Patents

Literature

99results about How to "Strong stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

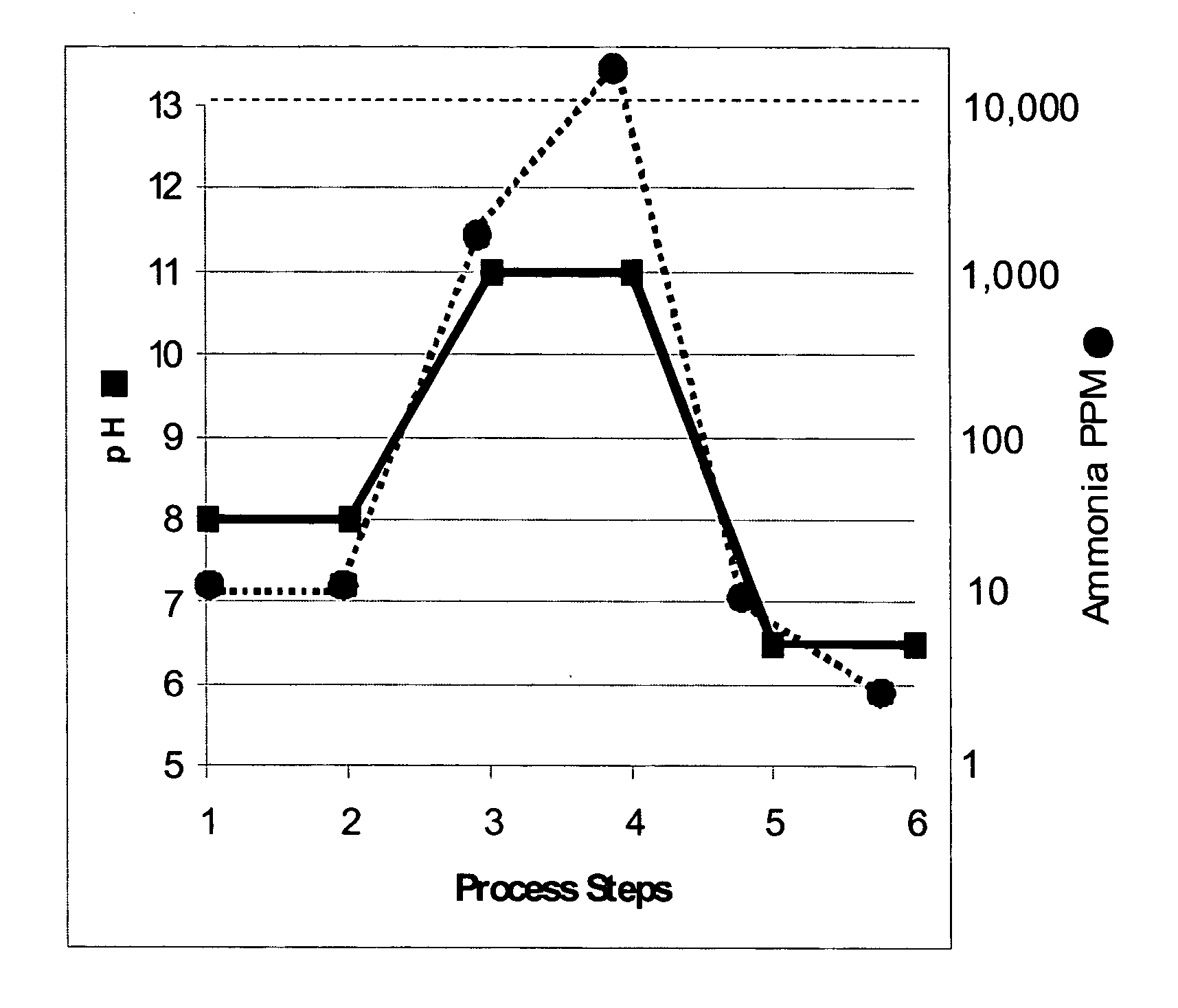

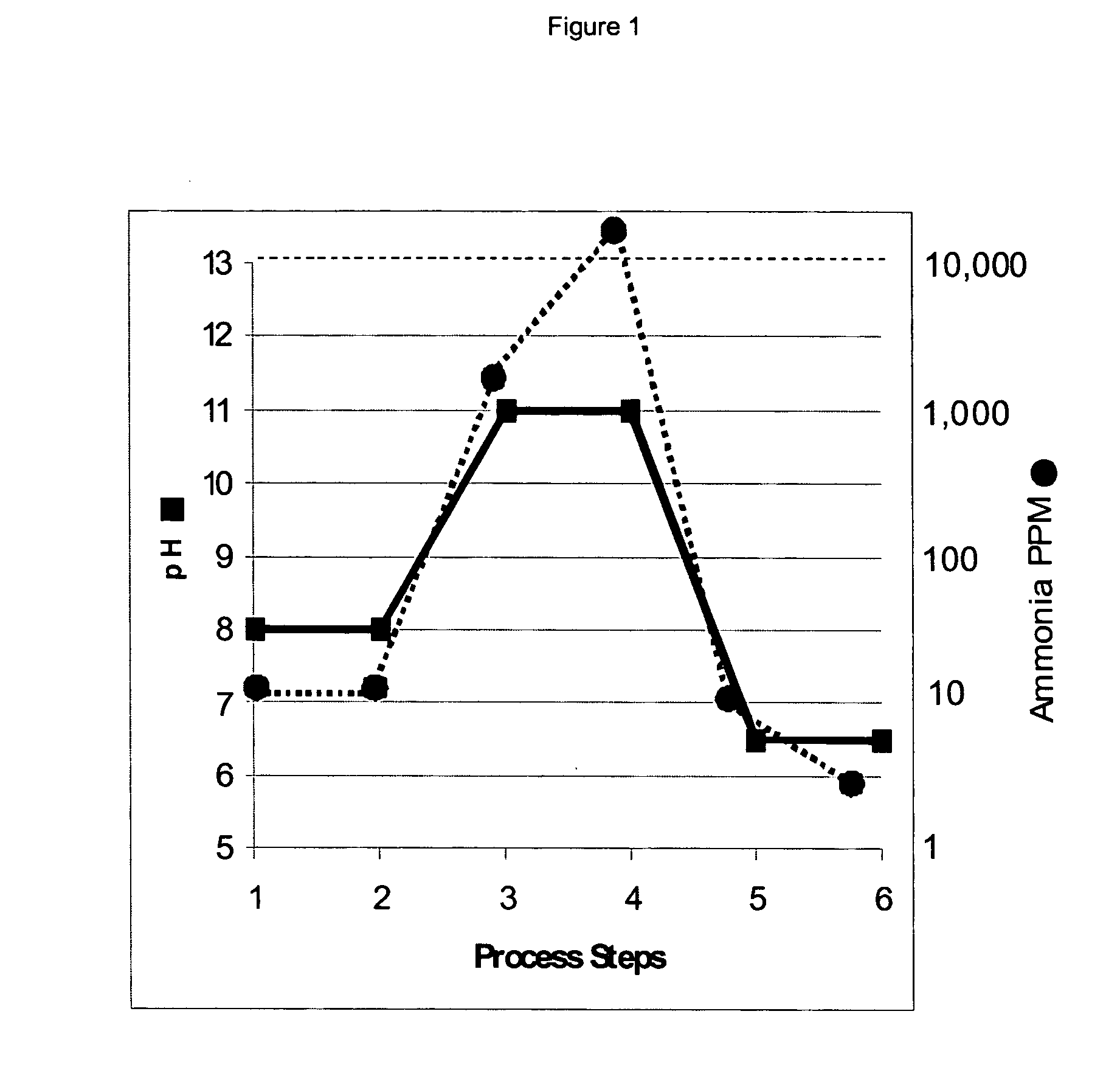

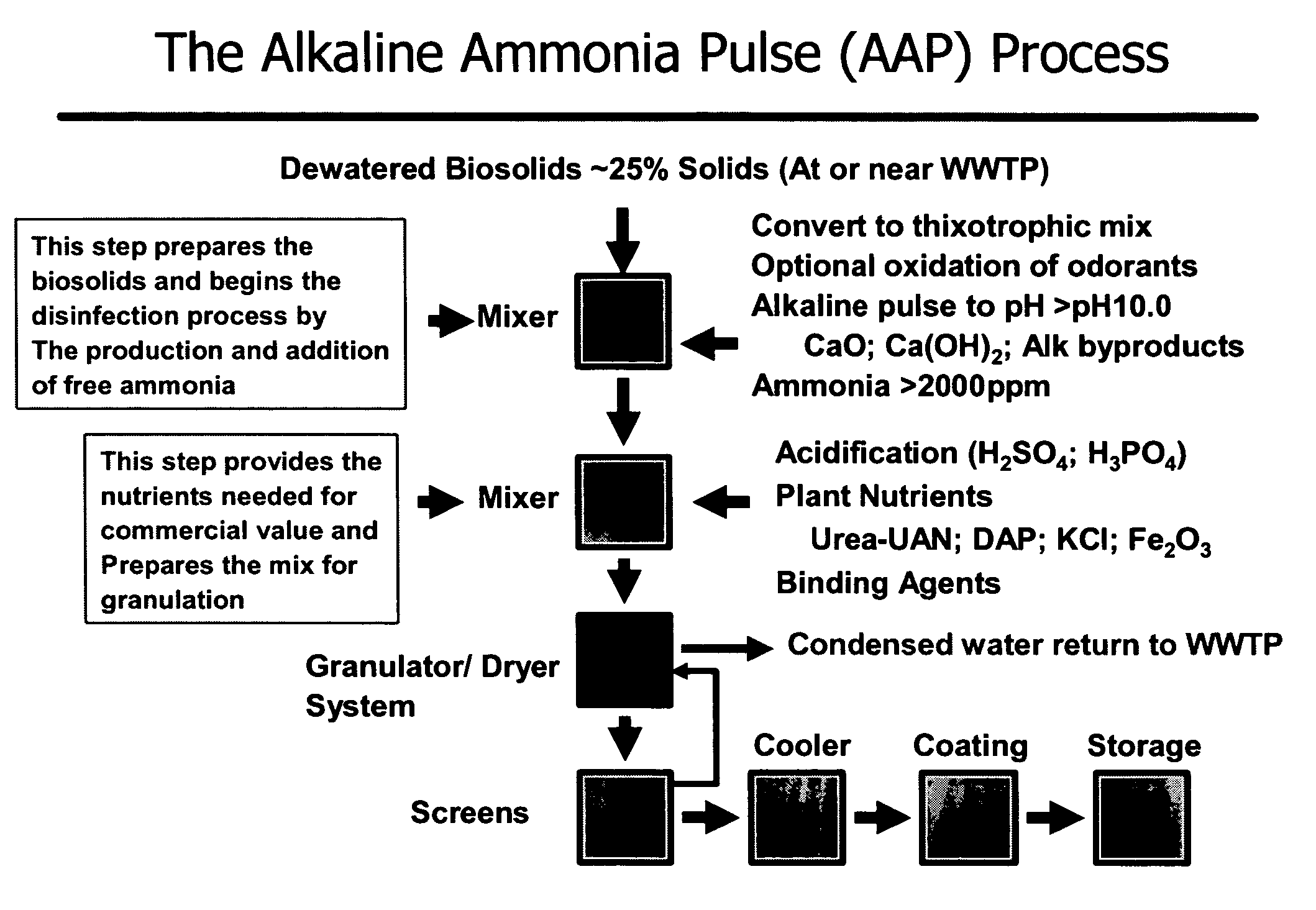

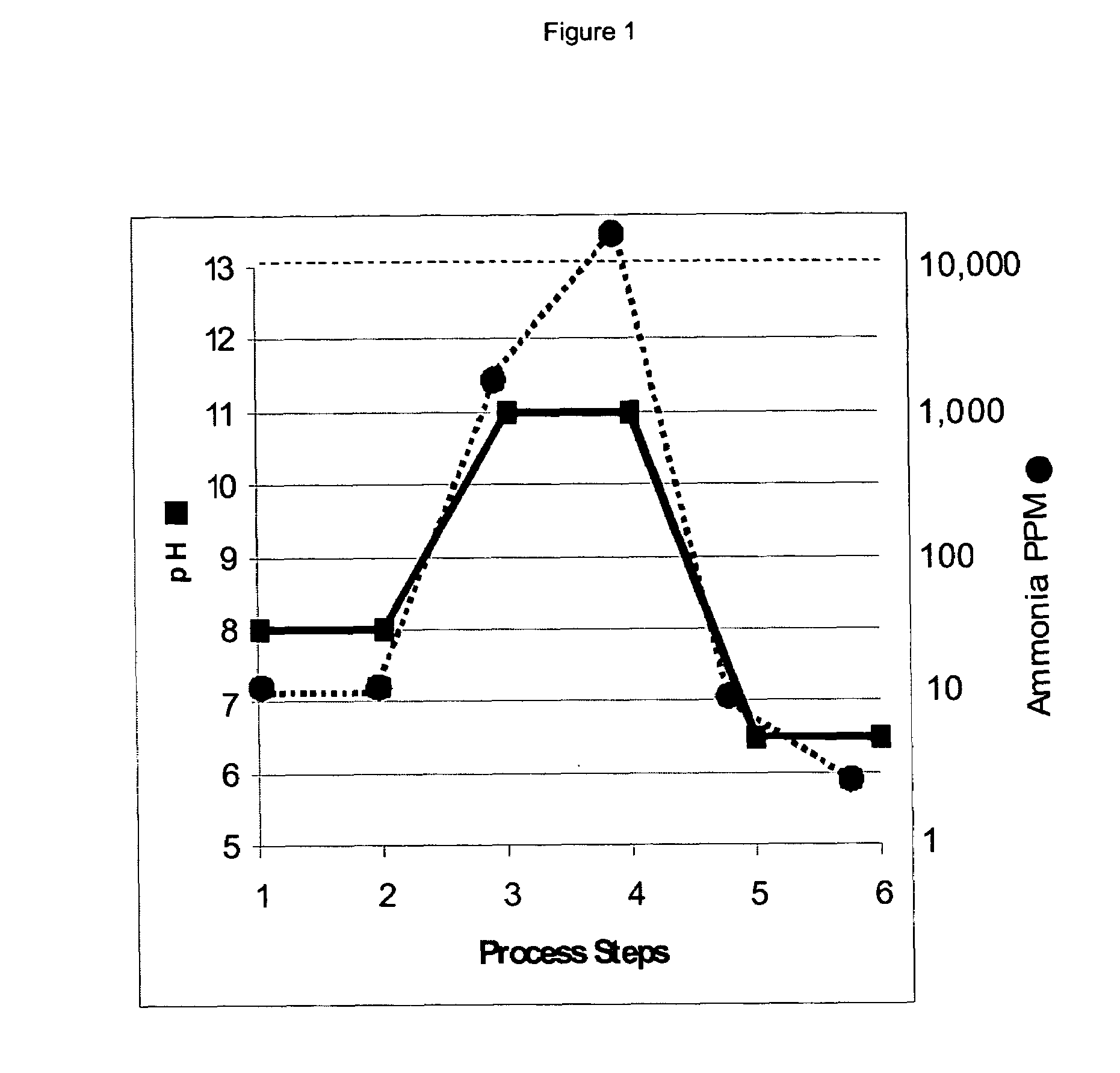

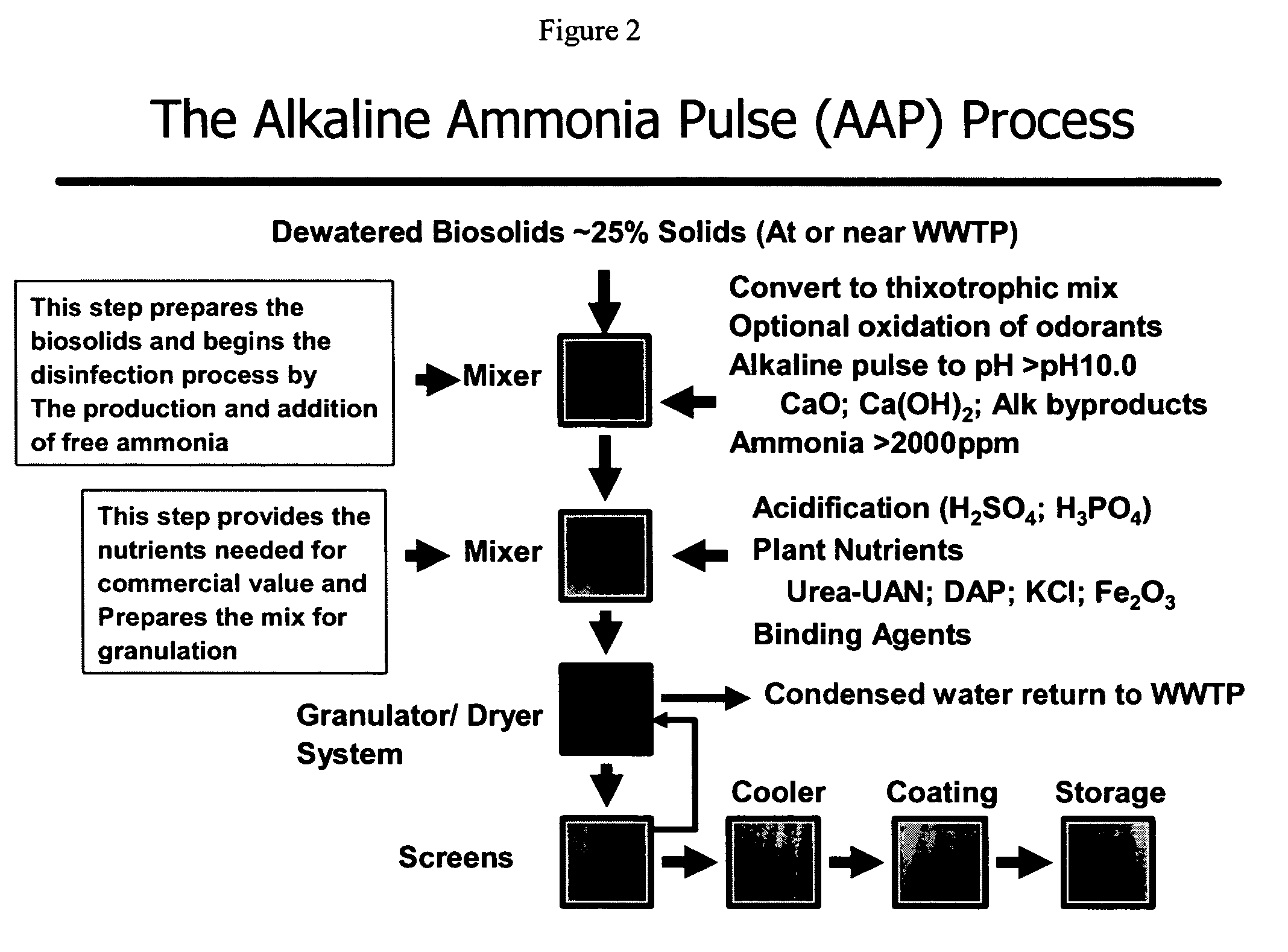

Organic containing sludge to fertilizer alkaline conversion process

InactiveUS20070062233A1Increases plant nutrient contentReduce odorCalcareous fertilisersBio-organic fraction processingSludgeOrganic manure

This invention is directed to systems, devices and methods for treating organic-containing sludges and converting such sludges to high value fertilizers containing both inorganic and organic fertilizer components, which creates an inorganically-augmented bioorganic fertilizer. The invention describes methods to create a thixotrophic or paste-like material via the application of mixing energy to the organic sludge followed by an alkaline treatment and a subsequent ammoniation. The invention further describes a method to increase the plant nutrient content in the organic containing product to a level which permits the finished granular fertilizer product to compete in the commercial agricultural fertilizer marketplace. Further, the invention reduces odors associated with said organic-containing sludges.

Owner:GENERATE LENDING LLC

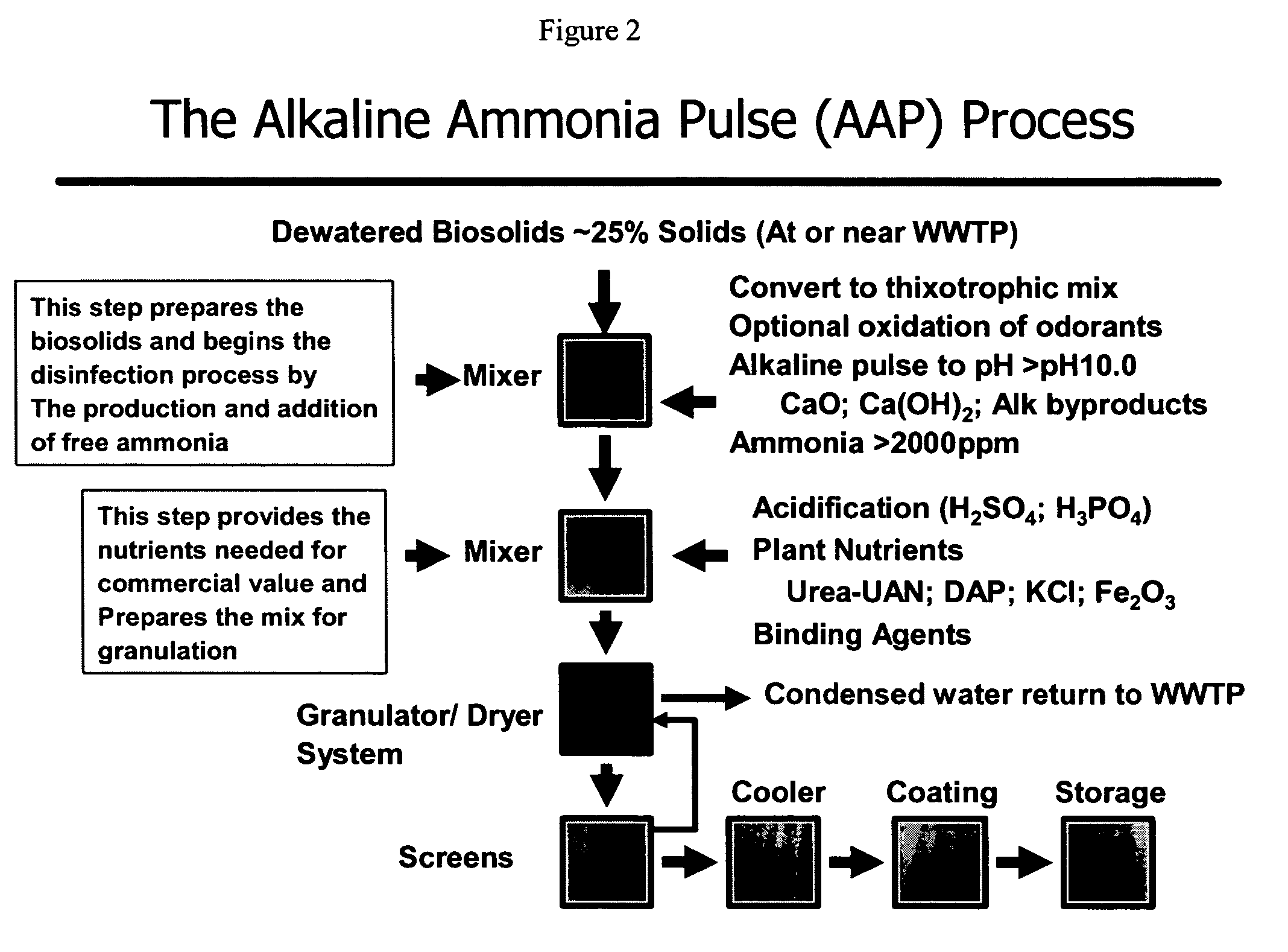

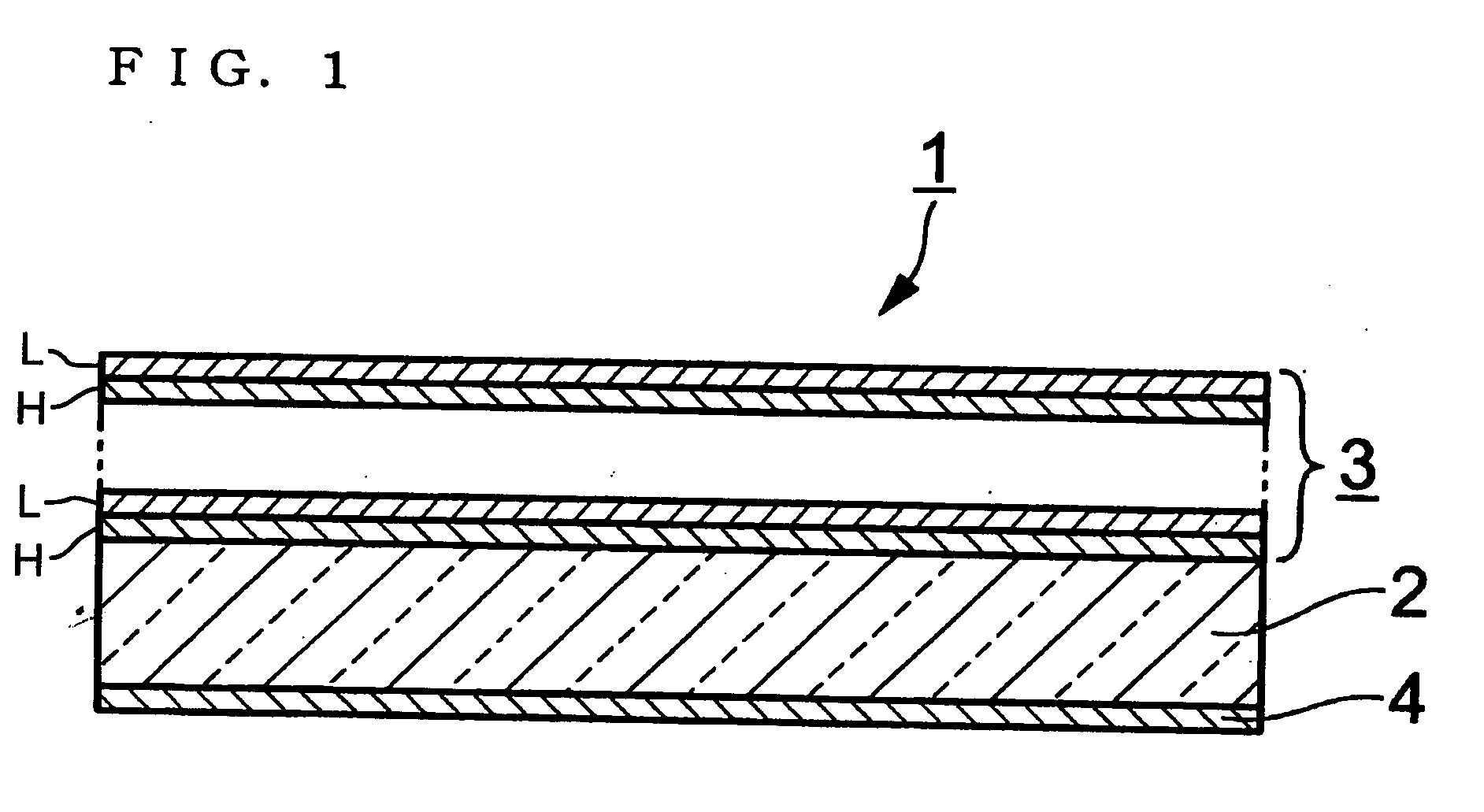

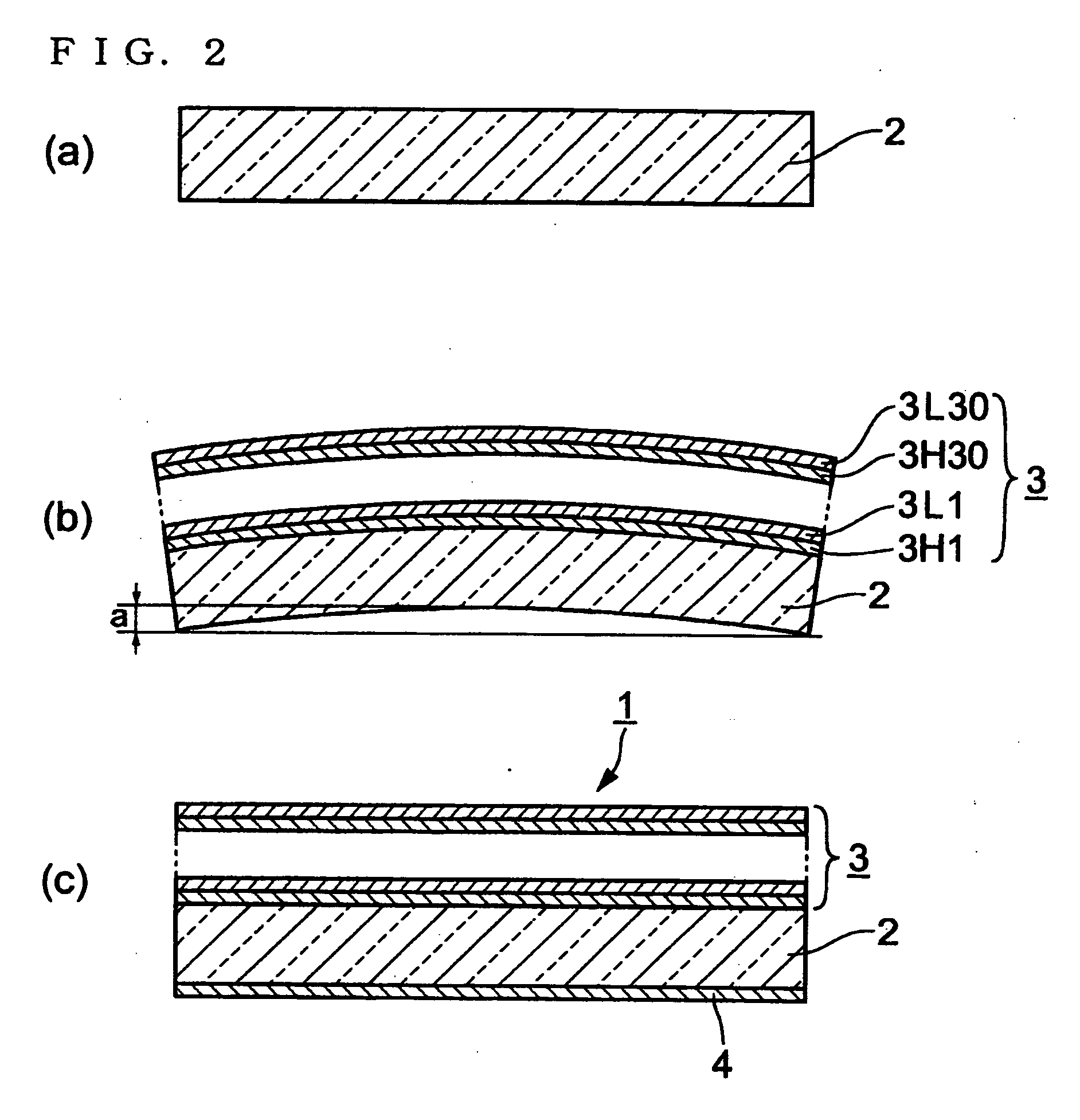

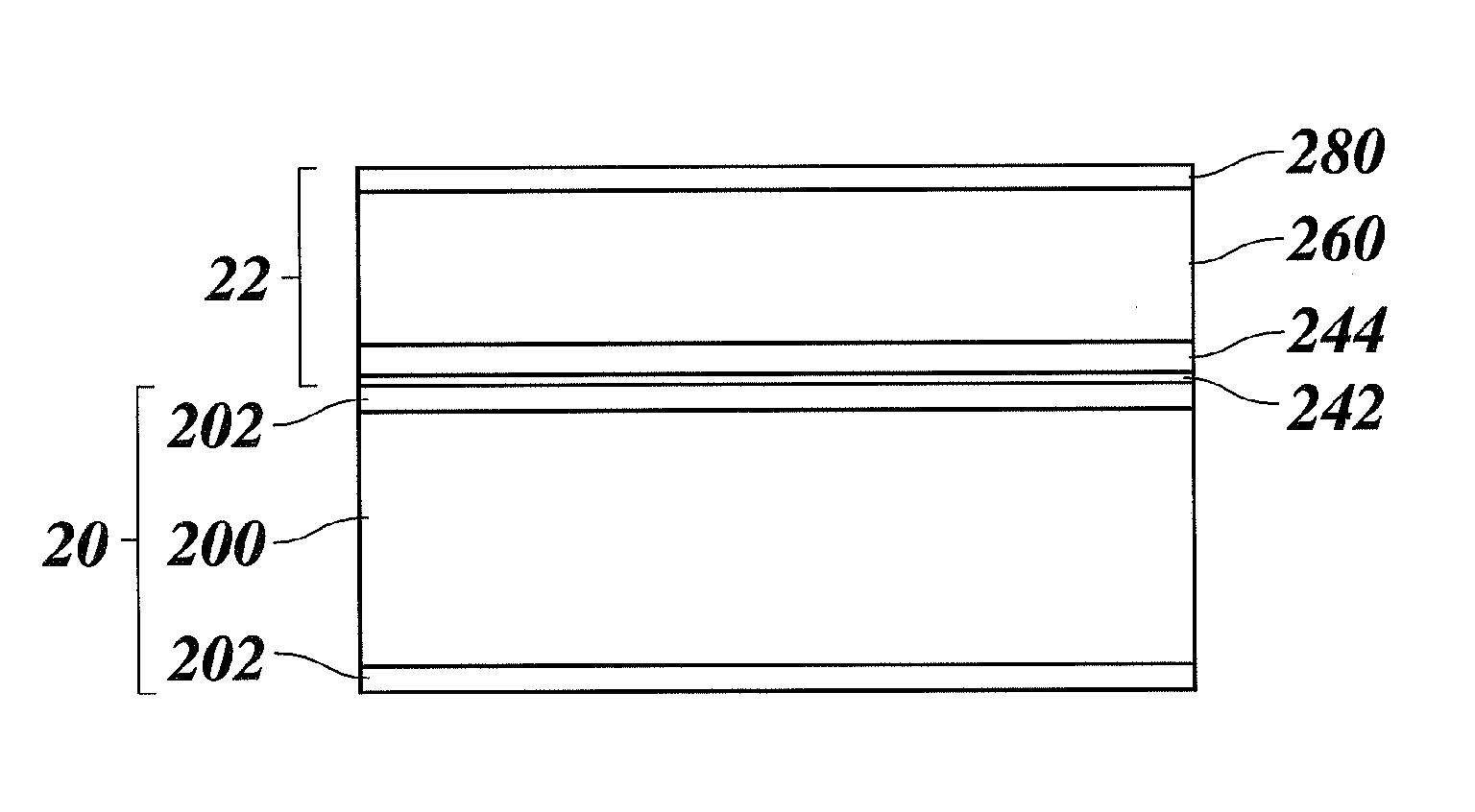

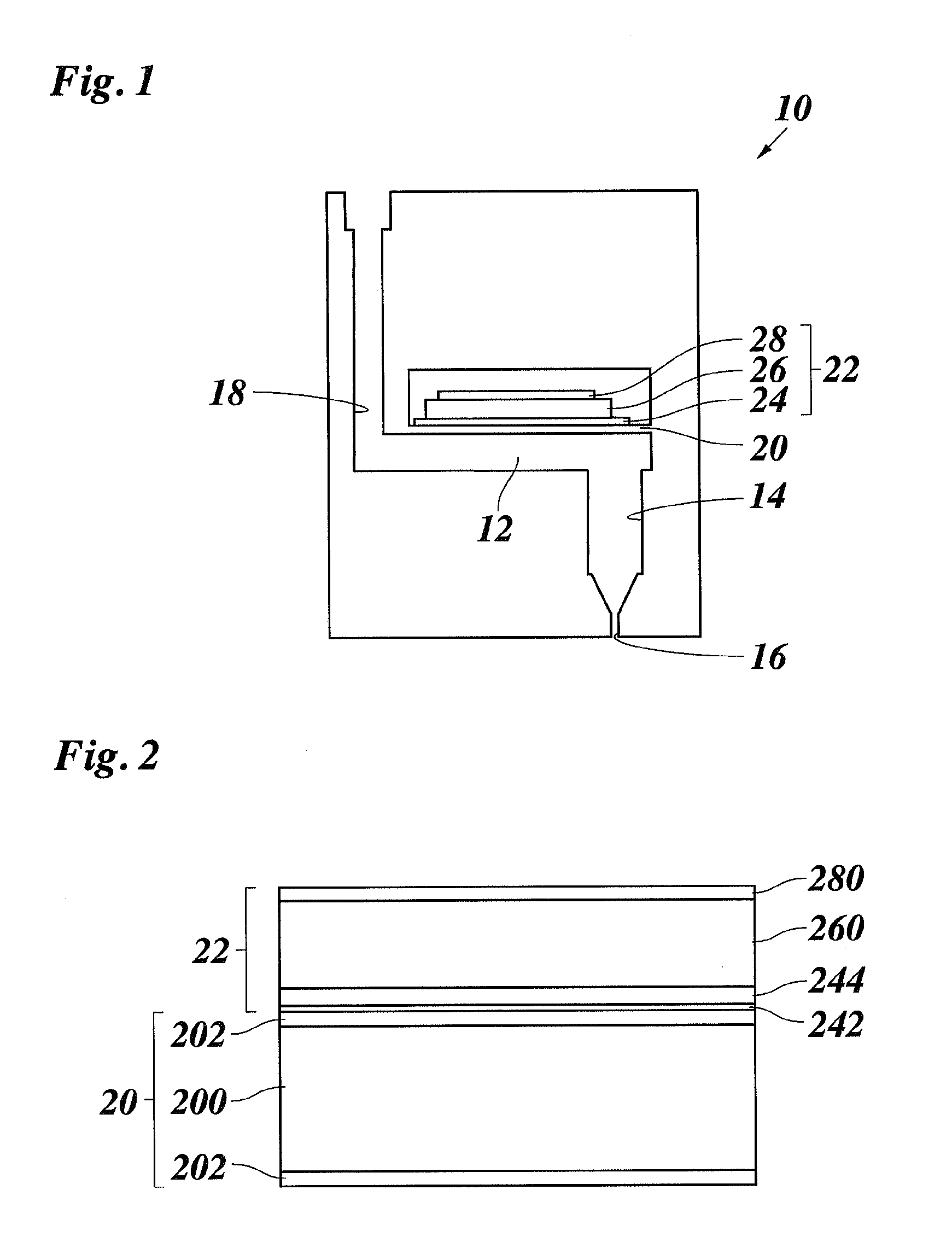

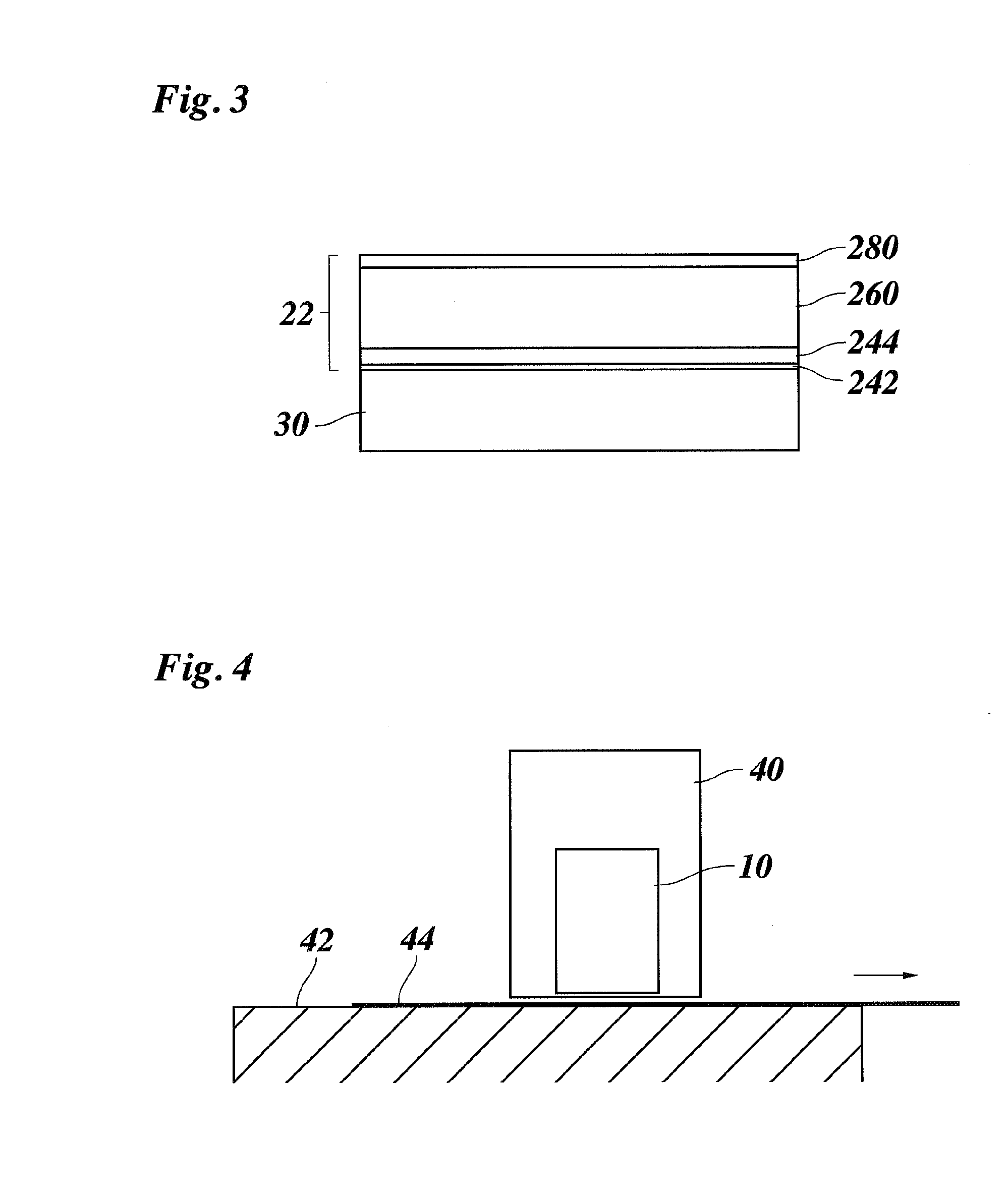

Optical multilayer-film filter, method for fabricating optical multilayer-film filter, optical low-pass filter, and electronic apparatus

InactiveUS20050018302A1Reduce widthGood prevention of optical strainTelevision system detailsMirrorsRefractive indexDielectric thin films

An optical multilayer-film filter formed by laminating dielectric thin films on a transparent substrate has a structure in which a dielectric multilayer film formed by alternately laminating high-refractive-index material layers and low-refractive—index material layers is formed on one surface of the transparent substrate, a dielectric monolayer film is formed on the other surface of the transparent substrate, and the dielectric monolayer film is composed of a dielectric material having substantially the same refractive index as that of the transparent substrate. With this structure, a warp width of the substrate due to stresses of the dielectric thin films laminated in the transparent substrate can be further reduced, thereby achieving an optical multilayer-film filter which is protected from optical strain.

Owner:SEIKO EPSON CORP

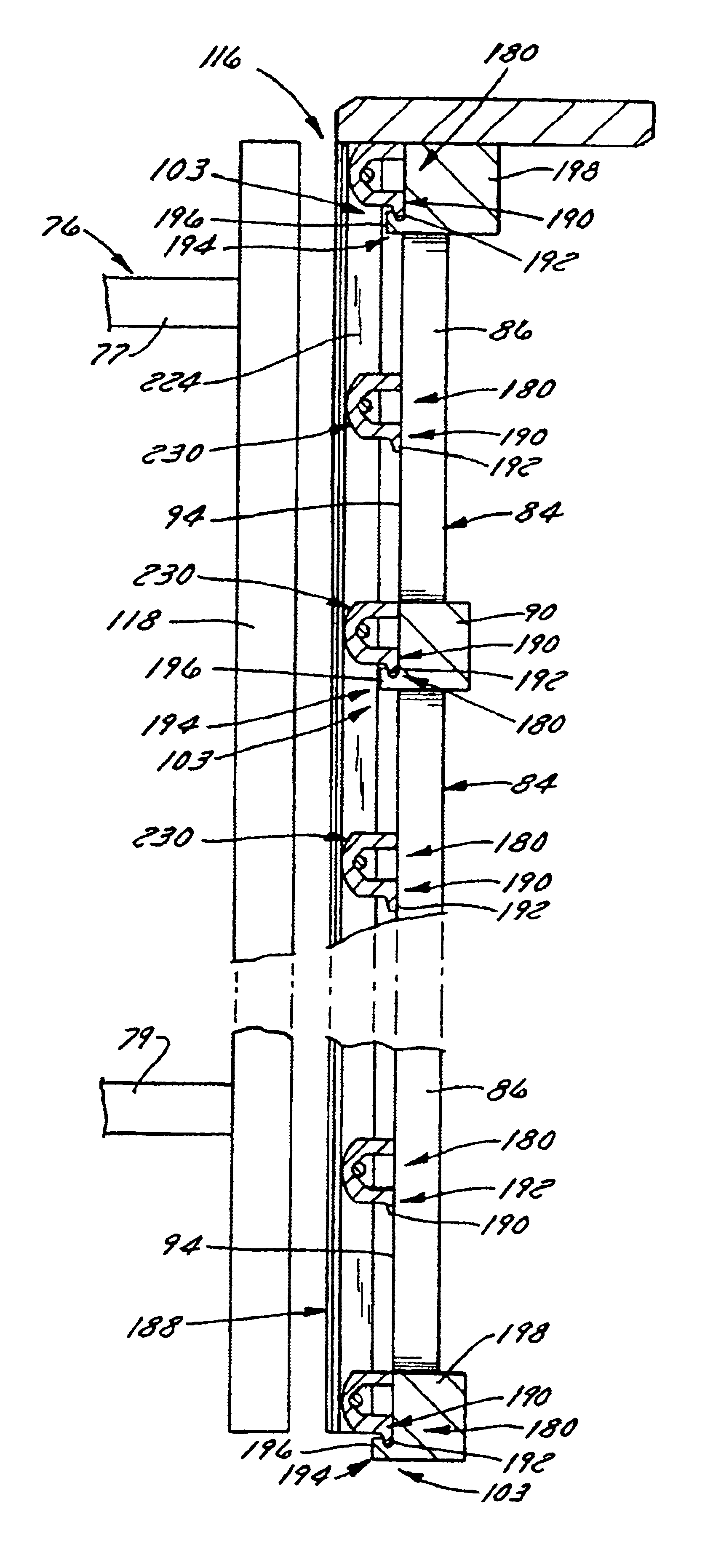

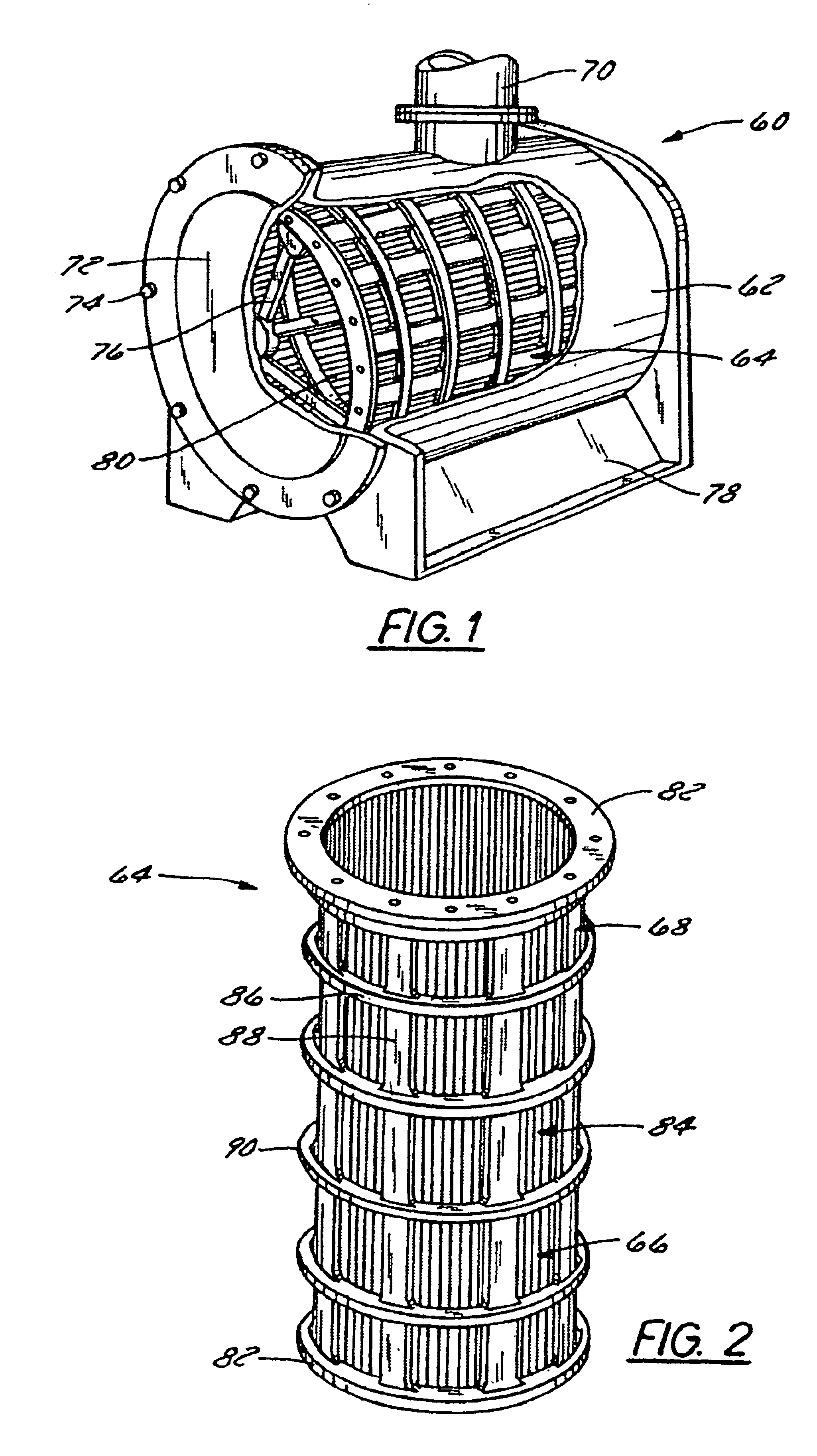

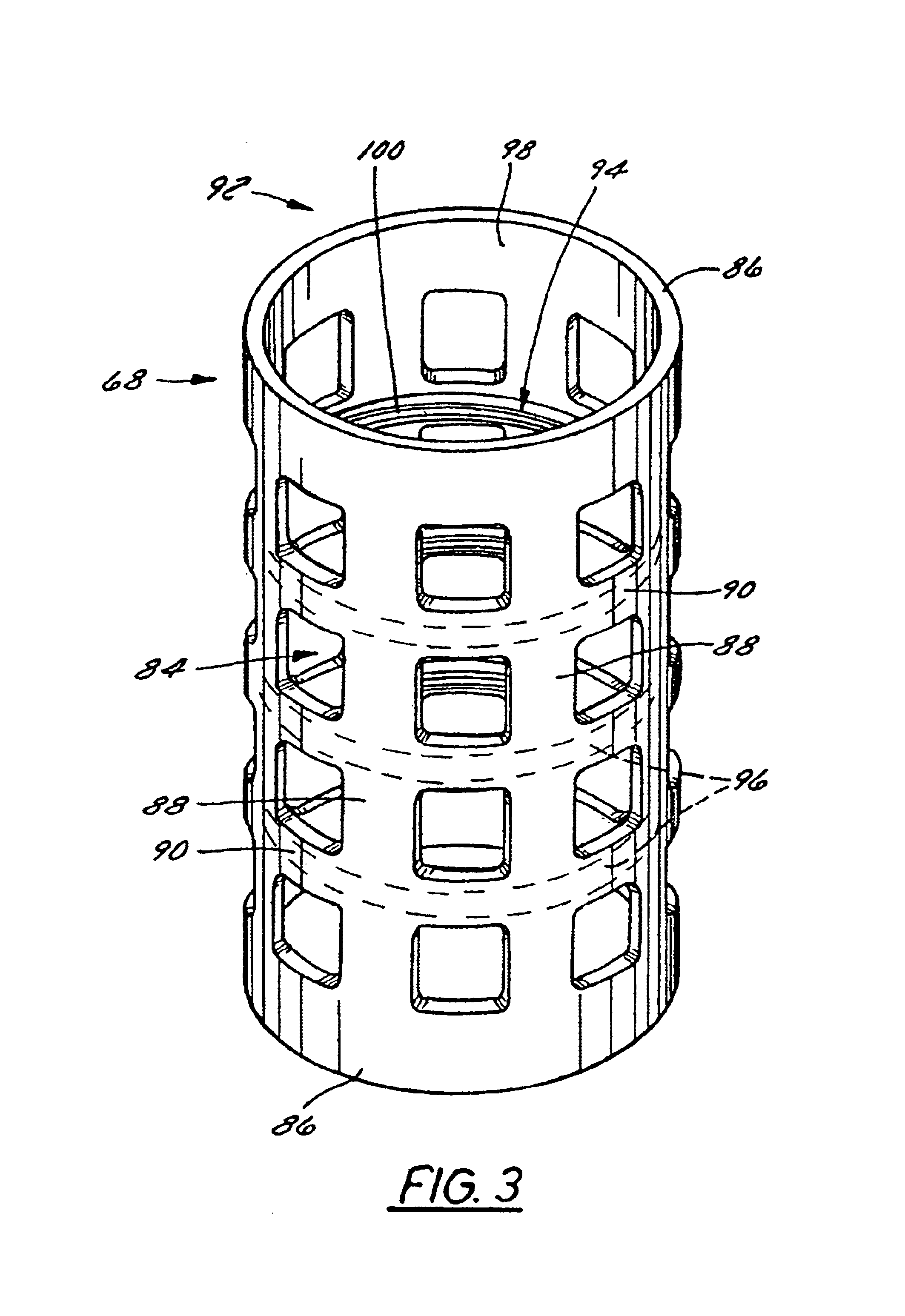

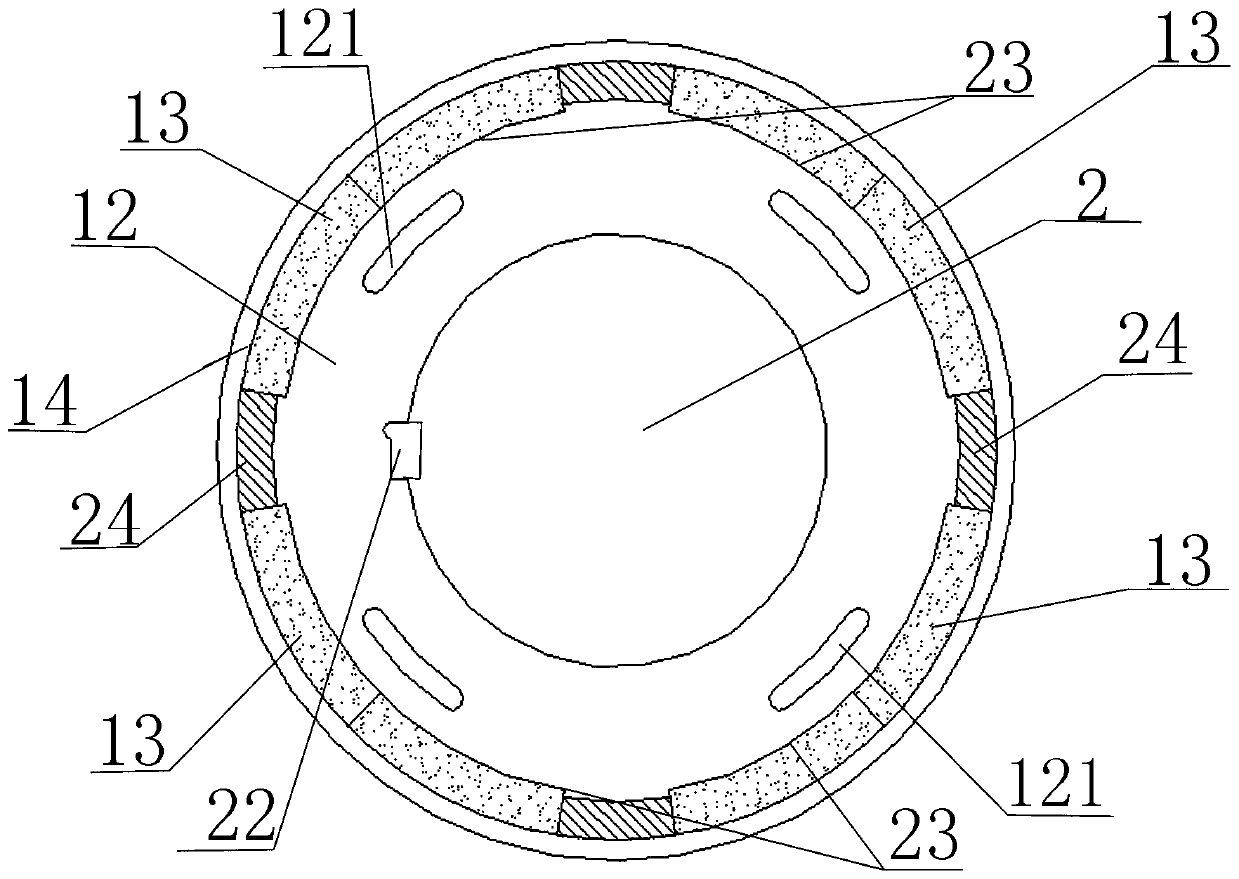

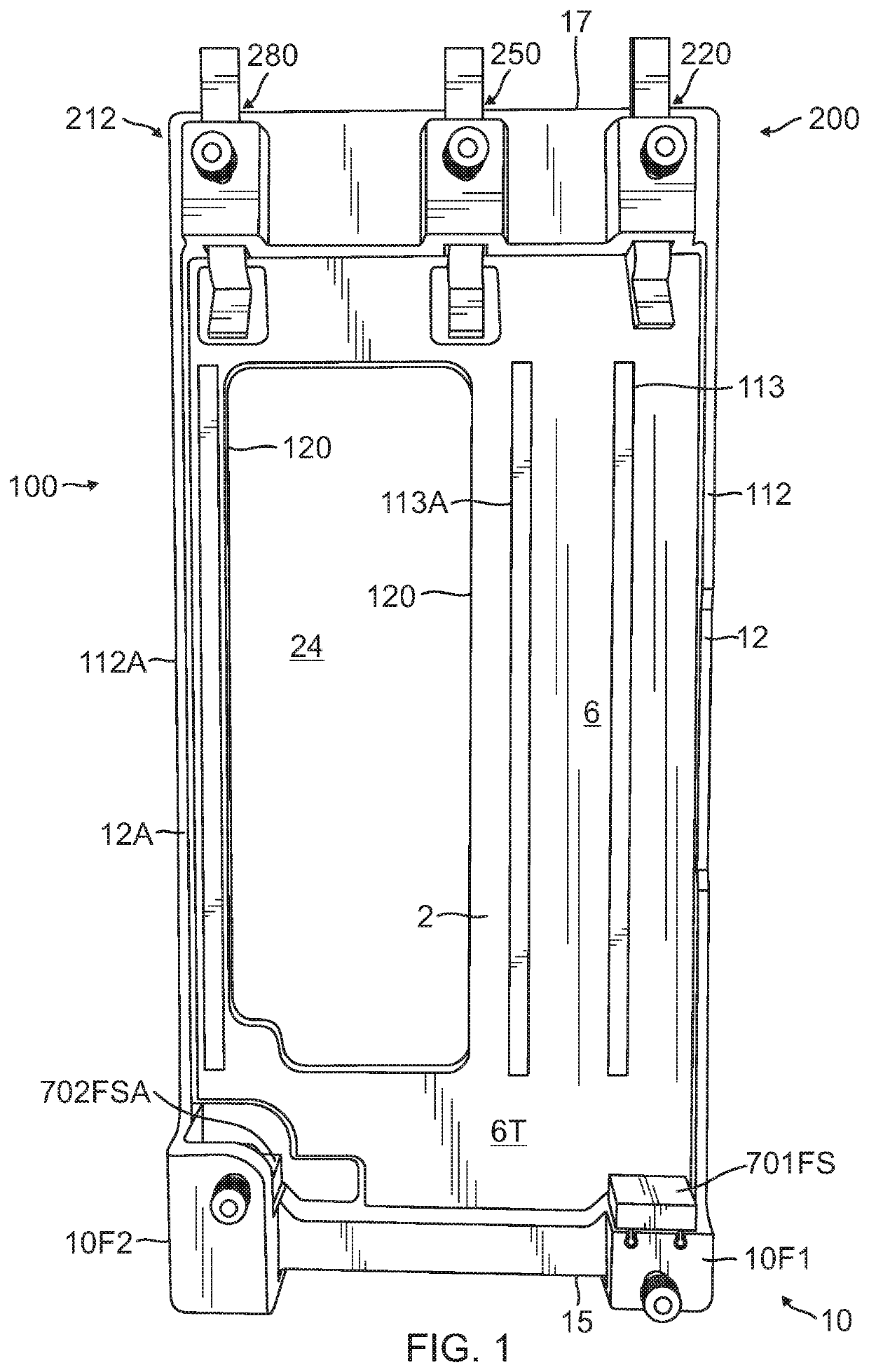

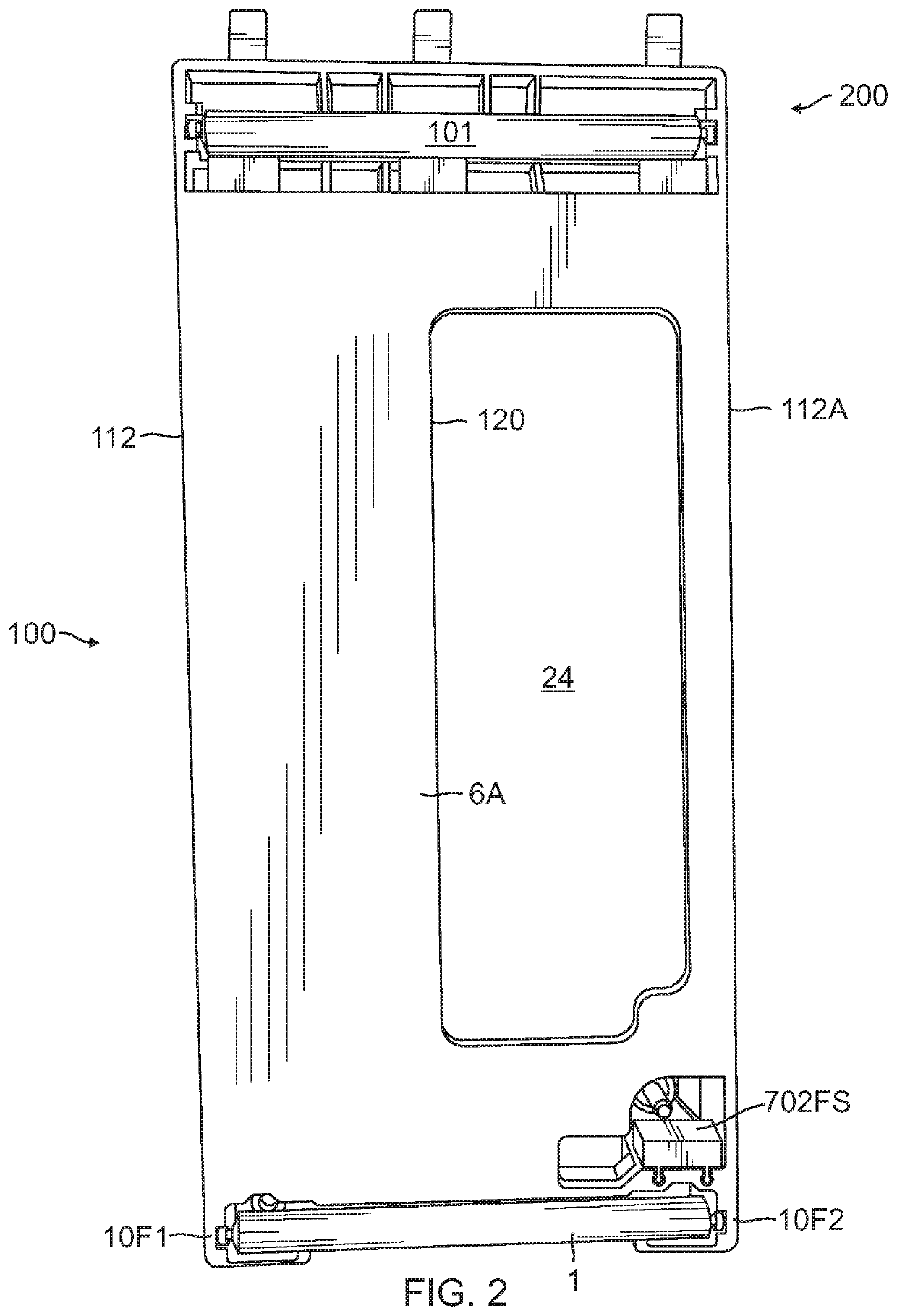

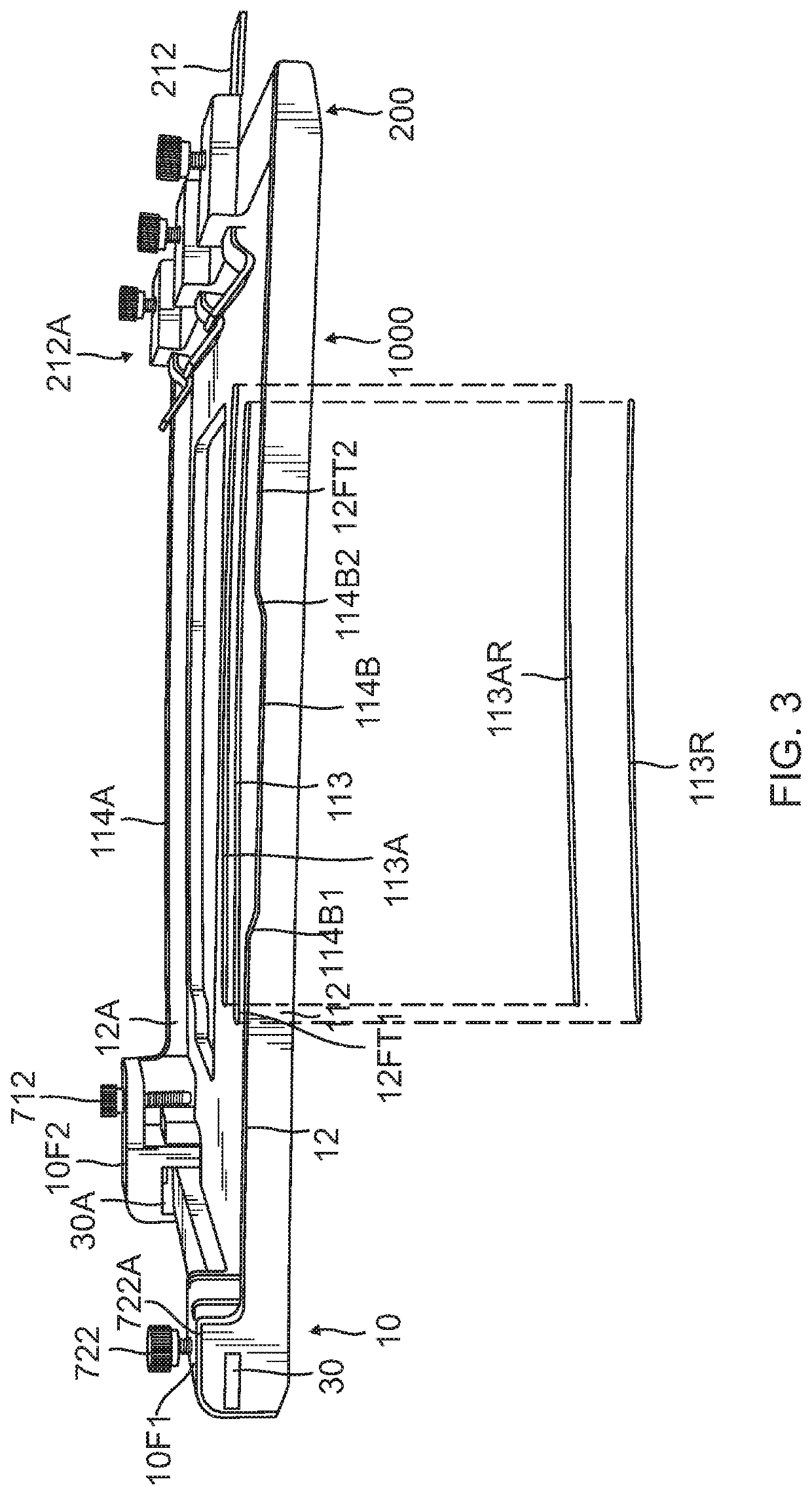

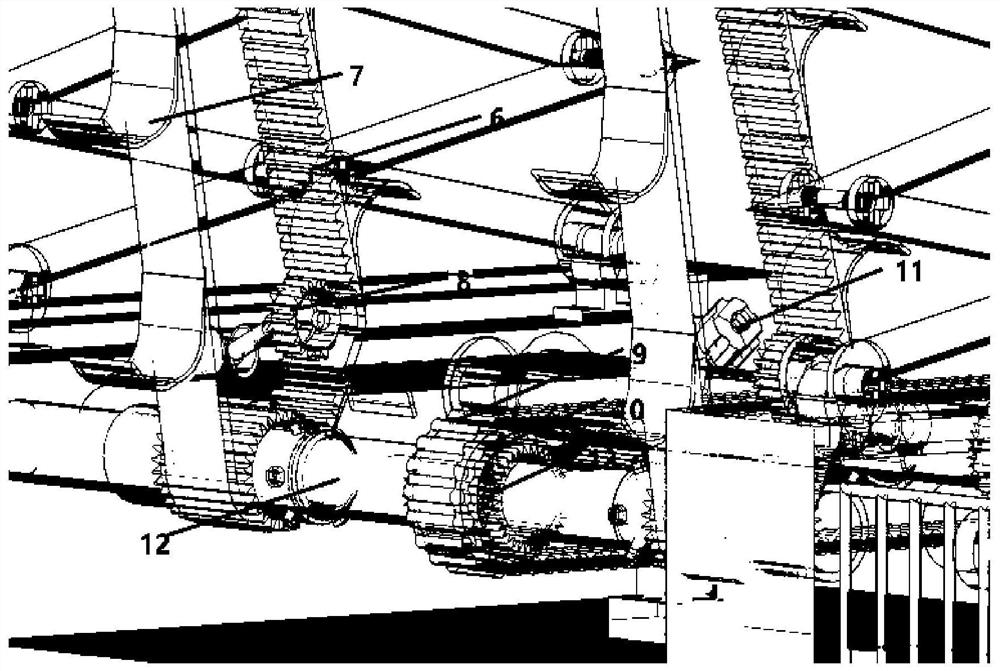

Screen cylinder and method

InactiveUS6915910B2Increase the circulation areaStrong stressSievingScreeningPreferred frameMechanical engineering

A pulp screen cylinder that includes screen media releasably engaged with a frame at spaced locations opposing movement of the media away from the frame during screening. A preferred frame includes a plurality of spaced engaging structures that releasably engage screen media. A preferred frame includes an arrangement of flow windows that are triangular or rhomboid. A preferred method includes producing a frame cylinder by centrifugal casting and machining flow windows using a jet cutting process. A preferred screen media has a plurality of spaced apart engaging structures that each releasably engages the frame at spaced apart locations. A preferred screen media is of wedgewire construction having engaging structure carried by a plurality of spaced wire retaining clips. A preferred clip has vee-shaped rounded slots and an arm thicker than an end wall. A preferred engaging structure includes a projection that has a lip or hook for releasable interlocking engagement.

Owner:KADANT BLACK CLAWSON LLC

Organic containing sludge to fertilizer alkaline conversion process

InactiveUS7662206B2Reduce odorHigh in nutrientsCalcareous fertilisersBio-organic fraction processingSludgeOrganic manure

This invention is directed to systems, devices and methods for treating organic-containing sludges and converting such sludges to high value fertilizers containing both inorganic and organic fertilizer components, which creates an inorganically-augmented bioorganic fertilizer. The invention describes methods to create a thixotrophic or paste-like material via the application of mixing energy to the organic sludge followed by an alkaline treatment and a subsequent ammoniation. The invention further describes a method to increase the plant nutrient content in the organic containing product to a level which permits the finished granular fertilizer product to compete in the commercial agricultural fertilizer marketplace. Further, the invention reduces odors associated with said organic-containing sludges.

Owner:GENERATE LENDING LLC +1

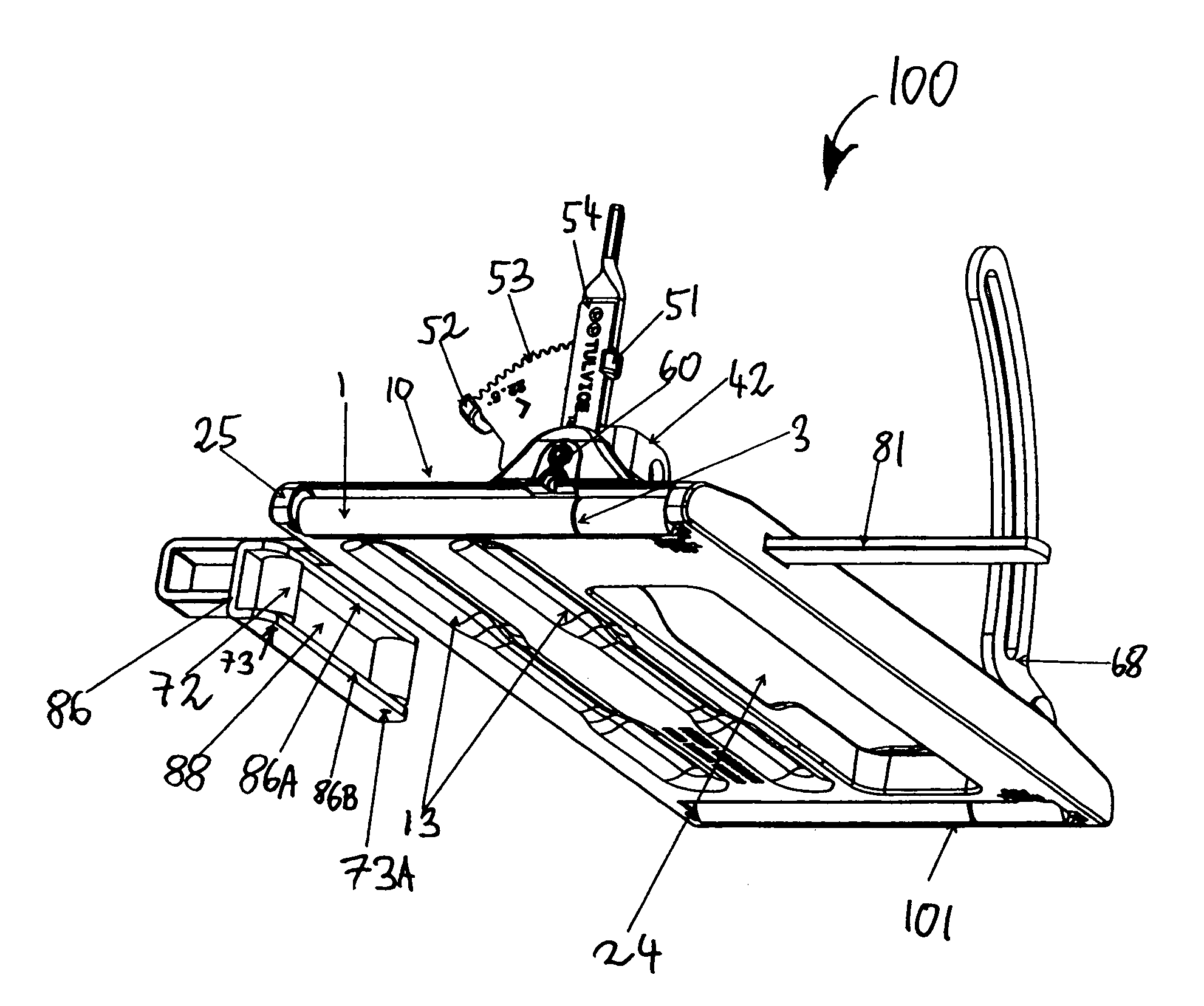

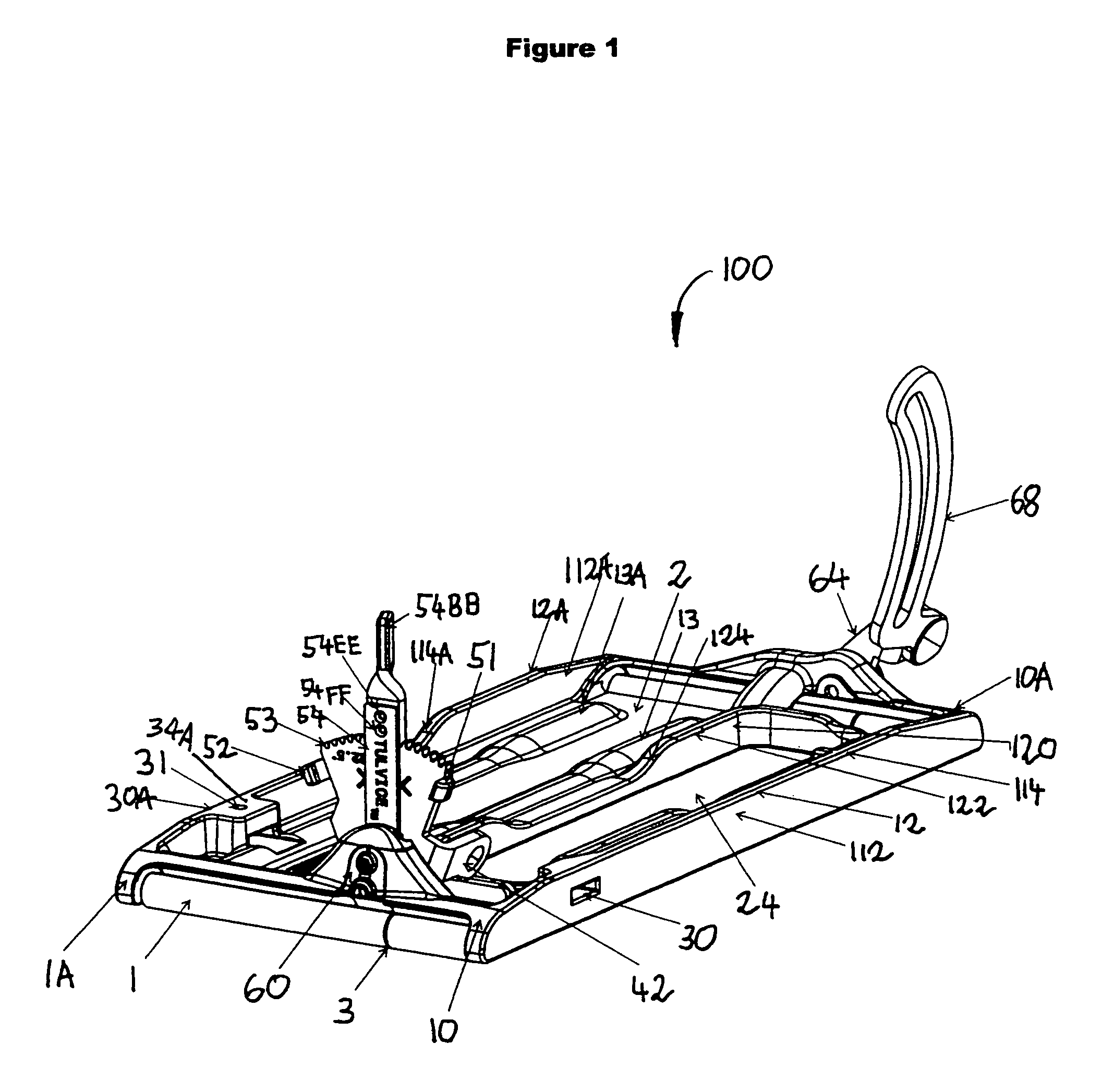

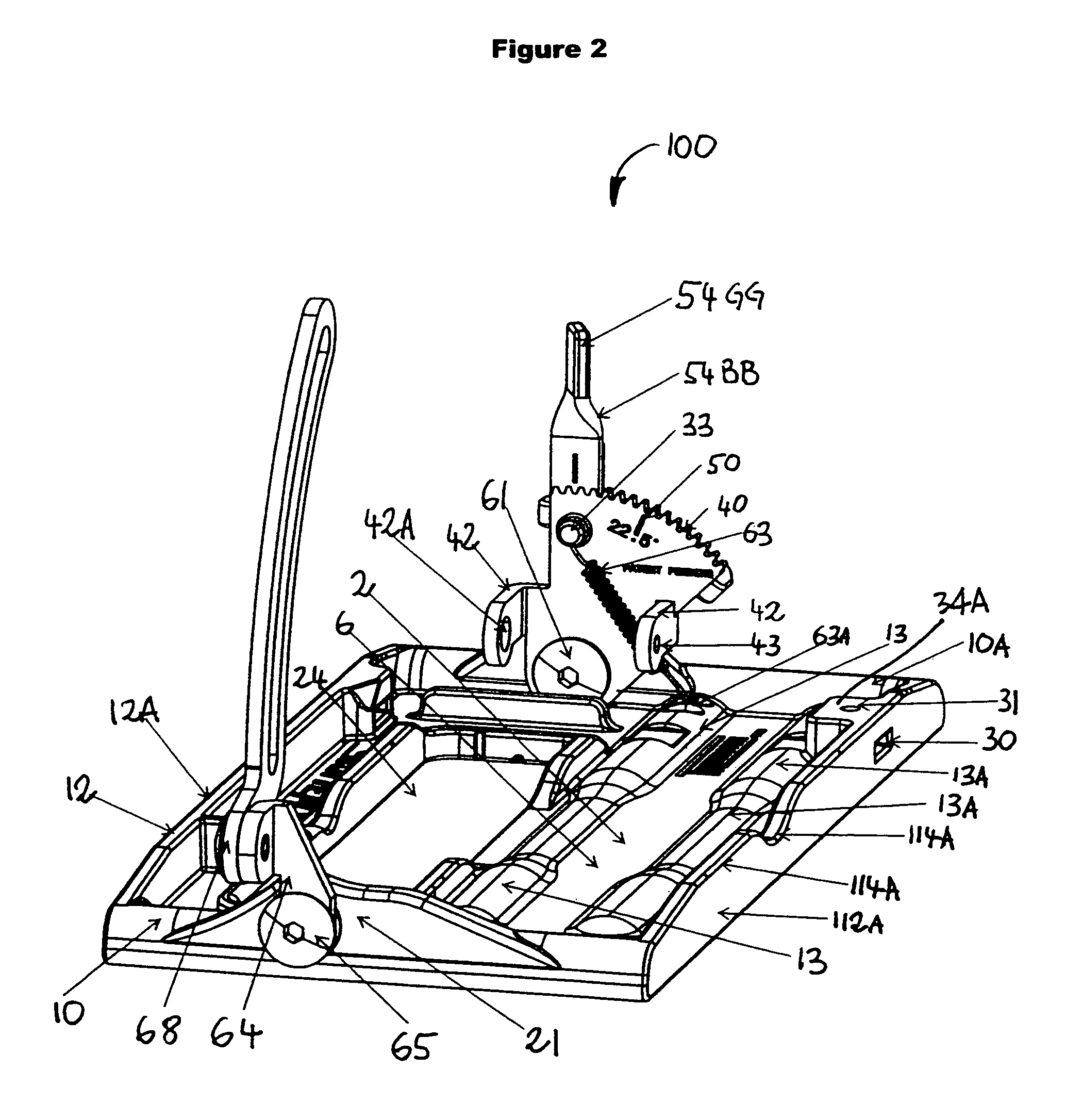

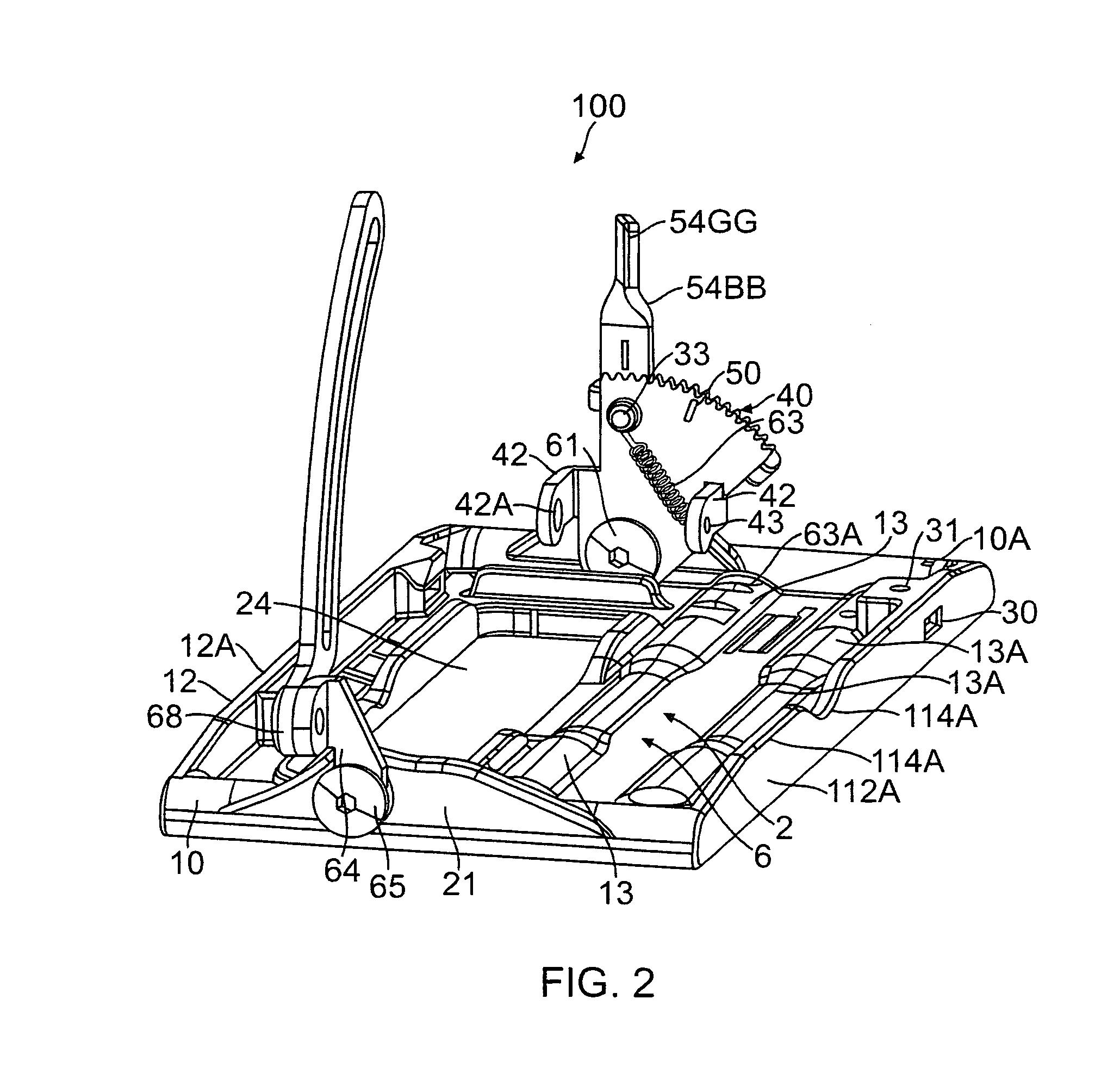

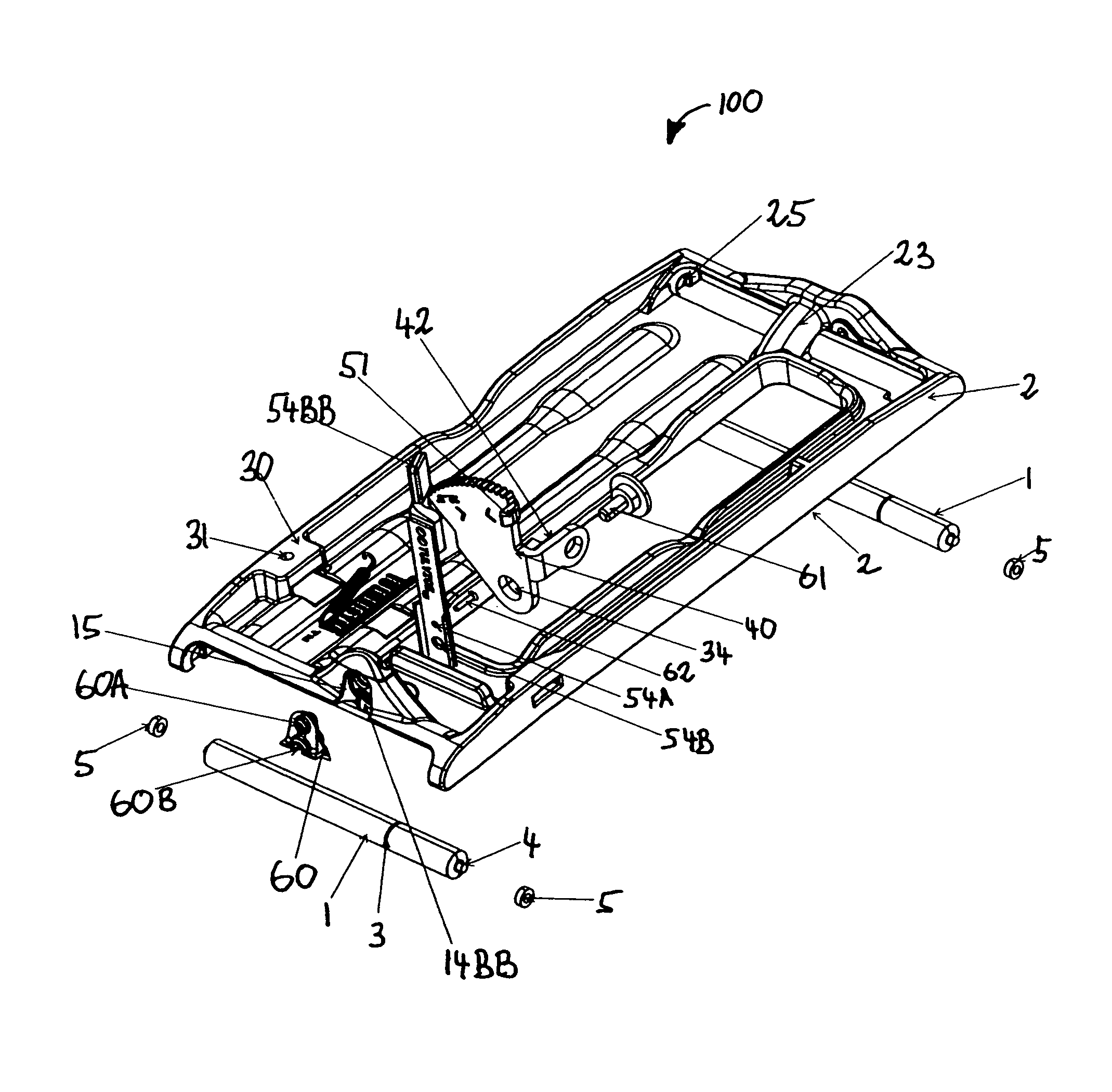

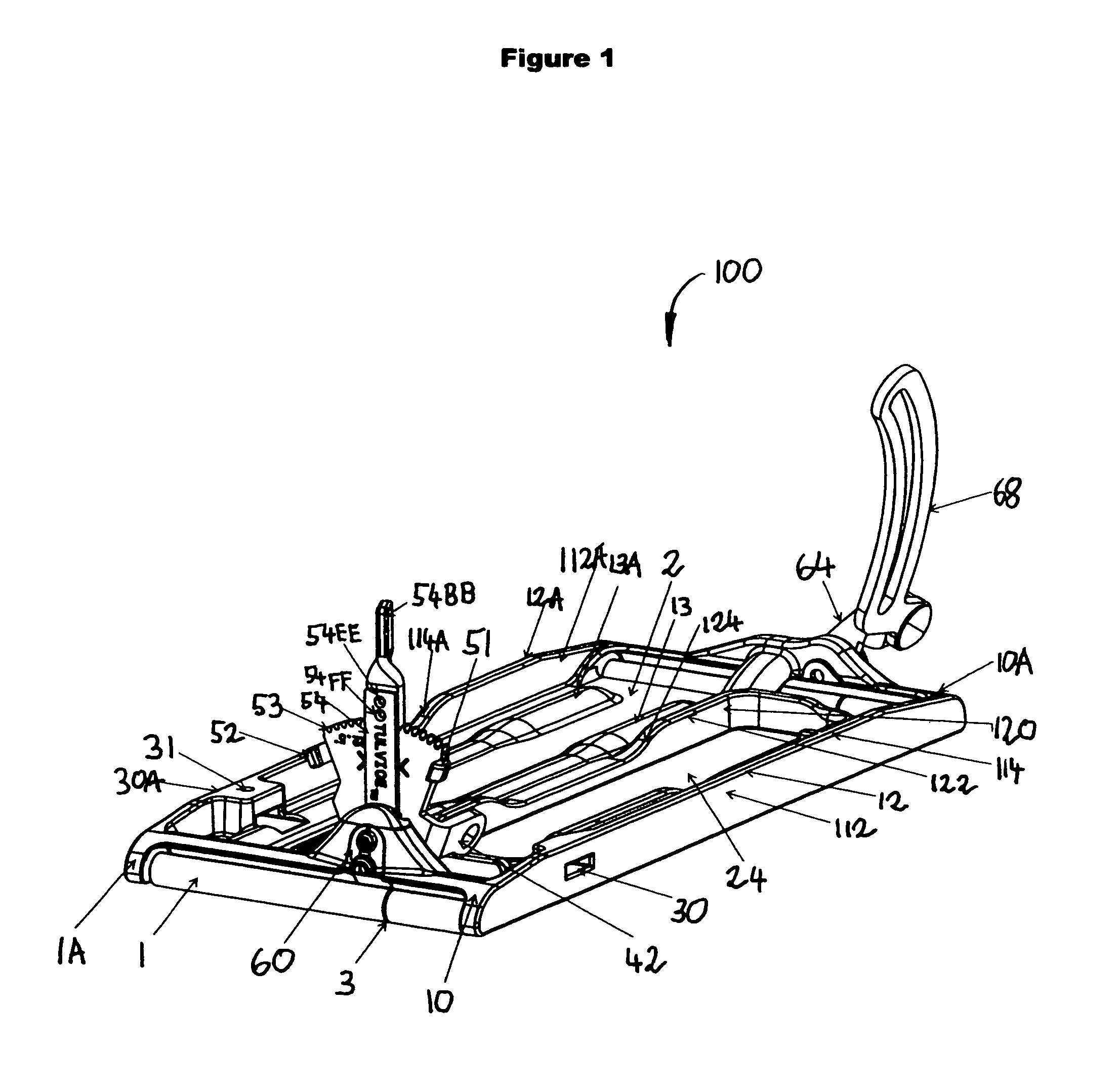

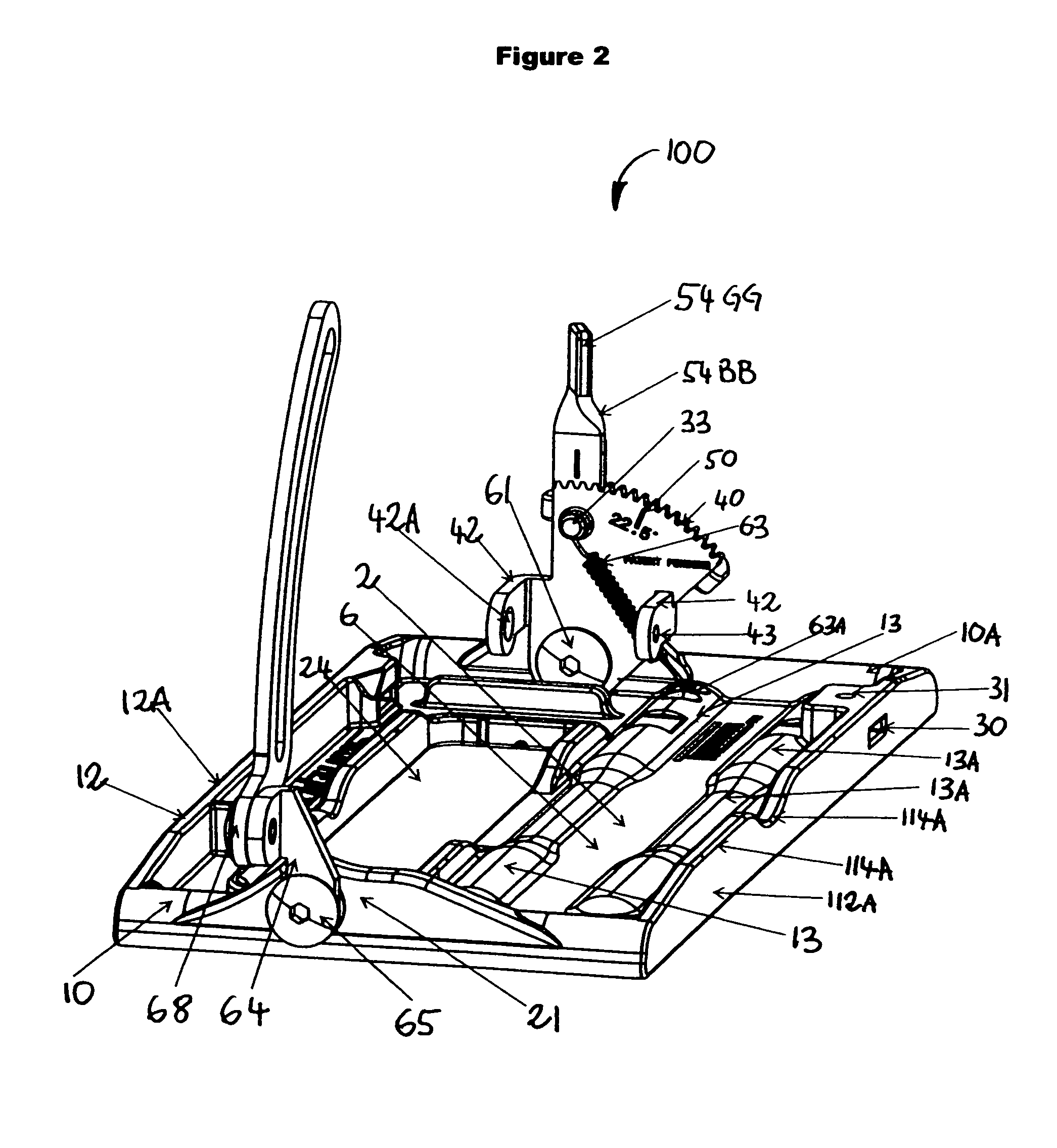

Rolling plate assembly attachment for portable power cutting tools including an improved structural design and manufactured out of improved materials, an improved wheel configuration, and an adjustable bevel gear and a cutting guide

ActiveUS7958641B1Facilitate safe rolling movementFacilitates strong weightMetal sawing devicesMetal sawing accessoriesFiberPortable power

The present invention is an attachable rolling plate assembly which can be attached as a single unit to a portable cutting tool to facilitate the safe rolling movement of the portable cutting tool on the workpiece. The invention comprises a frame assembly formed from a single piece of molded material such as fiber enriched plastic having a pair of oppositely disposed longitudinal sidewalls with stabilizer fins extending therefrom, and a flat base portion having a pair of parallel stabilizer tubes molded therein. The invention further includes an adjustable bevel gear assembly by which the angle of orientation of the cutting blade can be quickly changed. The invention also includes a cutting guide assembly to facilitate a straight cut, reduce torsional rotation of the saw blade and reduce kickback of the saw.

Owner:CIRCSAW TECH LLC

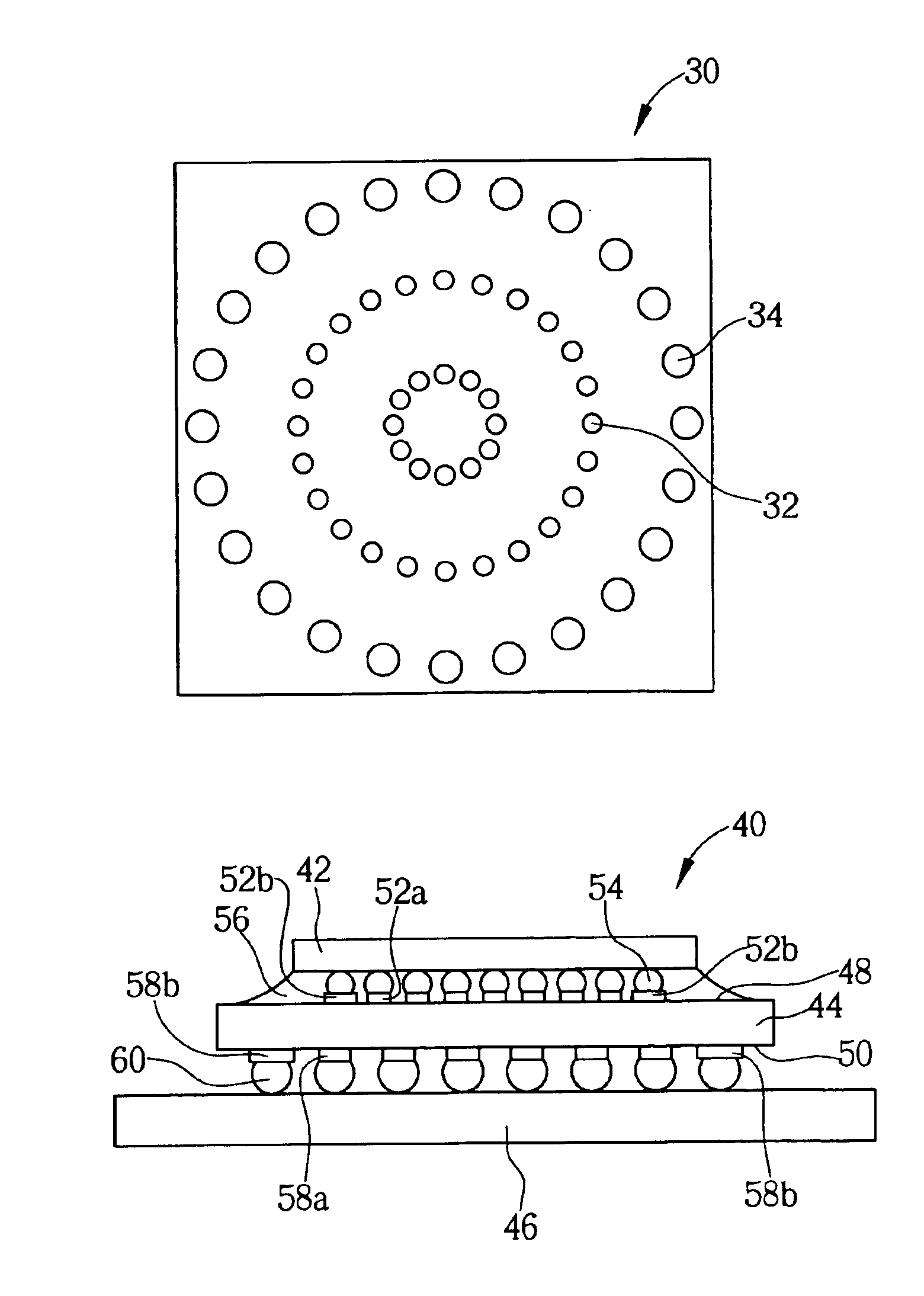

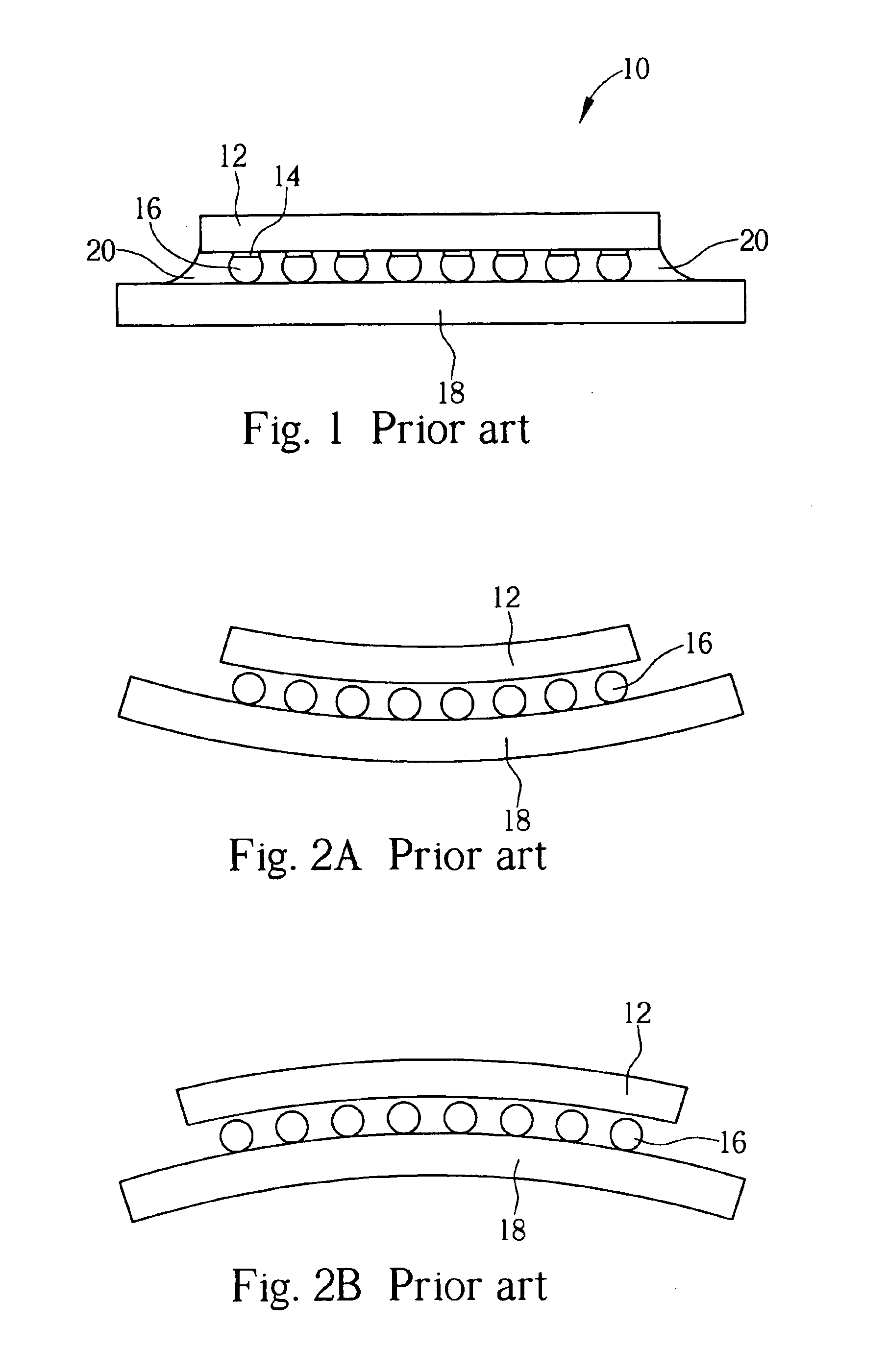

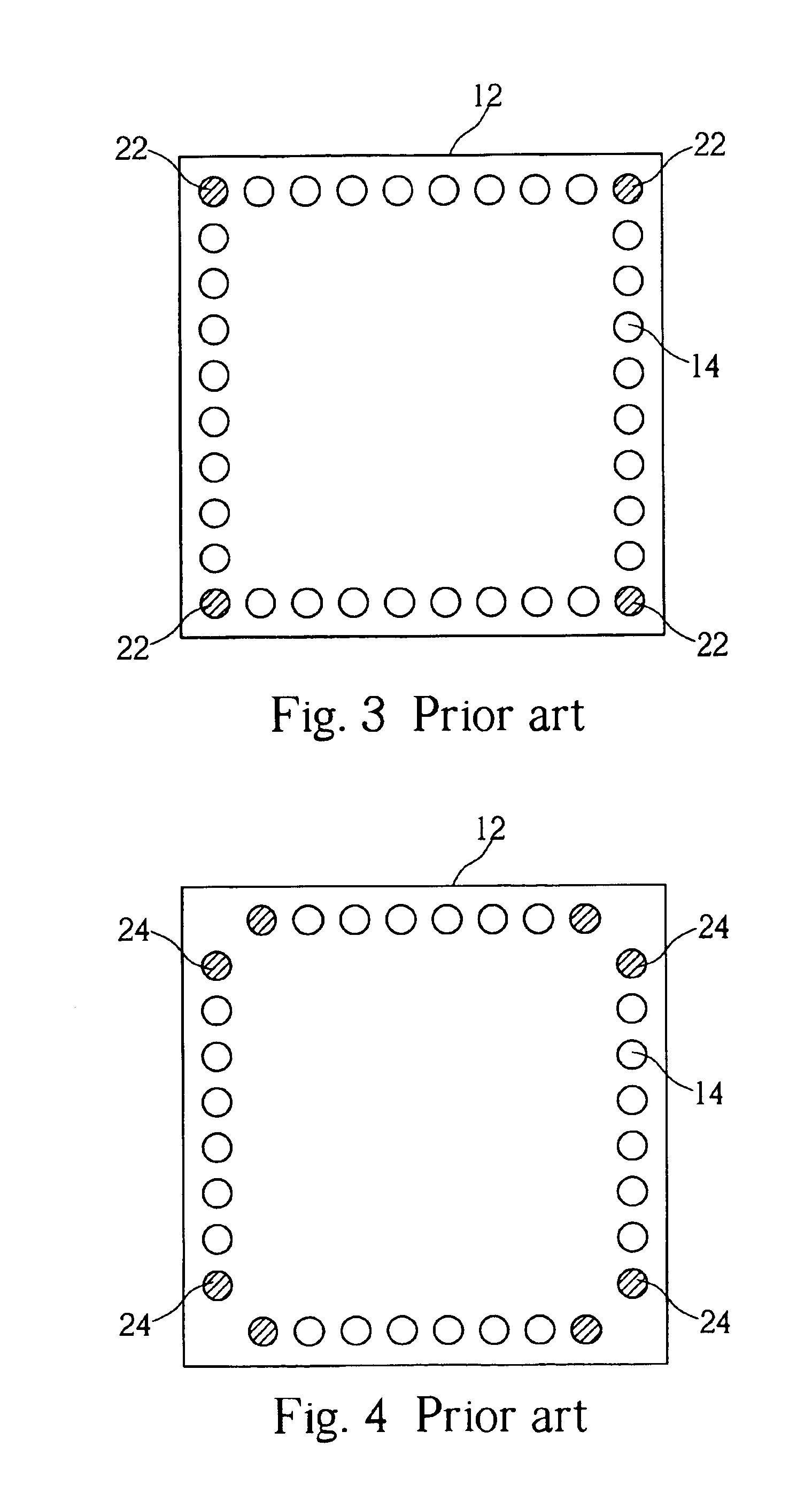

Solder pads for improving reliability of a package

InactiveUS6940176B2Improve package reliabilityImprove reliabilityPrinted circuit assemblingFinal product manufactureSemiconductor packageEngineering

Solder pads for improving reliability of a semiconductor package are provided. The package includes a substrate and / or a chip. The solder pad includes a plurality of first solder pads located on a surface of the substrate and / or the chip, and at least a second solder pad located on a predetermined region of the surface of the substrate and / or the chip. Each of the first solder pads has a first diameter. The second solder pad has a second diameter greater than the first diameter so as to sustain a stronger thermal stress on the substrate and / or the chip.

Owner:UNITED MICROELECTRONICS CORP

Rolling plate assembly attachment for portable power cutting tools including an improved structural design and manufactured out of improved materials, an improved wheel configuration, and an adjustable bevel gear and a cutting guide

ActiveUS8209872B1Facilitate safe rolling movementFacilitates strong weightMetal sawing devicesMetal sawing accessoriesFiberPortable power

The present invention is an attachable rolling plate assembly which can be attached as a single unit to a portable cutting tool to facilitate the safe rolling movement of the portable cutting tool on the workpiece. The invention comprises a frame assembly formed from a single piece of molded material such as fiber enriched plastic having a pair of oppositely disposed longitudinal sidewalls with stabilizer fins extending therefrom, and a flat base portion having a pair of parallel stabilizer tubes molded therein. The invention further includes an adjustable bevel gear assembly by which the angle of orientation of the cutting blade can be quickly changed. The invention also includes a cutting guide assembly to facilitate a straight cut, reduce torsional rotation of the saw blade and reduce kickback of the saw.

Owner:CIRCSAW TECH LLC

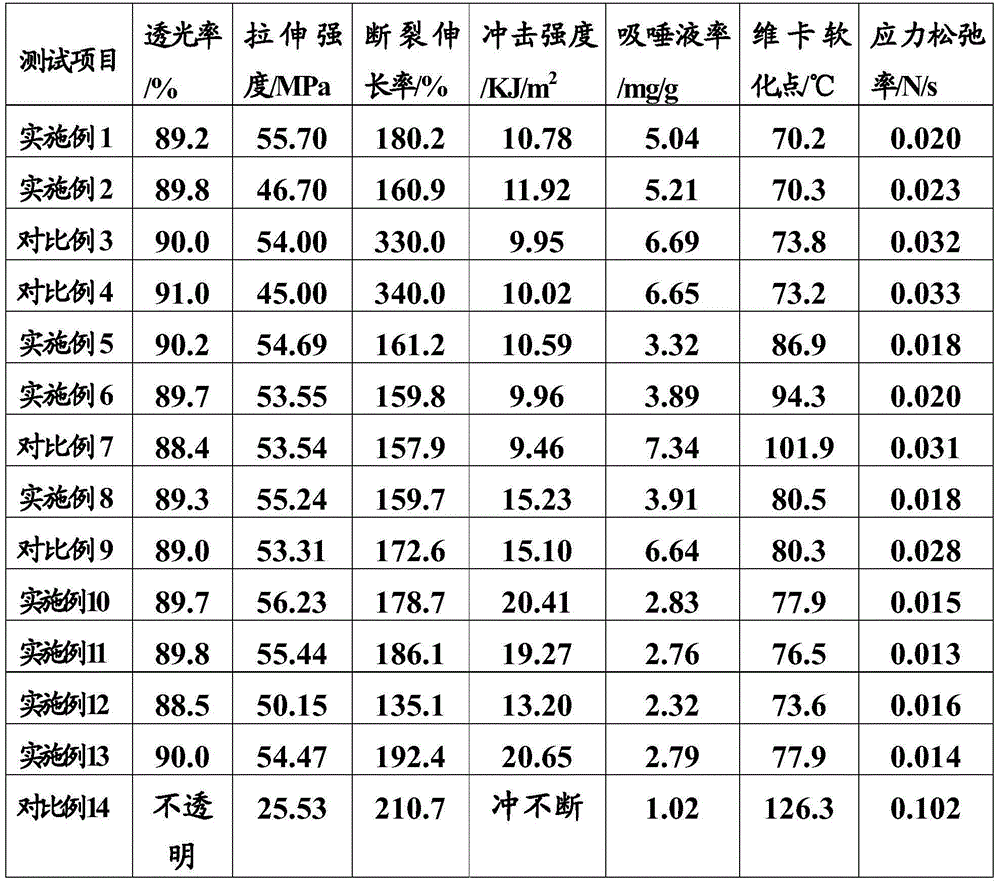

Teeth orthodontic material, preparation and application thereof

InactiveCN105315624AImprove mechanical propertiesReduce saliva intakeOthrodonticsCyclohexanedimethanolPolyethylene glycol

The invention relates to a teeth orthodontic material. On the basis of the total weight of the orthodontic material, the orthodontic material includes, by weight: A) 50-99.7% of polyethylene glycol terephthalate-1,4-cyclohexanedimethanol ester; B) 0-40% of polycarbonate, C) 0-20% of a thermoplastic polyurethane elastomer; and D) 0.3-5% of nano silicon dioxide, the sum of percentage contents of the components is 100 wt%. The teeth orthodontic material has excellent transparent performance, is excellent in mechanical and chemical performances, satisfies sanitary grade, especially is low enough in water absorption rate (or saliva absorption rate) and stress relaxation rate. The invention also relates to preparation of the teeth orthodontic material and an application of the material for preparing a teeth orthodontic device which preferably is dental braces.

Owner:BEIJING UNIV OF CHEM TECH +1

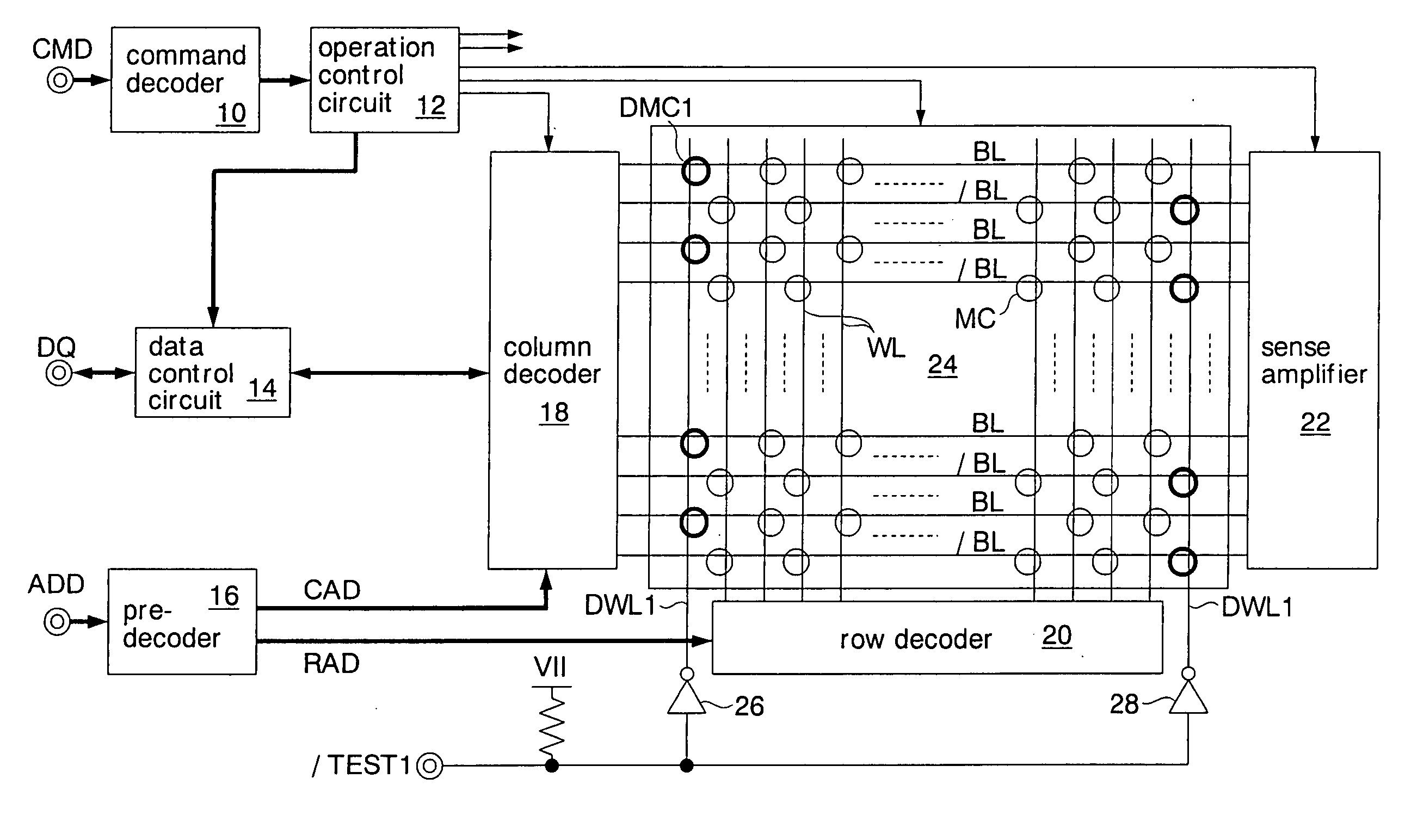

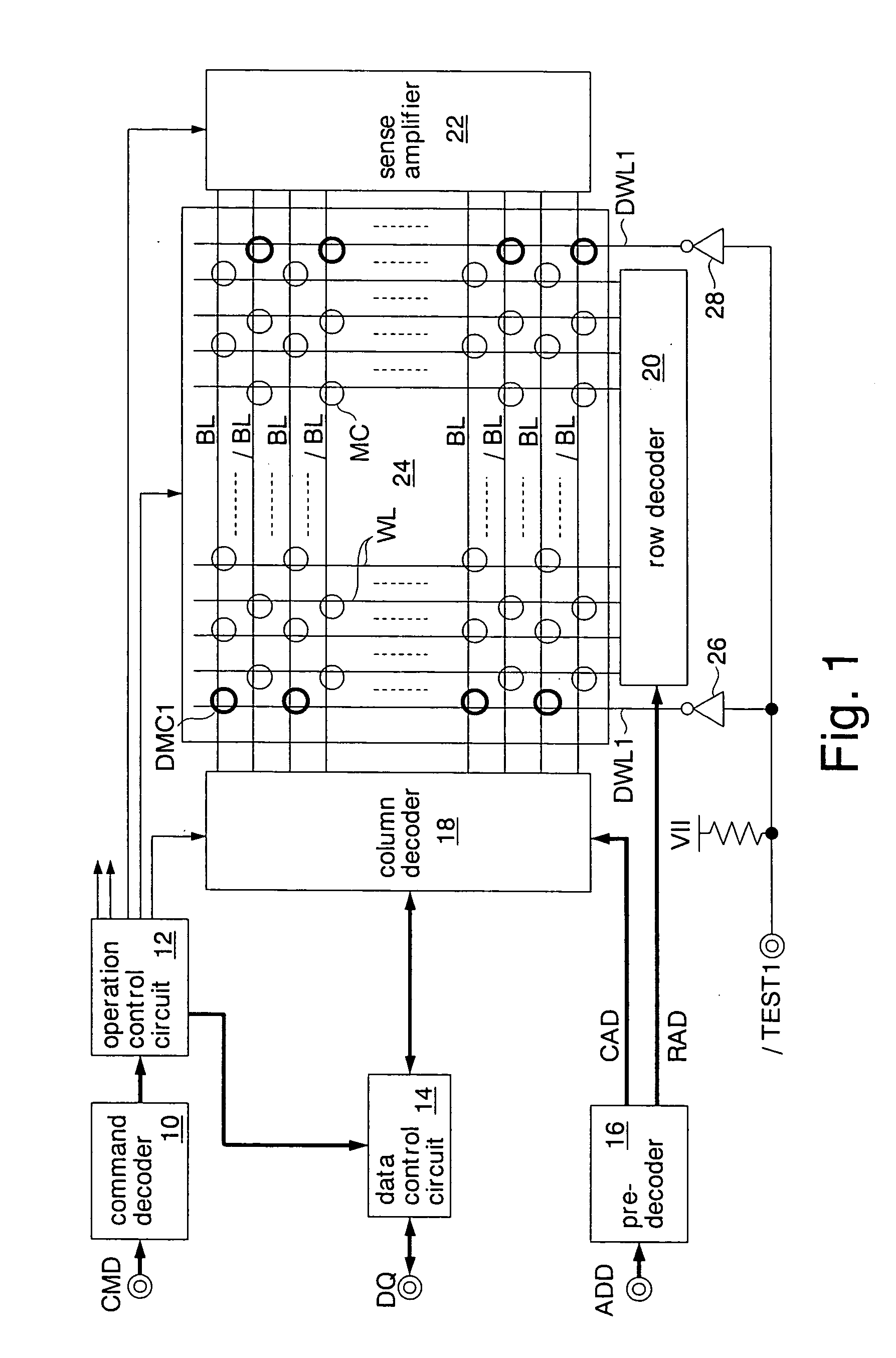

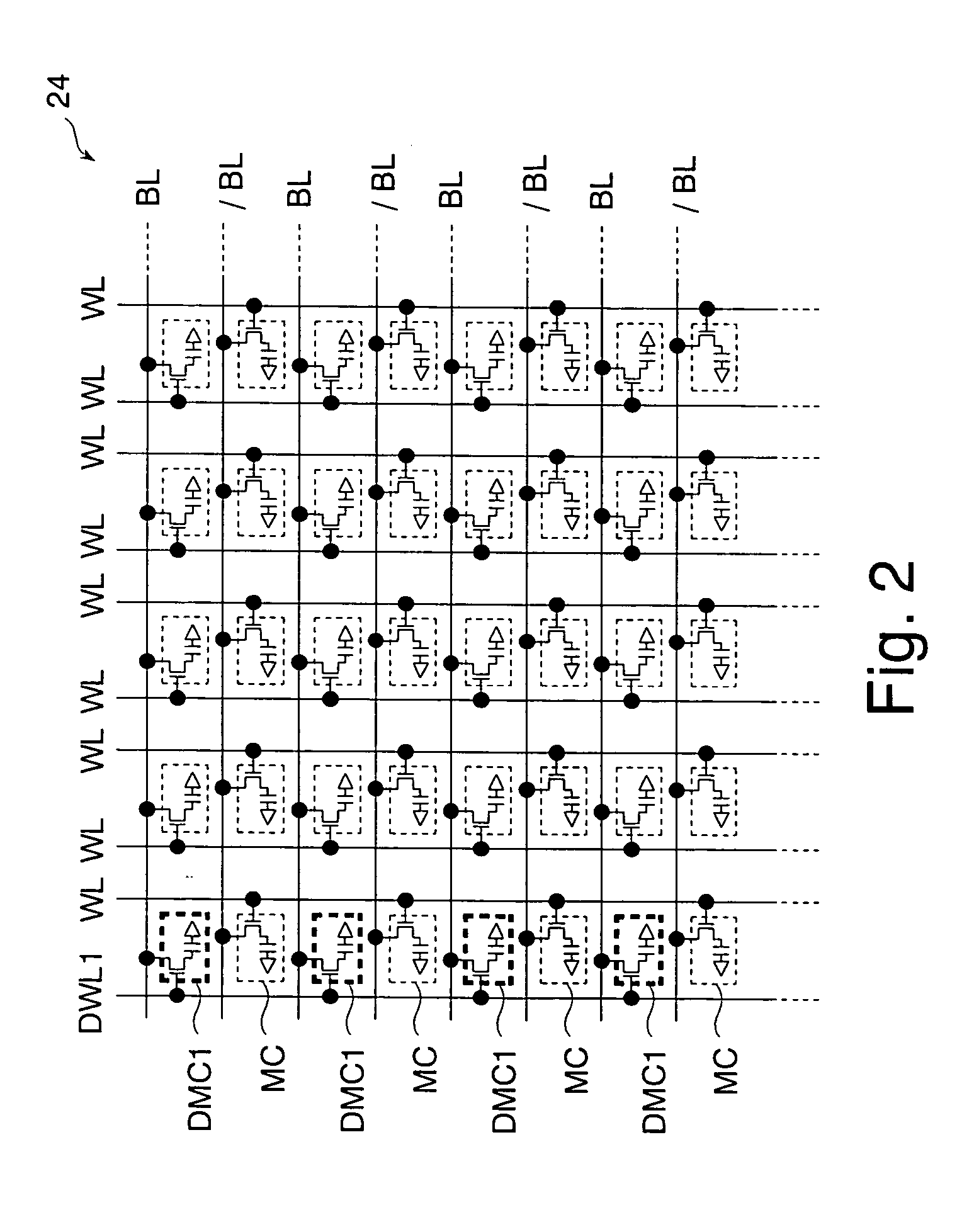

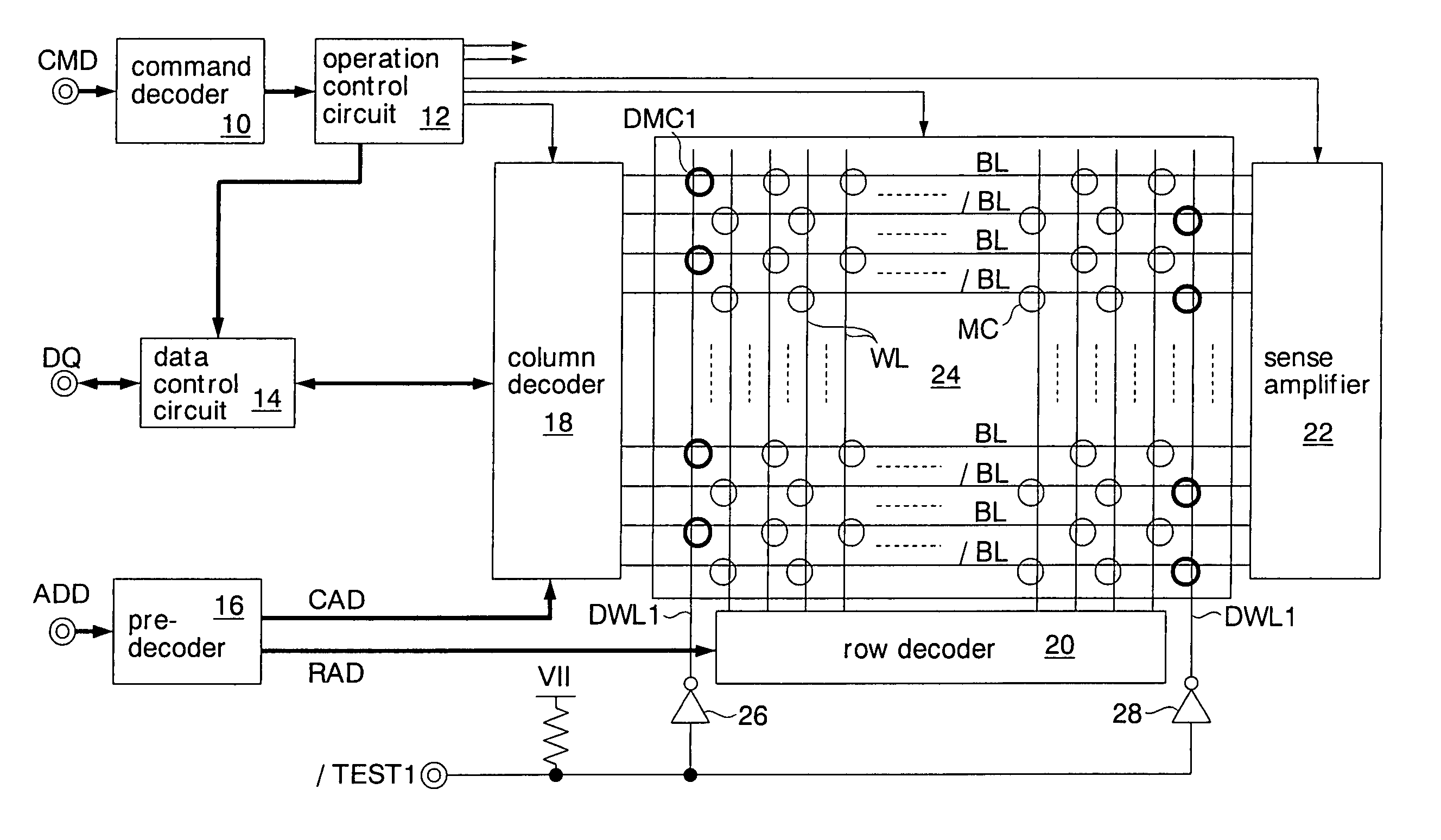

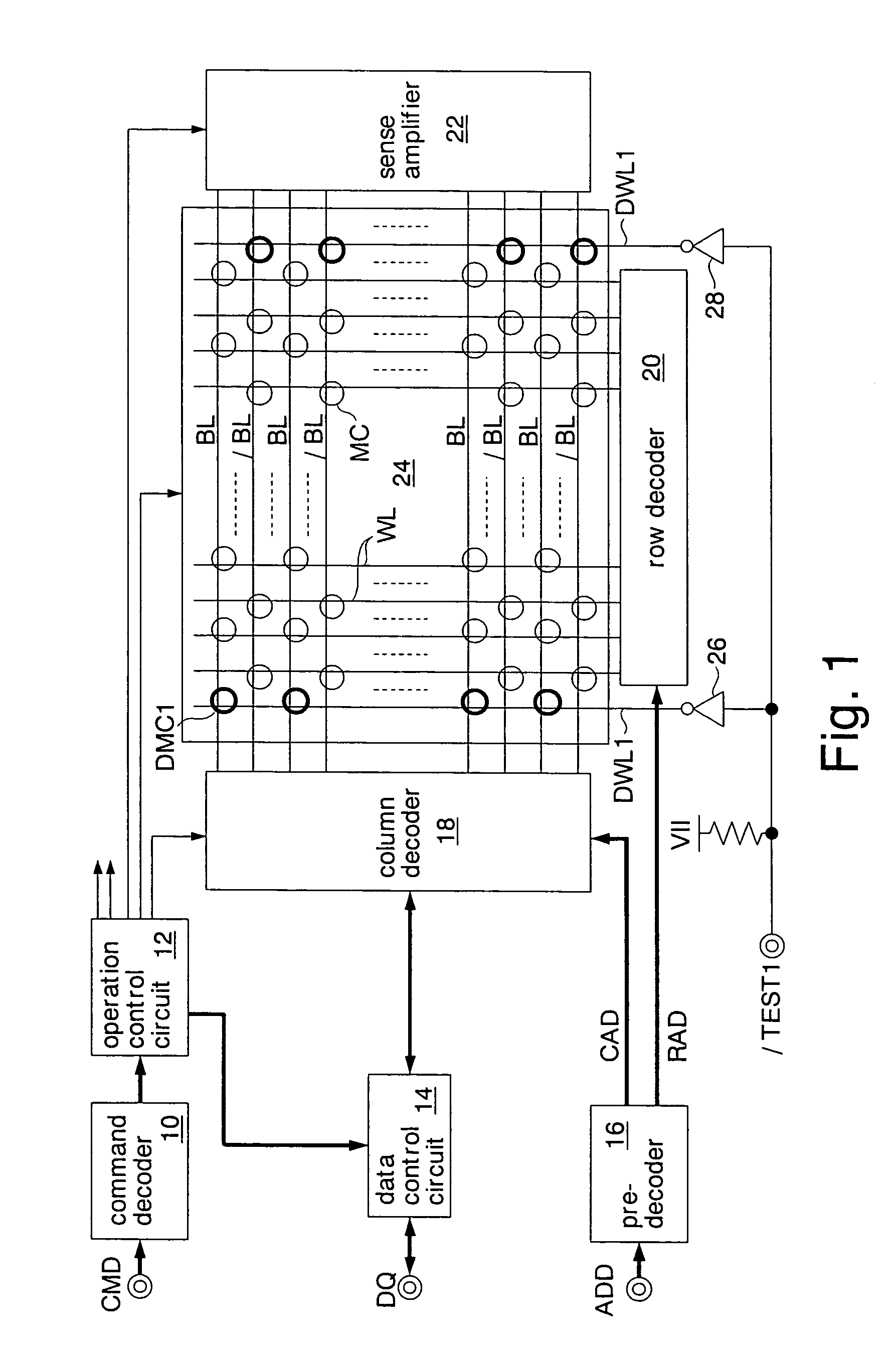

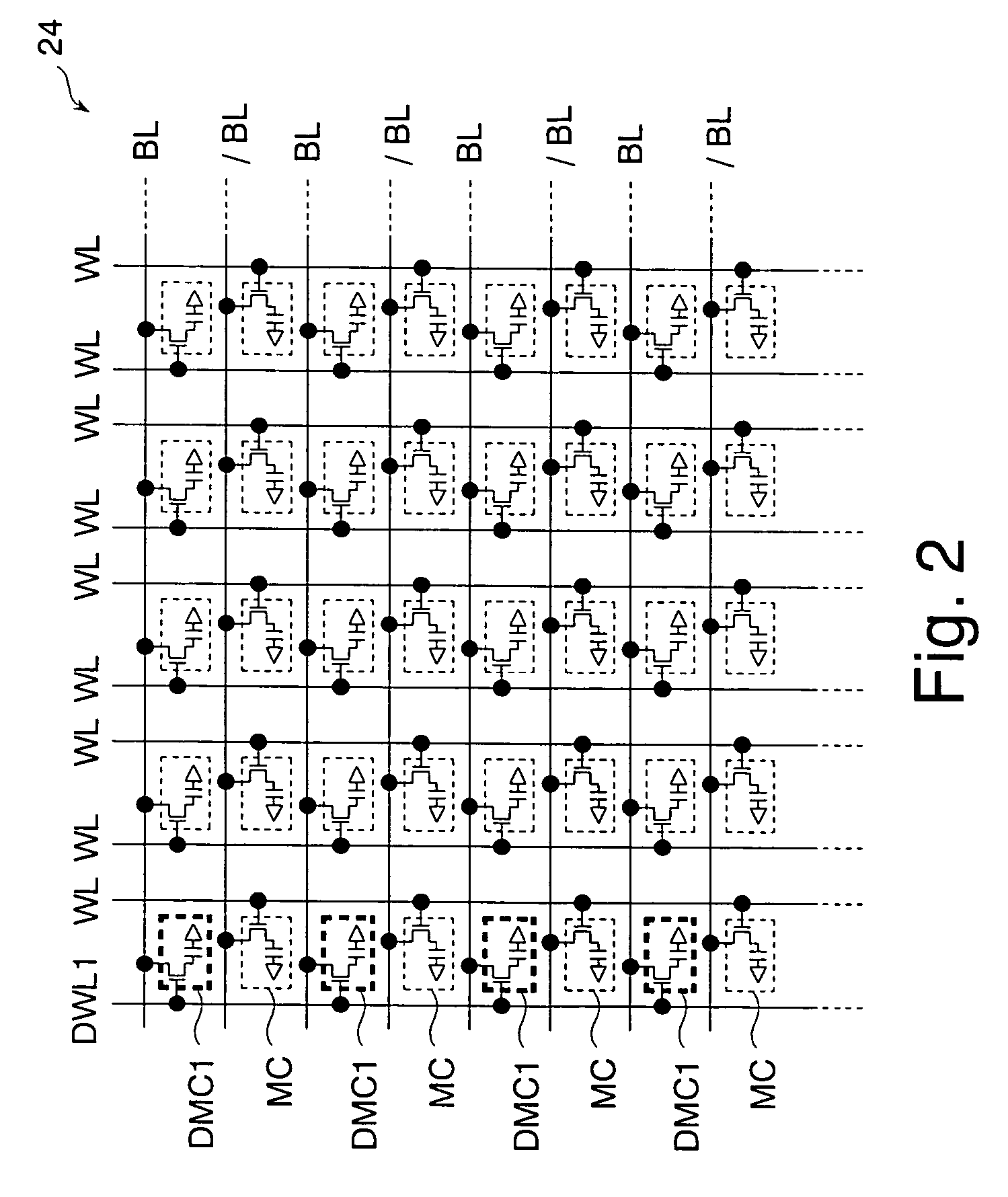

Semiconductor memory

InactiveUS20050278592A1Easily carry outIncrease in chip sizeElectronic circuit testingDigital storageVoltageSignal lines

First dummy memory cells connected to a first dummy signal line have the same shape and characteristics as those of a real memory cell. The first dummy memory cells are arranged to be adjacent to outermost real memory cells. A voltage setting circuit changes the voltage of the first dummy signal line from a first voltage to a second voltage in order to write test data onto the first dummy memory cell during a test mode. By writing data of a logic opposite to that of the test data onto the real memory cell adjacent to the first dummy memory cell by means of an operation control circuit, a leak failure that may occur between the first dummy memory cell and the real memory cell adjacent thereto can be checked.

Owner:SOCIONEXT INC

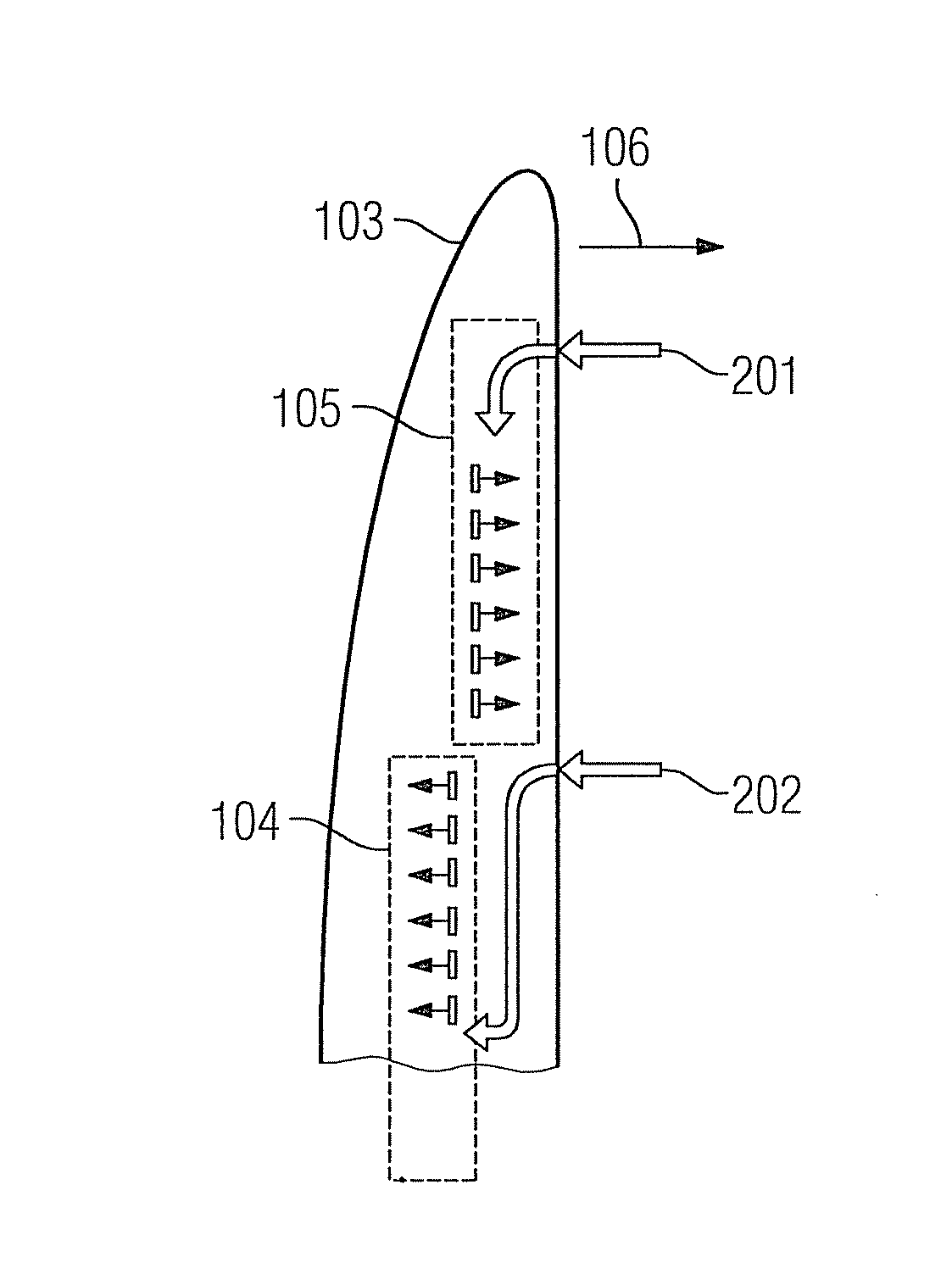

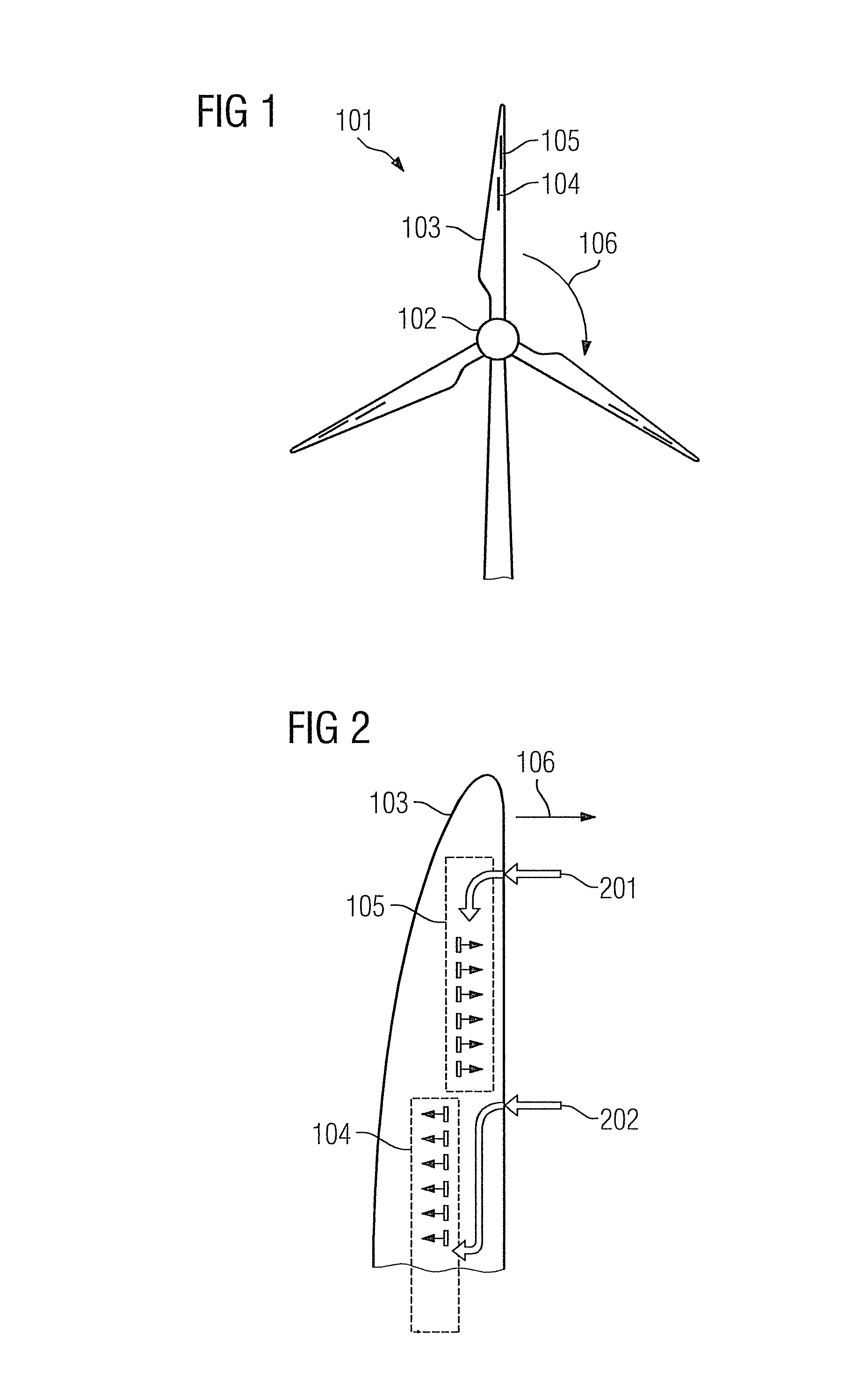

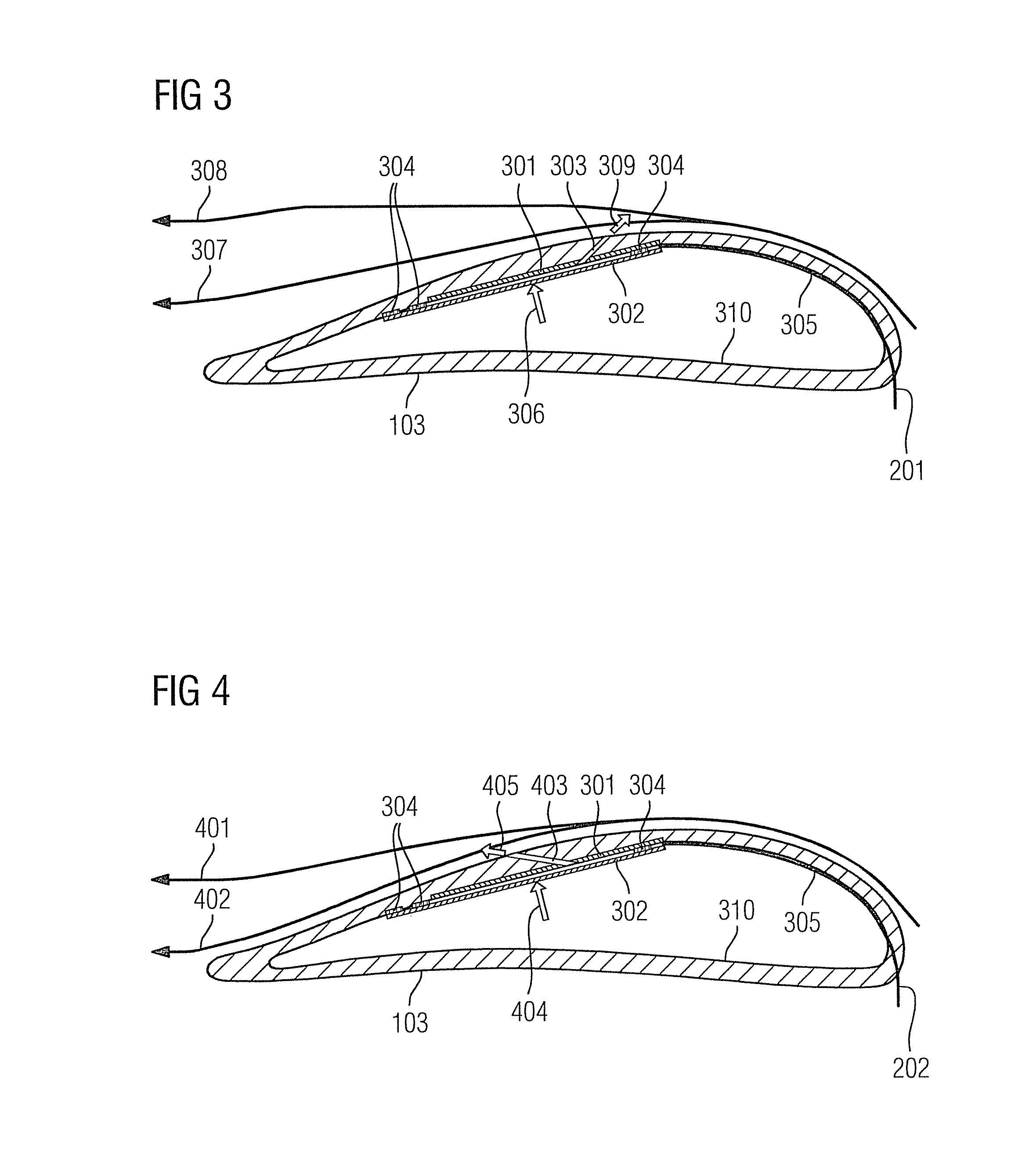

Control of a wind turbine, rotor blade and wind turbine

InactiveUS9194369B2Extended service lifeStrong stressPropellersWind motor controlRecreationEngineering

A wind turbine rotor blade is equipped with an air chamber and equipped via the air chamber to route a modulation beam out of the rotor blade such that the air current along the rotor blade is changed. Thereby the laminar current is changed into a turbulent current on the one hand and its detachment and on the other hand its recreation is achieved in order to produce the laminar current. The control may occur via electrostatic actuators via a learnable control strategy based on neural forecasts, which take the complexity of the non-linear system into account and allow for the plurality of influencing factors. The stress on the rotor blades may be reduced, resulting in longer service life and reduced maintenance costs, a higher level of efficiency or quieter operation.

Owner:SIEMENS AG

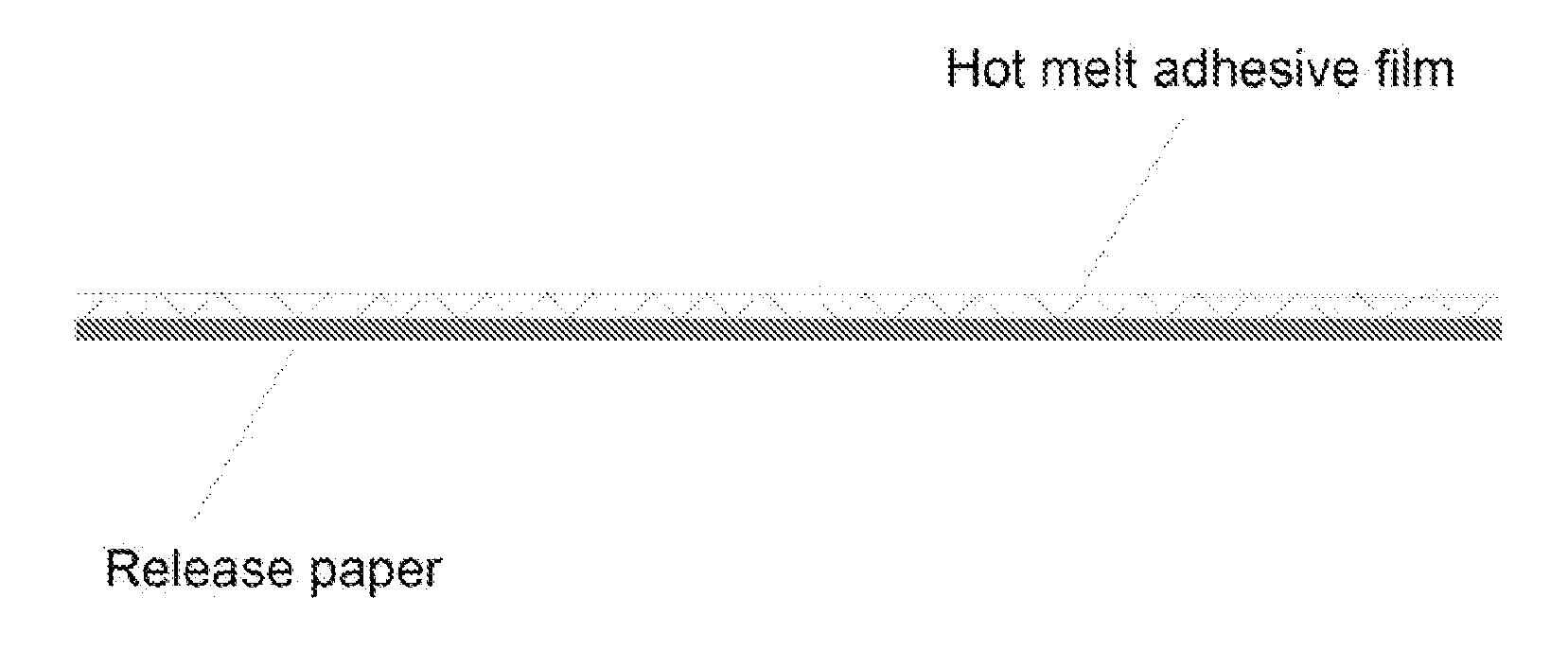

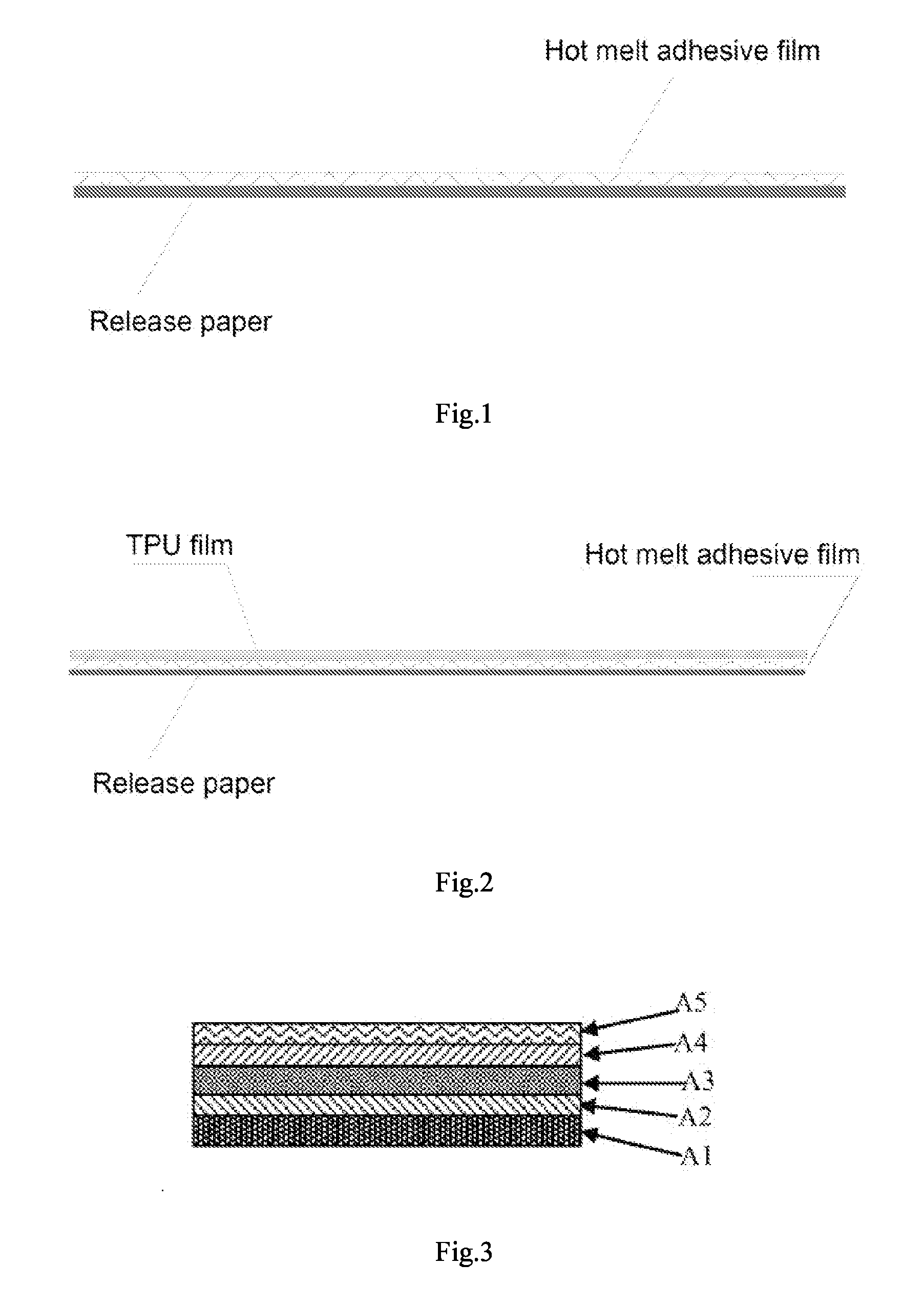

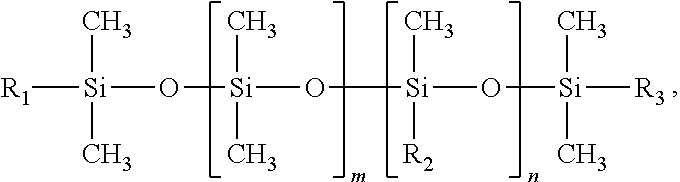

Sewing-free hot melt adhesive TPU leather and preparation method thereof

ActiveUS20160215174A1Excellent physicochemical performanceHigh bonding strengthFilm/foil adhesivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The present invention provides a novel sewing-free hot melt adhesive TPU leather and a preparation method thereof. The hot melt adhesive TPU leather comprises a release paper, a hot melt adhesive film, and a TPU film. The release paper comprises a bottom paper layer, an adhesive layer, a plastic layer, a transition layer, and a release layer; a hot melt adhesive raw material comprises polyester polyol, diisocyanate, polyether polyol, and a plurality of additives; and a TPU raw material comprises polymer polyol, 1,4-cyclohexane-diisocyanate, a chain extender, and a plurality of functional additives. According to the present invention, innovations are conducted on raw material components of the release paper, the hot melt adhesive, and the TPU film, and extrusion shaping is conducted by utilizing the hot melt adhesive with strong plasticity and the TPU thin film; and the prepared sewing-free TPU leather has the technical advantages of firm adhesion, durability, environmentally-friendly materials, no invisible harm to human body, and the like.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

Rolling plate assembly attachment for portable power cutting tools including an improved structural design and manufactured out of improved materials, an improved wheel configuration, and an adjustable bevel gear and a cutting guide

ActiveUS8181559B1Facilitate safe rolling movementQuick changeMetal sawing devicesTurning machine accessoriesFiberGear wheel

The present invention is an attachable rolling plate assembly which can be attached as a single unit to a portable cutting tool to facilitate the safe rolling movement of the portable cutting tool on the workpiece. The invention comprises a frame assembly formed from a single piece of molded material such as fiber enriched plastic having a pair of oppositely disposed longitudinal sidewalls with stabilizer fins extending therefrom, and a flat base portion having a pair of parallel stabilizer tubes molded therein. The invention further includes an adjustable bevel gear assembly by which the angle of orientation of the cutting blade can be quickly changed. The invention also includes a cutting guide assembly to facilitate a straight cut, reduce torsional rotation of the saw blade and reduce kickback of the saw.

Owner:CIRCSAW TECH LLC

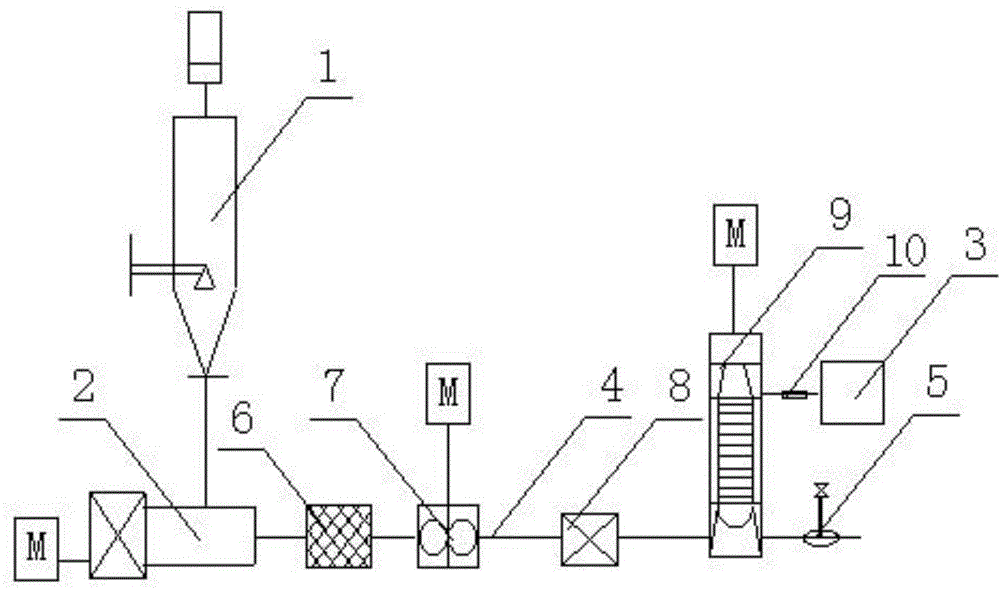

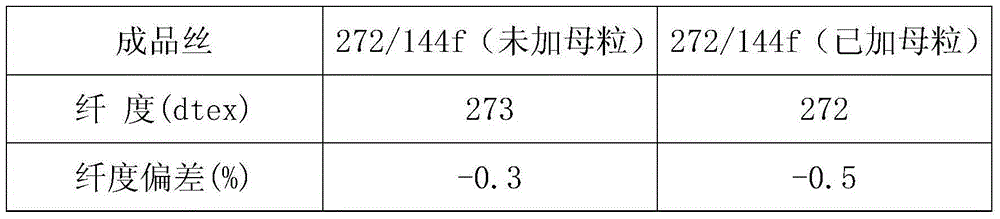

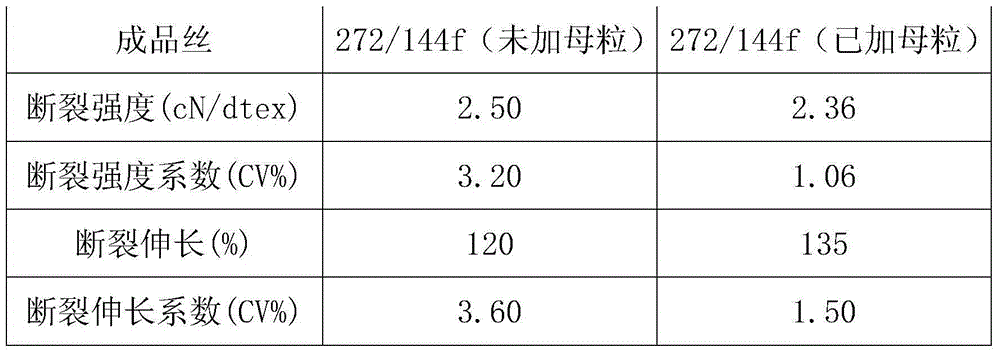

Preparation method of high-comfort triangular hollow microporous fiber

ActiveCN103603070AIncrease the amount of controlSimple production processFilament forming substance formingHollow filament manufacturePolyesterMoisture

The invention discloses a preparation method of a novel polyester fiber and particularly relates to the preparation method of a high-comfort triangular hollow microporous fiber which is newly developed and has the advantages of being dry, comfortable, cool and refreshing, capable of absorbing sweat and draining moisture, light, good in warm keeping, easy to clean, fast to dry and the like. According to the preparation method of the high-comfort triangular hollow microporous fiber, the online measurement addition technique and a melt spinning process are adopted, three symmetrical V-shaped spinneret plates serve as spinneret assemblies to obtain the fiber, and an alkali reduction process is performed to obtain the high-comfort triangular hollow microporous fiber. The fiber fabric has the advantages of being dry, comfortable, cool and refreshing, capable of absorbing sweat and draining moisture, easy to clean, fast to dry, light, good in warm keeping and the like.

Owner:湖州市中磊化纤有限公司

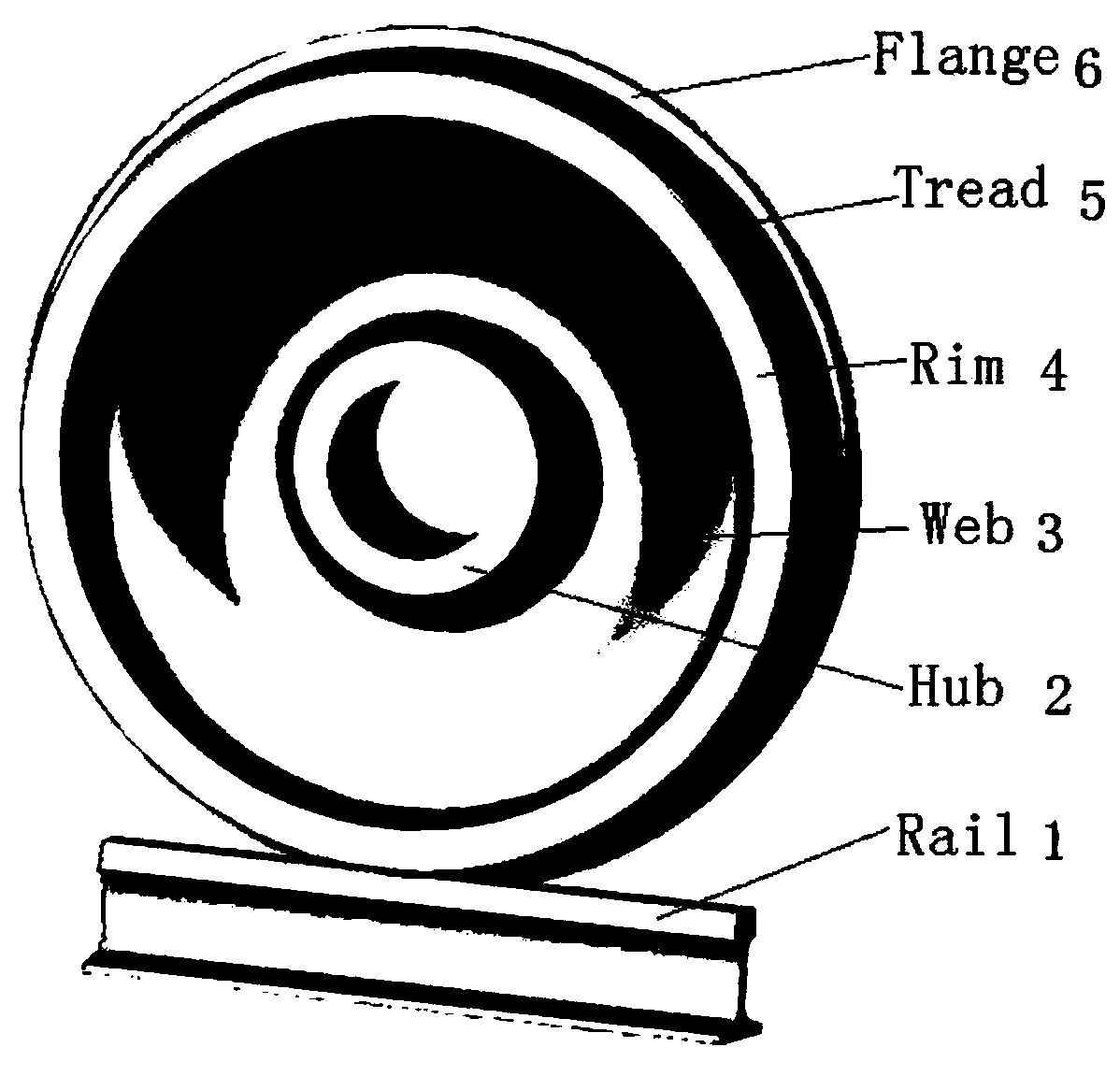

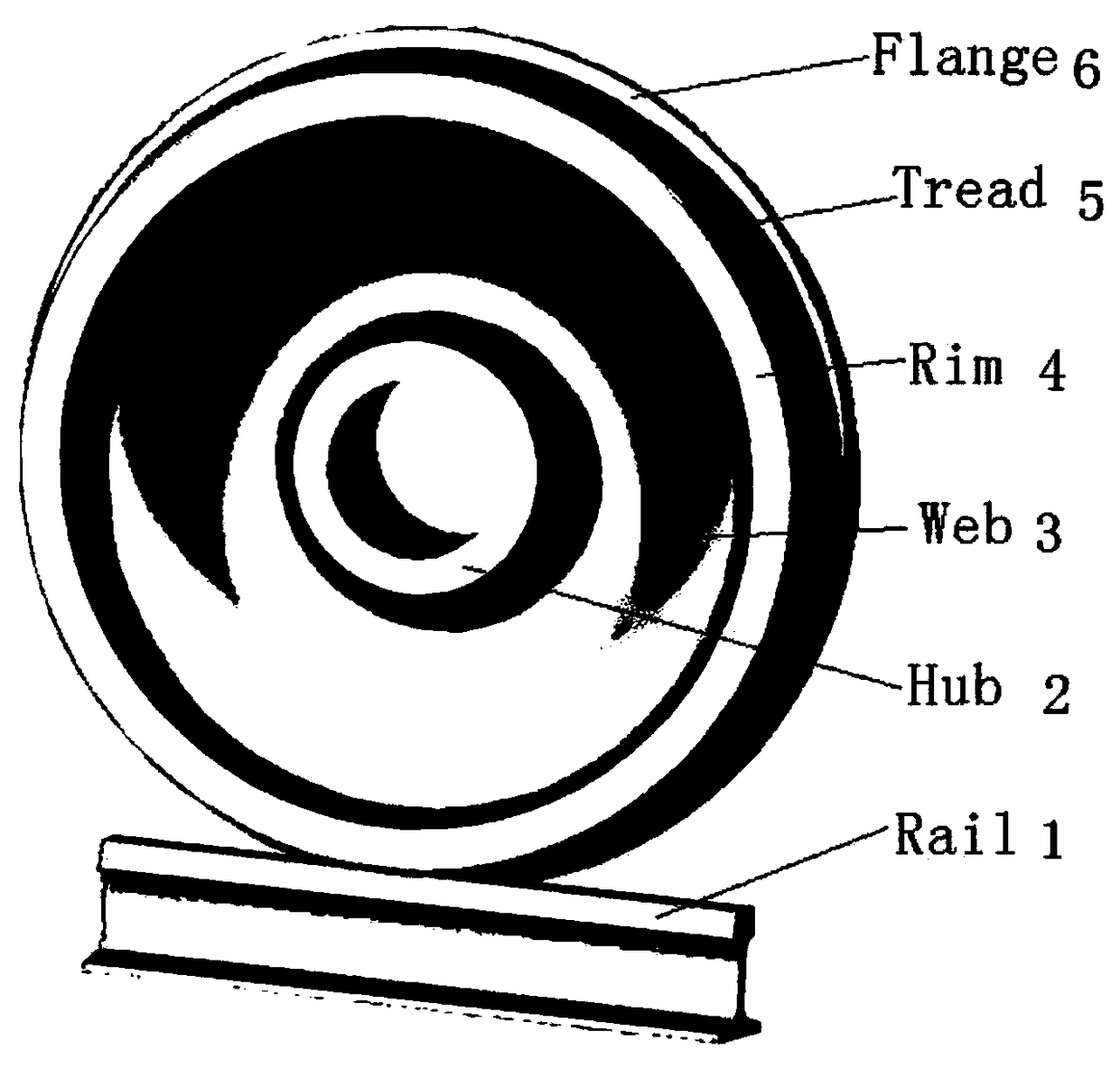

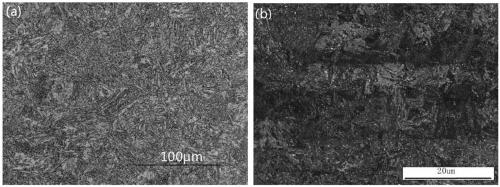

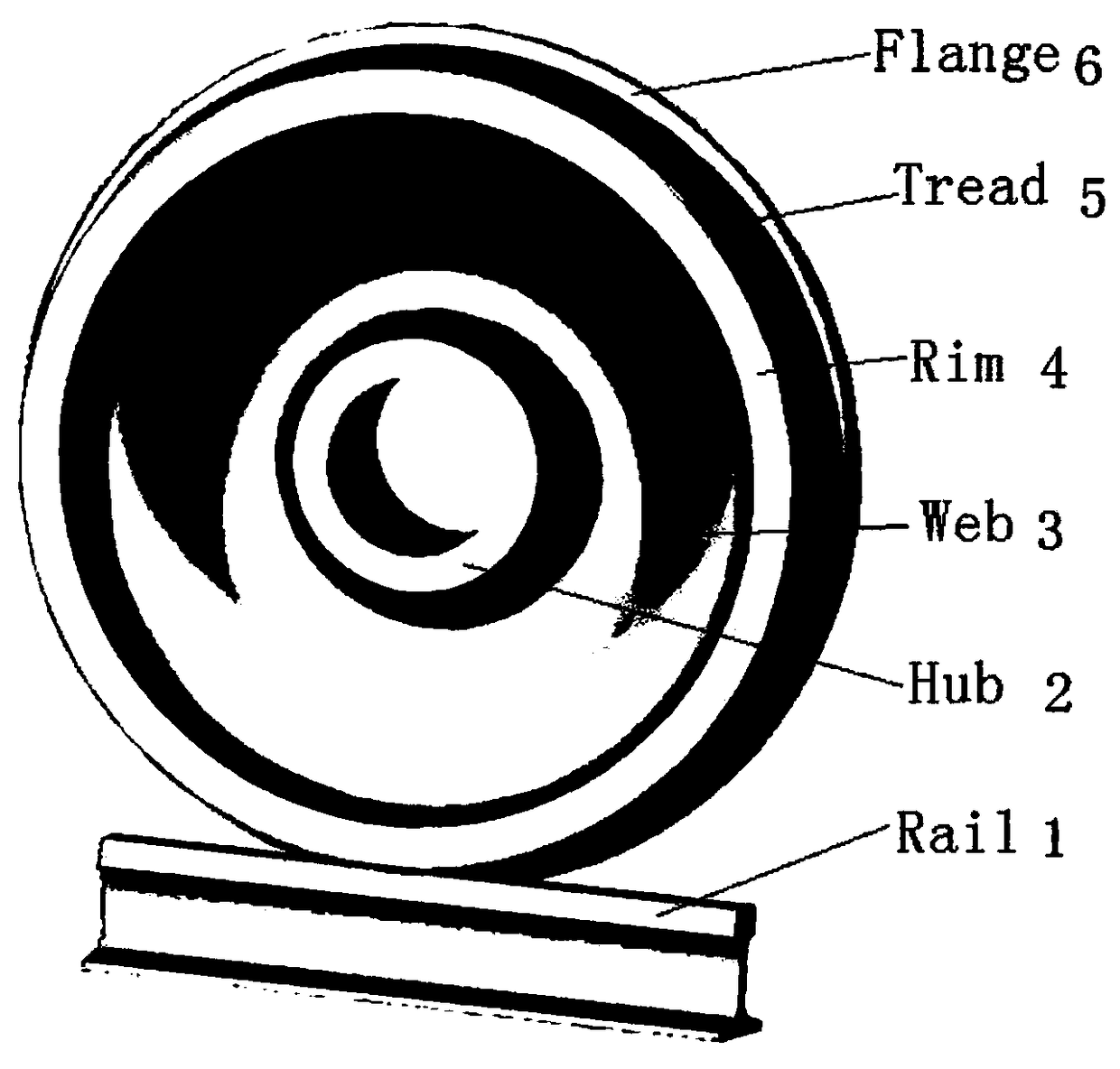

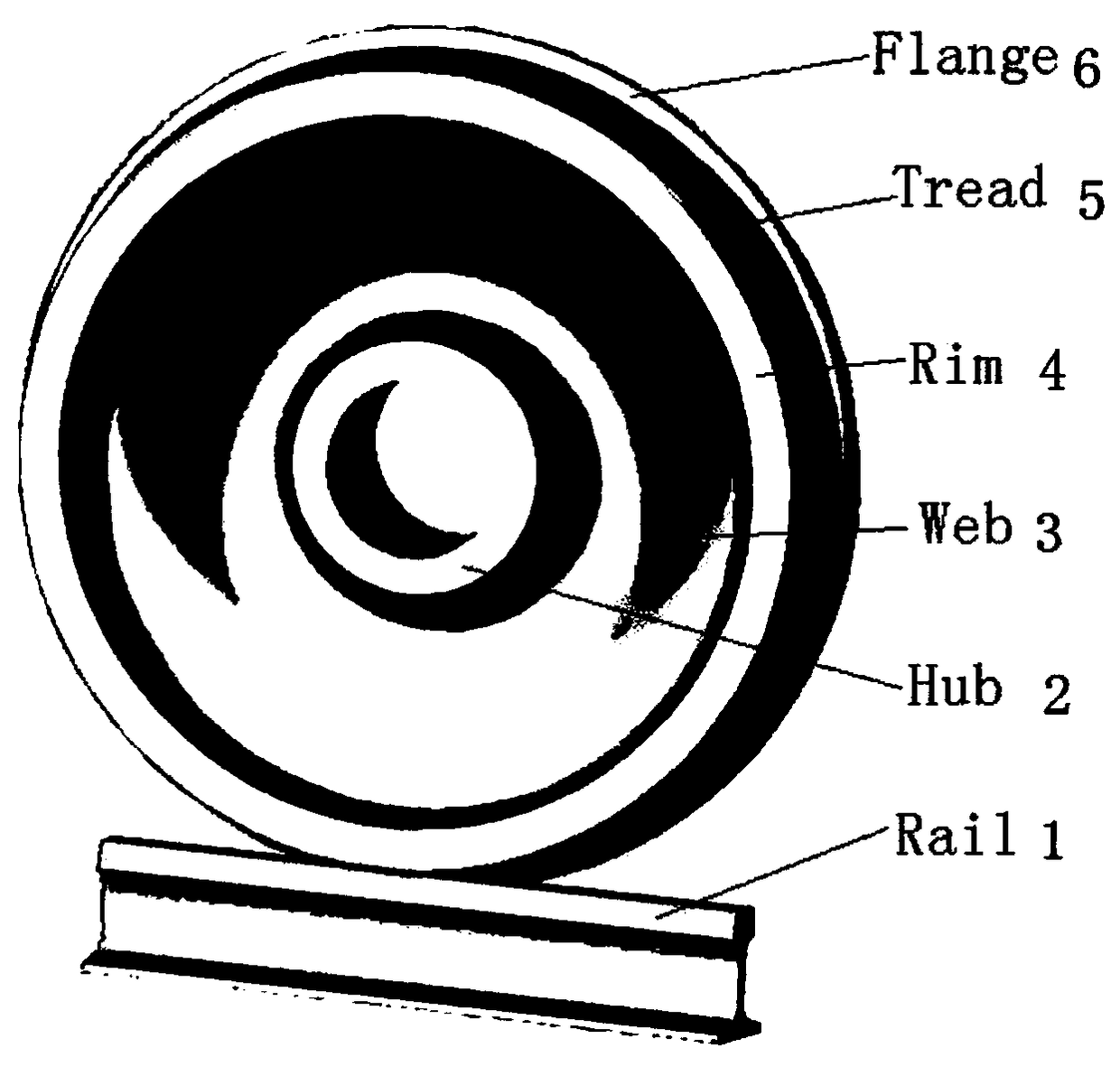

Common rail traffic bainite steel wheel used under cold and rigor service environment and manufacturing method of common rail traffic bainite steel wheel

InactiveCN108707831AHigh yield strengthHigh tensile strengthRail-engaging wheelsFurnace typesChemical compositionCommon rail

The invention discloses a common rail traffic bainite steel wheel used under the cold and rigor service environment and a manufacturing method of the common rail traffic bainite steel wheel. The common rail traffic bainite steel wheel comprises chemical components including 0.05%-0.30% of C, 0.50%-1.50% of Ni, 0.01%-1.20% of Cr, 0.70%-2.10% of Mn, 0.20%-1.00% of Si, 0.01%-1.00% of W, 0.05%-0.60% of Mo, 0.01%-0.80% of Cu, 0.01%-0.20% of V, 0.001%-0.20% of Nb, 0.0001%-0.0350% of B, 0.001%-0.040% of RE, not larger than 0.020% of P, not larger than 0.020% of S and the balance Fe and inevitable residual elements, wherein the sum of Mn and Cr is larger than or equal to 2.0% and smaller than or equal to 3.0%. By adopting a new alloy design system and alloying principle of C-Ni-Mn-Cr-Mo, after thewheel is molded, a rim obtained after advanced heat treatment obtains a carbide-free bainite organization structure, and the wheel has the excellent comprehensive mechanical property, decay resistance and service performance, in particular has the high low-temperature toughness and low-temperature breaking toughness, meets performance and service safety requirement under the low-temperature environment and is suitable for the cold zone under rigor conditions.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

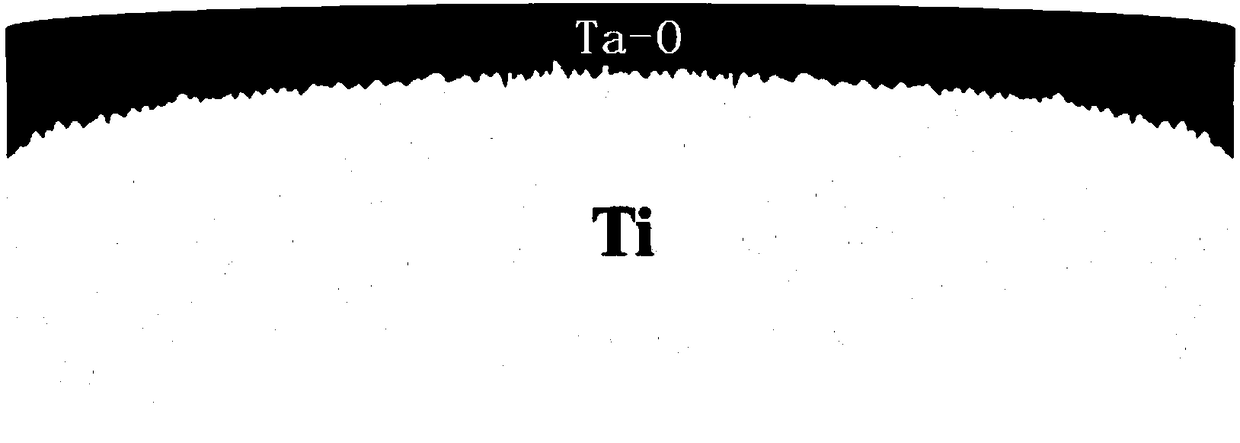

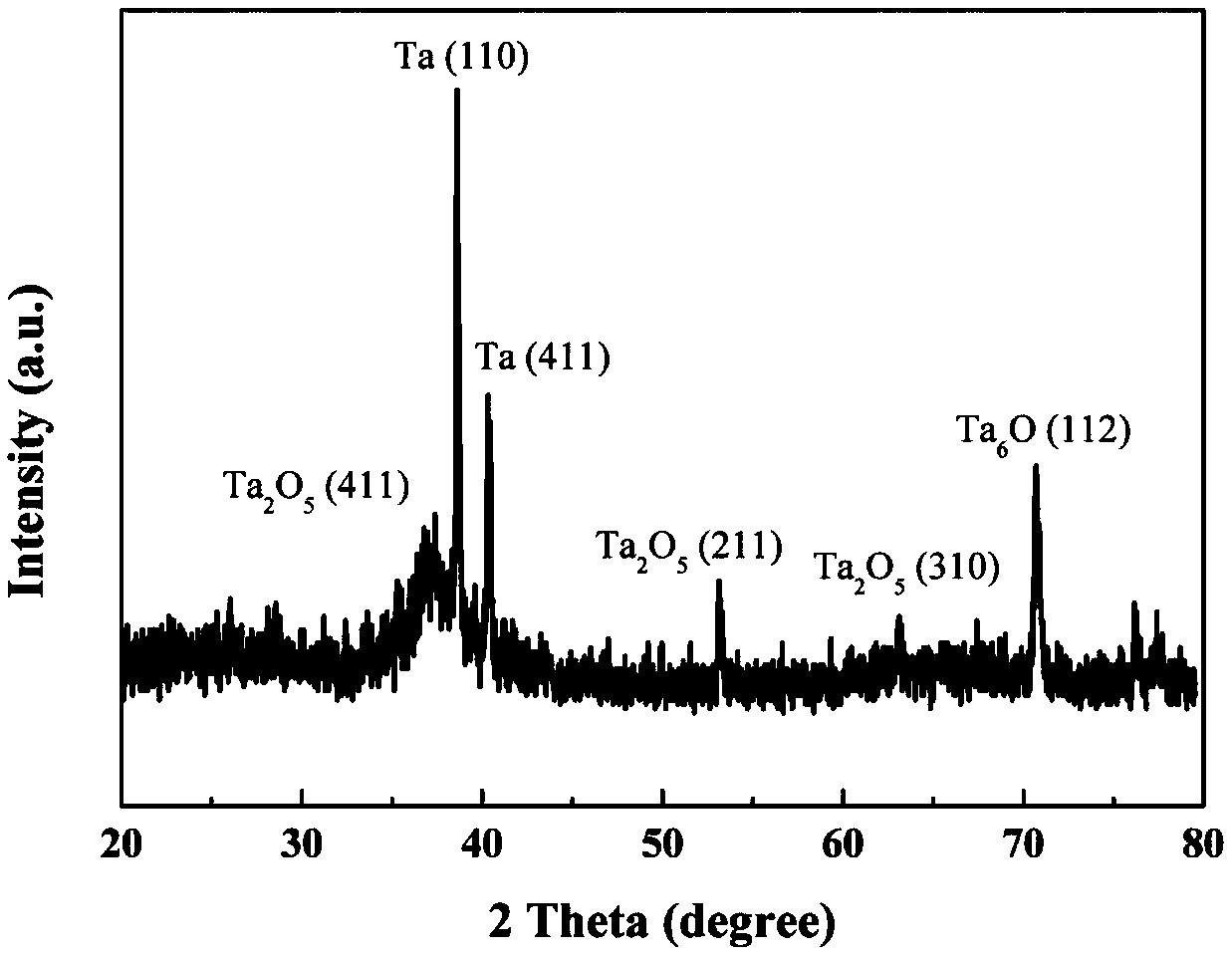

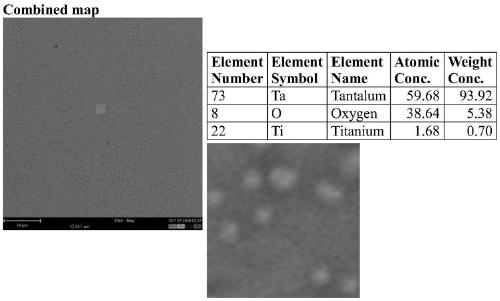

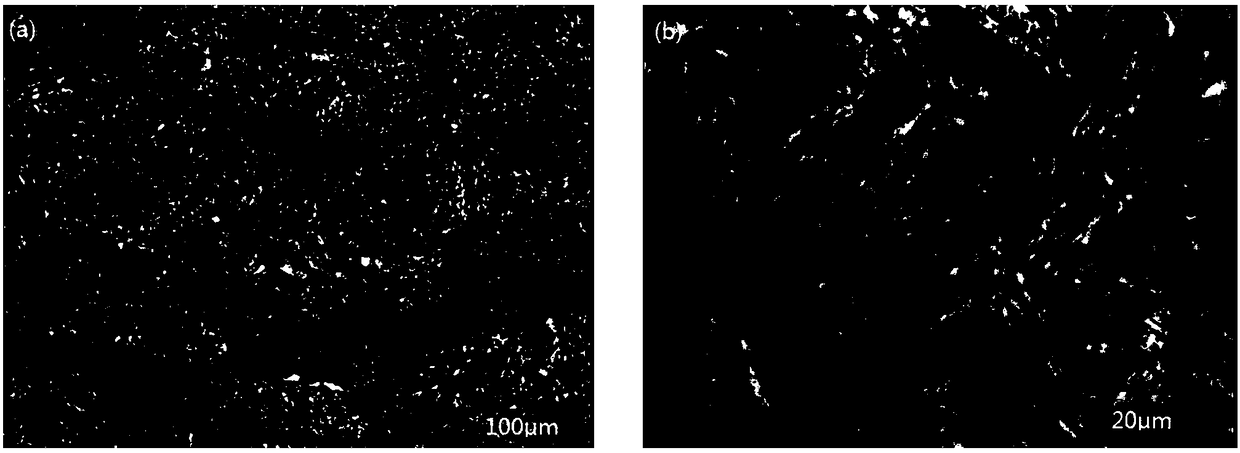

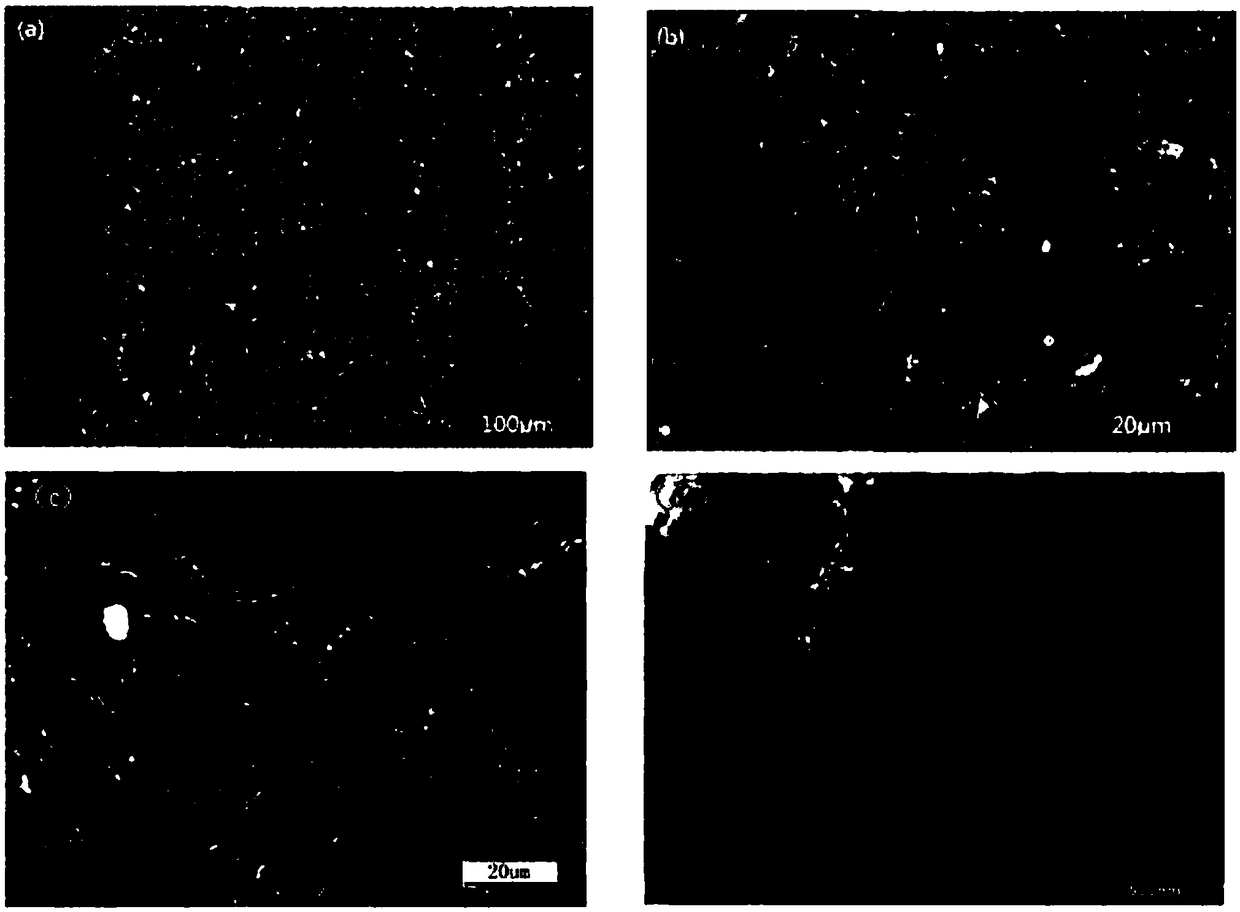

Surface-modified coating and preparation method and application thereof

ActiveCN109487199AGood chemical stabilityIon dissolution is smallMolten spray coatingVacuum evaporation coatingIon beam sputteringWear resistance

The invention discloses a surface-modified coating and a preparation method and application thereof. The surface-modified coating comprises from inside to outside an inner-layer porous titanium coating and an outer-layer Ta-O layer. The preparation method for the surface-modified coating comprises the steps that titanium powder is adopted as a raw material, and plasma spraying is adopted so that aporous-structured titanium coating is prepared on the surface of a base material; and tantalum is adopted as a target material, through oxygen, an ion beam sputtering coating method is adopted, and aTa-O coating is prepared on the surface of the porous titanium coating. The surface-modified coating can be used for preparing a repair and substituent material of hard tissues. The surface-modifiedcoating has both good wear resistance and anti-corrosion property and low elastic modulus; and in addition, the surface-modified coating is bonded closely with the base material and small in stress.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Semiconductor memory having a dummy signal line connected to dummy memory cell

InactiveUS7184333B2Avoid Leakage FailuresReduce testing costsElectronic circuit testingDigital storageHemt circuitsEngineering

First dummy memory cells connected to a first dummy signal line have the same shape and characteristics as those of a real memory cell. The first dummy memory cells are arranged to be adjacent to outermost real memory cells. A voltage setting circuit changes the voltage of the first dummy signal line from a first voltage to a second voltage in order to write test data onto the first dummy memory cell during a test mode. By writing data of a logic opposite to that of the test data onto the real memory cell adjacent to the first dummy memory cell by means of an operation control circuit, a leak failure that may occur between the first dummy memory cell and the real memory cell adjacent thereto can be checked.

Owner:SOCIONEXT INC

Bainitic steel wheel for rail traffic with capability of resisting against damp, hot and corrosive environments and manufacturing method thereof

InactiveCN109182920AHigh yield strengthHigh tensile strengthRail-engaging wheelsFurnace typesCarbideAlloy

The invention discloses a bainitic steel wheel for rail traffic with capability of resisting against damp, hot and corrosive environments and a manufacturing method thereof. The bainitic steel wheel comprises the following chemical components: 0.05-0.40% of C, 0.40-1.50% of Ni, 0.25-1.50% of Cr, 0.70-2.10% of Mn, 0.20-1.00% of Si, 0.01-1.00% of W, 0.05-0.60% of Mo, 0.01-0.80% of Cu, 0.01-0.20% ofV, 0.001-0.20% of Nb, 0.0001-0.0350% of B, 0.001-0.040% of RE, less than or equal to 0.020% of P, less than or equal to 0.020% of S and the balance of Fe and inevitable residual elements, wherein Mn+Cr is more than or equal to 2.0% but less than or equal to 3.0%. The new alloy design system of C-Ni-Mn-Cr-Mo-Cu and alloying principle are adopted by the invention; after a wheel is formed, a rim after advanced thermal treatment is endowed with a carbide-free bainite structure; the wheel has excellent comprehensive mechanical property and service performance, especially, atmospheric corrosion resistance; the wheel is capable of resisting against damp, hot and corrosive environments and reducing the harmful influences of stress corrosion and medium corrosion; the service life and running safetyof the wheel can be further promoted.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

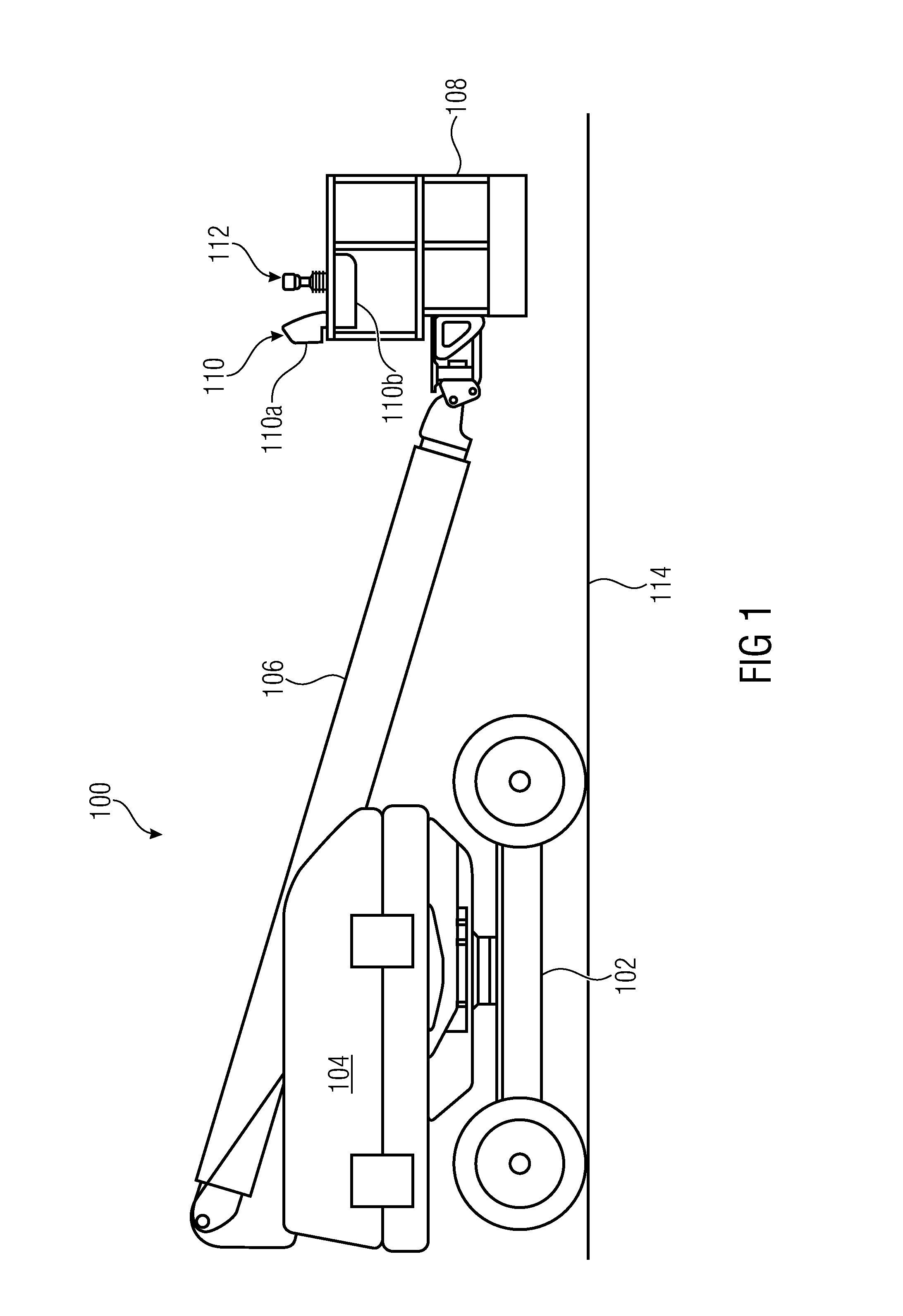

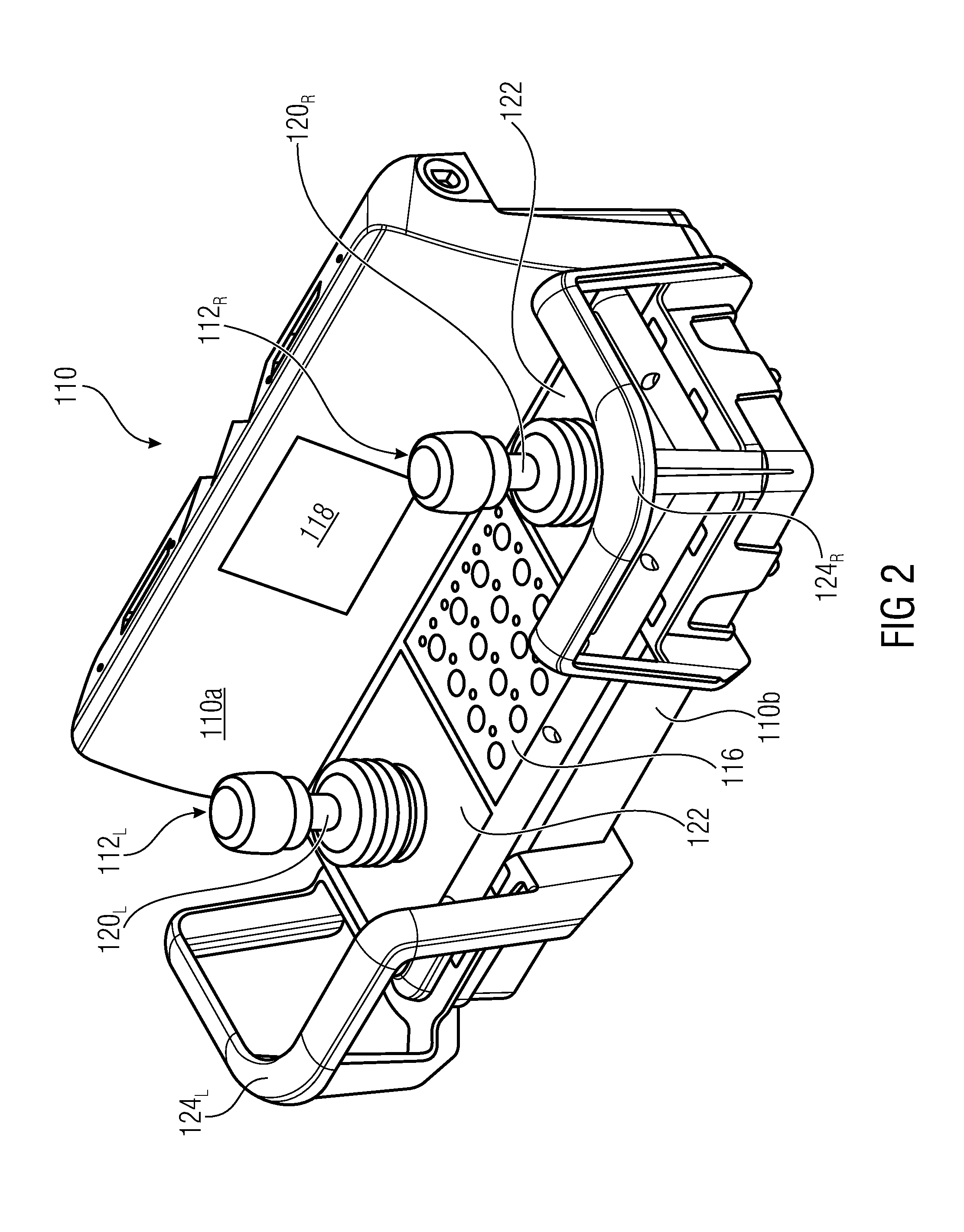

Manual control device, control and operating unit including a manual control device, and work machine or construction machine

ActiveUS20160306379A1Easy to implementSpend lessManual control with multiple controlled membersControlling membersEngineeringMagnetic field

A manual control device for a control and operating unit of a lifting work platform, work machine or construction machine has at least one actuating unit which has an actuation element having at least one magnetic position element, and an evaluating unit having at least one magnetic field sensor unit. The evaluating unit is configured to detect a position and / or movement of the actuation element in a plane of movement based on a sensor signal from the magnetic field sensor unit. The actuation element is movable relative to the sensor unit along a further direction of movement perpendicularly to the plane of movement, wherein the evaluating unit is configured to detect a movement of the actuation element along the further direction of movement based on a sensor signal from the magnetic field sensor unit.

Owner:MOBA MOBILE AUTOMATION

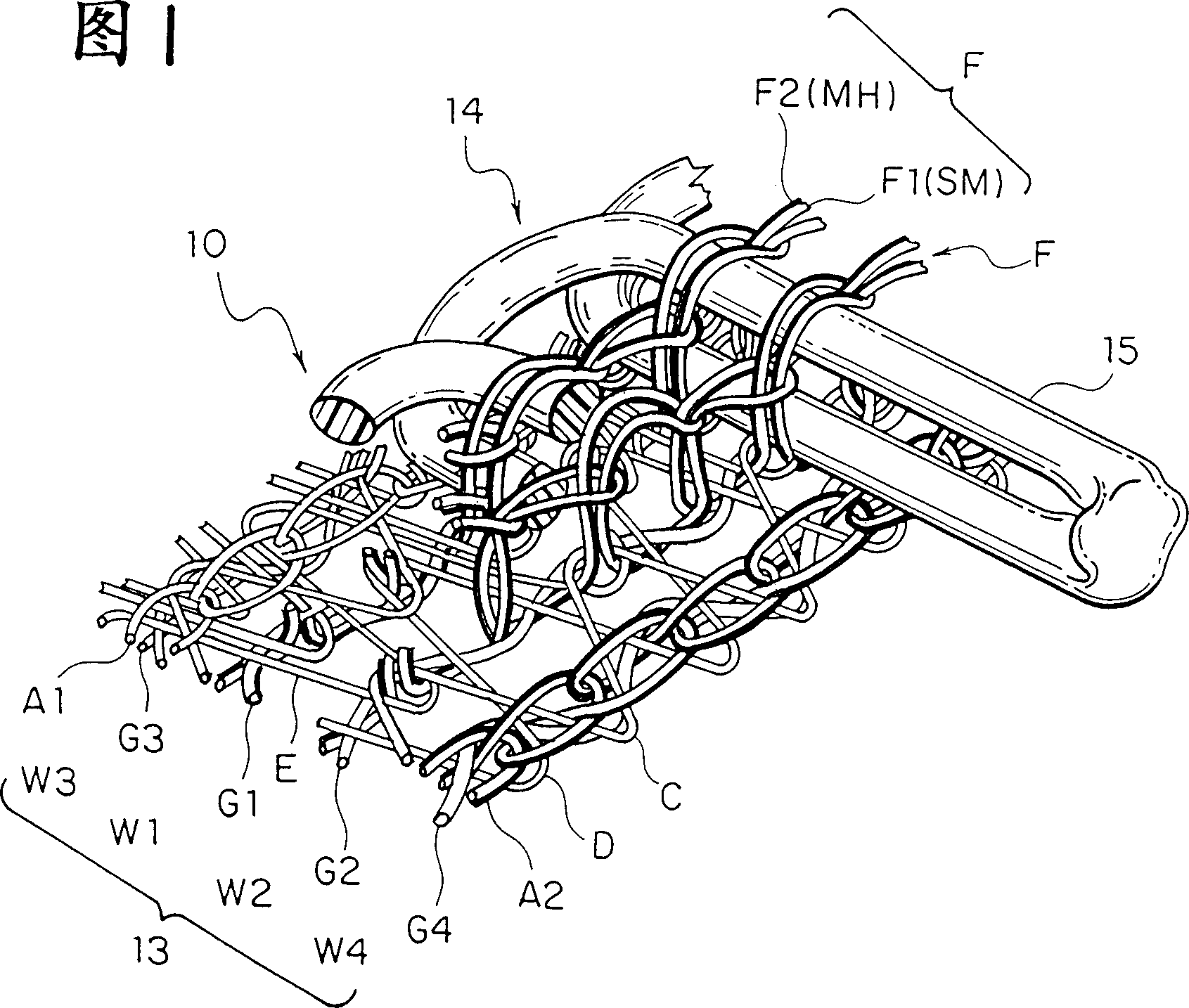

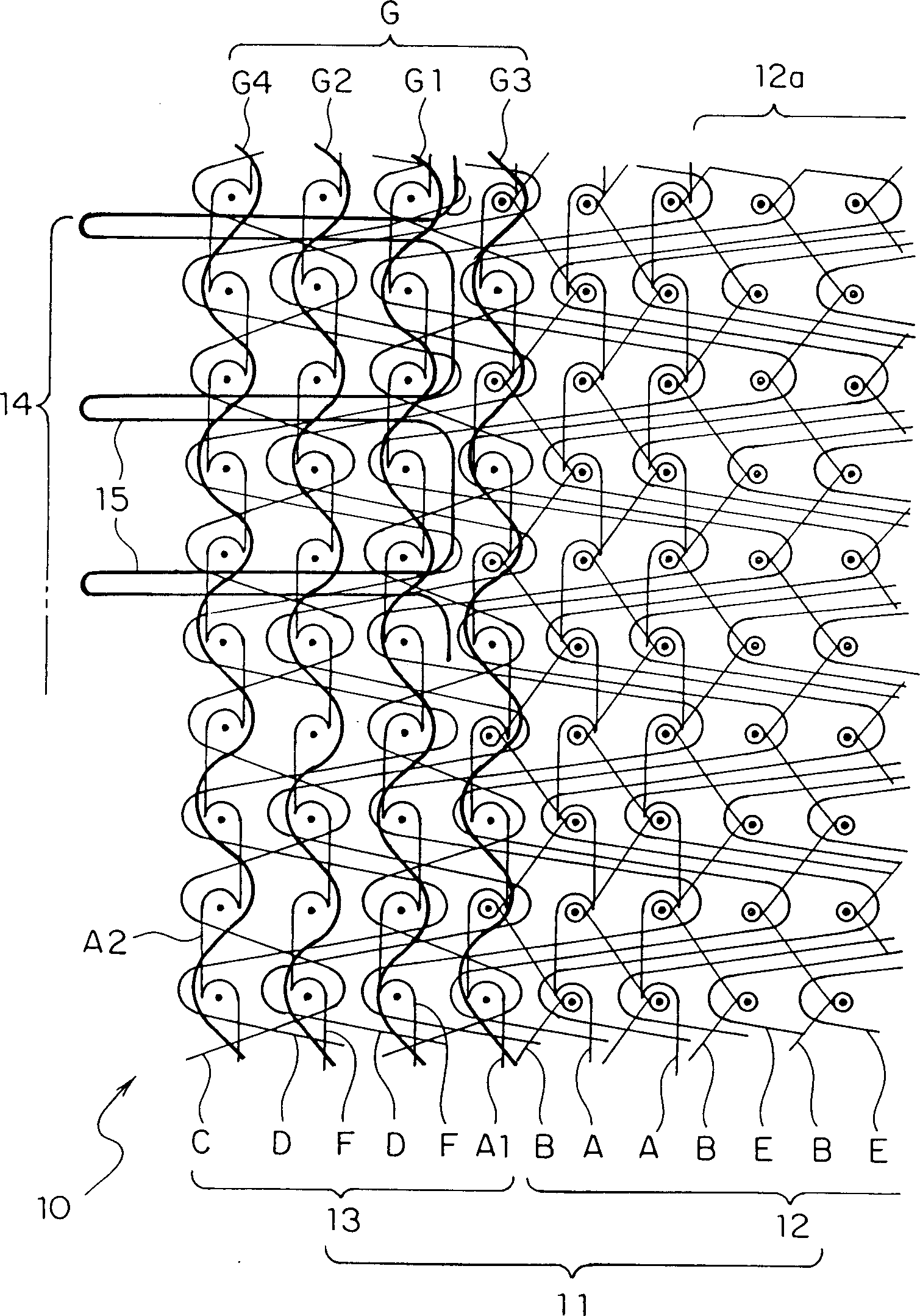

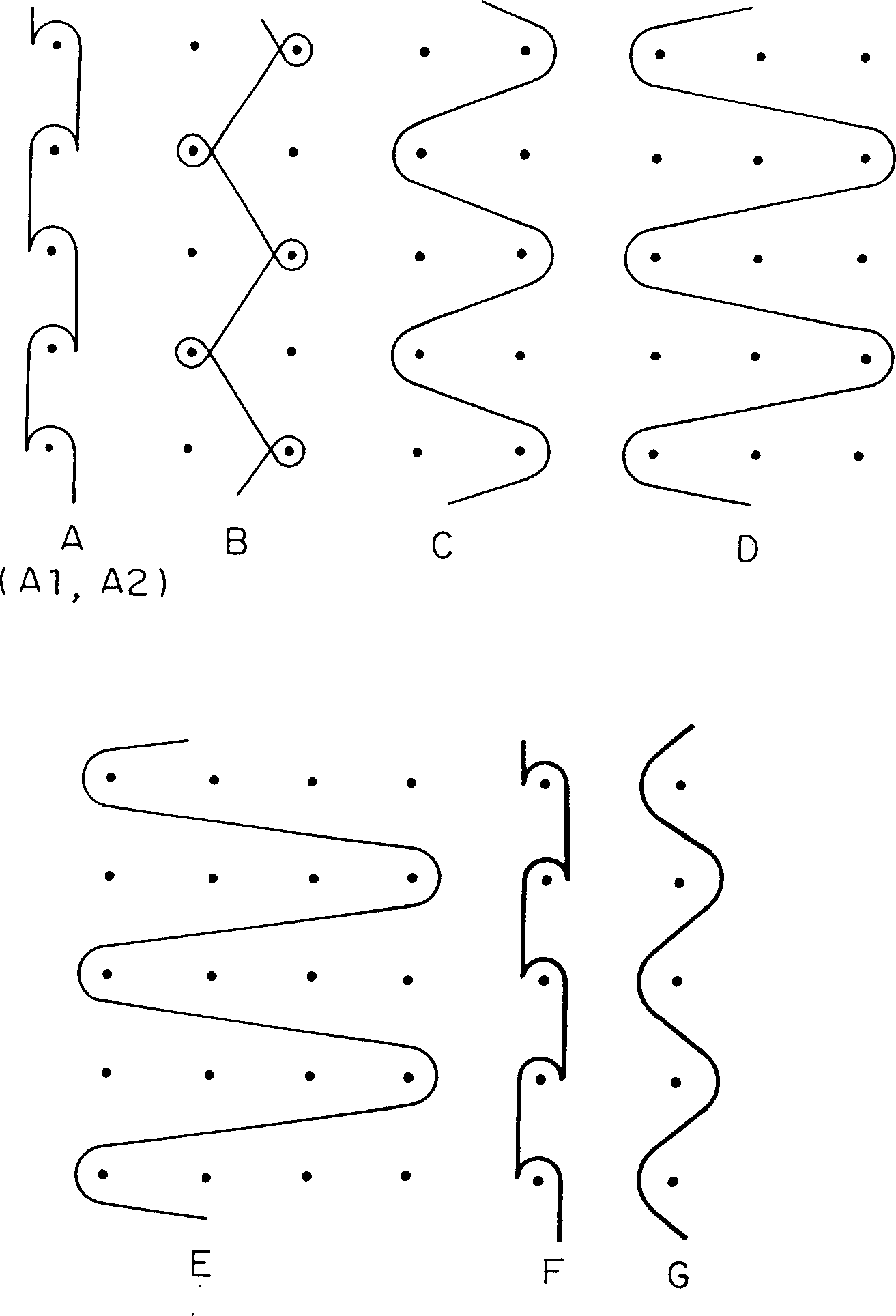

Knit zippers

A knitted-in slide fastener comprising a continuous fastener element row (14) which is knitted in at the same time as knitting of a fastener tape (11), wherein a fastener element mounting portion (13) on a side edge portion in the longitudinal direction of the warp knitted fastener tape (11) is knitted with a fixing knitting yarn (F) for sandwiching and fixing upper and lower leg portions of each fastener element (15) in a direction of front and rear of the fastener tape and other knitting yarns (C, D, G1 to G4). Part of these composition yarns is composed of composite fiber yarns formed of heat shrinkage fiber material (SM) and heat fusion fiber material (MM), and the heat shrinkage fiber material (SM) is shrunk by heat treatment and at the same time, the heat fusion fiber material (MM) is fused with other the composition yarns (F, C, D, G1 to G4) in the vicinity thereof. Consequently, no fraying occurs in yarns even if a knitting yarn, which forms the fastener element mounting portion, is cut out so that the fastener element row of that portion is not separated from the fastener tape.

Owner:YKK CORP

Bainite steel wheel for rail traffic D-series high-speed train and manufacturing method thereof

PendingCN108796372AHigh yield strengthHigh tensile strengthFoundry mouldsFurnace typesDesign systemsChemical composition

The invention discloses a bainite steel wheel for a rail traffic D-series high-speed train and a manufacturing method thereof. Chemical components of the bainite steel wheel comprise 0.05-0.30% of C,0.10-1.50% of Ni, 0.01-1.20% of Cr, 0.70-2.10% of Mn, 0.20-1.00% of Si, 0.01-1.00% of W, 0.05-0.60% of Mo, 0.01-0.80% of Cu, 0.01-0.20% of V, 0.001-0.20% of Nb, 0.0001-0.0350% of B, 0.001-0.040% of RE, smaller than or equal to 0.020% of P, smaller than or equal to 0.020% of S and the balance Fe and inevitable residual elements, and the sum of Mn and Cr is larger than or equal to 2.0% and smaller than or equal to 3.0%. According to the bainite steel wheel, the novel C-Ni-Mn-Cr-Mo alloy design system and the alloying principle are adopted, after the wheel is formed and subjected to advanced heattreatment, a rim obtains a no-carbide bainite structure, and the wheel has excellent comprehensive mechanical performance, anticorrosion performance and service performance, and especially has the beneficial effects of being high in strength, high in hardness, high in toughness, high in low-temperature toughness, high in wheeltrack rolling contact fatigue resisting performance (RCF), high in heatcrack resisting performance and the like.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Bainite steel wheel for rail traffic truck and manufacturing method of bainite steel wheel

InactiveCN108754329AReduce coefficient of frictionReduce wearFurnace typesProcess efficiency improvementCrack resistanceAlloy

The invention discloses a bainite steel wheel for a rail traffic truck and a manufacturing method of the bainite steel wheel. The bainite steel wheel for the rail traffic truck comprises the followingchemical components: 0.10-0.40% of C, 0.10-1.50% of Ni, 0.25-1.50% of Cr, 0.70-2.10% of Mn, 0.20-1.00% of Si, 0.01-1.00% of W, 0.05-0.60% of Mo, 0.01-0.80% of Cu, 0.01-0.20% of V, 0.001-0.20% of Nb,0.0001-0.0350% of B, 0.001-0.040% of RE, less than or equal to 0.020% of P, less than or equal to 0.020% of S and the balance of Fe and inevitable residual elements; and moreover, 2.0%< / = Mn+ Cr< / = 3.0%. A novel alloy design system of C-Ni-Mn-Cr-Mo and an alloying principle are adopted, after wheels are formed and subjected to advanced heat treatment, a carbide-free bainite organization structureis obtained, and the wheels have excellent integrated mechanical property, corrosion resistance and service performance, and particularly have the characteristics of high strength, hardness and toughness, high wheel track rolling contact fatigue (RCF) resistance, hot crack resistance and the like.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

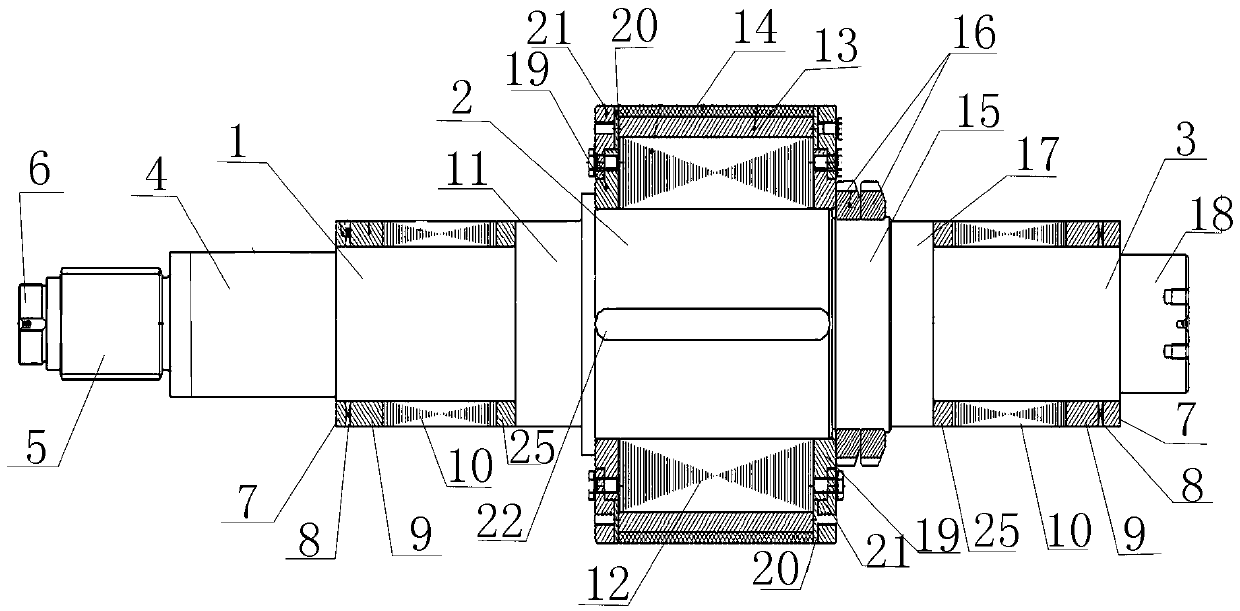

A high-speed permanent magnet motor rotor and its processing method

ActiveCN108988534BCompact structureStable structureMagnetic circuit rotating partsManufacturing stator/rotor bodiesFiberCarbon fibers

The invention belongs to the field of electric machines, in particular to a high-speed permanent magnet motor rotor and a processing method thereof, the high-speed permanent magnet motor rotor comprises a high-speed permanent magnet motor rotor, including a rotating shaft, the rotating shaft includes a first shaft body from left to right, a second shaft body and a third shaft body, A magnetic levitation bear sensor rotor assembly is provided on that first shaft body and the third shaft body, A maglev bearing sensor rotor silicon steel sheet, a maglev bearing rotor assembly and a maglev bearingrotor silicon steel sheet, a rotor iron core is sleeved on a second shaft body, a surface-mount permanent magnet is arranged on an outer periphery of that rotor iron core, and a carbon fiber sheath is wrapped on the outer periphery of the permanent magnet. The whole structure of the rotor of the invention is compact and reliable. Strong ability to resist radial tension and tangential stress; Effective protection of permanent magnets in permanent magnet motors; Strong heat dissipation ability; The processing method of the invention can reasonably and efficiently realize the processing of the high-quality high-speed permanent magnet motor rotor through the close cooperation between different steps.

Owner:CRRC YONGJI ELECTRIC CO LTD

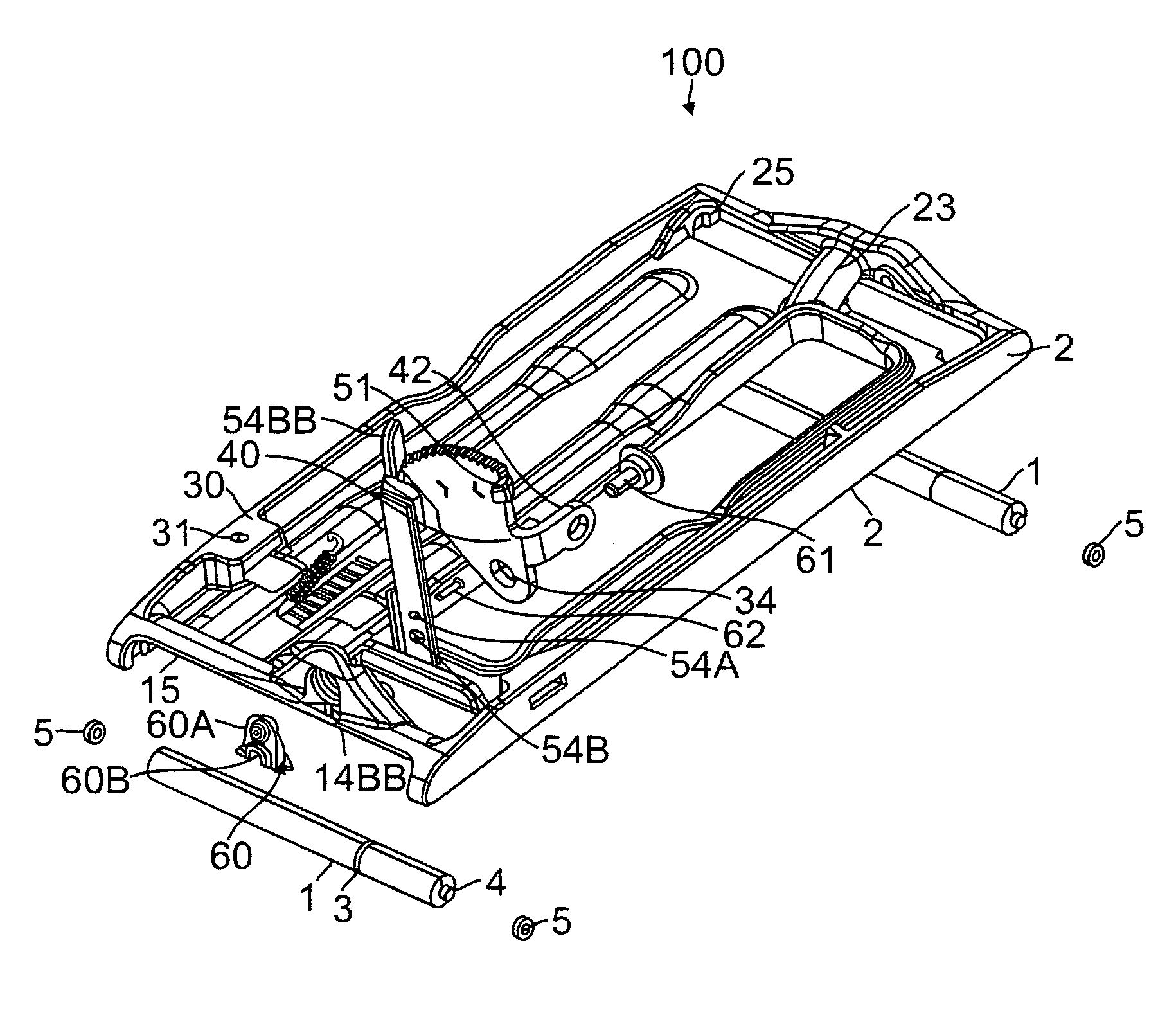

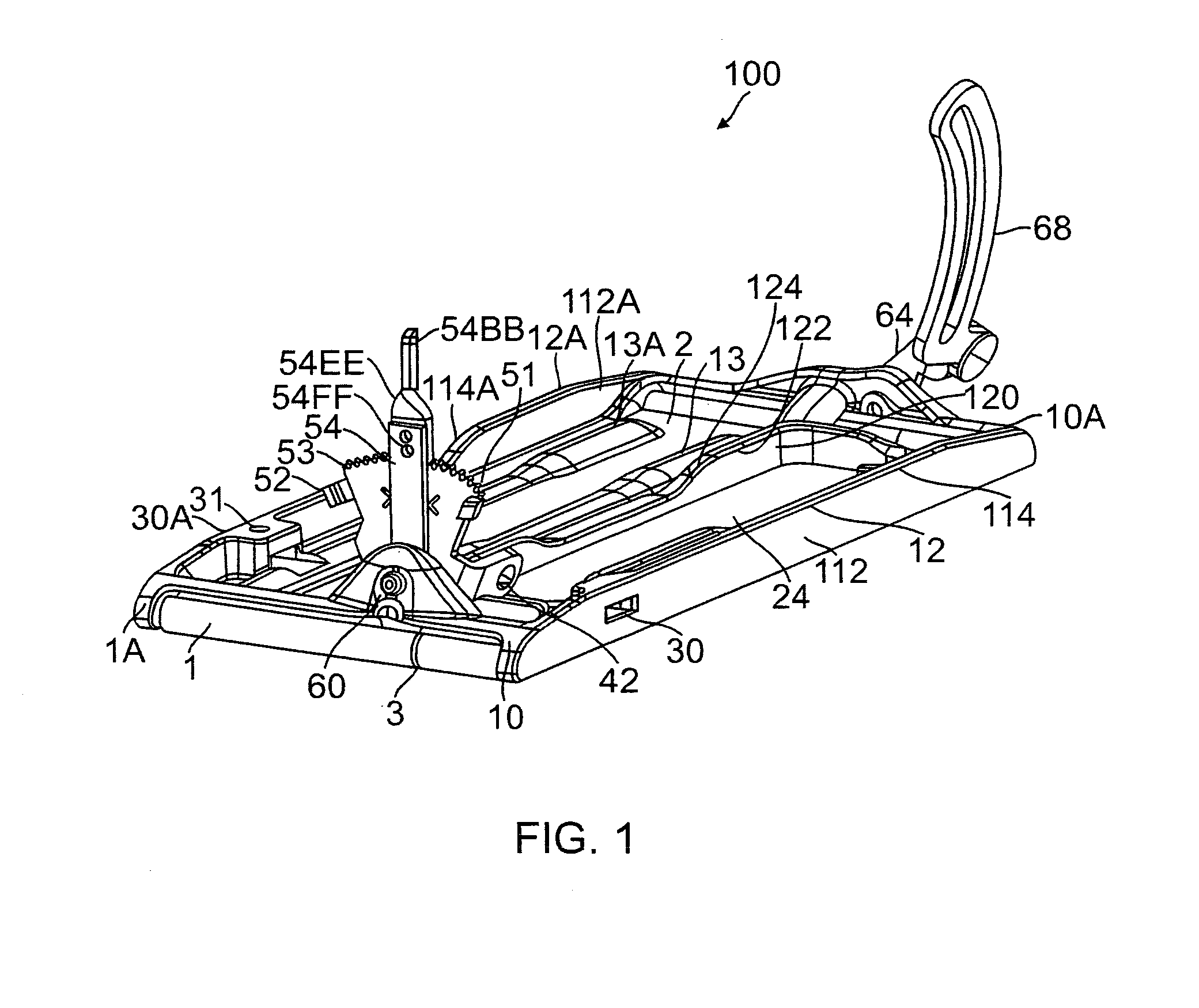

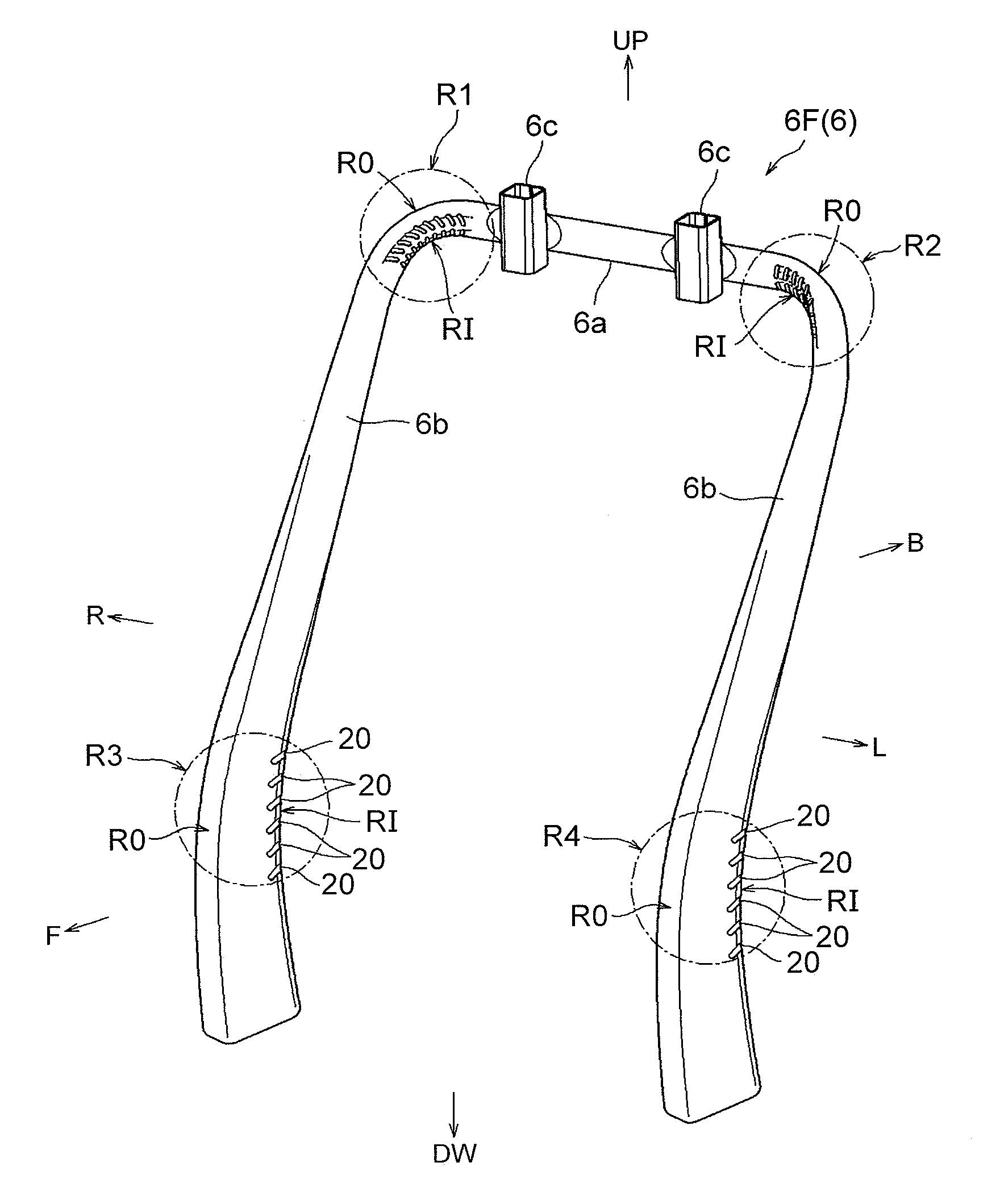

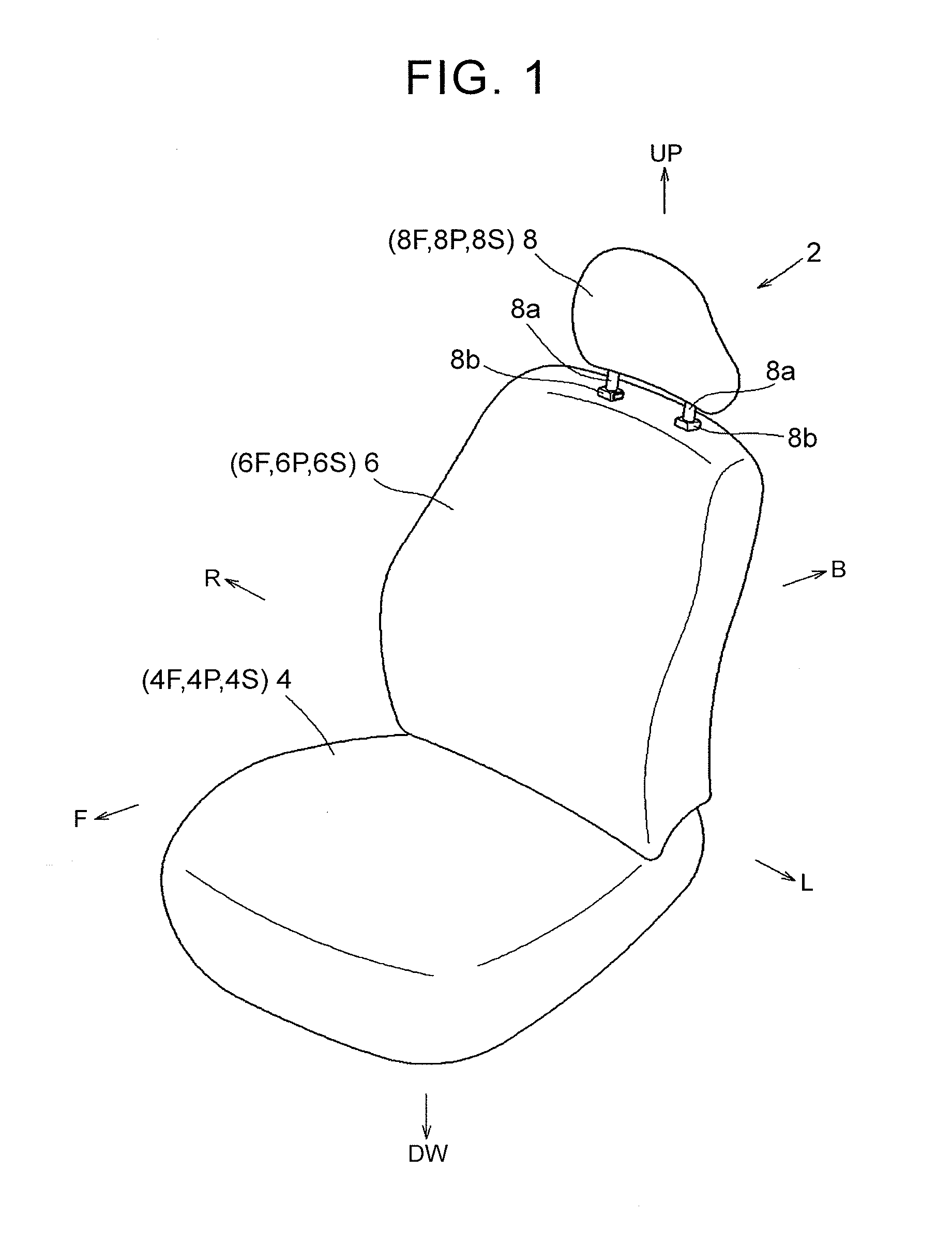

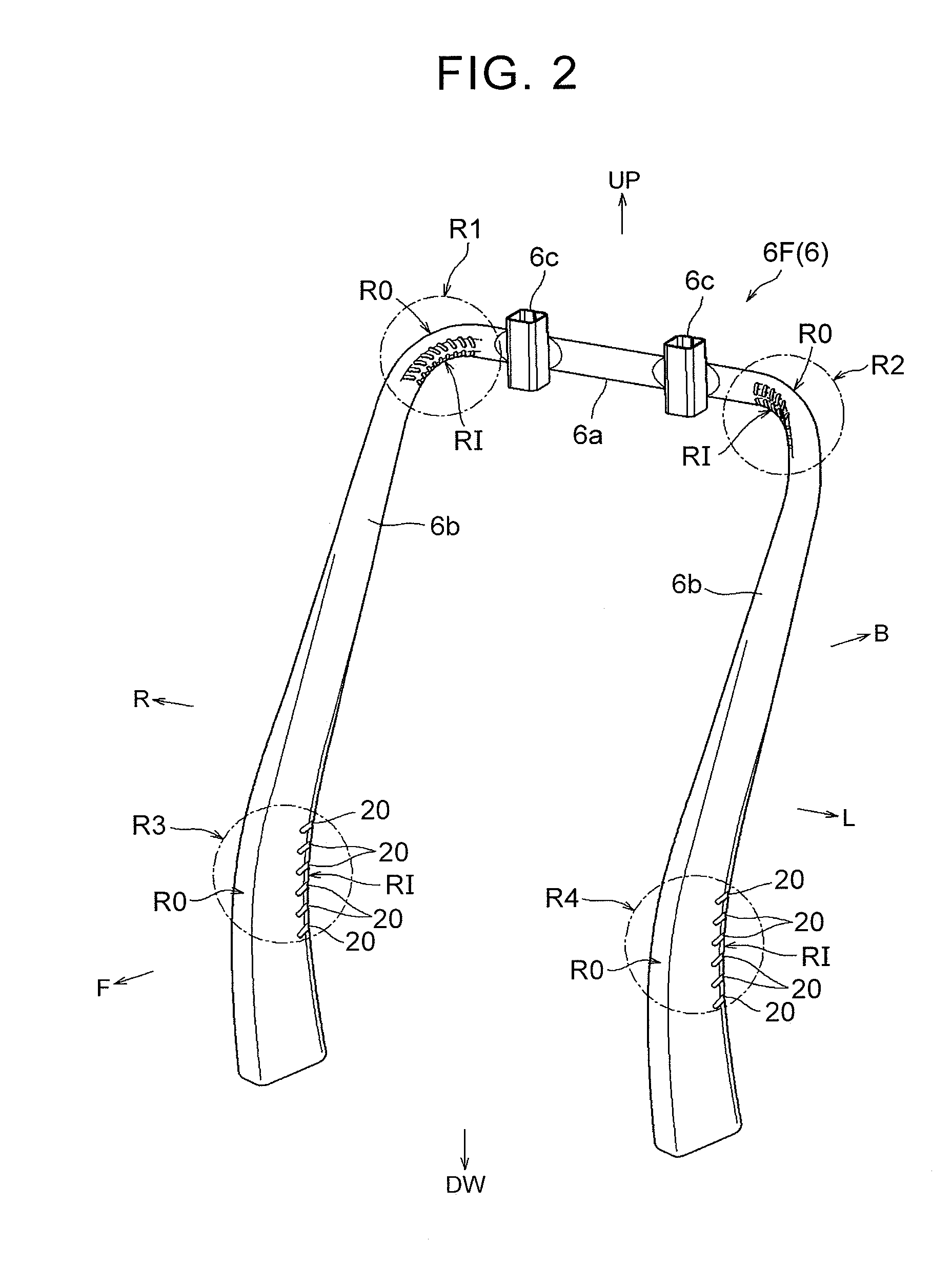

Vehicle seat

InactiveUS20160257230A1Prevent excessive deformationImprove balanceBack restsSeat framesEngineeringMechanical engineering

A vehicle seat includes a seat frame. The seat frame has a hollow deformable portion that is bent, and linear recessed portions formed by partially recessing an inner side of the deformable portion. The deformable portion has a linear separation portion formed in a projecting manner relative to the recessed portions and extending on the inner side of the deformable portion. A plurality of recessed portions is formed on each of one side and the other side of the separation portion so as to sandwich the separation portion, and placed independently from each other such that adjacent recessed portions are not connected to each other.

Owner:TOYOTA BOSHOKU KK

Water saw system for use in conjunction with a rolling plate assembly attachment for both a portable sidewinder power saw and a portable worm drive power saw

InactiveUS20200094433A1Facilitate safe rolling movementFacilitates strong weightMetal sawing accessoriesPortable power driven sawsFiberClassical mechanics

An attachable rolling plate assembly which is attached as a single unit to a portable cutting tool to facilitate the safe rolling movement of the portable cutting tool on a workpiece. The invention comprises a frame assembly formed from a single piece of molded material such as fiber enriched high-impact nylon having a pair of oppositely disposed longitudinal sidewalls and a flat base portion having an opening through which a saw blade of a power saw extends. The invention also includes a cutting guide assembly to facilitate a straight cut, reduce torsional rotation of the saw blade and reduce kickback of the saw. A water spray hose is retained to spray water in front of a saw blade of a retained worm drive power saw.

Owner:CIRCSAW TECH LLC

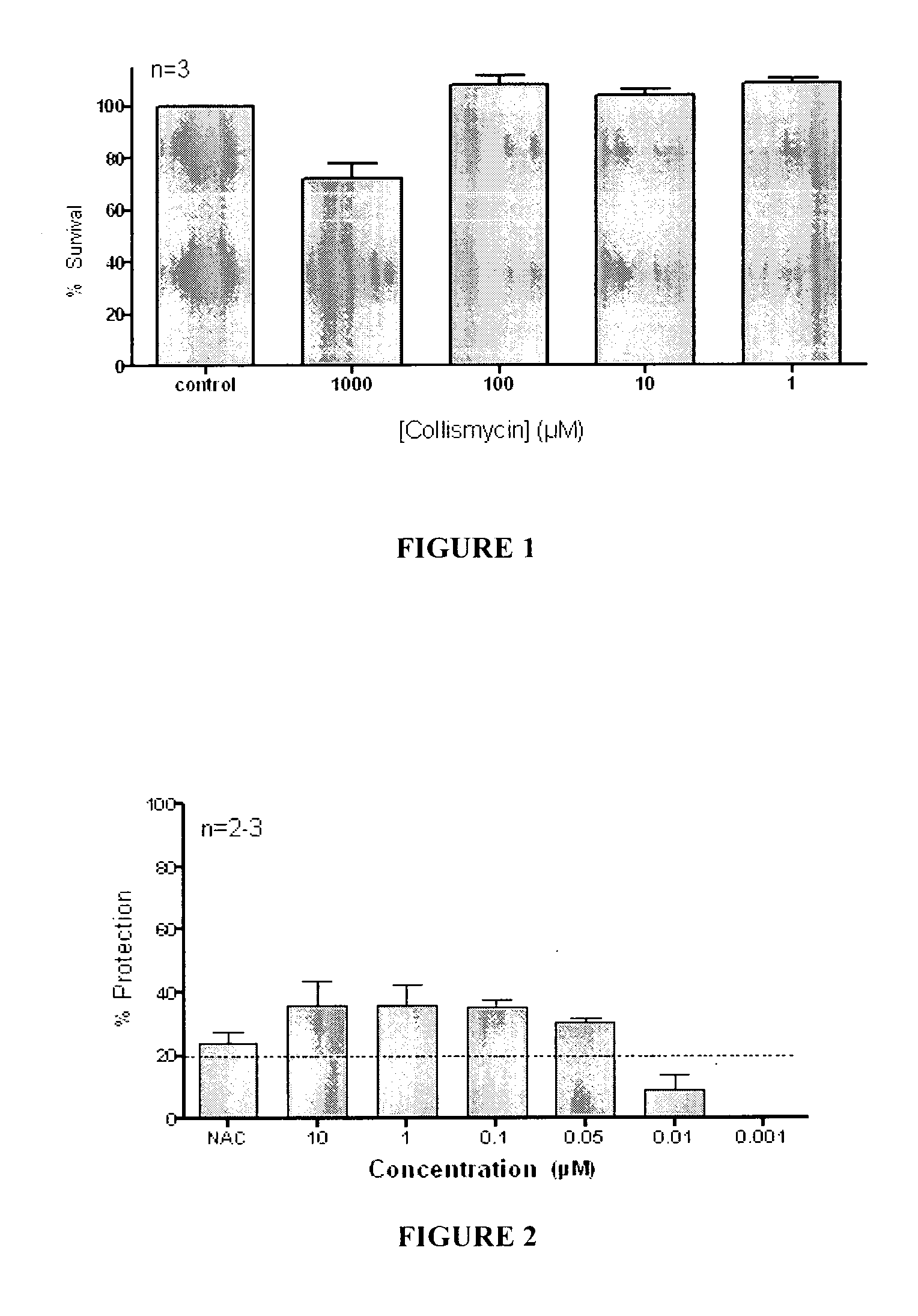

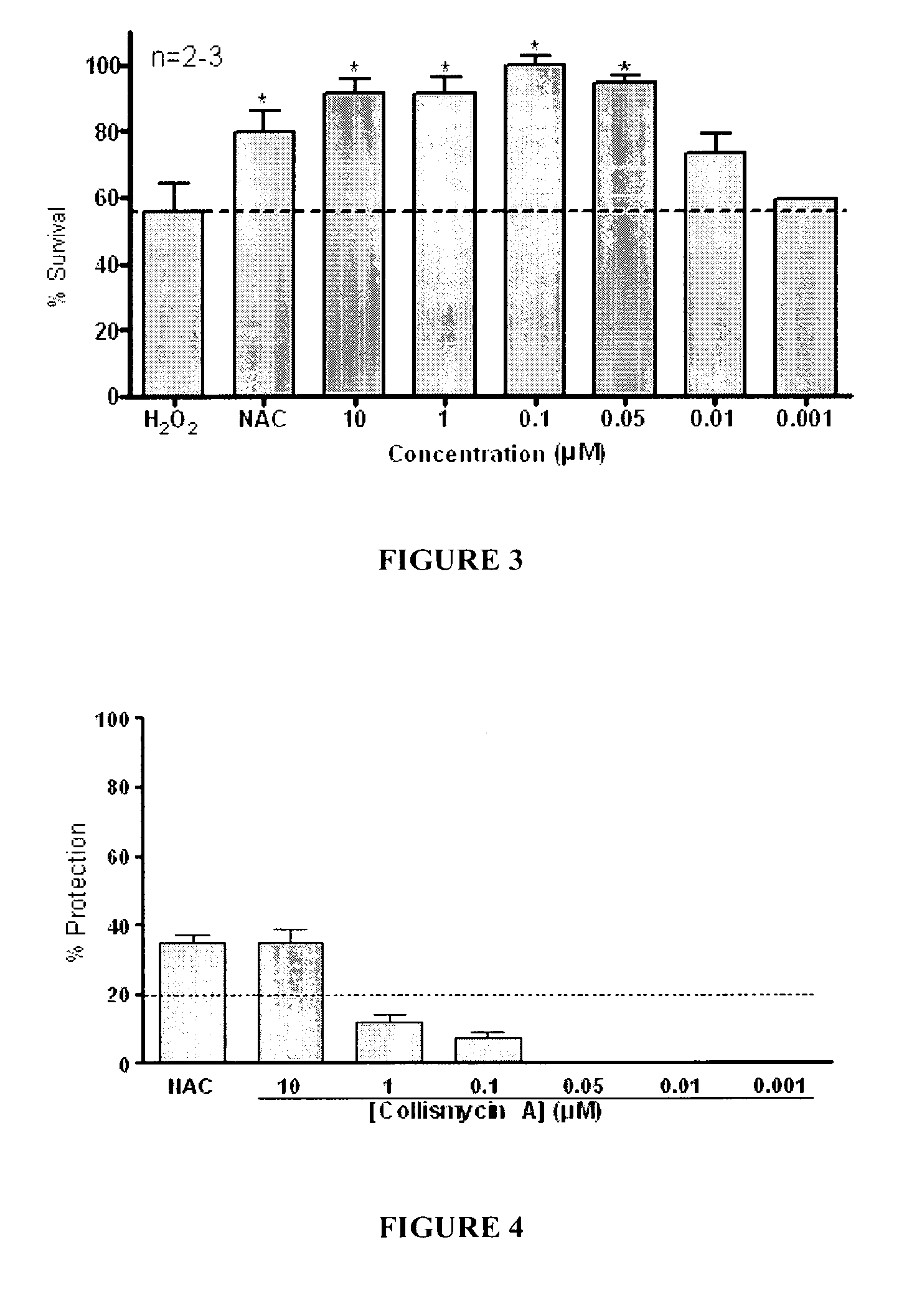

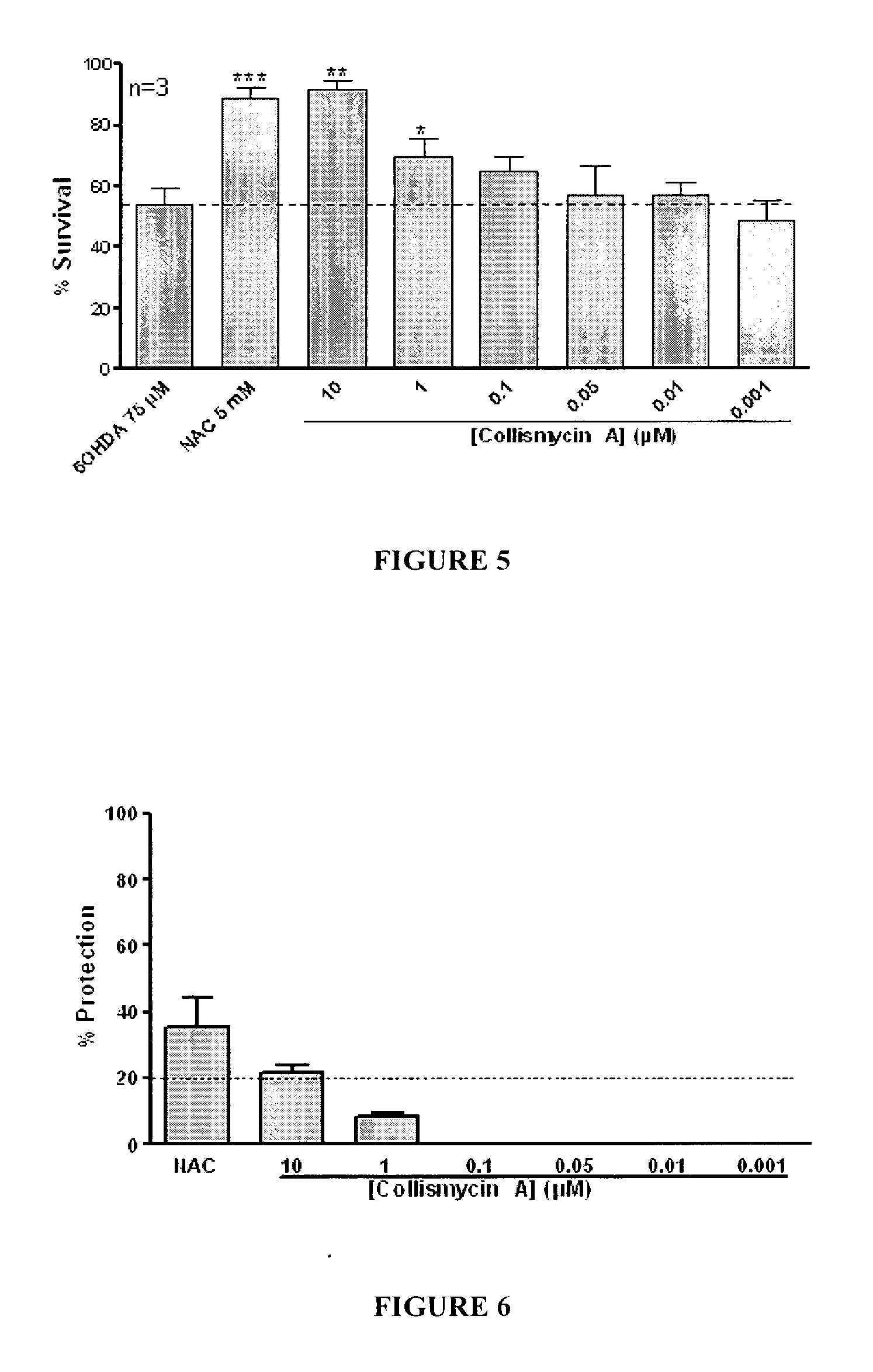

Use of Collismycin and Derivatives Thereof as Oxidative Stress Inhibitors

InactiveUS20080275088A1Strong oxidative stressStrong stressBiocideNervous disorderOxidative stressMedicine

The present invention relates to the use of Collismycin and derivatives thereof as inhibitors of oxidative stress in cells and their use for the preparation of medicaments for the treatment and / or prevention of oxidative stress-induced diseases or conditions, especially neurodegenerative diseases, such as Alzheimer's Disease and Parkinson's Disease.

Owner:INST BIOMAR SA +1

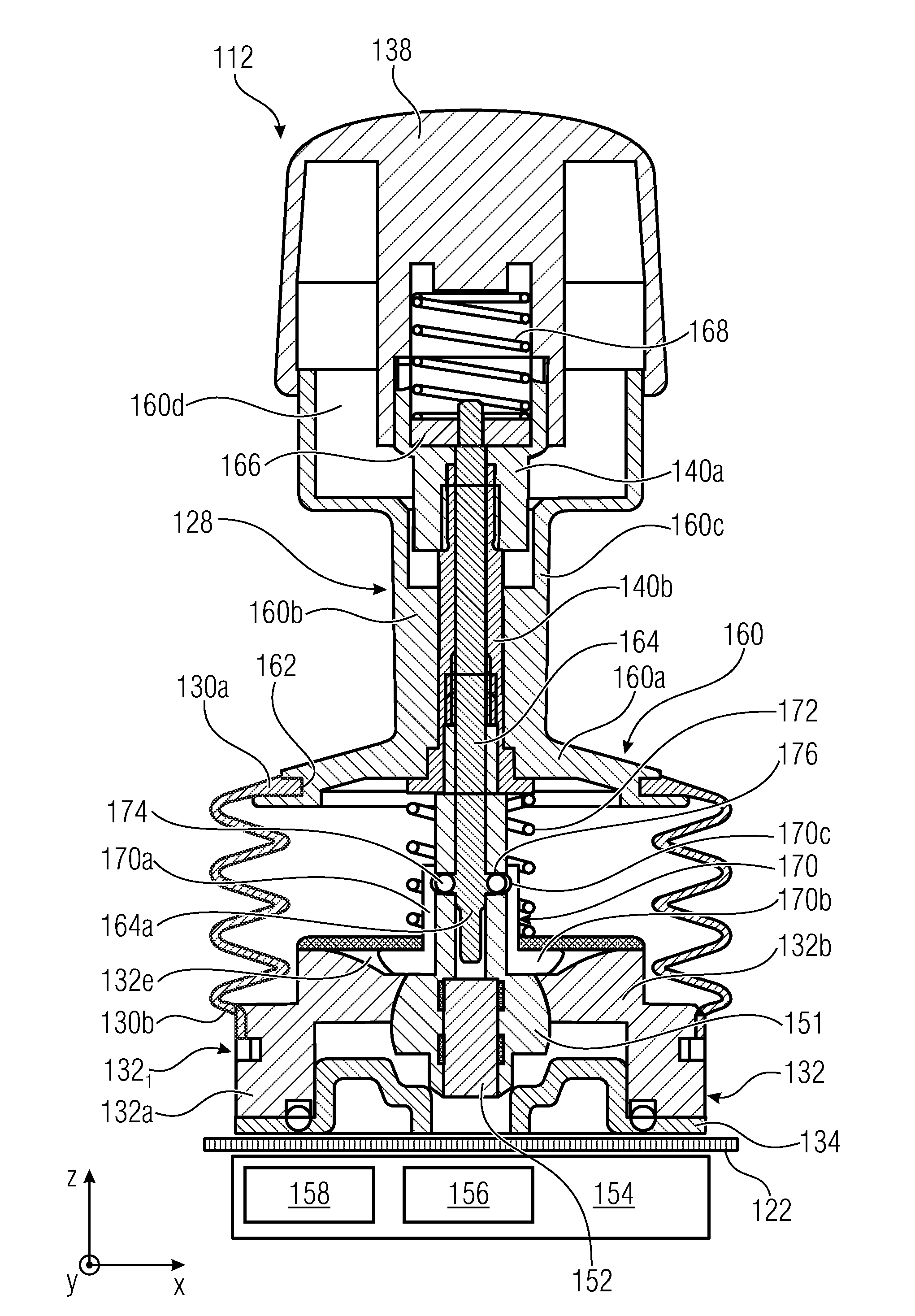

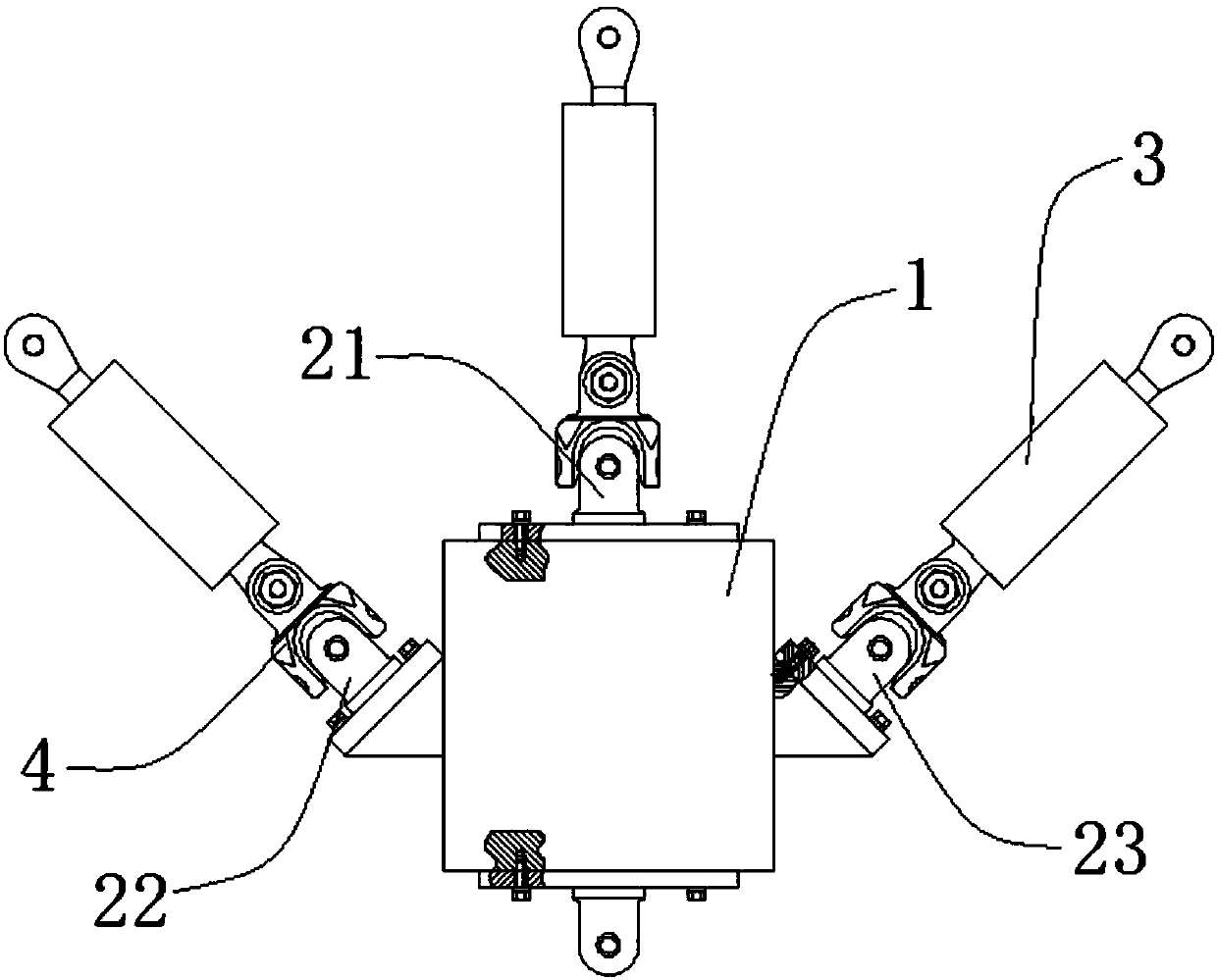

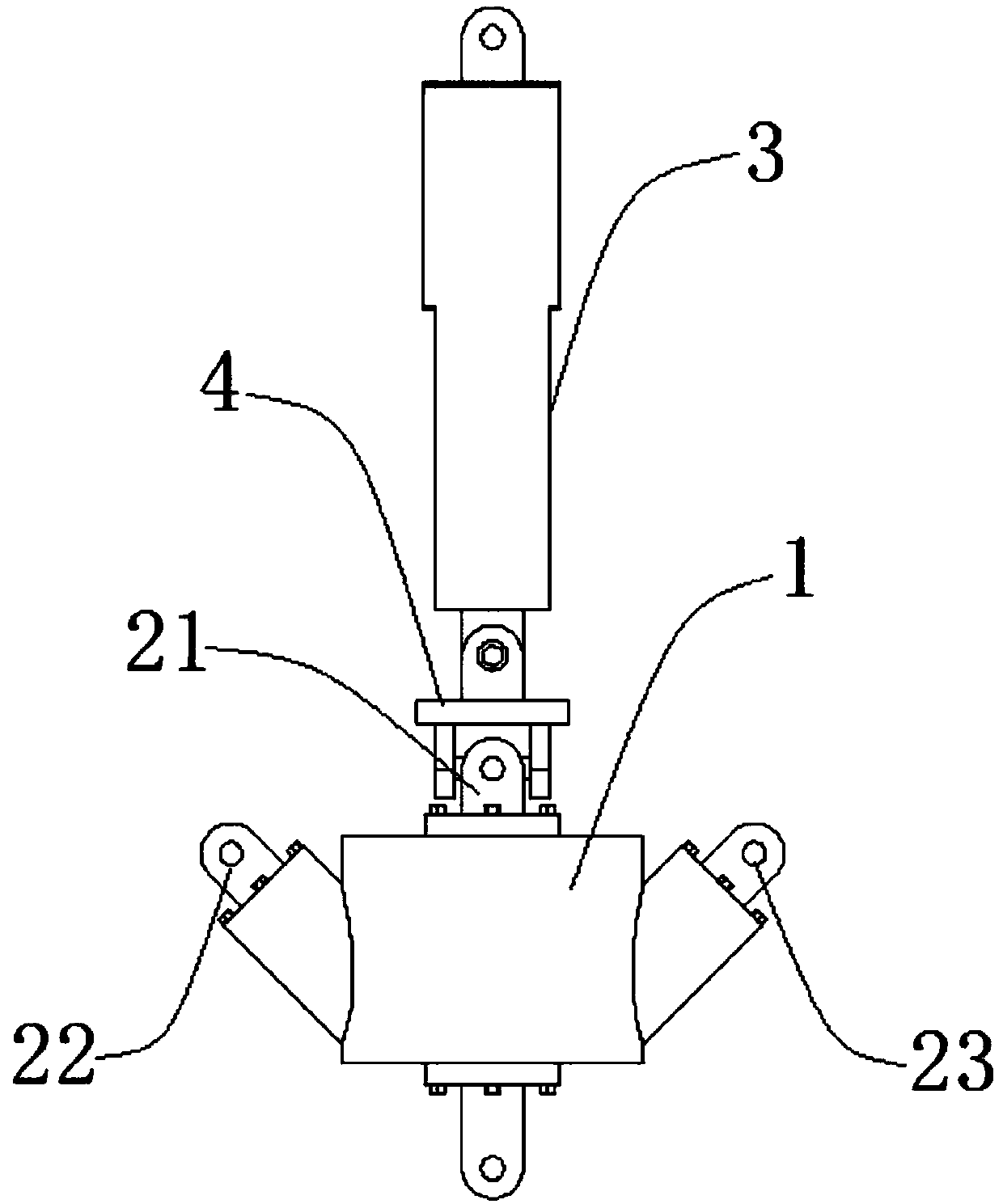

Anti-shock support hanger

PendingCN107781510ASimple structureAchieve shock resistance and shock absorptionPipe supportsVibration dampersStructural engineeringMechanical engineering

Owner:江苏奇佩建筑装配科技有限公司

Ink jet print head with piezoelectric actuator

ActiveUS20130201259A1Improved pressure generation abilityReduce deflectionPrintingSpray nozzleTungsten film

An ink jet print head, having a pressure generation chamber arranged for being in communication with a print head nozzle and an actuator membrane for delimiting the pressure generation chamber. The actuator membrane has a substrate and a piezoelectric actuator provided on the substrate, said piezoelectric actuator having a lower electrode, an upper electrode and at least one piezoelectric layer arranged between the lower electrode and the upper electrode; the substrate and the upper electrode are arranged on opposite sides of the piezoelectric layer, and the upper electrode has a Titanium-Tungsten film.

Owner:OCE TECH

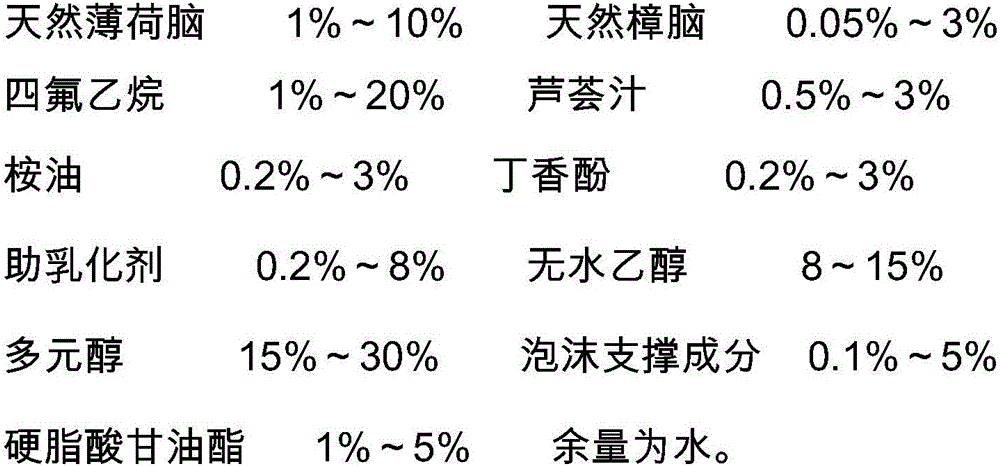

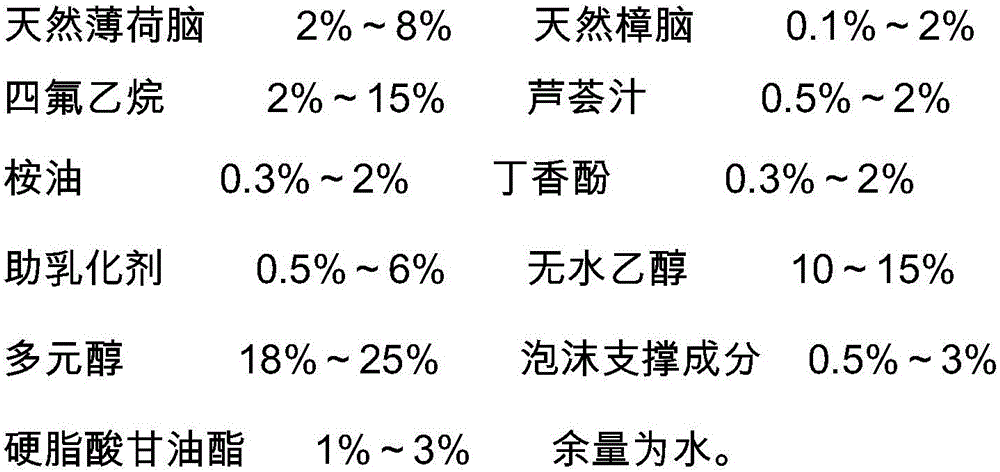

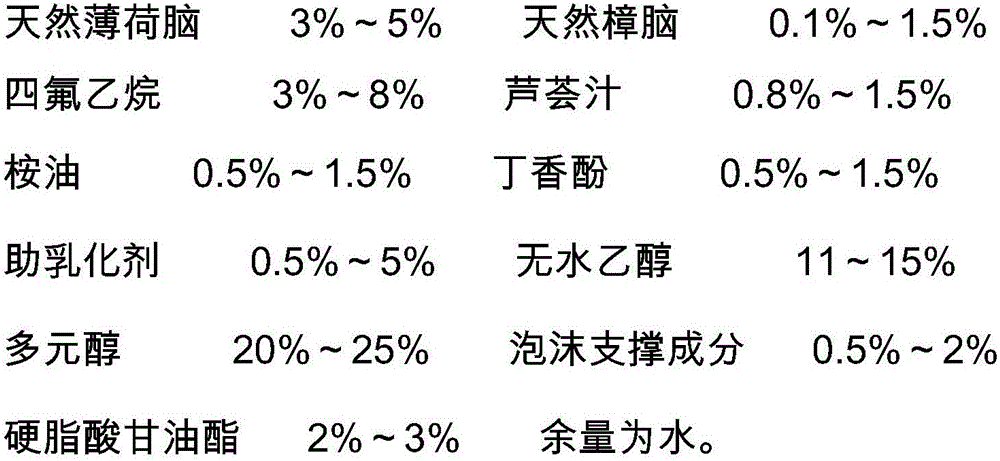

Foaming agent with itching-relieving and inflammation-diminishing effects and preparation method of foaming agent

ActiveCN105770237AEasy to useStrong stickinessHydroxy compound active ingredientsAntipyreticEugenolInflammation

The invention discloses a foaming agent with itching-relieving and inflammation-diminishing effects and a preparation method of the foaming agent. The foaming agent comprises the following components in percentage by mass: 1-10% of natural menthol, 0.05-3% of natural camphor, 1-20% of tetrafluoroethane, 0.5-3% of aloe juice, 0.2-3% of eucalyptus oil, 0.2-3% of eugenol, 0.2-8% of a co-emulsifier, 8-15% of absolute ethyl alcohol, 15-30% of polyhydric alcohols, 0.1-5% of foam support components, 1-5% of glyceryl stearate and the balance of water. The foaming agent disclosed by the invention can be relatively well applied to skin inflammation, itching relieving, mosquito bite treatment and the like, and compared with a similar product, the foaming agent has the advantages of rapid absorption, rapid effect taking, good effect and the like, and is high in medicine release speed, high in bioavailability, free of skin irritation and convenient to carry and use.

Owner:GUANGDONG HONGSHANHU PHARM CO LTD

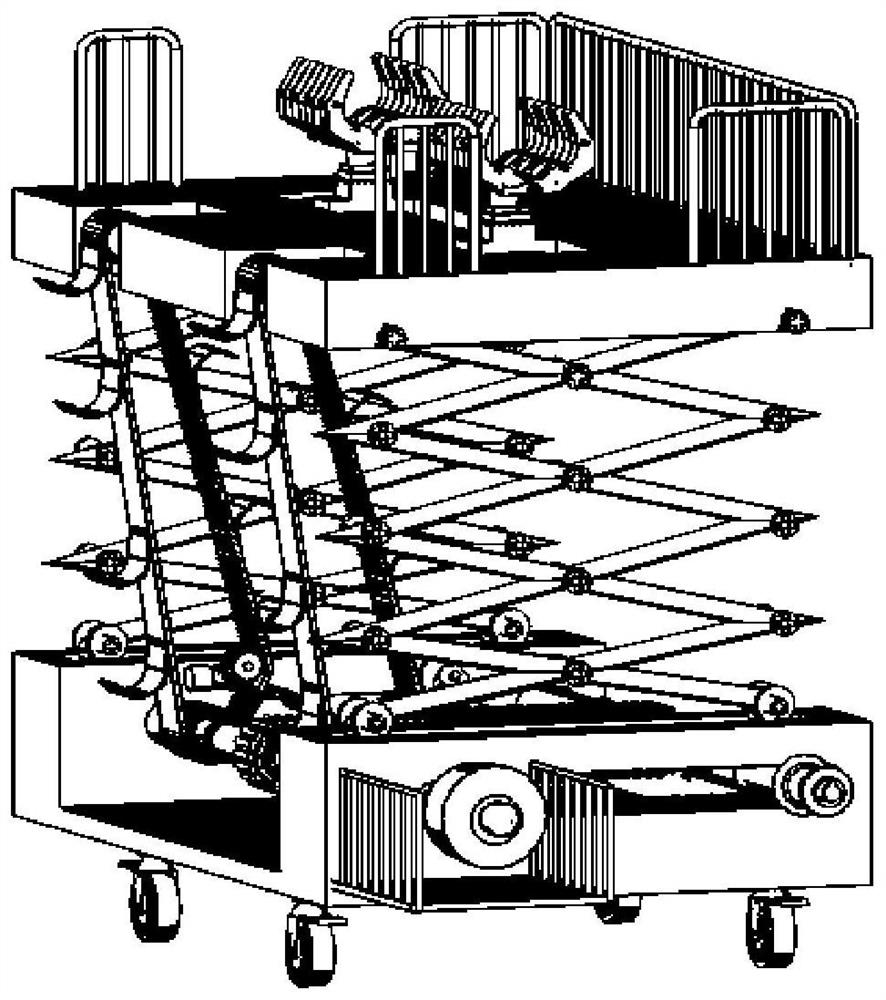

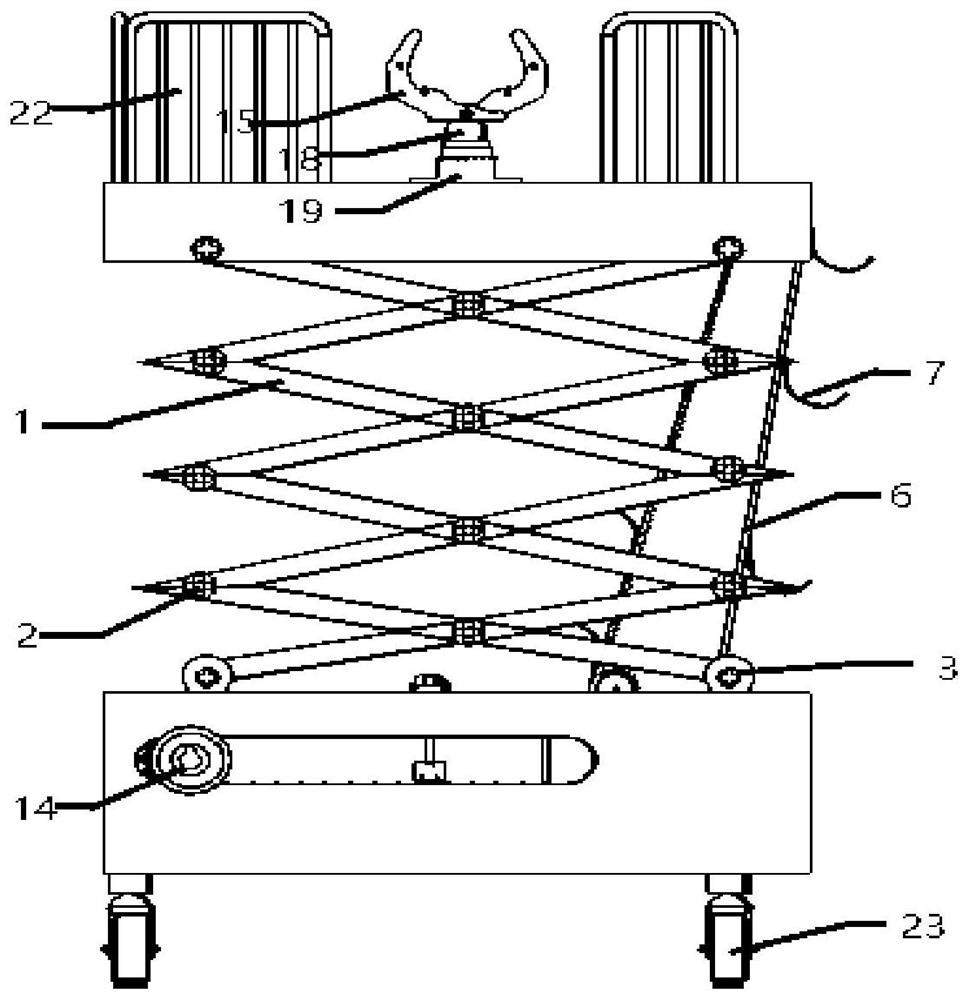

Movable pipeline installation assisting device

ActiveCN112809337AProtection securityPrevent fallingMetal working apparatusManipulatorRobot handButt joint

The invention discloses a movable pipeline installation assisting device. The movable pipeline installation assisting device comprises a one-way moving joint type mechanical arm, a conveying and transporting system, a lifting steel frame system, a conveying and connecting system, an enclosure structure and a fixable wheel train. The one-way moving joint type mechanical arm serves as a body and is matched with the conveying and transporting system and the conveying and connecting system, the pipeline position can be adjusted on an actual construction engineering project site, constructors are assisted in completing pipeline butt joint hoop groove pressing work, the labor cost is saved, the site wiring efficiency is improved, by adjusting the conveying and transporting system, the conveying and connecting system, the fixable wheel train and a lifting steel frame system, the height position can be flexibly changed along with the change of the construction site, and the assembly working efficiency of site wiring is improved. Through combined assembly of the one-way moving joint type mechanical arm, the conveying system and an elevator, the movable pipeline installation assisting device with a brand new using effect is achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

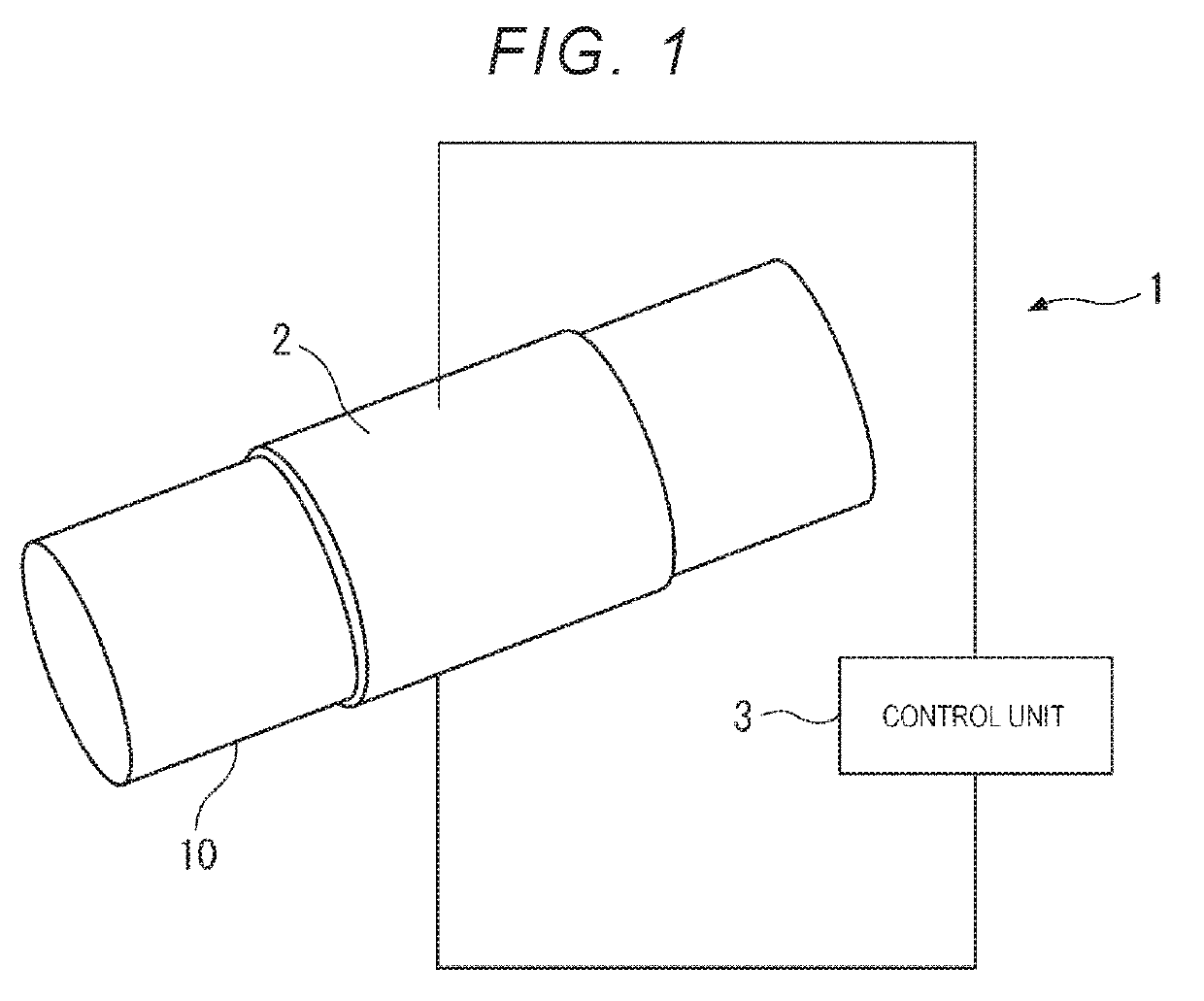

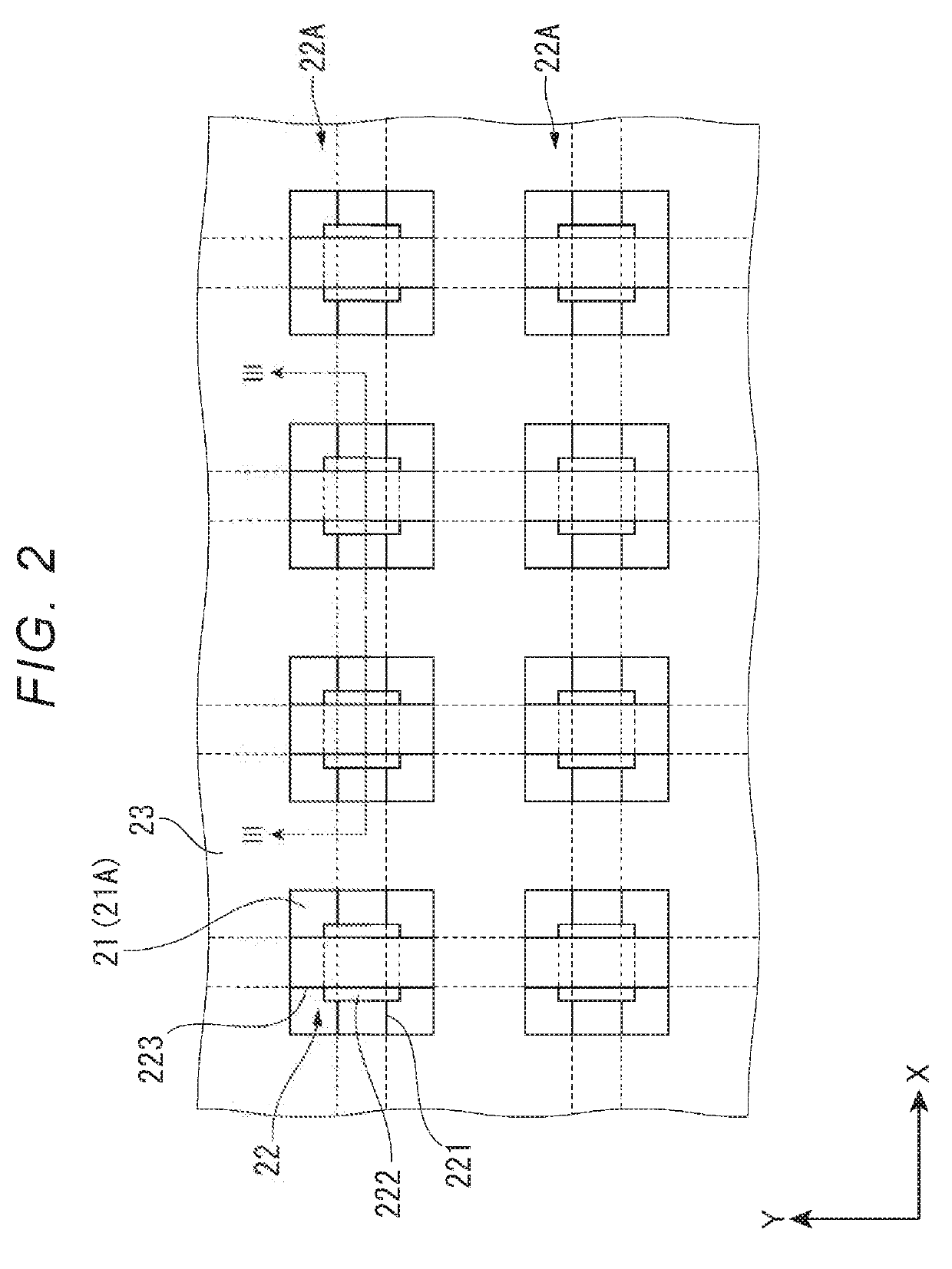

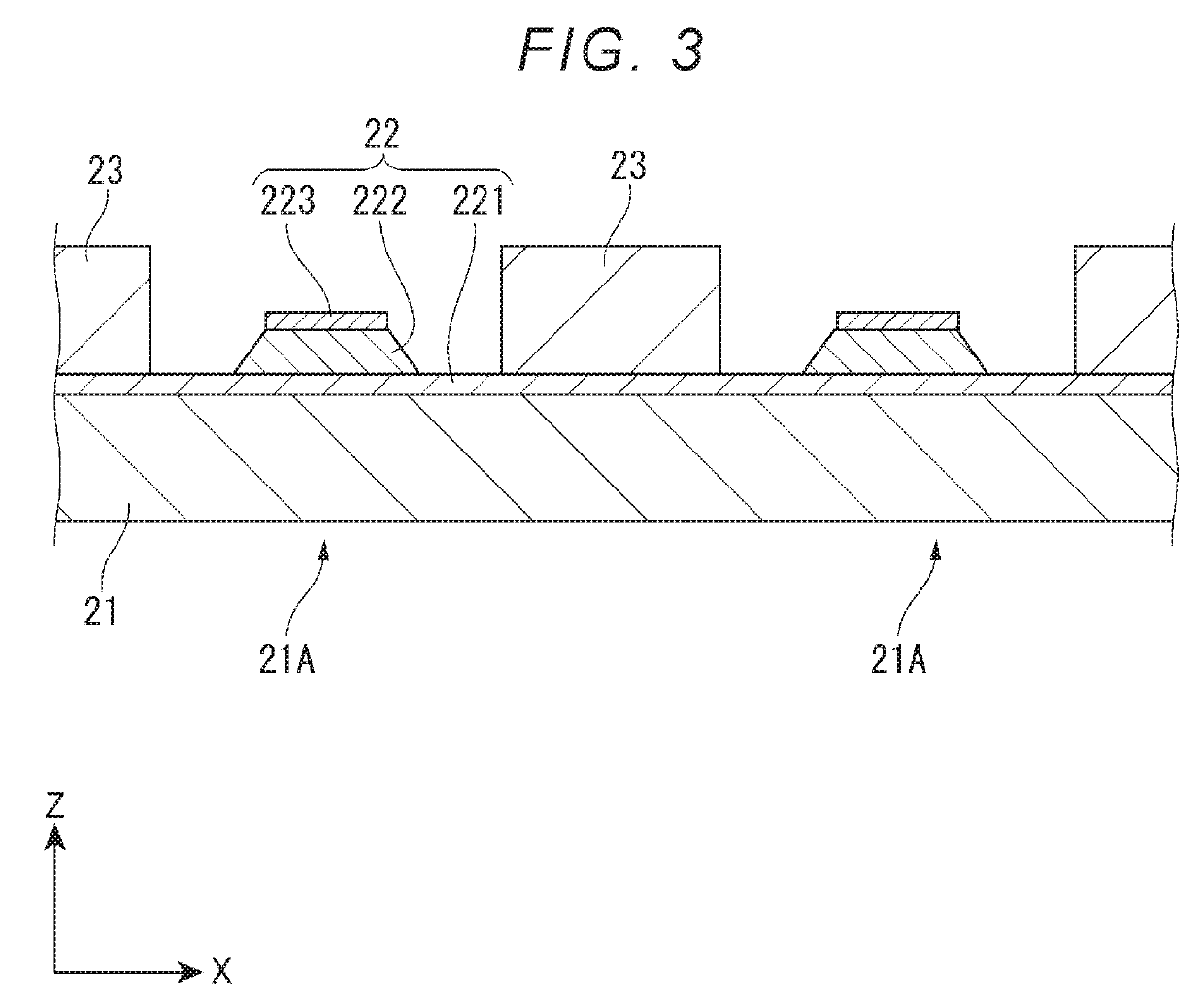

Ultrasonic sensor, ultrasonic device, and method of manufacturing ultrasonic sensor

ActiveUS20190255568A1Easily formGood flexibilityPiezoelectric/electrostrictive device manufacture/assemblySubsonic/sonic/ultrasonic wave measurementUltrasoundUltrasonic device

An ultrasonic sensor includes a vibration plate that includes a vibration portion and is formed of a resin; a wall portion that is provided on the vibration plate, surrounds the vibration portion and is formed of a resin; and a piezoelectric element that is provided in the vibration portion of the vibration plate. Accordingly, the wall portion surrounding the vibration portion can suppress a frequency variation of an ultrasonic wave output from the ultrasonic sensor and can deform the ultrasonic sensor into a shape corresponding to a surface of an object having various shapes.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com