Patents

Literature

1102 results about "Graphene flake" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

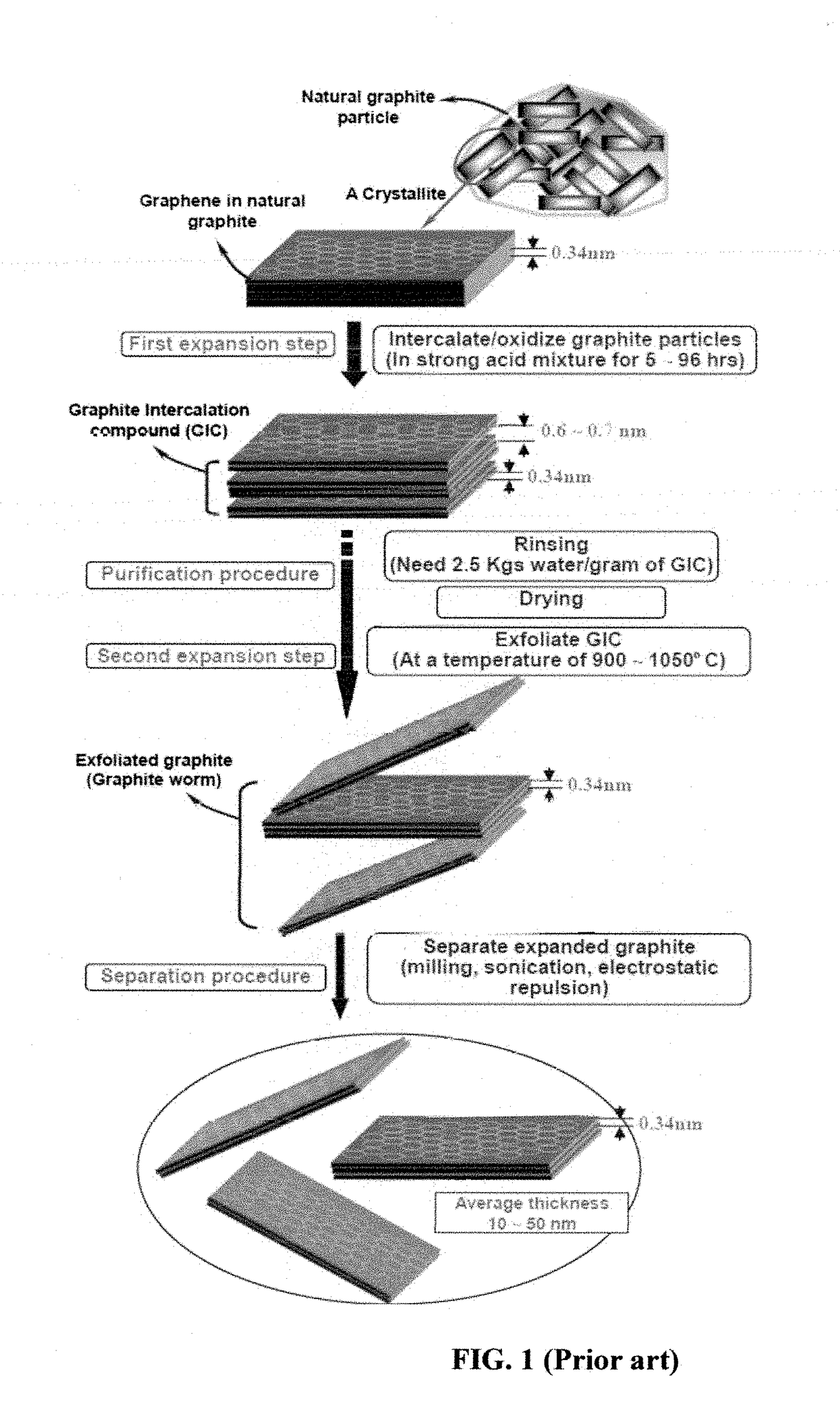

Nano graphene platelet-based composite anode compositions for lithium ion batteries

ActiveUS20090117467A1Improve conductivityLower internal resistanceElectrolytic capacitorsSecondary cellsGraphene flakeGraphite

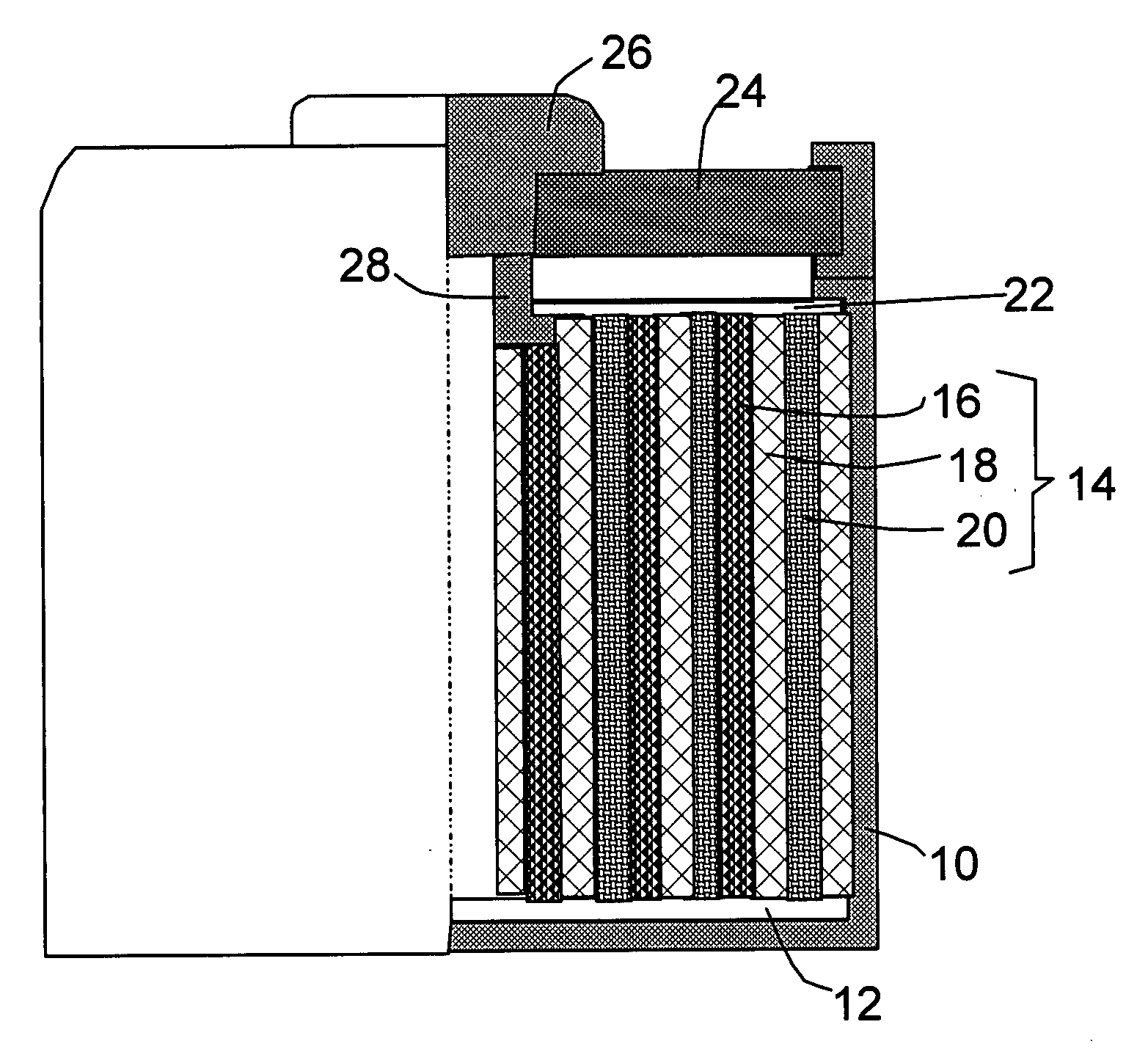

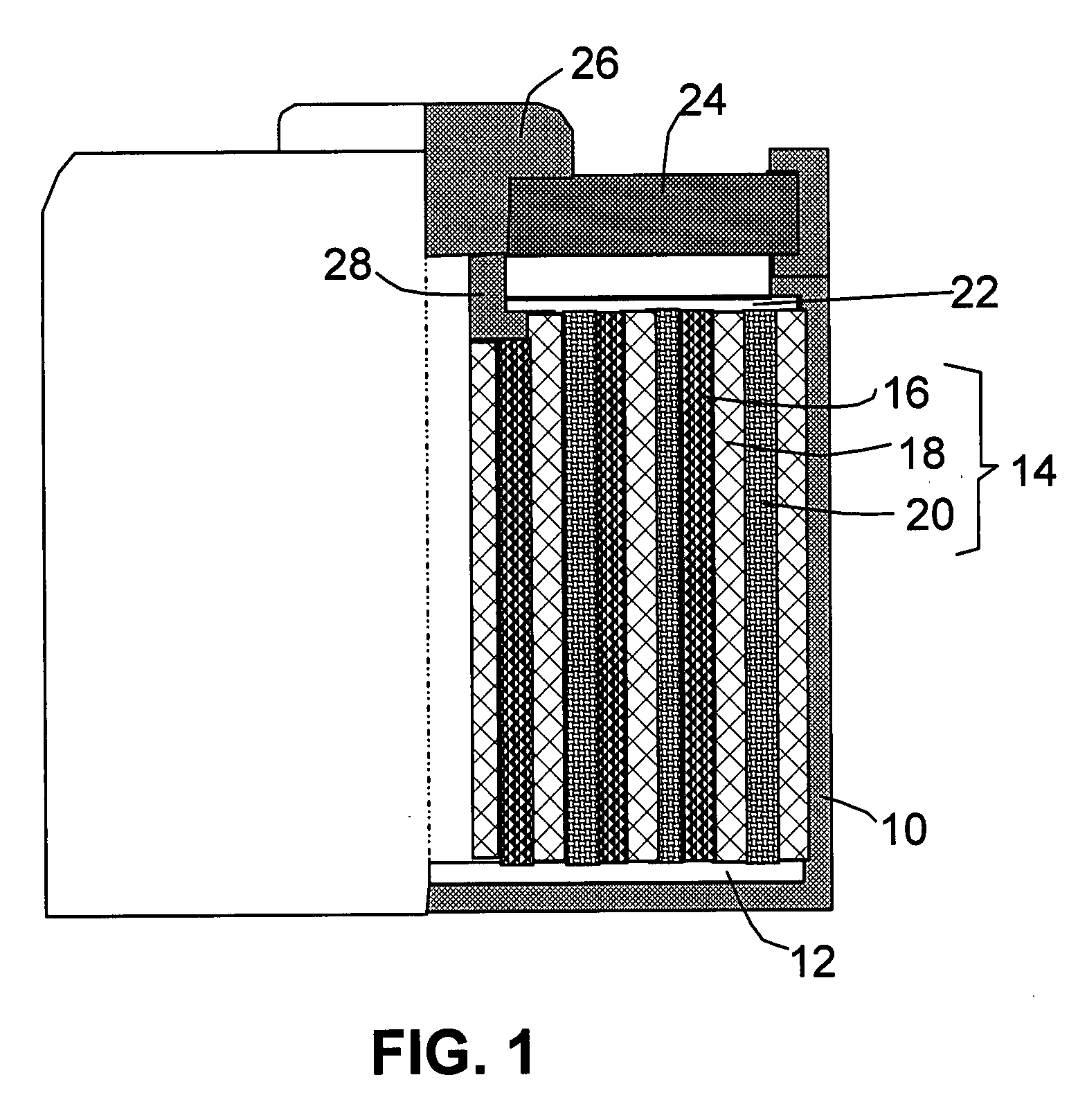

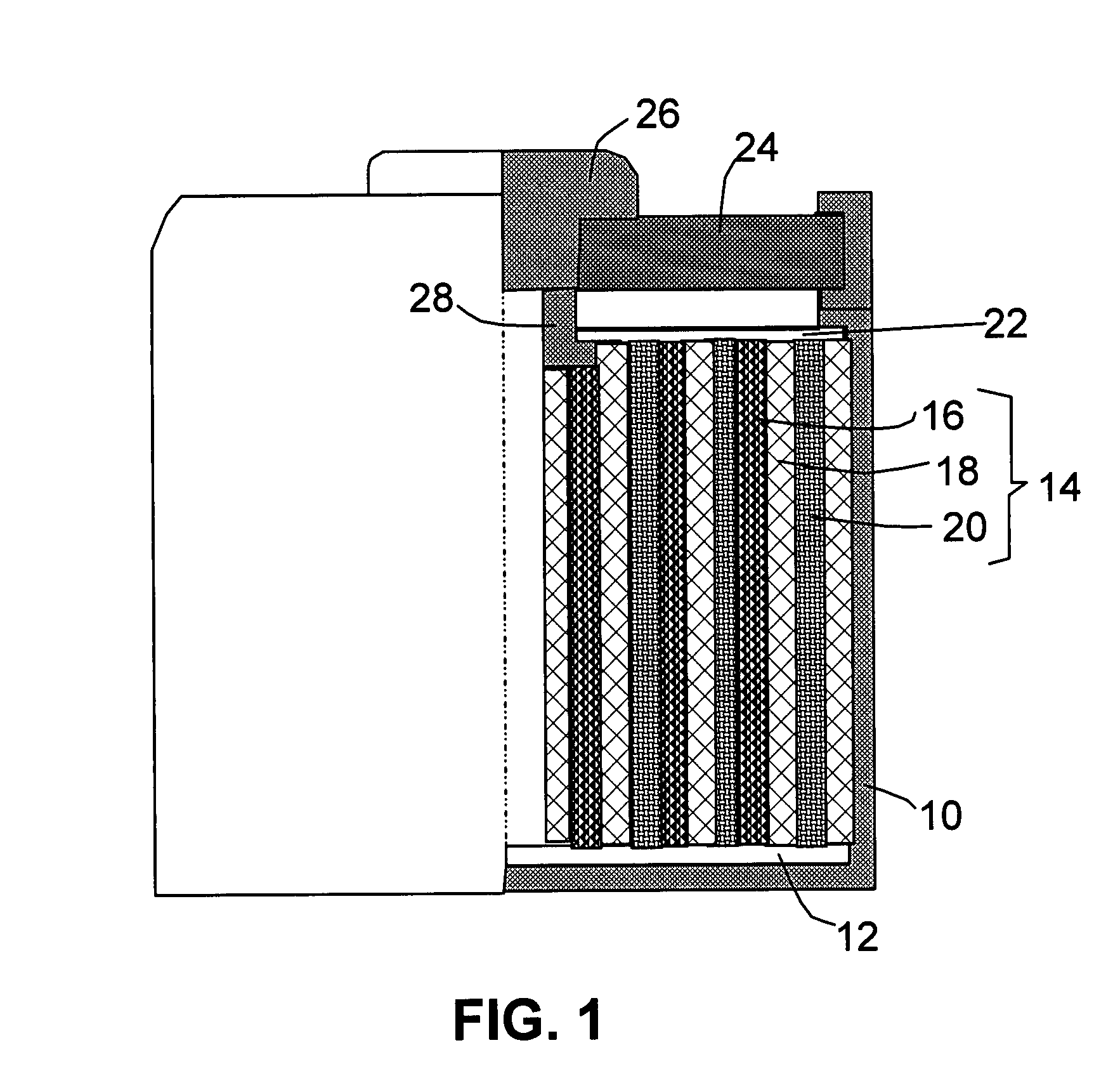

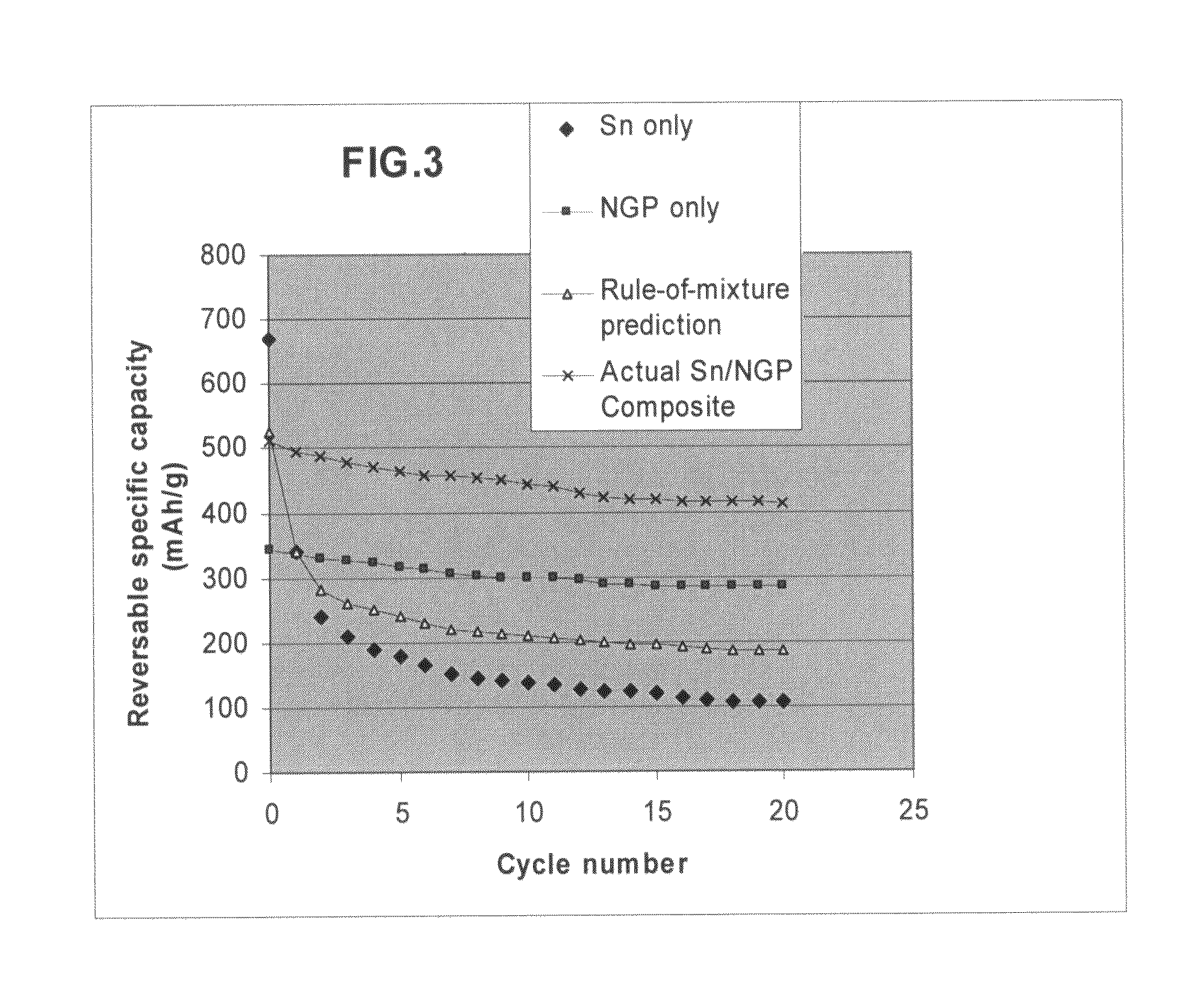

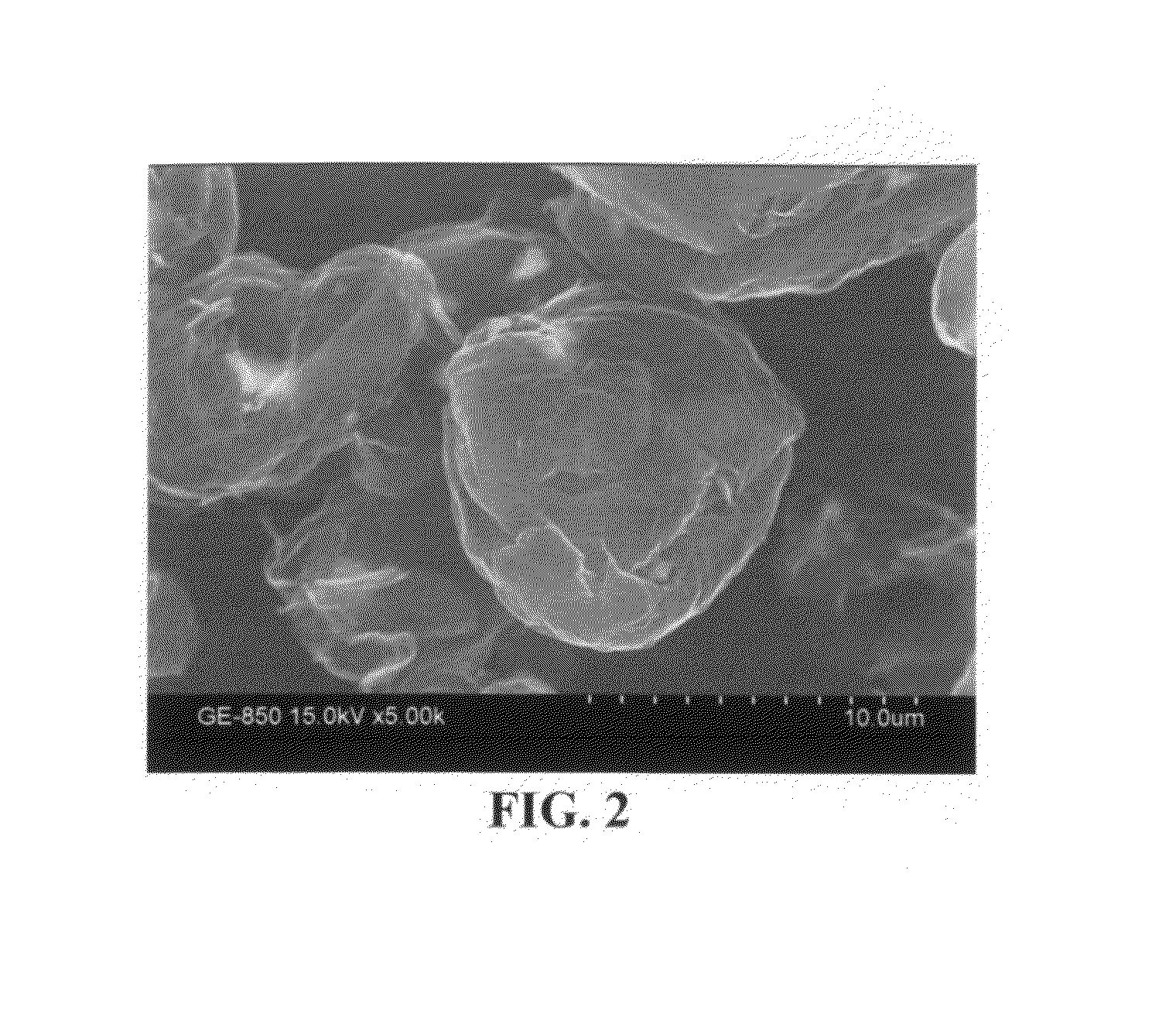

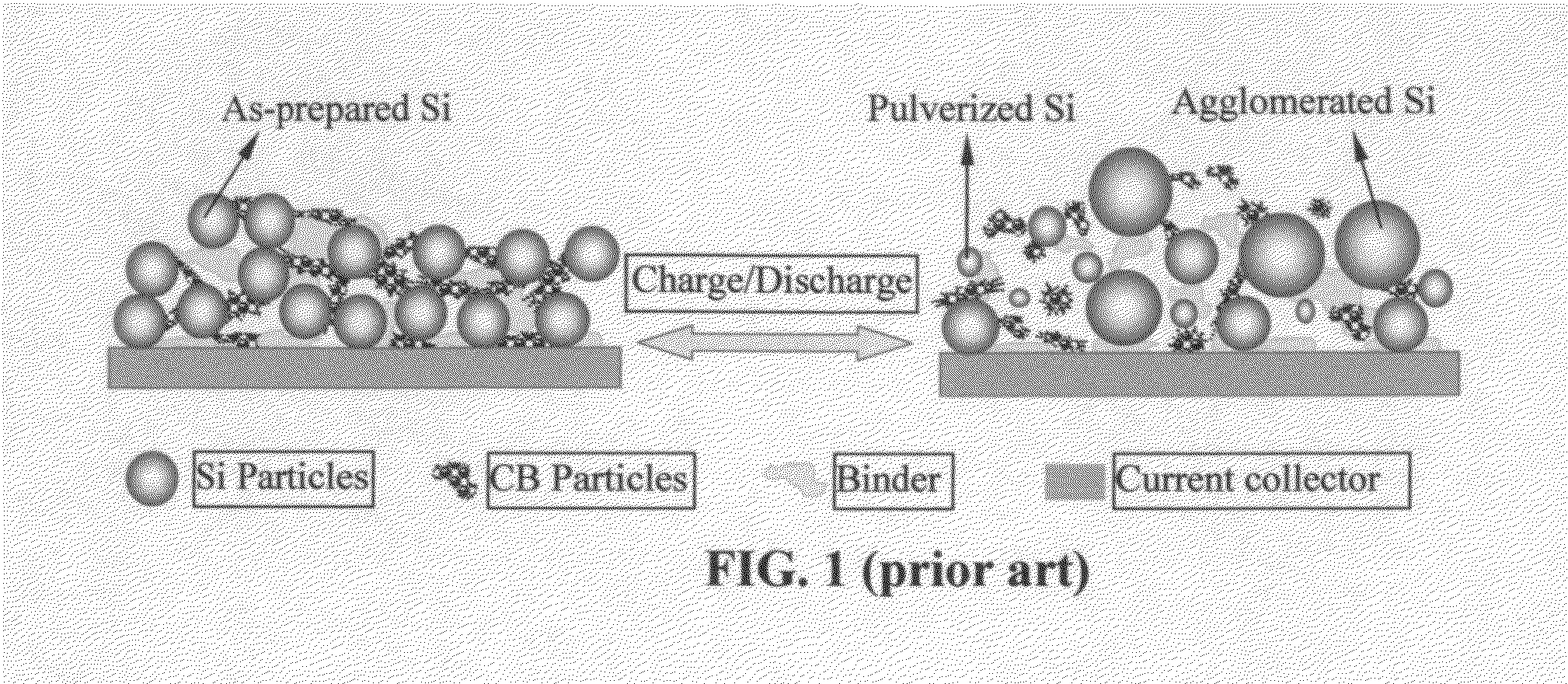

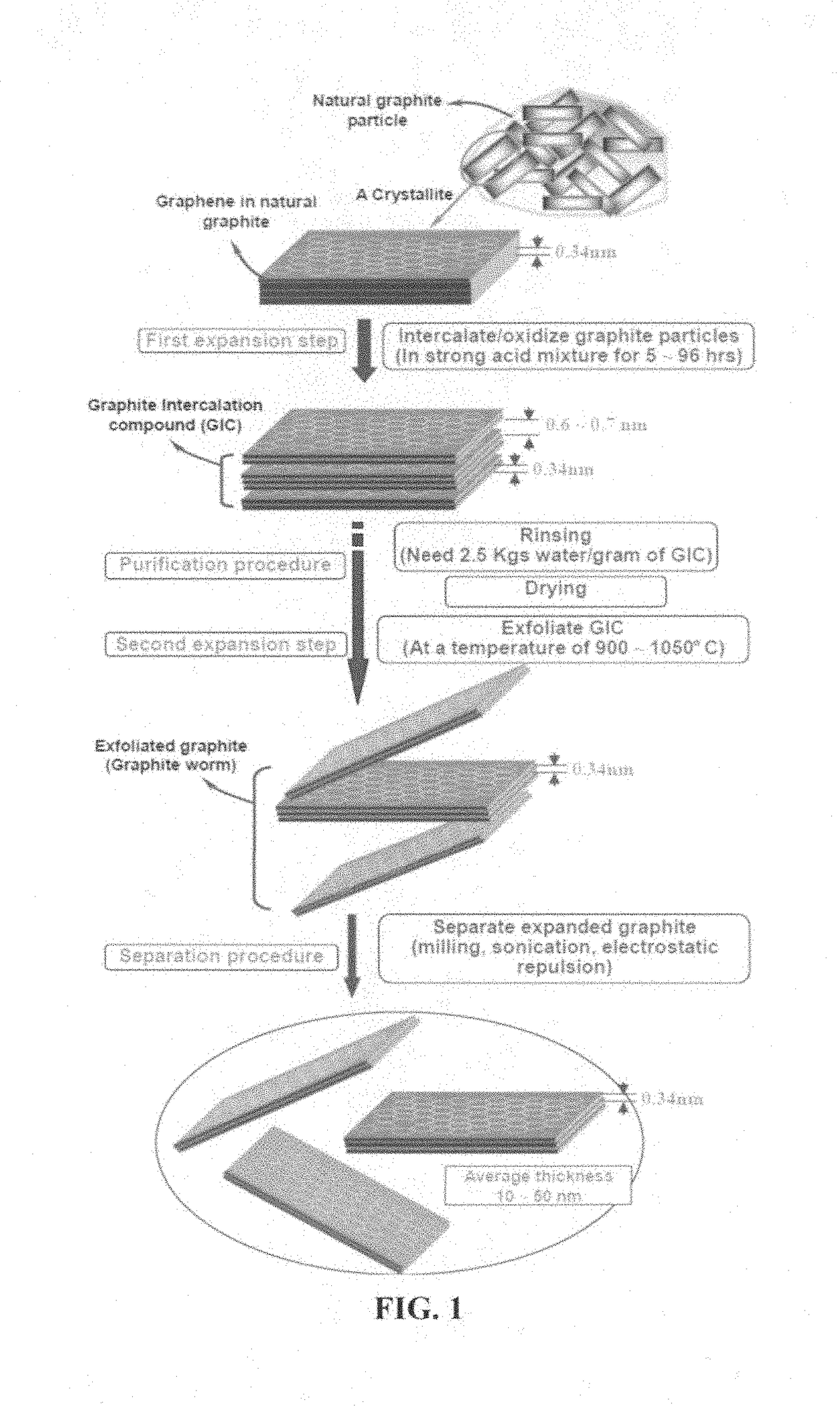

The present invention provides a nano-scaled graphene platelet-based composite material composition for use as an electrode, particularly as an anode of a lithium ion battery. The composition comprises: (a) micron- or nanometer-scaled particles or coating which are capable of absorbing and desorbing lithium ions; and (b) a plurality of nano-scaled graphene platelets (NGPs), wherein a platelet comprises a graphene sheet or a stack of graphene sheets having a platelet thickness less than 100 nm; wherein at least one of the particles or coating is physically attached or chemically bonded to at least one of the graphene platelets and the amount of platelets is in the range of 2% to 90% by weight and the amount of particles or coating in the range of 98% to 10% by weight. Also provided is a lithium secondary battery comprising such a negative electrode (anode). The battery exhibits an exceptional specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

Graphene film as transparent and electrically conducting material

ActiveUS20070284557A1Material nanotechnologyConductive materialGraphene flakeTransparent conducting film

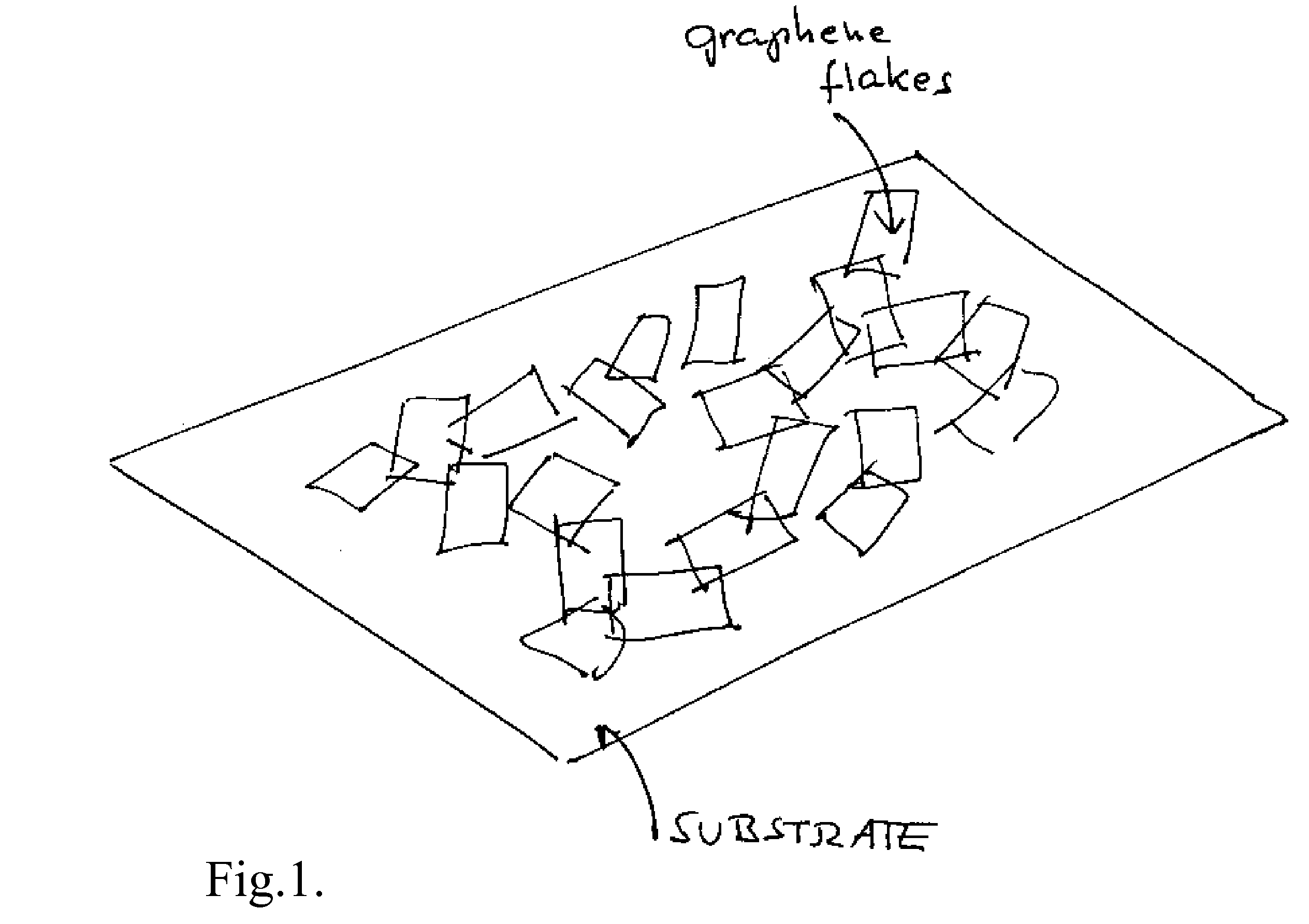

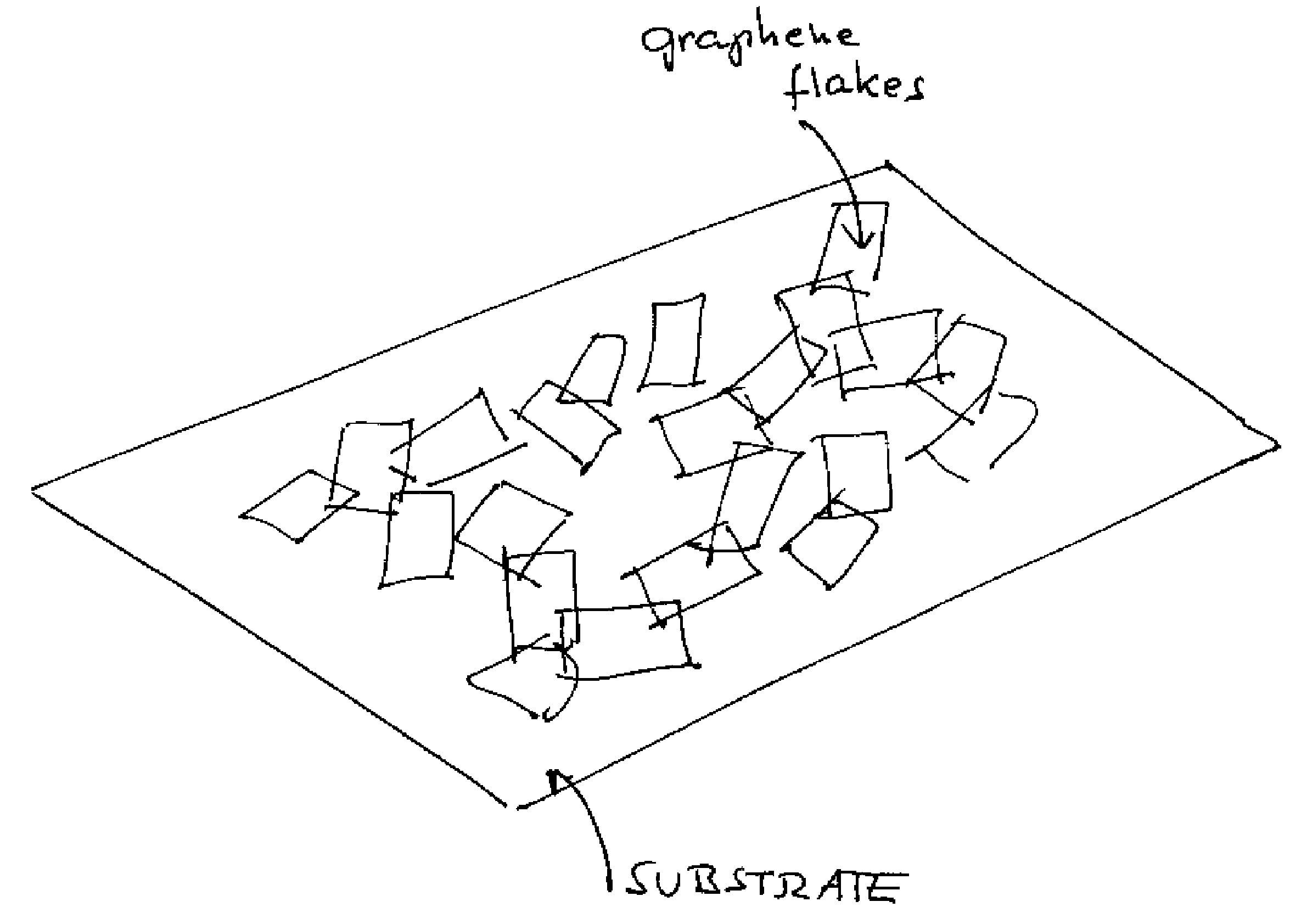

A transparent and conductive film comprising at least one network of graphene flakes is described herein. This film may further comprise an interpenetrating network of other nanostructures, a polymer and / or a functionalization agent(s). A method of fabricating the above device is also described, and may comprise depositing graphene flakes in solution and evaporating solvent therefrom.

Owner:SAMSUNG ELECTRONICS CO LTD

Nano graphene platelet-base composite anode compositions for lithium ion batteries

ActiveUS7745047B2Improve conductivityLower internal resistanceAlkaline accumulatorsElectrolytic capacitorsGraphiteGraphene

The present invention provides a nano-scaled graphene platelet-based composite material composition for use as an electrode, particularly as an anode of a lithium ion battery. The composition comprises: (a) micron- or nanometer-scaled particles or coating which are capable of absorbing and desorbing lithium ions; and (b) a plurality of nano-scaled graphene platelets (NGPs), wherein a platelet comprises a graphene sheet or a stack of graphene sheets having a platelet thickness less than 100 nm; wherein at least one of the particles or coating is physically attached or chemically bonded to at least one of the graphene platelets and the amount of platelets is in the range of 2% to 90% by weight and the amount of particles or coating in the range of 98% to 10% by weight. Also provided is a lithium secondary battery comprising such a negative electrode (anode). The battery exhibits an exceptional specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

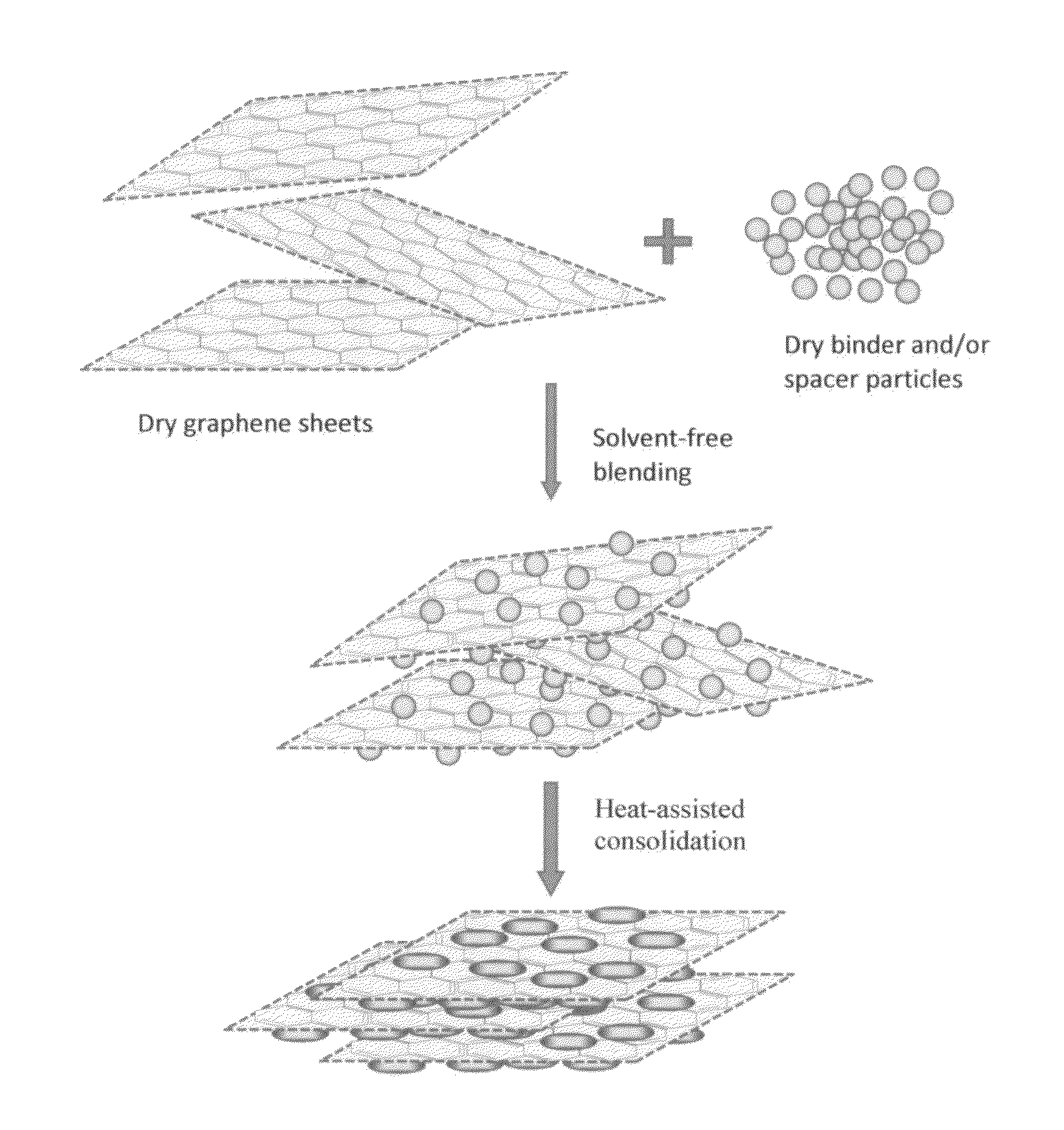

Solvent-free process based graphene electrode for energy storage devices

PendingUS20140030590A1Inexpensive and durable and highly reliableHigh capacitanceMaterial nanotechnologyHybrid capacitor electrodesGraphene flakeSolvent free

Disclosed is an electrode for an electrochemical energy storage device, the electrode comprising a self-supporting layer of a mixture of graphene sheets and spacer particles and / or binder particles, wherein the electrode is prepared without using water, solvent, or liquid chemical. The graphene electrode prepared by the solvent-free process exhibits many desirable features and advantages as compared to the corresponding electrode prepared by a known wet process. These advantages include a higher electrode specific surface area, higher energy storage capacity, improved or higher packing density or tap density, lower amount of binder required, lower internal electrode resistance, more consistent and uniform dispersion of graphene sheets and binder, reduction or elimination of undesirable effect of electrolyte oxidation or decomposition due to the presence of water, solvent, or chemical, etc.

Owner:GLOBAL GRAPHENE GRP INC

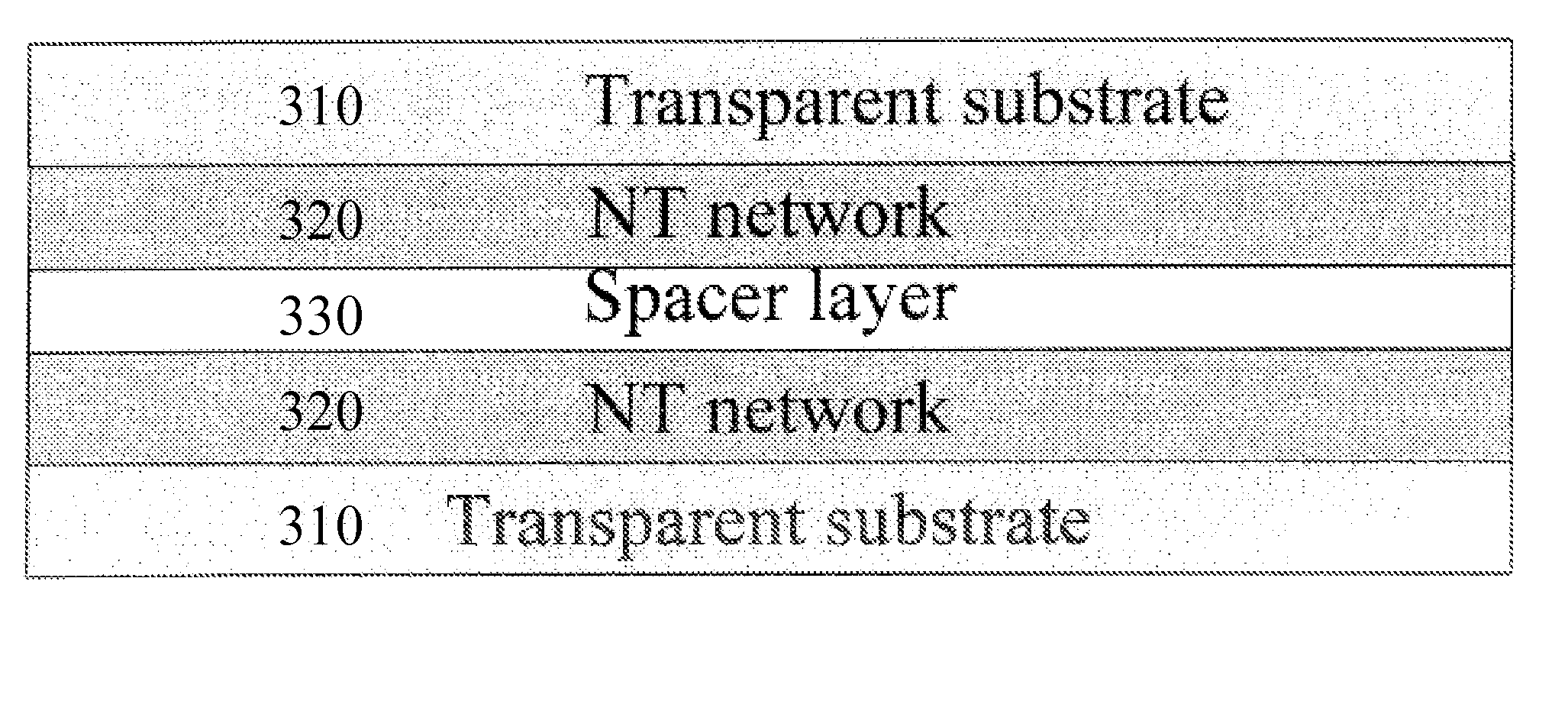

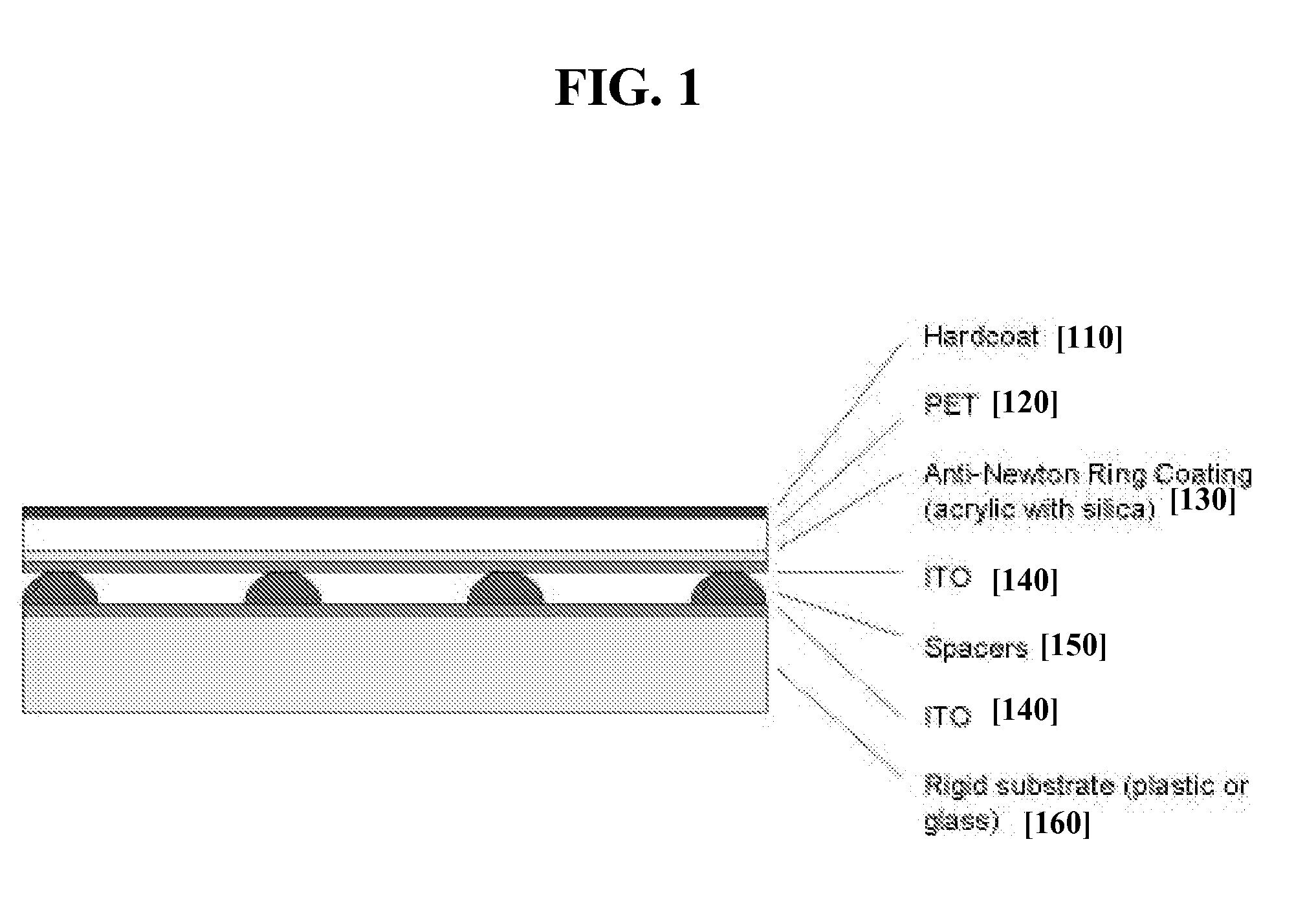

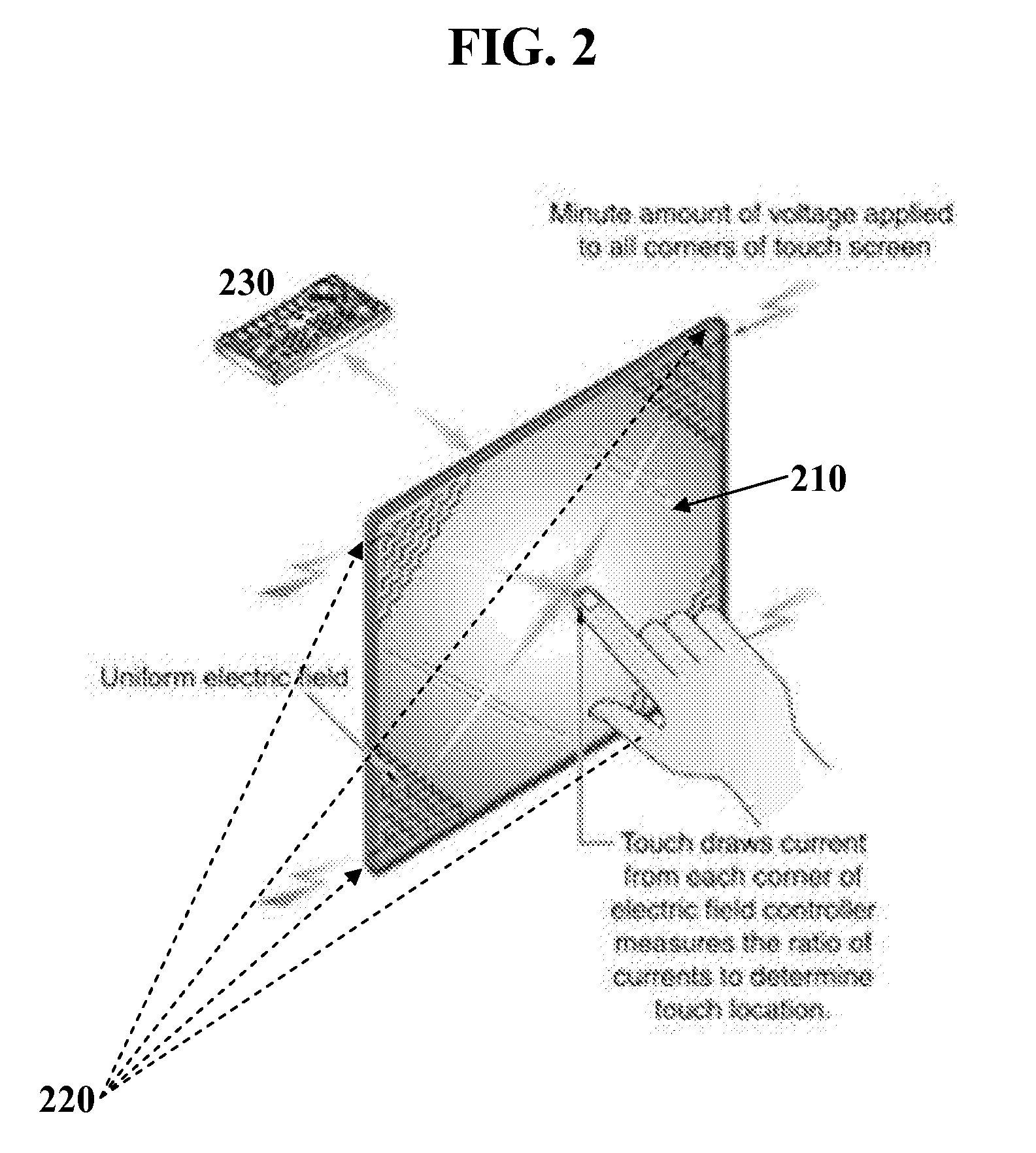

Touch screen devices employing nanostructure networks

Touch screen displays comprising at least one nanostructure-film, and fabrication methods thereof, are discussed. Nanostructure-films may comprise, for example, a network(s) of nanotubes, nanowires, nanoparticles and / or graphene flakes. Such films are preferably at least semi-transparent and relatively flexible, making them well-suited for use in a variety of touch screen applications.

Owner:UNIDYM

Graphene composite material and preparation method thereof

ActiveCN104495811ALarge specific surface areaImprove conductivityMaterial nanotechnologyPtru catalystElectrical battery

The invention relates to a graphene composite material and a preparation method thereof. The graphene composite material provided by the invention is characterized in that a graphene material plate fixed on a metallic matrix serves as a carrier, and the elementary substance and / or a compound are compounded on the graphene surface. Meanwhile, the invention also discloses a method for preparing the graphene composite material. The graphene composite material prepared by the invention is opened between graphene sheets and is compounded with a chemical substance under the condition that a space body structure is formed, and the obtained material has high conductivity, high specific surface area and excellent performance of low electrical resistivity between the sheets, and can be widely applied to the fields of energy storage materials such as lithium ion batteries, super-capacitors, super lead carbon batteries, super nickel-carbon electrodes, solar energy and fuel cells, the field of heat dissipation materials, the field of environment-friendly adsorbing materials, the field of sea water desalination materials, the field of photoelectric sensor materials, the biological relevance field, the field of catalyst materials and the fields of conductive ink and coating materials.

Owner:YANCHENG TEACHERS UNIV

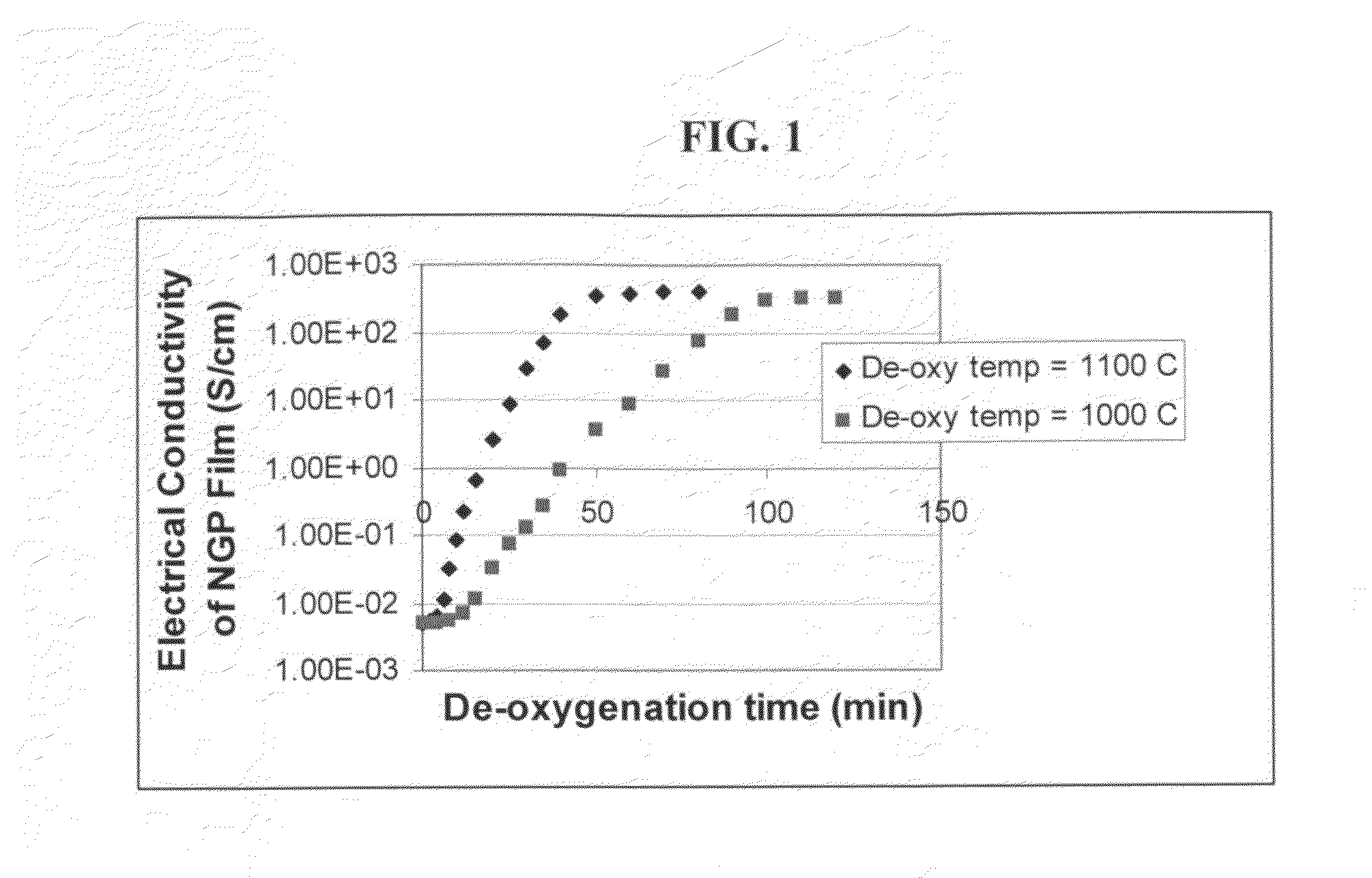

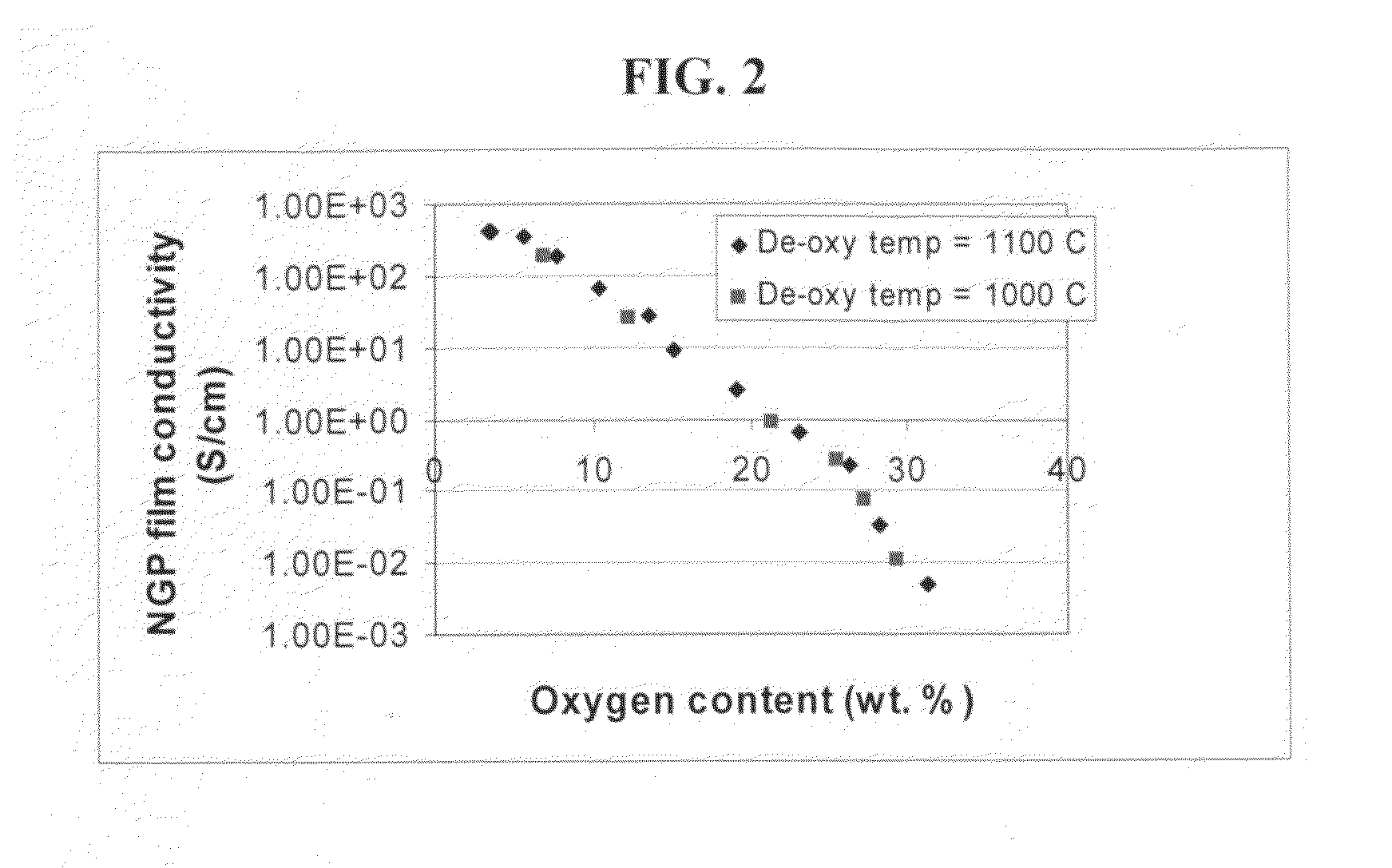

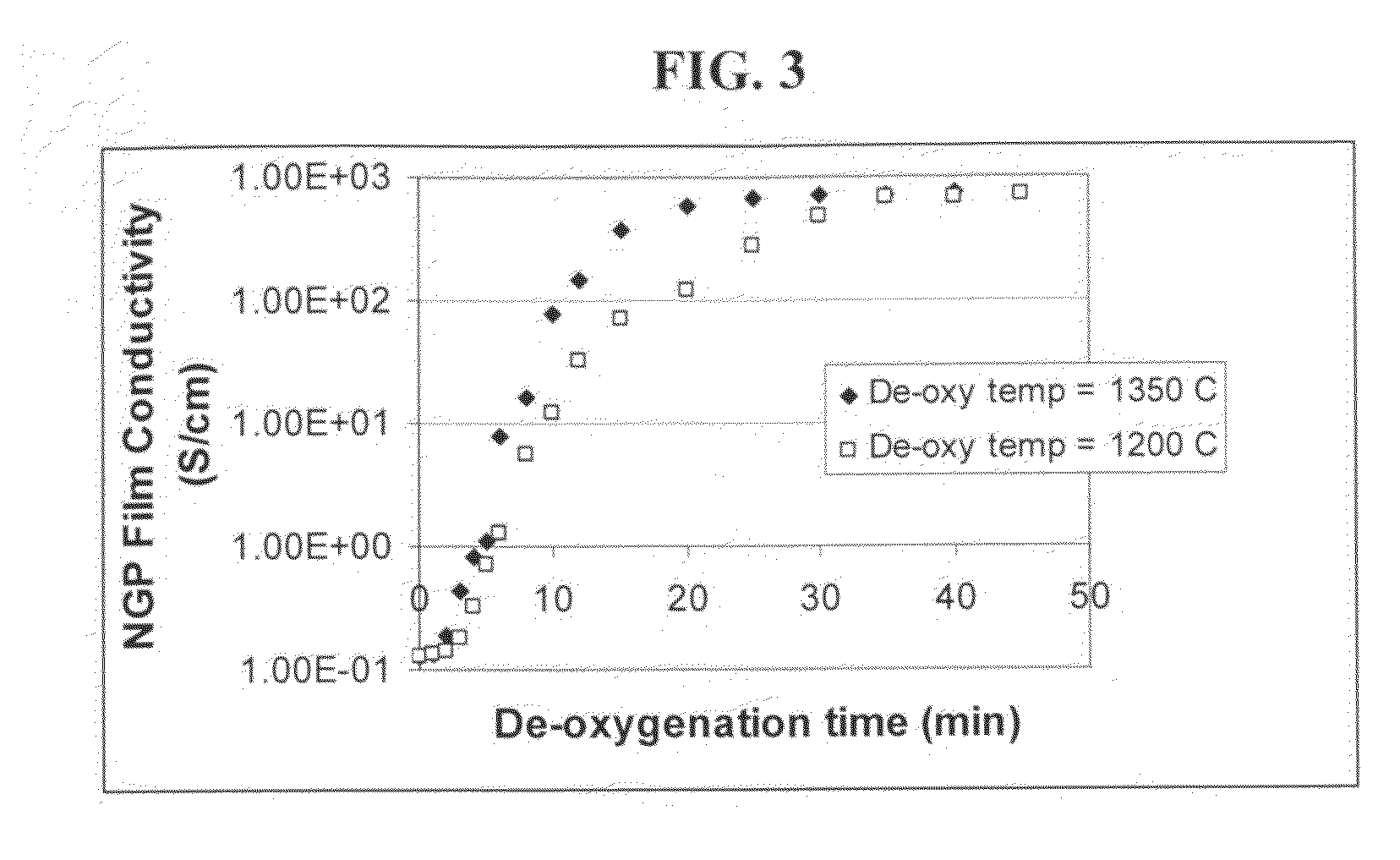

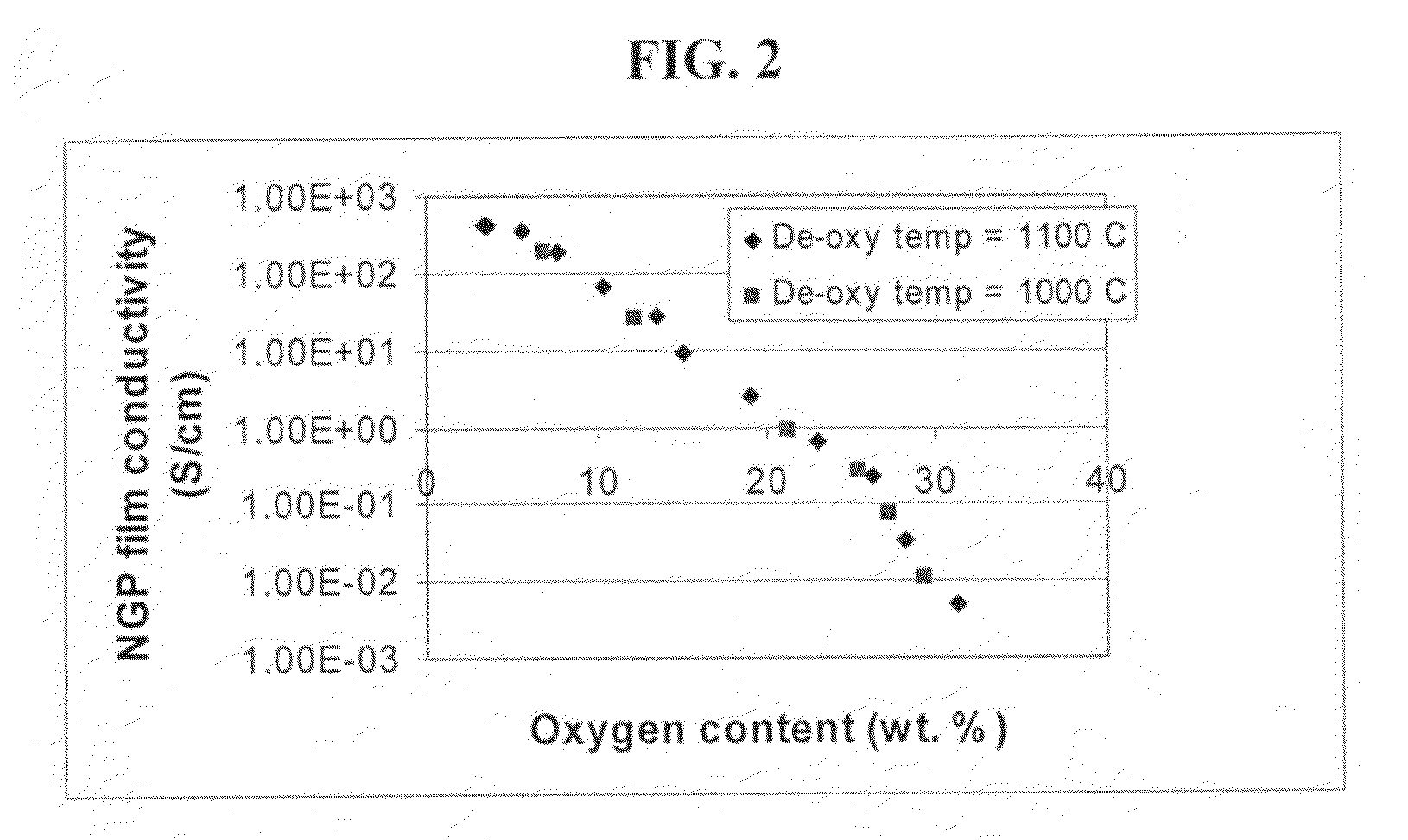

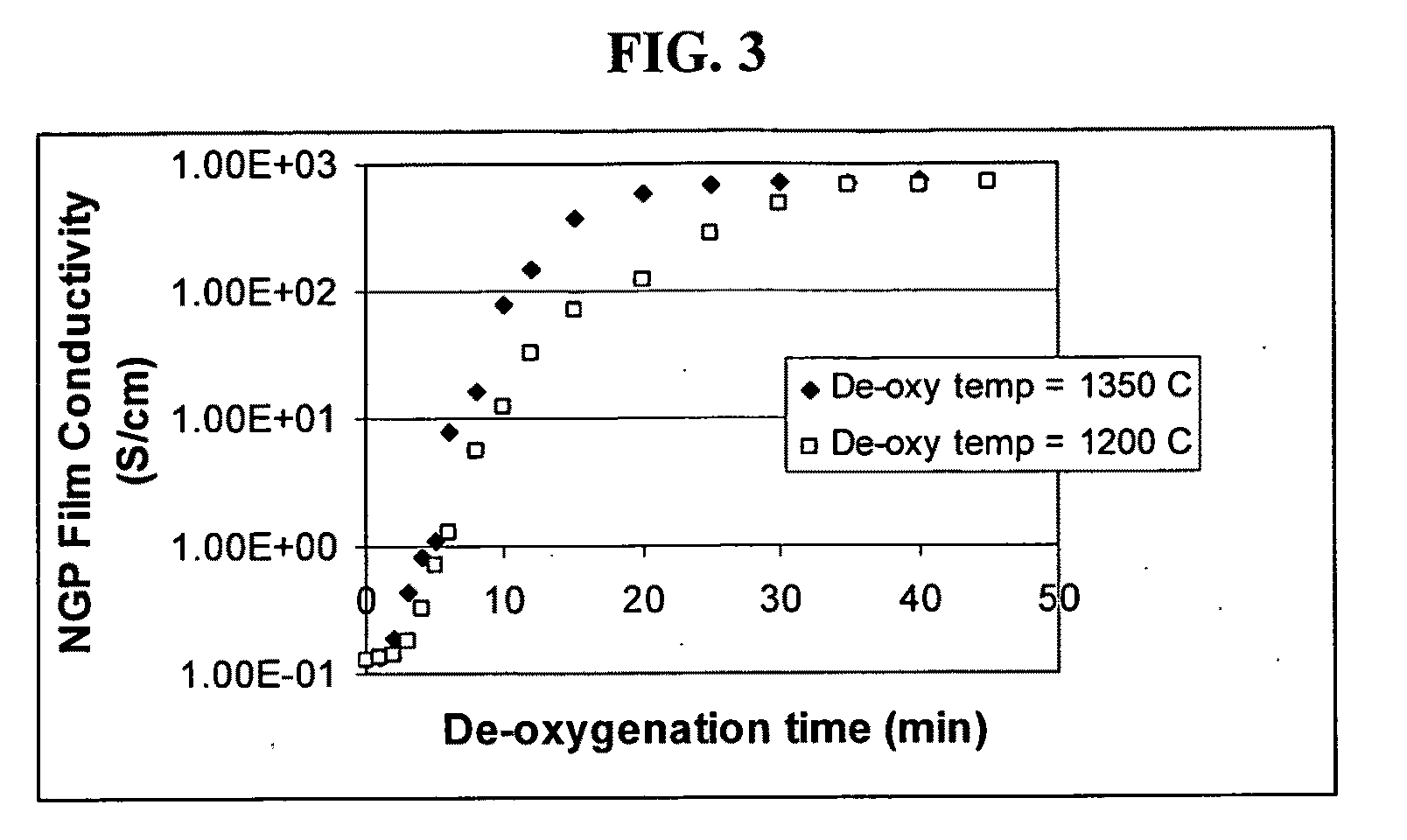

Process for producing dispersible and conductive Nano Graphene Platelets from non-oxidized graphitic materials

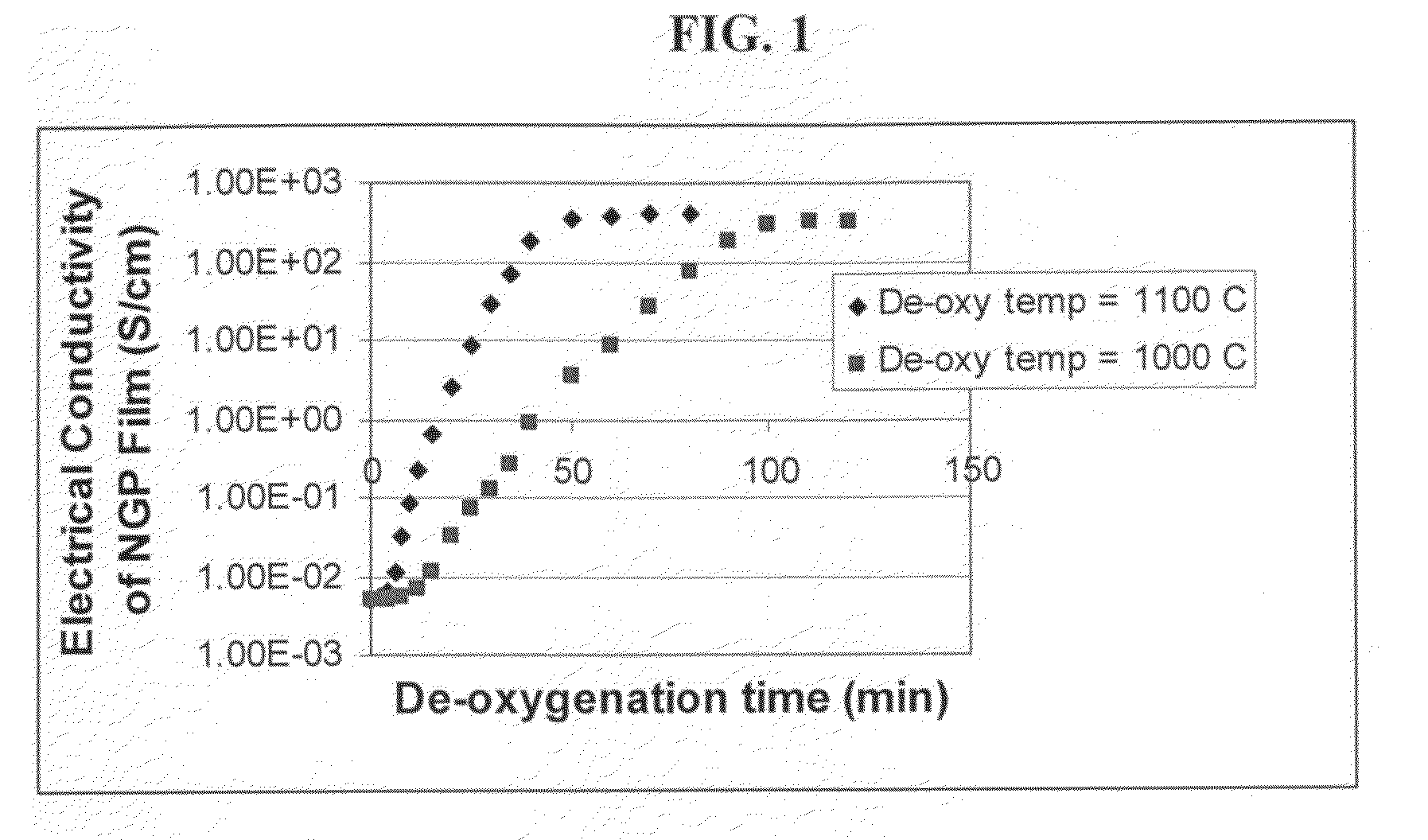

ActiveUS20100056819A1Impart dispersibilityImpart solubilityMaterial nanotechnologyPigmenting treatmentDisplay deviceSolar cell

The present invention provides a process for producing nano graphene platelets (NGPs) that are both dispersible and electrically conducting. The process comprises: (a) preparing a pristine NGP material from a graphitic material; and (b) subjecting the pristine NGP material to an oxidation treatment to obtain the dispersible NGP material, wherein the NGP material has an oxygen content no greater than 25% by weight. Conductive NGPs can find applications in transparent electrodes for solar cells or flat panel displays, additives for battery and supercapacitor electrodes, conductive nanocomposite for electromagnetic wave interference (EMI) shielding and static charge dissipation, etc.

Owner:GLOBAL GRAPHENE GRP INC

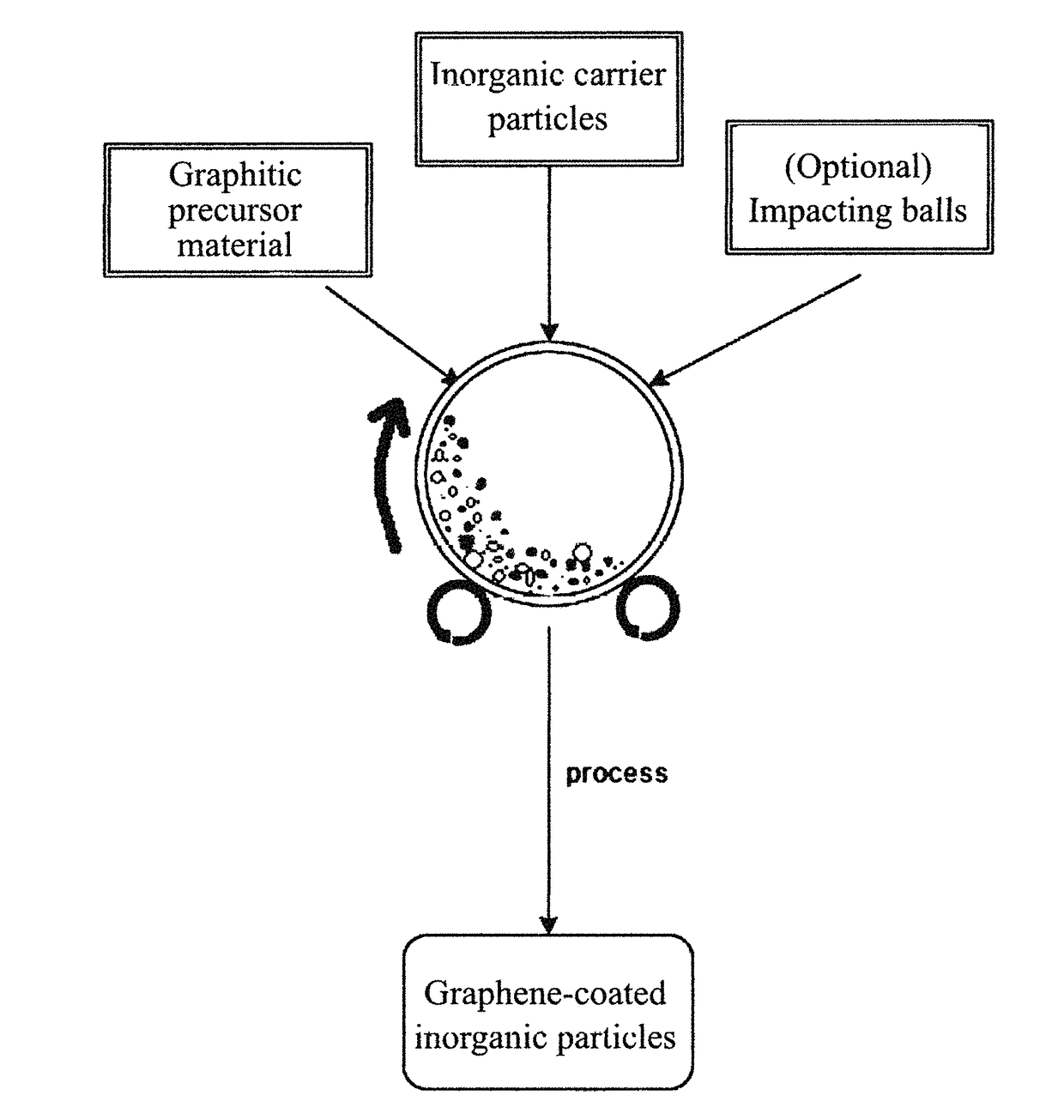

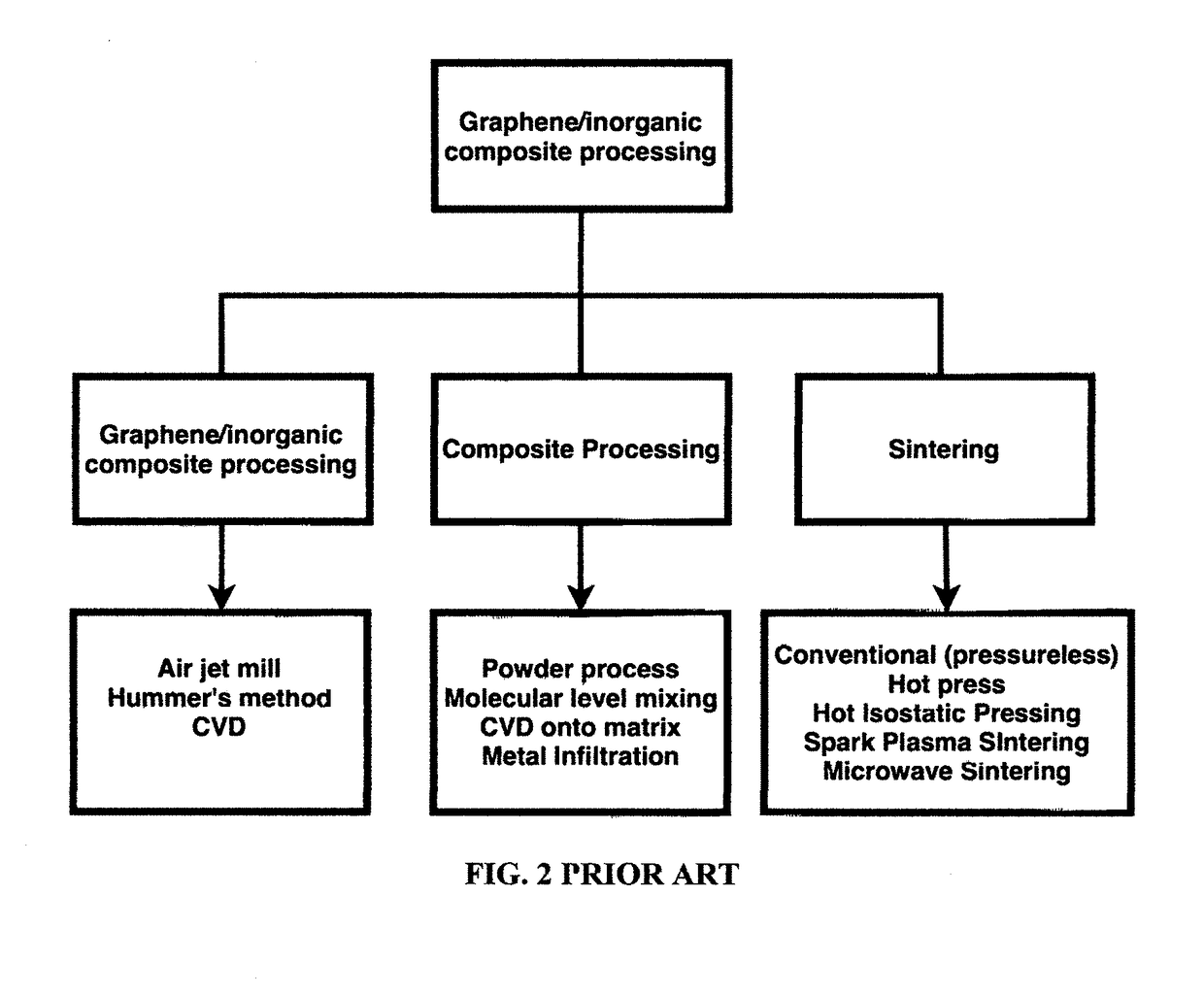

Chemical-free production of graphene-reinforced inorganic matrix composites

ActiveUS20170225233A1Low costAdditive manufacturing apparatusTransportation and packagingInorganic particleGraphene flake

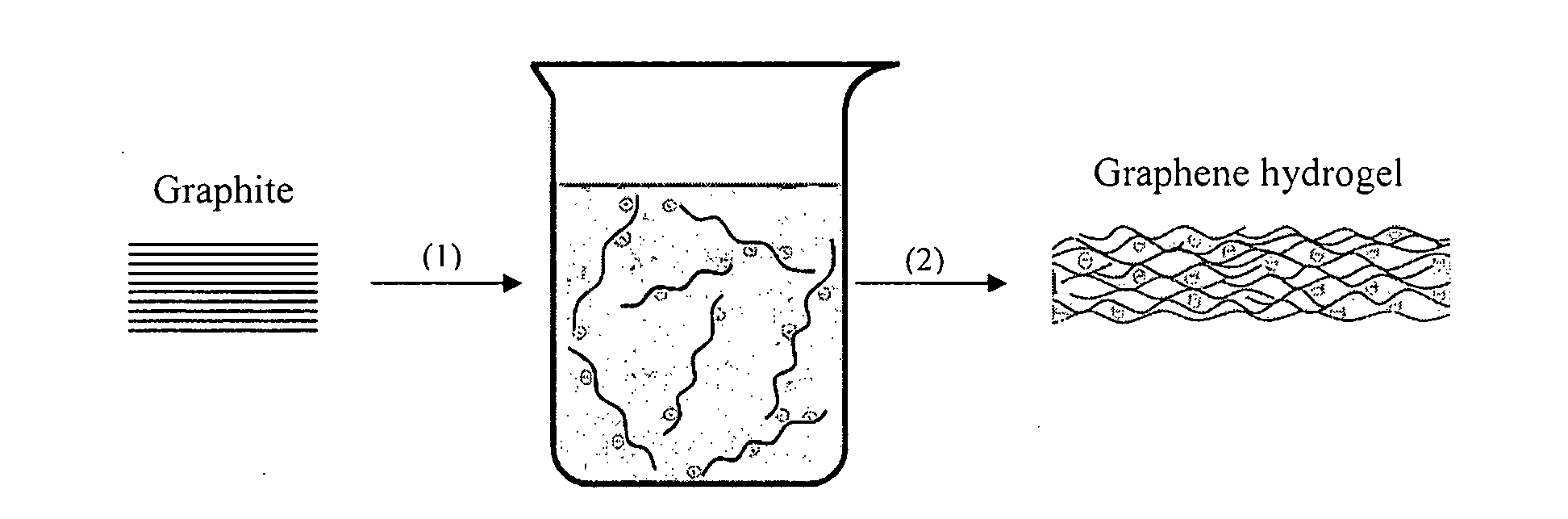

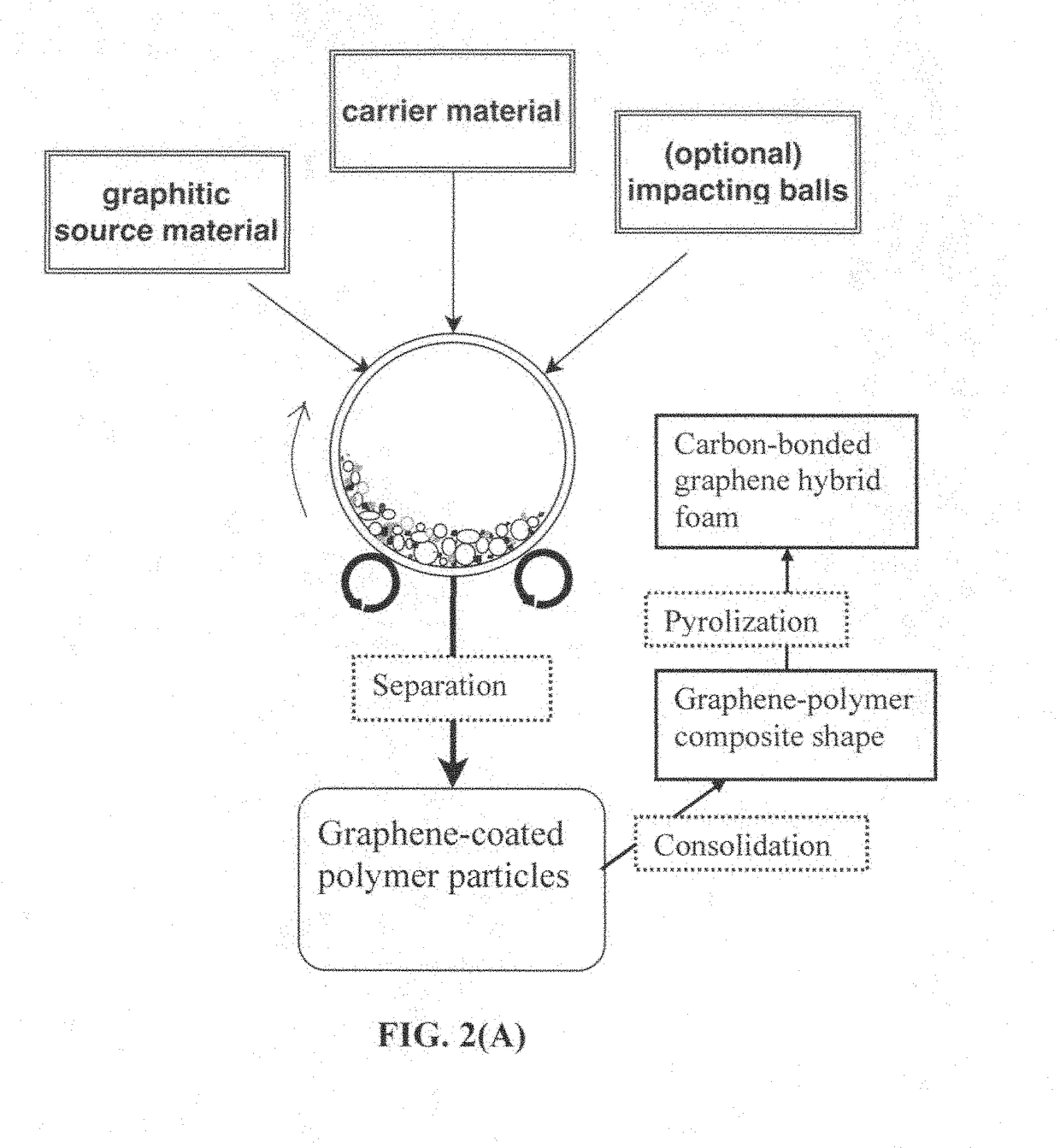

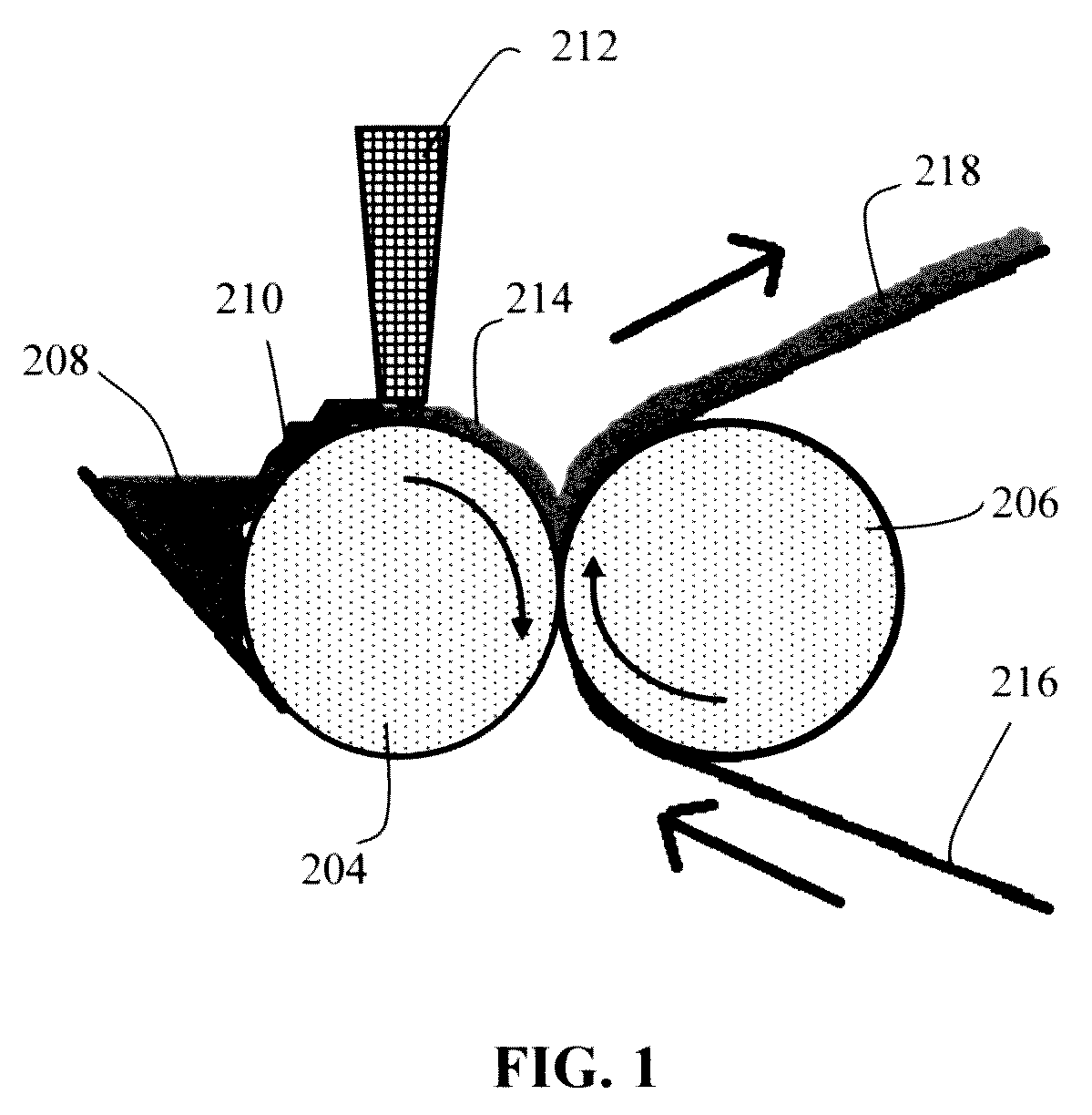

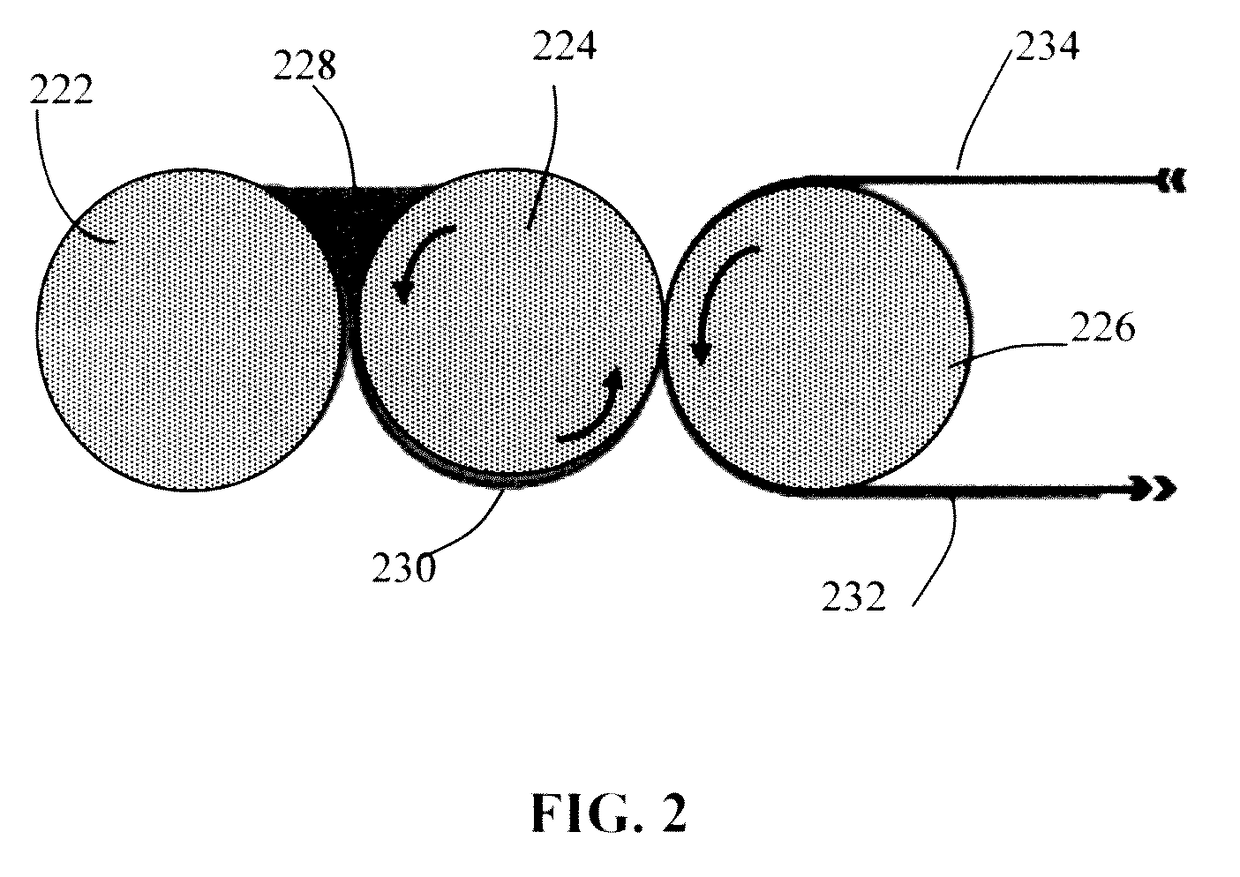

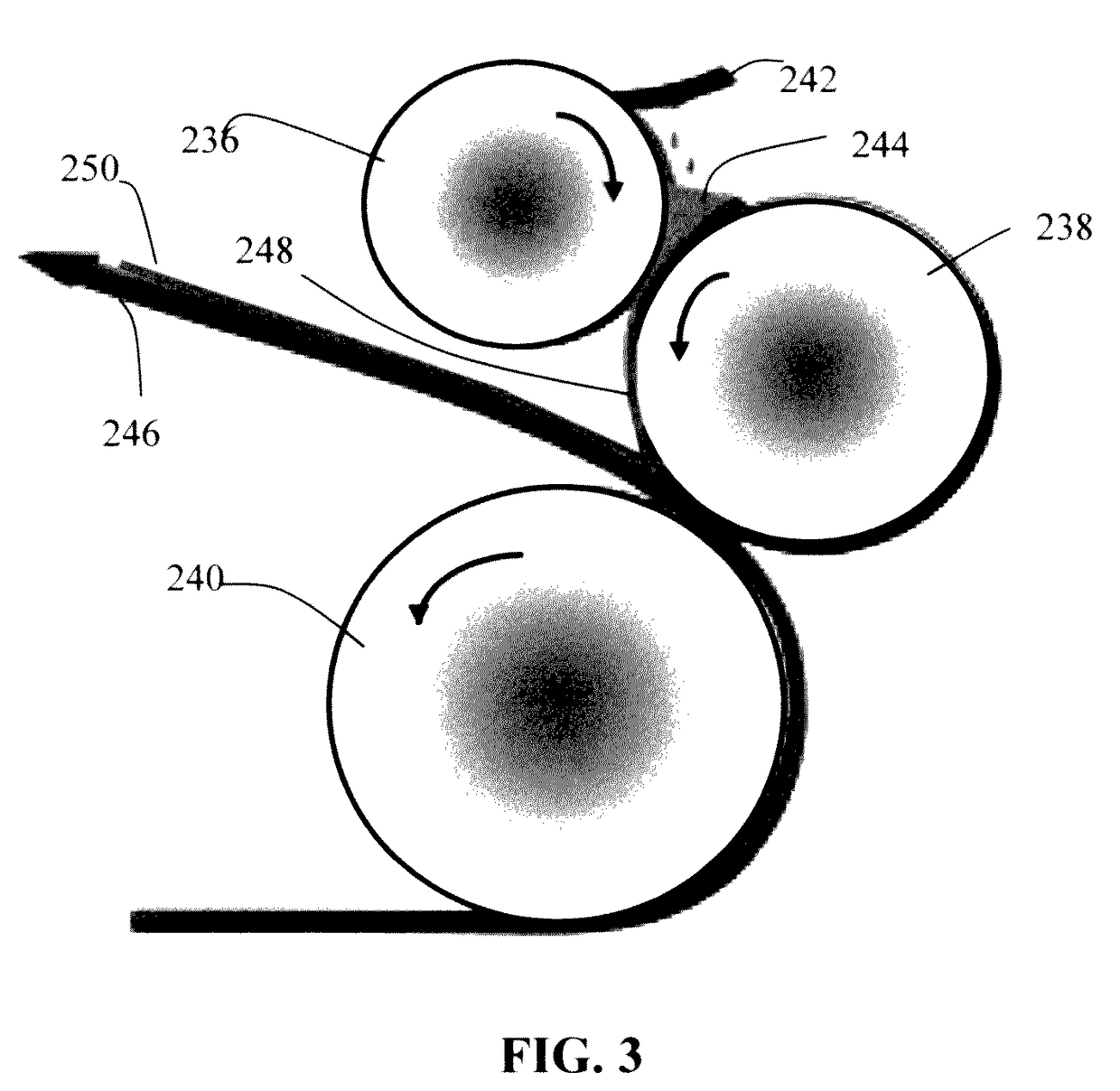

Provided is a simple, fast, scalable, and environmentally benign method of producing a graphene-reinforced inorganic matrix composite directly from a graphitic material, the method comprising: (a) mixing multiple particles of a graphitic material and multiple particles of an inorganic solid carrier material to form a mixture in an impacting chamber of an energy impacting apparatus; (b) operating the energy impacting apparatus with a frequency and an intensity for a length of time sufficient for peeling off graphene sheets from the graphitic material and transferring the graphene sheets to surfaces of solid inorganic carrier material particles to produce graphene coated or graphene-embedded inorganic particles inside the impacting chamber; and (c) forming graphene-coated or graphene-embedded inorganic particles into the graphene-reinforced inorganic matrix composite. Also provided is a mass of the graphene-coated or graphene-embedded inorganic particles produced by this method.

Owner:GLOBAL GRAPHENE GRP INC

Anode active material-coated graphene sheets for lithium batteries and process for producing same

ActiveUS20150044565A1Enhanced Li-ion insertionIncrease capacityElectric discharge heatingFinal product manufactureMetallurgyLithium-ion battery

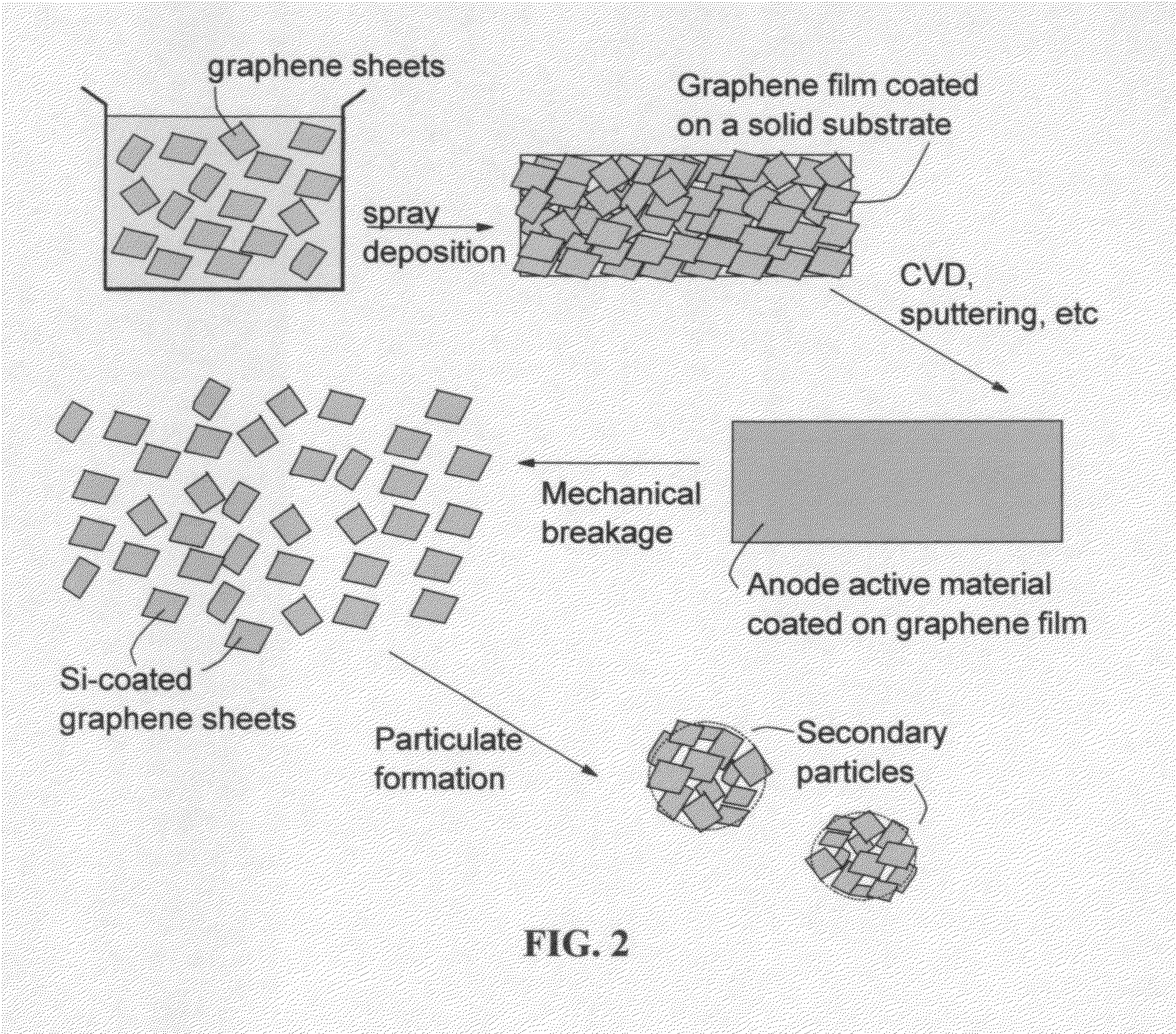

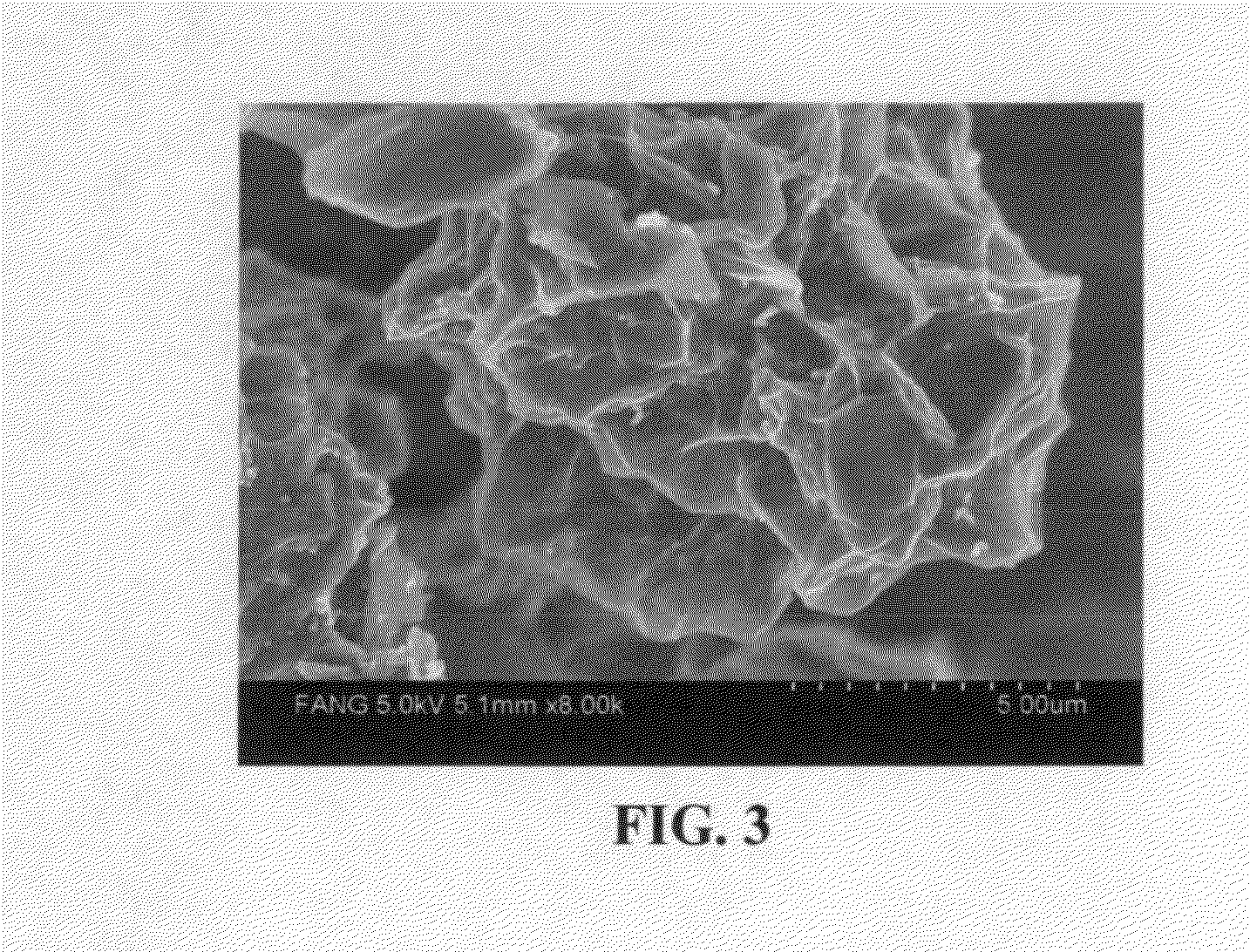

The present invention provides a process for producing a graphene-enhanced anode active material for use in a lithium battery. The process comprises (a) providing a continuous film of a graphene material into a deposition zone; (b) introducing vapor or atoms of a precursor anode active material into the deposition zone, allowing the vapor or atoms to deposit onto a surface of the graphene material film to form a sheet of an anode active material-coated graphene material; and (c) mechanically breaking this sheet into multiple pieces of anode active material-coated graphene; wherein the graphene material is in an amount of from 0.1% to 99.5% by weight and the anode active material is in an amount of at least 0.5% by weight, all based on the total weight of the graphene material and the anode active material combined.

Owner:GLOBAL GRAPHENE GRP INC

Dispersible and conductive Nano Graphene Platelets

ActiveUS20100055458A1Impart dispersibilityImpart solubilityMaterial nanotechnologySynthetic resin layered productsDisplay deviceSolar cell

The present invention provides a dispersible and electrically conductive nano graphene platelet (NGP) material comprising at least a single-layer or multiple-layer graphene sheet, wherein the NGP material has an oxygen content no greater than 25% by weight and no less than 5% by weight. This NGP material can be produced by: (a) preparing a pristine NGP material from a graphitic material; and (b) subjecting the pristine NGP material to an oxidation treatment. Alternatively, the production process may comprise: (A) preparing a graphite oxide (GO) from a laminar graphite material; (b) exposing the GO to a first temperature for a first period of time to obtain exfoliated graphite; and (c) exposing the exfoliated graphite to a second temperature in a protective atmosphere for a second period of time. Conductive NGPs can find applications in transparent electrodes for solar cells or flat panel displays, additives for battery and supercapacitor electrodes, conductive nanocomposite for electromagnetic wave interference (EMI) shielding and static charge dissipation, etc.

Owner:GLOBAL GRAPHENE GRP INC

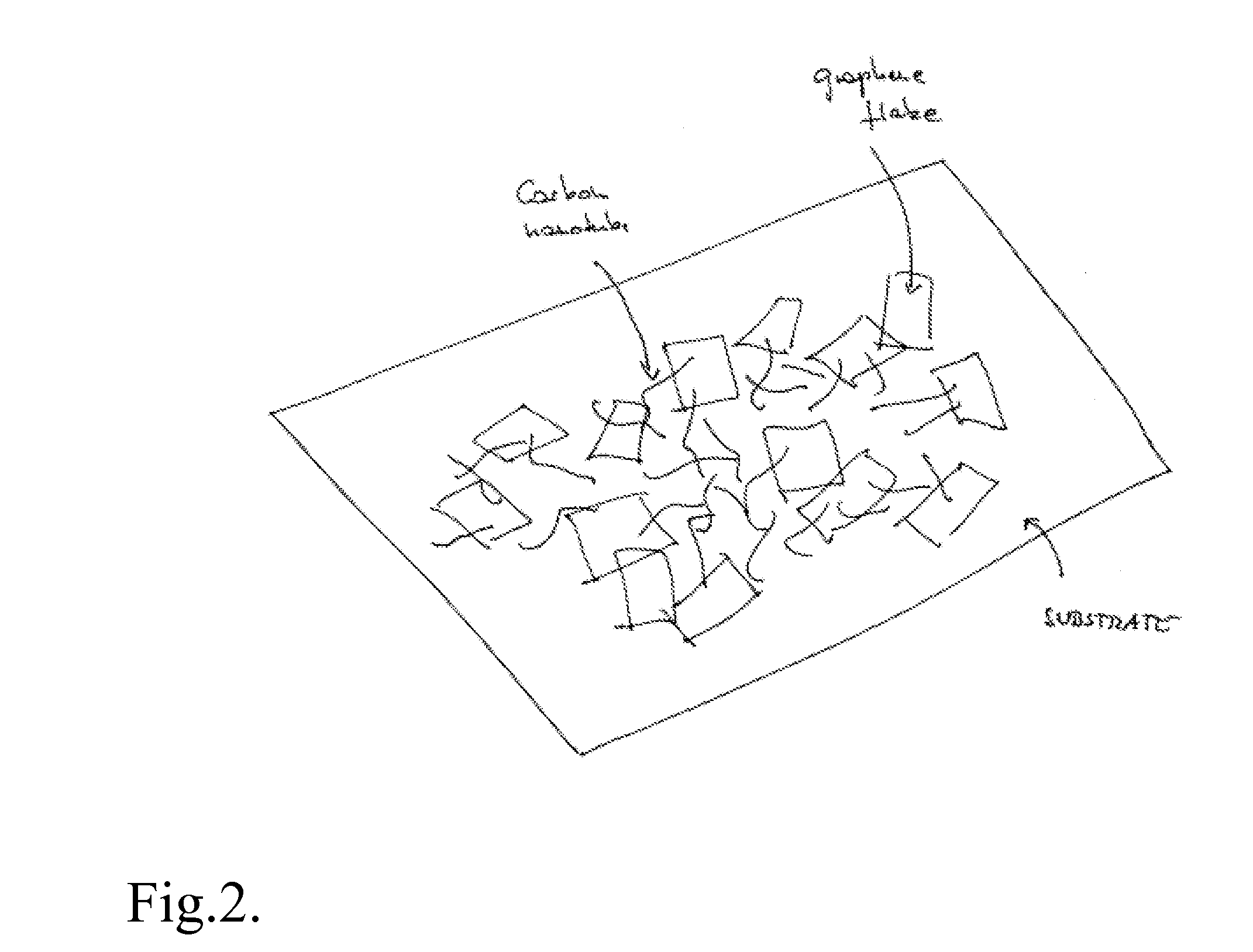

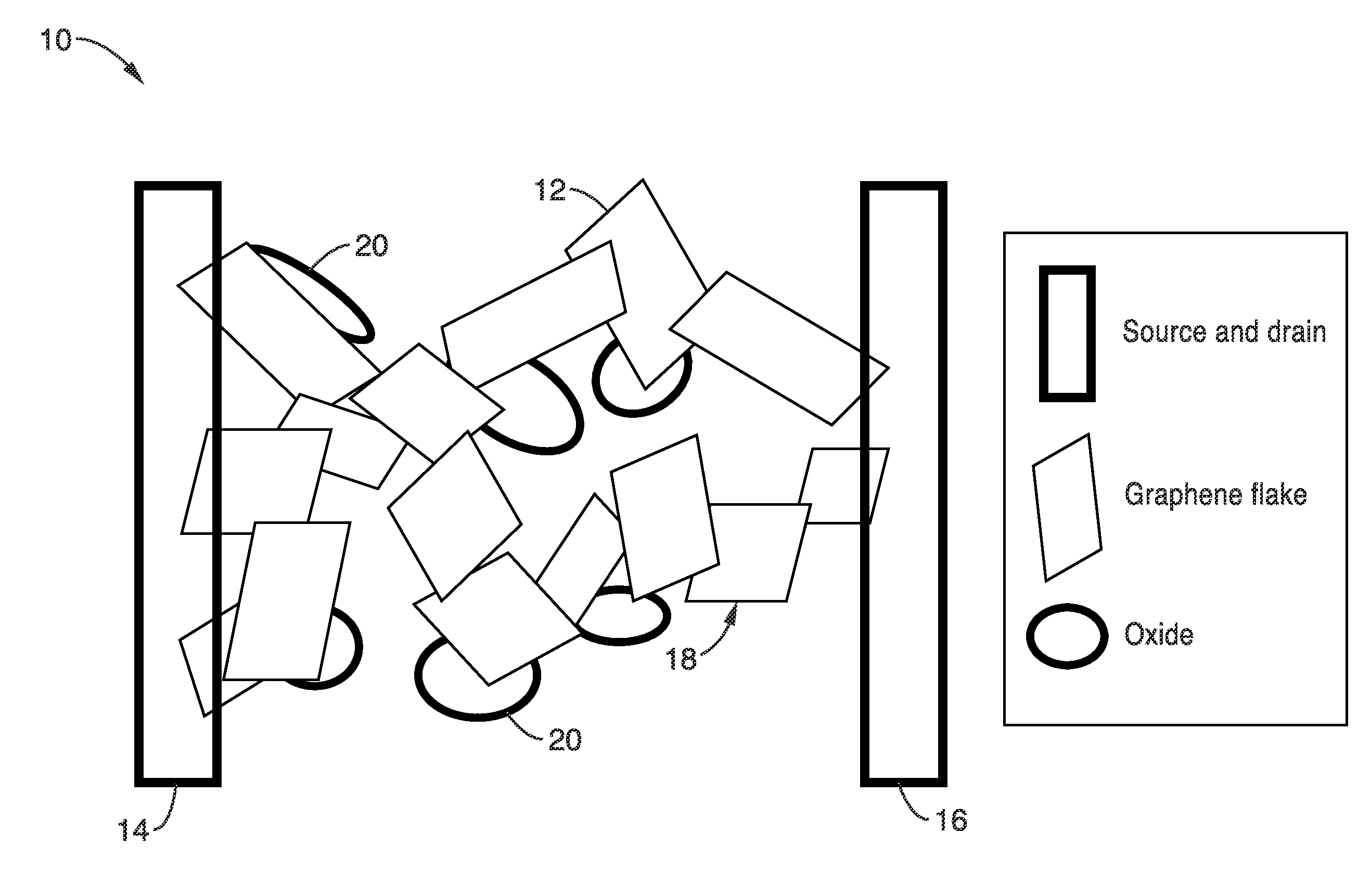

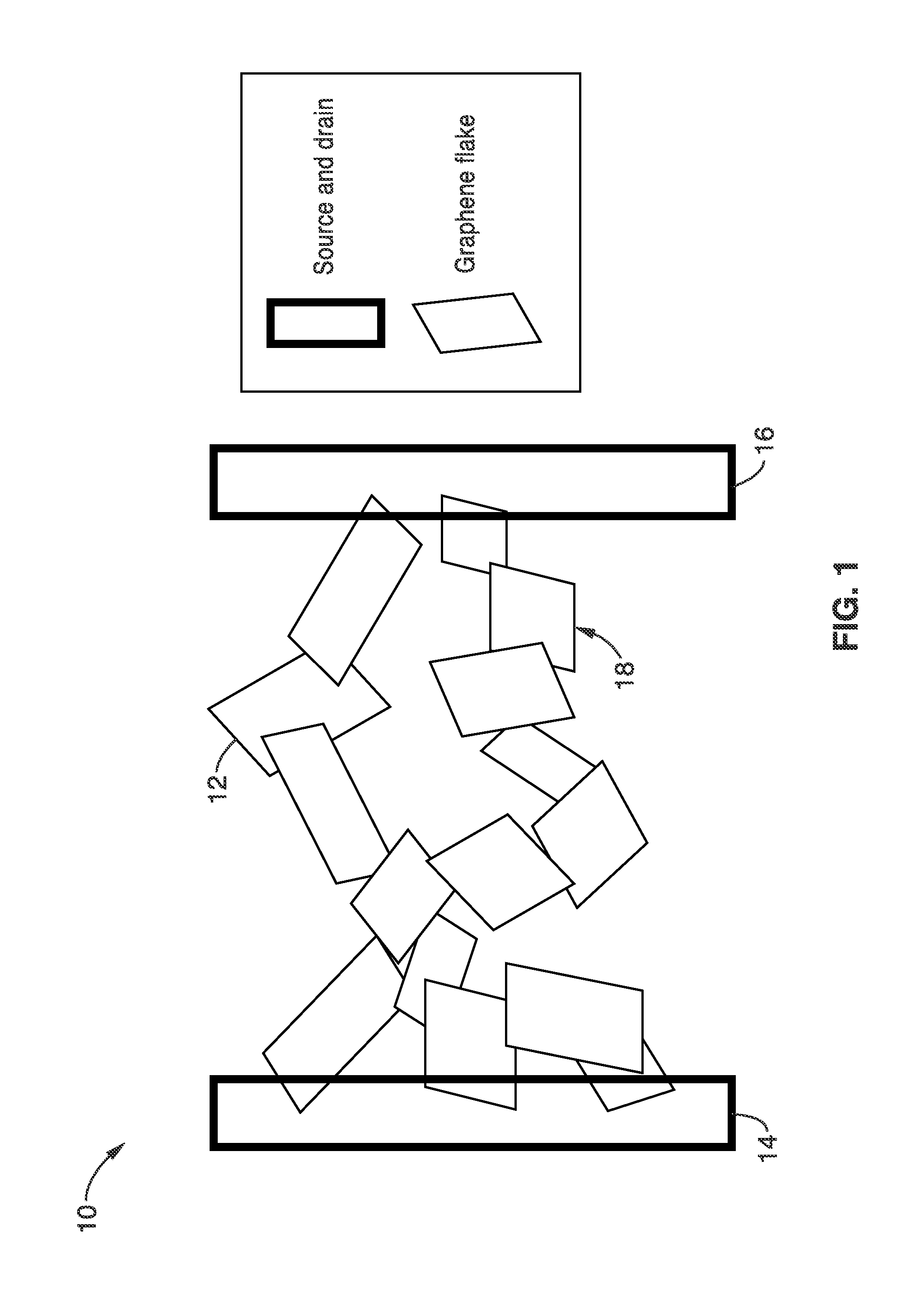

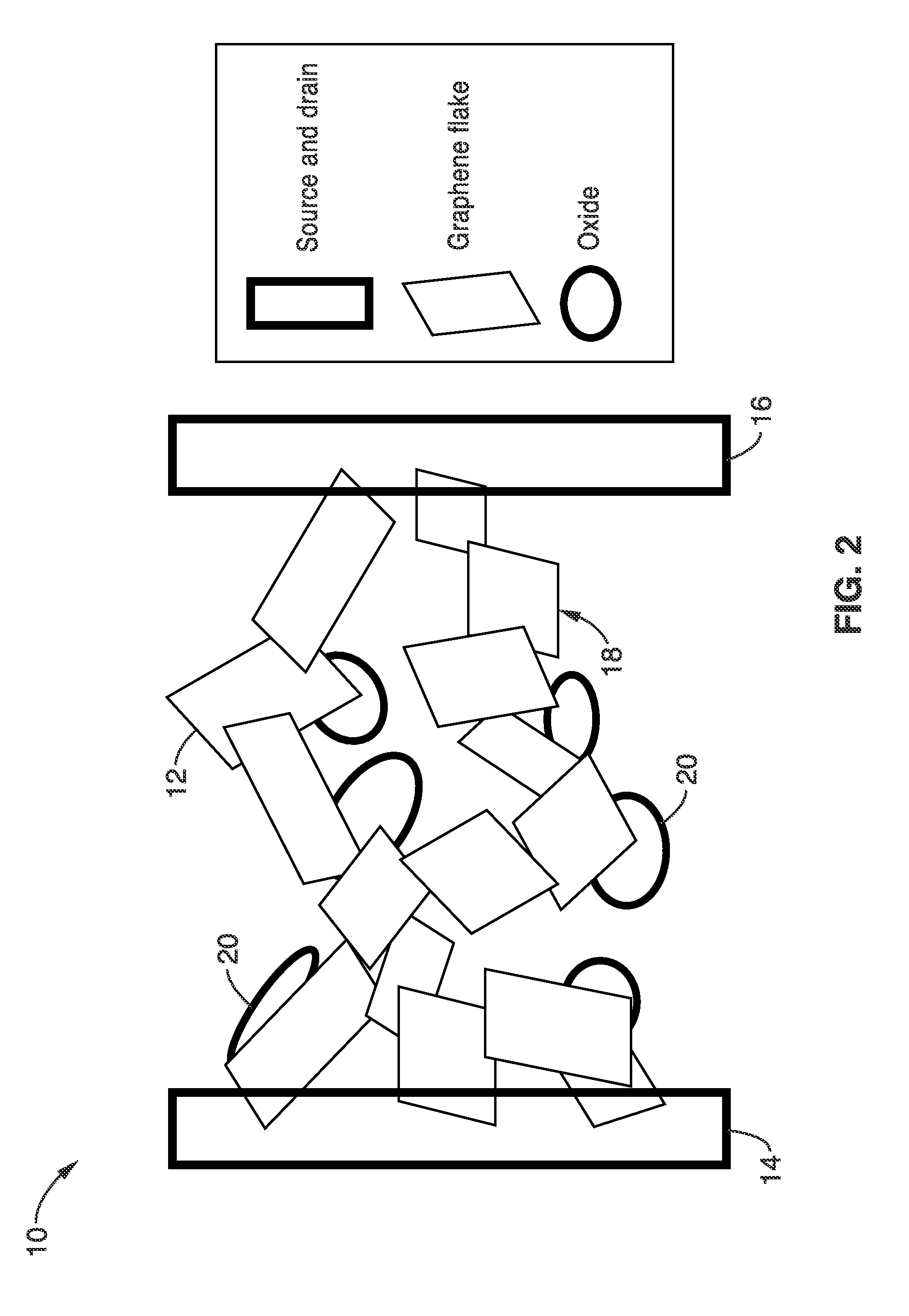

Interpenetrating networks of carbon nanostructures and nano-scale electroactive materials

InactiveUS20140042390A1Improve conductivityLarge specific surface areaElectrolytic capacitorsHybrid capacitor electrodesActivated carbonGraphene flake

An interpenetrating network assembly with a network of connected flakes of nano-scale crystalline carbon and nano-scale particles of an electroactive material interconnected with the carbon flakes is provided. The network assemblies are particularly suited for energy storage applications that use metal oxide electroactive materials and a single charge collector or a source and drain. Interpenetrating networks of graphene flakes and metal oxide nanosheets can form independent pathways between source and drain. Nano-scale conductive materials such as metal nanowires, carbon nanotubes, activated carbon or carbon black can be included as part of the conductive network to improve charge transfer.

Owner:RGT UNIV OF CALIFORNIA

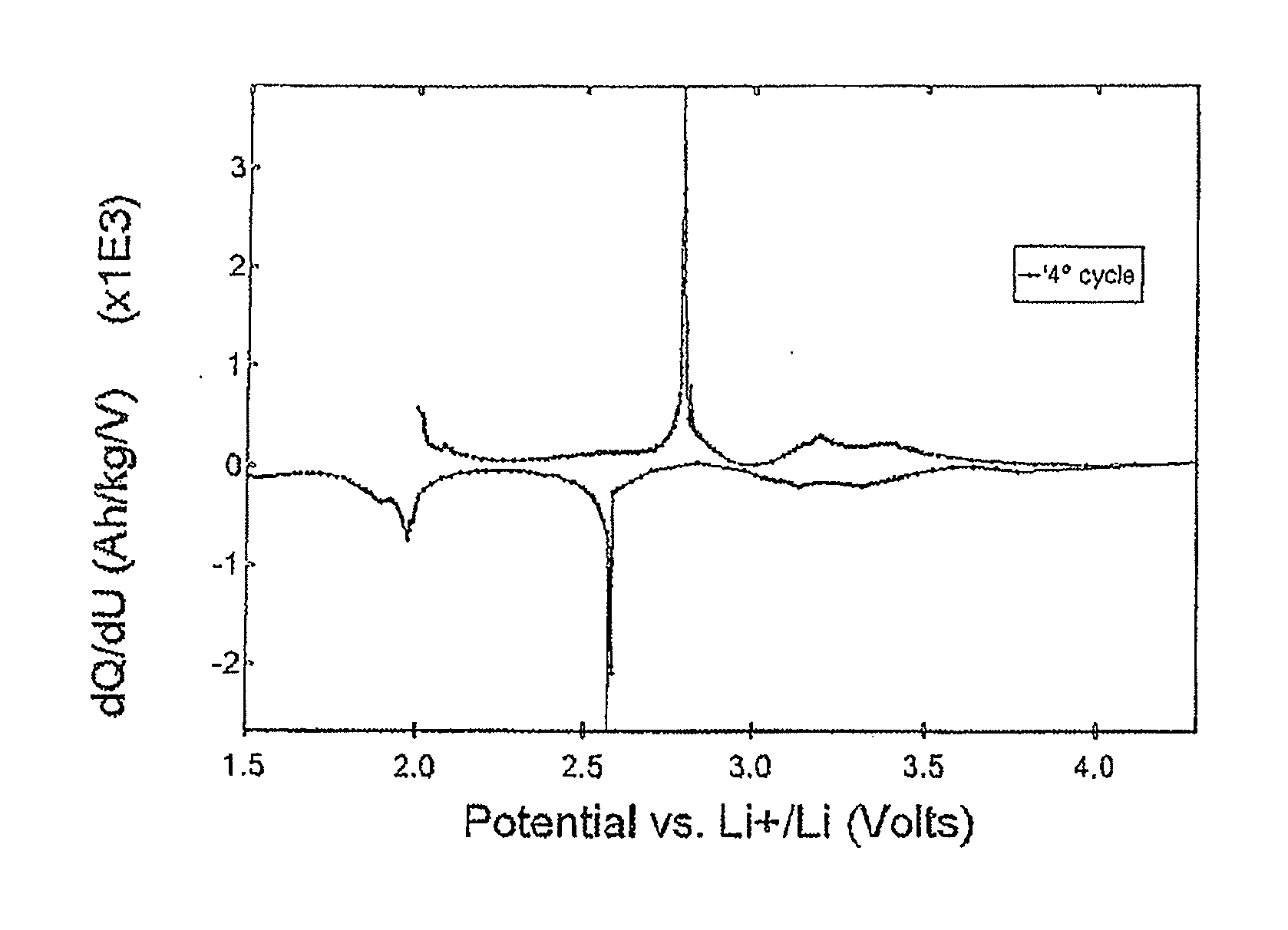

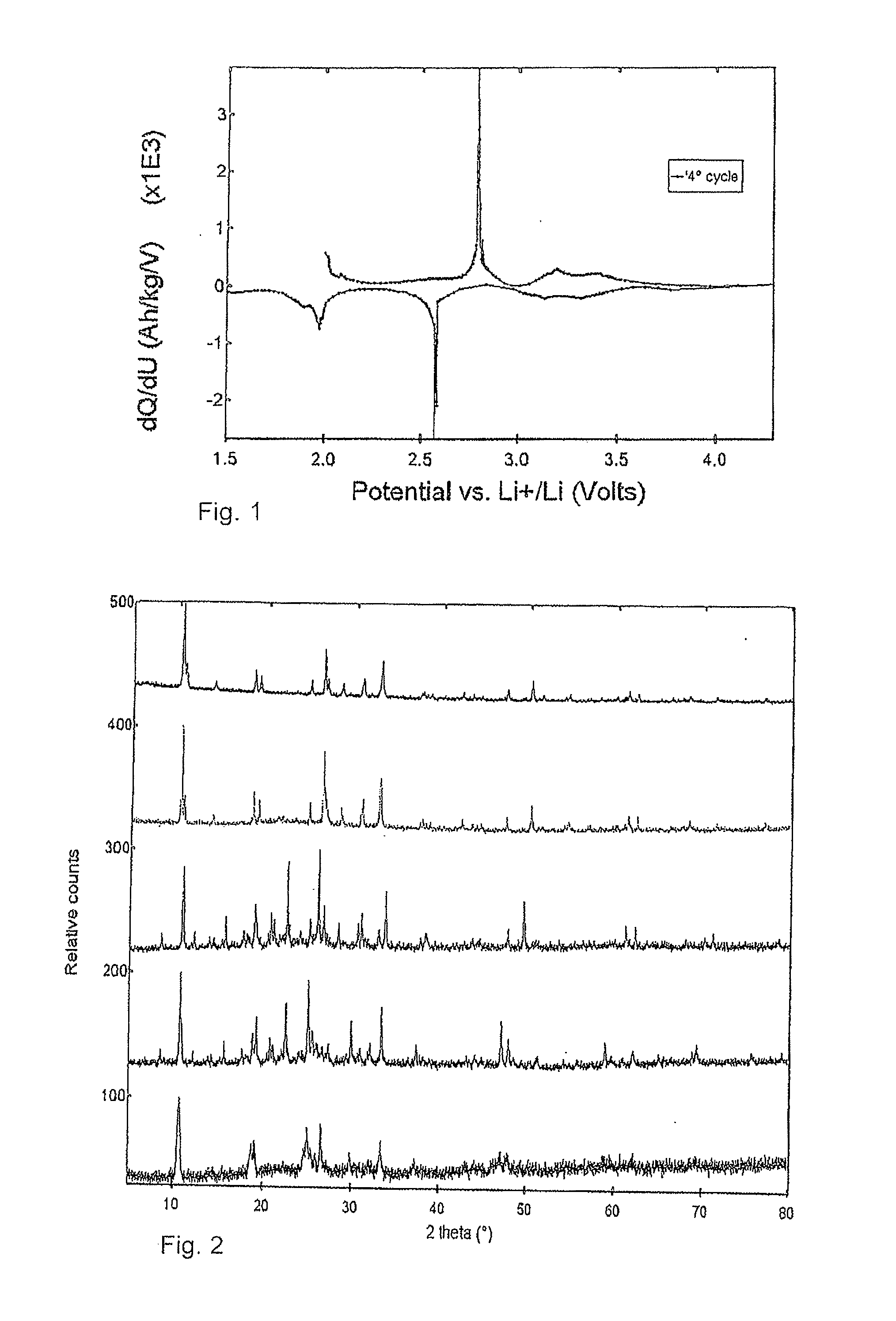

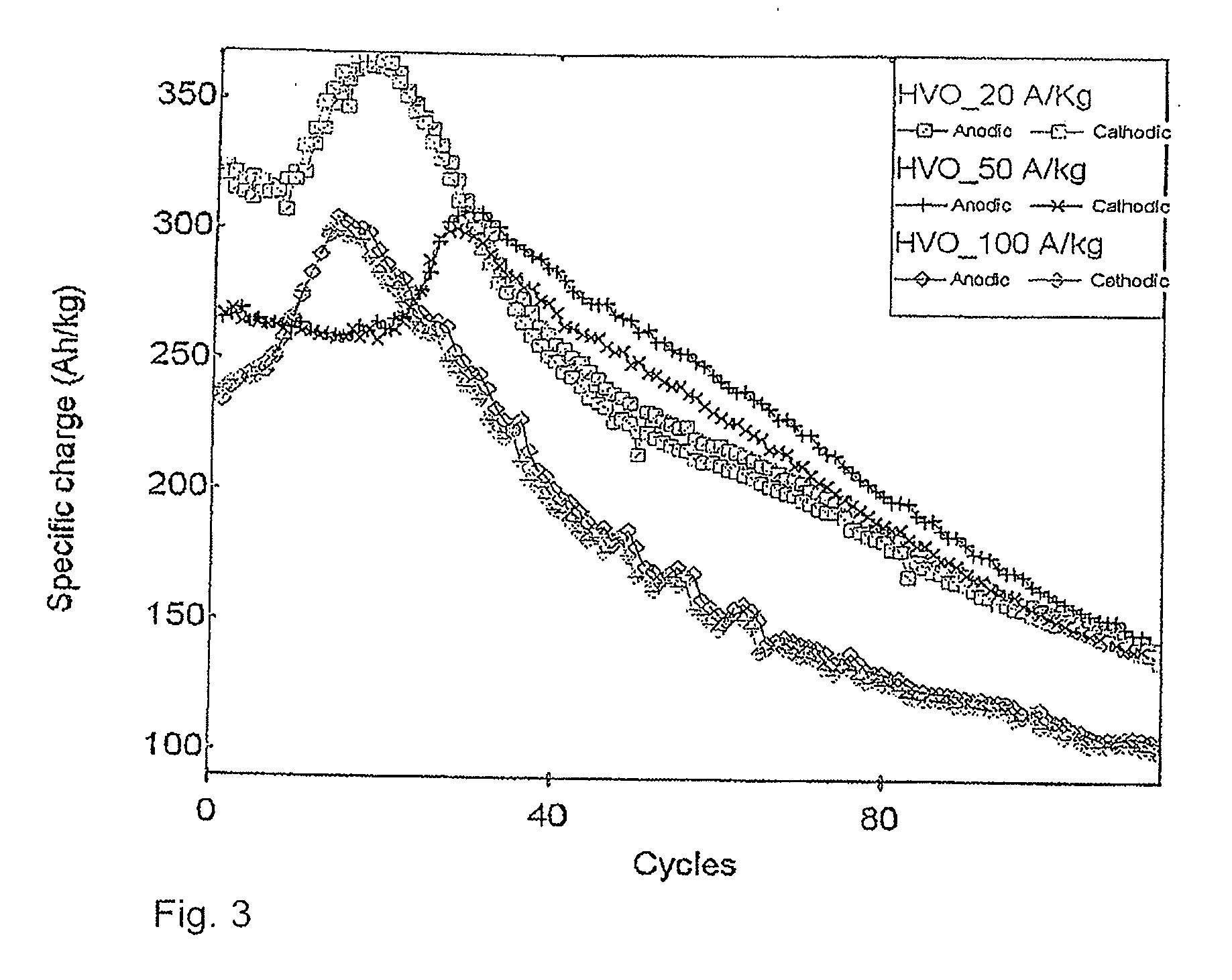

Electrode (anode and cathode) performance enhancement by composite formation with graphene oxide

ActiveUS20120100402A1Low and reduced matrix contentHigh matrix conductivityMaterial nanotechnologyBatteries circuit arrangementsFiberPerformance enhancement

Described is an electrode comprising and preferably consisting of electronically active material (EAM) in nanoparticulate form and a matrix, said matrix consisting of a pyrolization product with therein incorporated graphene flakes and optionally an ionic lithium source. Also described are methods for producing a particle based, especially a fiber based, electrode material comprising a matrix formed from pyrolized material incorporating graphene flakes and rechargeable batteries comprising such electrodes.

Owner:BELENOS CLEAN POWER HLDG

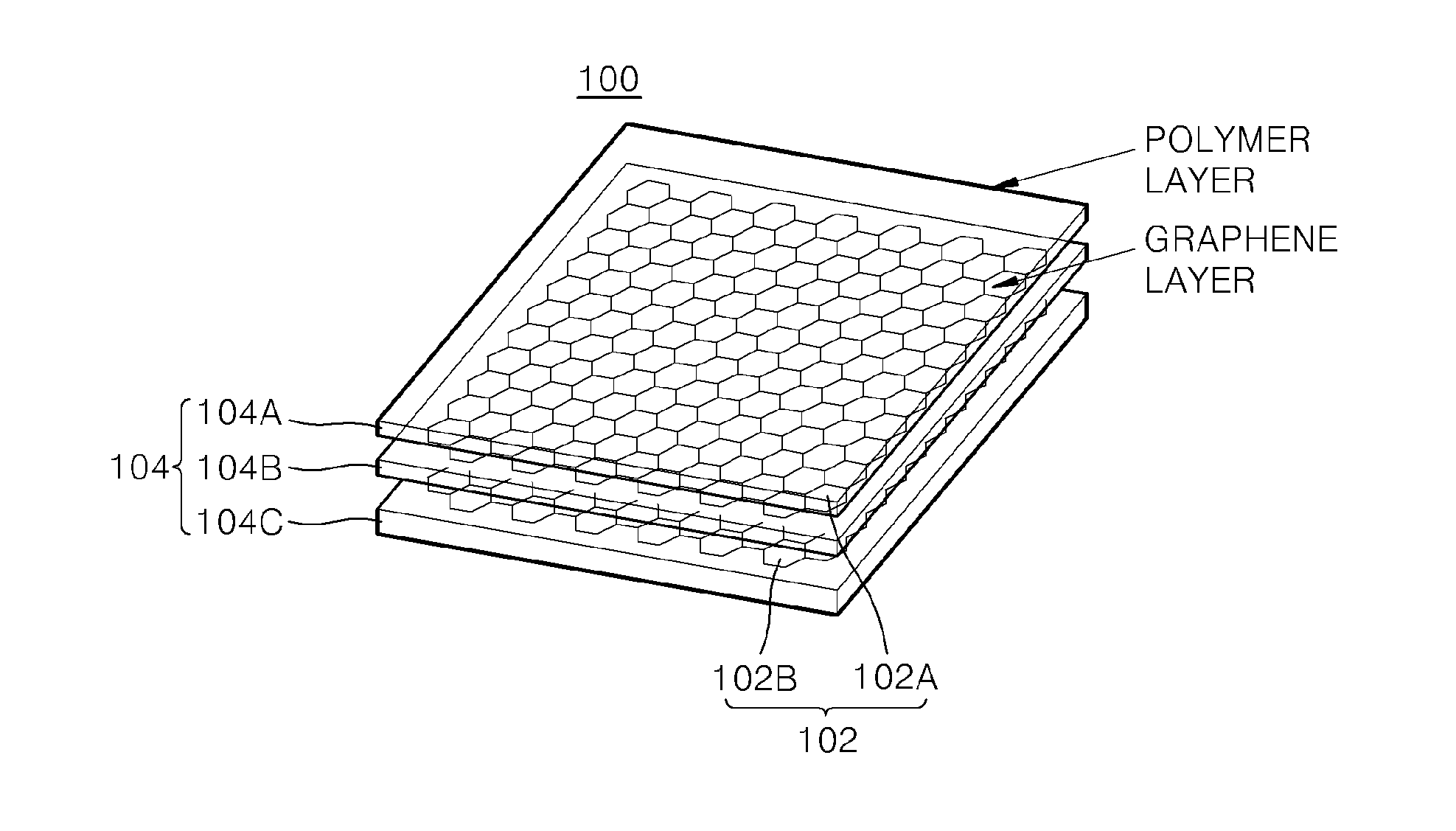

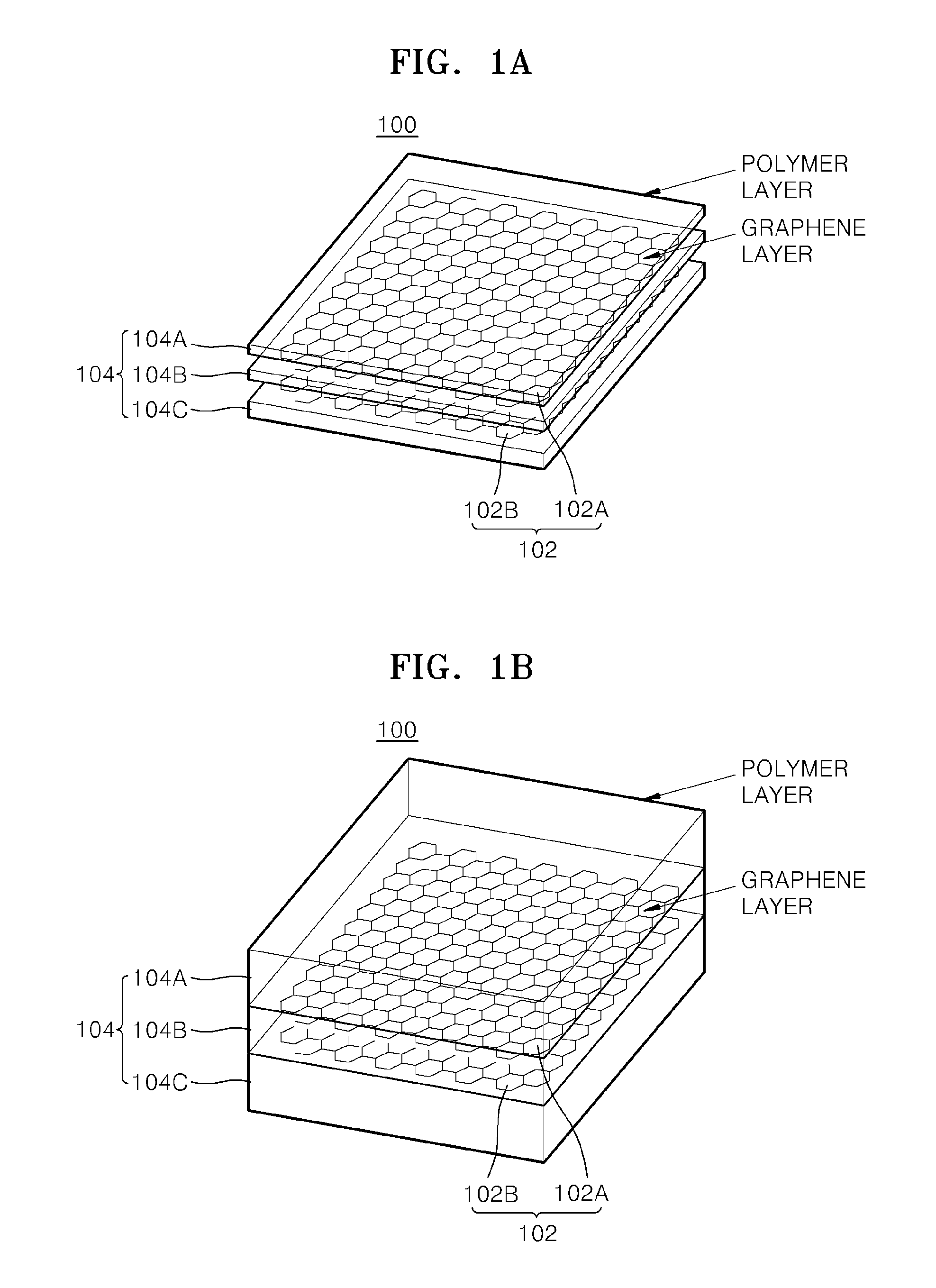

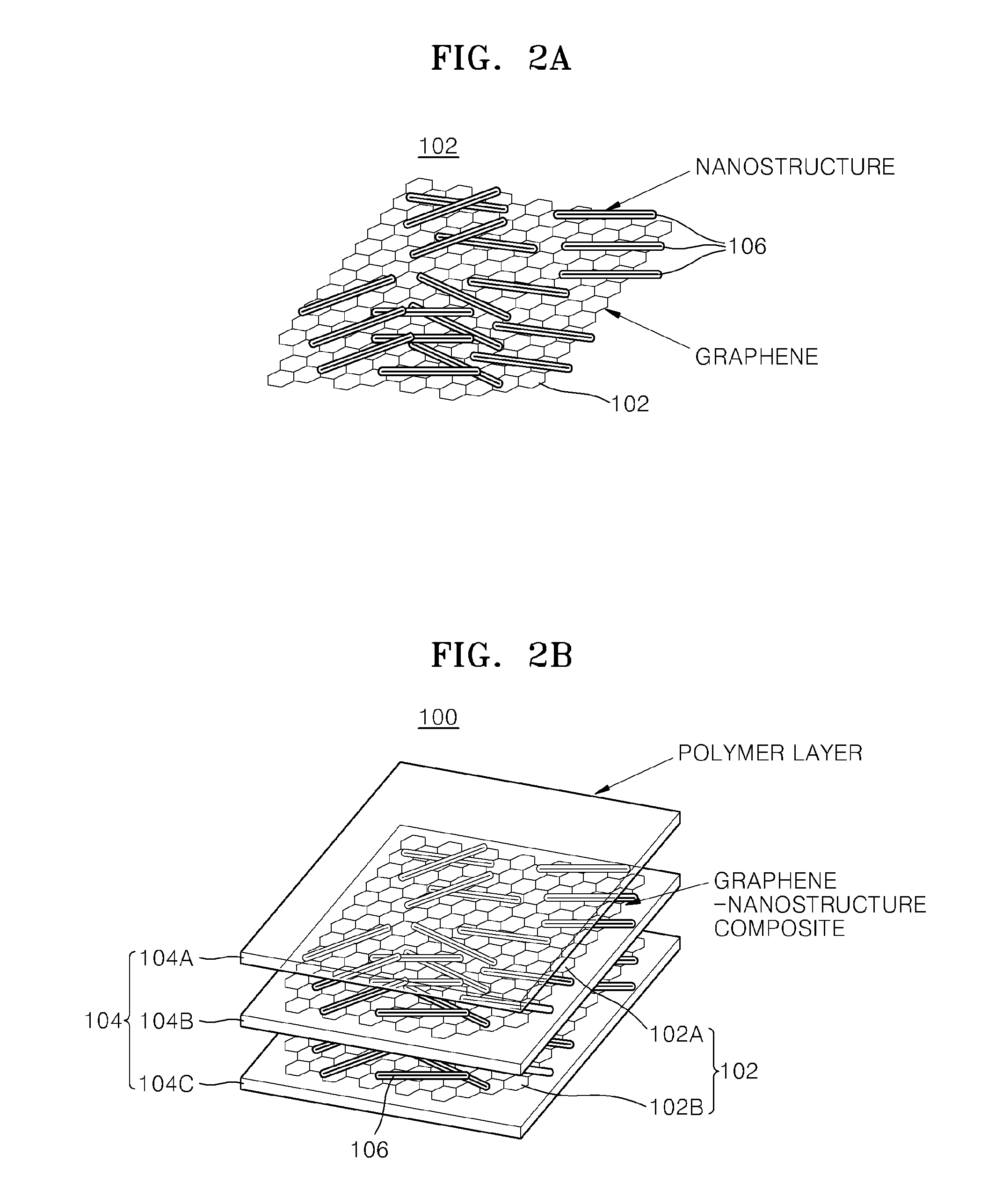

Graphene-polymer layered composite and process for preparing the same

ActiveUS20120070612A1Low thermal conductivityImprove conductivityMaterial nanotechnologyDecorative surface effectsThermoelectric materialsPliability

A graphene-polymer layered composite and a method of manufacturing the same is provided. A graphene-polymer layered composite includes polymer layers surrounding a graphene sheet, and may include numerous polymer layers and graphene sheets in an alternating stacked configuration. The graphene-polymer layered composite has the characteristics of a polymer in that it provides flexibility, ease of manufacturing, low manufacturing costs, and low thermal conductivity. The graphene-polymer layered composite also has the characteristics of graphene in that it has a high electrical conductivity. Due to the low thermal conductivity and high electrical conductivity, the graphene-polymer layered composite may be useful for electrodes, electric devices, and thermoelectric materials.

Owner:SAMSUNG ELECTRONICS CO LTD

Preparation method of graphene oxide/waterborne polyurethane nanometer composite material

InactiveCN103254400AImprove thermal performanceImprove mechanical propertiesTriethoxysilaneGraphene flake

The invention relates to a preparation method of a graphene oxide / waterborne polyurethane nanometer composite material. Especially, the preparation method comprises the following steps of: utilizing gamma-aminopropyl triethoxysilane (KH550) to carry out surface modification (functionalization of graphene oxide) onto graphene oxide; lowering hydrophily of a graphene oxide sheet layer; improving dispersion of the graphene oxide sheet layer in an organic solvent and compatibility of the graphene oxide and the polymer; and utilizing an in-situ polymerization method to prepare the graphene oxide / waterborne polyurethane nanometer composite material. The preparation method of the graphene oxide / waterborne polyurethane nanometer composite material belongs to the preparation field of composite materials.

Owner:CHANGZHOU UNIV

Method for preparing high-strength conductive graphene fiber by large-size graphene oxide sheet

ActiveCN102534869AWide variety of sourcesConvenient sourceGrapheneArtificial filament chemical after-treatmentFiberCarbon fibers

The invention discloses a method for preparing high-strength conductive graphene fiber by a large-size graphene oxide sheet. The method comprises the steps of: oxidizing expanded graphite and obtaining graphene oxide; dispersing the graphene oxide into water, carrying out centrifugal classification treatment on the dispersed graphene oxide, and obtaining the large-size even graphene oxide sheet; and finally, dispersing the graphene oxide into water or polar organic solvent, preparing spinning solution liquid crystal sol with the mass concentration of 1-20%, transferring the spinning solution liquid crystal sol into a spinning device, continuously squeezing spinning solution out from a spinning head capillary tube at the uniform velocity, leading the squeezed spinning solution into solidification liquid, drying the solidified primary fiber, obtaining graphene oxide fiber, and then obtaining the graphene fiber by chemical reduction. A spinning technology is simple; and the obtained graphene fiber is good in electrical conductivity, excellent in mechanical property and better in toughness, can be woven into pure-graphene fiber cloth, and also can be woven with other fibers in a blending way so as to make various functional fabrics, so that the high-strength conductive graphene fiber can be used for replacing carbon fiber in a plurality of fields.

Owner:杭州德烯科技集团有限公司

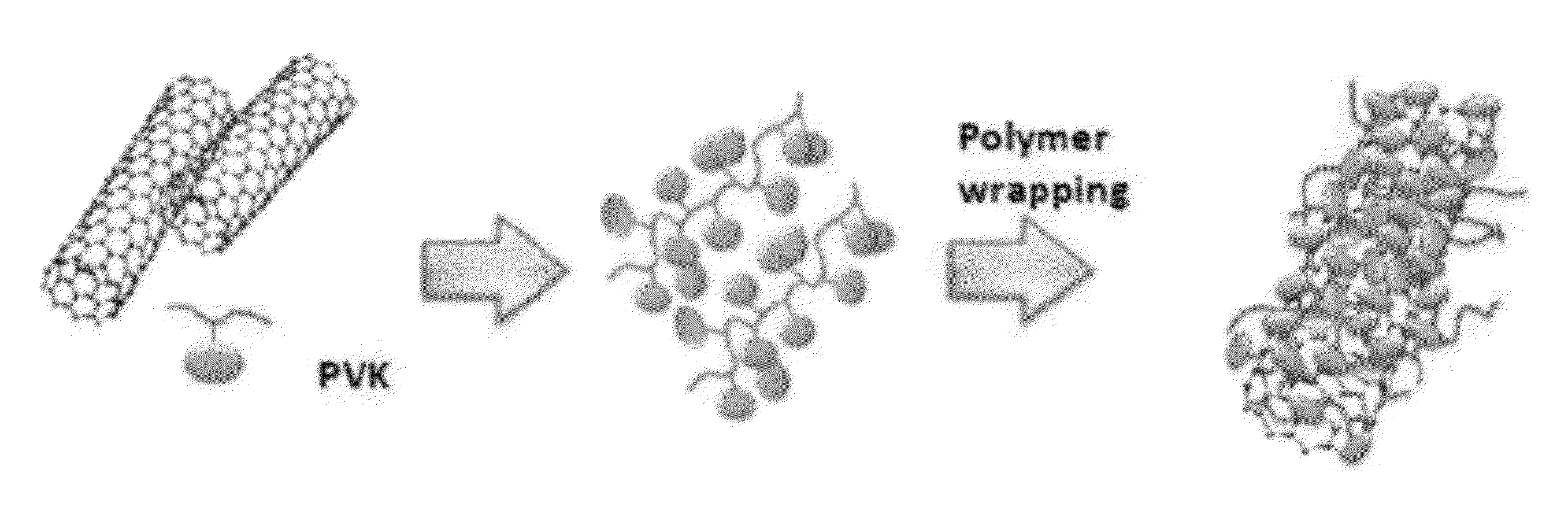

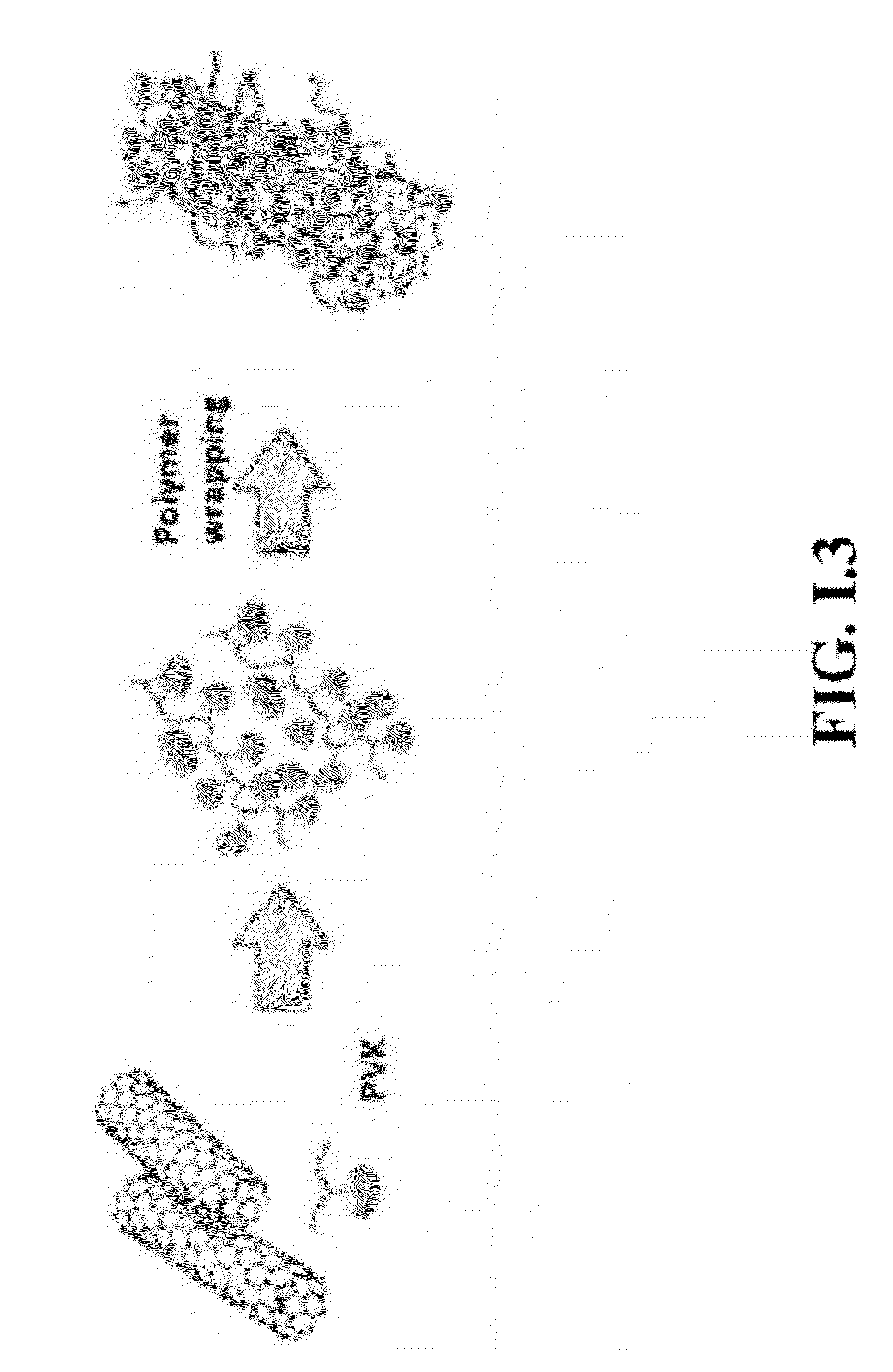

Polymer nanocomposite precursors with carbon nanotubes and/or graphene and related thin films and patterning

ActiveUS20120164433A1Simple materialIncrease productionMaterial nanotechnologyPigmenting treatmentNano compositesCarbon nanotube

Nano-composites include a graphite material such as nanotubes or graphene sheets and a partial or complete coating of a polymer including sufficient π-conjugated moieties to interact with surfaces of the graphite material. The polymers may also include electropolymerizable or oxidatively polymerizable moieties so the films may be crosslinked. The films may be used to form layers on substrates or patterned layers on substrates.

Owner:UNIV HOUSTON SYST

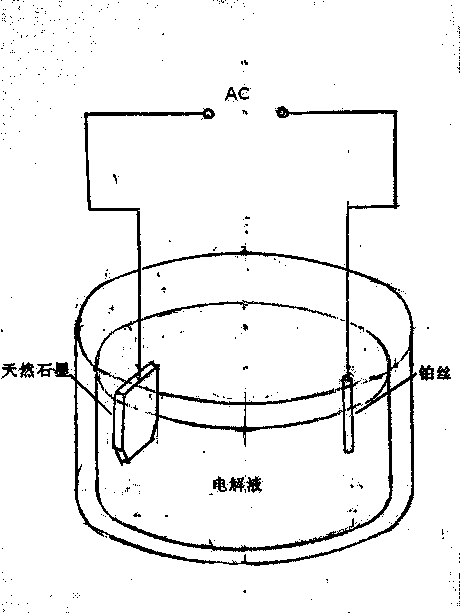

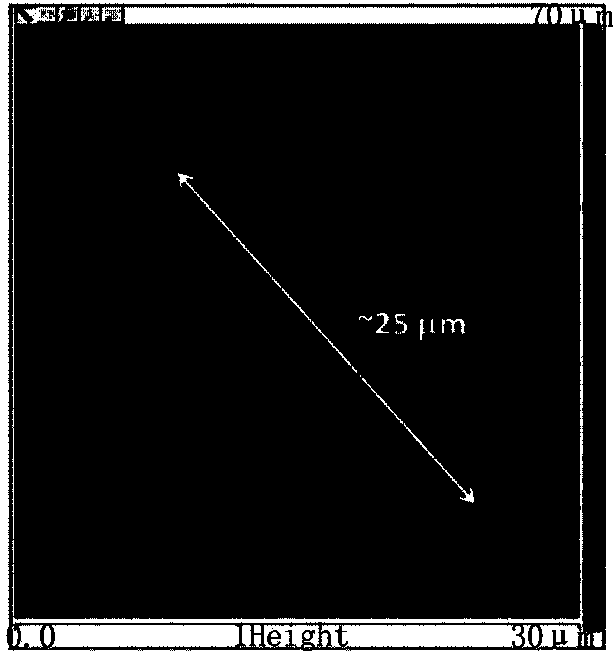

Method for preparing high-quality graphene through electrochemical high-efficiency exfoliation

The invention relates to a preparation method for graphene, especially to a method for preparing high-quality graphene through electrochemical high-efficiency exfoliation. The method mainly overcomes the technical problems that the honeycomb lattice structure of graphene is severely destroyed in the process of oxidation, an obtained membrane resistance is 1 K to 70 K omega / square (wherein light transmittance is less than 80%), the resistance is too high and much higher than requirements of ITO, etc. The method comprises the following steps: with graphite as a positive electrode and a platinum filament as a negative electrode, repeatedly applying high offset voltage and negative offset voltage on the graphite electrode, which enables graphite to be rapidly disassociated and decomposed into double-layer graphene floating on the surface of an electrolyte; collecting graphene and then filtering and drying graphene; dispersing obtained powder of a graphene film in a DMF solution; and carrying out water-bath ultrasonic treatment and centrifugation so as to obtain desired 1.5-nm-grade graphene flakes.

Owner:杭州金马新能源科技有限公司

Material and applications therefor

ActiveUS20130180912A1Increase temperatureLarge inter-sheet spacingMaterial nanotechnologyCarbon compoundsPolymer scienceDispersed media

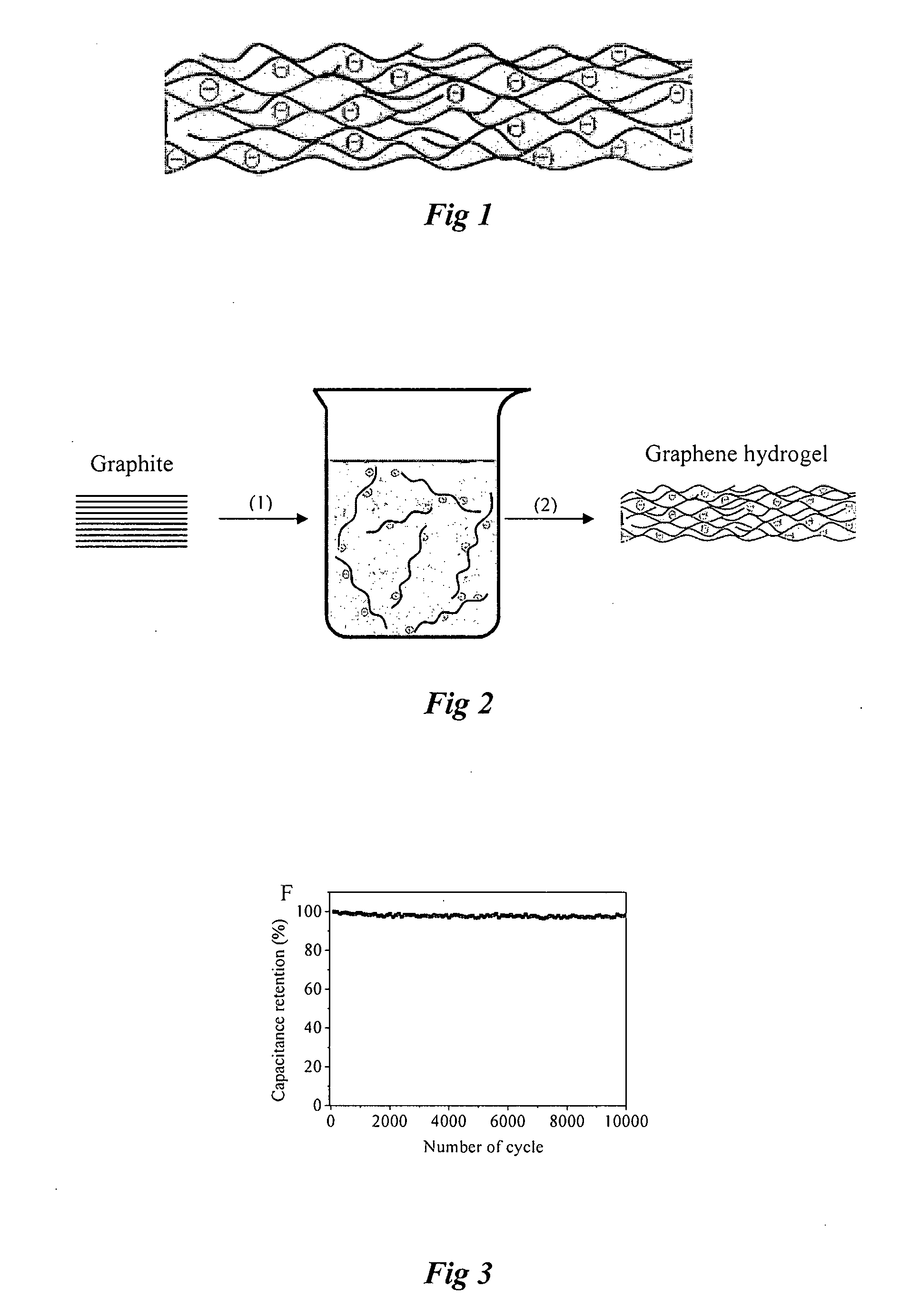

A gel film or an isolated gel film comprising sheets of graphene or chemically converted graphene at least partially separated by a dispersion medium, such as water, and arranged in a substantially planar manner to form an electrically conductive matrix.

Owner:MONASH UNIV

Graphene film as transparent and electrically conducting material

ActiveUS7449133B2Material nanotechnologyConductive materialGraphene flakeTransparent conducting film

Owner:SAMSUNG ELECTRONICS CO LTD

Integral 3D graphene-carbon hybrid foam and devices containing same

ActiveUS20170182474A1Increase heightReduce yieldIon-exchange process apparatusOther chemical processesDoped grapheneIodide

Provided is an integral 3D graphene-carbon hybrid foam composed of multiple pores and pore walls, wherein the pore walls contain single-layer or few-layer graphene sheets chemically bonded by a carbon material having a carbon material-to-graphene weight ratio from 1 / 100 to 1 / 2, wherein the few-layer graphene sheets have 2-10 layers of stacked graphene planes having an inter-plane spacing d002 from 0.3354 nm to 0.40 nm and the graphene sheets contain a pristine graphene material having essentially zero % of non-carbon elements, or a non-pristine graphene material having 0.01% to 25% by weight of non-carbon elements wherein said non-pristine graphene is selected from graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenated graphene, nitrogenated graphene, doped graphene, chemically functionalized graphene, or a combination thereof. Also provided are a process for producing the hybrid form, products containing the hybrid foam, and its applications.

Owner:GLOBAL GRAPHENE GRP INC

Production of graphene materials directly from carbon/graphite precursor

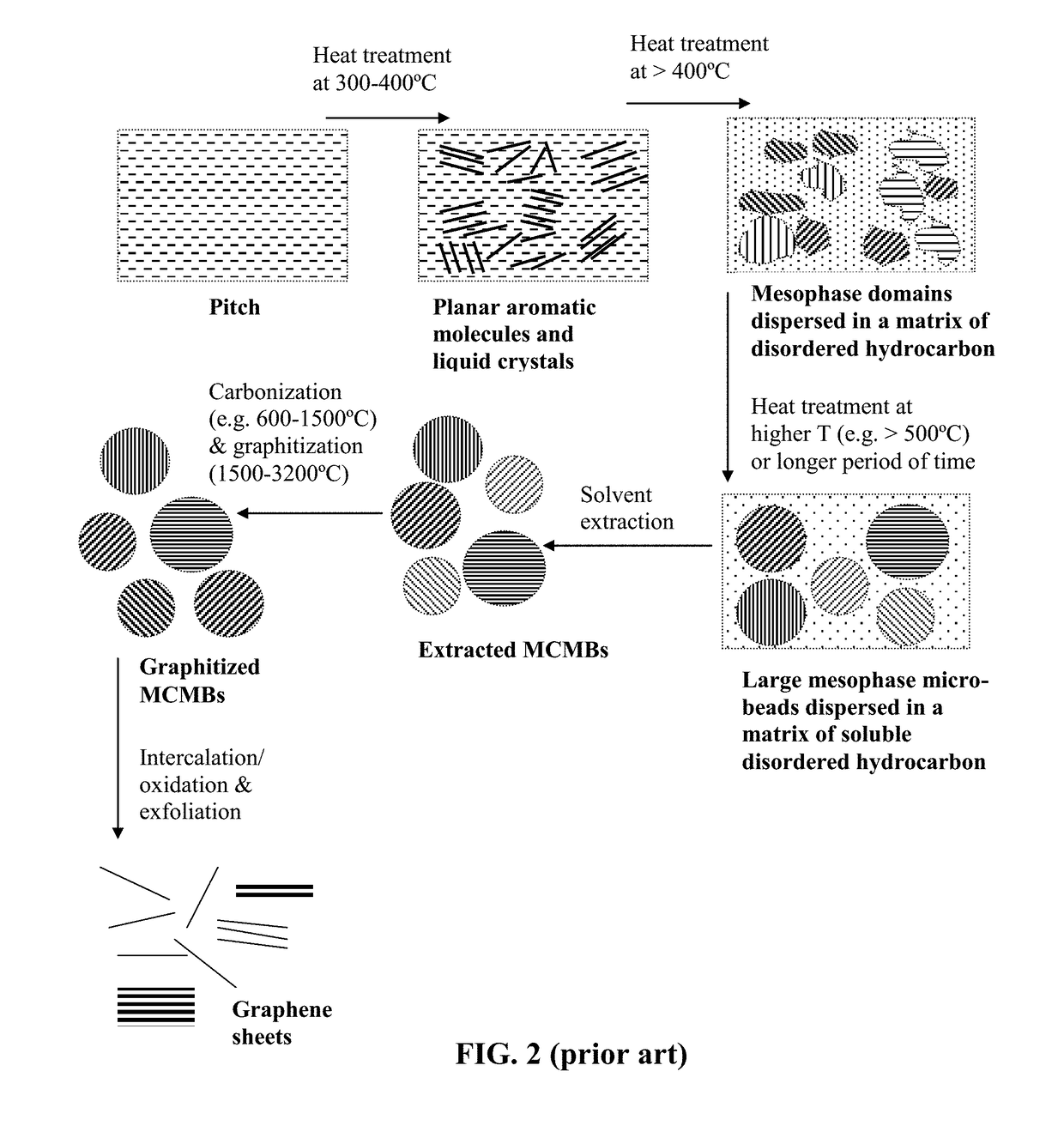

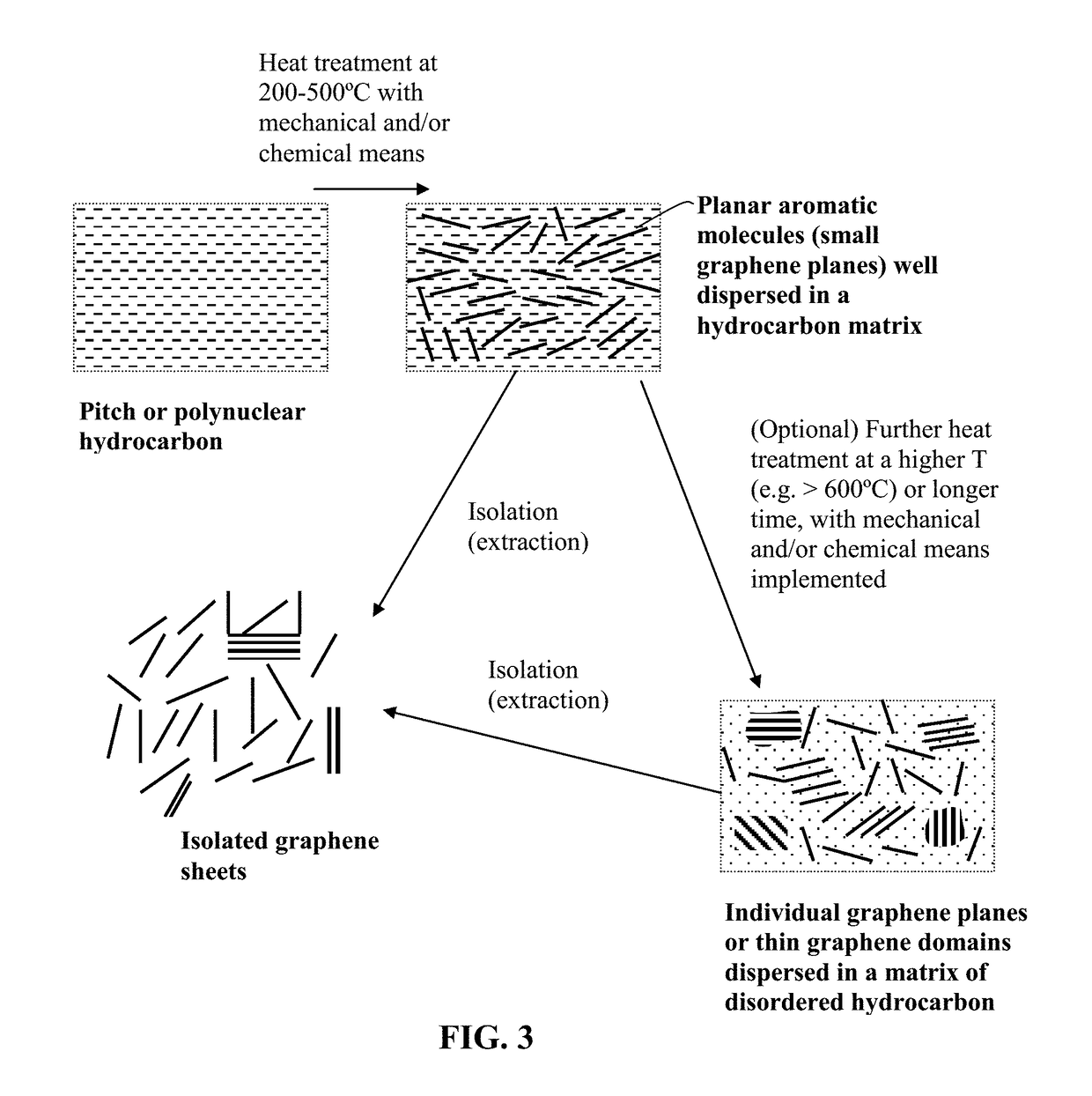

Provided is a method of producing isolated graphene sheets directly from a carbon / graphite precursor. The method comprises: (a) providing a mass of aromatic molecules wherein the aromatic molecules are selected from petroleum heavy oil or pitch, coal tar pitch, a polynuclear hydrocarbon, or a combination thereof; (b) heat treating this mass and using chemical or mechanical means to form graphene domains dispersed in a disordered matrix of carbon or hydrocarbon molecules, wherein the graphene domains are each composed of from 1 to 30 planes of hexagonal carbon atoms or fused aromatic rings having a length or width from 5 nm to 20 μm and an inter-graphene space between two planes of hexagonal carbon atoms or fused aromatic rings no less than 0.4 nm; and (c) separating and isolating the planes of hexagonal carbon atoms or fused aromatic rings to recover graphene sheets from the disordered matrix.

Owner:GLOBAL GRAPHENE GRP INC

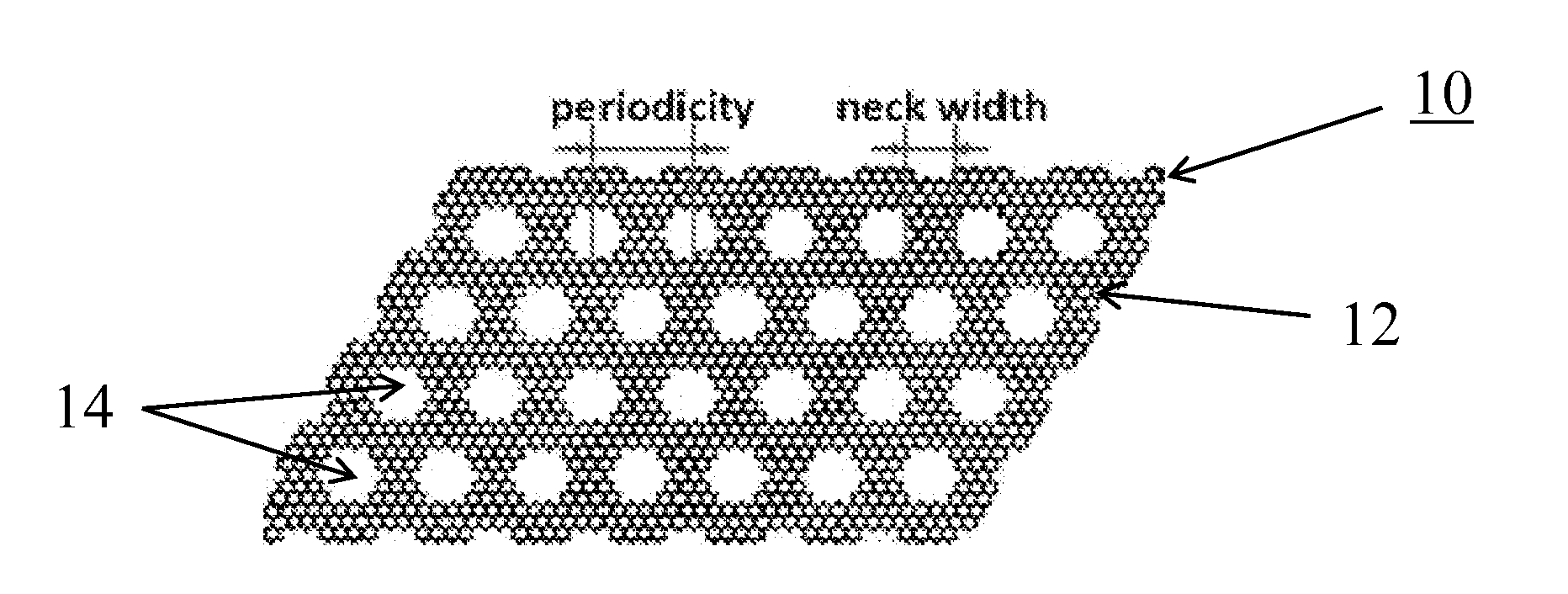

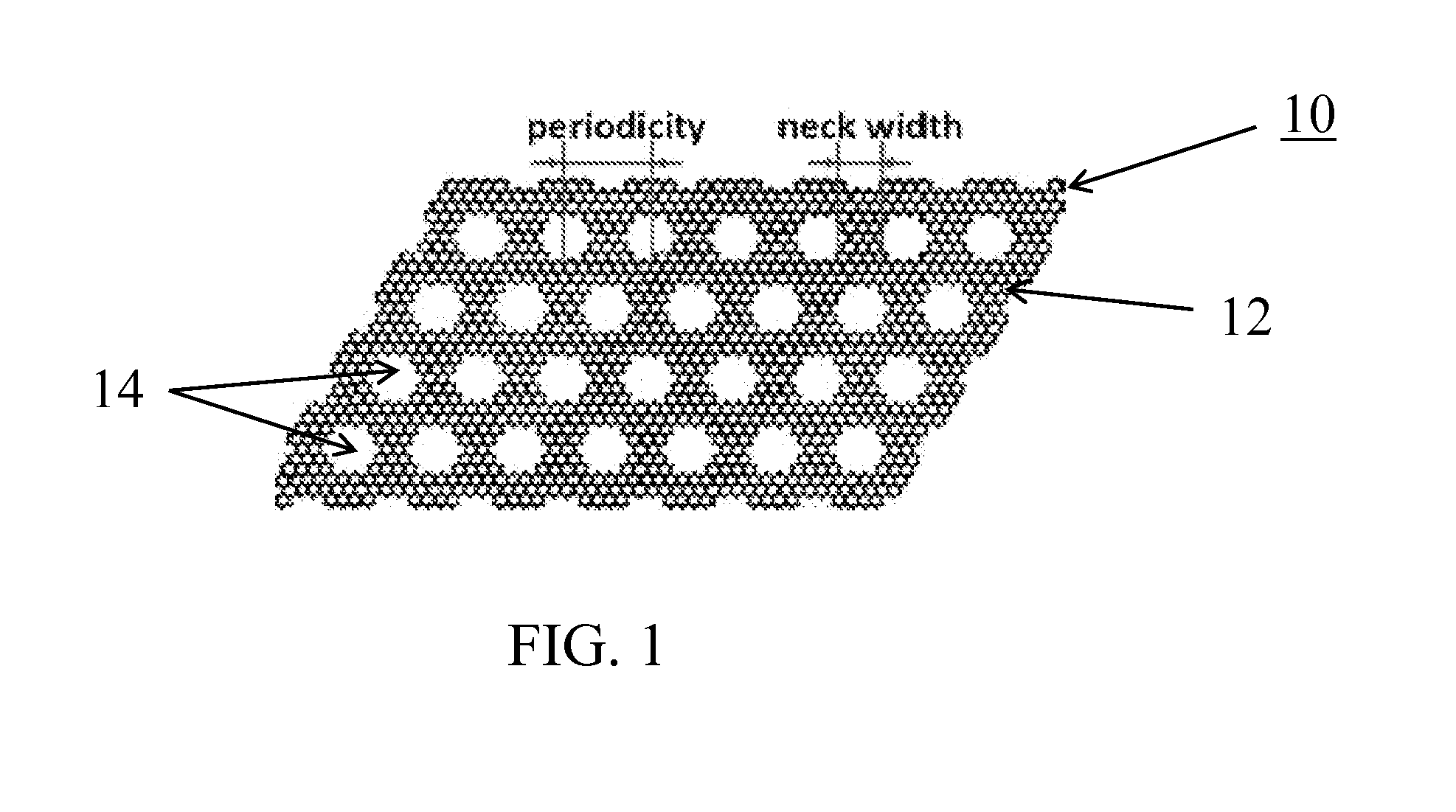

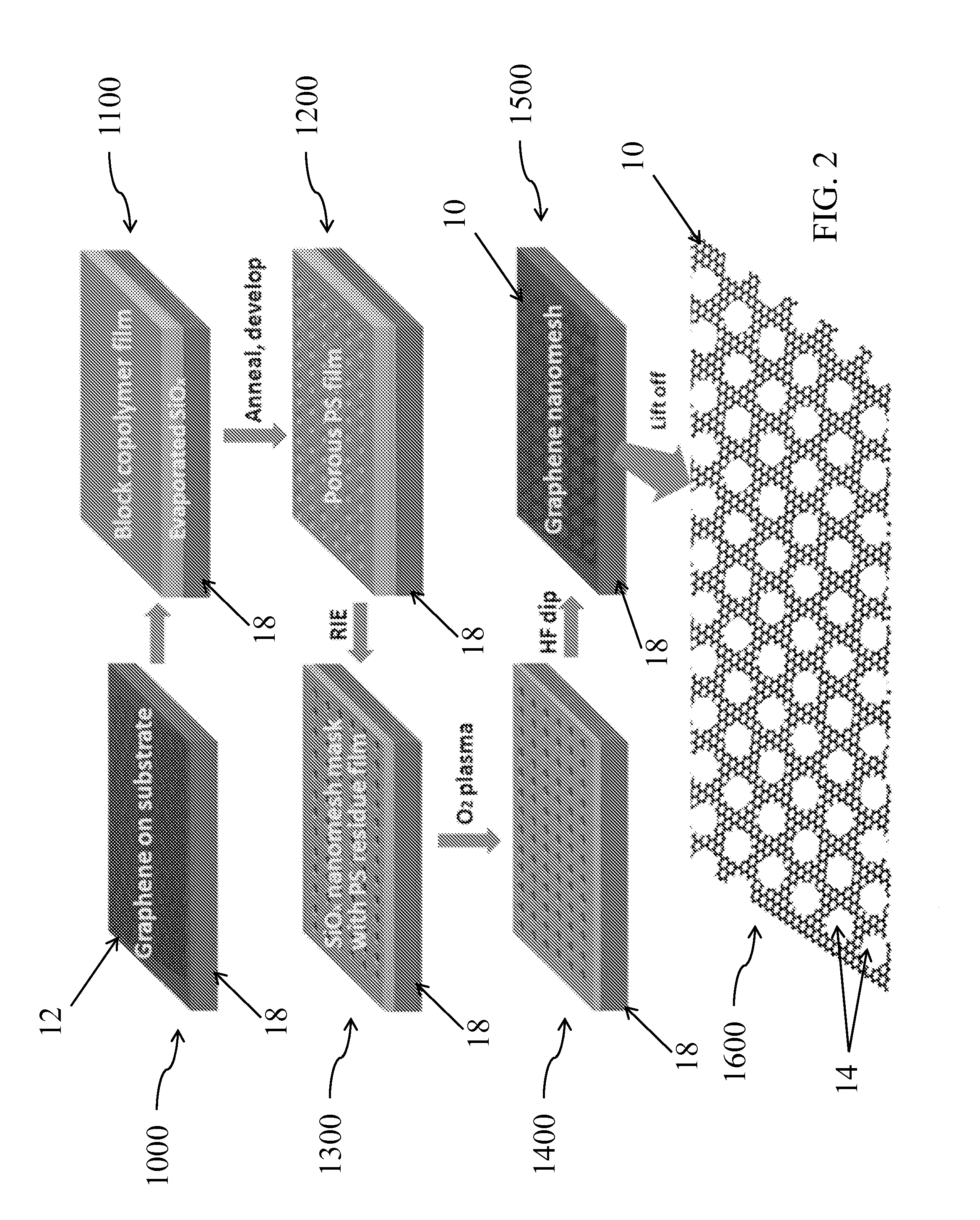

Graphene nanomesh and method of making the same

InactiveUS20120301953A1Uniform periodicityUniform widthMaterial nanotechnologyBioreactor/fermenter combinationsGraphene nanoribbonsGraphene flake

A graphene nanomesh includes a sheet of graphene having a plurality of periodically arranged apertures, wherein the plurality of apertures have a substantially uniform periodicity and substantially uniform neck width. The graphene nanomesh can open up a large band gap in a sheet of graphene to create a semiconducting thin film. The periodicity and neck width of the apertures formed in the graphene nanomesh may be tuned to alter the electrical properties of the graphene nanomesh. The graphene nanomesh is prepared with block copolymer lithography. Graphene nanomesh field-effect transistors (FETs) can support currents nearly 100 times greater than individual graphene nanoribbon devices and the on-off ratio, which is comparable with values achieved in nanoribbon devices, can be tuned by varying the neck width. The graphene nanomesh may also be incorporated into FET-type sensor devices.

Owner:RGT UNIV OF CALIFORNIA

Method for preparing graphene reinforced metal-based composite material through discharge plasma (SPS) sintering

The present invention relates to a method for preparing a graphene reinforced metal-based composite material through discharge plasma (SPS) sintering. The method is characterized in that the graphene reinforced metal-based block material is prepared through SPS sintering and has the following advantages that: the preparation method is simple, the material is compact and does not have pores, the graphene mass fraction can be arbitrarily regulated, the distribution is uniform, no aggregation is generated, the material mechanical property isotropy is provided, and the wettability of the metal and the graphene interface is good. The method comprises: (1) reducing graphene oxide through a chemical method or a hydrothermal method to obtain graphene sheets with a sheet layer thickness of not more than 4 nm and sheet layer diameter of not more than 50 [mu]m; and (2) preparing metal powder with a particle size of not more than 200 [mu]m through a rotating electrode atomization method, mechanical crushing or a high-speed ball milling method; (3) carrying out mechanical or ball milling mixing on the graphene powder and the metal powder according to the required mass ratio; and (4) carrying out SPS sintering forming on the mixed powder, wherein the obtained material has characteristics of improved mechanical property, decreased density, good heat conduction capability, and good electric conduction capability, and the performance customizing can be achieved by adjusting the preparation parameters.

Owner:BEIHANG UNIV

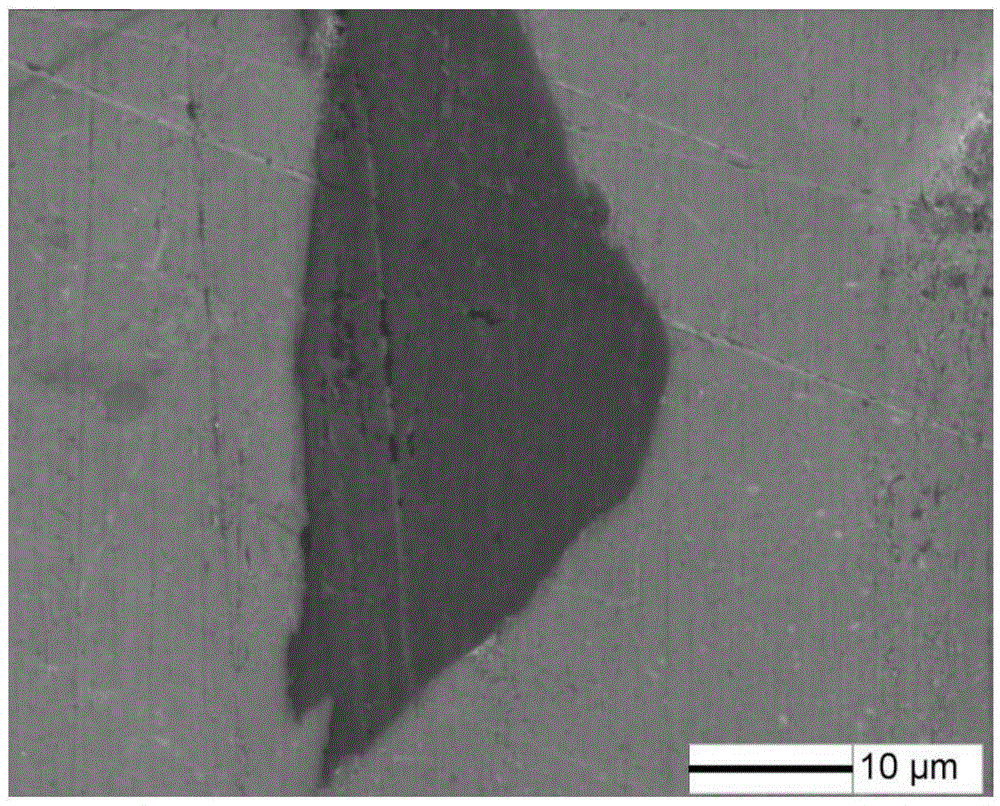

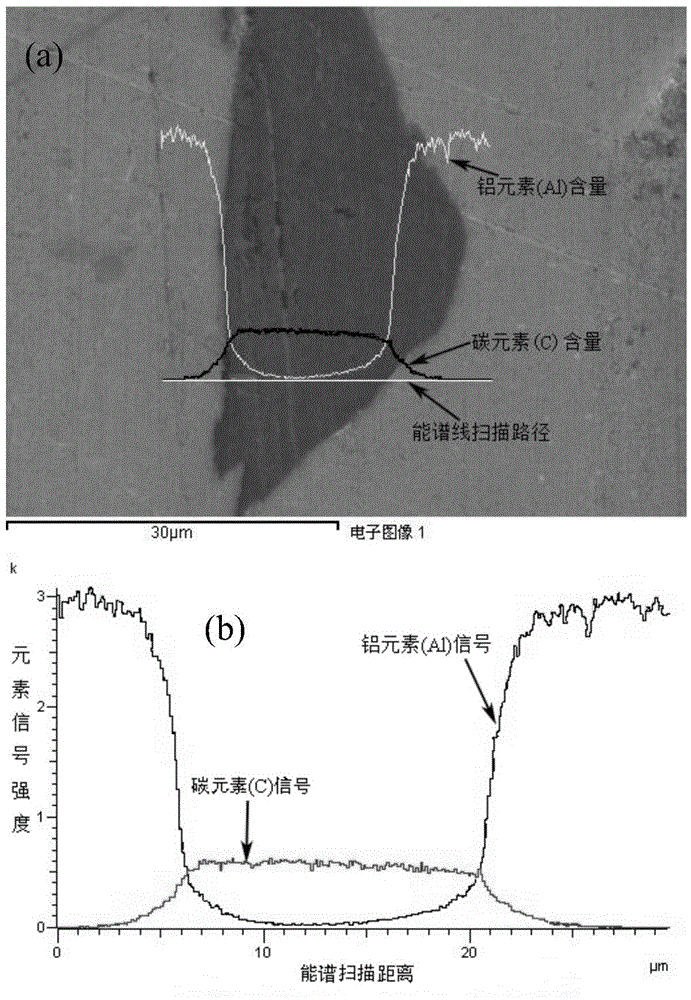

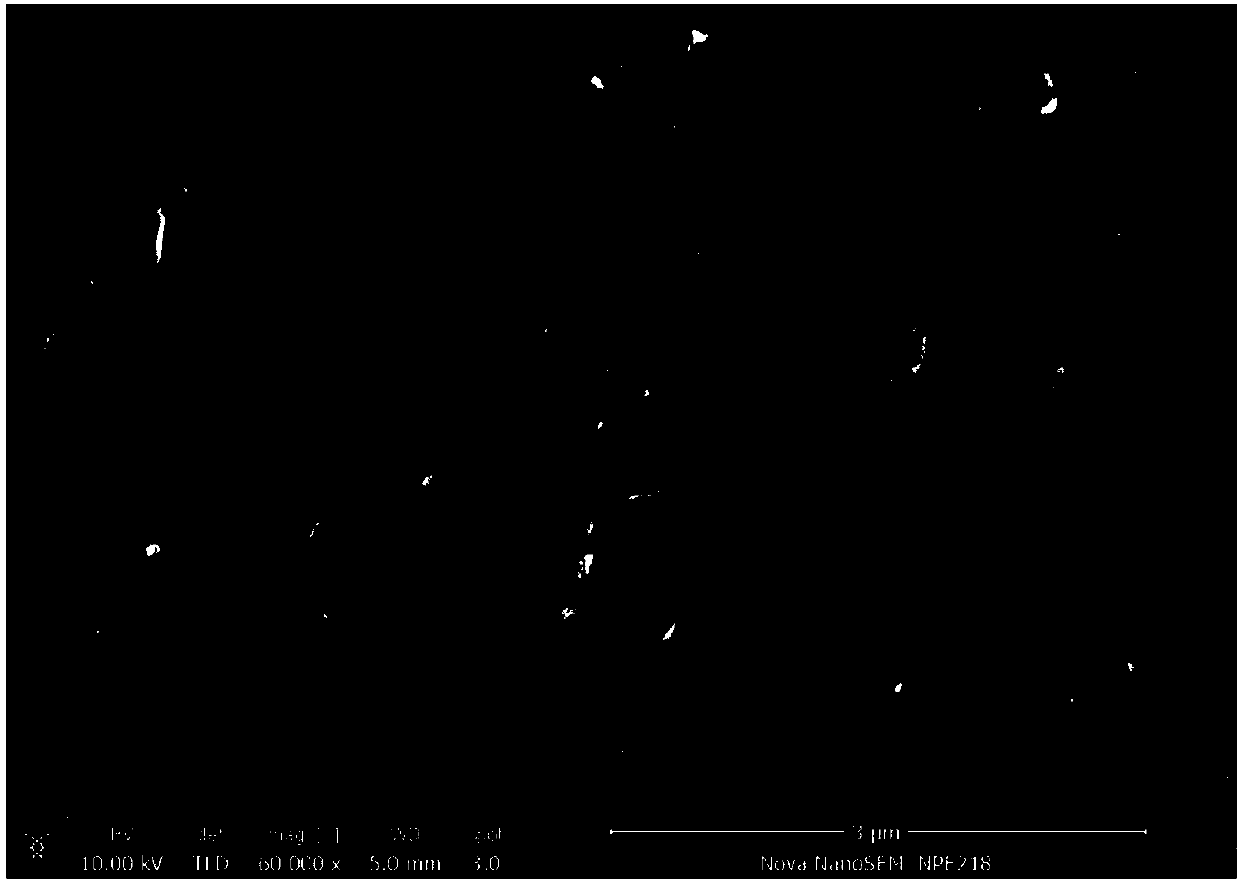

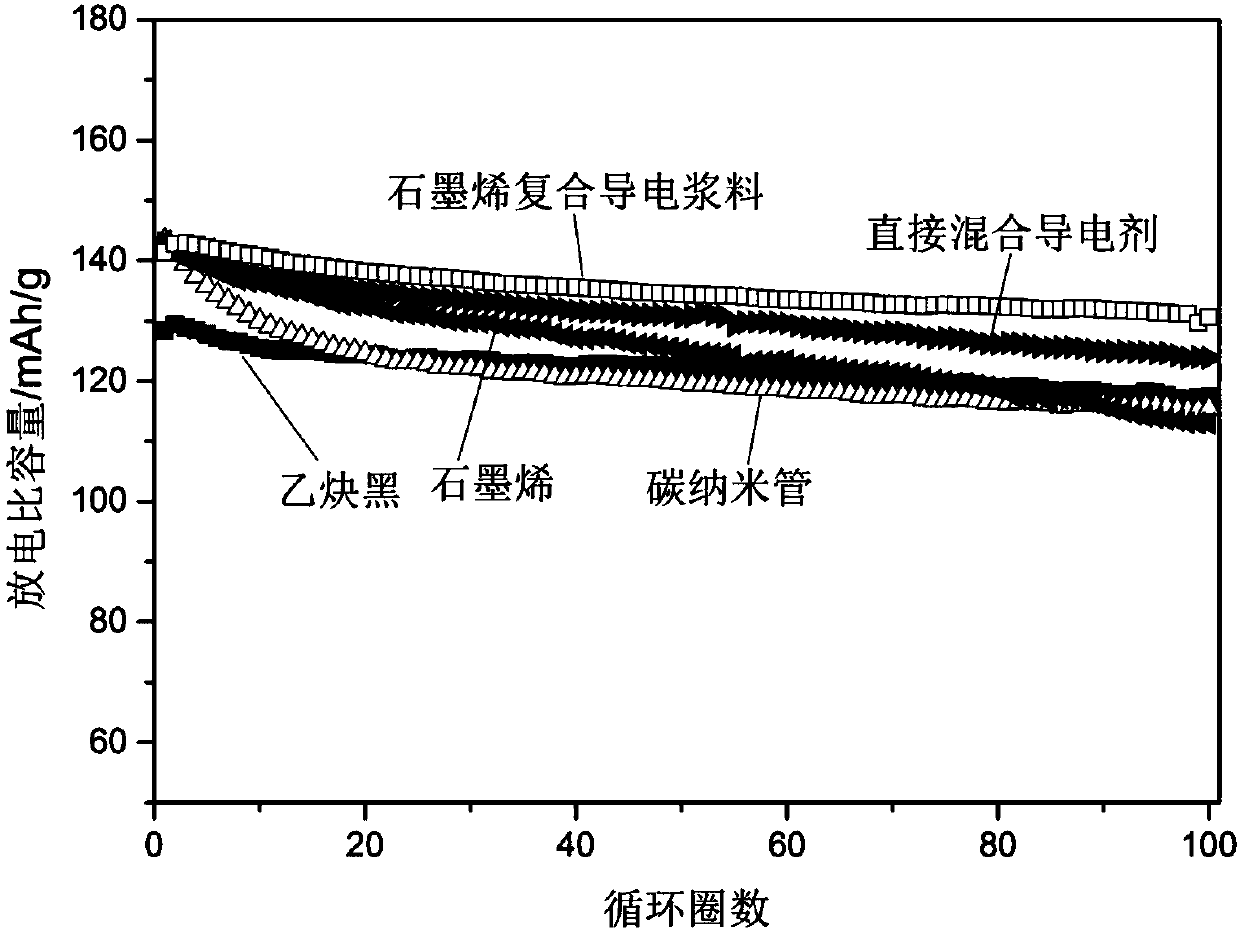

Graphene composite conductive slurry as well as preparation method and application thereof

InactiveCN107689452AImprove electrochemical performanceLower internal resistanceCell electrodesSecondary cellsInternal resistanceGraphene flake

The invention discloses graphene composite conductive slurry as well as a preparation method and application thereof. The graphene composite conductive slurry comprises graphene, a non-flaky conducting agent, a dispersing agent, a solvent and a viscosity regulator; the non-flaky conducting agent is at least partially embedded between graphene flakes. The preparation method comprises the followingsteps: mixing expanded graphite, the dispersing agent and the solvent uniformly and performing shear stripping to prepare first slurry; adding the non-flaky conducting agent into the first slurry, andperforming partial intercalation treatment at least through a grinding mode to disperse the non-flaky conducting agent and the graphene flakes uniformly to prepare second slurry. The graphene composite conductive slurry has excellent dispersing stability, enables an active material to show up excellent electrochemical property when being in a lithium ion battery, and can improve the electrode capacity, reduce the internal resistance of the battery and improve cycling performance; meanwhile, the preparation method has the advantages of simple process, high operability, wide raw material source, low cost and the like.

Owner:鹏威多凌(浙江)新材料科技股份有限公司

Highly conducting and oriented graphene film and production process

ActiveUS20170162291A1Reduce resistanceGood orientationProductsConductive layers on insulating-supportsElectrical conductorShear stress

A process for producing a highly conducting film of conductor-bonded graphene sheets that are highly oriented, comprising: (a) preparing a graphene dispersion or graphene oxide (GO) gel; (b) depositing the dispersion or gel onto a supporting solid substrate under a shear stress to form a wet layer; (c) drying the wet layer to form a dried layer having oriented graphene sheets or GO molecules with an inter-planar spacing d002 of 0.4 nm to 1.2 nm; (d) heat treating the dried layer at a temperature from 55° C. to 3,200° C. for a desired length of time to produce a porous graphitic film having pores and constituent graphene sheets or a 3D network of graphene pore walls having an inter-planar spacing d002 less than 0.4 nm; and (e) impregnating the porous graphitic film with a conductor material that bonds the constituent graphene sheets or graphene pore walls to form the conducting film.

Owner:GLOBAL GRAPHENE GRP INC

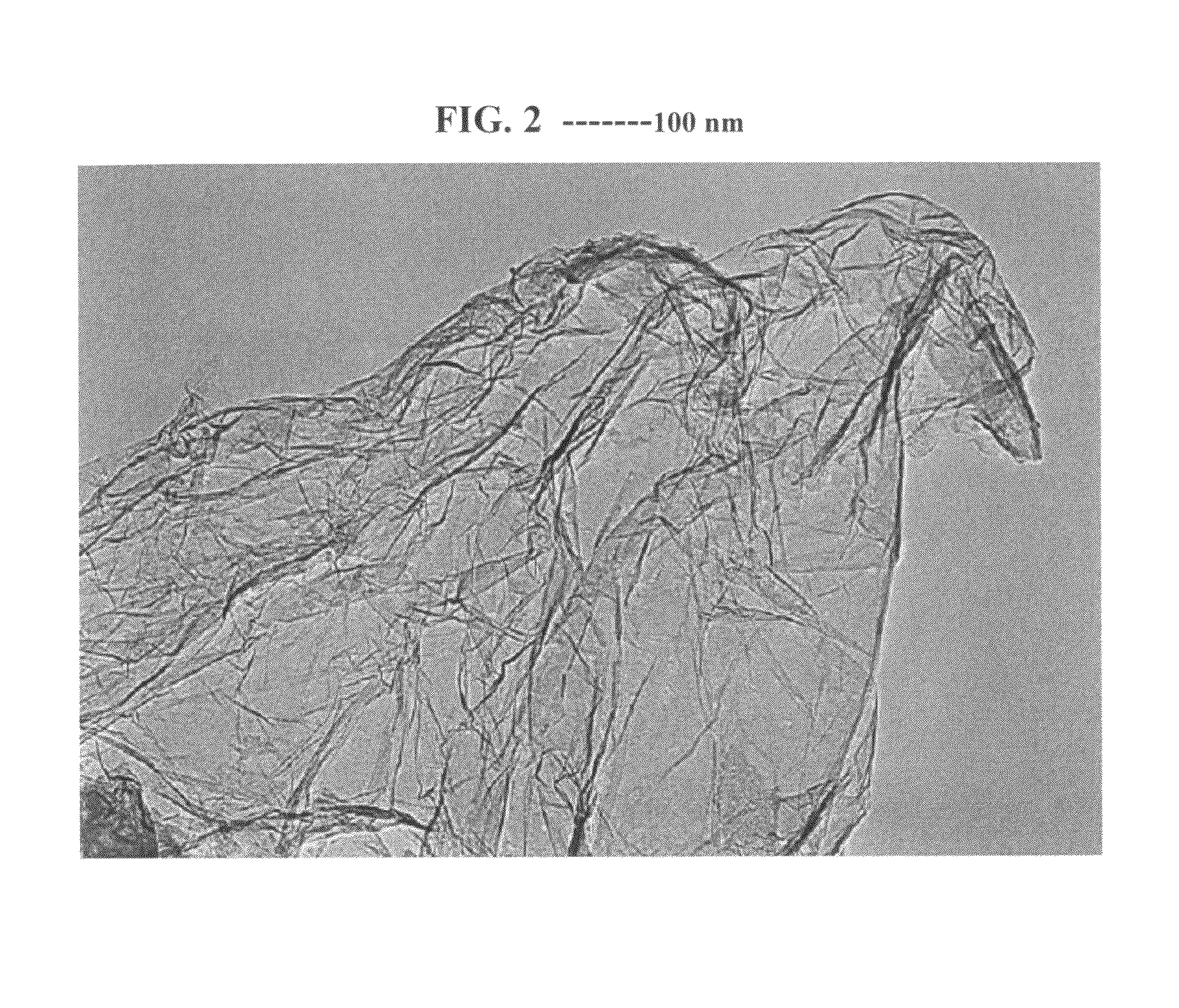

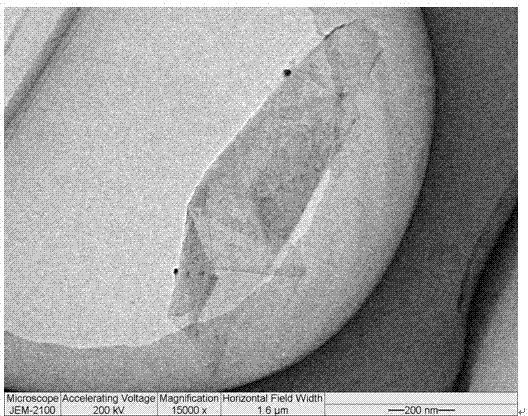

Preparation method of functional nano-graphene

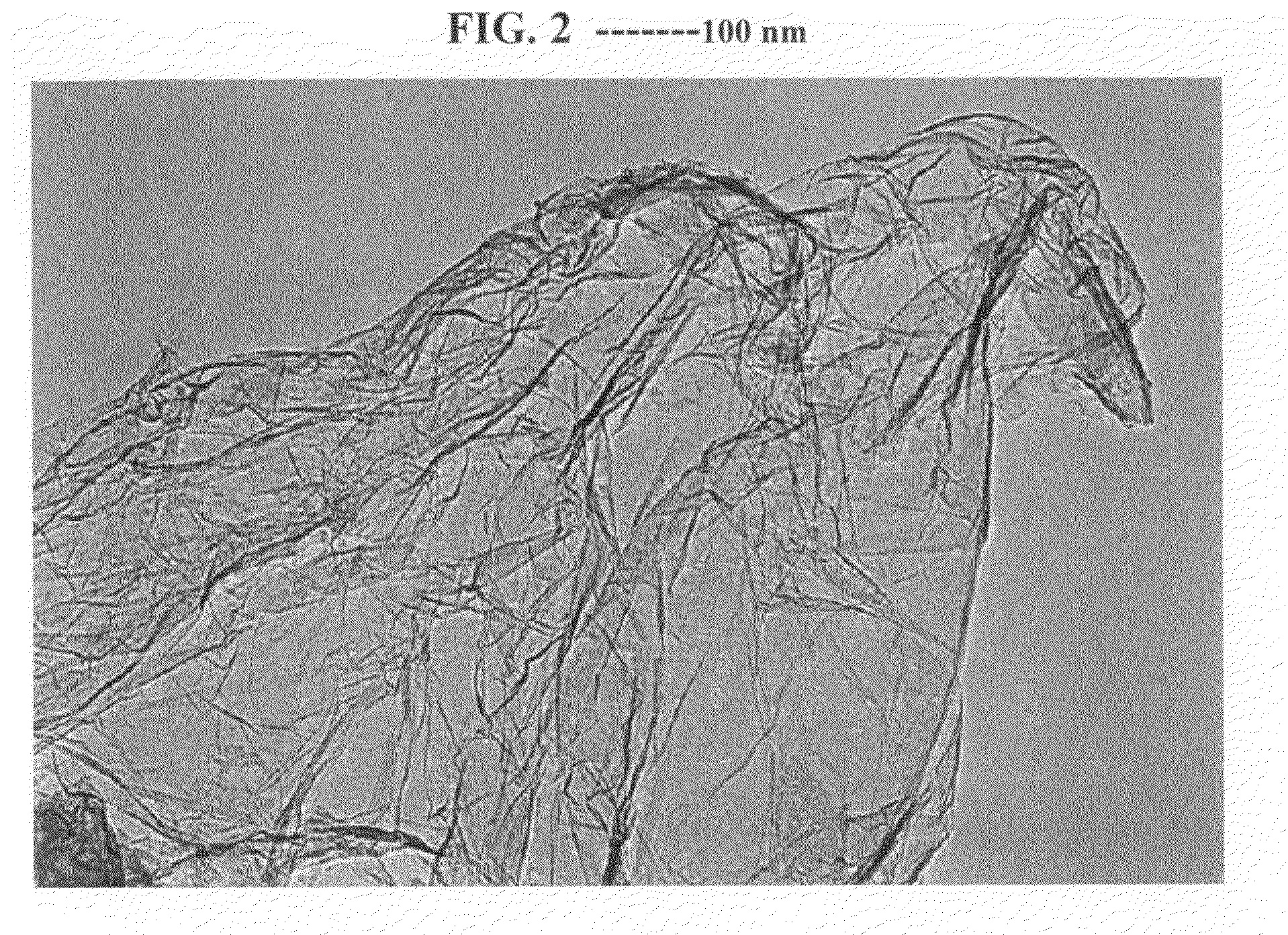

The invention relates to a preparation method of functional nano-graphene, belonging to the technical field of nano-graphene functional material. The method comprises the following steps: adding graphite oxide in water while adding one or more kinds of penetrants, stirring with ultrasonic wave or a rapid machine to form brown or black uniform suspension, heating to 70-100 DEG C, refluxing, washingwith water and drying to obtain the nano-graphene containing monolayer or multilayer graphene, wherein in the mixing process, graphite oxide absorbs penetrants and performs interlaminar swelling andthe swelled graphite oxide becomes loose and performs dissociation under the ultrasonic oscillation or the mechanical agitation of the rapid machine. The analysis of TEM finds that the nano-graphene has fold property and high radius-thickness ratio, simple technological process, reliable production principle, accessible raw material, low cost, good nanometer functionality, stable structural performance and good application effect.

Owner:QINGDAO UNIV

Preparation method of graphene-carbon nano-tube composite nanofiltration membrane with high flux

The invention discloses a graphene-carbon nano-tube composite nanofiltration membrane with high flux and a preparation method of the graphene-carbon nano-tube composite nanofiltration membrane. The composite nanofiltration membrane is prepared by uniformly depositing a full-carbon selective separation layer on a porous polymer supporting layer by using the method disclosed by the invention, wherein the full-carbon selective separation layer is formed by compounding and assembling graphene and a carbon nano-tube. By using the method disclosed by the invention, the carbon nano-tube can be effectively intercalated among graphene sheet layers which are compactly stacked. The nanofiltration membrane prepared by using the preparation method disclosed by the invention is high in water flux, good in pollution resistance, high in retention rate (approach to 100%) of organic dyes, relatively high in salt removing rate of the organic dyes and capable of keeping relatively high flux under the conditions of high operation pressure and high salinity. The preparation method disclosed by the invention is simple and easy, strong in controllability, relatively low in production cost and free of pollution so as to have favorable application prospects in the nanofiltration field.

Owner:ZHEJIANG TANGUSHANGXI MATERIAL SCI & TECH

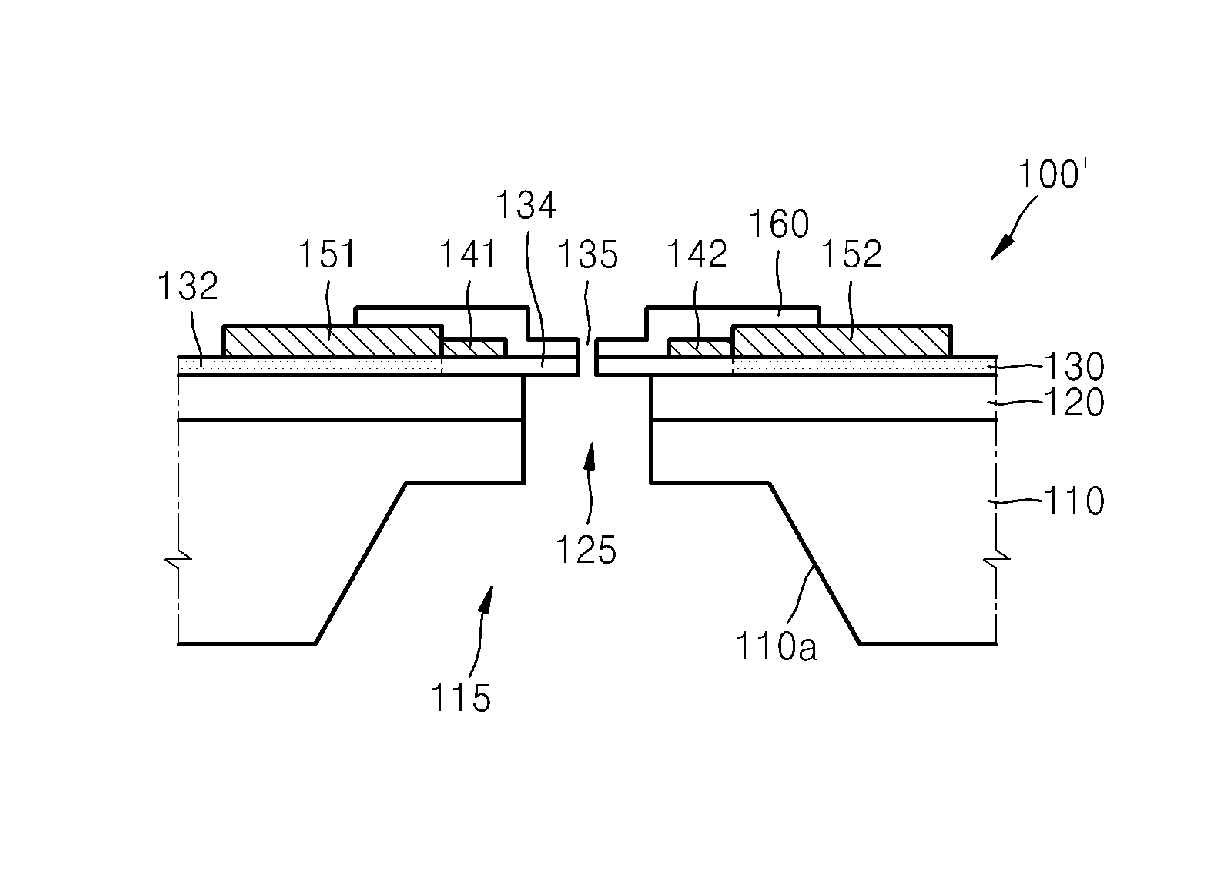

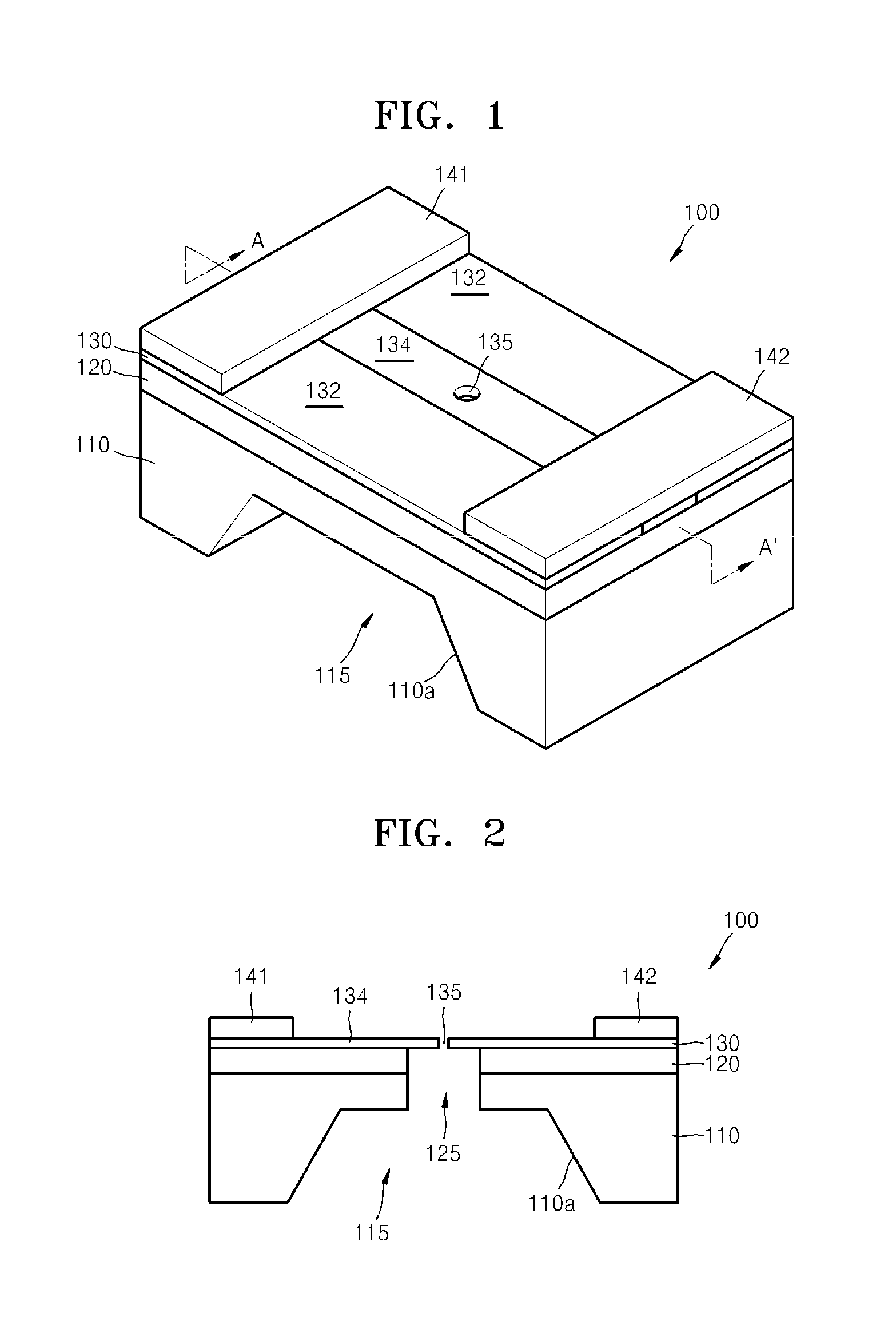

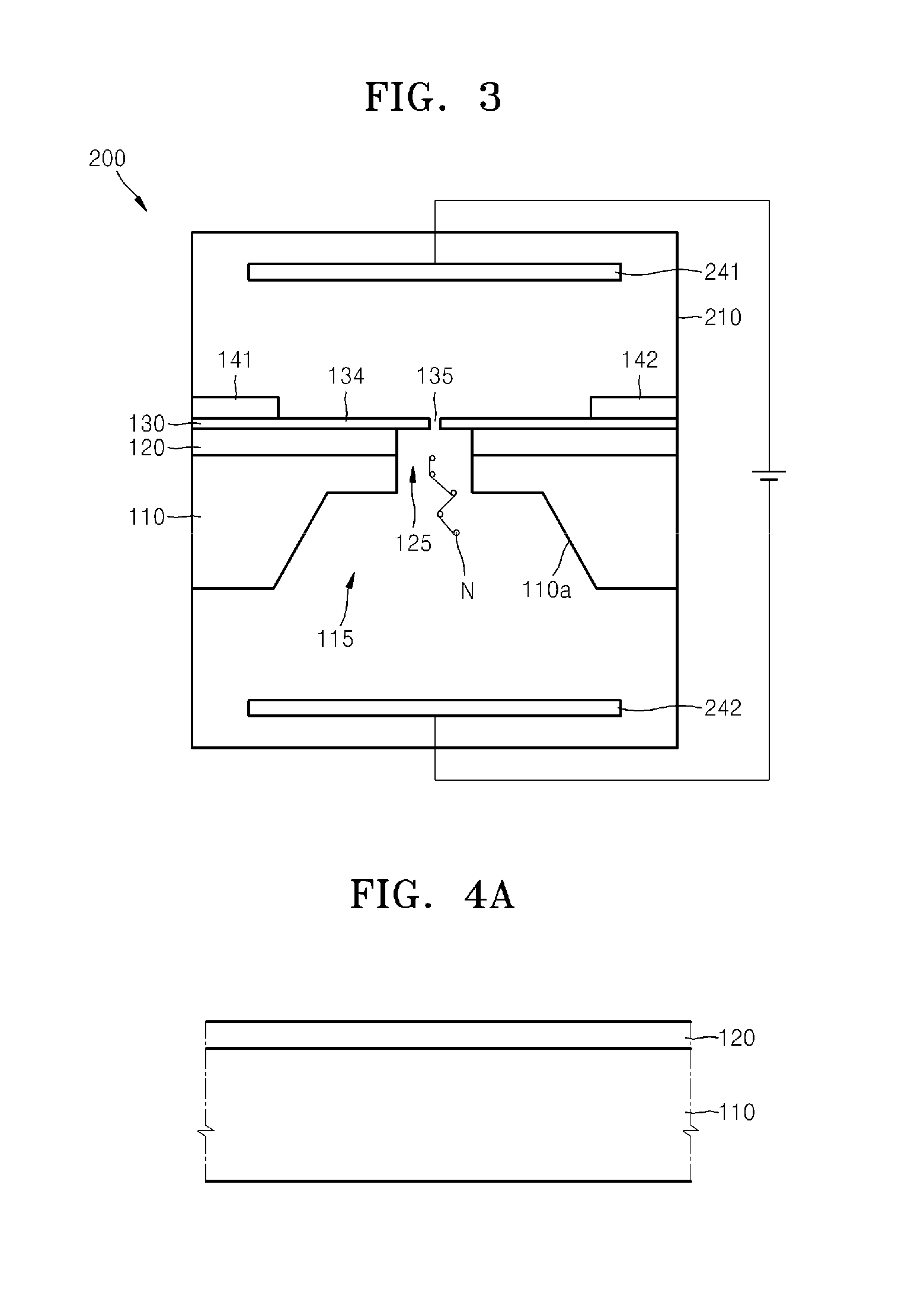

Nanogap sensor and method of manufacturing the same

ActiveUS20130265031A1Easy to manufactureNanoparticle analysisMaterial analysis by electric/magnetic meansPhysicsGrapheme

A nanogap sensor includes a first layer in which a micropore is formed; a graphene sheet disposed on the first layer and including a nanoelectrode region in which a nanogap is formed, the nanogap aligned with the micropore; a first electrode formed on the grapheme sheet; and a second electrode formed on the graphene sheet, wherein the first electrode and the second electrode are connected to respective ends of the nanoelectrode region.

Owner:SAMSUNG ELECTRONICS CO LTD

Preparation method and application of graphene oxide composite membrane

InactiveCN105727758AAdjustable spacingImprove performanceSemi-permeable membranesDispersed particle separationGas separationHummers' method

The invention discloses a preparation method and application of a graphene oxide composite membrane, and belongs to the technical field of gas separation membranes.The preparation method of the graphene oxide composite membrane comprises the steps that an aqueous dispersion liquid of graphene oxide is prepared through a Hummer method, and ultrasonic dispersion is conducted; metal salt or oxysalt is added, and heating and mixing are conducted; the surface of a micro-filtration membrane is covered with the prepared dispersion liquid through a vacuum filtration method; the membrane is put into a drying oven to be dried.The preparation method of the graphene oxide composite membrane has the advantages that the preparation method is simple, the thickness of the obtained membrane is smaller than 10 nm, the space between graphene sheet layers is adjustable, the obtained composite membrane is used for gas separation and has excellent comprehensive performance.Particularly, the graphene oxide composite membrane prepared from sodium tetraborate has high CO2 permeation flux and CO2 / CH4 and CO2 / N2 selectivity, and it is obtained through mixed gas tests under the humidifying condition that the CO2 permeation flux can reach 650 GPU, CO2 / CH4 selectivity is 75, and CO2 / N2 selectivity is 58.

Owner:TIANJIN UNIV

Method for preparing polyamide-amine in-situ intercalation graphene composite material

ActiveCN102390830AStructural damage is smallSolve the problem of not being conductivePolymer scienceOrganic solvent

The invention discloses a method for preparing a polyamide-amine in-situ intercalation graphene composite material. The method comprises the following steps of: (1) dispersing graphite in an imidazole-compound-containing organic solvent with ultrasonic, and centrifuging to obtain multi-layer graphene suspension; and (2) polymerizing to generate polyamide-amine in the multilayer graphene by adopting an in-situ polymerization method to prepare the polyamide-amine in-situ intercalation graphene composite material. According to the method, natural graphite is directly subjected to ultrasonic exfoliation in the organic solvent to obtain single-layer or multi-layer graphene suspension, the original sp2 structure of the graphene is slightly damaged because an oxidation step is not carried out, the polyamide-amine in-situ intercalation graphene composite material is prepared by using an in-situ polymerization method, so that graphene laminas are spread, interlamellar spacings are enlarged, the polyamide-amine on the surface of the graphene functionally prevents agglomeration of the graphene laminas, the graphene laminas are uniformly dispersed, and the product has good stability and is hardly precipitated.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com