Nylon engineering plastics for high-speed transit railway track and manufacture method thereof

A technology for rail transit and high-speed railway, which is applied in the field of nylon engineering plastics for high-speed railway rail transit and its manufacturing, can solve the problems of not being able to meet the low temperature environment, the impact performance is not very good, etc., to improve production efficiency, shorten mixing time, The effect of good impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

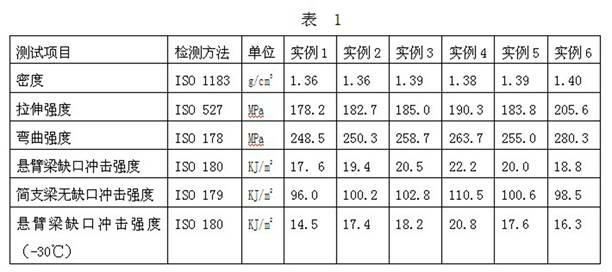

Examples

Embodiment 1

[0020] formula:

[0021] ① 50.9 parts by weight of nylon 6 resin; 0.3 parts by weight of light stabilizer; 0.2 parts by weight of coupling agent; 0.2 parts by weight of antioxidant; 0.4 parts by weight of lubricant;

[0022] ② 18 parts by weight of maleic anhydride grafted POE; 25 parts by weight of short glass fibers; 5 parts by weight of glass microspheres.

[0023] The manufacture method of above-mentioned engineering plastics comprises the steps:

[0024] Step 1: Fully mix the above components ① through a medium-speed mixer;

[0025] Step 2: Feed the extruded raw materials obtained in Step 1 into a twin-screw extruder for melt blending, extrude and granulate, and use side feeding at different positions of the extruder to simultaneously add components part ②. The extrusion process parameters are: melt temperature 220-250°C (melt temperature is a range), screw speed 300rpm, mixing time 1min.

Embodiment 2

[0027] formula:

[0028] ① 53.9 parts by weight of nylon 6 resin; 0.3 parts by weight of light stabilizer; 0.2 parts by weight of coupling agent; 0.2 parts by weight of antioxidant; 0.4 parts by weight of lubricant;

[0029] ② 16 parts by weight of maleic anhydride grafted POE; 29 parts by weight of continuous glass fiber.

[0030] The manufacture method of above-mentioned engineering plastics comprises the steps:

[0031] Step 1: Fully mix the above components ① through a medium-speed mixer;

[0032] Step 2: Feed the extruded raw materials obtained in Step 1 into a twin-screw extruder for melt blending, extrude and granulate, and use side feeding at different positions of the extruder to simultaneously add components part ②. The extrusion process parameters are: melt temperature 220-250°C, screw speed 350rpm, mixing time 2min.

Embodiment 3

[0034] formula:

[0035]① 38.6 parts by weight of nylon 66 resin; 0.4 parts by weight of light stabilizer; 0.2 parts by weight of coupling agent; 0.3 parts by weight of antioxidant; 0.5 parts by weight of lubricant;

[0036] ② Maleic anhydride grafted EPDM rubber 25 parts by weight; short glass fiber 30 parts by weight; talcum powder 5 parts by weight.

[0037] The manufacture method of above-mentioned engineering plastics comprises the steps:

[0038] Step 1: Fully mix the above components ① through a medium-speed mixer;

[0039] Step 2: Feed the extruded raw materials obtained in Step 1 into a twin-screw extruder for melt blending, extrude and granulate, and use side feeding at different positions of the extruder to simultaneously add components part ②. The extrusion process parameters are: melt temperature 250-280°C, screw speed 400rpm, mixing time 3min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com