Patents

Literature

2804 results about "Erosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Erosion Resistant Coating. Friction between a surface and wear particles or between two surfaces cause erosion. Erosion resistance is critical to a material’s durability or an application’s service life. Erosion and abrasion result in increased downtime and decreased operational efficiency.

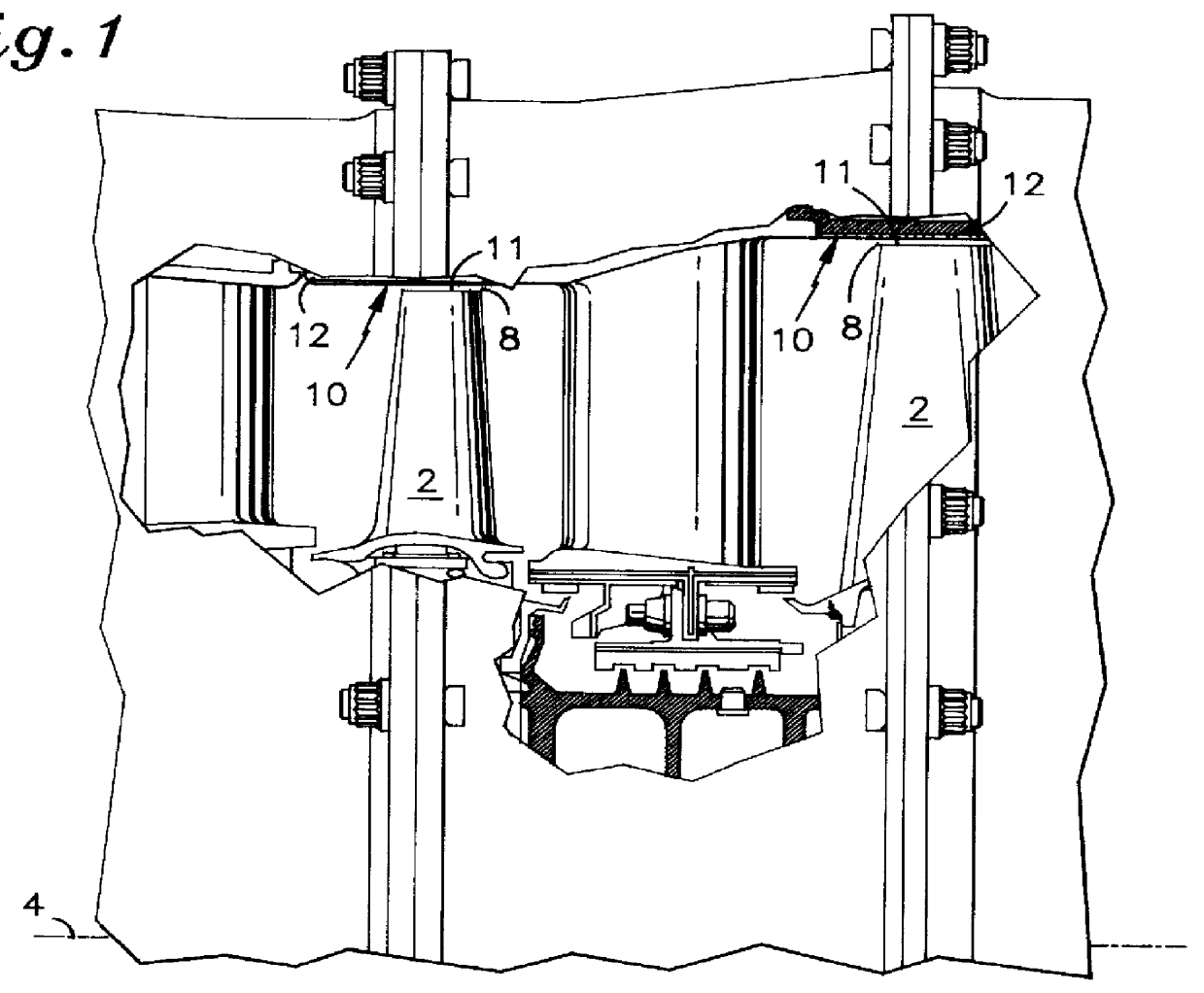

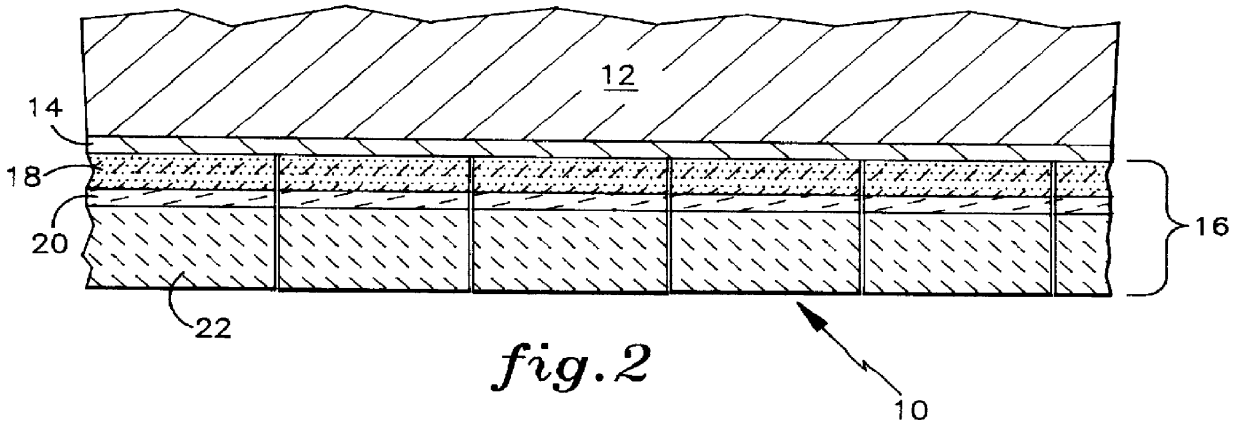

Segmented abradable ceramic coating

InactiveUS6102656AImprove wear resistanceSufficient resistanceMolten spray coatingPump componentsCeramic coatingWear resistance

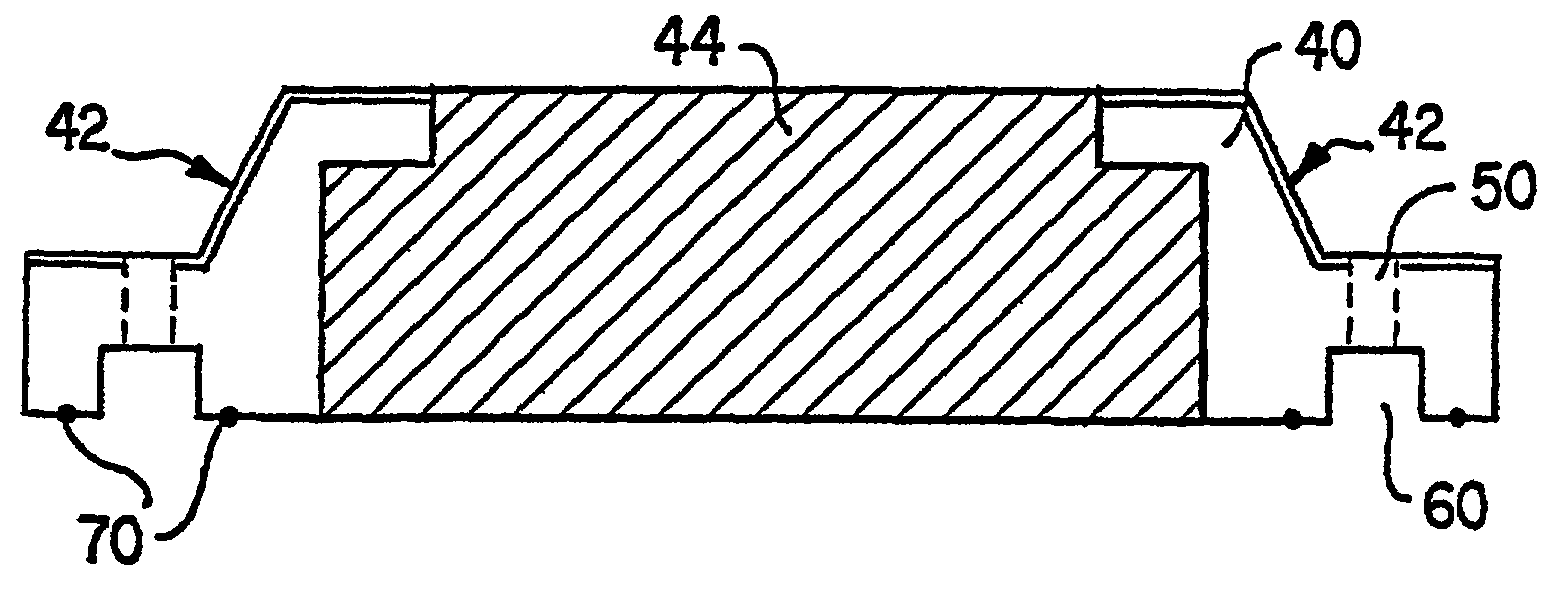

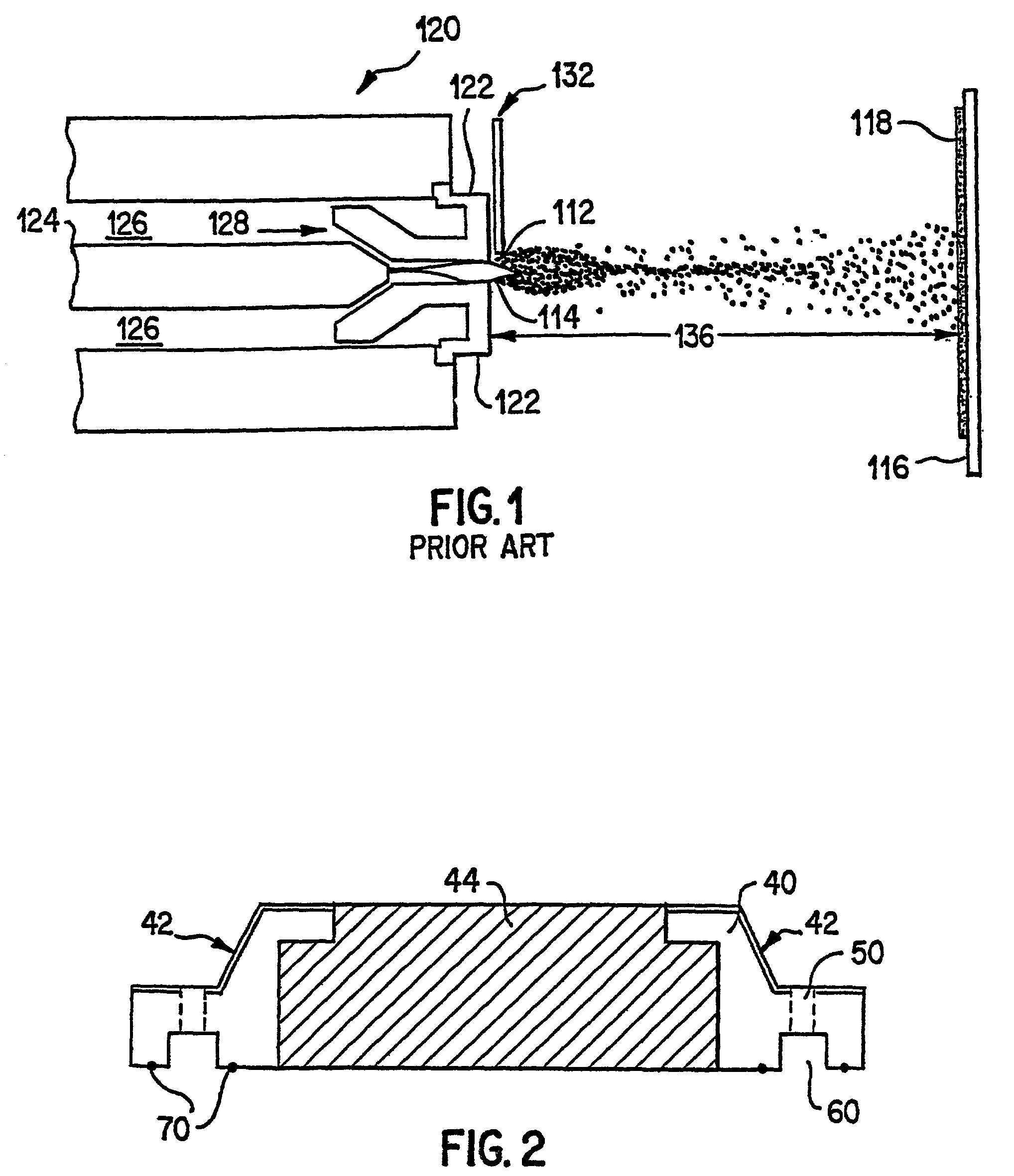

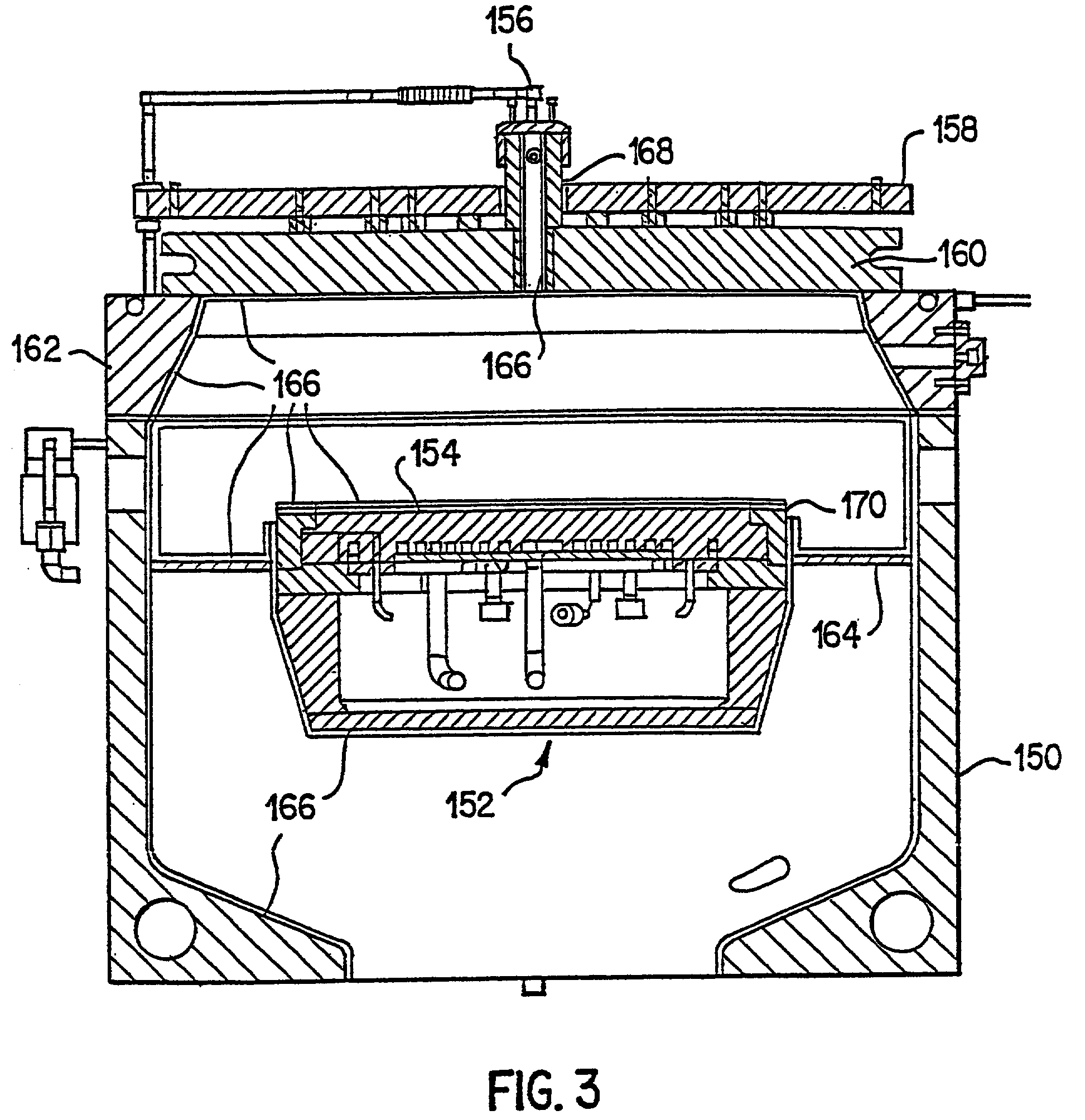

A segmented abradable ceramic coating system having superior abradability and erosion resistance is disclosed. The system includes a duct segment having a metallic substrate, a MCrAlY bond coat on the substrate and a segmented abradable ceramic coating on the bond coat. The segmented abradable ceramic coating includes a base coat foundation layer, a graded interlayer and an abradable top layer for an overall thickness of preferably about 50 mils (1.270 mm). The coating is characterized by a plurality of vertical microcracks. By precisely controlling the deposition parameters, composition of the layers and layer particle morphology, segmentation is achieved, as well as superior abradability and erosion resistance.

Owner:UNITED TECH CORP

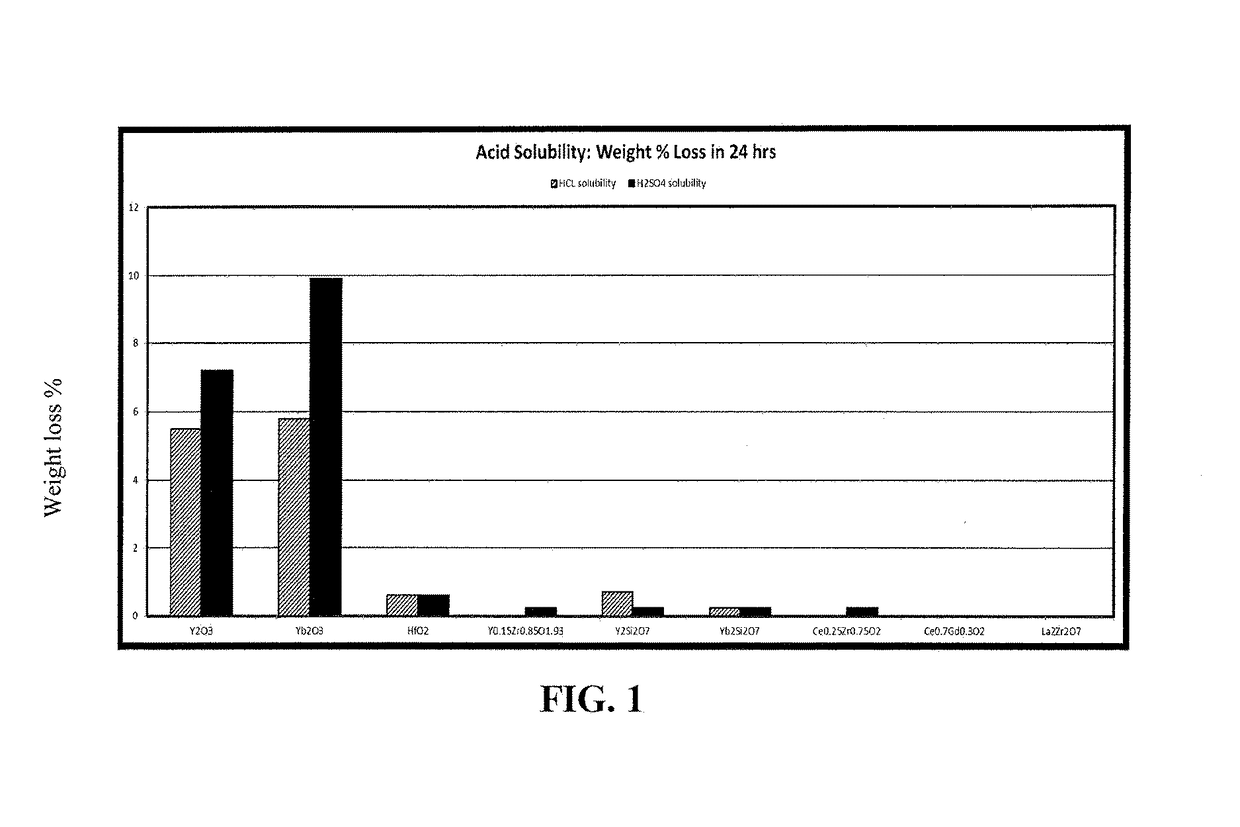

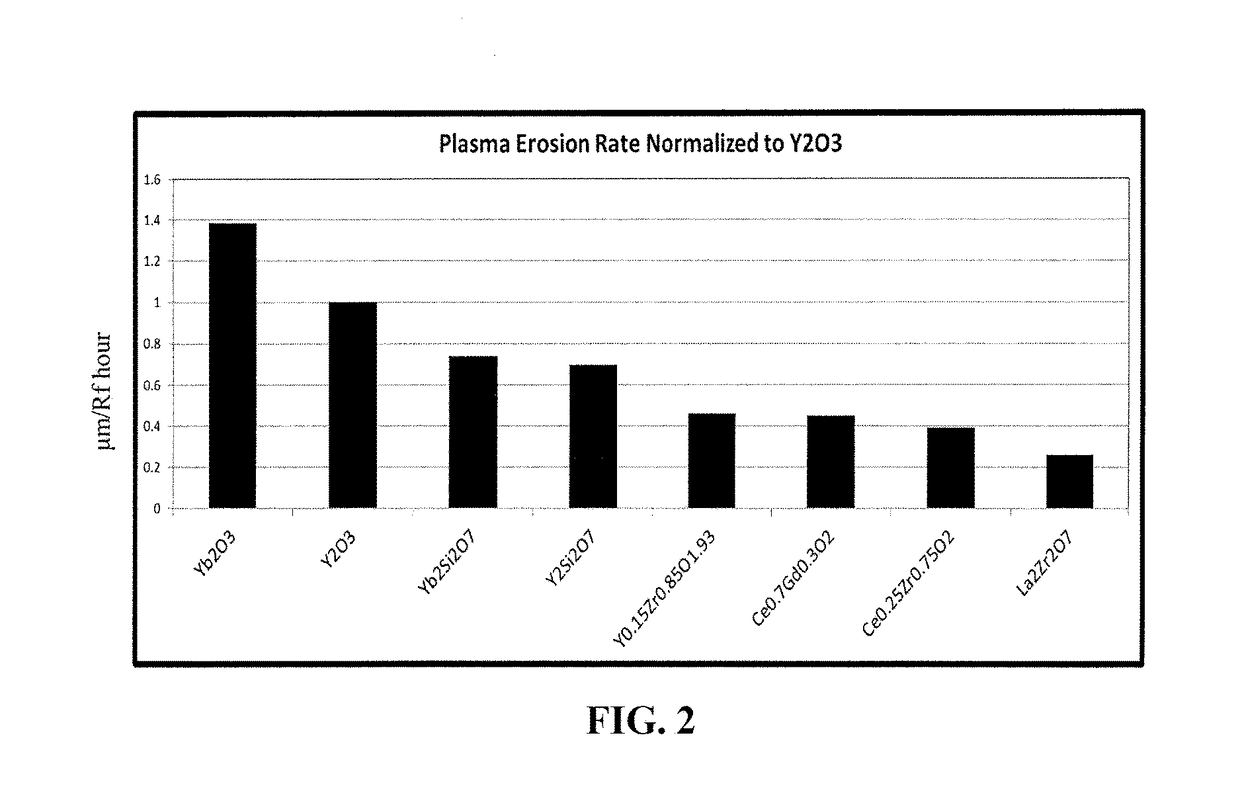

Coated semiconductor processing members having chlorine and fluorine plasma erosion resistance and complex oxide coatings therefor

ActiveUS20170301519A1High tensile bond strengthReduce pollutionMolten spray coatingElectric discharge tubesSolid solutionPlasma sprayed

A semiconductor processing member is provided, including a body and a plasma spray coating provided on the body. The coating is an ABO or ABCO complex oxide solid solution composition, where A, B and C are selected from the group consisting of La, Zr, Ce, Gd, Y, Yb and Si, and O is an oxide. The coating imparts both chlorine and fluorine plasma erosion resistance, reduces particle generation during plasma etching, and prevents spalling of the coating during wet cleaning of the semiconductor processing member.

Owner:FM INDS

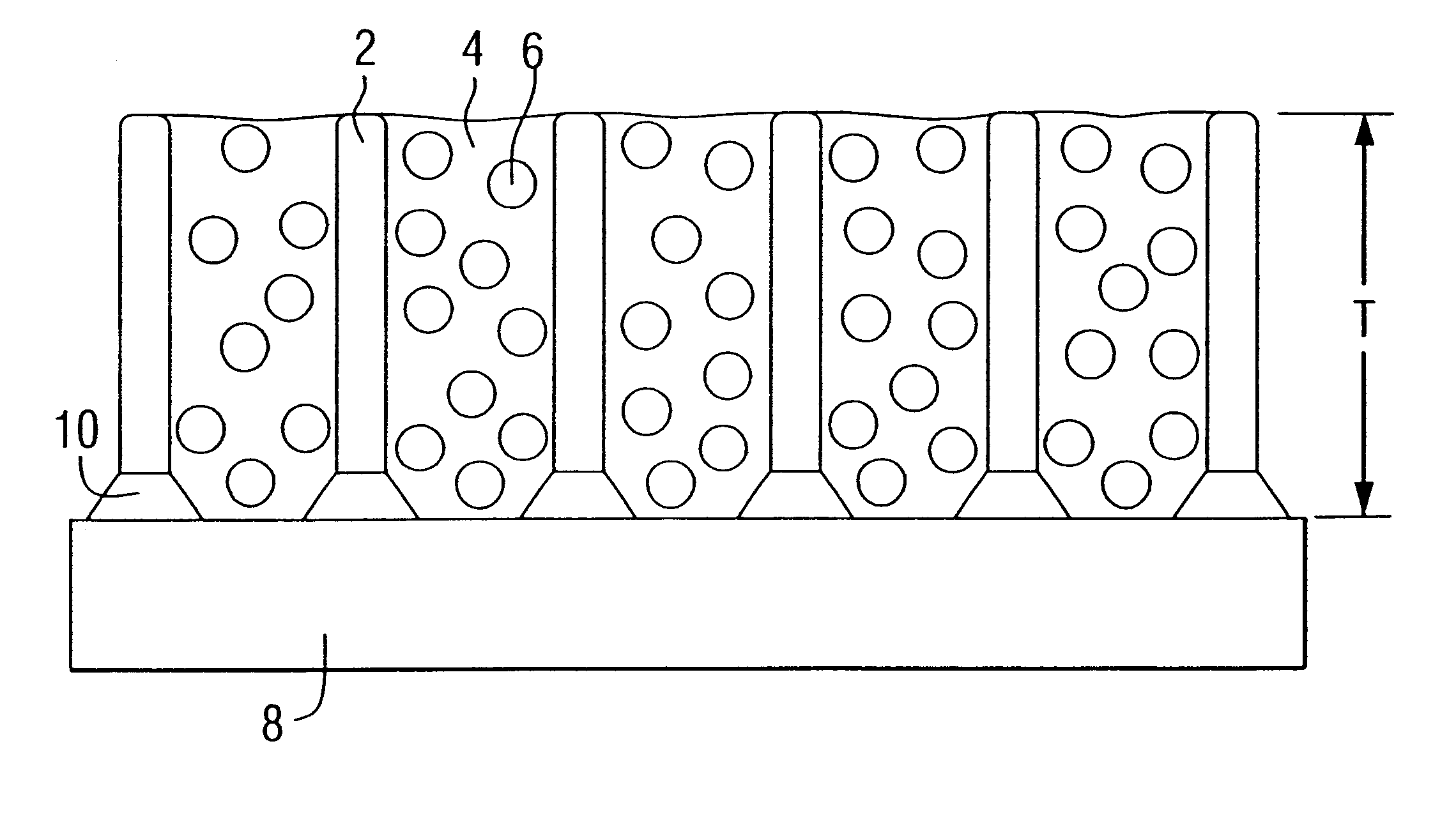

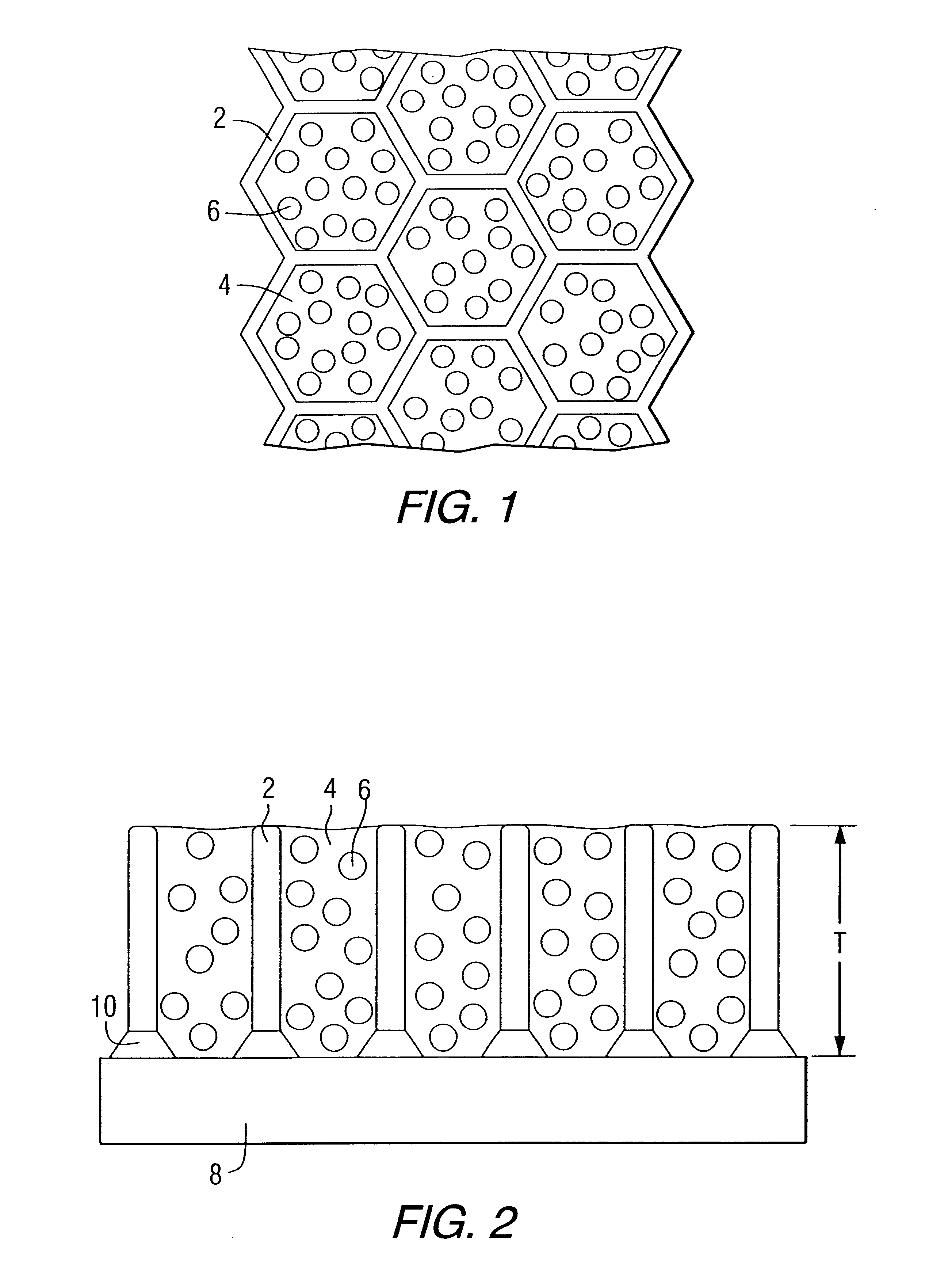

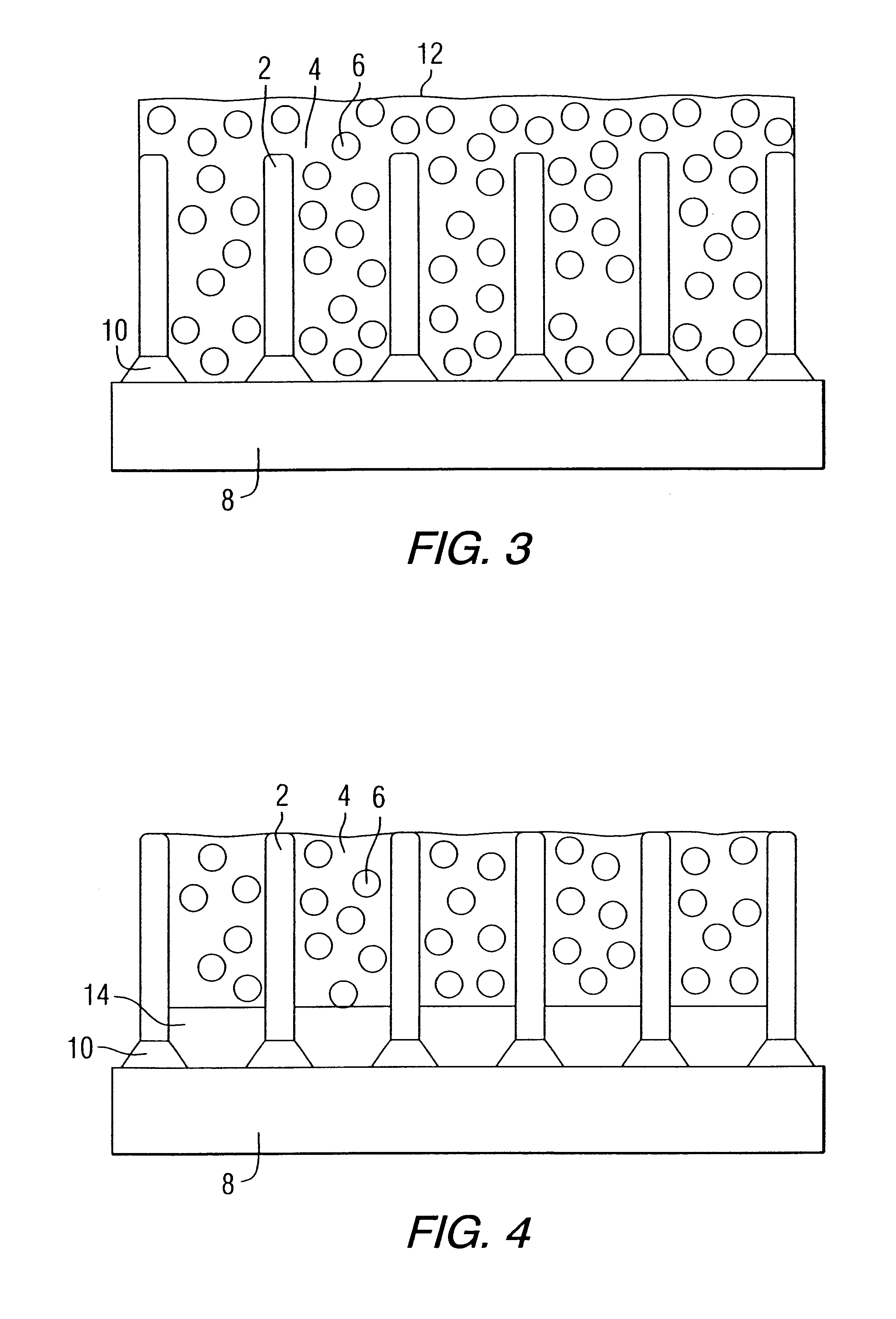

High temperature erosion resistant, abradable thermal barrier composite coating

InactiveUS6235370B1Improve wear resistanceImprove adhesionMolten spray coatingPump componentsCombustorHoneycomb

A composite thermal barrier coating system includes a honeycomb metallic structure filled with high thermal expansion ceramic hollow spheres in a phosphate bonded matrix. The composite thermal barrier coating system may be manufactured to thicknesses in excess of current thermal barrier coating systems, thereby imparting greater thermal protection. Superior erosion resistance and abrasion properties are also achieved. The composite thermal barrier coating is useful on combustion turbine components such as ring seal segments, vane segment shrouds, transitions and combustors.

Owner:SIEMENS ENERGY INC

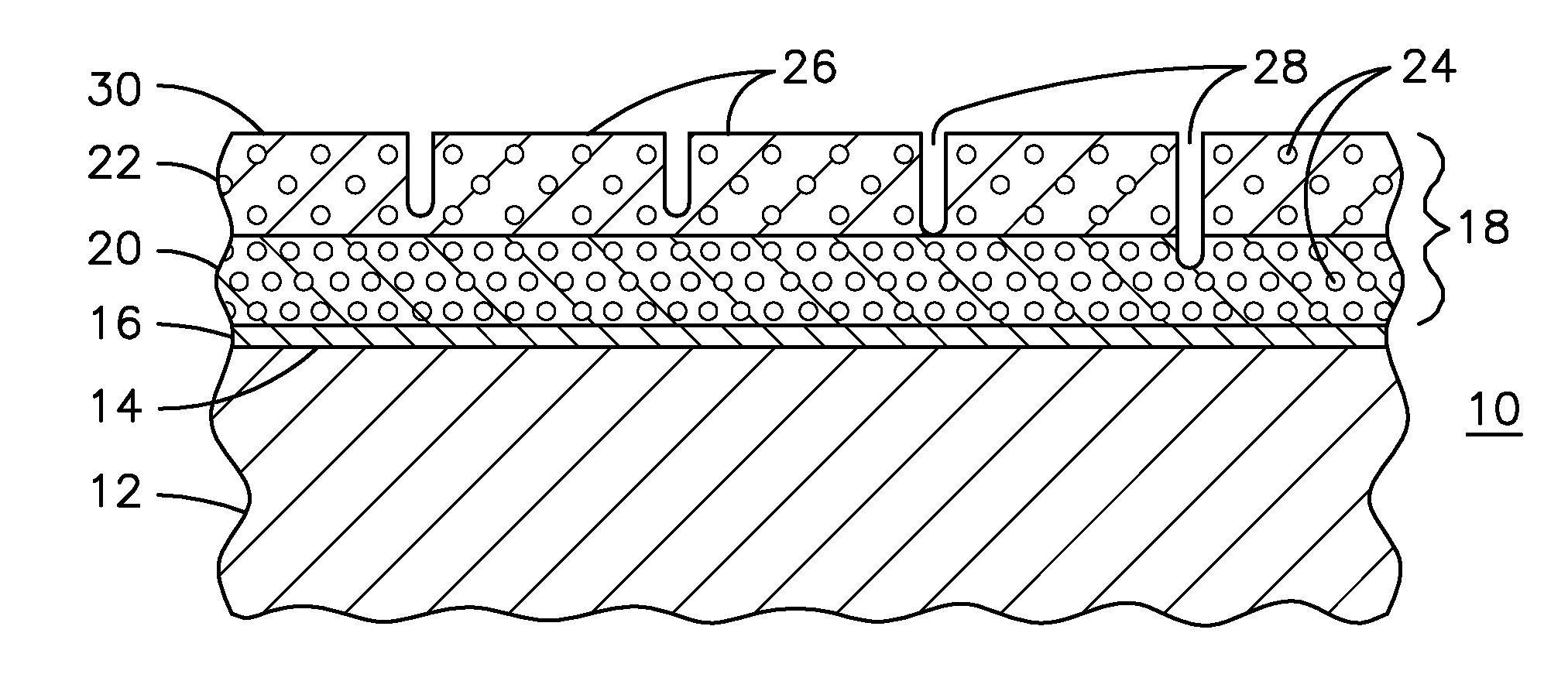

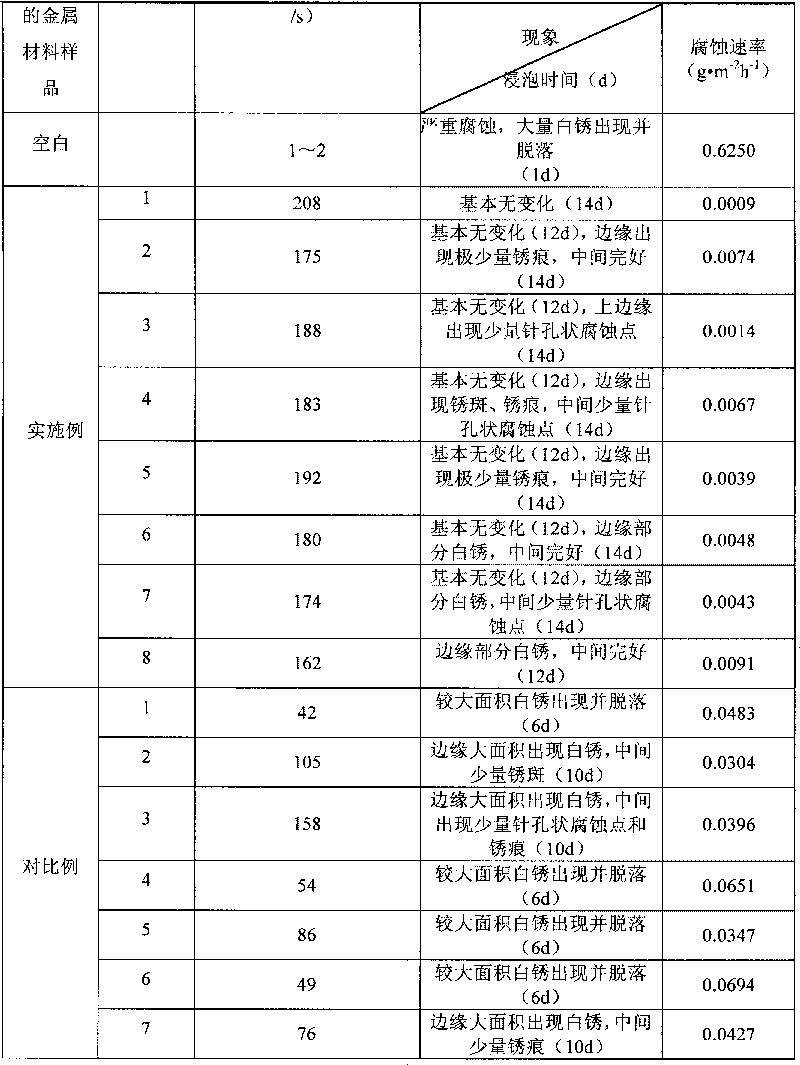

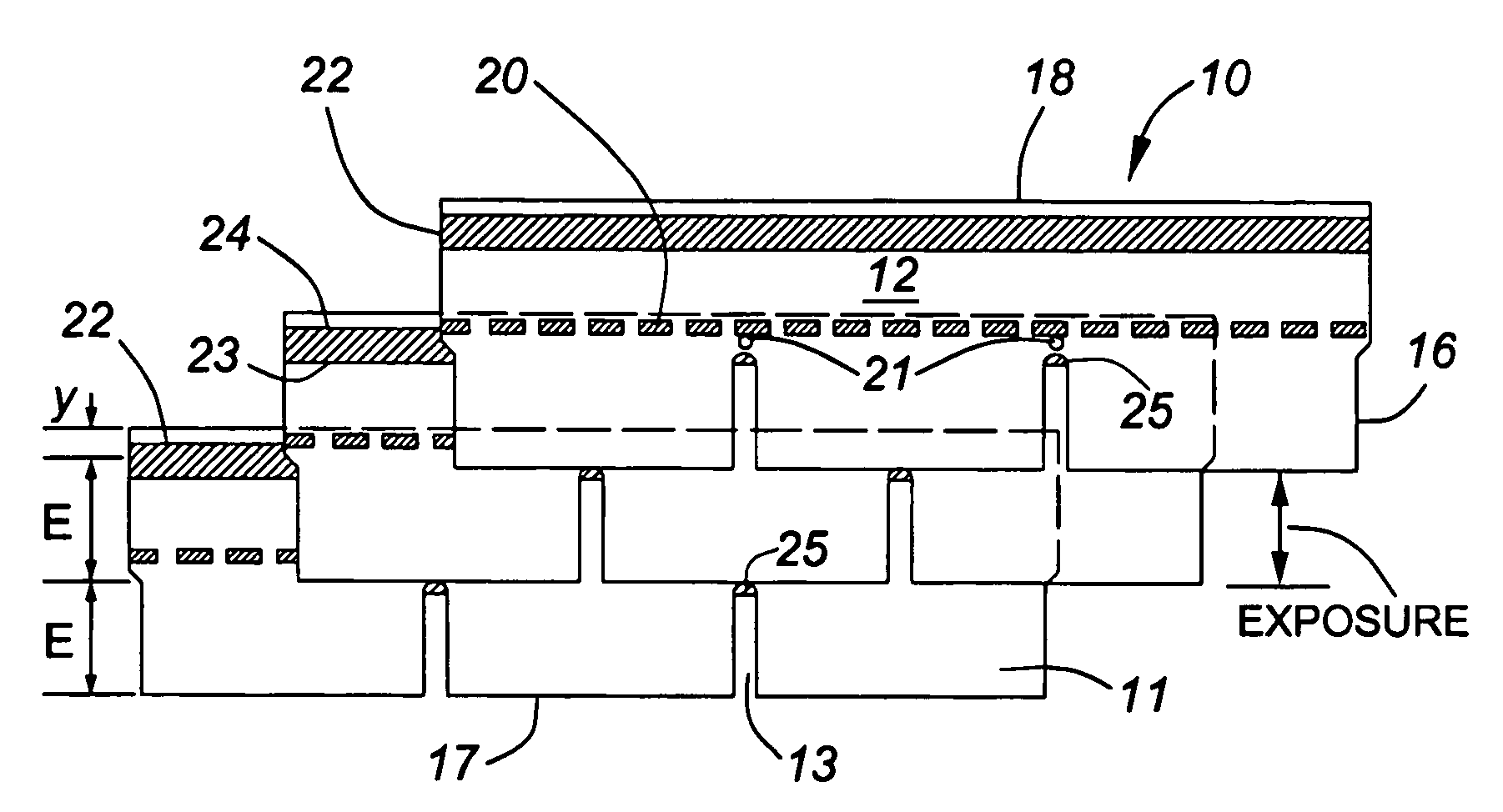

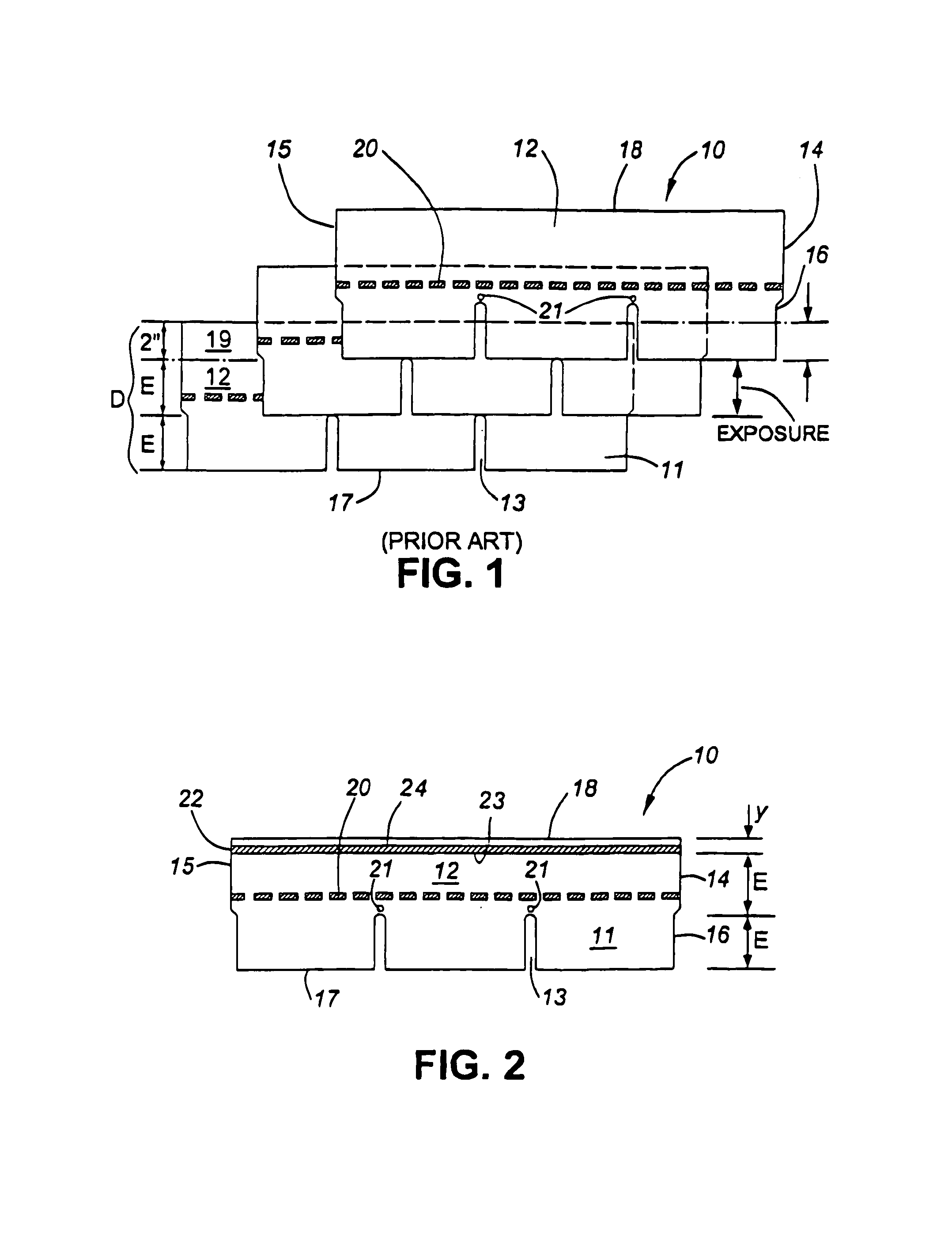

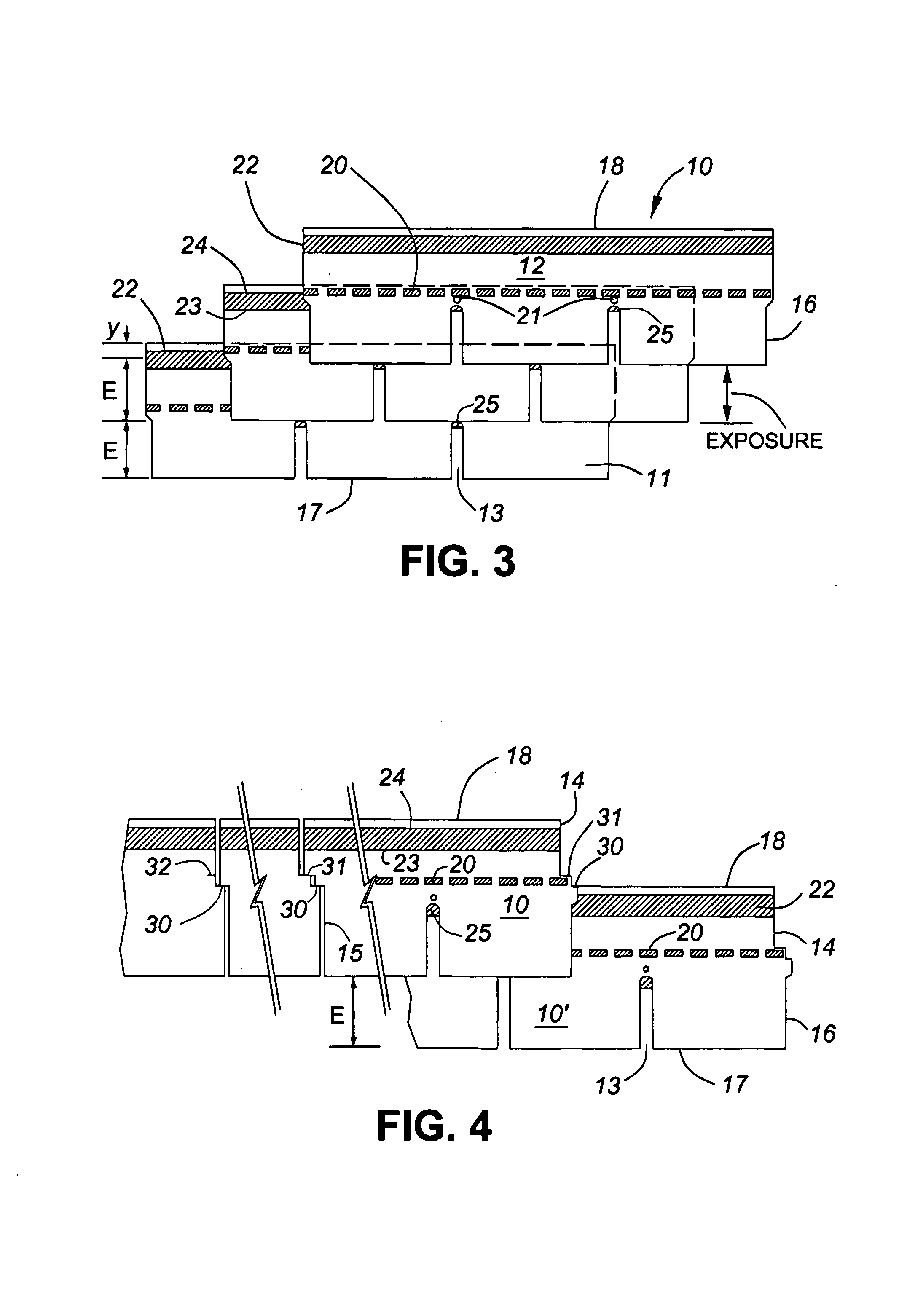

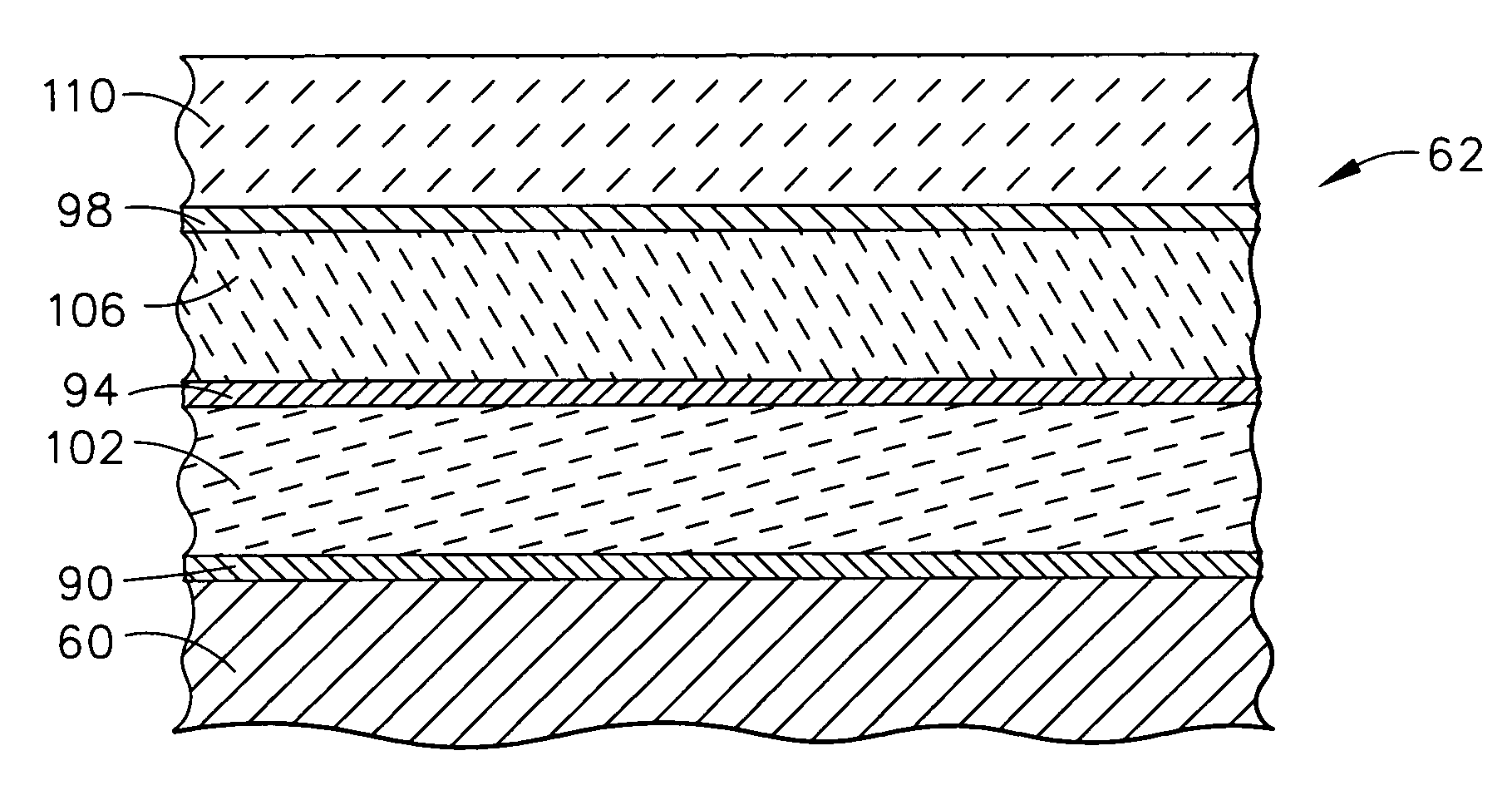

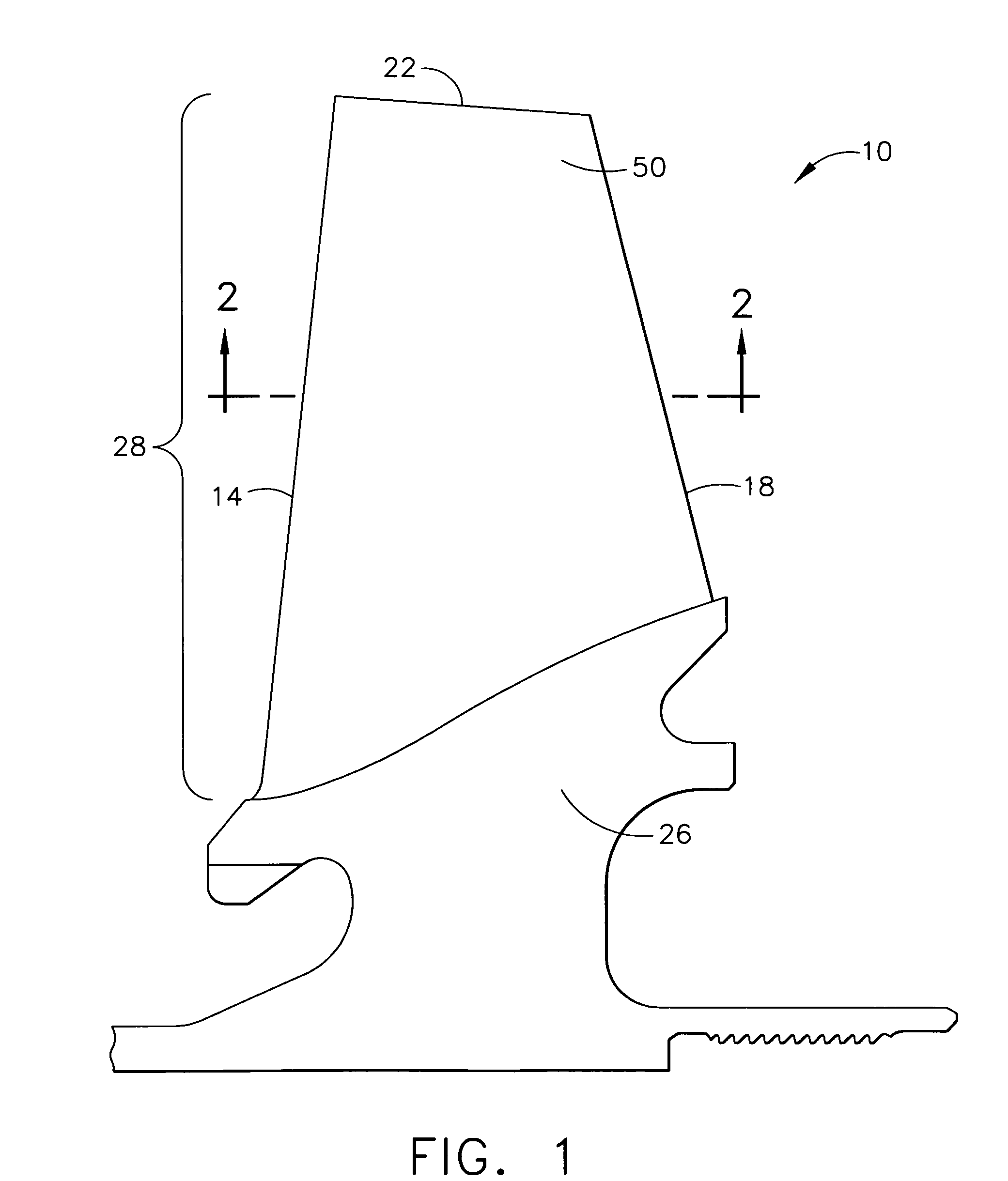

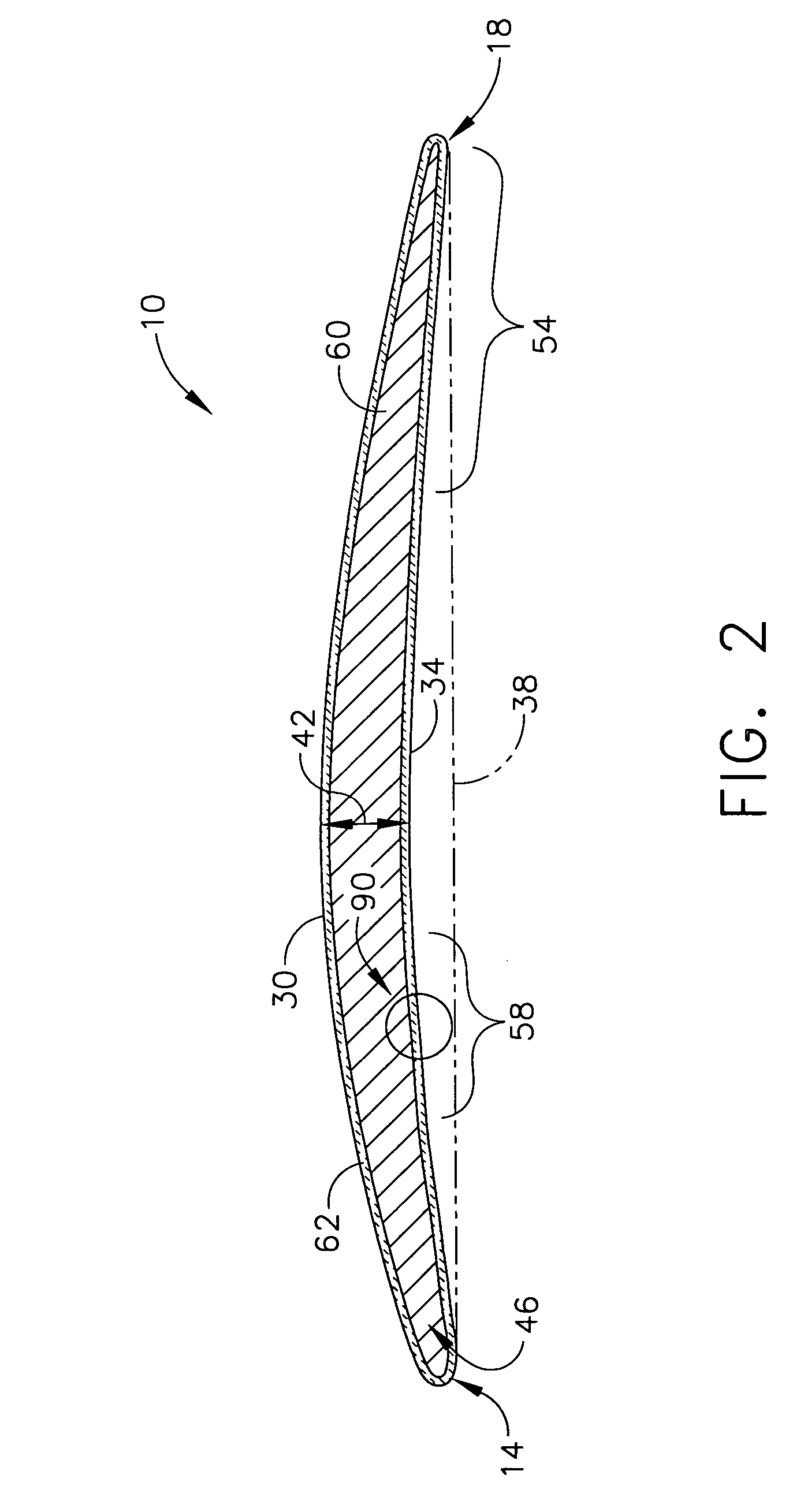

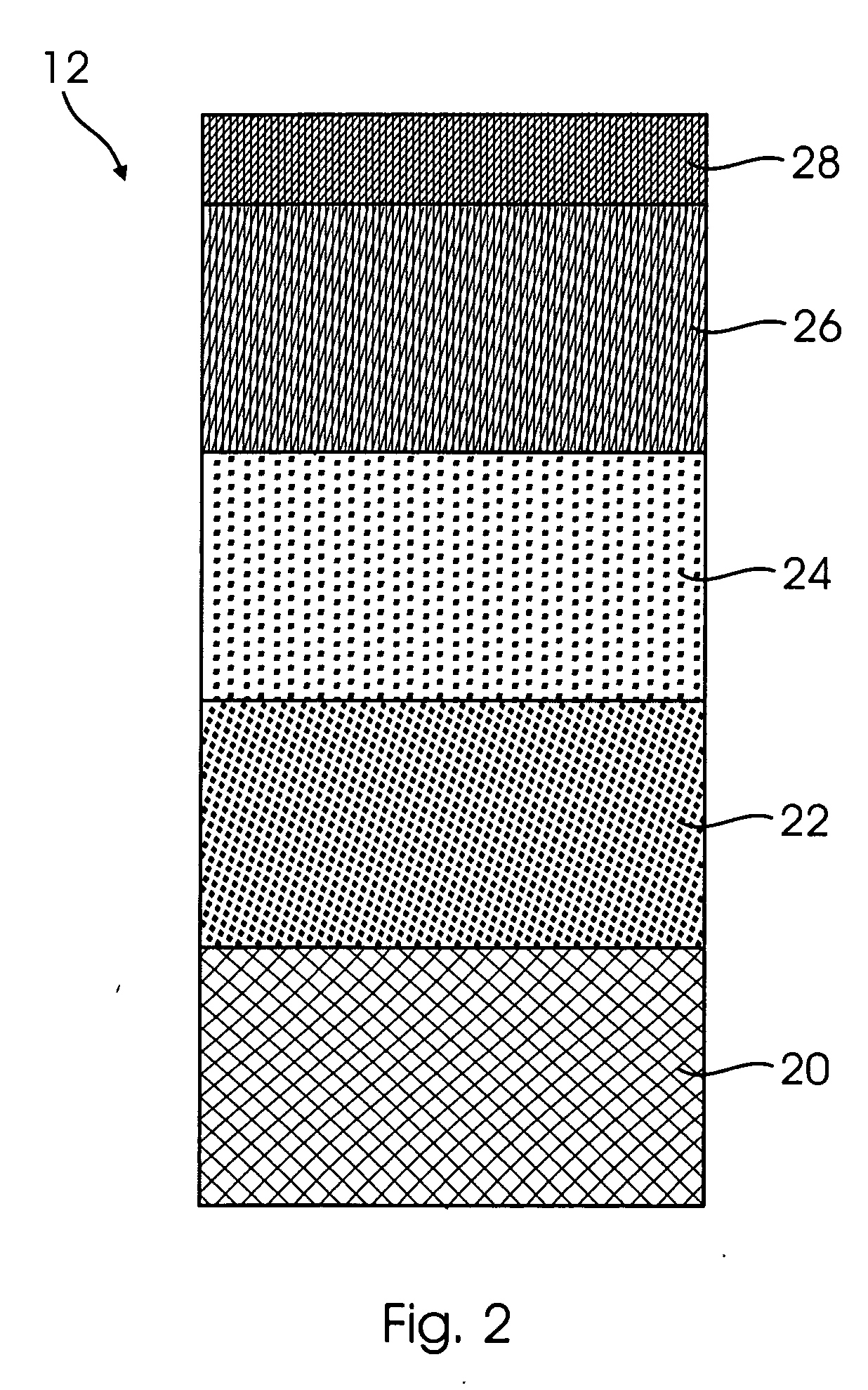

Segmented thermal barrier coating

A ceramic thermal barrier coating (TBC) (18) having first and second layers (20, 22), the second layer (22) having a lower thermal conductivity than the first layer for a given density. The second layer may be formed of a material with anisotropic crystal lattice structure. Voids (24) in at least the first layer (20) make the first layer less dense than the second layer. Grooves (28) are formed in the TBC (18) for thermal strain relief. The grooves may align with fluid streamlines over the TBC. Multiple layers (84, 86,88) may have respective sets of grooves (90), Preferred failure planes parallel to the coating surface (30) may be formed at different depths (A1, A2, A3) in the thickness of the TBC to stimulate generation of a fresh surface when a portion of the coating fails by spalling. A dense top layer (92) may provide environmental and erosion resistance.

Owner:SIEMENS ENERGY INC

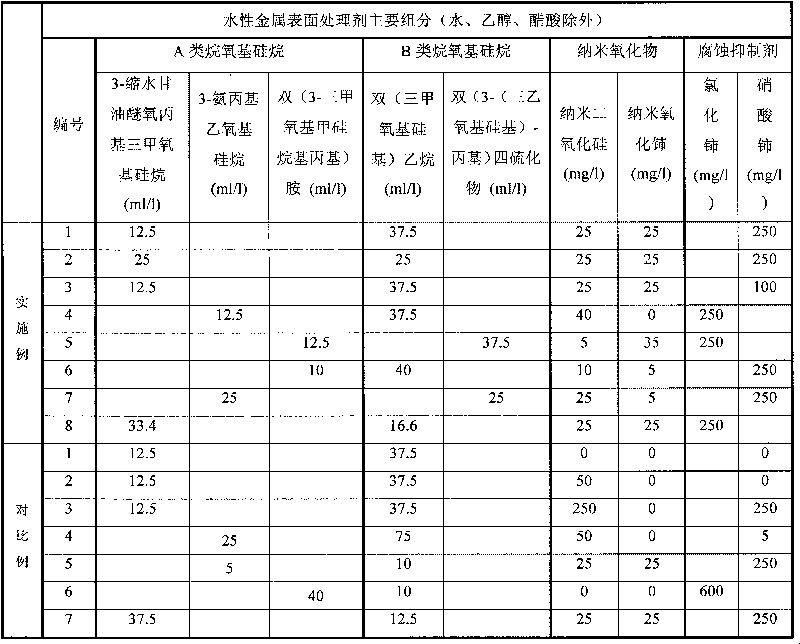

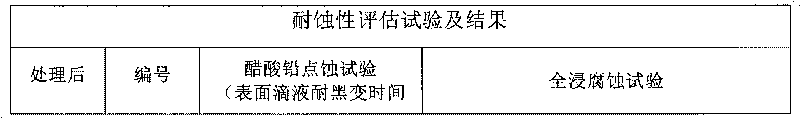

Environment-friendly nano water-based silane treatment agent capable of improving anti-corrosion performance of metal surface

ActiveCN101717930ASimple processApplicable industrial scaleMetallic material coating processesWater basedEpoxy

The invention discloses an environment-friendly nano water-based silane treatment agent capable of improving anti-corrosion performance of metal surface. The treatment agent is water-based silane solution which consists of at least one alkoxy silane containing epoxy or at least one alkoxy silane containing amino, at least one disilyl silane, nano-silicon dioxide, rare earth salt type corrosion inhibitor or rare earth salt type and rare earth nano oxide, water, or acetic acid and a small amount of ethanol. The metal material is coated by using the silane solution for impregnation, brushing, spraying or spin-coating, a siloxane layer is formed on the metal surface, then the long-acting corrosion resistance is formed by curing for 3 hours at the temperature of 100 DEG C, and a nano organic silane film which has close bonding force with a coating is formed. Nanoparticles can not only improve the corrosion resistance and enhance the mechanical strength of the silane film in a coating layer, but also realize the synergistic corrosion resistance with the corrosion inhibitor. The technology has the advantages of simple process, greenness, environmental protection and strong practicality.

Owner:HAISO TECH

Conductive, plasma-resistant member

InactiveUS20070248832A1Improve corrosion resistanceSuppress particle contaminationMolten spray coatingNatural mineral layered productsDisplay deviceFlat panel display

An electrically conductive, plasma-resistant member adapted for exposure to a halogen-based gas plasma atmosphere includes a substrate having formed on at least part of a region thereof to be exposed to the plasma a thermal spray coating composed of yttrium metal or yttrium metal in admixture with yttrium oxide and / or yttrium fluoride so as to confer electrical conductivity. Because the member is conductive and has an improved erosion resistance to halogen-based corrosive gases or plasmas thereof, particle contamination due to plasma etching when used in semiconductor manufacturing equipment or flat panel display manufacturing equipment can be suppressed.

Owner:SHIN ETSU CHEM IND CO LTD

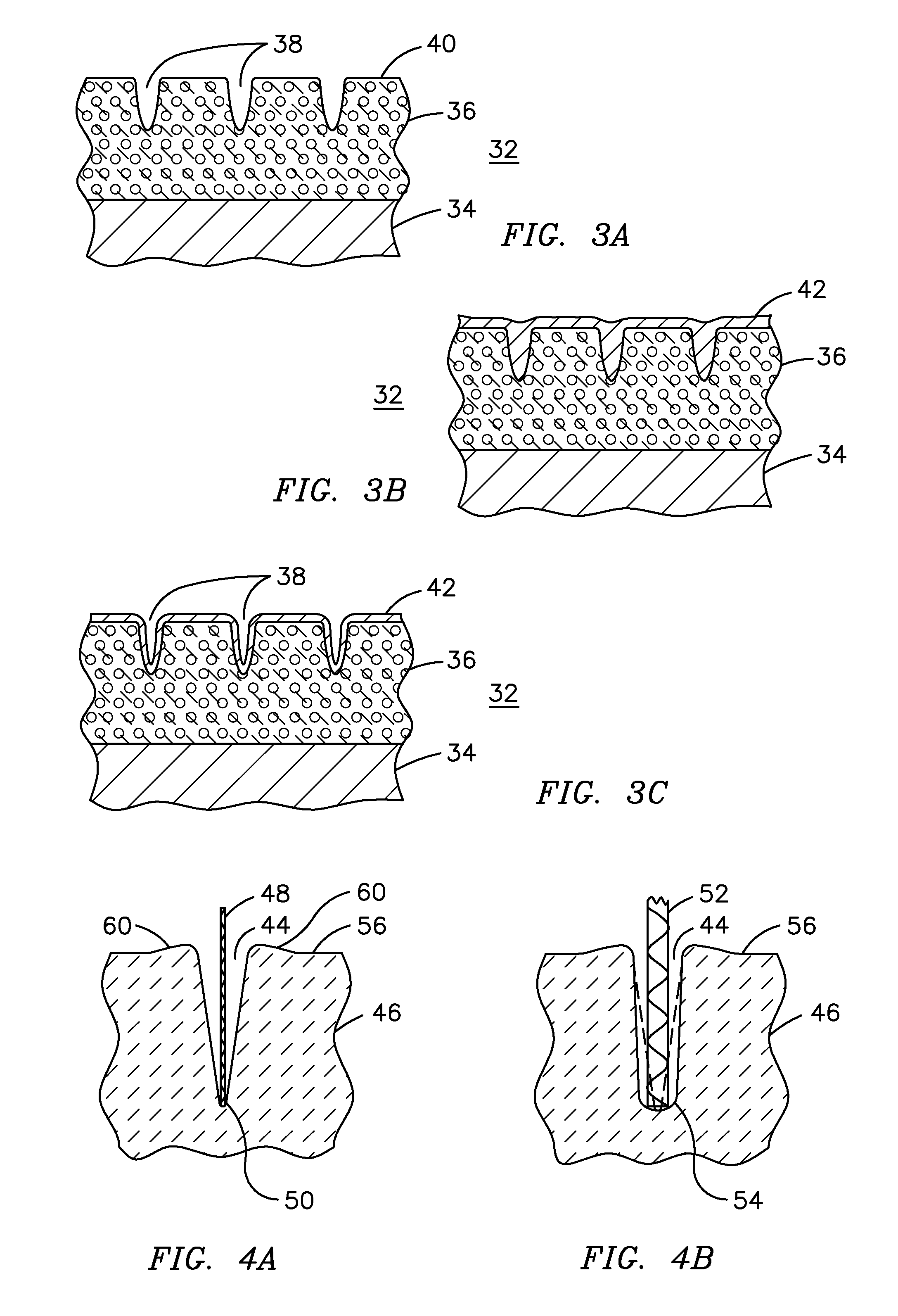

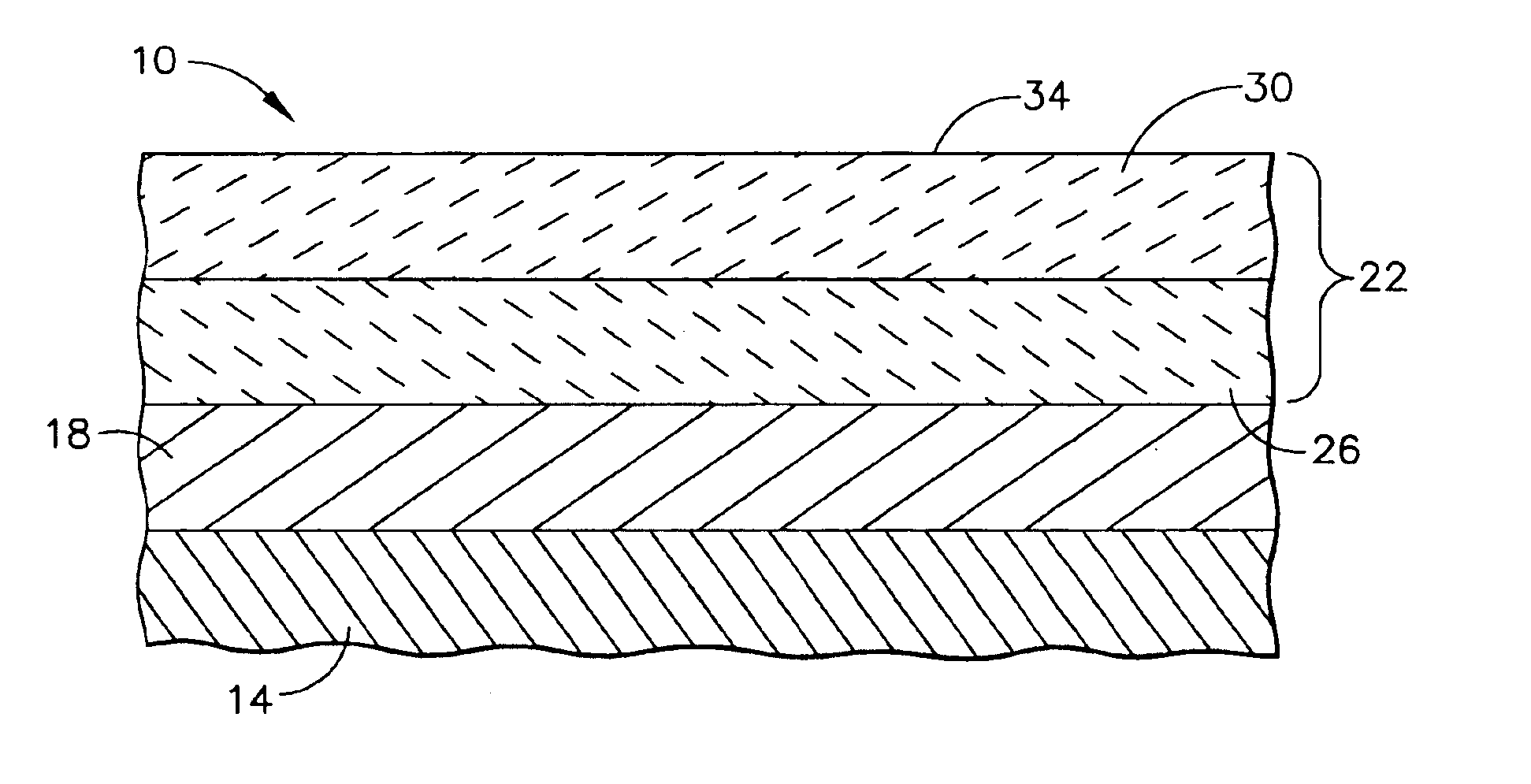

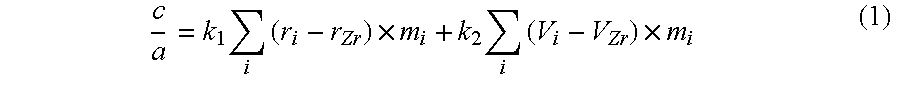

Thermal barrier coatings with protective outer layer for improved impact and erosion resistance

InactiveUS6875529B1Improve erosion resistanceImprove impact resistanceMolten spray coatingVacuum evaporation coatingBond coatMetallic substrate

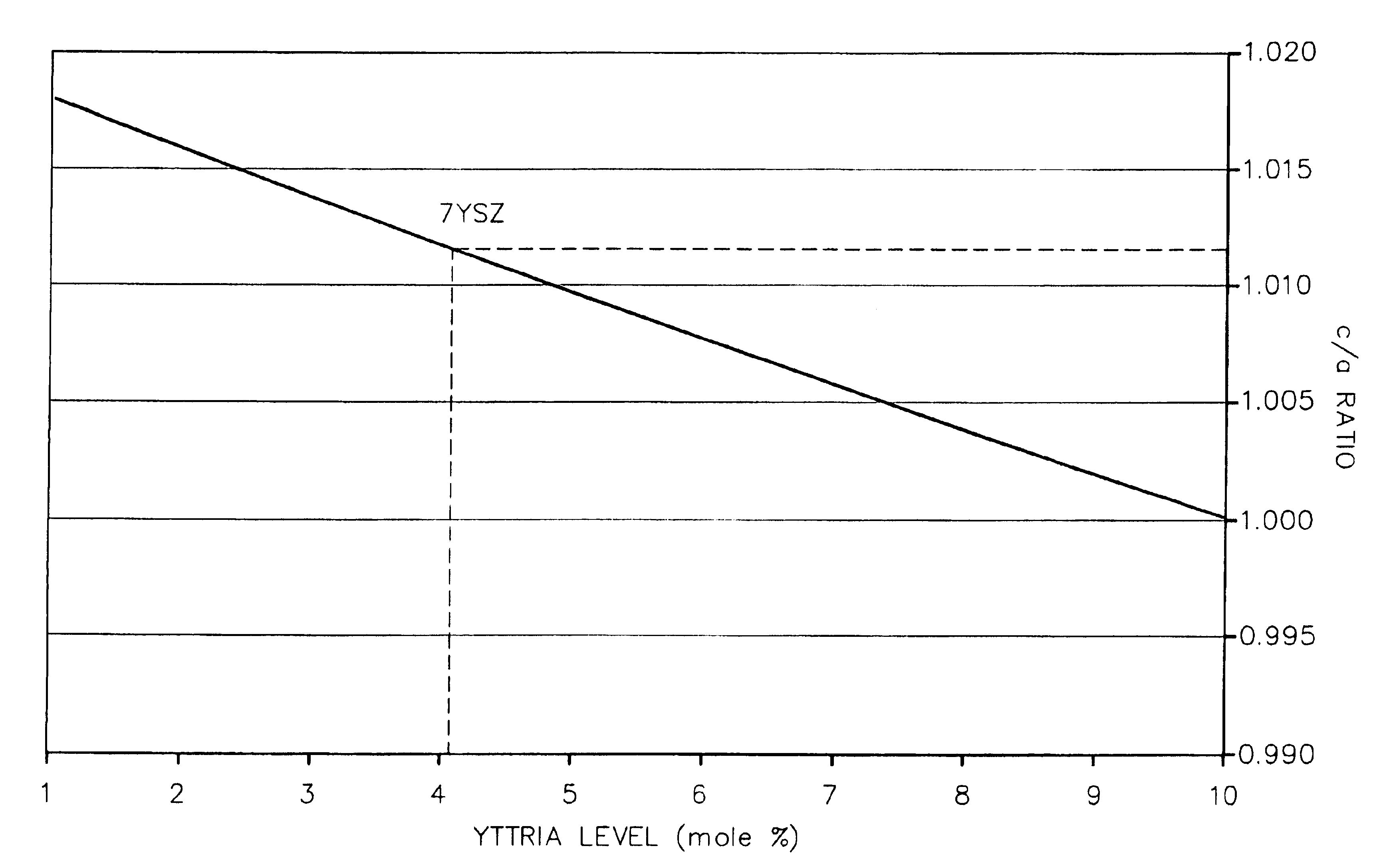

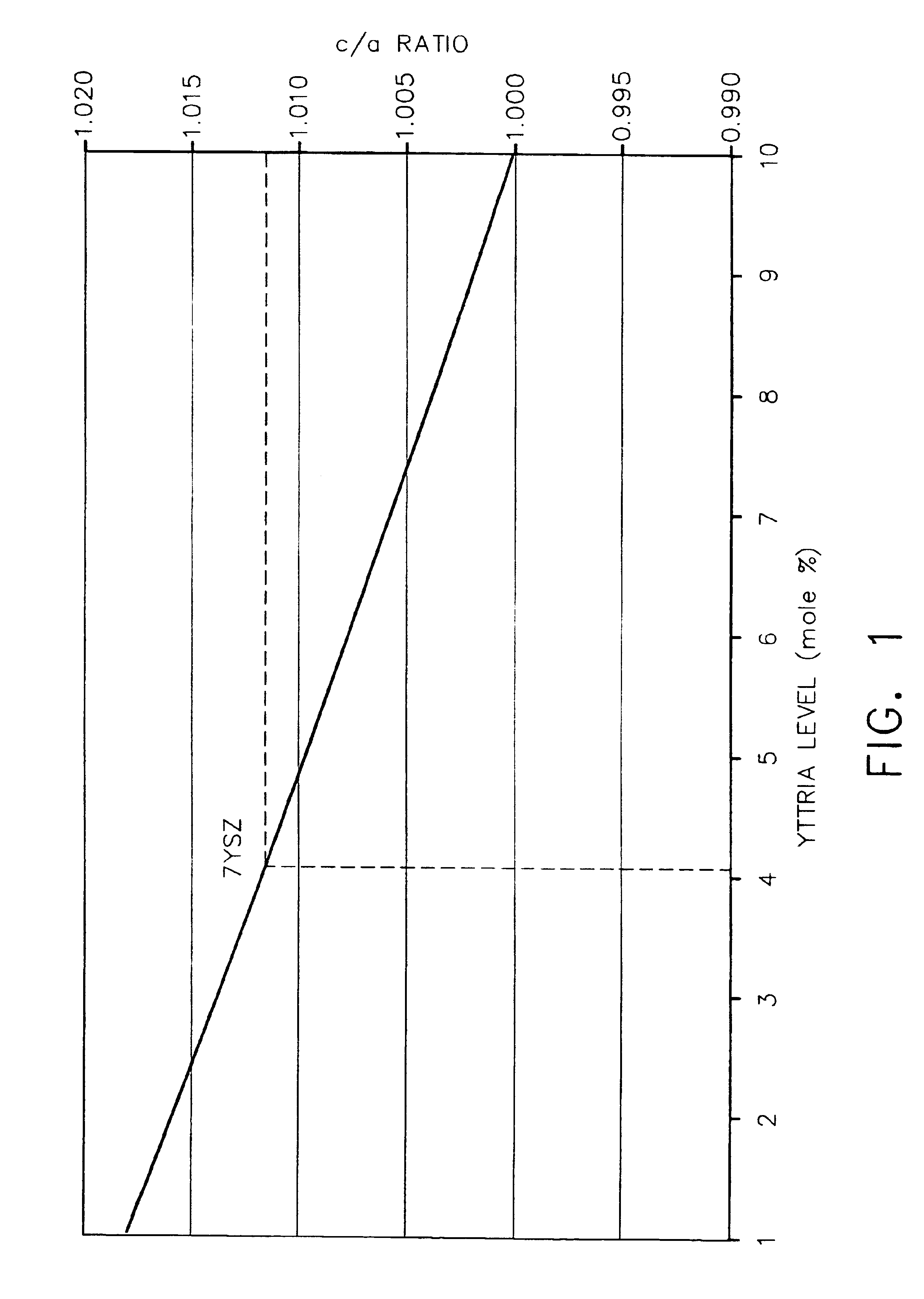

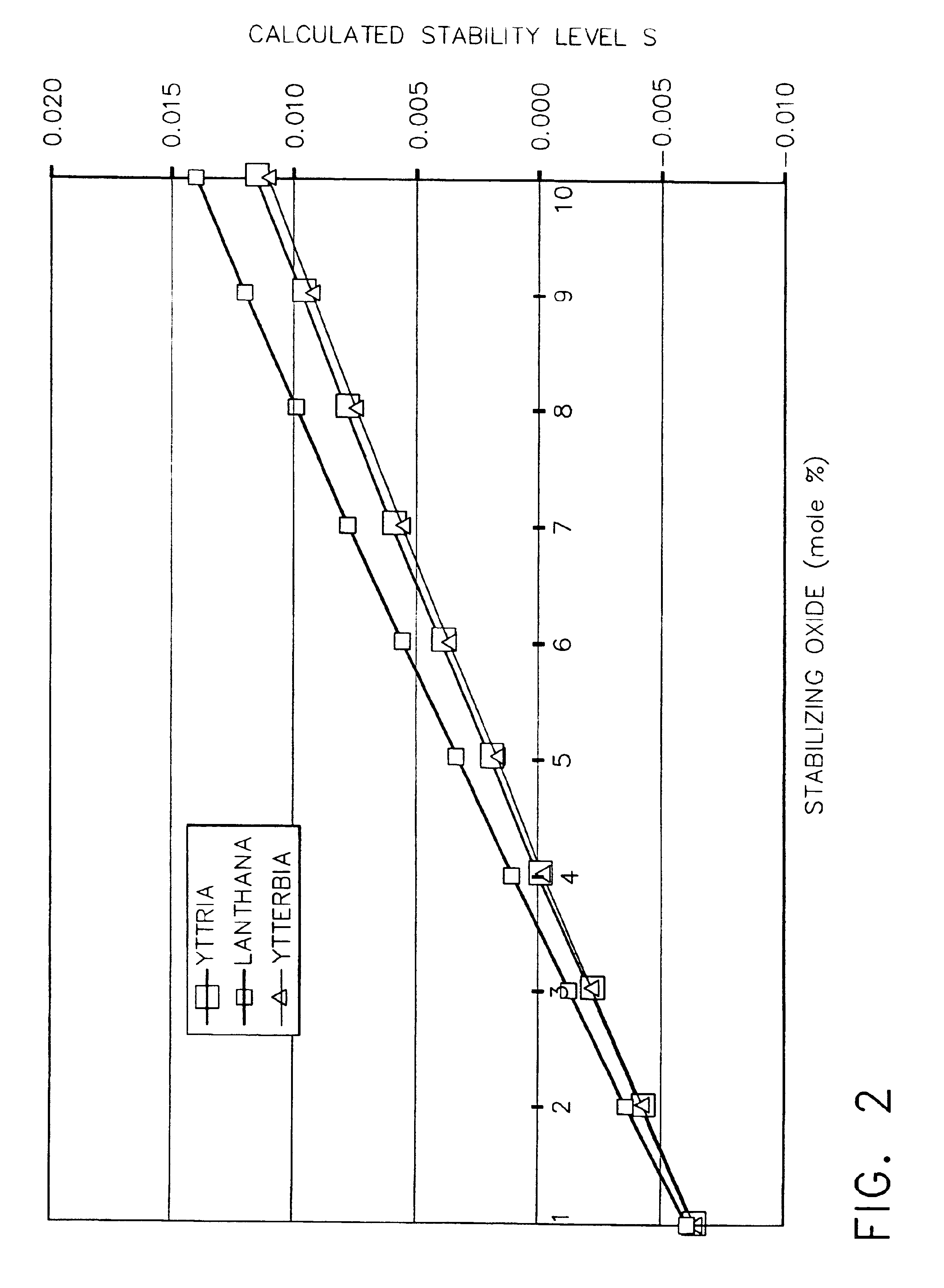

A reduced thermal conductivity thermal barrier coating having improved impact and erosion resistance for an underlying metal substrate of articles that operate at, or are exposed to, high temperatures. This coating comprises an inner layer nearest to the underlying metal substrate comprising a ceramic thermal barrier coating material, as well as a protective outer layer adjacent to and overlaying the inner layer and having an exposed surface. The outer layer has a thickness up to about 5 mils (127 microns) sufficient to impart impact and erosion resistance to the thermal barrier coating, and comprises a zirconia-containing ceramic composition having a c / a ratio of the zirconia lattice in the range of from about 1.011 to about 1.016 and stabilized in the tetragonal phase by a stabilizing amount of a stabilizing metal oxide selected from the group consisting of yttria, calcia, ceria, scandia, magnesia, india, ytterbia and mixtures thereof. This coating can be used to provide a thermally protected article having a metal substrate and optionally a bond coated layer adjacent to and overlaying the metal substrate. The thermal barrier coating can be prepared by forming the inner layer comprising the ceramic thermal barrier coating material, followed by forming on the inner layer the protective outer layer.

Owner:GENERAL ELECTRIC CO

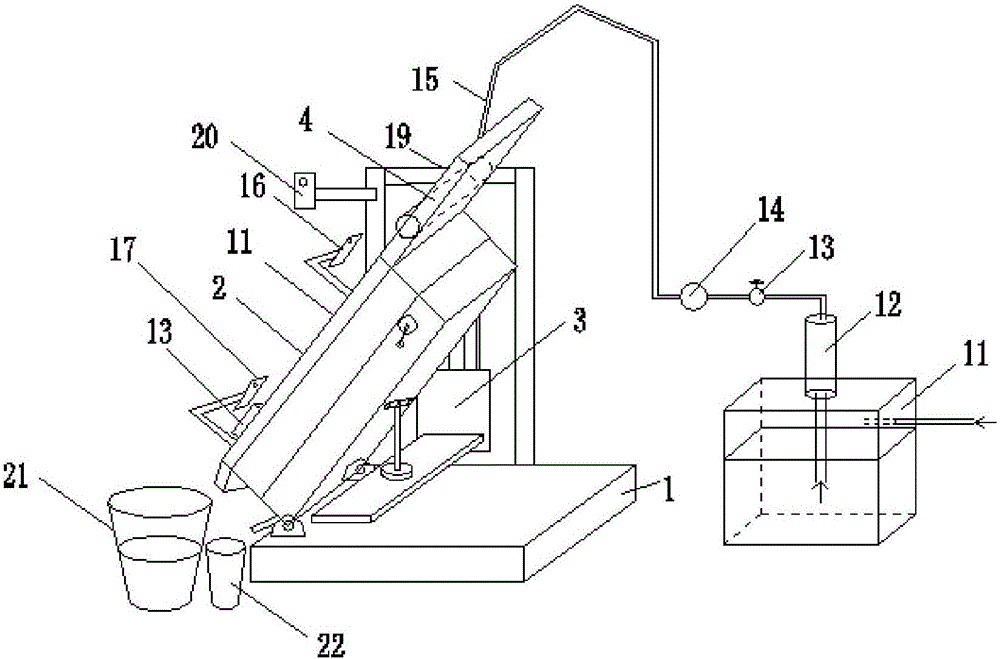

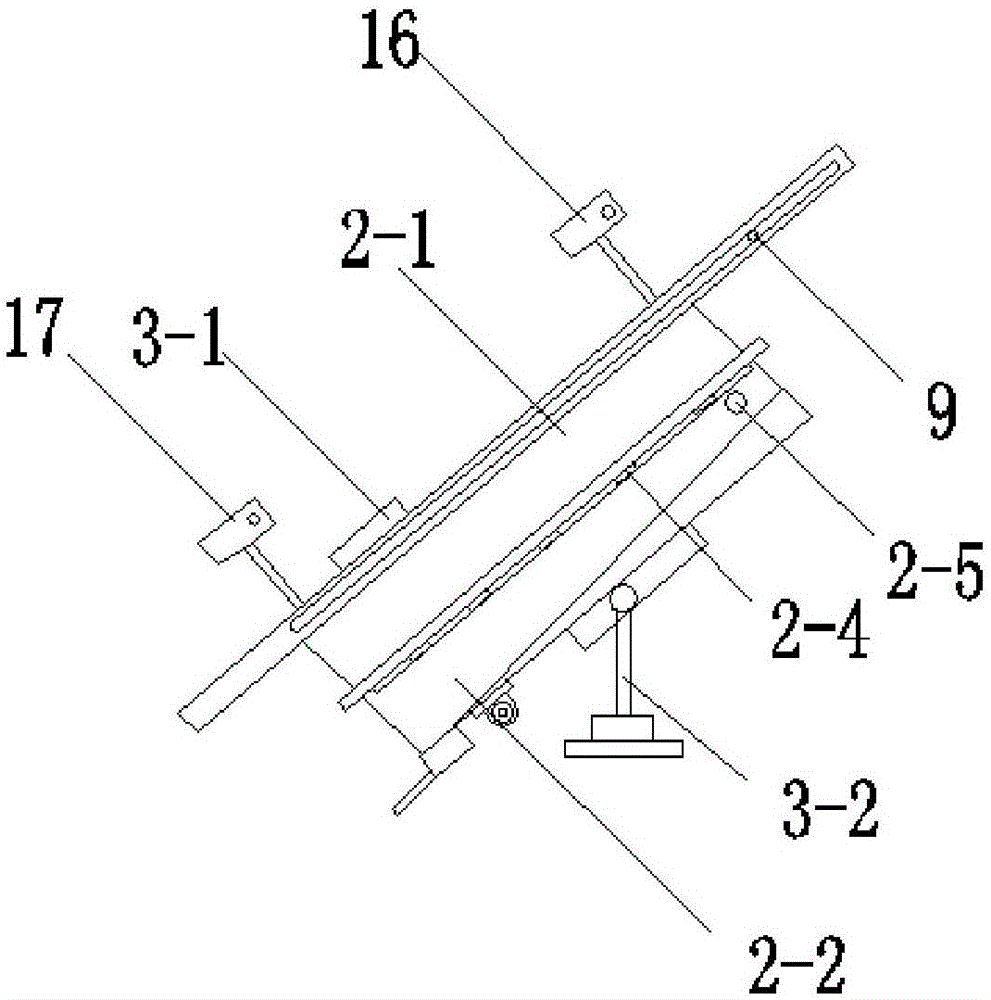

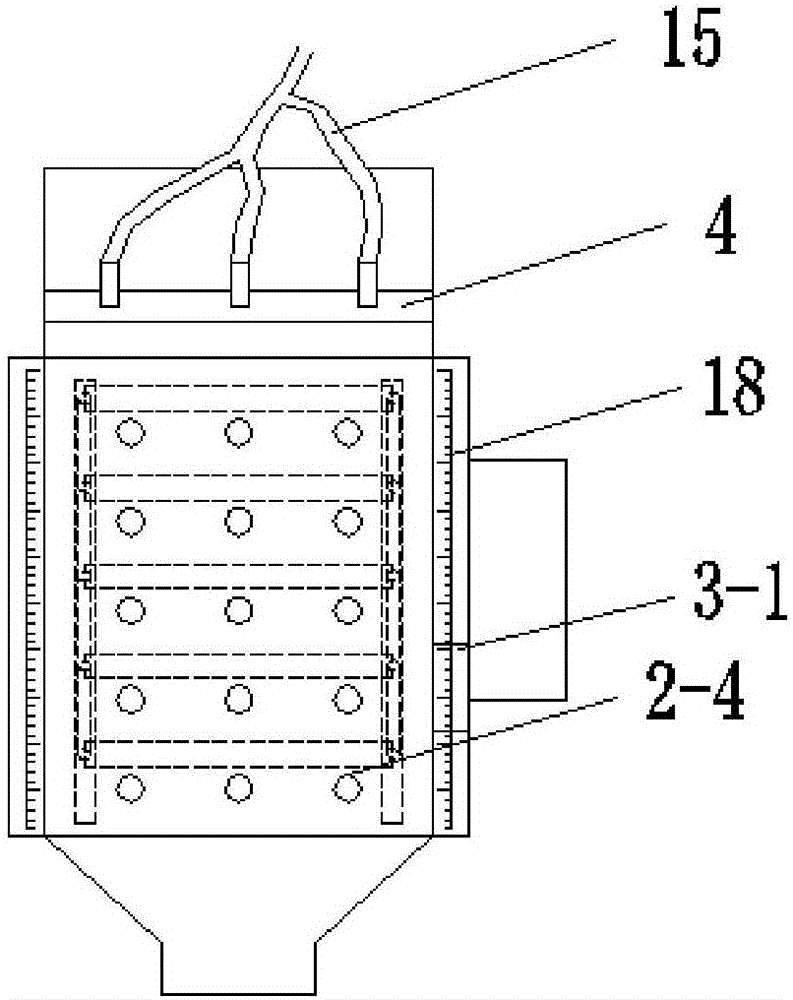

Soil slope water flow erosion resistance simulation test method and device

ActiveCN106290800AIncrease the time to gatherReduce wasteInvestigating moving fluids/granular solidsEarth material testingSoil scienceMaximum depth

The invention relates to a soil slope water flow erosion resistance simulation test method and device. The device comprises a liftable slope simulation device, a sheetflood scouring simulation device, a water and soil collecting device, a flow velocity determining device and a slope surface form camera device. According to the test method, the water flow is controlled, surface flow and seepage are formed, and sheetflood water, seepage water and sediment quantity formed by scouring slopes by sheetflood water are collected. The flow, the flow velocity, the erosion depth, the sand yield and the like of the water flow are measured quantitatively. Compacted soil is soaked in water until saturation for simulation, the efficiency of an indoor simulation test on slope scouring is improved, the test period is shortened, the test result proves the maximum depth of a slope erosion gully and the change rule of the sand yield with time, discloses the relation between the water flow erosion capacity of catchment behind slopes and the slope length, gradient and time and provides a basis for prediction of the water flow erosion scale and the need of slope protection and reinforcement. The device is simple in structure, convenient to operate and suitable for measurement of soil mechanics parameters of slope soil mass.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Acidic solution for treating surface of magnesium alloy and processing method

InactiveCN101285193AFully activatedHigh activityMetallic material coating processesGlutaric acidBinding force

The invention relates to acid solution used for processing the magnesium alloy surface. The acid solution is water solution which contains acids, inhibitor and wetting agent, wherein, the acids are first acids or mixture of first acids and second acids; the first acids are selected from one type or a plurality of types among citric acids, oxalic acids, tartaric acids, methanoic acids, acetic acids, metacetonic acids, butyric acids, glutaric acids, phenylformic acids, benzene dicarboxylic acids, lactic acids, glycolic acids, glyoxylic acids and amino acids; and the second acids are hydrochloric acids and / or nitric acids. By adoption of the acid solution, the magnesium alloy surface can be fully activated; the membranous layer of a converting film which is formed on the magnesium alloy surface after chemical conversion process is compact, has erosion resistance and good binding force with a paint film. Moreover, the method is a environment-friendly method for processing the magnesium alloy surface.

Owner:BYD CO LTD

Roofing shingle with headlap seal and improved coverage

A roofing shingle for enhanced wind / rain durability embodies two transverse lines of adhesion. A first discontinuous line of adhesive joins the butt edge of an overlying shingle to the underlying shingle. Secondly, a band of sealant adjacent the top edge of an underlying shingle seals against an overlying shingle to prevent penetration by wind driven rain to the roof deck. A reduced headlap is thereby permitted, thereby either reducing shingle size or extending shingle coverage. Exposed portions of the sealant band improve the erosion resistance of underlying shingles.

Owner:BUILDING PROD OF CANADA CORP

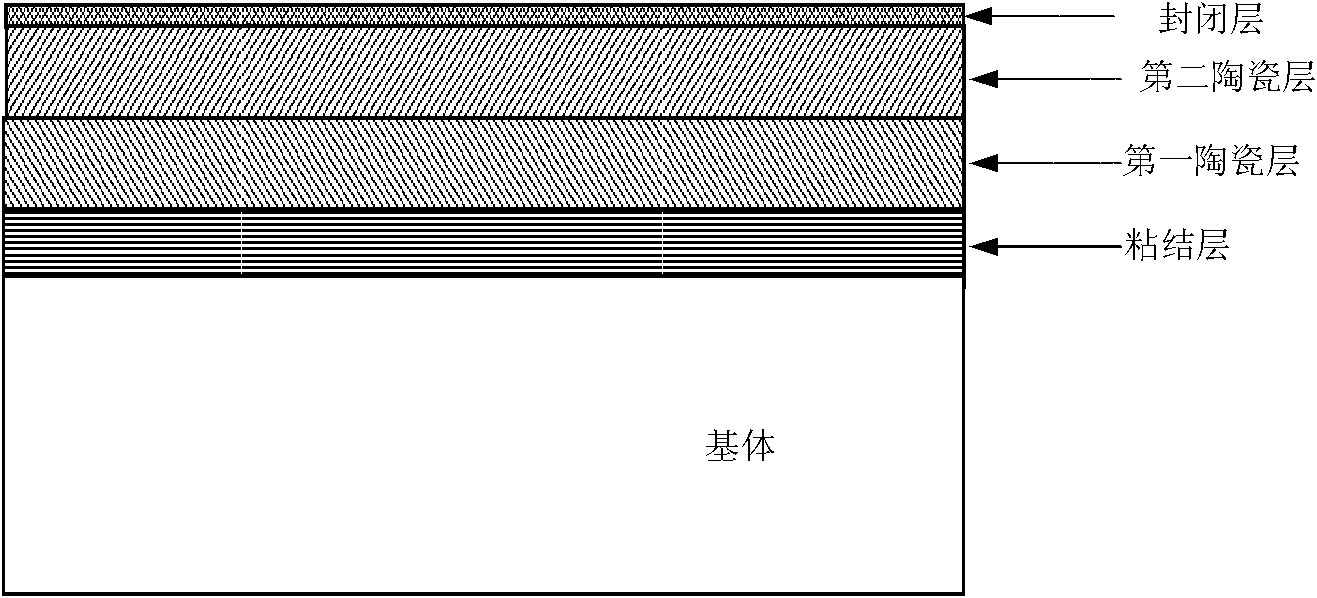

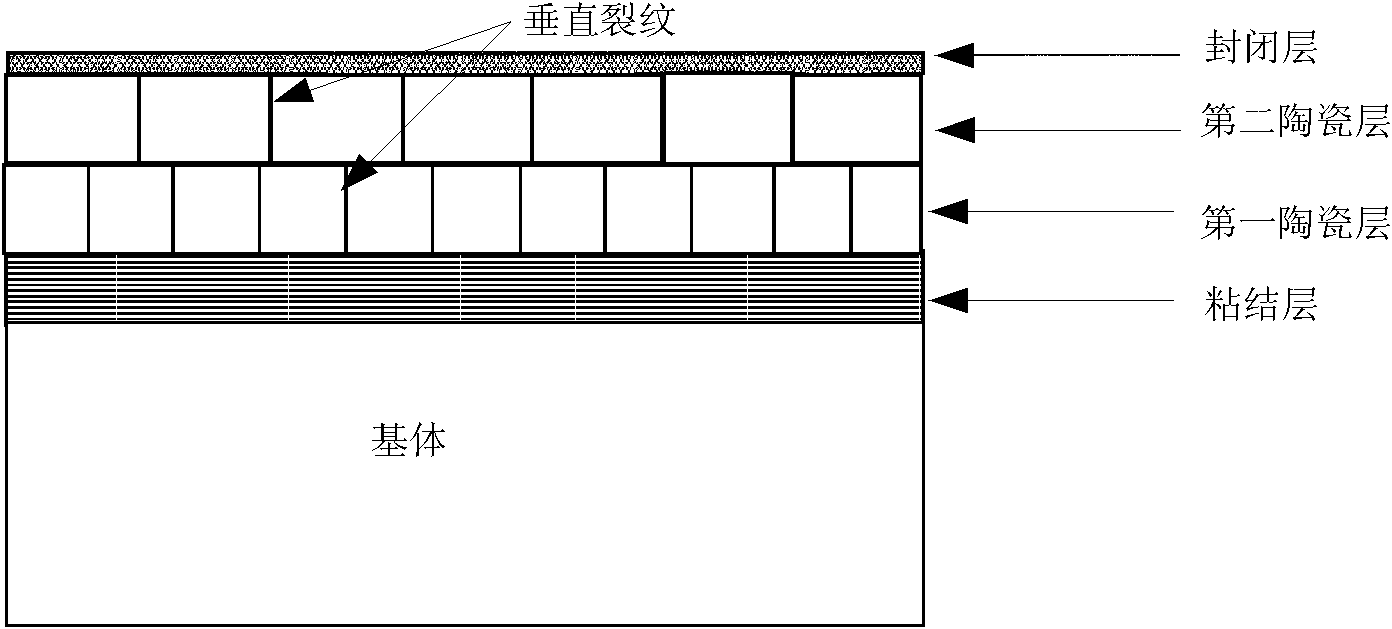

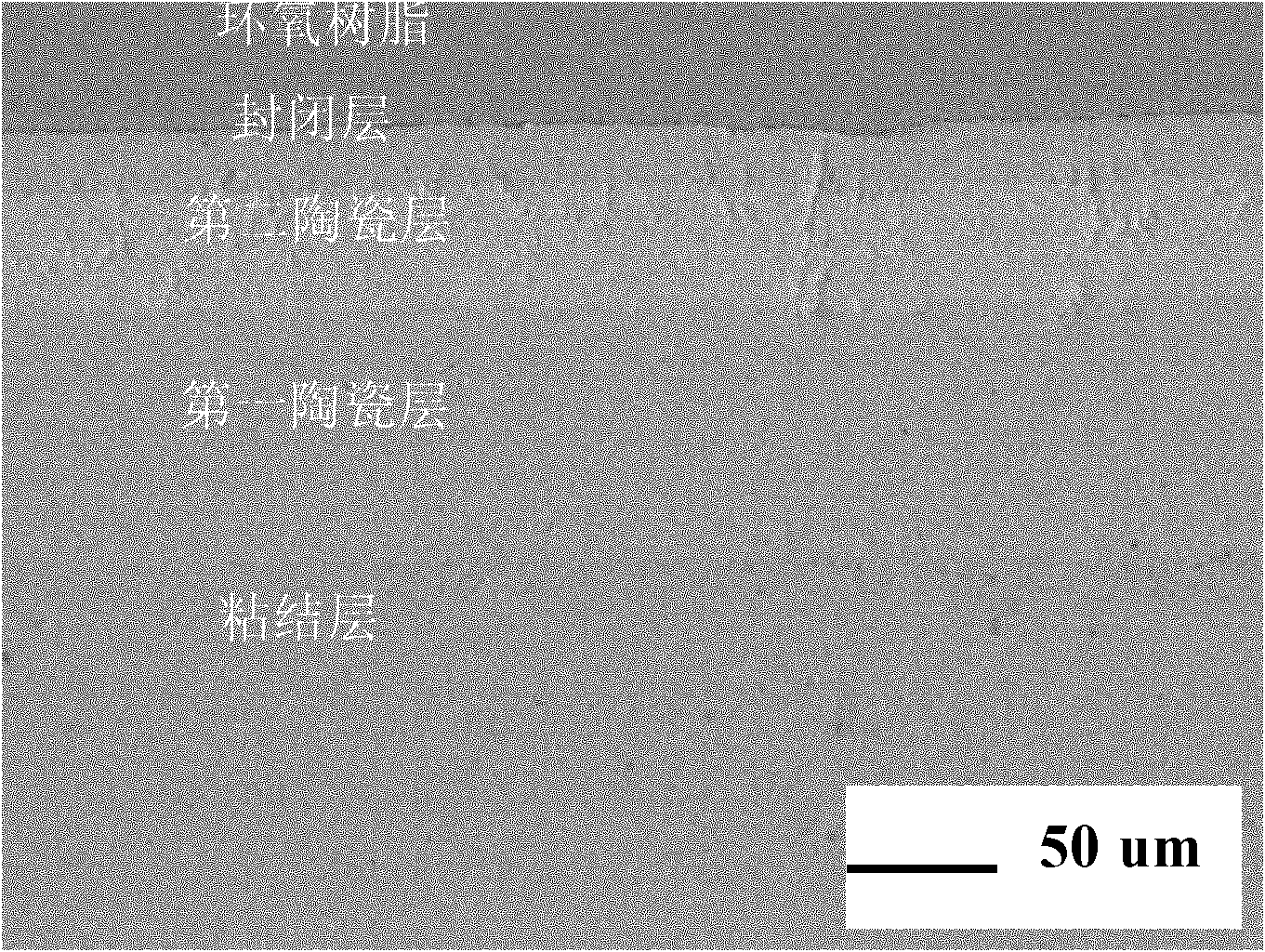

Multilayer thermal barrier coating and preparation method thereof

InactiveCN102127738ANo layer peeling phenomenon occursImprove hot corrosion resistanceMolten spray coatingVacuum evaporation coatingPorosityElectron beam physical vapor deposition

The invention provides a multilayer thermal barrier coating and a preparation method thereof. The multilayer thermal barrier coating sequentially comprises an adhesion layer, a first ceramic layer, a second ceramic layer and a closing layer from bottom to top, wherein the closing layer has the thickness of 10-30 micros and the porosity of 2-8 percent and is made from the Al2O3. The thermal barrier coating can be prepared by adopting an electron beam physical gas-phase deposition technology or a plasma spraying method. The multilayer thermal barrier coating provided by the invention can avoid the stripping of the ceramic layers in a thermal circulating process, the thermal erosion resistance of the thermal barrier coating is greatly improved than the dual ceramic layers; and vertical crackles are introduced in the ceramic layer through improving a conventional plasma spraying process so that the thermal shock life of the thermal barrier coating is greatly prolonged.

Owner:BEIHANG UNIV

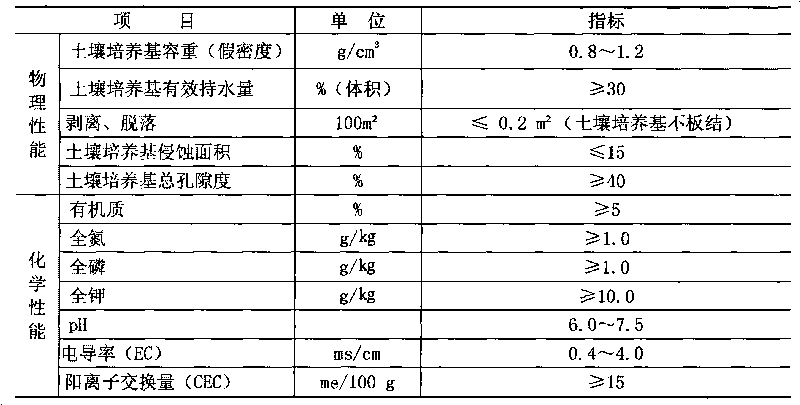

Ecological protection method for high steep side slope

The invention relates to an ecological protection method for a high steep side slope. The method mainly comprises the steps of slope surface treatment, concrete shotcrete and rock bolt support, vegetating hole arrangement, net spreading, spray material preparation, granule spray sowing, maintenance, management, and the like. In the method, guest soil materials such as humus loam rich in organic matters and clay are utilized to undergo a granule reaction after mixed with a granule agent at the moment of spray sowing so as to form a greening template which has the same high order granule structure as natural soil and strong erosion resistance and can suppress water and soil loss. After a diversified mature plant community which is in harmony with surrounding vegetation environment is formed, the slope surface can be protected, which can effectively resist diseases and insect pests and maintain the ecological balance. Post maintenance management and expenses can be saved. All used materials can be naturally degraded, have no pollution to the environment and can purify air and beautify the environment. Equipment of the method does not need to be hung on the slope surface for construction, and spray sowing operations are carried out only below the slope surface, thus the method has high construction speed and safety. The method is suitable for slope surfaces which are difficult to green, and the like, such as various high steep and unstable slope surfaces, bare slope surfaces having high greening expected values, and the like.

Owner:河南国网宝泉抽水蓄能有限公司

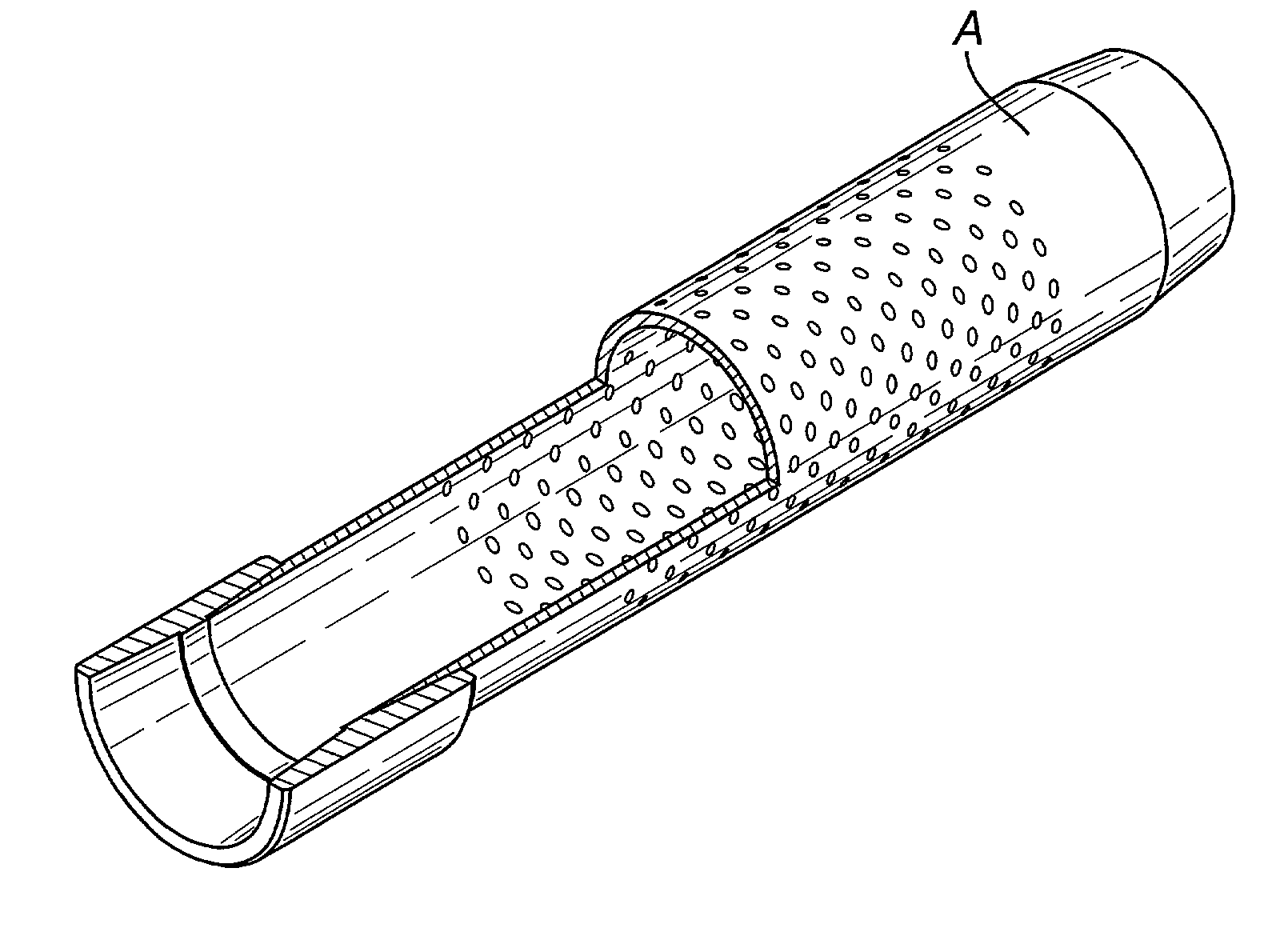

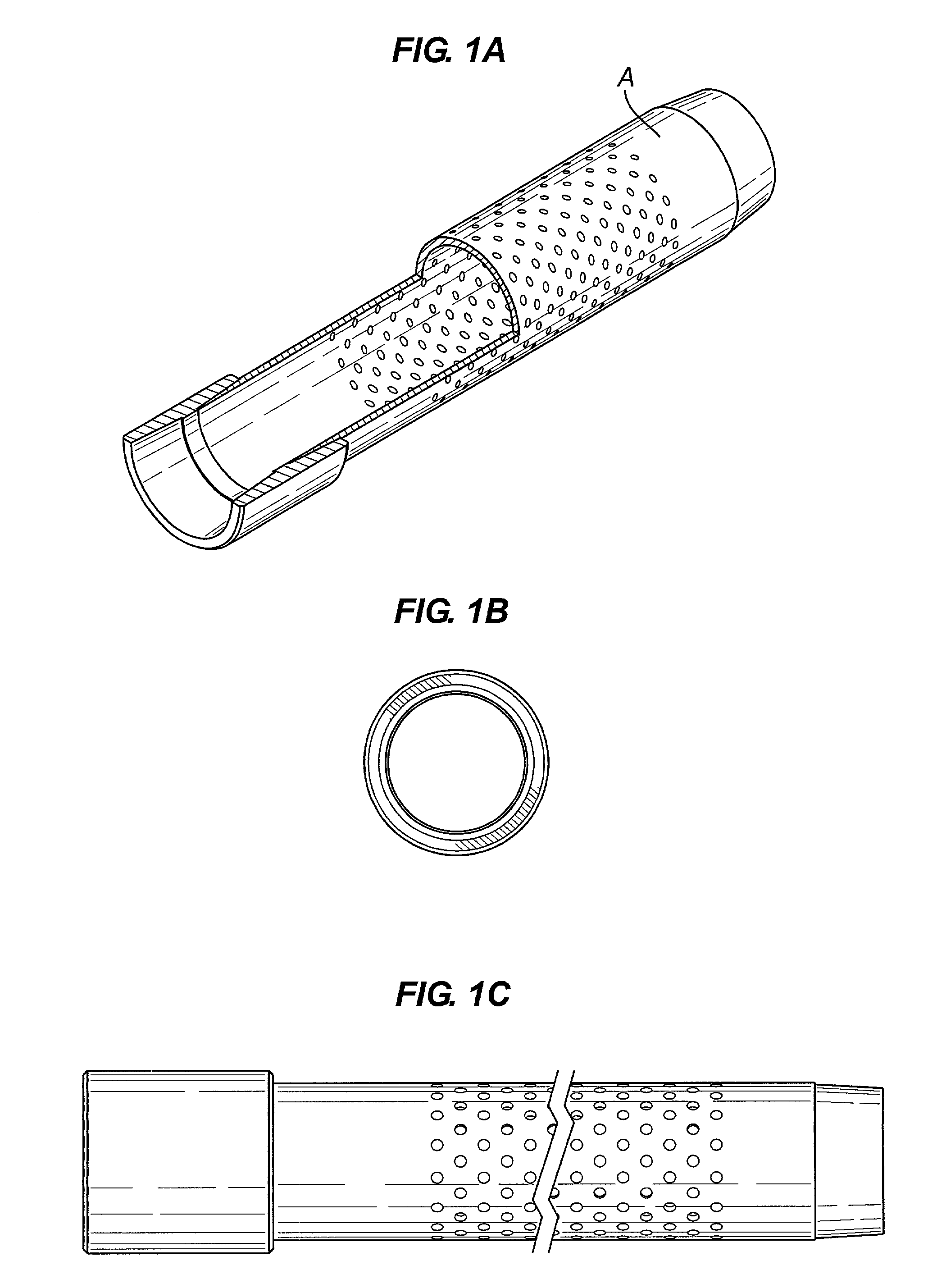

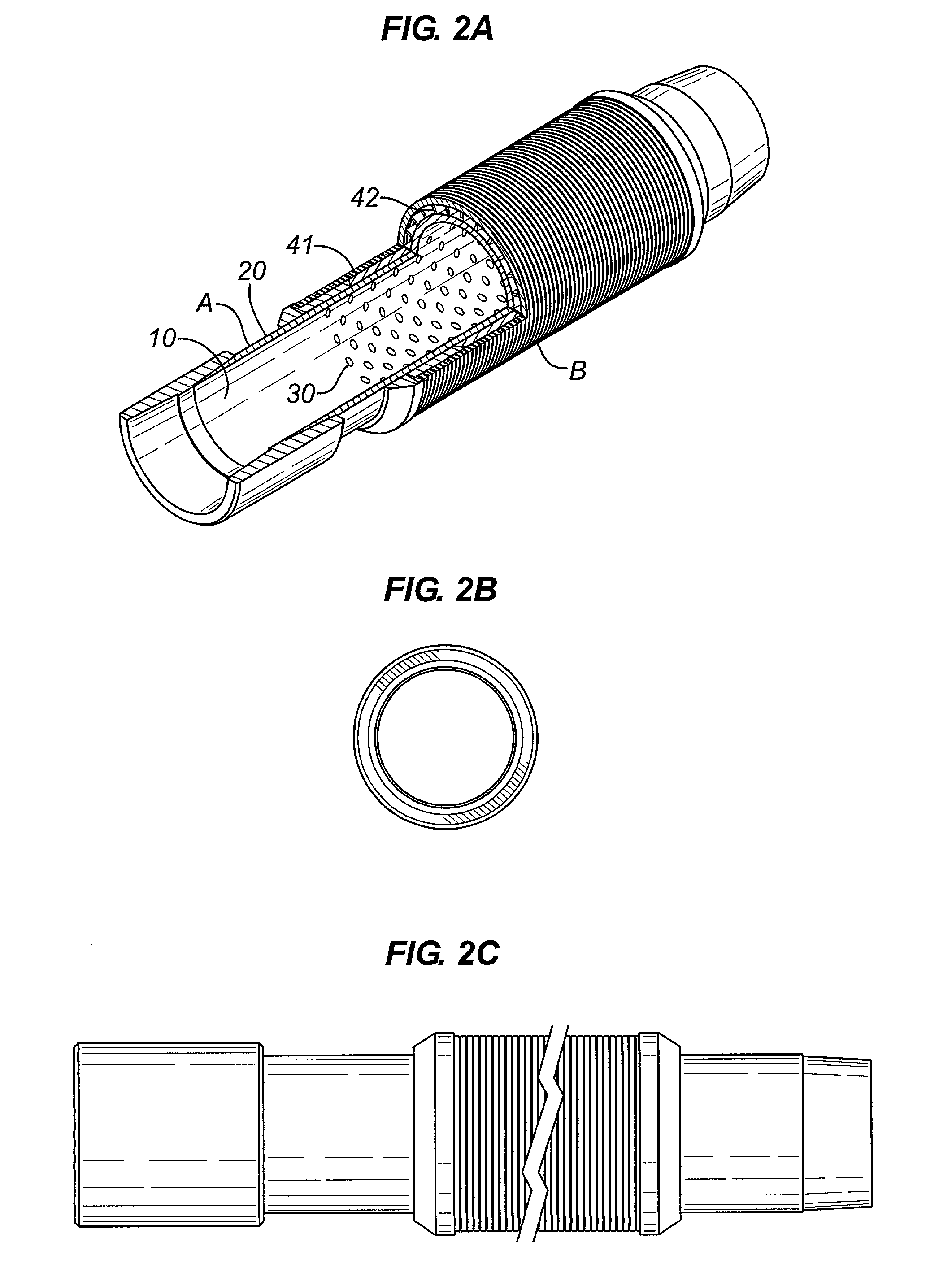

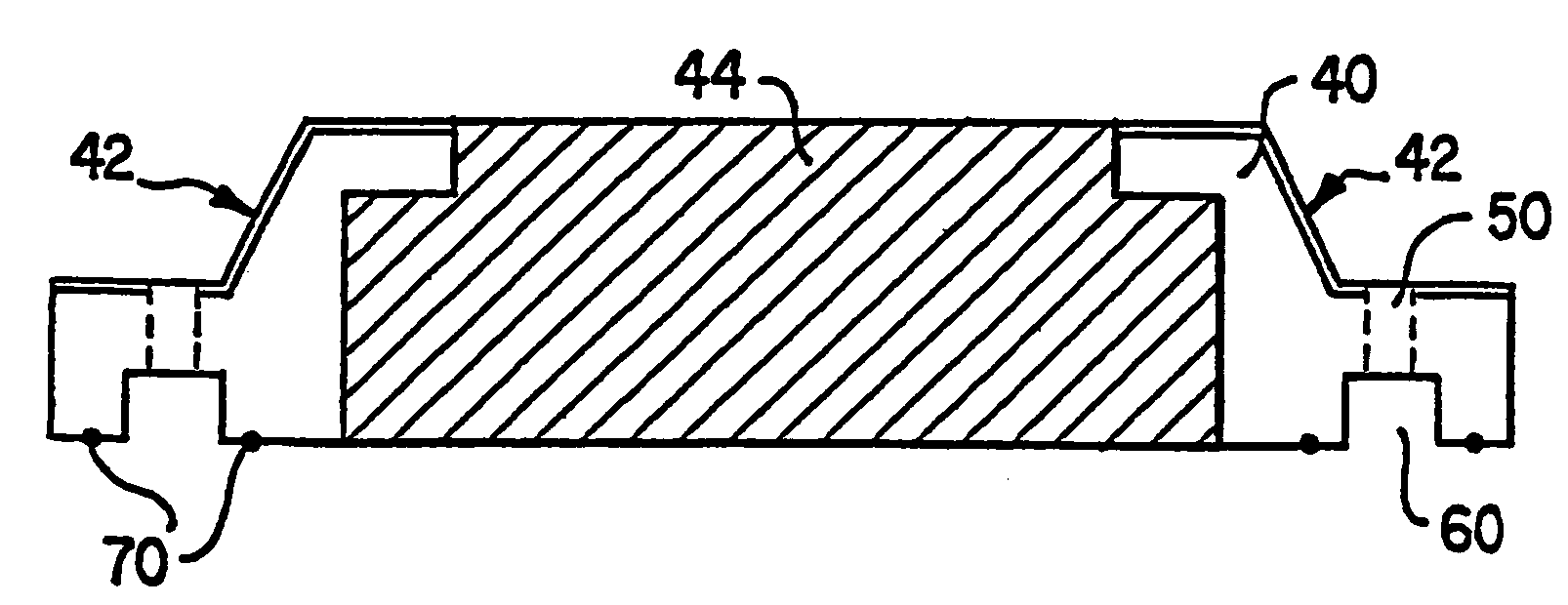

Knitted wire fines discriminator

InactiveUS20030173075A1Reduce riskReduce erosion damageFluid removalDrinking water installationDiscriminatorTerrain

Particularly, the knitted wire fluid / gas energy absorber and fines discriminator is designed to provide significantly, enhanced erosion resistance and durability through absorbing energy from fluid moving at elevated and erosive velocities through an energy absorbing and flexible structure, providing also a tortuous path for the fluid / gas, thereby, reducing the risk of sand production and sub terrain erosion damage to tubulars. The wire used for the knitted wire fluid / gas energy absorber and fines discriminator may be made from a range of different materials which possess the desired combination of properties required for this process, and lend themselves to knitting, may be compressed, exhibit desired mechanical strength and flex. Such materials may be: Stainless steel of various grades, metallic alloys of various kinds, (zinc, copper etc), wire made of various fibers such as Kevlar, Aramid and a range of other suitable materials.

Owner:MORVANT DAVE +1

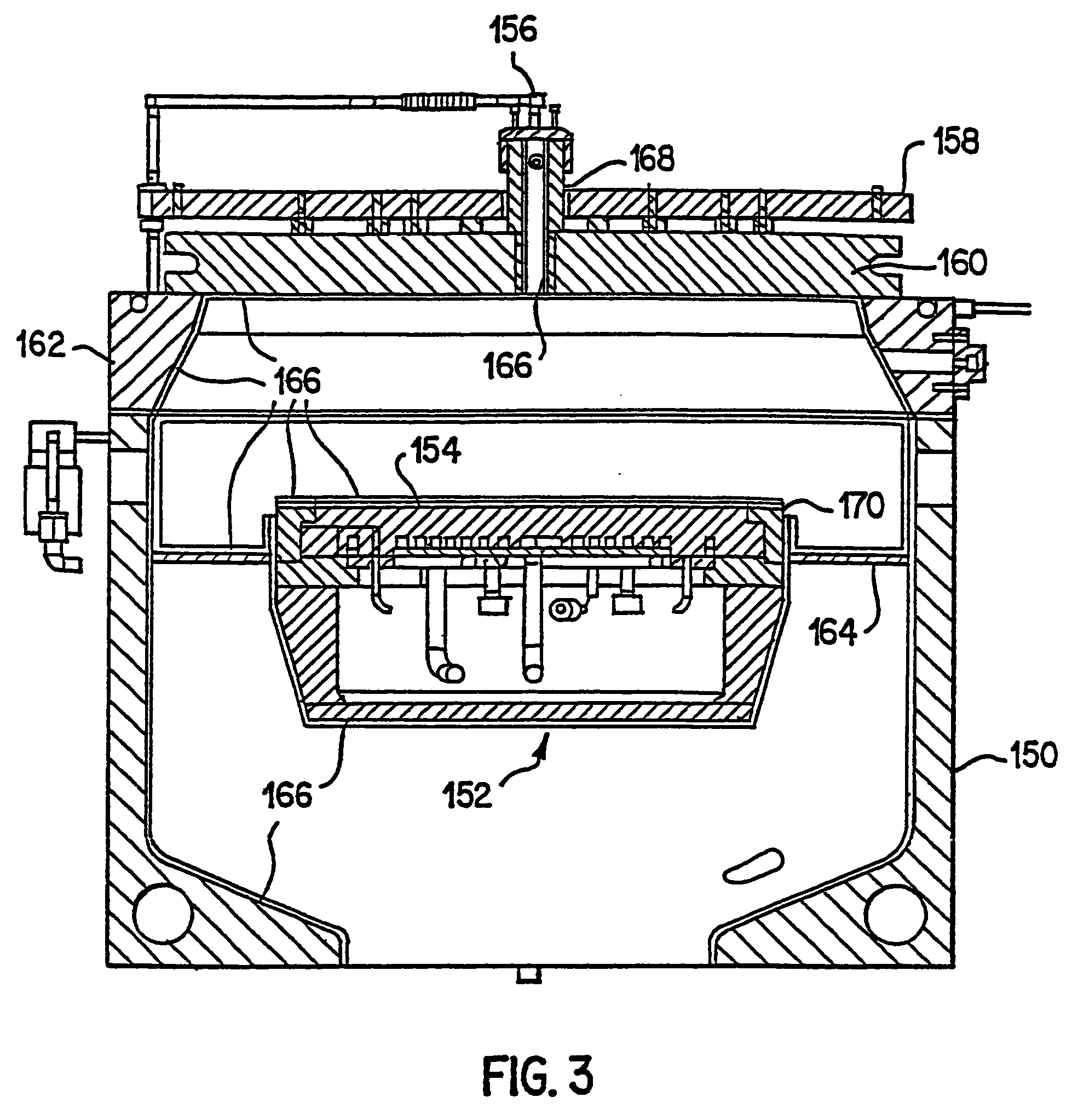

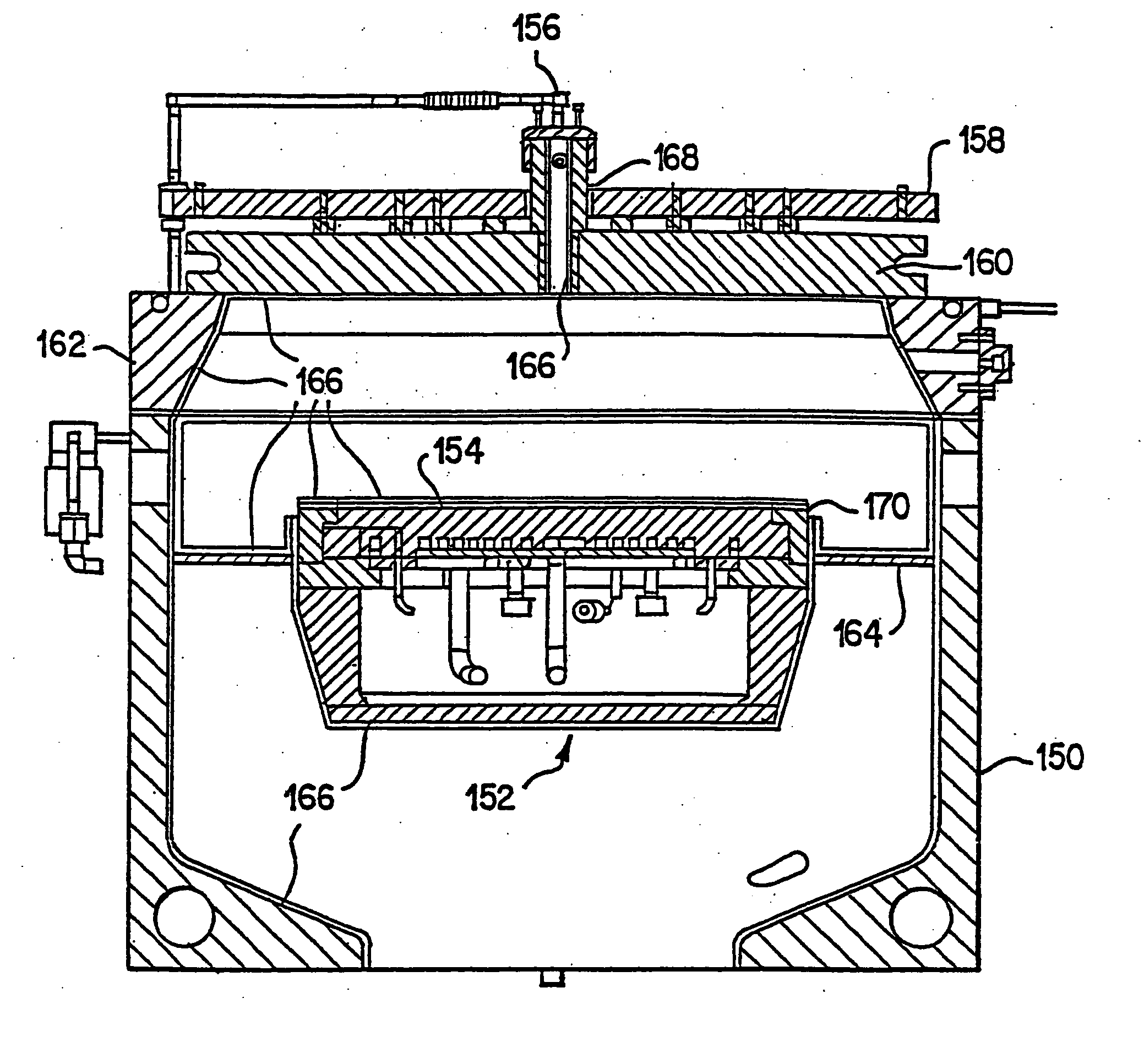

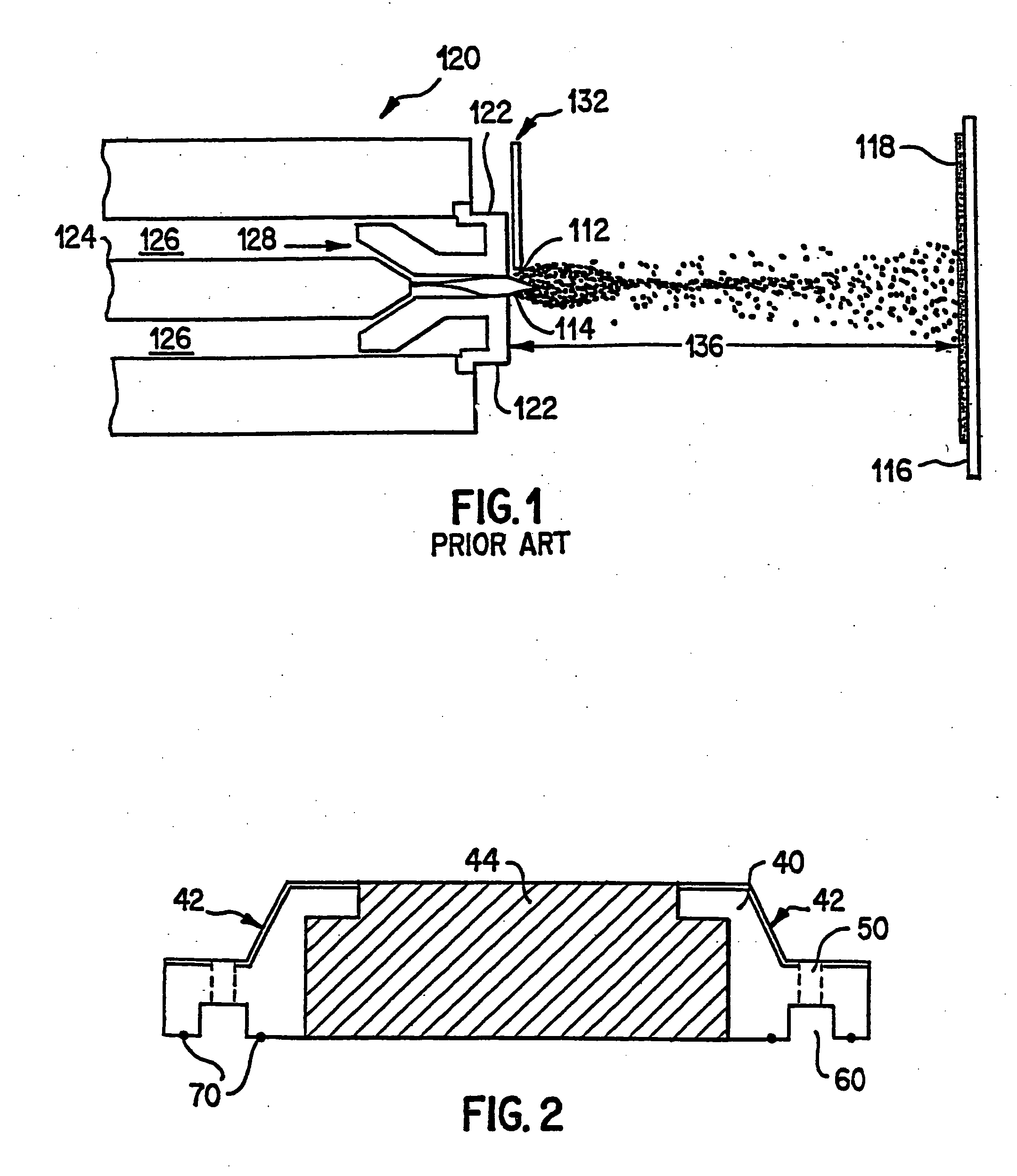

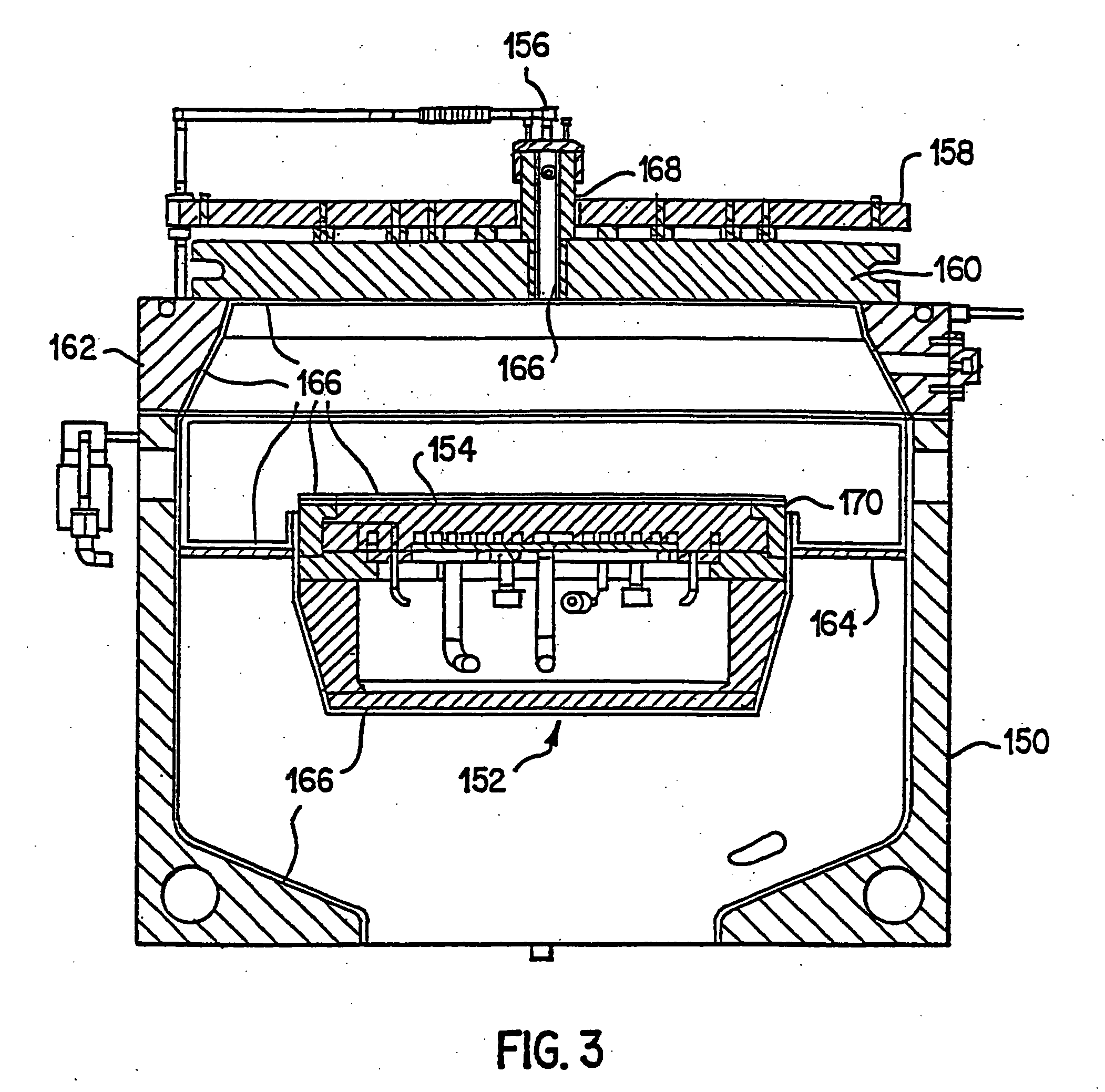

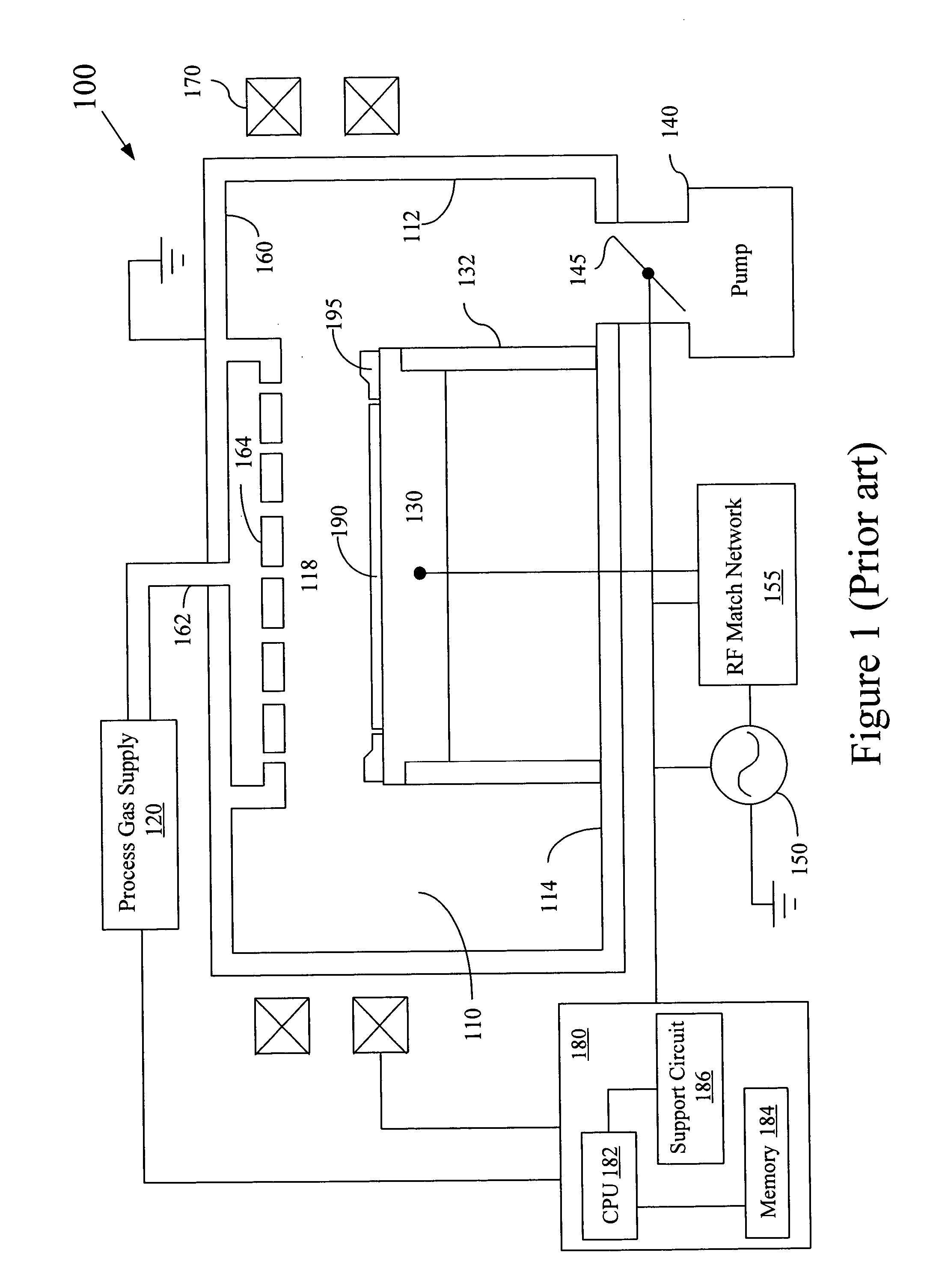

Productivity enhancing thermal sprayed yttria-containing coating for plasma reactor

InactiveUS7300537B2Improve wear resistanceLow level of contaminationCellsElectric discharge tubesProduction ratePlasma reactor

Components of semiconductor processing apparatus comprise thermal sprayed yttria-containing coatings that provide erosion, corrosion and / or corrosion-erosion resistance in plasma atmospheres. The coatings can protect substrates from physical and / or chemical attack.

Owner:LAM RES CORP

Productivity enhancing thermal sprayed yttria-containing coating for plasma reactor

InactiveUS20050150866A1Improve wear resistanceLow level of contaminationElectric discharge tubesDecorative surface effectsProduction rateThermal spraying

Components of semiconductor processing apparatus comprise thermal sprayed yttria-containing coatings that provide erosion, corrosion and / or corrosion-erosion resistance in plasma atmospheres. The coatings can protect substrates from physical and / or chemical attack.

Owner:LAM RES CORP

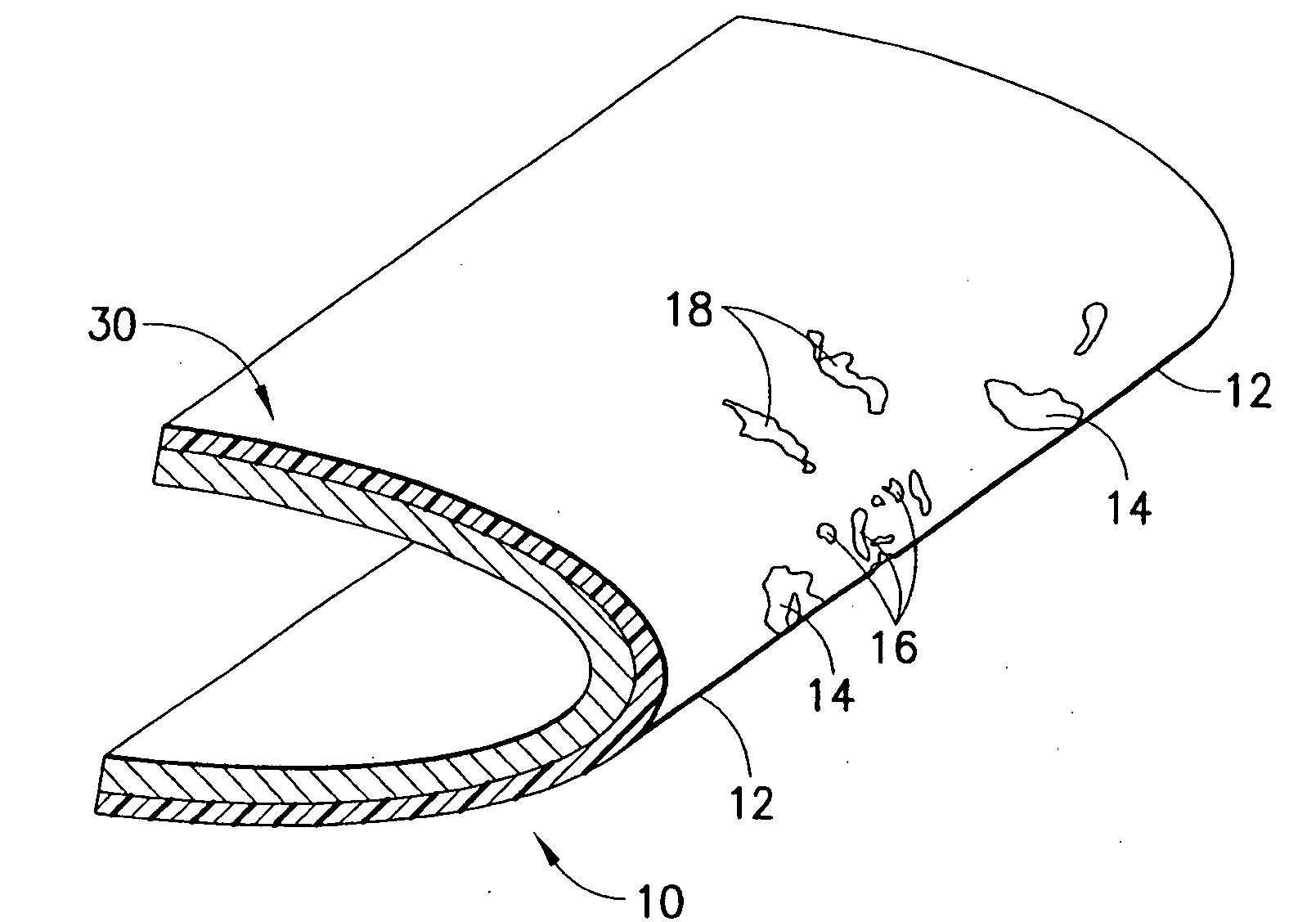

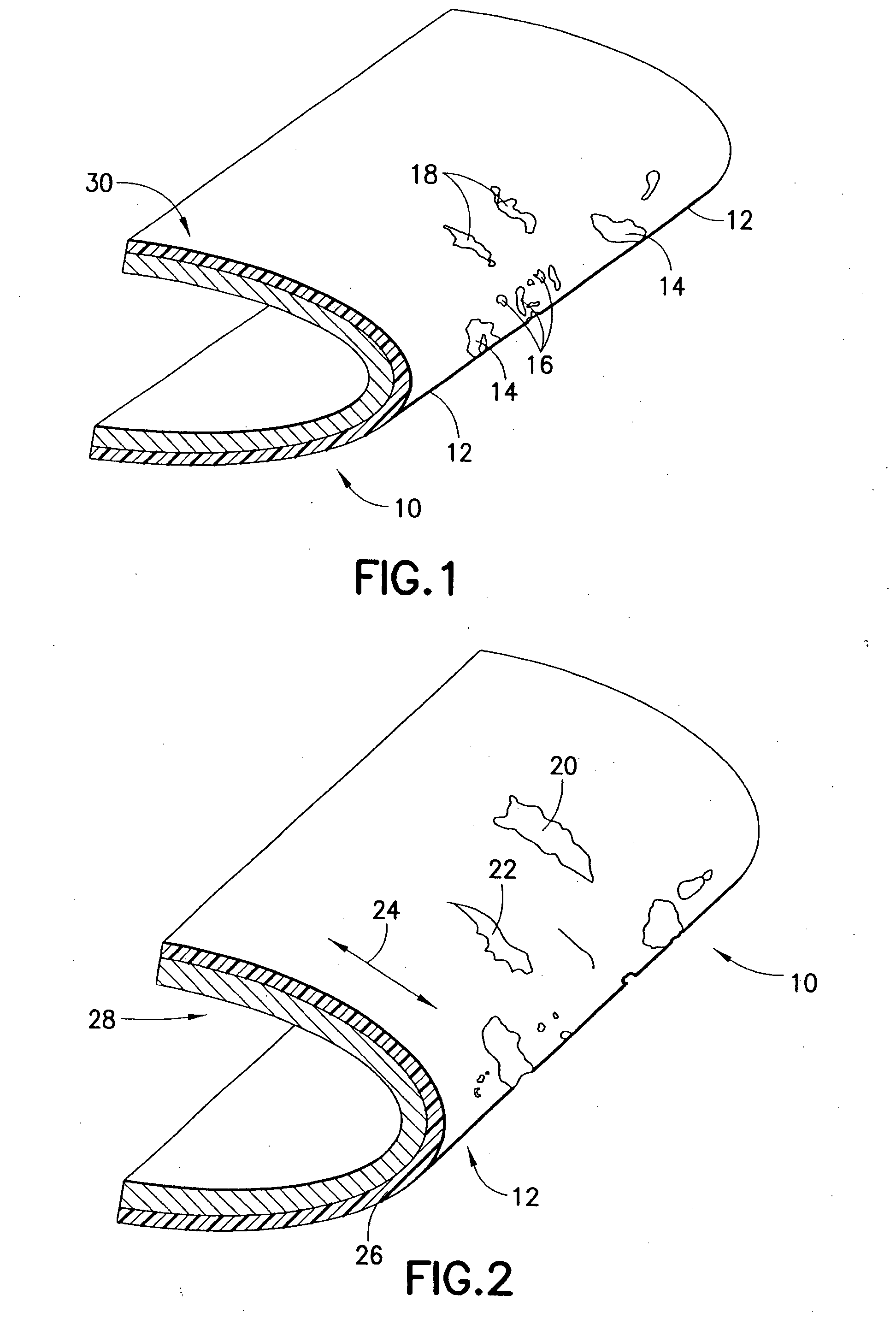

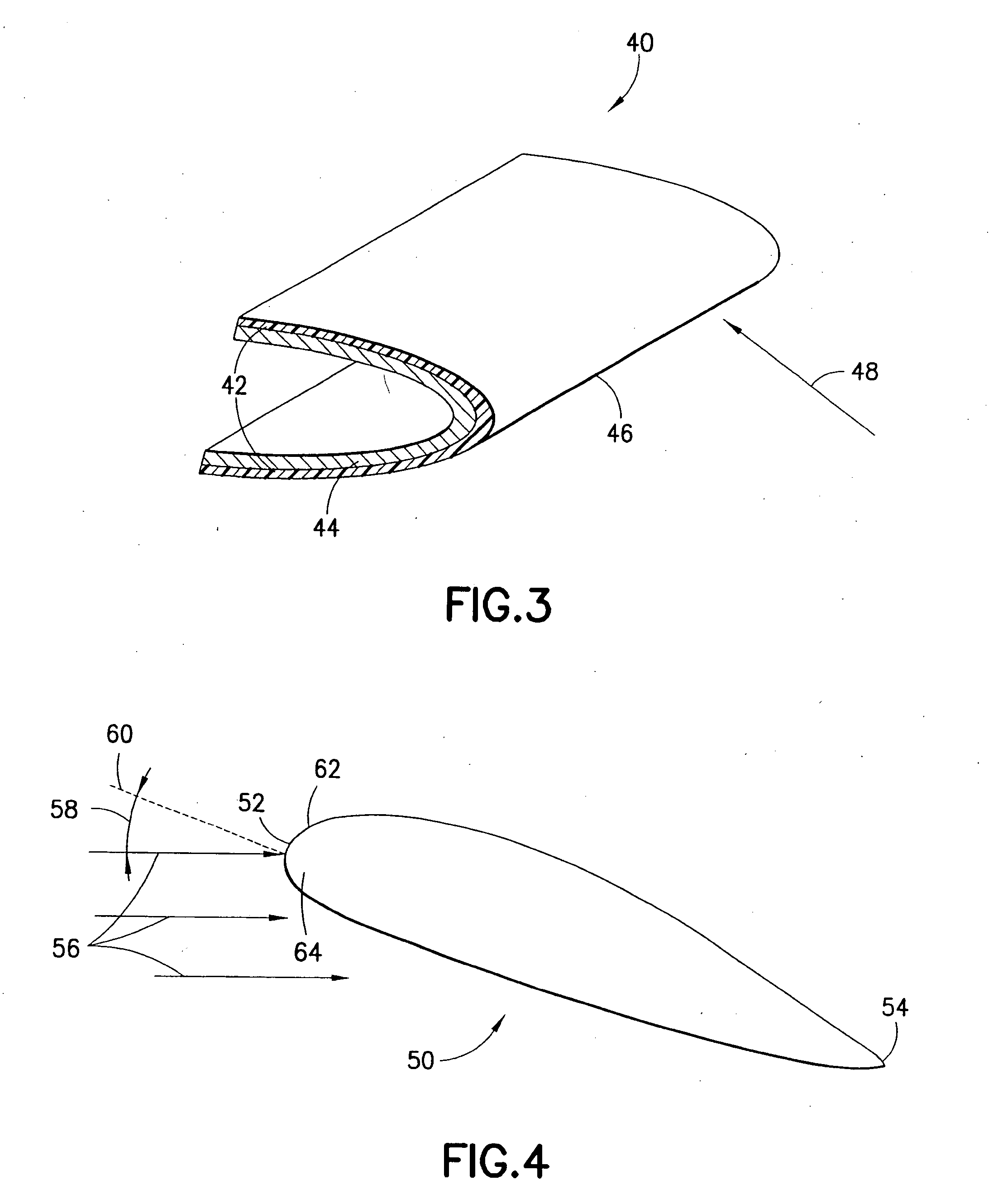

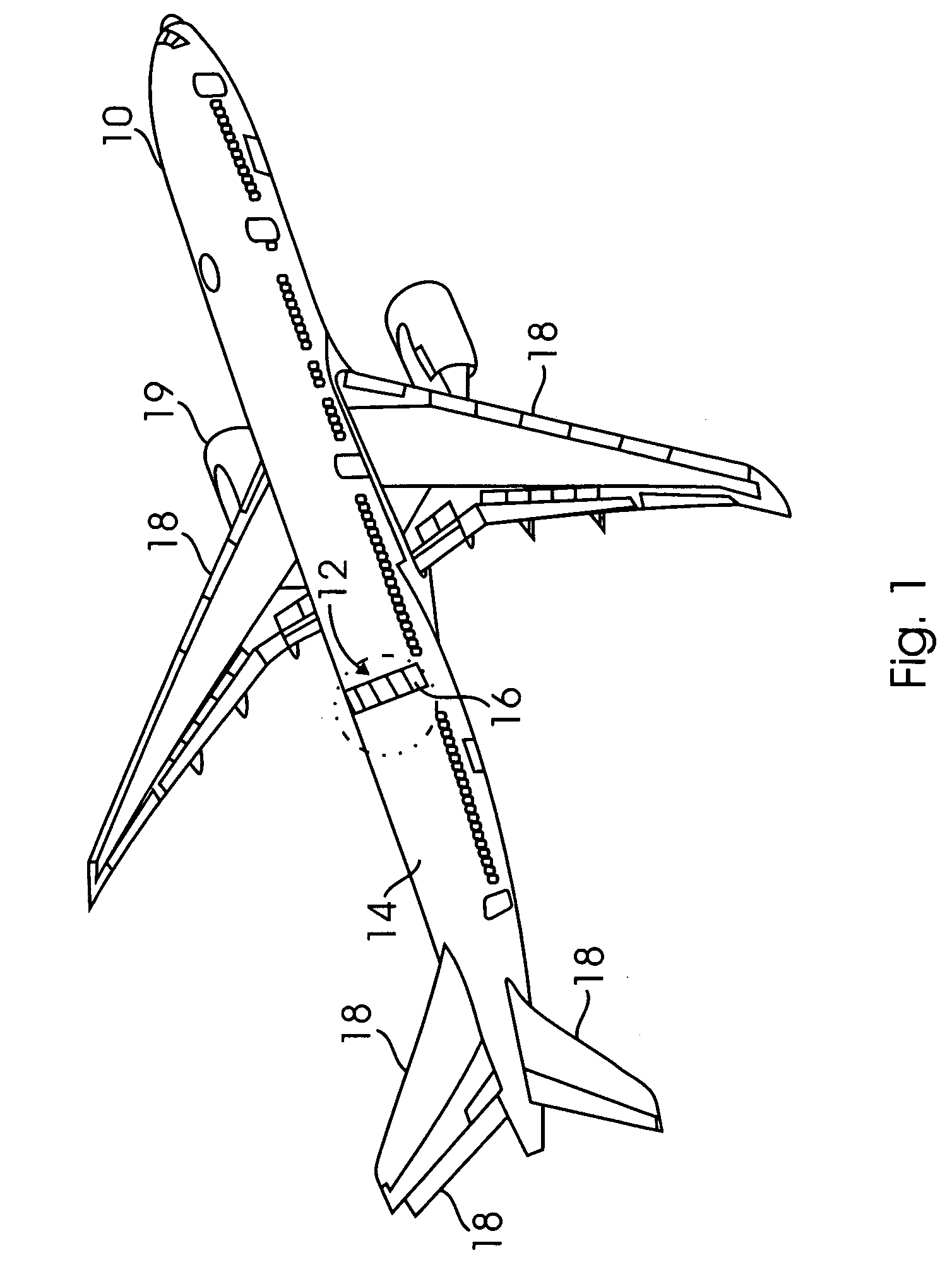

Method and coating for protecting and repairing an airfoil surface using molded boots, sheet or tape

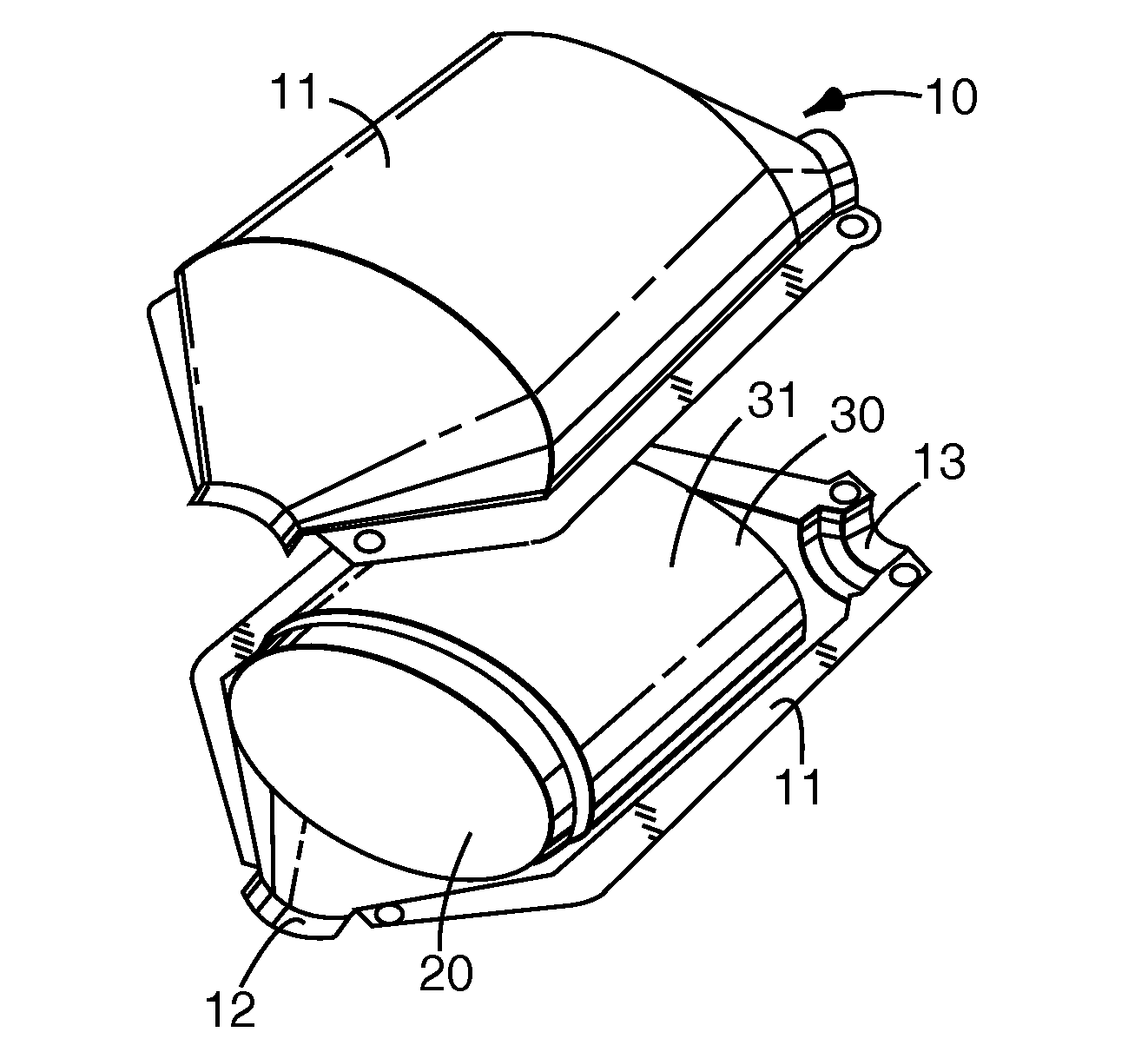

Disclosed is a field repairable airfoil structure such as a wing or a rotor blade and a method for repair and removal of erosion or impact damage to elastomeric coatings on surfaces such as the leading edge of the airfoil using special hand sandable coatings and preformed molded boots, preformed sheets or tapes with an optional topcoat applied thereto having higher sand erosion resistance.

Owner:HONTEK CORP

Airfoil having improved impact and erosion resistance and method for preparing same

InactiveUS7186092B2Improve impact resistanceImprove corrosion resistanceSpecific fluid pumpsPropellersLeading edgeStructural engineering

Owner:GENERAL ELECTRIC CO

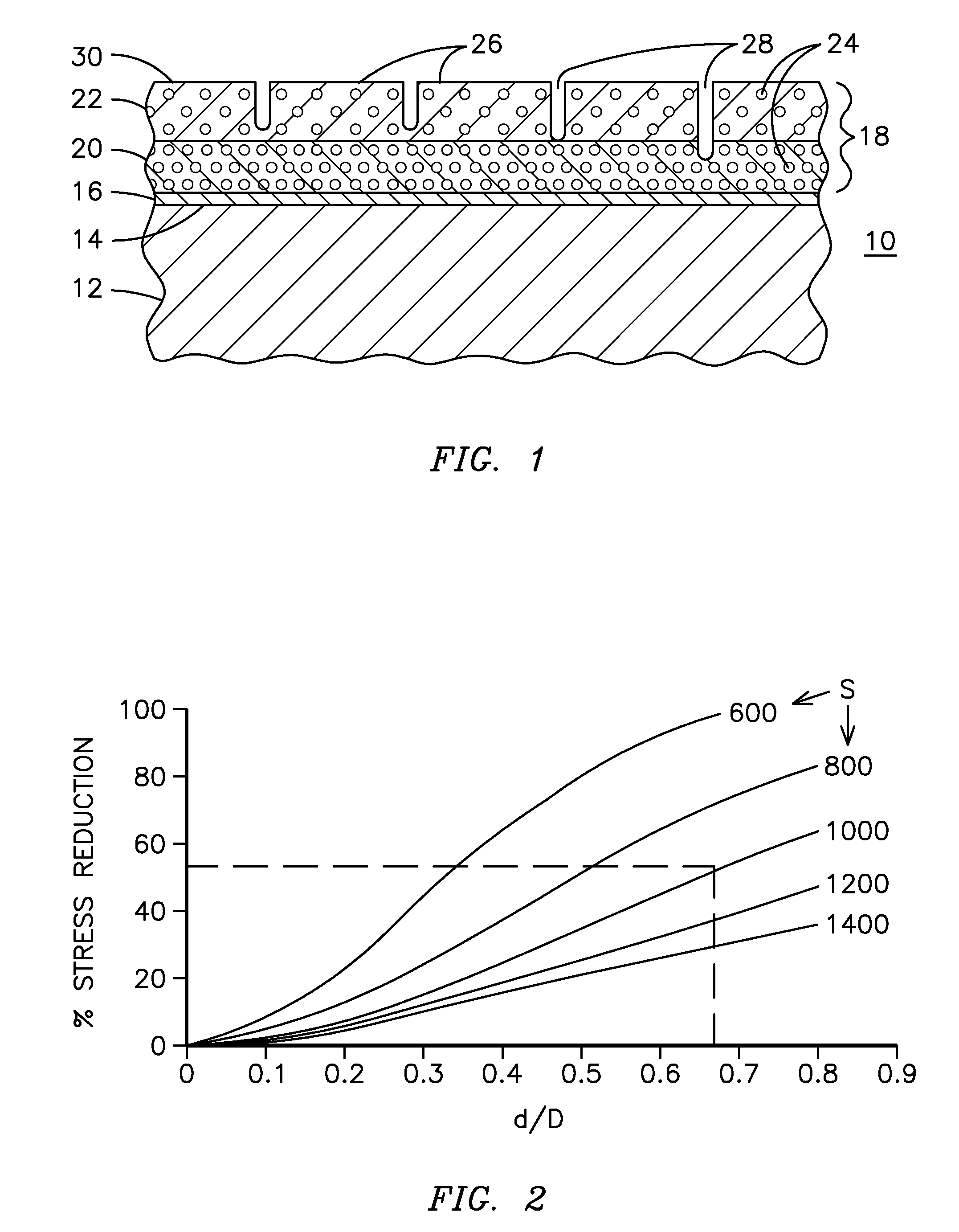

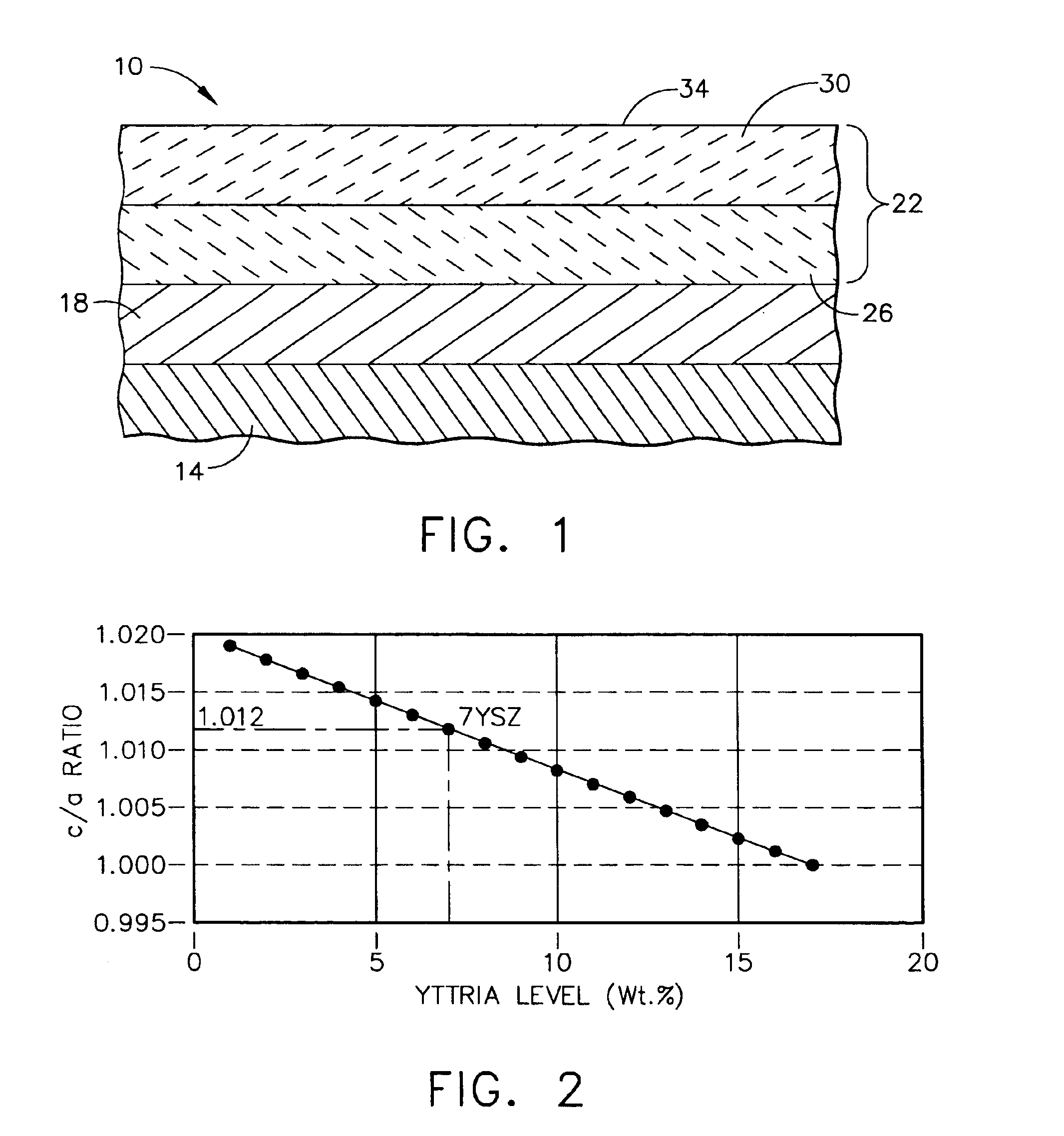

Thermal barrier coatings with improved impact and erosion resistance

InactiveUS6869703B1Increase impactIncrease resistanceMolten spray coatingVacuum evaporation coatingPorosityBond coat

A reduced thermal conductivity thermal barrier coating having improved impact and erosion resistance for an underlying metal substrate of articles that operate at, or are exposed to, high temperatures. This coating comprises a zirconia-containing ceramic composition having a c / a ratio in the range of from about 1.0117 to about 1.0148 and stabilized in the tetragonal phase by a stabilizing amount of a stabilizer metal oxide. The coating has a fraction of porosity of from about 0.10 to about 0.25, and an impact and erosion resistance property defined by at least one of the following formulas: (a) I=exp.[5.85−(144×s)−(3.68×p)]; and / or; (b) E=[187−(261×p)−(9989×s)], wherein s=1.0117−c / a ratio; p is the fraction of porosity; I is least about 140 g / mil; and E is least about 130 g / mil. This coating can be used to provide a thermally protected article having a metal substrate and optionally a bond coat layer adjacent to and overlaying the metal substrate. The thermal barrier coating can be prepared by depositing the zirconia-containing ceramic composition on the bond coat layer, or the metal substrate in the absence of the bond coat layer.

Owner:GENERAL ELECTRIC CO

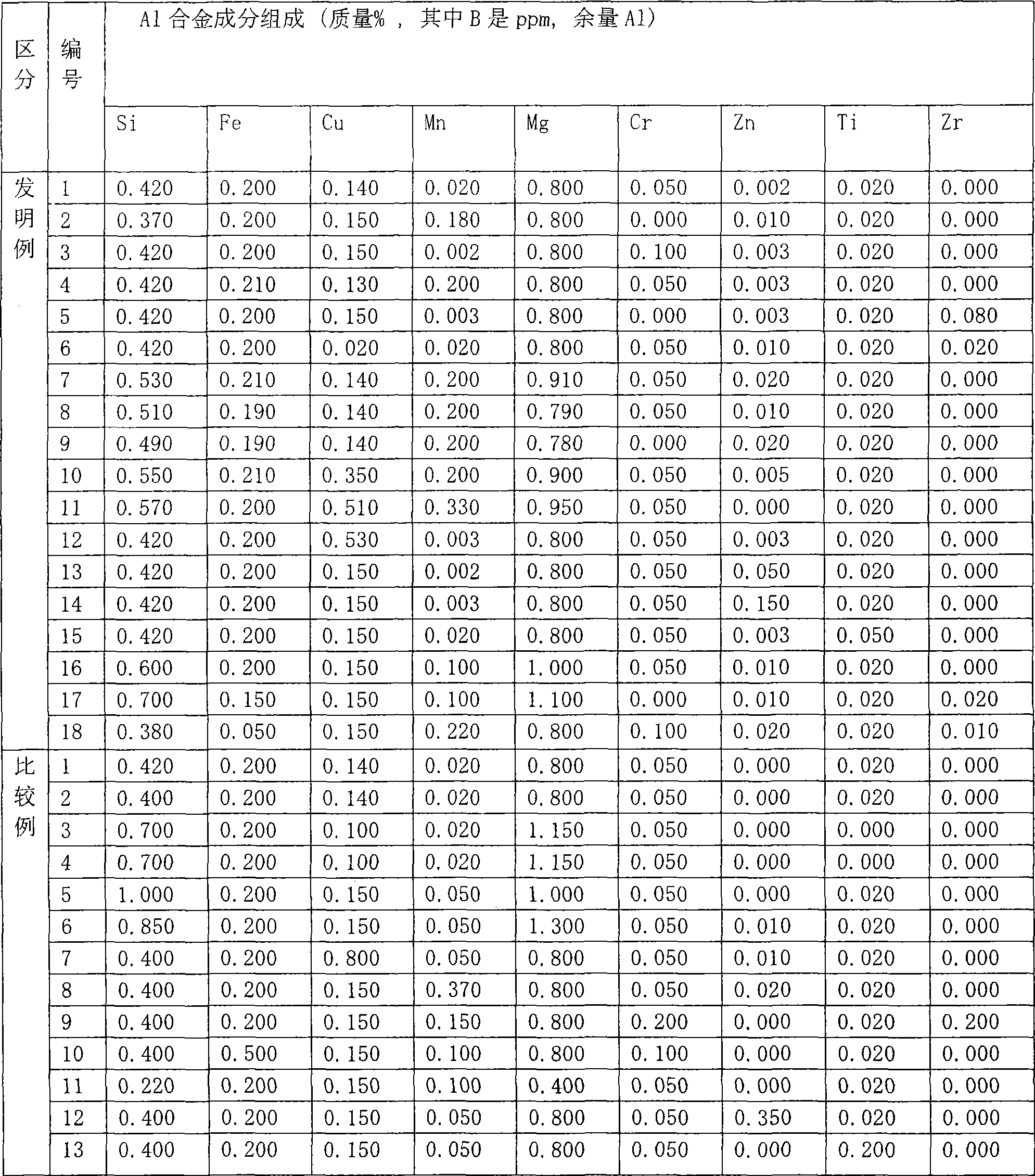

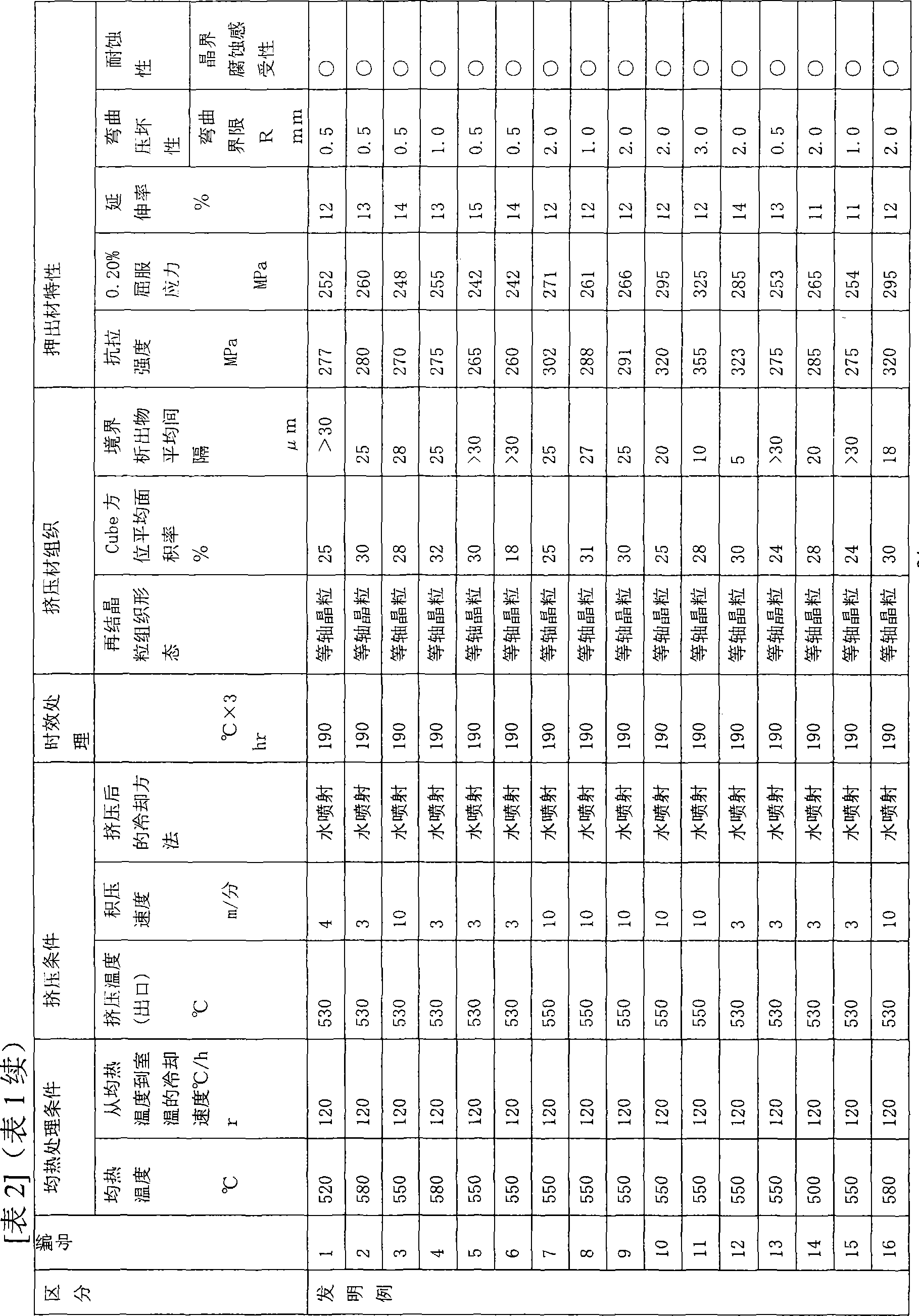

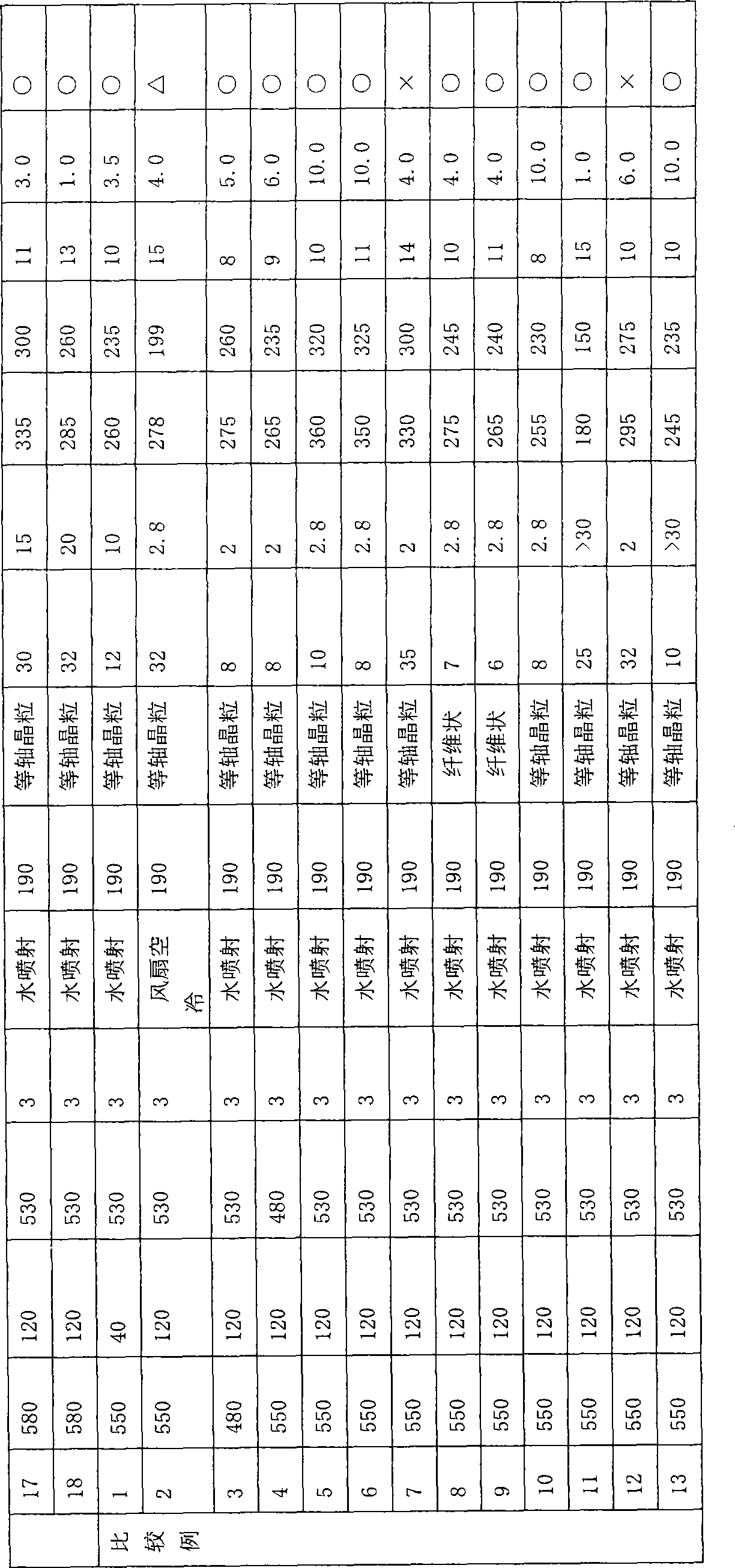

Extruded member of aluminum alloy excelling in flexural crushing performance and corrosion resistance and method for production thereof

An extruded member of Al-Mg-Si aluminum alloy specially composed of Mg, Si, Fe, Cu, Zn, Ti, etc. which has the equiaxed re-crystallized grain structure in which intergranular precipitates 1 mum or lager are separate from one another at large average intervals and there are many cube orientations over the entire thickness region thereof so that it excels in both flexural crushing performance and corrosion resistance. The extruded member is suitable for use as automotive body reinforcement members which need outstanding lateral crushing performance under severe collision conditions as well as good corrosion resistance.

Owner:KOBE STEEL LTD

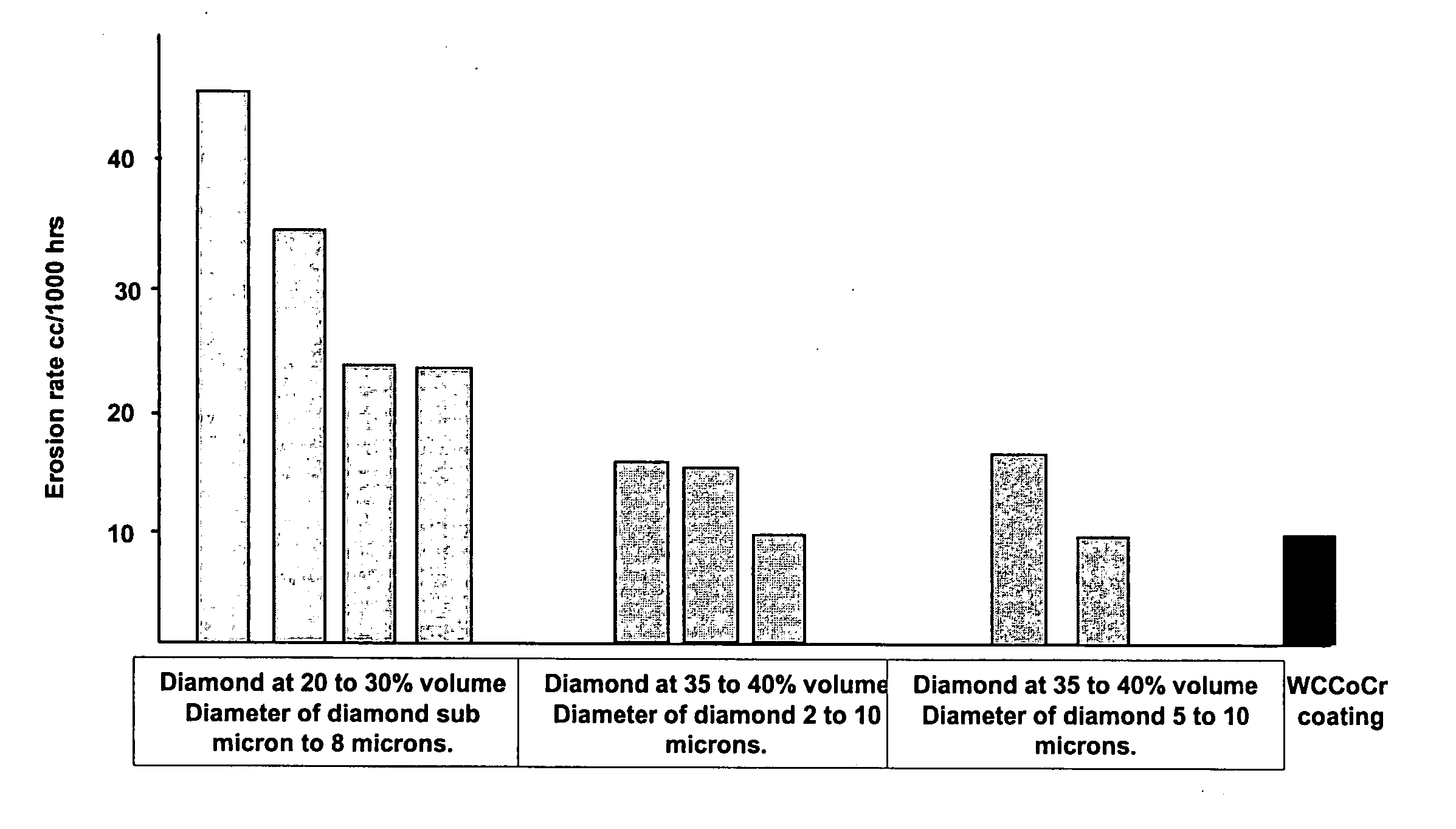

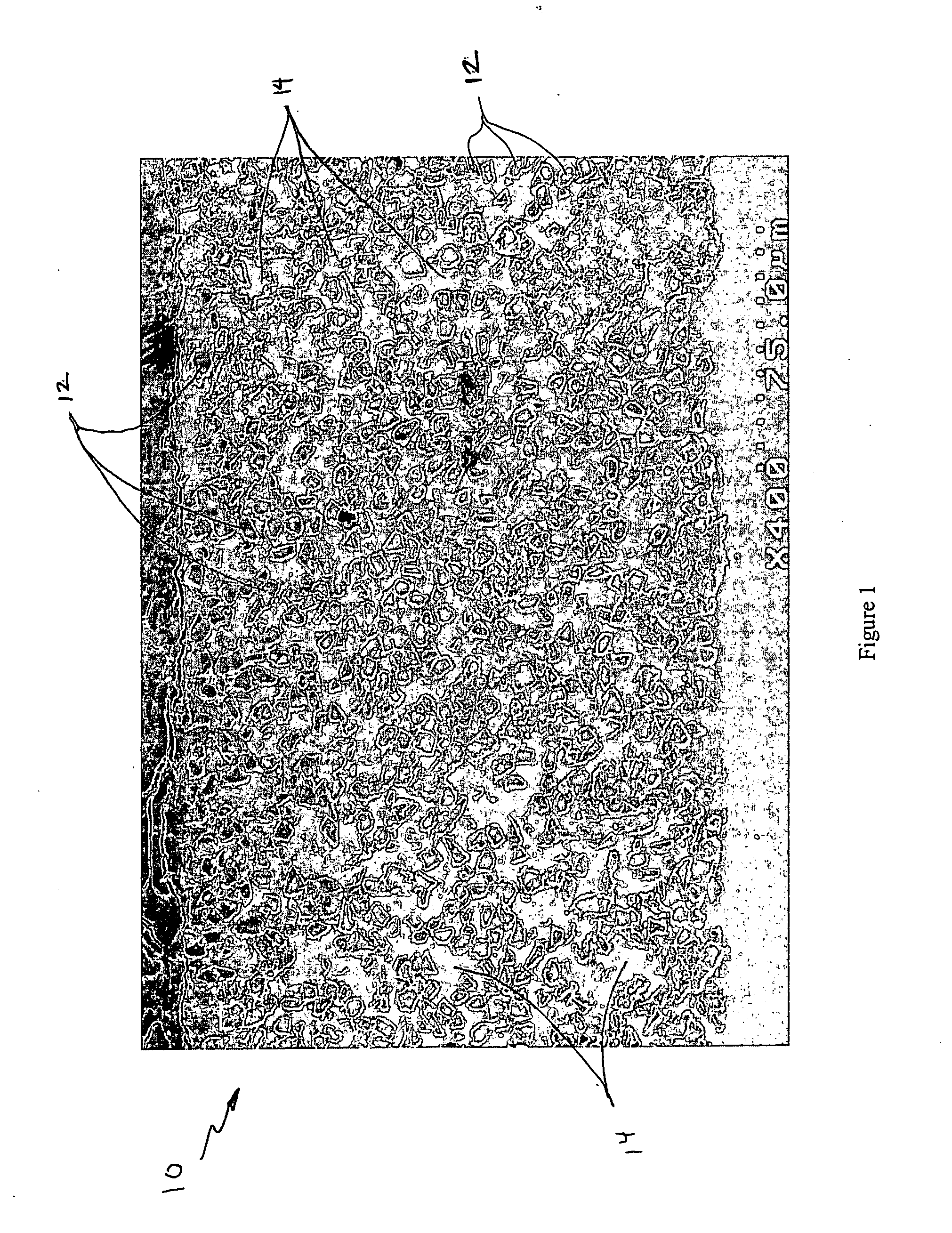

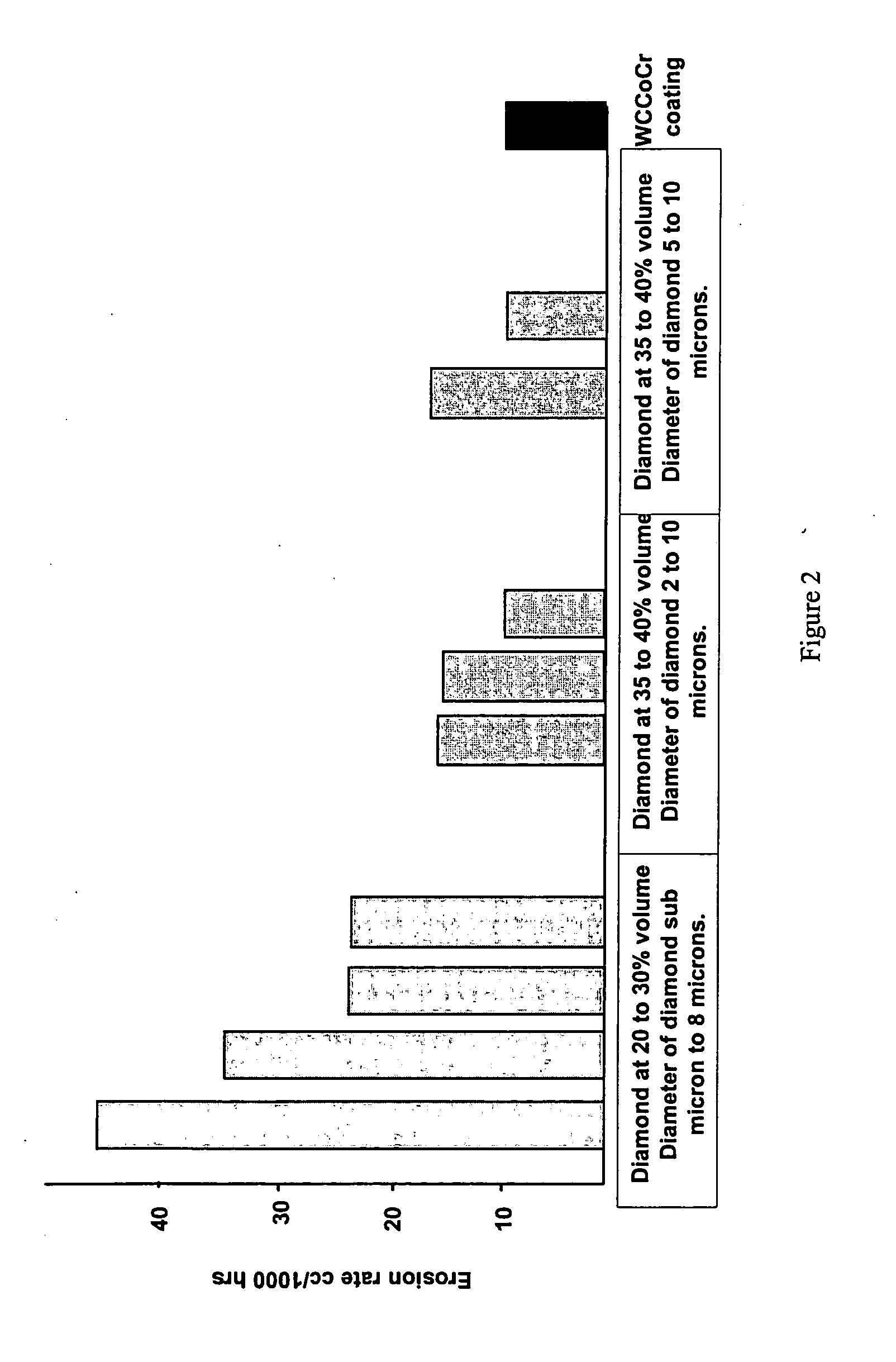

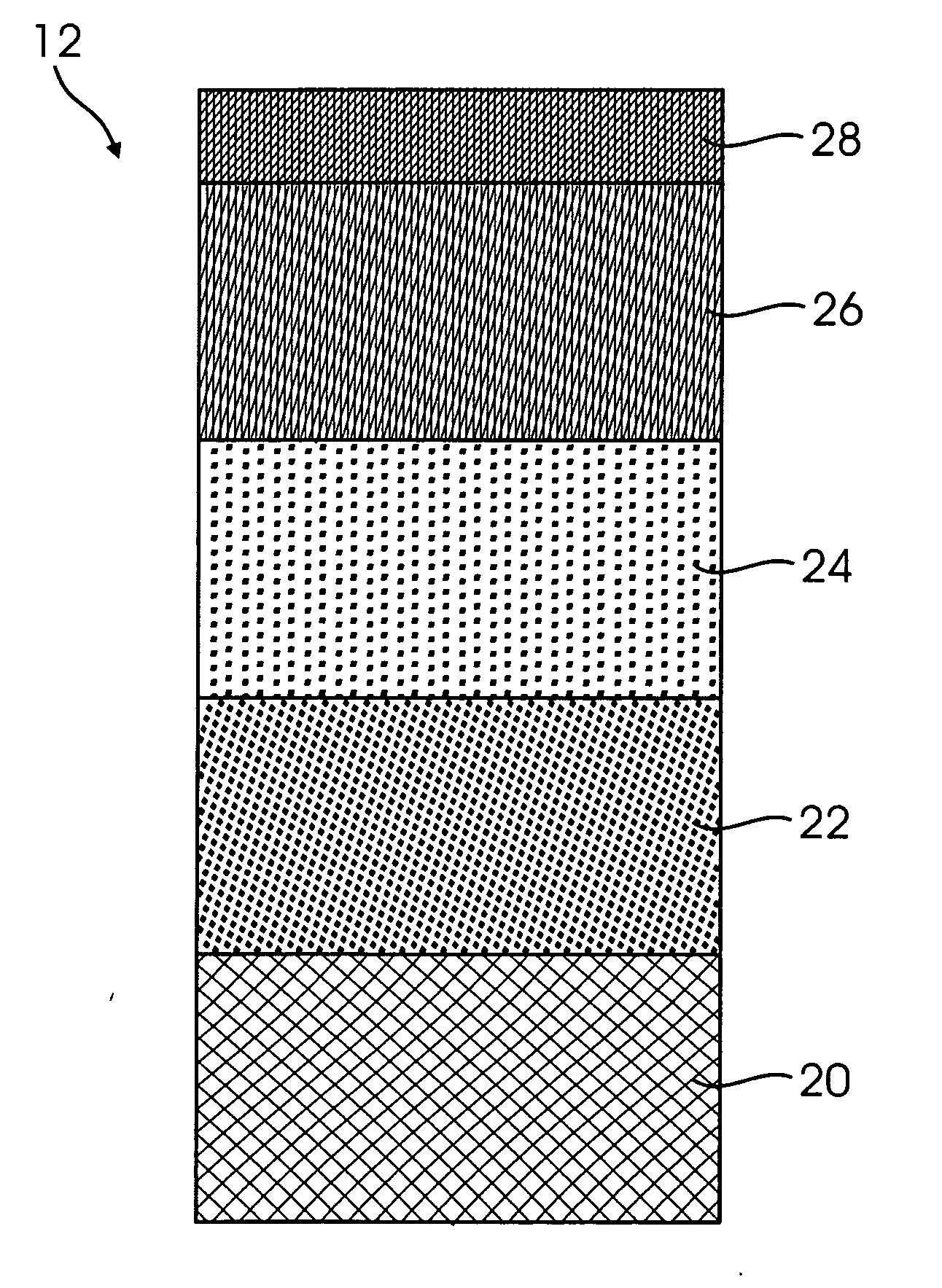

Erosion resistant coatings and methods thereof

Erosion resistant coating compositions include hard particles in a metal matrix such as nickel-based, cobalt-based and iron-based matrices applied by a plating process for complex geometry or hard to access component surfaces or by thermal spray processes for line of sight applications. These materials and processes are especially suited for providing erosion resistance to hydroelectric turbine components.

Owner:GENERAL ELECTRIC CO

Method and system for exterior protection of an aircraft

InactiveUS20070141927A1Improve structural durabilityReduce weightSynthetic resin layered productsAircraft lighting protectorsEngineeringMetal

Owner:THE BOEING CO

Microporous Aluminophosphate Molecular Sieve Membranes for Highly Selective Separations

InactiveUS20090114089A1High selectivityGood chemical and thermal stabilityPhosphatesPretreated surfacesChemical stabilityPolymer

The present invention discloses microporous aluminophosphate (AlPO4) molecular sieve membranes and methods for making and using the same. The microporous AlPO4 molecular sieve membranes, particularly small pore microporous AlPO-14 and AlPO-18 molecular sieve membranes, are prepared by three different methods, including in-situ crystallization of a layer of AlPO4 molecular sieve crystals on a porous membrane support, coating a layer of polymer-bound AlPO4 molecular sieve crystals on a porous membrane support, and a seeding method by in-situ crystallization of a continuous second layer of AlPO4 molecular sieve crystals on a seed layer of AlPO4 molecular sieve crystals supported on a porous membrane support. The microporous AlPO4 molecular sieve membranes have superior thermal and chemical stability, good erosion resistance, high CO2 plasticization resistance, and significantly improved selectivity over polymer membranes for gas and liquid separations, including carbon dioxide / methane (CO2 / CH4), carbon dioxide / nitrogen (CO2 / N2), and hydrogen / methane (H2 / CH4) separations.

Owner:UOP LLC

Thermal spray coatings for semiconductor applications

InactiveUS20100272982A1Erosion is goodImproved corrosion resistant coatingLiquid surface applicatorsMolten spray coatingThermal sprayingIntegrated circuit manufacturing

This invention relates to thermal spray coatings on a metal or non-metal substrate. The thermal spray coating comprises a partially or fully stabilized ceramic coating, e.g., yttria stabilized zirconia coating, and has sufficiently high thermodynamic phase stability to provide corrosion and / or erosion resistance to the substrate. This invention also relates to methods of protecting metal and non-metal substrates by applying the thermal spray coatings. The coatings are useful, for example, in the protection of integrated circuit manufacturing equipment, internal chamber components, and electrostatic chuck manufacture.

Owner:PRAXAIR ST TECH INC

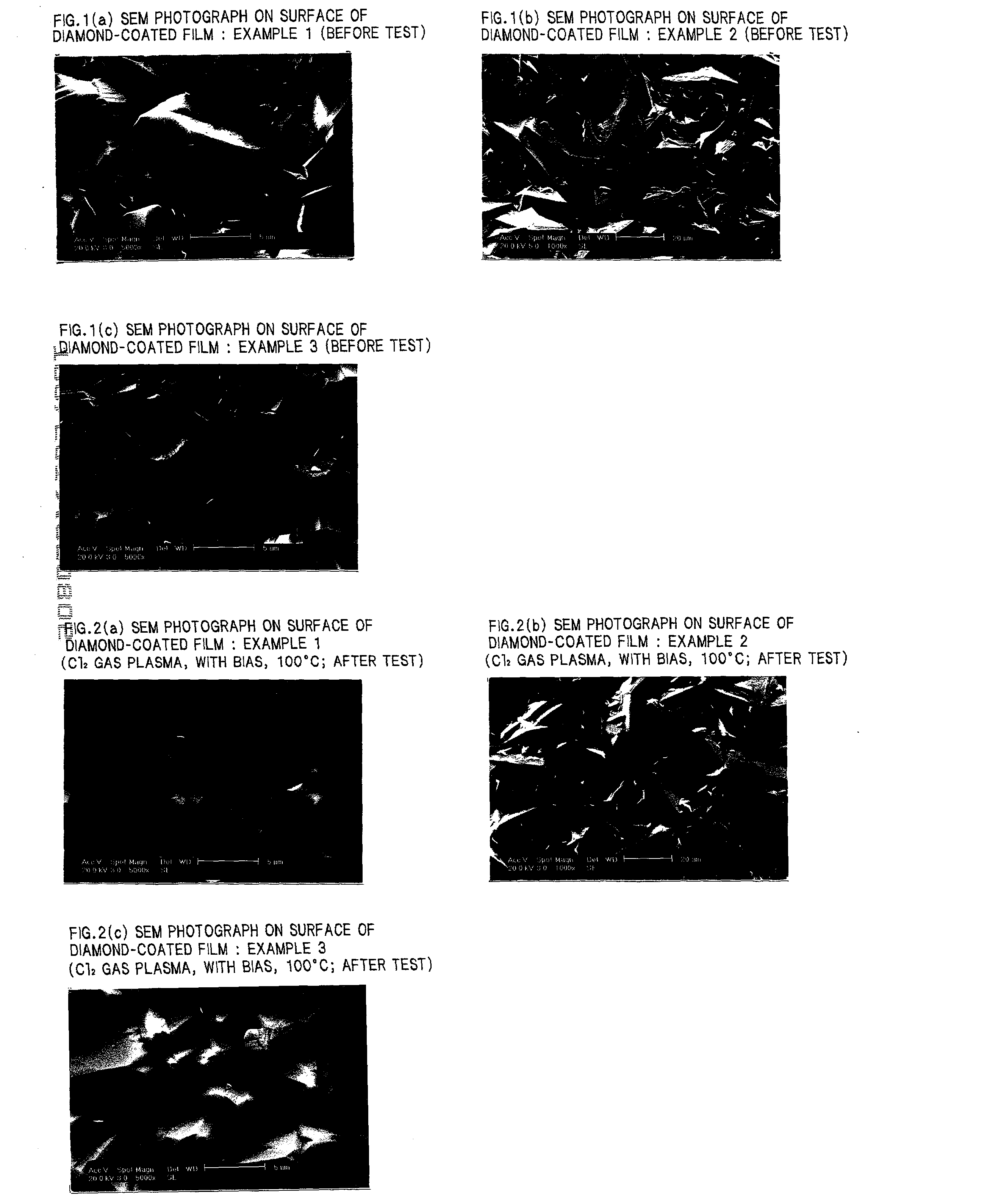

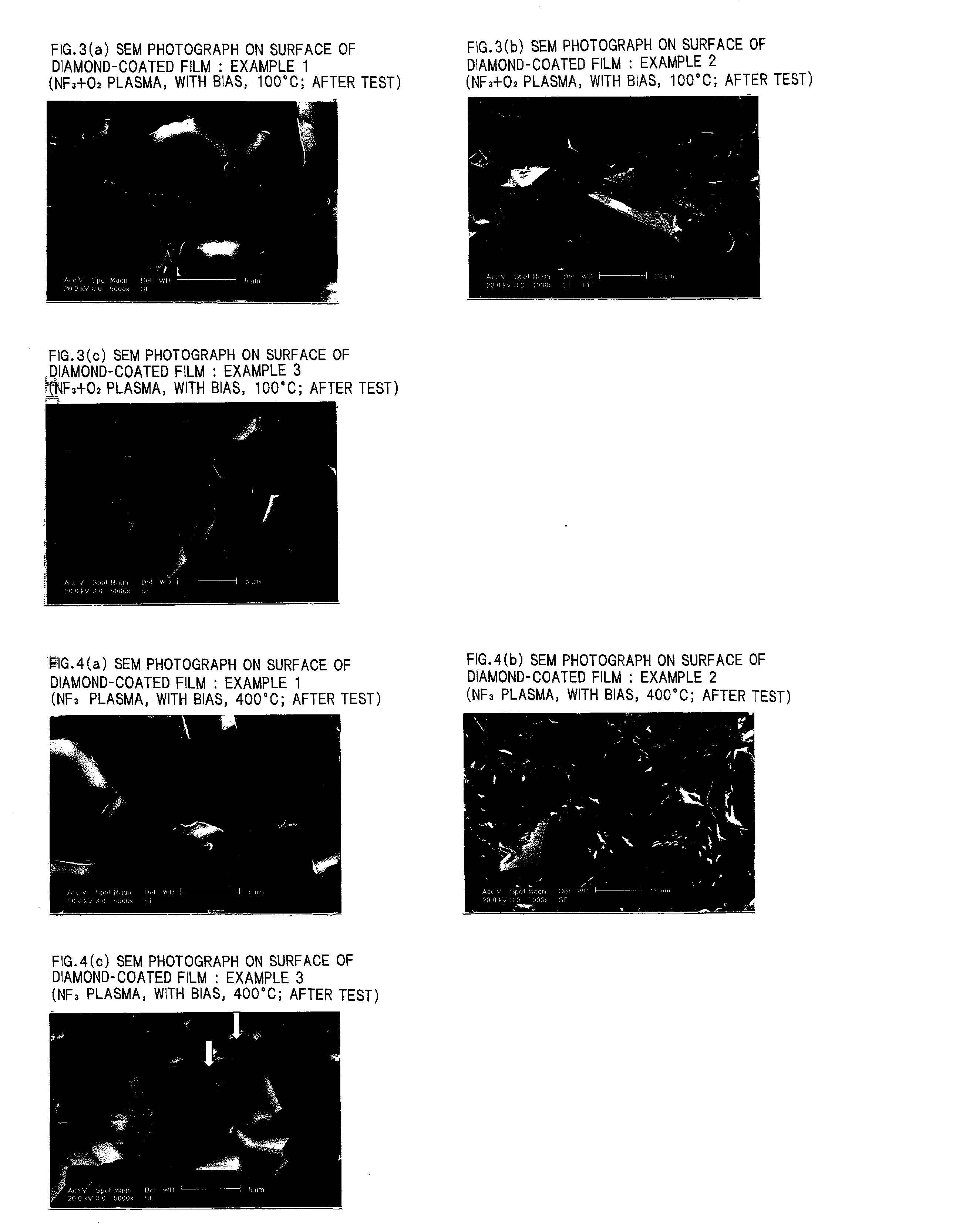

Diamond-coated member

InactiveUS20030064225A1Polycrystalline material growthElectric discharge tubesSusceptorAdhesion strength

A diamond-coated member includes a basal material such as aluminum nitride, and a diamond thin film coating at least one part of a surface of the basal material, being adhered thereto, and has corrosion-erosion resistance. Adhesion strength between the thin film and the basal material is 15 MPa or more. Or, in diamond thin film, degree of orientation of diamond {220} plane present in faces parallel to the basal material is expressed by following formula: [Im220 / (Im220+Im111)] / [Ip220 / (Ip220+Ip111)]<1. The diamond-coated corrosion-erosion resistant member has excellent corrosion-erosion resistance, and is used mainly for a semiconductor producing apparatus; being preferably applied as a member inside a reaction chamber where a substrate, represented by silicon wafer, is exposed to plasma, corrosion gas or the like, inclusive of rings, a chamber inner lining, a gas shower plate, nozzles, a susceptor, an electrostatic chuck, a heater, or the like.

Owner:NGK INSULATORS LTD

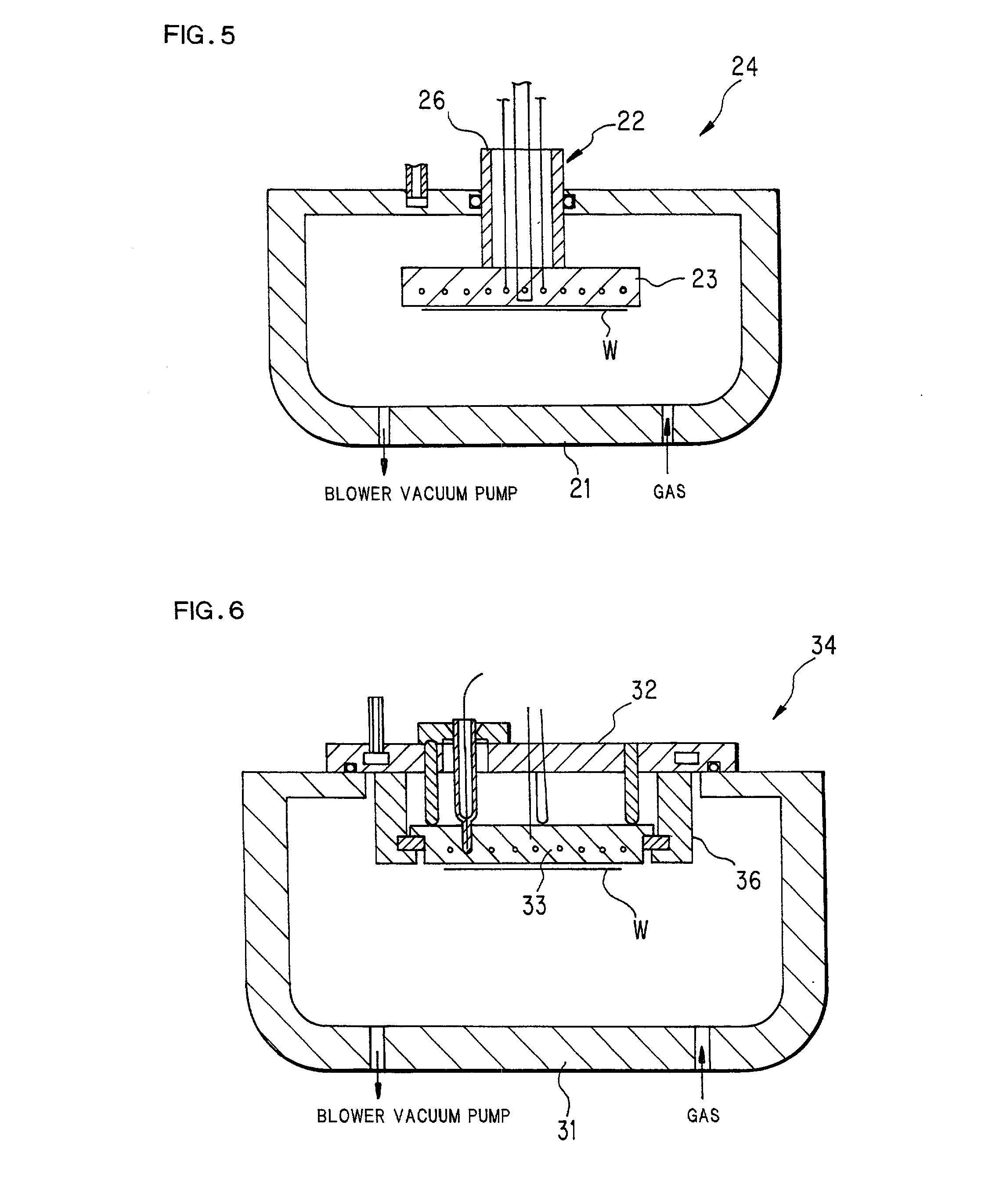

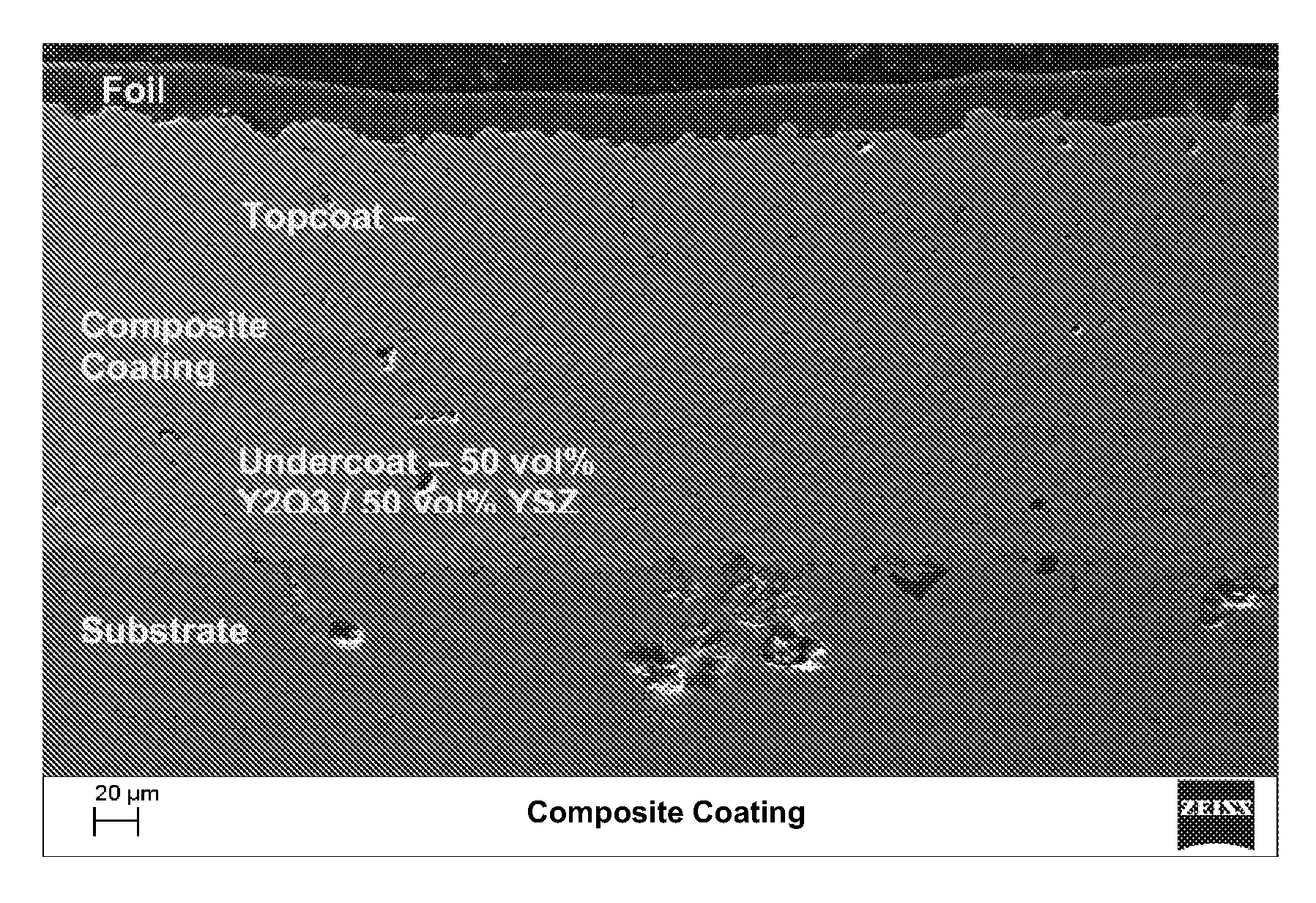

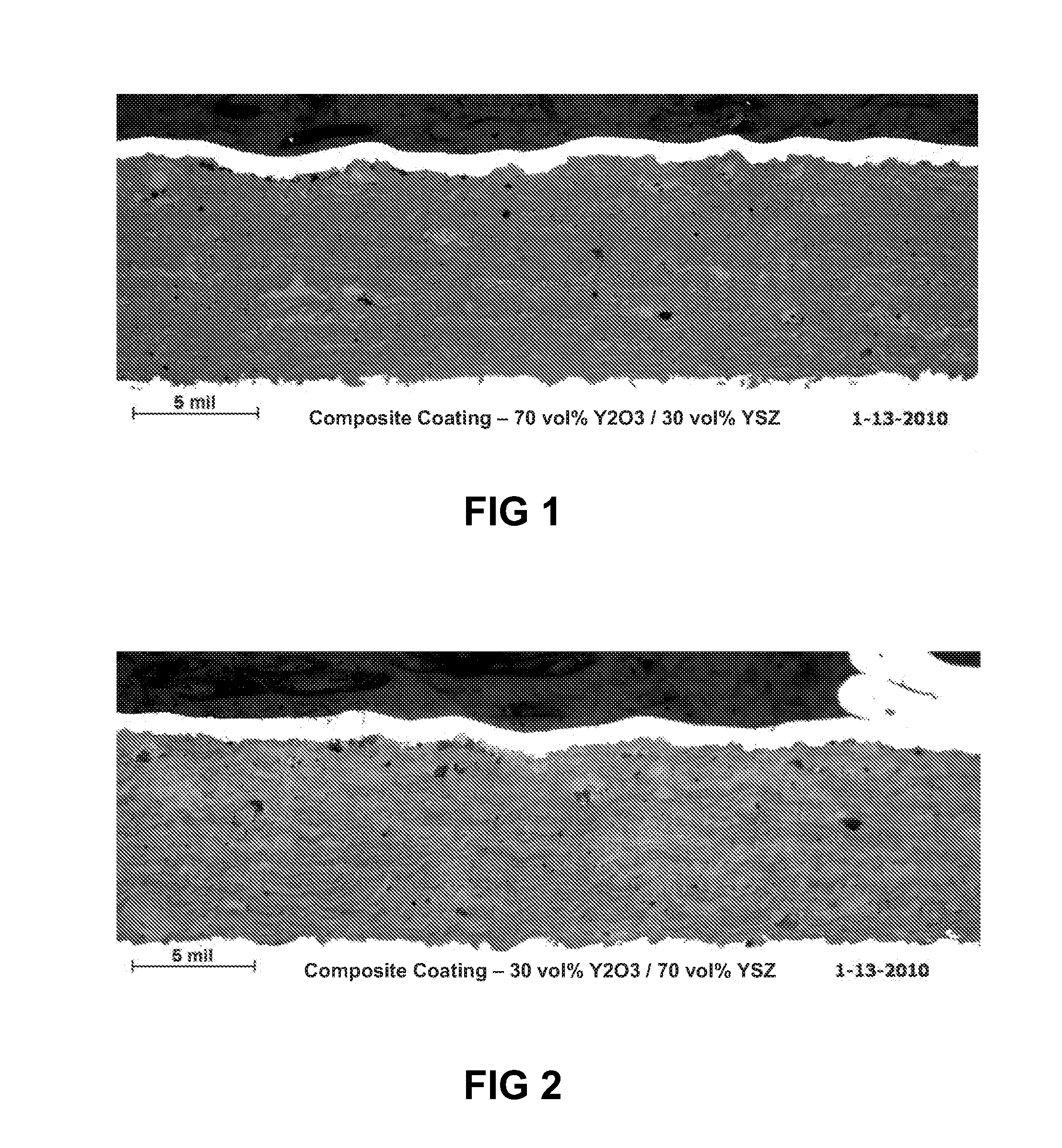

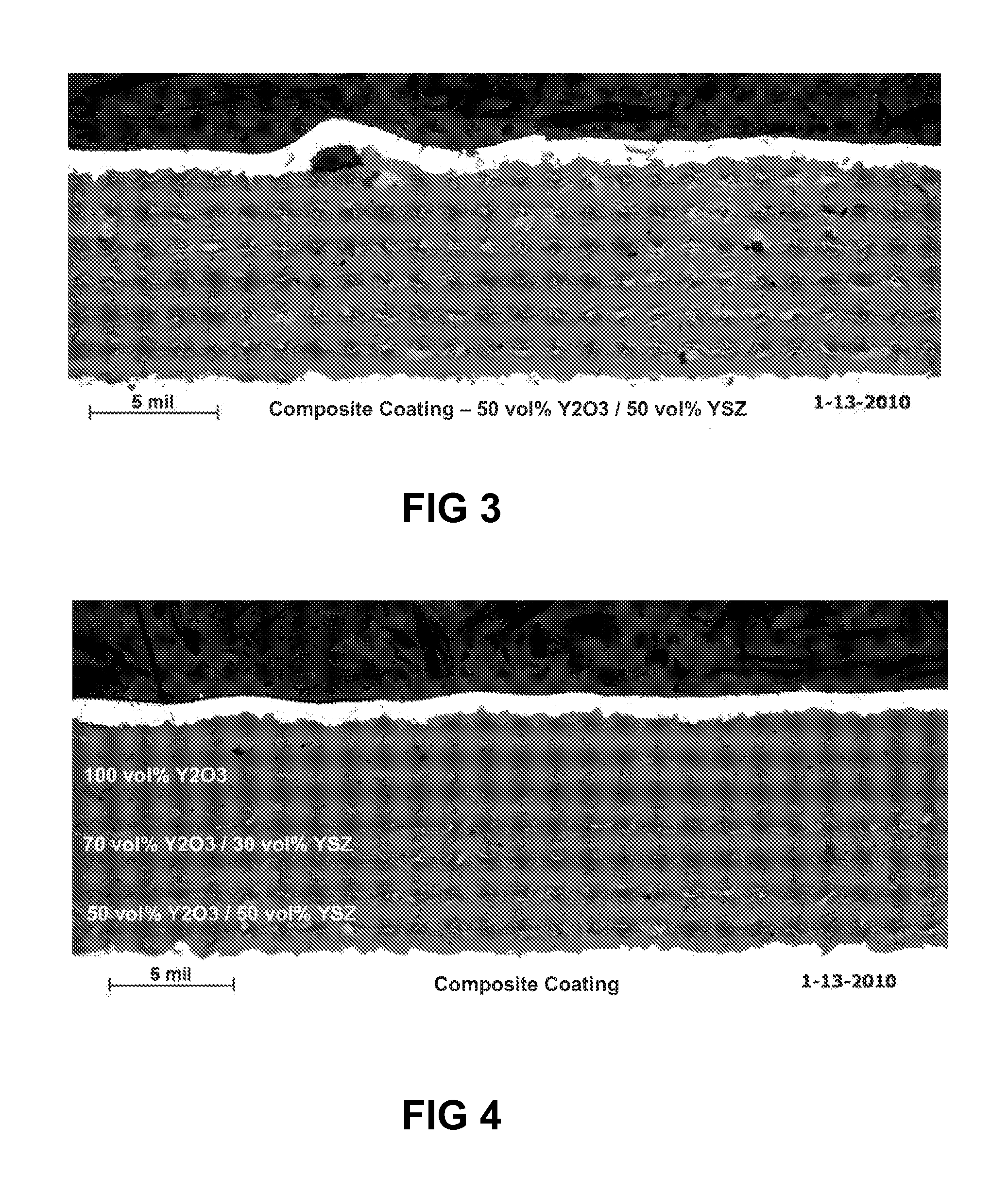

Thermal spray composite coatings for semiconductor applications

InactiveUS20120196139A1Improved erosion and corrosion resistantLower Level RequirementsLiquid surface applicatorsMolten spray coatingThermal sprayingCeramic composite

This invention relates to thermal spray composite coatings on a metal or non-metal substrate. The thermal spray composite coatings comprise (i) a ceramic composite coating undercoat layer having at least two ceramic material phases randomly and uniformly dispersed and / or spatially oriented throughout the ceramic composite coating, and (ii) a ceramic coating topcoat layer applied to the undercoat layer. At least a first ceramic material phase is present in the undercoat layer in an amount sufficient to provide corrosion resistance to the ceramic composite coating, and at least a second ceramic material phase is present in the undercoat layer in an amount sufficient to provide plasma erosion resistance to the ceramic composite coating. This invention also relates to methods of protecting metal and non-metal substrates by applying the thermal spray coatings. The composite coatings provide erosion and corrosion resistance at processing temperatures higher than conventional processing temperatures used in the semiconductor etch industry, e.g., greater than 100° C. The coatings are useful, for example, in the protection of semiconductor manufacturing equipment, e.g., integrated circuit, light emitting diode, display, and photovoltaic, internal chamber components, and electrostatic chuck manufacture.

Owner:PRAXAIR ST TECH INC

Productivity enhancing thermal sprayed yttria-containing coating for plasma reactor

InactiveUS7311797B2Improve wear resistanceLow level of contaminationCellsElectric discharge tubesProduction ratePlasma reactor

Components of semiconductor processing apparatus comprise thermal sprayed yttria-containing coatings that provide erosion, corrosion and / or corrosion-erosion resistance in plasma atmospheres. The coatings can protect substrates from physical and / or chemical attack.

Owner:LAM RES CORP

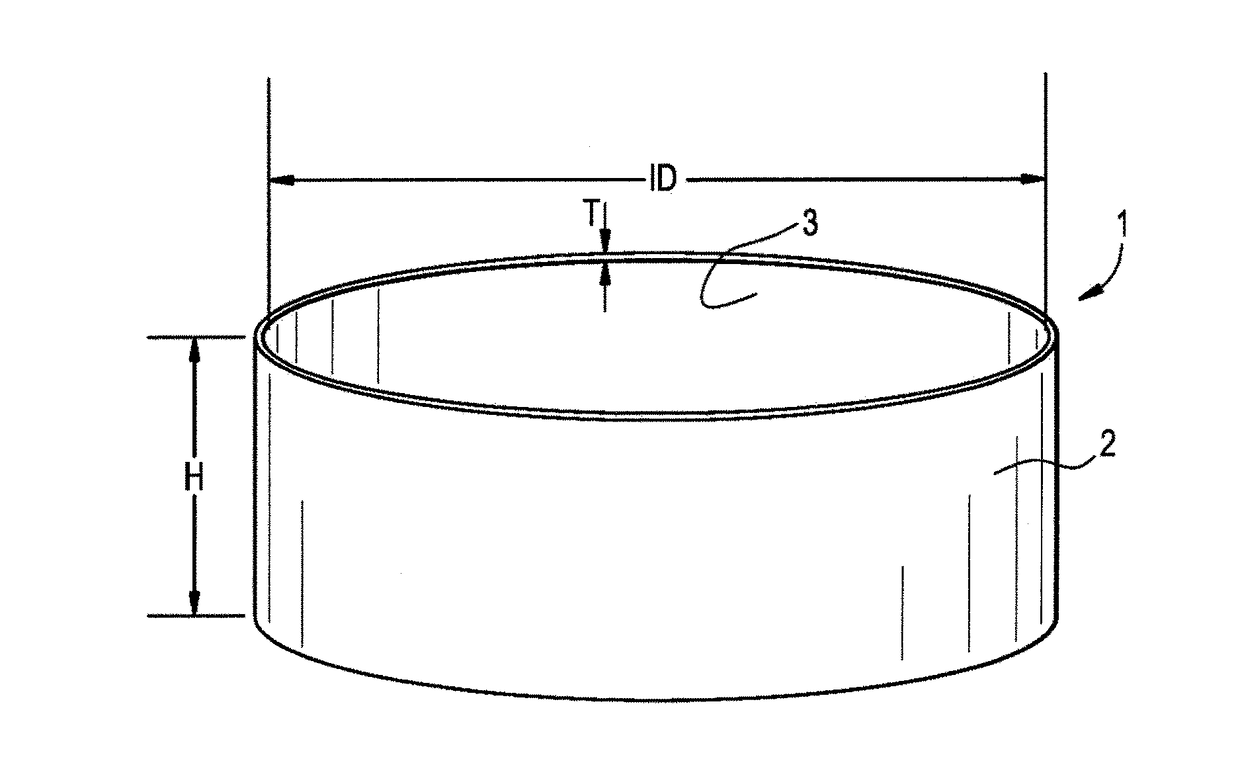

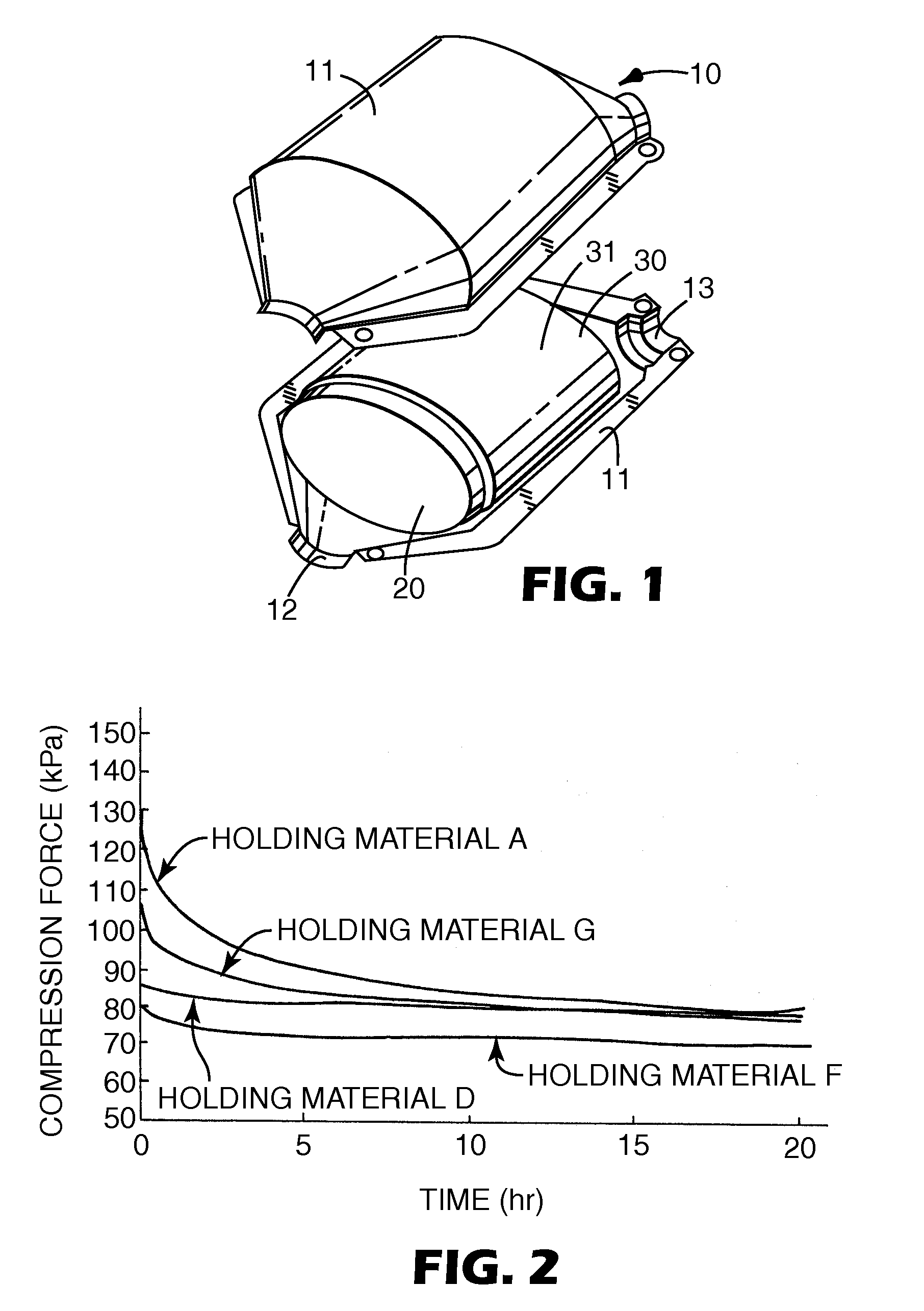

Catalyst carrier holding material and catalytic converter

ActiveUS7261864B2Improve stress resistanceExcellent wind erosion resistanceCombination devicesPhysical/chemical process catalystsFiberHeat resistance

To provide a catalyst carrier holding material which is particularly useful for catalytic converters, by exhibiting heat resistance and high compression resistance in high temperature ranges, as well as excellent wind erosion resistance. The catalyst carrier holding material comprises inorganic fibers comprising alumina and silica, and the mullite ratio of the inorganic fibers is in the range of greater than 30% and less than 75%, and preferably in the range of 35% to 70%.

Owner:3M INNOVATIVE PROPERTIES CO

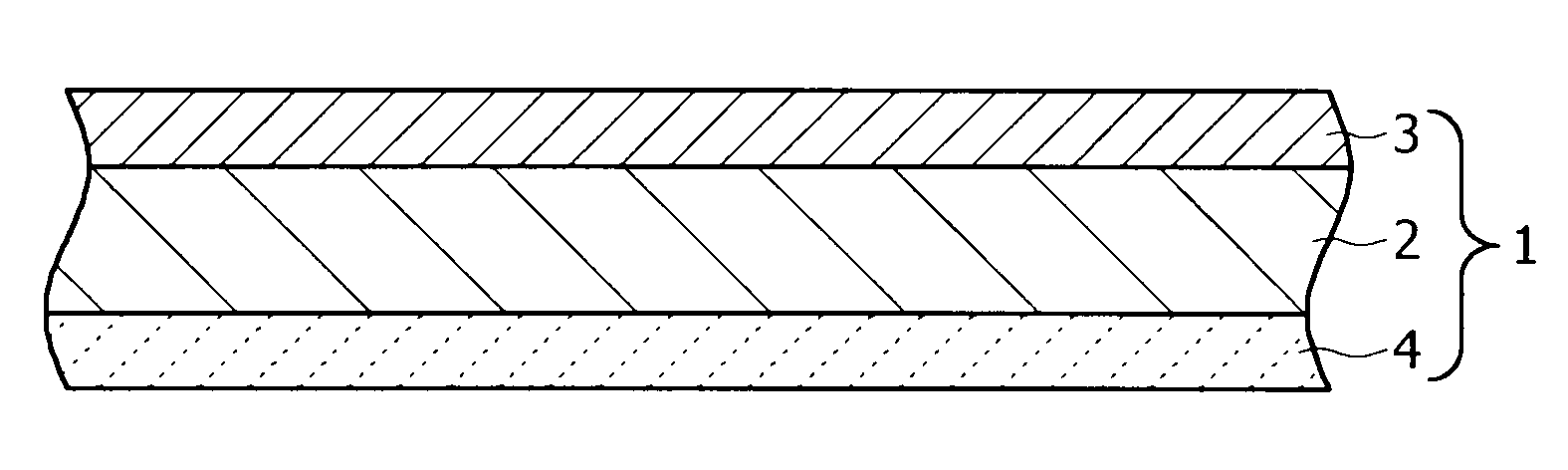

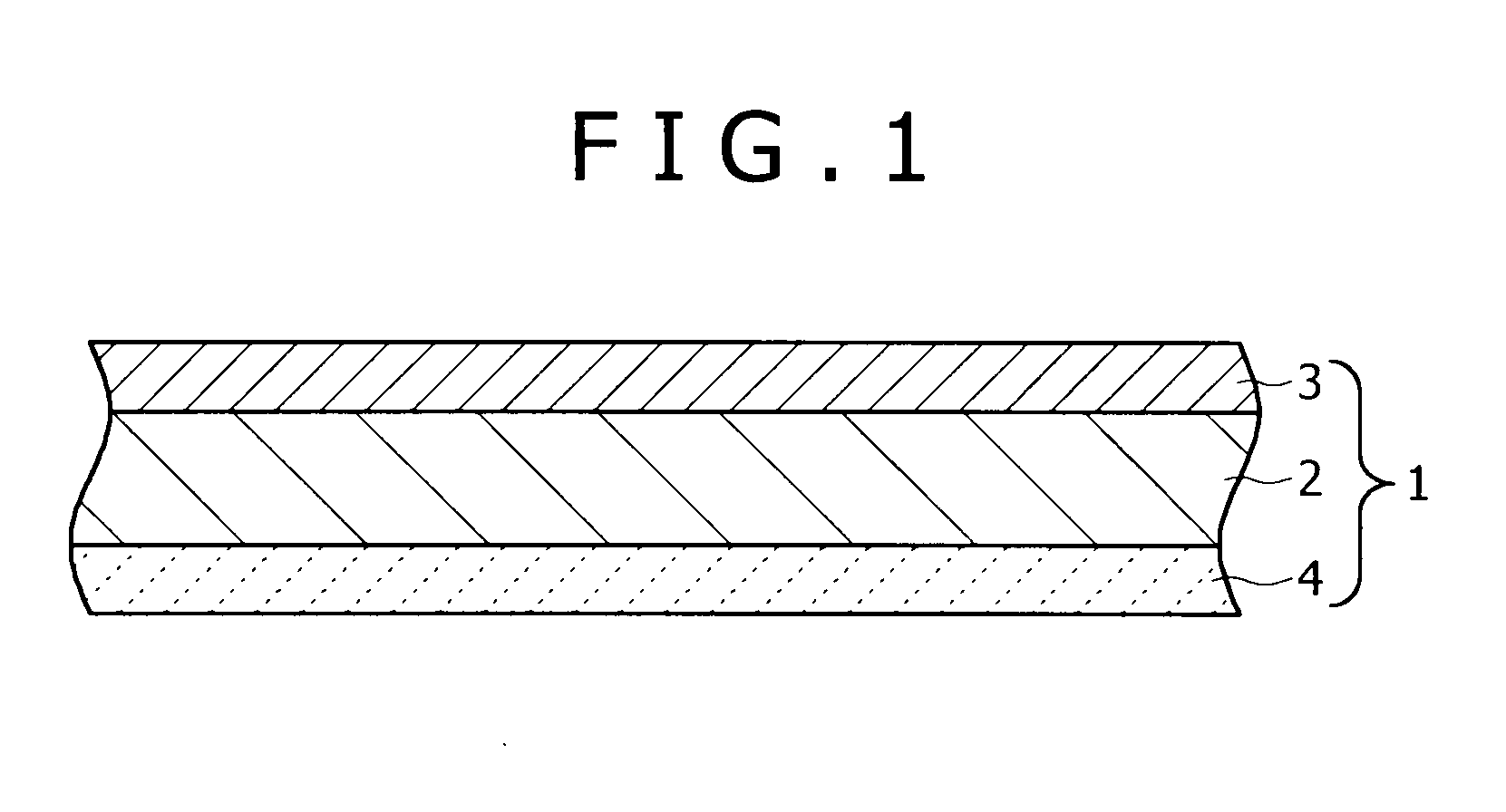

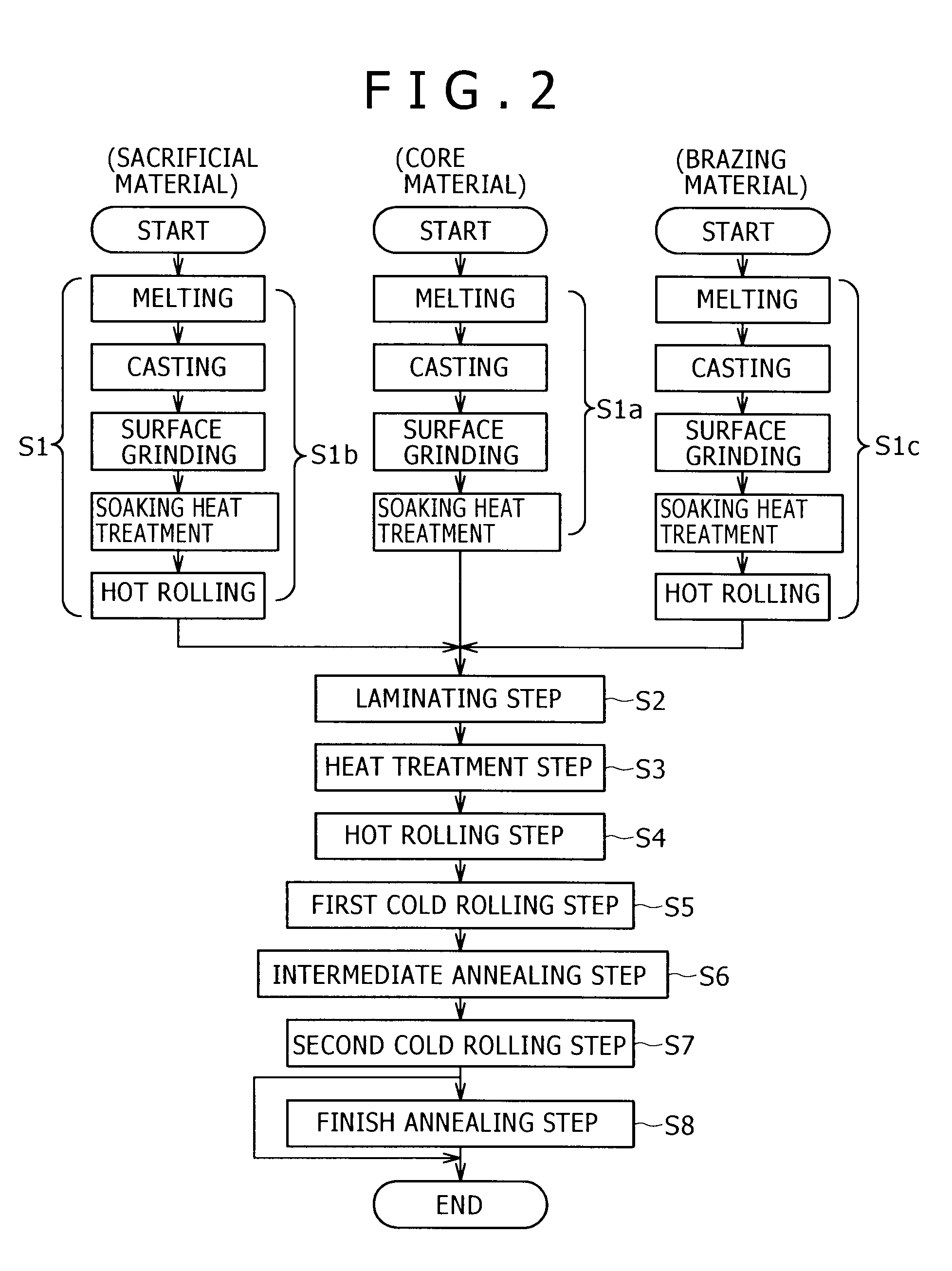

Aluminum alloy clad sheet for a heat exchanger and its production method

ActiveUS20090165901A1High elongationGood formabilityWelding/cutting media/materialsThin material handlingUltimate tensile strengthImpurity

Disclosed herein is an aluminum alloy clad sheet for a heat exchanger including a core layer, a sacrificial layer formed on one surface of the core layer, and a filler layer including an Al—Si based alloy formed on the other surface of the core layer. The core layer includes a predetermined amount of Si, Cu, Mn, Ti, and Mg, the remainder including Al and inevitable impurities, and the sacrificial layer includes a predetermined amount of Si, Mn, and Zn, the remainder including Al and inevitable impurities. The core layer has a crystal grain size after the brazing heat treatment at 595° C. for 3 minutes of at least 50 μm and less than 300 μm. The filler layer and the sacrificial layer are defined for their thickness, and the number of intermetallic compounds in the core layer is also defined to a predetermined range. By such constitution, the aluminum alloy clad sheet has improved fatigue life and post-braze strength, high corrosion resistance, and excellent erosion resistance and brazeability.

Owner:KOBE STEEL LTD

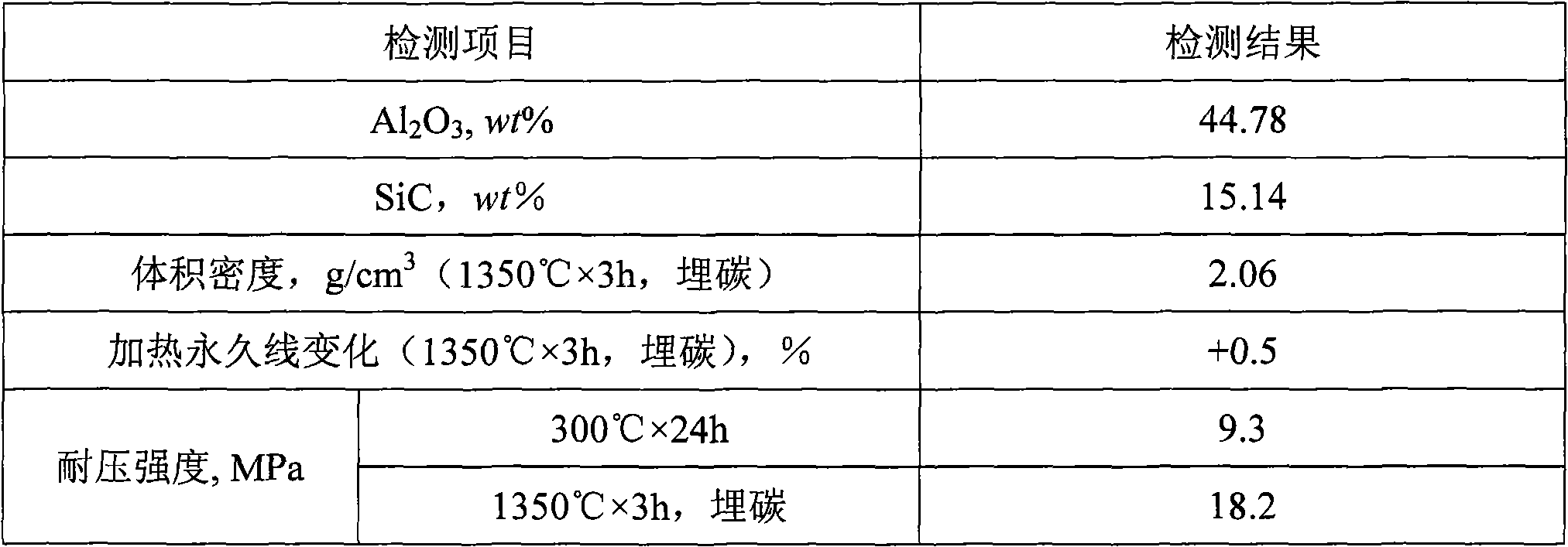

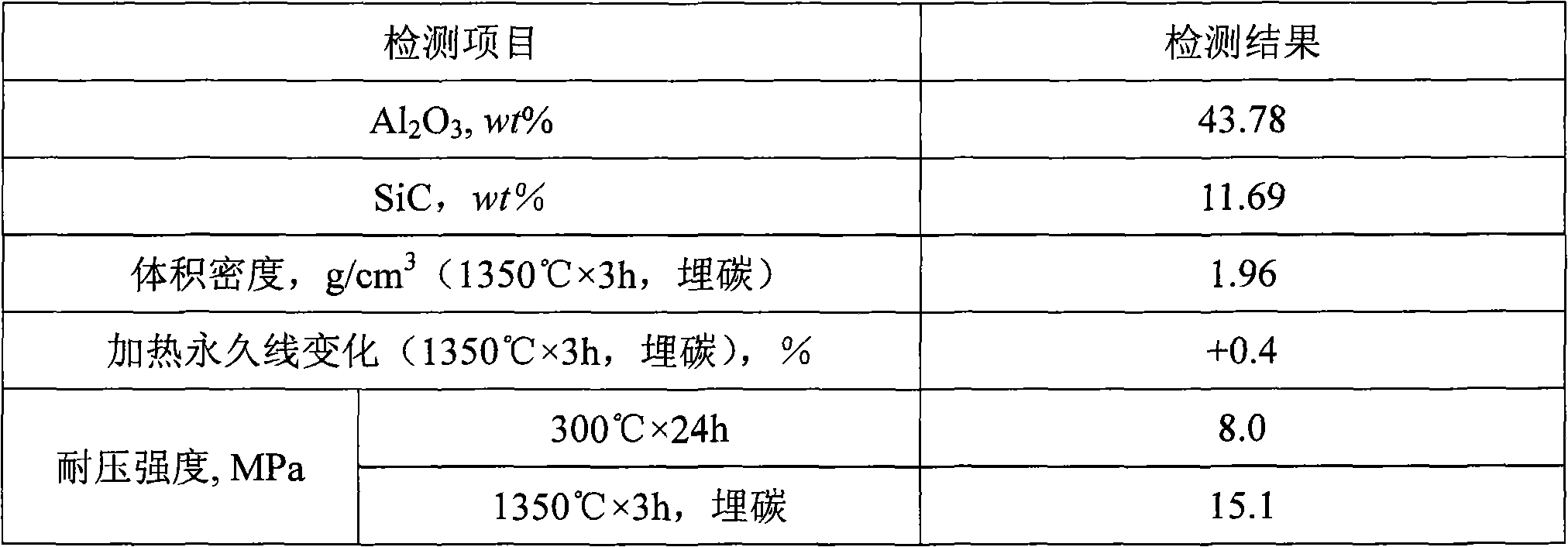

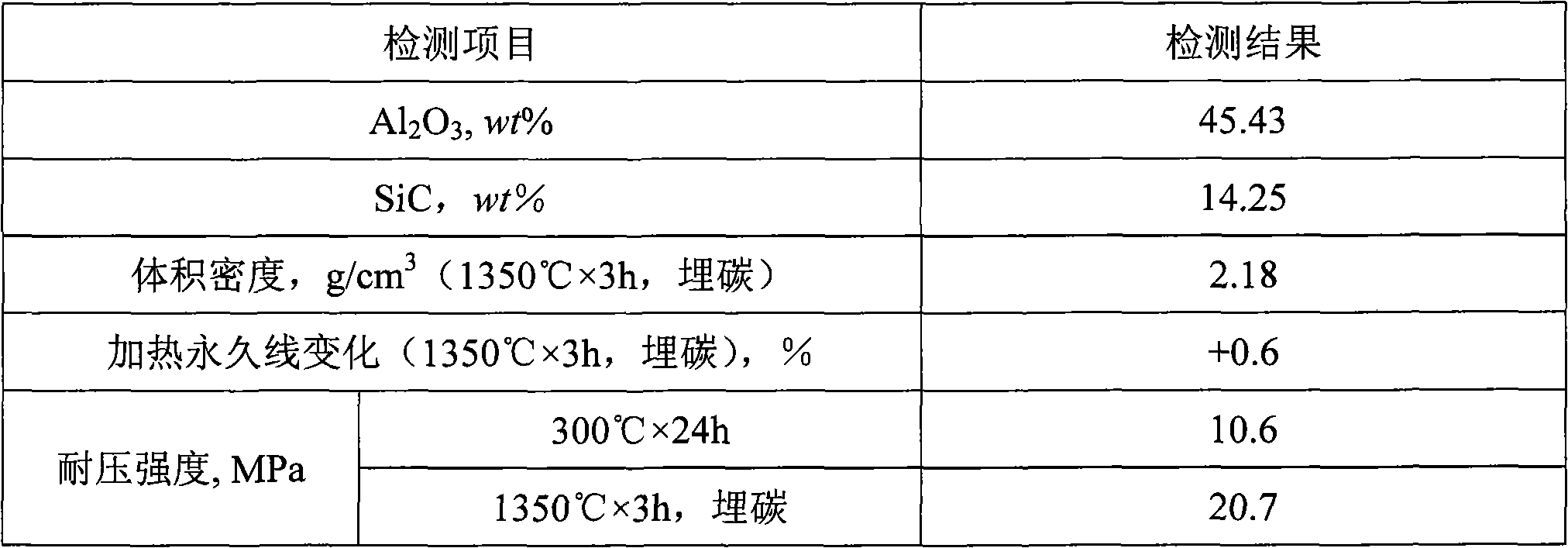

Method for producing waterless taphole mix for blast furnace from high-alumina waste refractory materials

The invention discloses a method for producing a waterless taphole mix for a blast furnace from high-alumina waste refractory materials. The produced low-cost waterless taphole mix can satisfy the operating requirements for plugging tapholes of large and medium blast furnaces. The method comprises the selection of raw materials for production, the processing of the raw materials for production, the proportioning of the raw materials for production, and the production process. The waterless taphole mix produced by the method has the characteristics of low cost, good plasticity and sintering property, high middle-and-high-temperature strength, favorable slag and iron erosion resistance and the like, and can completely satisfy the operating requirements of large and medium blast furnaces. Compared with the existing waterless taphole mix, the cost can be reduced by 40-60%; since a great amount of waste refractory materials are used, the emission of the solid waste can be decreased, and a great amount of high-quality refractory materials such as brown corundum, premium / extra grade alumina and the like can be saved; and meanwhile, the energy consumption and the emission of carbon dioxide gas during the smelting of brown corundum and premium / extra grade alumina can be decreased.

Owner:UNIV OF SCI & TECH LIAONING

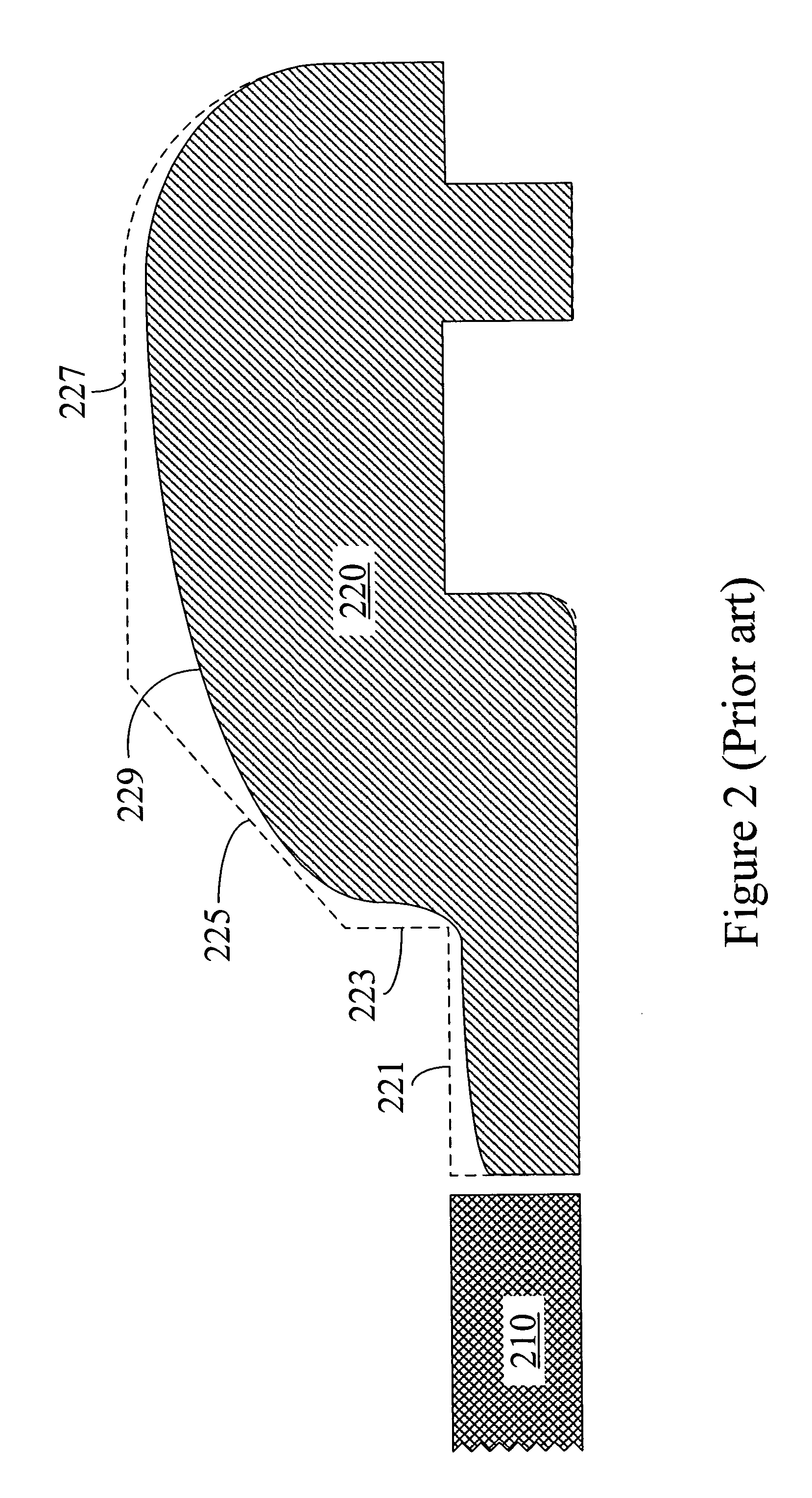

Process kit for erosion resistance enhancement

InactiveUS20050016684A1Minimize impactExtended service lifeElectric discharge tubesSemiconductor/solid-state device manufacturingPolymer sciencePermittivity

A process kit is described that resists plasma erosion, preserves the spatial uniformity of plasma properties, reduces particle generation in the chamber, and significantly enhances the lifetime of the process kit. A layer of polymer material covers the top surface of the process kit. The polymer material is fluorocarbon-based and not reactive with the species in the plasma. The polymer material not only protects the process kit from progressive erosion, but also prevents the generation of particles in the chamber. The polymer material has similar permittivity to that of the process kit and therefore maintains the spatial uniformity of plasma properties, e.g., etch rate, near the wafer perimeter. The thickness of the layer is controlled between 0.5 and 1.5 mm such that the difference between its coefficient of thermal expansion and that of the process kit will not cause the layer to peel off the process kit's top surface.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com