Patents

Literature

655 results about "Mechanical crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

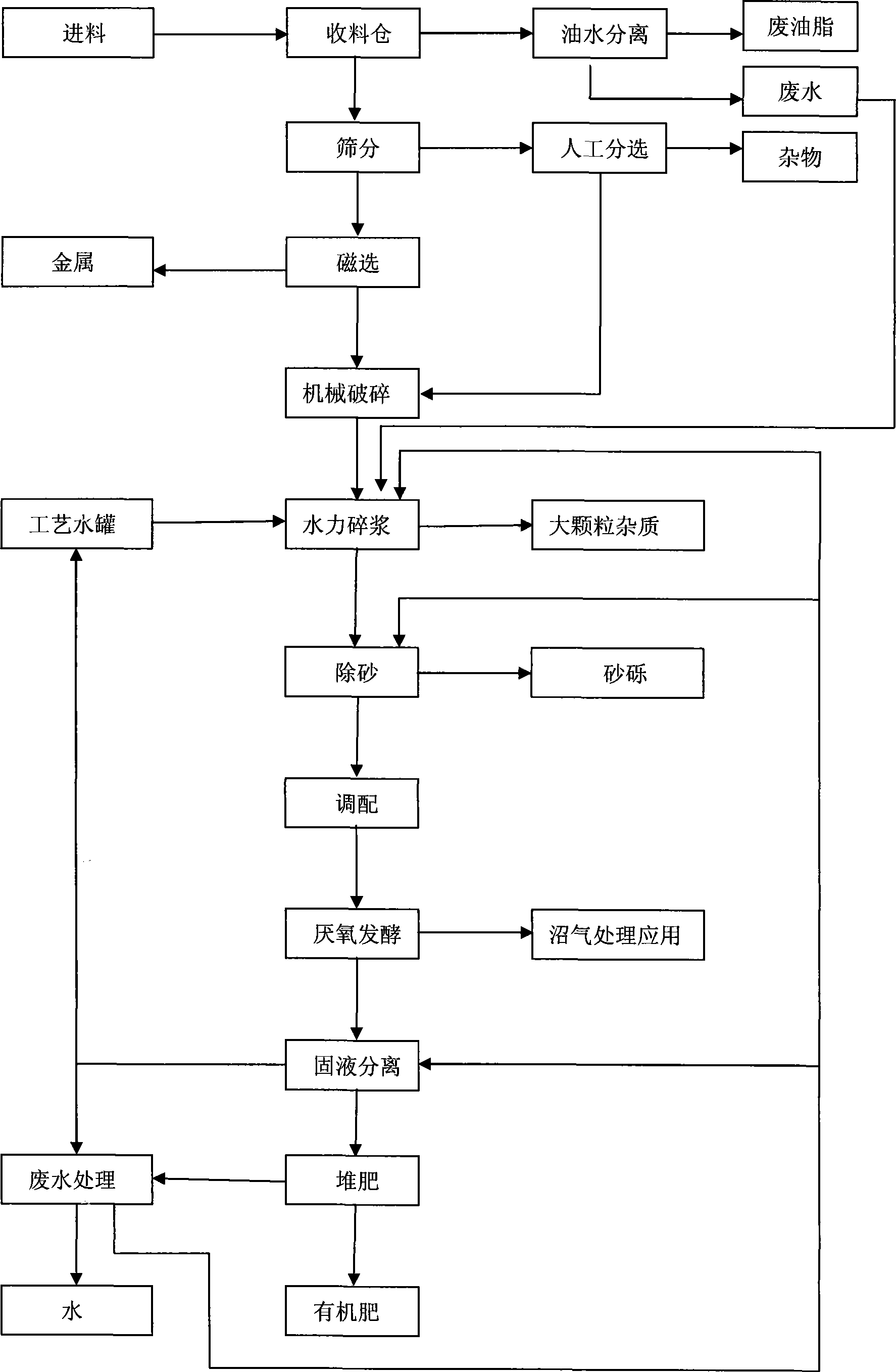

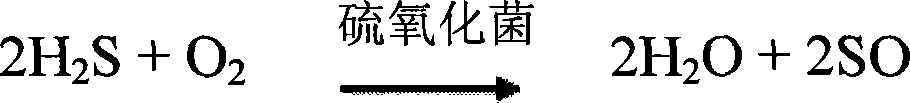

Anaerobic digestion handling method for restaurant garbage

ActiveCN101224999AHarmlessRealize resource processingBio-organic fraction processingClimate change adaptationSlurryOxygen

The invention provides a method for resourceful treatment of restaurant garbage, which is characterized in that the restaurant garbage is completely degraded after treatment with the working procedures of oil separating, preliminary selecting, mechanical crushing, hydraulic pulping, slurry blending, anaerobic fermentation and oxygen-control composting, finally the marsh gas is decomposed via anaerobic digestion and is utilized as energy after desulfurization treatment; the high-quality organic manure is produced from the biogas residues via oxygen-control composting; the separated oil can be recycled as the regenerated industrial raw oil; the wastewater generated in the treatment process can be recycled, and finally the redundant wastewater reaching the standard is discharged after biochemical treatment; and the odor generated by the garbage in the treatment process is directly discharged after reaching the standard via biofiltration treatment, thus the restaurant garbage can be transformed into the clean regenerated energy of electric power and the pollution-free organic manure to completely realize resourceful treatment of restaurant garbage. The resourceful treatment of restaurant garbage has the advantages of innocuity, no peculiar smell, no secondary pollution during the treatment process and realization of harmless and resourceful treatment of restaurant garbage.

Owner:宝林

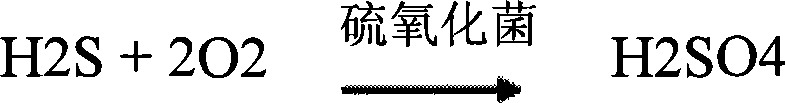

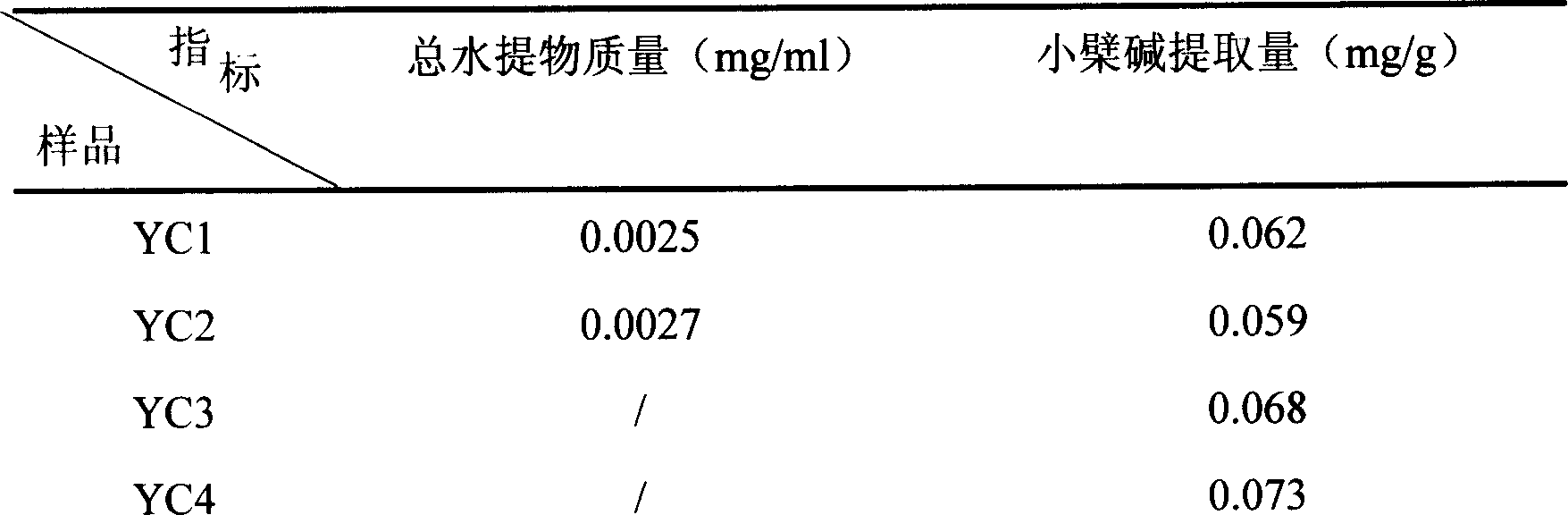

Effective plant component extracting process

InactiveCN1986029AChange microscopic propertiesEasy extractionSolid solvent extractionOrganic solventAlcohol

The effective plant component extracting process includes mechanically crushing the mixture of solid plant material and proper amount of chemical assistant, and the subsequent extraction of the effective component with water or alcohol. The mechanical crushing can produce micro shearing strain in the interface, break cell wall, expose fresh cut surface and produce mutual adsorption and other action between the grain clusters and molecular groups of the chemical assistant and the effective component, so as to alter the microscopic performance of the effective plant component, raise the leached amount by 80-400 %, short the extracting period greatly, raise the extracting efficiency obviously raise the extraction specificity and selectivity, minimize the organic solvent in use, lower the extraction cost and raise the bioavailability of the extracted matter.

Owner:DALIAN SEM BIOLOGICAL ENG TECH

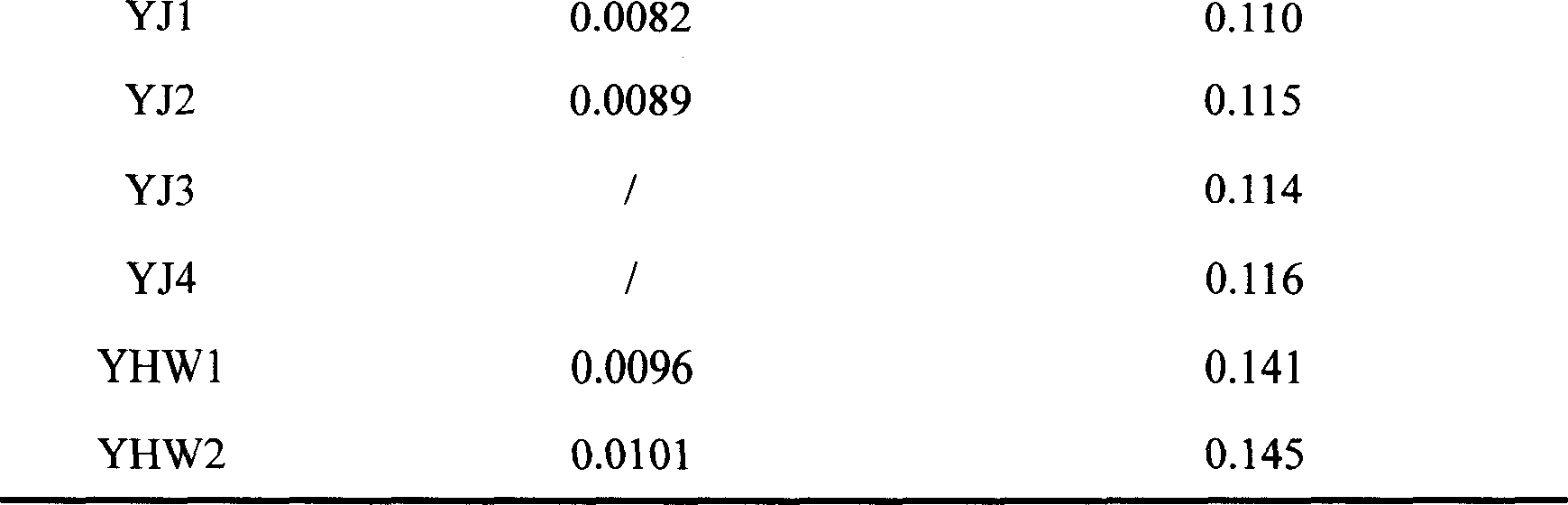

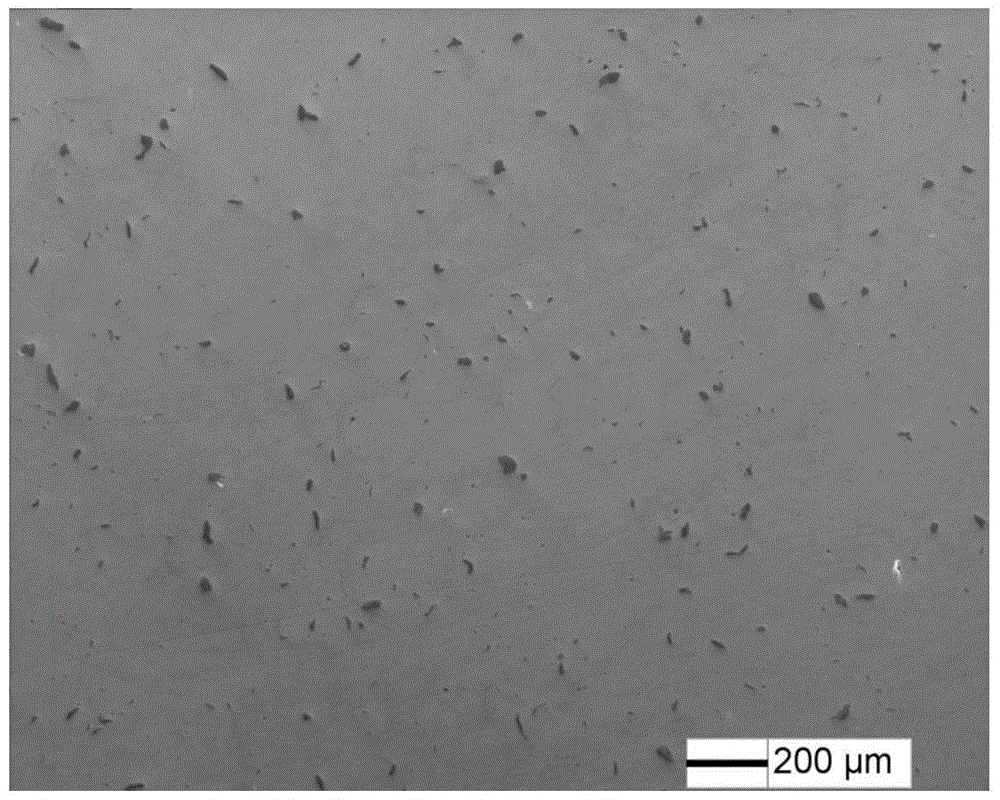

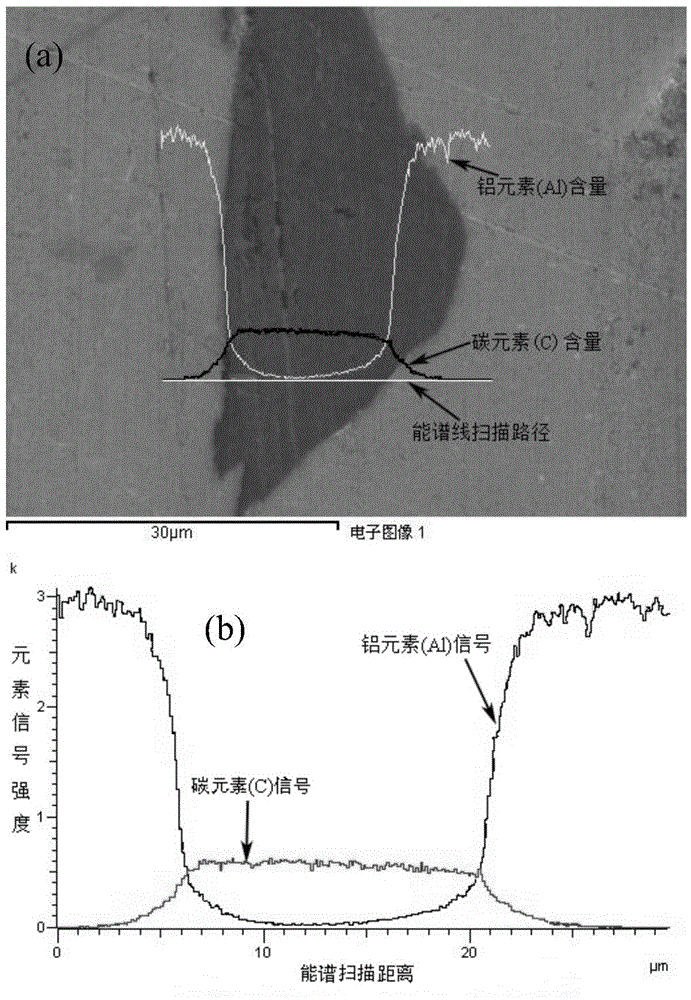

Method for preparing graphene reinforced metal-based composite material through discharge plasma (SPS) sintering

The present invention relates to a method for preparing a graphene reinforced metal-based composite material through discharge plasma (SPS) sintering. The method is characterized in that the graphene reinforced metal-based block material is prepared through SPS sintering and has the following advantages that: the preparation method is simple, the material is compact and does not have pores, the graphene mass fraction can be arbitrarily regulated, the distribution is uniform, no aggregation is generated, the material mechanical property isotropy is provided, and the wettability of the metal and the graphene interface is good. The method comprises: (1) reducing graphene oxide through a chemical method or a hydrothermal method to obtain graphene sheets with a sheet layer thickness of not more than 4 nm and sheet layer diameter of not more than 50 [mu]m; and (2) preparing metal powder with a particle size of not more than 200 [mu]m through a rotating electrode atomization method, mechanical crushing or a high-speed ball milling method; (3) carrying out mechanical or ball milling mixing on the graphene powder and the metal powder according to the required mass ratio; and (4) carrying out SPS sintering forming on the mixed powder, wherein the obtained material has characteristics of improved mechanical property, decreased density, good heat conduction capability, and good electric conduction capability, and the performance customizing can be achieved by adjusting the preparation parameters.

Owner:BEIHANG UNIV

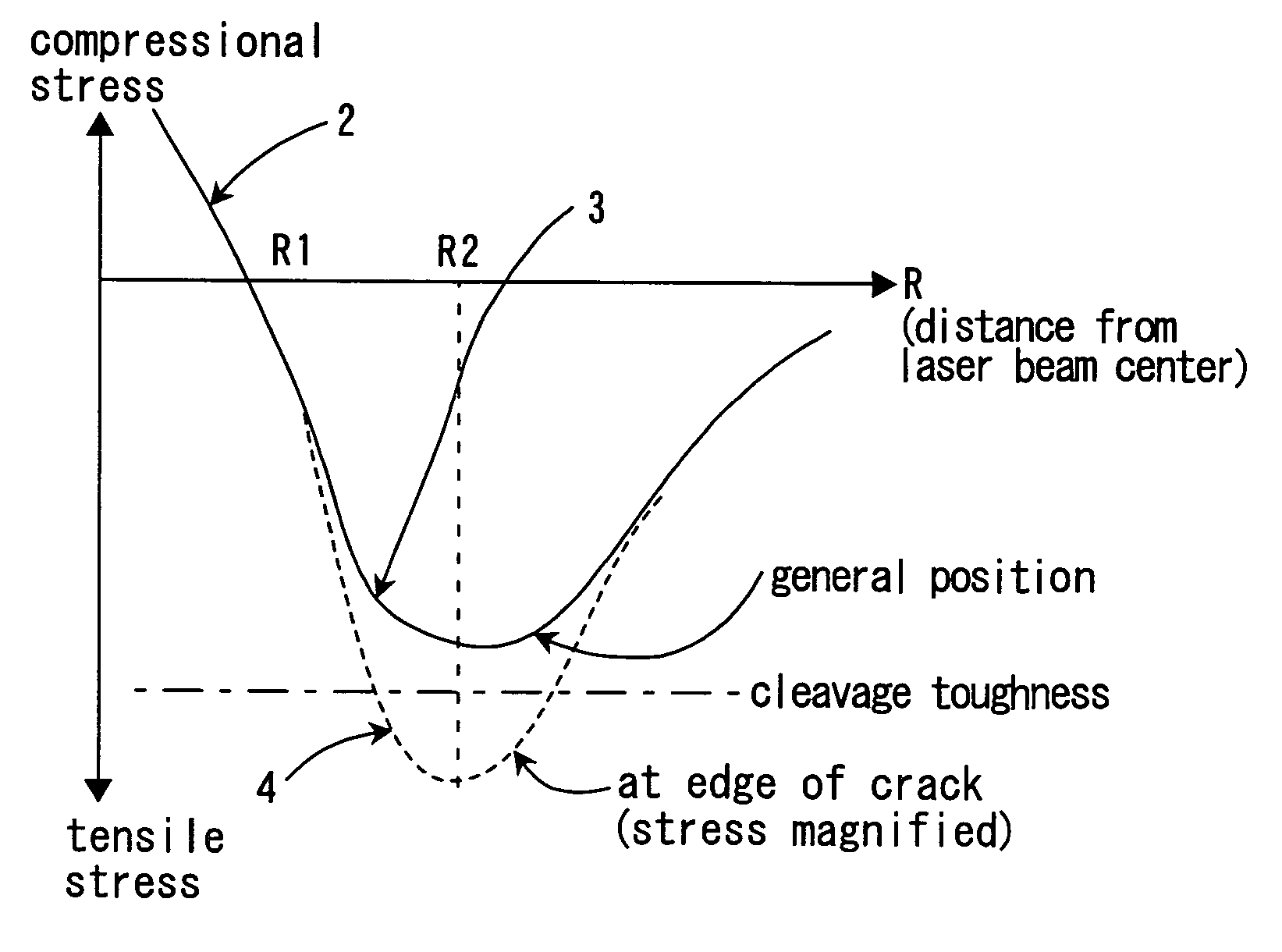

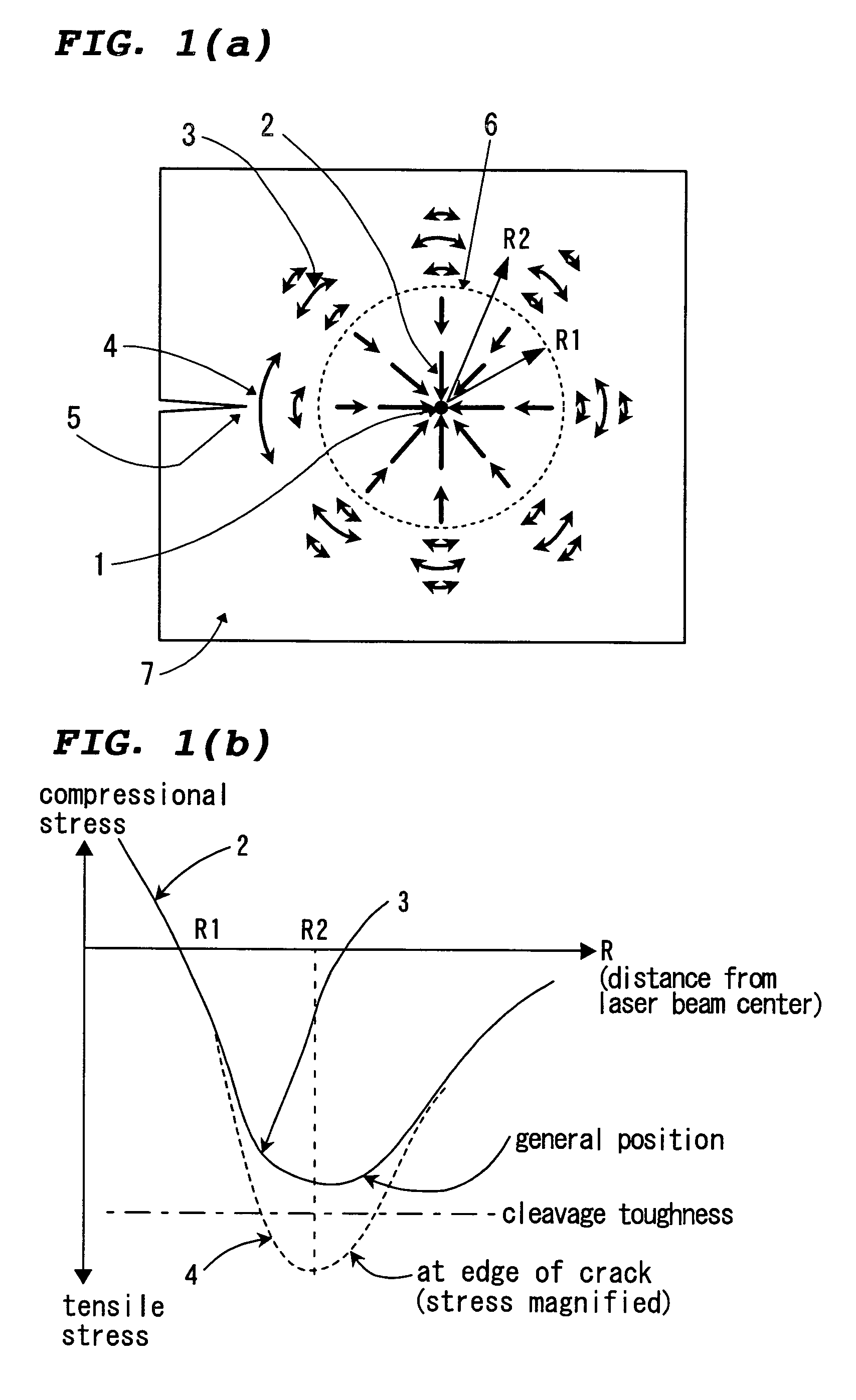

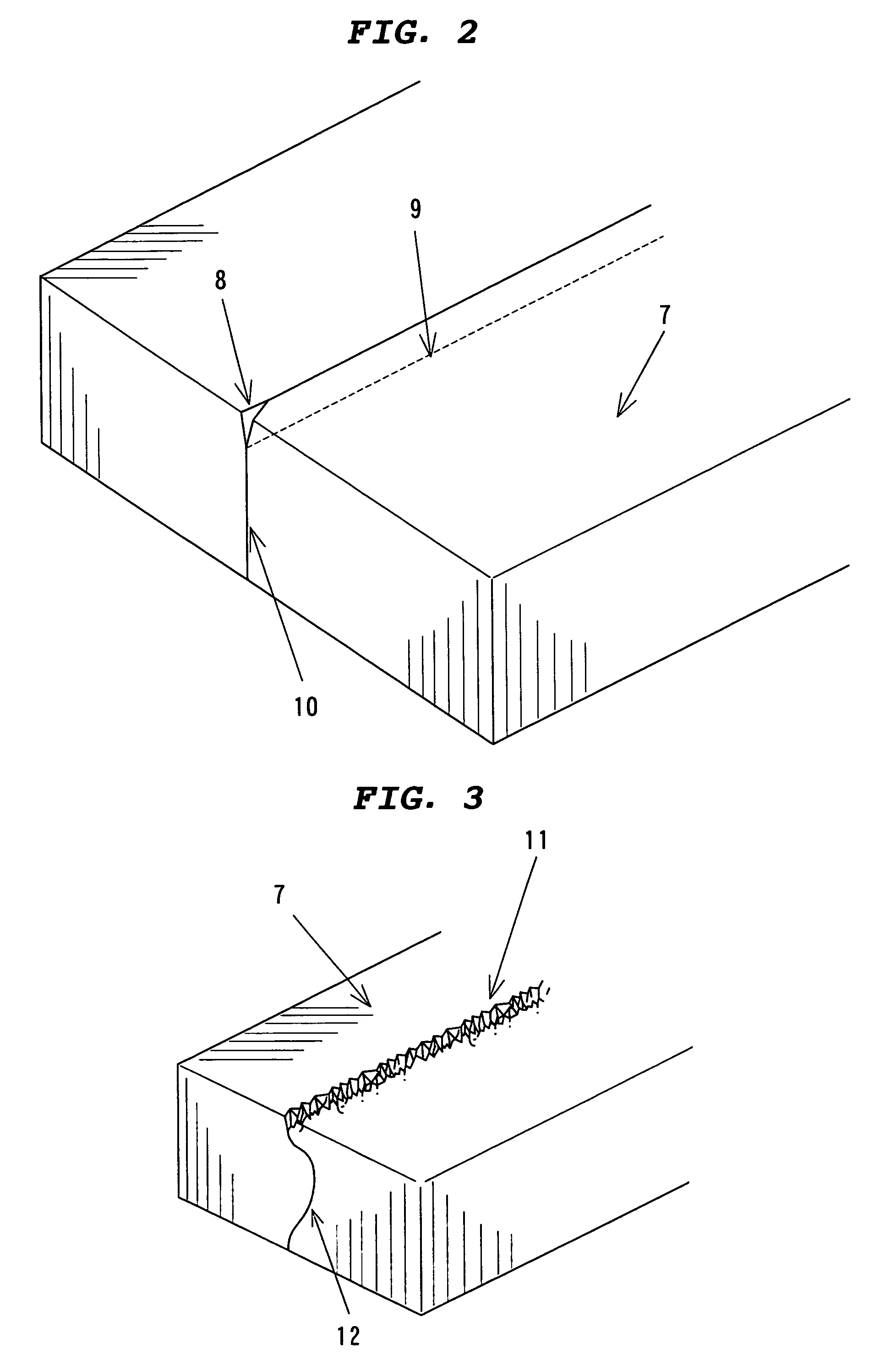

Full-body laser scribing method of fragile material

InactiveUS20070062921A1Glass severing apparatusWelding/soldering/cutting articlesHigh power lasersWhole body

This invention enables the full-body (throughout the entire thickness) scribing of a plate made of fragile material such as glass by irradiating the work with the laser beam for heating with or without cooling and thereby generating the tensile thermal stress in the work which exceeds the cleavage toughness of the material, dispensing with the mechanical breaking. In this invention, the absorption of the beam in the work is so controlled that the beam, while being absorbed in it, is either transmitted through it or reaches the adequate thickness of the work and the entire thickness scribing is realized. This absorption control is done by selecting the laser beam wavelength so as to achieve the proper absorption in the absorption spectra of the material either due to the electronic transition or the lattice vibration. The doping of the material, in which the commercially available high power laser beam can be absorbed properly and either of the absorption or emission in the visible light spectral range does not exist, can also be utilized for this absorption control. In this case, the quenching of the fluorescence which may arise after the beam absorption is useful. This invention enables the profile scribing of work or the selective scribing of piled work consisting of plural number of plates.

Owner:LEMI

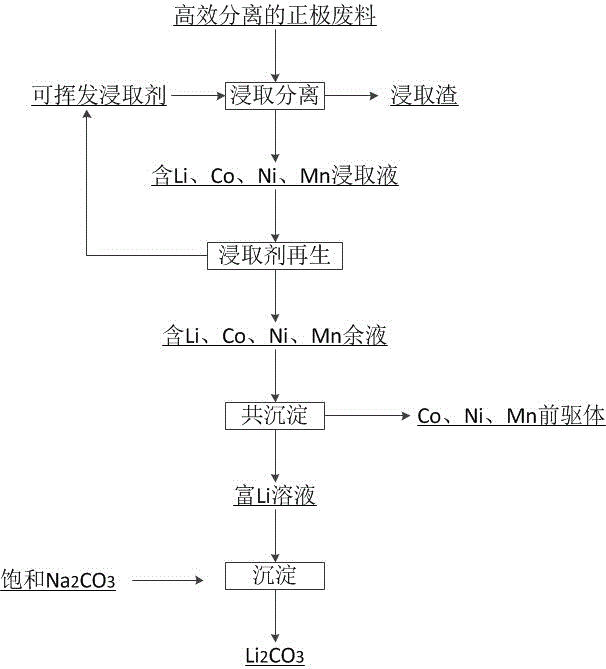

Method for recovering positive electrode material precursor and lithium carbonate from positive electrode waste material of lithium ion battery

ActiveCN106848474AWide range of sourcesLow priceWaste accumulators reclaimingProcess efficiency improvementAdditive ingredientMixed materials

The invention provides a method for recovering a positive electrode material precursor and lithium carbonate from a positive electrode waste material of a lithium ion battery. The method comprises carrying out mechanical crushing on the waste produced by battery production or waste or old batteries, carrying out sorting to obtain impurity-containing positive electrode powder, carrying out immersion through a reducing agent-containing volatile leaching agent to obtain extract, carrying out concentration rectification, regenerating the volatile leaching agent, adjusting ingredients of the raffinate containing Co, Ni, Mn and Li, carrying out coprecipitation on Co, Ni and Mn, carrying out solid-liquid separation, further treating the Li-rich solution to obtain high-purity lithium carbonate, and carrying out a high temperature solid-phase reaction process on the mixed materials of Co, Ni and Mn precursors to obtain a positive electrode active material. The method is simple and is free of a complicated impurity removal process and an extraction enrichment technology. The extraction agent has a wide source, high extraction selectivity and high extraction efficiency. After the extraction reaction, the extraction agent can be recovered and recycled through concentration rectification. The method reduces a cost, can produce high-quality Co, Ni and Mn precursors and high-quality lithium carbonate and has a good application prospect.

Owner:BOTREE CYCLING SCI &TECH CO LTD

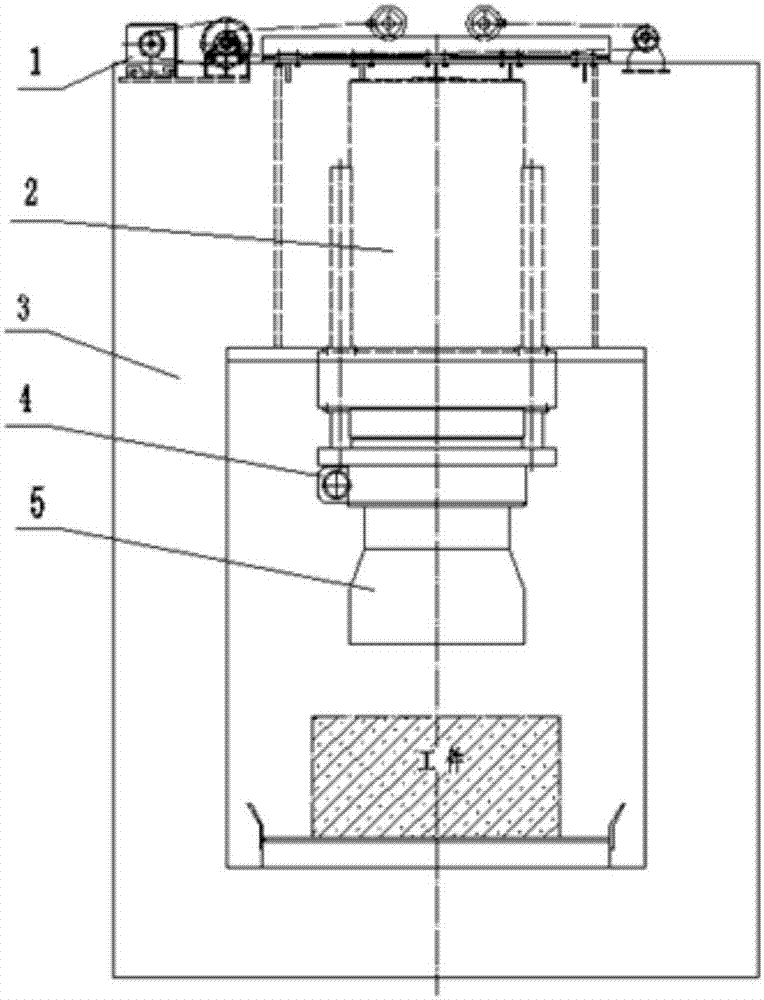

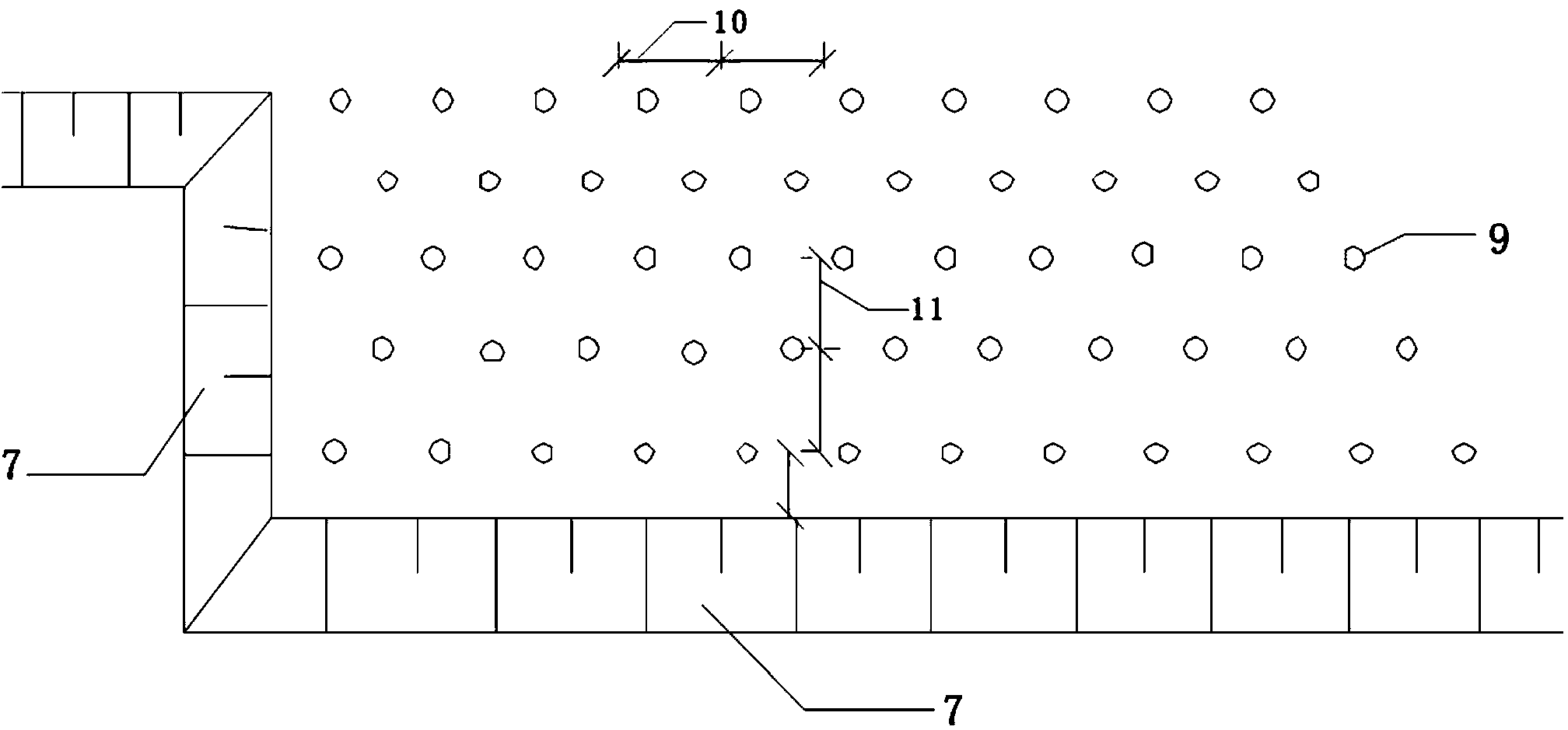

Reinforced concrete beam precrushing device

The invention discloses a reinforced concrete beam precrushing device. The reinforced concrete beam precrushing device comprises a workbench, a shearing device, a crushing device and a moving device used for moving reinforced concrete beams. A track used for allowing the reinforced concrete beams to move is arranged on the workbench. The shearing device and the crushing device are fixed on the workbench and are above the track. The moving device is movably arranged at one end of the track and moves from one end of the track to the other end of the track. Hydraulic power is adopted for static pressing shearing and crushing of the large reinforced concrete beams, reinforced concrete is rapidly crushed, rebars and concrete are separated, the speed is high, the yield is high, the noise is low, dust is few, the automation degree is high, the worker labor intensity is low, and thus a quite environmentally friendly mechanical crushing method is achieved. The reinforced concrete beam precrushing device has the advantages of being simple in structure, convenient to operate and maintain, safe, efficient, environmentally friendly and the like.

Owner:JIANGSU HUAHONG TECH STOCK

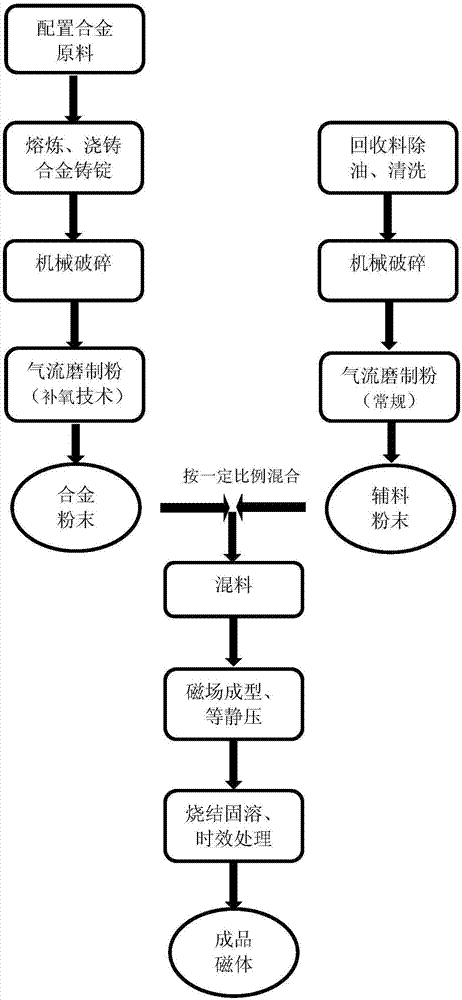

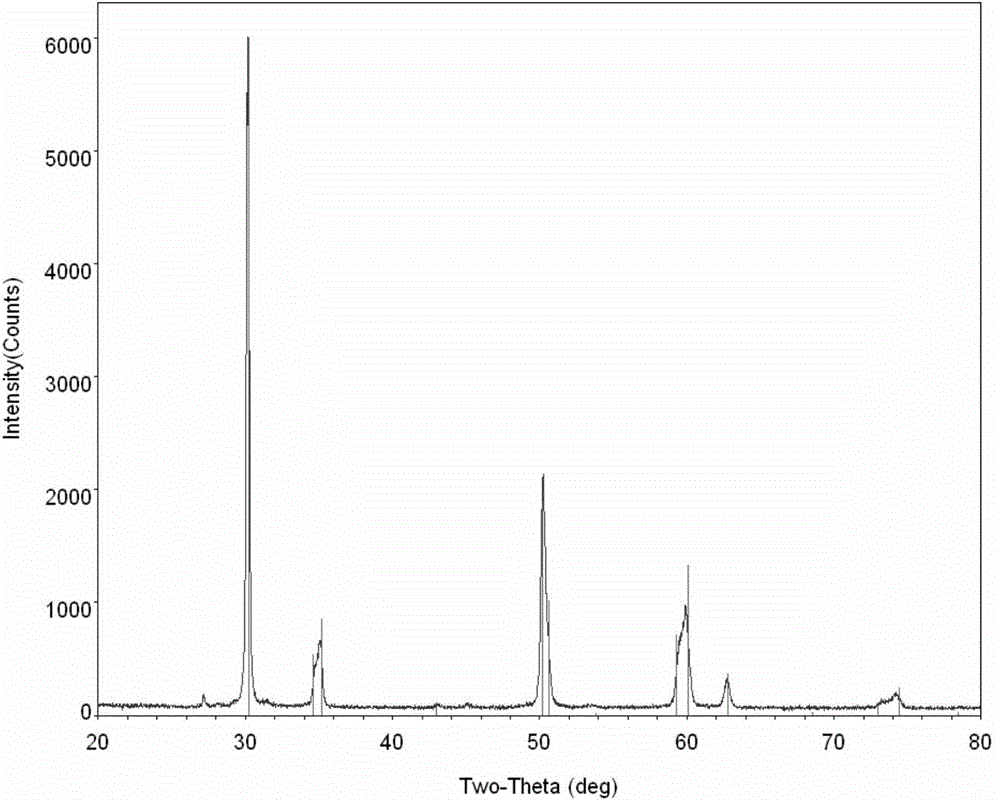

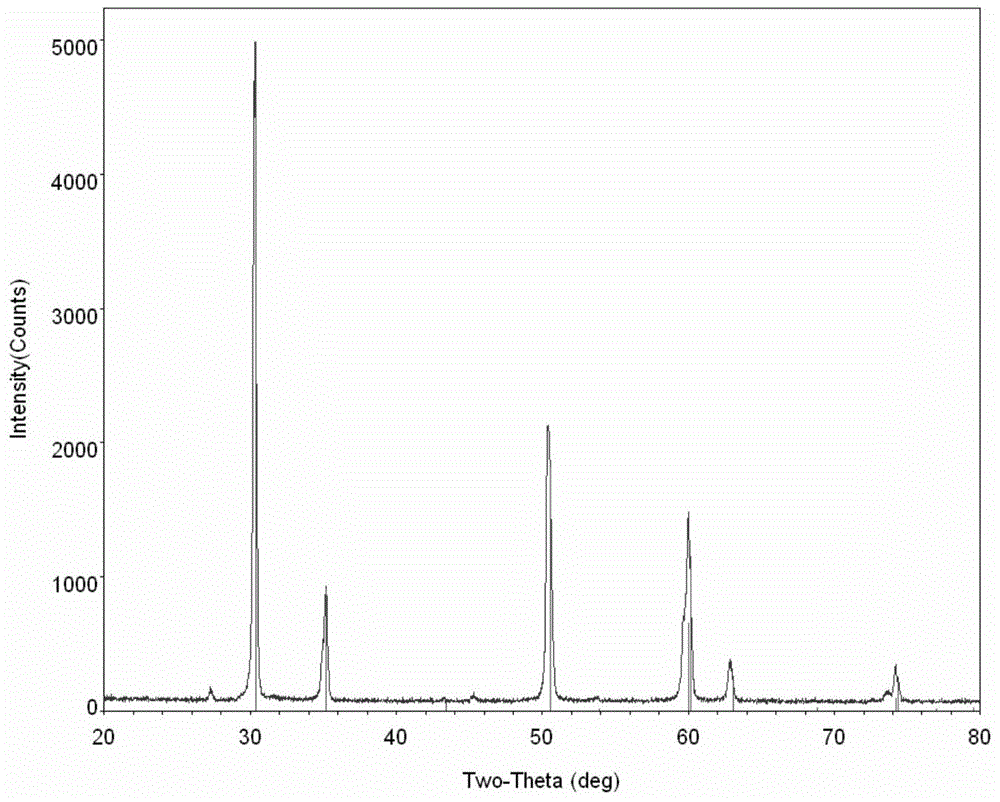

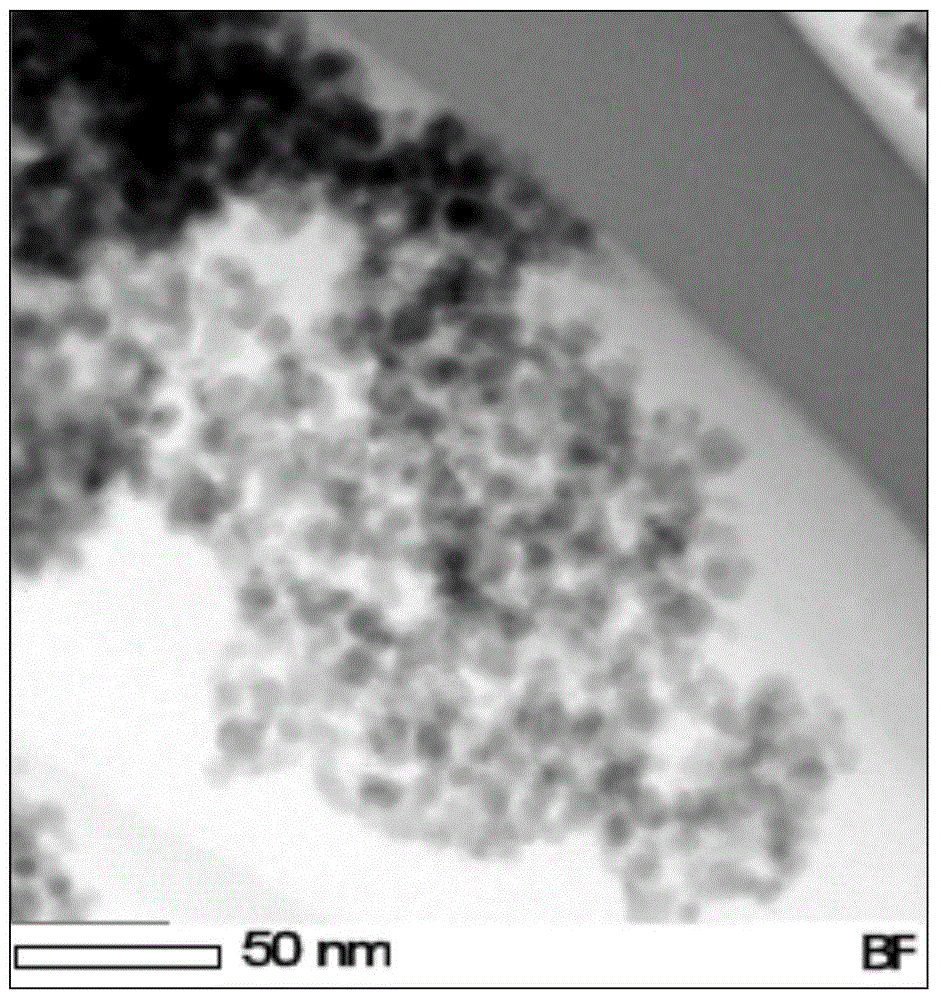

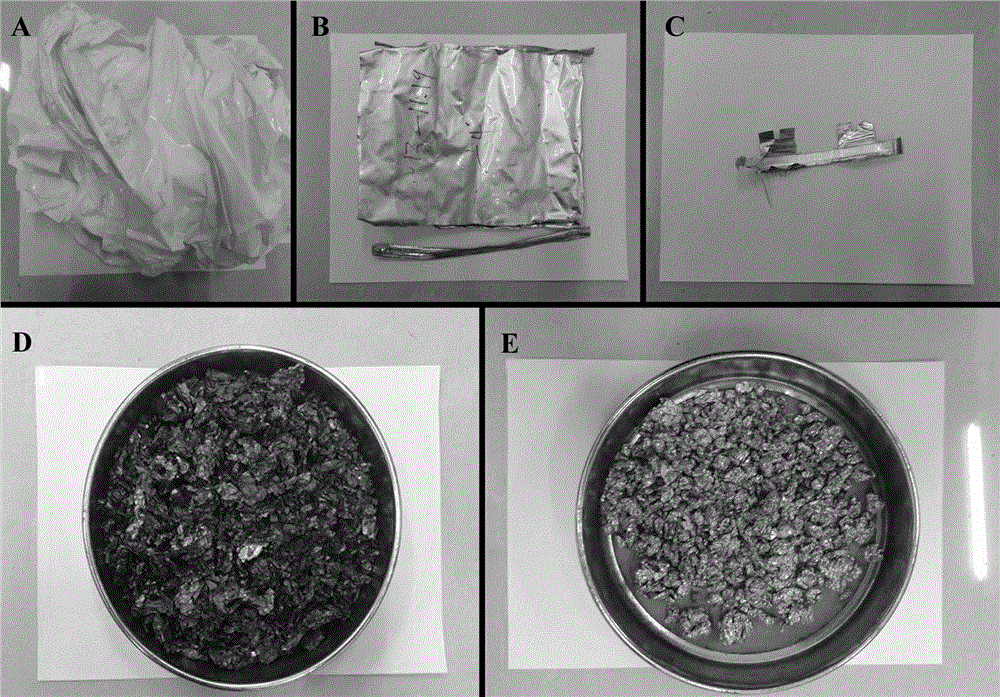

Preparation method of sintered samarium-cobalt magnet

ActiveCN107316726AControl magnet oxygen contentGood mechanical propertiesInductances/transformers/magnets manufactureMagnetic materialsSamarium–cobalt magnetAlloy

The invention relates to a preparation method of a sintered samarium-cobalt magnet. The preparation method comprises the steps that alloy powder is prepared, wherein samarium-cobalt alloy raw materials are prepared, by weight, 25%-27% of (Sml-xRx), 6%-25% of Fe, 2%-3.5% of Zr, 3%-8% of Cu and the balance Co, 0<=x<=0.9, R is one or more of Ce, Pr, Nd, Gd, Tb, Dy, Ho and Er, and the samarium-cobalt alloy raw materials are subjected to smelting, casting and mechanical crushing and then subjected to an oxygen supplementary flow powder grinding technique to prepare the alloy powder; 2, leftover materials and waste materials which have the components similar to those of the alloy powder are subjected to cleaning, crushing and conventional air flow powder grinding and then fully mixed with a lubricant to prepare auxiliary material powder; 3, the materials are mixed, wherein the alloy powder and the auxiliary material powder are mixed in proportion to prepare samarium-cobalt alloy powder; 4, magnetic field molding and isostatic pressing are conducted to prepare a green body; and 5, sintering, solid solution and aging processing is conducted, and the samarium-cobalt magnet is prepared. The sintered samarium-cobalt magnet prepared through the method has the good mechanical performance and has the bending strength higher than 100 MPa.

Owner:CENT IRON & STEEL RES INST

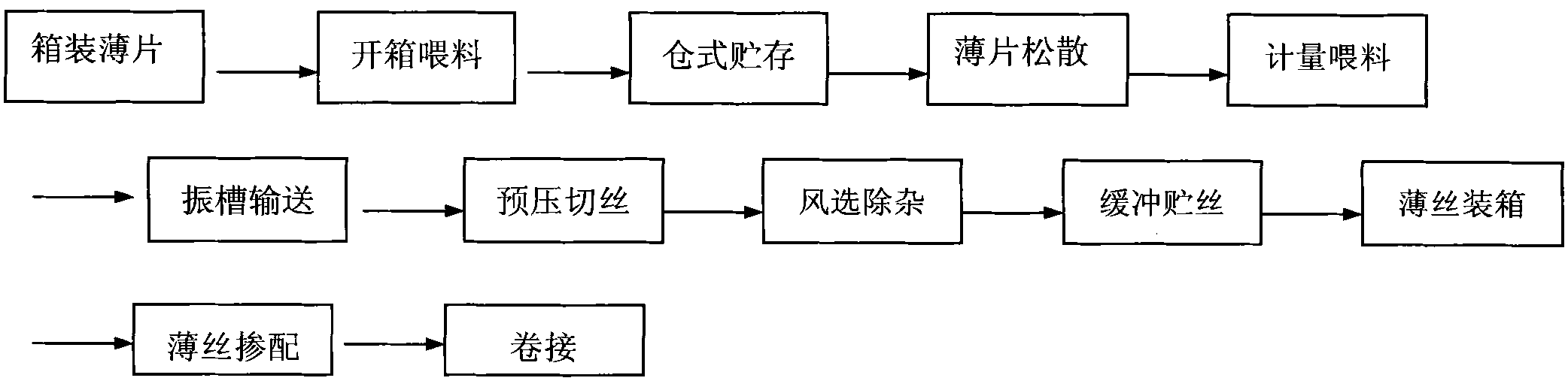

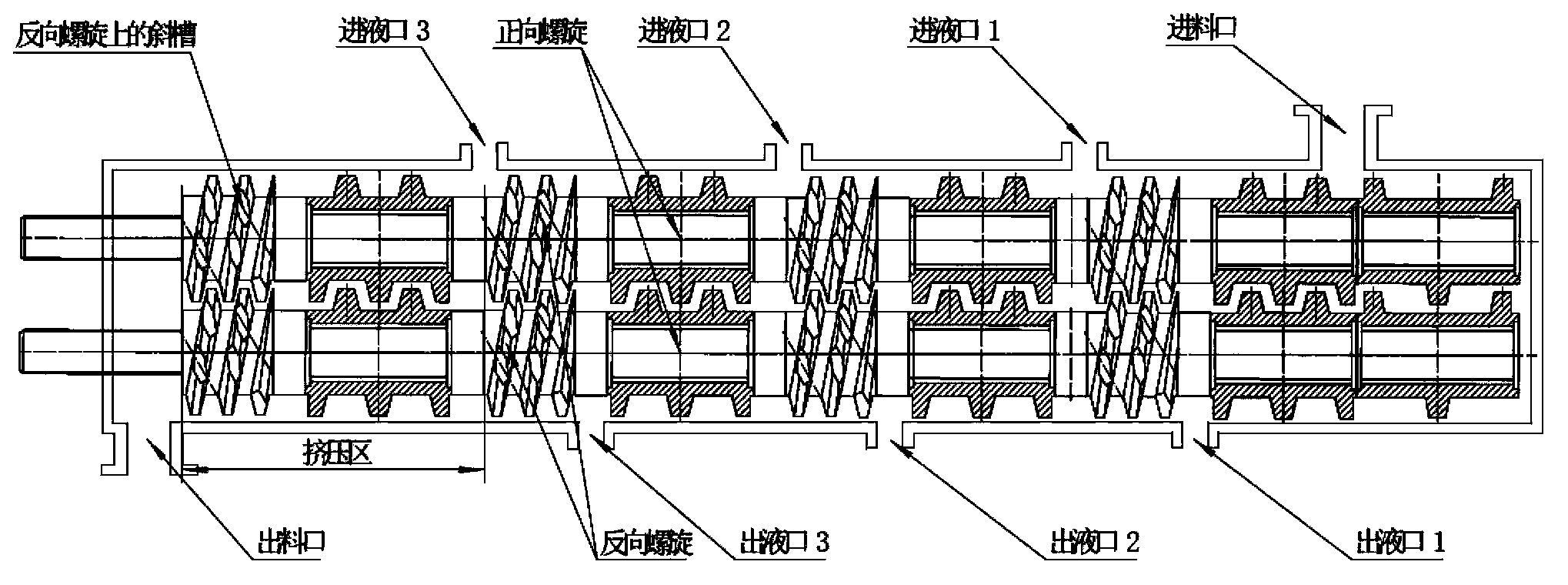

Method and equipment for manufacturing cigarettes by filamentization of tobaccos reconstituted by papermaking process

ActiveCN102008122AIncrease forming timeHigh densityTobacco preparationMechanical crushingPapermaking

The invention relates to the manufacturing field of cigarettes, in particular to a method for manufacturing cigarettes by the filamentization of tobaccos reconstituted by a papermaking process. The method comprises the following steps of: (1) scattering boxed finished reconstituted tobaccos, and storing the scattered reconstituted tobaccos in a bin cabinet; (2) lifting the reconstituted tobaccos in the bin cabinet, and controlling the flow of the reconstituted tobaccos by using an electronic belt scale; (3) conveying the reconstituted tobaccos to a reversible belt by a high-position vibrationgroove with a metal detector; (4) after the reconstituted tobaccos on the reversible belt falls off the conveying vibration groove, prepressing the reconstituted tobaccos by a prepressing device, andallowing the reconstituted tobaccos to enter a tobacco filament cutter; (5) winnowing the reconstituted tobaccos to remove dust, allowing the reconstituted tobaccos to enter a buffering cabinet, and metering and boxing for blending; and (6) mixing the boxed reconstituted tobaccos and cut tobaccos directly by a blending filament mixing system, perfuming, storing and rolling to form the cigarettes of finished products. The reconstituted tobaccos are blended directly without undergoing a high-strength processing process, so resource waste caused by mechanical crushing in the process of blending the reconstituted tobaccos is reduced.

Owner:CHINA TOBACCO ZHEJIANG IND

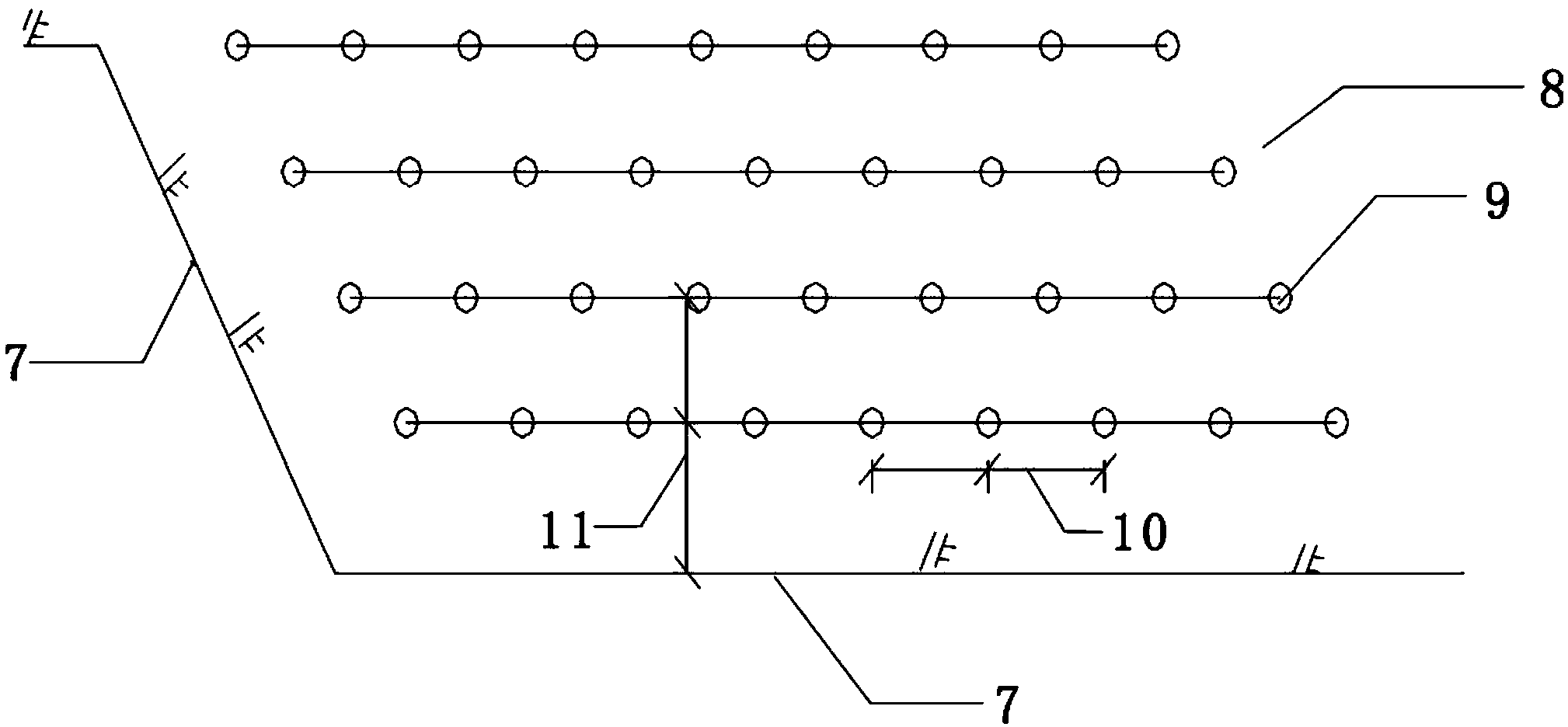

Foundation integrated processing construction method of cover type karst area

ActiveCN101864763ASpeed up the progress of the projectSave construction fundsSoil preservationBedrockSleeve valve

The invention relates to a foundation processing method, in particular to a foundation integrated processing construction method of a cover type karst area. The method comprises the following steps of: evacuating earth moving machinery when a foundation pit is excavated until a limestone formation is exposed in a large area; basically exposing rocks of the bottom of the foundation pit after excavating, wherein rock buds are exposed from a foundation base, and the storage quantity of damic earth among the rock buds does not influence the next procedure construction; adopting weakened loose blasting operation, aiming at solution cracks, intermountain gulches and locally crushing bedrocks, and mechanically crushing and clearing; adopting a complex geophysical prospecting technological means that a high-density resistivity method is combined with a geological radar, arranging a high-density electrical geophysical prospecting wire in a construction site according to an arrangement rule, meanwhile, arranging a detailed exploratory hole in a building planning position, and mechanically picking the solution cracks, the intermountain gulches and the locally crushing bedrocks; adopting sleeve valve cement flour and coal ash slurry injecting constriction and cement flour and coal ash slurry filling constriction by a solution cavity slurry-injection method; and filling and casting concrete. The invention can quicken a work progress and can save construction cost compared with other foundation processing modes.

Owner:CHINA 22MCC GROUP CORP +1

Method for pretreating cellulosic biomass

InactiveCN103790056ASimple processing methodIncrease contact areaEnergy inputFermentationMechanical crushingLignocellulosic biomass

The invention relates to relates to a method for pretreating cellulosic biomass, which comprises the following steps: before or after the cellulosic biomass is mechanically crushed, or when the cellulosic biomass is mechanically crushed, the cellulosic biomass is contacted with a chemical drug capable of degrading the cellulosic biomass, and the heat generated due to mechanical crushing is used for increasing the temperature of a mixture of the cellulosic biomass and the chemical drug.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Preparation method of high corrosion resistance sintered neodymium iron boron

InactiveCN1913053AImprove corrosion resistancePromote sinteringInorganic material magnetismChemical platingMechanical crushing

This invention discloses a preparation method for anti-corrosion sintered NdFeB including: 1, preparing the NdFeB alloy by casting or rapid hardening rejection band strip technology then applying ball grinding or gas flow grinding to process powder after hydrogen explosion or mechanical crushing, 2, confecting oil eliminator, activated solution and chemical plating solution, 3, eliminating oil from the magnetic powder with oil eliminator then dunk rinsing with activated solution, 4, adding the powder into a plating solution for chemical-plating copper then drying it with vacuum drier, 5, pressing the dried powder to molded-blanks, 6, preparing the molded-blanks to sintered magnet in a high vacuum sintering oven.

Owner:ZHEJIANG UNIV

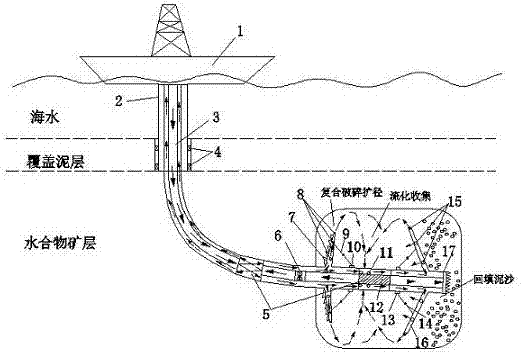

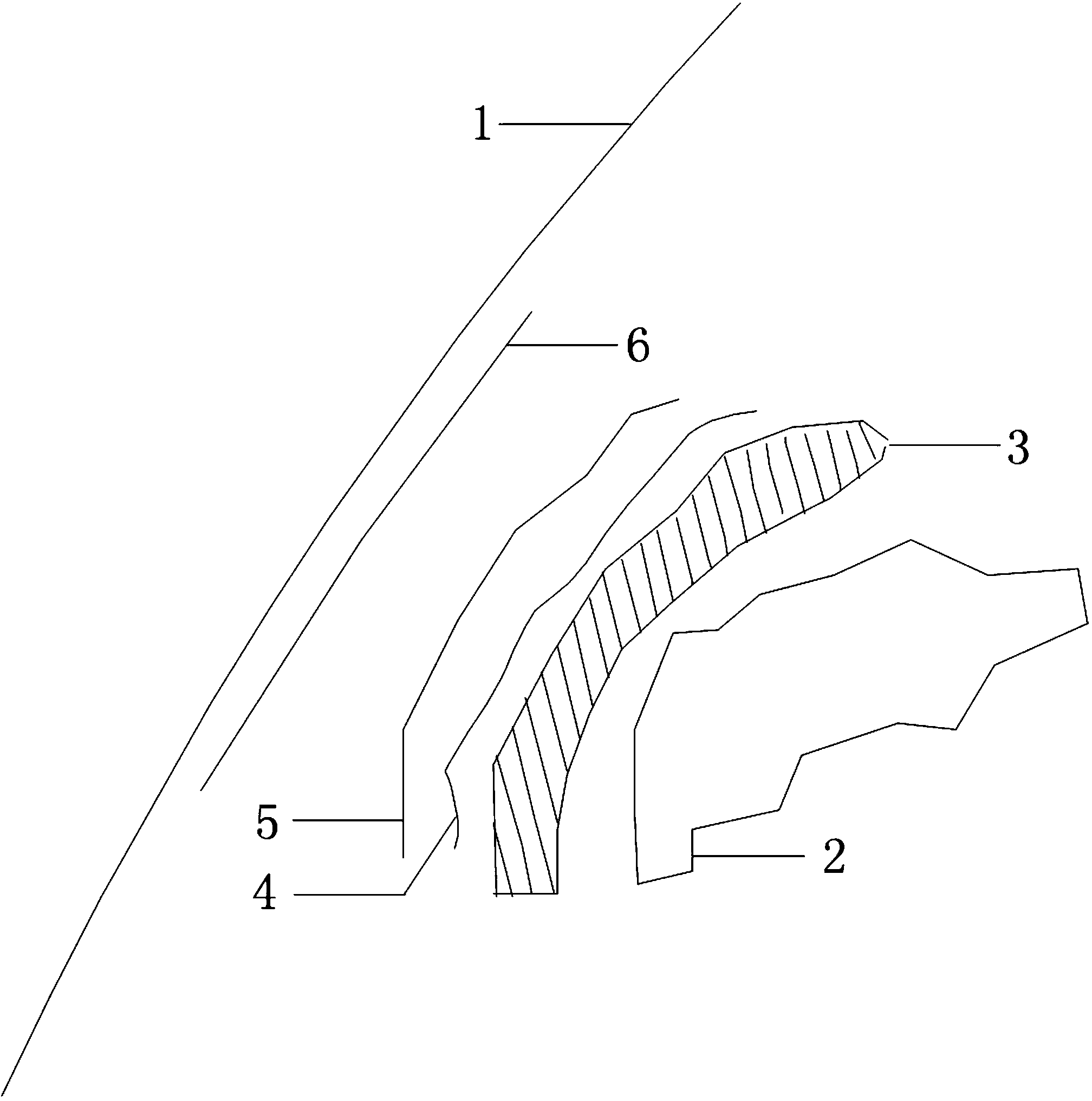

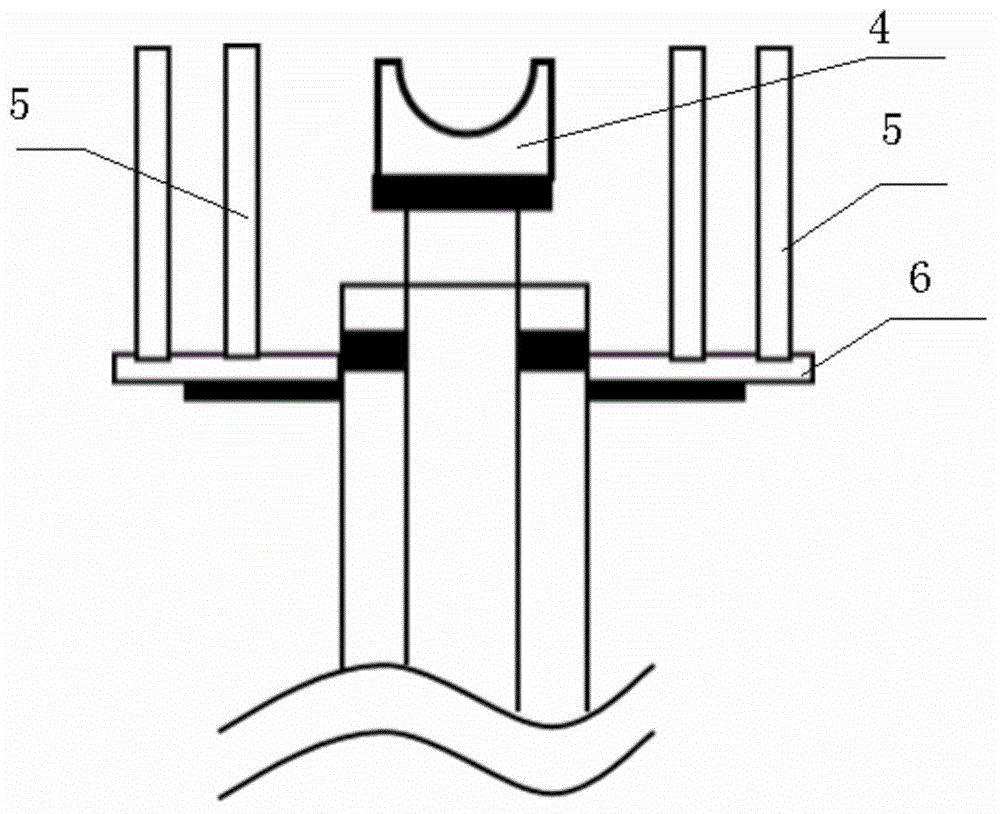

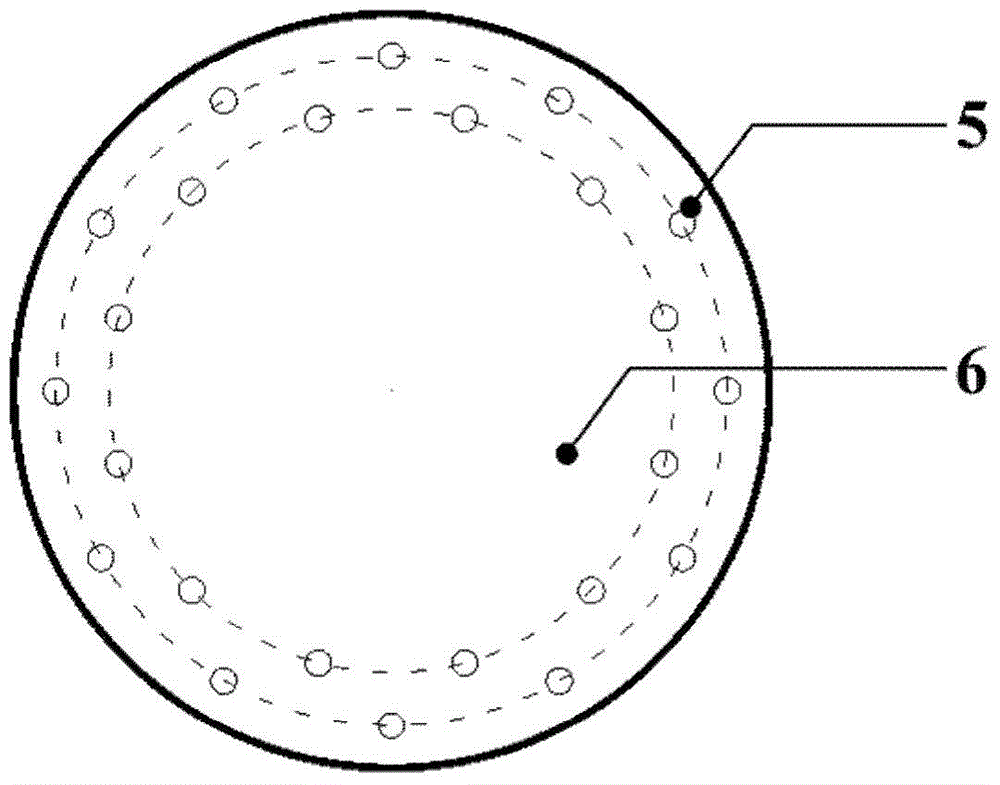

Mechanical and jet flow combined exploitation method and mechanical and jet flow combined exploitation device for natural gas hydrates in non-stratified rock of shallow strata in seabed

ActiveCN107448176AAvoid blendingPrevent collapseConstructionsFluid removalSpray nozzleMechanical crushing

The invention discloses a mechanical and jet flow combined exploitation method and a mechanical and jet flow combined exploitation device for natural gas hydrates in non-stratified rock of shallow strata in seabed. The mechanical and jet flow combined exploitation method and the mechanical and jet flow combined exploitation device are used for crushing and exploiting the natural gas hydrates in the non-stratified rock of the shallow strata in the seabed in a composition manner. The mechanical and jet flow combined exploitation method includes drilling pilot holes by an intelligent guide drilling tool, unfolding a mechanical crushing cutter arm after the intelligent guide drilling tool reaches preset locations, carrying out rotary cutting and crushing, starting to carry out jet flow crushing by spray nozzles, opening a flow regulating device, isolating recovery regions from goaves, separating hydrates from sediment by a downhole separator, filling the sediment with CO2, realizing effects of curing backfilled particles and backfilling the sediment in an in-situ manner. The mechanical and jet flow combined exploitation method and the mechanical and jet flow combined exploitation device have the advantages that the crushing radiuses and the exploitation spaces can be enlarged; crushed particles and the backfilled particles can be prevented from being mixed with one another; the sediment which is sorted by the downhole separator is filled with the CO2, accordingly, natural gas in the sediment can be displaced, effects of curing agents can be realized, the strength of backfilled layers can be enhanced, and the goaves can be prevented from collapsing.

Owner:SOUTHWEST PETROLEUM UNIV

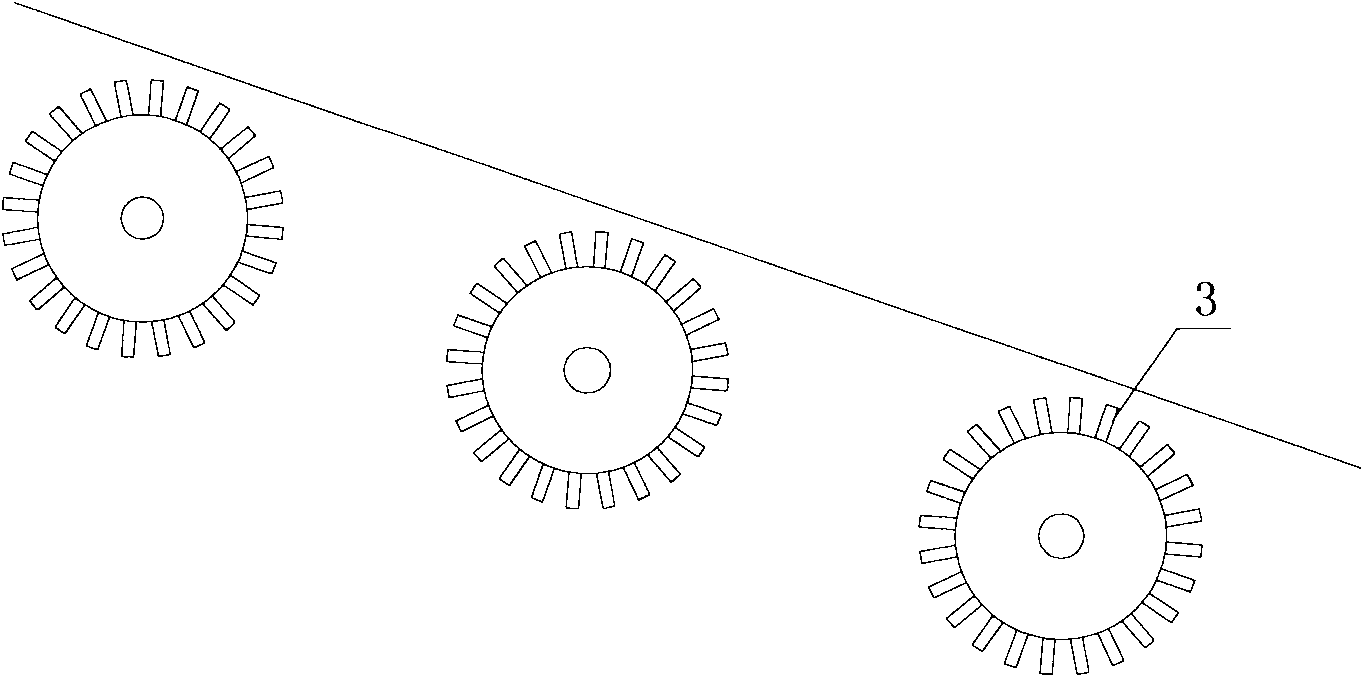

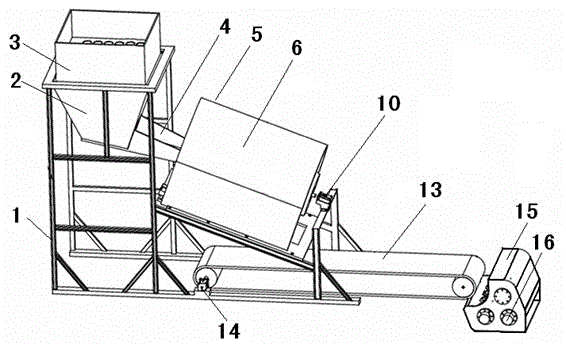

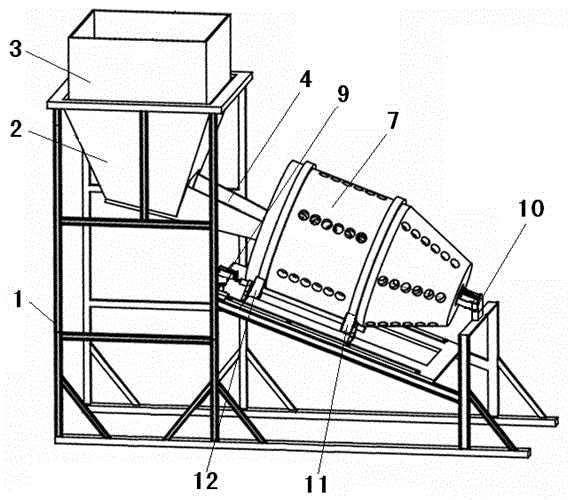

Soil sieving and crushing device

ActiveCN104984991AEasy to operateActively and effectively addSievingScreeningMechanical crushingGear wheel

The invention discloses a soil sieving and crushing device. The device contains a bracket which is of an L-shaped frame structure, wherein a hopper and a vibrating sieve are arranged at the top end of the bracket; a filtering sieve, a supporting spring, a fifth motor and a cam shaft are arranged at the bottom end of the vibrating sieve; a guide groove is formed below the hopper; a slope-shaped platform is arranged on the middle lower part of the bracket; a sieving drum, a first motor, a second motor, a rolling wheel and a gear are arranged on the slope-shaped platform; the sieving drum consists of an outer cover, a sieving outer drum and a sieving inner drum; the sieving inner drum is driven by the second motor; the sieving outer drum is driven by the first motor; a conveying belt and a third motor are arranged on the bracket below the front end of the sieving drum; a rotary-cutting and rolling hammer device with a rolling hammer device and a rotary-cutting device is arranged at the front end of the conveying belt; the rotary-cutting and rolling hammer device is driven by a fourth motor. The electromechanical structure provided by the invention can finish work, such as quickly crushing and sieving soil, automatically adding medicine, mixing, stirring and the like, and is the relatively effective mechanical crushing equipment used for treating heavy metal pollution soil.

Owner:EAST CHINA UNIV OF SCI & TECH

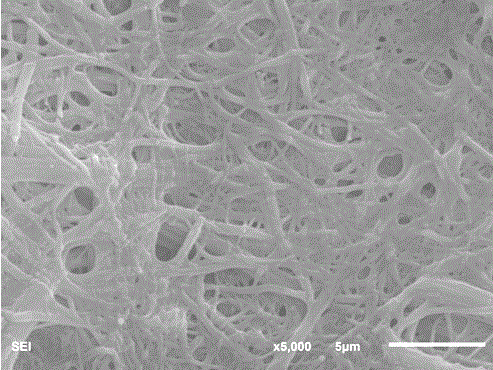

Silk nanofiber manufacturing method

InactiveCN104532365APromote swellingAvoid influenceAnimal materialSilk filament obtainingInorganic saltsFiber

The invention relates to a silk nanofiber manufacturing method, and belongs to the technical field of nano material manufacturing. The manufacturing method includes the steps that silk obtained after degumming treatment is transferred to a solution composed of an inorganic salt or weak acid or weak alkali small molecule compound, deionized water and alcohols, after binding force between nano fibrils in the silk is weakened through soaking, the silk solution is transferred to a high-voltage cell crushing machine or an emulsification machine or a pulp refiner or a crushing machine of a high-speed stirring device, and the soaked silk is mechanically crushed to obtain silk nanofibers. A silk nanofiber solution obtained through the method is similar to the shape of hydrogel, the silk nanofibers are obtained through centrifuging or filtering separation, manufacturing time is short, equipment is simple, operation influence factors are few, and control is convenient. The adopted small molecule compound avoids influences of strong acid or strong alkali on the silk nano fibrils, and the crushing machine can be used for quickly manufacturing the silk nanofibers on a large scale.

Owner:WUHAN TEXTILE UNIV

Adjacent existing railway steep mountain loosen control blast construction method

ActiveCN103629980AAgainst rockfall riskAvoid security risksBlastingMechanical crushingBlasting vibration

The invention relates to the field of railway construction, and in particular relates to an adjacent existing railway steep mountain loosen control blast construction method, comprising a pre-protecting step and a blasting step; the pre-protecting step comprise procedures of reinforcing and constraining an anchor rod steel wire gauze, exerting horizontal constraining force, building a concrete stopping retaining wall, mounting a profile steel protecting frame bent, and constructing a rock fall groove and a bamboo protecting frame bent; the blasting step comprises a trail blasting step and a formal blasting step; the trail blasting step comprises the procedures of minor diameter shallow hole control blasting, minor diameter air drill vertical drilling, large diameter deep hole control blasting and mechanical crushing. By designing the blasting order and screening the blasting parameter, the blasted rolling stones are effectively controlled, the security of the operation railway is guaranteed, the blasting harmful effect control such as blasting vibration and blasting flyrock can achieve rule and scene safety requirement, and the interference to surroundings is maximally reduced.

Owner:中铁二十三局集团第四工程有限公司

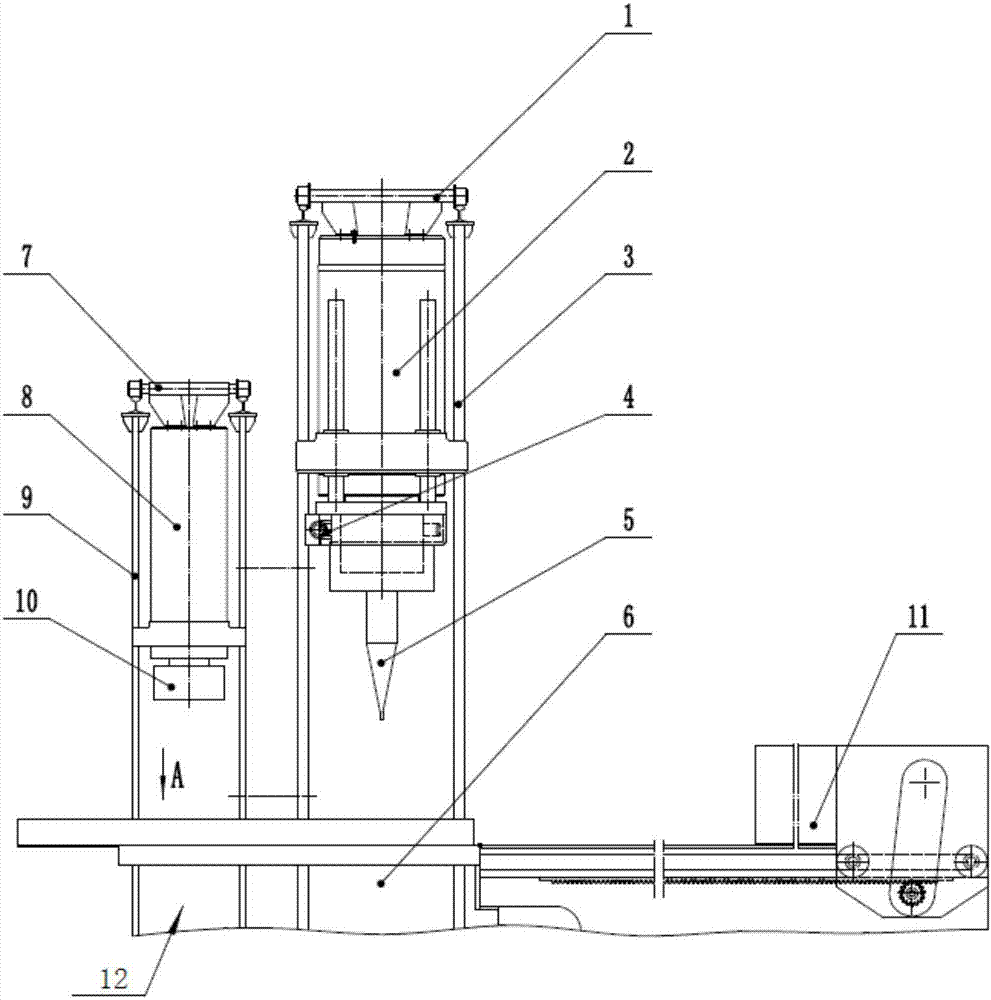

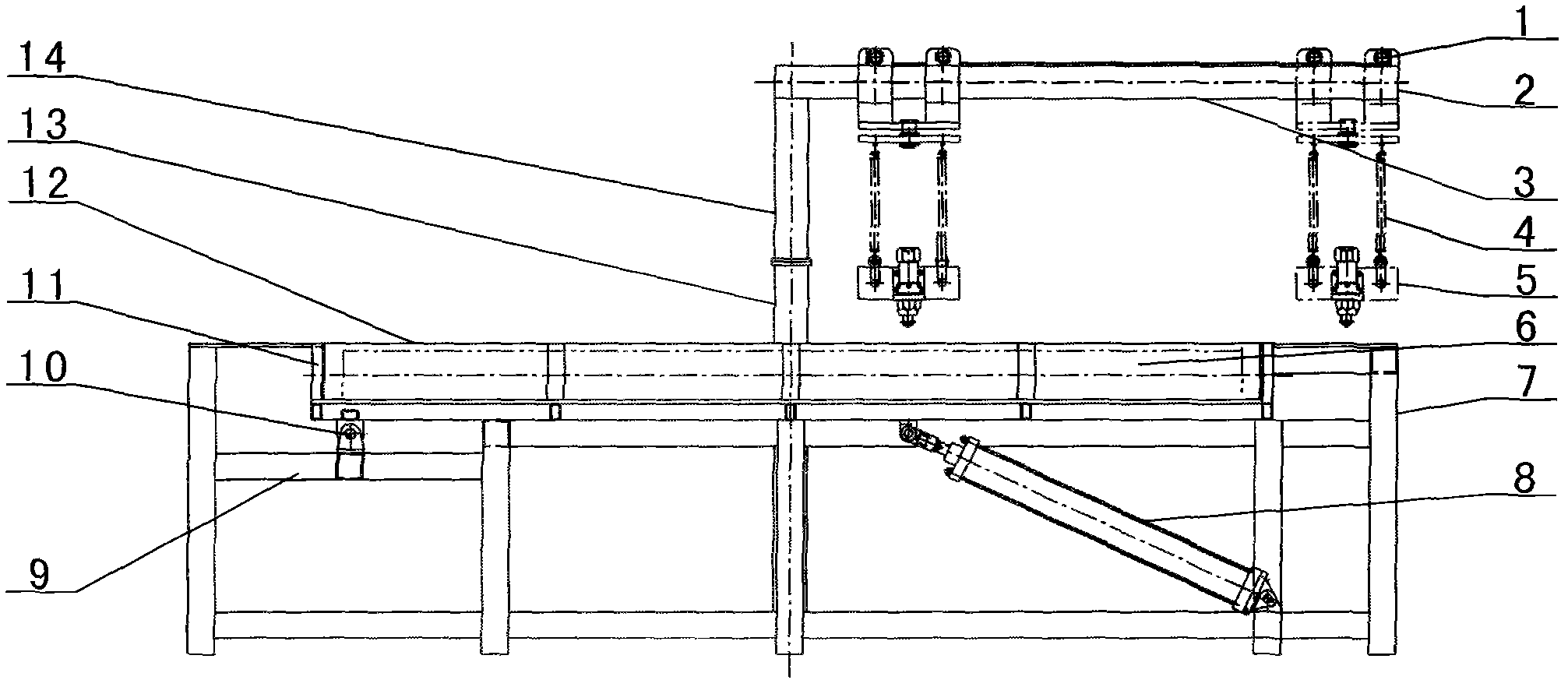

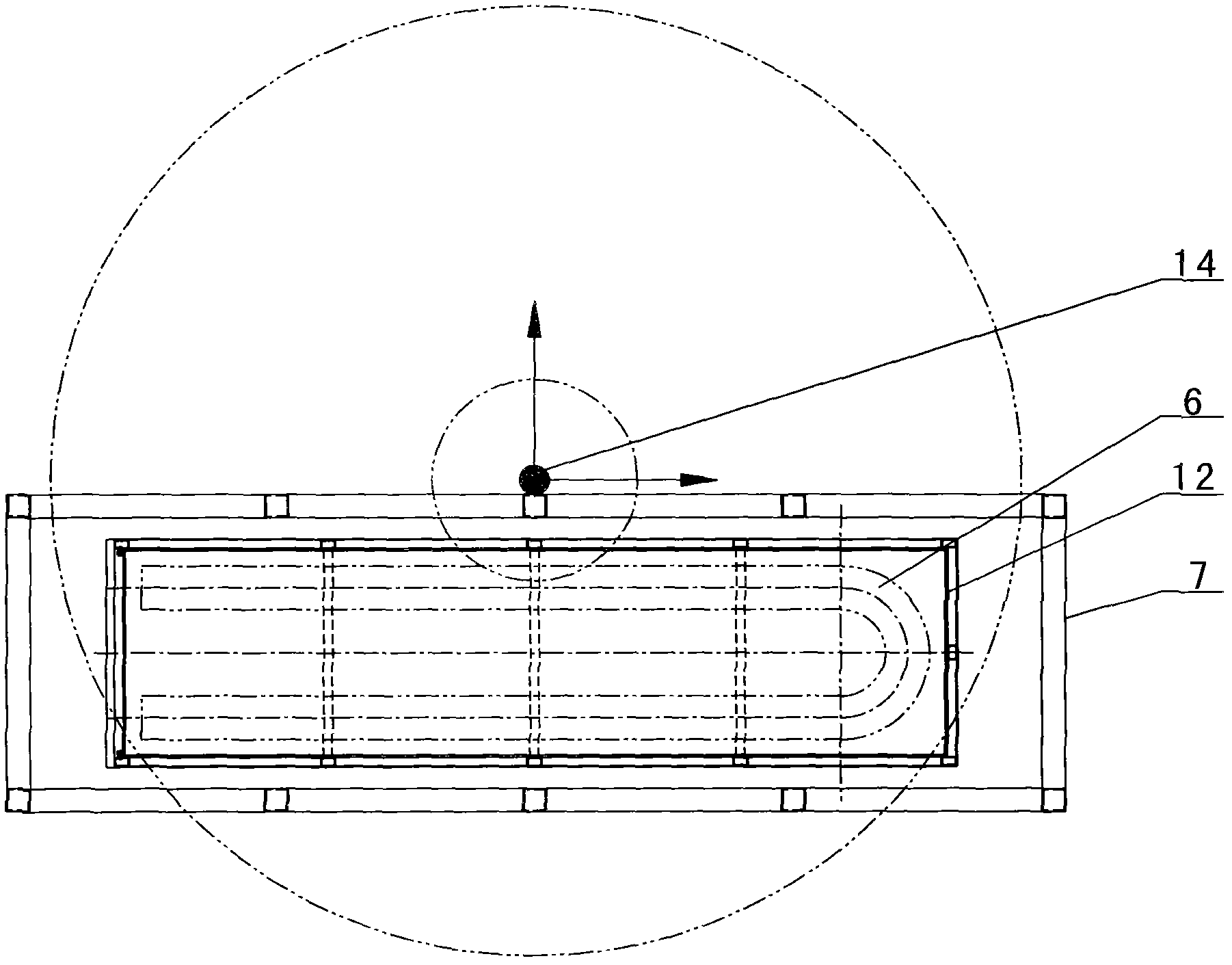

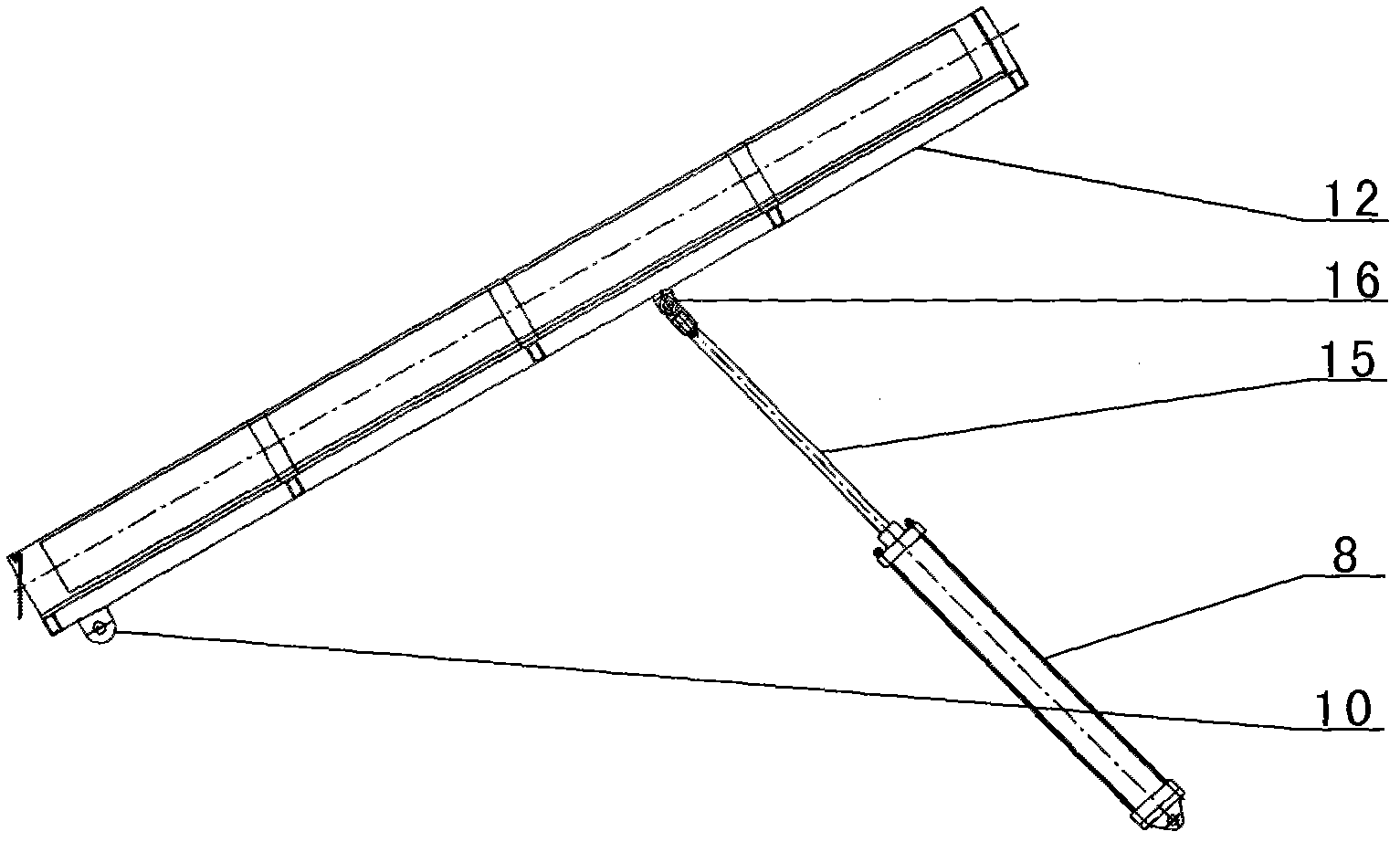

Polysilicon crushing device

InactiveCN102319594AEasy to operateExpand the working areaGrain treatmentsMechanical crushingMechanical engineering

The invention discloses a polysilicon crushing device and relates to a polysilicon crushing appliance. An upright post (13) is arranged at the middle part of any side of a material box (12), a rotating shaft (14) is movably connected with the upper part of the upright post in an inserting manner, one end of a guide rail (3) is fixedly connected with the upper end of the rotating shaft (14) or one end of the guide rail is movably connected with the upper end of the upright post so as to form a horizontal rotating structure of the guide rail, a sliding mechanism is in sliding fit with the guide rail, an elastic body connected with an impact cylinder (17) is arranged at the lower part of the sliding mechanism, and an impact head (18) is arranged at the lower end of the impact cylinder so as to form a structure enabling the impact head to be in multi-station correspondence with polysilicon (6) in the material box (12). In the invention, an extension spring arranged on the guide rail is used to flexibly control a silicon rod beating structure consisting of the impact cylinder and the impact head, thereby effectively overcoming the defects of manual crushing, such as high cost, low efficiency, unsafety and the like, effectively improving the production efficiency and achieving the purpose of mechanical crushing.

Owner:洛阳佑东光电设备有限公司

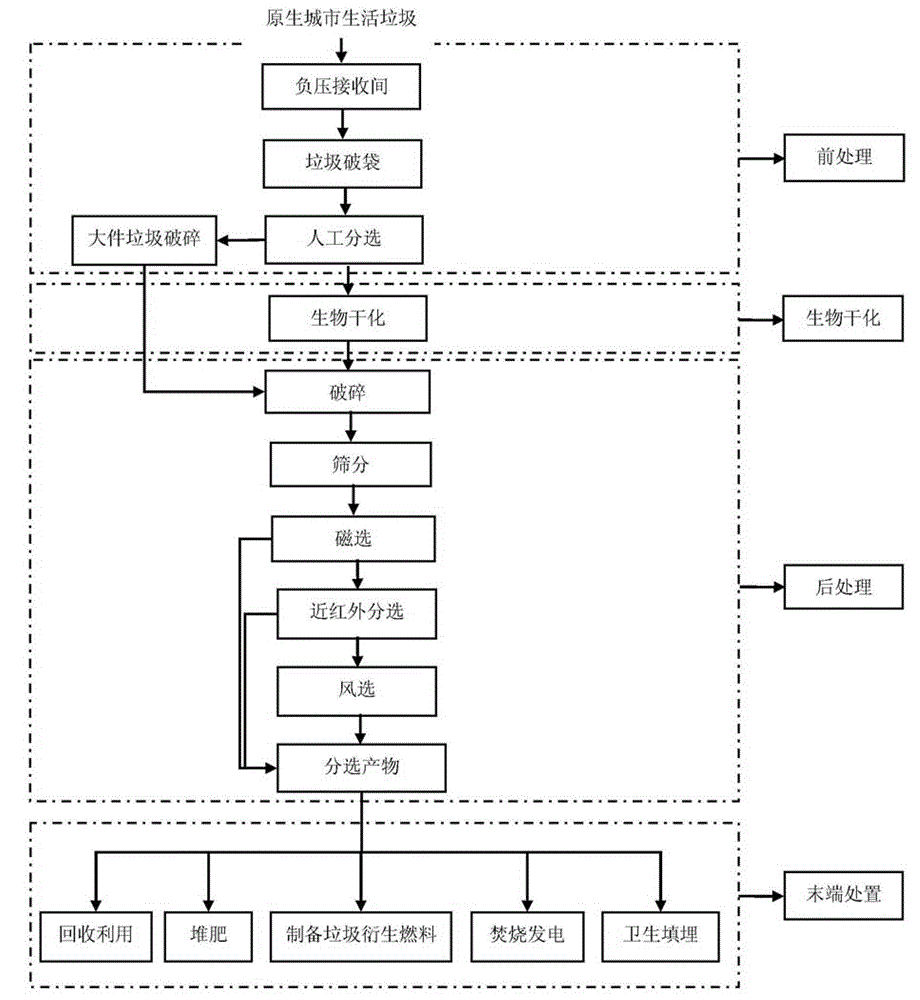

Bio-drying-based domestic refuse treatment method

The invention provides a bio-drying-based domestic refuse treatment method. The method comprises the following steps: (1), pre-treatment: feeding domestic refuses into a negative-pressure receiving room to break bags and manually select; performing innocent treatment on selected harmful refuses which have potential pollution threats to the soil and the underground water, and crushing selected large-size refuses in a large-size refuse crusher, wherein the crushed large-size refuses are treated in a step (3), residual domestic refuses are treated in a step (2), and the air change rate of the negative-pressure receiving room is five to seven times per hour; (2), bio-drying: feeding the residual domestic refuses treated in the step (1) into a bio-drying storehouse, stacking to form a refuse dump body, and covering the refuse dump body with a selective semi-permeable membrane; (3), post-treatment: sequentially performing mechanical crushing, drum screen screening, magnetic separation, near-infrared separation and air separation on the dried products obtained in the step (2) and large-sized refuses crushed in the step (1); (4), tail end treatment: respectively recovering and utilizing according to property difference of products selected according to the step (3).

Owner:BEIJING GEOENVIRON ENG & TECH

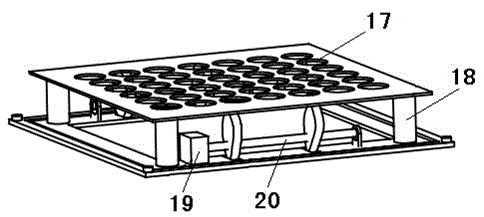

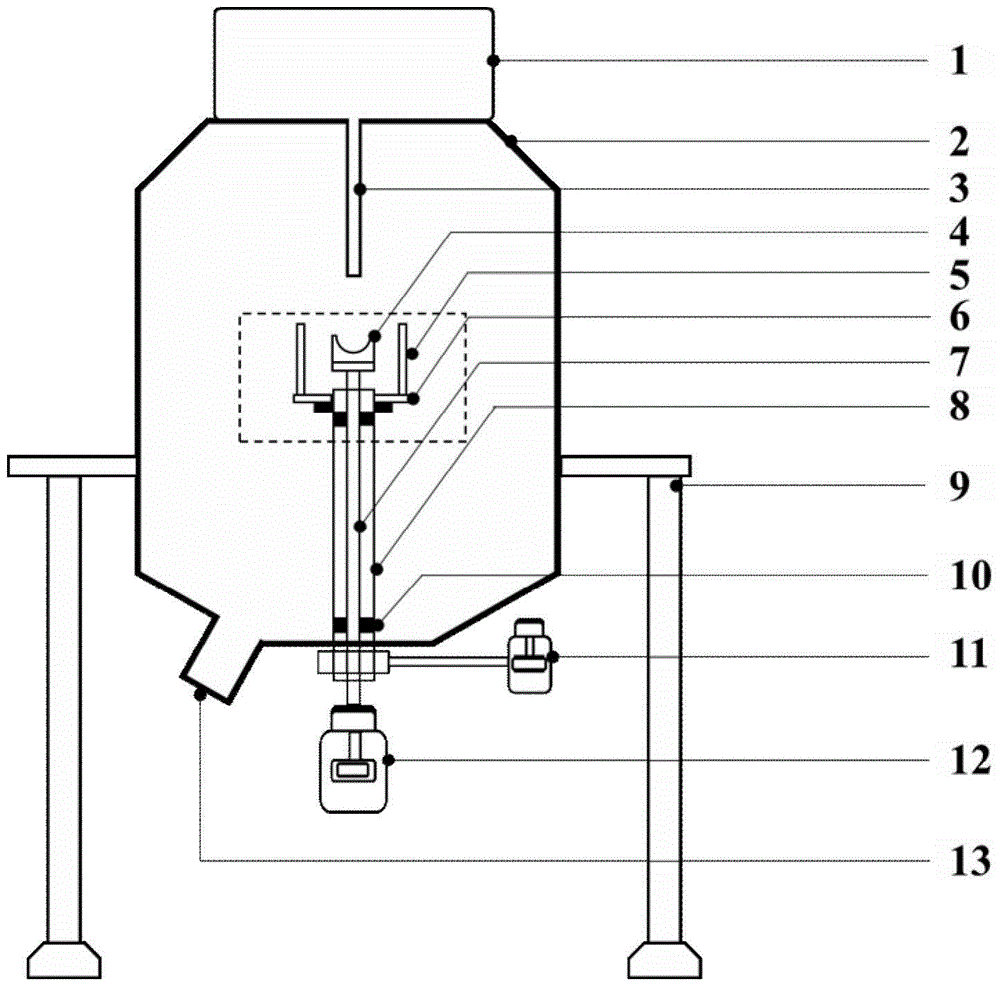

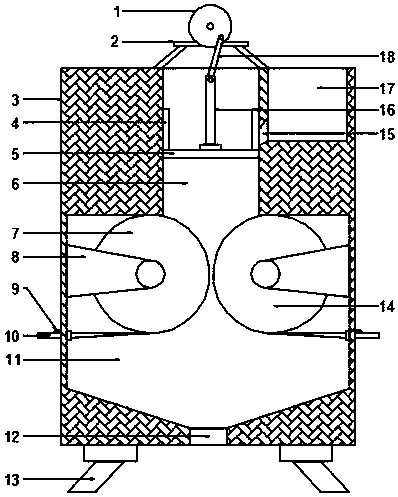

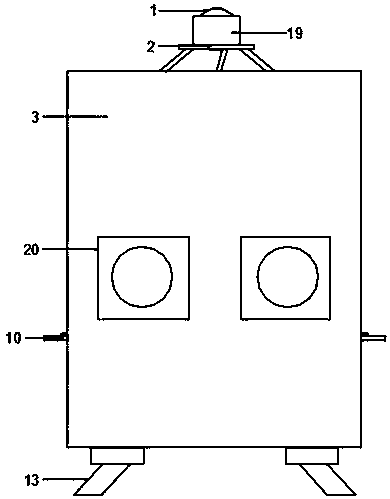

Combined type mechanical crushing centrifugal pelletization device

ActiveCN104313209AIncrease slag handling capacityPrevent solidificationRecycling and recovery technologiesMechanical crushingMolten slag

The invention discloses a combined type mechanical crushing centrifugal pelletization device which comprises a slag storage cabin, a feeding hole, a pelletization cabin and a slag outlet, wherein the feeding hole is formed in the lower part of the slag storage cabin; the slag outlet is formed in the lower part of the pelletization cabin; the feeding hole is communicated with the slag storage cabin; the pelletization cabin is fixed through a support column. The combined type mechanical crushing centrifugal pelletization device is characterized in that a rotating cup is arranged inside the pelletization cabin; the rotating cup is positioned below the feeding hole; the rotating cup fixedly sleeves an inner rotating shaft; the inner rotating shaft is arranged on a hollow rotating shaft in a penetration manner; the inner rotating shaft is driven by a motor I; the hollow rotating shaft is supported by the inner rotating shaft through a bearing; the hollow rotating shaft is driven by a motor II; a rotating disc is arranged below the rotating cup; the rotating disc fixedly sleeves the hollow rotating shaft; crushing cutters are arranged on the rotating disc along the circumference; the crushing cutters are positioned on the outer side of the rotating cup. By adopting a method that the rotating cup is combined with the rotating disc, the molten slag treatment capacity of a single pelletizer is greatly increased, and thus the combined type mechanical crushing centrifugal pelletization device can be widely used in the fields of steel, metallurgy and the like.

Owner:CHONGQING UNIV

Nano diamond-macromolecular composite abrasive for solidifying abrasive polishing pad

InactiveCN102528648AReduce hardnessAchieving "soft impactAbrasion apparatusLapping toolsEpoxySynthesis methods

The invention provides a method for preparing a diamond-macromolecular composite abrasive. The cores of composite abrasive particles are diamond powder prepared by a mechanical crushing method, an explosive synthesis method or a static pressure method, and the particle diameter range of the powder is 1 to 100 nanometers; the powder serving as the core is modified to form an intermediate transition layer through a silane coupling agent, and the intermediate transition layer is grafted and wrapped to form the composite abrasive by using epoxy resin and polyacrylate, wherein the mass of the silane coupling agent is 0.2 to 2 percent of that of the nano particles; and the mass of the epoxy resin and the polyacrylate is 0.2 to 2 percent of that of inorganic nano particles. The compatibility between the abrasive and a polishing pad base body is improved, and the nano diamond composite abrasive treated by different macromolecules can be selected according to different polishing pad base bodies. By introducing groups to the surface of the diamond abrasive, the bonding force between the diamond abrasive and the polishing pad base body is improved, drop of the diamond abrasive is reduced, and surface damage of a machined workpiece due to drop of the diamond abrasive in the polishing process is prevented.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Mechanical crushing device for rapeseed grains

The invention discloses a mechanical crushing device for rapeseed grains. The mechanical crushing device comprises a feeding channel, scrapers and a crushing cavity, the crushing cavity is formed in the bottom of a mechanical crushing device body, a left grinding roller and a right grinding roller are arranged in the crushing cavity, the two scrapers are arranged on the side walls of the left sideand the right side of the crushing cavity separately, the feeding channel is formed in the position, on the upper side of the crushing cavity, inside the mechanical crushing device body, a pressing plate is inserted into the feeding channel, an annular baffle is fixed to the upper end of the pressing plate, a fixing rod is arranged at the center position of the upper end of the pressing plate, arotating rod is hinged to the upper end of the fixing rod, and the upper end of the rotating rod is fixed to the eccentric position of a rotating disc in a rotating mode through a fixing shaft. The mechanical crushing device for the rapeseed grains has the advantages that the rapeseed grains can be rapidly and efficiently crushed, the problems that the rapeseed grains are prone to slide and are not liable to be crushed, the speed is low, and the efficiency is low due to the fact that no pressing plate presses the rapeseed grains downwards can be solved,and meanwhile, the scrapers are arranged,so that the phenomenon that crushing of the rapeseed grains is influenced due to the fact that the rapeseed grains adhere to the surfaces of the left grinding roller and the right grinding roller canbe avoided.

Owner:盐城元之元机械有限公司

Preparation method of YSZ ceramic powder for plasma spraying

The invention provides a preparation method of YSZ ceramic powder for plasma spraying, which comprises the following steps: 1. proportionally adding yttrium salt and zirconium salt into deionized water, and stirring to completely dissolve the yttrium salt and zirconium salt, thereby obtaining a mixed solution; 2. carrying out coprecipitation treatment, filtering and drying to obtain a solid mixture; 3. carrying out hydrothermal reaction on the solid mixture to obtain a hydrothermal reaction product; 4. filtering the hydrothermal reaction product, washing, drying, and uniformly mixing deionized water and an adhesive to obtain a slurry; 5. carrying out spray drying treatment to obtain granules; and 6. sintering the granules, and screening to obtain the YSZ ceramic powder for plasma spraying. The YSZ ceramic powder prepared by the method is a complete square phase structure, has the characteristics of uniform distribution of yttrium oxide, high solid solution alloying of yttrium oxide and zirconium dioxide, and the like, is simple in equipment in the technical process, is not related to high temperature and mechanical crushing in the whole production process, and is low in production cost.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

Environmentally friendly recovery and treatment method of waste and old lithium iron phosphate power cells

ActiveCN104810566AReduce energy consumptionReduce recycling costsWaste accumulators reclaimingBattery recyclingPower batteryLithium iron phosphate

The invention discloses an environmentally friendly recovery and treatment method of waste and old lithium iron phosphate power cells. The method comprises the following steps of 1, after discharge, cutting and disassembling, immersing waste and old cells into a solvent and directly recovering the immersed aluminum-plastic membrane and tabs, 2, separating the immersed cells to obtain positive plates, negative plates and diaphragms and directly recovering the diaphragms, 3, respectively carrying out mechanical crushing on the positive plates and the negative plates, immersing the crushed positive plates and negative plates in a dilute alkali solution with stirring, carrying out washing and filtration and carrying out vacuum drying, 4, respectively carrying out mechanical stirring on the dried positive and negative materials, carrying out screening to obtain aluminum foil pieces, positive crude powder, copper foil pieces and negative crude powder, recovering the separated aluminum foil pieces and the copper foil pieces, and respectively carrying out ball milling and screening on the positive crude powder and the negative crude powder, and 5, carrying out heat treatment on the screened positive crude powder and the negative crude powder and carrying out recovery. The method has simple processes, can acquire clean powder, reduces energy consumption and does not pollute the environment.

Owner:WANXIANG 123 CO LTD

Method for preparing graded nano-crystalline cellulose from ramie raw material

ActiveCN103774481AAvoid influenceAvoid harmPaper material treatmentPolymer scienceMechanical crushing

The invention relates to a method for preparing graded nano-crystalline cellulose from a ramie raw material. In the method, waste ramie is used as the raw material. The method comprises the following steps: carrying out purification screening, mechanical crushing, cooking with alkali liquor, low-grad fiber removing, bleaching, decomposition, ultrasonic crushing / ultrasonic dispersion, and centrifugal grading; the waste ramie is subjected to component separation and cellulose fining transforming to obtain a cellulose alcohol dispersion solution or cellulose alcohol colloidal solution with the certain concentration; the dispersion solution is subjected to centrifugal grading, so as to obtain nano-crystalline cellulose geodes with the uniform grain sizes and nano-crystalline cellulose fiber with the high draw ratio. The nano-crystalline cellulose with the high draw ratio after the grading has the characteristics of being good in mechanical property, biodegradable, easy to compound and the like. The method is simple, and easy to implement, the energy consumption is low, and the production cost is low; the graded nano-crystalline cellulose has the potential application value when being functionally compounded in the fields of optics, electricity, magnetic, biology, semiconductor devices and the like.

Owner:SHANGHAI UNIV

Filled skutterudite-base thermoelectrical composite material and its prepn

ActiveCN1888105ALower lattice thermal conductivityDoes not affect electrical transmission performanceMolten stateMechanical crushing

The present invention relates to filled skuterudite-base thermoelectrical composite material and its preparation process, and belongs to the field of thermoelectrical material preparing technology. The thermoelectrical composite material has the composition of IyA4B12 / zIOx, where I is one of Yb, Eu, Ce, La, Nd, Ca and Sr; A is Sb or its mixture with one of Ge, Sn, Te and Se; B is Co or its mixture with Fe or Ni; y is the amount of I element, y+z=m, and m is greater than the filling limit of filling atom. The thermoelectrical composite material is prepared through first smelting process to produce block material, the subsequent mechanical crushing and grinding to obtain powder, and the final fast sintering with pulse DC current to form compact block. The material has lowered lattice heat conductivity, maintained electric transmission performance and raised thermoelectrical conversion performance.

Owner:中科西卡思(苏州)科技发展有限公司

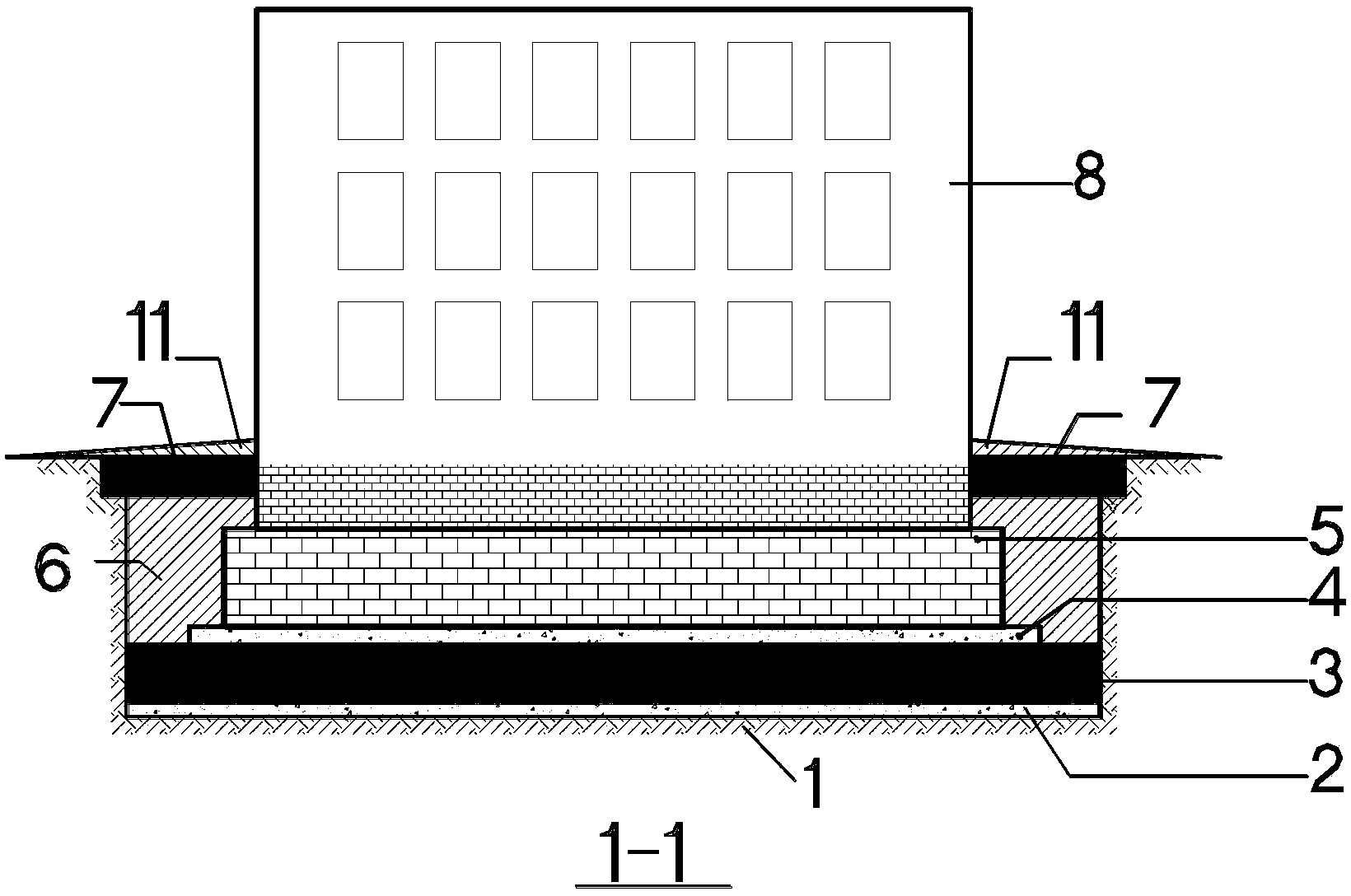

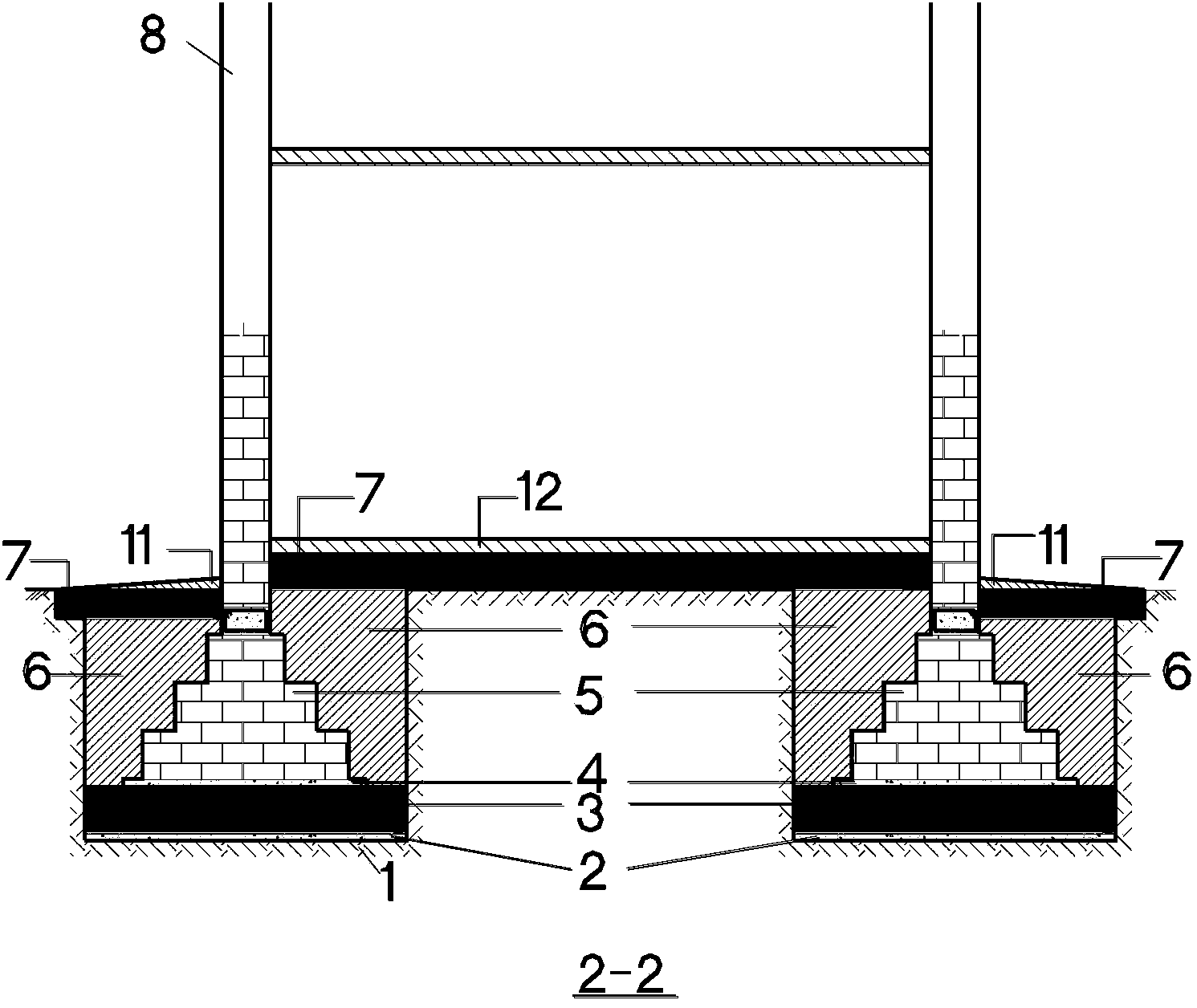

Geocell reinforced rubber particles-sand mixture compound shock insulation layer and strip

The invention discloses a geocell reinforced rubber particles-sand mixture compound shock insulation layer and strip, which belongs to the technical field of structure shock absorbing and shock insulation, and is mainly used for solving the problem of serious destructions of a general multi-story building in an earthquake. According to the invention, the compound shock insulation layer and strip are manufactured by the filling and layered punning of rubber particles-sand mixture mixed by an optimal mix proportion in geocell inner layers; the shock insulation layer is arranged at the bottom of a base; shock insulation strips are arranged on two sides of the base; the geocell is a geotechnique material which can be bought easily and is low in cost; the rubber particles are rubber fragments with certain particle diameters, and are obtained by the mechanical fragmentation of junked tires; the sands are ordinary river sands used for construction. The shock insulation layer and strip have good shock insulation effect, low cost, environmental protection, simple structure, and convenience in construction, and is generally suitable for the compound shock insulation technology of the multi-story building; the technical scheme can effectively solve the problems of bad shock resistance and serious destructions of a low story dwelling in a town, and has a wide application prospect.

Owner:刘方成 +2

Surface modified aluminium hydroxide fire retardant and its prepn process

InactiveCN101089122ALow priceHigh decomposition temperaturePigment treatment with non-polymer organic compoundsMechanical crushingFoaming agent

Owner:HANGZHOU HI TECH FINE CHEM

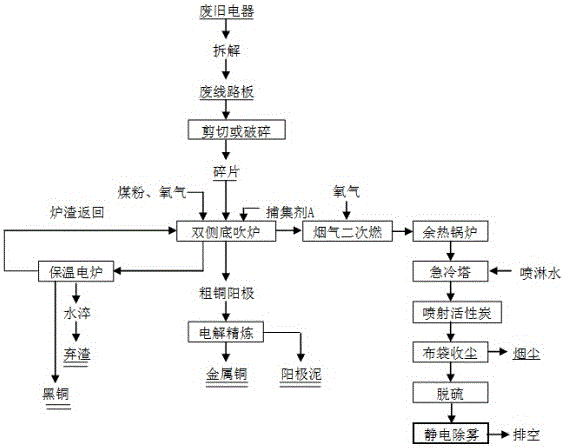

Waste circuit board material disposal and utilization technology

ActiveCN106086416AComponent adaptabilitySimple preparationPhotography auxillary processesProcess efficiency improvementMelting tankElectrolysis

The invention discloses a waste circuit board material disposal and utilization technology. Waste circuit board materials serve as raw materials, and are subjected to mechanical crushing and smelting in an oxygen enrichment side-blowing molten pool at the temperature of 1100-1400 DEG C to produce crude copper rich in rare and noble metals; then metallic copper and anode mud rich in rare and noble metals are obtained through electrolytic refining; smelting gas restrains resynthesis of dioxin after being subjected to secondary combustion and quick cooling; and a bag collector recycles oxides of volatile metals such as tin, lead and zinc, and the dust content of the drained gas is 0-15 mg / Nm<3>. A trapping agent can make the copper content of slag be lower than 0.2%, recycling of all rare and noble metals is achieved, and the slag is waste slag containing silicate and can be used as cement raw materials or road foundation laying materials. The waste circuit board materials and the like are recycled and utilized, effective separation and respective enrichment and recycle of various metals are achieved, organic substances are used as fuel, and no secondary pollution is generated for the environment. The process procedure is short, and the remarkable economic, environment-friendly and social benefits are achieved.

Owner:江西自立环保科技有限公司

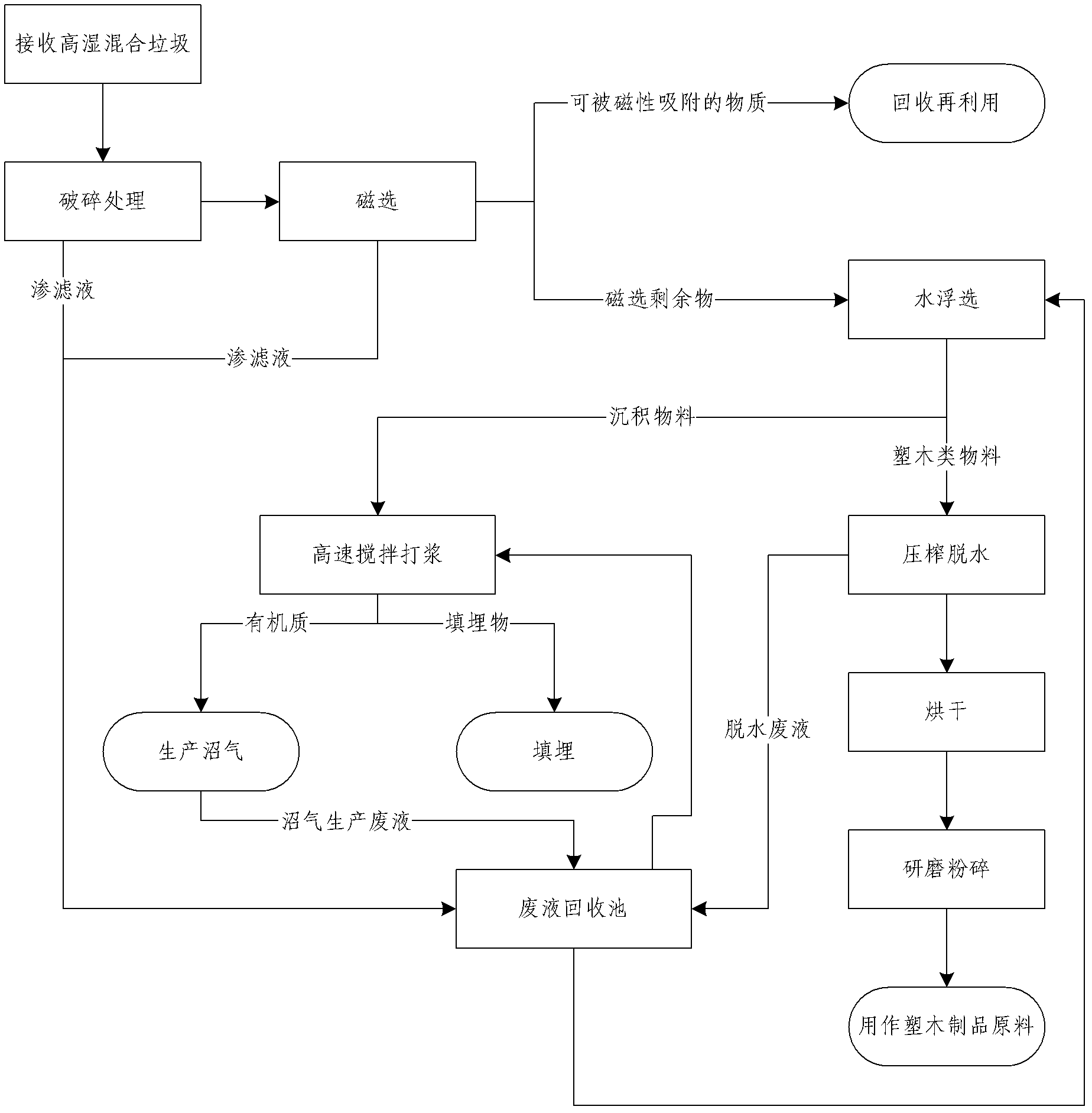

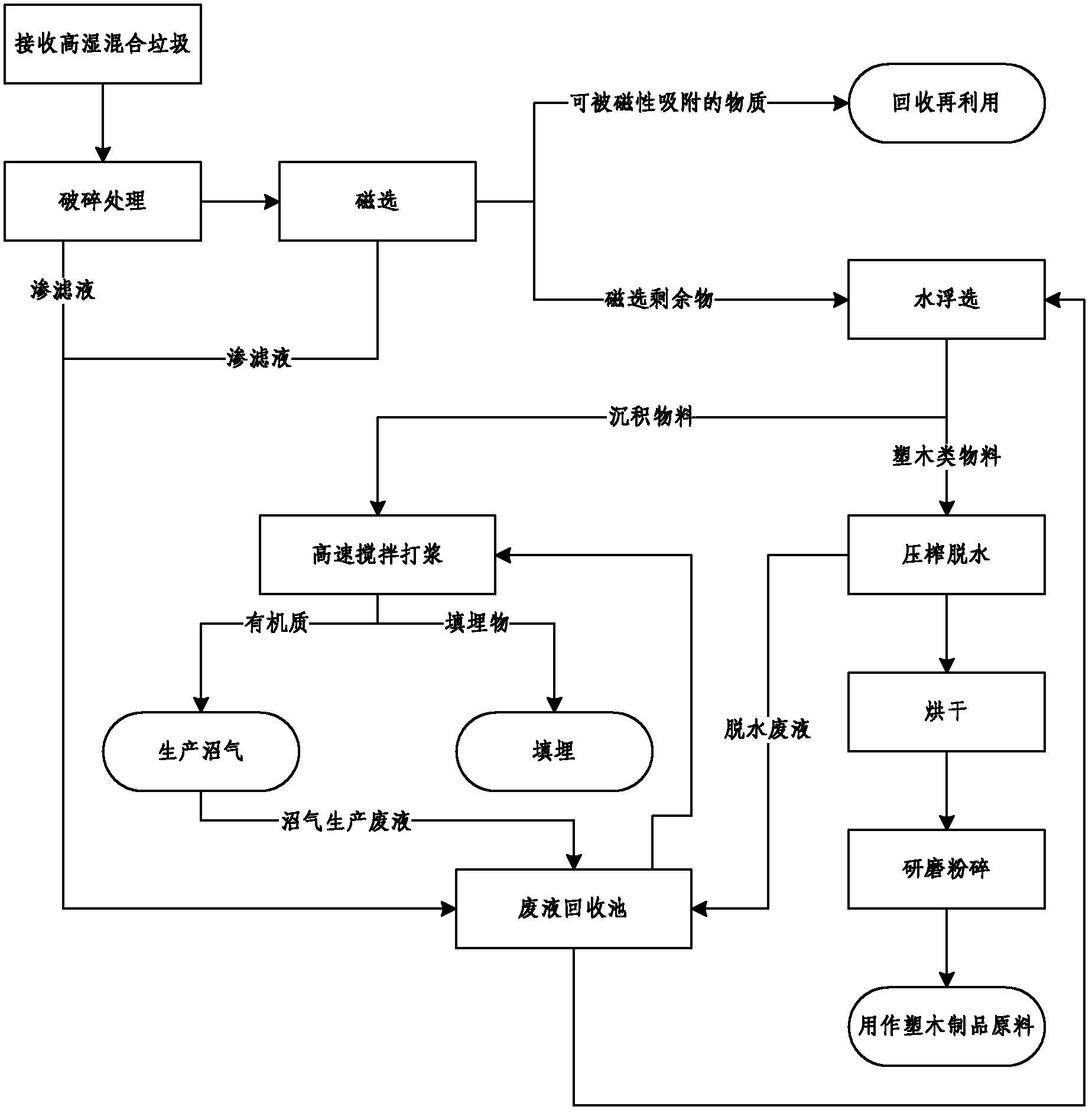

Municipal solid waste compressive classification treatment method

The invention provides a municipal solid waste compressive classification treatment method. The method comprises the following steps of: crushing: carrying out crushing treatment on the high humidity mixed waste; magnetic separation: sorting the matters which can be magnetically adsorbed through magnetic adsorption; water flotation: transporting the residues after magnetic selection treatment into a flotation tank, and with matching of stirring, dividing the materials into two layers, wherein the upper plastic wood materials are blown out from an upper discharge hole; and the bottom deposited materials are discharged from the bottom; and organic matter and landfill material separation: feeding the matters discharged from the bottom of the flotation tank into a high-speed wet type stirrer to undergo beating treatment so that the materials are divided into two layers, wherein the upper materials are slurry which mainly comprises degradable organic matters and is output by a slurry pump to be used for producing biogas; and the bottom materials are discharged via a gate valve to undergo landfill treatment. The method has the following beneficial effects that: firstly the municipal solid waste undergoes mechanical crushing and then the matters which can be magnetically adsorbed, the plastic wood raw materials, the organic matters which can be used for producing biogas and the landfill materials are separated from the municipal solid waste in sequence, thus effectively utilizing the useful components.

Owner:SHENZHEN ICOSTAR INVESTMENT

Preparation method of nanocellulose

InactiveCN104846679ASmall particle sizeGood dispersionCellulose treatment using microorganisms/enzymesDispersityMechanical crushing

The present invention relates to a preparation method of nanocellulose. The preparation method is characterized by comprising the following steps: (1) mechanical crushing: grinding raw material reed pulp to be at 60-80 meshes using a refiner; (2) hydrolyzing the reed pulp through cellulase enzyme under the effect of mechanical stirring; (3) adding cellulase enzyme at an amount of NaClO solution to react for 15-20 h, and then adding HCl to stop the reaction; (4) conducting ultrasonic treatment for 30-40 min to disperse samples, centrifugally washing the samples for more than 3 times until milky colloid appears in the solution; (5) placing the colloid in a dialysis bag for more than 5 days to obtain nanocellulose colloid, freezing and drying the nanocellulose colloid in vacuum for 20-25h to obtain powder nanocellulose with above 80% crystallinity. According to the preparation method, the nanocellulose with small particle size and good dispersity is prepared by combining enzyme hydrolysis and alkali hydrolysis, and the purity of the nanocellulose prepared by the method can reach above 95%.

Owner:HAO YU ADDITION AGENT

Production method of ultrahigh magnetic permeability of iron-based nanocrystalline magnetic powder core

InactiveCN103745791ASolving Press Molding ProblemsEasy to press and formInorganic material magnetismMechanical crushingCoupling

The invention belongs to the technical field of alloy soft magnetic powder cores and particularly relates to a production method of an ultrahigh magnetic permeability of iron-based nanocrystalline magnetic powder core. The production method comprises step 1, performing mechanical crushing treatment on an iron-based nanocrystalline thin belt so as to obtain iron-based nanocrystalline powder; step 2, screening and matching the iron-based nanocrystalline powder and mixing into mixed powder which is formed by coarse powder and fine powder; step 3, performing passivation, coupling and insulation coating treatment on the mixed powder in turn through a passivation agent, a coupling agent, an insulating agent and a binding agent and performing compression forming; step 4, performing annealing treatment and spraying insulation treatment on the formed magnetic powder core in turn. According to the production method of the ultrahigh magnetic permeability of iron-based nanocrystalline magnetic powder core, the coarse powder and fine powder mixing and coupling treatment is adopted and accordingly the problem of the compression forming of large particle nanocrystalline powder can be effectively solved and the ultrahigh magnetic permeability of iron-based nanocrystalline magnetic powder core can be produced, wherein the magnetic permeability can reach more than 200.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com