Patents

Literature

1513results about "Paper material treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellulose-solvent-based lignocellulose fractionation with modest reaction conditions and reagent cycling

InactiveUS20100170504A1Lower cost of capitalReduce operating costsBiofuelsChemical recyclingFractionationProcessing cost

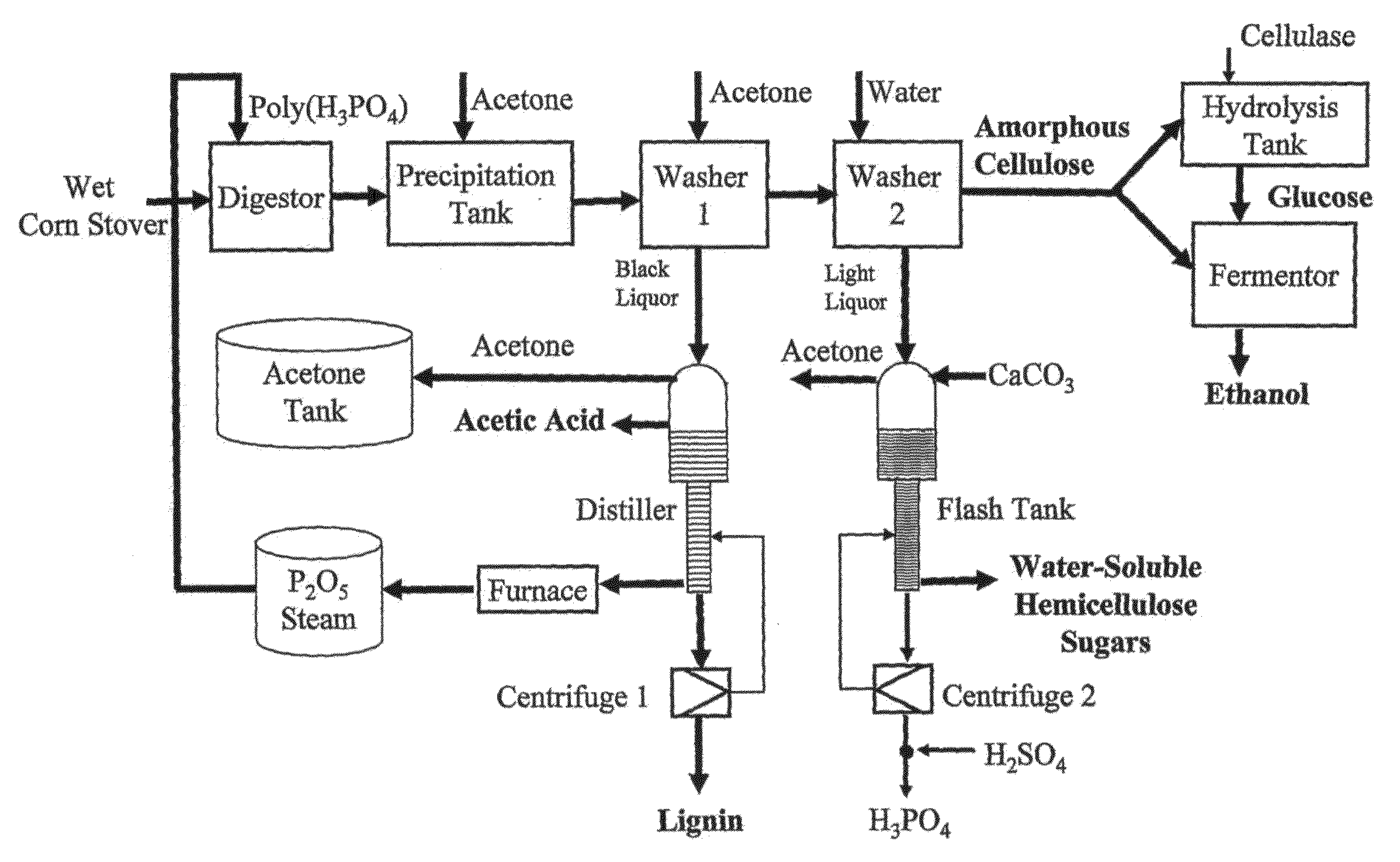

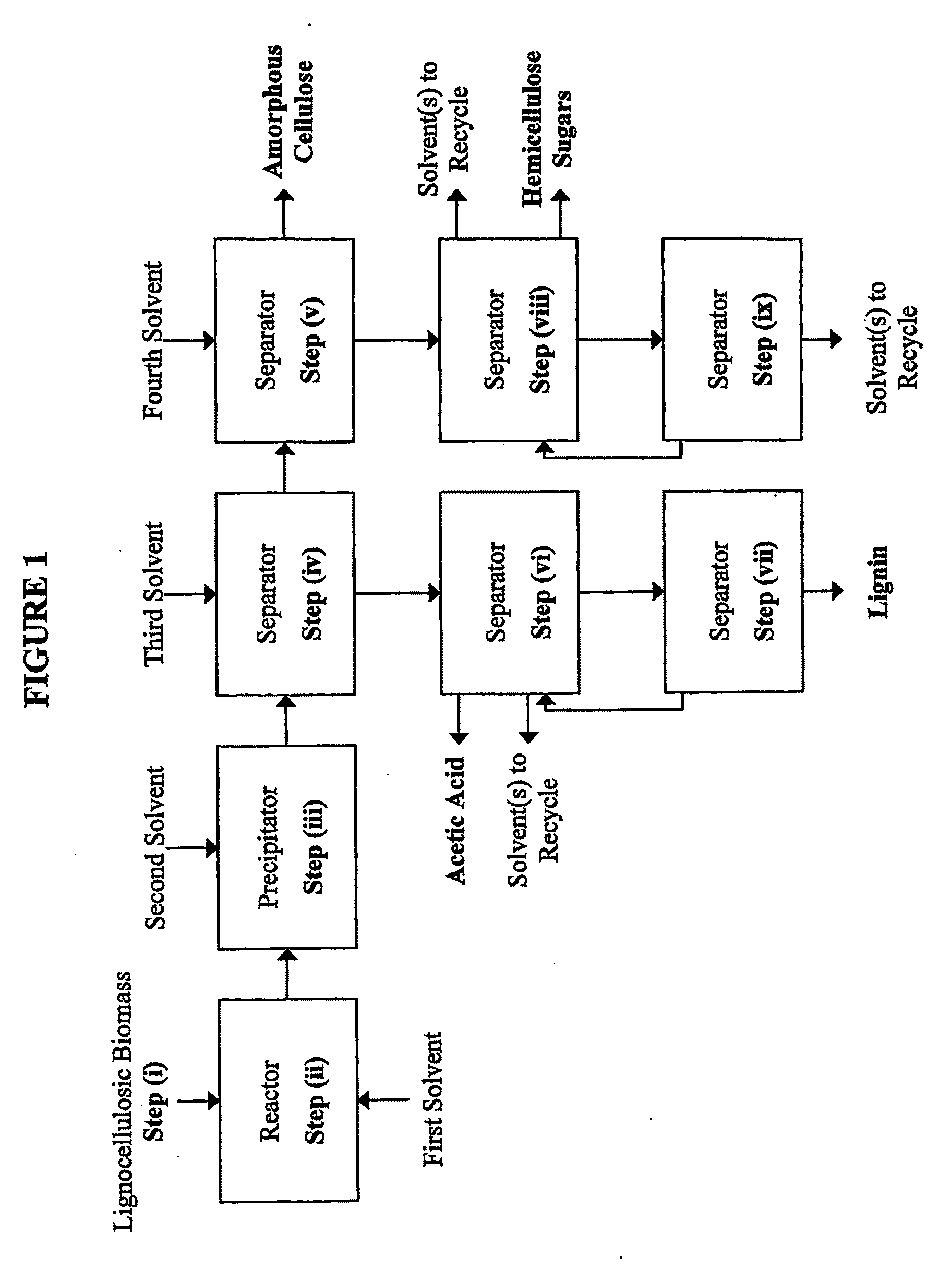

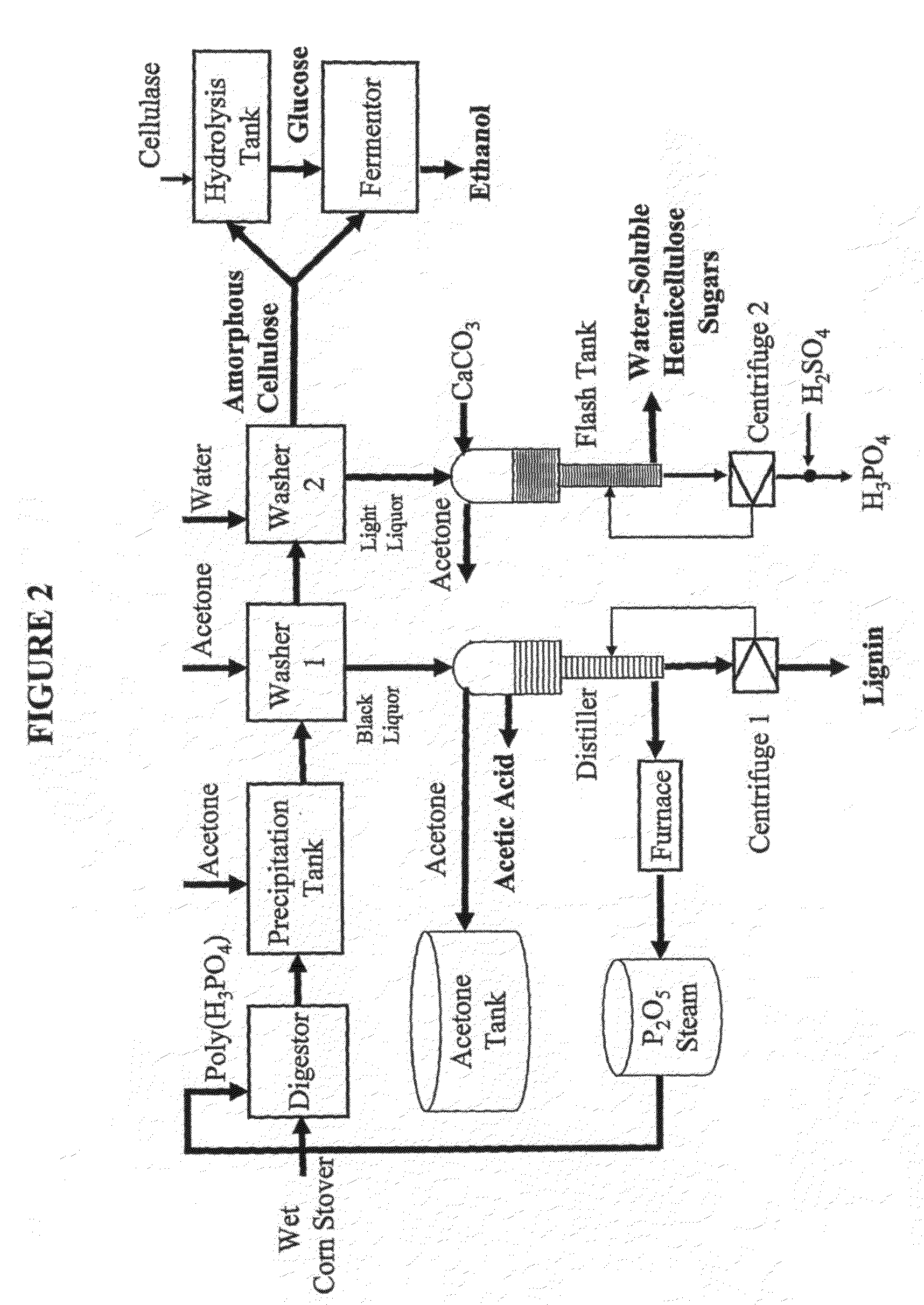

Embodiments of the present invention overcome the well-known recalcitrance of lignocellulosic biomass in an economically viable manner. A process and system are provided for the efficient fractionation of lignocellulosic biomass into cellulose, hemicellulose sugars, lignin, and acetic acid. The cellulose thus obtained is highly amorphous and can be readily converted into glucose using known methods. Fermentable hemicellulose sugars, low-molecular—weight lignin, and purified acetic acid are also major products of the process and system. The modest process conditions and low solvent / solid ratios of some embodiments of the invention imply relatively low capital and processing costs.

Owner:VIRGINIA TECH INTPROP INC

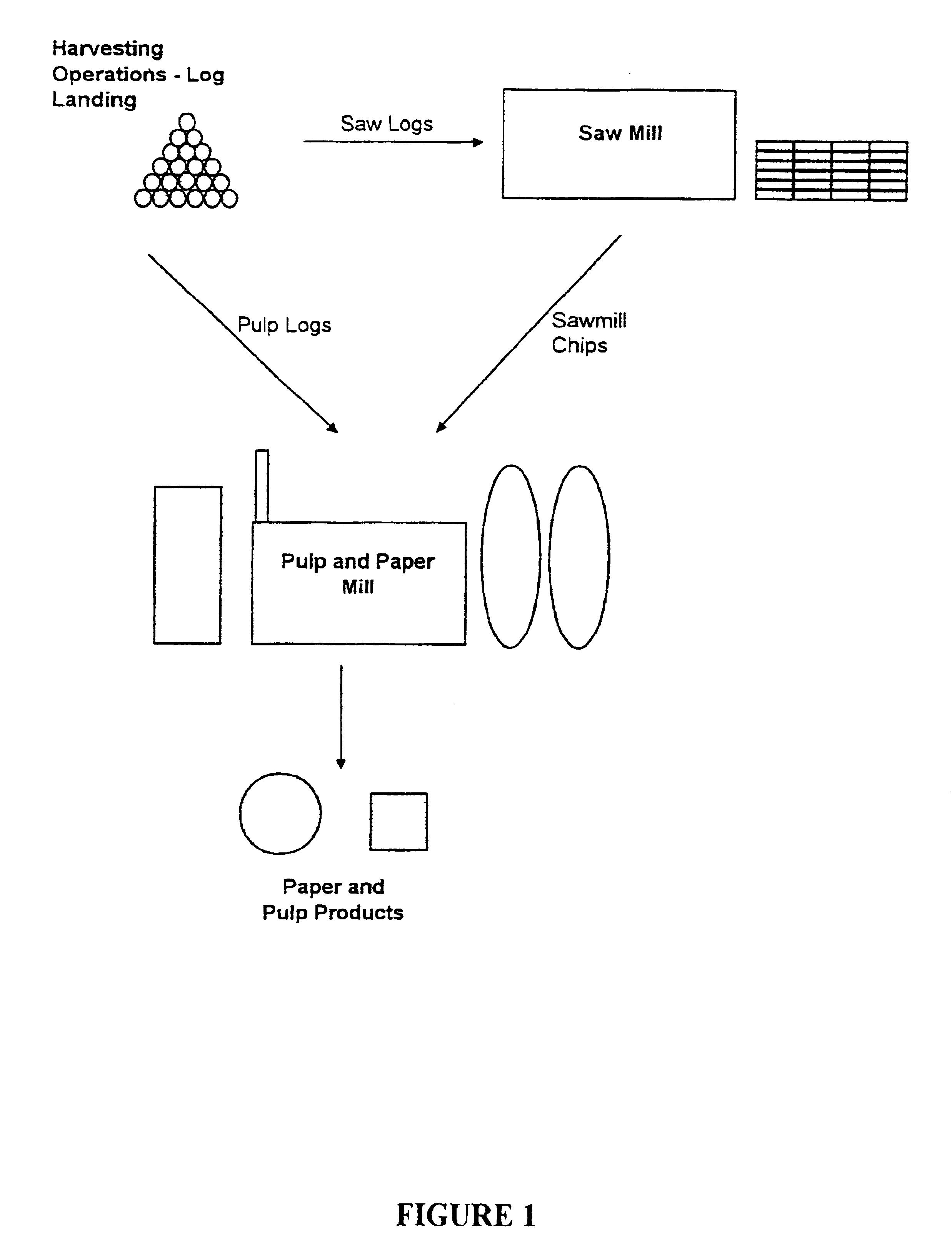

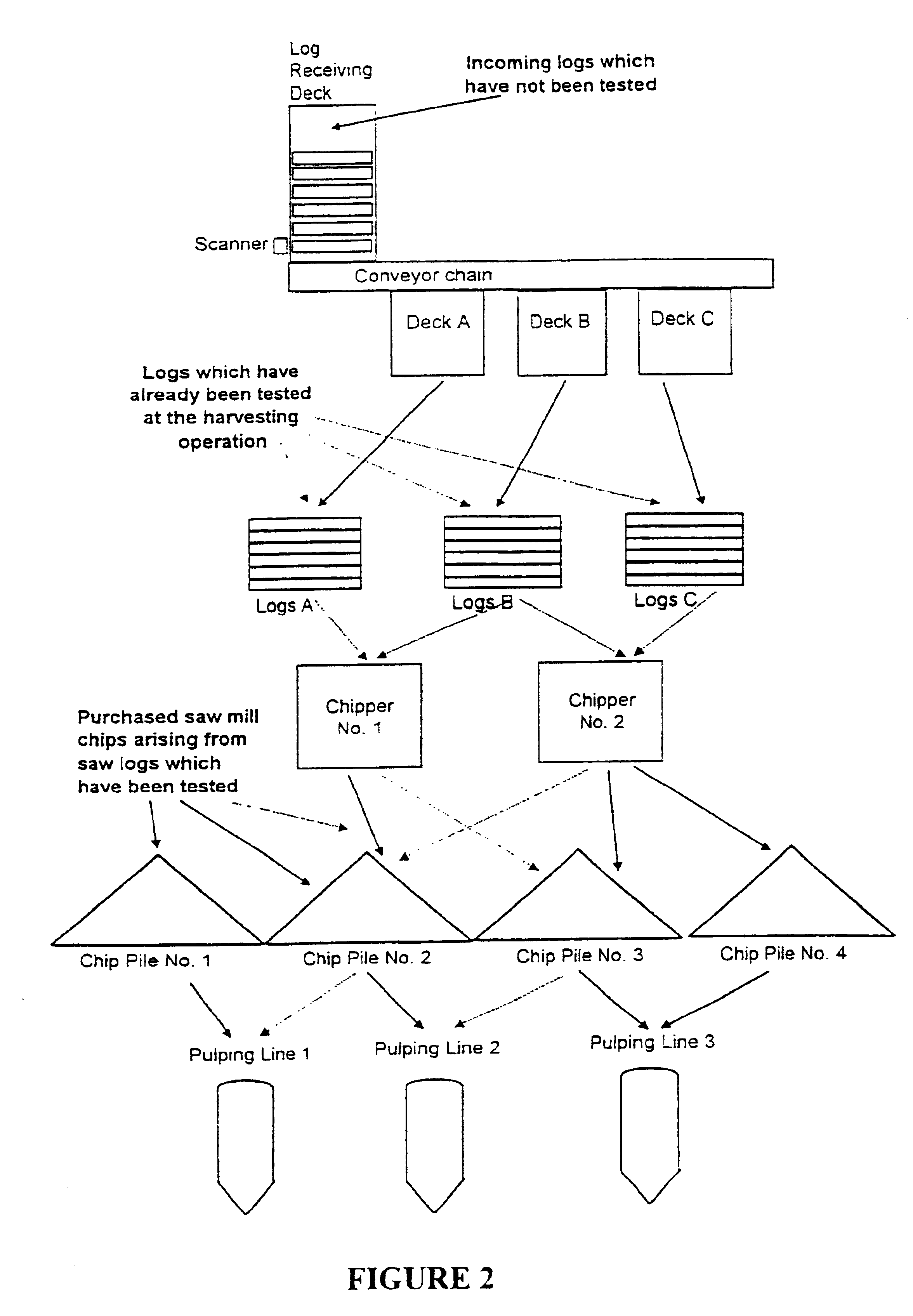

Method of selecting and/or processing wood according to fibre characteristics

InactiveUS6773552B1Analysing solids using sonic/ultrasonic/infrasonic wavesDigestersSolid woodWood fibre

The invention provides a method for predictively assessing one or more characteristics of wood pulp produced from solid wood. The method comprises the steps of determining the velocity of sound through the solid wood, and assessing characteristic(s) of wood fiber or wood pulp produced from the wood by reference to the velocity of sound through the solid wood. The method may also comprise the steps of causing a sound wave to be transmitted through the wood, determining the velocity of the sound wave through the wood, and comparing the result to stored information on fiber characteristic(s) versus sound velocity through the wood-type to determine the fiber characteristic(s) for the wood.

Owner:FIBER GEN INSTR

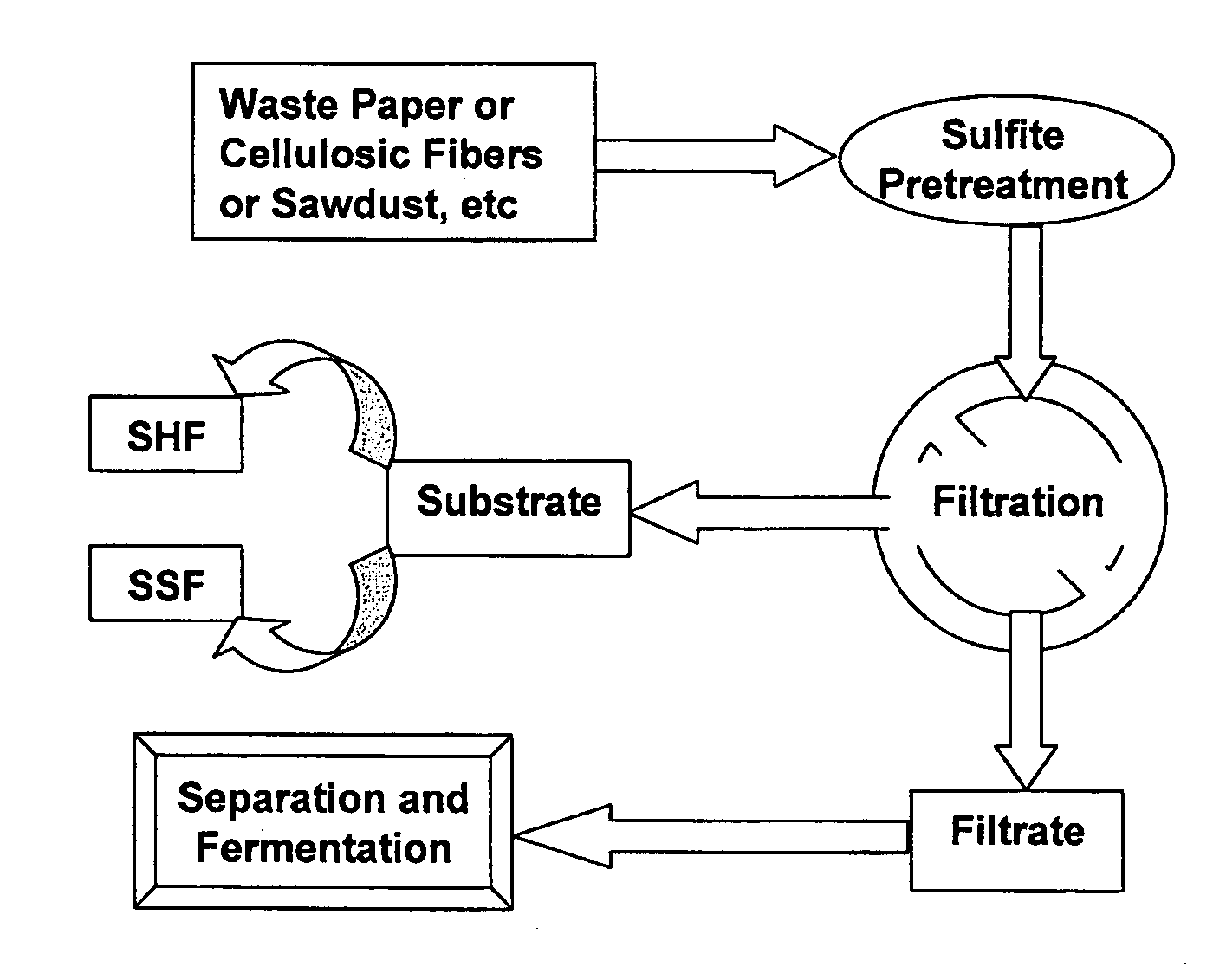

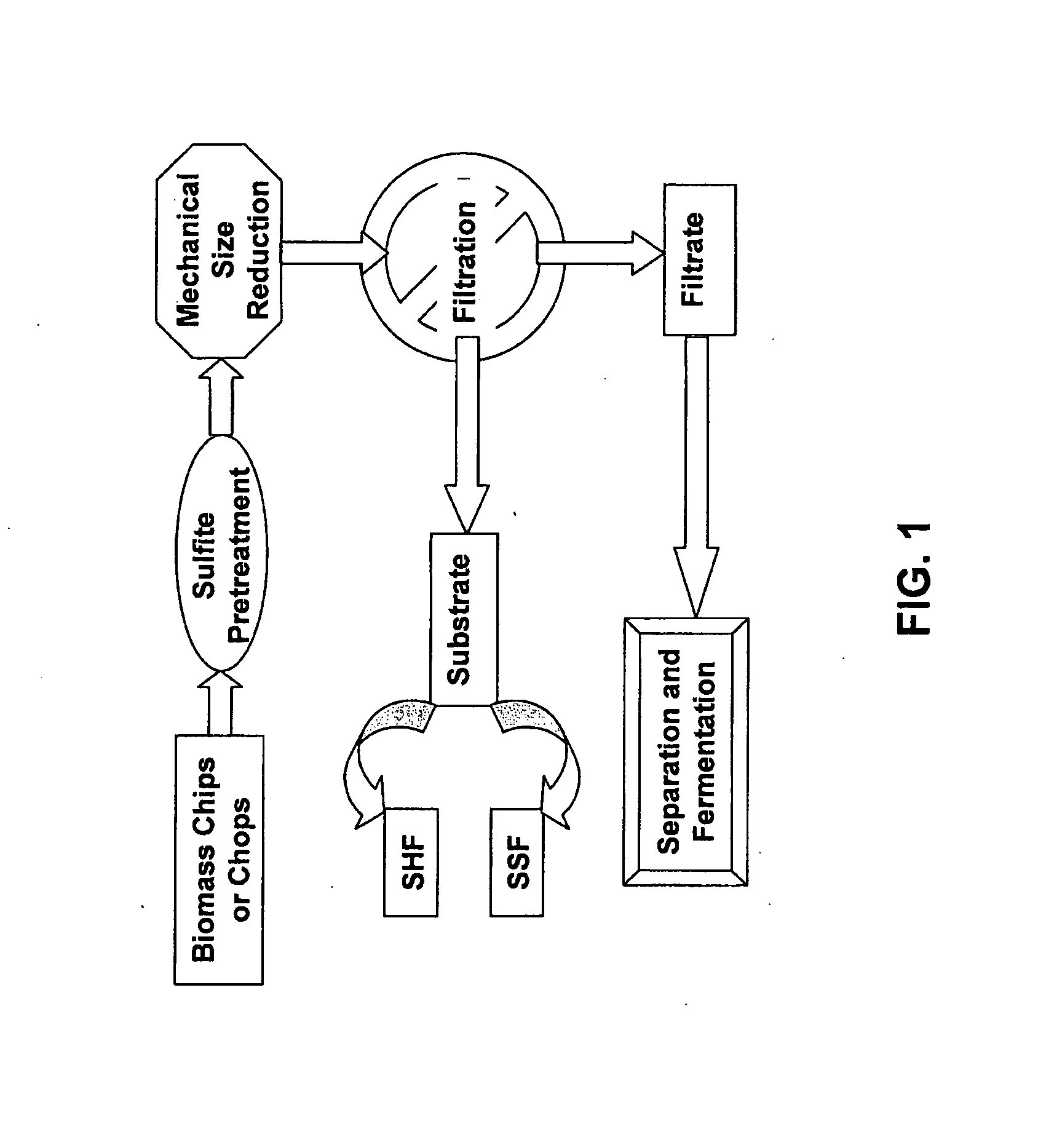

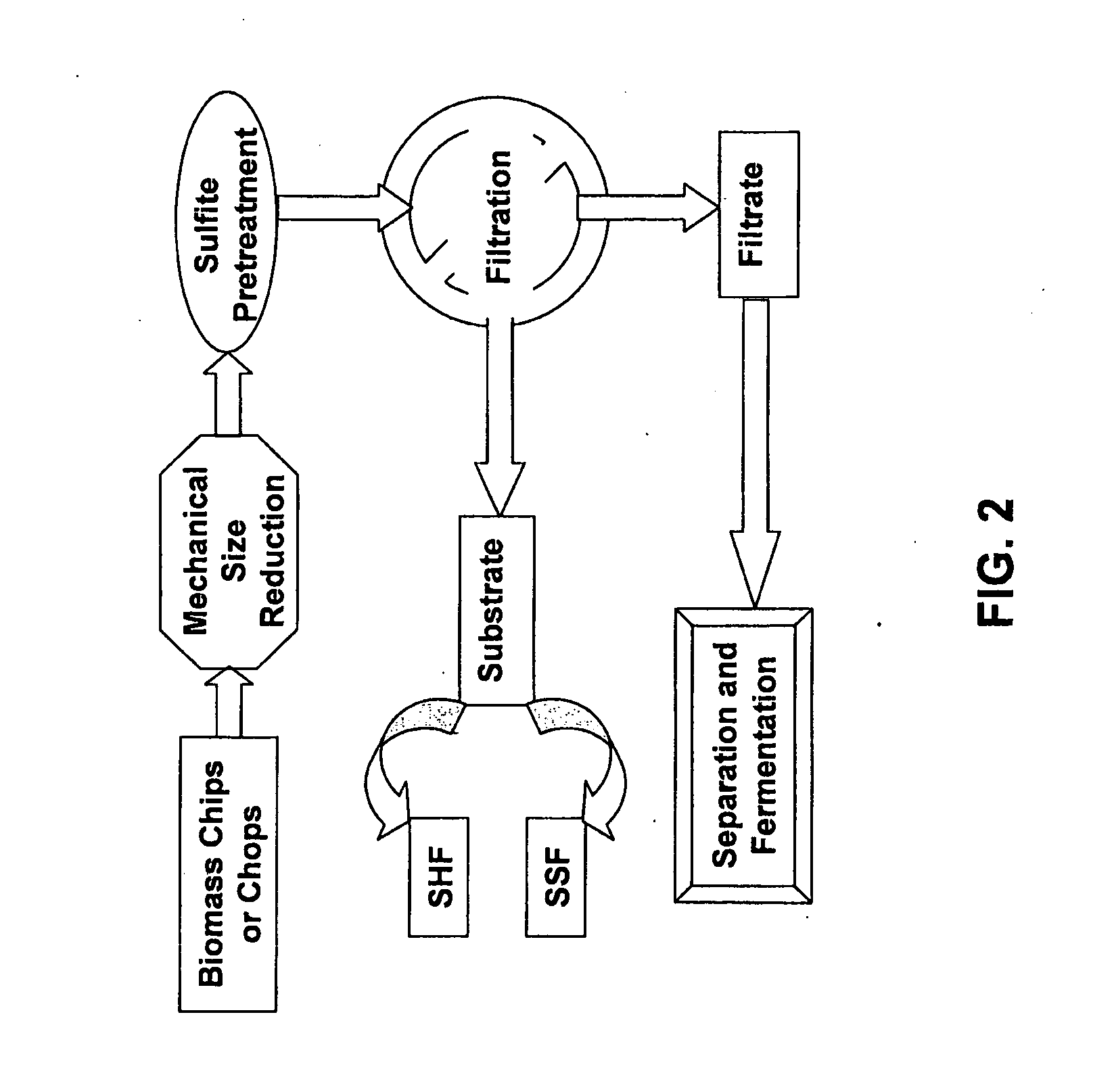

Sulfite Pretreatment For Biorefining Biomass

ActiveUS20090298149A1Save thermal energy consumptionImprove conversion efficiencyBiofuelsPaper recyclingCelluloseSulfite

The present invention relates to a method using sulfite pretreatment to overcome recalcitrance of lignocellulose (SPORL). More specifically, it relates to a sulfite-based chemical process for pretreating biomass in solutions to reduce access barriers of enzymes to the lignocellulose, resulting in efficient conversion through enzymatic saccharification.

Owner:US SEC AGRI +1

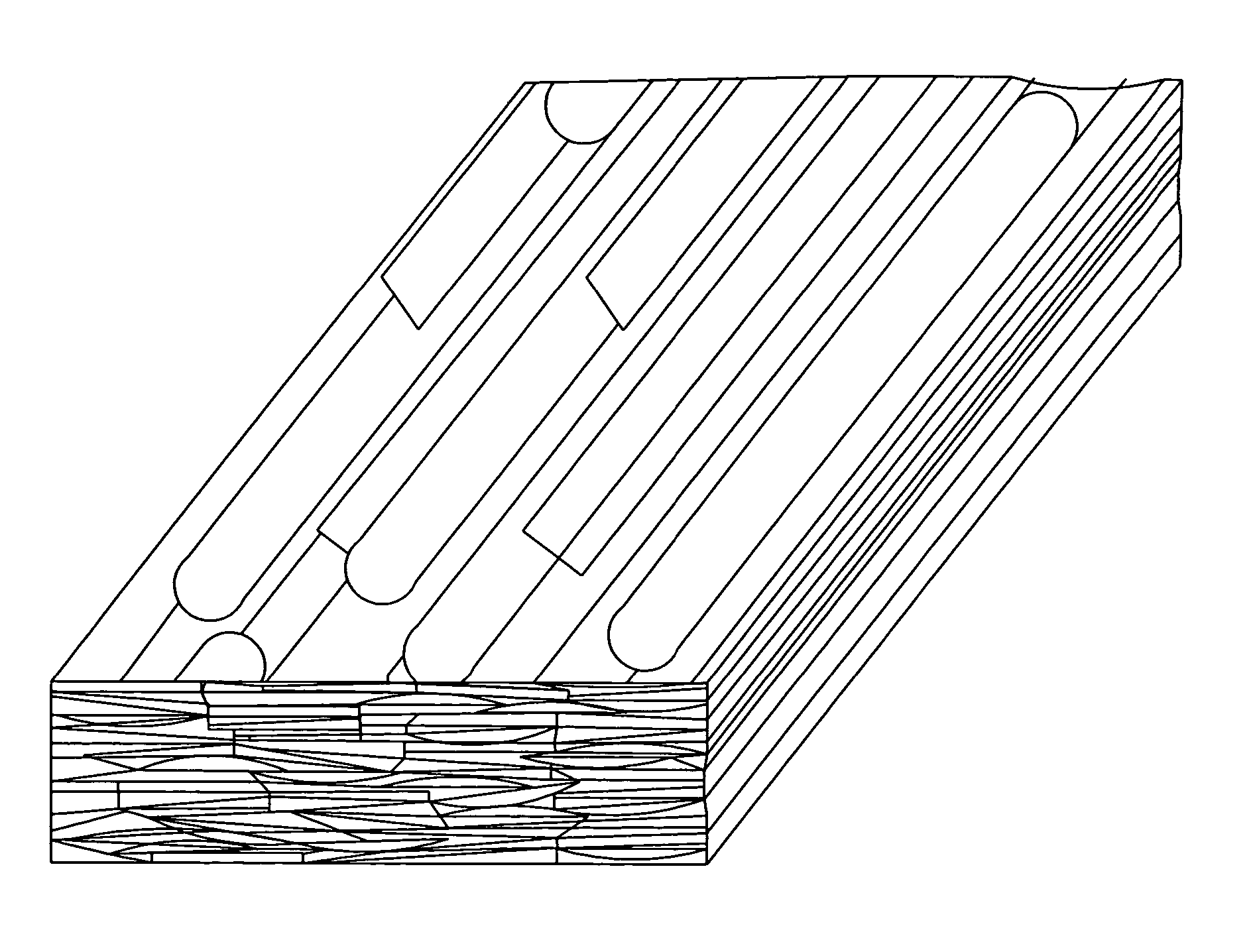

Bamboo chip treatment and products

InactiveUS20050161852A1Equally distributedVoid space is smallWood working apparatusAbsorbent padsEngineeringUltimate tensile strength

Thin elongated bamboo chips are produced and then are softened and dried. The softening of the chips reduces void spaces which uses less glue and produces stronger members. The chips are then joined together with glue under pressure to form a bamboo board. By varying the depth and length of the chip form, the member produced can form a board, chipboard, beams, or columns of any size. Additional boards may be produced and glued together to form a larger board, beam, or column. Several chipboard layers fabricated in large sheets and glued together will form ‘multi-ply bamboo’, a bamboo substitute for plywood. Once cured, the member is kiln dried and sealed for moisture. The resulting bamboo member's strength and geometrical form is stable and consistent enough to be used as a structural grade member for frames, homes, buildings, and furniture.

Owner:DECKER EMIL GUY +1

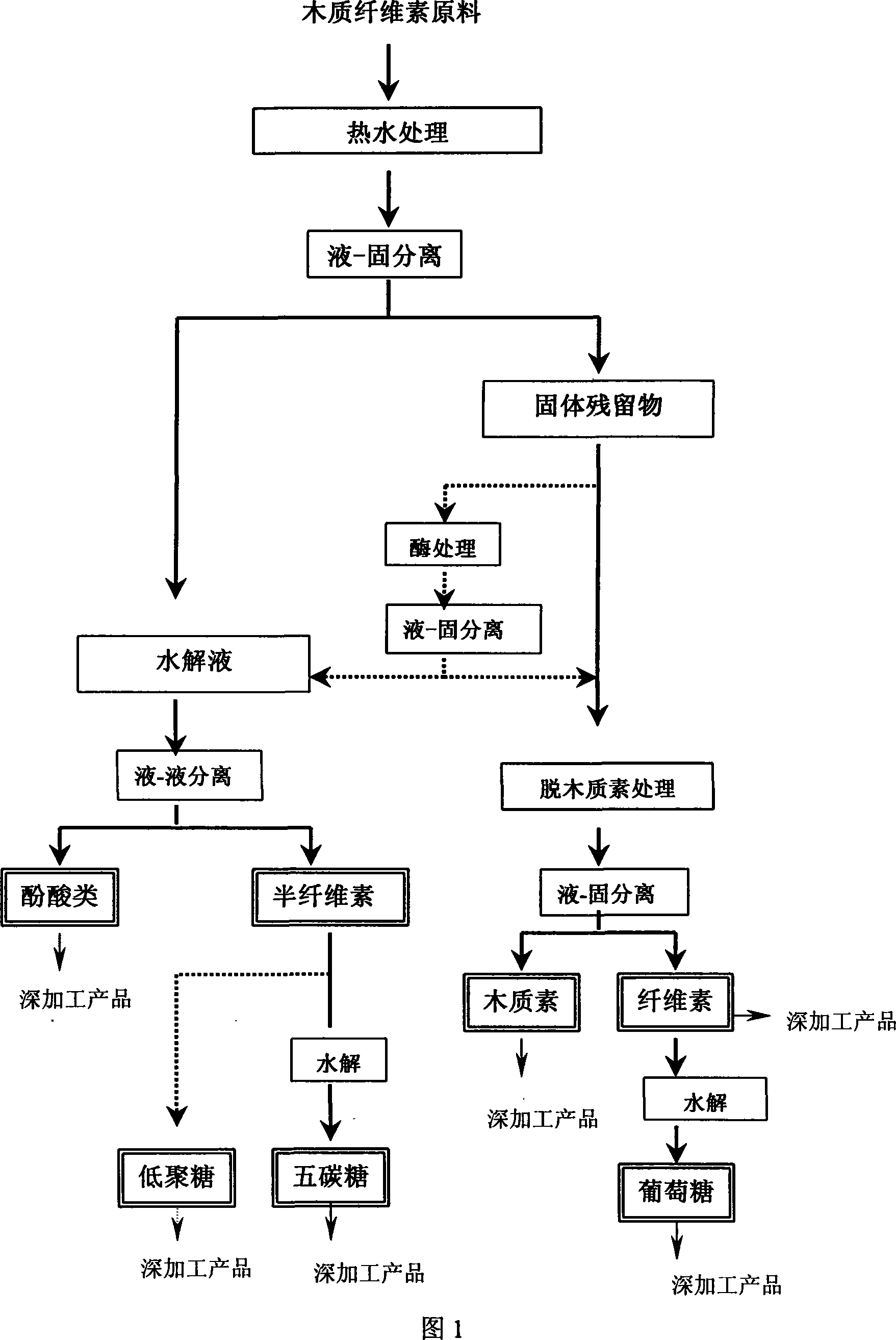

Method for synchronously extracting hemicellulose, cellulose and lignin and reclaiming phenolic acid compounds

InactiveCN101143881AProtect chemical structureReduce generationLignin derivativesPaper material treatmentOrganic solventChemical composition

The present invention provides a technique method which separates lignose, hemicellulose, cellulose and phenolic acid from lignocellulosic biomass. Under the selected pH value and temperature, the lignocellulosic biomass is processed by hot water, so that the hemicellulose and the phenolic acid are preferentially resolved in aqueous solution, delignification processing is carried out, organic solvent or alkaline solution is applied to carry out high-temperature cooking, the generated liquid-solid phase product can be easily and effectively separated, and thus the hemicellulose, the cellulose and the phenolic acid can be respectively obtained. Moreover, enzymatic treatment can be selectively added, and a solid phase product is obtained at the first stage of a group of enzymatic treatment with a cooperative effect. Because the ferulic acid linkage between the hemicellulose and the lignose can be selectively broken, the separation of the chemical components has a high yield rate and high purity.

Owner:孔延华

Preparation method of cellulose nano-fiber/polylactic acid composite membrane

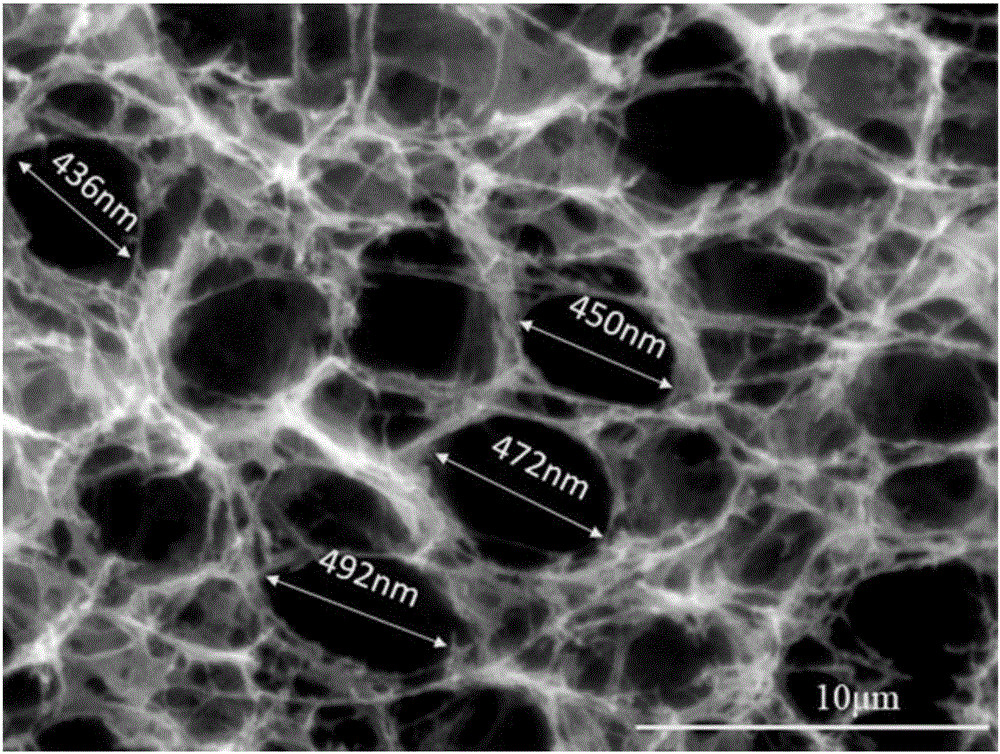

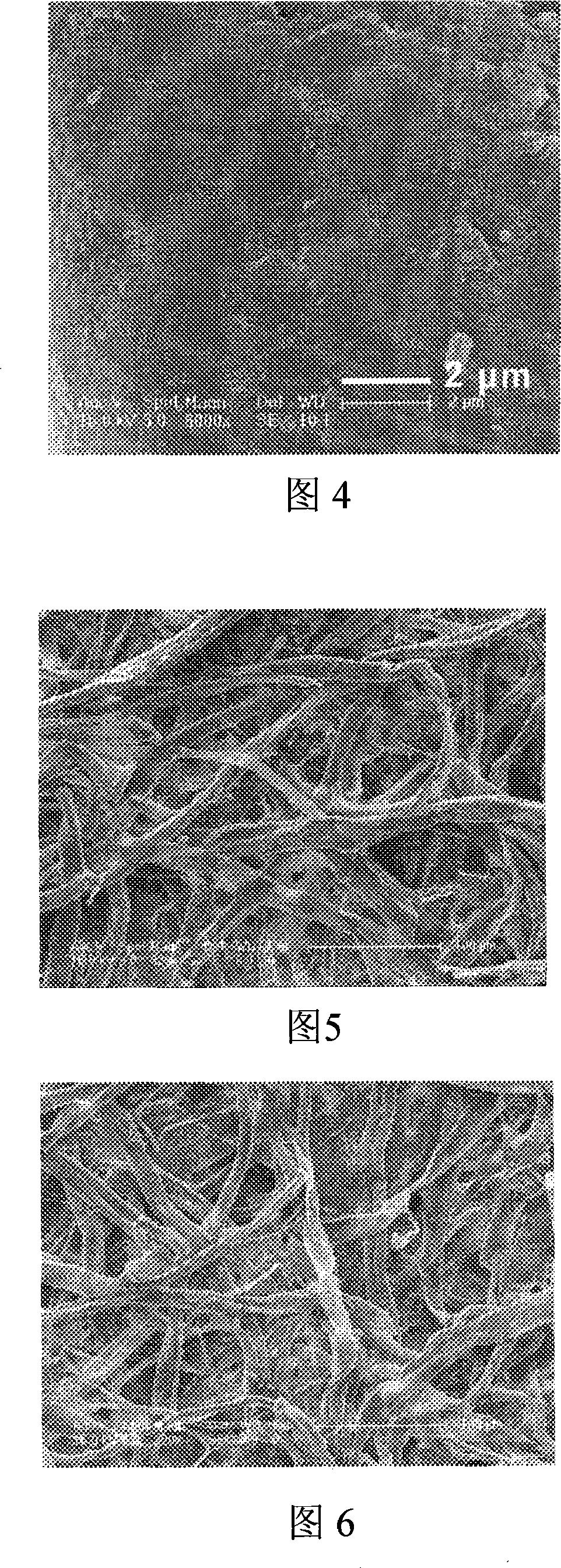

InactiveCN103387688AUniform diameter distributionReduce hydrogen bondingPaper material treatmentFiberChemical treatment

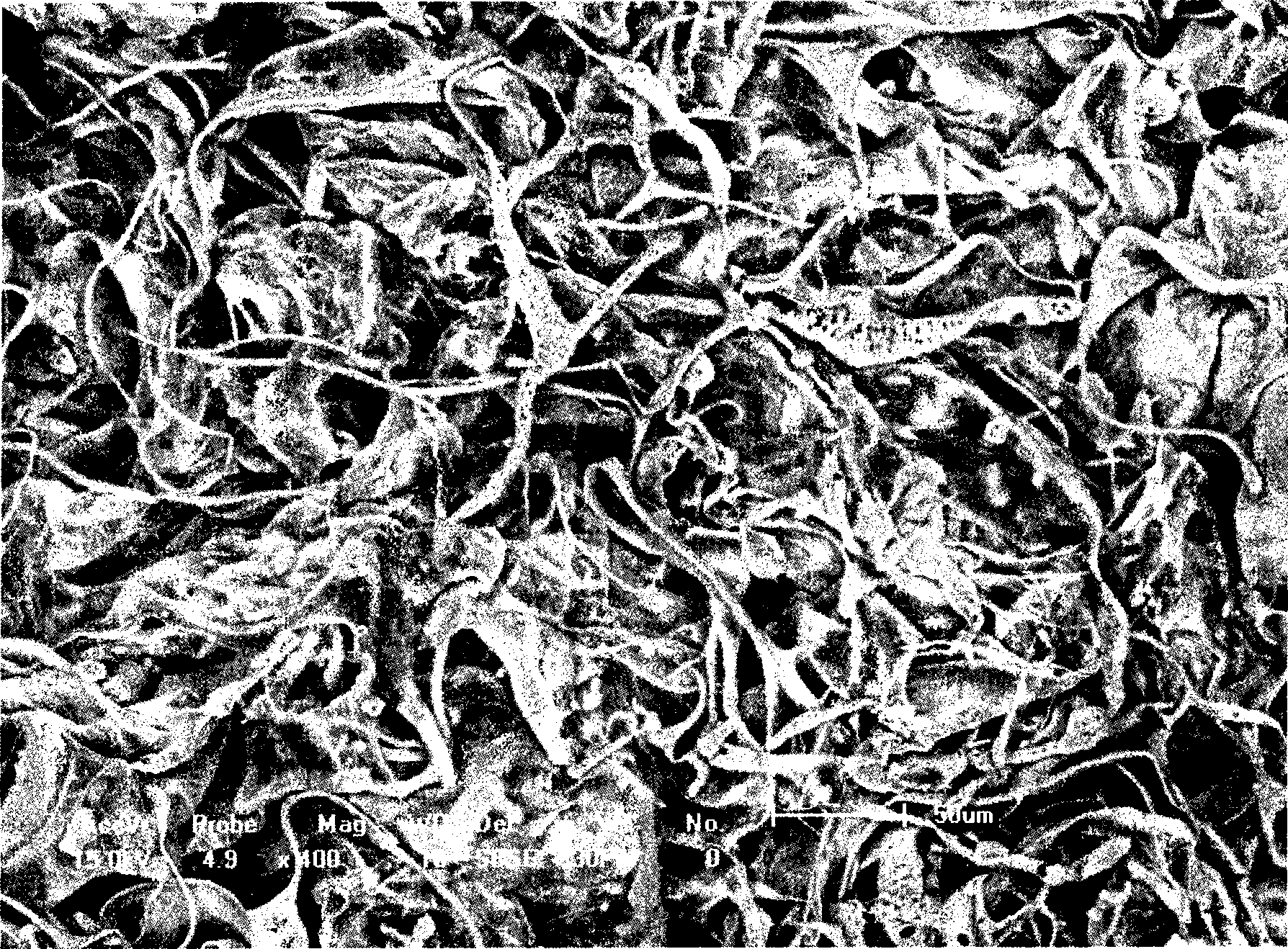

The invention provides a preparation method of a cellulose nano-fiber / polylactic acid composite membrane. The preparation method comprises the following steps of: (1) treating raw materials; (2) performing chemical treatment; (3) performing mechanical treatment; (4) preparing a nano cellulose membrane; (5) preparing a nano cellulose / polylactic acid composite membrane material by using a mixing and dissolving method or an immersion method. The preparation method has the advantages that lignin and most of hemicellulose are removed by using a chemical method, and under a water wet swelling condition, water fills the positions in which most of the hemicellulose and the lignin are removed, so that the hydrogen bond acting force among fibrillae is reduced; then lignocellulose nano fibrillae with uniform morphological sizes and mesh gangles are prepared by adopting mechanical treatment. The nano celluloses prepared by grinding for 30 minutes and homogenizing are small in diameter size and are uniformly distributed, the diameters of the nano fibrillae is 15-50nm, and the length-diameter ratio is high and reaches 1200. The cellulose nano-fiber / polylactic acid composite membrane can be used as a substitute and the like for a flexible display, electronic paper, a solar battery, a flexible circuit and a glass substrate.

Owner:NANJING FORESTRY UNIV

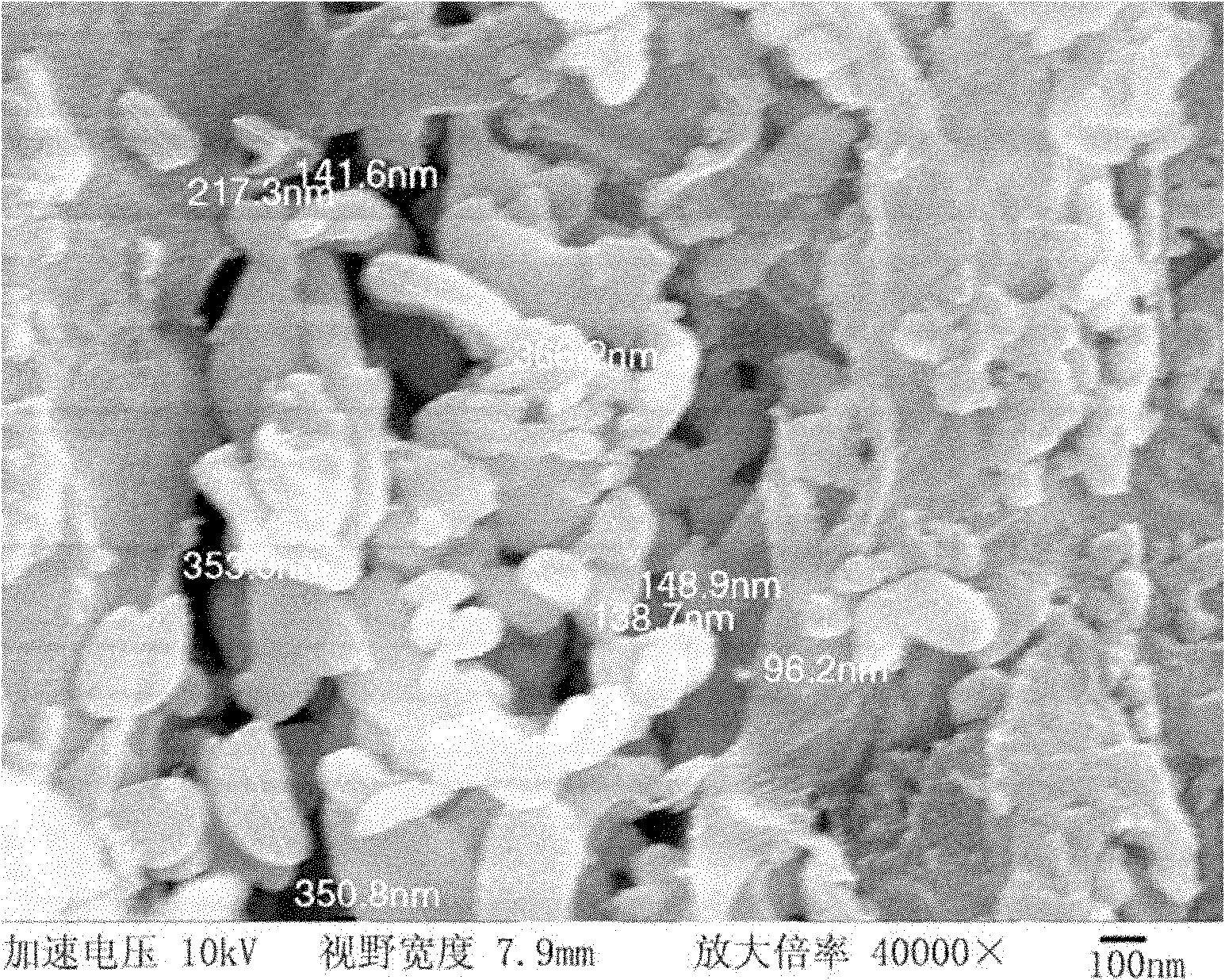

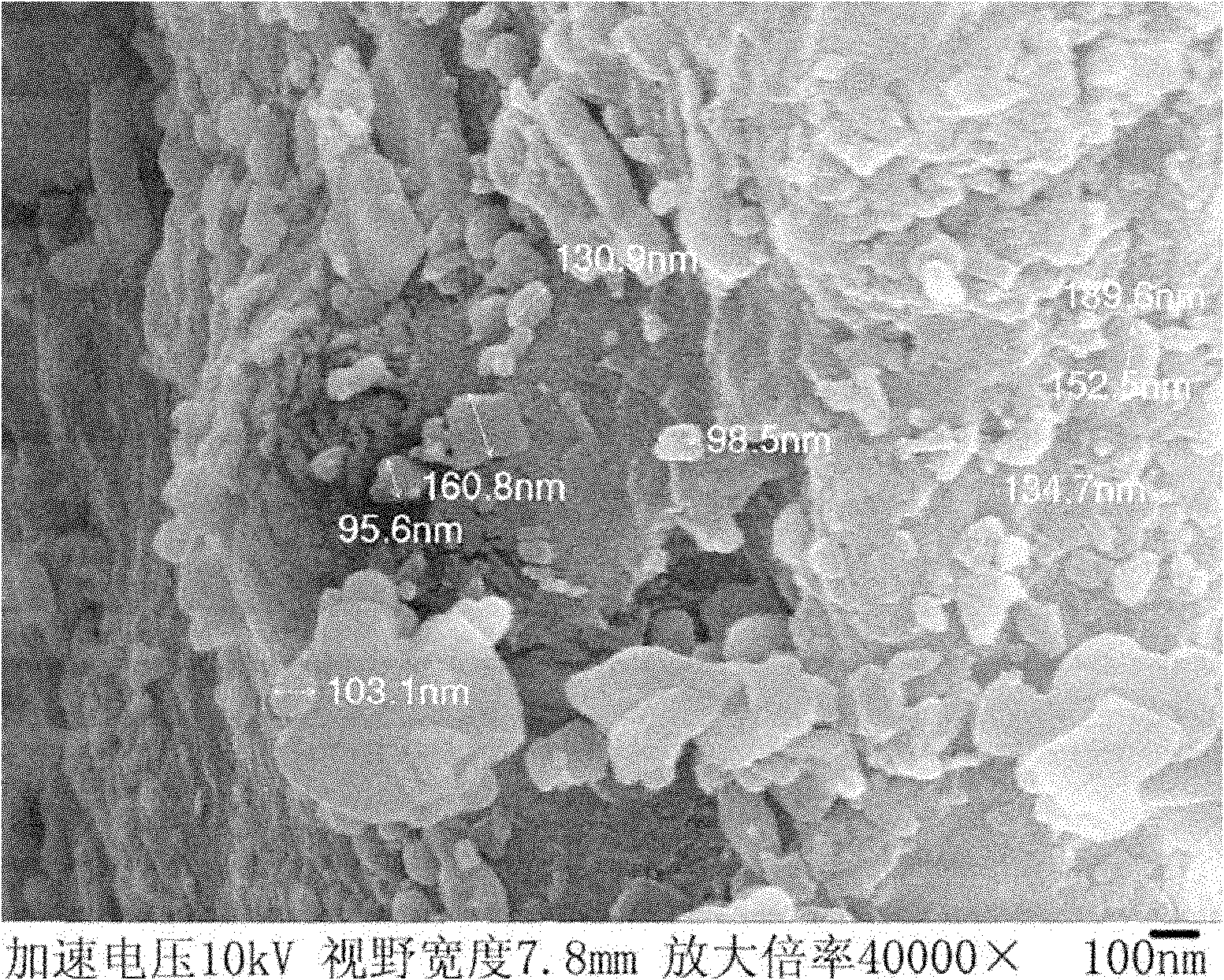

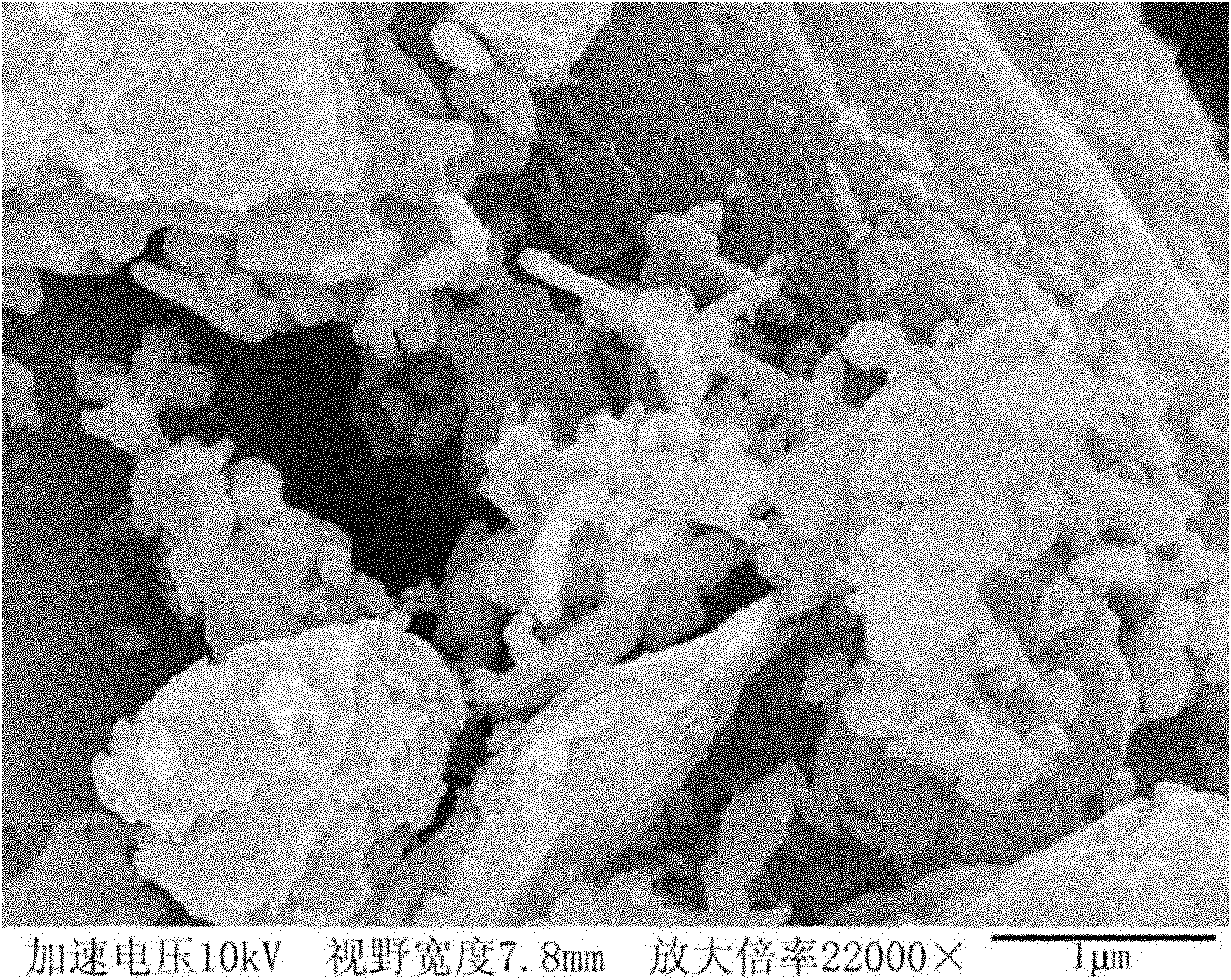

Preparation method of straw micro-nano cellulose

ActiveCN101949103AHigh aspect ratioLarge specific surface areaPaper material treatmentMicro nanoHydrolysis

The invention discloses a preparation method of straw micro-nano cellulose, relating to a preparation method of micro-nano cellulose. The invention solves the problems that the prior art for preparing nano cellulose comprises more steps, and rodlike nano cellulose has low draw ratio. The preparation method is as follows: 1, stewing; 2, dipping and washing; 3, screening; 4, bleaching; 5, carrying out hydrolysis and supersonic treatment; and 6, neutralizing, rinsing, breaking, decentralizing and drying to obtain the straw micro-nano cellulose. The micro-nano cellulose prepared by the preparation method of the invention has fibroid appearance, has the diameter of 10-200 nm and the length of 200-10 mu m, and has high draw ratio and large specific surface area. The invention is applied to the field of composite materials.

Owner:NORTHEAST FORESTRY UNIVERSITY

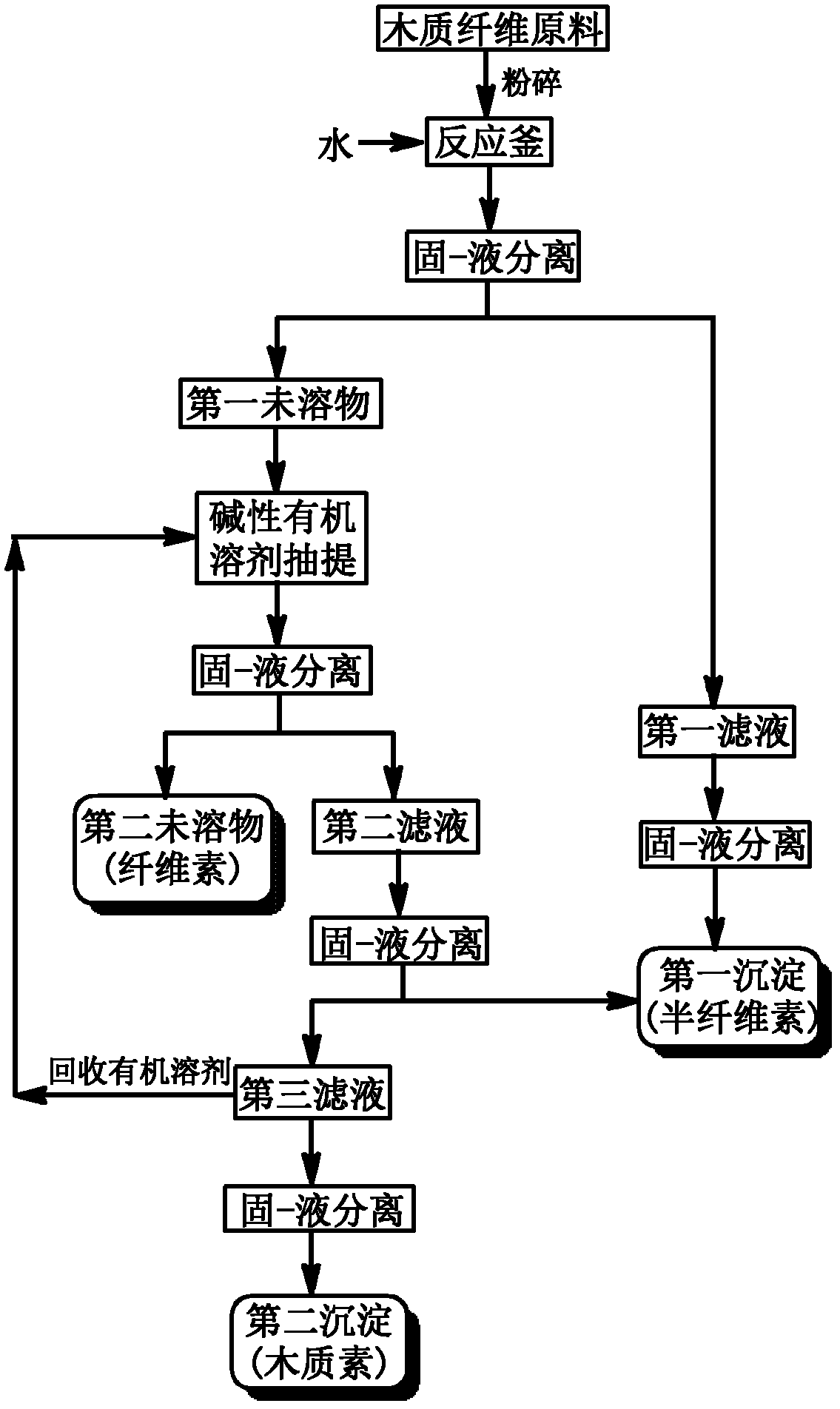

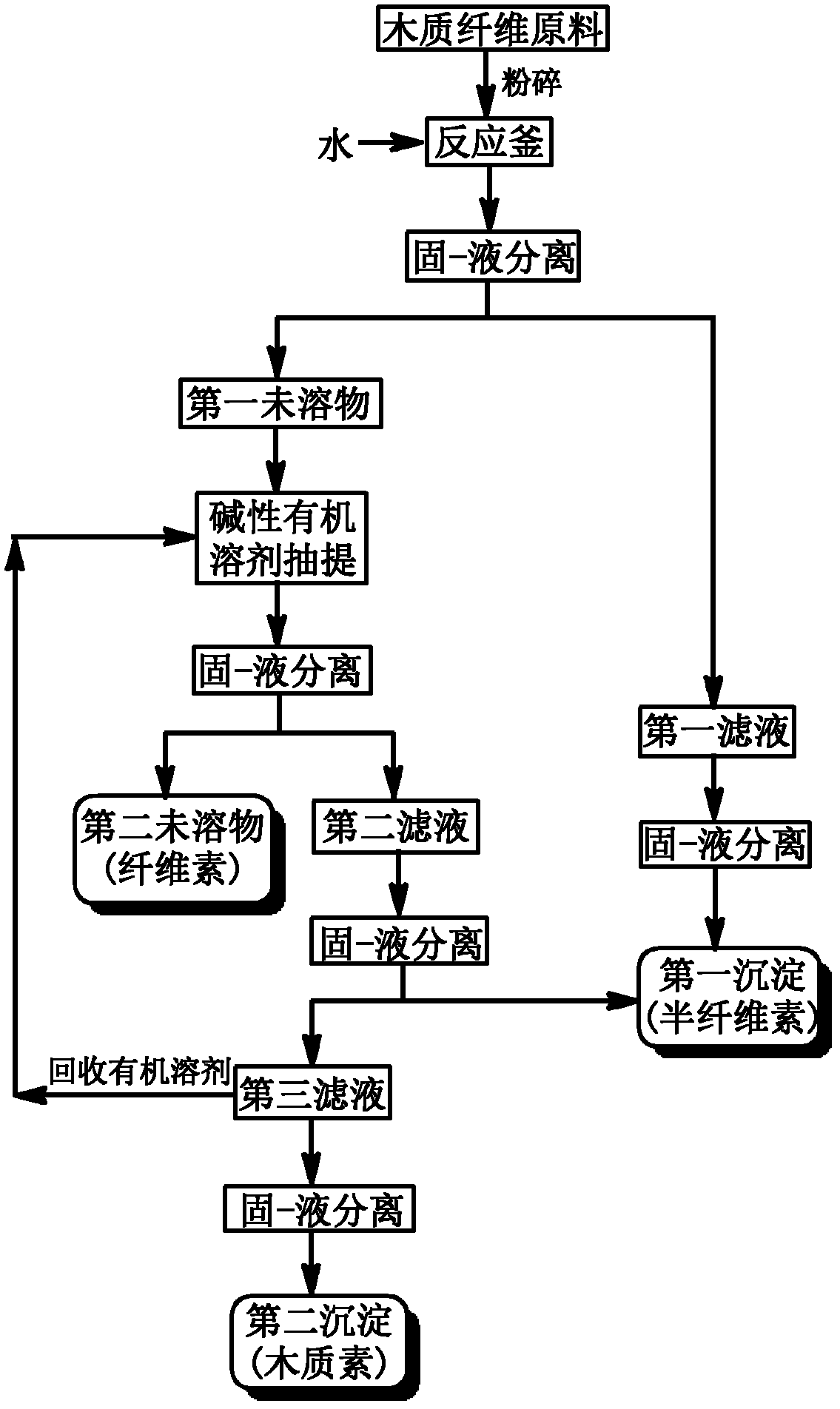

Method of extracting hemicellulose, cellulose and lignin from wood fiber raw materials

The invention relates to a method of extracting hemicellulose, cellulose and lignin from wood fiber raw materials and belongs to the field of utilization and technology of biomass resources of agriculture and forestry. In the method, the hemicellulose is extracted from the wood fiber raw materials by using hot water, then the lignin is extracted by using alkaline organic solvent under mild conditions; and residual ingredients rich in the cellulose are further used for enzyme hydrolysis to prepare fermentable sugar solution, thereby achieving full-ingredient utilization of the hemicellulose, cellulose and lignin in the biomass resources of the agriculture and forestry. The method has simple process, and is environmentally friendly, the organic solvent can be recycled, thereby promoting the development of the green agriculture and forestry, and the method has wide social and economic benefits.

Owner:BEIJING FORESTRY UNIVERSITY

Solvent dehydrated microbially-derived cellulose for in vivo implantation

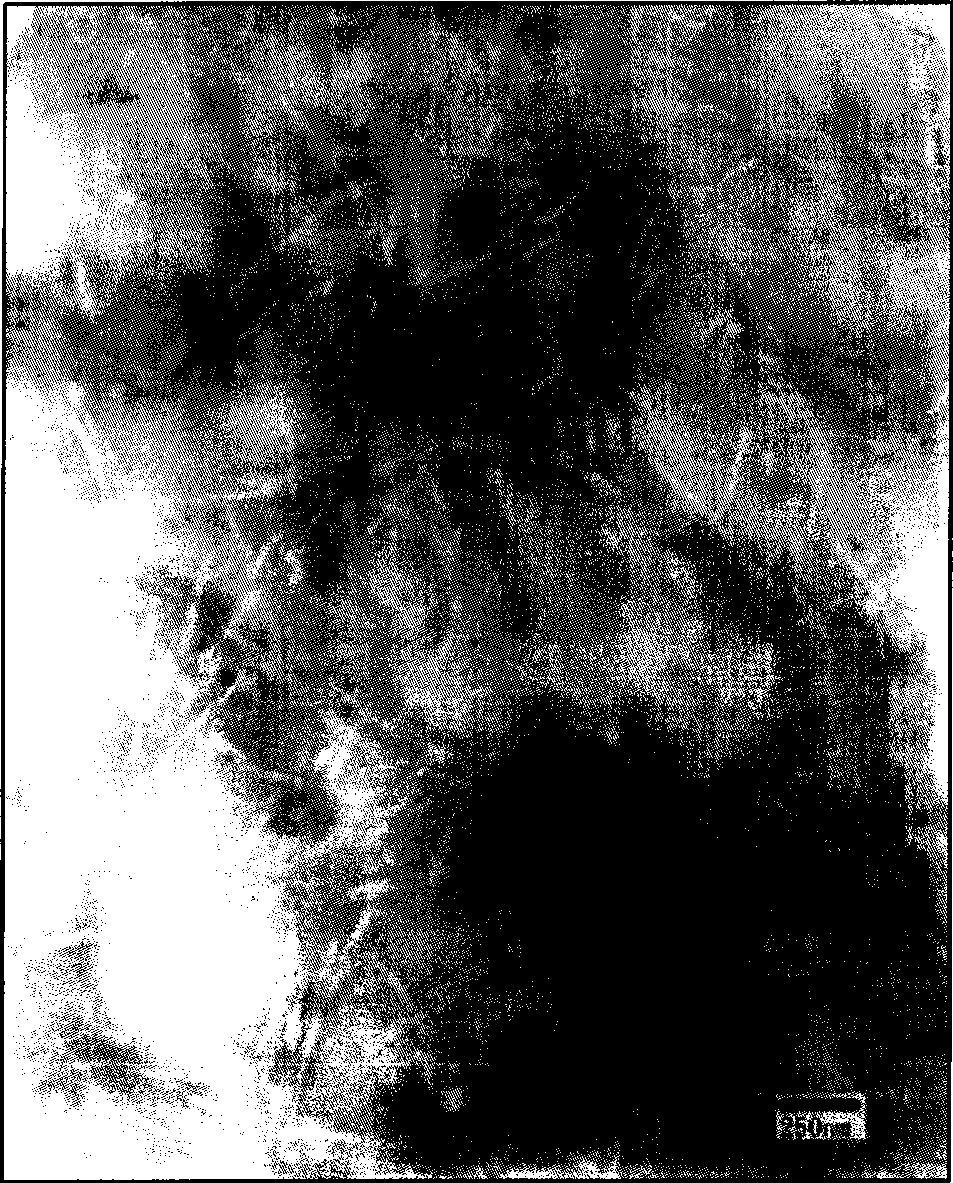

InactiveUS20020107223A1Less inter-fibril surface tensionReduce surface tensionOrganic active ingredientsBiocideCelluloseOrganic chemistry

A solvent dehydrated microbially-derived cellulose material is described for use as an implantable material in general and plastic surgery.

Owner:DEPUY SYNTHES PROD INC

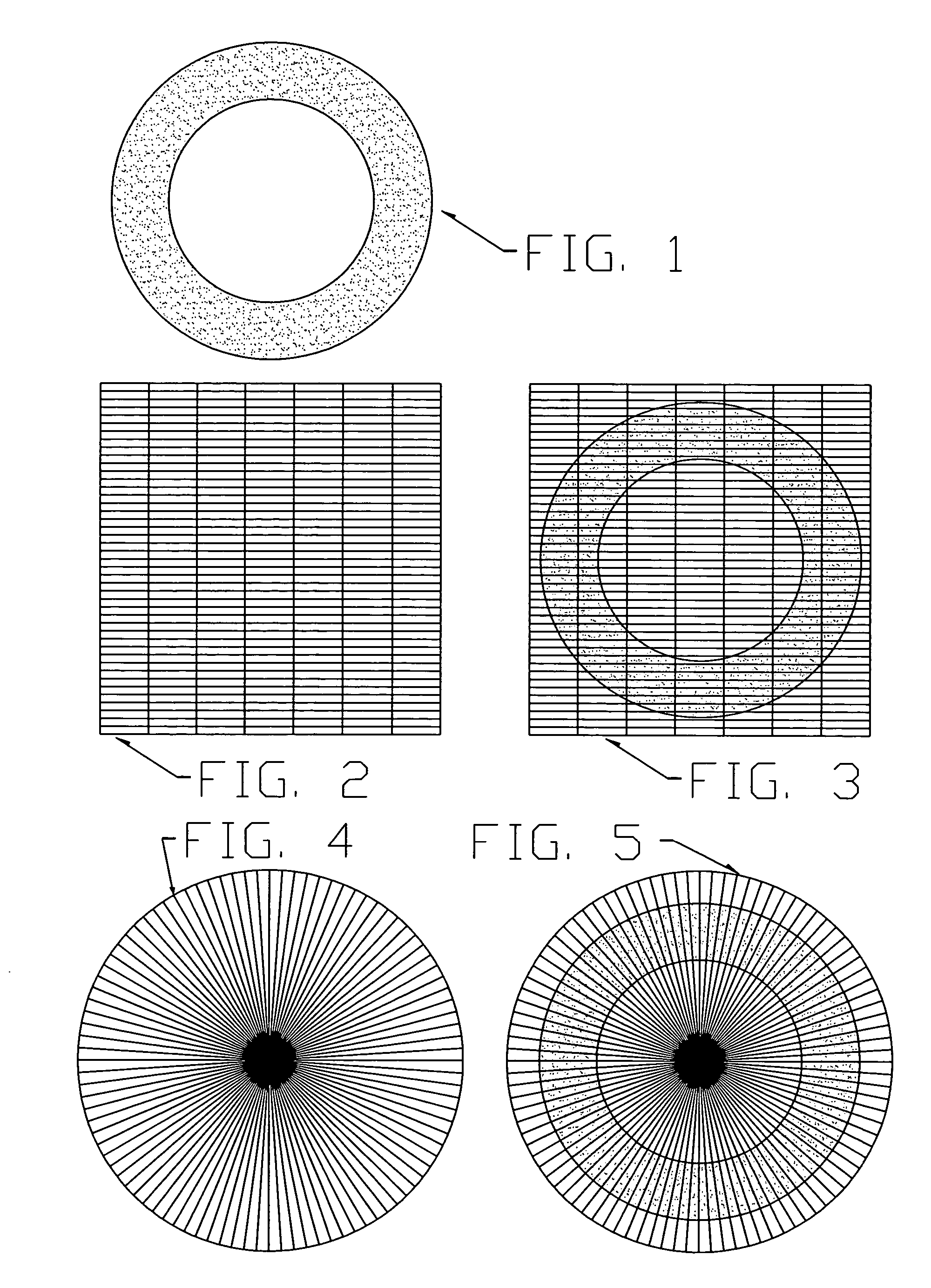

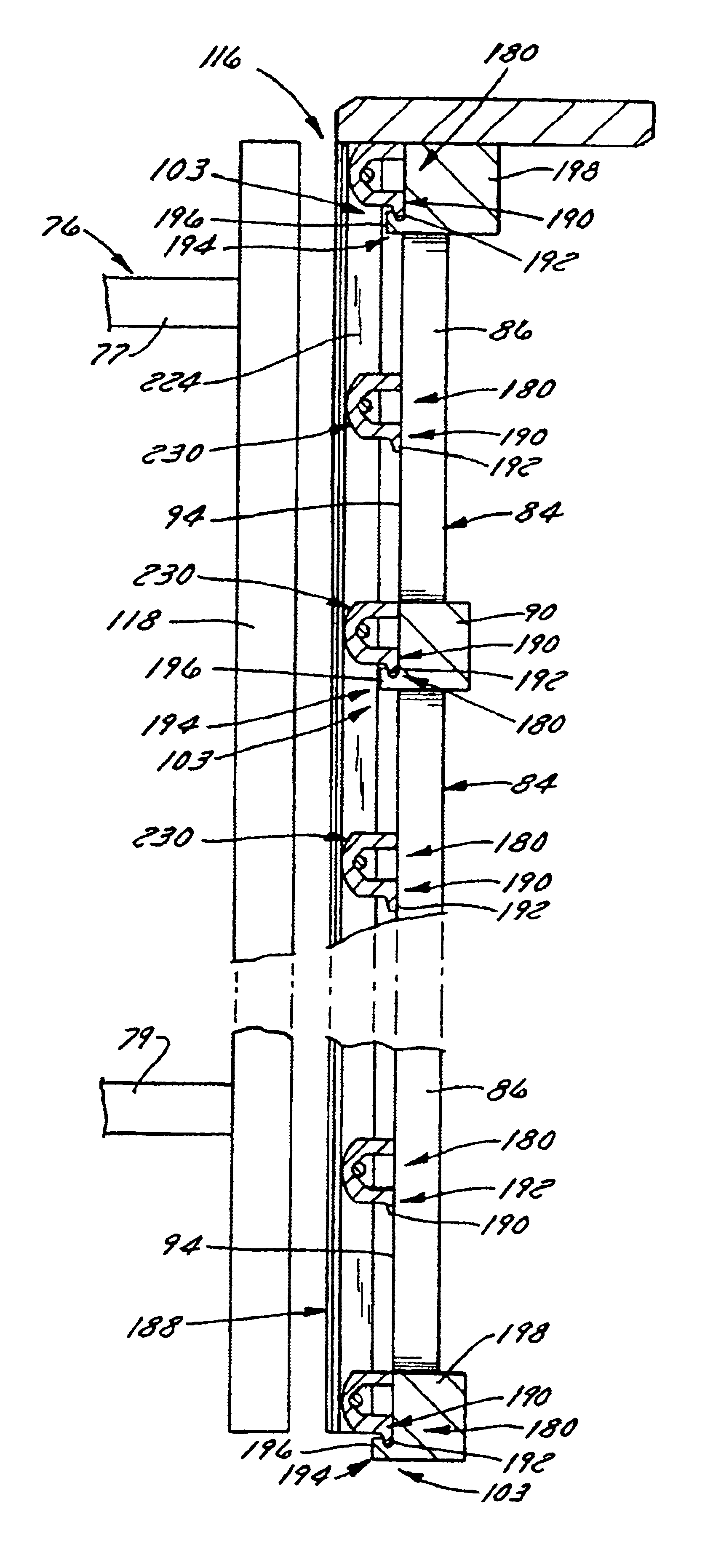

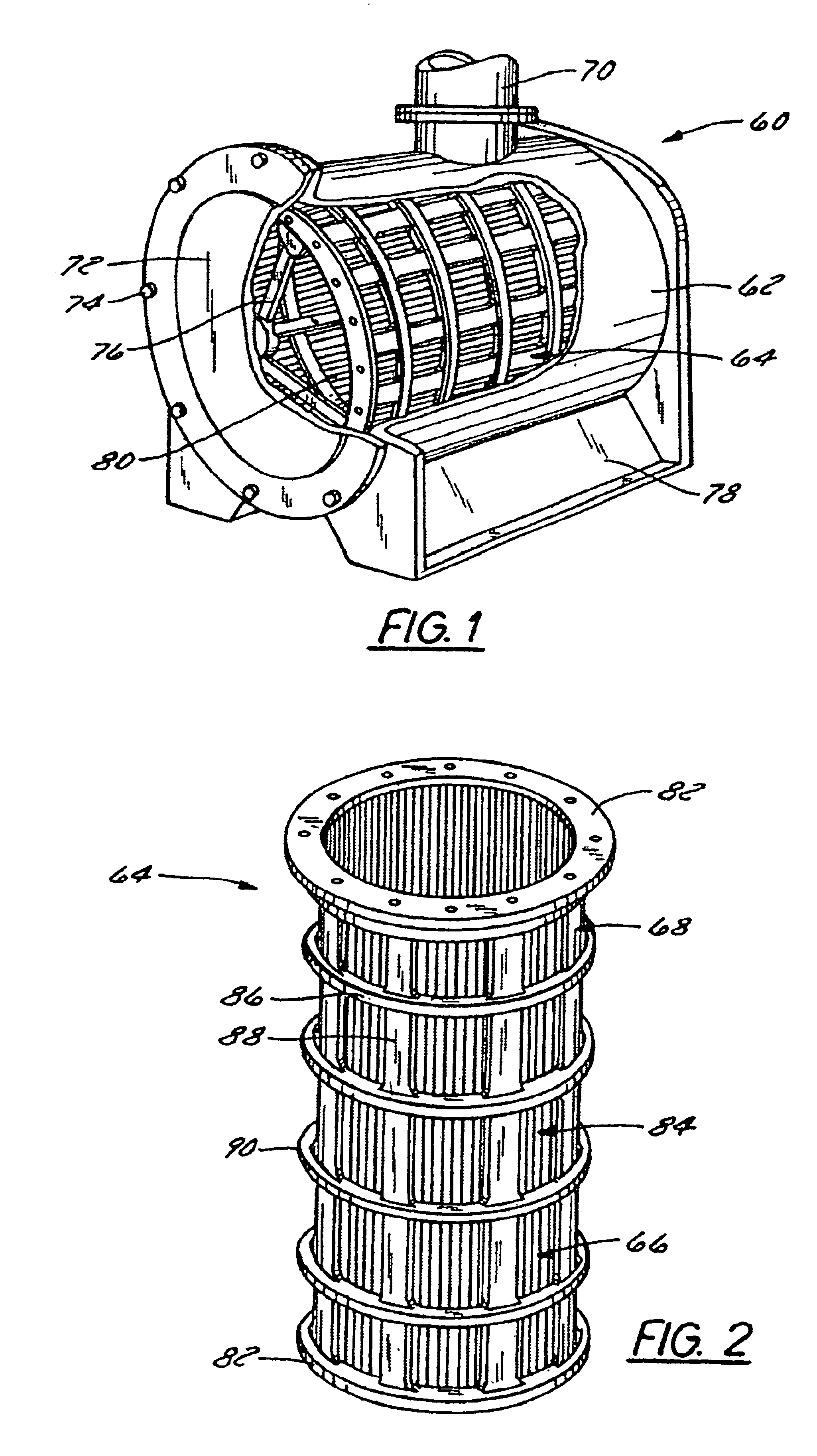

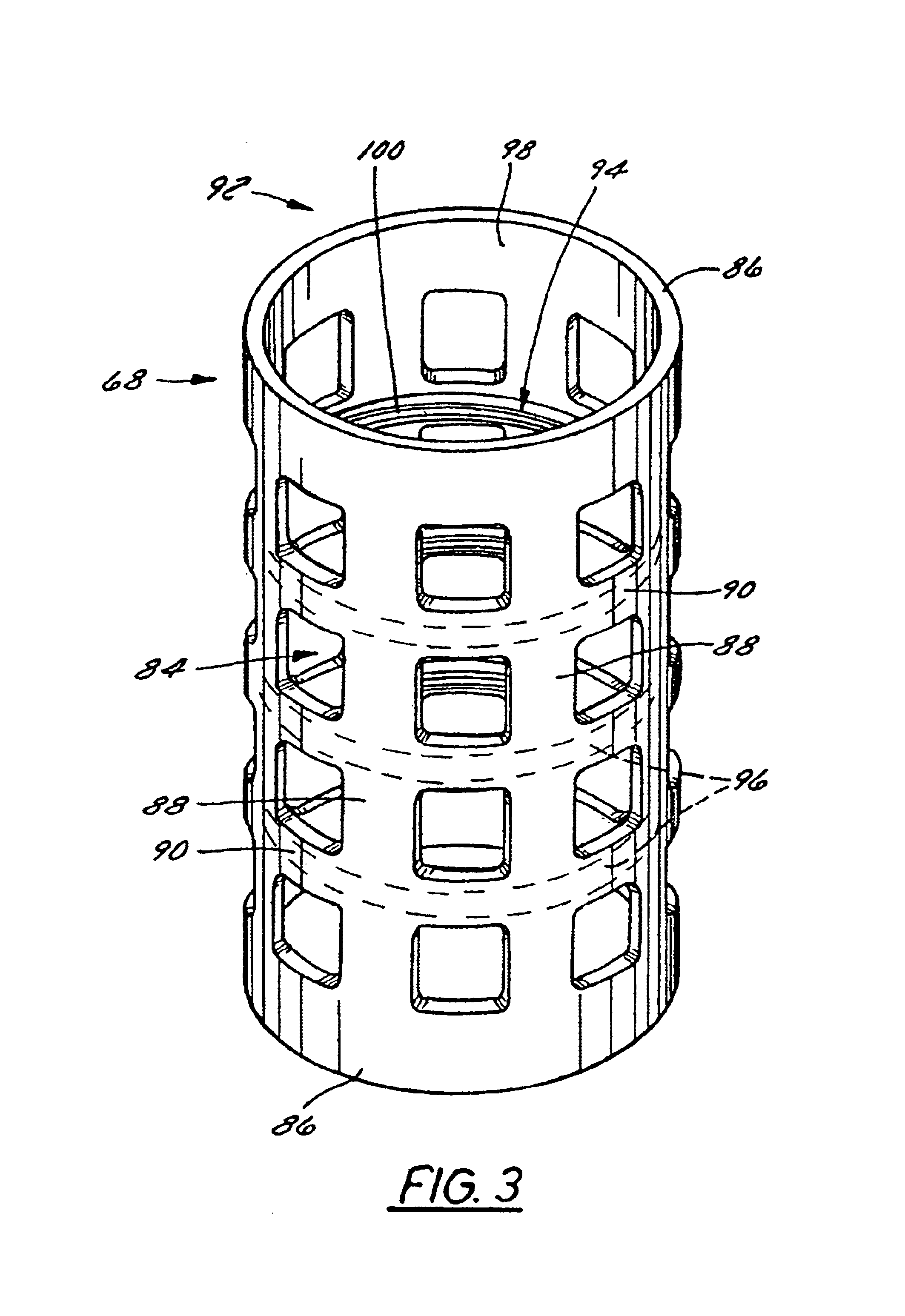

Screen cylinder and method

InactiveUS6915910B2Increase the circulation areaStrong stressSievingScreeningPreferred frameMechanical engineering

A pulp screen cylinder that includes screen media releasably engaged with a frame at spaced locations opposing movement of the media away from the frame during screening. A preferred frame includes a plurality of spaced engaging structures that releasably engage screen media. A preferred frame includes an arrangement of flow windows that are triangular or rhomboid. A preferred method includes producing a frame cylinder by centrifugal casting and machining flow windows using a jet cutting process. A preferred screen media has a plurality of spaced apart engaging structures that each releasably engages the frame at spaced apart locations. A preferred screen media is of wedgewire construction having engaging structure carried by a plurality of spaced wire retaining clips. A preferred clip has vee-shaped rounded slots and an arm thicker than an end wall. A preferred engaging structure includes a projection that has a lip or hook for releasable interlocking engagement.

Owner:KADANT BLACK CLAWSON LLC

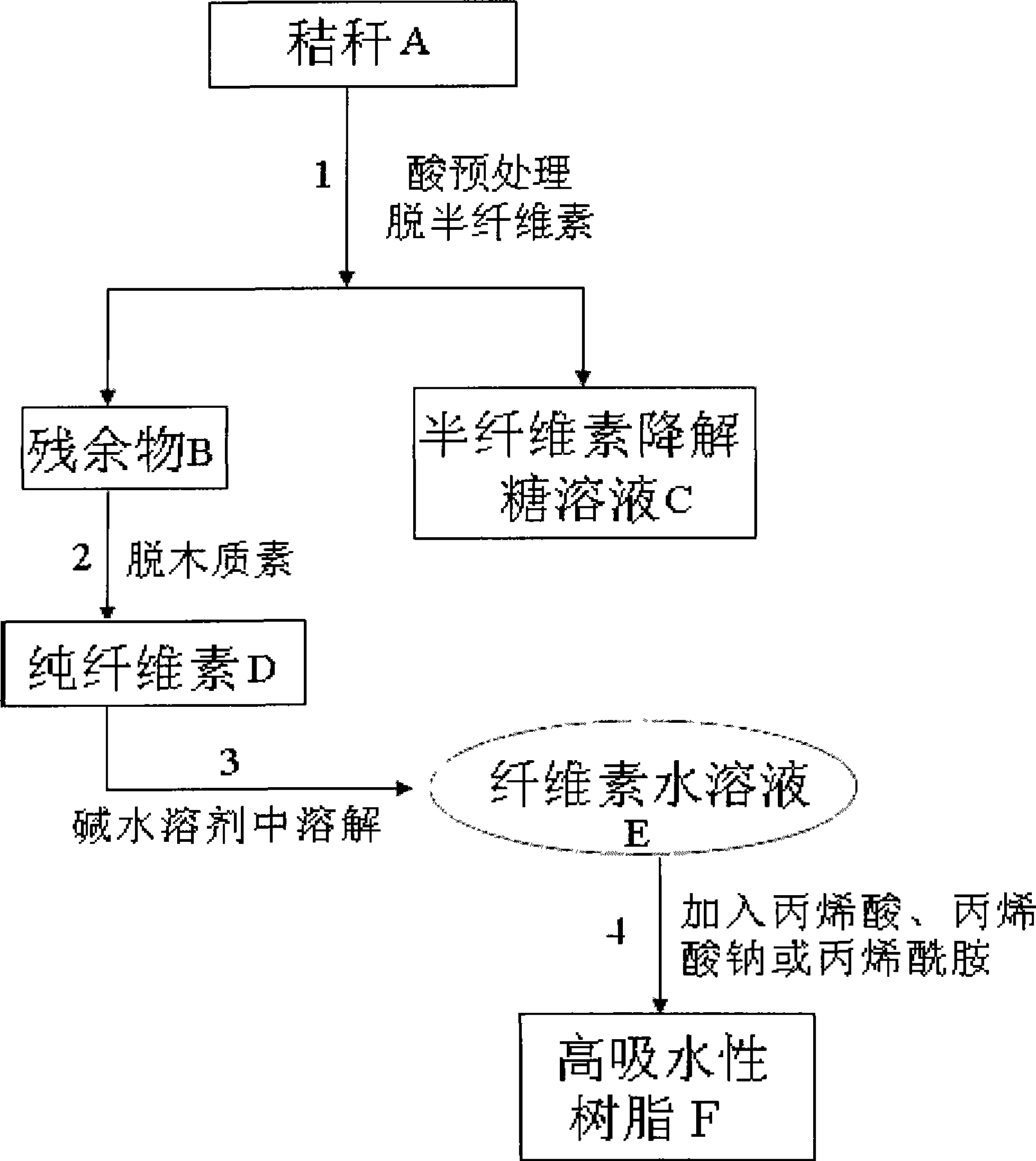

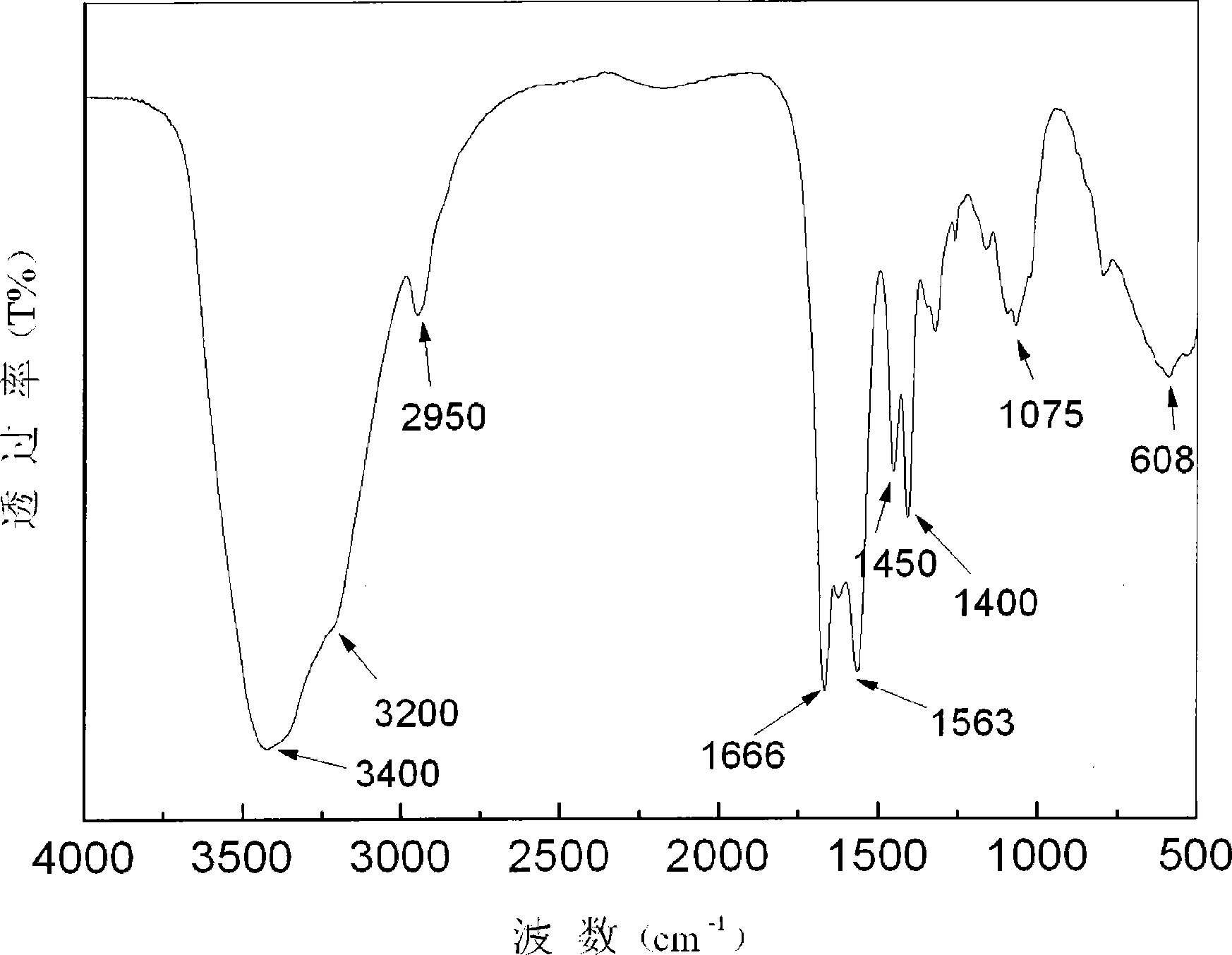

Method for preparing high-hydroscopicity resin in homogeneous aqueous medium by using straw as raw material

InactiveCN101519476AAvoid the disadvantages of microscopic heterogeneous phase separationHas biodegradable propertiesPaper material treatmentCelluloseDouble phase

The invention relates to a method for preparing high-hydroscopicity resin in uniform-phase aqueous medium by using straw as a raw material. The method comprises the following steps: adopting a double-phase saline aqueous solution system of inorganic acid and polyethylene glycol to sequentially process the straw to obtain cellulose; then, adding the cellulose to a pre-prepared sodium hydroxide-urea aqueous solution or a lithium hydroxide-urea aqueous solution; putting the solution in a refrigerator to be cooled, taking out the solution for mechanically stirring to obtain a uniform cellulose solution; afterwards, adding propenyl monomer to the obtained cellulose aqueous solution and carrying out homogeneous glycerol polymerization to obtain the high-hydroscopicity resin. The hydroscopicity resin has the advantages of low cost, high hydroscopicity and potential biodegradable characteristic and has wide application space in the fields, such as agriculture, forestry, sanitary health products, building materials, perfume emission, and the like.

Owner:UNIV OF SCI & TECH OF CHINA

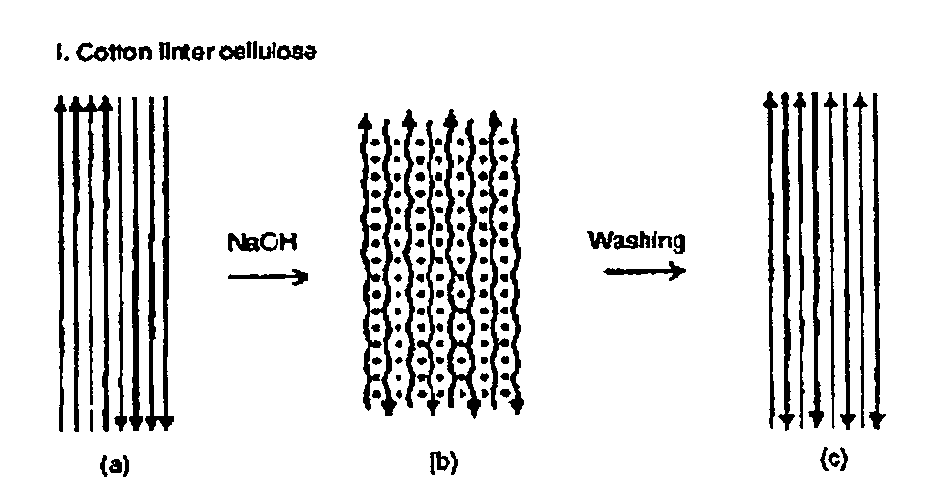

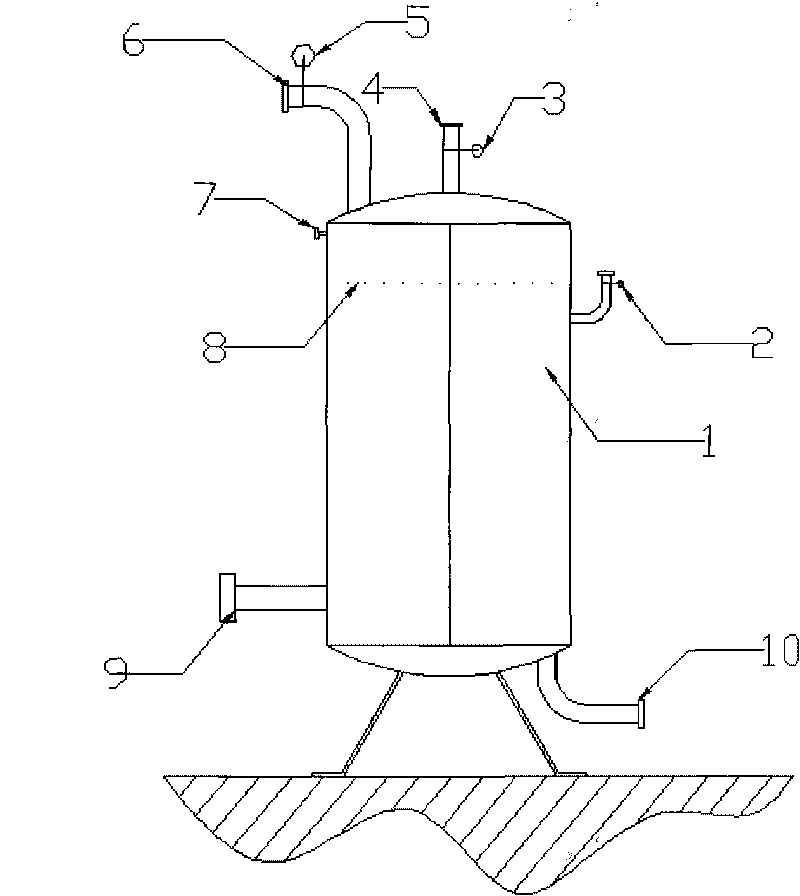

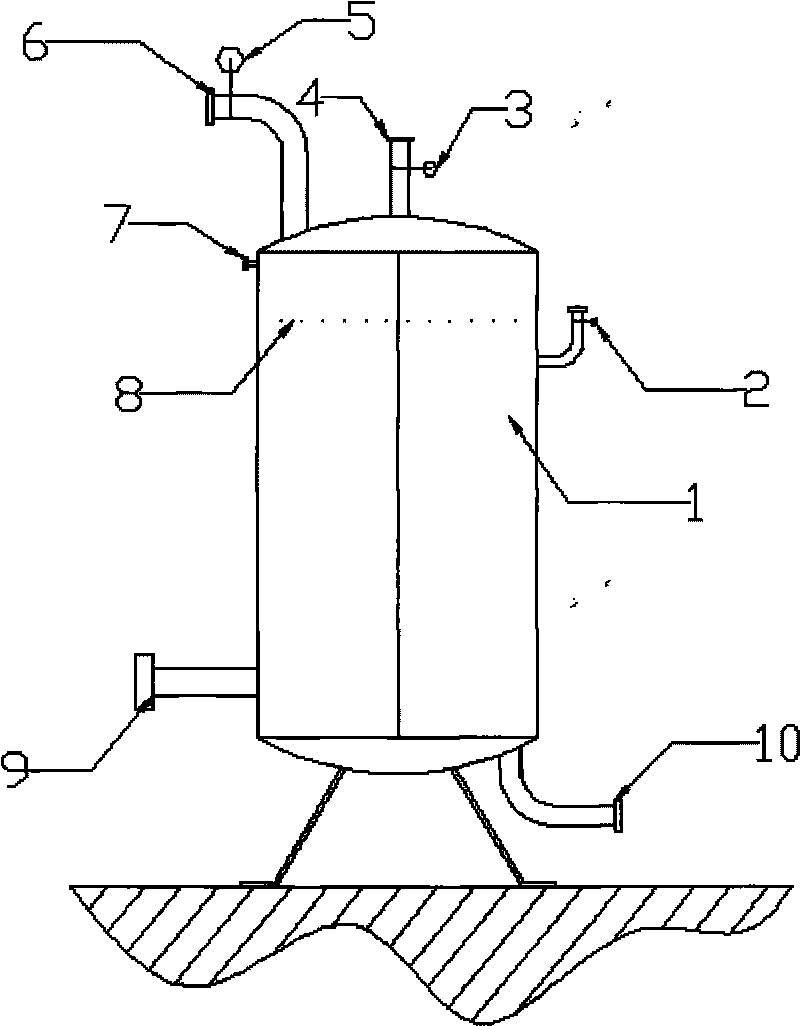

Method for producing dissolving pulp by oxygen continuous digesting method

InactiveCN101333778AReduce the degree of polymerizationAchieve continuous cookingPaper material treatmentCyclonic separationCooking methods

The invention relates to a production method for preparing a dissolving pulp by an oxygen-dissolving and continuous-cooking method, which applies the preparation of cotton linters in the production of viscose fibers in the textile industry, and the method comprises the following steps of: I. cotton linter pretreatments: including cotton linter loosening, cyclone separation and dust removal, feeding, two-roll grinding treatment, etc. to the cotton linters by a two-roll pulping machine; and II. oxygen dissolving and continuous cooking: a horizontal continuous cooking digester is adopted to realize the continuous, fast and low-pollution preparation of dissolving cotton pulp through the actions of high temperature, alkali, oxygen or hydrogen peroxide. The horizontal continuous cooking digester includes a pre-reaction bin, a two-roll gauge, a feeding screw, a T-shaped tube, a continuous-cooking tube and a cold discharge device. The method can effectively solve the problems of: cutting, tearing and cell primary wall breakage to the cotton linters by dry method after feed preparation, physical and chemical stripping to mass impurities in the cotton linters, fast accumulation reduction of the cotton linters in a continuous-cooking device and the purification of alpha cellulose under fast accumulation reduction, recycling of waste heat in the production link, and reduction of total amount of COD in a black liquor, and the method has advantages of even cooking and short cooking cycle.

Owner:宜宾长毅浆粕有限责任公司

Method of preparing clubbed nano-cellulose

The invention discloses a method for preparing nano-rod cellulose, which comprises the following steps: dispersing fiber raw material into sulphuric acid water solution of which mass concentration is 50 to 65 percent, hydrolyzing the fiber raw material by single-mode microwave radiation for 5 to 60 minutes at a temperature of between 20 and 50 DEG C and at the microwave radiation power of 10 to 100 watts, then adding distilled water into hydrolysis solution and diluting the hydrolysis solution to have 10 times of volume, and obtaining stable nano-rod cellulose suspension through post treatment processes such as centrifugal separation, dialysis, filter, ultrasonic dispersion and the like of the diluent, so as to obtain the nano-rod cellulose of which width is about 10 nanometers and length is about 200 to 300 nanometers.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

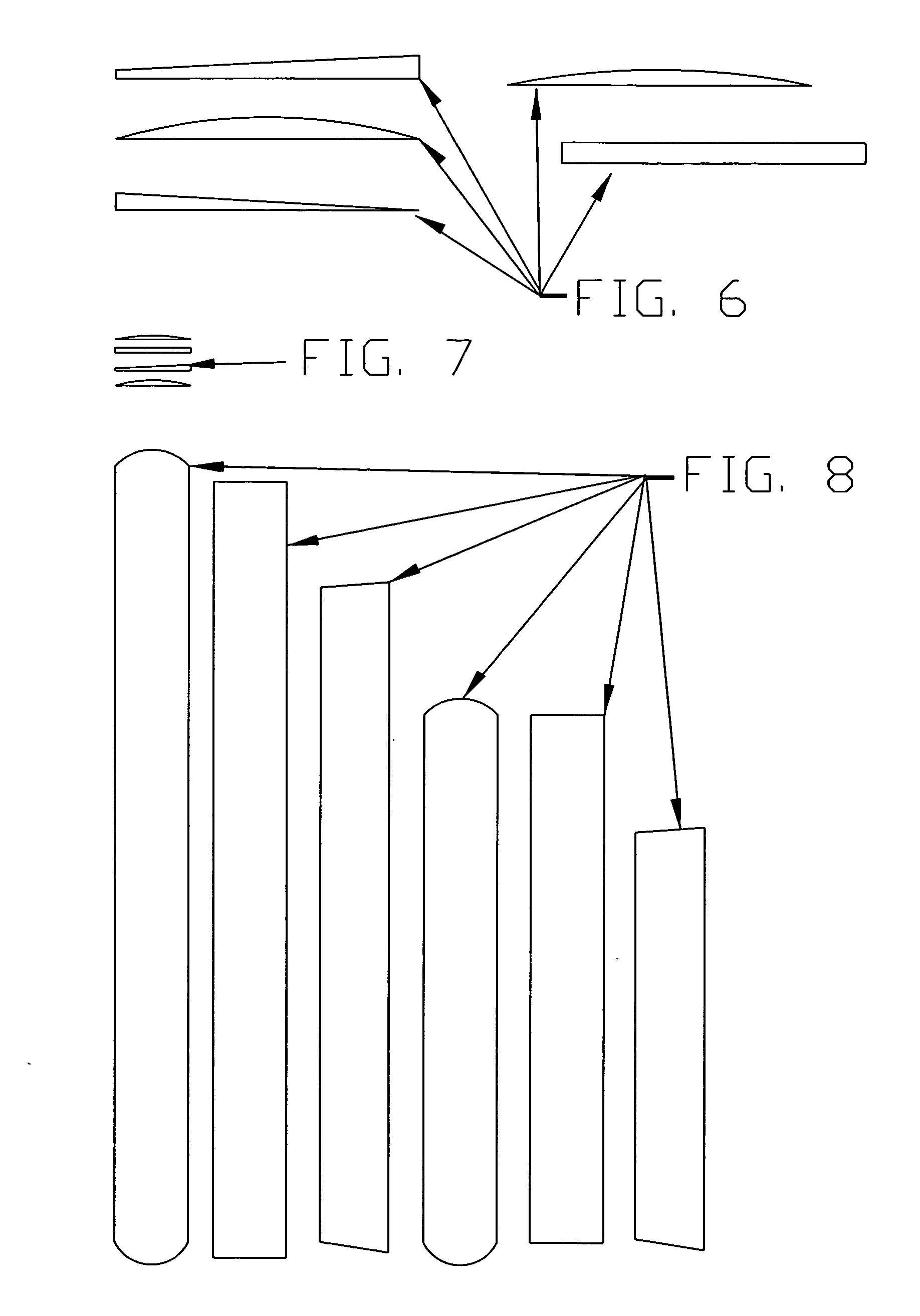

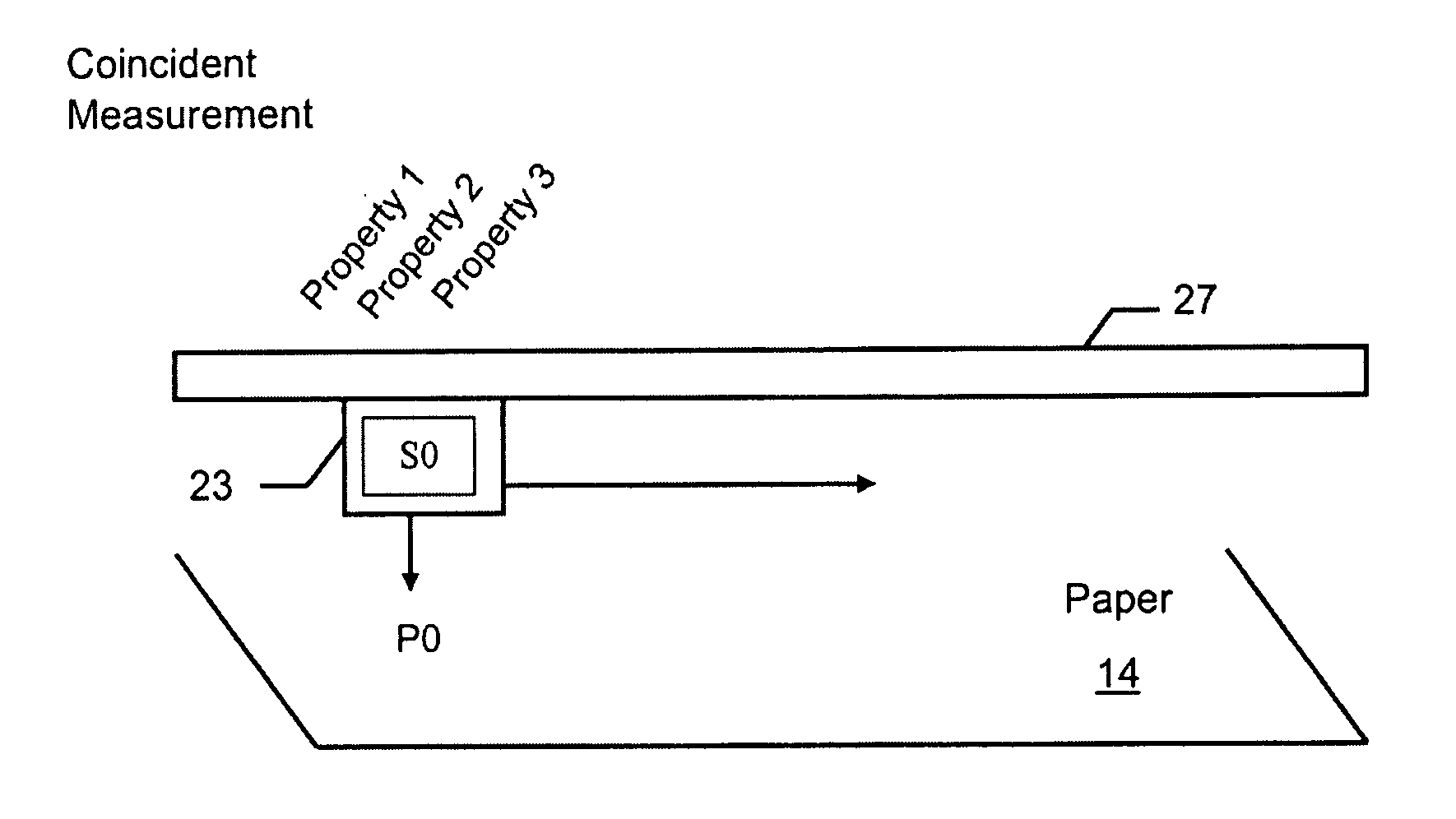

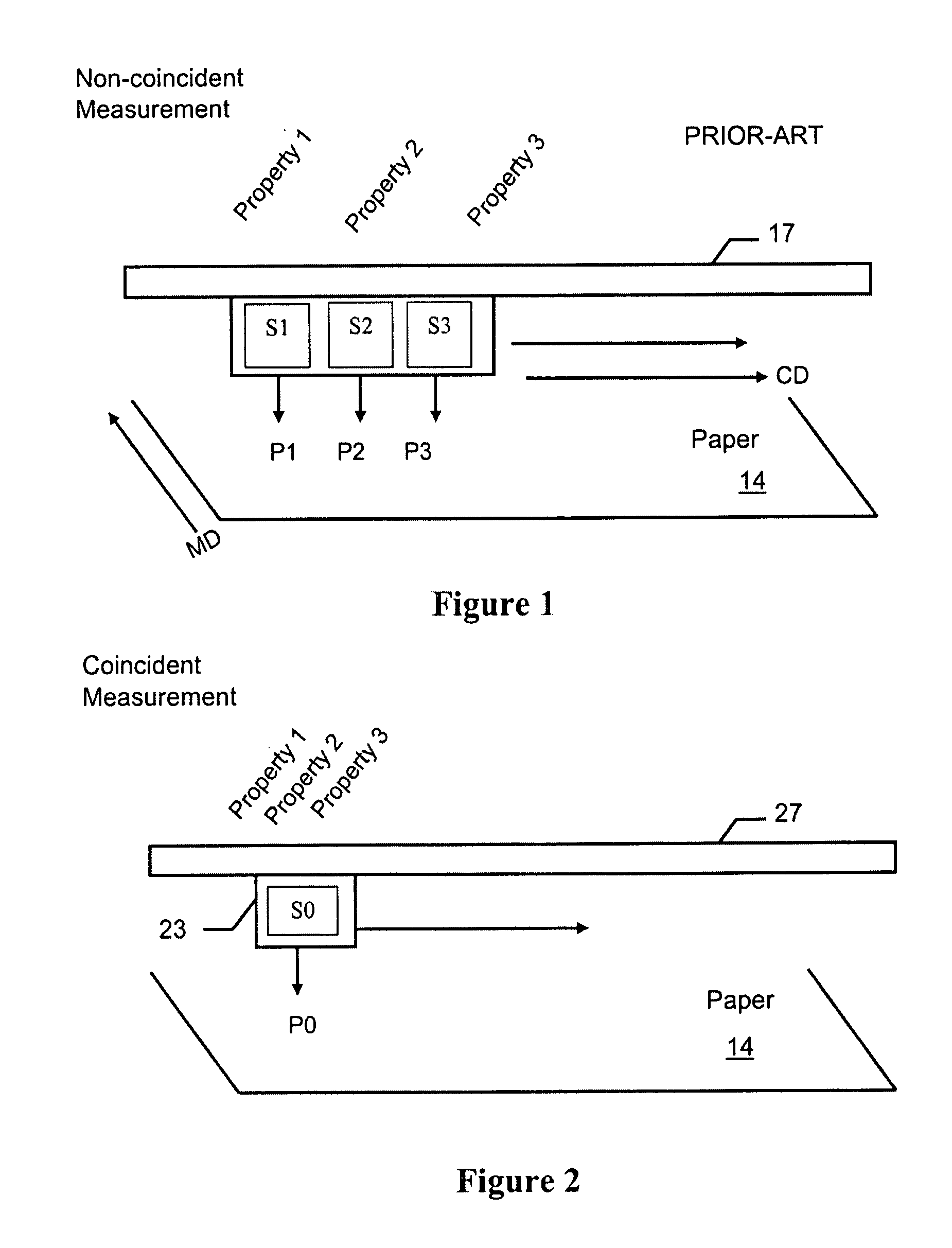

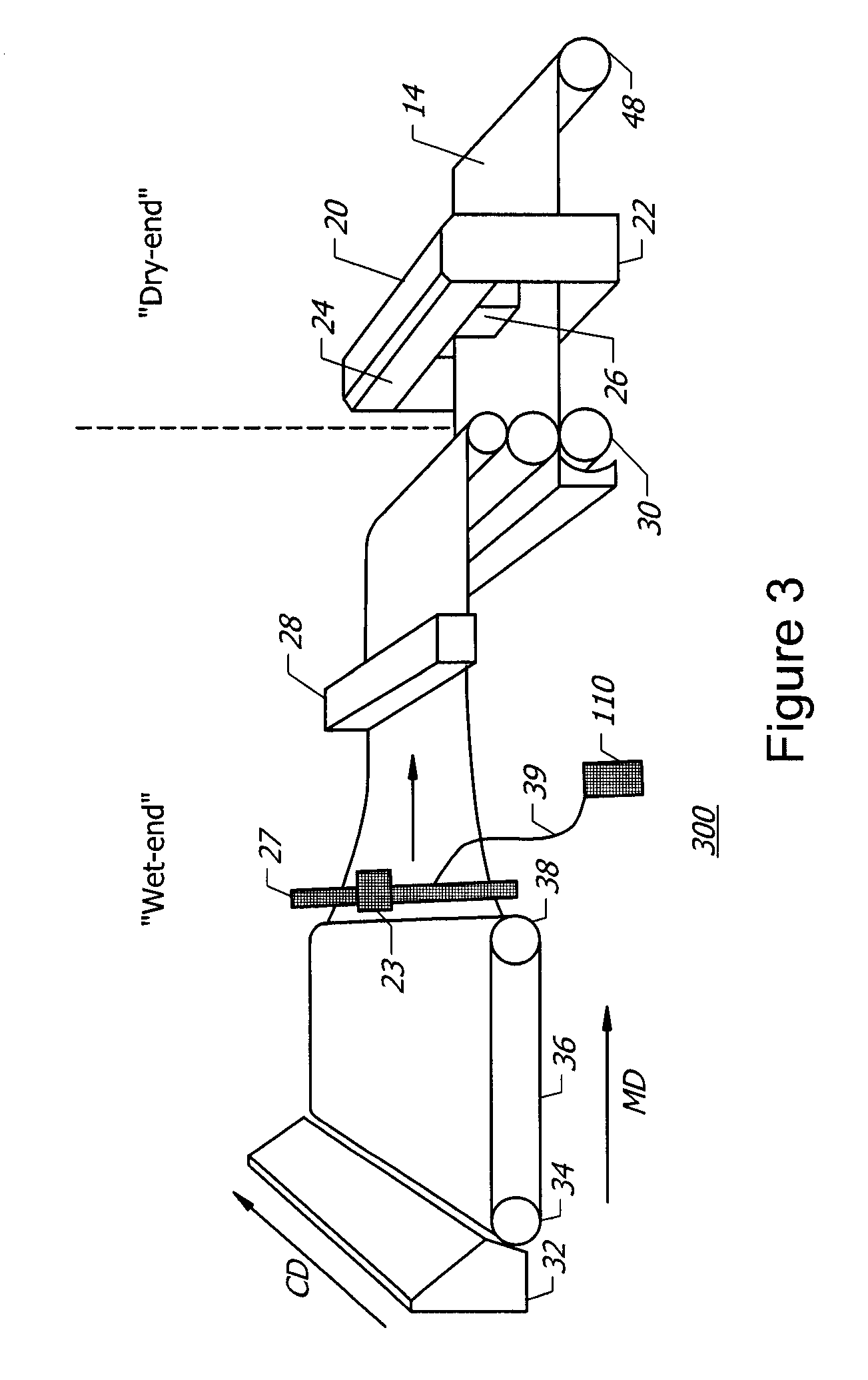

Material measurement system for obtaining coincident properties and related method

A material measurement system (500) includes a THz generator including at least one laser source (111) for emitting optical pulses, the optical pulses coupled to a THz emitter (51) operable for emitting pulsed THz radiation at a sample location on material while being processed (14) by a manufacturing system. A receiver (52) is operable to receive the optical pulses and to detect reflected or transmitted THz radiation from the sample location (14) synchronously with the optical pulses and provide electrical detection signals. Synchronizing optics (112, 113, 114) is operable to receive the optical pulses from said laser and provide the optical pulses to both the receiver (52) and the THz emitter (51). A controller (25) includes at least one processor (87) for receiving the electrical detection signals and providing a processed electrical detection signal, and an analyzer (88) operable to determine at least one, and generally a plurality of properties of the material from the processed electrical detection signal.

Owner:HONEYWELL ASCA INC

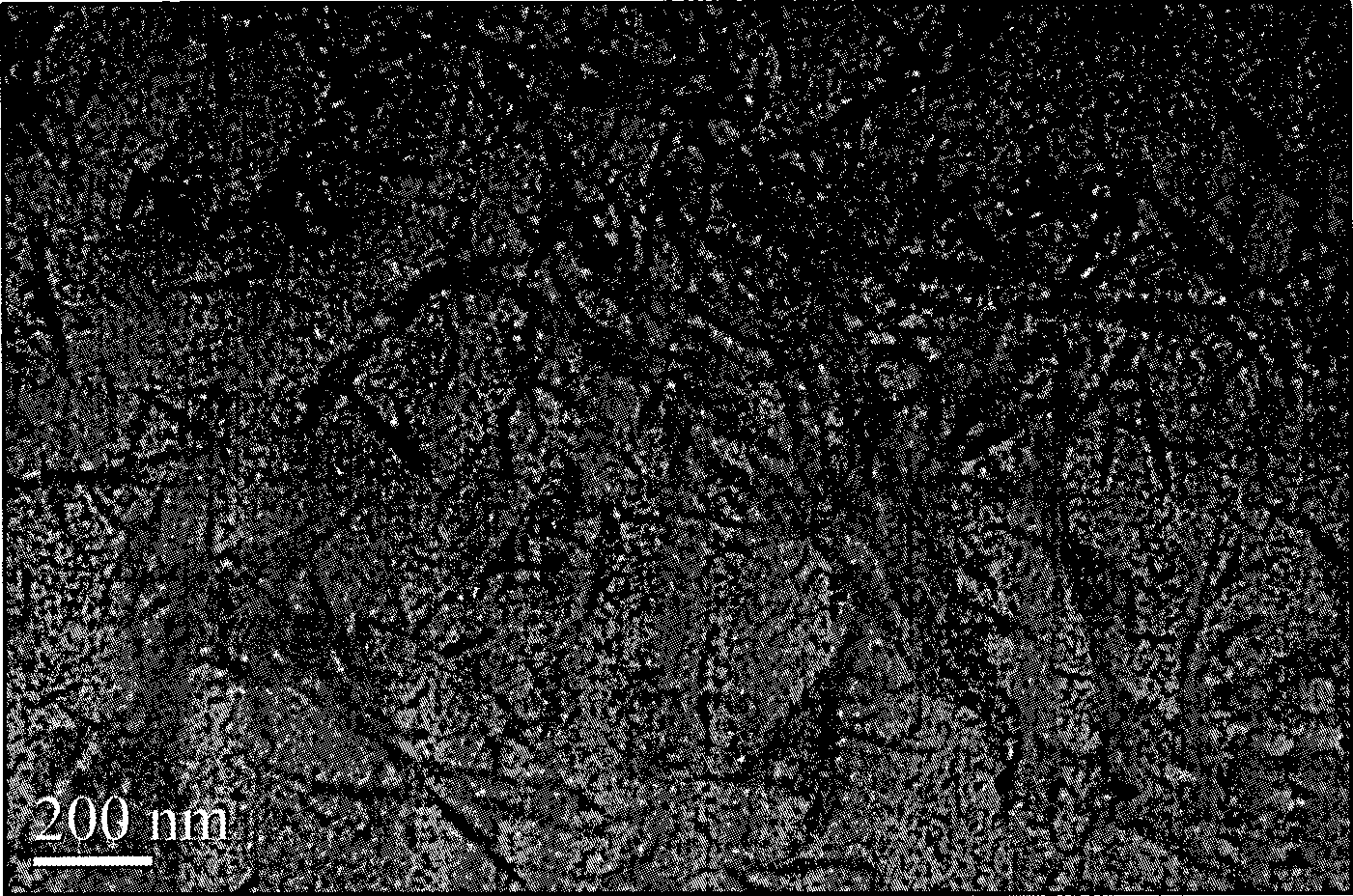

Method for preparing micro nano-crystalline cellulose with mechanical force chemical method

ActiveCN102433786AShort reaction timeReduce energy consumptionPaper material treatmentMicro nanoCellulose

The invention discloses a method for preparing micro nano-crystalline cellulose with a mechanical force chemical method. The micro nano-crystalline cellulose is obtained by mixing and grinding cellulose and a chemical aid. The method has the advantages of small using amount of chemical aid, easiness for operating and low energy consumption. Due to the adoption of the mechanical force chemical method for preparing the micro nano-crystalline cellulose, the synergistic effect of mechanical force, thermal force and chemical force generated in the process can be fully utilized by the cellulose under the multiple actions of mechanical force, thermal force and chemical force, a system is in the chemical active state, the reaction activation energy is reduced, and the occurrence and performance of a chemical reaction are catalyzed and excited. The aim of well preparing a large amount of micro nano-crystalline cellulose quickly in a saving way is fulfilled.

Owner:FUJIAN AGRI & FORESTRY UNIV

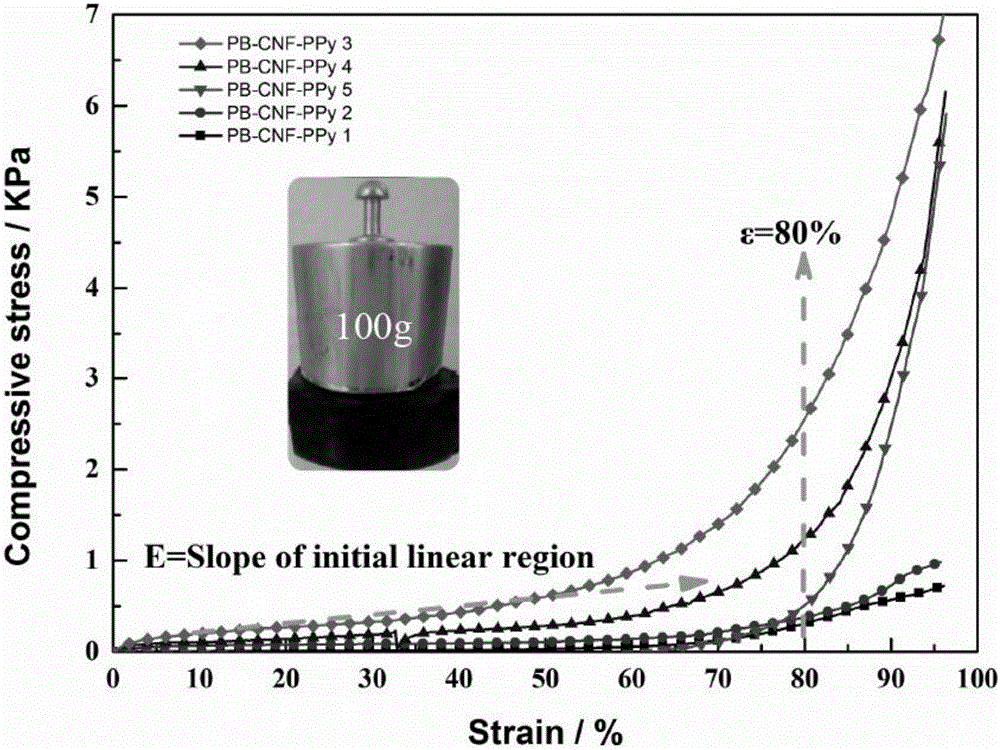

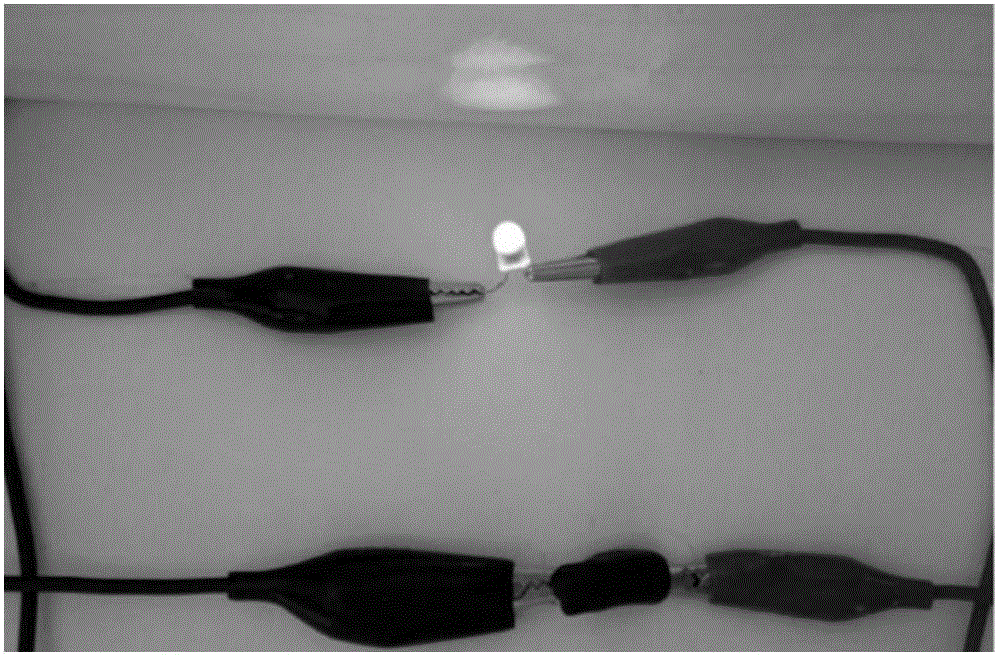

Nanocellulose-polypyrrole-polyvinyl alcohol composite conductive hydrogel as well as preparation method and application thereof

InactiveCN106496639ARich sourcesHigh mechanical strengthPaper material treatmentCross-linkSurface layer

The invention belongs to the field of polymer composite conductive materials, and discloses a nanocellulose-polypyrrole-polyvinyl alcohol composite conductive hydrogel as well as a preparation method and application thereof. The hydrogel is prepared by adopting the following method: a, preparing nanocellulose; b, polymerizing on the surface layer of the nanocellulose to obtain a nanocellulose-polypyrrole compound; c, adding a cross-linking agent and polyvinyl alcohol in a nanocellulose-polypyrrole compound solution, and stirring to form gel, thus obtaining a finished product. The hydrogel can be used for preparing a flexible conductive material, and has a better application prospect.

Owner:NANJING FORESTRY UNIV

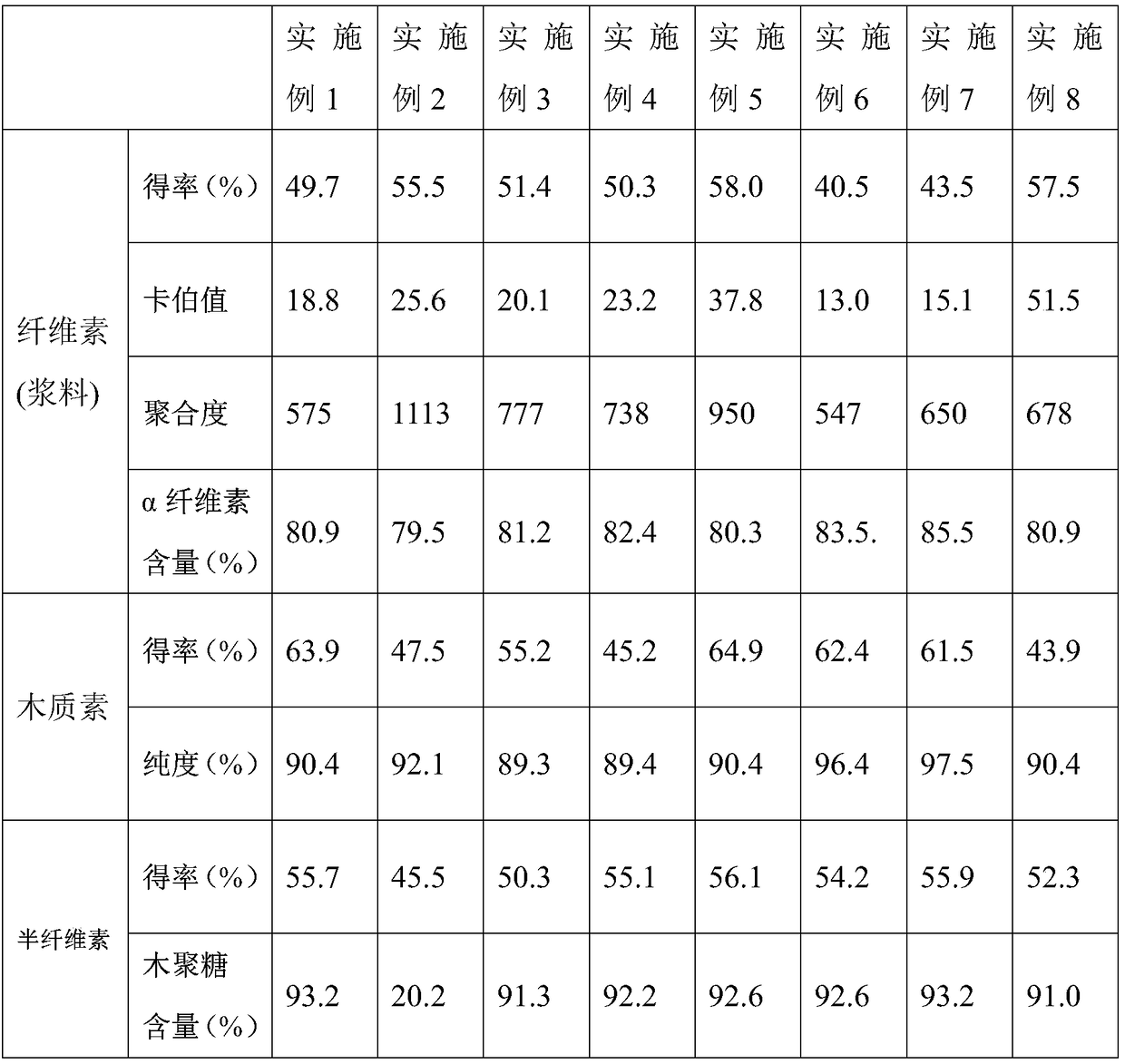

Method for separating three components of cellulose, hemicellulose and lignin in plant fiber raw materials

The invention discloses a method for separating three components of cellulose, hemicellulose and lignin in plant fiber raw materials. The method comprises the following steps of heating, steaming andboiling the plant fiber raw materials by a lactic acid / choline chloride low-eutectic solvent in a pressurizing or normal-pressure way, selectively dissolving out the lignin and hemicellulose, and washing the remaining insoluble matters, so as to obtain the cellulose; adding water into a dissolution solution of the low-eutectic solvent containing lignin and hemicellulose, the lignin is separated out, washing and separating, so as to obtain the lignin; separating the remaining water solution of low-eutectic solvent containing the hemicellulose in a nanofiltration way, so as to obtain the hemicellulose; concentrating and dewatering the water solution of the low-eutectic solvent, so as to recycle. The method has the advantages that the components of the plant fiber raw materials can be fully separated, so as to obtain the cellulose with content of alpha-cellulose greater than 79.5% and polymerizing degree of 1,113, the lignin with purity greater than 89%, and the hemicellulose with yield rate greater than 45%; the production energy consumption is low, the property of the obtained slurry is excellent, and the industrialized application prospect is realized.

Owner:NANJING FORESTRY UNIV

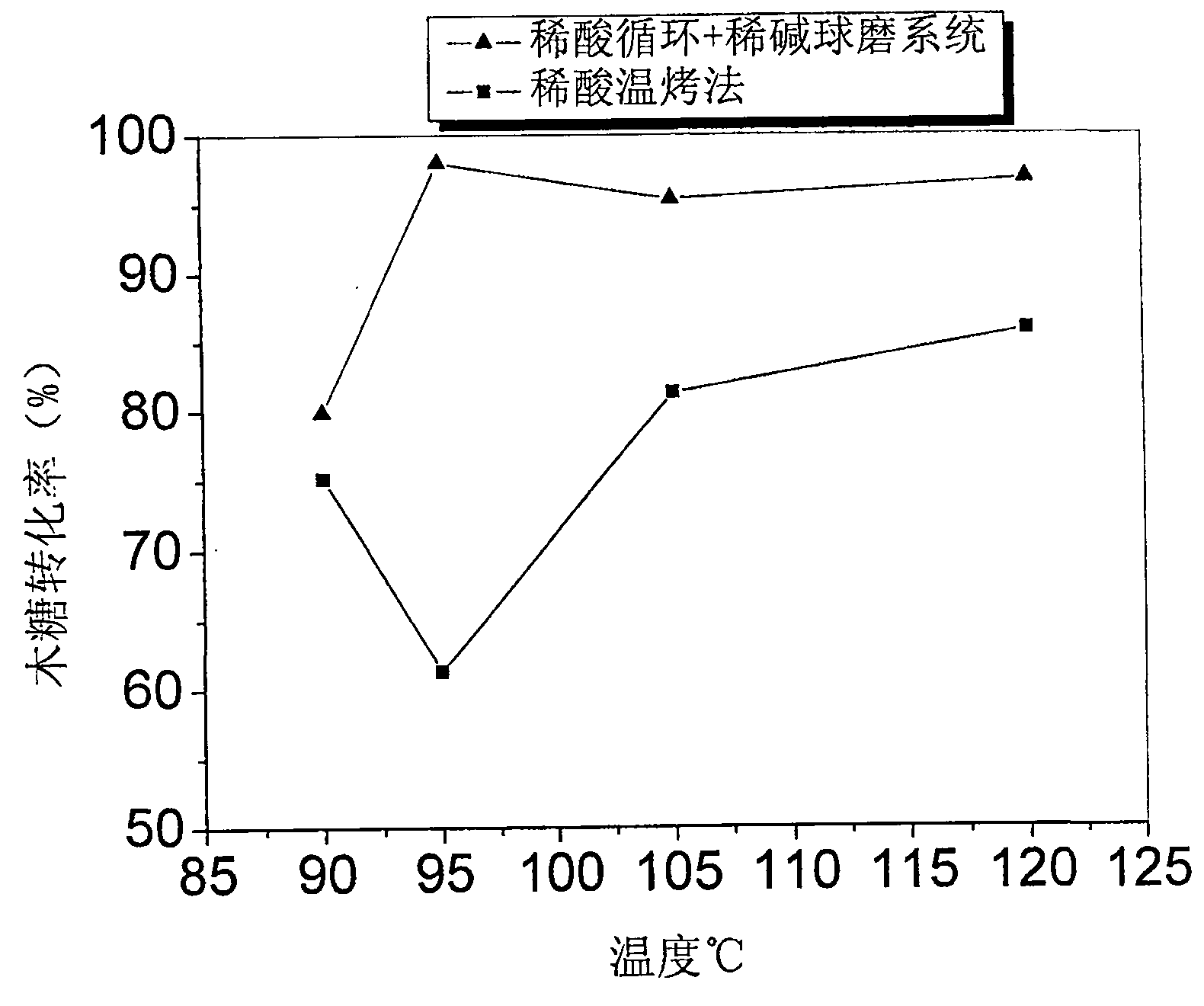

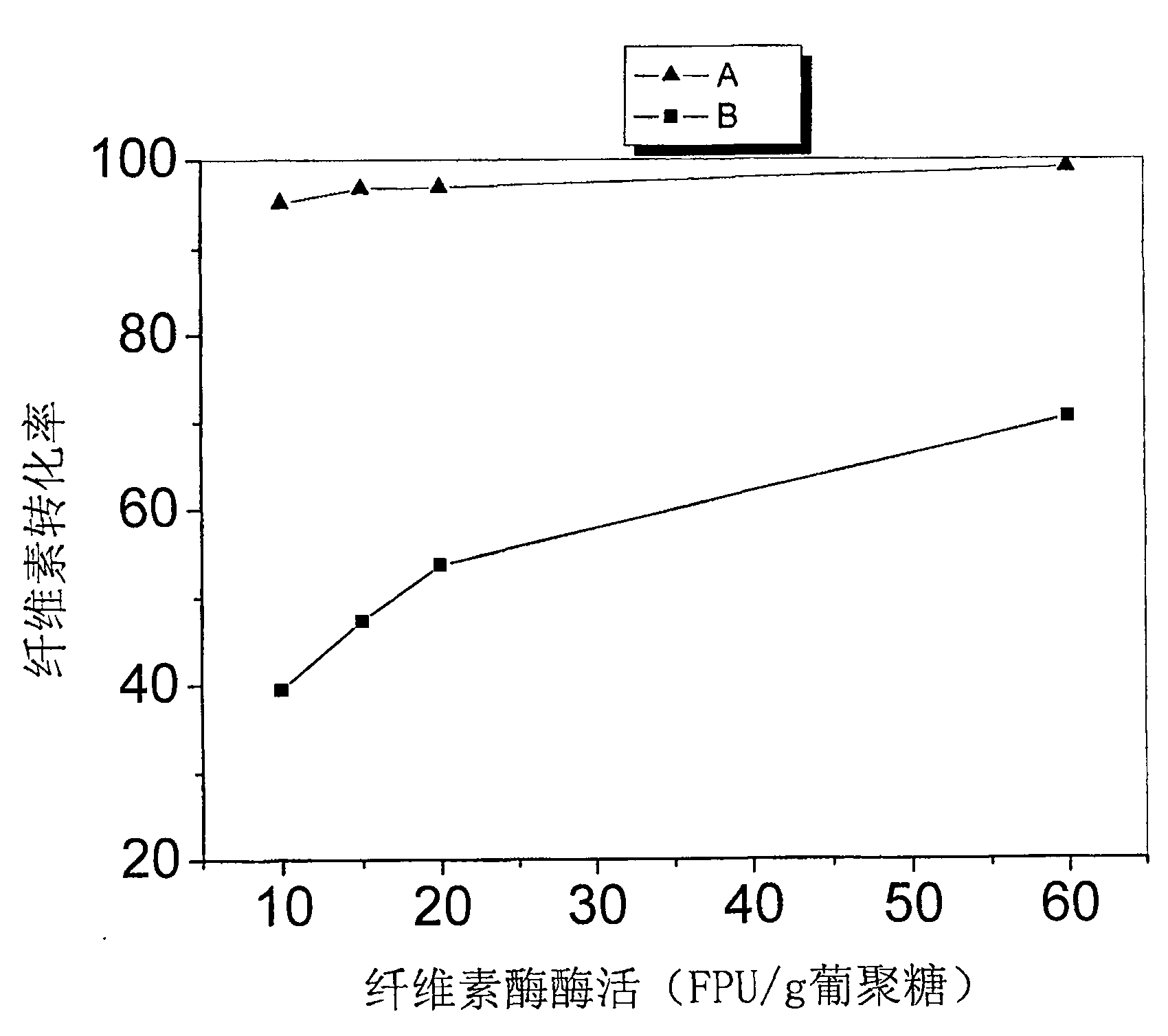

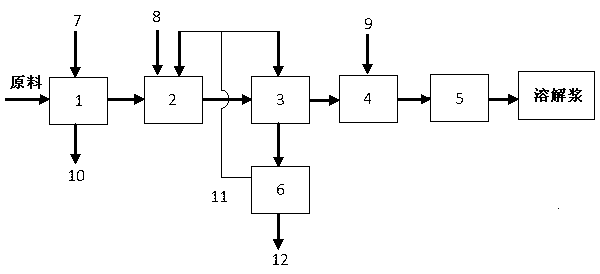

Combined pretreatment method of wood cellulose and system thereof

InactiveCN100564667CImprove conversion rateHigh removal ratePaper material treatmentPretreatment methodEnzymatic hydrolysis

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for high-efficiency hydrolyzing lignocellulose raw material in ionic liquid

ActiveCN101333777ALow costQuick responsePaper material treatmentBulk chemical productionFiberCellulose

The invention relates to a method for hydrolyzing lignocellulose materials, in particular to a method for efficiently hydrolyzing the lignocellulosic materials in ionic liquid; and the ionic liquid is taken as a solvent, greater than or equal to 1mol equivalent of water serves as a reactant, and an inorganic acid or an organic acid from catalytic amount to chemometry is taken as a catalyst, the lignocellulose materials such as crop straws, pine powder are reacted under ordinary pressure and at a temperature of not above 100 DEG C for 2 minutes to 34 hours; after the reaction is finished, a hydrolysate is obtained by quenching action with cold water and neutralization with alkali, generating immediately; and the quantitative chemical analysis is conducted to the total reducing sugar in the hydrolysate, indicating that the yield of the reducing sugar can reach 81 percent maximally and the hydrolysis efficiency can reach 58 percent. Compared with the traditional method of hydrolysis, the method has advantaged of non pretreatment process, low acid consumption, mild reaction condition, high hydrolytic activity, fast reaction speed, low corrosion resistance requirements for a reactor, high yield of reducing sugar, and easy tracking of extent of reaction. The method opens a new way for solving the problem of full utilization of lignocellulose existing for a long time.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

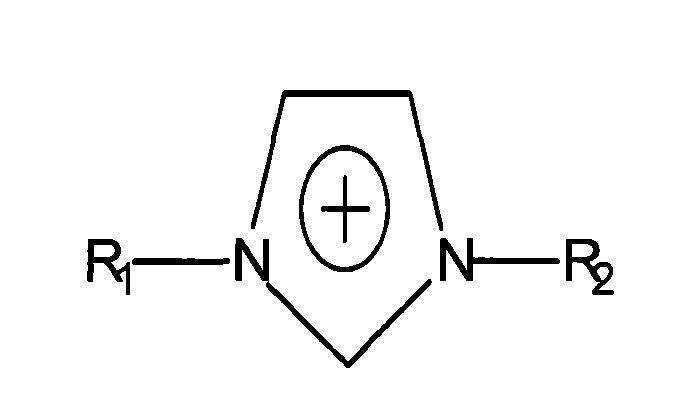

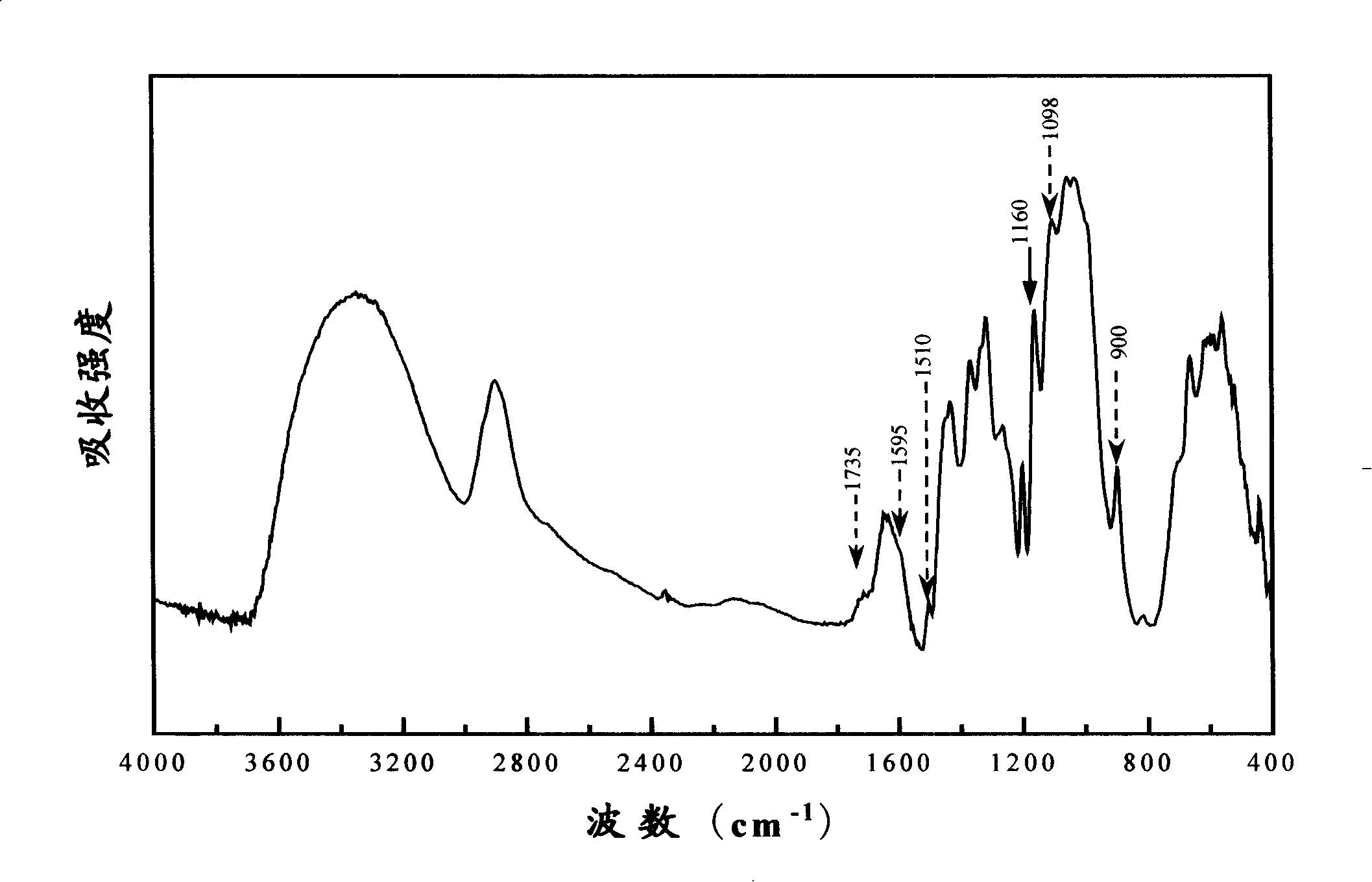

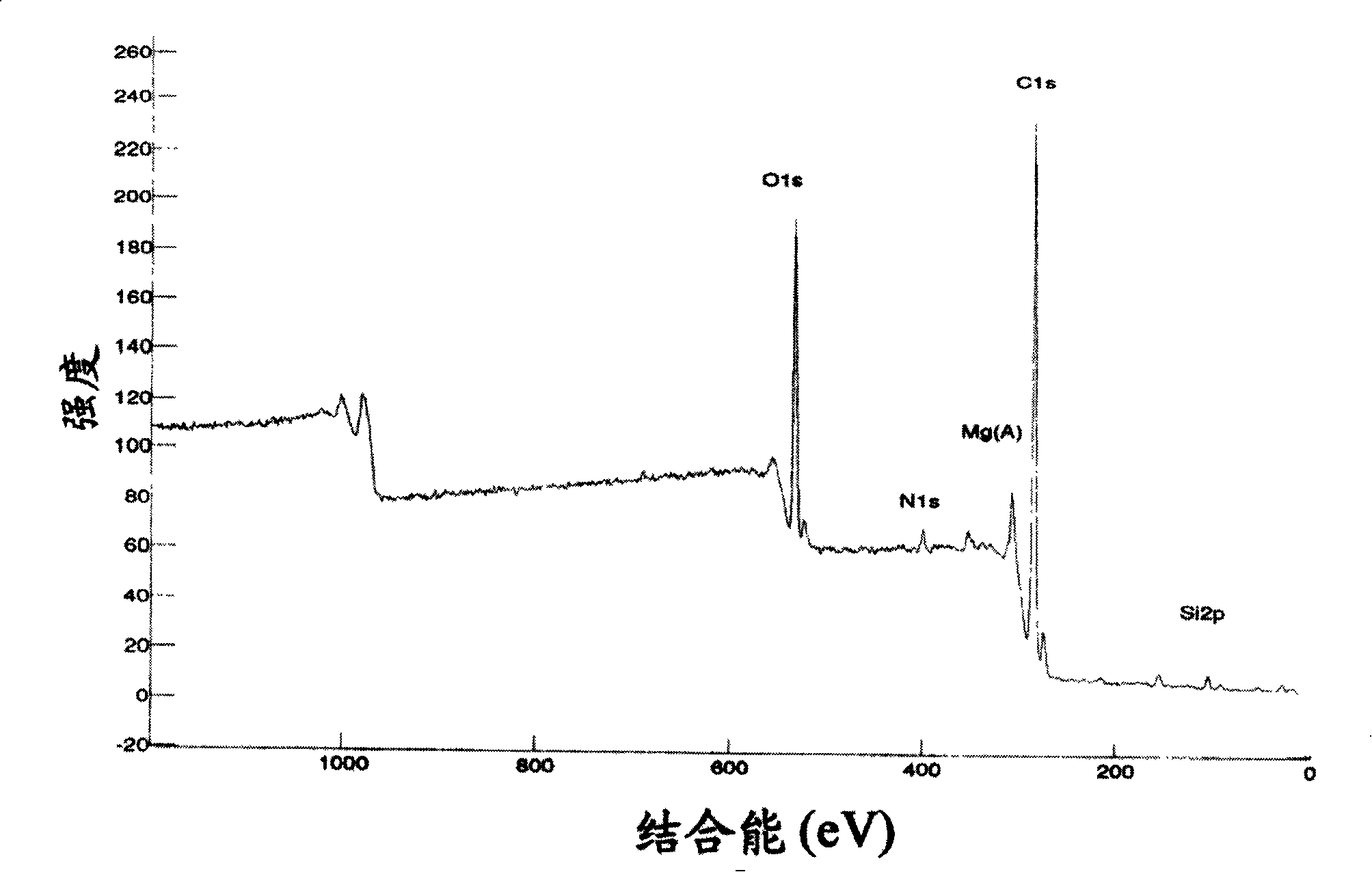

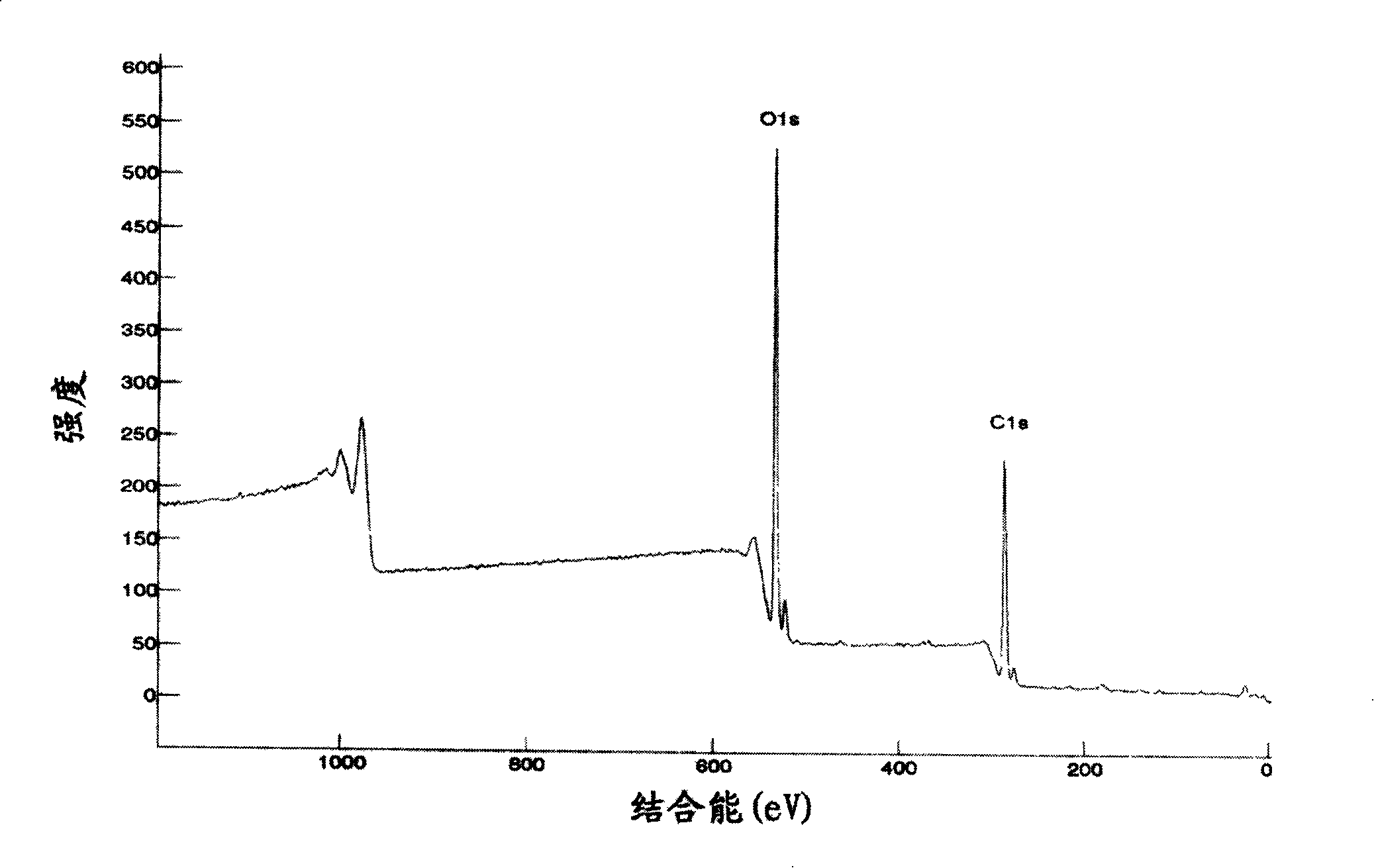

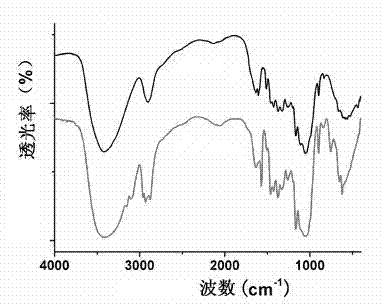

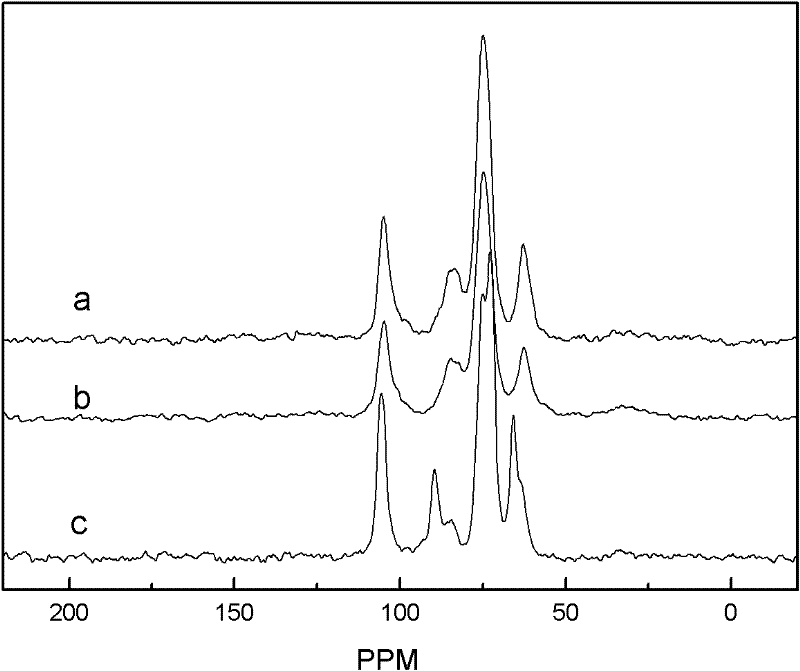

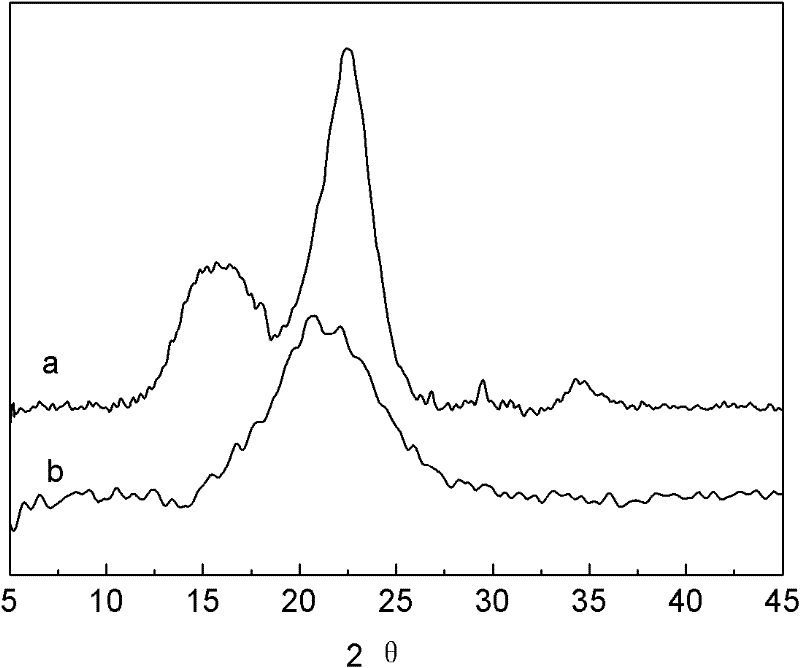

Method for separating lignin and cellulose from lignocellulose by using ionic liquid solvent

InactiveCN101580522AReduce stressImprove thermal stabilityLignin derivativesPaper material treatmentAlkaneSolvent

The invention relates to a method for separating lignin and cellulose from lignocellulose by using ionic liquid solvent, which comprises the following steps: adopting ionic liquid synthesized from an imidazole compound and halogenated alkane and water to form a liquid phase system which is added with wood flour, wood chips or vegetation plants to separate the lignin and the cellulose in a high-pressure autoclave at certain pressure and temperature, wherein the lignin is dissolved in ionic liquid water solution; filtering, separating, cleaning and drying the solid phase to obtain a cellulose product; and diluting, filtering, separating and drying the liquid phase to obtain a lignin product, wherein the ionic liquid can be recycled. The method achieves the separation of the lignin and the cellulose, the prepared cellulose product can be used as a raw material for papermaking directly and also can be used for preparing cellulose derivatives applied to the fields of daily use chemicals, medicaments, biology and the like; and the lignin can be used for preparing lignin modified products. The method does not volatile organic solvents and causes no environmental pollution, the used solvent can be recycled, and the production cost is low, thus the method has strong industrial application prospect.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Method for extracting cellulose from straw

The invention relates to a method for abstracting cellulose from non-woody plants fiber raw materials such as straws and the like and in particular relates to a method for removing silicon and lignin to abstract the cellulose from the straws. The invention can simultaneously remove the silicon, the lignin and the like from the straws and can obtain the cellulose through processing organic solvent, inorganic alkaline solution, oxidizing solution and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

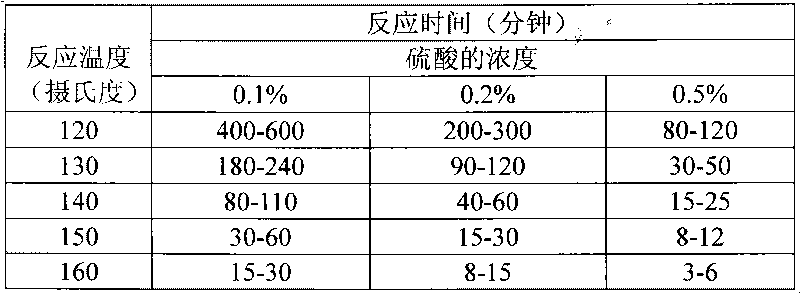

Process for efficiently preprocessing lignocellulose

InactiveCN101736631ALess side effectsReduce usageFermentationPaper material treatmentDecompositionReaction temperature

The invention relates to a process for efficiently preprocessing lignocellulose. The process adopts the following procedures of stepwise optimizing and hydrolyzing: firstly, boiling the lignocellulose in overheated water to ensure that most hemicellulose is dissolved into oligosaccharide; continuously reacting the boiled mixture in a special flash evaporation reactor; and gradually changing reaction temperatures in the process of reaction to slow down xylose decomposition as far as possible and ensure that the hemicellulose is more completely transformed into xylose. The process has the advantages of simpleness, low cost, reasonable energy utilization, no solid-liquid separation in stepwise process, direct hydrolysis on the hot mixture, energy saving and high hydrolysis efficiency of processed cellulose on enzyme.

Owner:熊鹏

Method for producing high whiteness cotton pulp by using cotton linter

InactiveCN101105012AReduce pollutionReduce dosagePaper material treatmentMaterials preparationMaterial consumption

The invention discloses a simple method for producing high-whiteness cotton pulp from cotton linters as raw materials. The method comprises the steps of material preparation, prehydrolysis, boiling, loosening, desanding, concentration, chloridization, alkali purification, bleaching, acid treatment, desanding, concentration, paper making, and oven-drying. A mixture of NaOH and green oxygen is used in the boiling step. The invention has the advantages of simple and controllable process, low processing load posterior to the boiling step, reduced material consumption, less waste discharge, and low environmental pollution. The produced cotton pulp has high pulping fiber strength, yield and whiteness.

Owner:CHTC HELON

Production method of dissolving pulp

The invention relates to a production method of dissolving pulp. The method comprises the steps of pre-hydrolyzing plant fibrous raw materials by water, steam or diluted acid, then digesting the materials by peroxy acid, and processing the materials by hemicellulase, thus obtaining the dissolving pulp. The dissolving pulp produced by the method has the whiteness more than 90% ISO (International Standards Organization), and the content of Alpha-cellulose is more than 92%, and the content of pentosan is less than 2.0%. The method is applicable to wood and non-wood fibrous raw materials.

Owner:济南绿泉新材料科技有限公司

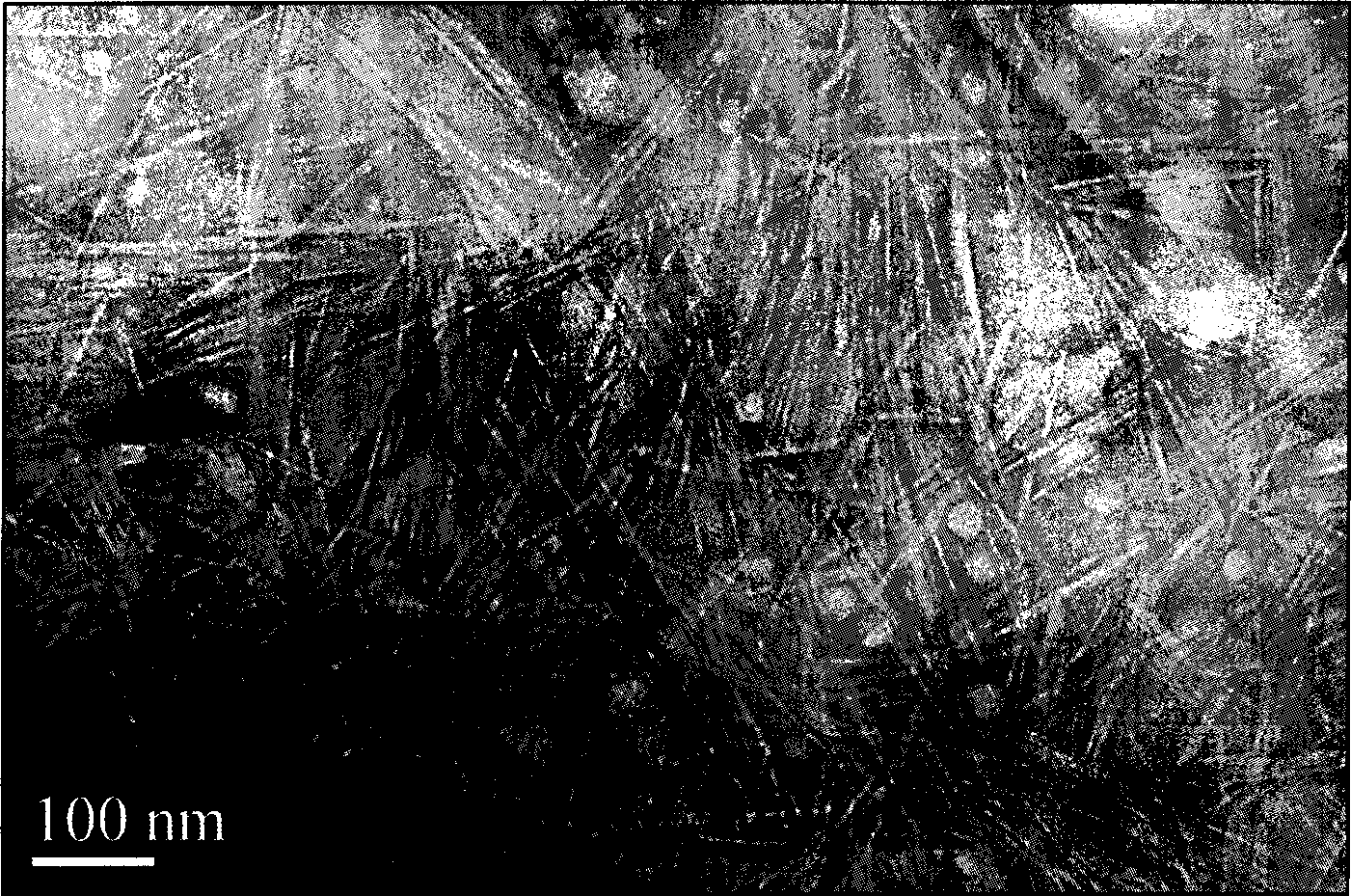

Method for preparing nanocellulose by using homogeneous method

ActiveCN102505546AClean thoroughlyIncrease production capacityPaper material treatmentMicrowaveWood fibre

The invention discloses a method for preparing nanocellulose by using a homogeneous method, relating to a method for preparing modified cellulose, i.e., the nanocellulose. The method comprises the following steps of: adding ionic liquid into crushed wood fibers to ensure that the mass percentage of the cellulose is 1-15%; carrying out microwave heating, and meanwhile, continuously stirring for 1-5h; then, carrying out high-pressure homogenization treatment; regenerating the obtained solution and drying to obtain the nanocellulose. The wood fibres being used as the raw materials in the method and belonging to a regenerative resource of waste crops are prepared into the nanocellulose, and the nanocellulose can be widely applied to the aspects such as medicines, fine chemistry and preparation of novel materials, and a new method can be provided for the efficient utilization of the regenerative resource.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Tobacco extraction method based on steam explosion

InactiveCN102391390AHigh yieldGood colorTobacco treatmentPaper material treatmentBiotechnologyPectinase

The invention relates to a chemical extraction technology, and especially relates to a method for extracting pectin from tobacco. The method comprises specific steps that: tobacco is crushed, such that tobacco powder is obtained; the tobacco powder is soaked by using water for at least 8 hours, and is processed through steam explosion for at least 60 seconds under a pressure of 0.04 to 0.3Mpa, such that a tobacco extract is obtained; an acid is added to the tobacco extract, and a pH value of the solution is regulated to 1.0 to 3.0; the solution is completely hydrolyzed under a temperature of 70 to 90 DEG C; residues are removed, such that a hydrolysate is obtained; the hydrolysate obtained in the step A is precipitated by using a ethanol precipitation method, and the obtained precipitate is pectin. Compared to a traditional method wherein a tobacco material is boiled by using boiled water, and wherein pectinase is passivated, the tobacco extract preparation method provided by the invention is advantaged in low pollution, low energy consumption, and complete pectinase passivation. With themethod provided by the invention, 1 hour can be saved, and the yield of pectin can reach approximately 12.2%, which is increased by 3.2% comparing to that of a traditional ethanol extraction method. Meanwhile, the color of the obtained pectin is good.

Owner:CHONGQING HENGYUAN JINTONG TECH

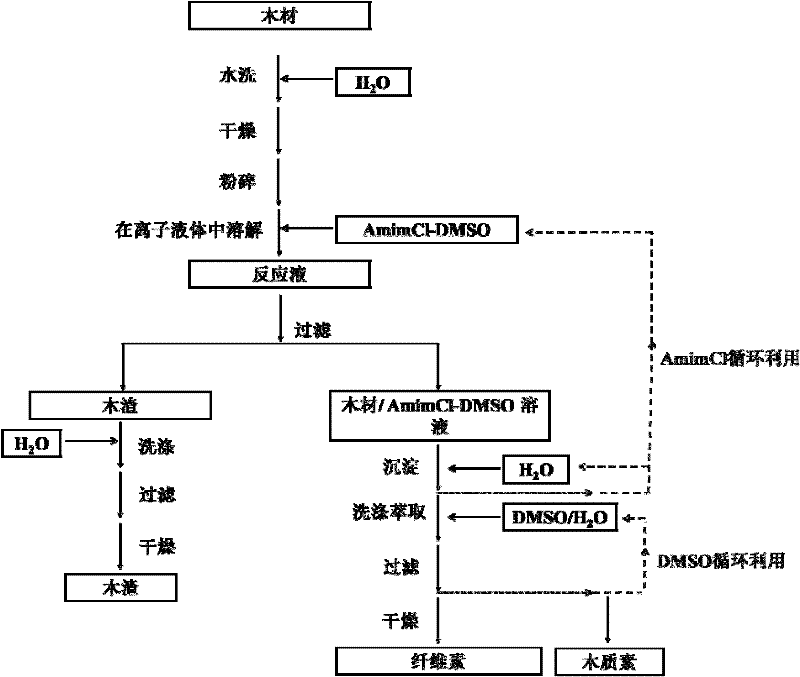

Method for separating cellulose and lignin from plant fiber raw material by utilizing ion liquid

InactiveCN102677510ARealize resource utilizationNo pollution in the processPaper material treatmentIonSolvent

The invention relates to the field of treatment of plant fibers and particularly relates to a method for separating cellulose and lignin from a plant fiber raw material by utilizing ion liquid. According to the invention, the method comprises the following steps of: 1) mixing DMSO (Dimethylsulfoxide) and the ion liquid according to a mass ratio of 1: 4-9 to be used as a solvent, and adding the plant fiber raw material; 2) dissolving at 80 to 140 DEG C for 4-48 hours to obtain a reaction mixed liquid; 3) filtering and separating the reaction mixed liquid by a stainless steel filter screen or a nylon filter cloth, adding water into the obtained filtrate, and depositing a mixed extract of the cellulose and the lignin; 4) washing and extracting a mixed extract of the cellulose and the lignin by a water / DMSO mixed solvent, and filtering to obtain mixed liquid of a cellulose solid and lignin / DMSO / water; 5) drying the cellulose solid to obtain a cellulose product; and 6) decompressing and distilling the mixed liquid of the cellulose / DMSO / water to obtain a cellulose product. The method, provided by the invention, is simple, feasible and high in purity of the obtained cellulose.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

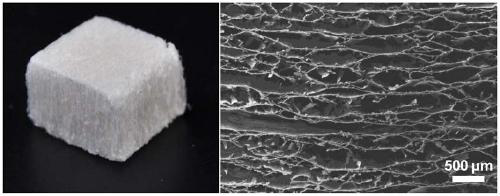

Anisotropic wood-based nanofiber aerogel and preparation method thereof

The invention discloses an anisotropic wood-based nanofiber aerogel. The aerogel is obtained by the following steps: light wood with a density of 80-150 mg / cm<3> is adopted, delignification treatmentis performed, dehemicellulose treatment is performed to prepare a wood-based nanofiber hydrogel, water in the hydrogel is replaced to obtain a nanofiber alcohol sol, freeze drying is performed, and therefore the aerogel is obtained. The invention also discloses the specific preparation method. According to the method provided by the invention, the wood-based nanofiber aerogel prepared by the method has a low density, high porosity, good compression performance and elasticity, is a green environmentally-friendly aerogel material, has low preparation costs, can be produced in a large scale, andhas board application prospects in the fields of thermal insulation, noise insulation, adsorption catalysis, biomedicine, energy storage and the like.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

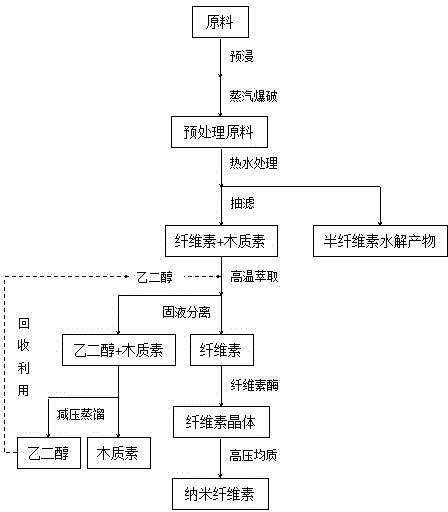

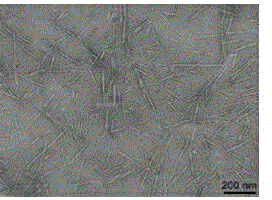

Preparation method of cellulose nanofiber

InactiveCN104651964ALarge specific surface areaHigh activityMonocomponent cellulose artificial filamentFermentationFiberHydrolysate

The invention relates to a preparation method of a cellulose nanofiber. The method comprises the following steps: with wood fiber biomass as a raw material, presoaking, and carrying out steam explosion pretreatment; carrying out high-temperature hydro-thermal treatment on pretreated materials; hydrolyzing hemicellulose, and carrying out washing suction filtration to obtain hemicellulose hydrolysate and filter residues rich in lignin; putting the filter residues into a high-pressure reaction kettle, adding an ethylene glycol solution, heating and extracting the lignin from the residues with ethylene glycol; extracting and carrying out solid-liquid separation to obtain a lignin extract liquid and cellulose solid; carrying out enzymolysis on the cellulose solid with cellulase and removing an amorphous region of the cellulose to obtain cellulose crystal; and carrying out high-pressure homogenizing on the cellulose crystal to obtain a cellulose nanofiber product. The cellulose nanofiber prepared by the method has the advantages of nanoscale, large specific surface area, high activity and high security.

Owner:NANTONG LIANHAIWEIJING BIOLOGY

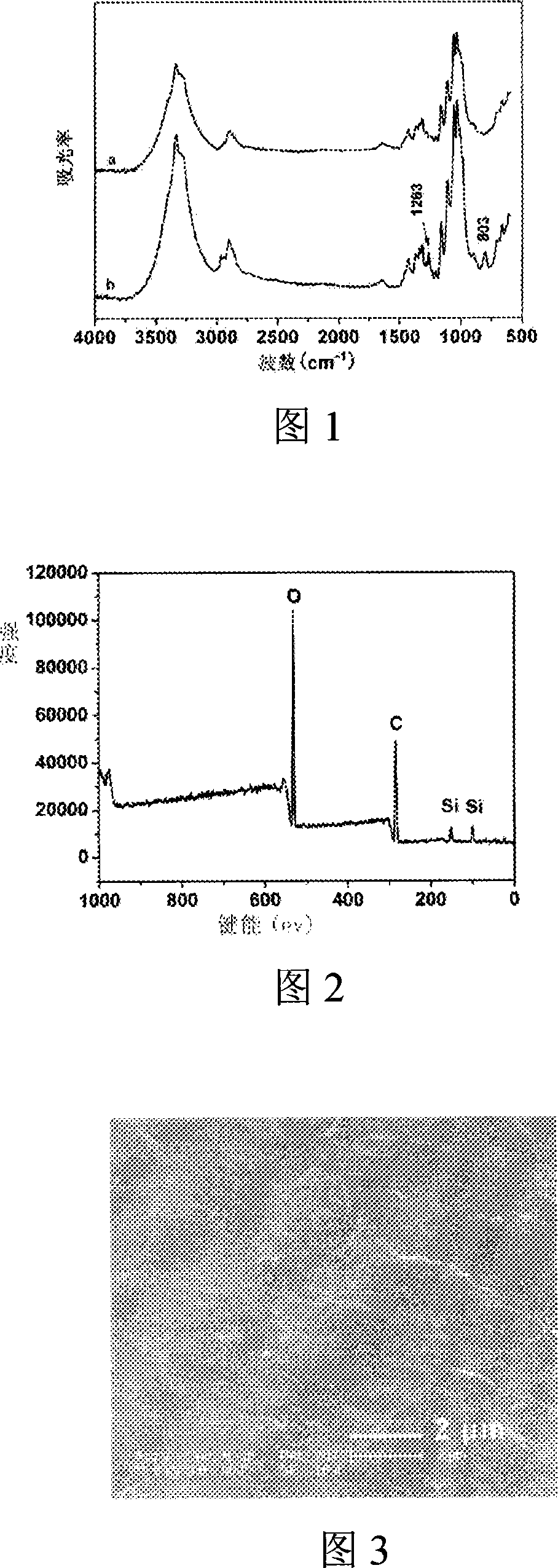

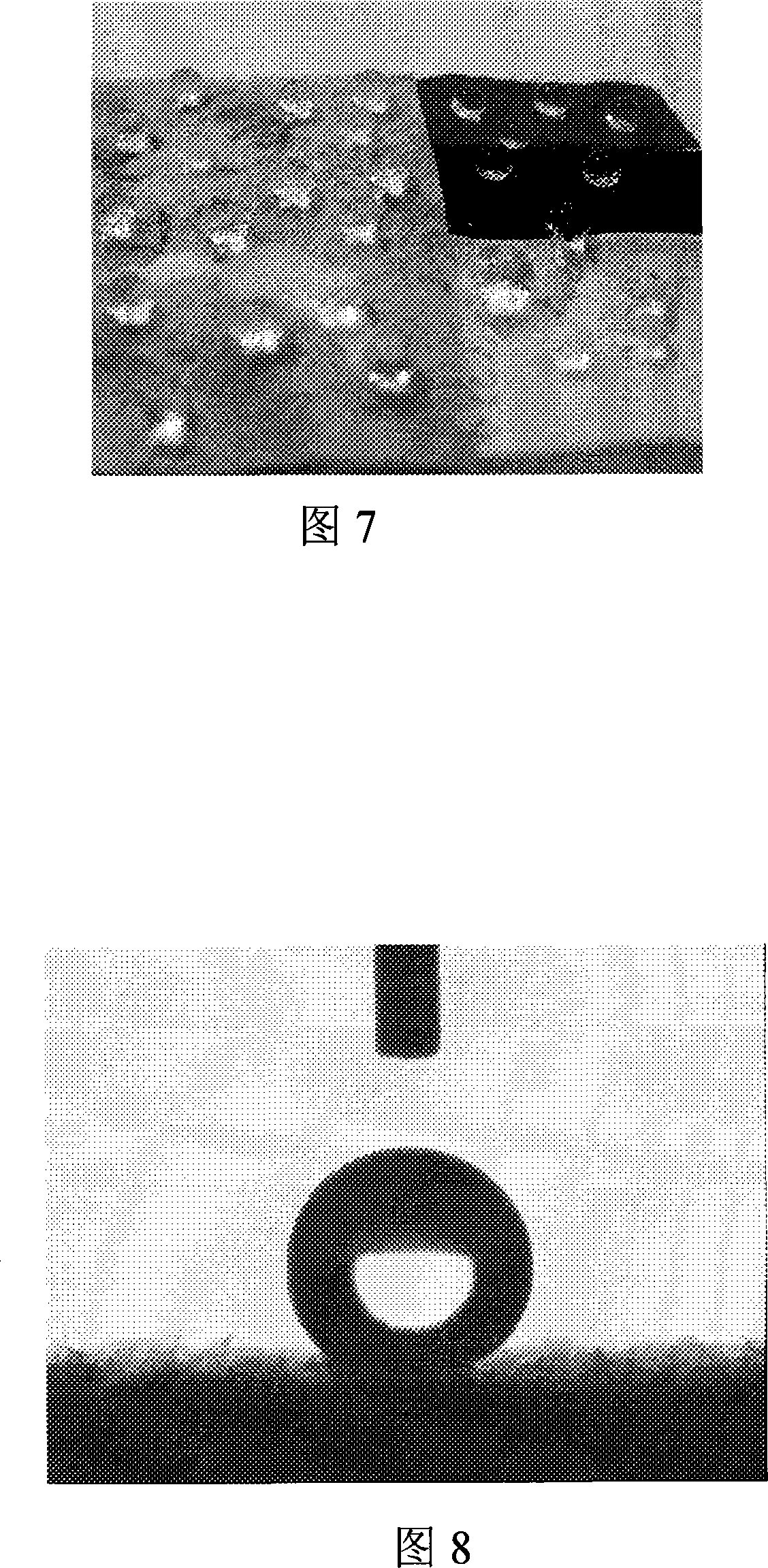

Preparation method and use for ultra-hydrophobic cotton fibrous material or ultra-hydrophobic paper fibrous material

The invention relates to super hydrophobic cotton or paper fiber material manufacturing method and their use. It is processed surface modification for the cellulose by silicon material which can be methane sodium silicate, methane potassium silicate, or chlorosilane. Thus the processed cellulose has good super hydrophobic property and air permeability, can be used in garment material, package, health aids fields etc.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com