Patents

Literature

703results about How to "Increased chance of collision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

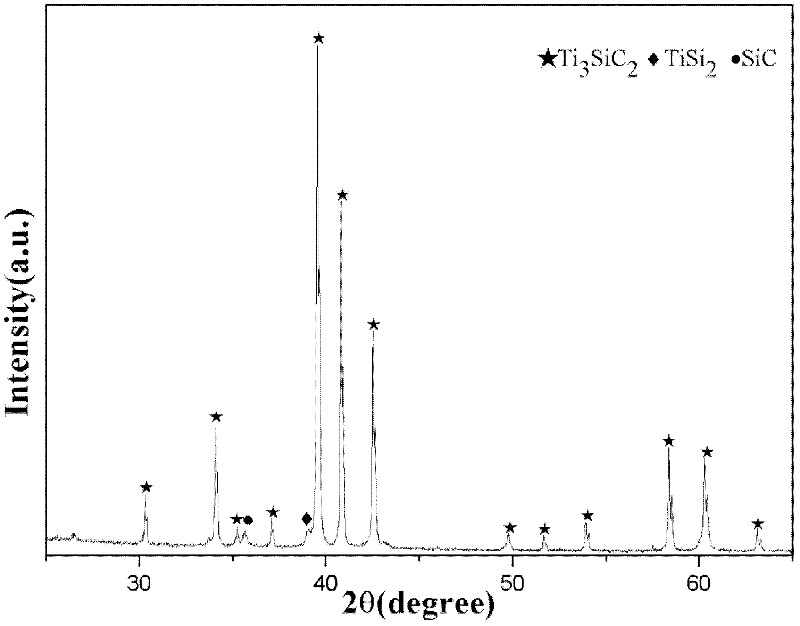

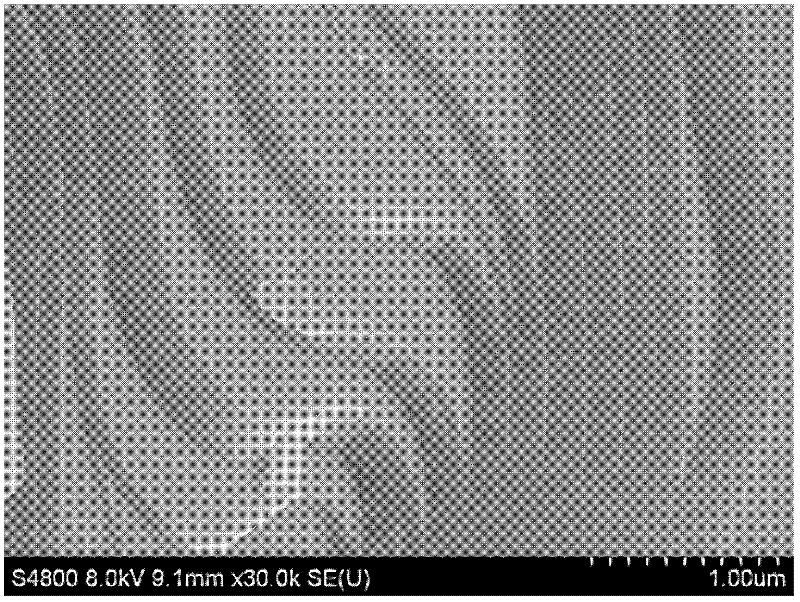

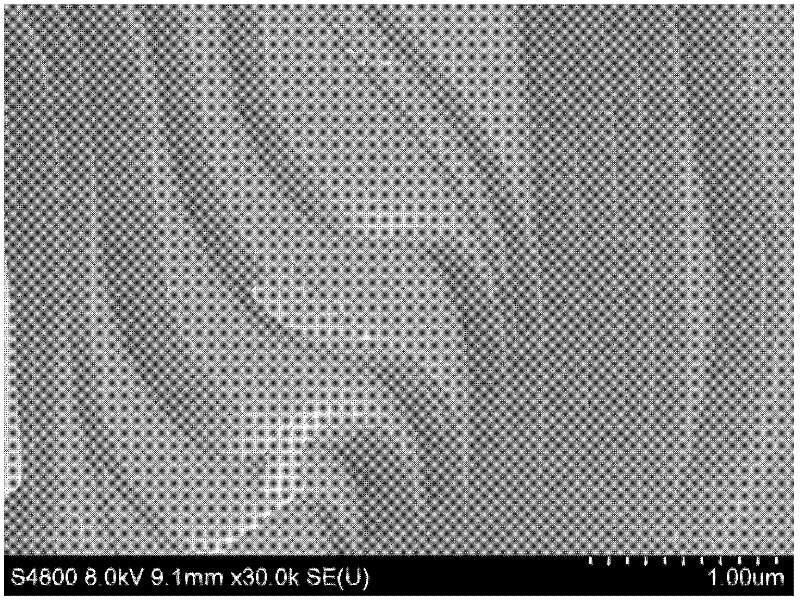

Method for preparing high-purity MAX-phase ceramic powder

InactiveCN102633505AHigh activityUniform distribution of temperature fieldChemical measurementBall mill

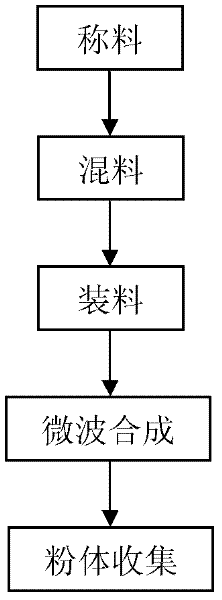

The invention discloses a method for preparing high-purity MAX-phase ceramic powder. The method includes approximately weighing raw materials according to stoichiometric ratios of various elements in a chemical formula of a MAX-phase ceramic material at first; then uniformly mixing the raw materials by the aid of a ball mill, placing mixture of the raw materials in a mold and prepressing the mixture to obtain a prepressed intermediate body; and finally placing the prepressed intermediate body into a special microwave oven, controlling the temperature rise rate by means of adjusting the microwave power in inertial atmosphere, increasing the temperature to a sintering temperature, keeping heat for a certain period, realizing furnace cooling to the room temperature, and grinding the mixture to obtain the MAX-phase ceramic powder with high purity, an excellent shape and a unique layered structure. The method for preparing the MAX-phase ceramic powder is speedy, efficient, energy-saving and environment-friendly and is low in cost and easy to realize large-scale production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

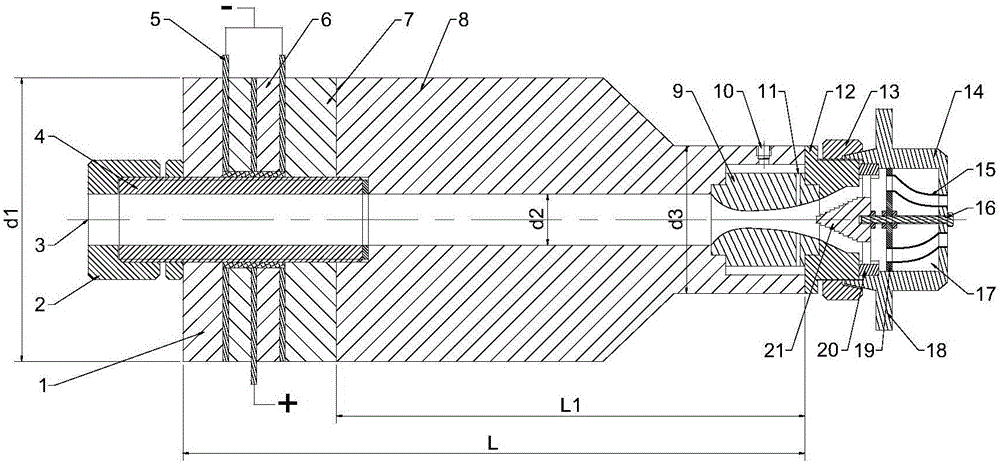

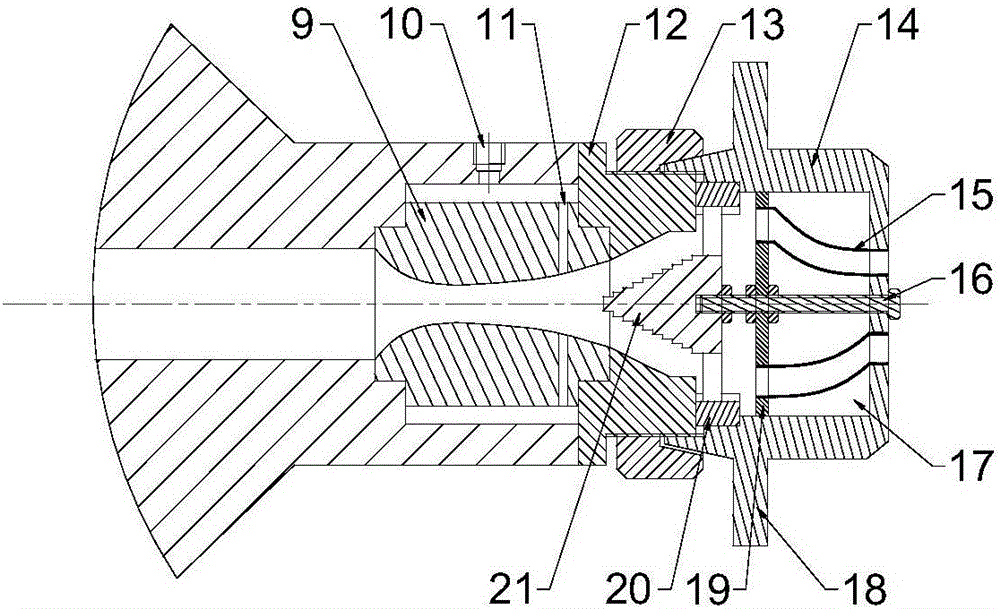

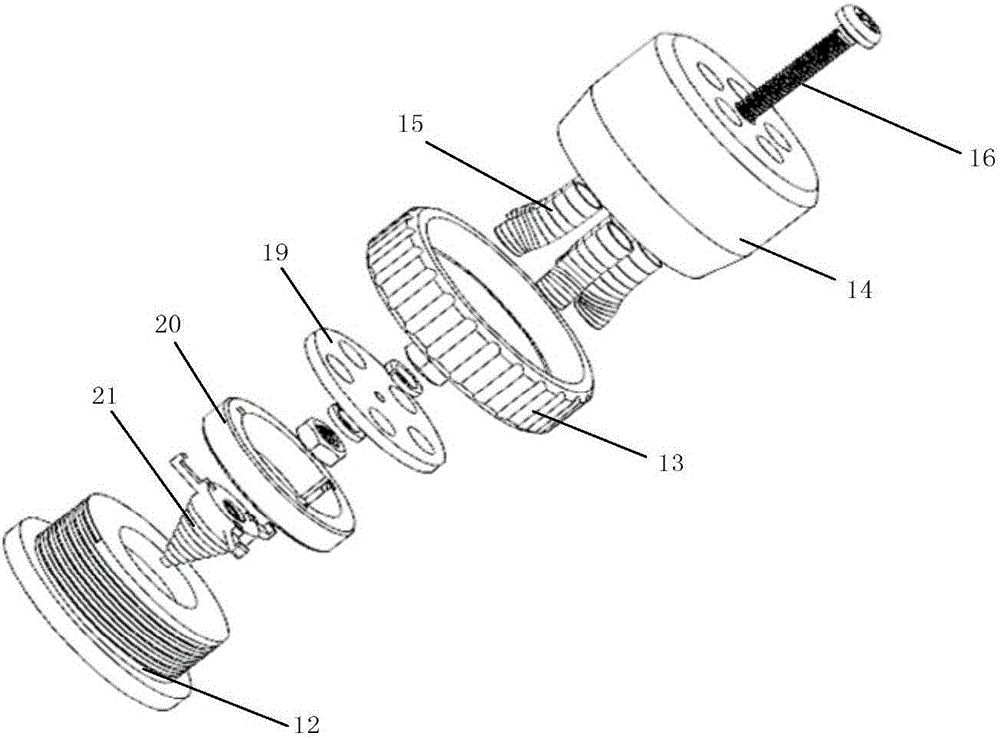

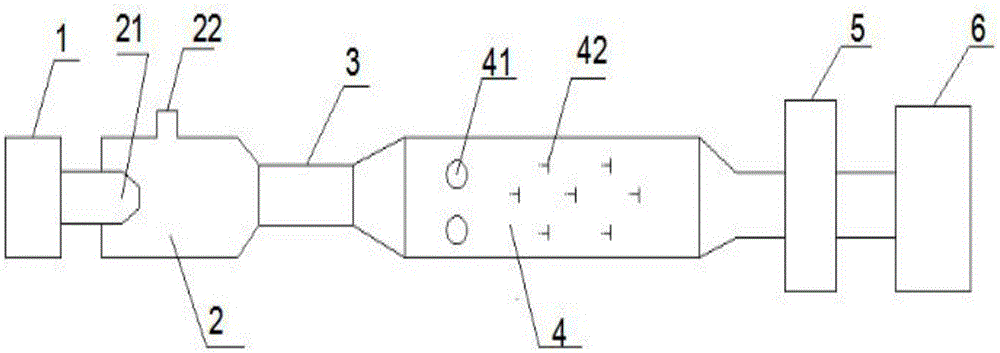

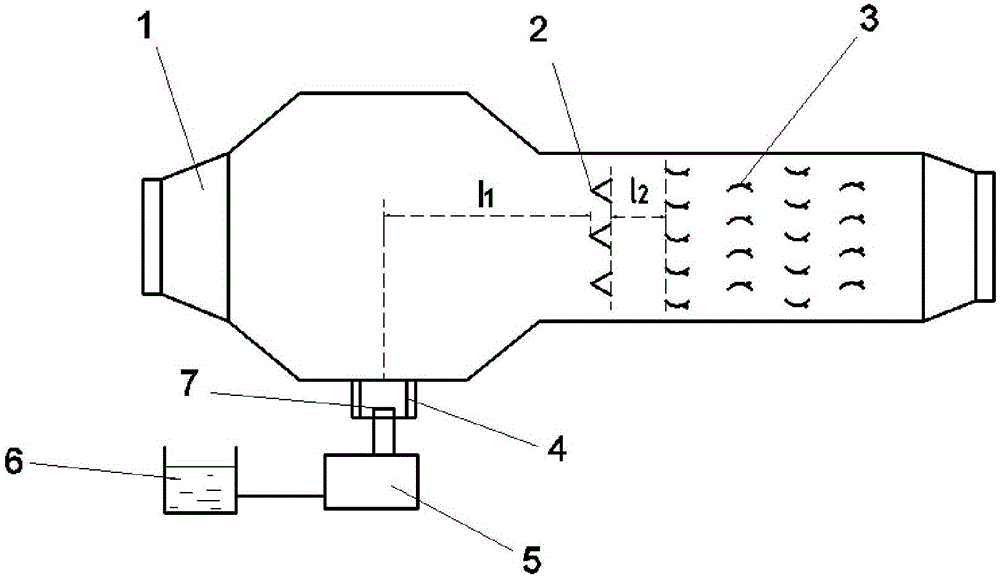

Piezoelectric two-phase flow ultrasonic atomization spraying nozzle

InactiveCN105834054ALarge amount of atomizationSmall dropletLiquid spraying apparatusElectricitySpray nozzle

The invention provides a piezoelectric two-phase flow ultrasonic atomization spraying nozzle. The piezoelectric two-phase flow ultrasonic atomization spraying nozzle comprises a piezoelectric vibrator, an amplitude-change pole, a second end cover and a first end cover; the piezoelectric vibrator and the amplitude-change pole are connected through a connecting bolt; an air inlet connector is installed at the tail of the connecting bolt; the second end cover is fixed to the front end of the amplitude-change pole; a laval type valve element is fixed into a step hole of the amplitude-change pole and a groove of the second end cover; a liquid inlet hole is formed in the hole wall face of the step hole of the amplitude-change pole; a plurality of flow guide holes are formed in the positions, close to an outlet, of the laval type valve element in the radial direction; the first end cover is threaded connection to the second end cover; a radial positioning ring is arranged at the position of a clamping groove in the back end of the first end cover; a step type taper valve is installed on the radial positioning ring; the step type taper valve and a vibration separating plate are connected through an adjusting bolt; a resonance chamber is formed between the vibration separating plate and the top end of the first end cover; and a plurality of flexible pipes are arranged in the resonance chamber. According to the piezoelectric two-phase flow ultrasonic atomization spraying nozzle, a large number of superfine fog drops are generated under the low-energy working condition, and the shortcoming that large pulverization amount, small grain size, low power dissipation and directed spraying cannot be considered at the same time through in the traditional technology is overcome.

Owner:JIANGSU UNIV

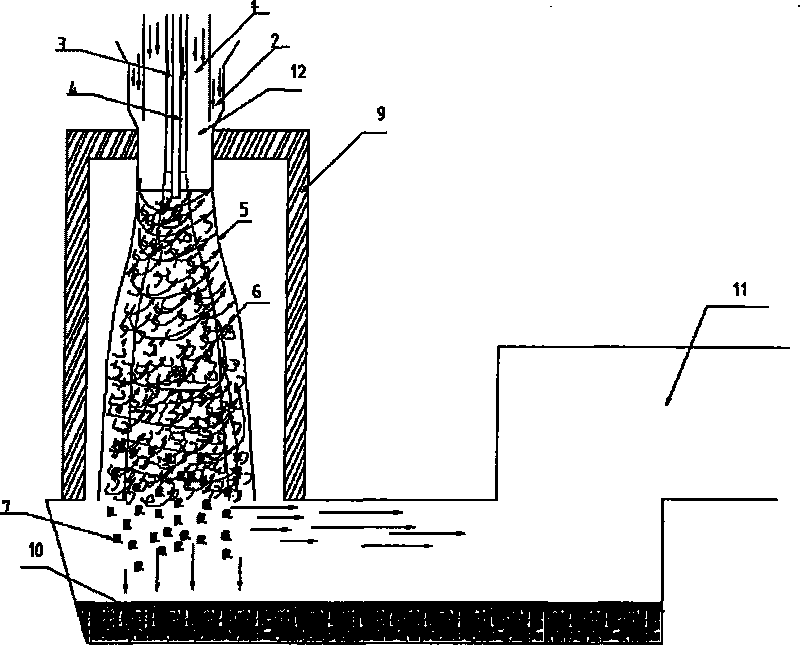

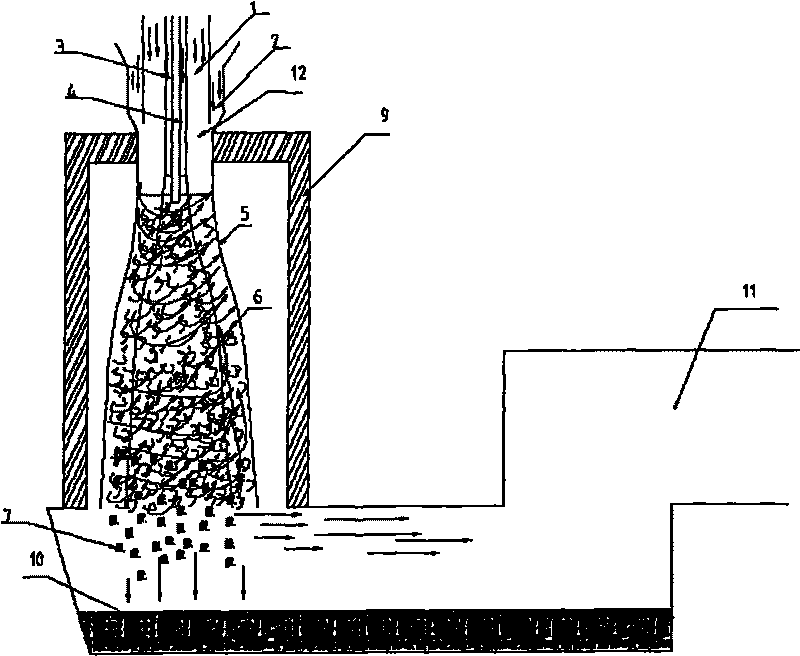

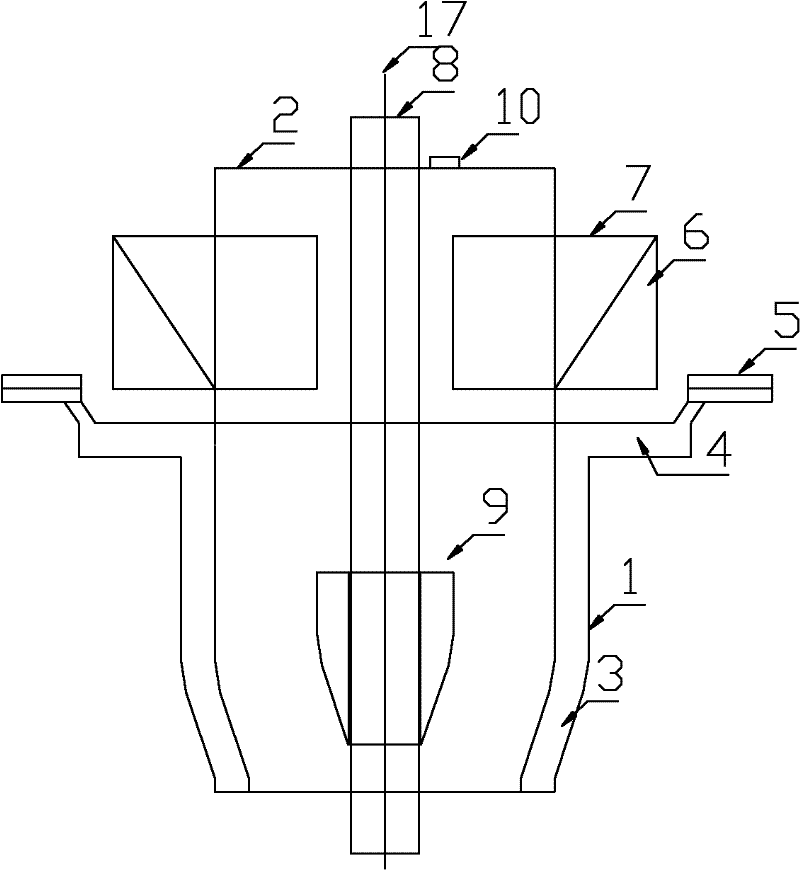

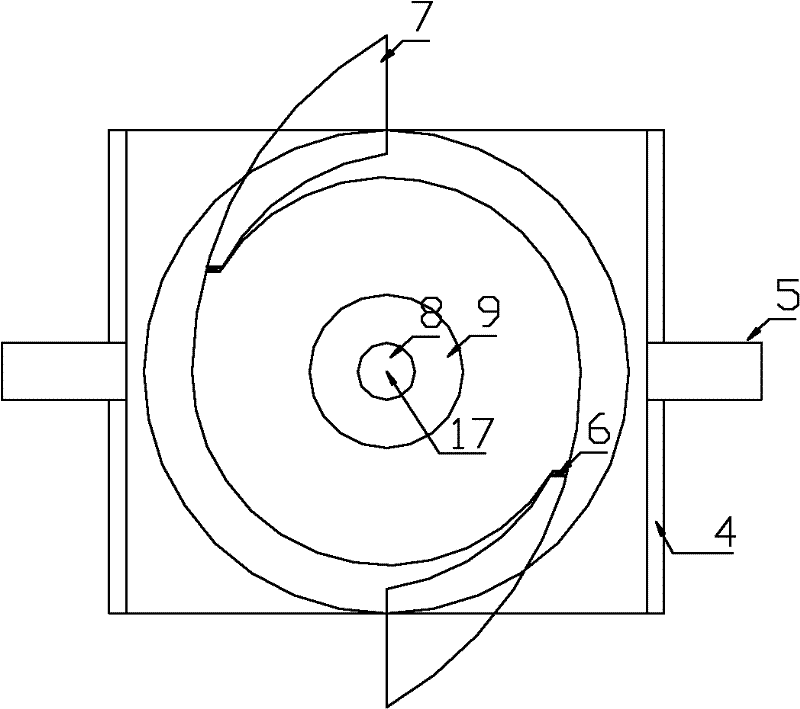

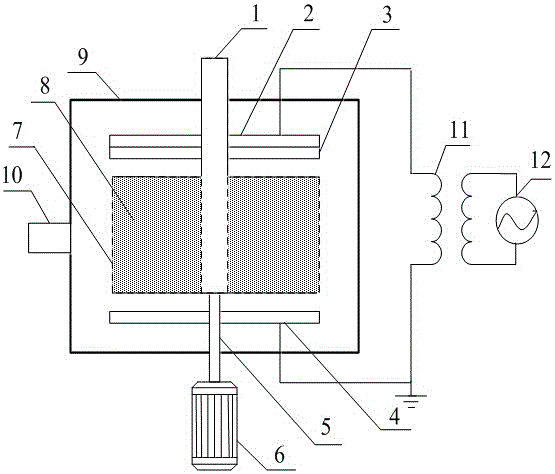

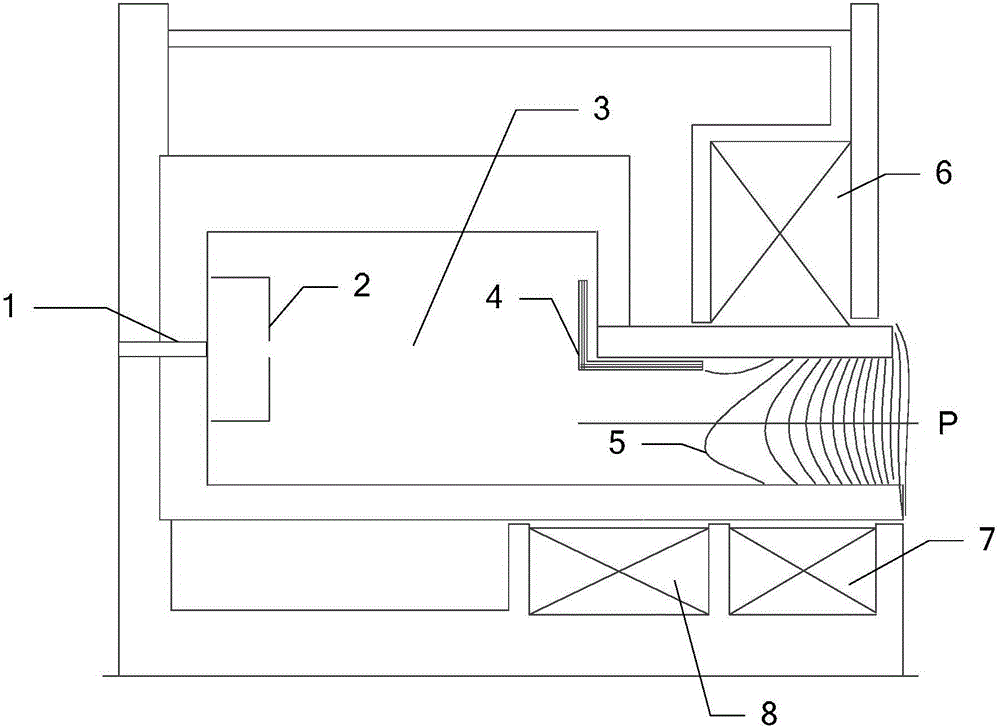

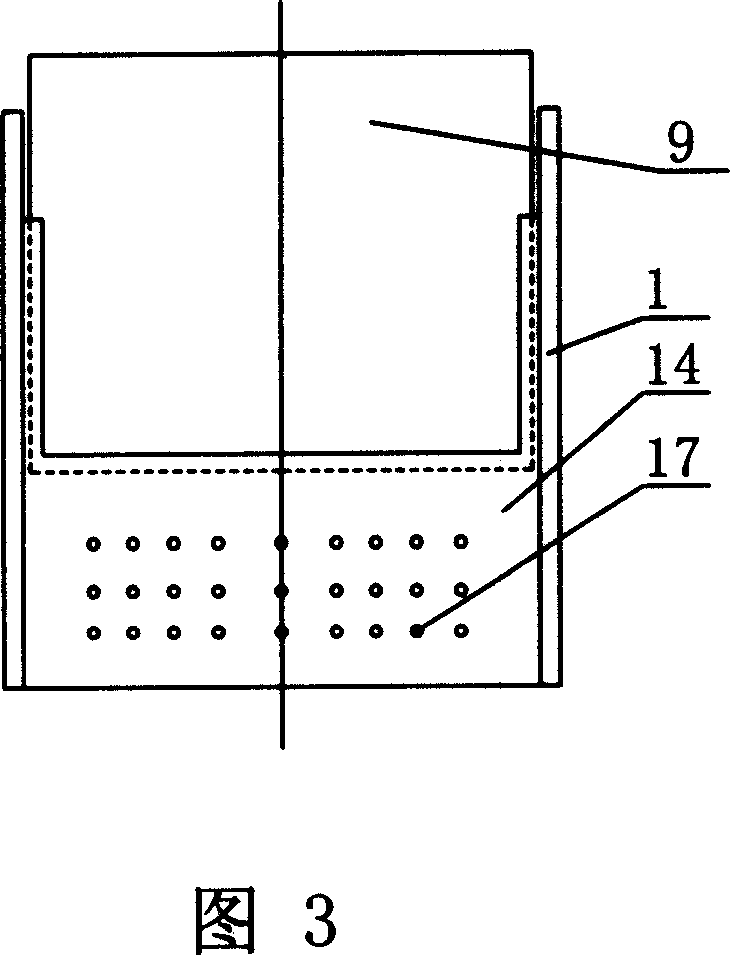

Process and device for smelting copper by pulsation vortex method

ActiveCN101705369AIncreased chance of collisionHigh oxygen utilizationRotary drum furnacesCrucible furnacesSlagProcess engineering

The invention relates to a process and a device for smelting copper by a pulsation vortex method. The process comprises the following steps of: mixing dry copper concentrate powder or matte powder with oxygen-enriched air, and putting the mixture in a reactor to form high-speed vortex taking an axis as a center; introducing pulsation oxygen into the center of the high-speed vortex, performing pulsation combustion to generate pulsation turbulent flow in the high-speed vortex so as to promote particles to collide with one another, then forming a pulsation vortex reaction area with a high-temperature field, a high oxygen field and a high particle field, and completing a reaction of manufacturing the matte and slag from the copper concentrate or manufacturing crude copper and slag from the matte; after the reaction, precipitating fused materials in a fusing pool at the bottom of the reactor, and then separating the matte and slag or the crude copper and slag; and sending SO2 gas fume to an acid preparation process. The process and the device have the advantages of: 1, high reaction efficiency, high oxygen utilization efficiency and low fume yield; 2, high capacity, low energy consumption, small reaction space, centralized heat energy reacted, low loss of a refractory material of a furnace body, no need of a huge metallurgical hearth and low investment cost; and 3, environmental protection and simple, convenient and reliable technological operation.

Owner:YANGGU XIANGGUANG COPPER

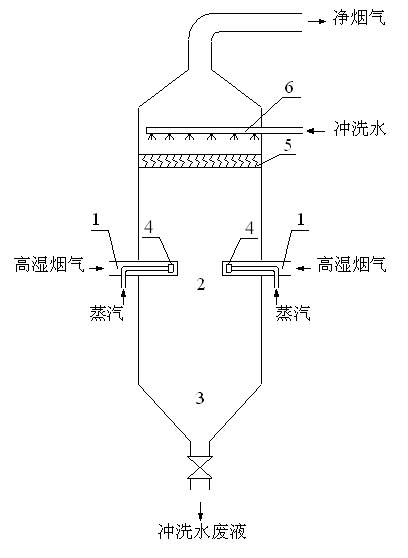

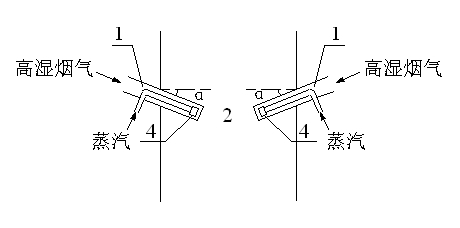

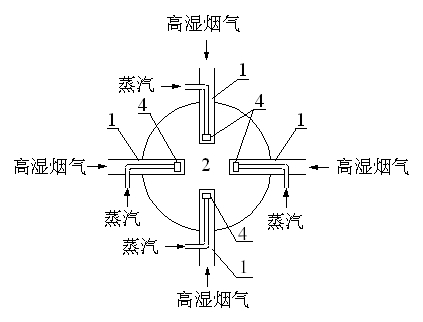

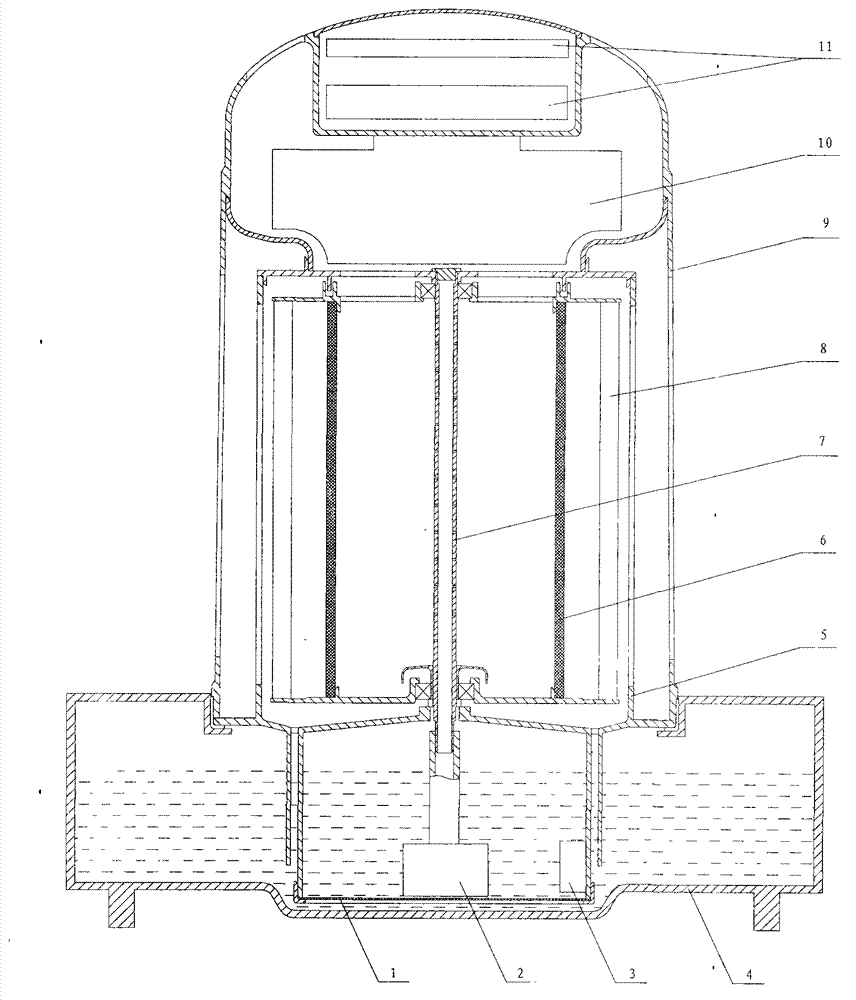

Method and device for removing fine particles in high-humidity gas fume

InactiveCN102059029ASimple processSolve the defect of particle size for efficient removalUsing liquid separation agentRinse waterEngineering

The invention relates to a method and a device for removing fine particles in high-humidity gas fume. The high-humidity gas fume enters a gas fume pipe; saturated steam under normal pressure is injected into the gas fume pipe and is premixed with the high-humidity gas fume; the high-humidity gas fume and the saturated steam under normal pressure enters a bombarding current phase change chamber main body and bombard each other so as to form a highly-turbulent bombardment area with highest concentration of fine particles in the center of the bombarding current phase change chamber main body and promote the saturated steam to be condensed on the surfaces of the fine particles; meanwhile, the fine particles of which the surfaces are condensed with water films collide each other to be coagulated to ensure that the granularity of the fine particles is increased further; and the coagulated and grown fine particles are removed by an efficient demister arranged at the gas fume outlet at the upper end of the bombarding current phase change chamber main body. The device consists of the gas fume pipe, the bombarding current phase change chamber main body, the efficient demister, a demister washing water system, and a washing waste liquor storage tank; a vapor nozzle is arranged in the gas fume pipe; and the efficient demister is arranged at the gas fume outlet at the upper end of the bombarding current phase change chamber main body.

Owner:SOUTHEAST UNIV

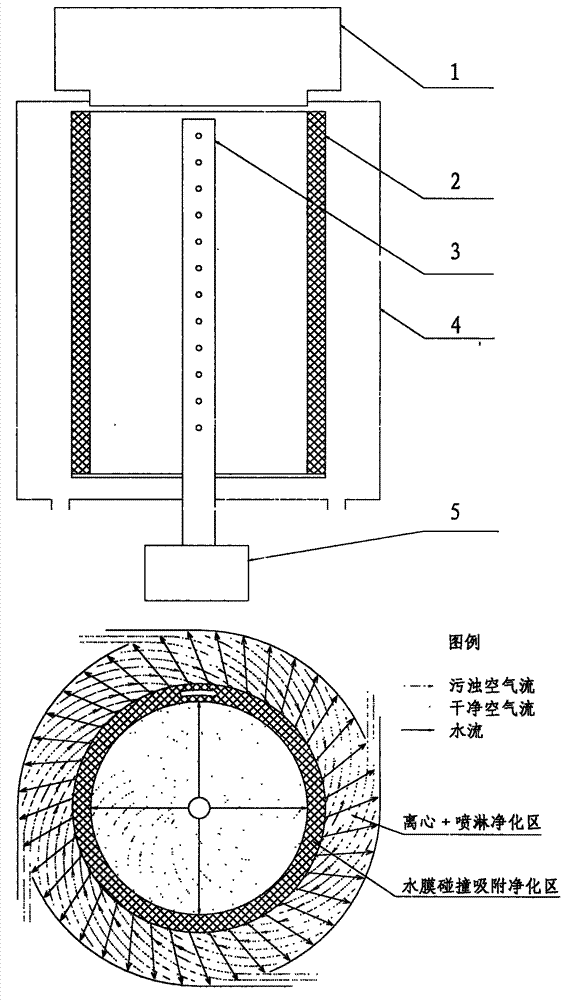

Wet air purification method and air purification apparatus

InactiveCN103203150ARealize centrifugal purificationAchieve high efficiencyCombination devicesMiniaturizationProduct gas

The invention provides a wet air purification method which integratedly uses the three purification technologies of centrifugal purification, water spray purification and water film purification. A dynamic water film purifying process is used in the water film purification; i.e., a water film maintains moving with an included angle of the water film and an air flowing direction being 90 DEG and actively cuts air flow so as to increase probability and frequency of collision between air and the water film, so purifying efficiency is improved, and finally, miniaturization and high efficiency of a purification apparatus are realized. The wet air purification method is applicable to any apparatus carrying out gas purification. An air purification system is characterized by comprising a rotary cylindrical filter screen, a spray pipe, a cylindrical vessel and other necessary parts like a water pump and a blower fan. A household washable air purifier designed based on the wet air purification method comprises two parts, i.e., a freely separable water tank and a purification host machine, wherein the bottom of the purification host machine is provided with a water pump, the upper part of the water pump is connected with a spray pipe having an open pore, the exterior of the spray pipe is provided with a cylindrical metal filter screen assembly using the spray pipe as a rotating shaft, the filter screen assembly is disposed in a cylindrical purification chamber, the upper part of the purification chamber is connected with a centrifugal fan, and a control circuit is mounted on the upper part of the centrifugal fan.

Owner:龙习文

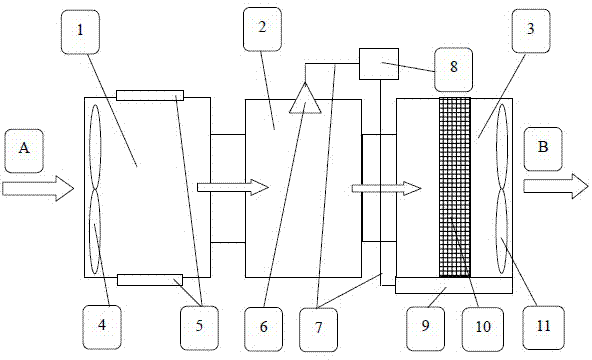

Air comprehensive purifying and regulating method and air comprehensive purifying and regulating device

InactiveCN104764098ALittle impact on liquidityIncreased chance of collisionMechanical apparatusSpace heating and ventilation safety systemsAir purifiersAerosolize

The invention introduces an air comprehensive purifying and regulating device. The air comprehensive purifying and regulating device is composed of an air input fan, an electronic air purifier, an atomized water generator, an air and atomized water mixing chamber, an atomized water recovering device and a purified air output fan; an air comprehensive purifying and regulating is realized; the air comprehensive purifying and regulating device has the functions of sterilization, disinfection, elimination of odor, removal of chemical pollution and smoke suppression; ozone residue is apt to satisfy standard requirement, later maintenance workload is reduced and the air comprehensive purifying and regulating device is simple and effective in implementation and convenient to use.

Owner:CHENGDU AOCTER TECH CO LTD

Device and method for removing ultrafine particles in flue gas of coal boiler

InactiveCN105597477AReduce dosagePromote sportsCombination devicesGas treatmentFlue gasProcess engineering

The invention relates to a device and a method for removing ultrafine particles in flue gas of a coal boiler. The device is characterized by being sequentially provided with a flue gas steam ejector, a steam phase transformation gathering chamber, a turbulence gathering chamber and a demister behind a desulfuration device along the flow direction of flue gas during a technological process, wherein the outlet of the demister is connected with an electrostatic dust collector; one end, which is connected with the desulfuration device, of the flue gas steam ejector is provided with a flue gas inlet, and the upper part of the flue gas steam ejector is provided with a steam inlet; the turbulence gathering chamber is internally provided with turbulent flow cylinders and turbulent flow vortex sheets; the turbulent flow cylinders are distributed in the front part of the turbulence chamber, and a plurality of turbulent flow vortex sheets are distributed at equal intervals behind the turbulent flow cylinders in a staggered manner; one end of the turbulence chamber is connected with the outlet of the steam phase transformation gathering chamber, and the other end of the turbulence chamber is connected with the inlet of the demister.

Owner:HEBEI UNIV OF TECH

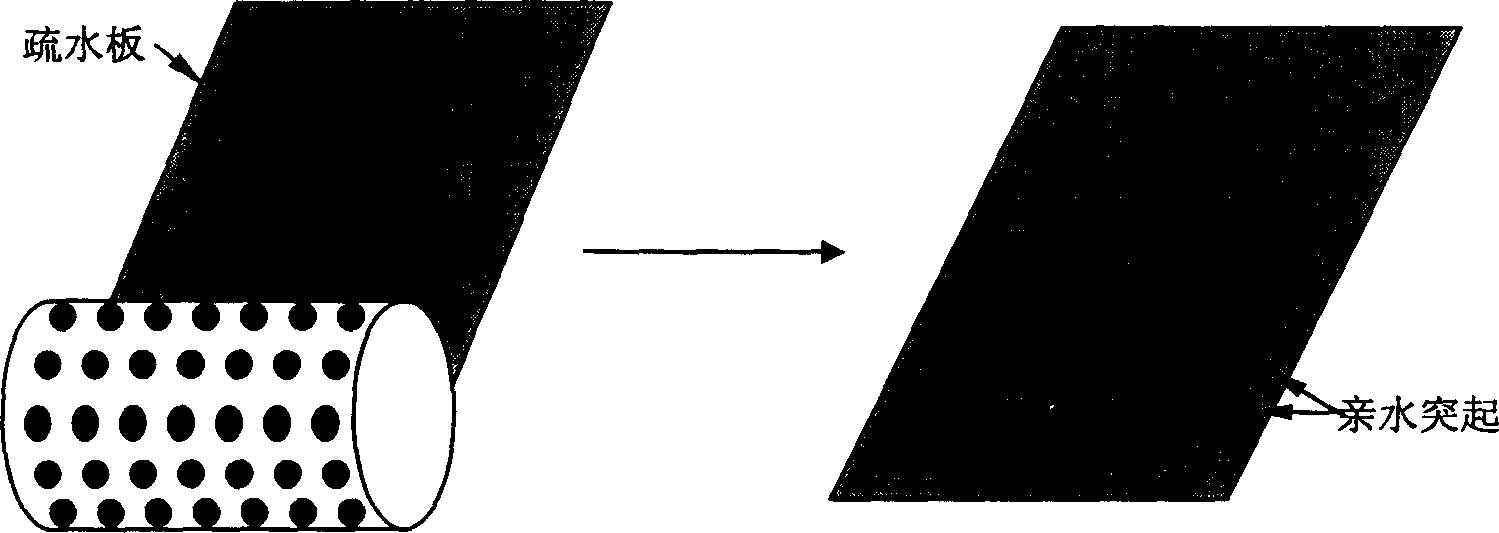

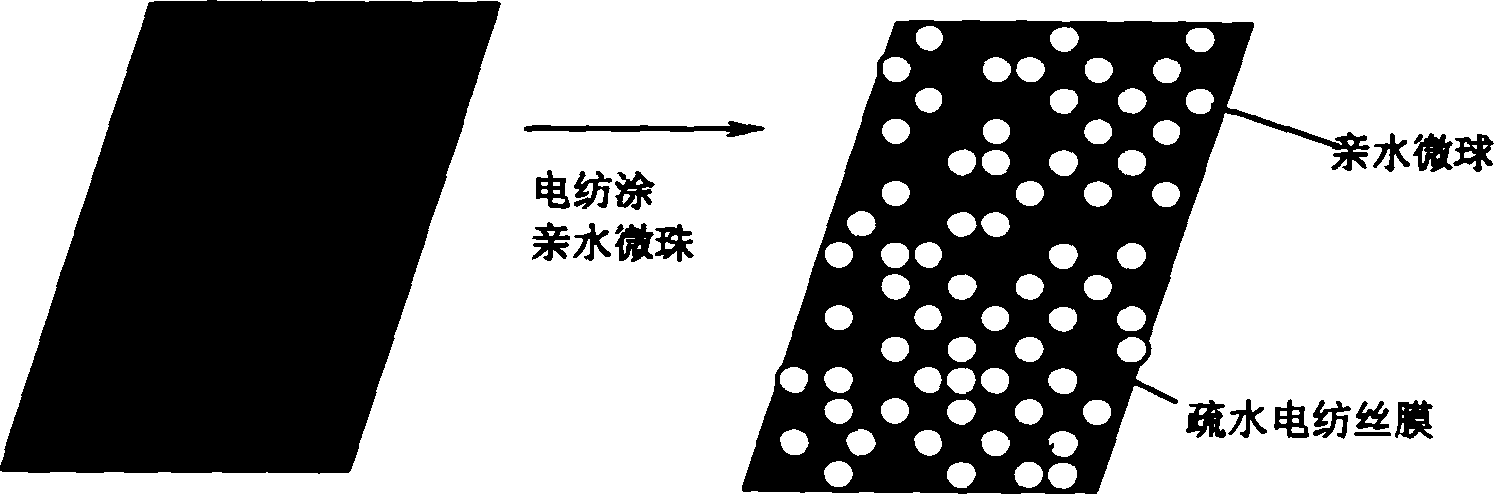

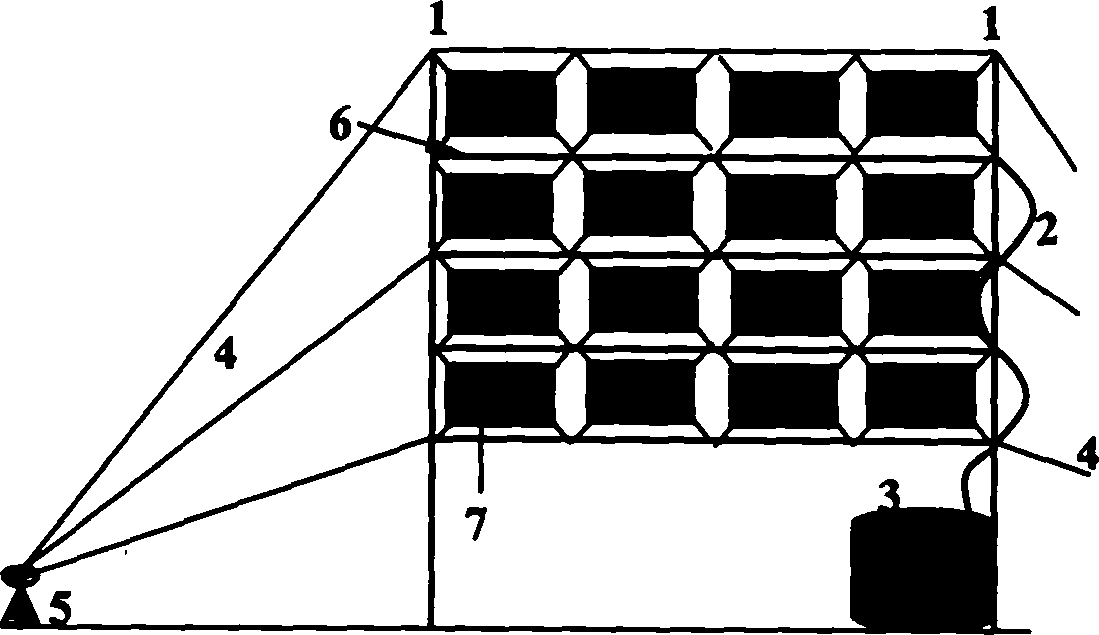

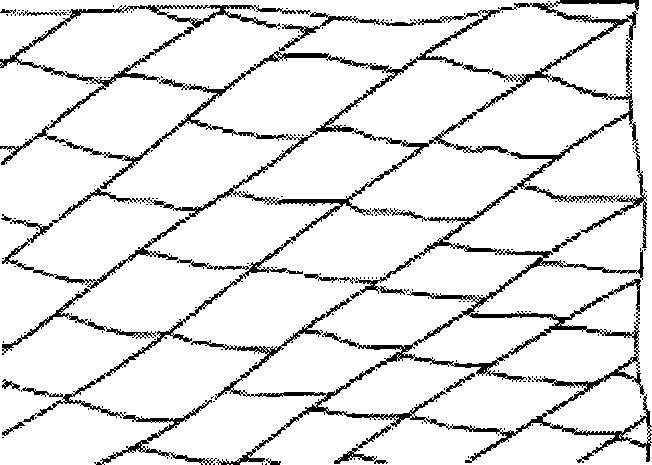

Composite membrane of biomimetic water catchment, preparation method and usage

InactiveCN1872533AIncrease the areaIncreased collision chance and spread speedLayered productsChemistryHydrophilic polymers

A bionic composite film for collecting fog drops or dispersing dense fog is composed of a substrate, a hydrophobic polymer film on said substrate, and several lines of small circular humps made of glass microbead or hydrophilic polymer containing inorganic oxide particles. Its preparing process includes such steps as coating the solution of hydrophobic polymer on the substrate, and applying the glass microbeads or the concentrated solution of hydrophilic polymer onto the film of hydrophobic polymer by a rolling screen.

Owner:INST OF CHEM CHINESE ACAD OF SCI

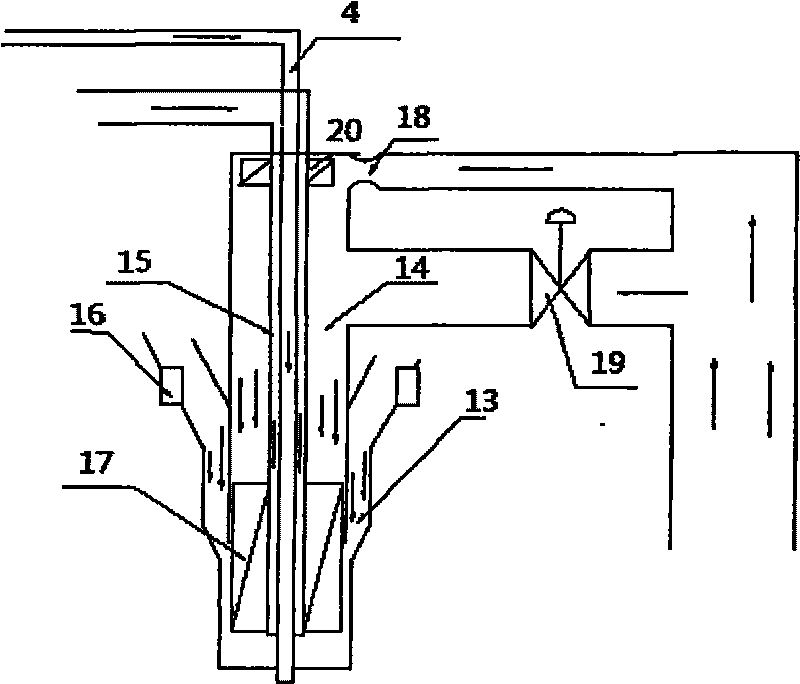

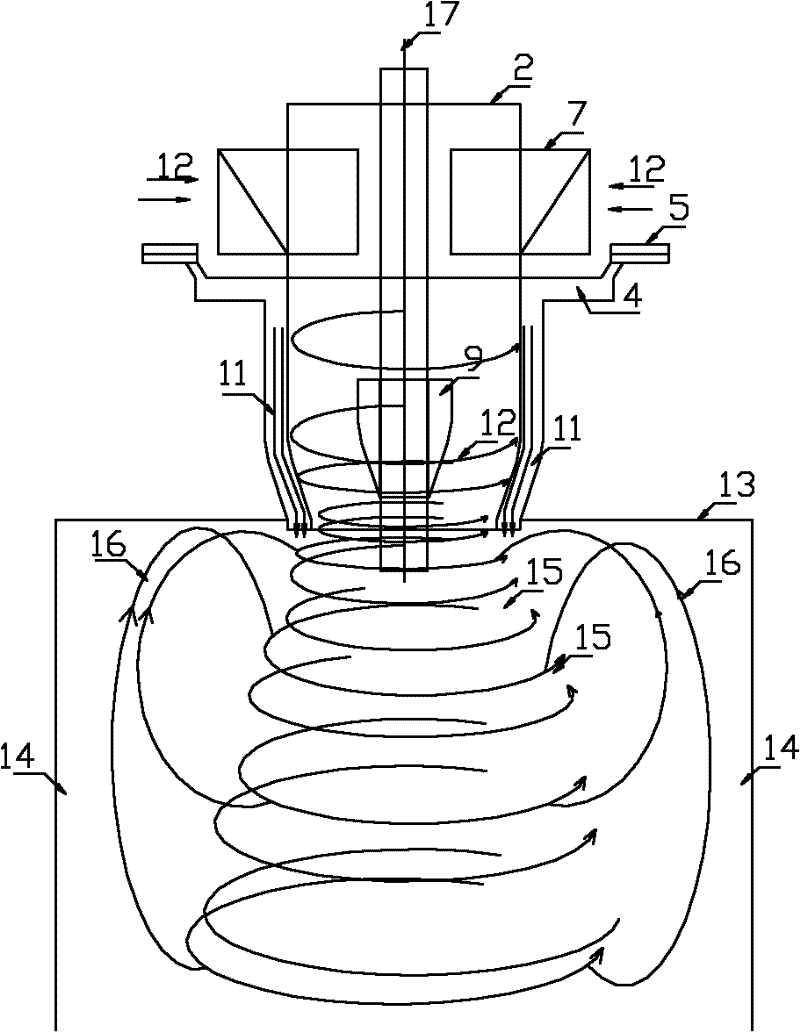

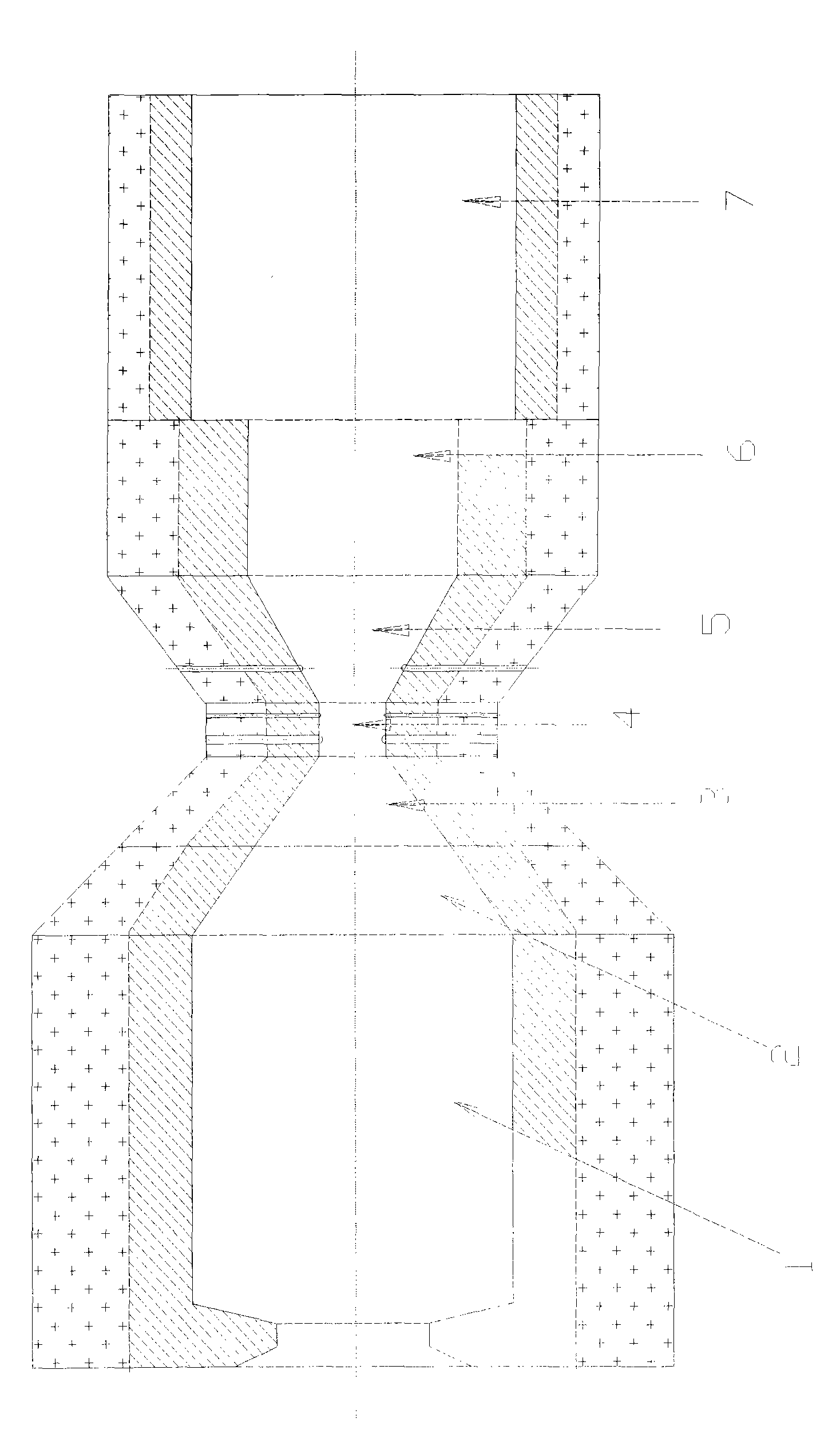

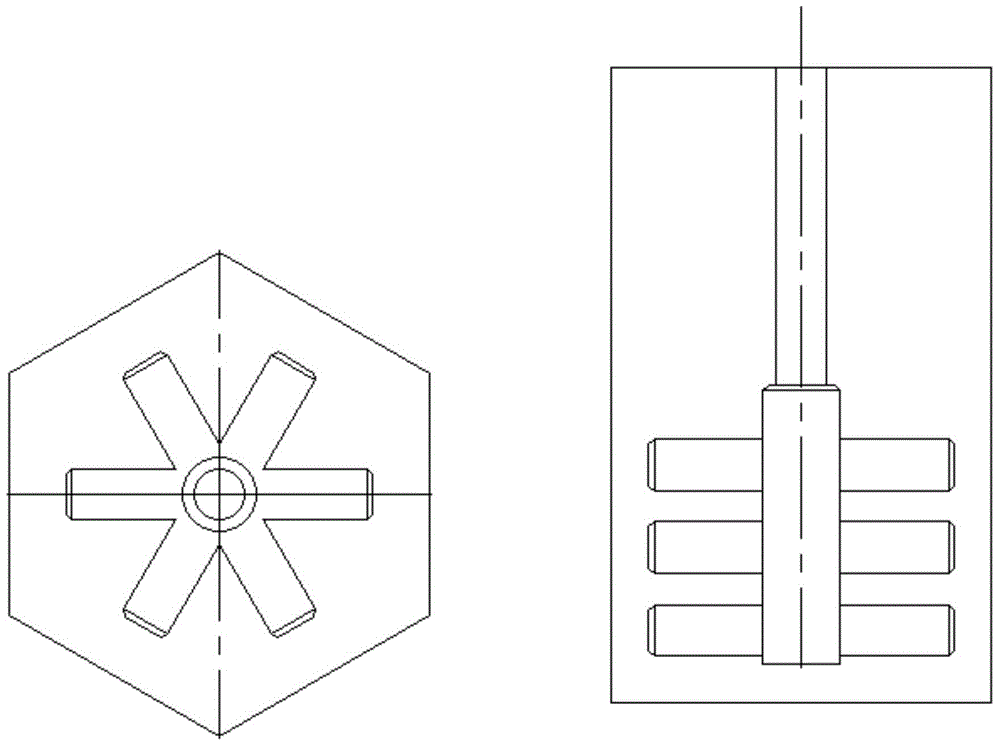

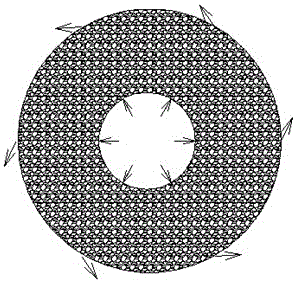

A spin-floating entrainment metallurgical process and its reactor

The invention relates a floating entrainment metallurgical process. In this process, the reaction gas and the powdery materials are injected into the reaction furnace, aiming to obtain a controllable highly rotating and floating state and reach the ignition point under the high-temperature radiation of the reaction furnace to combust intensely. Meanwhile, the rotating fluid injected in the reaction furnace will drive the furnace gas, and forms a relatively low-temperature circular backflow protection area around the rotating fluid. The reaction gas is tangentially fed into the rotating generator along numbers of rotary channels to form a controllable rotating airflow, in addition, a conical exit air controller that can be moved up and down is adopted to control the exit area of the rotating generator, thus controlling the velocity of the reaction gas into the reaction furnace; the powdery materials fall freely around the reaction gas and are involved in the high-speed rotating airflow, forming a rotating fluid, of which the powdery materials are highly dispersed into the reaction gas, moving downwards along the radial high-speed rotating axle. For the purpose of this invention, a steplessly adjusted reactor is as well referred to in this invention.

Owner:YANGGU XIANGGUANG COPPER

Bionic water-collecting composite electrospun film and its preparation method and use

InactiveCN1880592AReduce areaIncrease the areaDrinking water installationComposite filmHydrophilic polymers

The invention relates to a bionic water collect composite film, which comprises a base with many round micro hydrophilic polymer projections on its above hydrophobic polymer film; said hydrophobic polymer is the polystyrene that doped with 20-30wt% silica dioxide whose average diameter is 2-100nm; the hydrophilic polymer is the polymer of amido, hydroxyl or carboxyl doped with 10-70wt% titania whose average diameter 1-100micrometer; the hydrophobic polymer film comprises one or several of ultraviolet stabilizer, ultraviolet absorber, ozone stabilizer, and antioxidant. The inventive film can collect fog drop or disperse dense fog. The invention has high water collecting efficiency, long service life, and better hydrophilic / hydrophobic property.

Owner:INST OF CHEM CHINESE ACAD OF SCI

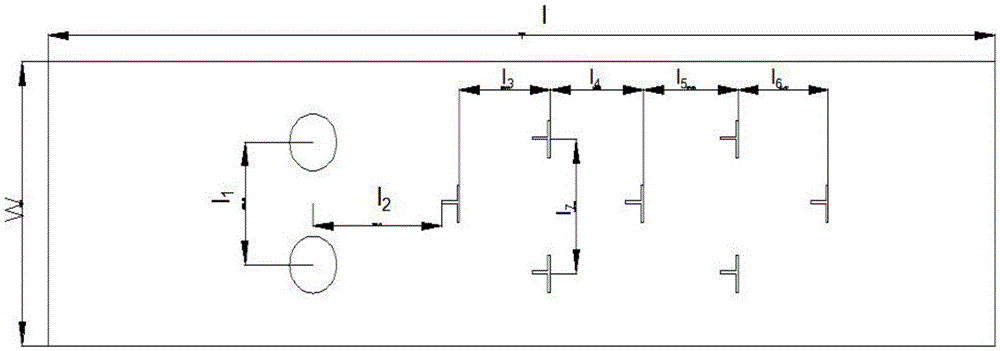

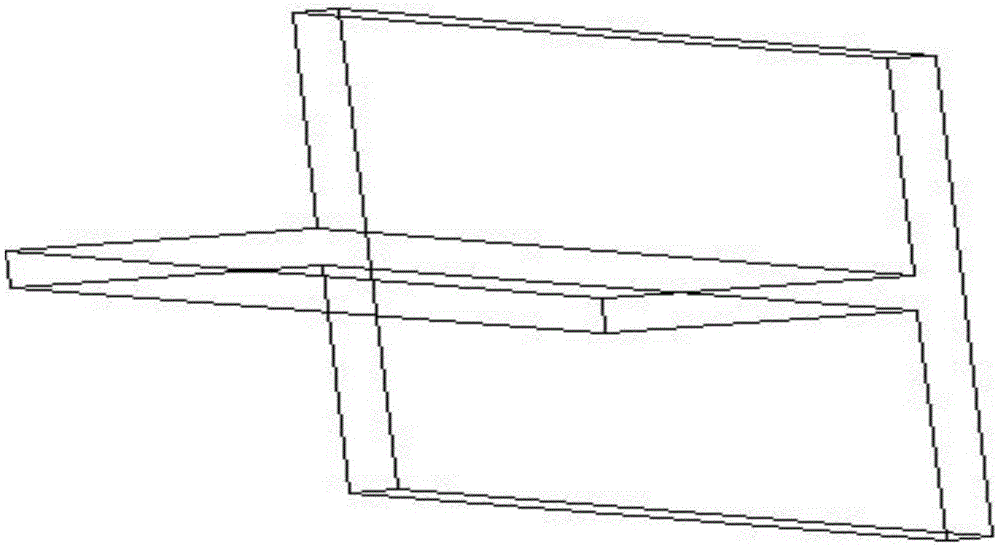

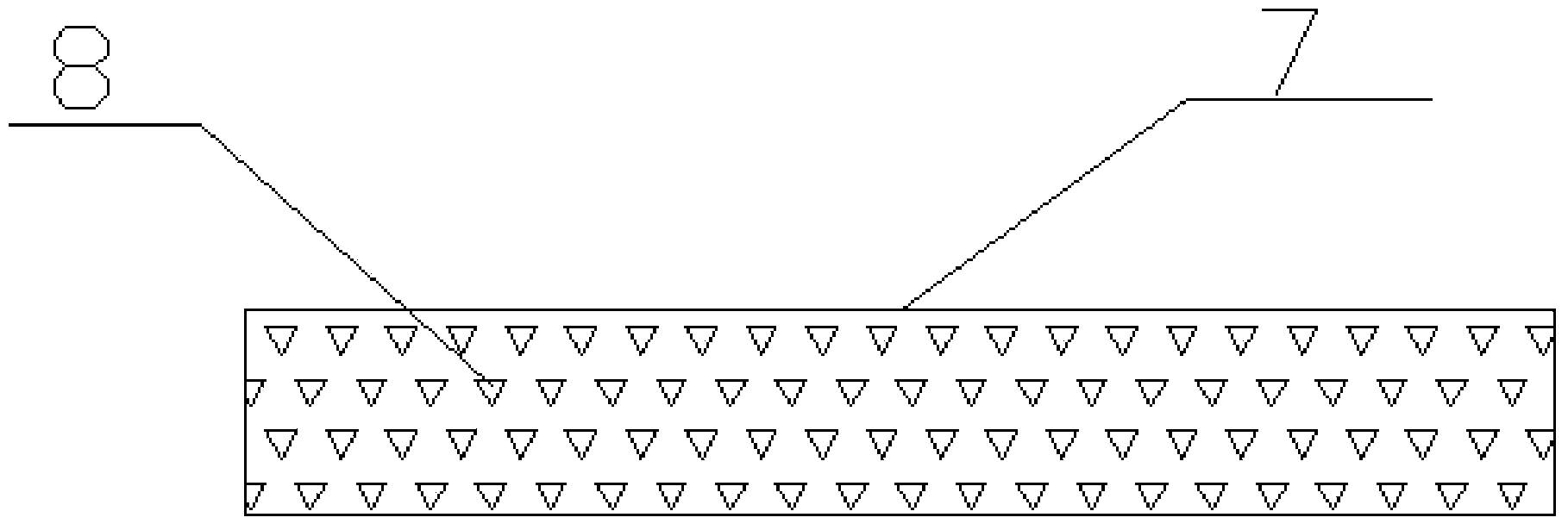

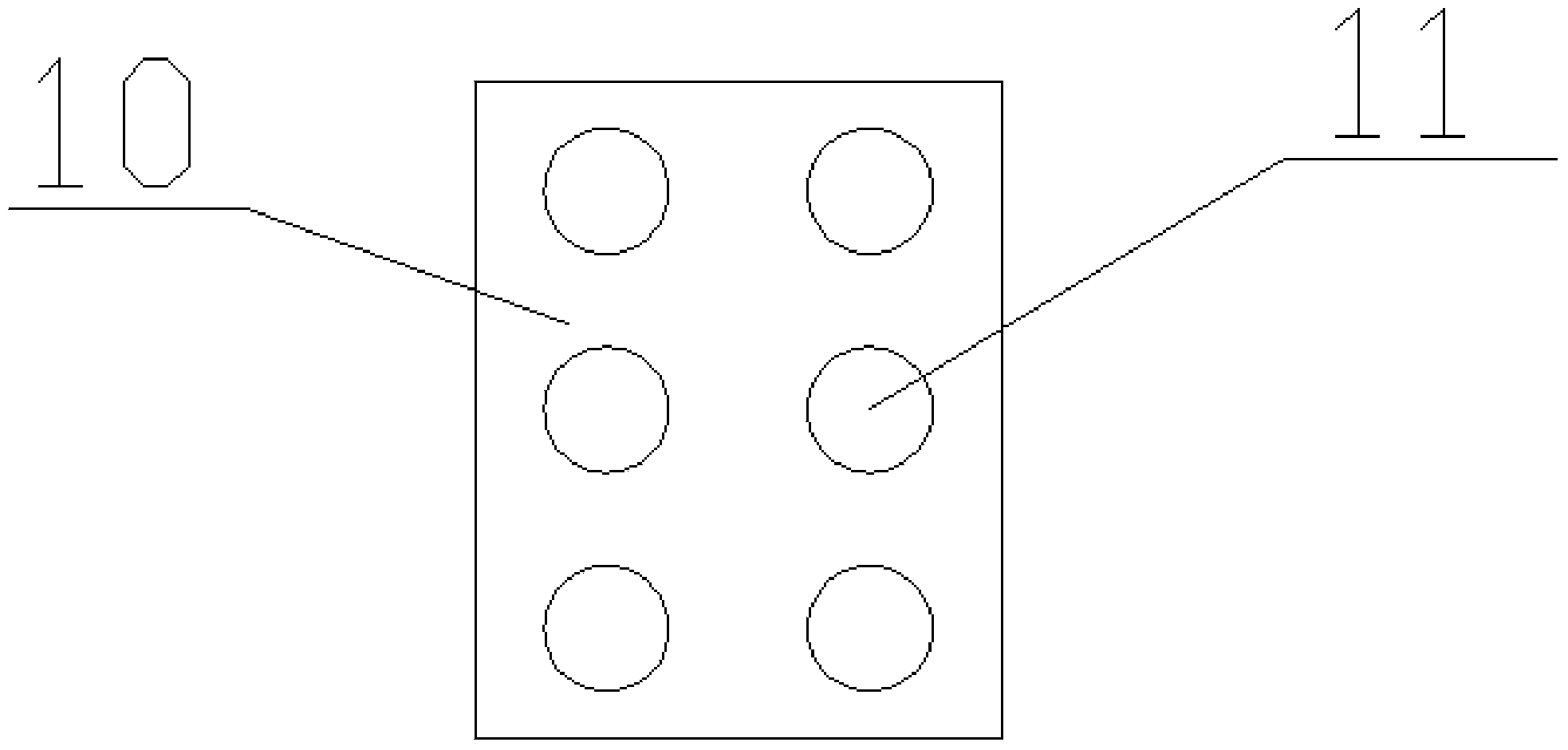

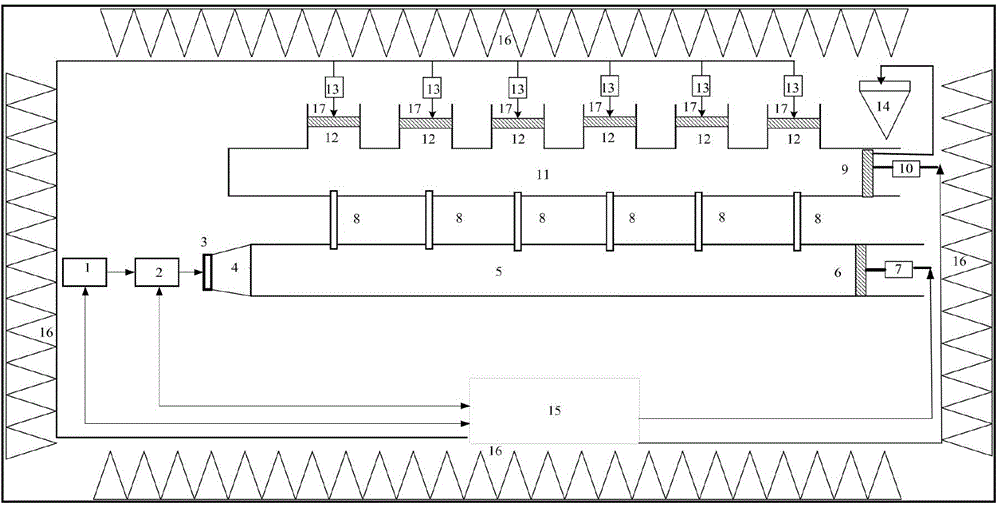

System and method for agglomerating particulate matters through ultrasonic atomization of charged turbulence

ActiveCN106823652AIncrease the chance of sticking to each otherIncreased chance of collisionCombination devicesExhaust gasEngineering

The invention relates to a system and method for agglomerating particulate matters through ultrasonic atomization of charged turbulence. The system comprises a runner main body, an entrance section, an atomization charging device, a premixing section and a turbulence disturbance section, wherein the entrance section, the atomization charging device, the premixing section and the turbulence disturbance section are sequentially arranged on the runner main body; the atomization charging device is used for spraying charged ultrasonically-atomized drops into the runner main body; a plurality of V-shaped mixing blades are distributed in the premixing section, openings of the V-shaped mixing blades back to an incoming flow direction, and two ends of the V-shaped mixing blades are fixedly arranged on the inner wall of the runner main body; the turbulence disturbance section comprises a plurality of turbulence disturbance components; the turbulence disturbance components include round arc plate surfaces and protruded bluff bodies; the protruded bluff bodies are arranged on arched side surfaces of the round arc plate surfaces; the turbulence disturbance components are distributed in the runner main body by taking the flow direction of exhaust gas as a row and the flow direction of vertical exhaust gas as a column; and the turbulence disturbance components in the same row are distributed along the same direction, and the turbulence disturbance components in the adjacent rows are distributed along the opposite direction.

Owner:XI AN JIAOTONG UNIV

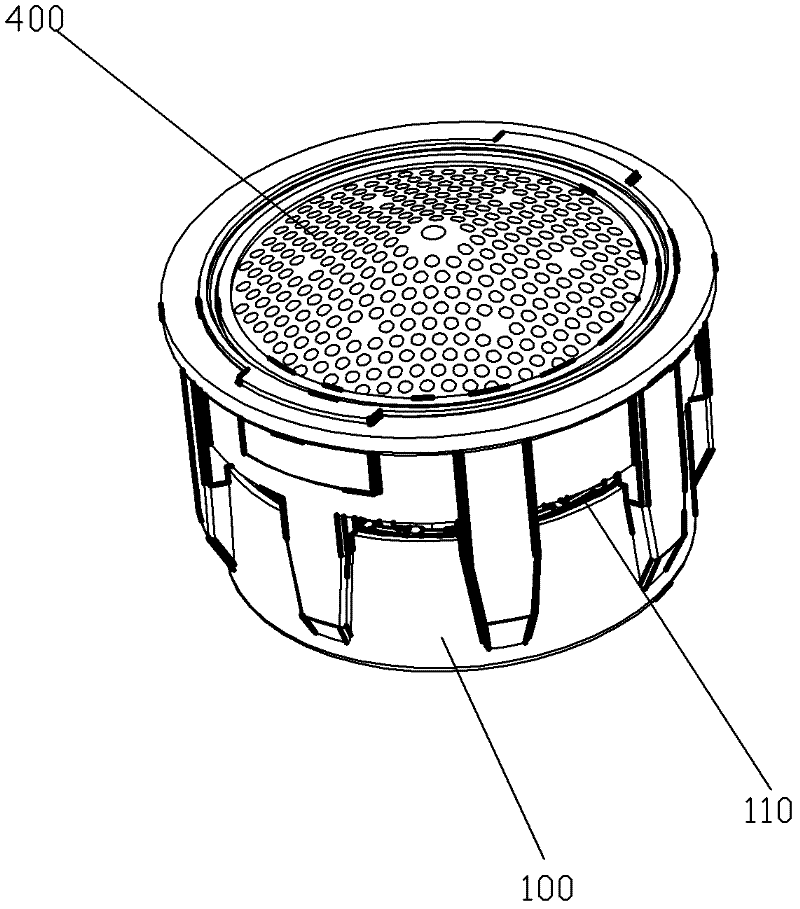

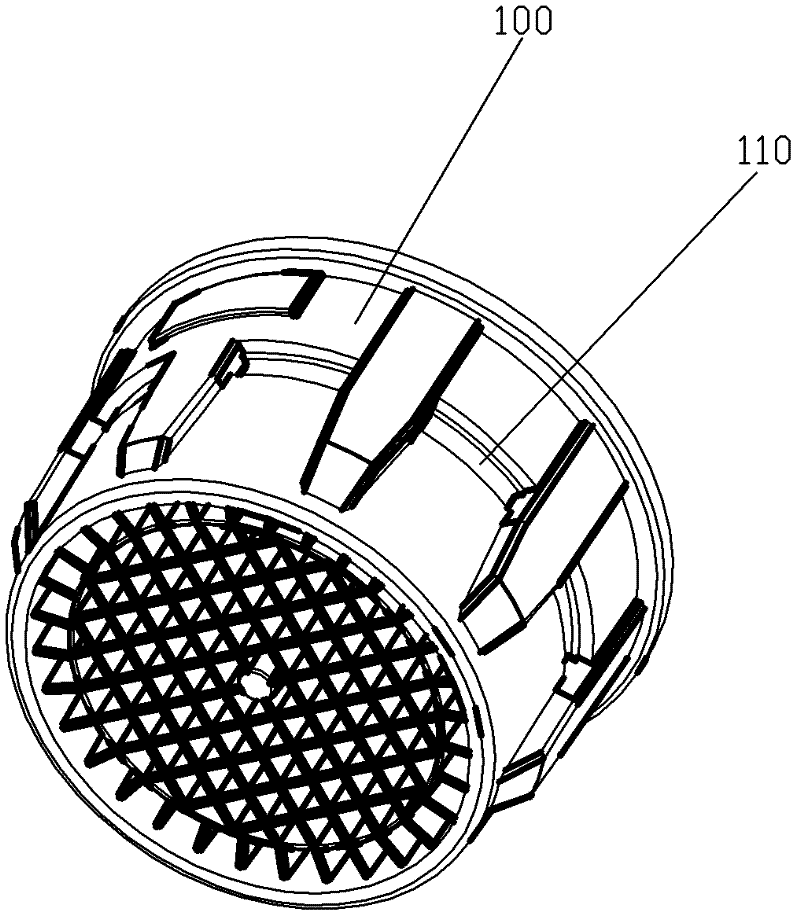

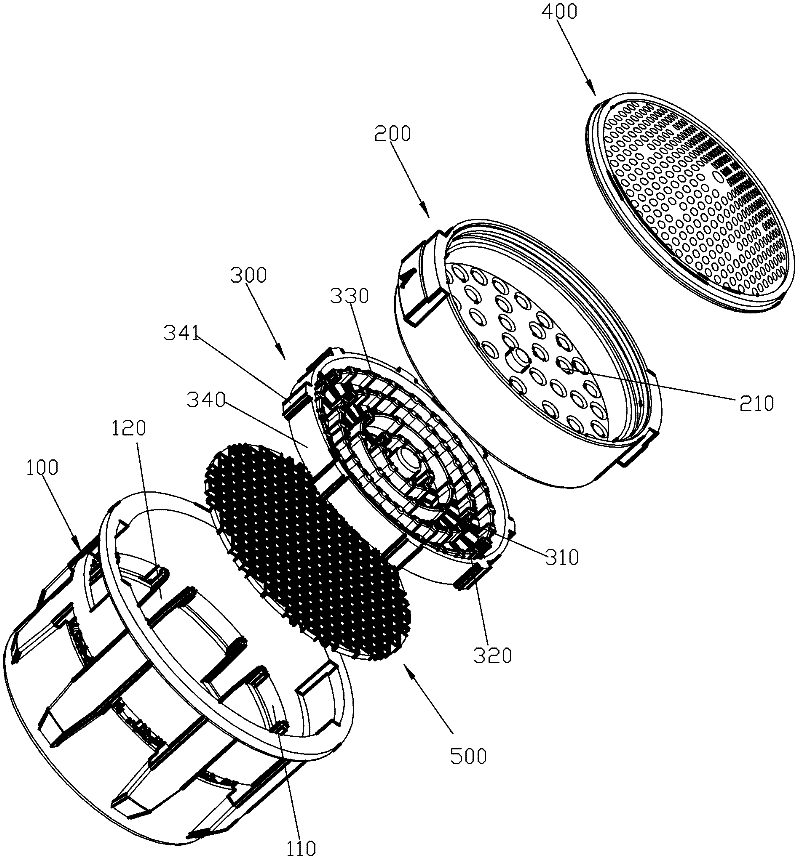

Gas-water mixing bubbler

InactiveCN102359154AIncreased jet collision chanceAchieve multiple hitsWater resource protectionDomestic plumbingWater particleJet flow

The present invention discloses a gas-water mixing bubbler. The gas-water mixing bubbler comprises a body, a splitter and an insertion part. The body is hollow, and forms an assembly hole. The insertion part and the splitter are arranged and connected inside the assembly hole. The body is provided with a suction hole, wherein the internal of the suction hole and the external of the suction hole are penetrated. The splitter is provided with jet flow holes. The insertion part comprises a lower-layer grid portion and an upper-layer grid portion. The lower-layer grid portion comprises a pluralityof spokes. The upper-layer grid portion comprises a plurality of round rods, wherein the round rods are arranged concentrically. The round rods form fixed connections with the spokes. The round rods are provided with plural pairs of projections, wherein the projections form annular arrays. Each pair of the projection is respectively convexly arranged on the inner rod surface and the outer rod surface of the round rod, and is matched to form a cylinder. The positions of the cylinders are relative to the fixed connection positions of the round rods and the spokes. The position of the upper end surface of the cylinder is at the same level as the position of the upper end surface of the round rod. The jet flow holes of the splitter are corresponding to the cylinders of the insertion part, such that the water flow passes through the jet flow holes, and directly impacts on the cylinders of the insertion part. The gas-water mixing bubbler has the following advantages that: the jet flow impacting opportunity is increased, the multiple impacting opportunities of the jet flow are increased, the water-saving effect is excellent, and the water particles are full.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

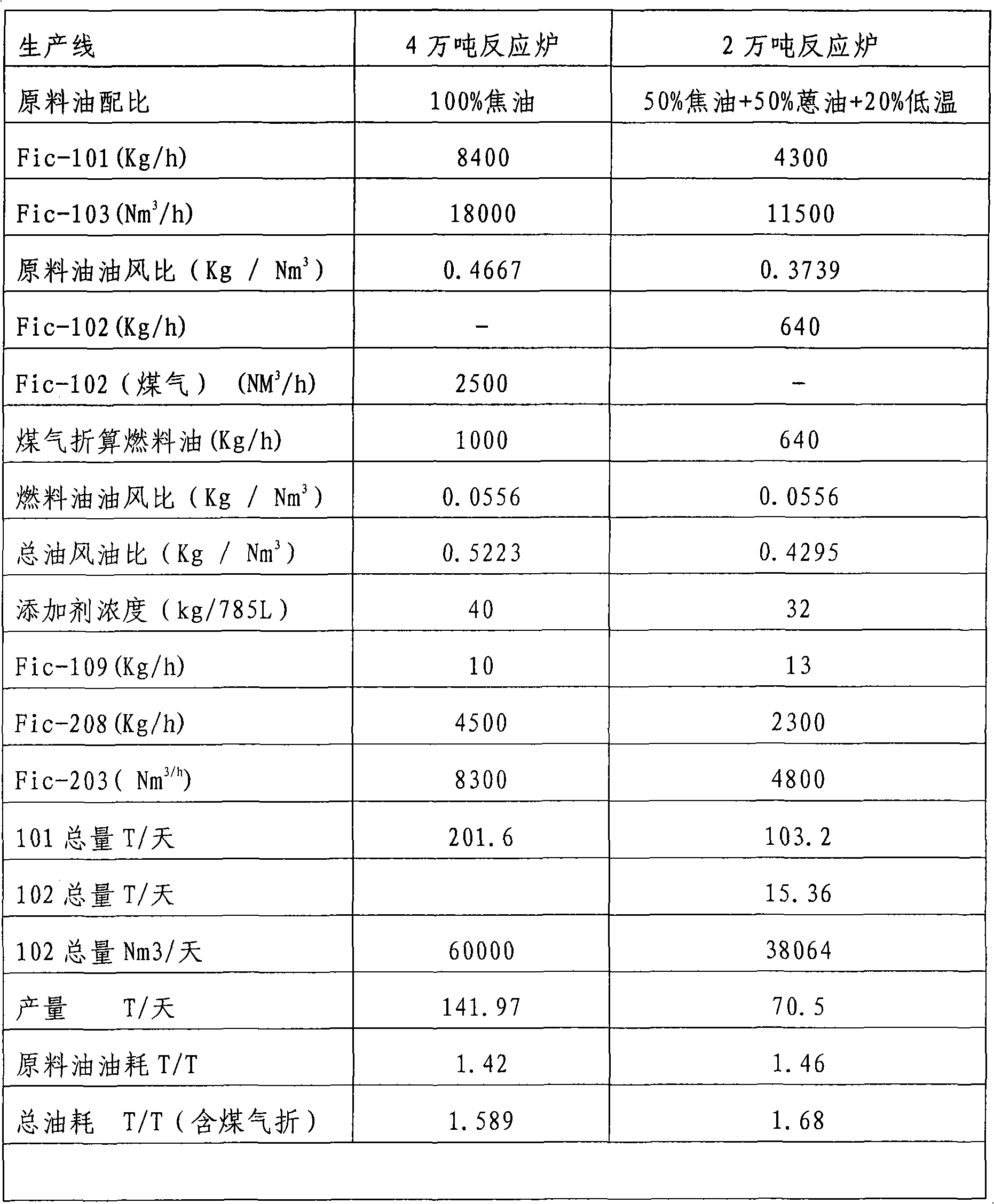

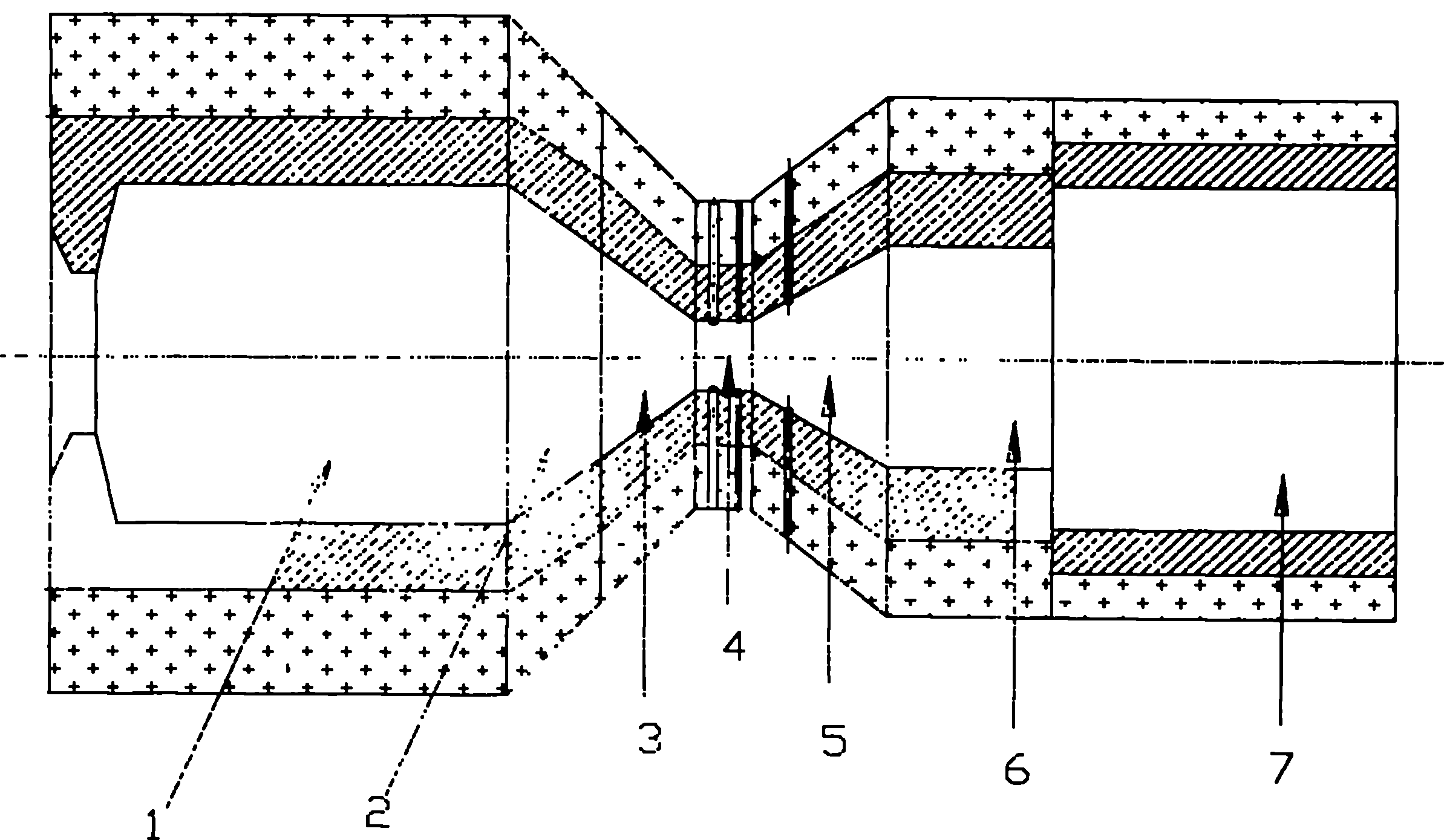

40-thousand-ton hard carbon black reaction furnace and production process of carbon black

The invention discloses a 40-thousand-ton hard carbon black reaction furnace and a production process of carbon black. The carbon black reaction furnace comprises a combustion chamber, a venturi tube, a reaction chamber, and a quench zone. The uniquely designed combustion chamber of the reaction furnace ensures that the distribution of the temperature field of the carbon black production is more reasonable, the appropriate angle, length and inner diameter of the venturi tube ensure that raw oil is fully vaporized and sheared on the venturi tube part; and the reasonably designed reaction section and the matched quench zone ensure that the carbon black cracking reaction can be performed quickly, and the side reaction can be inhibited. Coal gas or natural gas is used as a fuel, the range of the raw oil is wider, the production capacity of the carbon black is high, unit consumption is low, a small amount of polluted product is discharged and the quality of the carbon black is high.

Owner:WUHAI BLACK CAT CARBON BLACK

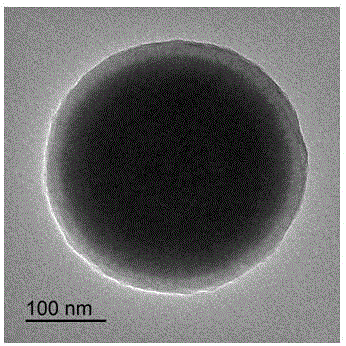

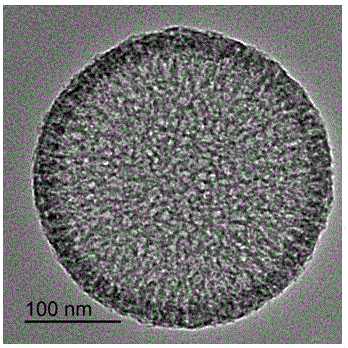

Preparation method of hollow carbon nanospheres with MOFs (metal-organic frameworks) formed through limited-range growth inside

ActiveCN107522867AUniform particle sizeStable structureNanotechnologyNano-carbonMicrosphereMetal-organic framework

The invention discloses a preparation method of hollow carbon nanospheres with MOFs (metal-organic frameworks) formed through limited-range growth inside and belongs to the technical field of nanomaterial production. Tetraethyl orthosilicate, ethanol, deionized water, ammonium hydroxide, resorcinol and methanol are mixed for a reaction, SiO2@resorcinol-formaldehyde resin microspheres are obtained and calcined in argon, SiO2@C nanospheres with a core-shell structure are obtained and dispersed in a sodium hydroxide water solution to be etched, and mesoporous hollow carbon nanospheres are obtained; finally, the mesoporous hollow carbon nanospheres are dispersed in methanol, metallic nitrates and 2-methylimidazole are added for a reaction, and the hollow carbon nanospheres with MOFs formed through limited-range growth inside are obtained. Equipment used in the method is simple, the method is low in cost and simple in operation process, materials required in the reaction process are low in toxicity and harmless, the stoichiometric ratio of multi-component materials can be effectively controlled, and the obtained products are uniform in size, uniformly distributed and are good in morphological control.

Owner:YANGZHOU UNIV

Noble metal-rare-earth catalyst for purifying waste gas and its preparation

InactiveCN1473651AIncreased durabilityIncreased chance of collisionDispersed particle separationCatalyst activation/preparationMischmetalMixed oxide

The catalyst includes alumina, RE metal oxide, composite Al-La oxide, and active metal Pt, Pd and Rh. It features that the mixed oxide grain with aluina, cerium oxide and Al-La oxide carries at least one of Pt and Pd as well as Rh. The mixed oxide grain is prepared through dissolving salt of Al, Ce and La in water, adding NH3OH to produce precipitate, and heating to decompose the precipitate. The catalyst preparing process includes carrying mixed oxide grains onto the carrier, carrying least one of Pt and Pd onto the mixed oxide grains, and carrying Rh finally. The catalyst is especially suitable for purifying automobile tail gas of gasoline engine near the theoretical air / fuel ratio, and has the features of lasting use, less noble metal consumption, high purifying efficiency and powerful sulfur poison resistance.

Owner:昆明贵研催化剂有限责任公司

Emulsion containing diesel oil, alcohol and water and its preparation method

InactiveCN1428405AImprove stabilityExtended shelf lifeLiquid carbonaceous fuelsEmulsionUltrasound - action

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

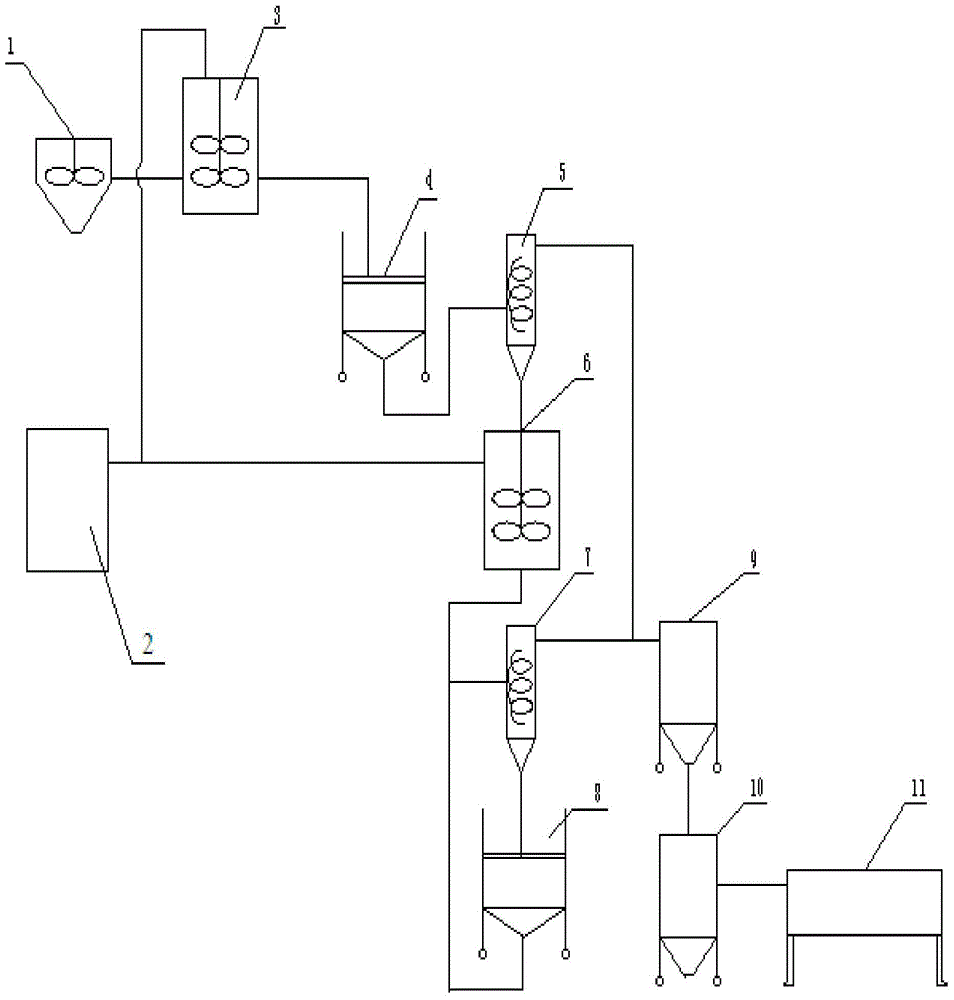

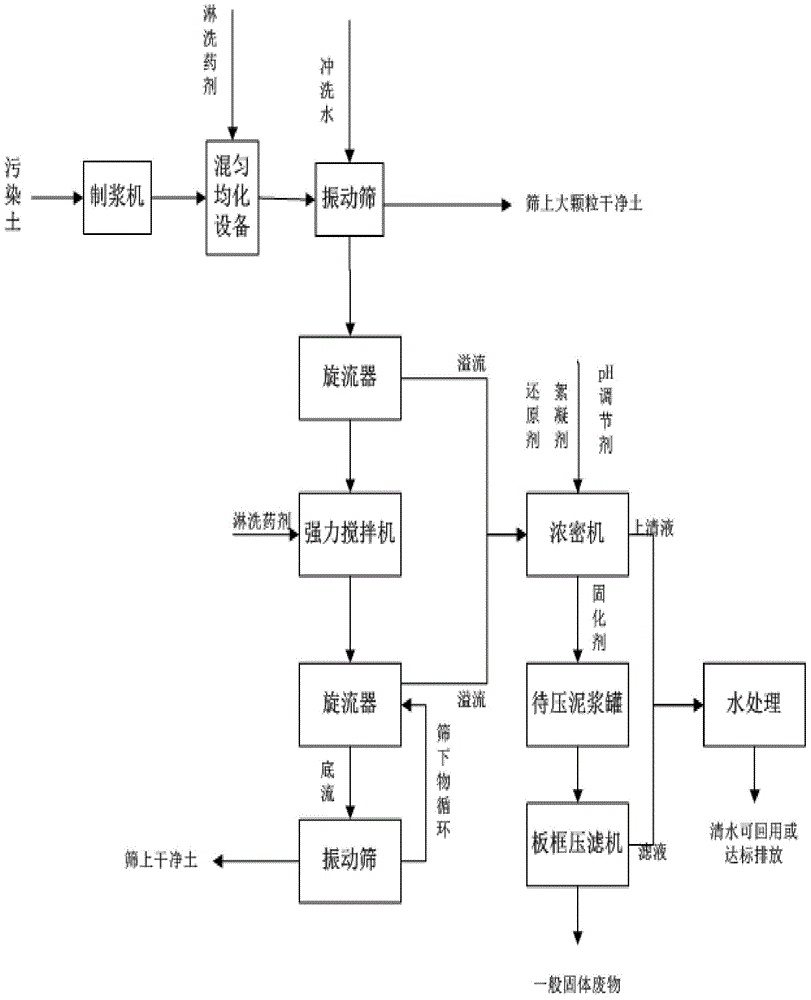

Chromium-contaminated soil different-position leaching repairing technology and device

ActiveCN105057340AGood removal effectIncreased chance of collisionContaminated soil reclamationCycloneFilter press

The invention belongs to the technical field of contaminated soil repairing treatment, and particularly relates to a heavy metal (chromium VI)-contaminated soil different-position chemical leaching repairing technology and device. The chromium-contaminated soil different-position leaching repairing device comprises a one-level scrubbing unit, a two-level scrubbing unit, a waste liquid treatment unit and a medicament adding unit. The one-level scrubbing unit comprises a pulper, an even mixing and homogenizing device, a one-level vibration screen and a one-level cyclone. The two-level scrubbing unit comprises a strong stirrer, a two-level cyclone and a two-level vibration screen. The waste liquid treatment unit comprises a thickener, a to-be-pressed mud tank and a plate-and-frame filter press. The medicament adding unit comprises a medicament tank. The chromium contaminated soil different-position leaching repairing technology comprises one-level leaching, two-level leaching and waste liquid treatment. The different-position leaching repairing technology can be flexibly adjusted according to the situation of soil or bottom mud containing various pollutants. The different-position leaching repairing technology device can be moved to a next project site to be used again after the project is over, and therefore the equipment utilization rate can be increased, and cost can be reduced.

Owner:SAFECLEEN TECH

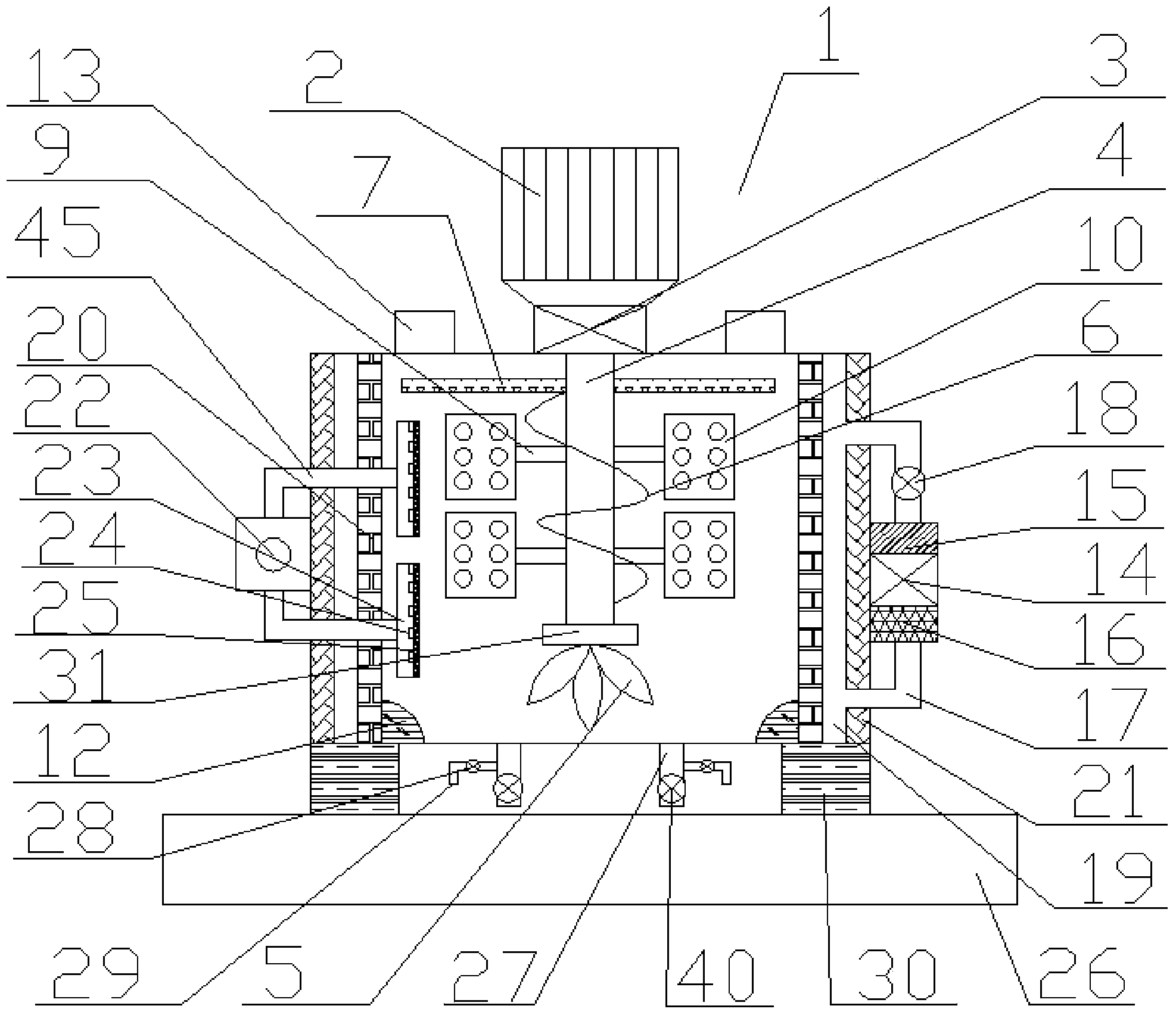

Device and method for cooperatively removing gaseous pollutants by plasma-supergravity coupling

ActiveCN105032136AImprove joint removal efficiencyReduce removal costsDispersed particle separationChemical reactionHigh energy

The invention discloses a device and a method for cooperatively removing gaseous pollutants by plasma-supergravity coupling. According to the device and the method disclosed by the invention, multiple gaseous pollutants are decomposed and oxidized by using high-energy electrons and active groups generated by low-temperature plasma discharge; in a process that the gaseous pollutants flow through a solid adsorbent reactor rotating at high speed, gas containing the pollutants are in sufficient contact with a solid adsorbent by means of a supergravity effect generated by high-speed rotation of gas and solid, to generate a gas phase-solid phase adsorption and chemical reaction to finish substance conversion and purification processes between multiple gaseous pollutants and the solid adsorbent, and thus the pollutants are converted into non-toxic and pollution-free substances. The device and the device are applicable to dry-process combined removal of multiple pollutants in flue gases and various wastes gas generated by combustion, gasification, incineration and the like in the fields of energy resources, chemical engineering, building materials, metallurgy and the like containing multiple gaseous pollutants.

Owner:SOUTHEAST UNIV

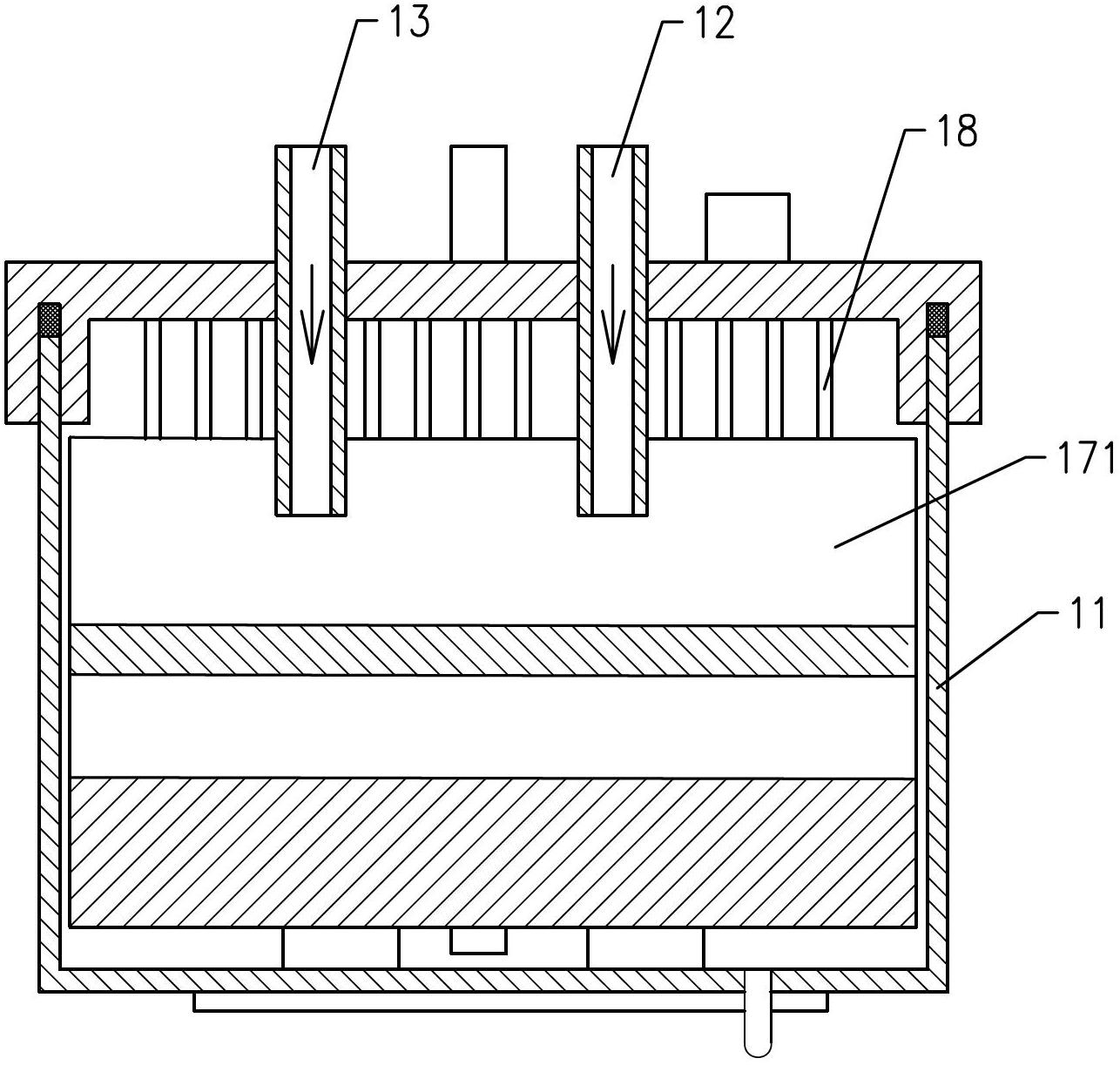

Industrial reaction kettle suitable for feed liquid of chemical industry and medicine

ActiveCN104307455AImprove dispersionEliminate swirl effectsProcess control/regulationChemical industryChemical industryAir pump

The invention discloses an industrial reaction kettle suitable for feed liquid of chemical industry and medicine. The industrial reaction kettle comprises a reaction kettle body, wherein the reaction kettle body comprises a variable frequency motor, a feeding hole, a speed reducer, a stirring shaft and a base; the variable frequency motor and the feeding hole are respectively arranged and formed above the reaction kettle body; the stirring shaft extends into an inner cavity of the reaction kettle body; an output part of the variable frequency motor is connected with an input end of the speed reducer, and an output end of the speed reducer is connected with the stirring shaft; the end of the stirring shaft is provided with a connecting piece and a fan-shaped stirring wheel; a spiral mixing wheel is arranged at the periphery of the stirring shaft; the stirring shaft is also provided with a connecting rod; two stirring pieces are symmetrically arranged on the connecting rod at left and right; the outer wall of the cavity of the reaction kettle body is provided with an air pump and a liquid collection box; the air pump is connected with a baffle plate by a guide pipe, and the baffle plate is arranged on the inner wall of the cavity of the reaction kettle body; the bottom of the cavity of the reaction kettle body is also provided with a discharge hole. The industrial reaction kettle has the advantages of reasonable structural design, good using effect, full stirring, etc.

Owner:寿光市荣晟新材料有限公司

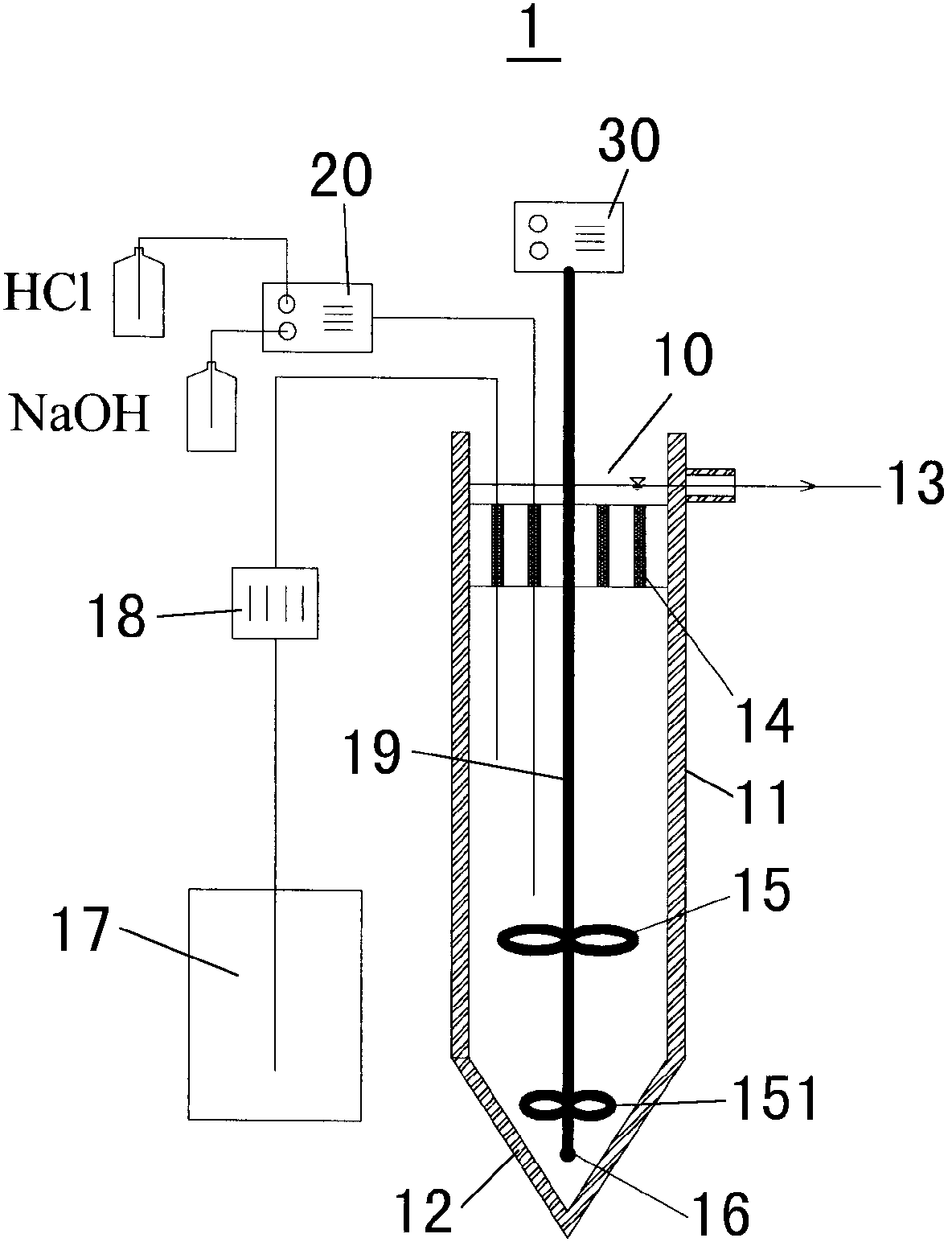

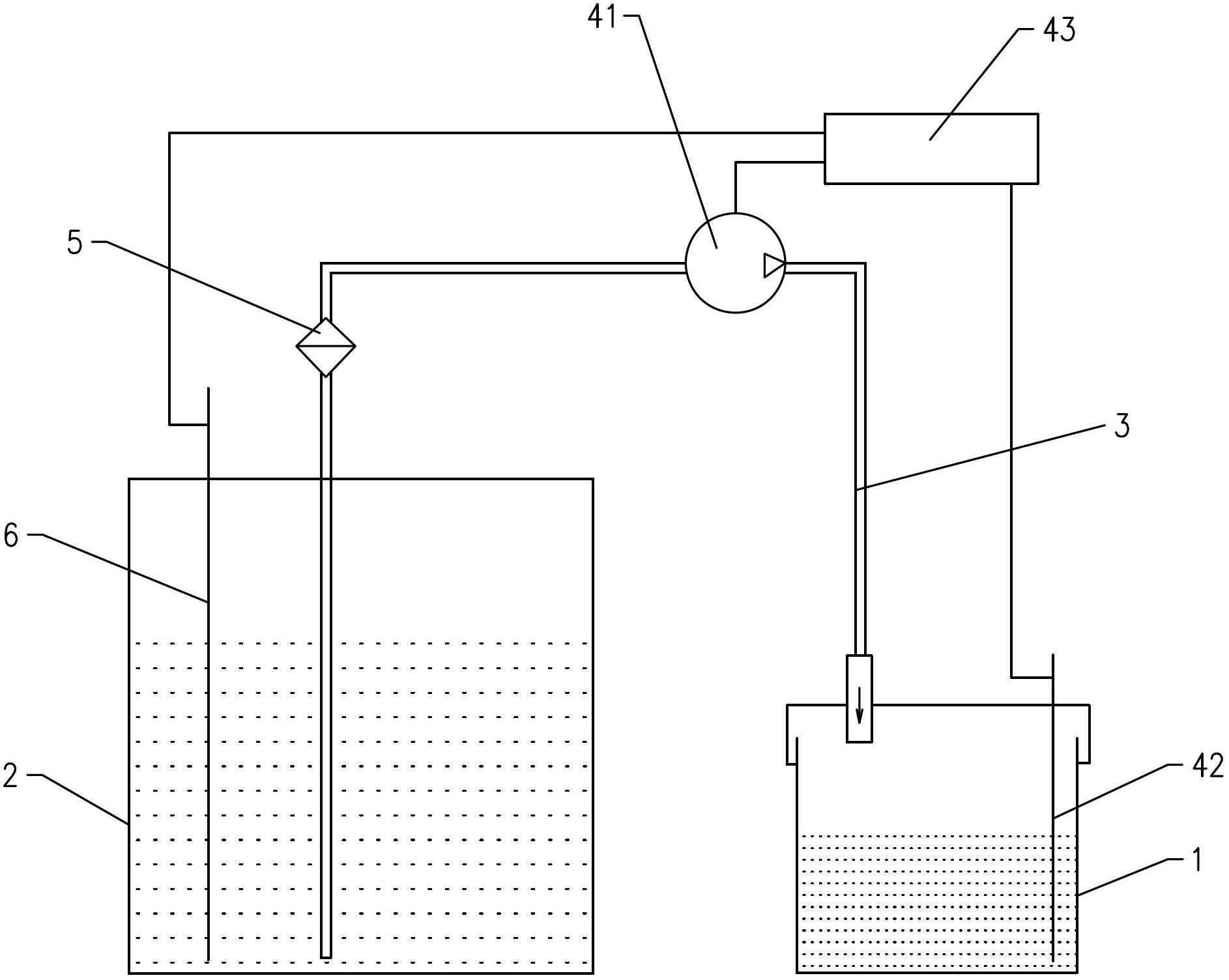

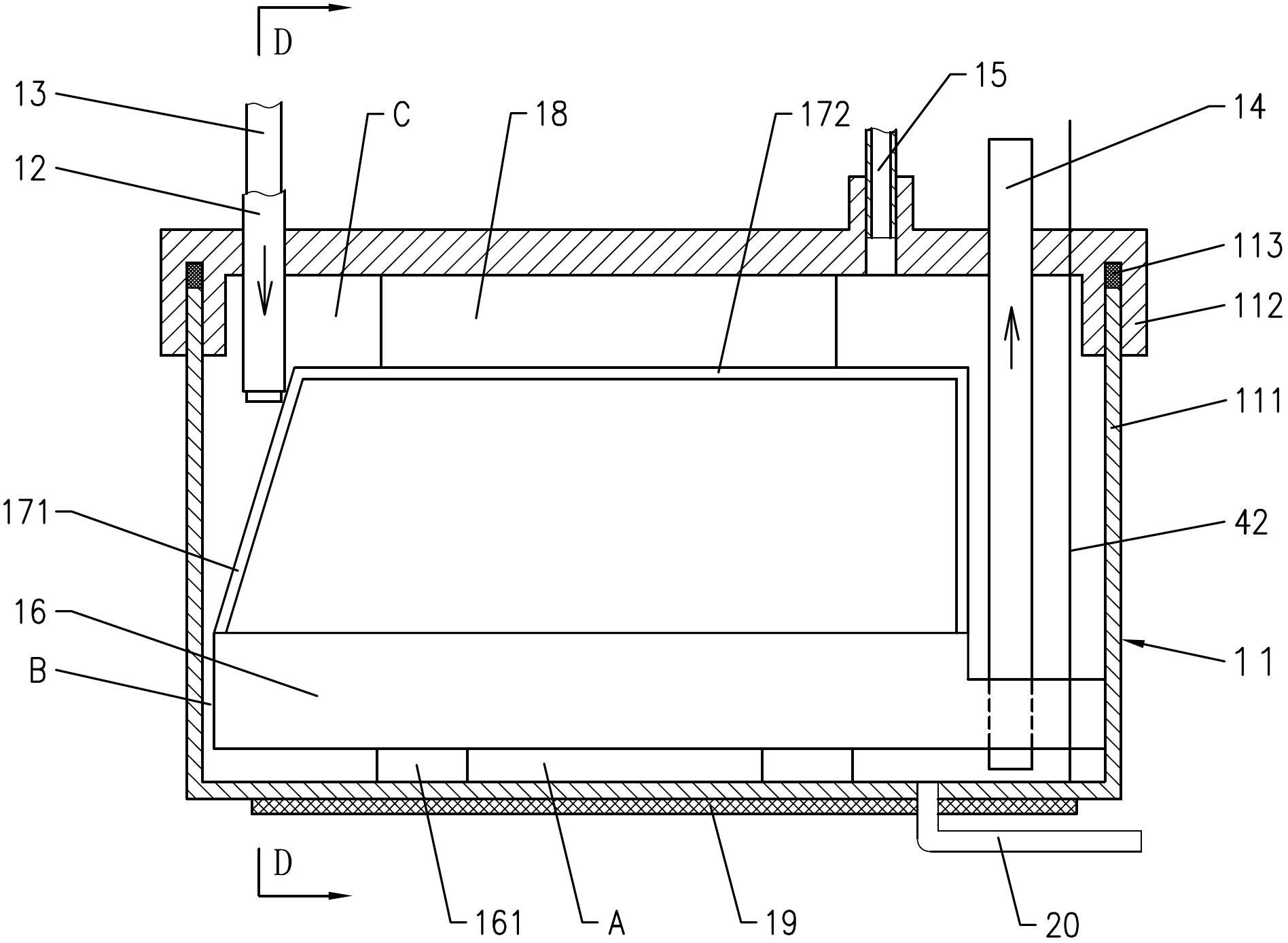

Whole-process autotrophic nitrogen removal method and device

InactiveCN103288213APromote rapid formationIncreased chance of collisionTreatment with aerobic and anaerobic processesNitrationTotal nitrogen

The invention discloses a whole-process autotrophic nitrogen removal method. The method mainly comprises the following steps: 1) inoculating anammox sludge into a reactor; 2) introducing nitrogen into the wastewater so as to reduce the DO (Dissolved Oxygen) concentration of wastewater to 0mg / L (milligram per liter) by filling nitrogen into the wastewater, and regulating the pH value of a water inflow barrel to reach 7 to 8; 3) gradually increasing the water inflow load by increasing the total nitrogen concentration of the wastewater and reducing the hydraulic retention time; 4) gradually increasing the DO concentration in the wastewater after a reaction is stable, thereby culturing bacteria capable of consuming oxygen in the reactor; 5) forming the oxygen-containing bacteria on the outer layer of the anammox sludge after performing the culturing acclimatization for half a month; 6) inoculating nitrosobacteria into the reactor and properly lowering the nitrate nitrogen concentration in the inflowing water while performing aeration to the reactor and controlling aeration quantity at the same time, thereby partially converting ammonia nitrogen entering the reactor into the nitrate nitrogen, i.e., the concentration (mg / L) ratio of the ammonia nitrogen to the nitrate nitrogen is 1:1 or so; regulating the pH value in the reactor to reach 7.5 to 7.7 by using a pH controller; 7) gradually increasing the water inflow load, thereby removing the nitrogen stably. The invention further discloses a device for realizing the whole-process autotrophic nitrogen removal method.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Preparation method of dual-purpose filter material for dedusting and decomposing dioxins

The invention discloses a preparation method for double action filtering material capable of dedusting and decomposing dioxin. The material comprises the following five-layer structure: a first layer is a dust receiving layer formed by polytetrafluoroethylene fibers through carding process; a second layer is a buffer layer formed by fine denier polytetrafluoroethylene fiber through preneedling processing; a polytetrafluoroethylene film carrying a catalyst is processed into reticular structure fibers by a film splitting method, and a plurality of films are laminated to form a catalysis layer which is a third layer; a fourth layer is a Teflon base cloth reinforced layer; and the four layers are laminated, then the dust receiving layer is laminated on the base cloth reinforced layer, and finally the material is formed through needling processing. The material can be widely applied to the dedusting and dioxin decomposition of high temperature off gas. Compared with the prior art, the preparation method has the advantages of simple and feasible process, low processing cost, and lower requirements on the equipment; and simultaneously the preparation method removes the defects of great fiber loss and a great drag force for the filtering material.

Owner:ZHEJIANG SCI-TECH UNIV

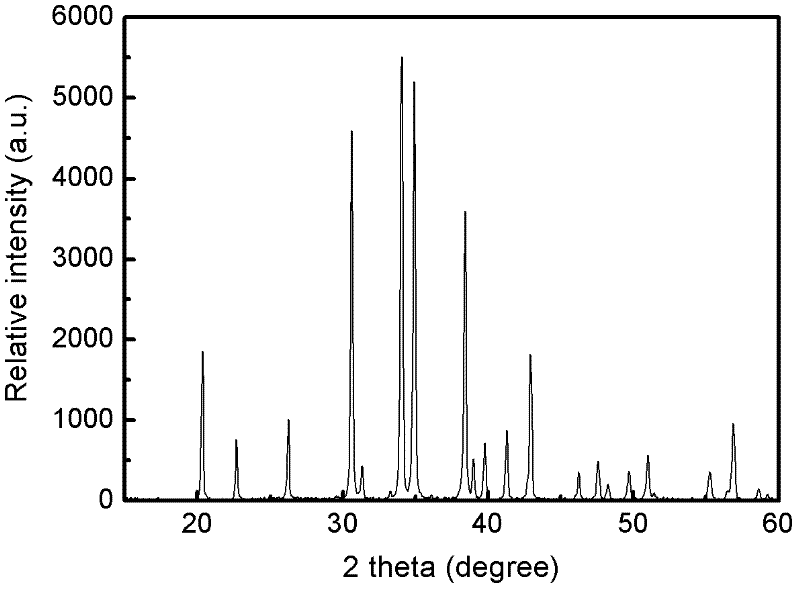

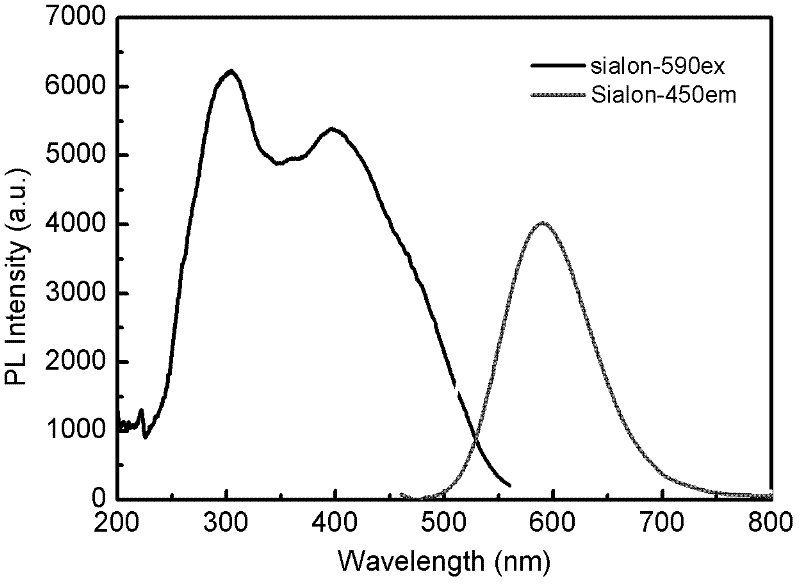

A kind of preparation method of nitride/oxynitride fluorescent powder for white light LED

InactiveCN102260500AUniform distribution of temperature fieldReduce temperature gradientElectroluminescent light sourcesGas discharge lamp usagePolymer scienceHigh pressure

Provided is a method for preparing a nitride / oxynitride fluorescent powder used by a white LED. The raw material is weighted according to the chemometry of each element in the chemical formula of a nitride / oxynitride fluorescent powder and loaded into a sagger made of a wave-transparent material after being mixed uniformly, then the sagger is placed into a professional microwave oven, in a fixed gas atmosphere, and the fluorescent powder is obtained by adjusting the microwave power to control the warming rate, heating to the resultant temperature, and finally cooling and grinding. As compared to methods in the prior art, the method is performed under normal pressure, reducing the resultant temperature, shortening the production period, and greatly reducing the production costs; and the fluorescent powder obtained has good crystallinity, fine grain size, a narrow granularity distribution range, good grain dispersibility, and a regular shape.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

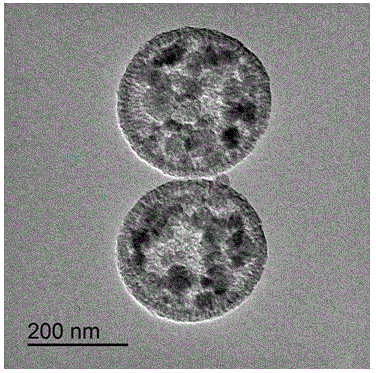

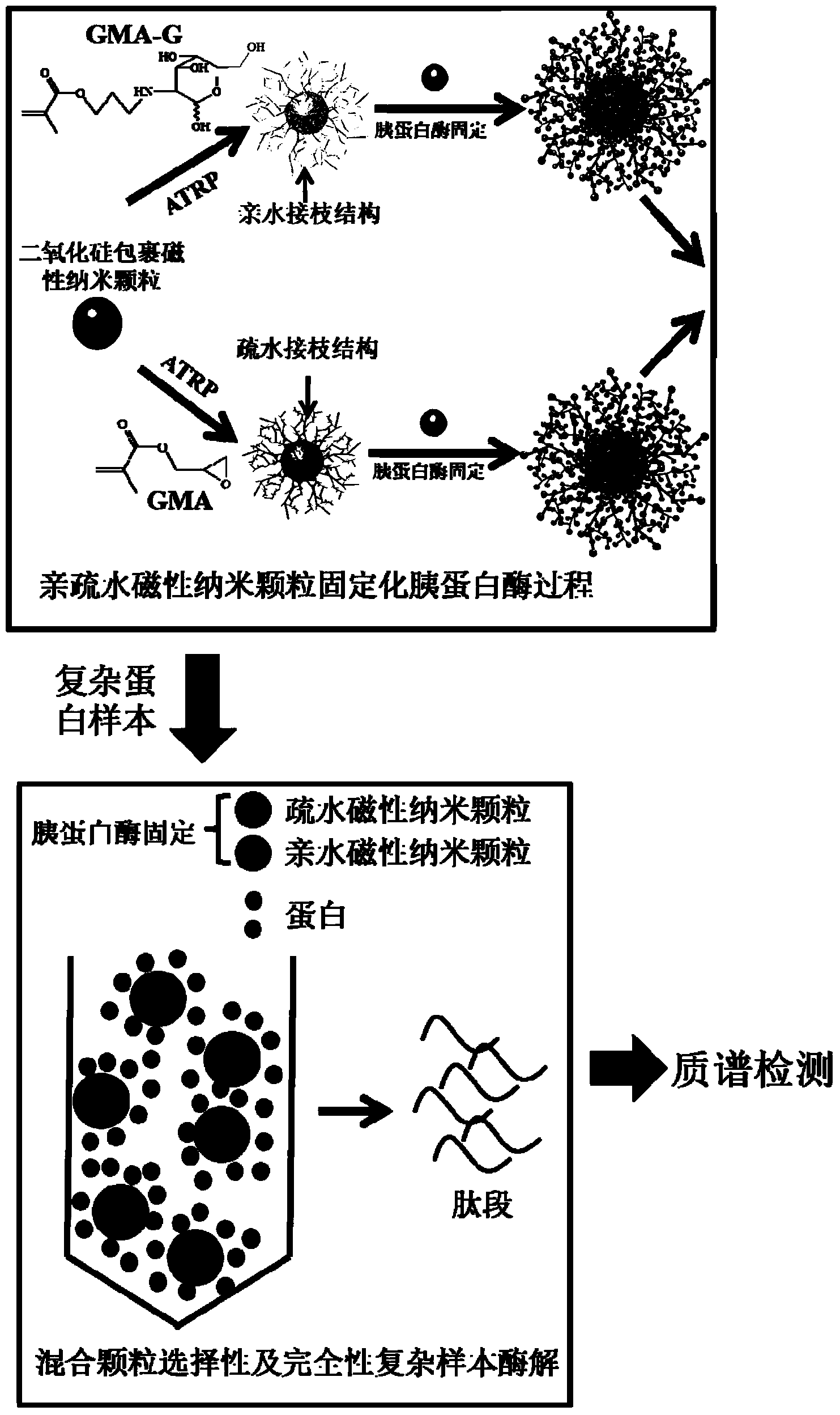

Preparation and application of immobilized protease reagent

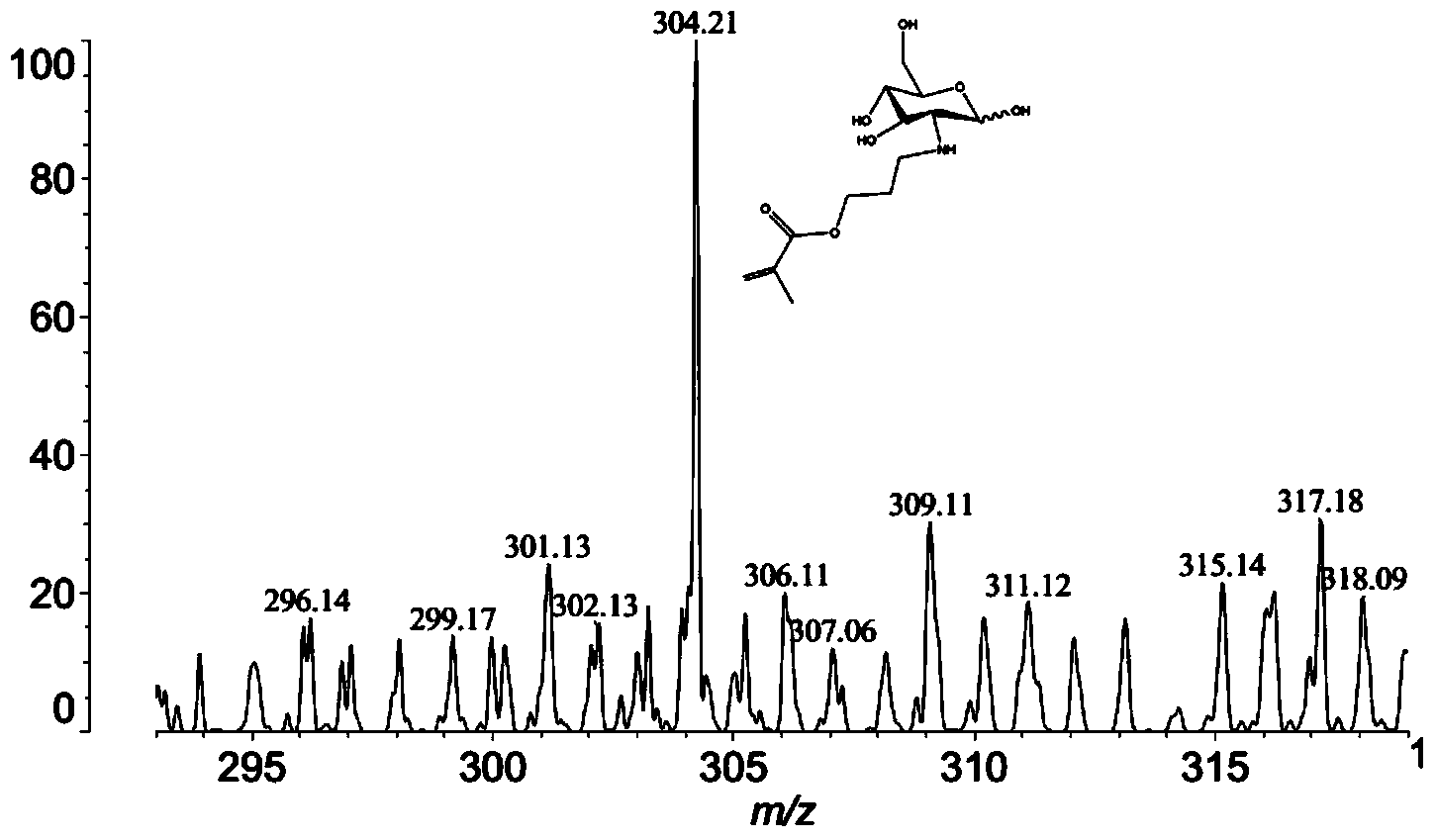

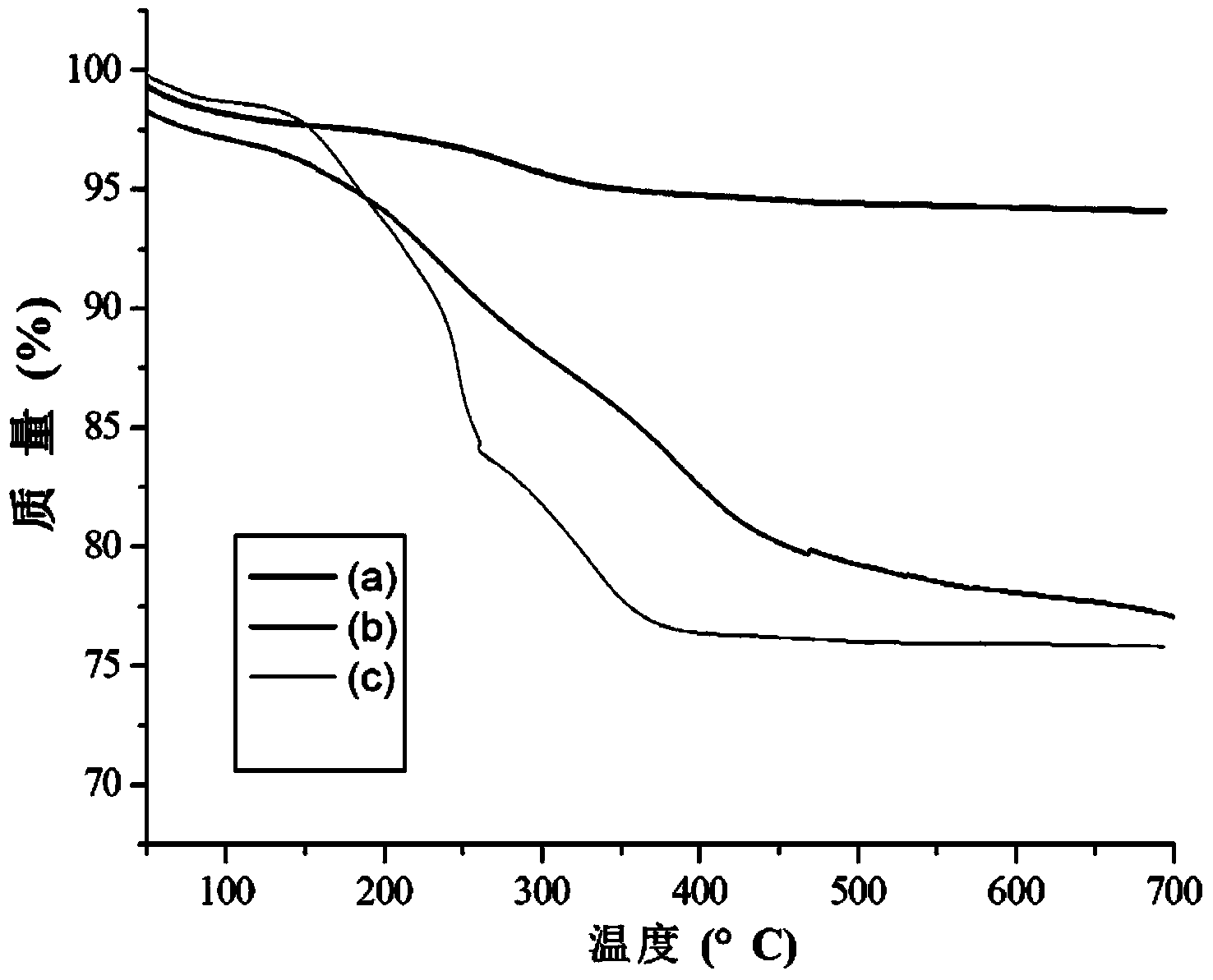

ActiveCN103882002AIncrease the loading capacityIncreased chance of collisionOn/in organic carrierFermentationComputational chemistryImmobilized enzyme

The invention discloses preparation and application of an immobilized protease reagent. An immobilized enzyme disclosed by the invention is composed of a hydrophobic carrier material and a protease immobilized on the hydrophobic carrier material. Two different-property, namely one hydrophilic and one hydrophobic, polymer chain modified magnetic nanoparticle immobilized trypsins prepared independently by using a surface initiate atom transfer radical polymerization (SI-ATRP) realize quick, efficient and complete enzymolysis of a protein, and the two, one hydrophilic and one hydrophobic, immobilized proteases are combined to use so that complementary enzymolysis is realized, and therefore, enzymatic bias caused by the selectivity of the carrier can be effectively reduced, the comprehensiveness of protein enzymolysis can be improved, and then the identification number of proteins and peptide fragments can be remarkably increased.

Owner:INST OF RADIATION MEDICINE ACAD OF MILITARY MEDICAL SCI OF THE PLA

Ink storage device for ink-jet printer

The invention discloses an ink storage device for an ink-jet printer. The ink storage device comprises an ink box and an ink barrel used for feeding ink into the ink box. The ink box comprises a shell, a flow guide plate and an ink baffle, the flow guide plate is mounted in the shell and comprises an ink guide plate and an upper ejector plate, the ink guide plates are obliquely arranged at outlets of an ink inlet tube and an ink return tube, the upper ejector plate is connected with the upper ends of the ink guide plates, and a bubble passage is formed between the upper ejector plate and the upper top face of the shell. The ink baffle is arranged on the lower portion of the flow guide plate, a gap for ink feeding is reserved between the ink baffle and the side wall of the shell, an ink containing gap is reserved between the ink baffle and the inner bottom face of the shell, the lower end of an ink outlet tube penetrates through the ink baffle to extend into the ink containing gap, and a bubble guide device is arranged in the bubble passage and used for guiding bubbles away and eliminating the bubbles. Replacement of the ink box is not needed, so that printing cost is saved. In addition, bubbles in the ink box are effectively eliminated, and accordingly printing quality is improved.

Owner:潍坊东航印刷科技股份有限公司

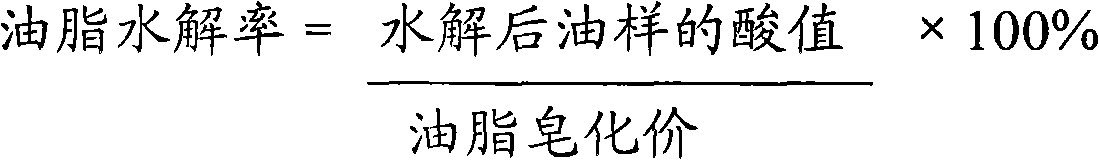

Method for preparing fatty acid by using lipase hydrolyzation of oil and fat

ActiveCN101294170AIncrease hydrolysis rateIncrease chance of collisionFermentationHigh pressureEnergy consumption

The invention discloses a method for producing fatty acid by hydrolyzing animal and vegetable oils or waste animal and vegetable oils using lipase. The method can achieve a hydrolysis rate above 90% by carrying out hydrolysis reaction using lipase in the presence of emulsifying agent. The enzymatic method of the invention is carried out under a mild condition to overcome the disadvantages of prior alkaline saponification, high-temperature high-pressure continuous cracking and medium-pressure cracking reaction, and has the advantages of less energy consumption, low equipment cost, no contaminant discharge, and high applicability for raw materials. Accordingly, the enzymatic method of the invention has wide application prospect.

Owner:领先生物农业股份有限公司

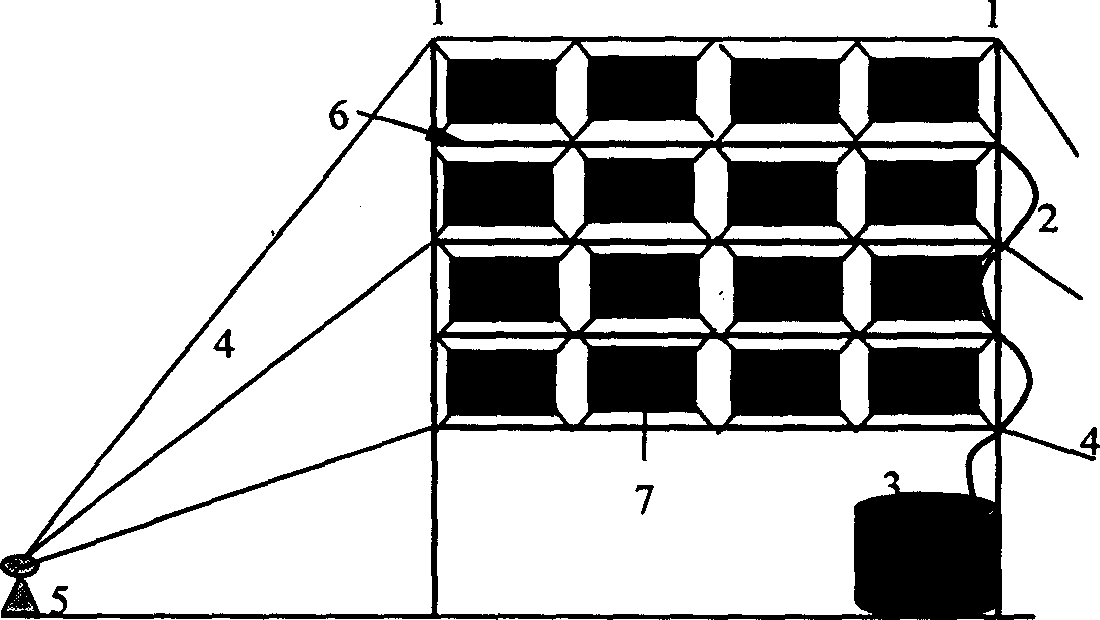

Helmholtz resonator array based suspended particles sound wave agglomerating system and method

ActiveCN104587789ALow costReduce energy consumptionAuxillary pretreatmentSuspended particlesSound sources

The invention discloses a Helmholtz resonator array based suspended particles sound wave agglomerating system and method. The Helmholtz resonator array based suspended particles sound wave agglomerating system comprises a sound source device, a Helmholtz resonance device, a control device and a protection device, wherein the sound source device comprises a signal generator, a signal amplifier, a sound source, a horn and a standing wave tube which are connected sequentially; the Helmholtz resonance device comprises a short pipe, a flue and a Helmholtz resonator; the control device comprises a controller and three groups of piston components; the protection device comprises a cyclone dust collector and a soundproofing wedge which are arranged on the flue; the signal generator generates sound wave to drive the sound source by the signal amplifier, the low-frequency sound wave is radiated to the standing wave tube by the horn, and the first piston component moves to adjust the volume of the Helmholtz resonator, so as to make the resonance frequency of the flue be the same as the frequency of the low-frequency sound wave. The system and method have the advantages of high agglomerating efficiency, low energy consumption, simple operation, and reasonable structure.

Owner:NAT UNIV OF DEFENSE TECH

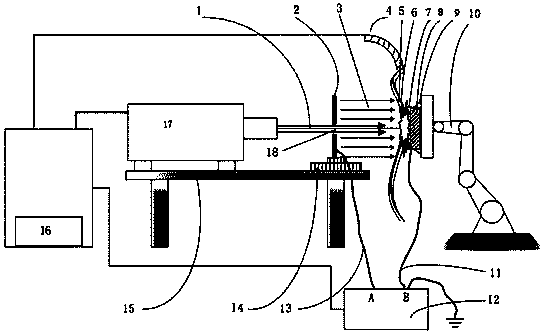

Laser shock peening method and device for outer intensified electric field

The invention discloses a laser shock peening method for an outer intensified electric field. The method comprises the steps as follows: a laser shock peening device for the outer intensified electric field is provided, wherein the laser shock peening device for the outer intensified electric field comprises a high-powder Q-tuning laser shock peening power supply, a Q-tuning high-pulse energy laser device, a high-voltage power supply, a copper pole plate coupled to the high-voltage end A of the high-voltage power supply, an automatic spray device, a work bench and a six-axis manipulator; a DSP control system is internally built inside the high-powder Q-tuning laser shock peening power supply to achieve control of the intensified electric field and a laser shock peening time sequence; a light hole is formed in the center of the copper pole plate to ensure that the laser passes through the light hole; a work-piece is connected with the low-voltage end B of the high-voltage power supply through a high-voltage lead; the strong electric field of 100000-3000000V / m exists in the laser shock peening area; the laser is loaded before exiting, so as to affect the plasma excitation and constrained states of the laser shock peening process, and improve the laser shock peening efficiency and effect.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

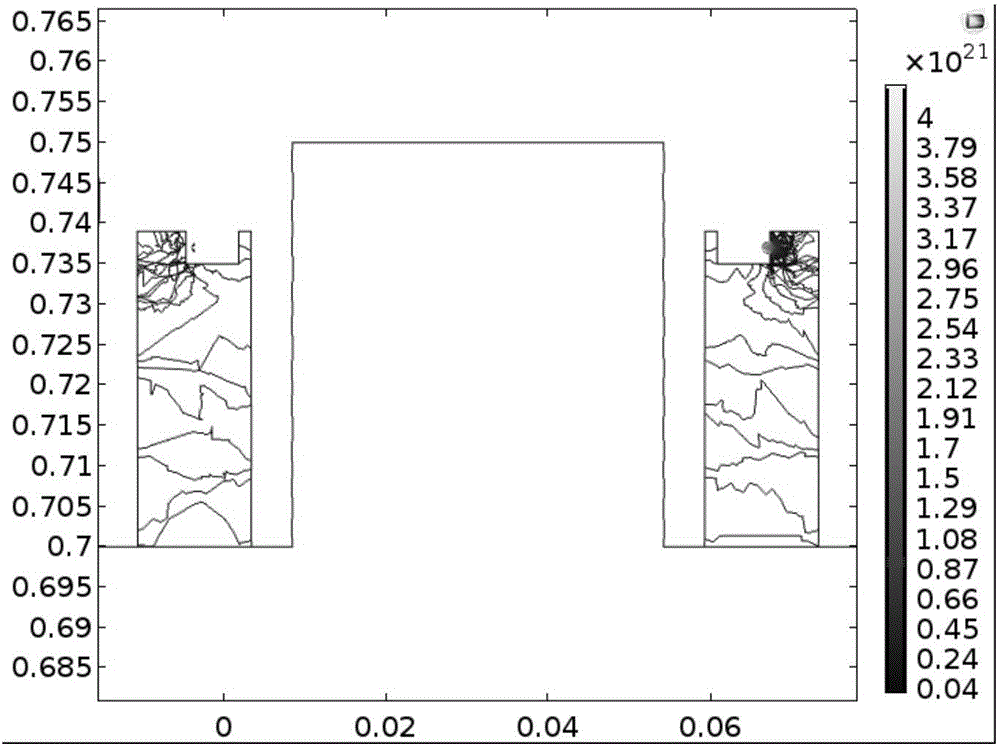

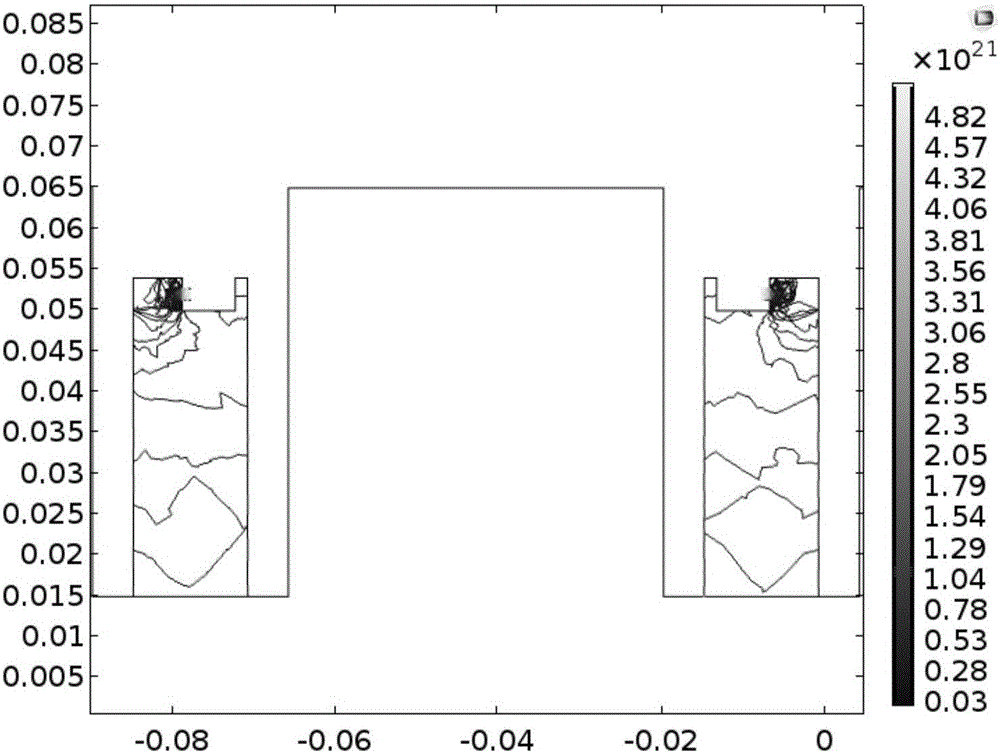

Gas flow control method for improving ionization efficiency of Hall thruster

ActiveCN105822516AImprove ionization efficiencyIncrease the peripheral velocity componentMachines/enginesUsing plasmaIonizationEngineering

The invention discloses a gas flow control method for improving the ionization efficiency of a Hall thruster and relates to the technical field of plasma propulsion. The gas flow control method aims at solving the problem that the staying time of neutral gas in a discharge channel of an existing Hall thruster is too short, and consequently the ionization efficiency is low. A gas distributor or a guiding gas outlet structure or the gas distributor and the guiding gas outlet structure is / are adopted. Each of the gas distributor and the guiding gas outlet structure is of an annular structure and can make gas have the circumferential speed component. The gas distributor and the guiding gas outlet structure are fixed to the upstream portion of the discharge channel. The axis of the gas distributor, the axis of the guiding gas outlet structure and the axis of the discharge channel coincide with one another. The gas distributor is located at the upper portion of the upstream part, and the guiding gas outlet structure is located at the lower portion of the upstream part. By means of the gas flow control method for improving the ionization efficiency of the Hall thruster, the ionization efficiency is effectively improved, and the gas flow control method is suitable for Hall thrusters.

Owner:HARBIN INST OF TECH

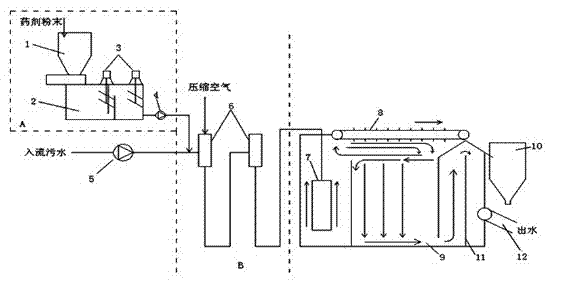

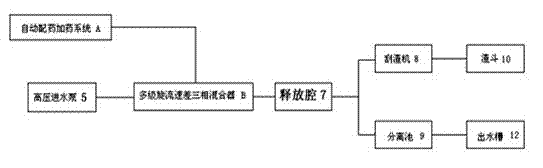

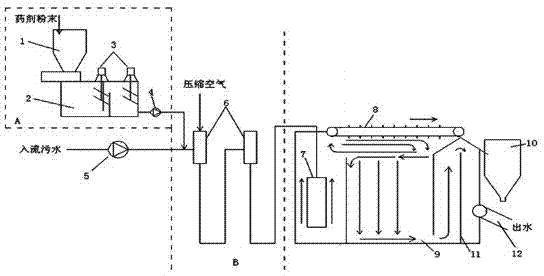

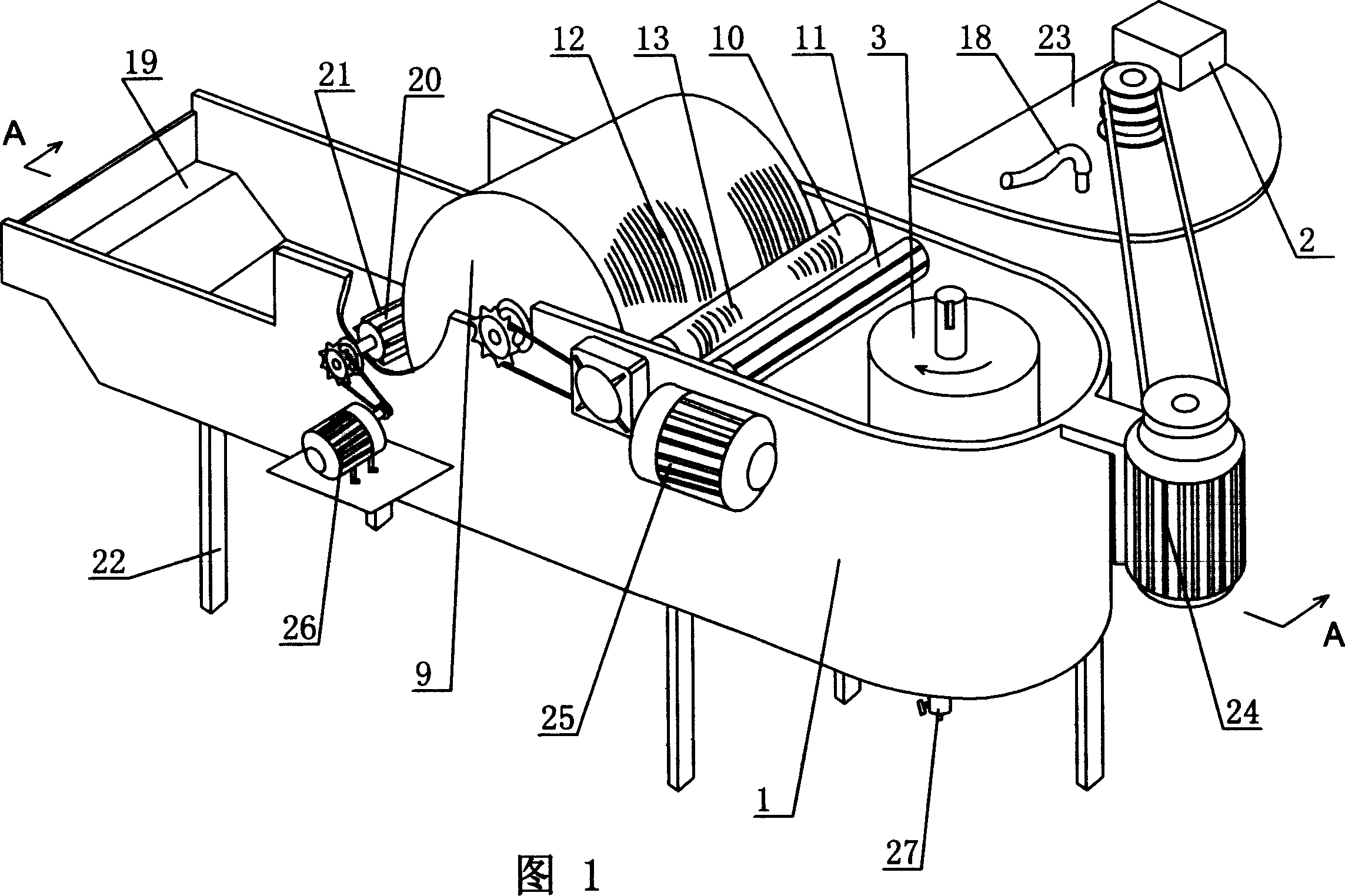

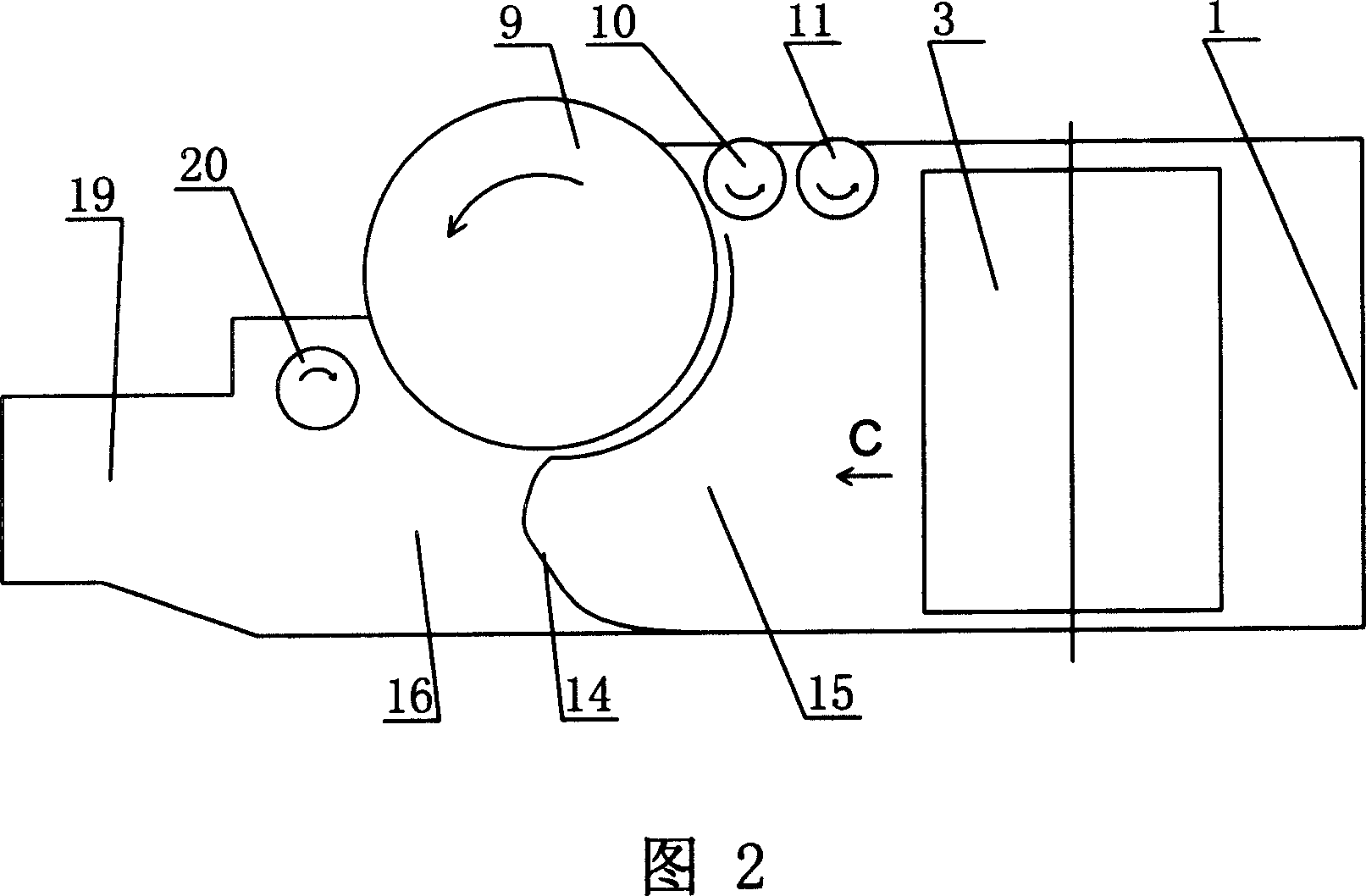

Oil-contained sewage treatment method and eddy energy fast-cyclone separating system of special equipment for method

ActiveCN102642884AIncrease profitIncreased chance of collisionWater/sewage treatment by flocculation/precipitationWater/sewage treatment by flotationCycloneSludge

The invention discloses an oil-contained sewage treatment method and an eddy energy fast-cyclone separating system (Haynes) of special equipment for the method. Oil-contained sewage enters a multilevel cyclone speed three-phase mixer together with a prepared reagent and compressed air, the multilevel three-phase mixer makes the reagent be adequately contacted with the contaminants to form micro floc and makes the compressed air enter a releasing cavity after being adequately dissolved in the sewage, the dissolved gas in the floc is slowing released in the releasing cavity as the pressure is reduced, so the moisture inside the floc is squeezed out, the gas and solid floc form a porous hollow shape, the moisture content is remarkably reduced, the specific gravity is lighter, finally the floc after forming the scum enters a separating tank, the scum is scraped by a scraping machine above the separating tank, the scraped scum is discharged by a connected hopper to be subsequently dehydrated, the separated water overflows to a water outlet groove through a water outlet weir plate to be discharged through a water outlet pipe. According to the oil-contained sewage treatment method and the separating system, advantages of good treatment effect, reagent conservation, less sludge, less investment, simpleness in control, low maintenance expense and the like can be realized.

Owner:上海齐国环境科技有限公司

Liquid opening machine

InactiveCN101063237ASimple structureWork resistance is smallTextile disintegration and recoveryFibre disintegrationEquipment useEnergy consumption

The invention discloses a liquid open machine comprising a frame arranged with a liquid inlet and a liquid outlet, wherein the frame comprises an open device, a fiber leather separator and a discharge device communicated with a material outlet at one side of the frame, the open device, the fiber leather separator and the discharge device are all connected with a power transmitter. The open device is composed of a rotor and a casing in a chamber of the frame, while the rotor can be arranged with a dial flake or cam. The invention uses the rotor to move liquid and leather block in frame at high speed, to impact the block at high speed to be opened. Compared with prior art, the invention has simple structure, improved working efficiency, better leather fiber quality, long service life of device and low energy consumption.

Owner:ZHEJIANG HONGZHAN NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com