Patents

Literature

2324 results about "High speed train" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A fast handover method of a td-lte communication system based on target cell pre-carrying

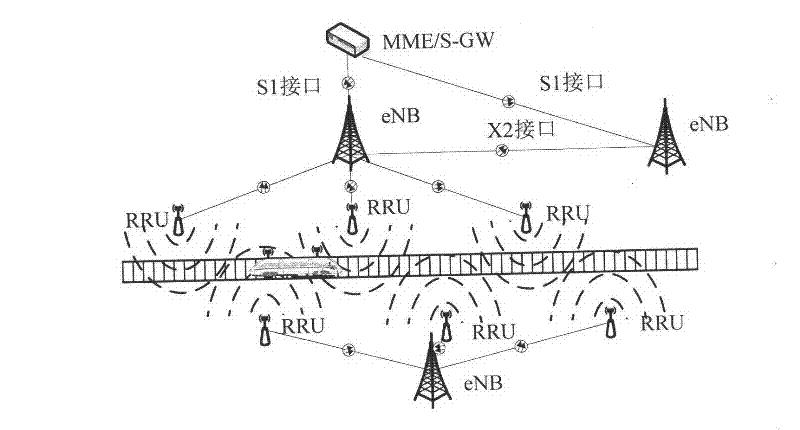

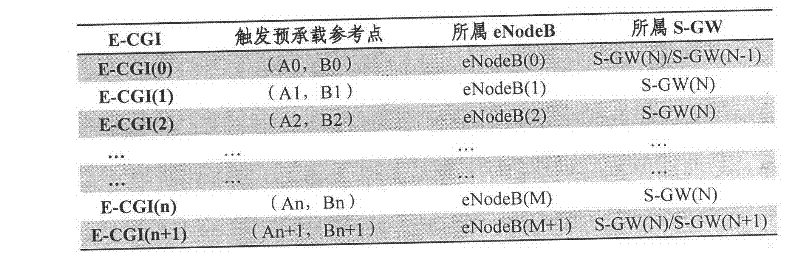

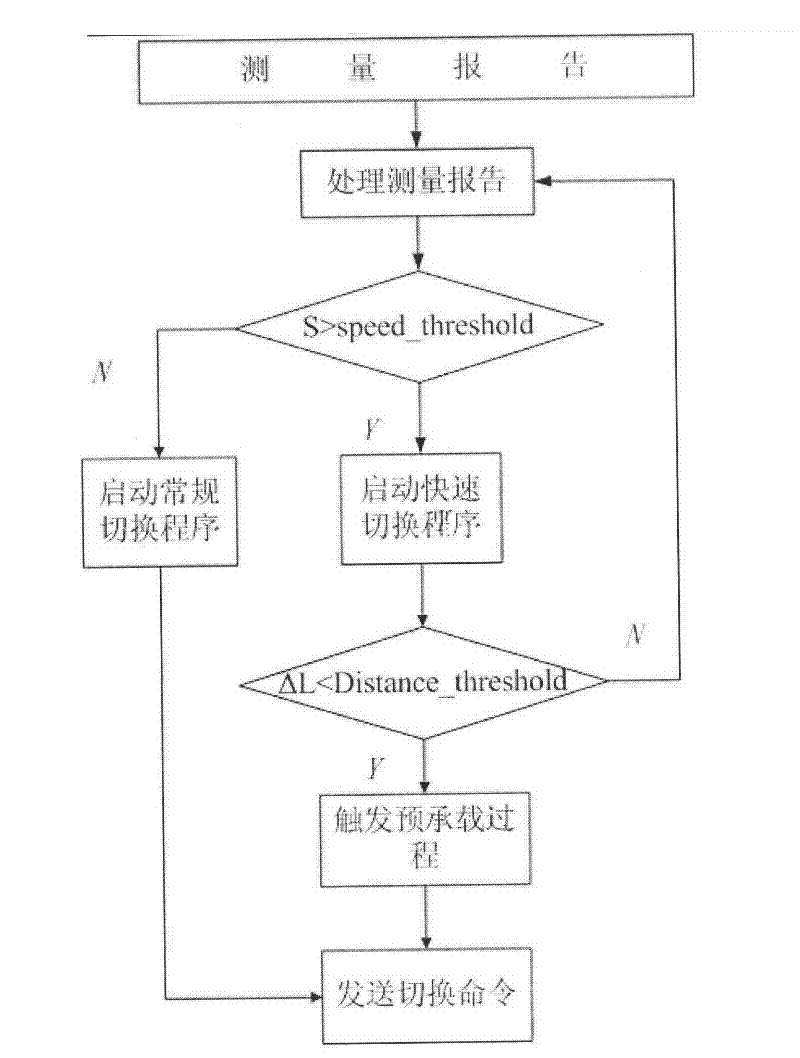

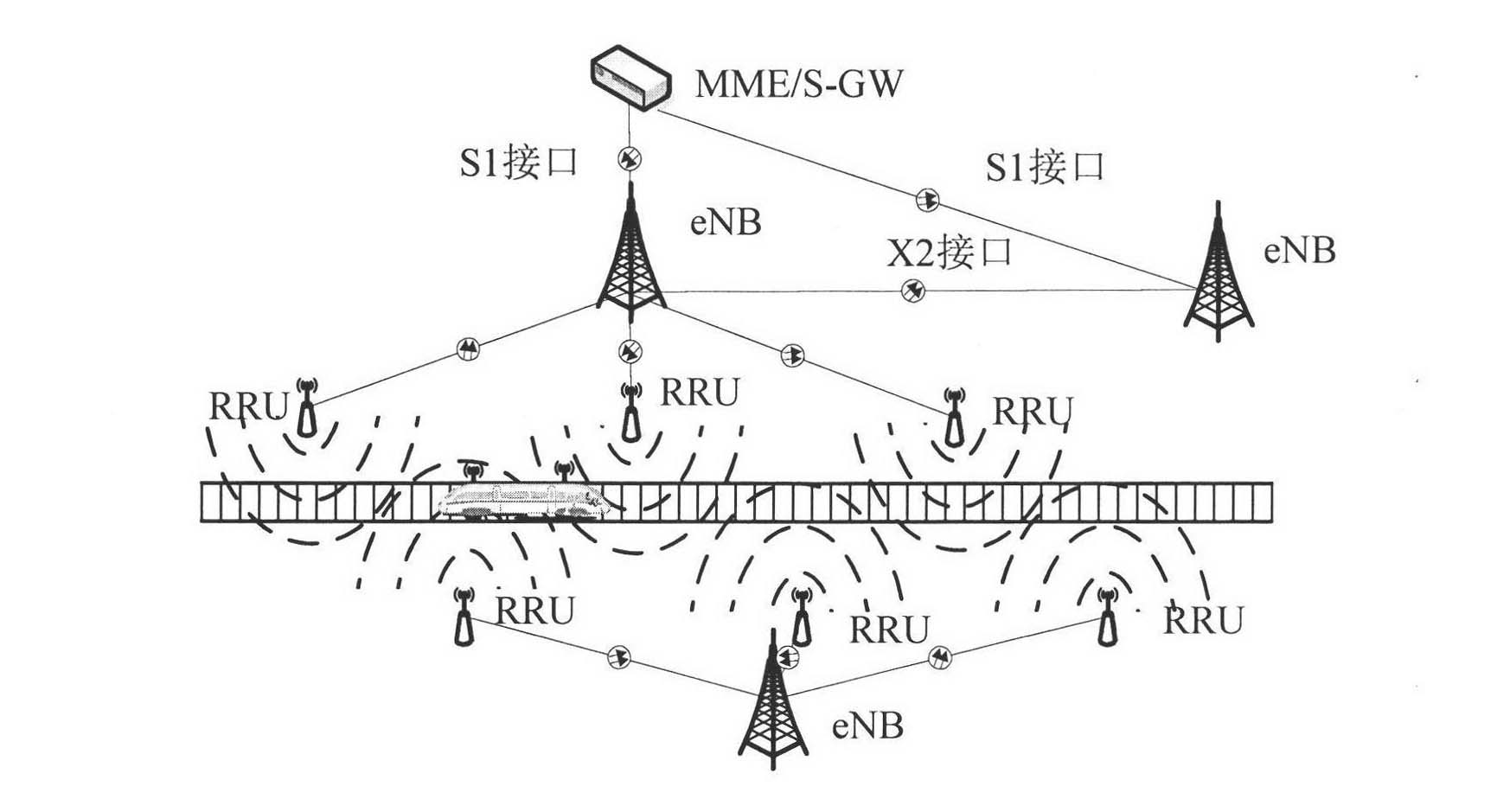

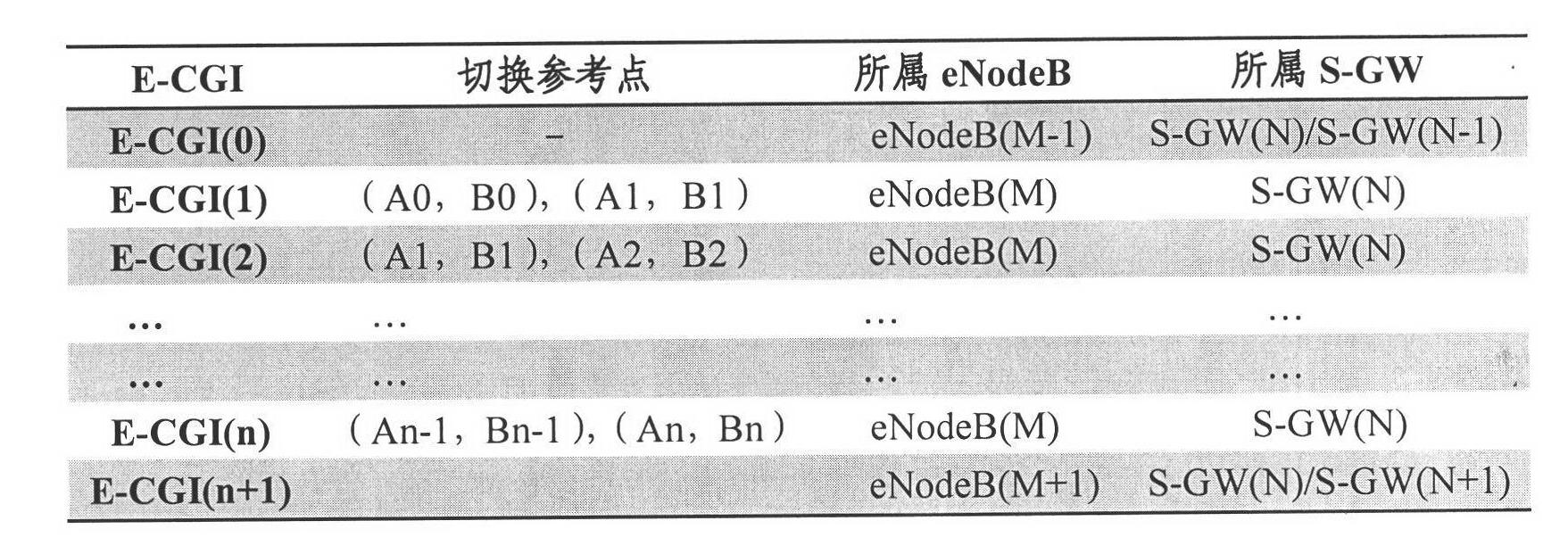

Aiming at the requirements of frequent cell handover, short handover time and high handover success rate in high-speed railway TD-LTE communication system, a fast handover method of TD-LTE communication system based on target cell pre-carrying is proposed. According to the train's running position, speed and direction, after the network planning is completed, a list of neighboring cells is generated in advance, and the switching position of each switching zone is preset, that is, the longitude and latitude position information. Before the train enters the overlapping area of switching between two cells , when the distance from entering the handover zone is a certain value L, the source base station eNodeB determines and sends the pre-bearer information to the target base station eNodeB according to the measurement report of the user terminal UE, and the target base station eNodeB performs the evolution packet system ( Evolved Packet System (EPS) resources to bear the load, when the train enters the handover zone, if the train meets the handover criteria, the train will be handed over from the source cell to the target cell. Therefore, this method reduces the handover delay and is beneficial to improve the handover success rate. The method can dynamically adjust the switching method according to the mobile speed of the UE, solve the problem of fast switching in a high-speed mobile environment, reduce the number of communication drops, improve the success rate of switching, enhance the service quality of high-speed broadband mobile services, and promote high-speed railway trains. The development of domestic multimedia broadband mobile Internet services meets the growing needs of passengers for mobile communication services.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Interior noise analysis and prediction method of high speed train

InactiveCN105590003AShorten the development cycleAccuracy impactGeometric CADSustainable transportationEngineeringInterior noise

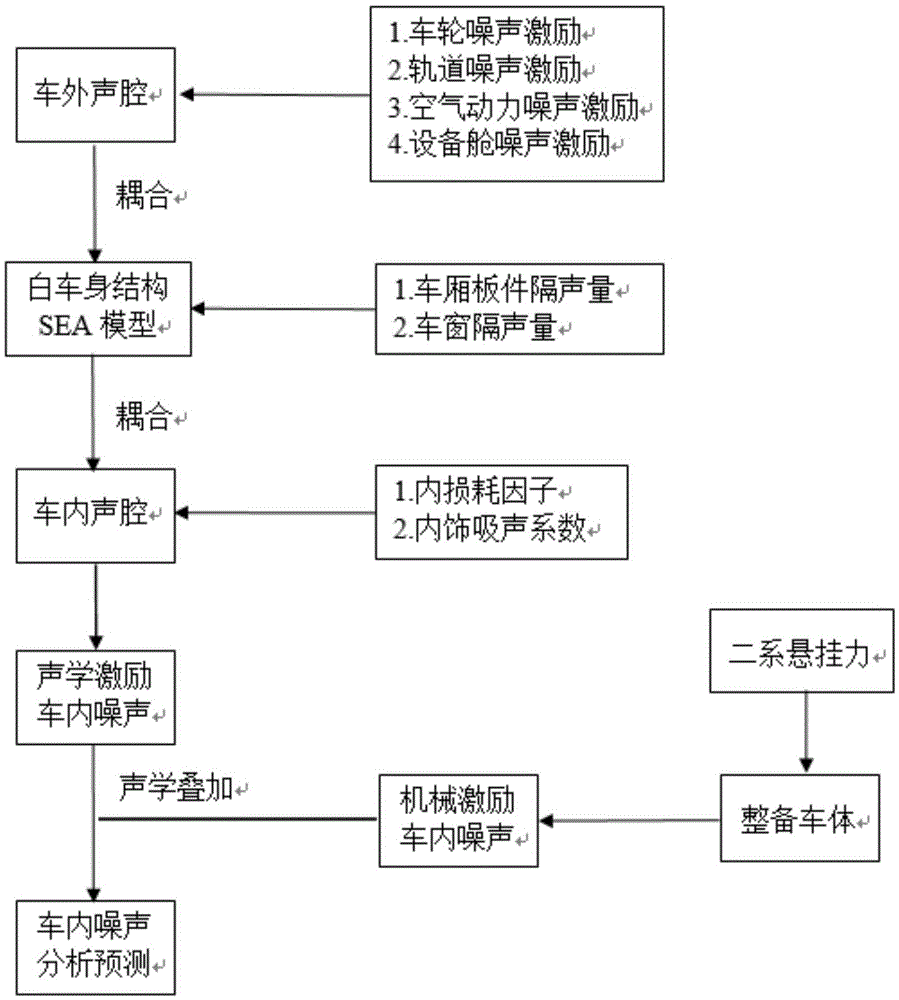

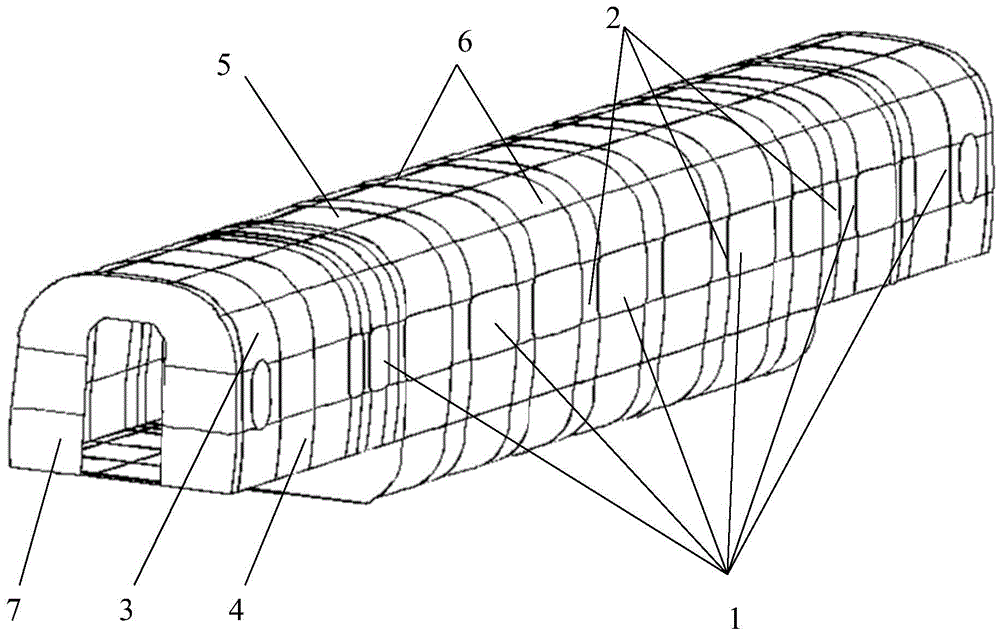

The invention discloses an interior noise analysis and prediction method of a high speed train. The method comprises the following steps: establishing a train reconditioning train body model, a statistical energy analysis model of a body in white structure and an interior and exterior vocal cavity statistical energy analysis model, and carrying out simplification and subsystem division; obtaining the statistical energy analysis parameters of the train body structure and an interior vocal cavity model, and loading the statistical energy analysis parameters onto a train body structure model plate subsystem and a vocal cavity model subsystem; and obtaining exterior vocal excitation source energy borne on the train body, applying the exterior vocal excitation source energy onto the exterior vocal cavity statistical energy analysis model, causing the exterior vocal excitation source energy to reach an interior vocal cavity after the exterior vocal excitation source energy is attenuated by the sound insulation property of a structural plate in a body in white structure model so as to obtain structural noise energy radiated into the train by the reconditioning train body under the function of the two-line suspension force of a compartment, and then, carrying out interior noise analysis and prediction. The problem that the interior noise of the train is difficult in prediction and the problems of the upper limit boundedness of a frequency domain, complex calculation flow, incomplete motivation consideration in the traditional method are overcome, calculation efficiency and prediction accuracy are improved, and development and test cost is lowered.

Owner:ZHEJIANG UNIV

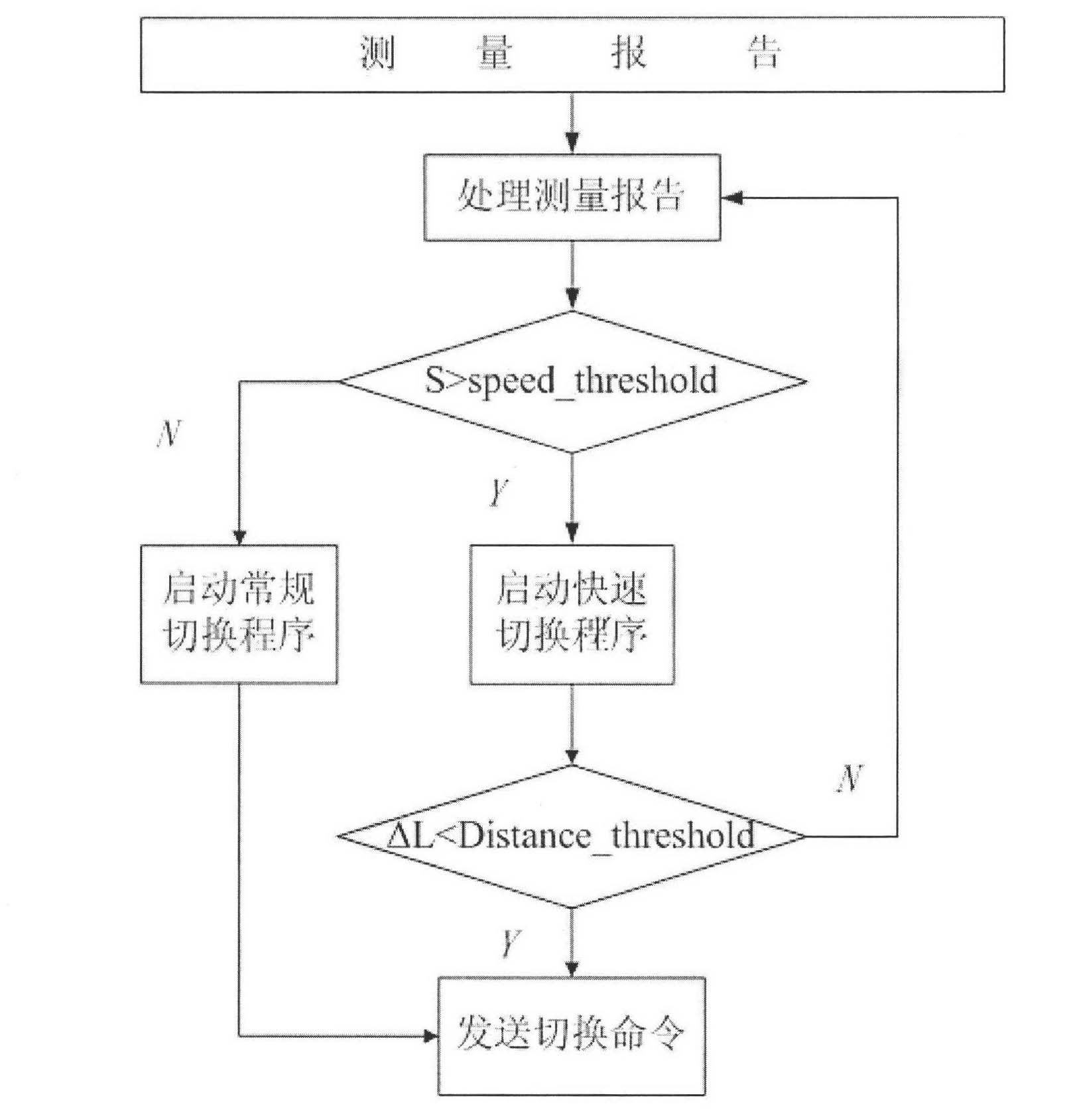

A fast switching method of td-lte communication system based on geographic location information

A fast switching method for TD-LTE communication system based on geographic location information Aiming at the phenomenon of frequent cell switching in high-speed railway TD-LTE communication system, as well as the requirements of short switching time and high switching success rate, a method based on geographic location is proposed. TD-LTE fast switching method of information. According to the train's running position, speed and direction, after the network planning is completed, a list of neighboring cells is generated in advance, and the switching position of each cell switching zone is pre-set, that is, the longitude and latitude position information. When the train enters the overlapping area of the two cells and arrives When the handover position is scheduled, the source base station eNodeB performs handover according to the measurement report of the user terminal UE. The method can dynamically adjust the handover method according to the mobile speed of the user terminal UE, so as to solve the problem of fast handover in a high-speed mobile environment, reduce the number of communication drops, improve the handover success rate, enhance the service quality of high-speed broadband mobile services, and promote The development of multimedia broadband mobile Internet services in high-speed railway trains meets the growing needs of passengers for mobile communication services.

Owner:BEIJING UNIV OF POSTS & TELECOMM

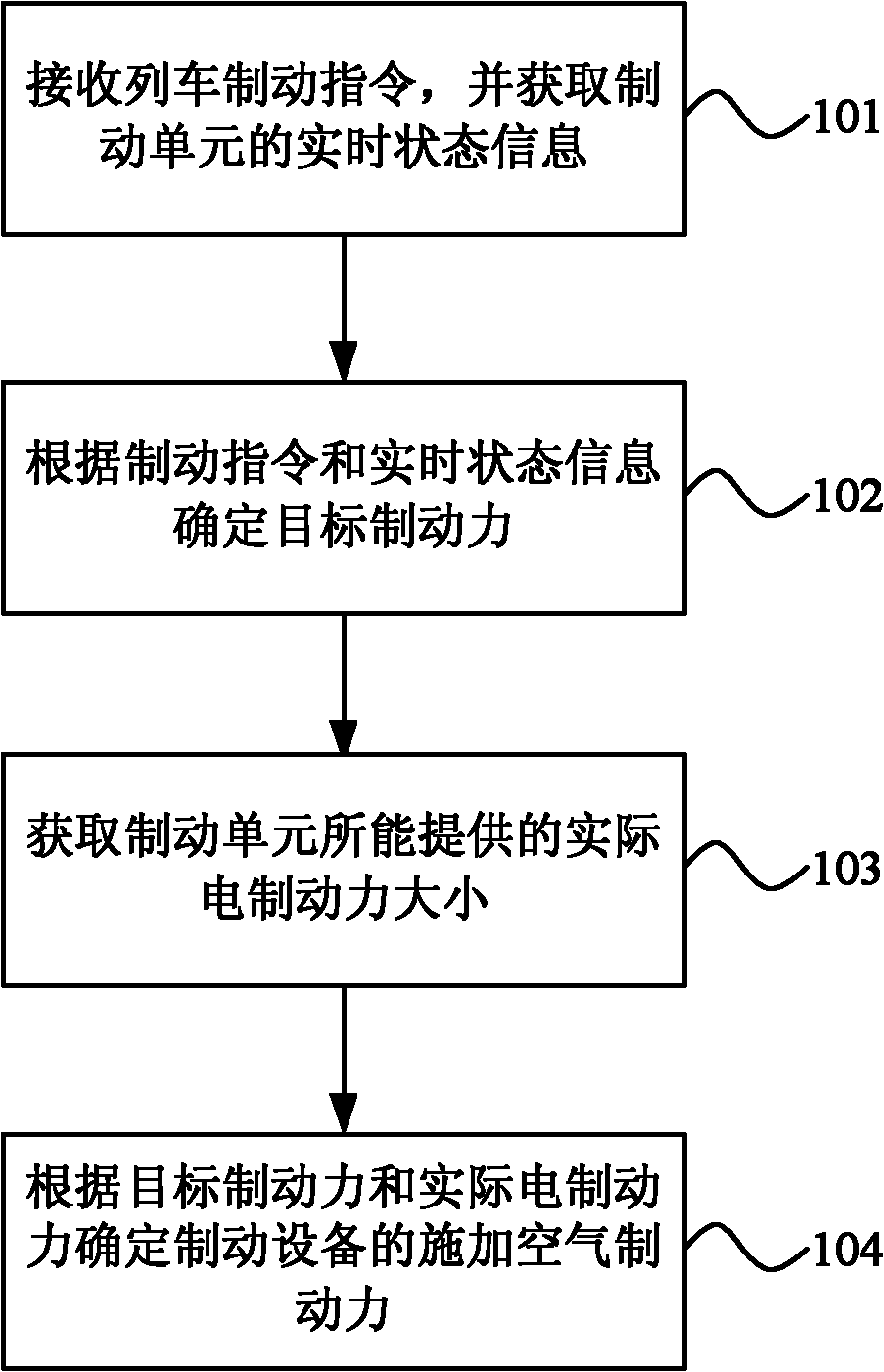

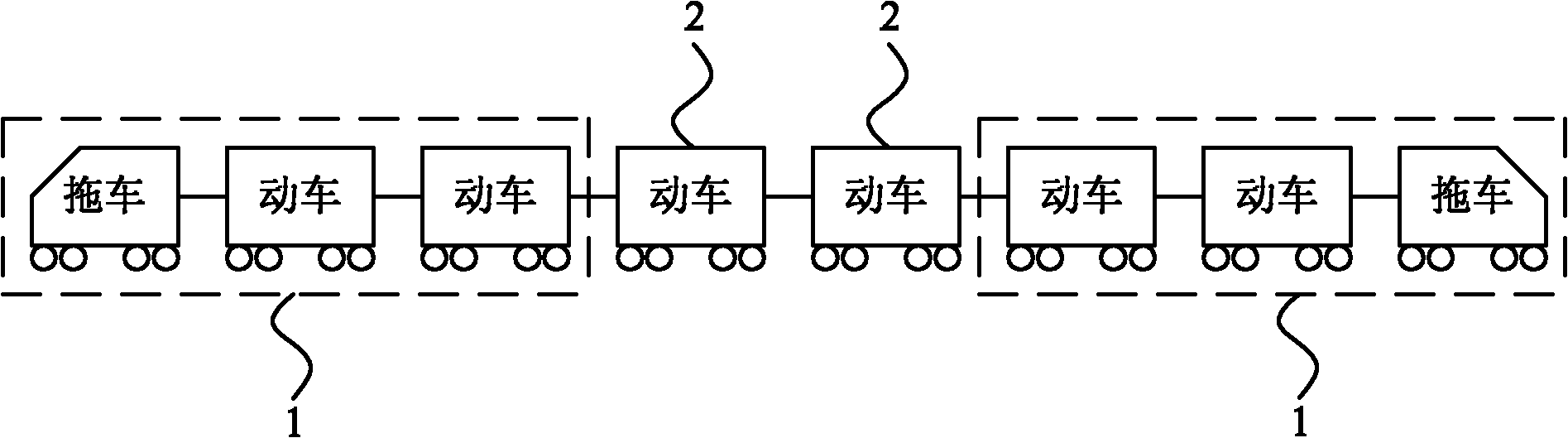

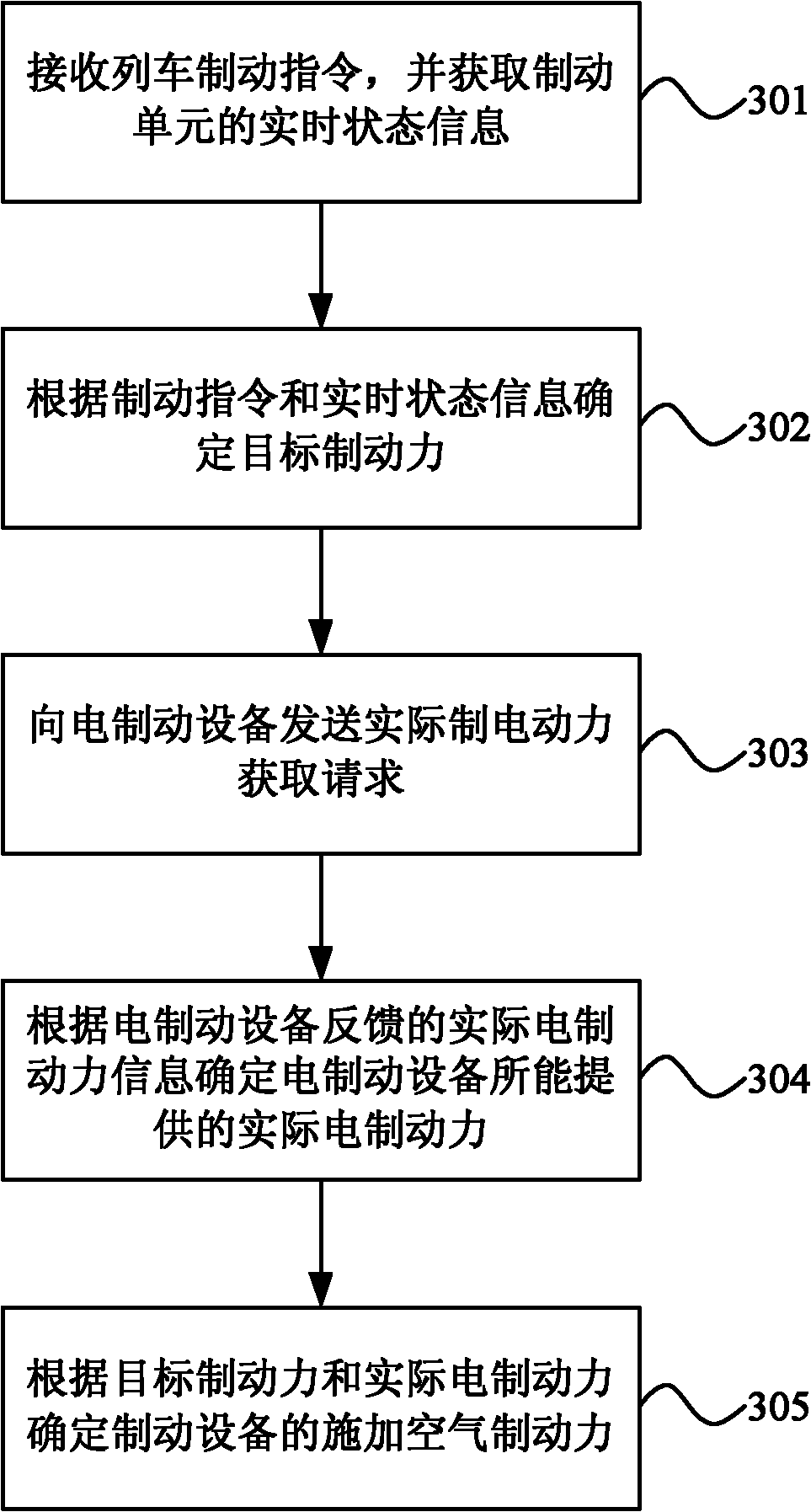

Method and system for braking high-speed train and brake control device

ActiveCN102602386AControl braking distanceImprove braking efficiencyBraking action transmissionRailway braking systemsElectricityBraking distance

The invention provides a method for braking a high-speed train, a system for braking the high-speed train, and a brake control device. The method for braking the high-speed train comprises the steps of: receiving a train braking instruction, and acquiring real-time state information of a braking unit; determining target brake force according to the braking instruction and the real-time state information; acquiring the actual electric braking force provided by the braking unit; and determining the air braking force exerted by braking equipment according to the target braking force and the actual electric braking force. According to the method for braking the high-speed train, the system for braking the high-speed train and the brake control device, the braking force can be determined according to the real-time sate of the braking unit of the train; the braking force can be reasonably distributed according to the actual conditions of an electric braking device and an air braking device, thus, the braking distance of the high-speed train can be effectively controlled; the braking efficiency can be improved; and the energy can be effectively saved.

Owner:CHINA RAILWAYS CORPORATION +1

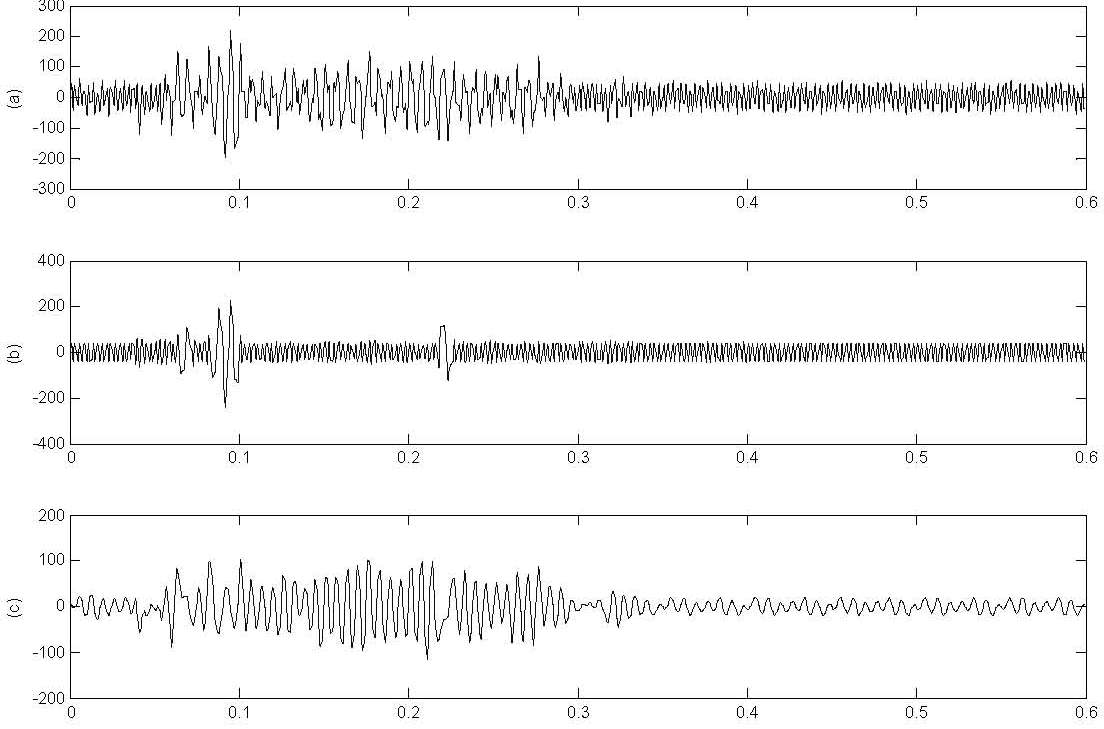

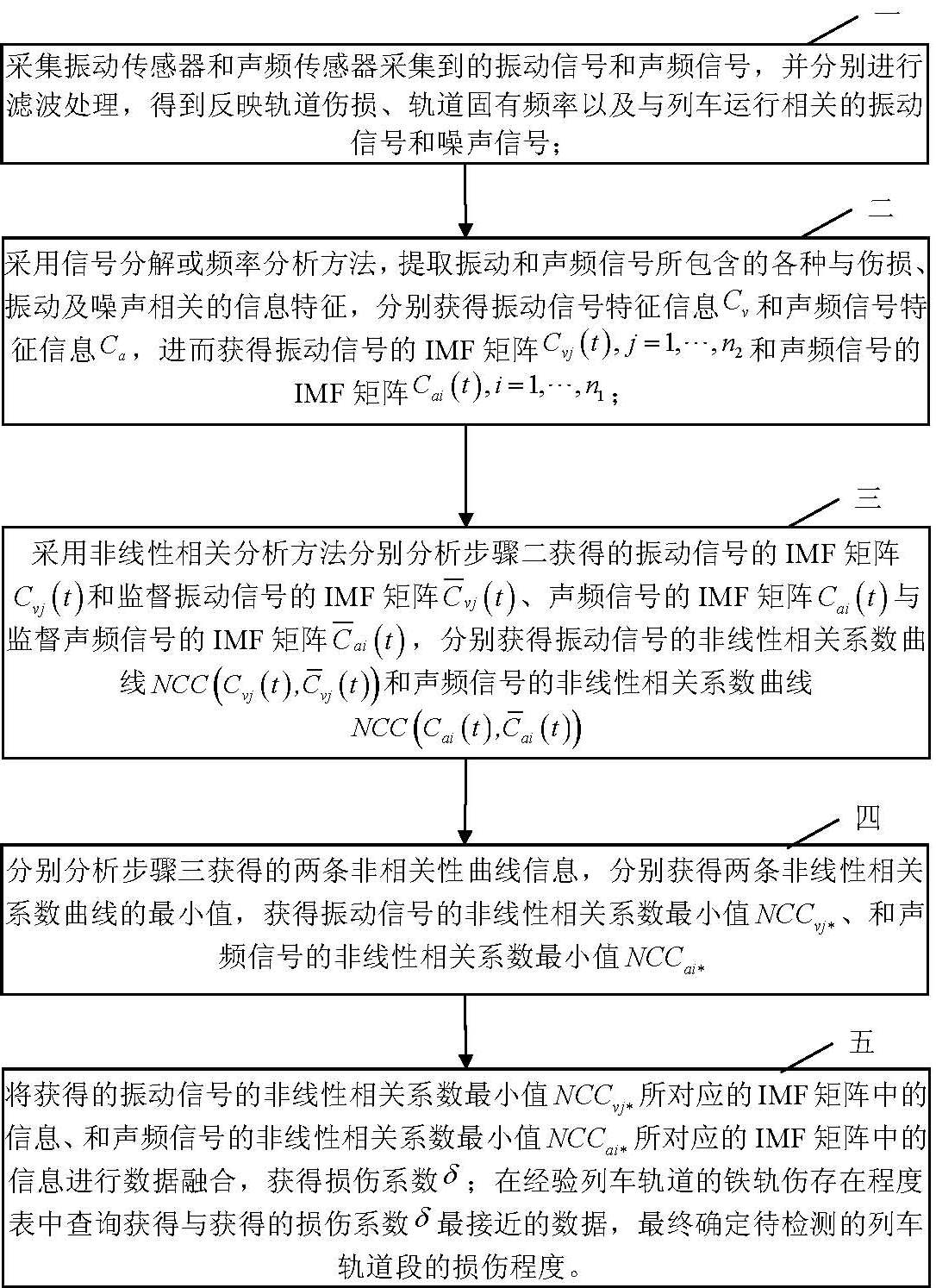

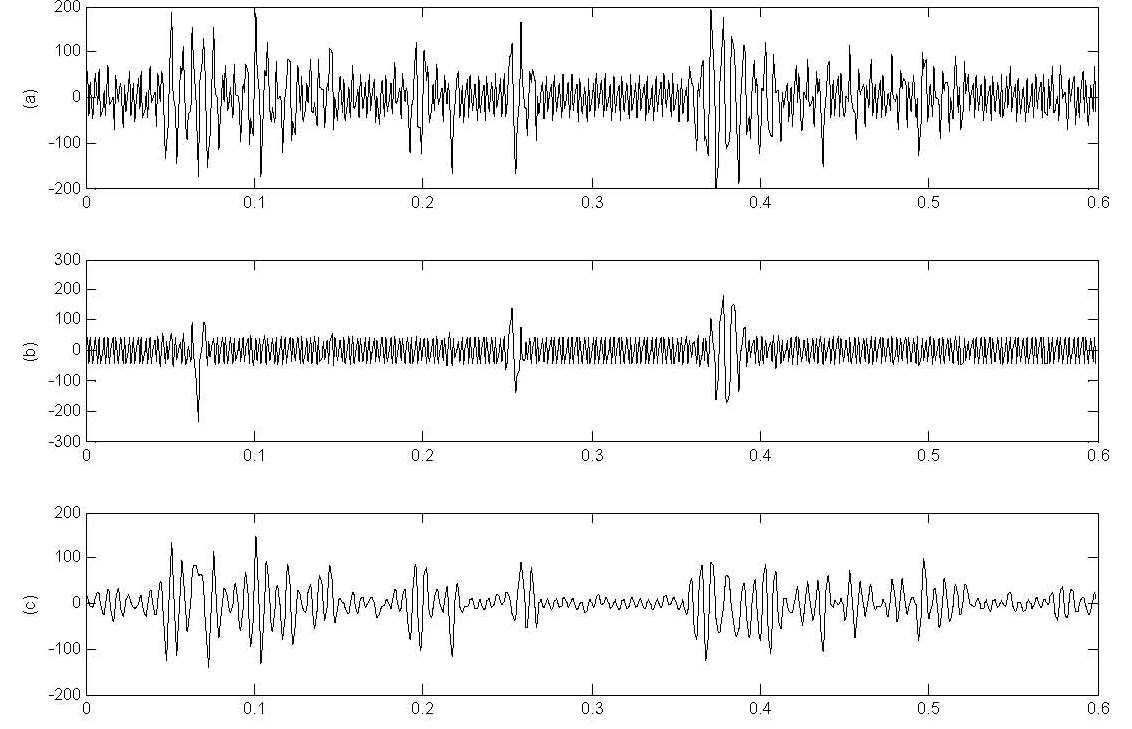

Vibration and audio signal-based high-speed train track defect detecting method

ActiveCN101900708AReflect damage informationEasy to analyzeAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalLinear correlationEngineering

The invention discloses a vibration and audio signal-based high-speed train track damage detecting method, belongs to the field of signal detection and processing as well as safety monitoring, and solves the problems of low detection speed and single detection method in the conventional train track damage detection. The method comprises the following steps: 1, acquiring vibration signals and audio signals of a train track through sensors arranged at train track detection points; 2, respectively extracting information characteristics included in the vibration signals and the audio signals; 3, respectively obtaining a nonlinear correlation curve of the vibration signals and a nonlinear correlation curve of the audio signals by using a nonlinear correlation analysis method; 4, respectively analyzing the information of the two nonlinear correlation curves obtained in the step 3 so as to respectively obtain minimum values of the two nonlinear correlation curves; and 5, carrying out data fusion on the two minimum values and corresponding information thereof so as to obtain a damage coefficient, and looking up a table to obtain the damage degree according to the coefficient. The method is suitable for detecting the damage on railway train tracks and monitoring the safety operation of trains.

Owner:哈尔滨工业大学高新技术开发总公司

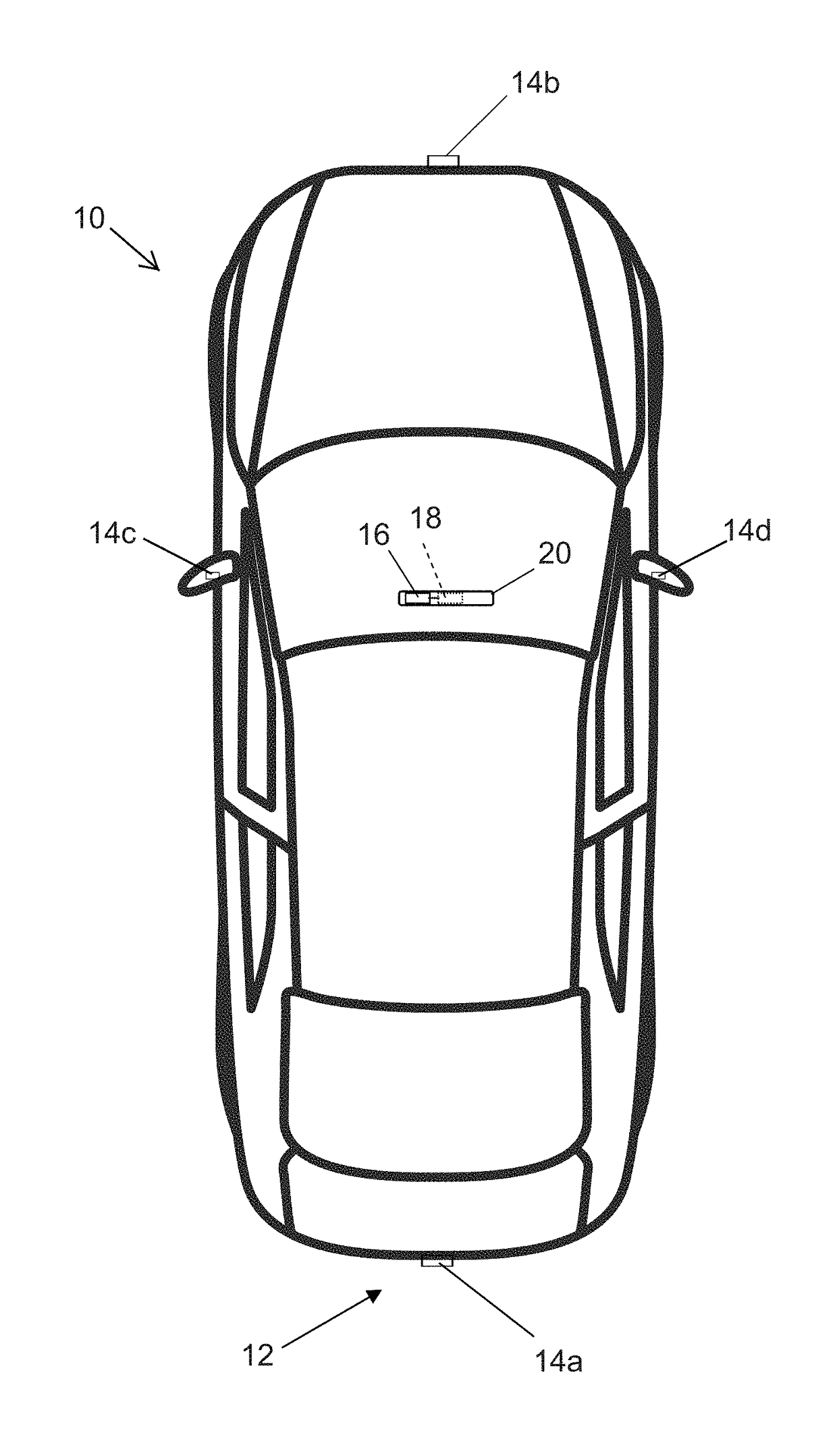

Vehicle camera with connector system for high speed transmission

ActiveUS20170201661A1Reliable electrical connectionEasy to GrindOne pole connectionsTelevision system detailsEngineeringHigh transmission

A camera for a vision system of a vehicle includes a front housing portion having a lens, a circuit board having circuitry established thereat, and a plastic rear housing portion having a connector for electrically connecting to a connector end of a wire harness of the vehicle when the camera is disposed at the vehicle. The front housing portion is mated with the rear housing portion with the circuit board disposed therein. The rear housing portion includes internal wall structure establishing internal surfaces of the rear housing portion. The connector of the rear housing portion includes a multi-pin connector having terminals for electrically connecting to circuitry at the circuit board. An electrically conductive metallic shield element is formed to be disposed within the rear housing portion and to correspond with the internal surfaces of the rear housing portion.

Owner:MAGNA ELECTRONICS

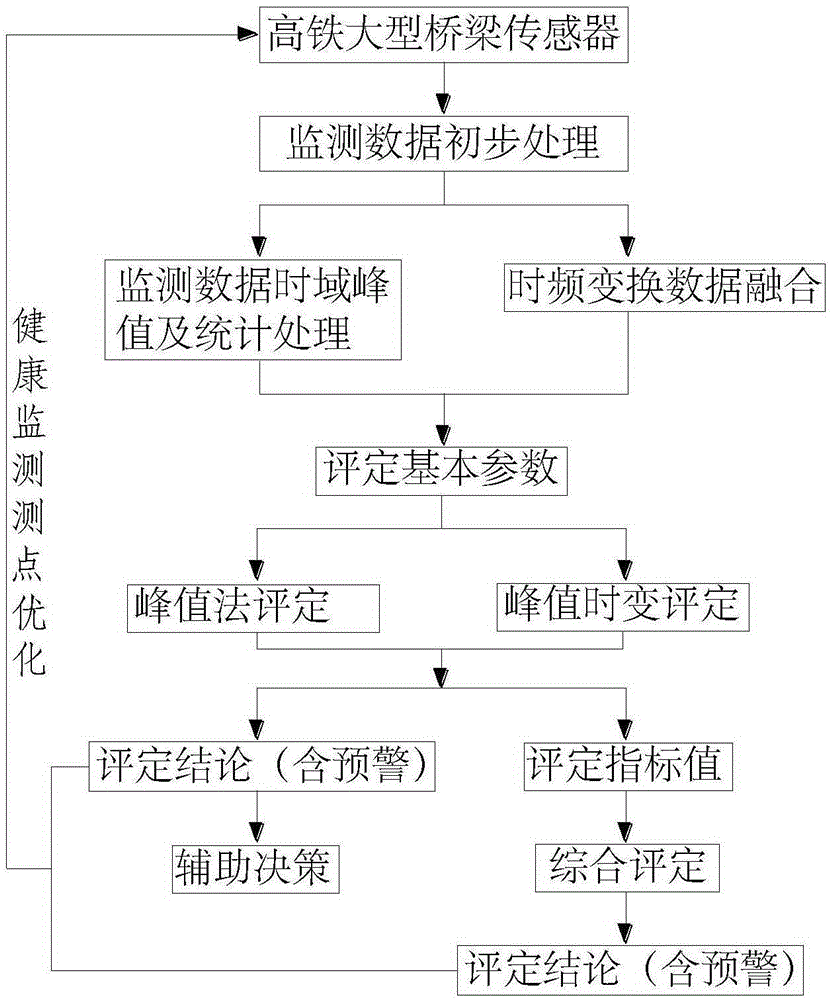

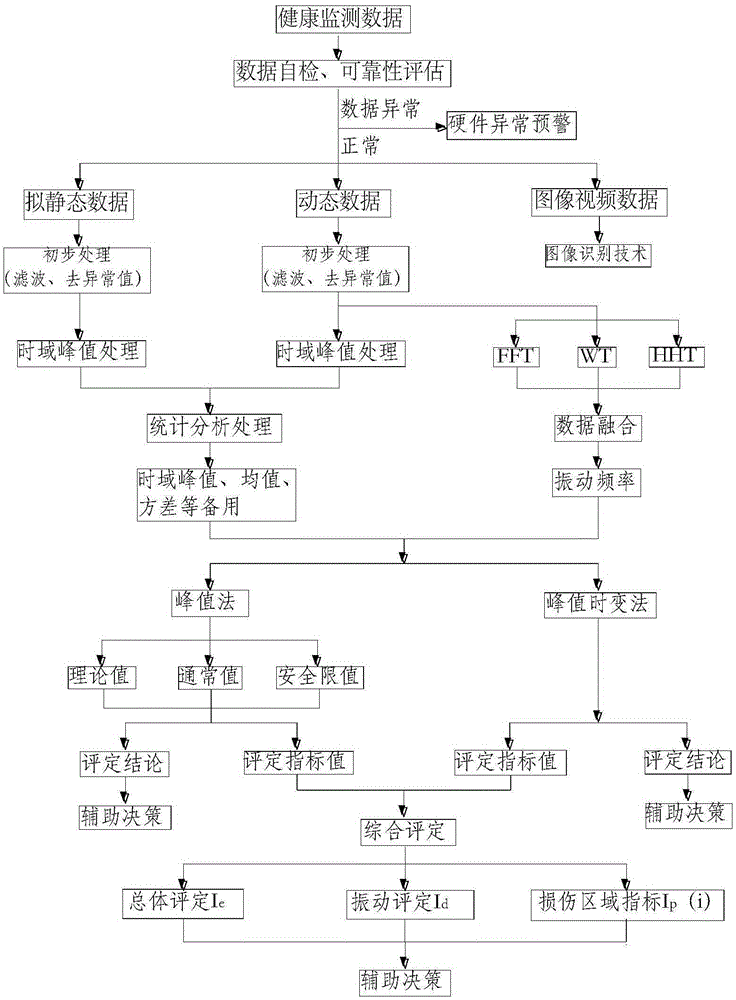

High-speed rail large-scale bridge performance evaluation method based on health monitoring data

ActiveCN105241660AImprove maintenance efficiencyAvoid difficultiesMachine part testingSubsonic/sonic/ultrasonic wave measurementBridge engineeringData acquisition

The invention discloses a high-speed rail large-scale bridge performance evaluation method based on health monitoring data, which relates to the field of bridge engineering detection. The high-speed rail large-scale bridge performance evaluation method comprises the steps of arranging an automatic sensor hardware equipment system on a high-speed rail bridge in an optimized manner, achieving automatic data acquisition, carrying out denoise processing, time domain statistical processing, frequency domain processing and the like on measured data in sequence, and evaluating bridge running safety performance based on the health monitoring data. The high-speed rail large-scale bridge performance evaluation method meets the actual requirements of high-speed rail bridge detection and evaluation, can reflect the running safety of the high-speed rail bridge accurately and timely, and provides important guarantee for the safe running of high-speed trains; the evaluation results obtained through adopting the method are unified with the high-speed rail conventional detection and evaluation results, thereby facilitating the actual application of the method for the bridge managers; and decision-making suggestions for targeted bridge maintenance and repair are made on the basis of the evaluation results obtained through adopting the method, thereby being conductive to implementing timely maintenance and dynamic maintenance, and greatly improving the bridge overhaul efficiency.

Owner:SOUTHWEST JIAOTONG UNIV

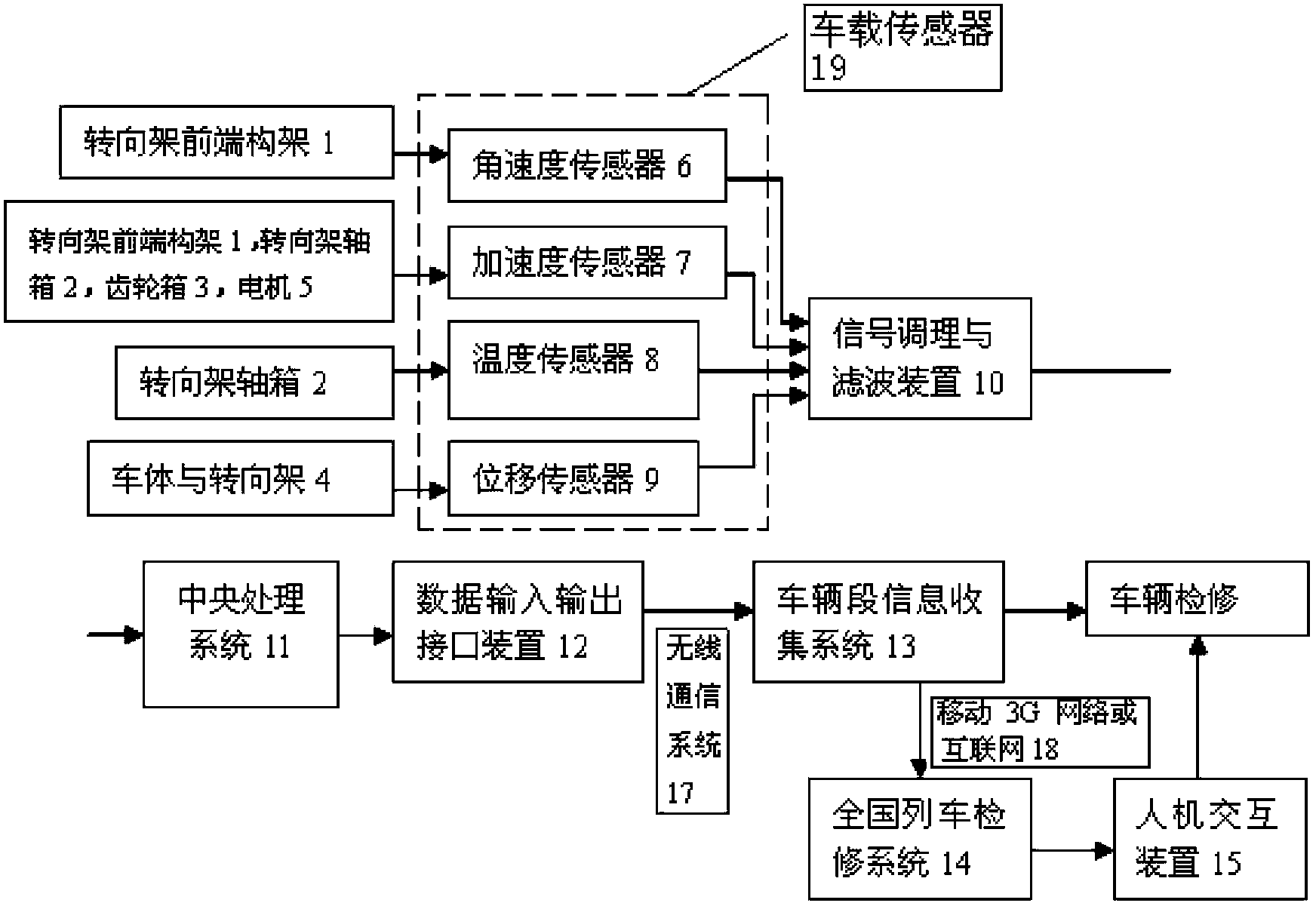

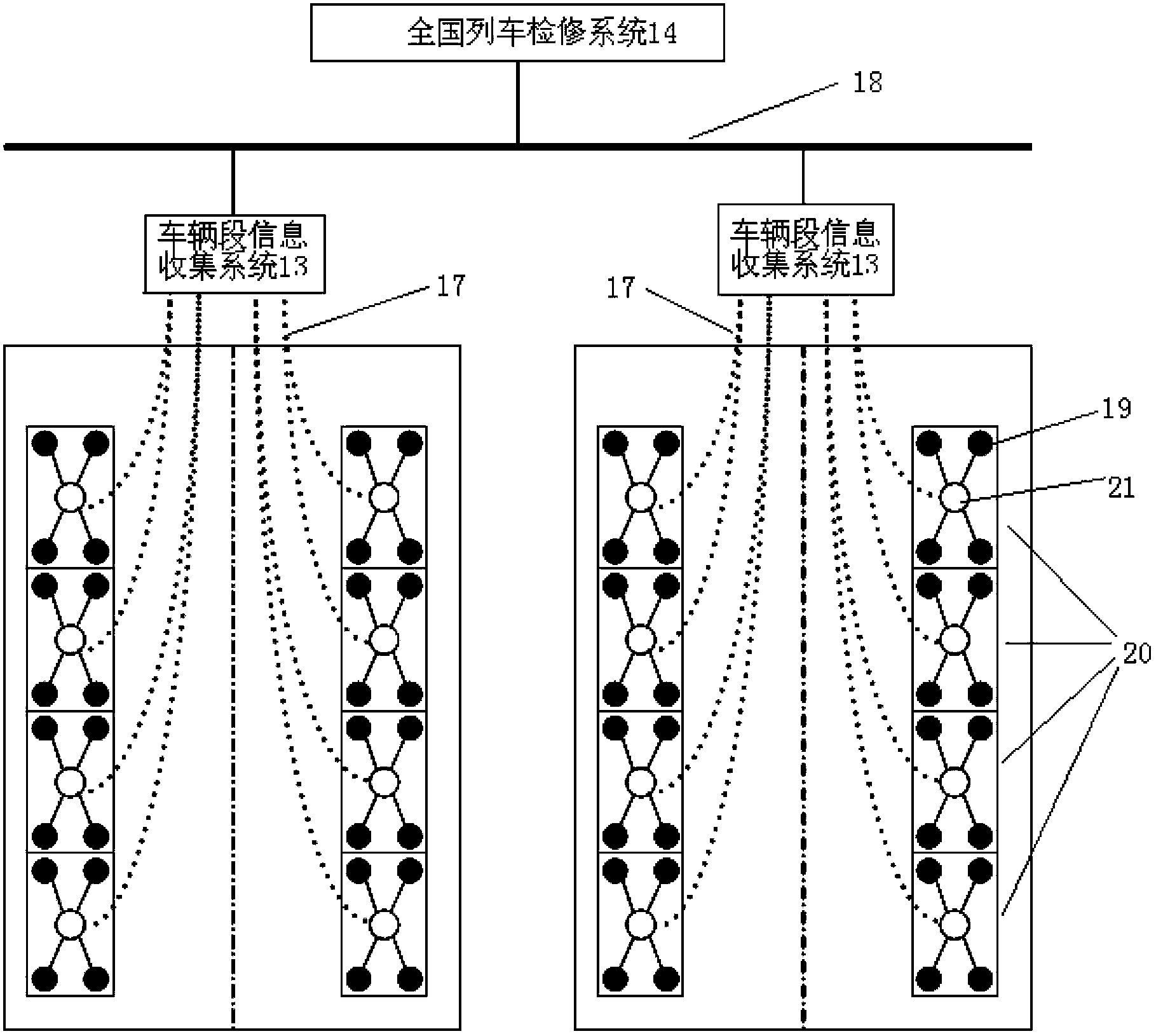

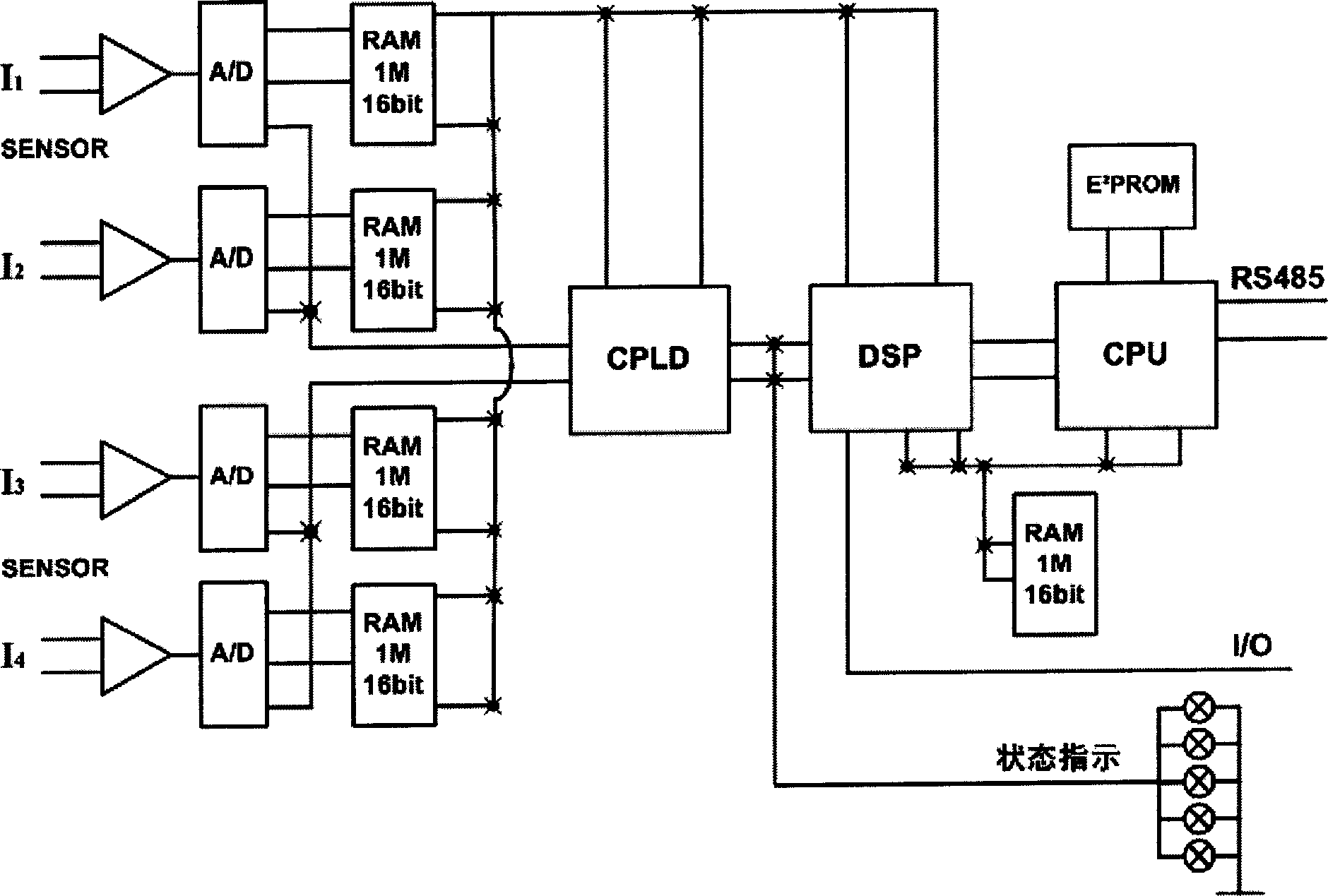

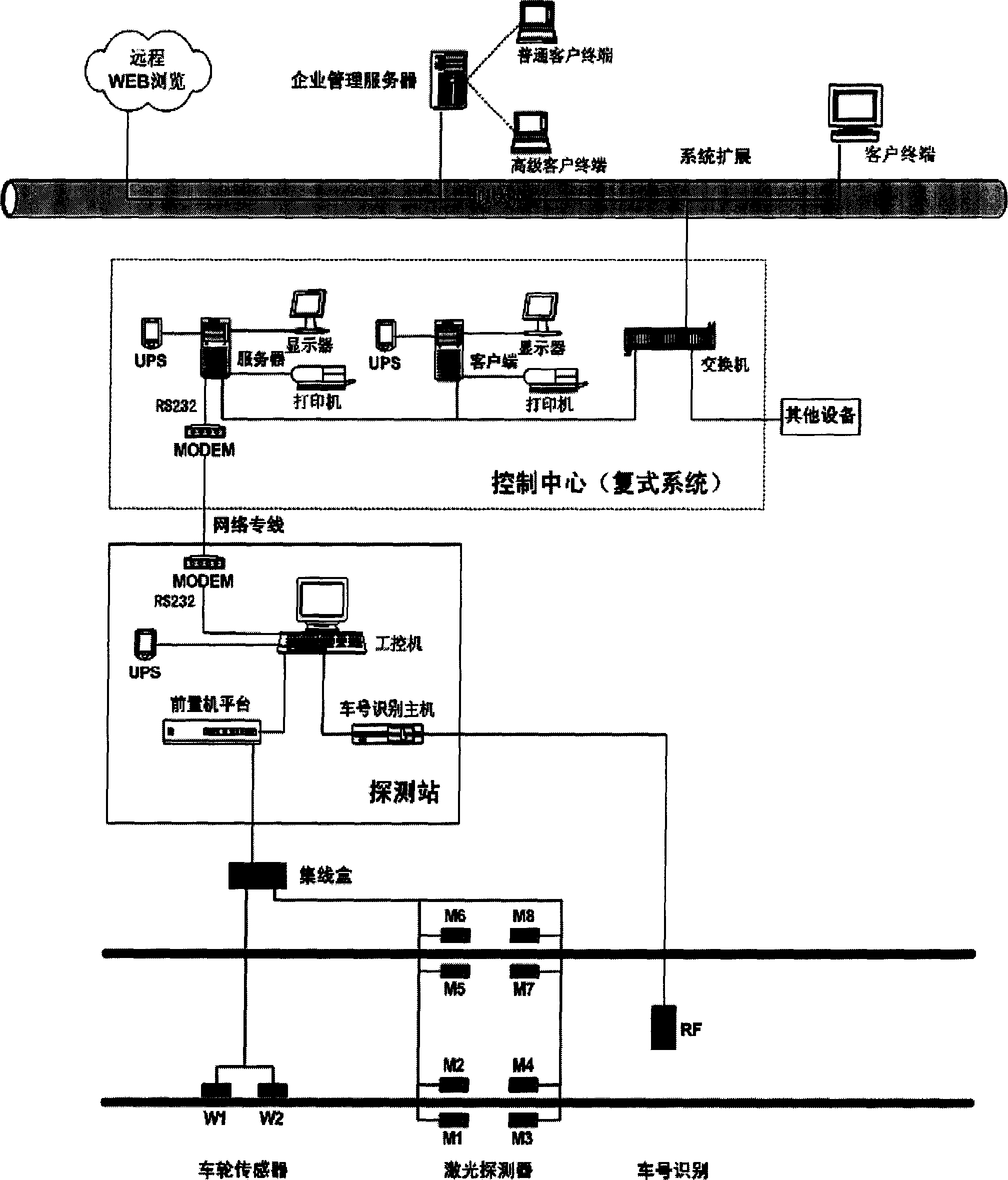

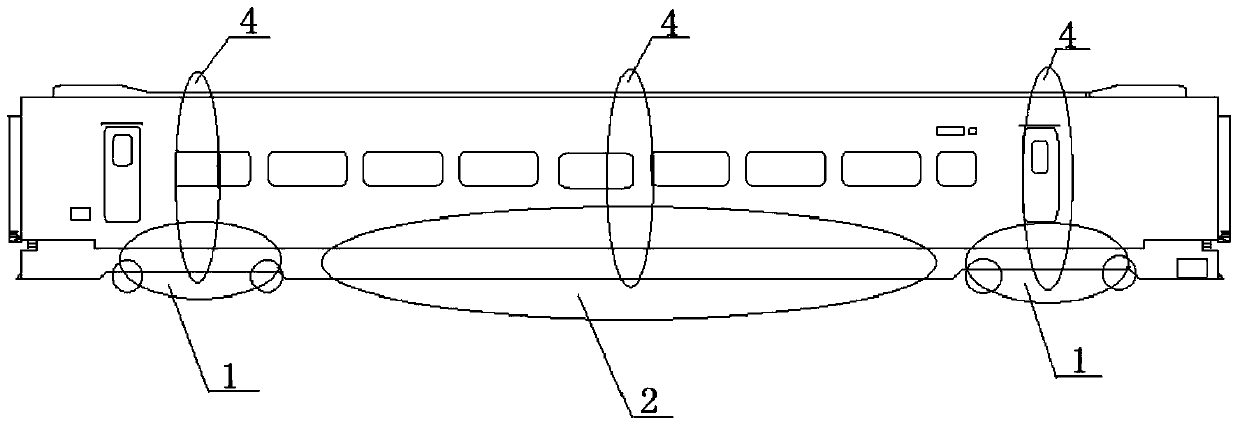

High-speed train running gear fault diagnosis and remote monitoring system based on Internet of Things

ActiveCN103852271AImprove maintenance efficiencyReduce operational riskRailway vehicle testingCollection systemEngineering

The invention relates to a high-speed train running gear fault diagnosis and remote monitoring system based on Internet of Things (IOT). The system provided by the invention comprises vehicle-mounted sensors, a signal conditioning and filtering device, a central processing system, a data input and output interface device, a vehicle depot information collection system, a nationwide train maintenance system and a man-machine interaction device. With the arrangement of a plurality of the vehicle-mounted sensors, accurate fault identification and positioning of key equipment of running gears are realized, prediction of faults is realized, train operational risks are reduced, remote diagnosis of faults is achieved, fault diagnosis cost is lowered, and fault diagnosis cycle is shortened.

Owner:CRRC QINGDAO SIFANG CO LTD

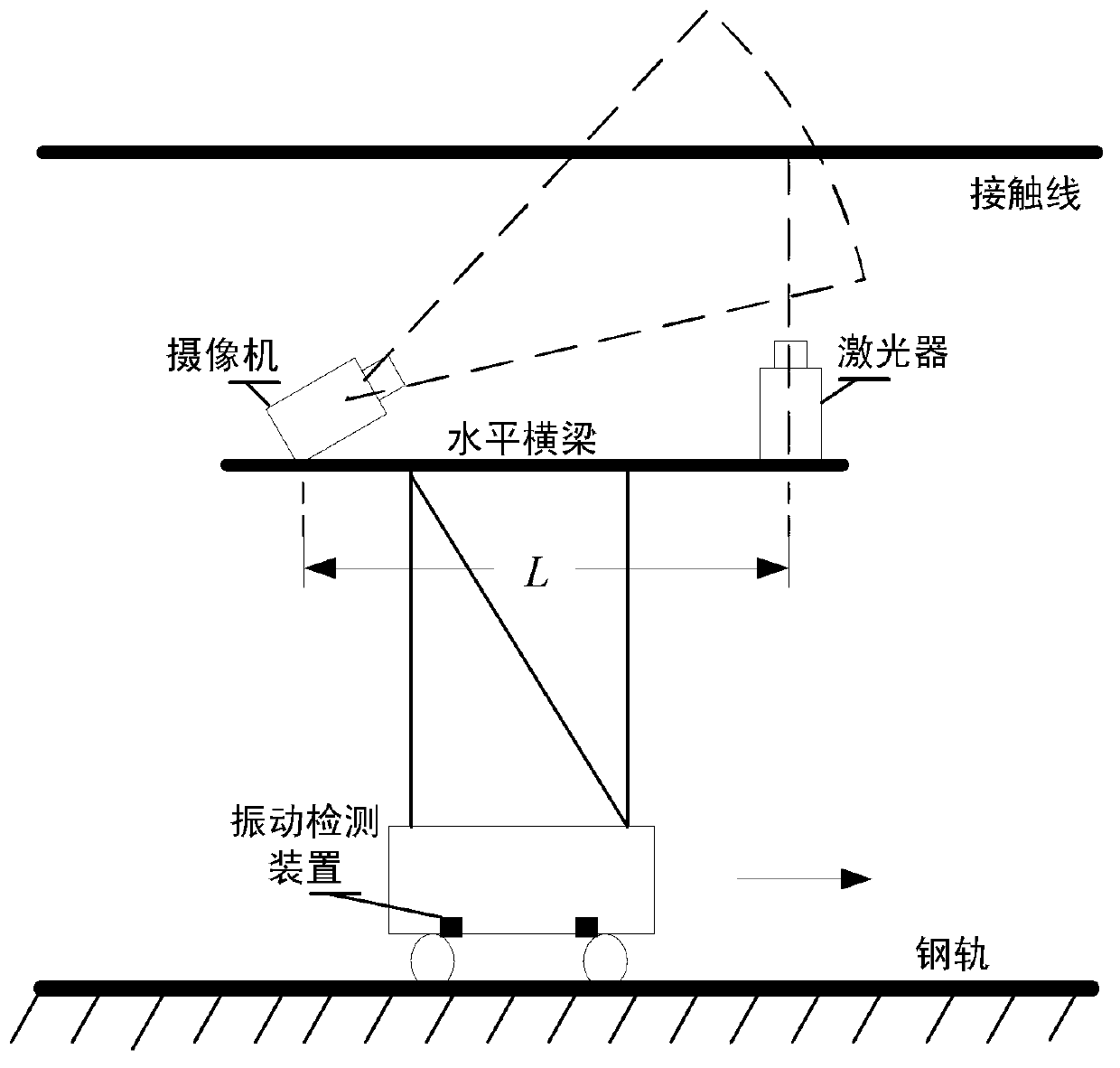

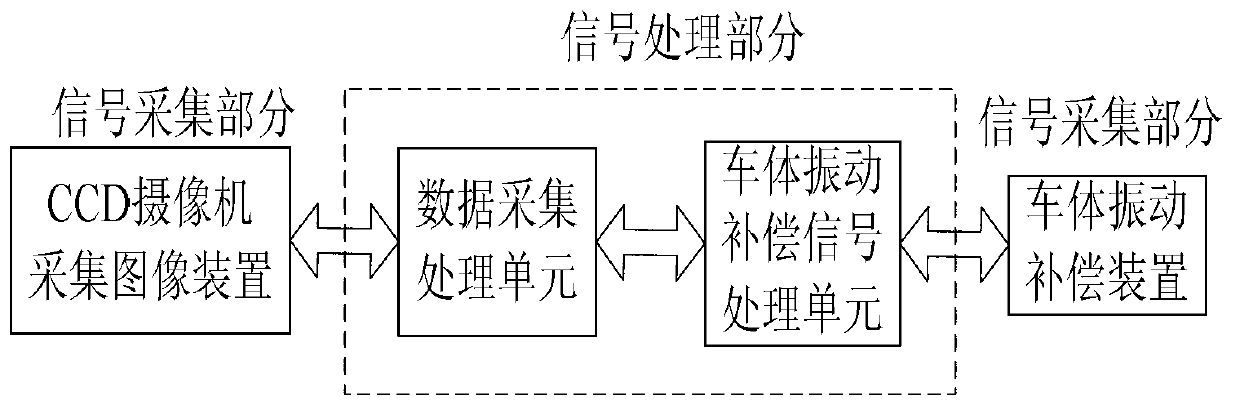

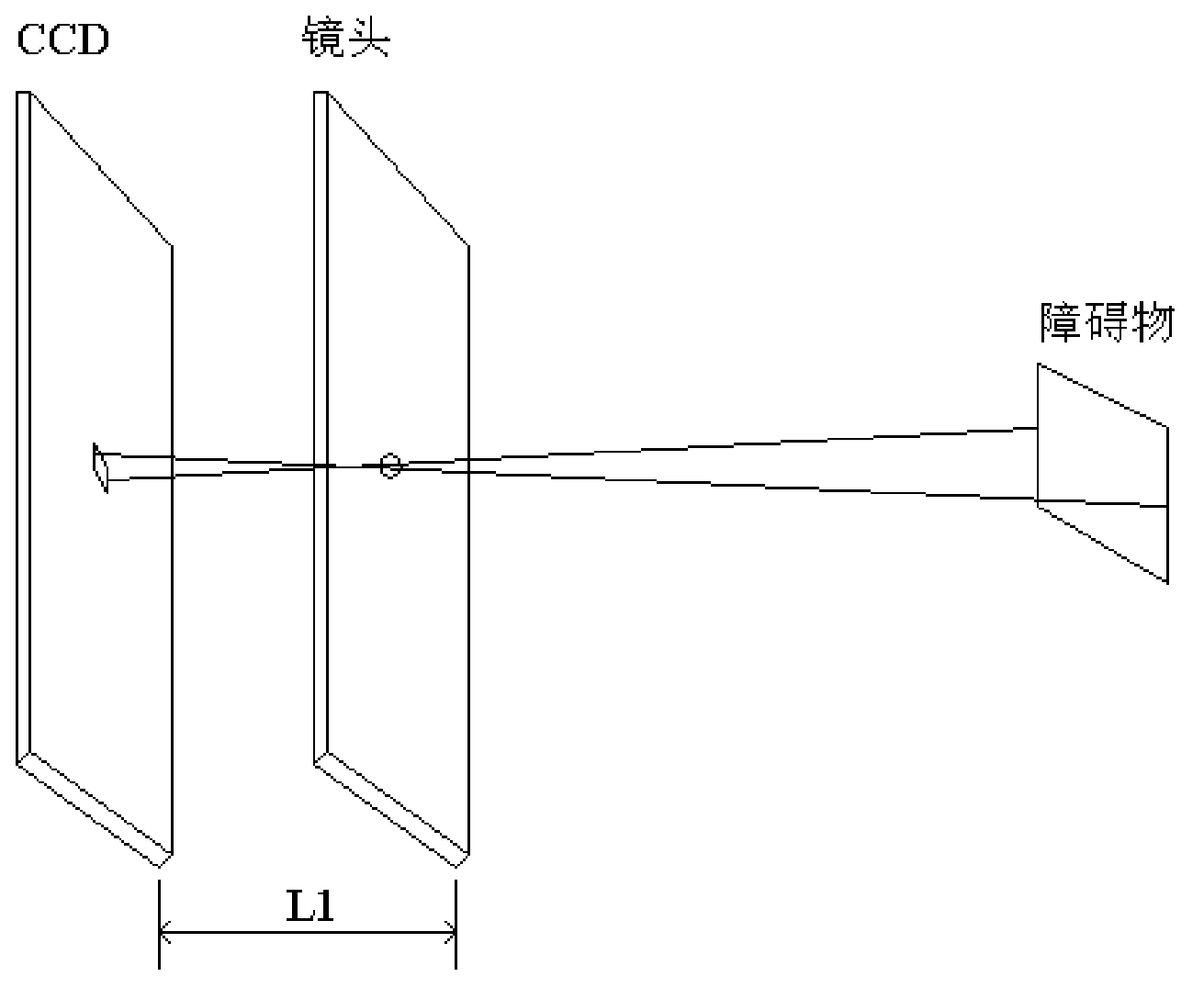

Non-contact contact line geometrical parameter detecting method

InactiveCN103217111AAvoid defectsIncrease flexibilityUsing optical meansControl signalComputer vision

The invention discloses a non-contact contact line geometrical parameter detecting method. The method includes a first step of collecting high-definition images at equal time intervals by means of collection of control signals and finishing image preprocessing by means of the median filtering technique, the image graying technique and the like, a second step of locating a laser spot center point and extracting a coordinate of the center point by means of the iterative thresholding algorithm and a method of removing isolated noise in mathematical morphology, a third step of extracting a matched target region and detecting a transverse gray singular value of the target region, a fourth step of giving the wire height and a stagger value of a contact line by means of conversion from an image coordinate system to a camera coordinate system and from the camera coordinate system to a detection vehicle coordinate system, and compensating vibration of a vehicle body, and a fifth step of giving precise detection values of the wire height and the stagger value and displaying information of a plurality of parameters in a developed graphic monitoring interface. The method effectively improves detection efficiency of geometrical parameters of a contact net, simplifies the algorithm, improves precision of fault detection, and specifically improves safe reliability of the contact net of a high-speed train.

Owner:SOUTHWEST JIAOTONG UNIV

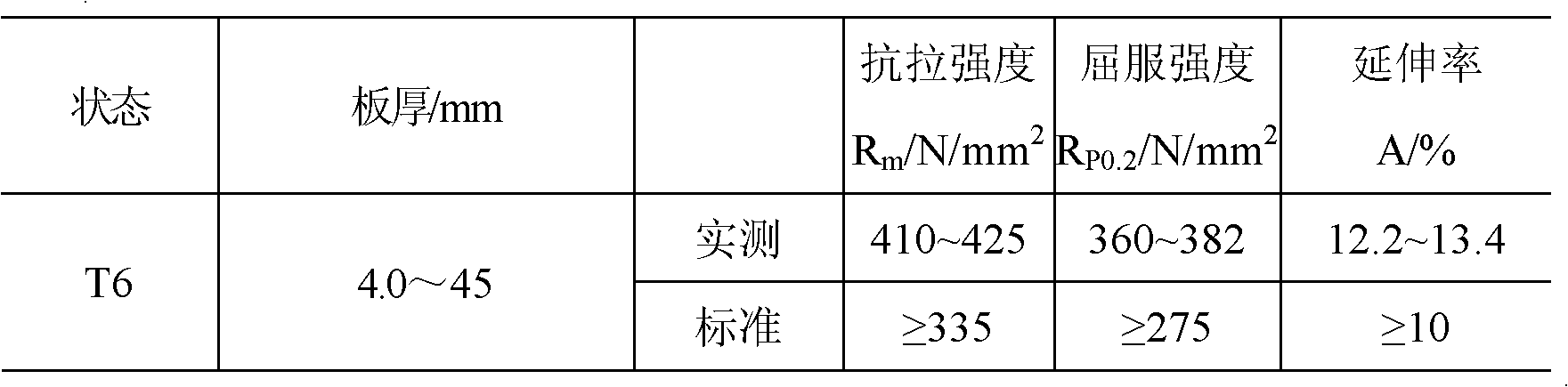

Aluminum alloy sheet for high-speed train structure and manufacture thereof

The invention relates to an aluminum alloy sheet for a high-speed train structure and a manufacture thereof, in particular to an aluminum alloy sheet and a manufacture thereof. The sheet of the invention is prepared from the following elements: Zn, Mg, Mn, Cr, Zr, V, Cu, Si, Fe, Ti and Al. The preparation method comprises the following steps of: (1) weighting raw materials; (2) melting; (3) casting; (4) homogenized annealing; (5) hot rolling; (6) cold rolling; (7) quenching; and (8) one-stage ageing treatment. The aluminum alloy sheet for the high-speed train structure has the tensile strength of 410-425 Rm / N / mm<2>, the yield strength of 360-382 RP0.2 / N / mm<2> and the elongation rate of 12.2-13.4 percent.

Owner:NORTHEAST LIGHT ALLOY CO LTD

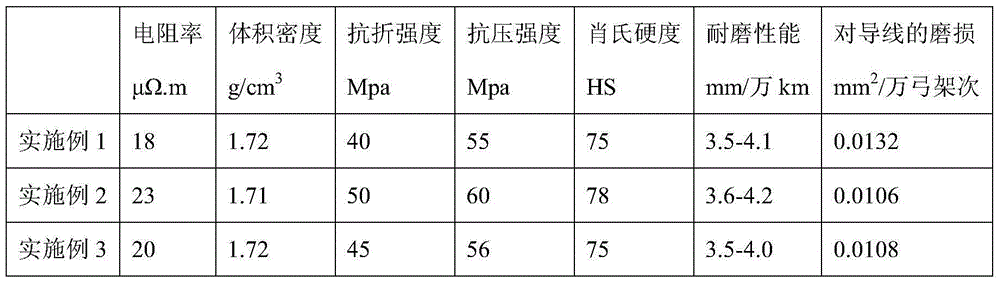

Carbon contact strip of pantograph and manufacturing method thereof

The invention discloses a carbon contact strip of a pantograph and a manufacturing method thereof. The carbon contact strip is prepared from following raw materials, by weight, 28-43 parts of petroleum coke powder, 25-28 parts of asphalt coke powder, 10-12 parts of sprayed carbon black, 2-5 parts of sulfur, 3-5 parts of boron nitride, 5-8 parts of carbon fiber, 4-6 parts of natural graphite, 5-7 parts of artificial graphite, 1-3 parts of calcium chloride powder and 30-35 parts of modified asphalt. The carbon contact strip is high in mechanical strength, is good in self-lubricating performance and electric arc resistance and is wear-resistant. The carbon contact strip can be not only used in various locomotives in railway main lines with speed per hour being 120-250 km / h, but also used in motor train units and high-speed trains with speed per hour being higher than 250 km / h. The carbon contact strip is free of limit of environment and climate conditions.

Owner:SUZHOU DONEKA NEW MATERIALS CORP LTD

Friction materials for high-speed train braking and method for preparing same

InactiveCN1844204AReduce high temperature performance degradationGood synergyFriction liningCompression moldingAfter treatment

The invention relates to a friction material used in express train brake and its method for preparing. The materials include rubber, gum cement, resin, friction-type mix, fibrous material and mineral filler. It is characterized in that the materials also include tripoly cyanoamine cyanurate, mineral filler, didymia rare-earth powdered ore, lanthanum chlor rare earth powdered ore, the proportion of the weight part of each component is: rubber of 5-10 parts,fibrous material of 8-13 parts, gum cement of 0.2-0.6 part, mineral filler of 2-7 parts,resin of 5-12 parts, tripoly cyanoamine cyanurate of 0.5-1 parts,and friction-type mix of 40-50 parts. The method for preparing includes preparing moulded materials, compression molding and after-treatment. The invention reduces the high-temperature degeneracy of the friction material because it has selected tripoly cyanoamine cyanurate which has self-lubricating property and is of good fire-retardancy as addition agent and improves the cooperating knife-bar among gasket materials because it has added rare-earth powdered ore. The method for preparing moulded materials adopting rubber-making technology is of simple technology and suitable for commercial manufacture, and is of zero environmental contamination, zero noise and nuisance free.

Owner:SHANGHAI PEIMENG MATERIAL SCI & TECH

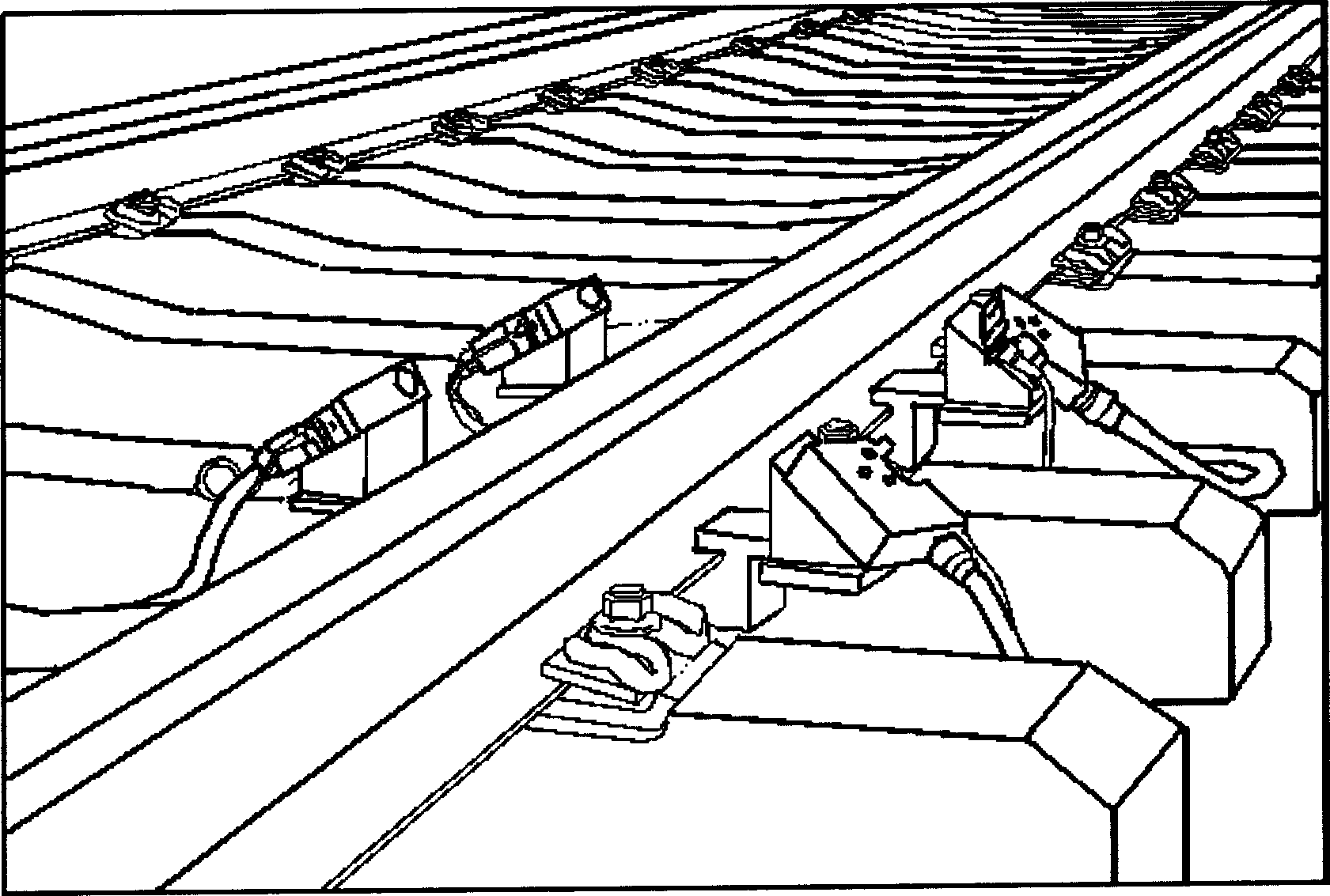

Online detection mthod and device for train wheel pair size

InactiveCN1899904AEasy to controlRealize high-precision detectionWheel-rims surveying/measuringUsing optical meansData acquisitionEngineering

The present invention discloses on-line detection method and device for train wheel pair size. There are two pairs or four coaxial laser displacement detectors set on two sides of two tracks to send laser beams projected obliquely to the wheel pair for detecting the distances between each wheel end place to the laser detector, one high speed data acquisition and treat circuit, and one industrial control computer for recording, analysis and displaying. Based on PSD laser position measurement, the present invention can measure the flange thickness, flange height, wheel diameter and distance between backs of wheel flanges of high speed train in high precision.

Owner:GUANGZHOU AUTO TRANSPORT MEASURE & CONTROL TECH

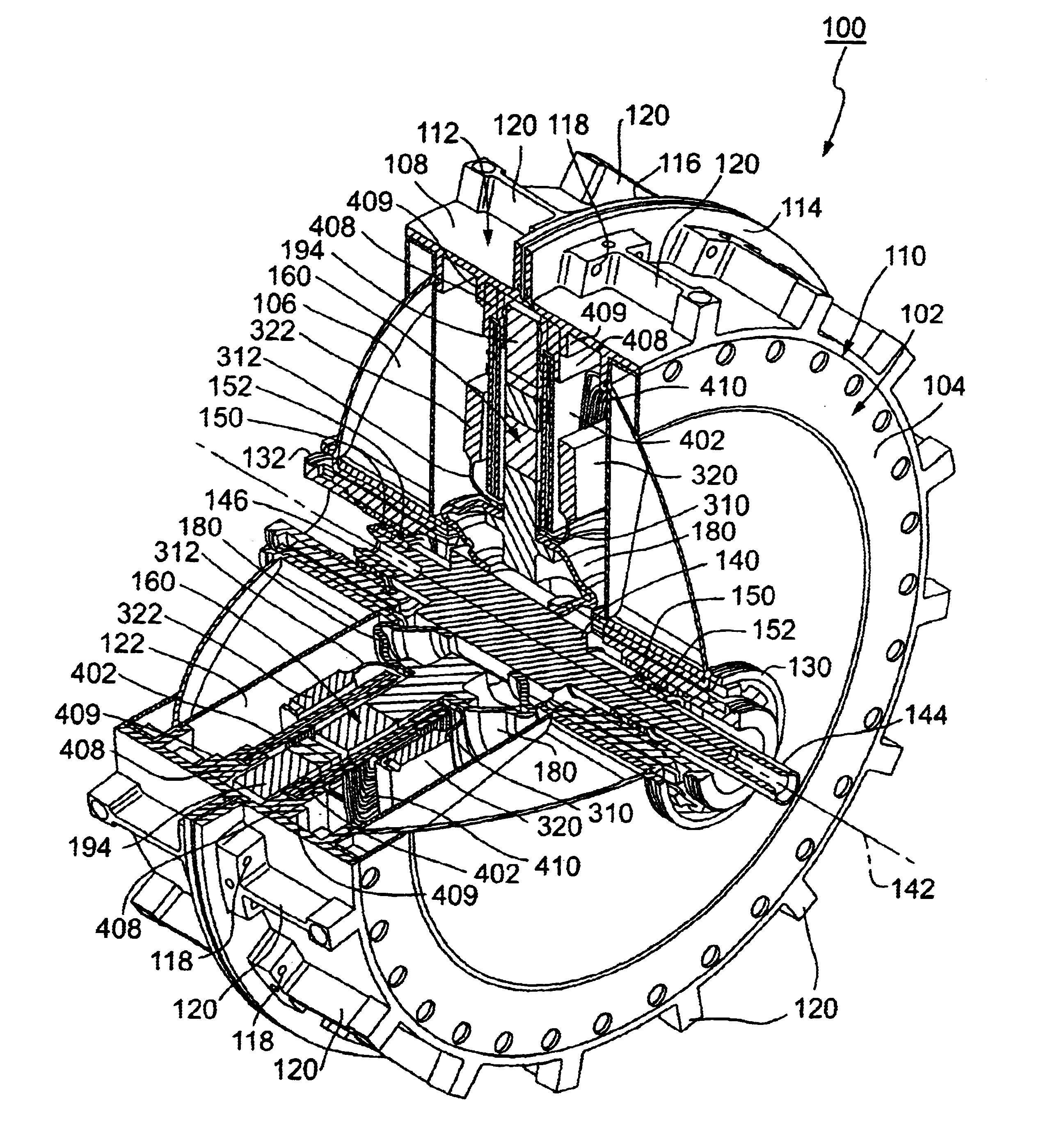

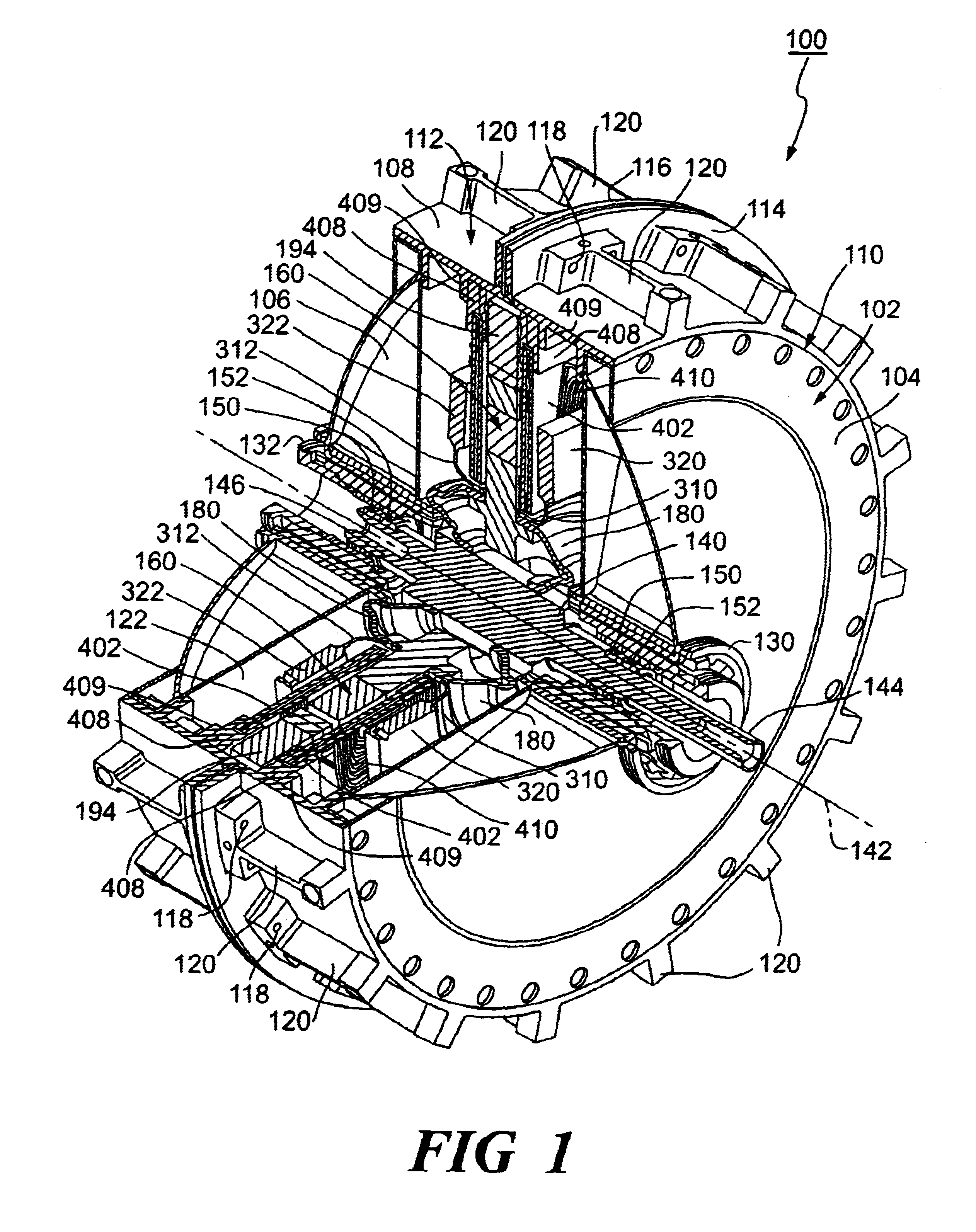

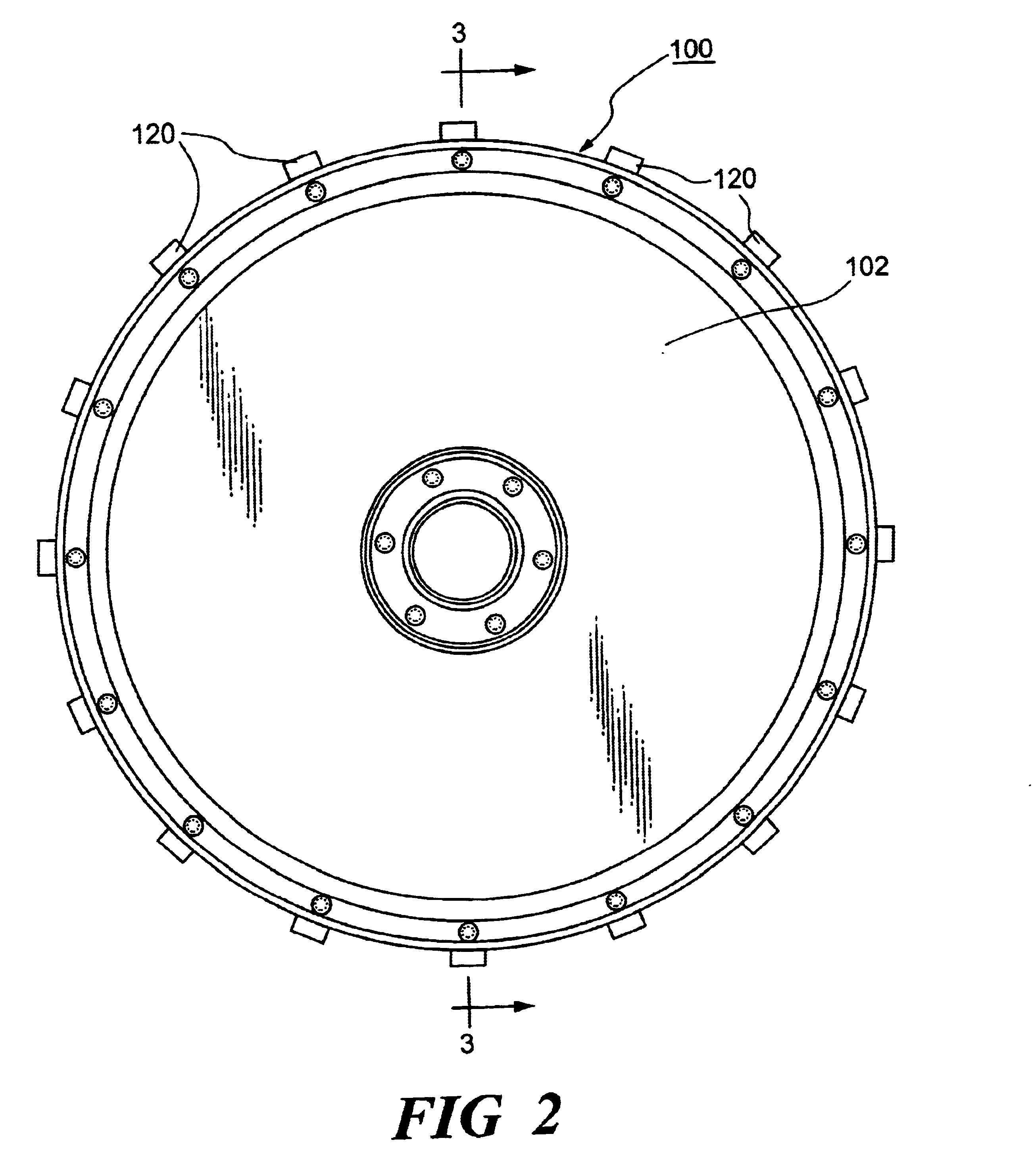

Axial gap motor-generator for high speed operation

InactiveUS6633106B1Easy to operatePreserve integrityMagnetic circuit rotating partsMechanical energy handlingEngineeringConductor Coil

An axial gap motor-generator of the type coupled to a shaft having an axis of rotation. The motor-generator comprises a rotor having a rotor body rotatably disposed about the shaft and having an outer region. The rotor includes a plurality of openings disposed in the outer region and spaced from one another. Each of the openings includes an outer edge. The motor-generator also includes a plurality of magnets equal in number to the openings. Each of the magnets includes an outer edge corresponding to the outer edge of a corresponding one of the openings. The outer edge of the magnets generally is non-conformal to and is slightly smaller than the outer edge of the openings, and each of the magnets is shaped to be inserted into the corresponding one of the openings. The motor-generator further includes a stator assembly positioned adjacent to the rotor. The stator assembly includes windings positioned to be adjacent to the magnets when the rotor is rotated. The outer edge of each of the magnets is dimensioned to substantially conform to the outer edge of the corresponding one of the openings when the axial gap motor-generator is operated at the operational speed and the outer edge of the corresponding one of the openings is thereby deformed. The motor-generator further includes a backiron assembly that is adapted to conform to the rotor when the rotor is operated at its operational state. A vibration isolator also is provided for isolating vibrations of the motor-generator from the shaft. Related methods also are provided.< / PTEXT>

Owner:OPTIMAL ENERGY SYST

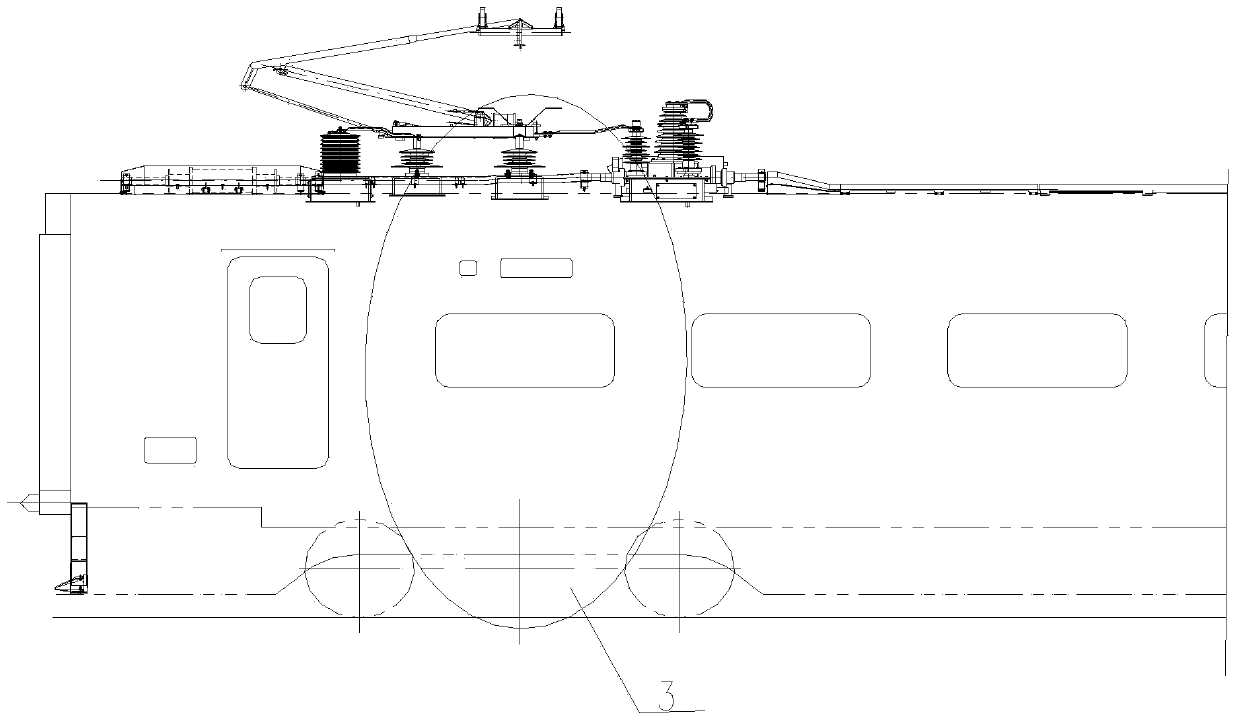

Noise source identifying and testing method for high speed train

ActiveCN103630232ARealize sound source controlImplement path controlSubsonic/sonic/ultrasonic wave measurementBogieSound sources

The invention relates to a noise source identifying and testing method for high speed train. The method comprising the following steps: partitioning noise sources into a steering frame wheel track noise testing area, an equipment noise testing area, a pantograph noise testing area and a pneumatic noise testing area; distributing testing points respectively according to the transmission paths of air sound and structure sound in each area; acquiring testing point data; analyzing through sound and vibration transmission paths; separating the air sound from the structure sound; calculating the contribution of each noise source to interior noise. According to the noise source identifying and testing method, sound sources and vibration sources causing interior noise of the high speed train can be identified, the contribution of each noise source and each vibration source to the interior noise is determined, sound source control and path control of the interior noise are realized fundamentally, and a scientific basis is laid for the vibration and noise reduction structural design of the high speed train.

Owner:CRRC QINGDAO SIFANG CO LTD

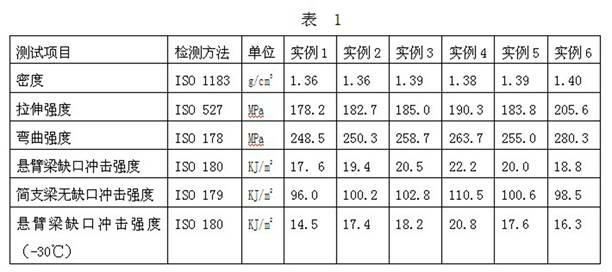

Nylon engineering plastics for high-speed transit railway track and manufacture method thereof

The invention relates to nylon engineering plastics and a manufacture method thereof, in particular to nylon engineering plastics for high-speed transit railway tracks and a manufacture method thereof. The nylon engineering plastics comprise the following components in percentage by weight: 35 to 60 percent of nylon resin, 20 to 35 percent of glass fibre, 0 to 10 percent of inorganic mineral, 16 to 30 percent of compatilizer, 0.3 to 0.5 percent of light stabilizer, 0.1 to 0.3 percent of coupling agent, 0.1 to 0.5 percent of antioxygen and 0.4 to 1 percent of lubricant, wherein the compatilizer is one kind of or a mixture of two kinds of Maleic anhydride grafted EPDM (Ethylene Propylene Diene Monomer) rubber and maleic anhydride grafted POE (Polyolefin Elastomer), and the melt flow rate of the compatilizer is 0.5 to 1.5g / 10min. The manufacture method comprises the steps of: adding the compatilizer into an extruder in a lateral feeding addition method under the condition that the melt temperature is 220 to 280 DEG C and the mixing time is 1-5min; and controlling the rotate speed of a screw between 300 and 450rpm. According to the invention, the tensile strength, the impact toughness and the size stability can all meet the requirements for the operation of high-speed trains with running speed more than 300km / h.

Owner:NANJING JULONG SCI&TECH CO LTD

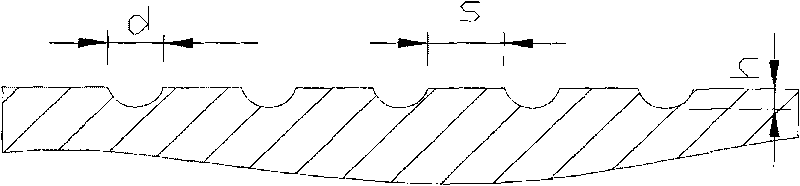

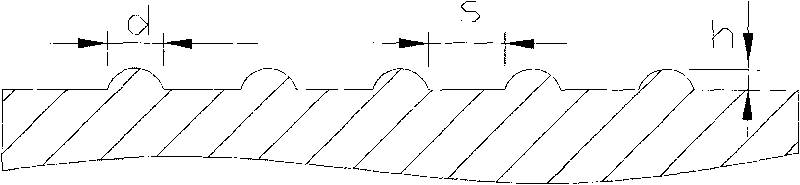

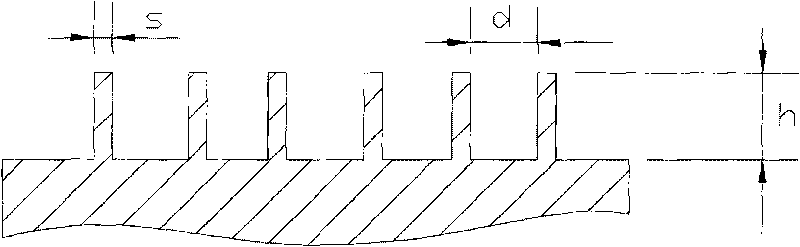

Bionic non-smooth surface film with pneumatic drag reduction effect

InactiveCN101758864ALower air resistance coefficientVehicle body stabilisationAerodynamic dragEngineering

The invention discloses a bionic non-smooth surface film with pneumatic drag reduction effect, which is composed of a basal surface and non-smooth units distributed on the basal surface evenly, wherein the non-smooth units are projections, recesses, L-shaped grooves or V-shaped channels; attaching the bionic non-smooth surface film with pneumatic drag reduction effect to the surface of cars, passenger cars or high-speed trains can effectively lower the coefficient of air drag of vehicle body.

Owner:ZHEJIANG UNIV

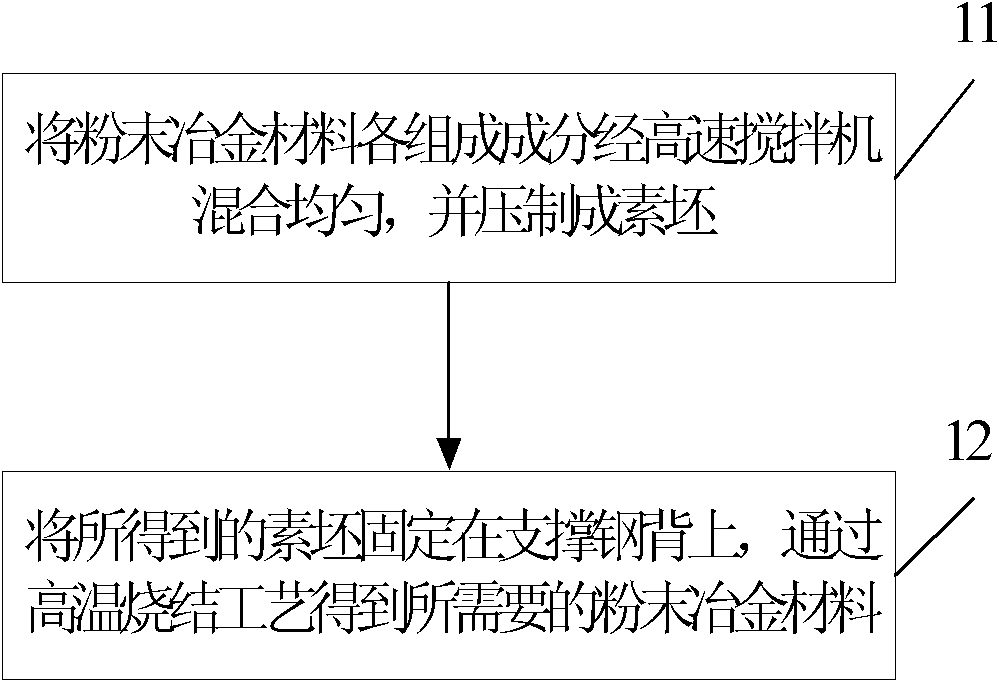

Preparation method of powder metallurgy material for train brake pad

The embodiment of the invention provides a preparation method of a powder metallurgy material for a train brake pad. The powder metallurgy material comprises the following components by weight percent: 40-50% of copper powder, 10-25% of iron powder, 8-15% of ferro-manganese ore powder, 2-7% of silica, 5-9% of molybdenum disulfide, 2-8% of aluminum oxide, 1-5% of boron nitride, 15-25% of graphite and 0.2-1% of polyacrylonitrile fiber. In the preparation method, the components are evenly mixed by a high speed stirrer and then pressed into a biscuit; and the biscuit is fixed on a support steel back, and the required powder metallurgy material is obtained by a high temperature sintering technology. The powder metallurgy material obtained by implementation of the technical scheme has the advantages of over 125 MPa of compressive strength, excellent friction stability and heat resistance, thus the compressive strength and braking performance of the brake pad can meet the braking requirements of a high-speed train with a speed of 300km / h or beyond.

Owner:BEIJING RAILWAY STAR FORTUNE HIGH TECH

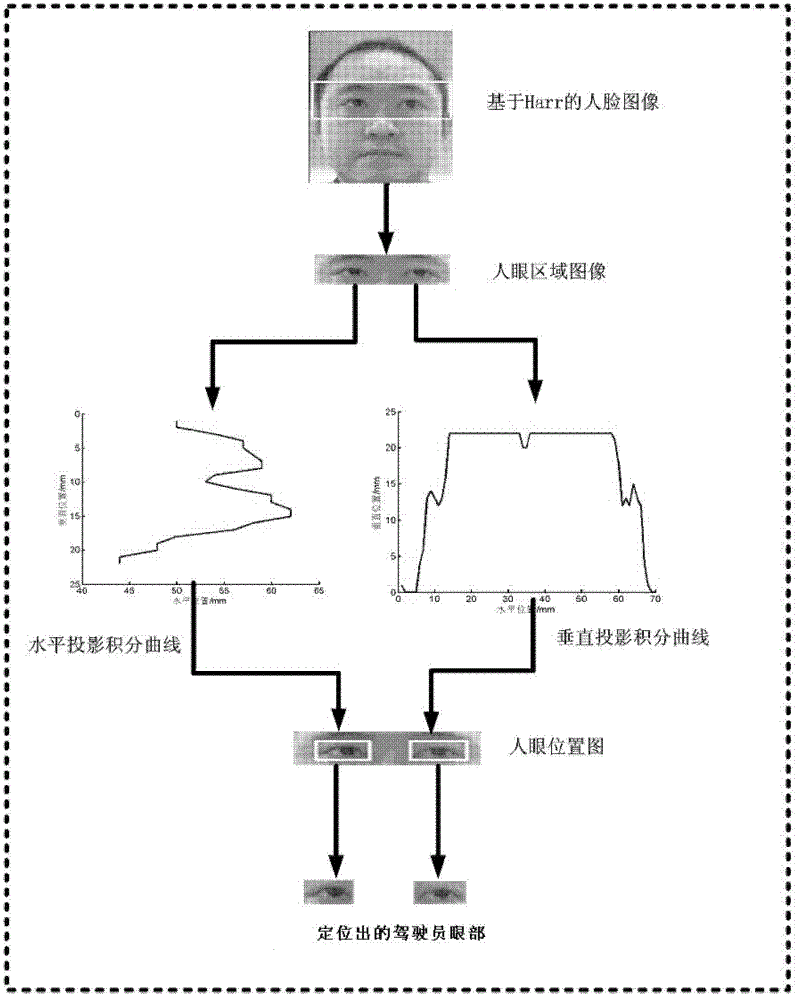

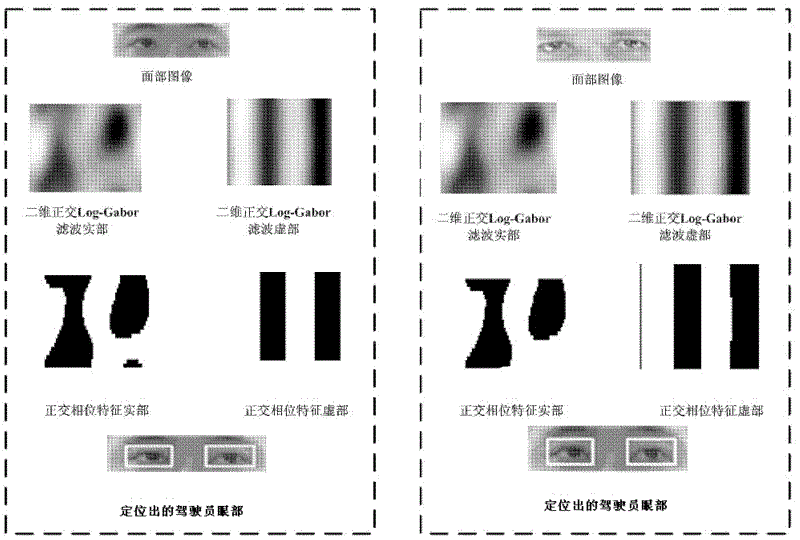

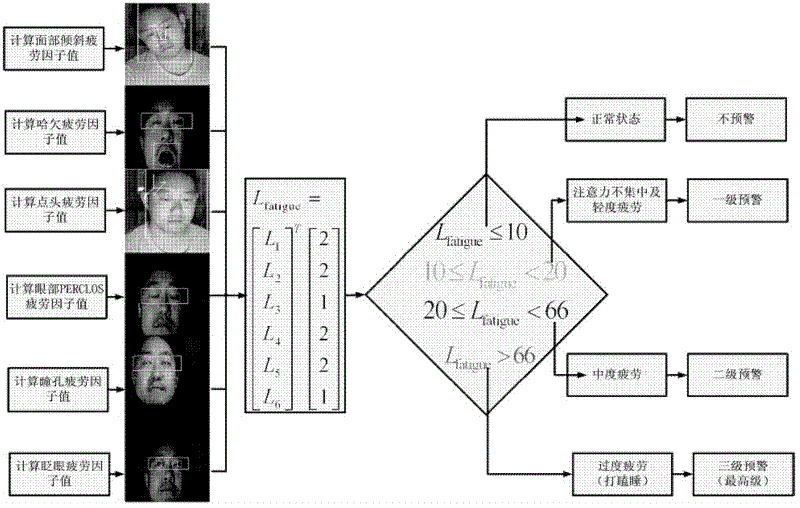

High-speed train driver alertness detecting method based on face image and eye movement analysis

InactiveCN102622600AComprehensive alertness detectionAccurate alertness detectionImage analysisCharacter and pattern recognitionMultiscale decompositionDriver/operator

Disclosed is a high-speed train driver alertness detecting method based on face image and eye movement analysis. The method includes steps of acquiring images of the head of a driver by a primary camera and a secondary camera simultaneously, extracting characteristics of the head of the driver step by step by the aid of wavelet multi-scale, recognizing the head of the driver via a neural network training method, and detecting the face of the driver via an AdaBoost arithmetic; respectively starting a Harr characteristic and a two-dimensional orthogonal Log-Gabor filtering phase characteristic to detect human eyes under different illuminations; building an adaptive non-linear level-log model of the driver; realizing eye movement tracking analysis for the driver via a strong tracking particle filter arithmetic; and finally realizing weight sum for an eye movement characteristic fatigue factor value and six face images including PERCLOS, pupilla, blinking, nodding, yawning and face inclination so as to obtain an alertness value of the driver. The calculated alertness value is high in accuracy and robustness.

Owner:SOUTHWEST JIAOTONG UNIV

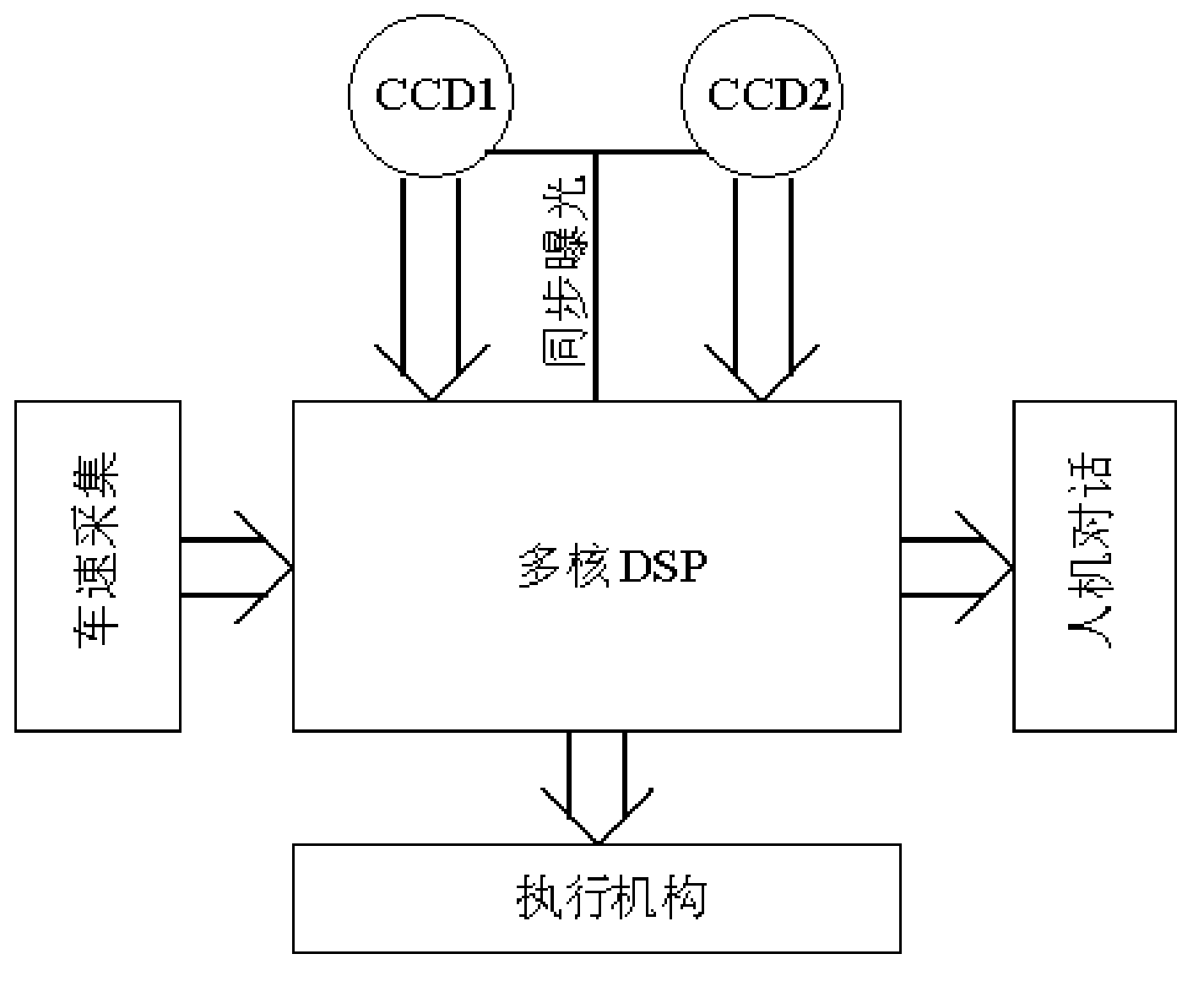

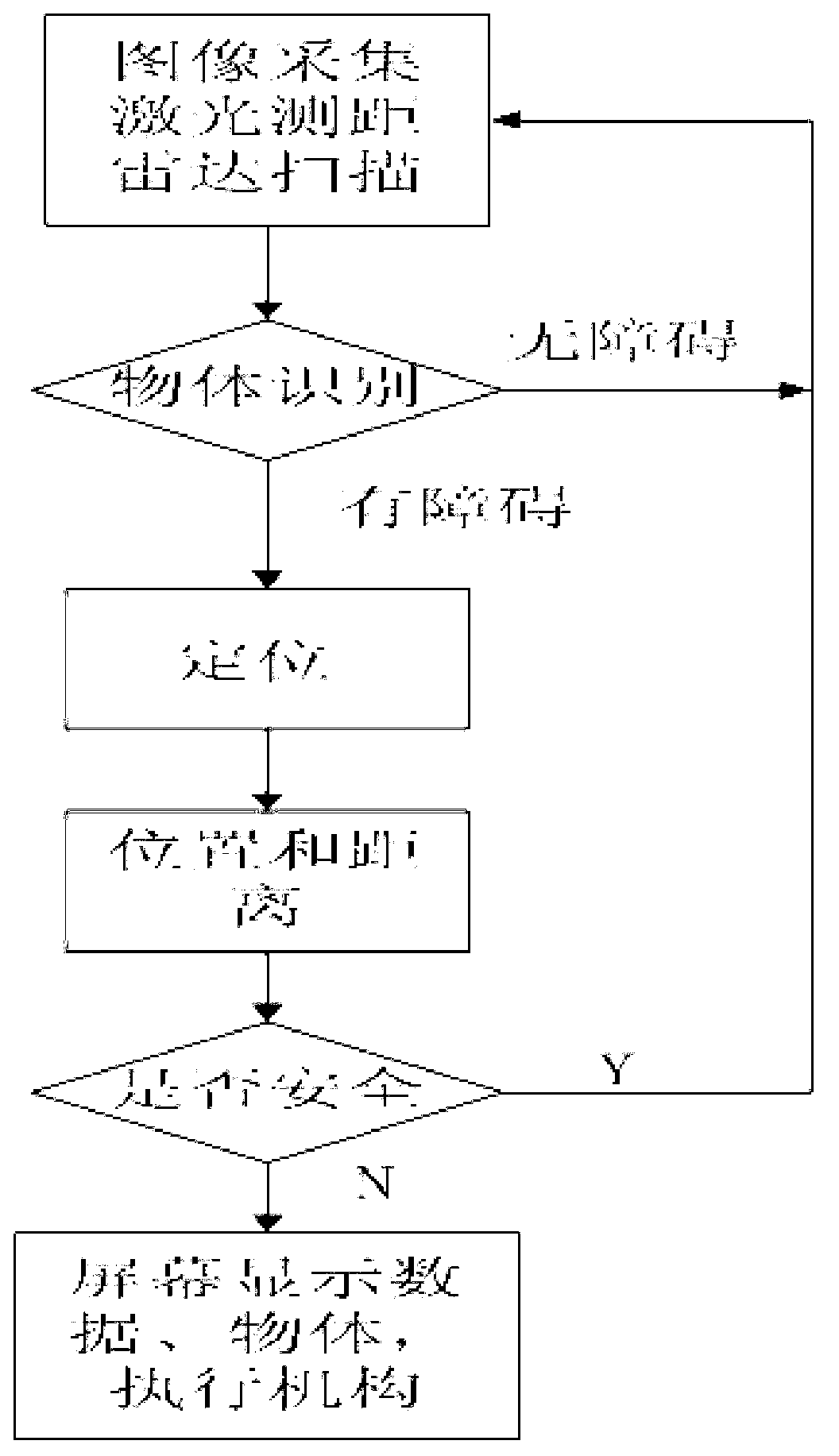

Automobile anti-collision safe protecting method based on image processing

InactiveCN103287372ASimple methodEasy to implementPedestrian/occupant safety arrangementAutomatic initiationsImaging processingOperand

The invention discloses an automobile anti-collision safe protecting method based on image processing. The automobile anti-collision safe protecting method based on image processing comprises an automobile safe automatic protector image identifying system, the automobile safe automatic protector image identifying system comprises a multi-core processor, an automobile-speed collecting module, a plurality of cameras, a displaying module, an alarming device and a positioning device, the automobile-speed collecting module, the cameras, the displaying module, the alarming device and the positioning device are all connected with the multi-core processor, and the multi-core processor is connected with a braking motor for an automobile safe automobile protector. The automobile anti-collision safe protecting method based on image processing is simple and easy to achieve, small in operand and capable of effectively avoiding occurrence of collision accidents, and ensures traveling safety of an automobile. The automobile anti-collision safe protecting method based on image processing can further be applied to transportation tools like airplanes, ships and high-speed trains.

Owner:北京亮才科技有限公司

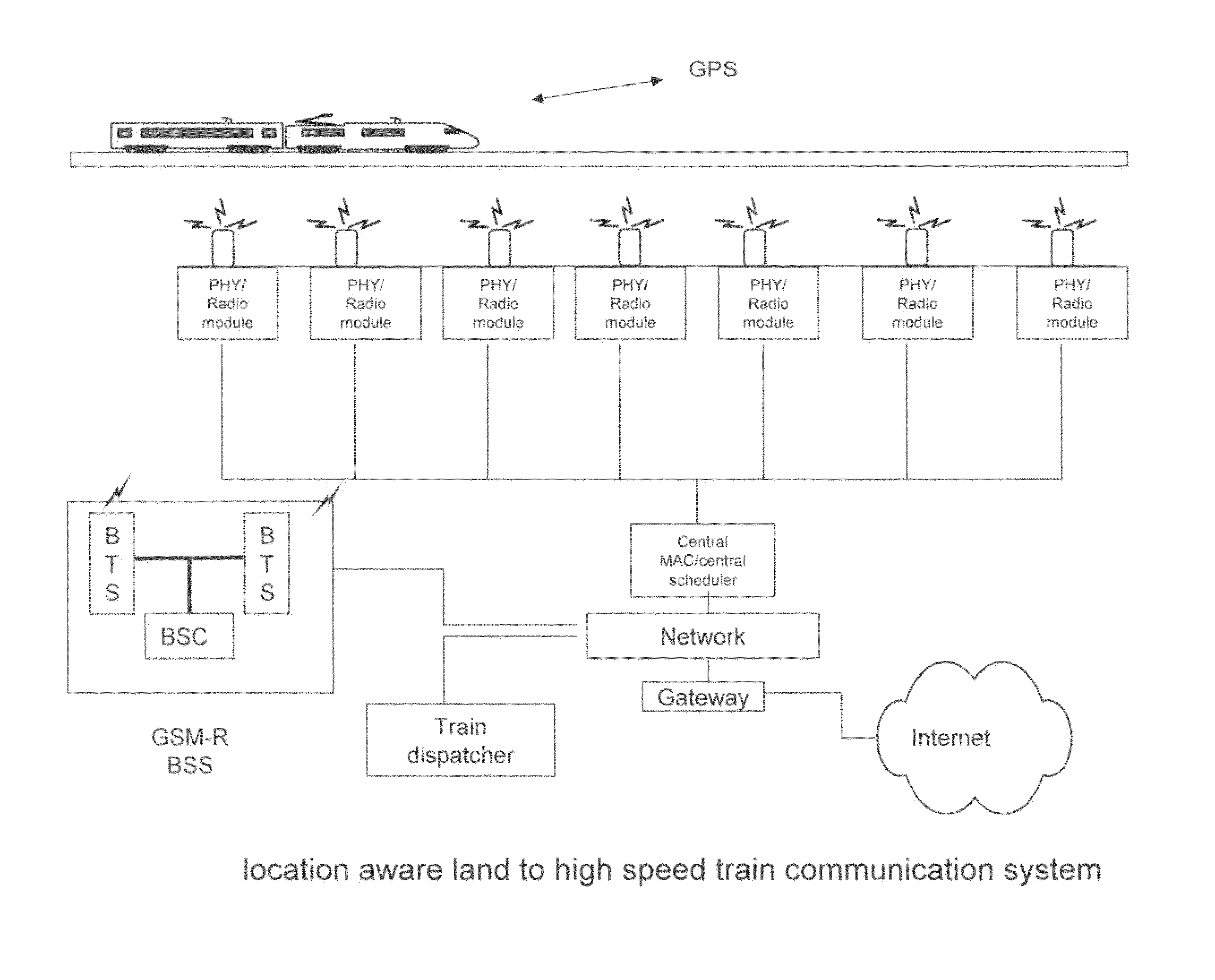

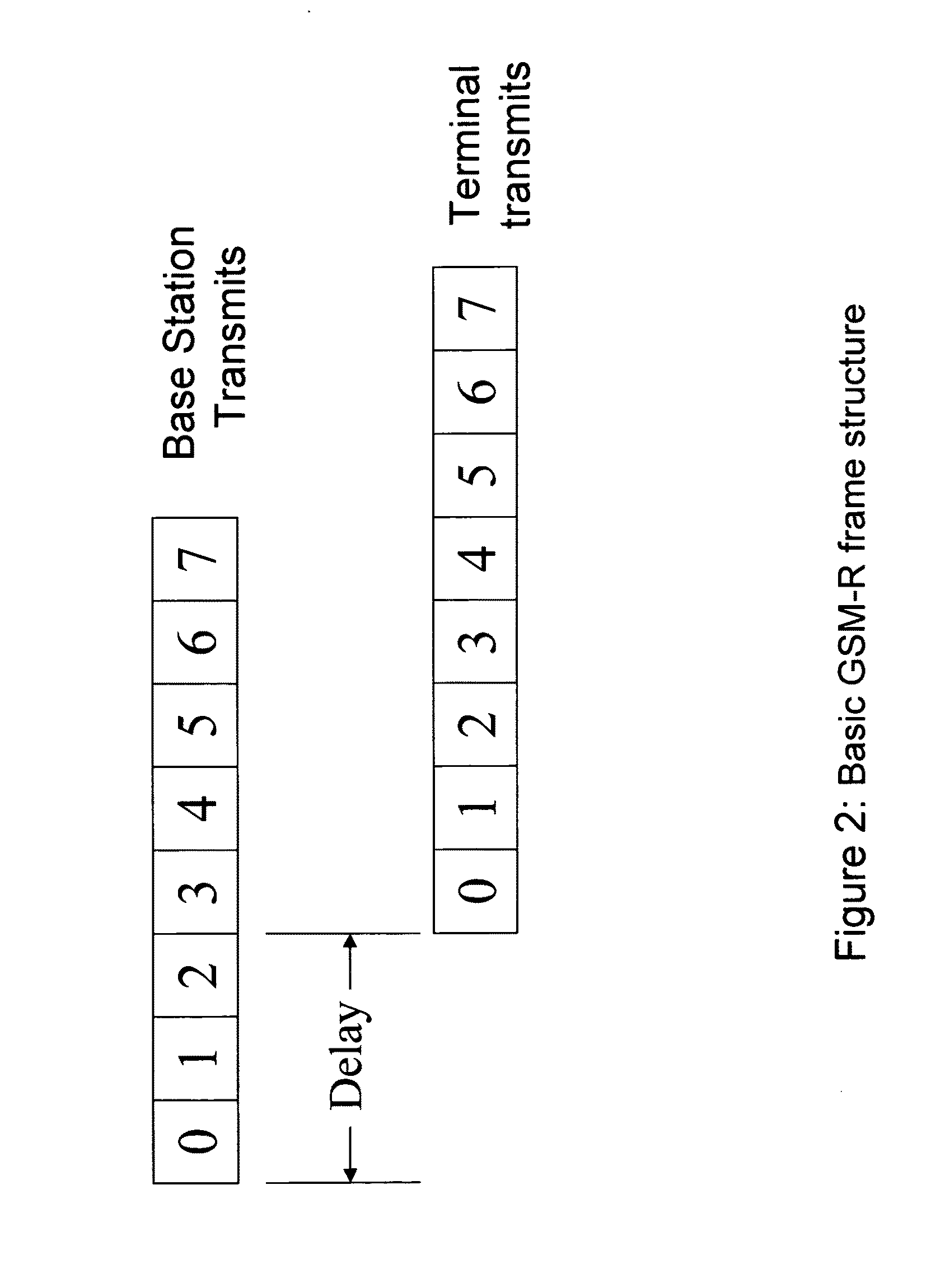

System and apparatus for high speed train communication

This invention discloses a wireless communication system and apparatus for ground to high speed train communication. Unlike other priori arts, the proposed system exploits the train time table, train operating scenarios and GSM-R timing provision so that the train-presence triggered broadband wireless communication can be realized with better performance and less cost. There are provided system architectures and functionality of each apparatus and implementation details.

Owner:WU SHIQUAN +1

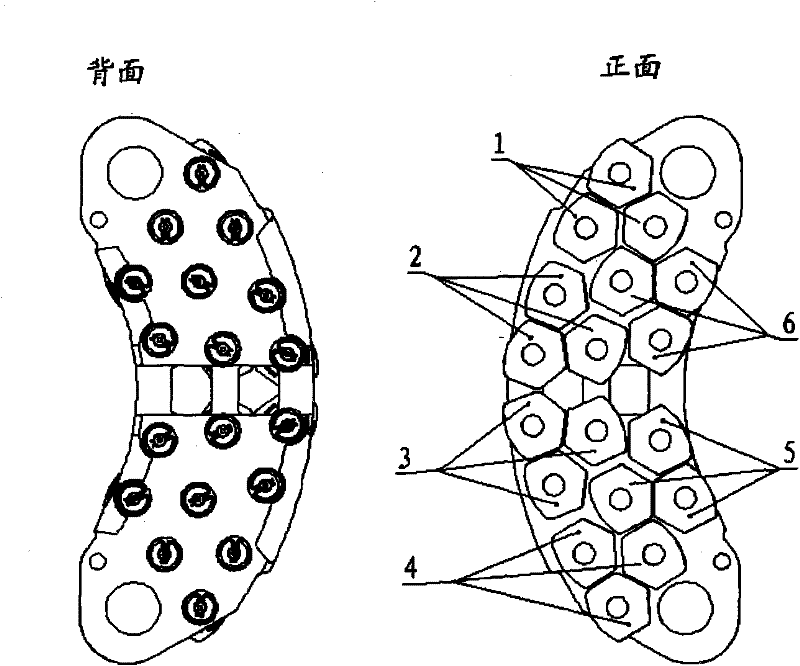

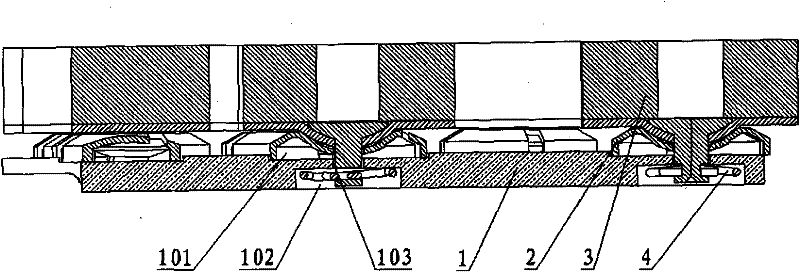

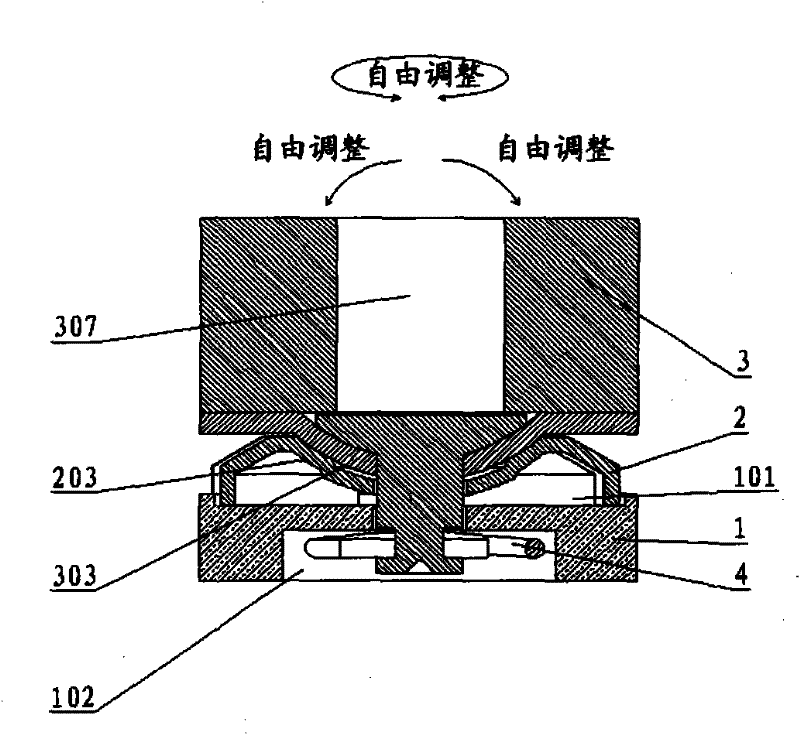

Floating type train brake pad capable of replacing friction block

InactiveCN102359523ASafe and reliable workIncrease contact friction areaBraking elementsFriction liningMetallic materialsEngineering

The invention discloses a brake pad which is applied to a disc type brake system of a high-speed train. A friction block constituted by the brake pad can be flexibly replaced. The brake pad comprises a brake pad back plate which is made of a metal material, an elastic supporting sheet, the friction block and a circular spring clamp, wherein the elastic supporting sheet is provided with a spherical supporting surface and a central guide hole; the lower part of the friction block is provided with a spherical supporting surface and a positioning and connecting shaft which is provided with a clamping groove; the connecting shaft can penetrate through the central guide hole and a back plate positioning hole of the elastic supporting sheet and is locked on the back plate by the circular spring clamp to realize floating connection; the friction block is provided with a polygonal block with a blind hole in the center; and every three friction blocks form an interlocking group, so that the rotation of the friction block during working of the brake pad is prevented. The brake pad can achieve the maximum contact friction area of the brake pad and a brake disc in a train braking process, so that the braking process is stable and the brake pad has the functions of damping, vibration reduction, noise reduction, heat dissipation and the like. The friction block is easy to replace, so that the train operation cost is lowered.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

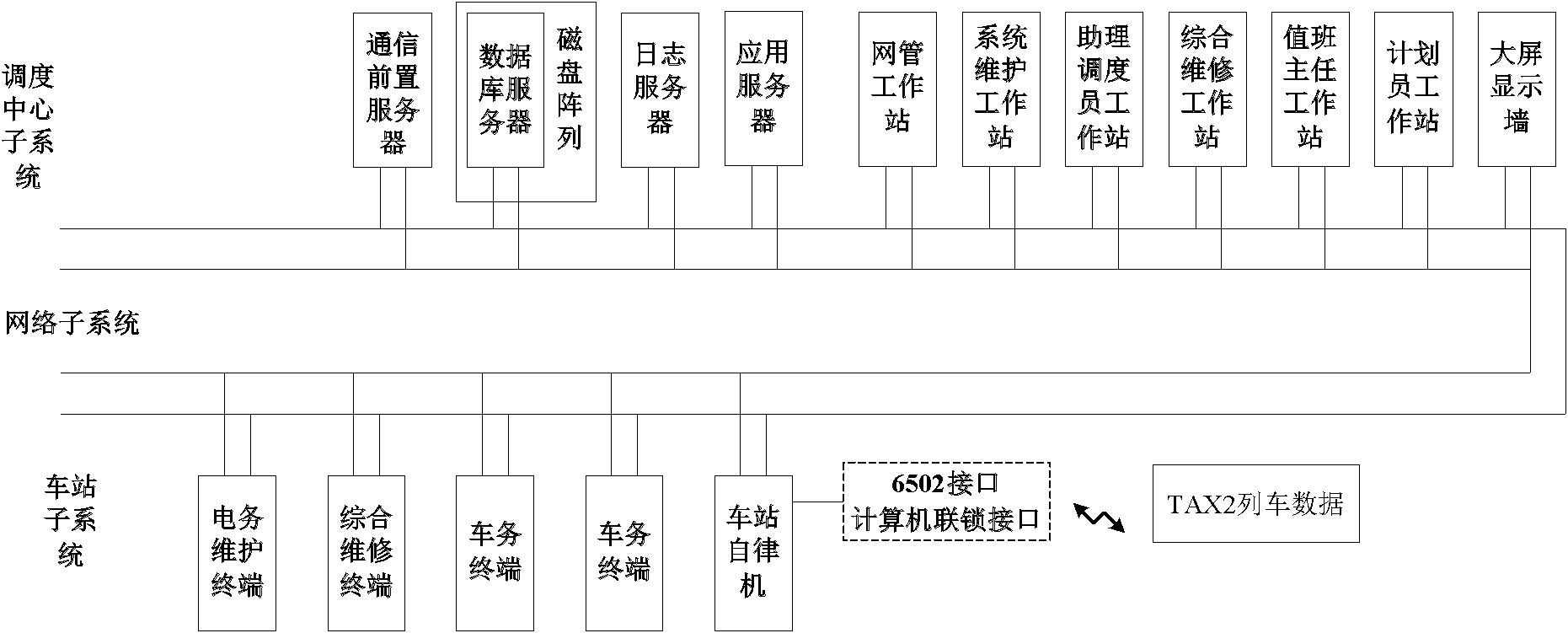

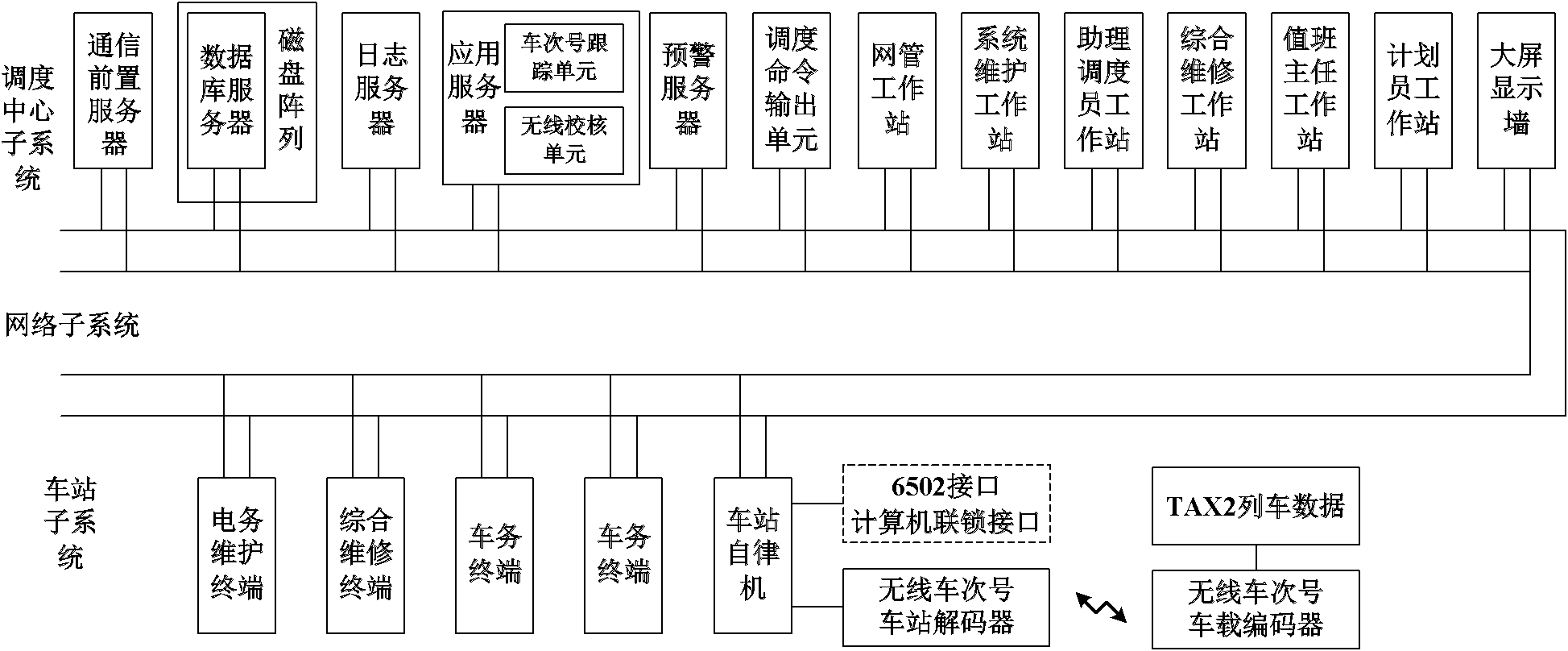

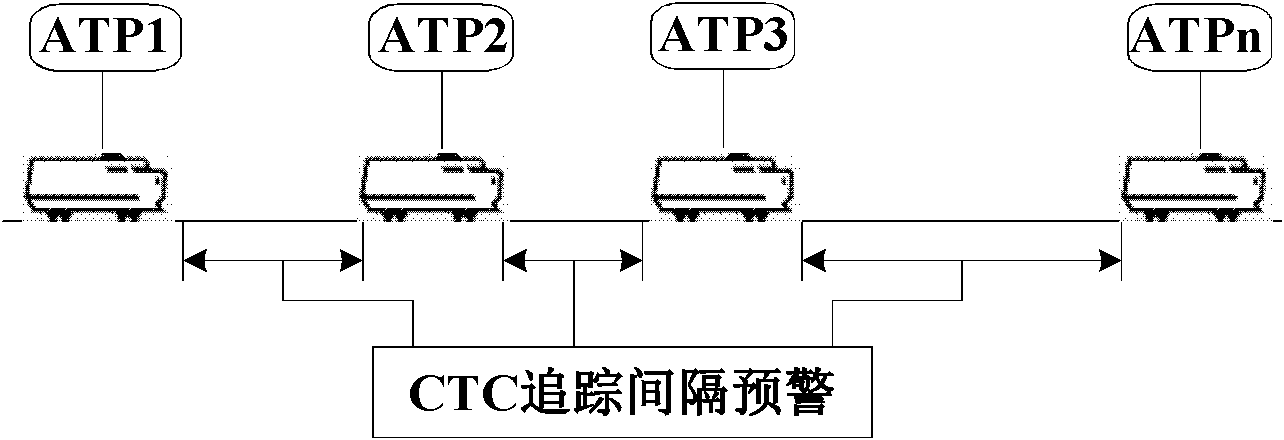

Train tracking interval real-time early warning system based on CTC (central traffic control) and early warning method

ActiveCN102514601APlay a supervisory roleImprove securityAutomatic systemsEarly warning systemApplication server

The invention discloses a train tracking interval real-time early warning system based on CTC (central traffic control) and an early warning method, which belong to the field of high-speed train safety control technology. A dispatching center subsystem early warning server of the system consists of an early warning server and a dispatching command output unit, an application server of the dispatching center subsystem consists of a train number tracking unit and a wireless checking unit, vehicular equipment comprises a wireless train number vehicular encoder, and the system comprises a wireless train number decoder. The method includes acquiring a train number from decoded train comprehensive information by the aid of the wireless checking unit, comparing the acquired train number with a train number obtained by the train number tracking unit, and acquiring an accurate and reliable train number; and computing tracking intervals of a train by the aid of the early warning server, and controlling the dispatching command output unit to output control instruction according to a computation result. The train tracking interval real-time early warning system based on CTC and the early warning method form double channels with an ATP (automatic train protection) computation tracking interval method, a monitoring effect for a train tracking interval ATP control effect is realized, and integral safety of a train control system is improved.

Owner:BEIJING JIAOTONG UNIV

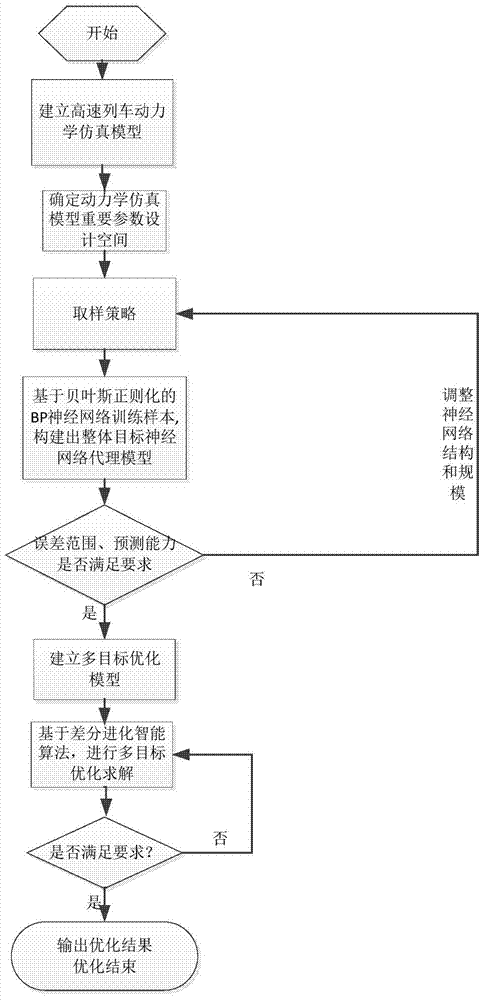

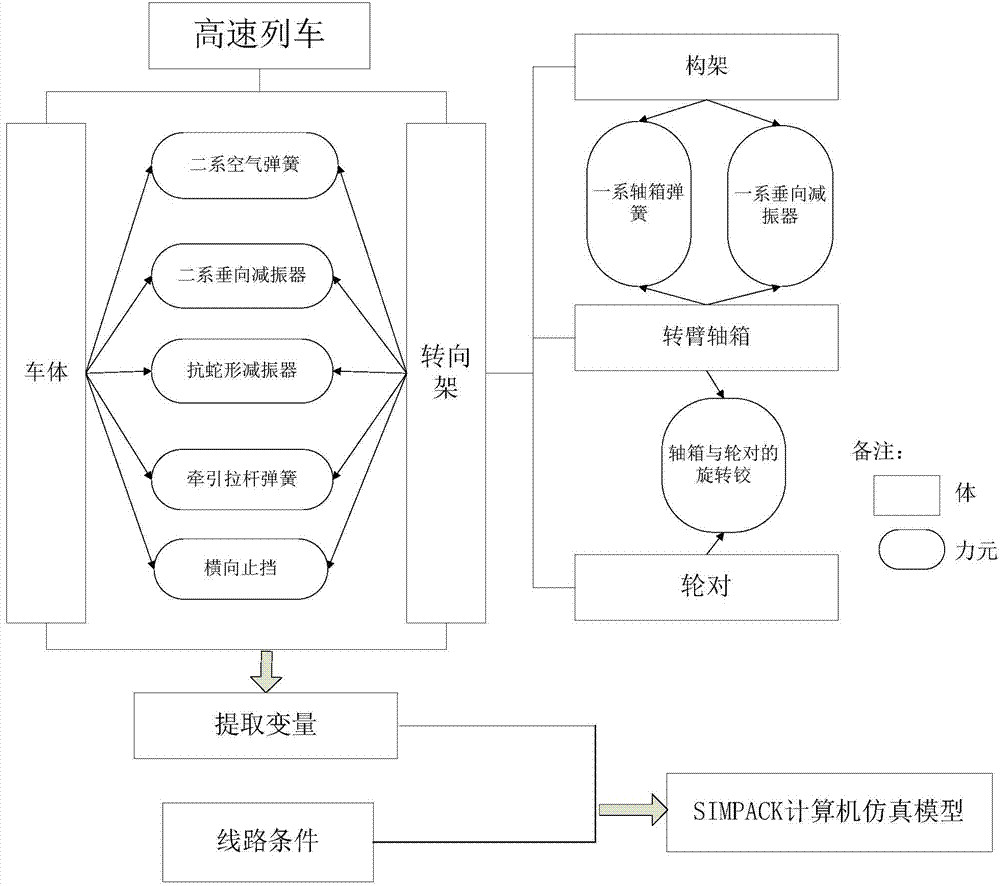

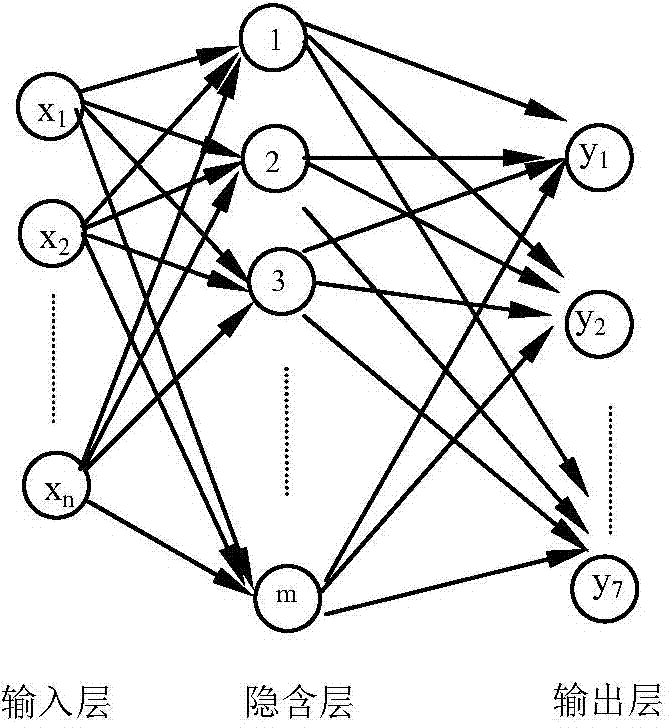

Dynamics performance parameter optimizing method of high-speed train

ActiveCN104765916AImprove operational safetyImproved smoothness and comfortSpecial data processing applicationsNetwork modelDesign space

The invention provides a dynamics performance parameter optimizing method of a high-speed train, relates to the field of parameter design optimizing based on the dynamics simulation analysis of the high-speed train, and aims at effectively replacing a dynamics simulation model of the high-speed train by a comprehensive target neural network agent model and combining the design analysis and the multi-target optimization algorithm of the high-speed train in the multi-disciplinary field to analyze and optimize the dynamics simulation approximation model of the high-speed train. The method specifically comprises the steps of building a multi-rigidity dynamics simulation model for the high-speed train; determining related important input / output design spaces; selecting sampling strategy to obtain a design space sample set suitable for the dynamics performance analysis of the high-speed train; improving the generalization accuracy of the comprehensive target neural network by the bayesian regularization method; adjusting the number of nodes in a hidden layer to build the comprehensive target neural network agent network model of which the error is controlled to be within a certain of range; performing multi-target optimization through the intelligent differential evolution algorithm by using the improved comprehensive target neural network agent network model to obtain the optimized high-speed train design parameters. The method is mainly applied to the dynamics analysis and design optimization of the high-speed train.

Owner:成都天佑创软科技有限公司

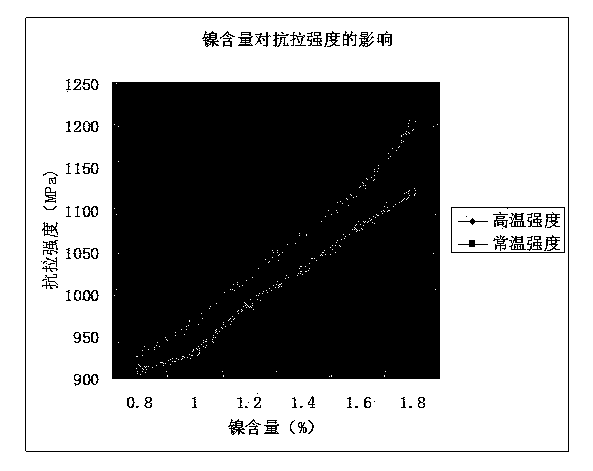

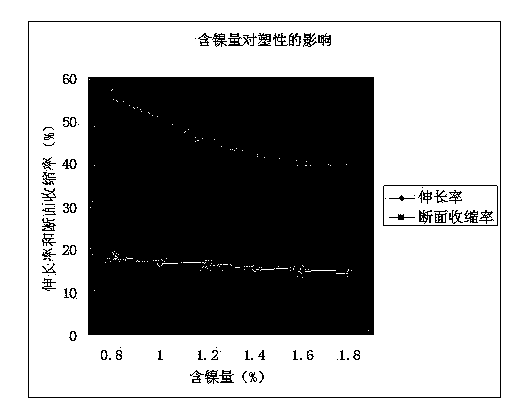

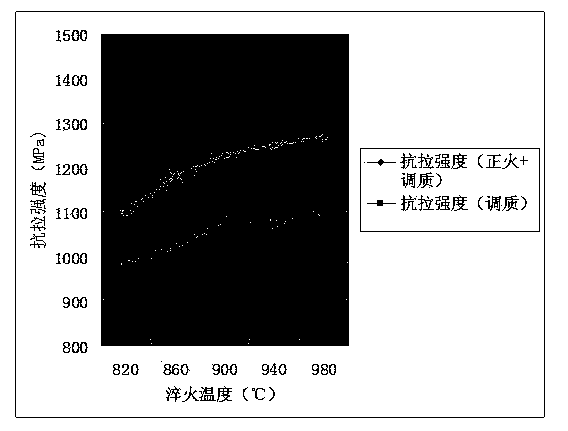

Alloy cast steel for high speed train brake disc, heat treatment method thereof and high speed train brake disc manufactured by the alloy cast steel

The invention discloses an alloy cast steel for a high speed train brake disc, a heat treatment method thereof and a high speed train brake disc manufactured by the alloy cast steel. The alloy cast steel is composed of the following components in percentage by weight: 0.18-0.26% of carbon, 0.16-0.50% of silicon, 0.55-1.40% of manganese, not larger than 0.03% of phosphorus, not larger than 0.03% of sulfur, 0.90-2.00% of chromium, 0.71-1.80% of nickel, 0.65-1.20% of molybdenum, 0.20-0.35% of vanadium, not larger than 0.30% of other components, smaller than 0.1% of tungsten and the balance of ferrum; and the heat treatment method comprises two steps of normalizing and tempering. The alloy cast steel disclosed by the invention has the beneficial effects that such alloy elements as manganese, nickel, chromium, molybdenum, vanadium, and the like, and such main components in the cast steel material as carbon, silicon and the like are reasonably mixed and are effectively thermally treated to refine the crystalline grain and improve the hardenability and heat resistant properties of the alloy cast steel material, and the normal temperature strength and the high temperature strength are greatly improved, so that the alloy cast steel material has excellent comprehensive mechanical properties. A brake disc manufactured by the alloy cast steel can meet the application requirements of high speed trains.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

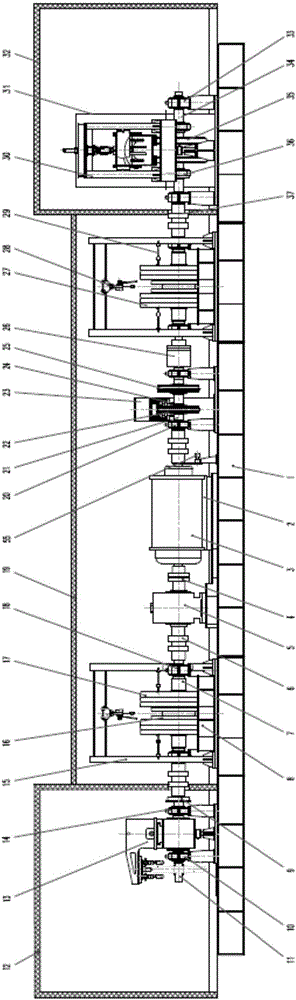

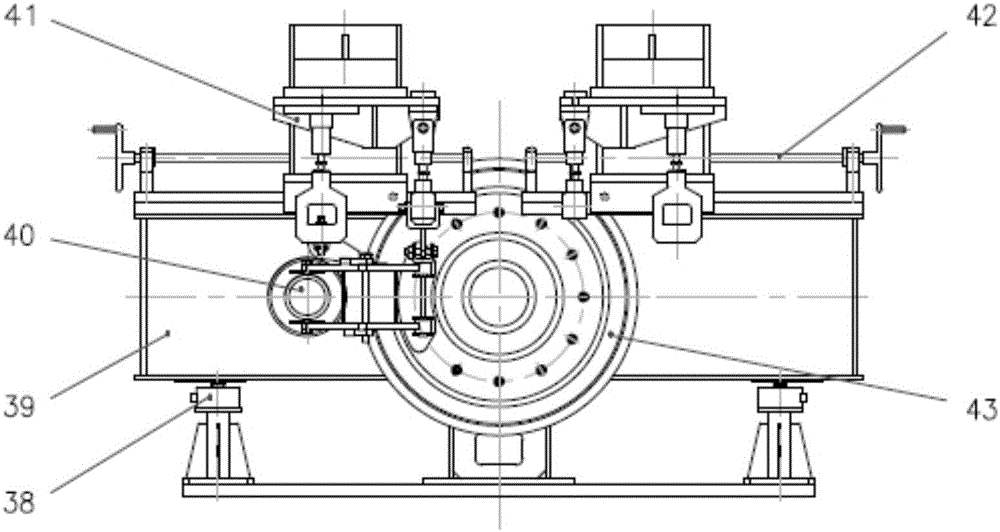

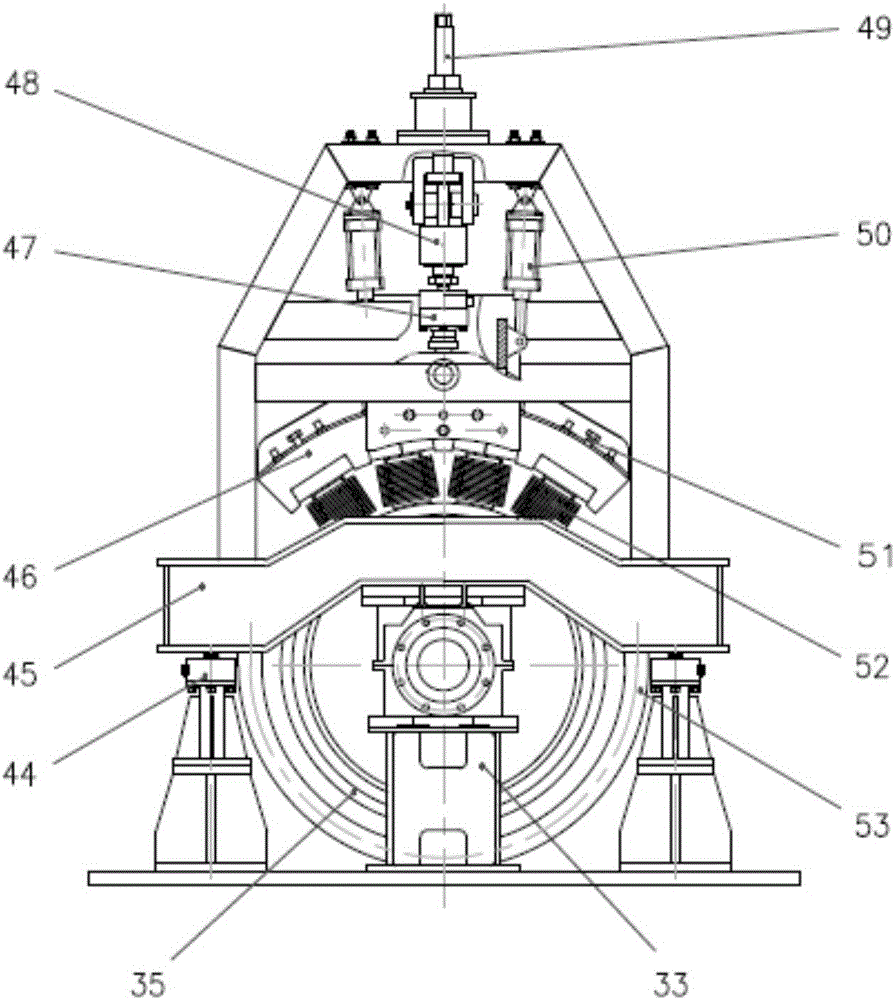

Rail vehicle multifunctional braking power testing platform

InactiveCN105738133AIncrease heating capacityInhibit temperature riseRailway vehicle testingTrack brakePower unit

The invention relates to a multifunctional braking power testing platform which comprises the components of a base; a power and inertia chamber which is arranged on the base and comprises a power unit and a mechanical inertia unit; a first testing chamber which is arranged on the base and is mounted on one end of the power and inertial chamber; and a second testing chamber which is arranged on the base and is mounted on the other end of the power and inertia chamber, wherein a first braking device in the first testing chamber is different from a second braking device of the second testing chamber. The multifunctional braking power testing platform can be used for disc braking, tread braking, eddy current braking or magnetic rail braking tests of high-speed train and other rail vehicles, thereby reproducing a braking energy conversion process in a 1:1 manner and testing braking performance in real time.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +2

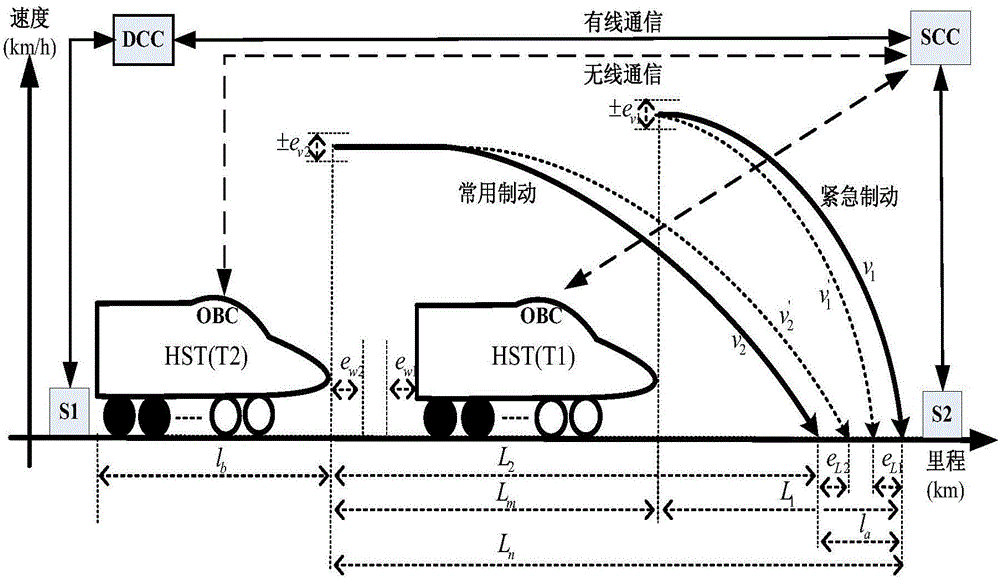

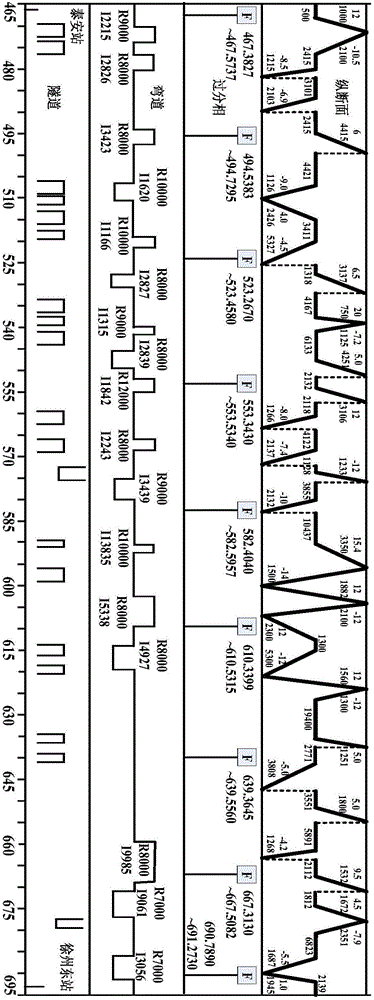

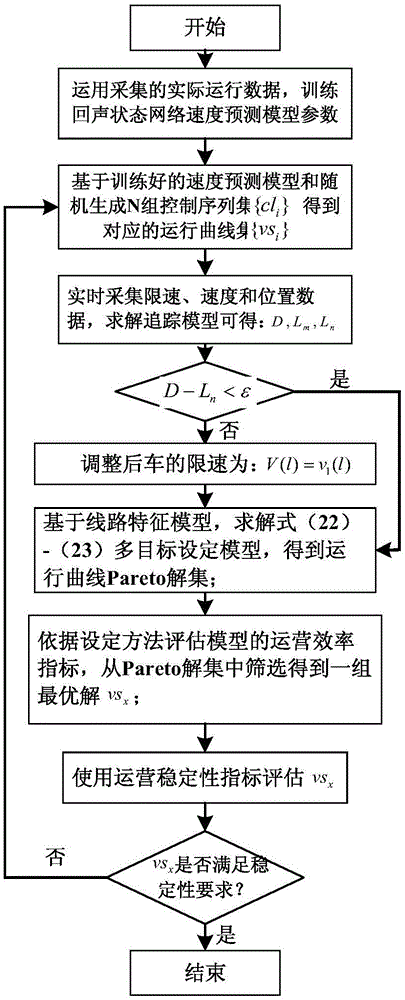

High-speed train tracking running curve optimization setting method

ActiveCN106777752AImprove efficiencySimplified Computational ComplexityGeometric CADDesign optimisation/simulationReal-time dataEcho state network

The invention discloses a high-speed train tracking running curve optimization setting method. According to the characteristic of 'movable and dynamic length' of a tracking section of a high-speed train under movable blocking condition, the method establishes a high-speed train echo state network speed prediction model, a movable blocking based tracking running model, a line network and a tracking running curve multi-target setting model adopting innovative evaluation indexes based on line and high-speed train running data acquired in a site; an efficient multi-target particle swarm optimization is adopted to use an algorithm convergence condition as one of model setting constraints, and high-speed train tracking running curve optimization setting is performed based on the real-time data; finally, section operation efficiency and stability are used as the evaluation indexes of the setting method, and a group of optimal running curves are screened out, so that the high-speed train running process is safe and efficient, and meanwhile the high-speed train section operating efficiency and stability under the movable blocking condition are improved.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Brake pad friction plate manufactured by powder metallurgy and used for high-speed train and preparation process of brake pad friction plate

InactiveCN102605209AGuaranteed densificationImprove wear resistanceFriction liningMatrix strengthSilicon dioxide

The invention discloses a brake pad friction plate manufactured by powder metallurgy and used for a high-speed train and a preparation process of the brake pad friction plate. The brake pad friction plate comprises the following components in percentage by weight: 65-70% of copper, 3-5% of zinc, 8-10% of iron, 5-8% of graphite, 2-6% of lead powder, 1-3% silicon dioxide and 1-4% of silicon carbide. The preparation process comprises the following steps: (1) preprocessing raw materials: grinding into powder, and baking; (2) preparing and mixing the materials; (3) carrying out compression moulding: compressing a mixture into a pressed shape; (4) sintering: heating the pressed shape to 800-900 DEG C at a constant pressure, holding the temperature, controlling a heat preservation pressure to be 1.3-2.0MPa, and feeding hydrogen to protect; (5) cooling: naturally cooling the pressed shape to below 100 DEG C in the hydrogen, and discharging; and (6) carrying out mechanical processing. By the brake pad friction plate provided by the invention, a friction component is led to be alloyed and diversified, so that the wear-resisting and heat-resisting performances of the friction plate are improved, therefore, not only the matrix strength of the materials is ensured, but also the friction plate has good thermophysical properties and stable friction properties, and the service life and the brake performance of the brake pad can be remarkably improved.

Owner:锦州捷通铁路机械股份有限公司

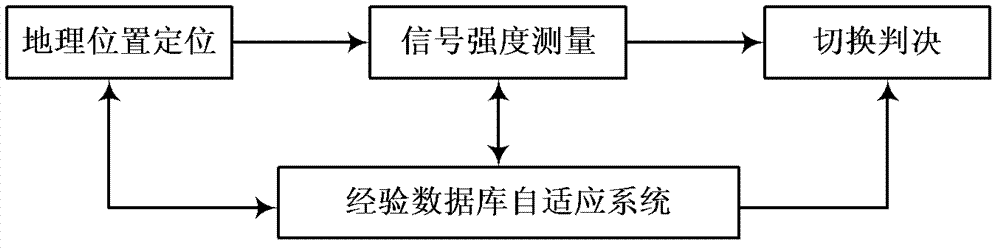

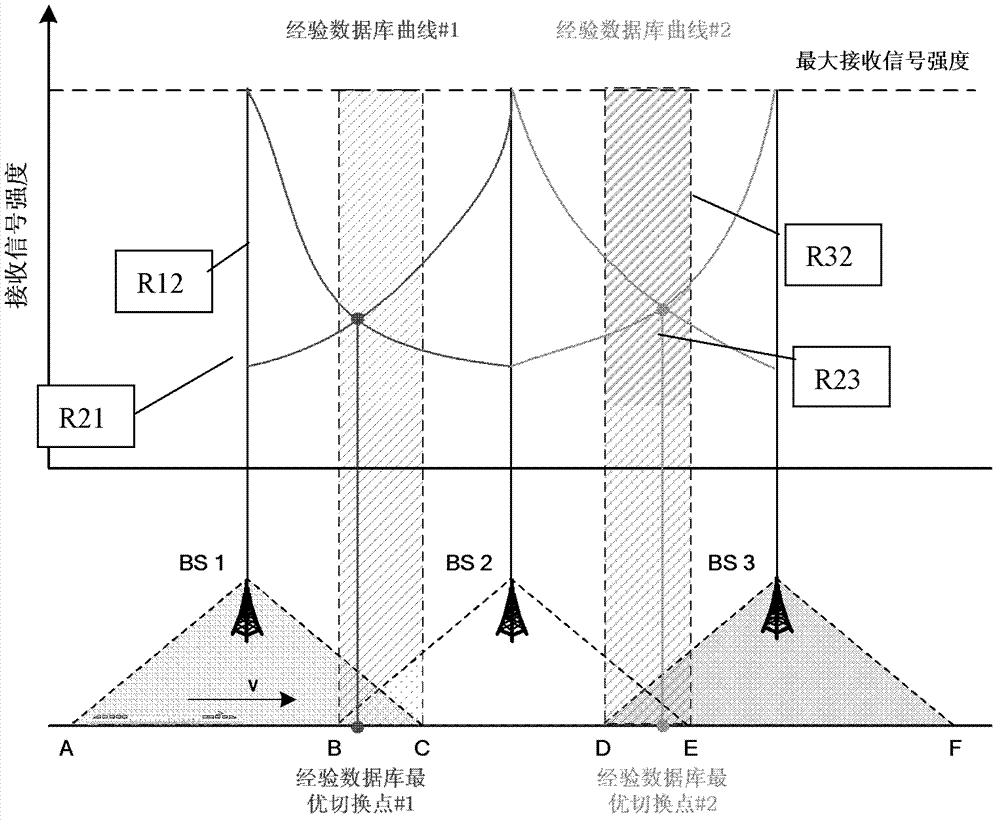

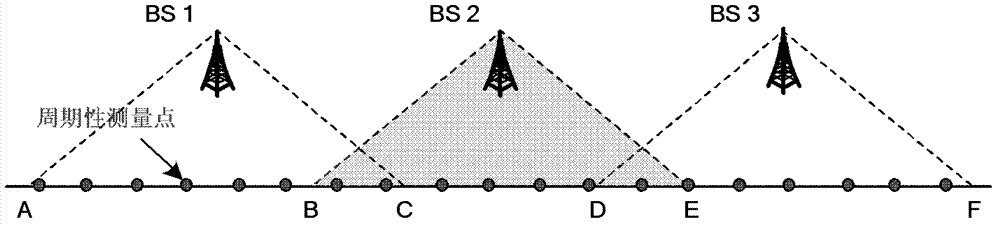

Self-adaptation switching method and device

ActiveCN103096403AHigh switching reliabilityWireless communicationSelf adaptiveElectrical and Electronics engineering

The invention provides a self-adaptation switching method and a device. The method comprises the following steps: when a high-speed train travels between two adjacent base stations BS1 and BS2, the high-speed train fits signal strength curves of the BS1 and signal strength curves of the BS2 according to signal strength information received by the BS1 and the BS2 and recorded by an empirical data self-adaptation system; intersections of the signal strength curves of the BS1 and the signal strength curves of the BS2 are confirmed, and the intersections are the optimal switching points of the high-speed train between the base stations BS1 and the BS2; and the corresponding position information of the intersections is confirmed, when the high-speed train moves to the corresponding switching areas of the intersections, switching between the base stations BS1 and the BS2 is started at an appropriate switching moment. The self-adaptation switching method and the device can confirm the optimal switching points, switching areas and switching moments.

Owner:SHANGHAI RES CENT FOR WIRELESS TECH +1

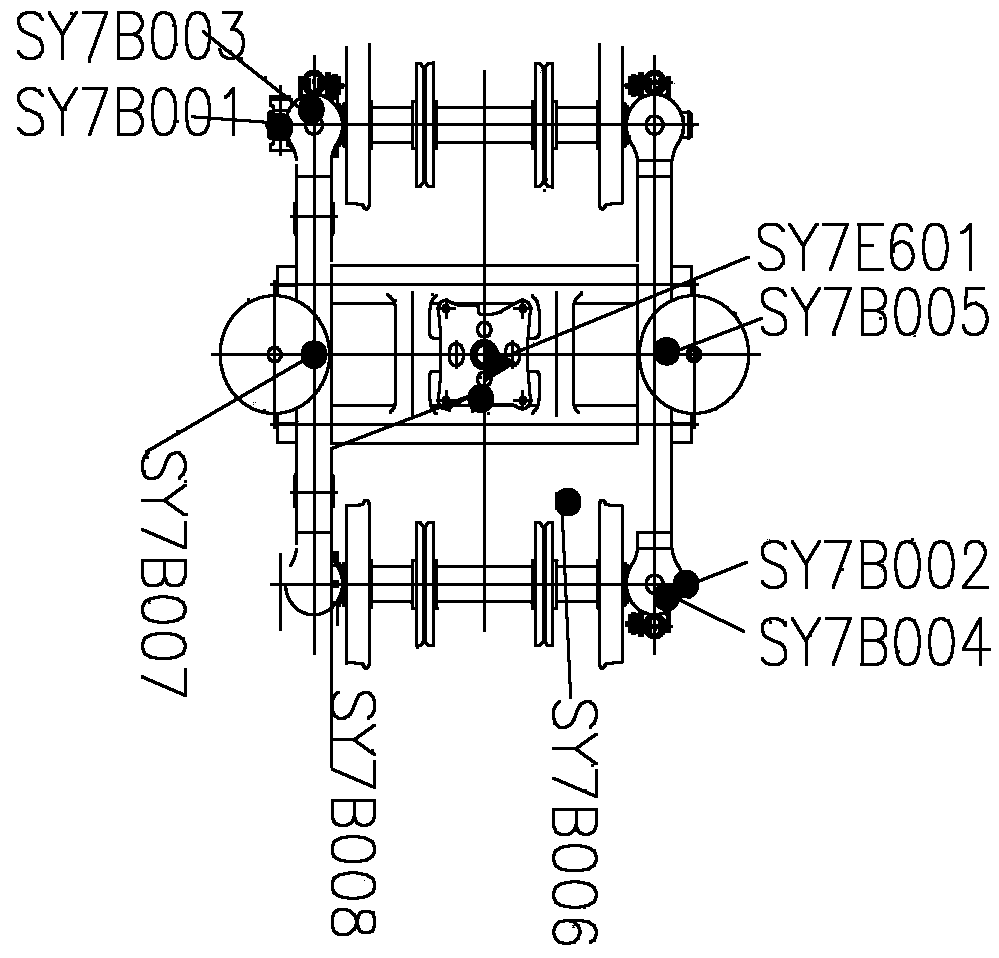

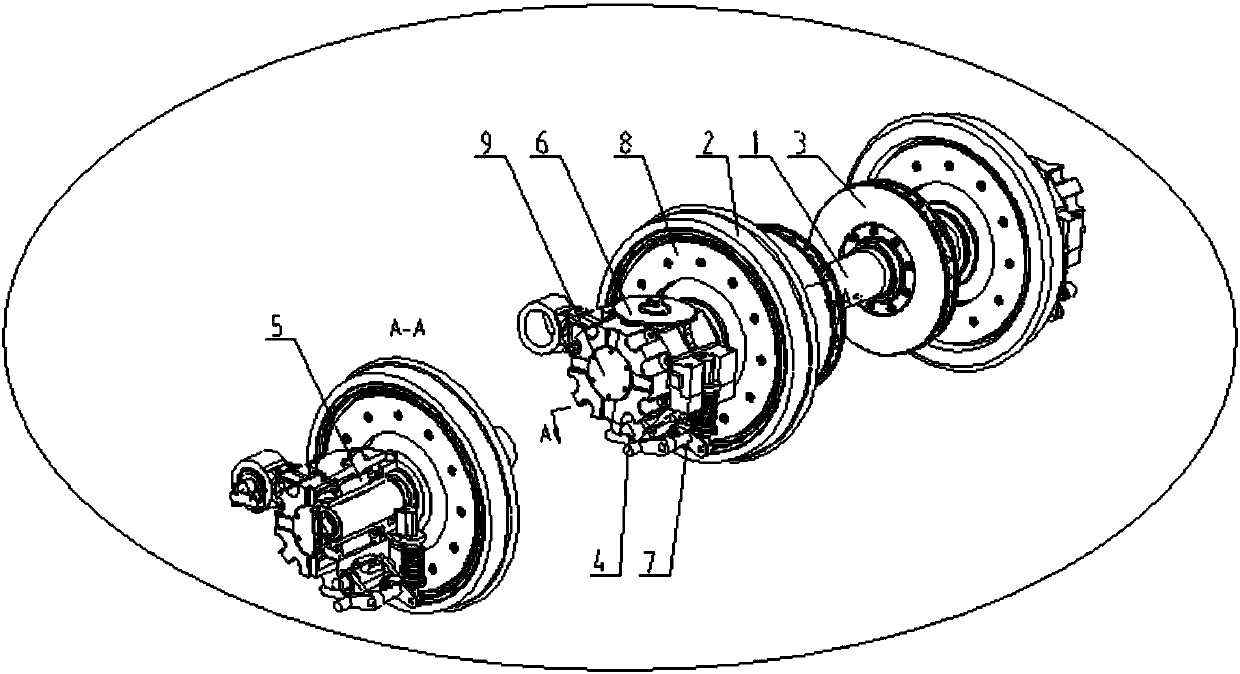

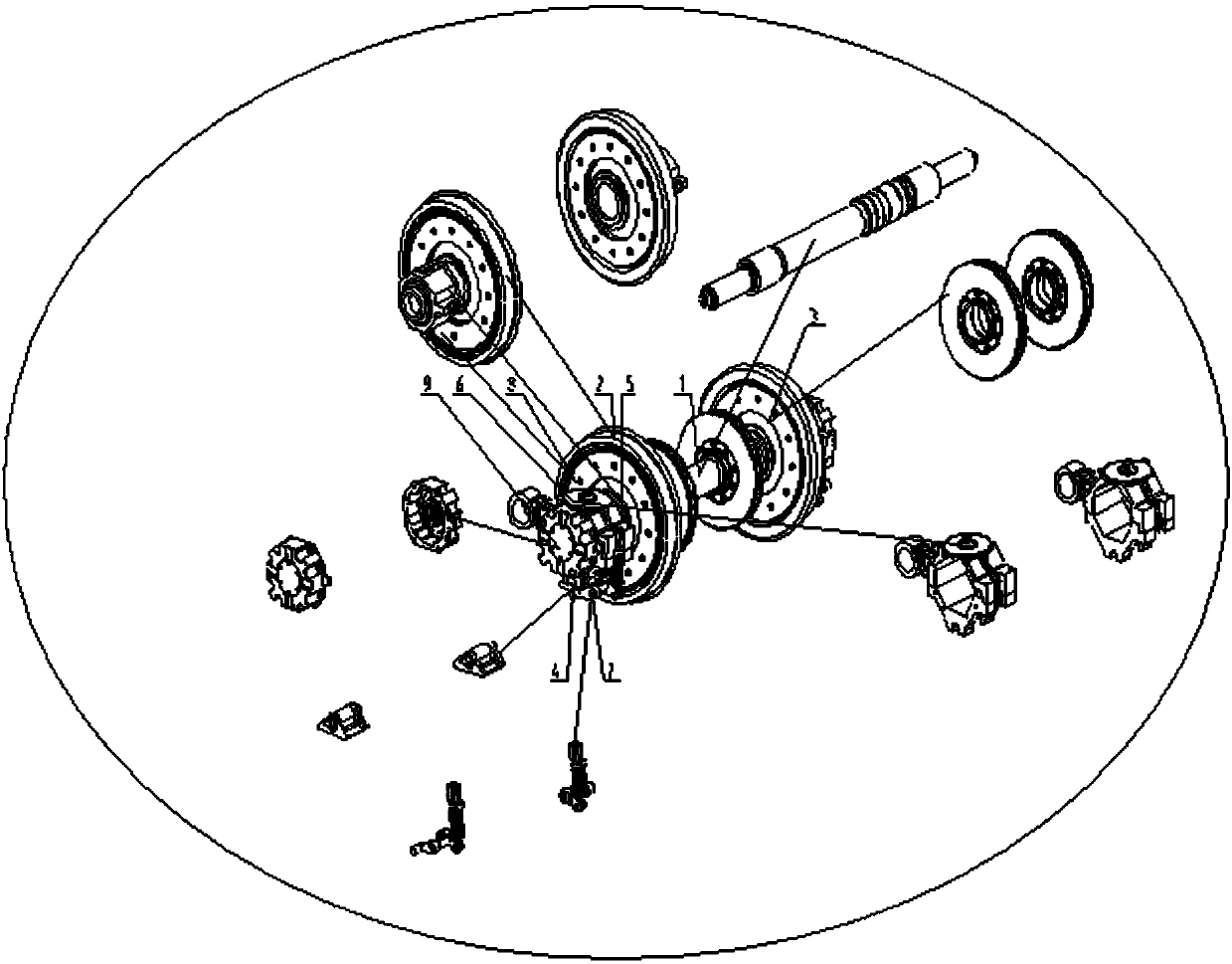

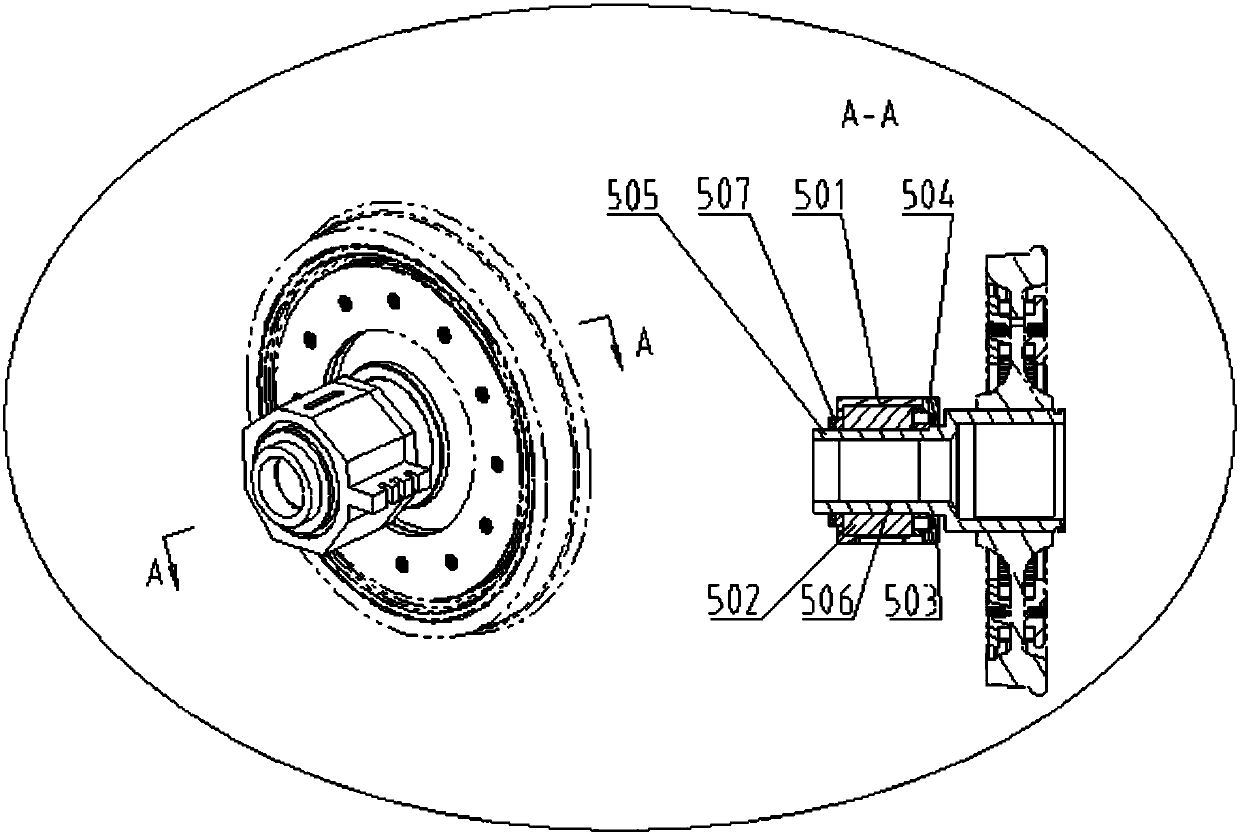

Axle box device of non-power wheel pair of D-series high-speed train for realizing standard gauge and wide gauge conversion

InactiveCN107757652ALimited Axial Sliding CapabilitySolve the problem that the bogie needs to be replaced due to the inability to adapt to gauge changesAxle unitsAxle-boxesBogieLocking mechanism

The invention provides an axle box device of a non-power wheel pair of a D-series high-speed train for realizing standard gauge and wide gauge conversion. The device is characterized in that a slidingmechanism is mounted on a non-power axle; a non-power wheel and an axle box assembly sleeve the sliding mechanism and are fixed on the sliding mechanism; the sliding mechanism is used for driving thenon-power wheel to slide on the non-power axle when a gauge is changed and used for being matched with the non-power axle to transfer torque so as to drive the non-power wheel to rotate during operating; a locking mechanism is arranged between the sliding mechanism and the axle box assembly and is used for locking and fixing the sliding mechanism before and after the gauge is changed; a bearing base is mounted at the bottom of the axle box assembly and is used for bearing a vehicle when the sliding mechanism slides; and axial positioning mechanisms are arranged at two ends of the non-power axle and are used for realizing axial positioning of the axle. The structure can enable the distance between the inner sides of the wheel pair to adapt to a new gauge value, thereby solving the problemsin the prior art that the distance between the inner sides of the wheel pair is fixed and can not adapt to gauge change and a bogie needs to be replaced.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com