Patents

Literature

323results about How to "Erosion is good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of forming vias in silicon carbide and resulting devices and circuits

InactiveUS6515303B2Promote differentiationErosion is goodSemiconductor/solid-state device detailsSolid-state devicesLead bondingInductance

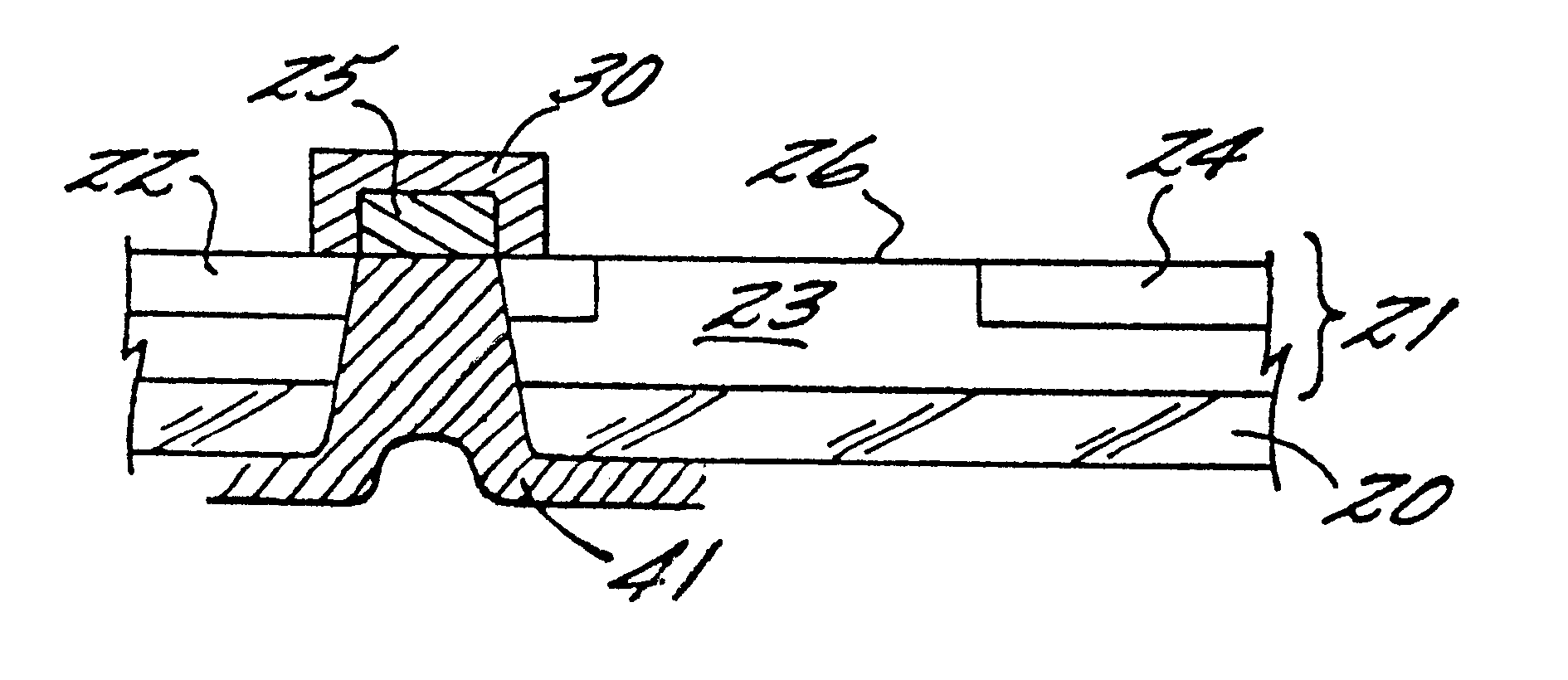

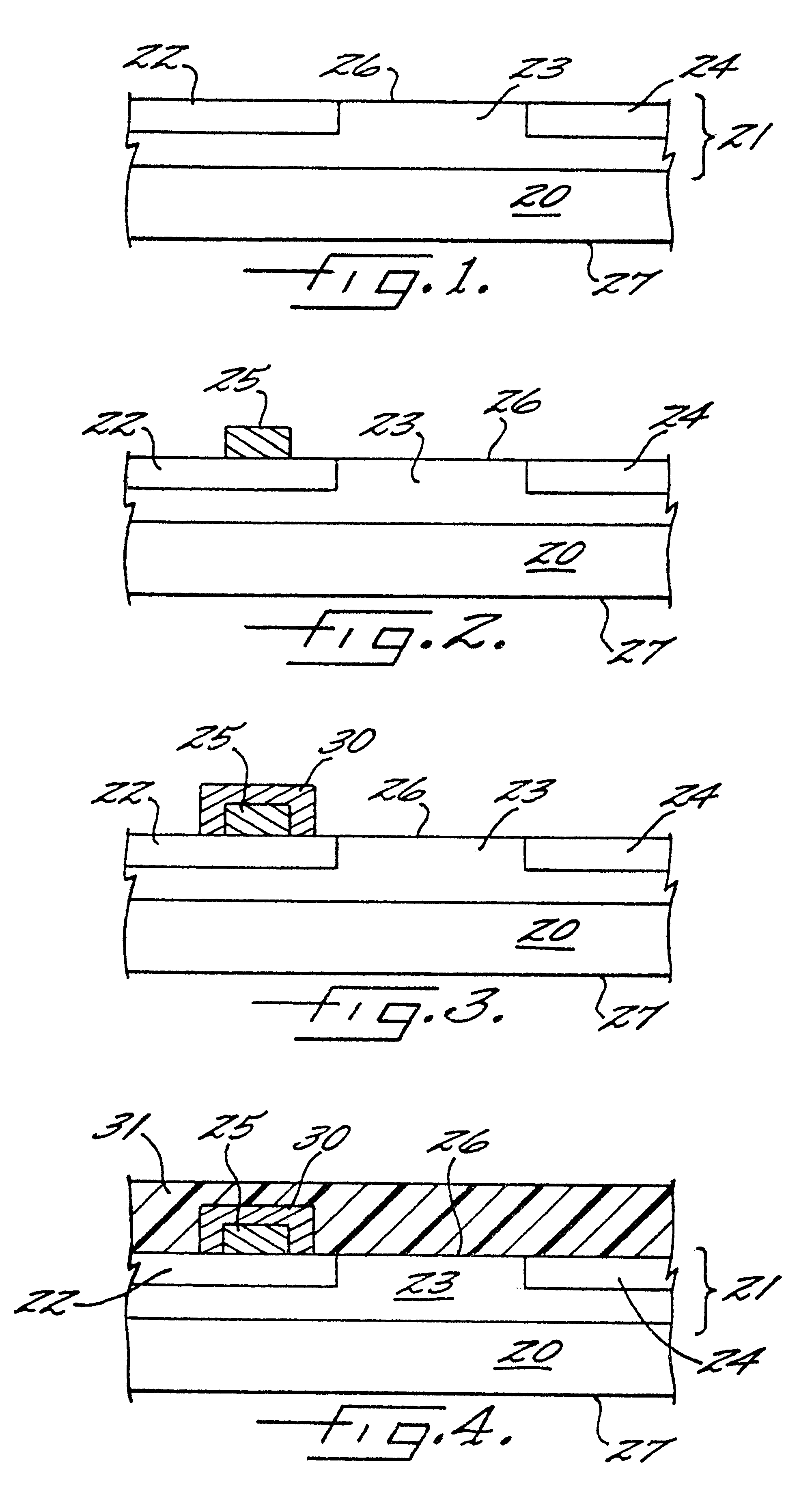

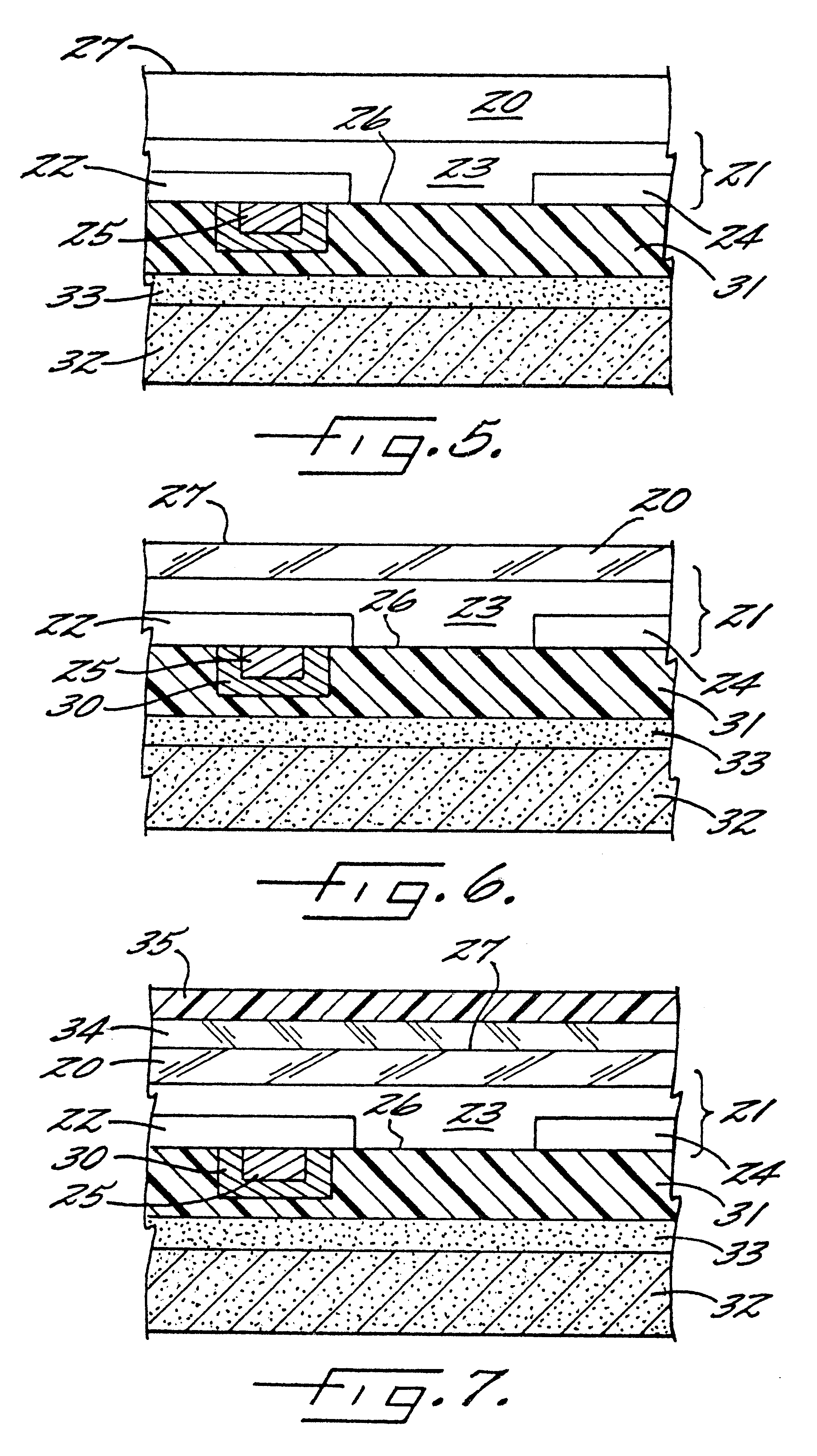

A method of fabricating an integrated circuit on a silicon carbide substrate is disclosed that eliminates wire bonding that can otherwise cause undesired inductance. The method includes fabricating a semiconductor device on a first surface of a silicon carbide substrate and with at least one metal contact for the device on the first surface of the substrate. The opposite, second surface of the substrate is then ground and polished until it is substantially transparent. The method then includes masking the polished second surface of the silicon carbide substrate to define a predetermined location for a via that is opposite the device metal contact on the first surface; etching the desired via through the desired masked location until the etch reaches the metal contact on the first surface; and metallizing the via to provide an electrical contact from the second surface of the substrate to the metal contact and to the device on the first surface of the substrate.

Owner:WOLFSPEED INC

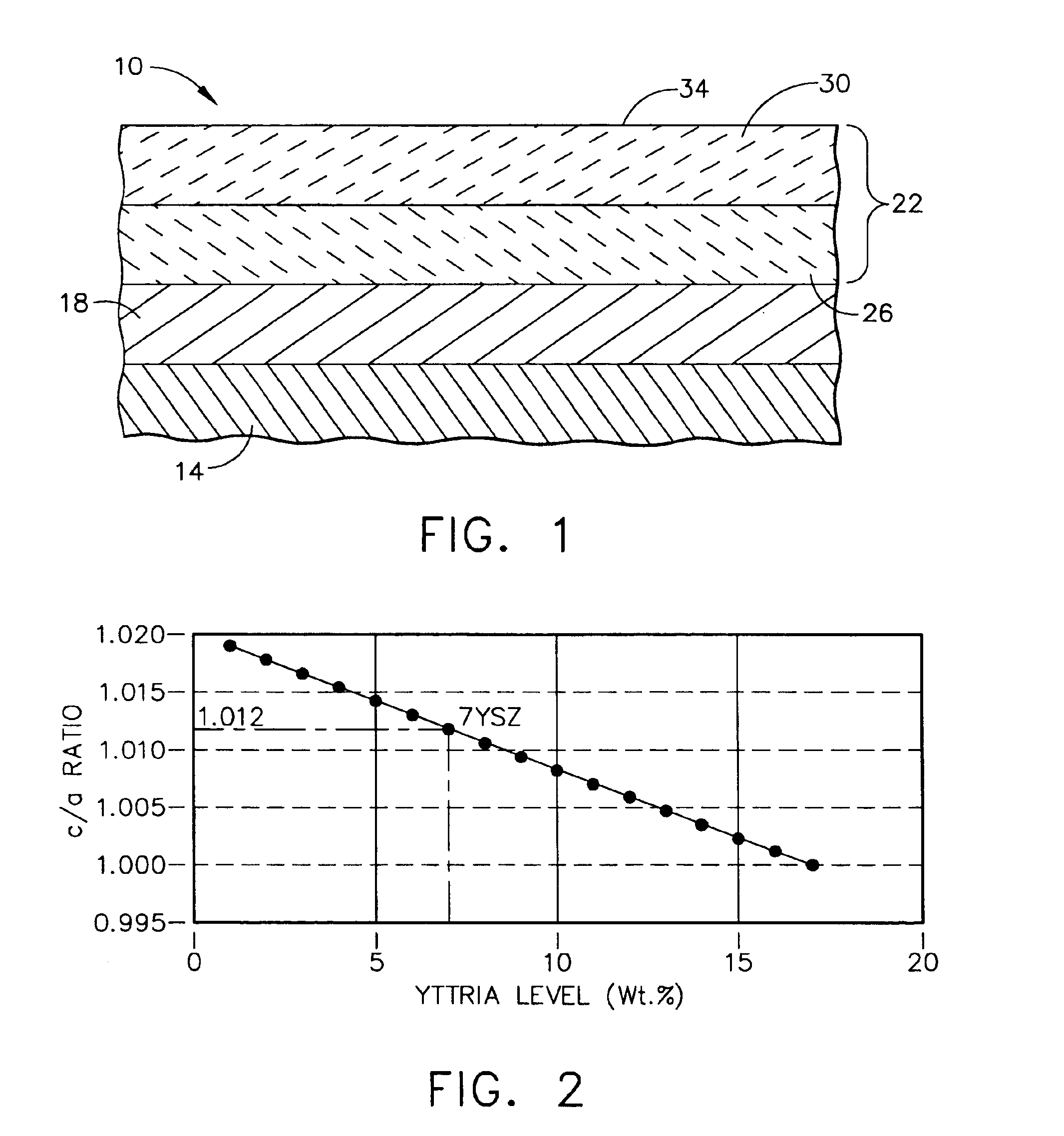

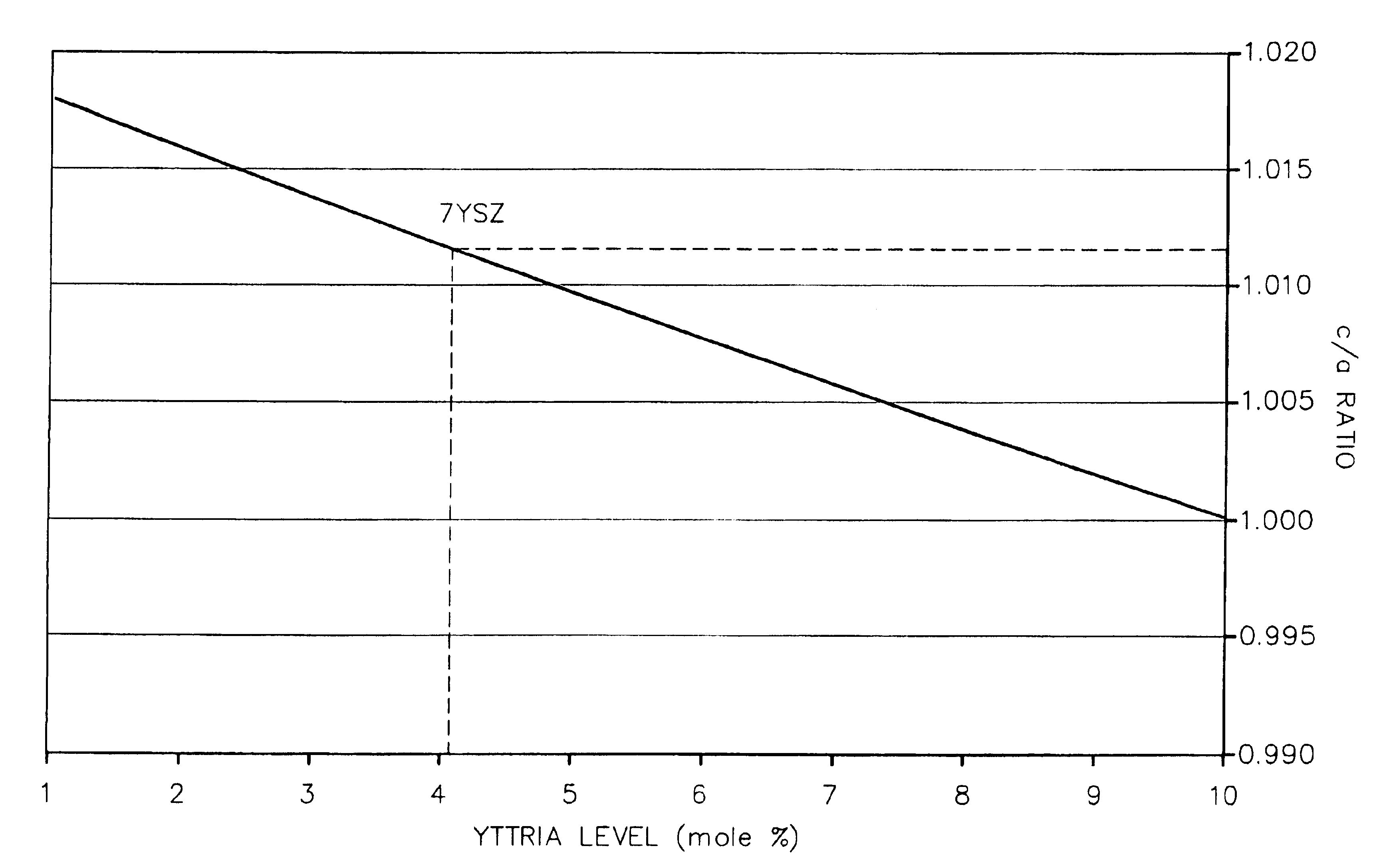

Thermal barrier coatings with protective outer layer for improved impact and erosion resistance

InactiveUS6875529B1Improve erosion resistanceImprove impact resistanceMolten spray coatingVacuum evaporation coatingBond coatMetallic substrate

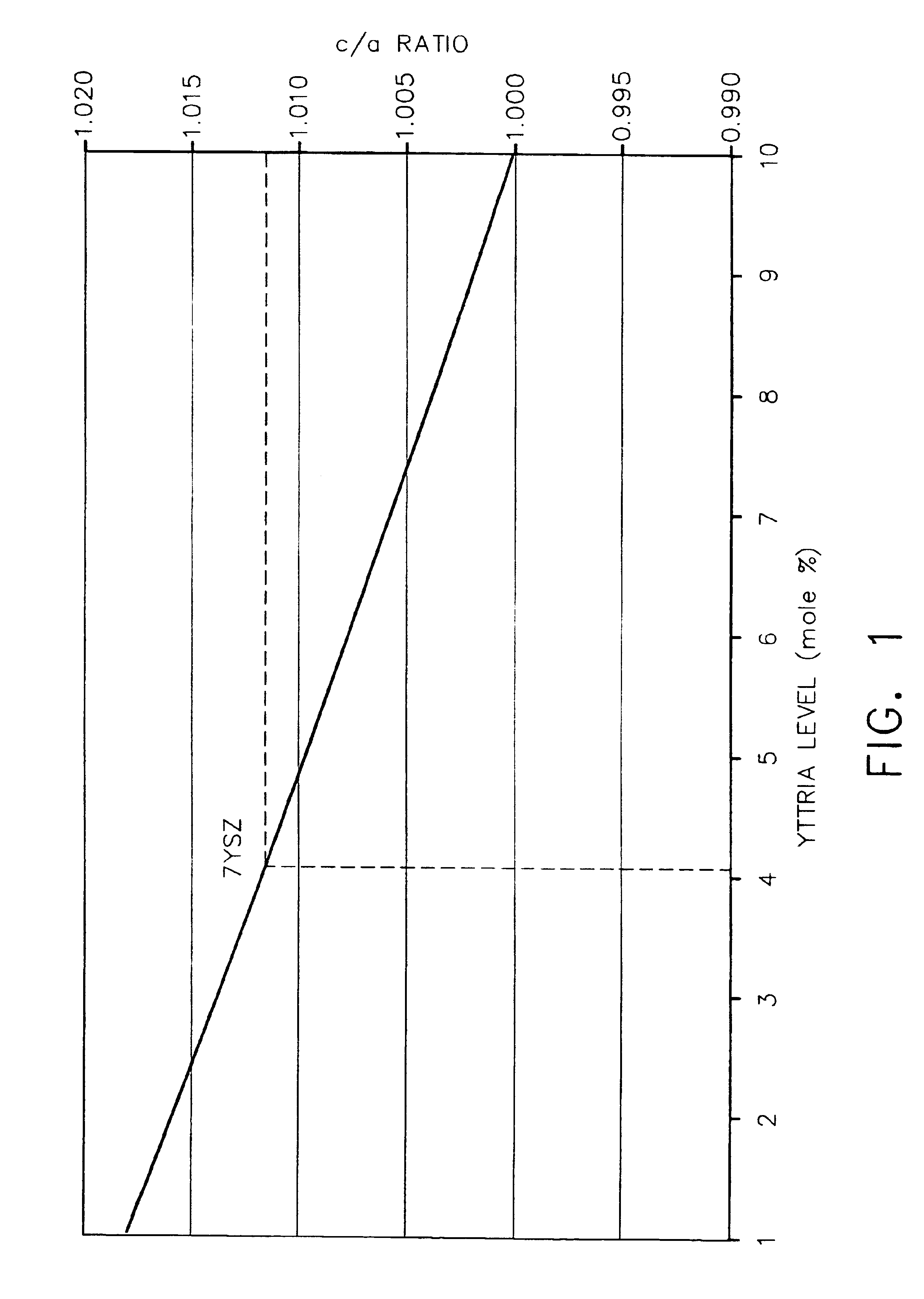

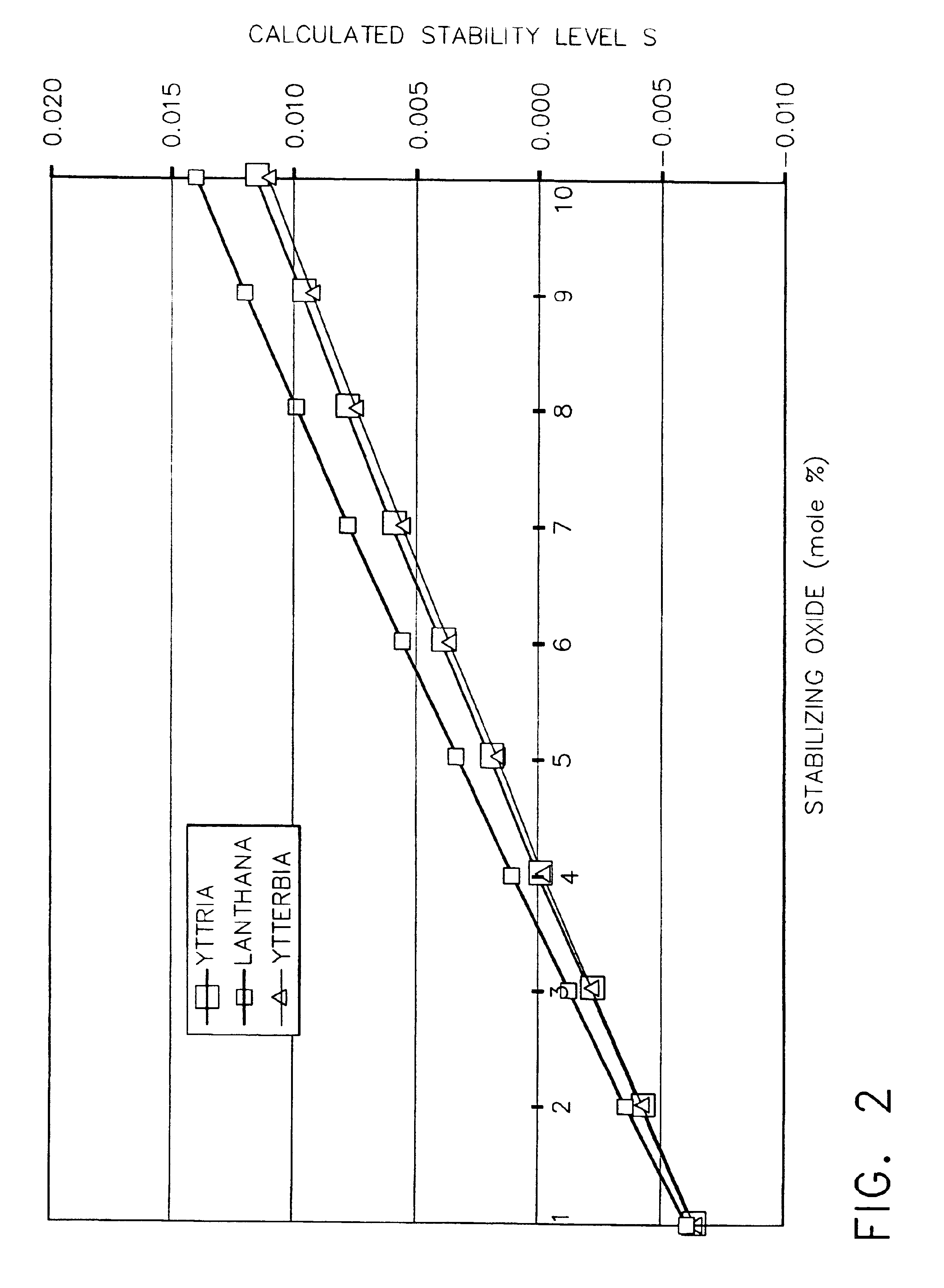

A reduced thermal conductivity thermal barrier coating having improved impact and erosion resistance for an underlying metal substrate of articles that operate at, or are exposed to, high temperatures. This coating comprises an inner layer nearest to the underlying metal substrate comprising a ceramic thermal barrier coating material, as well as a protective outer layer adjacent to and overlaying the inner layer and having an exposed surface. The outer layer has a thickness up to about 5 mils (127 microns) sufficient to impart impact and erosion resistance to the thermal barrier coating, and comprises a zirconia-containing ceramic composition having a c / a ratio of the zirconia lattice in the range of from about 1.011 to about 1.016 and stabilized in the tetragonal phase by a stabilizing amount of a stabilizing metal oxide selected from the group consisting of yttria, calcia, ceria, scandia, magnesia, india, ytterbia and mixtures thereof. This coating can be used to provide a thermally protected article having a metal substrate and optionally a bond coated layer adjacent to and overlaying the metal substrate. The thermal barrier coating can be prepared by forming the inner layer comprising the ceramic thermal barrier coating material, followed by forming on the inner layer the protective outer layer.

Owner:GENERAL ELECTRIC CO

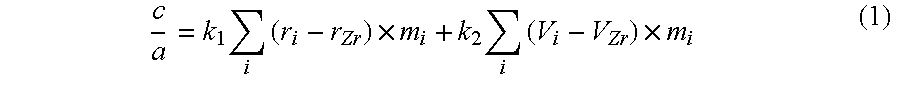

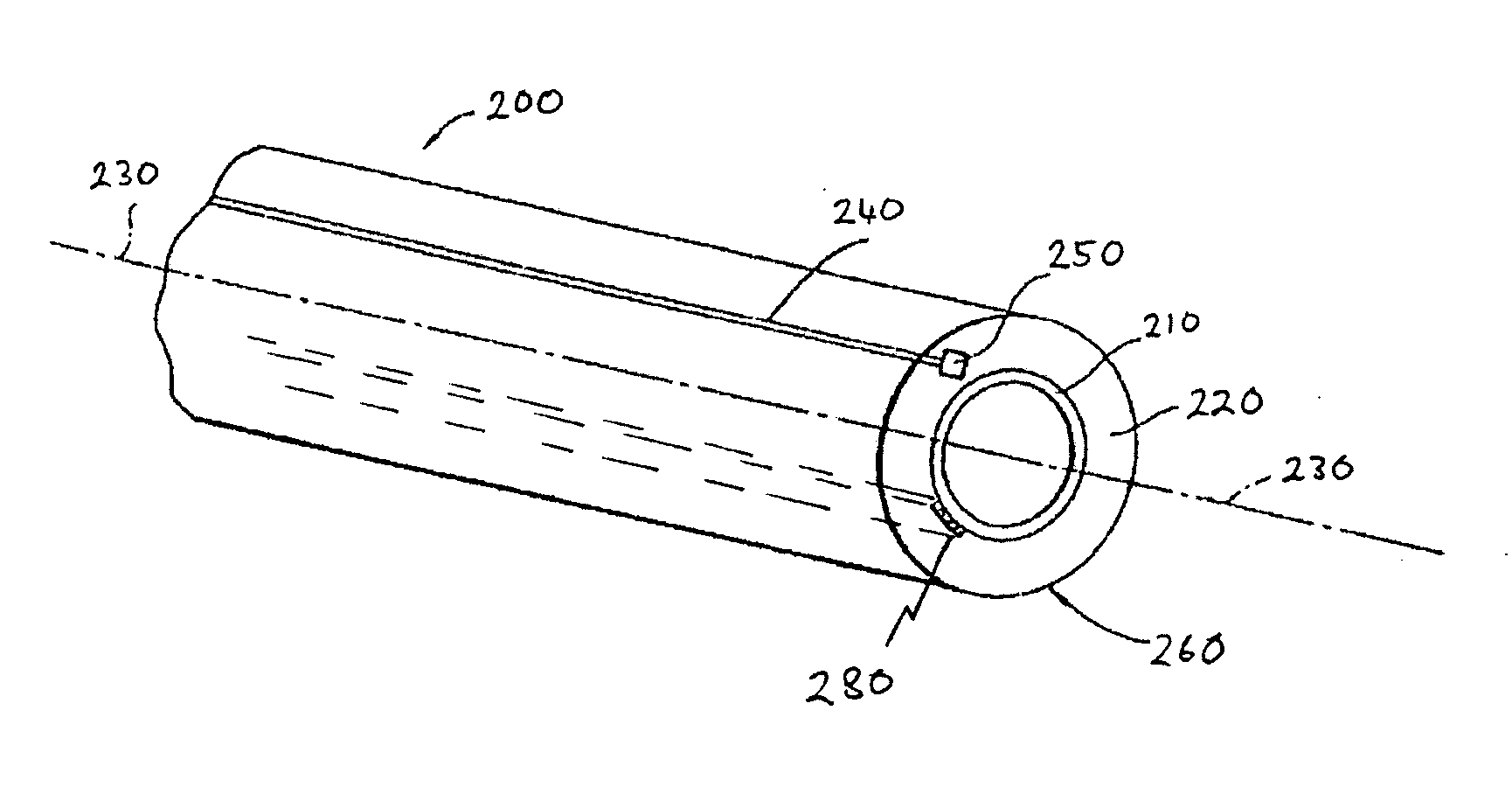

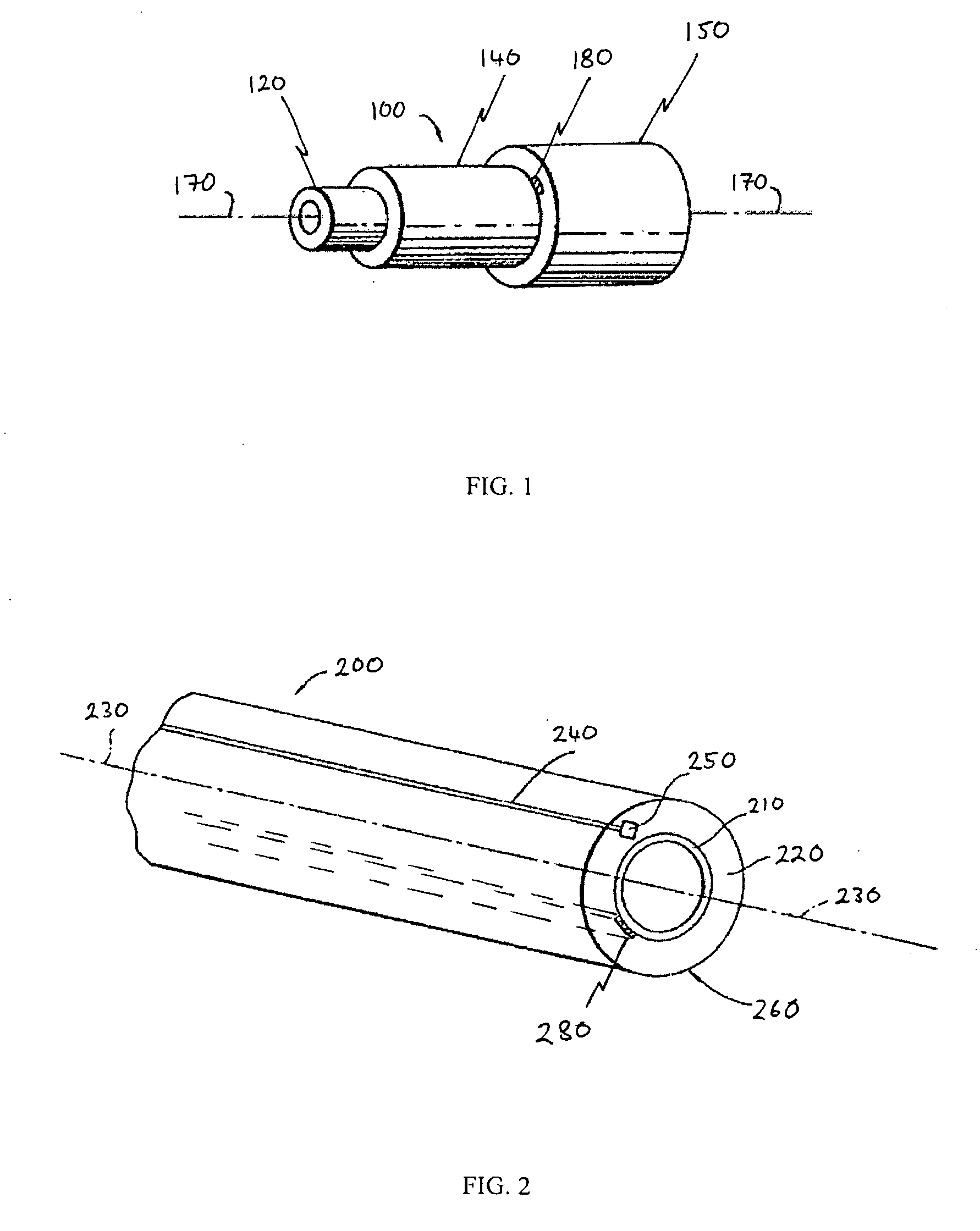

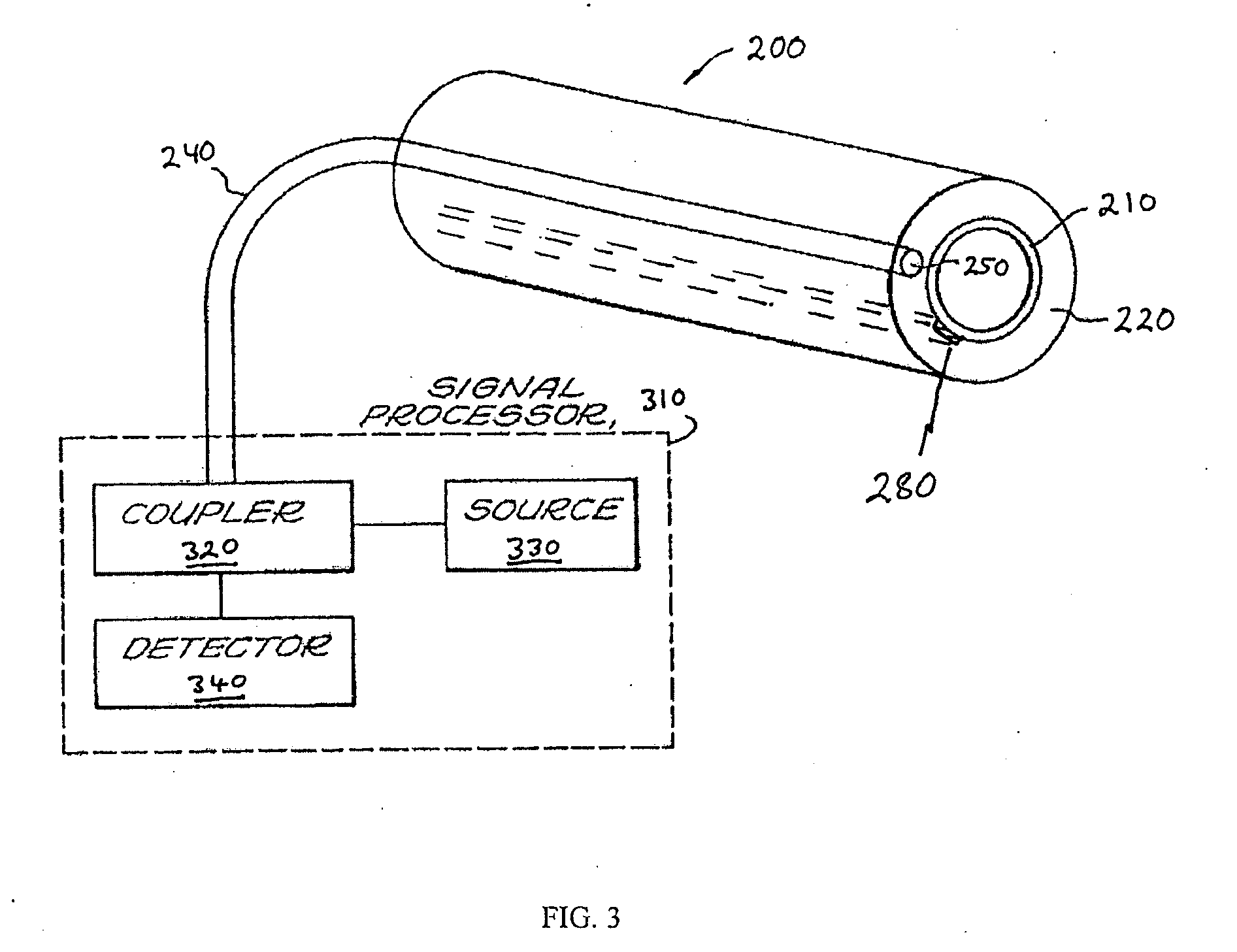

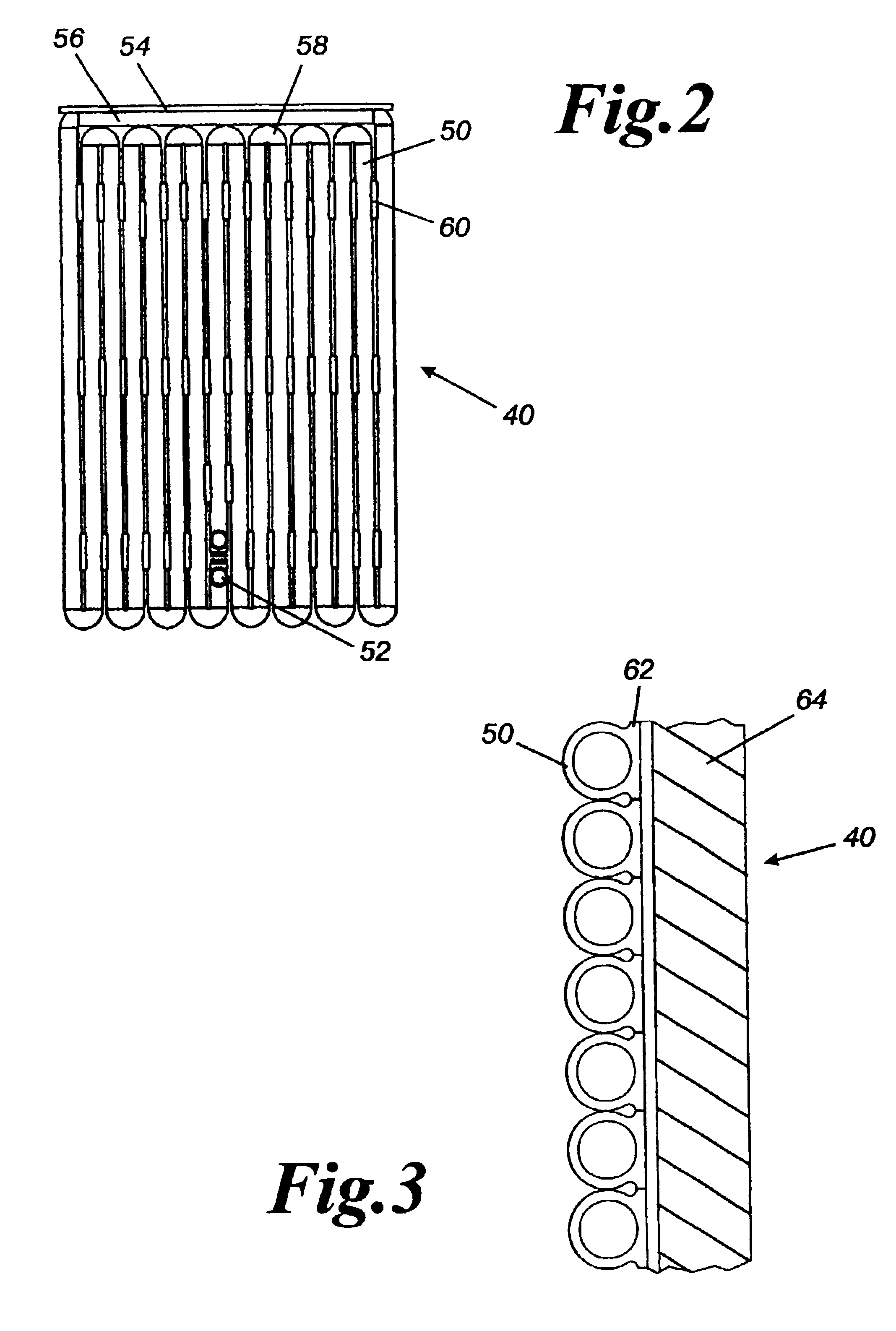

Heated pipe and methods of transporting viscous fluid

InactiveUS20090107558A1Good erosion barrierImprove thermal performanceValve members for heating/coolingHollow article cleaningFiberInsulation layer

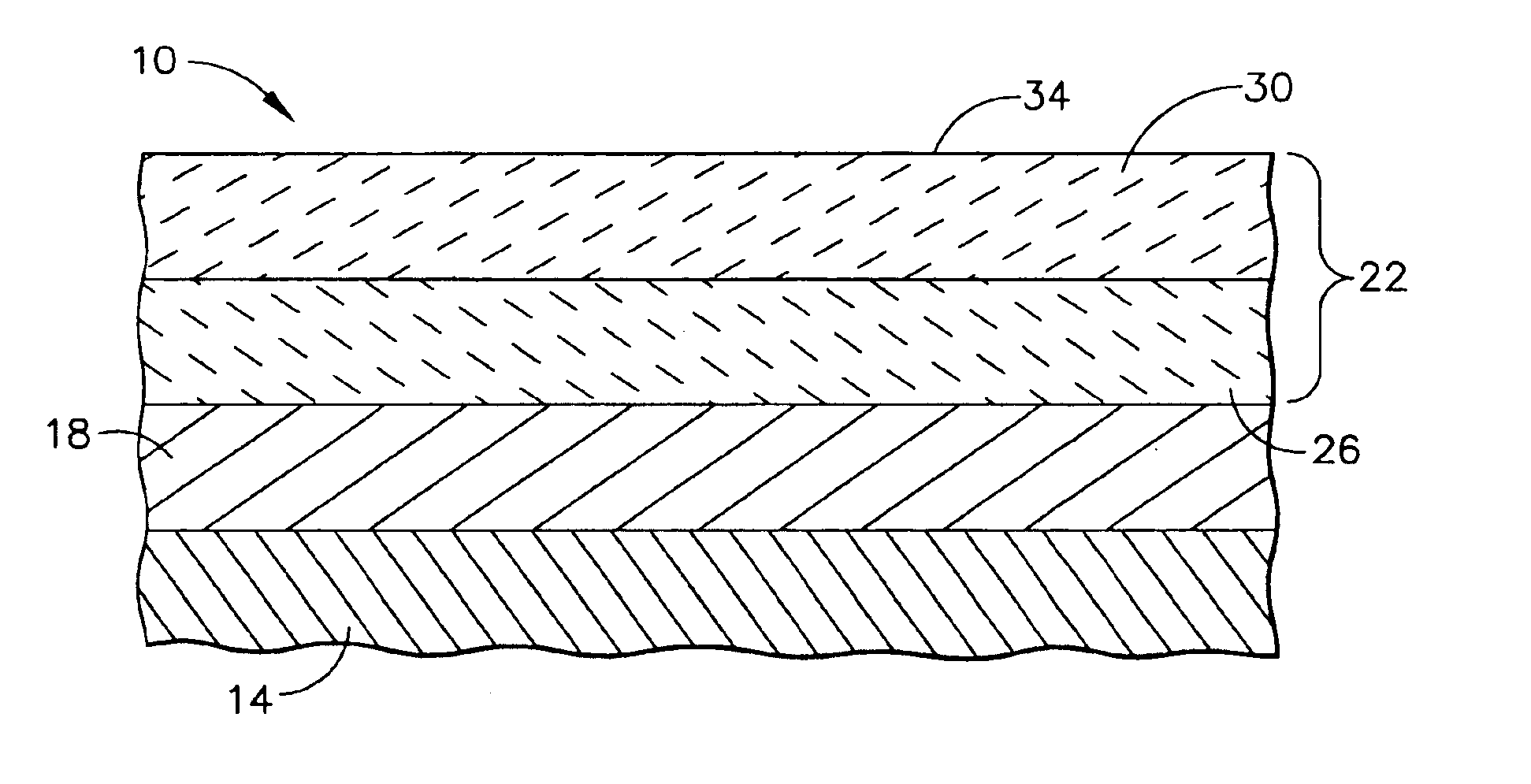

The invention includes systems and methods for heating a fluid and transporting the fluid at an elevated temperature. The system includes a fiber reinforced spoolable pipe. This spoolable pipe may include an inner layer, at least one reinforcing layer, at least one heating element, and at least one insulation layer. The heating element may be located external to the inner layer. The invention also includes methods of deploying and rehabilitating a spoolable pipe for transporting a fluid at elevated temperature.

Owner:FIBERSPAR

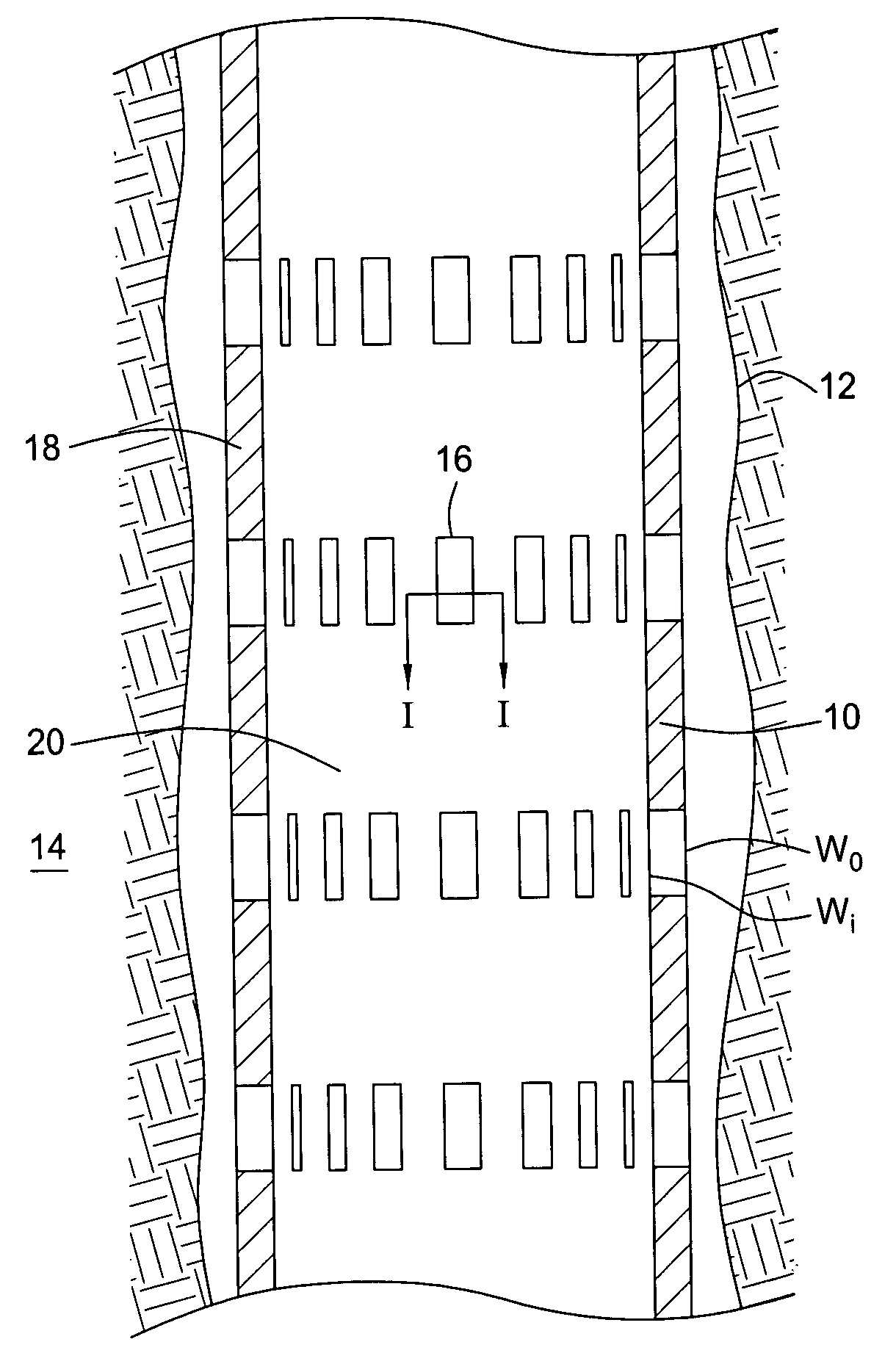

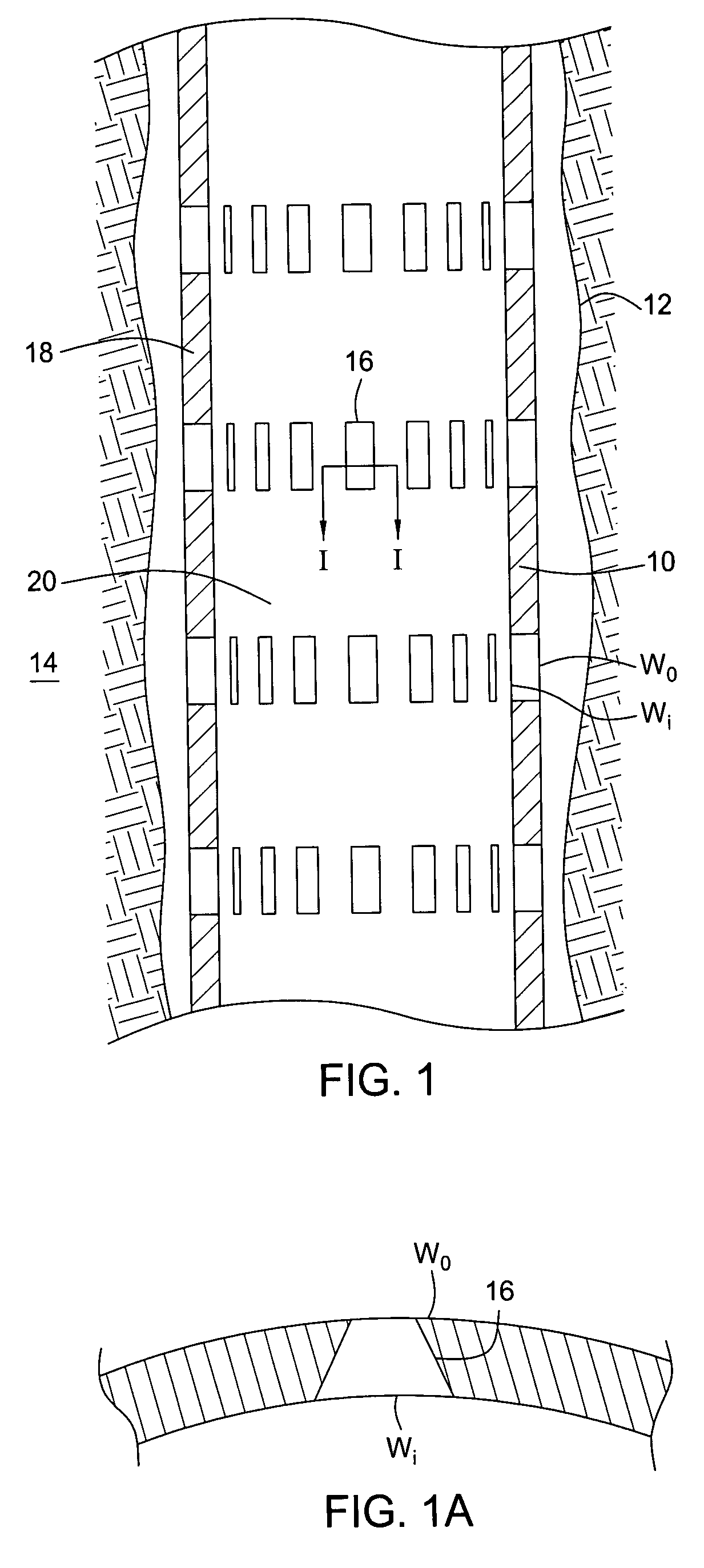

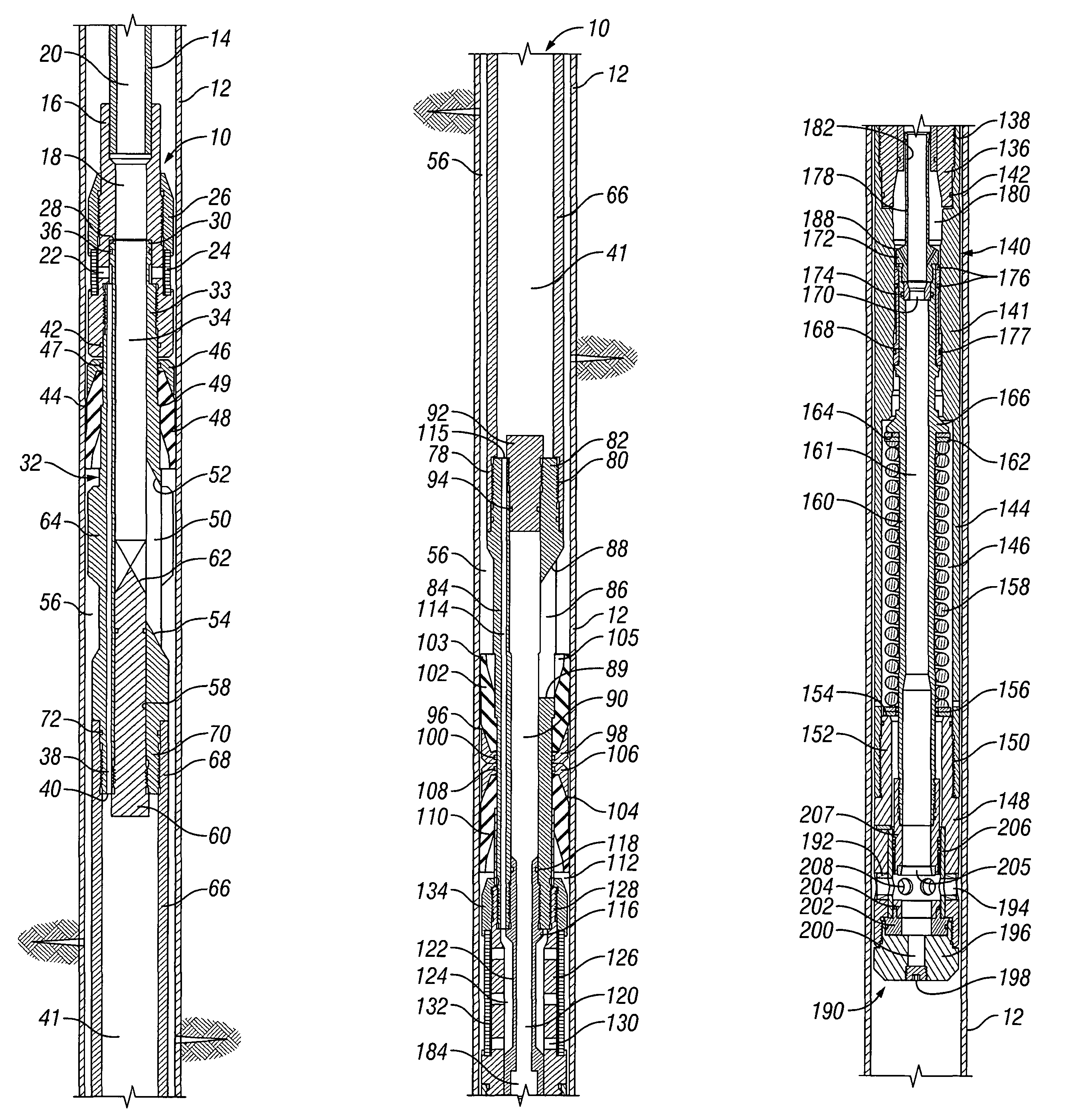

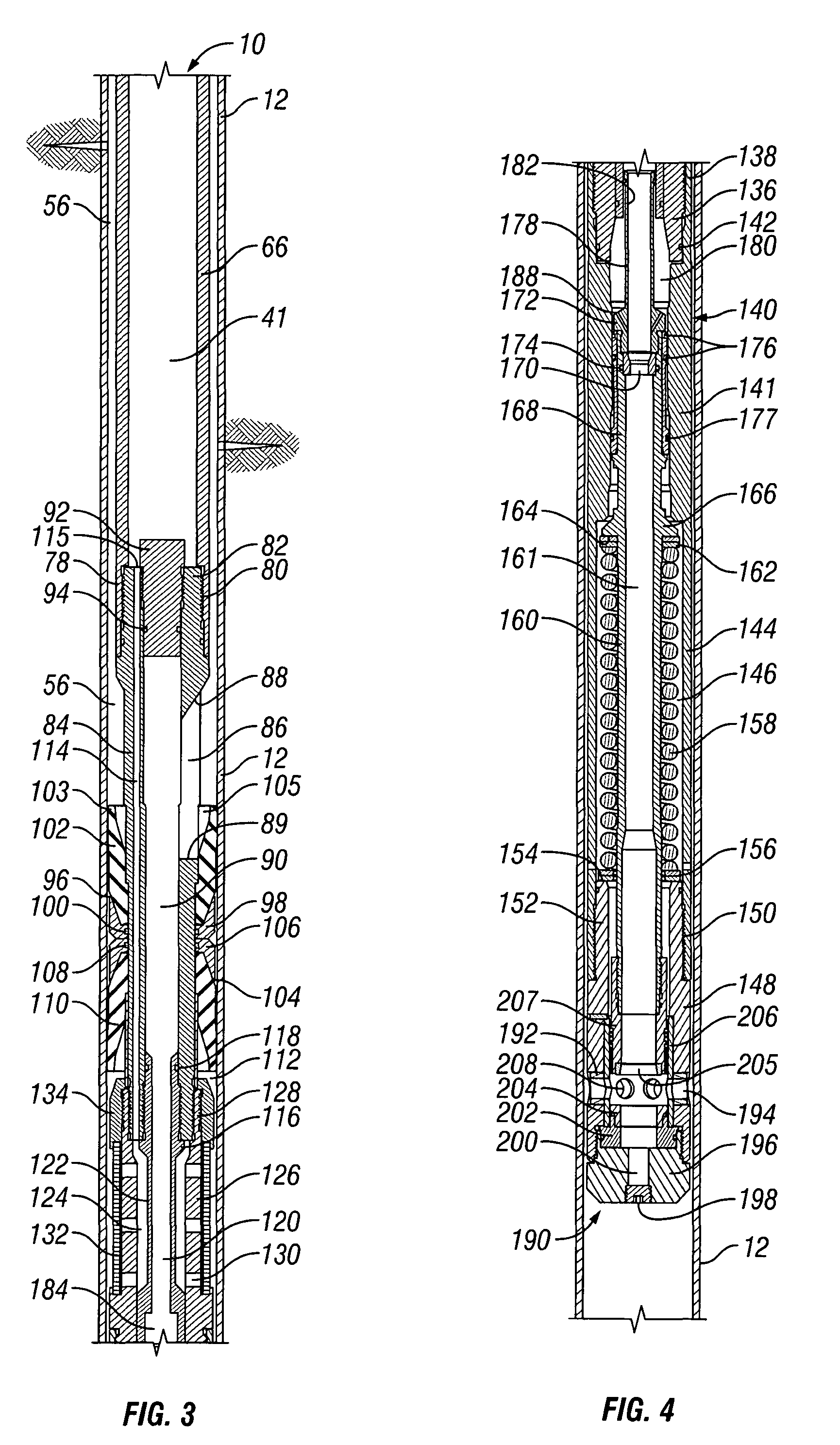

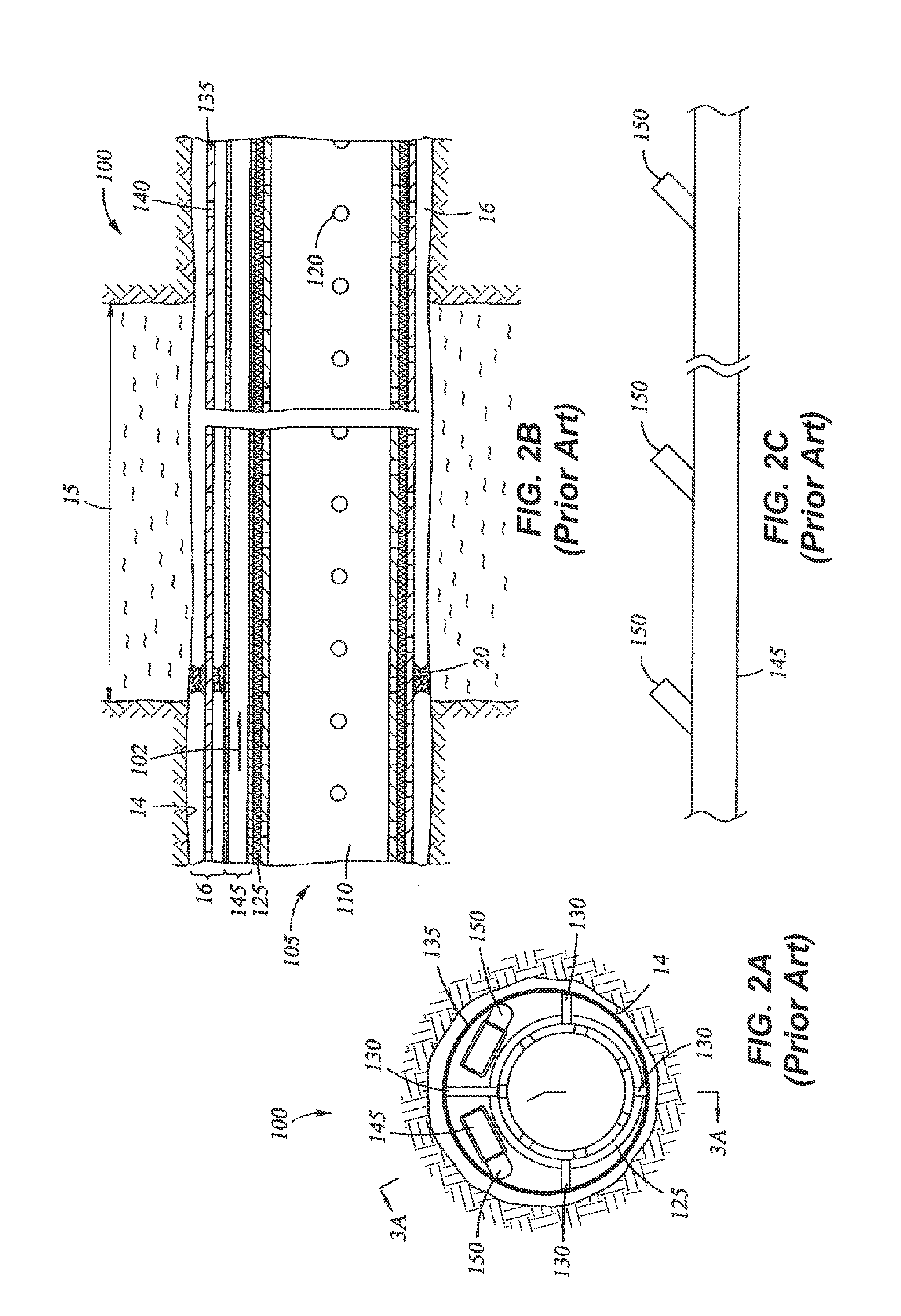

Downhole filter

InactiveUS7188687B2Without complexityWithout expenseDrilling rodsConstructionsParticulatesEngineering

A downhole filter comprises a tubular member having a wall defining a plurality of openings. The openings have an outer width less than an inner width. The parts of the opening defining the smaller width are defined by radially outer parts of the openings, such that particulates or sand prevented from passing through the openings will tend to be retained to the outside of the tubular member. A method comprises providing a tubular string having a non-porous tubular portion and a porous tubular portion, and installing the tubular string within a wellbore such that the porous tubular portion is located adjacent a fluid-producing formation within the wellbore. In another embodiment, an apparatus comprises a drill string comprising a non-porous tubular portion and a porous tubular portion, and an earth removal member operatively connected to a lower end of the drill string.

Owner:WEATHERFORD TECH HLDG LLC

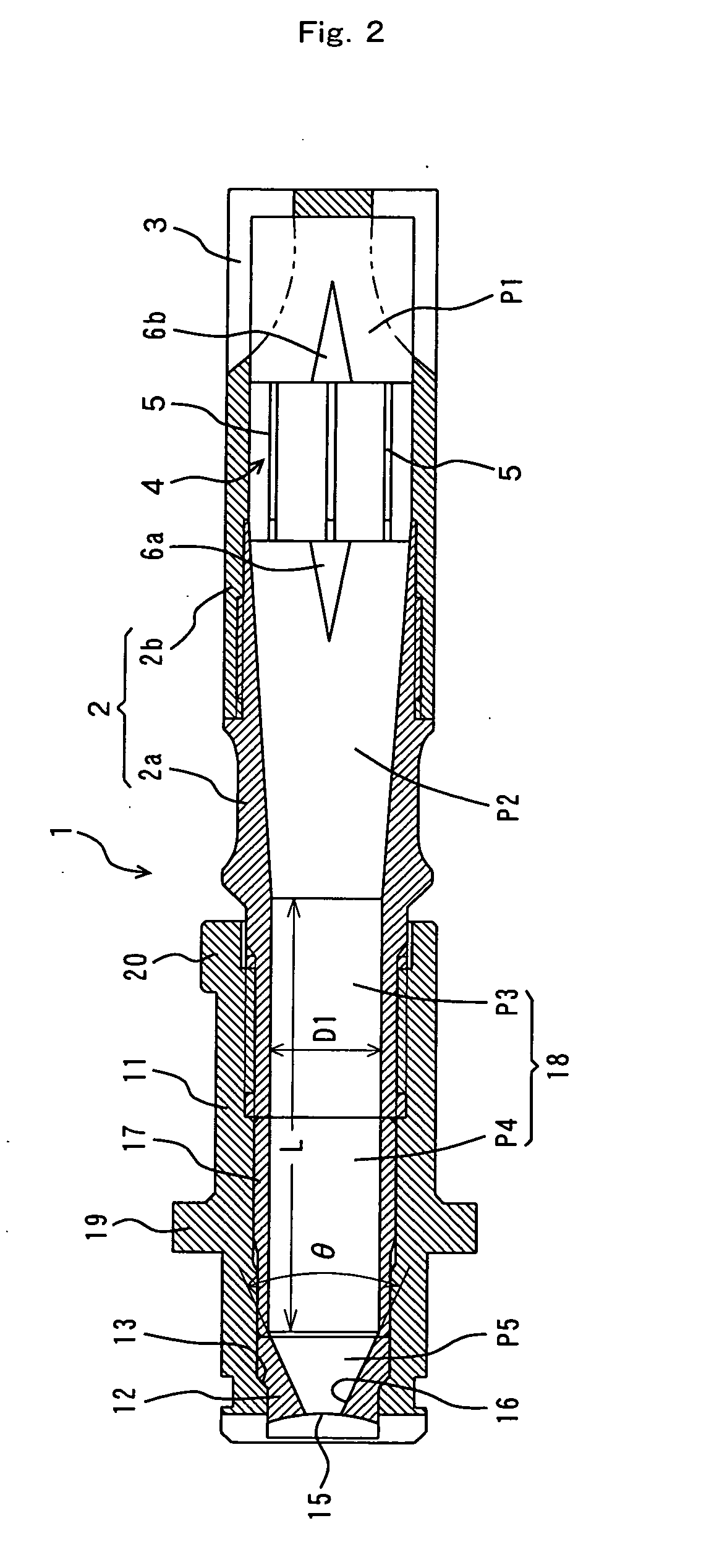

Descaling nozzle

ActiveUS20050156064A1Improve descaling efficiencyIncrease forceSpray nozzlesWork treatment devicesEngineeringErosion

A nozzle orifice of a nozzle 1 comprises a tapered segment 16 extending from an elliptical discharge orifice 15 and having a taper angle θ of 30 to 80°, and a large-diameter segment 18 continuing with the tapered segment, and scale on a steel plate is removed by discharging water from the nozzle at a distance between discharge orifice 15 and the steel plate of not more than 600 mm, a pressure of 5 to 30 MPa, and a discharge flow rate of 40 to 200 l / minute. The ratio of the inner diameter of large-diameter segment 18 relative to the minor diameter of the discharge orifice 15 is not less than 3 and less than 7. Also, the discharge flow from the nozzle spreads in a single direction (width direction) within a plane perpendicular to the central axis of the nozzle and the erosion thickness angle is 1.5 to 30 in the direction (thickness direction) perpendicular to the width direction. Such a descaling nozzle enables that scale is removed efficiently at low pressure and / or low flow rate while restraining the cooling of a steel plate.

Owner:KYORITSU GOKIN +1

Thermal barrier coatings with improved impact and erosion resistance

InactiveUS6869703B1Increase impactIncrease resistanceMolten spray coatingVacuum evaporation coatingPorosityBond coat

A reduced thermal conductivity thermal barrier coating having improved impact and erosion resistance for an underlying metal substrate of articles that operate at, or are exposed to, high temperatures. This coating comprises a zirconia-containing ceramic composition having a c / a ratio in the range of from about 1.0117 to about 1.0148 and stabilized in the tetragonal phase by a stabilizing amount of a stabilizer metal oxide. The coating has a fraction of porosity of from about 0.10 to about 0.25, and an impact and erosion resistance property defined by at least one of the following formulas: (a) I=exp.[5.85−(144×s)−(3.68×p)]; and / or; (b) E=[187−(261×p)−(9989×s)], wherein s=1.0117−c / a ratio; p is the fraction of porosity; I is least about 140 g / mil; and E is least about 130 g / mil. This coating can be used to provide a thermally protected article having a metal substrate and optionally a bond coat layer adjacent to and overlaying the metal substrate. The thermal barrier coating can be prepared by depositing the zirconia-containing ceramic composition on the bond coat layer, or the metal substrate in the absence of the bond coat layer.

Owner:GENERAL ELECTRIC CO

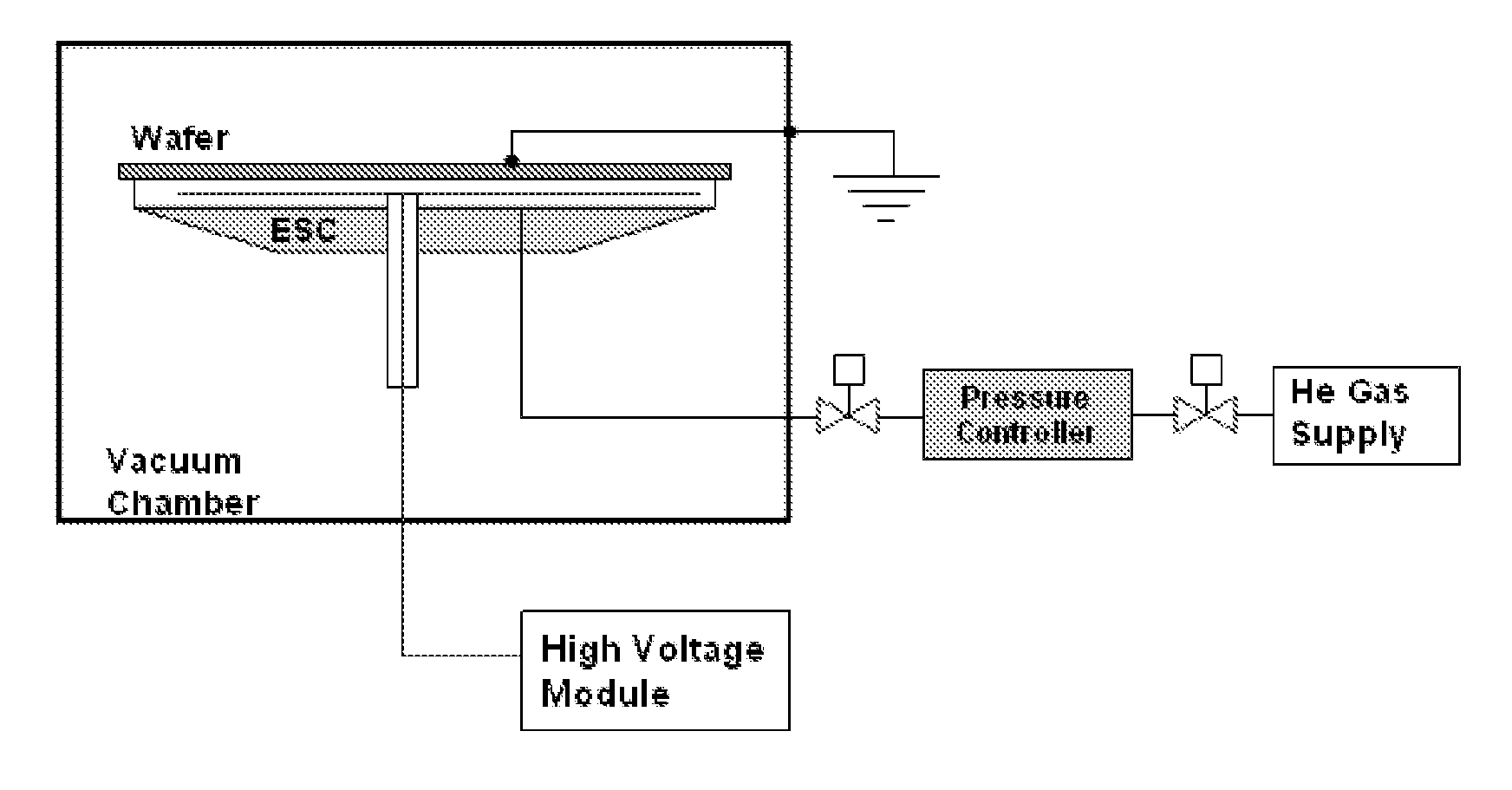

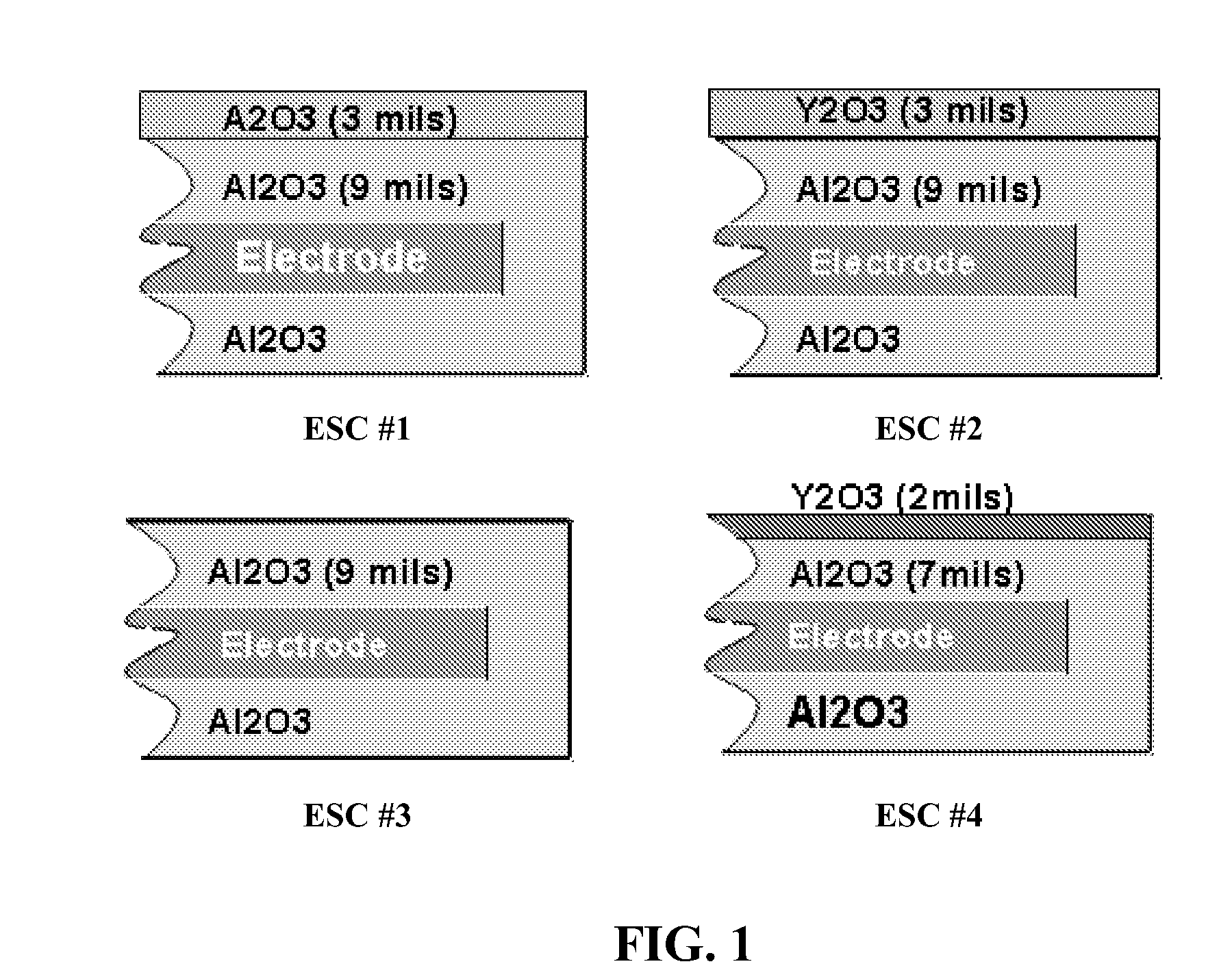

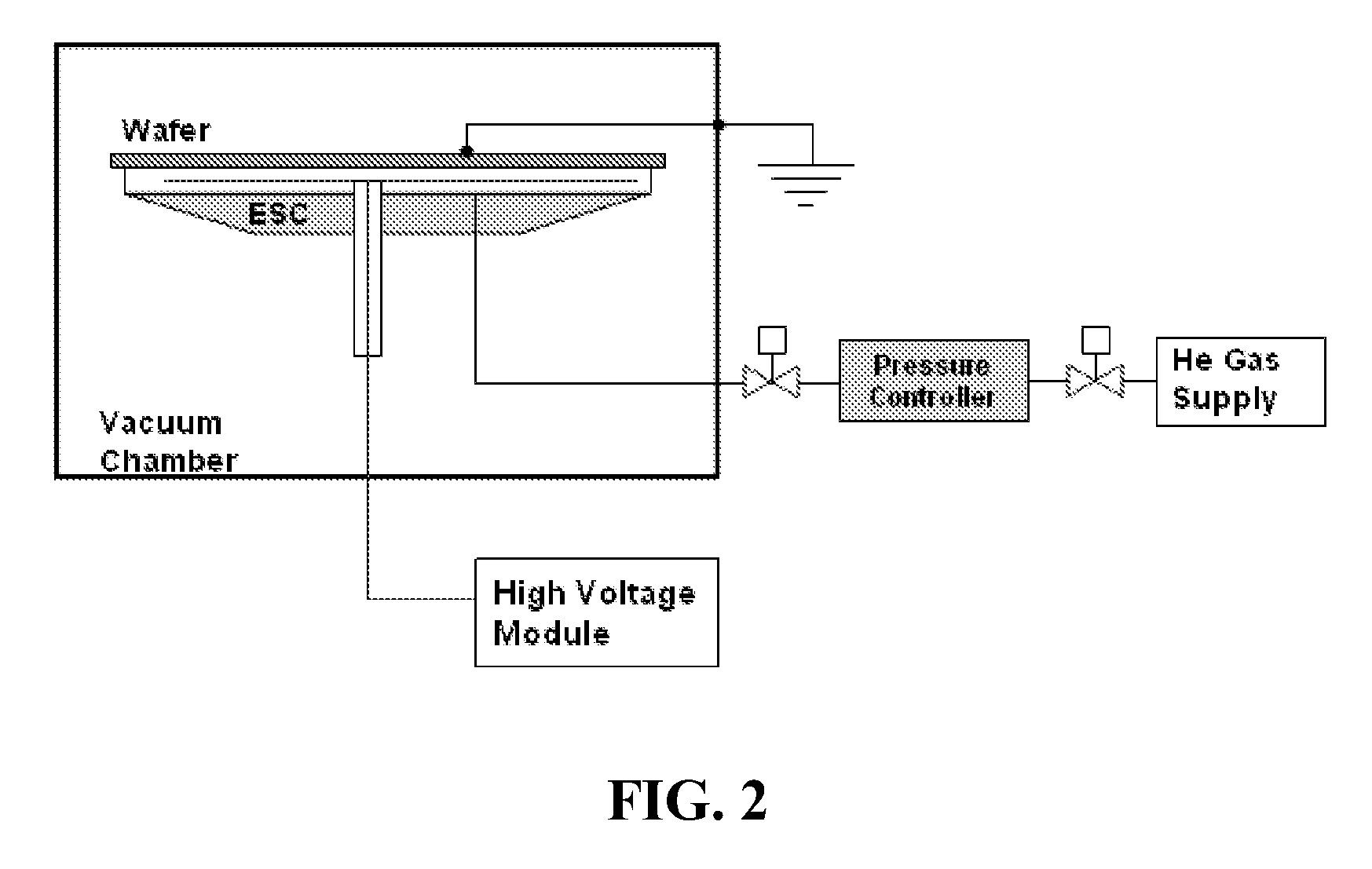

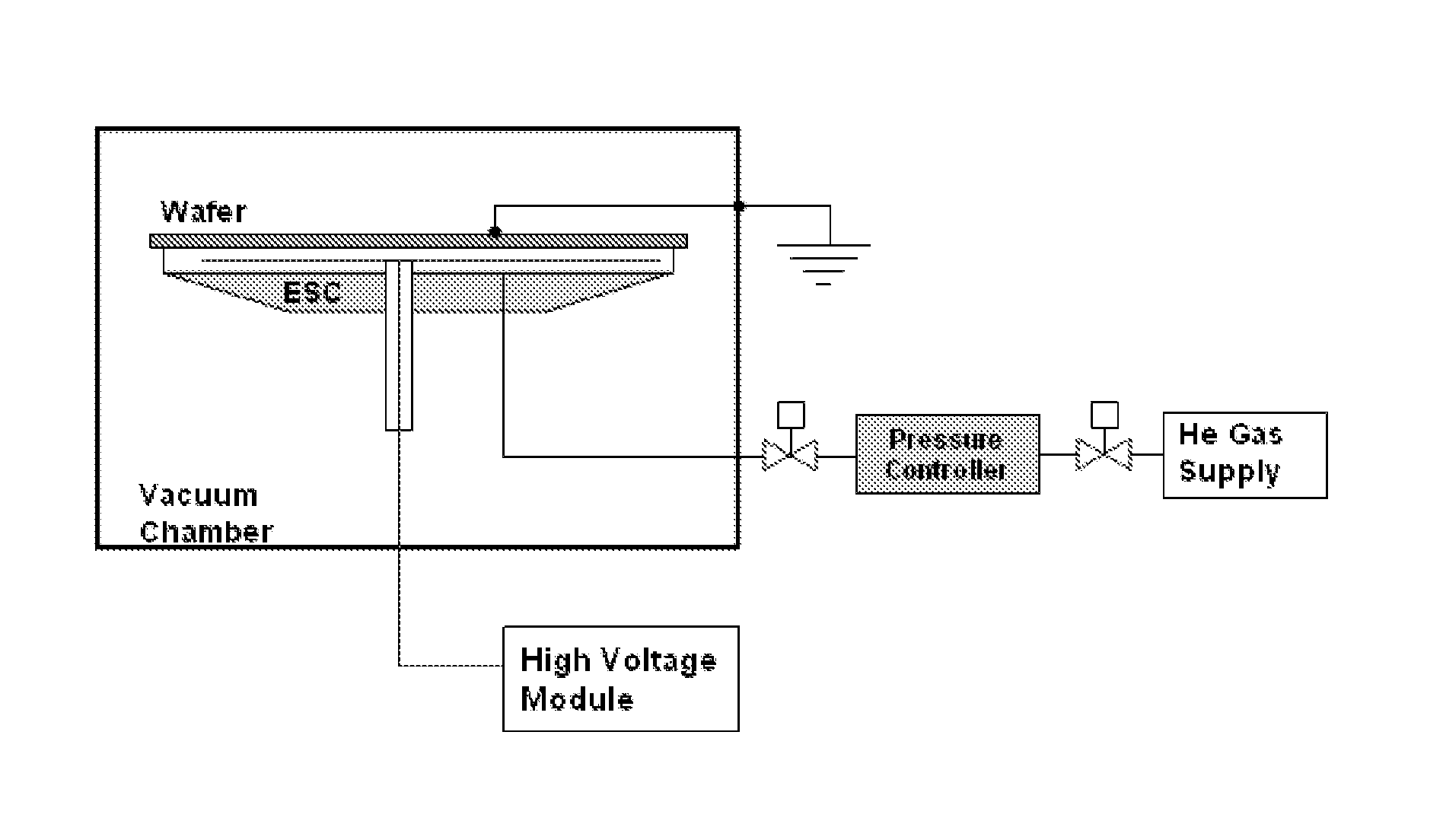

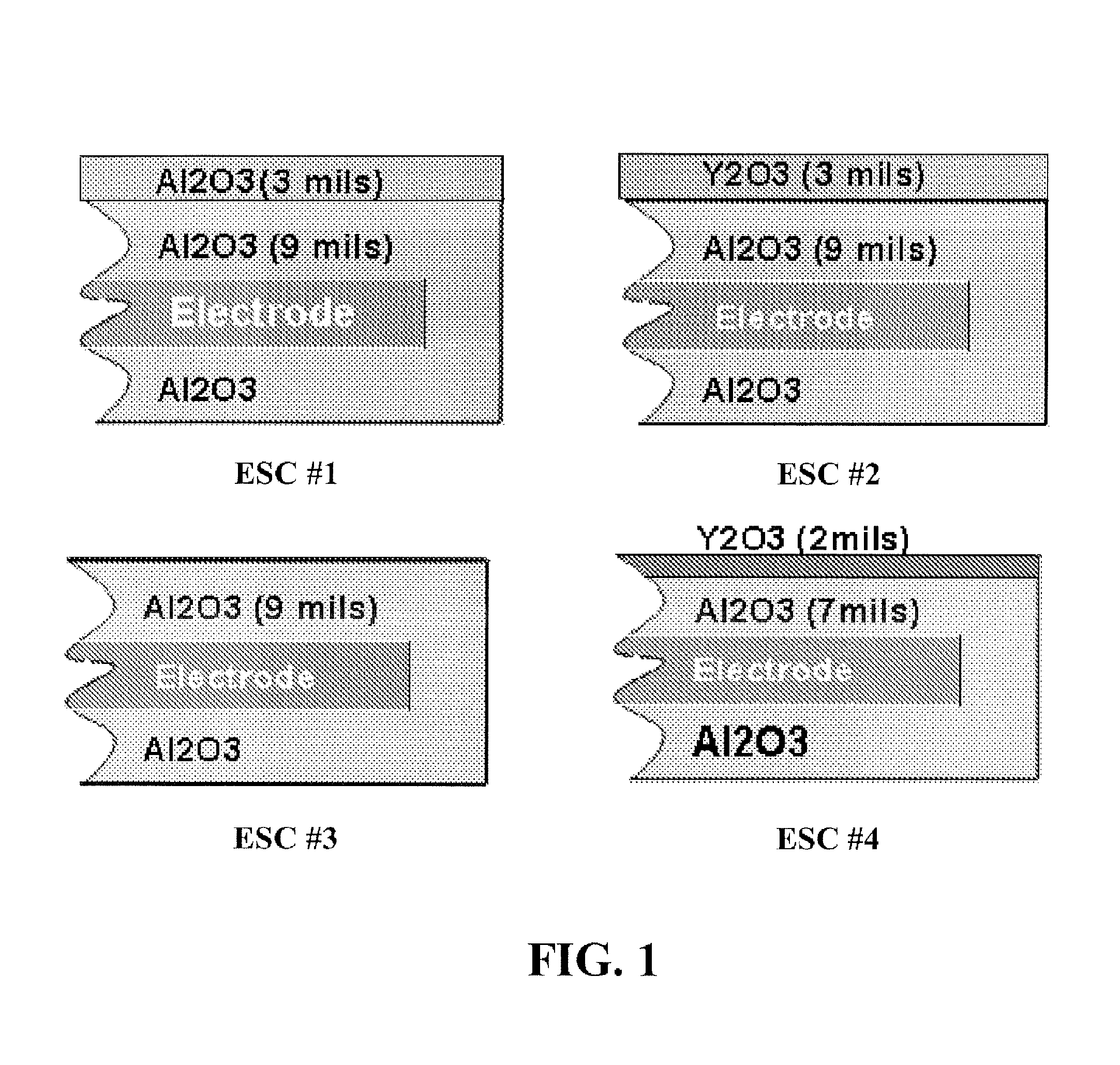

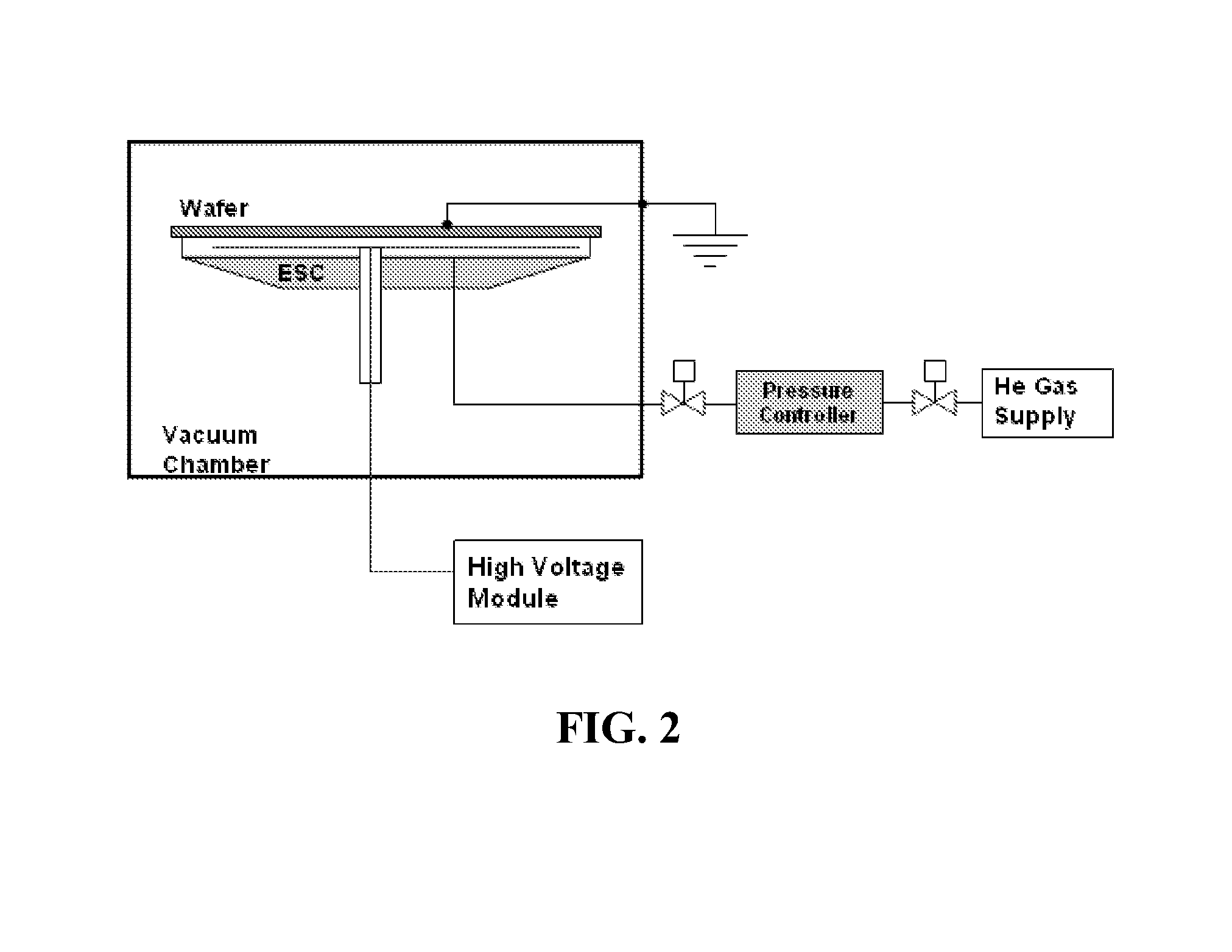

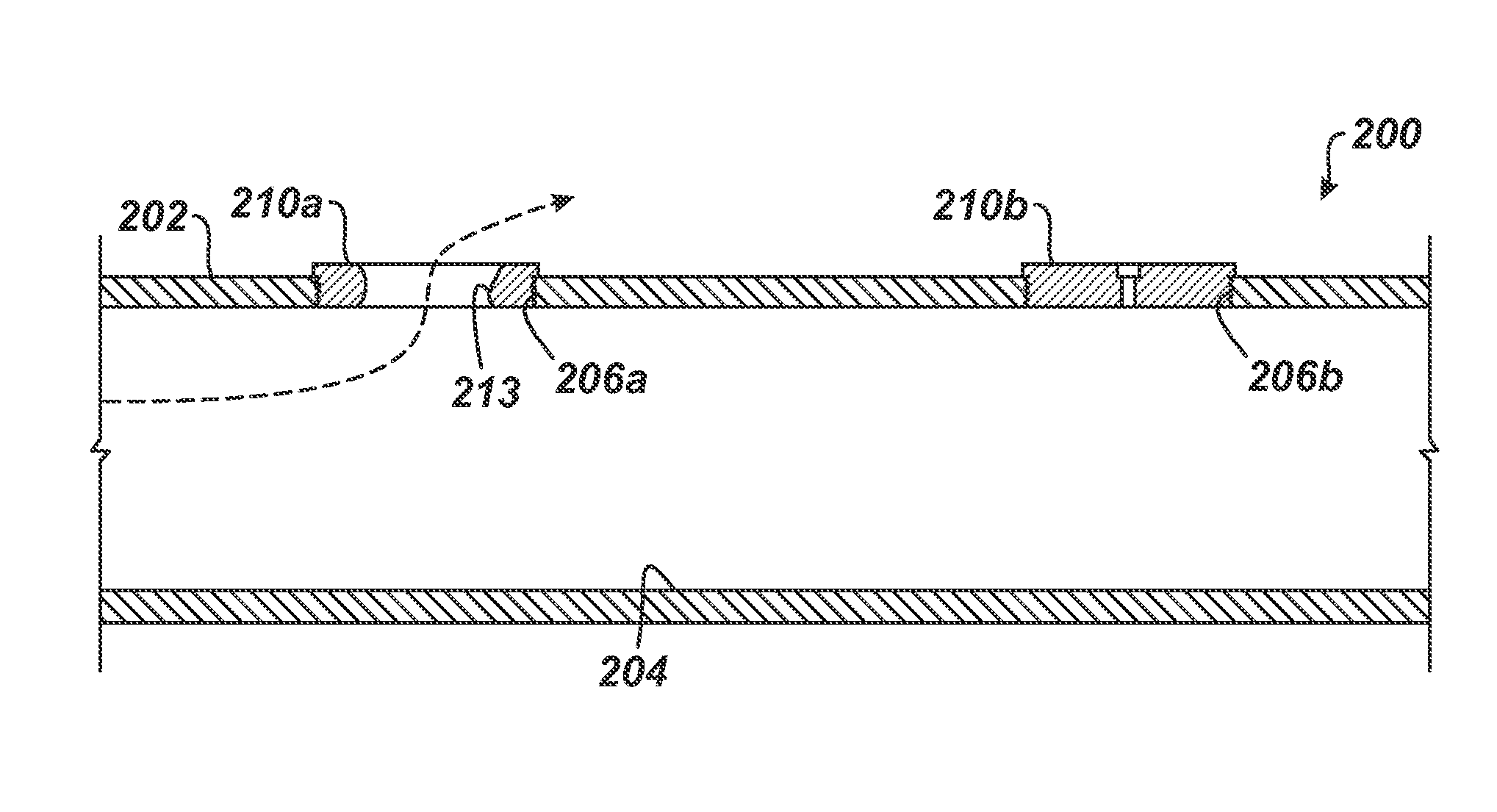

Substrate supports for semiconductor applications

ActiveUS20120141661A1Enhance attractive and chuck forceMinimize currentSemiconductor/solid-state device manufacturingCoatingsCorrosionOxide

This invention relates to substrate supports, e.g., coated electrostatic chucks, having a dielectric multilayer formed thereon; dielectric multilayers that provide erosive and corrosive barrier protection in harsh environments such as plasma treating vessels used in semiconductor device manufacture; process chambers, e.g., deposition chambers, for processing substrates; methods for protecting substrate supports; and methods for producing substrate supports and electronic devices. The dielectric multilayer comprises (a) an undercoat dielectric layer comprising a metal oxide or metal nitride formed on a surface; and (b) a topcoat dielectric layer comprising a metal oxide formed on the undercoat dielectric layer. The topcoat dielectric layer has an aluminum oxide content of less than about 1 weight percent. The topcoat dielectric layer has a corrosion resistance and / or plasma erosion resistance greater than the corrosion resistance and / or plasma erosion resistance of the undercoat dielectric layer. The undercoat dielectric layer can have a resistivity greater than the resistivity of the topcoat dielectric layer. The topcoat dielectric layer can have a dielectric constant greater than the dielectric constant of the undercoat dielectric layer. The undercoat dielectric layer can have a porosity greater than the porosity of the topcoat dielectric layer. The invention is useful, for example, in the manufacture and protection of electrostatic chucks used in semiconductor device manufacture.

Owner:FM INDS

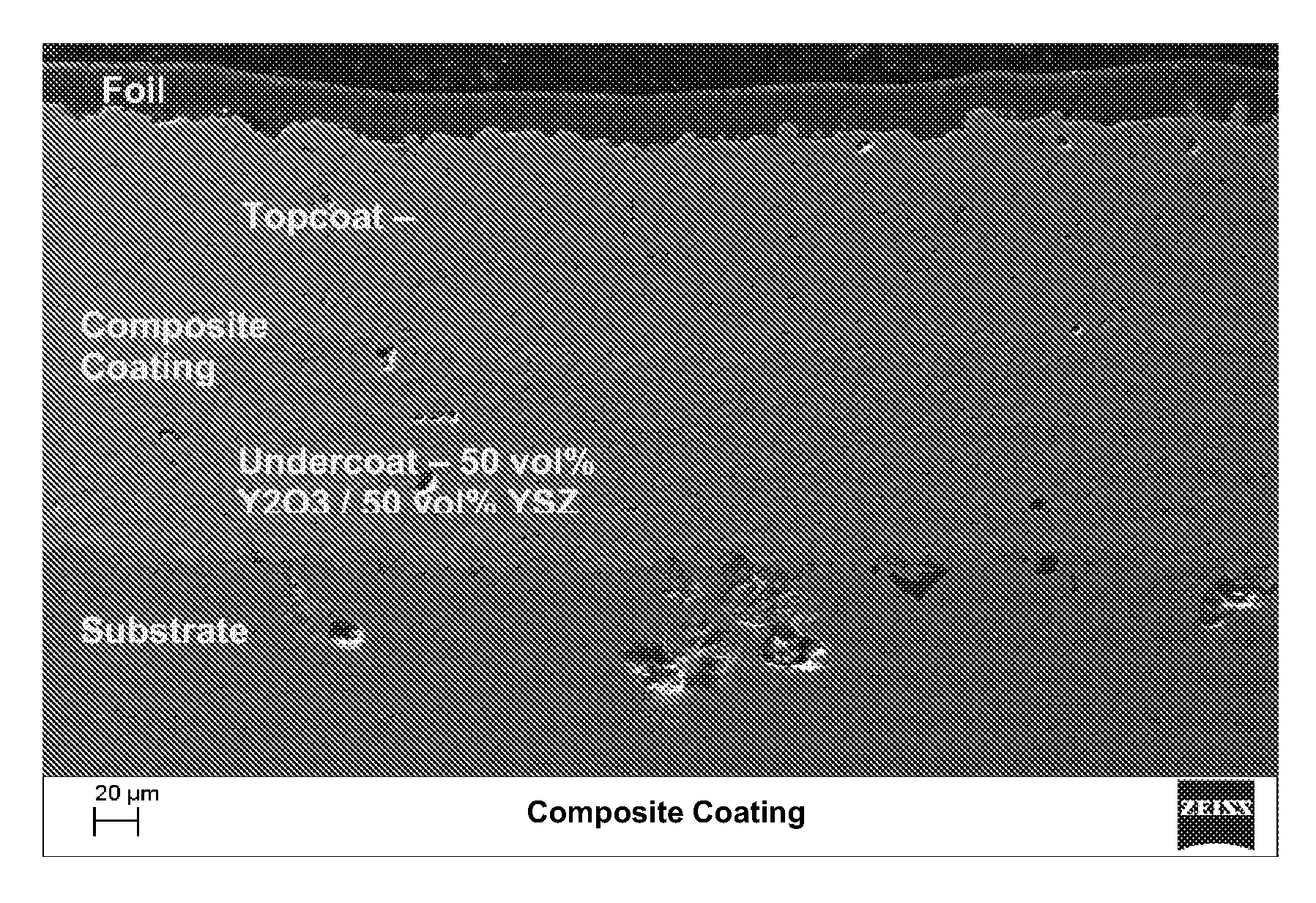

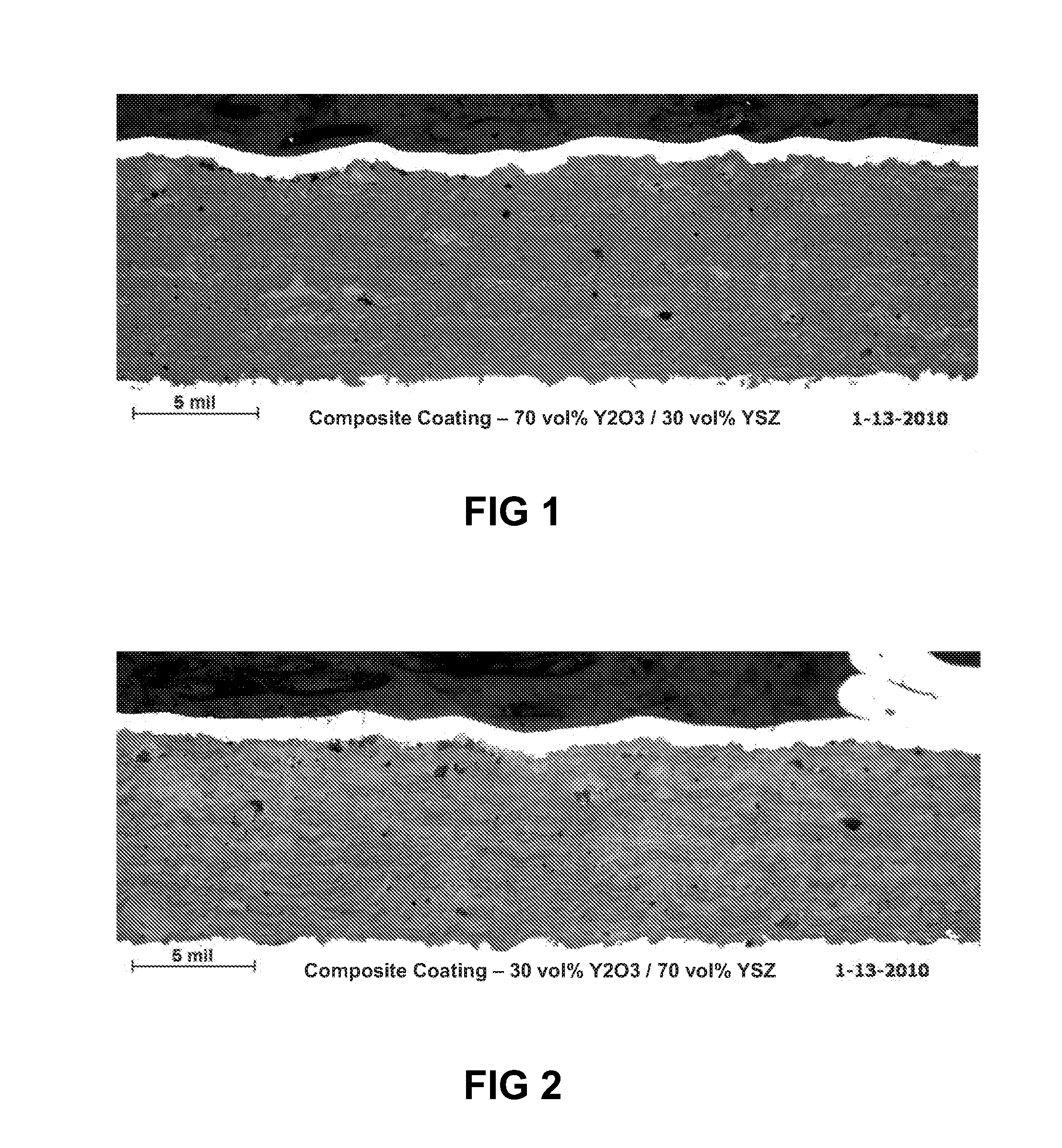

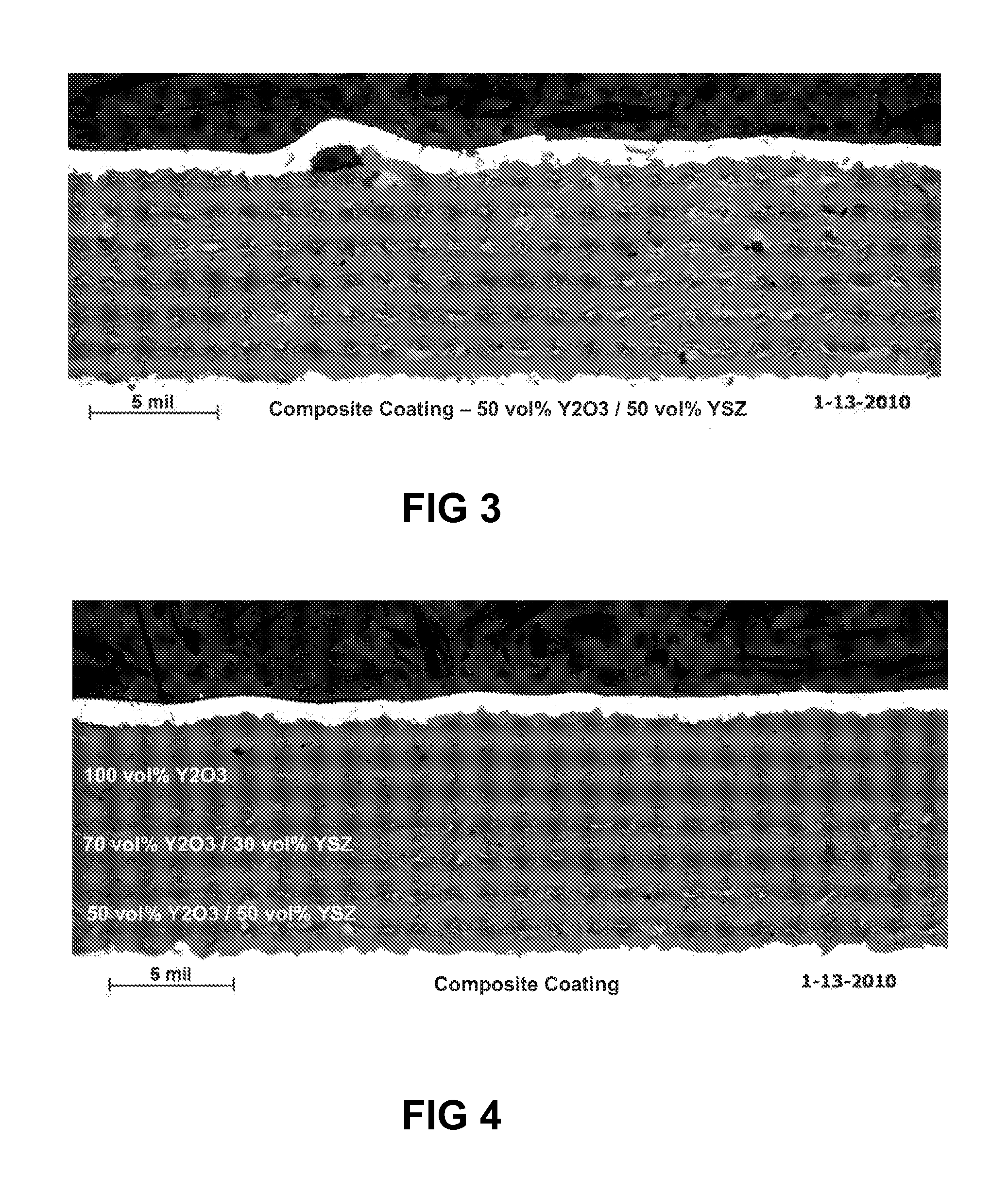

Thermal spray composite coatings for semiconductor applications

InactiveUS20120196139A1Improved erosion and corrosion resistantLower Level RequirementsLiquid surface applicatorsMolten spray coatingThermal sprayingCeramic composite

This invention relates to thermal spray composite coatings on a metal or non-metal substrate. The thermal spray composite coatings comprise (i) a ceramic composite coating undercoat layer having at least two ceramic material phases randomly and uniformly dispersed and / or spatially oriented throughout the ceramic composite coating, and (ii) a ceramic coating topcoat layer applied to the undercoat layer. At least a first ceramic material phase is present in the undercoat layer in an amount sufficient to provide corrosion resistance to the ceramic composite coating, and at least a second ceramic material phase is present in the undercoat layer in an amount sufficient to provide plasma erosion resistance to the ceramic composite coating. This invention also relates to methods of protecting metal and non-metal substrates by applying the thermal spray coatings. The composite coatings provide erosion and corrosion resistance at processing temperatures higher than conventional processing temperatures used in the semiconductor etch industry, e.g., greater than 100° C. The coatings are useful, for example, in the protection of semiconductor manufacturing equipment, e.g., integrated circuit, light emitting diode, display, and photovoltaic, internal chamber components, and electrostatic chuck manufacture.

Owner:PRAXAIR ST TECH INC

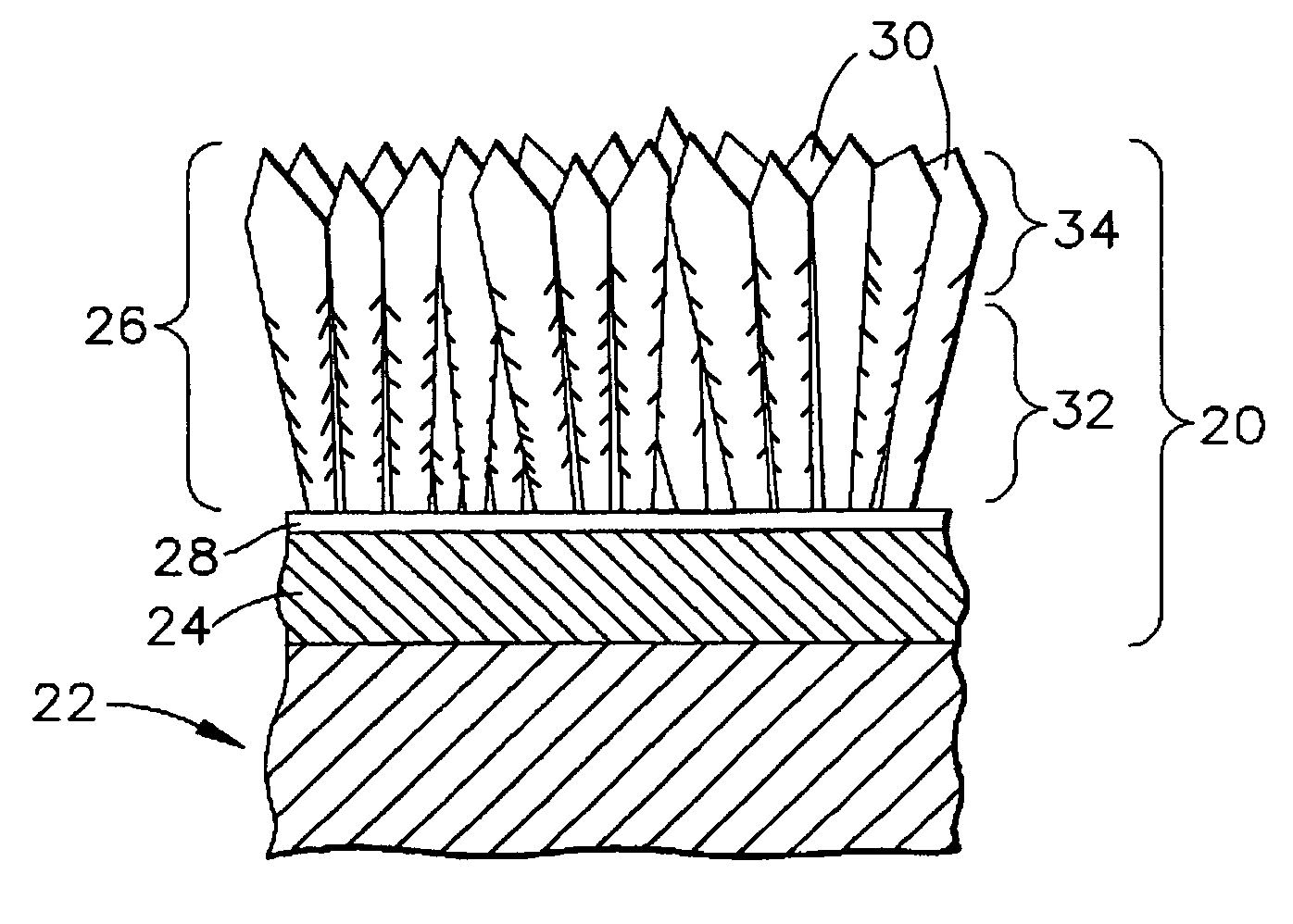

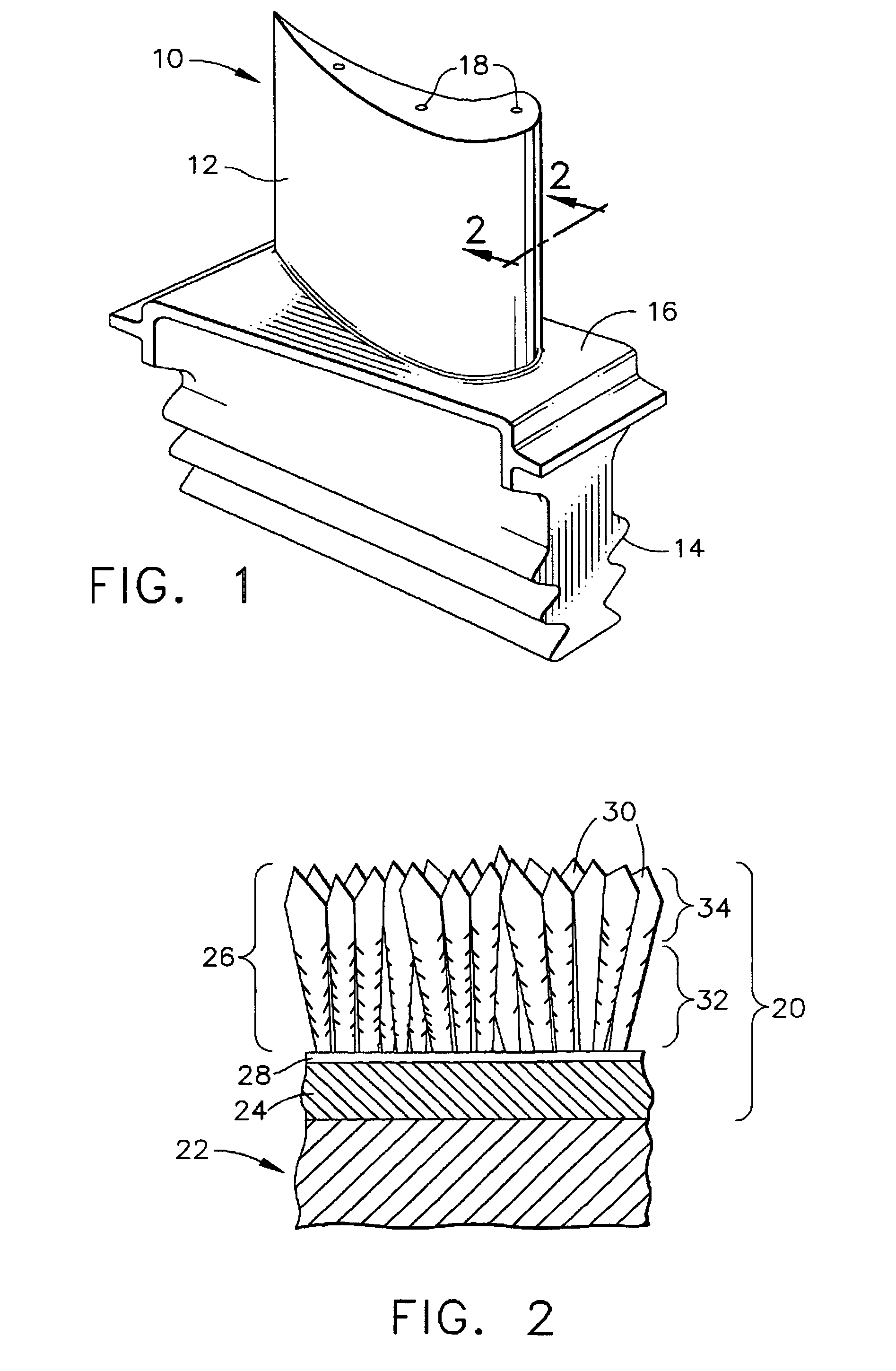

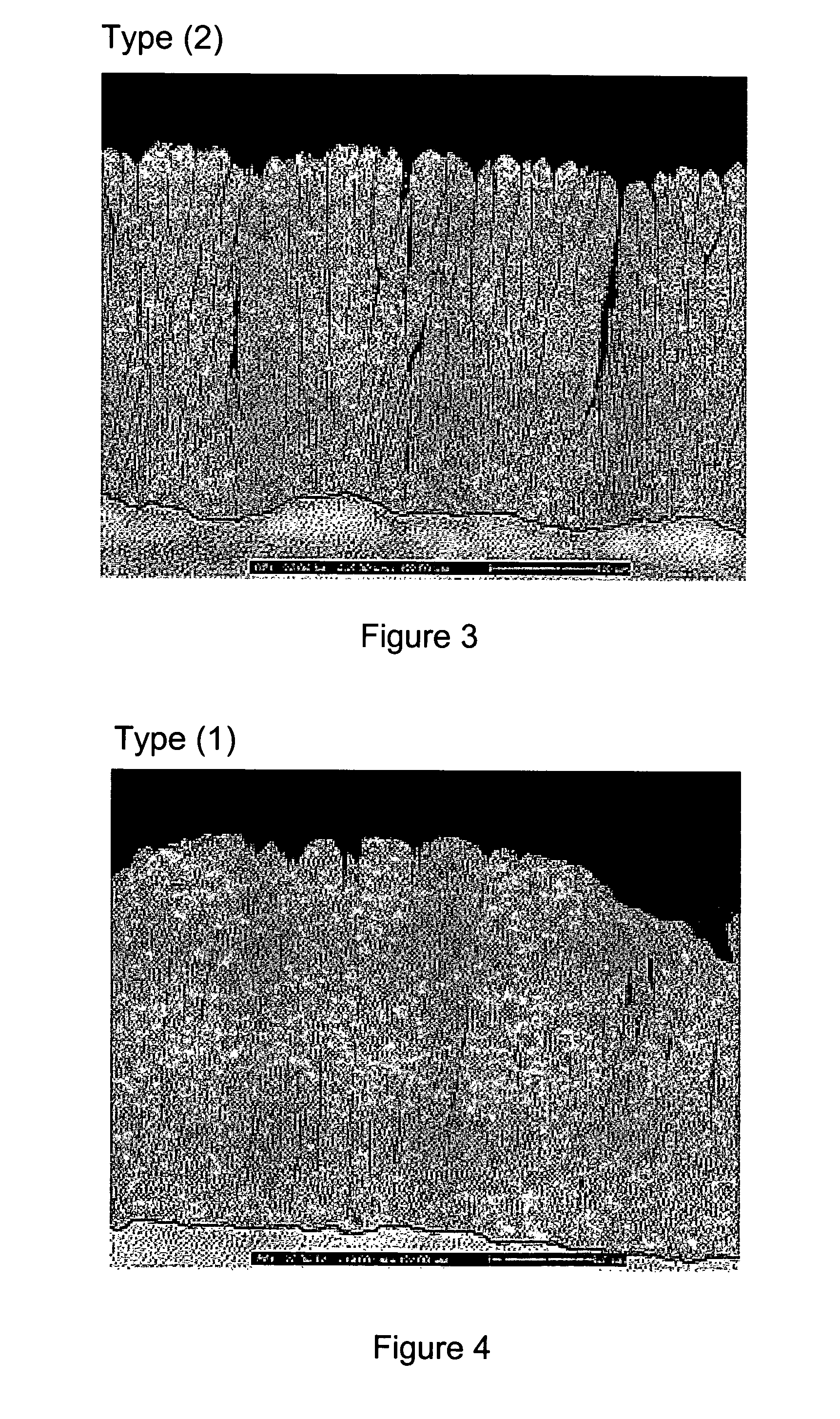

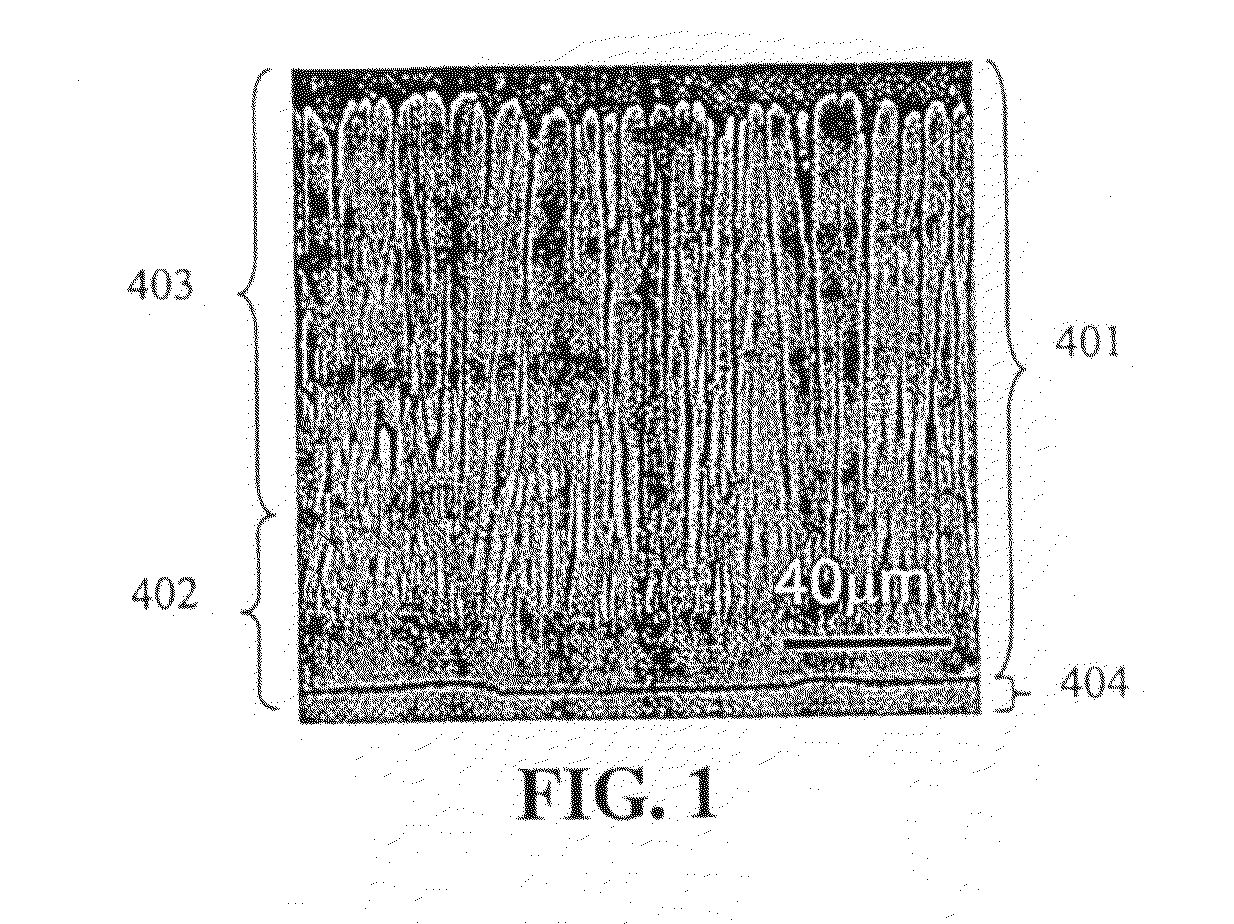

Thermal barrier coating

InactiveUS6982126B2Low thermal conductivityLess erosion-resistantPropellersVacuum evaporation coatingInterior designThermal barrier coating

A thermal barrier coating (TBC) for a component intended for use in a hostile thermal environment. The TBC has an interior region and an outer surface region on and contacting the interior region. Both regions are formed of a ceramic material, with the interior region having a lower thermal conductivity than zirconia partially stabilized by about seven weight percent yttria. The interior region constitutes more than half of the thickness of the TBC, and the outer surface region constitutes less than half of the thickness of the TBC. The TBC has a columnar microstructure whereby the interior region and the outer surface region comprise columns of their ceramic materials. The outer surface region is more erosion and impact resistant than the interior region at least in part as a result of the columns thereof being more closely spaced than the columns of the interior region.

Owner:GENERAL ELECTRIC CO

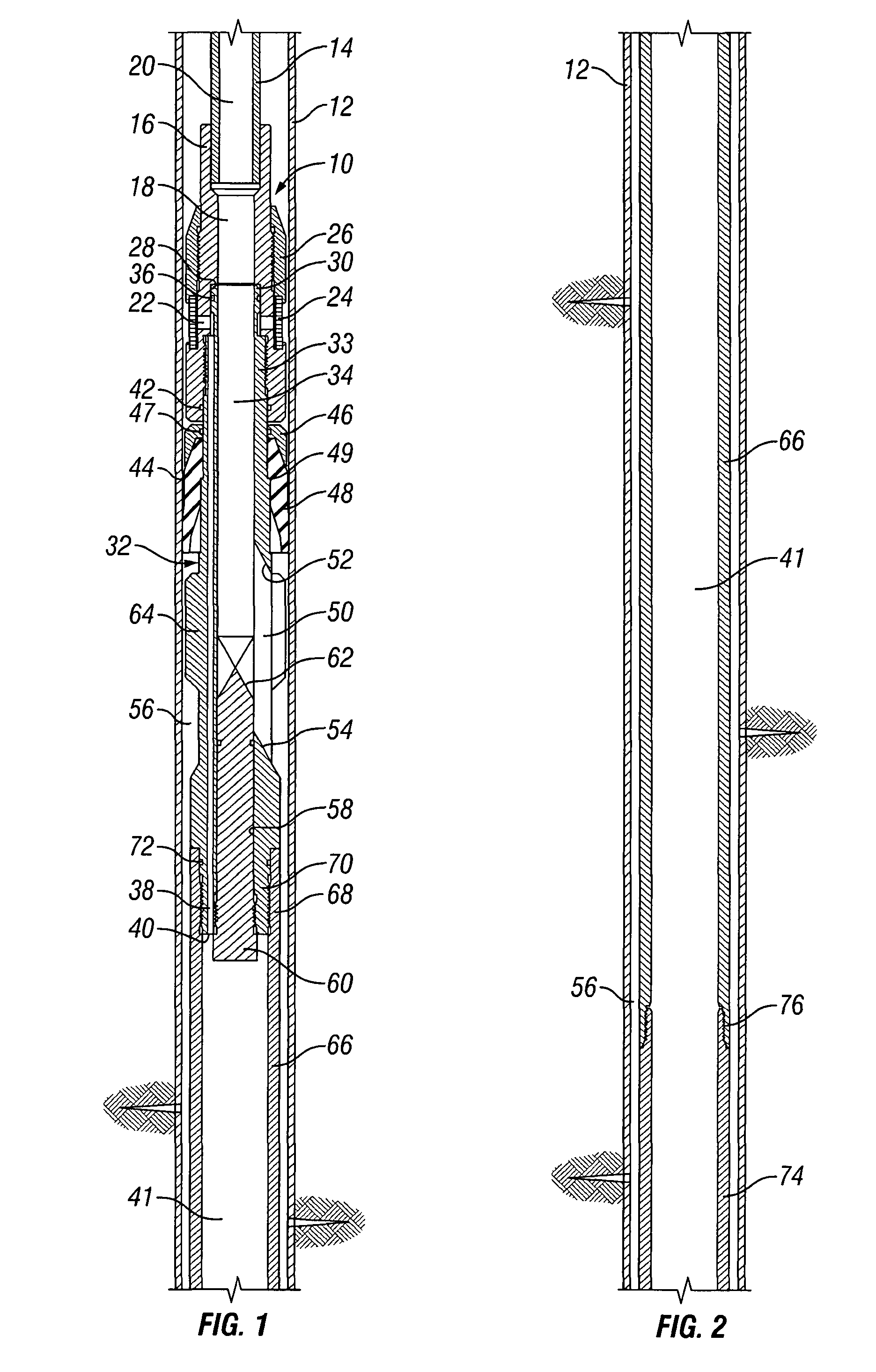

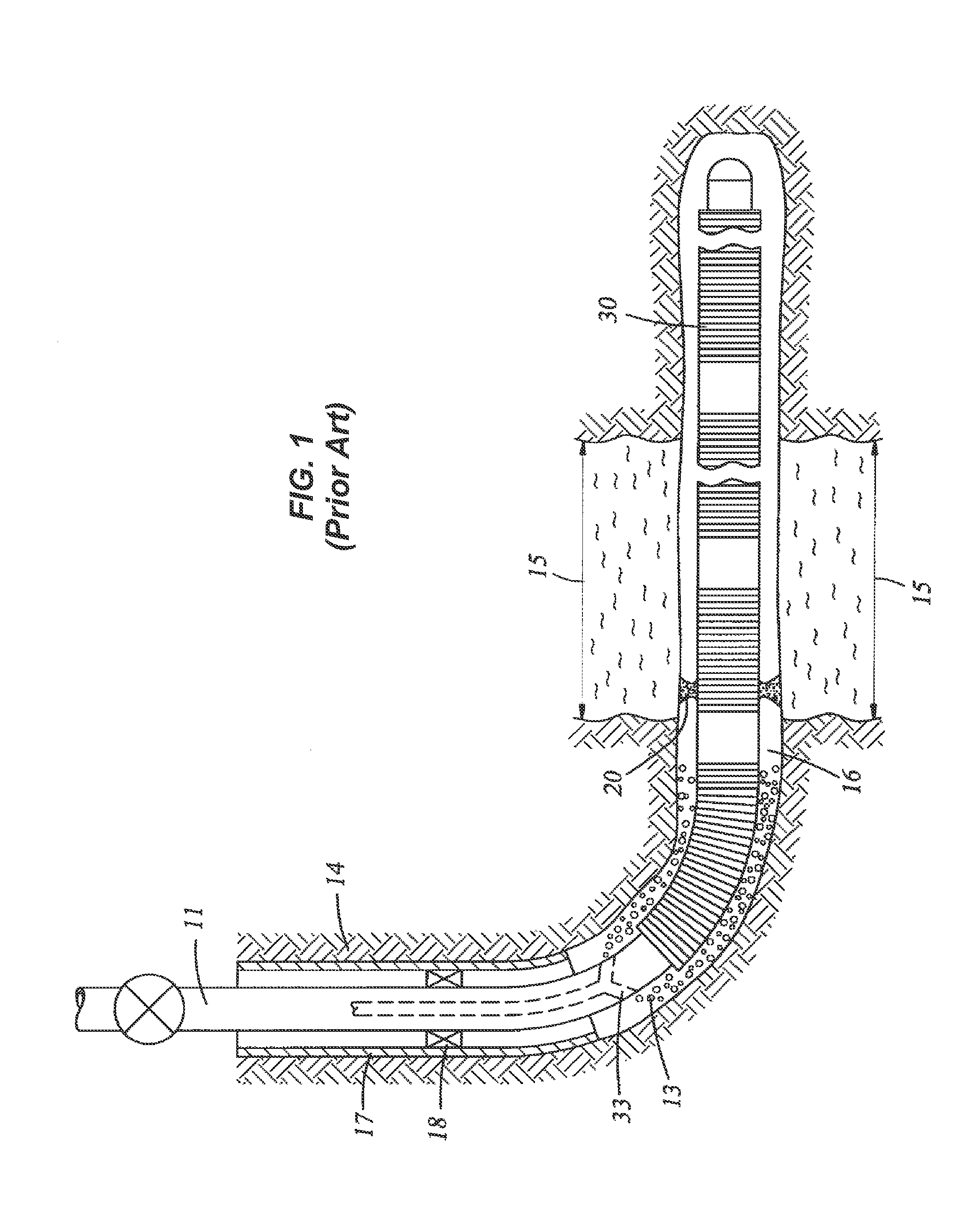

Method and apparatus for cleaning a fractured interval between two packers

InactiveUS7011157B2Minimize erosive wearEasy to moveCleaning apparatusFluid removalFracturing fluidEngineering

A method and apparatus for fluid treatment of a selected interval of a well and then cleaning the selected interval and the apparatus of treatment residue. An straddle tool is run into the well to treatment depth on fluid supplying tubing and has upper and lower packers that establish sealing with the casing and define an annular interval between the packers and between the tool and casing. Fluid, such as fracturing fluid, is pumped through the tubing to the tool and is diverted through an outlet port of the tool into an upper portion of the annular interval. Fluid then flows from a lower portion of the annular interval through an inlet port below the outlet port and at low flow rate is dumped into the casing through a pressure responsive dump valve. The outlet port and inlet port are located to accomplish cleaning of residue from the packers.

Owner:SCHLUMBERGER TECH CORP

Composite components for use in high temperature applications

InactiveUS6847699B2Well formedImprove thermal shock resistanceX-ray tube laminated targetsAdditive manufacturing apparatusFiberThermal shock

Fibrous monolith composites suitable for use in high temperature environments and / or harsh chemical environments are provided, along with methods of preparation thereof. The fibrous monolith composites exhibit such beneficial properties as enhanced strength, corrosion resistance, thermal shock resistance and thermal cycling tolerance.

Owner:BAE SYST UNMANNED AIRCRAFT PROGRAMS

Substrate supports for semiconductor applications

ActiveUS8619406B2Minimize current leakageEliminate concernsSemiconductor/solid-state device manufacturingSpecial surfacesPorosityElectron

Owner:FM INDS

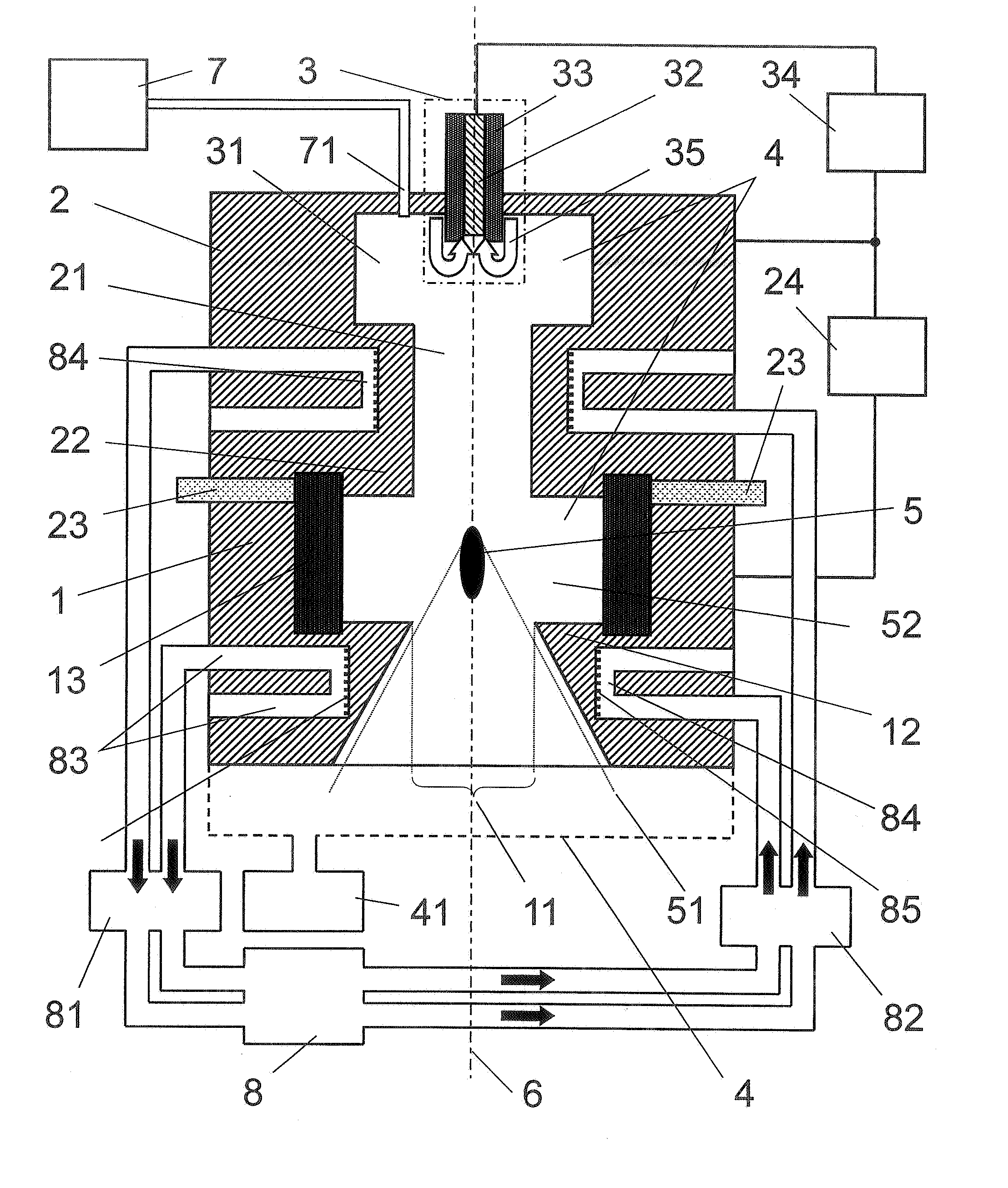

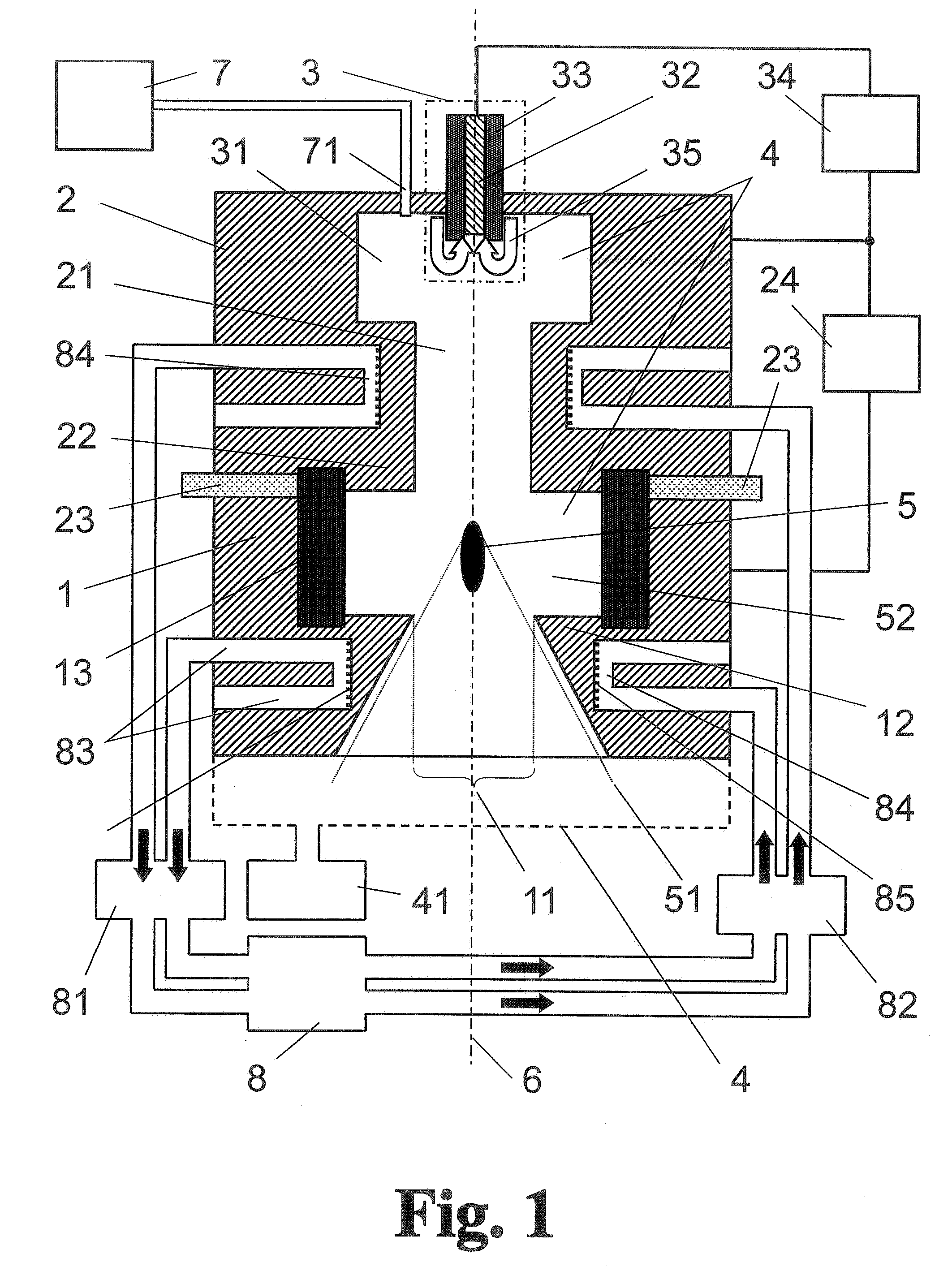

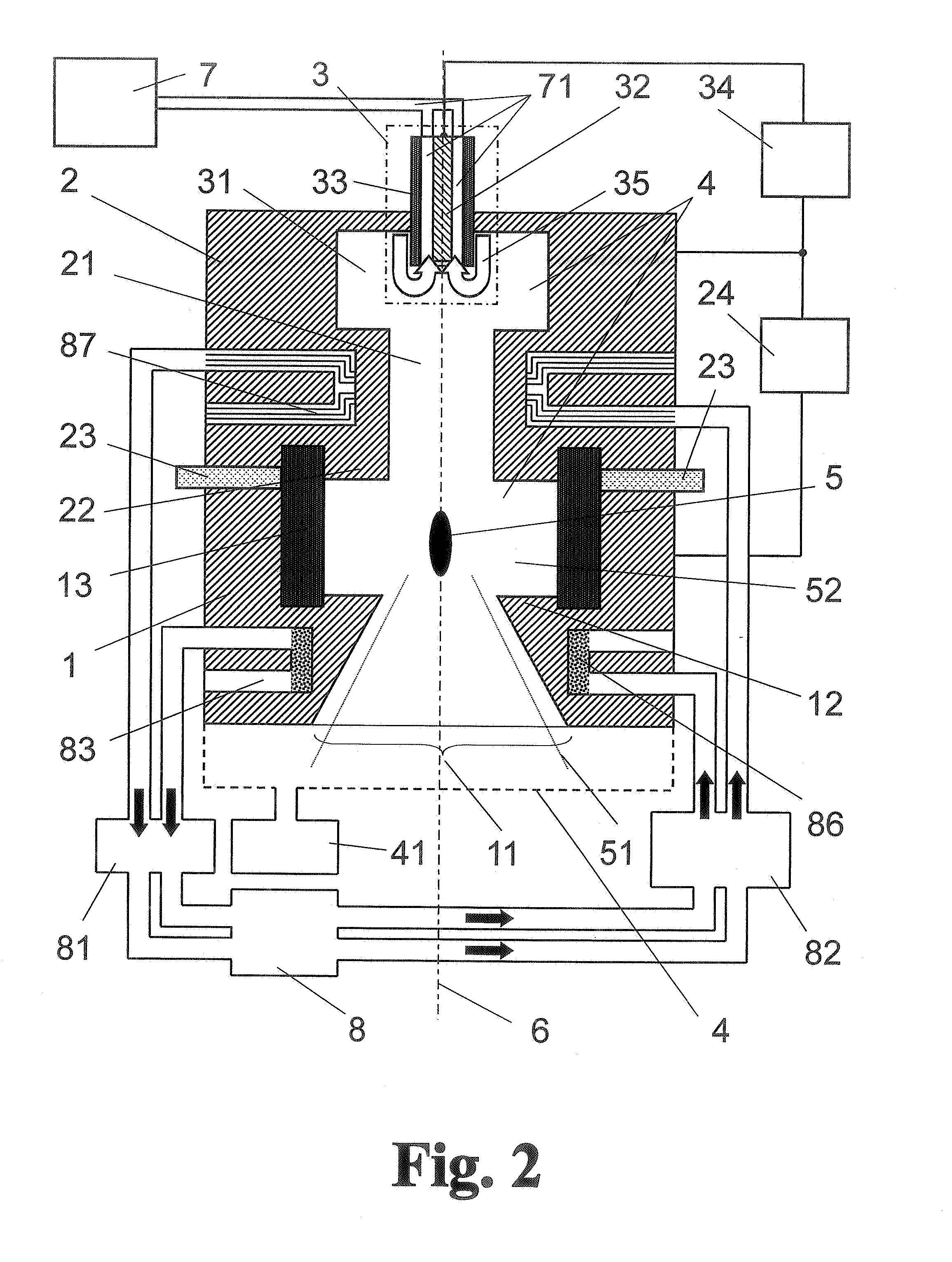

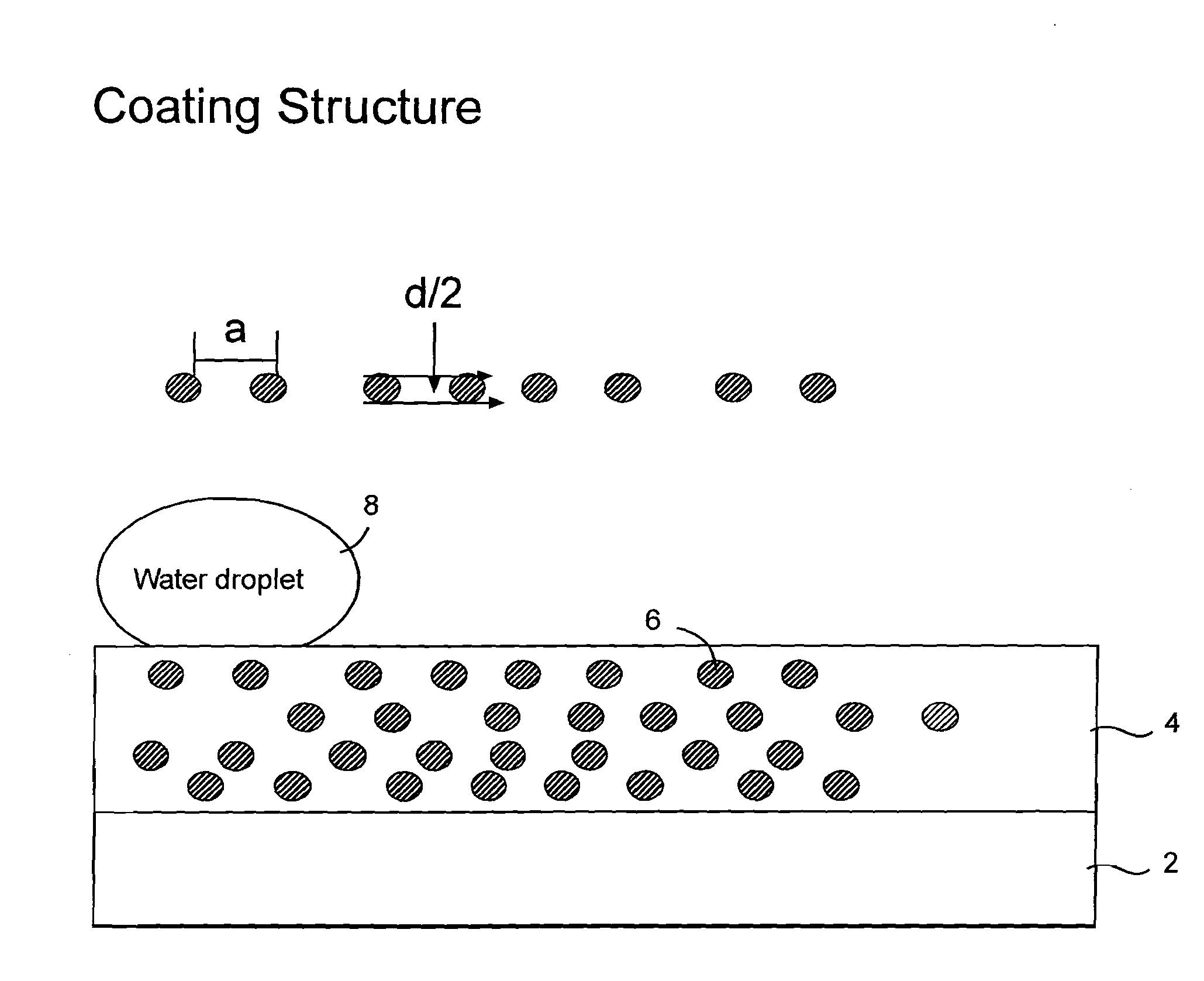

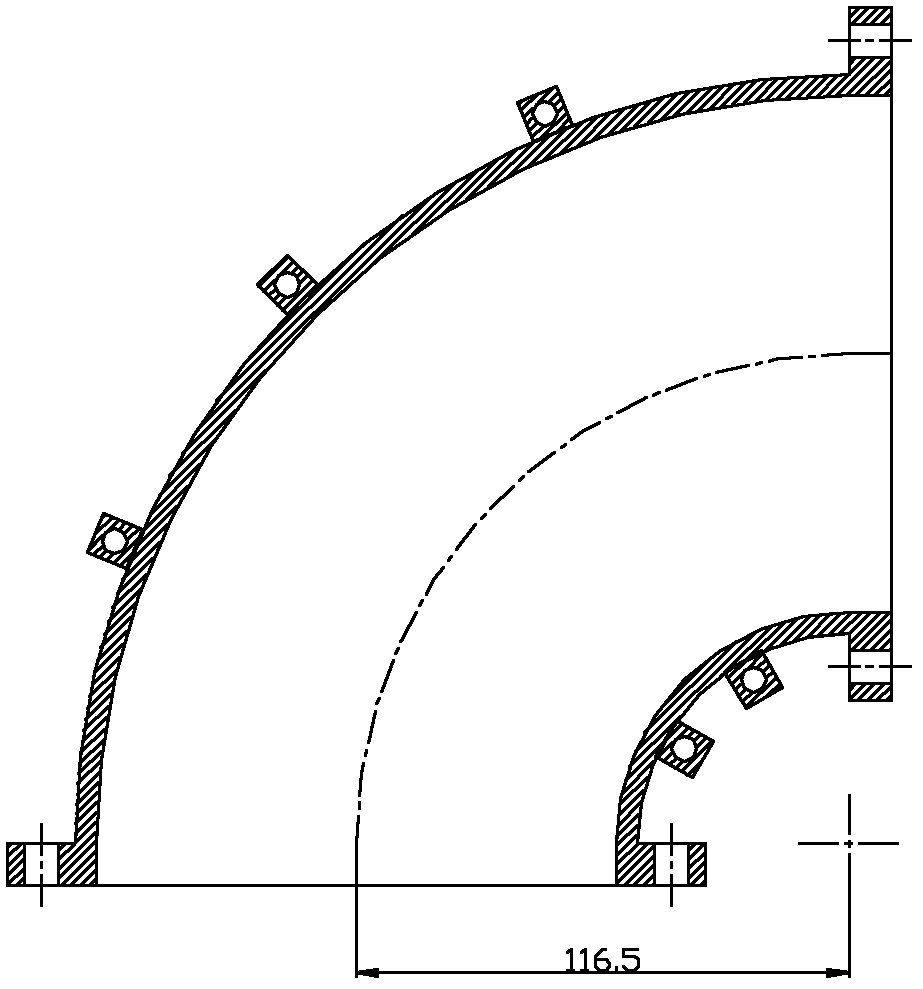

Arrangement for the generation of short-wavelength radiation based on a gas discharge plasma and method for the production of coolant-carrying electrode housing

ActiveUS20070114946A1Long life-timePrevent surfaceElectric arc lampsMaterial analysis by optical meansAxis of symmetryLength wave

The invention is directed to an arrangement for the generation of short-wavelength radiation based on a hot plasma generated by gas discharge and to a method for the production of coolant-carrying electrode housings. It is the object of the invention to find a novel possibility for gas discharge based short-wavelength radiation sources with high average radiation output in quasi-continuous discharge operation by which efficient cooling principles can be implemented using inexpensive and simple means in order to prevent a temporary melting of the electrode surfaces and, therefore, to ensure a long lifetime of the electrodes. According to the invention, this object is met in that special cooling channels for circulating coolant are integrated in electrode collars of the electrode housings. The cooling channels are advanced radially up to within a few millimeters of the highly thermally stressed surface regions and are connected by necked-down channel portions which are arranged coaxial to the axis of symmetry and which are provided with channel structures for increasing the inner surface and for increasing the flow rate of the coolant.

Owner:USHIO DENKI KK

Calcium titanium-aluminate prefabricated part for vanadium smelting reverberatory furnace lining and preparation method thereof

The invention relates to a calcium titanium-aluminate prefabricated part for a vanadium smelting reverberatory furnace lining and a preparation method thereof. According to the technical scheme, 60-75 wt% of calcium titanium-aluminate particles, 10-20 wt% of calcium titanium-aluminate fine powder, 2-7 wt% of titanium dioxide micro powder, 5-10 wt% of alpha-Al2O3 micro powder and 1-6 wt% of rho-Al2O3 micro powder are used as raw materials; 0.05-0.30 wt% of water reducing agent and 3.5-6.0 wt% of water of the raw materials are added; stirring is conducted for 5-8 minutes, vibration forming is achieved, maintenance is carried out for 18-24 hours under the natural condition, demolding is performed, heat preservation is conducted for 18-24 hours at the temperature of 90-110 DEG C, and accordingly the calcium titanium-aluminate prefabricated part for the vanadium smelting reverberatory furnace lining is obtained. The calcium titanium-aluminate prefabricated part has the advantages of being low in production cost, and capable of saving resources and protecting the environment. The obtained calcium titanium-aluminate prefabricated part for a vanadium smelting reverberatory furnace is high in high-temperature strength, good in acidity vanadium slag corrosion resistance and good in permeability.

Owner:WUHAN UNIV OF SCI & TECH

Erosion and corrosion resistant coating system for compressor

InactiveUS20110165433A1Improve corrosion resistanceImprove erosion resistanceLiquid surface applicatorsBlade accessoriesCoating systemVanadium nitride

Process for providing a protective coating to a metal surface by applying a nickel or tantalum plate layer to the surface and dispersing particles of a hard material such as diamond, alumina, vanadium nitride, tantalum carbide and / or tungsten carbide within the nickel or tantalum plate layer as the plating is occurring.

Owner:GENERAL ELECTRIC CO

Method for preparing environment-friendly high-modulus glass fiber

The invention relates to an environment-friendly high-modulus glass fiber composition, and discloses a glass component combination used for preparing the high-modulus glass fiber. The glass fiber prepared by glass components is particularly applied to preparing glass fiber reinforced plastic composite material with higher rigidity requirement. The glass composition has no emission of harmful gas, greatly reduces the emission of greenhouse gas, and is an environment-friendly glass fiber formula. The environment-friendly high-modulus glass fiber composition is characterized in that: a blast furnace slag preferably serves as one of major raw materials for reducing the operational difficulty and prepares the high-modulus glass fiber, and the high-modulus glass fiber can be produced and wiredrawn on a tank furnace having an electro-boost structure on a large scale by adopting a direct method. The fiber mainly comprises the following main components: 57 to 62.5 weight percent of SiO2, 14.5 to 19.5 weight percent of Al2O3, 16 to 23.5 weight percent of RO (wherein RO is the sum of CaO, MgO, SrO and BaO), and less than and equal to 1.5 percent of alkali metal oxide. The glass composition and the adopted raw material mode are suitable for the mass production under the production technological condition of the electro-boost tank furnace, and the glass composition has low production cost.

Owner:TAISHAN FIBERGLASS INC

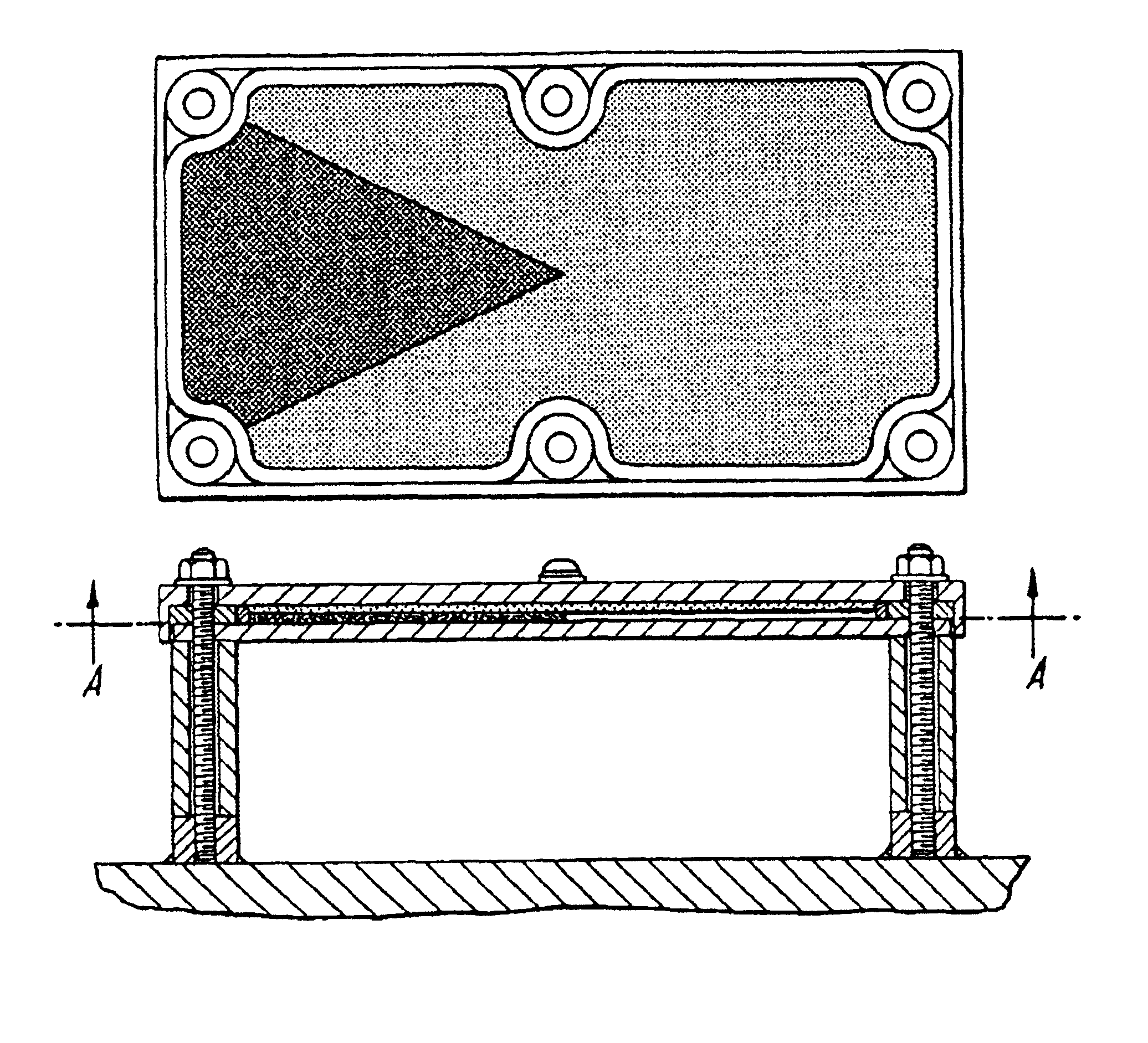

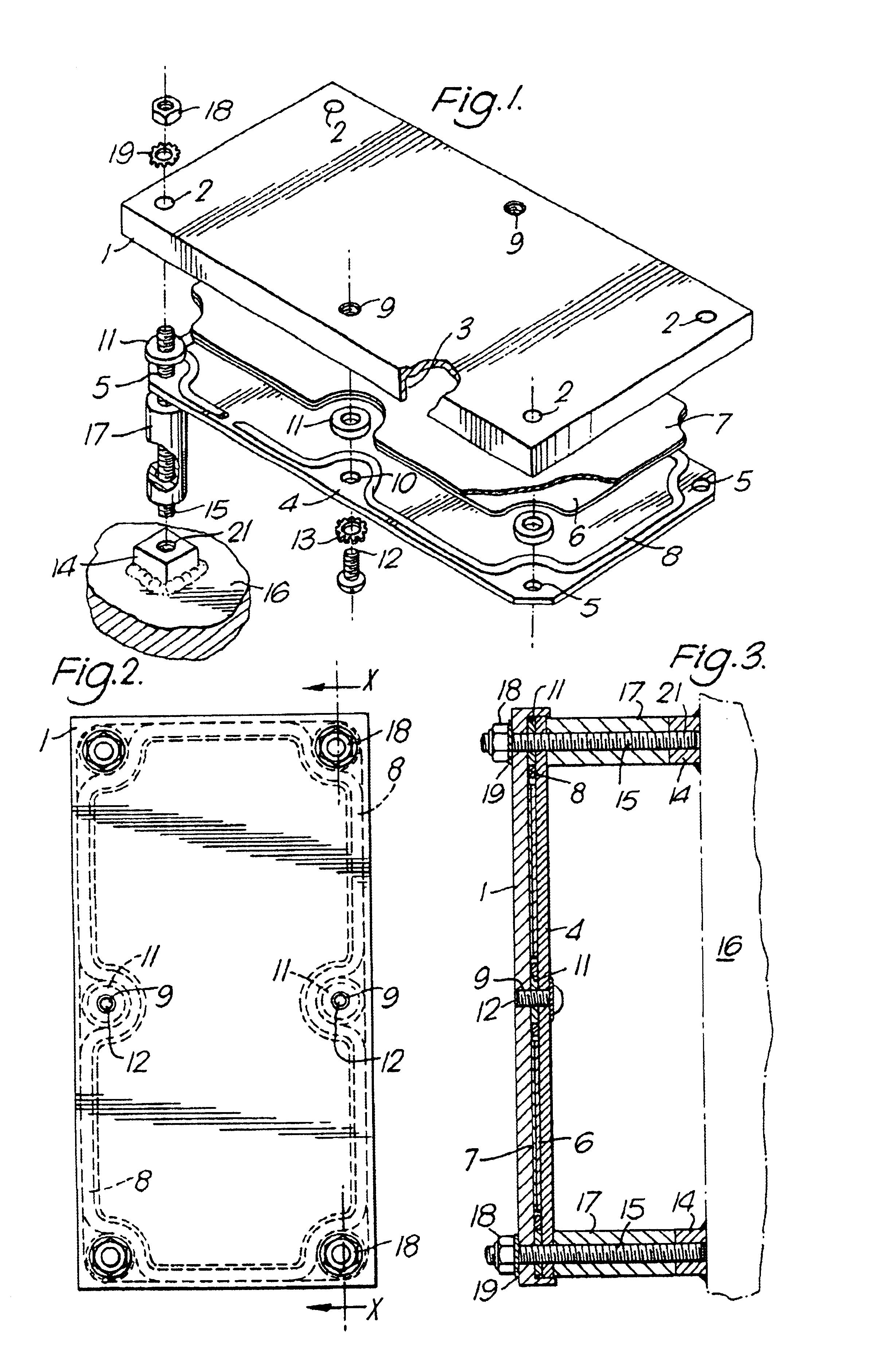

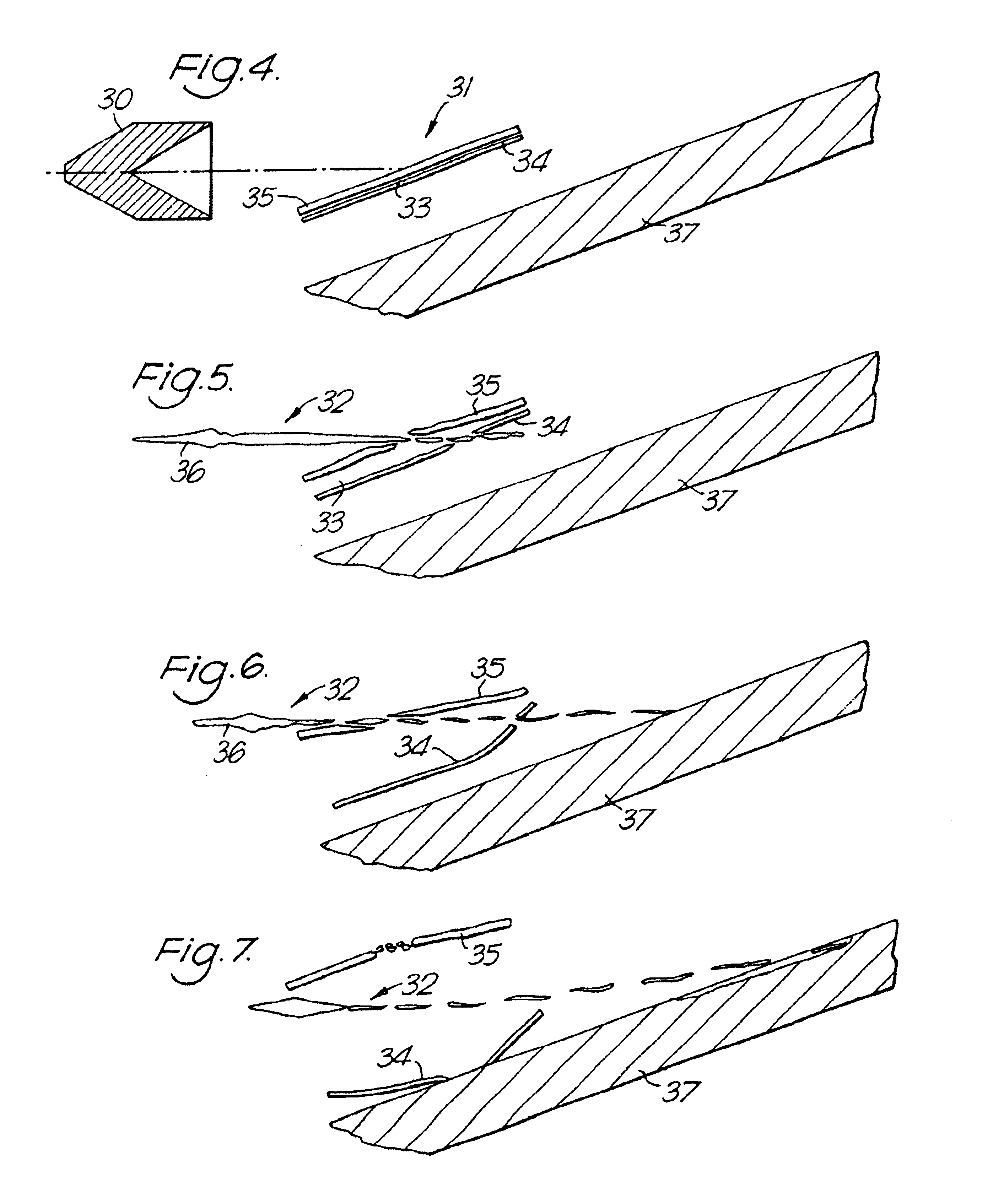

Armour constructions

InactiveUS6962102B1Erosion is goodReduce thicknessDefence devicesArmoured vehiclesExplosive materialMissile

An applique armour panel for fitting to a substrate and for protecting the substrate from missile or other projectile attack which panel comprises an exterior plate (1), an interior plate (4) and a layer or layers (7) of explosive material therebetween. The explosive material is detonated by an incoming missile to cause disruption of the incoming missile and reduce its penetrative effect. The panel is constructed so that upon reactive explosion the interior and exterior plates are driven apart more rapidly at one edge of the panel than at an opposite edge by a rotating moment of one plate relative to the other.

Owner:BAE SYSTEMS PLC

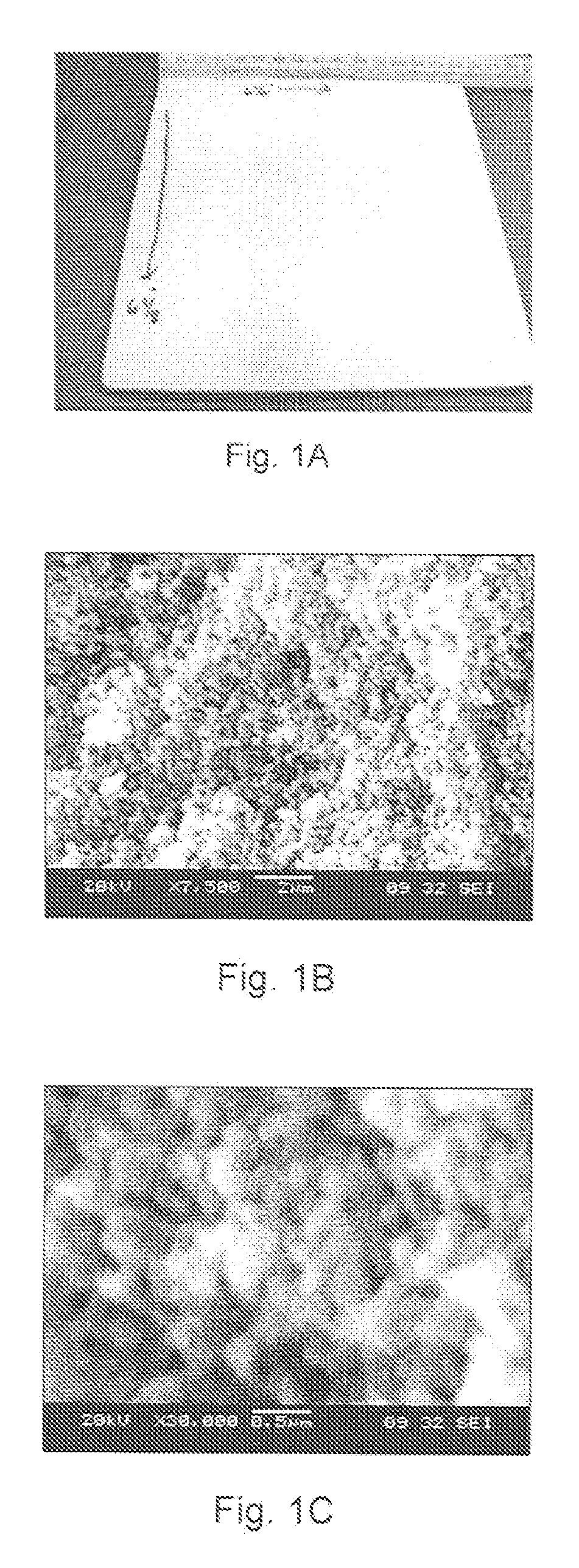

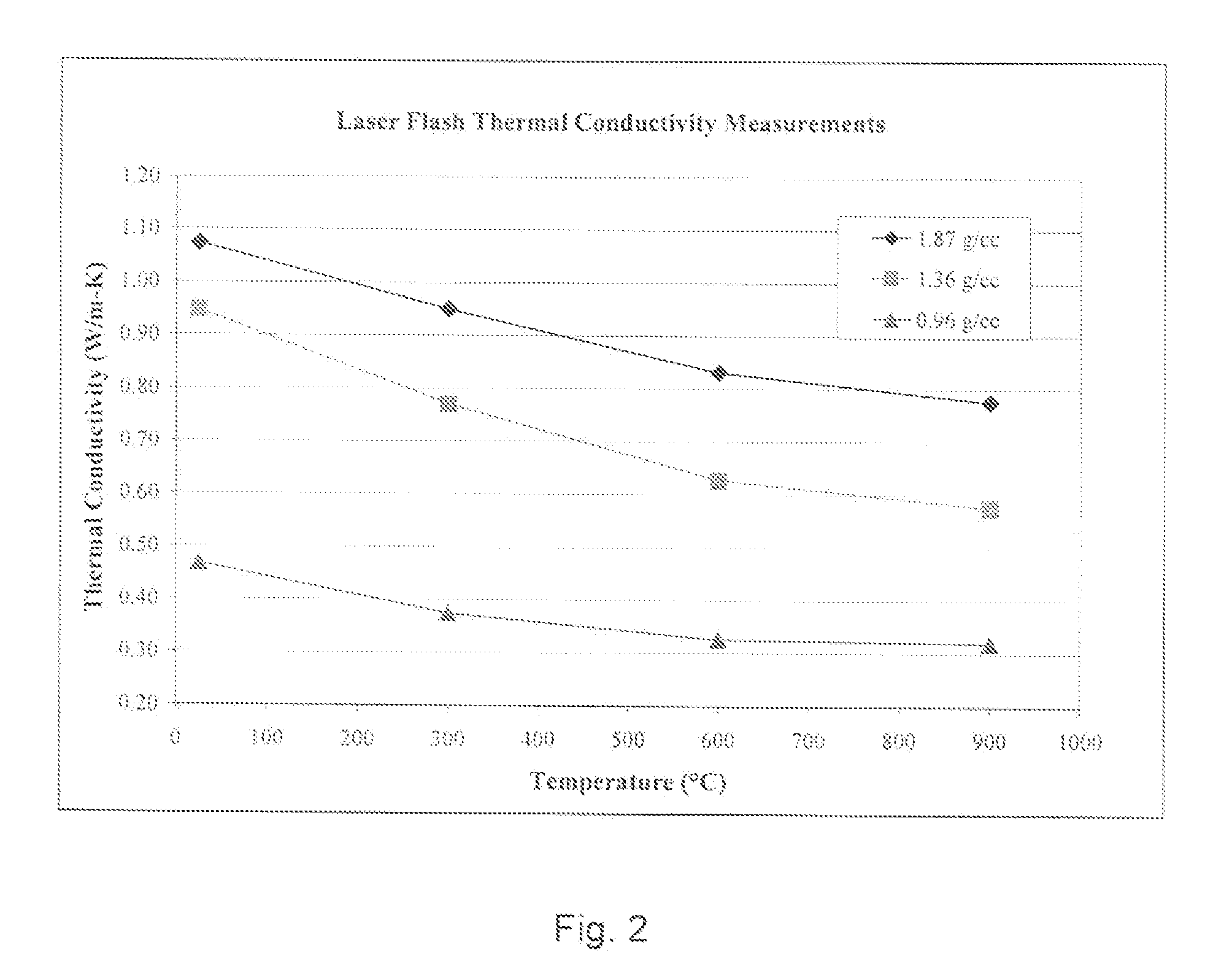

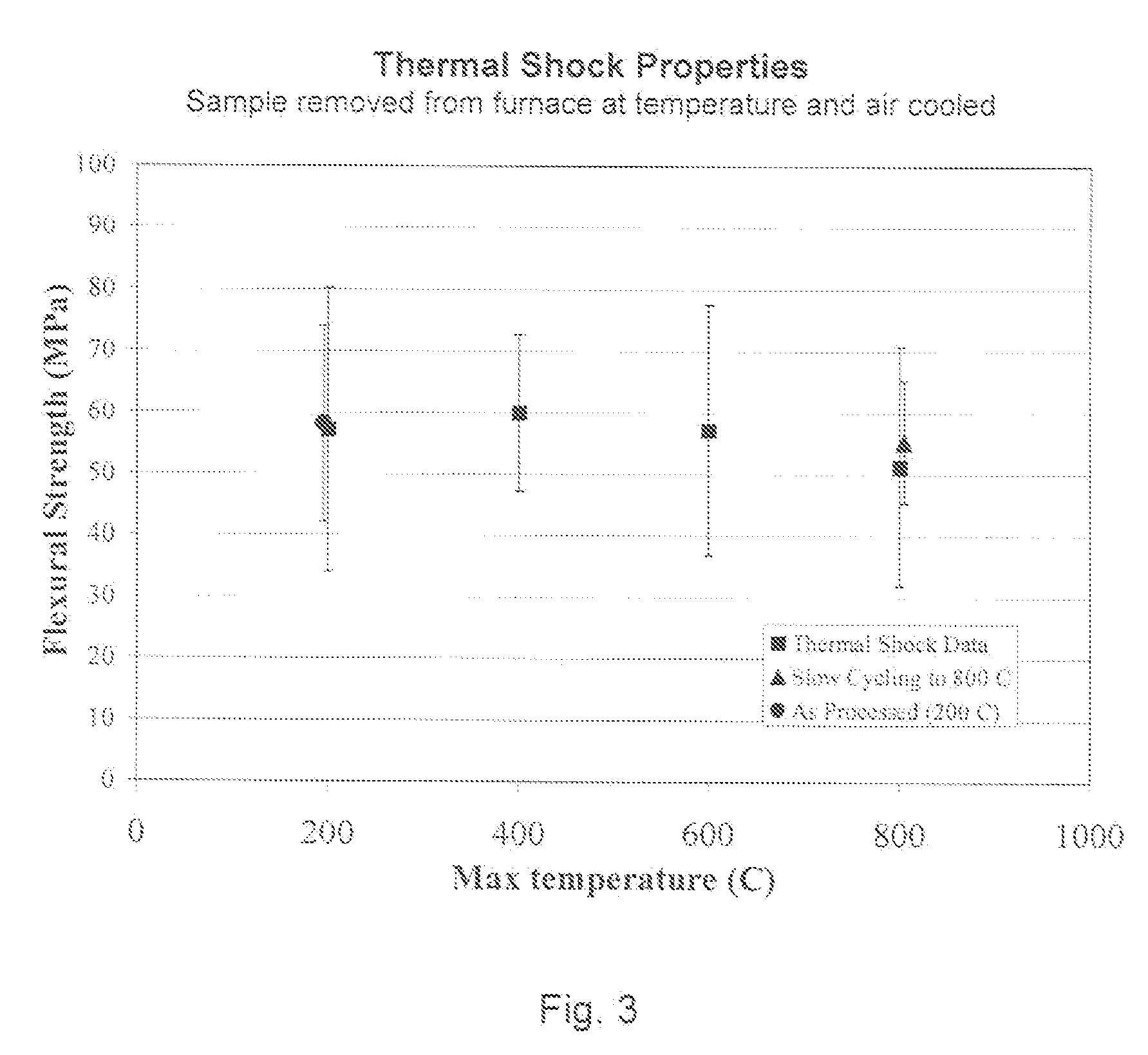

Process for making ceramic insulation

InactiveUS20090295045A1Low costImprove performanceFinal product manufactureCeramic shaping apparatusPorosityFuel cells

A method is provided for producing insulation materials and insulation for high temperature applications using novel castable and powder-based ceramics. The ceramic components produced using the proposed process offers (i) a fine porosity (from nano-to micro scale); (ii) a superior strength-to-weight ratio; and (iii) flexibility in designing multilayered features offering multifunctionality which will increase the service lifetime of insulation and refractory components used in the solid oxide fuel cell, direct carbon fuel cell, furnace, metal melting, glass, chemical, paper / pulp, automobile, industrial heating, coal, and power generation industries. Further, the ceramic components made using this method may have net-shape and / or net-size advantages with minimum post machining requirements.

Owner:CERAMTEC

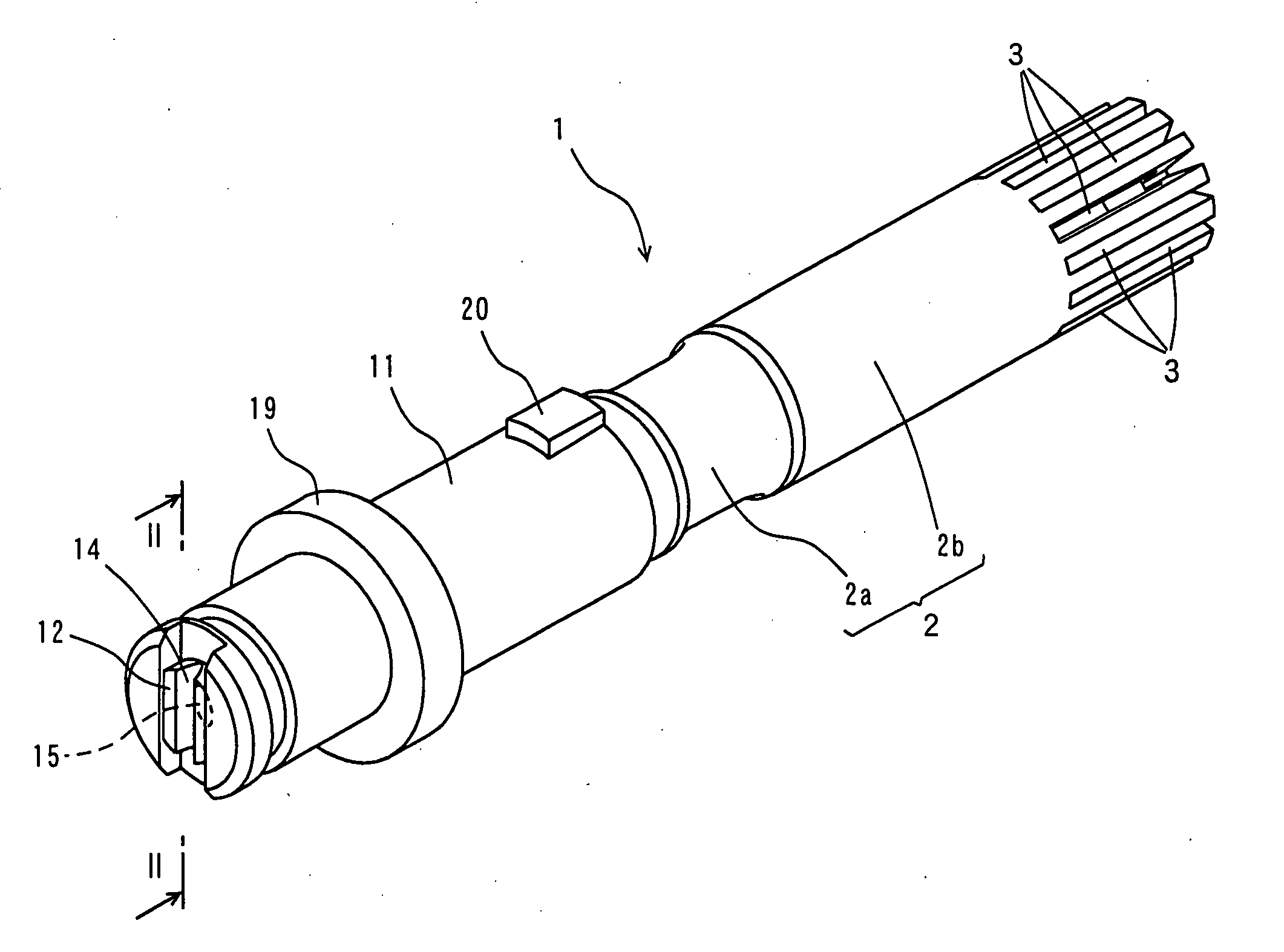

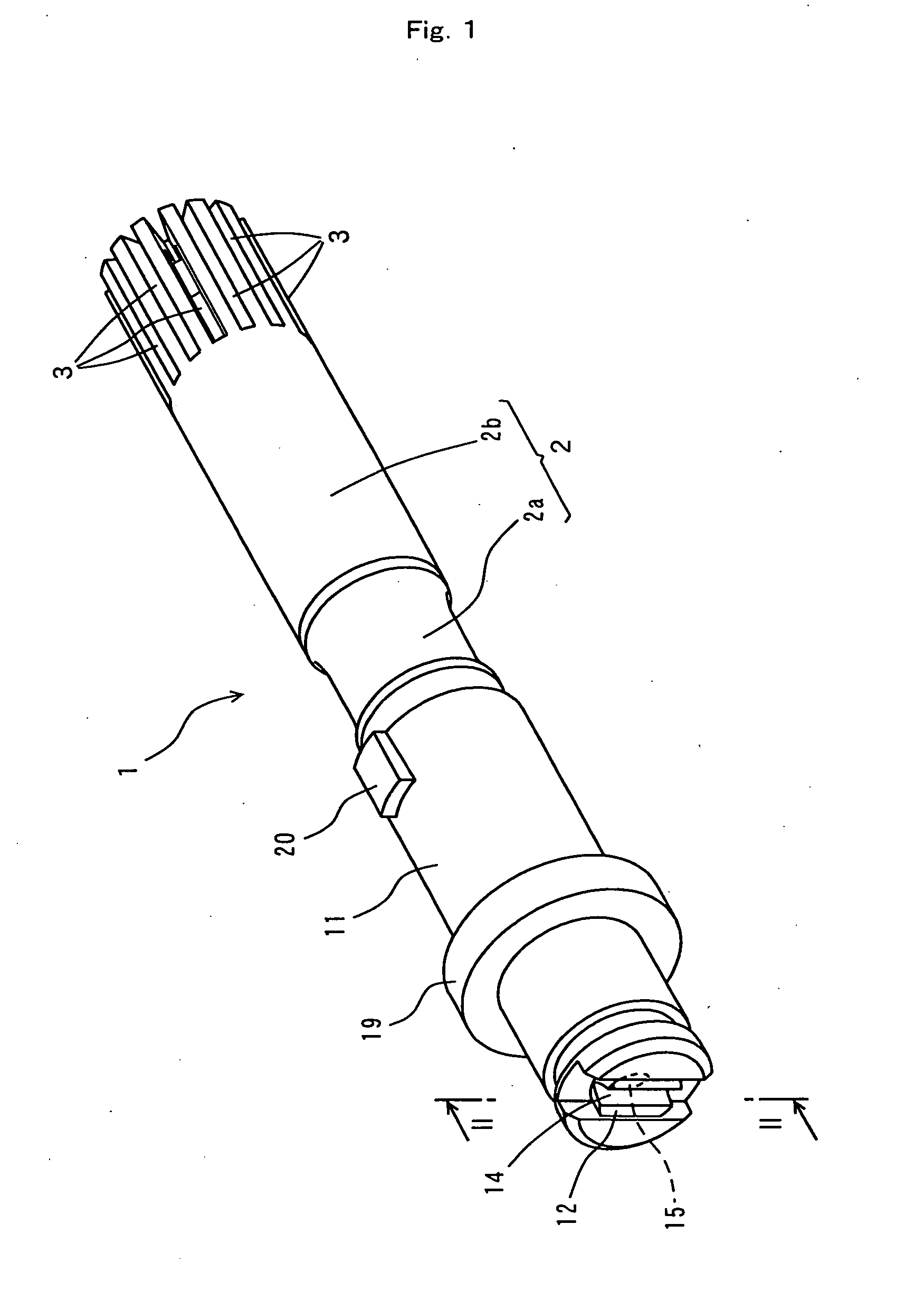

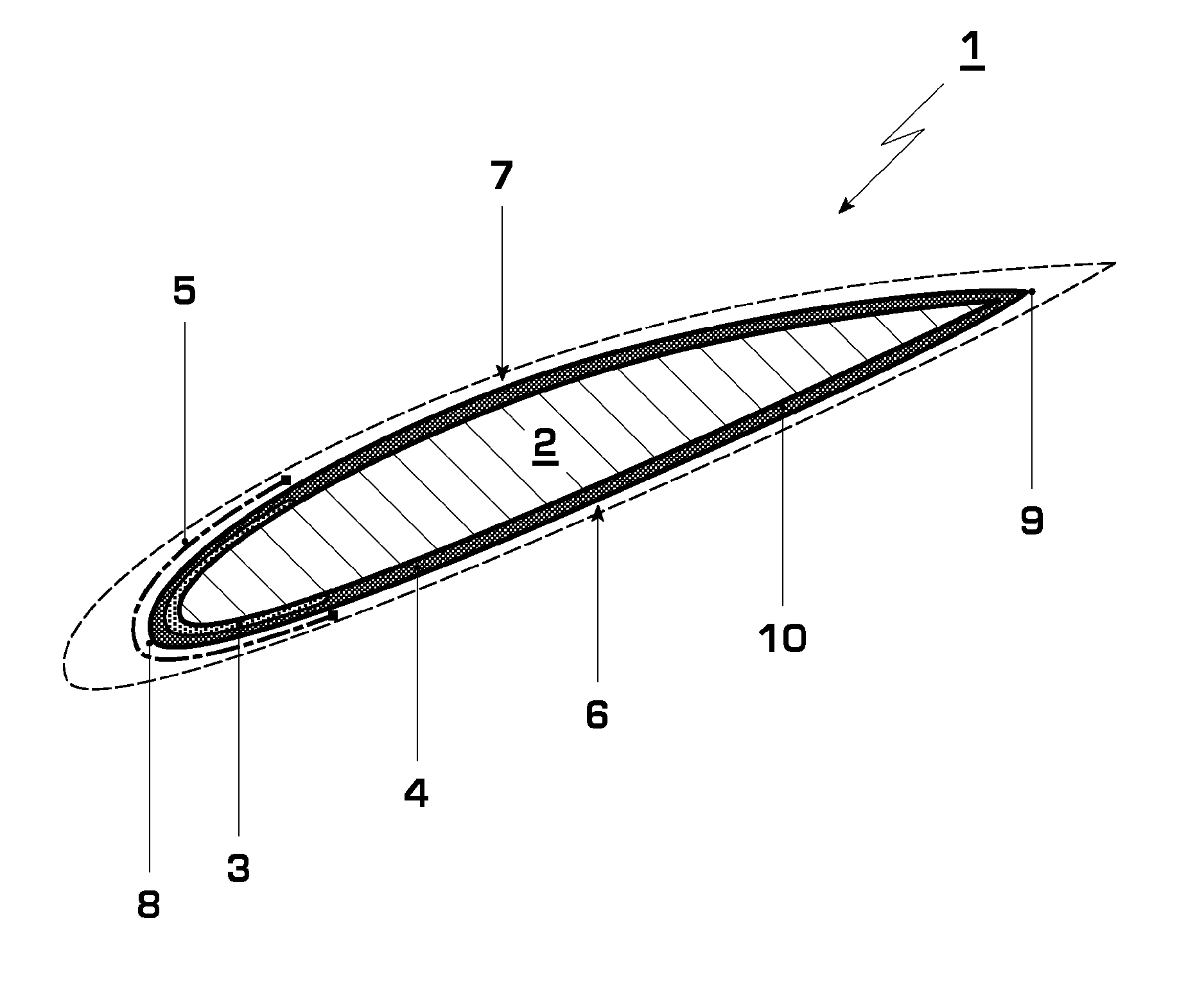

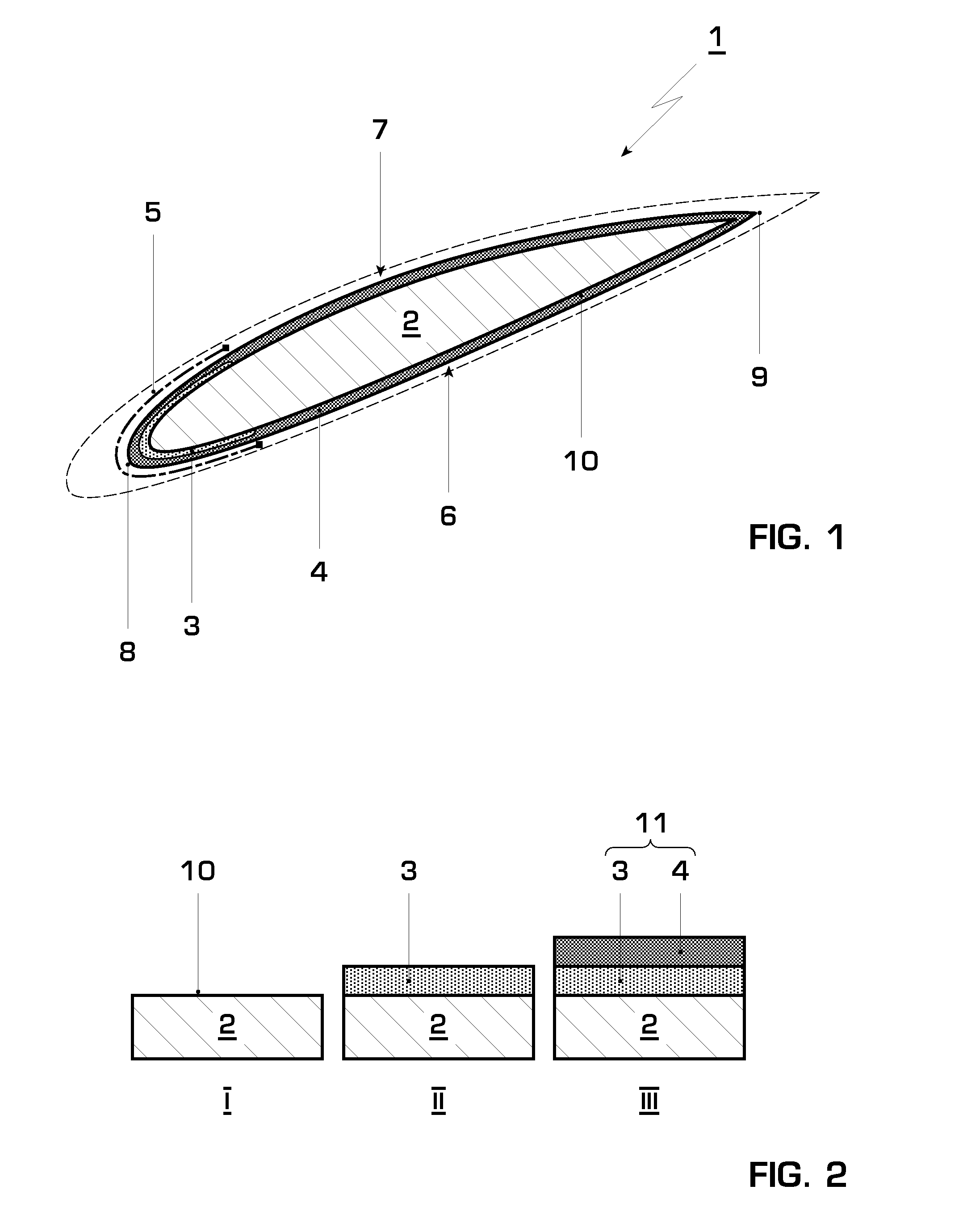

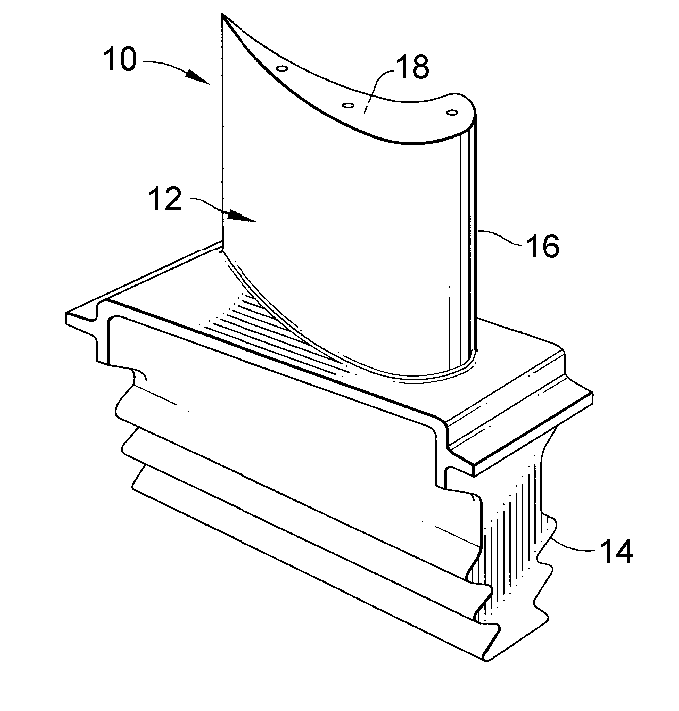

Turbomachine blade with erosion and corrosion protective coating and method of manufacturing

InactiveUS8113787B2Extend working lifeSuppressing pitting corrosion of a turbomachine bladePropellersRotary propellersEngineeringErosion

A turbomachine blade (1) includes a blade body (2) and a corrosion and erosion protective multilayered coating (11) bonded thereto, the multilayered coating (11) including an erosion resistant first layer (3) at least covering a corrosion and erosion critical area (5) of the blade body (2) and a sacrificial second layer (4) provided over the first layer (3) at least covering the first layer (3), preferably covering the blade totally. A method of manufacturing such a turbomachine blade includes the steps of providing a blade and depositing the erosion resistant first layer on the blade body so as to cover at least the corrosion and erosion critical area, followed by depositing the sacrificial second layer over the first layer at least covering the first layer.

Owner:ANSALDO ENERGIA IP UK LTD

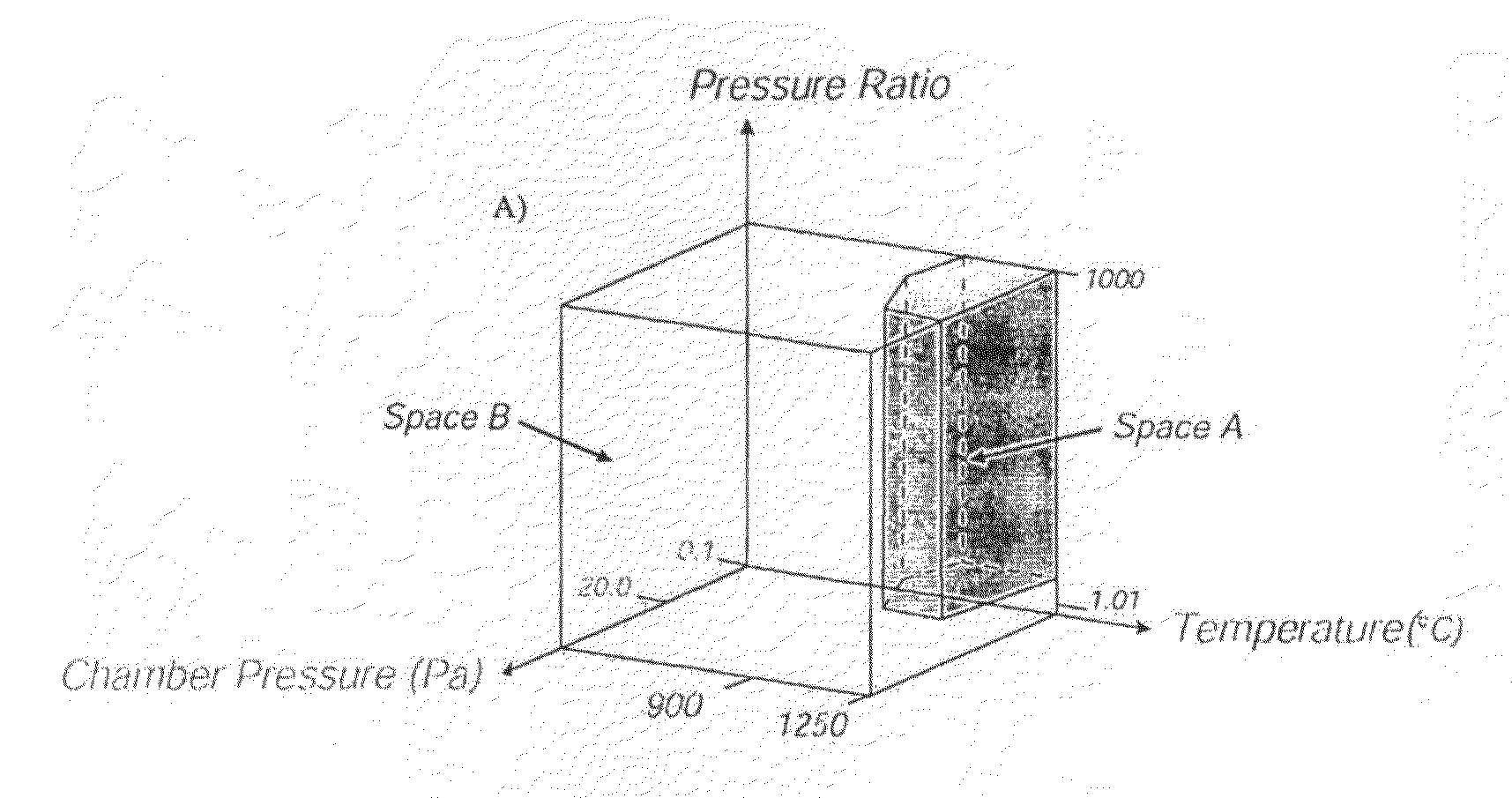

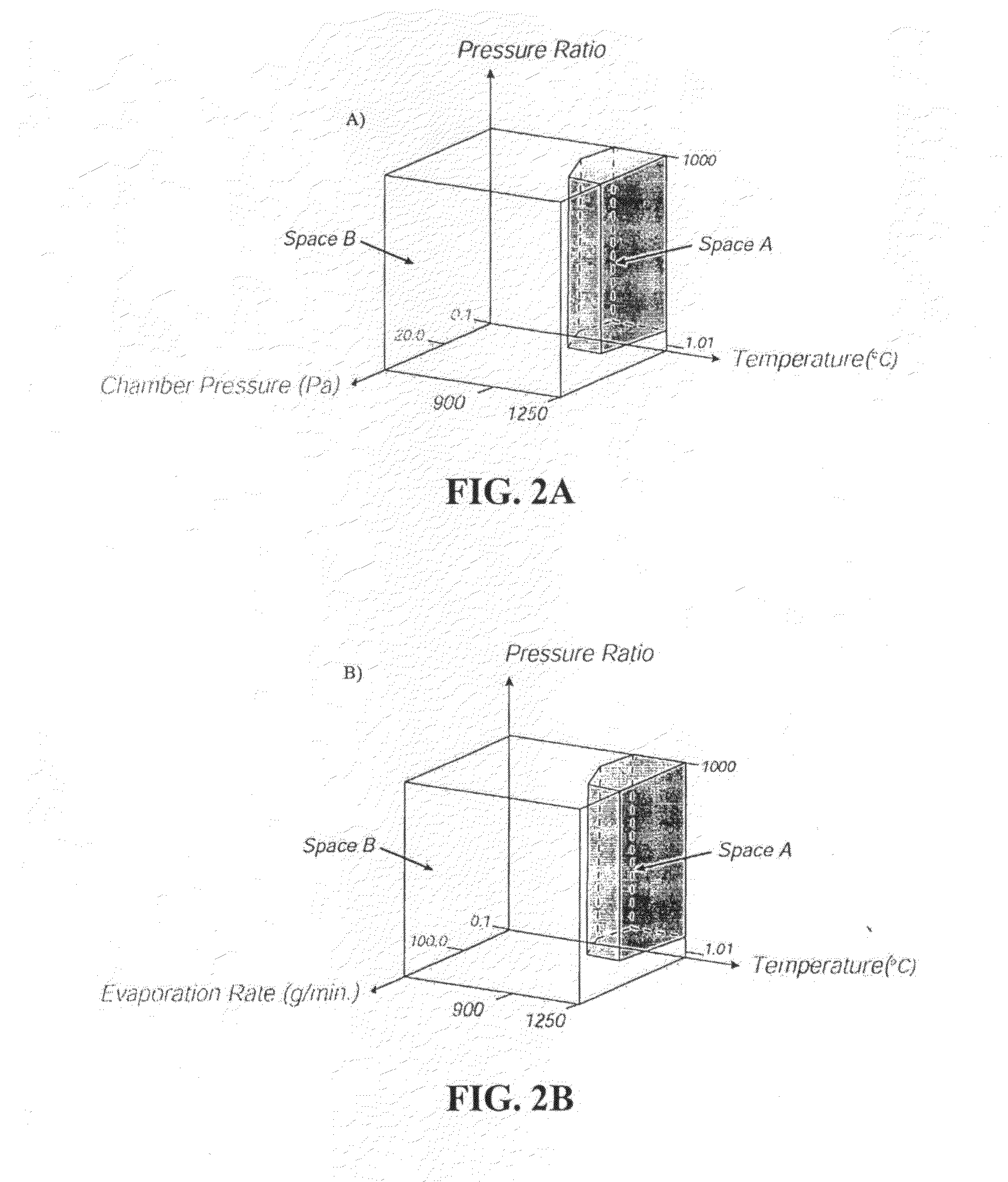

Method for Application of a Thermal Barrier Coating and Resultant Structure Thereof

InactiveUS20080131611A1Low thermal conductivityHigh elastic complianceMolten spray coatingVacuum evaporation coatingIn planeForeign object damage

Provided herein are methods and apparatuses, and resulting structures, for depositing ceramic coatings with preferred coating density, morphology and adherence for applications such as thermal protection of internally cooled components. Such components are found in, but not limited thereto, the hot sections of gas turbine and diesel engines and in turbo machinery. These coatings require a low thermal conductivity in the through thickness of the coating, high in-plane elastic compliance, high erosion and foreign object damage resistance and resistance to hot corrosion. The methods and apparatuses discussed herein provide, among other things, how to manipulate the process conditions in EB-DVD systems to deposit high quality, highly efficient TBS top coats as well as how to deposit high quality TBC top coats onto positions that are in the line-of-sight, as well as non-line of sight, of the vapor source.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

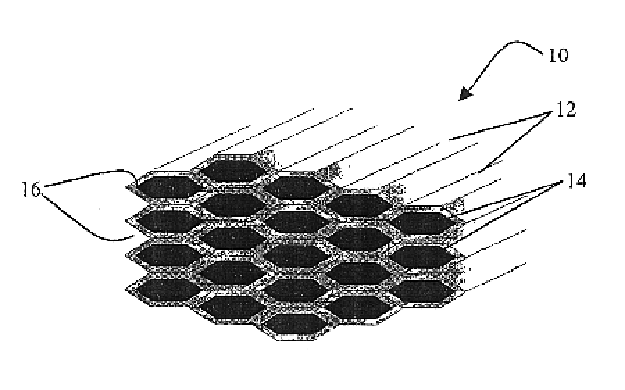

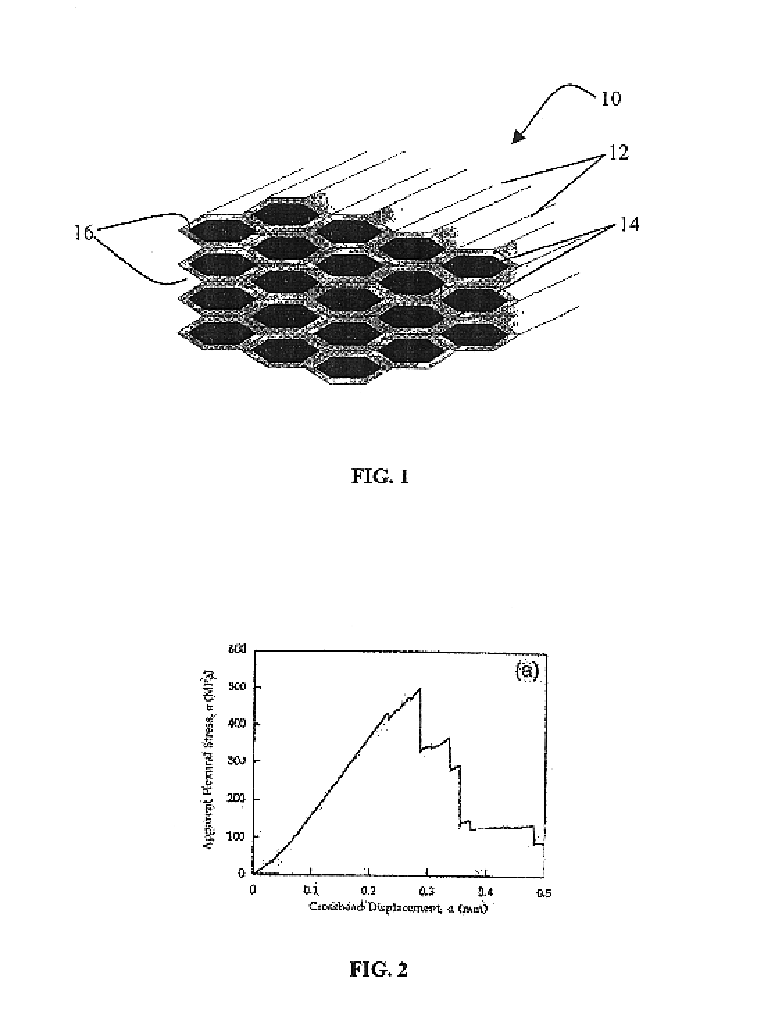

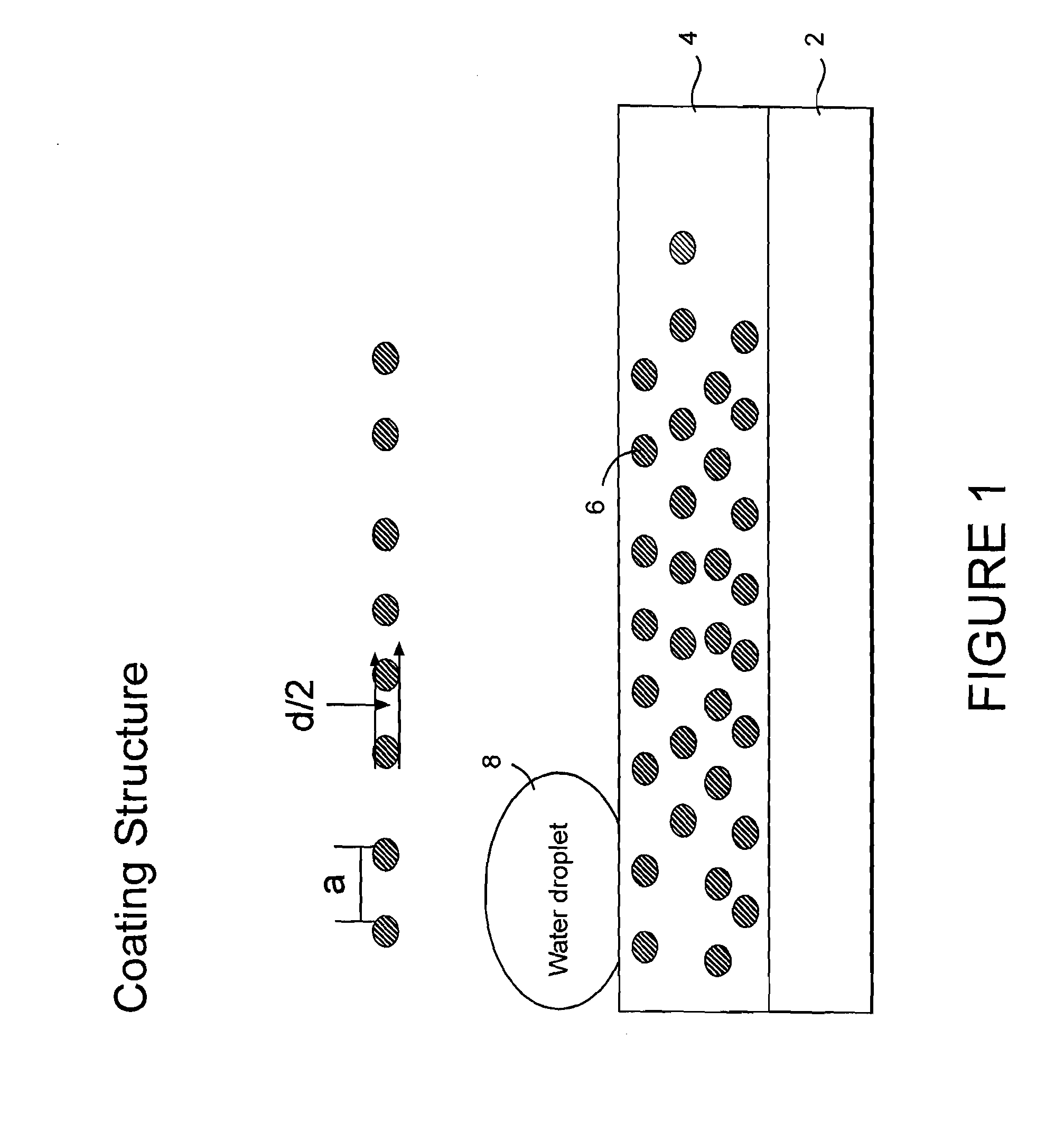

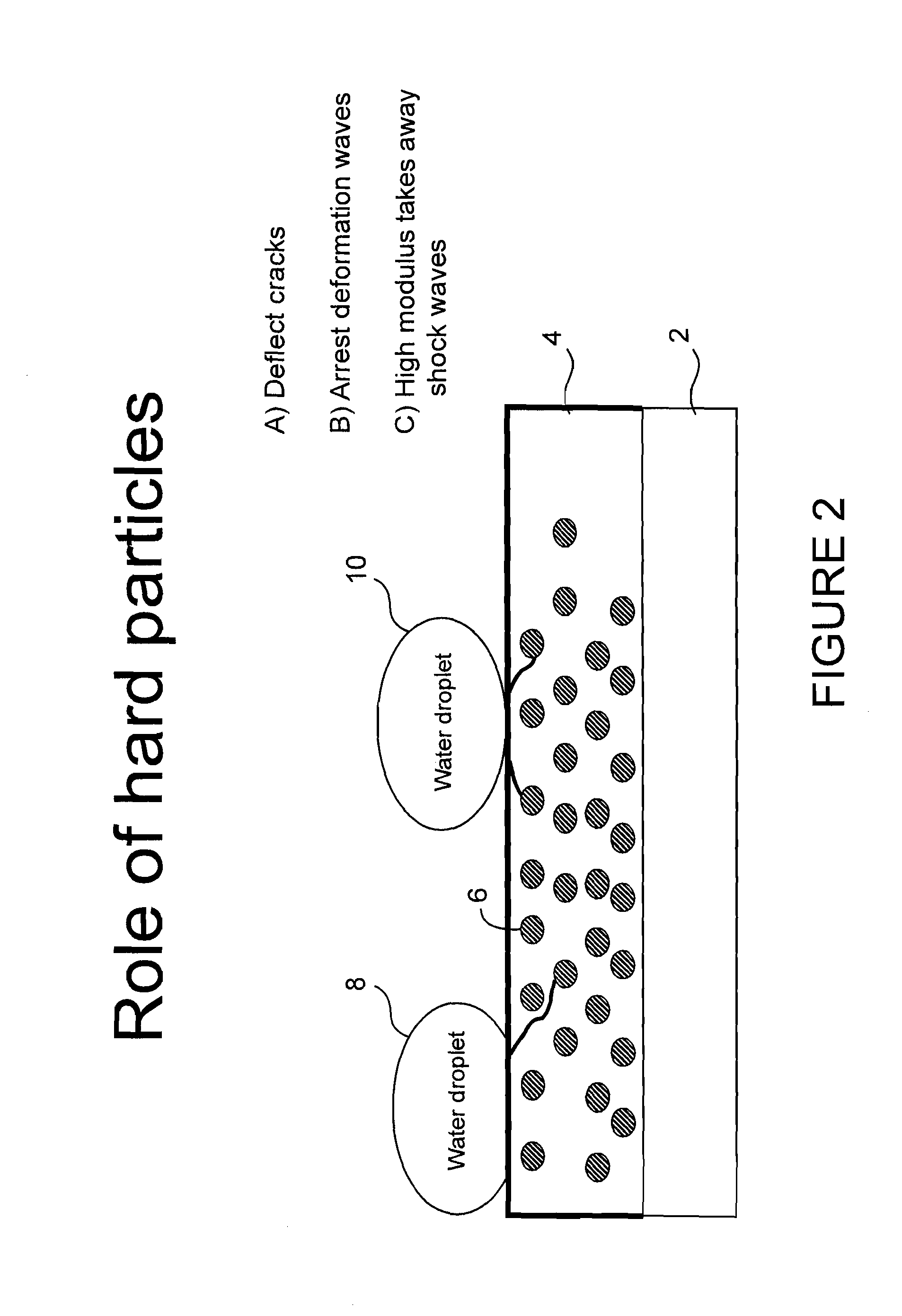

Composite thermal barrier coating with improved impact and erosion resistance

ActiveUS20070141367A1Improved impact and erosion resistanceErosion is goodNatural mineral layered productsSuperimposed coating processMicrometerMaximum dimension

A thermal barrier coating (TBC) for a component intended for use in a hostile environment, such as a component of a gas turbine engine. The TBC exhibits improved impact and erosion resistance as a result of being a composite material consisting essentially of particles of a ceramic reinforcement material dispersed in a ceramic matrix material. The ceramic reinforcement material has a yield strength greater than the ceramic matrix material at about 1100° C., and the particles of the ceramic reinforcement material have an average maximum dimension of greater than five micrometers.

Owner:GENERAL ELECTRIC CO

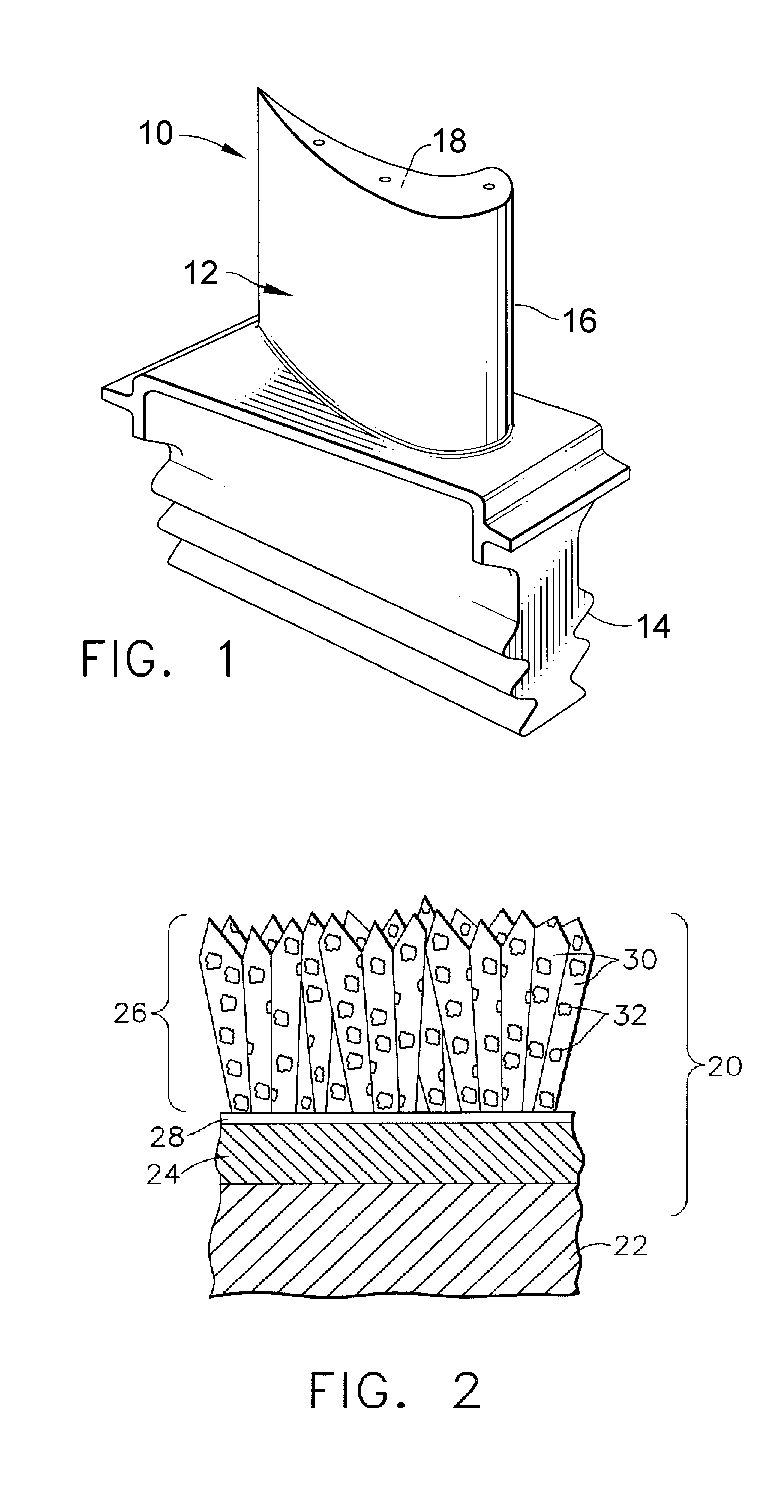

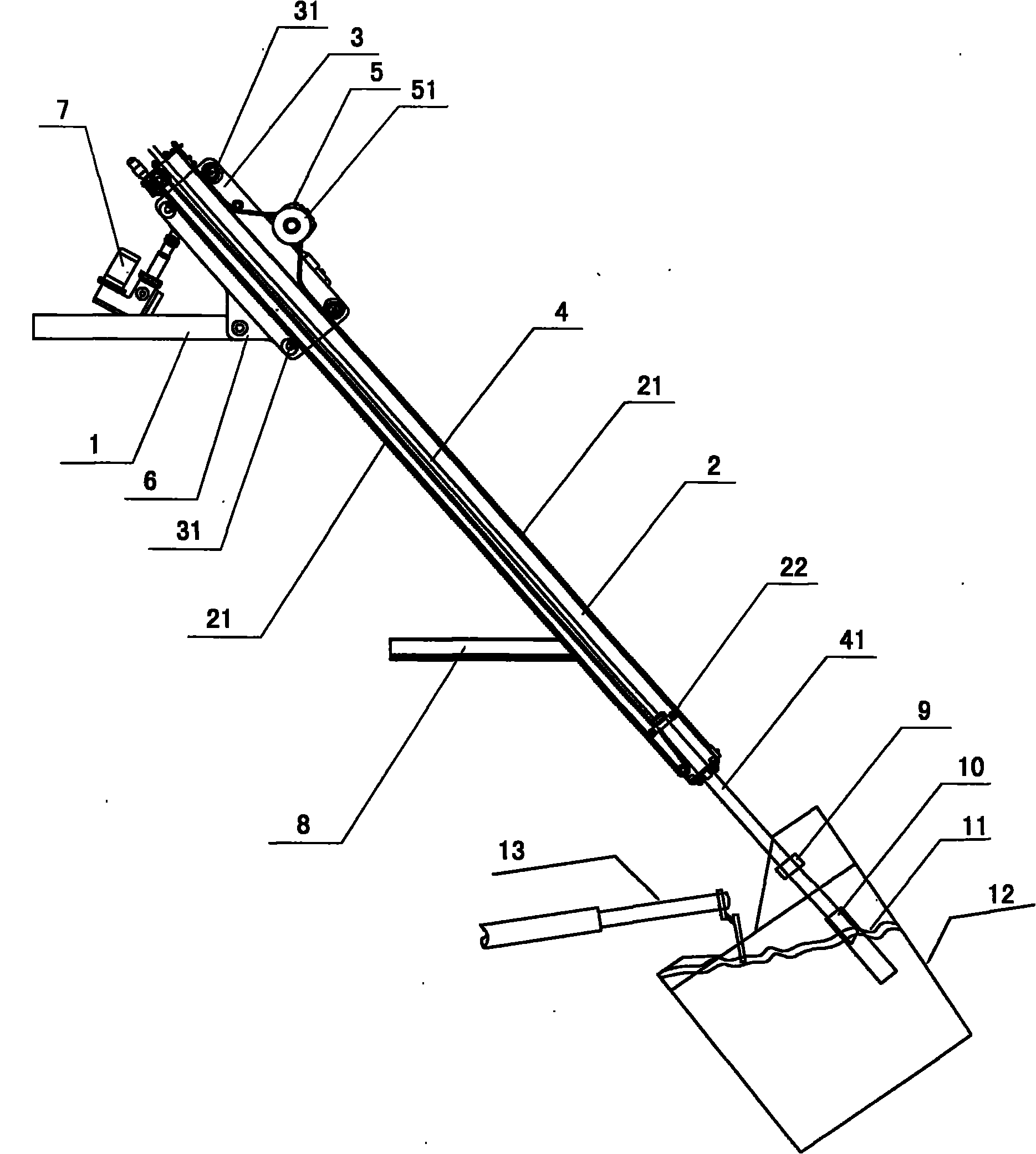

Gas-blowing and slag-removing device and slag-removing method

The invention relates to a gas-blowing and slag-removing device and a process, mainly solving the technical problems that the slag removing is difficult to realize and the slag-removing effect is poor in the existing slag-removing device. The technical scheme of the invention is as follows: the gas-blowing and slag-removing device comprises a gas-blowing mechanism, a hot-iron ladle and a slag-skimming machine, and is characterized in that the gas-blowing mechanism is fixed at one side of a supporting platform by a hinge base and comprises an oblique rail frame which is provided with a rail chain; the gas-blowing and slag-removing device also comprises a bracket which is level to the upper surface of the rail frame and is provided with a speed-changing machine; an output shaft of the speed-changing machine is provided with a first chain wheel matched with the rail chain; the rail frame is also provided with a clamping trolley which forms a moving pair with the rail frame; the clamping trolley is provided with a second chain wheel which is fixed together with the rail chain; a connecting rod positioned in the middle of the rail frame is clamped and fixed in the middle of the clamping trolley, and is equidirectional with the rail frame; and the lower end of the connecting rod is provided with a connector and is connected with a gas-blowing and slag-removing gun by a connecting flange. The invention is mainly used for removing the slag on the surface of hot iron in the hot-iron ladle.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD +1

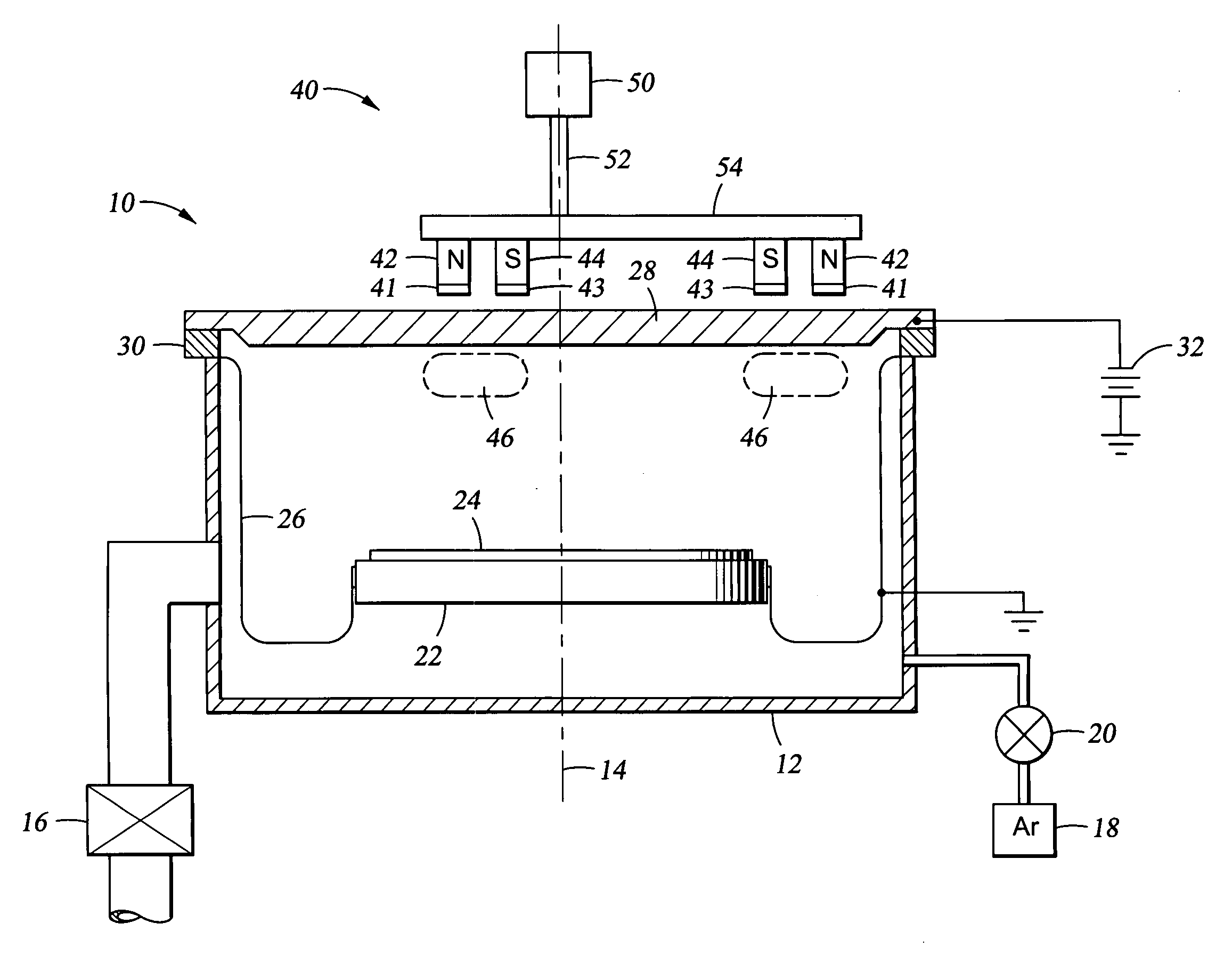

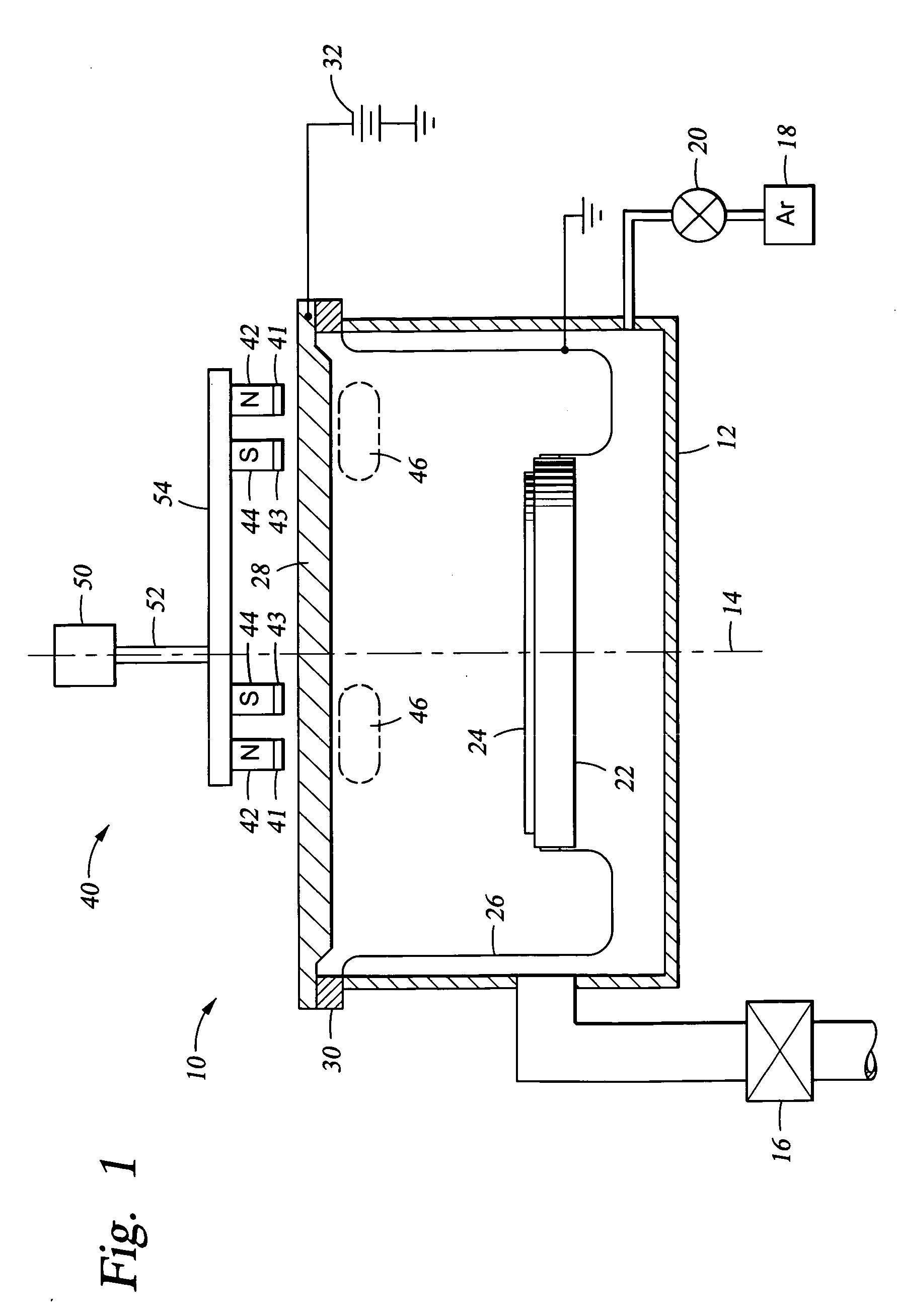

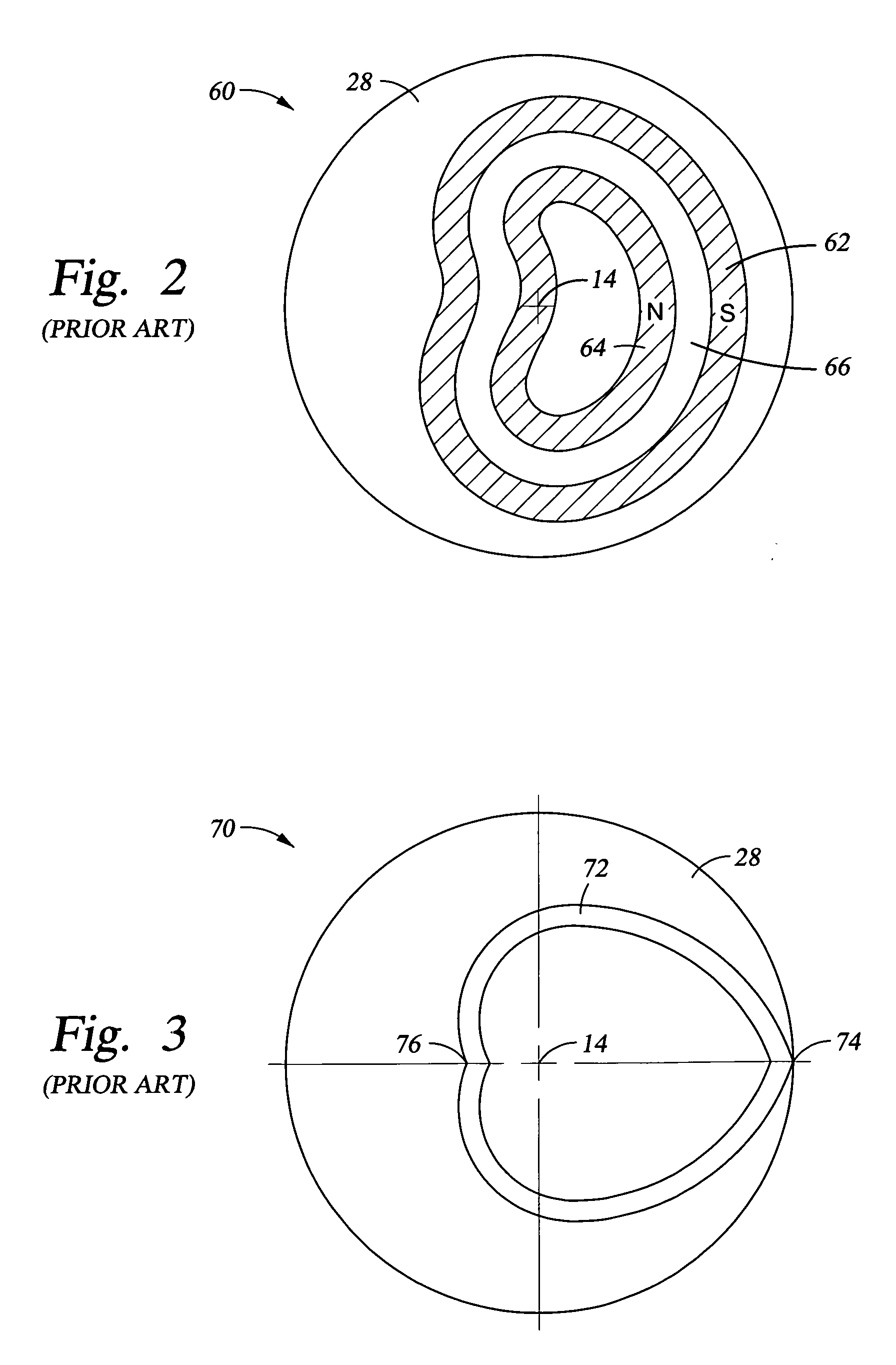

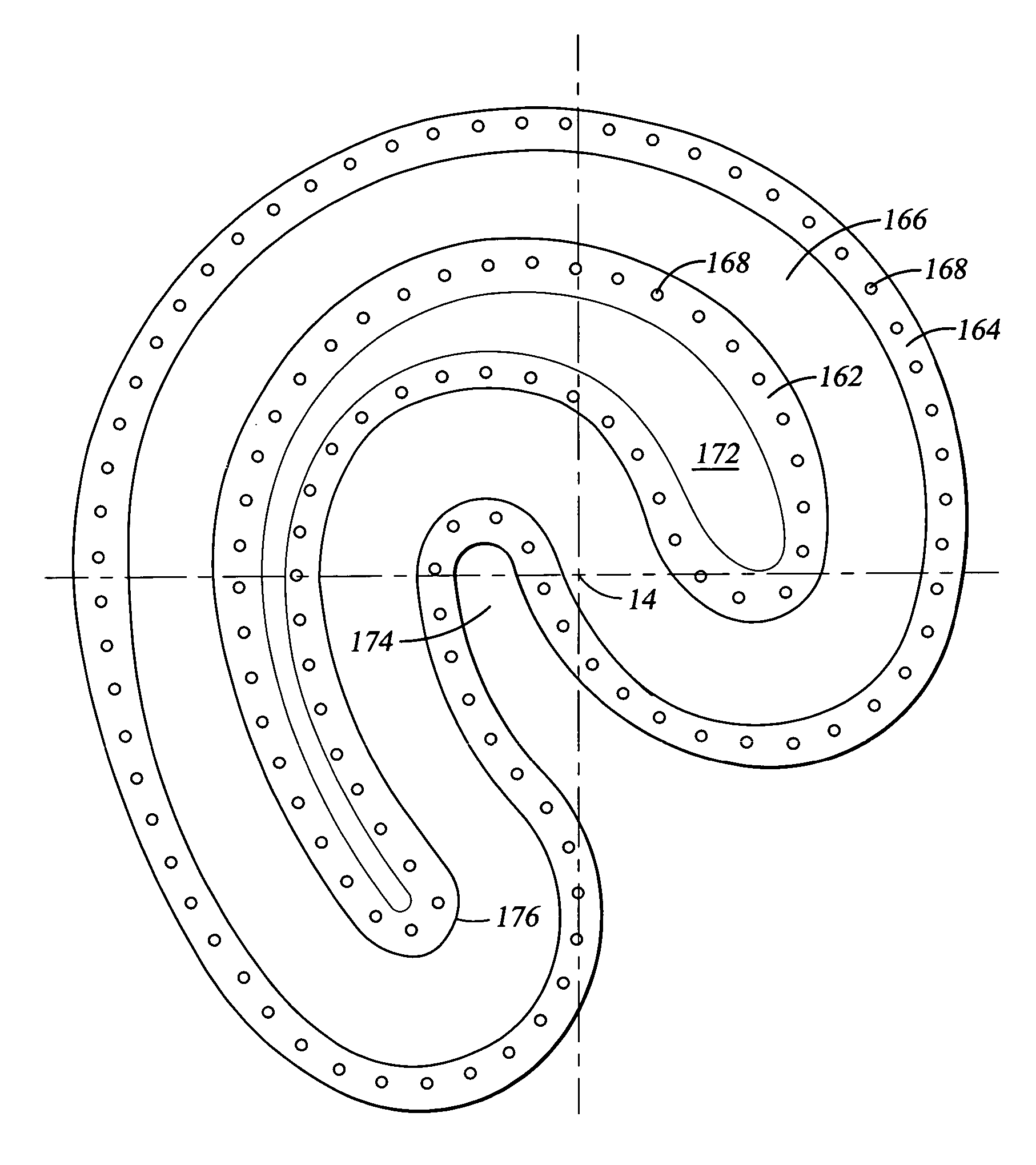

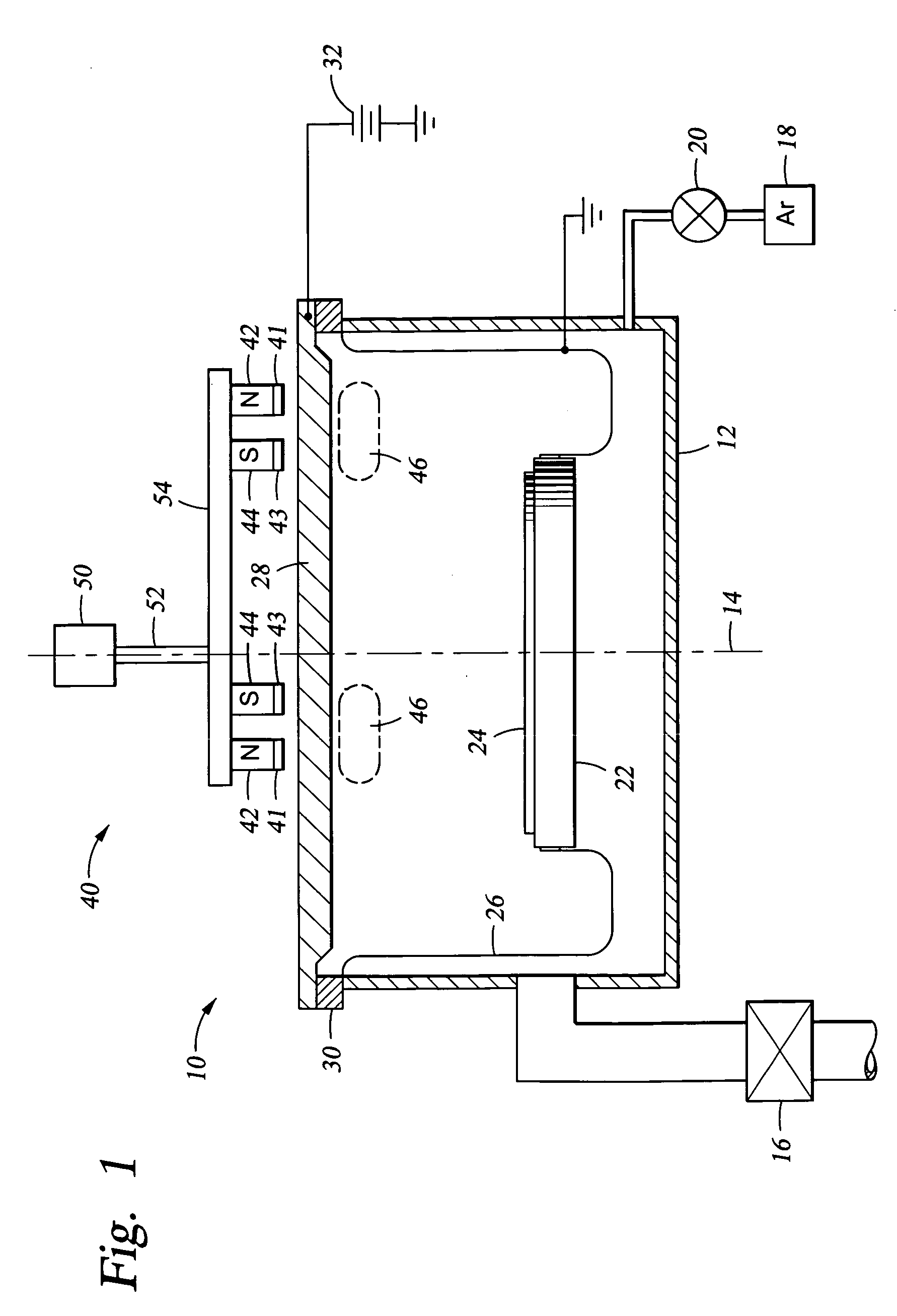

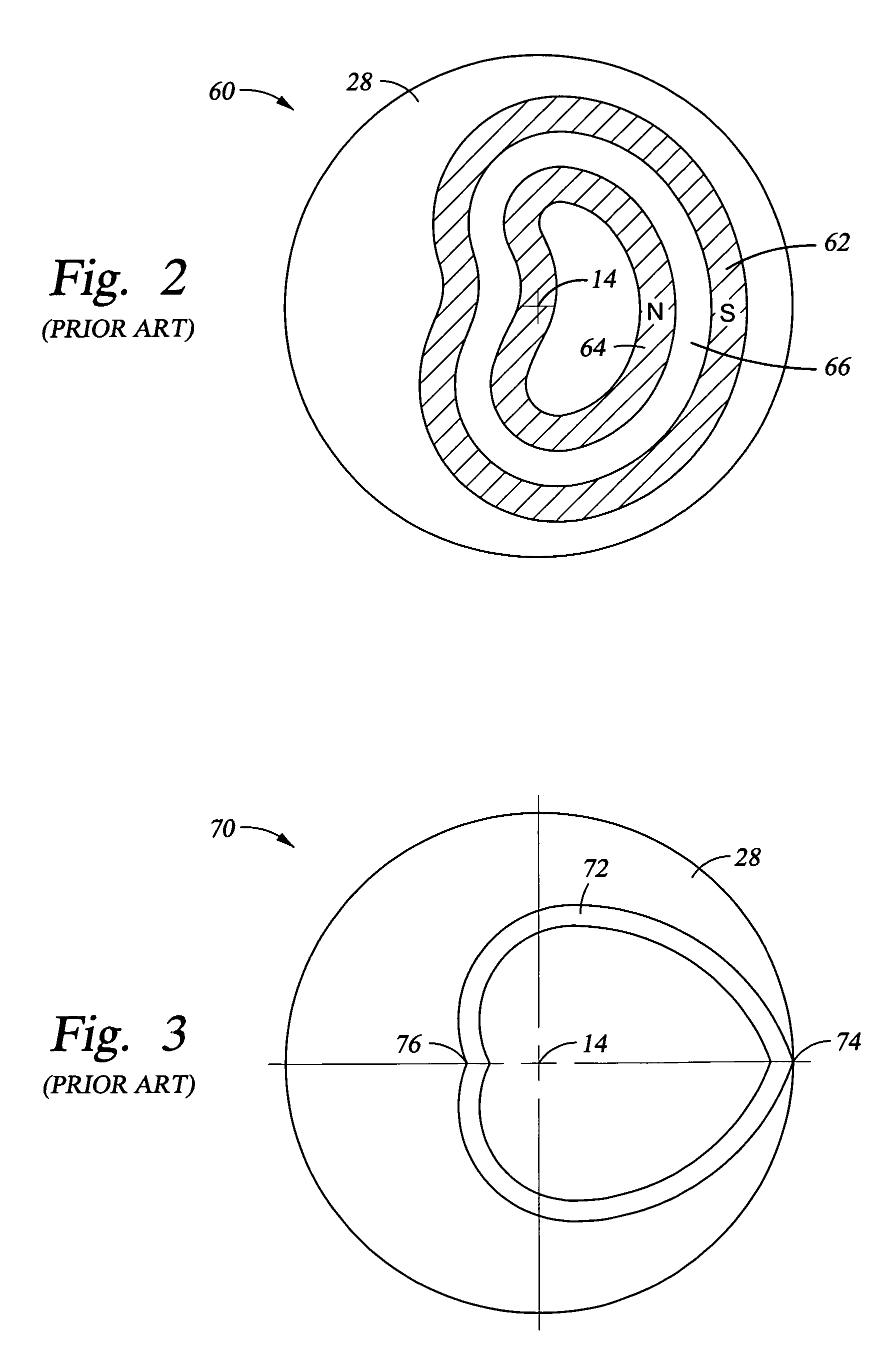

Multi-track magnetron exhibiting more uniform deposition and reduced rotational asymmetry

ActiveUS20060144703A1Improves radial erosion uniformityImprove deposition uniformityCellsElectric discharge tubesRotational axisMagnetic poles

A multi-track magnetron having a convolute shape and asymmetric about the target center about which it rotates. A plasma track is formed as a closed loop between opposed inner and outer magnetic poles, preferably as two or three radially arranged and spirally shaped counter-propagating tracks with respect to the target center and preferably passing over the rotation axis. The pole shape may be optimized to produce a cumulative track length distribution conforming to the function L=arn. After several iterations of computerized optimization, the pole shape may be tested for sputtering uniformity with different distributions of magnets in the fabricated pole pieces. If the uniformity remains unsatisfactory, the design iteration is repeated with a different n value, different number of tracks, or different pole widths. The optimization reduces azimuthal sidewall asymmetry and improves radial deposition uniformity.

Owner:APPLIED MATERIALS INC

Waterless stemming for blast furnace

InactiveCN1523120AImprove workabilityEasy to squeeze outBlast furnace componentsBlast furnace detailsAnthraceneContraction rate

The present invention provides an anhydrous stemming for blast furnace. Its composition includes (wt%) coarse brown corundun 1-4%, fine brown corundum 2-5%, coarse mullite 7-15%, fine mullite 9-20%, coke powder 15-20%, clay 10-19%, silicon carbide 7-11%, sericite 5-8%, bitumen 2-4% and anthracene oil 15-25%. It has good working property, stable high temperature resistance, excellent caking property, quick agglutinating property, low ton-iron stemming consumption, low contraction rate and high strength, it can raise tap up-to-standard rate to 100% from original 61.5%, can raise production safety of blast furnace, and can raise smelting strength.

Owner:WUKUN STEEL

Free layer blade damper by magneto-mechanical materials

InactiveUS20080124480A1Maximum damping capabilityLarge resistanceLiquid surface applicatorsMolten spray coatingThermal sprayingGas phase

A coating for an article is provided to enhance vibration damping and fatigue strength, without diluting resistance to erosion, wear, and corrosion for metallic components such as blades, blisks, shafts and bearings of a gas turbine engine operating in a hostile environment. The invention includes a metallic substrate and a thin layer of magneto-mechanical material bonded to the surface of the substrate by a coating process. The coating material is made of the Fe—Cr—Al or Fe—Cr—Mo based magneto-mechanical materials and deposited to the surface of the substrate via a thermal spraying process in vacuum or in air. In order to achieve maximum damping capability and resistance to erosion, wear, and corrosion, several optimal compositions of the coating material in conjunction with new application methods have been developed. The coating is often very thin and smooth in order not to dilute aerodynamic efficiency and fatigue strength. The thin layer of magneto-mechanical material can also be applied and bonded to the substrate by a variety of methods, for example using a self-adhesive foil, made by Fe—Cr—Al or Fe—Cr—Mo alloys, on the surface of the substrate and via thermal spraying or physical vapor deposition processes.

Owner:SHEN MO HOW HERMAN

Method for modifying wear resistance and corrosion prevention of metal component surface

ActiveCN102506268AImprove wear resistanceImprove corrosion resistanceCorrosion preventionPipe protection against corrosion/incrustationCeramicCorrosion prevention

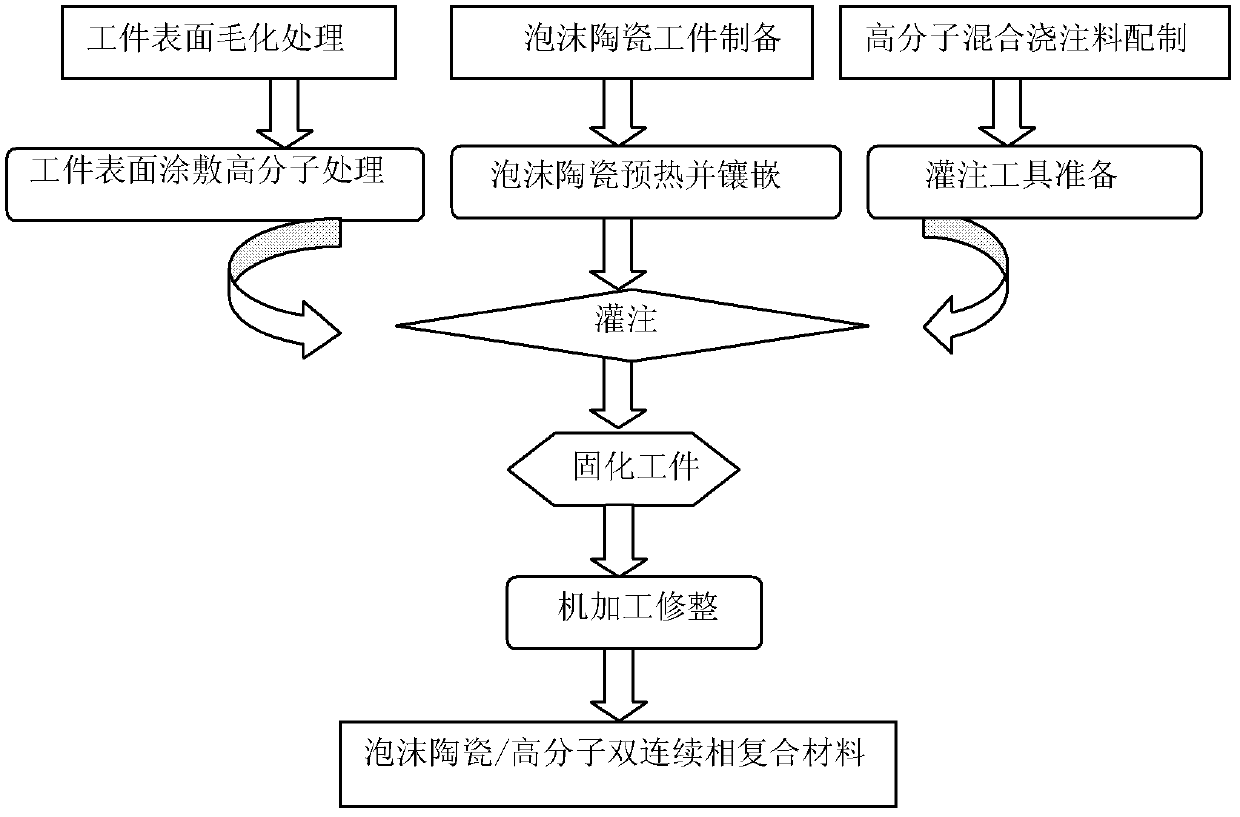

The invention relates to preparation technology for a wear-resistant and corrosion-prevention protective layer of a metal component surface, in particular to a method for modifying wear resistance and corrosion prevention of a metal component surface, which solves the problems that a valve, a pump and the like in the prior art are short in service life and the like due to serious wear and corrosion. Firstly, a component in a needed shape and of a needed size is made of foamed ceramics and fixed to the metal component surface by means of mechanical matching, connecting, welding, adhering or inlaying; and secondly, high polymer mixing castables are poured into foamed ceramic meshes by means of normal-pressure pouring, centrifugal pouring, vacuum suction pouring or injection molding, the foamed ceramic / high polymer co-continuous composite protective layer is obtained after curing, vulcanization or solidification, and the protective layer is firmly combined with the metal component surface. After the inner wall surface of a steel pipeline in a desulfurization system of a thermal power plant is protected by the method, the service life of the pipeline is five times longer than that of an existing pipeline protected by a lining rubber pipe.

Owner:LIAONING ZHUOYI NEW MATERIAL +1

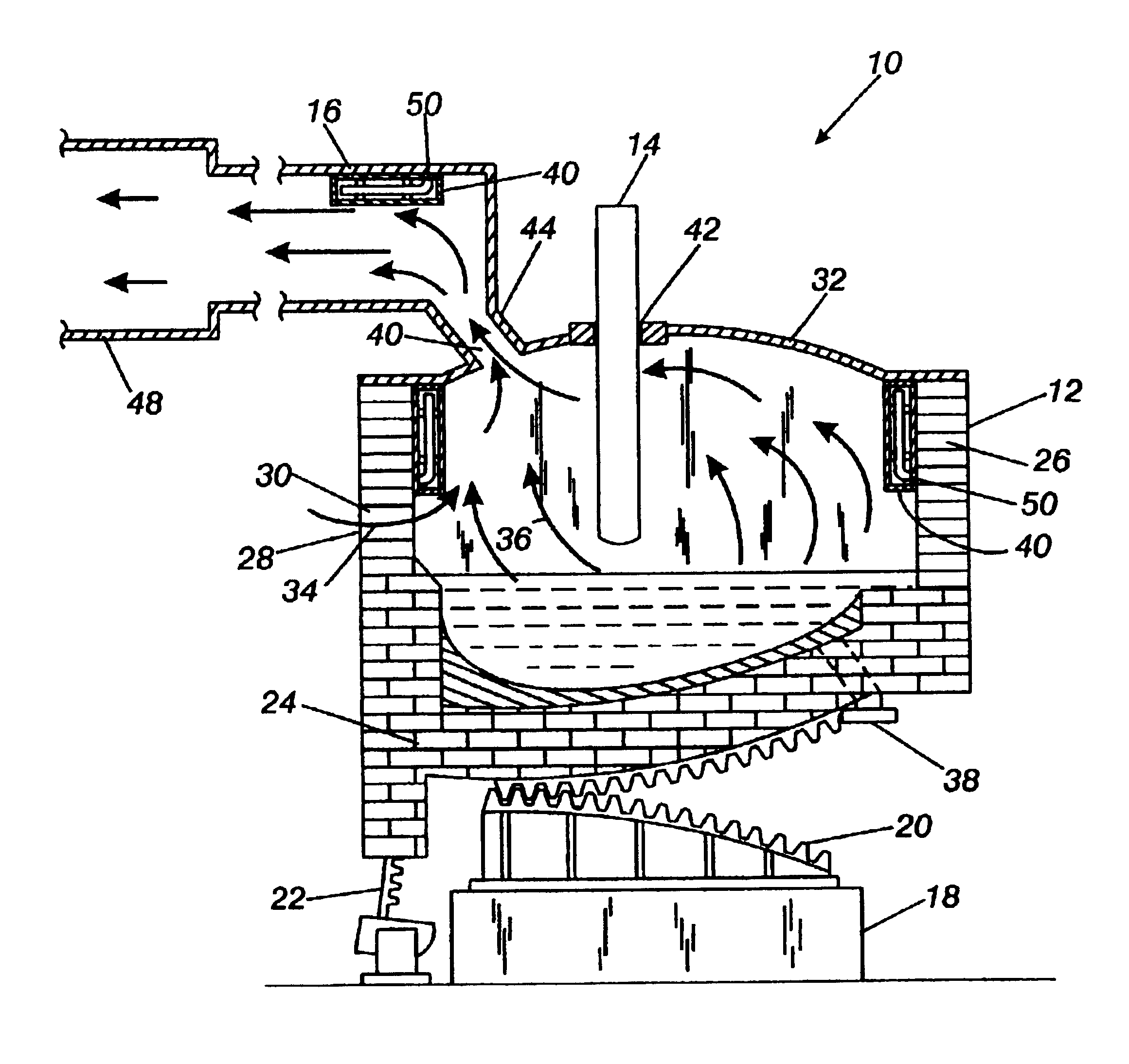

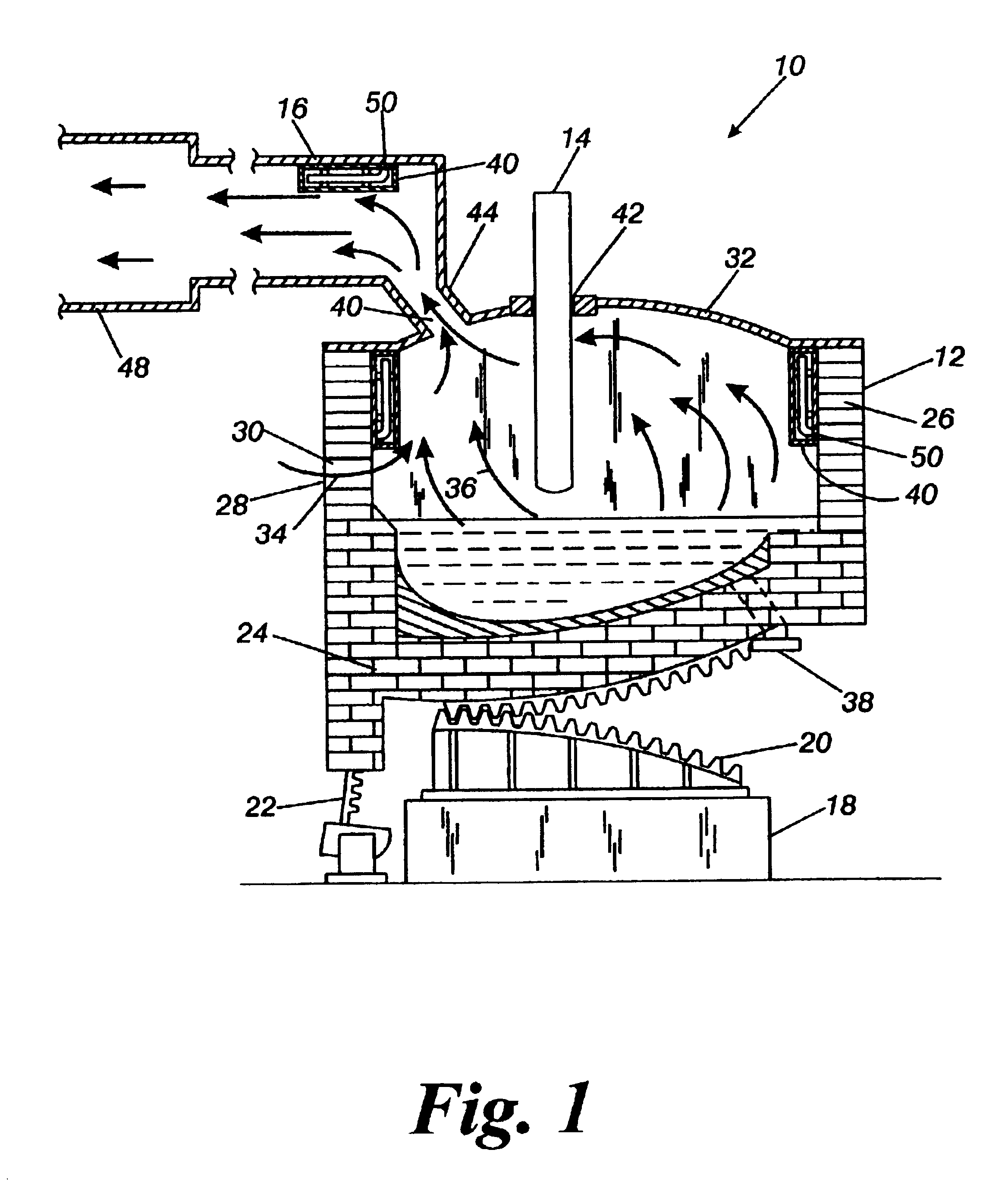

System and method for steel making

InactiveUS6890479B2Improve conductivityHigh hardnessTuyeresBlast furnace detailsProduction rateAlloy

A metallurgical furnace, which includes a furnace shell, an exhaust system, and a gas cleaning system, further includes a plurality of improved pipes and fume ducts throughout to increase operational life and productivity. The pipes and fumes ducts are comprised of an aluminum-bronze alloy which provides enhanced properties over prior art materials including thermal conductivity, modulous of elasticity and hardness. The use of the alloy also minimizes maintenance requirements of the pipes and fume ducts, thereby extending their operational life. In operation, gases formed from smelting or refining are evacuated from the furnace shell through the exhaust system into the gas cleaning system. The gases, as well as the system, are water cooled by way of the plurality of pipes displaced throughout.

Owner:AMERIFAB INC

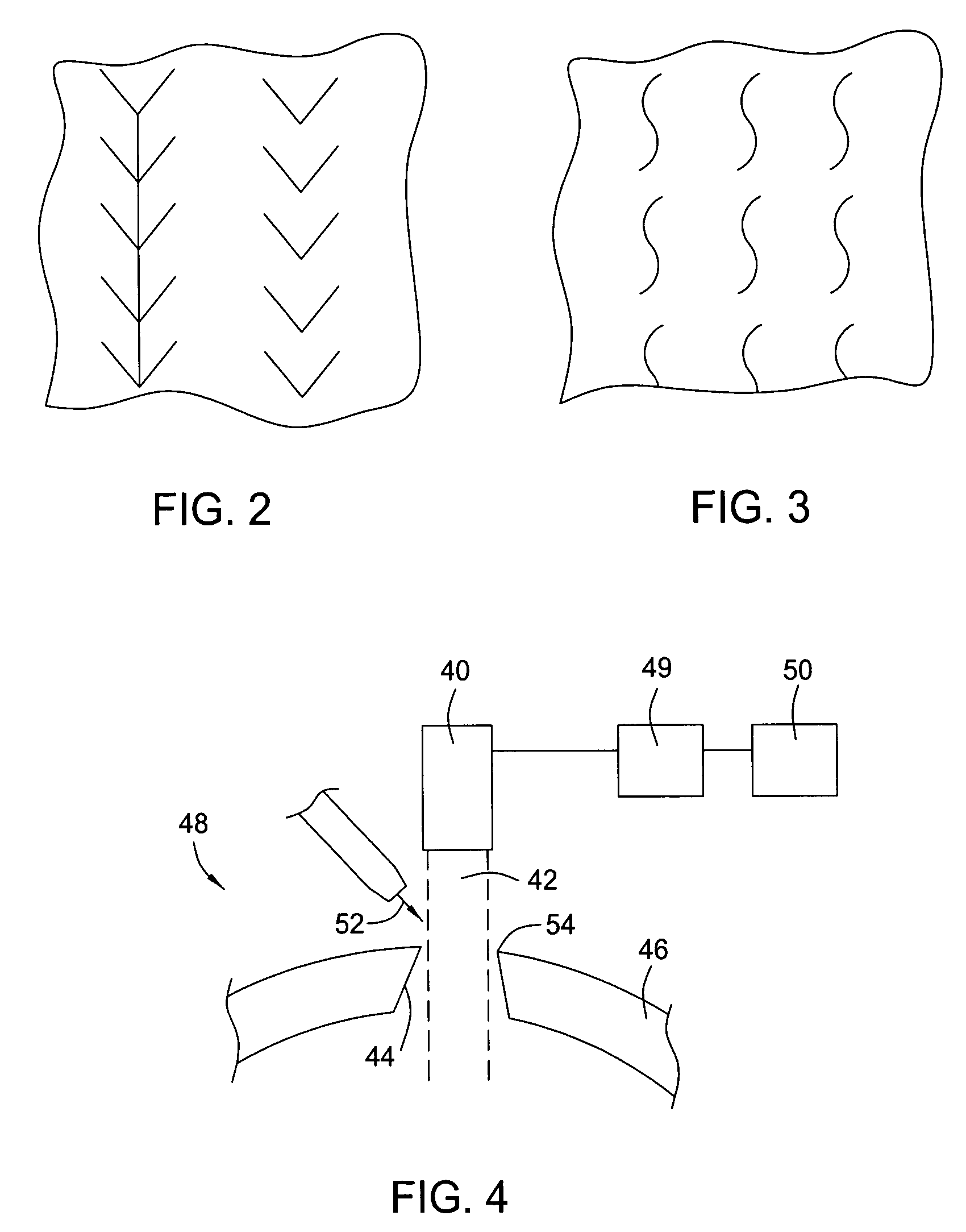

Erosion Ports for Shunt Tubes

A gravel pack apparatus for a wellbore has a shunt tube disposed along the apparatus near a wellscreen. The shunt tube is typically composed of stainless steel and has an internal passage for conducting slurry. Along its length, the tube has flow ports for passing the conducted slurry into the wellbore. The exit ports can use erosion inserts composed of erodible material, barrier inserts having breakable barriers, flow nozzles with external sheaths or caps, erosion-resistant bushings disposed on the flow nozzles, etc. The tube can also include a tube body having the exit ports and flow nozzles integrally formed thereon. The tube body can couple end-to-end with sections of shunt tube.

Owner:WEATHERFORD TECH HLDG LLC

Oxide and non-oxide composite integral stopper rod

InactiveCN102489695ASmall coefficient of thermal expansionImprove erosion resistanceMelt-holding vesselsOxide compositeRefractory

The invention belongs to the field of novel refractory materials with a continuous casting function, and provides an oxide and non-oxide composite integral stopper rod for continuous casting. The rod body of the integral stopper rod is made of an aluminum-carbon material; the head of the stopper rod is made of an oxide and non-oxide composite material; the space between the rod head and the rod body is formed by a mixed transition material between the rod head and the rod body; and the rod head comprises 65 to 80 percent of electric melting magnesia serving as a main raw material and is added with 5 to 20 percent of non-oxide, 7 to 12 percent of graphite and 8 to 12 percent of phenolic resin. According to the stopper rod, the molten steel scouring and corrosion resistance of the rod head material during use is improved by adding the non-oxide, appropriately reducing the content of the graphite and fully utilizing the advantages of high melting point, low thermal expansion rate, high thermal shock stability and difficulty in molten steel infiltration of the non-oxide.

Owner:北京利尔高温材料股份有限公司 +2

Multi-track magnetron exhibiting more uniform deposition and reduced rotational asymmetry

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com