Patents

Literature

1662 results about "Plastic optical fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plastic optical fiber (POF) (or Polymer optical fibre) is an optical fiber that is made out of polymer. Similar to glass optical fiber, POF transmits light (for illumination or data) through the core of the fiber. Its chief advantage over the glass product, other aspect being equal, is its robustness under bending and stretching. Optical fiber used in telecommunications is governed by European Standards EN 60793-2-40-2011.

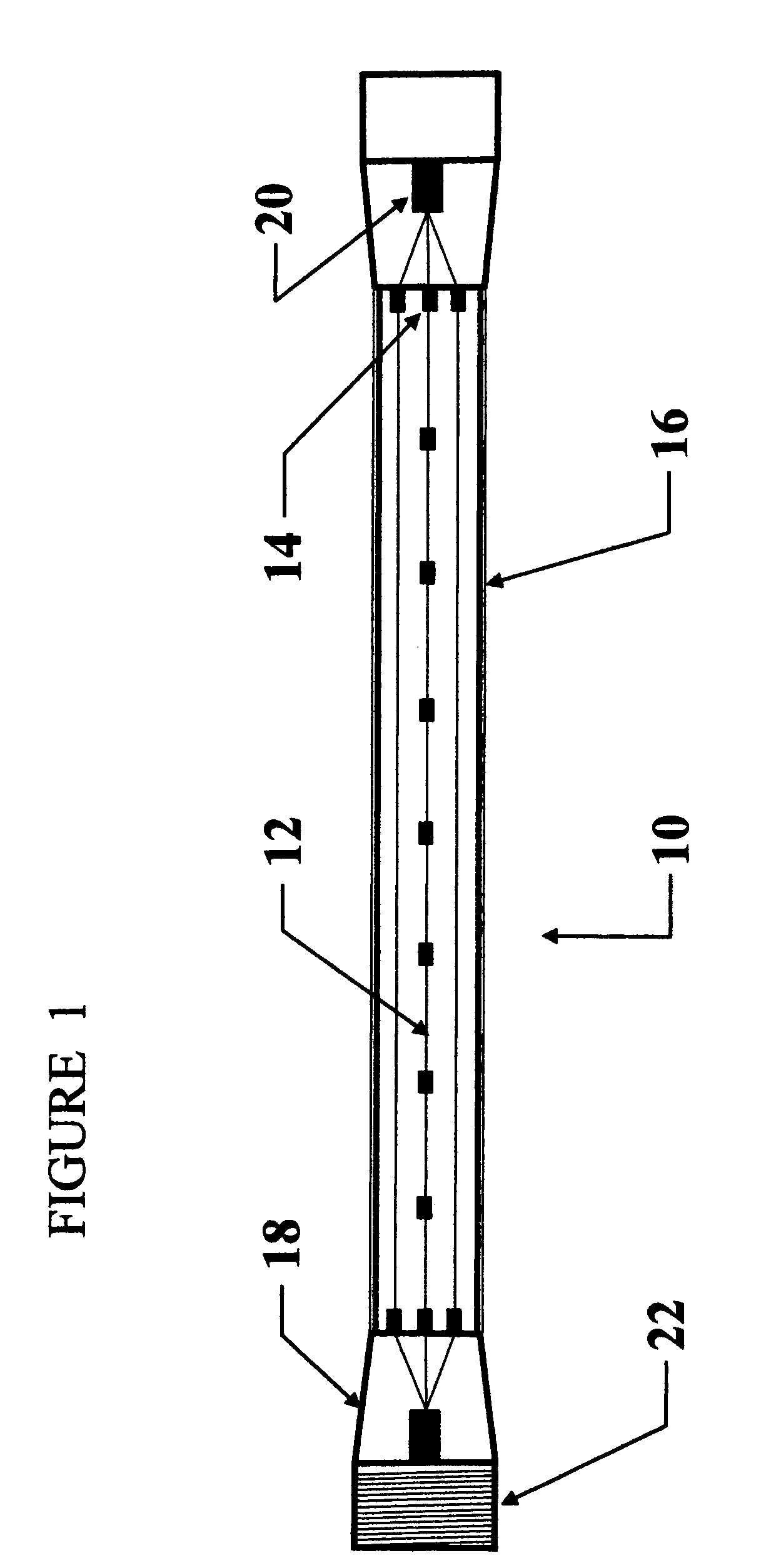

Fabric or garment with integrated flexible information infrastructure

InactiveUS6381482B1Raise the ratioImprove high temperature stabilityWeft knittingOrnamental textile articlesInformation processingEngineering

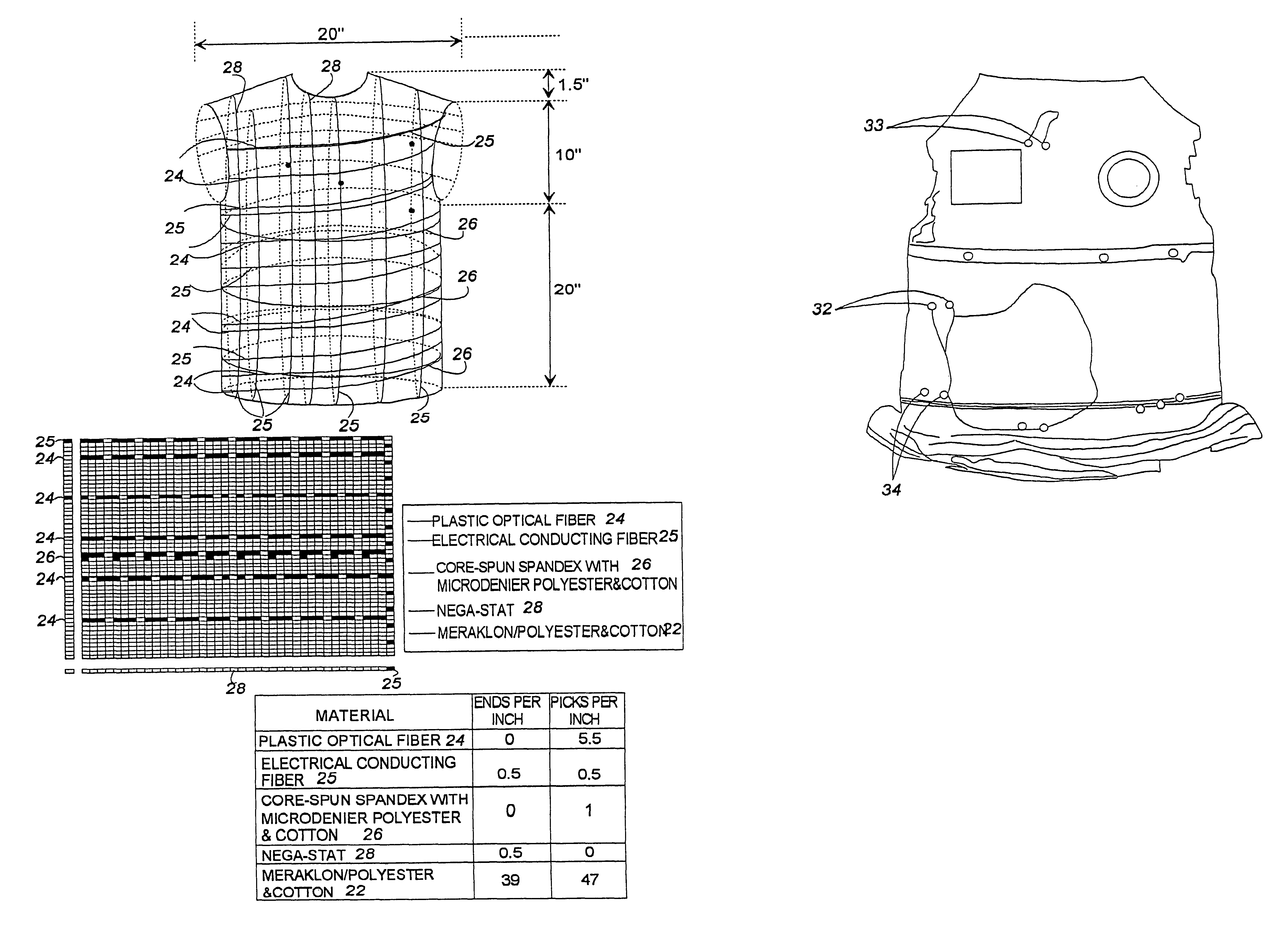

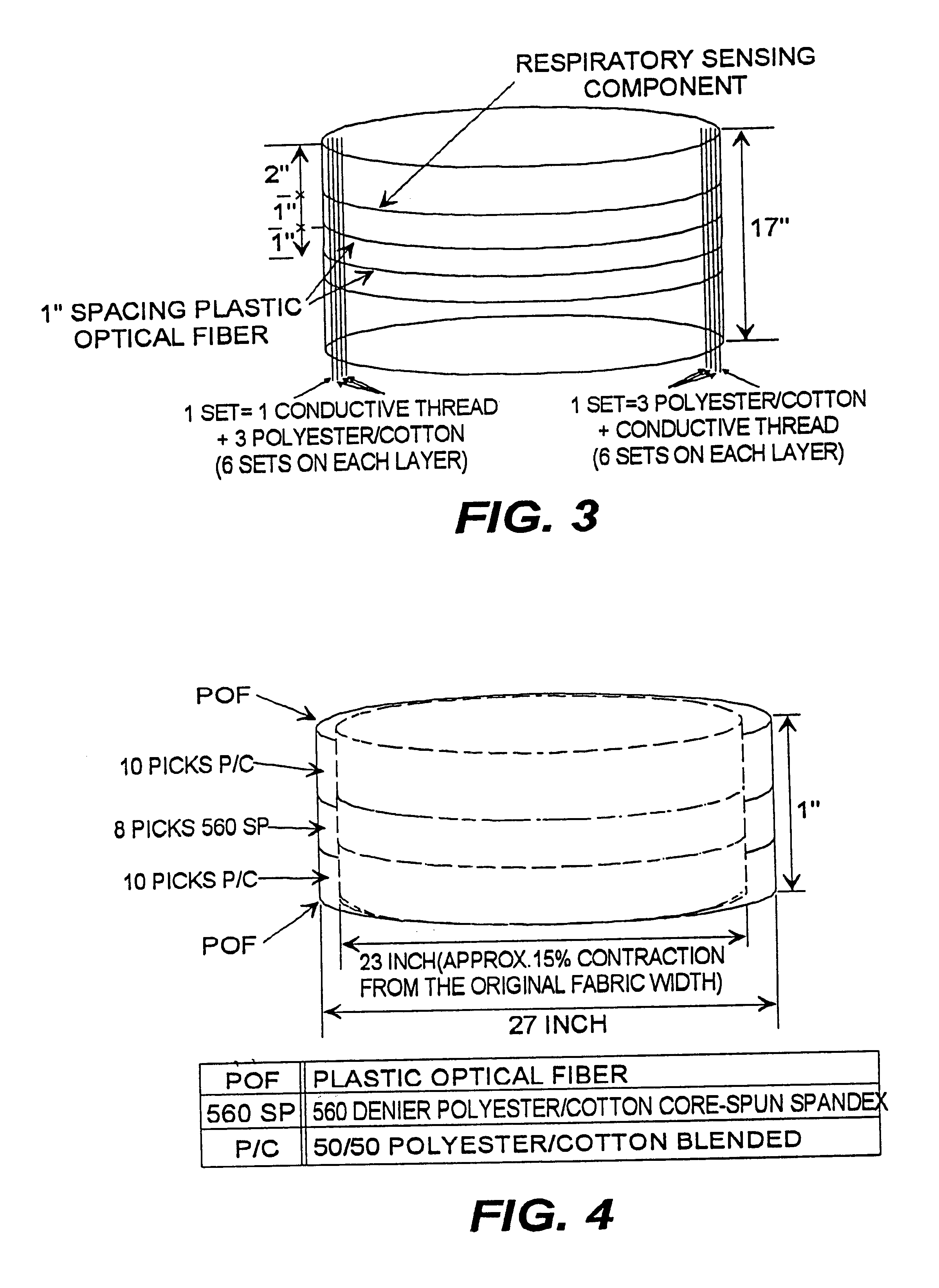

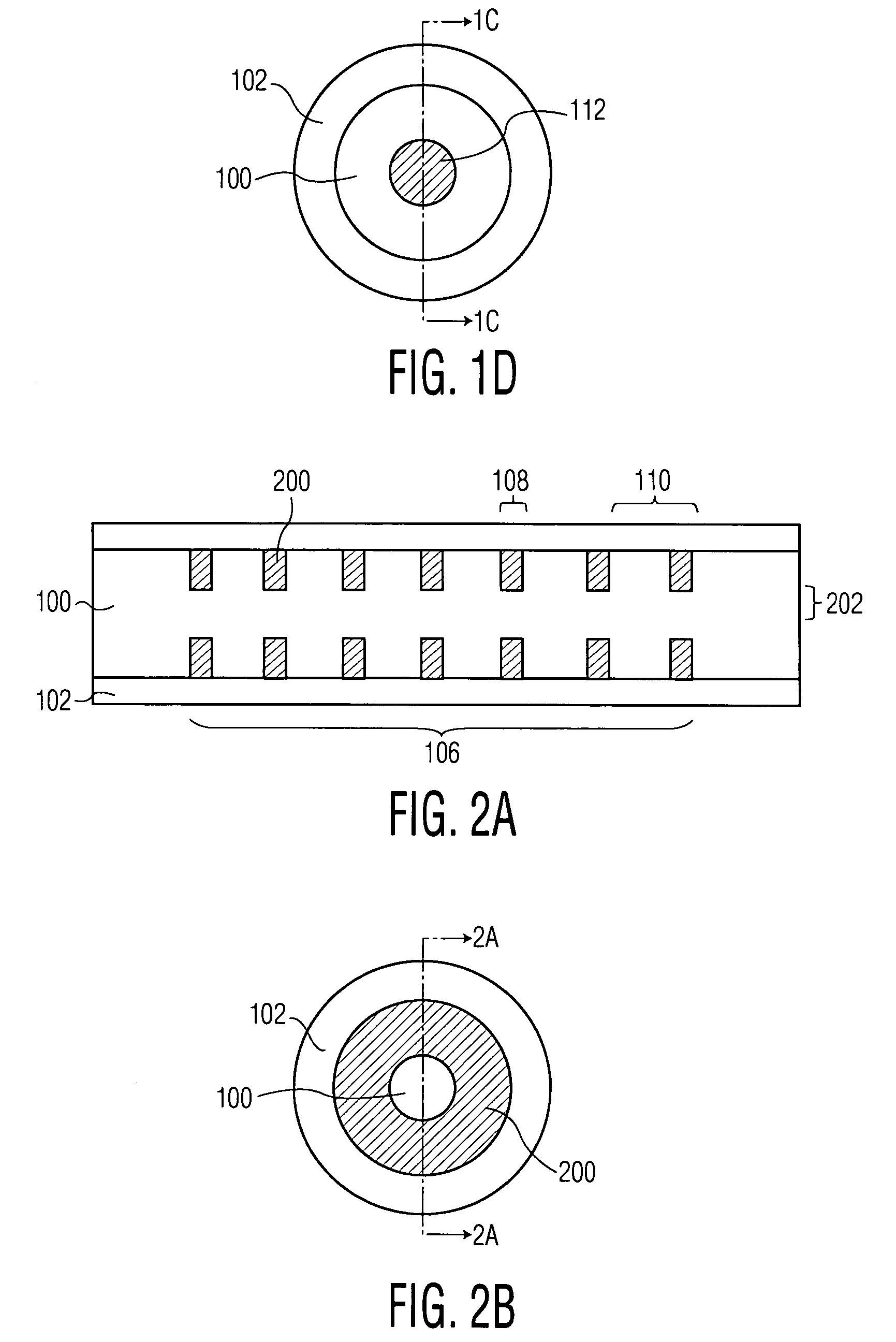

A fabric, in the form of a woven or knitted fabric or garment, including a flexible information infrastructure integrated within the fabric for collecting, processing, transmitting and receiving information concerning-but not limited to-a wearer of the fabric. The fabric allows a new way to customize information processing devices to "fit" the wearer by selecting and plugging in (or removing) chips / sensors from the fabric thus creating a wearable, mobile information infrastructure that can operate in a stand-alone or networked mode. The fabric can be provided with sensors for monitoring physical aspects of the wearer, for example body vital signs, such as heart rate, EKG, pulse, respiration rate, temperature, voice, and allergic reaction, as well as penetration of the fabric. The fabric consists of a base fabric ("comfort component"), and an information infrastructure component which can consist of a penetration detection component, or an electrical conductive component, or both. The preferred penetration detection component is a sheathed optical fiber. The information infrastructure component can include, in addition to an electrically conductive textile yarn, a sensor or a connector for a sensor. A process is provided for making an electrical interconnection between intersecting electrically conductive yarns. Furthermore, a process is established for sheathing the plastic optical fiber and protecting it.

Owner:GEORGIA TECH RES CORP

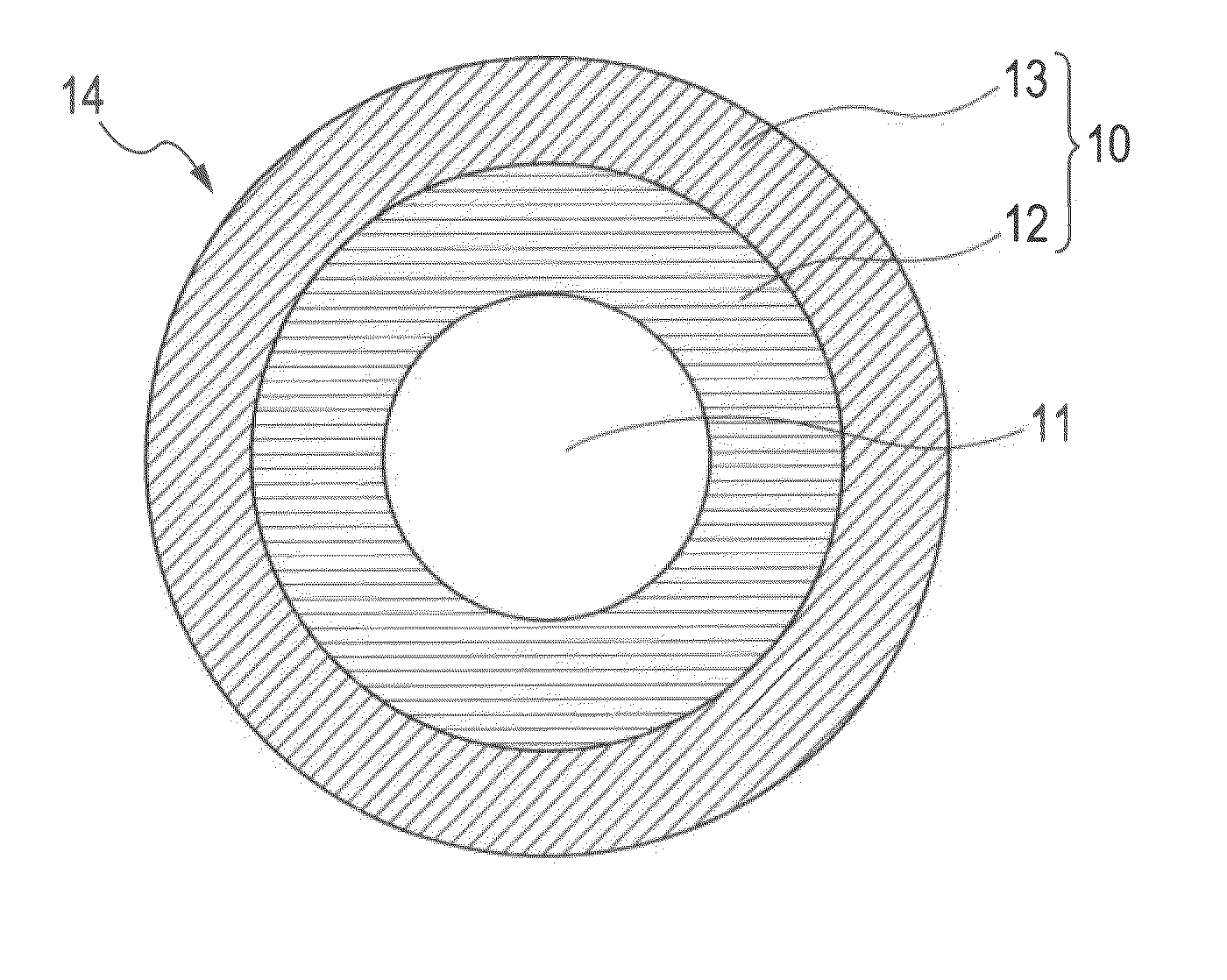

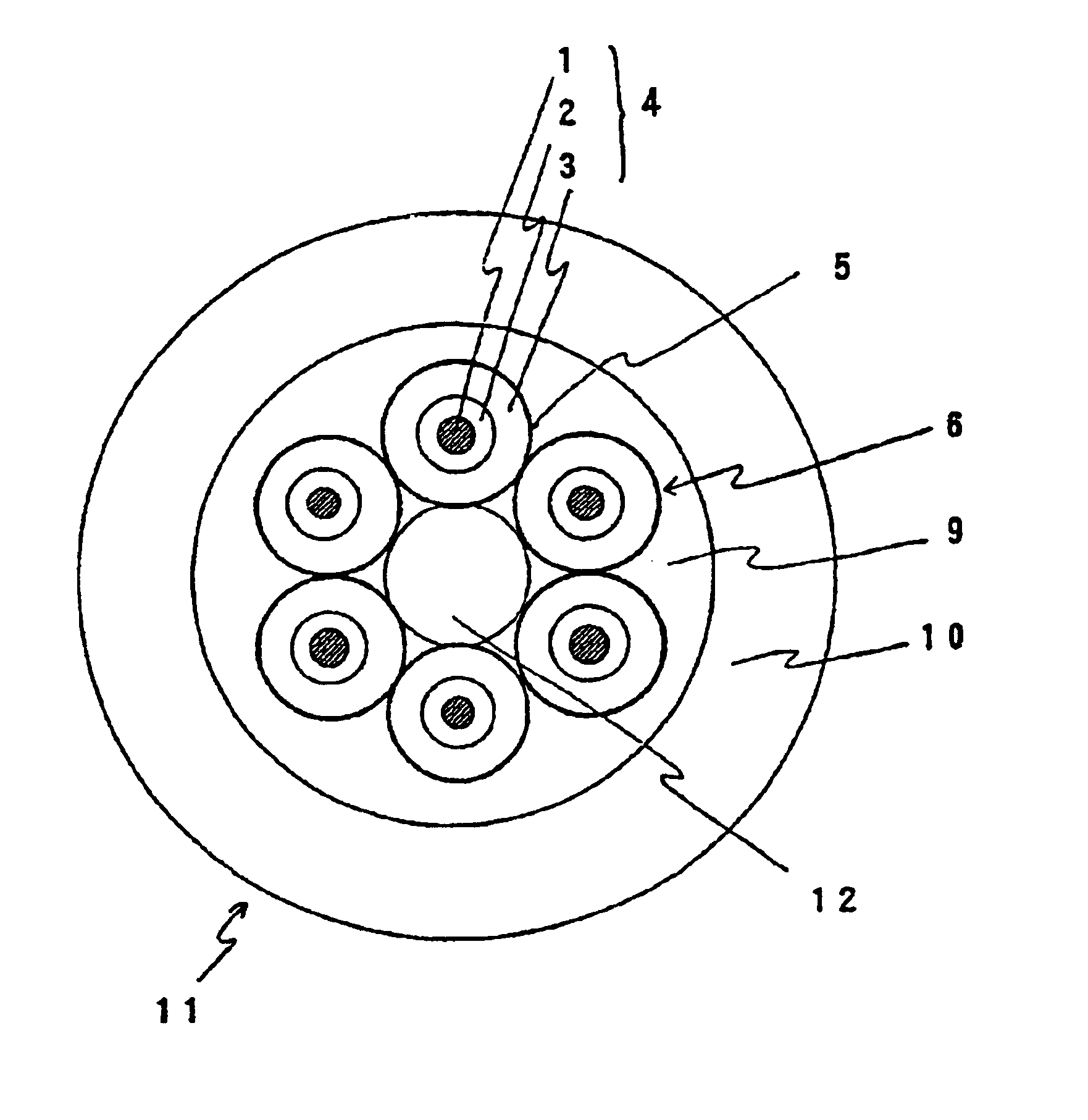

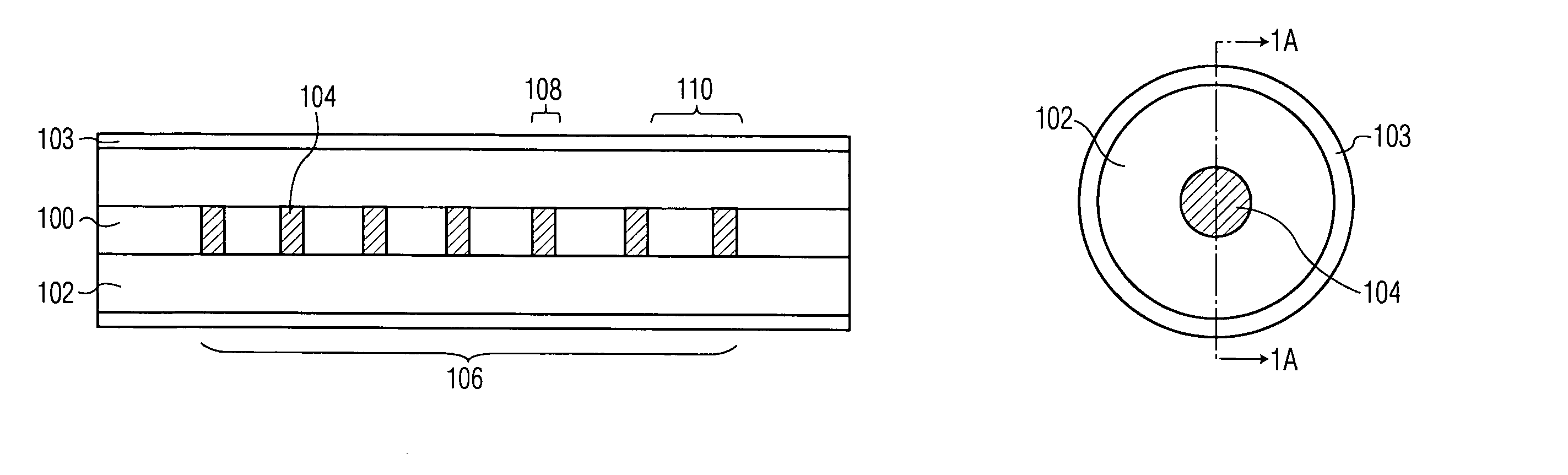

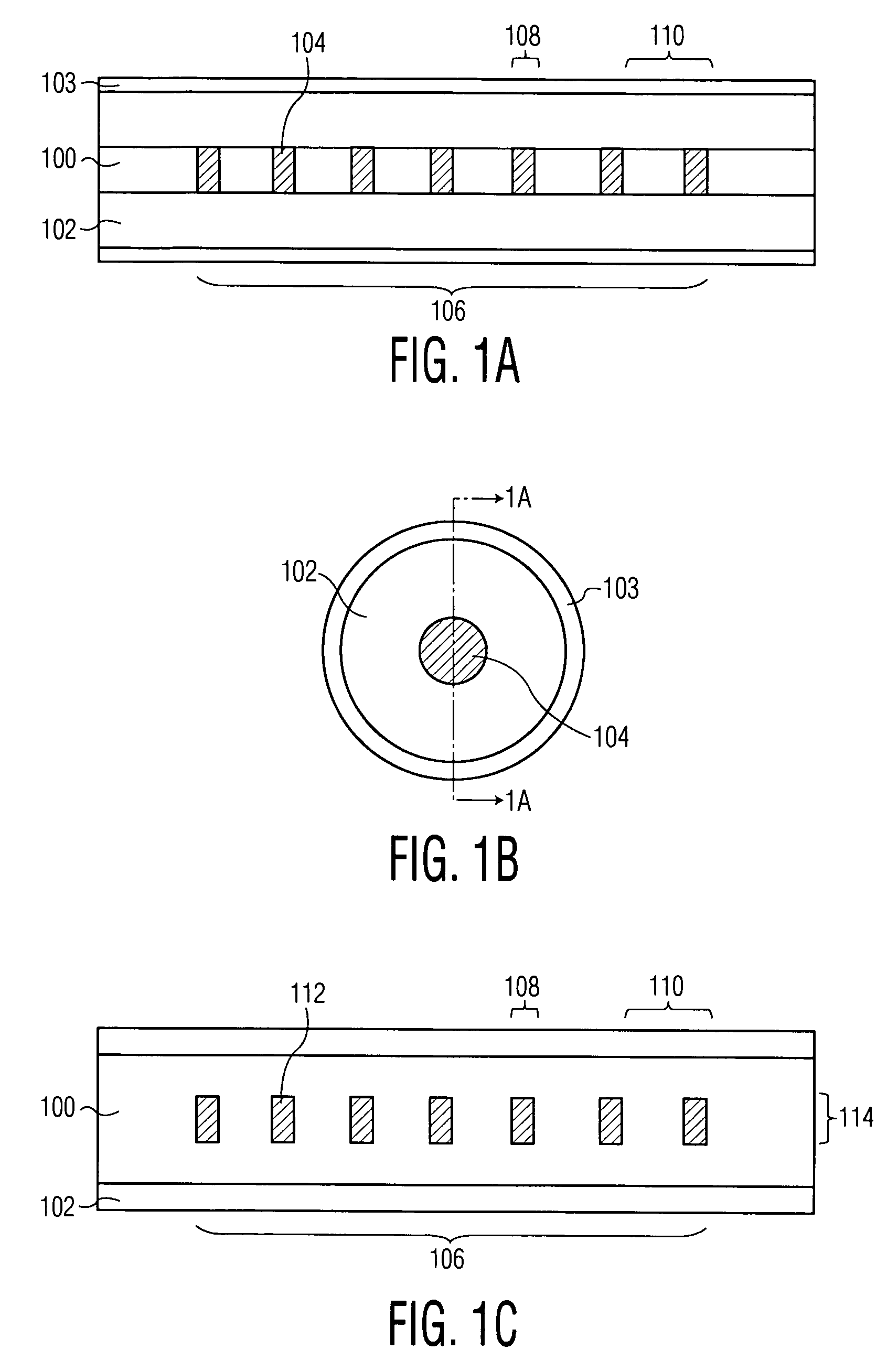

Active optical fiber and method for fabricating an active optical fiber

ActiveUS8433168B2Reduce the overall diameterLarge volumeLaser detailsMetal rolling stand detailsFiberActive core

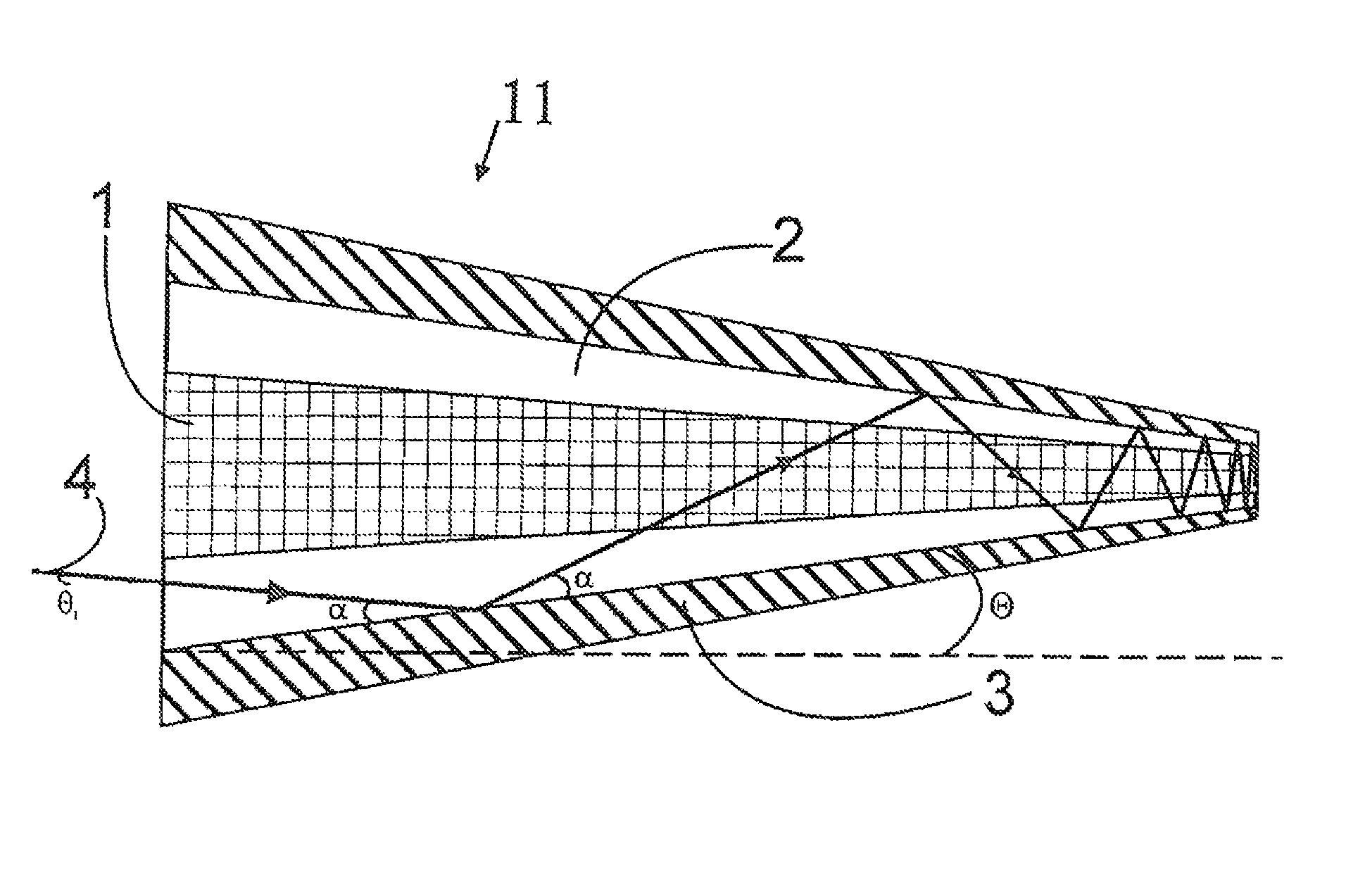

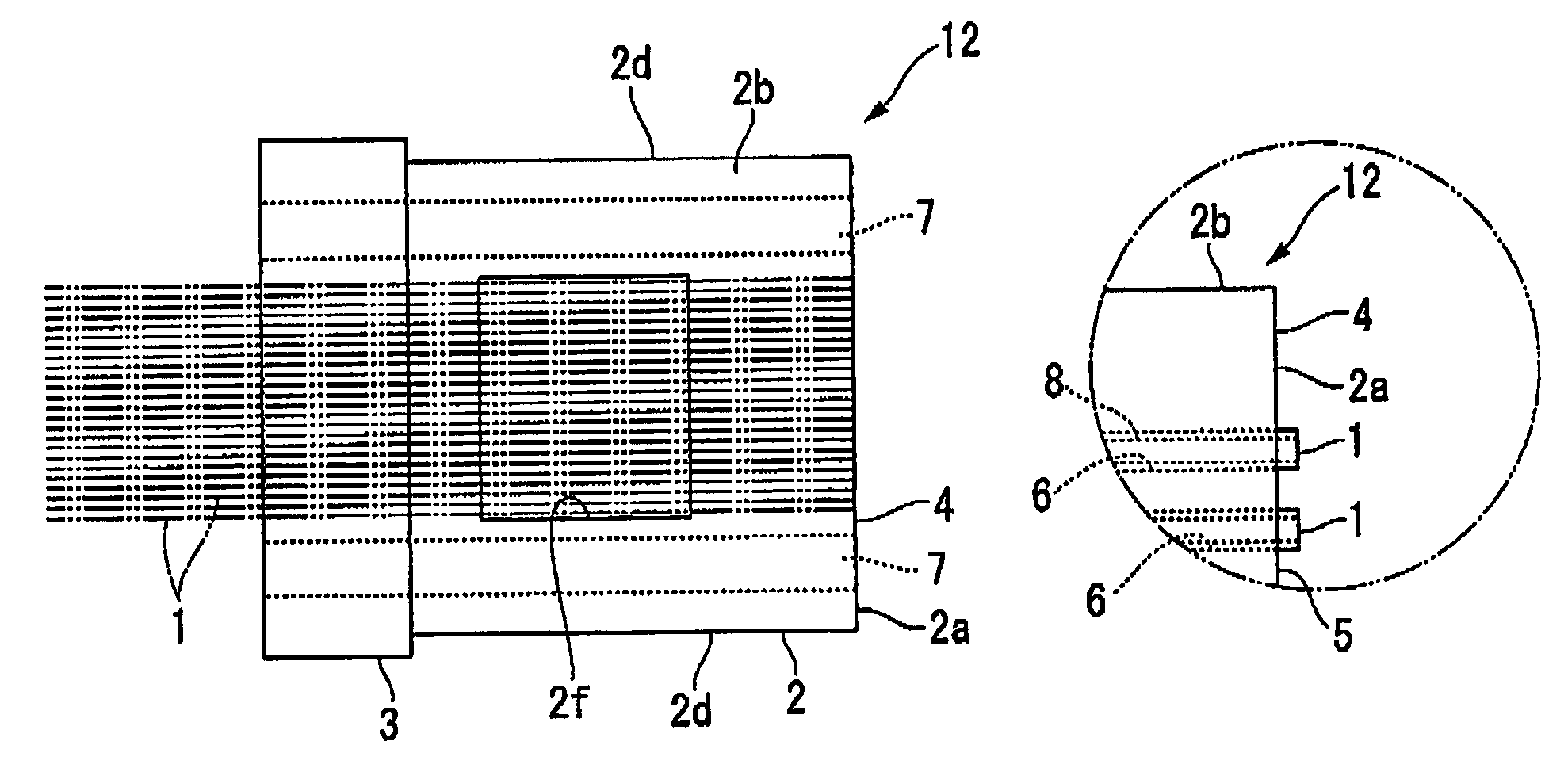

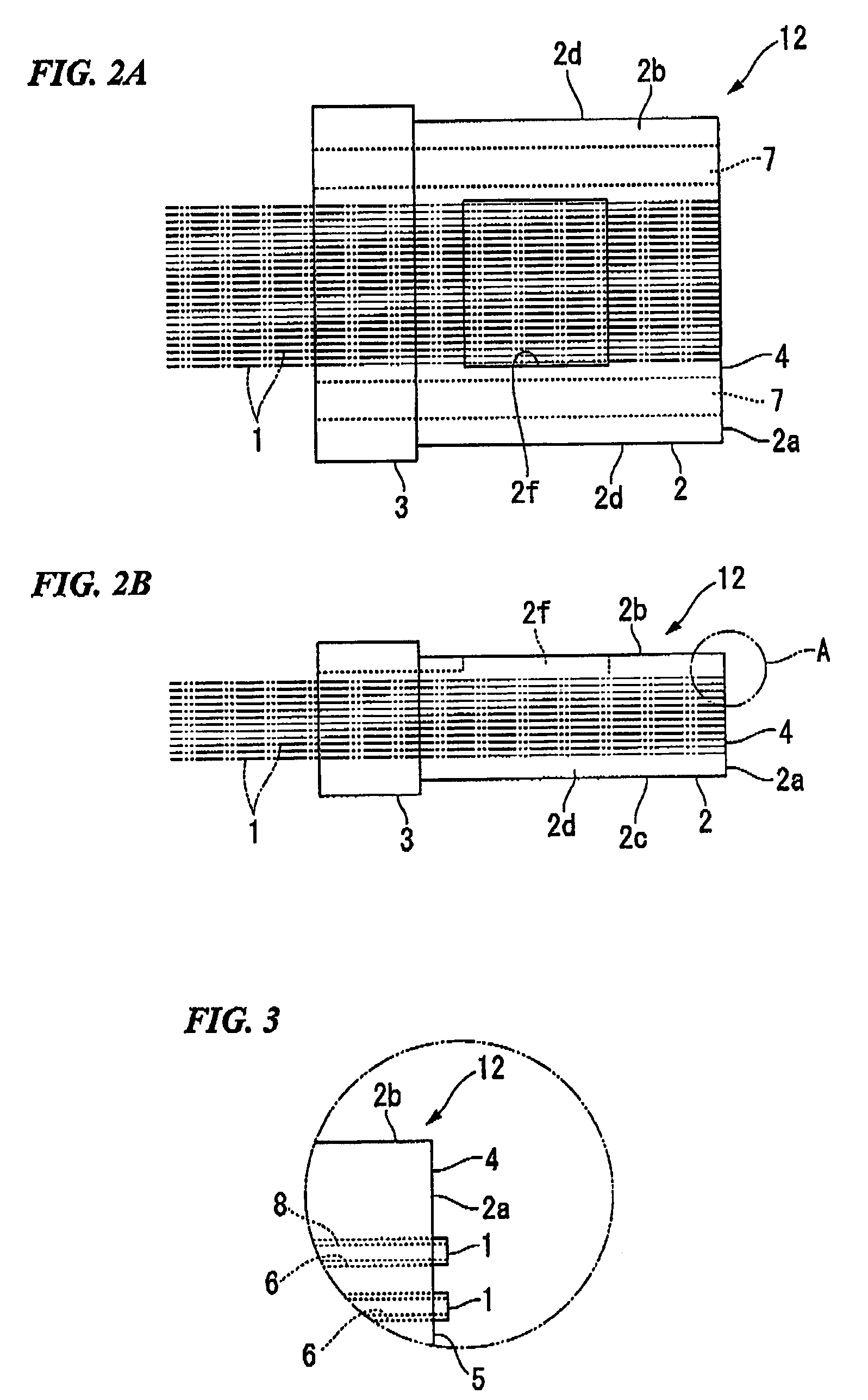

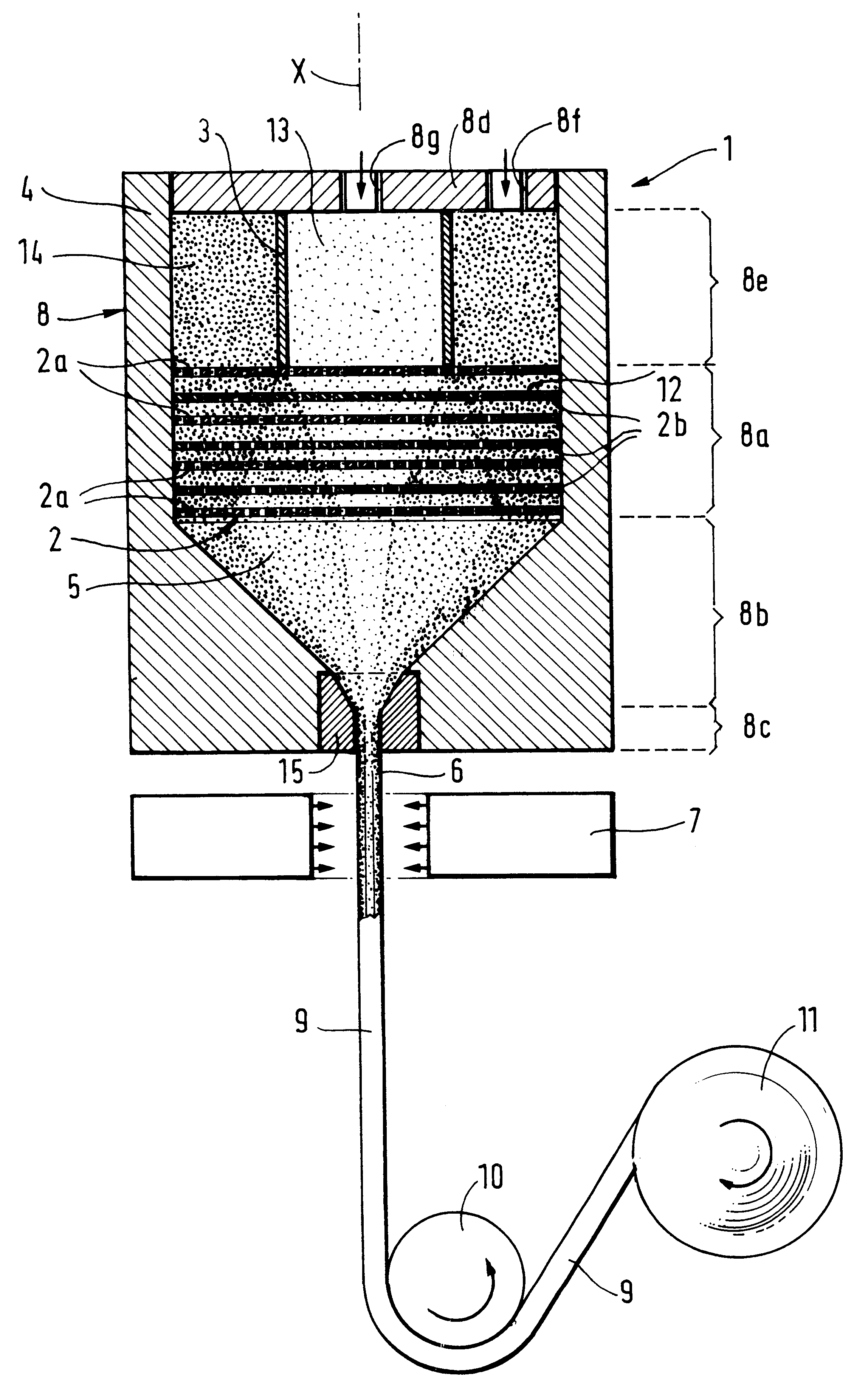

A section of active optical fiber (11) which comprises an active core (1), an inner cladding layer (2) and an outer cladding layer (3). The diameter of said core 1) and the thickness of said inner cladding (2) change gradually along the length of said section of active optical fiber (11). This forms tapered longitudinal profile enabling a continuous mode conversion process along the length of the section of fiber (11). The method for fabricating a section of tapered active optical fiber comprises the steps of fabricating a preform for drawing active optical fiber from said preform, installing said preform into a drawing tower, drawing optical fiber in said drawing tower and altering at least one of the two parameters including the take-off preform speed and the take-up fiber speed during drawing of the optical fiber.

Owner:AMPLICONYX OY

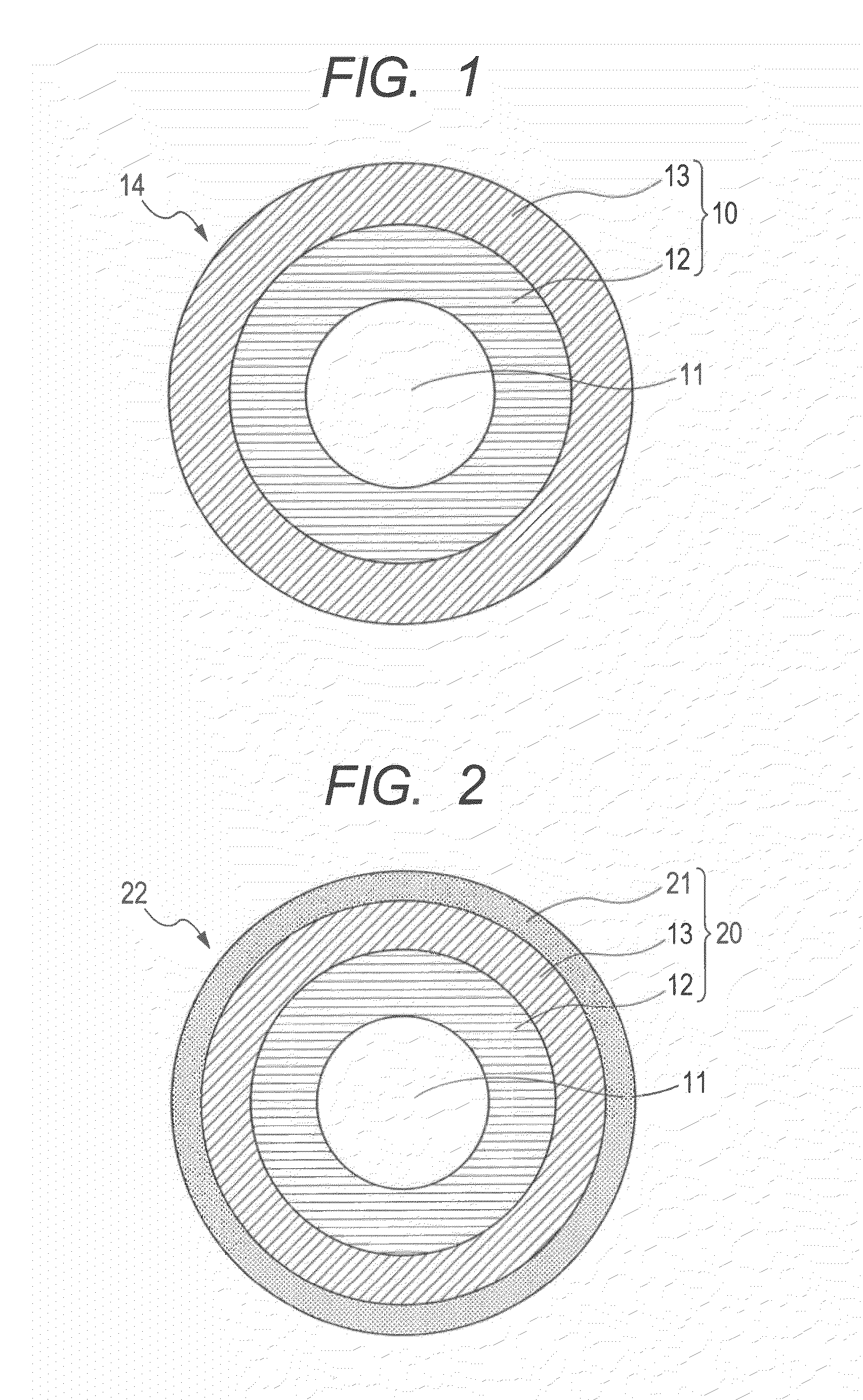

Optical fiber

ActiveUS20110274396A1Increased transmission lossTransmission loss is hardGlass optical fibreOptical fibre with multilayer core/claddingHigh humidityThermal expansion

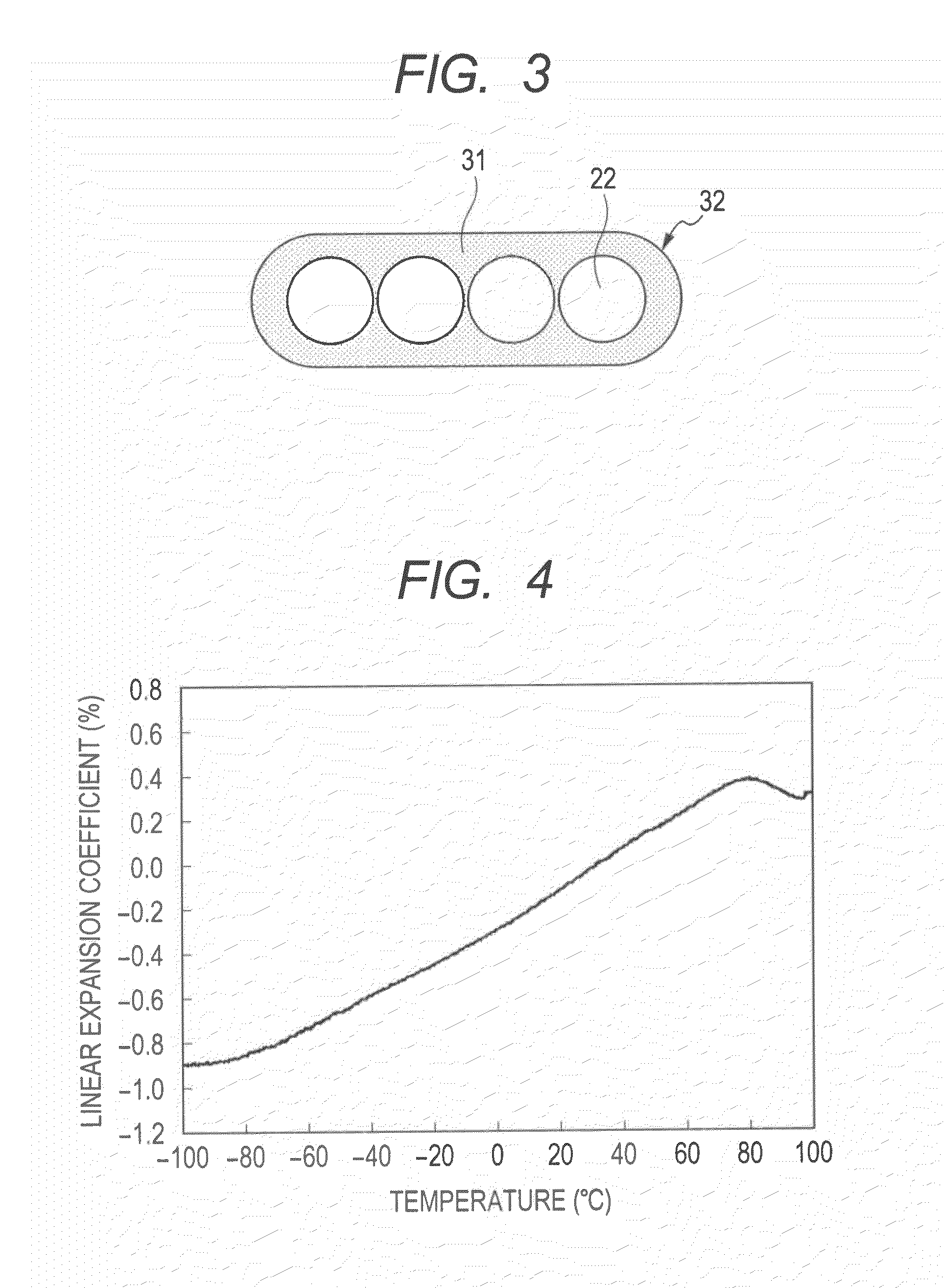

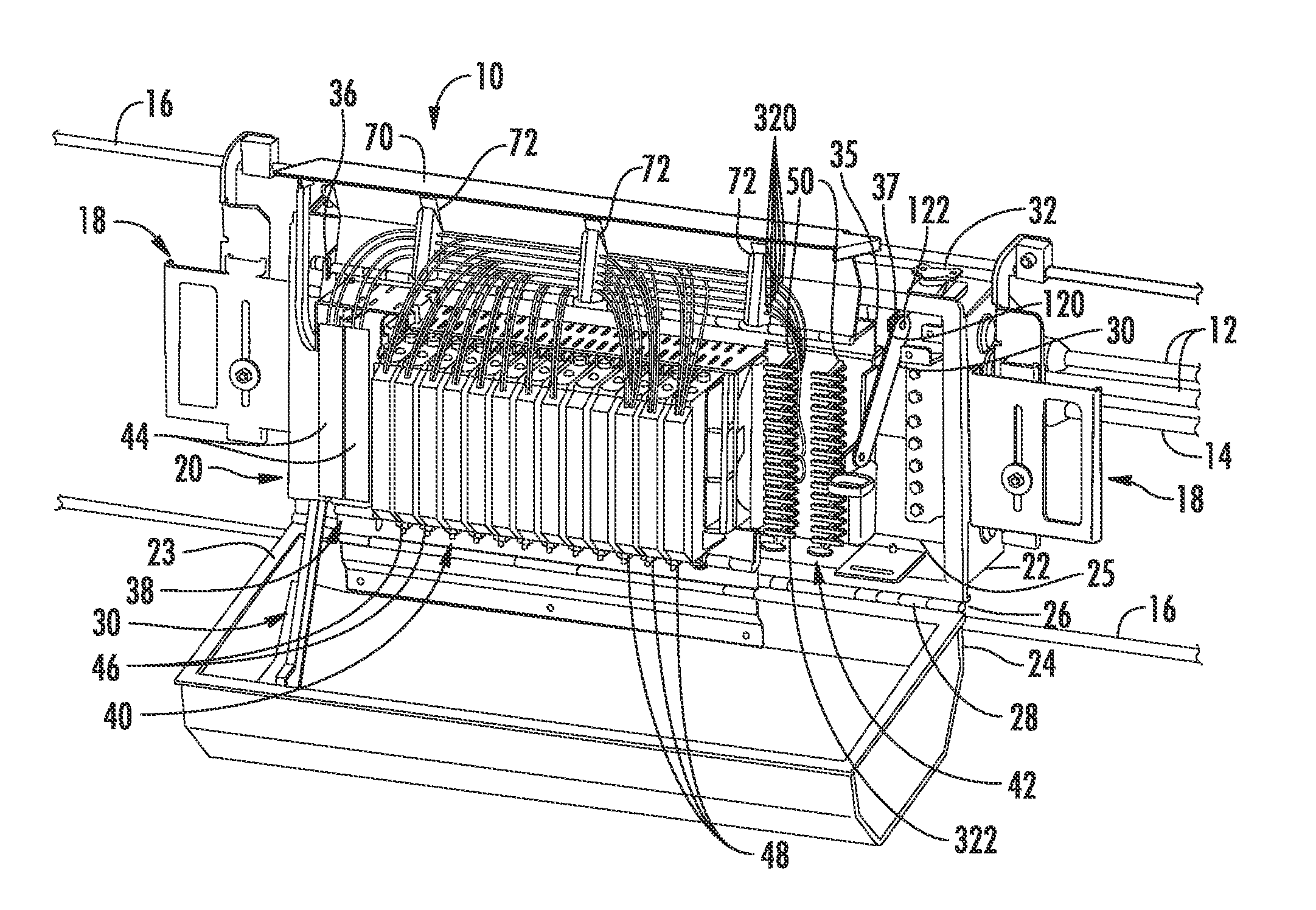

The present invention provides an optical fiber in which the transmission loss increase is suppressed even under a high-humidity condition or under a water-immersed condition. A colored optical fiber (22) according to an embodiment of the present invention is a colored optical fiber (22) formed by applying a colored layer to an optical fiber (14) including a glass optical fiber coated with at least a double-layered coating layer of a soft layer and a hard layer, and the ratio of thermal expansion coefficient between the coating layer after the colored layer of the colored optical fiber (22) is applied and the coating layer of the optical fiber (14) before the colored layer is applied is 0.87 or more. Furthermore, an optical fiber ribbon (32) according to another embodiment of the present invention is an optical fiber (32) formed by arranging a plurality of the colored optical fiber (22) in the form of a plane and coating them all together with a ribbon resin and the ratio of thermal expansion coefficient between the coating layer after the colored layer of the colored optical fiber (22) is applied and the coating layer of the optical fiber before the colored layer is applied is 0.90 or more.

Owner:FURUKAWA ELECTRIC CO LTD

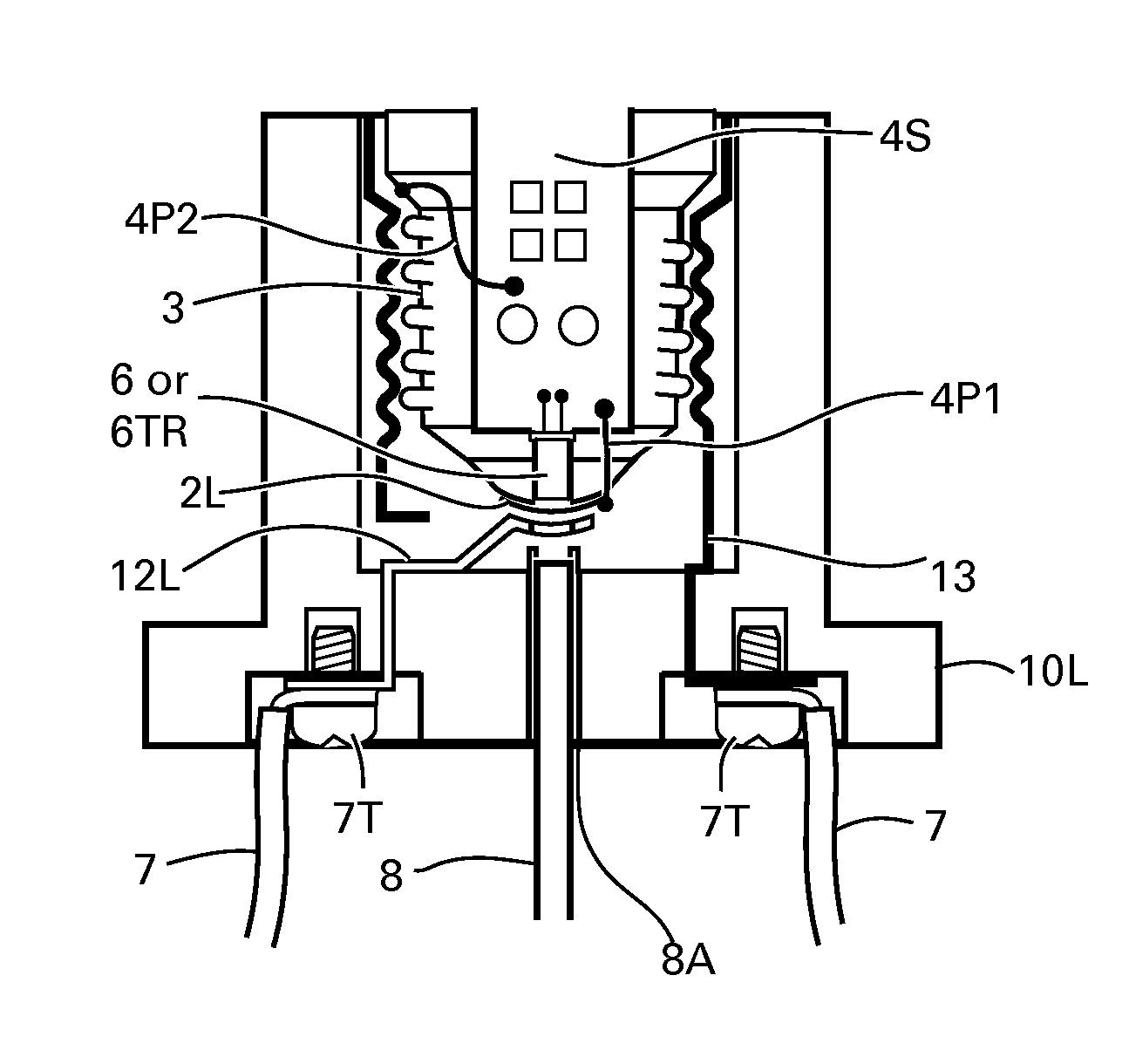

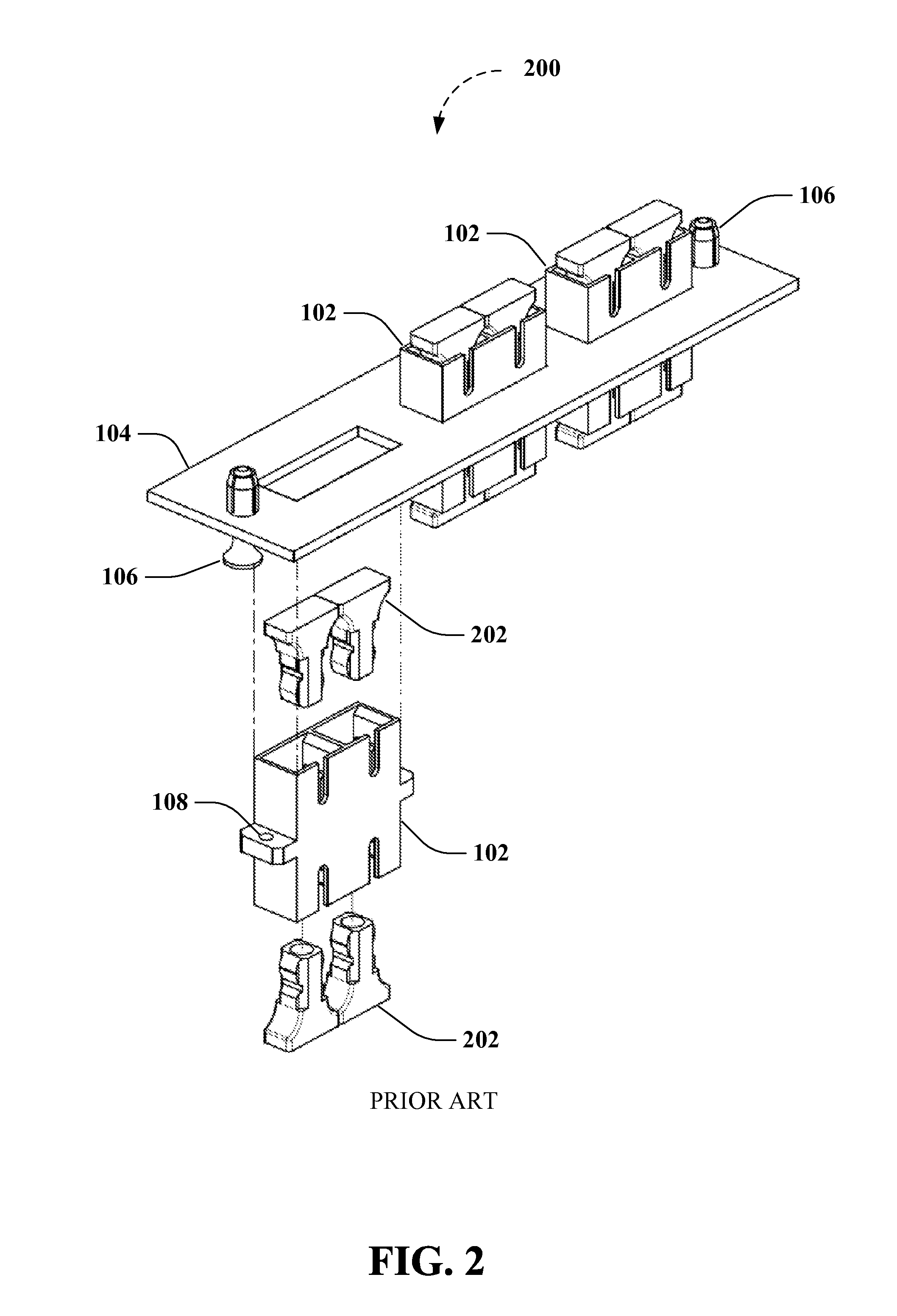

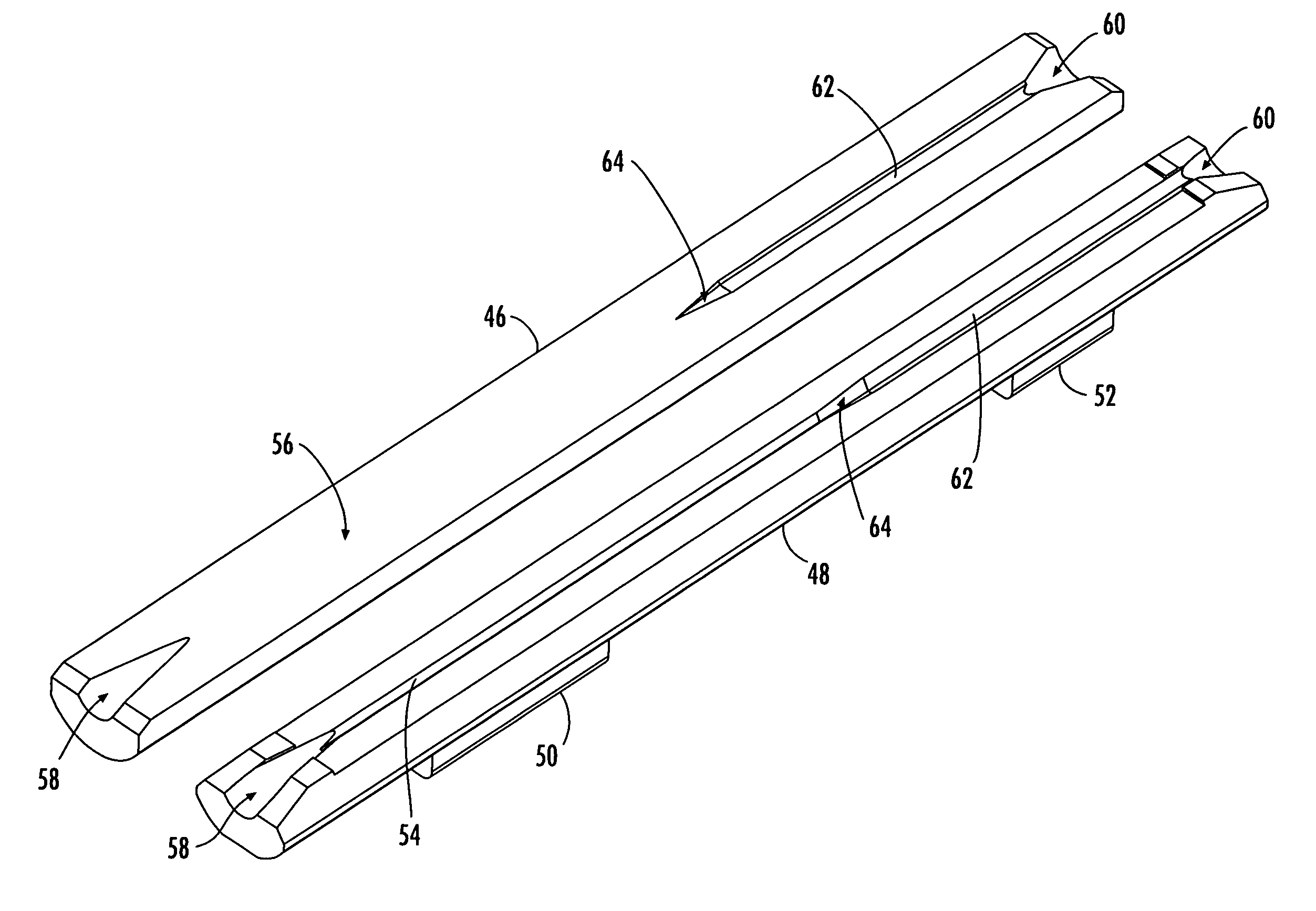

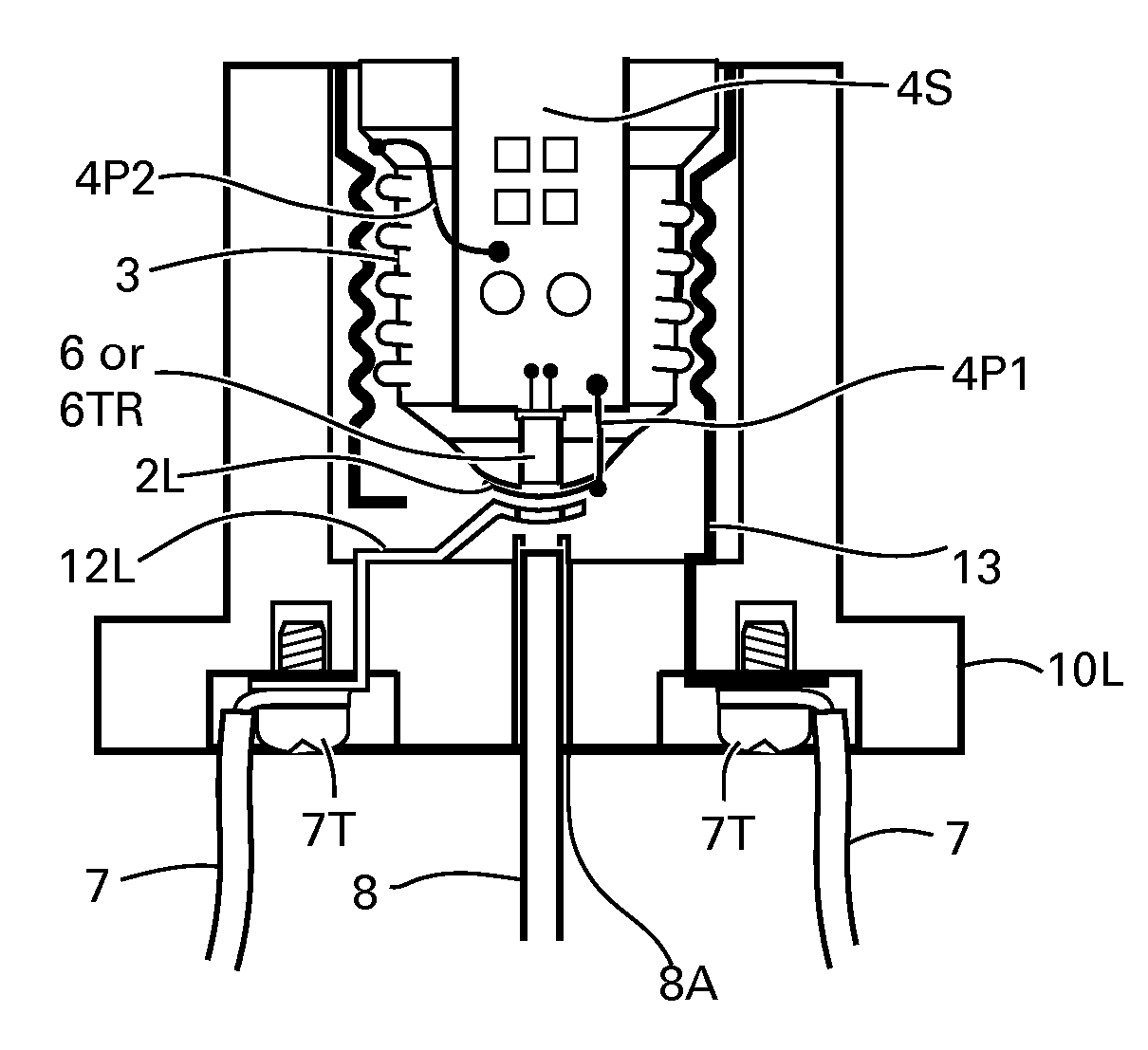

Variably configurable and modular local convergence point

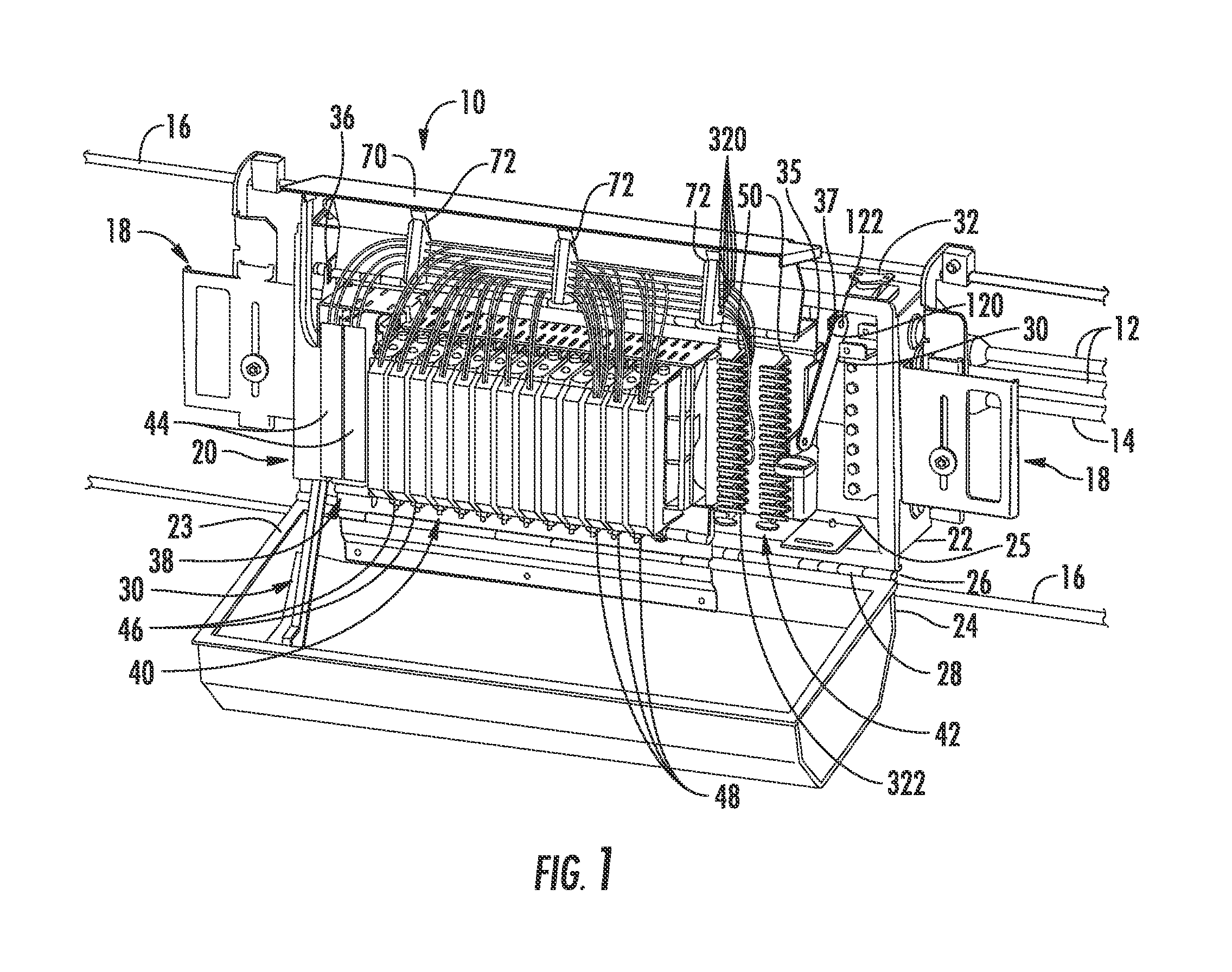

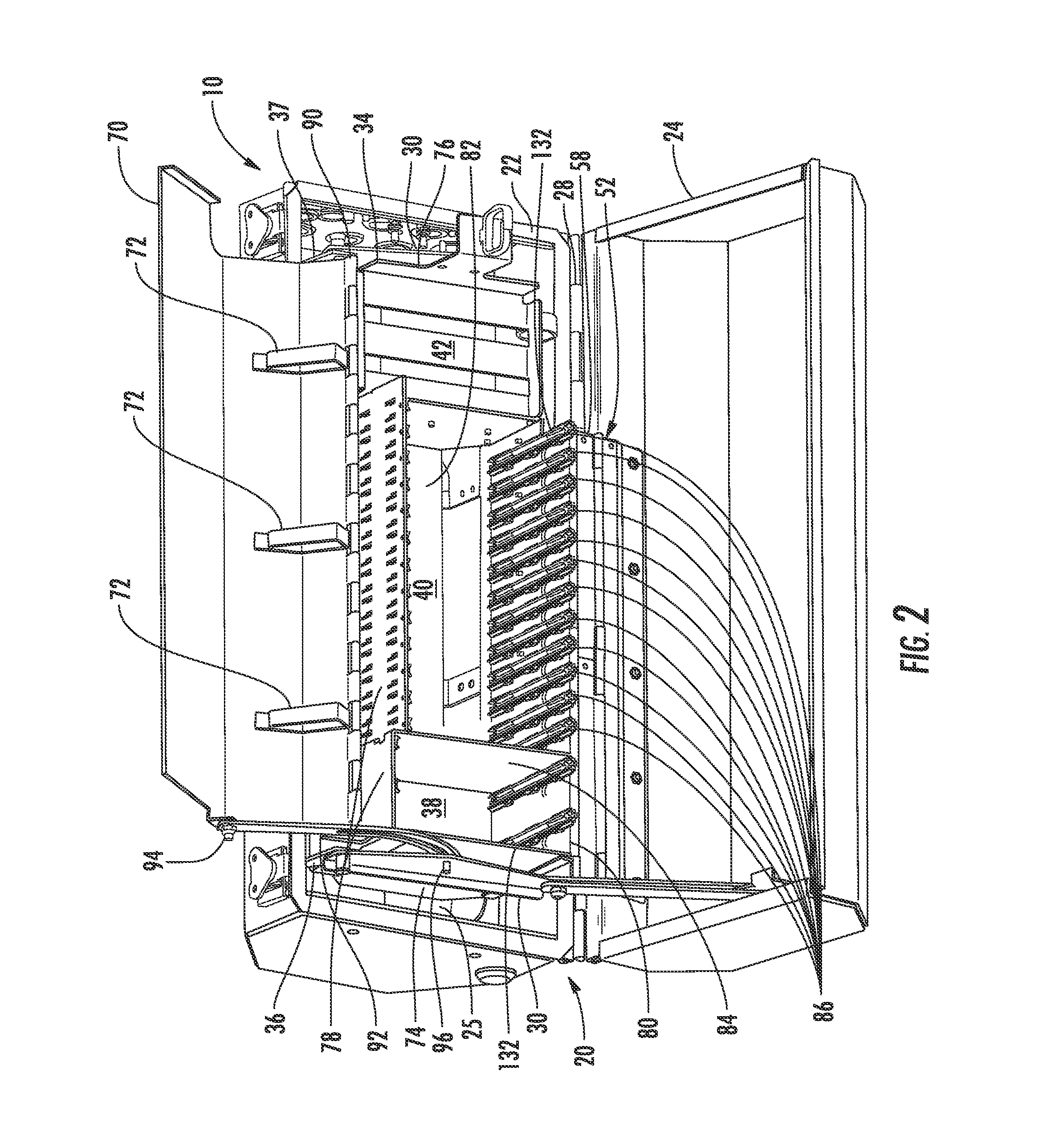

ActiveUS20110211799A1Easy accessOptical fibre/cable installationMetal working apparatusInterior spaceParking area

A variably configurable fiber optic terminal as a local convergence point in a fiber optic network is disclosed. The fiber optic terminal has an enclosure having a base and a cover which define an interior space. A feeder cable having at least one optical fiber and a distribution cable having at least one optical fiber are received into the interior space through a feeder cable port and a distribution cable port, respectively. A movable chassis positions in the interior space and is movable between a first position, a second position and third position. The movable chassis has a splitter holder area, a cassette area and a parking area. A cassette movably positions in the cassette area. A splitter module holder having a splitter module movably positioned therein movably positions in the splitter holder area. The optical fiber of the feeder cable and the optical fiber of the distribution cable are optically connected through the cassette, which also may be through the splitter module. In such case, the optical fiber of the feeder cable optically connects to an input optical fiber to the slitter module, where the optical signal is split into a plurality of output optical fibers. One of the plurality of output optical fibers connects to the optical fiber of the distribution cable for distribution towards a subscriber premises. The interior space is variably configurable by changeably positioning the cassette and splitter modules in the movable chassis.

Owner:CORNING OPTICAL COMM LLC

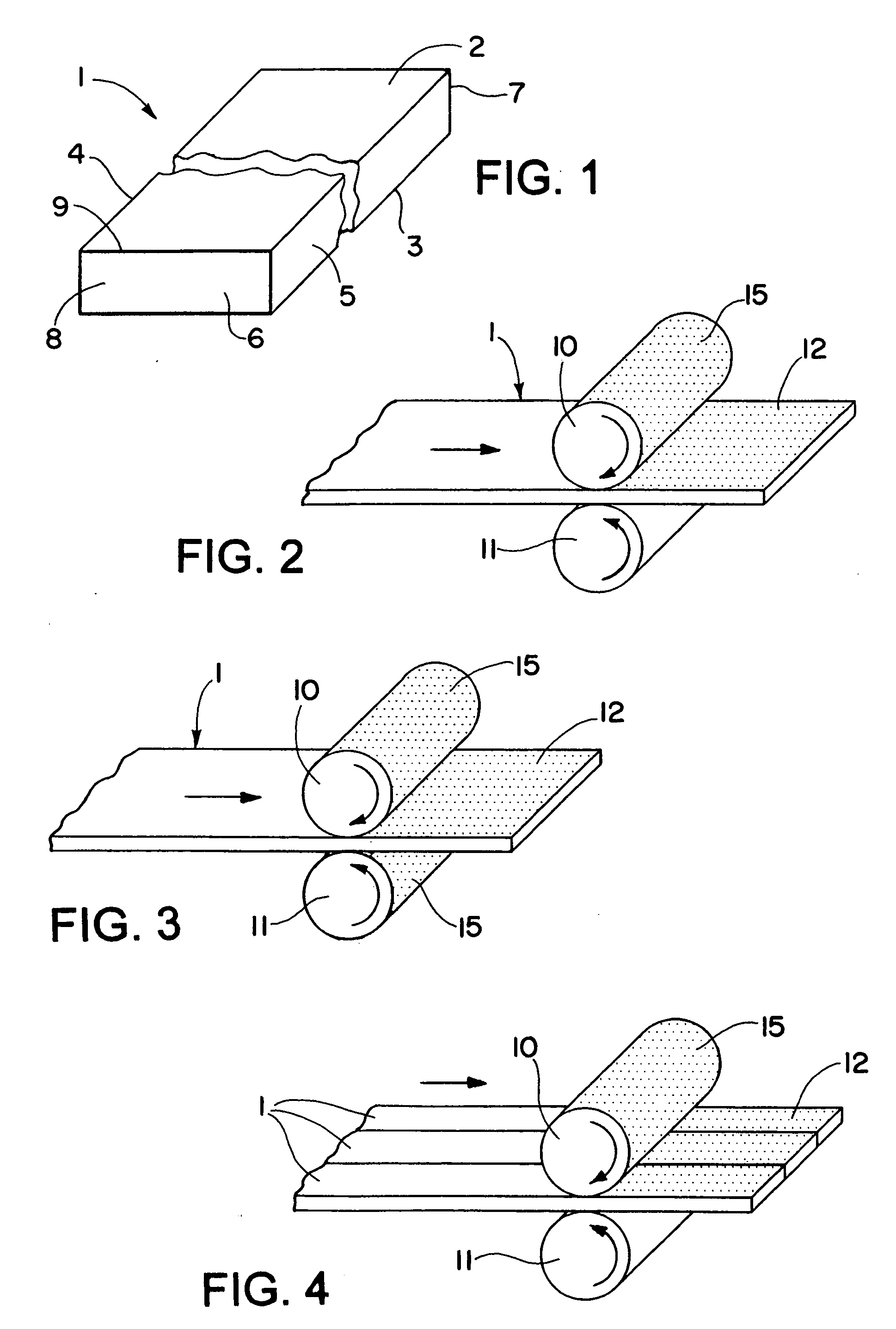

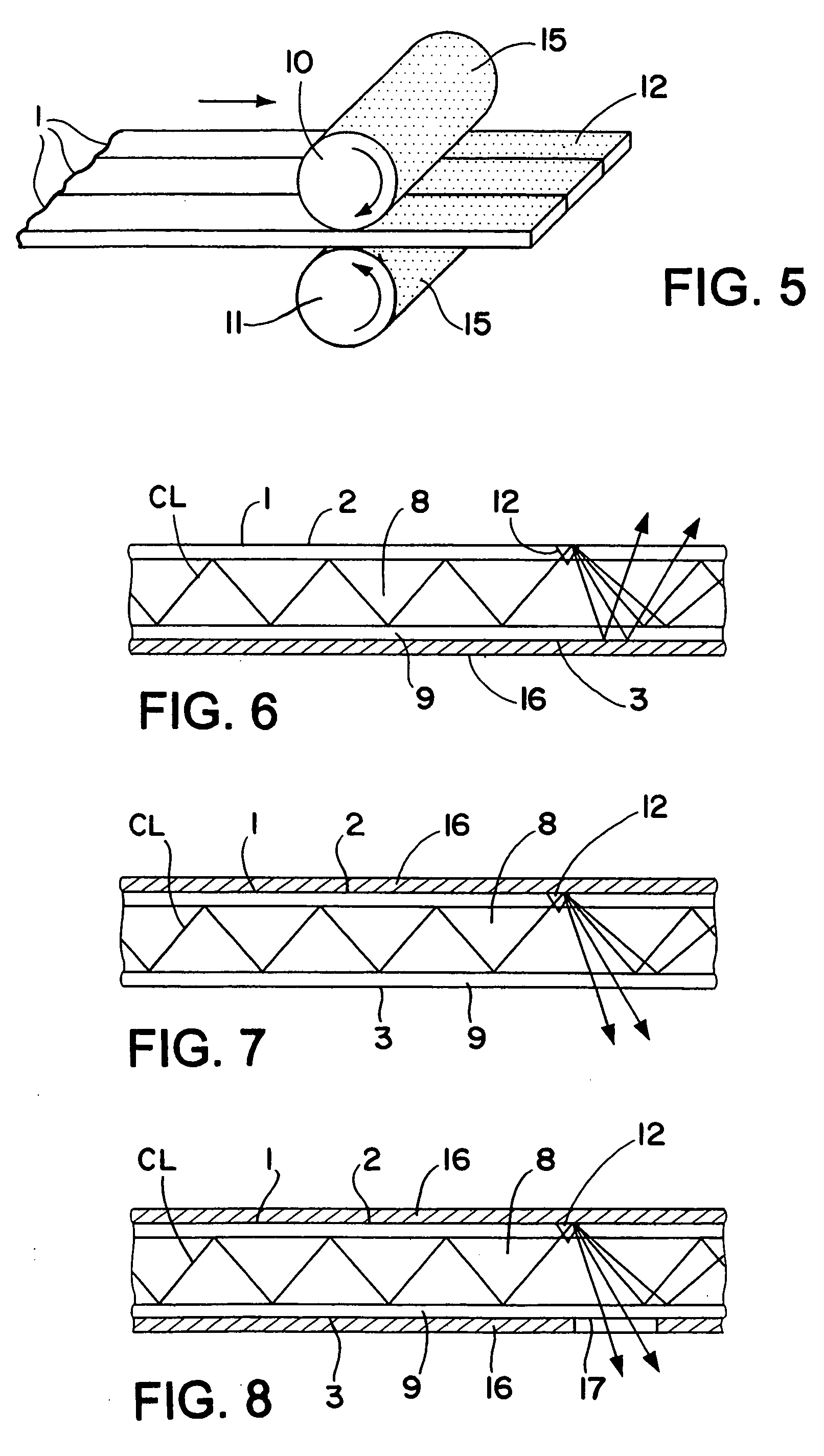

Flat optical fiber light emitters

InactiveUS20060024017A1Improve efficiencyLight is longCladded optical fibrePlanar/plate-like light guidesFiberPlastic optical fiber

Light emitters are made of one or more cladded flat optical fibers having opposite flat sides and disruptions along at least a portion of the length of the fibers to cause light entering at least one end to be emitted from at least one side. The ends of the flat optical fibers may have substantially the same thickness as a light source and a width substantially equal to or substantially greater than the width of the light source for ease of optically coupling one or more such light sources to the flat optical fiber ends.

Owner:LUMITEX

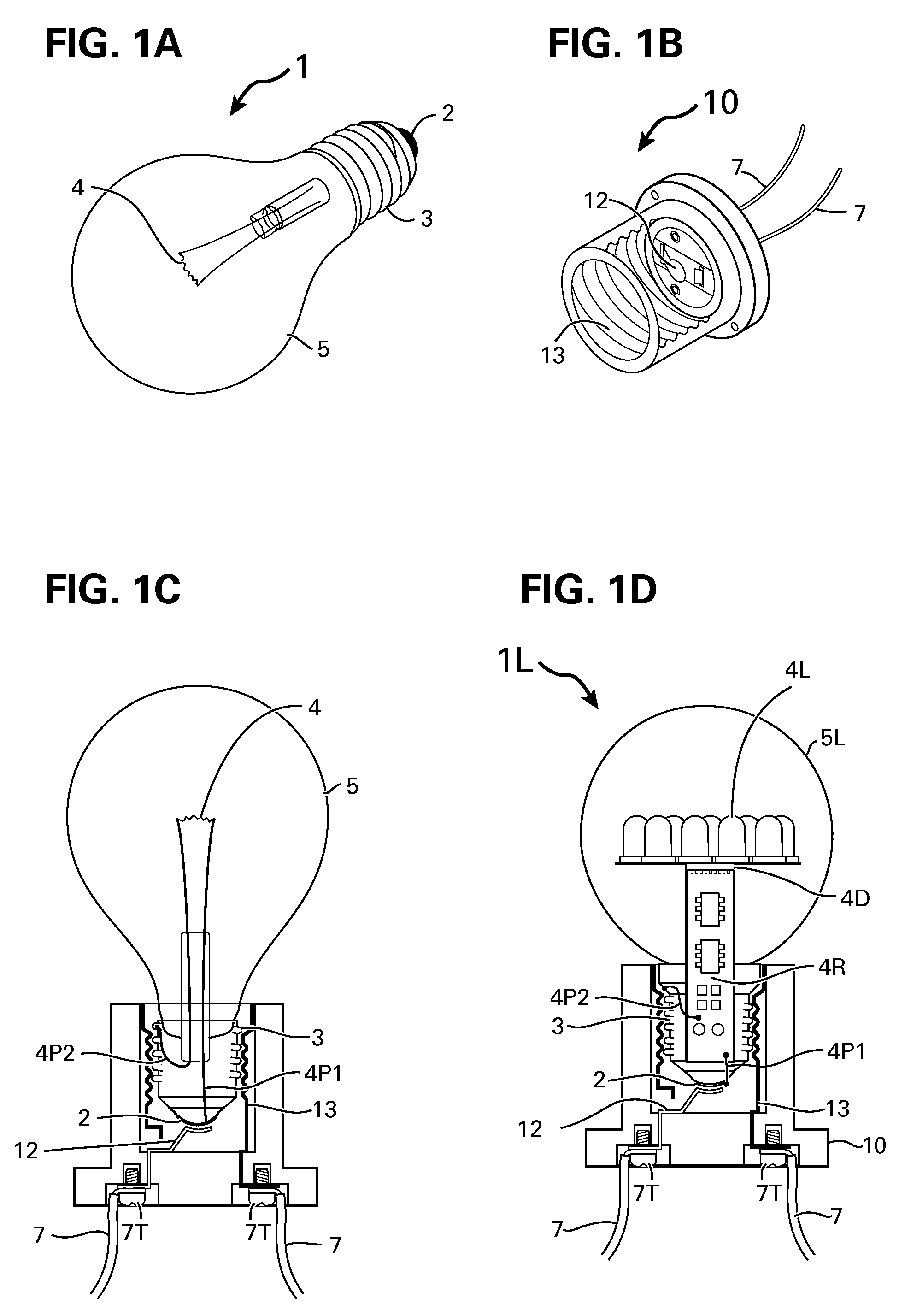

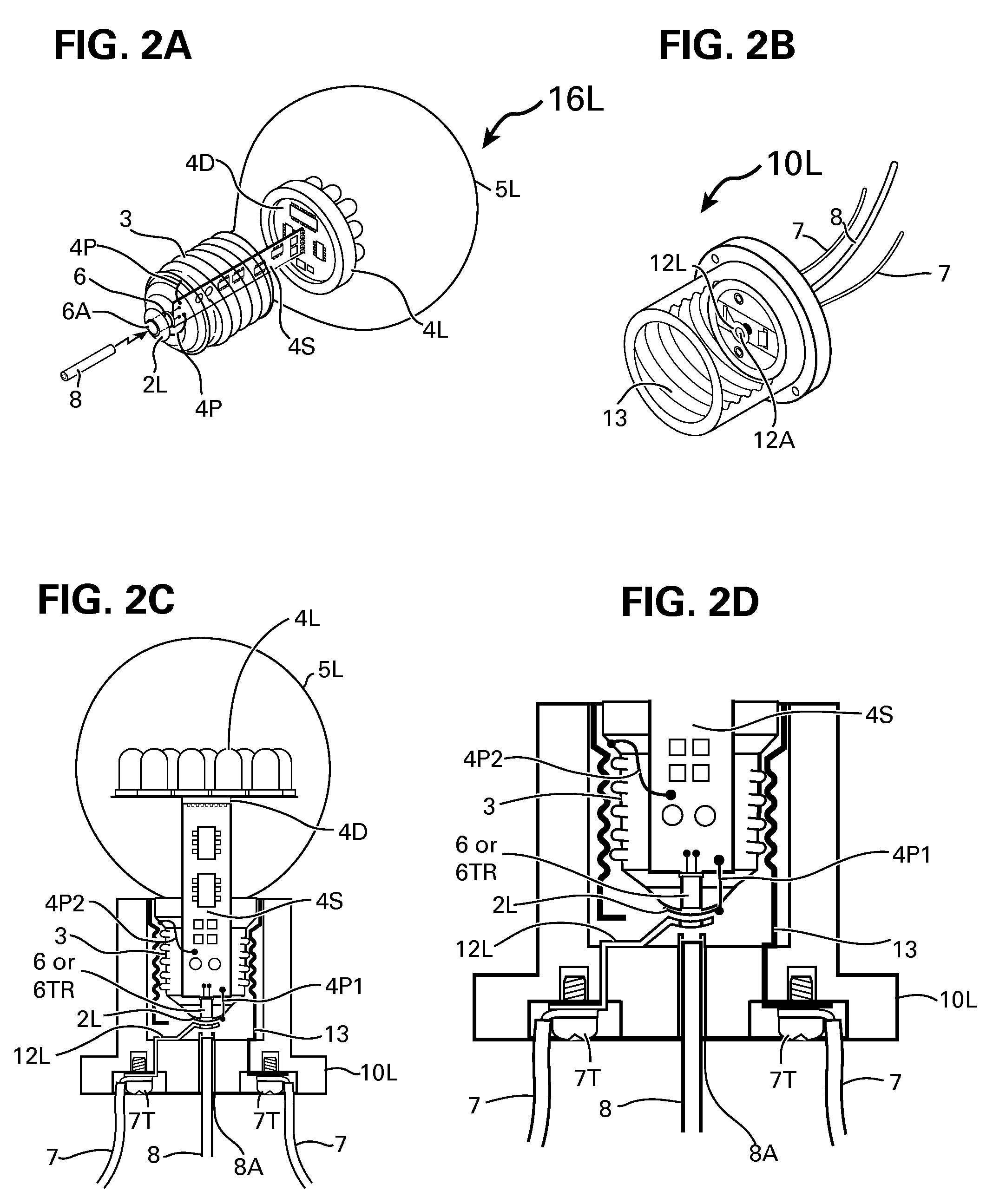

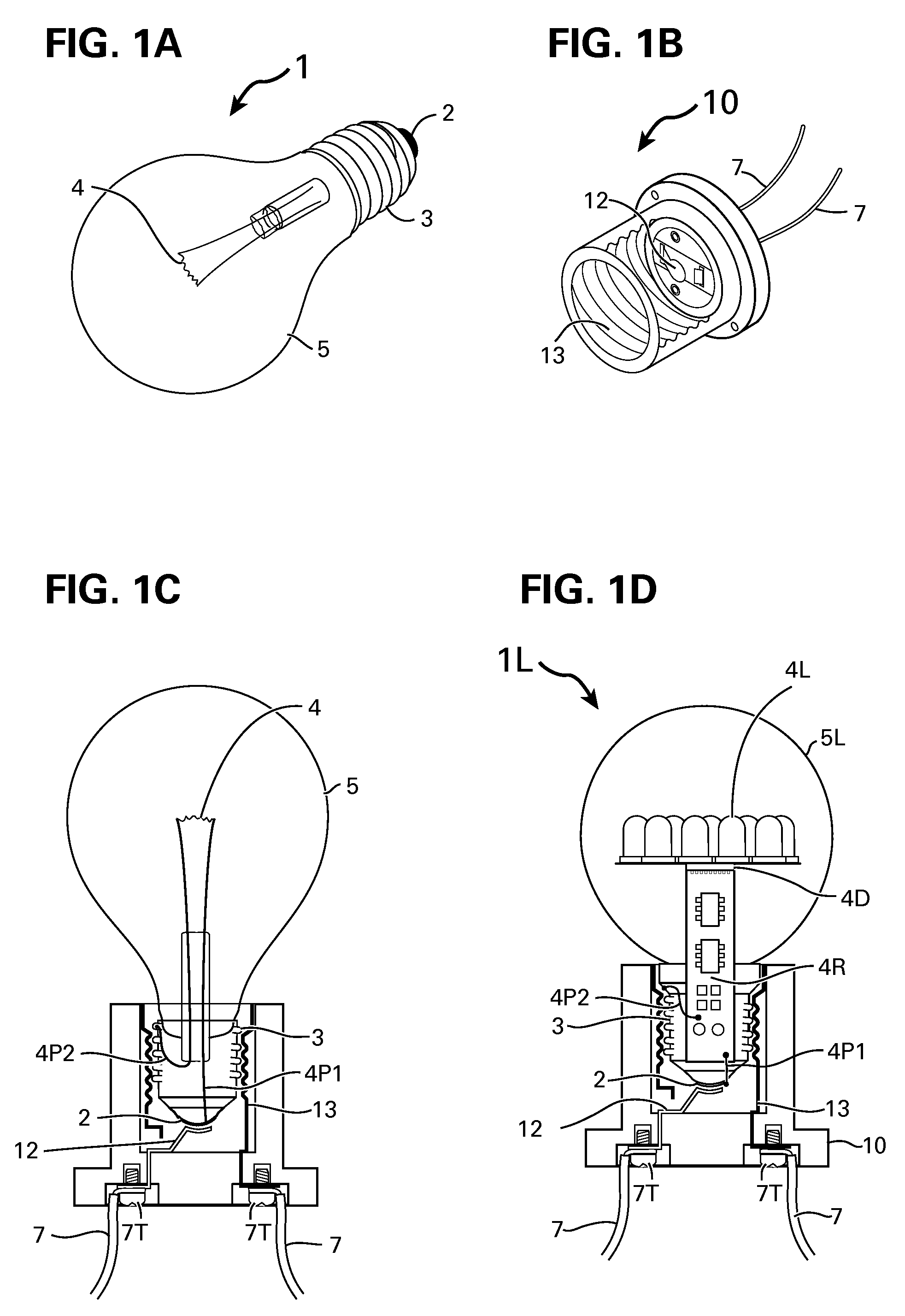

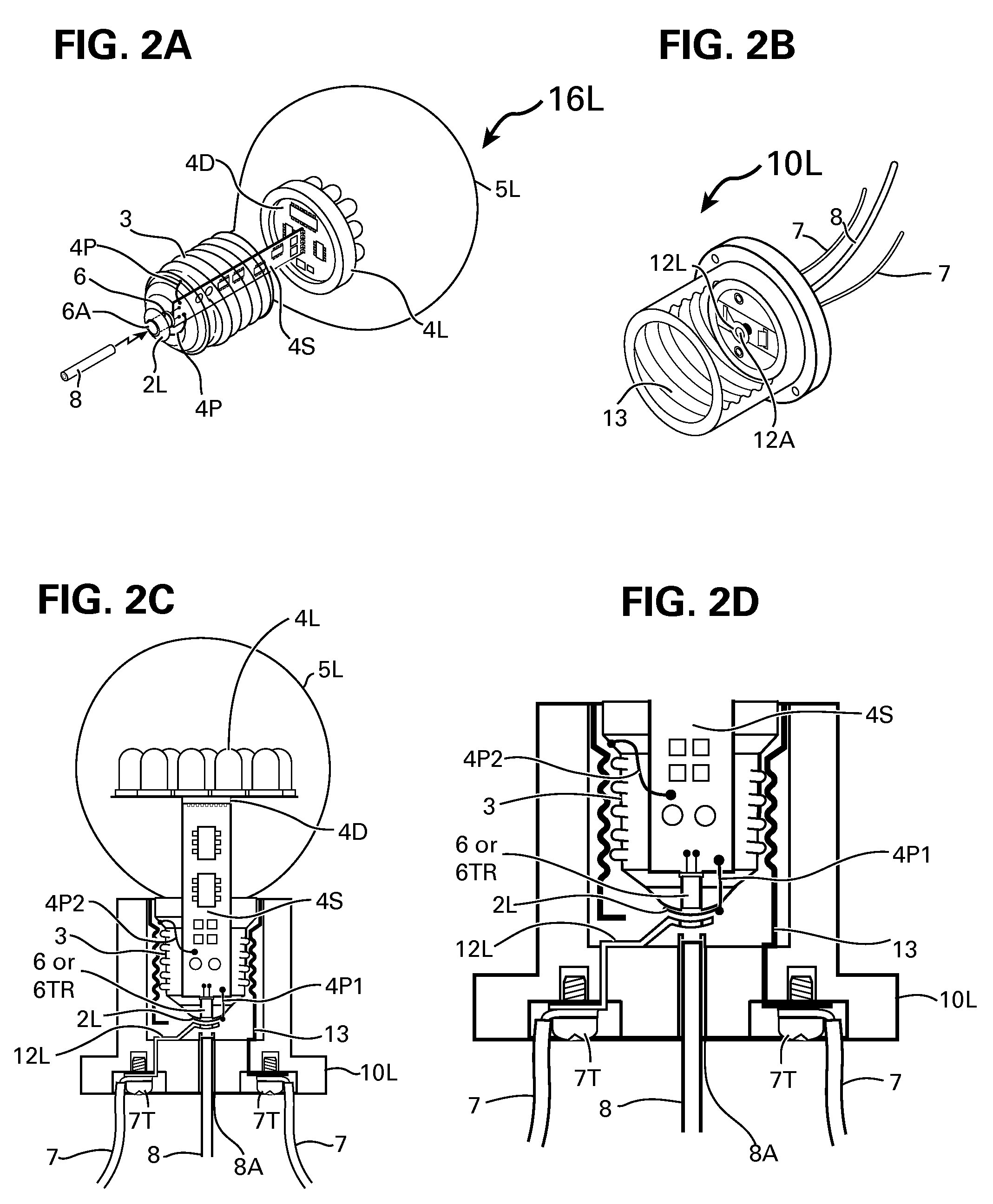

Method and apparatus for propagating optical signals along with power feed to illuminators and electrical appliances

ActiveUS8148921B2Firmly connectedEfficient solutionCoupling device connectionsLine/current collector detailsEngineeringElectric cables

In a method and apparatus for propagating optical signals via optical cables such as plastic optical fiber, known as lightguide joint and mingled with the electrical wiring and home automation system for controlling LED illuminators enclosed in standard screw type bulb bases or plug-in bases, such as used for halogen lamp via optical signal propagated through such standard bases. Same optical signals are propagated through power outlets and via power cable assemblies to electrical appliances for controlling the appliances operation and on-off switching. Full range of control, distribution, signal conversion, keypads and touch screen including video interphones monitors and shopping terminals operate and controls such home automation via the optical cables.

Owner:ELBEX VIDEO LTD

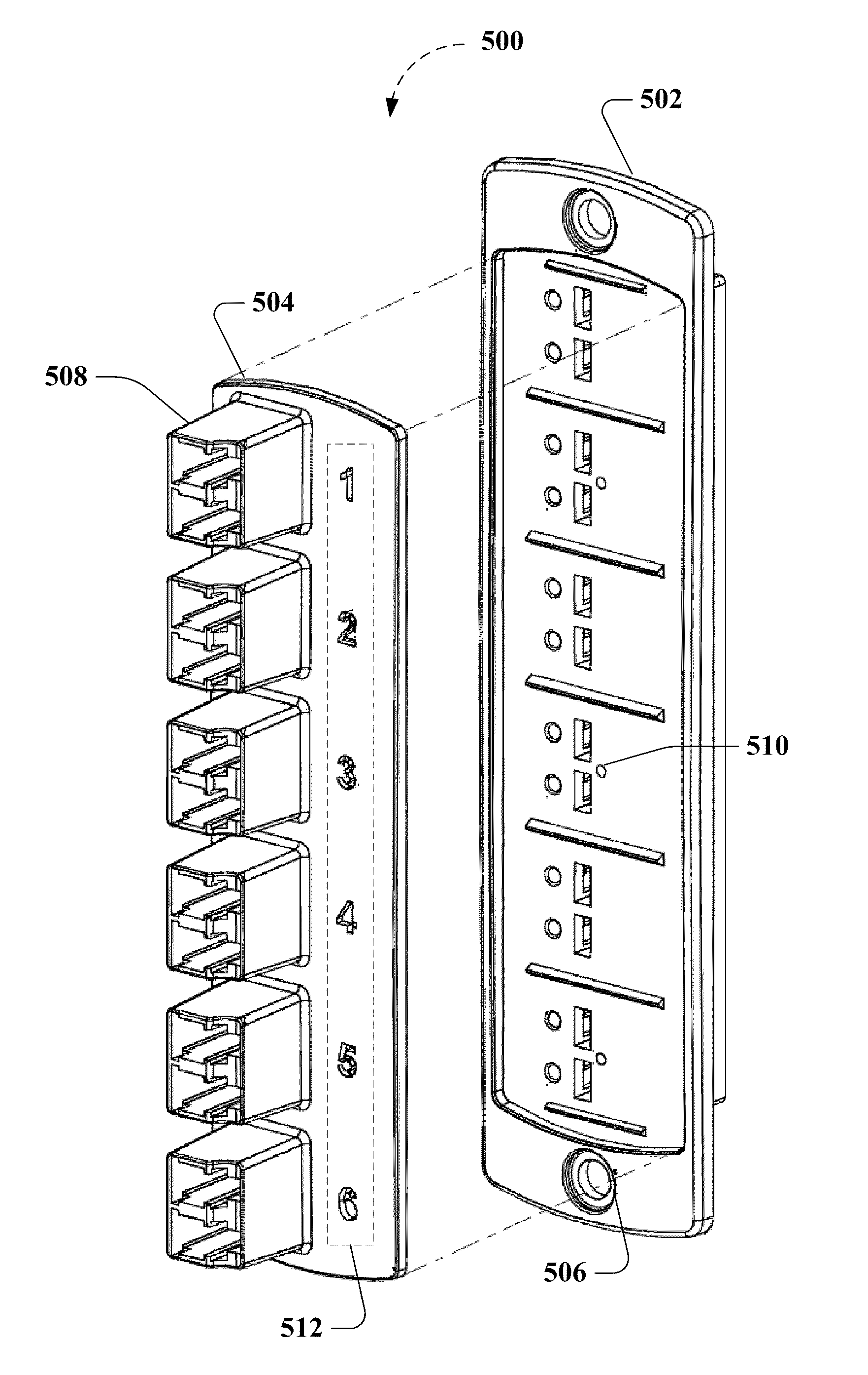

Fiber optic adapter plates with integrated fiber optic adapters

Structures, devices and methods are provided for creating fiber optic adapter plates with integrated fiber optic adapters. In one aspect, fiber optic adapter plates having integrated fiber optic adapter subassemblies are formed from a moldable plastic. For example, a molded plastic fiber optic adapter plate can include a molded plastic adapter back plate having a plurality of integrated fiber optic adapter subassemblies and one or more attachment mechanisms that facilitate locating and attaching an adapter front plate having a corresponding plurality of integrated fiber optic adapter subassemblies on the adapter front plate. Advantages provided by integrating fiber optic adapters into the molded plastic assemblies include superior mechanical strength, manufacturing cost reductions and adapter placement flexibility among other advantages.

Owner:LEVITON MFG

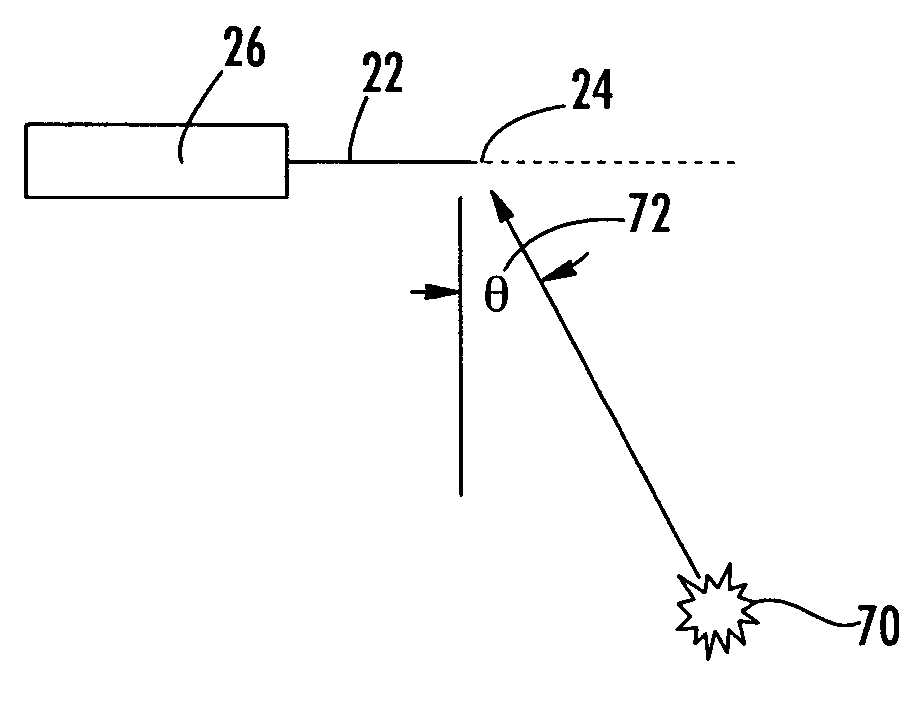

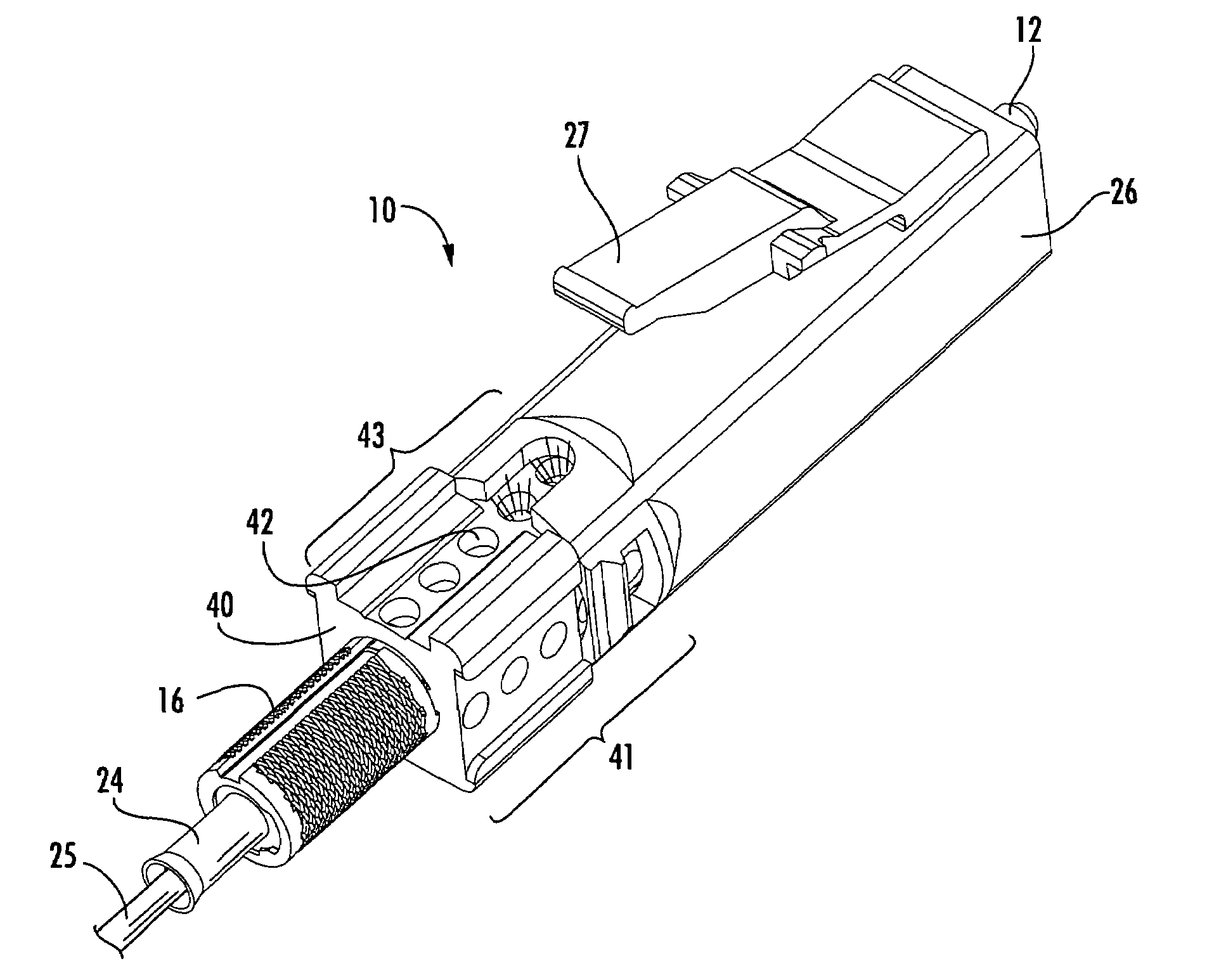

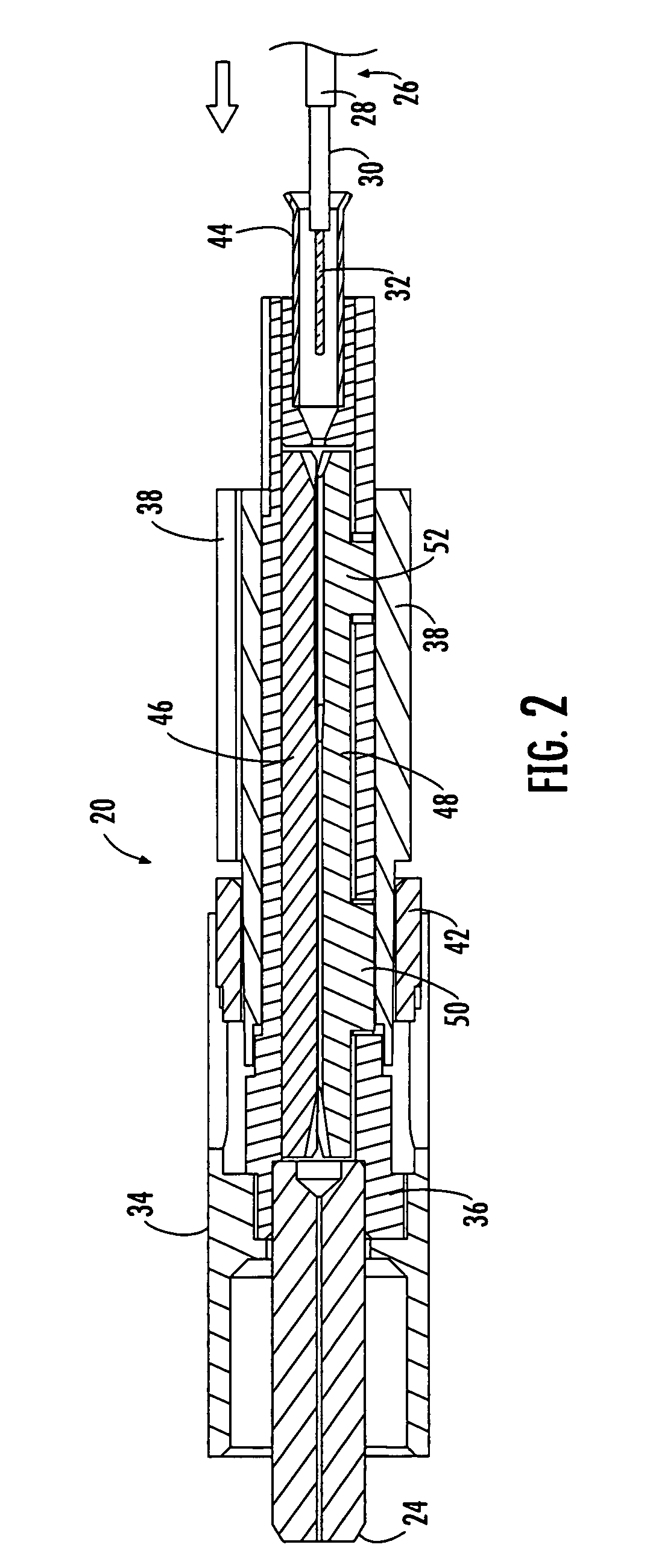

Method of making an optical fiber by laser cleaving

ActiveUS7216512B2Gap minimizationReduce or eliminate a glass defect zoneCoupling light guidesGlass reforming apparatusFiberLaser processing

A field-installable connector includes a connector housing and a ferrule having front and rear opposed faces and at least one fiber bore defined longitudinally therethrough. A laser processed stub optical fiber is disposed within the one fiber bore of the ferrule and extends a predetermined distance beyond the rear face of the ferrule. An alignment feature is operable for self-centering the stub optical fiber and a field optical fiber to perform a mechanical splice using a camming means. A method of laser processing a stub optical fiber includes rotating the stub optical fiber and sweeping a laser beam directed at a desired angle back and forth across a surface of the optical fiber. An oscillating motion of the laser is driven by an intermittent sinusoidal signal that results in two deposits of energy onto the stub optical fiber followed by a cooling period before subsequent deposits of energy occur.

Owner:CORNING OPTICAL COMM LLC

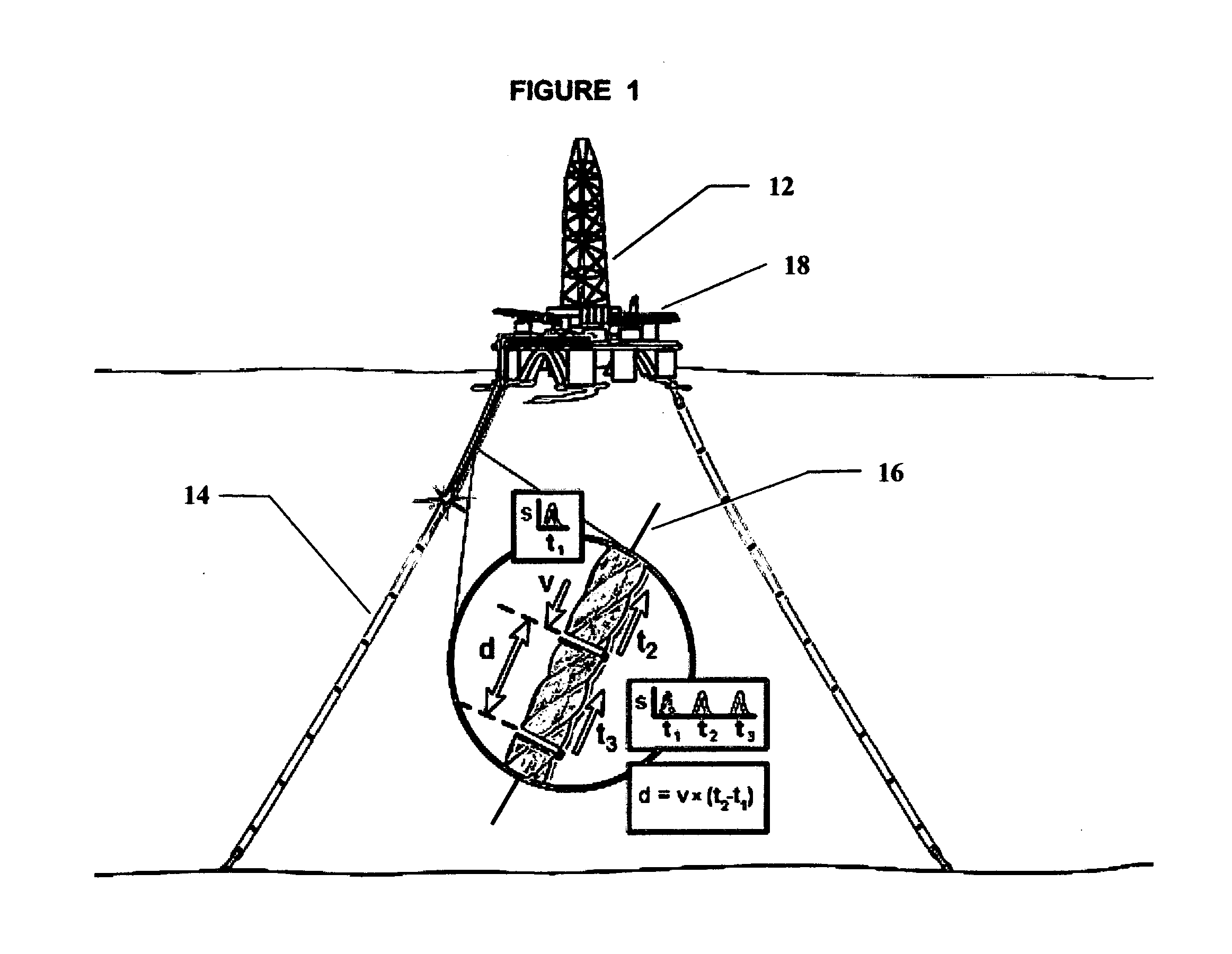

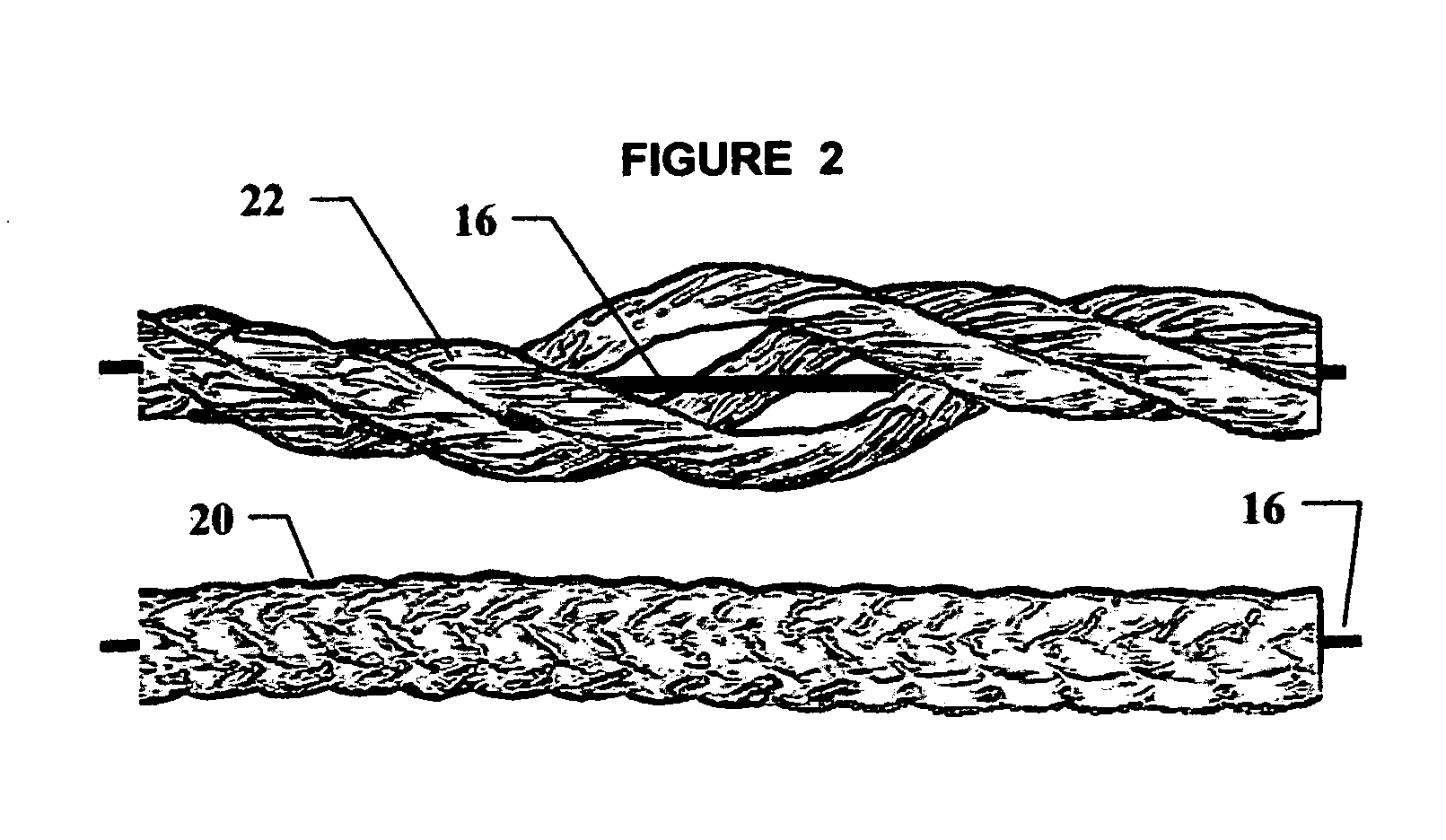

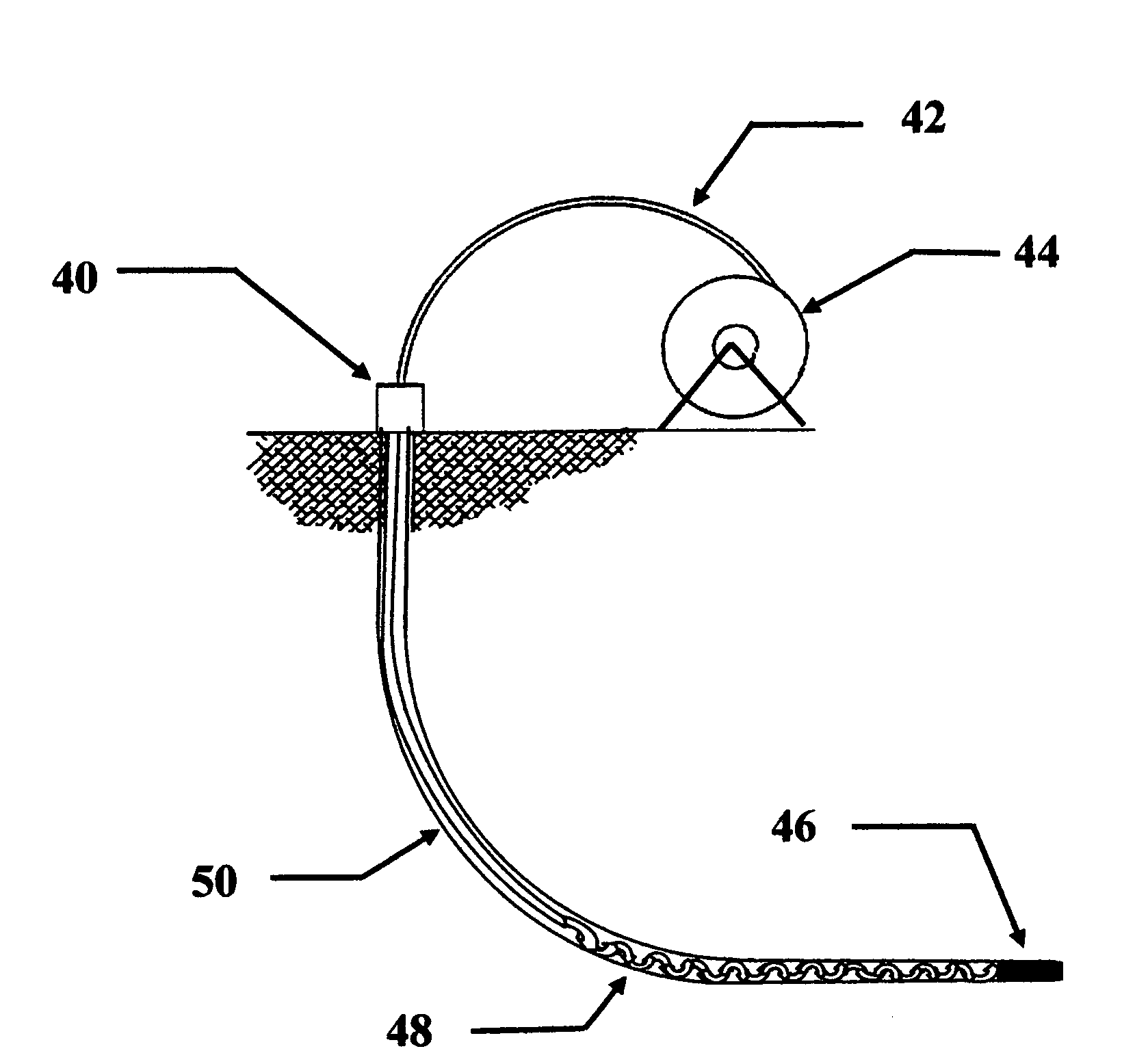

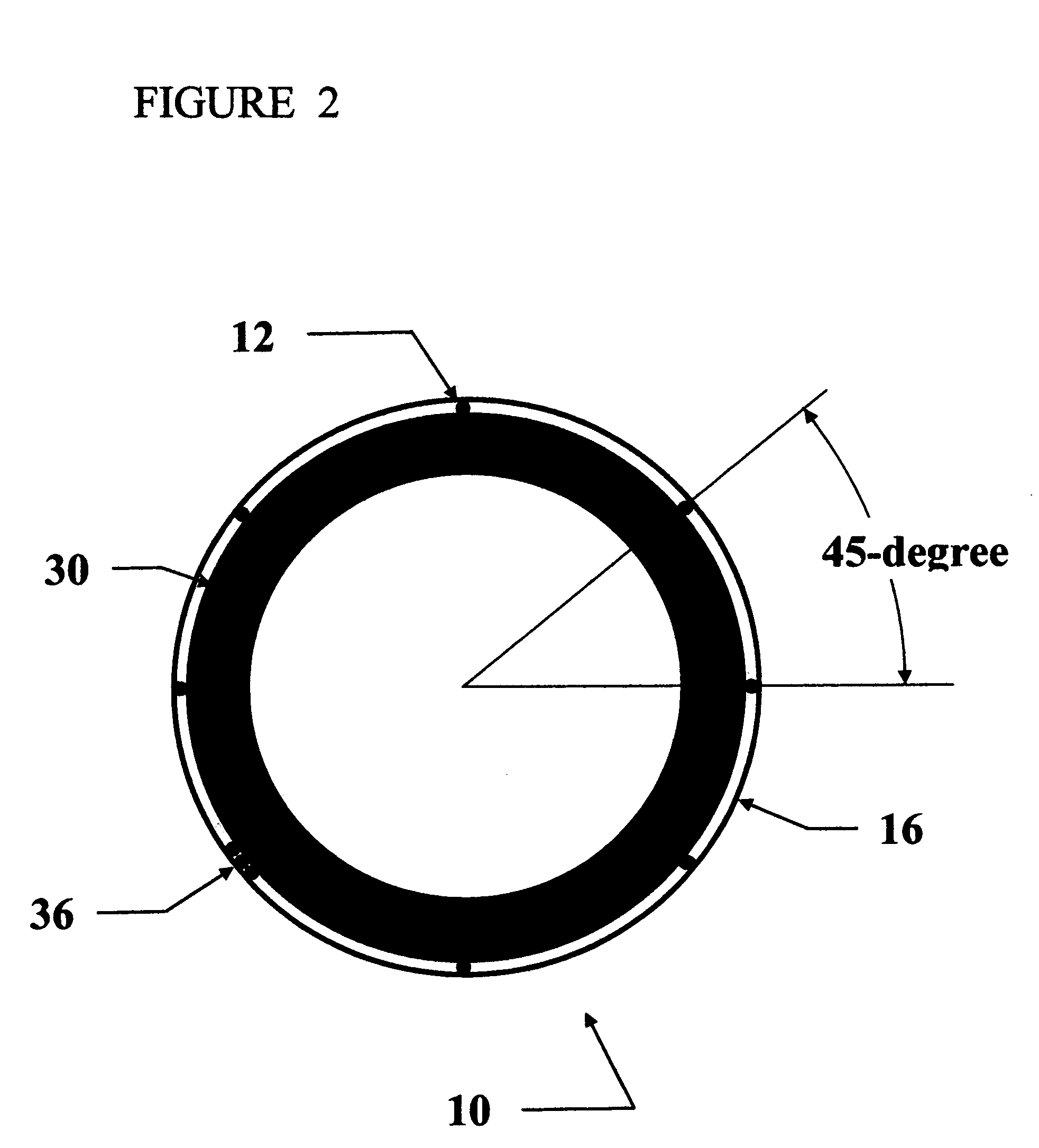

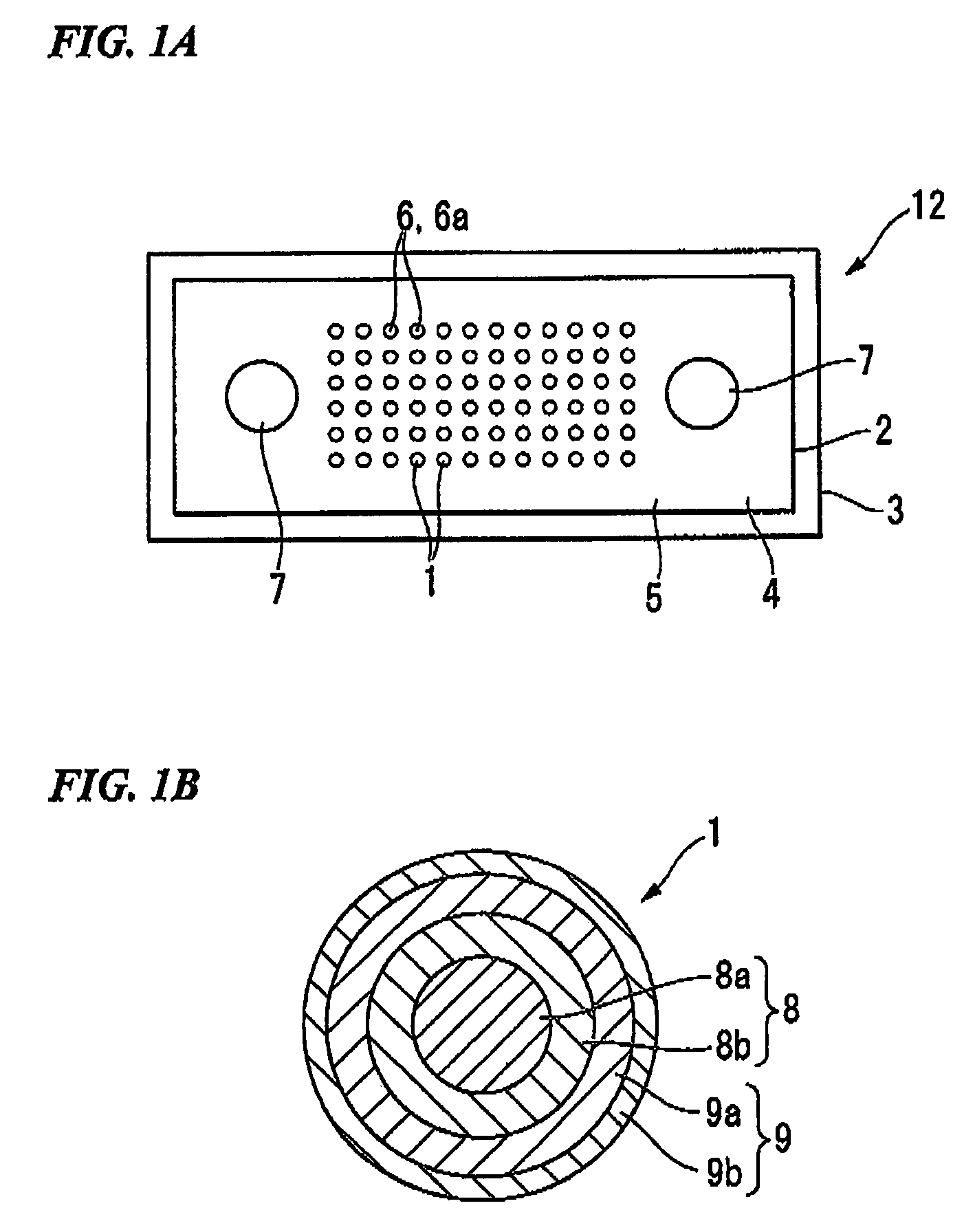

Measurement of large strains in ropes using plastic optical fibers

InactiveUS20050226584A1Minimal intrusionPrevent slippingControlOptical rangefindersTime domainEngineering

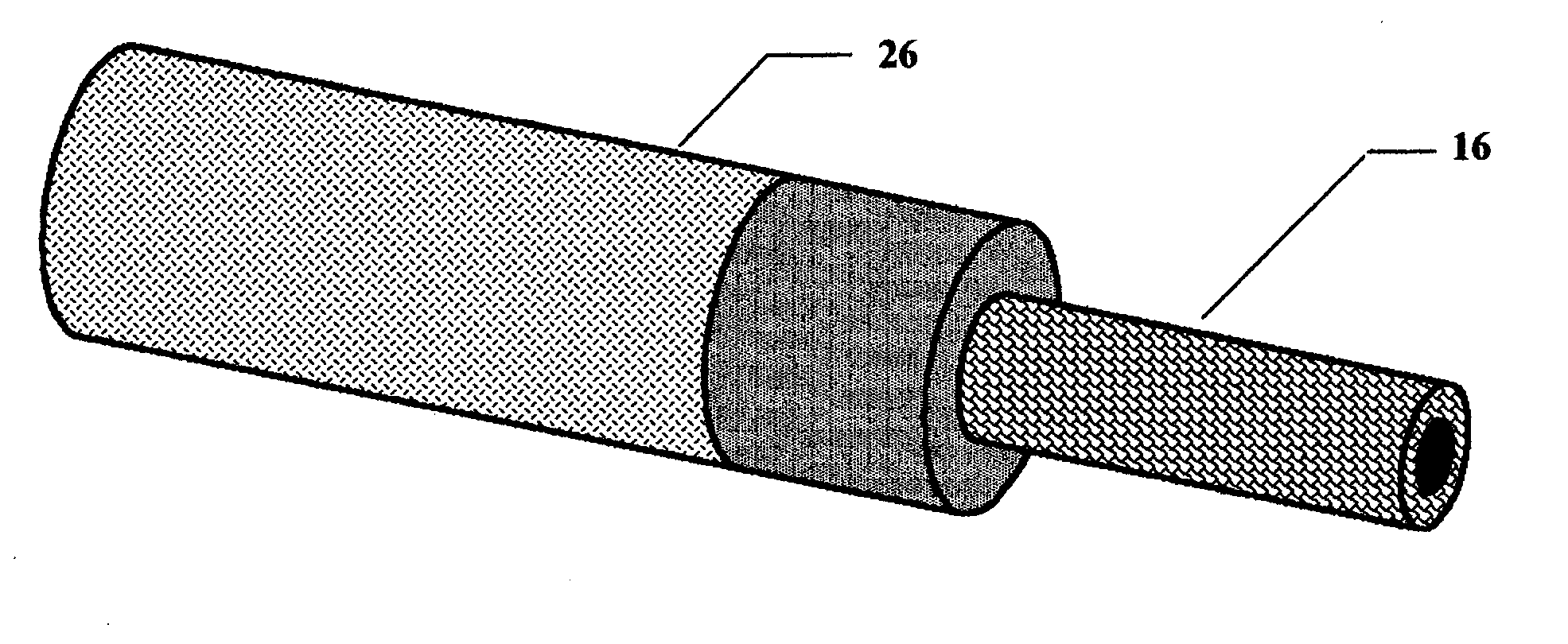

A method for the direct measurement of large strains in ropes in situ using a plastic optical fiber, for example, perfluorocarbon or polymethyl methacrylate and Optical Time-Domain Reflectometer or other light time-of-flight measurement instrumentation. Protective sheaths and guides are incorporated to protect the plastic optical fiber. In one embodiment, a small rope is braided around the plastic optical fiber to impose lateral compressive forces to restrain the plastic optical fiber from slipping and thus experience the same strain as the rope. Methods are described for making reflective interfaces along the length of the plastic optical fiber and to provide the capability to measure strain within discrete segments of the rope. Interpretation of the data allows one to calculate the accumulated strain at any point in time and to determine if the rope has experienced local damage.

Owner:WILLIAMS JERRY GENE +2

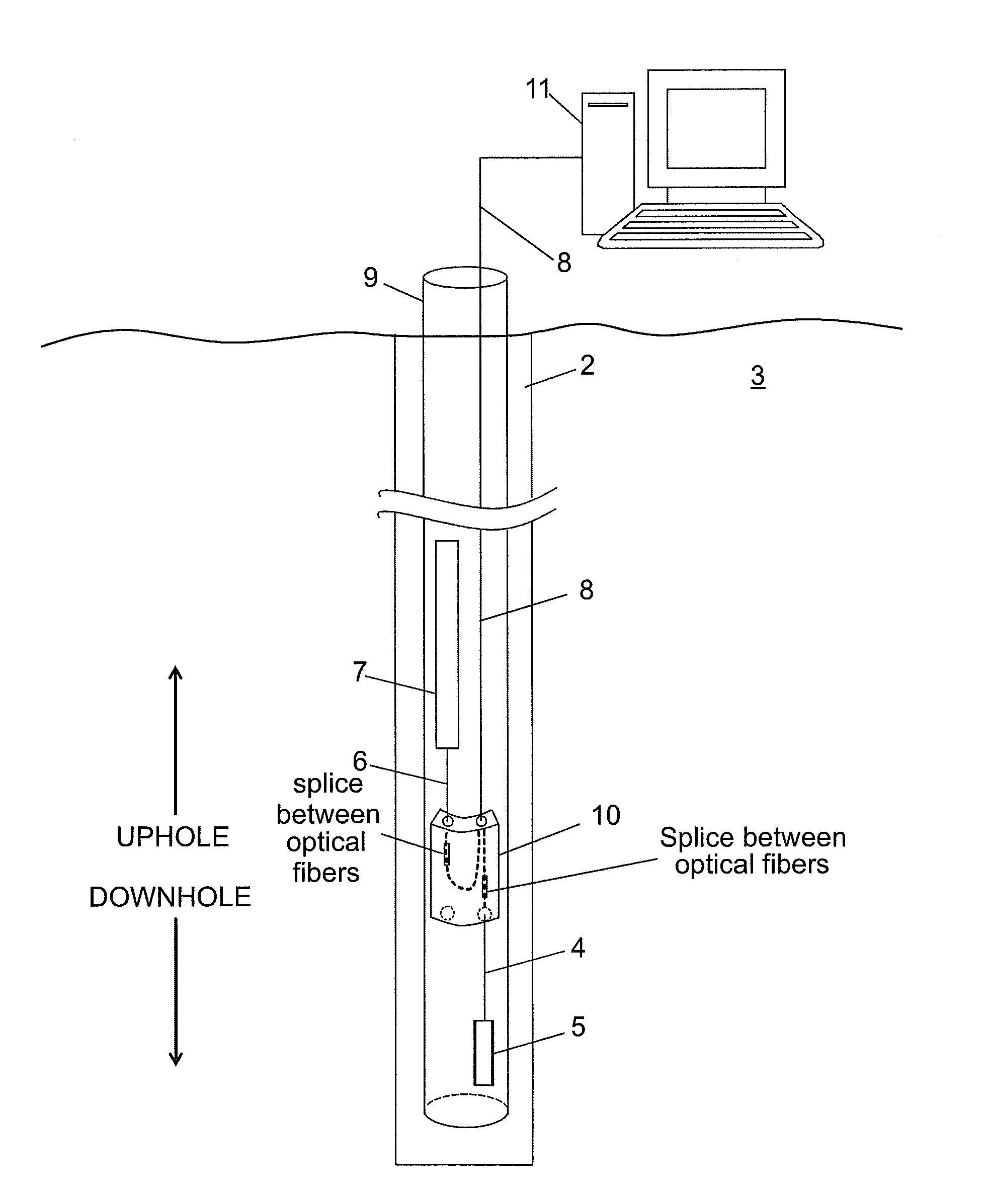

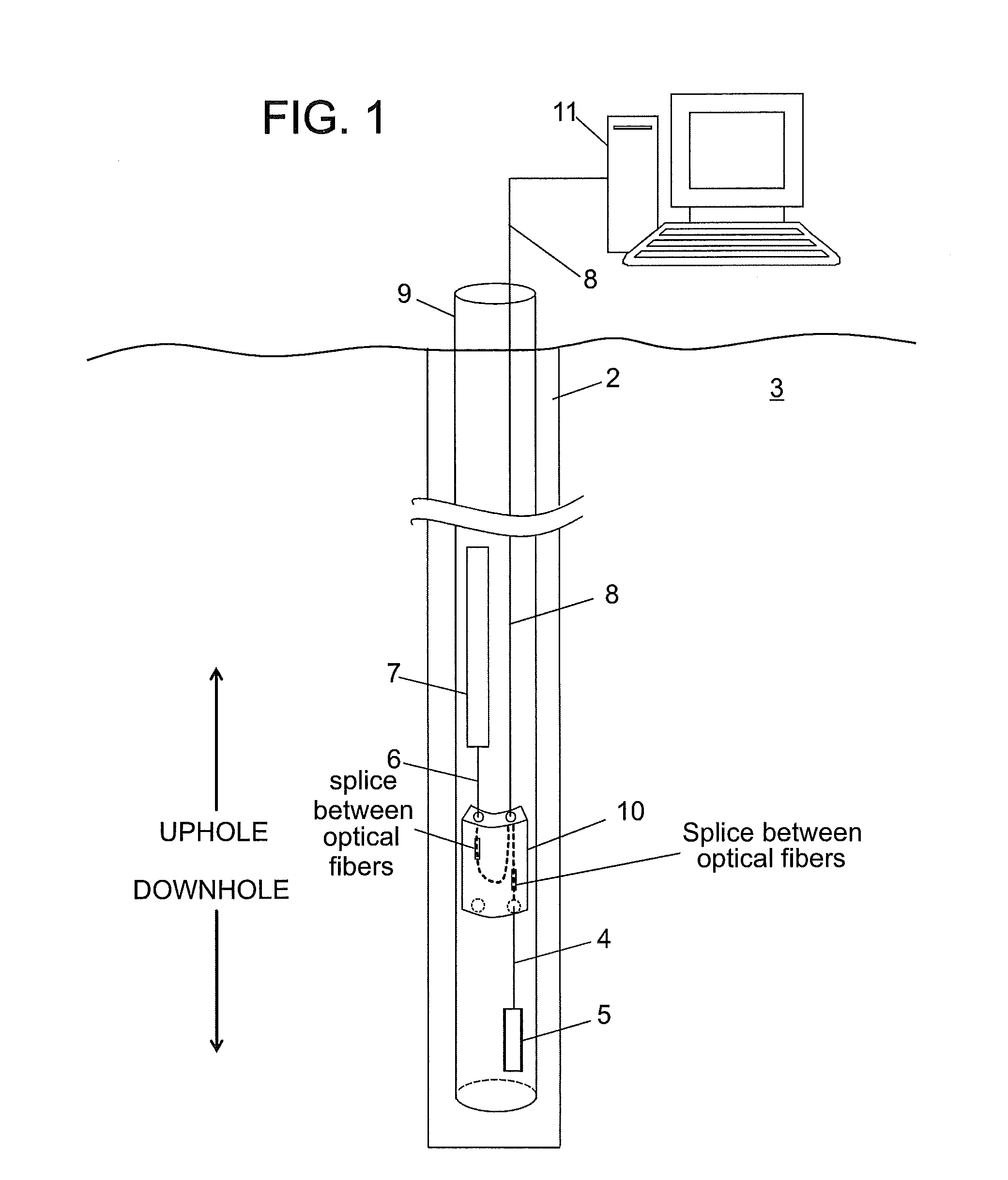

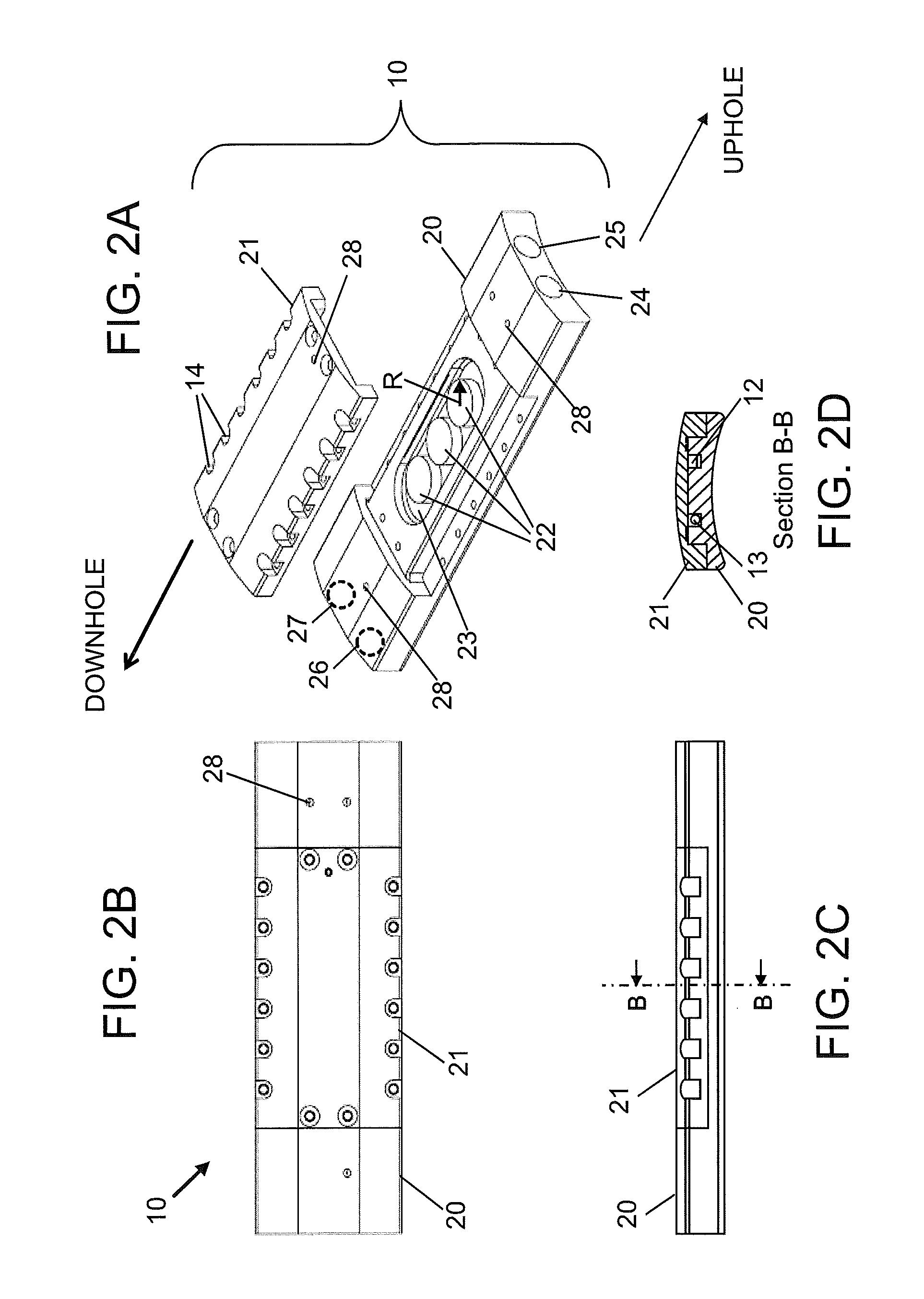

Downhole optical fiber spice housing

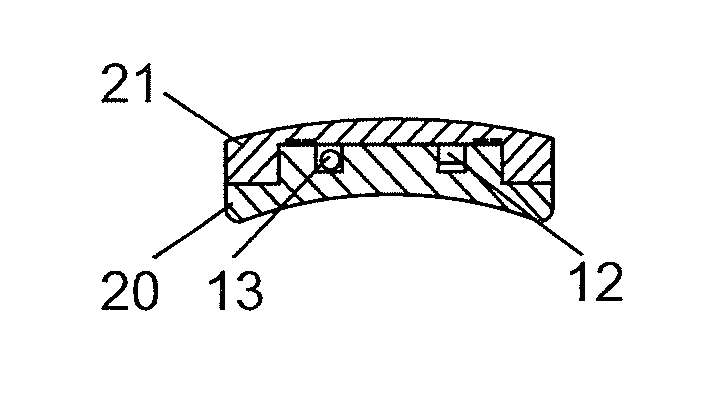

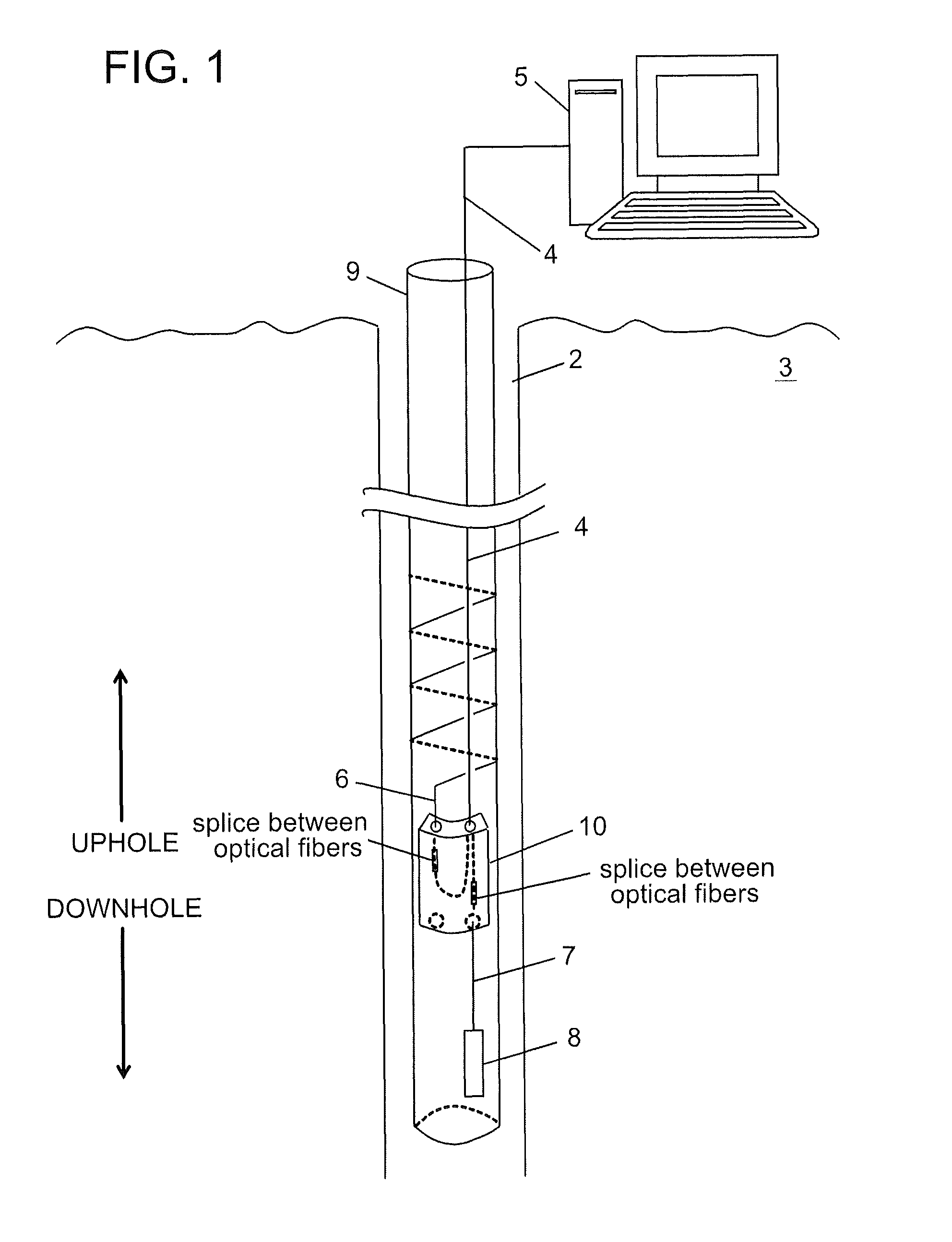

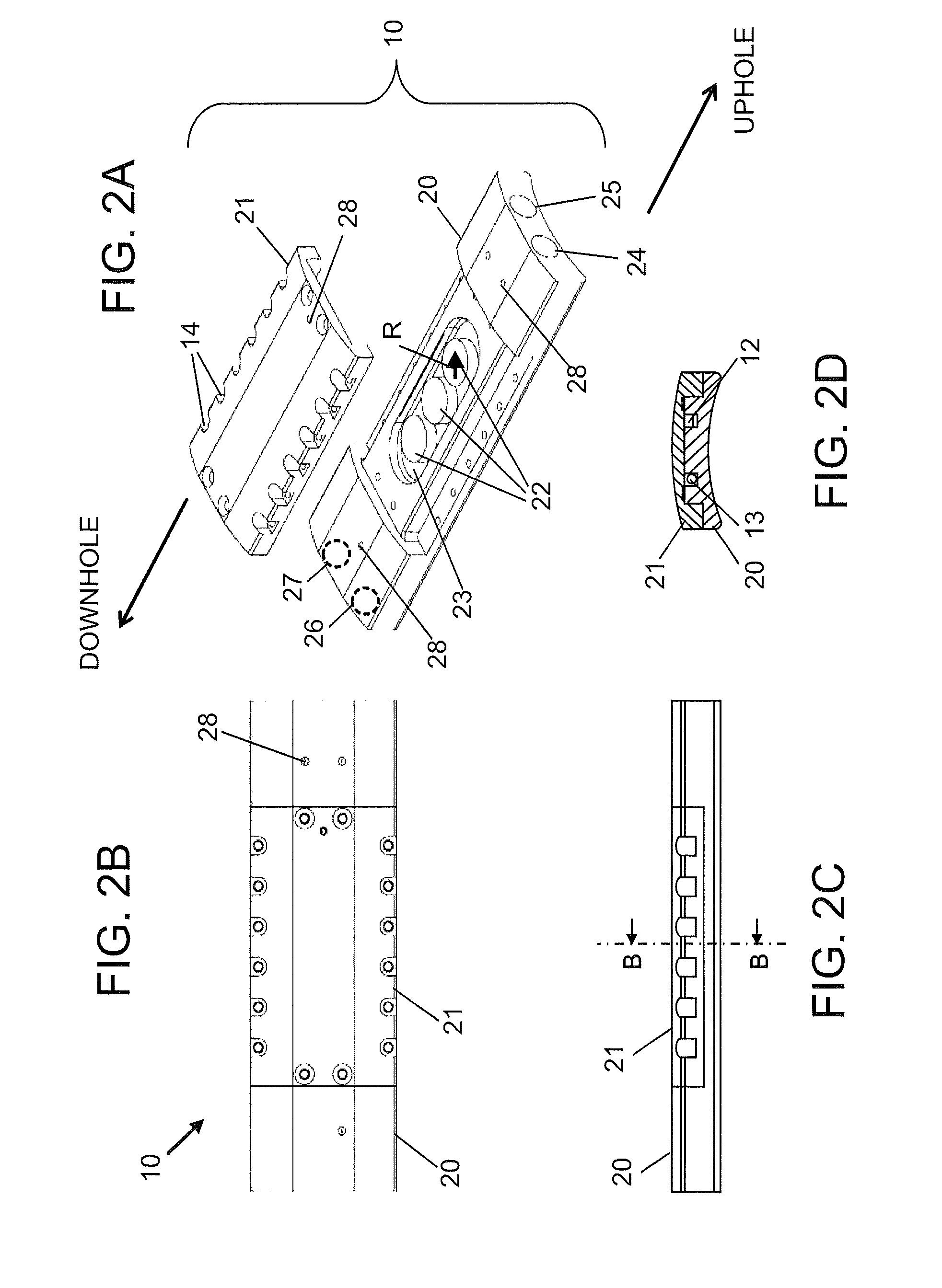

An apparatus for protecting a splice between optical fibers disposed in a borehole penetrating the earth, the apparatus including: a housing configured to be disposed in the borehole and having a first port and a second port, each port being configured to seal the housing to an associated fiber optic cable containing an optical fiber to be spliced; wherein the housing includes a sealed interior volume sufficient to contain a splice of the optical fibers for protection and to enable a functional bend of at least ninety degrees for at least one spliced optical fiber.

Owner:BAKER HUGHES INC

Dynamic performance monitoring of long slender structures using optical fiber strain sensors

A method is described using optical fiber technology to measure the vibration characteristics of long slender structures subjected to dynamic disturbances imposed by water or wind generated loads. The method is based on making bending strain measurements at selected locations along the length of long slender structures such as marine risers or large ropes using fiber optics technology including Optical Time Domain Reflectometry and Bragg diffraction gratings. Engineering interpretation of information obtained from bending strains determines the vibration characteristics including frequency, amplitude, and wave length. Maximum bending strain measurements assess pending structural damage. One application is measurement of vortex induced vibrations (VIV) response of marine risers. The fiber optics based method is also applicable to the measurement of the bending characteristics of spoolable pipe using plastic optical fibers which can be interpreted to assess the pipe structural integrity and to prevent lock-up during deployment into a small diameter annulus.

Owner:WILLIAMS JERRY GENE

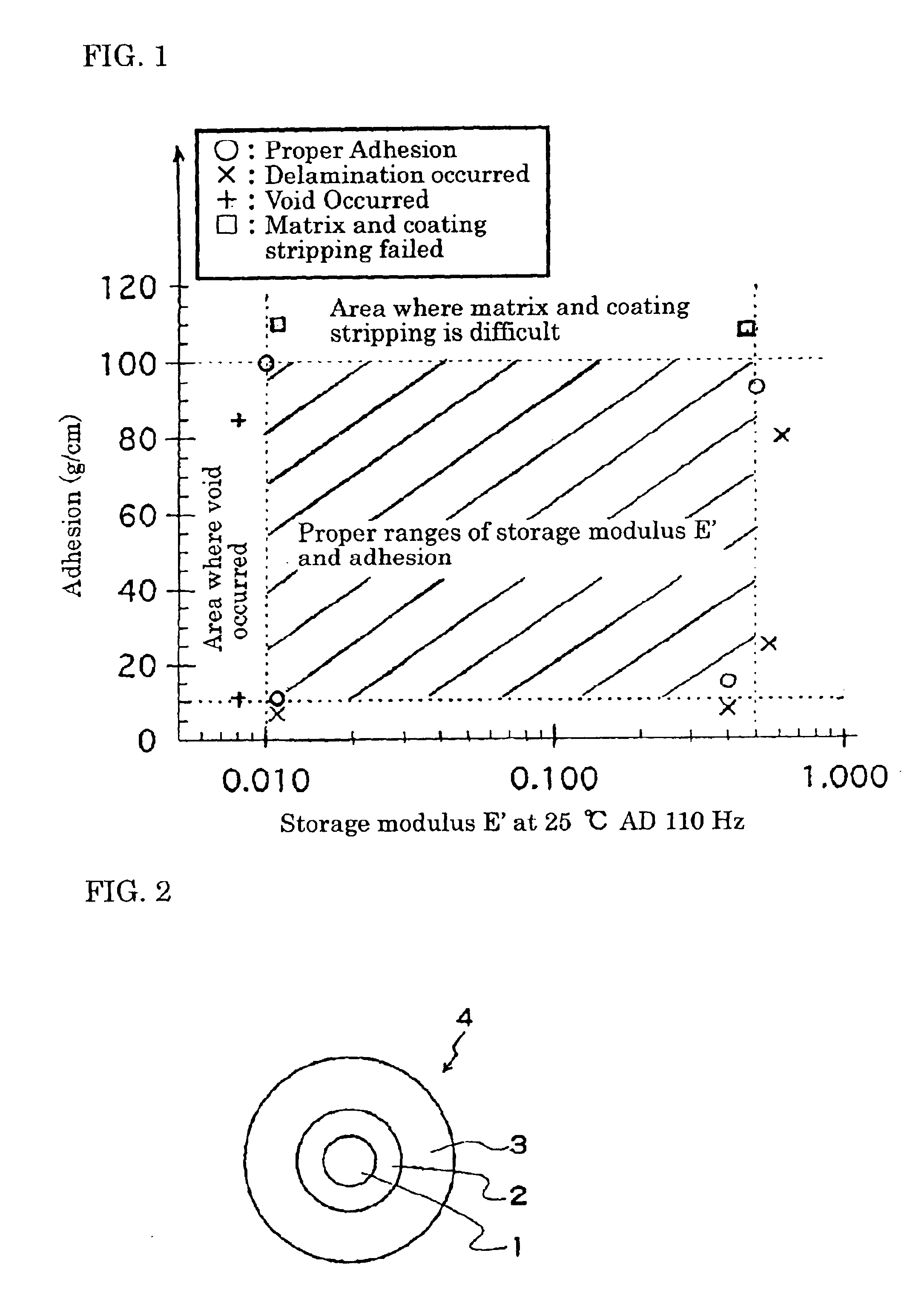

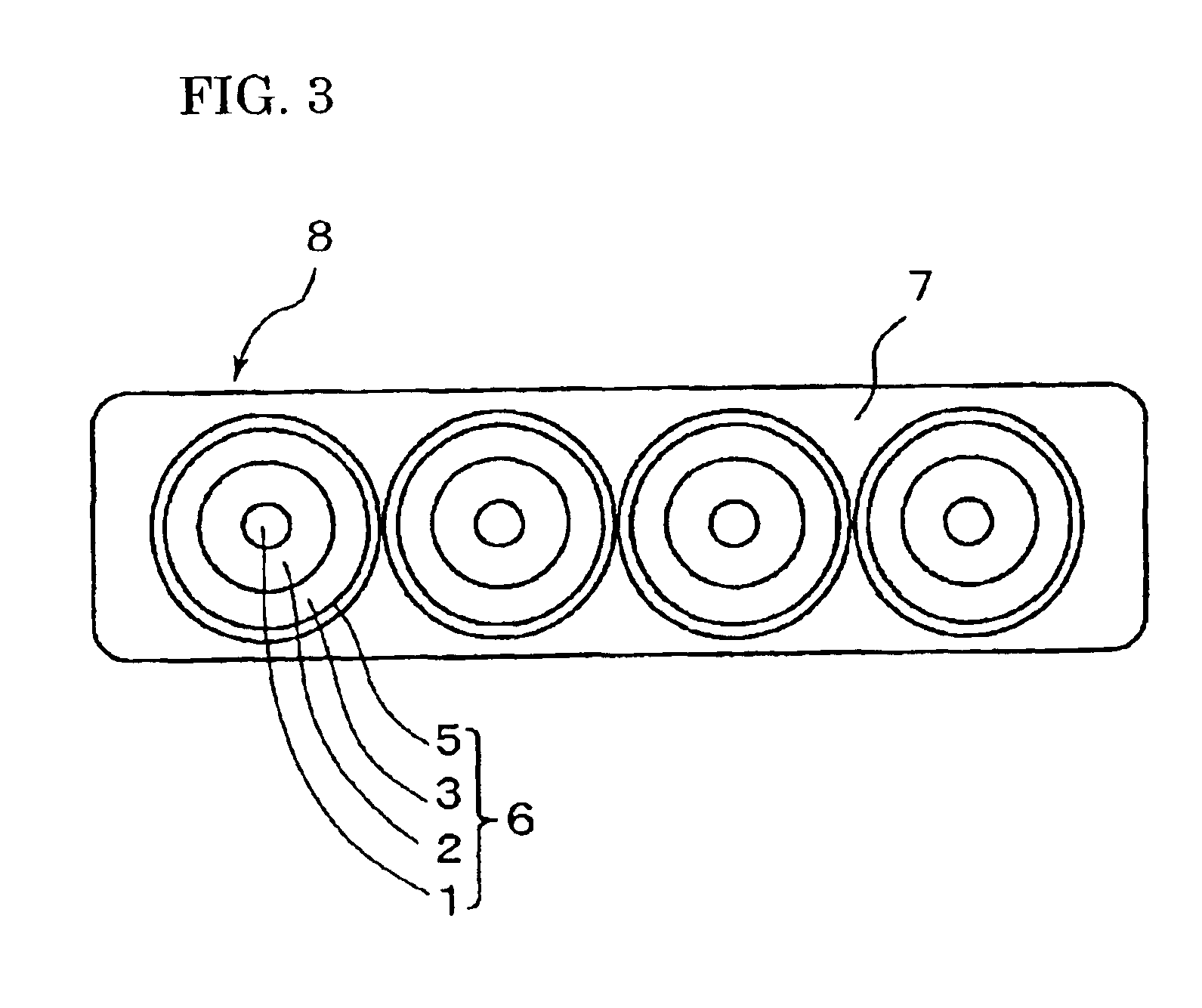

Coated optical fiber

InactiveUS6810188B1Shorten the production lineExcellent peelabilityGlass optical fibreOptical fibre with multilayer core/claddingOptoelectronicsPlastic optical fiber

A coated optical fiber is shown in which, by coating a glass optical fiber with a primary coating having a storage modulus E' of 0.01 kg / mm<2 >to 2.0 kg / mm<2 >at 25° and 110 Hz and an adhesion of 10 g / cm to 200 g / cm to the glass optical fiber, delamination at the interface between the glass optical fiber and the primary coating, and voids are prevented during and after the production, for example, on the line during drawing and winding. An optical fiber ribbon of the present invention, which is formed by collectively coating the coated optical fibers each including a primary coating with a storage modulus E' of 0.01 kg / mm<2 >to 0.5 kg / mm<2 >and an adhesion of 10 g / cm to 100 g / m, has a high delamination resistance and a good collective strippability of coatings. In an optical fiber unit of the present invention which is formed by collectively coating the coated optical fibers having a storage modulus E' of 0.01 kg / mm<2 >to 0.5 kg / mm<2 >and an adhesion of 100 g / cm to 200 g / cm, delamination and voids will not occur.

Owner:SUMITOMO ELECTRIC IND LTD

Intelligent management system of ODN (optical distribution network) based on RFID (radio frequency identification)

InactiveCN102307107AAccurate and error-free operabilityExact changeSensing record carriersData switching networksIntelligent managementPlastic optical fiber

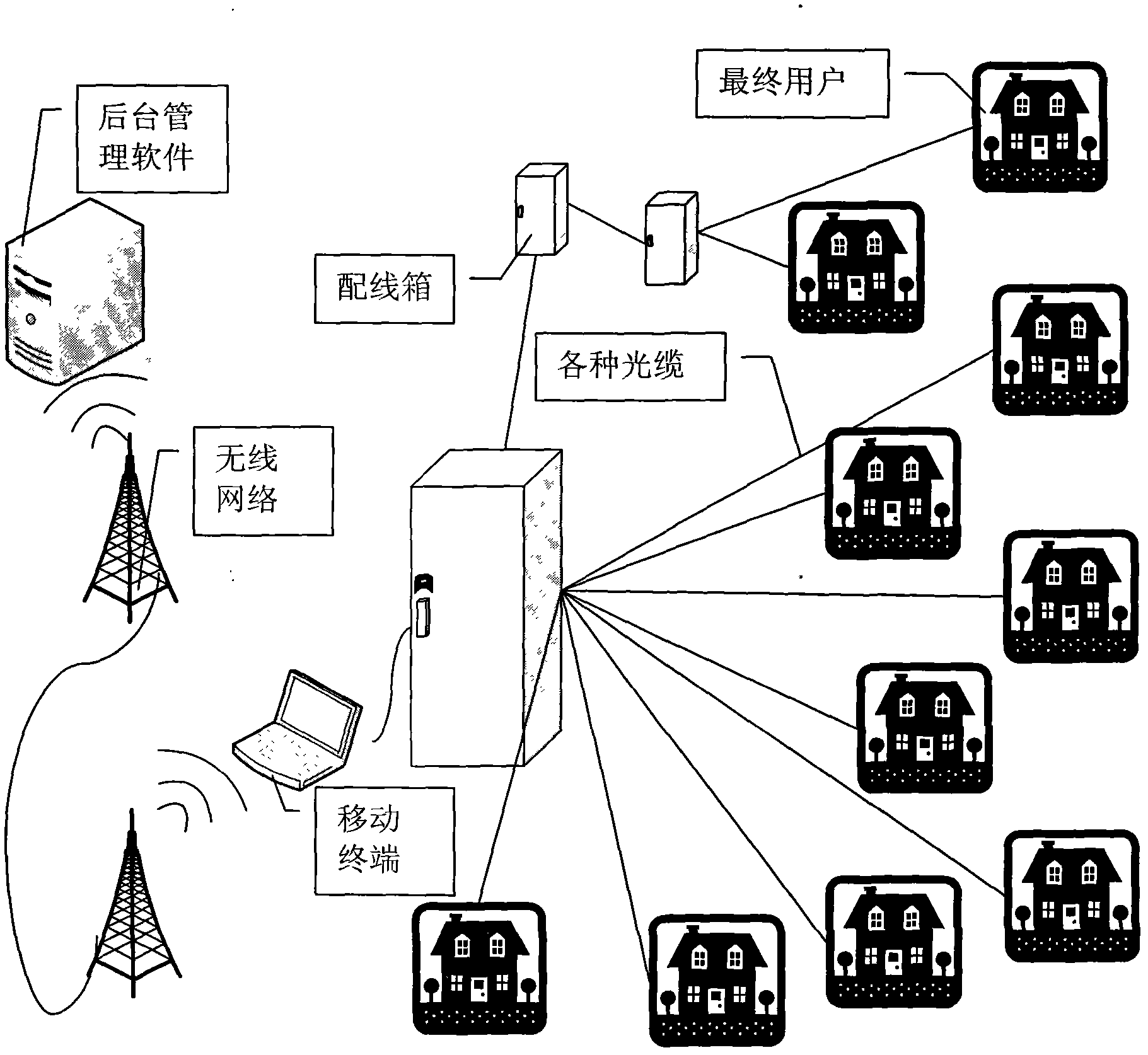

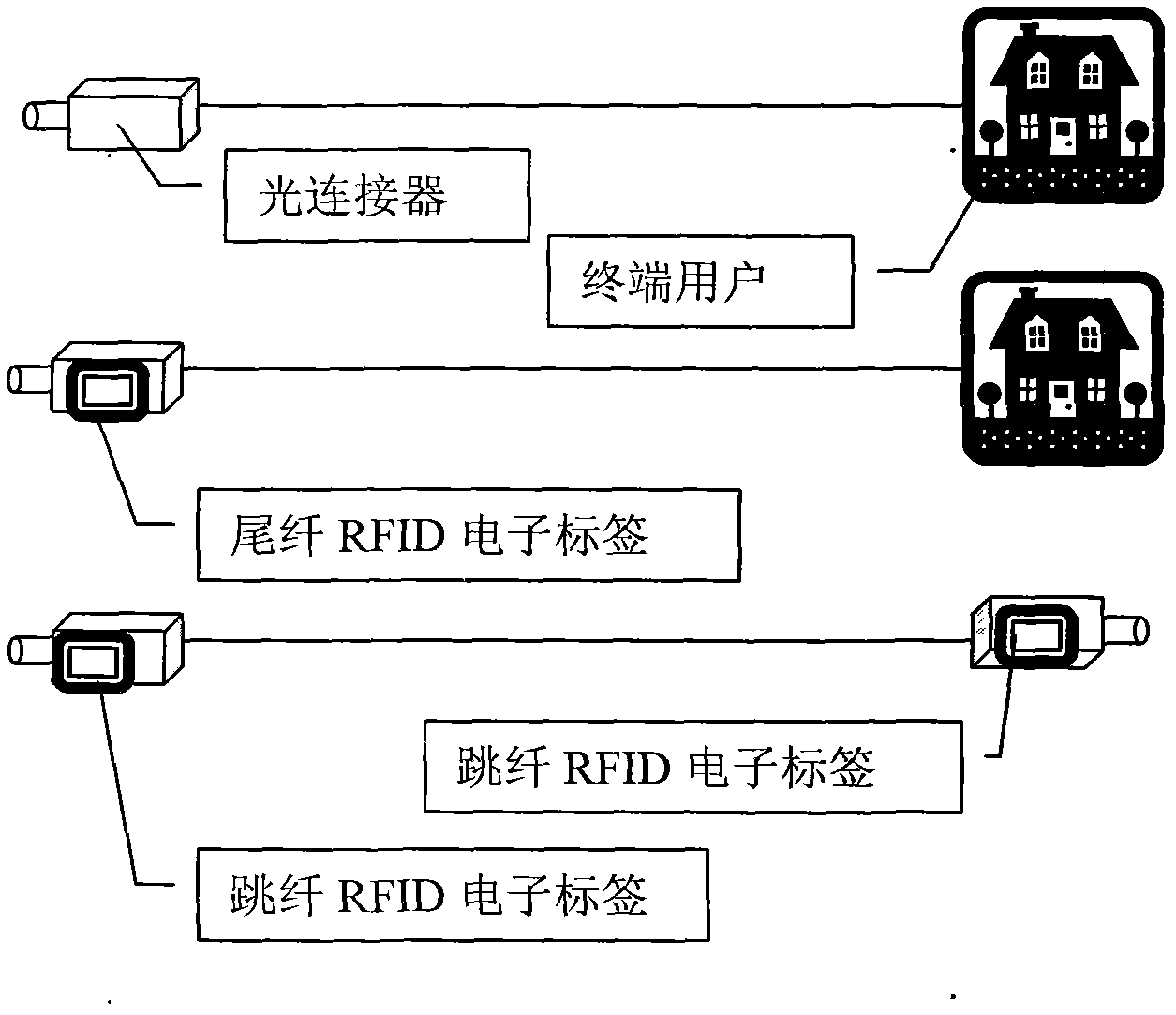

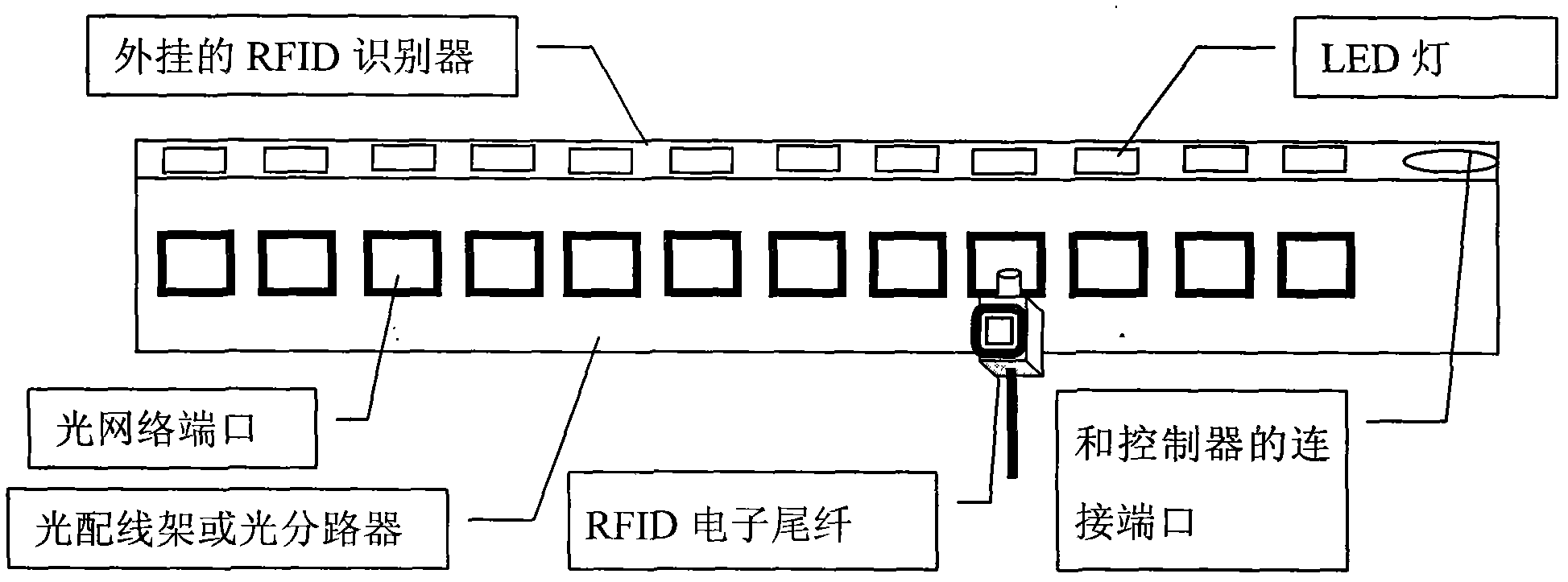

The invention discloses an intelligent management system of an ODN (optical distribution network) based on RFID (radio frequency identification). An RFID technology is utilized to bind an RFID electronic tag with a global unique ID (identifier) to each optical fiber connector; an RFID identifier and an electronic gate lock are added in a distribution box; by matching with back-ground management software and a mobile terminal, when any optical fiber is changed, the back-ground management software is used for sending an instruction to the mobile terminal of an operator; the mobile terminal uses a GIS (geographic information system) to guide the operator to search the position of an optical fiber connecting end, the electronic gate lock is opened, and all the optical fibers are scanned; and the operation is finished under the guidance of the RFID identifier and an LED (light-emitting diode) lamp, so that any misoperation can be perceived in time. By using the technical scheme, thousands of optical cables and tail optical fibers dispersed in the fields can be found out in time if necessary, and the accuracy of all the operations and the changes of the optical fibers can be further ensured.

Owner:SHANGHAI GOKEI INFORMATION TECH

Coated optical fibers

InactiveUS20020146225A1Sufficient high cavitation strengthLow modulusGlass optical fibreSynthetic resin layered productsHigh resistanceCavitation

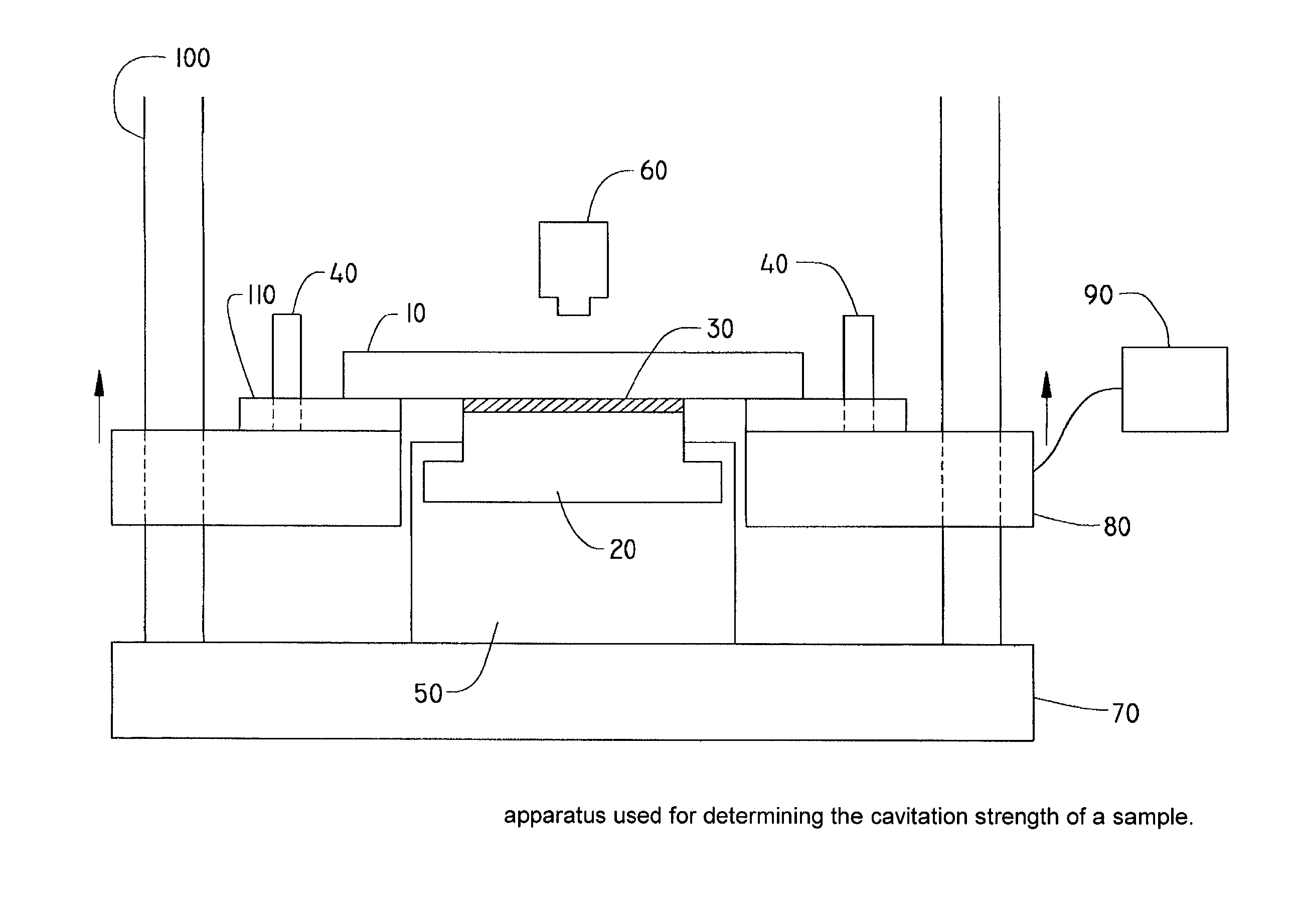

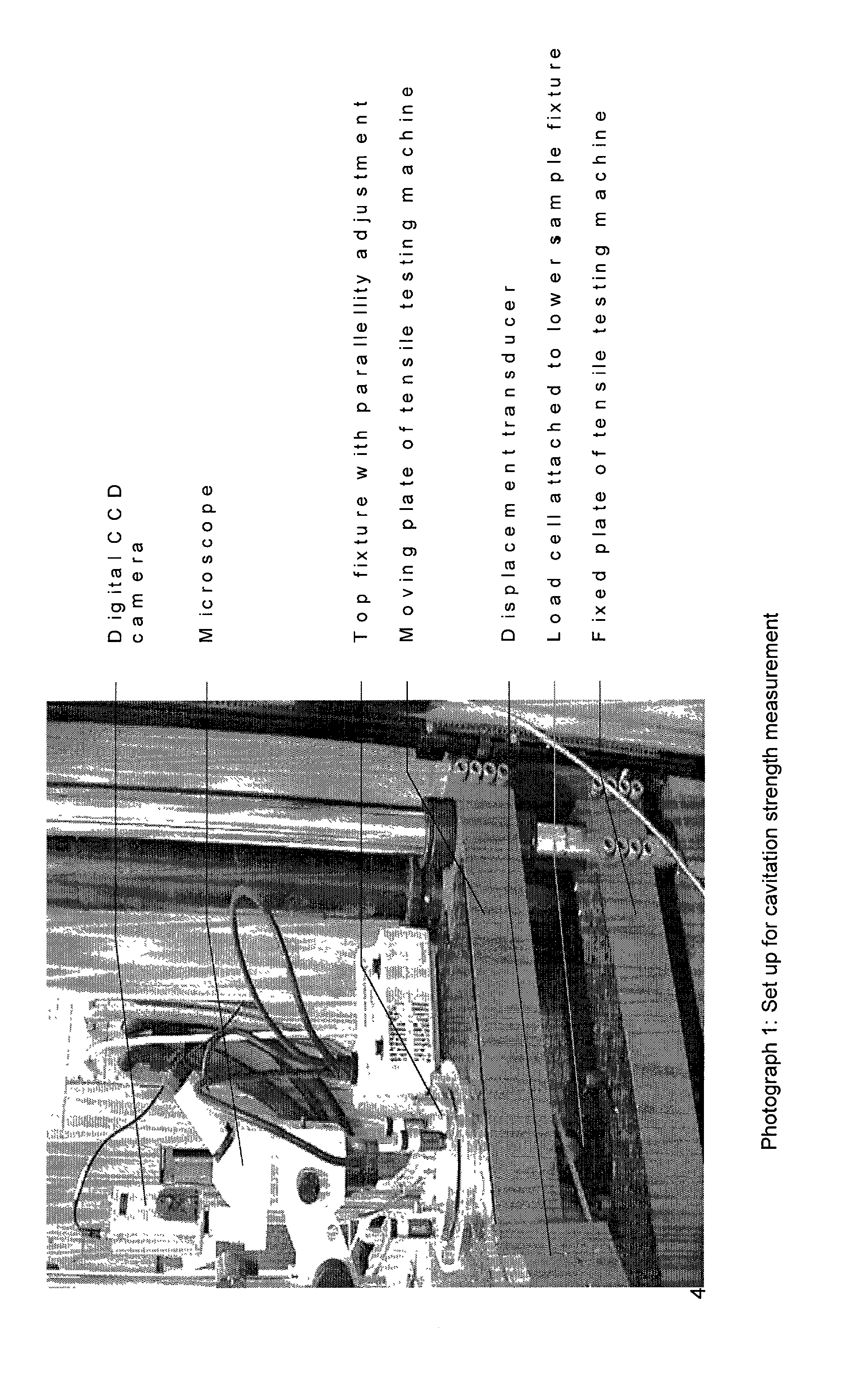

The invention relates to coated optical fibers comprising soft primary coatings and to such primary coatings for protecting glass optical fibers having a sufficient high resistance against cavitation. In particular, the primary coatings have a cavitation strength at which a tenth cavitation appears (sigma10cav) of at least about 1.0 MPa as measured at a deformation rate of 0.20% min-1 and of at least about 1.4 times their storage modulus at 23° C. The coating preferably shows strain hardening in a relative Mooney plot, preferably has a strain energy release rate Go of about 20 J / m2 or more, and preferably has a low volumetric thermal expansion coefficient. The invention furthermore provides a method and apparatus for measuring the cavitation strength of a primary coating.

Owner:DSM IP ASSETS BV

Optical connector with optical fiber

In an optical connector with optical fibers in which silica glass optical fibers with resin coating layers remaining attached are connected in optical fiber openings of a ferrule made from resin, at least a part of the resin coating layer of the optical fiber is glued to an inner face of the optical fiber opening, an outer diameter of the resin coating layer of the optical fiber is less than or equal to 125 μm, and the Young's modulus of the resin coating layer is less than the Young's modulus of the ferrule, and the Young's modulus of the resin coating layer is 1500 to 10000 MPa.

Owner:FUJIKURA LTD

Method of deployment for real time casing imaging

A method for imaging a structure disposed in a borehole penetrating the earth, the method including: selecting a splice housing having a first port configured to seal the housing to a first fiber optic cable and a second port configured to seal the housing to a fiber optic sensor configured to image the structure, wherein the housing includes a sealed interior volume sufficient to contain a splice of optical fibers for protection and to enable a functional bend of at least ninety degrees for at least one spliced optical fiber; disposing a splice between an optical fiber of the first fiber optic cable and an optical fiber of the fiber optic sensor in the splice housing; disposing the splice housing containing the splice in the borehole; attaching the fiber optic sensor to the structure; and disposing the structure in the borehole after the splice housing is disposed in the borehole.

Owner:BAKER HUGHES HLDG LLC

Fiber optic switch employing optical amplifiers

A method and apparatus of switching a digital signal from a single input optical fiber to one or more optical fibers comprising the steps of providing an input signal into the input optical fiber, splitting the input optical fiber to form a plurality of split optical fibers each carrying the input signal, amplifying the signal in at least one of the plurality of split optical fibers with a laser activated amplifier, and then attenuating the signal in all of the split optical fibers to produce at least one output signal in one or more of the designated split optical fibers.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

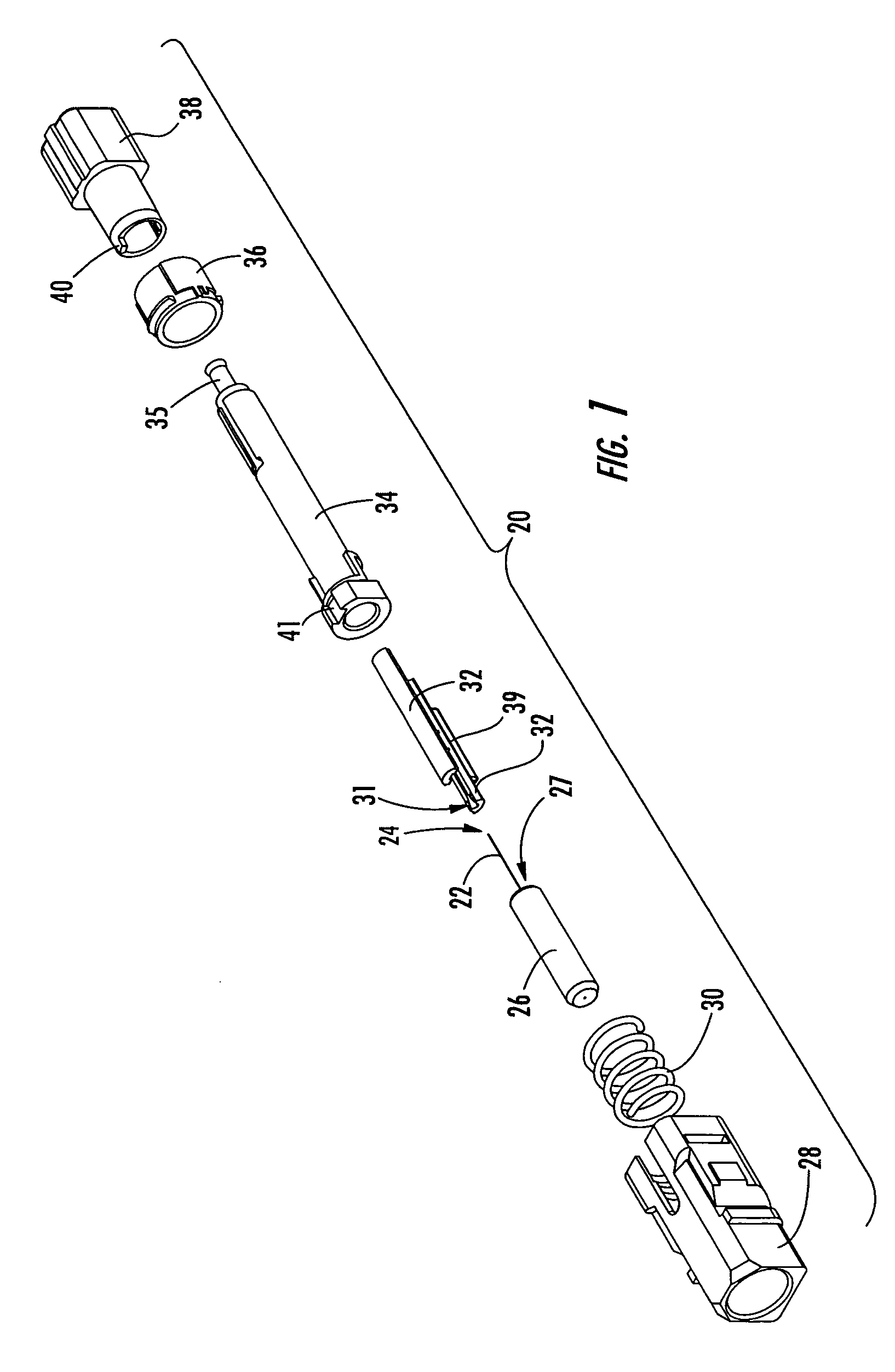

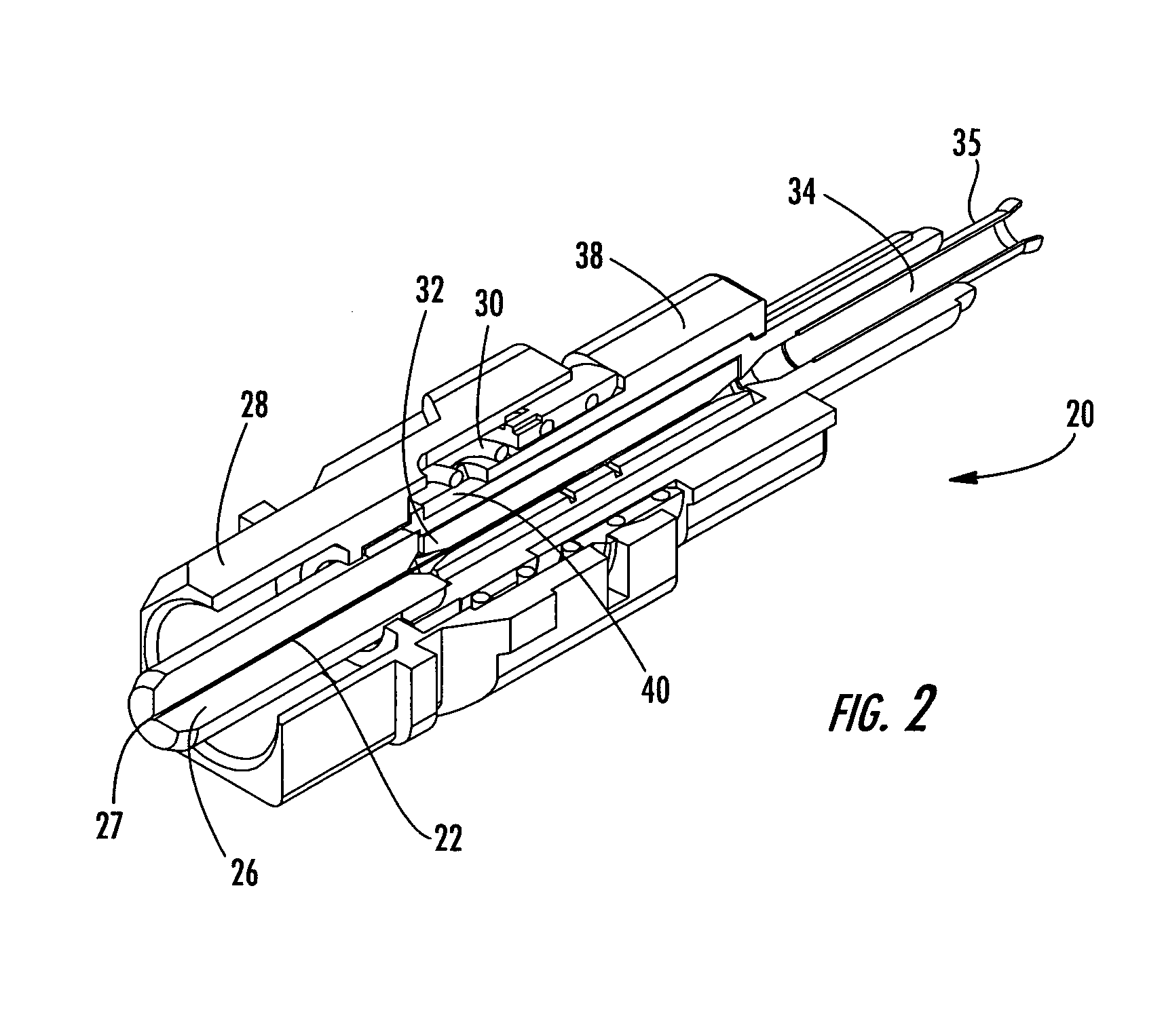

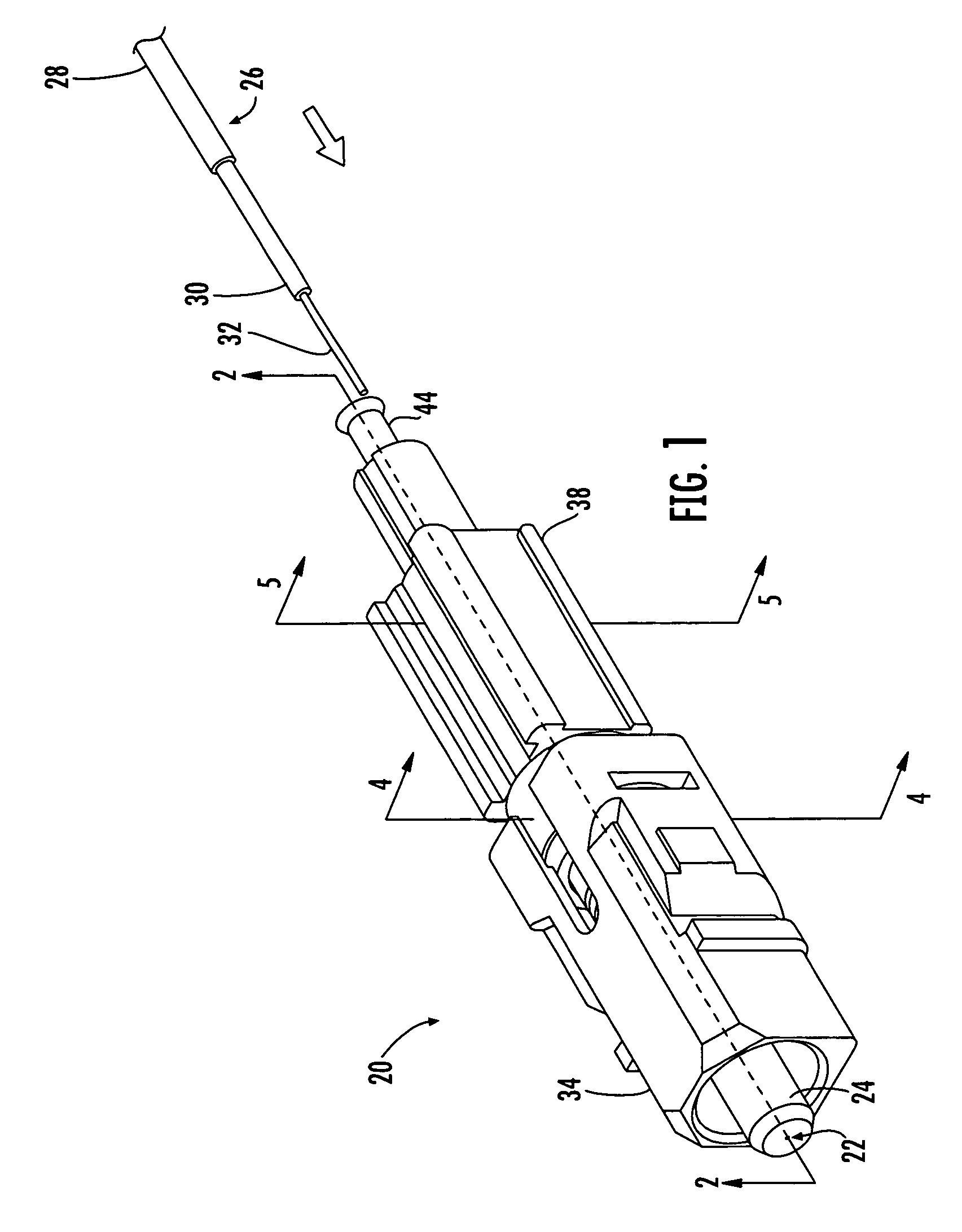

Splice connector for verifying an acceptable splice termination

A splice connector for verifying an acceptable splice termination includes a ferrule having a stub optical fiber, a ferrule holder for receiving the ferrule, opposed splice components within the ferrule holder for receiving and aligning the stub optical fiber and a field optical fiber, a cam member for engaging one of the splice components to terminate the field optical fiber, and means for viewing an amount of glow emanating from a termination area. In one embodiment, a splice component and the portion of the ferrule holder disposed between the splice component and the cam member are optically transmissive. The cam member has a first array of wells and a second array of wells for viewing the amount of glow before and after the field optical fiber is terminated. In another embodiment, the ferrule holder is opaque and has a view port, while the cam member has a first well having a first depth and a second well having a second depth.

Owner:CORNING OPTICAL COMM LLC

Multicore optical fiber with integral diffractive elements machined by ultrafast laser direct writing

InactiveUS7587110B2Optical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingRefractive indexPlastic optical fiber

A multicore optical fiber with an integral diffractive element. The multicore optical fiber includes: a first optical fiber core formed of a non-photosensitive material having an initial index of refraction; and a second optical fiber core including a second longitudinal core axis substantially parallel to the first longitudinal axis. The first optical fiber core includes: a first longitudinal core axis; and a number of index-altered portions having an altered index of refraction which is different from the initial index of refraction. The index-altered portions are arranged within the non-photosensitive material of the first optical fiber core to form a diffractive structure of the integral diffractive element.

Owner:PANASONIC HEALTHCARE HLDG CO LTD

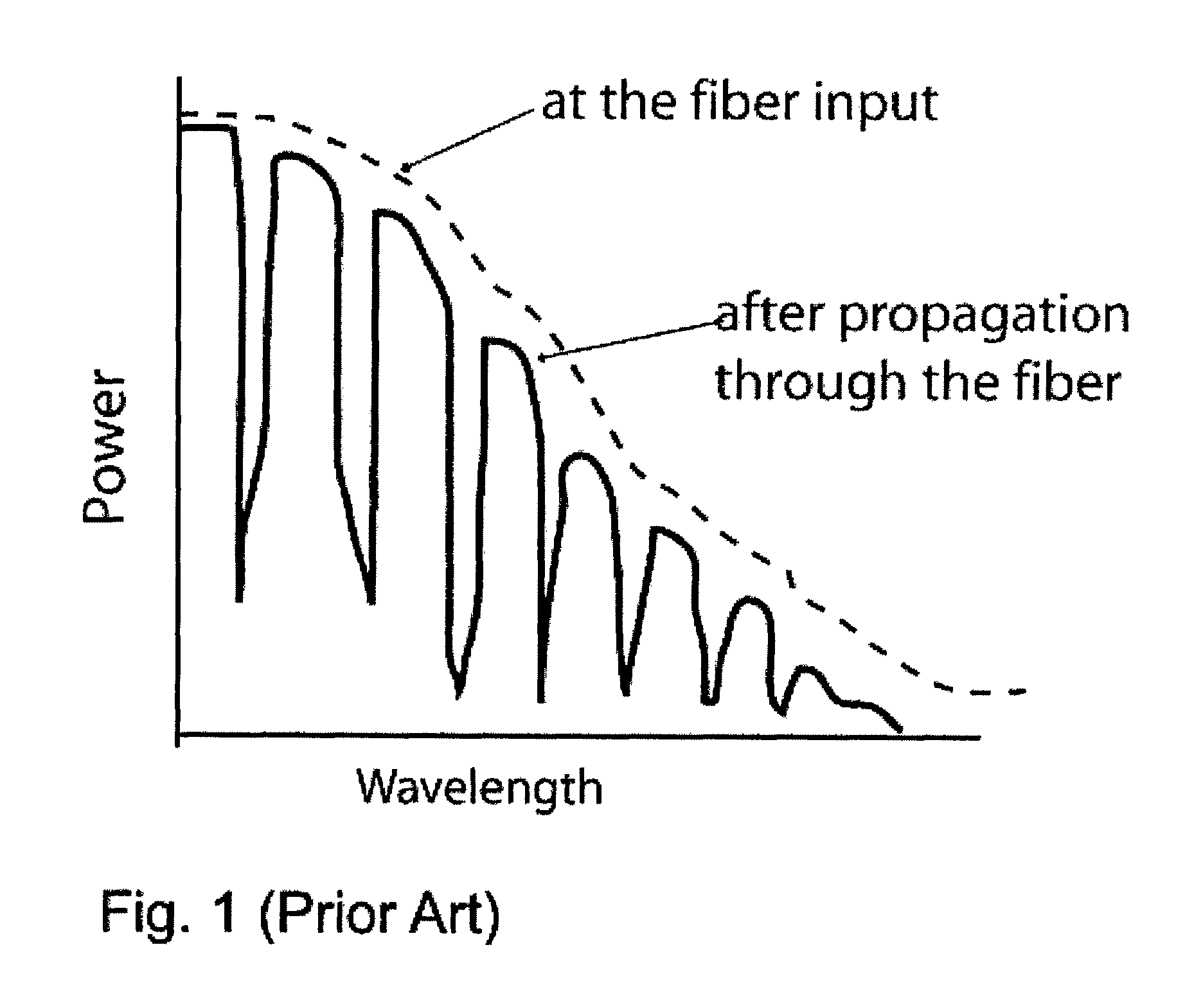

Systems and techniques for compensation for the thermo-optic effect in active optical fibers

ActiveUS9325151B1Prevent degradation of single-modednessPrevent degradationActive medium shape and constructionFiberEngineering

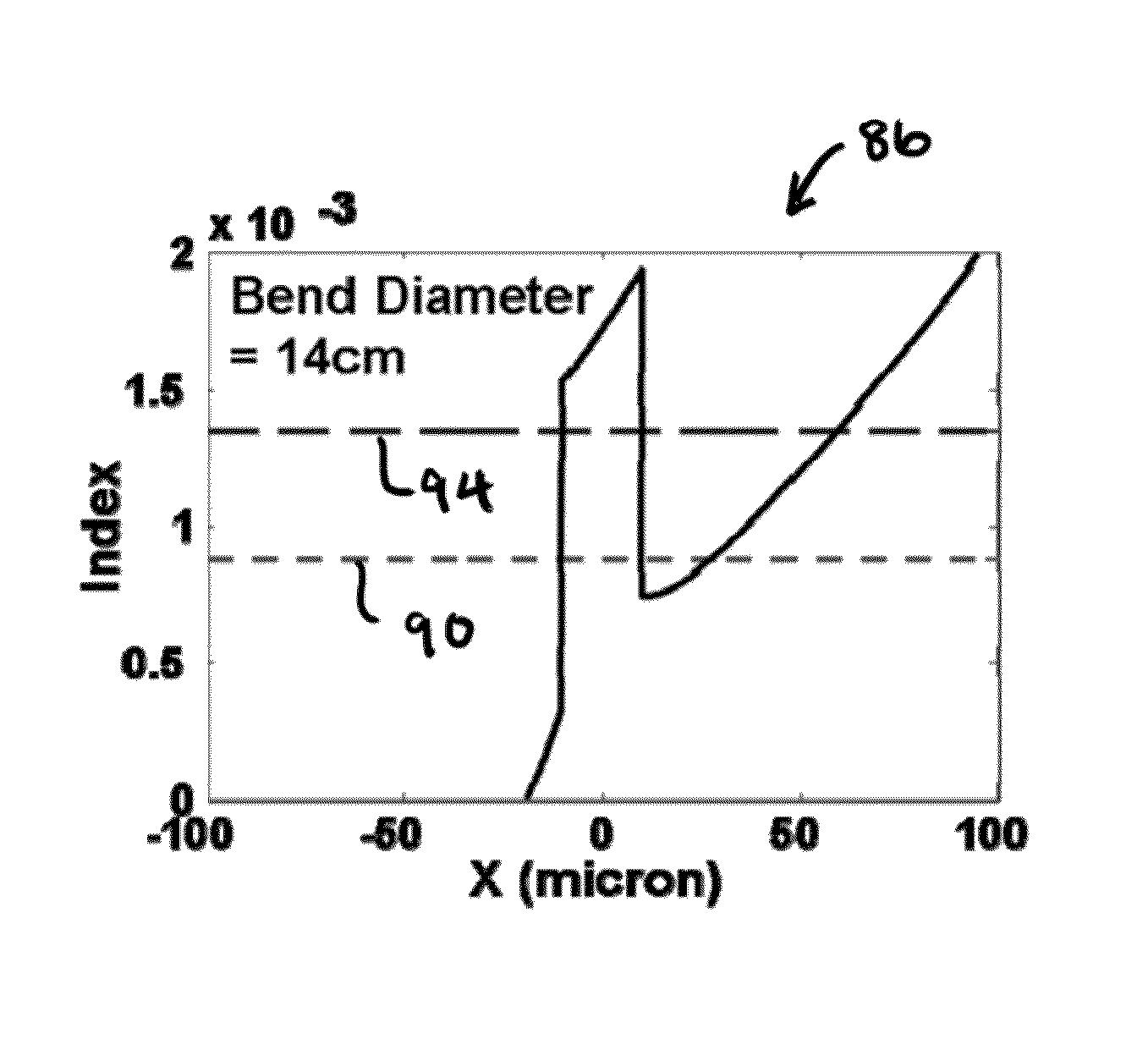

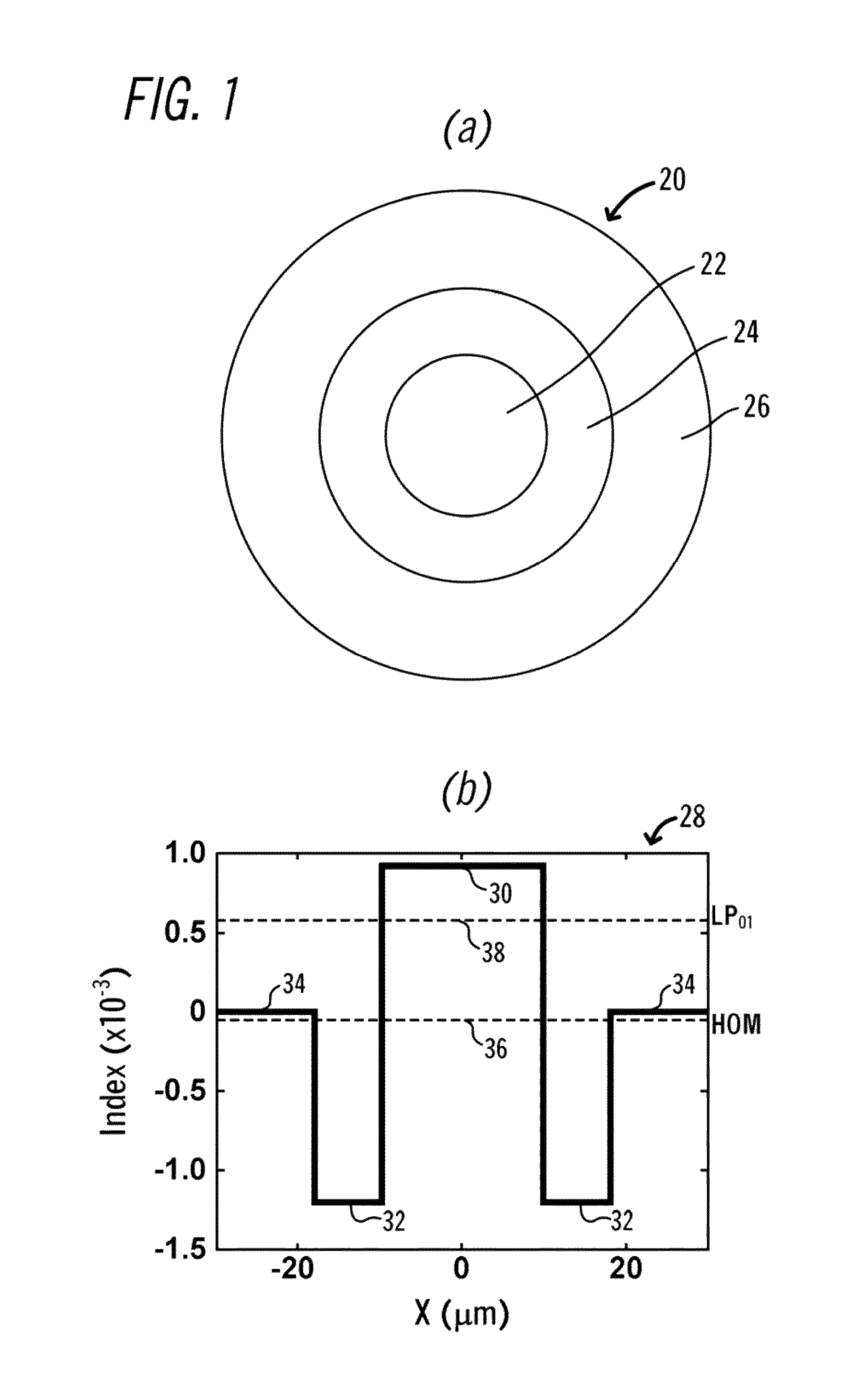

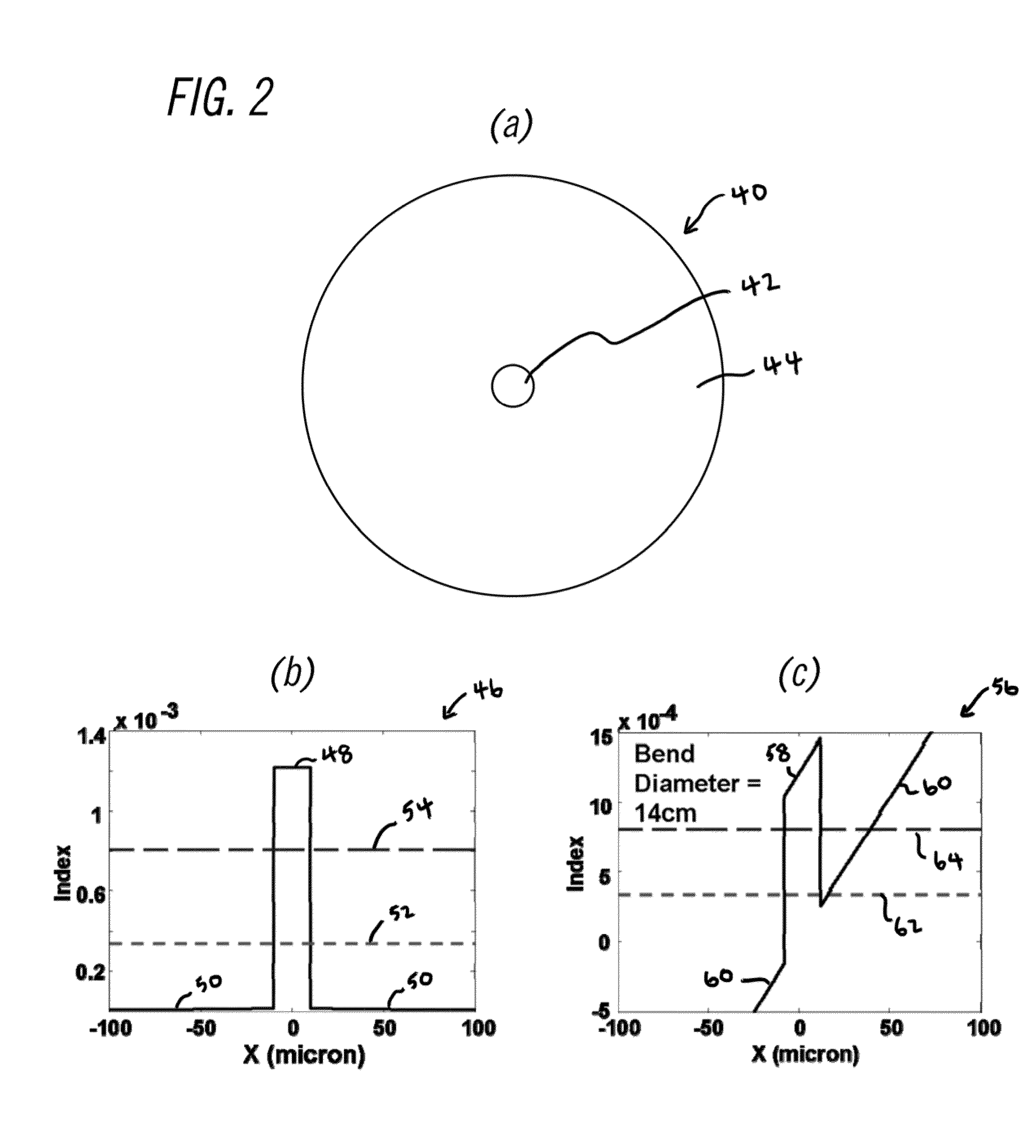

A technique is described for providing compensation for the thermo-optic effect in a large-mode-area optical fiber, filter fiber, or the like. An optical fiber is provided having a refractive index profile with ambient temperature loss characteristics including a low loss for a first type of light and a high loss for a second type of light. A hot region of the fiber connected into an optical system is identified, in which a thermal index gradient is induced in the fiber. The thermal index gradient, in the absence of a compensating index gradient, would result in degradation of the fiber's ambient temperature loss characteristics. The fiber is arranged according to a layout having a position-varying bending diameter. Throughout the identified hot region, the fiber has a compensating bending diameter that induces a compensating index gradient in the fiber. Outside of the identified hot region, the fiber has an applied operating bending diameter that maintains the fiber's ambient temperature loss characteristics.

Owner:OFS FITEL LLC

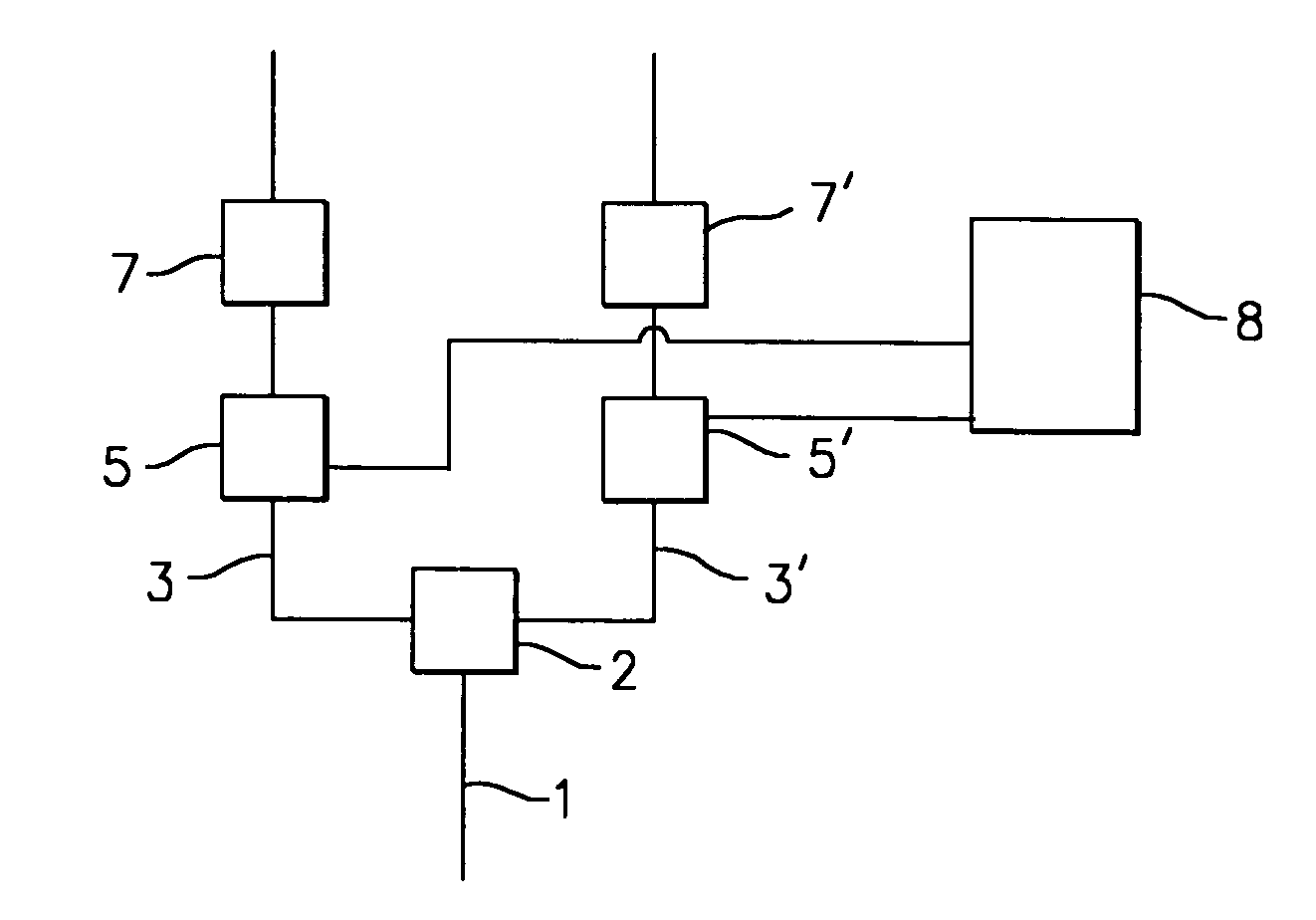

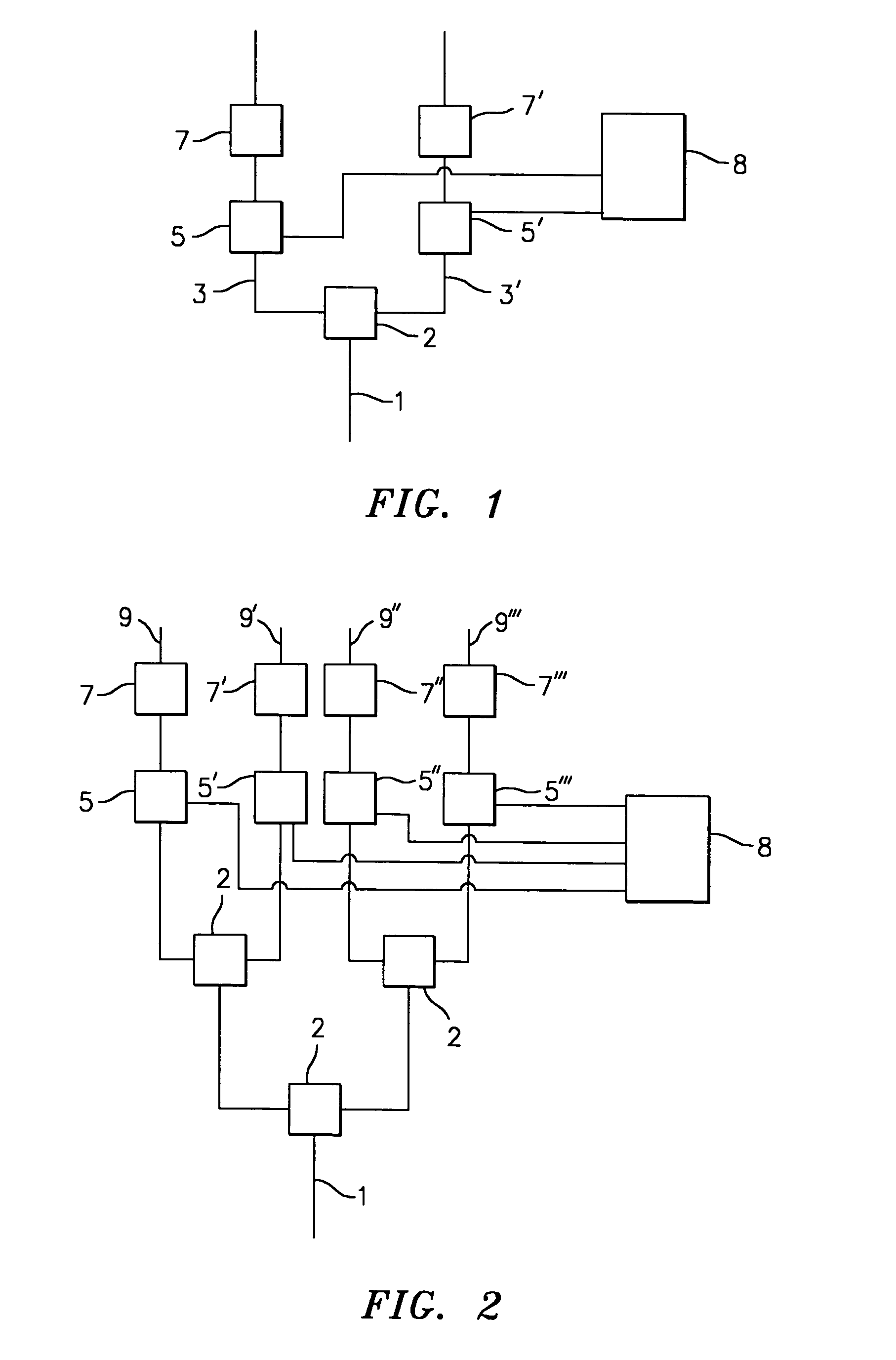

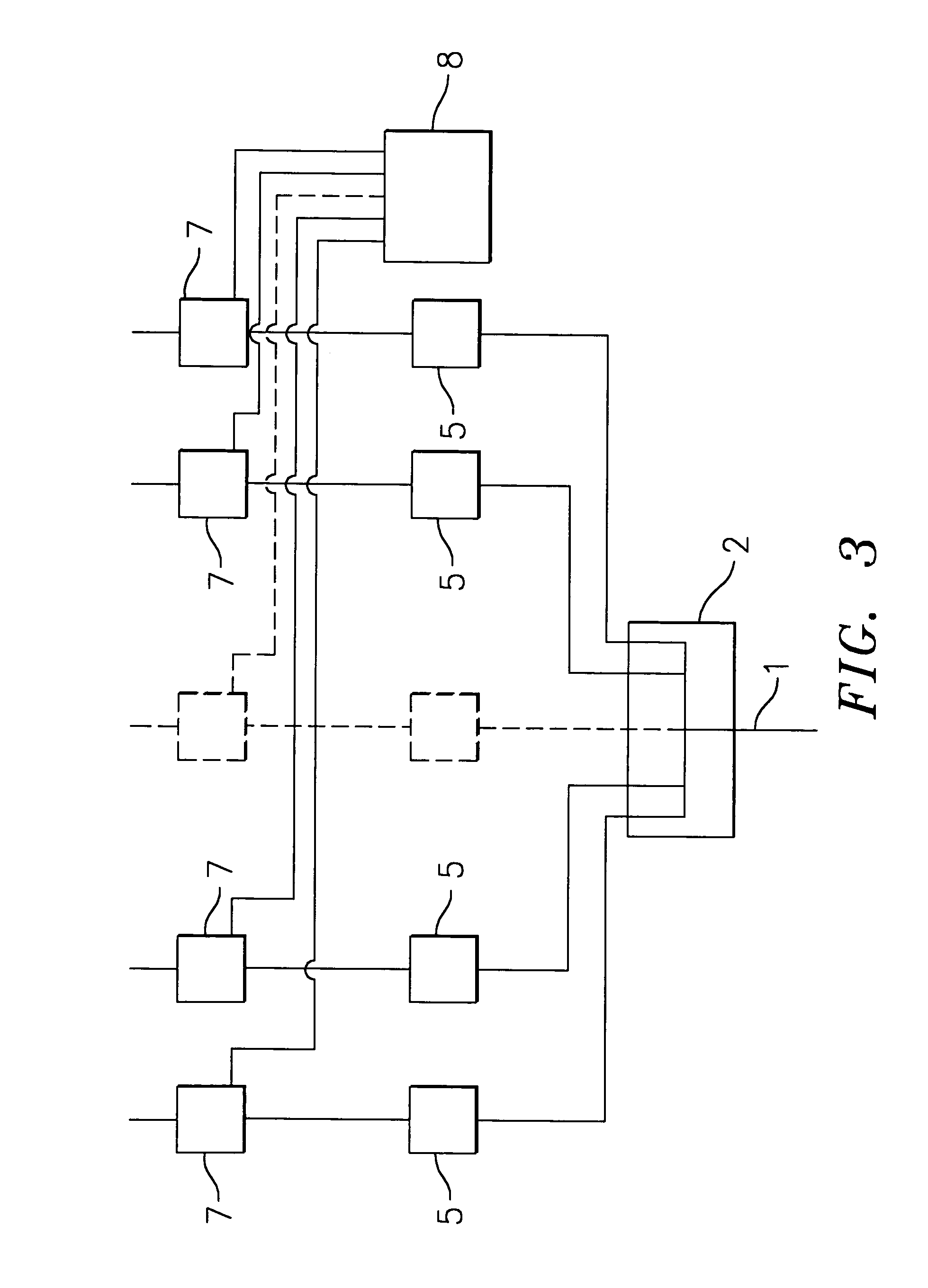

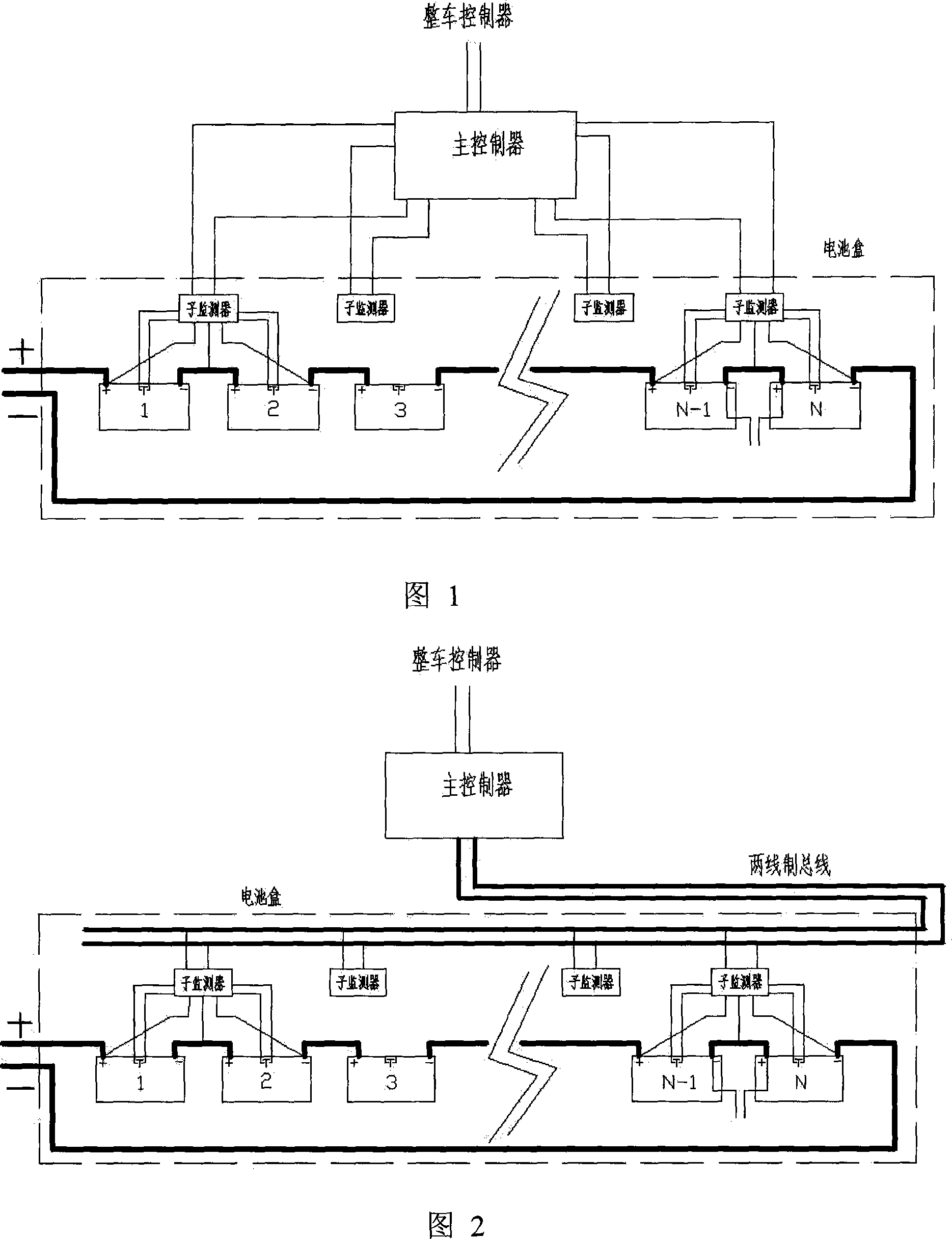

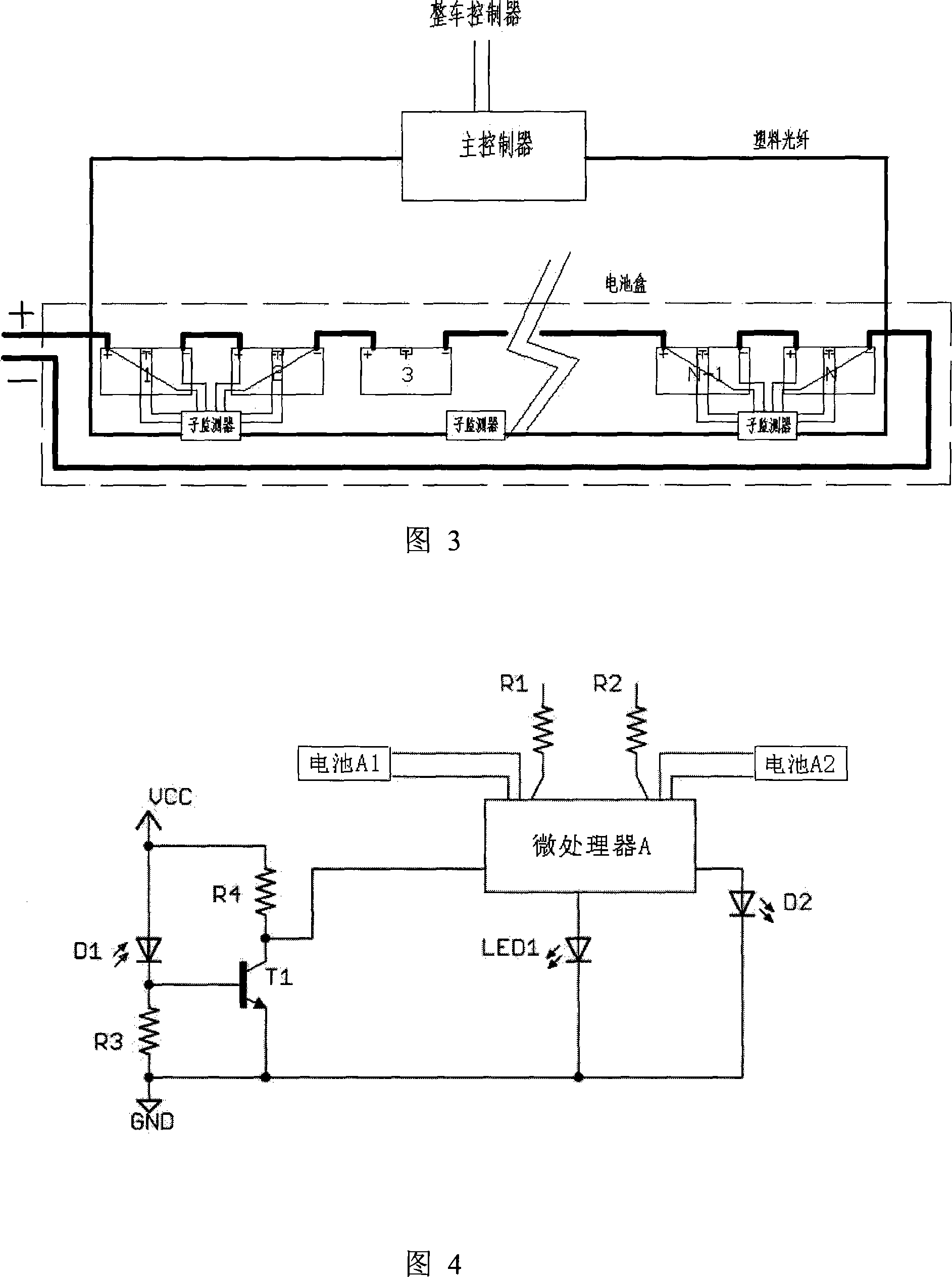

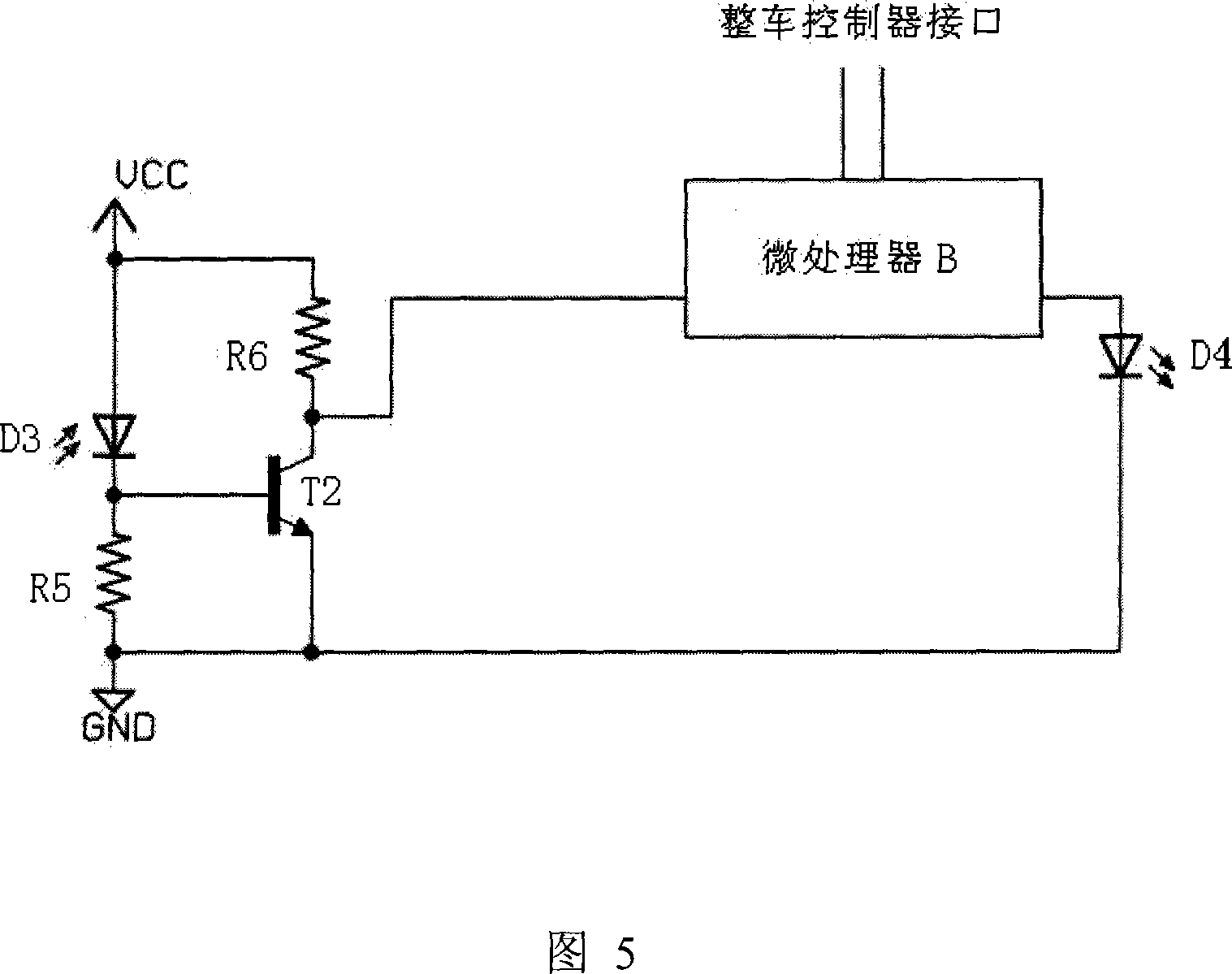

Battery management system for electric automobile

InactiveCN101119036AIncrease communication power consumptionCircuit monitoring/indicationCharge equalisation circuitElectrical batteryElectromagnetic interference

The present invention discloses a battery managing system for electromotive vehicle, which includes: a plurality of the monitors. Each monitor takes the sample for the voltage and temperature of a single battery or a plurality of the single batteries; a main controller which is used for receiving the voltage and temperature data emitted by the sub-monitor, and analyzing the data to realize the balance controlling for the battery, and simultaneously finish the communication with the whole vehicle controller. The main controller and a plurality of the sub-monitors are connected with each other in parallel by the plastic fiber, to form a loop circuit structure. Using the battery managing system with the structure, the main controller and the sub-monitor are connected with each other in parallel by the plastic fiber, to completely eliminate the potential safety hazard and the electromagnetic interference caused by the communication wires are distributed in the high voltage net of the pile with a large area.

Owner:北京亿马先锋汽车科技有限公司

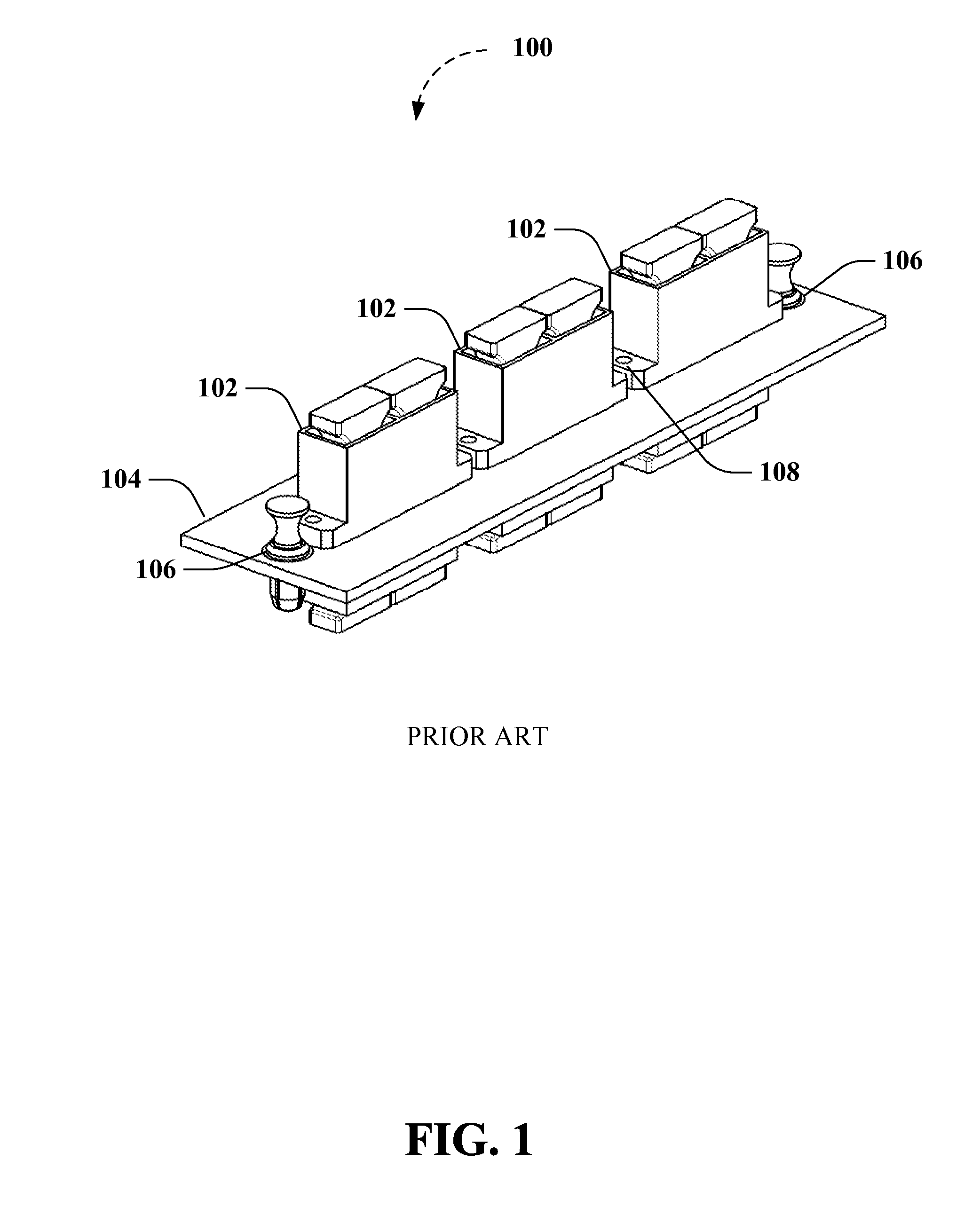

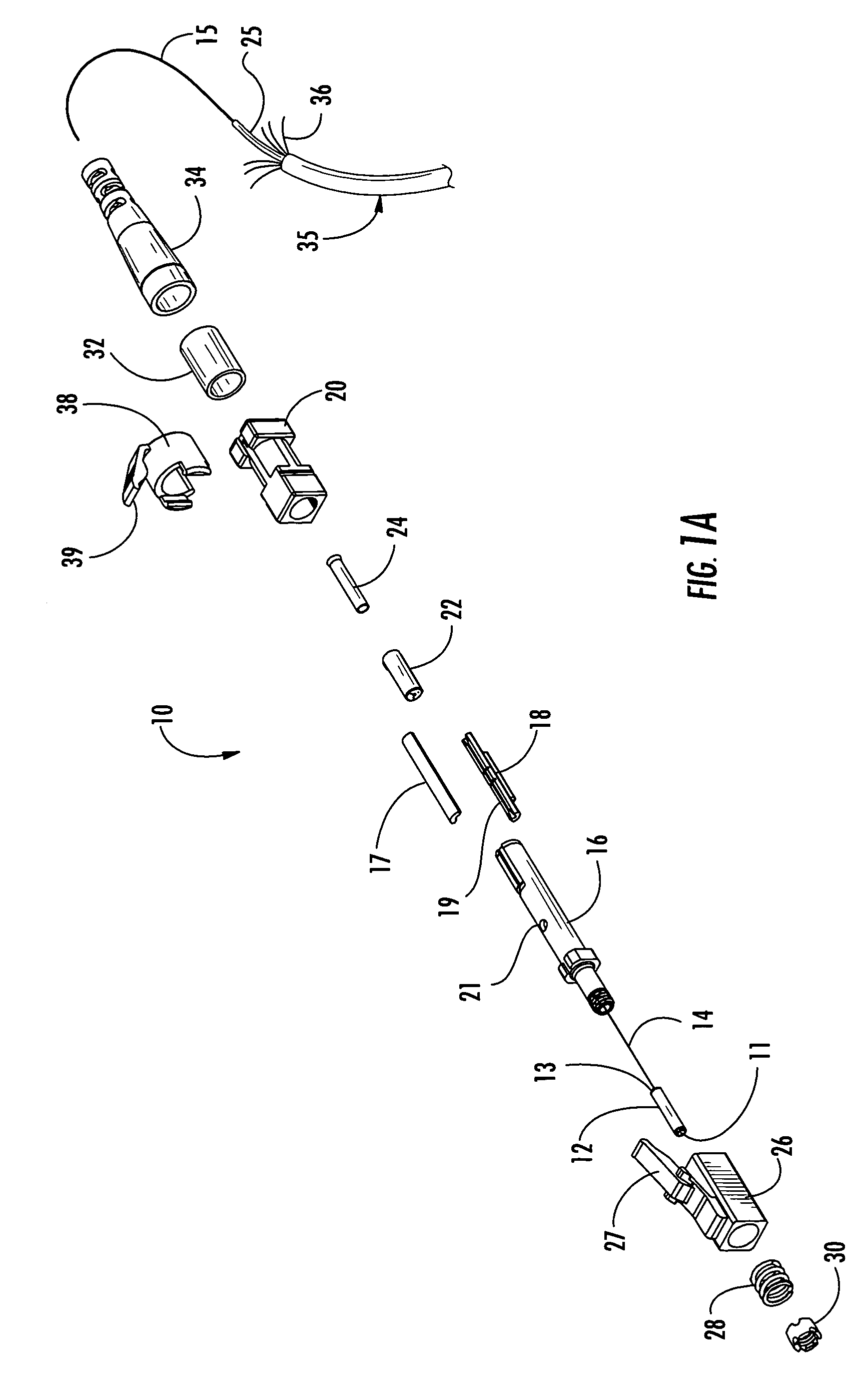

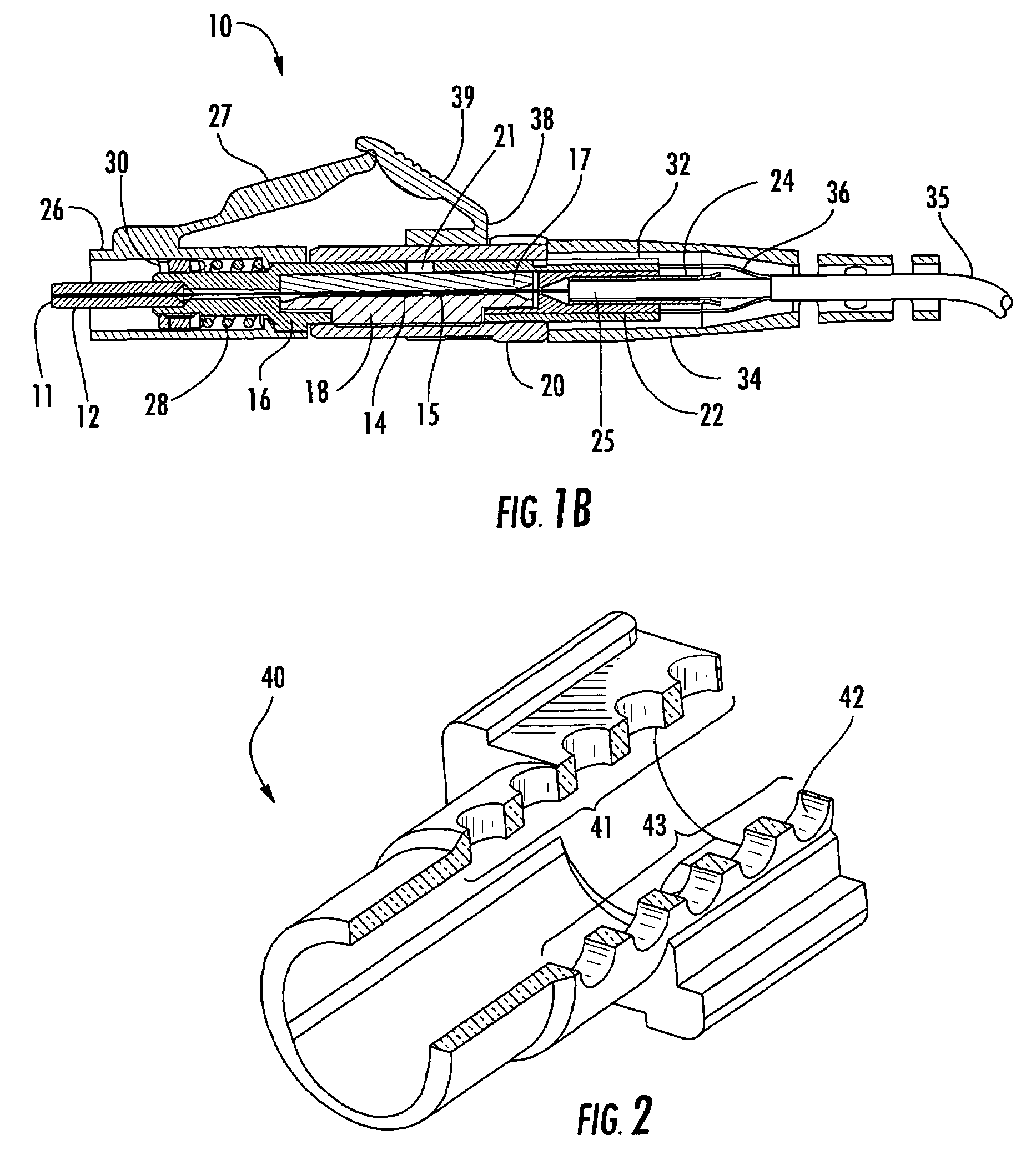

Dual function splice component for mechanical splice connector

ActiveUS7264410B1Eliminate positioning effectsOptical strainCoupling light guidesFiberMechanical splice

A fiber optic mechanical splice connector including a single connector element operable for providing optical fiber alignment and strain relief includes opposed splice components that define first and second grooves for receiving the bare glass portions of mating optical fibers, as well as the coated or buffered portion of at least one of the optical fibers when the splice components are biased together by an actuator. The mating optical fibers are aligned while the coated or buffered portion of one of the optical fibers is retained within the same connector element, thus eliminating positioning problems that occur when separate connector elements are utilized for fiber alignment and strain relief. The splice components may be unbiased to allow removal of at least one of the mating optical fibers without destroying the connector assembly or potentially damaging the optical fibers.

Owner:CORNING OPTICAL COMM LLC

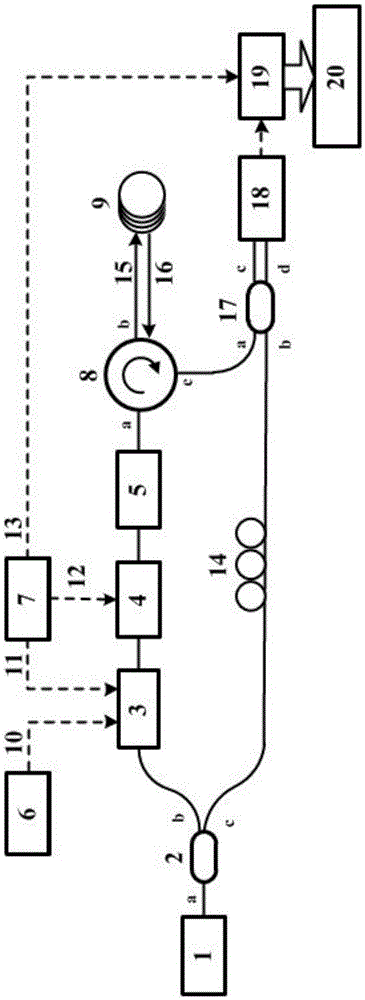

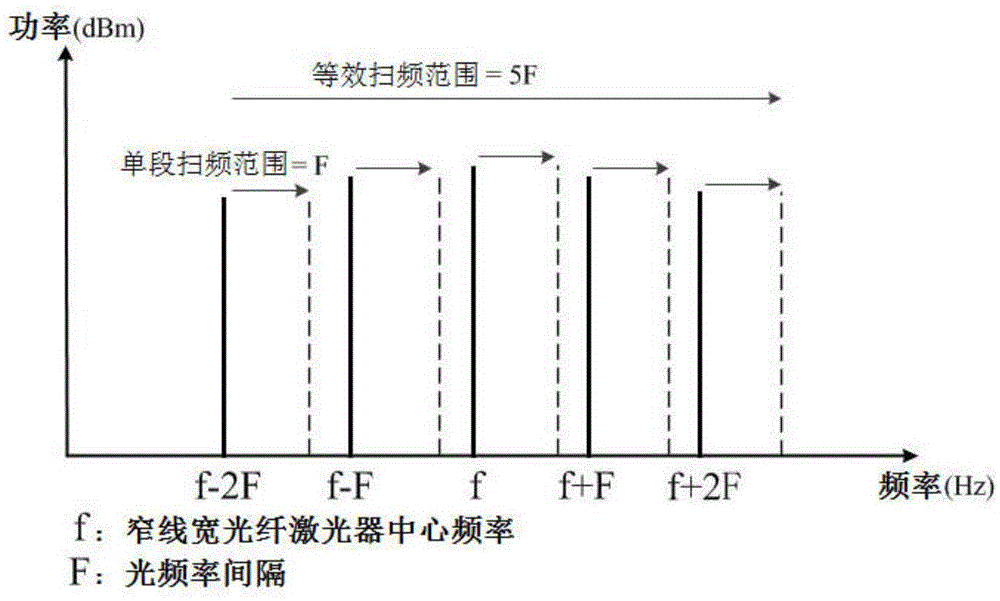

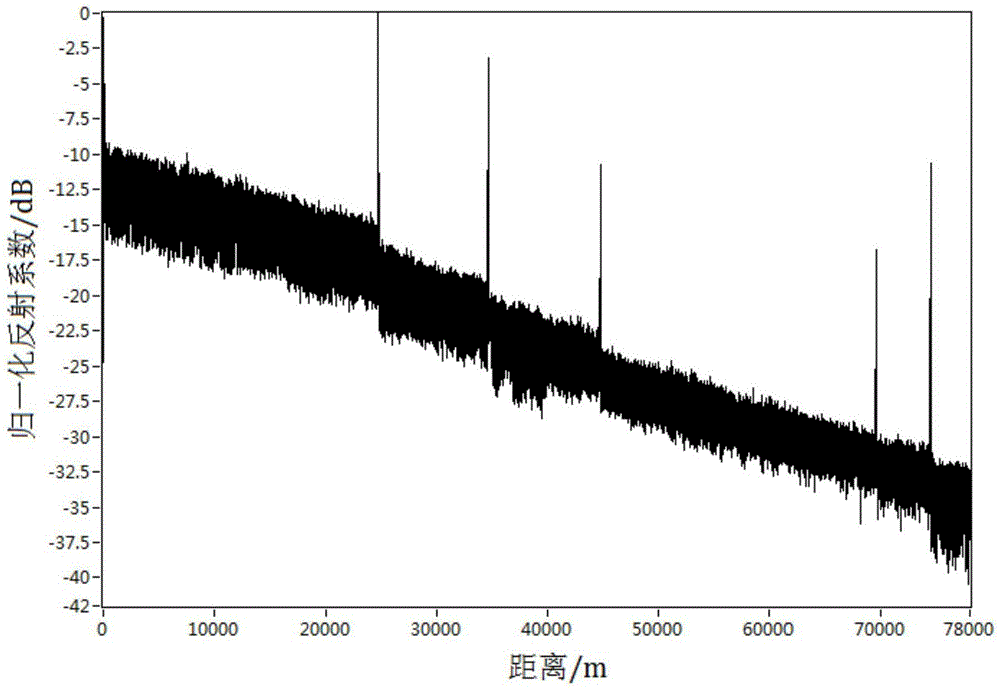

Frequency combination-based optical frequency domain reflection method and system

ActiveCN105490738AGood frequency sweepNo distractionElectromagnetic transmissionAcousto-opticsVIT signals

The invention relates to a frequency combination-based optical frequency domain reflection method and system. According to the frequency combination-based optical frequency domain reflection method and system, electro-optic modulation and acousto-optic modulation are performed on local light, so that optical pulses can be obtained; the optical pulses, adopted as detection pulse optical signals, are inputted into a test optical fiber; coupling and frequency beating are performed on obtained Rayleigh backscattered optical signals and the local light; obtained optical signals are subjected to photoelectric conversion and demodulation; and therefore, an optical frequency reflectometer can be obtained. According to the electro-optic modulation, single-frequency signals are adopted to perform modulation. According to the acousto-optic modulation, pulse signals are adopted to perform modulation. A plurality of frequency components of optical combed signals obtained through the electro-optic modulation are simultaneously subjected to frequency sweeping, so that optical pulses can be obtained. The frequency combination-based optical frequency domain reflection method and system have the advantages of large detection range, high spatial resolution, low hardware cost and low software complexity.

Owner:宁波联河光子技术有限公司

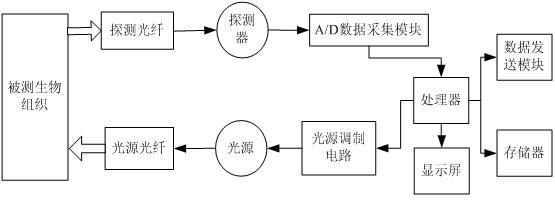

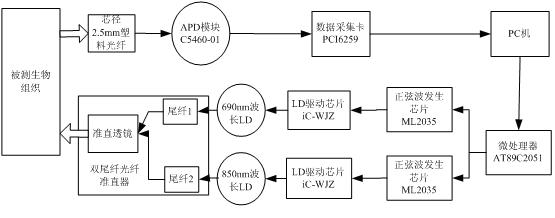

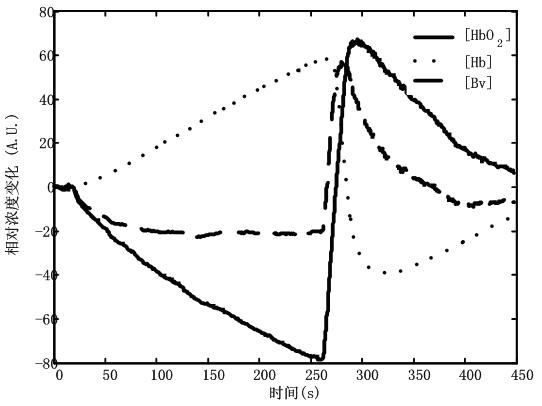

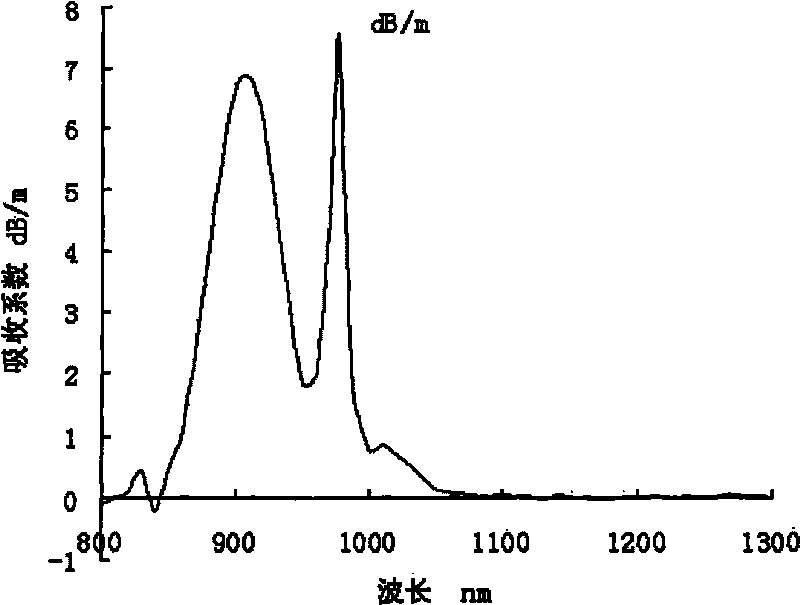

Optical fiber near-infrared spectrometer

InactiveCN101849821AReduce noise levelImprove time resolutionBlood flow measurementNoise levelSinusoidal modulation

The invention relates to an optical fiber near-infrared spectrometer in the technical field of medical devices. The optical fiber near-infrared spectrometer uses multi-tail optical fiber collimator as light source optical fiber, uses a number lock technology as a technical scheme for weak signal extraction, uses a laser diode with a PD as a light source for sinusoidal modulation, uses an avalanche photodiode (APD) or photomultiplier tube (PMT) as a detector, and uses thick core-diameter plastic optical fiber, liquid-core optical fiber, silica optical fiber, a silica optical fiber bundle or glass optical fiber bundle as detection optical fiber. The invention has the advantages that the instrument can conduct nondestructive real-time hemodynamic parameter detection to biological tissues sheltered by hairs, the noise level of the instrument is low, the time resolution is high, the stability is high, the price is cheap, the hardware circuit design is greatly simplified and the portability of the instrument is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

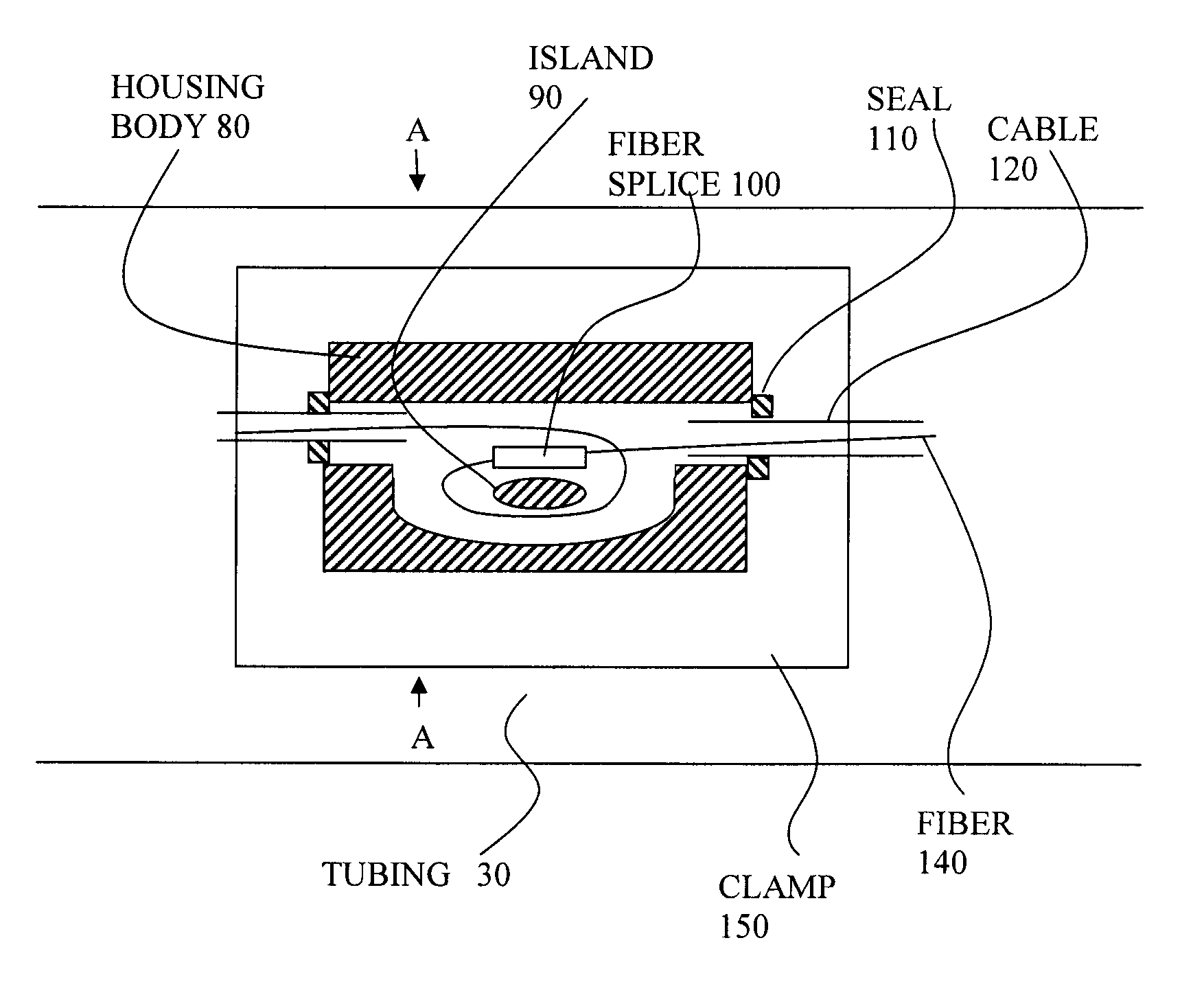

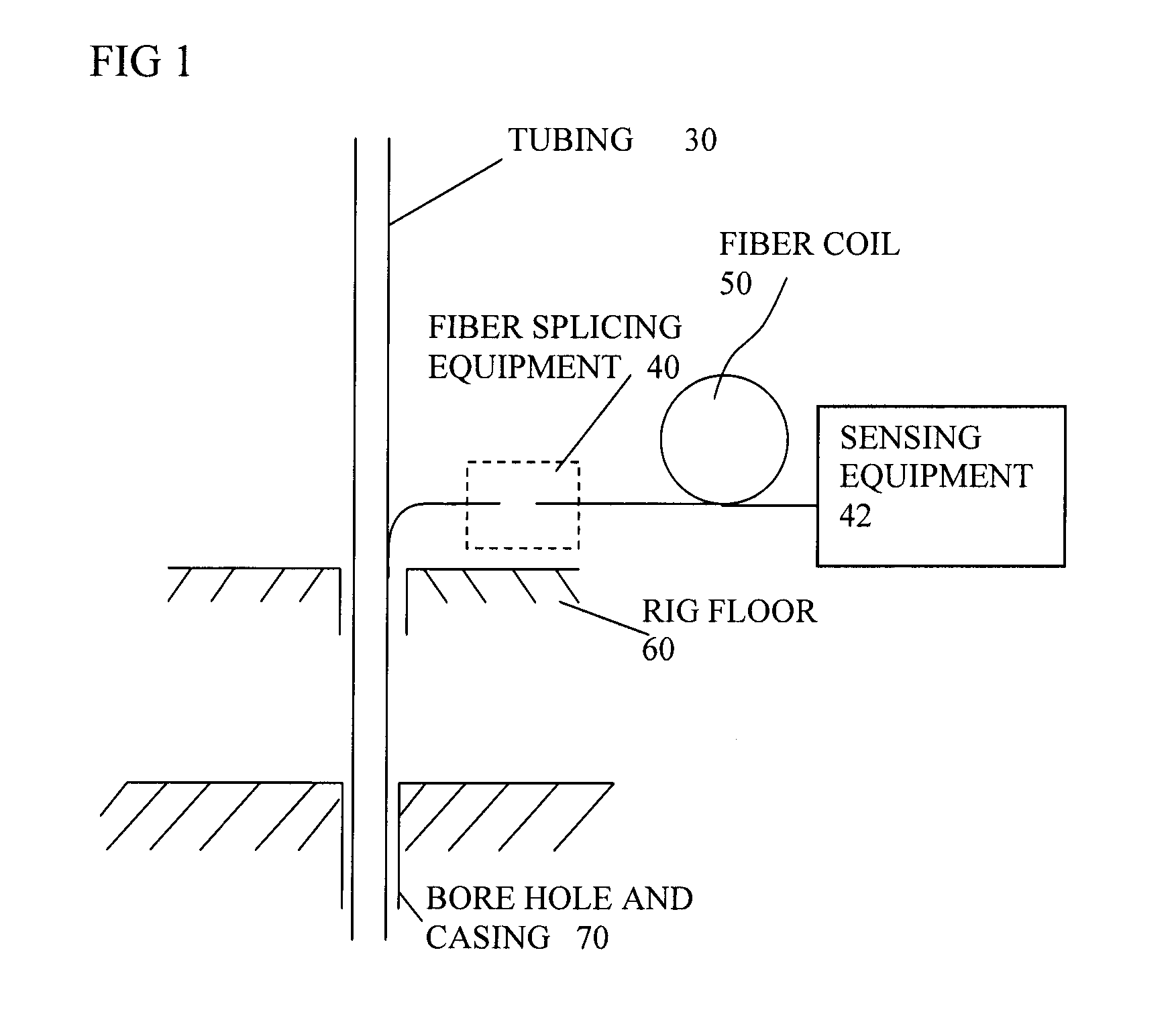

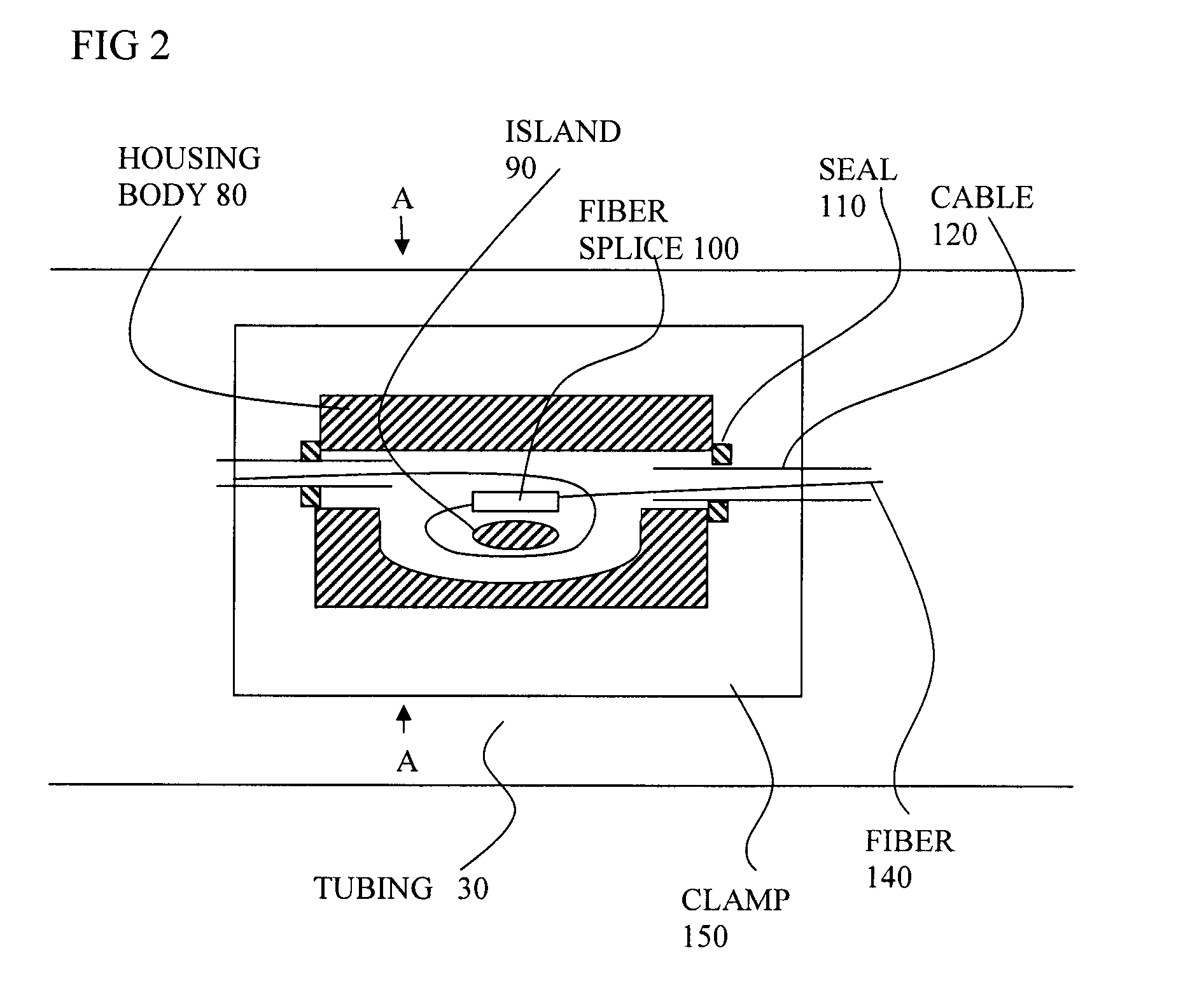

Fiber Splice Housing

Splicing optical fibers from cables running along an infrastructure involves passing the cables into a housing (80) having space to contain a fiber splice (100) and contain an additional length of slack fiber extending around a bend of at least 180 degrees, or a number of coils, in a substantially annular plane. After splicing, the fiber splice and slack fiber are placed in the housing, which is sealed to resist pressures of at least 200 psi, and the assembly is fixed to the infrastructure. The space in the housing can enable the housing to be used for protecting U-bends or to provide some slack fiber within the housing. This can enable faster onsite splicing operations or allow for rework without needing to relocate and strip more cable, to save costs. The housing can be suitable for fitting in the annular space between production tube and casing for use in sensing down boreholes.

Owner:SWELLFIX UK

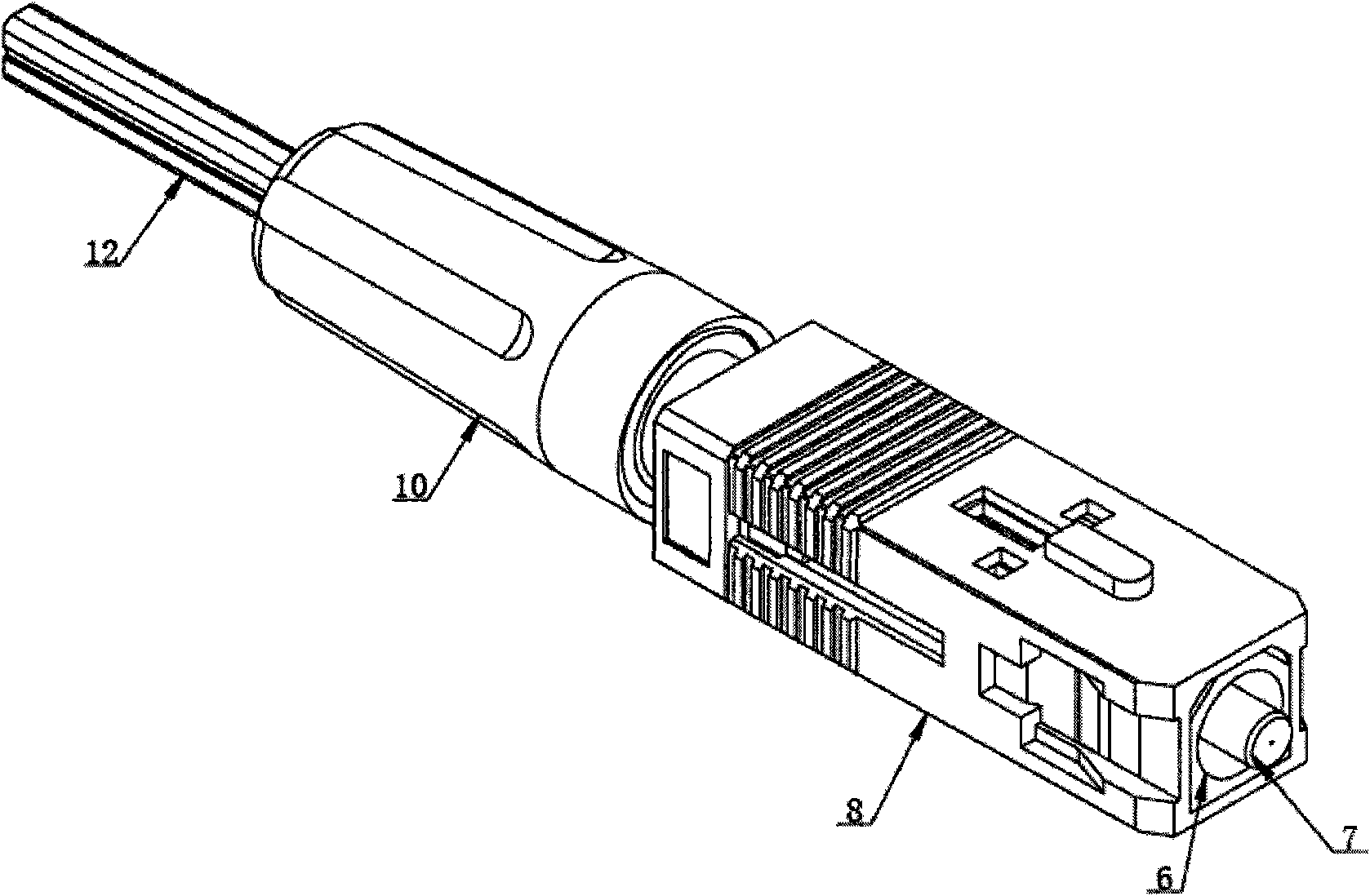

Optical fiber field connector

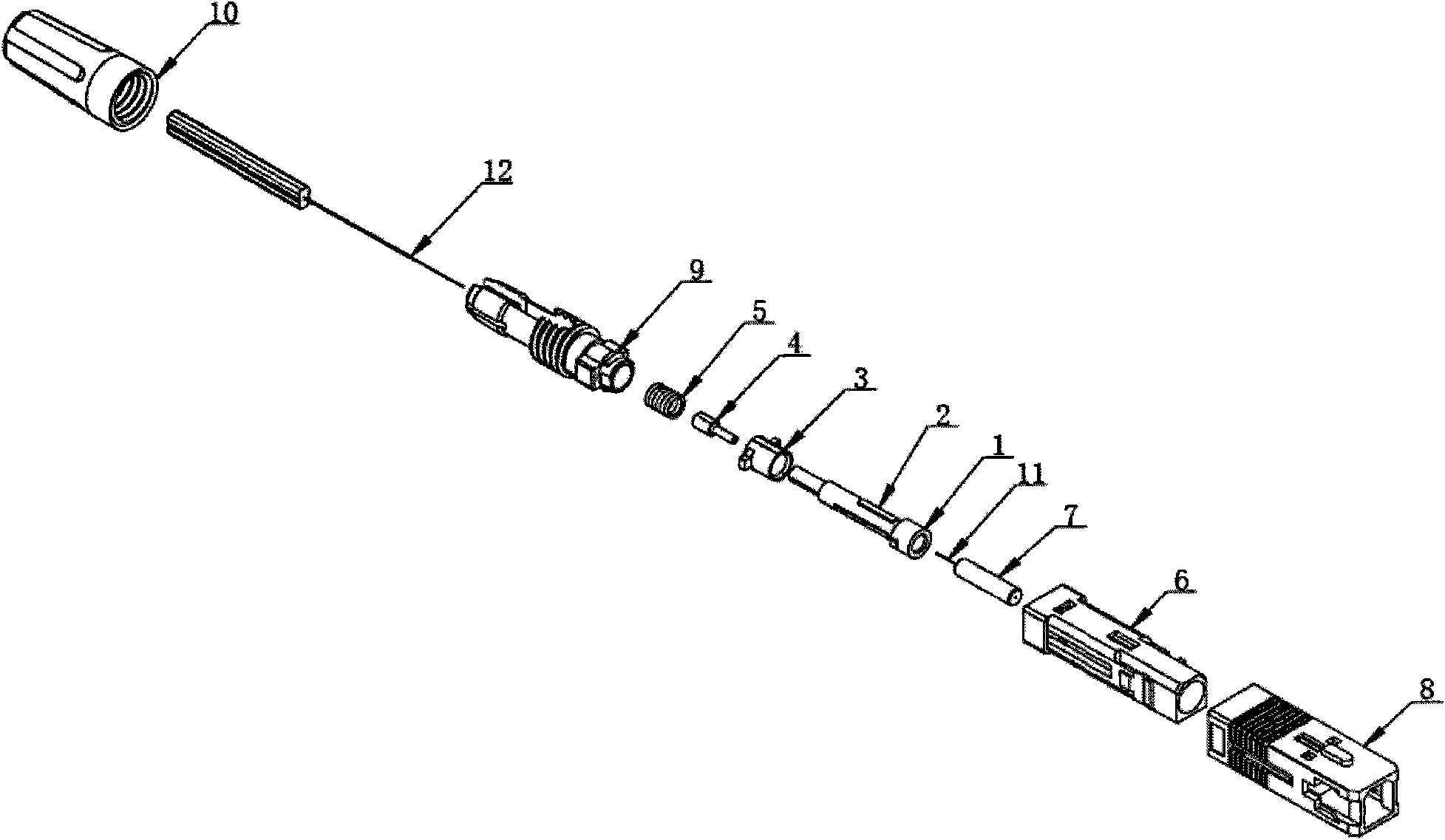

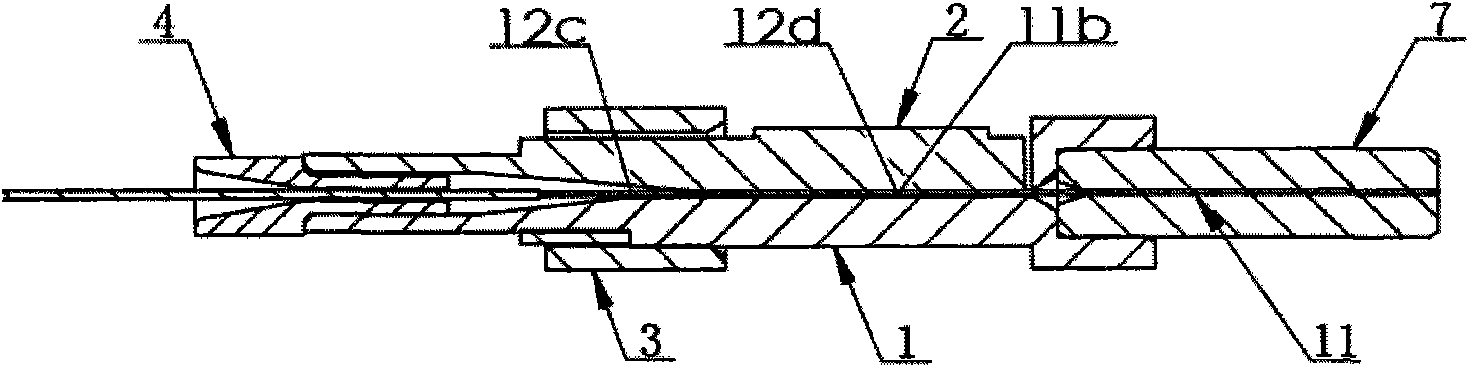

InactiveCN101806940AEliminates the need for storage protectionCoupling light guidesEngineeringPlastic optical fiber

The invention relates to an optical fiber field connector. A dismountable sleeve bin is sleeved outside a main body; the main body and the dismountable sleeve bin are provided with standard type interfaces; the main body is in a hollow structure; an optical fiber core insert is arranged at the front end of the main body; a preset optical fiber is arranged in the optical fiber core insert; a tail sleeve is arranged at the back end of the optical fiber core insert; a mechanical joint consisting of a substrate, a splint and a lantern ring is arranged in the main body; the front end of the mechanical joint is abutted with the optical fiber core insert, and the back end of the mechanical joint is connected with the tail sleeve through a guiding device and a damping device; a second optical fiber is arranged in the tail sleeve; and an outer protecting sleeve adopts a rotary screw thread structure to clamp the tail sleeve to prevent the second optical fiber from falling off and sliding. In the optical fiber field connector of the invention, the second tail end of the preset optical fiber is connected with the second optical fiber, a connection protecting box is not needed, storage protection for a bare optical fiber is unnecessary, when the optical fiber field connector is assembled, a special tool and grinding are not needed, whether the connection is successful can be detected at the field, and after installation, the field connector can be repeatedly opened for use.

Owner:FENGHUO COMM SCI & TECH CO LTD

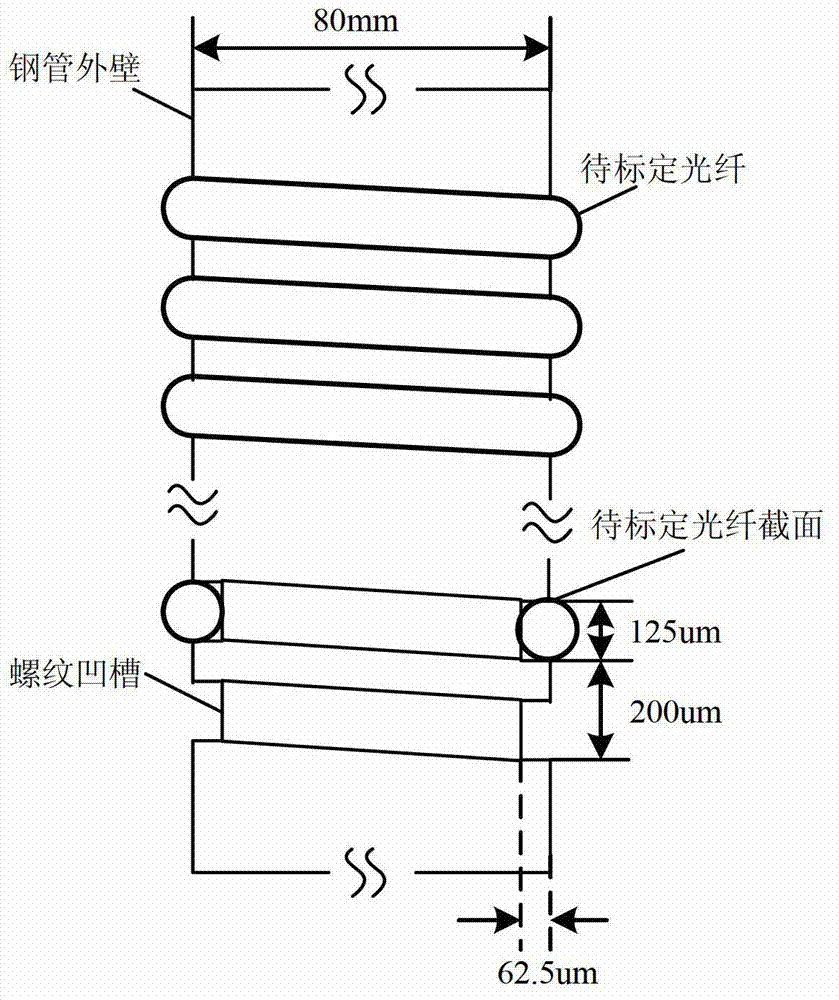

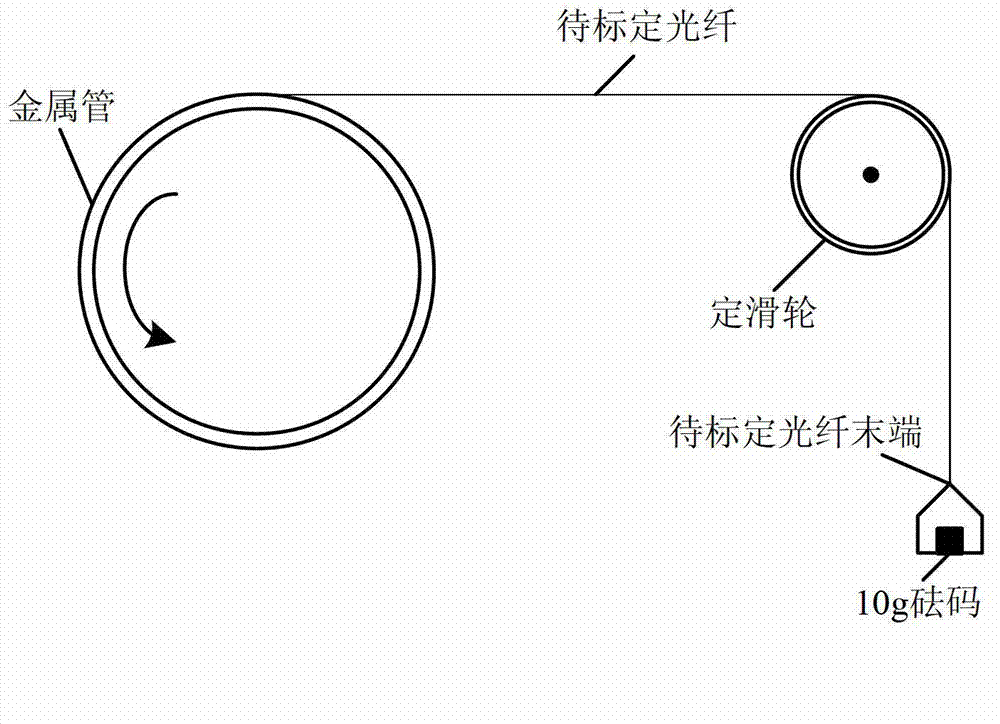

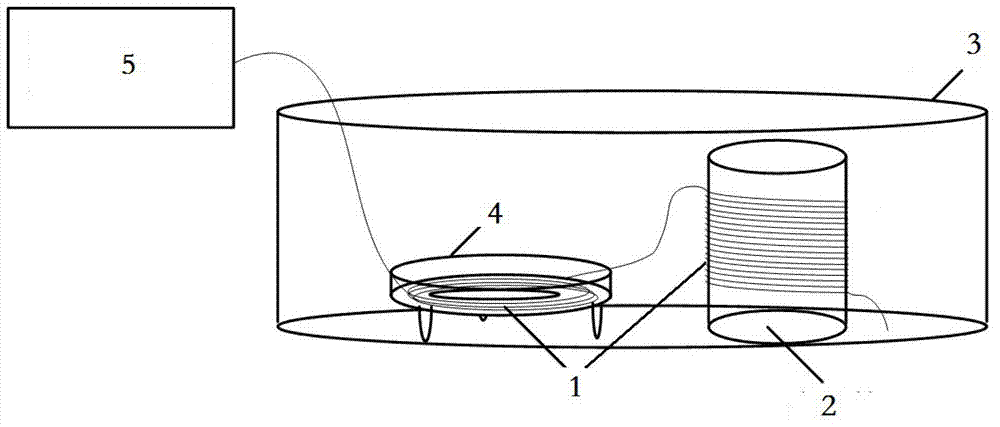

Optical fiber strain and temperature simultaneous calibration device and method based on Brillouin scattering

InactiveCN103115642AControl lengthEnsure consistencyMeasurement devicesPlastic optical fiberHigh strain

The invention belongs to the technical field of distribution-type optical fiber sensing measurement, in particular to an optical fiber strain and temperature simultaneous calibration device and a method based on Brillouin scattering. The optical fiber strain and temperature simultaneous calibration device comprises optical fiber Brillouin sensing measurement equipment, a shockproof support frame, a metal pipe and constant-temperature equipment. According to the method, the metal pipe with large and stable linear expansion coefficient is adopted to manufacture the strain calibration device, and the position of an optical fiber is accurately controlled by curving a thread on the outer wall of the metal pipe. Due to the characteristic that the optical fiber on the metal pipe bears strain and temperature at the same time, and the loose optical fiber only bears temperature, the temperature and the strain are calibrated simultaneously. The constant-temperature equipment is used for applying accurate and controllable strain and temperature on the optical fiber and the loose optical fiber on the metal pipe, and calibration of the strain of the optical fiber and temperature coefficient is carried out by means of detailed calibration steps. By means of the strain and temperature high-accuracy simultaneous calibration device and the method of the optical fiber Brillouin sensor, the problems of high strain calibration error and low efficiency of strain and temperature calibration are resolved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

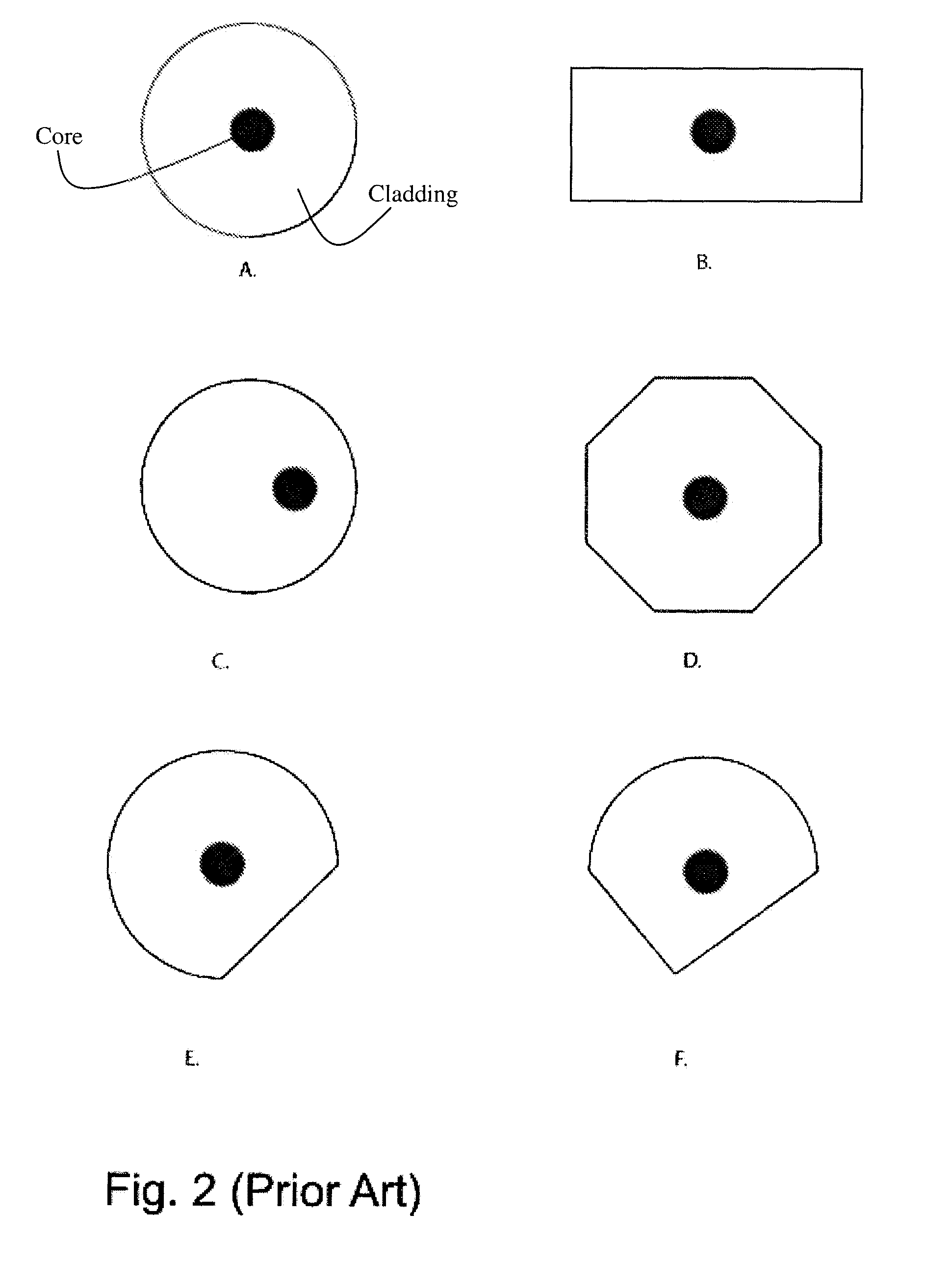

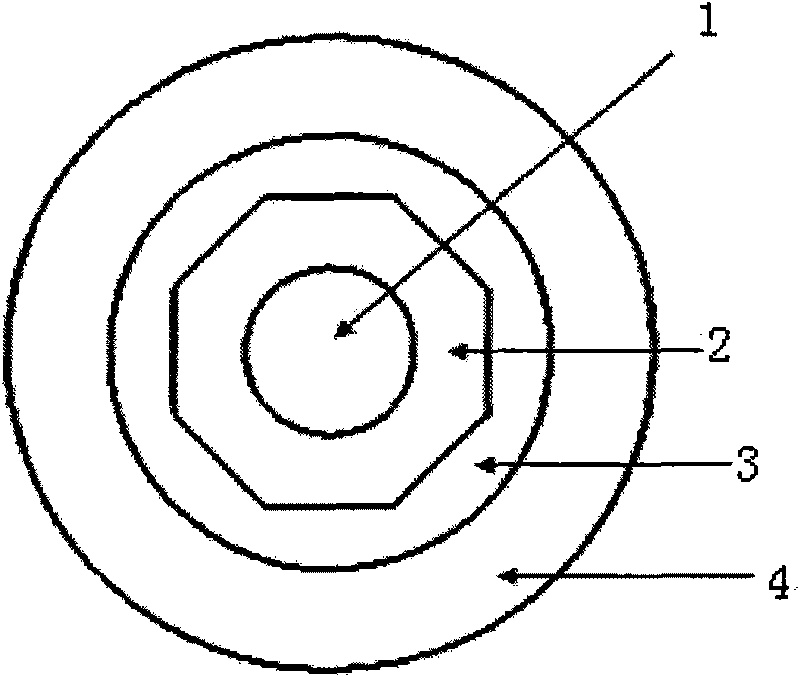

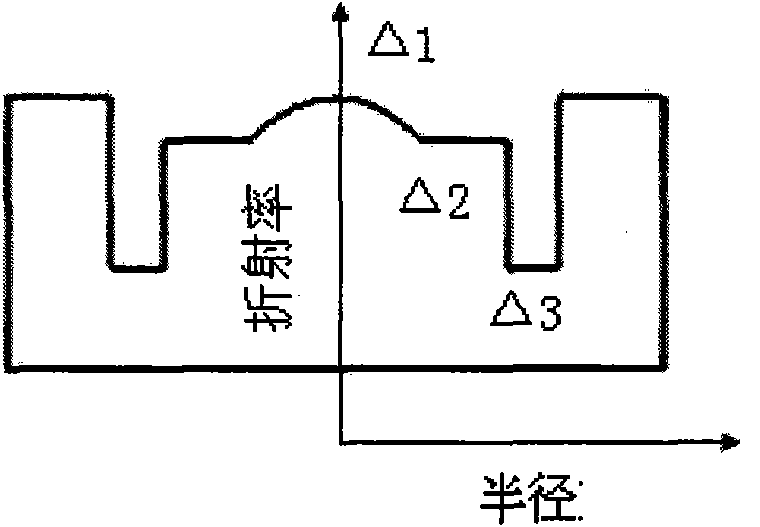

Large-mode active optical fiber and manufacture method thereof

ActiveCN101738682AIncrease powerHigh energy storage densityGlass making apparatusOptical fibre with graded refractive index core/claddingFiberRefractive index

The invention relates to optical fiber and a manufacture method thereof, in particular to large-mode active optical fiber and a manufacture method thereof. The large-mode active optical fiber is formed by drawing a fiber core and a quartz glass inner cladding, a quartz glass outer cladding and a coating which are sequentially coated on the outer surface of the fiber core, wherein the fiber core is formed by depositing, melting and collapsing silicon tetrachloride doped with rare-earth ions in a quartz glass tube; the refractive index of the fiber core is a gradually changed refractive index, and a fiber core refractive index section parameter alpha is not smaller than 1 and not larger than 3; and the appearance of the quartz glass inner cladding is in a regular gengon shape. The large-mode active optical fiber has the advantages of large mode and similar single-mode output, improves the capacity of bearing laser power and the energy storage density of the active optical fiber, improves the light beam quality of output laser, solves the problem of hollow ring of the output laser, greatly improves the reliability of high-power optical fiber laser devices and the utilization rate of raw materials and reduces the manufacture cost.

Owner:FENGHUO COMM SCI & TECH CO LTD

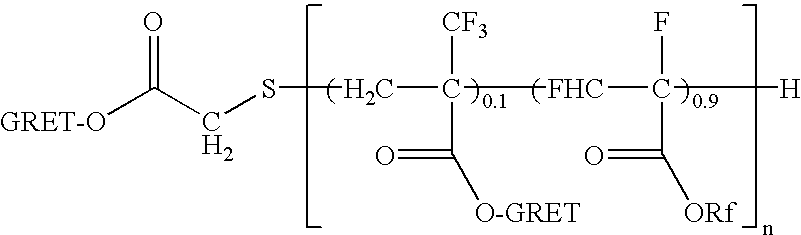

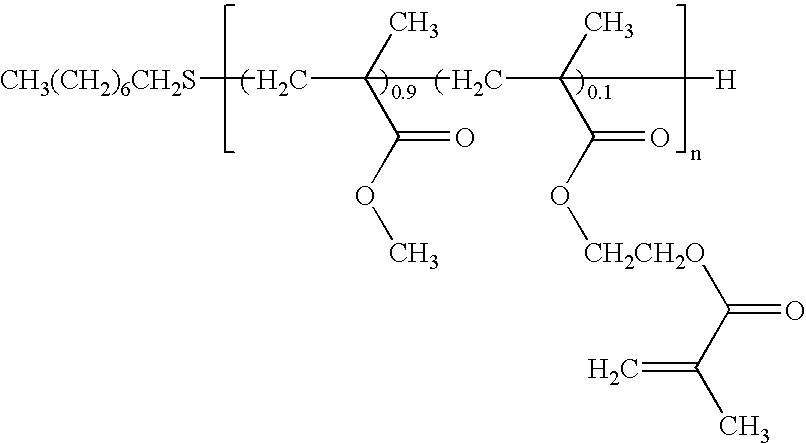

Method of manufacturing a graded-index plastics optical fiber

InactiveUS6576166B1Efficient preparationEasy to placeOptical fibre with graded refractive index core/claddingFlow mixersFiberPolymer science

A method and apparatus for manufacturing a graded-index plastics optical fiber of continuously varying index profile, starting from a particular polymer P and a particular compound M1, the method including the steps of: preparing two compositions of different refractive index, allowing the compositions to diffuse one into the other, and spinning the compositions so as to obtain the fiber, wherein, prior to extrusion, the two compositions are subjected to active mixing, and extrusion of the fiber is followed by curing.

Owner:NEXANS

Method and Apparatus for Propagating Optical Signals along with Power Feed to Illuminators and Electrical Appliances

ActiveUS20110227510A1Firmly connectedEfficient solutionCoupling device connectionsLine/current collector detailsPower cableEngineering

In a method and apparatus for propagating optical signals via optical cables such as plastic optical fiber, known as lightguide joint and mingled with the electrical wiring and home automation system for controlling LED illuminators enclosed in standard screw type bulb bases or plug-in bases, such as used for halogen lamp via optical signal propagated through such standard bases. Same optical signals are propagated through power outlets and via power cable assemblies to electrical appliances for controlling the appliances operation and on-off switching. Full range of control, distribution, signal conversion, keypads and touch screen including video interphones monitors and shopping terminals operate and controls such home automation via the optical cables.

Owner:ELBEX VIDEO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com