Hot spraying rare earth aluminum alloy coating steel bar

A thermal spraying, aluminum alloy technology, applied in the direction of coating, metal material coating process, melt spraying, etc., can solve the problems of increased anchorage length of steel bars, difficult repair of damaged parts, insufficient anti-corrosion durability, etc., to achieve the performance of metal alloys Optimize, prevent intergranular corrosion, improve the effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 3

[0041] The preparation of the rare earth aluminum alloy wire is shown in Table 1 for its components by weight percentage.

[0042] Table 1, Example 1-3 rare earth aluminum alloy wire material composition, performance and performance data of thermal sprayed rare earth aluminum alloy coating

[0043]

[0044] Melt Si, Mg, Li, Ti, B, Bi, Mn, rare earth metals, etc. contained in the components with 20% to 30% Al in a hollow induction furnace to make an intermediate alloy for later use;

[0045] Then put Zn and the remaining Al into the smelting furnace for smelting, the smelting temperature is 750±10°C, after Al and Zn are completely melted, refine, then add the master alloy prepared above, fully stir until it melts, and let it stand for 0.5~ After 2 hours, remove the slag and cast it into bars;

[0046] Put the bar into an electric furnace at 400±20°C for heat treatment for 3-6 hours, and obtain a rough alloy billet with a diameter of 4-8mm through horizontal continuous casti...

Embodiment 4- Embodiment 5

[0050] The water-based two-component polyurethane primer sealer is prepared, and its components are shown in Table 2 by weight percentage.

[0051] Table 2 Main performance test data of waterborne two-component polyurethane primer sealer

[0052]

[0053]The preparation method of the main agent part: add alcohol ether solvents, wetting and dispersing agents, wetting agents, leveling agents, anti-sedimentation agents, adhesion promoters, antioxidants, and ultraviolet light absorbers to deionized In water, stir and disperse until the fineness is below 30 μm, then add hydroxyl-containing polyacrylate dispersion, water-based elastic polyurethane dispersion, scaly zinc powder or aluminum powder, defoamer, thickener, and anti-sagging additives to stir and disperse After 30 minutes, it will be packaged.

[0054] The curing agent part includes the following raw materials: 60-80% water-dispersed polyisocyanate, 20-40% high-boiling point ether ester solvent, the two are mixed and di...

Embodiment 6

[0057] See figure 1 , figure 2 as shown,

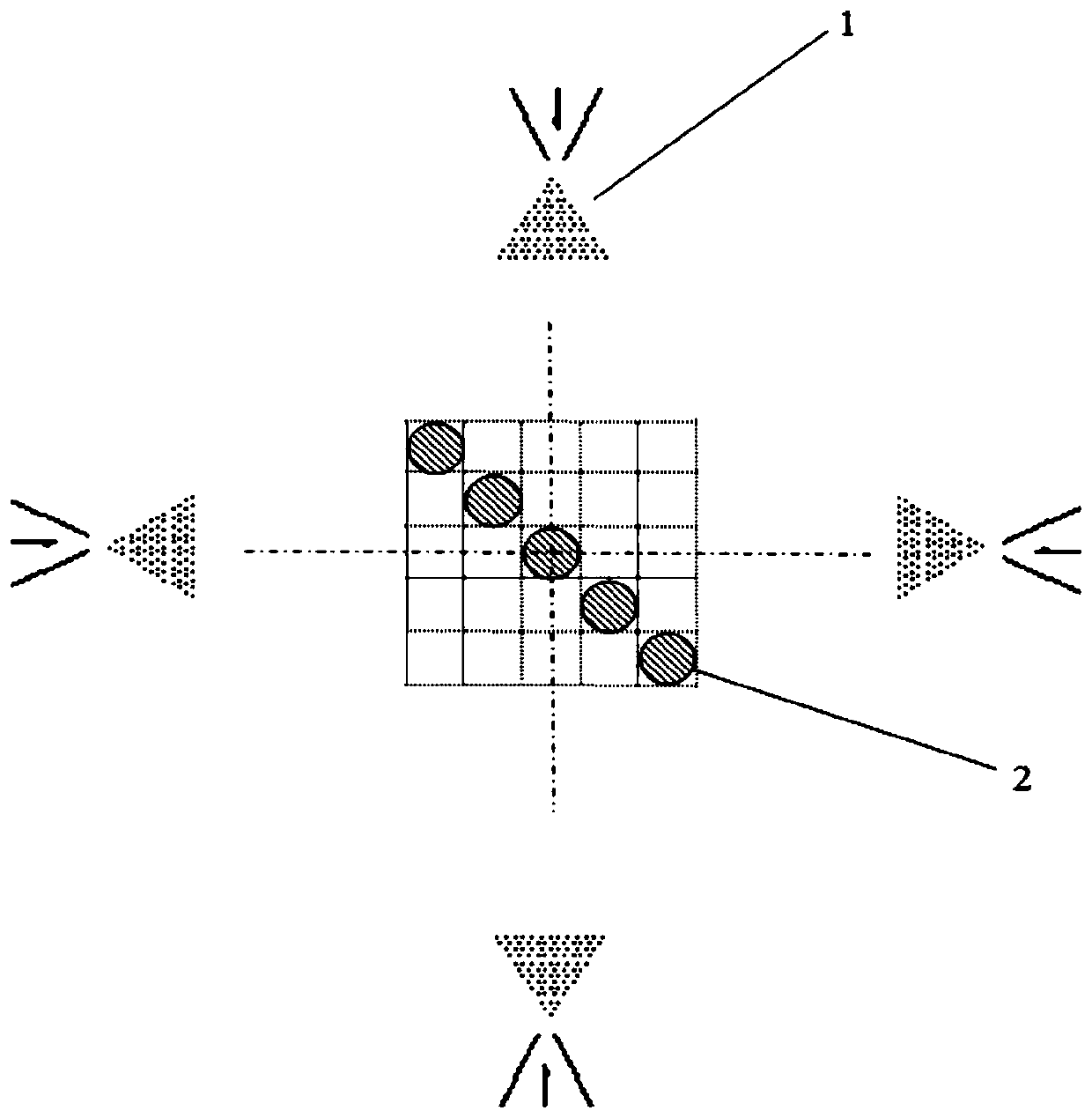

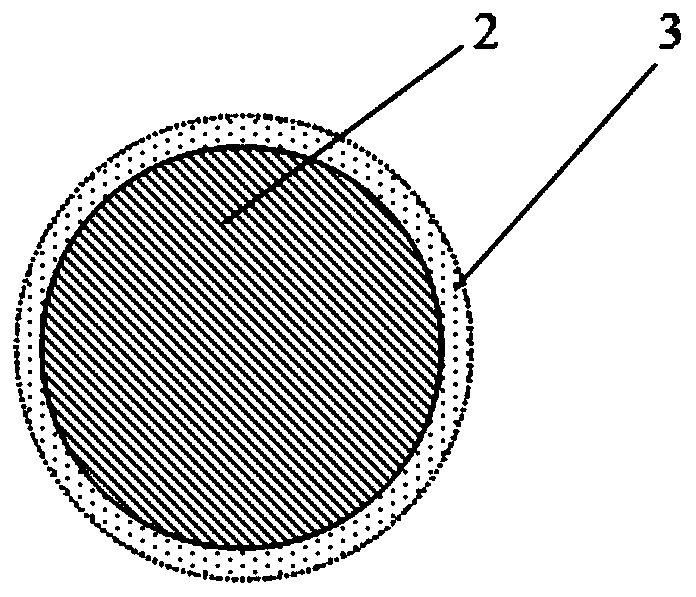

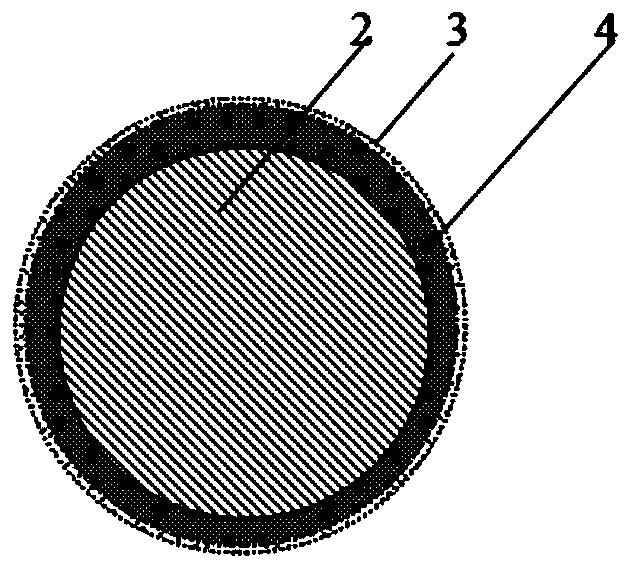

[0058] The preparation method of thermal spraying rare earth aluminum alloy cladding steel bar is as follows: The preparation method of thermal spraying rare earth aluminum alloy cladding steel bar is as follows: the steel bar assembly line adopts figure 1 Arranged in the manner shown, the thermal spraying spray gun 1 is arranged around the longitudinal cross-section of the steel matrix 2 assembly line, in a "ten"-shaped structure.

[0059] Step 1: Mechanical derusting Derusting by shot blasting machine to remove dust, impurities, scale and rust on the surface of the steel bar. The surface cleanliness of the steel bar base material can reach Sa3 level, and the surface roughness can reach Rz60-100μm;

[0060] Step 2: Immediately after thermal spraying mechanical rust removal, use an arc spray gun to spray the rare earth aluminum alloy wire material prepared in Example 1 on the surface of the qualified steel bar substrate that has be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com