Method for preparing graded nano-crystalline cellulose from ramie raw material

A technology of nanocellulose and ramie fiber, applied in fiber raw material processing, textiles and papermaking, etc., can solve problems such as limiting the application and development of multi-morphic crystal nanocellulose composites, inability to reuse resources, and intensifying the impact of the greenhouse effect , to achieve the effect of easy implementation, high mechanical performance and wide application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

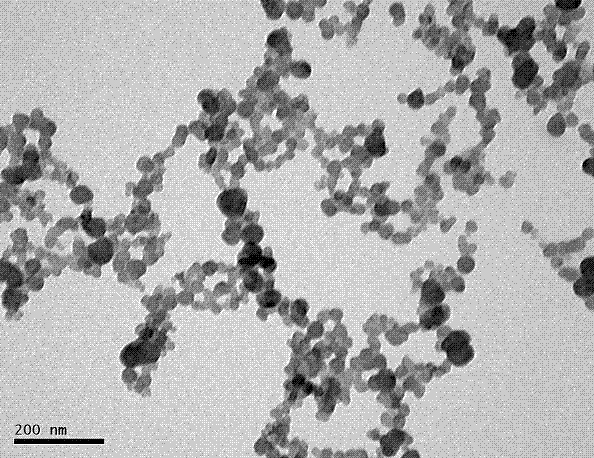

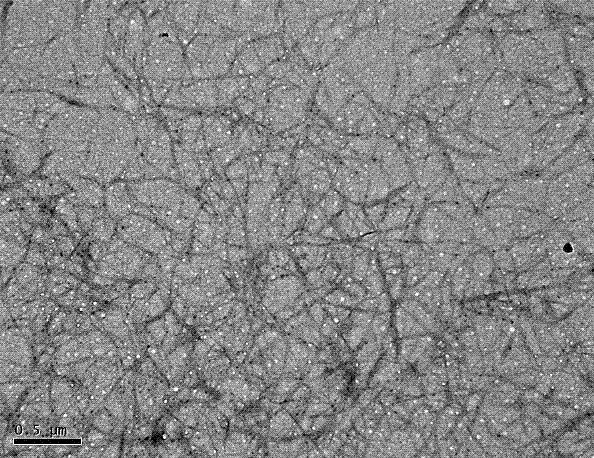

[0027] Embodiment one: Specific steps are as follows:

[0028] (1) Purification and screening: put 5 g of ramie waste into a beaker, add 300 g of NaOH aqueous solution with a mass percentage concentration of 3 wt%, stir at room temperature for 120 min, filter the fiber waste, wash and drain; (2) mechanical crushing: put The obtained fiber waste was processed with a high-speed pulverizer for 10 s to obtain a fiber powder with uniform particles. (3) Alkaline cooking: Add 300 g of NaOH aqueous solution with a mass percentage concentration of 2 wt% to the obtained powder, cook in an oil bath at a temperature of 105 °C for 2 h, filter the filter residue, wash and dry it to neutral; ( 4) Removal of low-grade fibers: Add 200 g of delignification agent (Na 3 PO 4 12H 2 O / Na 2 SiO 3 9H 2 O / NaOH / water mass percentage is 0.8 / 0.8 / 2 / 96.4), at 100°C, react for 120 min to remove lignin, filter the filter residue, wash and dry; (5) bleaching and decomposition treatment: after the obta...

Embodiment 2

[0030] Embodiment two: Specific steps are as follows:

[0031](1) Purification and screening: Put 5 g of ramie waste into a beaker, add 400 g of NaOH aqueous solution with a mass percentage concentration of 4 wt%, stir at room temperature for 90 min, filter the fiber waste, wash and drain; (2) Mechanical crushing: put The obtained fiber waste was treated with a high-speed pulverizer for 15 s to obtain a fiber powder with uniform particles. (3) Lye cooking: Add 300 g of NaOH aqueous solution with a mass percentage concentration of 3 wt% to the obtained powder, cook in an oil bath at a temperature of 110 °C for 1.5 h, filter the filter residue, wash and dry it to neutral; ( 4) Removal of low-grade fibers: Add 200 g of delignification agent (Na 3 PO 4 12H 2 O / Na 2 SiO 3 9H 2 O / NaOH / water mass percentage is 0.8 / 0.8 / 2 / 96.4), at 100°C, react for 120 min to remove lignin, filter the filter residue, wash and dry; (5) bleaching and decomposition treatment: after the obtained F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com