Patents

Literature

1227 results about "Thermal spray coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal sprayed coatings uniquely enhance and improve the performance of the component. Thermal Spray is versatile and is an effective alternative. Thermal sprayed coatings can be an effective alternative to several surface treatments including: nickel and chrome plating, nitride or heat treat processes, anodizing, and weld overlay.

Conductive, plasma-resistant member

InactiveUS20070248832A1Improve corrosion resistanceSuppress particle contaminationMolten spray coatingNatural mineral layered productsDisplay deviceFlat panel display

An electrically conductive, plasma-resistant member adapted for exposure to a halogen-based gas plasma atmosphere includes a substrate having formed on at least part of a region thereof to be exposed to the plasma a thermal spray coating composed of yttrium metal or yttrium metal in admixture with yttrium oxide and / or yttrium fluoride so as to confer electrical conductivity. Because the member is conductive and has an improved erosion resistance to halogen-based corrosive gases or plasmas thereof, particle contamination due to plasma etching when used in semiconductor manufacturing equipment or flat panel display manufacturing equipment can be suppressed.

Owner:SHIN ETSU CHEM IND CO LTD

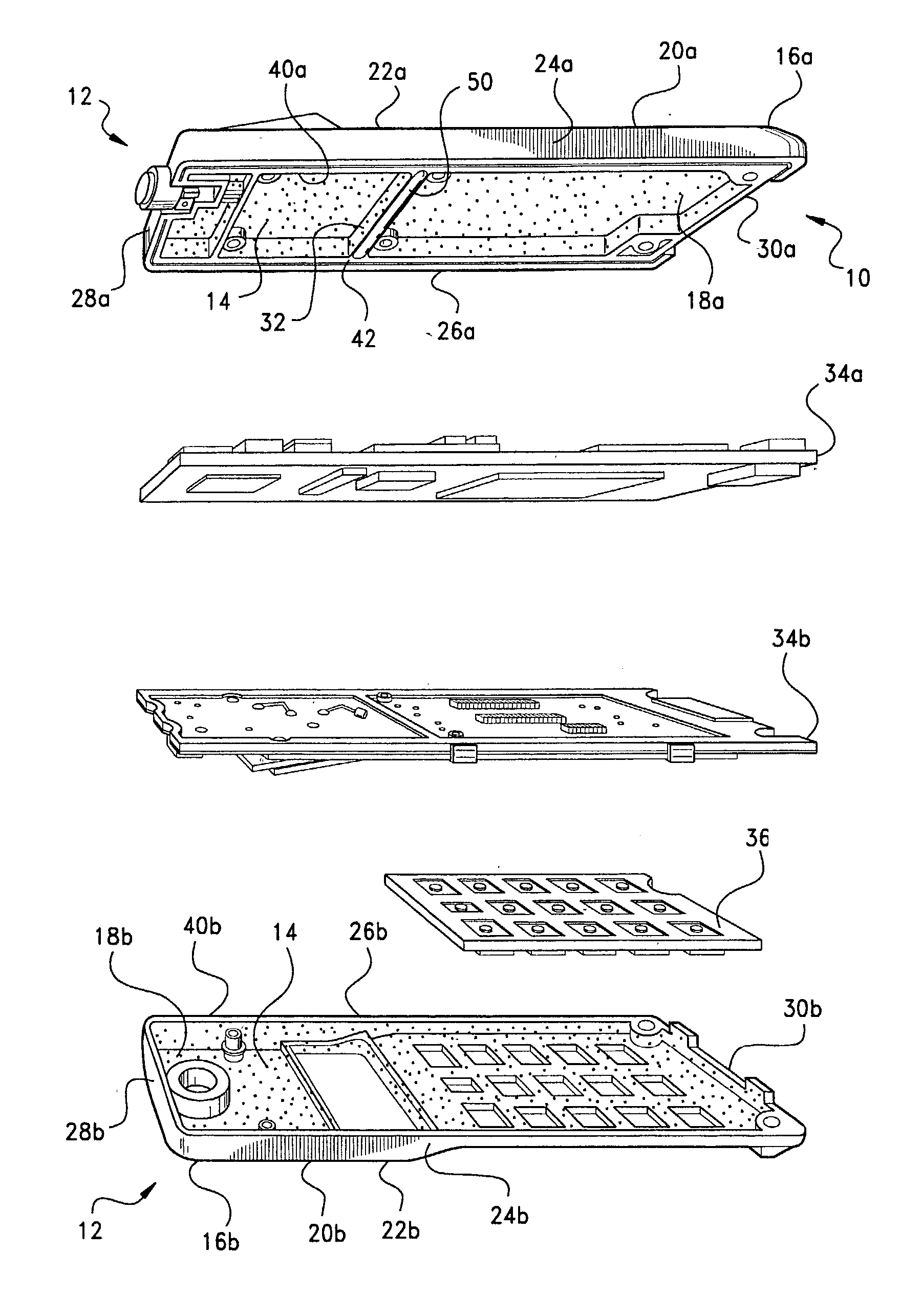

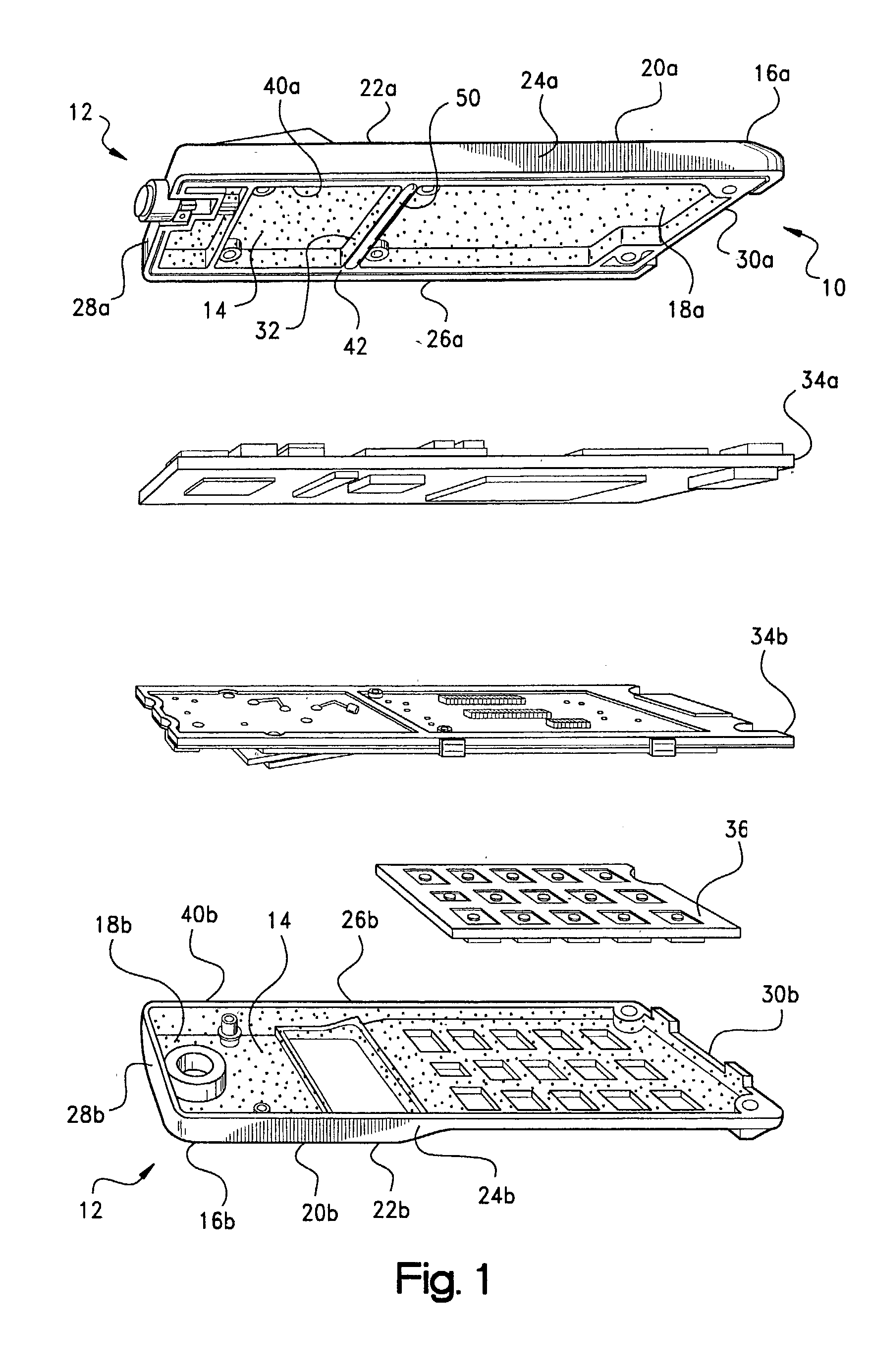

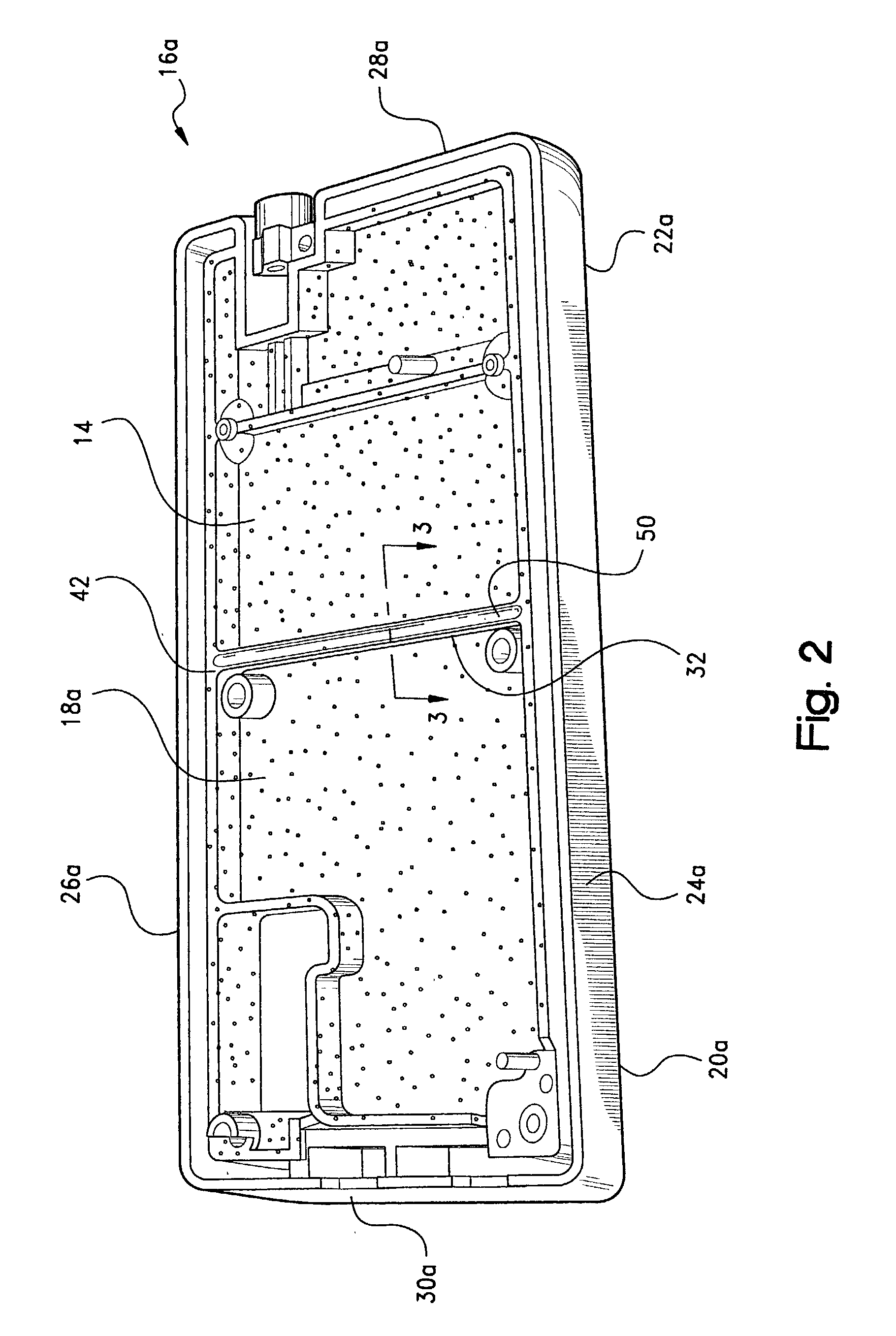

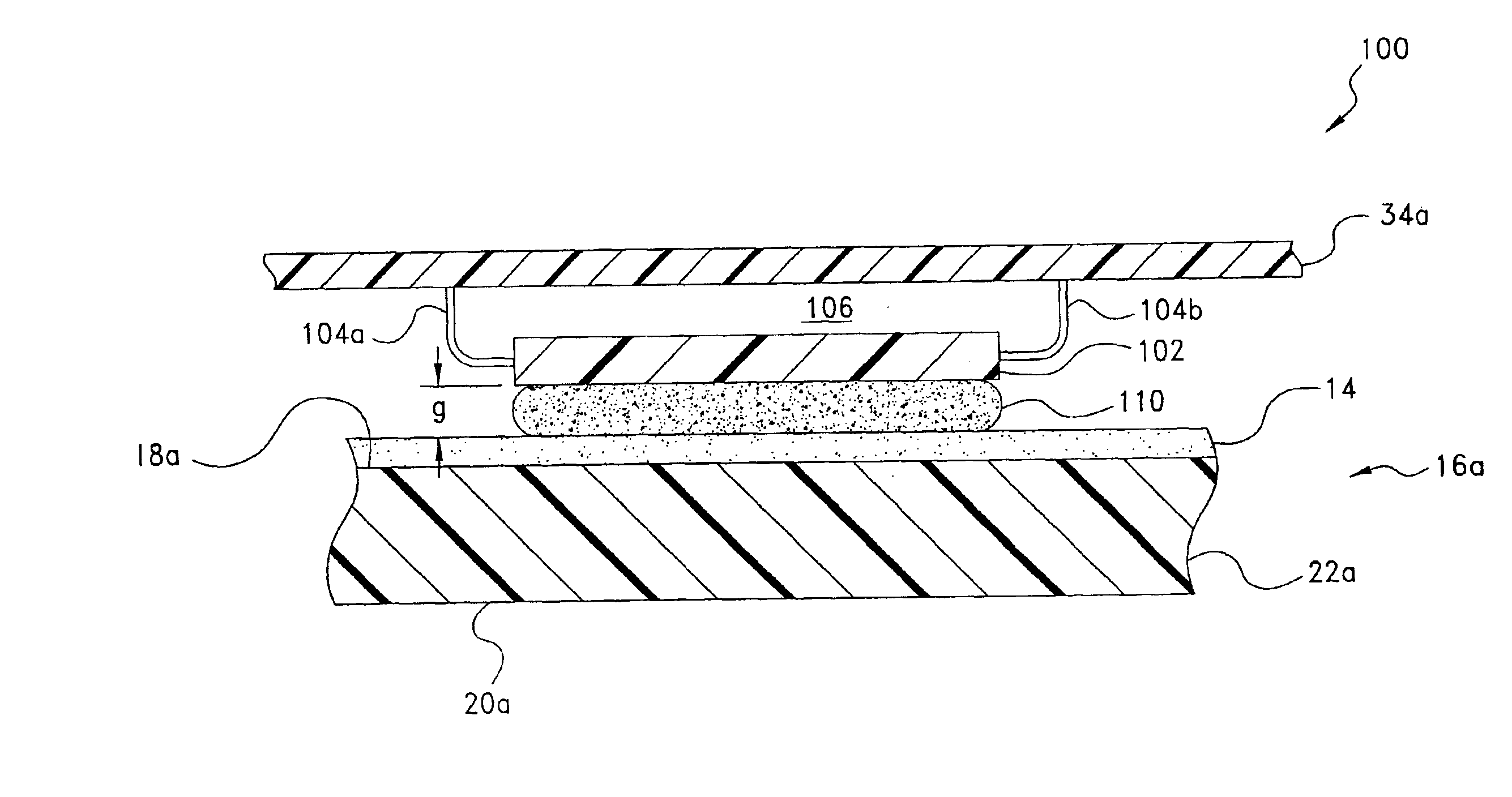

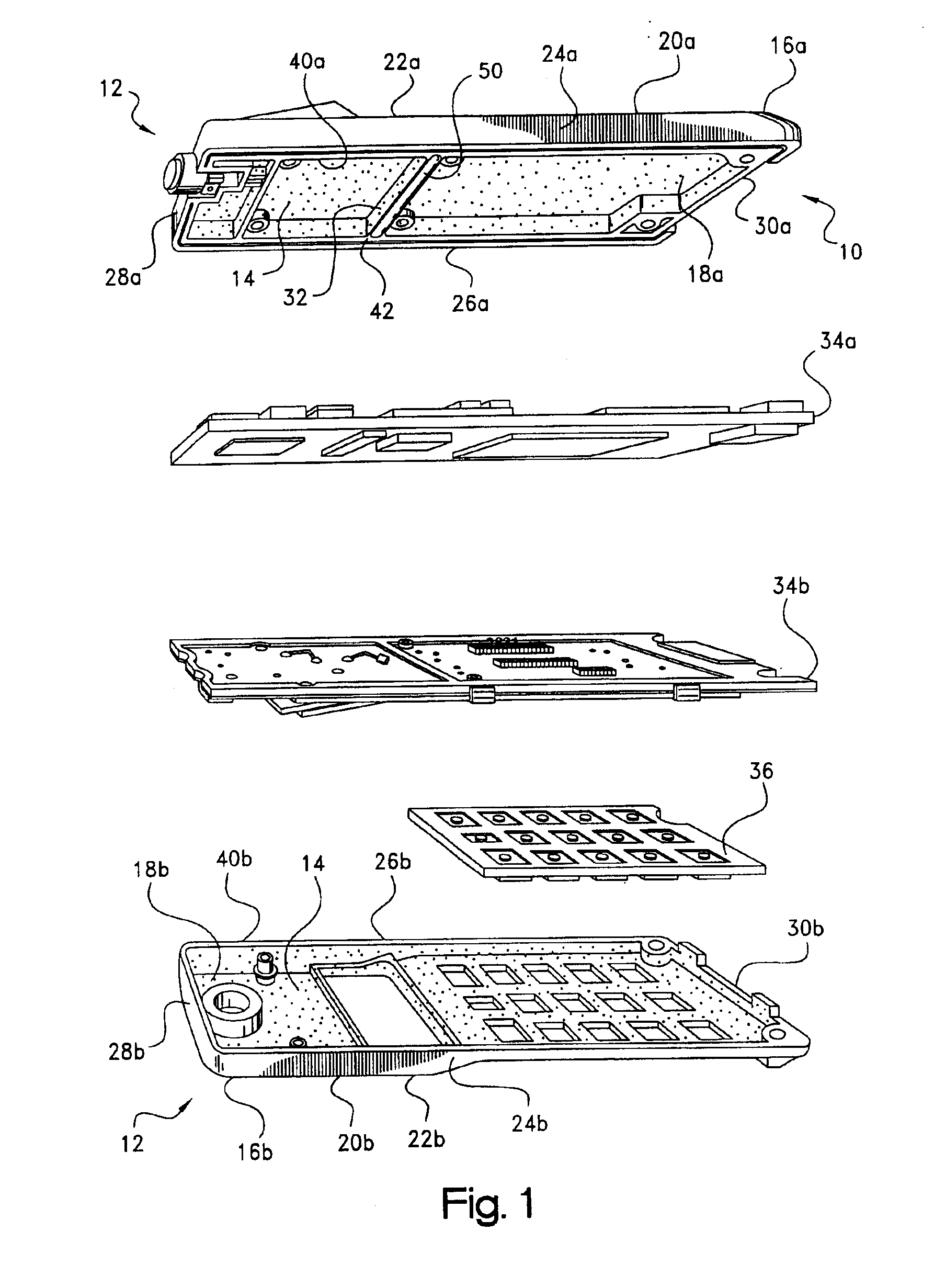

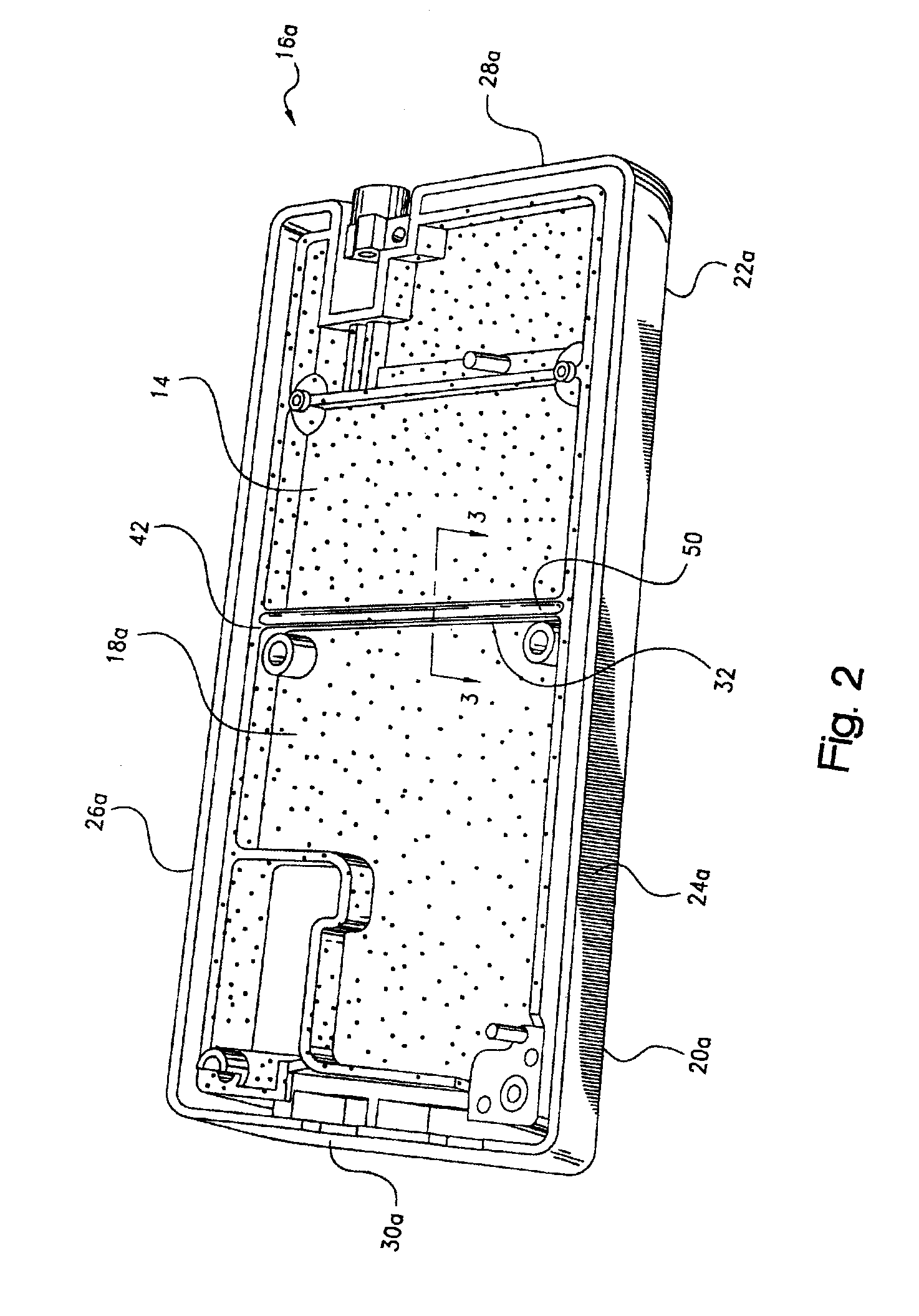

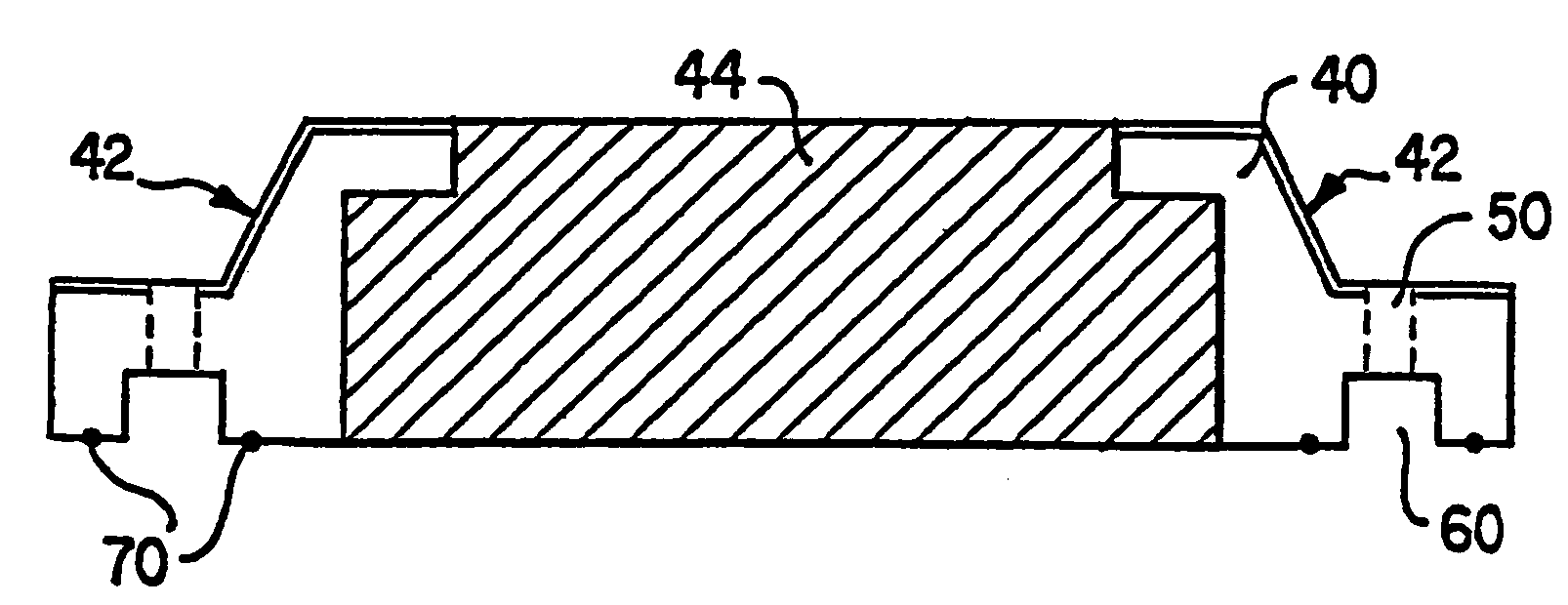

Thermal-sprayed metallic conformal coatings used as heat spreaders

InactiveUS20030066672A1Eliminate needHeat dissipationMolten spray coatingScreening gaskets/sealsMolten stateThermal spraying

Heat dissipation and electromagnetic interference (EMI) shielding for an electronic device having an enclosure. An interior surface of the enclosure is covered with a conformal metallic layer which, as disposed in thermal adjacency with one or more heat-generating electronic components or other sources contained within the enclosure, may provide both thermal dissipation and EMI shielding for the device. The layer may be sprayed onto the interior surface in a molten state and solidified to form a self-adherent coating.

Owner:PARKER INTANGIBLES LLC

Thermal-sprayed metallic conformal coatings used as heat spreaders

InactiveUS6965071B2Eliminate needReduce device temperatureMolten spray coatingScreening gaskets/sealsElectromagnetic interferenceEngineering

Owner:PARKER INTANGIBLES LLC

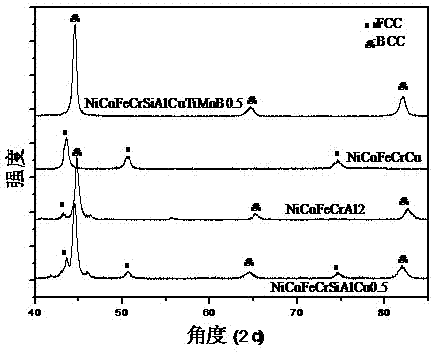

High-entropy alloy powder used for spraying

InactiveCN102828139AImprove self-fluxingImprove spraying effectMolten spray coatingHigh entropy alloysWear resistance

The invention discloses high-entropy alloy powder used for spraying, belonging to the technical field of alloy materials. The high-entropy alloy powder comprises five or more than five metal elements and non-metal elements Si and B, wherein addition amount of each metal element accounts for 5-35mol% of the total mole number of the high-entropy alloy powder, content of the added non-metal element Si accounts for 1-20mol% of the total mole number of the high-entropy alloy powder, and the content of the added non-metal element B accounts for 1-10mol% of the total mole number of the high-entropy alloy powder. The high-entropy alloy powder disclosed by the invention and a coating prepared by the high-entropy alloy powder after solidification can avoid precipitation of massive brittle phases after the traditional multi-element alloy is solidified, the coating has a simple fcc or bcc solid solution phase structure, brittleness of the multi-element alloy can be greatly reduced, the coating has multiple excellent performances such as high hardness, thermostability, wear resistance and corrosion resistance, and the high-entropy alloy powder can be applied to multiple surface coating technologies such as thermal spraying and laser cladding and has a wide application prospect.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Productivity enhancing thermal sprayed yttria-containing coating for plasma reactor

InactiveUS7300537B2Improve wear resistanceLow level of contaminationCellsElectric discharge tubesProduction ratePlasma reactor

Components of semiconductor processing apparatus comprise thermal sprayed yttria-containing coatings that provide erosion, corrosion and / or corrosion-erosion resistance in plasma atmospheres. The coatings can protect substrates from physical and / or chemical attack.

Owner:LAM RES CORP

Highly electrically conductive surfaces for electrochemical applications

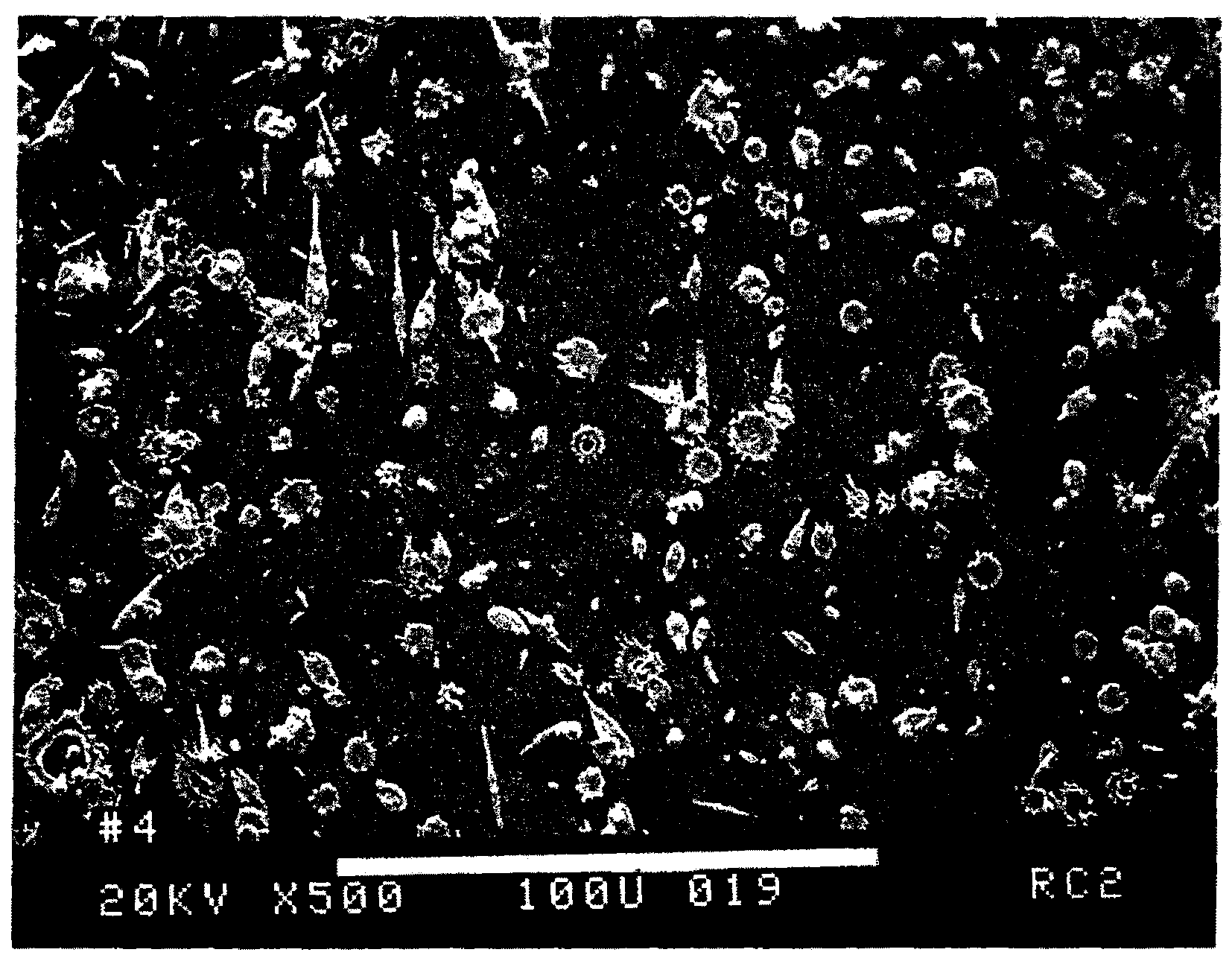

A method is described that can be used in electrodes for electrochemical devices and includes disposing a precious metal on a top surface of a corrosion-resistant metal substrate. The precious metal can be thermally sprayed onto the surface of the corrosion-resistant metal substrate to produce multiple metal splats. The thermal spraying can be based on a salt solution or on a metal particle suspension. A separate bonding process can be used after the metal splats are deposited to enhance the adhesion of the metal splats to the corrosion-resistant metal substrate. The surface area associated with the splats of the precious metal is less than the surface area associated with the top surface of the corrosion-resistant metal substrate. The thermal spraying rate can be controlled to achieve a desired ratio of the surface area of the metal splats to the surface area of the corrosion-resistant metal substrate.

Owner:TREADSTONE TECH INC

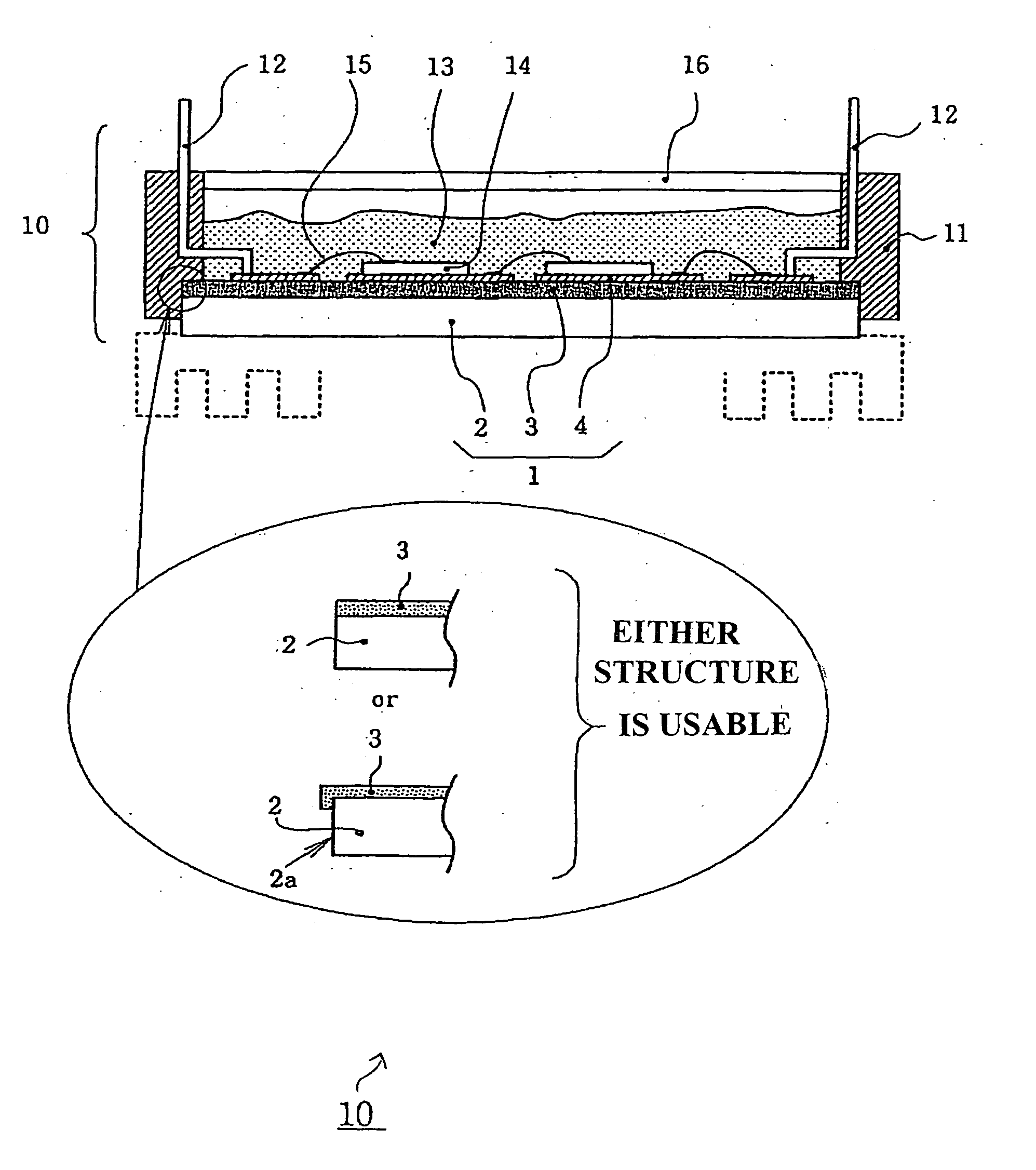

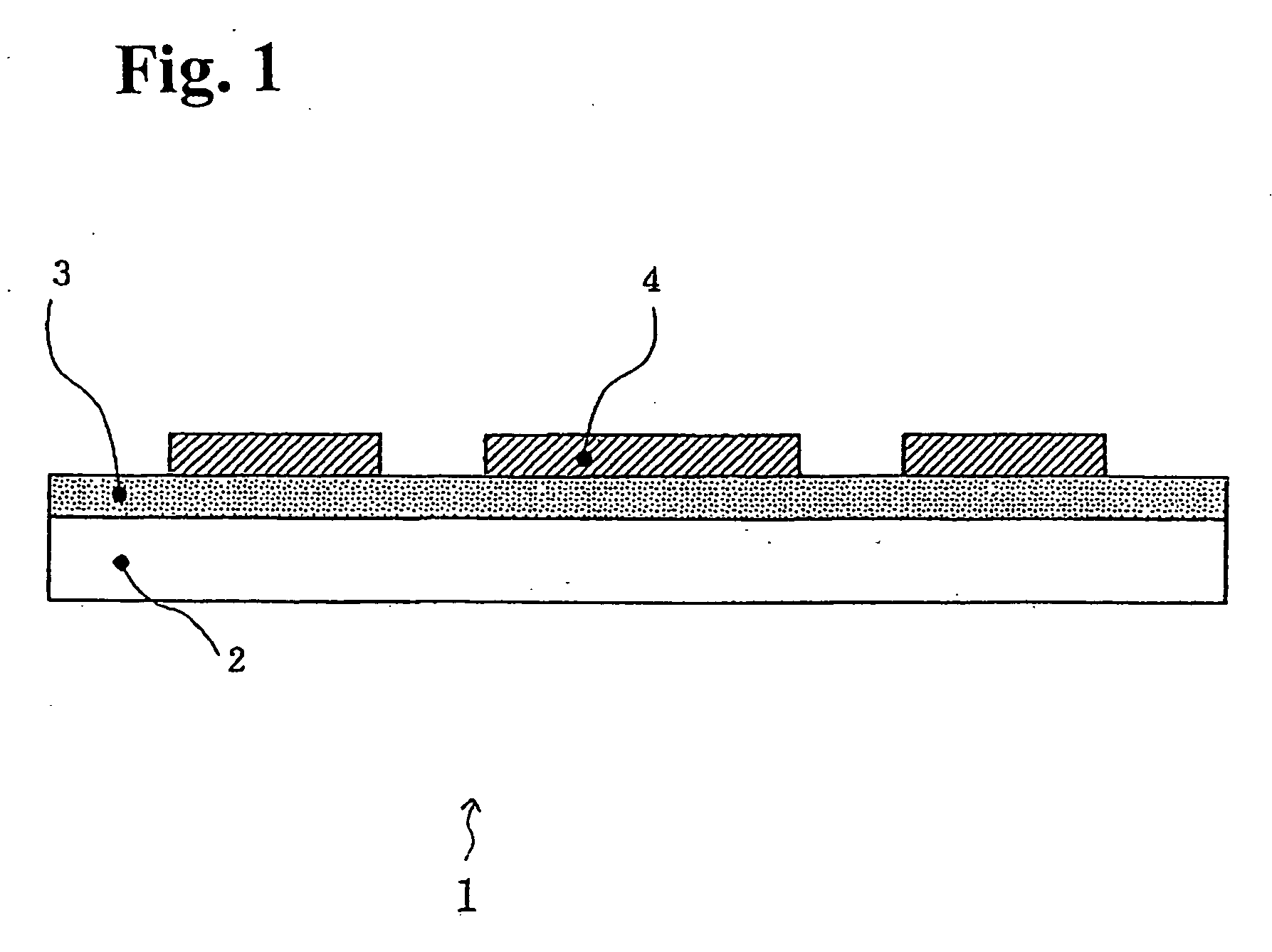

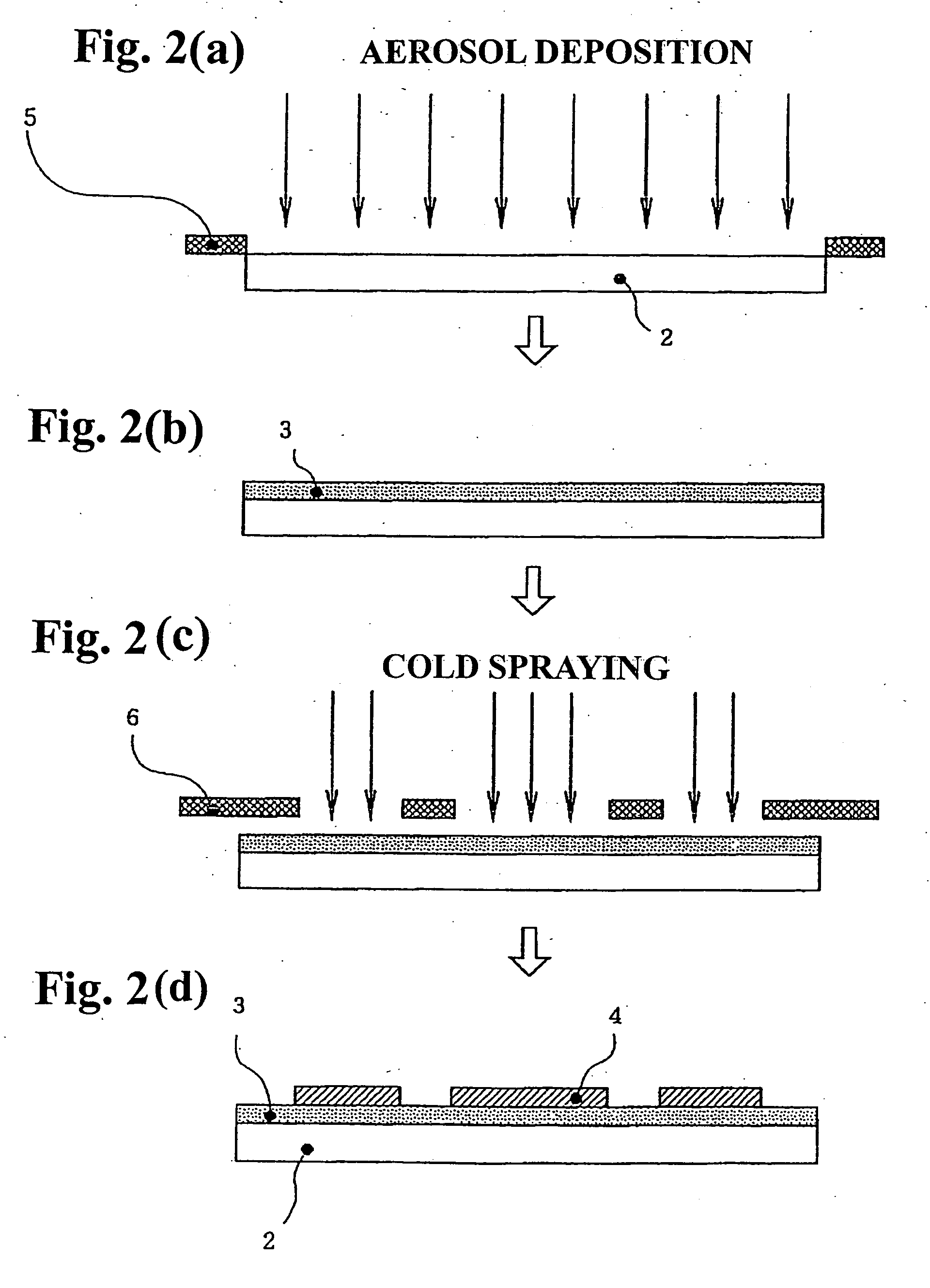

Insulating substrate and semiconductor device

ActiveUS20060108601A1Reduce manufacturing stepsImprove heat radiation performanceMolten spray coatingSemiconductor/solid-state device detailsDevice materialRoom temperature

An insulating substrate includes a metal base as a base member, an insulating layer which is a room temperature, aerosol deposited shock solidification film formed on the metal base, and a circuit pattern which is a cold sprayed thermal spray coating formed on the insulating layer. A semiconductor device incorporates the insulating substrate, and thereby has improved heat radiation characteristics.

Owner:FUJI ELECTRIC HLDG CO LTD

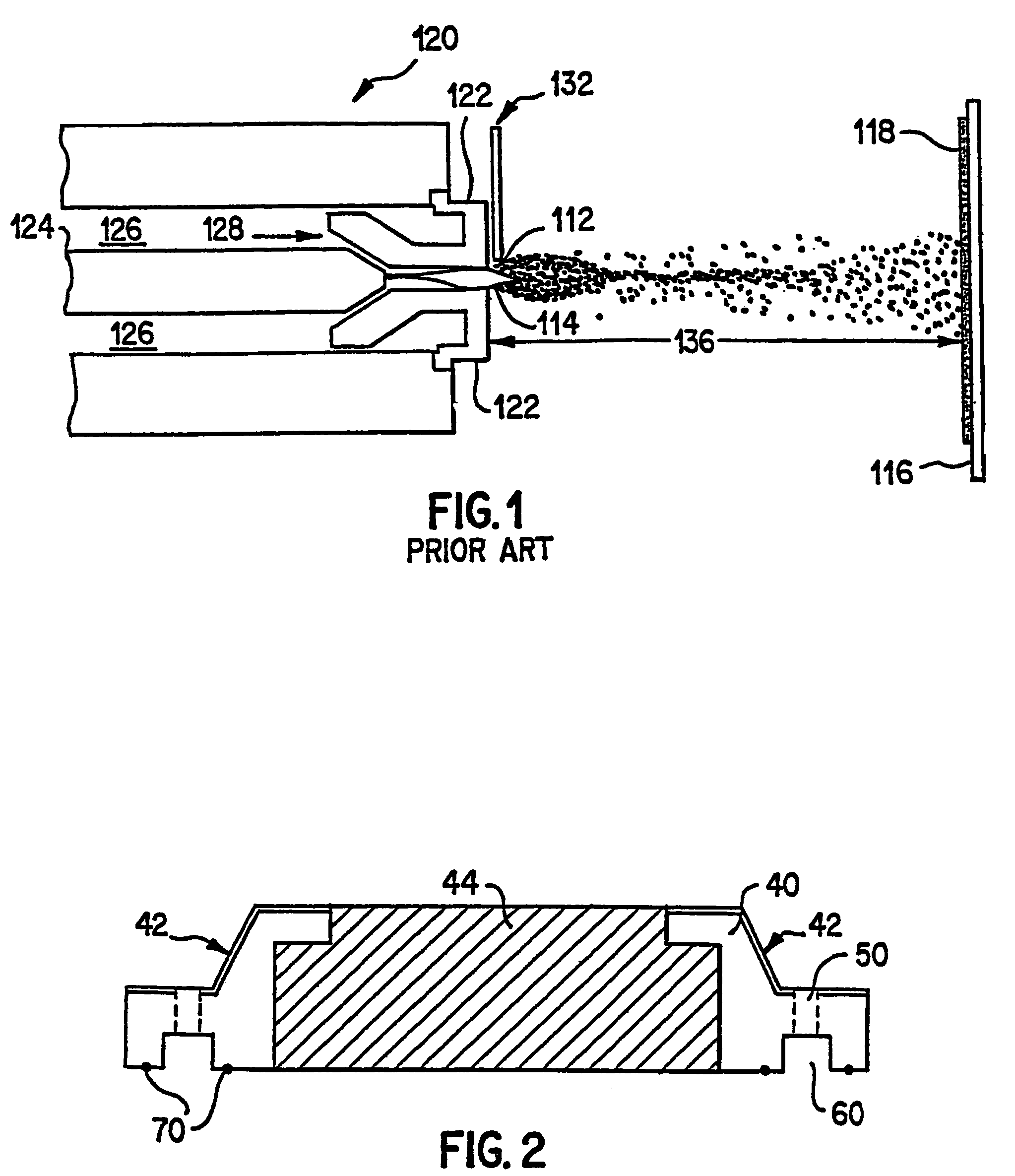

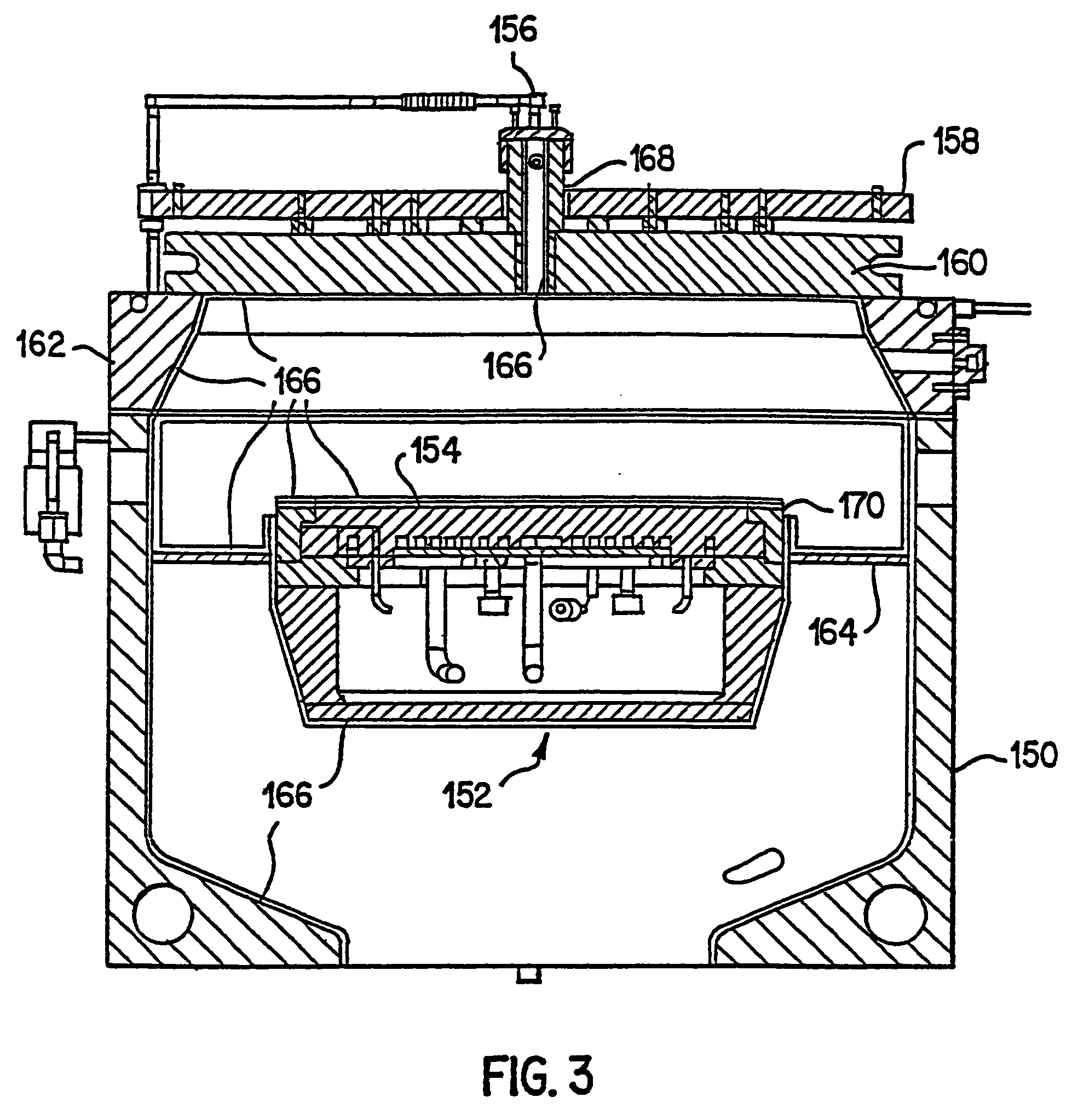

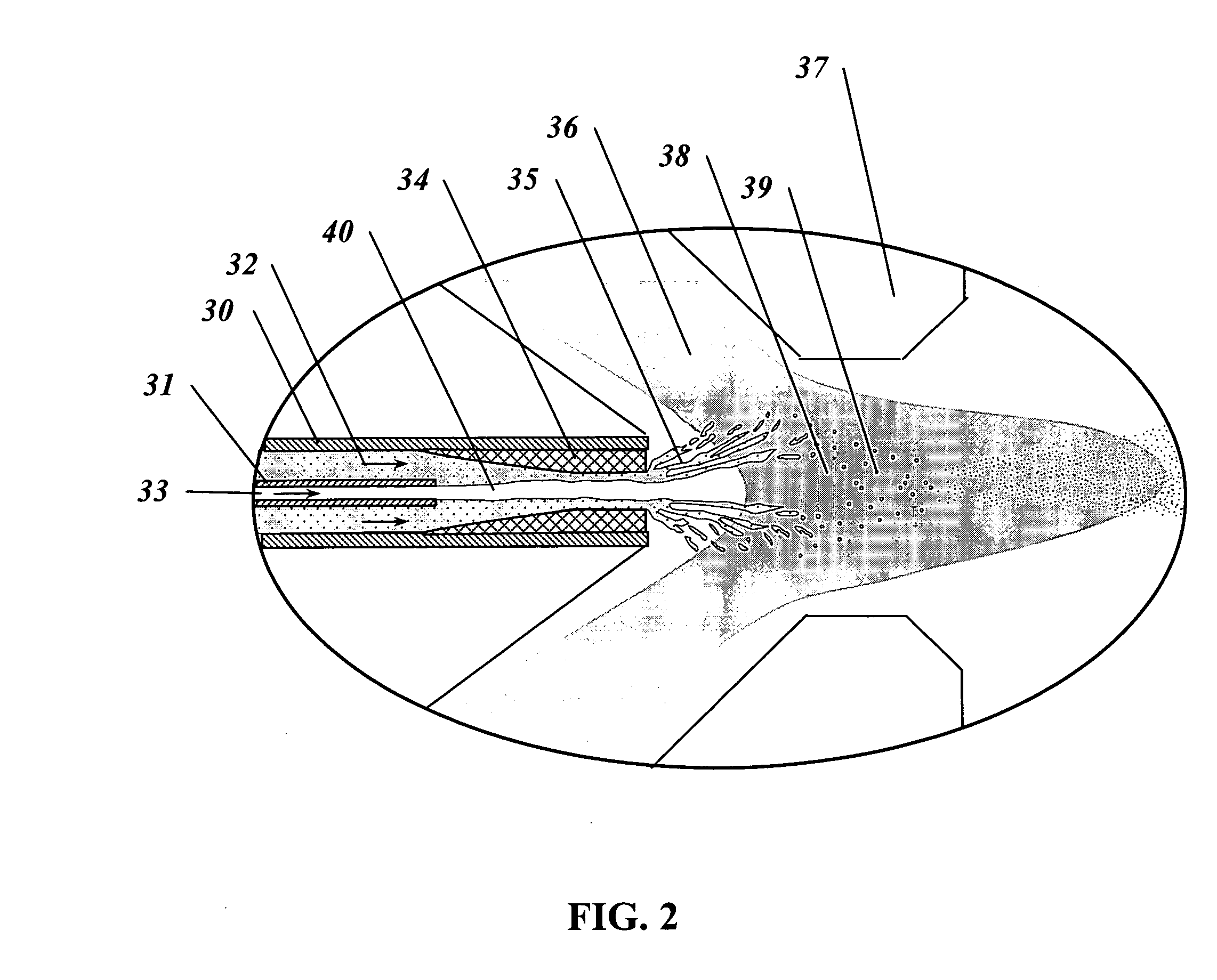

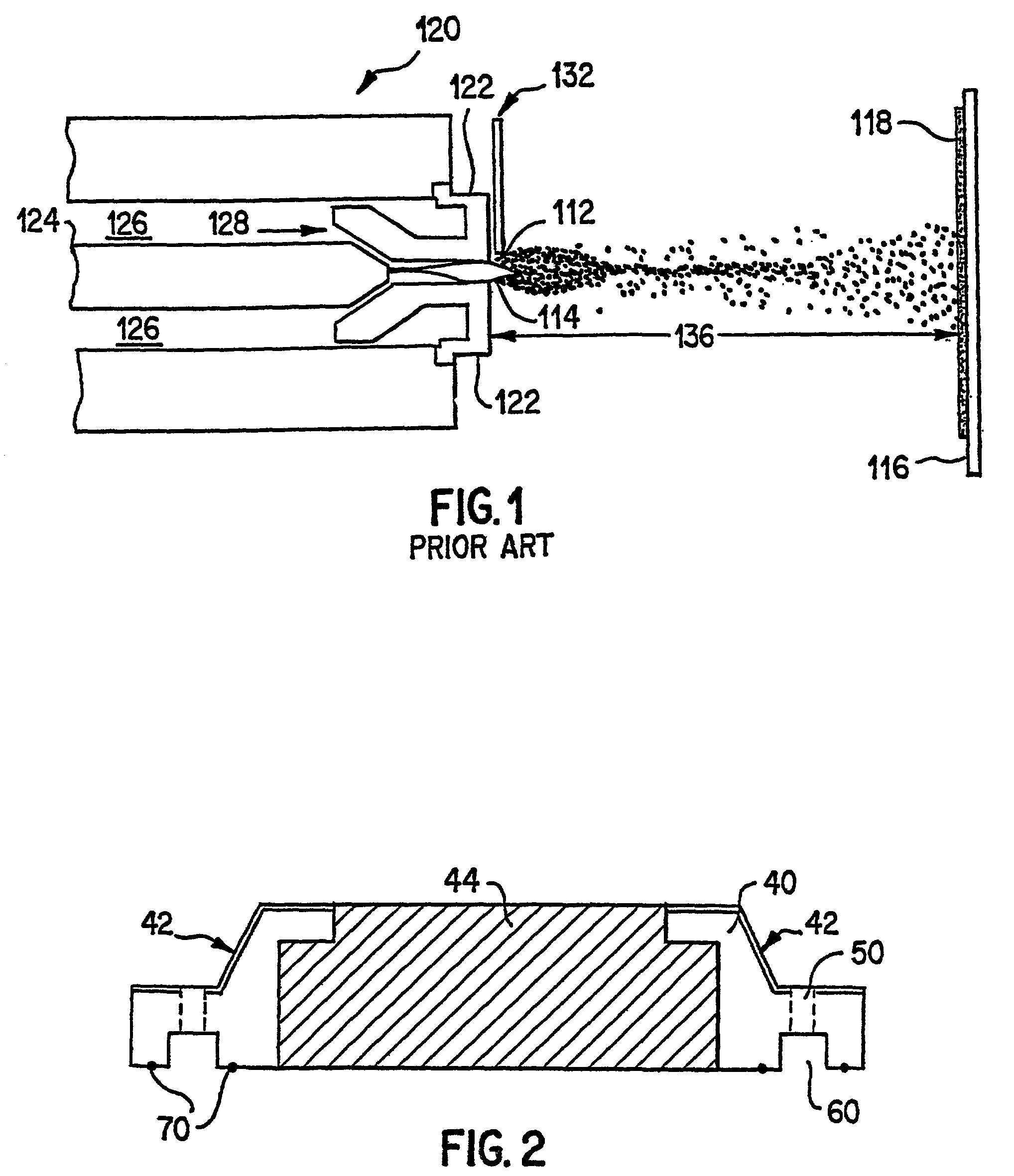

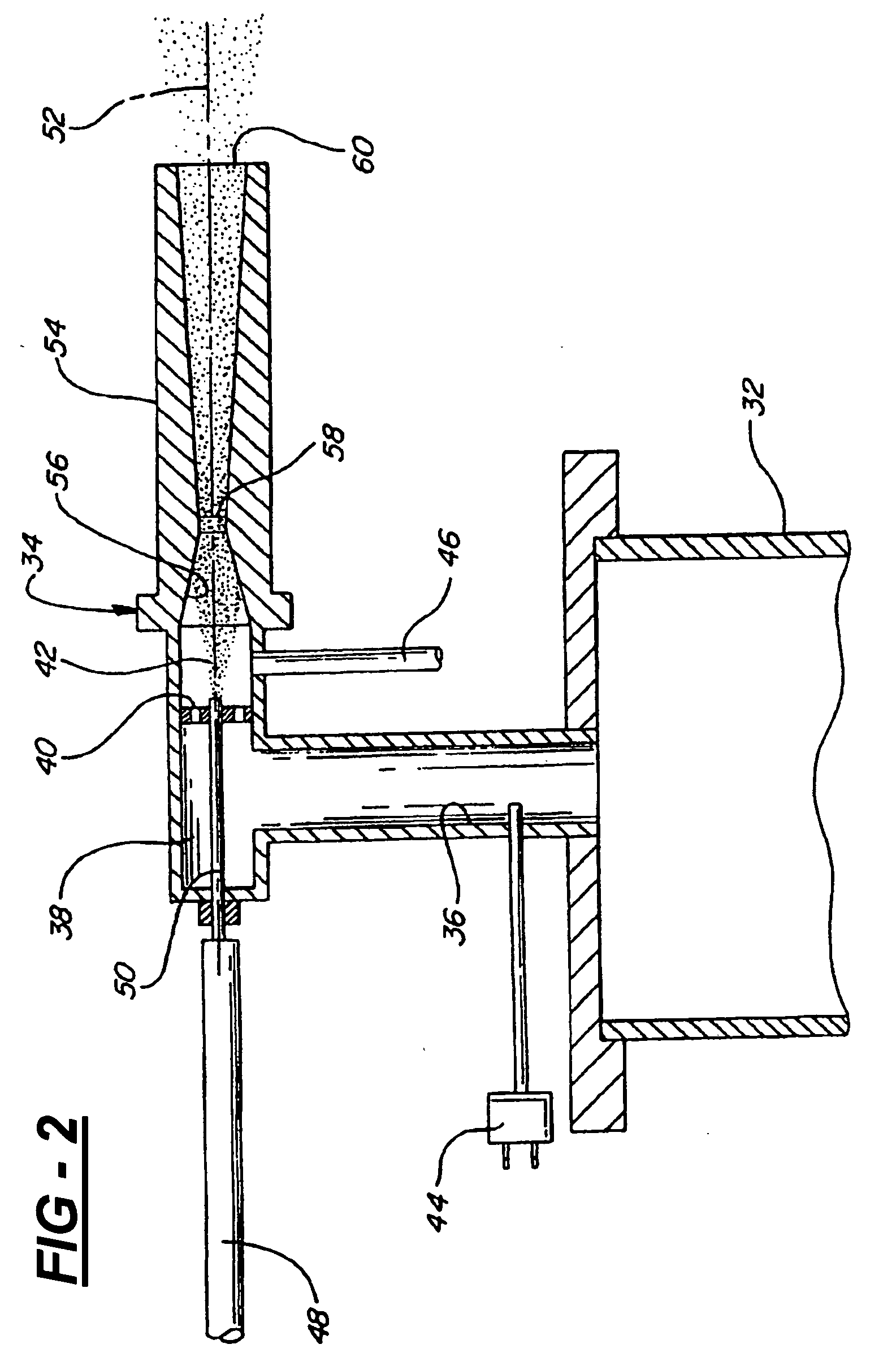

Method and apparatus for fine particle liquid suspension feed for thermal spray system and coatings formed therefrom

ActiveUS20060289405A1Efficient use ofImprove protectionMolten spray coatingCell electrodesThermal sprayingEngineering

This invention relates to a method by which liquid feedstock suspensions containing fine particles, micron- and nano-sized, are injected, with sufficient droplet velocity, preferably axially, into a thermal spray apparatus for the production of high-quality nanostructured coatings. The method allows complete entrainment of the droplets in a high temperature gas stream, while the injection orifice remains potentially blockage-free for long periods of operation.

Owner:NAT RES COUNCIL OF CANADA

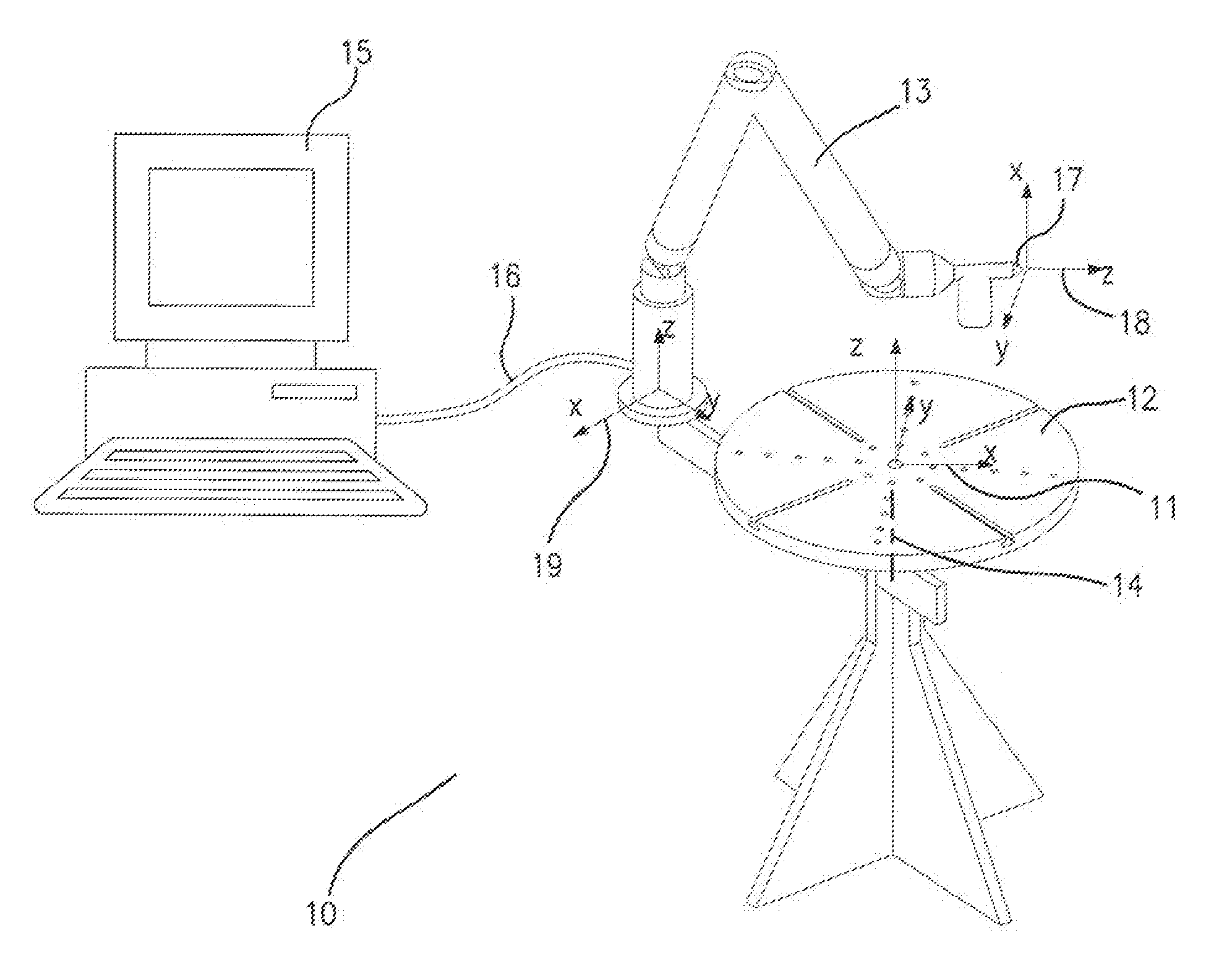

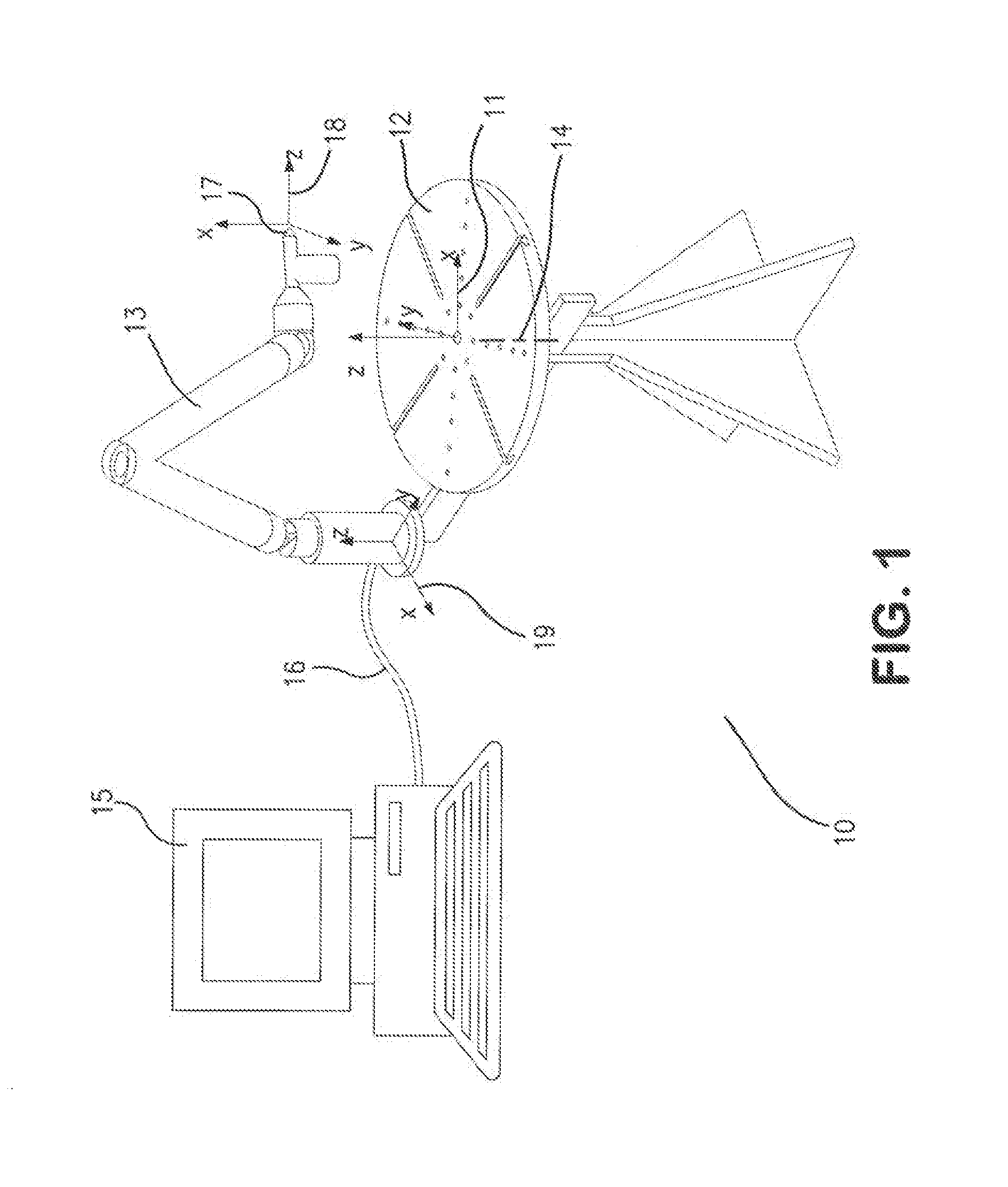

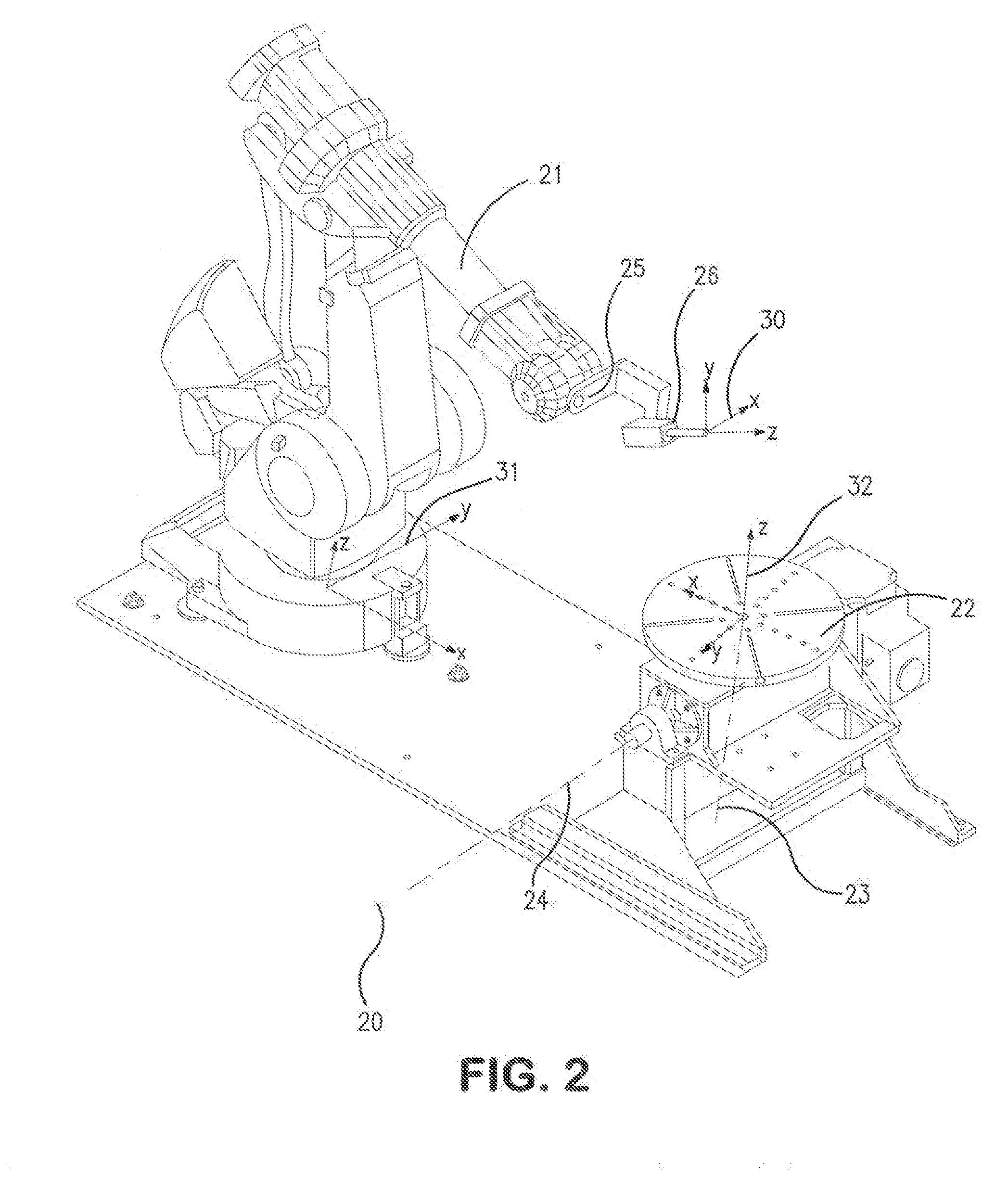

System and method for programming robots

ActiveUS20120123590A1Minimize amountMinimize of productivityProgramme controlProgramme-controlled manipulatorRobot positionActuator

Owner:PRAXAIR ST TECH INC

Productivity enhancing thermal sprayed yttria-containing coating for plasma reactor

InactiveUS7311797B2Improve wear resistanceLow level of contaminationCellsElectric discharge tubesProduction ratePlasma reactor

Components of semiconductor processing apparatus comprise thermal sprayed yttria-containing coatings that provide erosion, corrosion and / or corrosion-erosion resistance in plasma atmospheres. The coatings can protect substrates from physical and / or chemical attack.

Owner:LAM RES CORP

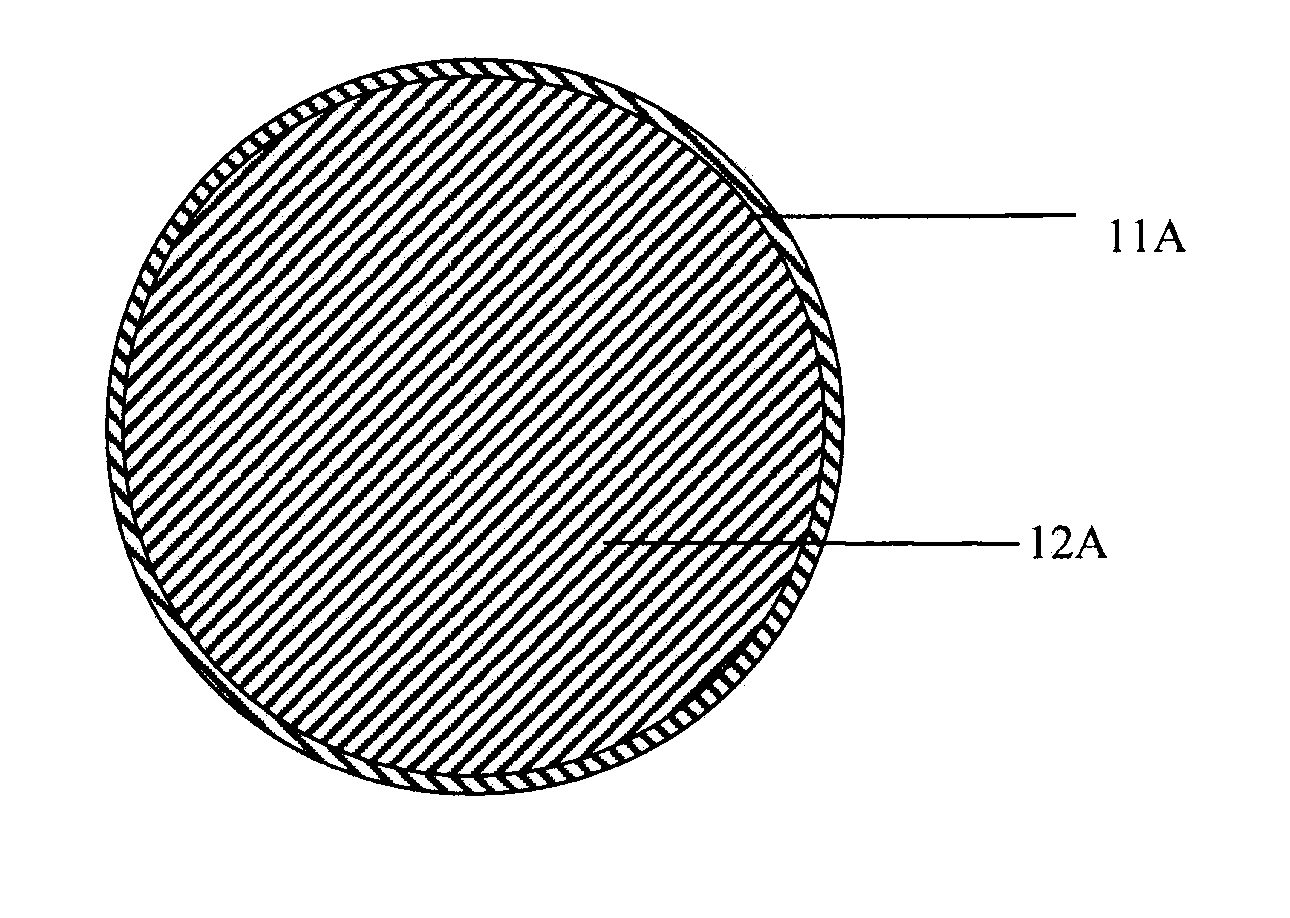

Highly electrically conductive surfaces for electrochemical applications and methods to produce same

InactiveUS20110076587A1High electrical conductanceImprove corrosion resistanceNon-metal conductorsMolten spray coatingElectrically conductiveCorrosion resistant

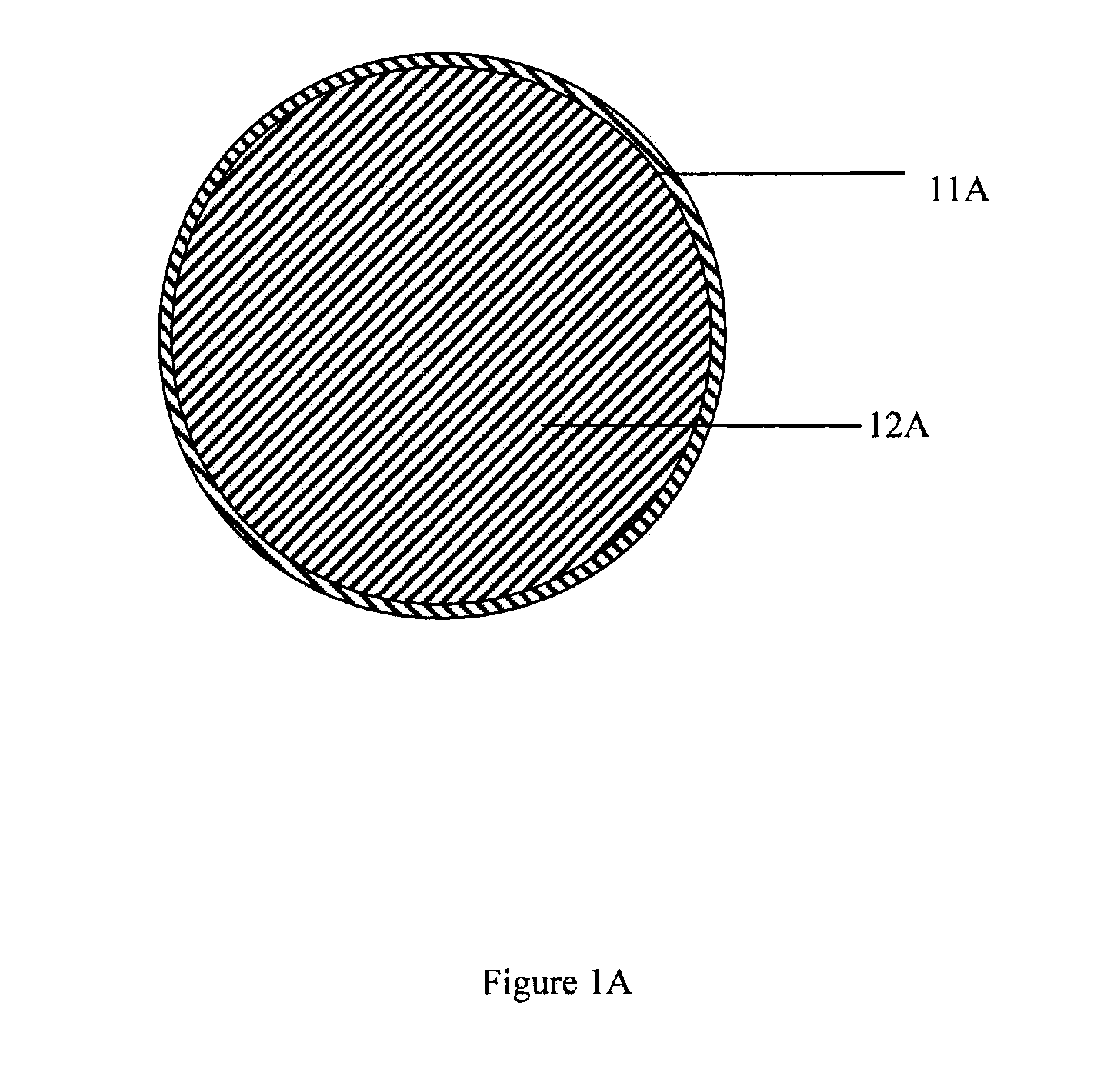

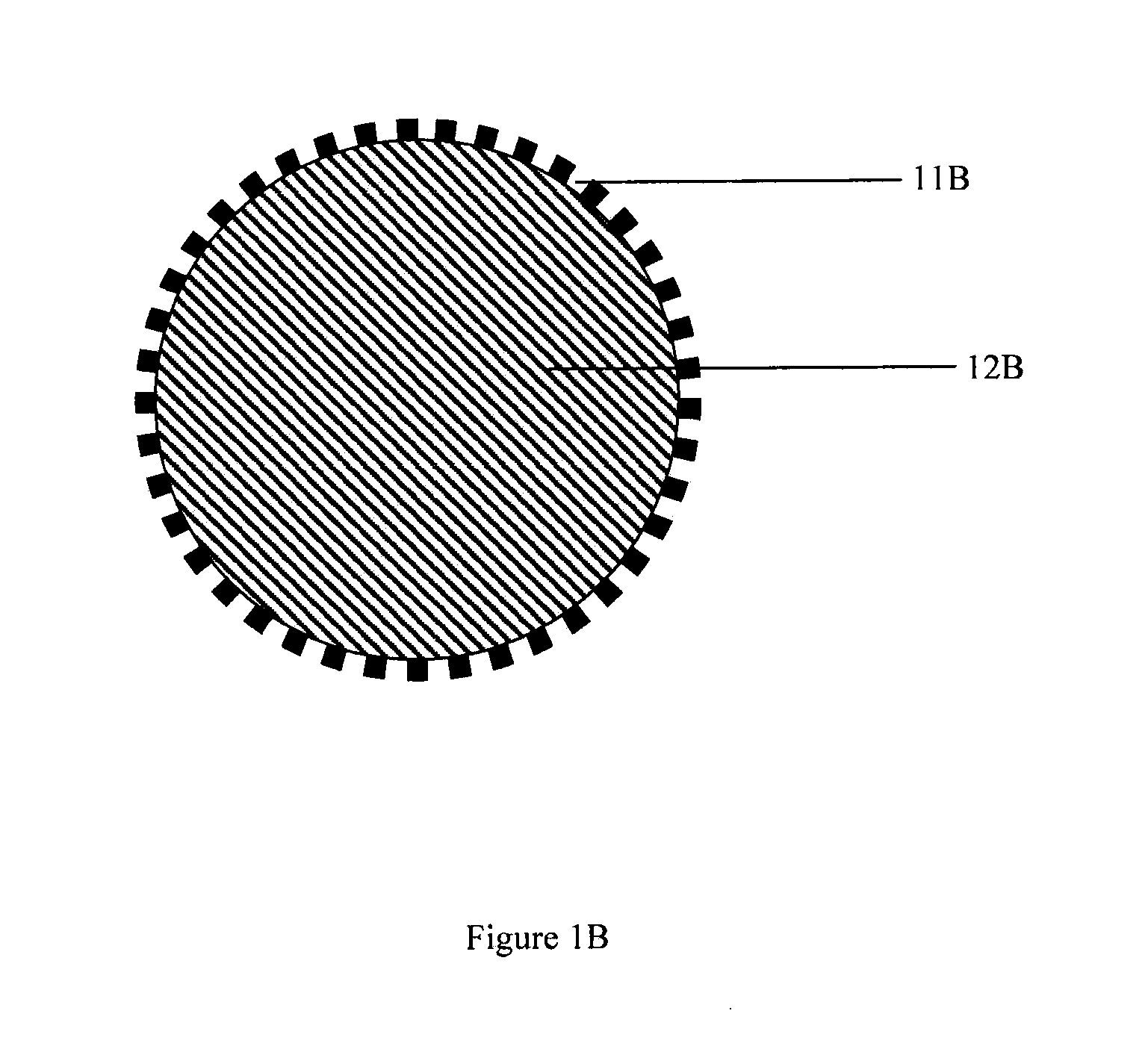

A method to use a novel structured metal-ceramic composite powder to improve the surface electrical conductivity of corrosion resistant metal substrates by thermal spraying the structured powder onto a surface of a metallic substrate is disclosed. The structured powder has a metal core and is wholly or partially surrounded by an electrically conductive ceramic material such as a metal nitride material. The metal cores may have the ceramic material formed on them prior to a thermal spraying process performed in an inert atmosphere, or the thermal spraying may be performed in a reactive atmosphere such that the ceramic coating forms on the cores during the thermal spraying process and / or after deposition. The metal cores will bond conductive ceramic material onto the surface of the substrate through the thermal spray process.

Owner:TREADSTONE TECH INC

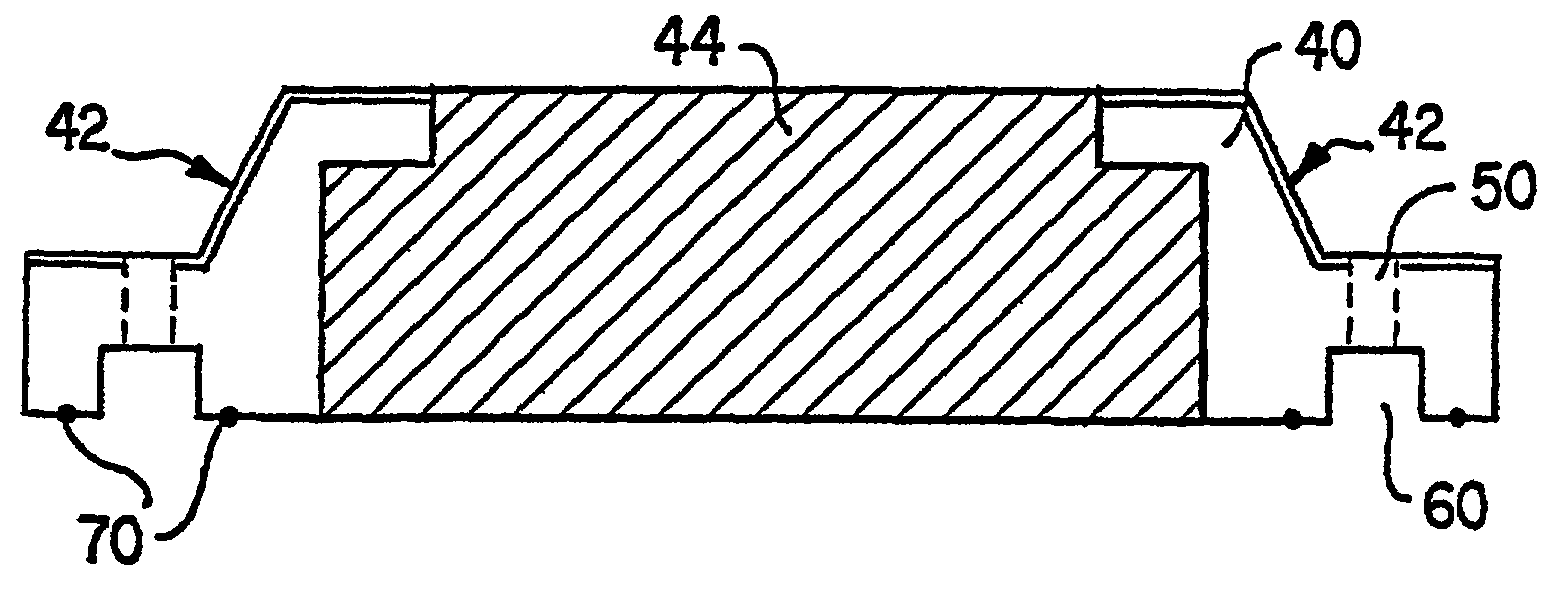

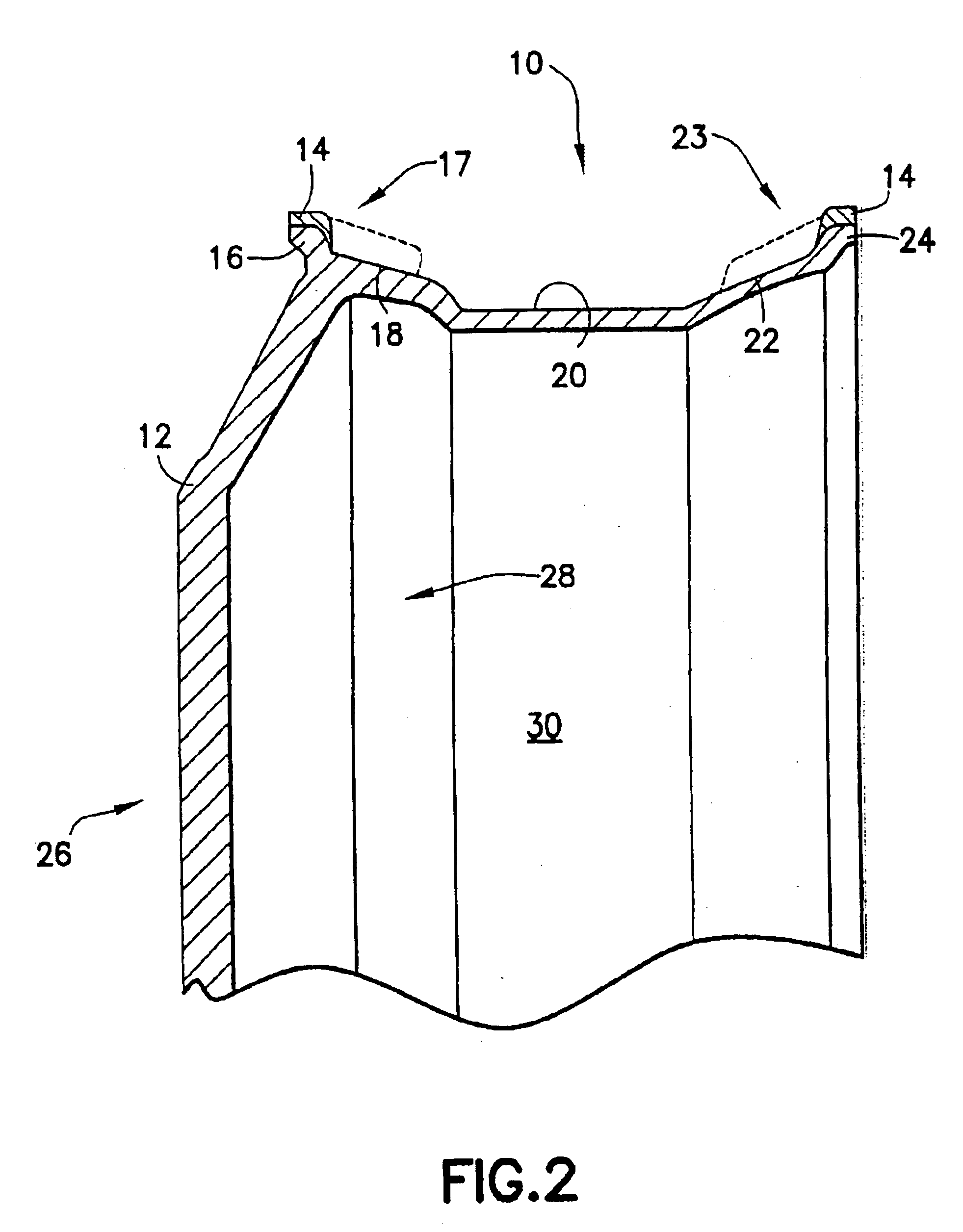

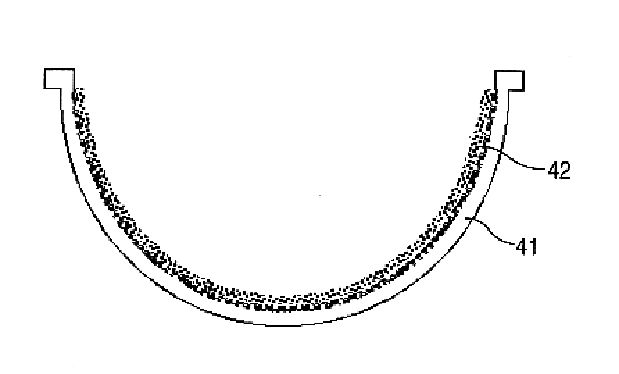

Coated vehicle wheel and method

InactiveUS6872425B2Improve wear conditionsIncrease resistanceMolten spray coatingRimsTire beadThermal spraying

A method of coating a vehicle wheel to increase wear and corrosion resistance of the vehicle wheel, includes the steps of providing a vehicle wheel and applying a wear and corrosion resistant coating onto a surface of the vehicle wheel. The coating is applied to at least a tire bead retaining flange of the vehicle wheel. The coating is of particular use with vehicle wheels made of forged aluminum. The coating is selected from tungsten carbide, optionally including cobalt or chrome, a nickel-based superalloy, aluminum and silicon carbide, or stainless steel.The coating is typically applied to a thickness of about 0.004-0.01 inch. The surface of the vehicle wheel may be prepared by mechanically abrading the surface or chemically etching the surface of the vehicle wheel. The coating may be applied by cold spraying, thermal spraying, or triboelectric discharge kinetic spraying and other similar processes.

Owner:ARCONIC INC

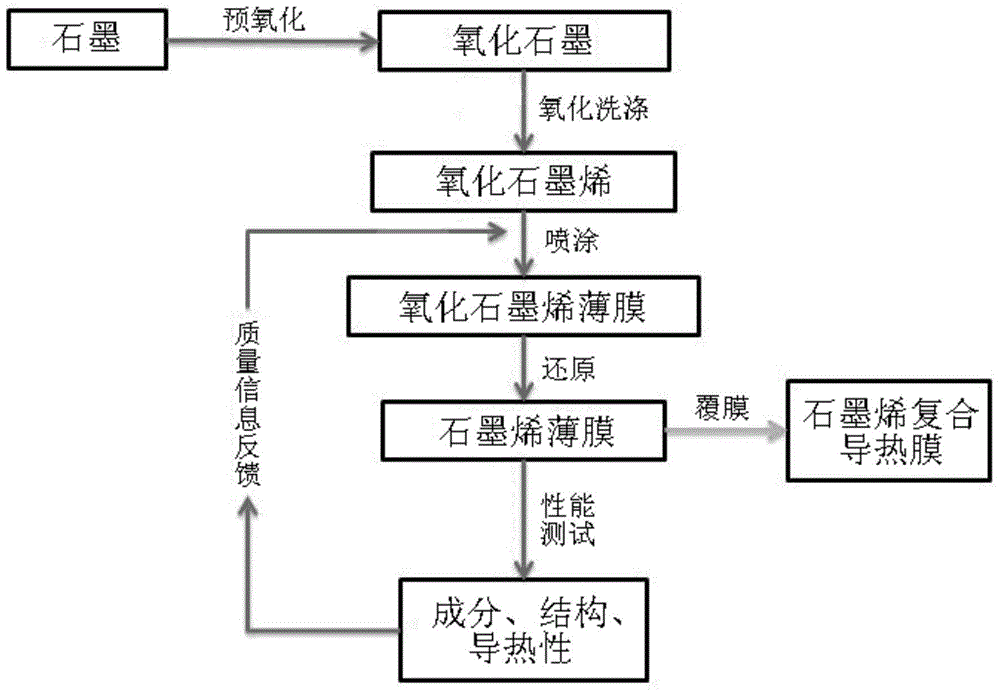

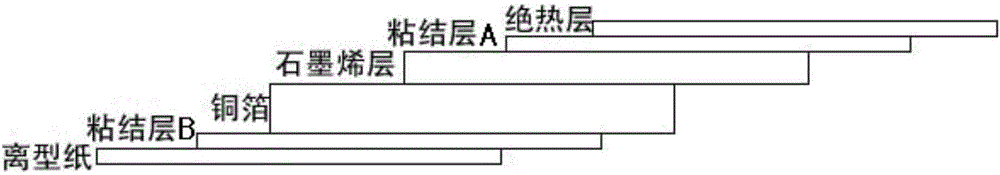

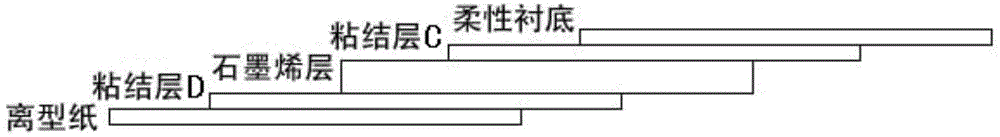

Preparation method of composite heat conduction graphene film and composite heat conduction graphene film

ActiveCN104085143AIncrease layer spacingThoroughly oxidizedMetal layered productsPotassium persulfateFiltration

The invention discloses a preparation method of a composite heat conduction graphene membrane and the composite heat conduction graphene film. The preparation method comprises the following steps: S1, putting crystalline flake graphite or graphite powder into a mixed solution of concentrated sulfuric acid, potassium persulfate and phosphorus pentoxide, soaking for a day and a night, then carrying out suction filtration, drying, and carrying out pre-oxidizing; S2, oxidizing pre-oxidized graphite further by adopting a Hummers method, that is, oxidizing fully in concentrated sulfuric acid and potassium permanganate, then adding deionized water for diluting, and carrying out repeated washing and suction filtration, so as to obtain an oxidized graphene aqueous solution; S3, spraying the oxidized graphene aqueous solution on a substrate by adopting a thermal spray method, and depositing, so as to obtain an oxidized graphene film; S4, reducing the oxidized graphene film, so as to obtain the graphene film; and S5, laminating the graphene film, so as to obtain the composite heat conduction graphene film. Compared with the prior art, the preparation method is simple, the cost is low, and the prepared composite heat conduction graphene film has a favorable heat conduction performance.

Owner:成都科愿慧希科技有限公司

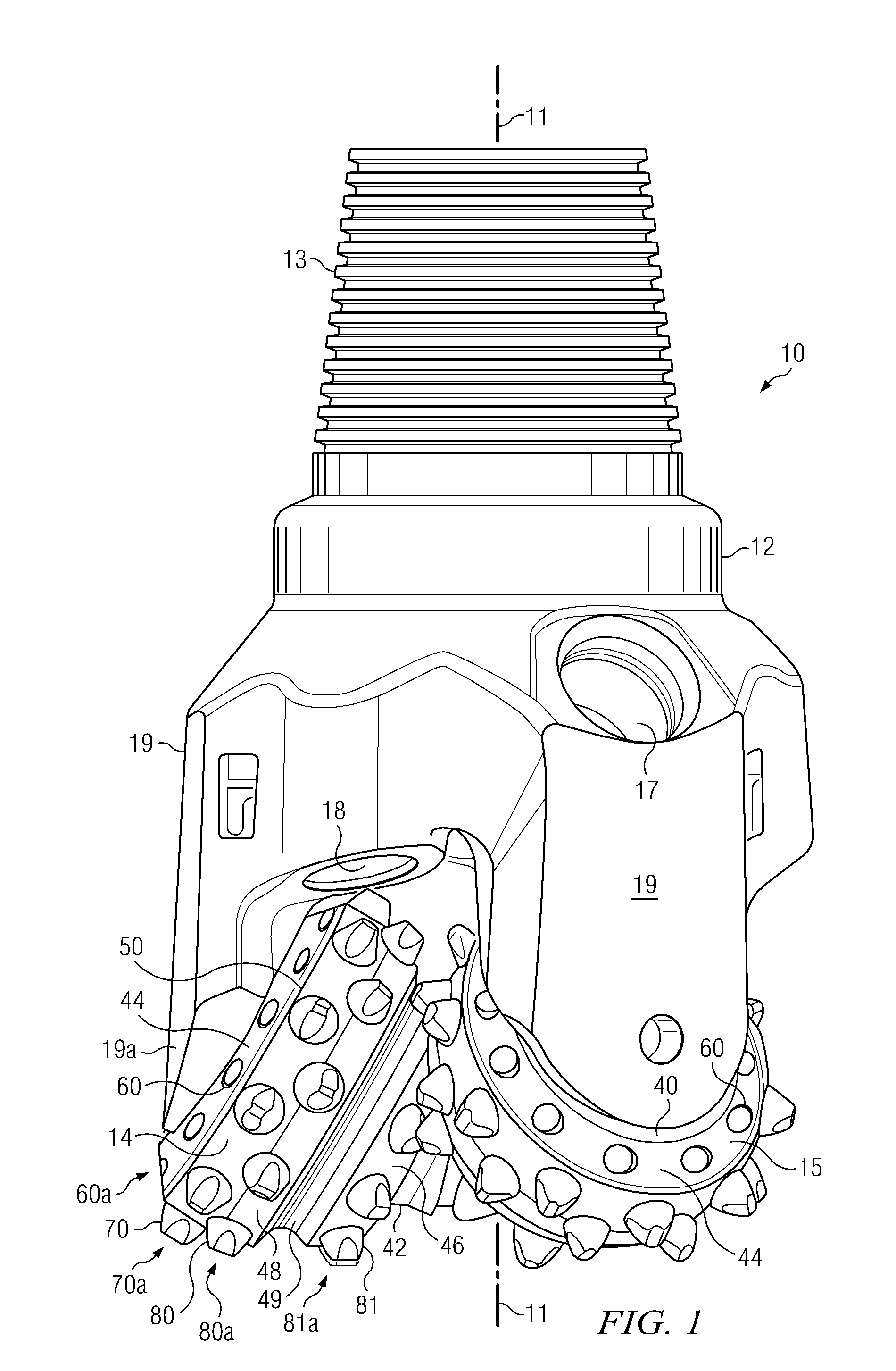

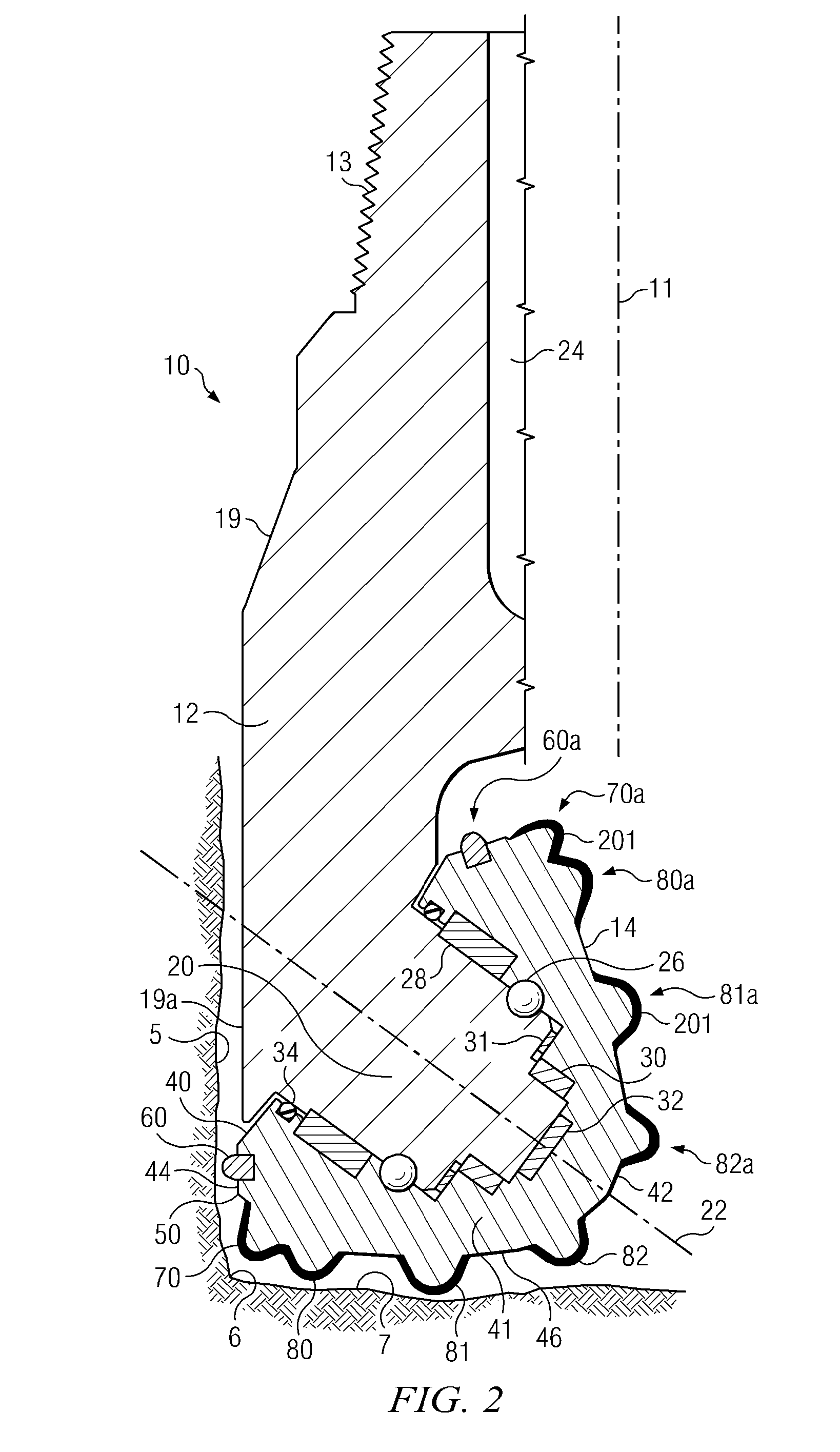

Roller Cones, Methods of Manufacturing Such Roller Cones, and Drill Bits Incorporating Such Roller Cones

A roller cone drill bit having a layer of wear resistant material applied thereon utilizing a thermal spray process and methods of manufacturing such drill bits.

Owner:SMITH INT INC

Annealing furnace roller surface peening coating and method for making same

InactiveCN101113487AImprove antioxidant capacityImprove wear resistanceMolten spray coatingFurnace typesThermal sprayingBond coating

The invention relates to a strengthening coating of the surface of an annealing furnace roller and a preparation method thereof. The preparation of the strengthening coating on the surface of a roller base is performed by a selected hot-spray method. The strengthening coating comprises a bonded coating, a working coating and a transition coating between the bonded coating and the working coating. The proportion of alloy and ceramic in every coating is changed according to gradient, which means that the proportion of alloy is decreased gradually from inner to outer in every coating; while the proportion of ceramic is increased gradually and at last a gradient coating is formed. The invention not only ensures the working coating to have good antioxidation, abrasion resisting and anti- nodulation performances, but also improves the binding performance of strengthening coating and the roller base and improves the cohesion binding performance of the coating inner. Under the function of the strengthening coating of the annealing furnace roller surface made by the method of the invention, the service life of the furnace roller can be prolonged and the using cost and repairing cost can be decreased.

Owner:常州杰耐机械有限公司

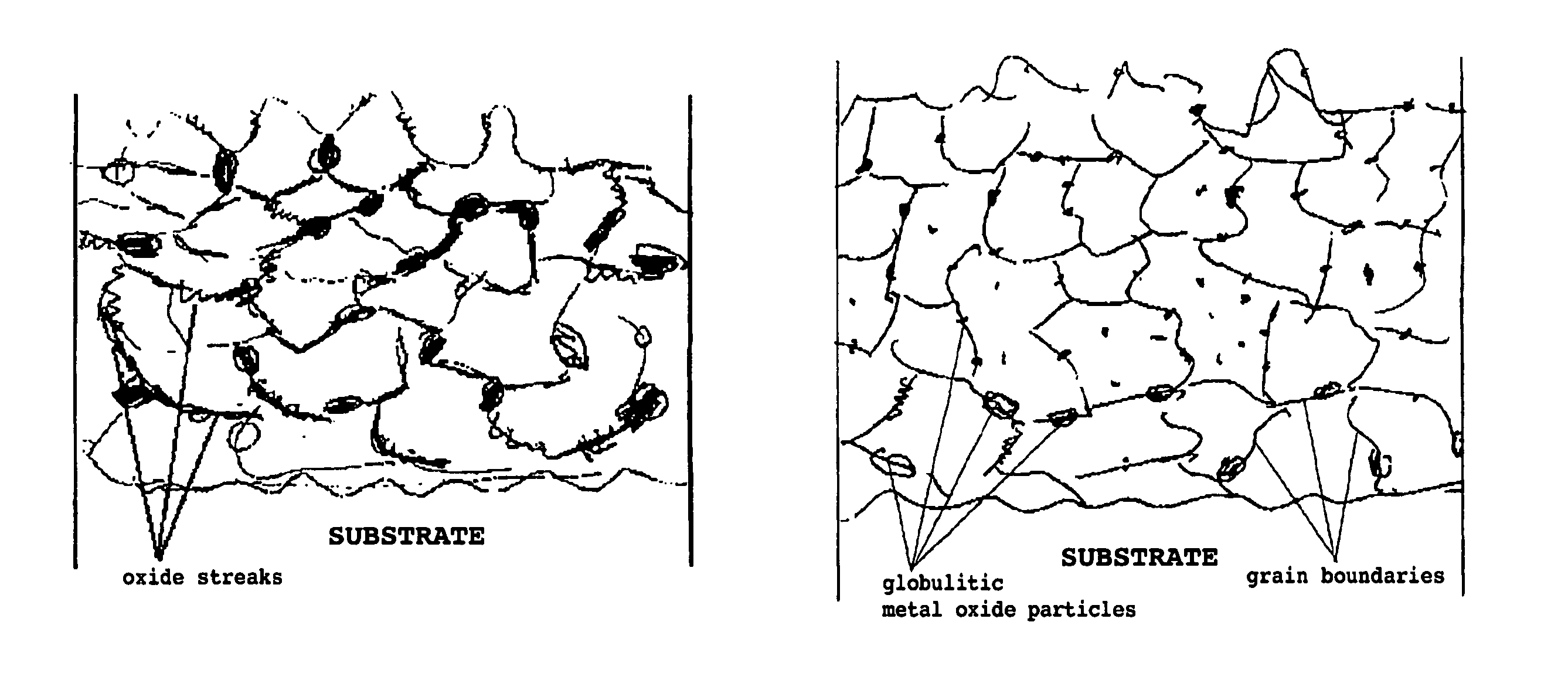

Protective coating for application to a substrate and method for manufacturing a protective coating

InactiveUS20060292390A1High heat and corrosion resistanceCost-effective manufacturingMolten spray coatingPretreated surfacesMetallic materialsSpray coating

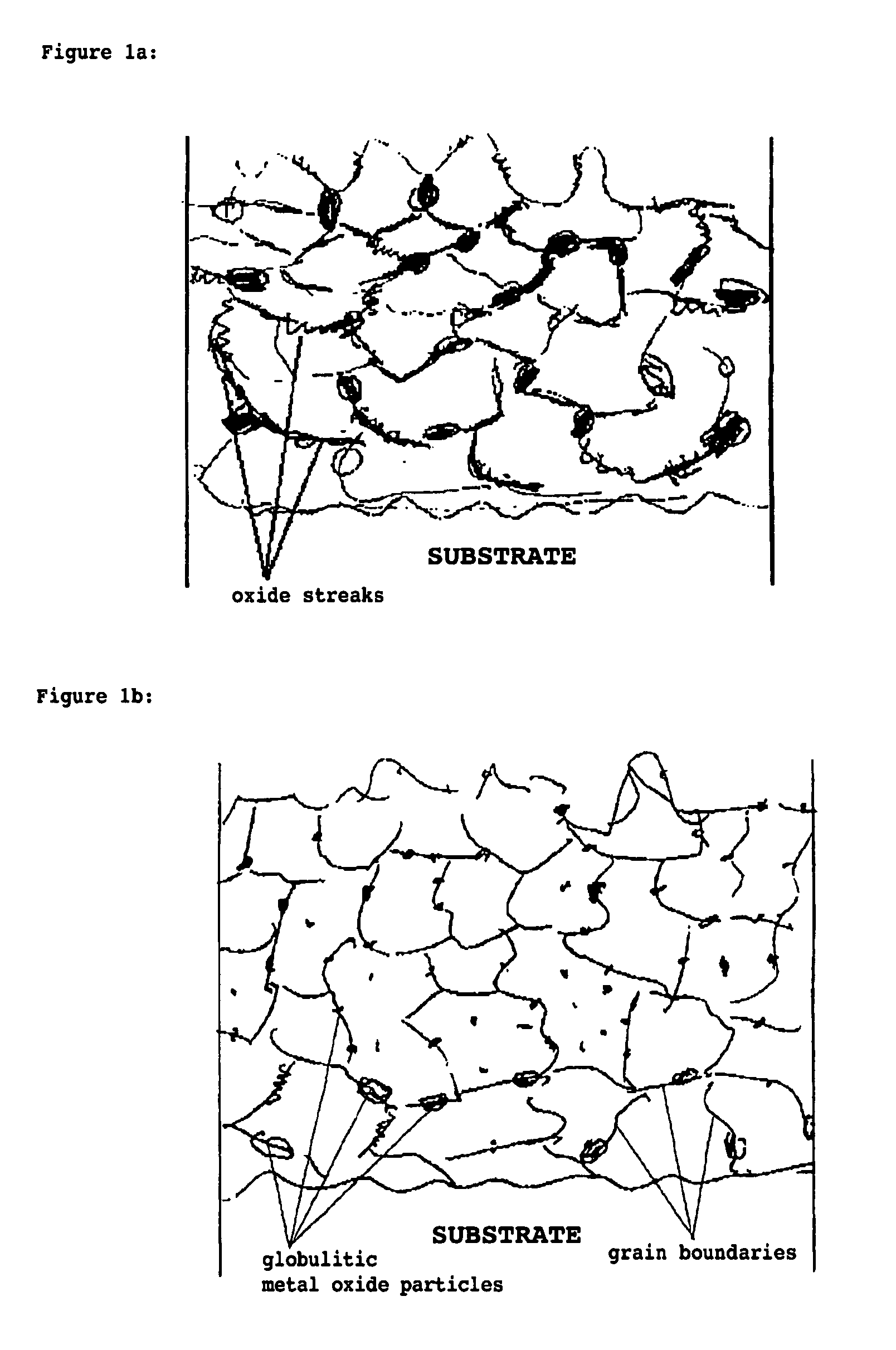

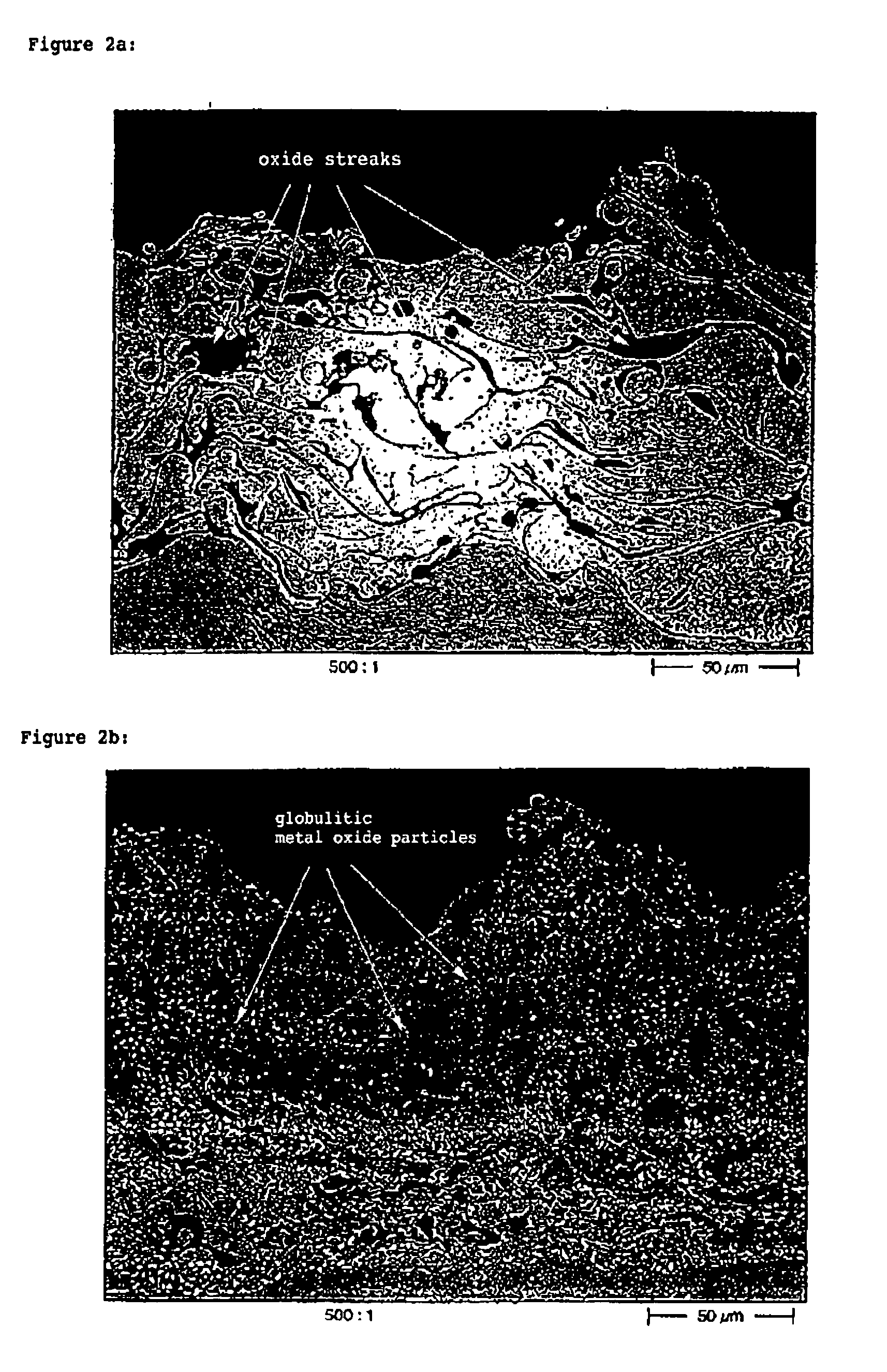

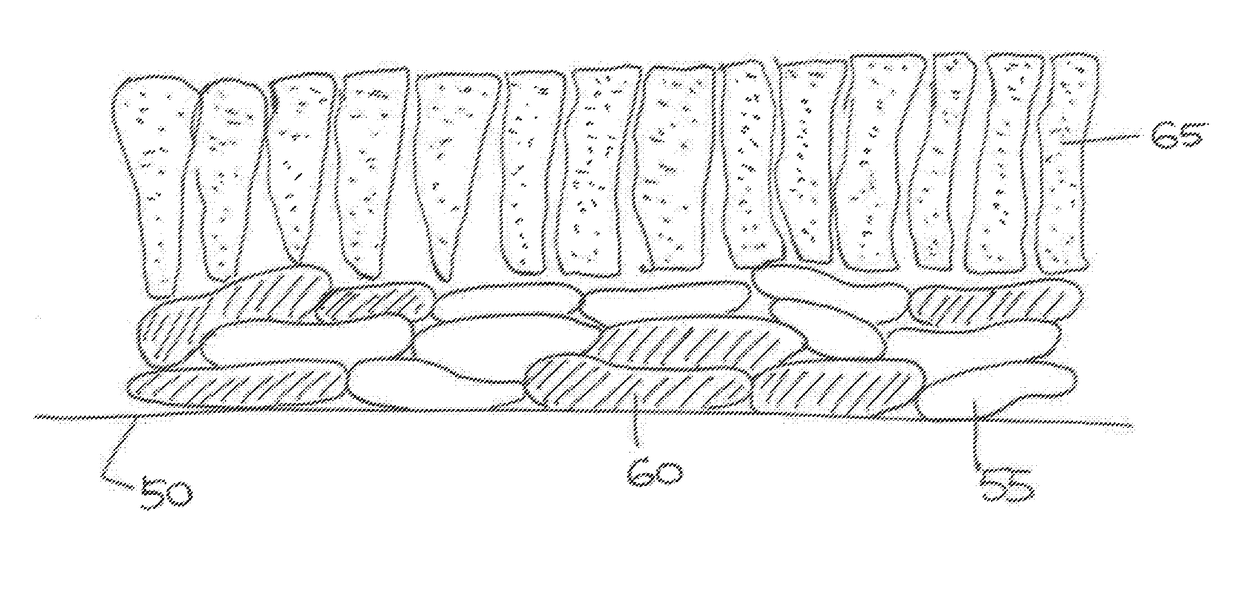

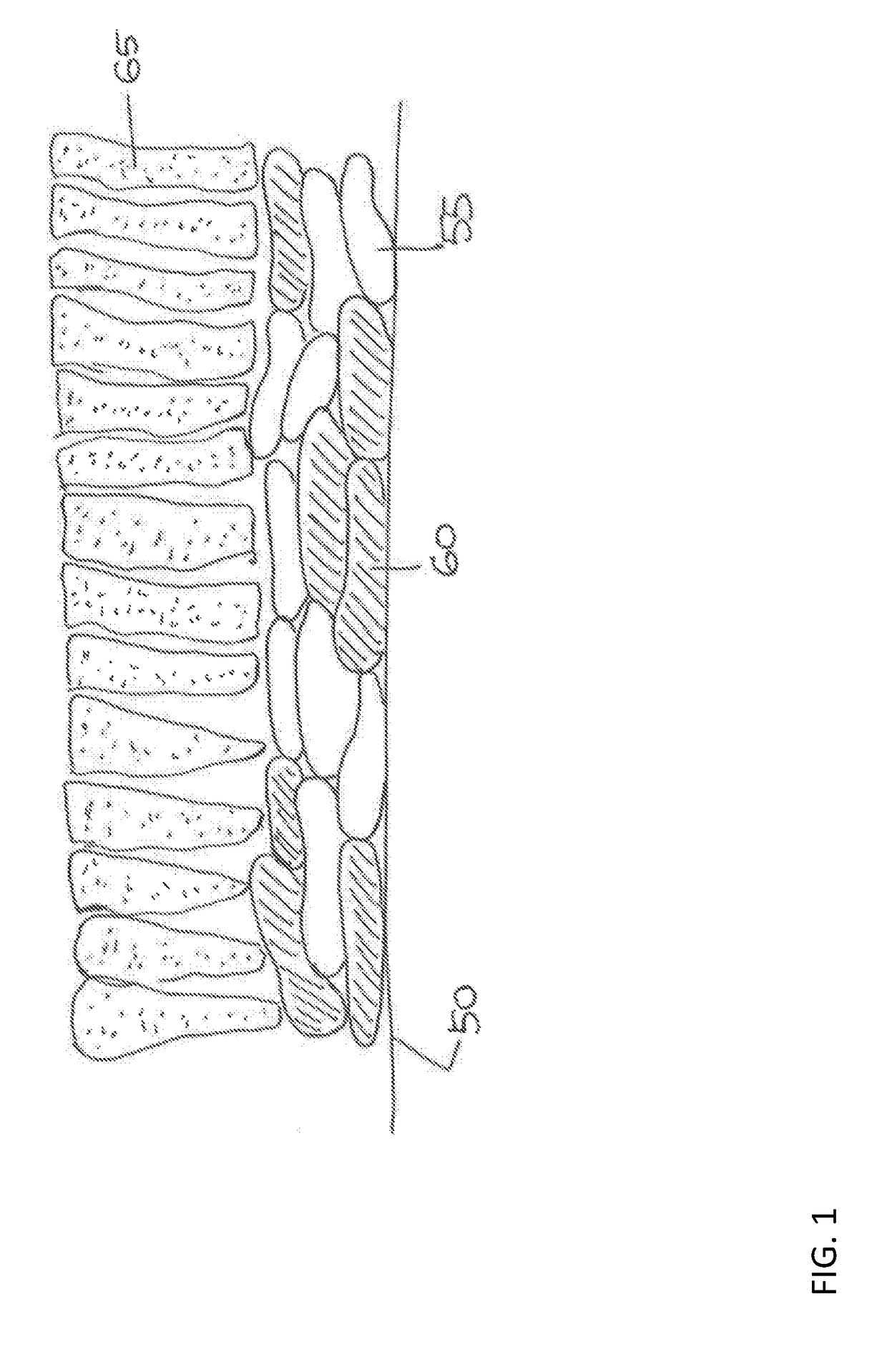

A refractory, oxidation-resistant, and corrosion-resistant protective coating for application to a substrate, in particular for application to parts of turbines or aircraft propulsion engines, is described, including a spray coating made of a thermally sprayed, primarily metallic material, the coating being at least partially subjected to a thermochemical aluminum (Cr, Si) deposition process having a specifically high aluminum deposition activity after the application of the protective coating to the substrate, in such a way that the protective coating has alloy gradients of Al (Cr, Si) which increase from the substrate surface to the coating surface and isolated globulitic metal oxide particles. Furthermore, a method for manufacturing this protective coating and its use are described.

Owner:MTU AERO ENGINES GMBH

Thermally sprayed resistive heaters and uses thereof

InactiveUS20170258268A1Low resistivityStable resistivityMolten spray coatingHeater elementsBorideThermal spraying

A heater is provided having at least one thermally sprayed resistive heating layer, the resistive heating layer comprising a first metallic component that is electrically conductive and capable of reacting with a gas to form one or more carbide, oxide, nitride, and boride derivative; one or more oxide, nitride, carbide, and boride derivative of the first metallic component that is electrically insulating; and a third component capable of stabilizing the resistivity of the resistive heating layer. In some embodiments, the third component is capable of pinning the grain boundaries of the first metallic component deposited in the resistive heating layer and / or altering the structure of aluminum oxide grains deposited in the resistive heating layer.

Owner:THERMOCERAMIX +1

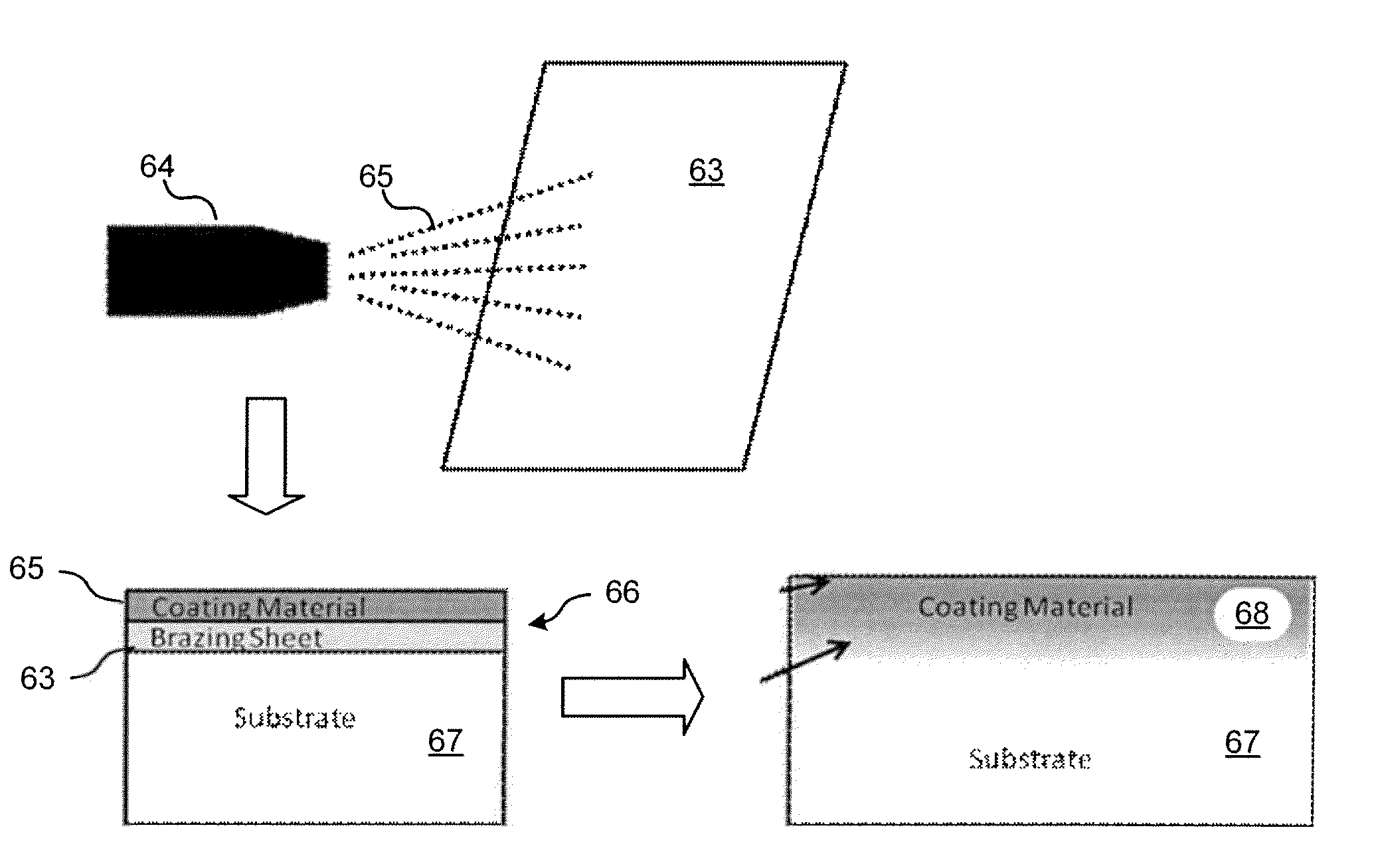

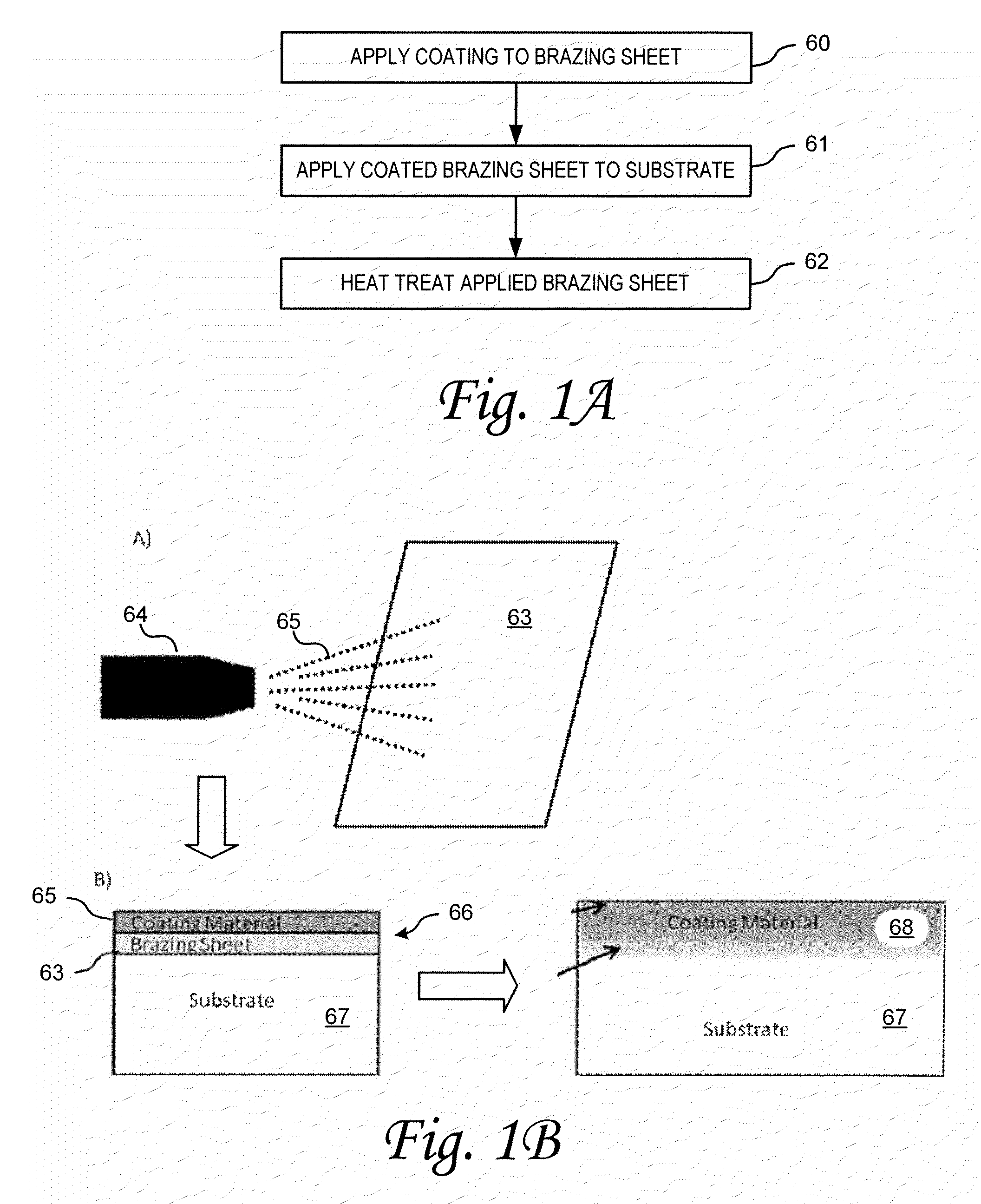

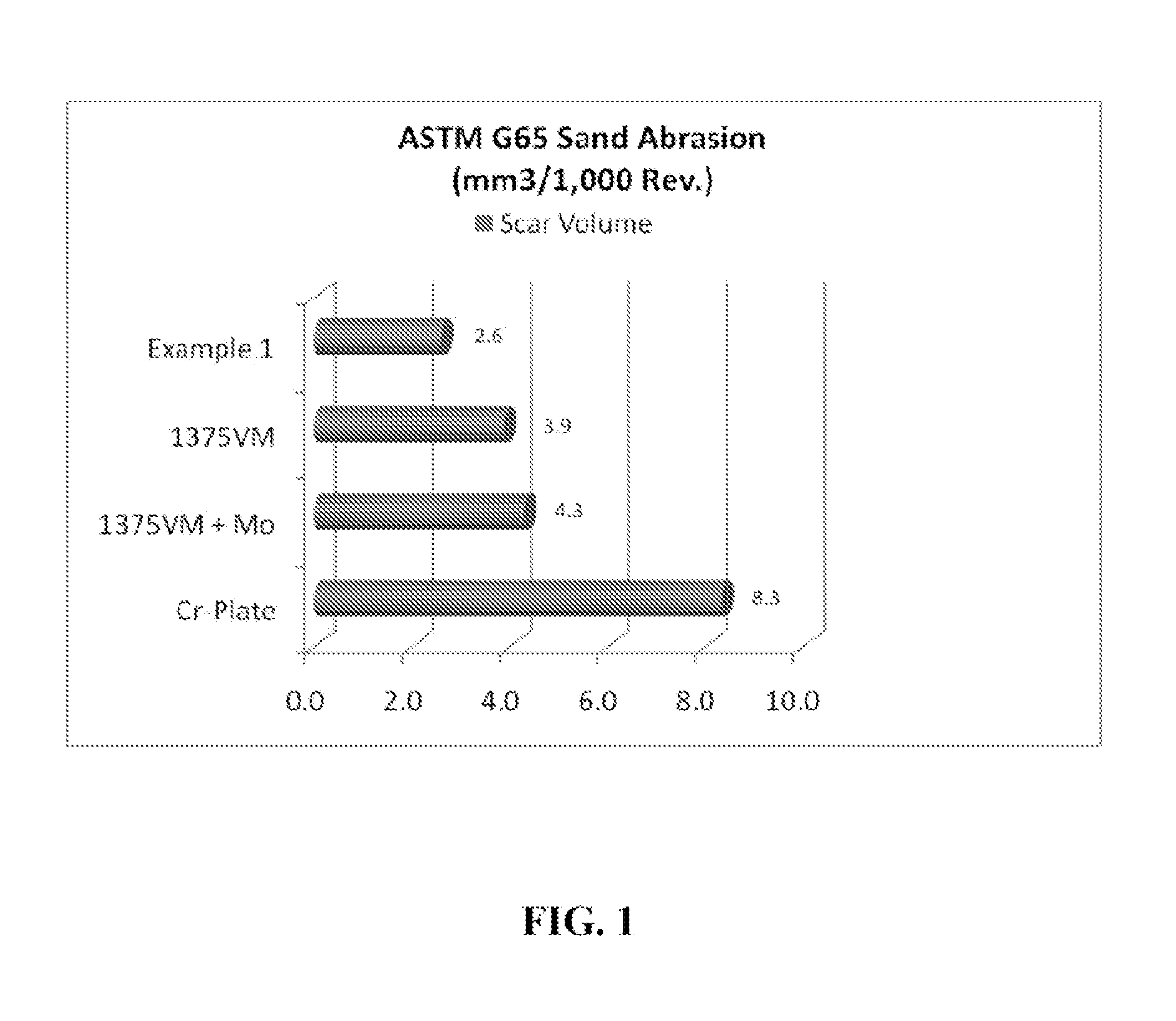

Thermal spray processes and alloys for use in same

The present invention provides a method for coating an article comprising applying a thermal spray coating to the article; applying a brazing material to the article; and heating the brazing material to at least a brazing temperature of the brazing material to form a resultant coating on the article, wherein the resultant coating is characterized by at least partial metallurgical bonding or at least partial alloying between the thermal spray coating and the brazing material.

Owner:SCOPERTA INC

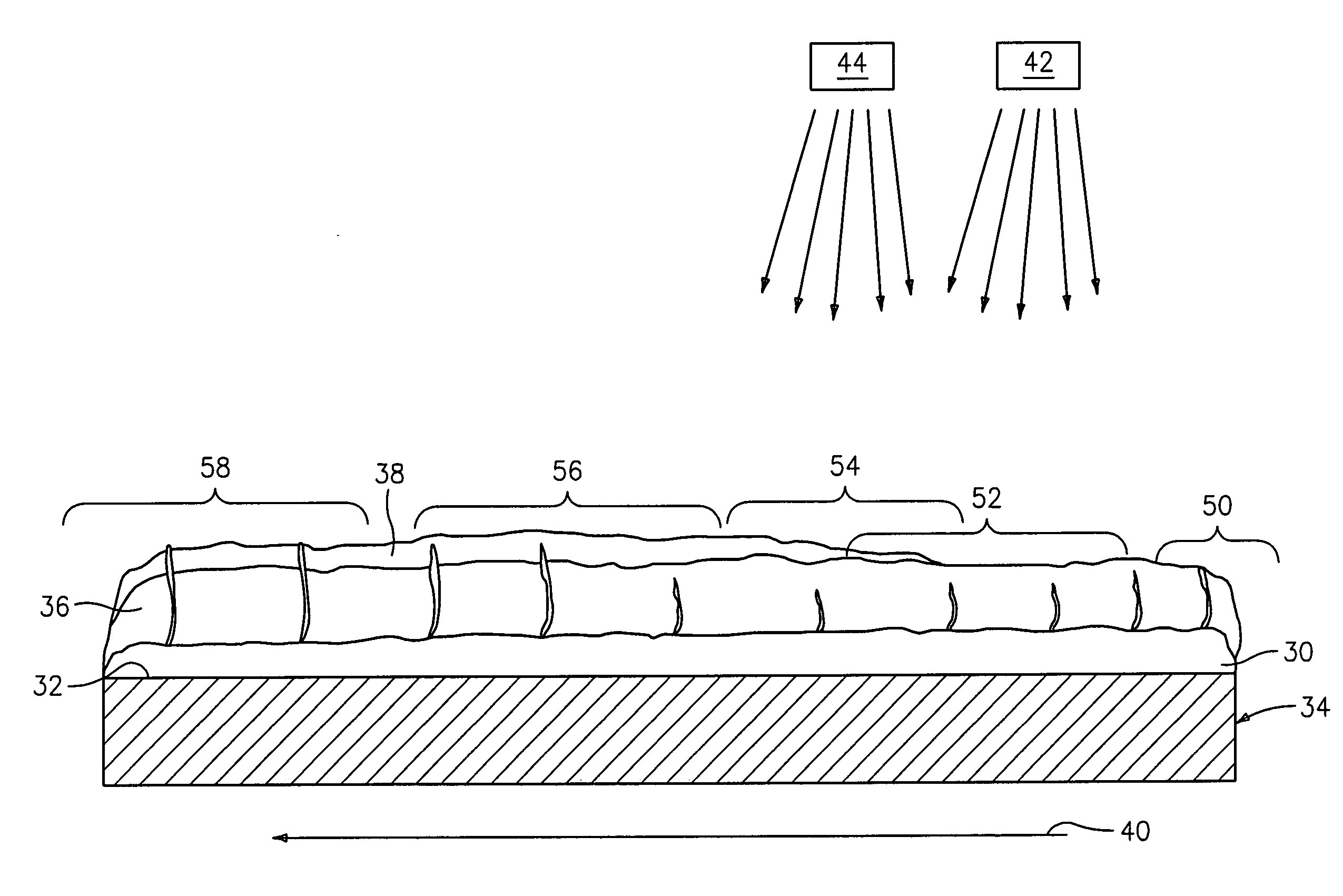

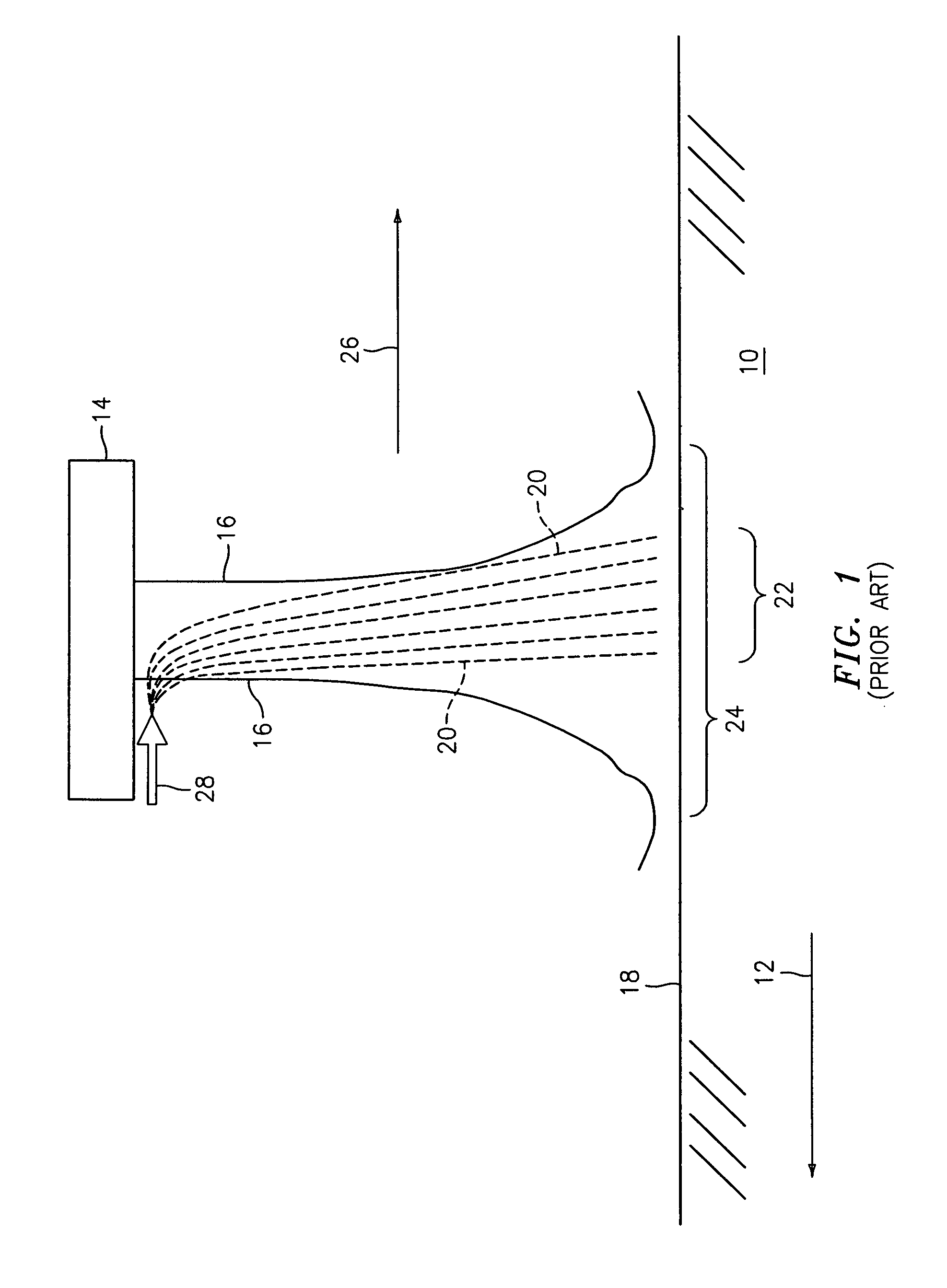

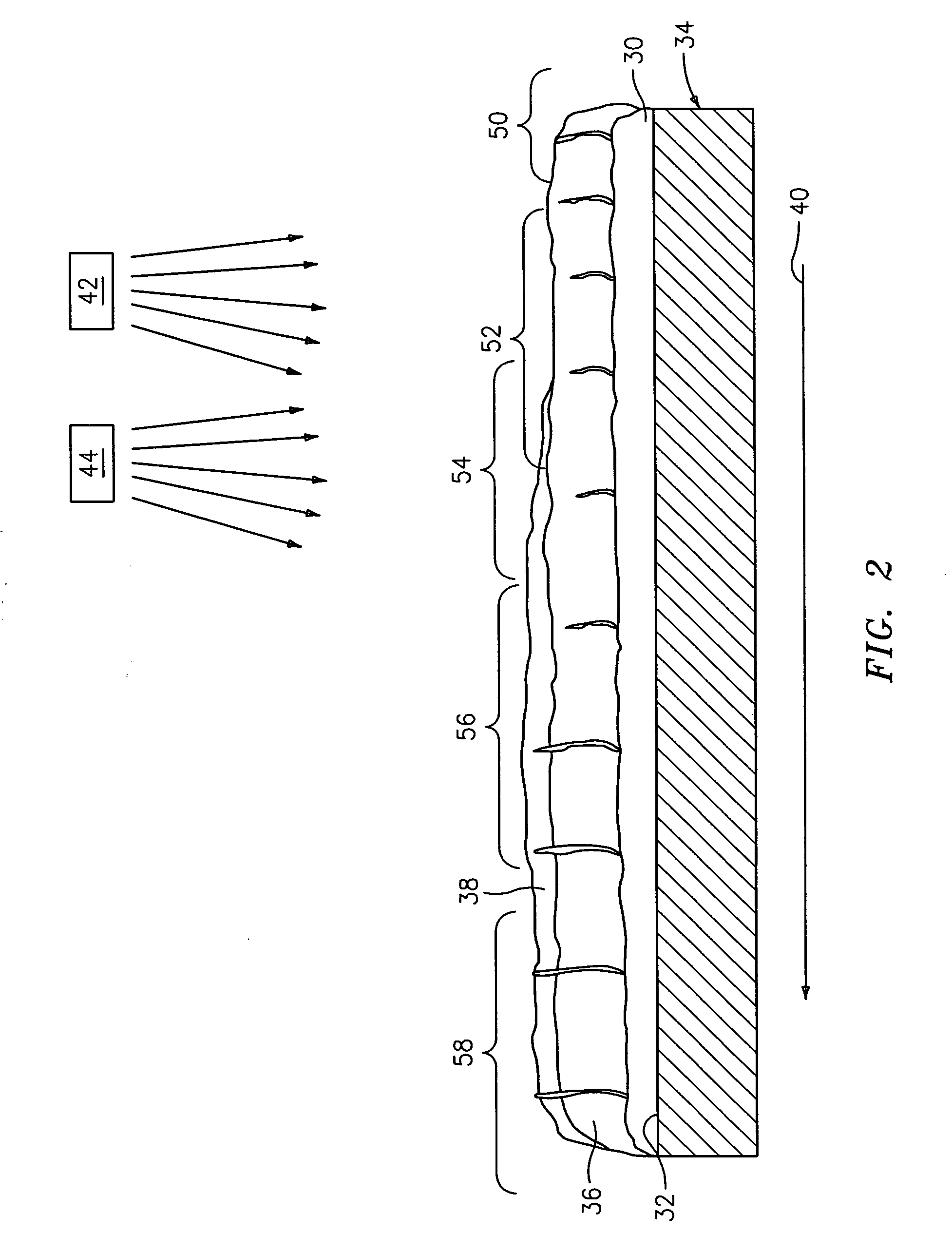

Method for microstructure control of ceramic thermal spray coating

InactiveUS20080166489A1Promote vertical crack propagationMolten spray coatingBlade accessoriesThermal sprayingCeramic coating

An apparatus for applying segmented ceramic coatings includes means for supporting and moving one or more substrates; one or more heat sources disposed proximate to one or more substrates, wherein at least one of the heat sources is positioned to apply a heat stream to pre-heat a thermal gradient zone on a surface of a substrate; a material deposition device disposed proximate to one or more heat sources, wherein the material deposition device is positioned to deposit a material on a deposition area located behind the thermal gradient zone on the surface; and means for monitoring a surface temperature of one or more substrates.

Owner:UNITED TECH CORP

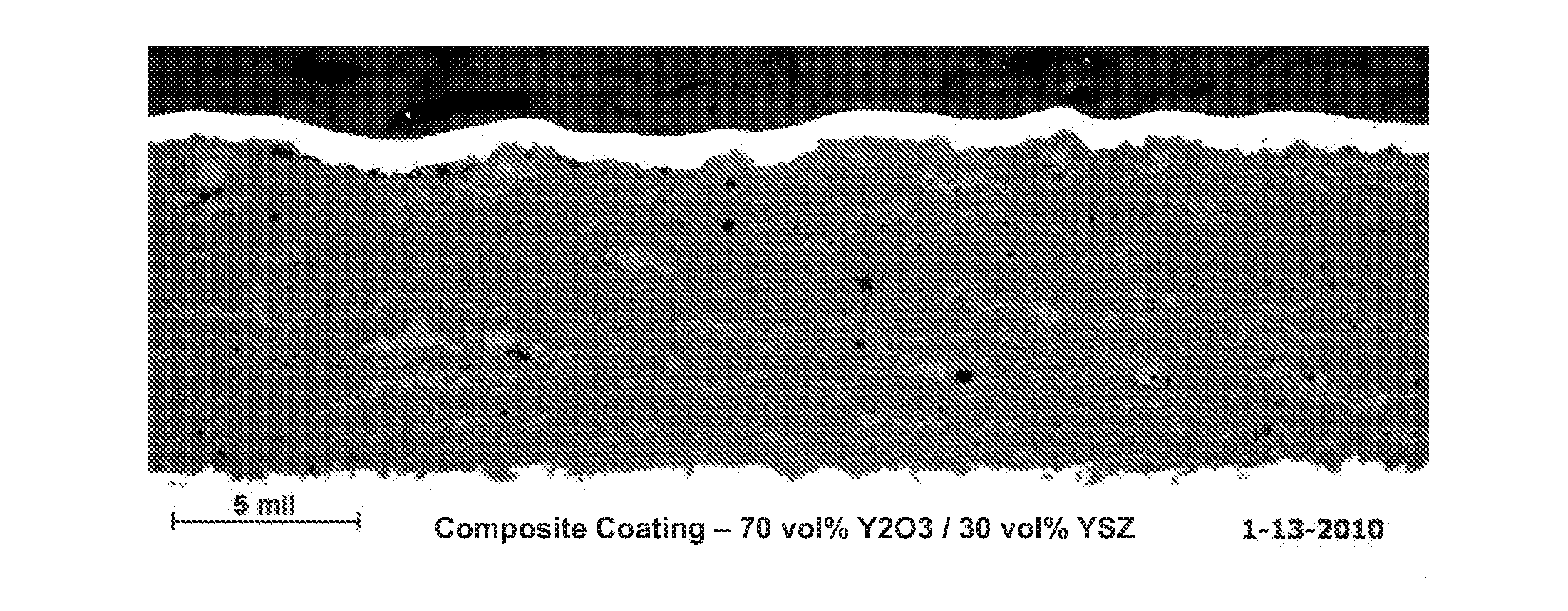

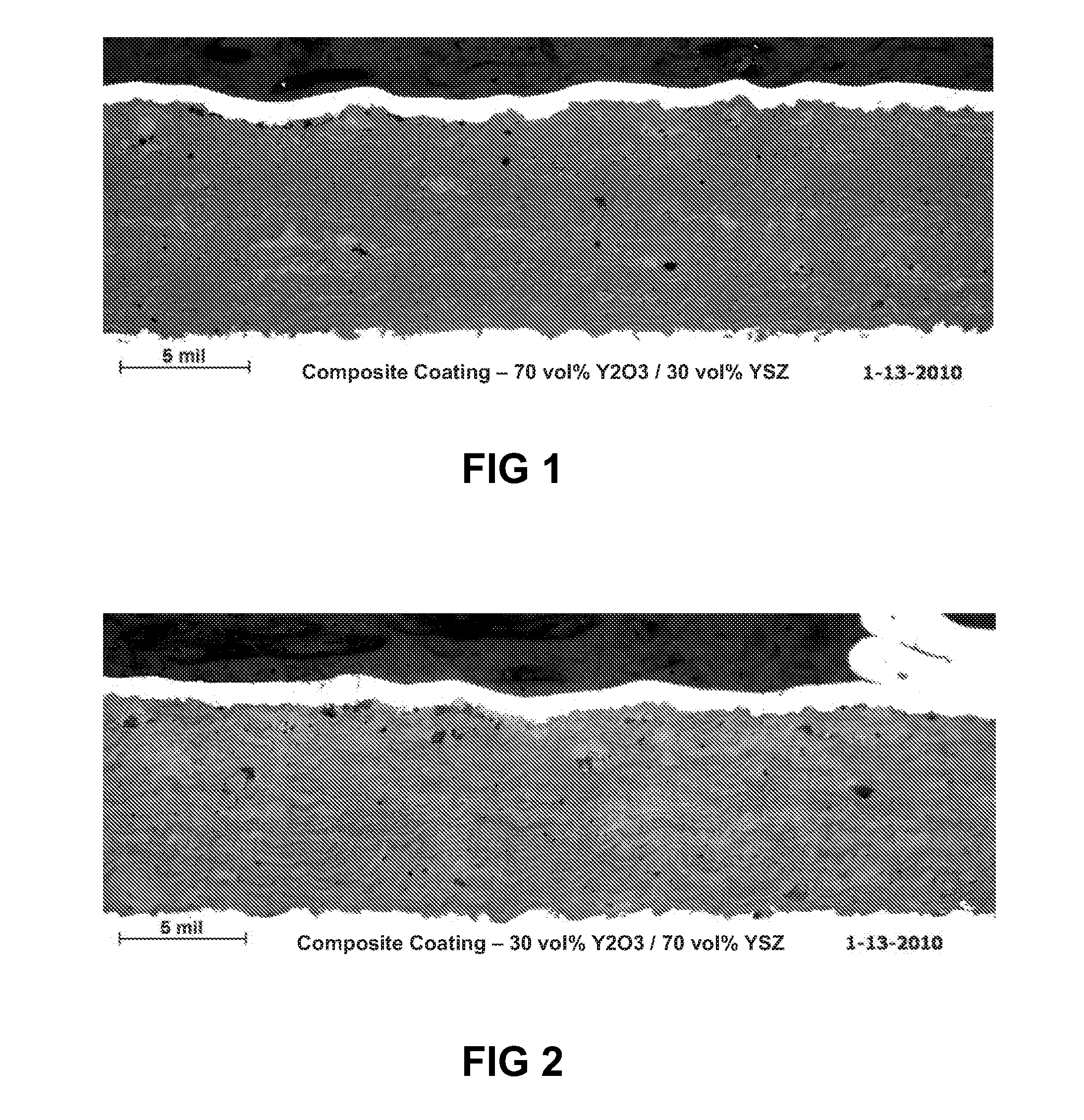

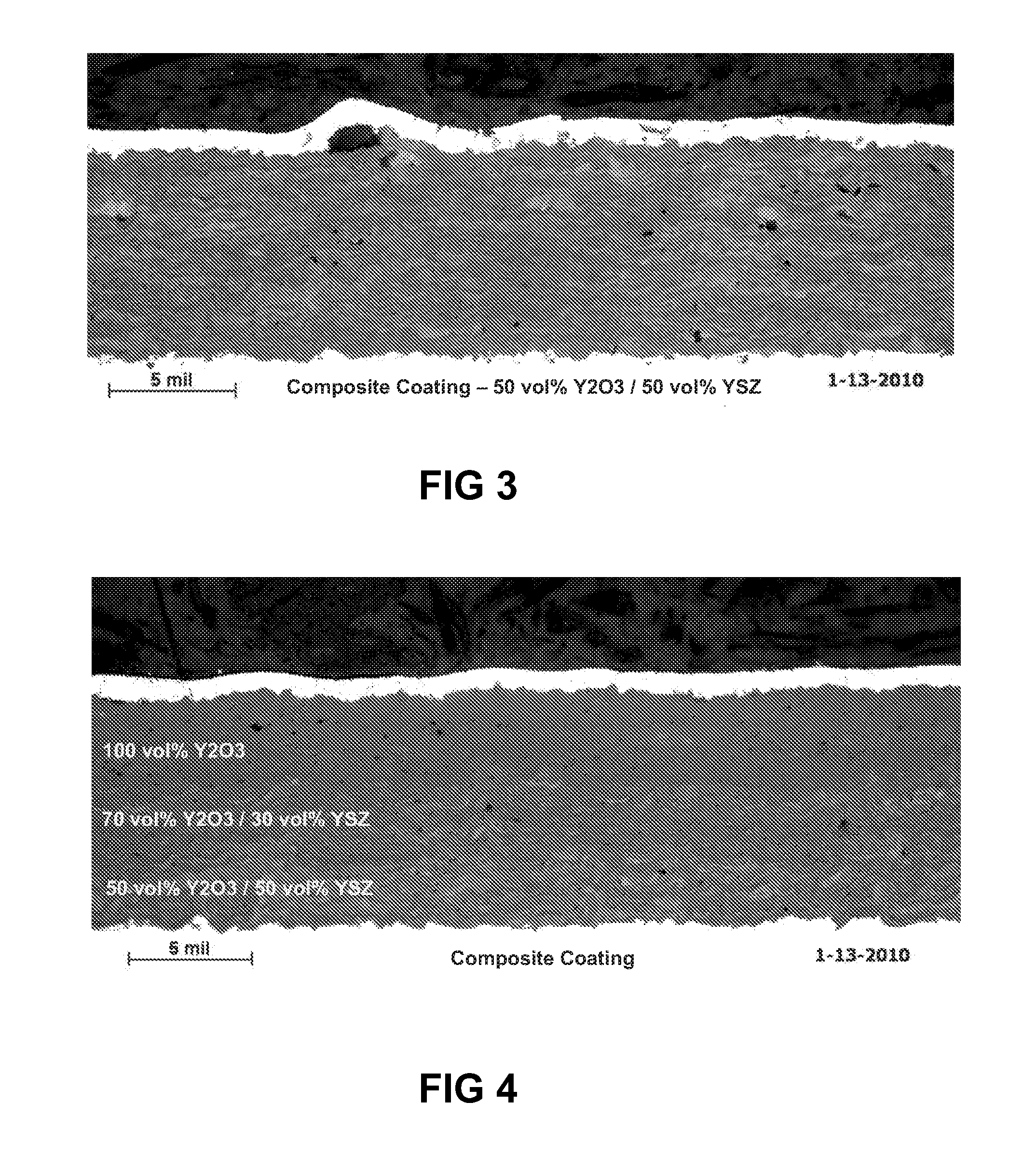

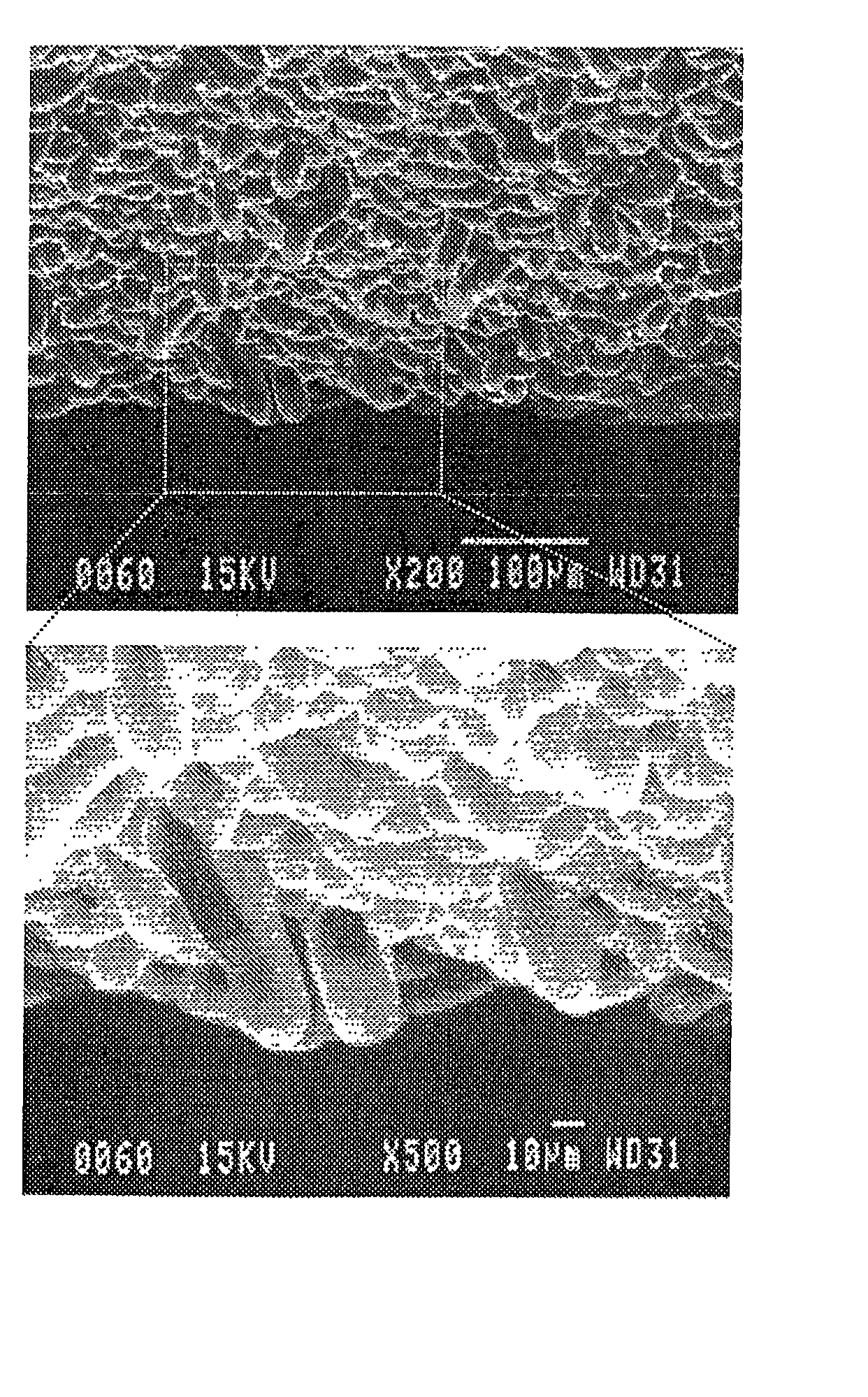

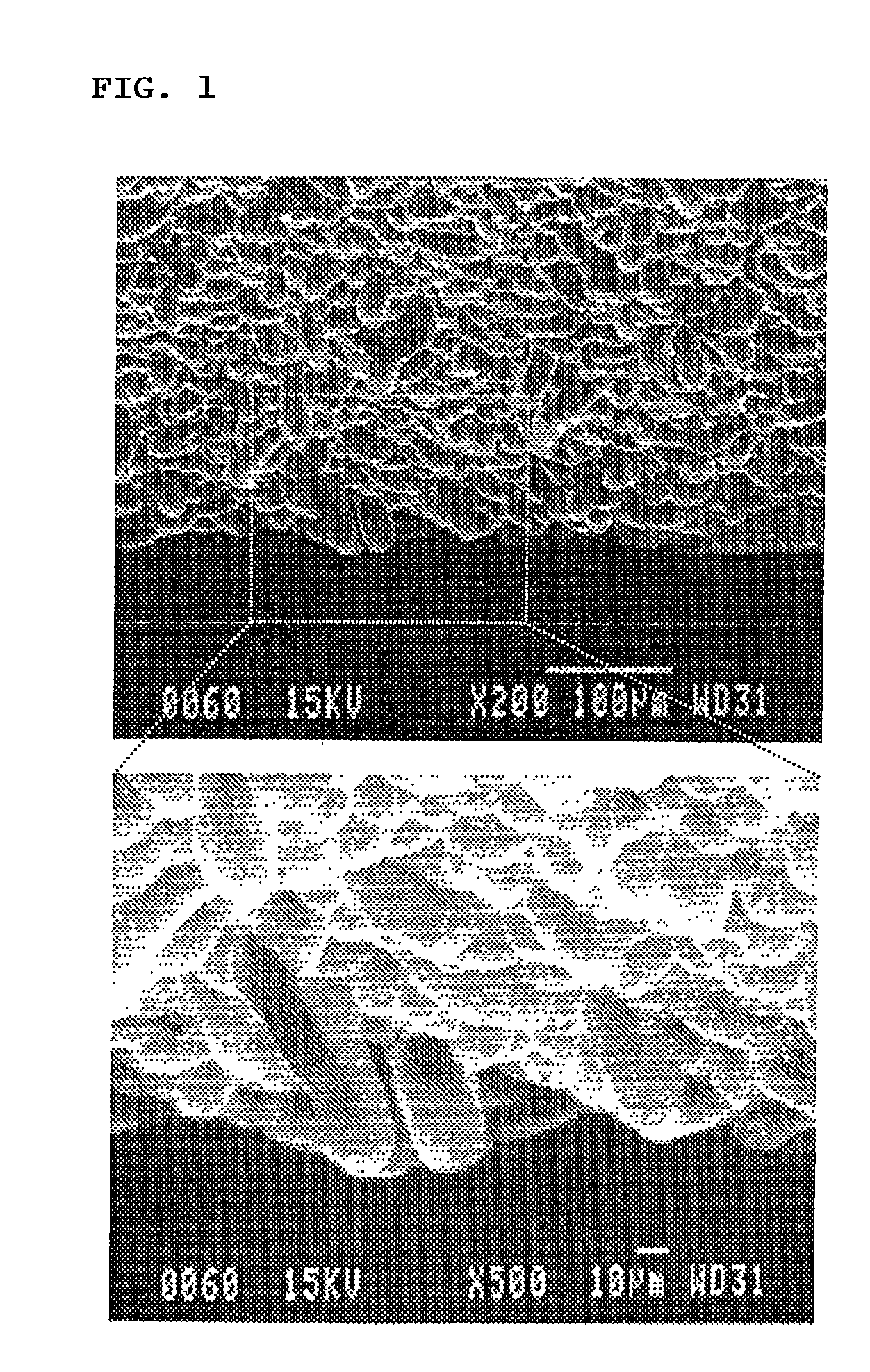

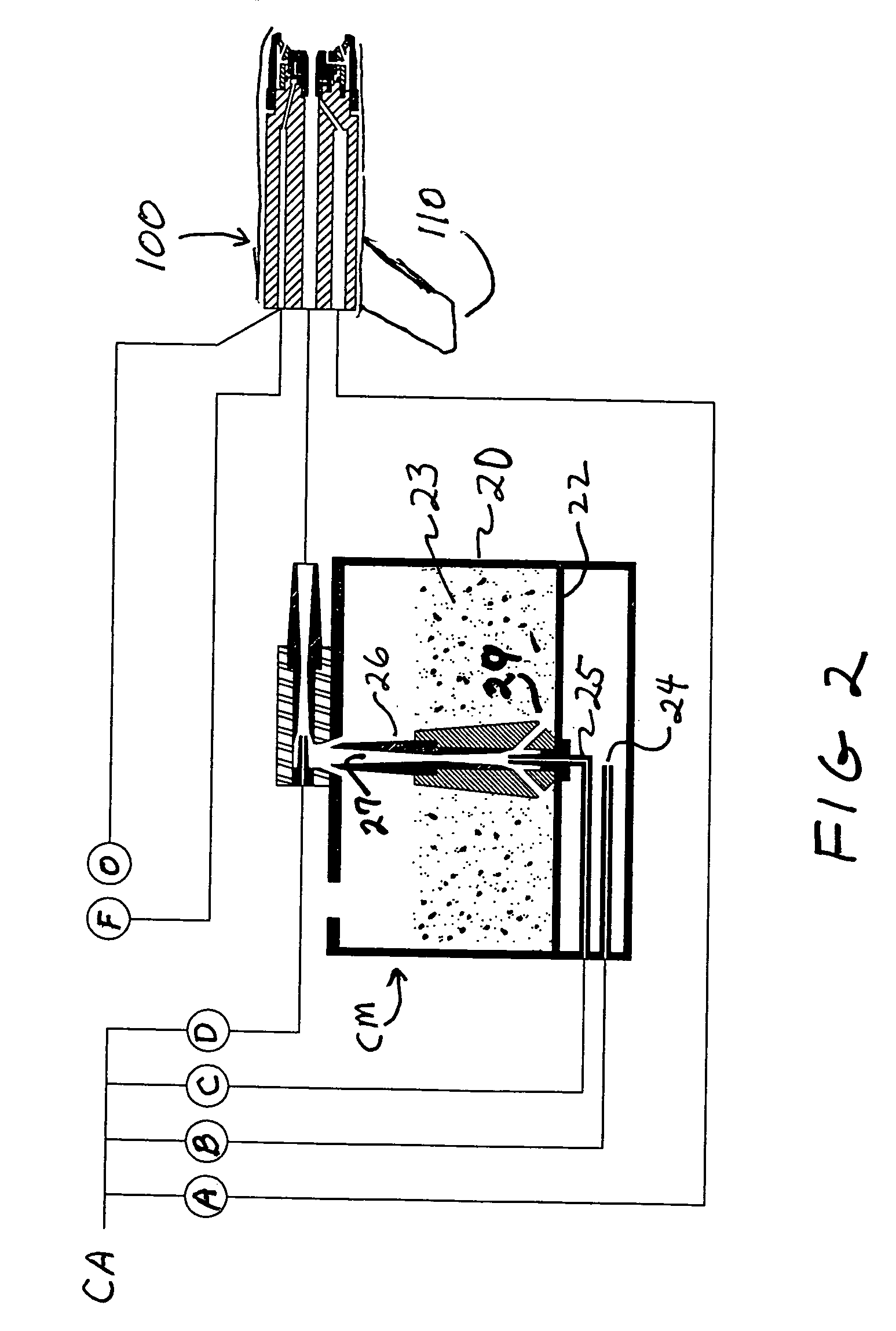

Thermal spray composite coatings for semiconductor applications

InactiveUS20120183790A1Erosion is goodImprove corrosion resistanceLiquid surface applicatorsMolten spray coatingCeramic compositeThermal spraying

This invention relates to thermal spray composite coatings on a metal or non-metal substrate. The thermal spray composite coatings comprise a ceramic composite coating having at least two ceramic material phases randomly and uniformly dispersed and / or spatially oriented throughout the ceramic composite coating. At least a first ceramic material phase is present in an amount sufficient to provide corrosion resistance to the ceramic composite coating, and at least a second ceramic material phase is present in an amount sufficient to provide plasma erosion resistance to the ceramic composite coating. This invention also relates to methods of protecting metal and non-metal substrates by applying the thermal spray coatings. The composite coatings provide erosion and corrosion resistance at processing temperatures higher than conventional processing temperatures used in the semiconductor etch industry, e.g., greater than 100° C. The coatings are useful, for example, in the protection of semiconductor manufacturing equipment, e.g., integrated circuit, light emitting diode, display, and photovoltaic, internal chamber components, and electrostatic chuck manufacture.

Owner:PRAXAIR ST TECH INC

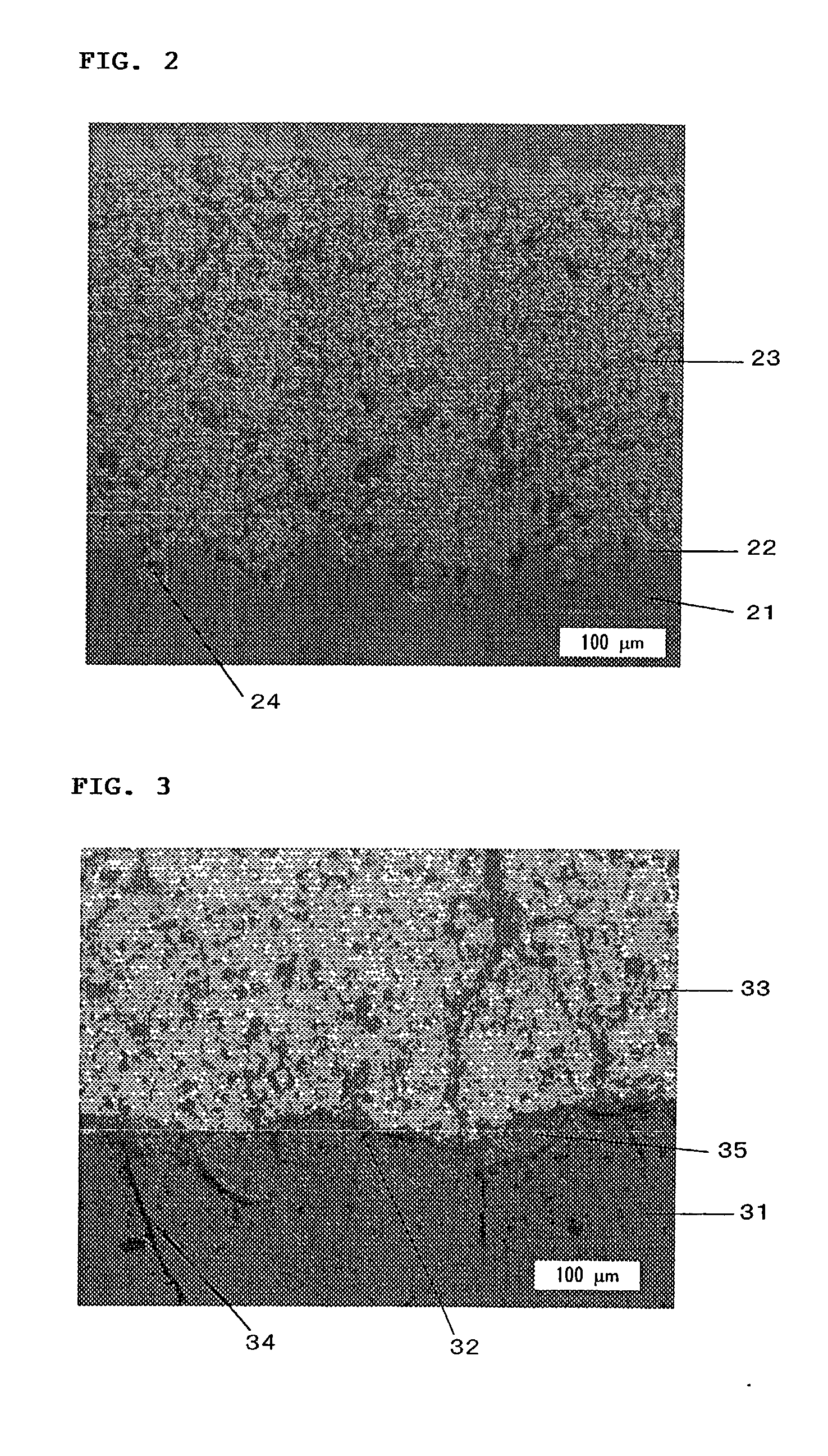

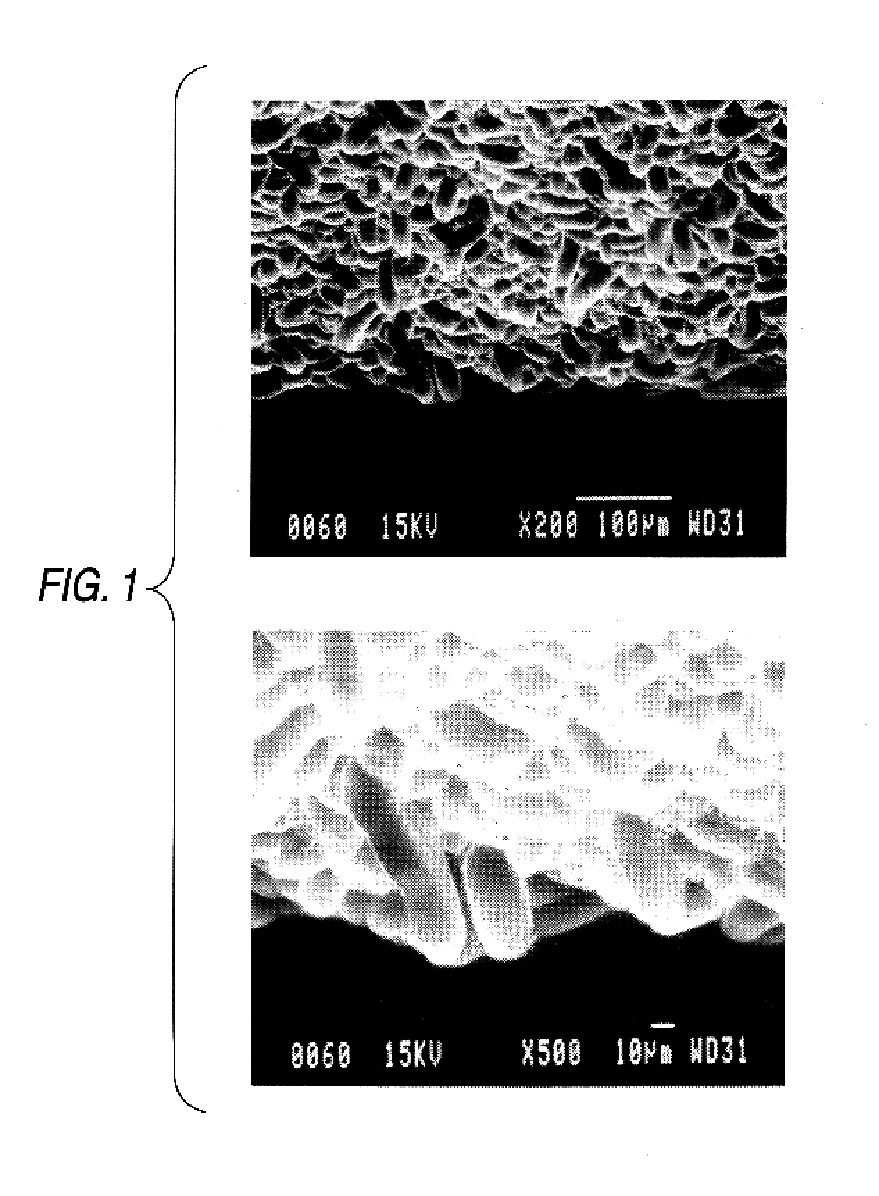

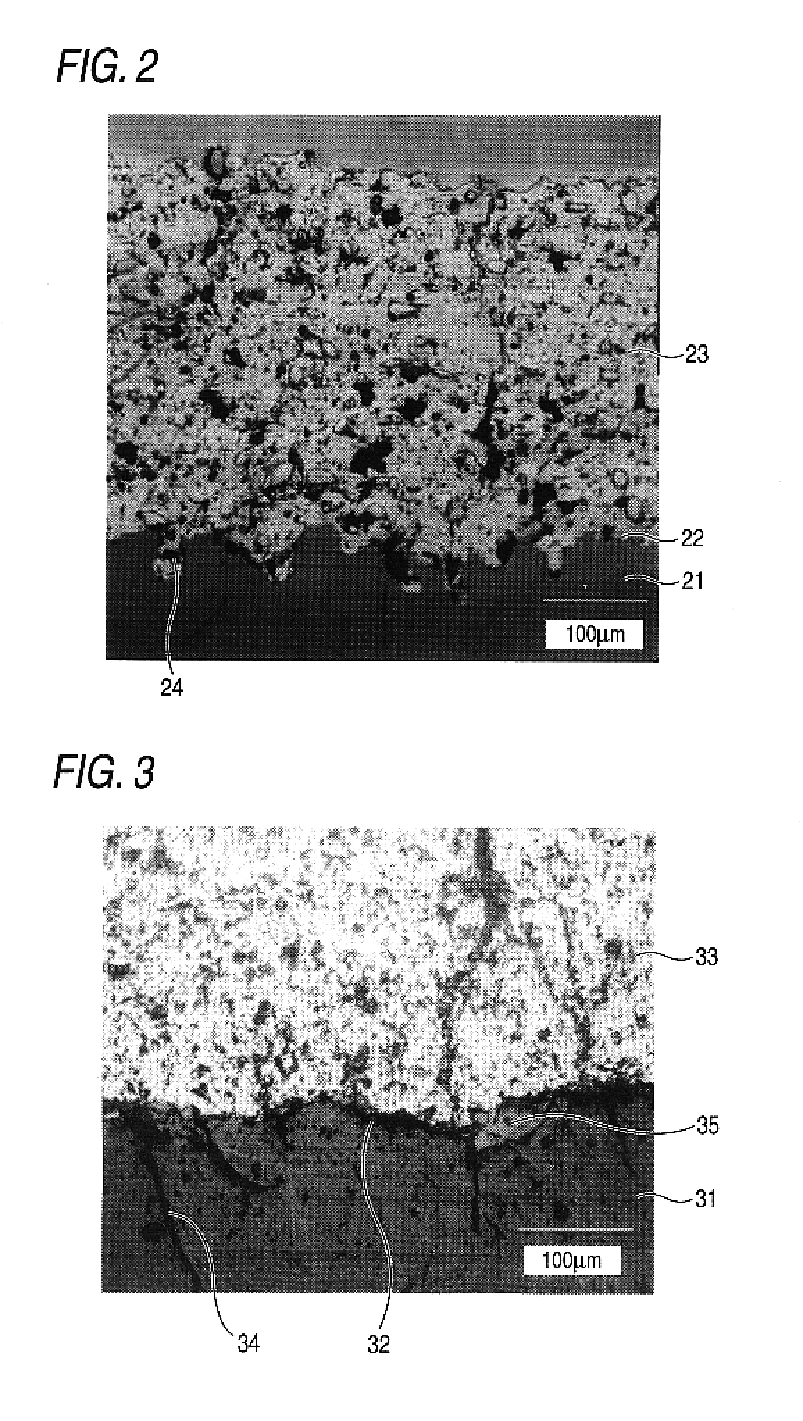

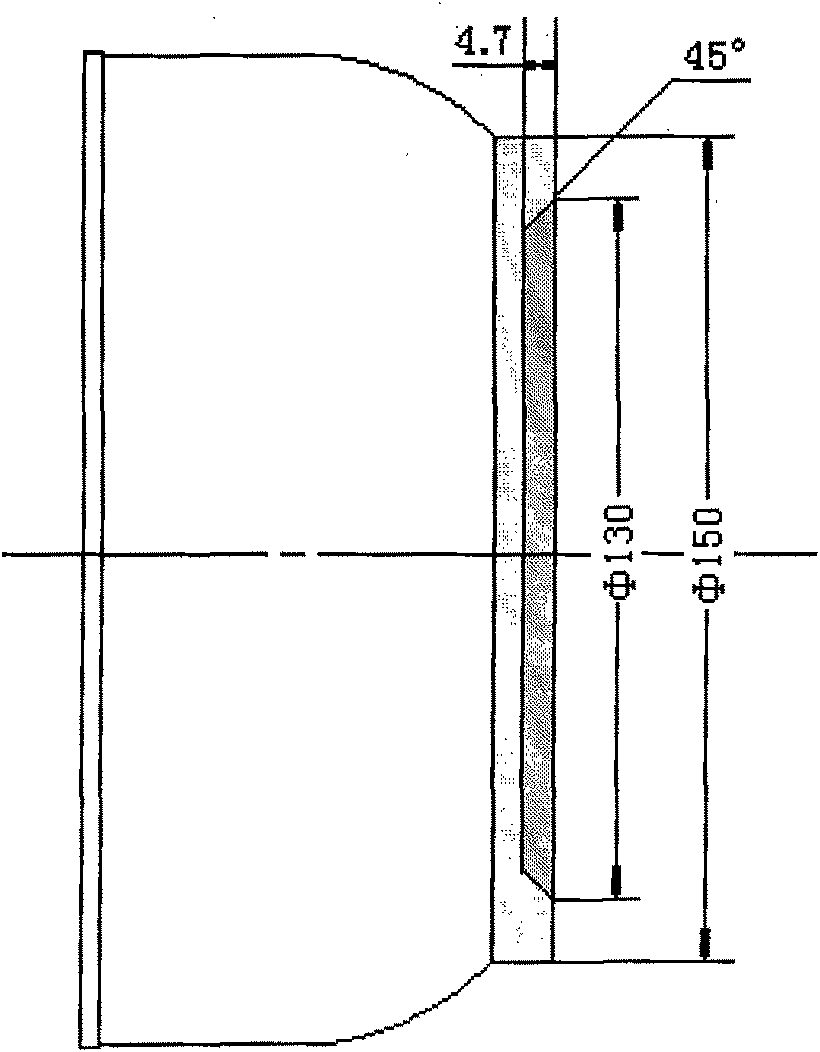

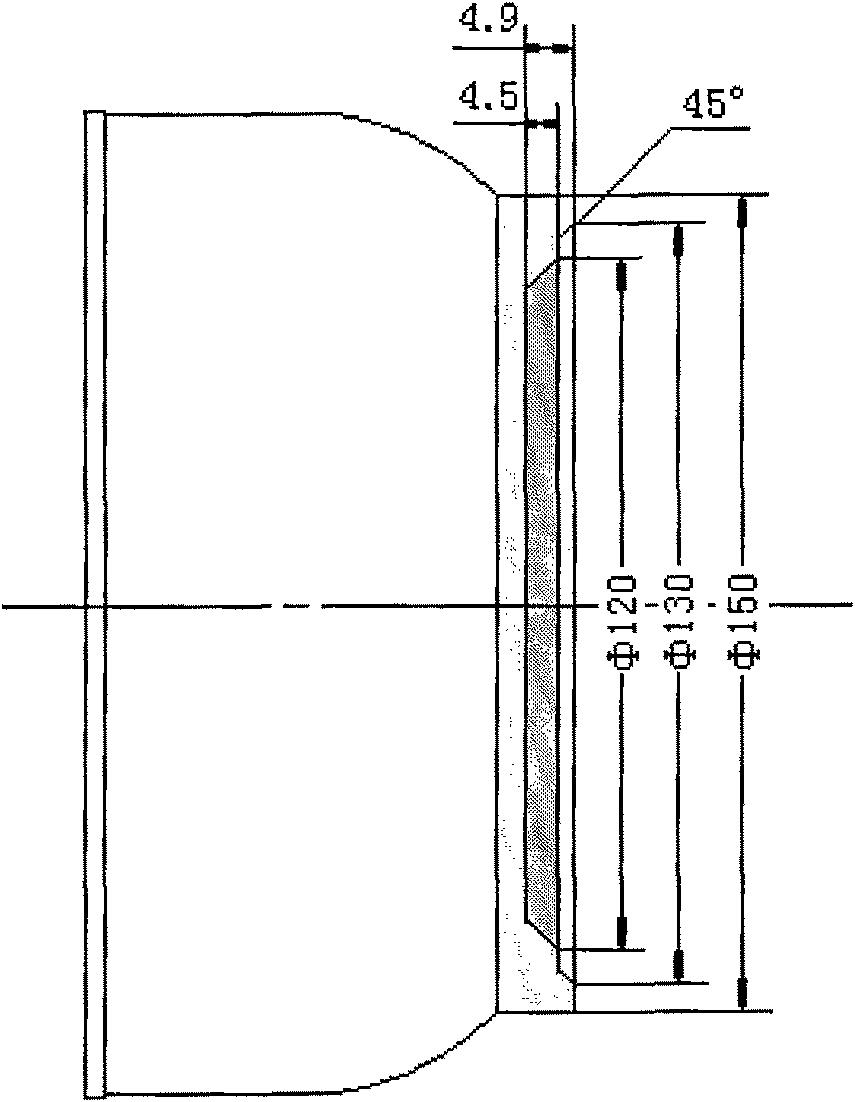

Quartz glass parts, ceramic parts and process of producing those

InactiveUS20030091835A1Improve adhesionImprove plasma resistanceMolten spray coatingFilm/foil adhesivesProduction rateSurface roughness

In quartz glass parts and ceramic parts that are used in film-deposition devices and pre-cleaning devices in the production of semiconductors, etc., there are problems such as peeling off of the parts themselves during the use, peeling off of film-like substances adhered to the part surfaces, contamination of the products and short life time of the parts caused by corrosion of the part surfaces by plasma, and reduction in the productivity by frequent exchange of the parts. In quartz glass parts and ceramic parts that are used in film-deposition devices and pre-cleaning devices in the production of semiconductors, etc., with respect to parts, the surface of which is constituted of a ceramic thermal sprayed coating, ones having the ceramic thermal sprayed coating having a surface roughness Ra of from 5 to 20 mum are high in adherence of a film-like adherence, ones having the ceramic thermal sprayed coating having a surface roughness Ra of from 1 to 5 mum are high in plasma resistance, and ones in which grooves having a large anchor effect to the thermal sprayed coating is formed on a substrate on which the ceramic thermal sprayed coating is formed are free from peeling off of the ceramic thermal sprayed coating from the substrate and are high in durability.

Owner:TOSOH CORP

Quartz glass parts, ceramic parts and process of producing those

InactiveUS6902814B2Improve adhesionImprove plasma resistanceMolten spray coatingFilm/foil adhesivesProduction rateSurface roughness

In quartz glass parts and ceramic parts that are used in film-deposition devices and pre-cleaning devices in the production of semiconductors, etc., there are problems such as peeling off of the parts themselves during the use, peeling off of film-like substances adhered to the part surfaces, contamination of the products and short life time of the parts caused by corrosion of the part surfaces by plasma, and reduction in the productivity by frequent exchange of the parts. In quartz glass parts and ceramic parts that are used in film-deposition devices and pre-cleaning devices in the production of semiconductors, etc., with respect to parts, the surface of which is constituted of a ceramic thermal sprayed coating, ones having the ceramic thermal sprayed coating having a surface roughness Ra of from 5 to 20 μm are high in adherence of a film-like adherence, ones having the ceramic thermal sprayed coating having a surface roughness Ra of from 1 to 5 μm are high in plasma resistance, and ones in which grooves having a large anchor effect to the thermal sprayed coating is formed on a substrate on which the ceramic thermal sprayed coating is formed are free from peeling off of the ceramic thermal sprayed coating from the substrate and are high in durability.

Owner:TOSOH CORP

Deposition of high melting temperature and variable resistance metal materials on plastic and metal surfaces using a combination of kinetic and thermal spray processes

InactiveUS20060013962A1Liquid surface applicatorsMolten spray coatingElectrical resistance and conductancePlastic materials

A method for deposition of a metal layer onto plastic materials is disclosed. The method allows for formation of long length strain gauges and deposition of high melting temperature metals onto plastic materials. The method comprises initially depositing a pattern of powder particles onto the plastic material using a kinetic spray process. Then the high melting temperature metal layer is deposited using a thermal spray process. The metal layer only adheres to the pattern of the powder particles and not to the plastic substrate. To form a stain gauge the powder particles are deposited in a discontinuous non-electrically conductive density on the plastic material. Then a metal layer is deposited using a thermal spray process and a metal having a variable resistance. The metal forms a continuous and electrically conductive pathway having a resistance that changes as stress is applied to the substrate.

Owner:DELPHI TECH INC

Coatings and powders, methods of making same, and uses thereof

ActiveUS20110254230A1Prolong lifeHigh temperature resistancePiston ringsMolten spray coatingPiston ringCarbide

This invention relates to thermal spray coatings, powders useful in deposition of the thermal spray coatings, methods of producing the powders, and uses of the thermal spray coatings, for example, coating of piston rings and cylinder liners of internal combustion engines. The coatings of this invention are applied by thermal spray deposition of a powder. The powder contains bimetallic carbides of chromium and molybdenum dispersed in a matrix metal. The matrix metal contains nickel / chromium / molybdenum.

Owner:PRAXAIR ST TECH INC

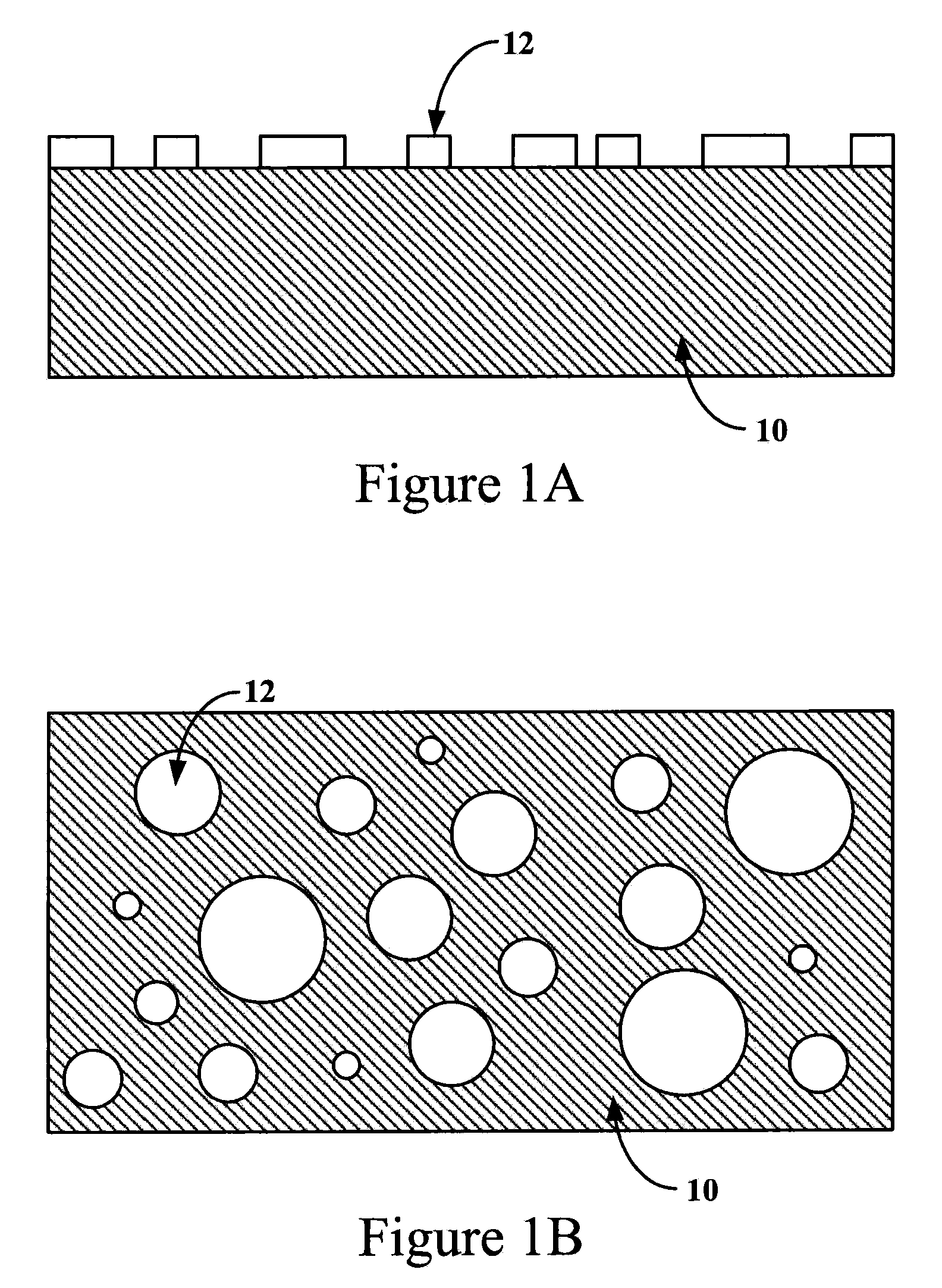

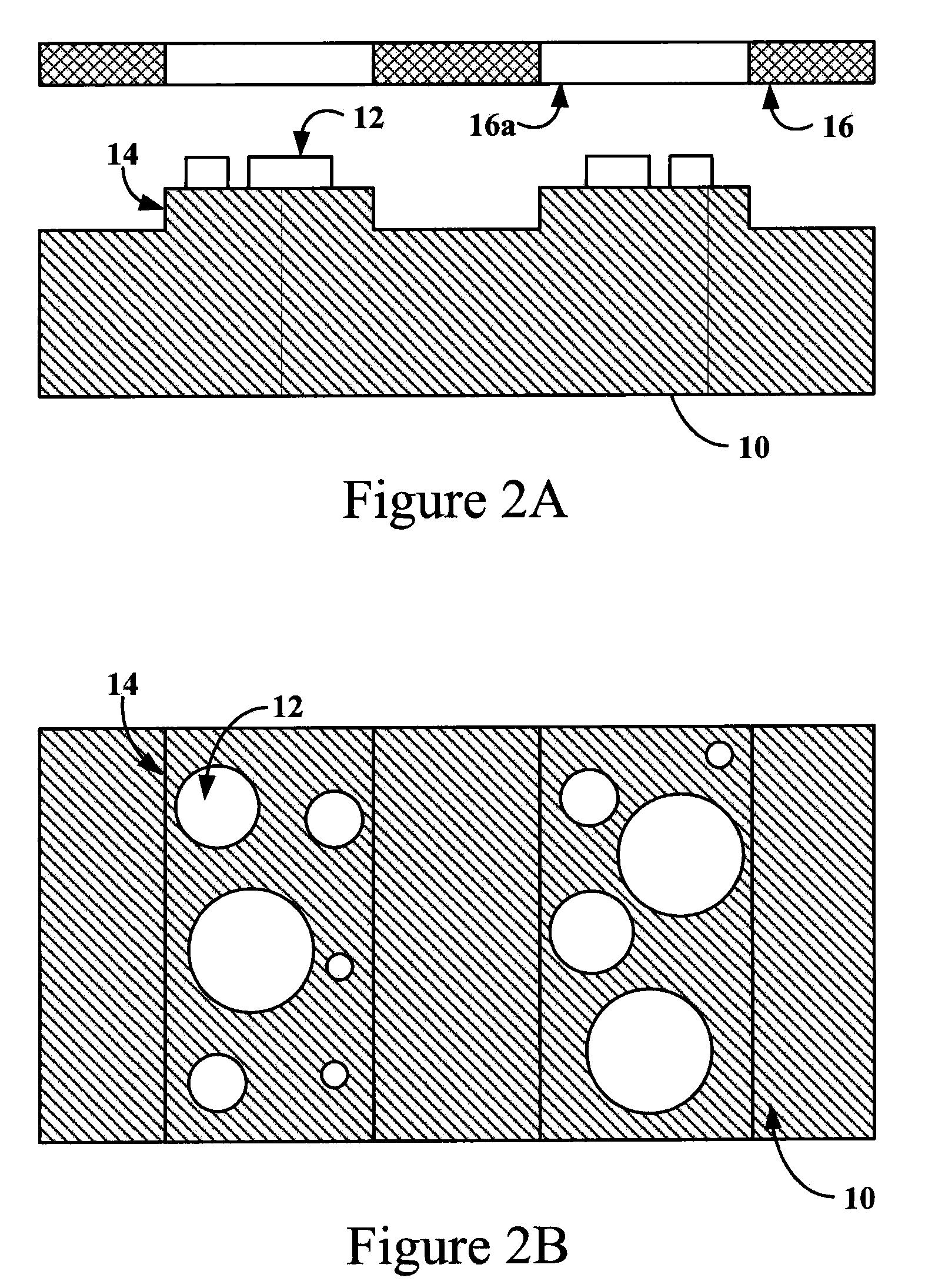

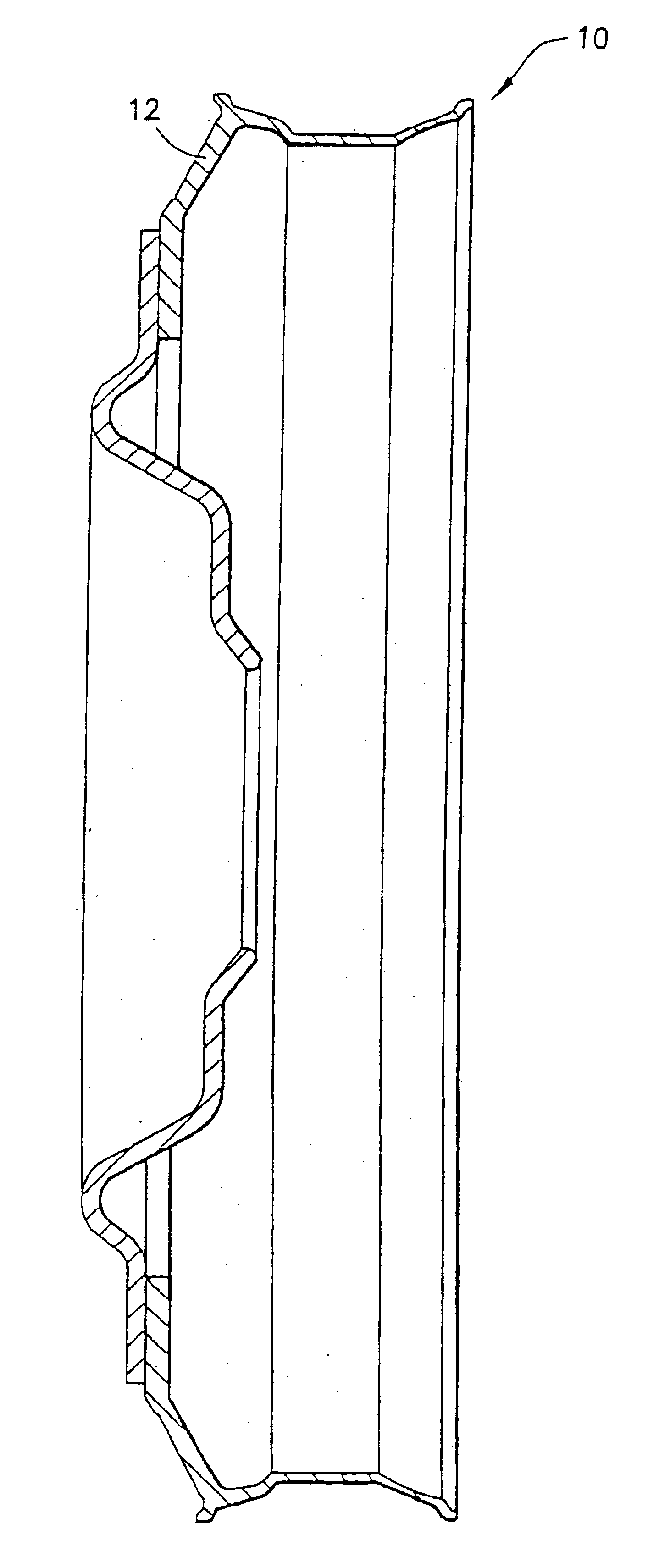

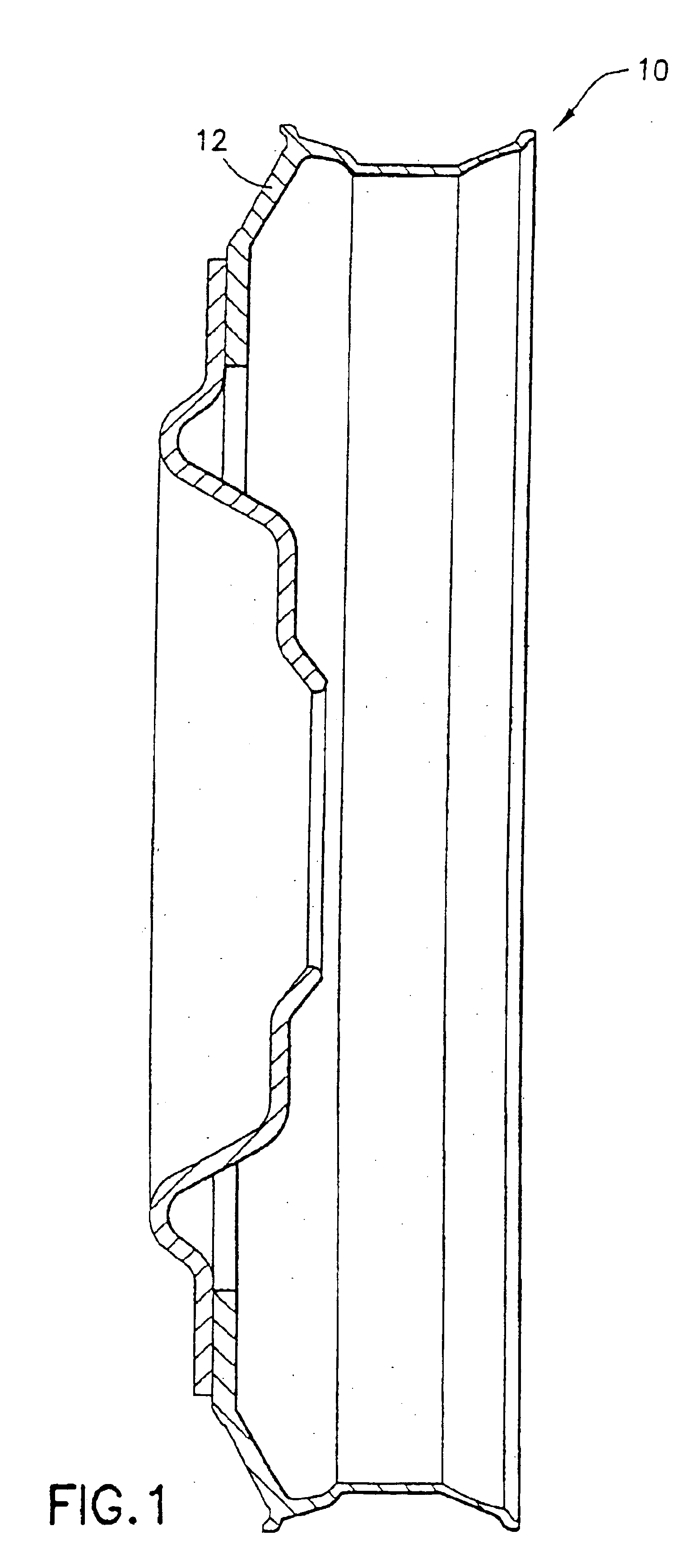

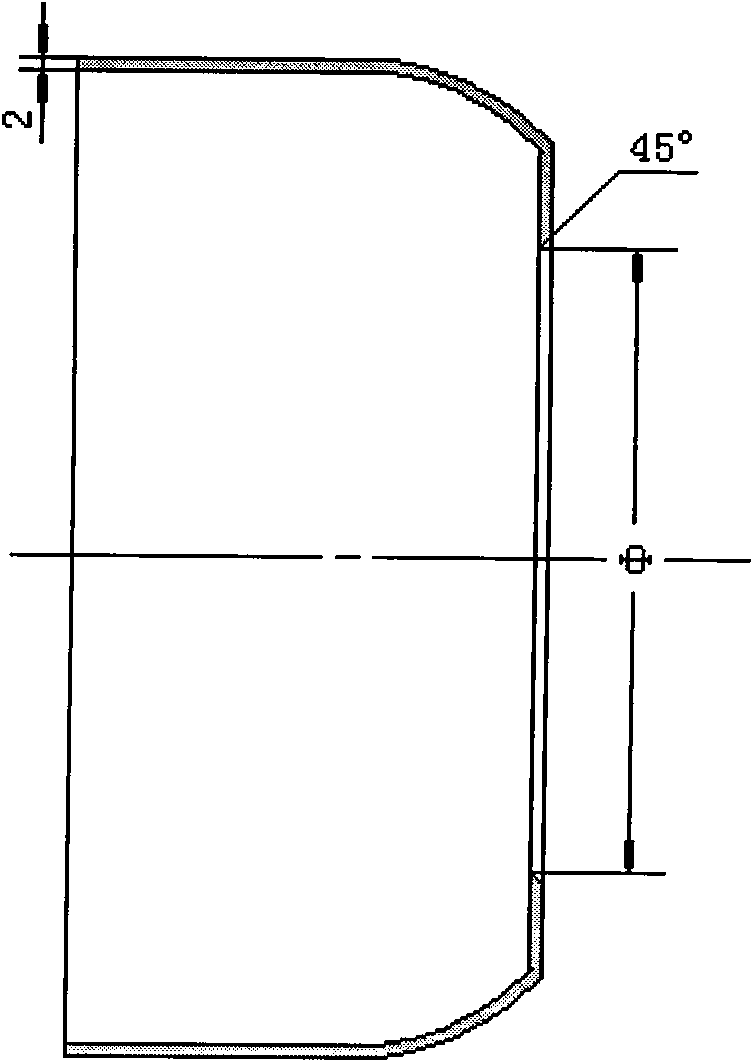

Method for thermal spraying of composite bottom layer of aluminum pan of electromagnetic oven

InactiveCN101880850AWide range of choicesImprove product qualityCooking-vessel materialsDomestic stoves or rangesThermal sprayingThermal printing

The invention discloses a method for thermal spraying of a composite bottom layer of an aluminum pan of an electromagnetic oven, which is used in the manufacturing industry of food cookers and is as shown by a drawing appended to the abstract. A magnetic composite layer with a certain thickness is formed by using an automatic spraying method, designing the joint of a coating and the pan bottom into a concave mosaic structure and spraying a magnetic material (pure iron, iron alloy or 430 stainless steel) to the bottom of the aluminum pan so as to meet the operating requirements of the electromagnetic oven. According to the requirements of a product, one or more material (copper, stainless steel, aluminum, nickel, chromium or ceramic) coatings with different thicknesses or functions can be sprayed to realize aesthetic property, practicability and functionality of the electromagnetic oven pan to ensure that the pans for the electromagnetic oven become various middle-grade and high-grade series products.

Owner:慈溪光华金属复合材料有限公司

Blade tip coating processes

InactiveUS20080026160A1Increase temperatureLiquid surface applicatorsMolten spray coatingYTTERBIUM OXIDEThermal spraying

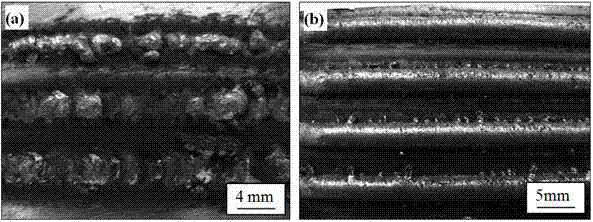

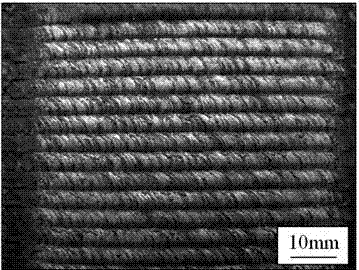

This invention relates to processes for coating blades for a gas turbine engine, said blades having an inner end adapted for mounting on a hub and a blade tip located opposite the inner end, and wherein at least a portion of the blade tip is coated with a thermally sprayed coating of a high purity yttria or ytterbia stabilized zirconia powder, said thermally sprayed coating having a density greater than 88% of the theoretical density with a plurality of vertical macrocracks substantially homogeneously dispersed throughout the coating in which a cross-sectional area of the coating normal to the blade tip exposes a plurality of vertical macrocracks extending at least half the coating thickness in length up to the full thickness of the coating and having from about 5 to about 200 vertical macrocracks per linear inch measured in a line parallel to the surface of the blade tip and in a plane perpendicular to the surface of the blade tip, and said high purity yttria or ytterbia stabilized zirconia powder comprising from about 0 to about 0.15 weight percent impurity oxides, from about 0 to about 2 weight percent hafnium oxide (hafnia), from about 6 to about 25 weight percent yttrium oxide (yttria) or from about 10 to about 36 weight percent ytterbium oxide (ytterbia), and the balance zirconium oxide (zirconia).

Owner:PRAXAIR ST TECH INC

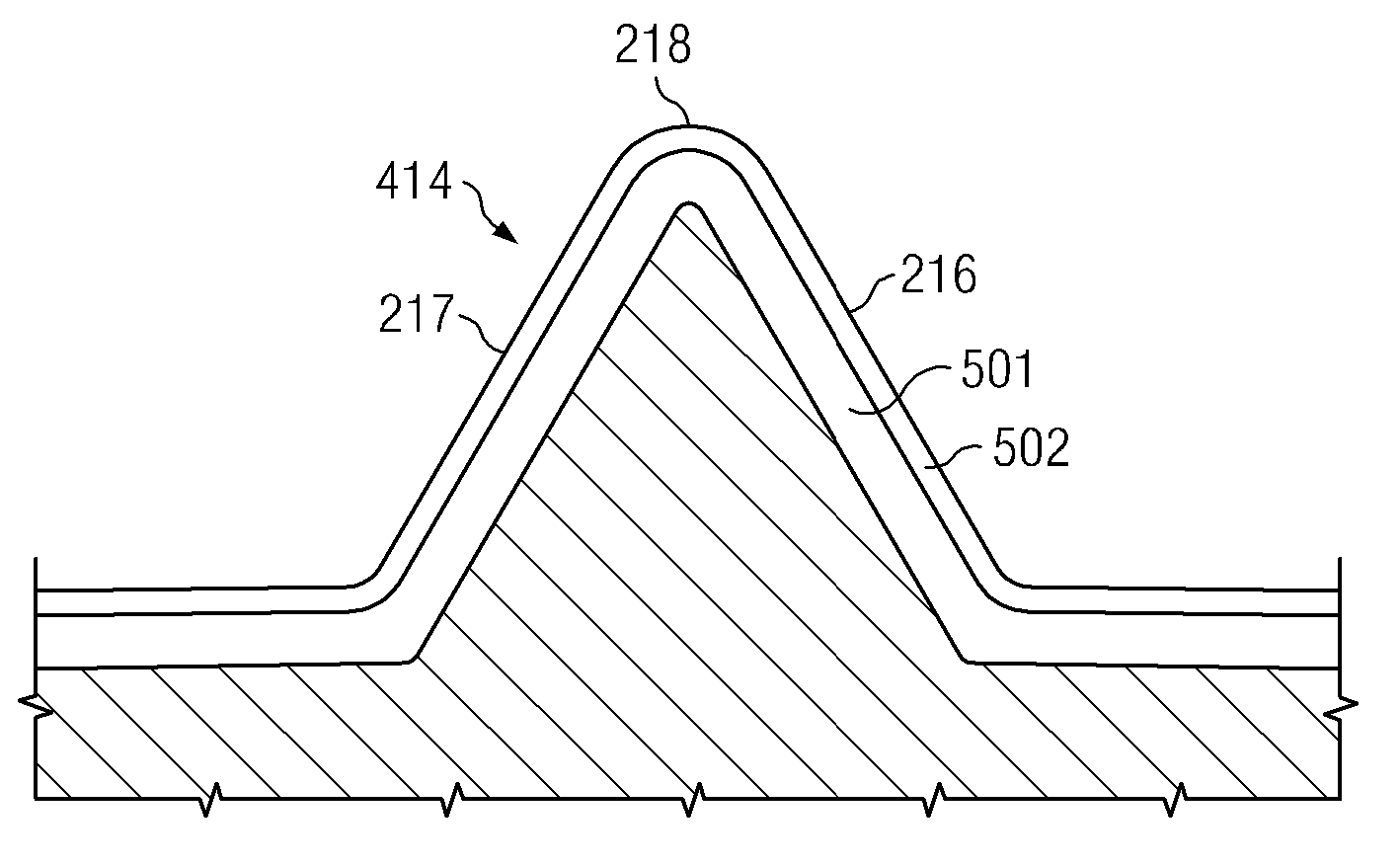

Thermal barrier coating systems

InactiveUS20110171488A1Highly preventive effectLow thermal conductivityMolten spray coatingBlade accessoriesComposite ceramicCoating system

This invention relates in part to thermal barrier coating systems that comprise at least one metallic or metallic / ceramic inner layer deposited onto a substrate, at least one ceramic intermediate layer deposited onto the inner layer, and at least one ceramic outer layer deposited onto the intermediate layer. The ceramic intermediate layer is a thermally sprayed coating having a plurality of macrocracks distributed throughout the intermediate layer. The ceramic outer layer is a thermally sprayed coating made from composite ceramic powder particles that include a zirconia-based component and an (alumina+silica)-based component. The ceramic outer layer is substantially free of macrocracks. This invention also relates in part to methods of forming thermal barrier coating systems, and articles coated with thermal barrier coating systems. The thermal barrier coating systems are suitable for protecting components exposed to high temperature environments, such as the thermal environment of a gas turbine engine.

Owner:PRAXAIR ST TECH INC

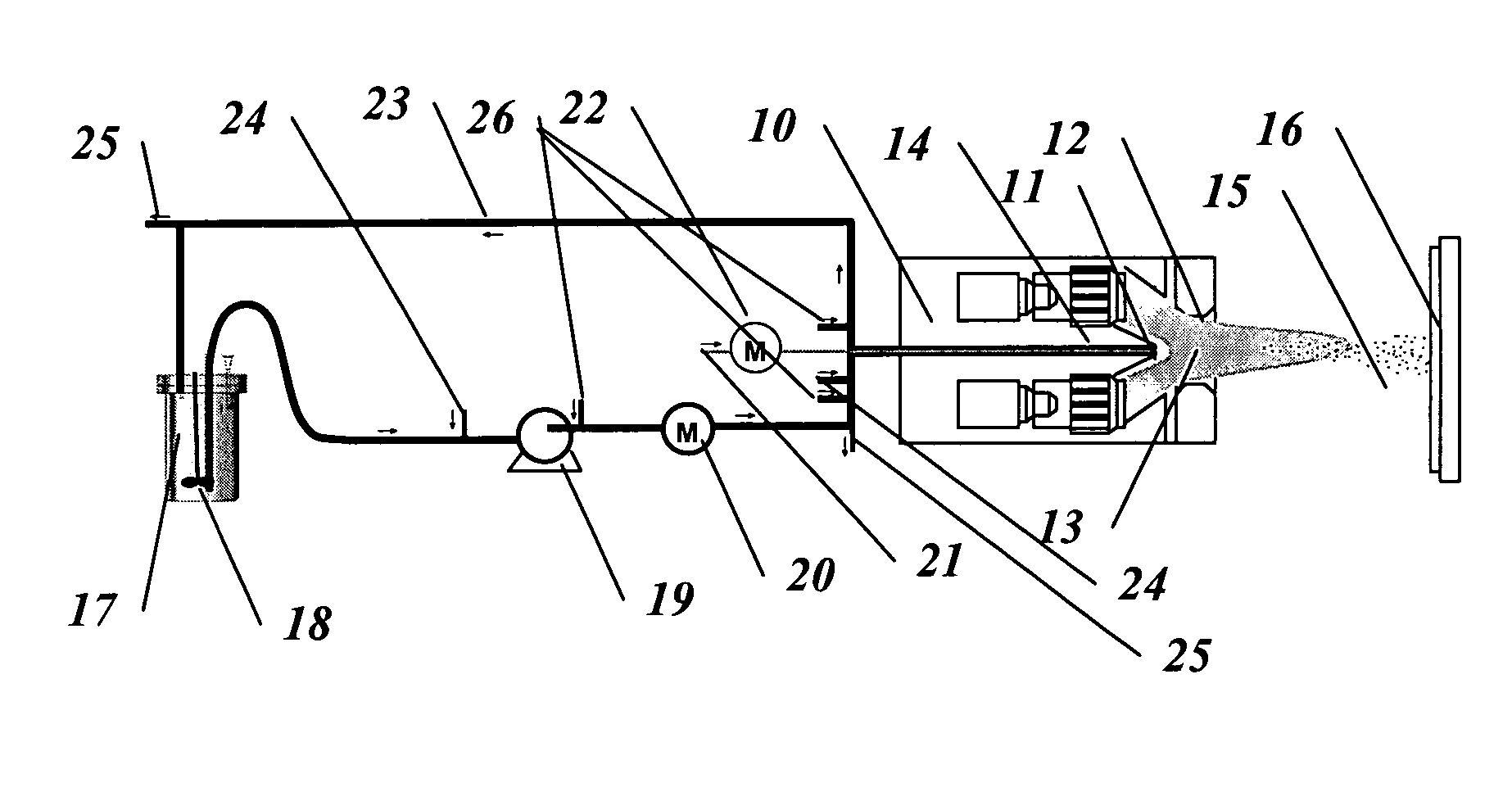

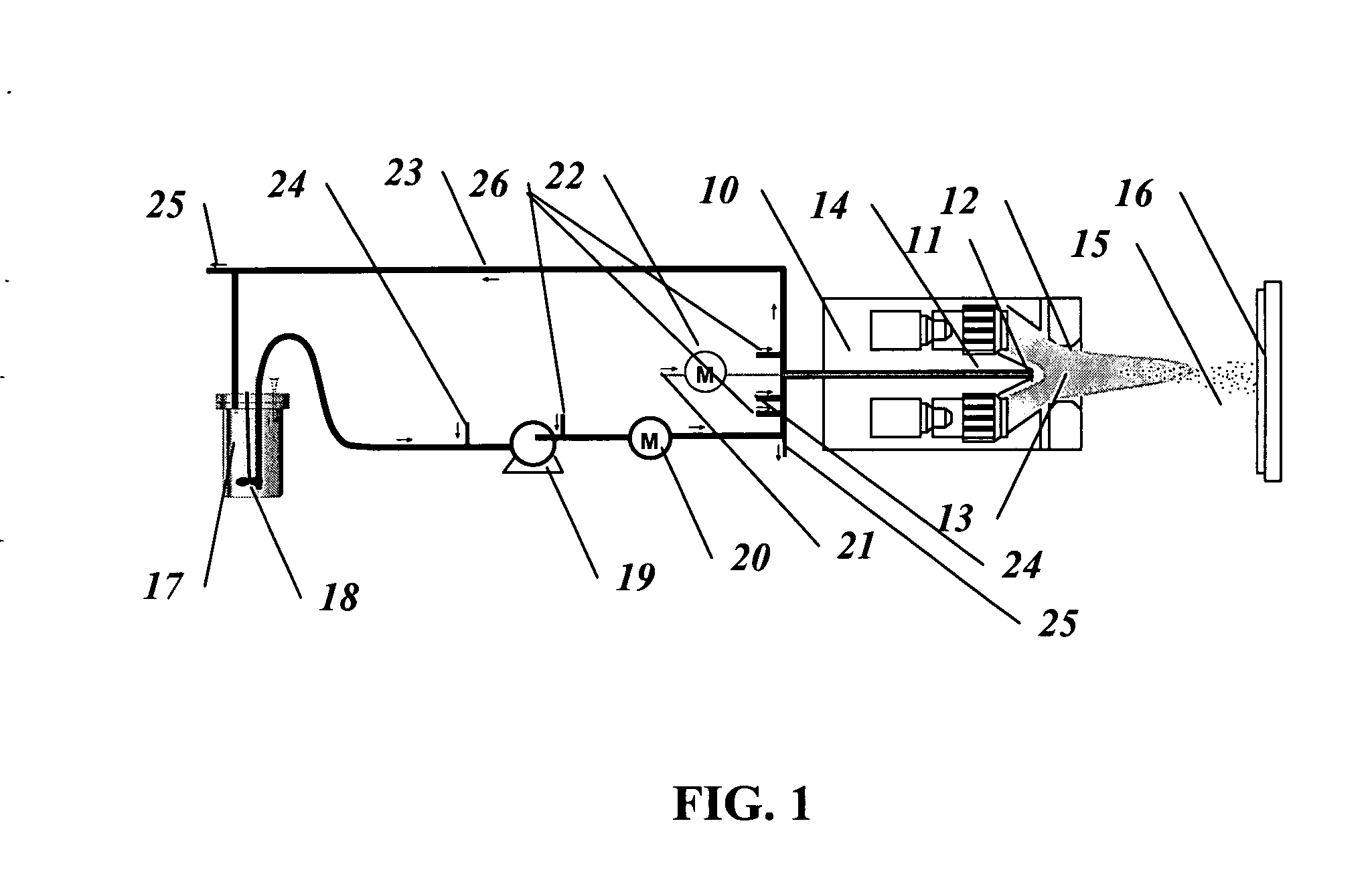

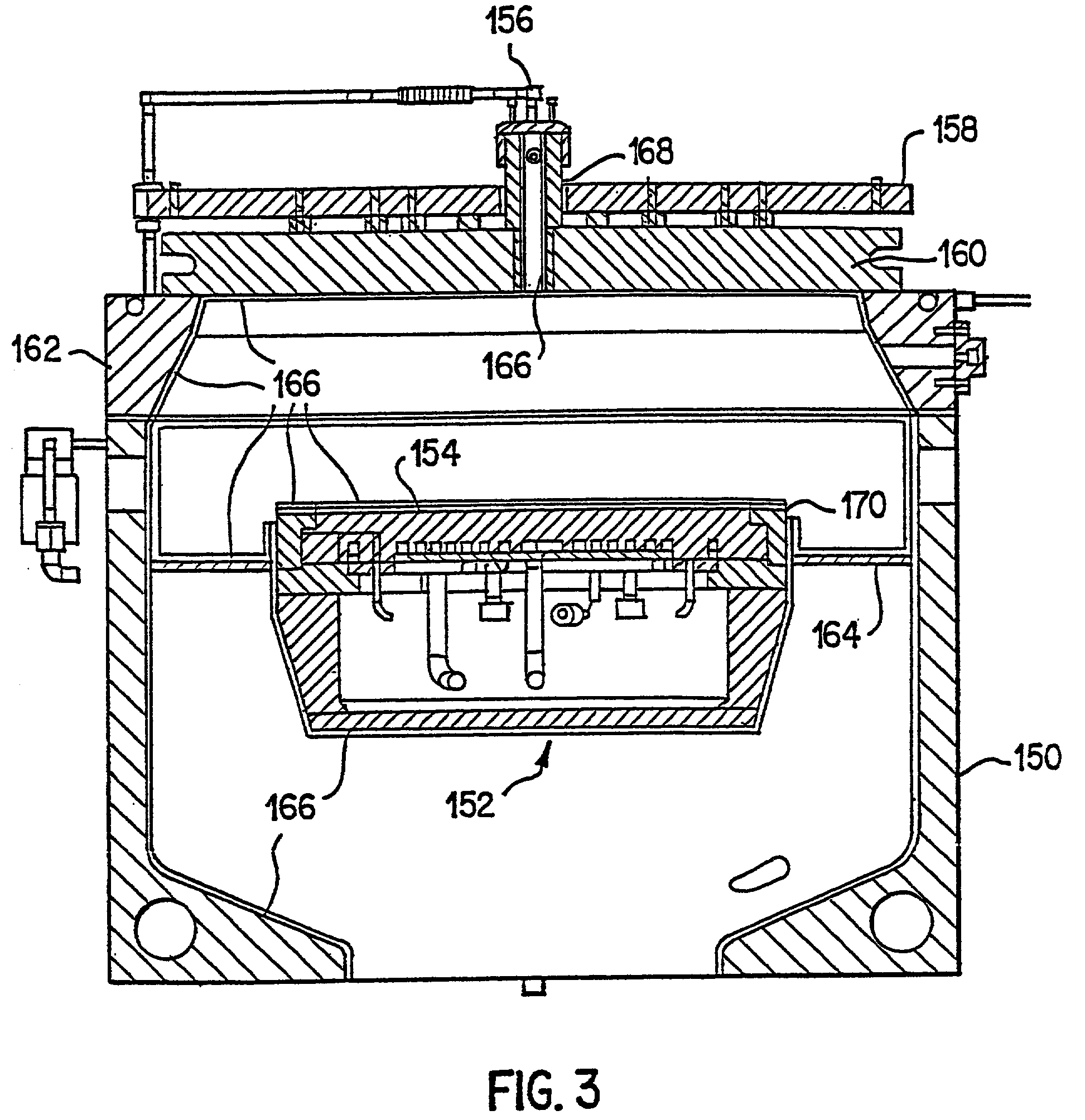

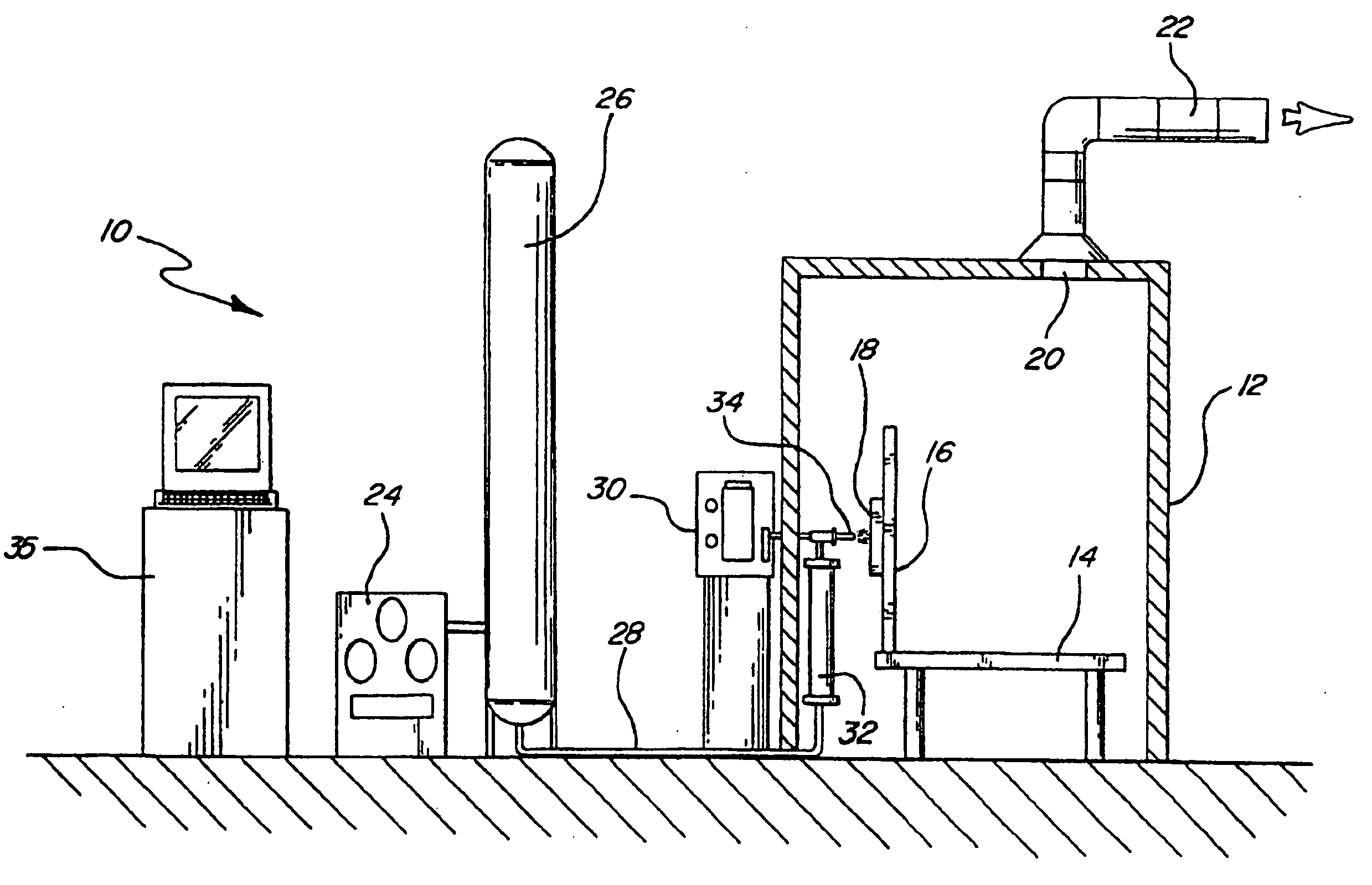

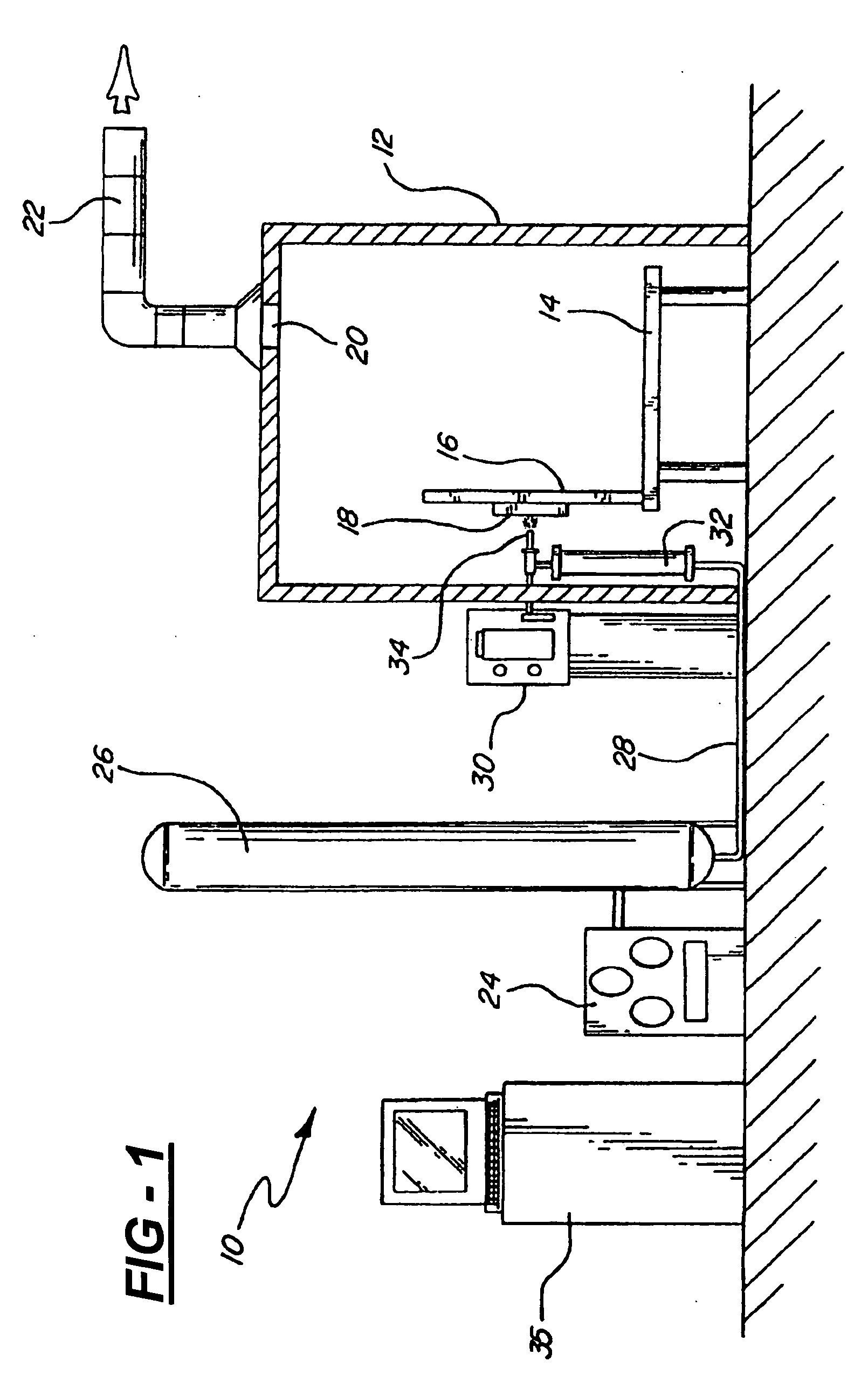

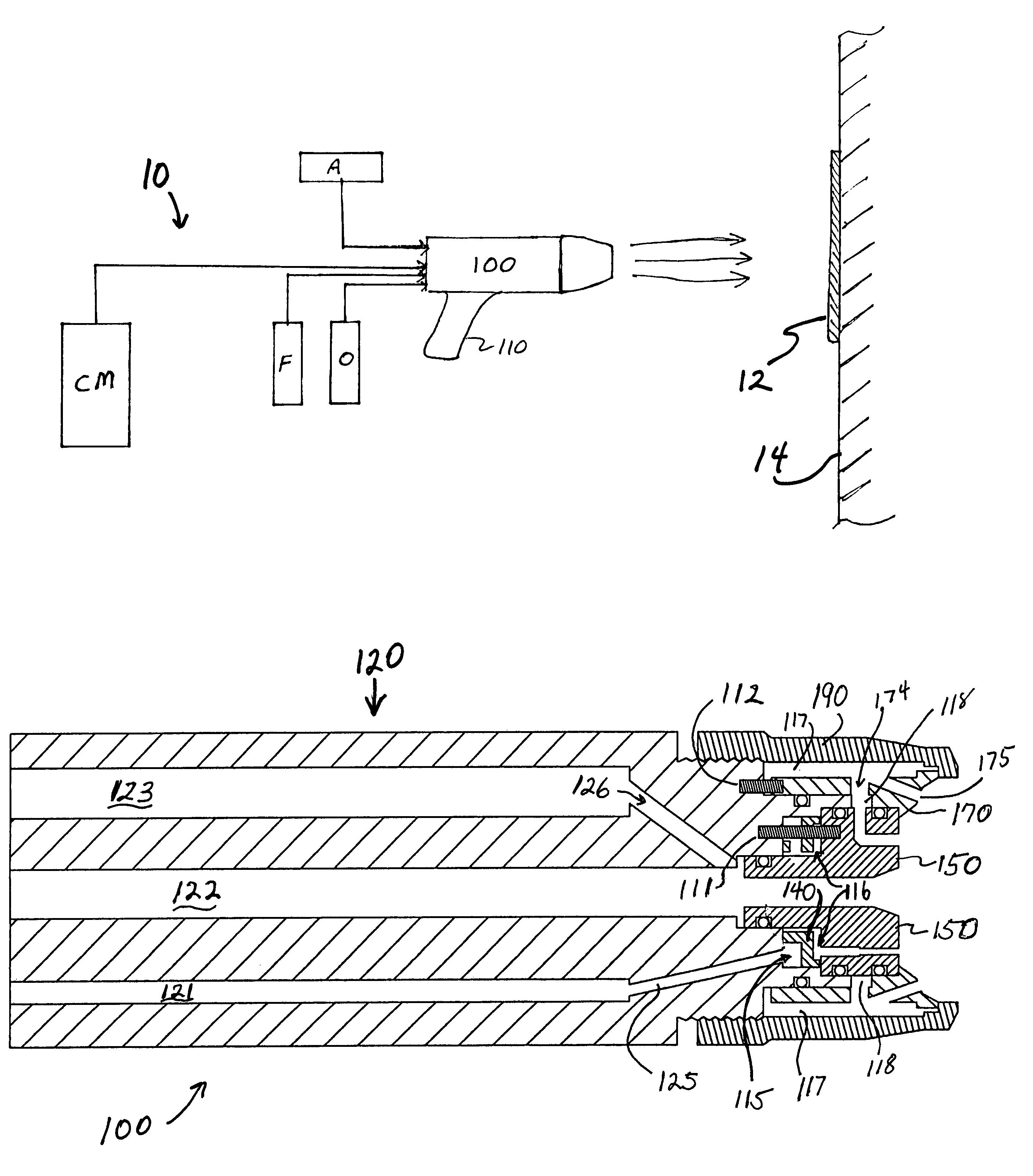

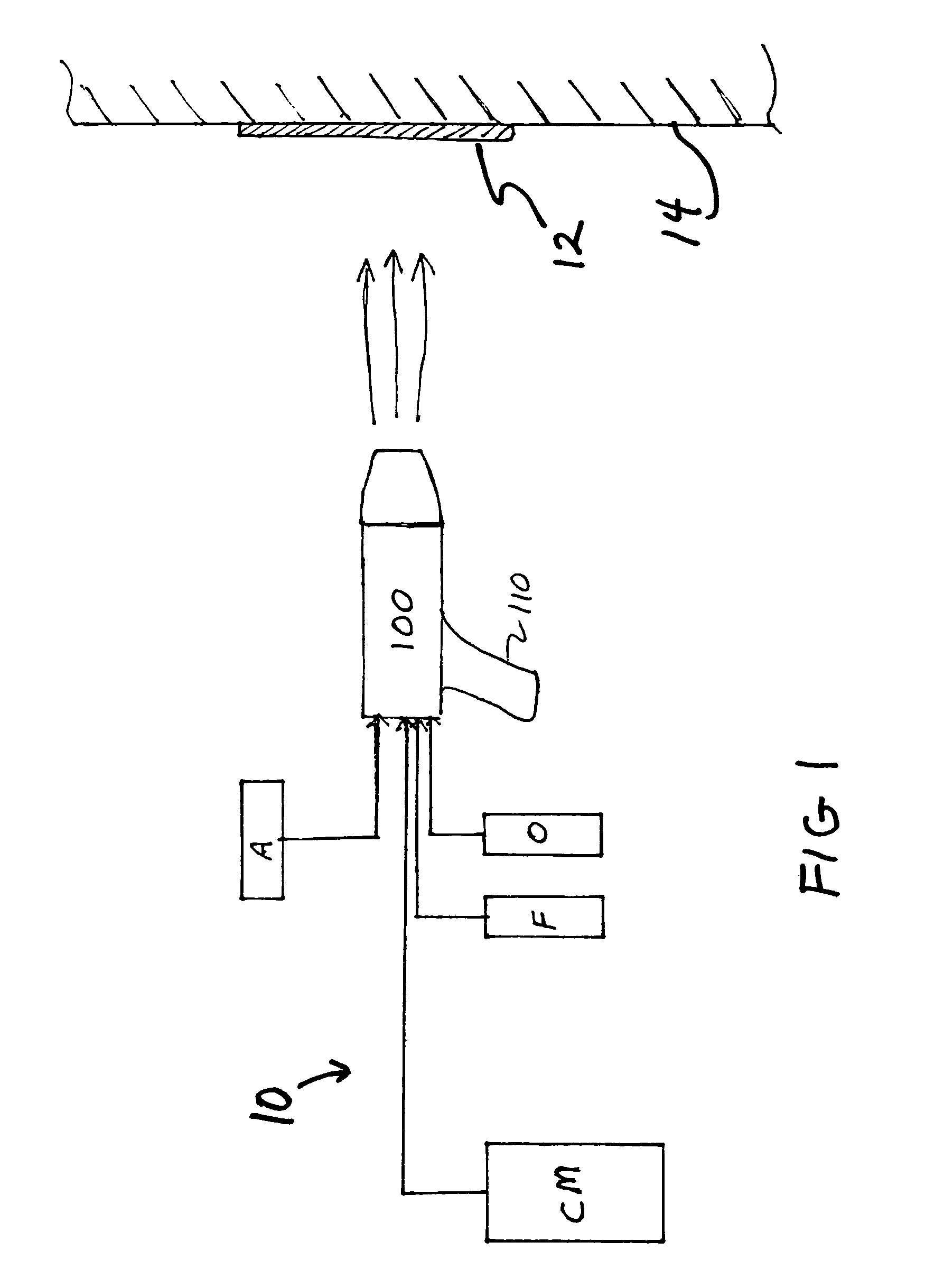

Apparatus for thermal spray coating

A system for thermal spray coating of a particulate material onto a substrate includes a spray gun apparatus having dual vortex chambers for the mixing of fuel gas and oxygen. The apparatus provides a jet flame resulting from a compression wave formed by compressed air. Dual venturis control the flow of fluidized coating material particles to provide smooth and controlled delivery of coating material to the spray gun.

Owner:XIOM CORPORATION

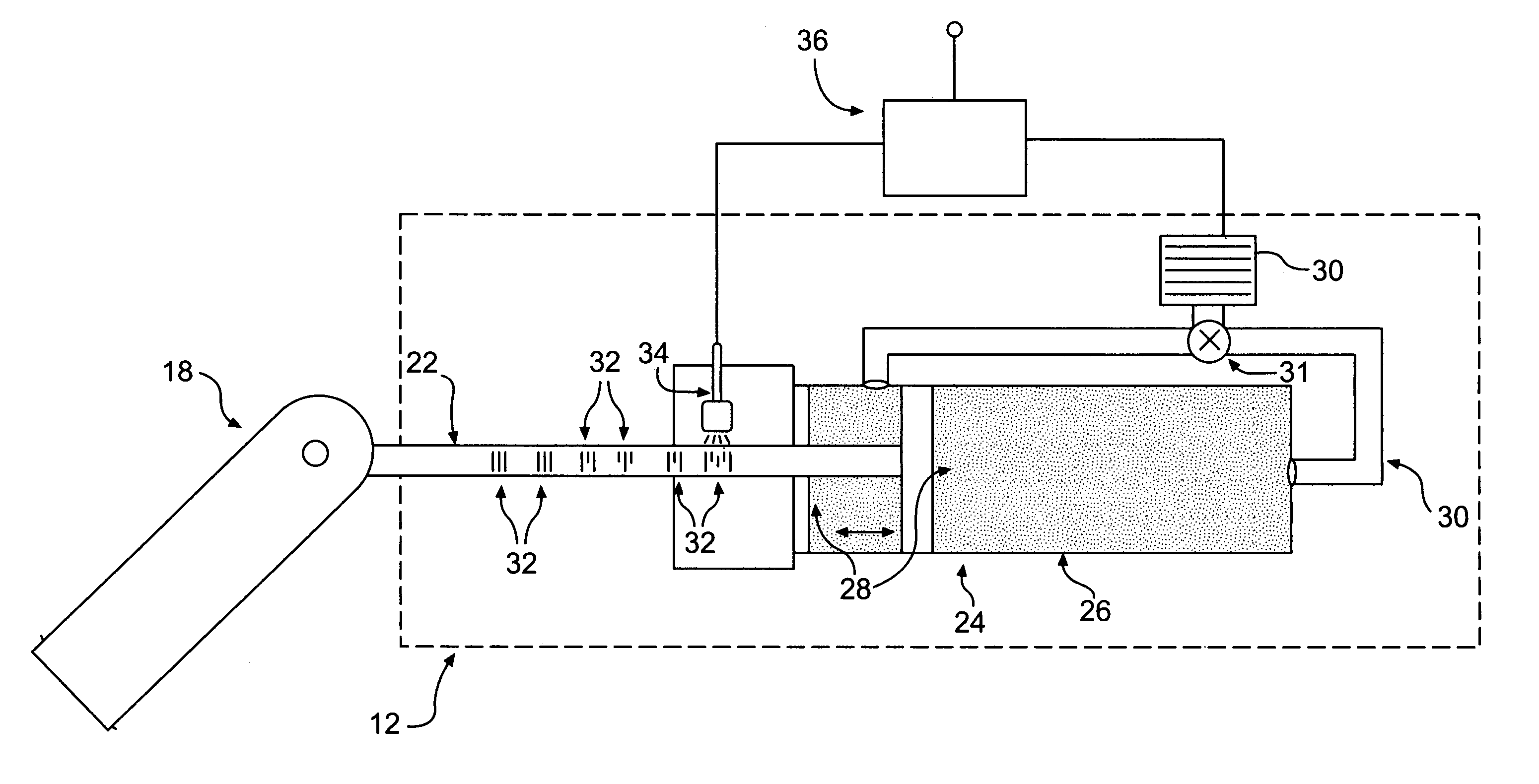

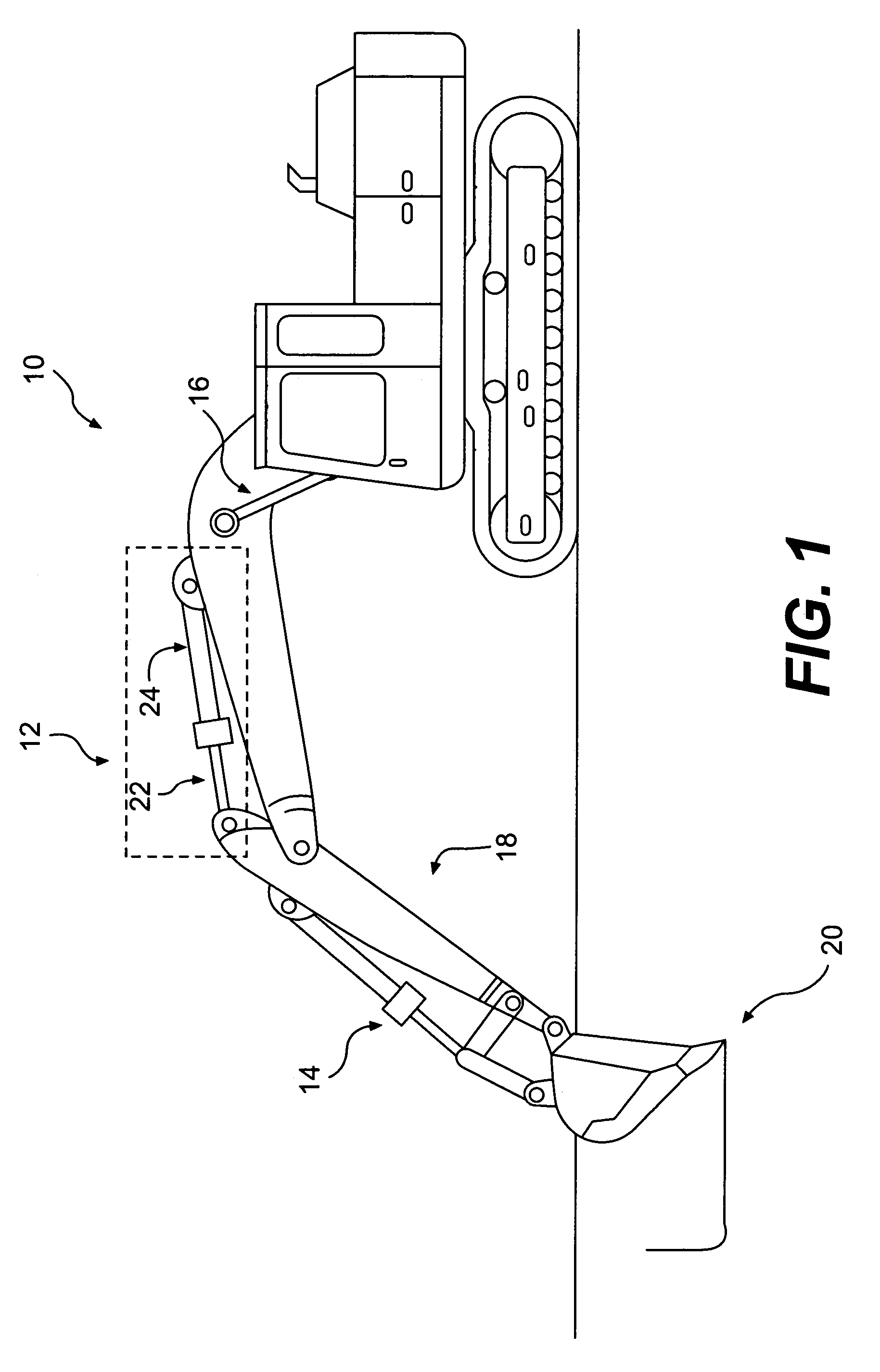

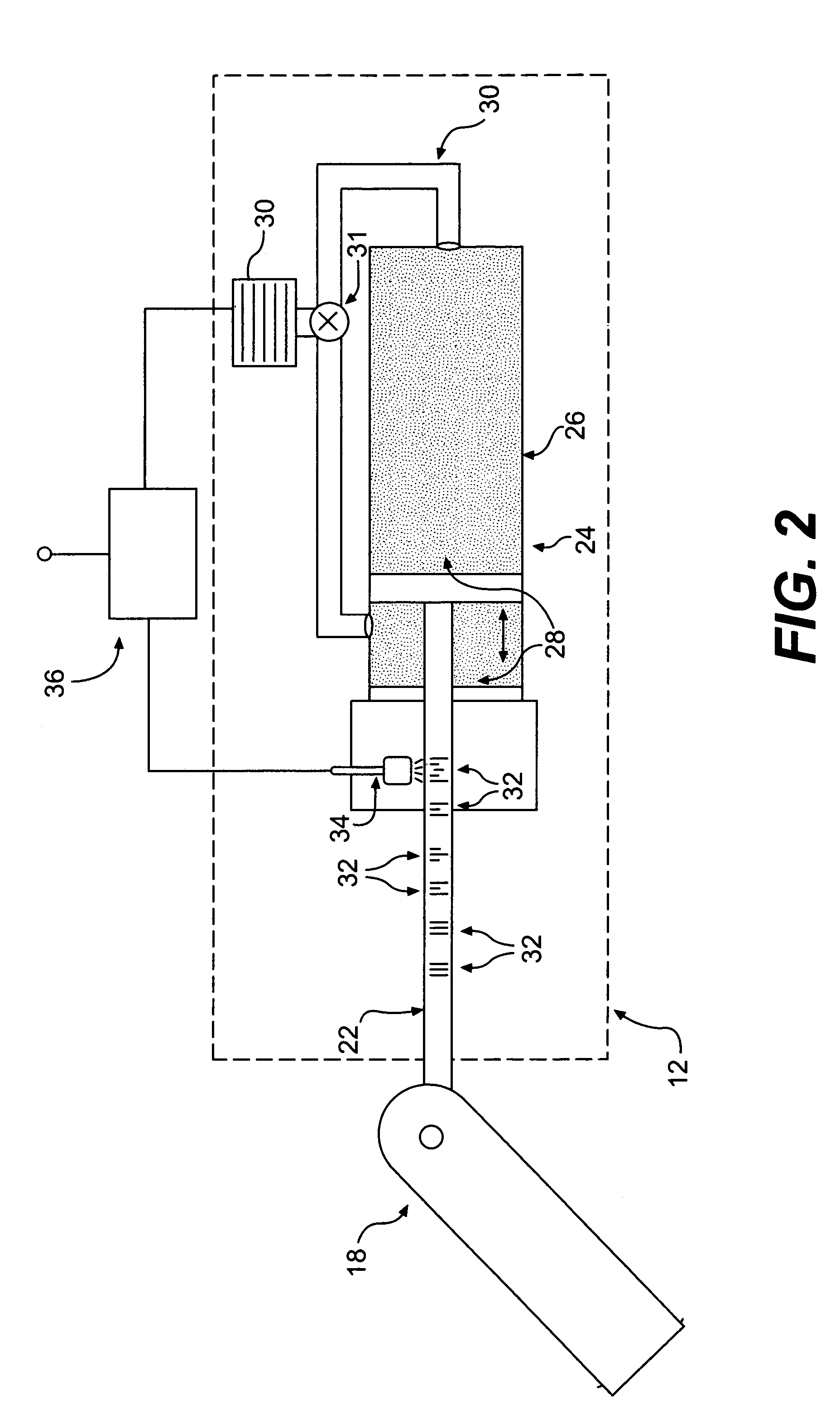

Cylinder rod with position sensor surface markings

A cylinder rod with wear-resistant surface markings is provided. The cylinder rod may include a rod substrate, a thermal-spray coating disposed on a surface of the substrate, and one or more surface markings disposed on the coating at predetermined locations along the length of the cylinder rod.

Owner:CATERPILLAR INC

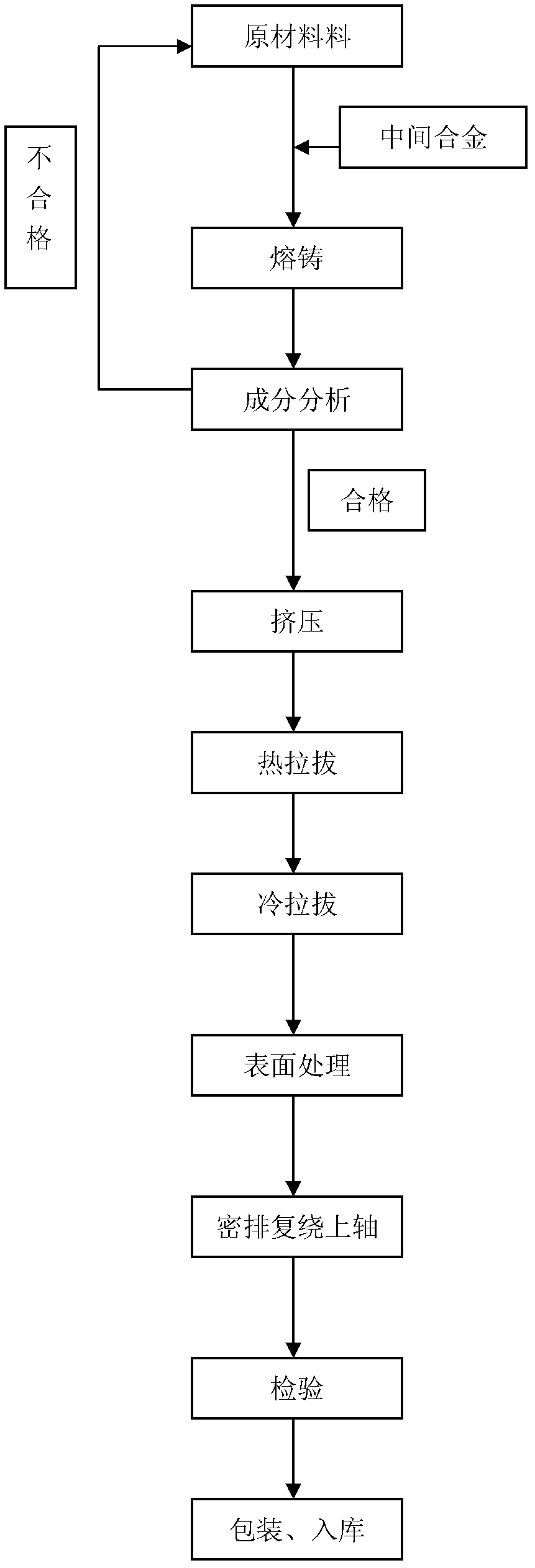

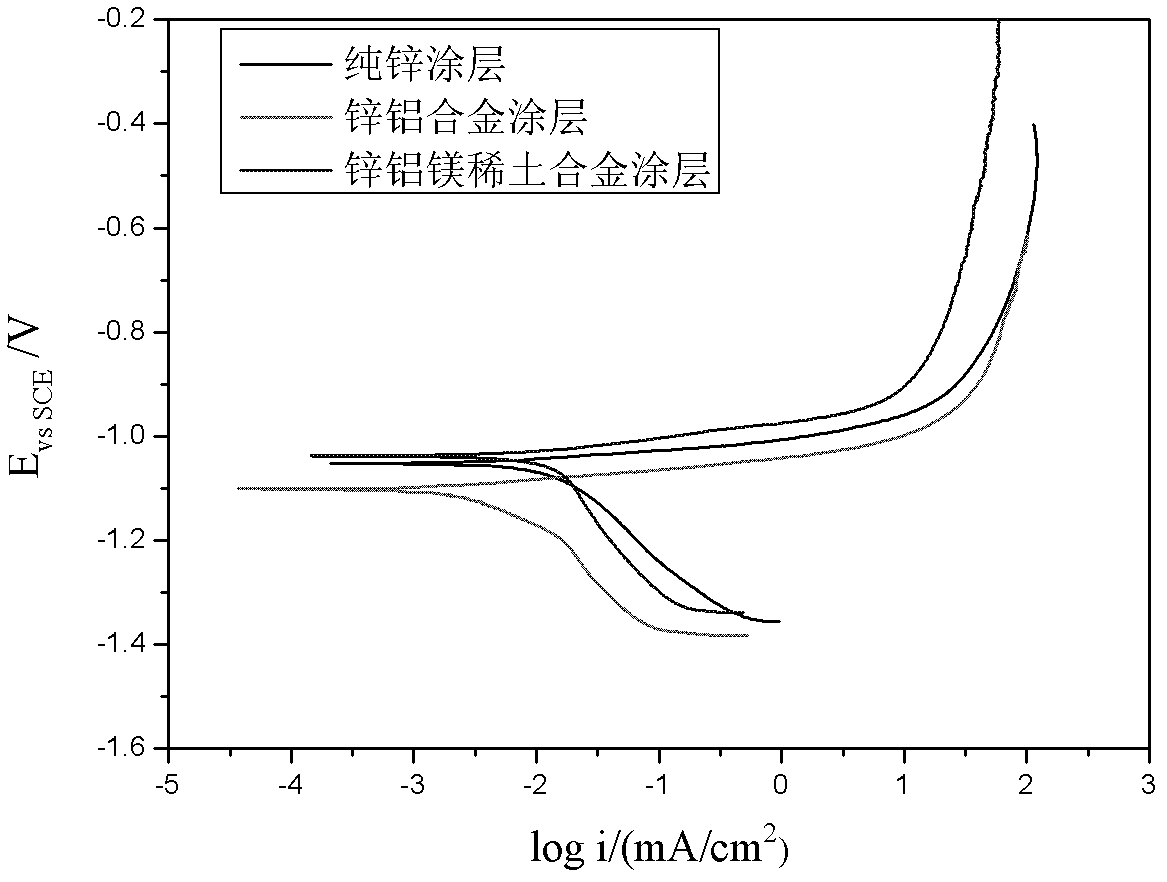

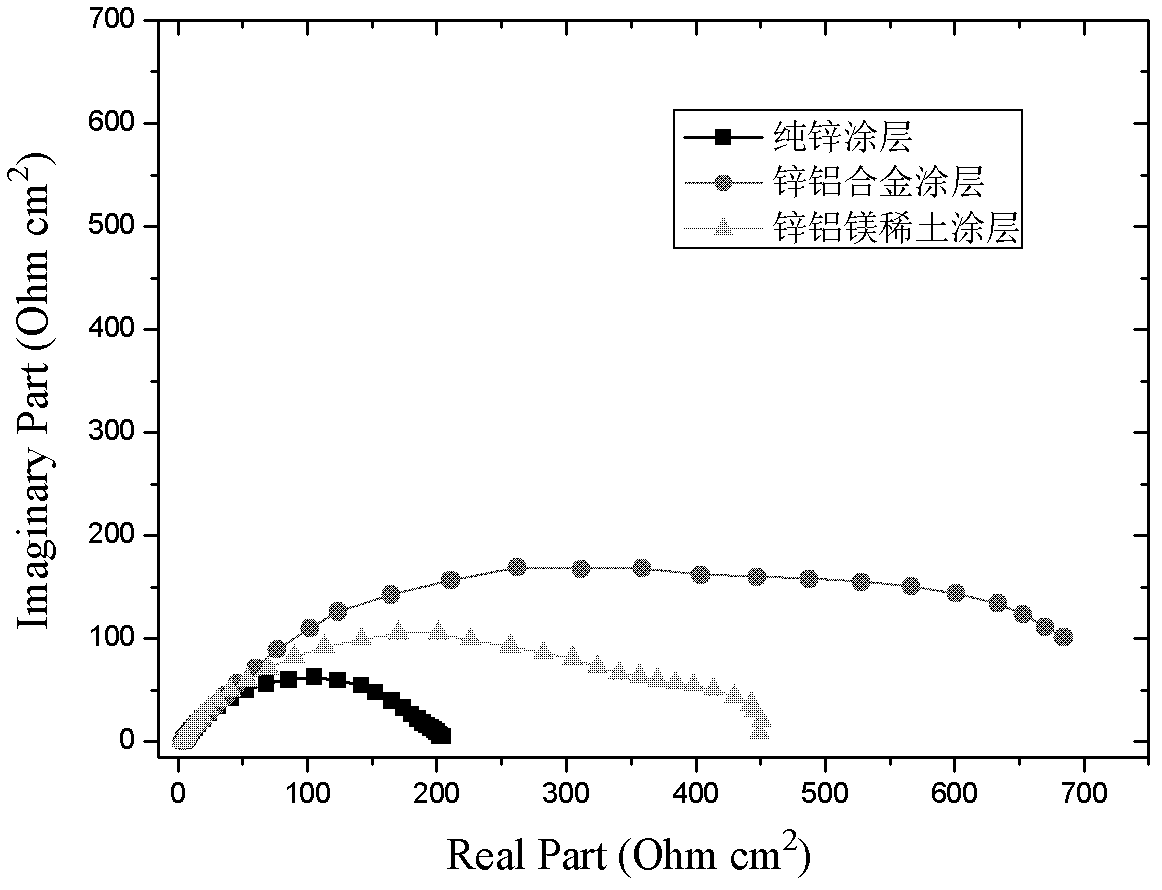

Zinc-aluminum-magnesium-rare earth multi-element alloy material and preparation method thereof

The invention relates to a composition design, a preparation method and application of a hot spraying zinc-aluminum-magnesium-rare earth multi-element alloy material, and belongs to the technical field of anti-corrosive metal anticorrosion. The zinc-aluminum-magnesium-rare earth multi-element alloy material comprises the following components in percentage by weight: 5.0 to 15.0 percent of aluminum, 0.1 to 1.0 percent of magnesium, 0.1 to 0.5 percent of rare earth (lanthanum and cerium), less than 1.0 percent of impurities and the balance of zinc. The preparation method comprises the following steps of: heating to smelt zinc ingots and aluminum ingots in an alloy smelting furnace, adding an intermediate alloy, stirring until the melt is clear, standing, slagging off, and casting; and performing homogenizing annealing on cast ingots, extruding to obtain zinc-aluminum-magnesium-rare earth multi-element alloy blank thick wires, and performing homogenizing annealing, drawing, diameter reducing, and wire surface cleaning to obtain zinc-aluminum-magnesium-rare earth multi-element alloy wire products. A corrosion resistant multi-element alloy coating prepared from the alloy wires prepared by the method through a hot spraying technology has the corrosion resistance obviously higher than that of a pure zinc coating, is suitable for protection construction of steel structural parts, and has important significance and wide application prospect for anti-corrosion engineering of water conservancy and hydropower, ports, bridges, ships and the like.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com