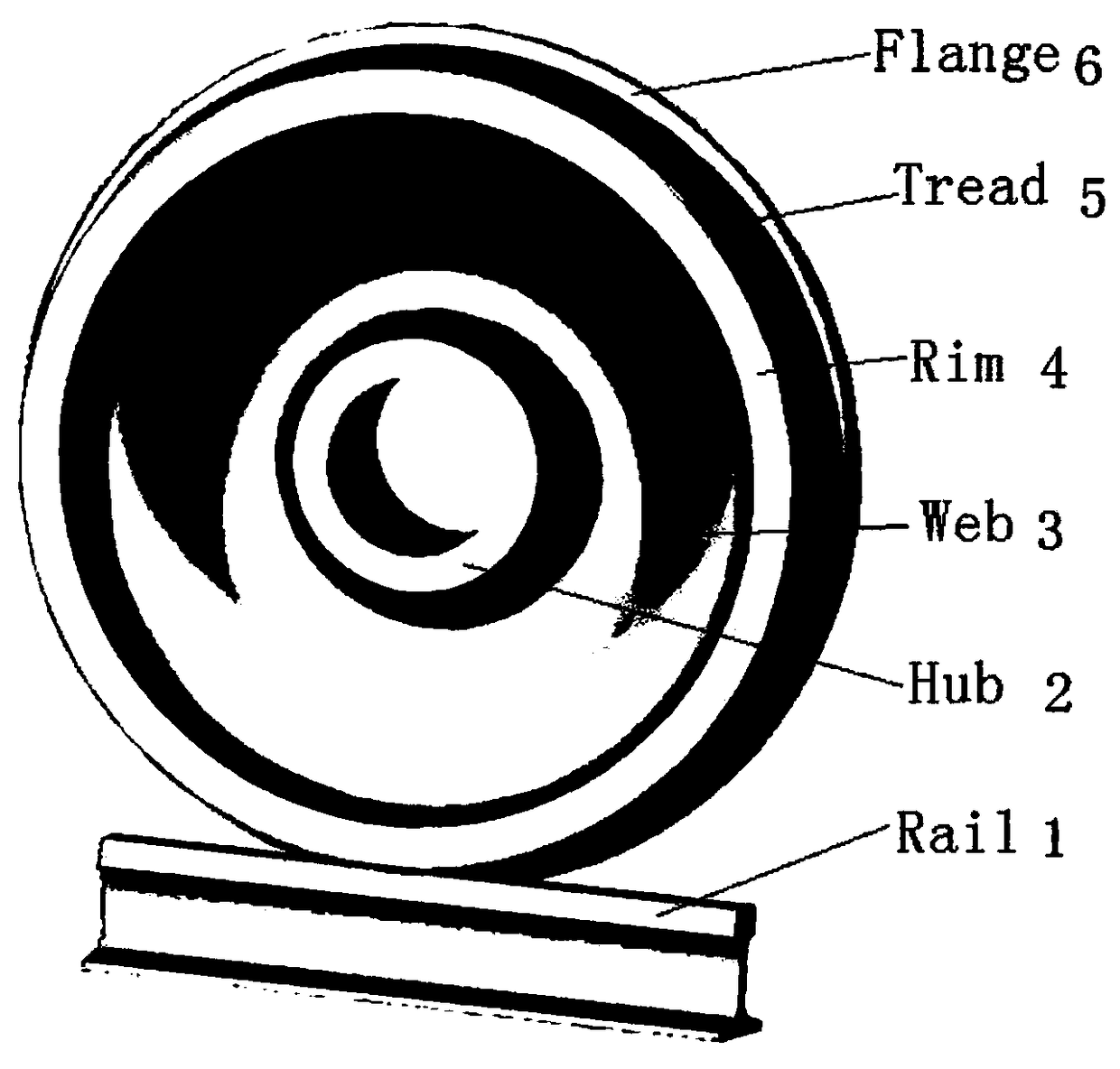

Bainite steel wheel for rail traffic D-series high-speed train and manufacturing method thereof

A rail transit and bainite steel technology, applied in the field of rail transit, can solve the problems of randomness, cracking, and low fracture toughness in the detection of internal non-metallic inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A kind of bainite steel wheel for rail transit EMU, containing the chemical composition as described in Table 2, Example 1.

[0070] The manufacturing method is as follows: the molten steel whose chemical composition is shown in Example 1 in Table 2 is passed through the steelmaking process, the refining process, the vacuum degassing process, the round billet continuous casting process, the ingot cutting process, the forging and rolling process, the heat treatment process, processing, and finished product inspection. formed by the process. The heat treatment process is as follows: heating to 920°C for 4.0 hours, cooling the rim tread to 220-400°C by spraying water under programmable control, and air cooling to room temperature, during which time the residual heat of the rim, web, and hub is used for self-tempering; and then Then heat to 270-400°C for medium and low temperature tempering for 4 hours, then air cool to room temperature after tempering.

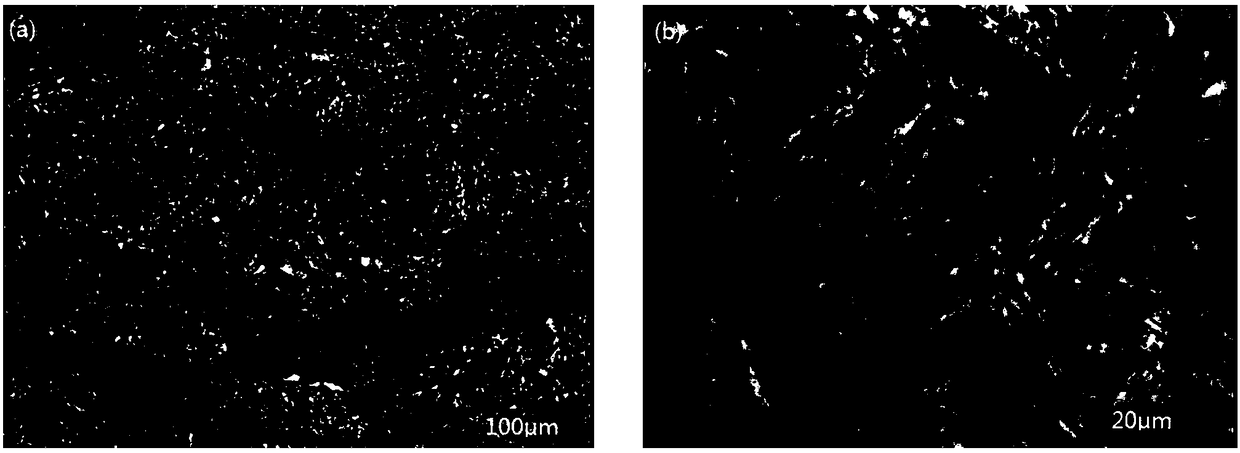

[0071] Such as ...

Embodiment 2

[0073] A kind of bainite steel wheel for rail transit EMU, containing the chemical composition as described in Table 2, Example 1.

[0074] The manufacturing method is as follows: the molten steel whose chemical composition is shown in Example 2 of Table 2 is passed through the steelmaking process, the refining process, the vacuum degassing process, the round billet continuous casting process, the ingot cutting process, the forging and rolling process, the heat treatment process, processing, and finished product inspection. formed by the process. The heat treatment process is as follows: heating to 940°C for 4.3 hours, cooling the rim tread to 220-380°C by spraying water under programmable control, and air cooling to room temperature, during which the waste heat of the rim, web, and hub is used for self-tempering; and then Then heat to 250-360°C for medium and low temperature tempering for 4 hours, then air cool to room temperature after tempering.

[0075] Such as image 3 ...

Embodiment 3

[0078] A kind of bainite steel wheel for rail transit EMU, containing the chemical composition as described in Table 2, Example 1.

[0079] The manufacturing method is as follows: the molten steel whose chemical composition is as shown in Table 2, Example 3, goes through the steelmaking process, the refining process, the vacuum degassing process, the round billet continuous casting process, the ingot cutting process, the forging and rolling process, the heat treatment process, processing, and finished product inspection. formed by the process. The heat treatment process is as follows: heating to 920°C for 4.5 hours, cooling the rim tread to 200-385°C by spraying water under programmable control, and air cooling to room temperature, during which the residual heat of the rim, web, and hub is used for self-tempering; and then Then heat to 300-400°C for medium and low temperature tempering for 3.5 hours, then air cool to room temperature after tempering.

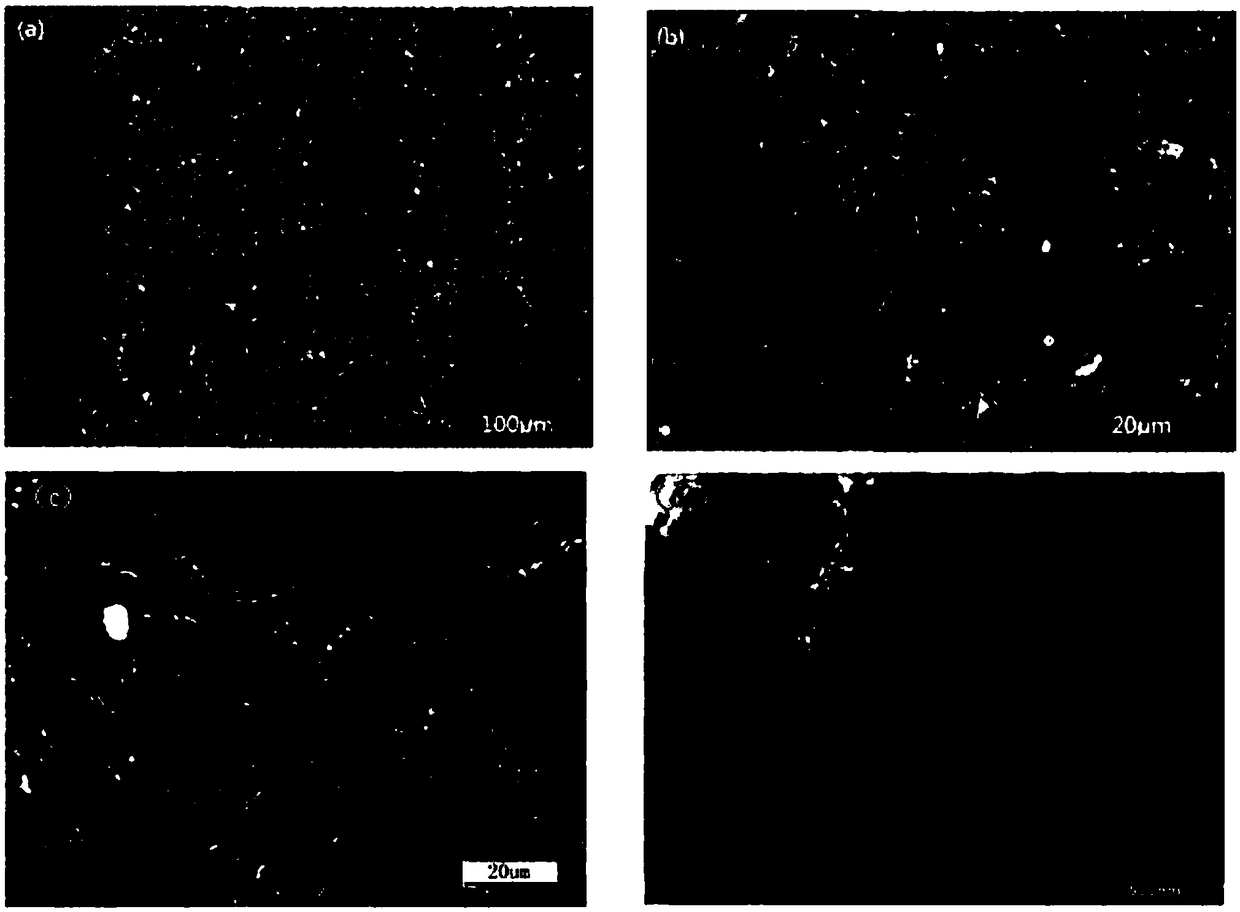

[0080] Such as Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com