Patents

Literature

461 results about "Short glass fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

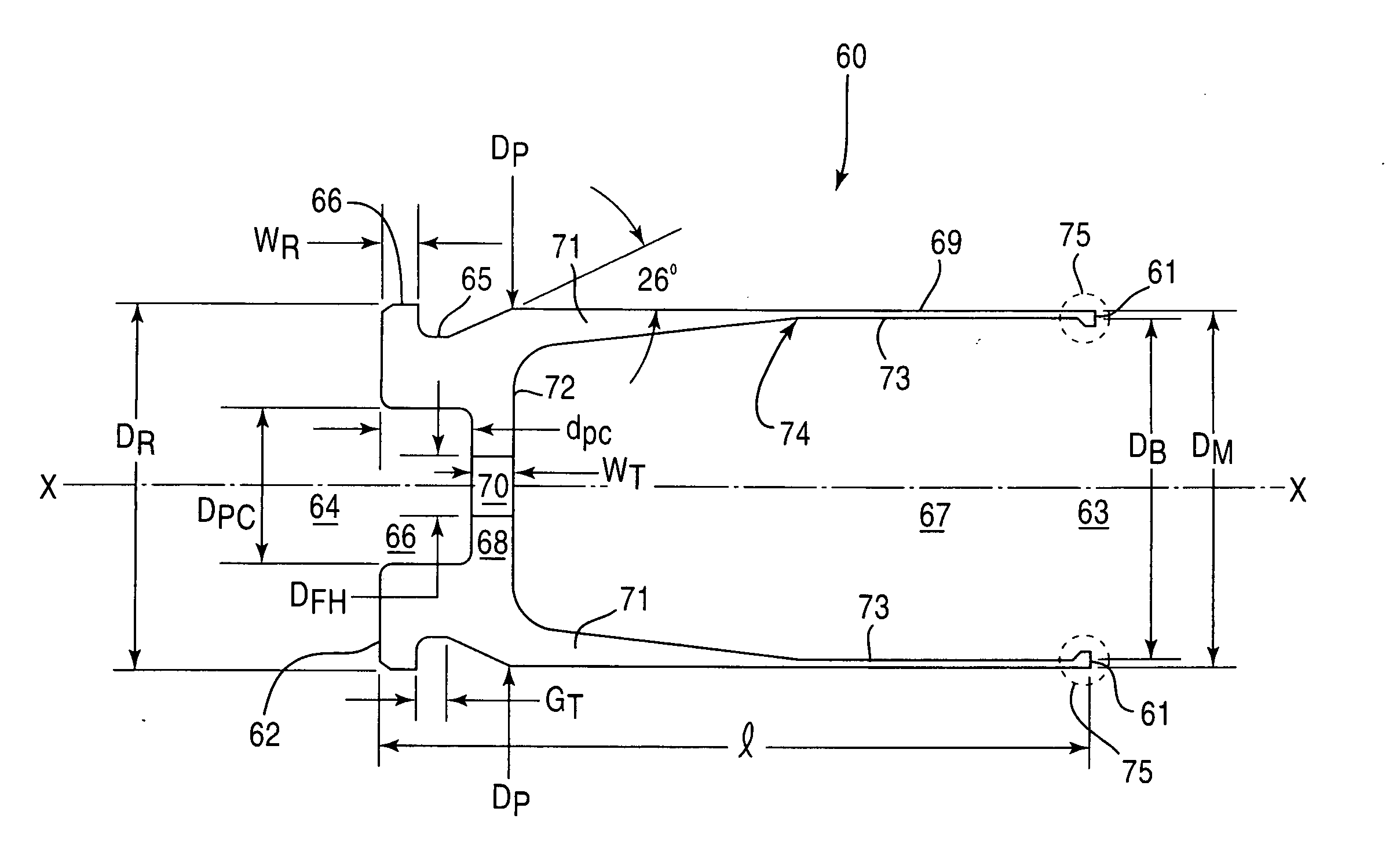

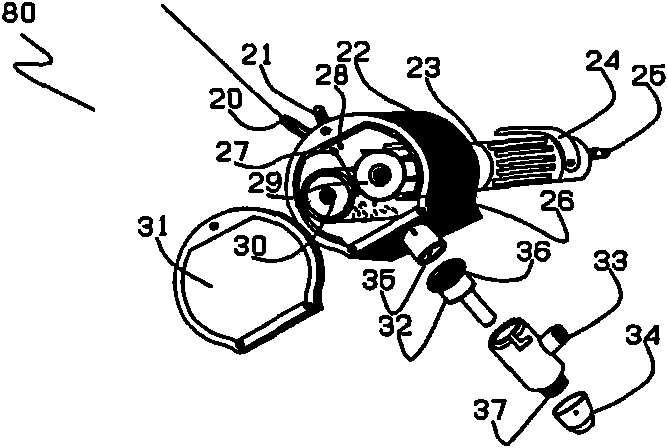

Lead free, composite polymer based bullet and cartridge case, and method of manufacturing

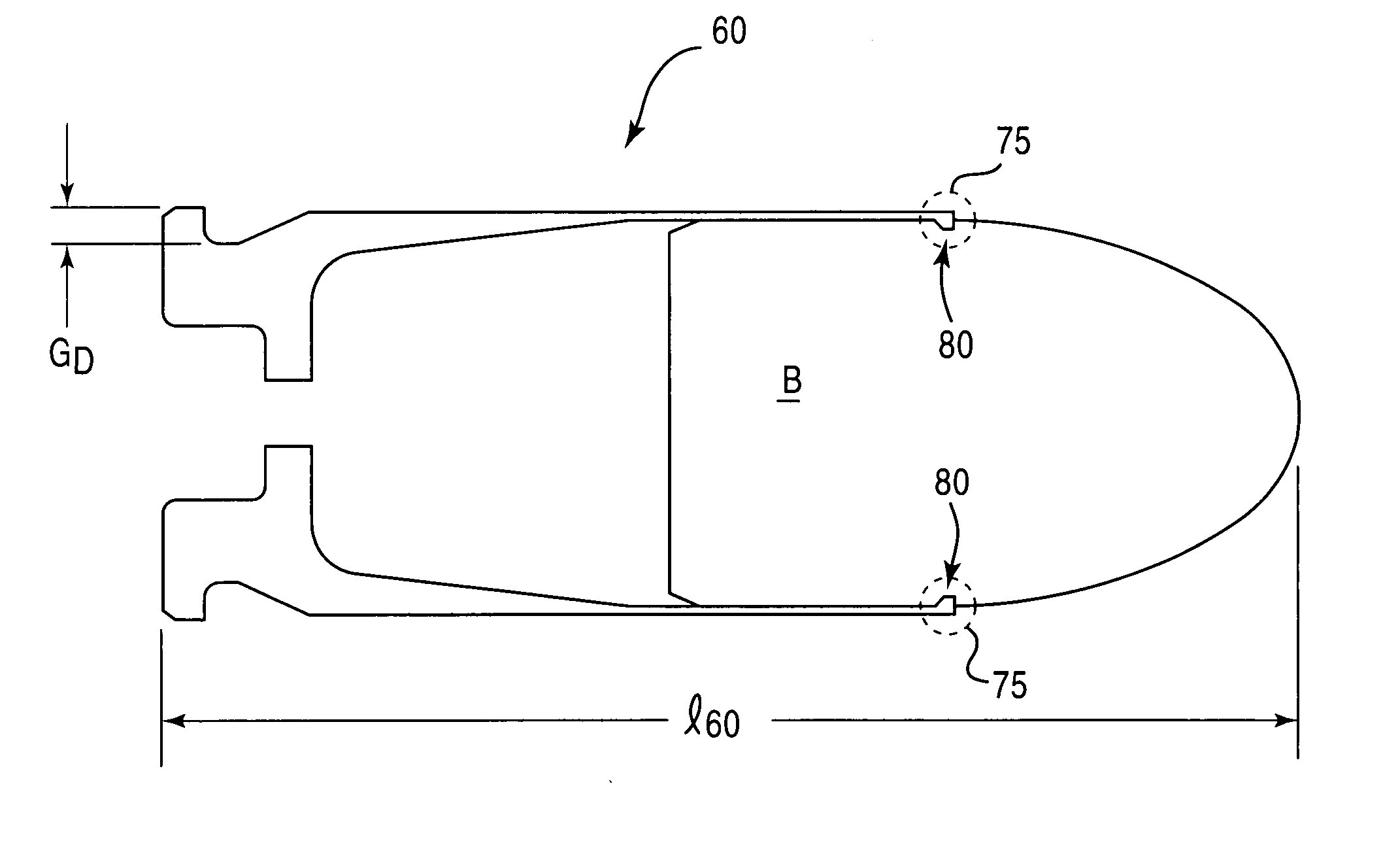

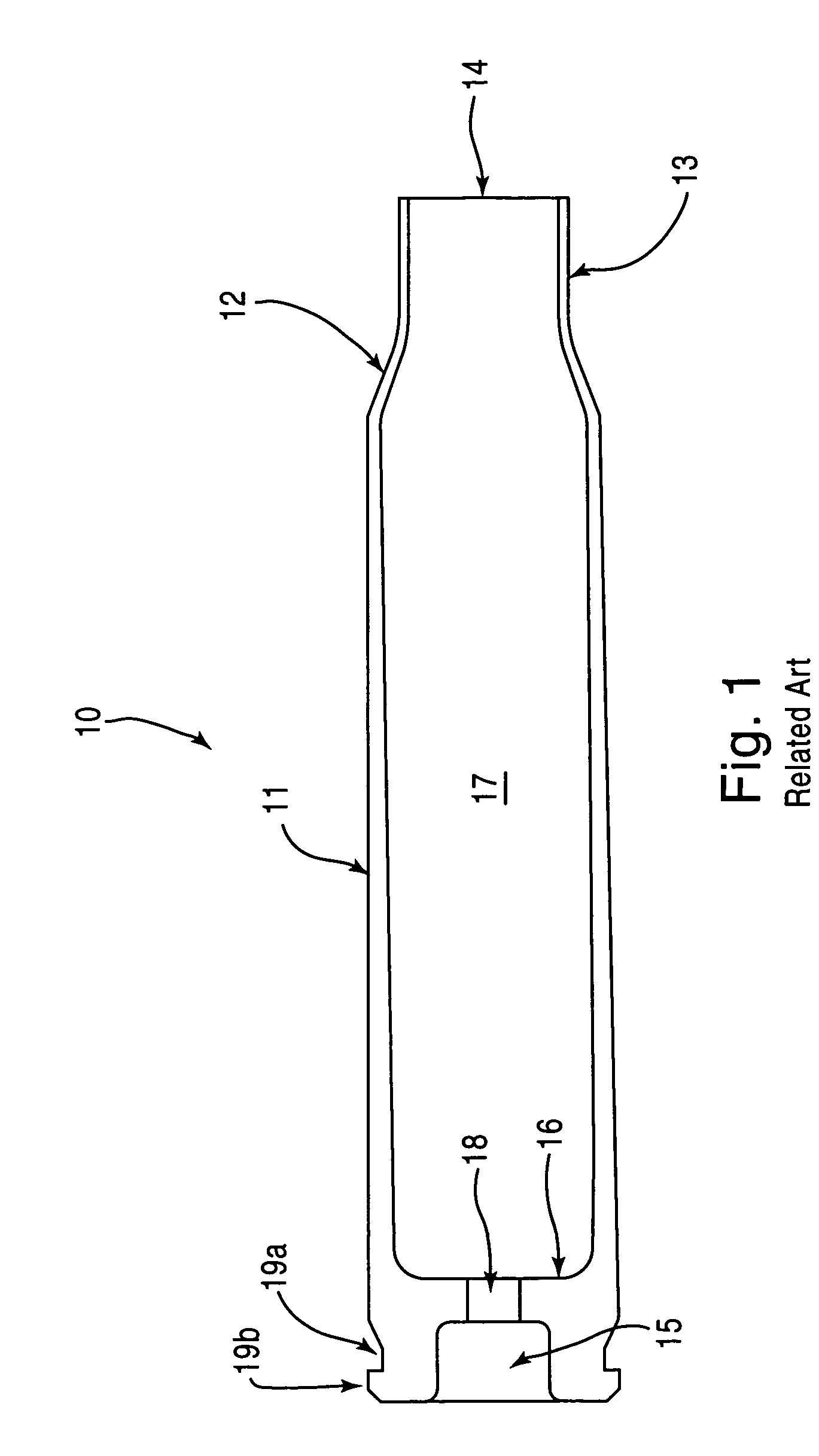

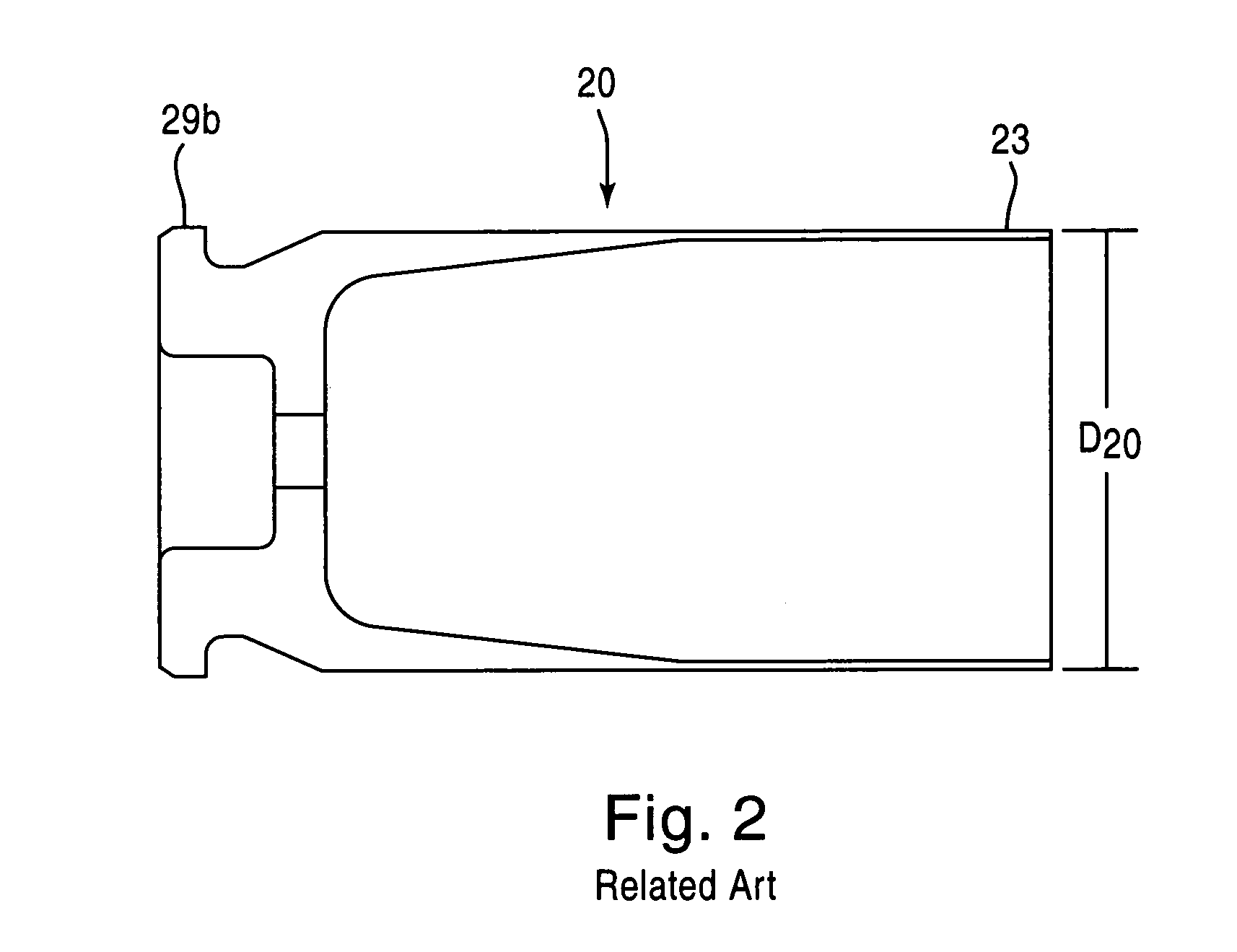

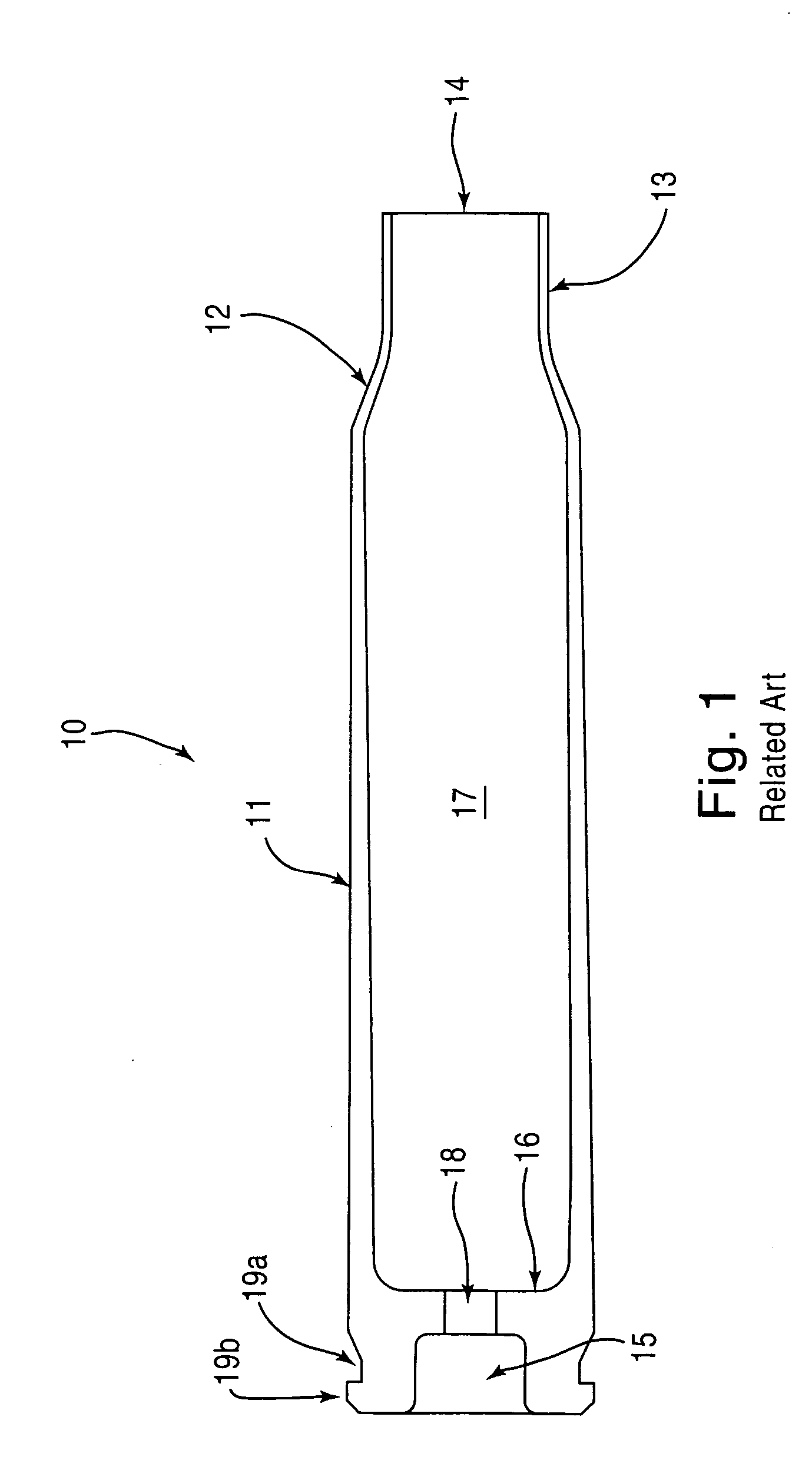

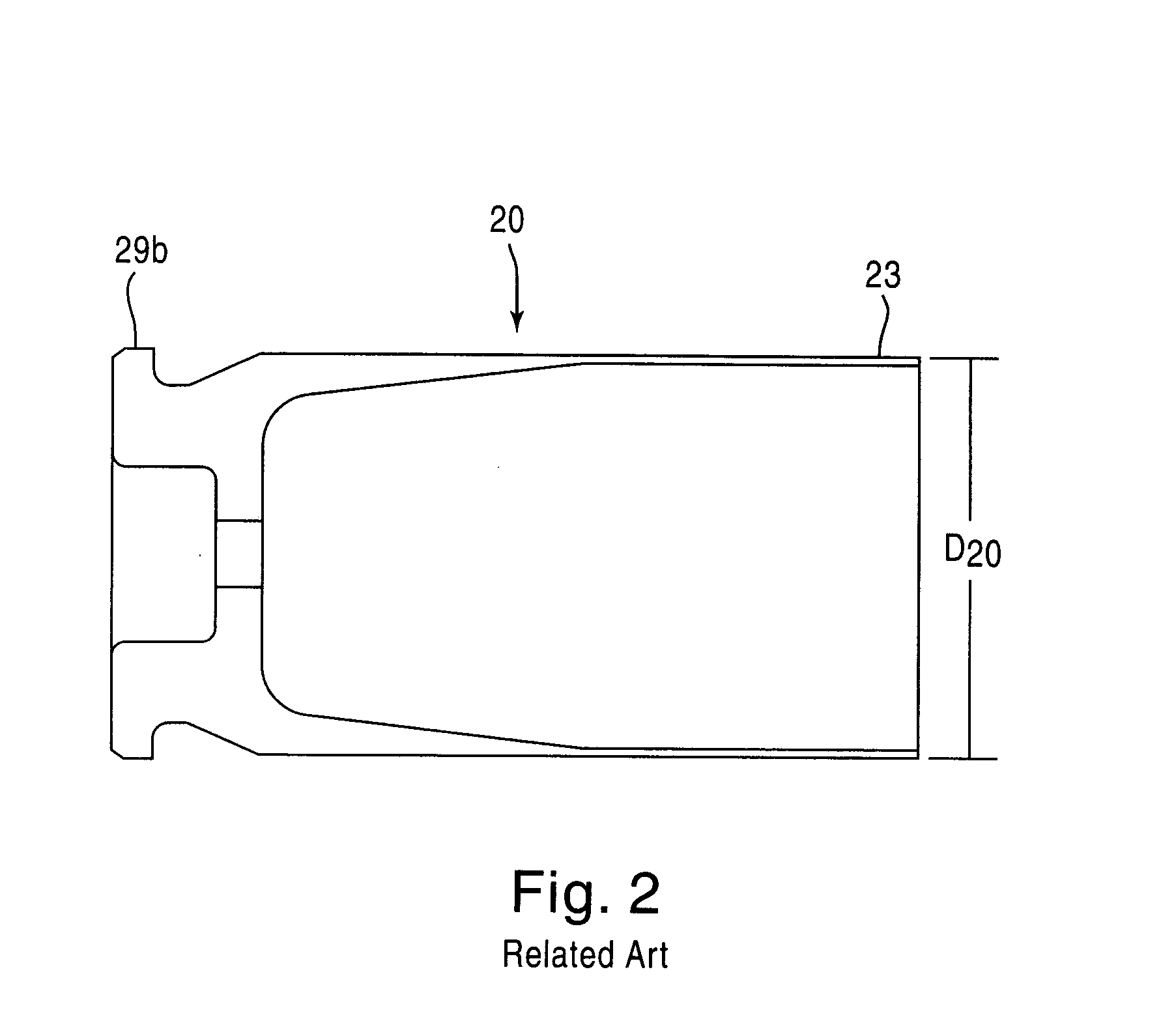

A lead-free, composite polymer based bullet and cartridge case and methods of manufacturing the same, wherein the composite polymer material includes a tungsten metal powder, nylon 6 / 6, nylon 6, short glass fibers, as well as additives and stabilizers. The cartridge case includes a lip lock configured to matingly engage a cannelure formed along an outer circumferential surface of the bullet. The cartridge case also includes resilient walls wherein the case may snap fit onto the bullet. The bullet and cartridge case may be formed in a single step process by injection molding or a two step process including injection molding and a welding process.

Owner:POLYTECH AMMUNITION

Polypropylene composite material and preparation method thereof

The invention discloses a composite polypropylene material. The composite polypropylene material contains polypropylene resin, glass fiber and an antioxidant, wherein the fiber length of the glass fiber is between 0.4 and 1 millimeter. The invention also discloses a method for preparing the composite polypropylene material. The mechanical properties of the composite polypropylene material such as the tensile strength, the impact strength, the bending strength, the flexural modulus and so on are between the mechanical properties of short glass fiber reinforced polypropylene material and the mechanical properties of long glass fiber reinforced polypropylene material, and the cost of raw materials and the manufacturing cost are low.

Owner:BYD CO LTD

Wood plastic composite material building mould board, its preparation method and use

InactiveCN1948665AGood flexibilityGood compatibilityDomestic articlesForming/stuttering elementsWear resistantMechanical property

This invention discloses a kind of wood-plastic composite materials for construction template and its preparation methods and purposes. It belongs to building materials area. Against poor toughness, small strength and high cost defects of existing technologies, the main materials of this invention are PVC resin and / or plastic (new materials or waste materials) and wood fiber powder, the second materials are calcium power PE resins, short glass fiber, then adds the assistant, through mixing, heating, agitating, extrusion to matrix and cooling to shape, cutting steps to made into templates. It can increase the strength of plate by increasing various forms of reinforced structure in the process of preparation. It can be used for construct template of concrete processing. This invention can be recycled for several times, environmental protected, save resources and of low cost; the template are wear resistant and defend worms, non-absorbent, and hard to deform, with good mechanical properties, low coefficient of thermal conductivity, anti-acid and alkali.

Owner:四川自强科技有限公司

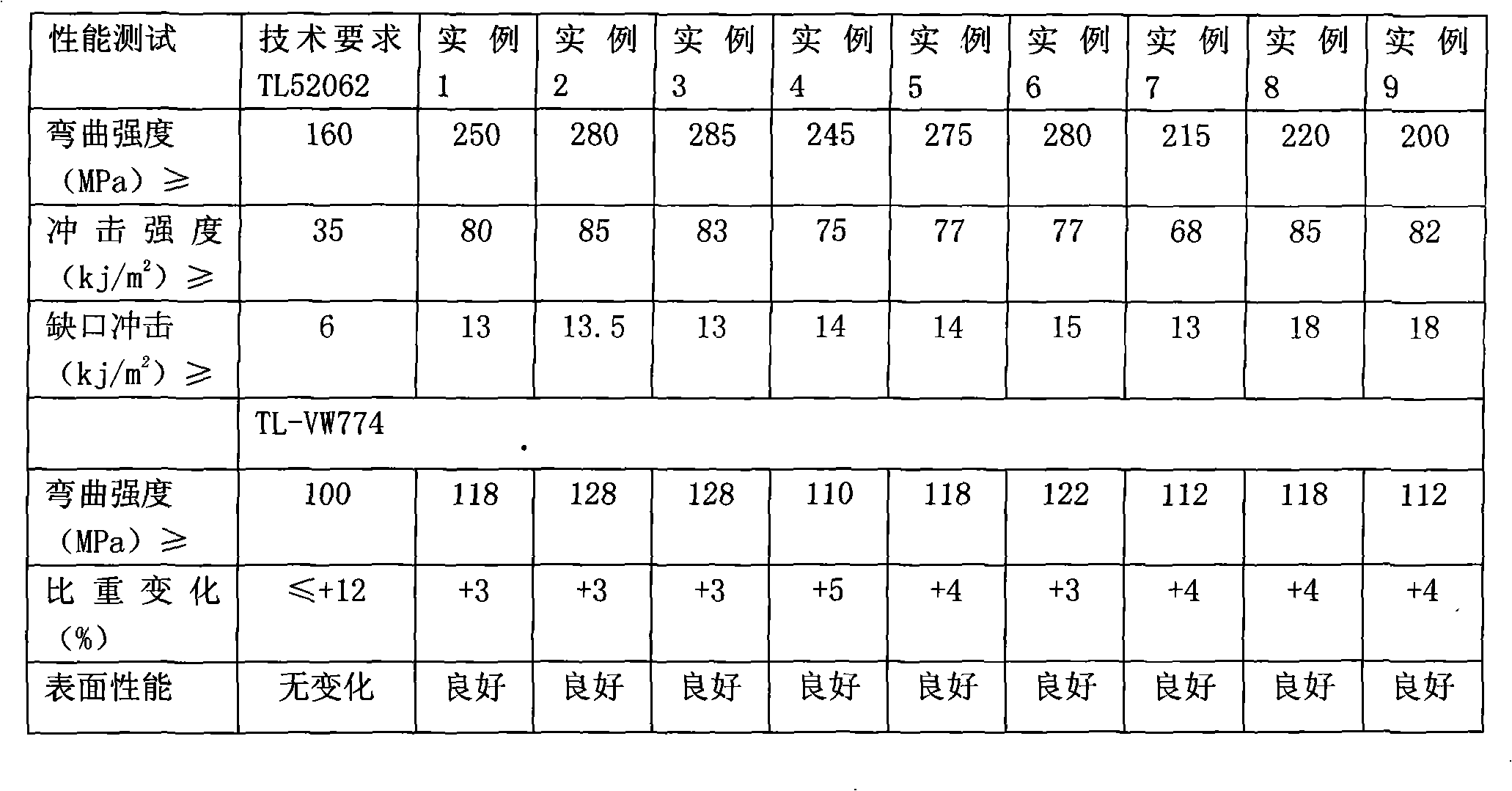

Alcoholysis resistance nylon composite material and preparation method thereof

The invention provides an alcoholysis resistance nylon composite material and a preparation method thereof; the composite material is applicable to the cooling water chamber of vehicles and comprises nylon, short glass fiber, glass fiber emergence resistance regulating additive, nucleating agent, colorant, heat stabilizer and alcoholysis resistance additive. The physical property of the nylon composite material provided by the invention can meet or exceed the TL52062 technical requirement and the alcoholysis resistance chemical property can meet the TL-VW774 technical requirement so that the surface of the product does not change and crack after being placing in 100% of glycol solution for 48h at 135 DEG C and the product has high shock resistance and dimension stability, thus ensuring that the stress cracking does not appear on joints.

Owner:辰东意普万新材料(广东)有限公司

Lead free, composite polymer based bullet and method of manufacturing

Owner:TRUE VELOCITY IP HLDG LLC

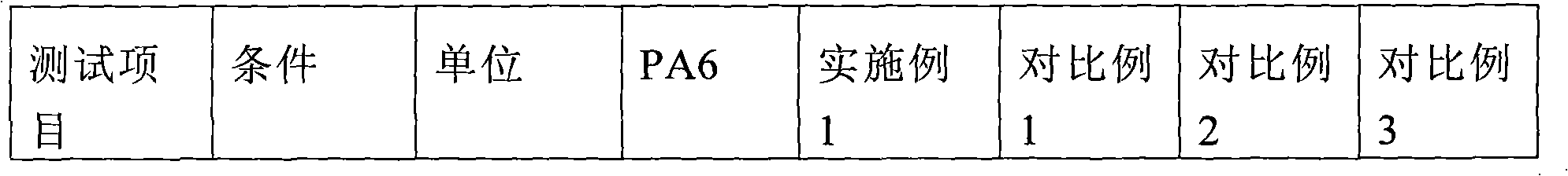

Low water absorption polyamide composite and preparation method thereof

The invention relates to a low water absorption polyamide composite and preparation method thereof. 10-90 parts by weight of polyamide and 3-10 parts by weight of phyllo-silicate clay and less than 2 parts by weight of additive are placed into a high speed mixer to be premixed for 20min and then are added into a double screw extrusion machine, and conveying, melting, cutting, extrusion, cooling and granulation are carried out, thus obtaining polyamide / phyllo-silicate master batch, then the polyamide / phyllo-silicate master batch, 10-60 parts by weight of styrene resin, 2-10 parts by weight of compatilizer and 5-20 parts by weight of short glass fiber are placed into the high speed mixer to be premixed for 20min, temperature is controlled to be 40-60 DEG C, and finally extrusion granulationis carried out in the double screw extrusion machine, thus obtaining the low water absorption polyamide composite. Compared with prior art, the invention has the advantages of solvent resistance, high tenacity and easy processability of polyamide and the advantage of low water absorption of ABS resin; besides, phyllo-silicate clay speeds up crystallization of nylon, degree of crystallization and mechanical strength are improved, extremely low water absorption is obtained, and size stability is greatly improved while impact toughness is maintained.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

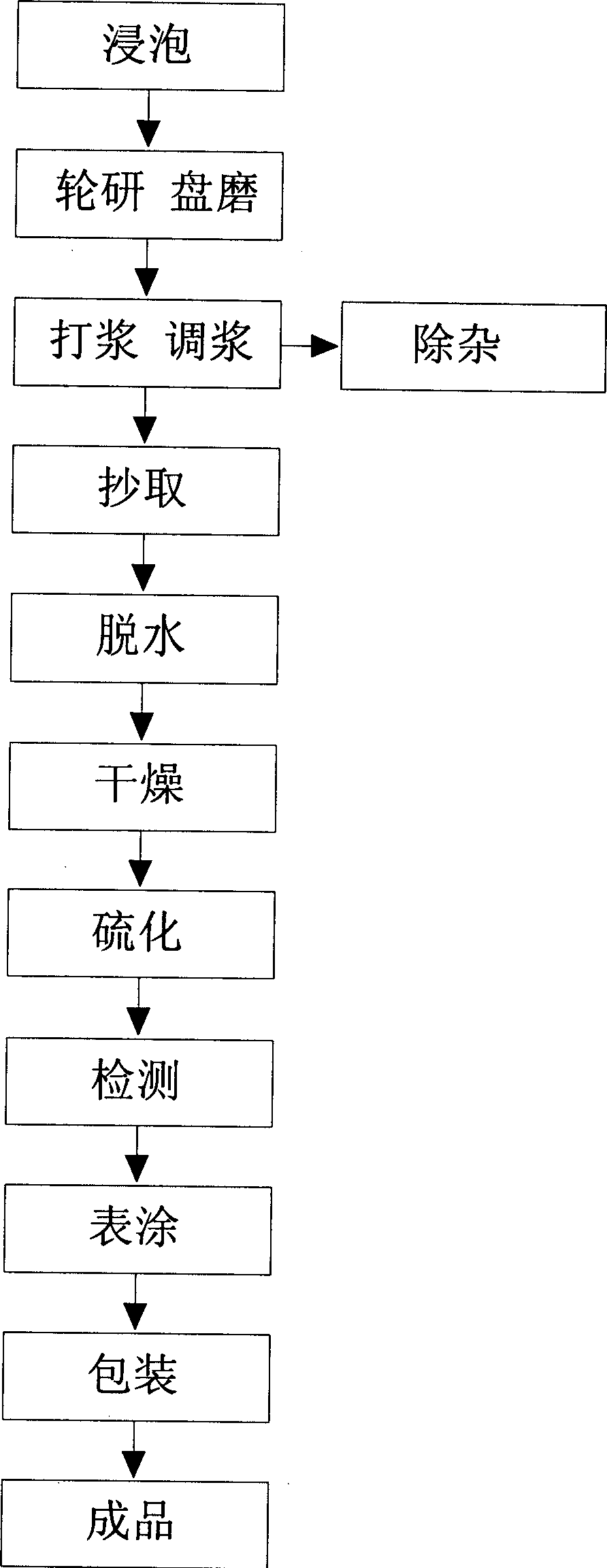

Screened sealing material without asbestos fiber and its prepn process

InactiveCN1847355ASo as not to damageHigh tensile strengthOther chemical processesHigh resistanceSodium Bentonite

The present invention is screened sealing material without asbestos fiber and its preparation process. The sealing material is prepared with fiber 10-70 wt%, stuffing 30-80 wt%, adhesive 1-10 wt%, latex 5-20 wt% and compounding agent 4-10 wt%, where the latex is synthetic latex or natural latex, the adhesive is polymer adhesive or polymer adhesive composition, the stuffing is graphite powder, bentonite, etc. of granularity over 120 meshes, and the fiber is 1000 deg.c over high temperature treated mineral wool fiber, short glass fiber, ceramic fiber, etc. The sealing material has high tensile strength, high oil tolerance, high heat resistance, long service life and no harmful asbestos.

Owner:舟山海山机械密封材料股份有限公司

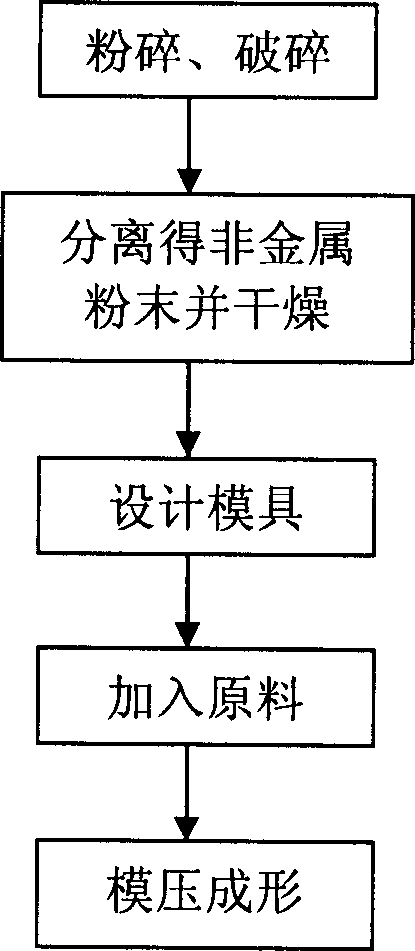

Method for mfg. glass fiber reinforced plastic product by nonmetal powder of waste circuit board

InactiveCN1792618AGood physical and mechanical propertiesImprove flexural strengthSolid waste disposalPlastic recyclingWaste productMetal powder

A process for preparing glass fiber reinforced plastic product from the non-metal powder prepared from rejected circuit board includes such steps as breaking the rejected circuit board, pulverizing, separating to obtain non-metal powder, designing die set, loading raw materials in the die set, and die pressing. Its bending strength is increased by 35%.

Owner:TSINGHUA UNIV

Copper toxicity-resistant glass fiber reinforced polypropylene composite material and preparation method thereof

InactiveCN101698725AStrong interface adhesionImprove adhesionPolypropylene compositesProcedure Agents

The invention relates to a copper toxicity-resistant glass fiber reinforced polypropylene composite material and a preparation method thereof, and the copper toxicity-resistant glass fiber reinforced polypropylene composite material consists of the following raw materials by weight percent: 60-65% of polypropylene, 2-7% of compatilizer, 0.7-2% of composite antioxidant, 0-0.02% of anti-copper toxicity agent, 0.1-0.8% of processing additives and 30-35% of glass fibers. The preparation method comprises the following steps: firstly mixing the polypropylene, the compatilizer, the composite antioxidant, the anti-copper toxicity agent and the processing additives in a high mixing machine, feeding into a twin-screw extruder via a precision meter, further adding the short glass fibers into the extruder via the meter after the materials in the extruder are softened, then melting, extruding and granulating, wherein the extrusion temperature is 200-220 DEG C. The bonding force between the polypropylene and a glass fiber interface is strong, and the product has the advantages of excellent mechanical performances, no obvious surface fiber revealed phenomenon, excellent heat aging resistance and excellent anti-copper toxicity performance; furthermore, the product almost has no loss of the mechanical performances when baking in a baking oven at 150 DEG C for 1000h.

Owner:KINGFA SCI & TECH CO LTD +2

Composite acupuncture filter bag used for smoke treatment of ceramic kiln

ActiveCN101695615AShort production processHigh porosityDispersed particle filtrationFiltration separationYarnAlkali free

The invention discloses a composite acupuncture filter bag used for smoke treatment of a ceramic kiln. Short fibers and base fabrics are acupunctured by adopting non-woven acupuncture technology to form a composite acupuncture plain felt, the plain felt is soaked and coated by adopting a surface chemical treatment agent, and then the plain felt is dried and cured at a high temperature and is tailored and sewn to form the filter bag, wherein the base fabrics adopt 30-count alkali-free glass fiber woven fabrics; the short fibers for acupuncture comprise polypropylene fibers, polyphenylene sulfide fibers and 80-count short glass fiber yarns; and the surface chemical treatment agent comprises polytetrafluoroethylene emulsion, polyacrylic ester emulsion, coupling agent, antistatic agent and water. The invention provides the composite acupuncture filter bag used for the smoke treatment of the ceramic kiln, which has the advantages of moisture resistance, good acid corrosion resistance, long service life, high strength of the base fabrics and lower production cost. The problems of poor moisture resistance, poor corrosion resistance, low strength, short service life and high production cost of the filter bag in the prior art are solved. The filter bag is suitable for dust removal and purification treatment for the smoke of the ceramic kiln.

Owner:山东兴国新力环保科技股份有限公司

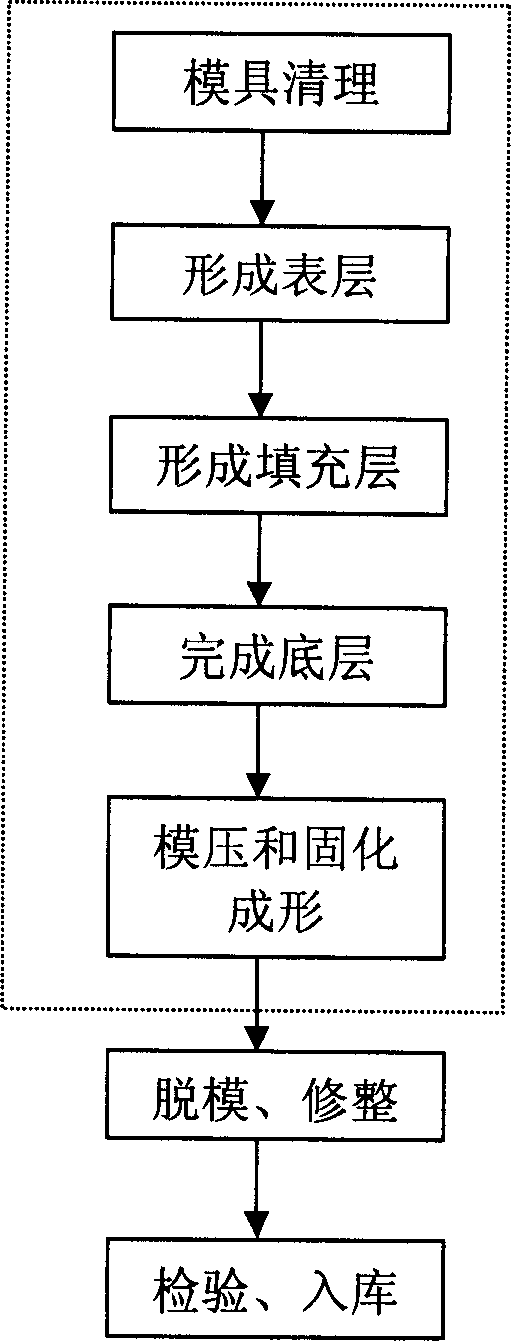

Resin composition for high water resistance sheet molding compound, high water resistance sheet molding compound, and high water resistance bathtub

ActiveCN102746466AImprove water resistanceNo cracks, brokenBathsDouchesMaterials scienceSurface modification

The invention discloses a resin composition for a high water resistance sheet molding compound, a high water resistance sheet molding compound, and a high water resistance bathtub. The resin composition is prepared by mixing 60-90 parts by weight of an unsaturated polyester resin, 10-40 parts by weight of a low shrink agent, 30-180 parts by weight of an inorganic filler, 20-40 parts by weight of short glass fibers, 1-2 parts by weight of an initiator, 2-10 parts by weight of an internal release agent, 1-10 parts by weight of a surface modification agent, 0.5-2 parts by weight of a thickening agent, 0-1 part by weight of a polymerization inhibitor, and 0-10 parts by weight of styrene, wherein the unsaturated polyester resin is a composition comprising one or a plurality materials selected from an o-phenyl type unsaturated resin, a meta-phenyl type unsaturated resin, an epoxy vinyl ester unsaturated resin and a vinyl resin, the unsaturated resin contains carboxyl groups, and the amount of the carboxyl groups is 0.001-0.002% of the total weight of the resin. The high water resistance bathtub of the present invention has excellent water resistance performance.

Owner:芜湖科逸建材有限公司

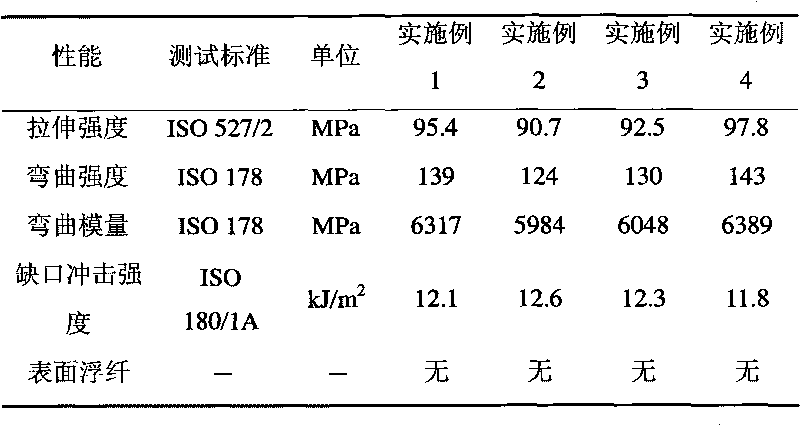

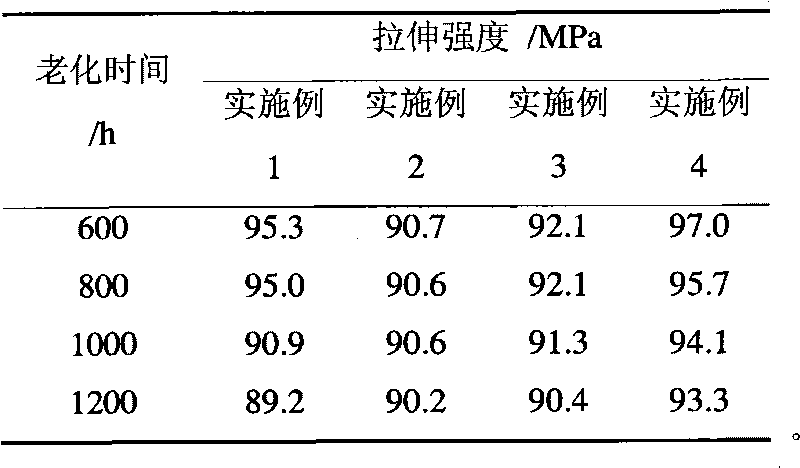

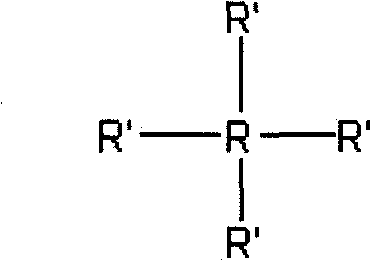

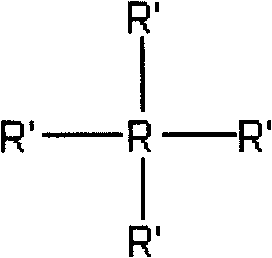

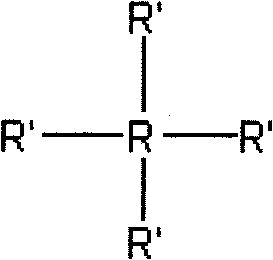

Nylon material with star branched structure and preparation method thereof

ActiveCN101798456AWide variety of sourcesLow priceCombustion-air/fuel-air treatmentMachines/enginesBursting strengthSurface finish

The invention provides a nylon composite material with star branched structure, applicable to automobile induction manifold. The nylon composite material is composed of the following components by mass percentage: 40-68% of nylon, 0-10% of POE elastic body, 0-35% of short glass fiber, 0.05-5% of star branching agent and 1.5-12% of assistant; wherein the short glass fiber is alkali-free short glass fiber treated by silane coupling agent; the molecular formula of the star branching agent is, R is aromatic chain segment, aliphatic chain segment or epoxy chain segment, R' is amino, carboxyl or hydroxyl functional group capable of reacting with nylon end group, and R' functional group quantity is more than or equal to 3. The composite material of the invention has the advantages of super bursting strength, excellent processing liquidity and high surface finishment and completely meets the production and application requirement of automobile nylon induction manifold, the raw material thereof is available, production processing is simple, and the invention is applicable to popularization and application.

Owner:辰东意普万新材料(广东)有限公司

Preparation of halogen-free flame-proof nylon 66 having high-mechanical property and composite material

The invention discloses a preparation method for high-mechanical performance halogen-free flame-retardant nylon 66 composite materials, comprising the following steps: (1) weighing; (2) mixing; (3) blending and extruding. The invention also discloses a composite material prepared with the method; the composite material has the following components: nylon 66, short glass fibers, main antioxidant, auxiliary antioxidant, compound flame retardant and lubricant. The method of the invention has the advantages that the composite material has the fire-retardant performance up to UL 94 V-0 (0.8mm) level, and has more prominent mechanical properties than the existing halogen-free flame retardant system, with equivalent mechanical properties with the halogen-containing flame retardant system; therefore, the composite material of the invention can completely replace the existing halogen-containing flame-retardant products and halogen-free flame-retardant products, with easy preparation method and easy operation. The high-mechanical performance halogen-free flame-retardant nylon composite material can be widely used in home appliances, electronics parts, auto parts, and so on.

Owner:刘成志

Preparation method of polytetrafluoroethylene copper-clad plate

InactiveCN110039851AMake up for the lack of large thermal expansion coefficient, soft texture, poor mechanical properties, etc.Improve reliabilitySynthetic resin layered productsLaminationDielectric loss factorAdditive ingredient

The invention discloses a preparation method of a polytetrafluoroethylene copper-clad plate. The preparation method comprises the following steps: 1, evenly mixing raw material ingredients of polytetrafluoroethylene powder, a lubricating agent, ceramic powder and short glass fiber and curing; 2, moulding pressing to prepare a preform; 3, calendering to obtain a raw substrate and then drying; 4, covering the two sides of the raw substrate by copper foils, sintering, maintaining pressure and then cooling to the room temperature to obtain the polytetrafluoroethylene copper-clad plate. The preparation method replaces a preparation mode applying PTFE dispersion liquid to coating and impregnating and avoids harm of toxic fluoride, nitric oxide and the like; a good filler dispersing effect, evenness in mixing and good dimensional stability of a product are achieved. By means of reasonable matching, the prepared PTFE copper-clad plate has different dielectric constants from 2.6 to 8.6 MHz, a dielectric loss factor is smaller than or equal to 0.003, the peel strength is greater than or equal to 1.7 kN / m, and overall performance can meet the use requirement. The preparation method disclosedby the invention has the advantages of simple technological process and ability in meeting the requirement of industrial batch product.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

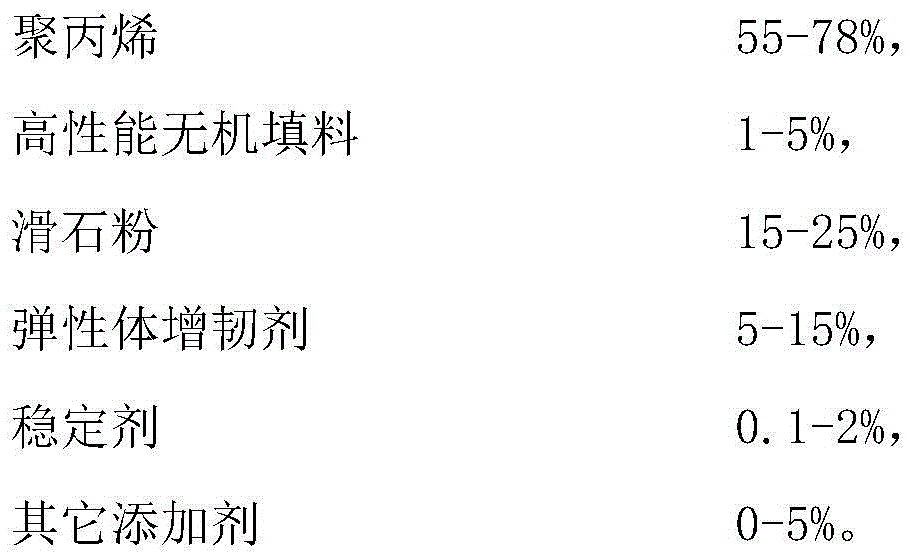

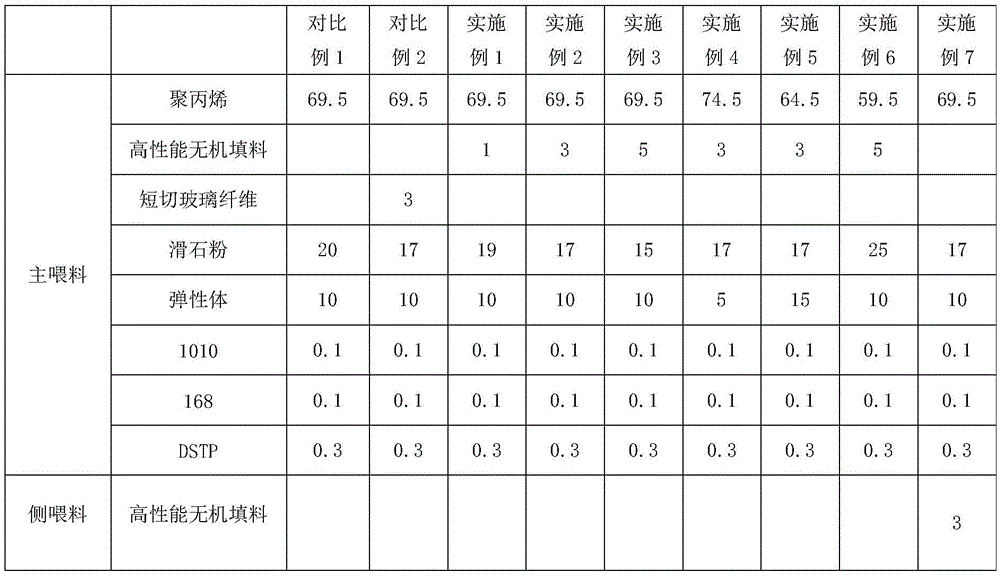

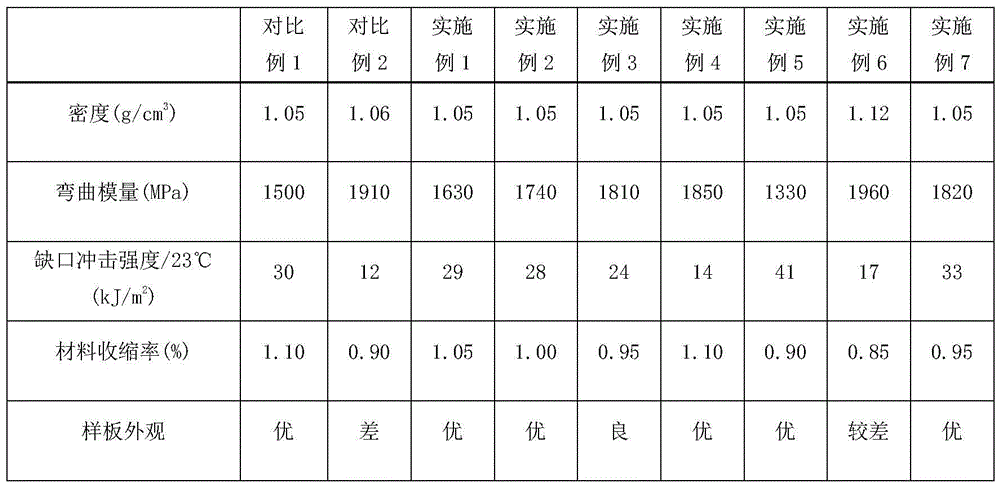

High-rigidity, low-shrinkage and good-appearance polypropylene composite material and preparation method thereof

The invention discloses a high-rigidity, low-shrinkage and good-appearance polypropylene composite material and a preparation method of the high-rigidity, low-shrinkage and good-appearance polypropylene composite material. The high-rigidity, low-shrinkage and good-appearance polypropylene composite material is prepared from the following raw materials in percentage by weight: 55 to 78 percent of polypropylene, 1 to 5 percent of high-performance inorganic filler, 15 to 25 percent of talcum powder, 5 to 15 percent of elastomer toughening agent, 0.1 to 2 percent of stabilizing agent and 0 to 5 percent of other additives. The high-rigidity, low-shrinkage and good-appearance polypropylene composite material and the preparation method, disclosed by the invention, have the advantages that 1, through the synergistic effect of the high-performance inorganic filler and the traditional talcum powder filler, the polypropylene composite material which is higher in rigidity and lower in shrinkage is obtained; 2, through a technological method of adding the high-performance inorganic filler from a side feeding opening, the polypropylene composite material which is better in comprehensive mechanical performance and lower in shrinkage is obtained; 3, compared with the disadvantages of a traditional short glass fiber modified material that glass fiber appearance is easy to appear and the like, the high-rigidity, low-shrinkage and good-appearance polypropylene composite material disclosed by the invention still has a good appearance which is equally matched with that of a traditional talcum powder modified polypropylene material, meanwhile, the high-rigidity, low-shrinkage and good-appearance polypropylene composite material is higher in rigidity and lower in shrinkage and is very suitable for appearance injection-molding parts which have higher requirements on rigidity and size stability.

Owner:SHANGHAI PRET COMPOSITES

Composition for porous plastics for intake housings

Disclosed is a porous plastic resin composition including a polypropylene-based resin, a polyamide-based resin, or an alloy resin made by alloying the two resins to each other with a compatibilizer, reinforced with an inorganic filler or a short glass fiber, and further including a porous inorganic filler and a special inorganic low blowing agent. When the disclosed porous plastic resin composition is used to make an intake housing part, it reduces the weight and cost of an automobile intake housing part.

Owner:HYUNDAI MOTOR CO LTD +1

Sound-insulating laminated structure and method for the production thereof

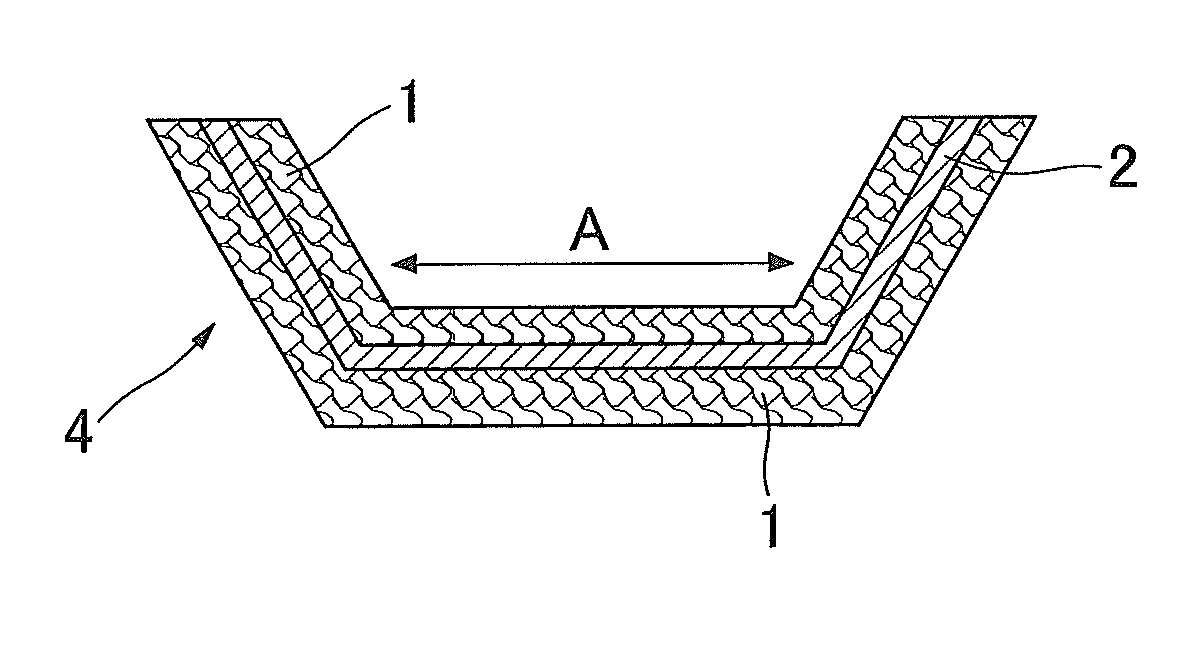

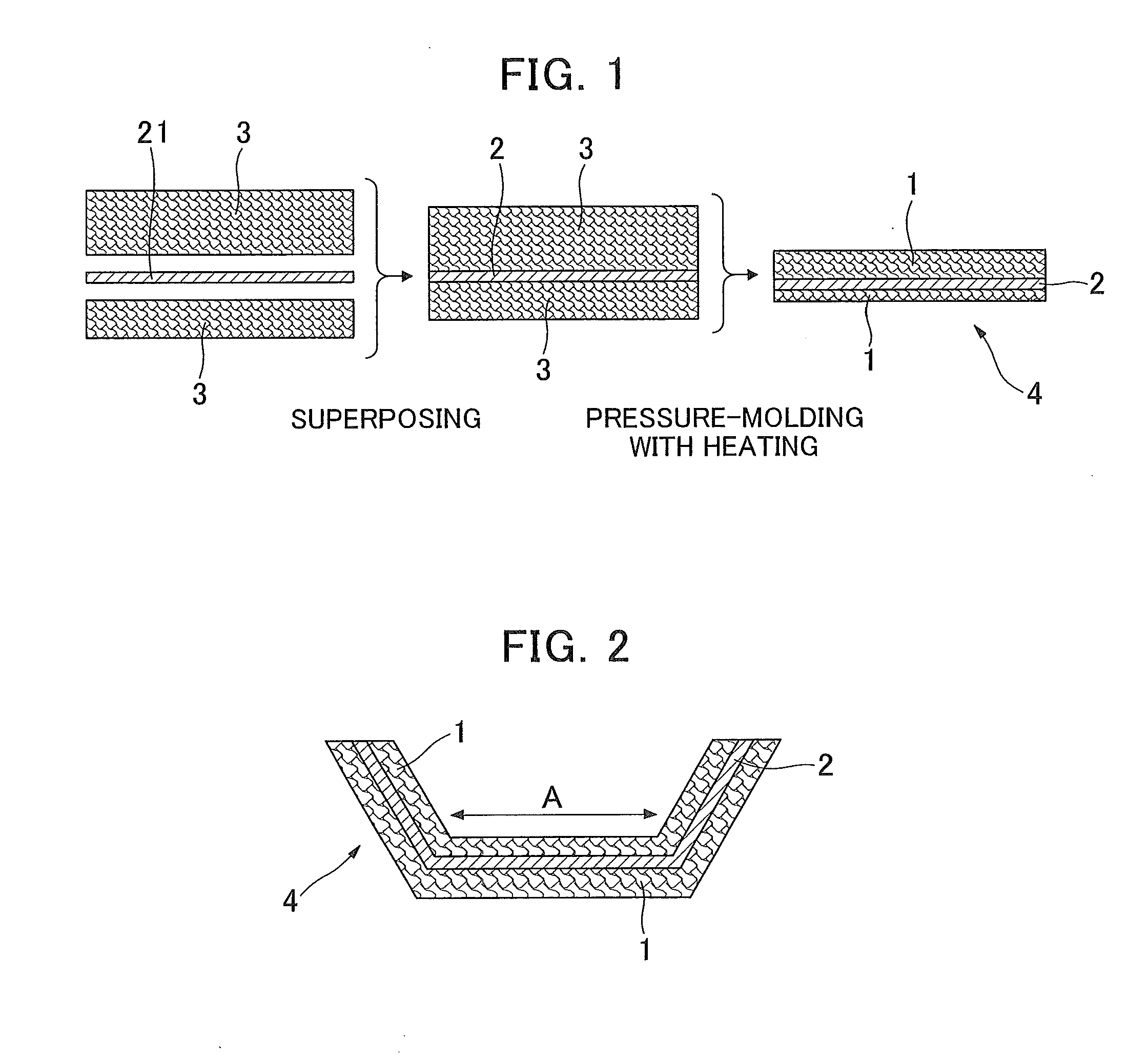

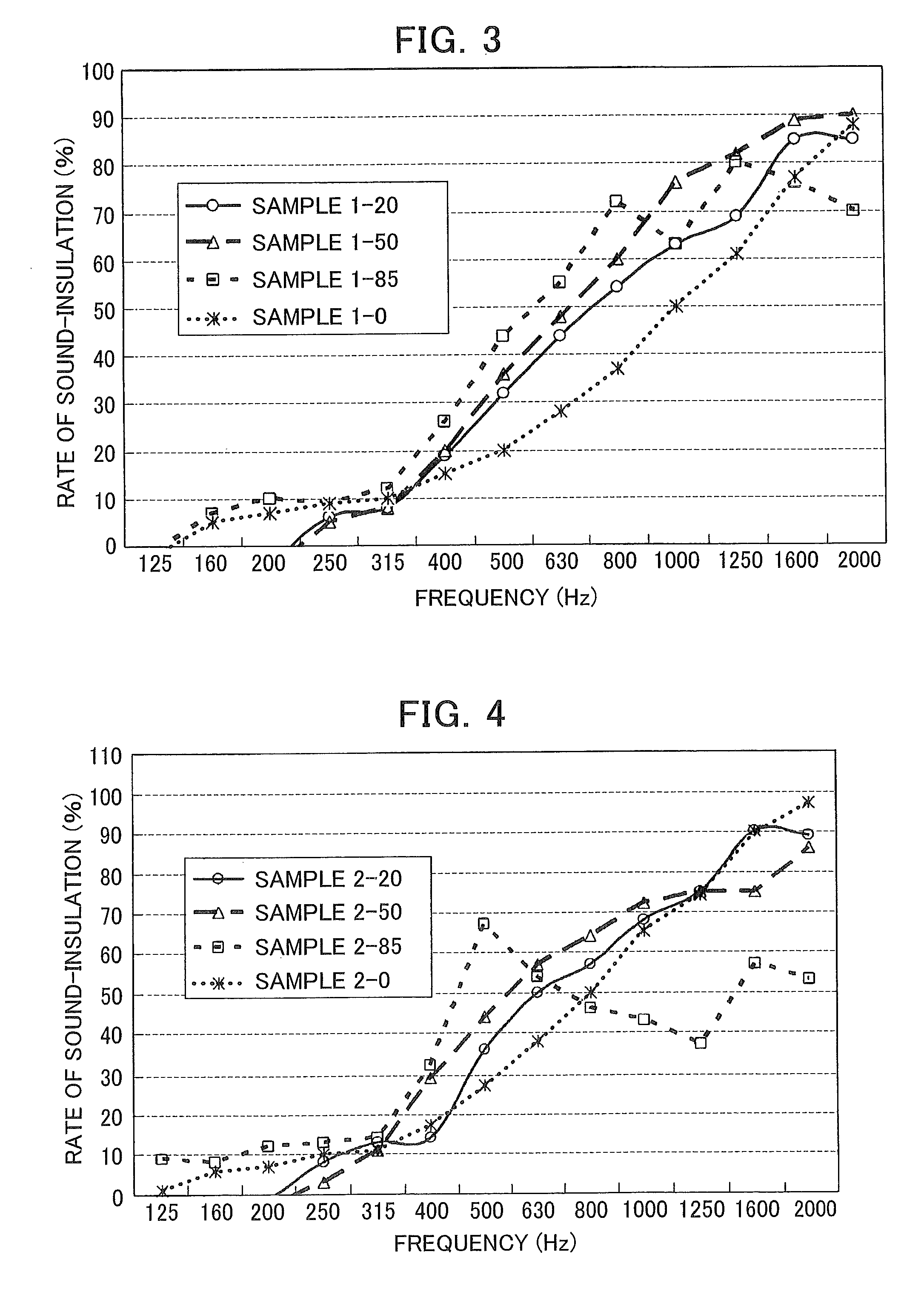

InactiveUS20100101891A1Good low frequencyImprove insulation performanceWallsSound proofingMetal foilGlass wool

Herein provided is a sound-insulating laminated structure which is excellent in the ability of insulating low frequency sounds whose frequency falls within the range of from 200 to 1000 Hz.The sound-insulating laminated structure comprises a first glass wool layer, a metal foil layer free of any opening and a second glass wool layer. The first and second glass wool layers are ones each prepared by collecting and combining short glass fibers through the application of an uncured thermosetting phenol resin to the short glass fibers to thus give a web of glass wool prepreg and then molding, with heating, the web into a sound-insulating laminated structure having a desired shape.

Owner:CENT GLASS CO LTD

High strength wearable polyamide composite material and preparation method thereof

InactiveCN103897387AReduce manufacturing costReduce the difficulty of productionPolyamideMelt extrusion

The invention discloses a high strength wearable polyamide composite material which comprises the following components in parts by weight: 50-55 parts of nylon 66 resin, 15-20 parts of nylon 1010 resin, 0.5-1.2 parts of coupling agent, 18-20 parts of flame retardant, 5-10 parts of molybdenum disulfide, 0.3-0.9 part of antioxidant, 6-12 parts of polytetrafluoroethylene and 15-20 parts of short glass fibers. The method of preparing the composite material comprises the following steps: preparing raw materials: weighing 50-55 parts of nylon 66 resin, 15-20 parts of nylon 1010 resin, 0.5-1.2 parts of coupling agent, 18-20 parts of flame retardant, 5-10 parts of molybdenum disulfide, 0.3-0.9 part of antioxidant, 6-12 parts of polytetrafluoroethylene and 15-20 parts of short glass fibers, putting in a high speed mixer, and uniformly stirring at a high speed to obtain a pelleting raw material; fusing and extruding the raw material by a twin-screw extruder, and controlling the extruding temperatures of region 1 to region 6 of the twin-screw extruder to obtain the composite material. The material disclosed by the invention has the advantages of good strength, low hygroscopicity and low friction coefficient.

Owner:JIANGSU KANGFEITE POWER TECH

Magnesium oxychloride fiber light wallboard

InactiveCN103979921AAvoid the phenomenon of moisture absorption and return to halogenHigh strengthSolid waste managementCompressive resistanceSlag

The invention provides a magnesium oxychloride fiber light wallboard, and relates to the wallboard field in the construction materials. The wallboard is composed of the following components in parts by weight: 40 to 60 parts of magnesium chloride water solution, 20 to 30 parts of magnesium oxide, 0.1 part of fly ash, 0.2 part of slag, 0.5 part of construction waste, 0.1 part of waste ceramic, 2 parts of short glass fiber, 2 parts of straw, 2 parts of saw dust, 3 parts of perlite, and 0 to 2 parts of modifier. The formula of the wallboard comprises industrial and agricultural wastes such as fly ash, slag, mineral slag, construction wastes, broken ceramics, straws, and saw dust, thus the wastes are fully recycled and reutilized, and moreover the using amount of sands and stones is reduced, so the destroy on mountain and river bed is avoided, resources are saved, and environment is protected. The prepared magnesium oxychloride fiber light wallboard has the advantages of good water resisting property, high compressive strength, good freeze resisting performance, good acid / alkali resistant property, no halogen appearance, no scumming, and no deformation.

Owner:四川省元程中博能源开发有限公司

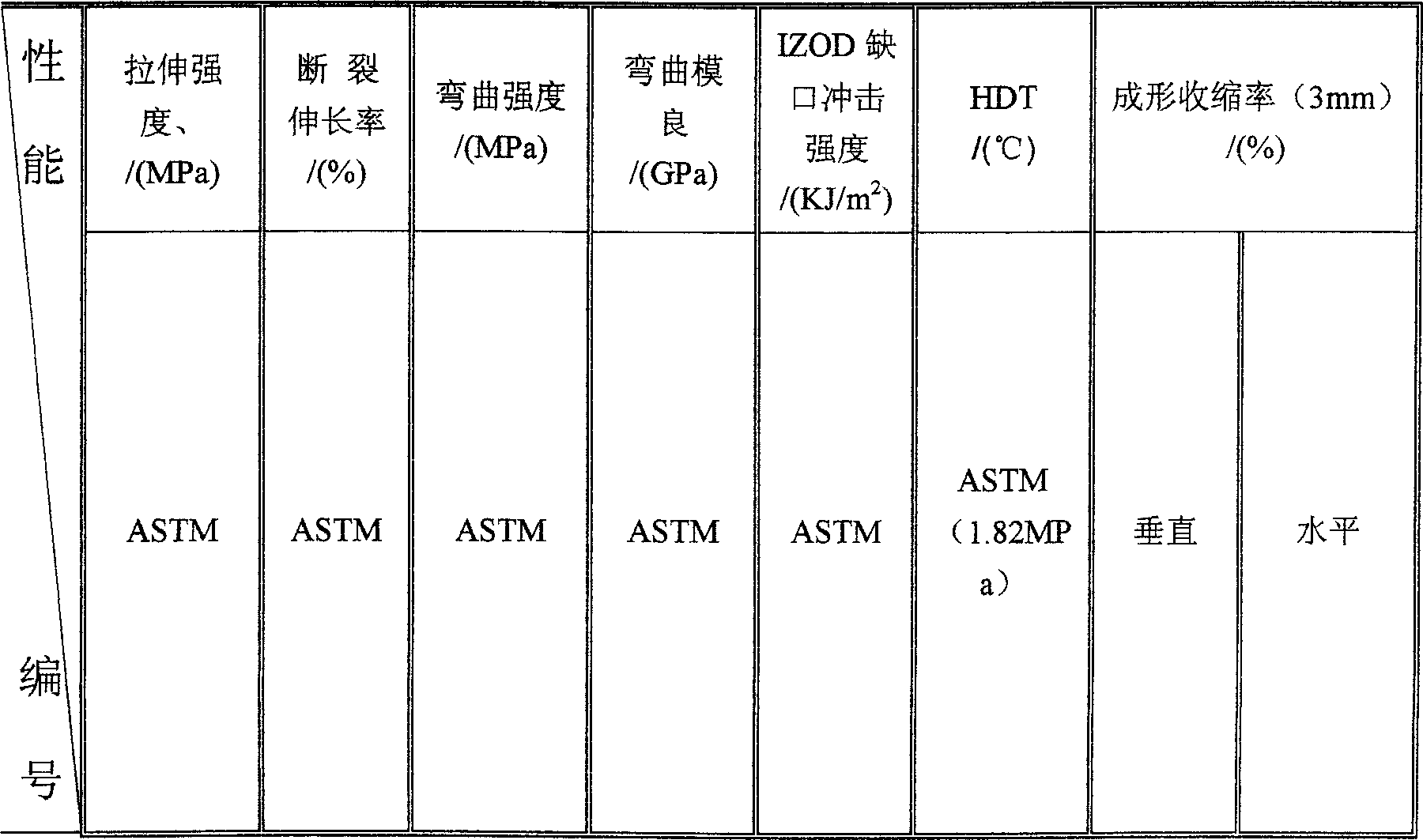

High-performance resin/ mica composite material and its production method

The invention discloses a high-property resin / mica composite material, which comprises the following parts: resin, mica powder, short glass fiber, coupling agent, anti-oxidant and lubricant, wherein the resin is nylon or polyterephthalic acid butanediol ester. The manufacturing method comprises the following steps: adding mica powder into coupling agent to do activating disposal; combining the screw component of double-screw squeezer; allocating screw block through three-segment kneading pattern; blending each component or transmitting each component into double-screw squeezer; squeezing; graining.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

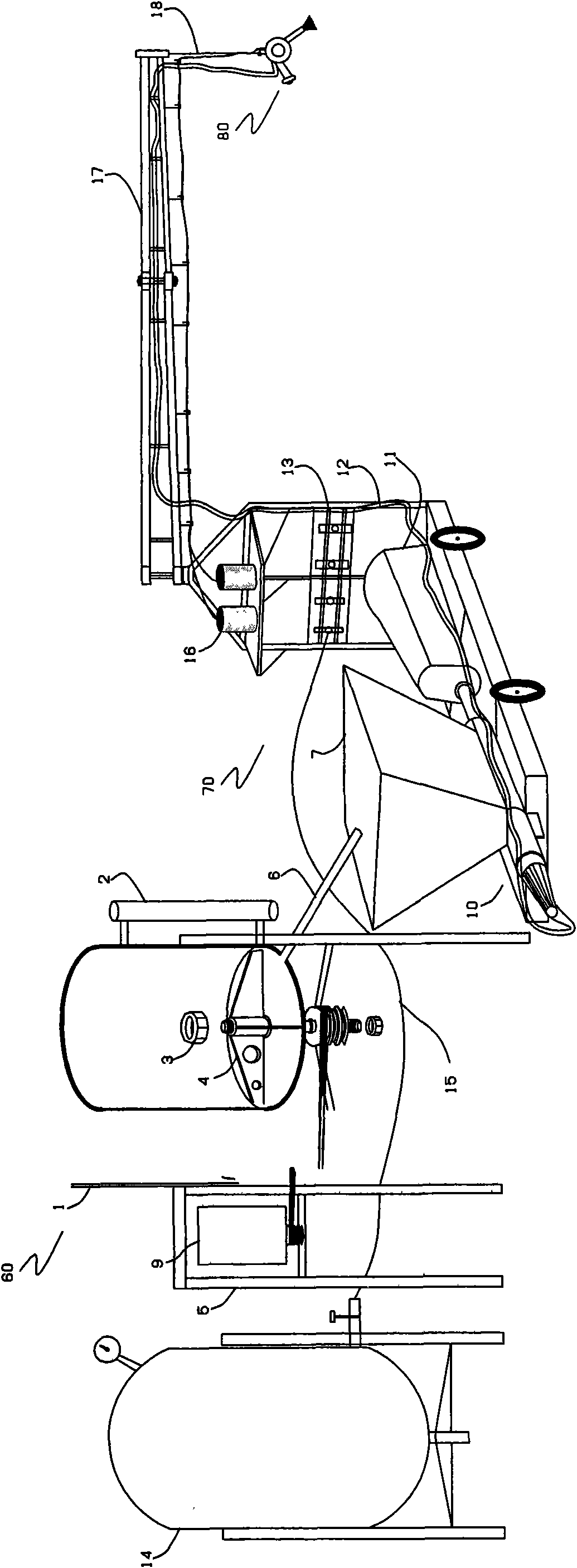

Technique and equipment for fabricating plastic sheet material produced from molding laminar die in low pressure

A plastic sheet able to be shaped by low-pressure moulding is proportionally prepared from unsaturated polyester resin, crystalline resin, low-shrinkage additive, trigger, polymerizing inhibitor, internal demoulding agent, filler and short glass fibers through mixing, thickening, shaping and packing. It can be moulded at 80-120 deg.C under 1-3 MPa for 2-3 hr.

Owner:山东海博新材料有限公司

Production method of centrifugal glass cotton-like fiber

InactiveCN103130410ALow densityLow thermal conductivityGlass making apparatusChemical reactionCentrifugation

The invention discloses a production method of a centrifugal glass cotton-like fiber. According to the production method of the centrifugal glass cotton-like fiber, materials of quartz sands, orthoclases, limestones, glass cullet, soda ashes, borax and the like are adopted, the materials are mixed in a reasonable proportion, glass liquids can be obtained after physical and chemical reactions through kiln high-temperature melting, and short glass fiber cotton aggregates can be thrown out through high-speed centrifugal injection. Material produced through the production method of the centrifugal glass cotton-like fiber has the advantages of being small in density, low in heat conductivity, high in acoustic absorptivity, flame-resistant, frost-resistant, and not prone to decay. The material is ideal heat preservation and heat insulation material, and is mainly used in the heat insulation process of building rail structures, industrial equipment, and pipe networks, and fireproofing and the like of the buildings. The material can further used as a sound absorber which absorbs and eliminates sounds, sound-absorbing barriers, sound-absorbing wall faces and the like.

Owner:吴振华

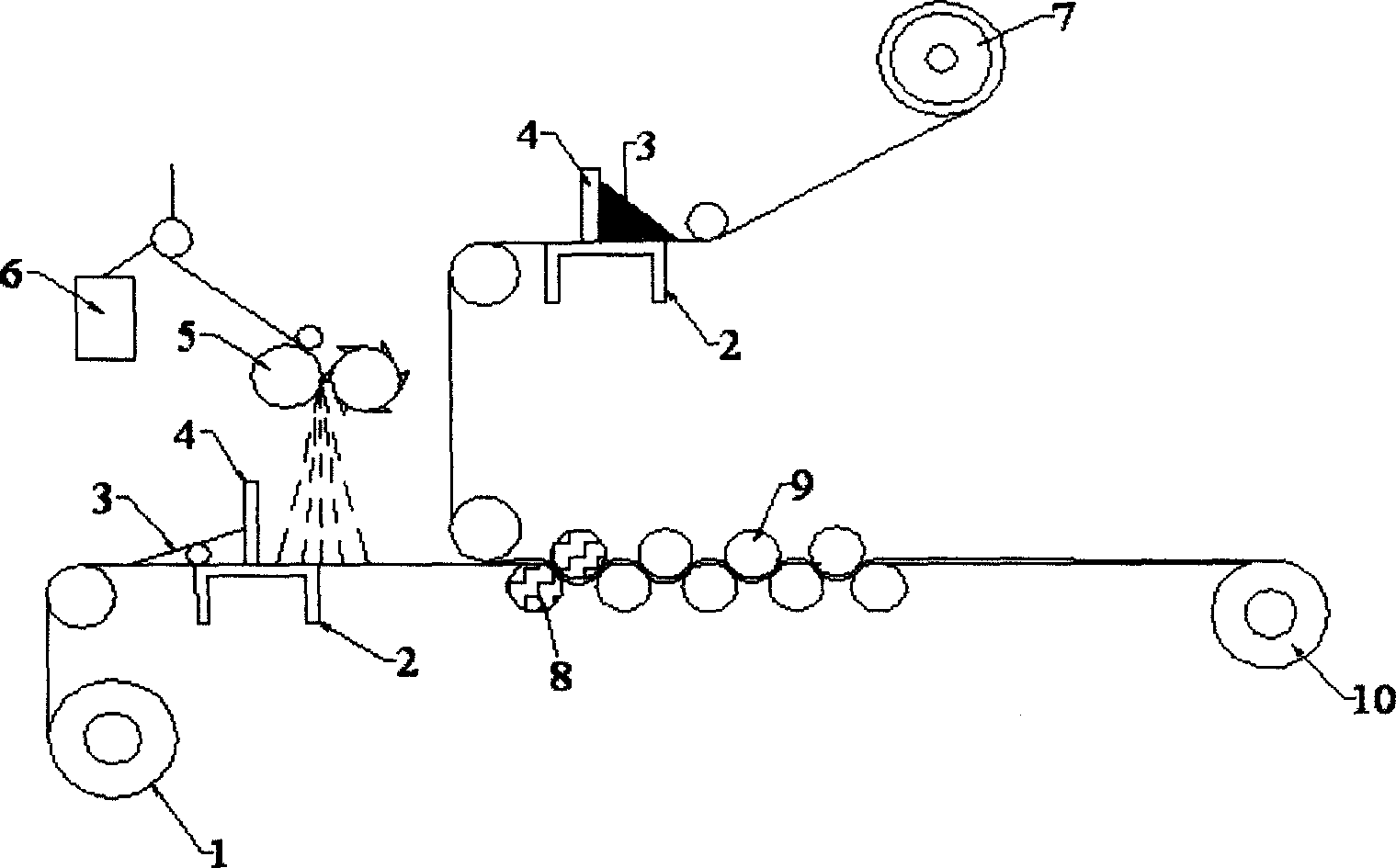

Universal waterproof coating

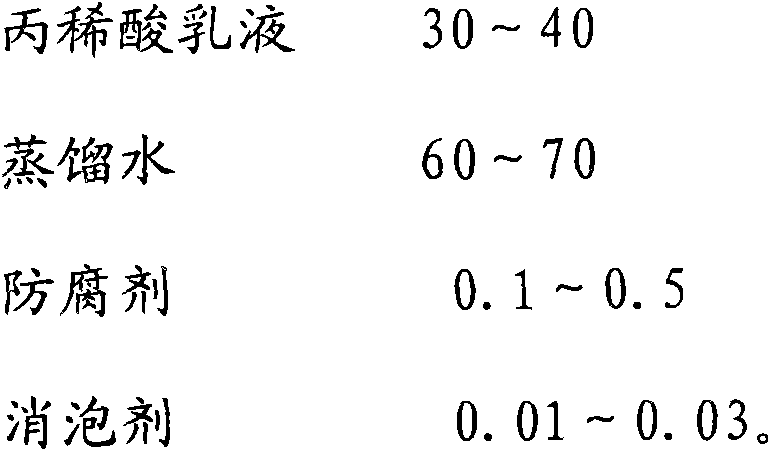

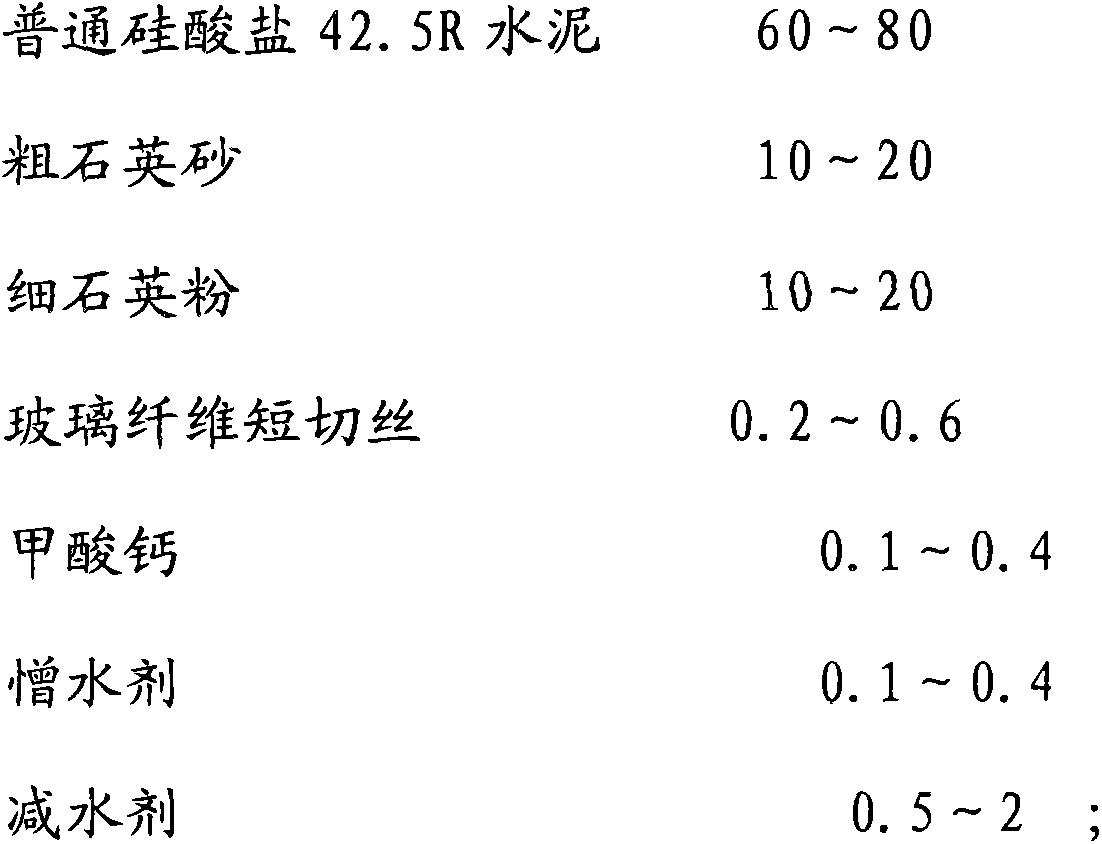

InactiveCN103275578AImprove water resistanceGood weather resistanceCoatingsEmulsionWeather resistance

The invention discloses a universal waterproof coating which is composed of 60-70% by weight of powder materials and 30-40% by weight of liquid materials. The powder materials comprise, by weight, 60-80 parts of ordinary Portland 42.5R cement, 10-20 parts of coarse quartz sand, 10-20 parts of fine quartz powder, 0.2-0.6 part of short glass fiber chopped strips, 0.1-0.4 part of calcium formate, 0.1-0.4 part of a water repellent and 0.5-2 parts of a water reducer; and the liquid materials comprise, by weight, 30-40 parts of an acrylic emulsion, 60-70 parts of distilled water, 0.1-0.5 part of a preservative and 0.01-0.03 part of a defoamer. The universal waterproof coating has the following beneficial effects that water tolerance, weather resistance and ageing-resistant performance of the waterproof coating are enhanced; the waterproof coating has the same service life with the concrete; the waterproof coating can permeate into pores of a substrate in a use process to block the pores, without phenomena of leakage or unstable fastness; the waterproof coating is non-toxic and environment-friendly; and the cost of raw materials is low.

Owner:XIAMEN LIKASAM WATERPROOF ENG

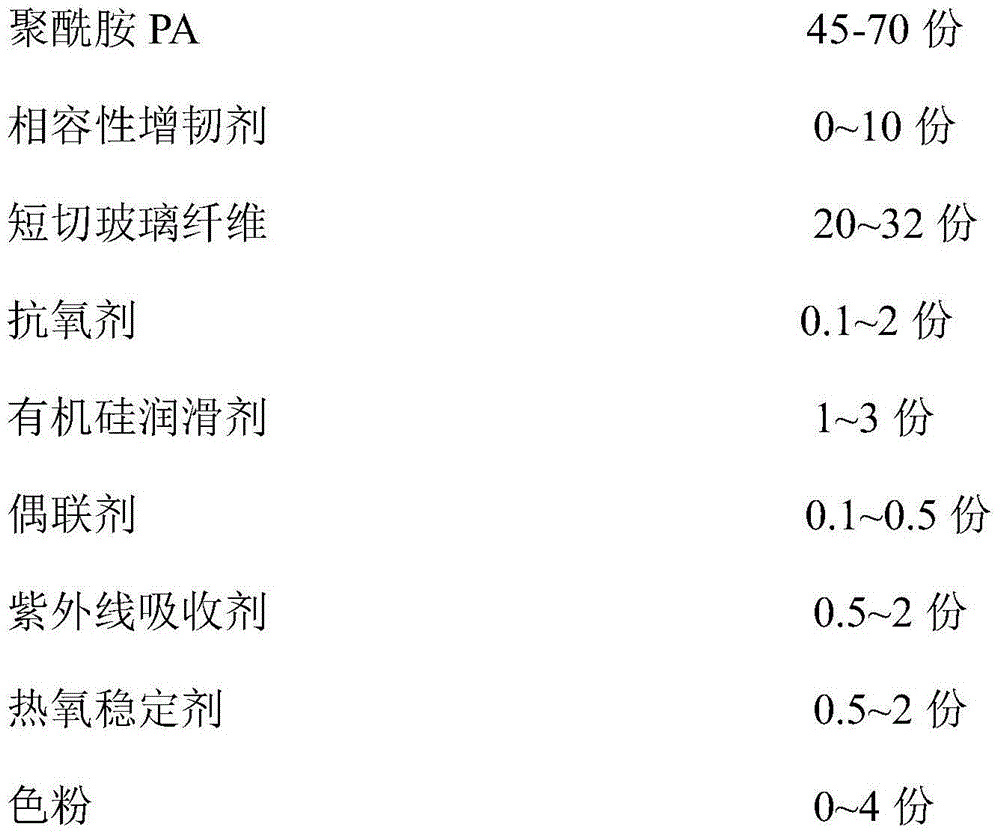

Colorful photoaging-resistant glass fiber reinforced polyamide and preparation method thereof

The invention discloses a colorful photoaging-resistant glass fiber reinforced polyamide material. According to the colorful photoaging-resistant glass fiber reinforced polyamide material, following components including polyamide, short glass fiber, a compatible toughening agent, an antioxidant, a lubricating agent, a coupling agent, an ultraviolet light absorber, a thermal-oxidation stabilizing agent and toner cooperate for use, specific weight is reasonably selected, so that chromatic aberration change of the color of a colorful glass fiber reinforced composite material is greatly reduced under the conditions of photoaging and thermal aging, the retention rate of mechanical property is high, and the problems of product performance reduction, product discoloration and the like can be effectively solved. Besides, according to a preparation method of the colorful photoaging-resistant glass fiber reinforced polyamide material, the operation is simple, the cost is low, the production benefit is high, all mechanical properties are high and stable, the method is applicable to industrial production, the service life of the material can be prolonged, the environmental pollution can be reduced, and the prepared colorful photoaging-resistant glass fiber reinforced polyamide material has excellent anti-aging mechanical property and color stability.

Owner:NANJING LIHUA ENG PLASTIC

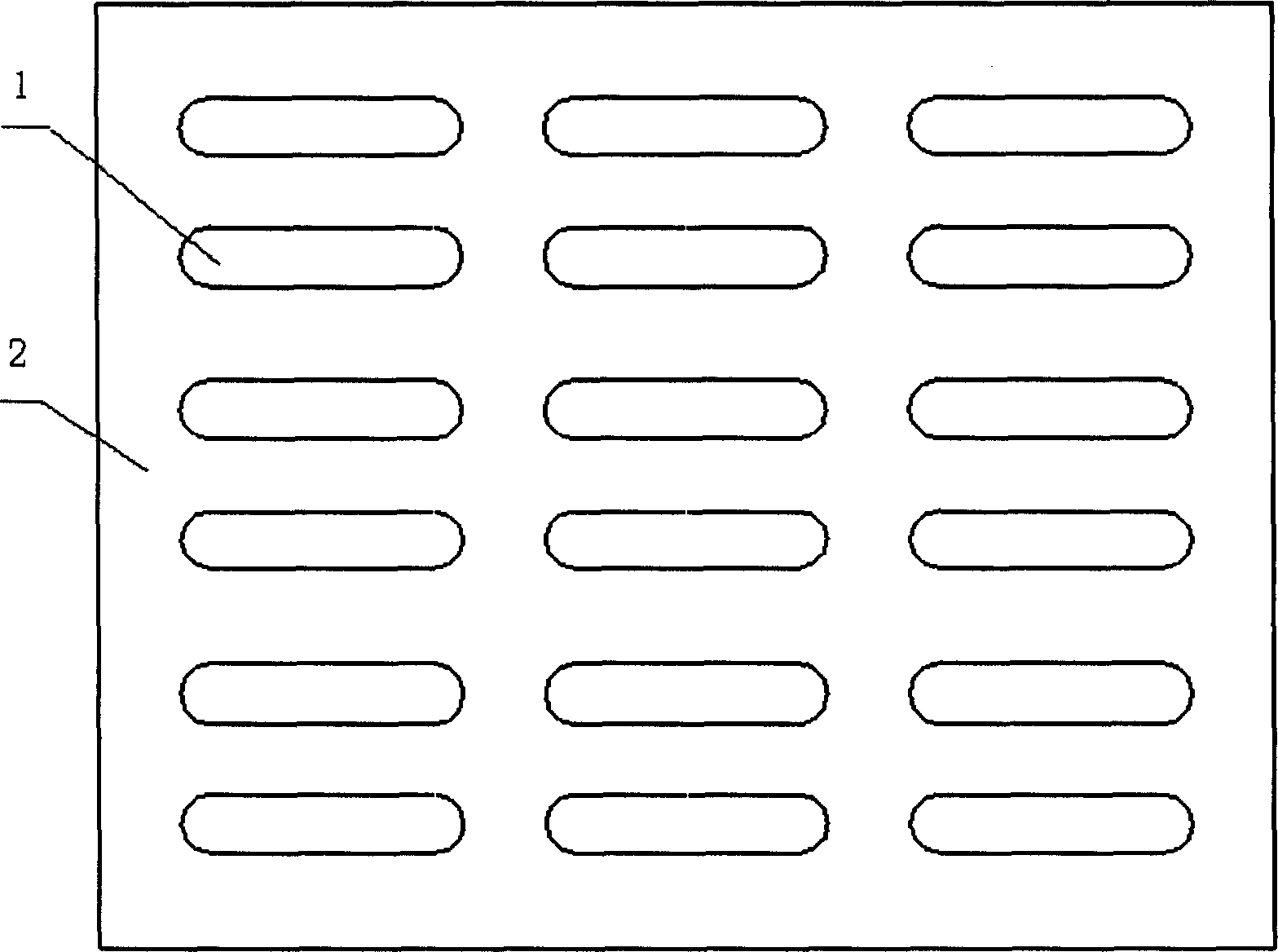

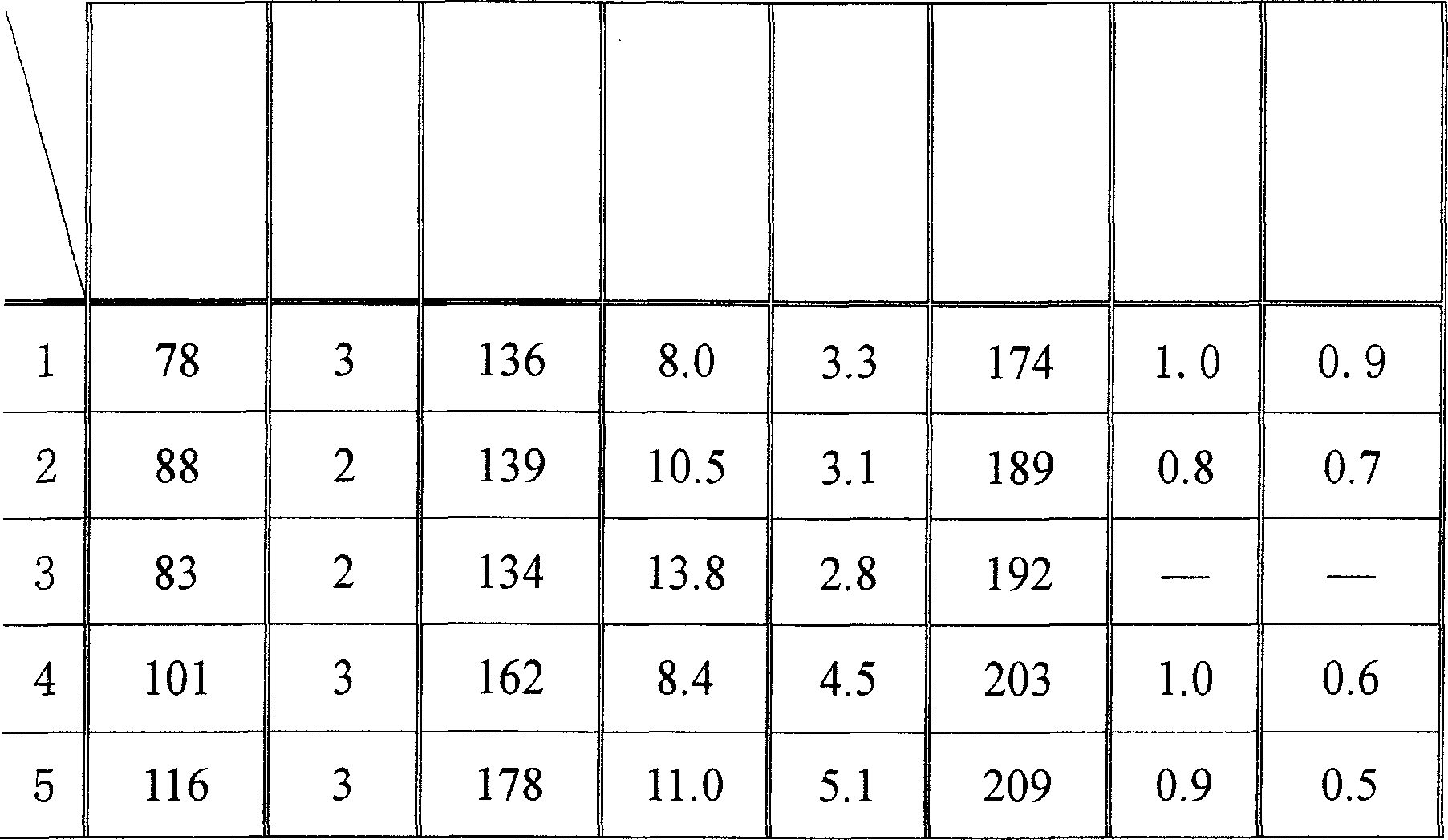

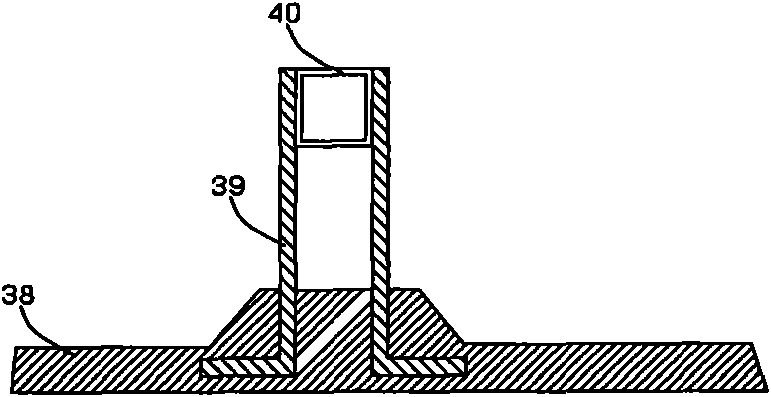

Glass fiber reinforced gypsum product, and preparation method and equipment thereof

The invention relates to a glass fiber reinforced gypsum product, which comprises the ingredients including gypsum powder, glass fiber, water reducing agents, retarding agents and water, wherein the glass fiber is short glass fiber with the length ranged form 1 to 3cm, and is uniformly distributed in the gypsum product. Because the glass fiber reinforced gypsum product of the invention adopts 1 to 3 cm of glass fiber uniformly and disorderly distributed in the gypsum product, the intensity and the toughness of each part of the gypsum product are enhanced, and the delamination structure is avoided. The invention also provides a method for preparing the glass fiber reinforced gypsum product, and special equipment for implementing the method.

Owner:秦永超

High heat resistant glass fiber enhanced halogen-free flame retardant polypropylene and preparation method thereof

The invention discloses high heat resistant glass fiber enhanced halogen-free flame retardant polypropylene and a preparation method of the high heat resistant glass fiber enhanced halogen-free flame retardant polypropylene, belonging to the technical field of high molecular materials. The high heat resistant glass fiber enhanced halogen-free flame retardant polypropylene comprises a polypropylene copolymer and / or a polypropylene homopolymer, a compatilizer, a short glass fiber, a flame retardant, an antioxidant, a plasticizer and a processing additive. The preparation method of the high heat resistant glass fiber enhanced halogen-free flame retardant polypropylene comprises the following steps: 1) weighing the raw materials; 2) adding the compatilizer, the flame retardant, the antioxidant, the plasticizer and the processing additive into a high-speed mixer according to parts by weight in sequence, fully mixing for 1-10 min, then adding the mixed material into a hopper of an extruder; and 3) feeding the polypropylene copolymer and / or the polypropylene homopolymer and the mixture in the step 2) into a main feeding mouth according to parts by weight respectively, feeding the short glass fiber into a side feeding mouth according to parts by weight, melting, blending and extruding in the extruder, drawing and pelletizing. According to the invention, the prepared polypropylene has excellent mechanical property, long-acting high temperature resistance and thermal oxidation performance and high flame retardance.

Owner:杭州金州高分子科技有限公司

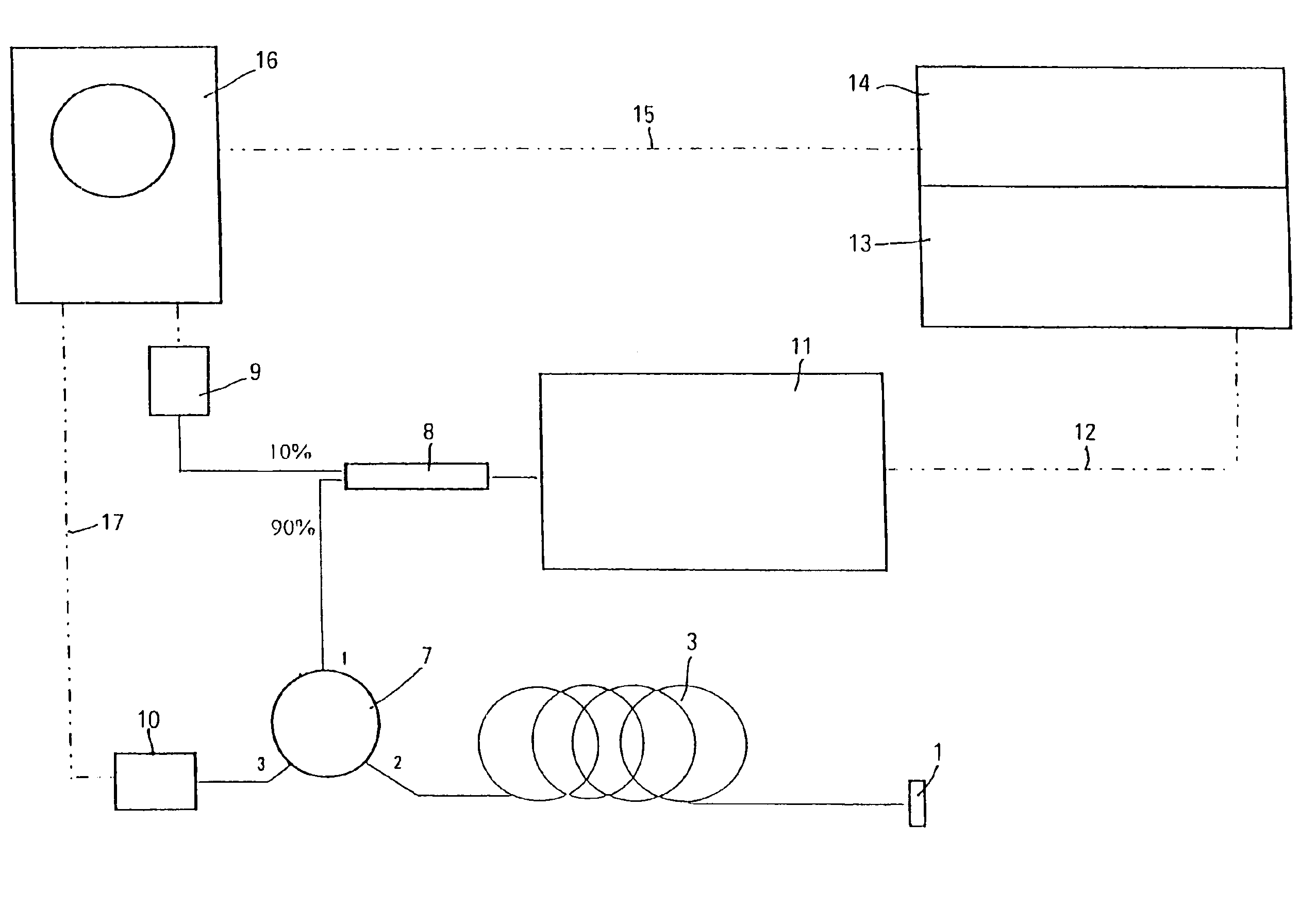

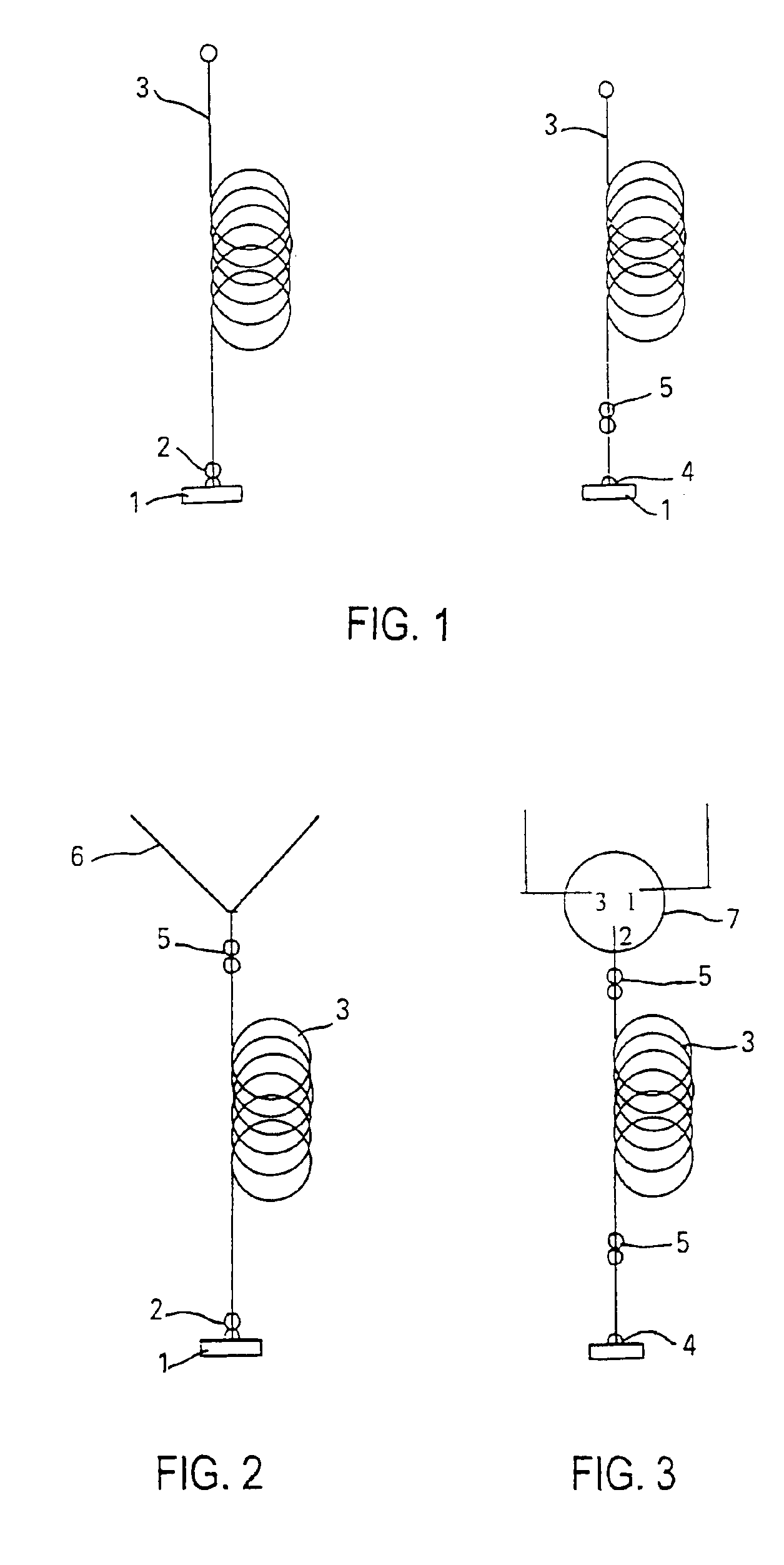

Measuring method for individual fibers of cables

InactiveUS6924890B1Improve accuracyIncrease speedMaterial analysis by optical meansReflectometers detecting back-scattered light in time-domainCouplingPlastic optical fiber

In a method for measuring relevant parameters of individual fibers of single-mode and multimode fibers of glass- or plastic-fiber cables, measuring radiation is reflected at the end of the test fiber to the fiber input by a mirror, particularly a Schmidt mirror having very high reflectivity (>99%), the measurement being carried out at the coupling-in site by a combined transmitting and receiving device. The Schmidt mirror is connected to the test fiber via a so-called fiber connector. The highly reflective mirror coating is applied to the end face of a given connector, so that the Schmidt connector provided with the mirror coating is connected to the test fiber either directly or via a short glass-fiber cable piece terminated with a standard connector and with the Schmidt mirror connector. With the use of a glass-fiber cable piece thus terminated the Schmidt mirror connector remains untouched and is protected.

Owner:DEUTSCHE TELEKOM AG

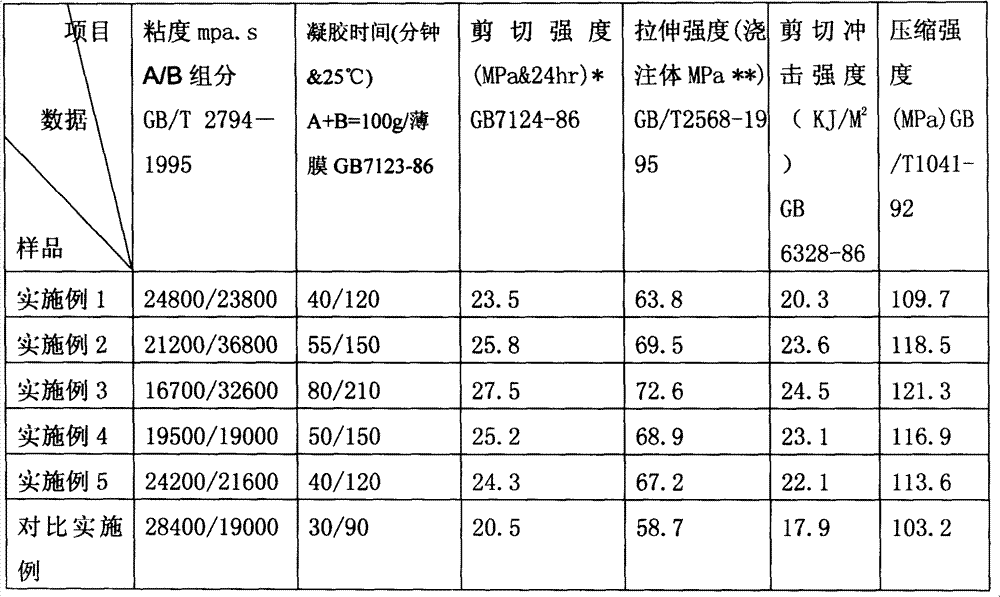

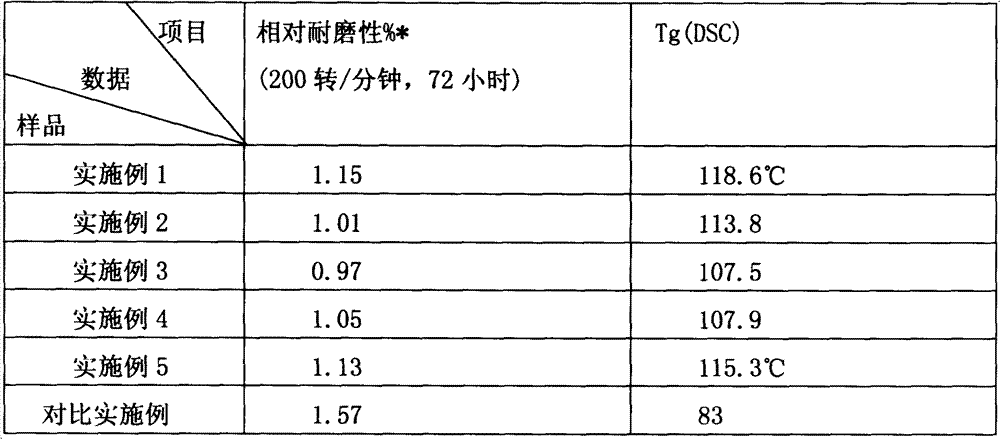

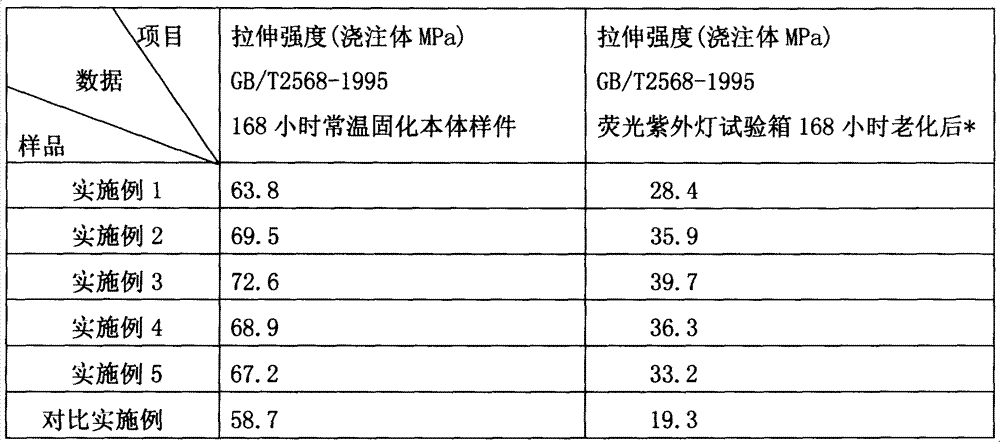

Wear-resistant and weather-resistant epoxy resin coating adhesive and its preparation method

ActiveCN102732201ANotable featuresSignificant and substantial progressNon-macromolecular adhesive additivesEpoxynovolac adhesivesWear resistantAdhesive

The invention which relates to a wear-resistant and weather-resistant epoxy resin coating adhesive and its preparation method belongs to the technical field of adhesives. The adhesive comprises a component A and a component B, wherein the component A comprises 6-16 parts of an alicyclic glycidyl ether epoxy resin, 15-25 parts of a novolac epoxy resin, 4-6 parts of an epoxy active diluent, 4-6 parts of a responsive flexibilizer, 0.5-1.2 parts of a coupling agent, 0.4-0.8 parts of organic bentonite, 0.3-0.5 parts of an antioxidant, 0.4-0.8 parts of an ultraviolet ray absorbent, 40-45 parts of white corundum powder, 3-5 parts of filler powder, 4-6 parts of a short glass fiber, 5 parts of a yellow color paste, and 1-2 parts of white carbon black; and the component B comprises 15-25 parts of an alicyclic amine, 10-15 parts of isophorone diamine, 6-9 parts of aminoethylpiperazine, 2-3 parts of a curing accelerator, 40-45 parts of the white corundum powder, 4-6 parts of the short glass fiber, 4-6 parts of the filler powder and 3-5 parts of the white carbon black. The preparation method comprises the steps of yellow color paste preparation, component A preparation and component B preparation. Compared with adhesives obtained through the prior art, the mechanical strength and the wear resistance of the adhesive of the invention are obviously improved.

Owner:YANTAI TIGHTSEN FINE CHEM

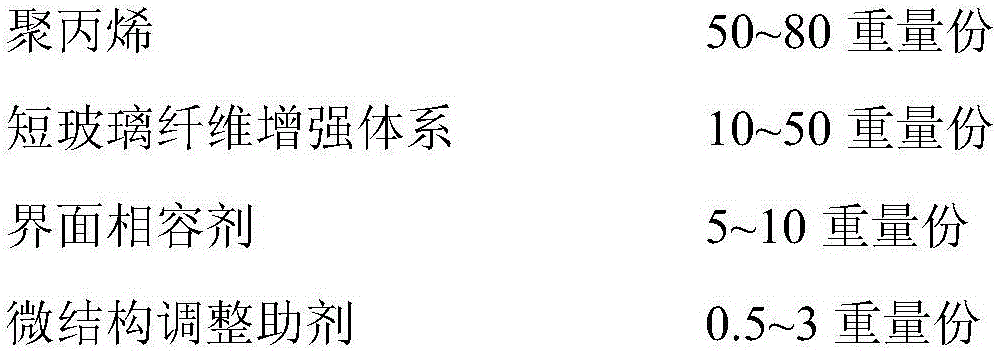

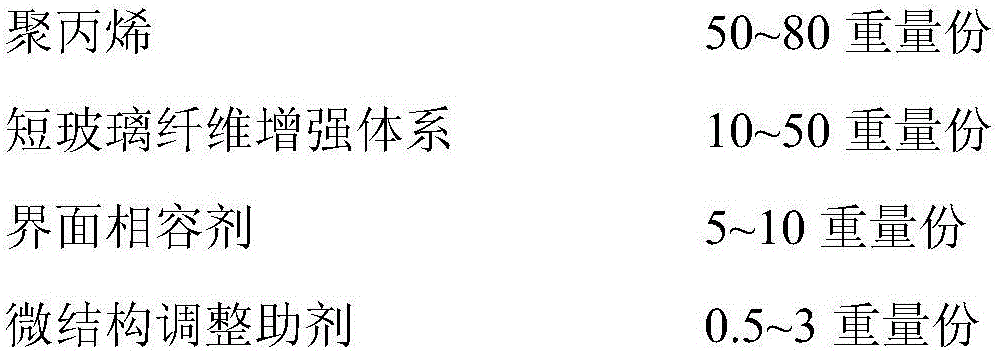

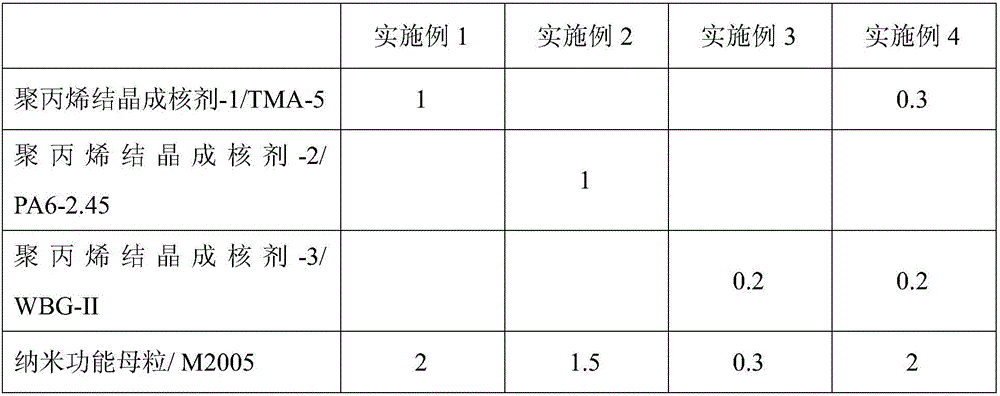

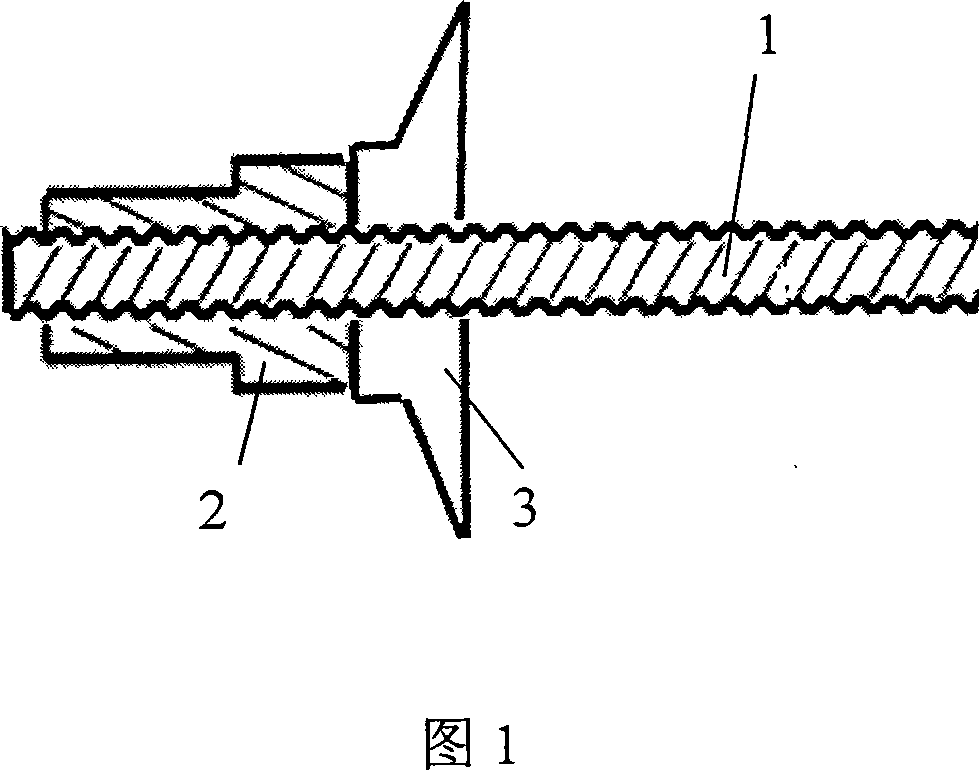

Glass fiber reinforced polypropylene composite material and preparation method thereof

The invention relates to a glass fiber reinforced polypropylene composite material and a preparation method thereof. The composite material comprises the following raw materials in parts by weight: 50-80 parts of polypropylene, 10-50 parts of short glass fiber reinforcement, 5-10 parts of interface compatilizer and 0.5-3 parts of micro-structure adjustment auxiliary. In the invention, the glass fiber reinforcing systems different in structure and diameter are matched to form an organic-inorganic two-phase reinforcing system with uniform distribution and good interface bonding under the auxiliary effect of efficient interface compatibilization and quick crystallization nucleation; the warping deformation of the obtained polypropylene composite material is reduced by 30-60% compared with a traditional material; particularly, the behaviors of the low-content glass fiber reinforcing system are more outstanding; the rigid indexes of the material such as bending strength and bending modulus are improved by 30%; and meanwhile, the material shrinkage is lower, and the dimensional stability is excellent in high- and low-temperature environments.

Owner:中广核俊尔(上海)新材料有限公司

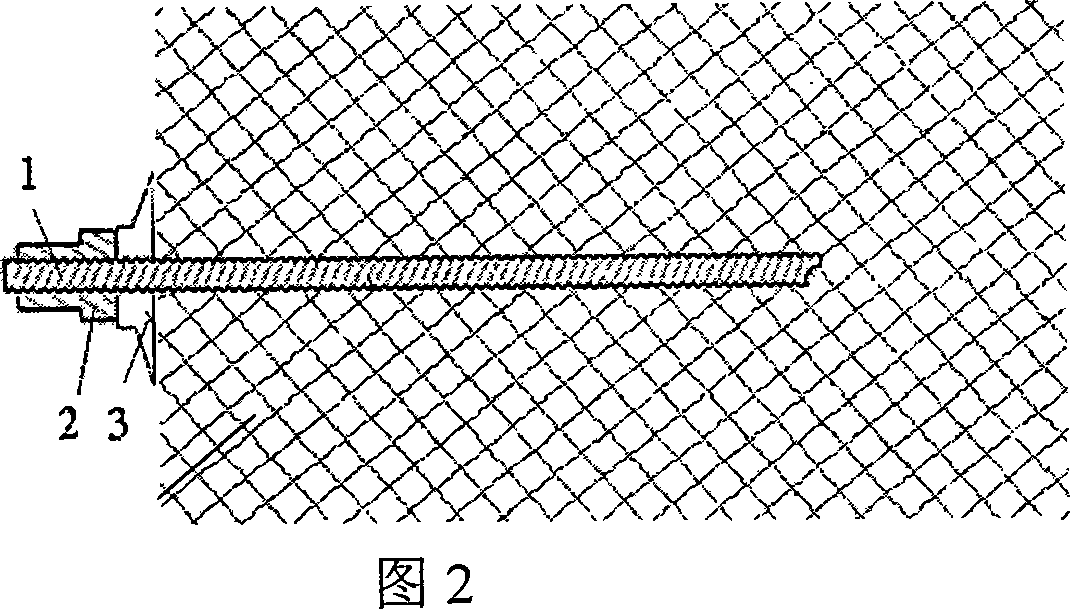

High-strength integral composite material anchor shaft

InactiveCN101078350AHigh strengthSimple preparation processAnchoring boltsAntistatic agentEngineering

The invention relates to an integrated composite anchor with high intensity, which solves the problem that because in prior composite anchor the bar is connected with the nut in screw thread fit with partial structure and the prescription of composite is not reasonable, the intensity of anchor is bad and it is broken at the connection position of screw thread by shear force or the nut is cracked in ring direction. It comprises composite bar body with screw thread, nut and pallet. The nut is molded to form at the end of bar directly. The composite constituting nut comprises 35%-42% of short glass fiber by wt, 30%-35% of 191# or 196# resin by wt, 2%-4% of methyl ethyl copper peroxide by wt, 3%-7% of isooctanoic cobalt styrene, 15%-20% of calcium carbonate by wt, 6%-12% of aluminum hydroxide by wt and 2%-6% of antistatic agent by wt. the invention can improve the intensity of composite anchor greatly. By using test for a long time, phenomena of shear breaking at the connection position of screw thread or ring crack of nut does not appear in the composite anchor.

Owner:SHANXI COKING COAL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com