Industrial reaction kettle suitable for feed liquid of chemical industry and medicine

A technology of industrial reaction and reactor body, applied in chemical industry, chemistry/physics/physicochemical fixed reactor, detailed information of chemistry/physics/physicochemical reactor, etc., can solve the problem that the reactor body cannot be cooled and heated , Stirring effect in general, etc., to save cost and manpower, shorten reaction time, improve stirring efficiency and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

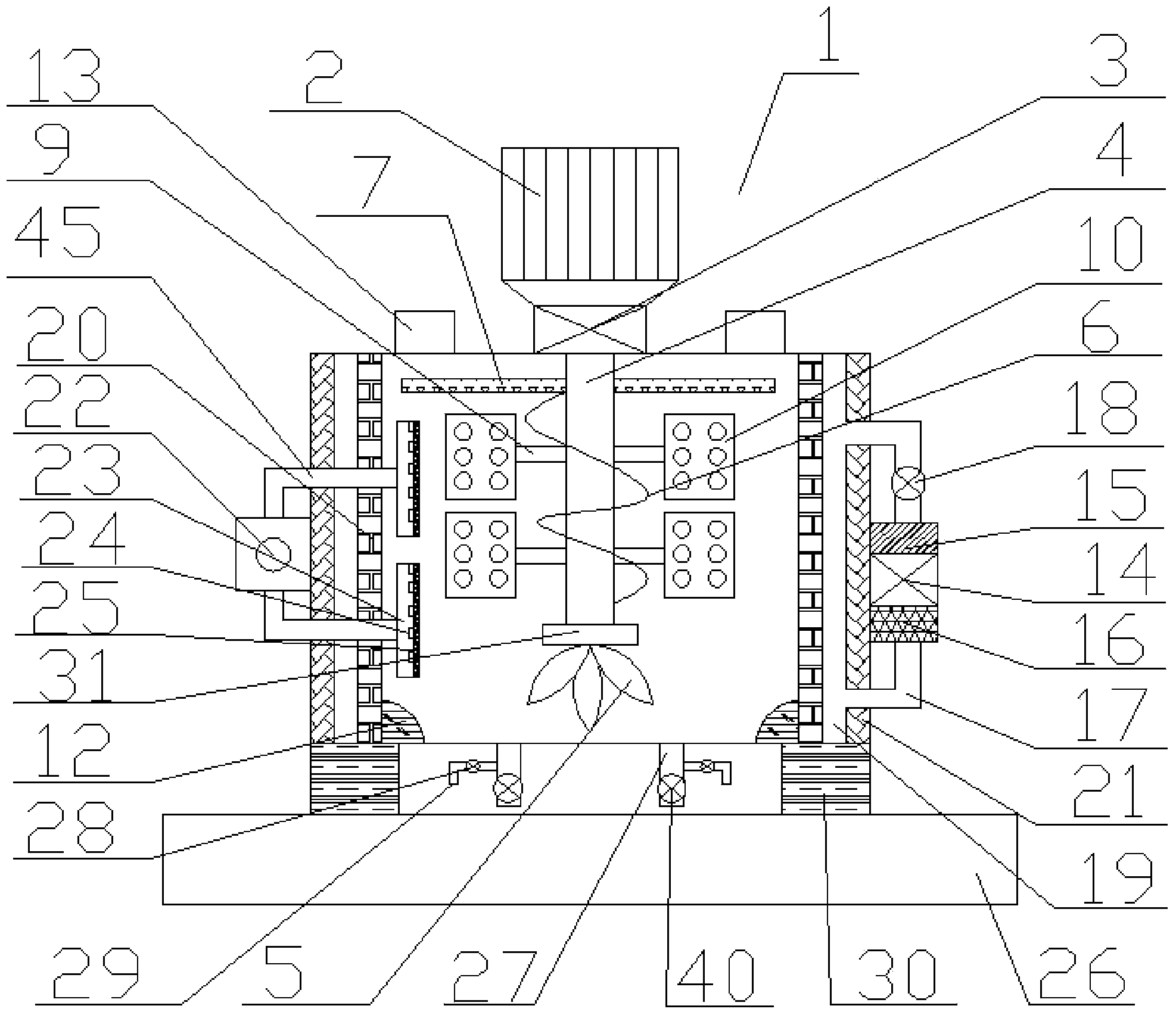

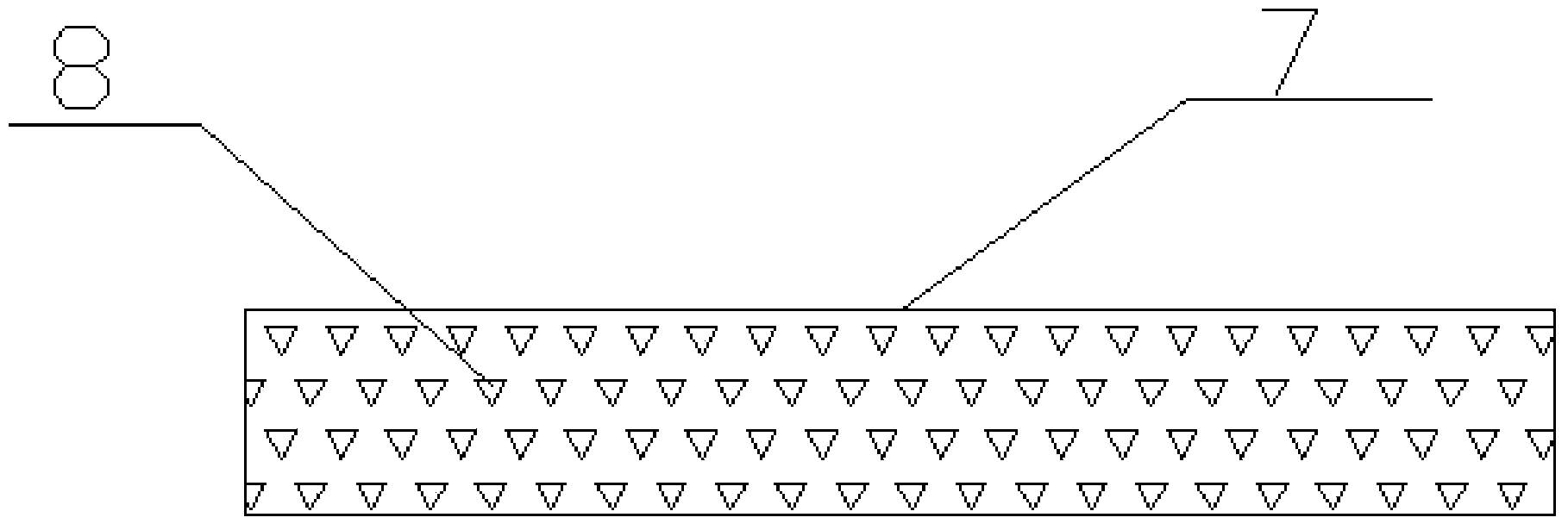

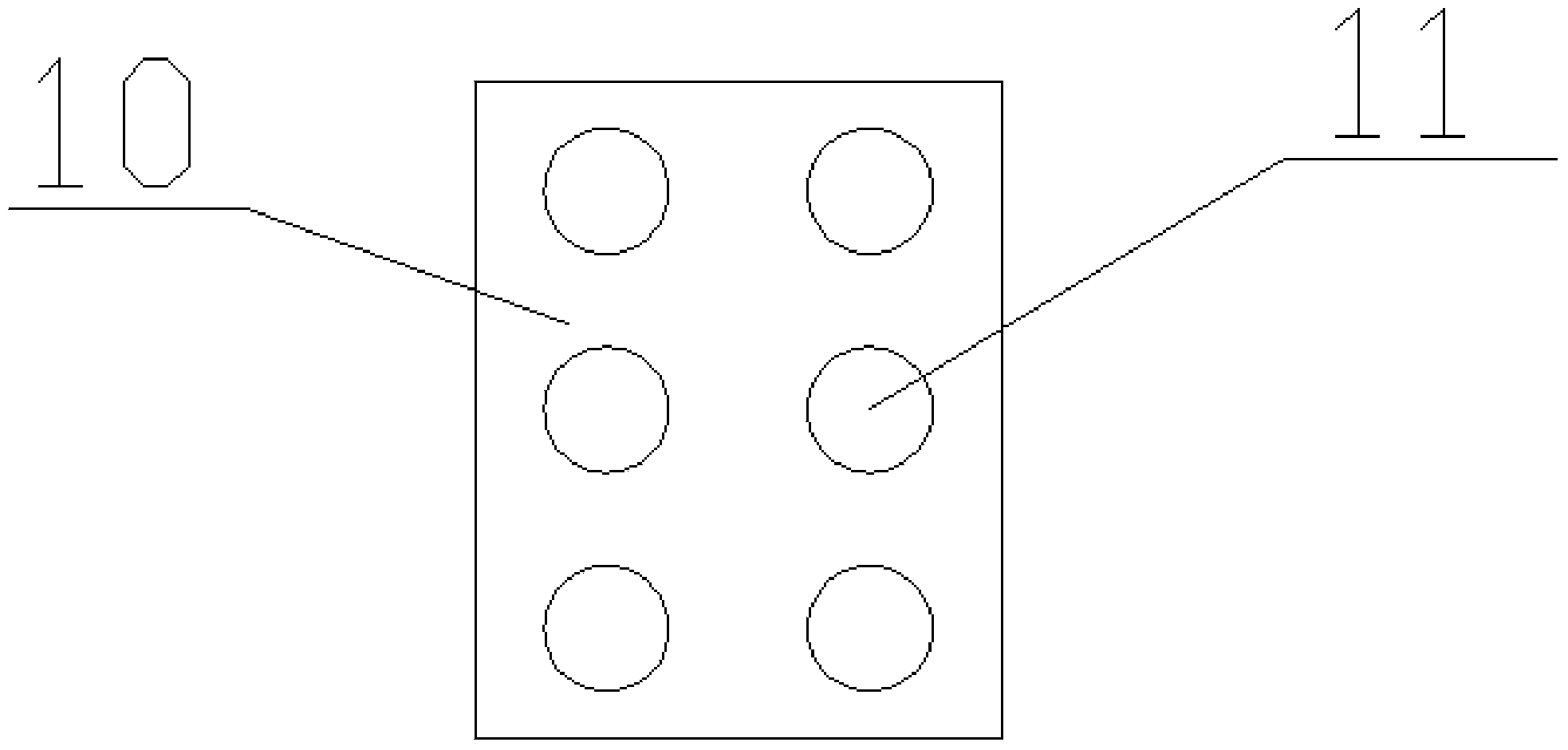

[0027] Such as Figure 1 to Figure 3 As shown, the first specific embodiment of the present invention is: a reaction kettle suitable for chemical and pharmaceutical feed liquid, which includes a reaction kettle body 1, and the reaction kettle body 1 includes a frequency conversion motor 2, a feed port 13, The speed reducer 3, the stirring shaft 4 and the base 26 are provided with a buffer device 30 between the base 26 and the reactor body 1, and the buffer device 30 is a rubber pad or a spring. In this embodiment, the buffer device is preferably a spring. The frequency conversion motor 2 and the feed inlet 13 are all arranged above the cavity of the reactor body 1, and the feed inlet 13 is provided with two altogether, which are respectively located on the left side and the left side of the reducer 3 above the reactor body 1 cavity. right sides. The base 26 is set under the cavity of the reactor body 1, the stirring shaft 4 extends into the inner cavity of the reactor body 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com