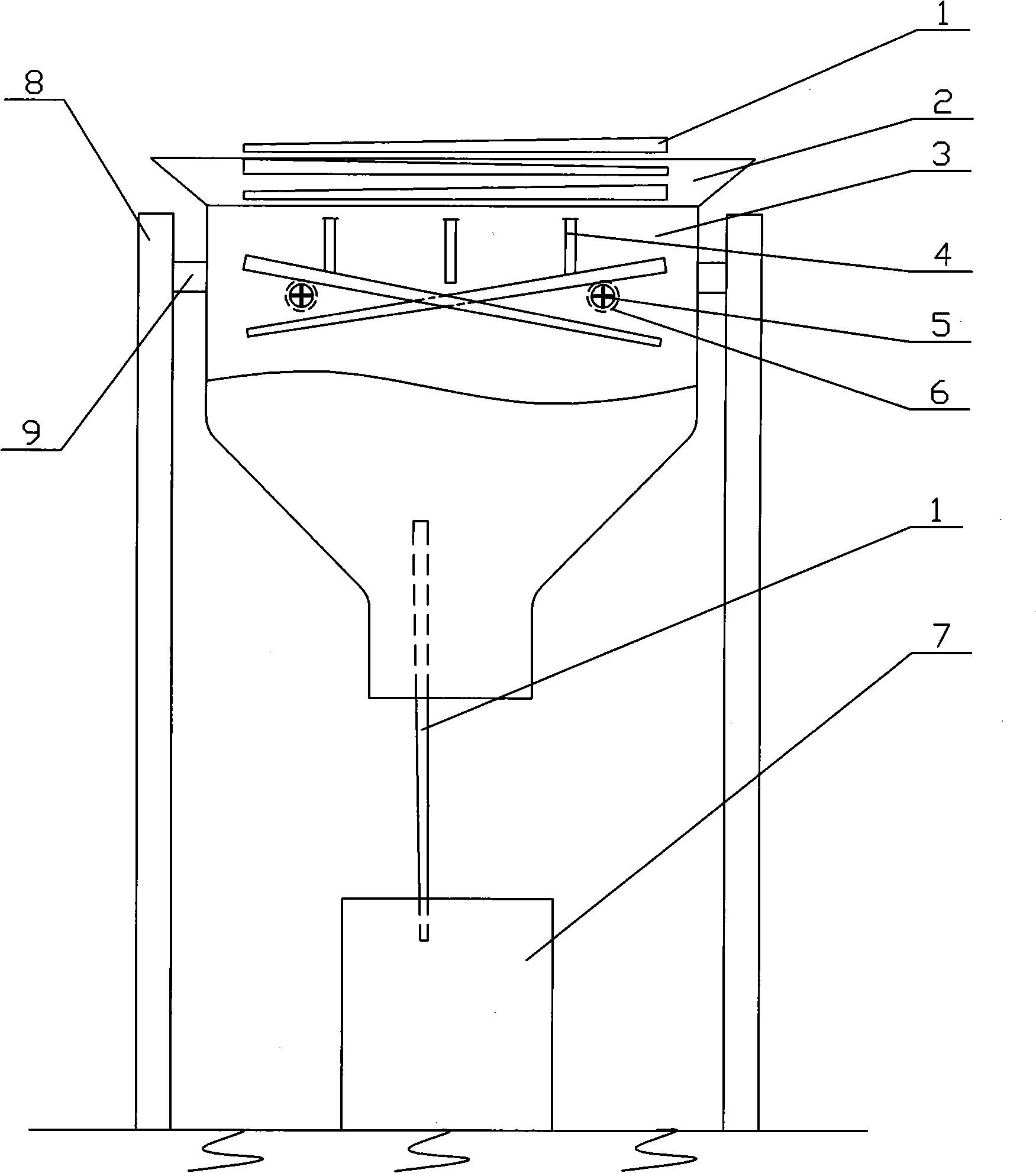

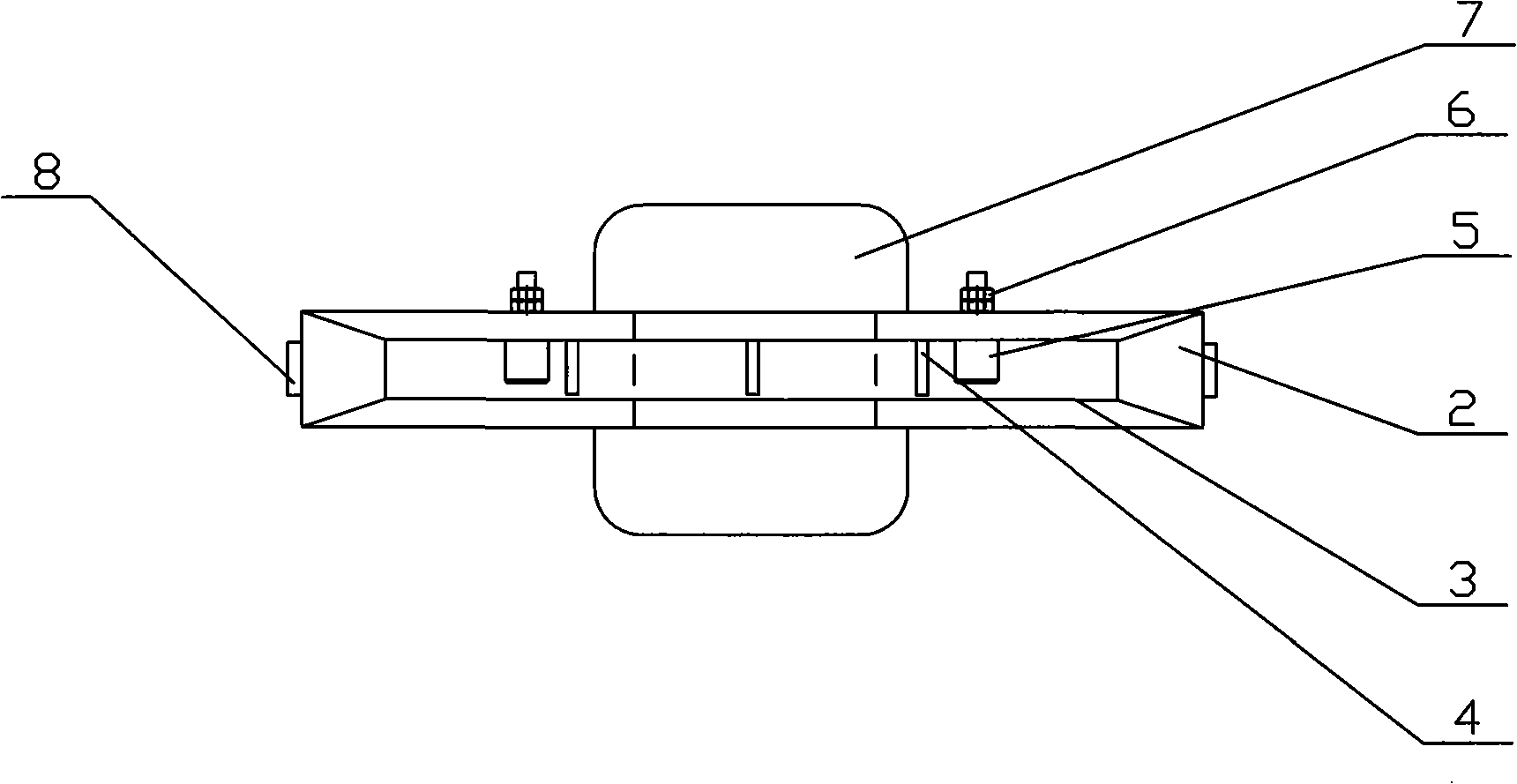

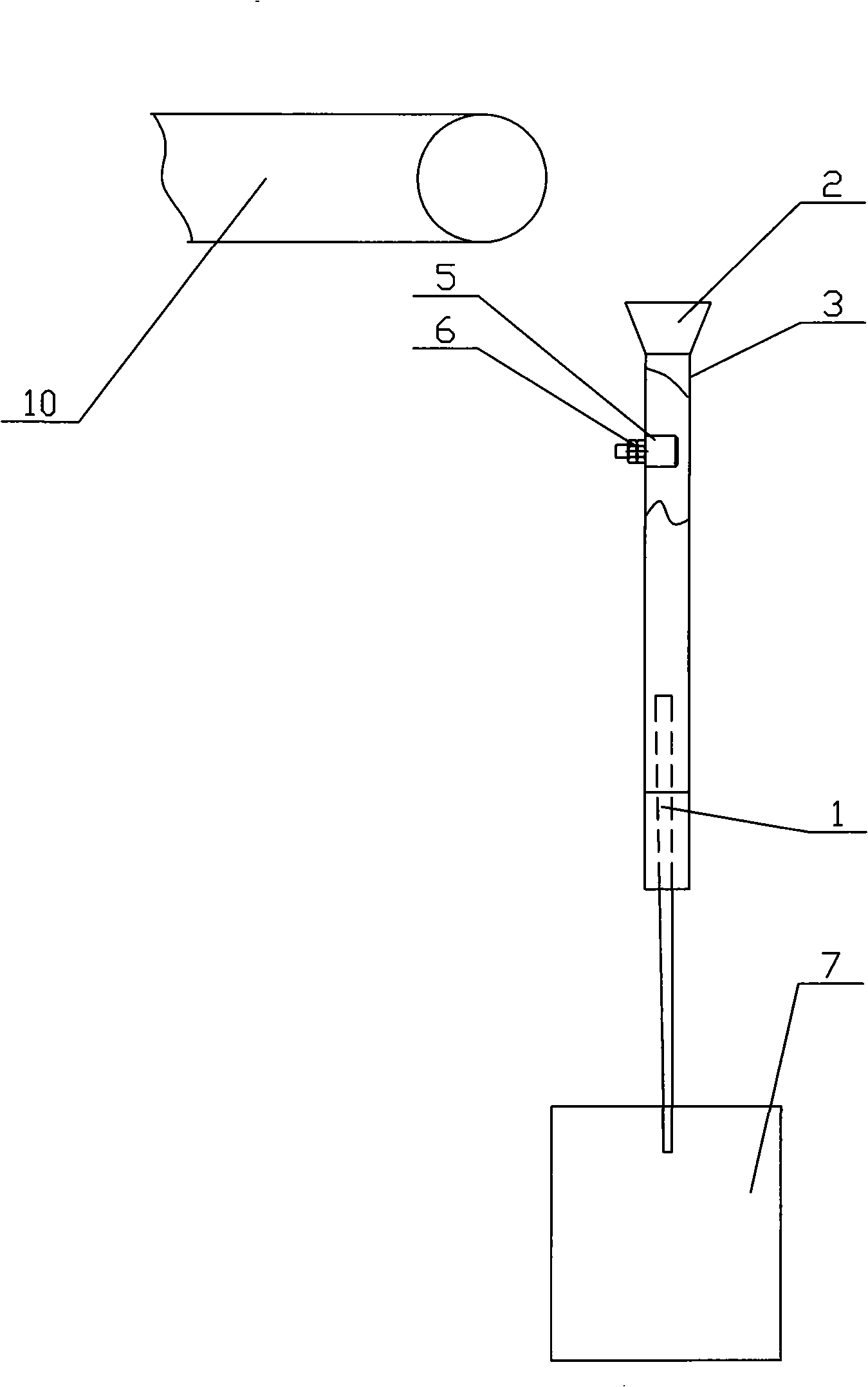

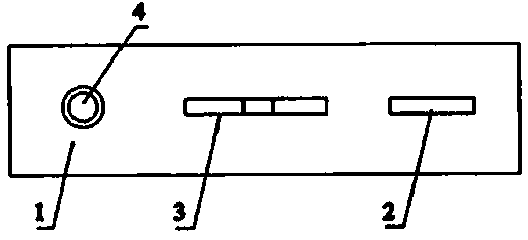

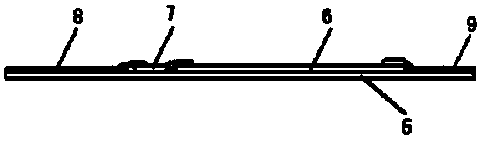

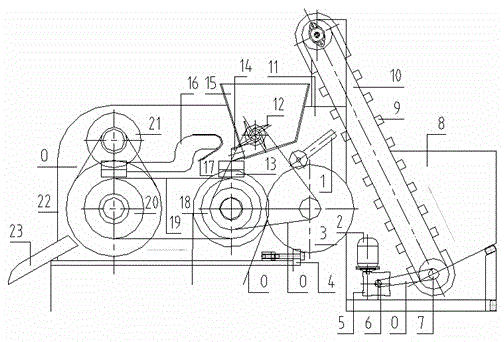

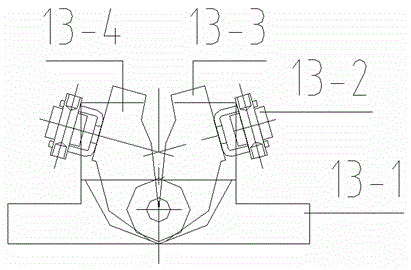

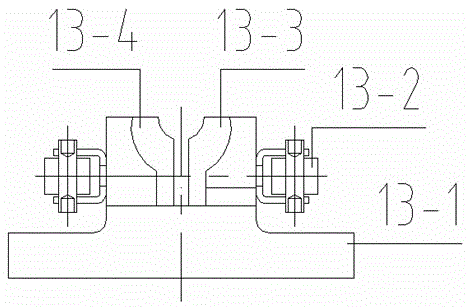

Chopsticks collating unit

InactiveCN101273869AReasonable designCompact structureTableware washing/rinsing machinesConveyor partsFood hygieneEnergy conservation

The invention pertains to tableware cleaning equipment, particularly relates to an arranging device of chopsticks, which is characterized in that: the arranging device is composed of a sorting mechanism and a collecting basket, the collecting basket is arranged below a bottom opening of the sorting mechanism; the sorting mechanism consists of a chopstick entering funnel, a sorting shell, flexible guide sheets and a mechanism for regulating the sizes of the small ends of the chopsticks, the upper part of the sorting shell is a flat cuboid, and the lower part is shaped like a hopper; the upper part of a top opening of the sorting shell is provided with the chopstick entering funnel, a plurality of flexible guide sheets are distributed along the long inner side surface below the top opening of the sorting shell, one end of each flexible guide sheet is connected on the long inner side surface, the other end thereof is suspended, and the mechanism for regulating the sizes of the small ends of the chopsticks which is composed of nuts and regulating pins is symmetrically arranged on the long side surface which connects the lower surfaces of the flexible guide sheets. The arranging device has the advantages of reasonable design, compact structure, simplicity, practicality, high arranging efficiency, energy conservation, low cost, very convenient usage and so on, which is further in line with food hygiene.

Owner:DALIAN JIAOTONG UNIVERSITY

Food EPT rubber filter-pressing plate and method for preparing same

ActiveCN101249324AIncrease elasticityExtended service lifeFiltration separationRubber materialPolymer science

The invention discloses a food-grade EPDM pressure filter plate and manufacturing method thereof. The pressure filter plate adopts the EPDM as the major raw material, which is the high-purity white or colorless EPDM raw rubber that is synthesized by adopting the solution polymerization method, wherein, the ENB content of a third monomer is 4 to 6 percent; and the content of ethylene is 50 to 55 percent. The manufacturing method is that the raw materials are firstly mixed according to the mixing ratio by the parts at weight, the conventional ethylene-propylene rubber mixing process is adopted for preparing the mixed rubber, the mixed rubber is heat bodying on a mixing roll machine and then sheet making to obtain rubber sheets and rubber strips, then a rubber material middle temperature upper mold gradually increases the temperature and the pressure for stamping and pressure keeping, and a flat vulcanizing machine is adopted for vulcanization, so as to obtain the food-grade EPDM pressure filter plate. The pressure filter plate of the invention can be applied in the pressure filters of the food industry, thereby meeting the food hygienic standard requirements and having good product elasticity, heat resistance, anti-aging property and long service life.

Owner:GUANGZHOU MECHANICAL ENG RES INST

Spectinomycin colloidal gold detection card

The invention relates to a spectinomycin colloidal gold detection card. According to the method, a sample liquid absorbing part, a colloidal gold labeling part, a detection reaction part and a water absorbing part are orderly stuck on a backing of test paper. The detection reaction part is coated by an antigen 1 bar which is applied to detection and is used as a detection line, and at the same time is coated by an IgG1 bar which resists the second species of animal protein and is used as a reference line. The rapid detection test paper bar has high specificity, can carry out semi quantitative detection, can be used at the environmental temperature of 4 to 40 DEG C, and is suitable for an individual farmer, a food hygiene and quality inspection department, customs and other animal source food to carry out rapid detection on spectinomycin residues. The spectinomycin colloidal gold detection card provided by the invention has the advantages of high specificity, high sensitivity, simple and convenient operation and the like, and can carry out semi quantitative detection.

Owner:JIANGSU WISE SCI & TECH DEV

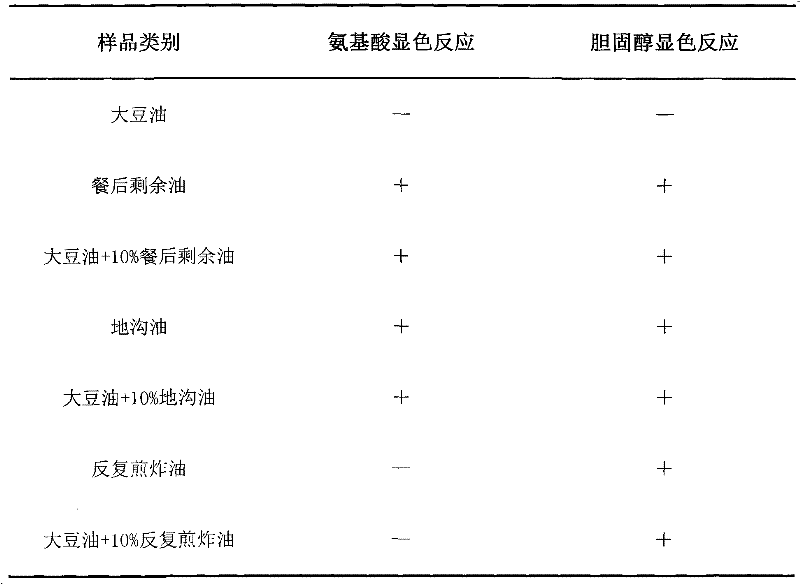

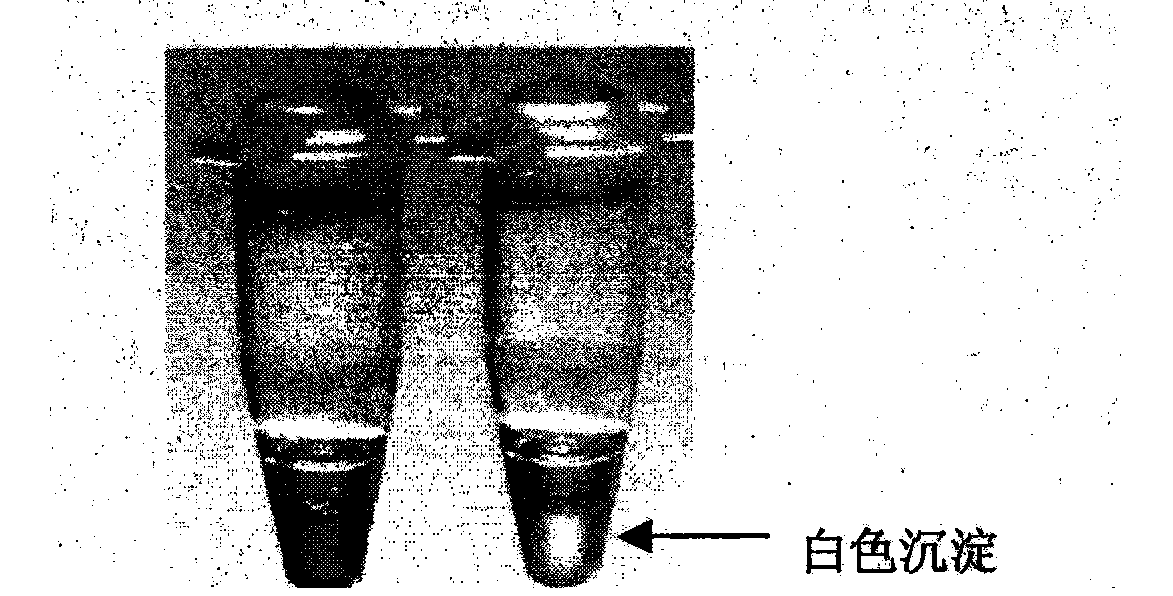

Method for rapidly identifying inferior edible oil

InactiveCN102519953ARapid identificationEasy to detectMaterial analysis by observing effect on chemical indicatorCholesterolPotassium hydroxide

The invention relates to a method for rapidly identifying inferior edible oil. According to the method, whether an edible oil sample contains cholesterol and amino acid impurities is determined to visually, accurately and rapidly identify inferior edible oil. The method contains the following steps of: firstly adding potassium hydroxide and ethanol into the edible oil sample for saponification, adding petroleum ether and sodium chloride solution for centrifugal extraction, respectively adding a jarosite reagent and a ninhydrin reagent into an upper layered extract and a lower layered extract for color development reaction, determining whether the edible oil sample contains corresponding exogenous substances through observation of color change and simultaneously carrying out quality identification. The method provided by the invention is applicable to the detection of inferior edible oil in food hygiene and safety supervision and inspection.

Owner:黄耀江 +2

Preparation method of swelled vermiculite/ polyacrylic acid potassium- acrylamide high water absorption composite material

InactiveCN100404612COptimize network structureImprove water absorptionChemical industryPolymer science

This invention discloses a method for preparating a kind of inflatable vermiculite / poly-potassium acrylate-acrylamide super water-retention property water -absorbent composite material, which is made by graft copolymerizing acrylic acid, acrylamide and inflatable vermiculite powder. In this invention, inflatable vermiculite powder takes a art of 50%, whose distilled water absorption could amount to 850 times. The absorbency of inflatable vermiculite / poly-potassium acrylate-acrylamide super water -absorbent composite material is a little lower than that of pure organic resin polymer(it can fulfill normal using requirements), while its manufacturing cost is apparently less than that of pure organic resin polymer. Also it has very good water-absorbency and water-retention property, so it has very extensive use in agriculture and forestry, plant planting, soil improvement, food hygiene, buiding, petroleum chemical industry, and so on.

Owner:HUAQIAO UNIVERSITY

Preparation method of fruit and vegetable preservative film

InactiveCN106832549AImprove antibacterial propertiesImprove preservation qualityFlexible coversWrappersMethacrylateFood hygiene

The invention discloses a preparation method of a fruit and vegetable preservative film. The preparation method comprises the following steps: preparation of a functional filler, preparation of a chitosan colloidal solution, preparation of chitosan / functional filler co-grafted isobutyl methacrylate, preparation of the fruit and vegetable preservative film and the like. The active carbon, travertine and six-ring stone added in the preservative film are all a porous structure. By adding the active carbon, travertine and six-ring stone into the preservative film, micropores are formed in the film, the film is endowed with good air permeability and adsorptivity, and gas and heat generated in the film can be discharged out of those micropores. Under synergistic effects of those substances, the fruit and vegetable preservative film has the following beneficial effects: fresh-keeping quality of fruit and vegetable can be remarkably enhanced, and shelf life of fruit and vegetable is prolonged. In addition, the raw materials used in the invention are all natural components, are nontoxic and harmless, and meet food hygiene requirements.

Owner:安徽民祯活性包装材料有限公司

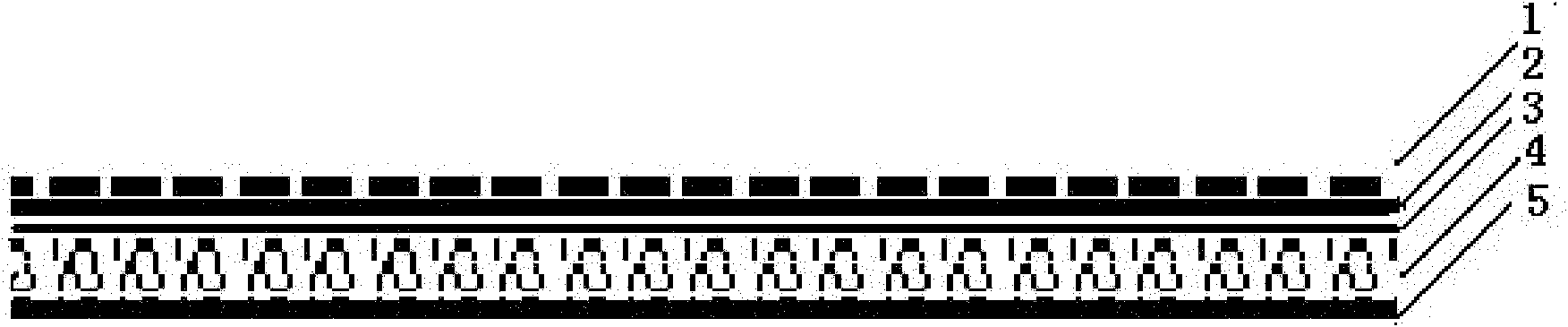

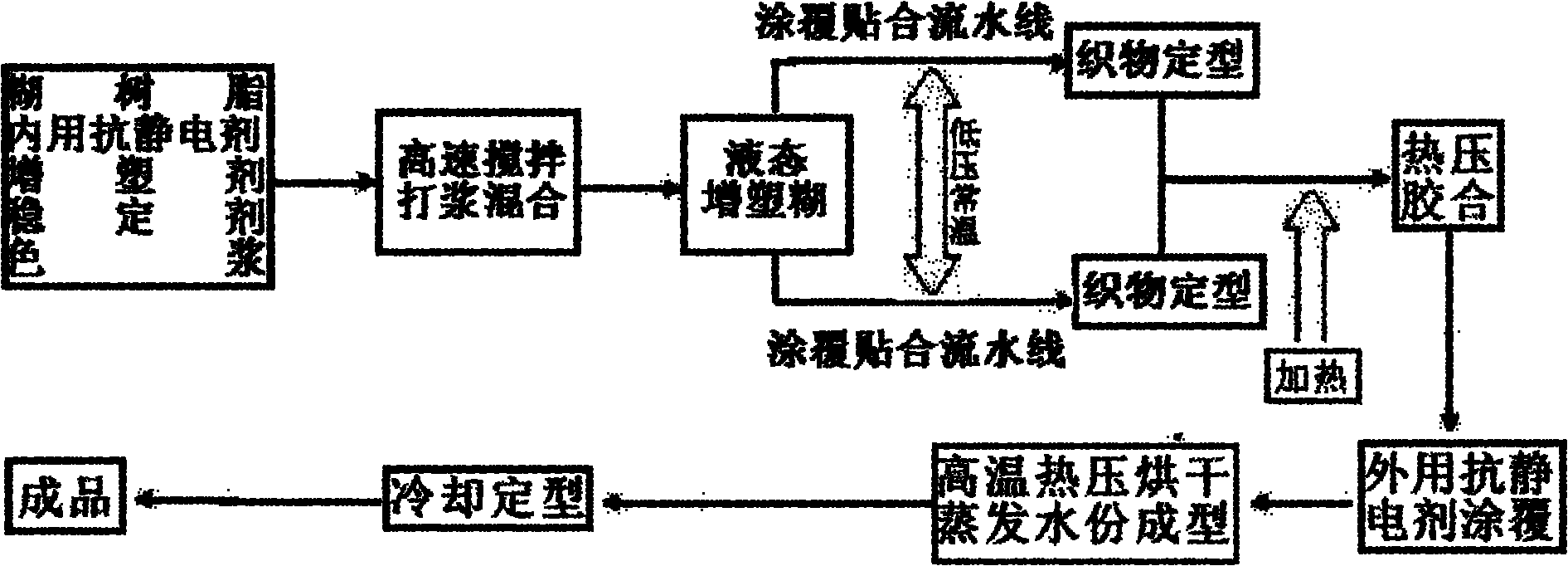

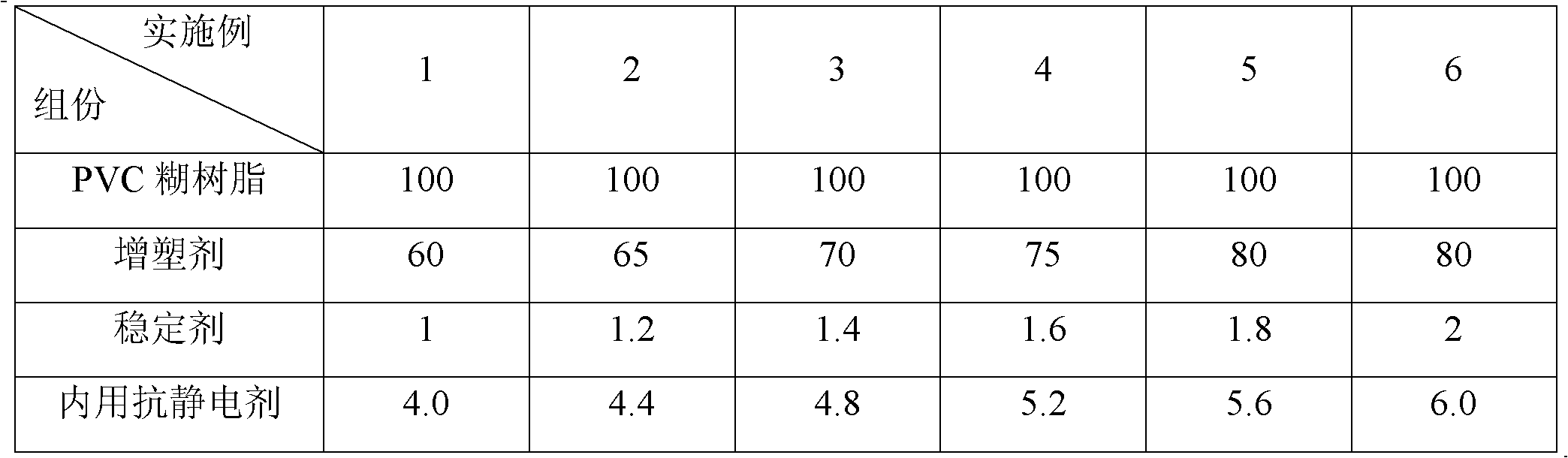

Antistatic poly vinyl chloride (PVC) conveyer belt

ActiveCN102126598AMeet the requirements of antistaticPaste making process has no effectConveyorsSynthetic resin layered productsFiberSurface layer

The invention relates to an antistatic poly vinyl chloride (PVC) conveyer belt. The conveyer belt sequentially comprises an external antistatic agent coating, an antistatic coating layer, a surface layer, a laminated layer and a bottom layer from top to down, wherein the surface layer and the bottom layer are fabrics coated with PVC paste resin, at least the fabric of the surface layer is doped with conductive fibers, and the antistatic coating layer is a PVC paste resin coating layer containing an internal antistatic agent. The surface resistance of the antistatic PVC conveyer belt is 107ohms, so the requirements of the food hygiene, tobacco, electronics and other fields on static resistance are melt, and no influence on a paste making process and product coloring is exerted because the internal PVC antistatic agent in a paste or liquid state is added into the antistatic coating layer. Moreover, different-color antistatic PVC conveyer belt can be made according to different demands.

Owner:内蒙古宁蒙活性炭有限公司

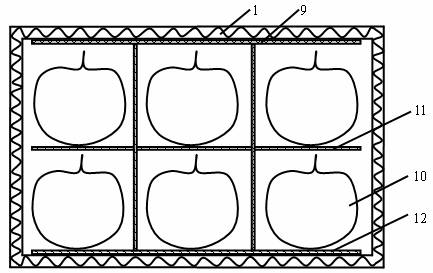

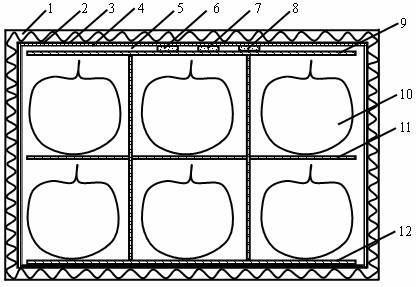

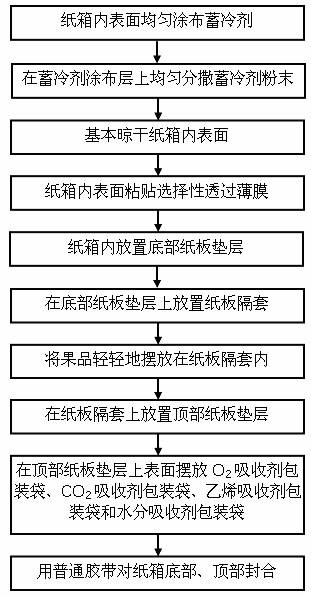

Fruit preserving carton and fruit preserving and storing method utilizing same

InactiveCN102009792AImprove preservation qualityExtended shelf lifeFruit and vegetables preservationPackaging under vacuum/special atmosphereCardboardCarton

The invention discloses a fruit preserving carton, wherein a coating layer is coated on the inner surface of the carton, a cold storing agent powder layer is uniformly scattered on the coating layer, then a selective permeable thin film is stuck on the inner surface of the cold storing agent powder layer, and an oxygen absorbent, a carbon dioxide absorbent, an ethylene absorbent and a water absorbent are respectively uniformly flatly laid and placed on the upper surface of a top paperboard cushion layer. The invention further discloses a carton preserving and storing method utilizing the fruit preserving carton, and the method comprises the following steps: placing fruits among partitions of the carton; then laying the top paperboard cushion layer on a paperboard spacing sleeve; uniformly flatly laying packaging bags filled with the oxygen absorbent, the carbon dioxide absorbent, the ethylene absorbent and the water absorbent respectively on the top paperboard cushion layer; and finally sealing the bottom and top of the carton in which fruits are well loaded. By utilizing the fruit preserving carton and the carton preserving and storing method, the preserving and storing quality of the fruits can be significantly improved, the preservation period is prolonged, requirements of food hygiene can be completely met, storage and transportation can be carried out conveniently, and the cost is low.

Owner:XIAN UNIV OF TECH

Feed additive for improving pigling intestinal canal function and immunity function, and use method thereof

InactiveCN101194674AReduce diarrhea rateIncrease conversion rateFungiAnimal feeding stuffAnimal scienceAnimal product

The invention relates to a feed additive which is capable of promoting intestinal function and immunologic function of piglets, wherein agaricus blazei murrill is used as strains, a fermentation medium which comprises a carbon source, a nitrogen source and inorganic salt is used to ferment and culture, the obtained things are mixed, froze and dried according to the weight radio of fermentation broth, which is 0.2-5:1. The using method is that based on compound feed of pigs, concentrated feed of pigs, pig premix or other feed additive of pigs, 0.05-2 percent of the feed additive which is capable of promoting intestinal function and immunologic function of piglets is added to feed, thereby being capable of obviously reducing the diarrhea rate of the piglets, improving the daily gain, increasing the conversion rate of feed, and increasing the health level and weaning weight of piglets. Through being tested by various tests and laboratories, the additive not only is efficient and safe but also is non-toxic, animal products for feeding accord with the requirements of food hygiene.

Owner:INST OF ANIMAL HUSBANDRY & VETERINARY FUJIAN ACADEMY OF AGRI SCI

Automatic positioning holding device and automatic splitting machine for areca nuts

The invention discloses an automatic positioning holding device for processing areca nuts and an automatic splitting machine for the areca nuts, and belongs to the technical field of food processing devices. A holder fixed to a conveying chain and an elastic clamping device fixed to a machine frame are designed to be matched, and the process that the areca nuts are clamped and fed into a cutter to be split is completed during the relative movement. Two hoppers are arranged on the automatic splitting machine for the areca nuts, the two hoppers are connected through a conveying chain with a stopping block, and the feeding height is reduced; a distributing wheel is installed in a conveying hopper to replace manual conveying. By means of the automatic positioning holding device and the automatic splitting machine for the areca nuts, labor is replaced with a machine, and workers are liberated from complicated labor. The number of the workers is decreased, cost is reduced, floor space is reduced, production efficiency is improved, safety is improved, and food hygiene is guaranteed. The machine is compact and reasonable in design and convenient to operate and maintain. Parts in contact with food are manufactured through food-grade materials, and safe and sanitary effects are achieved.

Owner:所广博

Processing method for convenient rice wine soaking duck food

The invention relates to a processing method for convenient rice wine soaking duck food, which belongs to the technical field of meat product processing. A fresh or frozen duck without viscera serves as raw materials, and the duck is orderly processed into rice wine sauce, a duck neck, a duck tongue and duck wings to obtain the convenient rice wine soaking duck food. The processing technology andparameters, brine and a drunk brine formula are determined. The fishy smell of the raw materials is eliminated by precooking and rising modes, the wine soaking time is shortened with a vacuum wine soaking slot, and the wine soaking consistency is enhanced. The vacuum packaging is integrated with a high temperature sterilization technology to ensure the food hygiene and the guarantee period. Soup made of the duck skeleton is used for processing the convenient rice wine soaking duck food so as to enhance the utilization ratio of the raw materials. The convenient rice wine soaking duck food has the flavors of the duck, the duck neck, the duck tongue or the duck wings and the rice wine, and has strong flavor of rice wine but no preservatives. The package of the convenient rice wine soaking duck food is small, and the convenient rice wine soaking duck food can be instantly eaten after being opened. The convenient rice wine soaking duck food is stored at the normal temperature, and the guarantee period of the convenient rice wine soaking duck food is longer than or equal to six months.

Owner:QIONGZHOU UNIVERSITY +1

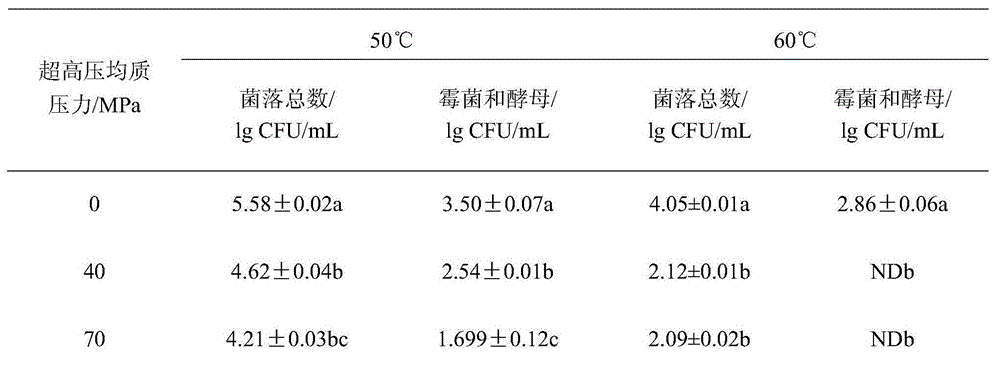

Method for sterilizing fruit and vegetable juice

PendingCN104432396AOvercome lossOvercome qualityFood preservationEscherichia coliAntioxidant capacity

The invention relates to a method for sterilizing fruit and vegetable juice. The method comprises the following steps: preheating the fruit and vegetable juice, and carrying out ultrahigh pressure homogenization treatment and mild heat treatment on the fruit and vegetable juice, wherein the feeding temperature in the ultrahigh pressure homogenization treatment is 50-60 DEG C, the pressure is 100-400MPa, and the temperature of the mild heat treatment is 50-60 DEG C. By adopting the method provided by the invention, indigenous flora in the fruit and vegetable juice can meet the national food hygiene standard, and escherichia coli is decreased by at least 5.0 log units to meet the requirements on health and safety of non-thermal sterilization regulated by American FDA. The quality and the nutritional ingredients of the fruit and vegetable juice prepared in the invention can be well kep under the condition of guaranteeing the requirements on the health and safety, and the color and luster, pH, titratable acid, soluble solids and antioxidant capacity have no remarkable change; sensory evaluation and analysis show that the smell, taste and flavor are much better than those of pasteurized fruit and vegetable juice.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Processing method of dehydrated shallot leaves

InactiveCN102972511AKeep the tasteKeep shapeFruit and vegetables preservationAdditive ingredientFreeze-drying

The invention discloses a processing method of dehydrated shallot leaves. The method comprises the following steps of: 1) processing raw materials; 2) pre-cooling the processed fresh shallot leaves at 2-8 DEG C for 0.5 hour to 1.5 hours; and 3) freezing and drying the shallot leaves in vacuum, wherein the pre-cooled fresh shallot leaves are heated and dried in a vacuum freezing and drying warehouse of vacuum freezing and drying equipment at a heating temperature of 70-90 DEG C, the vacuum degree of the vacuum freezing and drying warehouse in a drying process is 900pa-1500pa, the temperature of a cold trap is -18 to -20 DEG C, and the moisture content of the dried shallot leaves is less than 3%, thus obtaining the dehydrated shallot leaves. The processing method of the dehydrated shallot leaves provided by the invention overcomes the defects of 'hot air drying' or 'vacuum freeze-drying'; the original color, aroma and taste of the shallot leaves are preserved; a lot of nutritional ingredients of the shallot leaves can be prevented from being destroyed; and the product has distinct qualitative characteristics and accords with national standards for food hygiene and quality.

Owner:HUBEI TEMIAO FOOD CO LTD

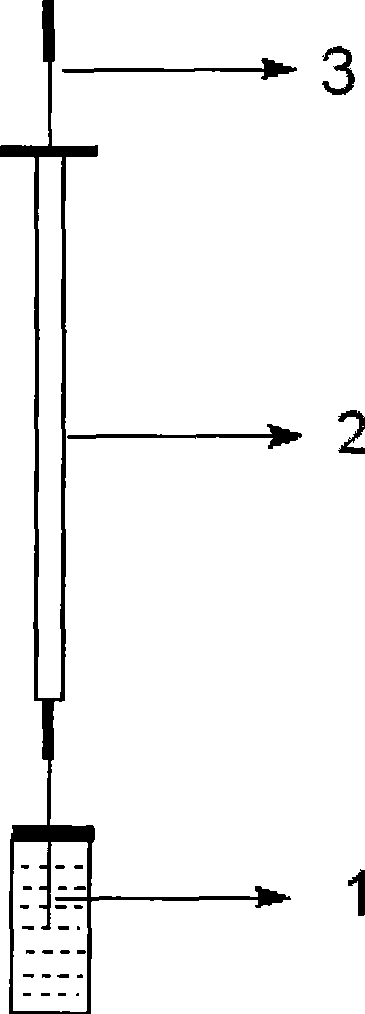

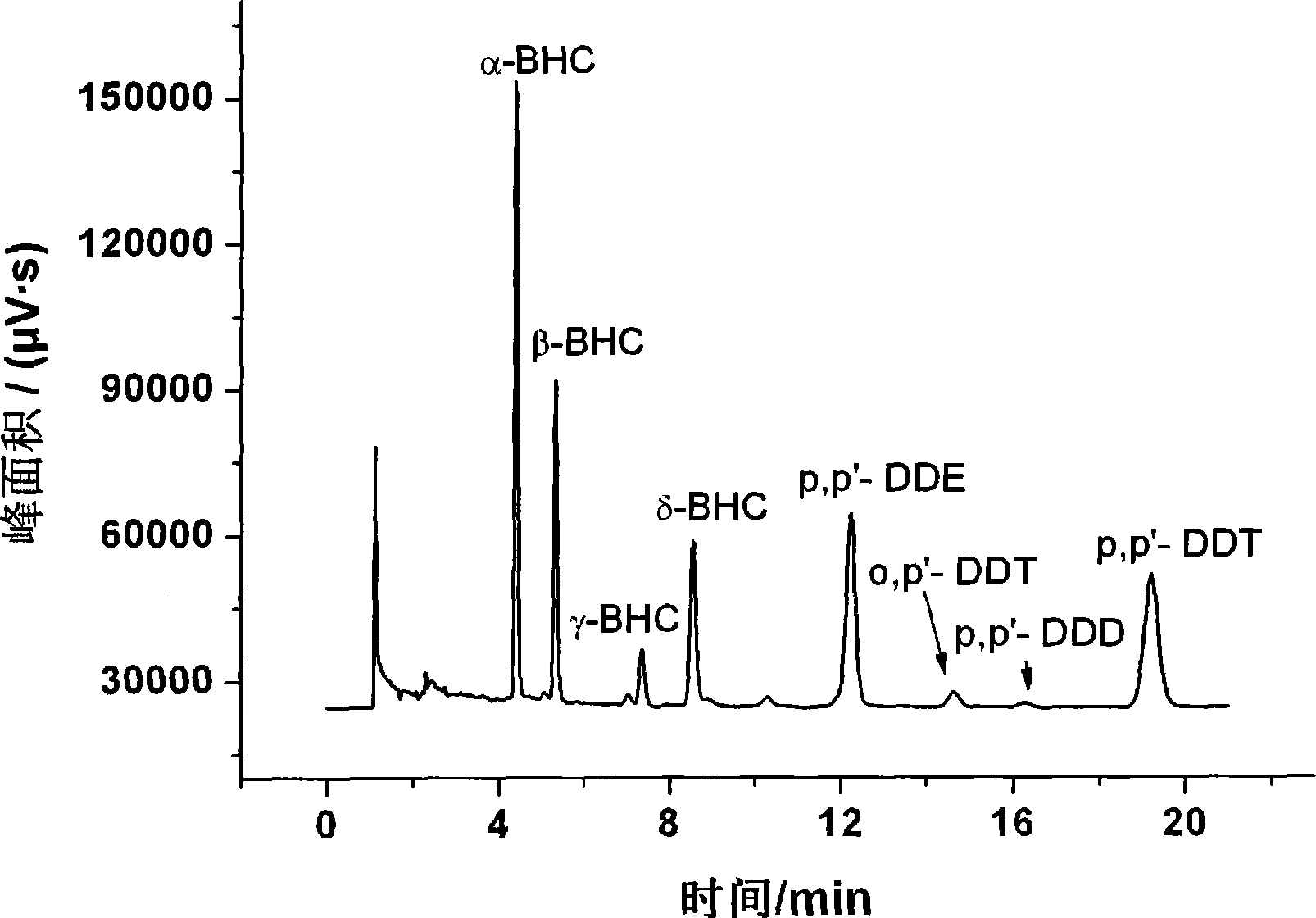

Solid phase micro-extraction stainless steel fiber and preparation method thereof

InactiveCN101530679ASimple methodFast wayIon-exchange process apparatusOther chemical processesNitrogenNitrogen gas

The invention relates to a novel solid phase micro-extraction stainless steel fiber and a preparation method thereof, which provides a method for easily and rapidly preparing the solid phase micro-extraction stainless steel fiber with high stability and high reproducibility. The preparation method is as follows: soaking the part of cleaned stainless steel wire into acid for treatment; washing by water; ageing under the protection of nitrogen, obtaining the solid phase micro-extraction stainless steel fiber; mounting the prepared solid phase micro-extraction stainless steel fiber in a microliter syringe, obtaining a simple solid phase micro-extraction device. The method is simple in operation and low in cost. The prepared solid phase micro-extraction stainless steel fiber has excellent extraction performance on all trace amount organic pollutants. Compared with commercial solid phase micro-extraction device, the solid phase micro-extraction device has better mechanical strength and thermal stability, and has low cost and long service life. The extraction fiber has excellent application potential in fields of environmental monitoring, food hygiene and the like.

Owner:NANKAI UNIV

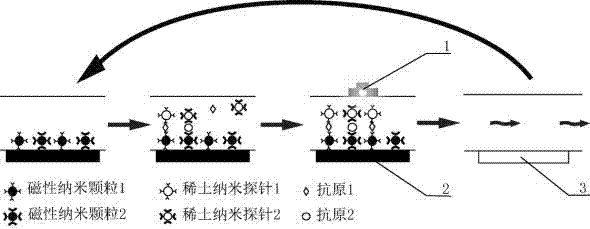

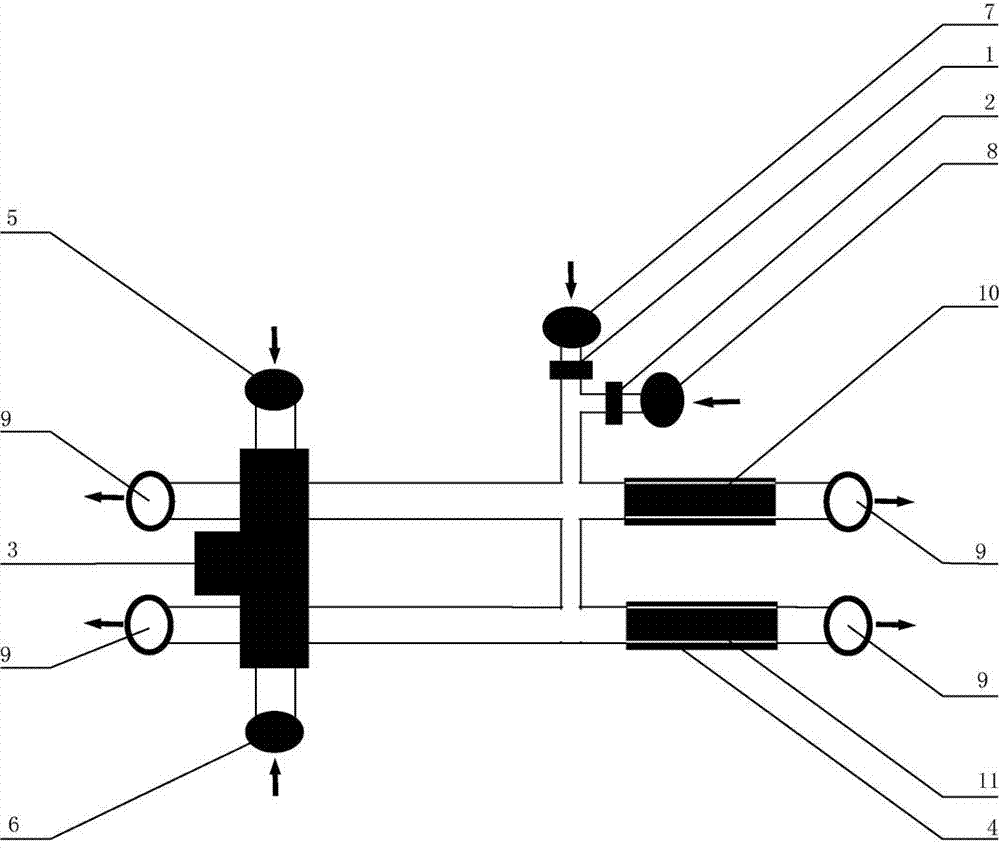

Rapid and continuous detection technology based on nanometer probe and magnetic micro-nano-particles

PendingCN107328931AAchieving Simultaneous DetectionImprove throughputLaboratory glasswaresMaterial analysisElectrochemical detectorInfectious Disorder

The invention provides simultaneous, rapid and continuous detection of multiple proteins, nucleic acids or pathogens by using a nanometer probe, paramagnetic micro-nano-particles and a microfluidic chip. According to the present invention, a monoclonal antibody or complementary nucleic acid sequence modified nanometer probe and antibody or nucleic acid modified magnetic micro-nano particle are used as detection reagents, a multi-channel microfluidic chip is used as a detection reaction cell, the antibody or nucleic acid modified magnetic micro-nano particle are immobilized on the bottom portion of the reaction cell by using a magnetic field to form a rewritable detection substrate, and an ultraviolet visible spectrophotometer, a fluorescence detector or an electrochemical detector is used as a signal acquisition device, such that the simultaneous and rapid detection of multiple proteins, nucleic acids or pathogens can be achieved; and based on the rewritability of the nanometer immune substrate and the anti-adhesion property of the chip material, the detector can achieve the continuous testing of different samples so as to substantially improve the detection automation and the sample treatment ability, and has wide application values in the fields of disease diagnosis, infectious disease monitoring, food hygiene and safety monitoring, and the like.

Owner:SUN YAT SEN UNIV

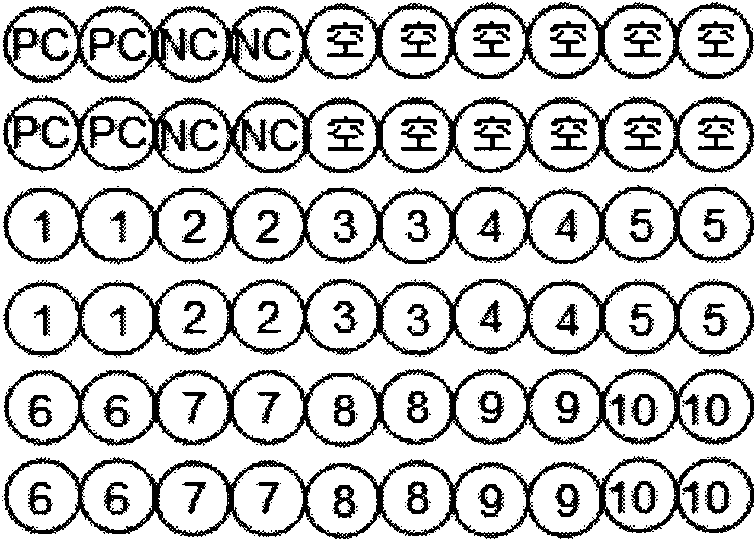

Oligonucleotide chip capable of detecting five enteroviruses simultaneously and application thereof

InactiveCN101654713AStrong specificityHigh compliance rateNucleotide librariesMicrobiological testing/measurementFluorescenceOligonucleotide chip

The invention discloses an oligonucleotide chip capable of detecting five enteroviruses simultaneously and an application thereof. The chip comprises a substrate, probes of pathogens of five enteroviruses coated on the substrate, negative contrast, positive contrast and blank contrast, wherein the probes of pathogens are five 54-70mer of HAV-P, ROV-P, NOV-P, ASV-P and ADV-PV1 probes. The chip of the invention adopts multiple PCR to amplify a plurality of target sequences of pathogens simultaneously and uses the downstream primer Tamara labeling method to perform fluorescence labeling to PCR product, the labeled PCR product is hybridized with the chip to realize the accurate detection of pathogens, the detection sensitivity is equal to that of PCR and the specificity is high. The detectionefficiency and accuracy are obviously shortened. The technology system of the invention is applicable to fields such as sea water and marine life specimens monitoring, food hygiene surveillance, customs quarantine, related clinical detection and the like.

Owner:SHANDONG MEDICAL BIO TECH RES CENT +1

Kit with RT-LAMP nucleic acid test strips for detecting porcine epidemic diarrhea virus and applications of kit

InactiveCN103276103ALow costReduce use costMicrobiological testing/measurementMicroorganism based processesBetaineNucleic acid test

The invention discloses a kit with RT-LAMP nucleic acid test strips for detecting a porcine epidemic diarrhea virus and applications of the kit. The kit comprises a primer group of a nucleic acid represented by SEQ ID No. 1-6 and test strips for detection of nucleic acid. The usage of the kit is as follows: first preparing a RT-LAMP reaction system comprising an AMV retrovirus, a 1* reaction buffer, a strand displacement DNA polymerase, a dNTP mixture, betaine, MgSO4, a FIP primer, a BIP primer, a LoopF primer, a LoopB primer, a F3 primer, a B3 primer and RNA of a sample to be measured; carrying out a reaction at a constant temperature, after testing the obtained products by using the nucleic-acid-detecting test strip, judging and reading directly: the positive result is that two red strips appear, and one strip is in the detection zone while the other strip is in the control zone. The kit has advantages of simple operation, low cost, easy observation of the reaction result, good specificity, easy popularization and application in large scope and being extremely suitable for export quarantine, food hygiene and on-site detection in animal husbandry.

Owner:SOUTH CHINA AGRI UNIV

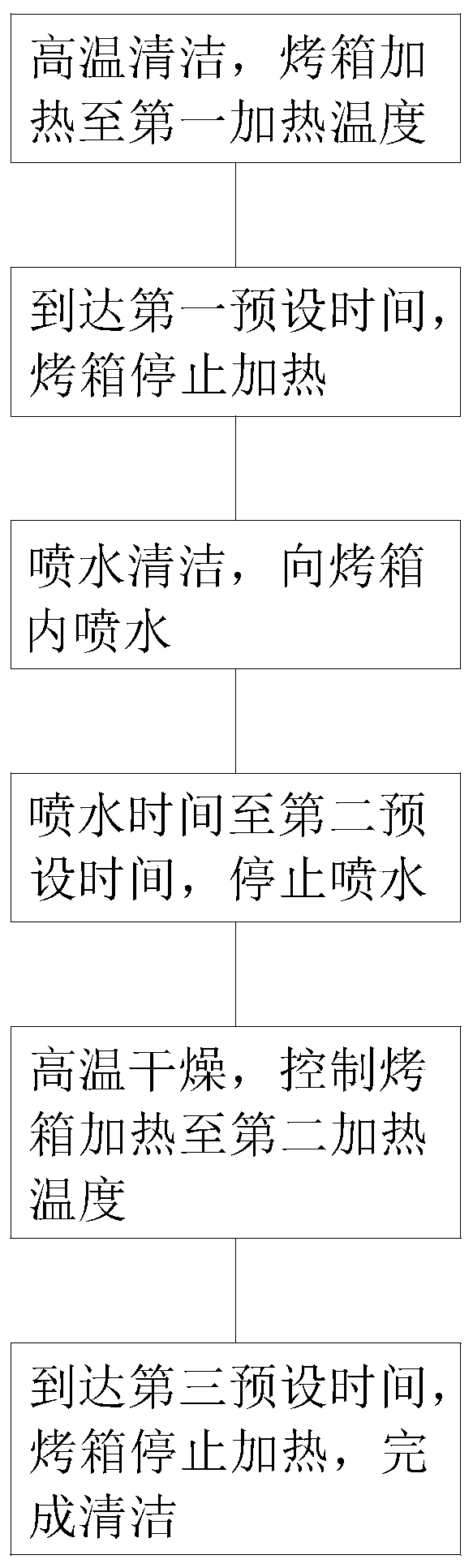

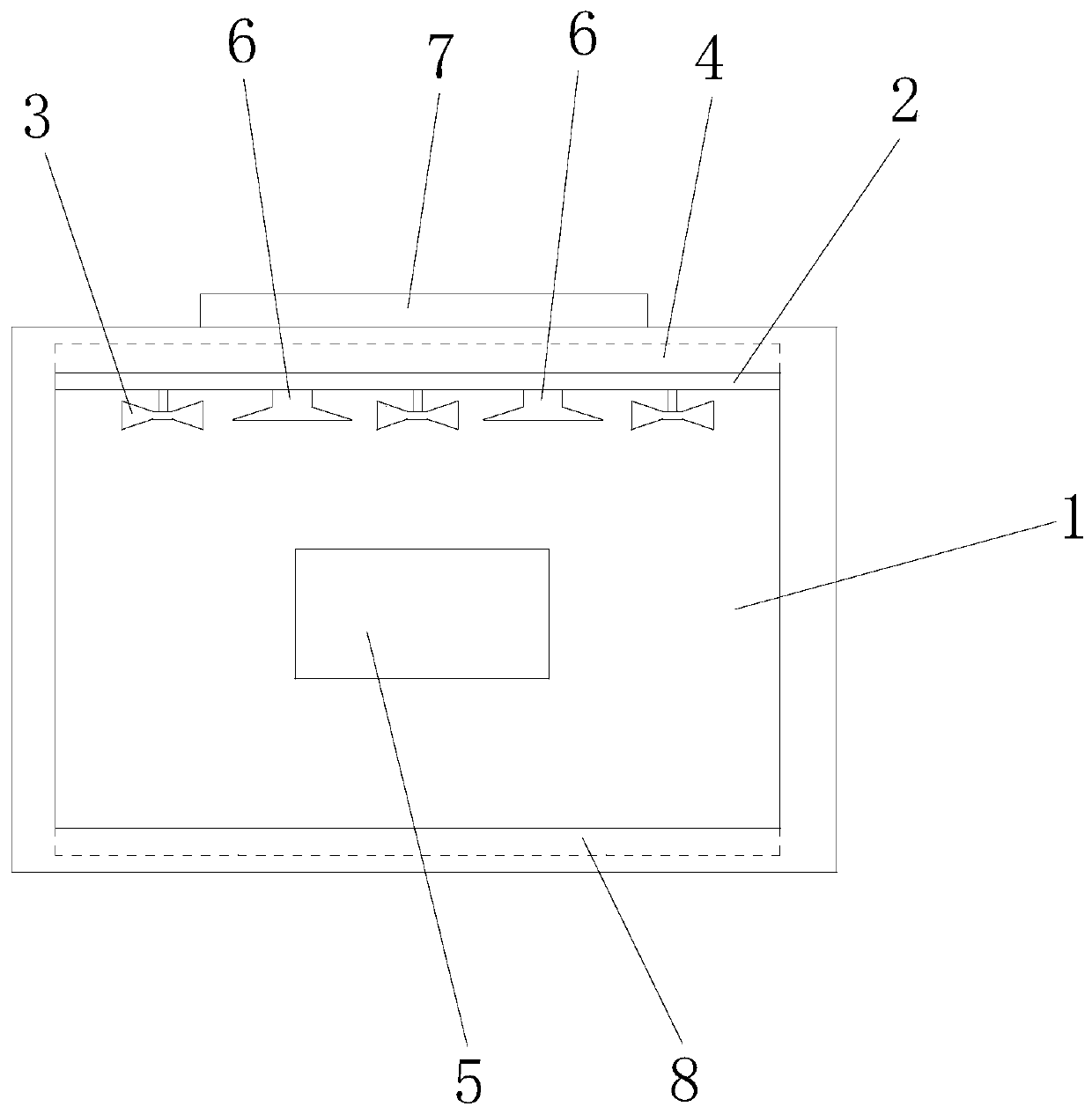

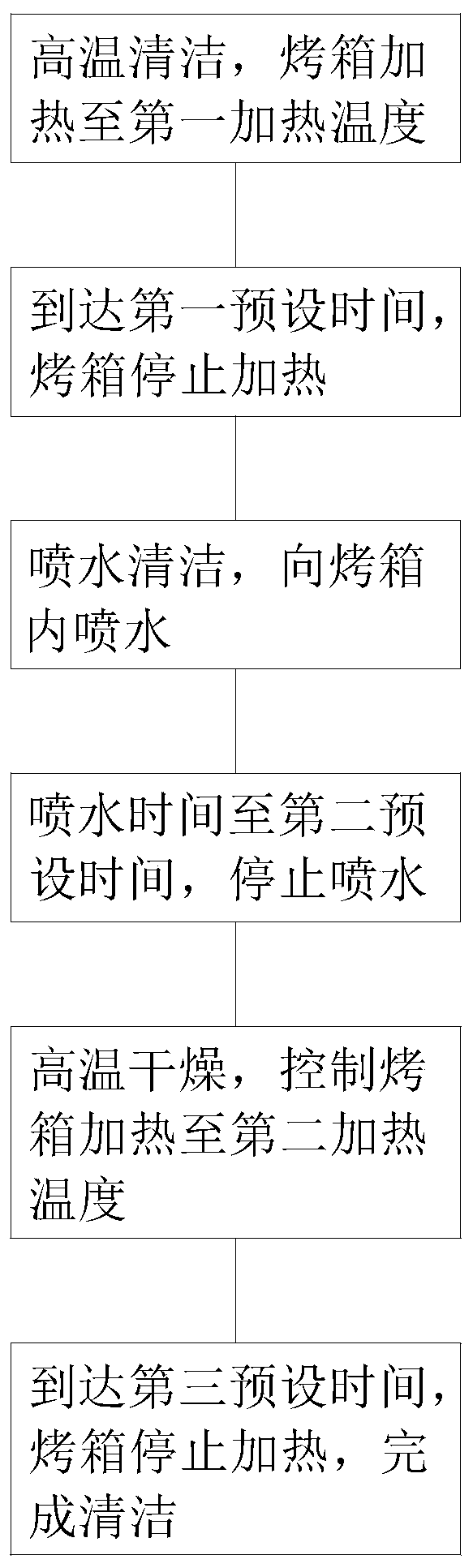

Oven self-cleaning method and oven

InactiveCN109699694AMaintain food hygiene and safetyImprove product experienceBaking surface cleaning/greasingSewageCleaning methods

The present invention relates to the technical field of oven equipment, in particular to an oven self-cleaning method and an oven. The method comprises: high-temperature cleaning: heating the oven toa first heating temperature, and stopping heating of the oven when reaching a first preset time; water-spray cleaning: spraying water into the oven, and stopping water spraying when the water sprayingtime reaches a second preset time; and high-temperature drying: controlling and heating the oven to a second heating temperature, and stopping heating of the oven when reaching a third preset time soas to complete cleaning. Compared with the prior art, the oven of the present invention is firstly subjected to the high-temperature cleaning so as to carbonize stains attached to the oven into ash,and then is subjected to the water-spray cleaning so as to clean the carbon ash on the inner wall of the oven. After the sewage in the oven is treated, the oven is dried to avoid water stain residuesin the oven and a problem of bacterium breeding due to long-time vacancy, and to maintain the user's food hygiene and safety. Besides, the oven cleaning method of the invention is convenient to operate, saves time and labor, has good cleaning effect, and improves the product experience of the oven user.

Owner:GREE ELECTRIC APPLIANCES INC

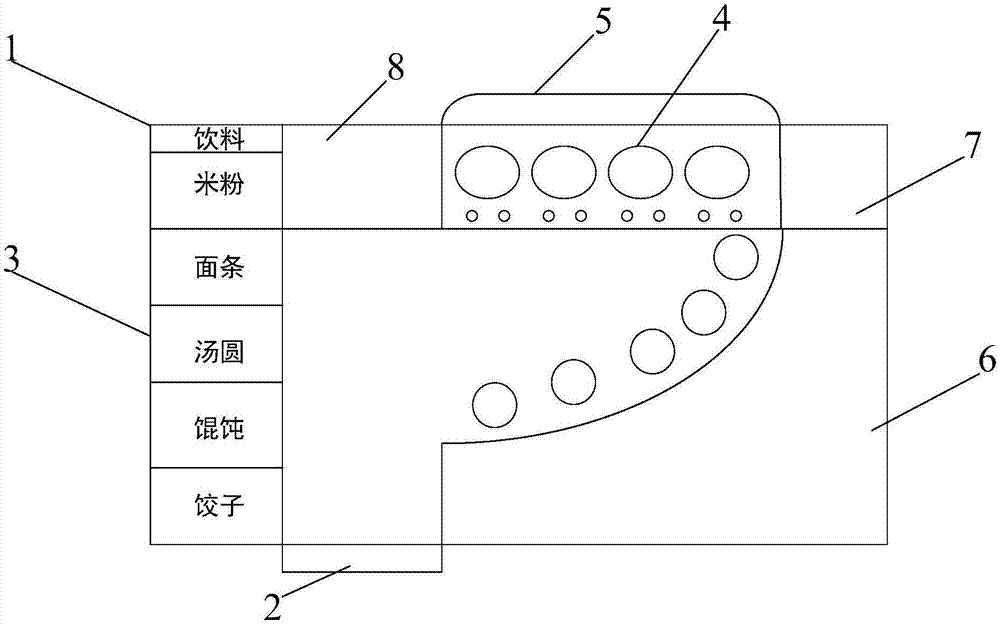

Movable intelligent sharing kitchen

PendingCN107065709AKeep Clean and HealthyImprove food hygieneProgramme controlComputer controlSoftware engineeringFood storage

A movable intelligent sharing kitchen disclosed by the present invention comprises a movable shell (1), and a food storage unit, a food cooking unit and a dining unit which are located in the shell (1), and the shell (1) comprises a door (2) equipped with a networking intelligent lock. The sharing kitchen of the present invention is equipped with the intelligent lock, so that the public can enter the kitchen to cook via an APP and after scanning the codes or inputting the ciphers, the situation that the food materials for cooking are clean and healthy, is guaranteed, and the food hygiene degree is improved.

Owner:武新国

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com