Patents

Literature

38results about How to "Improve hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation of light colore high softening point maleated rosin pentaerythritol

InactiveCN101475776AImprove hardnessHigh hardnessNatural resin chemical modificationRosinPentaerythritol

The invention relates to a method for preparing maleic rosin pentaerythritol ester with shallow color and high softening point. The method comprises the following steps that: under the conditions of vacuum degree of between 0 and 1 kPa and temperature of between 200 and 270 DEG C, rosin is refined to form refined rosin having a softening point of between 80 and 86 DEG C; under the protection of inert gas, the molten refined rosin is added with maleic acid anhydride accounting for 5 to 14 percent of the mass of the refined rosin and a reducing agent accounting for 0.03 to 1.0 percent of the mass of the refined rosin, and reacts for 0.5 to 2 hours at a temperature of between 150 and 230 DEG C; pentaerythritol accounting for 10 to 20 percent of the mass of the refined rosin, a catalyst accounting for 0.1 to 1.0 percent of the mass of the refined rosin and a discoloring agent accounting for 0.1 to 1.0 percent of the mass of the refined rosin are added to a reaction system and react at temperature of between 230 and 290 DEG C; reaction is finished till acid value is less than 20 mg / g; the reactants are decompressed, vacuumized and kept at vacuum degree of between 0 and 2 kPa for 5 to 60 minutes; and a low-boiling-point substance is removed and the maleic rosin pentaerythritol ester with shallow color and high softening point is perpared.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

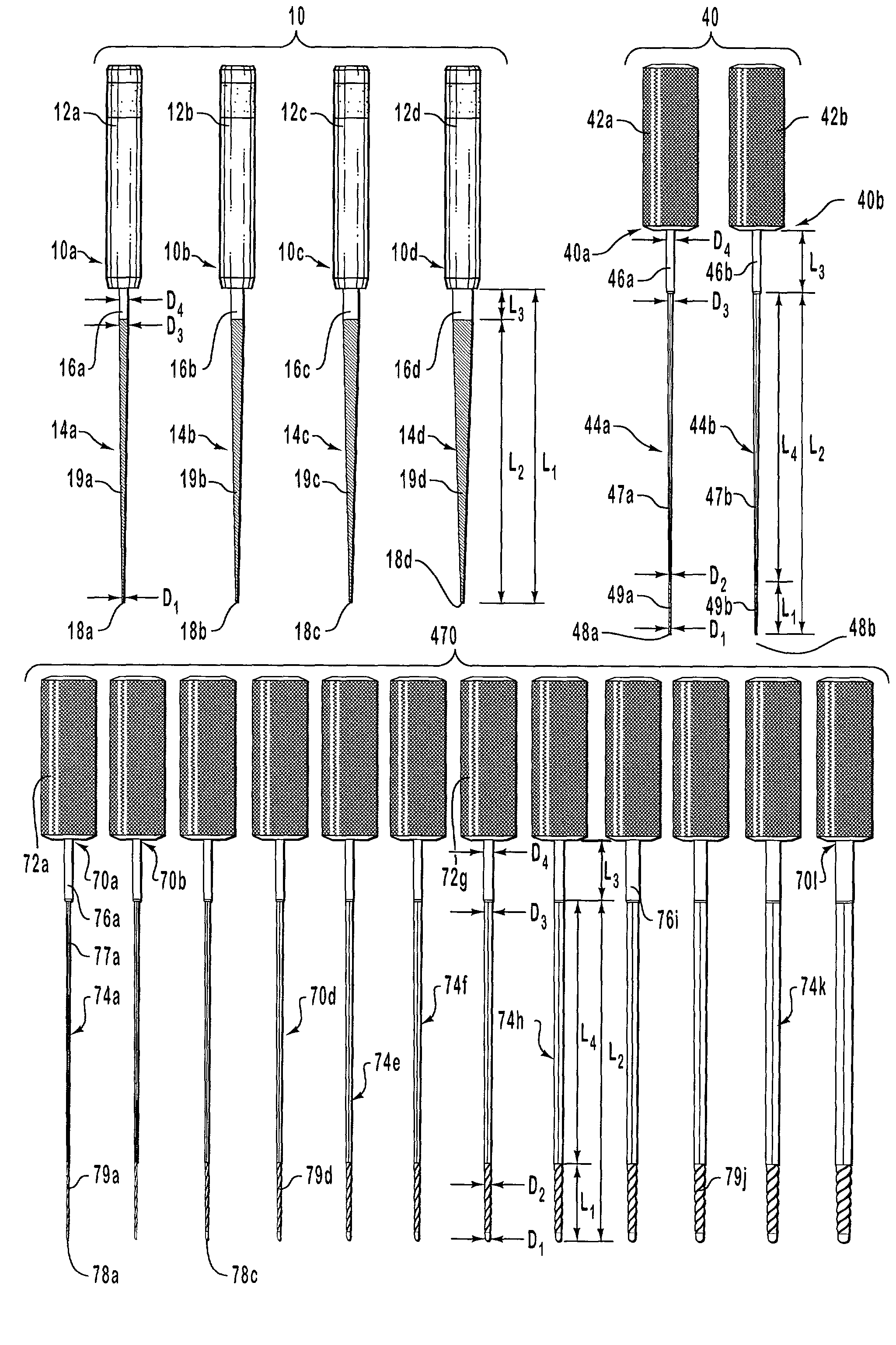

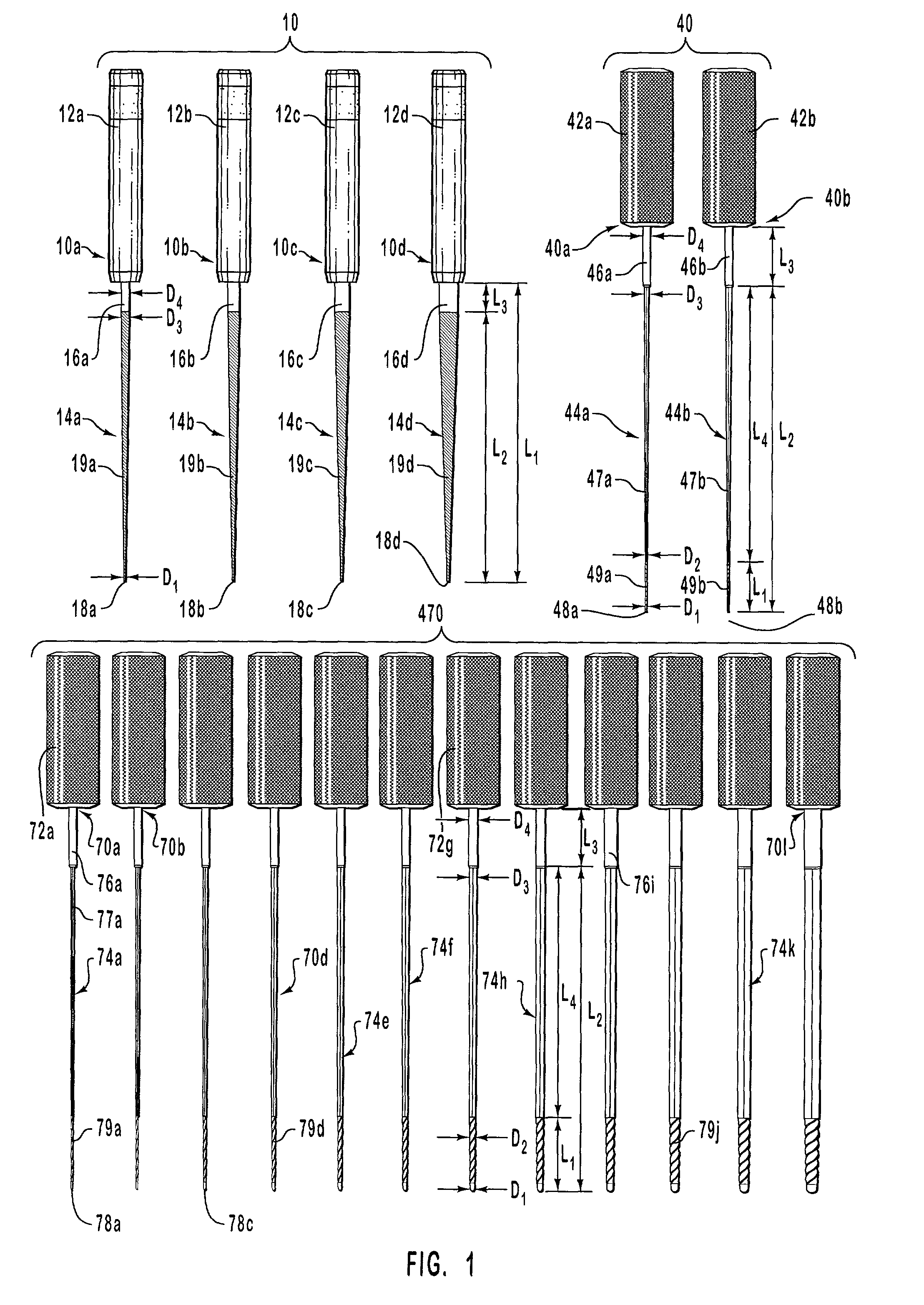

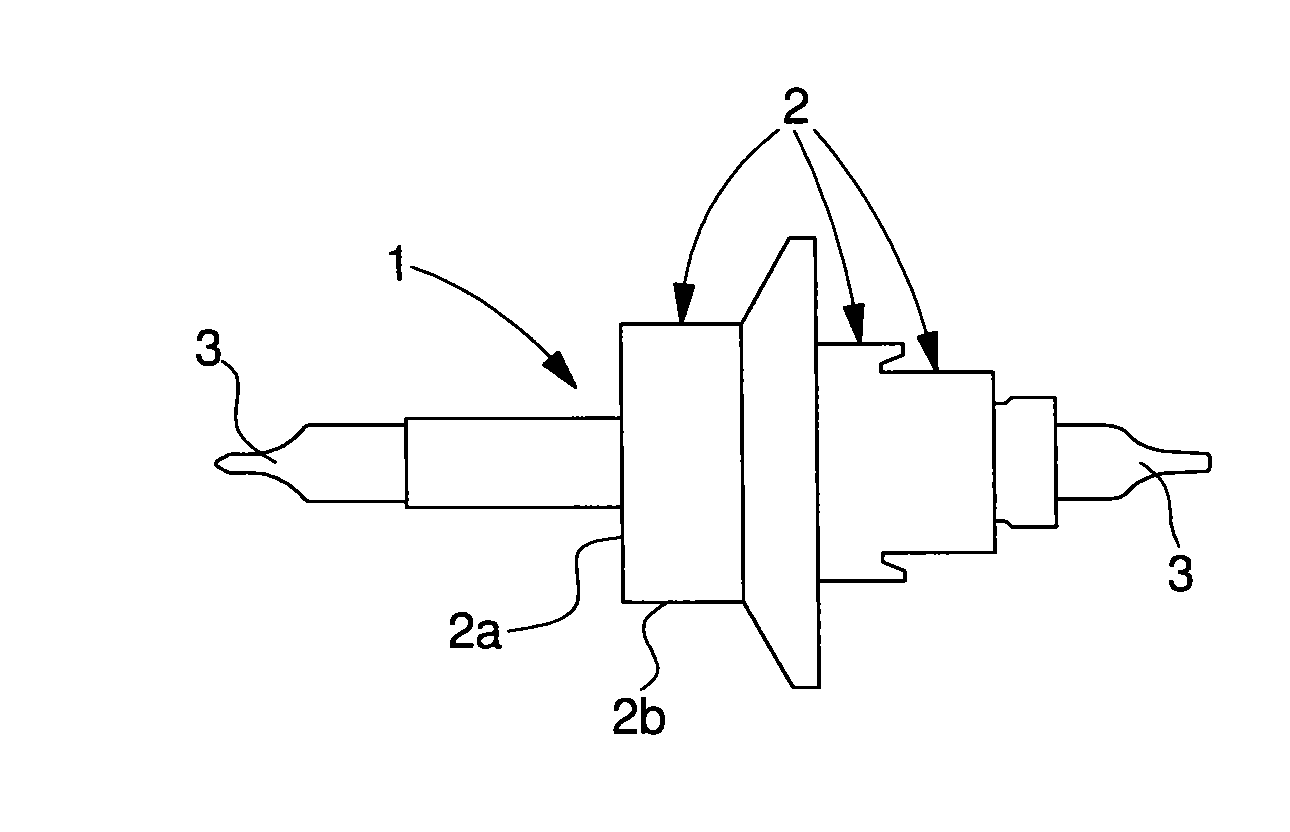

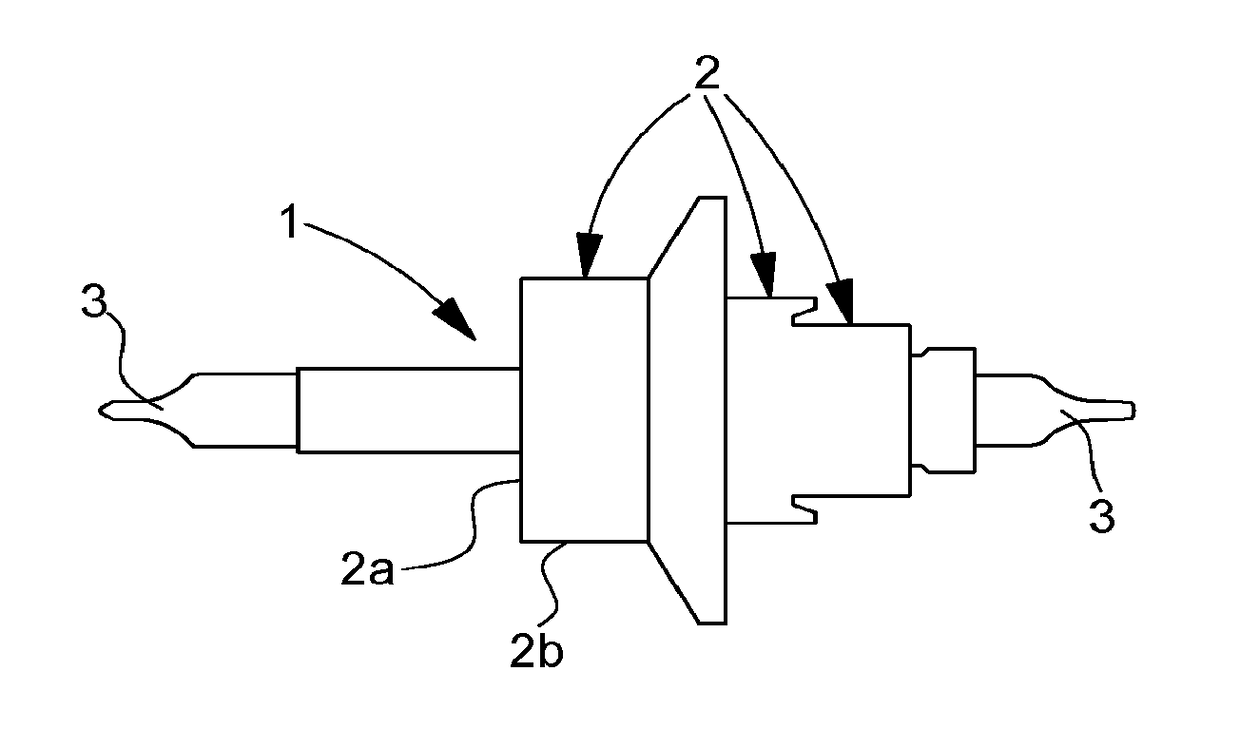

Precipitation hardenable stainless steel endodontic instruments and methods for manufacturing and using the instruments

InactiveUS20030013067A1Improve hardnessExcellent characteristicTeeth cappingTeeth nerve/root treatment implementsEndodontic filesBiocompatibility Testing

Precipitation hardenable stainless steel endodontic files and methods for their manufacture, wherein the most preferred precipitation hardenable stainless steel is 17-4PH and aging is preferably not one of the manufacturing steps. Precipitation hardenable stainless steels used in embodiments of this invention are iron-chromium-nickel grades that have the desired properties of flexibility, strength, hardness, wear resistance, stiffness, resistance to permanent deformation, resistance to variable torque, and biocompatibility for endodontic files.

Owner:ULTRADENT PROD INC

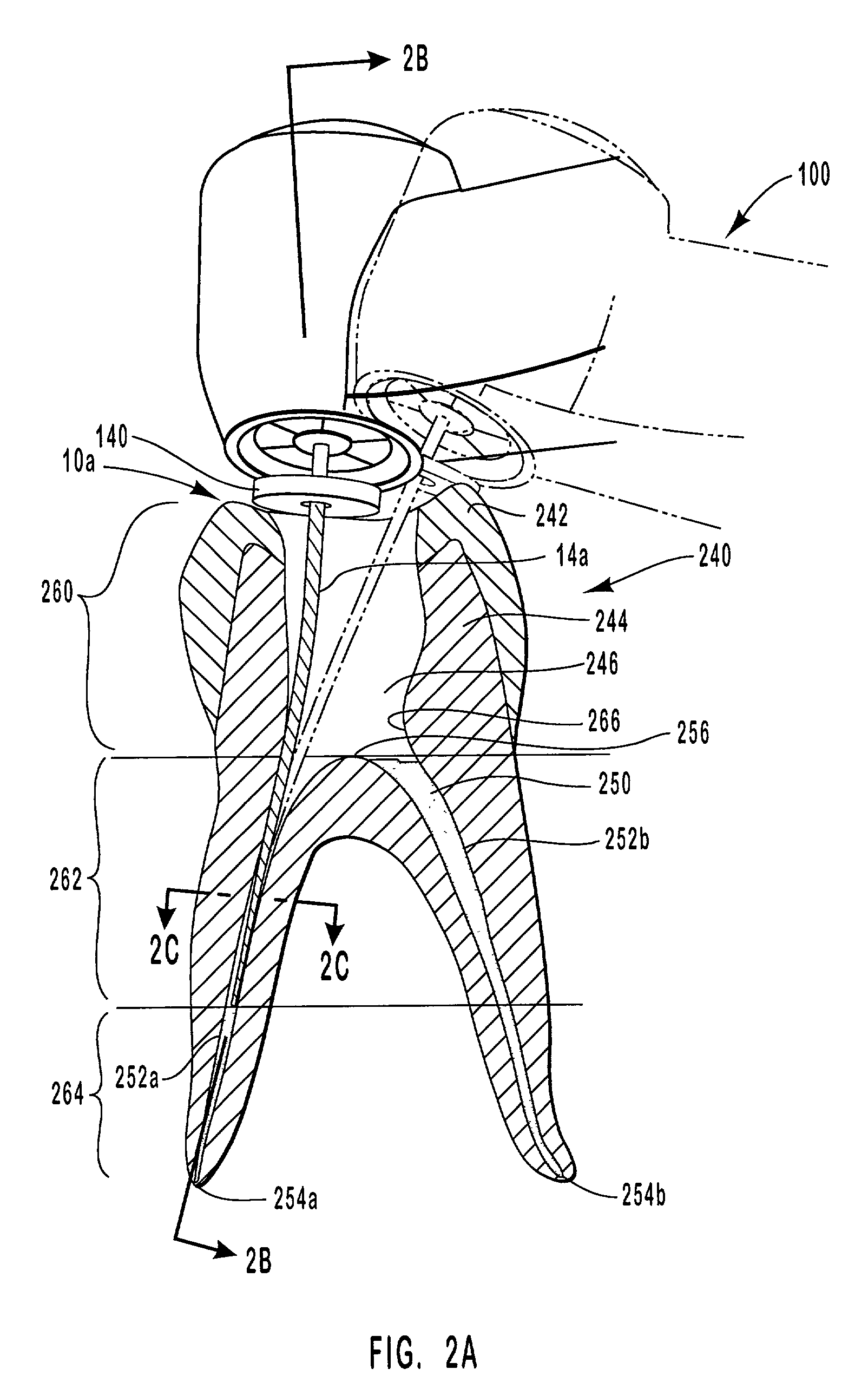

Biohaydite filter material and its prepn

InactiveCN1887790AImprove hardnessAeration bubble resistance is smallSustainable biological treatmentCeramicwareNatural organic matterIndustrial waste

The present invention is biohaydite filter material and its preparation process and belongs to the field of water treating engineering technology. The biohaydite filter material is prepared with shale 30-40 wt%, fly ash 30-45 wt%, sludge 10-20 wt%, pore creating agent 3-8 wt% and adhesive 0.5-2 wt%. The preparation process includes the steps of mixing material, forming, stoving, roasting, sintering and modifying. The preparation process has great amount of industrial waste utilized and low power consumption, may have microbes immobilized on its surface for biodegradation to result in raised organic matter degrading capacity, and may have its surface modified chemically for positively charging and hydroxylating favorable to eliminate natural organic matter from raw water.

Owner:HARBIN INST OF TECH

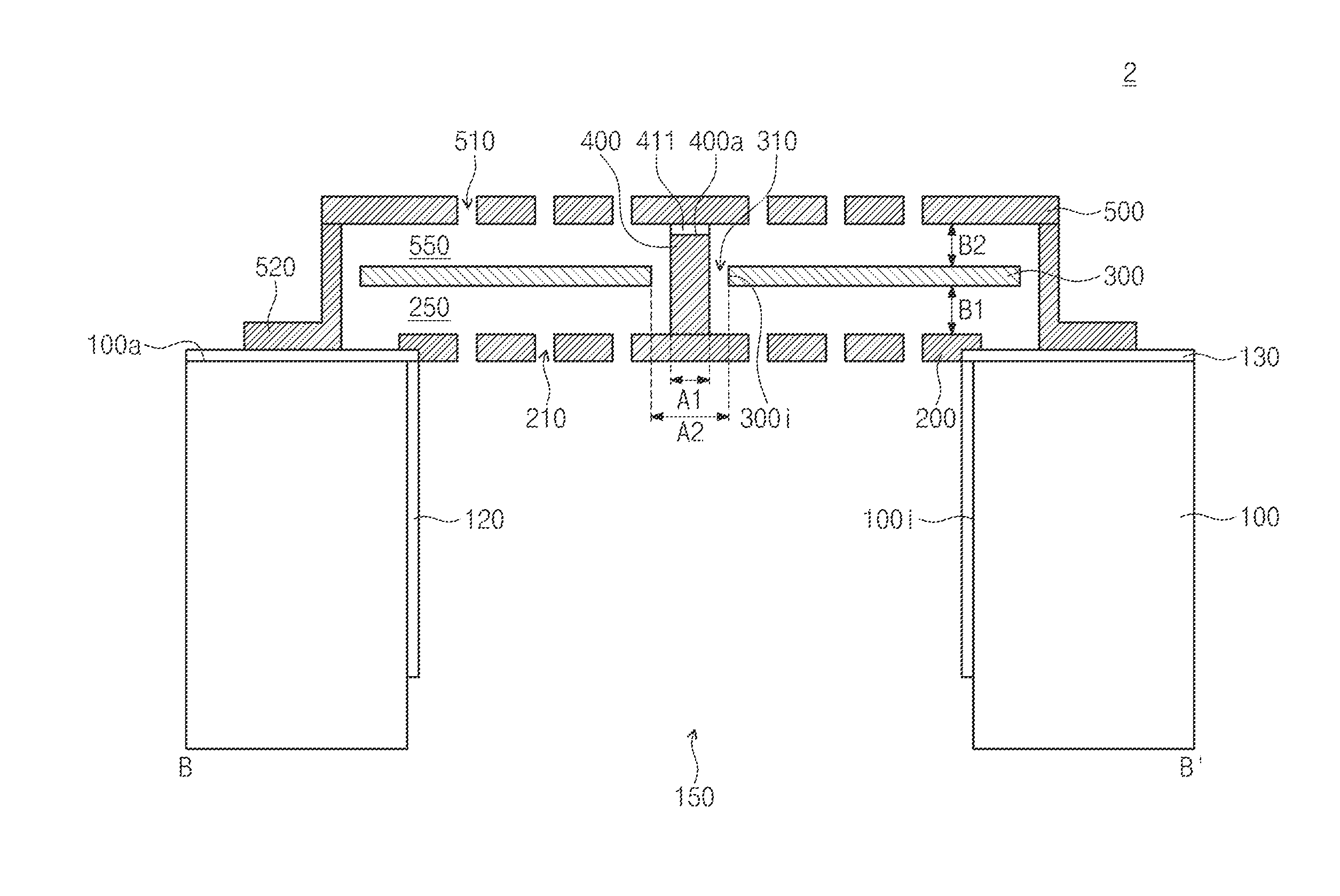

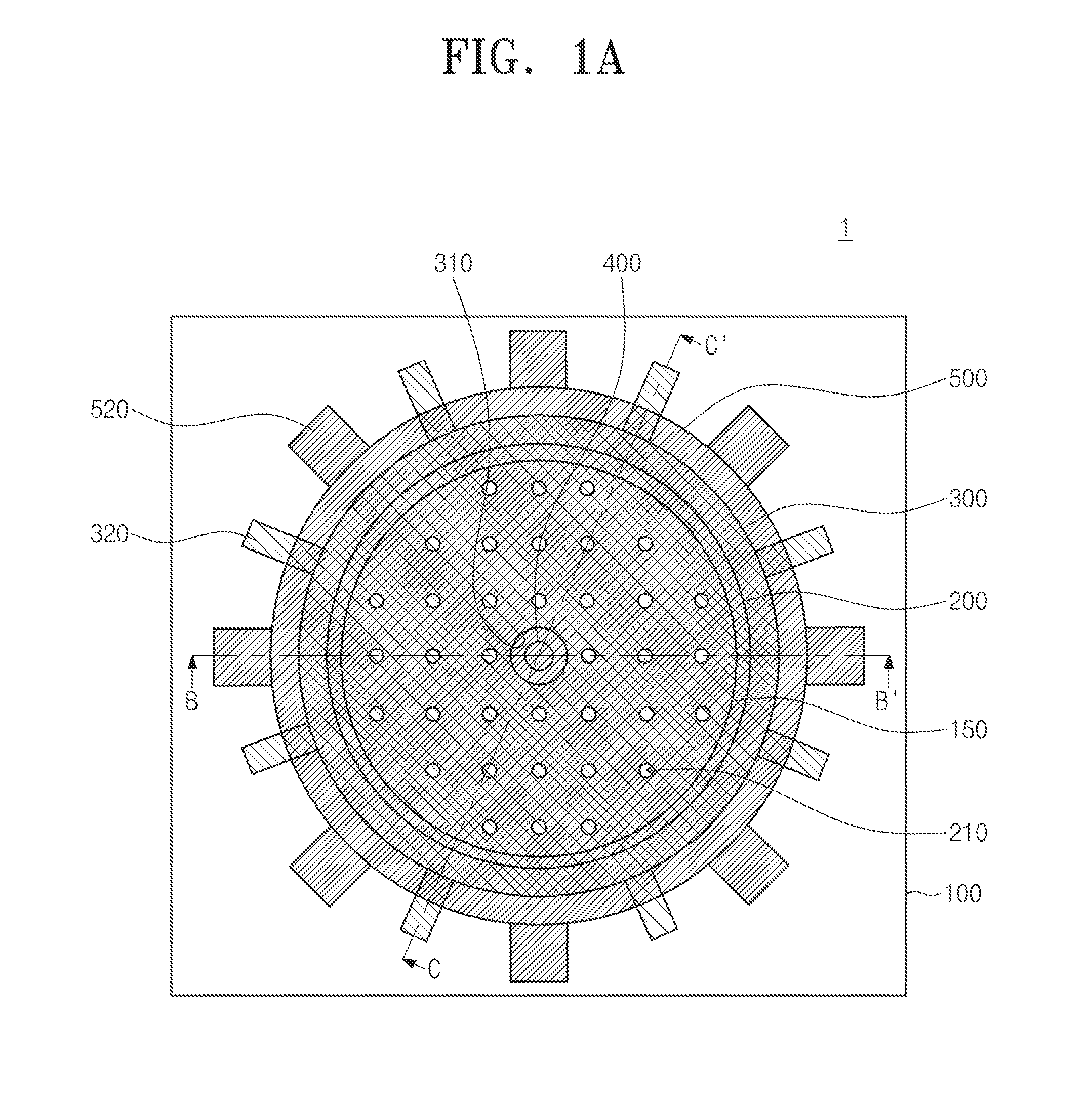

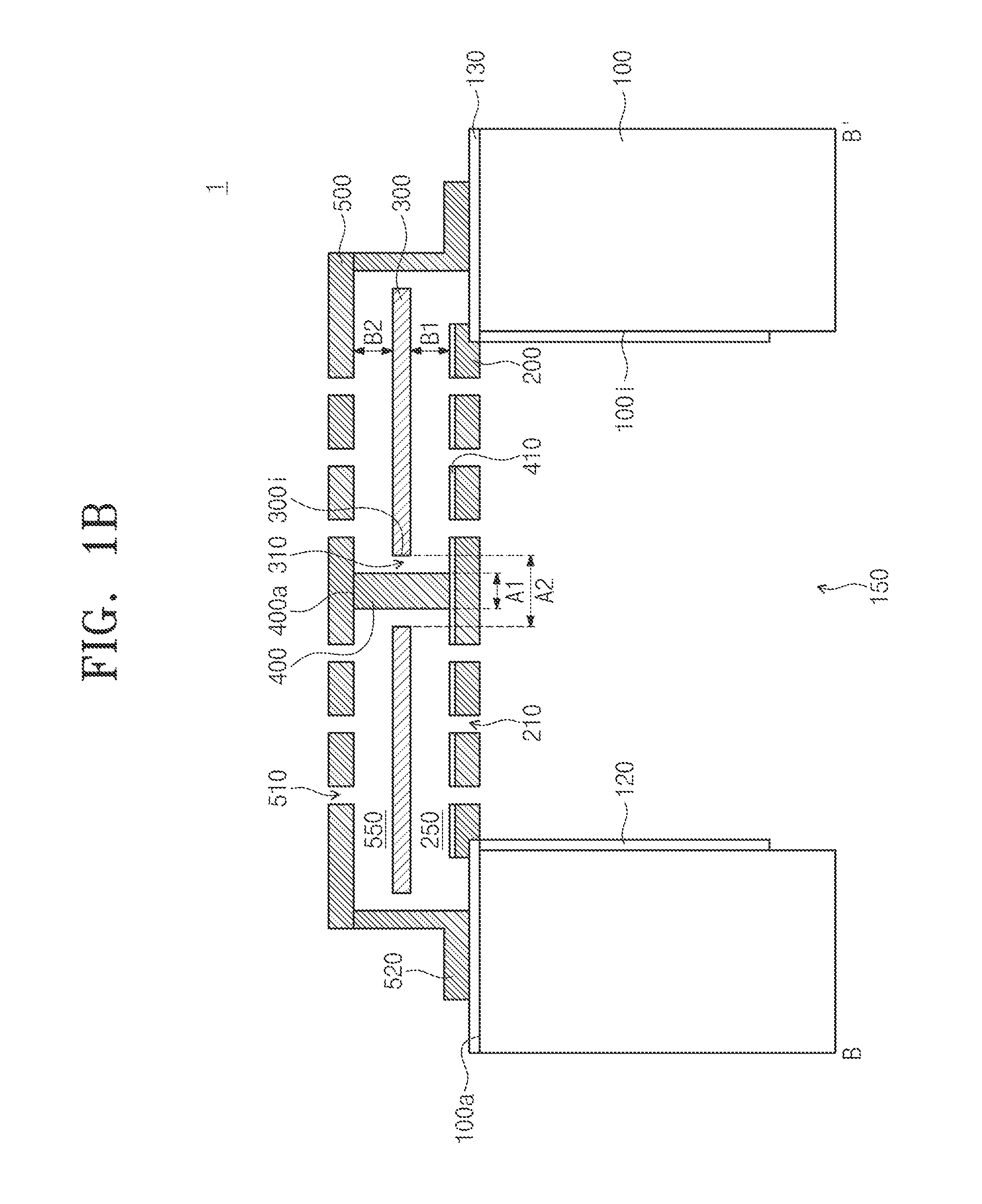

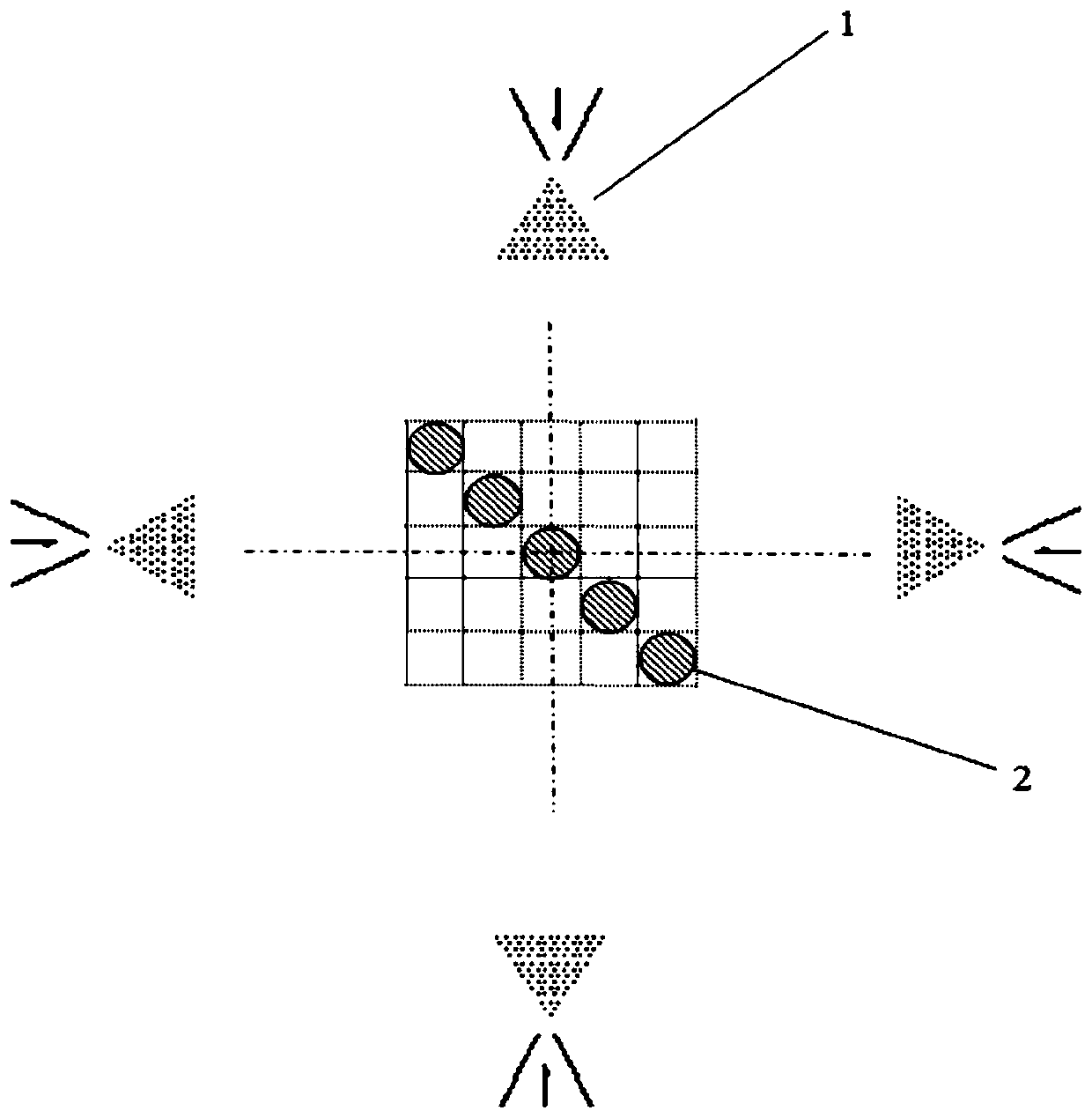

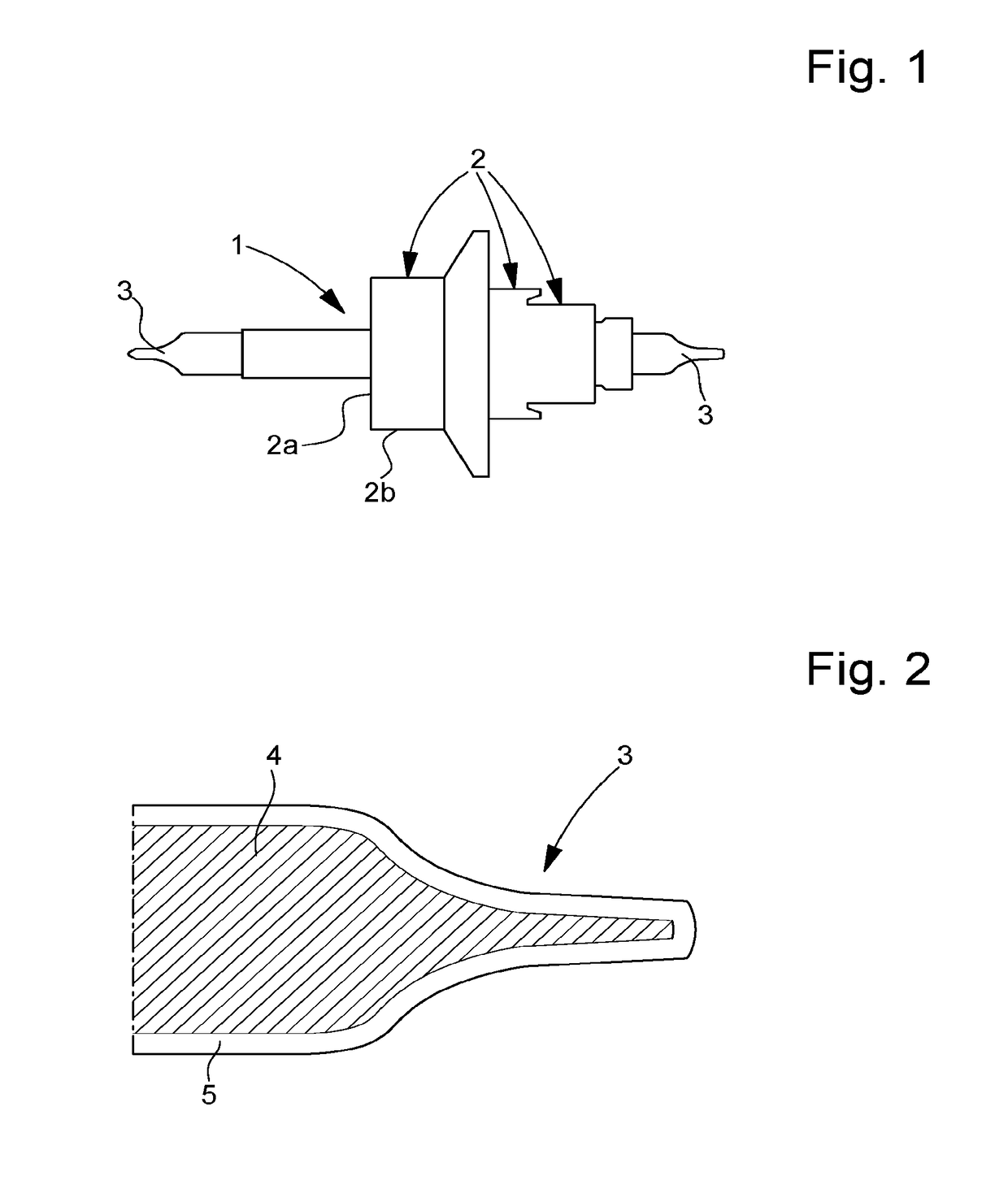

Microphone

ActiveUS20150146906A1Improve hardnessHigh sensitivityPiezoelectric/electrostrictive microphonesElectrostatic transducer microphonesBackplaneMicrophone

Provided is a microphone. The microphone includes a substrate including an acoustic chamber, a lower backplate disposed on the substrate, a diaphragm spaced apart from the lower backplate on the lower backplate, the diaphragm having a diaphragm hole passing therethrough, a connection unit disposed on the lower backplate to extend through the diaphragm hole, and an upper backplate disposed on the connection unit, the upper backplate being spaced apart from the diaphragm. Thus, the microphone may be improved in sensitivity and reliability.

Owner:ELECTRONICS & TELECOMM RES INST

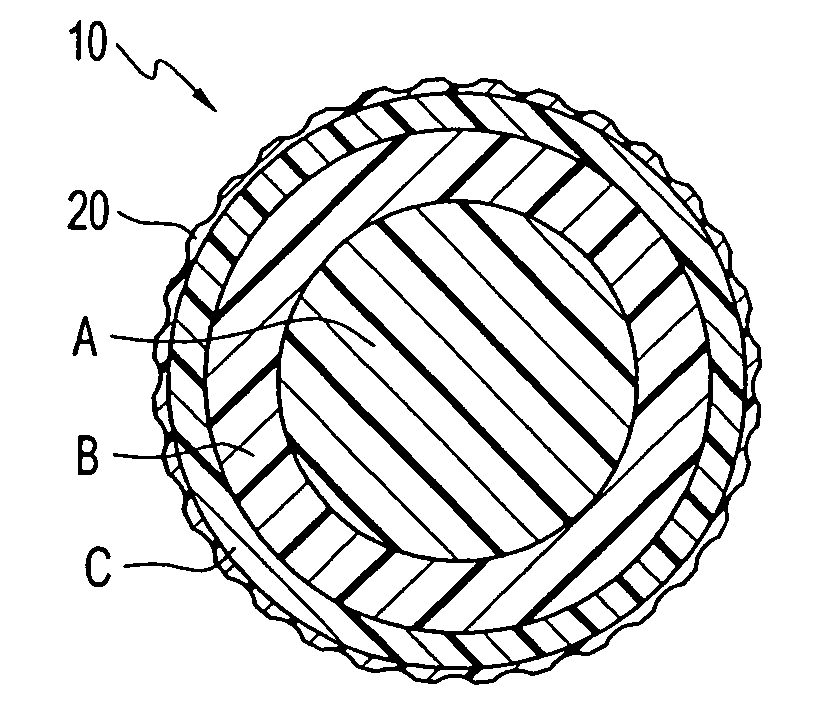

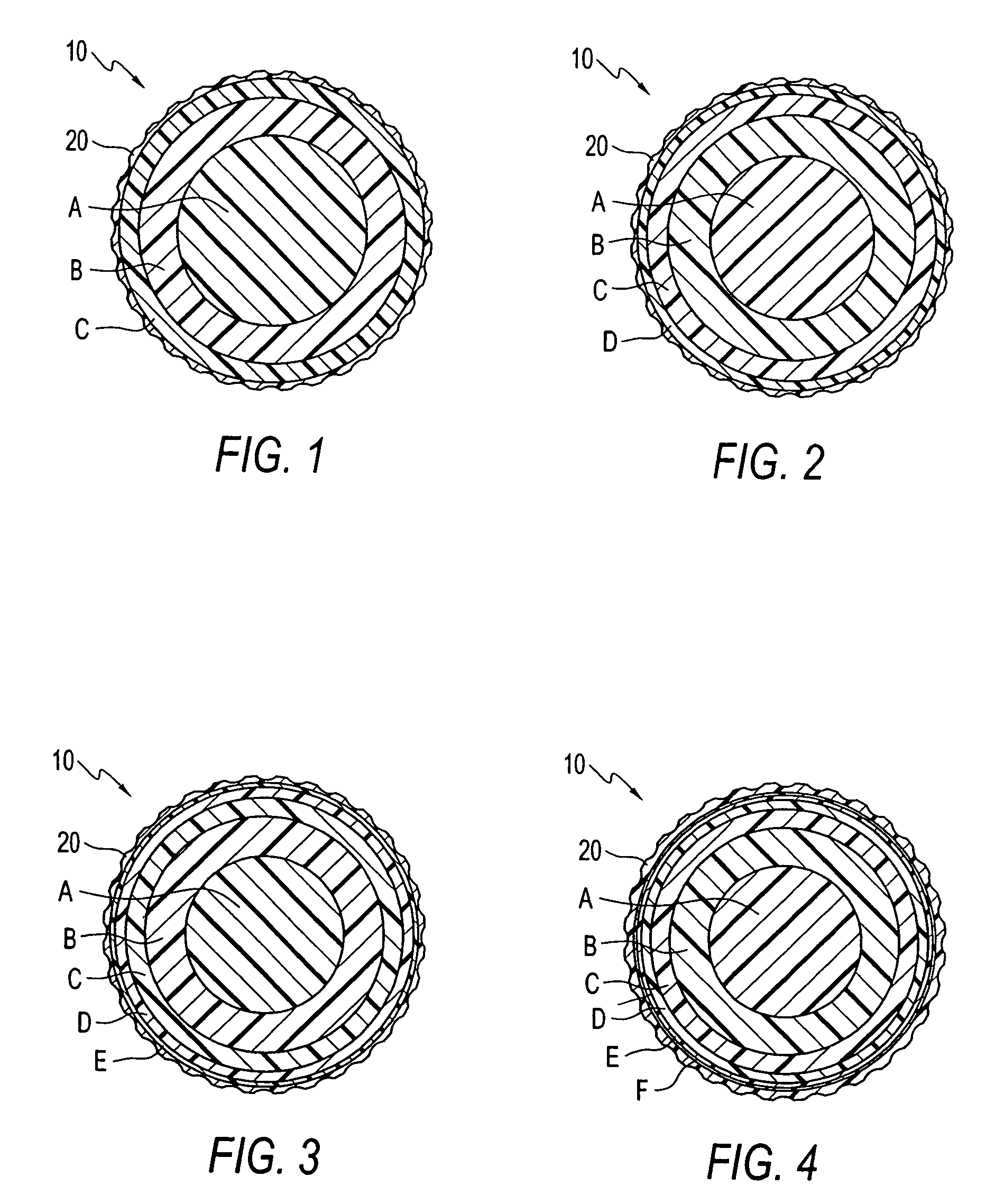

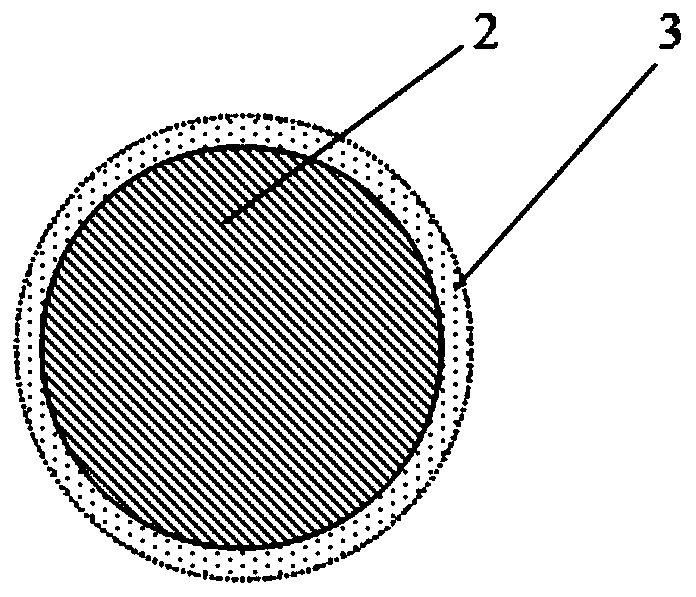

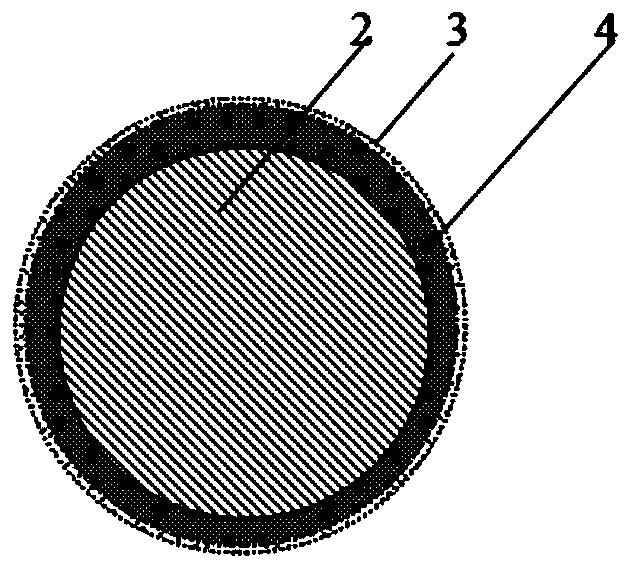

Golf ball with multi-layered core

InactiveUS7014575B2Reduce hardnessImprove hardnessGolf ballsSolid ballsSpecific gravityCoefficient of restitution

A golf ball having a multi-layered core comprising at least three core layers and a dimpled cover is disclosed. The core may have three layers, A, B and C, four layers, A, B, C and D, five layers, A, B, C, D and E or up to six layers, A, B, C, D, E and F. In accordance to the present invention, the radius or thickness of each core layer is at least twice as much as the adjacent outer core layer. One outer core layer can be a water vapor barrier layer to protect the ball from water vapor encroachment, which reduces the performance of the ball. Another outer core layer can be a thin dense layer with high specific gravity to increase the rotational moment of inertia to reduce the spin of the ball during flight. Another outer core layer can be a perforated spherical shell to increase the resilience and / or coefficient of restitution of the ball. Another outer core layer could be a cushioning layer to act as a shock absorber. The core layers may also have increasing or decreasing hardness.

Owner:ACUSHNET CO

Pharmaceutical composition with sodium lauryl sulfate as an extra-granular absorption/compression enhancer and the process to make the same

InactiveUS20050051922A1Improve compressibilityImprove hardnessOrganic active ingredientsWood working apparatusDosage formMedicine

A process for preparing a pharmaceutical dosage form or core wherein an absorption / compression agent is introduced into the formulation extra-granularly, and a pharmaceutical tablet prepared by said process.

Owner:ANDRX LABS

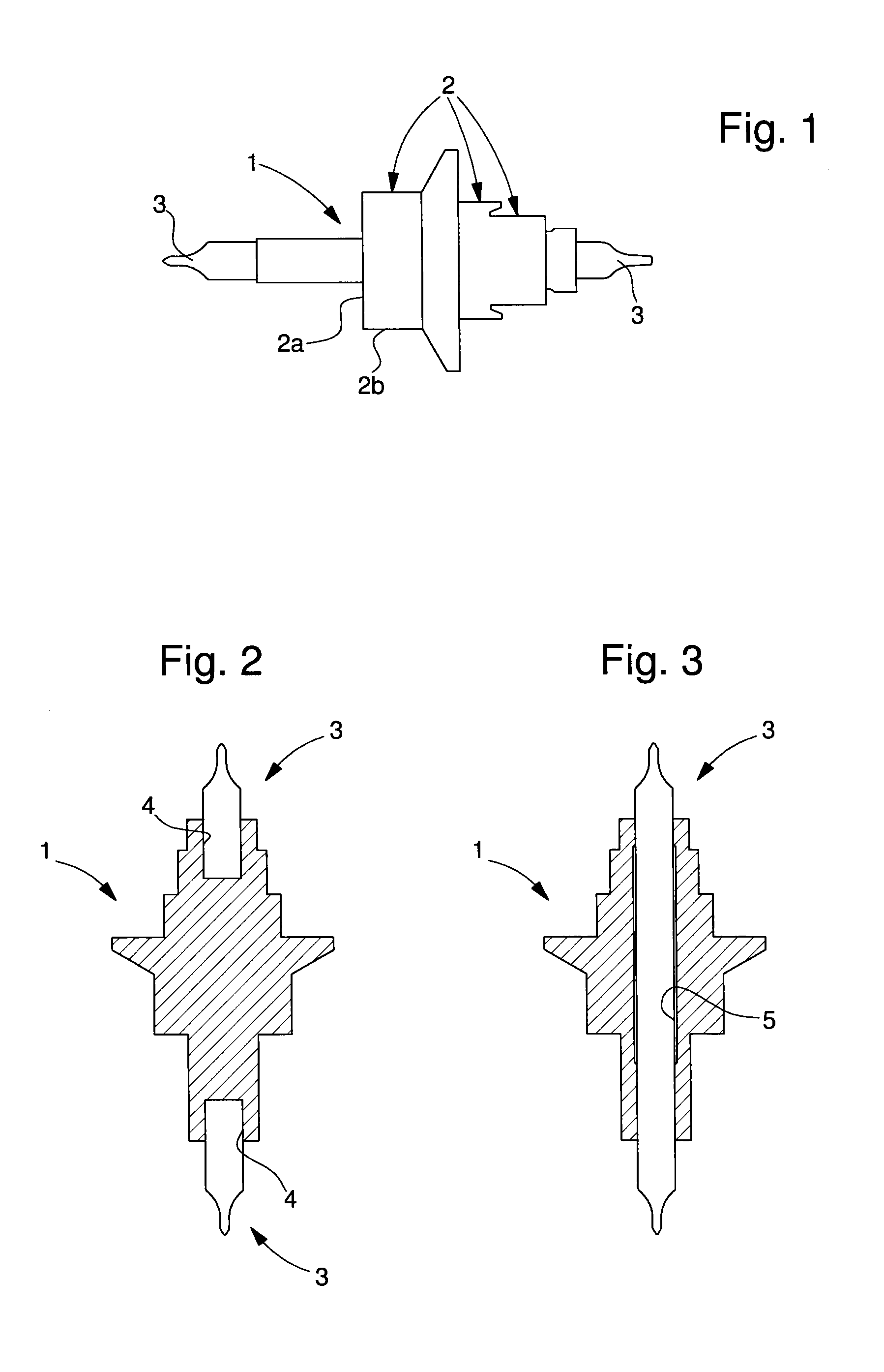

Part for a timepiece movement

The invention relates to a pivot pin for a timepiece movement including at least one pivot at at least one of the ends thereof, characterized in that said at least one pivot is formed of a composite material having a metallic matrix including at least one metal selected from among nickel, titanium, chromium, zirconium, silver, gold, platinum, silicon, molybdenum, aluminium or an alloy of the above metals, said matrix being charged with hard particles selected from among WC, TiC, TaC, TiN, TiCN, Al2O3, ZrO2, Cr2O3, SiC, MoSi2, Al N or a combination thereof, so as to limit the sensitivity of the pin to magnetic fields.The invention concerns the field of timepiece movements.

Owner:OMEGA SA

High-flame-retardancy polyurethane composite material

The invention discloses a high-flame-retardancy polyurethane composite material. The high-flame-retardancy polyurethane composite material is prepared from hydroxyl-terminated polybutadiene, 4,4'-diphenyl-methane-diisocyanate, toluene diisocynate, epoxy resin, acrylic resin, pentaerythritol triallyl ether, anilmomethyl triethoxy silane, 1,4-butanediol, dibromoneopentyl glycol, dibutyltin dilaurate, dimethythiotoluene diamine, nano-silica, white carbon black, iron-doped nano titanium dioxide, expanded vermiculite, epoxidized natural rubber and a flame retardant, wherein the flame retardant is prepared from expandable graphite, zinc stannate, tri(2-chloroethyl)phosphate, di(4-aminobenzene)phenyl phosphine oxide, tri(2,4-di-tert-butylphenyl)phosphite, aluminum hydroxide and zinc borate. The high-flame-retardancy polyurethane composite material has high intensity and excellent flame retardancy, and can meet use requirements in various fields.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

Hot spraying rare earth aluminum alloy coating steel bar

ActiveCN110923616AImprove surface conditionImprove hardnessMolten spray coatingRebarBonding strength

The invention discloses a hot spraying rare earth aluminum alloy coating steel bar. A hot spraying manner is adopted, and the hot spraying rare earth aluminum alloy coating steel bar is prepared by spraying a rare earth aluminum alloy wire to the surface of a steel bar base body through mechanical rust removal, hot spraying, after treatment and other steps, wherein Si, Li, Ti, B, Mn, rare earth metal and the like can improve hardness, plasticity, tenacity, shielding performance and cathode protection capability of an aluminum alloy and a clad layer. A double-component waterborne polyurethane sealing agent and a finishing coat are adopted for treatment, cleanliness and environment friendliness are achieved, surface drying is rapid, and compatible bonding with concrete is easier due to the surface of the hot spraying rare earth aluminum alloy coating steel bar. According to the hot spraying rare earth aluminum alloy coating steel bar, the common technical problems that according to a current epoxy coating steel bar and a zinc-aluminum clad layer steel bar, the relative bonding strength with concrete is greatly reduced, the steel bar anchoring length is increased by 25%, anti-corrosion durability is insufficient, and notch and damaged positions are hard to repair on the site are solved, and good application prospects are achieved.

Owner:XUZHOU ZHONGKUANG ANFENG ENG TECH

Blends of olefinic thermoplastic vulcanizate with high impact polystyrene

An olefinic thermoplastic vulcanizate is blended with a rubber-modified monovinylidene aromatic monomer, utilizing a flexible block copolymer as compatabilizing agent. The resulting composition demonstrates improved miscibility and bonding characteristics and increased hardness not previously achievable using unmodified thermoplastic vulcanizates.

Owner:ADVANCED ELASTOMER SYST LP

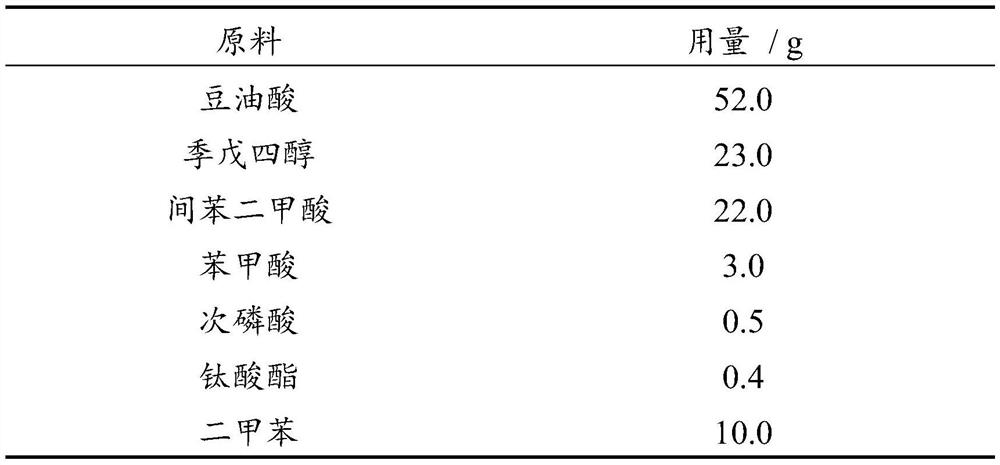

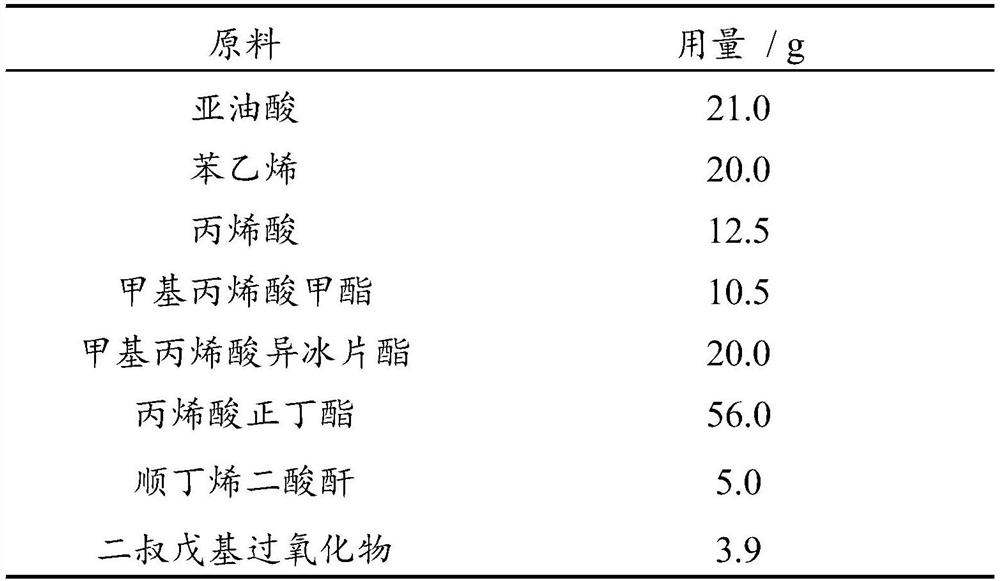

Water-based alkyd acrylic hybrid resin and preparation method thereof

PendingCN113024821AImprove hardnessImprove heat storage capacityCoatingsPrepolymerComposite material

The invention belongs to the technical field of high-performance environment-friendly coatings, and discloses water-based alkyd acrylic hybrid resin and a preparation method thereof.The hybrid resin is prepared from fatty acid modified acrylic prepolymer, basic alkyd resin, a solvent, a neutralizer and water. The preparation method comprises the following steps: carrying out local polycondensation on the fatty acid modified acrylic prepolymer and the basic alkyd resin, and neutralizing and dispersing. A coating prepared from the water-based alkyd acrylic hybrid resin has excellent water resistance, dryness, hardness, heat storage capacity and the like, water-based paint prepared from the resin combines excellent wettability and pigment and filler bearing capacity of alkyd resin and acrylic acid, and the gloss can reach 85-90; The coating is suitable for the large-scale civil paint field and the industrial paint field.

Owner:江苏富琪森新材料有限公司

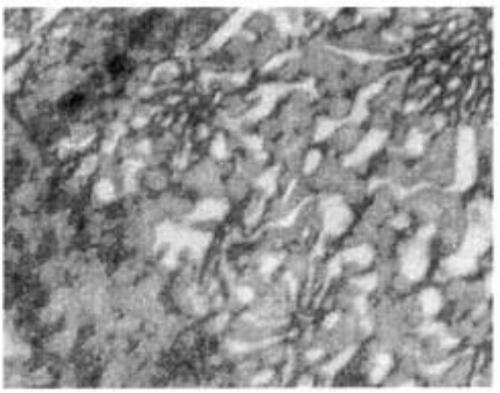

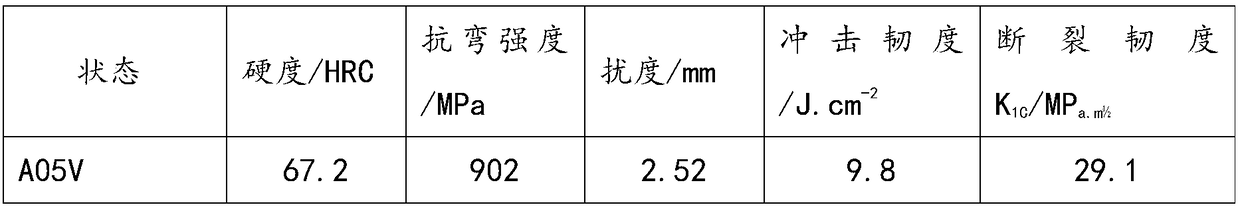

Non-magnetic hard alloy and preparation method thereof

The invention relates to the technical field of alloy manufacturing, in particular to hard alloy and a preparation method thereof. The non-magnetic hard alloy and the preparation method thereof aim to solve the technical problem that existing WC-Co hard alloy is poor in high pressure resistance and corrosion resistance in an alkaline environment. The non-magnetic hard alloy includes, by weight, 6.09%-6.11% of Ni powder, 0.19%-0.21% of Cr3C2 powder, 0.19%-0.21% of TaC powder, 0.19%-0.21% of Mo powder and the balance WC powder.

Owner:匡永刚

Edible fat continuous spreads

PendingUS20130122179A1Good organoleptic propertyImprove hardnessEdible oils/fats ingredientsFood preparationWater solubleOil soluble

Owner:UPFIELD EURO BV

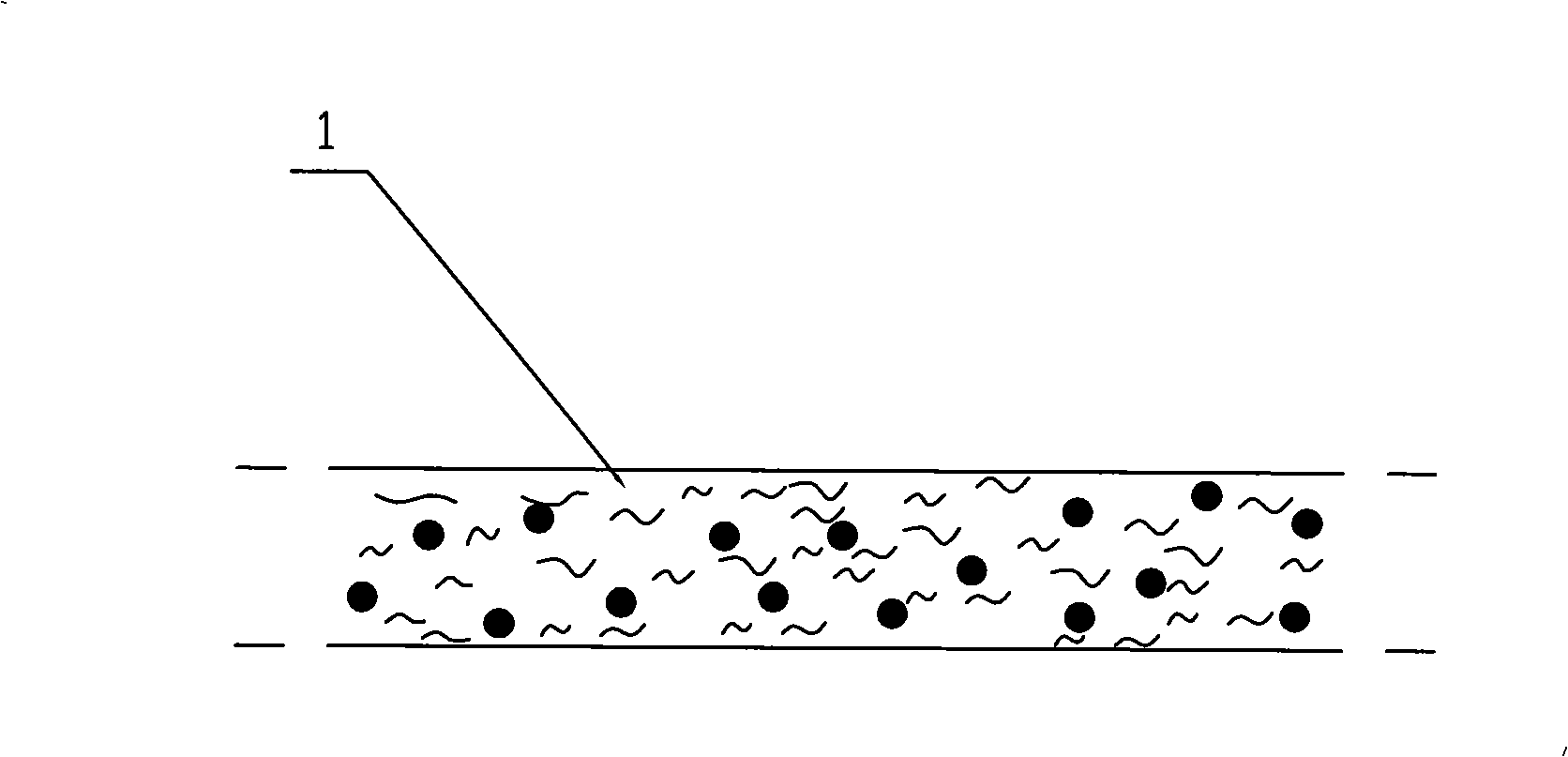

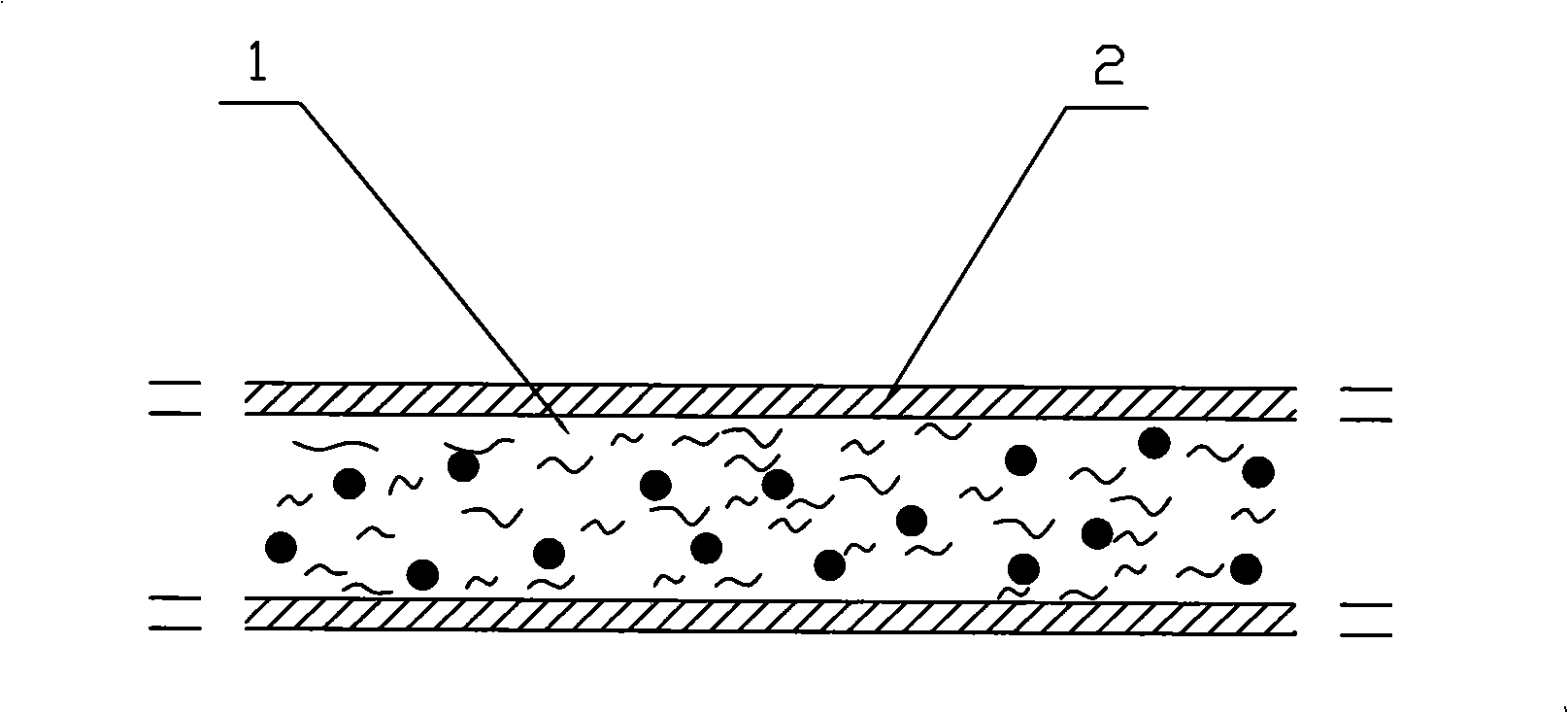

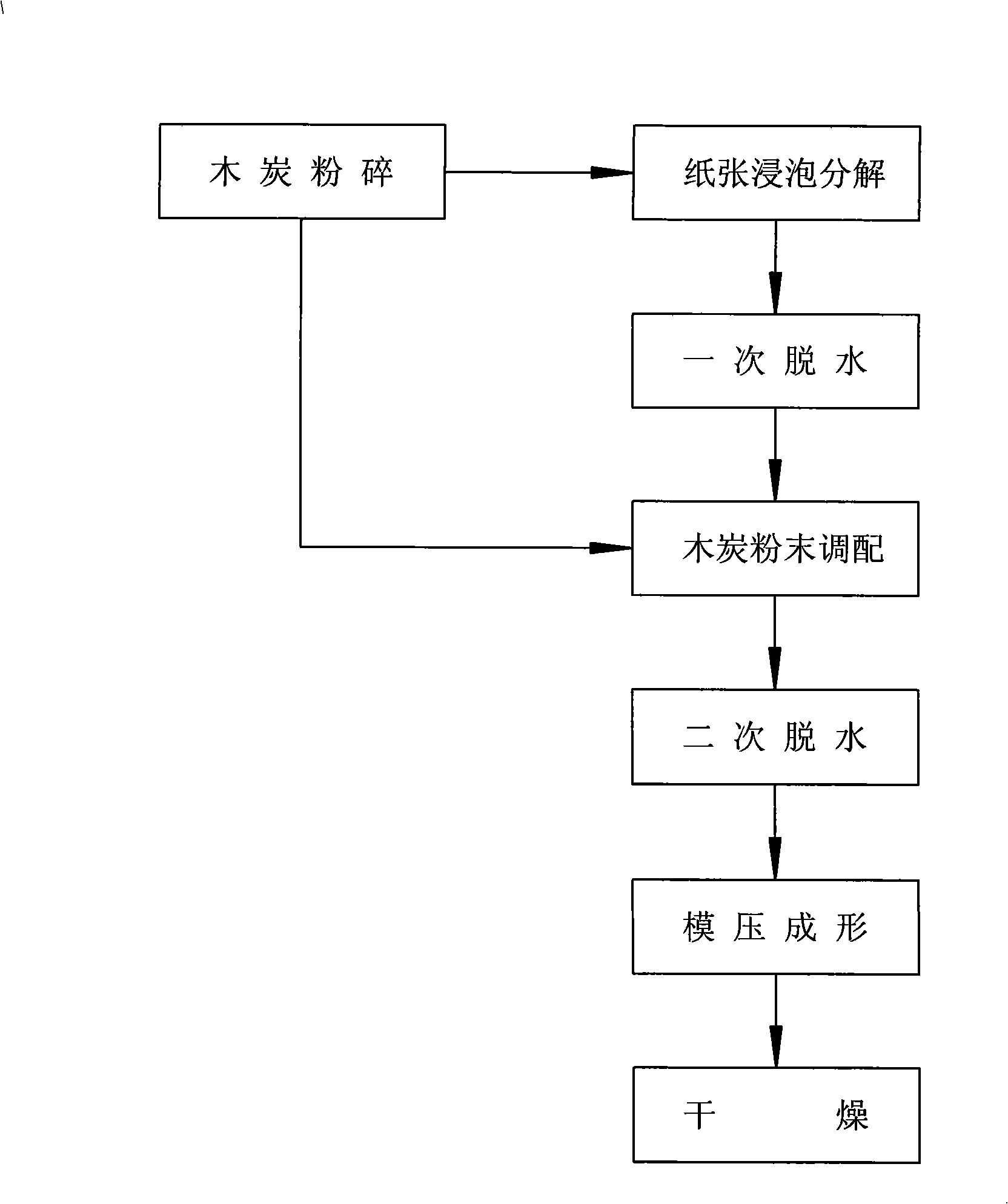

Architectural ornament material, manufacturing method and manufacturing equipment thereof

InactiveCN101269925AImprove hardnessEliminate unsafe hazardsSolid waste managementPaper sheetWater content

The present invention discloses a building decoration material, which is composed of a matrix (1), wherein, the basic raw materials and ratio by weight of the matrix (1) are stated as follows: 100 portions of paper fiber, and 200 to 1000 of portions wooden-carbon powder. The specific production method is performed with the following steps: the paper with 100 weight unit is taken to be soaked into the paper pulp, and is filtered to remove the water until the water content is 2000 to 3000 in weight unit; the wooden carbon in 2000 to 3000 weight unit is crushed into the powder, and is put into the paper pulp containing water that is prepared in the previous step to be uniformly mixed and dehydrated to be viscous; the ropiness mixture is pressed with mold to form the blank of the matrix (1) and is dried to fix the shape. Not only the rigidness of the wall body or the ground can be improved, the unsafe hidden problem can be eliminated; moreover, the function of the wooden carbon can be adequately displayed.

Owner:DALIAN SHIRONG CARBONIZING

Coated steel bar and preparation method thereof

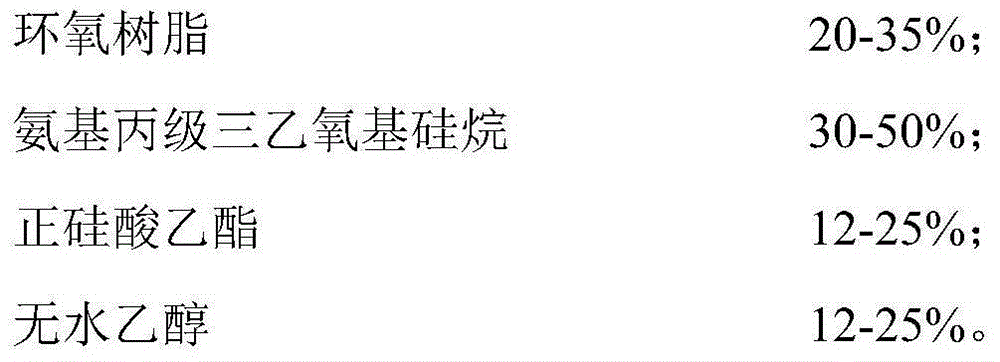

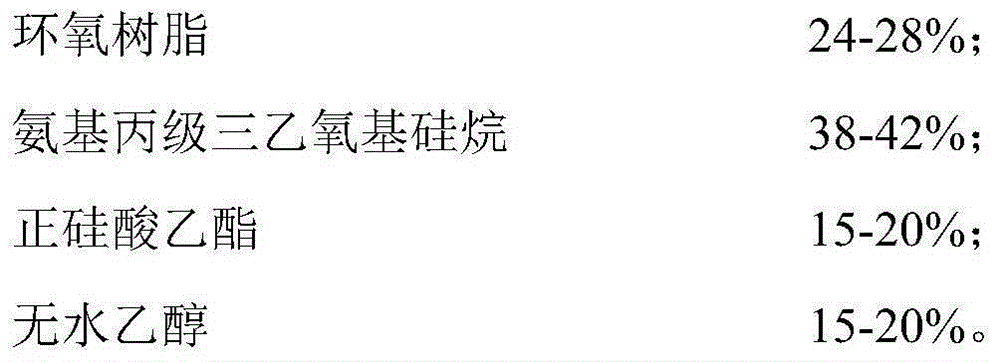

ActiveCN105176309AGood film formingImprove hardnessAnti-corrosive paintsBuilding reinforcementsMicrometerCorrosion

The invention provides a coated steel bar and a preparation method thereof. The coated steel bar comprises a steel bar and a coating on the surface of the steel bar; the coating is prepared from, by weight, 20%-35% of epoxy resin, 30%-50% of aminopropyltriethoxysilane, 12%-25% of ethyl orthosilicate and 12%-25% of absolute ethyl alcohol. The preparation method comprises the steps that sand blasting is conducted to make the roughness of the surface of the steel bar range from 3.0 micrometers to 3.5 micrometers; gravel and dust on the surface of the steel bar are removed, and it is guaranteed that the surface of a workpiece is clean and without any greasy dirt or other foreign bodies; the coating is evenly coated on the surface of the treated steel bar, and the thickness of a dry film is required to reach 5-15 micrometers; curing molding is conducted at the room temperature, and the coated steel bar is obtained. The coated steel bar is formed by spraying coating materials on the surface of the steel bar, and the hardness and the corrosion resistance of the coated steel bar are greatly improved.

Owner:SUNYOUNG CONSTR GROUP +1

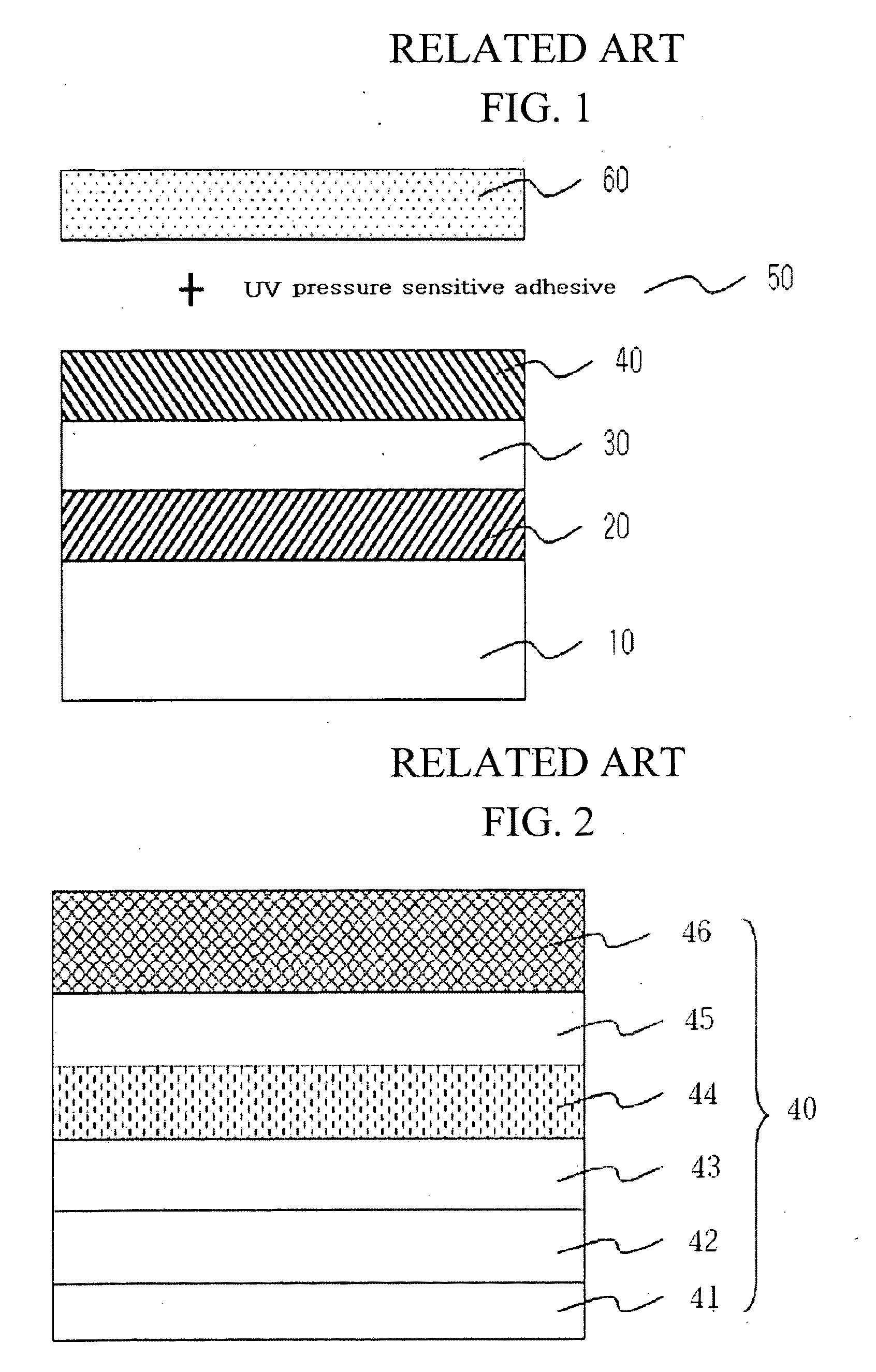

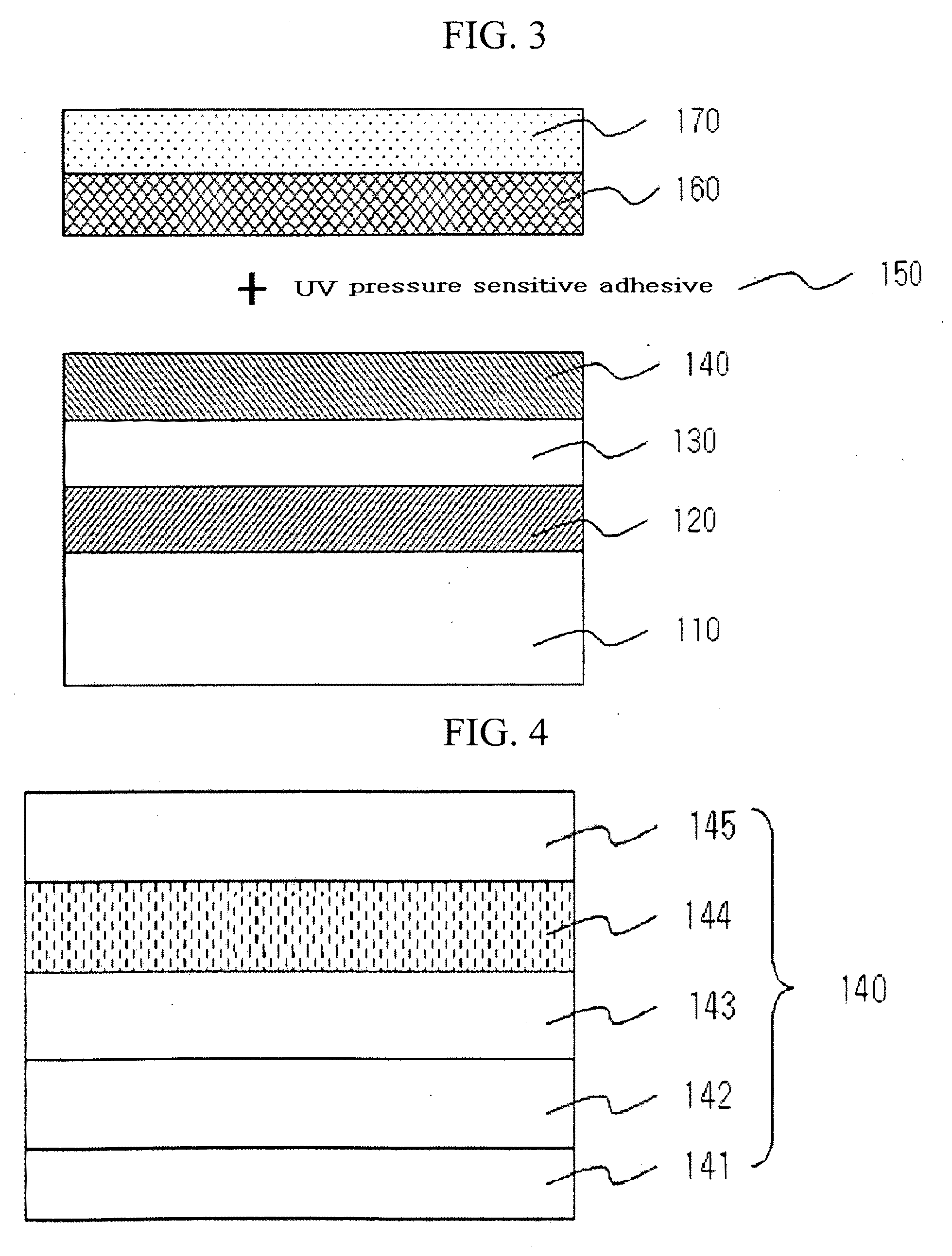

Display device

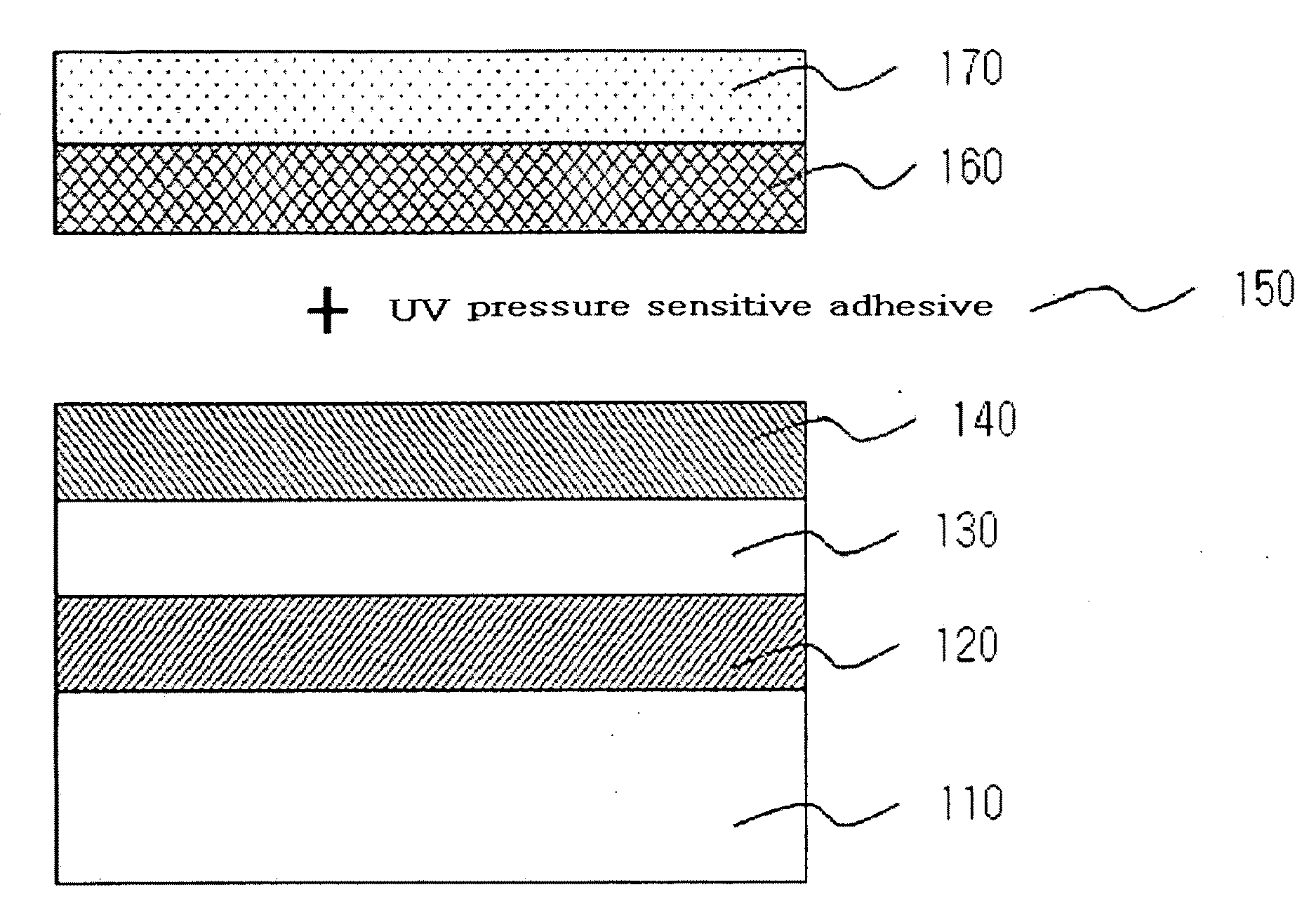

ActiveUS20100053524A1Improve mirror surfaceImprove hardnessSynthetic resin layered productsNon-linear opticsLiquid-crystal displayDisplay device

A display device includes: a back light unit for emitting a light; a lower polarization plate on the back light unit; a liquid crystal display panel on the lower polarization plate for displaying an image; an upper polarization plate on the liquid crystal display panel; an optical film bonded to the upper polarization plate; and a transparent material on the optical film for improving hardness of the optical film.

Owner:LG DISPLAY CO LTD

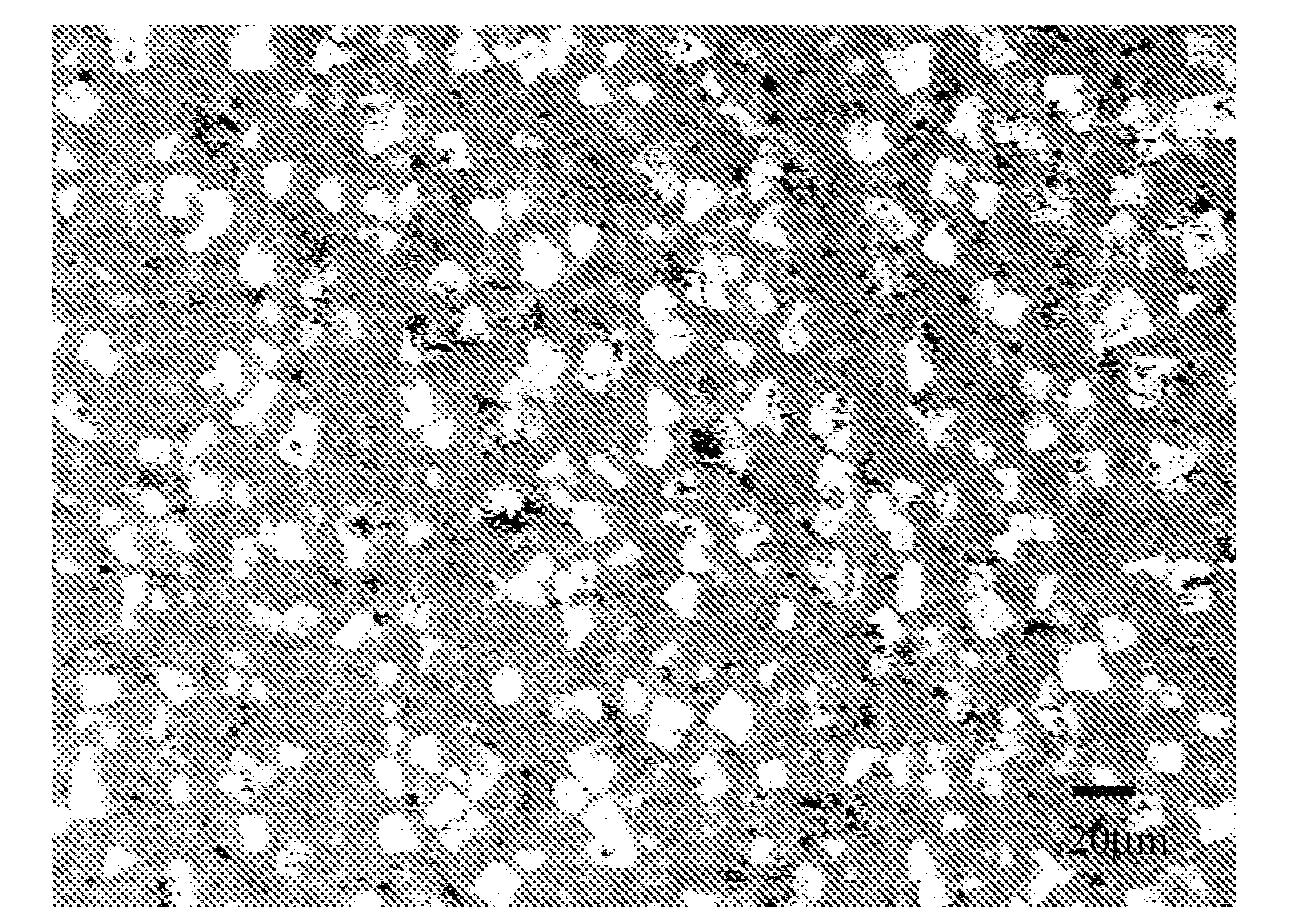

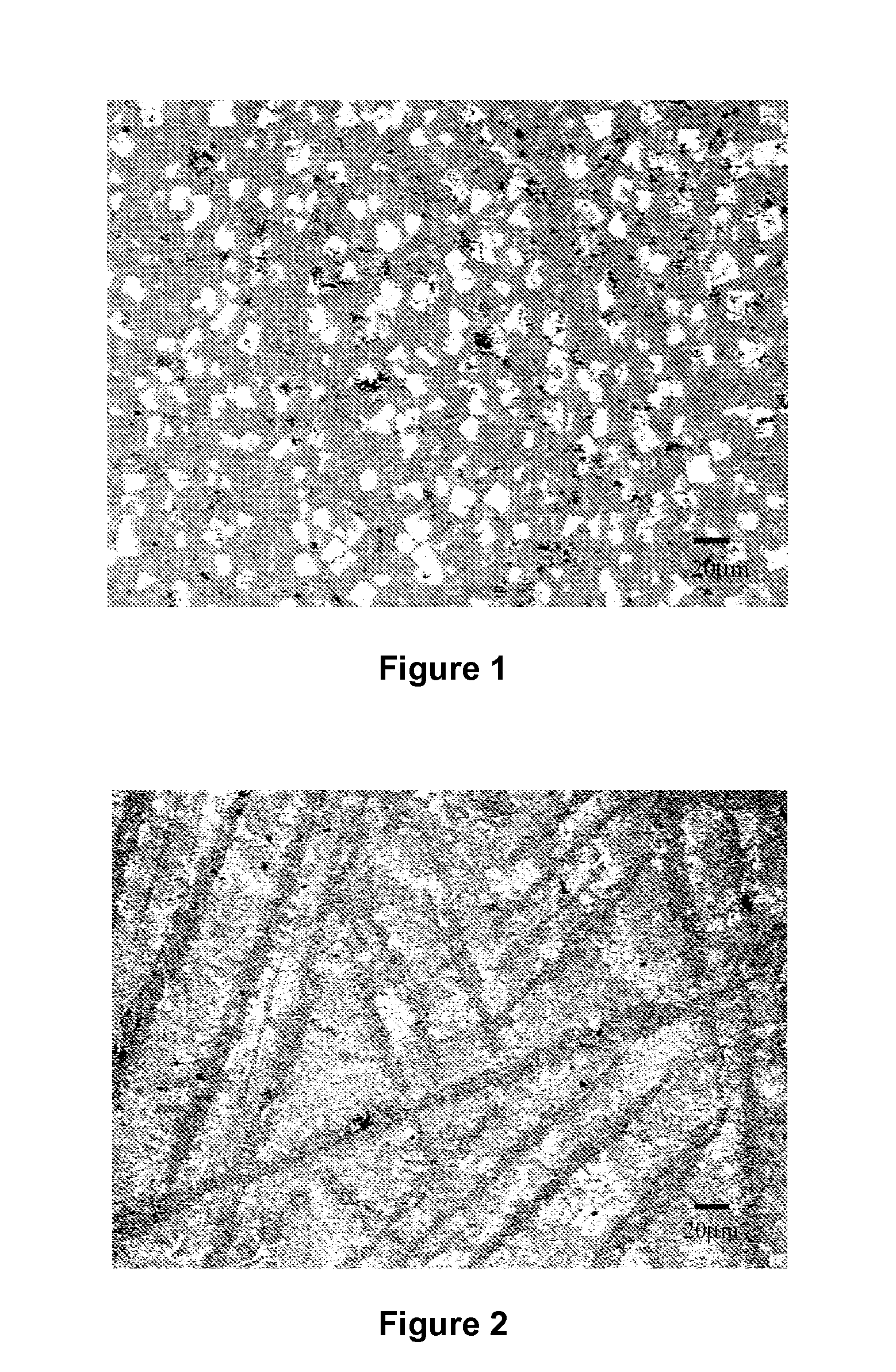

Wear Resistant Materials

InactiveUS20080293558A1Improve hardnessAluminium compoundsSynthetic resin layered productsWear resistantHardness

A hard phase material is provided for increasing the hardness of a matrix material and improving the wear resistance thereof. The hard phase material is an aluminum boride material having the structure AlB8-16. The aluminum boride hard phase may be incorporated into a matrix material by mixing particulate aluminum boride with the matrix material and through precipitation of aluminum boride from the matrix material. Materials including the aluminum boride hard phase may be used in coating applications to provide a hard and wear resistant coating. Aluminum boride hard phase may also be incorporated into metallurgical products to improve the hardness and wear resistance of the metallurgical products.

Owner:LINCOLN GLOBAL INC +1

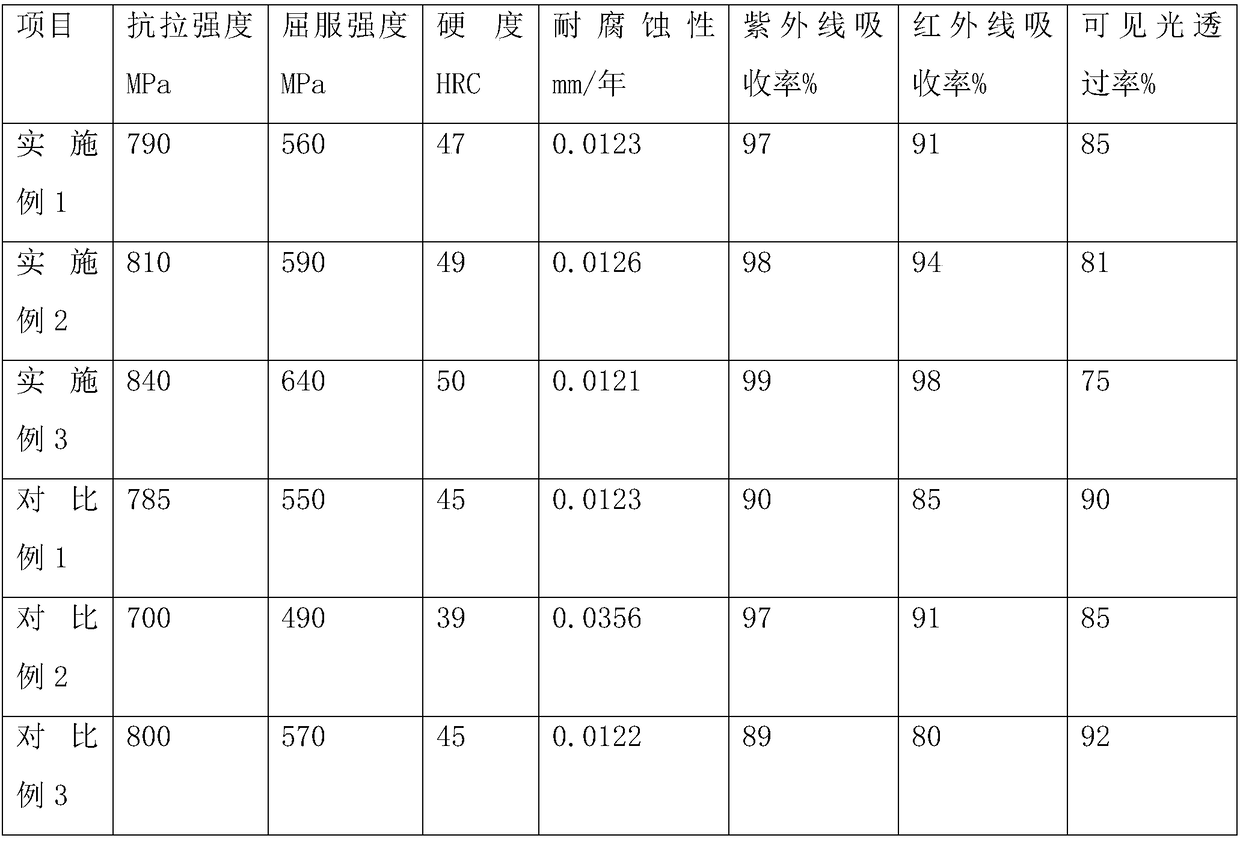

Stainless steel with ultraviolet-proof function and preparation method thereof

InactiveCN109023076AImprove hardnessImprove corrosion resistanceAntifouling/underwater paintsRosin coatingsRosinEmulsion

The invention discloses stainless steel with an ultraviolet-proof function. The stainless steel comprises, by weight part, C, Si, Mn, P, S, Cr, Ni, N, Nb, Tl and the balance iron and other inevitableelements. The surface of the stainless steel is coated with an ultraviolet-proof coating, and the coating comprises, by weight part, water-based rosin resin emulsion, polydiethyl p-phenyldiacetate, silver-series antibacterial master batch, triallyl isocyanate, palmitamide propyl betaine, uvioresistant organic silicone oil, a dispersing agent, dyhydroxyl polymethyl vinyl siloxane, a coupling agent,acidized graphite and a water repellent. According to the stainless steel, the corrosion resisting capacity is improved, and the stainless steel has ultraviolet-proof capacity.

Owner:合肥久新不锈钢厨具有限公司

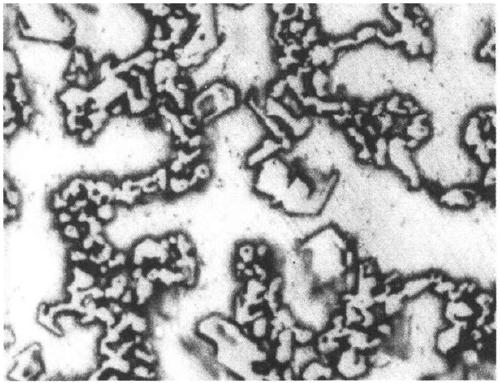

High-chromium cast iron for slurry pump flow passage component

InactiveCN109023032AImprove hardnessImproved morphology and distributionProcess efficiency improvementCast ironChromium

The invention relates to high-chromium cast iron for a slurry pump flow passage component and a preparation method thereof. The high-chromium cast iron comprises the following components including, bymass, 3.1%-3.4% of C, 0.4%-0.8% of Si, 0.9%-1.2% of Mn, 27%-29% of Cr, 0.5%-0.7% of Ni, 0.4%-0.6% of Mo, 0.03%-0.05% of RE, 0.1%-0.3% of V, 0.05%-0.07% of B, not larger than 0.1% of P, not larger than 0.1% of S and the balance Fe. The hardness, strength, toughness and heat resistance of the high-chromium cast iron are improved by adding V, B and rare earth as modifiers and strictly controlling the contents of all components, and the aim of comprehensively regulating abrasive wear, fatigue wear and corrosion wear is achieved; and meanwhile, the morphology and distribution of carbide are improved in cooperation with heat treatment, the high-chromium cast iron with excellent wear resistance is obtained, and the service life is 6-12 months after being prepared into the slurry pump flow passage component.

Owner:CHENGDU YONGYI PUMPS

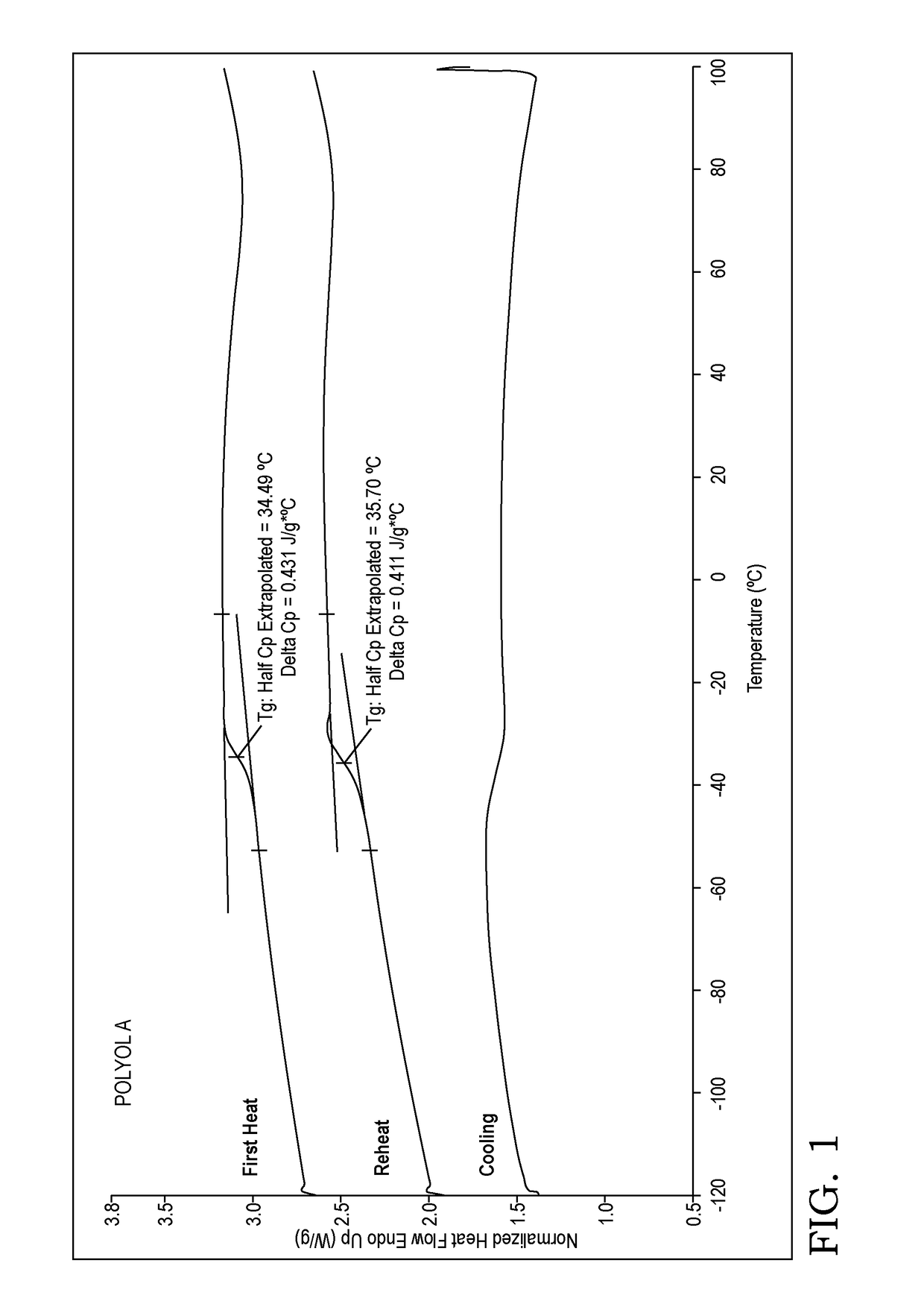

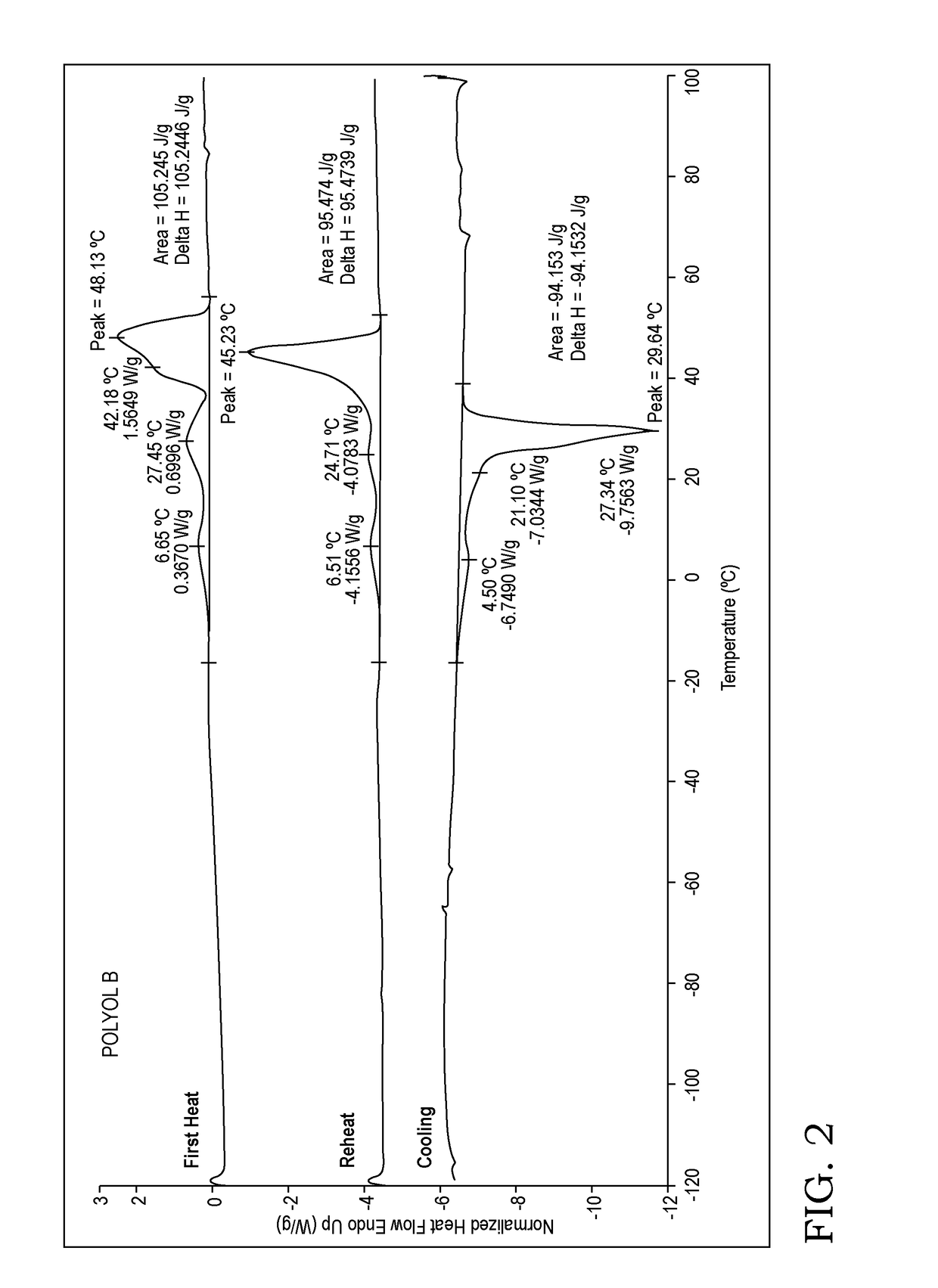

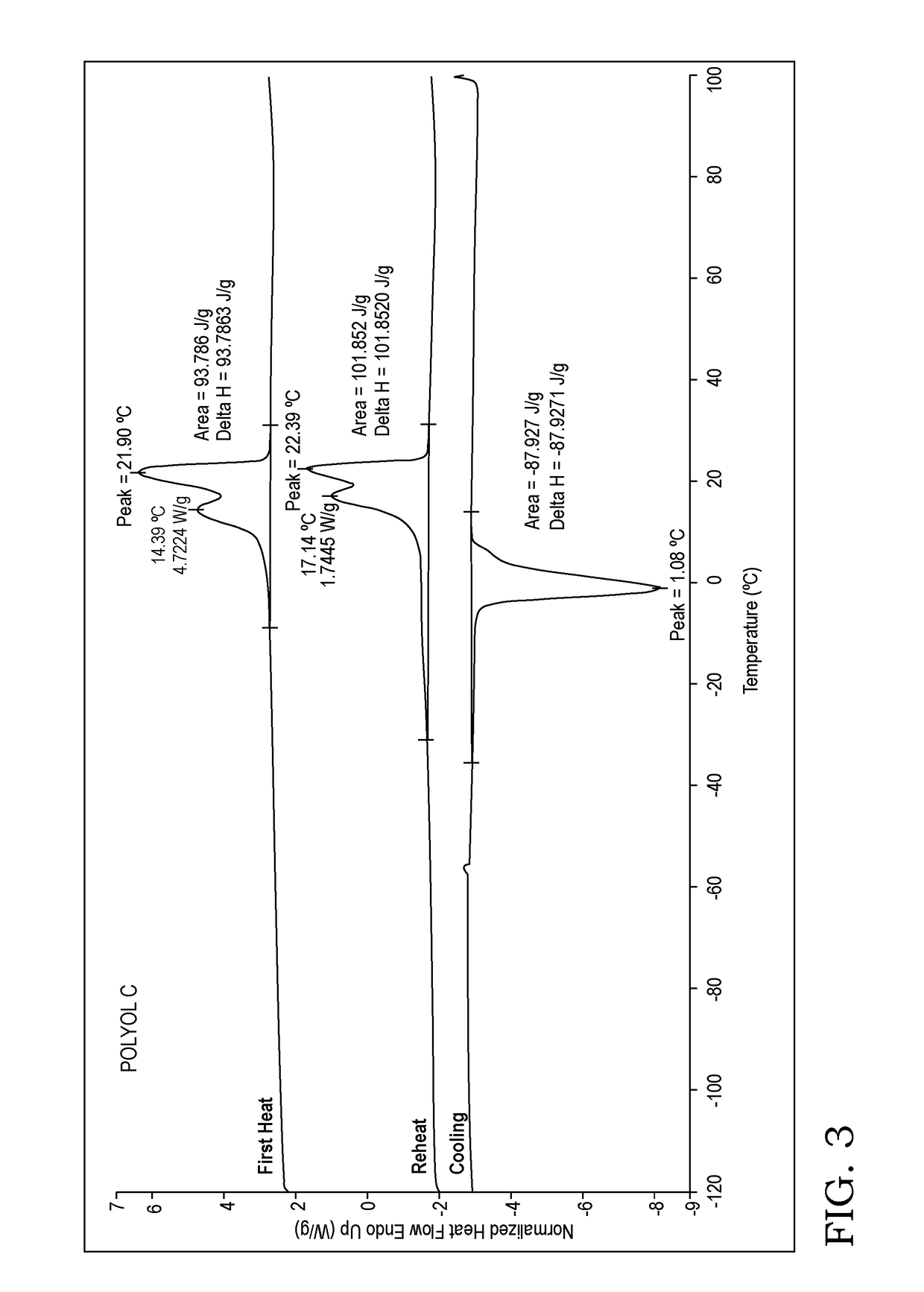

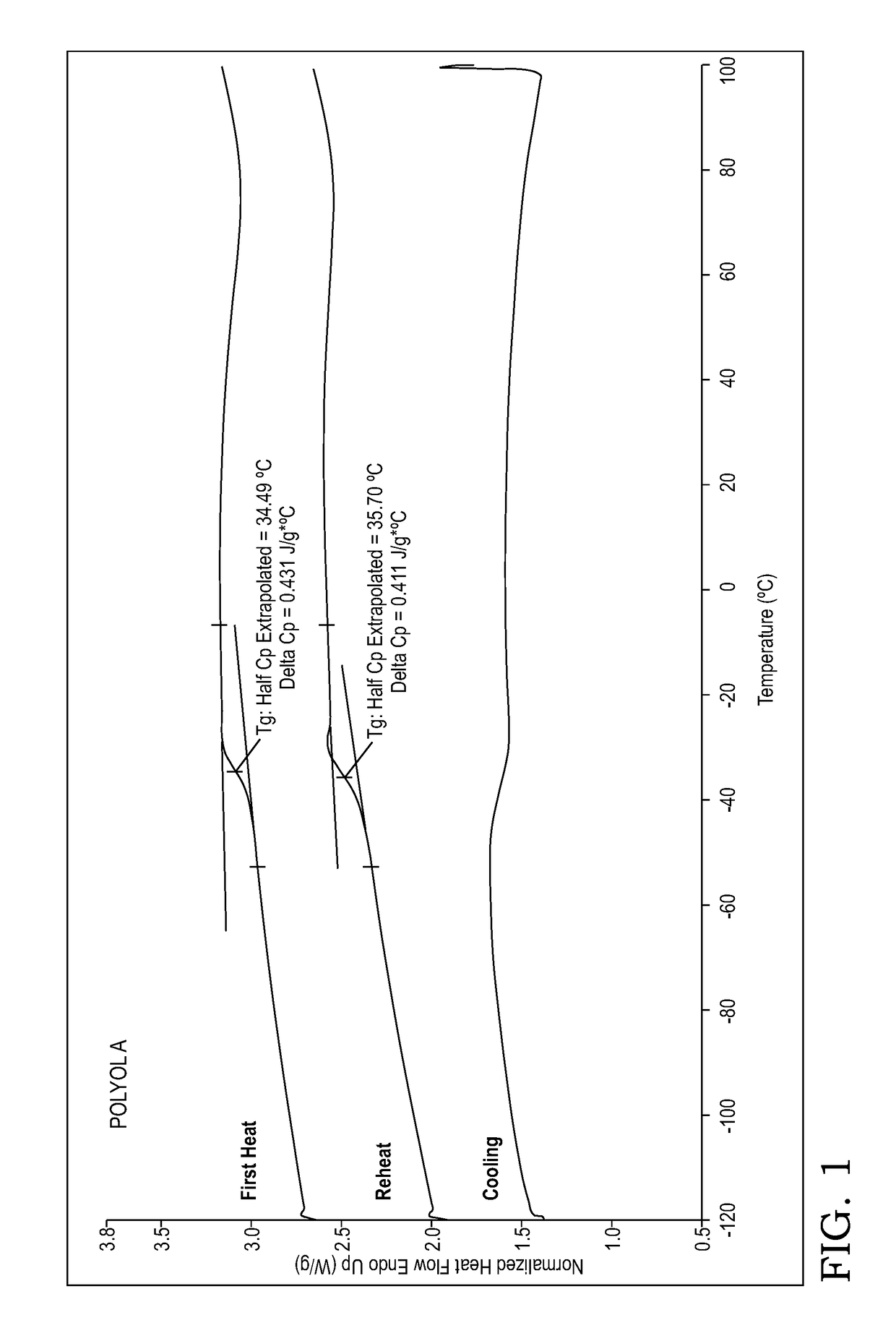

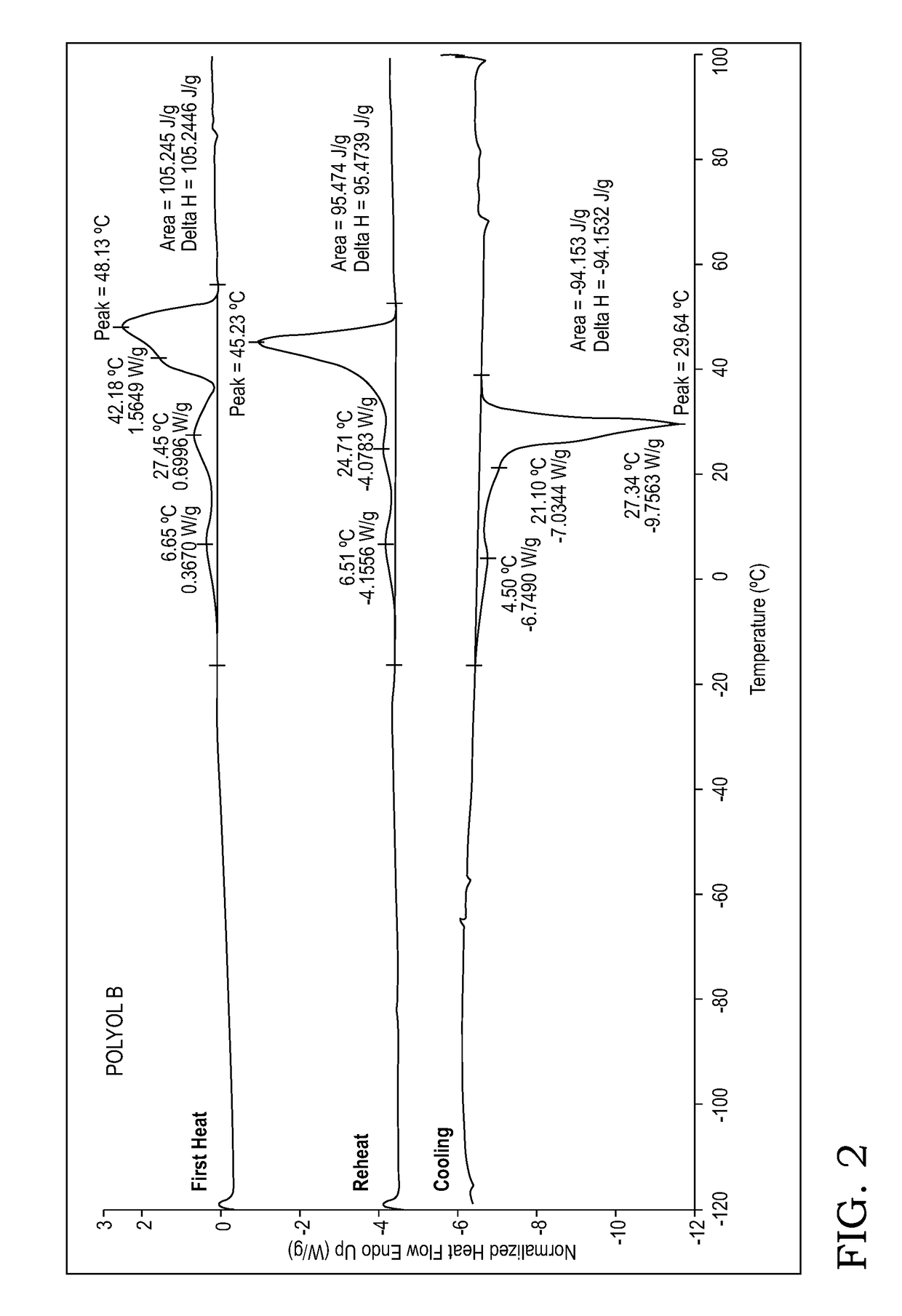

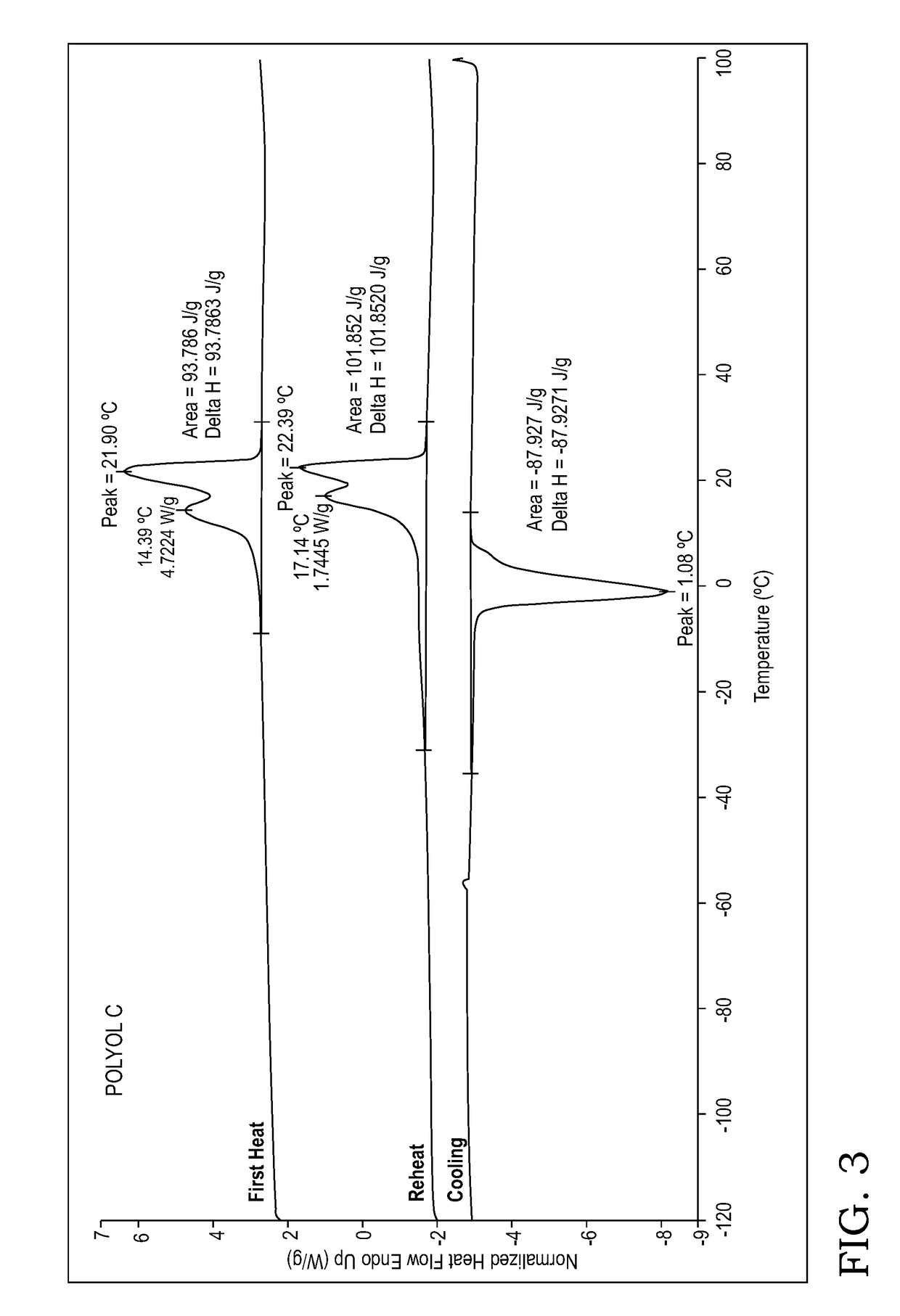

One component polyurethane dispersion for vinyl windows

InactiveUS20190040252A1Excellent chemical resistanceImprove hardnessPolyurea/polyurethane coatingsSurface energyChemistry

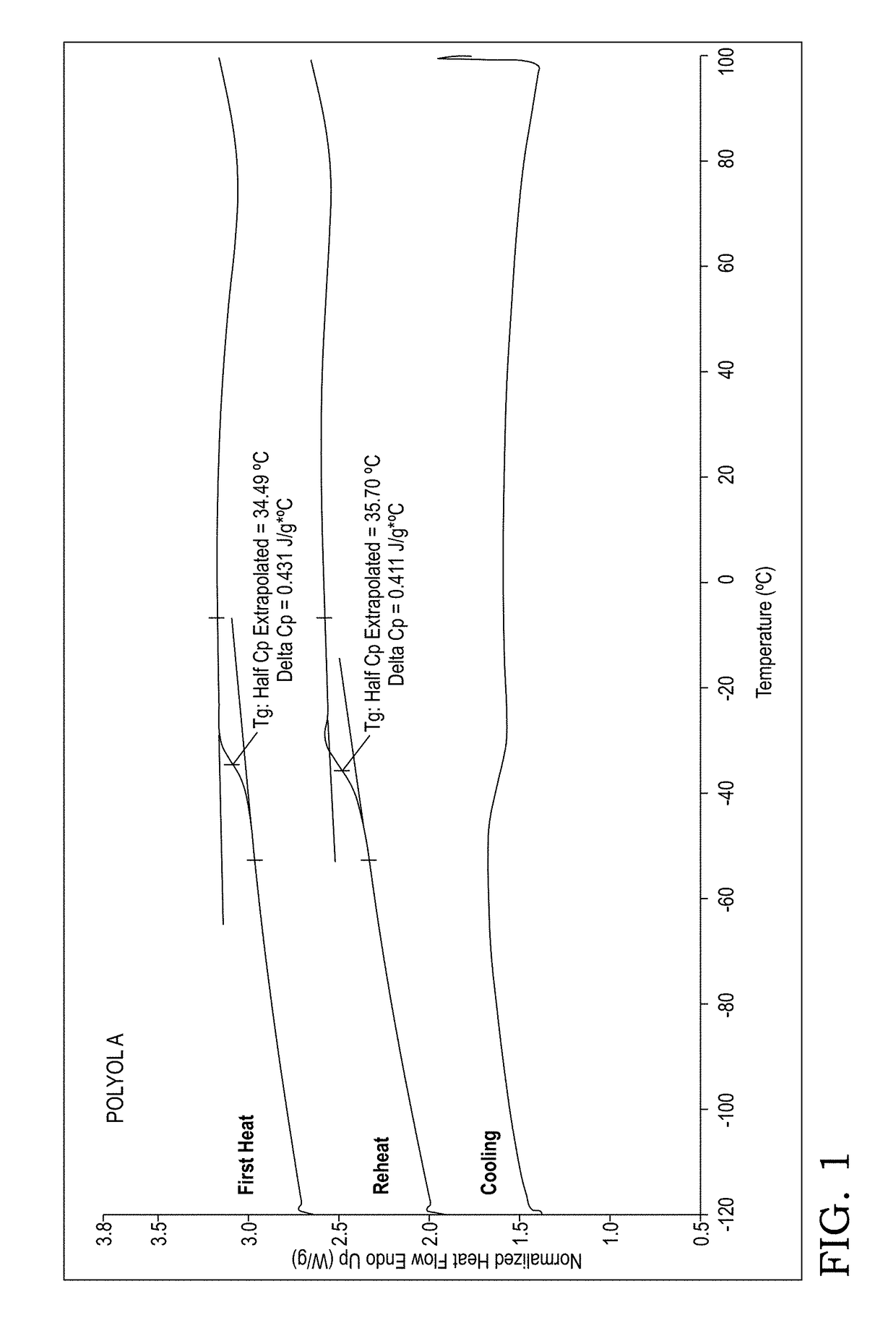

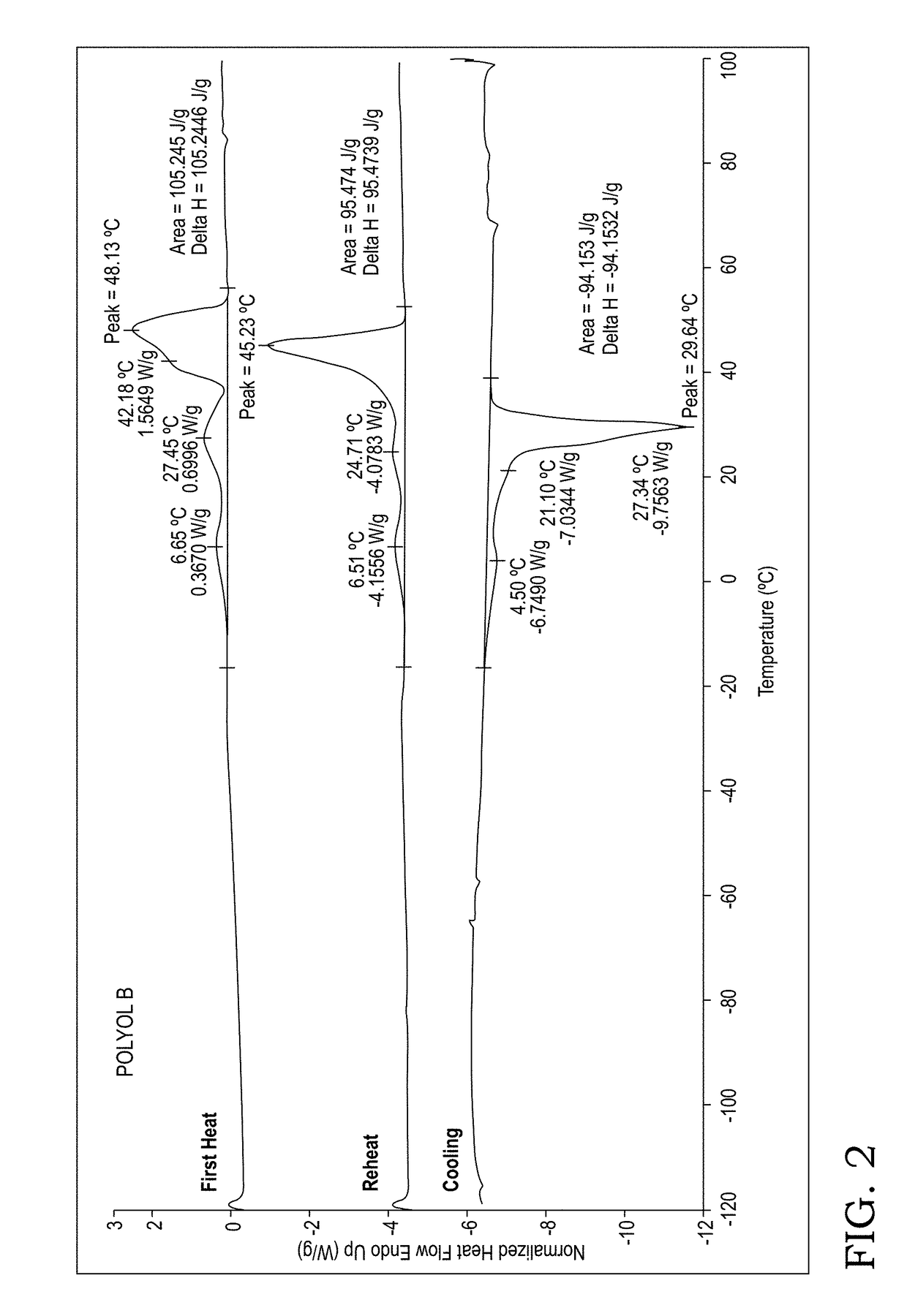

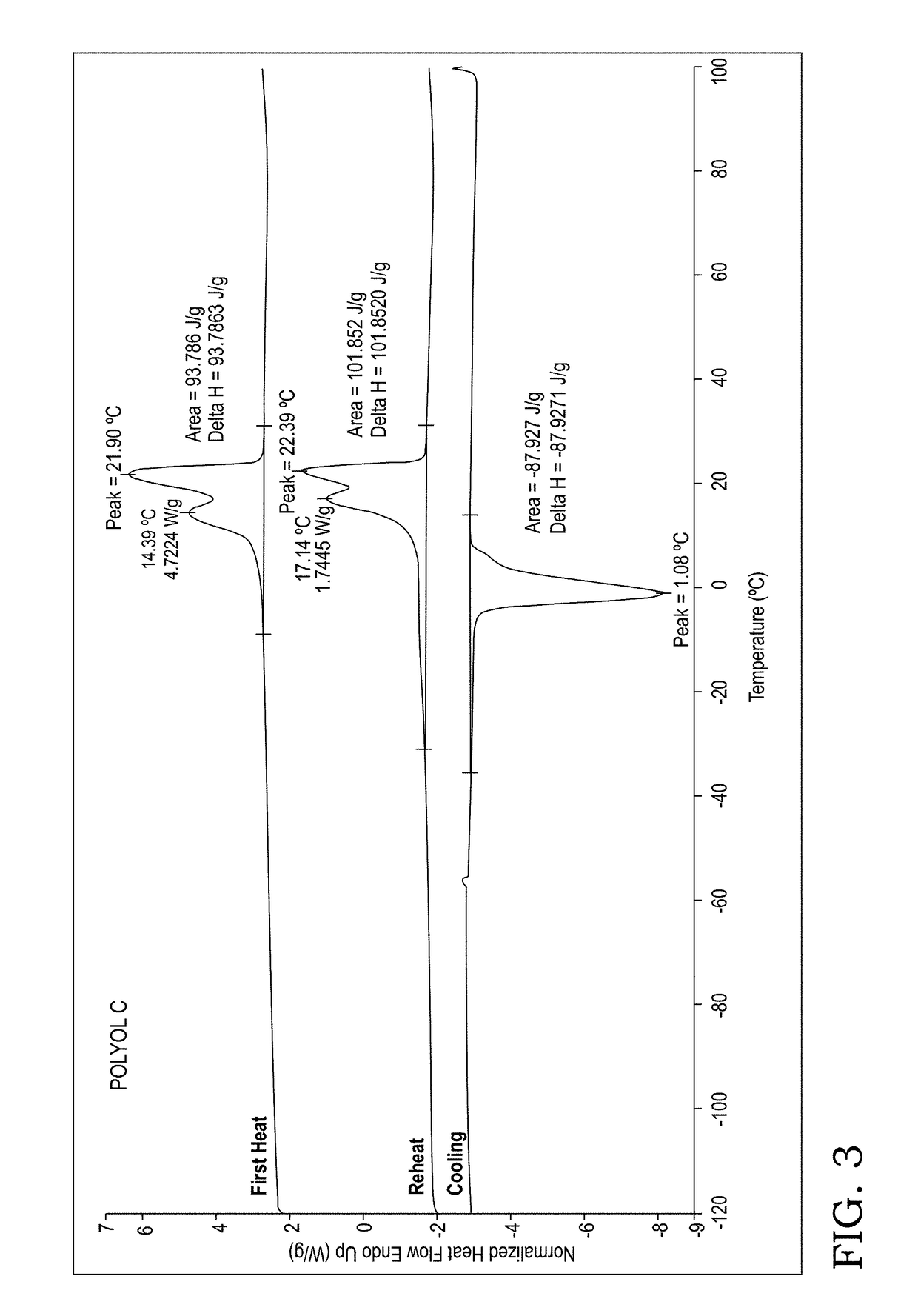

The present invention provides an aqueous polyurethane dispersion (PUD) comprising an amorphous polyester having a glass transition temperature (Tg) as determined by differential scanning calorimetry of less than −30° C.; wherein the aqueous polyurethane dispersion (PUD) has a glass transition temperature (Tg) as determined by differential scanning calorimetry (DSC) of 0° C. to 20° C. and a hard block content of greater than 50%. Coatings, adhesives, sealants and paints made from the inventive aqueous polyurethane dispersion (PUD) pass detergent resistance testing according to the American Architectural Manufacturers Association's standard, AAMA 615-13, have a pencil hardness according to ASTM D3363 of at least 3H, and are particularly suited for use on low surface energy substrates such as vinyl surfaces including floors, windows, doors, window frames, door frames, window shutters, railing, gates, pillars, arbors, pergolas, trellises, gazebos, posts, fencing, pipes and fittings, wire and cable insulation, automobile components, credit cards, and siding.

Owner:COVESTRO LLC +1

Component for a timepiece movement

A pivot arbor for a timepiece movement including at least one pivot made of a non-magnetic metal material at at least one of its ends in order to limit its sensitivity to magnetic fields. The non-magnetic metal material is a non-magnetic light metal or a non-magnetic alloy of the light metal, and at least the external surface of the pivot is coated with an anodic oxide layer of the material, obtained by anodic growth.

Owner:NIVAROX FAR

One component polyurethane dispersion for vinyl windows and other substrates with good chemical resistance

InactiveUS20190039362A1Excellent chemical resistanceImprove hardnessPolyureas/polyurethane adhesivesSynthetic resin layered productsKetoneChemistry

The present invention provides an aqueous polyurethane dispersion (PUD) comprising an amorphous polyester having a glass transition temperature (Tg) as determined by differential scanning calorimetry of less than −30° C.; wherein the aqueous polyurethane dispersion (PUD) has a glass transition temperature (Tg) as determined by differential scanning calorimetry (DSC) of 0° C. to 20° C. and a hard block content of greater than 50% and wherein the aqueous polyurethane dispersion (PUD) provides resistance to one or more selected from the group consisting of 10% HCl, water, motor oil, diesel fuel, 10% acetic acid, methyl ethyl ketone and 25% NaOH. Coatings, adhesives, sealants, paints, primers, and topcoats, made from the inventive aqueous polyurethane dispersion (PUD) provide good chemical resistance to a variety of surfaces including floors, windows, doors, window frames, door frames, window shutters, railing, gates, pillars, arbors, pergolas, trellises, gazebos, posts, fencing, pipes and fittings, wire and cable insulation, automobile components, credit cards, and siding.

Owner:COVESTRO LLC

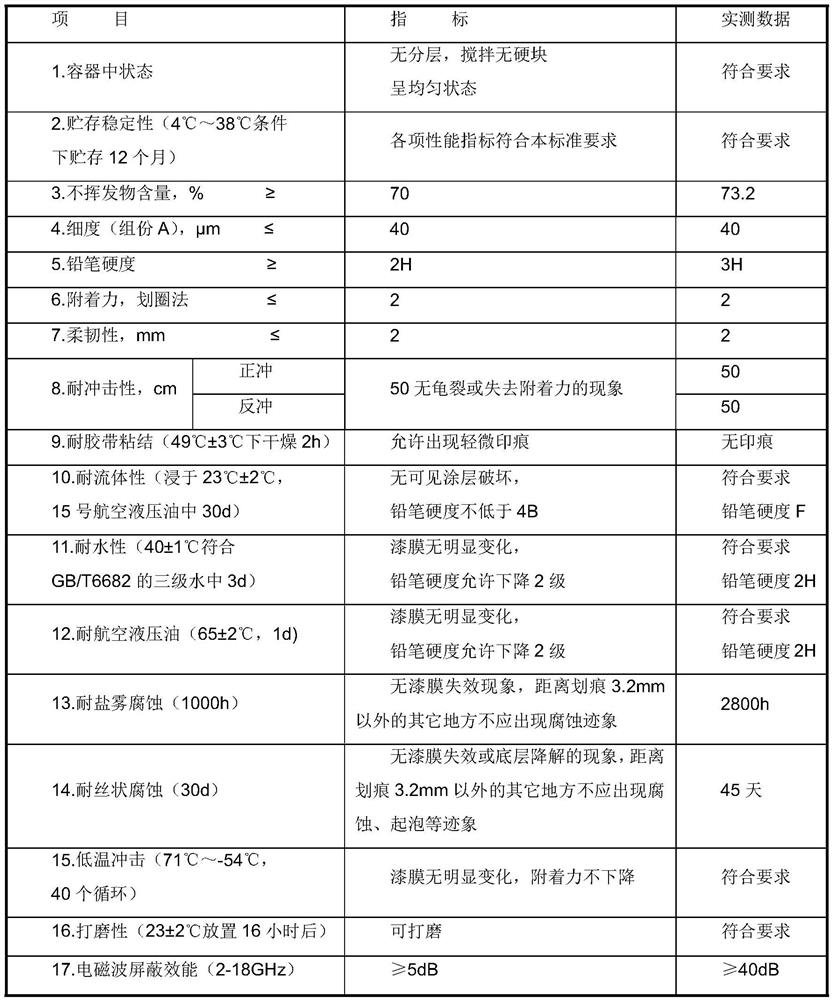

Graphene stealth skin primer as well as preparation method and application thereof

PendingCN114032009AGood electrical conductivityImprove hardnessAnti-corrosive paintsRadiation-absorbing paintsFlight vehicleWeather resistance

The invention discloses a graphene stealth skin primer as well as a preparation method and application thereof, belongs to the technical field of corrosion prevention, and solves the technical problems that an existing aircraft surface skin coating is liable to corrode, low in hardness, poor in toughness, poor in temperature change resistance and liable to generate cracks, and a problem that an aircraft shields radar waves. According to the graphene stealth skin primer disclosed by the invention, bisphenol A epoxy resin in the components can provide excellent salt fog resistance and adhesive force for a coating, graphene modified dispersion liquid greatly improves the hardness, impact resistance, flexibility and salt fog resistance of a paint film, and meanwhile, good static conductivity of the paint film is provided; titanium dioxide with good weather resistance is adopted as coloring pigment, and good covering power is provided for a paint film; the service life of an aircraft skin material can be prolonged, an aircraft is endowed with electromagnetic wave absorption performance, and the material is also applicable to other aircrafts and the like with shielding requirements.

Owner:SHAANXI COAL & CHEM TECH INST

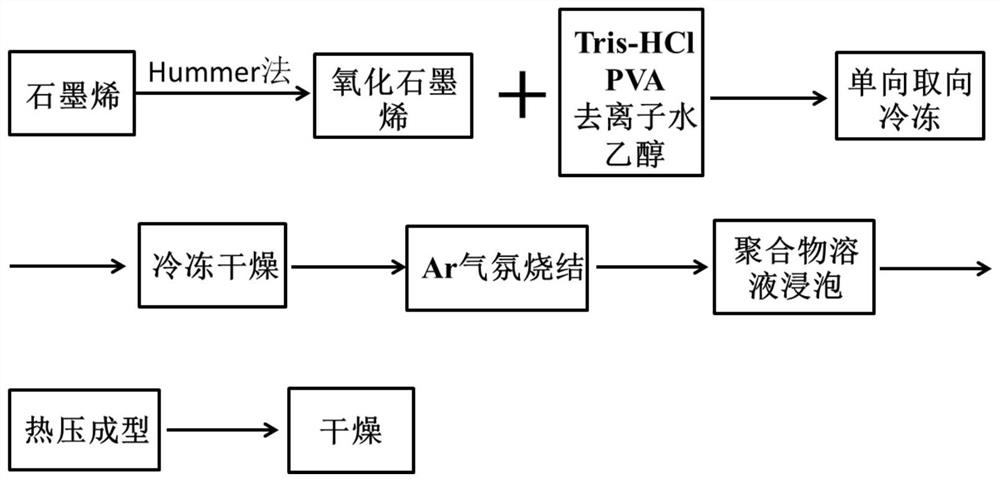

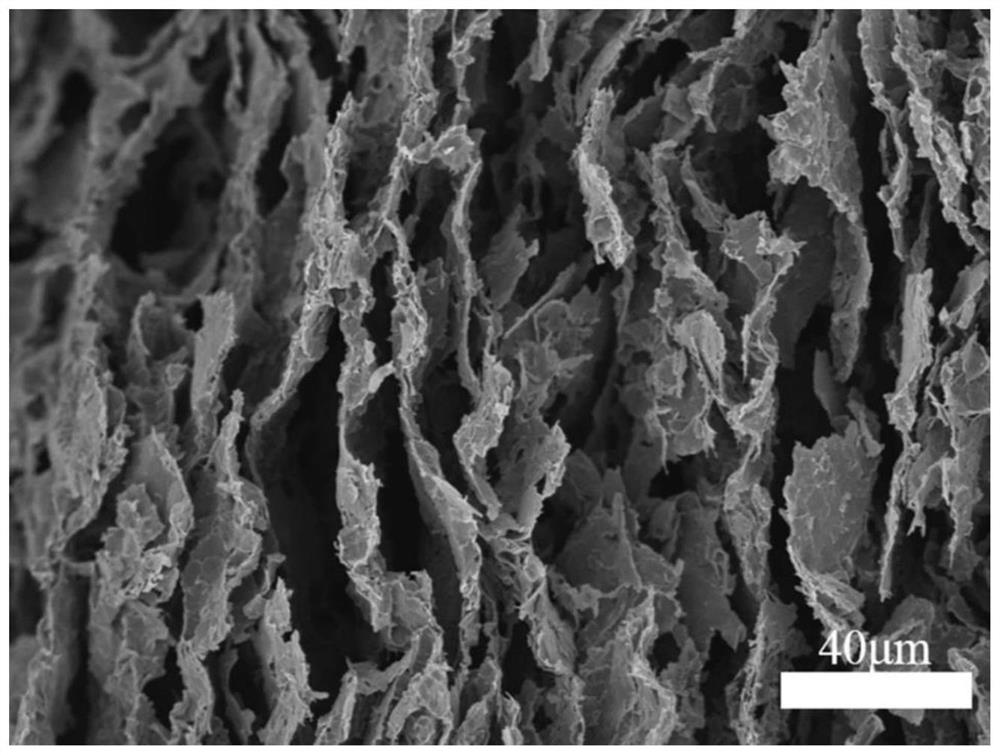

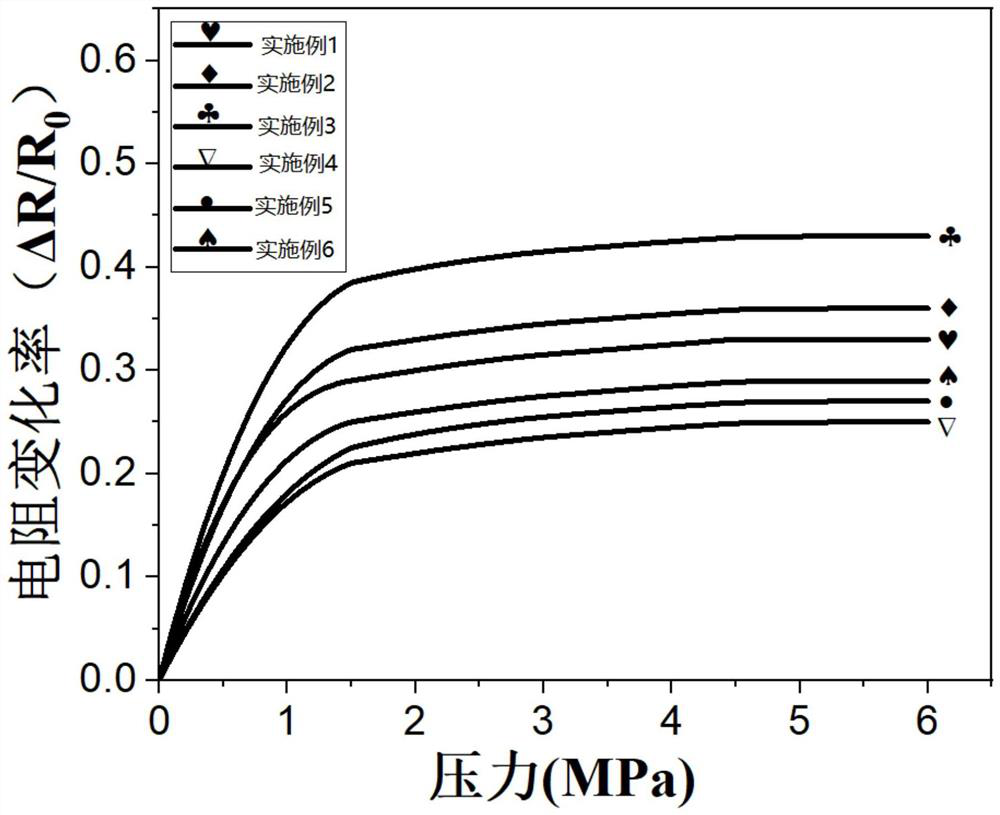

Preparation method of graphene composite material for detecting pressure change with high sensitivity

PendingCN114455576AImprove related performanceImprove hardnessCarbon compoundsForce measurementStress sensorsGraphene

The invention provides a preparation method of a graphene composite material for high-sensitivity detection of pressure change. When the prepared graphene composite material is applied to a pressure sensor, tiny pressure changes can be sensed under many severe conditions, and related conditions can be monitored in real time.

Owner:CHINA SOUTH POWER GRID ELECTRIC POWER RES INST

Method for improving surface of polymer lithium ion battery

InactiveCN106340676AImprove hardnessStable dischargeFinal product manufactureElectrolyte accumulators manufactureDefoamerChemistry

The invention discloses a method for improving surface of a polymer lithium ion battery. The method comprises the following steps: a) taking an alcohols or ketones substance as a solvent, slowly adding one or more alcohol-soluble or ketone-soluble resin in the solvent while stirring the solvent at high speed in a normal temperature state, wherein the stirring time is 10-30 min; b) adding an antifoaming agent and a levelling agent in the above mixing solution, and uniformly stirring the materials; c) continuously adding the alcohols or ketones solvent for adjust the viscosity of the mixing solution, stirring the materials for 15-30 min to obtain a resin solution; d) uniformly spraying the prepared resin solution on an intermediate part between an ultrathin battery pole piece and a plastic-aluminum membrane by a spray gun; and e) drying the processed ultrathin battery in the step d). The method is used for the manufacturing process field of the polymer lithium ion battery.

Owner:深圳市言九电子科技有限公司

Coal ash plate interlayer bulletproof door sheet and manufacturing method thereof

InactiveCN105569516AImprove hardnessIncrease utilization of fly ashSynthetic resin layered productsLaminationSteel platesProcess engineering

The invention discloses a coal ash plate interlayer bulletproof door sheet and a manufacturing method thereof. The door sheet comprises a coal ash plate, a wood board, and a bulletproof layer. The coal ash plate contains wood fibers. The wood board is one or more selected from finger-joint board, wood veneer, solid board, core-board, chipboard, density board, plywood, and fibreboard. The bulletproof layer is formed by a steel plate and a Kevlar. The door sheet is manufactured through respective tailoring and cutting, polishing, winding, and wrapping, bonding by an environmentally-friendly glue, and hot-pressing by a hot press. The coal ash plate and the wood board are combined to enhance flintiness of a wooden door, and use ratio of coal ash is improved, and hardness and tenacity of the coal ash plate are very strong. In a production process of the door sheet, the steel plate and the Kevlar are added, so that bulletproof performance of the door sheet is greatly enhanced.

Owner:HEILONGJIANG HUAXIN FURNITURE

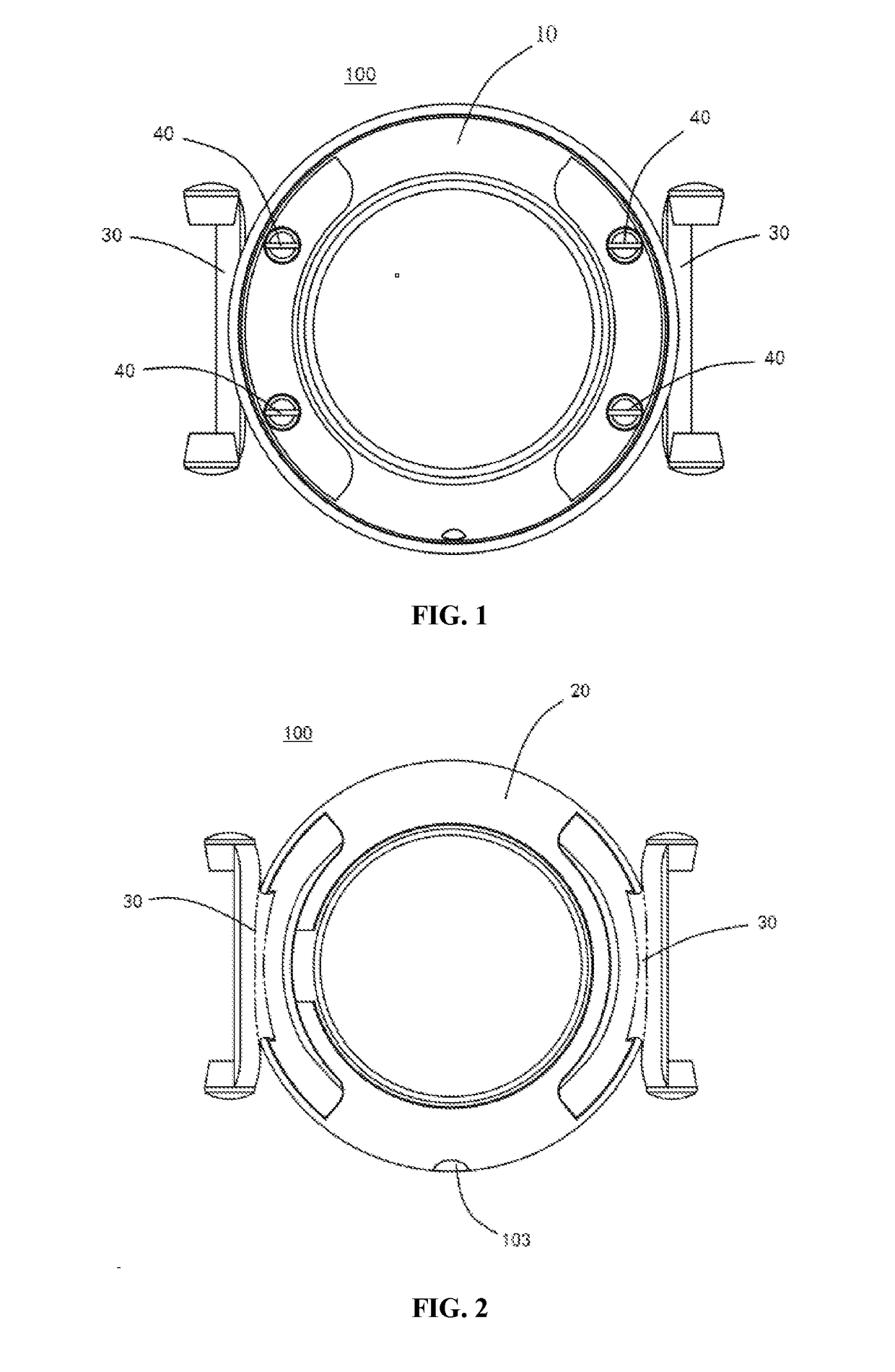

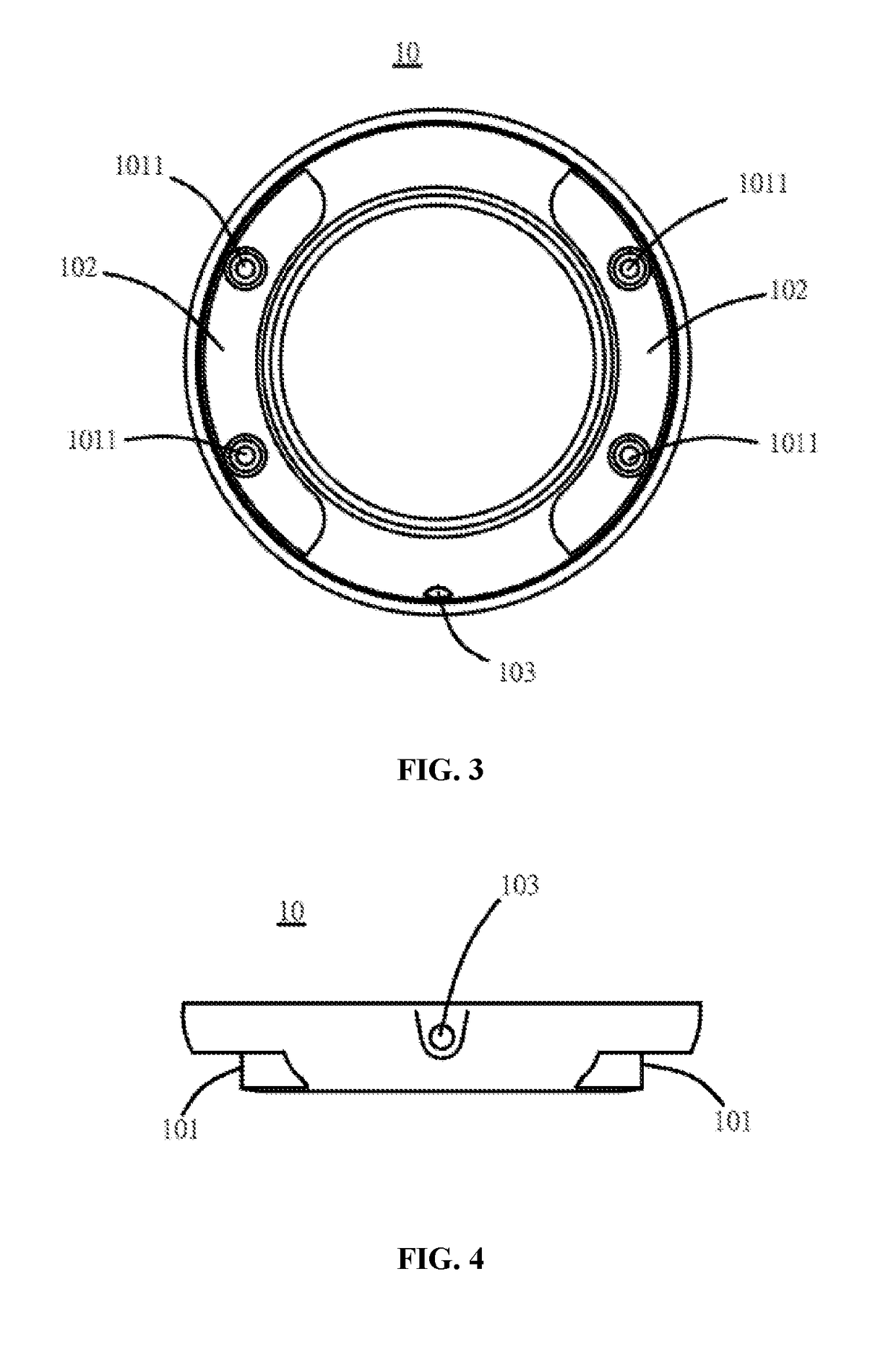

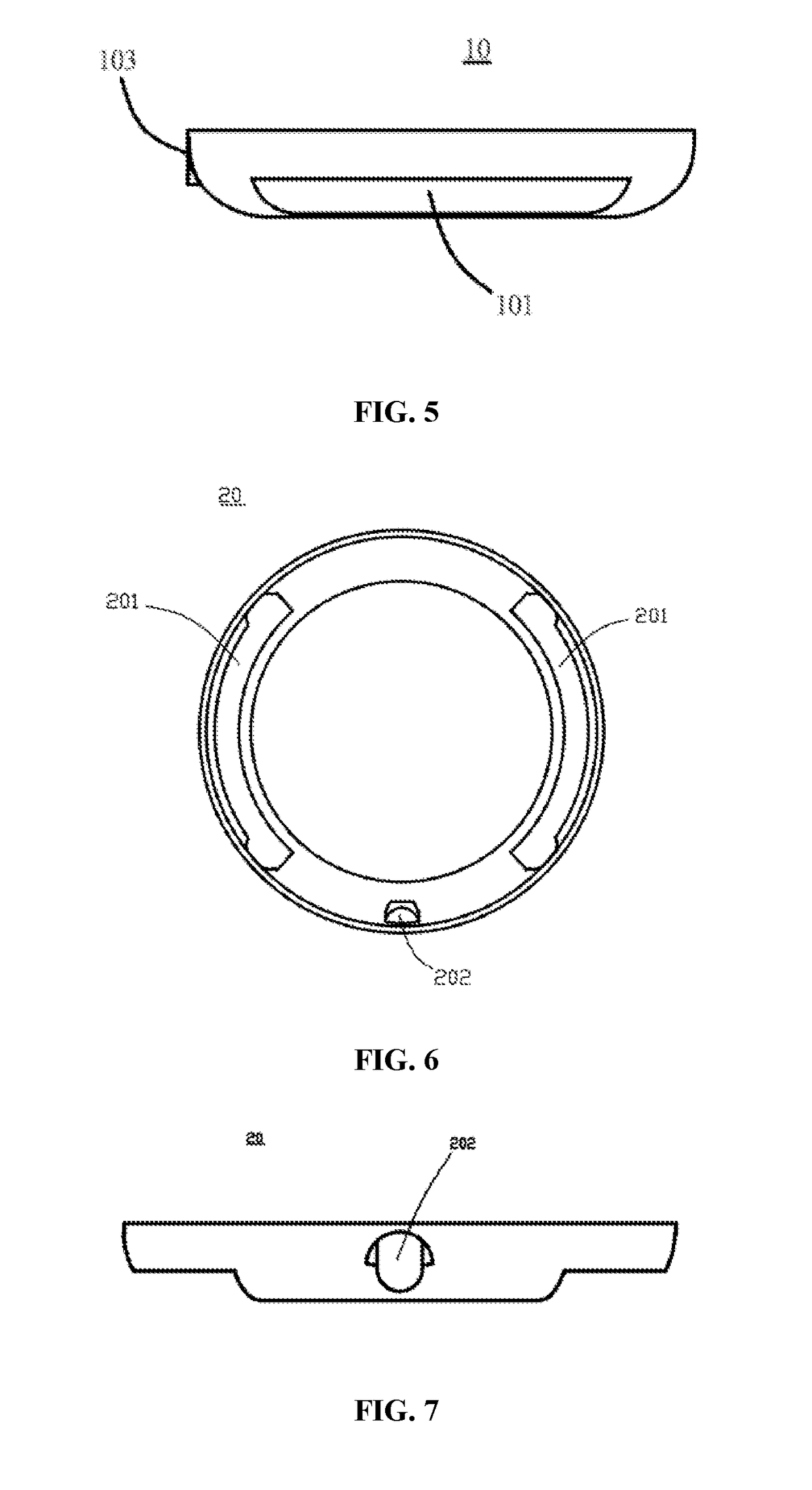

Double-Layered Watch Case

The invention relates to the technical field of clocks and watches and discloses a double-layered watch case, comprising an inner cover, an outer cover and two case lugs. Two symmetric sunken embedded portions are provided on the edge of the external bottom of the inner cover. The outer cover is arranged on the external surface of the inner cover in a sleeved and wrapped manner and provided with embedded slots corresponding to the locations of the embedded portions. The case lugs are provided with first connecting portions matching the embedded portions and connected to the embedded portions via the first connecting portions in a detachable manner to fit with the inner cover. In this way, the present invention not only may raise the hardness of the watch case but also has desirable water tightness and may be used in automatic production to save production cost and labor cost.

Owner:SHENZHEN XINGANG GEM WATCH CO LTD

One component polyurethane dispersion for vinyl windows and other substrates

InactiveUS20190040180A1Excellent chemical resistanceImprove hardnessPolyurea/polyurethane coatingsPriming paintsSurface energyChemistry

The present invention provides an aqueous polyurethane dispersion (PUD) comprising an amorphous polyester having a glass transition temperature (Tg) as determined by differential scanning calorimetry of less than −30° C.; wherein the aqueous polyurethane dispersion (PUD) has a glass transition temperature (Tg) as determined by differential scanning calorimetry (DSC) of 0° C. to 20° C. and a hard block content of greater than 50%. Coatings, adhesives, sealants, paints, primers and topcoats, made from the inventive aqueous polyurethane dispersion (PUD) pass detergent resistance testing according to the American Architectural Manufacturers Association's standard, AAMA 615-13, have a pencil hardness according to ASTM D3363 of at least 3H, and are particularly suited for use on low surface energy substrates such as vinyl and other surfaces including floors, windows, doors, window frames, door frames, window shutters, railing, gates, pillars, arbors, pergolas, trellises, gazebos, posts, fencing, pipes and fittings, wire and cable insulation, automobile components, credit cards, and siding.

Owner:COVESTRO LLC

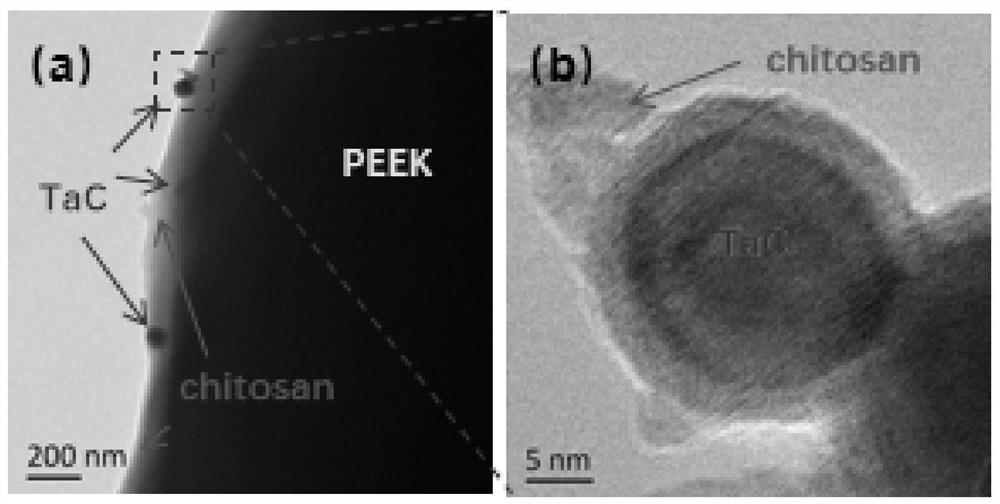

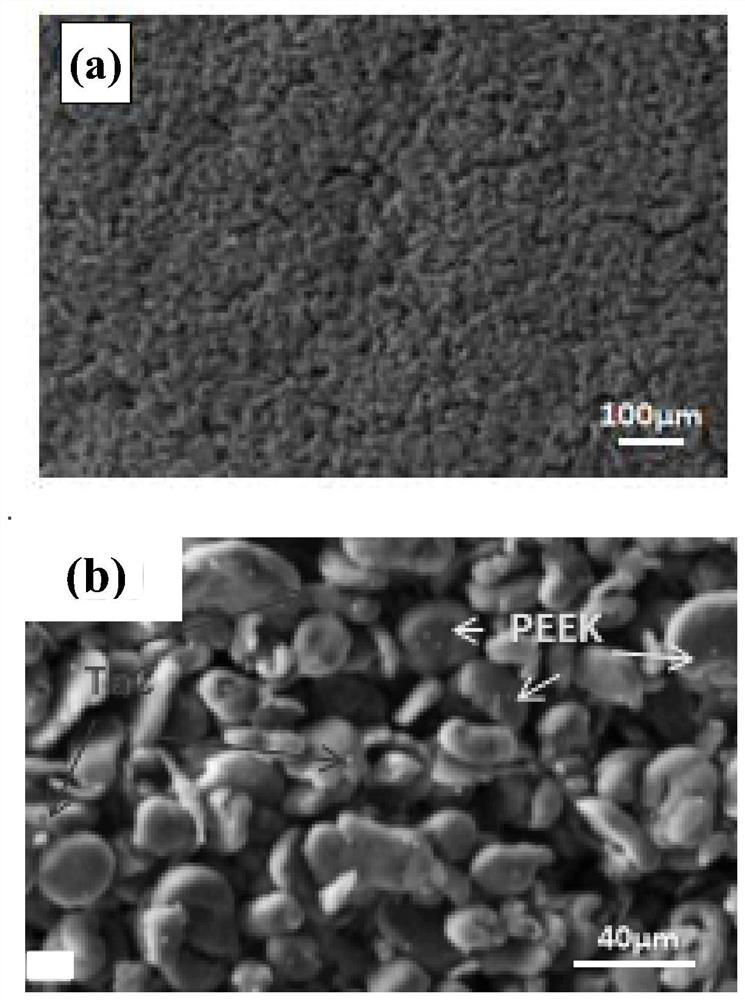

Tantalum carbide reinforced polyether-ether-ketone composite coating and preparation method and application thereof

ActiveCN113106520AImprove wear resistanceImprove hardnessElectrolytic coatingsPharmaceutical delivery mechanismPoly ether ether ketoneBiological materials

The invention belongs to the technical field of biological materials and particularly discloses a tantalum carbide reinforced polyether-ether-ketone composite coating and a preparation method and application thereof. The method comprises the following steps that (1), after a chitosan solution and ethanol are uniformly mixed, PEEK powder and nanometer TaC are sequentially added in to obtain a mixed solution, and nanometer suspension liquid is obtained by ultrasonic dispersion; and (2), a cathode material and an anode material are put in the nanometer suspension liquid obtained in the step(1), direct current is introduced in, and the nanometer TaC reinforced polyether-ether-ketone composite coating is obtained through deposition. According to the tantalum carbide reinforced polyether-ether-ketone composite coating and the preparation method and application thereof, a PEEK coating is prepared on substrates of titanium and alloy thereof, stainless steel and the like through a cathode electrodeposition method, and nanometer TaC particles are introduced in a PEEK material, the osteogenesis performance of PEEK can be enhanced, and the coating prepared through cathode electrodeposition is short in production time, simple in equipment, low in price and wide in application prospect.

Owner:JINAN UNIVERSITY

Preparation method of protective paint coated film

InactiveCN106811093AHigh mechanical strengthImprove hardnessAnti-corrosive paintsPolyurea/polyurethane coatingsChemistryCorrosion

The invention discloses a preparation method of a protective paint coated film. The preparation method comprises the following steps: 1) adding isophorone diisocyanate and the like into a first reaction kettle to obtain a primary product; 2) adding dimethylolpropionic acid into the primary product, and adding triethylamine to obtain an aliphatic water-based polyurethane emulsion; 3) preparing a modified silica sol; 4) preparing a mixed emulsion; 5) adding right amounts of acrylic acid copolymer potassium salt and the like into a distilled-water-containing fourth reaction kettle to obtain a mixed substrate; 6) adding the mixed emulsion into the mixed substrate to obtain a protective paint; 7) airing a plastic film, and diluting the protective paint; and 8) spraying the protective paint onto the plastic film, and airing to obtain the protective paint coated film. The coated film is convenient for testing the tensile property, corrosion resistance, moisture permeability, peel strength and other properties of the paint.

Owner:重庆市共赢包装制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com