Patents

Literature

13209results about "Non-conductive material with dispersed conductive material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanowires-based transparent conductors

ActiveUS20070074316A1Improve drawing legibilityMaterial nanotechnologyFrom normal temperature solutionsElectrical conductorNanowire

Owner:CHAMP GREAT INTL

Conductive adhesive agent and process for manufacturing article using the conductive adhesive agent

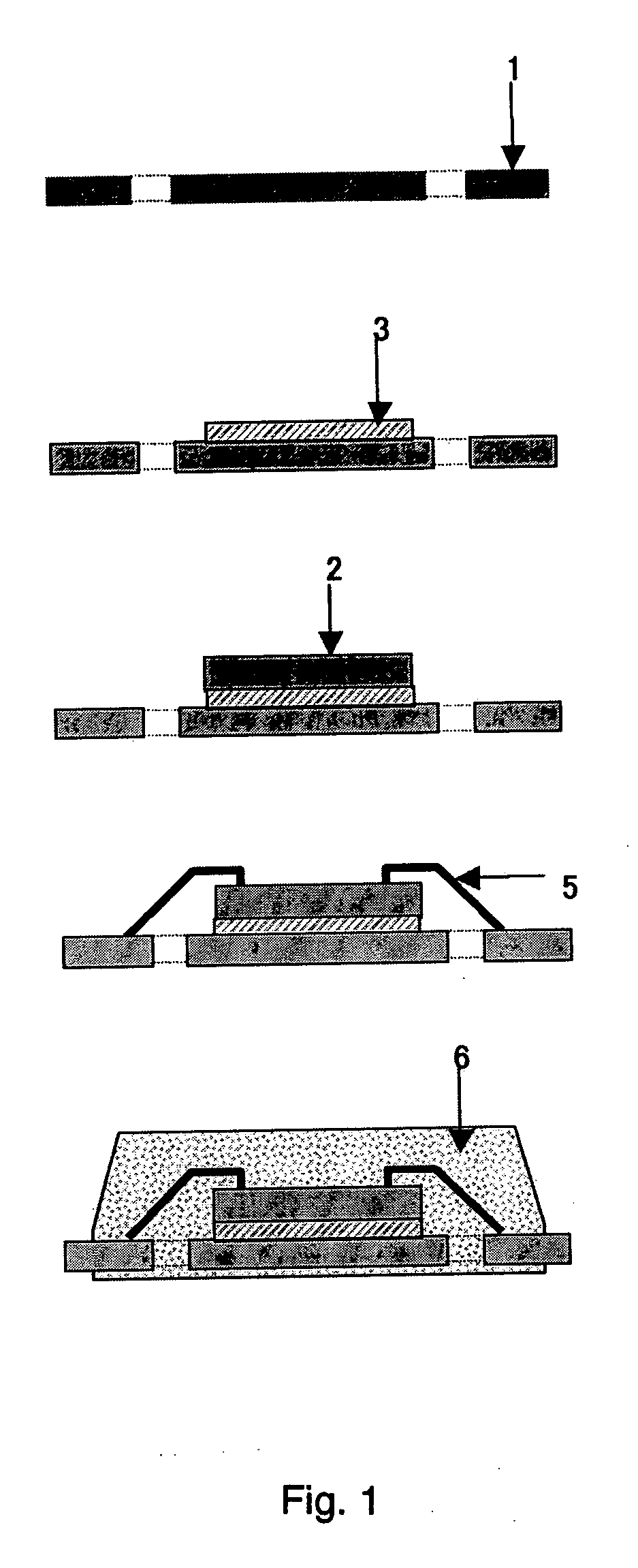

ActiveUS20060038304A1Fully curedUniform thicknessSemiconductor/solid-state device detailsConductive materialPolymer scienceFluid viscosity

The present invention provides a conductive adhesive agent capable of being diluted with a solvent to give good coating workability and allowing formation of a conductive joint excellent in both thermal conductivity and electrical conductivity by inhibiting a gas generated when a binder resin is heat-cured after attachment of a part. The conductive adhesive agent according to the present invention is a conductive adhesive agent wherein, based on 100 parts by weight of silver powder having an average particle diameter of micrometers, which is used for a conductive medium, e.g. as a main component, 1 to 10 parts by weight of silver fine particles having an average particle diameter of nanometers is used in combination therewith and 5 to 15 parts by weight of thermosetting resin as a binder resin component and 10 parts or less by weight of solvent for adjustment of a fluid viscosity are blended therein as essential components, and by selection of such a blending ratio, generation of a gas component during heating and curing of the thermosetting resin to prevent formation of voids, and at the same time, fabrication of a conductive joint excellent in thermal conductivity and electrical conductivity is achieved.

Owner:HARIMA CHEM INC +1

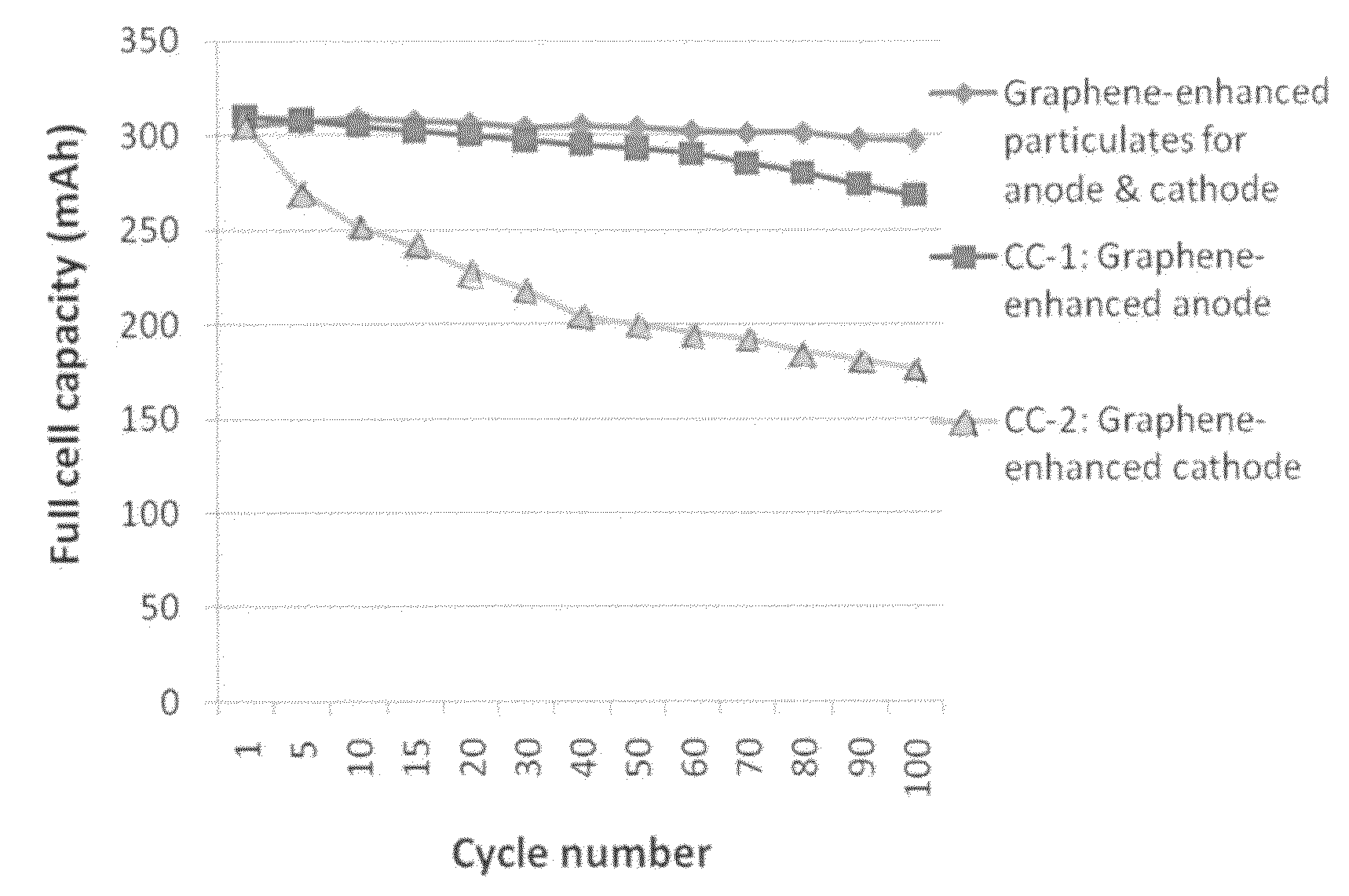

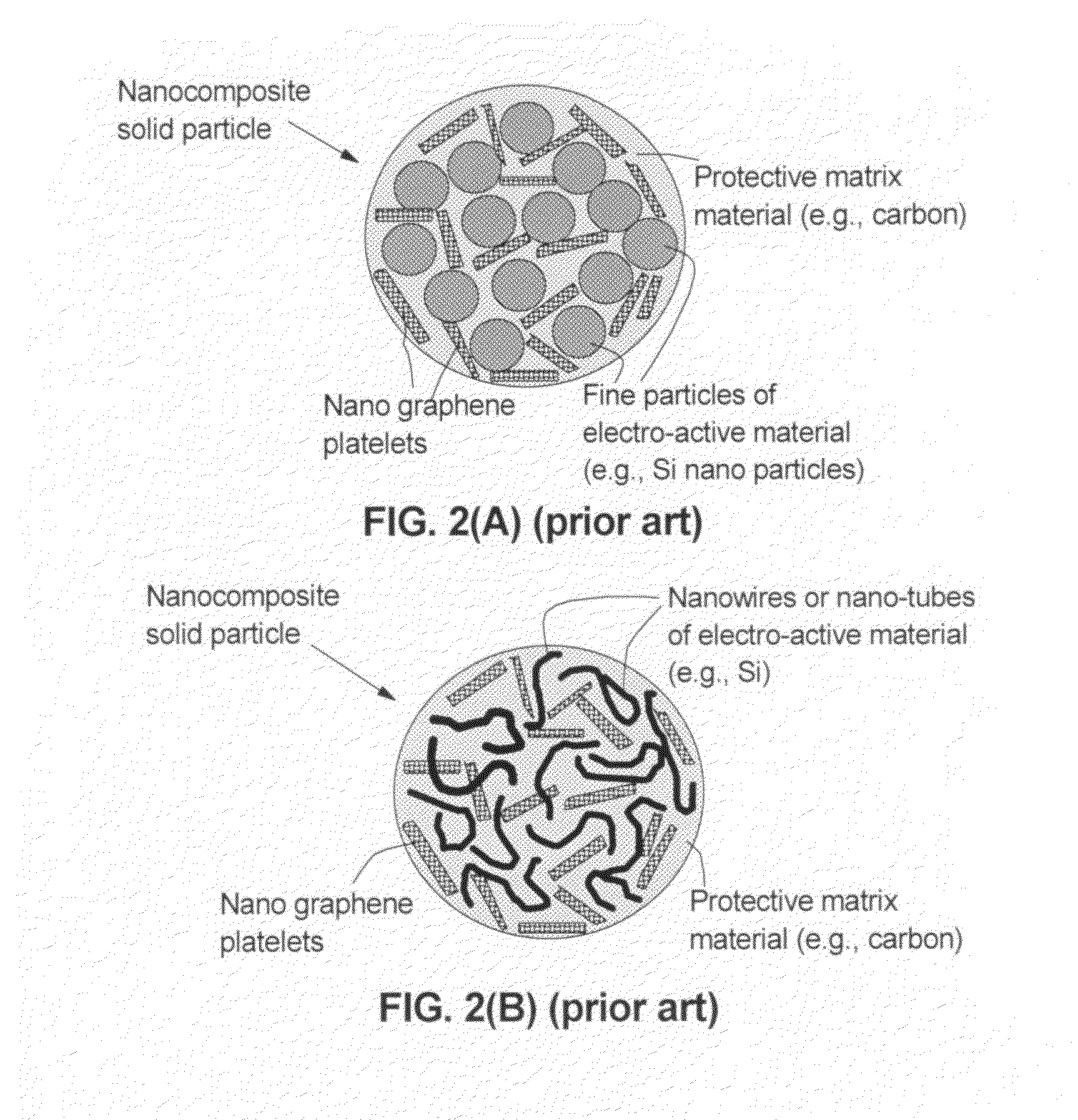

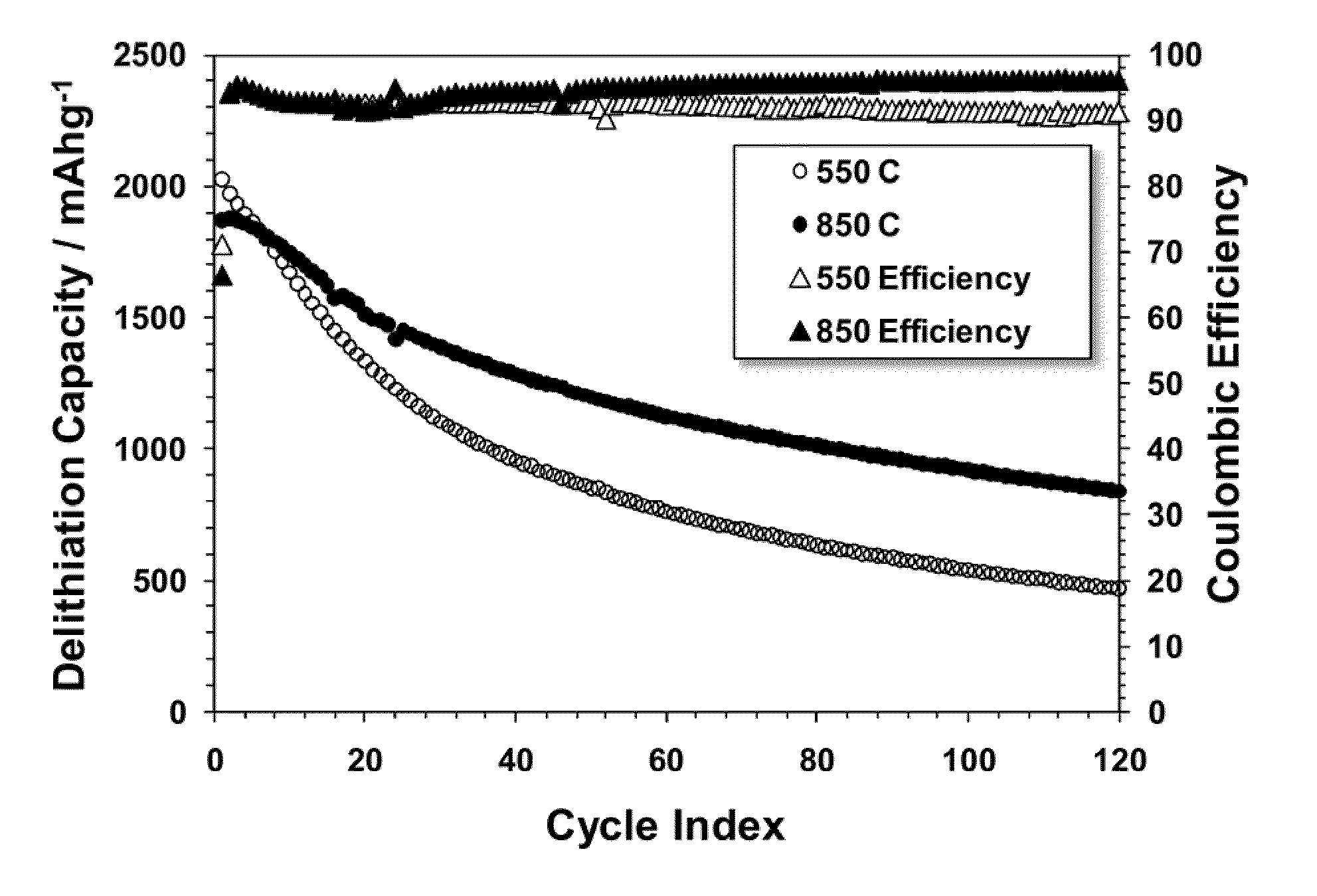

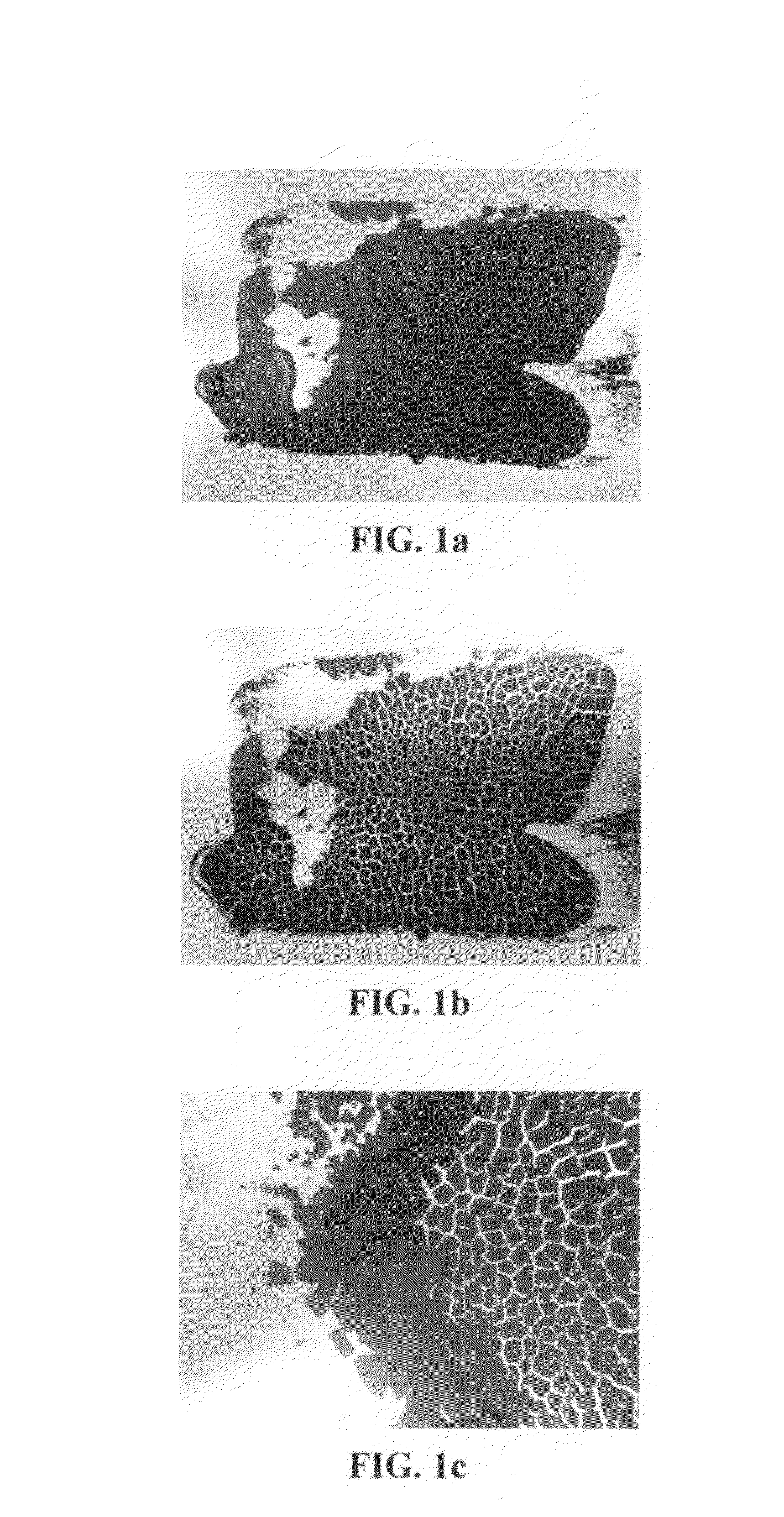

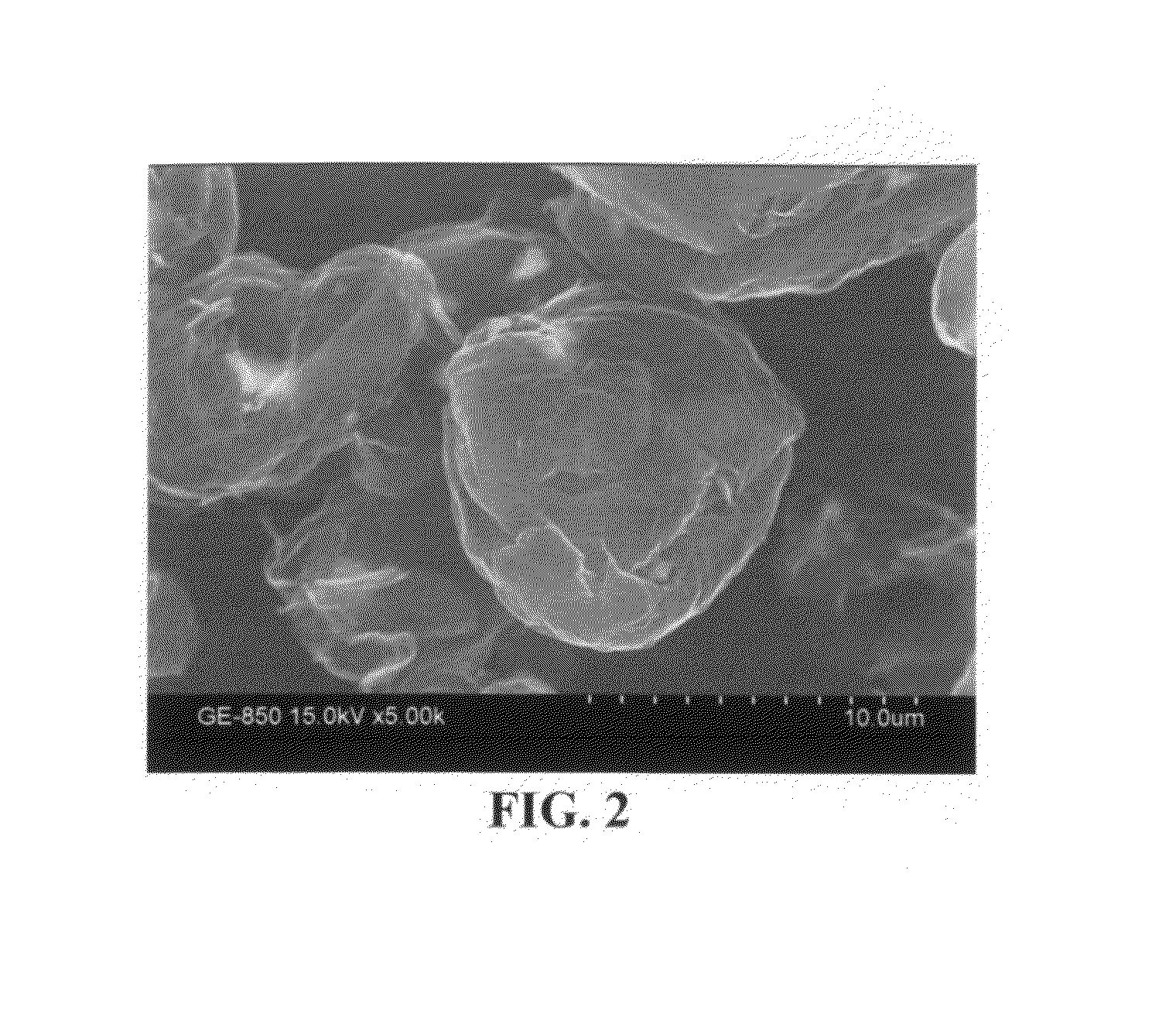

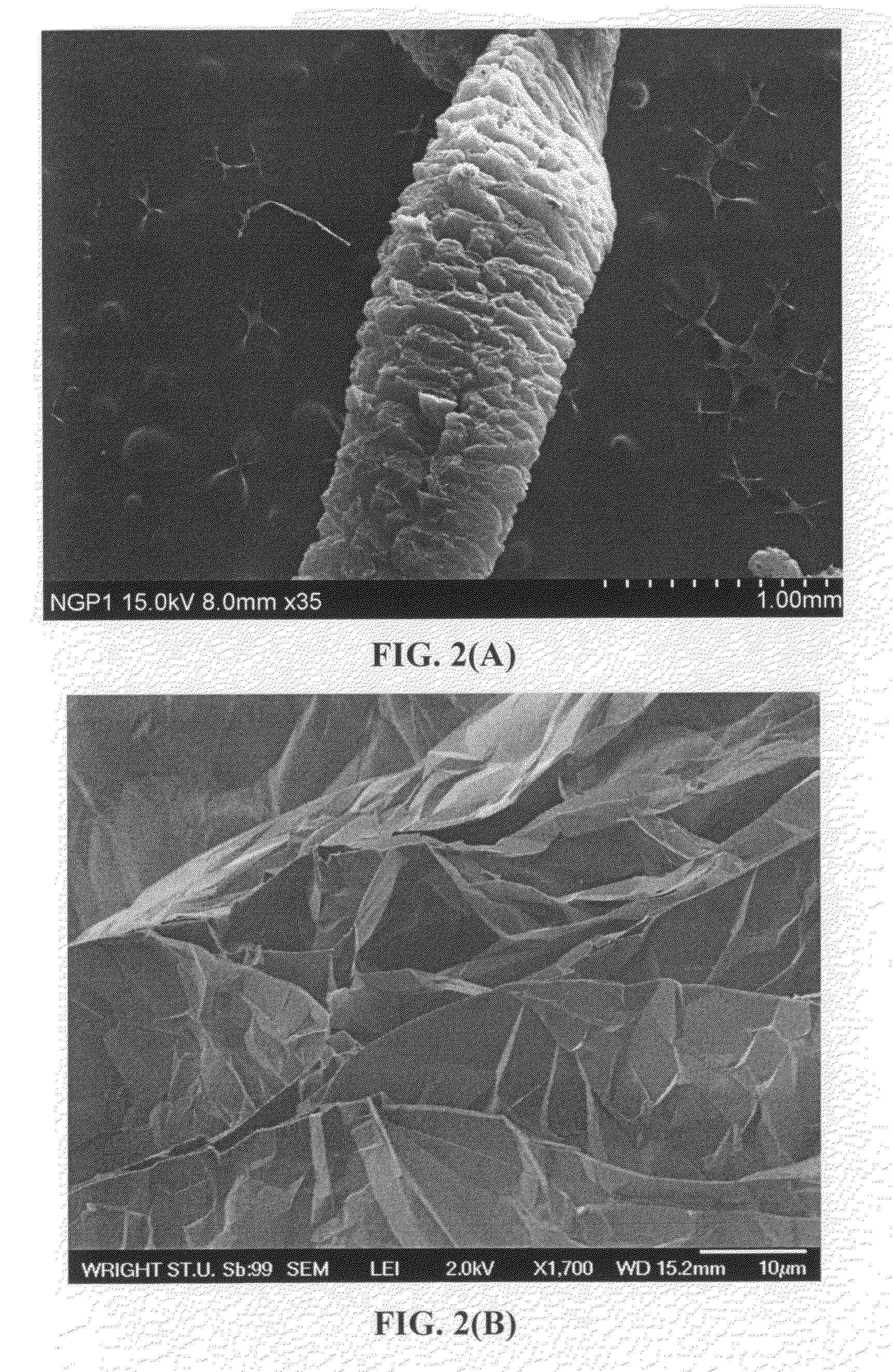

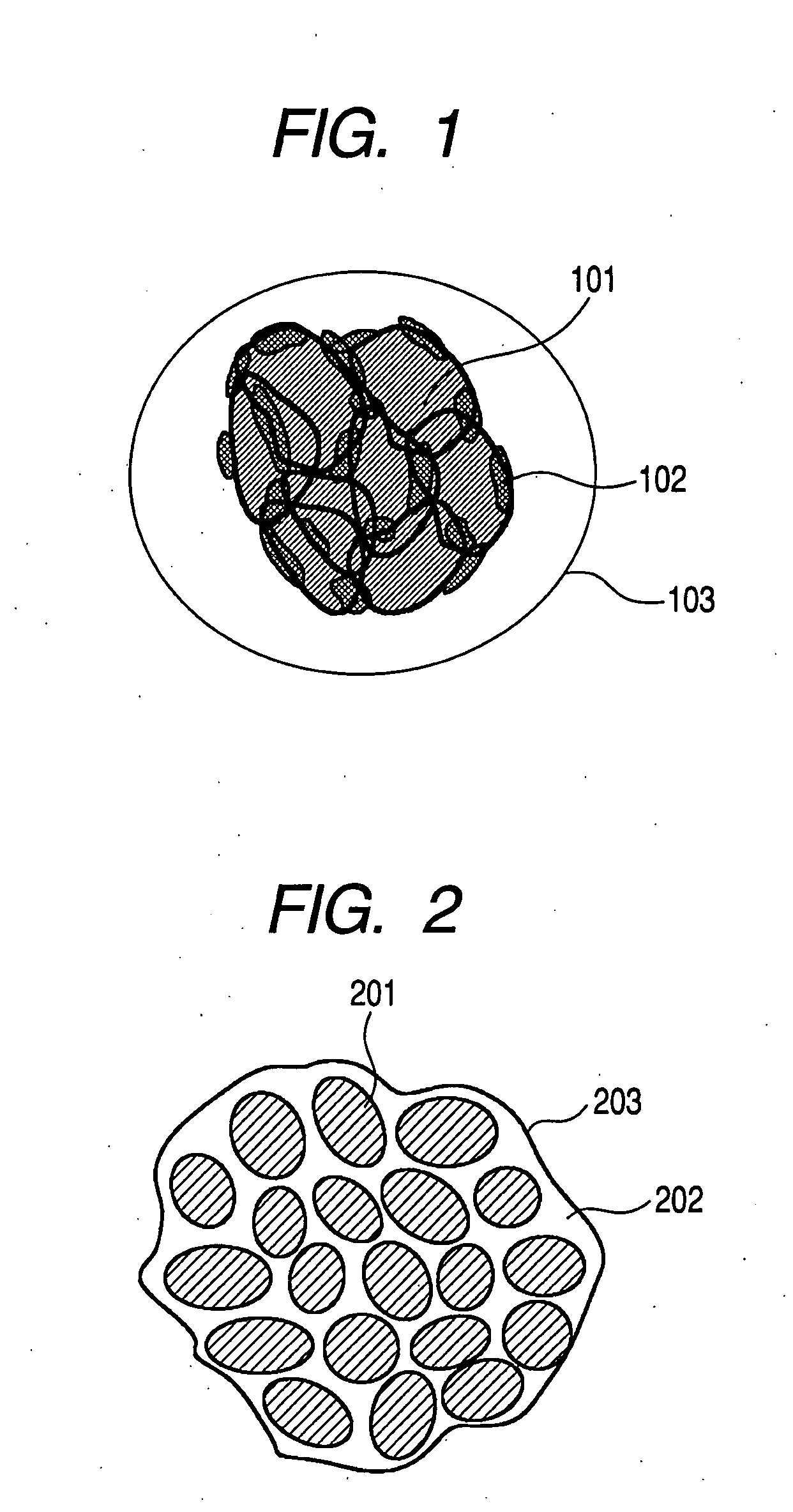

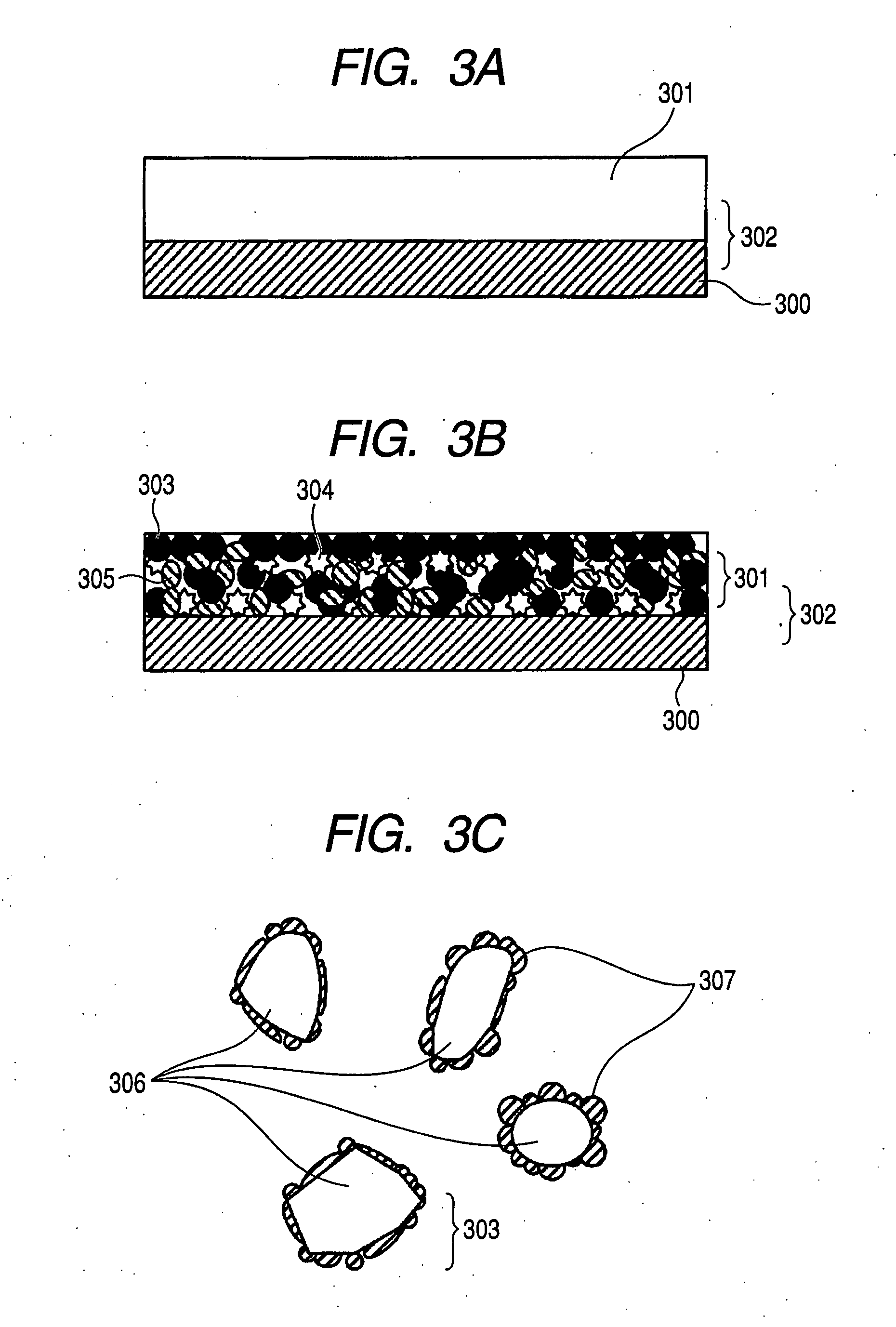

Graphene-enhanced anode particulates for lithium ion batteries

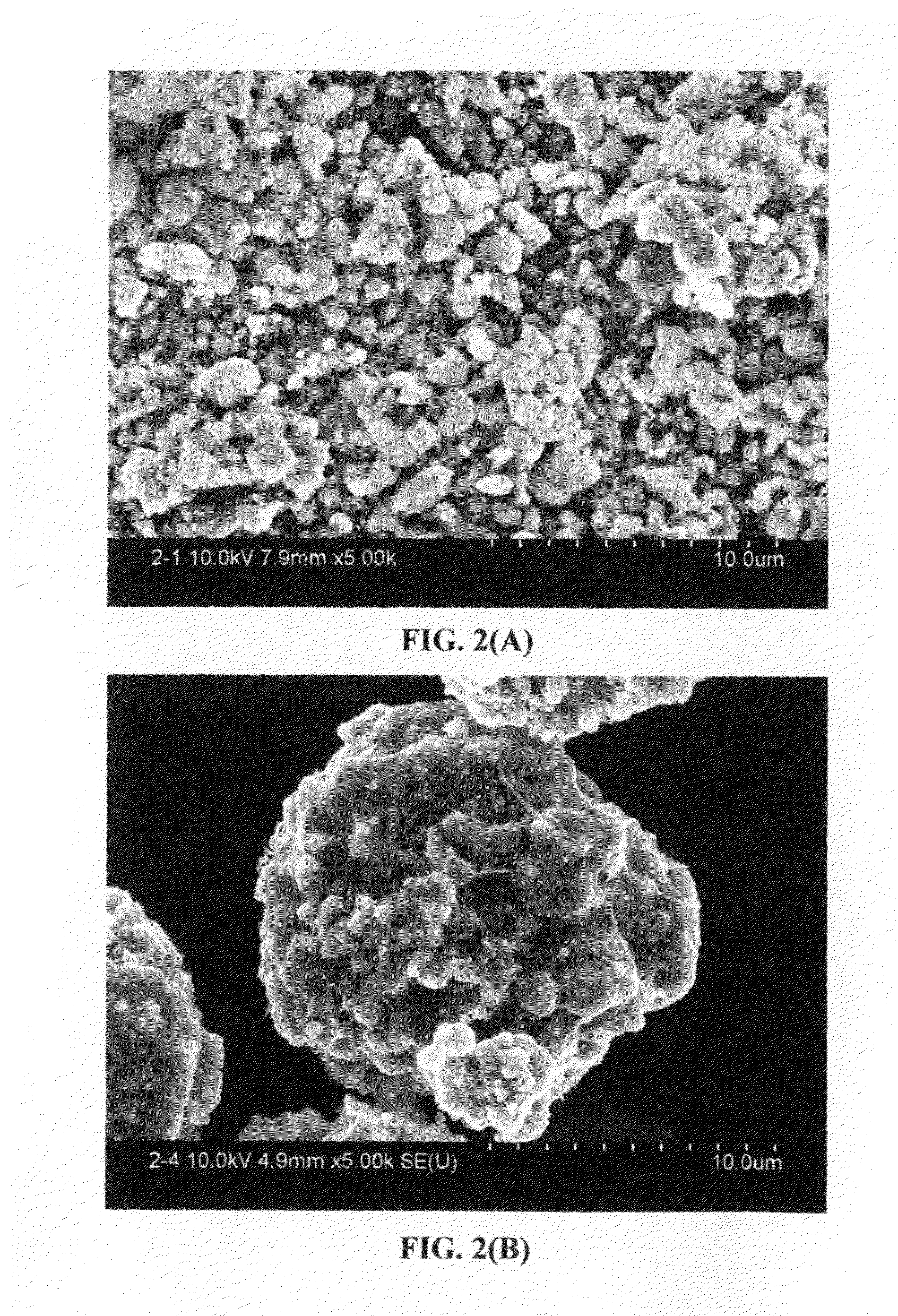

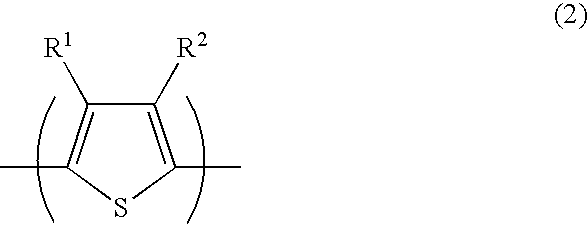

ActiveUS20120064409A1Enhanced Li-ion insertionIncrease capacityNon-metal conductorsMaterial nanotechnologyParticulatesMicroparticle

A nano graphene-enhanced particulate for use as a lithium-ion battery anode active material, wherein the particulate is formed of a single sheet of graphene or a plurality of graphene sheets and a plurality of fine anode active material particles with a size smaller than 10 μm. The graphene sheets and the particles are mutually bonded or agglomerated into the particulate with at least a graphene sheet embracing the anode active material particles. The amount of graphene is at least 0.01% by weight and the amount of the anode active material is at least 0.1% by weight, all based on the total weight of the particulate. A lithium-ion battery having an anode containing these graphene-enhanced particulates exhibits a stable charge and discharge cycling response, a high specific capacity per unit mass, a high first-cycle efficiency, a high capacity per electrode volume, and a long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD +1

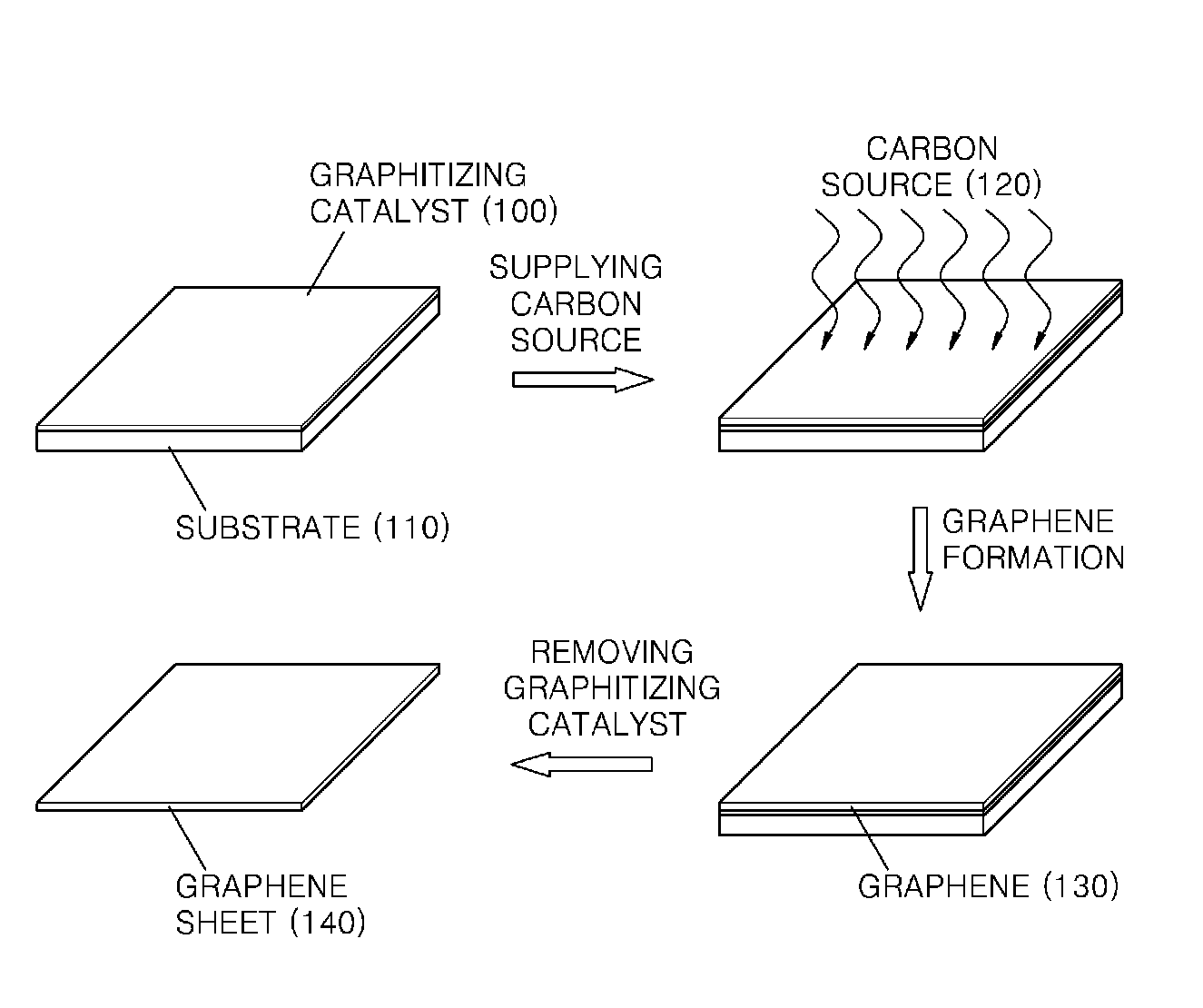

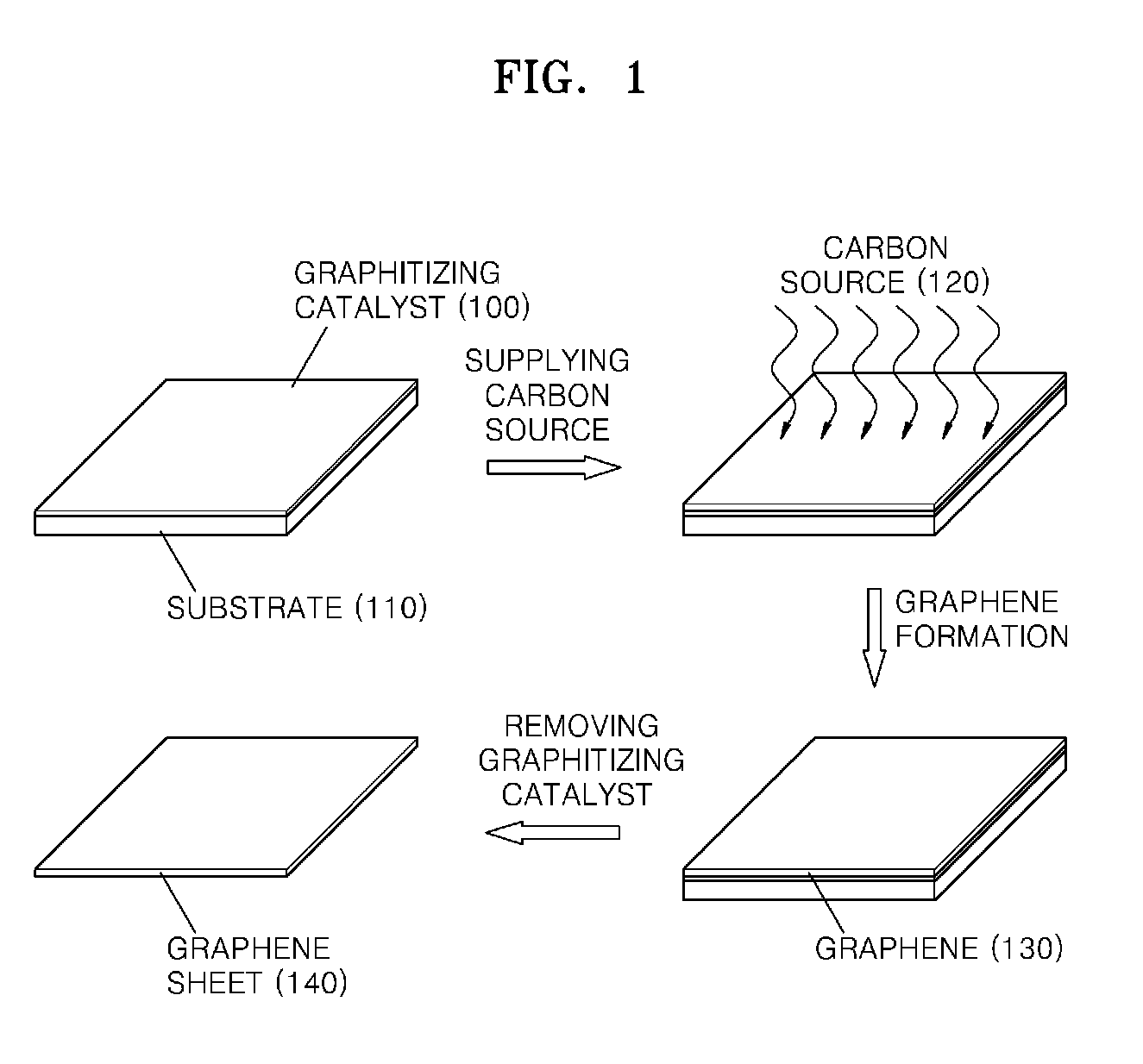

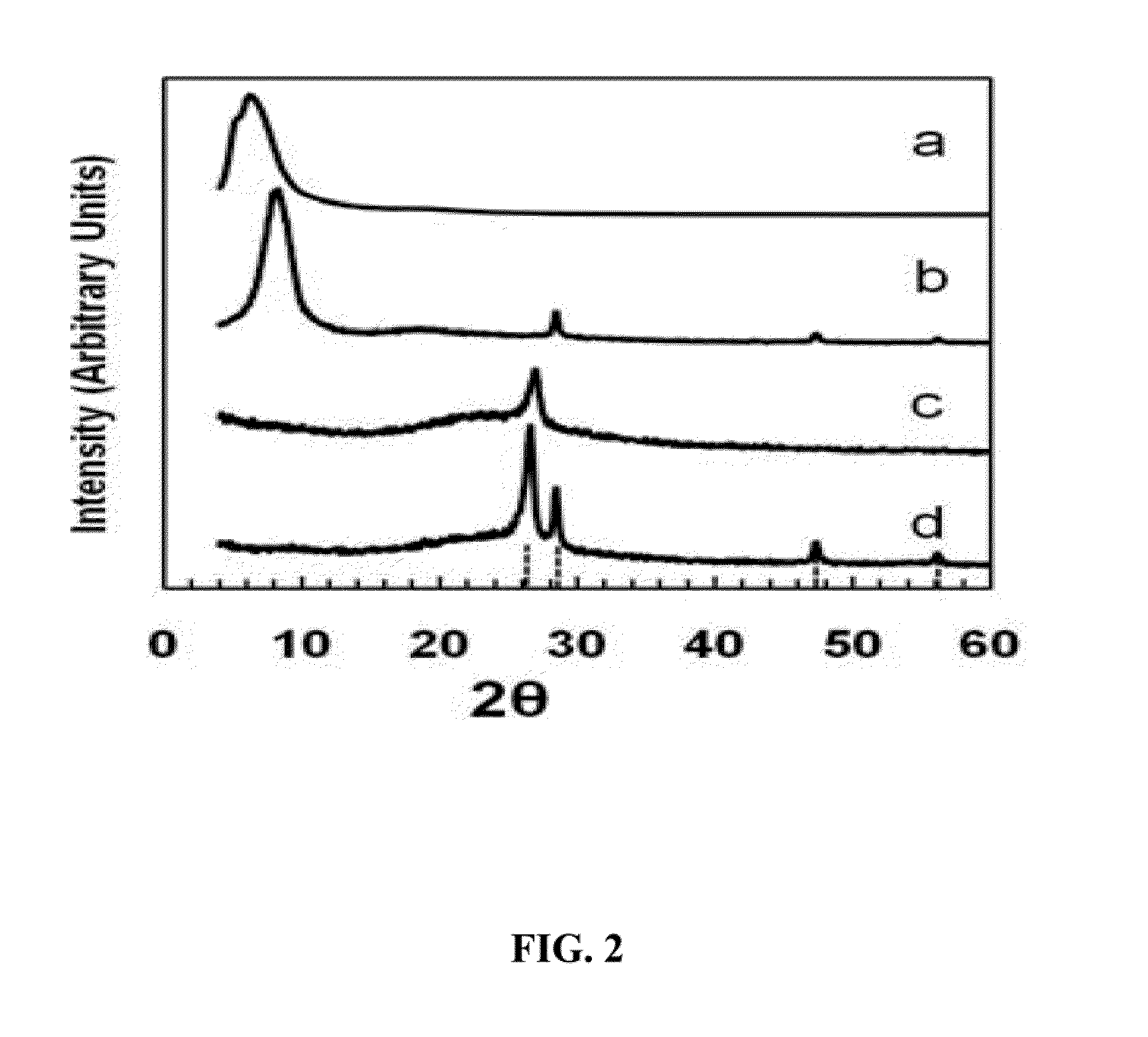

Graphene sheet and method of preparing the same

An economical method of preparing a large-sized graphene sheet having a desired thickness includes forming a film, the film comprising a graphitizing catalyst; heat-treating a gaseous carbon source in the presence of the graphitizing catalyst to form graphene; and cooling the graphene to form a graphene sheet. A graphene sheet prepared according to the disclosed method is also described.

Owner:SAMSUNG ELECTRONICS CO LTD

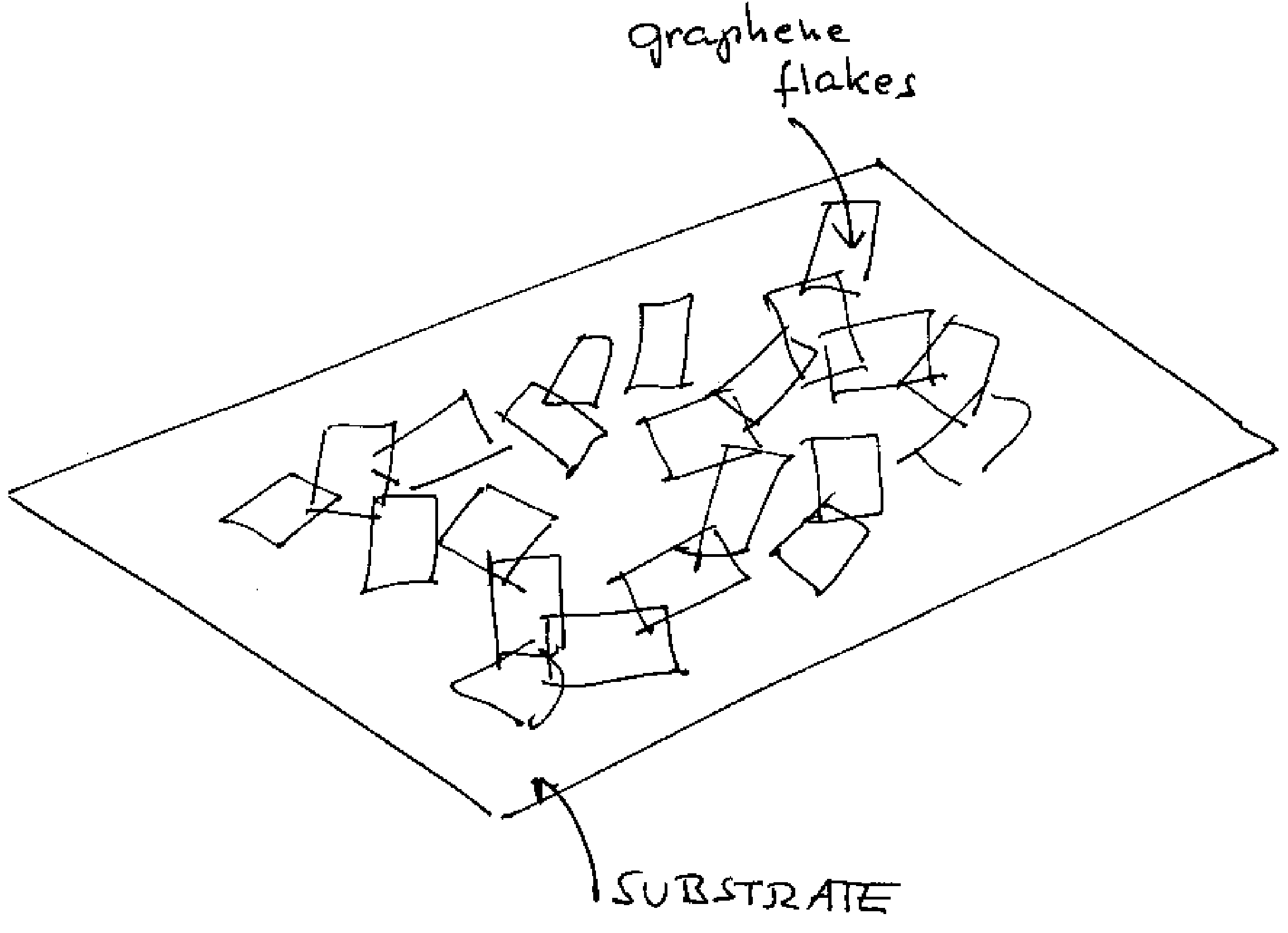

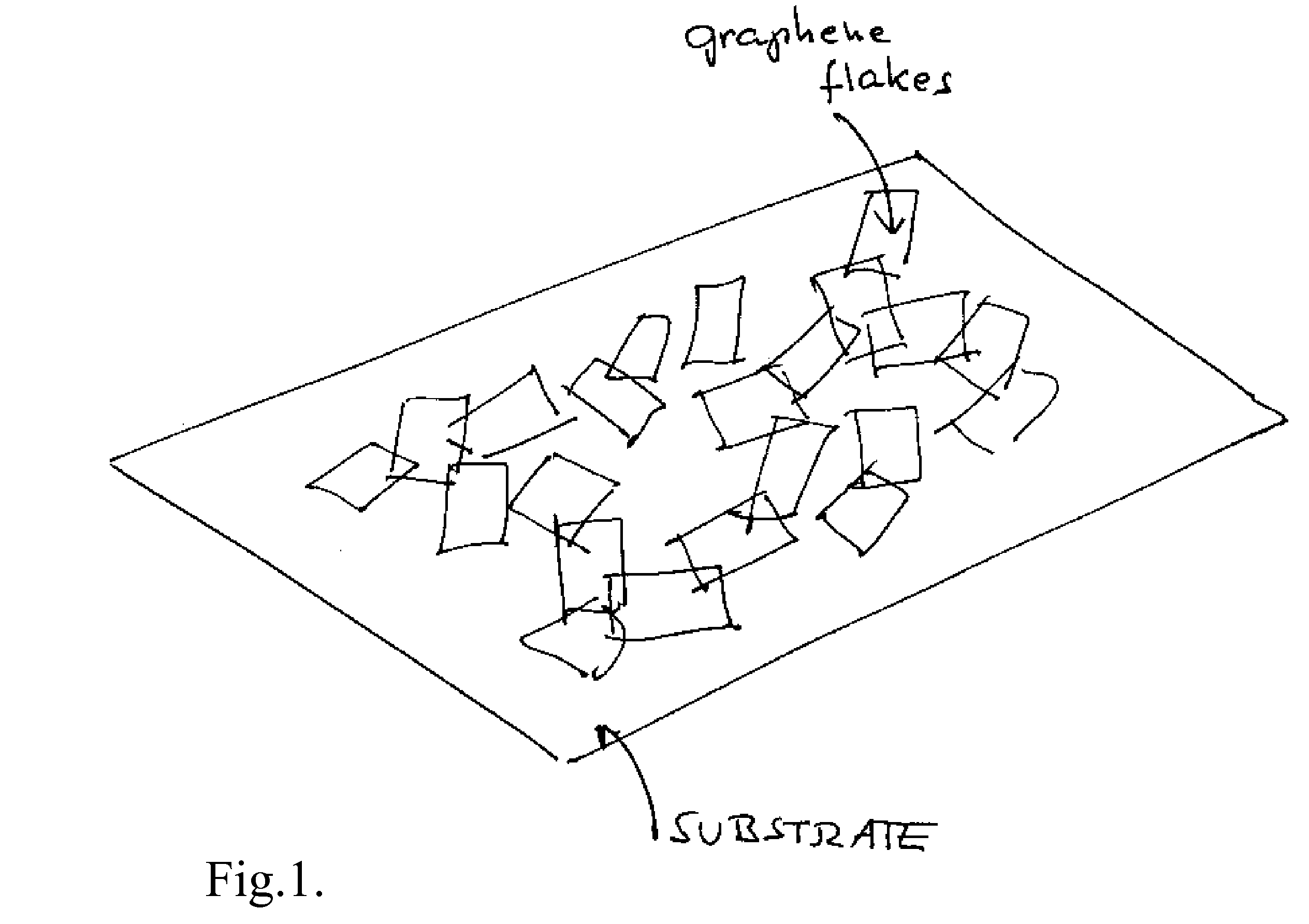

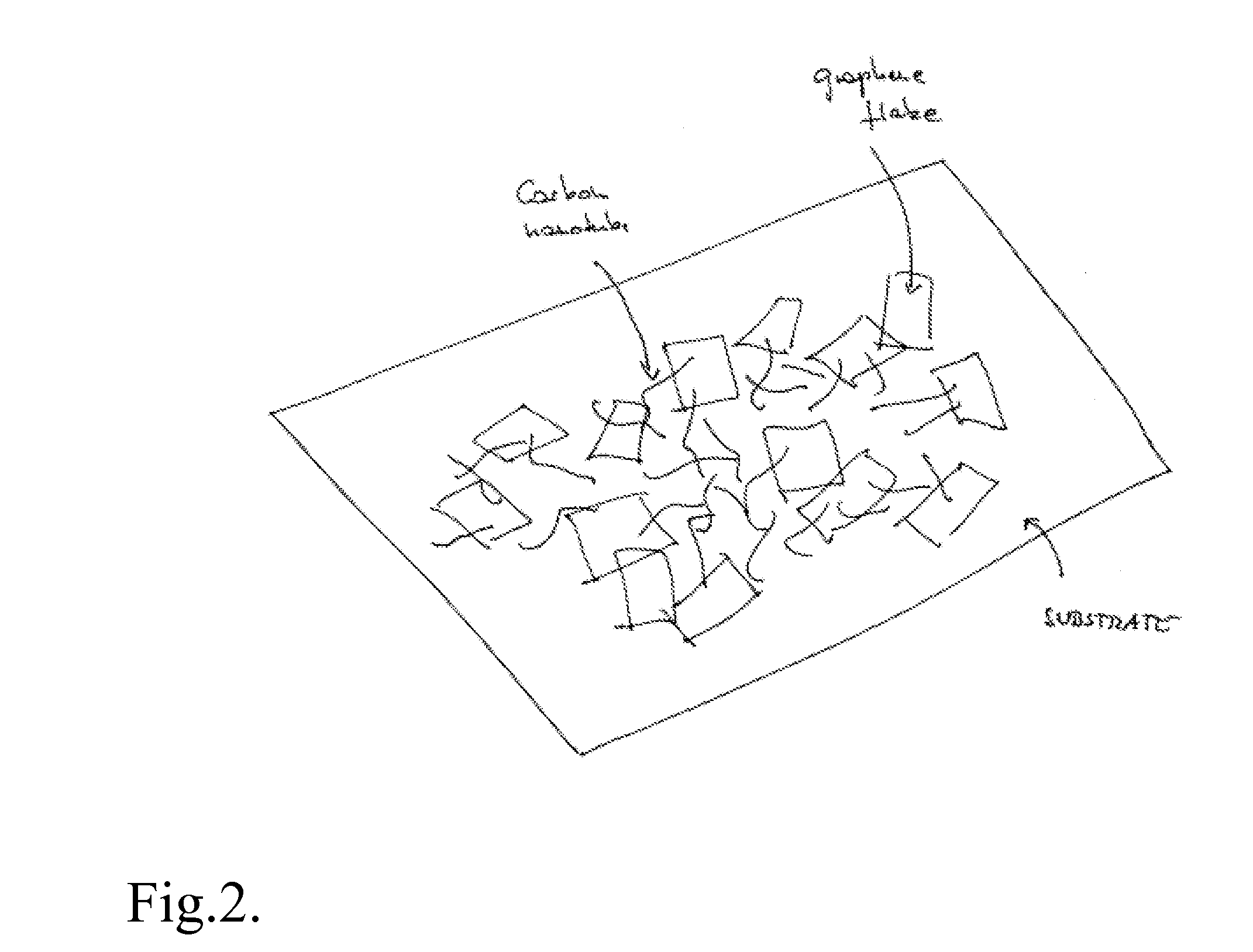

Graphene film as transparent and electrically conducting material

ActiveUS20070284557A1Material nanotechnologyConductive materialGraphene flakeTransparent conducting film

A transparent and conductive film comprising at least one network of graphene flakes is described herein. This film may further comprise an interpenetrating network of other nanostructures, a polymer and / or a functionalization agent(s). A method of fabricating the above device is also described, and may comprise depositing graphene flakes in solution and evaporating solvent therefrom.

Owner:SAMSUNG ELECTRONICS CO LTD

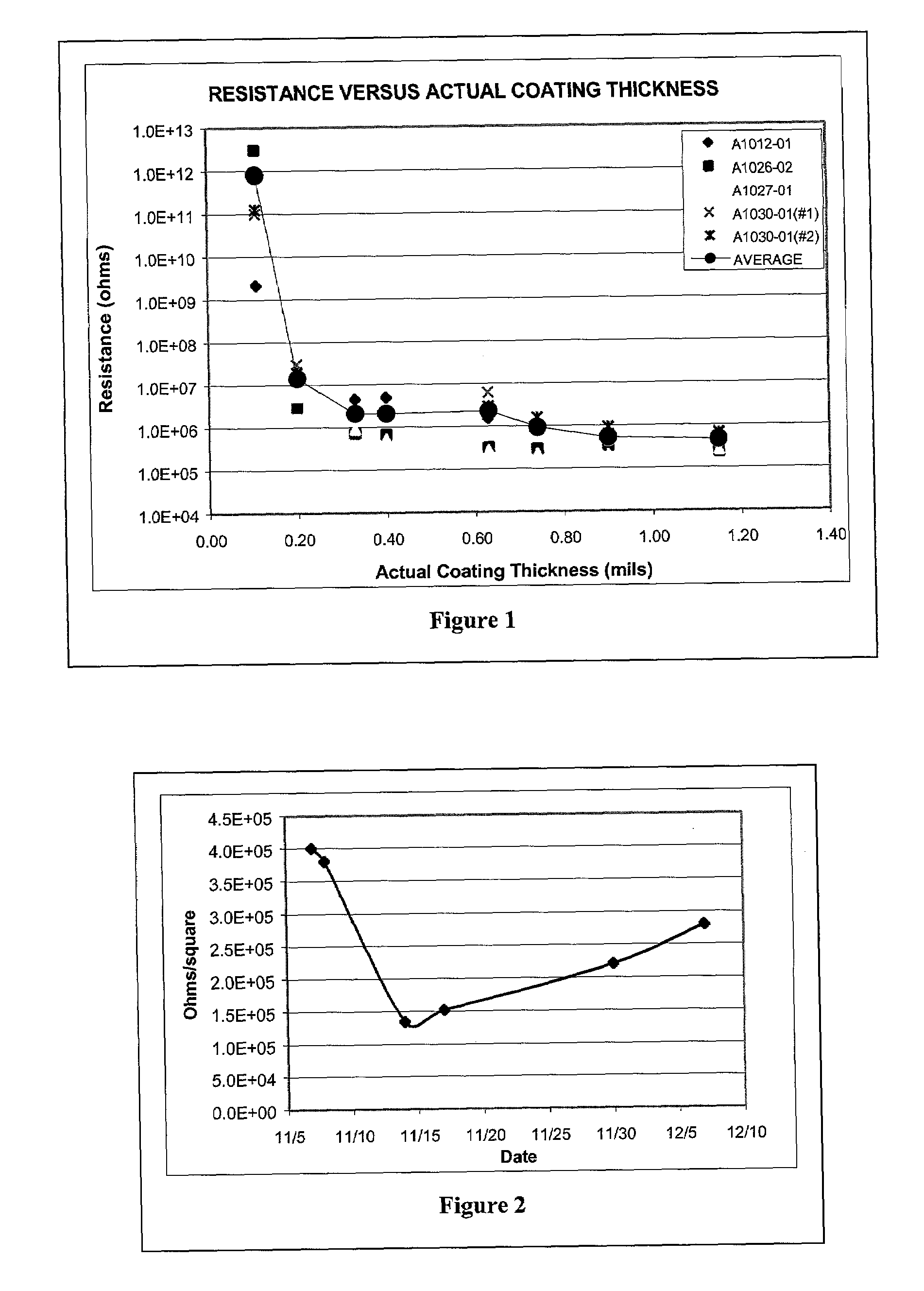

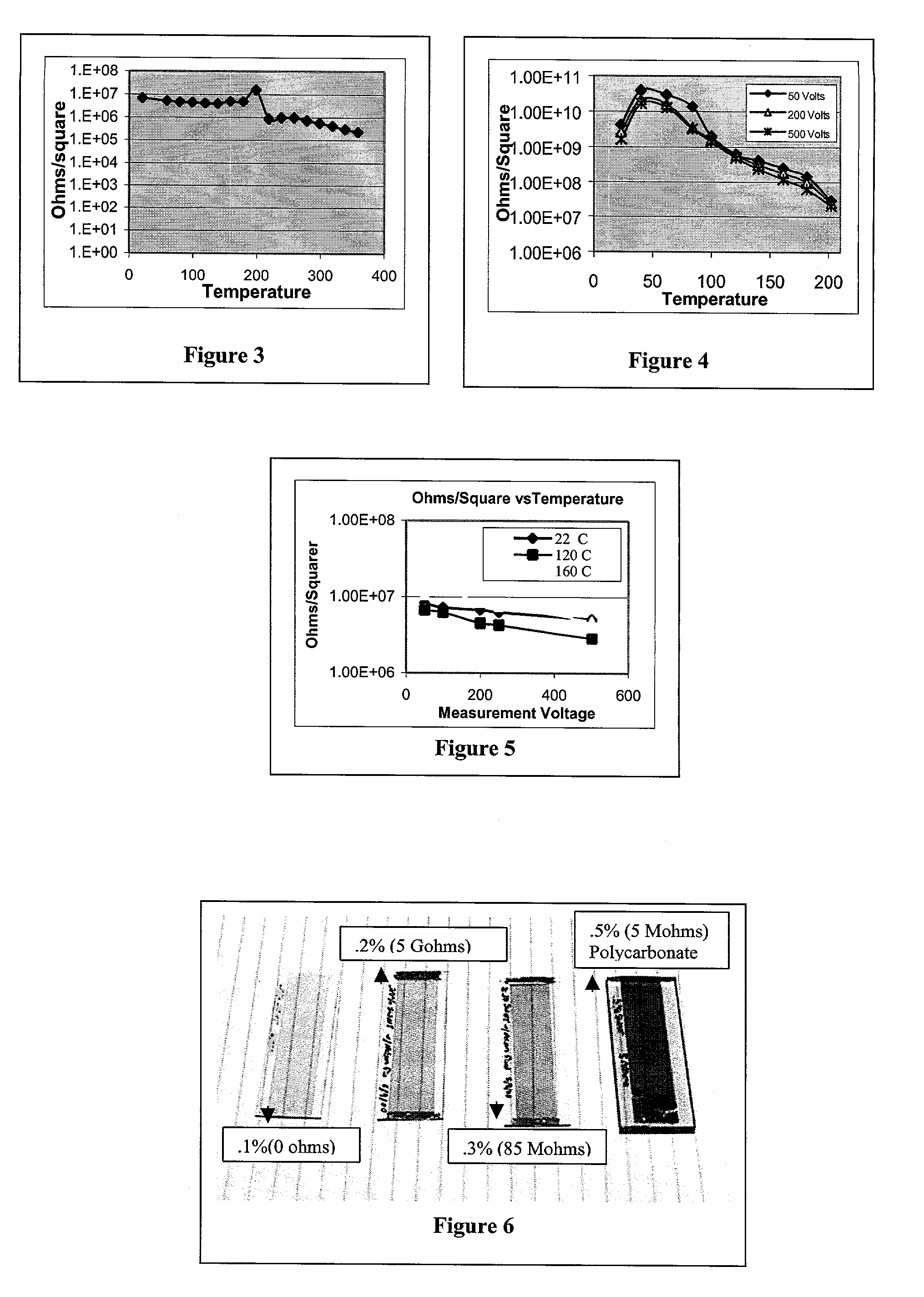

Coatings comprising carbon nanotubes and methods for forming same

InactiveUS7060241B2Reduce manufacturing costImprove efficiencyMaterial nanotechnologyConductive layers on insulating-supportsSingle-Walled NanotubeCoating

Owner:NANO C INC

Electrical conductors formed from mixtures of metal powders and metallo-organic decomposition compounds

The present invention relates to a thick film formed of a mixture of metal powders and metallo-organic decomposition (MOD) compounds in an organic liquid vehicle and a process for advantageously applying them to a substrate by silk screening or other printing technology. The mixtures preferably contain metal flake with a ratio of the maximum dimension to the minimum dimension of between 5 and 50. The vehicle may include a colloidal metal powder with a diameter of about 10 to about 40 nanometers. The concentration of the colloidal metal in the suspension can range from about 10 to about 50% by weight. The MOD compound begins to decompose at a temperature of approximately about 200 DEG C. to promote consolidation of the metal constituents and bonding to the substrate which is complete at temperatures less than 450 DEG C. in a time less than six minutes. The mixtures can be applied by silk screening, stencilling, gravure or lithography to a polymer-based circuit board substrate for producing rigid and flexible printed wiring boards in a single operation with negligible generation of hazardous wastes. The same mixtures can be used in place of solder to assemble circuits by bonding electrical components to conductors as well as to make the conductors themselves.

Owner:PARELEC

Electrically conductive polymer composition

InactiveUS6184280B1Sufficient electrical conductivityImprove polymer propertiesOther chemical processesConductive materialPolymer scienceCarbon fibers

An electrically conductive polymer composition comprises a moldable organic polymer having hollow carbon microfibers and an electrically conductive white powder uniformly dispersed therein, the carbon fibers being present in an amount of 0.01 wt. % to less than 2 wt. % and the electrically conductive white powder being present in an amount of 2.5-40 wt. %, each percent range based on the total weight of the composition, the amounts of carbon microfibers and white powder being sufficient to simultaneously impart the desired electrical conductivity to the composition and white pigmentation to the composition.

Owner:MITSUBISHI MATERIALS CORP +1

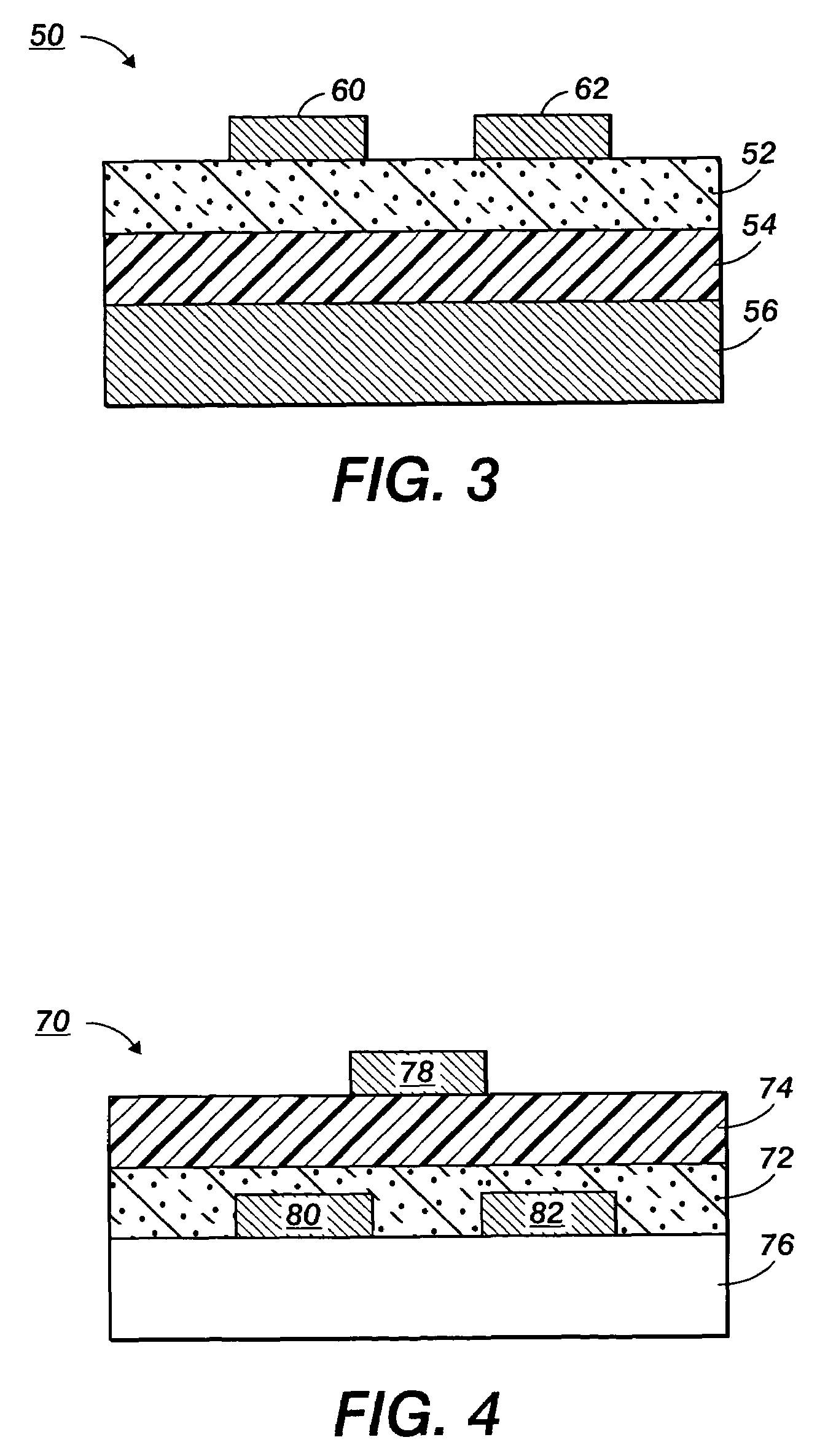

Multi-layer conductor with carbon nanotubes

The present invention is directed to an electronically conductive article comprising at least one conductive carbon nanotube layer in contact with at least one conductive layer comprising electronically conductive polymer.

Owner:EASTMAN KODAK CO

PVC nanocomposite manufacturing technology and applications

InactiveUS20080194736A1Material nanotechnologyPigmenting treatmentPolymer scienceManufacturing technology

The present invention relates to a process and a product of forming polymer (especially PVC) nanocomposites with a variety of nanofillers. The present invention provides a method for forming a polymer nanocomposite, comprising powder mixing a composition comprising polymer resin, a nanofiller, and a coupling agent for a residence time of about 4 to about 8 minutes to form a dry blend and extruding the dry blend in an extrusion process. Additionally, the present invention relates to a polymer nanocomposite formed by a process, comprising powder mixing a polymer resin, a nanofiller, and a coupling agent for a residence time of about 4 to about 8 minutes to form a dry blend and extruding the dry blend in an extrusion process to achieve homogeneous dispersion of nanofillers in the polymer matrix.

Owner:FORMOSA PLASTICCS CORP

Metal nanoparticle compositions

InactiveUS20060189113A1Low processing (curing)Improve mechanical propertiesMaterial nanotechnologyTransportation and packagingNanometreViscosity

Owner:CABOT CORP

Highly catalytic screen-printing ink

ActiveUS7018568B2Easy to produceConductive layers on insulating-supportsConductive materialConductive polymerPrinting ink

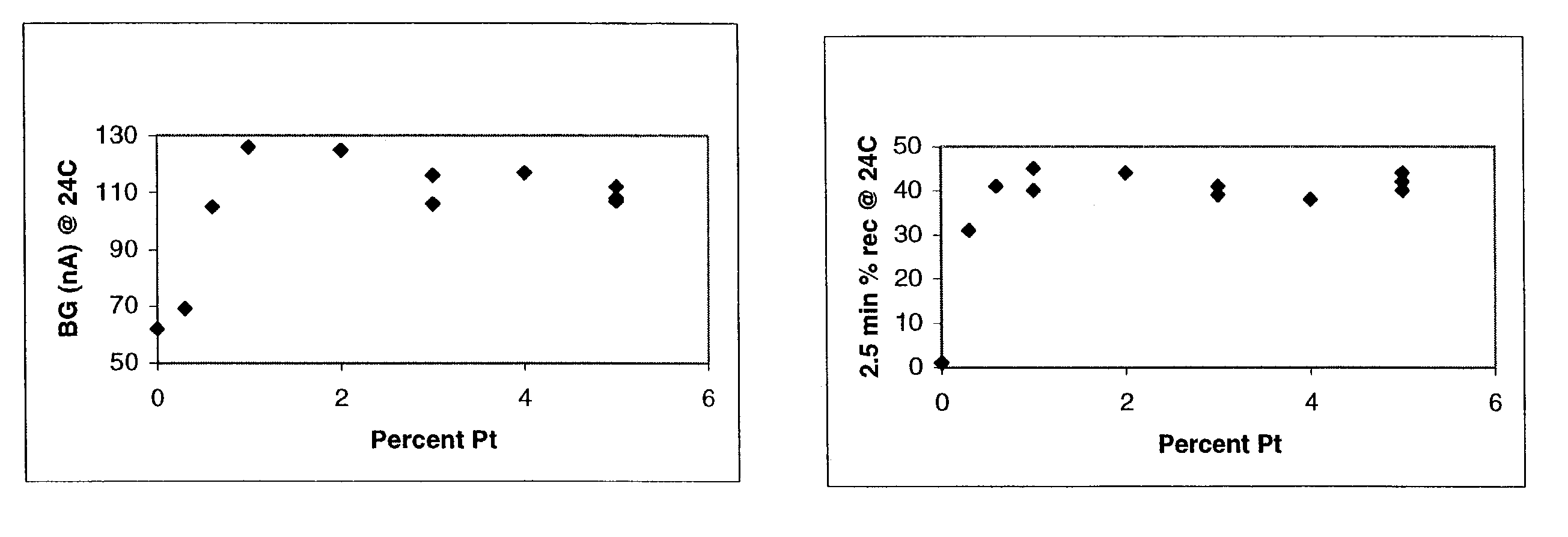

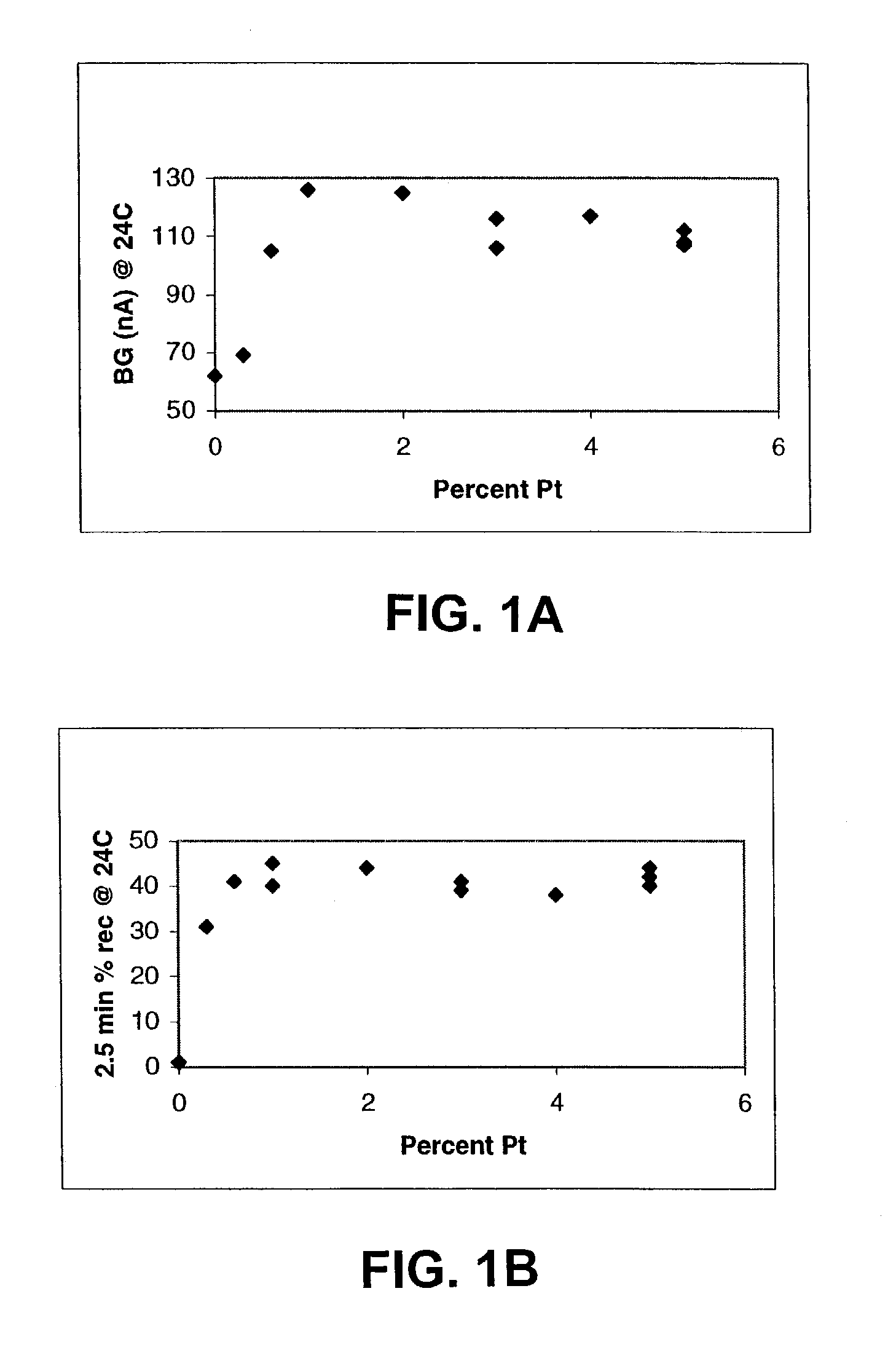

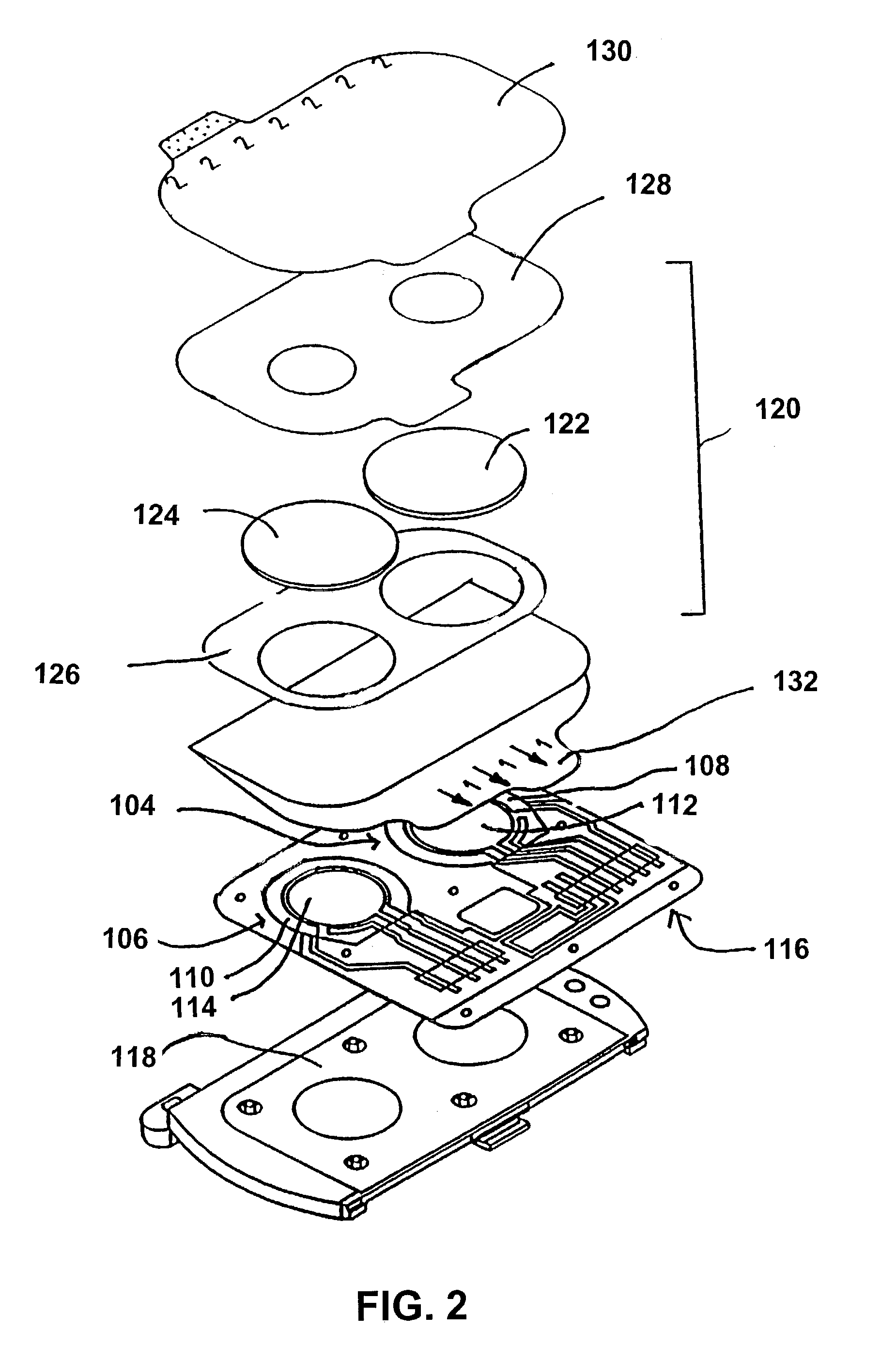

The invention is directed to conductive polymer compositions, catalytic ink compositions (e.g., for use in screen-printing), electrodes produced by deposition of an ink composition, methods of making, and methods of using thereof. An exemplary ink material comprises platinum black and / or platinum-on-carbon as the catalyst, graphite as a conducting material, a polymer binding material, and an organic solvent. The polymer binding material is typically a copolymer of hydrophilic and hydrophobic monomers. The conductive polymer compositions of the present invention can be used, for example, to make electrochemical sensors. Such sensors can be used in a variety of analyte monitoring devices to monitor analyte amount or concentrations in subjects, for example, glucose monitoring devices to monitor glucose levels in subjects with diabetes.

Owner:LIFESCAN IP HLDG LLC +1

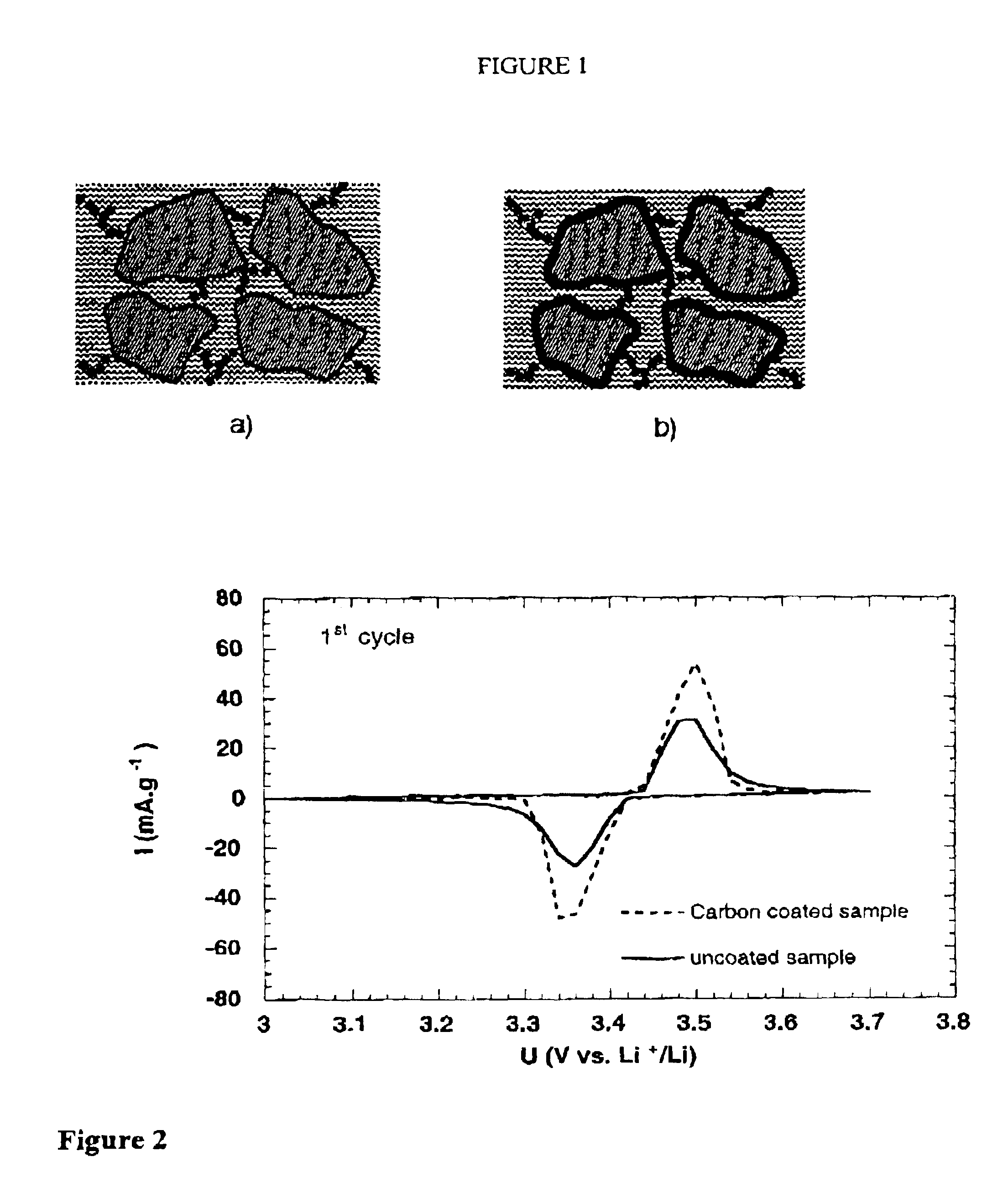

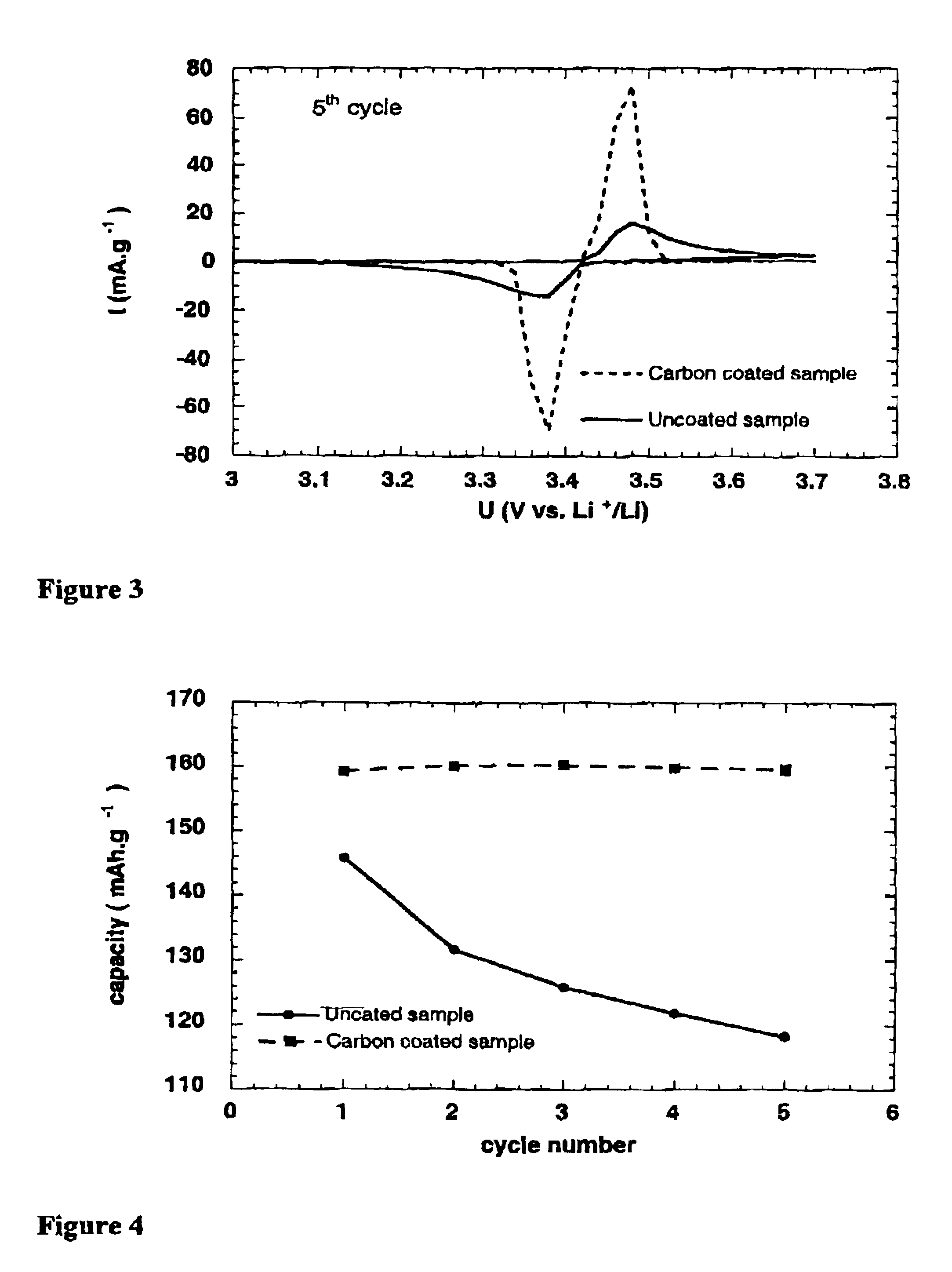

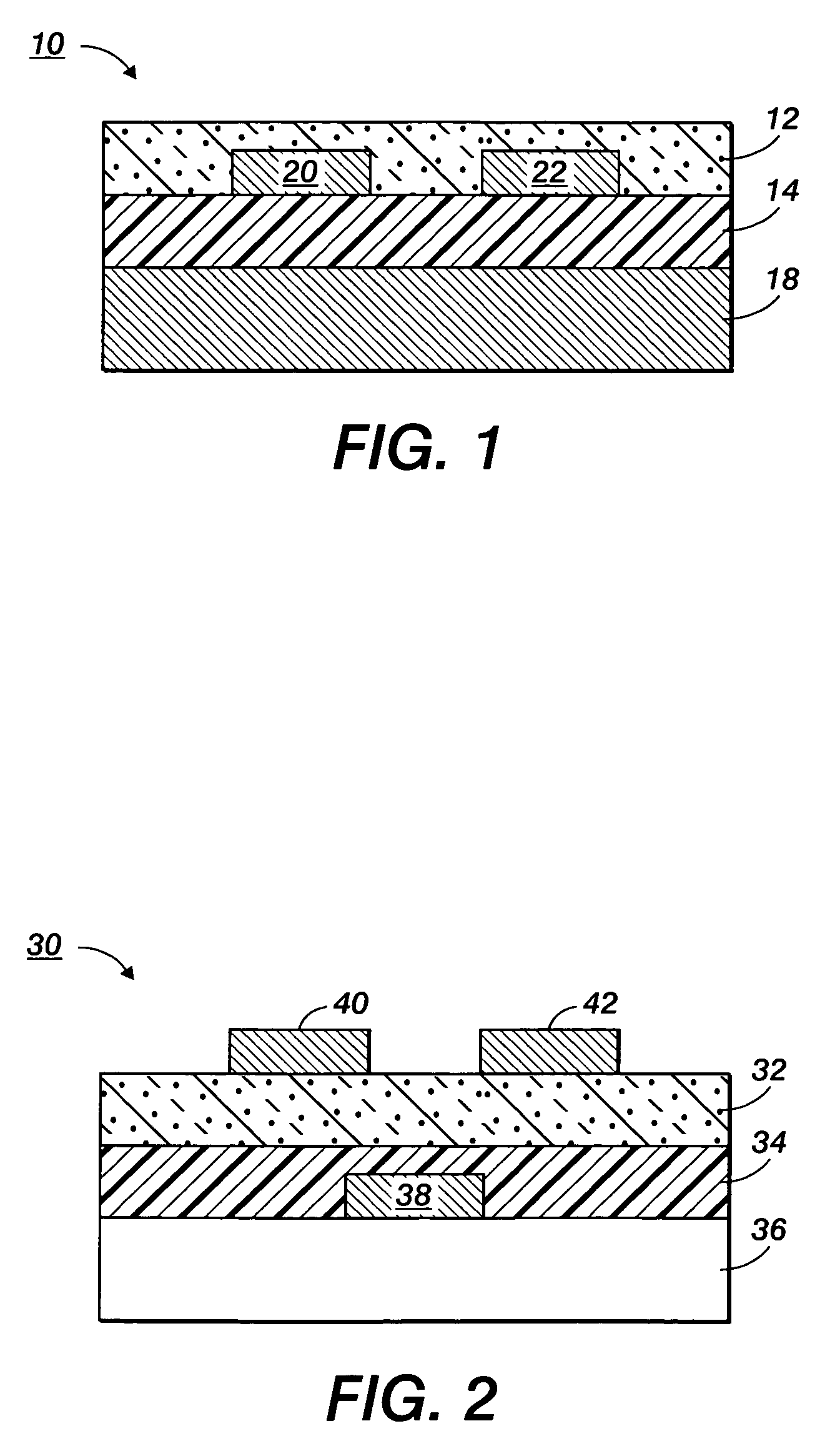

Electrode materials with high surface conductivity

InactiveUS6855273B2Electrode manufacturing processesDouble layer capacitorsSurface conductivityIon exchange

The present invention concerns electrode materials capable of redox reactions by electrons and alkaline ions exchange with an electrolyte. The applications are in the field of primary (batteries) or secondary electrochemical generators, super capacitors and light modulating system of the super capacitor type.

Owner:CENT NAT DE LA RECHERCHE SCI +2

Stabilized silver nanoparticles and their use

A process comprising: reacting a silver compound with a reducing agent comprising a hydrazine compound in the presence of a thermally removable stabilizer in a reaction mixture comprising the silver compound, the reducing agent, the stabilizer, and an optional solvent, to form a plurality of silver-containing nanoparticles with molecules of the stabilizer on the surface of the silver-containing nanoparticles.

Owner:XEROX CORP

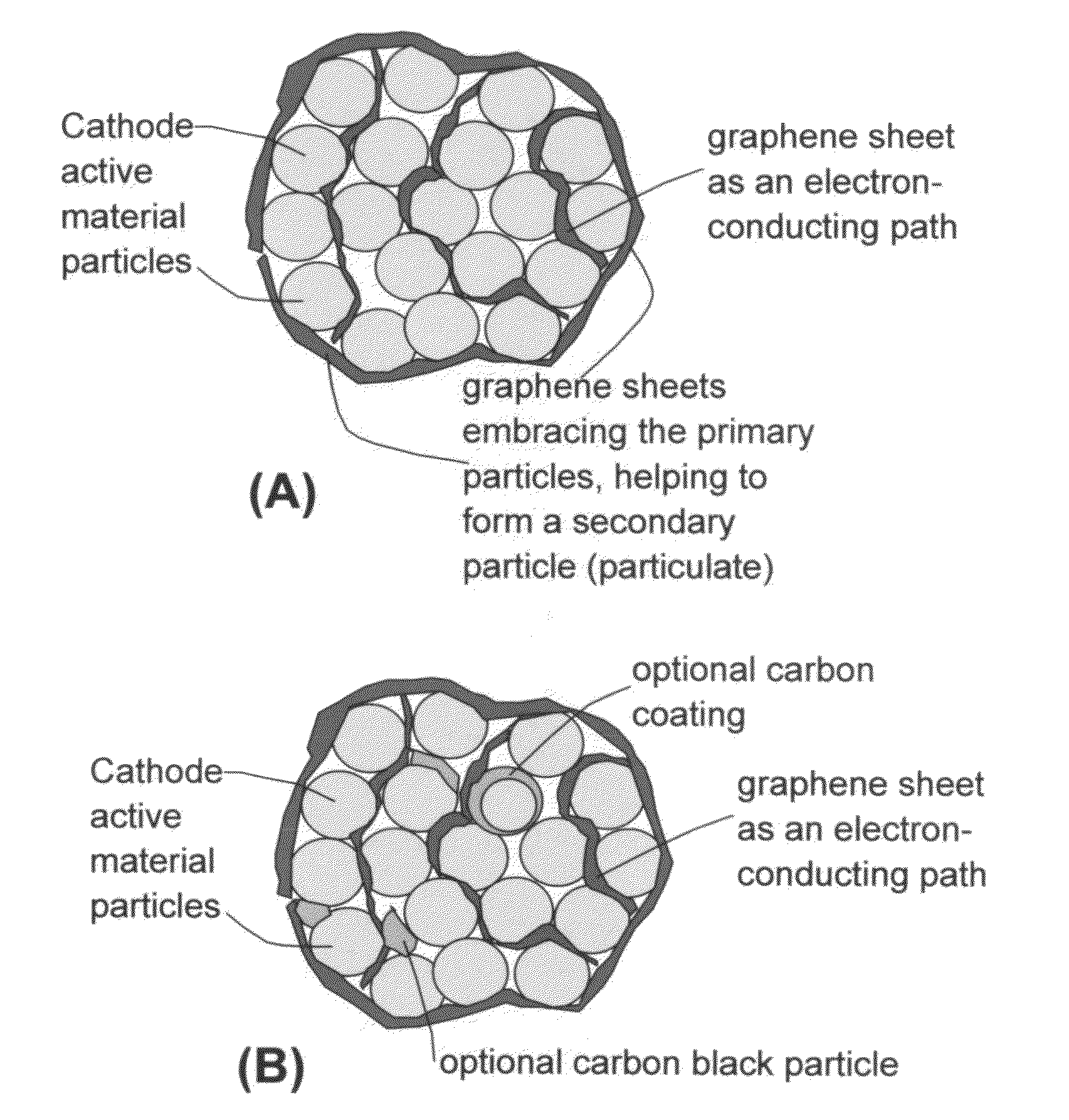

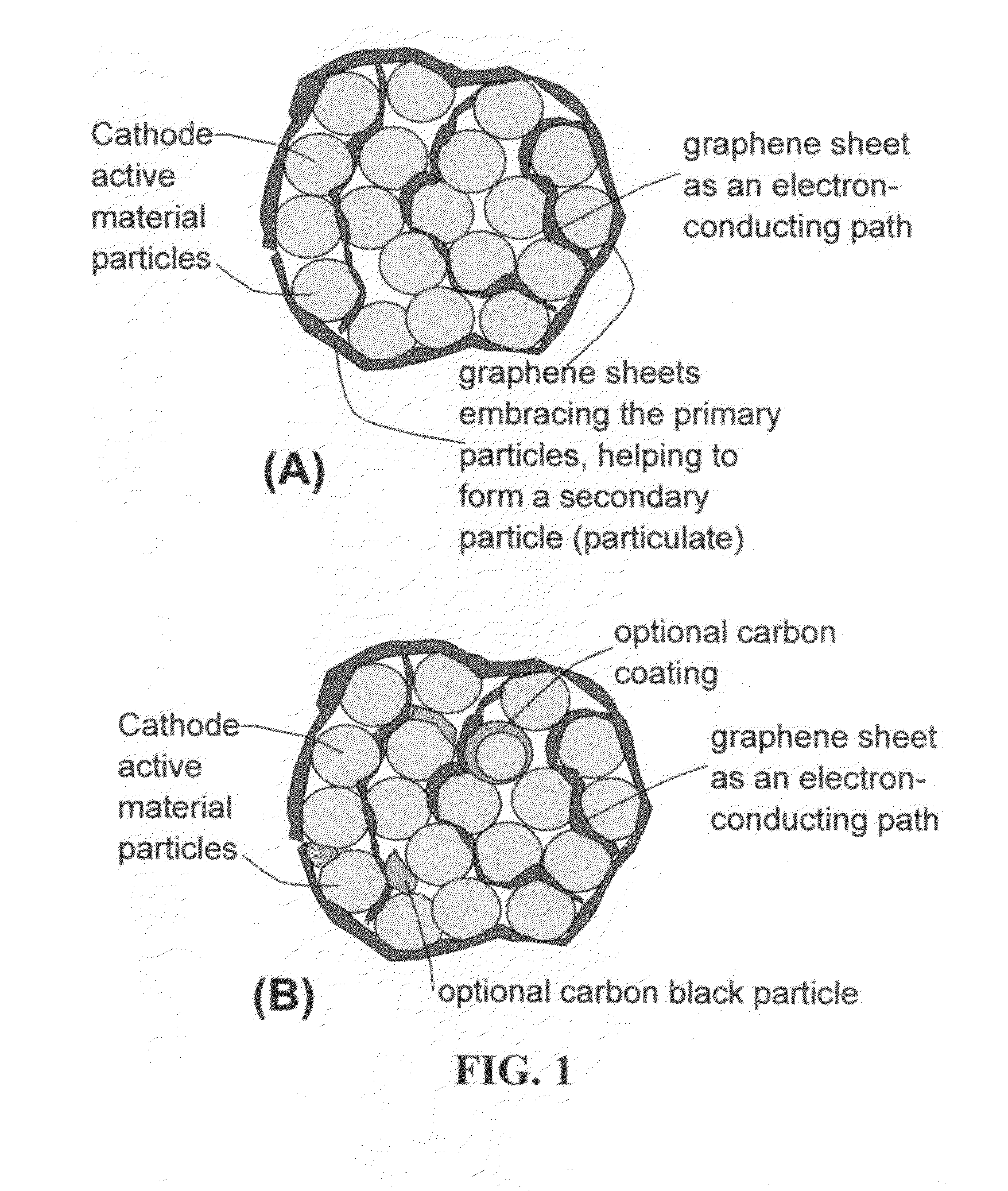

Graphene-Enhanced cathode materials for lithium batteries

ActiveUS20120058397A1Short timeEasy dischargeNon-metal conductorsMaterial nanotechnologyParticulatesCvd graphene

A nano graphene-enhanced particulate for use as a lithium battery cathode active material, wherein the particulate is formed of a single or a plurality of graphene sheets and a plurality of fine cathode active material particles with a size smaller than 10 μm (preferably sub-micron or nano-scaled), and the graphene sheets and the particles are mutually bonded or agglomerated into an individual discrete particulate with at least a graphene sheet embracing the cathode active material particles, and wherein the particulate has an electrical conductivity no less than 10−4 S / cm and the graphene is in an amount of from 0.01% to 30% by weight based on the total weight of graphene and the cathode active material combined.

Owner:GLOBAL GRAPHENE GRP INC

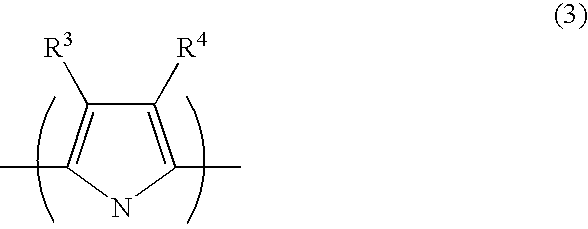

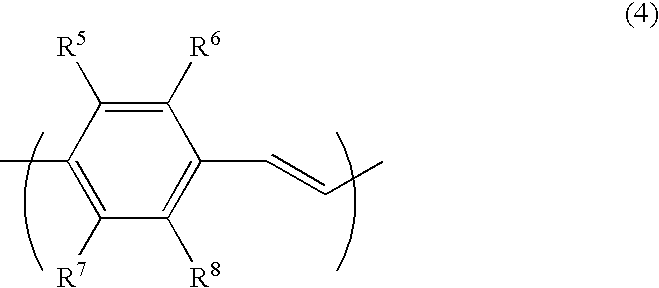

Composition containing carbon nanotubes having coating thereof and process for producing them

ActiveUS20060052509A1Not impair characteristicImprove conductivityMaterial nanotechnologySynthetic resin layered productsColloidal silicaConductive polymer

The object of the present invention is to provide a carbon nanotube composition that does not impair the characteristics of the carbon nanotubes itself, allows the carbon nanotubes to be dispersed or solubilized in a solvent, does not cause separation or aggregation of the carbon nanotubes even during long-term storage, has superior electrical conductivity, film formability and moldability, can be easily coated or covered onto a base material, and the resulting coated film has superior moisture resistance, weather resistance and hardness; a composite having a coated film composed thereof; and, their production methods. In order to achieve this object, the present invention provides a carbon nanotube composition that contains a conducting polymer (a) or heterocyclic compound trimer (i), a solvent (b) and carbon nanotubes (c), and may additionally contain a high molecular weight compound (d), a basic compound (e), a surfactant (f), a silane coupling agent (g) and colloidal silica (h) as necessary; a composite having a coated film composed of the composition; and, their production methods.

Owner:MITSUBISHI CHEM CORP

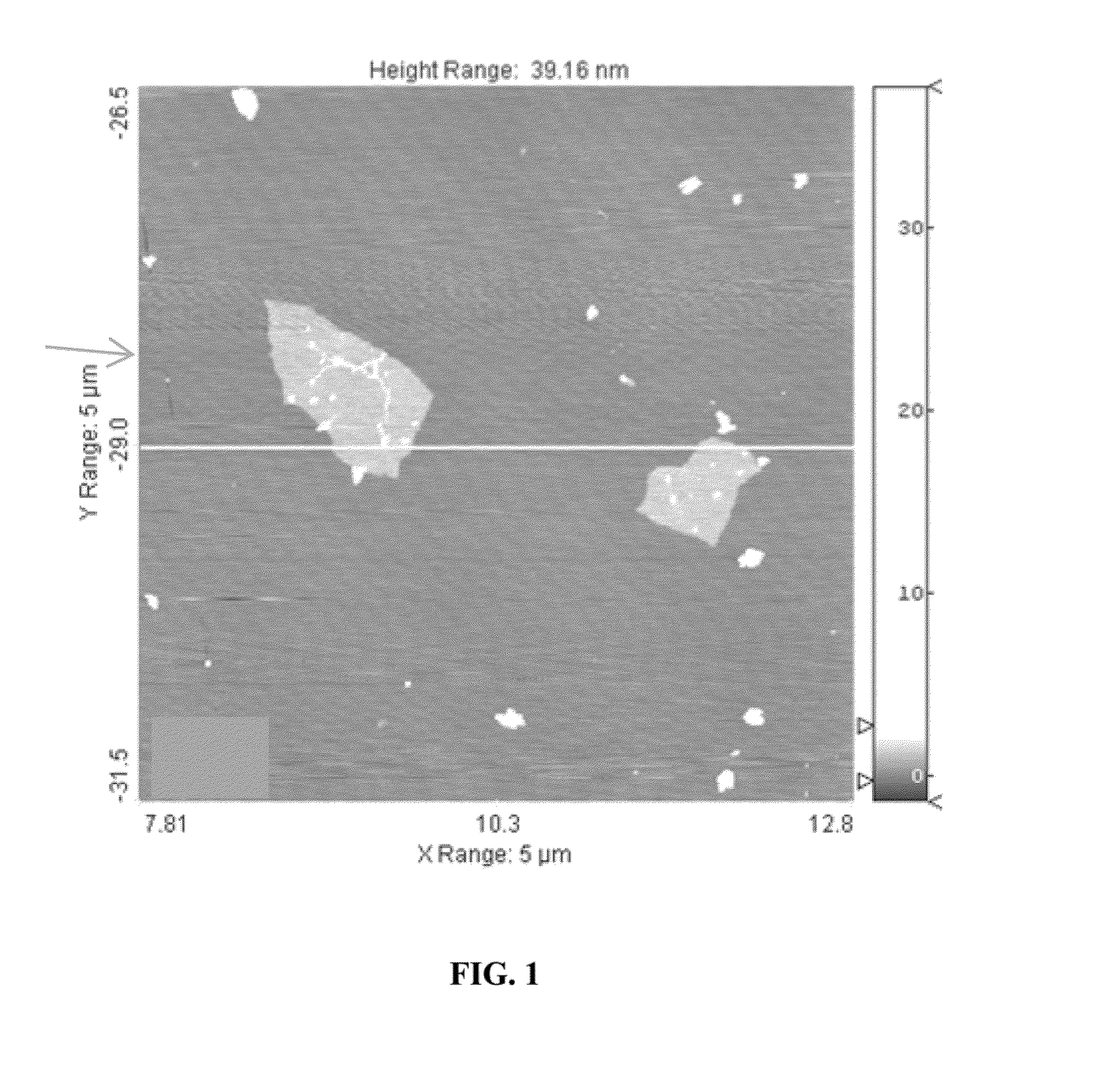

Electrode material comprising graphene composite materials in a graphite network formed from reconstituted graphene sheets

ActiveUS20110111303A1Weight increaseIncrease storage capacityConductive materialNon-conductive material with dispersed conductive materialGraphiteCvd graphene

A durable electrode material suitable for use in Li ion batteries is provided. The material is comprised of a continuous network of graphite regions integrated with, and in good electrical contact with a composite comprising graphene sheets and an electrically active material, such as silicon, wherein the electrically active material is dispersed between, and supported by, the graphene sheets.

Owner:NORTHWESTERN UNIV

Preparation method of polymer/graphene composite material through in situ reduction

ActiveCN101864098AEvenly dispersedQuality improvementSpecial tyresNon-conductive material with dispersed conductive materialElectrical conductorVulcanization

The invention relates to a preparation method of a polymer / graphene composite material through in situ reduction, which is characterized by comprising the following steps: adopting ultrasonic wave or grinding to evenly disperse the graphite oxide prepared by a Hummers method into polymer dispersion; introducing reducing agent into the polymer dispersion for in situ reduction, enabling the graphite oxide to be reduced into the grapheme so as to obtain stable polymer / graphene composite emulsion; carrying out demulsification, agglomeration and drying to obtain the composite polymer / grapheme composite master batch; adding the dried polymer / grapheme composite master batch and various assistants into the polymeric matrix according to a certain ratio; and carrying out double-roller mixing, vulcanization, melt extrusion or injection molding to obtain the polymer / graphene composite material with excellent physical and mechanical properties.

Owner:成都创威新材料有限公司

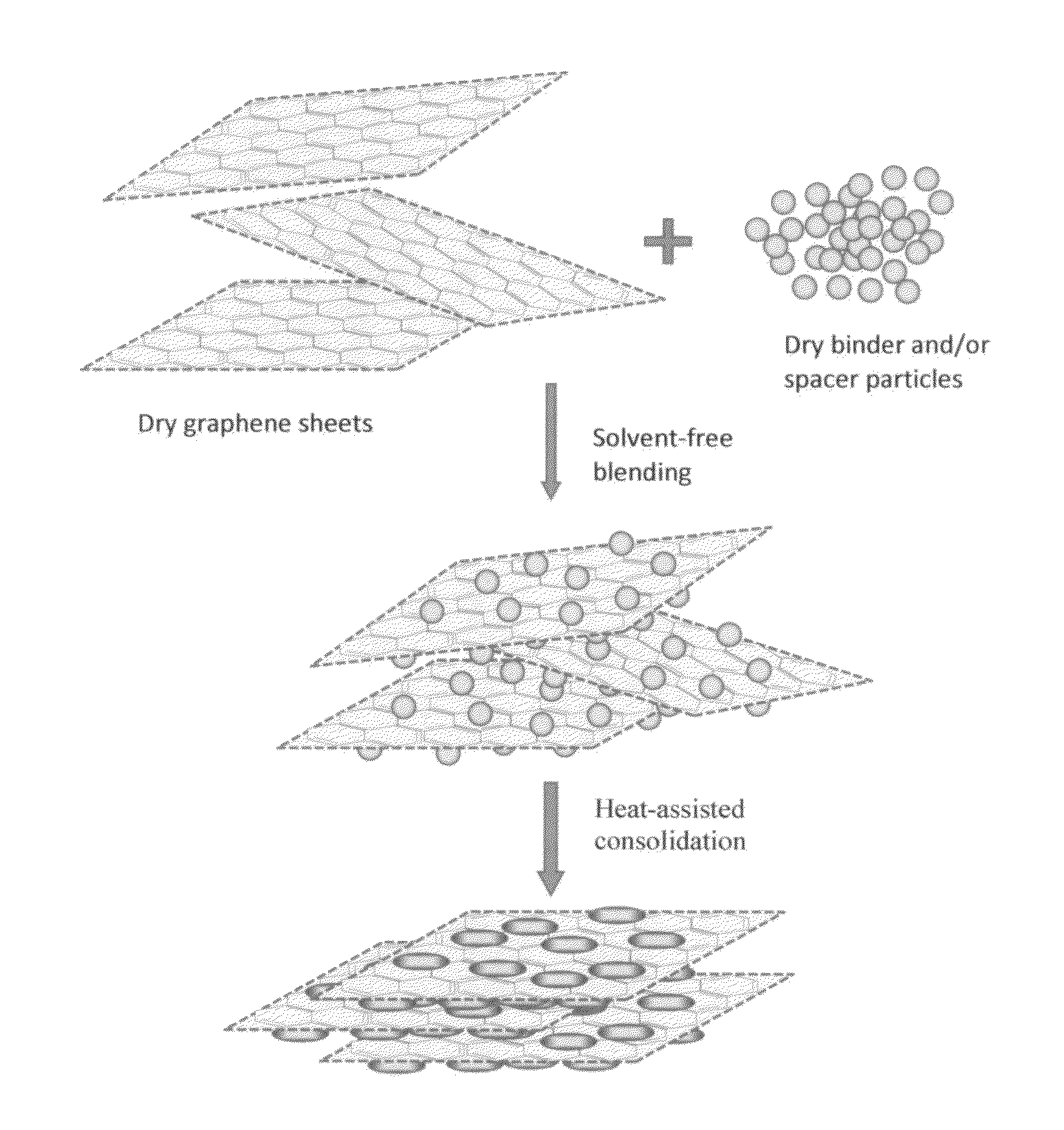

Solvent-free process based graphene electrode for energy storage devices

PendingUS20140030590A1Inexpensive and durable and highly reliableHigh capacitanceMaterial nanotechnologyHybrid capacitor electrodesGraphene flakeSolvent free

Disclosed is an electrode for an electrochemical energy storage device, the electrode comprising a self-supporting layer of a mixture of graphene sheets and spacer particles and / or binder particles, wherein the electrode is prepared without using water, solvent, or liquid chemical. The graphene electrode prepared by the solvent-free process exhibits many desirable features and advantages as compared to the corresponding electrode prepared by a known wet process. These advantages include a higher electrode specific surface area, higher energy storage capacity, improved or higher packing density or tap density, lower amount of binder required, lower internal electrode resistance, more consistent and uniform dispersion of graphene sheets and binder, reduction or elimination of undesirable effect of electrolyte oxidation or decomposition due to the presence of water, solvent, or chemical, etc.

Owner:GLOBAL GRAPHENE GRP INC

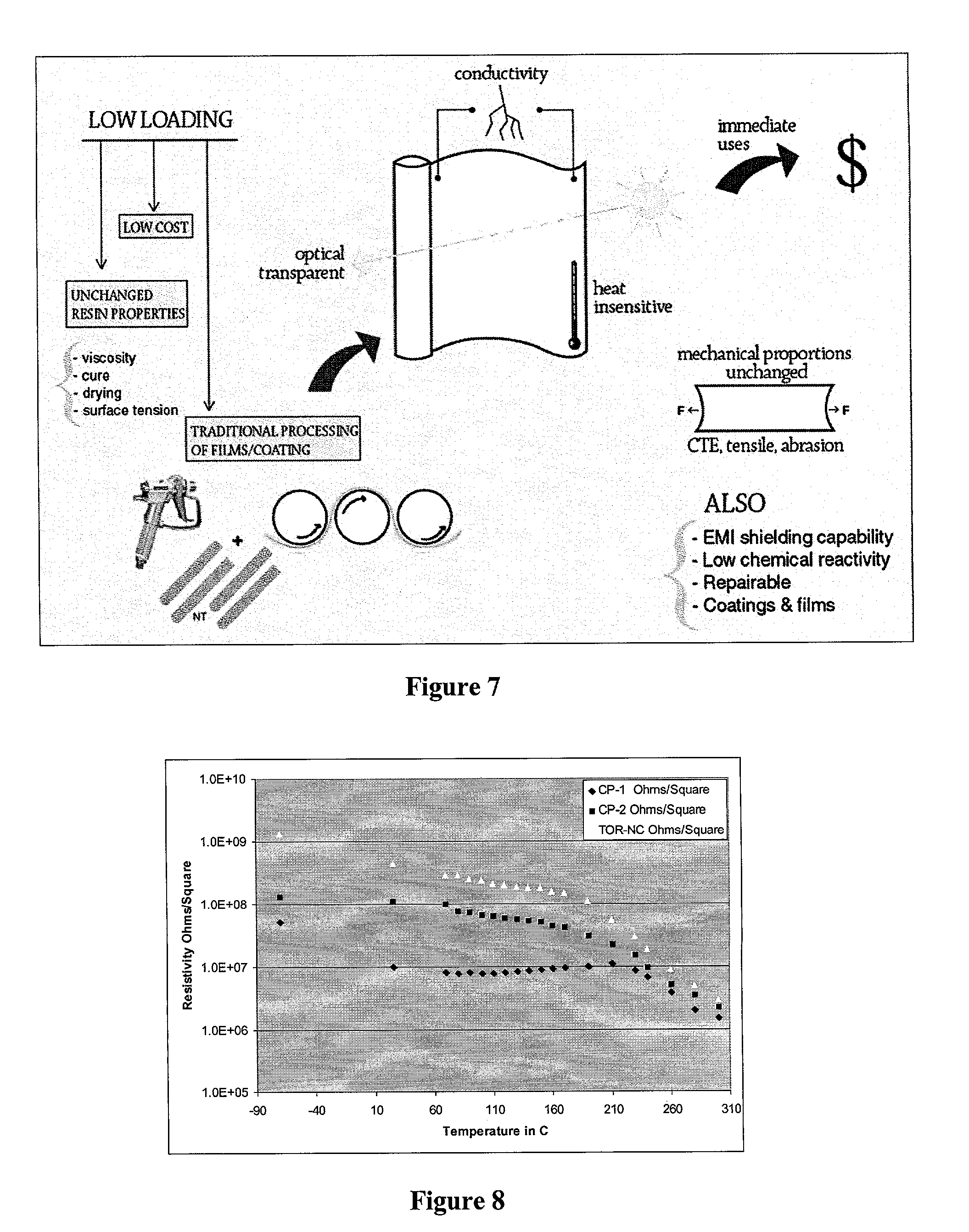

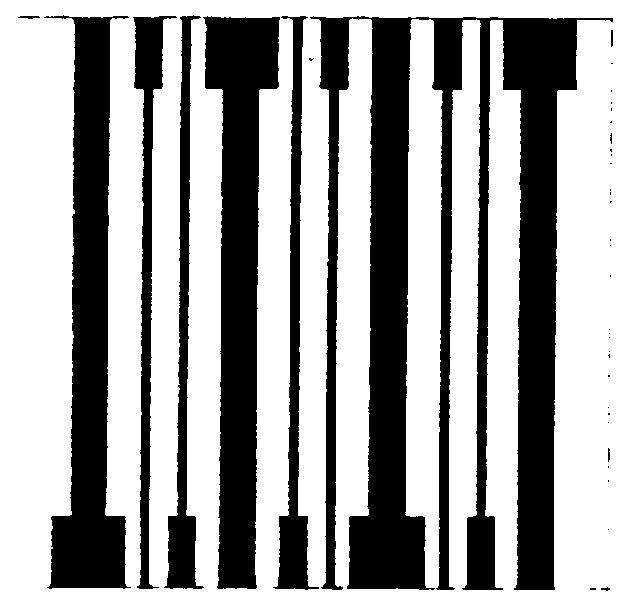

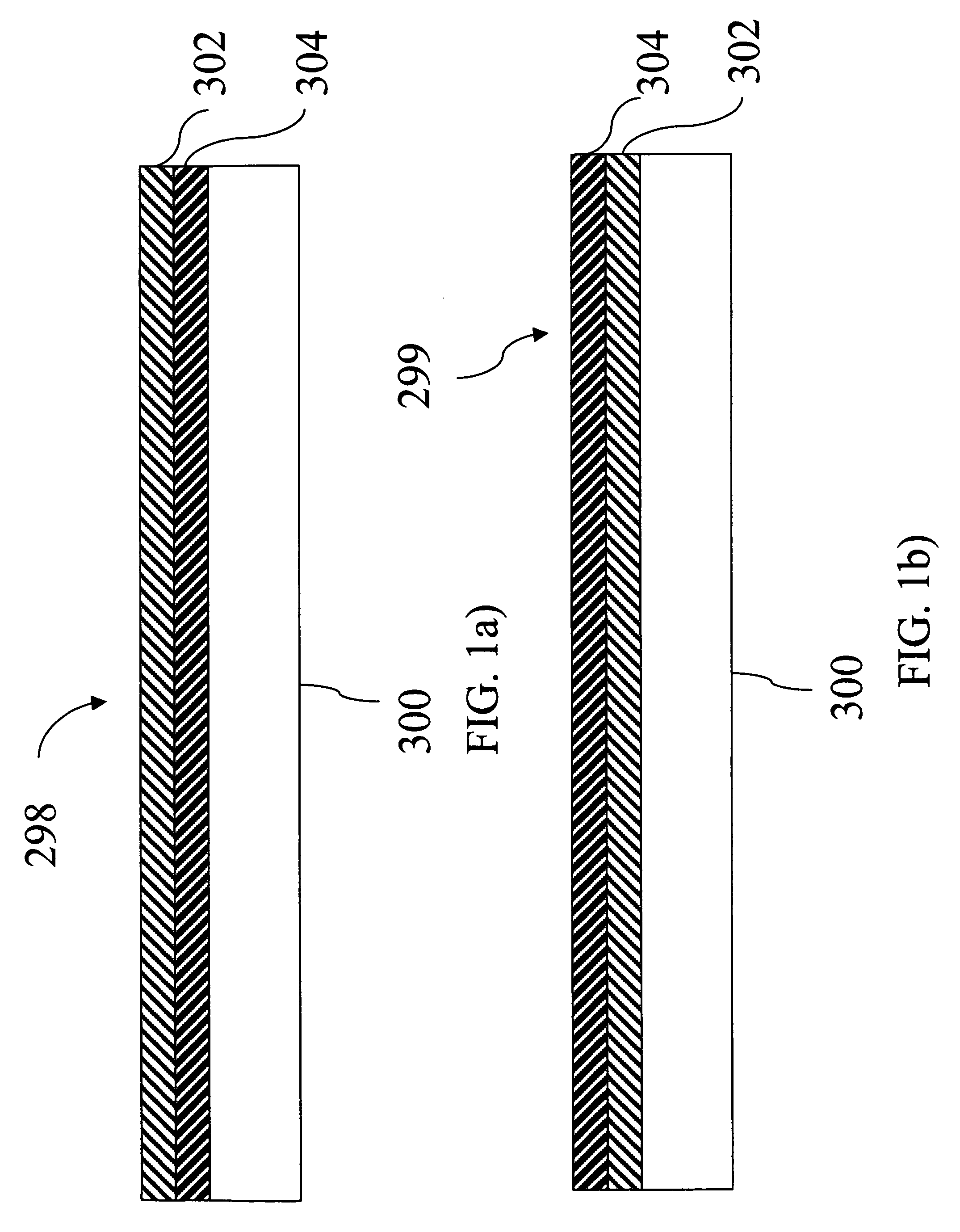

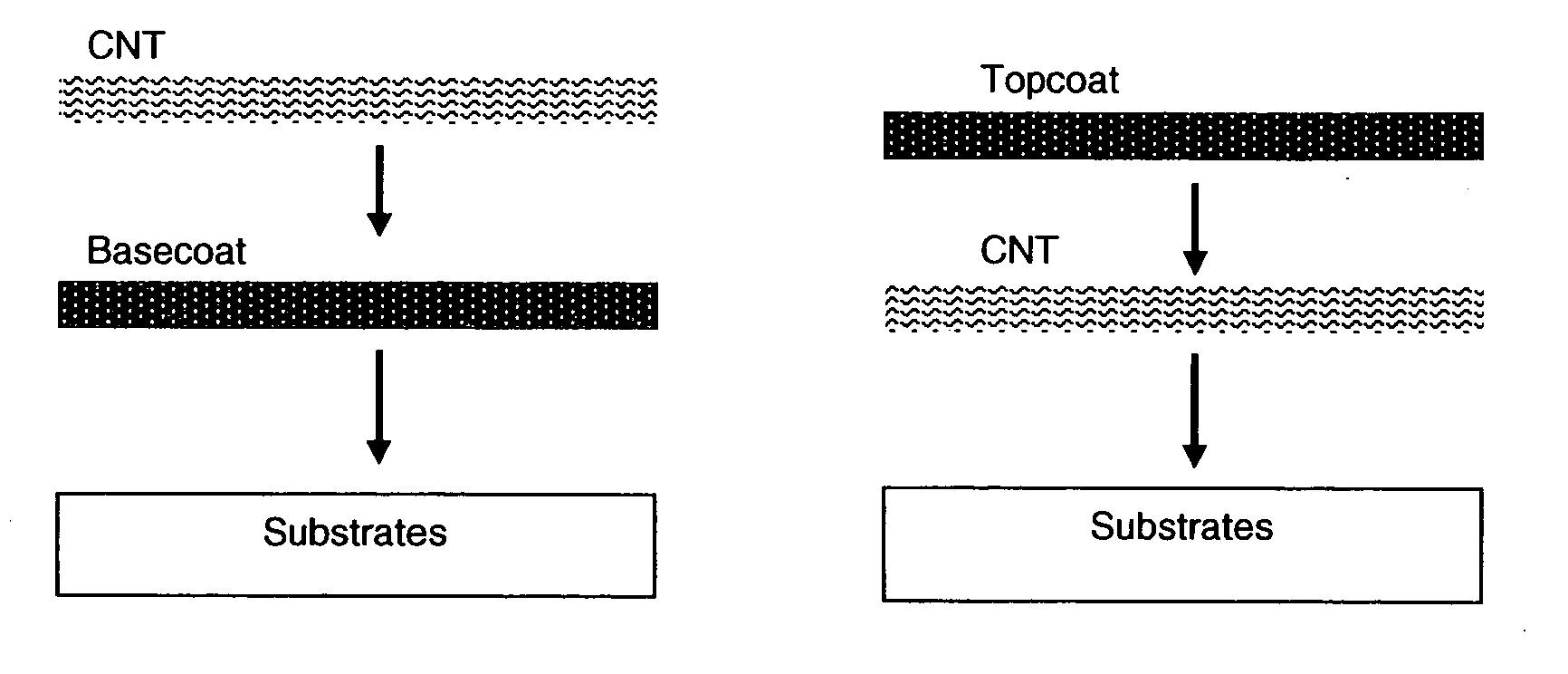

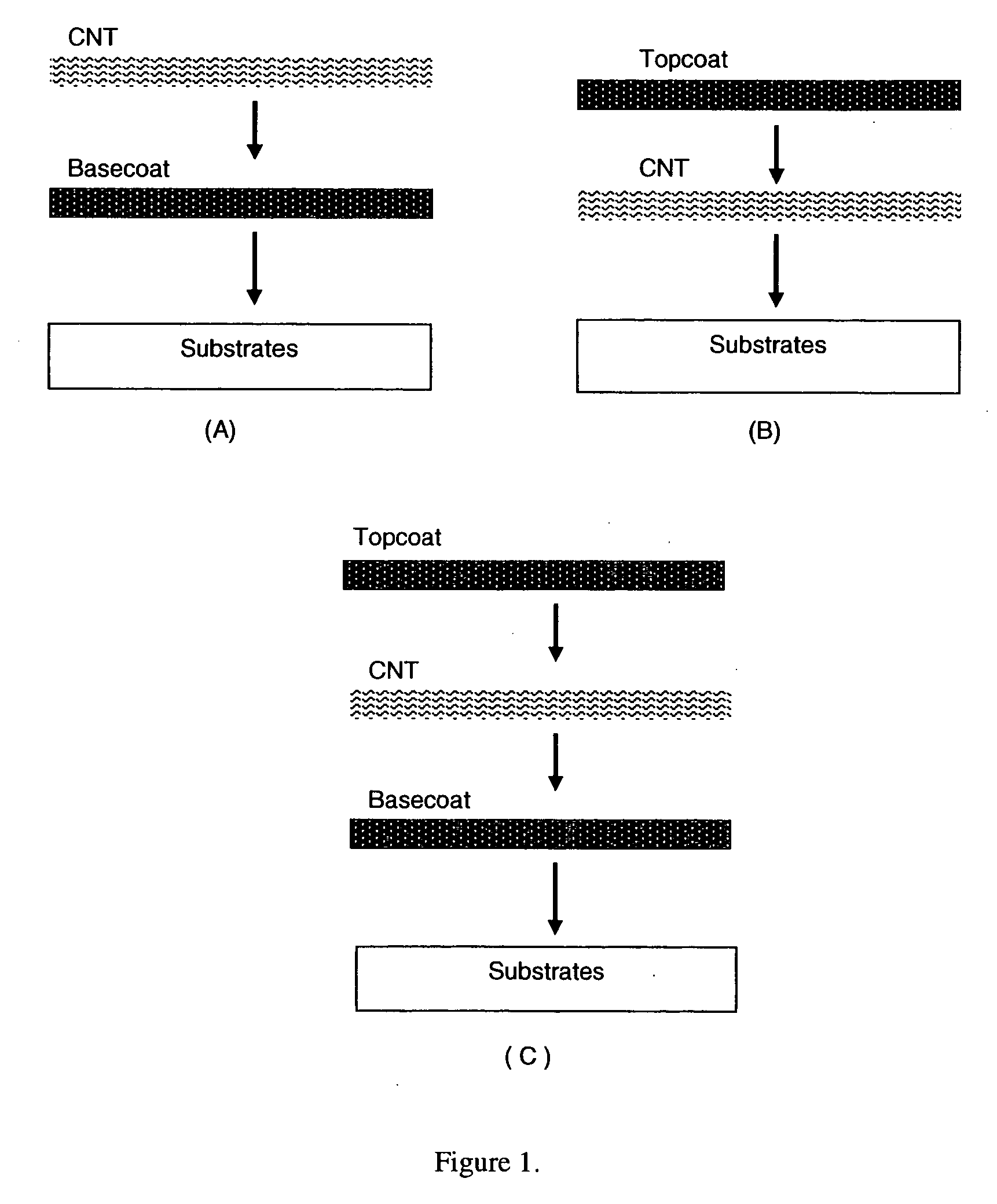

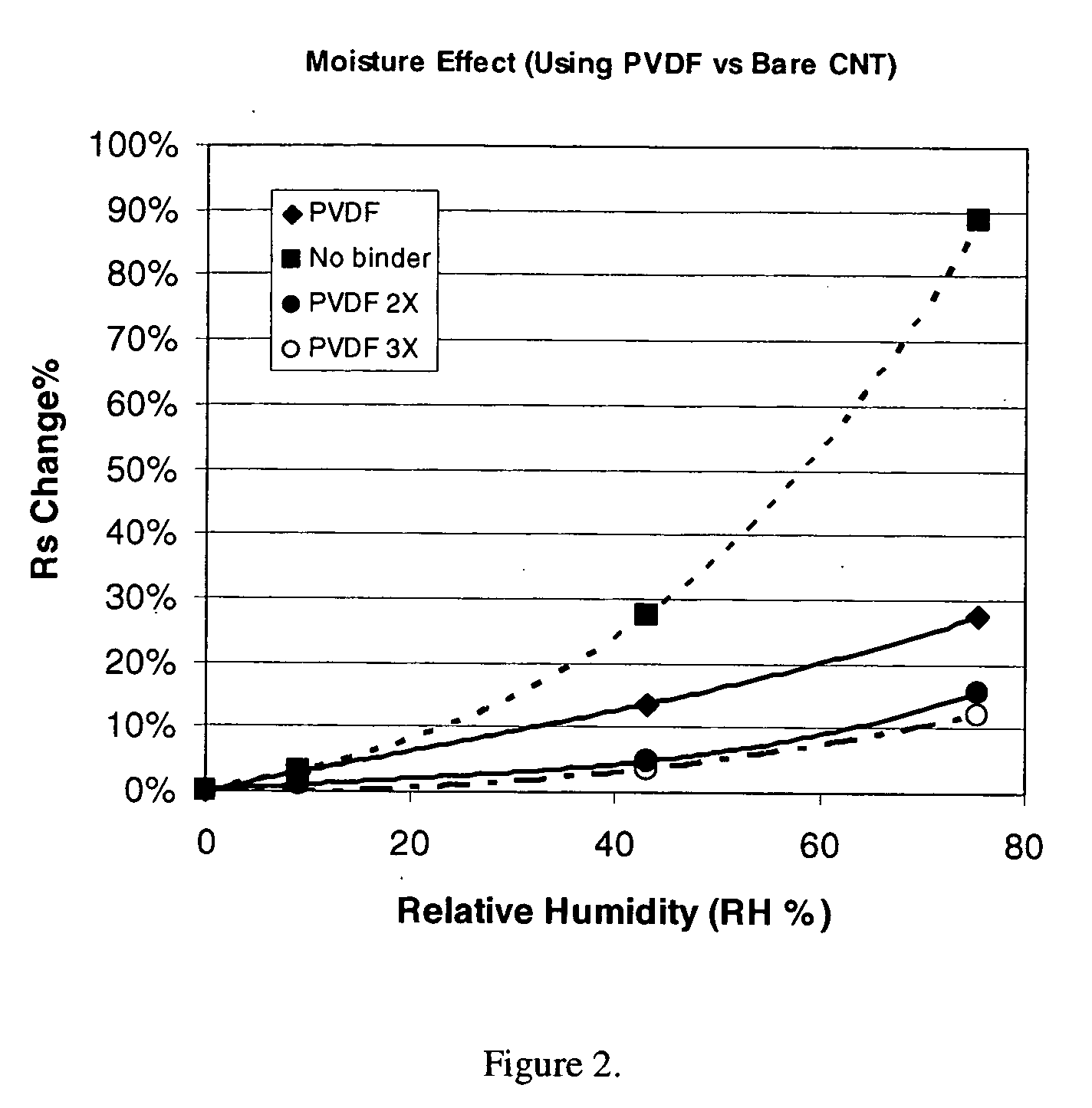

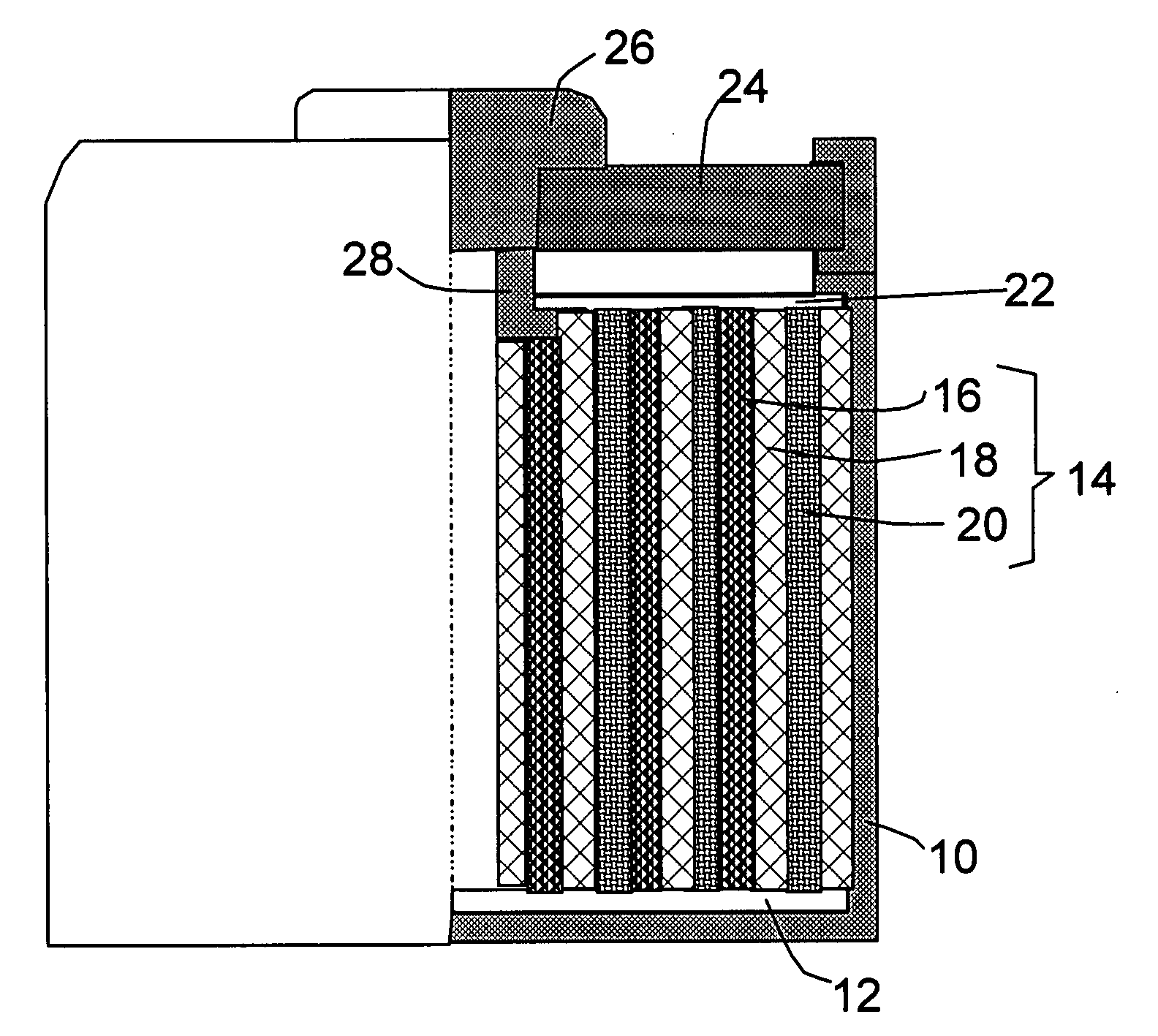

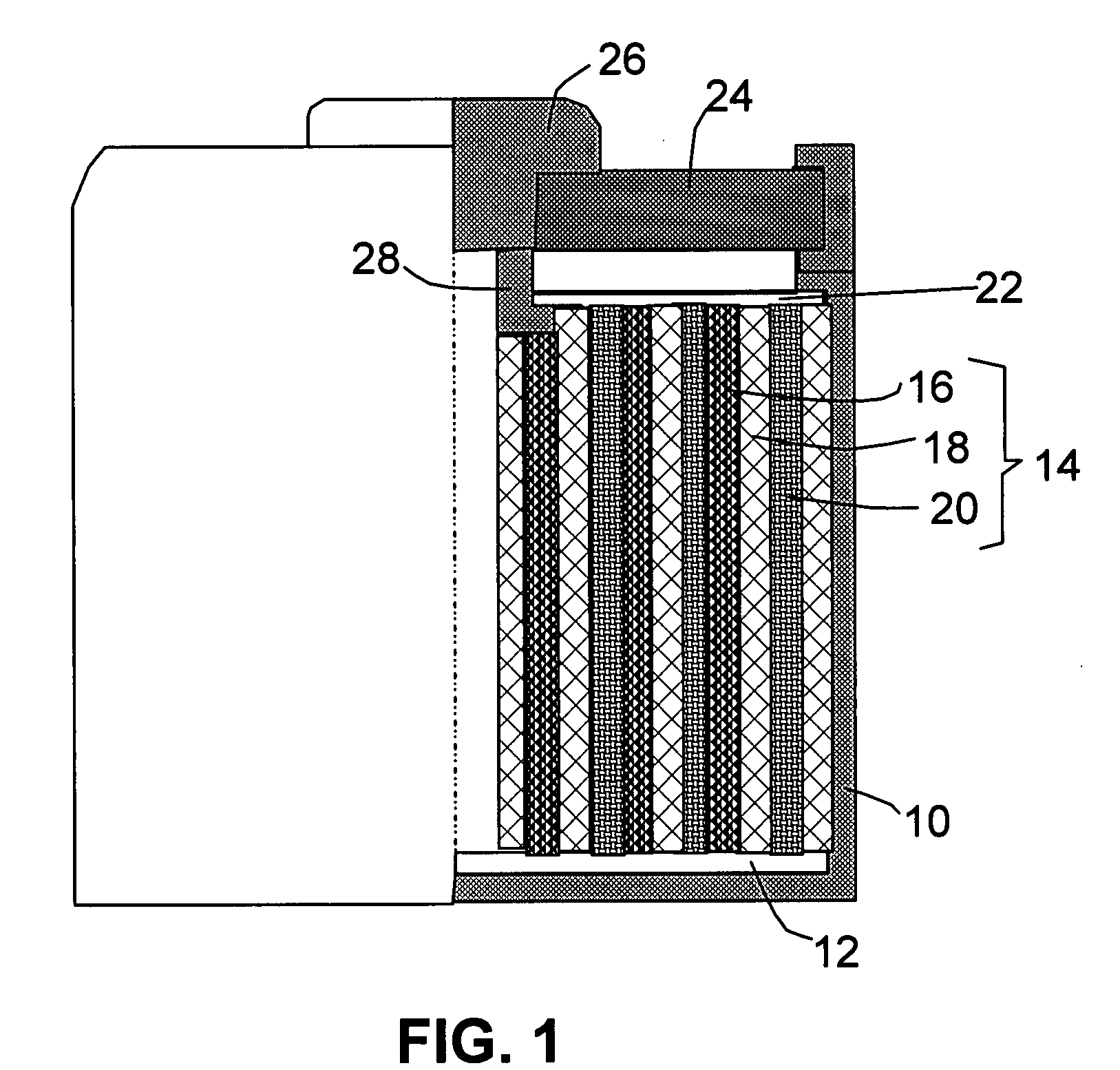

Fluoropolymer binders for carbon nanotube-based transparent conductive coatings

InactiveUS20060113510A1Reduce conductivityFunction increaseNanoinformaticsConductive materialThermoplasticOptical transparency

This invention relates to flexible, transparent and conductive coatings and films formed using carbon nanotubes (CNT) and, in particular, single wall carbon nanotubes, with polymer binders. Preferably, coatings and films are formed from carbon nanotubes applied to transparent substrates forming one or multiple conductive layers at nanometer level of thickness. Polymer binders are applied to the CNT network coating having an open structure to provide protection through infiltration. This provides for enhancement of properties such as moisture resistance, thermal resistance, abrasion resistance and interfacial adhesion. Polymers may be thermoplastics or thermosets, or a combination thereof. Polymers may also be insulative or inherently electrical conductive, or any combination of both. Polymers may comprise single or multiple layers as a basecoat underneath a CNT coating, or a topcoat above a CNT coating, or combination of the basecoat and the topcoat forming a sandwich structure. A fluoropolymer containing binder, which is a solution of one fluoropolymer or a blend of fluoropolymers, which may be formulated with additives, is applied onto a carbon nanotube-based transparent conductive coating at nanometer level of thickness on a clear substrate such as PET and glass. The fluoropolymers or blend can be either semi-crystalline (with low level of crystallinity) or amorphous, preferably to be amorphous with low refraction index. Binder coating thickness can be adjusted by changing binder concentration, coating speed and / or other process conditions. This binder coating significantly improves optical transparency, and also maintain or increases conductivity of the CNT-based coating. With other benefits such as abrasion, thermal and moisture resistance, this binder coating and the resulting products is used for display and electronic applications.

Owner:EIKOS

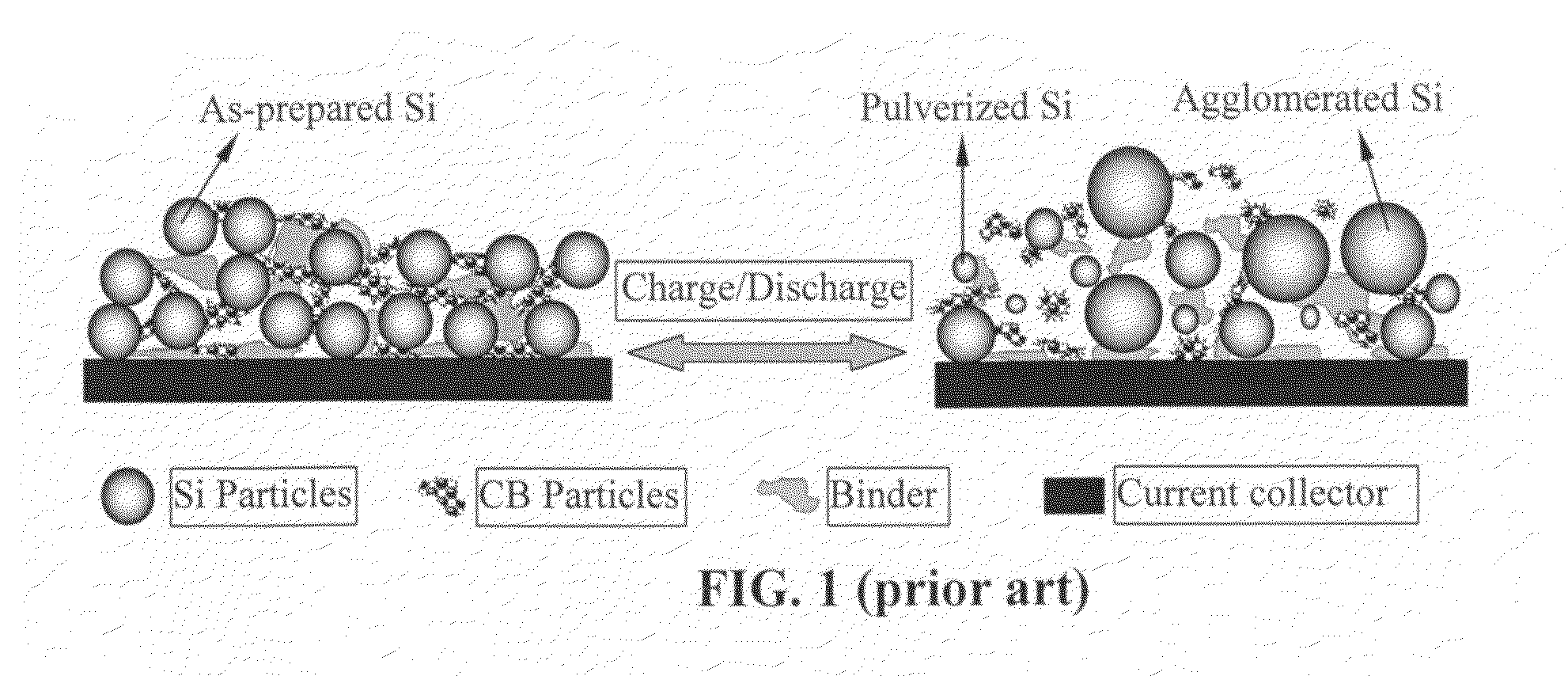

Hybrid anode compositions for lithium ion batteries

ActiveUS20090117466A1Superior multiple-cycle behaviorSmall capacity fadeAlkaline accumulatorsConductive materialHybrid materialSodium-ion battery

The present invention provides an exfoliated graphite-based hybrid material composition for use as an electrode, particularly as an anode of a lithium ion battery. The composition comprises: (a) micron- or nanometer-scaled particles or coating which are capable of absorbing and desorbing alkali or alkaline metal ions (particularly, lithium ions); and (b) exfoliated graphite flakes that are substantially interconnected to form a porous, conductive graphite network comprising pores, wherein at least one of the particles or coating resides in a pore of the network or attached to a flake of the network and the exfoliated graphite amount is in the range of 5% to 90% by weight and the amount of particles or coating is in the range of 95% to 10% by weight. Also provided is a lithium secondary battery comprising such a negative electrode (anode). The battery exhibits an exceptional specific capacity, excellent reversible capacity, and long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

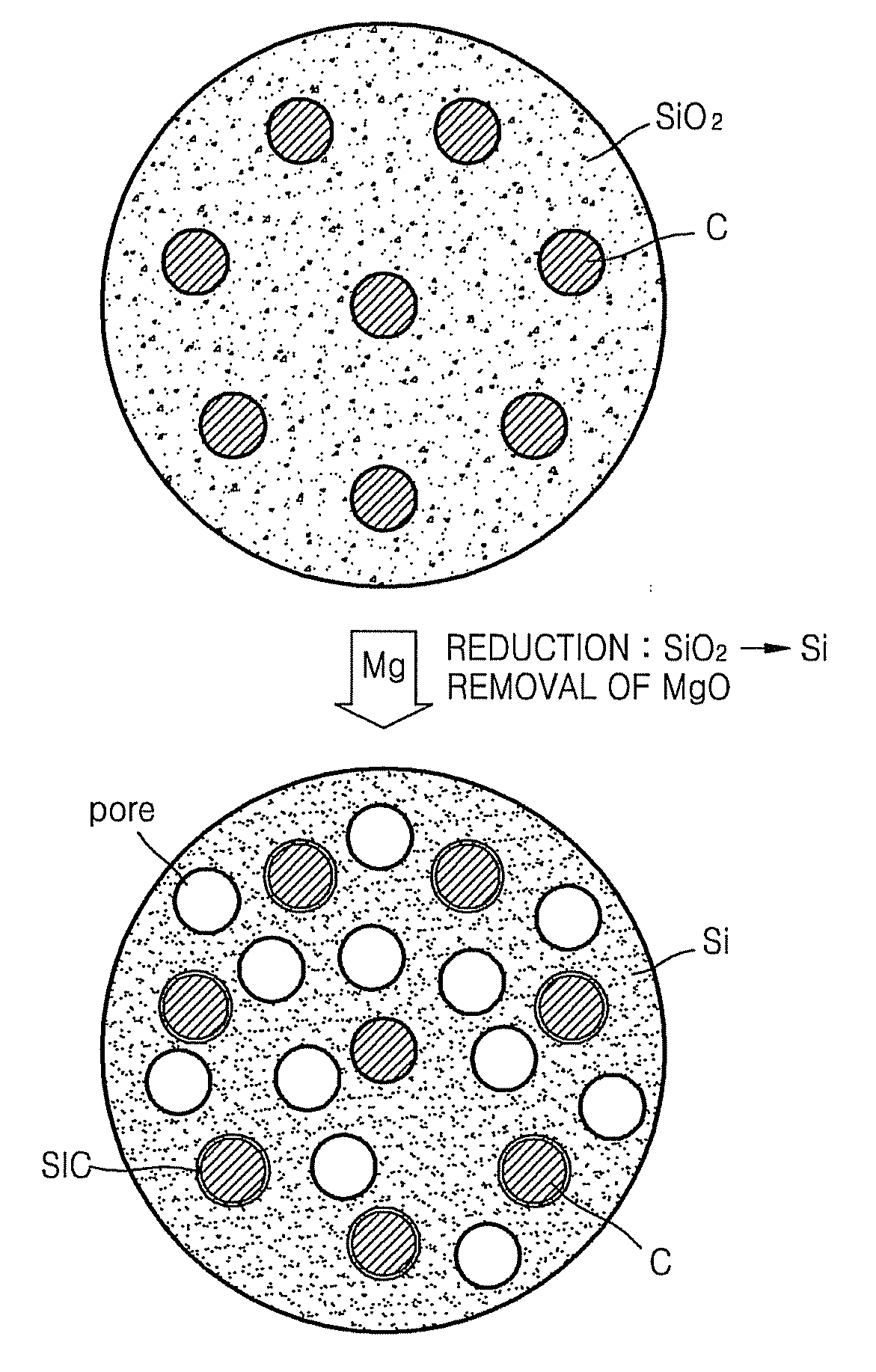

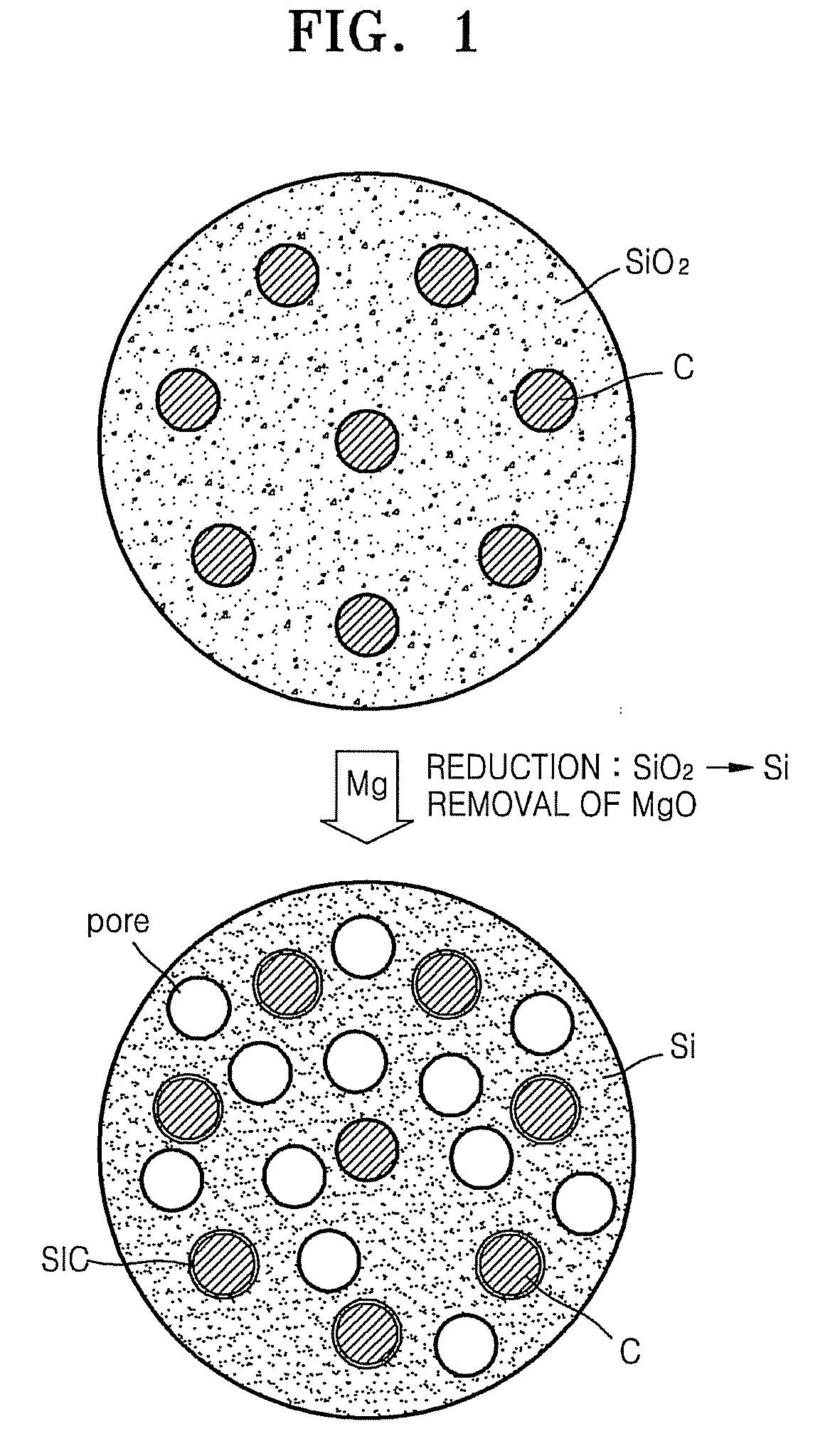

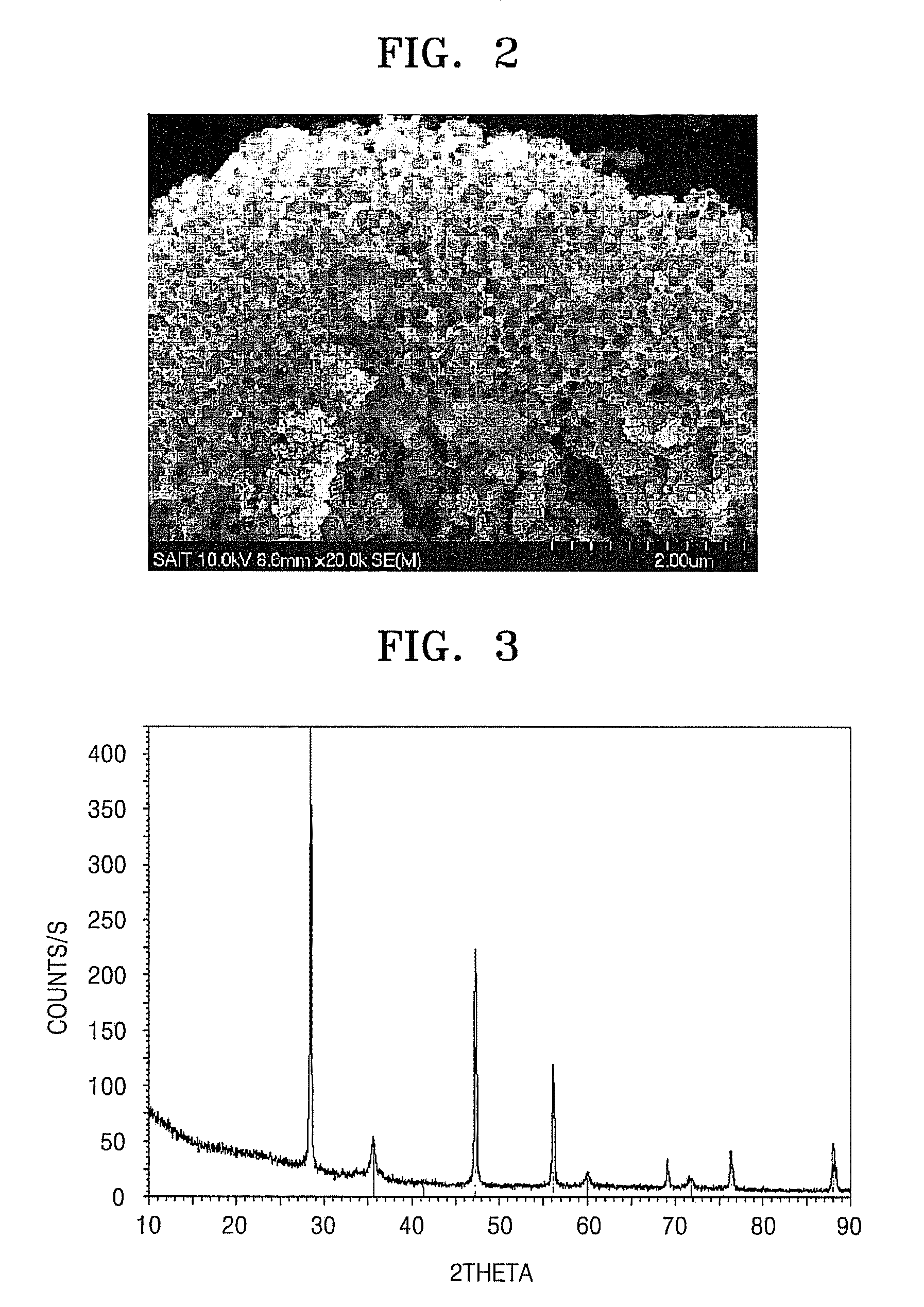

Si/c composite, anode active materials, and lithium battery including the same

ActiveUS20090029256A1Improve initial Coulombic efficiencyGood capacity retentionLiquid surface applicatorsElectrode manufacturing processesLithium-ion batteryPorous silicon

An Si / C composite includes carbon (C) dispersed in porous silicon (Si) particles. The Si / C composite may be used to form an anode active material to provide a lithium battery having a high capacity and excellent capacity retention.

Owner:SAMSUNG SDI CO LTD

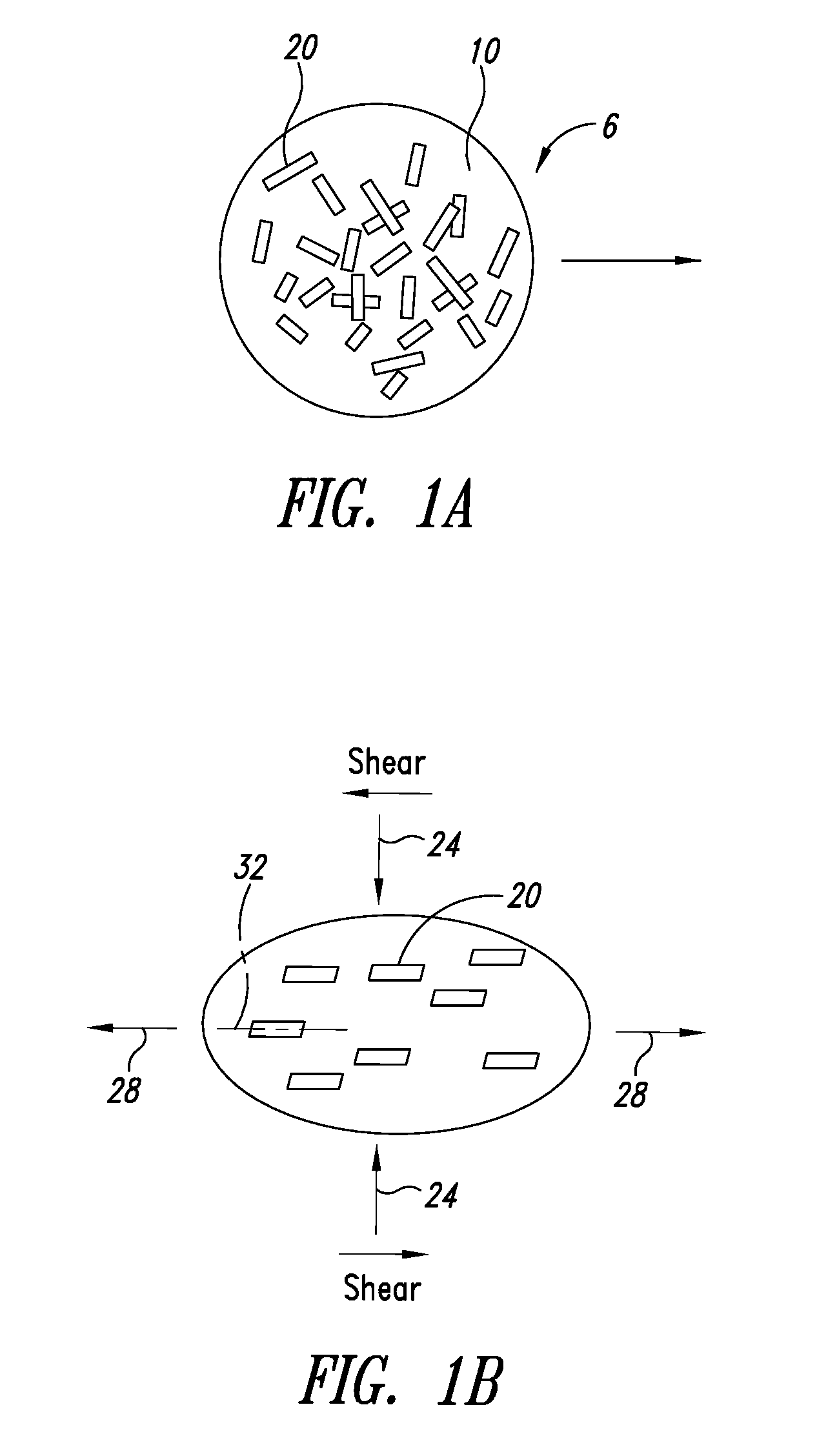

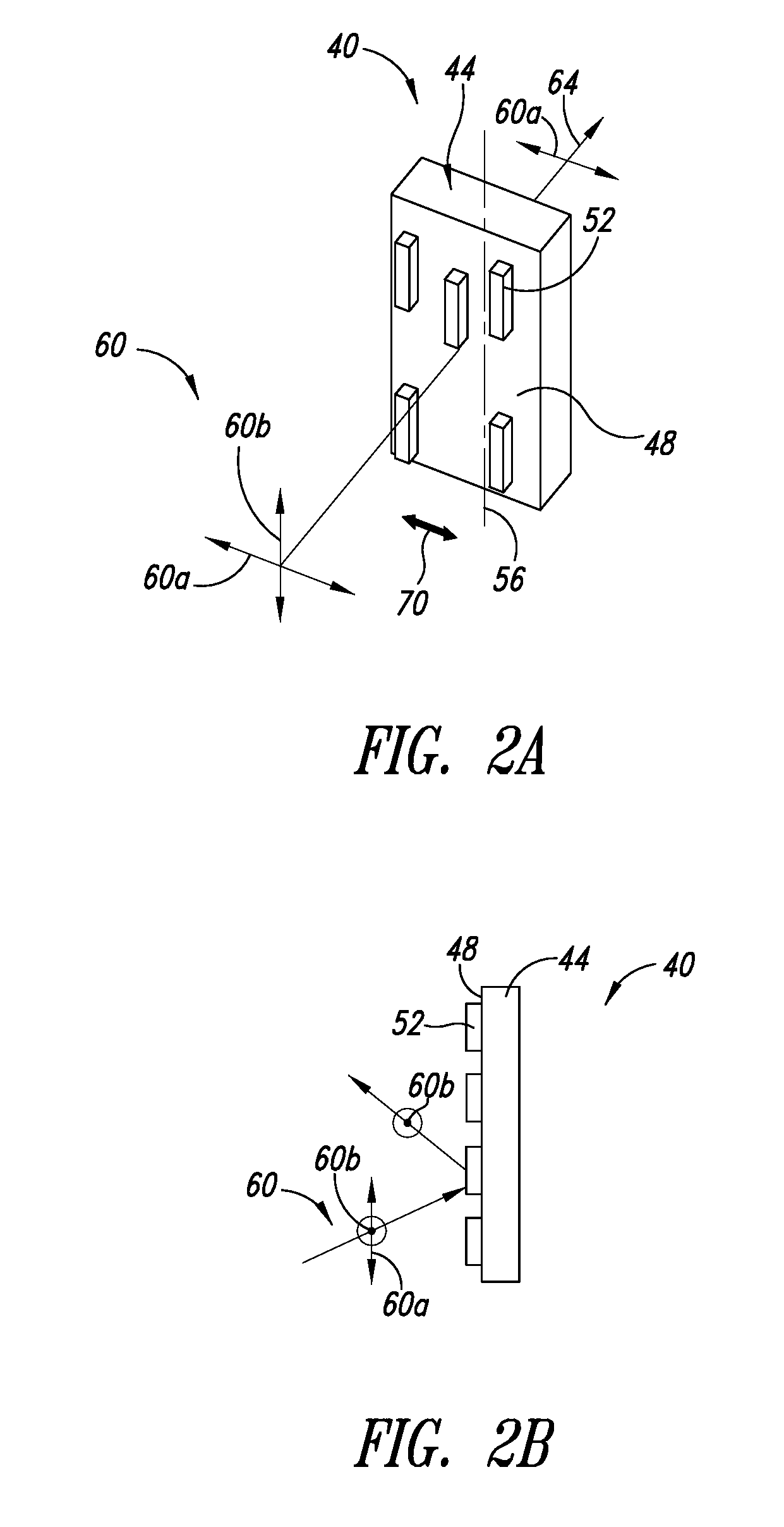

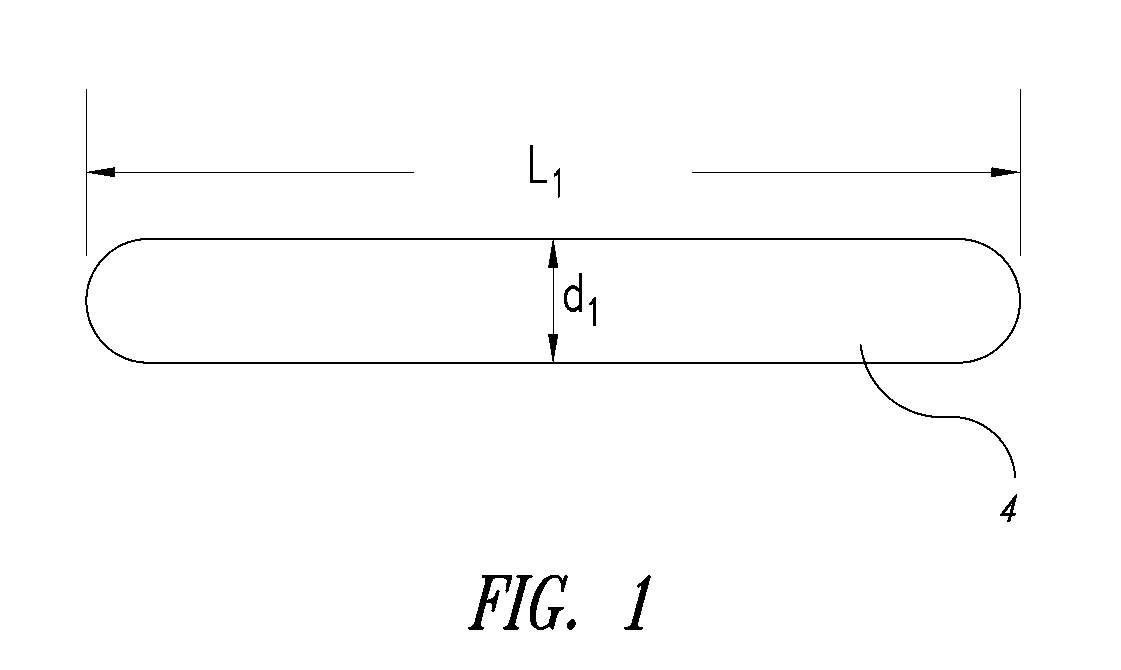

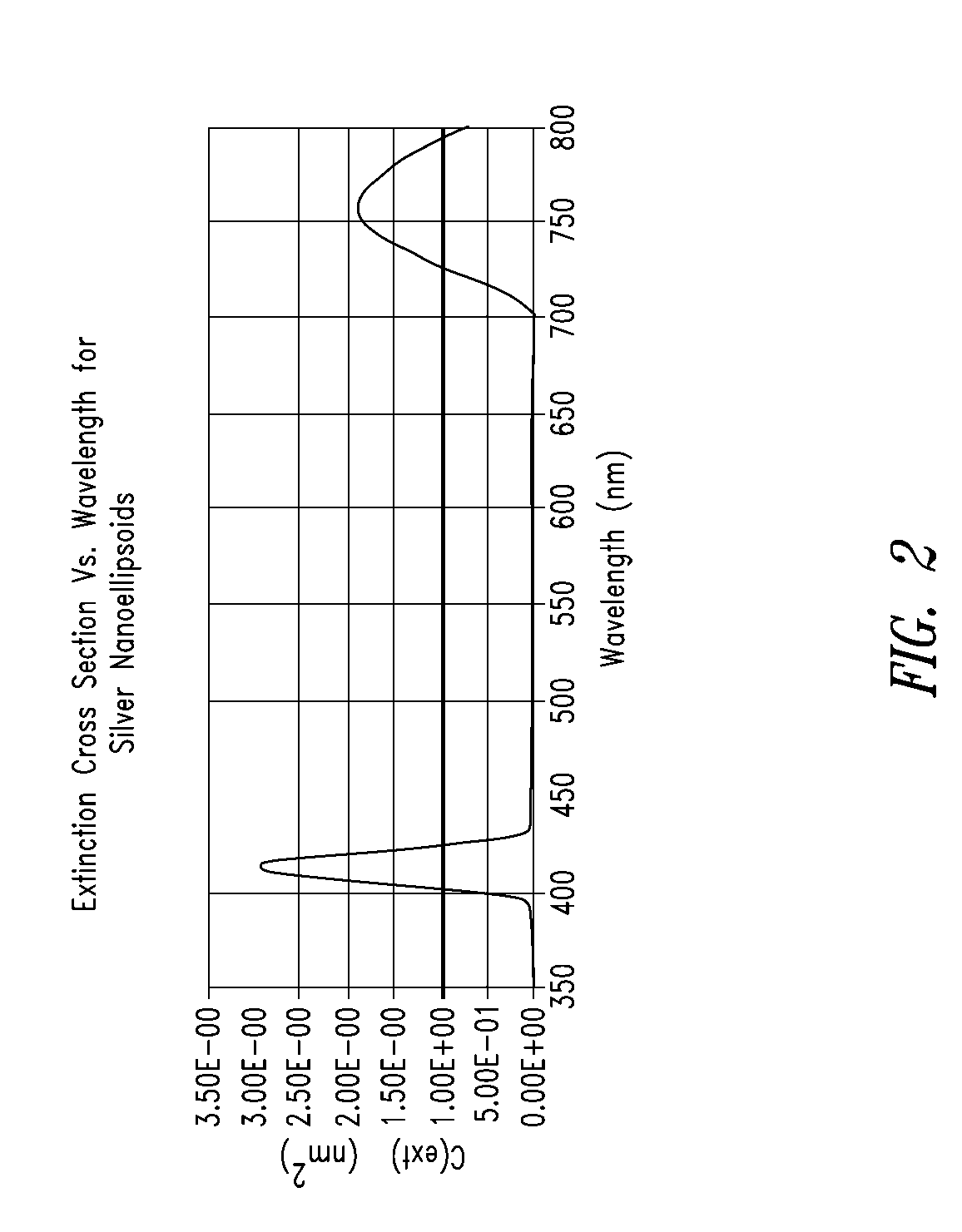

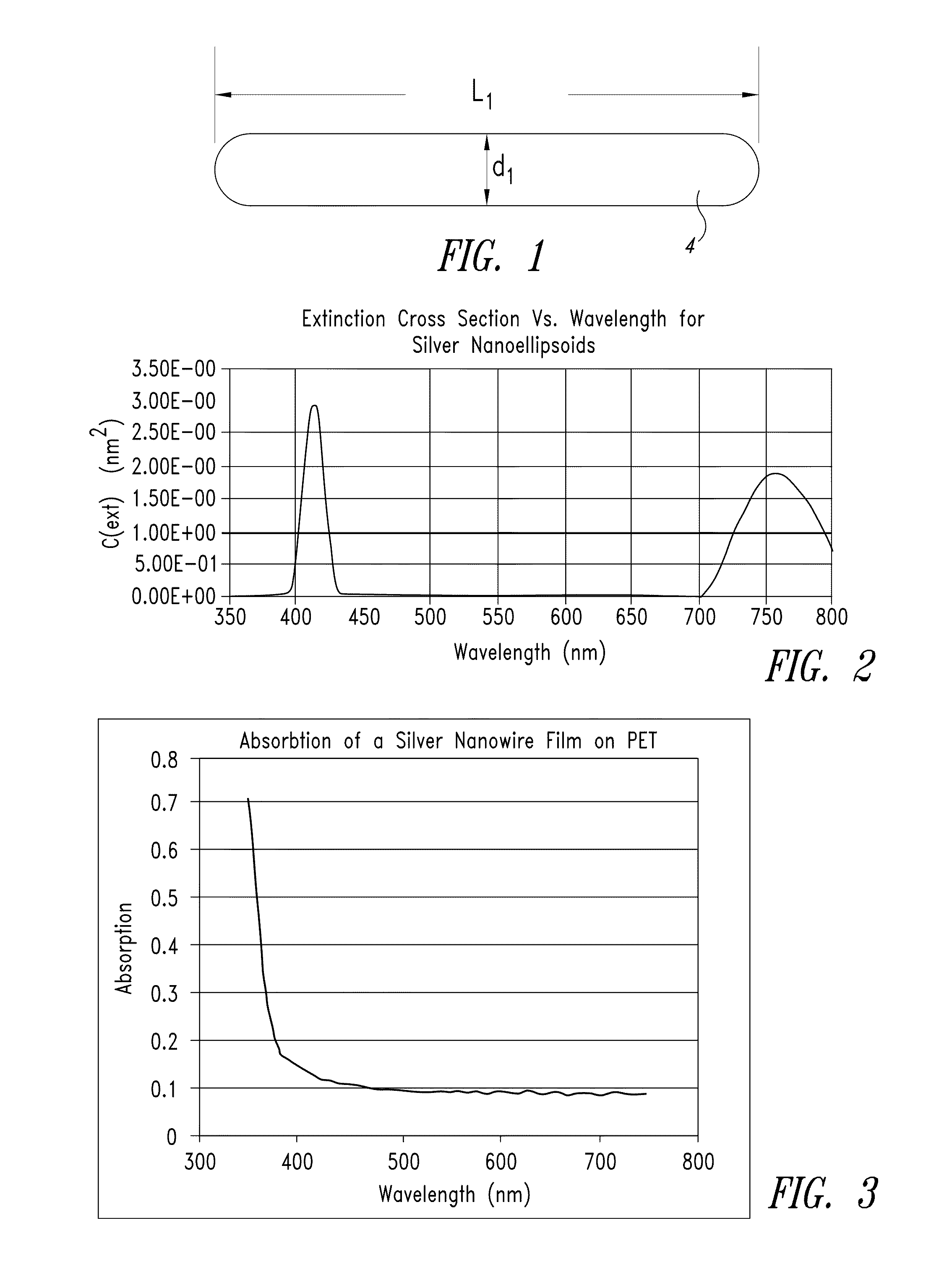

Functional films formed by highly oriented deposition of nanowires

InactiveUS20090052029A1Reduce manufacturing costIncreased durabilityMaterial nanotechnologyNon-insulated conductorsNanowireNanometre

Optical films formed by deposition of highly oriented nanowires and methods of aligning suspended nanowires in a desired direction by flow-induced shear force are described.

Owner:CAMBRIOS TECH +1

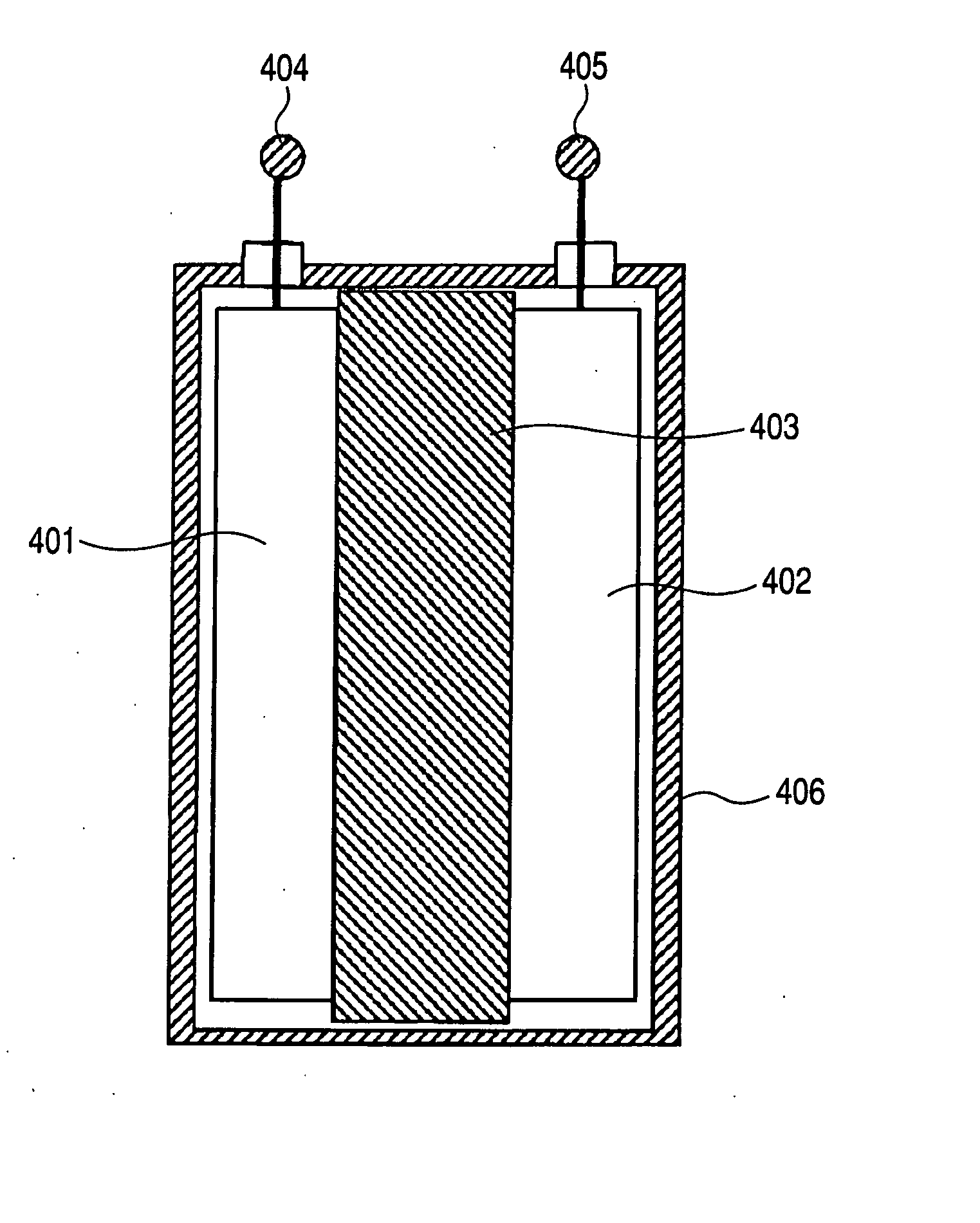

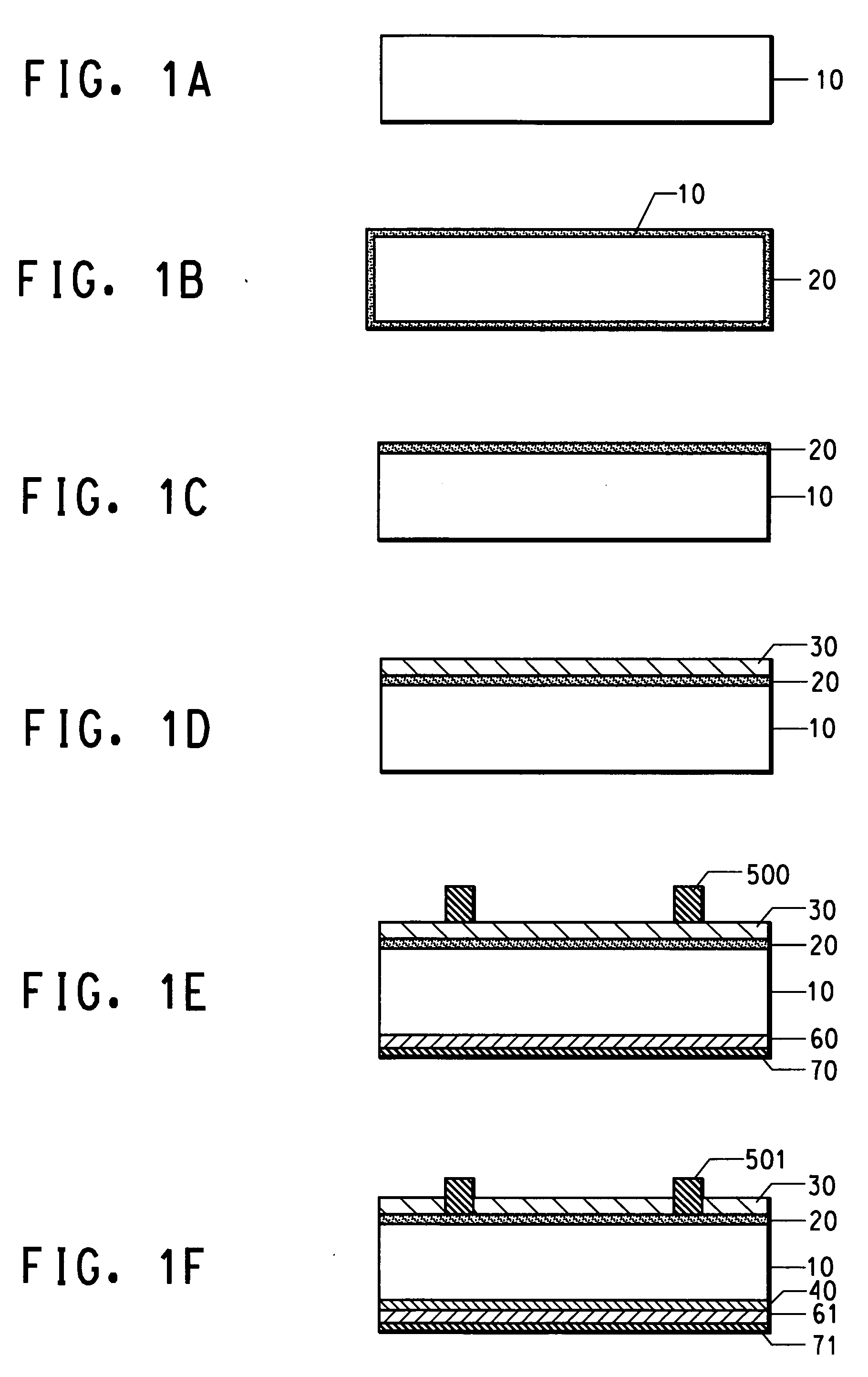

Powder material, electrode structure using the powder material, and energy storage device having the electrode structure

InactiveUS20080003503A1Fast chargingIncrease energy densityNon-metal conductorsElectrode manufacturing processesElectrical conductorHigh energy

A powder material which can electrochemically store and release lithium ions rapidly in a large amount is provided. In addition, an electrode structure for an energy storage device which can provide a high energy density and a high power density and has a long life, and an energy storage device using the electrode structure are provided. In a powder material which can electrochemically store and release lithium ions, the surface of particles of one of silicon metal and tin metal and an alloy of any thereof is coated by an oxide including a transition metal element selected from the group consisting of W, Ti, Mo, Nb, and V as a main component. The electrode structure includes the powder material. The battery device includes a negative electrode having the electrode structure, a lithium ion conductor, and a positive electrode, and utilizes an oxidation reaction of lithium and a reduction reaction of lithium ion.

Owner:CANON KK

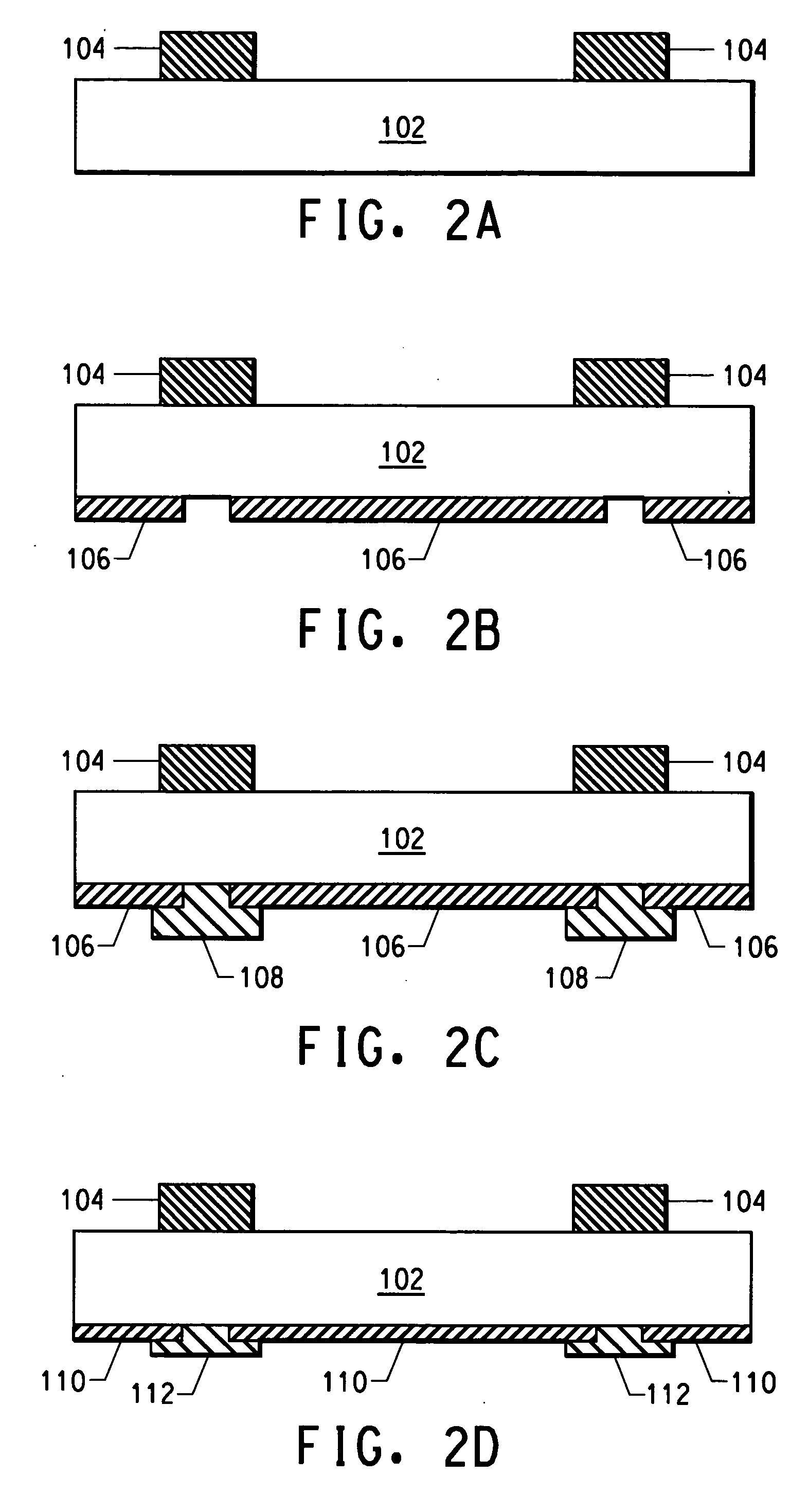

Electroconductive thick film composition(s), electrode(s), and semiconductor device(s) formed therefrom

The present invention is directed to an electroconductive thick film composition comprising: (a) electroconductive metal particles selected from (1) Al, Cu, Au, Ag, Pd and Pt; (2) alloy of Al, Cu, Au, Ag, Pd and Pt; and (3) mixtures thereof; (3) glass frit wherein said glass frit is Pb-free; dispersed in (d) an organic medium, and wherein the average diameter of said electroconductive metal particles is in the range of 0.5-10.0 μm. The present invention is further directed to an electrode formed from the composition as detailed above and a semiconductor device(s) (for example, a solar cell) comprising said electrode.

Owner:SOLAR PASTE LLC

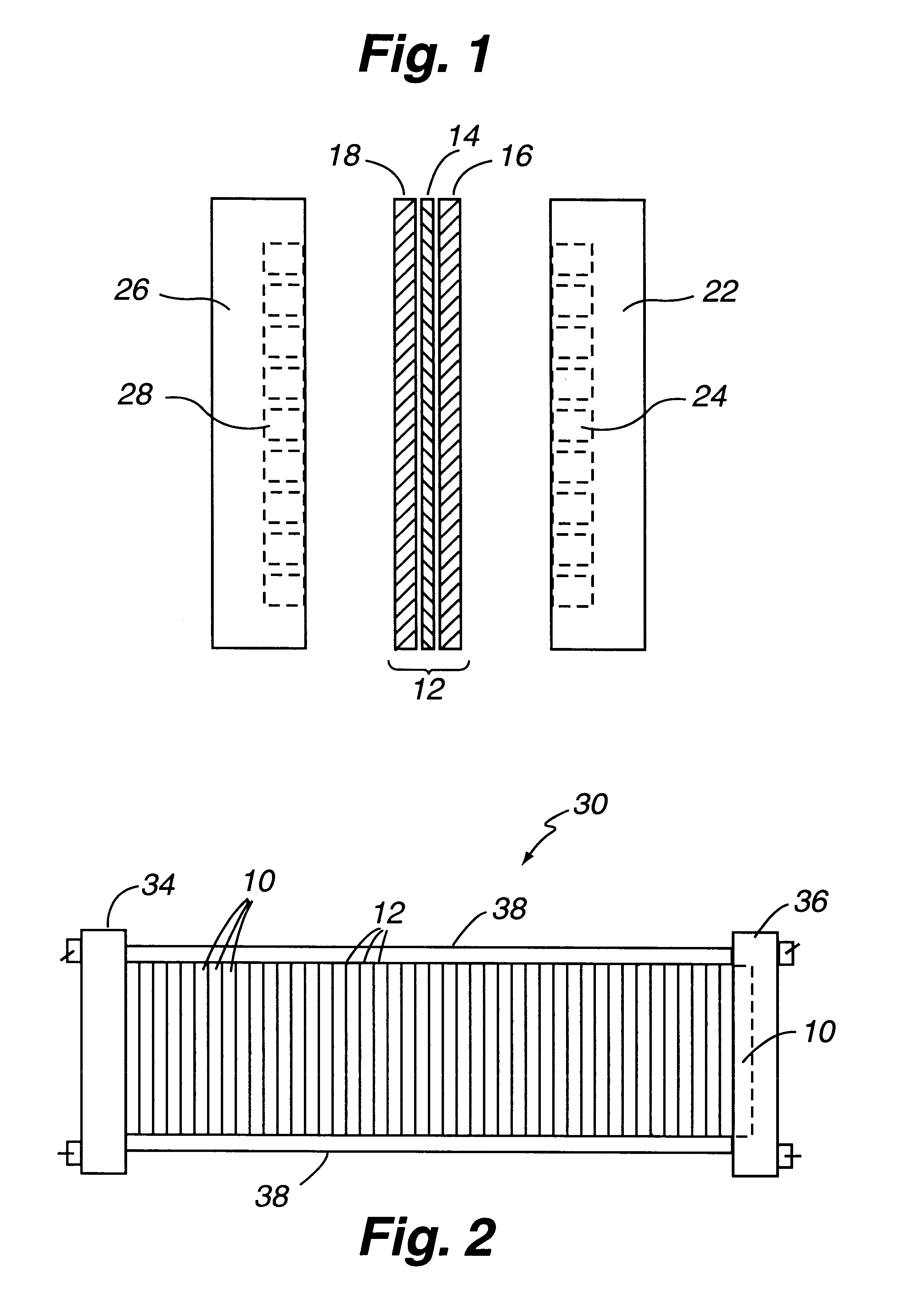

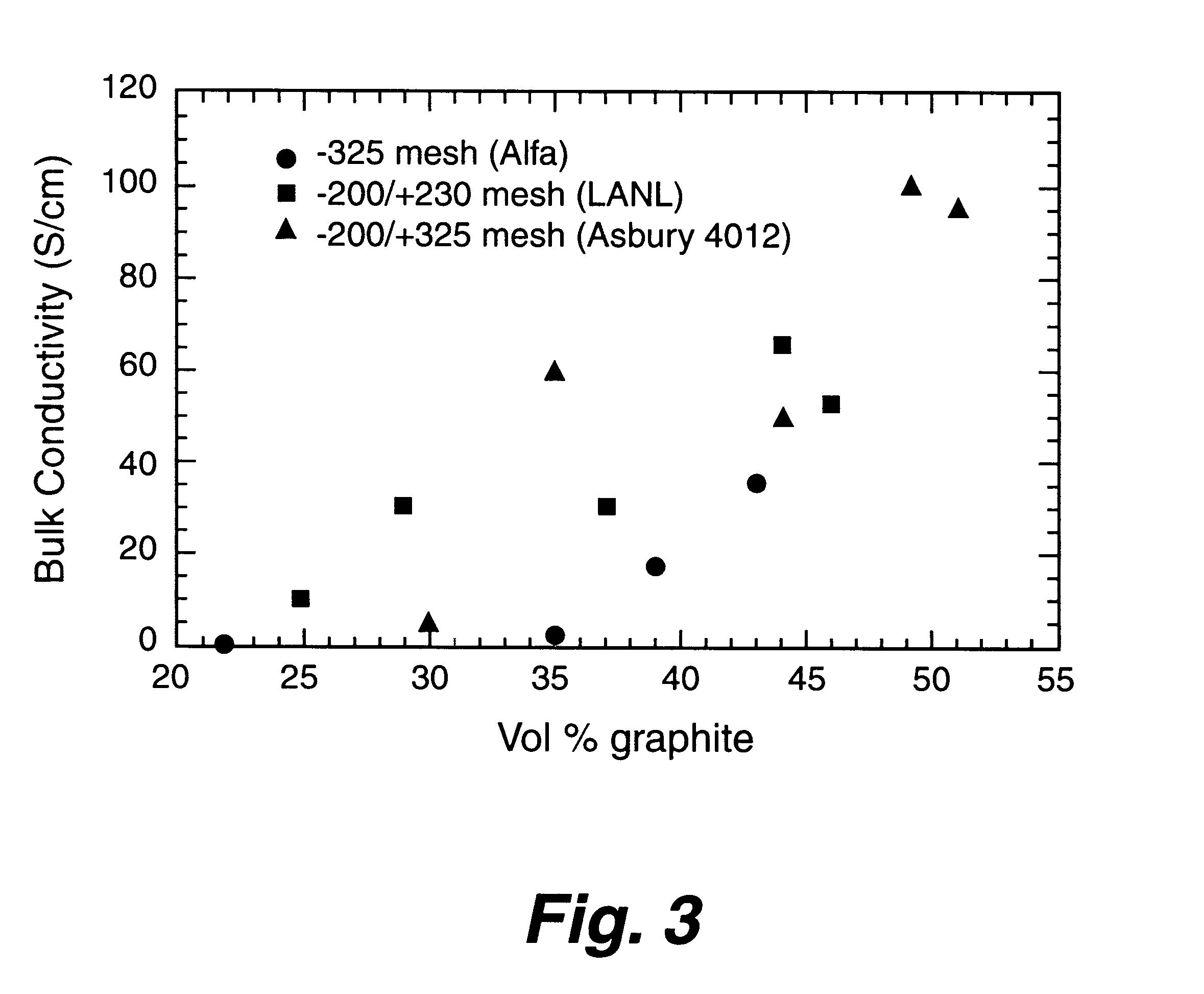

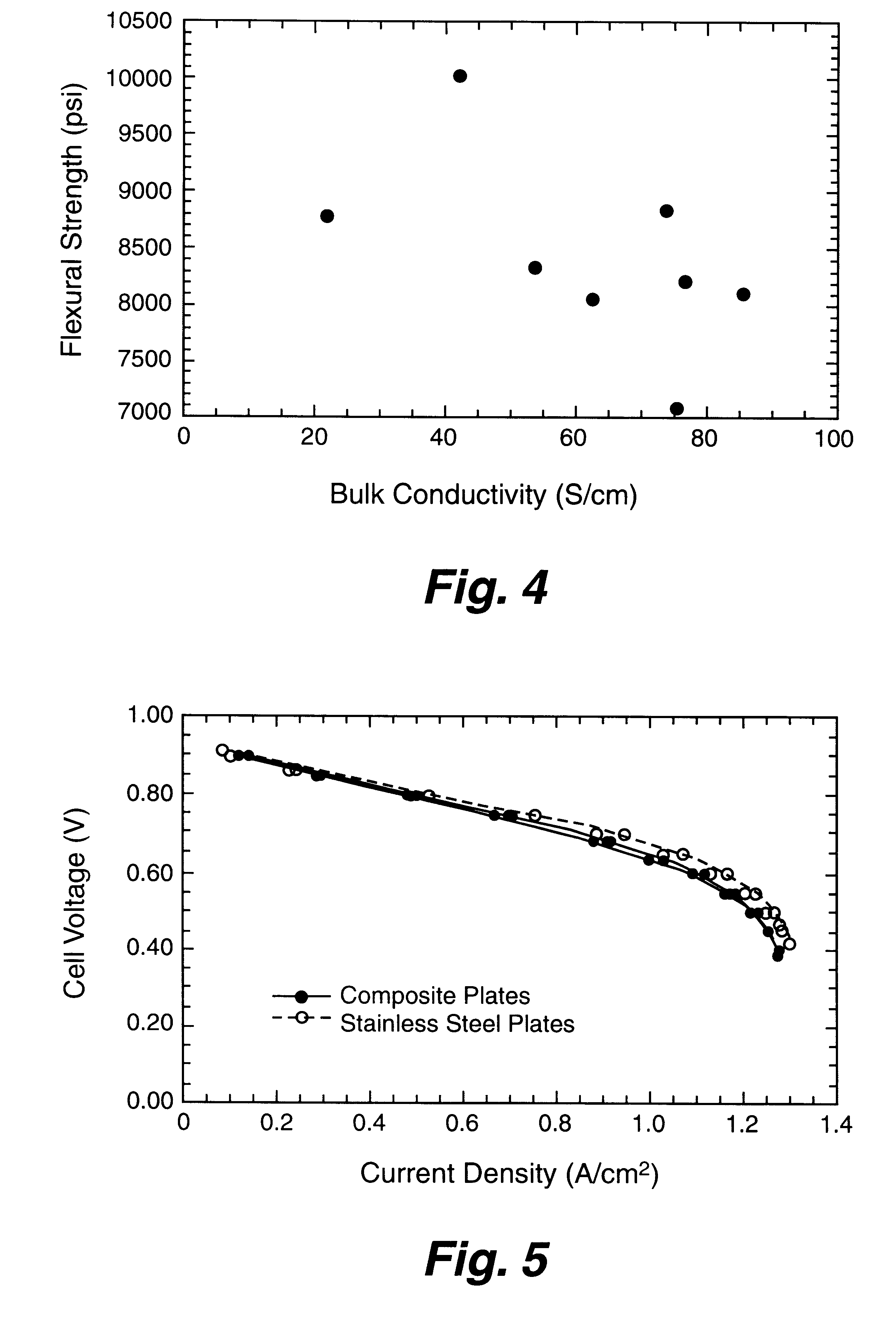

Composite bipolar plate for electrochemical cells

A bipolar separator plate for fuel cells consists of a molded mixture of a vinyl ester resin and graphite powder. The plate serves as a current collector and may contain fluid flow fields for the distribution of reactant gases. The material is inexpensive, electrically conductive, lightweight, strong, corrosion resistant, easily mass produced, and relatively impermeable to hydrogen gas. The addition of certain fiber reinforcements and other additives can improve the properties of the composite material without significantly increasing its overall cost.

Owner:TRIAD NAT SECURITY LLC

Nanowires-based transparent conductors

ActiveUS20080286447A1Material nanotechnologyFrom normal temperature solutionsNanowireElectrical conductor

Owner:CHAMP GREAT INTL

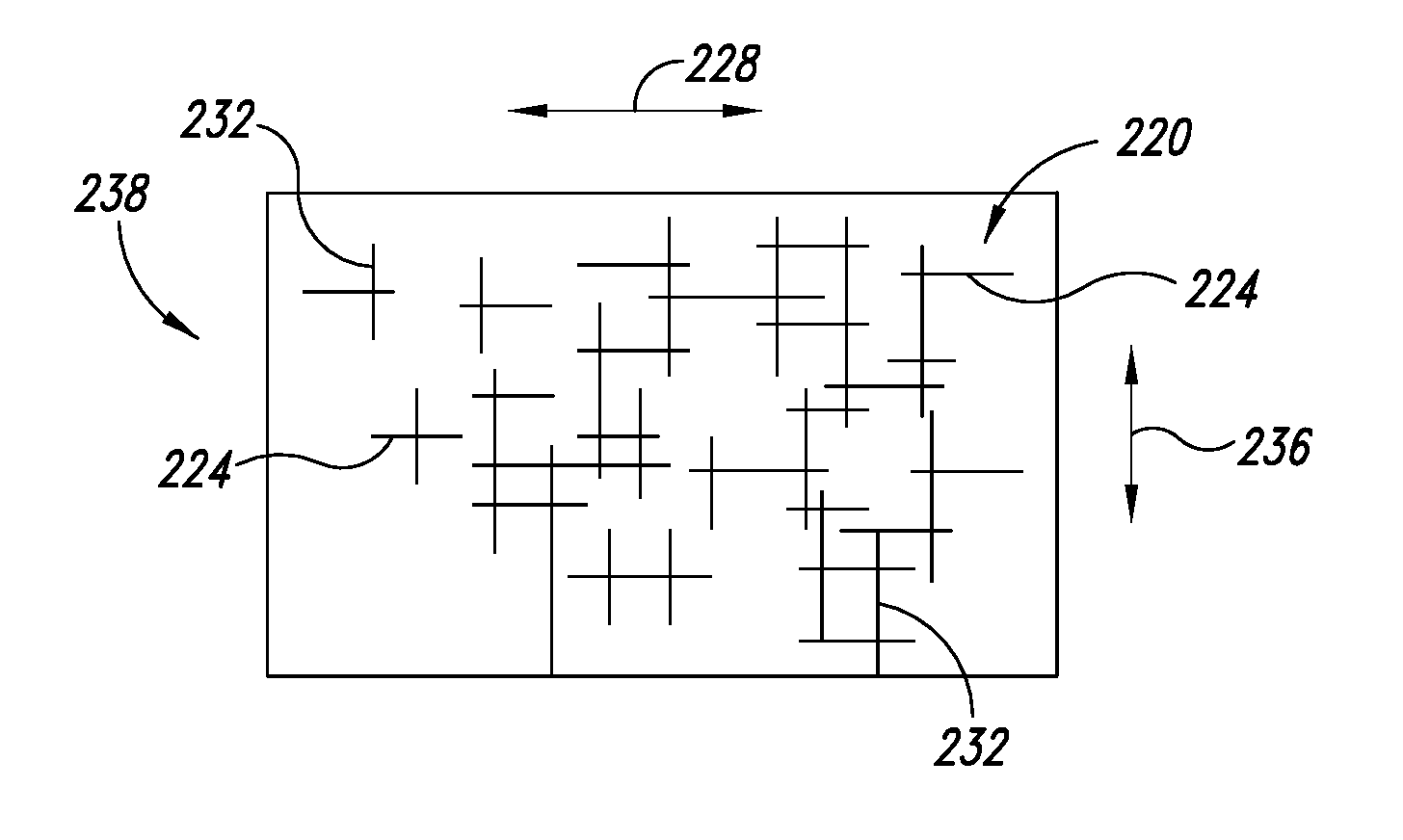

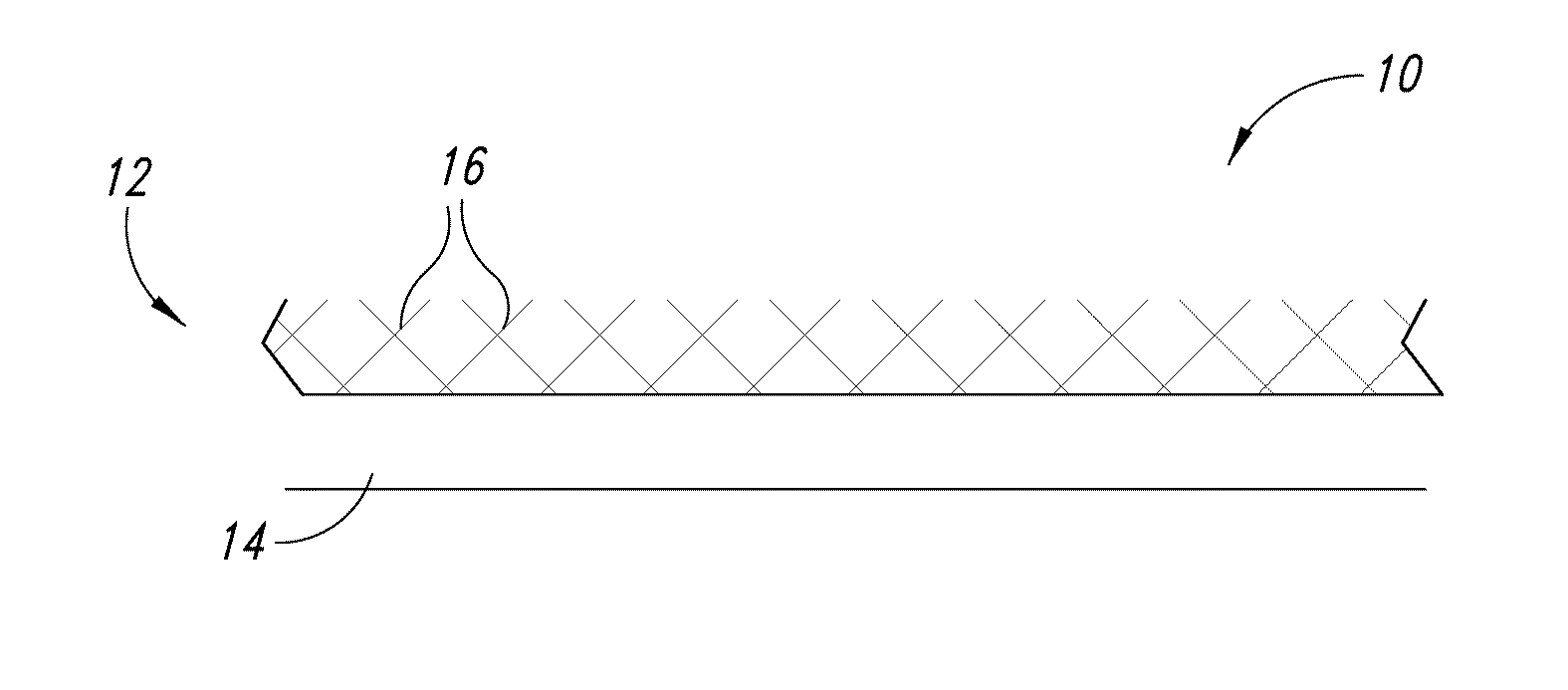

Nanowire-based transparent conductors and applications thereof

A transparent conductor including a conductive layer coated on a substrate is described. More specifically, the conductive layer comprises a network of nanowires that may be embedded in a matrix. The conductive layer is optically clear, patternable and is suitable as a transparent electrode in visual display devices such as touch screens, liquid crystal displays, plasma display panels and the like.

Owner:CHAMP GREAT INTL

Ink-jet inks containing metal nanoparticles

ActiveUS20050078158A1Slow sedimentation rateLow and viscosity gradeMeasurement apparatus componentsConductive materialWater basedNanometre

Compositions for use in ink jet printing onto a substrate comprising a water based dispersion including metallic nanoparticles and appropriate stabilizers. Also disclosed are methods for the production of said compositions and methods for their use in ink jet printing onto suitable substrates.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

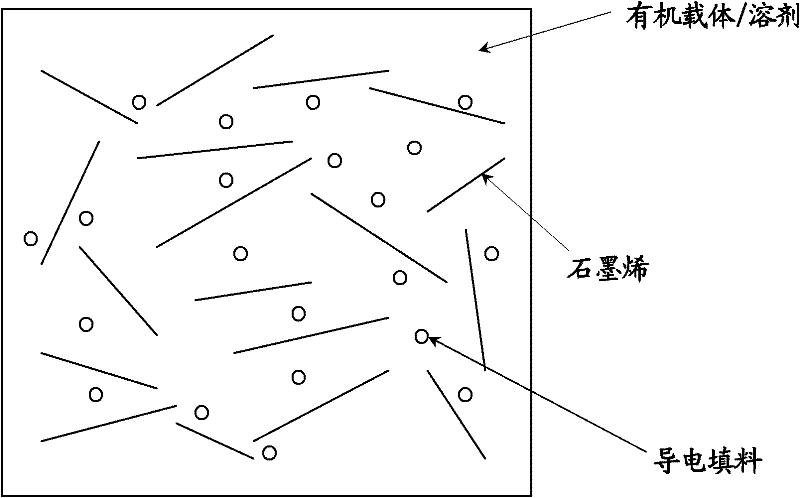

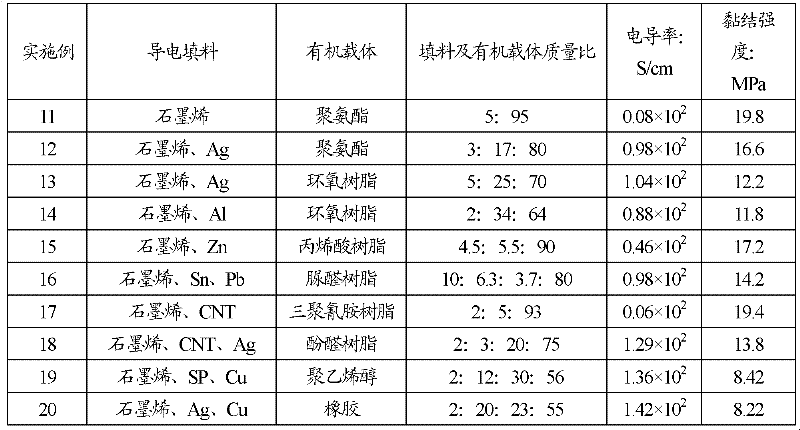

General electronic paste based on graphene filler

ActiveCN102254584AImprove conductivityConductivity regulationNon-conductive material with dispersed conductive materialNano structuringConductive coating

The invention discloses general electronic paste based on graphene filler. The electronic paste contains graphene-containing conductive filler, an organic carrier, a solvent and an auxiliary agent. Because the graphene has good electronic conductivity and a unique two-dimensional laminar nano structure, the graphene forms a conductive network in the organic carrier more easily, and the electric conductivity of the electronic paste is improved by adding the graphene. Further, the conductive filler also contains a conductive material with relatively high electric conductivity, so that the electric conductivity of the electronic paste is further improved. Because the graphene and the conductive material are compounded to form the conductive filler, the electronic paste has good electric conductivity. The electronic paste can obtain a relatively wide electric conductivity range by changing the category of the conductive material mixed with the graphene and adjusting the relative proportion of the graphene to the conductive material of different category. The electric conductivity of the electronic paste is 1*10<-3>S / cm to 1*10<3>S / cm. The paste can be widely applied, and can be particularly used as a conductive coating or adhesive.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com