Patents

Literature

3981results about How to "Improve grinding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

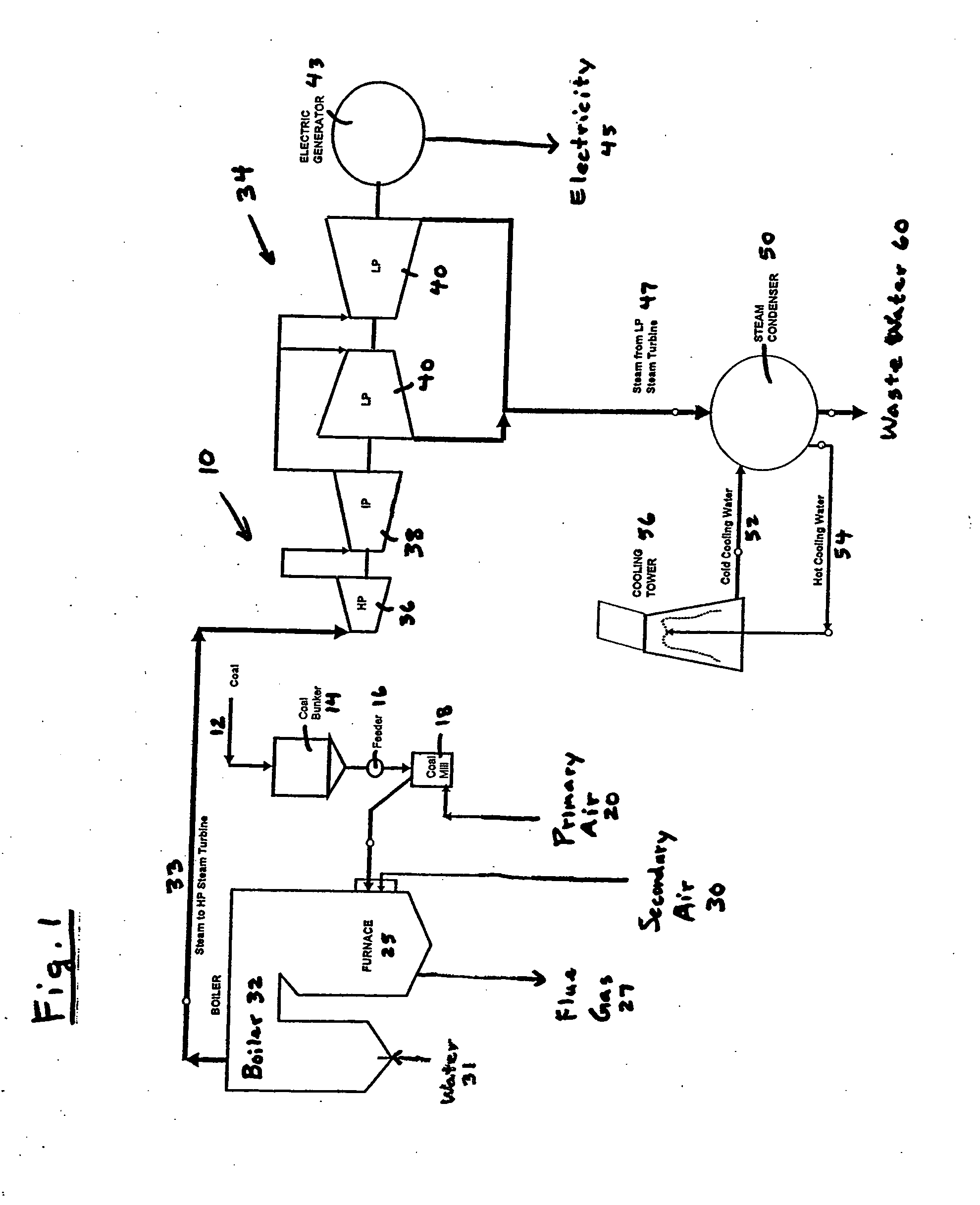

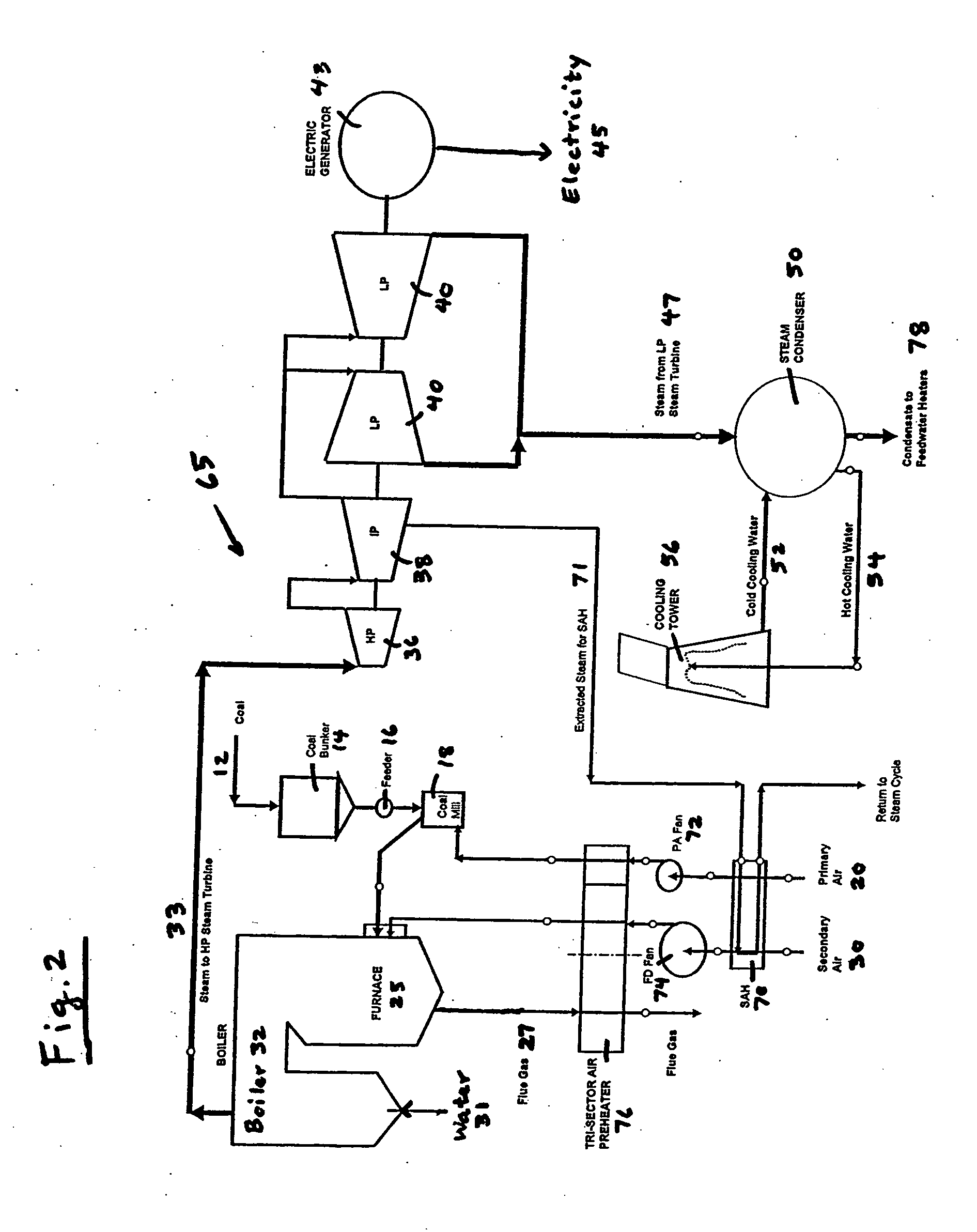

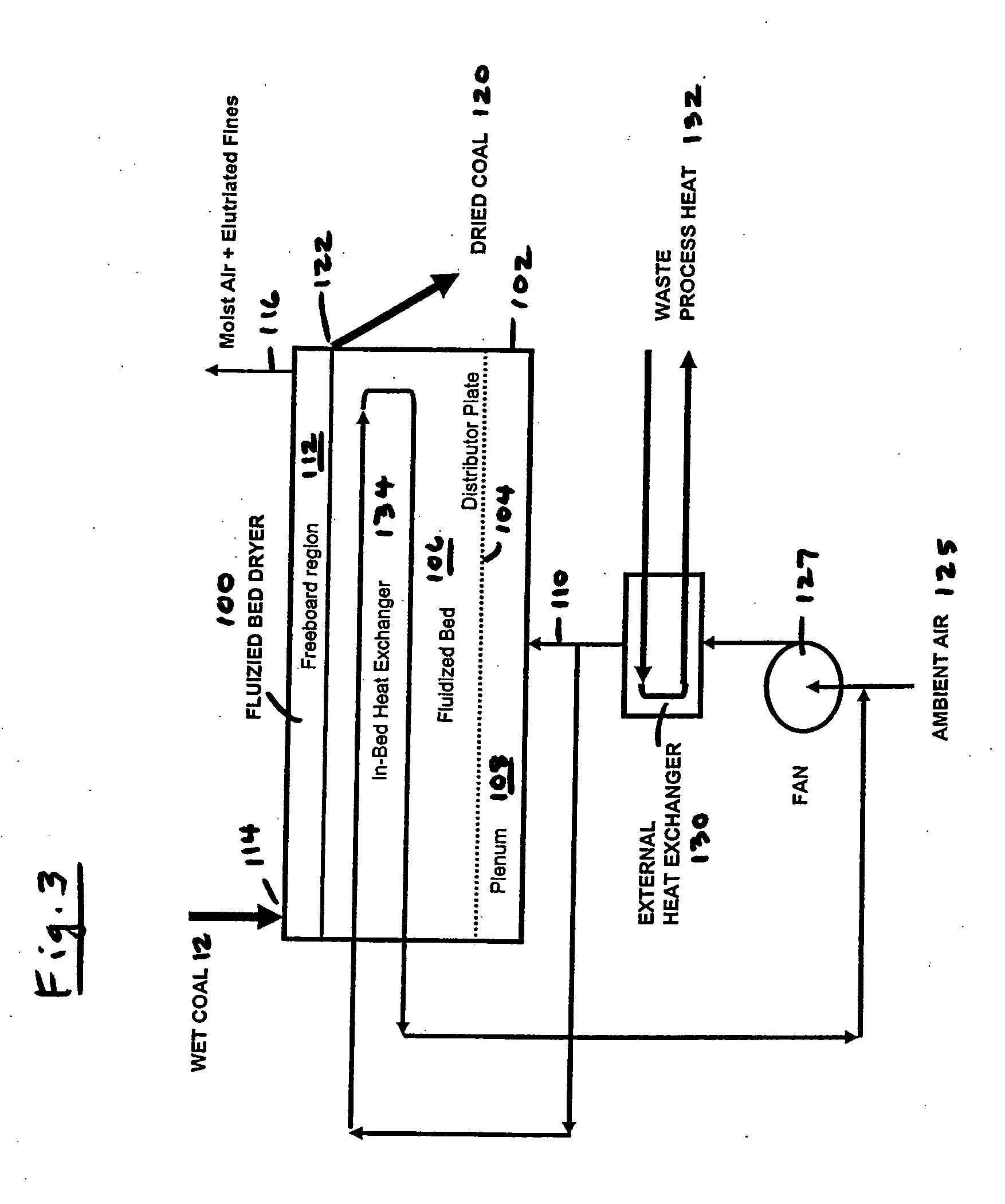

Method of enhancing the quality of high-moisture materials using system heat sources

ActiveUS20060075682A1Eliminates potential harmEmission reductionDrying solid materials with heatSolid fuelsFluidized bed dryingHeat flow

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement. Coal can be intercepted on current coal feed systems ahead of the pulverizers. Drying fuel, such as coal, is done to improve boiler efficiency and reduce emissions. A two-stage bed utilized in the process first “pre-dries and separates” the feed stream into desirable and undesirable feedstock. Then, it incrementally dries and segregates fluidizable and non-fluidizable material from the product stream. This is all completed in a low-temperature, open-air system. Elevation of fan room air temperature is also accomplished using waste heat, thereby making available to the plant system higher temperature media to enhance the feedstock drying process.

Owner:RAINBOW ENERGY CENT LLC

Tissue abrasives

InactiveUS7597900B2Beneficial biologicalAccelerated and improved wound healingCosmetic preparationsBiocideDermabrasionAnti oxidant

Abrasive compositions which include bioactive materials, such as bioactive glass and bioactive ceramics, which provide biological properties such as anti-inflammatory, anti-microbial, anti-oxidant effects, improved wound healing, and / or other beneficial effects are provided. Also provided are abrasive compositions comprising relatively non-toxic, bioinert glasses and ceramics which provide good abrasive effects, reduce or eliminate potentially harmful small particles; reduce or eliminate clogging of dermabrasion equipment; possess a relatively large surface area for applying coatings; and may be inexpensive and simple to make. Methods for abrading human or animal tissue, such as human skin, by contacting such tissue with these abrasive compositions is also provided.

Owner:SCHOTT AG

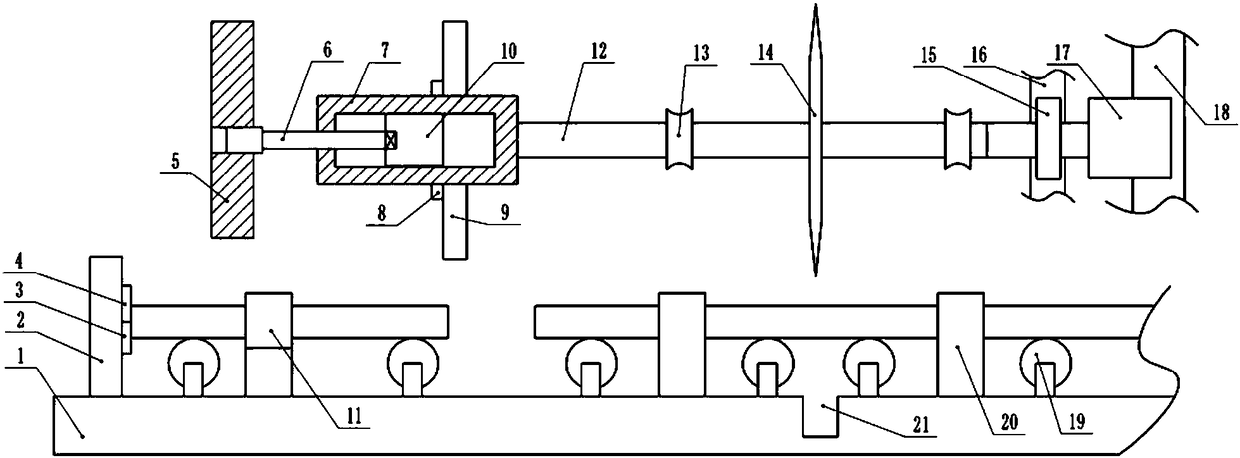

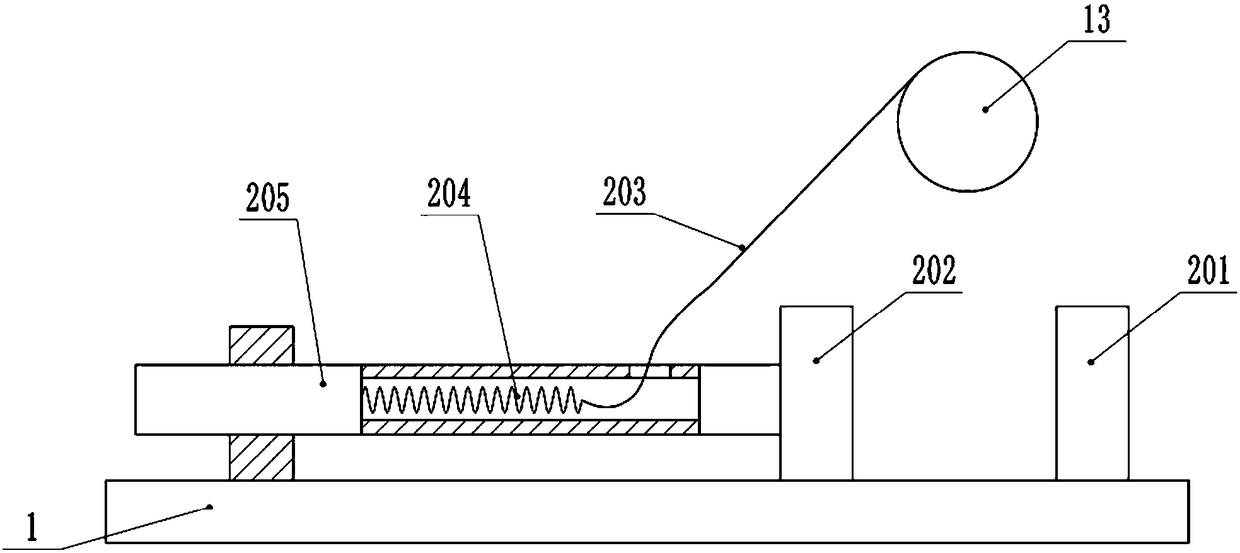

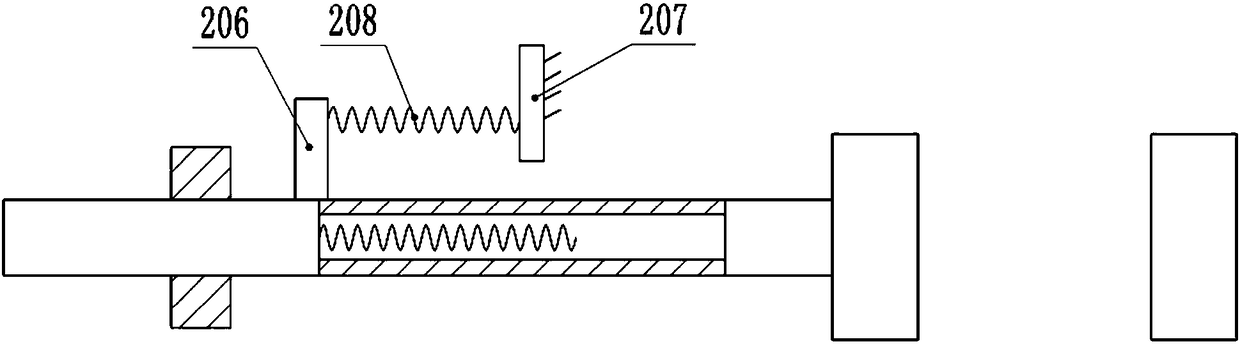

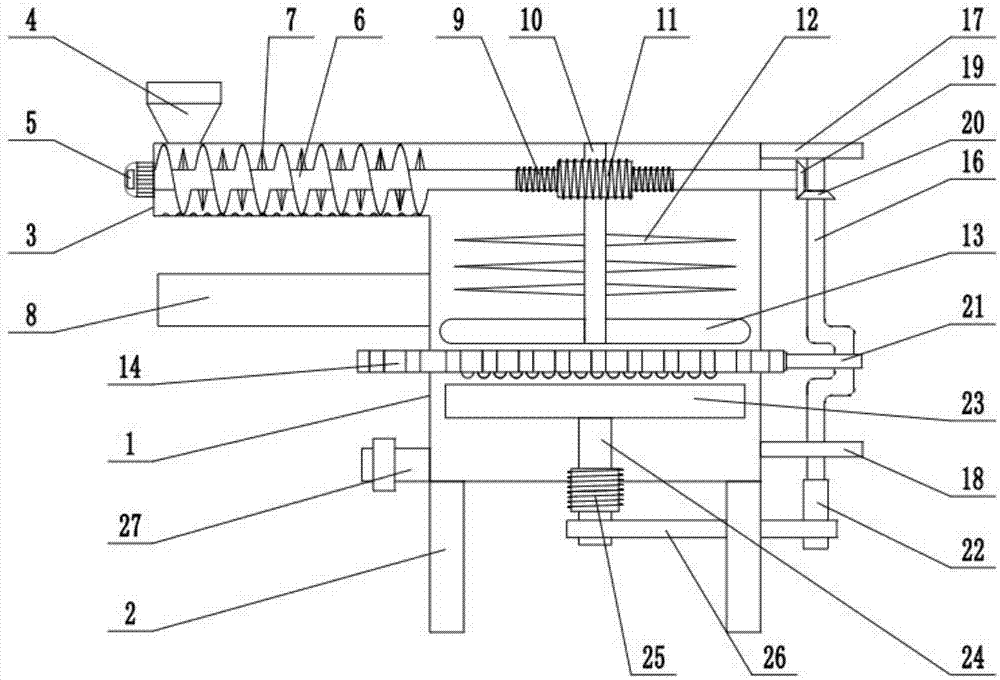

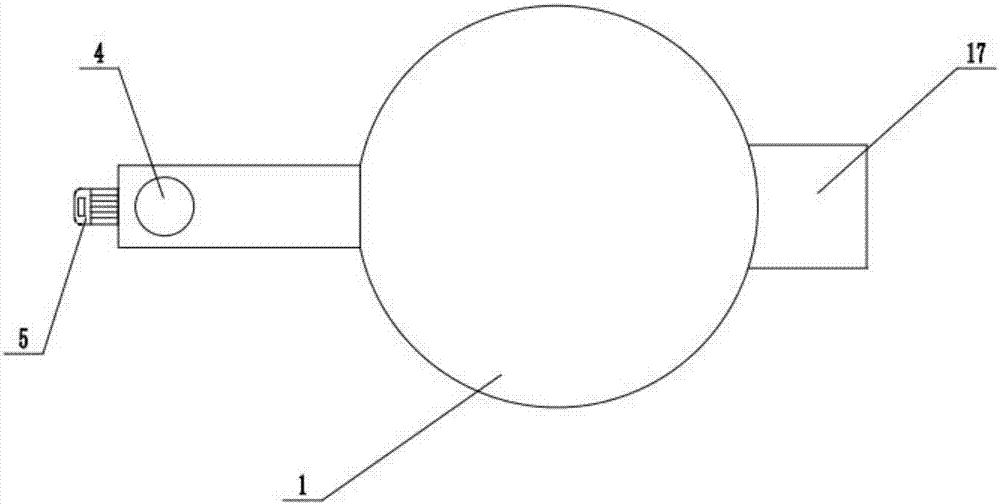

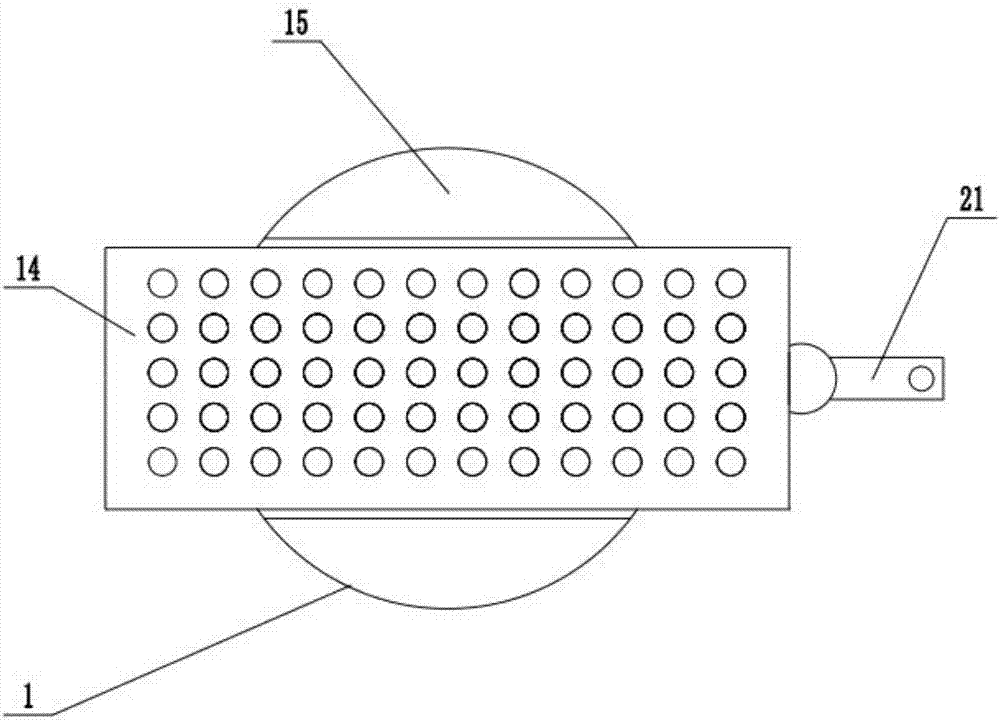

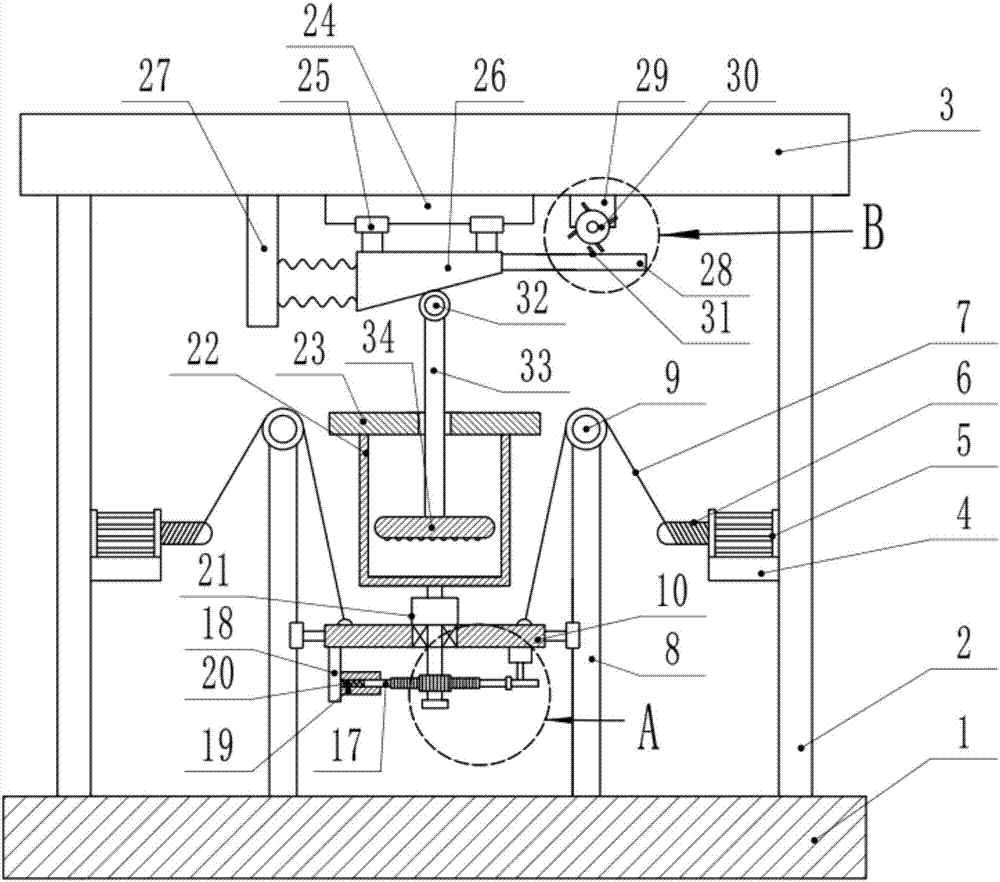

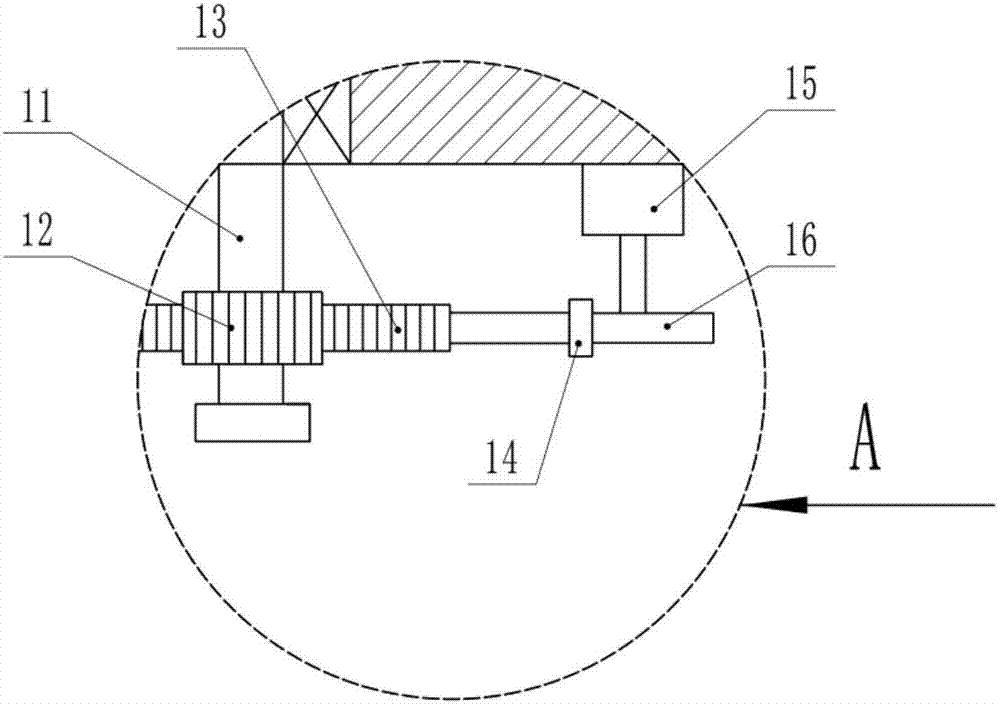

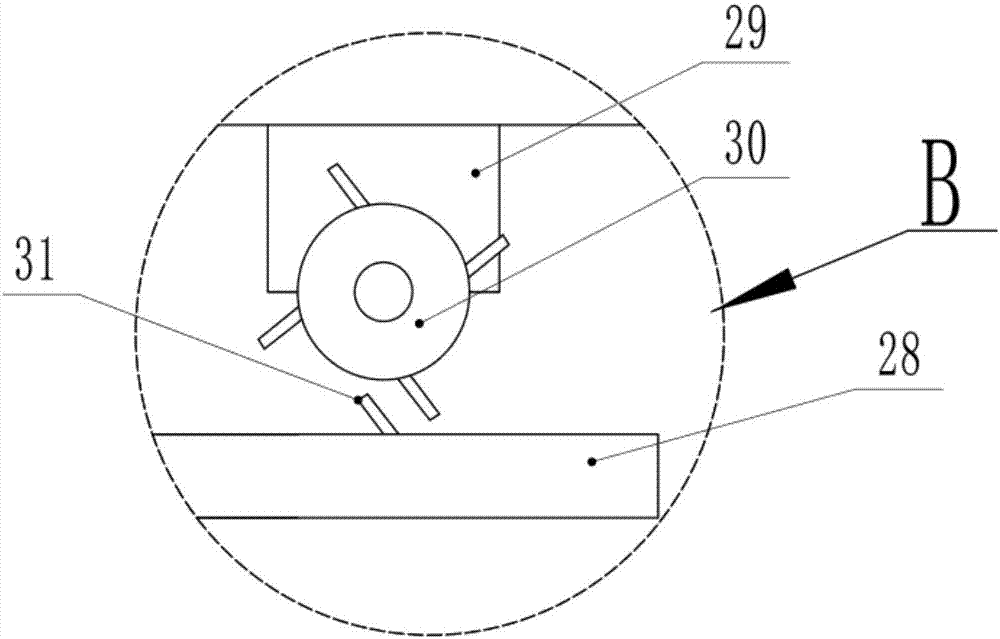

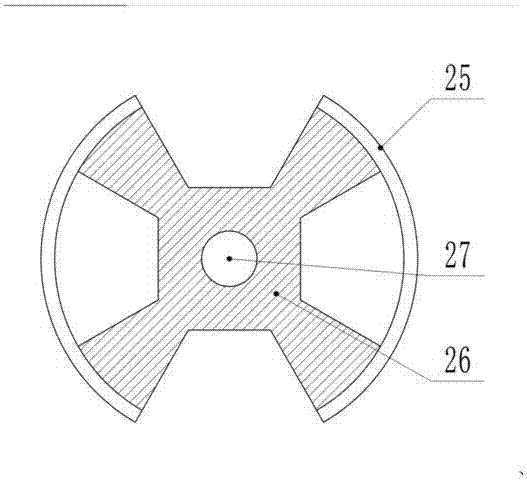

Pipe cutting and grinding device

ActiveCN108453508ARealize automatic clampingAchieve grindingEdge grinding machinesOther manufacturing equipments/toolsEngineeringSlide plate

The invention belongs to the technical field of cutting equipment, and specifically discloses a pipe cutting and grinding device. The pipe cutting and grinding device comprises a cutting mechanism anda grinding mechanism which are connected to the same rotating shaft, wherein a transmission gear and two fixed pulleys are arranged on the rotating shaft; a rack which is fixed to a machine frame isengaged with the transmission gear; the grinding mechanism comprises a rotating barrel which is fixed to the rotating shaft, and a grinding plate is arranged on the rotating barrel; a square shaft isin sliding connection with the interior of the rotating barrel, and a threaded rod which is in thread connection with the rotating barrel is rotatably connected to the square shaft; and the threaded rod is in sliding connection with a sliding plate, and the sliding plate is in sliding connection with the machine frame. The pipe cutting and grinding device further comprises a conveying roller, a first clamping mechanism and a second clamping mechanism; the first clamping mechanism comprises a clamping block and a fixing block; a sliding rope is connected between the clamping block and the corresponding fixed pulley; the second clamping mechanism is in sliding connection with a working platform; a baffle plate is arranged at the left end of the working platform; and magnetic parts which areattracted to and repelled by each other are arranged between the baffle plate and the second clamping mechanism. According to the scheme, the pipe cutting and grinding device has the advantages that anotch of a steel pipe can be ground while the steel pipe is cut, so that the working efficiency is improved.

Owner:苏州市振渭城镇建设发展有限公司

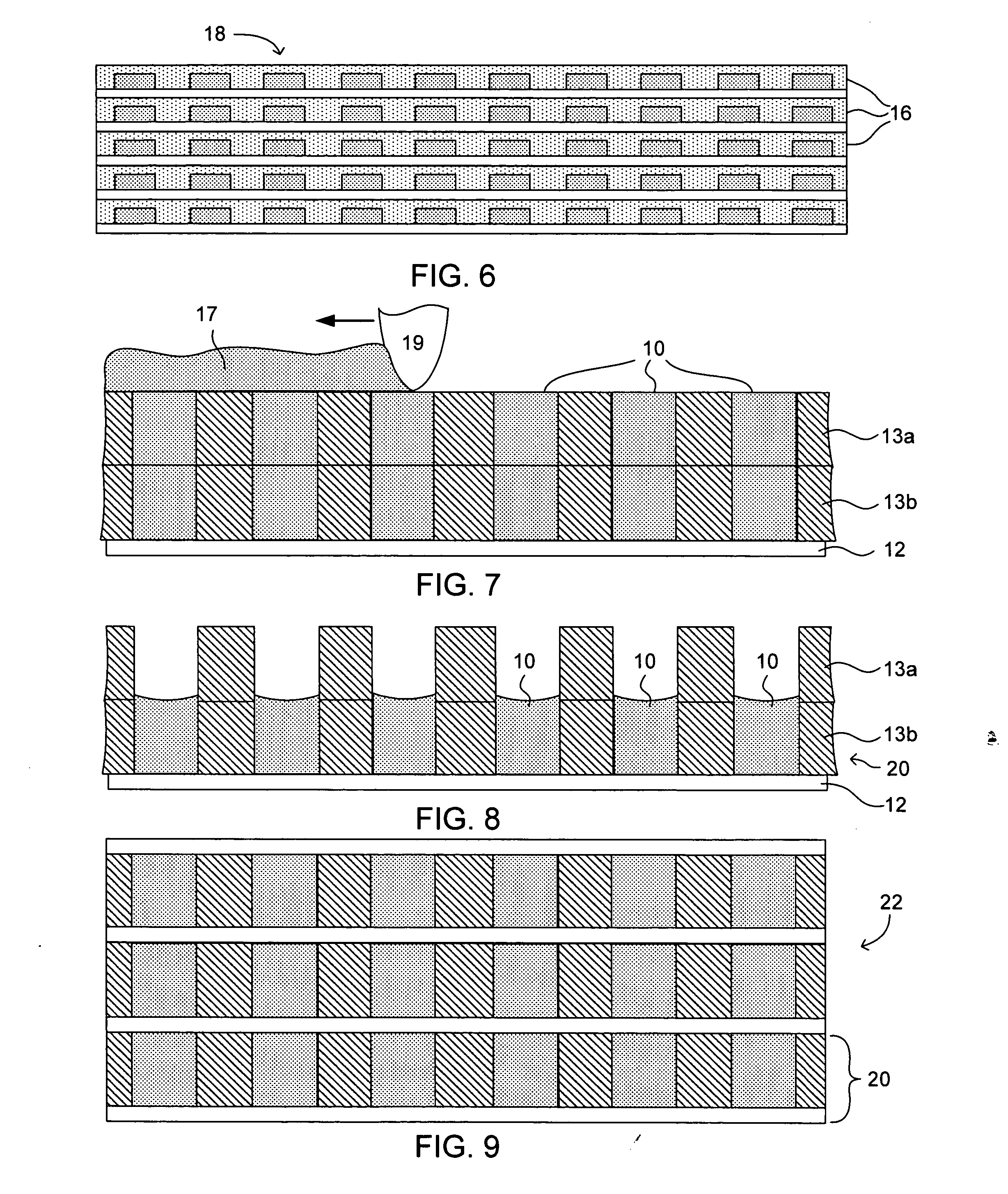

Polycrystalline grits and associated methods

InactiveUS20060042172A1Increase production volumeMaximize usePigmenting treatmentAdditive manufacturing apparatusMetallurgyMaterials science

Polycrystalline grits and methods of making grits which allow for a high degree of shape and size distribution control, as well as improved abrasive performance are described and disclosed. In one aspect, an abrasive slurry can be formed into a plurality of abrasive precursors arranged on a substrate using screen-printing or other techniques. The abrasive slurry can include a binder and a plurality of abrasive particles. The abrasive precursors on the substrate can then be covered with a pressure medium and then subjected to pressure and temperature conditions sufficient to cause sintering of the abrasive particles to form polycrystalline grits. The polycrystalline grits produced by such methods can have a substantially uniform shape and size distribution.

Owner:KINIK

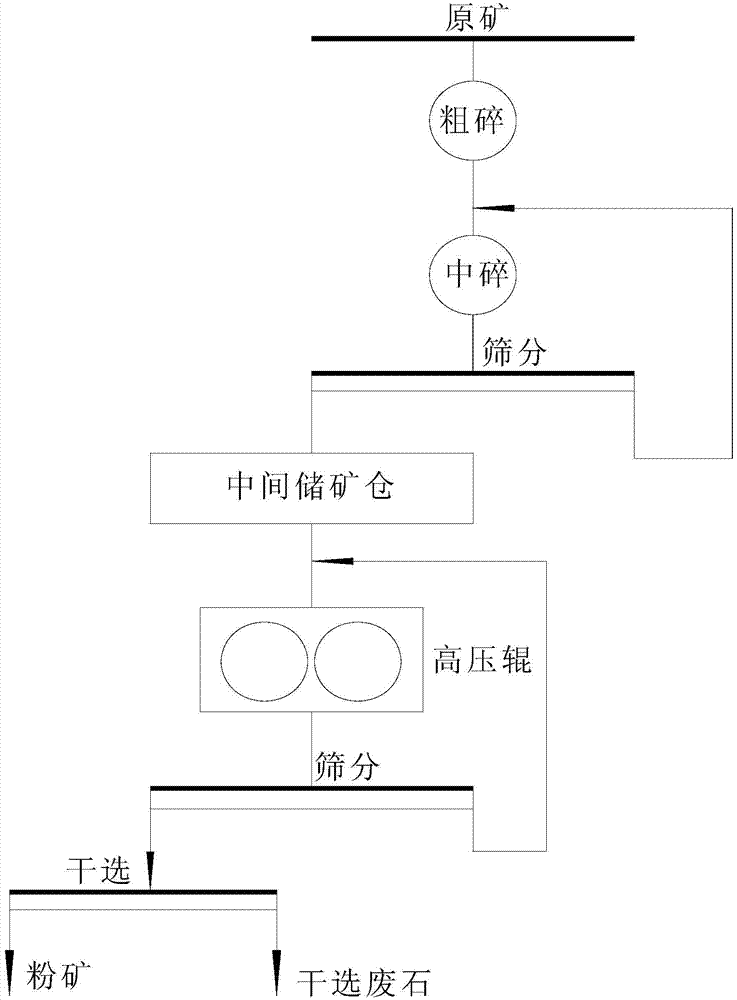

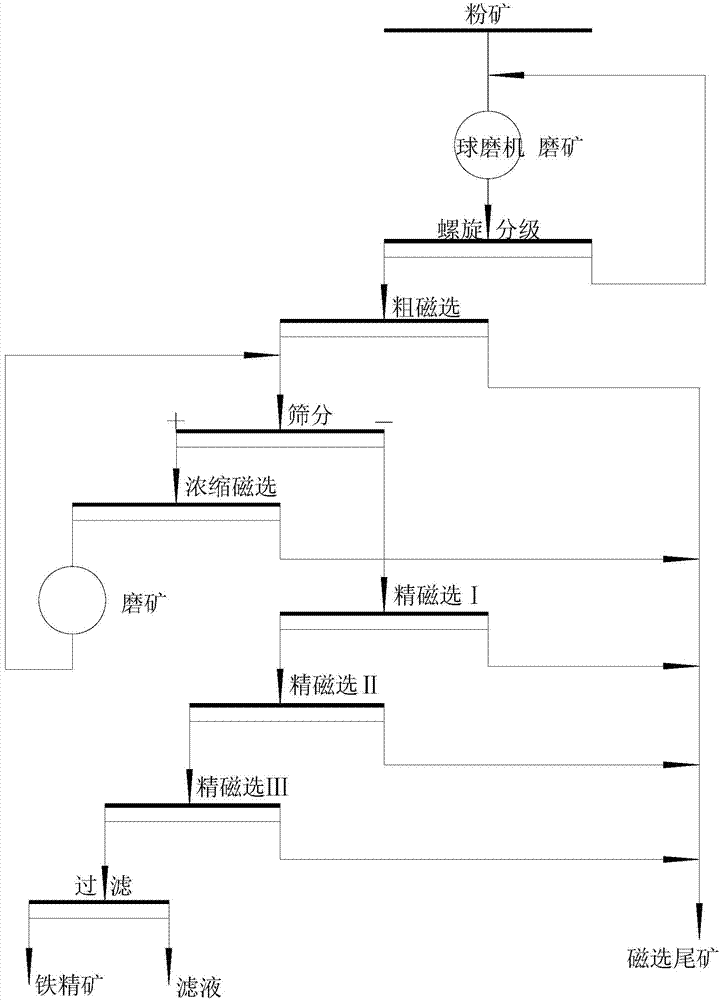

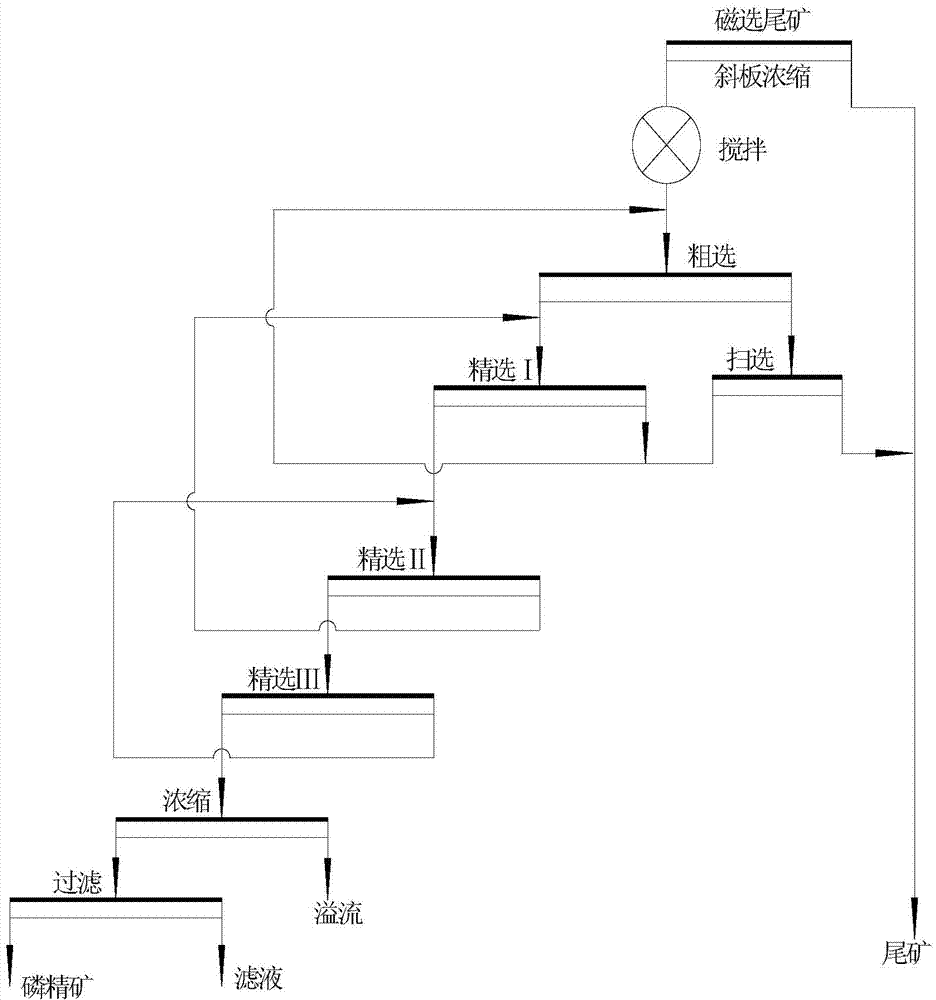

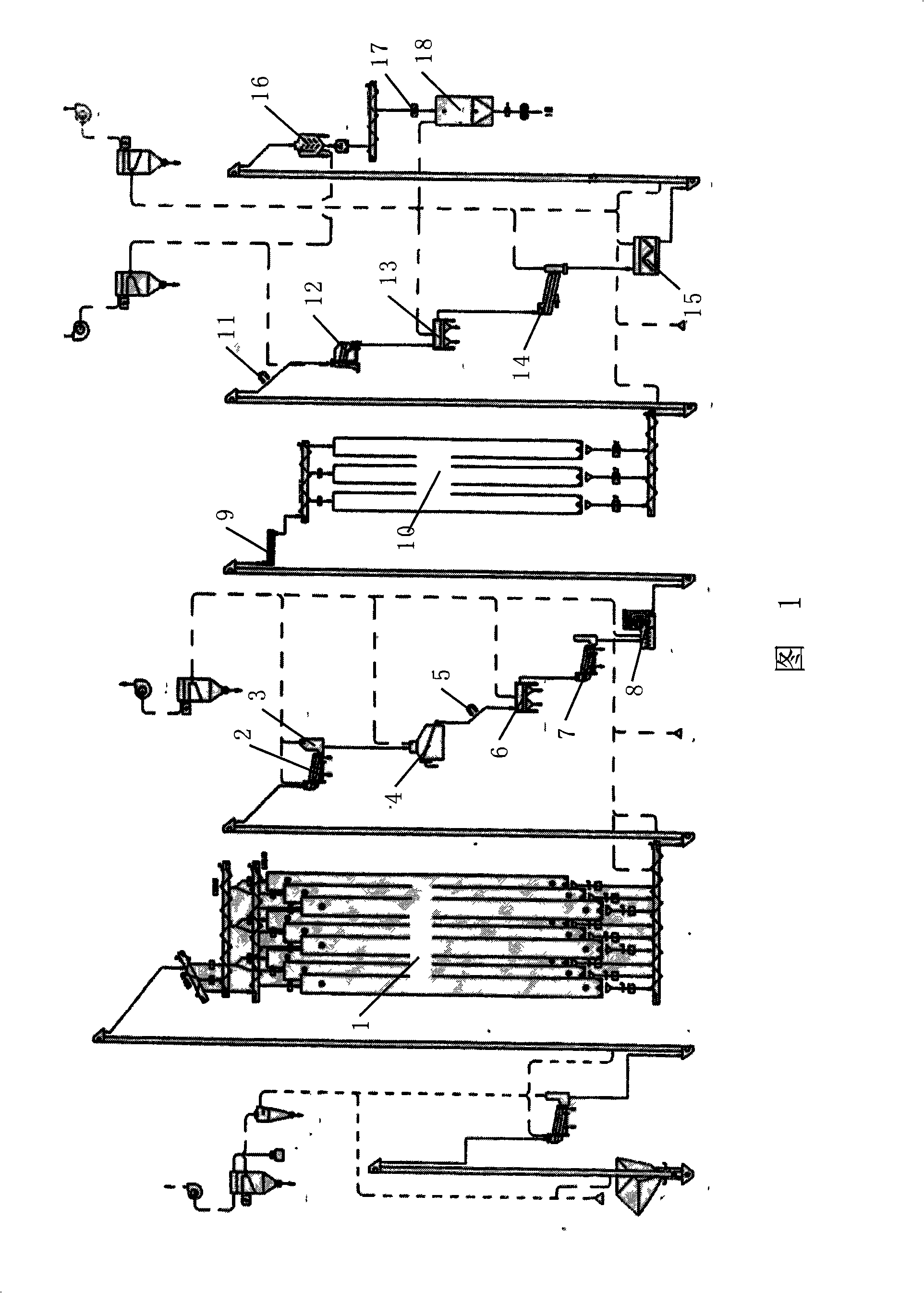

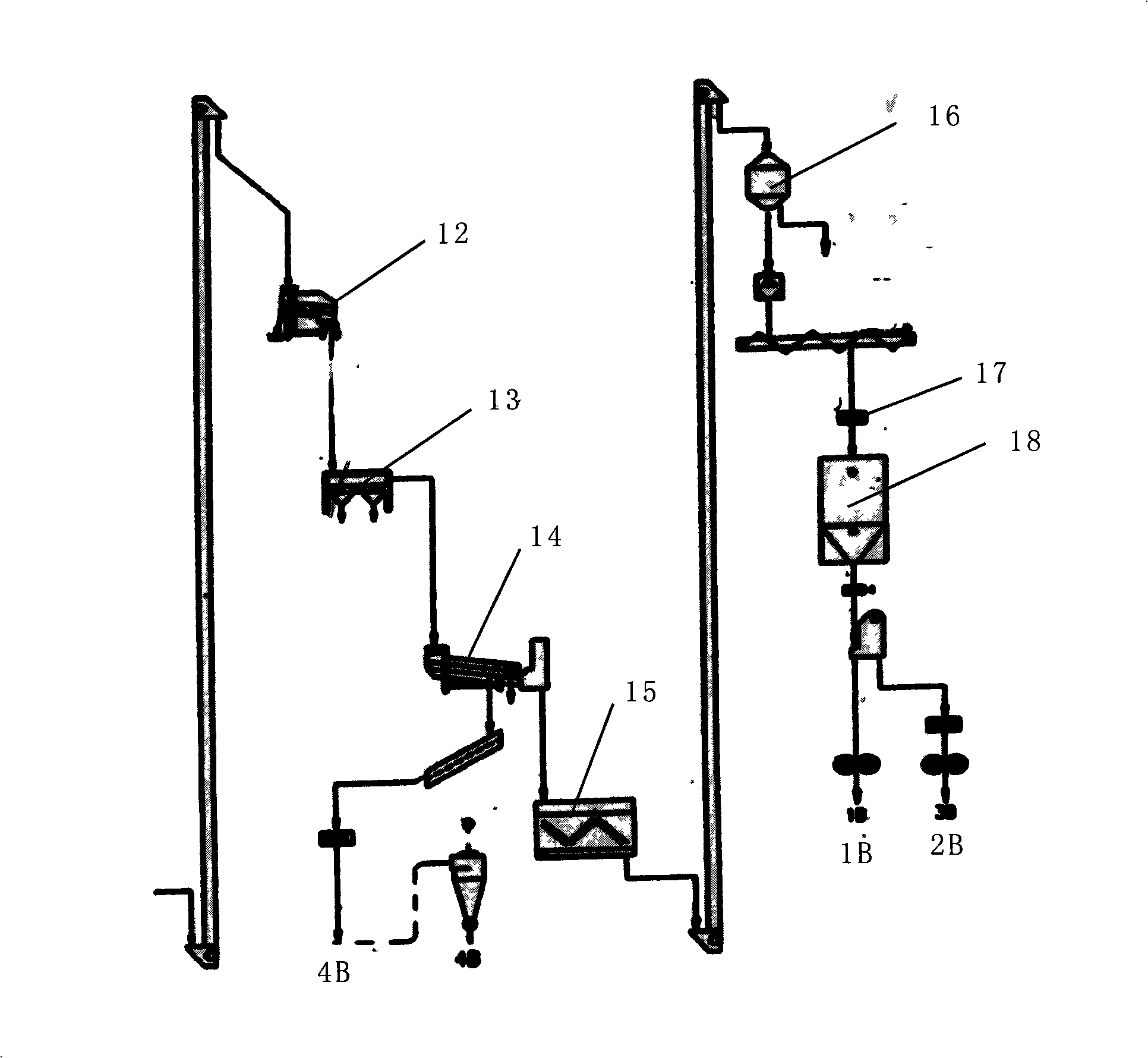

Combined beneficiation method and combined beneficiation system for comprehensive recovery of associated iron-phosphate minerals

The invention belongs to the technical field of efficient development of ultralow-grade ore resources and comprehensive utilization of associated minerals, and in particular relates to a combined beneficiation method and a combined beneficiation system for comprehensive recovery of associated iron-phosphate minerals. The combined beneficiation method for the comprehensive recovery of the associated iron-phosphate minerals comprises the following steps: sequentially performing three-section and two-closed-loop crushing and screening flow on raw ores, and performing dry separation to obtain fine ores; performing two-section closed-loop ore-grinding flow on the fine ores, performing fine magnetic separation for three times, and concentrating by using a wash mill to separate iron ore concentrate and discharge tailings; performing one-time roughing, one-time scavenging and three-time concentrating on the tailings at the temperature of 10-15 DEG C to obtain phosphate ore concentrate by floatation. Compared with the prior art, the invention provides a comprehensive recovery scheme for magnetic iron ore resources and phosphate ore resources in ultralow-grade associated iron-phosphate minerals. According to the scheme, the separation cost is low, the efficiency is high, energy is saved, the space occupation is low, and the comprehensive recovery of the magnetic iron ores and the phosphate ores can be realized.

Owner:中冶沈勘工程技术有限公司

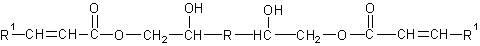

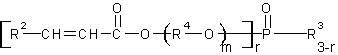

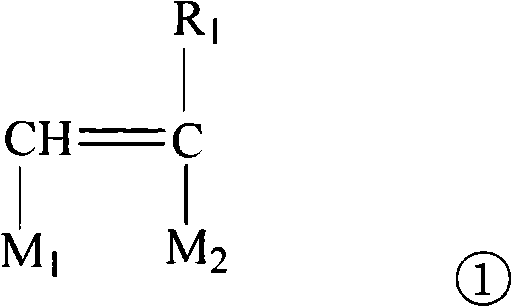

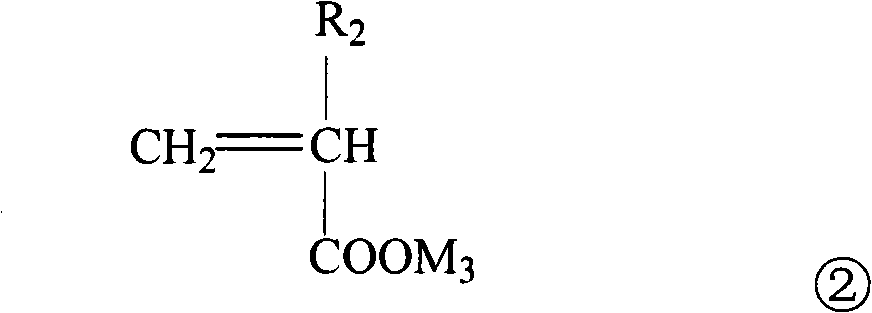

Polyester Resin for Toner, Toner Composition and Resin Particle

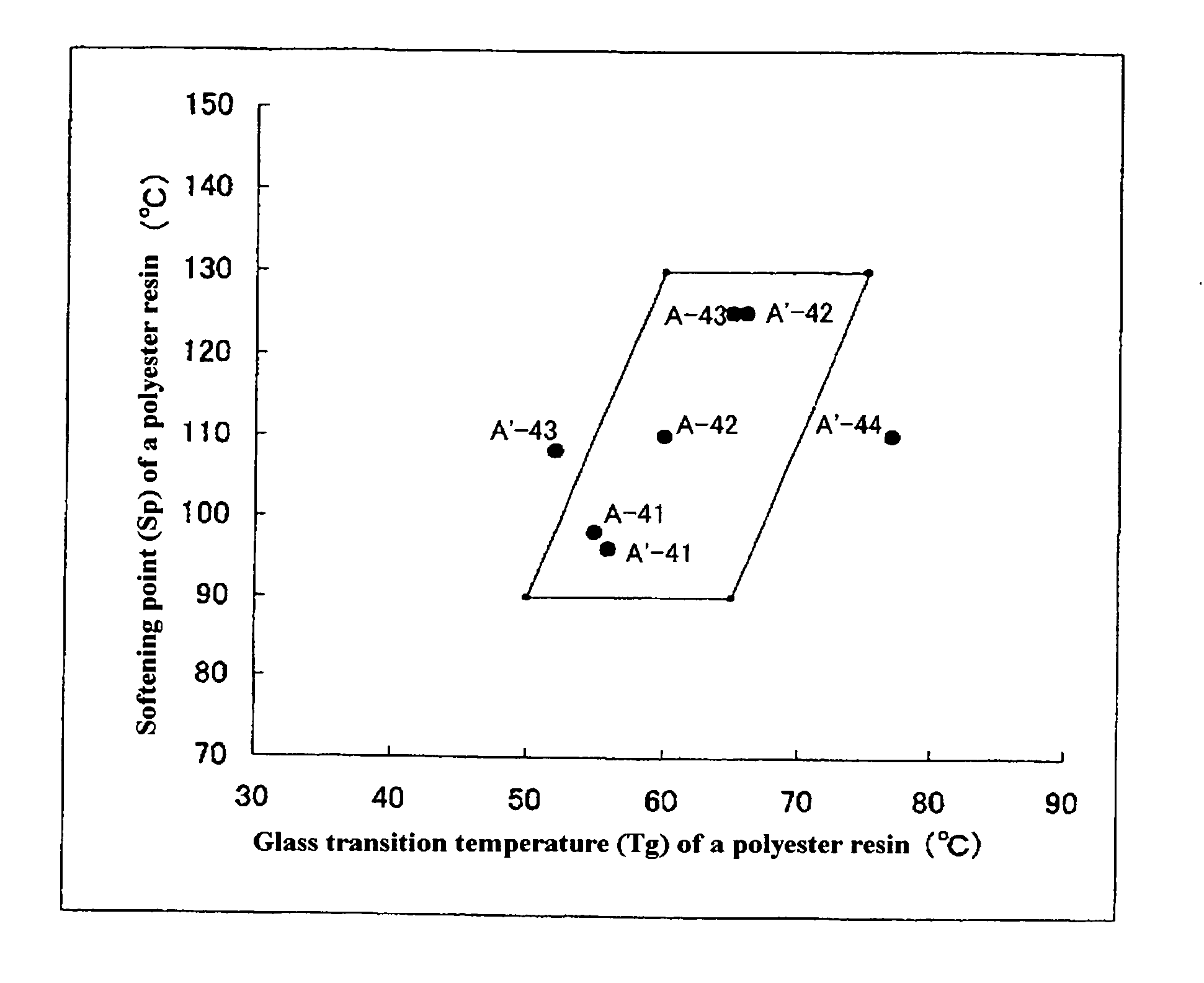

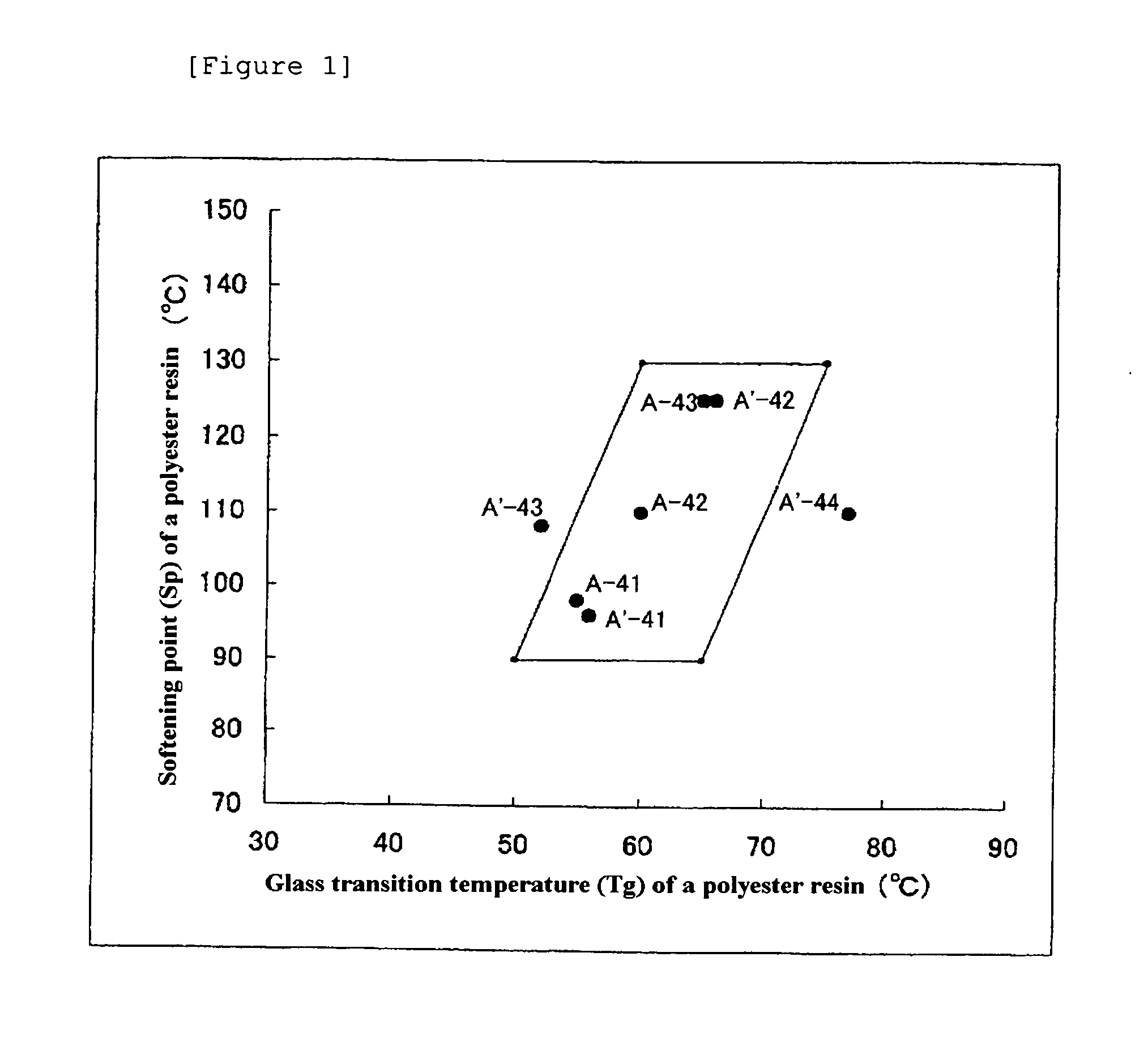

ActiveUS20070281235A1Excellent low-temperatureExcellent grindabilityMixingDevelopersChemistryPolyester

[PROBLEMS] Disclosed is a heat-fusible electrostatic image developing toner which has an excellent balance between fixability at low temperatures and grindability and is excellent in glossiness after fixing. Also disclosed is a resin for toners. [MEANS FOR SOLVING PROBLEMS] A polyester resin for toners which is obtained by polycondensing a polyol component and a polycarboxylic acid component is characterized by containing 20-100 weight % of one or more polyester resins (A1) having a storage elastic modulus from 2.5×103 Pa to 5×106 Pa at 150° C. wherein the molar average cohesive energy of the polyol component is between 7.0×104 and 1.4×105 J.

Owner:SANYO CHEM IND LTD

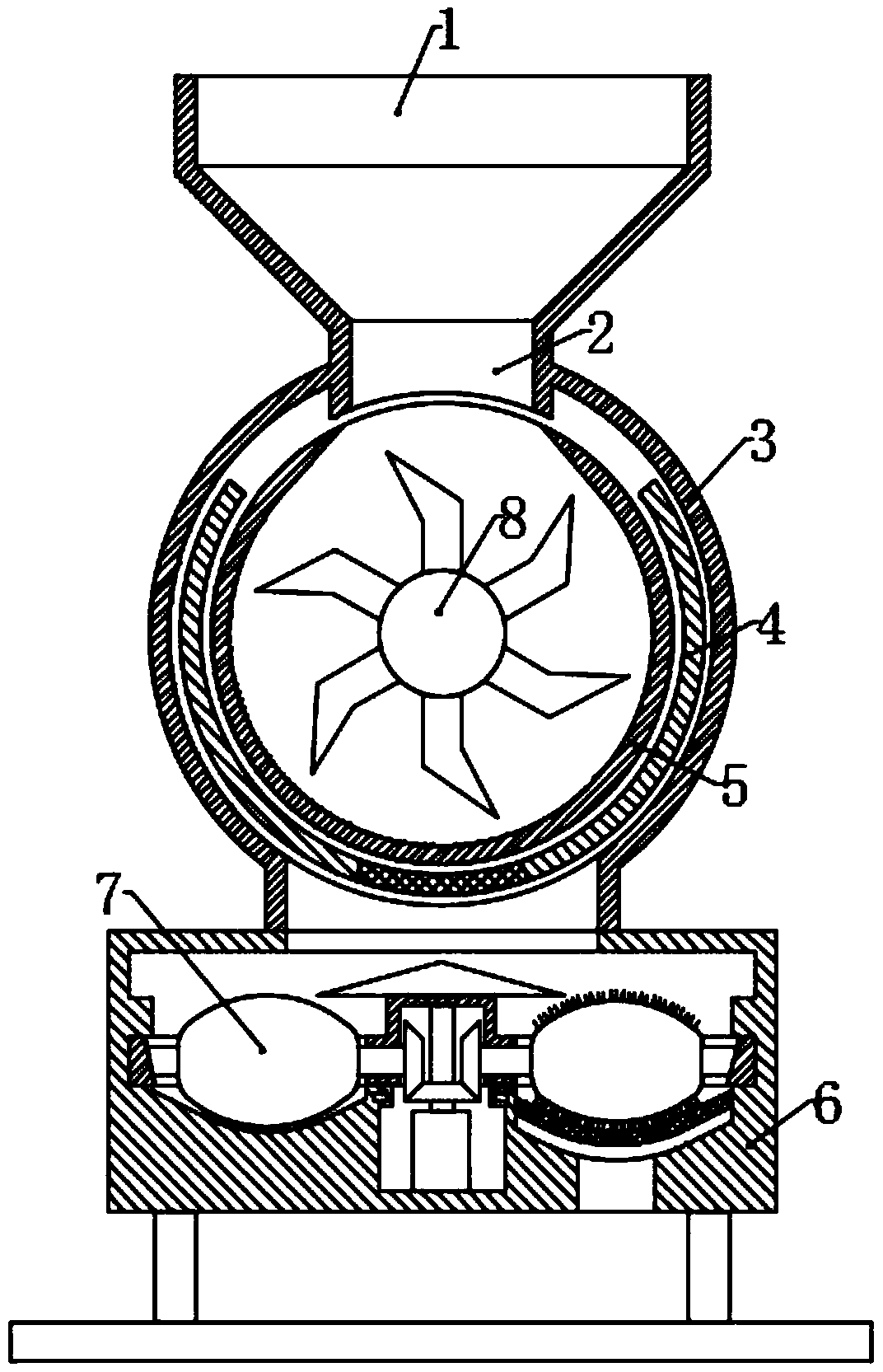

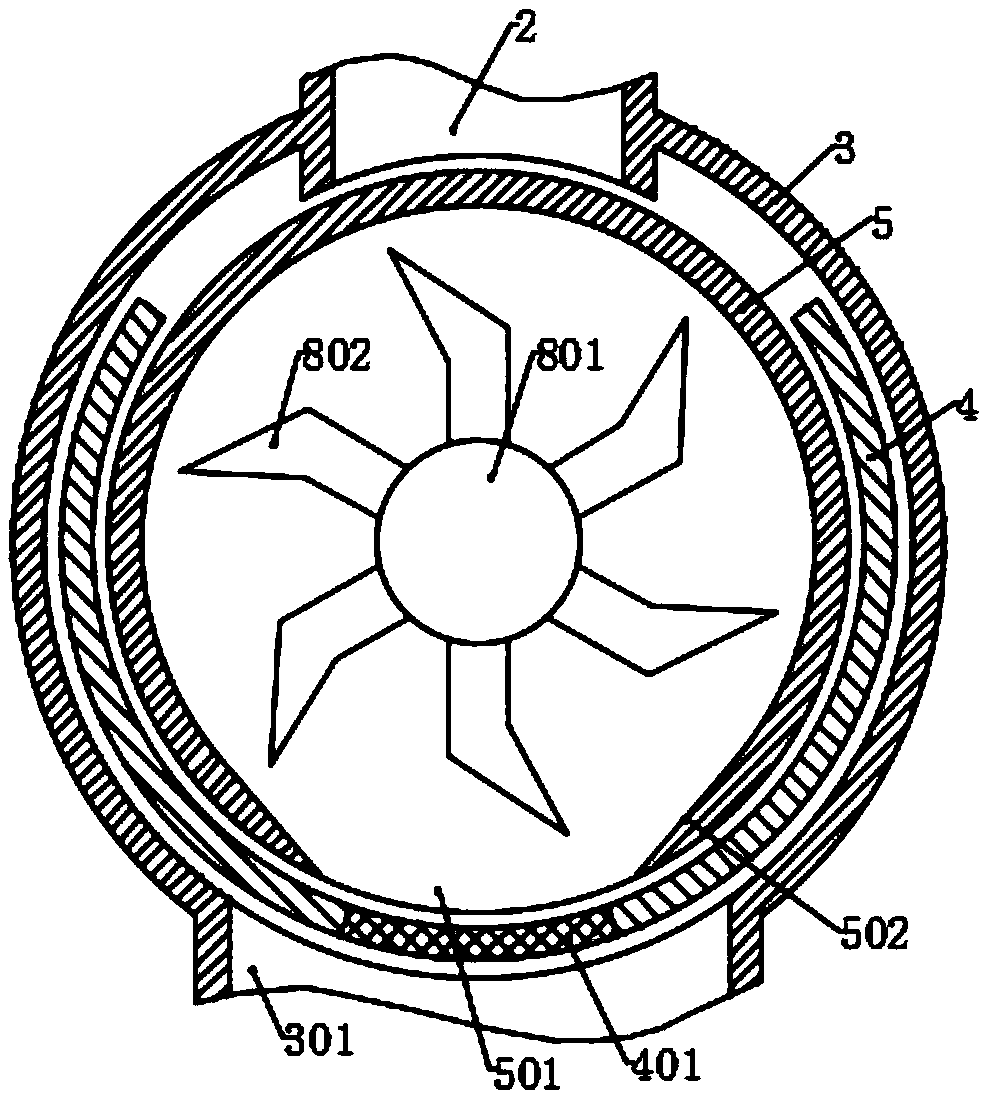

Smashing and grinding integrated machine for traditional Chinese medicine

The invention discloses a traditional Chinese medicine crushing and grinding integrated machine, which comprises a machine case, a foot, a feeding barrel, a feeding port, a crushing blade, a grinding disc and a feeding port; the left side wall of the case is fixedly connected with a feeding barrel, and The inside of the machine is provided with a screw, the right end of the screw is fixedly connected with a worm, the lower surface of the chassis is rotatably connected with an upper rotating shaft, the upper rotating shaft is covered with a worm wheel, the lower end of the upper rotating shaft is fixedly connected with a crushing blade, and a sieve plate is arranged below the crushing blade , the crankshaft is set on the right side of the case, and the grinding disc is set under the sieve plate. The Chinese medicine is preliminarily chopped by the crushing blade, and the Chinese medicine is transported to the right, and the Chinese medicine is screened at the same time; the Chinese medicine is crushed by the crushing blade and the crushing blade The material is crushed, and the sieve plate moves left and right, which is beneficial for the crushed Chinese herbal medicine to pass through the sieve plate. The lower surface of the sieve plate is processed with grinding protrusions. The grinding disc is used to cooperate with the sieve plate to grind the Chinese herbal medicine. The grinding effect is good. efficient.

Owner:陈鹏

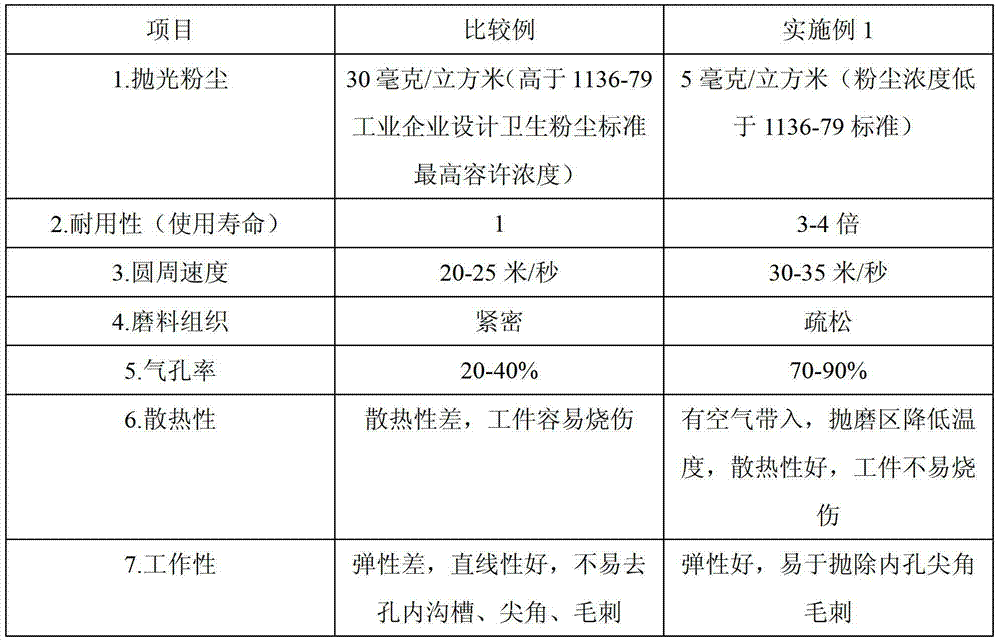

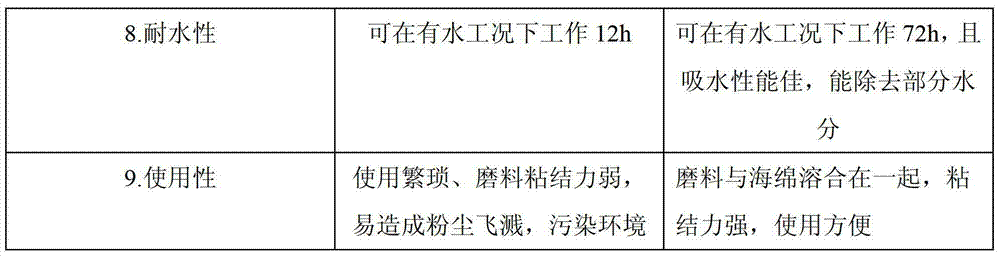

Polyvinyl alcohol-polyurethane elastic buffing wheel and preparation method thereof

InactiveCN103395011AUniform cellsNo stuffingAbrasion apparatusGrinding devicesWater bathsDistilled water

The invention discloses a polyvinyl alcohol-polyurethane elastic buffing wheel and a preparation method of the polyvinyl alcohol-polyurethane elastic buffing wheel. The preparation method comprises the steps that firstly, polyvinyl alcohol is mixed with distilled water, and the mixture is dissolved for 20-30 minutes under the condition of 50-95 DEG C water bath and at the rotation speed of 400-600r / min to obtain a polyvinyl alcohol aqueous solution; then, the polyvinyl alcohol aqueous solution is heated up to 30-100 DEG C, grinding materials are firstly added into the polyvinyl alcohol aqueous solution, after the mixture of the grinding materials and the polyvinyl alcohol aqueous solution is stirred and mixed evenly at the rotation speed of 400-600r / min, polyurethane pre-polymers, catalysts and air hole generating agents are added, and all the components are stirred and mixed evenly at the rotation speed of 400-600r / min and react for 5-10min; solidification is conducted for 2-4h under the condition of 30-100 DEG C, and then the buffing wheel which is good in elasticity, good in water resistance, good in heat-dissipating performance and high in mechanical strength is obtained. The elastic buffing wheel is even in foam hole, good in abrasion resistance and grinding force, not prone to deforming or curling in humid environment and applicable to long-time grinding work.

Owner:SOUTH CHINA UNIV OF TECH

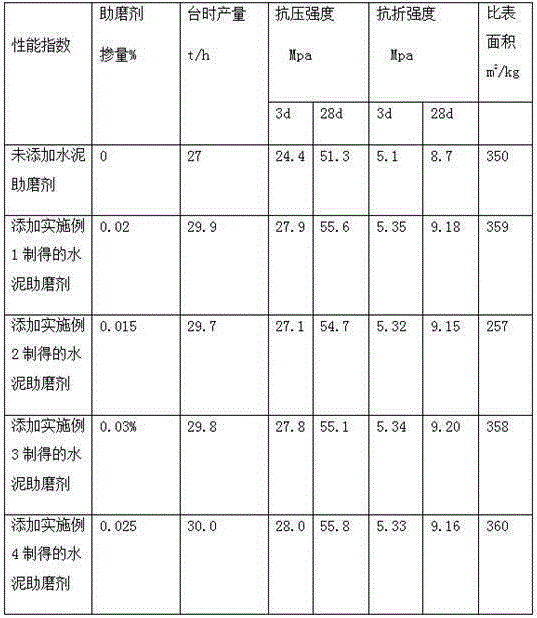

Cement grinding aid and preparation method thereof

The invention relates to a cement grinding aid, in particular to a cement grinding aid and a preparation method thereof. The cement grinding aid is prepared from, by weight, 13-18 parts of polymeric polylol, 8-12 parts of tri-isopropanolamine, 12-15 parts of polyol ether, 15-20 parts of ethanediol, 25-30 parts of triethanolamine, 15-18 parts of molasses, 13-15 parts of lignin, 0.03-0.06 part of sodium chloride, 0.5-1 part of silane coupling agents and 40-45 parts of water. By means of the obtained cement grinding aid, in the cement production process, the phenomena of clinker fine particle aggregation and ball pasting can be effectively improved, mobility of clinker particles is enhanced, thereby the pulverization effect of grinding media in a grinding machine for materials is enhanced, grinding efficiency can be improved by 15-20%, the cement machine-hour yield is increased, electricity consumption is greatly lowered, production cost is lowered, in addition, strength of cement at different ages can be remarkably improved, and flowability of the cement is improved.

Owner:内蒙古同佳技术发展有限公司

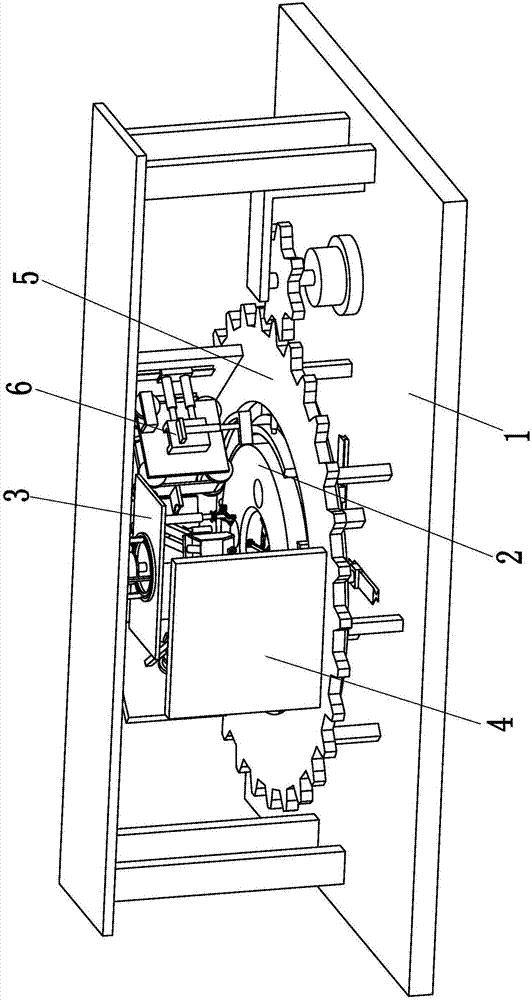

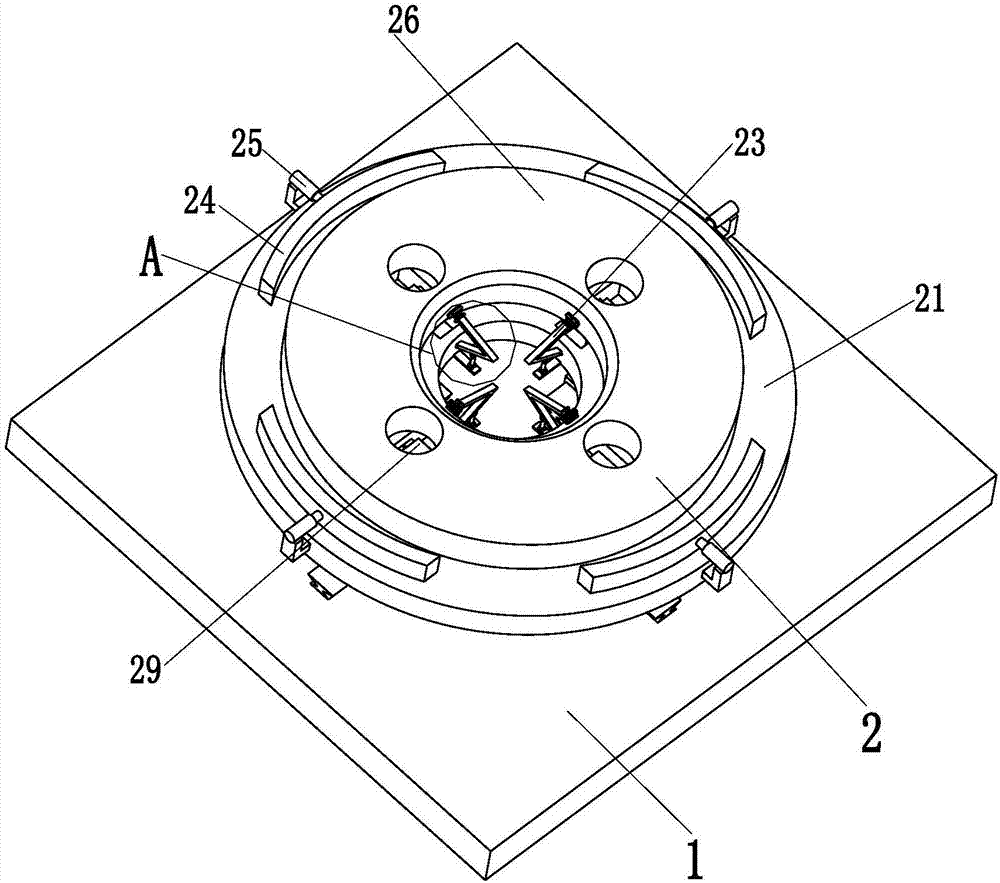

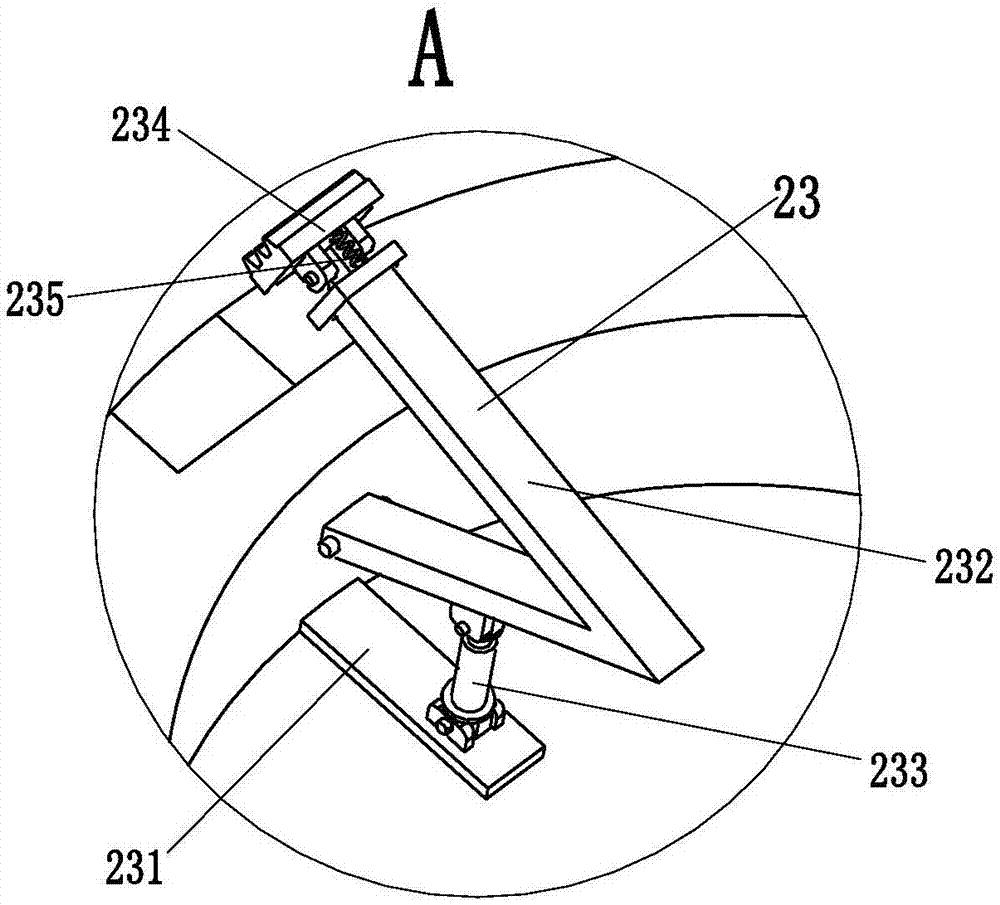

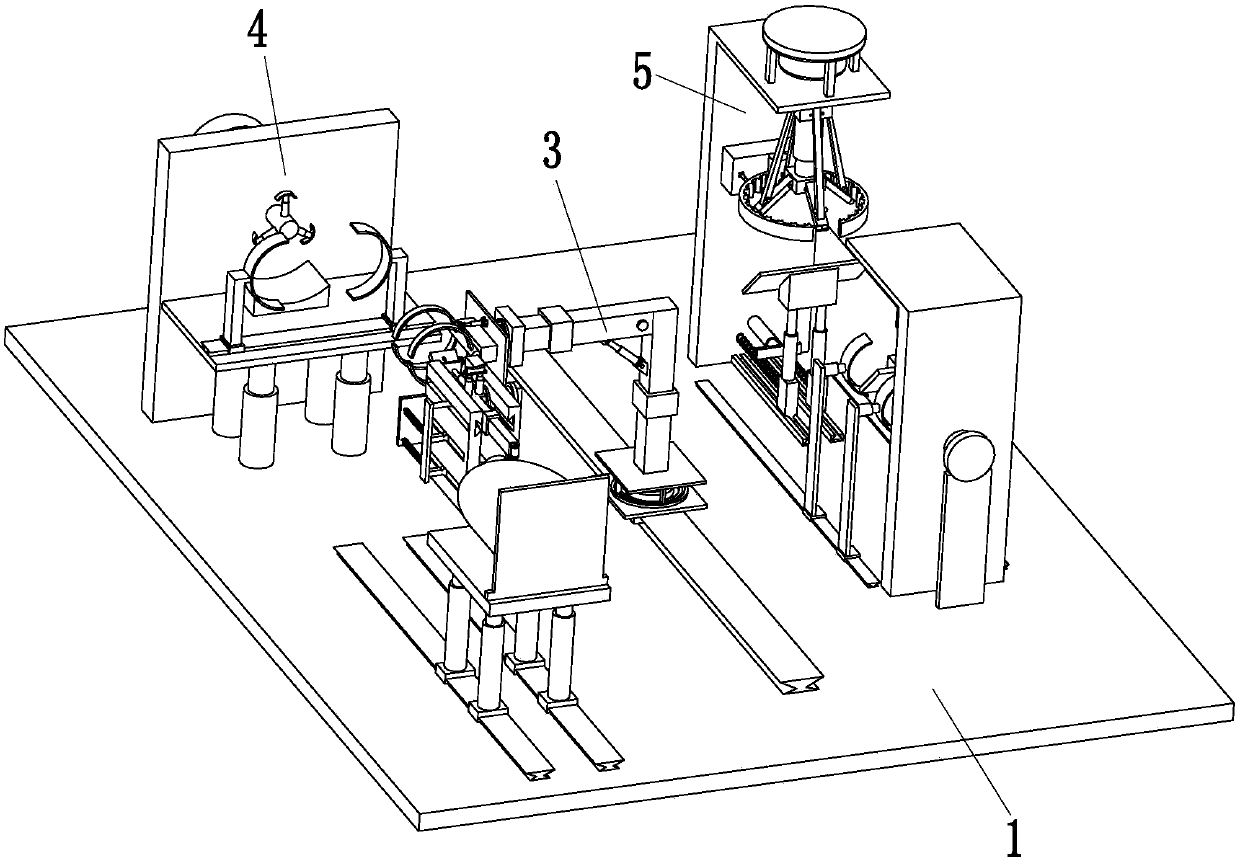

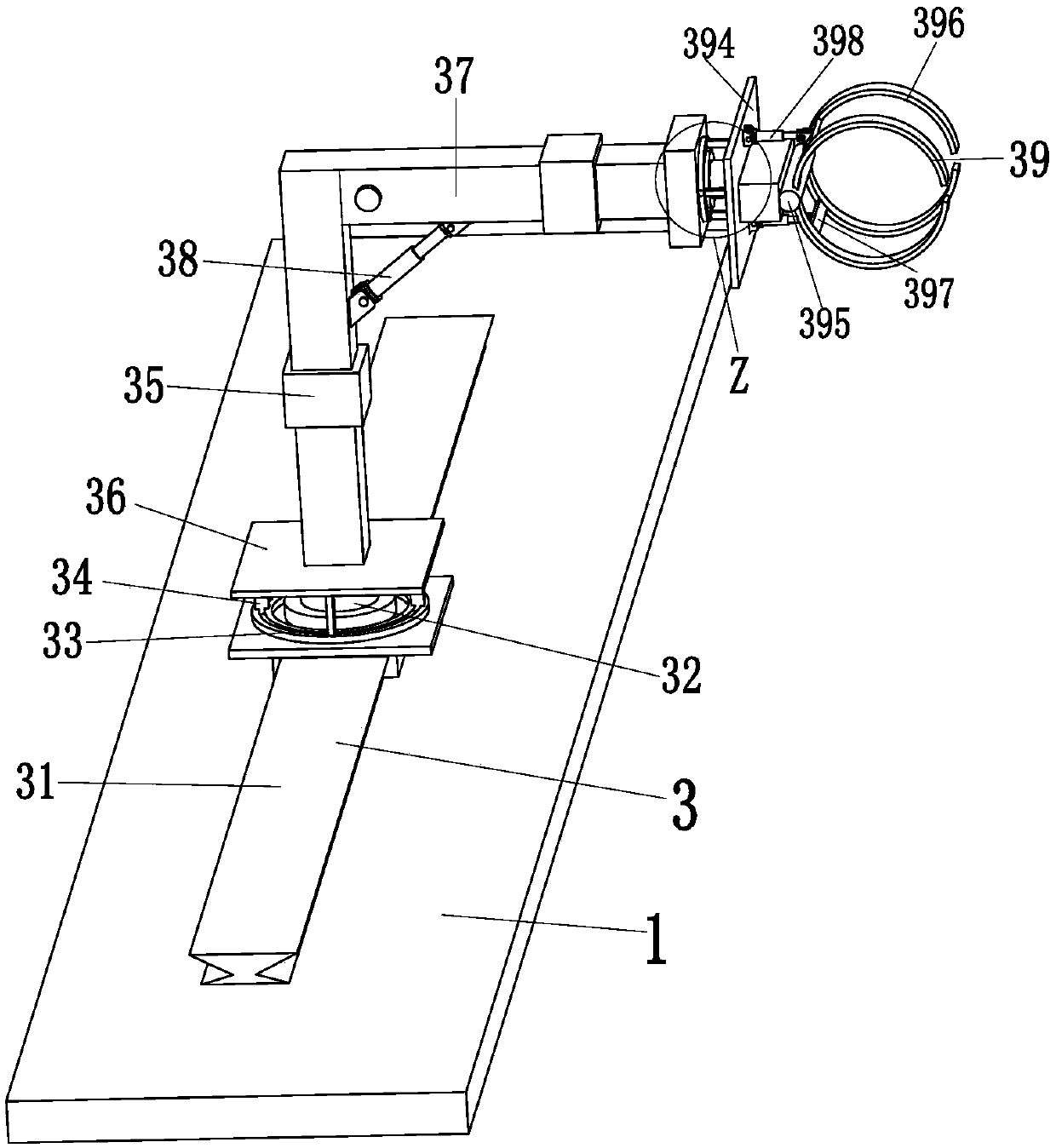

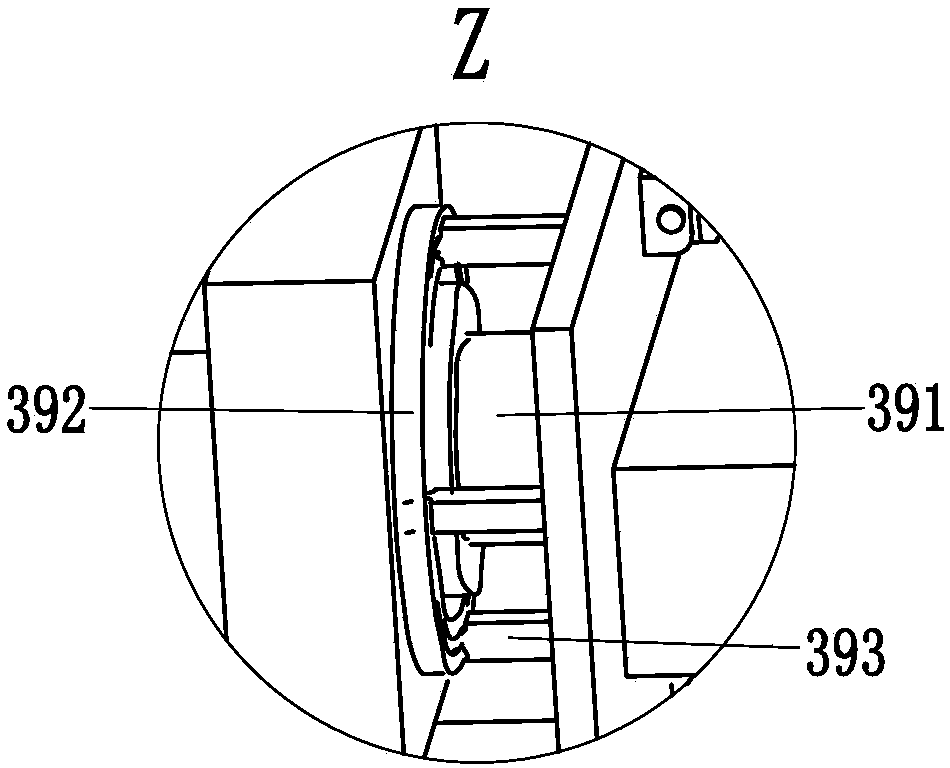

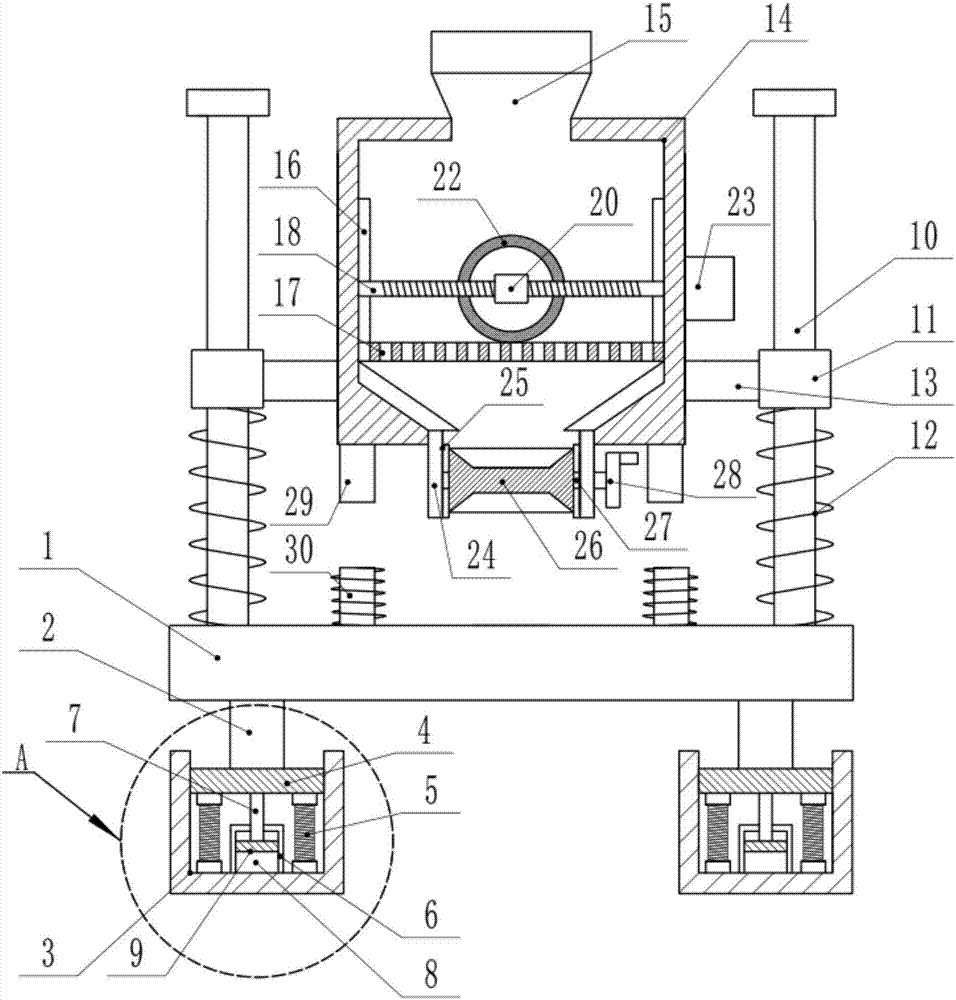

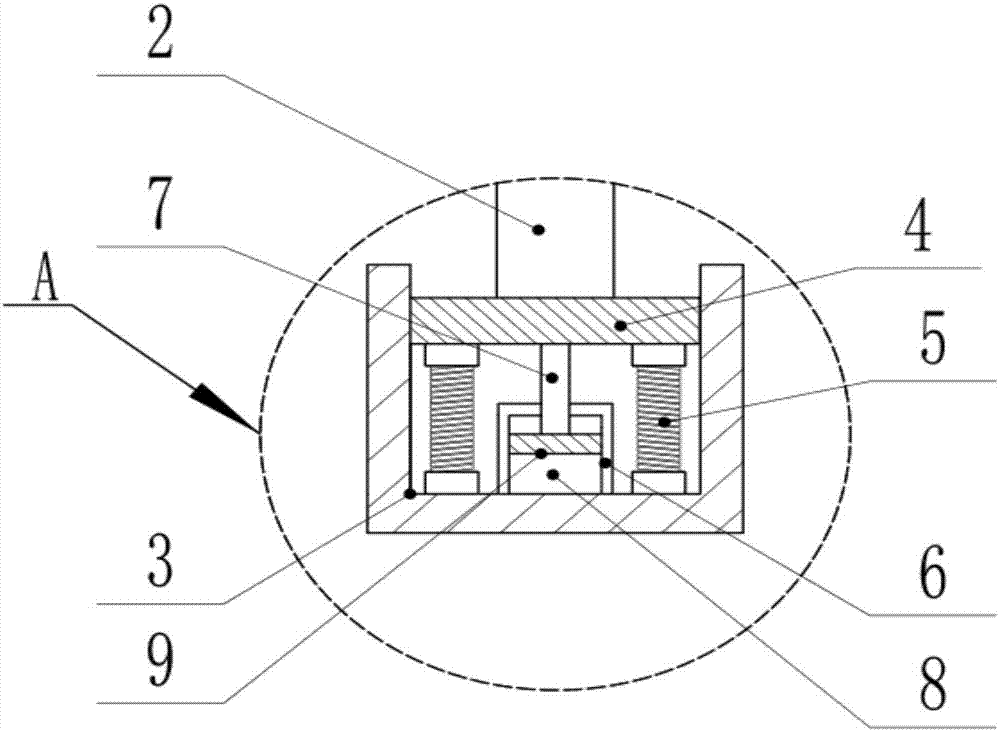

Automatic welding treatment integrated machine for flange plates of pipeline installing and connecting joints

InactiveCN107877075AImprove grinding effectEasy to fixWelding/cutting auxillary devicesAuxillary welding devicesAfter treatmentEngineering

The invention relates to an automatic welding treatment integrated machine for flange plates of pipeline installing and connecting joints. The automatic welding treatment integrated machine comprisesa supporting base plate, a fixing device, a polishing device, a welding device, a rotating device and a post-weld treatment device, wherein the fixing device is arranged in the middle of the supporting base plate, the polishing device is located above the fixing device and is arranged on the supporting base plate, the rotating device is located on the outer side of the fixing device and is connected to the supporting base plate, the welding device and the post-weld treatment device are arranged on the rotating device, and the welding device is located on the front side of the post-weld treatment device. The automatic welding treatment integrated machine has the advantage that the existing problems that when flanges are welded to steel tubes, multiple fixation cannot be carried out on the flanges, the flanges are not fixed firmly and need to be polished manually before welding, the polishing effect on the flanges before welding is not good, the welding operation cannot be performed automatically, the flanges and the steel tubes need to be subjected to post-weld treatment manually, and the manual post-weld treatment is not thorough can be solved.

Owner:范满香

Crushing and grinding device for production and processing of traditional Chinese medicinal materials

InactiveCN108940503AAvoid enteringImprove subsequent grinding efficiencyGrain treatmentsEngineeringMaterials processing

The invention discloses a crushing and grinding device for production and processing of traditional Chinese medicinal materials in the technical field of traditional Chinese medicinal material processing. The crushing and grinding device comprises a feeding hopper, a feeding pipe, a fixing case, a screening case, a crushing case and a grinding case. According to the crushing and grinding device, the traditional Chinese medicinal materials are put into the feeding hopper and then enter the crushing case along the feeding pipe, a crushing mechanism is used for crushing the traditional Chinese medicinal materials, and a feeding inlet of the crushing case conducting crushing rotates to face downwards; the traditional Chinese medicinal materials are screened through the screening case, and thenthe feeding inlet of the crushing case is rotated to face upwards; the traditional Chinese medicinal materials which do not penetrate through a first screening mesh return to the crushing case through the shovel face at the feeding inlet and are subjected to secondary crushing along with next batch of to-be-crushed medicinal materials, and the traditional Chinese medicinal materials enter the grinding case and are ground through a grinding mechanism; and meanwhile, completely ground medicine powder is fed into a powder outlet through a rotating brush, so that the situation that powder particles are too fine due to the fact that ground medicine powder is left in a grinding groove and ground repeatedly is avoided, and the grinding effect is good.

Owner:周意

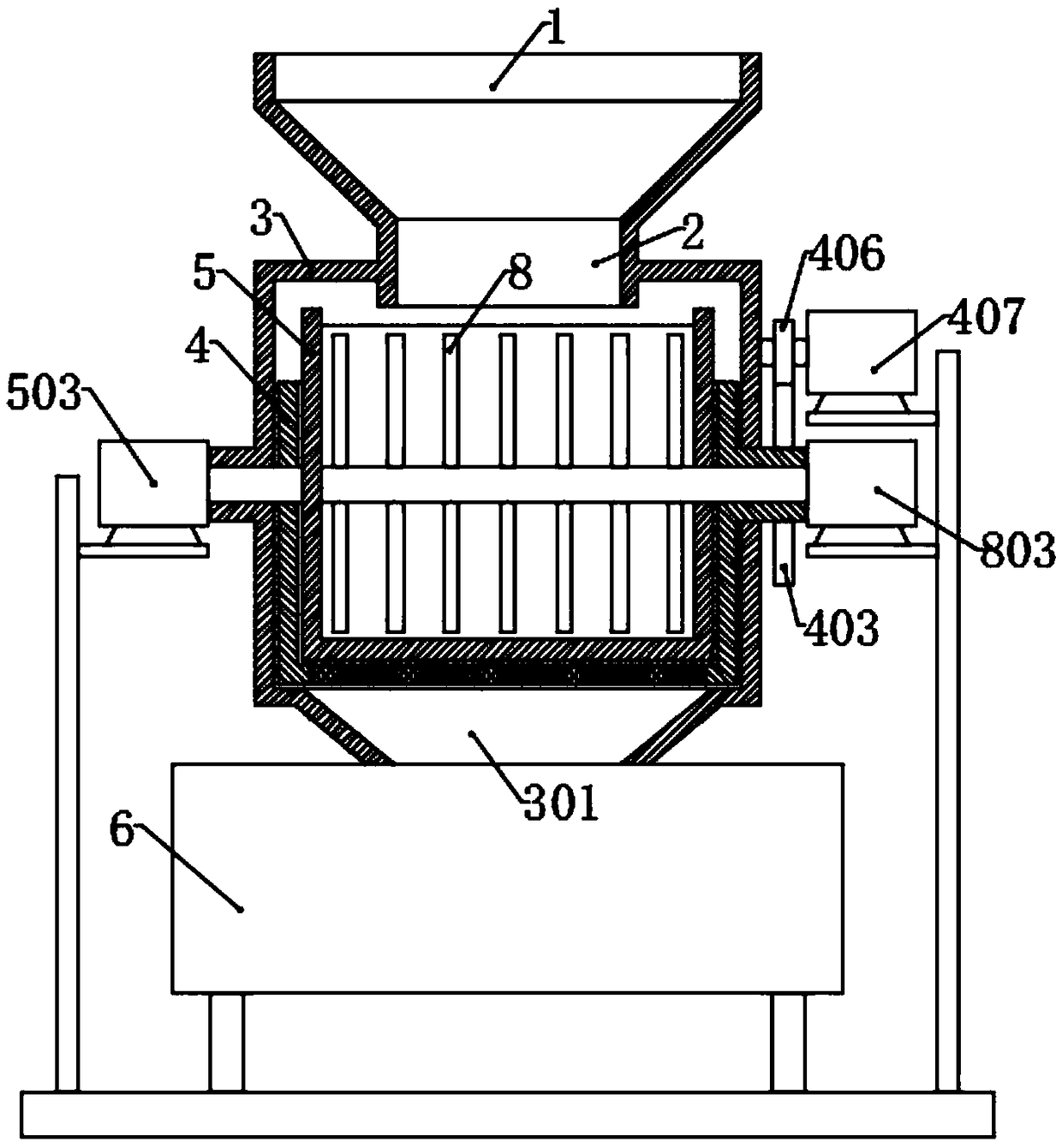

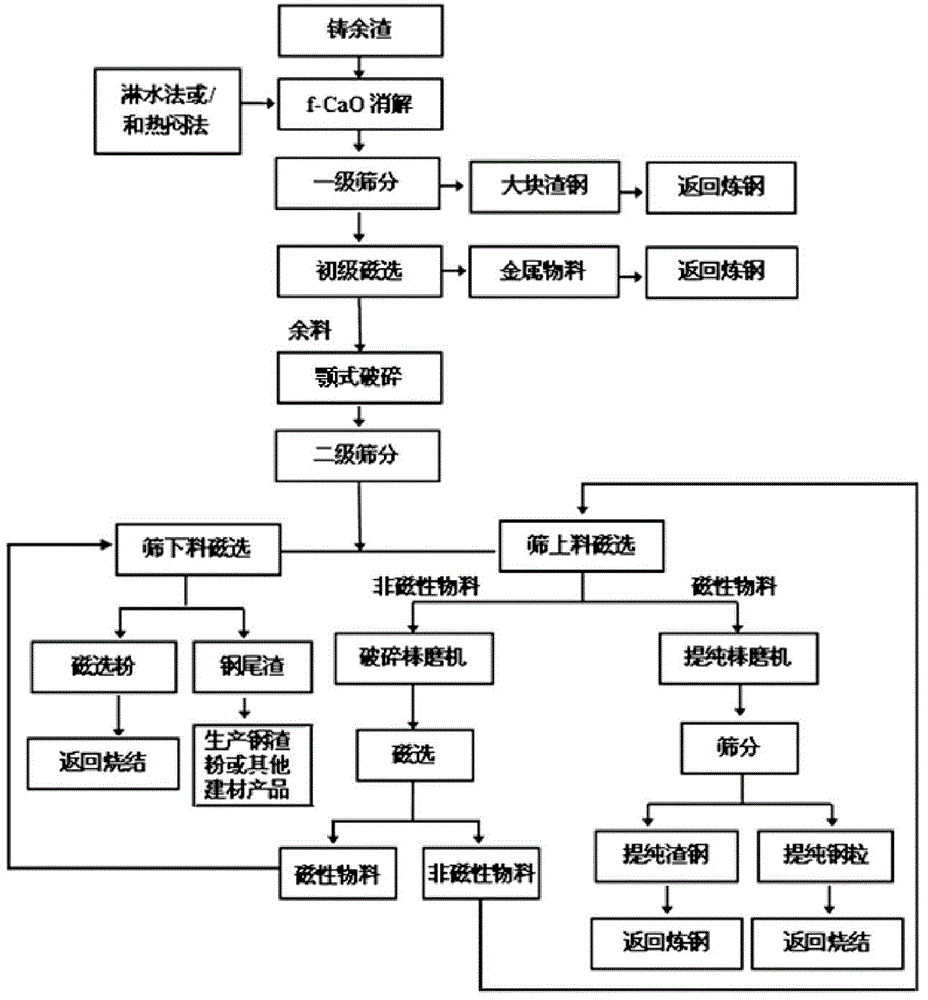

Molten steel casting residue treatment and recycling method

ActiveCN102978305APromote expansion and pulverizationSolve the separation problemSievingScreeningSlagMolten steel

The invention discloses a molten steel casting residue treatment and recycling method which comprises the circular treatment steps of slaking, screening, magnetic separation and the like. The f-CaO in casting residue is slaked by vapor to accelerate the expansion and efflorescence of the casting residue, thereby solving the problem on the separation of the casting residue from a tank body and reducing dust nuisance. According to the method, a mixture of water spray casting residue and pyrolytic steel slag is used as the raw material, and the pyrolytic steel slag has the advantage of low f-CaO content, thereby ensuring that the f-CaO content of the final product can meet the requirements of cement and construction material industries; and a rod grinder treatment process is used, thereby achieving favorable grinding effect and ensuring that the product is uniform and stable in particle size. For the product disclosed by the invention, slag steel of which the grade is greater than 80% can be returned for steel making; purified steel shots and magnetic separation powder of which the grade is greater than 42% can be used for a sintering procedure; and steel tailings of which the iron content is smaller than 2% and the f-CaO content is smaller than 3% can be used for producing steel slag powder, steel slag cement, construction material products and road materials. The invention maximally recycles the metal material in the casting residue, realizes the zero discharge of industrial solid waste and ensures that the casting residue can be recycled 100% at a high added value.

Owner:WUKUN STEEL

Phosphogypsum based plastering gypsum

The invention discloses a phosphogypsum based plastering gypsum, and relates to a plastering material for a building wall. The phosphogypsum based plastering gypsum mainly comprises 75 to 95 percent of phosphogypsum based building gypsum, 1 to 3 percent of sierozem powder, 0.1 to 0.5 percent of retarder, 1.1 to 5.5 percent of composite water retention agent, 0.3 to 1 percent of ethylene-vinyl acetate copolymerized latex powder, and 0 to 20 percent of stuffing. The phosphogypsum based plastering gypsum effectively improves water retention property and lowers cost by adopting the combination of cellulose ether water retention agent and bentonite, effectively adjusts settling time and prolongs operable time by adopting the retarder, improves construction property, cohesive property and cracking resistance by doping the stuffing and the latex powder, and reduces adverse effects of impurities on the strength of plastering gypsum by adding the sierozem powder. The phosphogypsum based plastering gypsum has the advantages of good workability and construction property, long operable time, high breaking resistance, compression resistance and adhesion strength, good volume stability, good cracking resistance and lower cost, and can be used for a plastering layer of the building wall.

Owner:CHONGQING UNIV

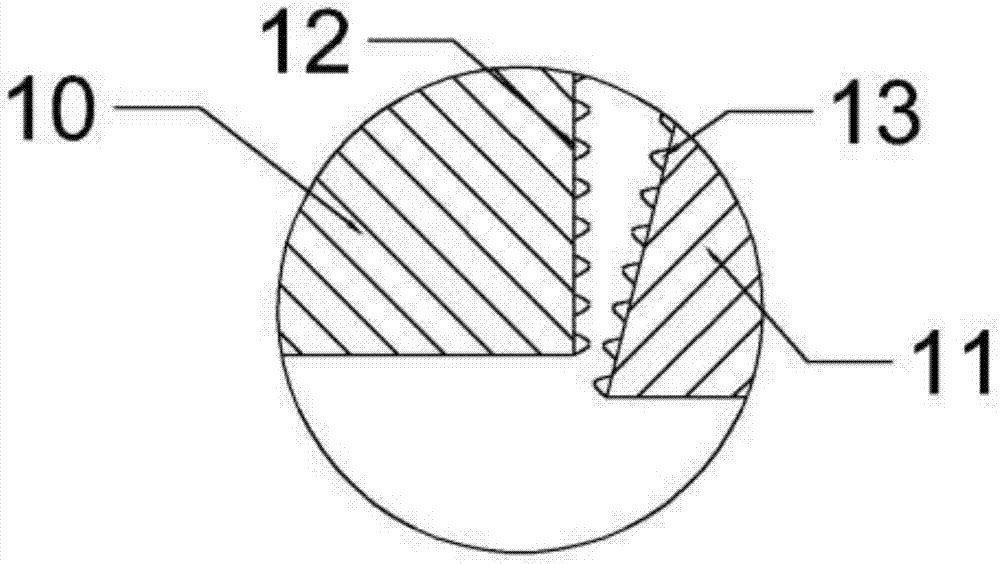

Traditional Chinese medicine pulverizing and grinding integrated machine

InactiveCN107350061ARealize crushing and grindingQuality assuranceGrain treatmentsReducerEngineering

The invention discloses a traditional Chinese medicine crushing and grinding machine, which comprises a crushing cylinder and a screw feeder. The top of the crushing cylinder is provided with a sealed installation box. The bottom of the cylinder is connected to the output end of the cylinder, the bottom of the cylinder is fixed on the top of the crushing cylinder, a rotating motor is installed inside the sealed installation box, the output end of the rotating motor is connected to the reducer, and the output end of the reducer is connected to the output The shaft is connected, and the output shaft passes through the sealed installation box downwards and extends into the inside of the crushing cylinder. The present invention can chop the Chinese herbal medicine through the cooperation between the fixed blade and the rotating blade, and then realize the grinding of the Chinese herbal medicine through the extrusion between the rotating grinding head and the fixed grinding seat, thereby realizing the crushing and grinding of the Chinese herbal medicine and A good grinding effect can be obtained.

Owner:周耀鑫

Preparation of light colore high softening point maleated rosin pentaerythritol

InactiveCN101475776AImprove hardnessHigh hardnessNatural resin chemical modificationRosinPentaerythritol

The invention relates to a method for preparing maleic rosin pentaerythritol ester with shallow color and high softening point. The method comprises the following steps that: under the conditions of vacuum degree of between 0 and 1 kPa and temperature of between 200 and 270 DEG C, rosin is refined to form refined rosin having a softening point of between 80 and 86 DEG C; under the protection of inert gas, the molten refined rosin is added with maleic acid anhydride accounting for 5 to 14 percent of the mass of the refined rosin and a reducing agent accounting for 0.03 to 1.0 percent of the mass of the refined rosin, and reacts for 0.5 to 2 hours at a temperature of between 150 and 230 DEG C; pentaerythritol accounting for 10 to 20 percent of the mass of the refined rosin, a catalyst accounting for 0.1 to 1.0 percent of the mass of the refined rosin and a discoloring agent accounting for 0.1 to 1.0 percent of the mass of the refined rosin are added to a reaction system and react at temperature of between 230 and 290 DEG C; reaction is finished till acid value is less than 20 mg / g; the reactants are decompressed, vacuumized and kept at vacuum degree of between 0 and 2 kPa for 5 to 60 minutes; and a low-boiling-point substance is removed and the maleic rosin pentaerythritol ester with shallow color and high softening point is perpared.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Coppering and porefilling process for circuit board

InactiveCN101951735AImprove grinding effectReduce drum platingPrinted element electric connection formationPower flowSolder mask

The invention discloses a coppering and porefilling process for a circuit board, which comprises the following steps of: A) performing cutting, inner layer multibond and plane pressing on a circuit board substrate, and then drilling the circuit board substrate; B) performing copper deposition and panel plating on the drilled substrate; C) performing image transfer on the substrate subjected to copper deposition and panel plating through a hole plating film; D) performing a coppering and porefilling process on the substrate subjected to image transfer; E) performing circuit image transfer through a circuit film; F) performing silk screen on a solder mask and characters; G) performing a plane immersion Ni / Au process; and H) testing and checking the electrical property and shape of a finished board, and producing the finished product. By using the coppering and porefilling process for the circuit board, a hole is subjected to the image transfer process before the coppering and porefilling process; and after a dry film is stuck, the hole is subjected to exposure and development by the hole plating film, and the hole which needs electroplating and copper filling is exposed; and by using a scheme of low copper low current density plating, the copper concentration in plating solution is controlled to be 50 to 60g / L, and the current density is controlled to be 10 to 14ASF, so that plump plating is reduced to a maximum extent, and the finished product ratio and finished product quality are improved.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

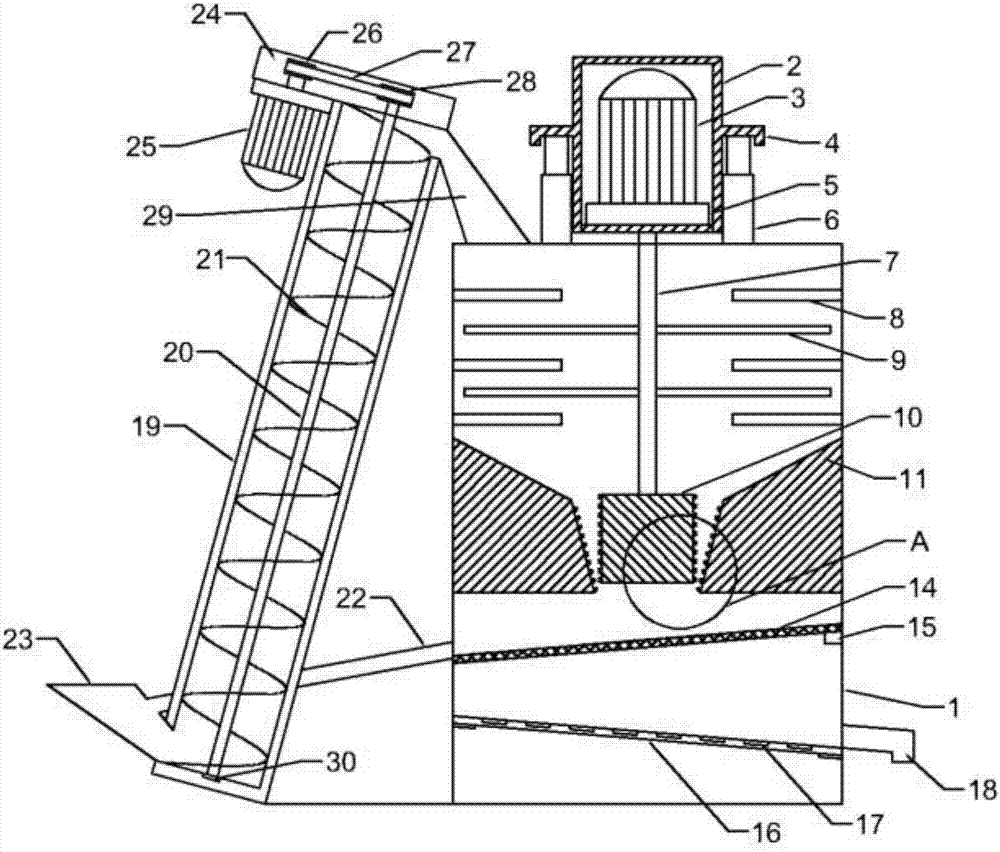

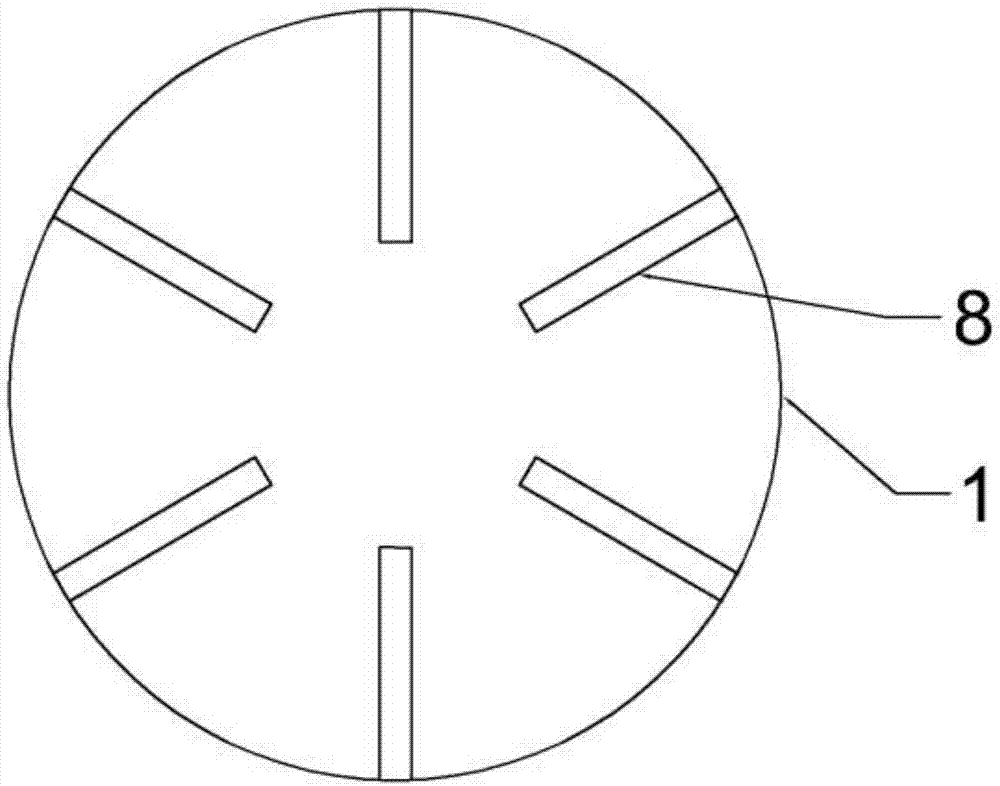

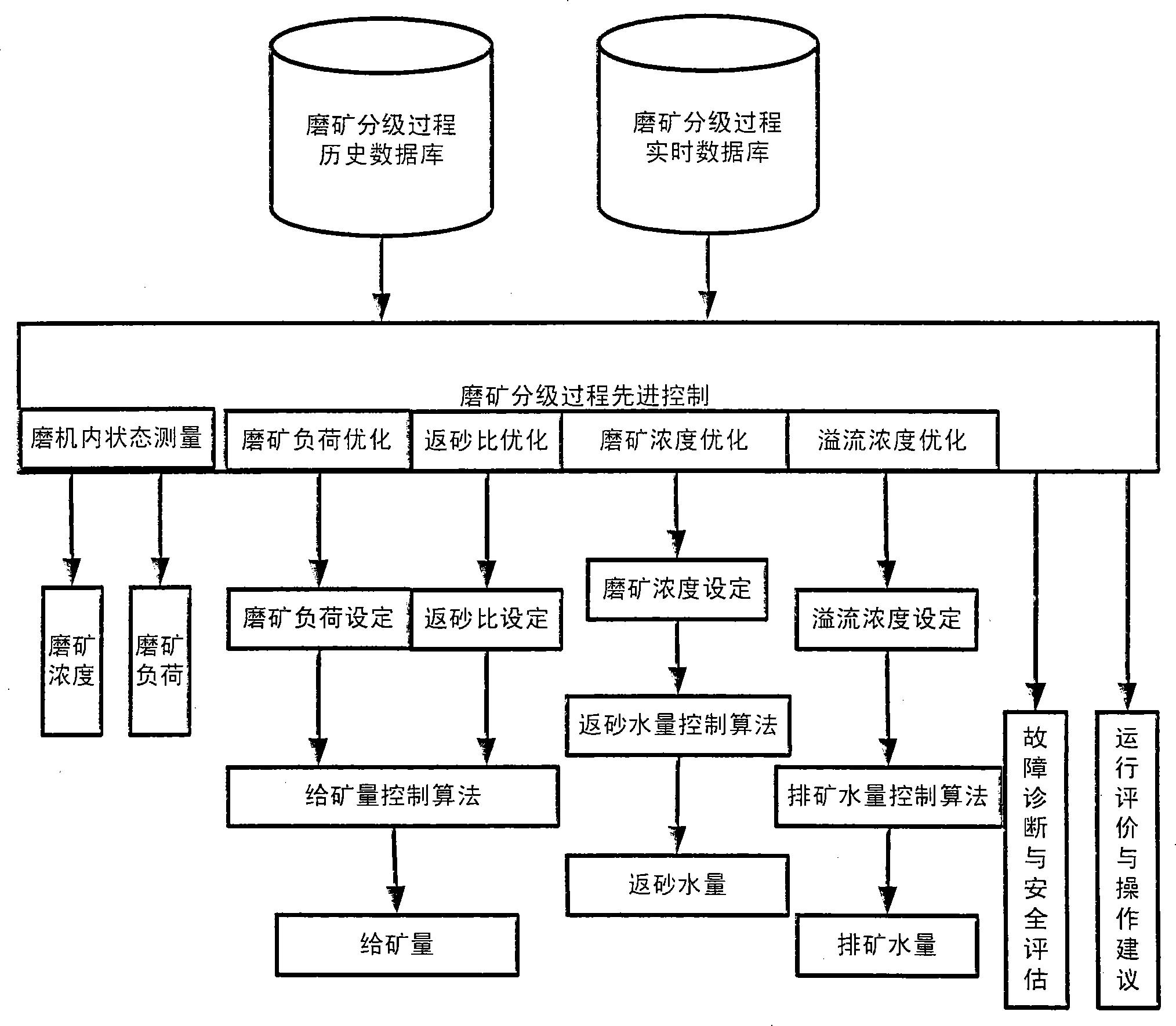

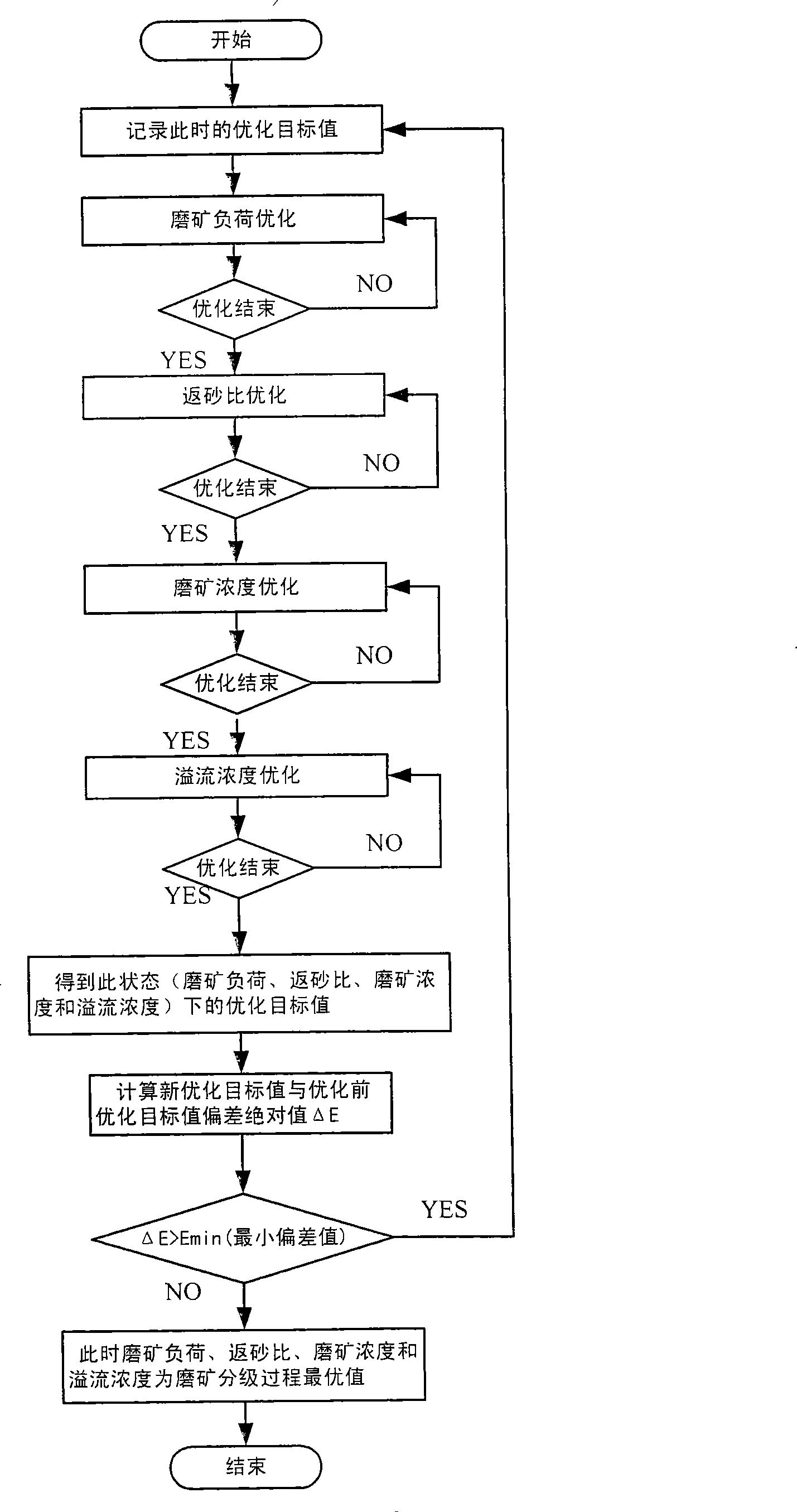

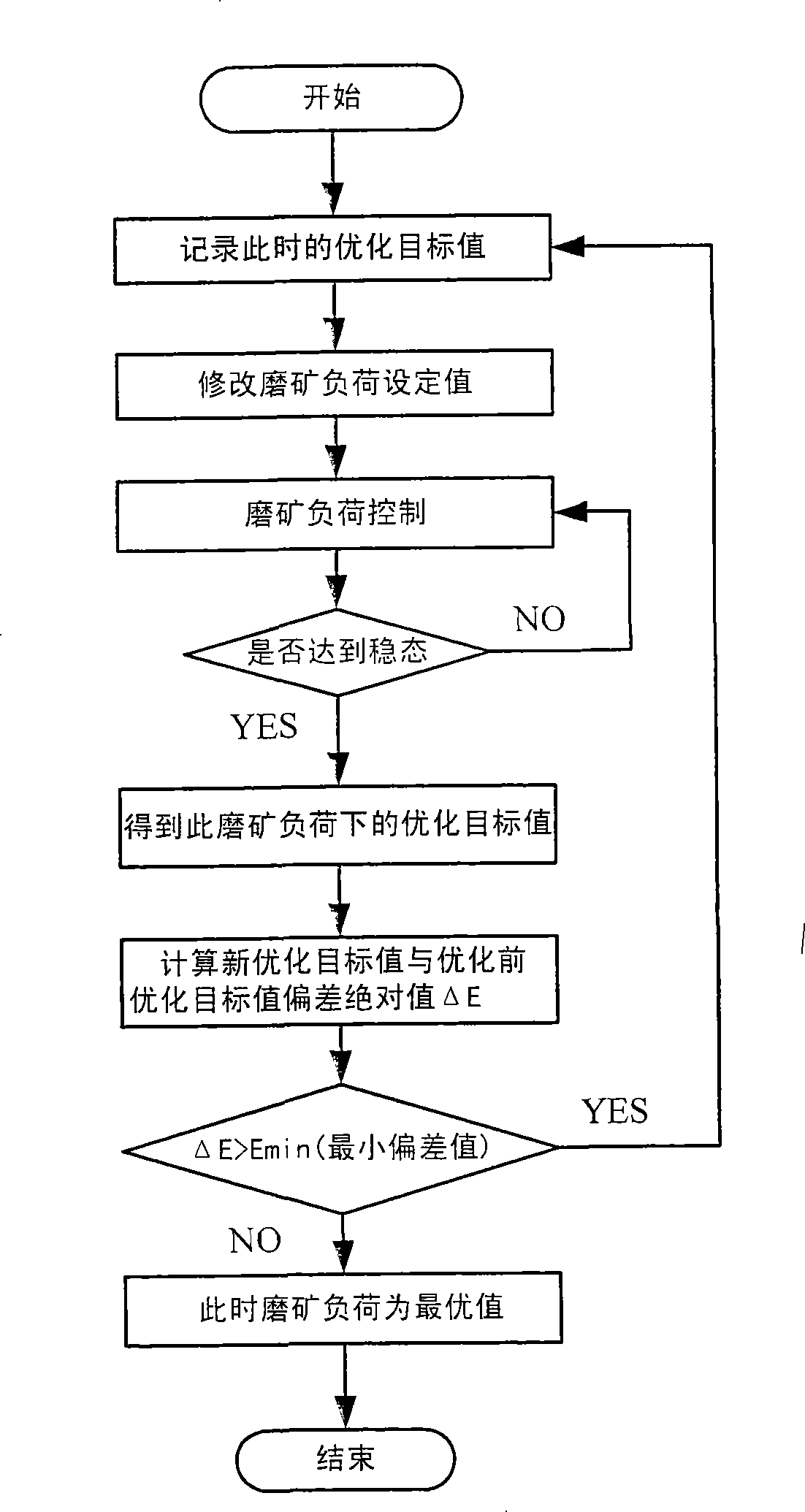

Optimization control method for grind grading process

InactiveCN101244403ARealize online measurementImprove pass rateElectric testing/monitoringGrain treatmentsComing outWater volume

The invention discloses an optimal control method for grinding and grading mineral powder, which is characterized in that: the grinding load and grinding concentration is obtained by sampling grinding-grading process signal, with the help of the advanced control and through testing the state in the grinder; the optimal grinding load, the optimal sand-returning ratio, the optimal grinding concentration and the optimal overflow concentration are obtained through the grinding load optimization, the sand-returning ratio optimization, the grinding concentration optimization and the overflow concentration optimization; the feeding quantity is obtained through the control algorithm of the feeding quantity ; the sand-returning water volume is obtained through the control algorithm of the sand-returning water volume; the discharging water volume is obtained through the control algorithm of the discharging water volume. The optimal control method has advantages that: the global optimization to the grinding-grading process is realized; and meanwhile the diagnosis is done to reveal the fault of the grinding-grading process; the appraisal and analysis is executed in the grinding-grading process; reasonable advice is come out; continuous, stable, safe and economic running is ensured; so the method is widely used in the grinding-grading process and similar wet milling process in other industry crafts.

Owner:徐宝平

Automatic polishing, correction and assembly equipment for chemical heat energy exchange steel pipe machining

InactiveCN107891333AImprove grinding effectAutomate shippingEdge grinding machinesGrinding carriagesAfter treatmentPosition error

The invention relates to an automatic grinding, straightening and splicing equipment for chemical heat exchange steel pipe processing, which includes a supporting base plate, a clamping device, a grinding device and a fixing device. The clamping device is installed on the middle of the supporting base plate, and the grinding device is installed on the On the top of the left end of the base plate, the fixing device is installed on the top of the right side of the supporting base plate. The invention can solve the problems existing in the welding of the existing steel pipes, such as the need to manually grind the cut of the steel pipe, the poor grinding effect of the cut of the steel pipe, the need to manually correct the position of the steel pipe before welding the steel pipe, and the position of the steel pipe after correction. The cut steel pipes are cut and polished, the polished steel pipes are automatically transported, the steel pipes are automatically corrected and spliced together. The position is corrected, and there is no error in the position of the steel pipe after correction.

Owner:范满香

Wheat cleaning and classifying process for flour milling of stone grinder

InactiveCN101342502AReduce bran starLow ashGas current separationGrain millingFood safetyEngineering

The invention relates to a grading technique for cleaning wheat-grains during the process of flour milling by a stone mill. The technical process includes that the wheat grains in compliance with the flour processing quality are processed by a wheat-grain receiving system, a coarse wheat-grain clearing system, a tempering system and a wheat-grain cleaning system. A graded specific-gravity stoner, a suction separator and a screening device are used to clean and process the wheat-grains in a graded manner according to the quality, the lightweight and heavyweight of the wheat grains. Compared with the traditional cleaning techniques, the invention can effectively separate the heavy-weight and light-weight wheat grains; separate the epidermises and the matters attached on the wheat grains to the largest extent; lower the residue of pesticide and microorganism in the flour, and reduce the bran quantity and dust content in the flour; as a result, the purity of the milled material is ensured, the milling effect and flour yield are improved, and the flour processing precision and food safety are enhanced.

Owner:宁夏长湖实业有限公司

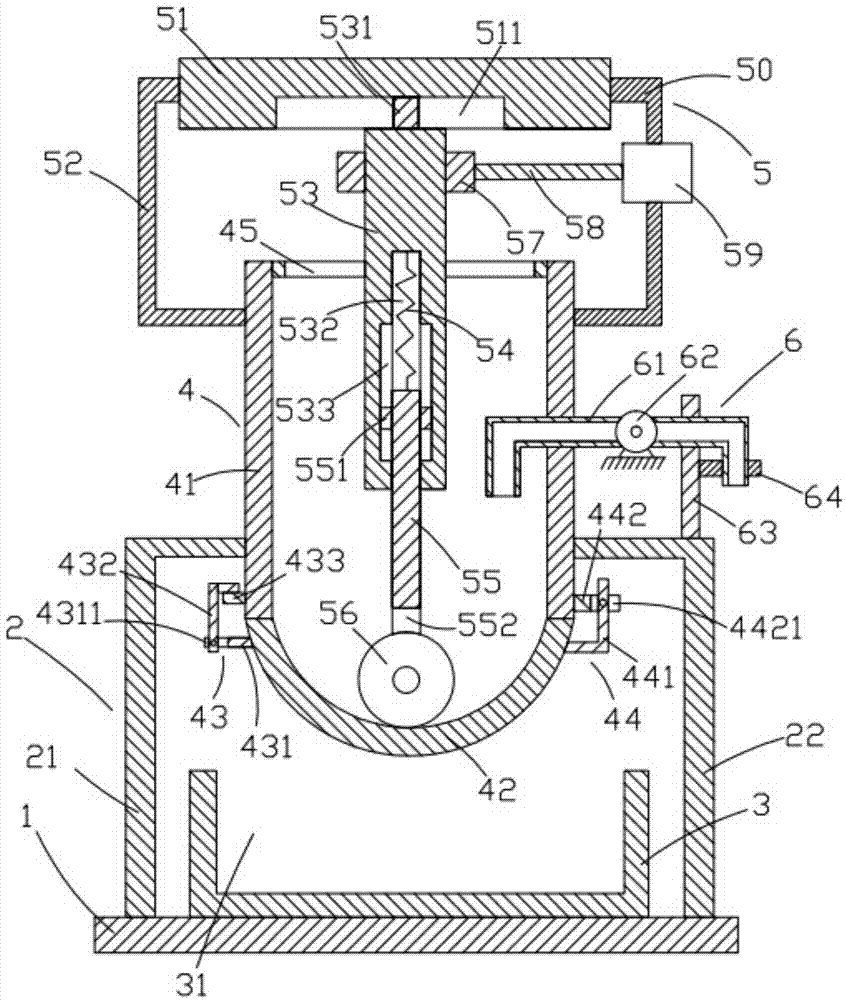

Medicine grinding device

The invention discloses a medicine grinding device. The medicine grinding device comprises a base, a bracket device, a frame body device, a grinding device, a blowing device and a material receiving box, wherein the bracket device comprises a first bracket and a second bracket; the frame body device comprises an upper frame body, a lower frame body, a first fastening device, a second fastening device and a first rectangular hole; the upper surface of the material receiving box is concave downwards to form a material receiving cavity; the lower surface of the upper frame body is concave upwards to form a first containing cavity; the upper surface of the lower frame body is concave downwards to form a second containing cavity; the first fastening device comprises a first horizontal rod, a first fastening rod and a second horizontal rod; the second fastening device comprises a connecting rod and a third horizontal rod; the grinding device comprises a positioning plate, a first supporting rod, a supporting column, a spring, an ejecting rod, a grinding wheel, a fixed block, a pushing rod, a cylinder, a second supporting rod and a third supporting rod; and the blowing device comprises a blowing pipe, a fan, a fourth supporting rod and a fifth supporting rod. The medicine grinding device disclosed by the invention has the advantages that the structure is simple, the use is convenient, the medicines can be effectively ground and the grinding effect is good.

Owner:CHAMFOND BIOTECH CO LTD

Method for producing sulfonated lignin

The method for producing sulfonated lignin from black liquor in straw pulp paper making process includes the following steps: taking black liquor from virgin pulp of rotary spherical digester, feeding the black liquor into evaporator to make evaporation and concentration; then make sulfonation reaction at normal temp. and normal pressure, firstly, adding formaldehyde, then adding sulfite and heating to more reaction, feeding the above-mentioned material into drying tower, drying to obtain the powder. Said product contains lots of active gene of sulfonic group and hydroxyl group, so that it has good solubility, high surface activity and dispersion property, mainly is used in disperse dyes, reduction dyes and dispersion and filling of water coal slurry.

Owner:邓州市老廷实业有限公司

Traditional Chinese medicinal material fine grinding device for pharmacy

The invention discloses a fine grinding device for Chinese medicinal materials used in a pharmacy, which comprises a base, a lifting motor, a rope winding shaft, a lifting slide plate, a first driving motor, a cam, a grinding bucket, a wedge block and a second driving motor. The lifting motor outputs A rope winding shaft is fixedly connected to the shaft, and a rotating shaft is installed in the center of the lifting slide, and a grinding bucket is connected to the upper end of the rotating shaft; several groups of sliders are slidably installed on the slide rail, and a The wedge-shaped block, the output shaft of the second driving motor is forward and is fixedly connected with a toggle wheel block to cooperate with the toggle wheel. Adjust the distance between the grinding head and the bottom of the grinding bucket through the lifting motor to adjust the size of the extrusion force, so as to obtain Chinese herbal medicine powder with different grinding degrees; through the cooperation between the wedge block and the roller, the grinding rod drives the grinding head down intermittently Movement, so as to increase the extrusion force between the grinding head and the Chinese herbal medicine, so as to make the grinding more fully and improve the grinding effect.

Owner:袁润栋

Cement grinding aid strengthening agent

The invention relates to a cement grinding-aid intensifier. The weight percent is that alkylol amine: polyalcohol: amide: initiator is equal to 1:1.2-1.6:0.1-0.5:0.01-0.04. The alkylol amine and the polyalcohol are mixed in a reaction tank evenly, the reaction acidity is controlled under stirring at 100-110 DEG C; the reaction time is 2-6 hours; the alkylol amine and the initiator are added, the pH value is adjusted to 7-7.5, then stirring is carried out for reaction for 3-5 hours; alkali is used for neutralization, the pH value is 8-10, and the finished product is obtained. The cement grinding-aid intensifier has the advantages that static electricity produced during powder grinding can be eliminated, thus facilitating the materials not to bond each other and penetrate into the cracks of grains and improving powder grinding efficiency; catalysis is acted during cement hydration, the diffluent complexing ions are produced, and the intensity of the testing body is improved; separation of cement powder grains in super thin grinding powder milling is restrained, thus avoiding the phenomenon of sticky balls, wall built-up and static electricity absorption; powder grinding ability of millers is improved, the specific surface of the thin powder is increased, and early strength, fast coagulation and hydration are fast; product cost is lowered, effect for aiding grinding is outstanding, the working environment is improved, performance of cement is improved obviously, production process is simple, and the products can be stored for a long period.

Owner:淄博宜龙实业有限公司

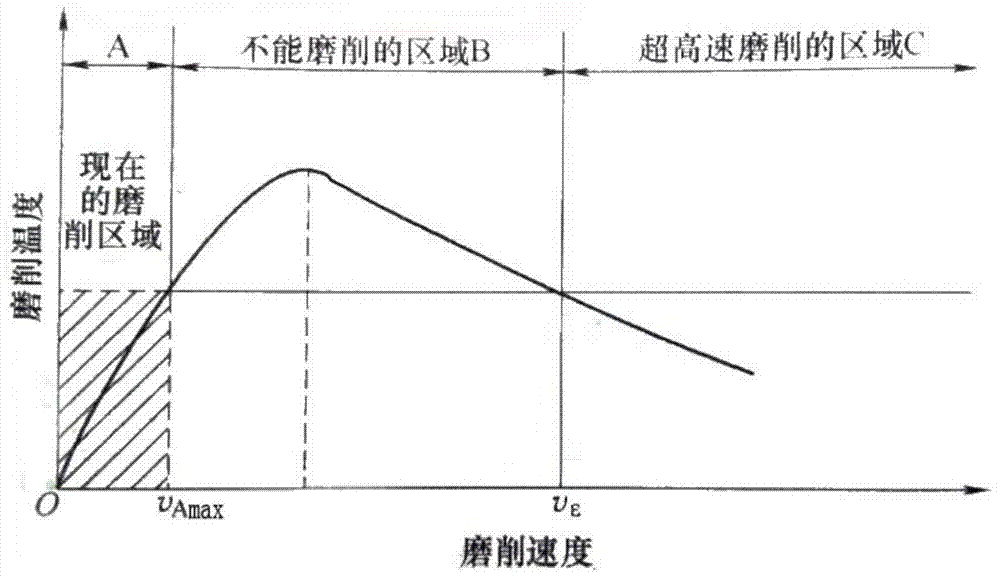

Ultraviolet (UV) light-curable polyurethane acrylic resin composite

ActiveCN102161862AAbsorb evenlyImprove adhesionPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

The invention discloses a UV light-curable polyurethane acrylic resin composite, which comprises the following components: polyurethane acrylic resin, epoxy acrylate, acrylic phosphate, an active diluent and a photoinitiator. The composite also may comprise a filler and an assistant. When the composite disclosed by the invention is used, the adhesive force of UV paint for metal substrates can be improved, the uniform absorption of UV paint can be guaranteed, the fullness of finish can be increased, a paint system can produce the best effect and has high adhesive force for various metal veneers, the paint film at a production position has high toughness and continuity and good rubbing property, and the paint is applicable to rolling painting and spray painting construction.

Owner:SHANGHAI CHANGRUNFA PAINT

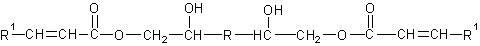

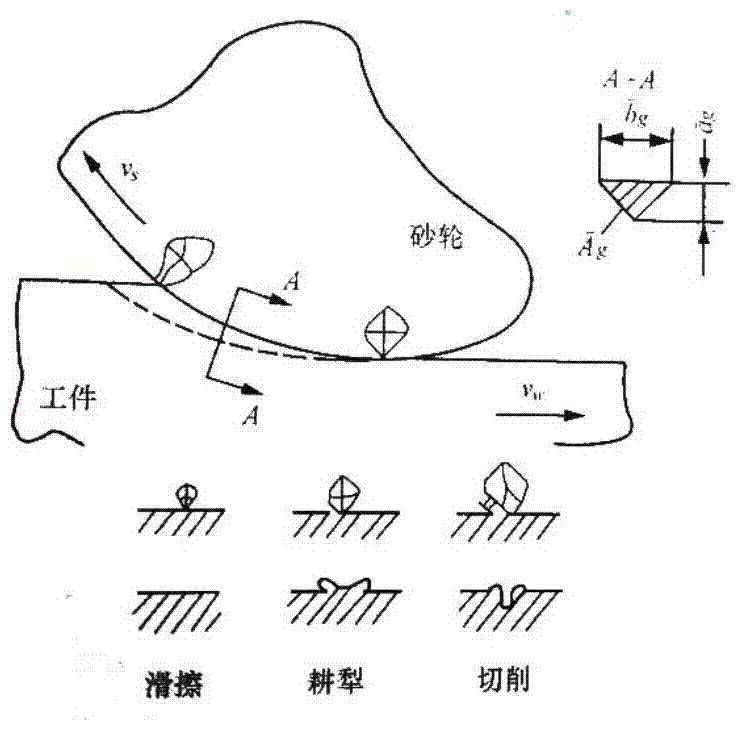

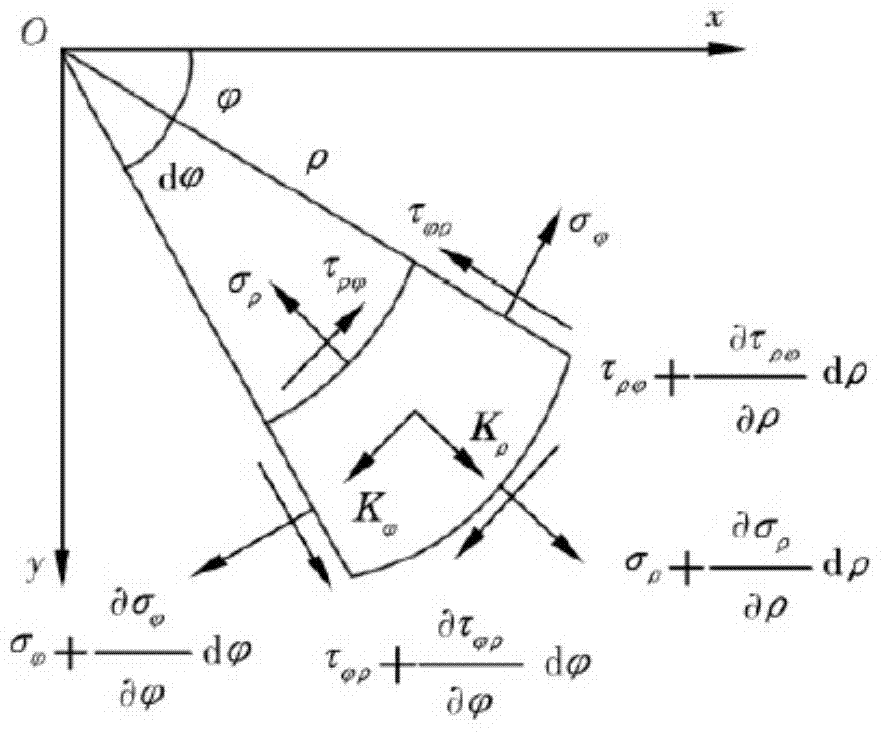

Prestress grinding method for revolved body workpiece

ActiveCN104759954ASimple structureStability is not affectedRevolution surface grinding machinesUltra high speedLow speed

The invention discloses a prestress grinding method for a revolved body workpiece. The method includes the following steps that (1) the workpiece to be machined is well clamped on a grinding machine; (2) tool setting operation is conducted, a grinding wheel and the workpiece are made to be in a low speed state first, the position of the grinding wheel is adjusted step by step, the linear speed of the grinding wheel is adjusted to be in an ultra high speed state of vs>=150 m / s after sparks just appear on the surface of the workpiece, and the rotating speed of the workpiece is adjusted to be in an ultra high speed centrifugal state; (3) abrasive machining is carried out according to a certain radial amount of feed; after machining is completed, the grinding wheel and the workpiece are separated first, and then the grinding wheel and the workpiece are decelerated to be zero. According to the prestress grinding method for the revolved body workpiece, there is no need to use a special force application mechanism to apply prestress to the workpiece, only the rotating speed of the workpiece in the machining process needs to be controlled, and residual compressive stress can be obtained on the surface of the workpiece after machining is completed; due to the fact that the rotating speed of the workpiece can be adjusted flexibly, different magnitudes of residual compressive stress can be obtained by controlling the rotating speed of the workpiece, so that the using requirements of different parts are met.

Owner:GUANGZHOU UNIVERSITY

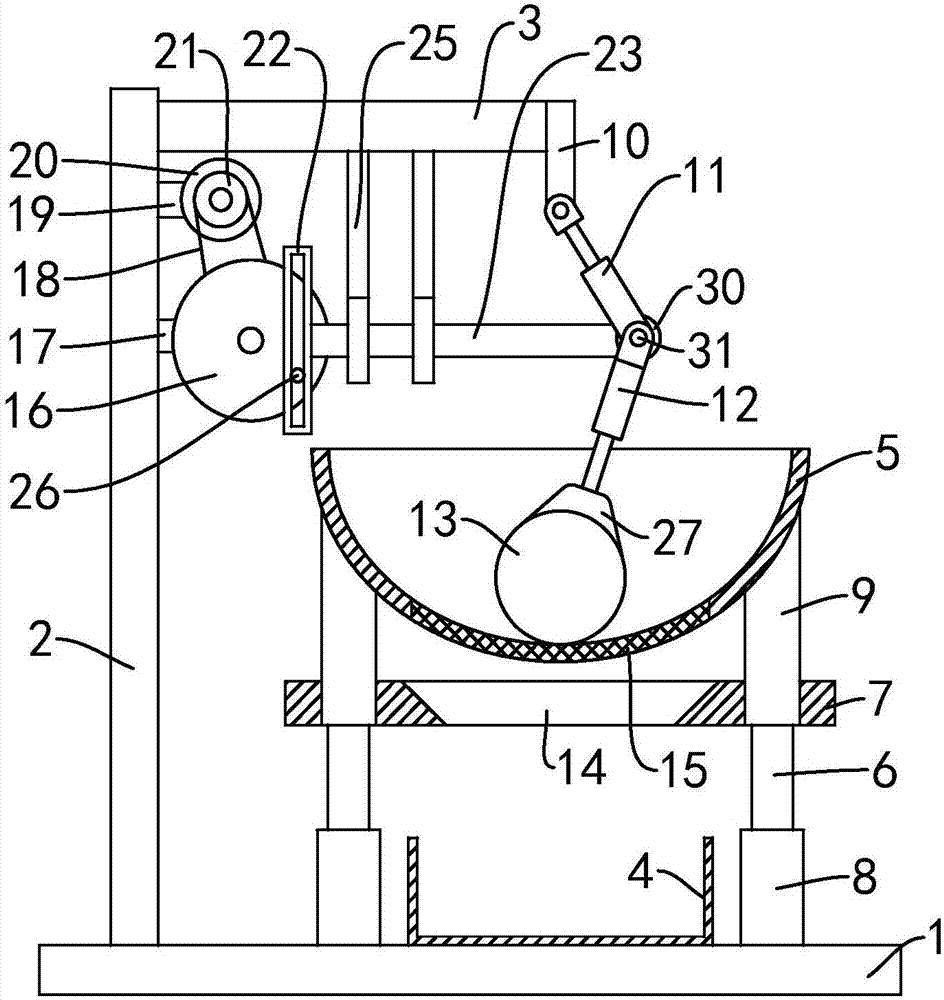

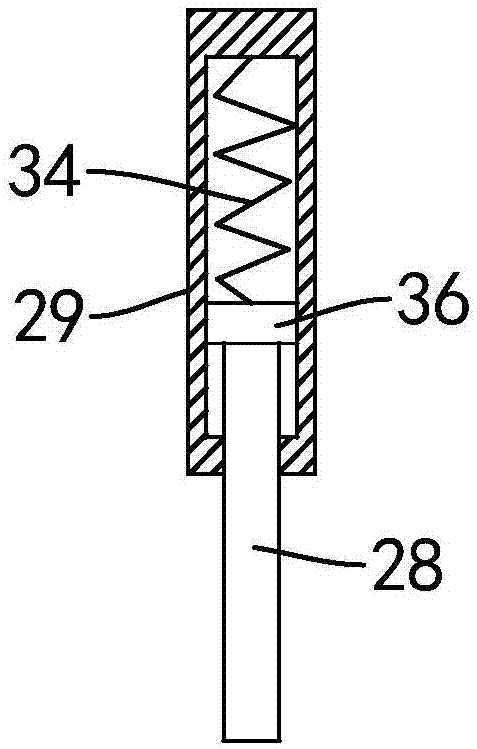

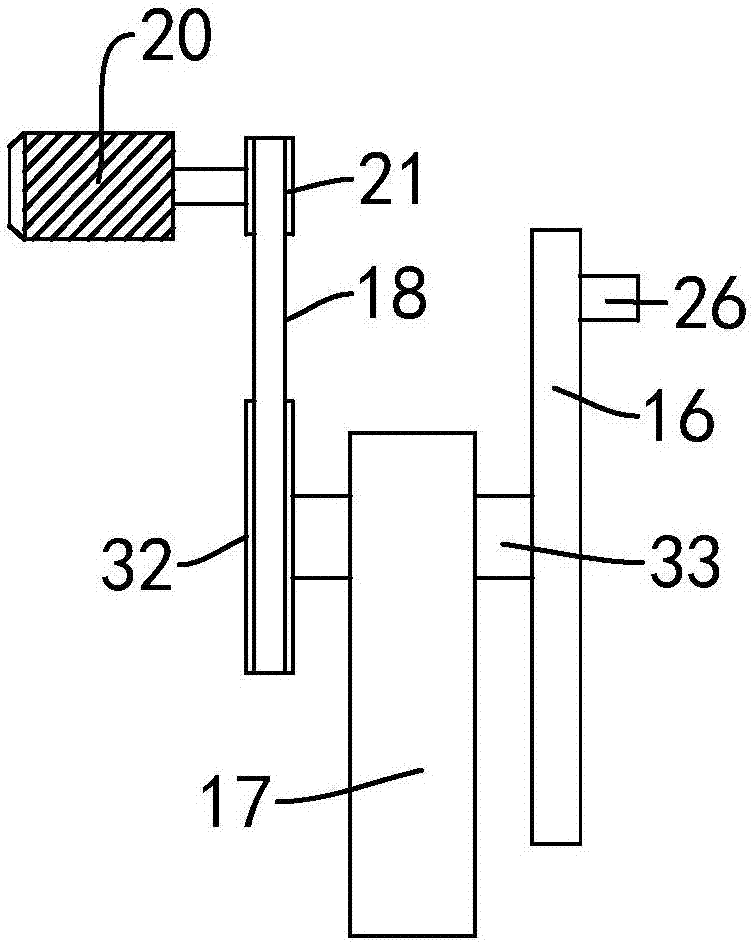

Refined grinding device for Chinese medicinal herbs

InactiveCN107282250AImprove grinding effectRealize the grinding operationGrain treatmentsCircular discMedicinal herbs

The invention discloses a refined grinding device for Chinese medicinal herbs. The refined grinding device comprises a base, a collecting box, a grinding groove, a support platform, a first telescopic sleeve rod, a second telescopic sleeve rod, grinding balls, a rotating disk, a movable sleeve plate and a push-pull rod. The bottom end of a coupling sleeve on the first telescopic sleeve rod is rotatably hinged with the top of the coupling sleeve on a second telescopic sleeve through an articulated shaft, and the end of the articulated shaft is fixedly provided with a connecting block; the upper part of the grinding balls is fixedly provided with a connecting plate, and the bottom end of a connection sliding rod on the second telescopic sleeve rod is connected to the connecting plate; the outer ring surface of the grinding balls is fixedly provided with a guide pillar, and the movable sleeve plate is sheathed on the guide pillar; and the movable sleeve plate is fixedly installed on one end of the push-pull rod of which the other end is fixedly connected to the connecting plate. The refined grinding device disclosed by the invention has the advantages of simple structure, easy operation, smart design, full and uniform grinding, and time and labor saving in the grinding process, and is suitable for popularization and application.

Owner:侯添有

Fine feed grinding device for fry breeding

InactiveCN107377091AReduce noiseEffective shock absorptionFeeding-stuffNon-rotating vibration suppressionElectromagnet

The invention discloses a feed fine grinding device for fish fry cultivation, which comprises a shock absorbing spring, a shock absorbing cylinder, a grinding box, a grinding tank, a screening plate, a screw rod, a grinding roller, a grinding motor, a feeding trough, and a quantitative circular wheel and a magnet, the inside of the grinding box is provided with a grinding tank, a sieve plate is installed at the bottom of the grinding tank, a screw rod is installed on the front side of the grinding tank, and a guide rod is fixedly installed on the rear side of the grinding tank. Grinding rollers are also fixedly installed, and a quantitative round wheel is also rotatably installed inside the cutting trough; a magnet is fixedly installed on the lower side of the grinding box, and an electromagnet is also fixedly installed on the base. When it is necessary to grind the fish feed, the electromagnet is powered on and off intermittently, so that the grinding box moves up and down, thereby speeding up the speed of sieving the feed after grinding; after the sieving is completed, it is realized under the action of the quantitative round wheel Quantitative discharge, so as to accurately control the feeding amount of fish food, so as to achieve reasonable feeding.

Owner:YUYAO WANZHEN HARDWARE FACTORY

Water-based primer for wood enamel sealing and preparation method thereof

ActiveCN104761992AAchieve water resistanceImprove permeabilityAntifouling/underwater paintsPaints with biocidesWater basedTemperature resistance

The invention discloses a water-based primer for wood enamel sealing. The water-based primer for wood enamel sealing contains the following raw materials in percentage by mass: 20-40% of an acrylic emulsion, 20-30% of silica sol, 6-15% of polyurethane, 12-25% of a lead-free pigment and 5-25% of deionized water, and further comprises the following auxiliaries: 0.1-0.5% of a dispersant, 0.1-0.5% of a defoamer, 0.1-0.3% of a wetter, 0.2-0.5% of a leveller, 0.2-1% of a thickener and the like. According to the water-based primer for wood enamel sealing, high-purity stable water-based acidic silica sol is selected, only contains moisture and volatile matters, has the characteristics of no smell, no toxicity, high-temperature resistance, no flash point and flame resistance, cooperates with the homogeneous-phase collocation of the other materials in the formula, and forms a glass enamel sealing film layer which is incapable of being dissolved and deteriorated after coating the surface of a wood material to form a film; the coated wood material can also be effectively protected; the scrubbing resistance and the contamination resistance are obviously improved.

Owner:上海君子兰新材料股份有限公司

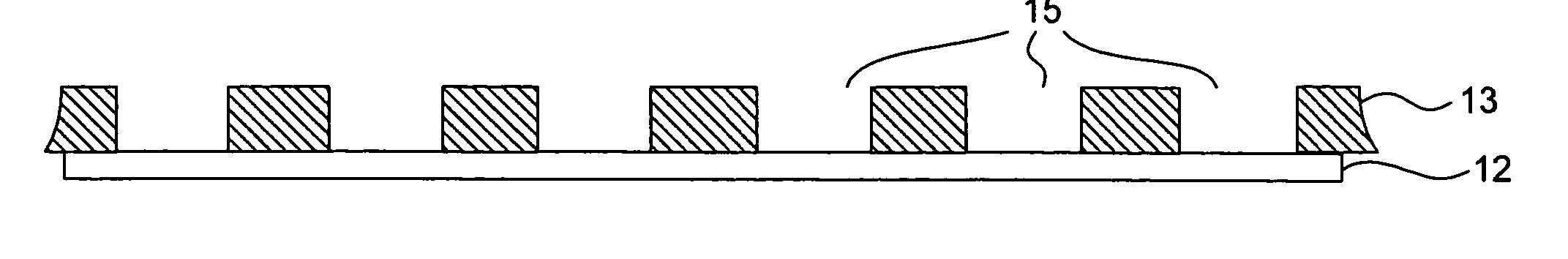

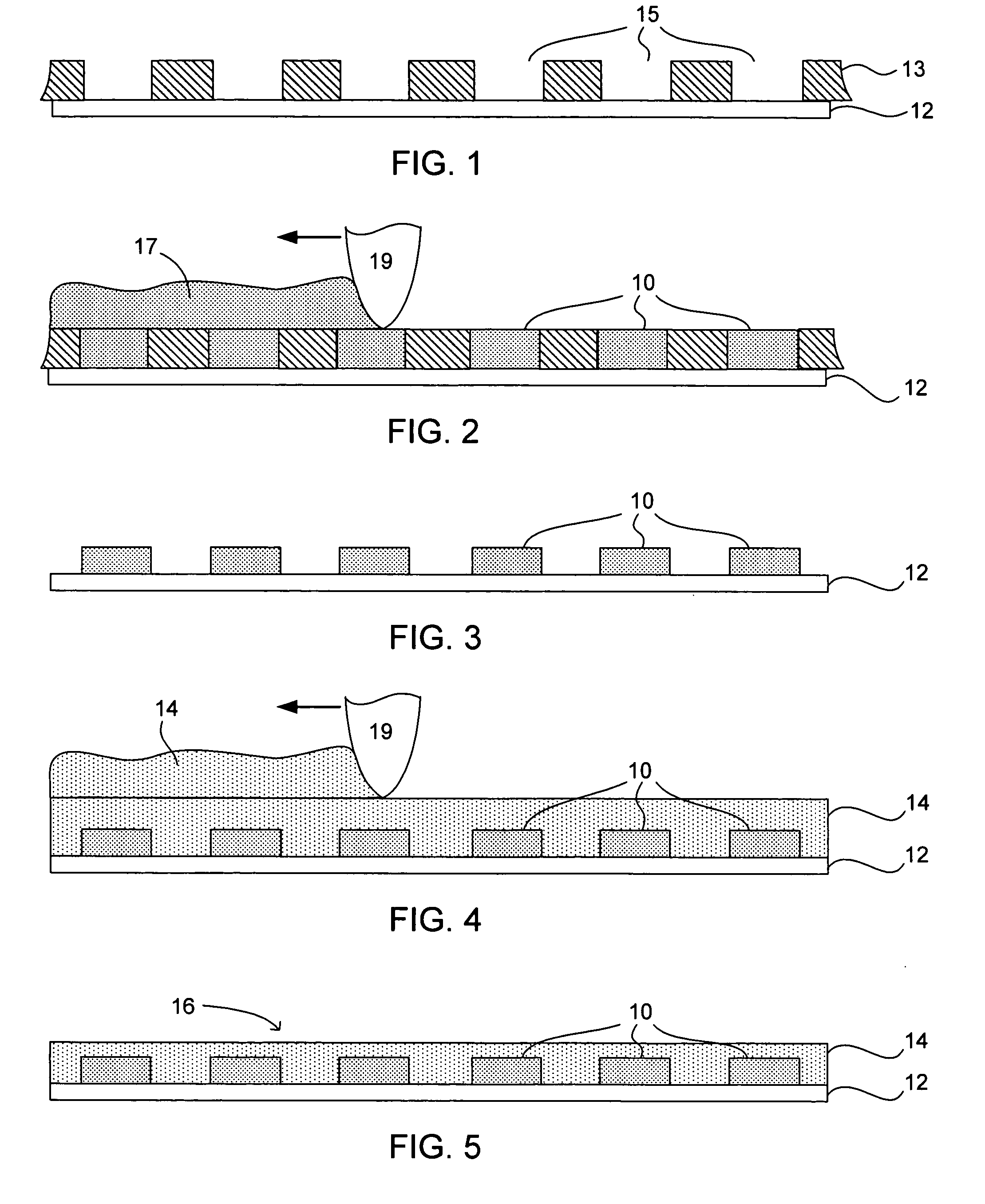

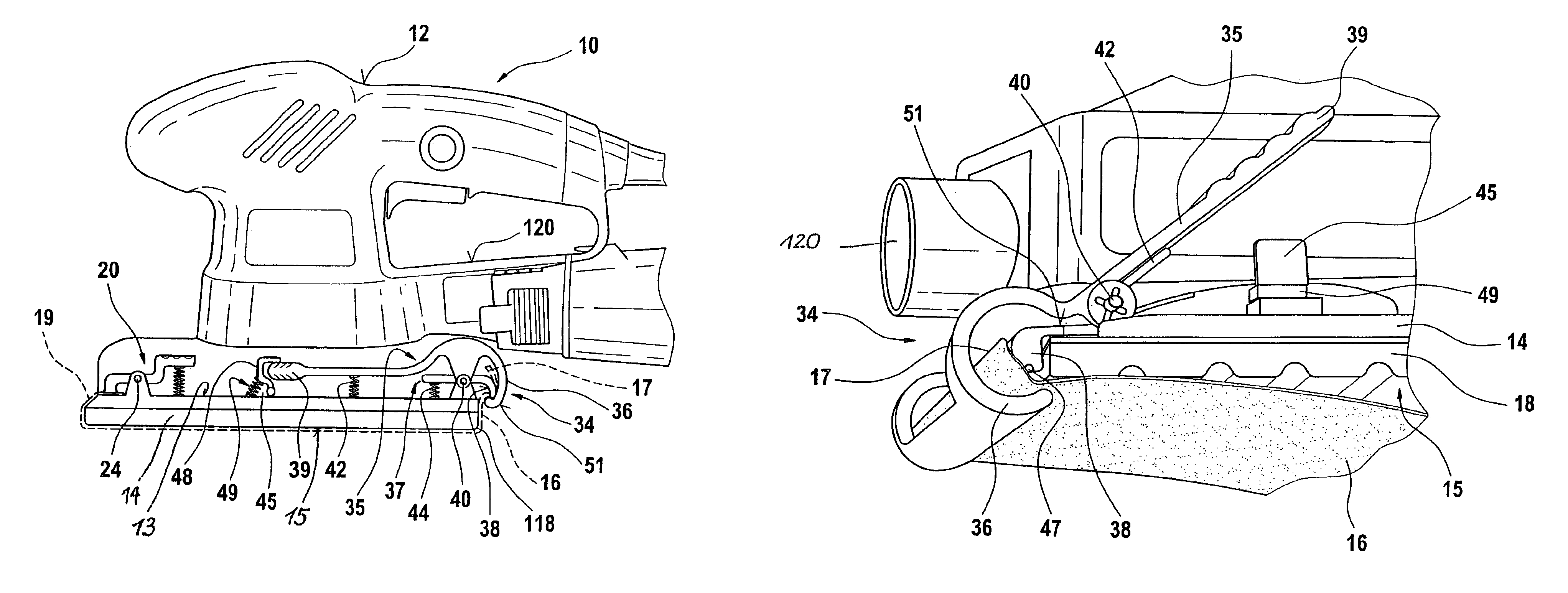

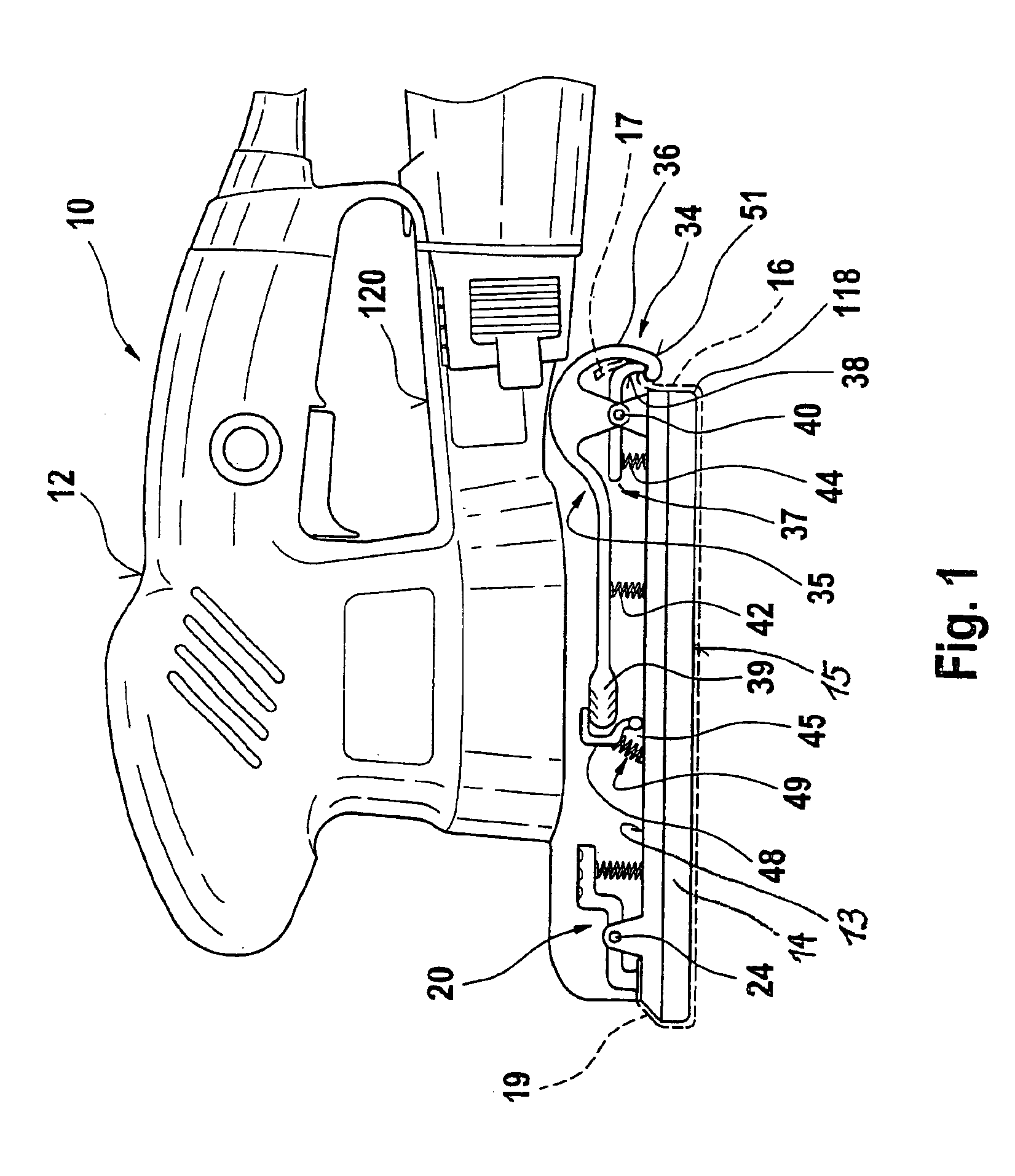

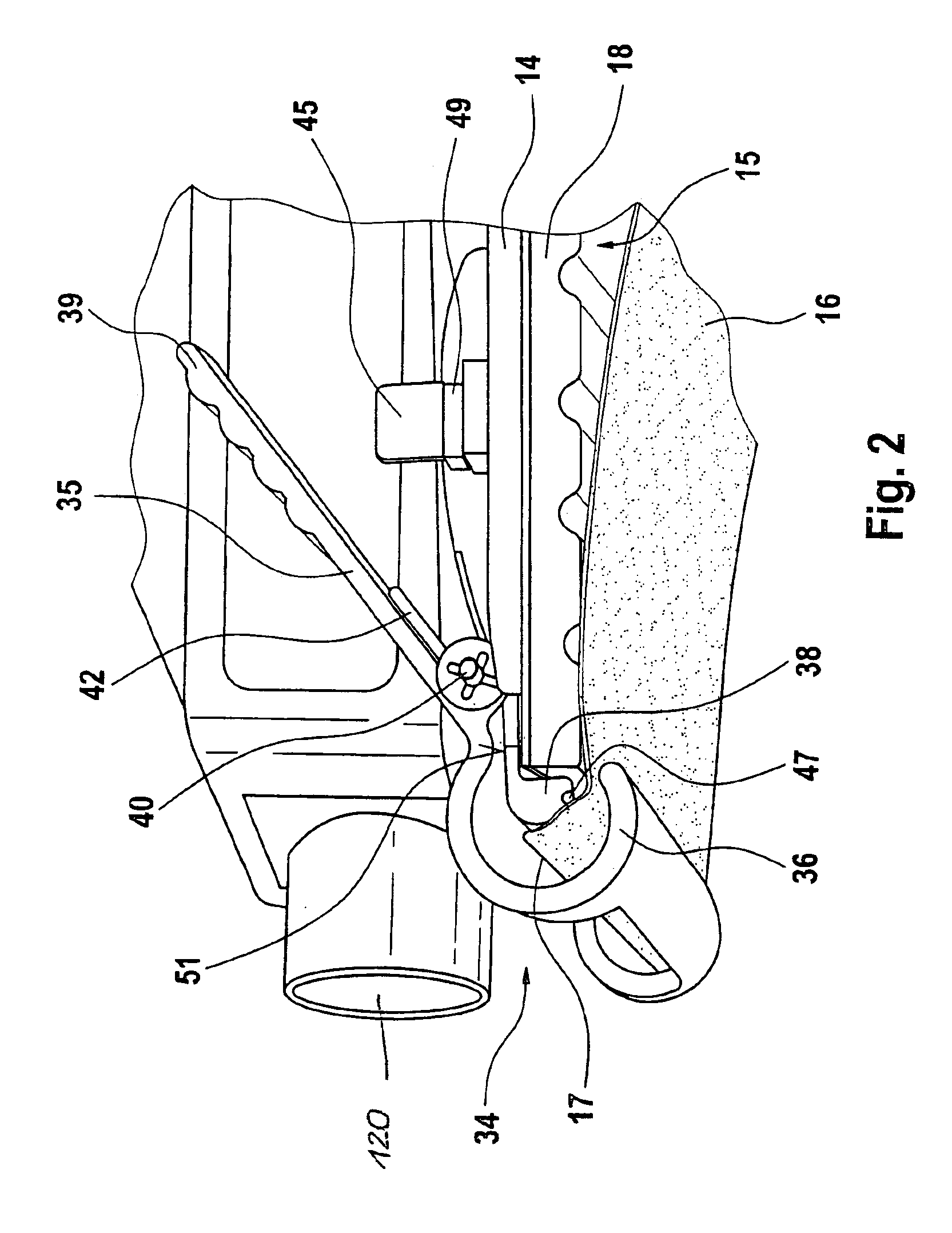

Abrasive strip carrier and hand sander

InactiveUS6857948B2Improve grinding effectImprove efficiencyPortable grinding machinesGrinding/polishing hand toolsSanderEngineering

A power grinder, in particular an oscillating grinder (10), having a housing (12) and a grinding sheet holder (14), on whose working face (15) a grinding sheet (16) to be received is braced, and its reception is effected by means of clamping means (20, 23) that lock opposite grinding sheet ends (17, 19) to the grinding sheet holder (14), is made easier to operate, and its machining capacity is improved, by providing that for equipping it with the grinding sheet, the clamping means (20, 23) are movable jointly with a grinding sheet end (17) clamped to them away from the opposite, likewise clamped grinding sheet end (19), so that the latter is locked, while under tensile stress.

Owner:ROBERT BOSCH GMBH

Method for preparing polymer ceramic dispersants

InactiveCN101274242AAppropriate viscosityImprove liquidityTransportation and packagingMixingPolymer sciencePolyethylene glycol

The invention discloses a preparation method of a polymer ceramic dispersant, which is characterized in that polyethylene glycol and maleic anhydride are uniformly mixed and polymerized to obtain a semi-esterification product; the semi-esterification product, vinyl monomer and water are uniformly mixed to carry out free radical polymerization under the inducement of initiating agent so as to obtain the polymer ceramic dispersant. The product prepared by adopting the invention has excellent dispersion dilution effect and grinding-aid effect on the ceramic slurry, improves the billet strength and the billet yield, thus reducing the production cost; meanwhile, the indexes such as the density and the folding resistance strength, etc. of the ceramic product are greatly reinforced. Furthermore, the product can be also used for the dispersion of dye and coating, etc.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com