Patents

Literature

98results about How to "Improve deposition uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

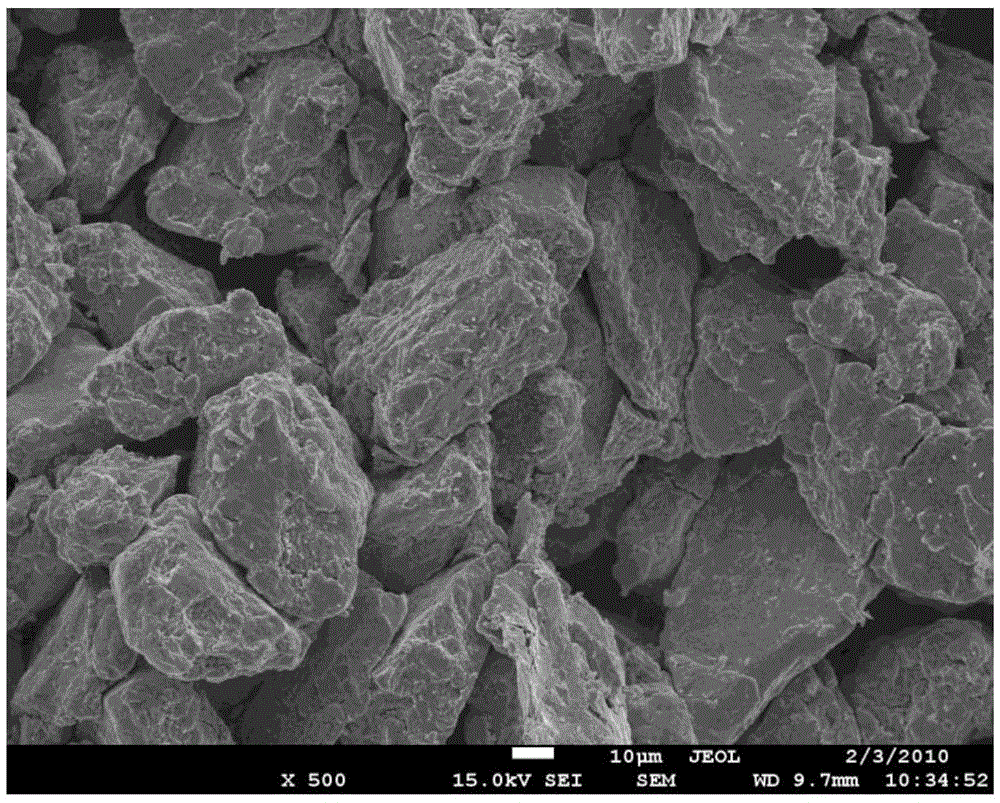

Diamond wire saw production method of surface modified diamond

InactiveCN101812710AAchieve electroplating depositionEasy to operateElectrophoretic coatingsElectrophoresisDiamond wire saw

The invention relates to a diamond wire saw production method of a surface modified diamond, which comprises the following steps: 1. removing surface grease and surface metal oxides on the surface of the diamond; 2. placing diamond micropowder into a cationic surfactant solution, applying positive potential and forming a layer of positive charge film on the surface of the diamond under the electrophoretic action by action of a cationic surfactant; and 3. carrying out composite electroplating of a diamond wire saw. In the invention, conductive processing is carried out on the diamond, so that diamond grains can orderly move in a plating solution under the action of an electric field to realize the electroplating deposition on the surface of a metal wire without the influence of the size of the diamond grains; the surfactant is adsorbed on the surface of the diamond, so that a plating layer and the diamond present an infiltrative type interface, and a Ni plating layer has strong holding capability on the diamond; and the diamond micropowder has high utilization ratio. The invention has simple process method and convenient operation, the diamond grains have rapid deposition speed, good deposition uniformity and high deposition density on the metal wire, an electroplating layer has high holding force on the diamond grains, and the diamond micropowder has high utilization ratio. The invention can realize industrialized production and provides a method for efficiently and rapidly producing the diamond wire saw.

Owner:CHANGSHA DIAT NEW MATERIAL SCI & TECH

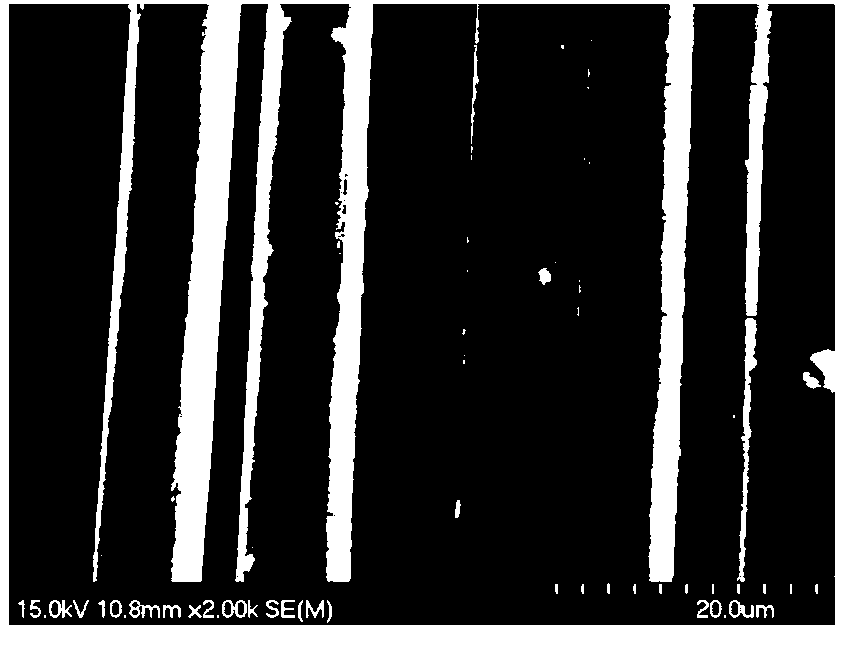

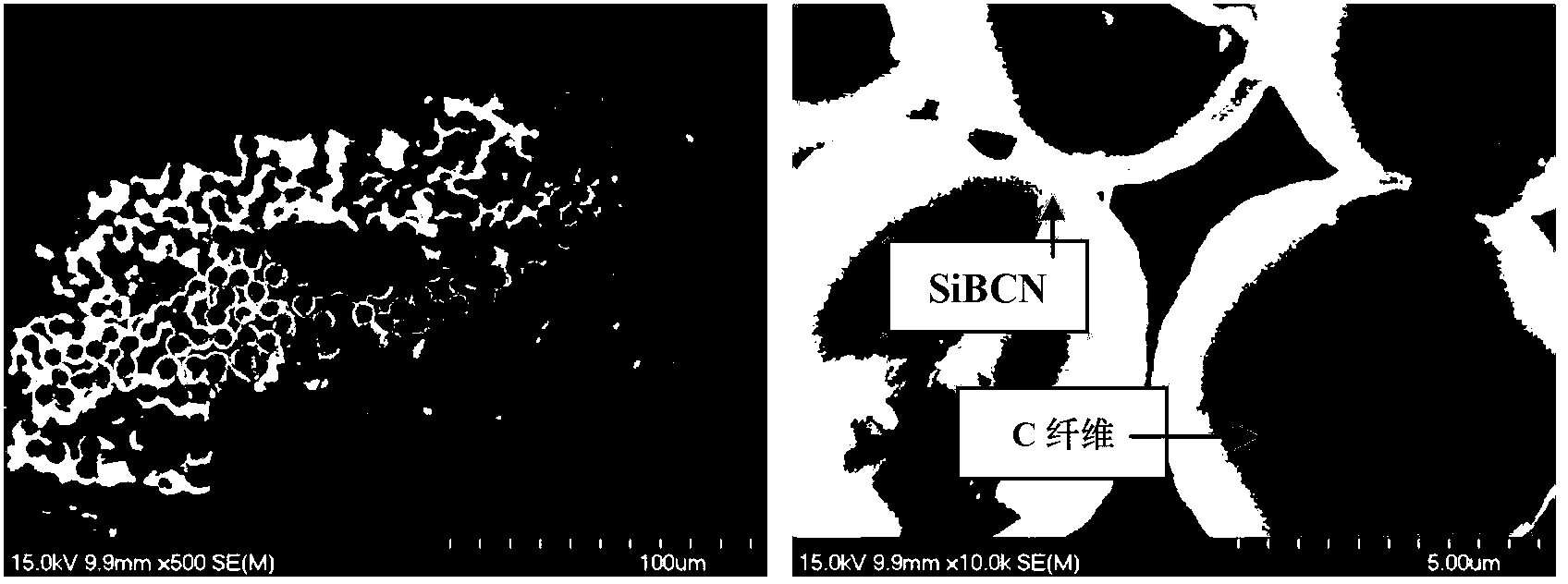

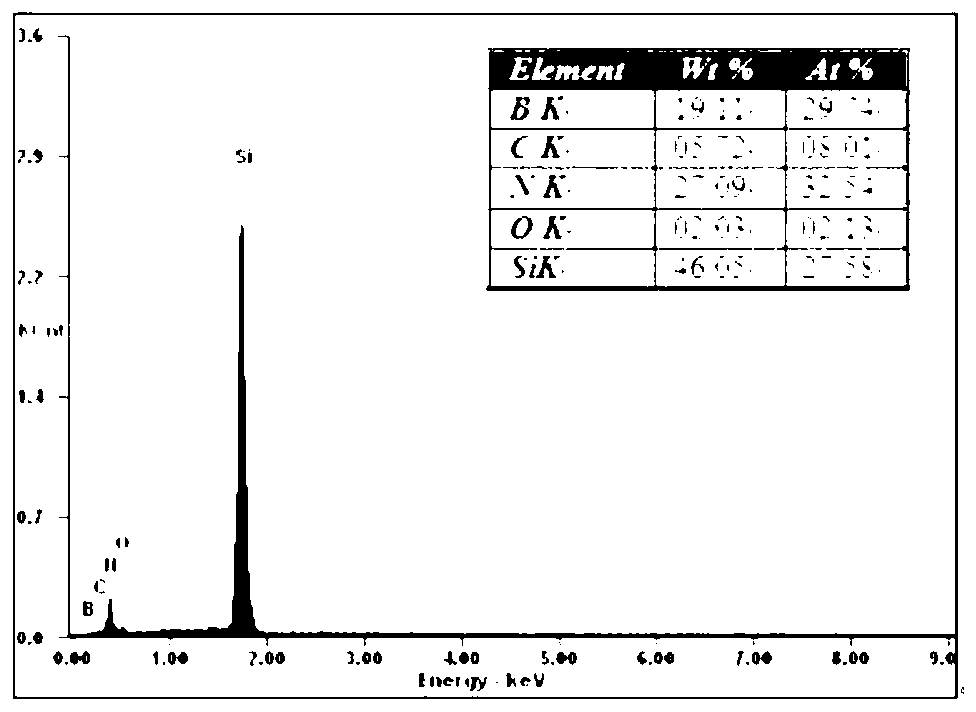

Chemical vapor deposition method of Si-B-C-N amorphous ceramic

The invention relates to a chemical vapor deposition method of a Si-B-C-N amorphous ceramic. The chemical vapor deposition method comprises the following steps of: suspending a substrate material on a matching sample bracket of a vacuum furnace, putting samples in a centre of an isothermal region in the furnace and preparing even Si-B-C-N amorphous ceramic on the surface / interior of the substrate material by using a CVD (Chemical Vapor Deposition) / CVI (Chemical Vapor Infiltration) method. The Si-B-C-N amorphous ceramic prepared by the chemical vapor deposition method can be applied to an interface, a matrix and a coating of a continuous fiber-reinforced ceramic matrix composite, has the advantages of excellent properties such as good high-temperature stability, good anti-oxidation property, strong creep resisting capability, low density, low coefficient of thermal expansion and low heat conductivity coefficient and the like, can replace materials such as SiC and Si3N4, further improves the using temperatures and prolongs the service lives of thermal structure ceramics and ceramic matrix composites and has a great application potentiality in the isothermal and long-life field of aircraft engines and industrial gas turbines; and meanwhile, the Si-B-C-N amorphous ceramic also has electrical properties similar to the semiconductors and interesting optical properties and is widely used in the fields of high-temperature invisibility, semiconductors, photoelectricity, communication and control.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

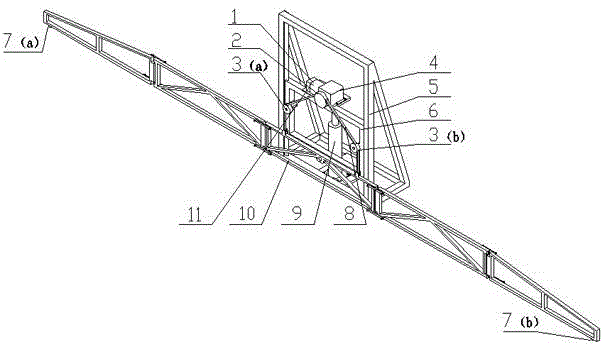

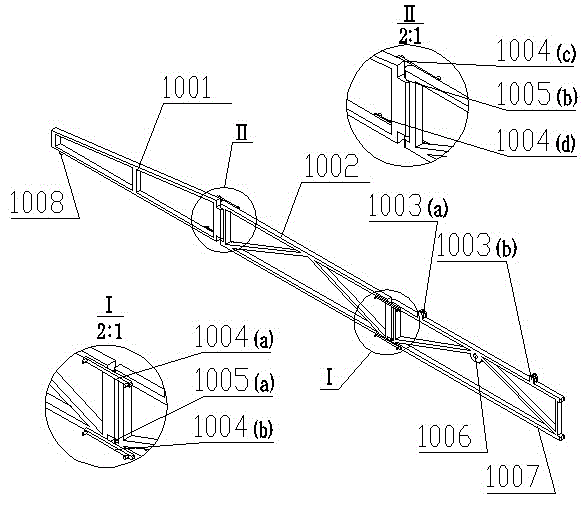

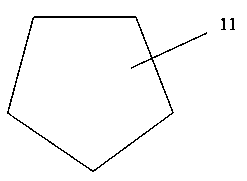

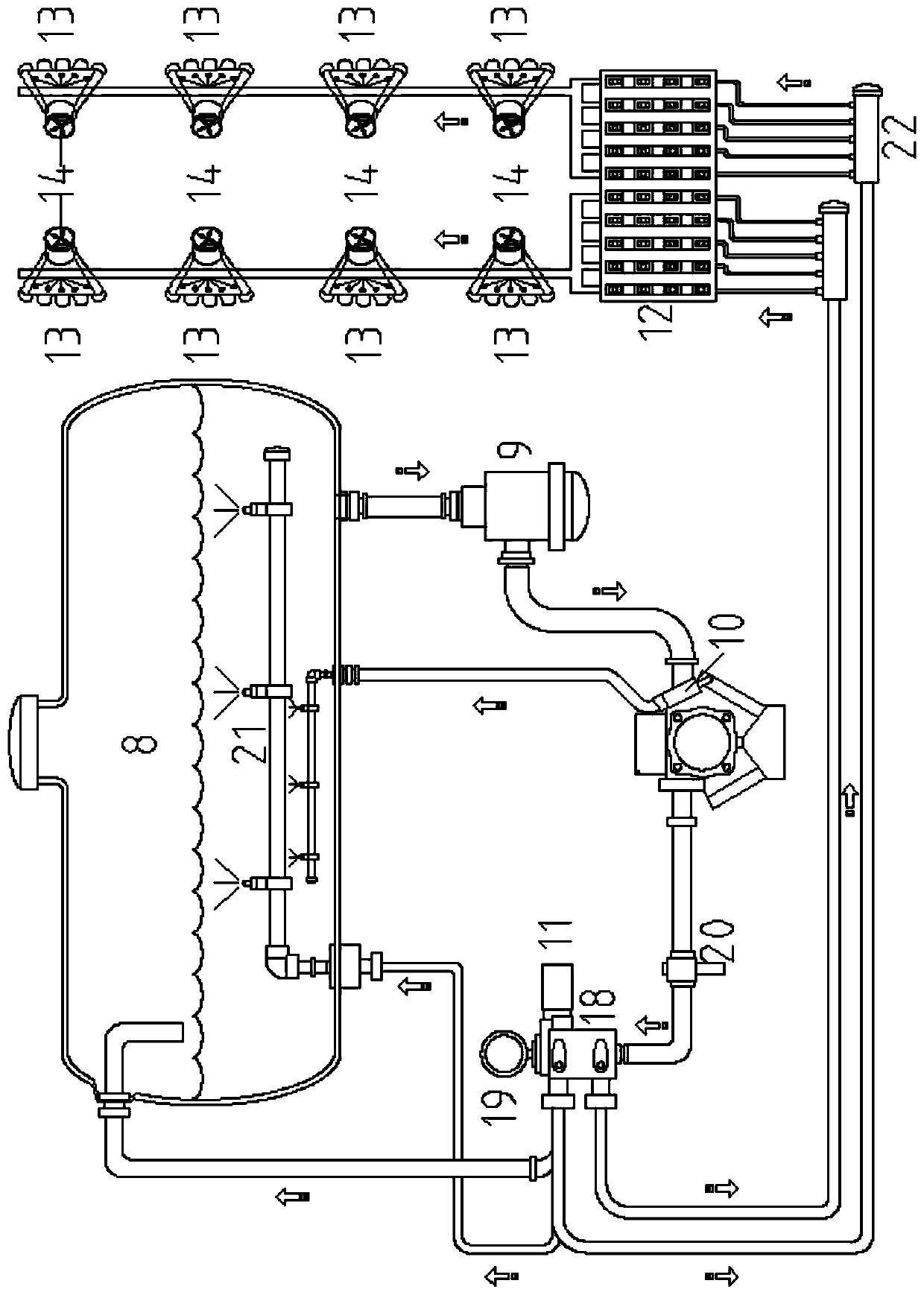

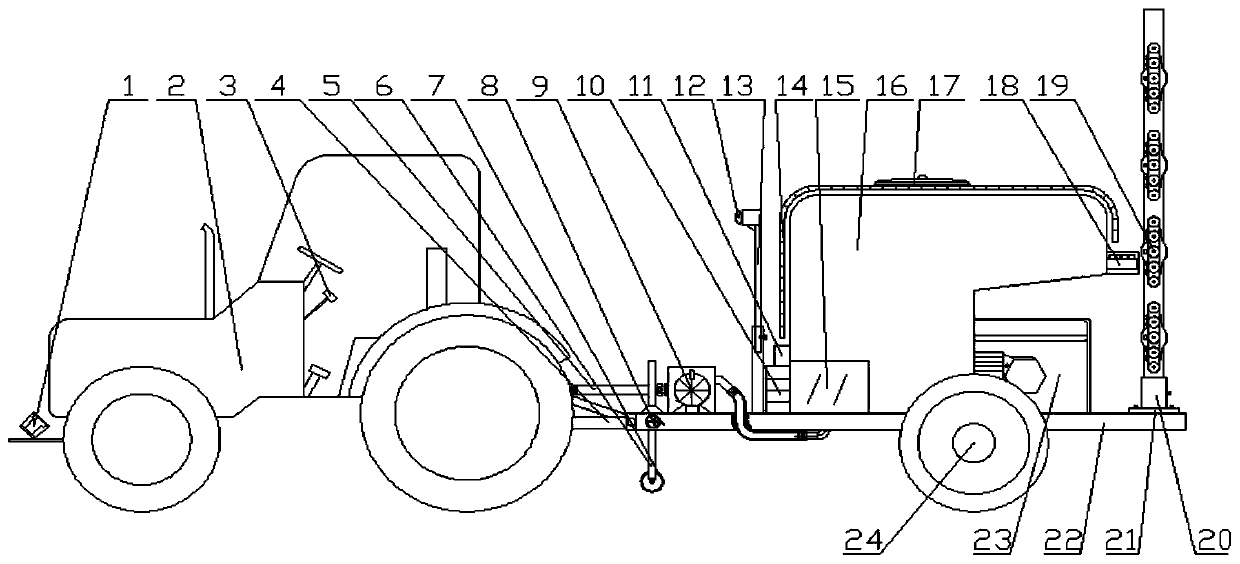

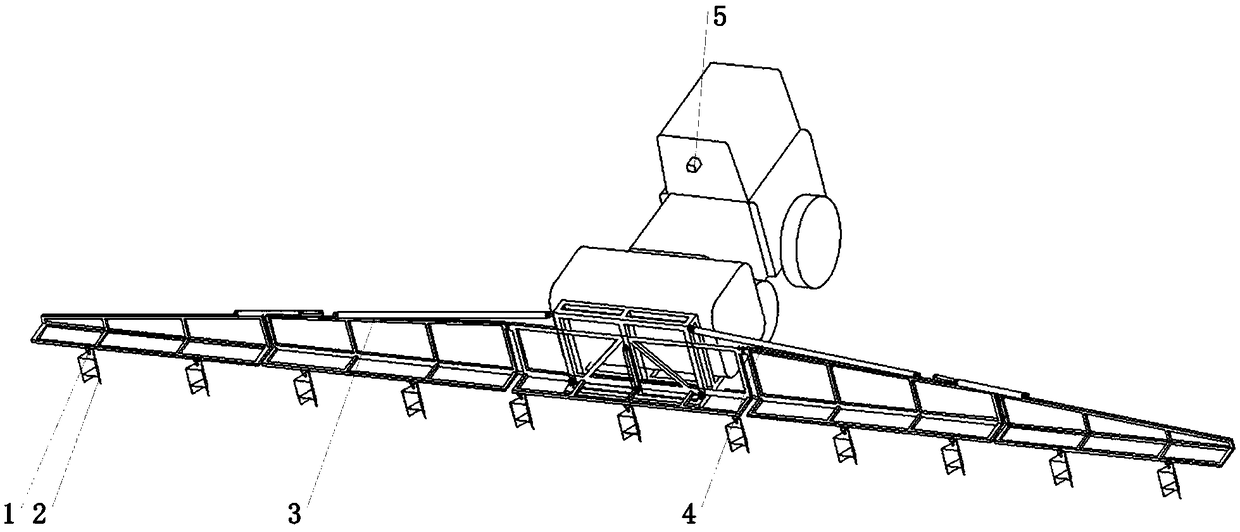

Lance boom capable of actively adjusting pose

ActiveCN103141461ASuppresses irregular movement in the vertical directionOvercome the effects of deposition uniformityInsect catchers and killersHydraulic cylinderWorking environment

The invention discloses a lance boom capable of actively adjusting the pose, which relates to the field of plant protection machinery. The lance boom consists of a mechanical part and a control part. The mechanical part comprises a direct-current servomotor, a driving pulley, two auxiliary pulleys, a worm-gear reducer, a frame, a hydraulic lifting frame, a rope, a lifting hydraulic cylinder and a lance boom assembly. The control part comprises distance sensors and a controller. When a spraying machine operates, the direct-current servomotor is controlled by the control part to drive the lance boom, so that the pose of the lance boom is adjusted. The spraying machine structured with the lance boom can inhibit the vertical irregular motion of the lance boom, and can ensure that the lance boom can be adapted to the working environment of the slope, and the uniformity of spray deposition is increased.

Owner:JIANGSU UNIV

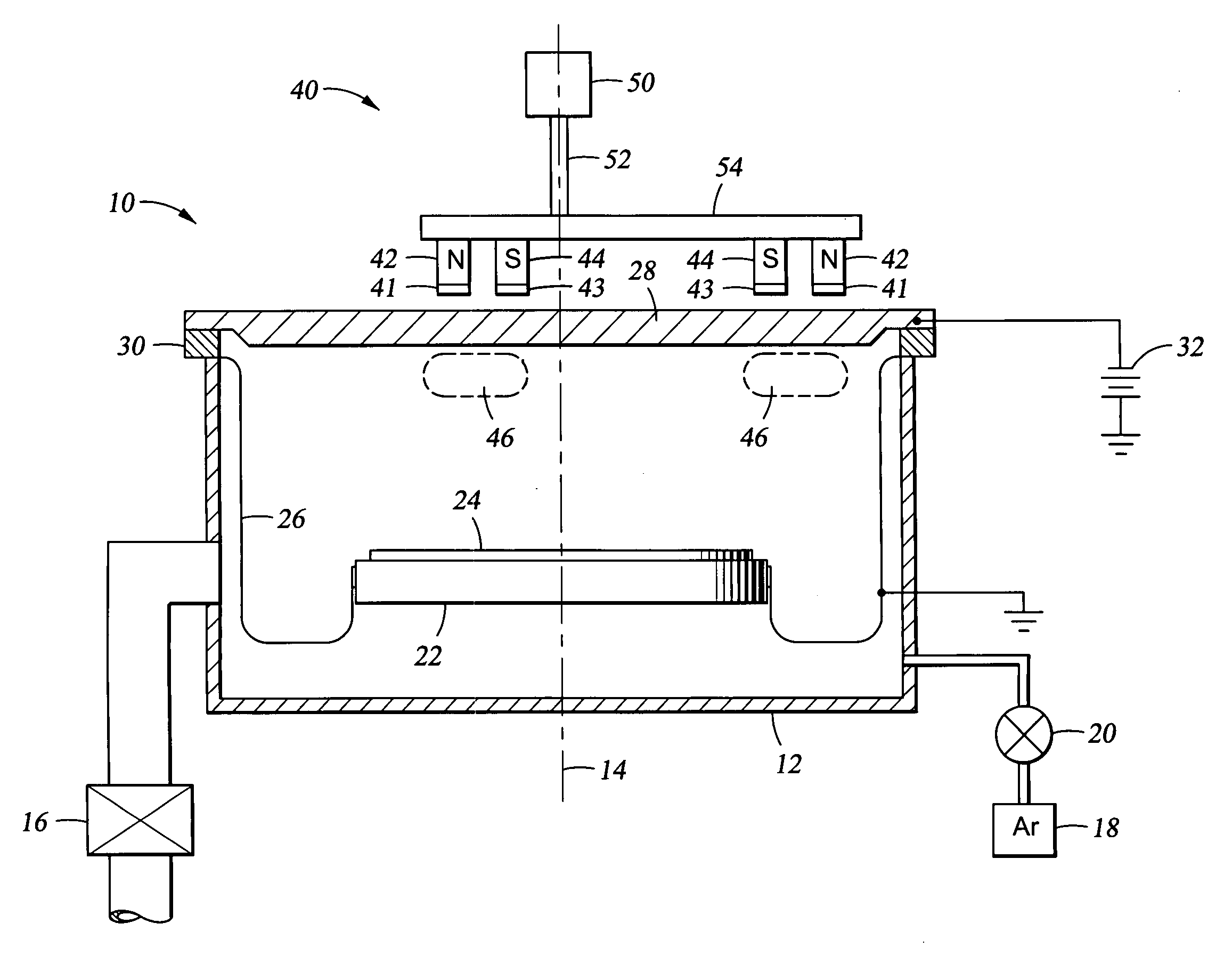

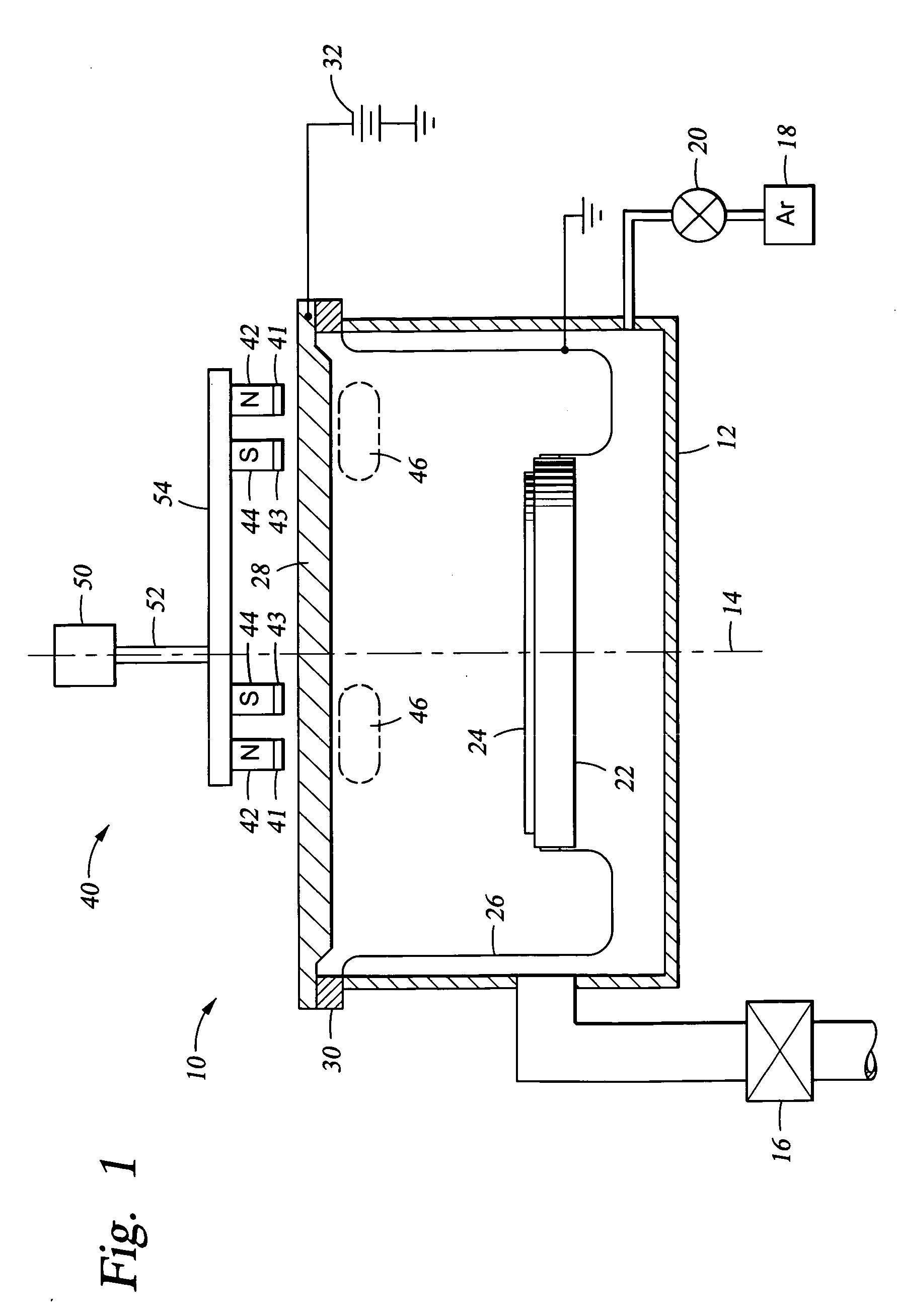

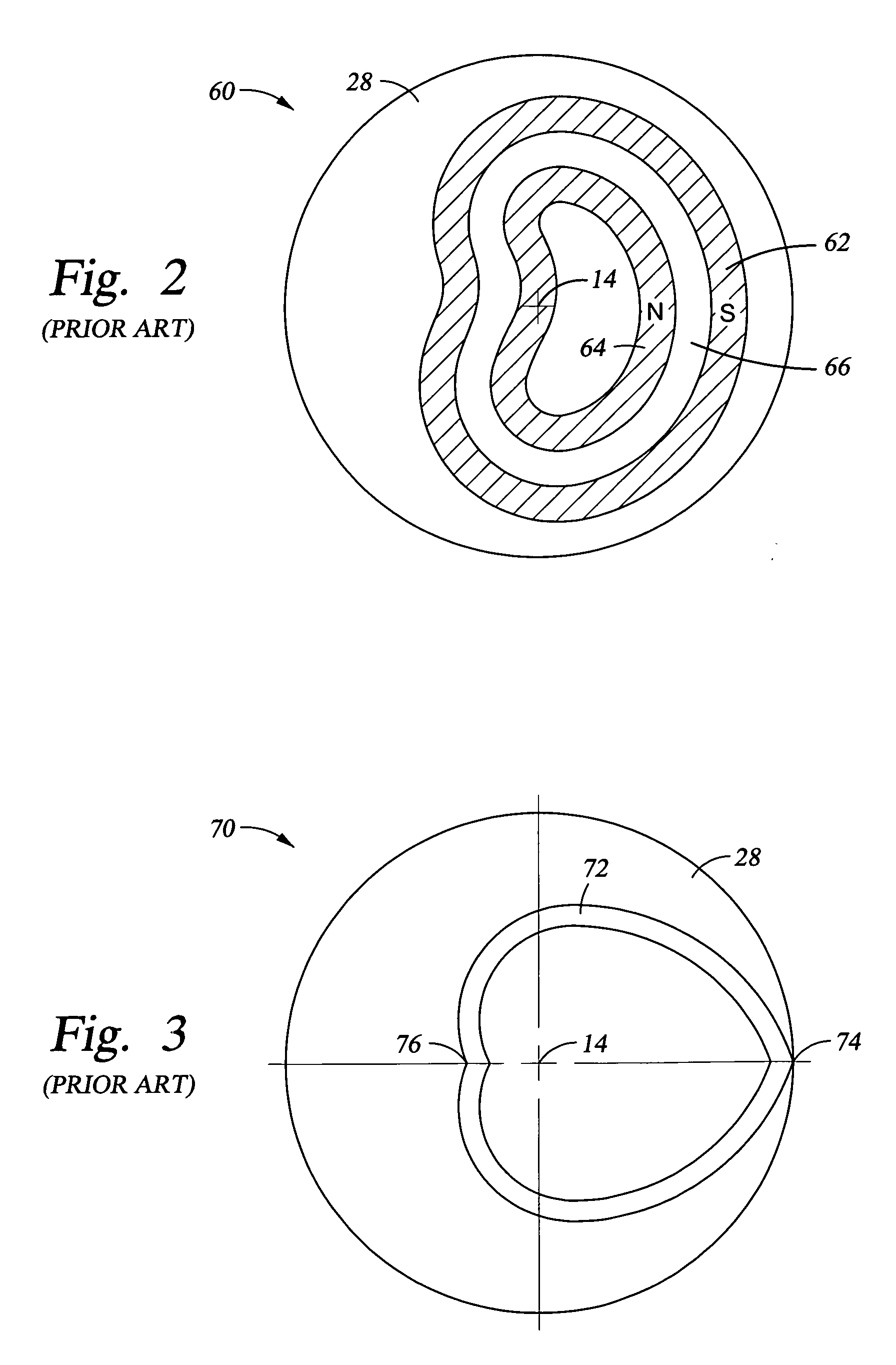

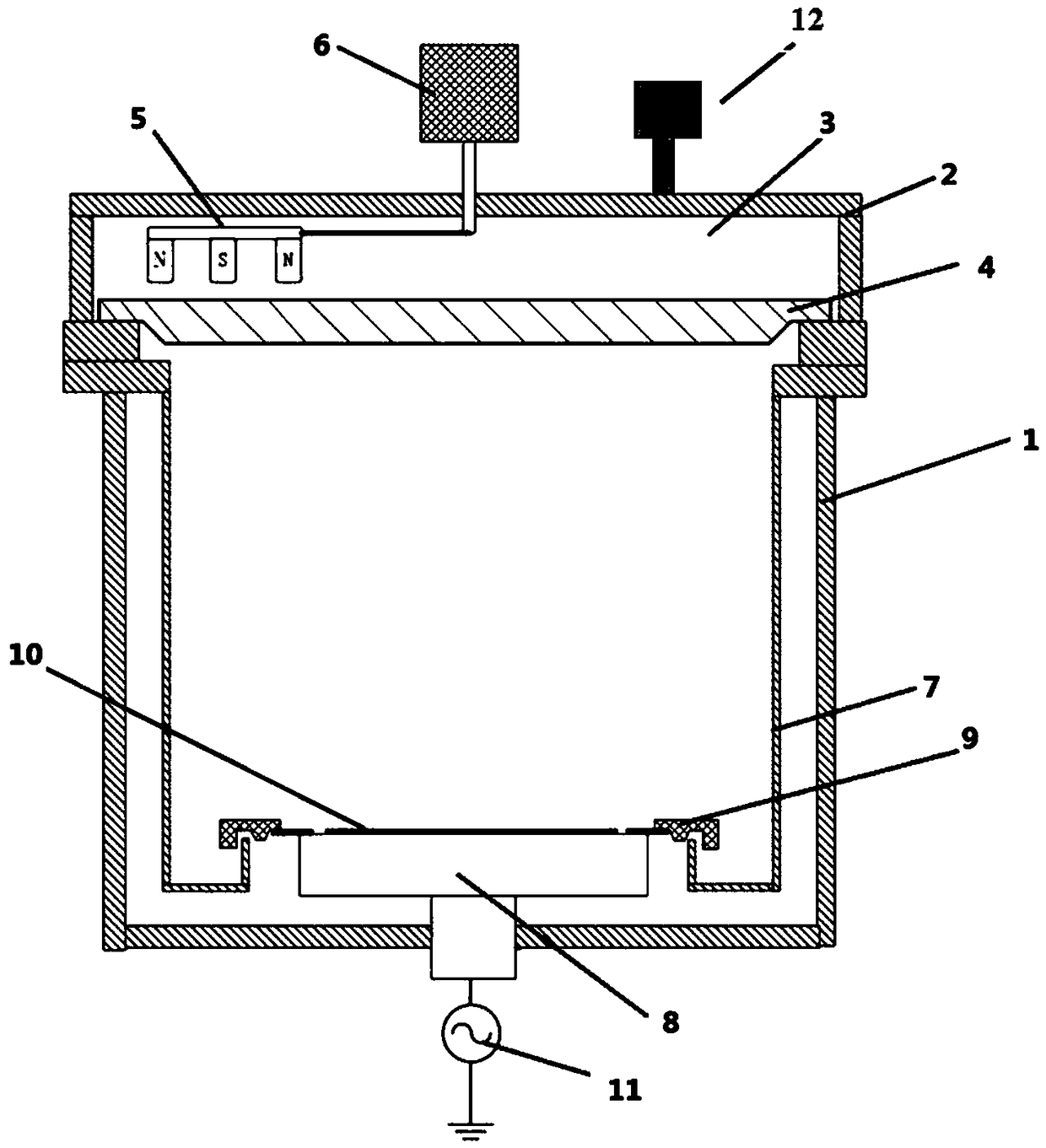

Multi-track magnetron exhibiting more uniform deposition and reduced rotational asymmetry

ActiveUS20060144703A1Improves radial erosion uniformityImprove deposition uniformityCellsElectric discharge tubesRotational axisMagnetic poles

A multi-track magnetron having a convolute shape and asymmetric about the target center about which it rotates. A plasma track is formed as a closed loop between opposed inner and outer magnetic poles, preferably as two or three radially arranged and spirally shaped counter-propagating tracks with respect to the target center and preferably passing over the rotation axis. The pole shape may be optimized to produce a cumulative track length distribution conforming to the function L=arn. After several iterations of computerized optimization, the pole shape may be tested for sputtering uniformity with different distributions of magnets in the fabricated pole pieces. If the uniformity remains unsatisfactory, the design iteration is repeated with a different n value, different number of tracks, or different pole widths. The optimization reduces azimuthal sidewall asymmetry and improves radial deposition uniformity.

Owner:APPLIED MATERIALS INC

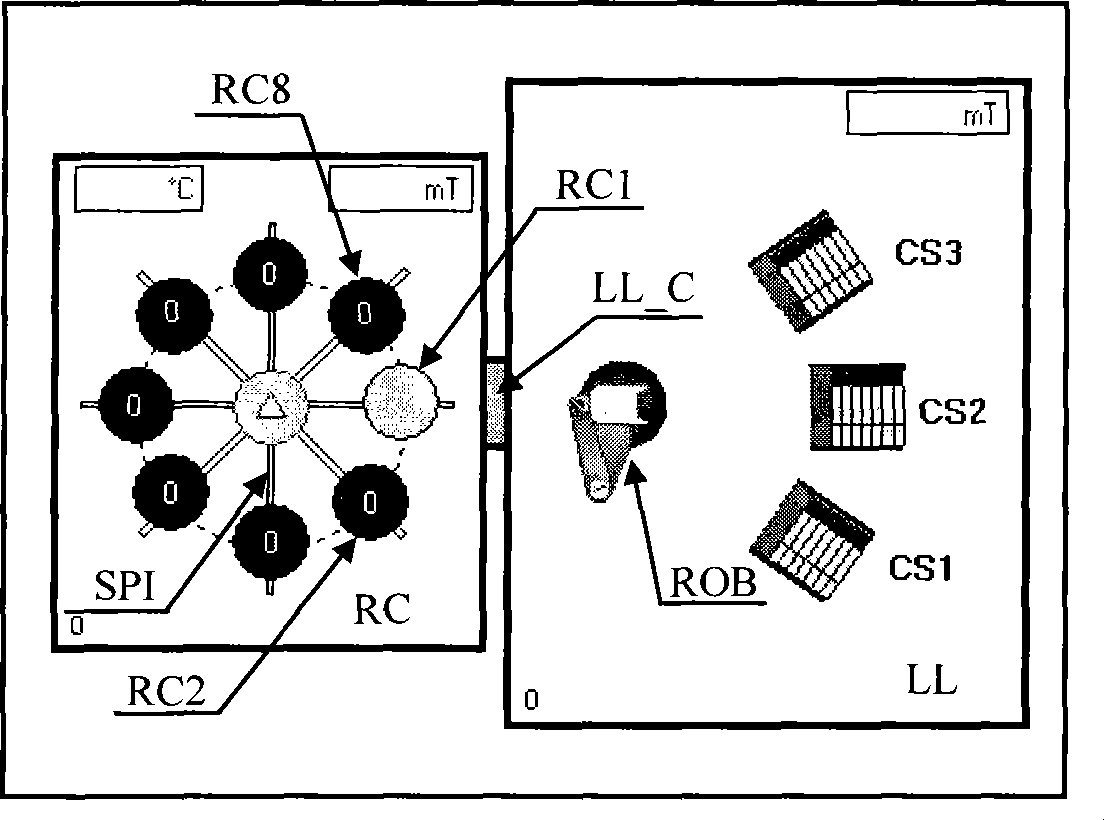

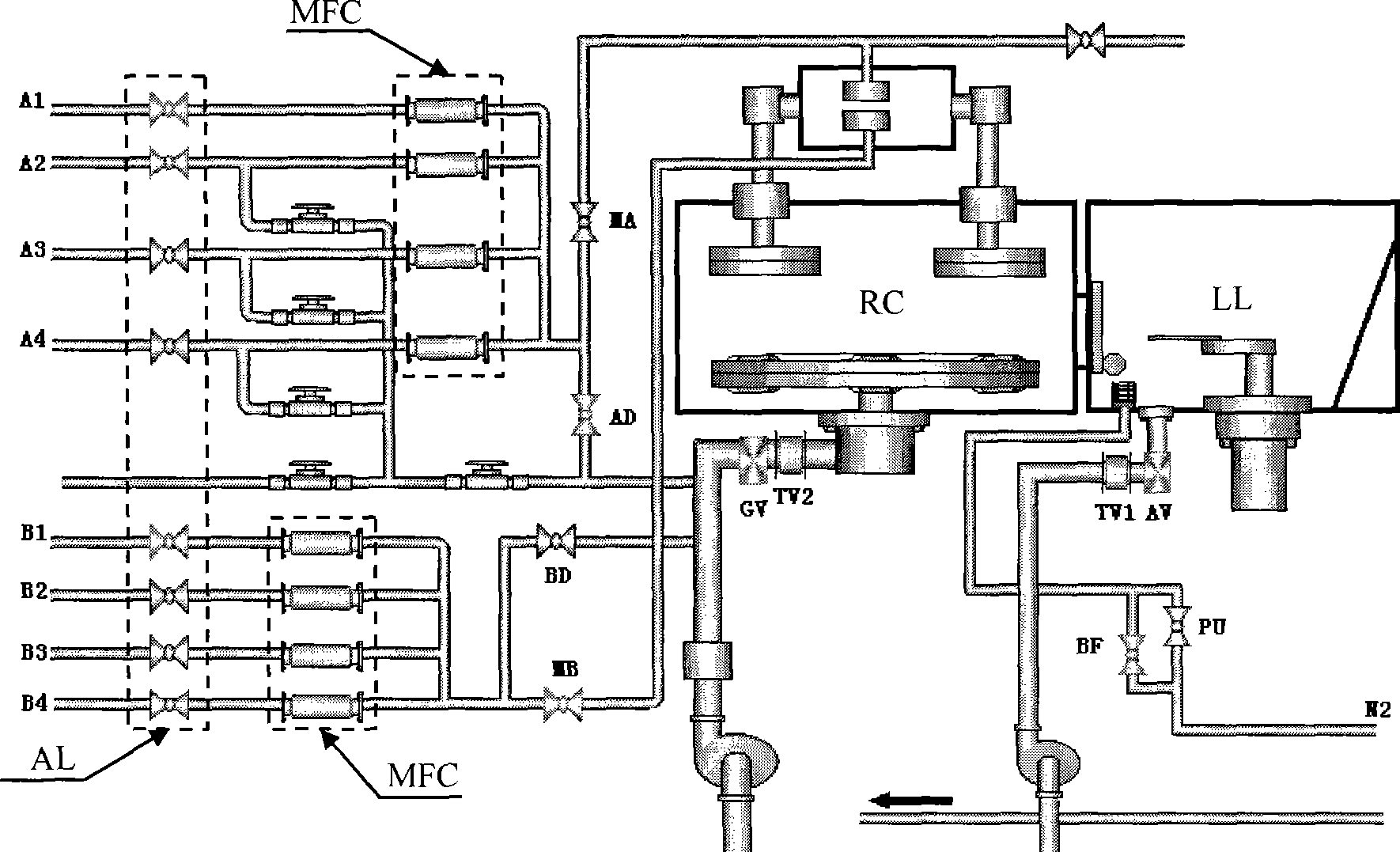

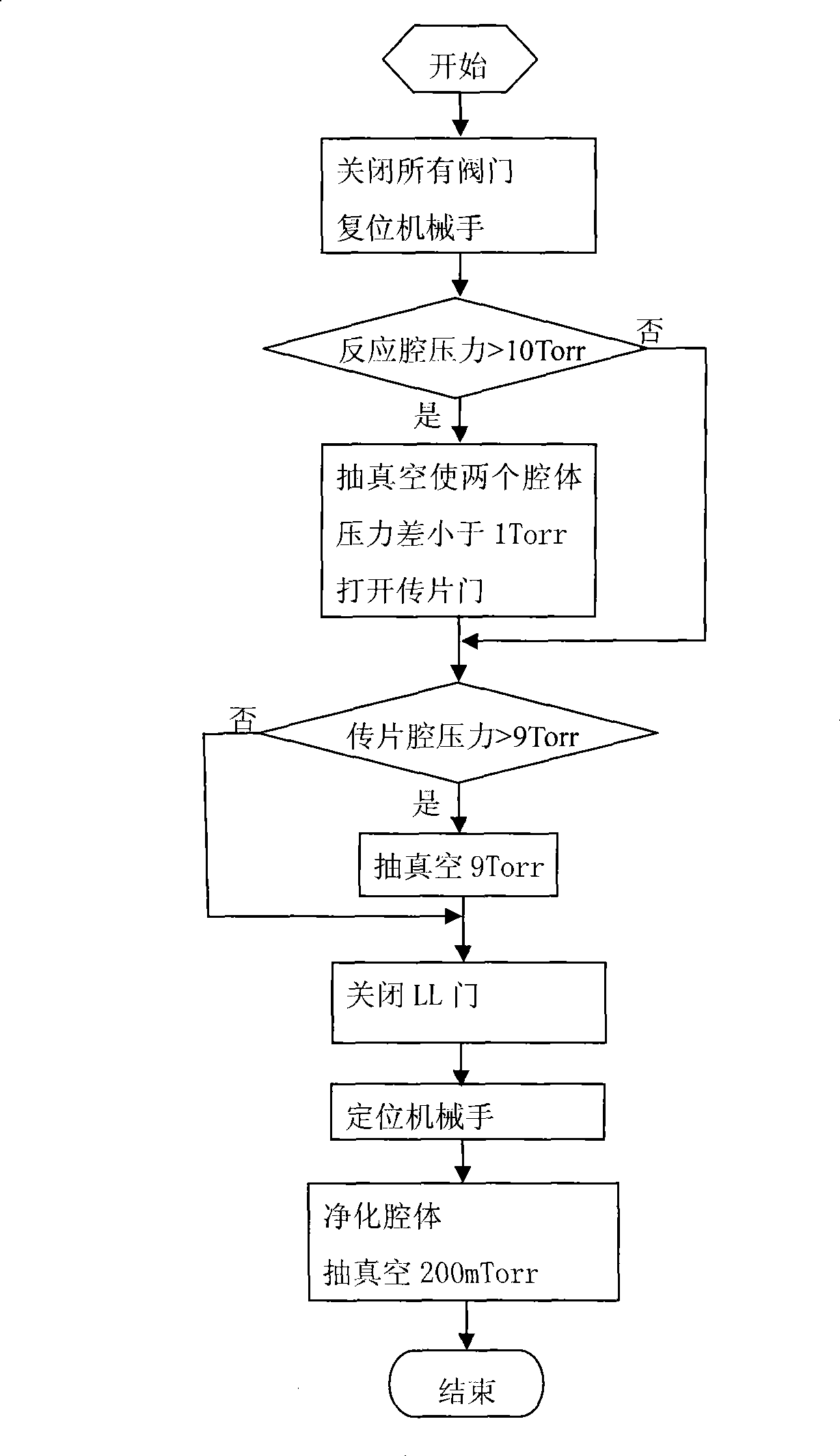

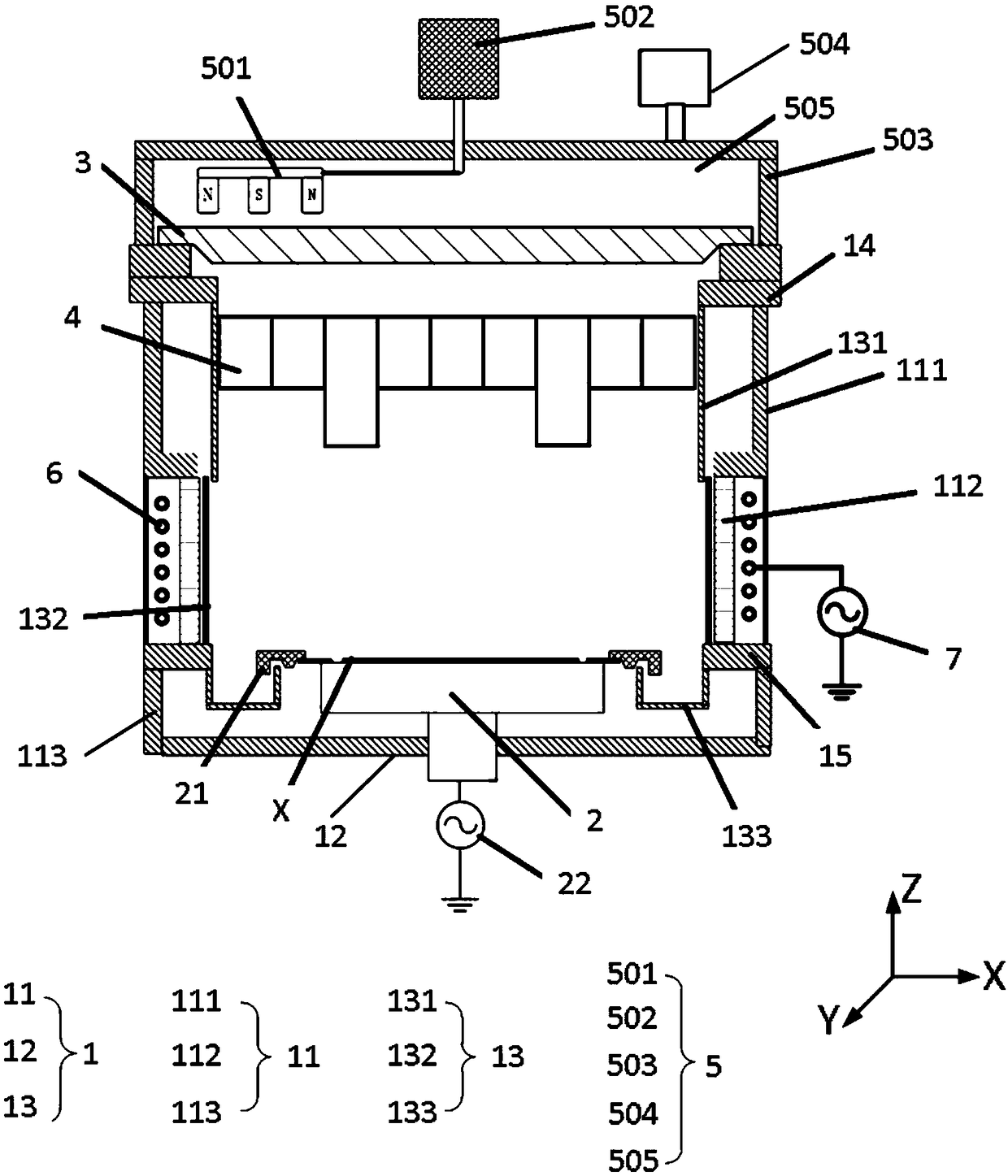

Control method for plasma reinforced chemical meteorology deposition apparatus

InactiveCN101469418AAddressing the needs of the future development of the processImprove deposition uniformityChemical vapor deposition coatingProcess mechanismEngineering

The invention belongs to a control system technique, in particular to a method for controlling plasma intensified chemical vapor phase deposition equipment. The method comprises the equipment initialization control, the wafer processing flow control and the equipment exception alarming control, wherein the equipment initialization control comprises the steps of starting a power supply of the equipment, turning on an alarm monitor, and sending initialization instructions of a sheet transmitting cavity and a reaction cavity; the wafer processing flow control comprises the steps of leading in a technique formulation, and using a batch or layer formulation to perform processing initialization, water processing and processing ending control; the equipment exception alarming control realizes the monitoring of equipment exception and failure, and performs the step treatment on the equipment alarming through an exception pretreating mechanism and an alarming response processing mechanism. The invention realizes the accurate process control to the chemical vapor phase deposition, and meets the process requirement in the process of manufacturing semiconductor devices.

Owner:MICROCYBER CORP +1

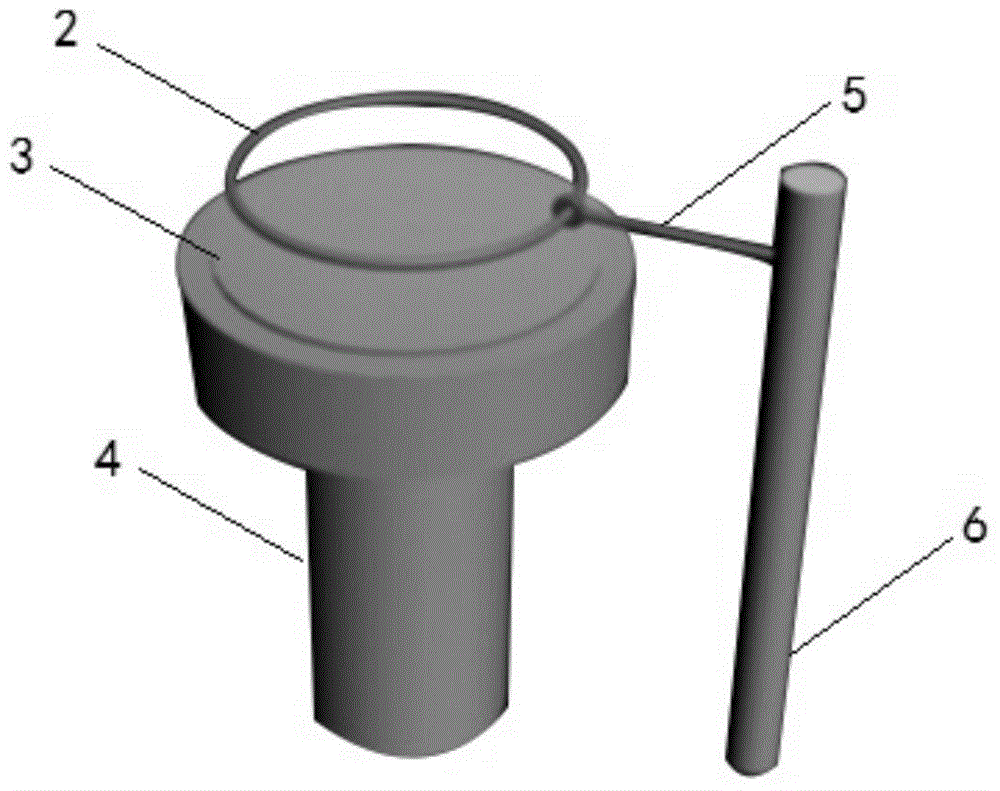

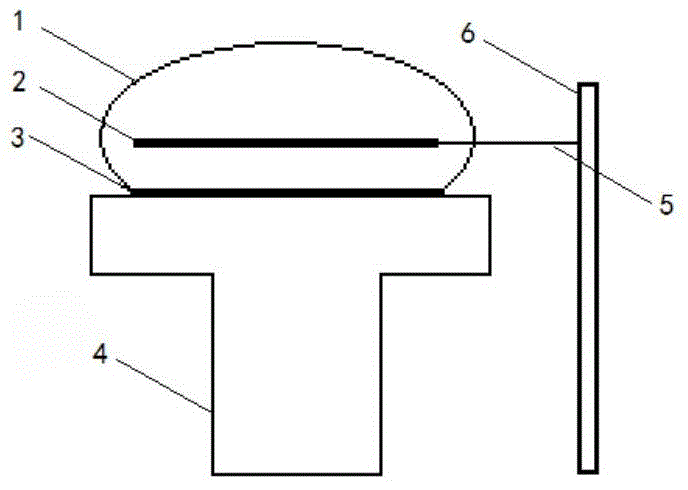

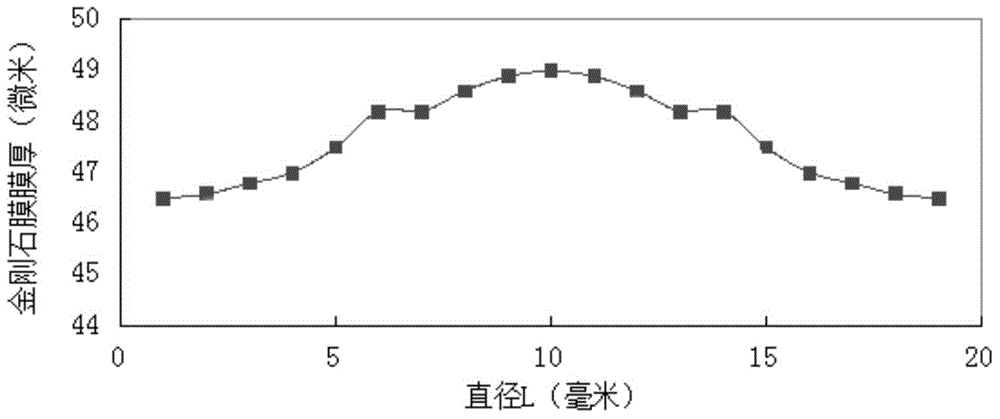

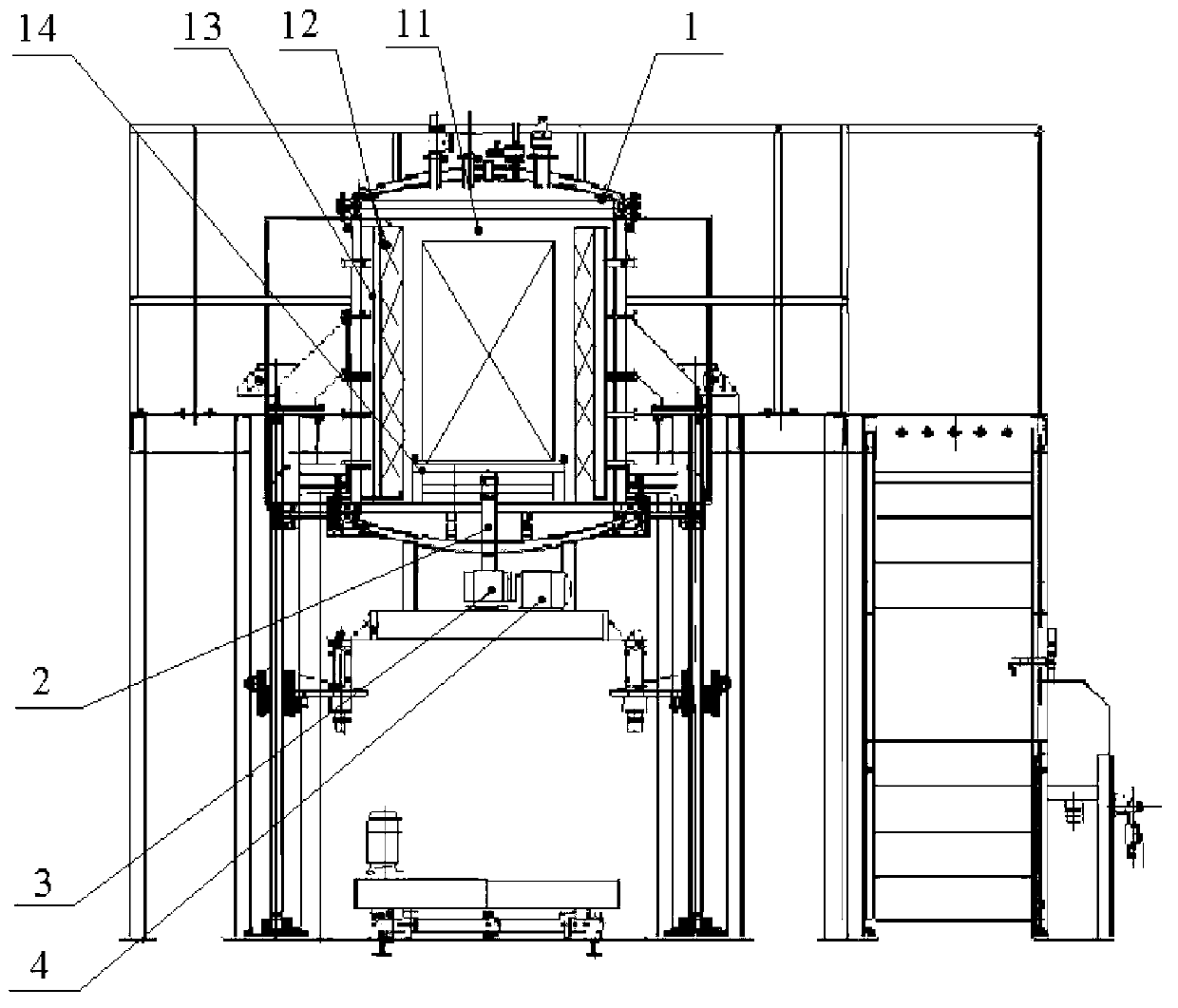

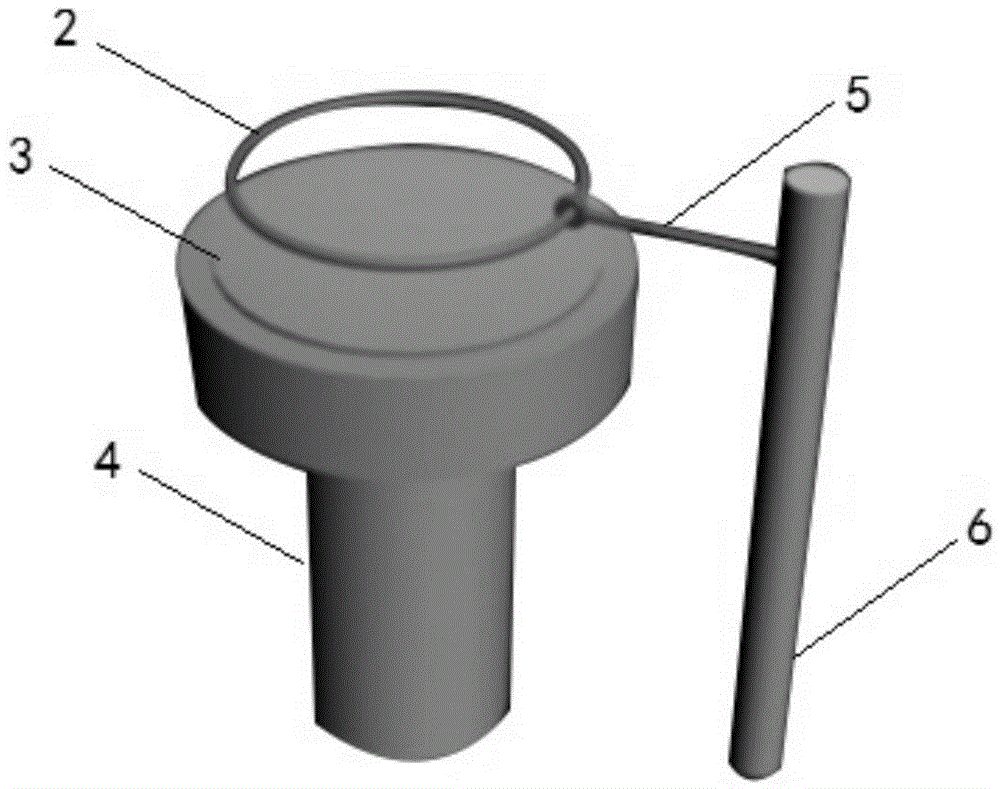

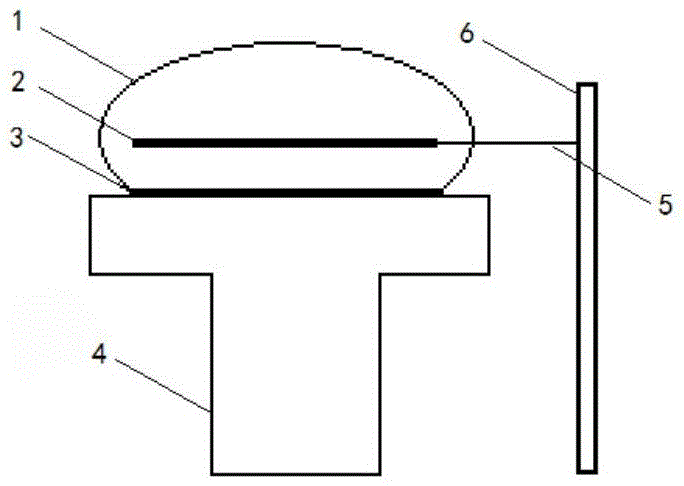

Preparation apparatus for diamond film and method for preparing diamond film by using apparatus

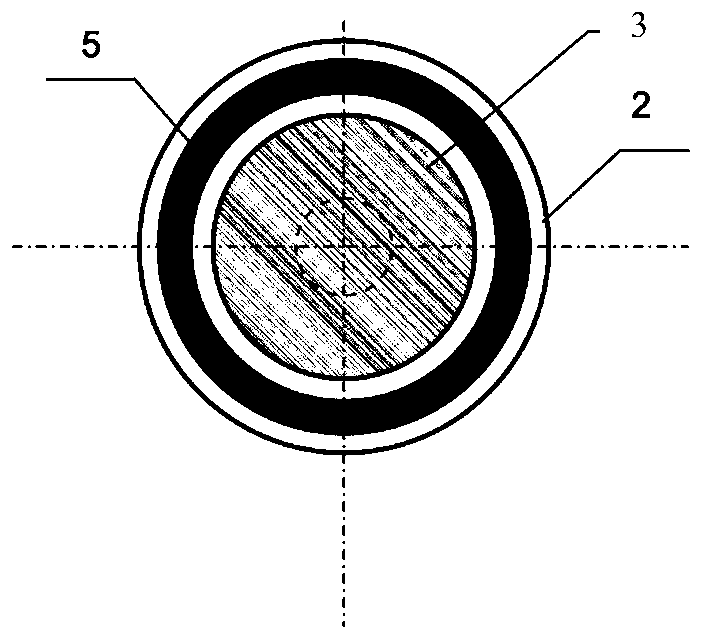

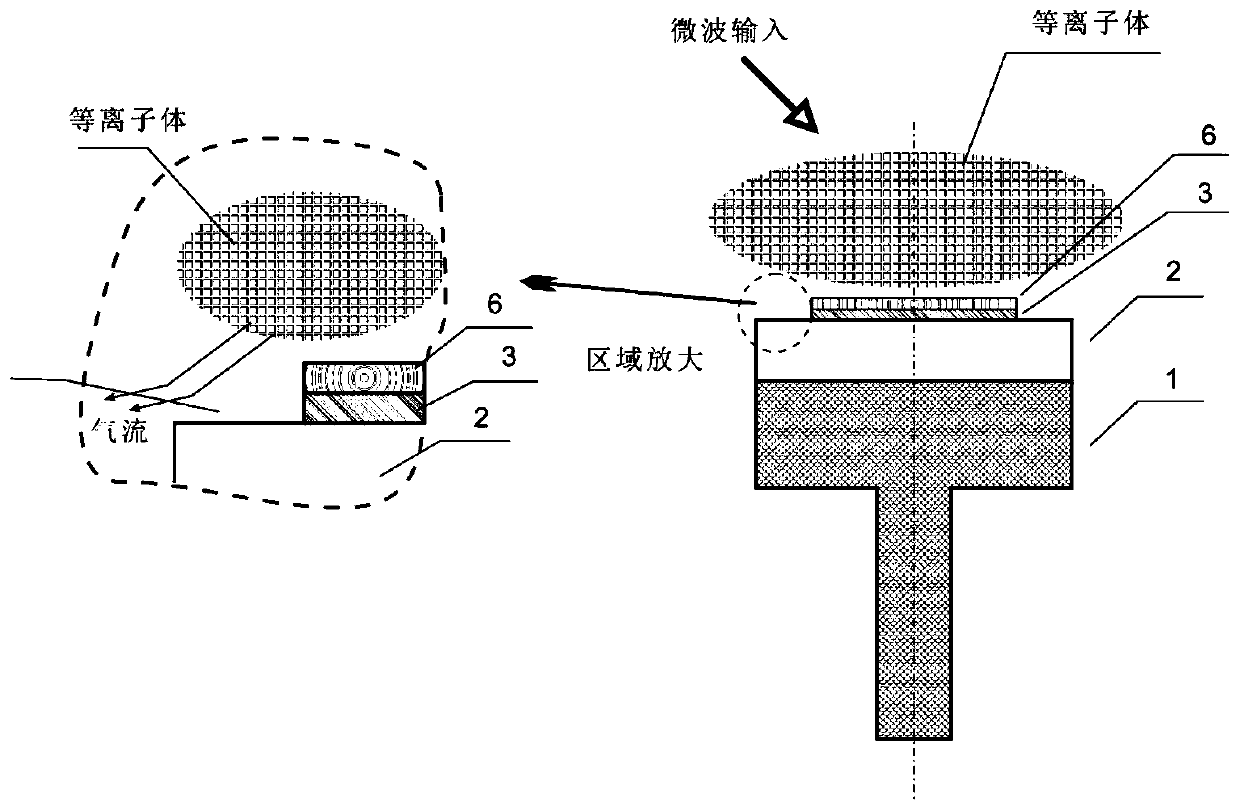

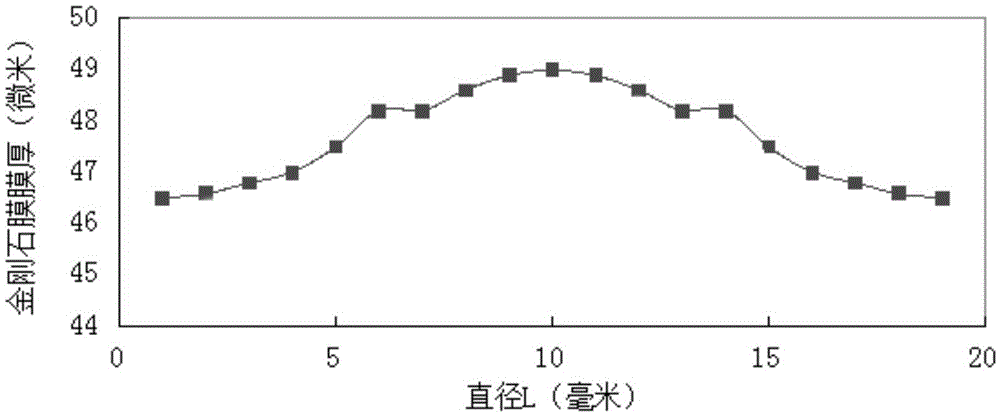

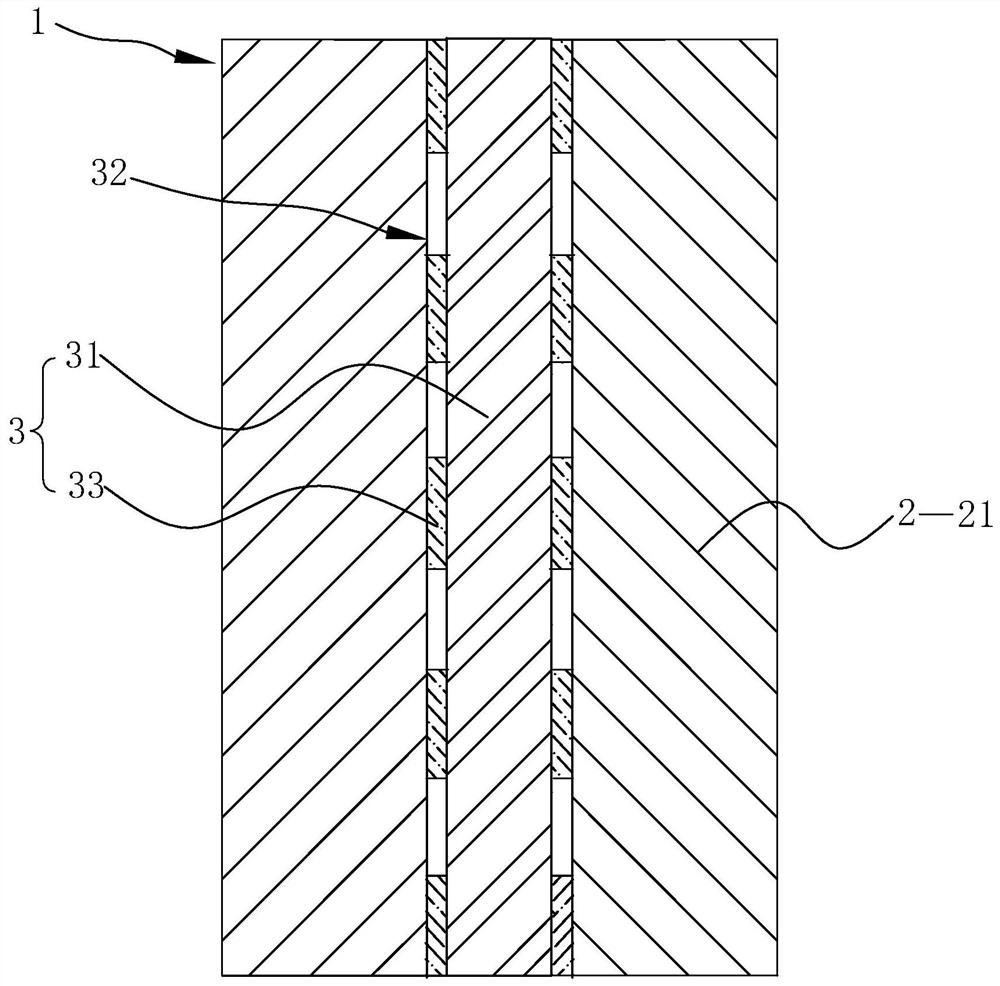

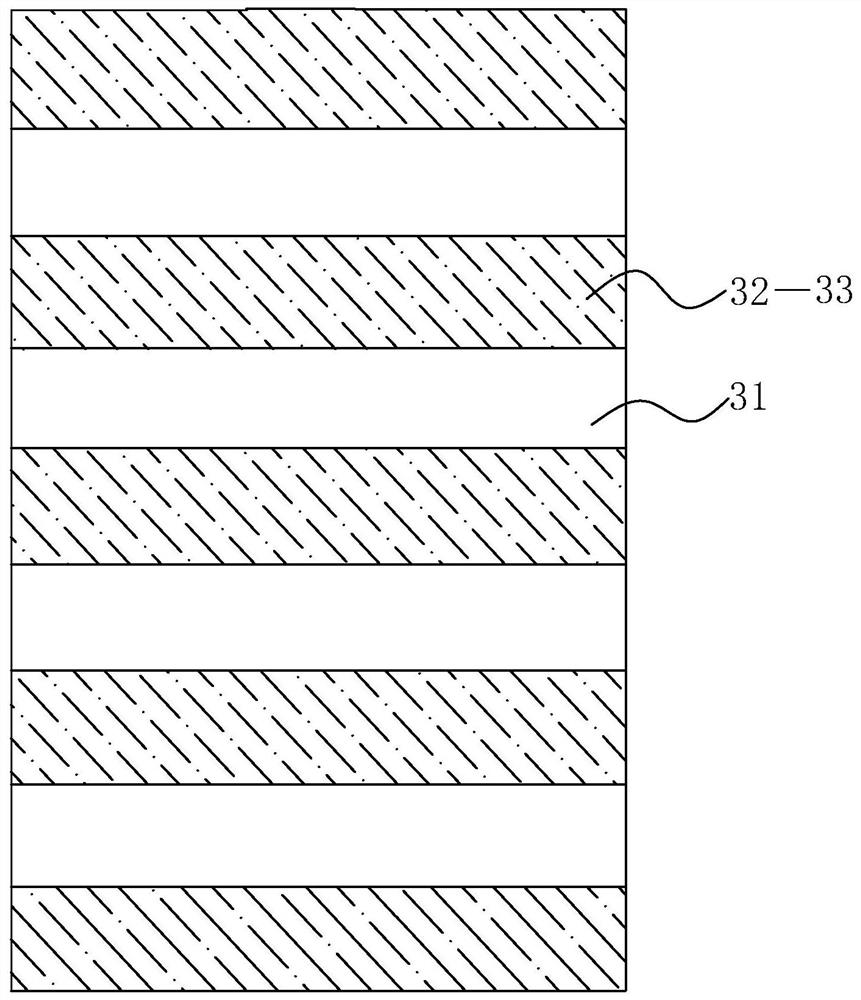

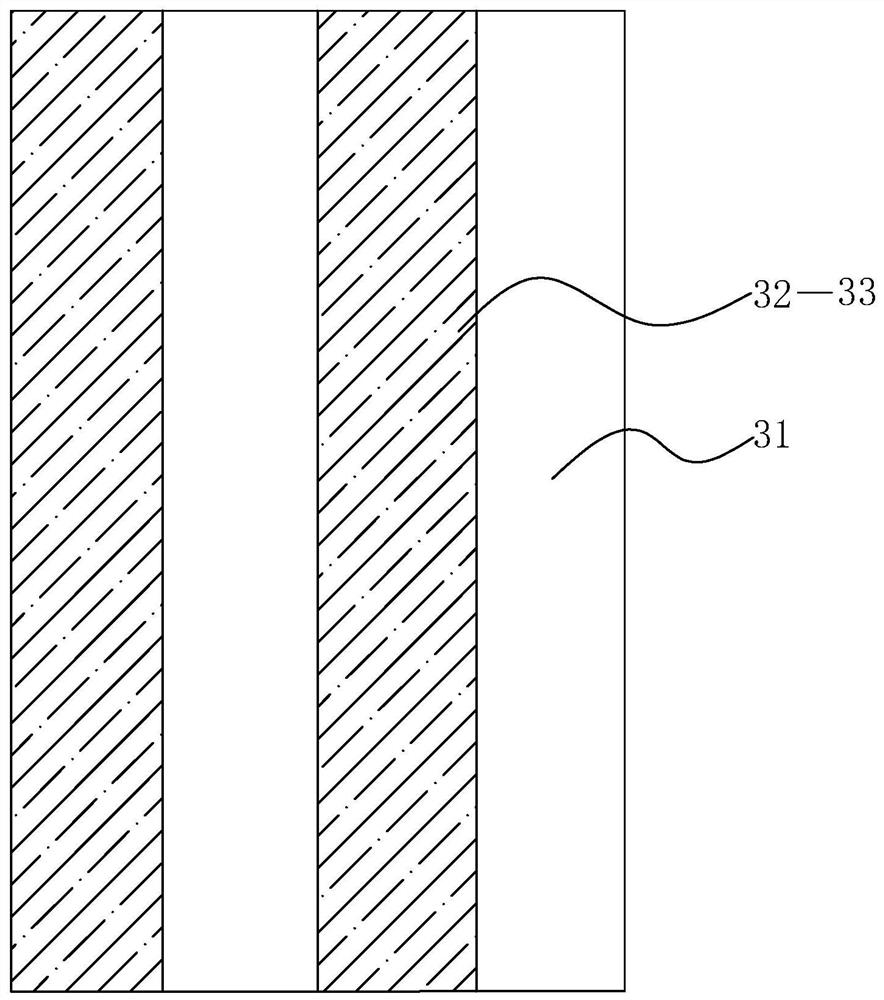

ActiveCN103911596AChange density distributionImprove deposition uniformityChemical vapor deposition coatingMicrowavePlasma reaction

The invention provides a preparation apparatus for a diamond film. The apparatus employs a microwave plasma chemical vapor deposition device and comprises a microwave system, a vacuum system, a gas supply system and a plasma reaction chamber, wherein an autogyration substrate table is arranged in the plasma reaction chamber, microwaves generated by the microwave system during working enter into the plasma reaction chamber and excite gas supplied by the gas supply system above the autogyration substrate table to generate a plasma ball, and a refractory metal circular ring is arranged above the autogyration substrate table and located in the lower half part of the plasma ball.

Owner:SHANGHAI ZHENGSHI TECH CO LTD

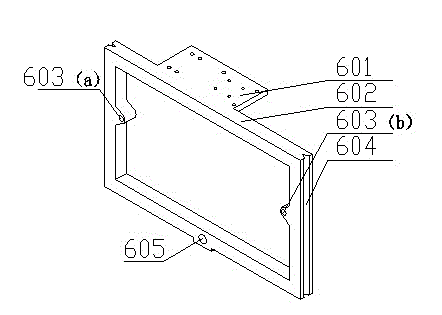

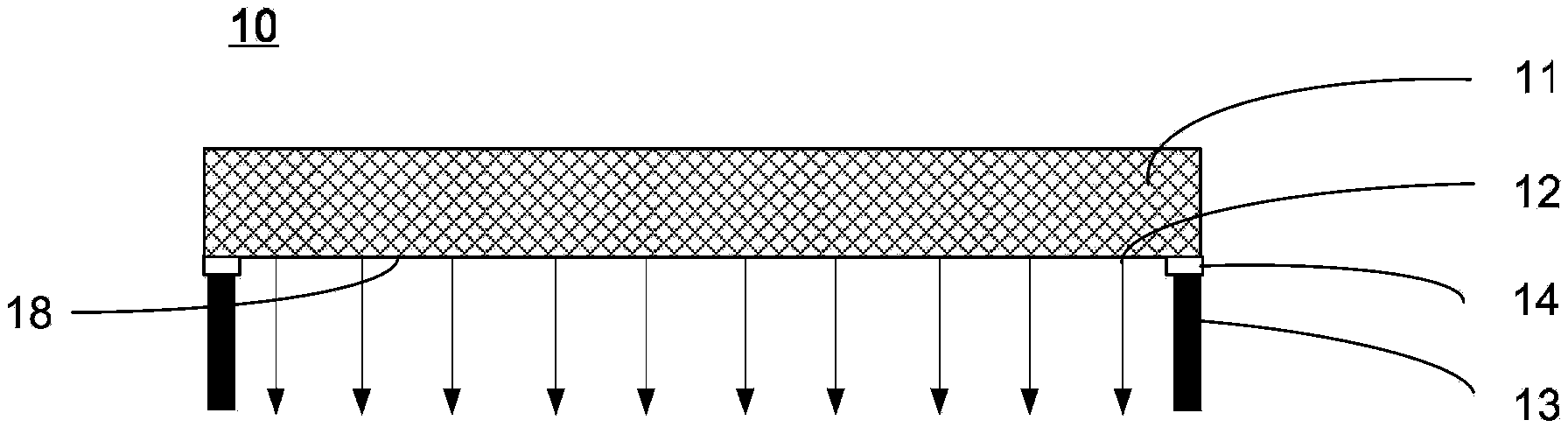

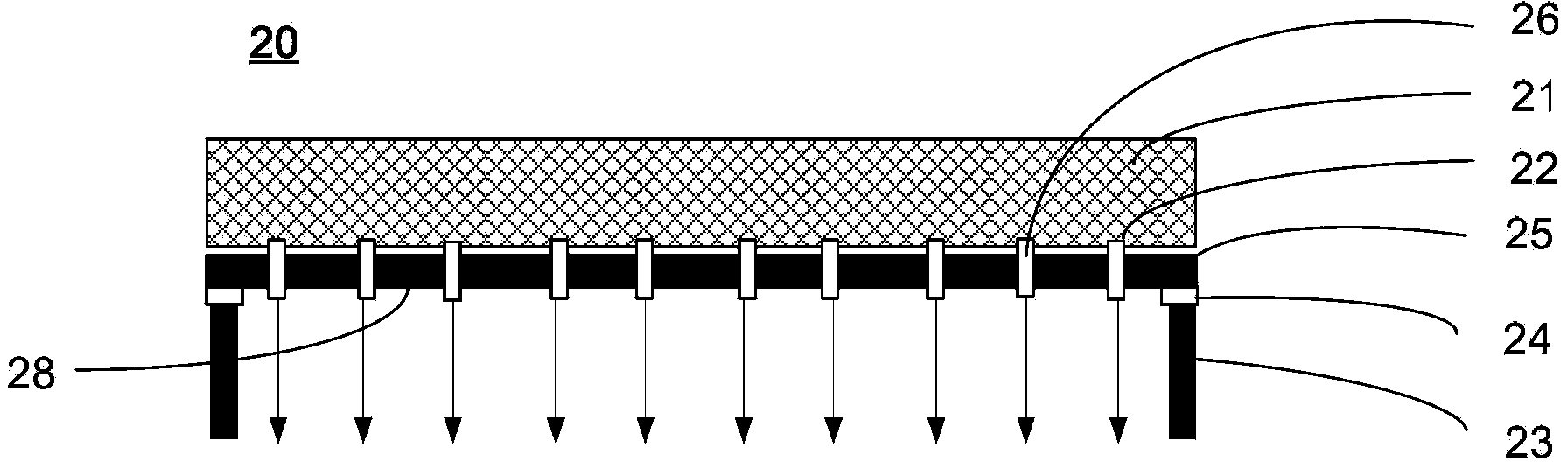

Vacuum evaporation device

InactiveCN103866238AReduce manufacturing costGraphicalVacuum evaporation coatingSputtering coatingGraphicsEngineering

The invention provides a vacuum evaporation device. The vacuum evaporation device comprises a baseplate driving mechanism which is used for bearing and moving a baseplate, and a first mask plate driving mechanism which is used for bearing and moving a first mask plate positioned below the baseplate, a second mask plate driving mechanism which is used for bearing and moving a second mask plate positioned below the first mask plate so as to be matched with the first mask plate driving mechanism to change a mutual overlapping state of mask plate graphic areas of the first mask plate and the second mask plate, and an evaporation source which is positioned below the second mask plate. According to the vacuum evaporation device, at least two mask plates are arranged, so that the mutual overlapping state of the mask plate graphic areas of at least two mask plates is changed according to the graphic characteristics of graphic areas to be evaporated on the surface of the baseplate so as to be matched with graphics of the graphic areas to be evaporated on the surface of the baseplate. Thus, the graphic treatment of each layer of evaporated film is realized. As a result, the manufacturing cost of the mask plates is decreased.

Owner:BOE TECH GRP CO LTD +1

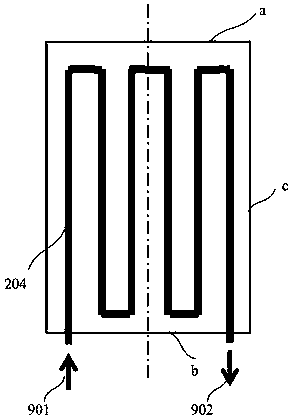

Reciprocating type rotary CVD equipment and application method

ActiveCN111364026AImprove uniformityCompensation for uneven depositionChemical vapor deposition coatingWafer fabricationThin membrane

The invention provides reciprocating type rotary CVD equipment and an application method. The reciprocating type rotary CVD equipment comprises a cavity, a wafer heating base and a rotating device, the rotating device is located outside the cavity and comprises a rotary power mechanism and a rotary sealing mechanism, and the rotary sealing mechanism comprises a rotating part and a fixed part; andthe fixed part is fixedly connected with the cavity in a sealed mode, the rotating part is fixedly connected with the wafer heating base in a sealed mode, the rotating part is movably connected with the fixed part in a sealed mode, the rotating part is connected with the rotary power mechanism, and the rotary power mechanism drives the rotating part and the wafer heating base to perform reciprocating rotary operation. According to the reciprocating type rotary CVD equipment, through the rotation of the rotating device, the uniformity of thin film deposition in the circumferential direction ofthe wafer can be improved, and the manufacturing cost of equipment and the wafer is reduced.

Owner:BETONE TECH SHANGHAI

Diamond wire saw and rapid production method thereof

ActiveCN103388170AIncreased chance of collisionIncrease capture rateElectrolytic coatingsChemical platingHeat treated

The invention discloses a diamond wire saw and a rapid production method thereof. The surfaces of diamond grits are respectively coated with a nickel layer by chemical plating, the nickel layers are fixed on a copper-plated piano wire substrate pre-plated with a nickel layer through electroplating, and then the nickel layers are thickened, so that the diamond grits are solidified more firmly. The rapid production method of the diamond wire saw comprises the following steps of: 1, removing greases and oxides on the surfaces of diamond grits, and carrying out sensitization, activation and chemical nickel plating on the diamond grits; 2, removing greases and oxides on the surface of a metal substrate, and pre-plating nickel layers as buffer layers; and 3, carrying out composite electroplating, thickened electroplating and heat treatment on the diamond wire saw. According to the invention, diamond grits are subjected to chemical nickel plating to achieve an effect of electric conduction, so that the diamond grits carry out sequential movement under the action of an electric field, and chemical consolidation is realized; and in addition, intense agitation is introduced in an electroplating process, so that high-current / density electroplating is realized, and a highly efficient and rapid method is provided for the industrial production of diamond wire saws.

Owner:江西核工业兴中科技有限公司

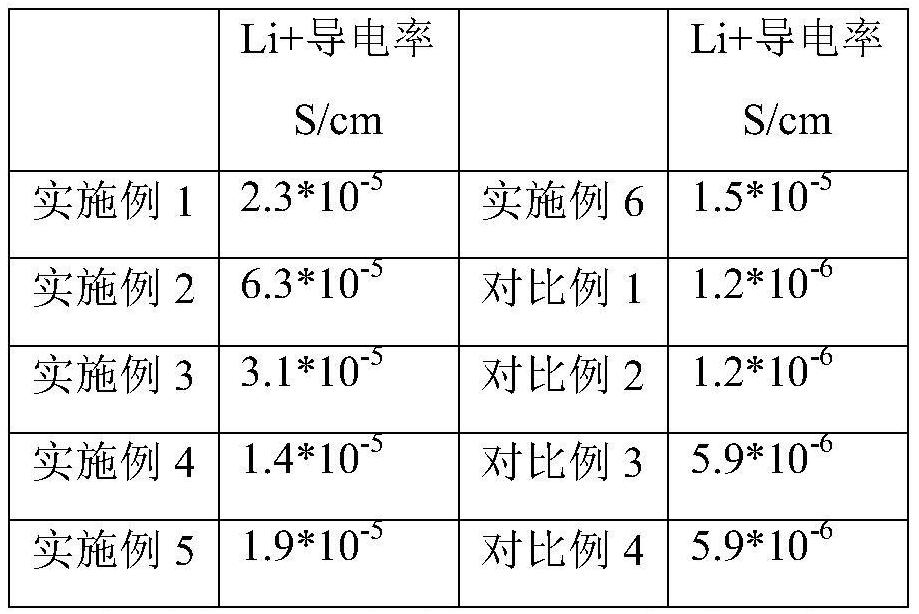

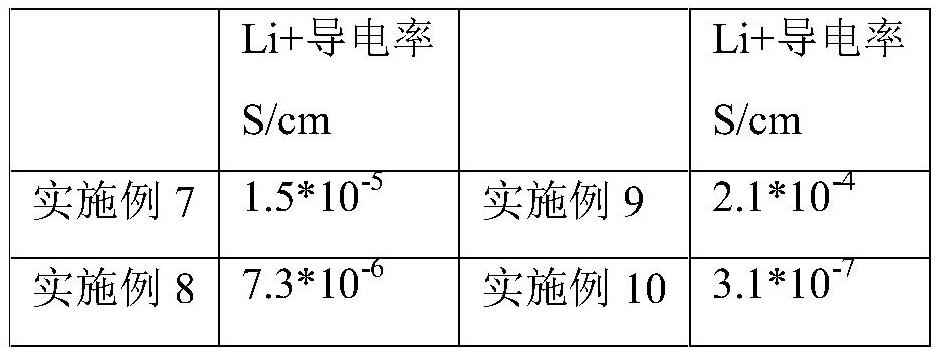

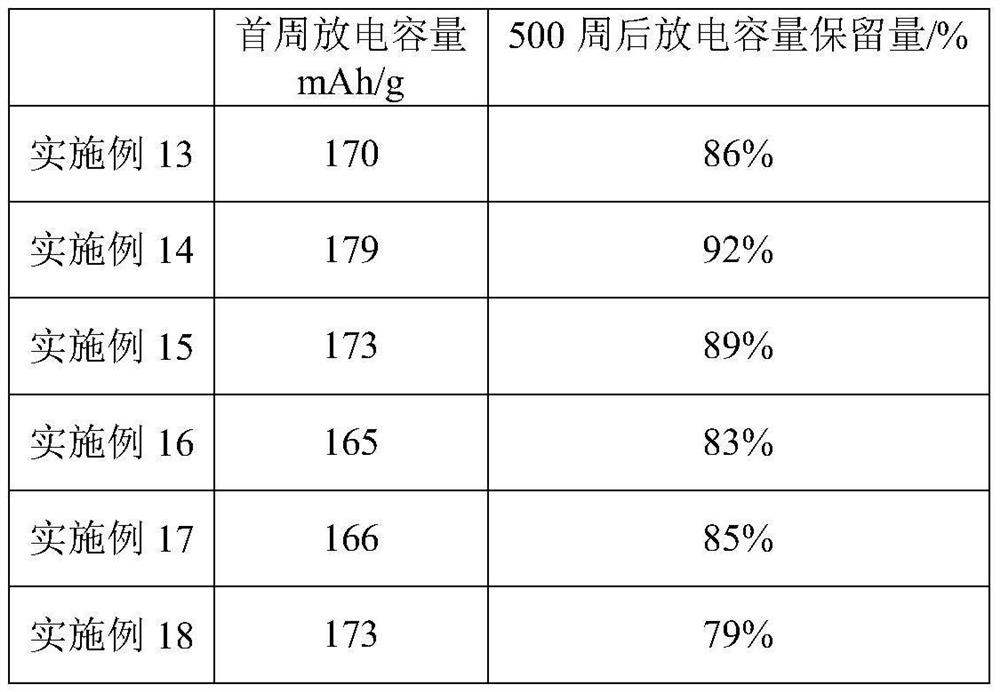

Lithium metal negative electrode with double-layer interface film, preparation thereof and application

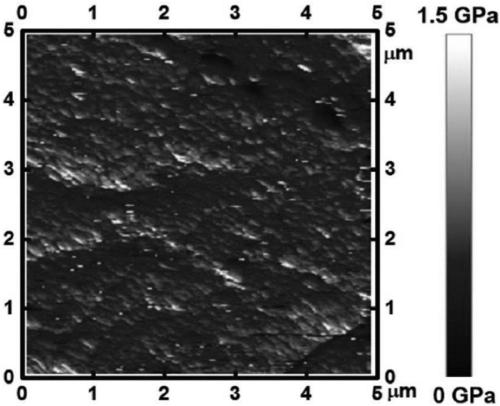

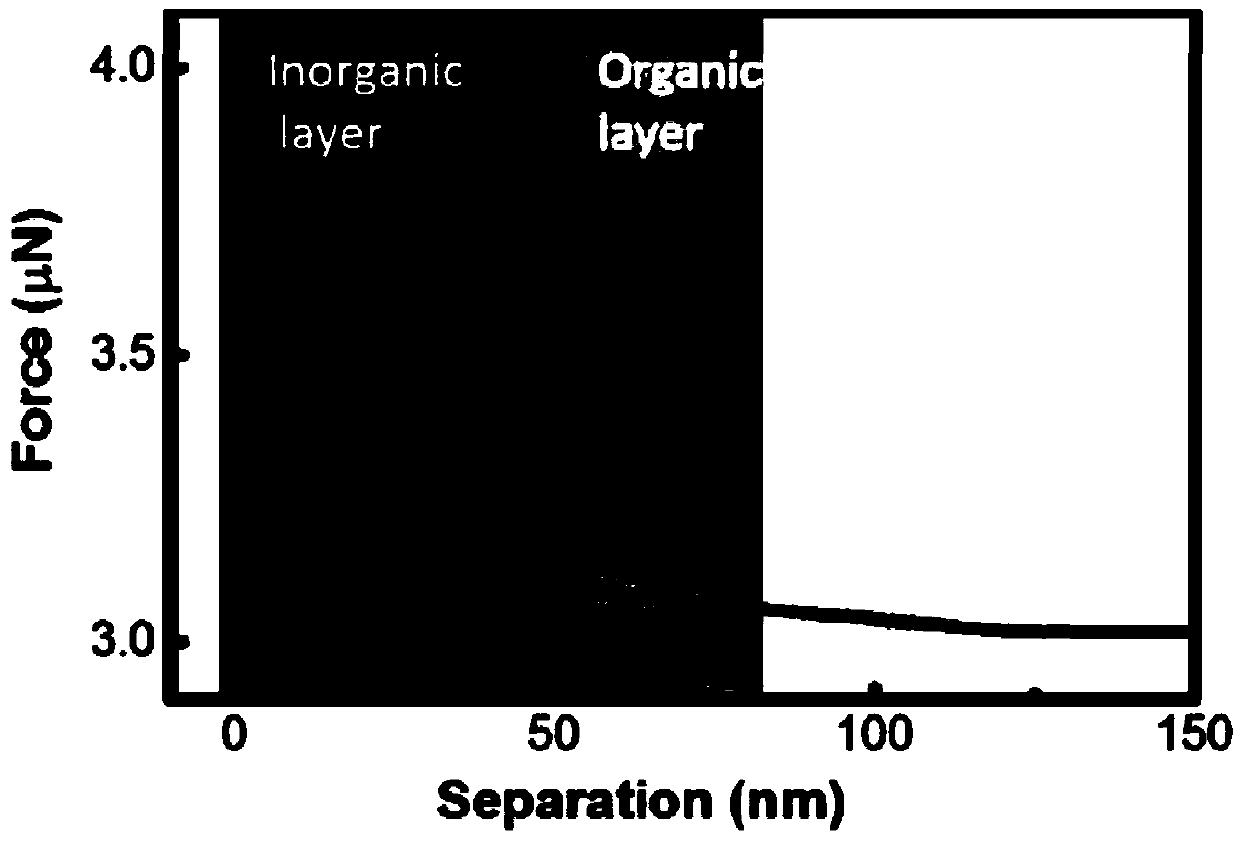

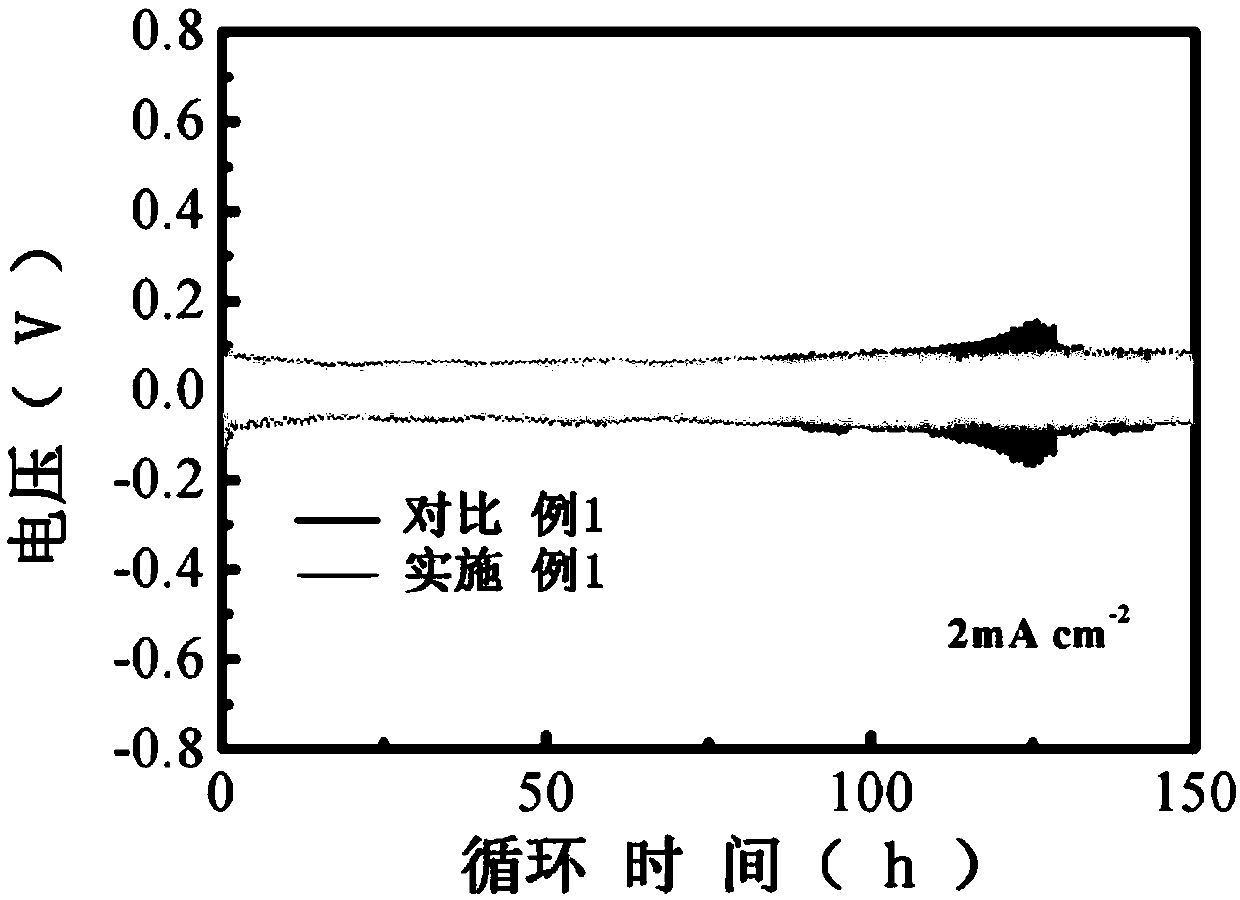

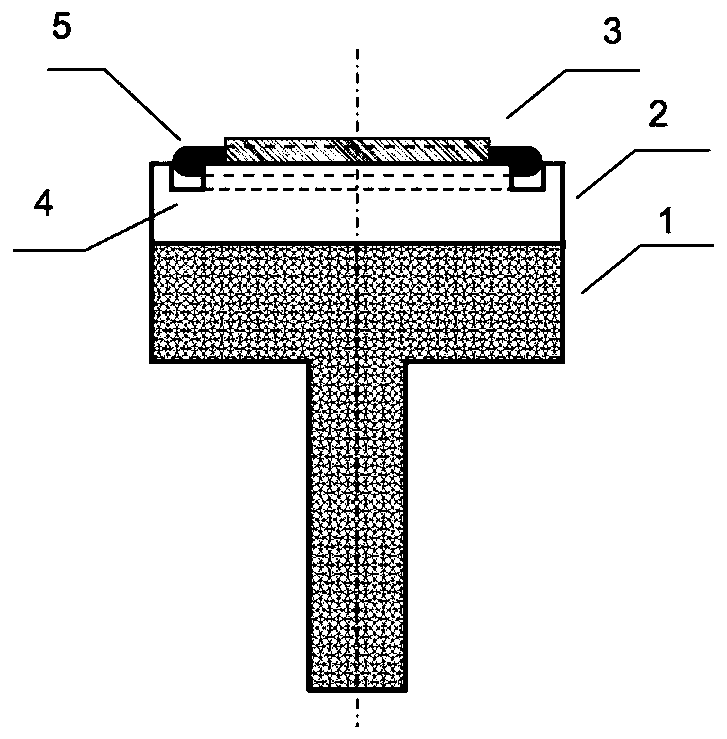

InactiveCN111293283AImprove deposition uniformityLong cycle lifeSecondary cellsNegative electrodesElectrolytic agentLithium metal

The invention relates to a lithium metal negative electrode with a double-layer interface film, preparation of the lithium metal negative electrode, and application. The double-layer interface film isattached to the surface of lithium metal; the inner layer of the double-layer interface film is a lithium fluoride inorganic layer; the outer layer of the double-layer interface film is an ether polymer layer. When the interface film is applied to a lithium metal battery, the inner-layer compact film of the interface film can inhibit dendrite growth on the surface of lithium metal, the outer-layer flexible film of the interface film can effectively relieve the breakage of the lithium fluoride layer caused by the volume expansion of a negative electrode, and therefore, interface stability is improved, continuous reaction and consumption of the lithium negative electrode and an electrolyte are inhibited, and the cycle life of the battery is prolonged. In addition, due to the introduction oforganic lithium salt into the interface film, interface lithium ion transmission is greatly accelerated, and lithium deposition uniformity is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

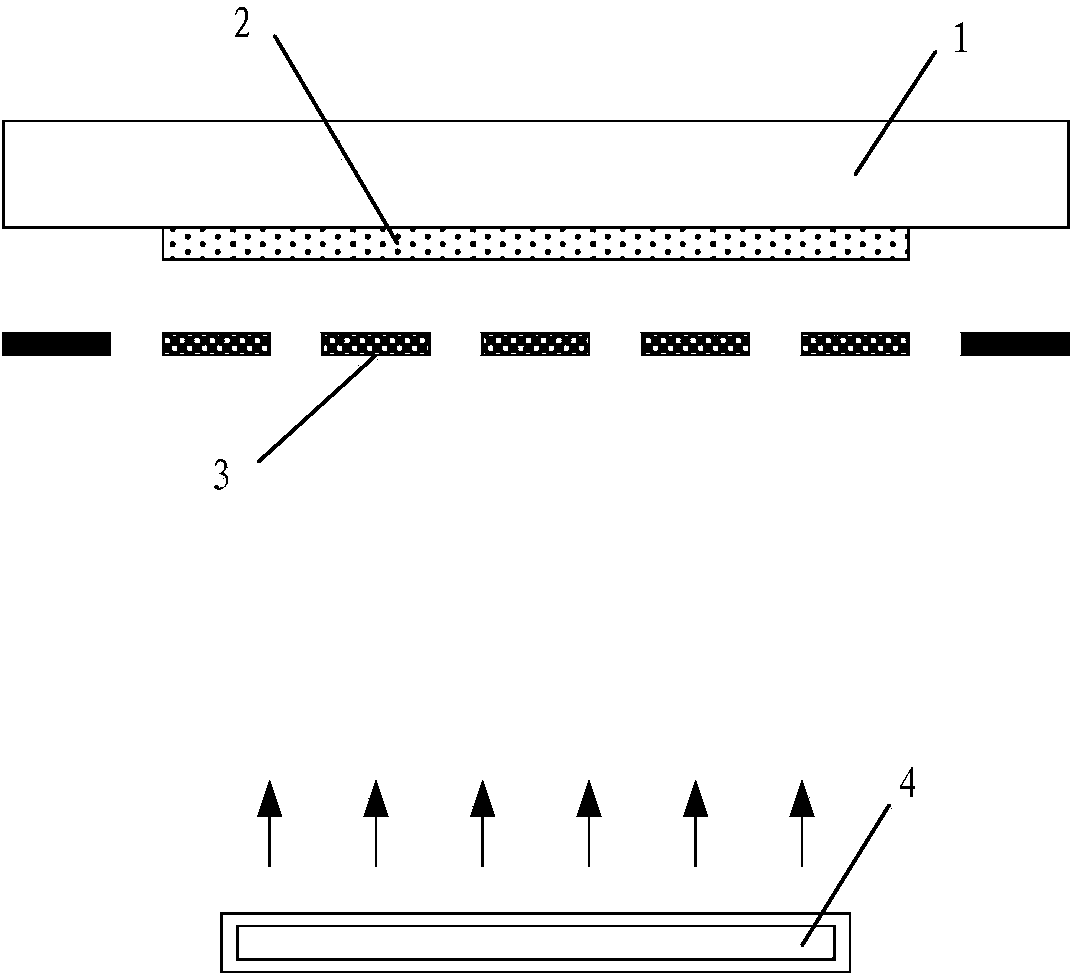

Diamond film preparing device and method

PendingCN111378954AChange density distributionImprove deposition uniformityChemical vapor deposition coatingMetallic materialsPlasma reaction

The invention provides a diamond film preparing device and method. The preparing device adopts a microwave plasma chemical vapor deposition device which comprises a microwave system, a vacuum system,a gas supply system and a plasma reaction chamber, wherein a self-rotating substrate table is arranged in the plasma reaction chamber, microwaves generated by the microwave system enter the plasma reaction chamber in the working process, gas provided by the gas supply system is excited above the self-rotating substrate table to generate plasma balls, a substrate material is arranged on the self-rotating substrate table, an annular pit is formed in the position, close to the outer edge, of the substrate material, the pit is filled with a metal material, and the metal material is higher than thesurface of the substrate material to form an annular metal protrusion. The preparing device and method have the advantages that the substrate material is improved, so that the surface of the film-forming substrate material has relatively proper air flow distribution and plasma distribution when a diamond film is deposited.

Owner:SHANGHAI ZHENGSHI TECH CO LTD

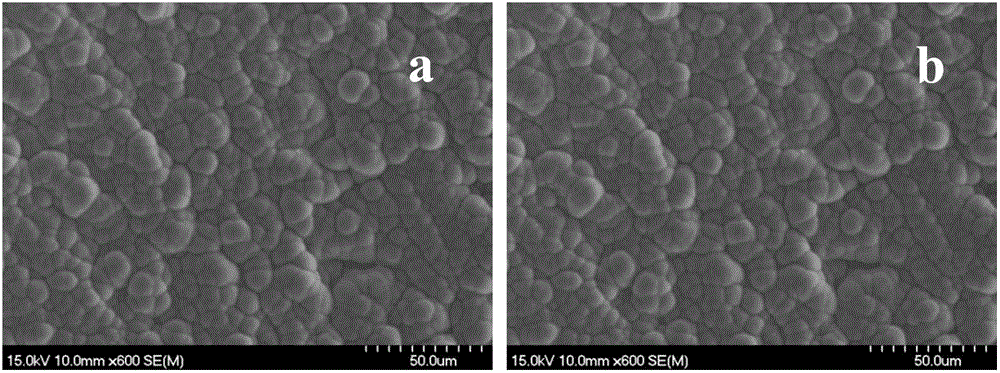

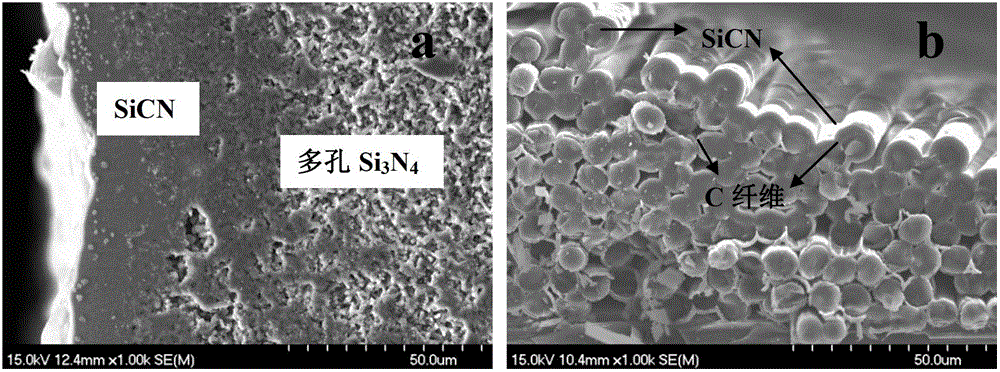

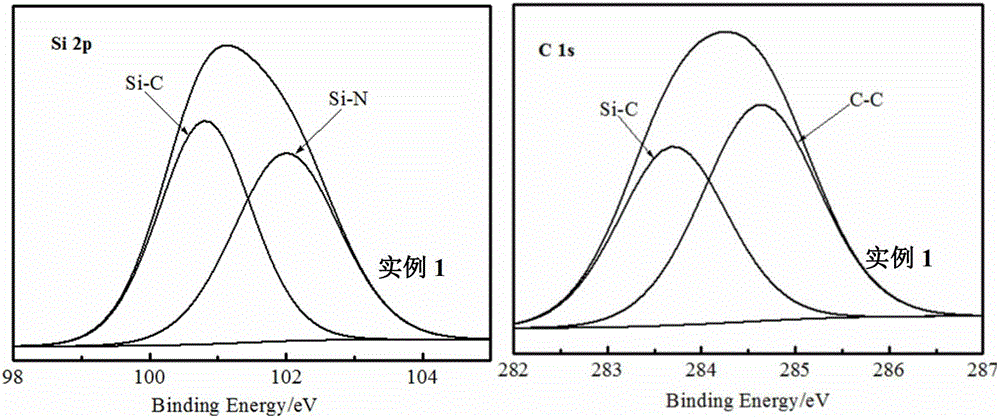

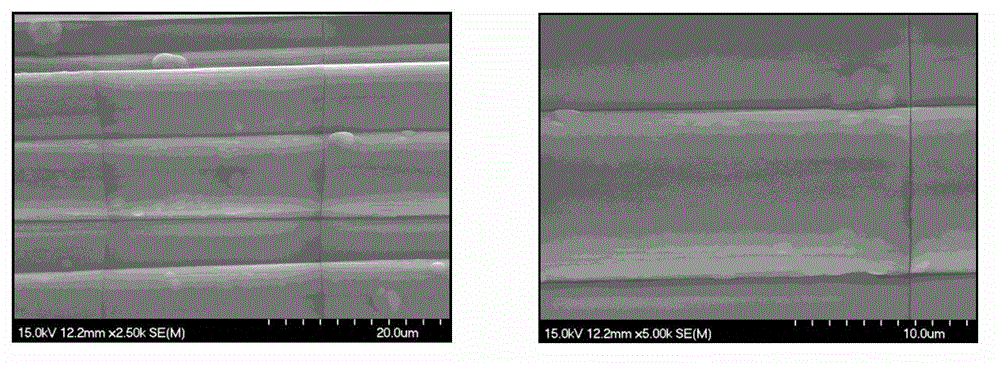

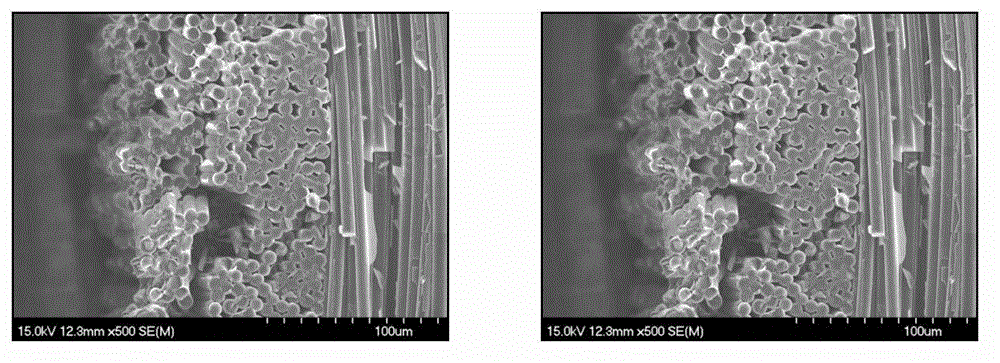

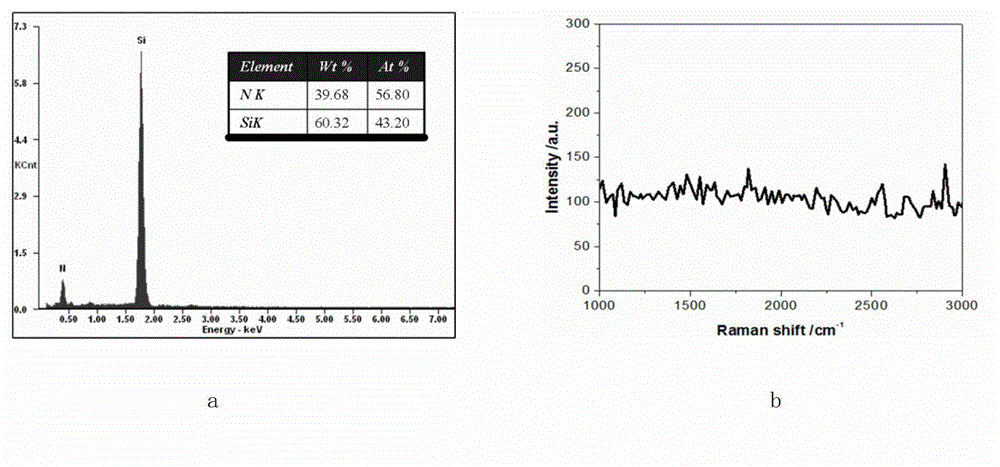

Preparing method of silicon-carbon-nitrogen wave absorbing ceramic base composite materials

The invention relates to a preparing method of silicon-carbon-nitrogen (SiCN) wave absorbing ceramic base composite materials. The preparing method includes: adopting chemical vapor deposition (CAD) or chemical vapor infiltration (CAI) technology, using SiC14, SiHC13 or other chlorine silicon compounds or silicane as a silicon source, using CH4, C3H6, C2H2 or other alkane, olefin or alkyne as a carbon source, using NH3 or N2 as a nitrogen source, using H2 as a carrier gas and a reaction gas, using argon as a diluting gas, synthesizing SiCN on substrate materials in situ, and obtaining a SiCN matrix and a coating which are uniform and compact, without impurities, and with devisable compositions and wave absorbing properties. The preparing method overcomes the shortcoming that CFCC-SiC prepared by adopting the prior art is insufficient in wave absorbing performance, and simultaneously facilitates achieving control of compositions, permeability, thickness and wave absorbing performance of a wave absorbing matrix.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

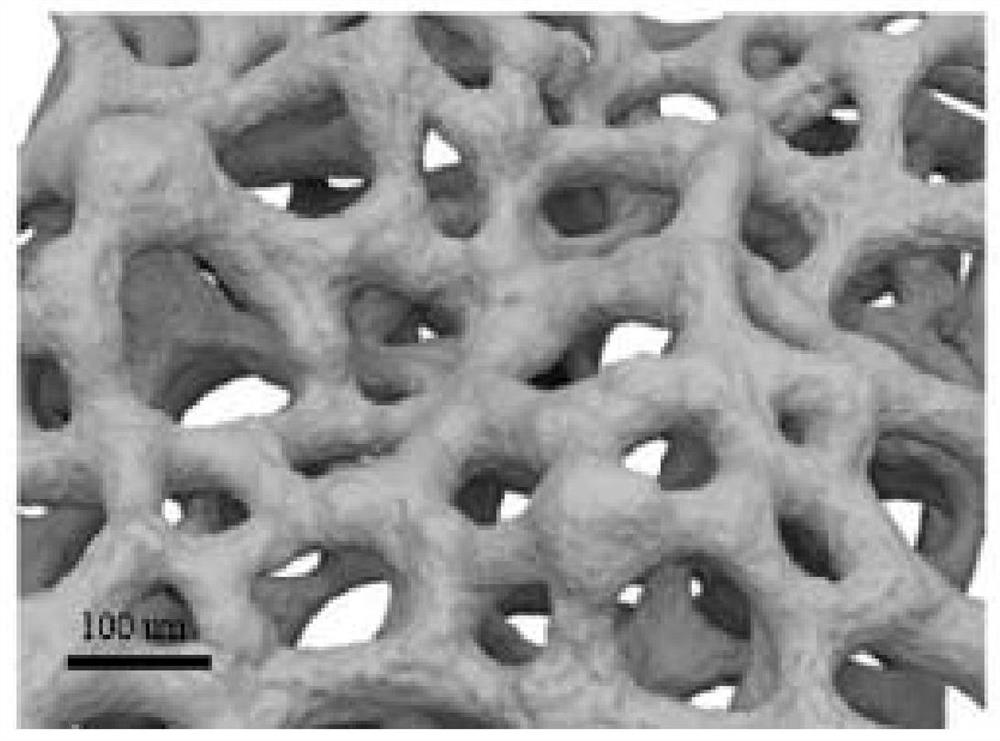

Preparation method for silicon nitride matrix

The invention relates to a preparation method for a silicon nitride matrix, which is mainly used for the preparation of fiber toughening ceramic matrix composite materials and porous ceramic material matrixes. The preparation method comprises the following steps of depositing a silicon nitride matrix / coating on the inner side / surface of a substrate material by a chemical vapor infiltration / chemical vapor deposition technology; and adjusting the deposition velocity, the deposition thickness and the infiltration uniformity of a ceramic matrix by controlling process parameters. According to the preparation method, the prepared silicon nitride matrix has the characteristics of deep deposition and infiltration depth, good combination with the substrate, high performance and the like by means of the advantages of a chemical vapor infiltration / chemical vapor deposition process. Combined with the ware transmission property of the silicon nitride matrix, the preparation method has the advantage that a foundation of integration design of structures and functions of the continuous fiber toughening ceramic matrix composite material is laid.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

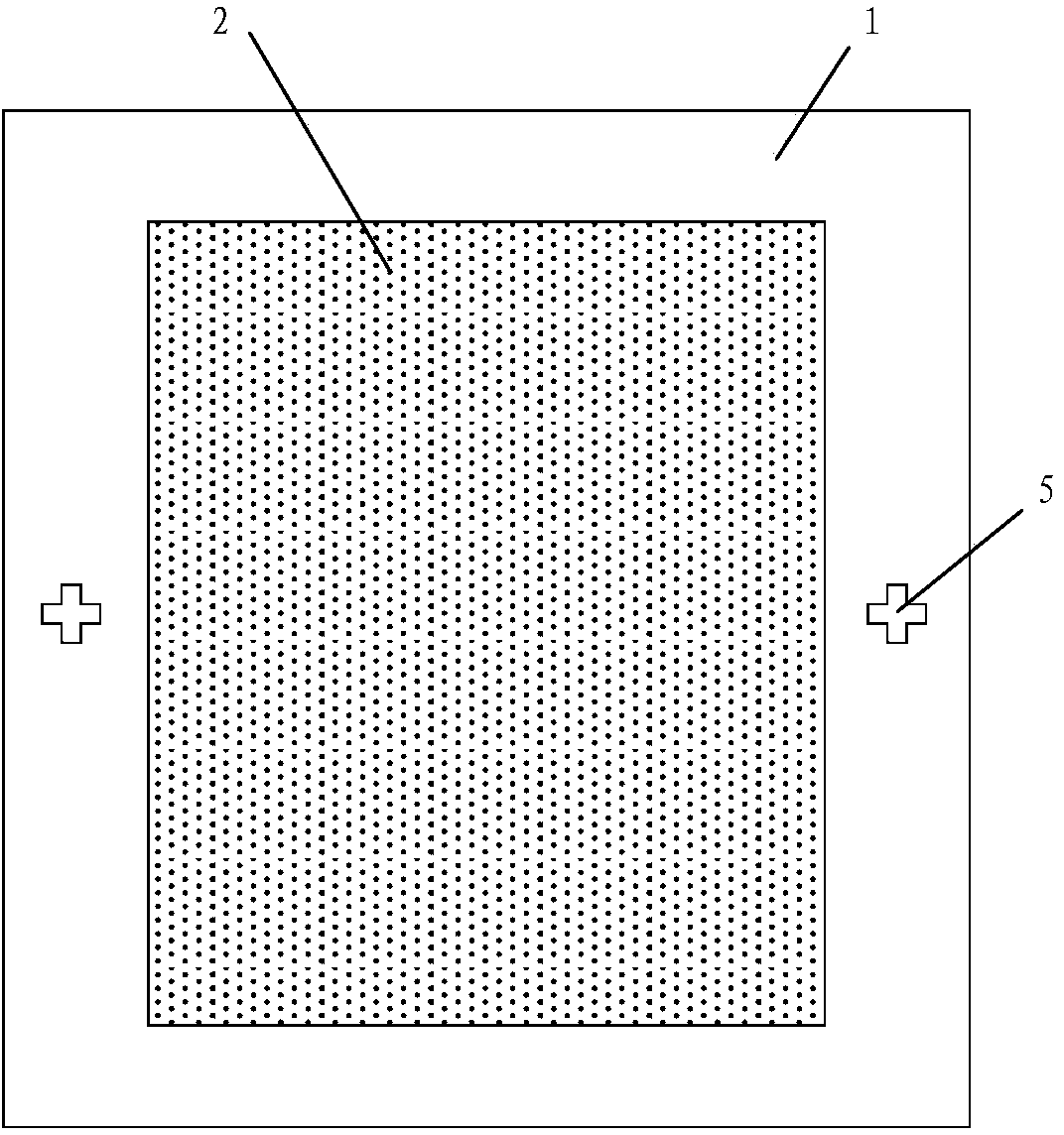

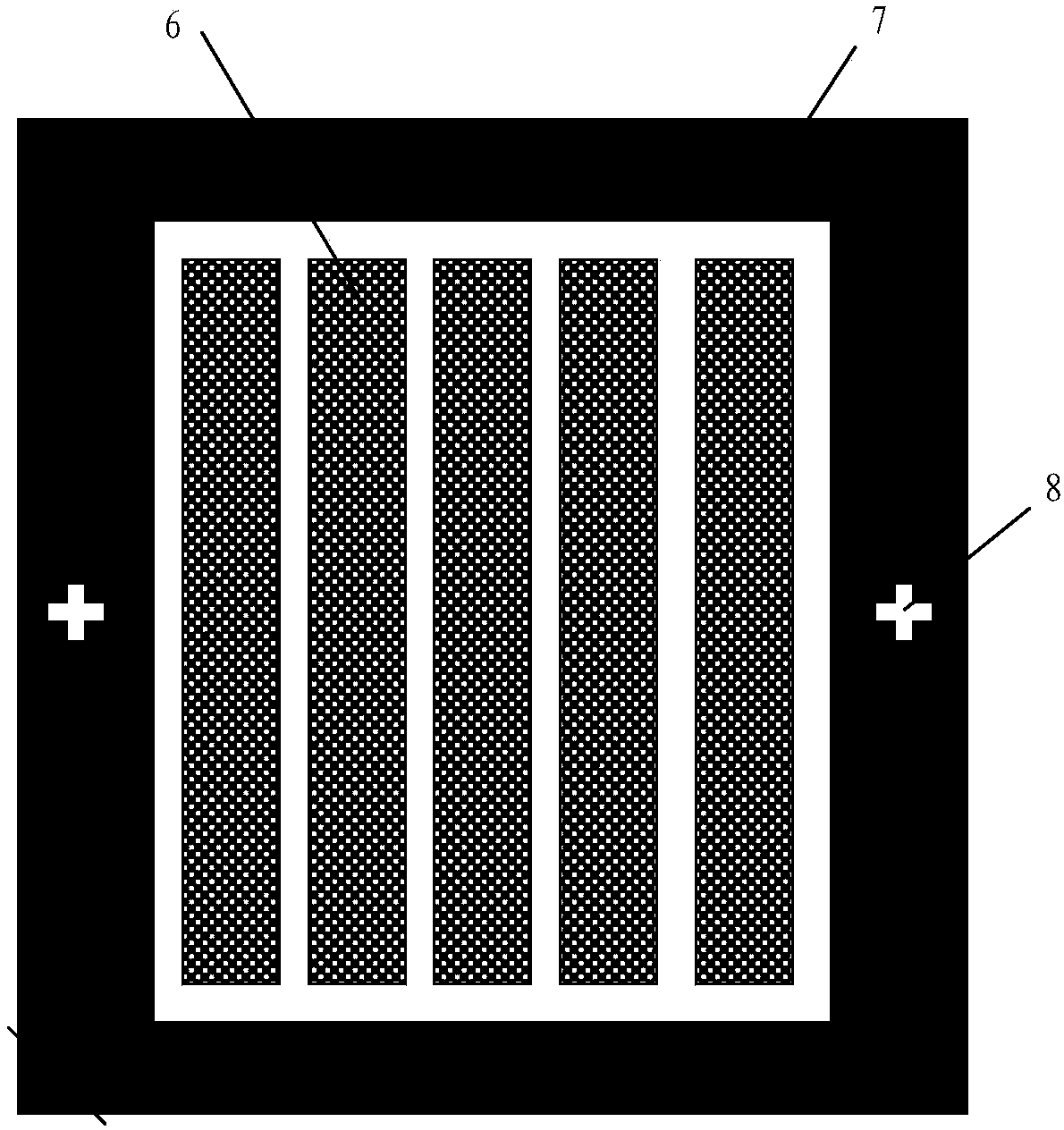

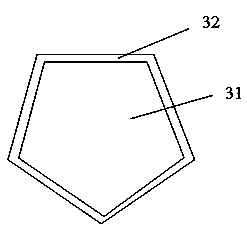

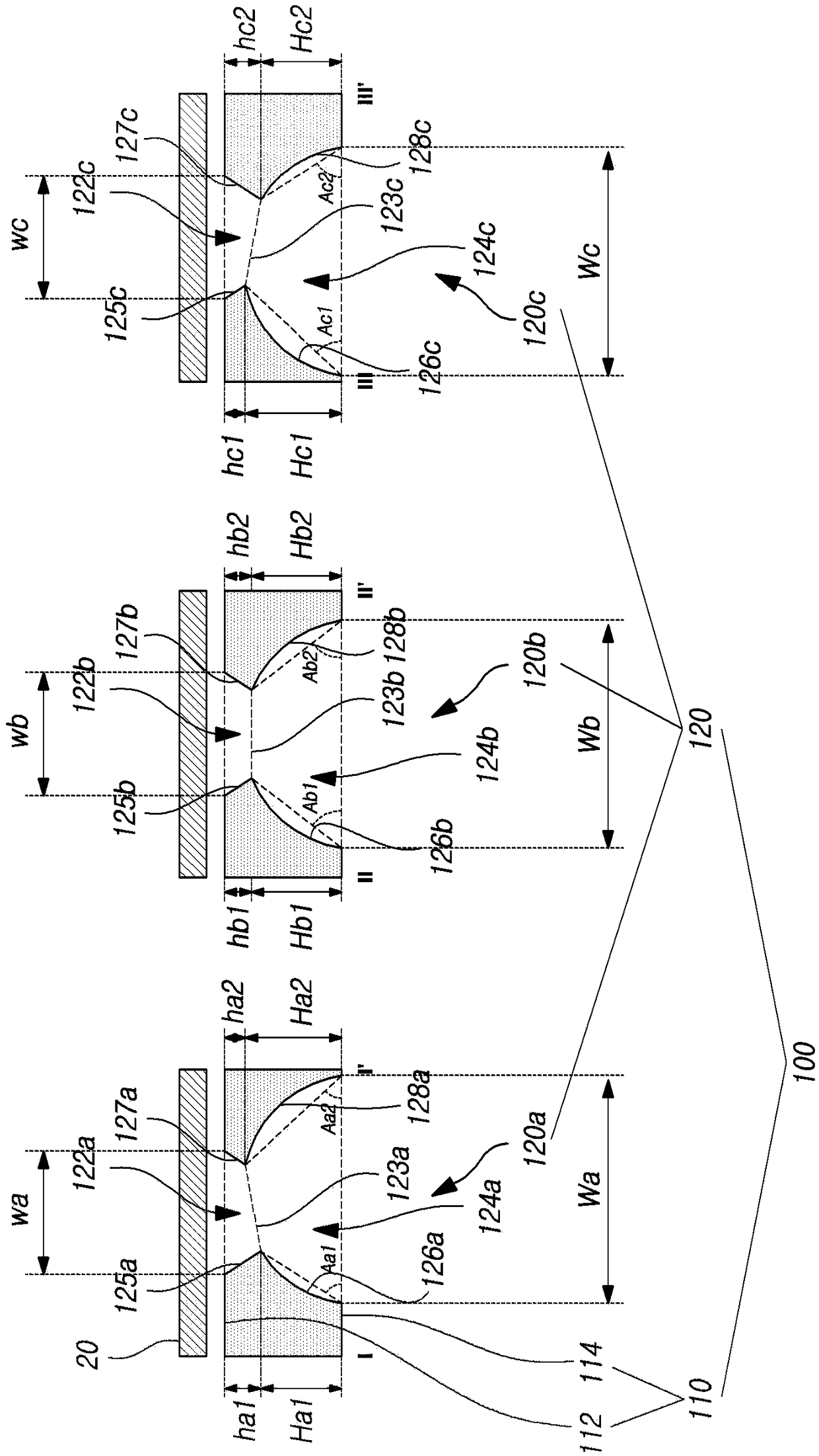

Deposition mask and deposition apparatus using same

ActiveCN108690951AShadow effects are minimizedImprove deposition uniformityVacuum evaporation coatingSputtering coatingEngineeringDeposition process

The invention provides a deposition mask and a deposition apparatus using the same. A deposition mask can include a base member including a first surface and a second surface which are divided into afirst region, a second region and a third region; a first opening in the first region; a second opening in the second region; and a third opening in the third region, in which each of the first, second and third openings can have a cross-section having an hourglass shape, in which the hourglass shapes of the first and third openings lean away from the second opening relative to the second surfaceof the base member. In this way, a shadow effect can be minimized during a deposition process and deposition uniformity can be improved.

Owner:LG DISPLAY CO LTD

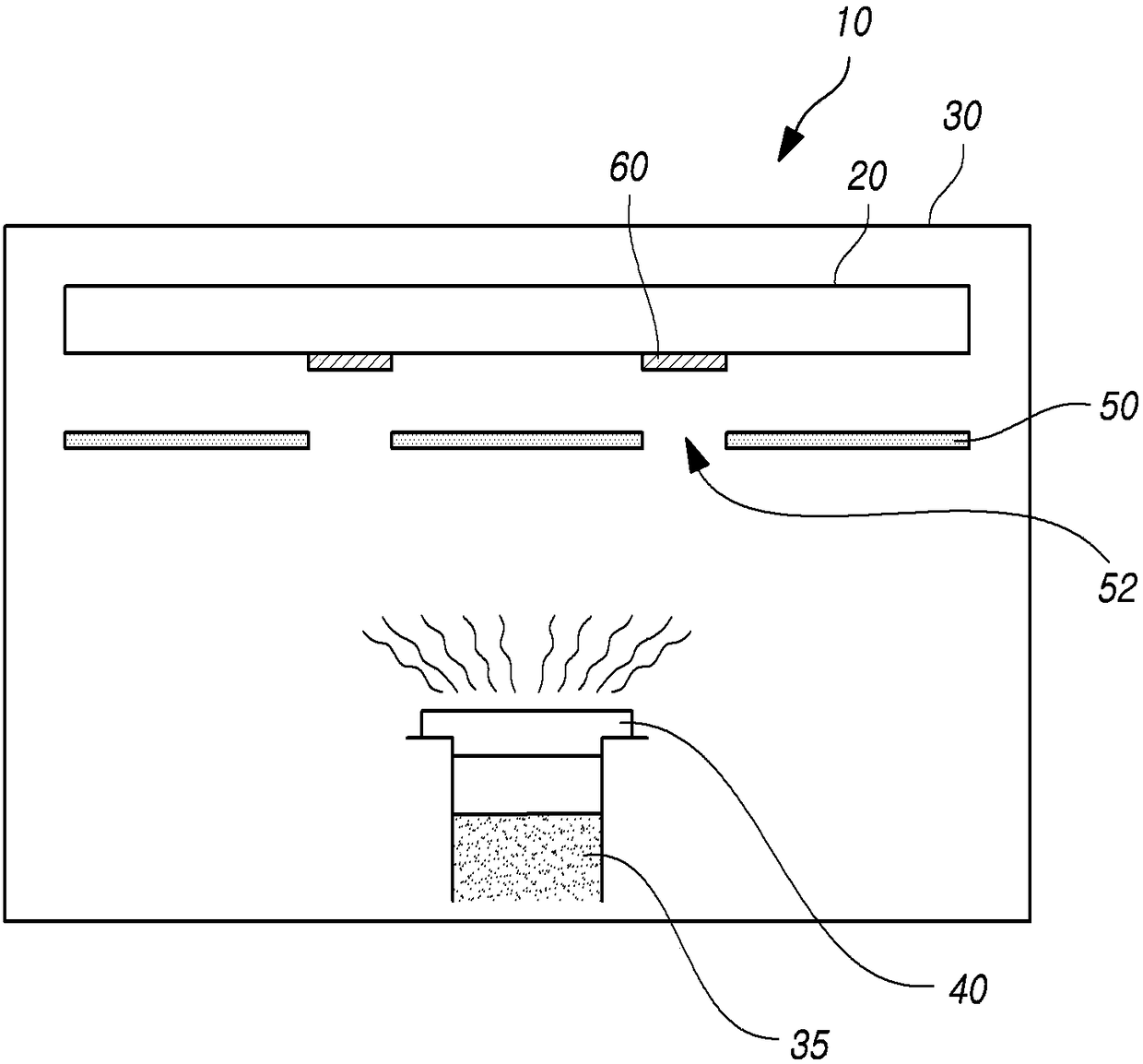

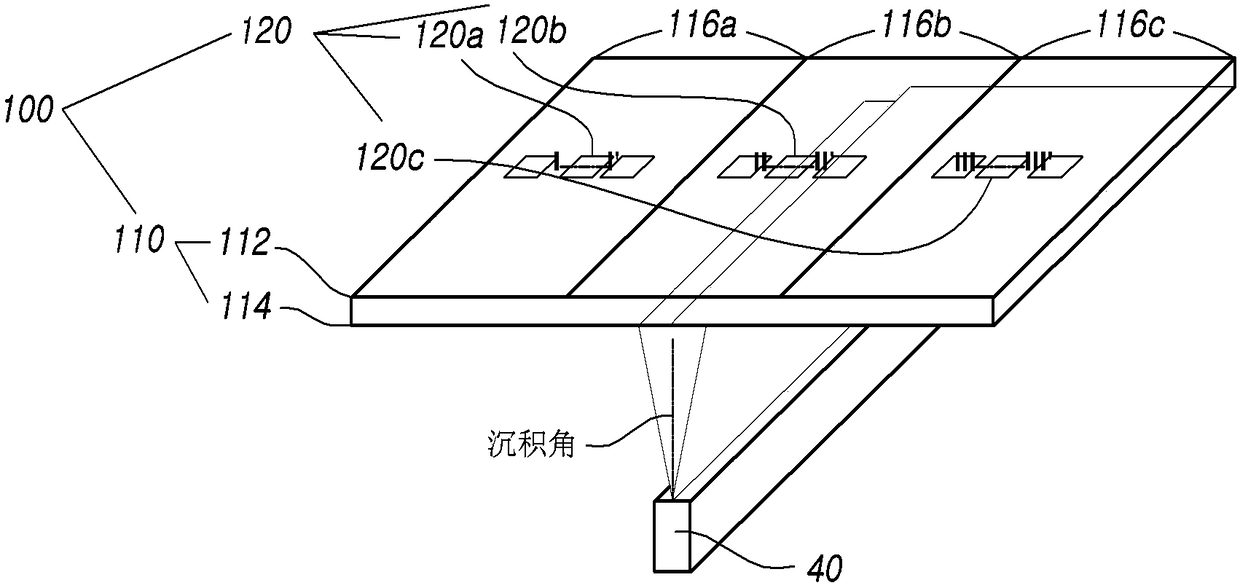

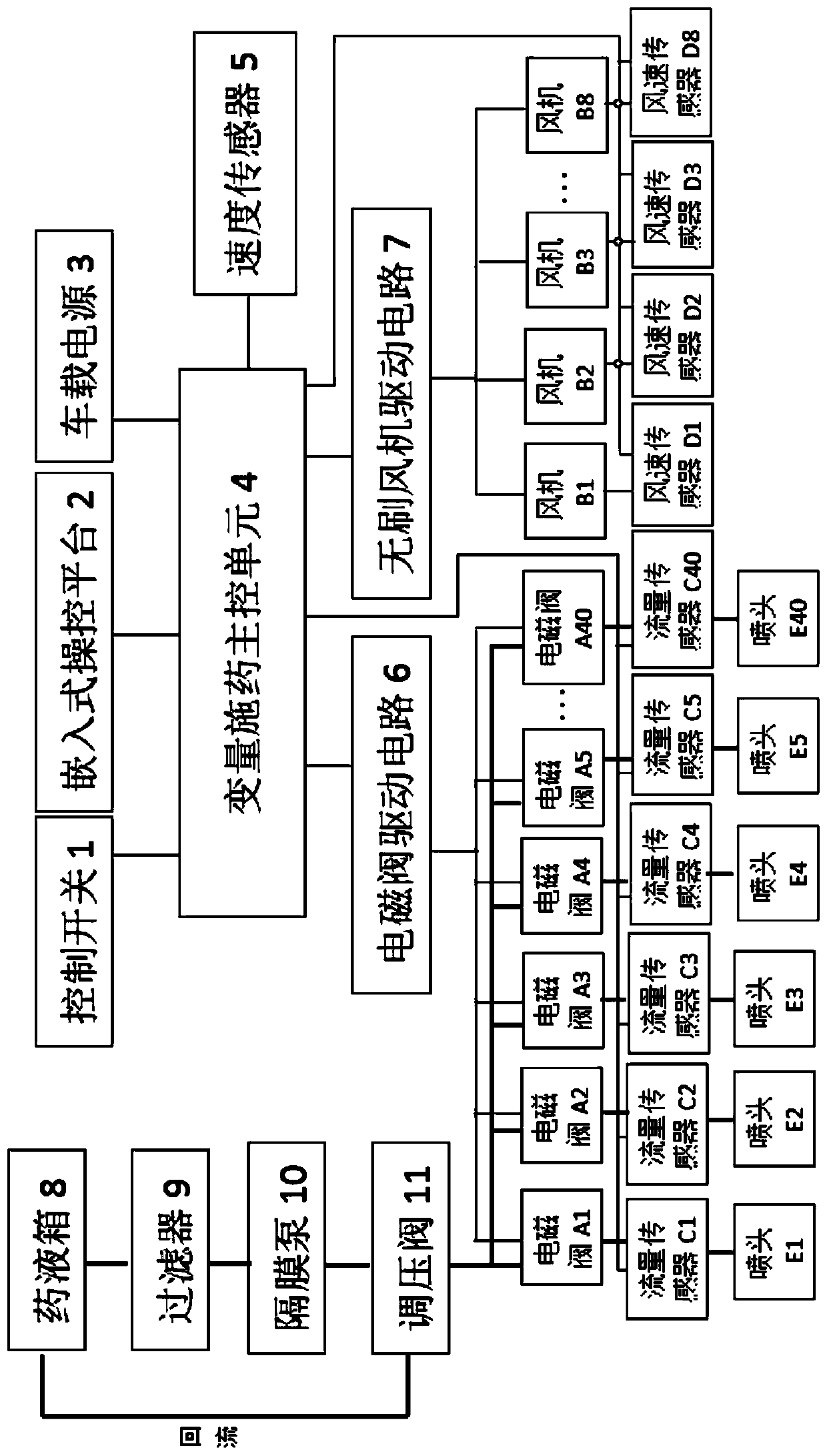

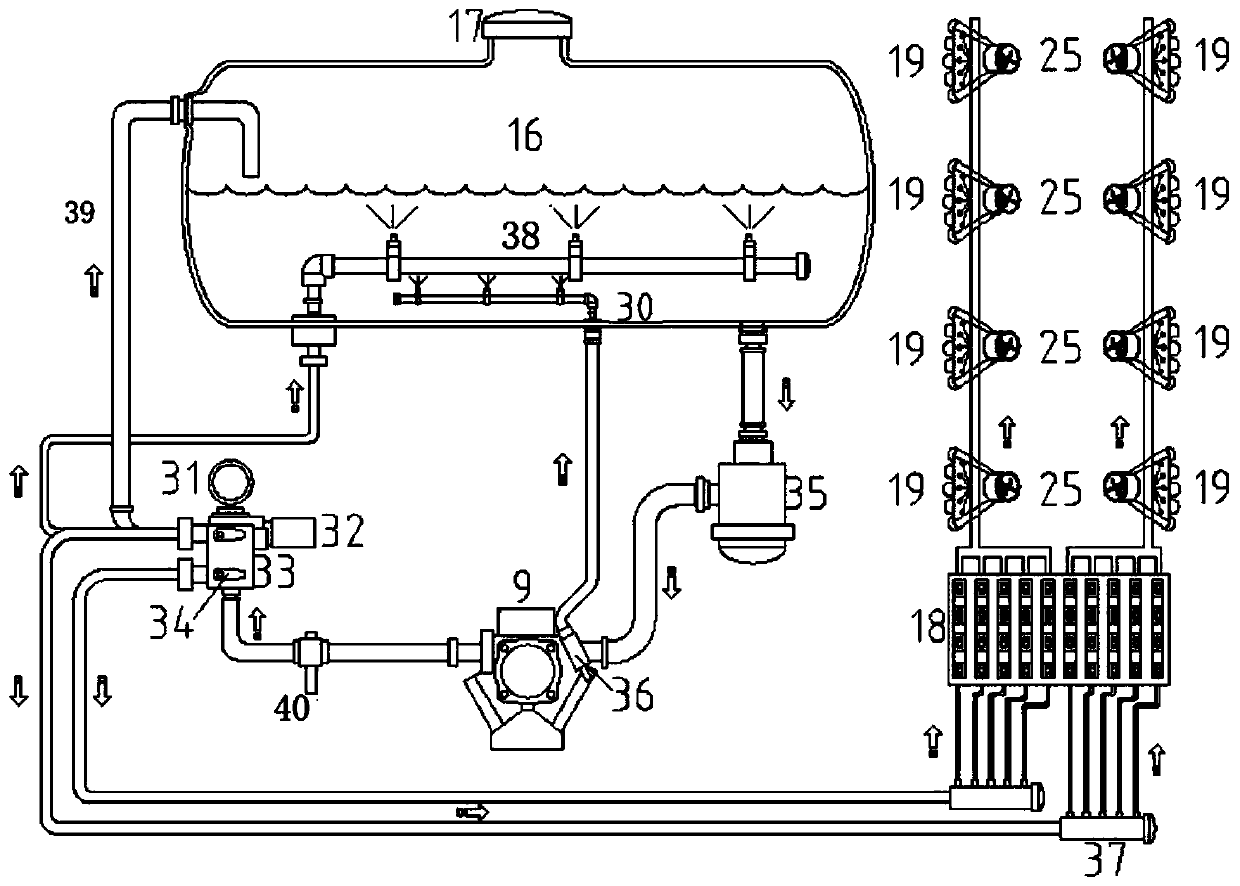

Method for automatically adjusting flow rate of sprinkler of profiling variable spraying system of spraying machine

PendingCN111084173AExtended working hoursKnow the dosage in real timeInsect catchers and killersControl signalAgricultural engineering

The invention belongs to the field of agricultural plant protection machinery, in particular to a method for automatically adjusting the flow rate of a sprinkler of a profiling variable spraying system of a spraying machine. The invention aims to provide a method for automatically adjusting the flow rate of the sprinkler of the profiling variable spraying system of the spraying machine. PWM control signals are adopted to adjust the flow rate of the sprinkler and the air flow of a fan which is used for assisting transportation of sprayed droplets, the flow rate of the sprinkler and the air flowof the fan are set according to the type of a tree crown, and a spray bar can be adjusted according to the growth trend of the crown so as to achieve profiling spraying, so that the utilization rateof pesticide is improved effectively, the uniformity of deposition of a chemical liquid on a canopy is improved, and environmental pollution and personal injury which are caused by the drifting pesticide are reduced in the spraying process. The method has the characteristics of good applicability, high working efficiency, fast response to a control system and precise application of pesticide, andpromotion of pesticide-saving technologies is facilitated.

Owner:CHINA AGRI UNIV

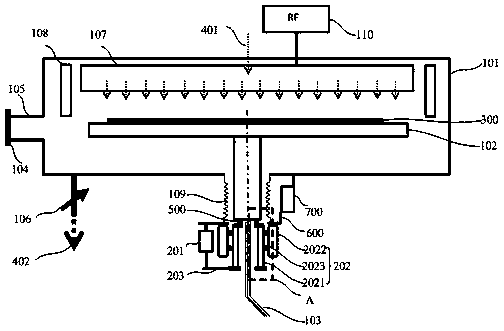

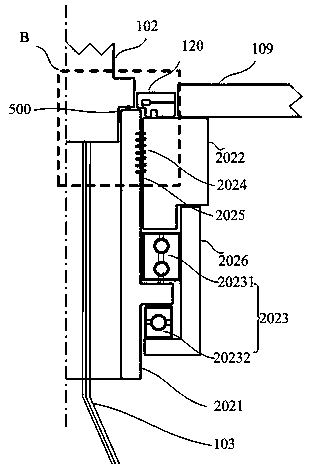

Reaction chamber and semiconductor processing device

PendingCN109300764AImprove deposition uniformityGood symmetryElectric discharge tubesEngineeringSemiconductor

The invention provides a reaction chamber, and the reaction chamber comprises a substrate which is used for bearing a to-be-processed workpiece; a target material which is disposed in the upper spaceof the reaction chamber; and a collimator which is disposed in a space below the target material and above a to-be-processed workpiece, so as to improve the symmetry of the coverage rate of the bottomof a deep hole of the to-be-processed workpiece and the coverage rate of the side wall of the deep hole. The invention also provides a semiconductor processing device.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

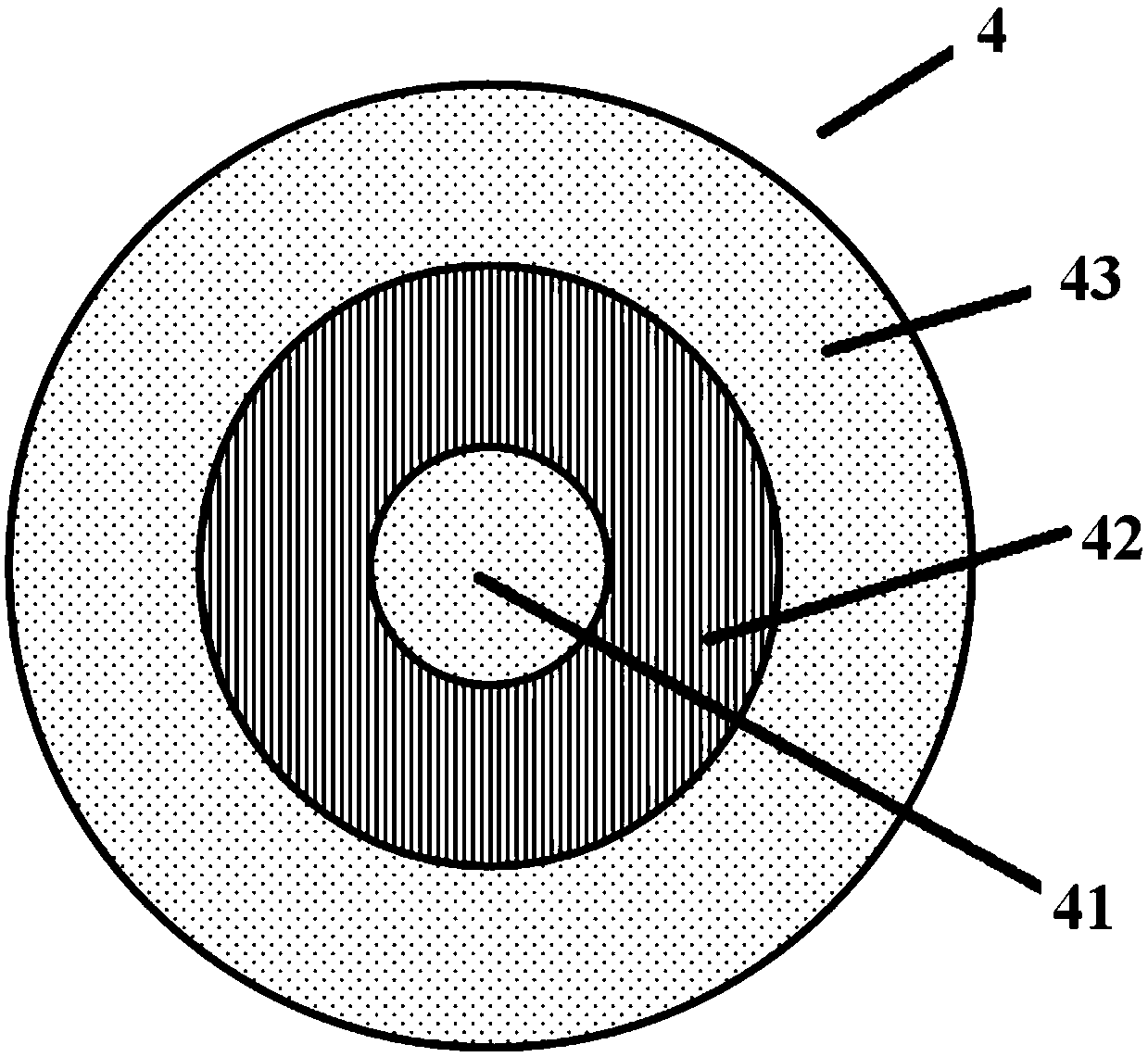

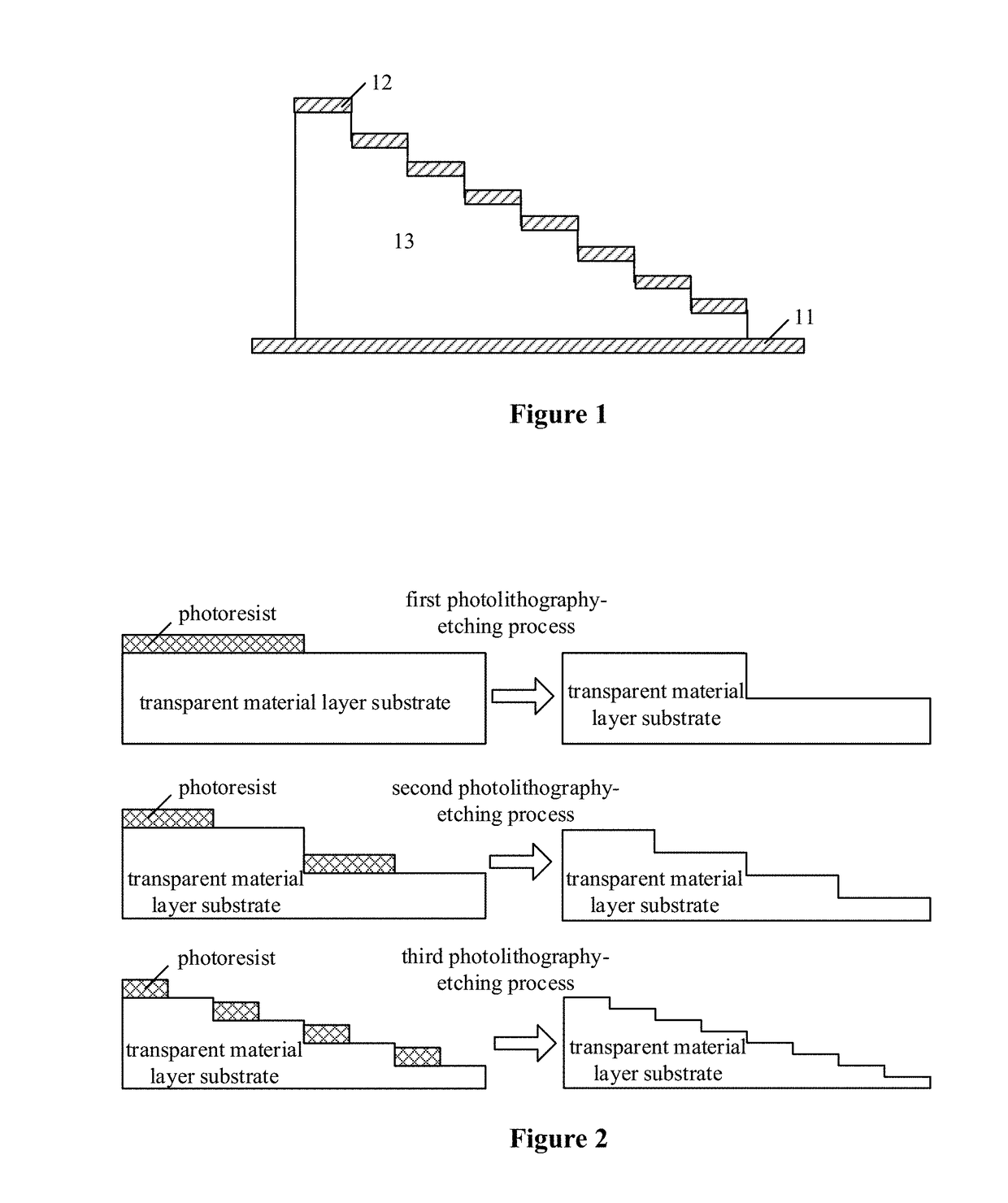

Monolithic integration method of hyperspectral image sensor

ActiveCN105742306AReduce failure rateImprove yieldSolid-state devicesSemiconductor/solid-state device manufacturingCMOSLight sensing

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

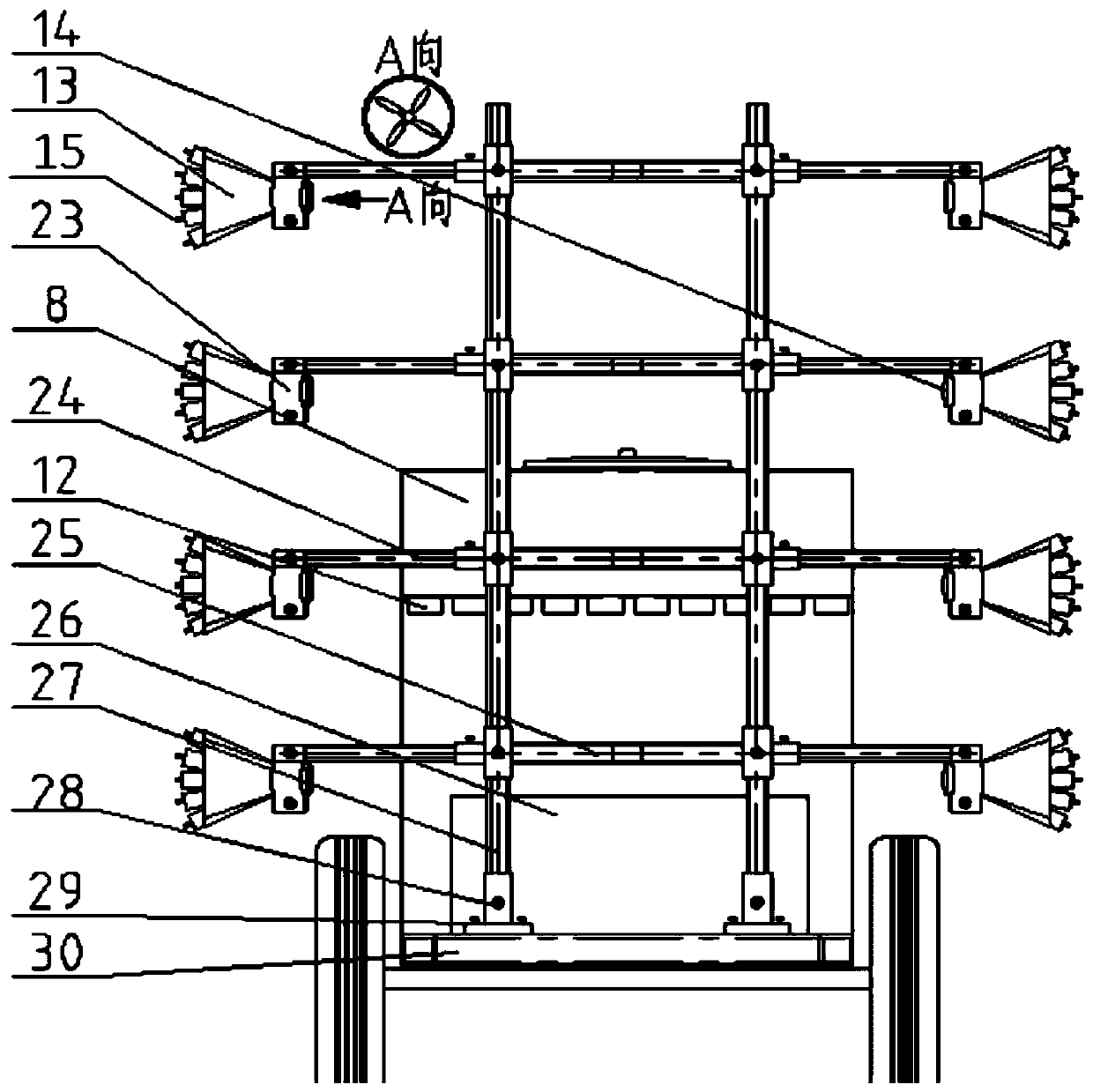

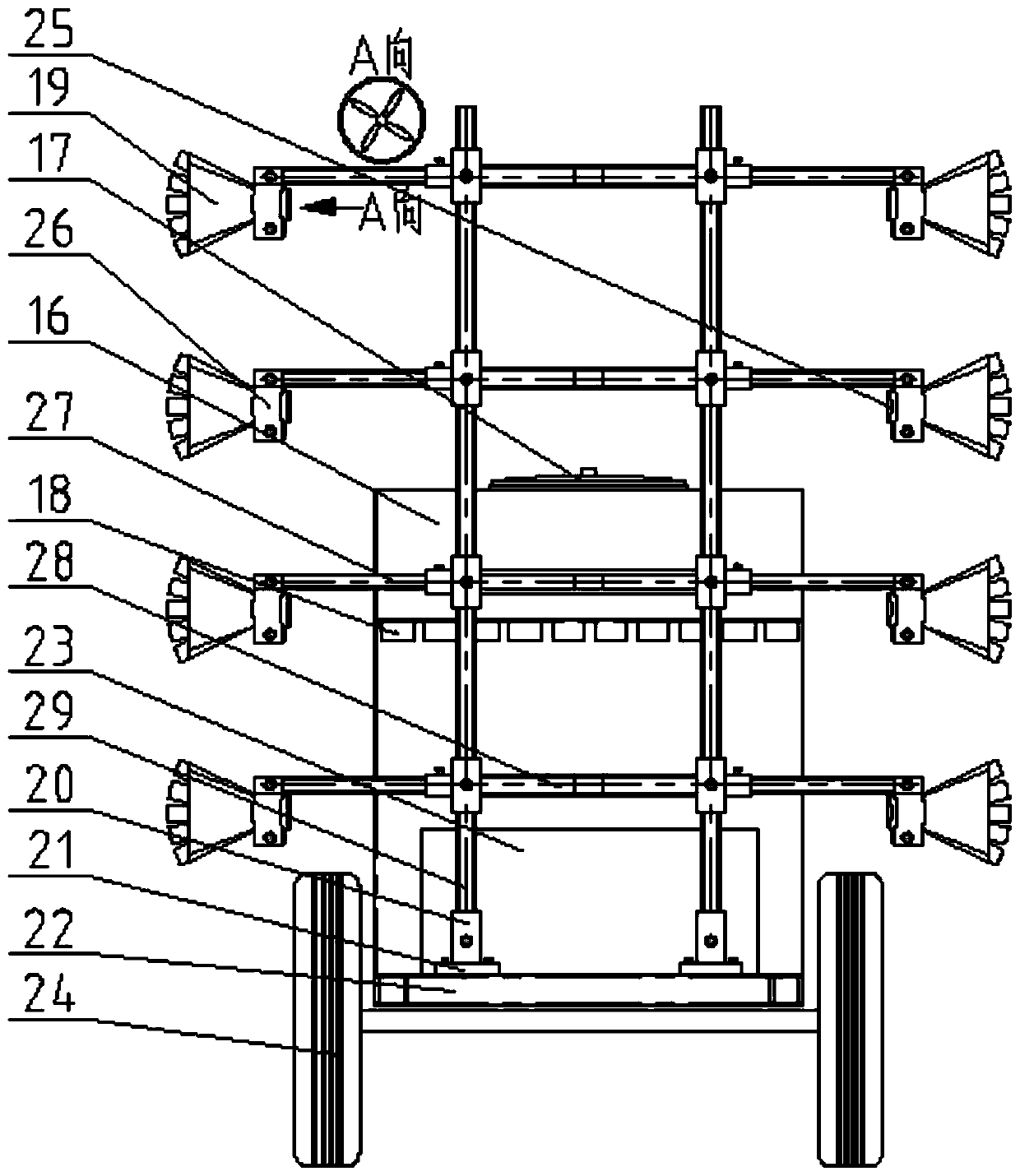

Automatic orchard variation spraying machine based on laser scanning technique

PendingCN111066765AQuick adjustment actionPrecision medicineInsect catchers and killersFruit treeAgricultural science

The invention relates to an automatic orchard variation spraying machine based on a laser scanning technique. The spraying machine comprises a traction chassis, a laser scanning detection device, a variation spraying device, an adjustable spraying rod device and a power supply device, wherein the laser scanning detection device comprises a laser scanner; the variation spraying device comprises anagent tank, a diaphragm pump, a voltage adjusting shunt, a first-stage shunt, a second-stage shunt, an electromagnetic valve group and a plurality of five-finger atomizer; and the power supply devicecomprises a power generator and a power transformer which are arranged on the traction chassis. By adopting the spraying machine, information of crowns of fruit trees on both sides of a tree row can be automatically acquired, the flow of each nozzle and the air amount of a single fan can be automatically and independently controlled according to an agent application algorithm, and spraying as required and air amount supply are achieved, so that the pesticide utilization rate and deposition uniformity can be improved, and environment pollution and body damage to operators, which are caused by pesticide drifting in the pesticide application process, can be reduced.

Owner:CHINA AGRI UNIV

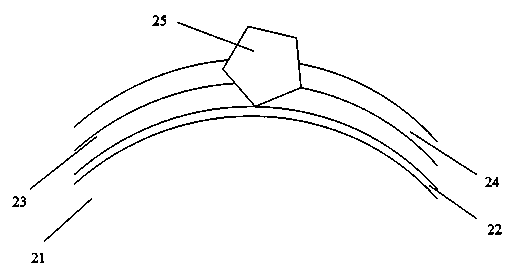

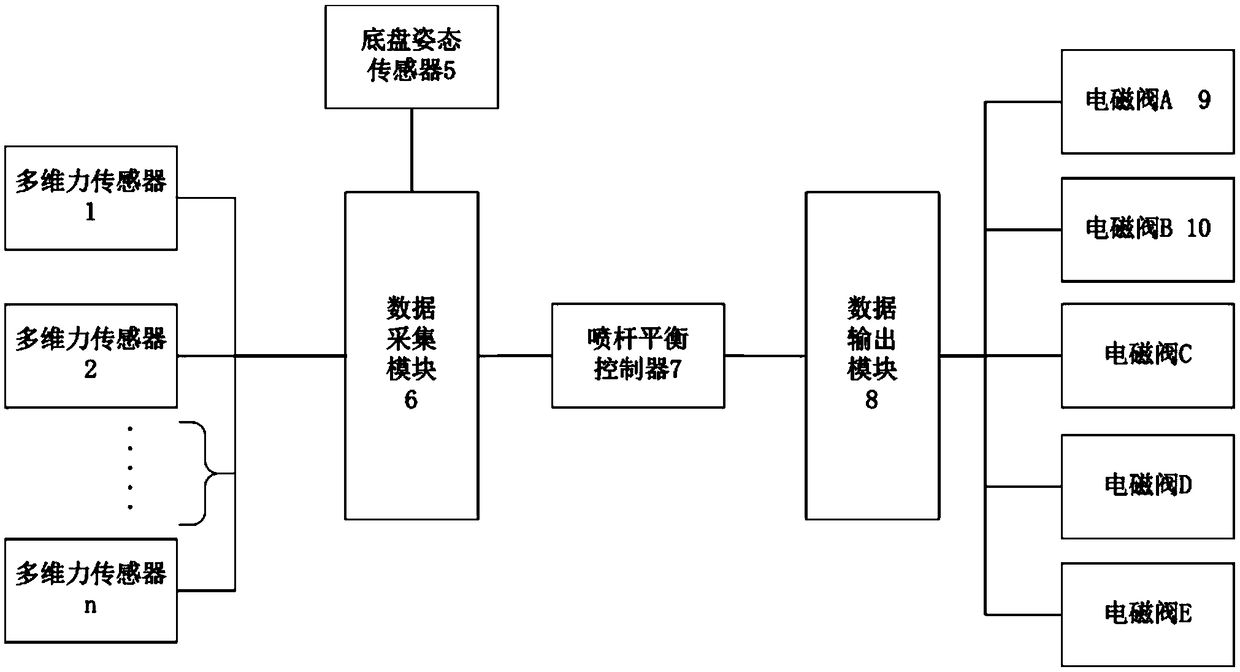

Spray bar balance active prediction adjustment system and method

ActiveCN108739730AImprove deposition uniformityReduce pollutionInsect catchers and killersHydraulic cylinderSolenoid valve

The invention discloses a spray bar balance active prediction adjustment system and method, and relates to the field of plant protection machinery. A mechanical part comprises a driving chassis, an atomizing machine main frame, a spray bar, a rolling column, branchers, a spray bar lifting hydraulic cylinder, a left side balance hydraulic cylinder, a right side balance hydraulic cylinder, a left transverse folding hydraulic cylinder and a right transverse folding hydraulic cylinder; a control part includes a chassis attitude sensor, multi-dimensional force sensors, a data acquisition module, aspray bar balance controller, a data output module and a solenoid valve; an atomizing spray bar is provided with a plurality of branchers, each of the branchers is provided with the multi-dimensionalforce sensors to detect random branch resistance, and the chassis attitude sensor is mounted on the driving chassis to detect the posture change and the trend. During the actual field operation of anatomizing machine, the spray bar balance controller predicts the change amount of spray bar postures according to the random branch resistance of each brancher and the posture change and trend of thedriving chassis, and the balance hydraulic cylinders on both sides are controlled to conduct servo-predictive control on the spray bar.

Owner:JIANGSU UNIV

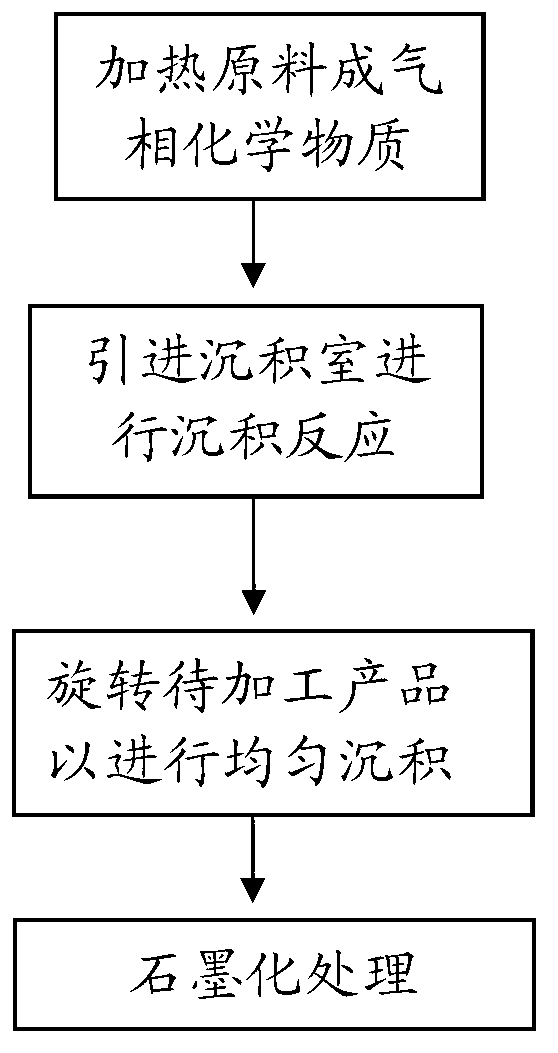

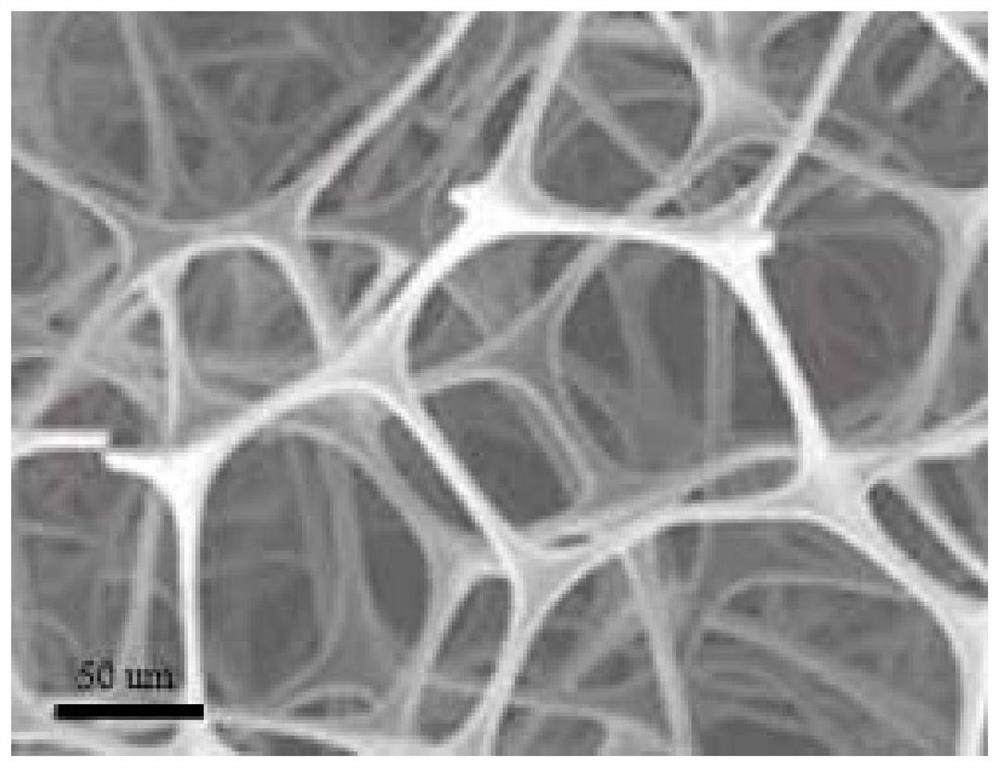

Vapor deposition method

InactiveCN103343334AImprove deposition uniformityEnsure consistencyChemical vapor deposition coatingCarbon compositesGas phase

The invention discloses a vapor deposition method comprising the following steps of: heating raw materials until the raw materials become a vapor chemical substance, wherein the raw materials participate in deposition reaction; introducing the vapor chemical substance to a deposition chamber with products to be processed to carry out deposition reaction; and rotating the products to be processed in the deposition chamber. Known from the technical scheme, the vapor deposition method provided by the embodiment of the invention has the advantages that the products to be processed in the deposition chamber are rotated when subjected to vapor deposition, then, gas in the deposition chamber is stirred to a certain extent, and the products are subjected to vapor deposition while being rotated in the deposition chamber, so that the deposition uniformity of the final products is favorably achieved, and the quality consistency of the products is ensured. Therefore, by using the vapor deposition method, a vapor deposition finished product which is uniform in material can be obtained, and the problem that the chemical deposition production of the current large carbon-carbon composite material is difficult is effectively solved.

Owner:ADVANCED FOR MATERIALS & EQUIP

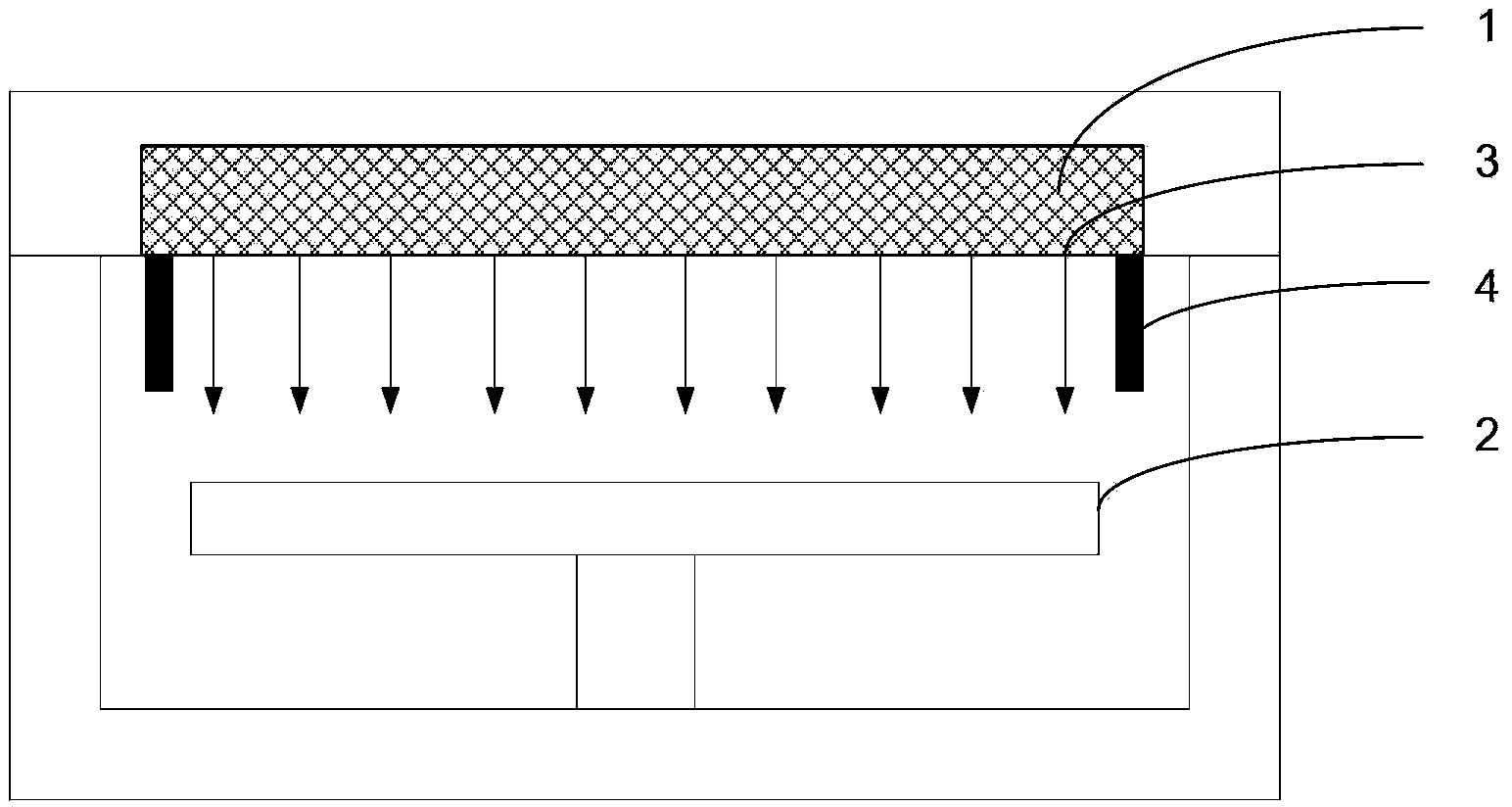

Spray head used for MOCVD equipment

InactiveCN103397308AImprove deposition uniformityImprove uniformityChemical vapor deposition coatingThermal insulationEngineering

The invention provides a spray head used for MOCVD equipment. The spray head is used for providing a substrate under the spray head with reaction gas. The spray head comprises a main body layer, wherein a side close to the substrate is a gas outlet face, and gas flows of the reaction gas are formed between the gas outlet face and the substrate; and a flow limiting ring, wherein the flow limiting ring is connected to the gas outlet face, and is arranged around the gas outlet face, so as to control the direction of the gas flows. A thermal insulation layer is arranged between the flow limiting ring and the gas outlet face. According to the spray head used for the MOCVD equipment, the thermal insulation layer is arranged between the flow limiting ring and the gas outlet face, and influences of the flow limiting ring on the temperature of the gas outlet face are avoided, so that uniformity of the deposition of the MOCVD equipment is increased.

Owner:光垒光电科技(上海)有限公司

A device for preparing diamond film and method for preparing diamond film using the device

ActiveCN103911596BChange density distributionImprove deposition uniformityChemical vapor deposition coatingMicrowavePlasma reaction

The invention provides a preparation apparatus for a diamond film. The apparatus employs a microwave plasma chemical vapor deposition device and comprises a microwave system, a vacuum system, a gas supply system and a plasma reaction chamber, wherein an autogyration substrate table is arranged in the plasma reaction chamber, microwaves generated by the microwave system during working enter into the plasma reaction chamber and excite gas supplied by the gas supply system above the autogyration substrate table to generate a plasma ball, and a refractory metal circular ring is arranged above the autogyration substrate table and located in the lower half part of the plasma ball.

Owner:SHANGHAI ZHENGSHI TECH CO LTD

Negative electrode current collector complex, preparation method thereof and lithium metal battery

ActiveCN113488659ALight in massLight weightElectrode carriers/collectorsSecondary cellsElectrical batteryLithium metal

The invention relates to the field of lithium batteries, in particular to a negative electrode current collector complex, a preparation method thereof and a lithium metal battery. The negative electrode current collector complex comprises a negative electrode and a current collector, the negative electrode is a lithium metal layer, the current collector comprises a polymer film, copper metal areas are arranged on the two side faces of the polymer film, copper metal layers are arranged on the copper metal areas, the lithium metal layer is attached to the side, away from the polymer film, of the copper metal layer, and the area of the copper metal layer is 20-70% of the area of the polymer film; the lithium metal layer and the polymer film coincide in size. The lithium metal battery provided by the invention adopts the current collector, so that the energy density of the lithium metal battery is improved, uneven lithium deposition on the surface of a negative electrode is also inhibited in the charging process of the battery, and the cycle life of the battery is further prolonged.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

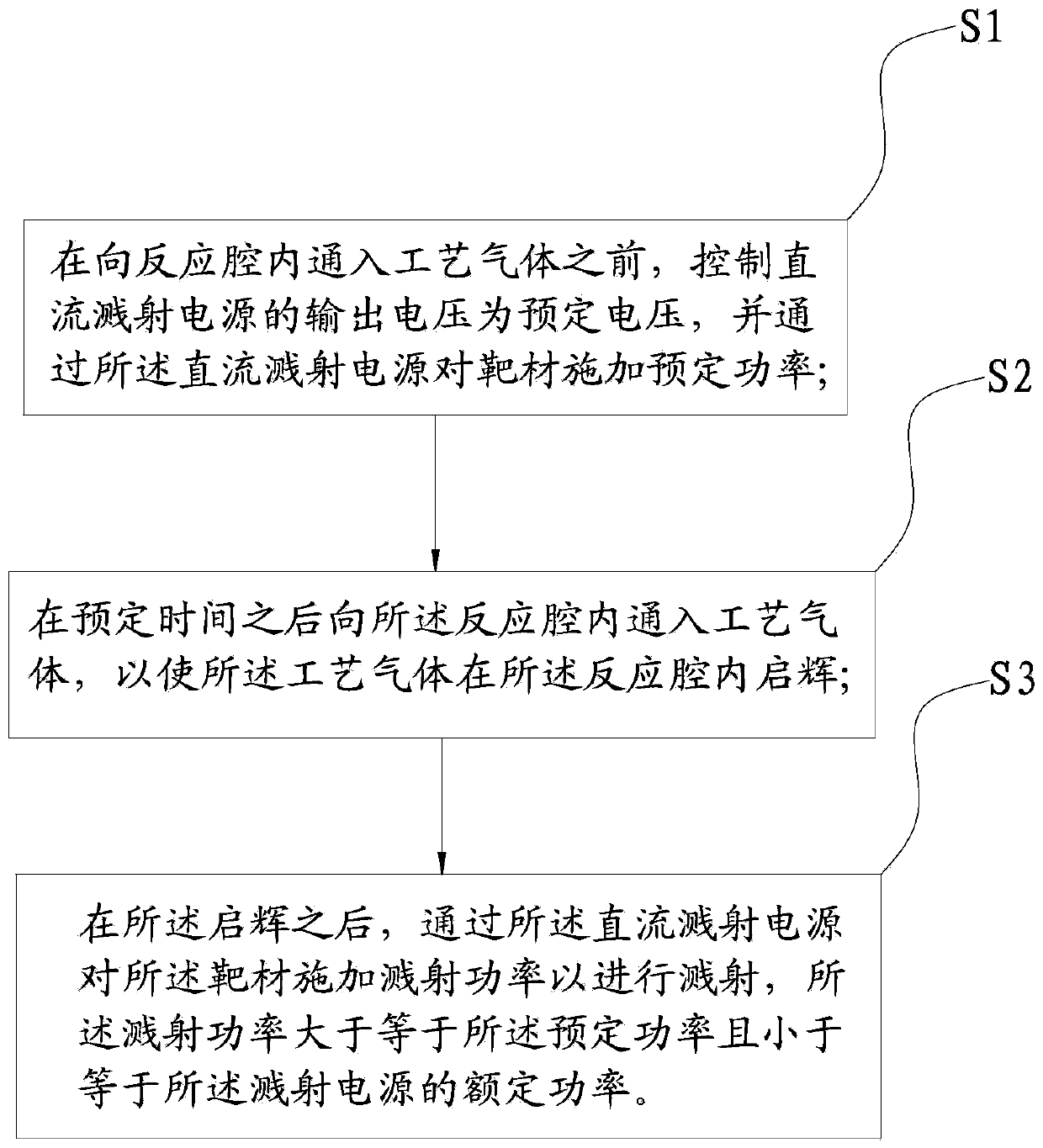

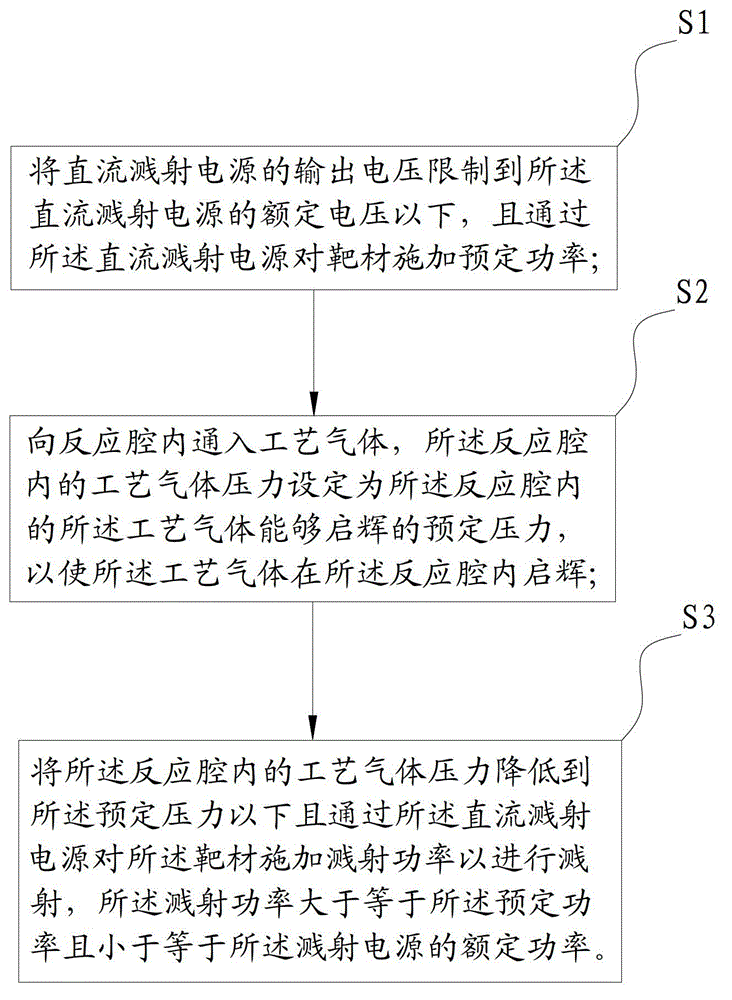

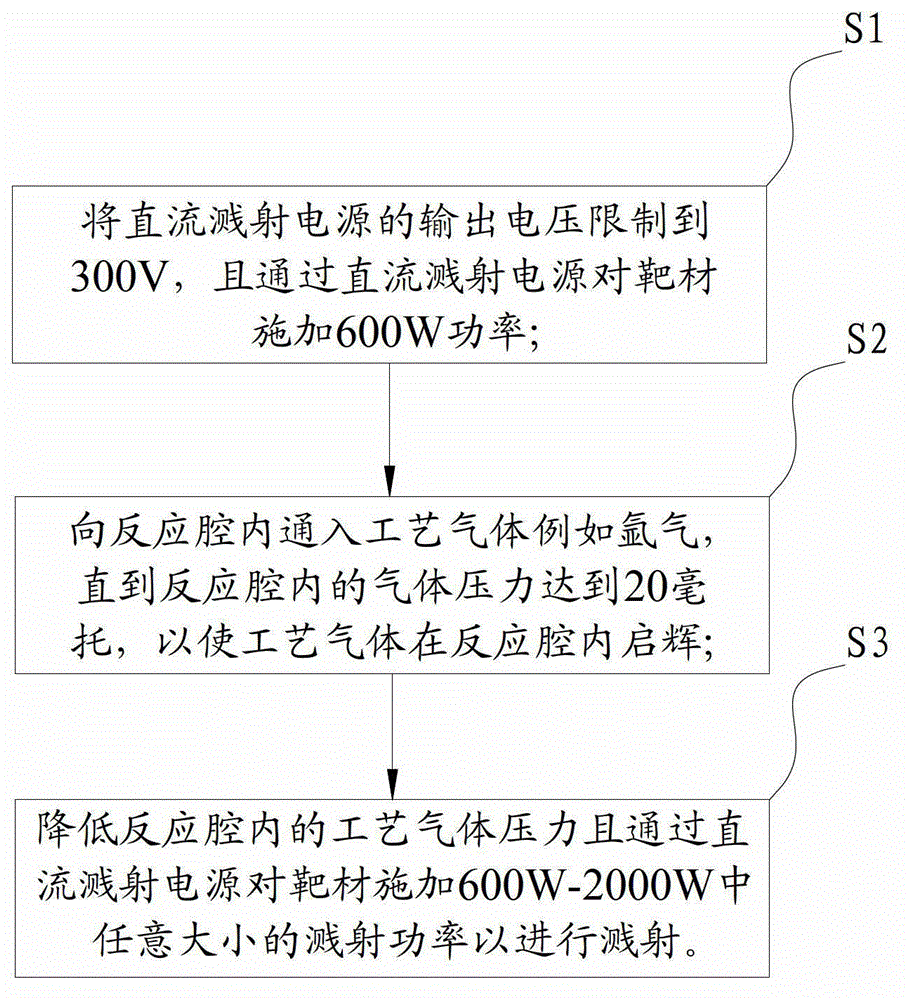

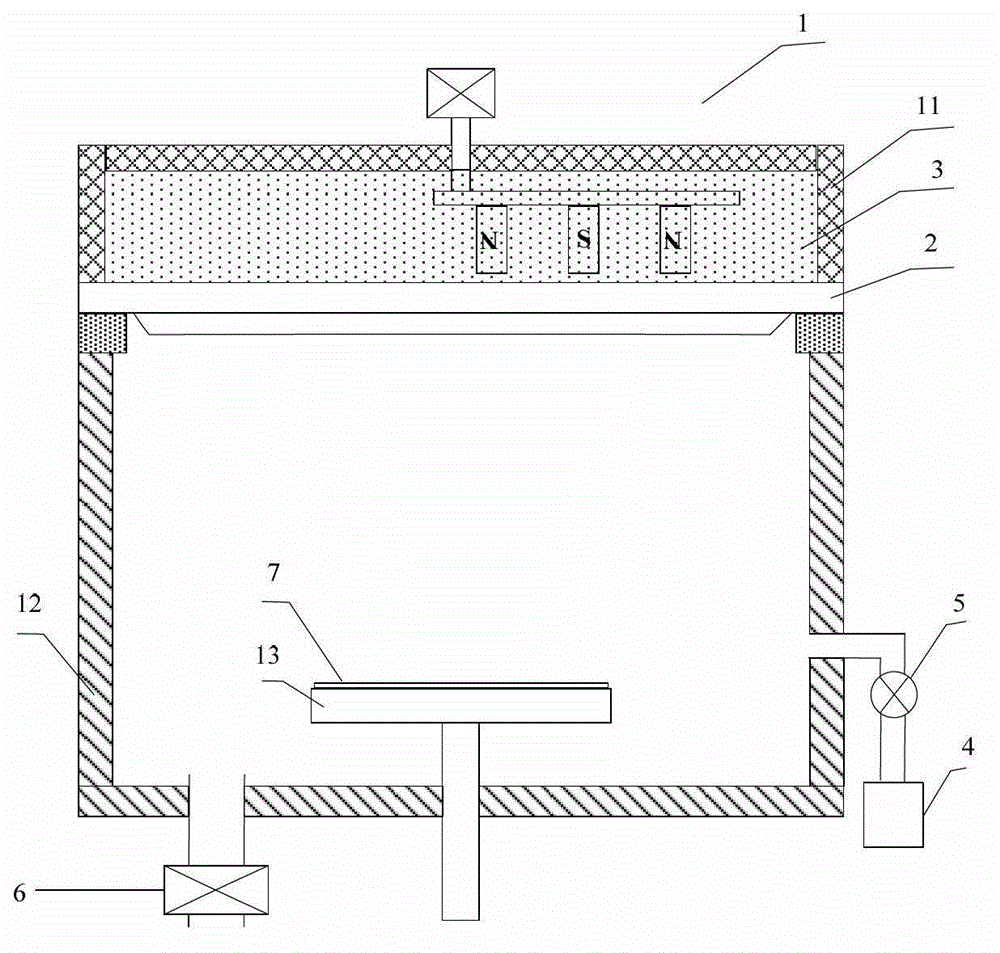

ITO thin film sputtering process and ITO thin film sputtering apparatus

ActiveCN103966557AImprove performanceImprove deposition uniformityVacuum evaporation coatingSputtering coatingSputteringDirect current

The invention discloses an ITO thin film sputtering process and an ITO thin film sputtering apparatus. The method comprises the following steps: before introducing process gas into a reaction chamber, controlling output voltage of a direct current sputtering power source to be predetermined voltage and applying predetermined power on a target material by using the direct current sputtering power source; introducing the process gas into the reaction chamber after predetermined time so as to allow the process gas to realize glow starting in the reaction chamber; and after glow starting, applying sputtering power on the target material by using the direct current sputtering power source to implement sputtering, wherein the sputtering power is more than or equal to the predetermined power but less than or equal to the rated power of the sputtering power source. The ITO thin film sputtering process provided by the invention can greatly reduce glow starting voltage, mitigates bombardment of a GaN layer caused by too high particle energy at the moment of glow starting and effectively reduces damage to the GaN layer. Moreover, since no new mechanism is needed, stability is improved, adjustment of the process can be conveniently carried out, and thin film deposition uniformity is enhanced.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Cesium releasing agent for realizing low-temperature controlled release of cesium and manufacturingmethod of releaser used for cesium releasing agent

The invention discloses a cesium releasing agent for realizing low-temperature controlled release of cesium and a manufacturing method of a releaser used for the cesium releasing agent, belonging to the field of cesium releasing agents for third-generation low-light level night vision devices and releasers used for the cesium releasing agents. The cesium releasing agent comprises a cesium salt and a reducing agent, wherein the cesium salt is cesium chromate or cesium tungstate, and the reducing agent is a modified ZrVFe getter. The releaser is produced by processing an NiCr alloy pipe, a Cs steam escape outlet is formed through laser boring in the pipe, the middle part of the pipe is filled with the cesium releasing agent and is subjected to press molding, and meanwhile two ends of the pipe are clamped to be flat so as to be used as heating electrodes. If being put into a low-light level night vision device, the manufacturedreleaser is found to have the cesium releasing temperature of 300-500 DEG C and the cesium releasing frequency of 300-400 times and to be freeof releasing harmful impurity gases and controllable in release rate and release amount; and the steam escape outlet of the releaser is reasonably designed, and the evaporation uniformity of Cs on a photoelectric cathode is good, so that the performance of the photoelectric cathode with negative electron affinity (NEA) is remarkably improved.

Owner:GRIMAT ENG INST CO LTD

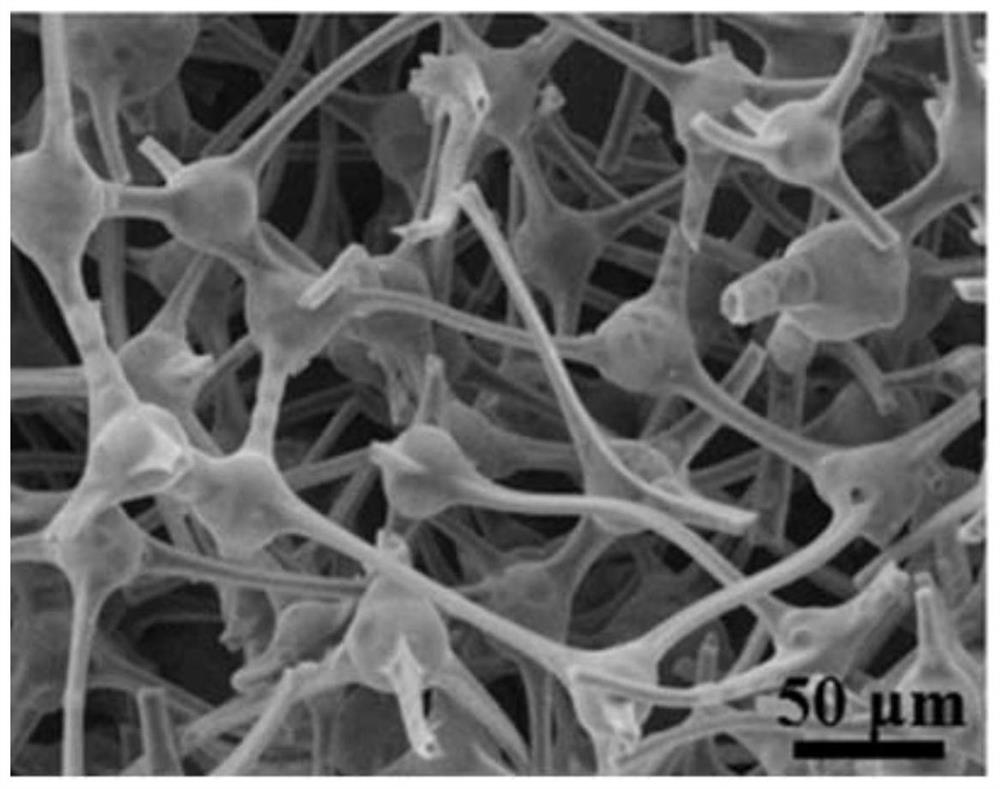

Composite negative electrode material, negative electrode, lithium ion battery and preparation method

ActiveCN111952576ALarge specific surface areaUniform depositionNegative electrodesSecondary cellsMetallic lithiumLithium-ion battery

The invention particularly discloses a composite negative electrode material, a negative electrode, a lithium ion battery and a preparation method. The preparation method comprises the following steps: carbonizing foam resin of melamine or derivatives thereof to obtain a matrix, and dipping the matrix into molten lithium to obtain the composite negative electrode material. The nitrogen-containingfunctional groups are uniformly distributed in the foam carbon matrix provided by the invention, so that the foam carbon matrix has relatively strong binding energy to lithium, lithium ion flow can behomogenized in a lithium ion deposition process, uniform deposition of metal lithium is facilitated, and formation of nucleation sites for lithium dendritic crystal growth is avoided; meanwhile, thefoam carbon matrix of the three-dimensional network structure further has a high specific surface area, the local current density can be reduced, the deposition uniformity of metal lithium in the matrix is further improved, the hollow structure of the foam carbon matrix serves as an ion transmission channel, carriers are provided in the lithium deposition process, and aggregation of lithium ions / electrons is dispersed. The continuous growth of the lithium dendrites is favorably relieved, so that the effects of inhibiting the lithium dendrites and buffering the volume expansion are achieved.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

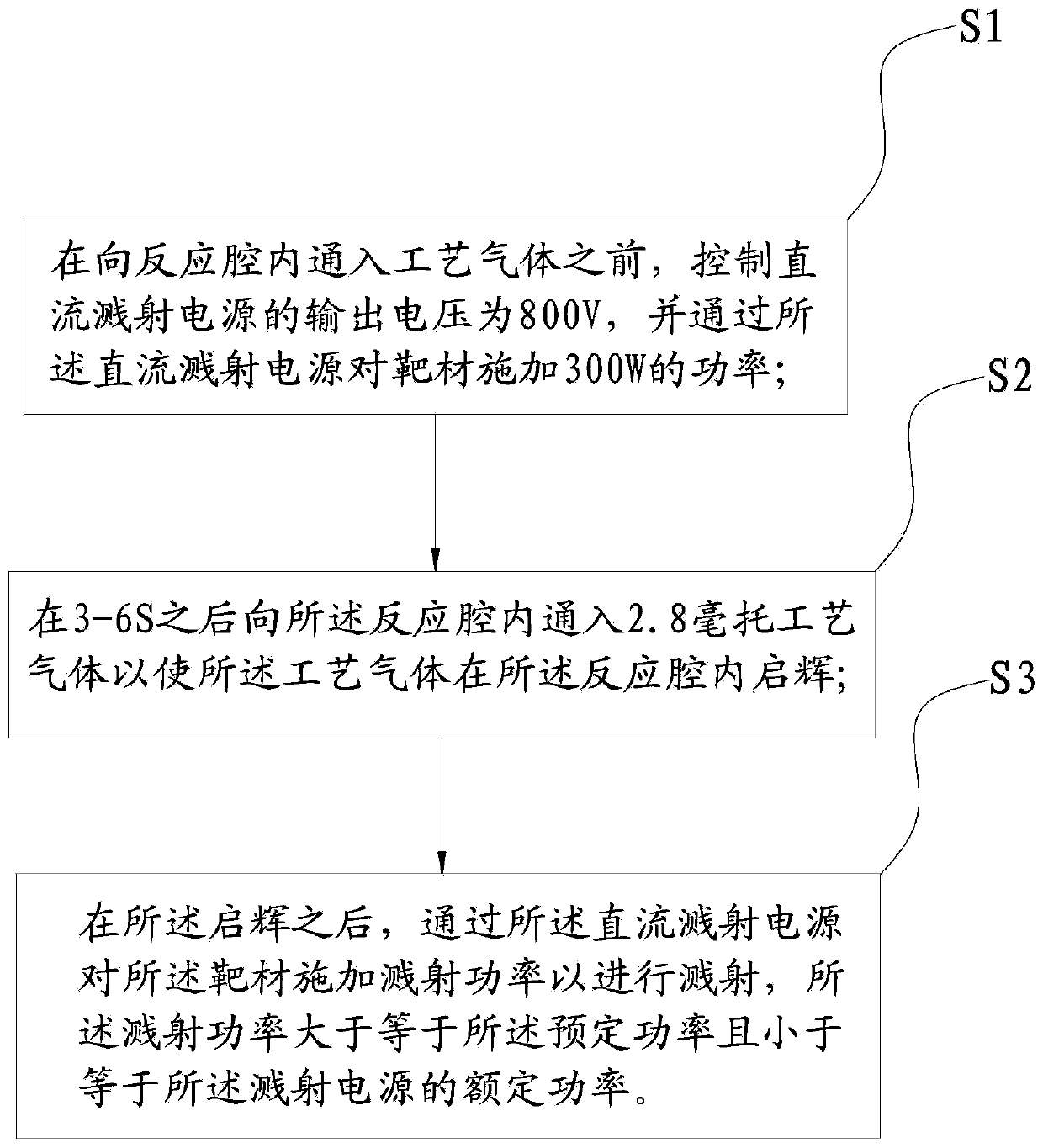

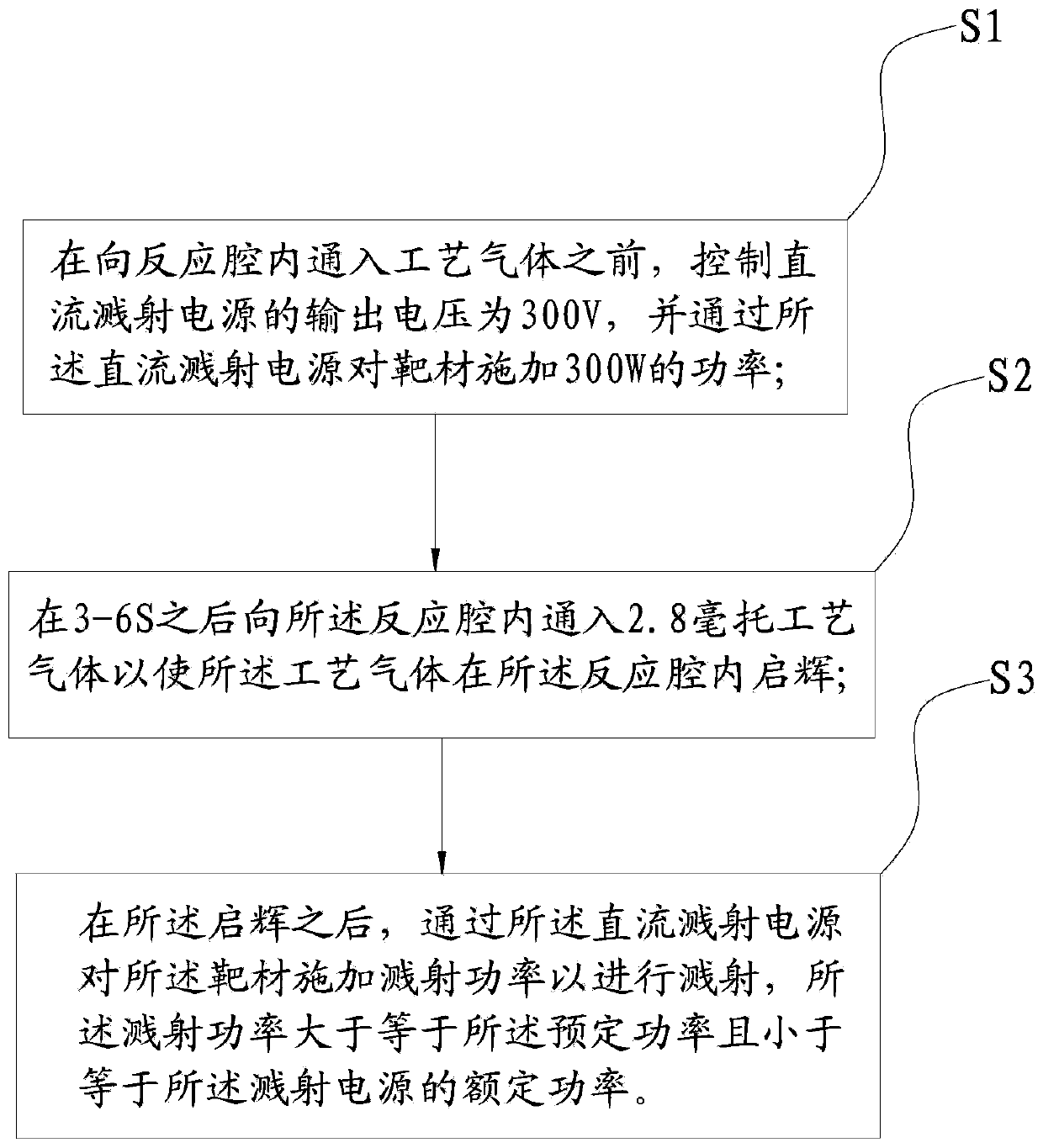

ITO thin film sputtering process and ITO thin film sputtering device

ActiveCN103938164AImprove deposition uniformityImprove uniformityVacuum evaporation coatingSputtering coatingSputteringPeak value

The invention discloses an ITO thin film sputtering process and an ITO thin film sputtering device. The ITO thin film sputtering process comprises steps of: 1) limiting the output voltage of a direct-current sputtering power supply to be lower than the nominal voltage of the direct-current sputtering power supply, and applying a preset power to a target material through the direct-current sputtering power supply; 2) feeding process gas into a reaction cavity, wherein the pressure of the process gas in the reaction cavity is set to be a preset pressure capable of glow starting of the process gas so that the process gas can be subjected to glow starting in the reaction cavity; and 3) lowering the pressure of the process gas in the reaction cavity to be lower than the preset pressure, applying a sputtering power to the target material through the direct-current sputtering power supply and sputtering, wherein the sputtering power is not less than the preset power and is not more than the rated power of the sputtering power supply. The ITO thin film sputtering process can lower the voltage peak value of glow starting.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

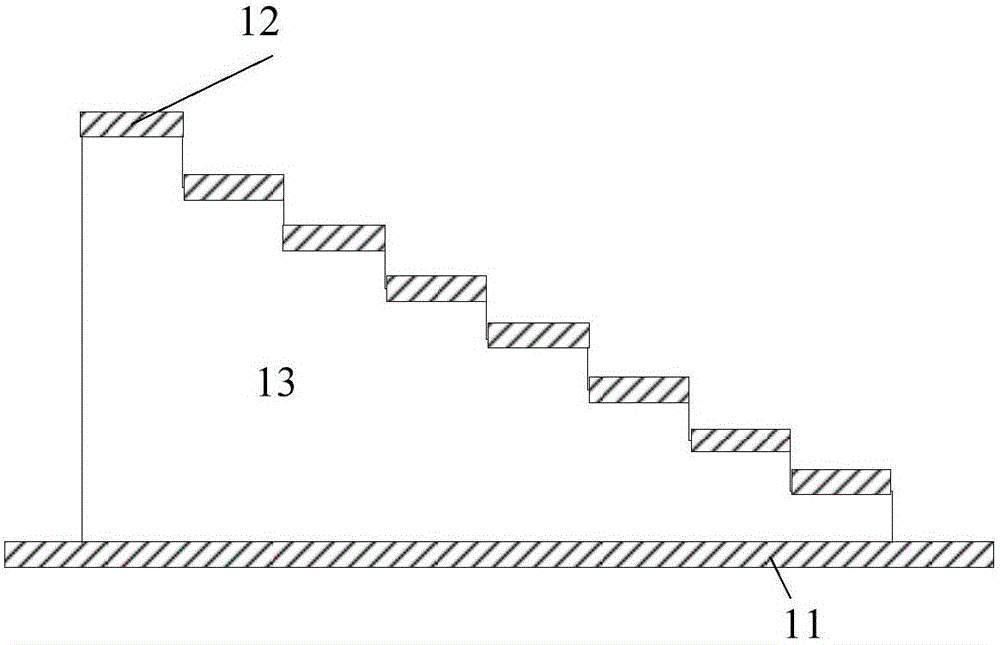

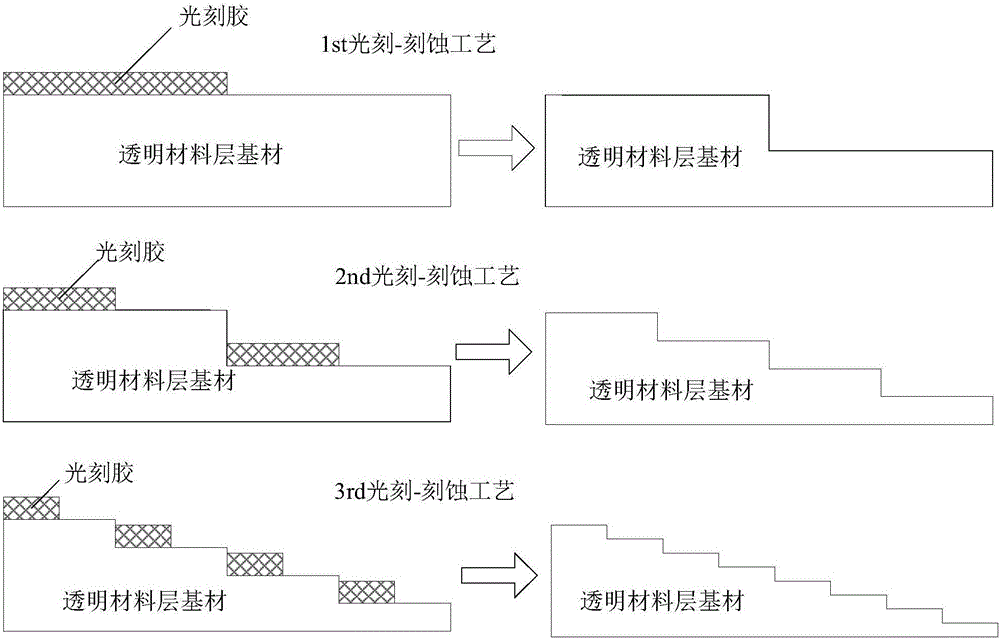

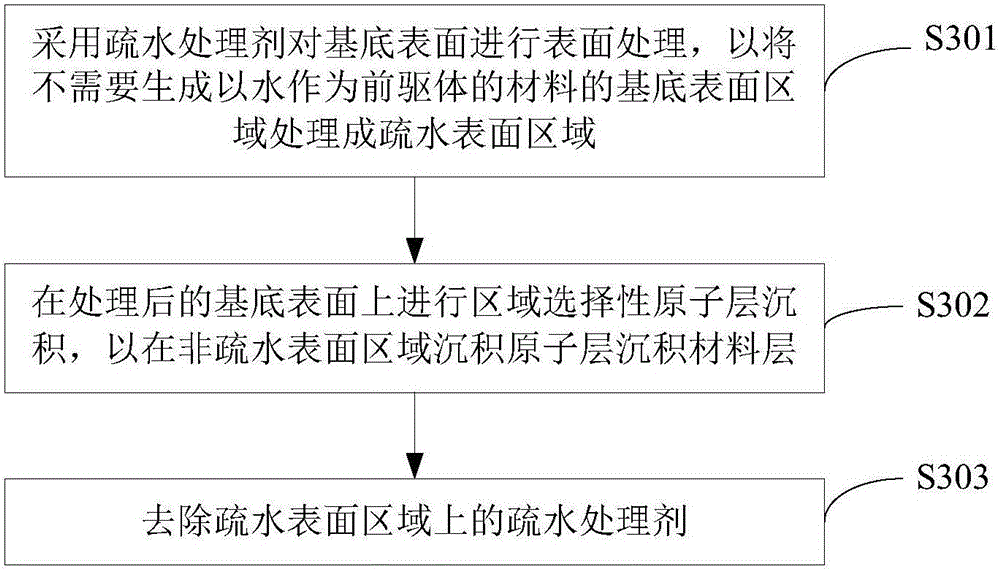

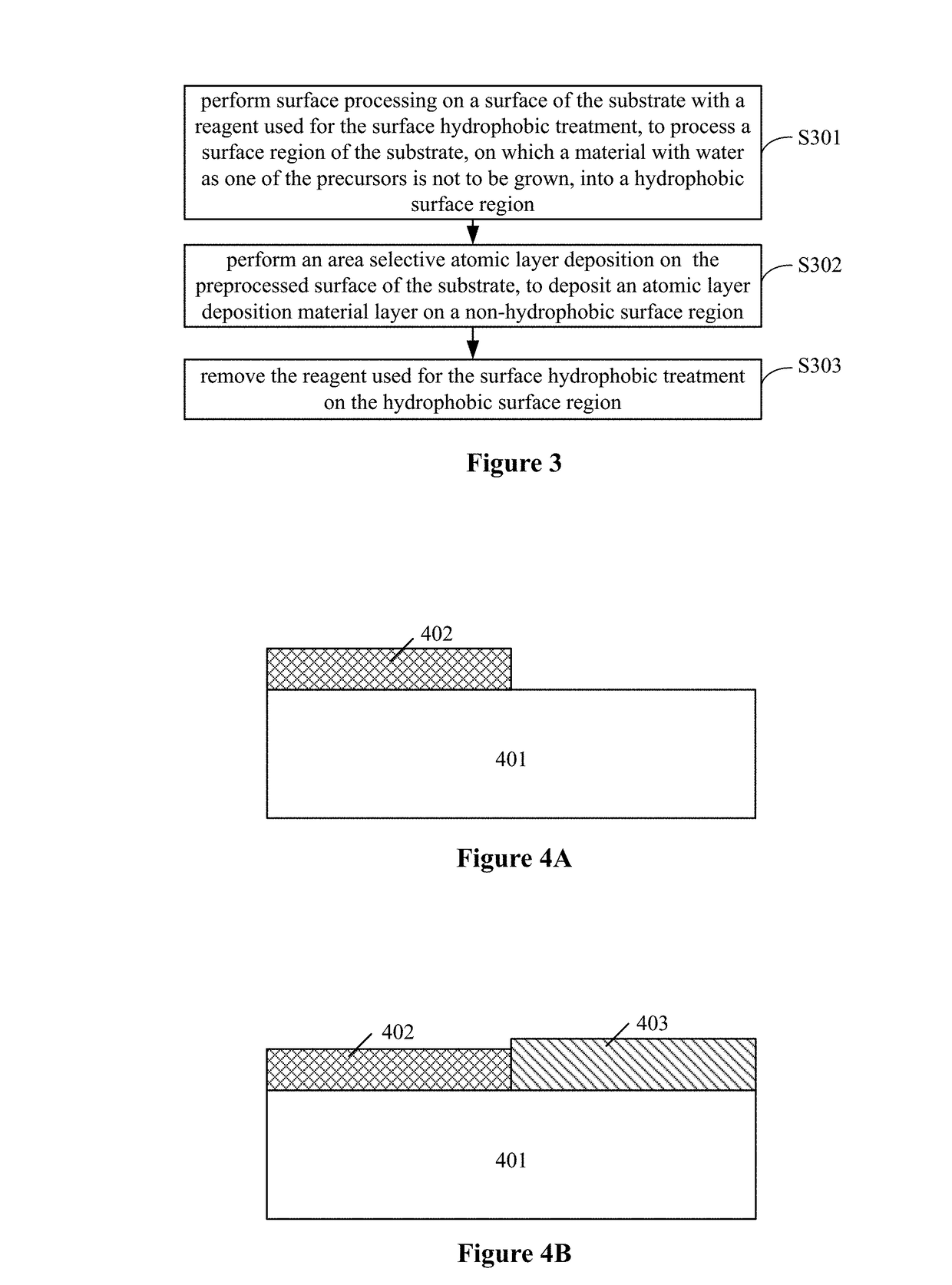

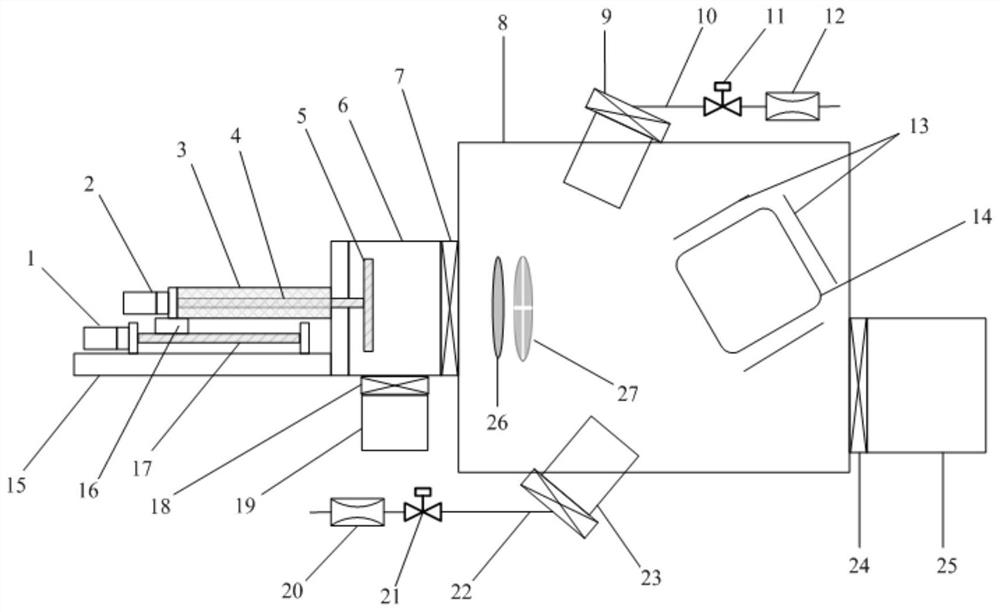

Method of monolithic integration of hyperspectral image sensor

ActiveUS20170294478A1Improve deposition uniformityReduce equipment failure rateSolid-state devicesRadiation controlled devicesCMOSRegioselectivity

A method for monolithic integration of a hyperspectral image sensor is provided, which includes: forming a bottom reflecting layer on a surface of the photosensitive region of a CMOS image sensor wafer; forming a transparent cavity layer composed of N step structures on the bottom reflecting layer through area selective atomic layer deposition processes, where N=2m, m≧1 and m is a positive integer; and forming a top reflecting layer on the transparent cavity layer. With the method, non-uniformity accumulation due to etching processes in conventional technology is minimized, and the cavity layer can be made of materials which cannot be etched. Mosaic cavity layers having such repeated structures with different heights can be formed by extending one-dimensional ASALD, such as extending in another dimension and forming repeated regions, which can be applied to snapshot hyperspectral image sensors, for example, pixels, and greatly improving performance thereof.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

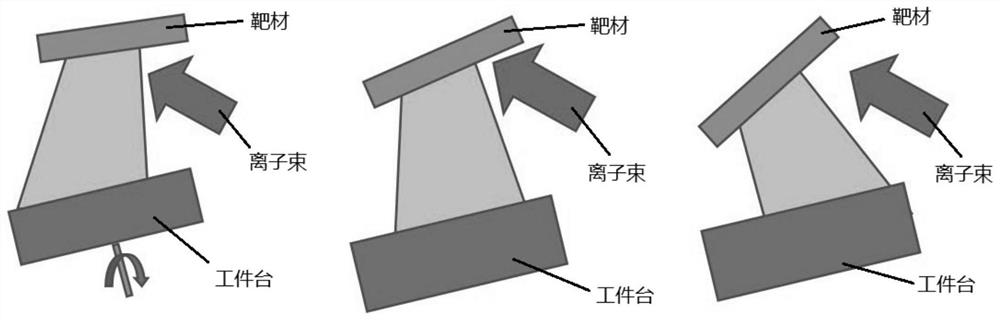

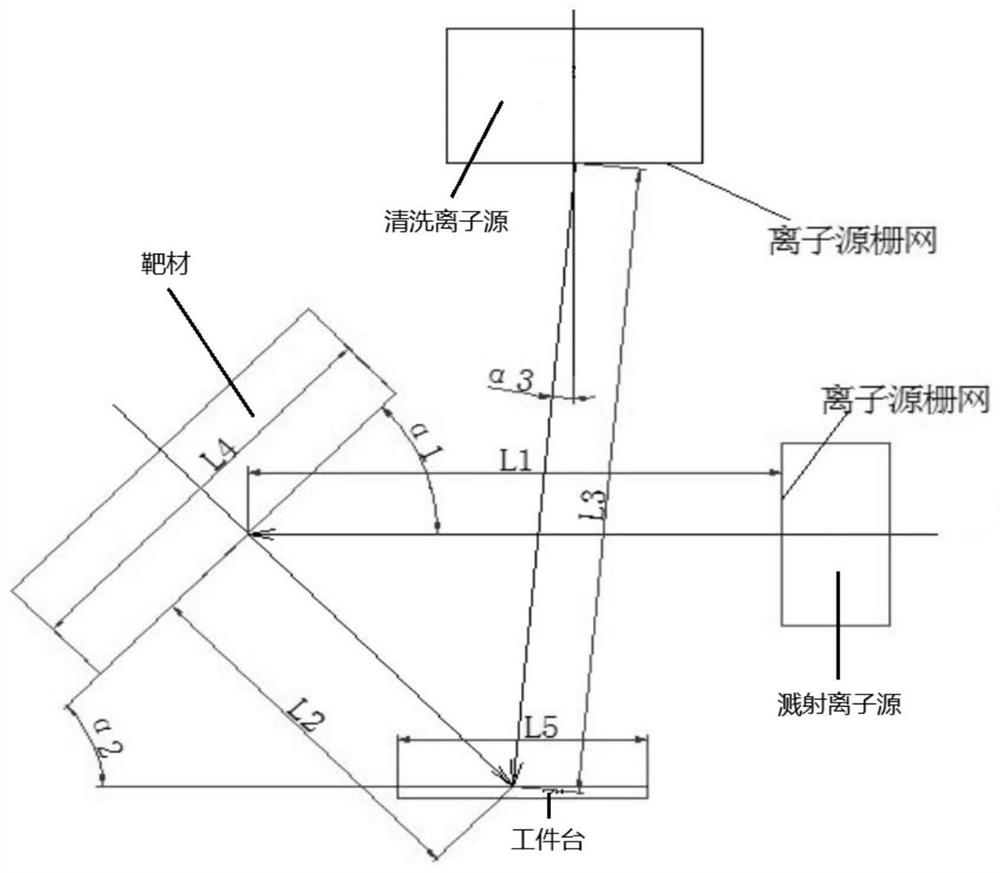

Ion beam deposition equipment for infrared metal film and film deposition method

ActiveCN112159967AImprove adhesionImprove deposition uniformityFinal product manufactureVacuum evaporation coatingPhysicsIon beam deposition

The invention discloses ion beam deposition equipment for an infrared metal film and a film deposition method. The equipment comprises a wafer loading and unloading cavity and a sputtering cavity, wherein a first high-vacuum isolation valve is arranged between the wafer loading and unloading cavity and the sputtering cavity, the wafer loading and unloading cavity is provided with a vacuum sealingdoor, a pushing rod penetrates through the vacuum sealing door, a workpiece table is arranged at the end, on the inner side of the vacuum sealing door, of the pushing rod, a pushing mechanism used forpushing the pushing rod is arranged on the outer side of the vacuum sealing door, and the wafer loading and unloading cavity is connected with a first vacuumizing device. The film deposition method adopts the equipment to perform film deposition. According to the invention, the wafer loading and unloading cavity is arranged, so that the cavity opening and vacuumizing times of the sputtering cavity can be reduced, the vacuumizing time can be shortened, the productivity can be improved, the vacuum environment can be always kept in the sputtering cavity, the target burning times can be reduced,and the utilization rate of a target material can be improved. The ion beam deposition equipment has the advantages of high productivity, high target material utilization rate and the like, can be widely used for depositing infrared metal films, and has very high use values and application prospects.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Composite solid electrolyte, preparation method thereof and lithium storage battery

PendingCN112490496APrecise thickness controlImprove performanceSecondary cellsElectrolyte immobilisation/gelificationComposite electrolytePolymer

The invention relates to a solid electrolyte, and discloses a composite solid electrolyte and a preparation method thereof, and a lithium storage battery. The composite solid electrolyte comprises a negative electrode side electrolyte layer, an ion dispersion layer and a positive electrode side electrolyte layer which are sequentially attached and compressed, the negative electrode side electrolyte layer is a PEO electrolyte membrane layer, the ion dispersion layer is Li3N, the positive electrode side electrolyte layer is a polymer solid electrolyte membrane layer, so that the lithium ion conductivity of the composite electrolyte is improved, the deposition uniformity of lithium ions in the charging process is improved, the lithium dendritic crystal forming rate is low, the cycle life of the lithium metal negative electrode is prolonged, and the cycle life of solid-state lithium storage is further prolonged; and the material still has a relatively high performance retention rate aftermultiple cycles.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com