Patents

Literature

162results about "Control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

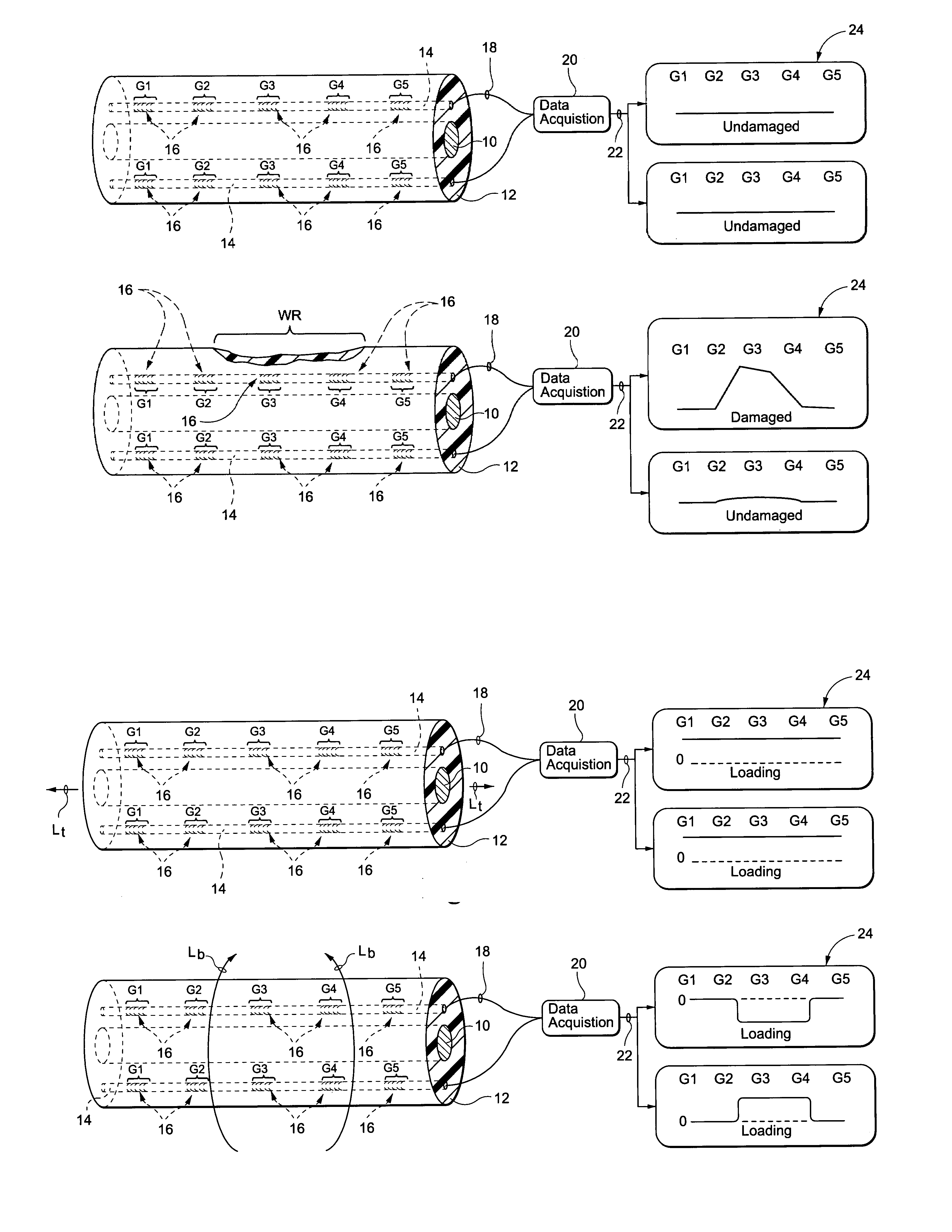

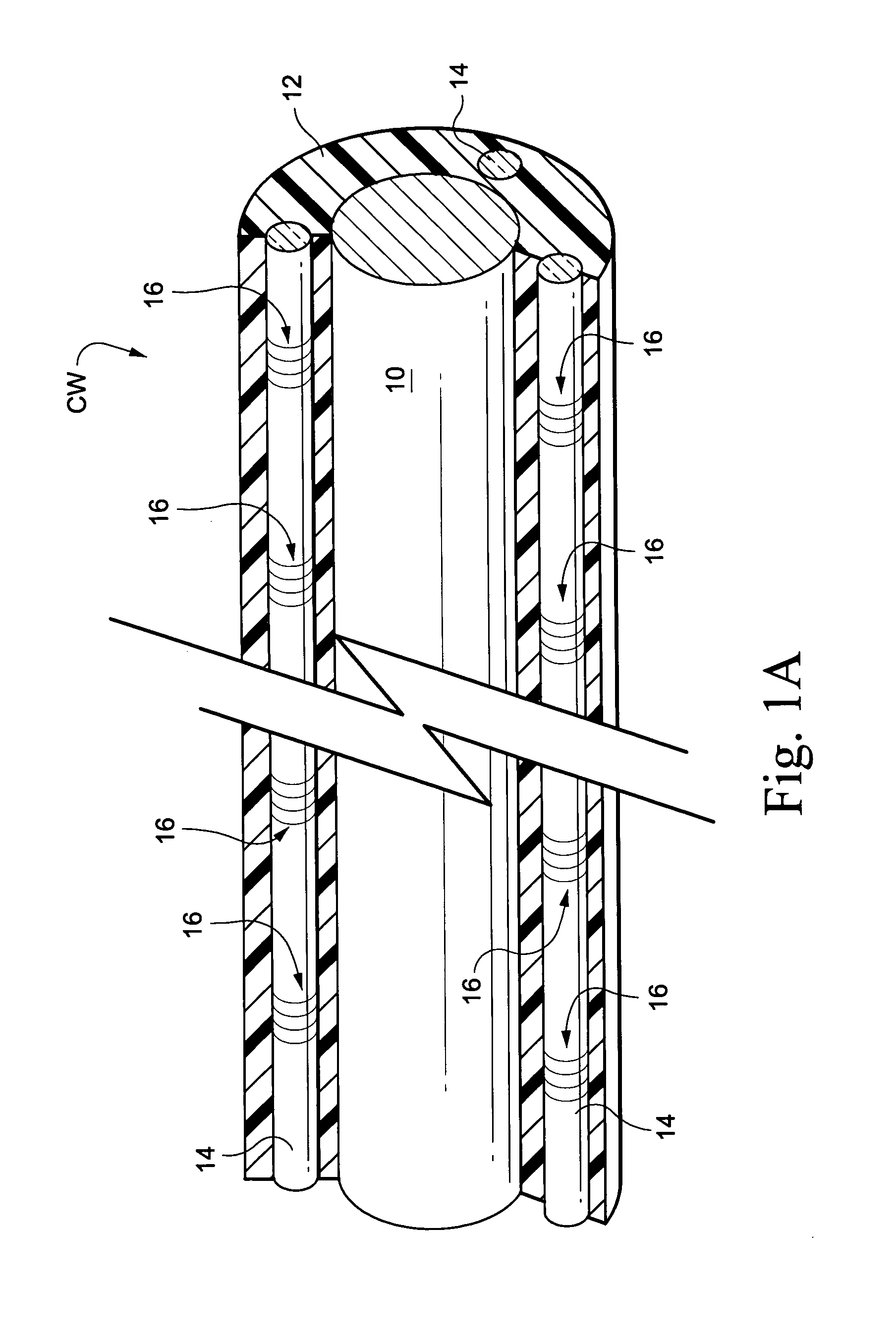

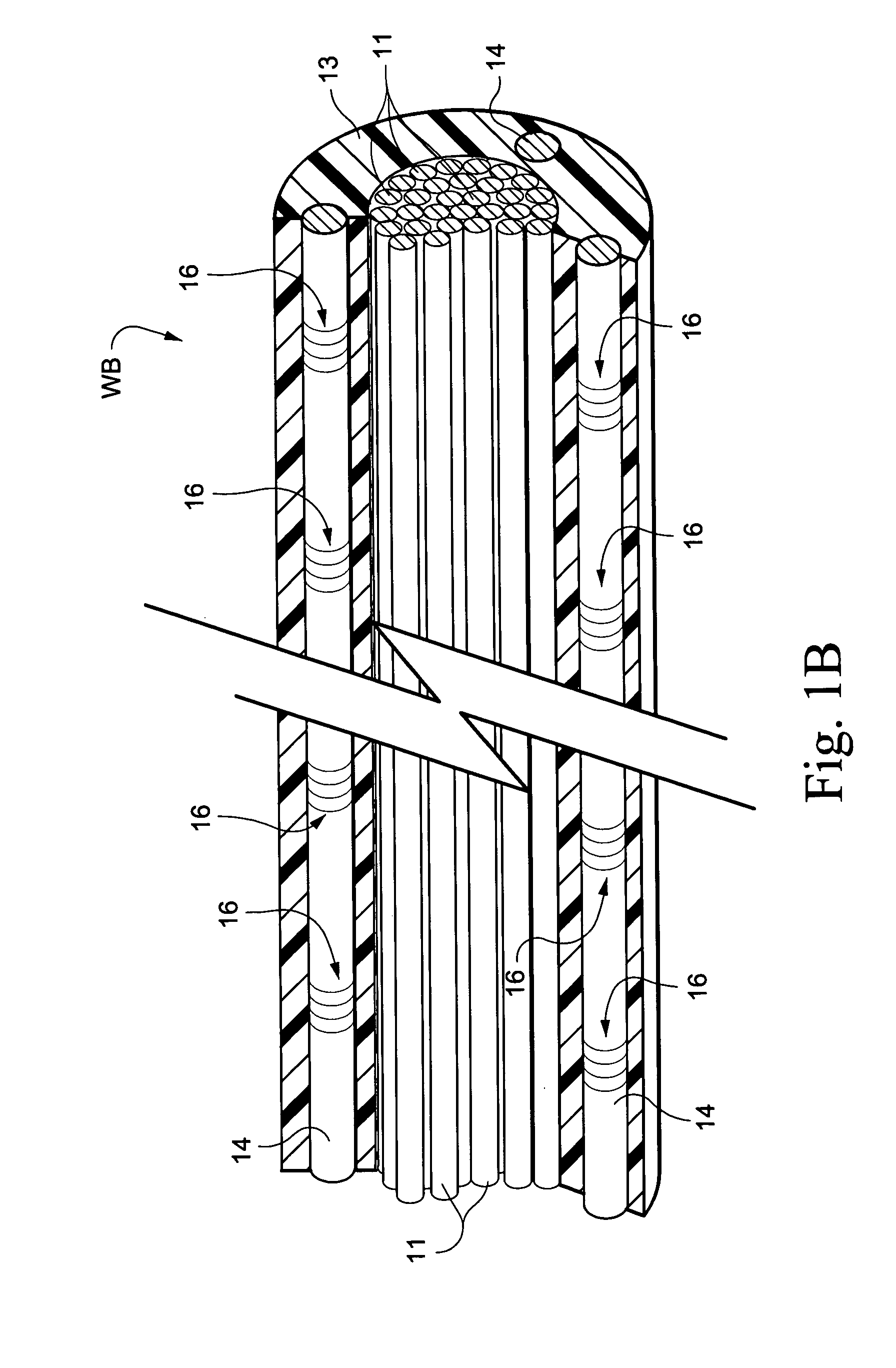

Composite structures, such as coated wiring assemblies, having integral fiber optic-based condition detectors and systems which employ the same

InactiveUS7154081B1Weakening rangeReducing compressive strainControlRadiation pyrometryElectrical conductorGrating

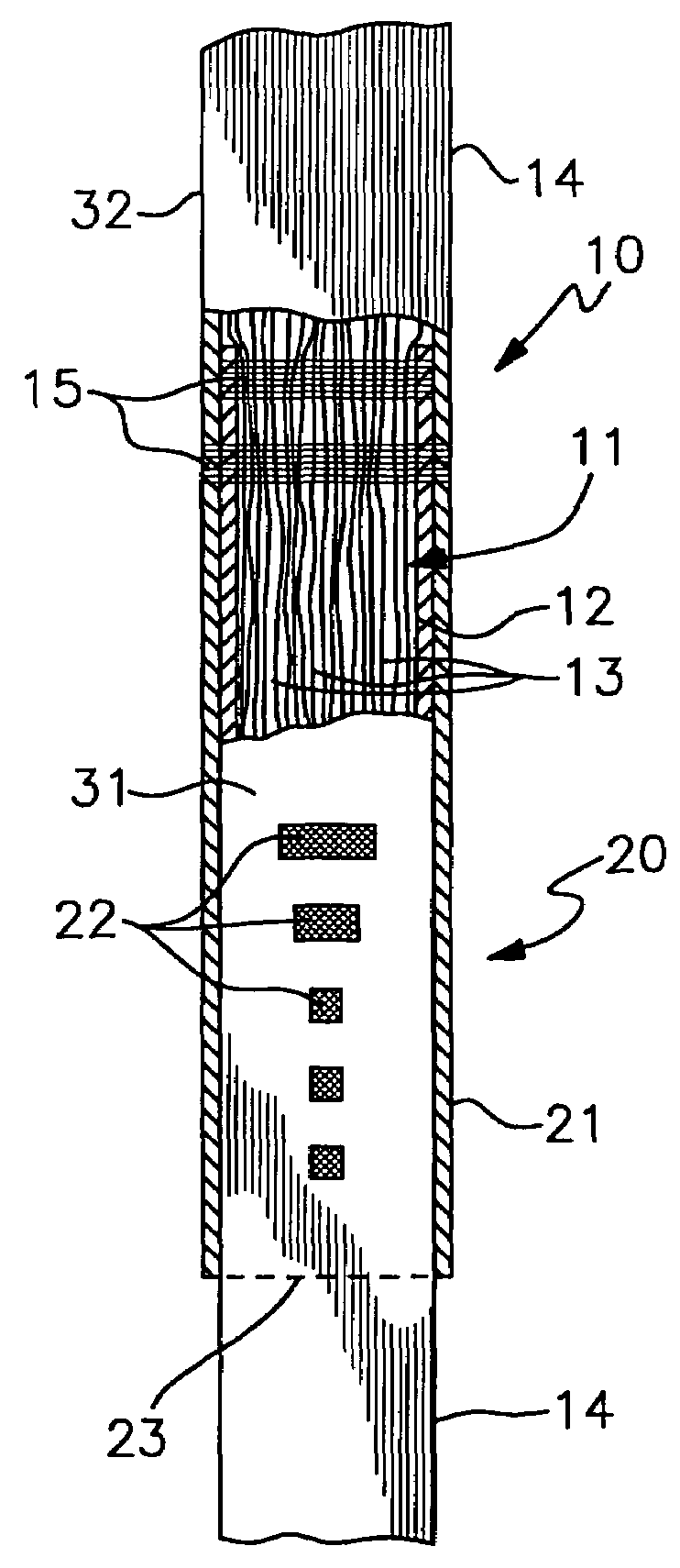

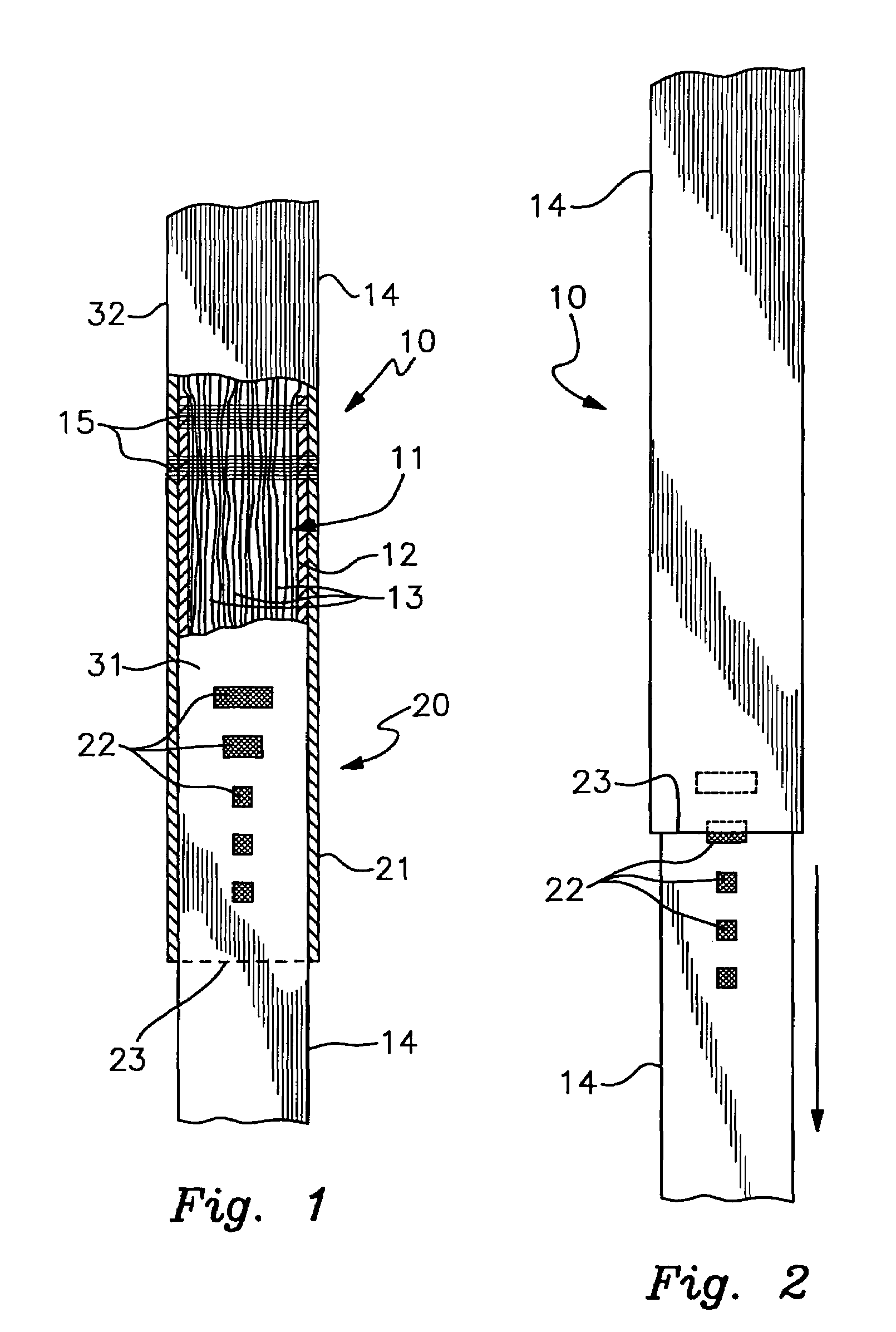

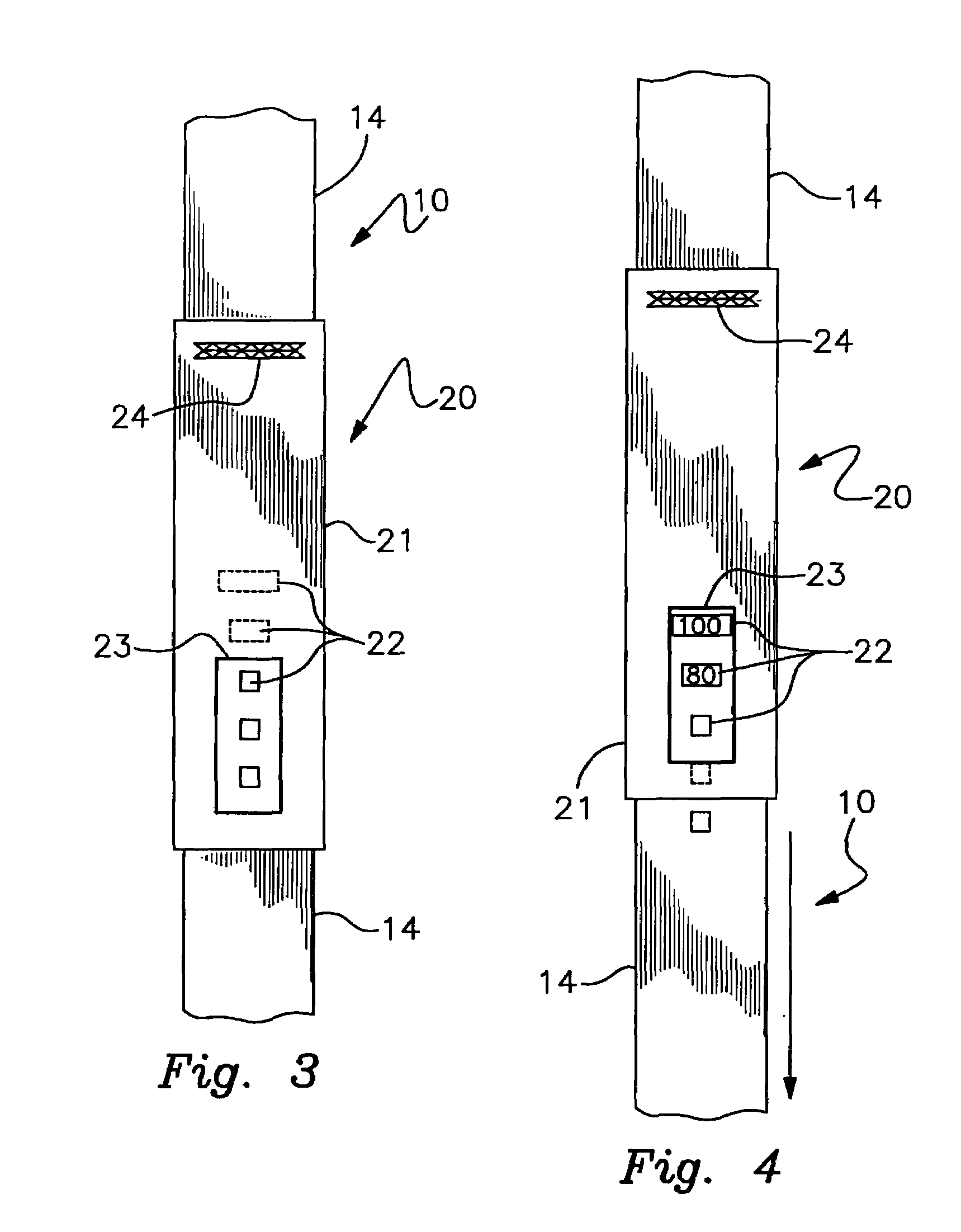

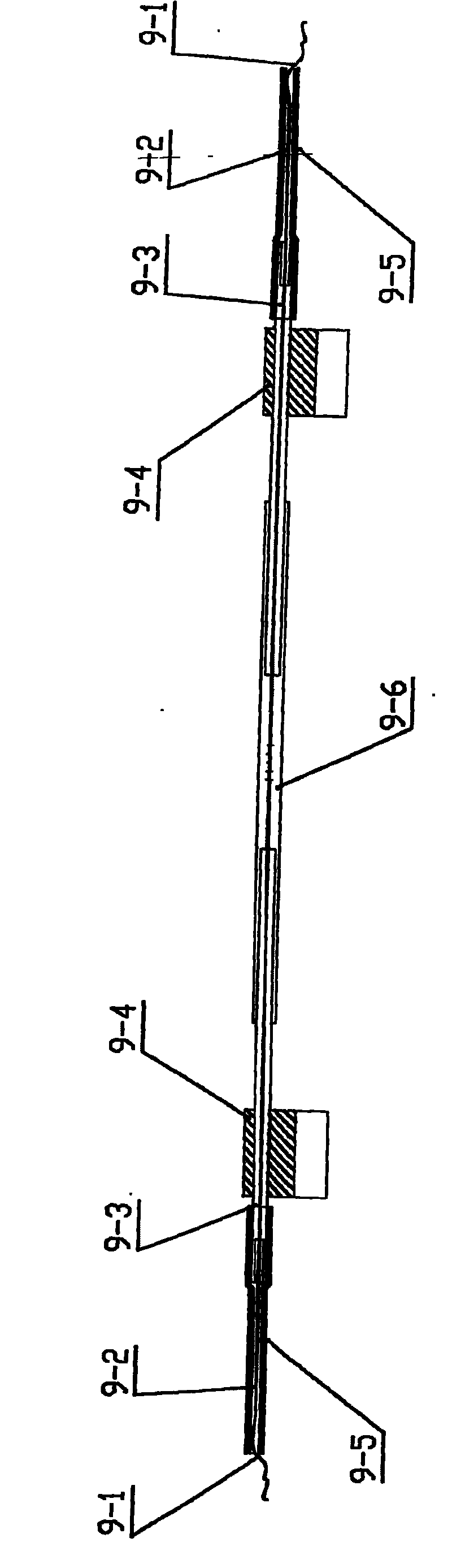

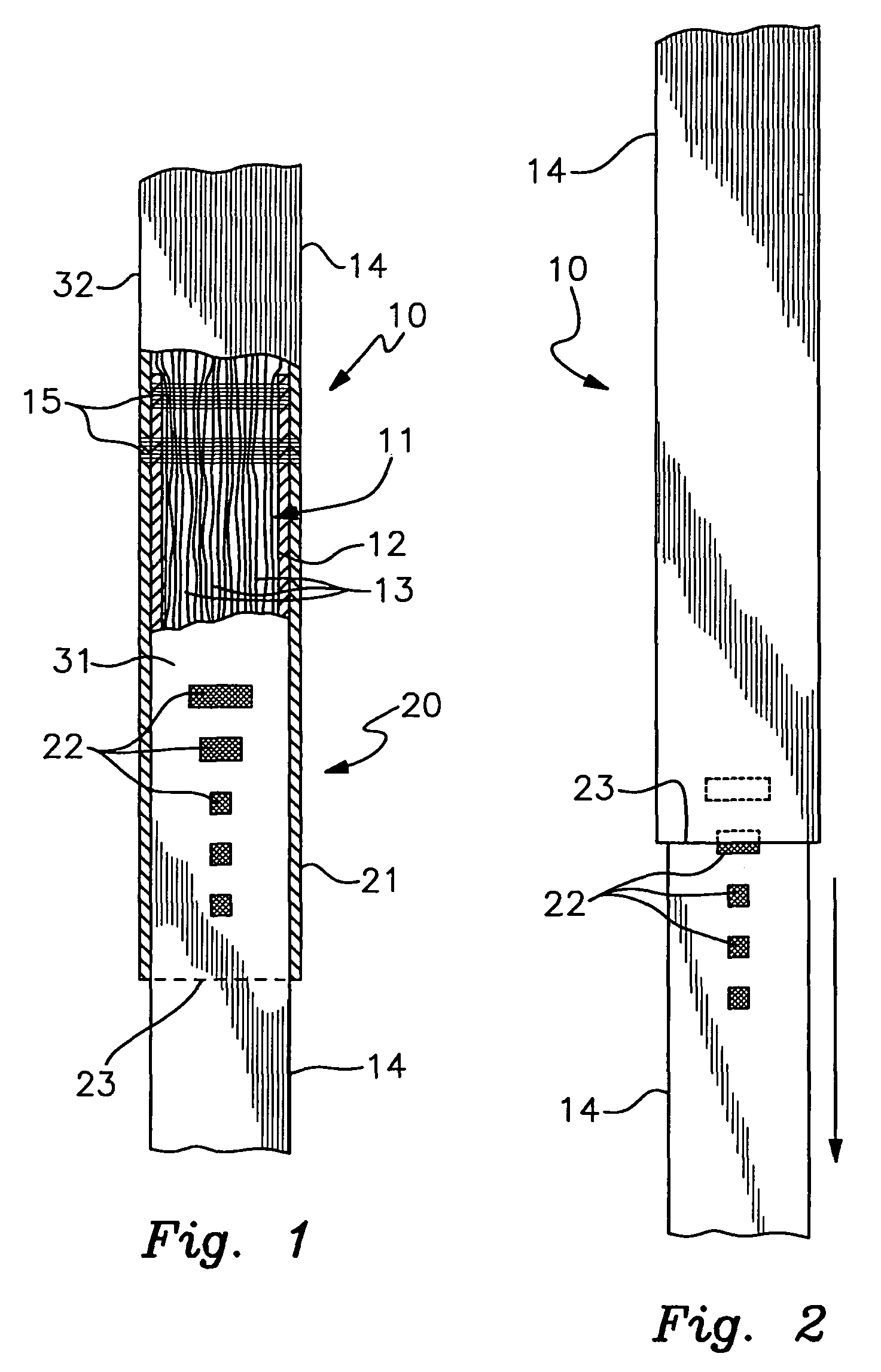

Integral fiber optic-based condition sensors detect conditions of a composite structure, e.g., a coated wire assembly so as to detect damage or conditions that may damage the same. Preferably, at least one optical fiber sensor having a plurality of Bragg gratings written into the fiber at spaced-apart locations along its axial length is integrated into the electrical insulator coating of a wire, wire bundle or wiring harness. The fiber optic sensor may thus be employed to measure the environmental loads on the electrical wiring including stresses from bending, axial loading, pinch points, high temperature excursions and chemical damage. The system is capable of detecting and locating transient conditions that might cause damage to a wiring system or permanent changes in state associated with damage events. The residual stress in the electrical insulator coating of a wire, wire bundle, or wiring harness are used to monitor the evolution of damage by wear or chaffing processes. Detected stress relief on one or more Bragg gratings will thus be indicative of damage to the insulator coating on the conductor. As such, the magnitude of such stress relief may be detected and used as an alert that the wire insulation is damaged to an unsafe extent.

Owner:LUNA INNOVATIONS

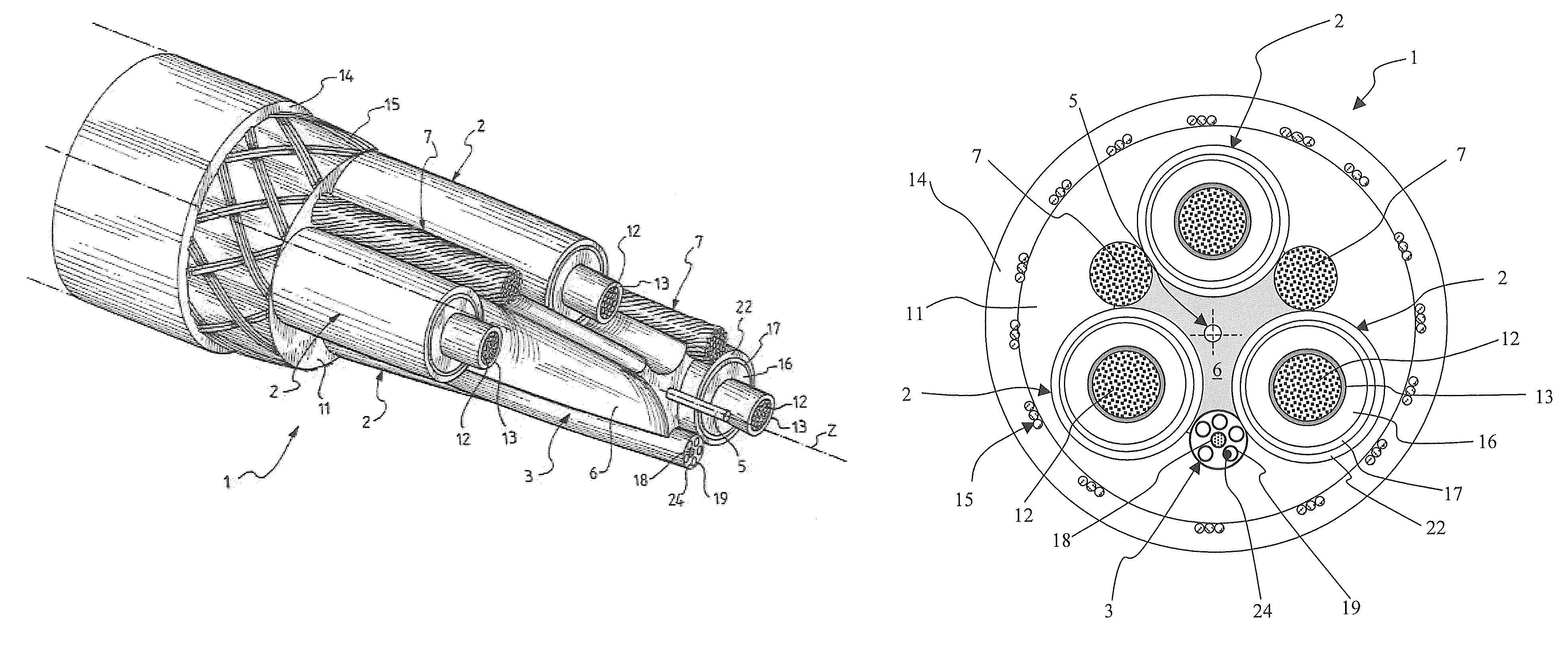

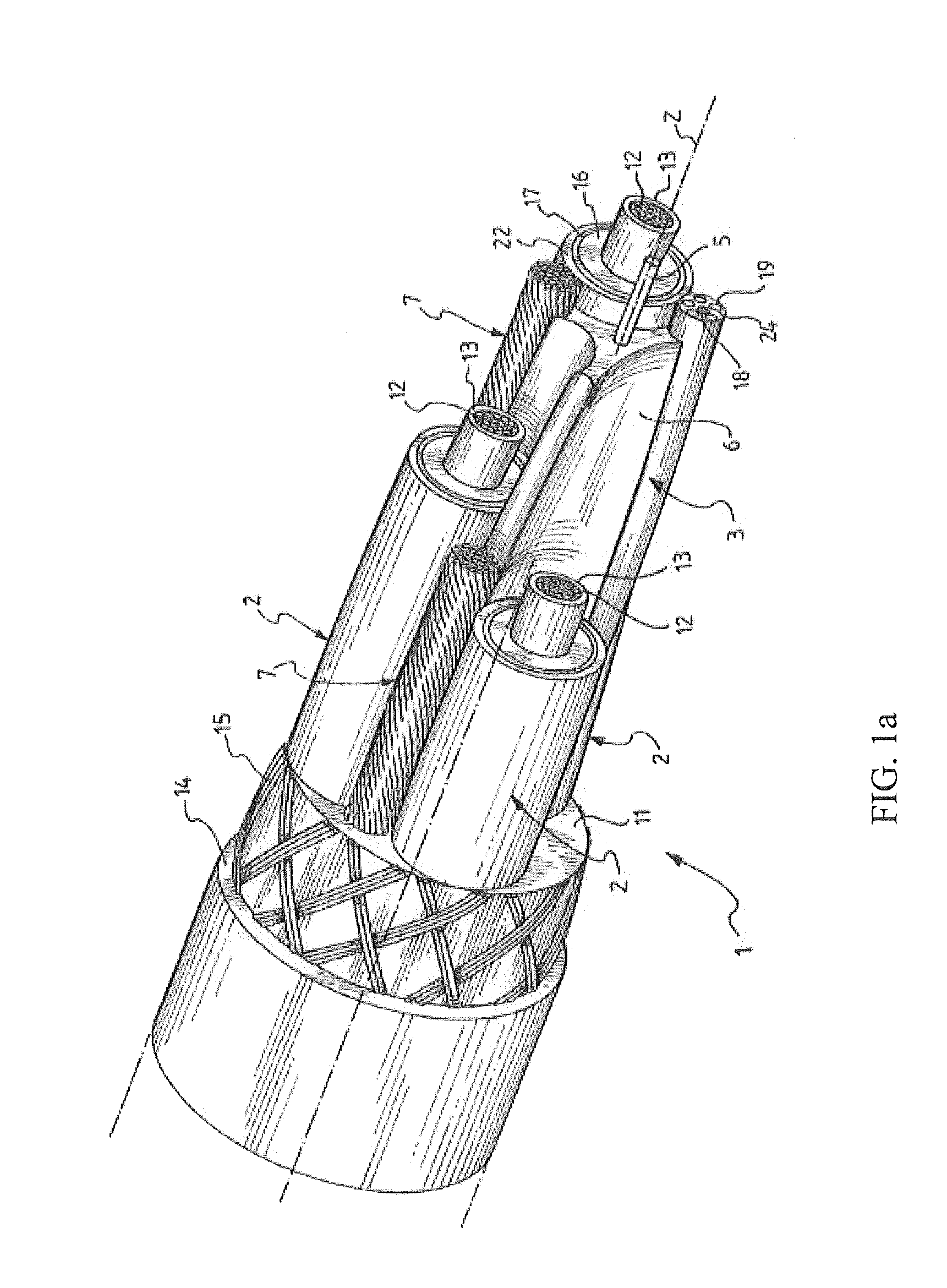

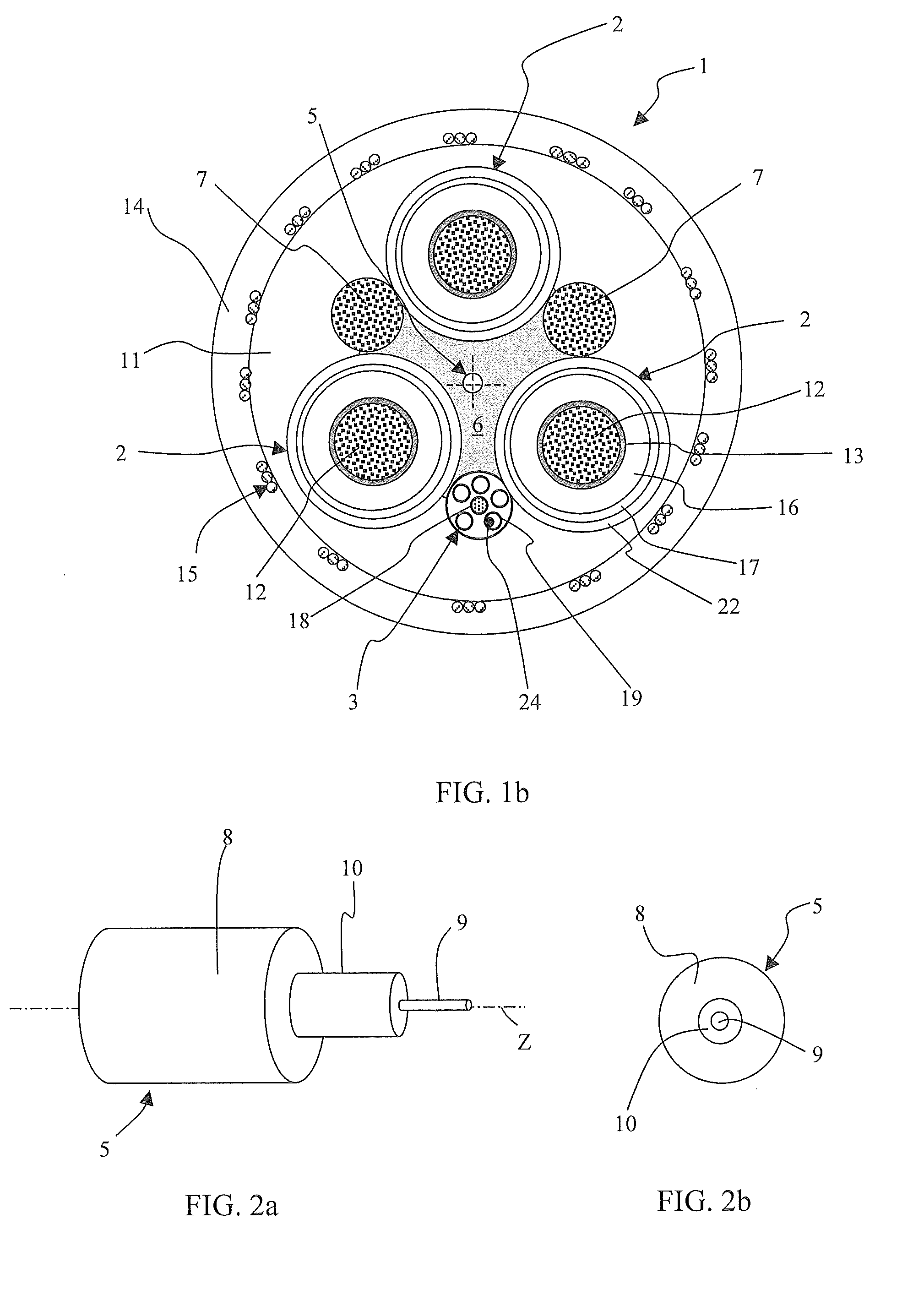

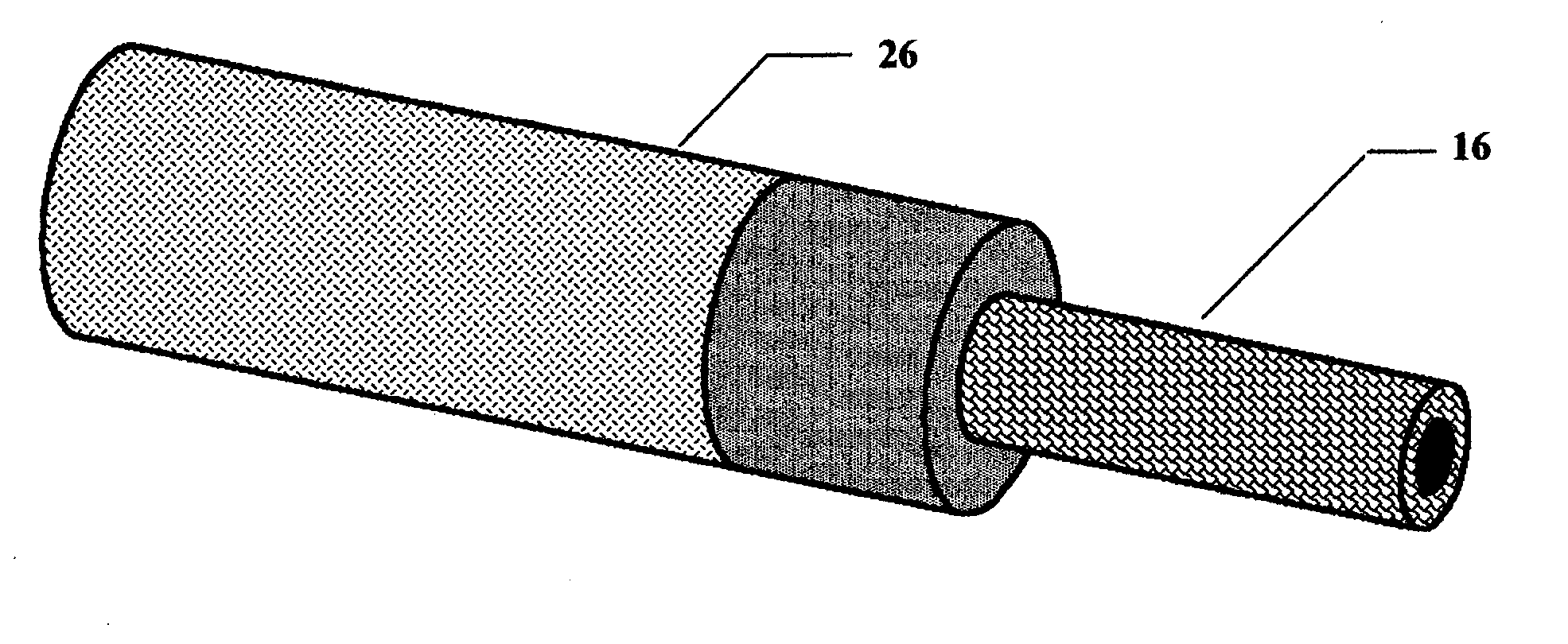

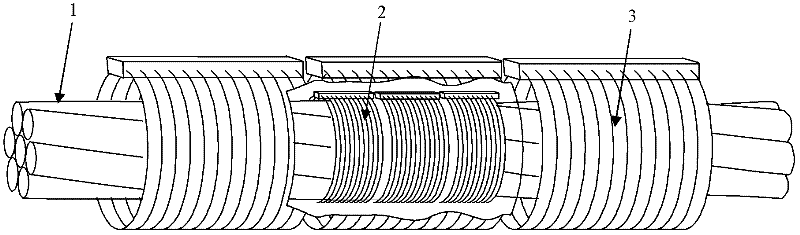

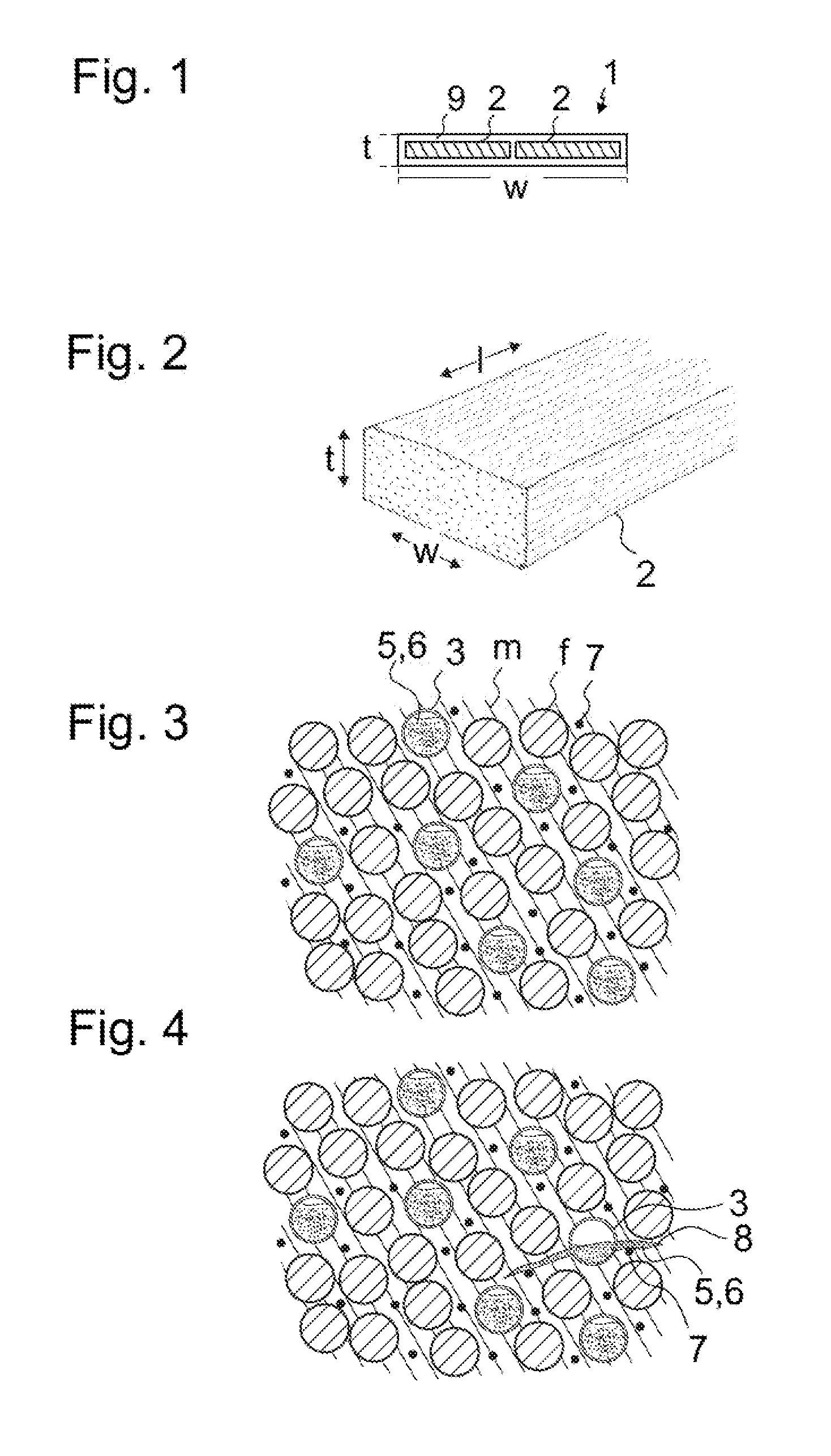

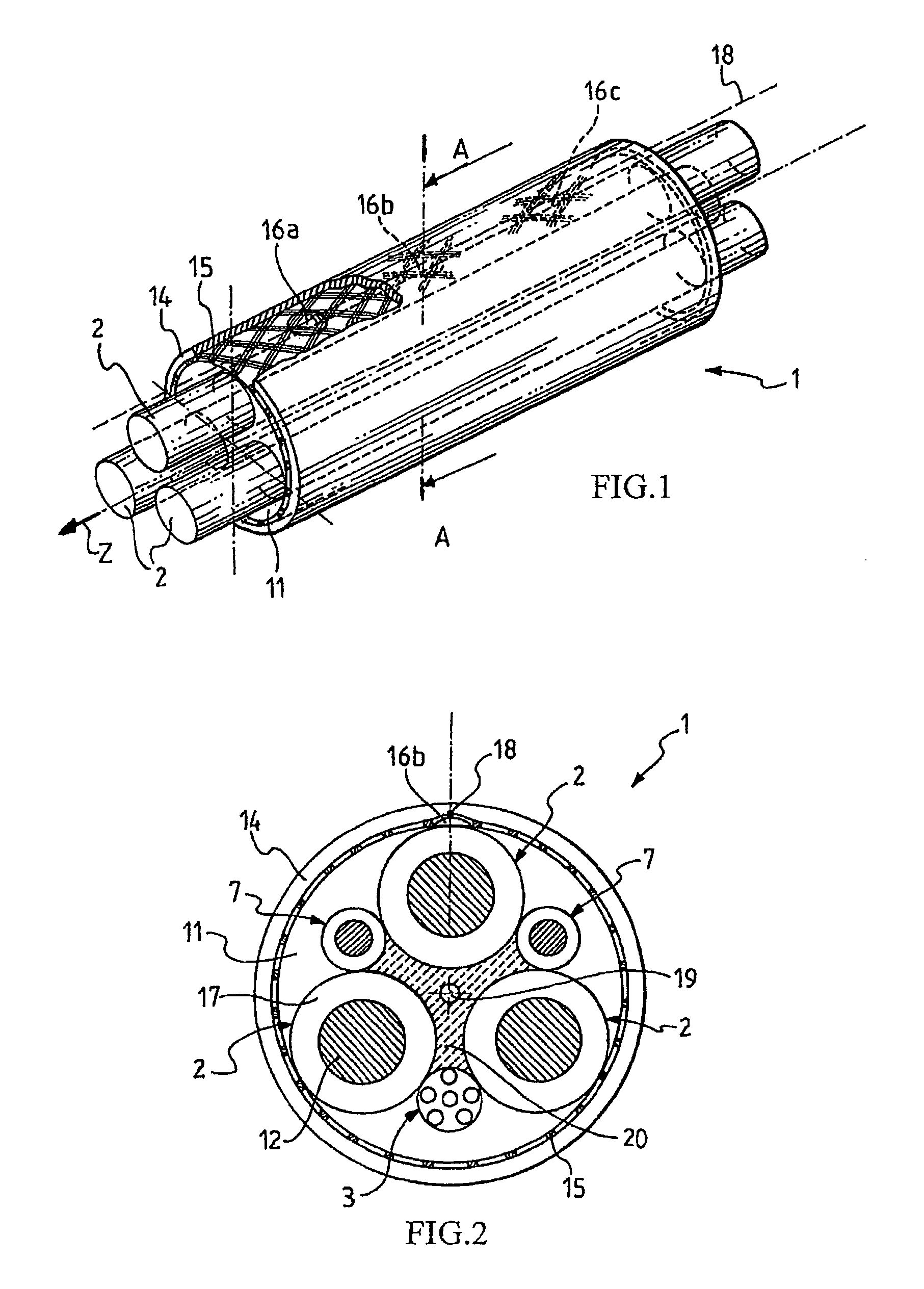

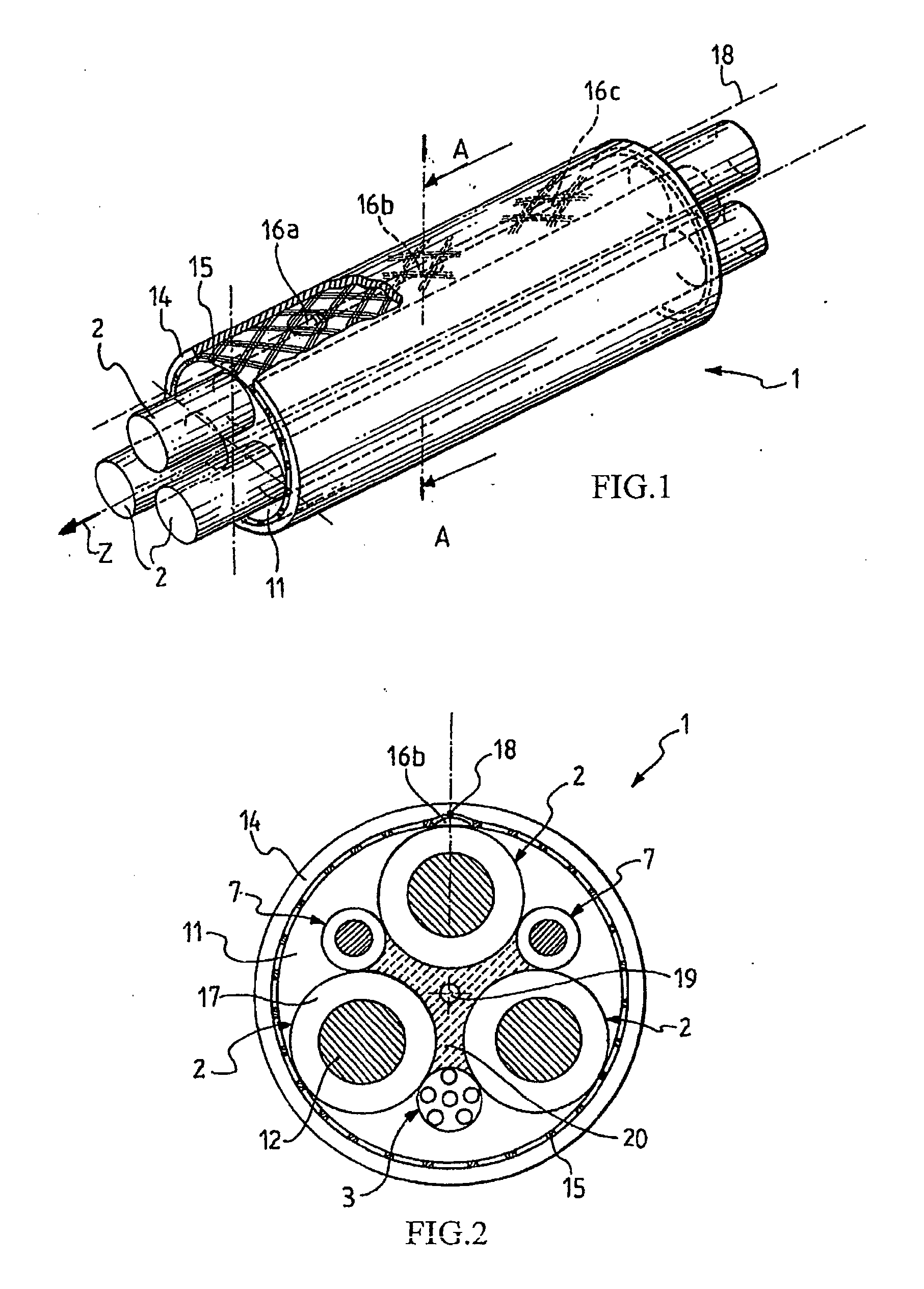

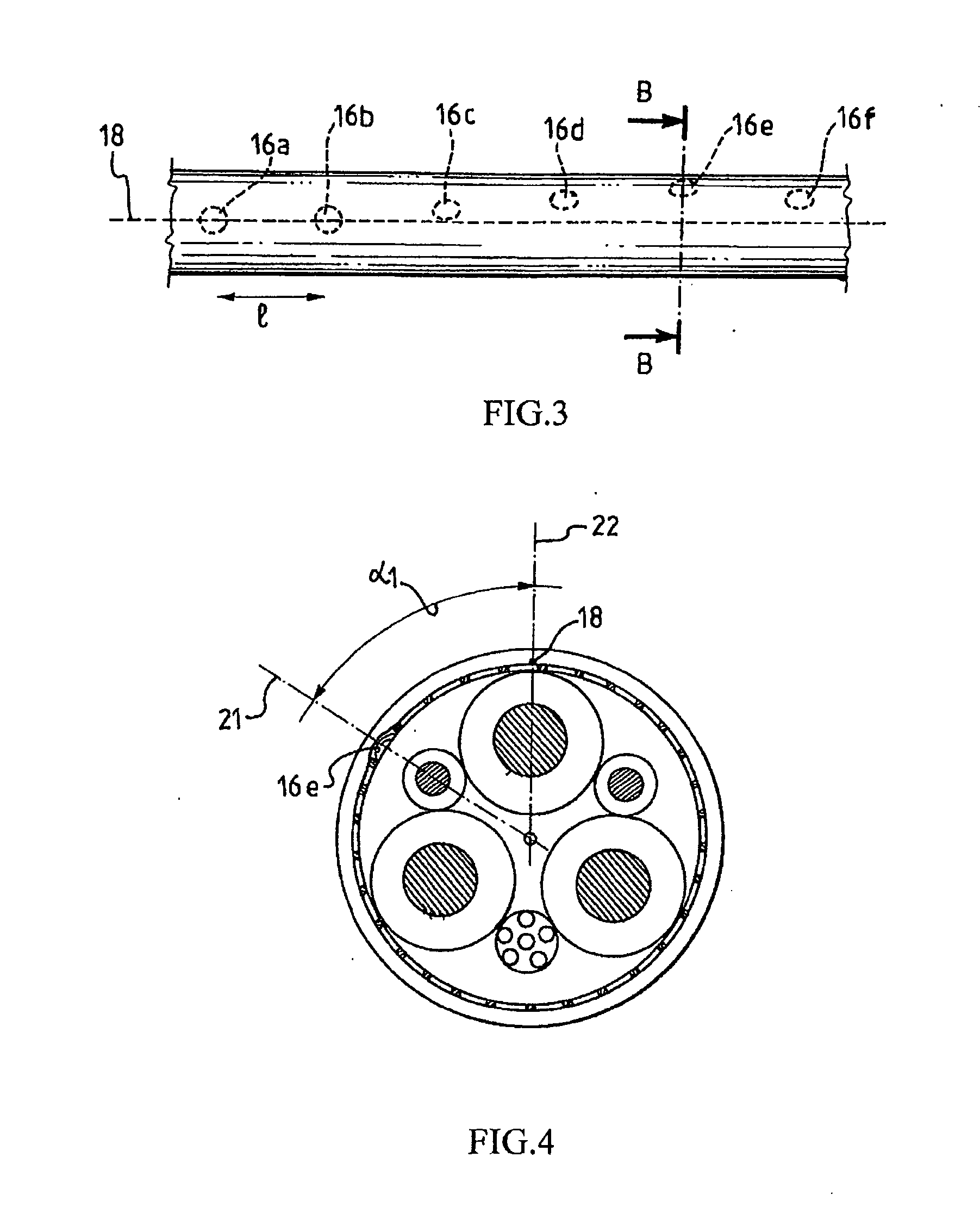

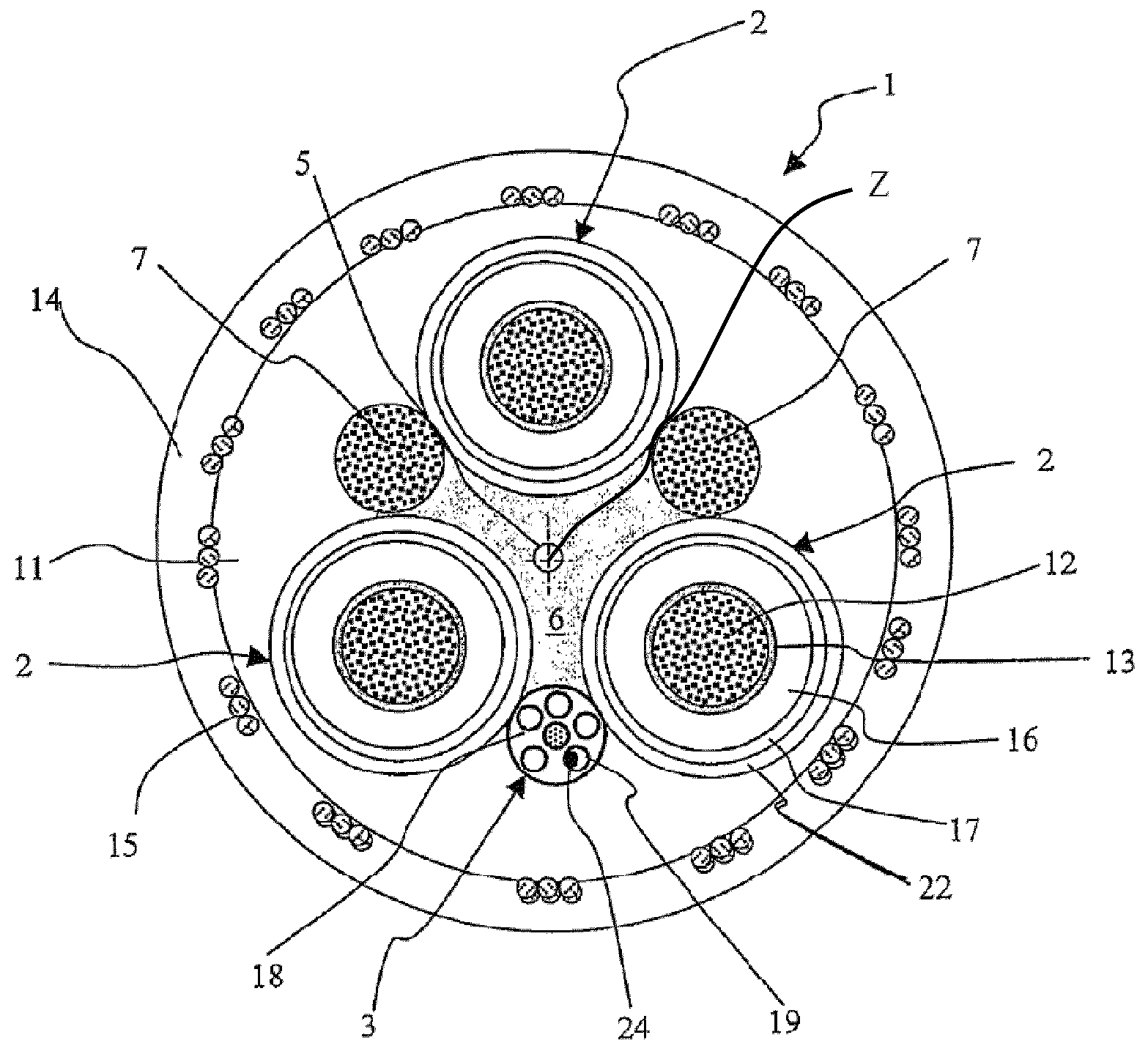

Electric cable with strain sensor and monitoring system and method for detecting strain in at least one electric cable

ActiveUS20120082422A1Effective periodic maintenanceHigh mechanical stressControlForce measurement by measuring optical property variationElectrical conductorMonitoring system

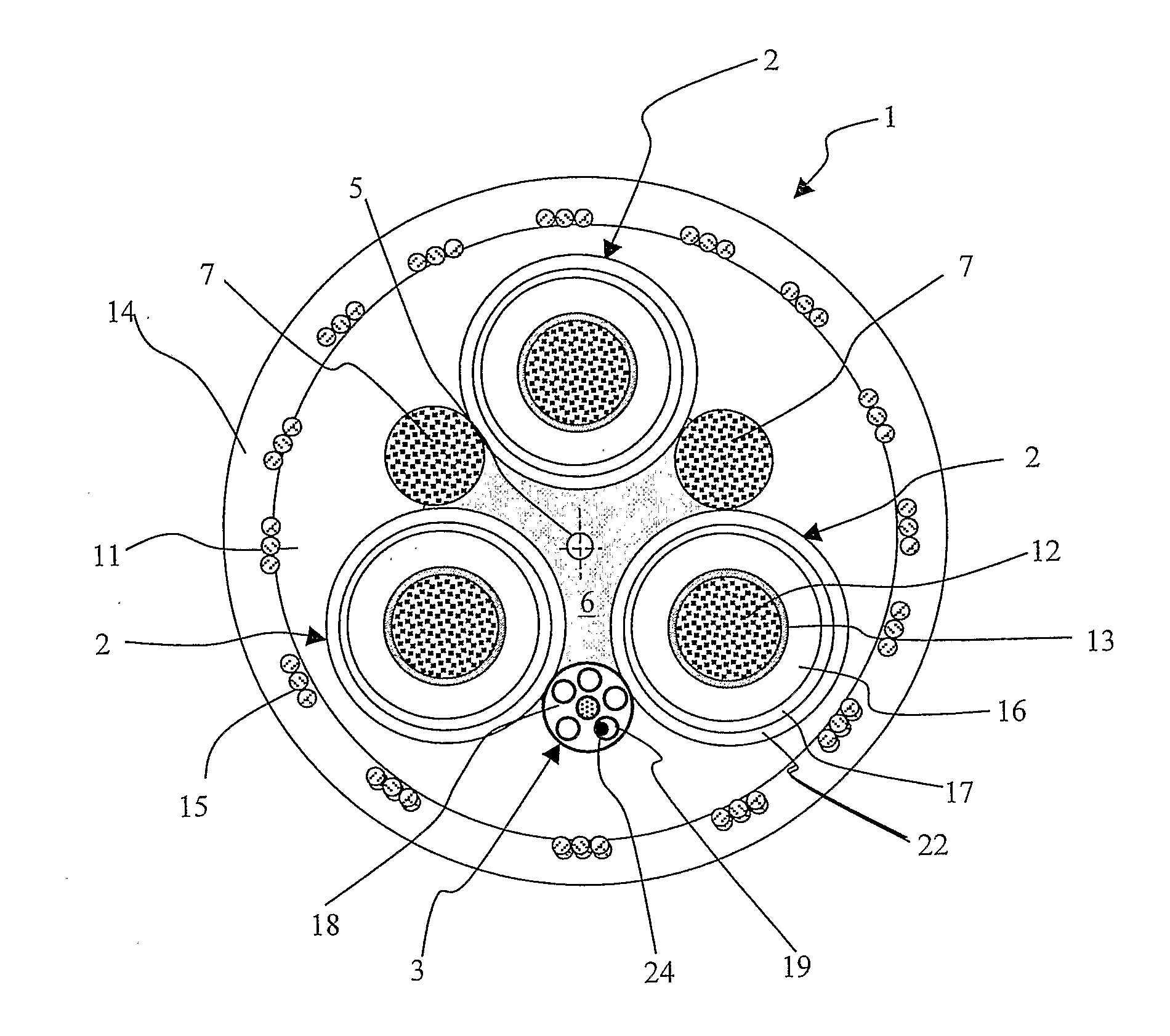

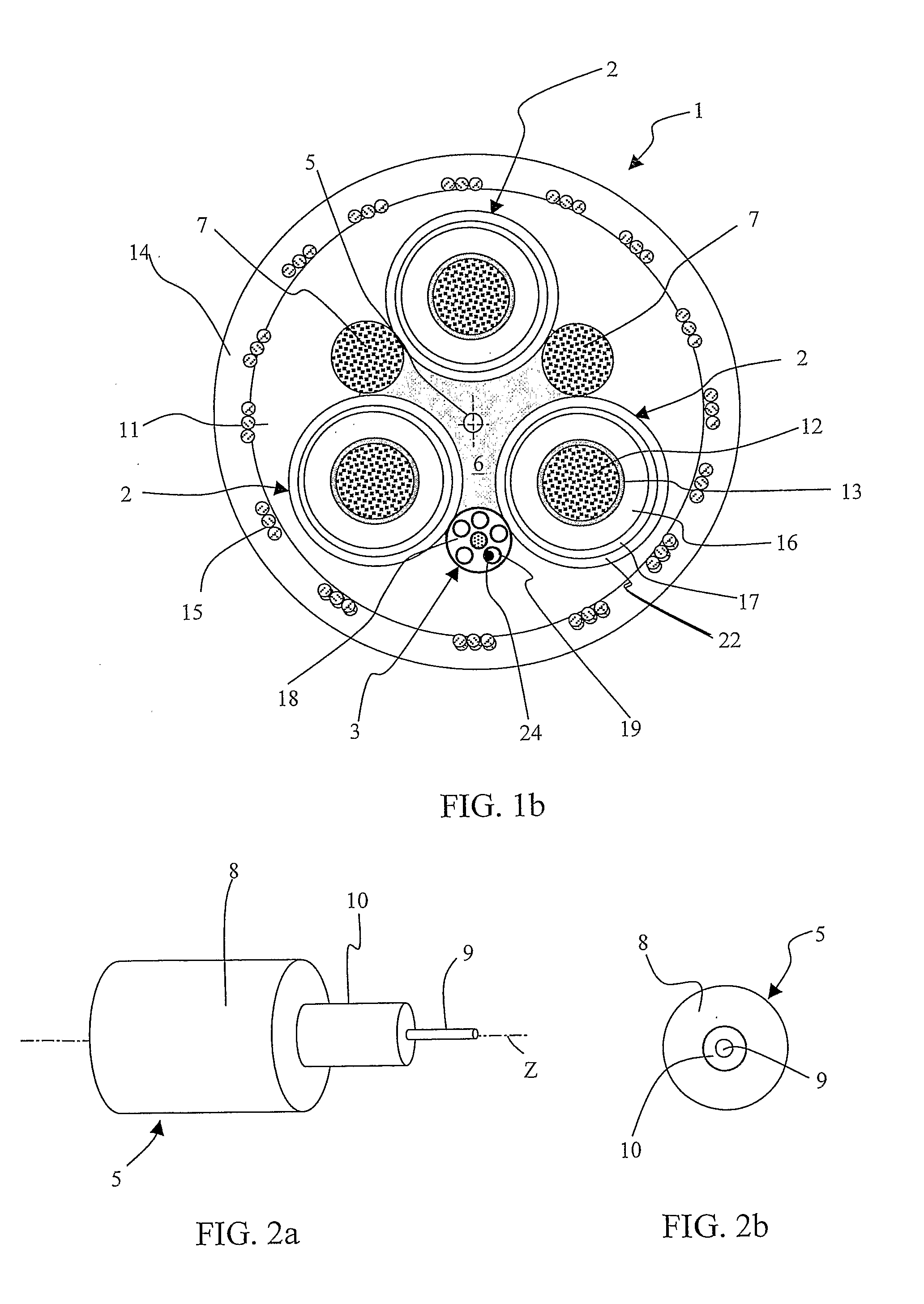

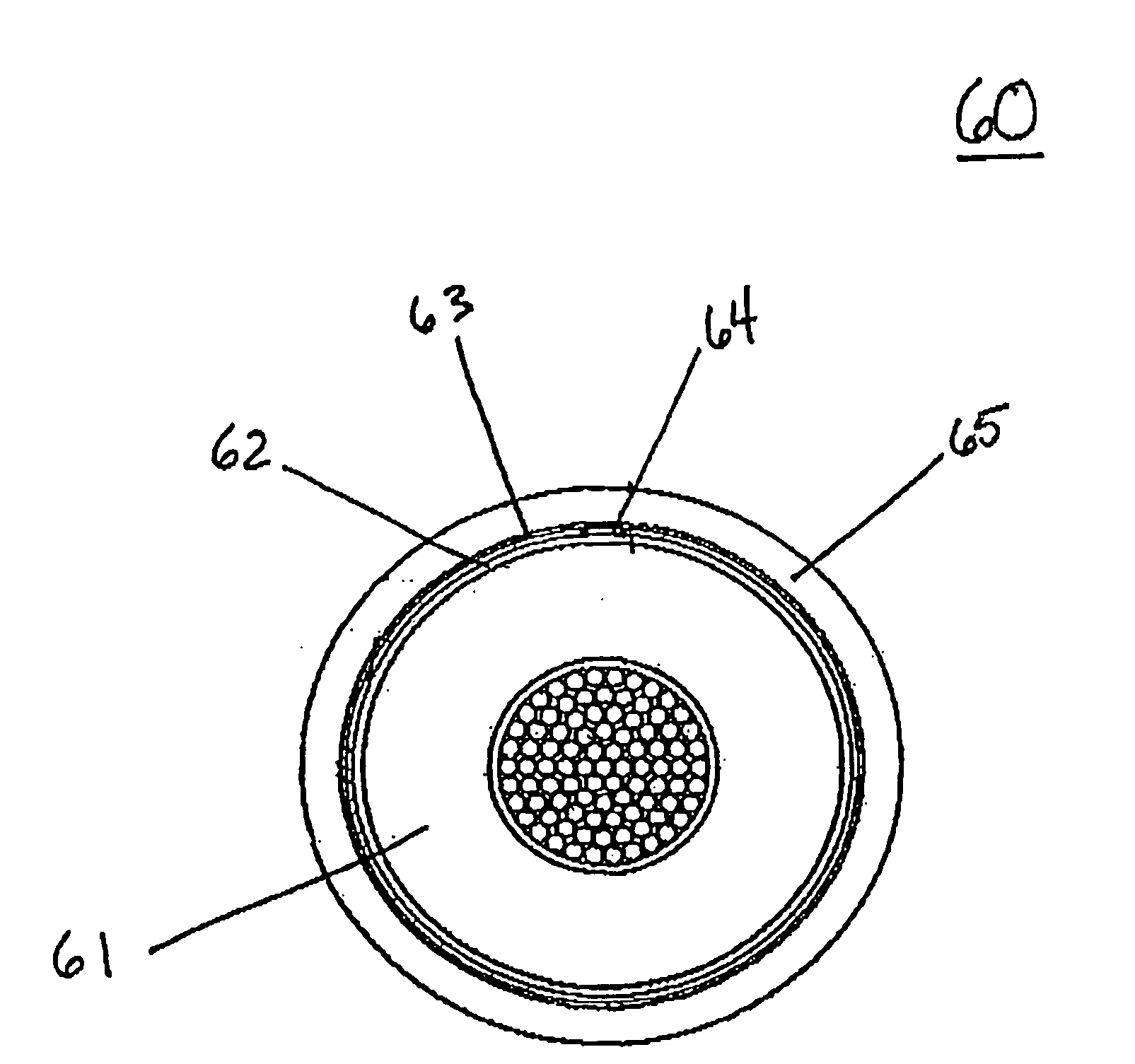

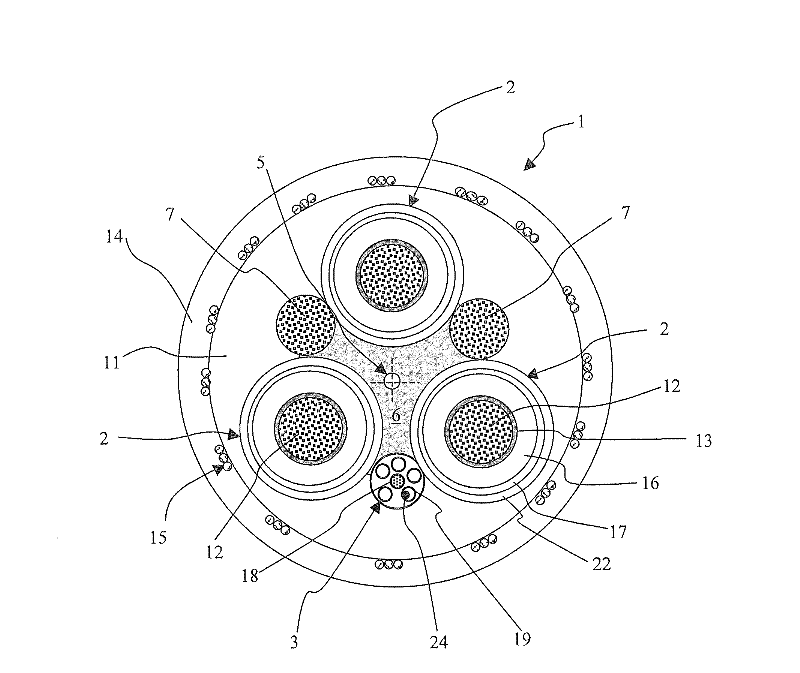

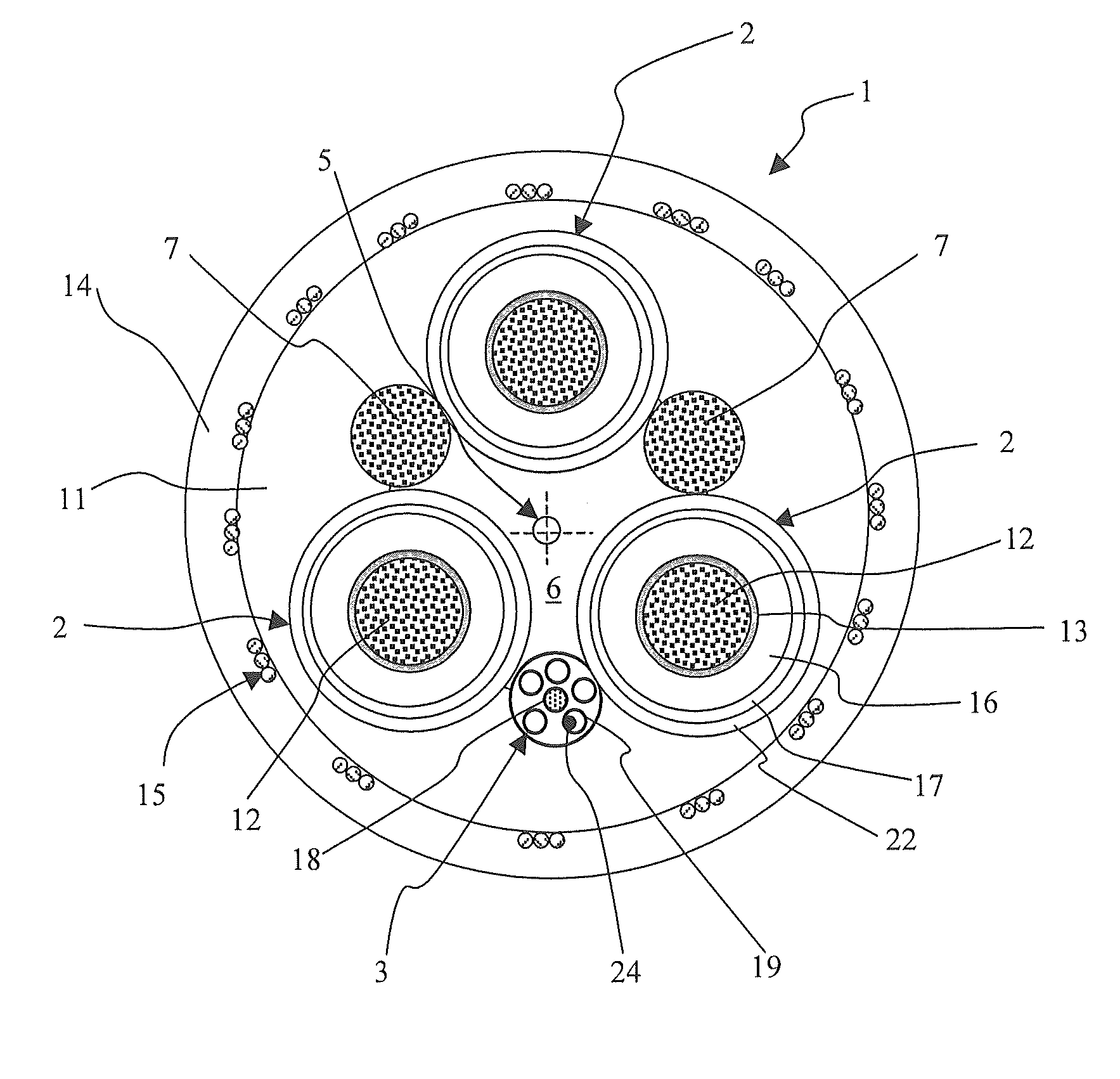

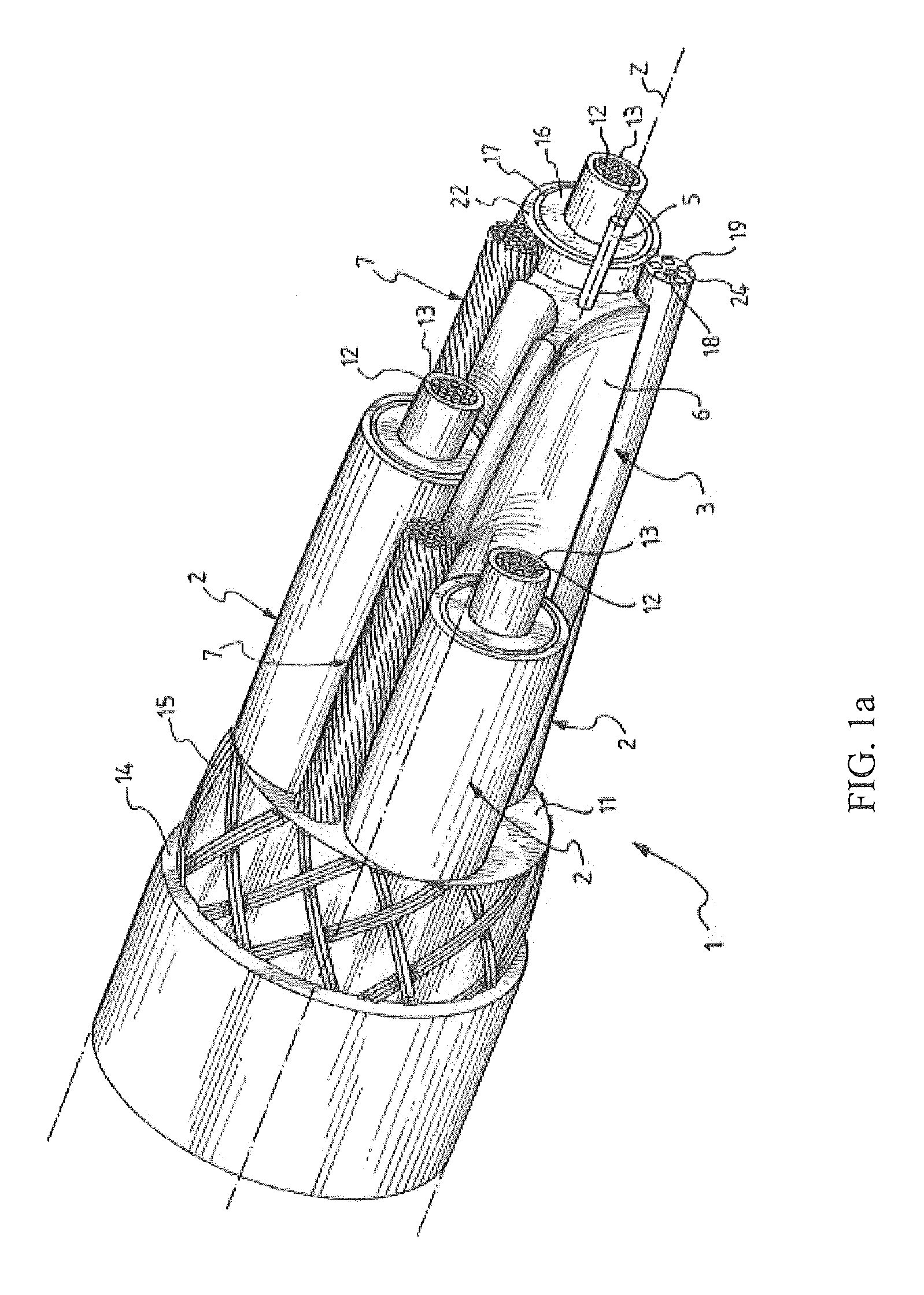

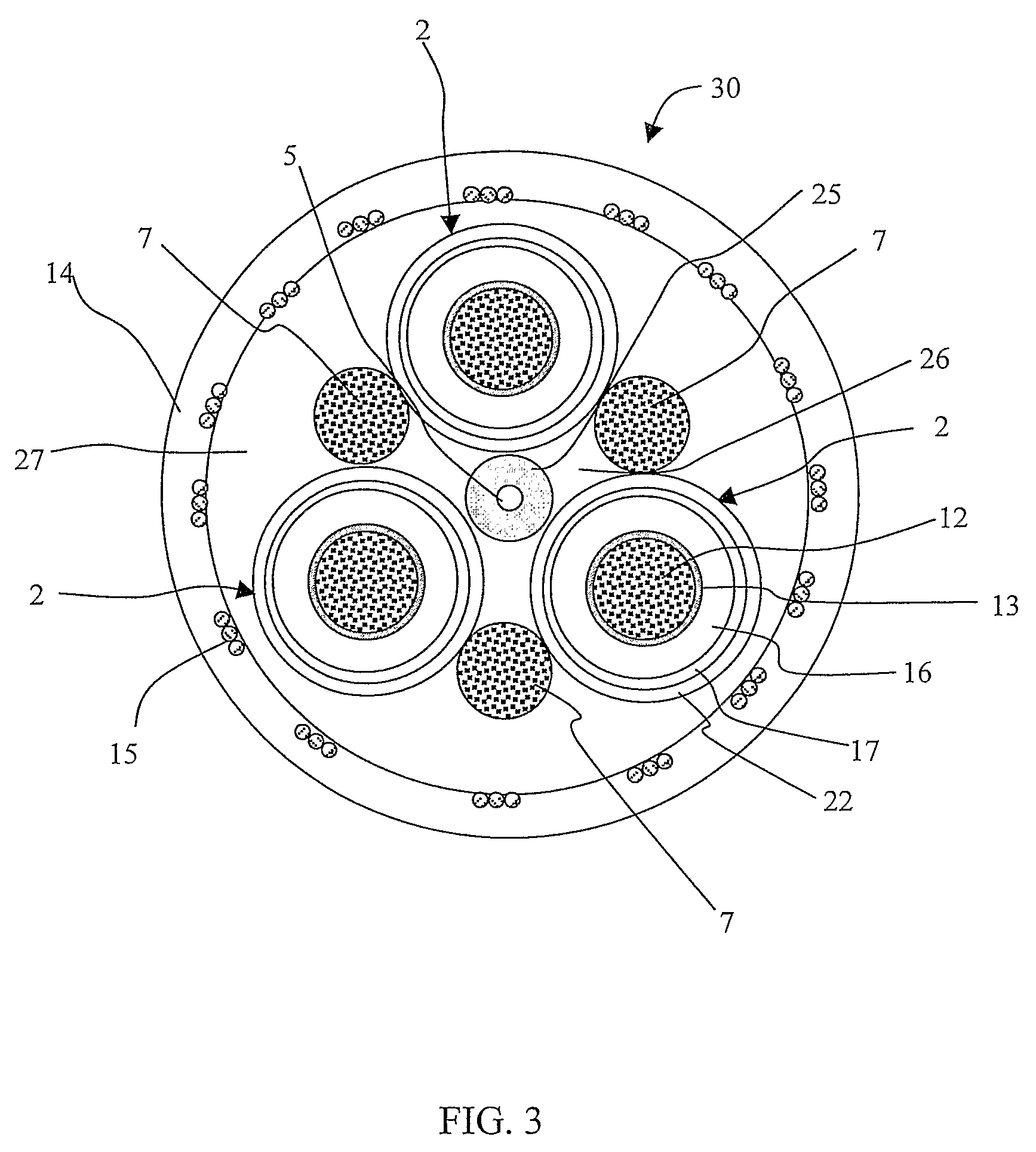

An electric cable includes a strain sensor longitudinally extending along the cable and including a strain optical fibre arranged within a bending neutral region surrounding and including a bending neutral longitudinal axis of the electric cable, and at least two longitudinal structural elements, at least one of the at least two longitudinal structural elements being a core including an electrical conductor, wherein the strain sensor is embedded in a strain-transferring filler mechanically coupling at least one of the at least two longitudinal structural elements with the strain sensor. With the disclosed cable construction, the strain experienced by the at least one of the at least two longitudinal structural elements is transferred to the strain sensor at least in a strained condition. In the preferred embodiments, the electric cable is a heavy-duty cable.

Owner:PRYSMIAN SPA

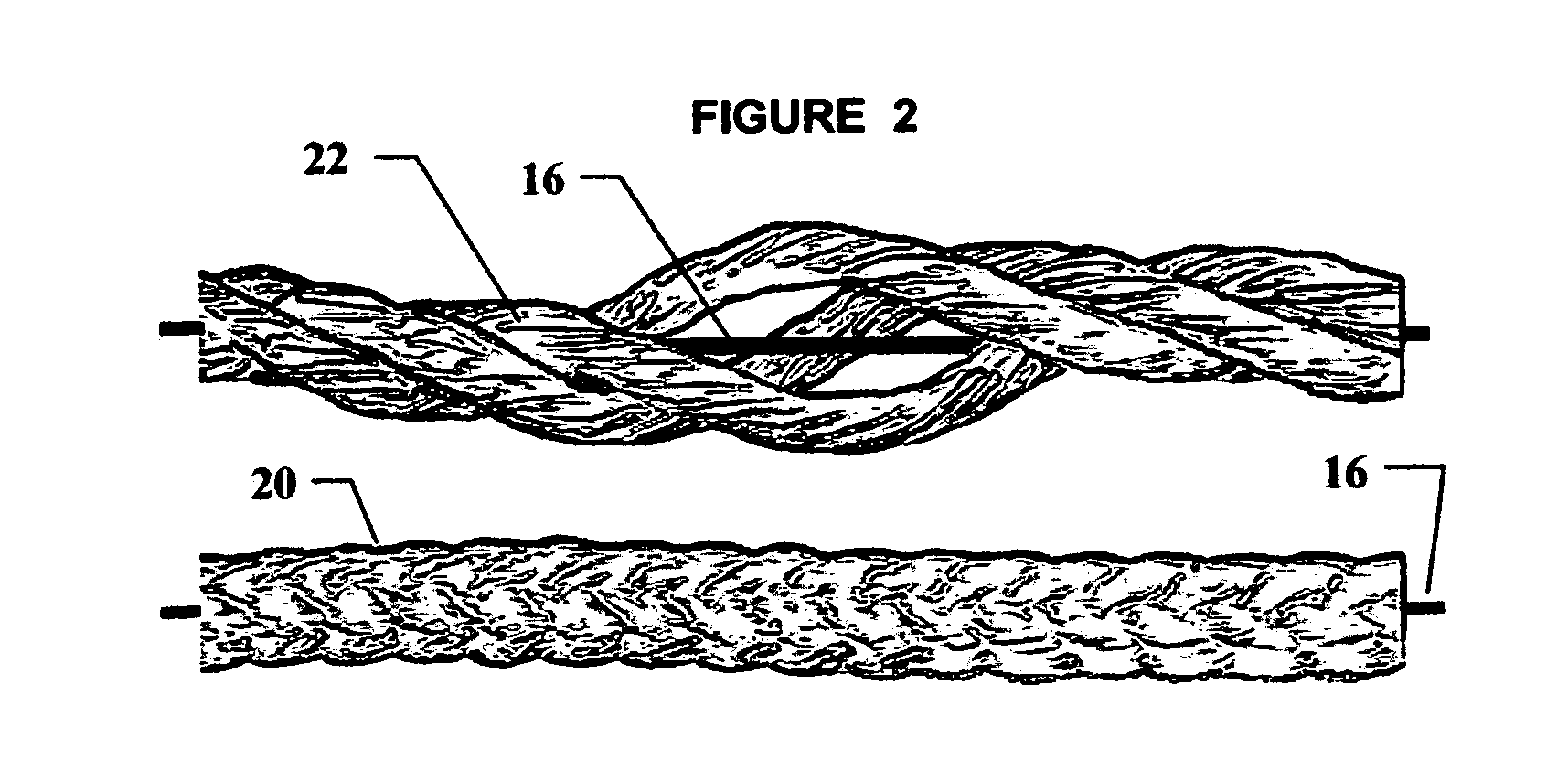

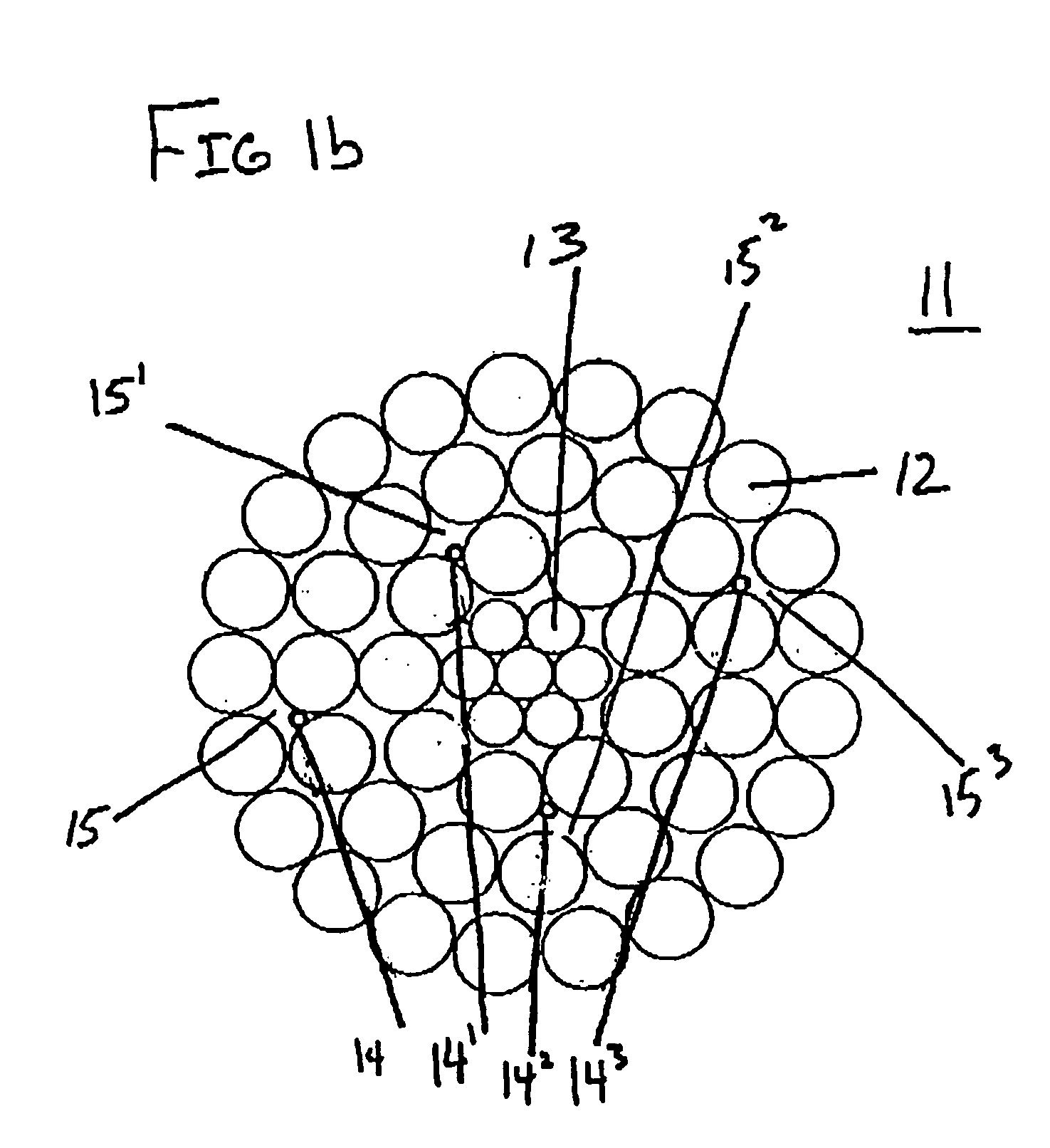

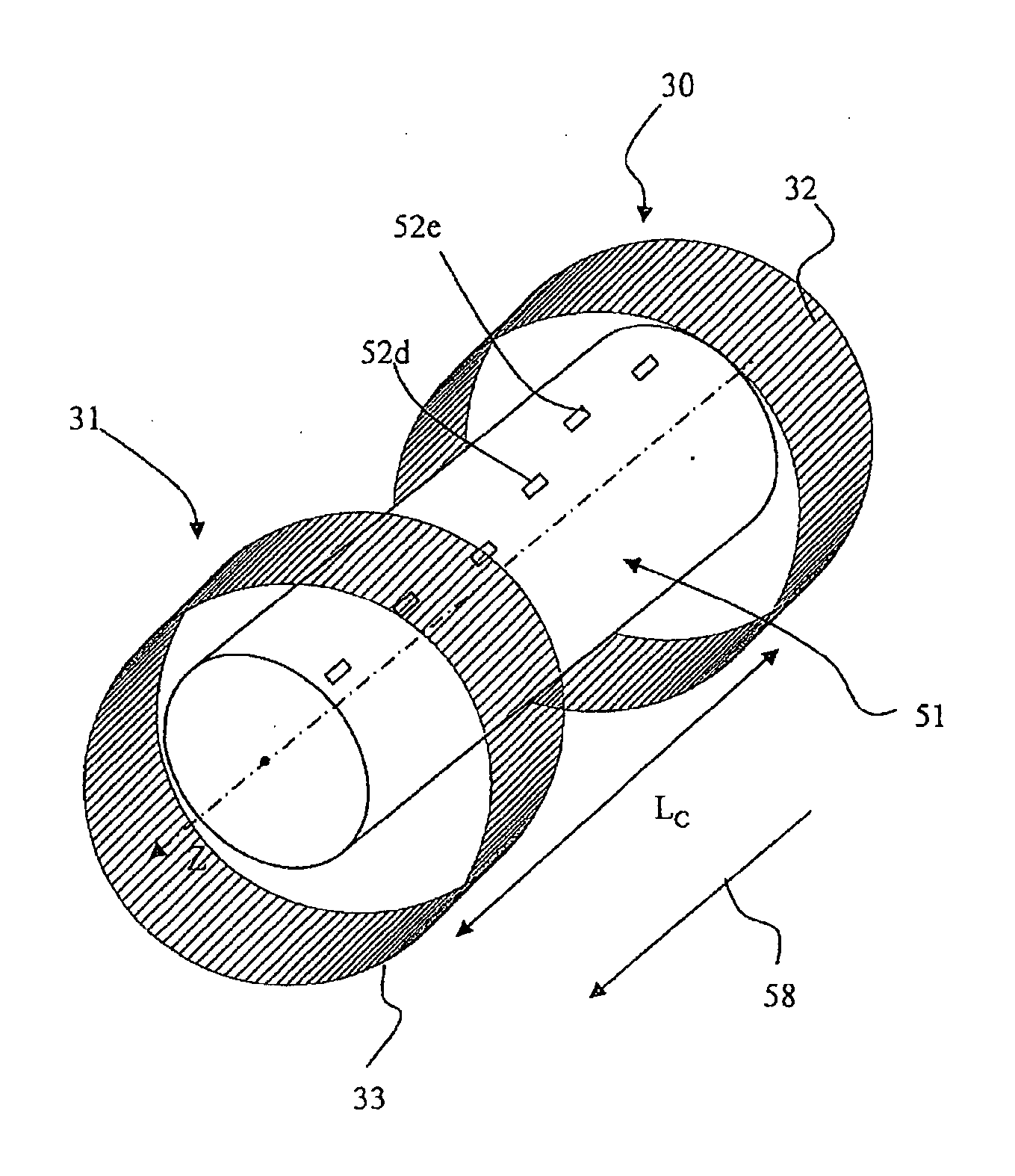

Measurement of large strains in ropes using plastic optical fibers

InactiveUS20050226584A1Minimal intrusionPrevent slippingControlOptical rangefindersTime domainEngineering

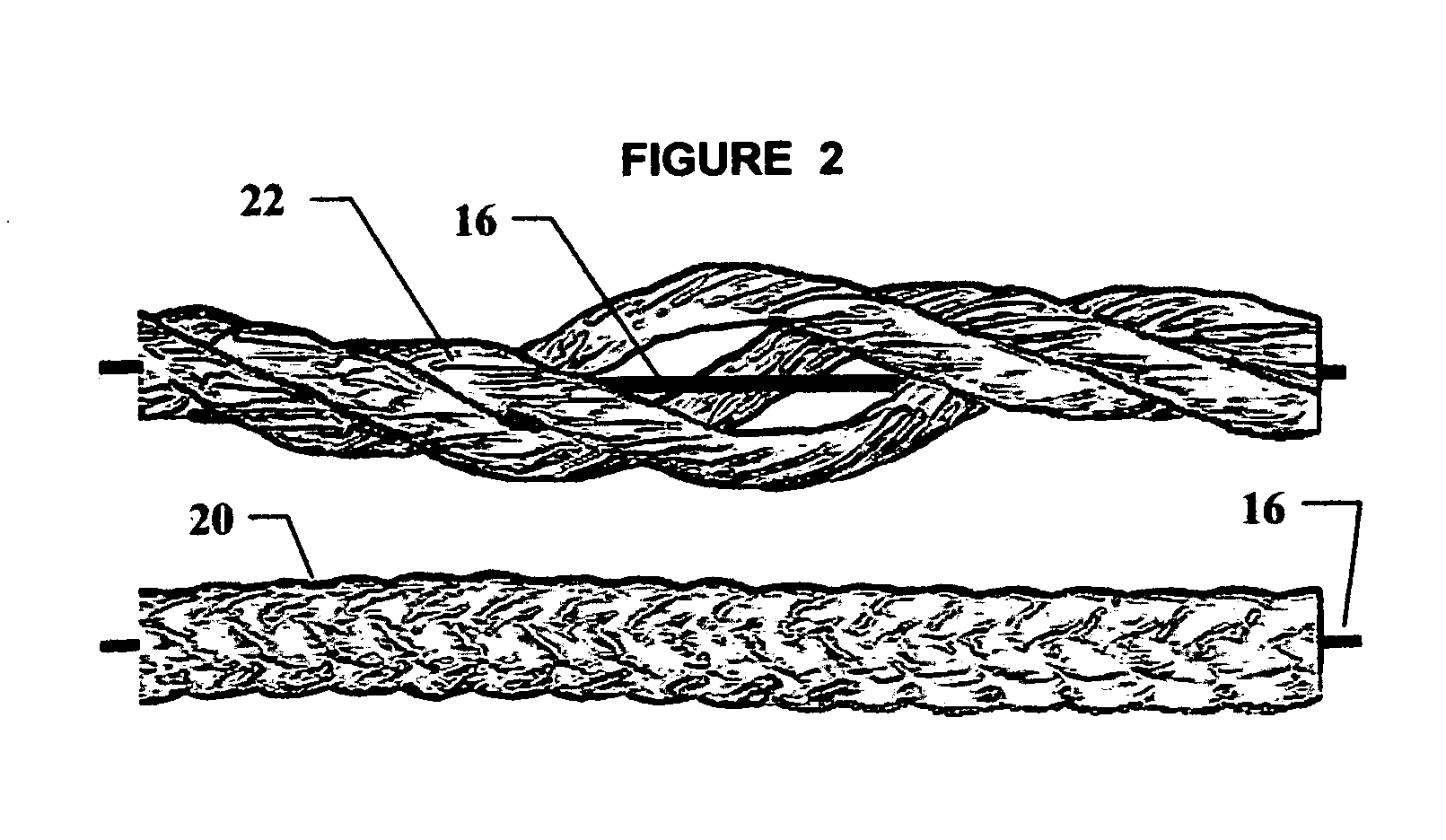

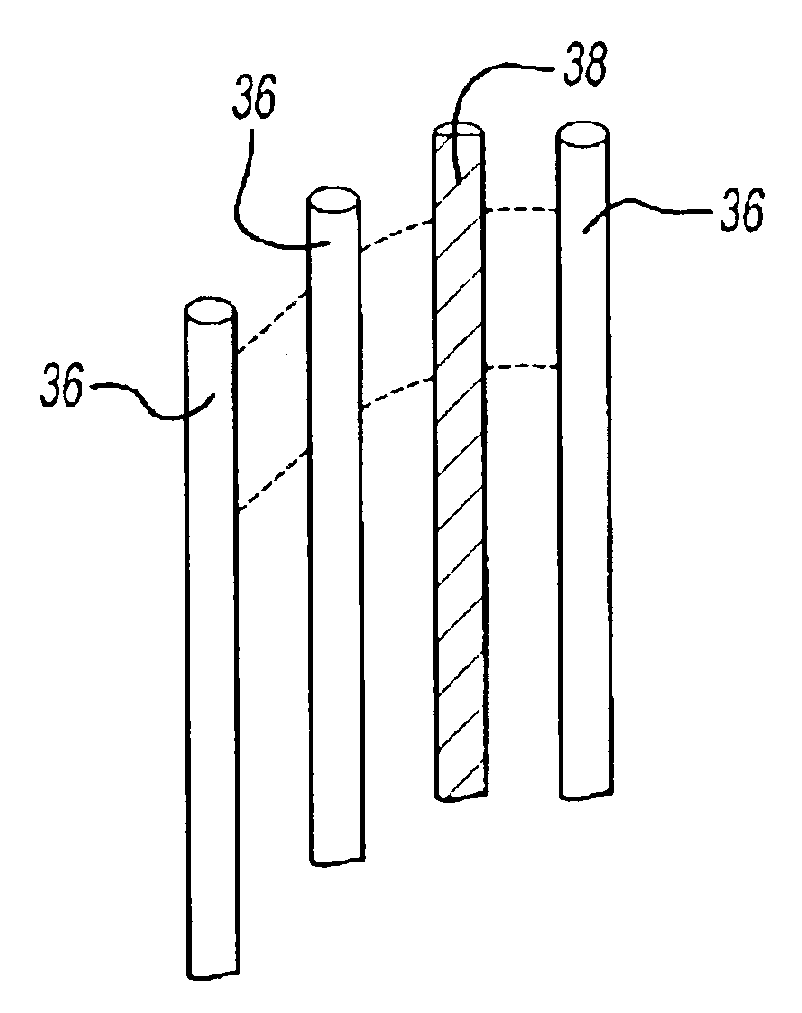

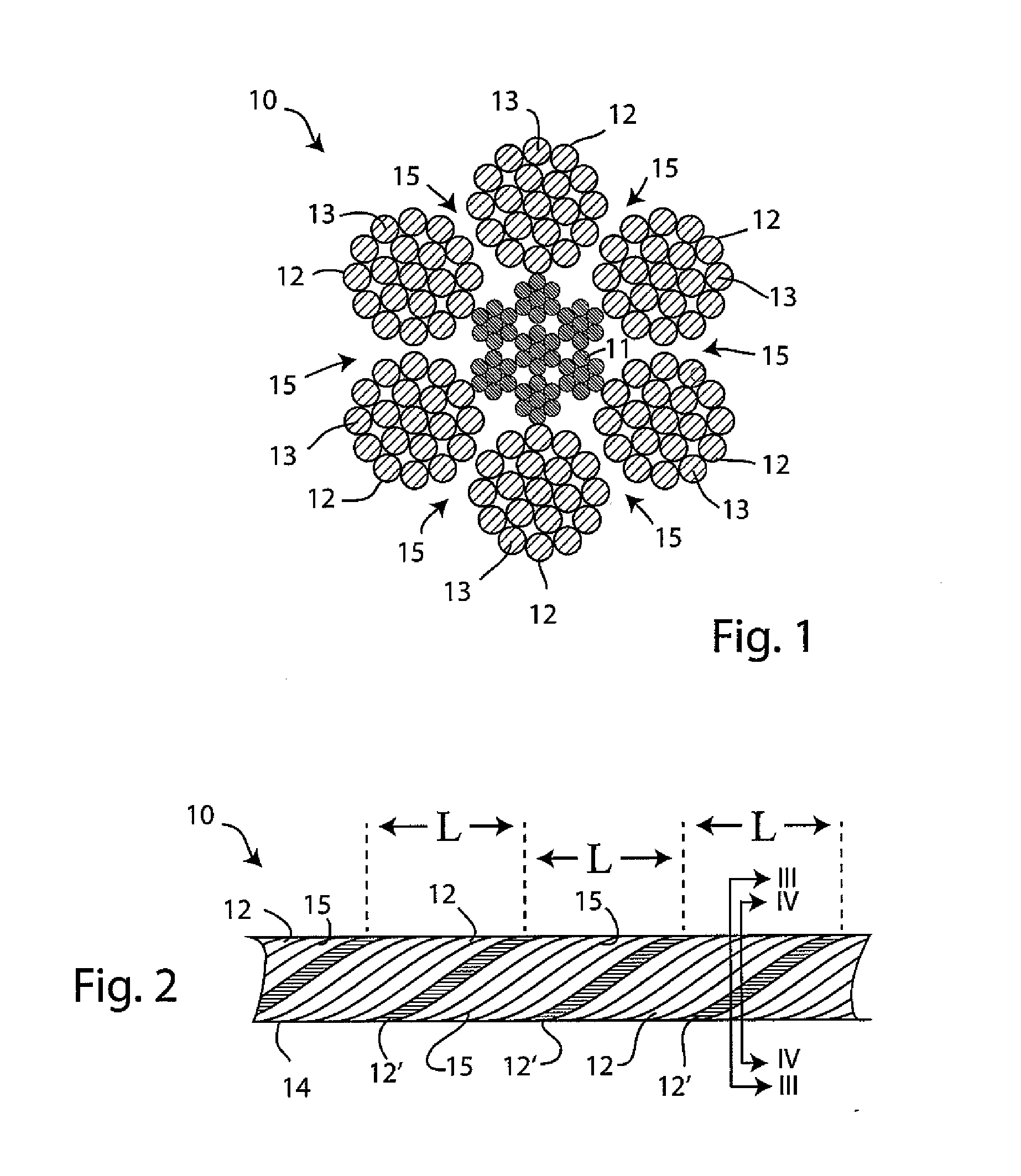

A method for the direct measurement of large strains in ropes in situ using a plastic optical fiber, for example, perfluorocarbon or polymethyl methacrylate and Optical Time-Domain Reflectometer or other light time-of-flight measurement instrumentation. Protective sheaths and guides are incorporated to protect the plastic optical fiber. In one embodiment, a small rope is braided around the plastic optical fiber to impose lateral compressive forces to restrain the plastic optical fiber from slipping and thus experience the same strain as the rope. Methods are described for making reflective interfaces along the length of the plastic optical fiber and to provide the capability to measure strain within discrete segments of the rope. Interpretation of the data allows one to calculate the accumulated strain at any point in time and to determine if the rope has experienced local damage.

Owner:WILLIAMS JERRY GENE +2

Lifting sling with excessive elongation warning indicator

Owner:MUELLER DEWAYNE

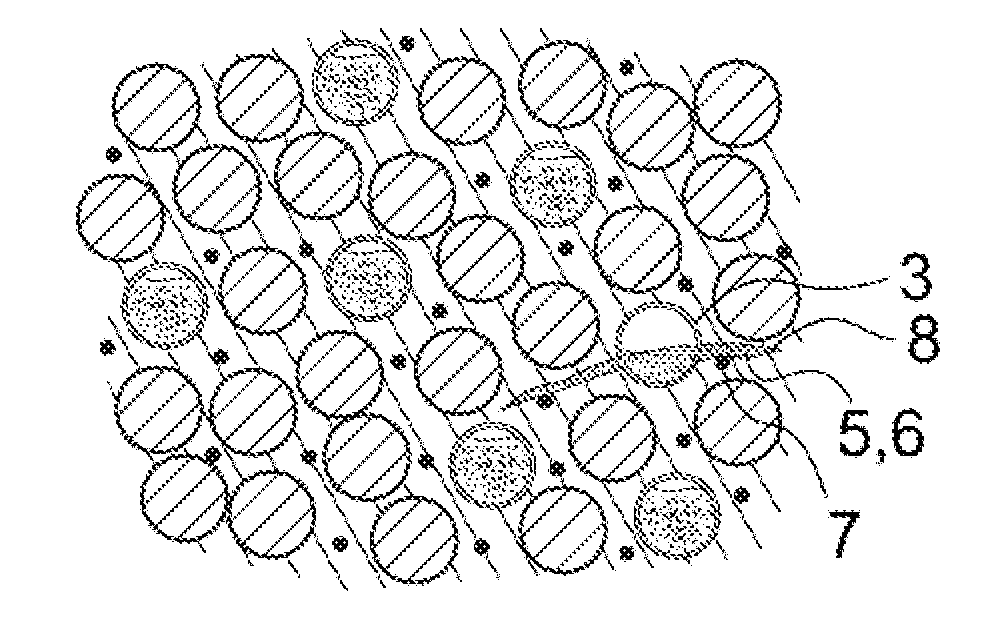

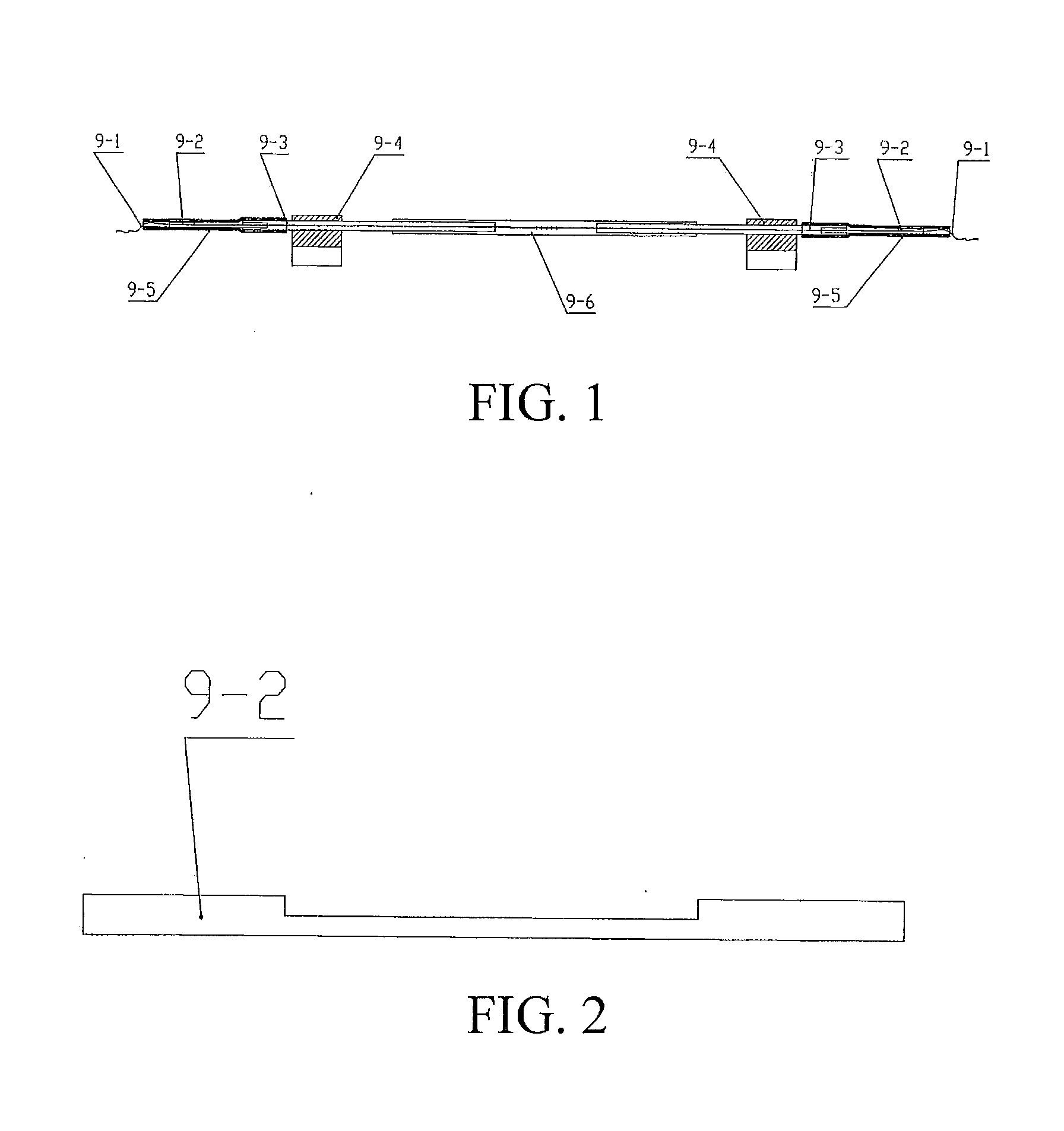

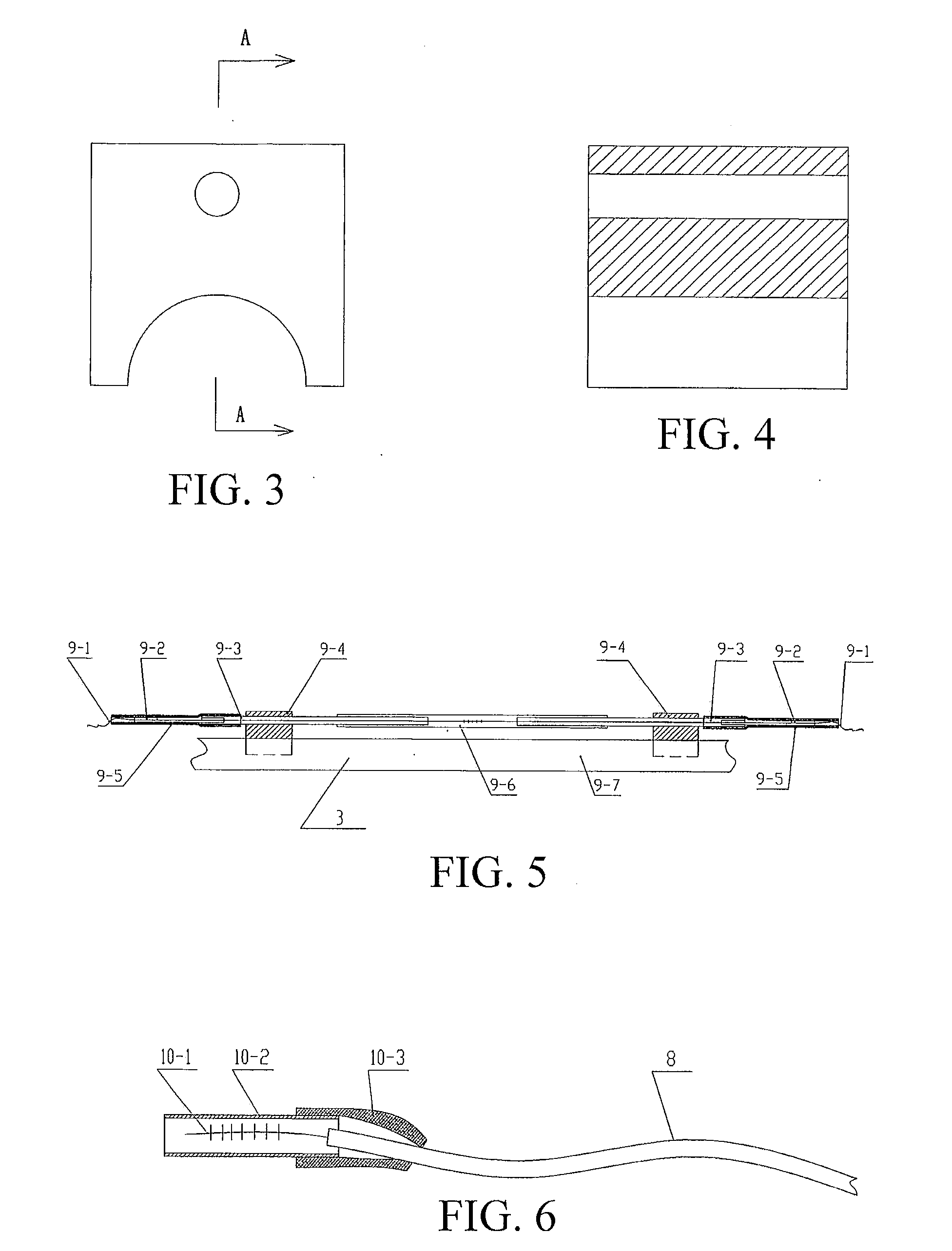

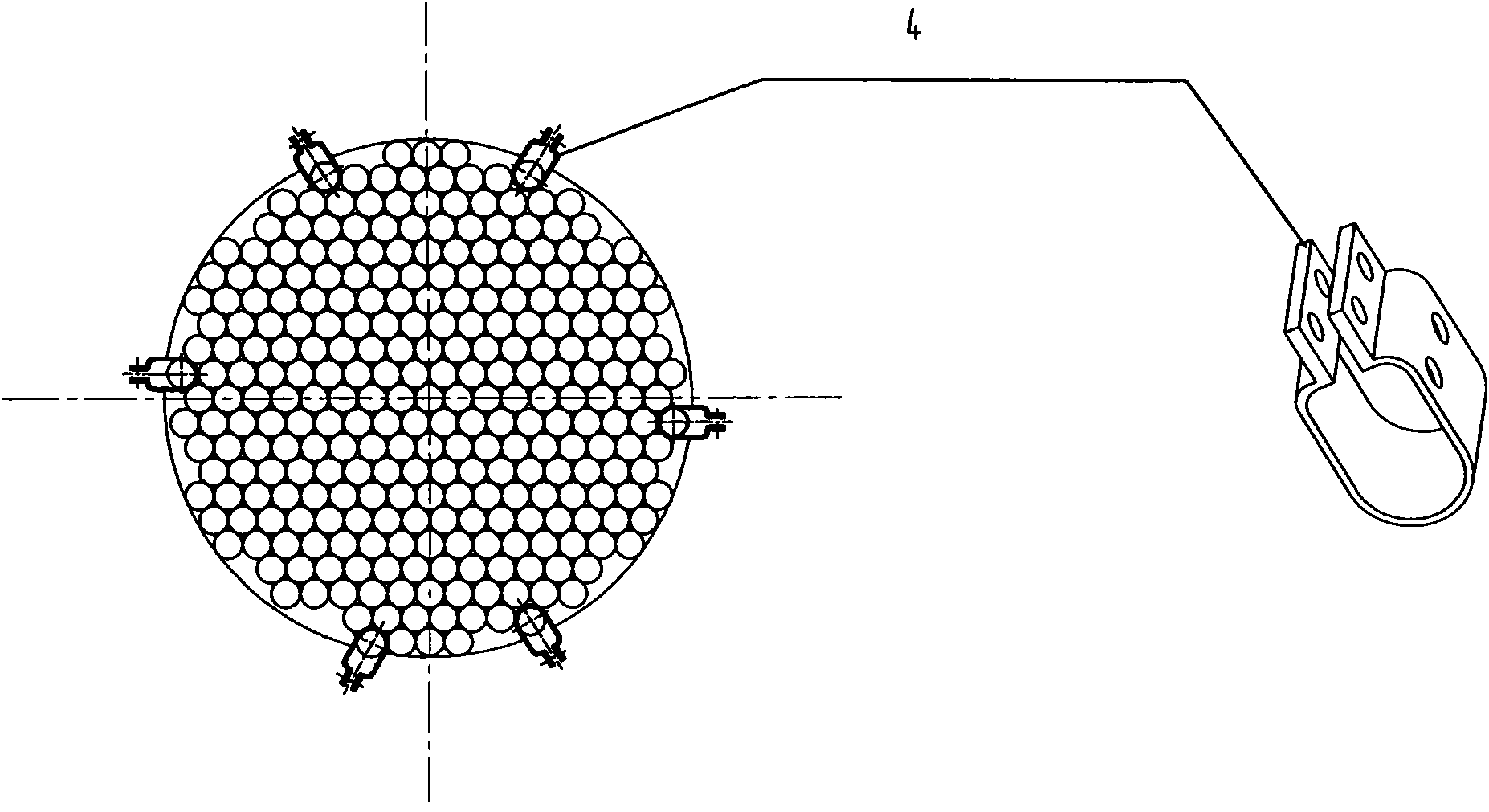

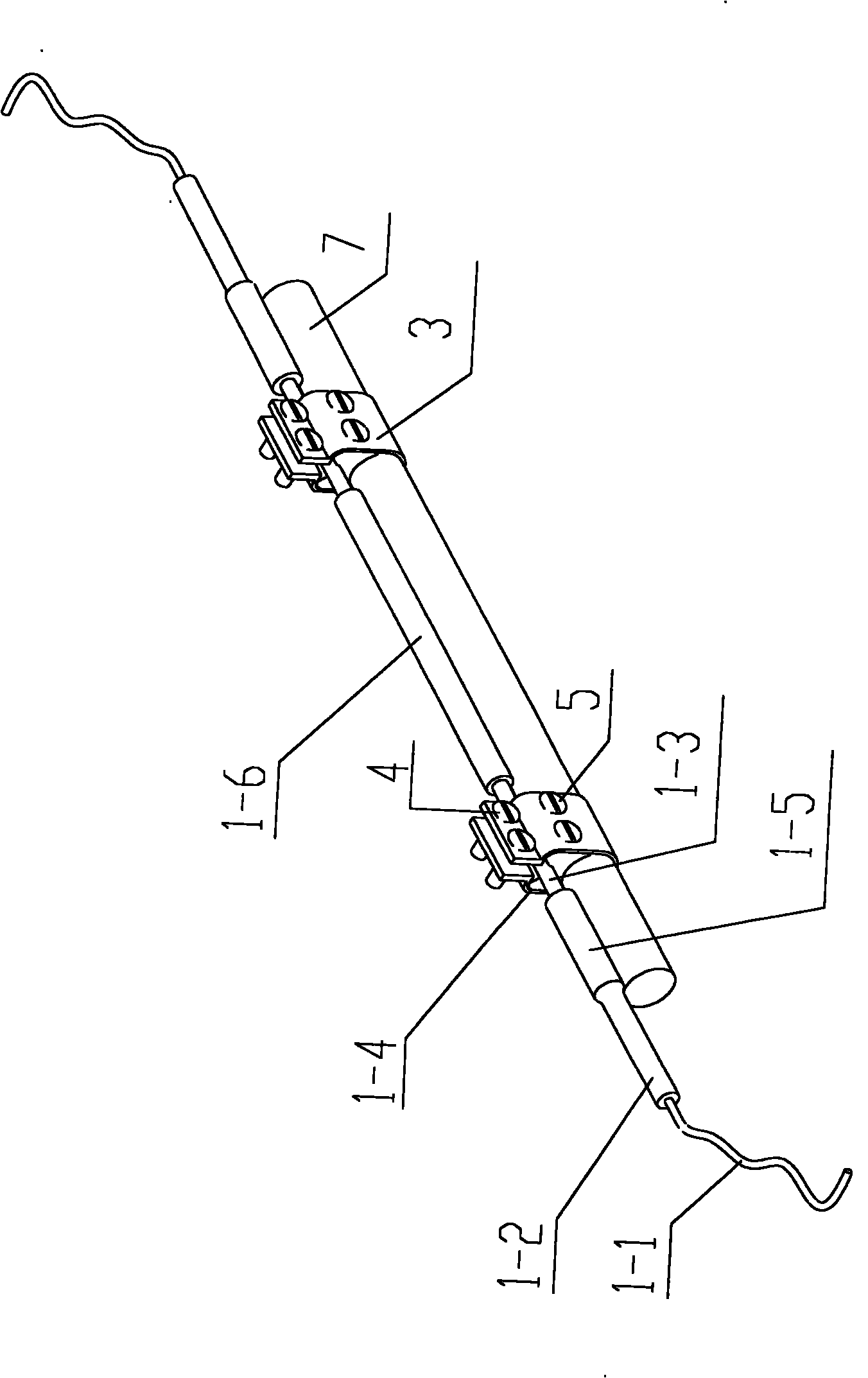

Bridge intelligent cable system with built-in fiber grating sensor

ActiveCN101701450AReal-time monitoring of force statusMeet health monitoring requirementsThermometer detailsControlFiberGrating

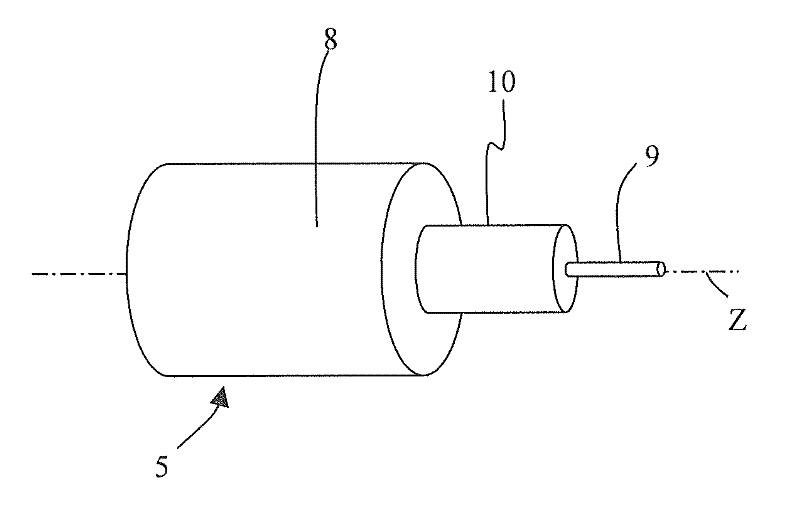

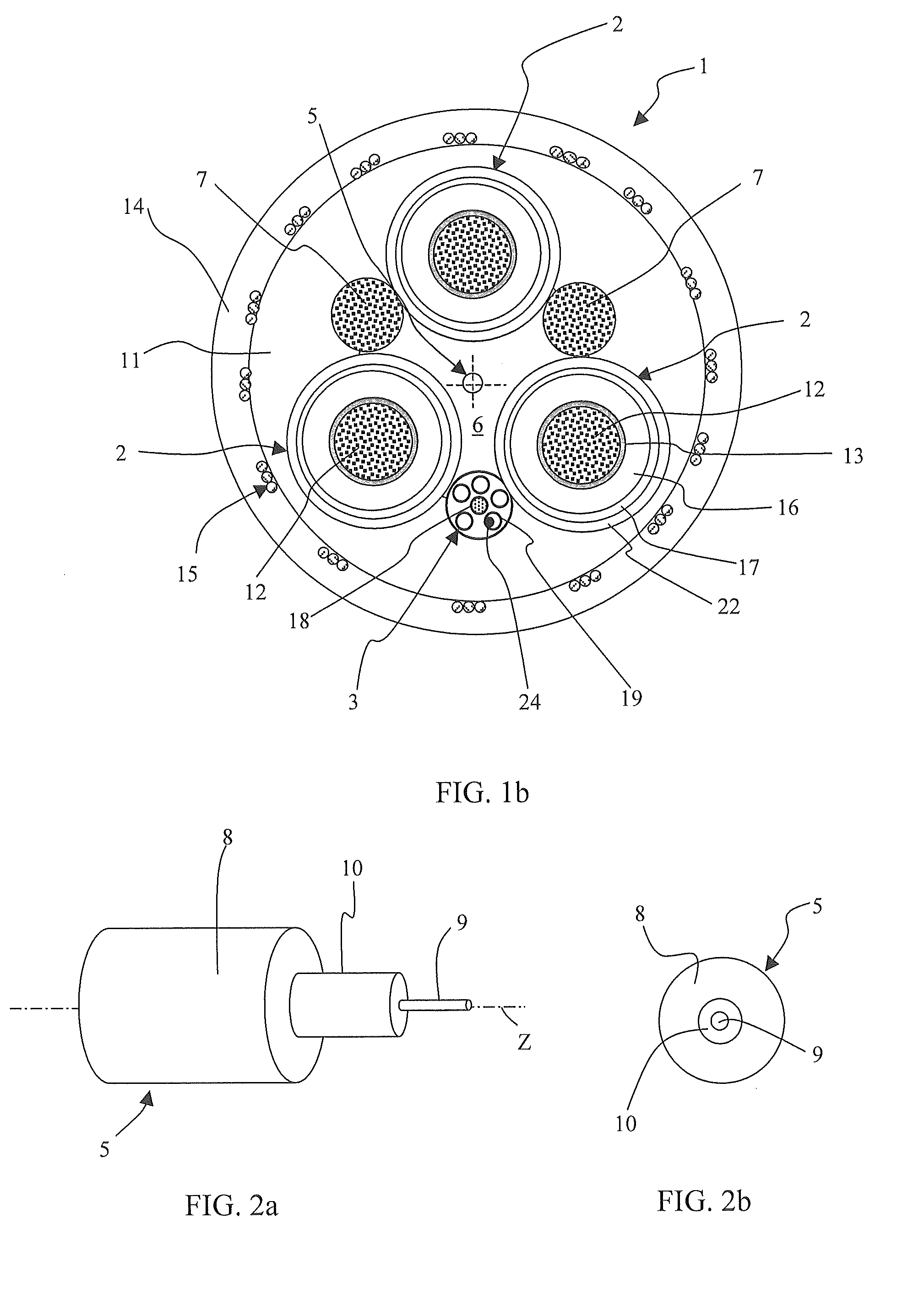

The invention relates to a bridge intelligent cable system with a built-in fiber grating sensor, which is used for cable bearing structures of a cable-stayed bridge, a suspension bridge, an arch bridge and the like. The bridge intelligent cable system comprises an anchoring cup (1), a dividing plate (5), a connecting cylinder (4), a fiber grating sensor and a cable body (11), wherein the fiber grating sensor comprises a fiber grating strain sensor (9) and a fiber grating temperature sensor (10), tail fibers of the fiber grating strain sensor (9) and the fiber grating temperature sensor (10) are led out, the packaged fiber grating strain sensor (9) is fixedly connected to an outer steel wire (3) at the position of the connecting cylinder (4), the packaged fiber grating temperature sensor is suspended on the steel wire (3) at position of the connecting cylinder (4), a hole (5-1) is penetrated in the dividing plate (5), and preserved steel pipes (7) are primarily imbedded in the connecting cylinder (4) and the anchoring cup (1) in advance. The invention can improve the survival rate of the fiber grating sensor and the optical fibers during the manufacture and the application of the cable, ensure a reliable embedding process of the fiber grating sensor and effectively lead fiber grating signals out of the cable body in a distortionless way.

Owner:FASTEN GRP CO LTD +1

Electric cable with bending sensor and monitoring system and method for detecting bending in at least one electric cable

ActiveUS20120174683A1Effective periodic maintenanceHigh mechanical stressControlForce measurement by measuring optical property variationNon symmetricMonitoring system

A method for monitoring at least the bending strain of at least one electric cable provided with at least one peripheral mechanically non-symmetric strength member is provided.

Owner:PRYSMIAN SPA

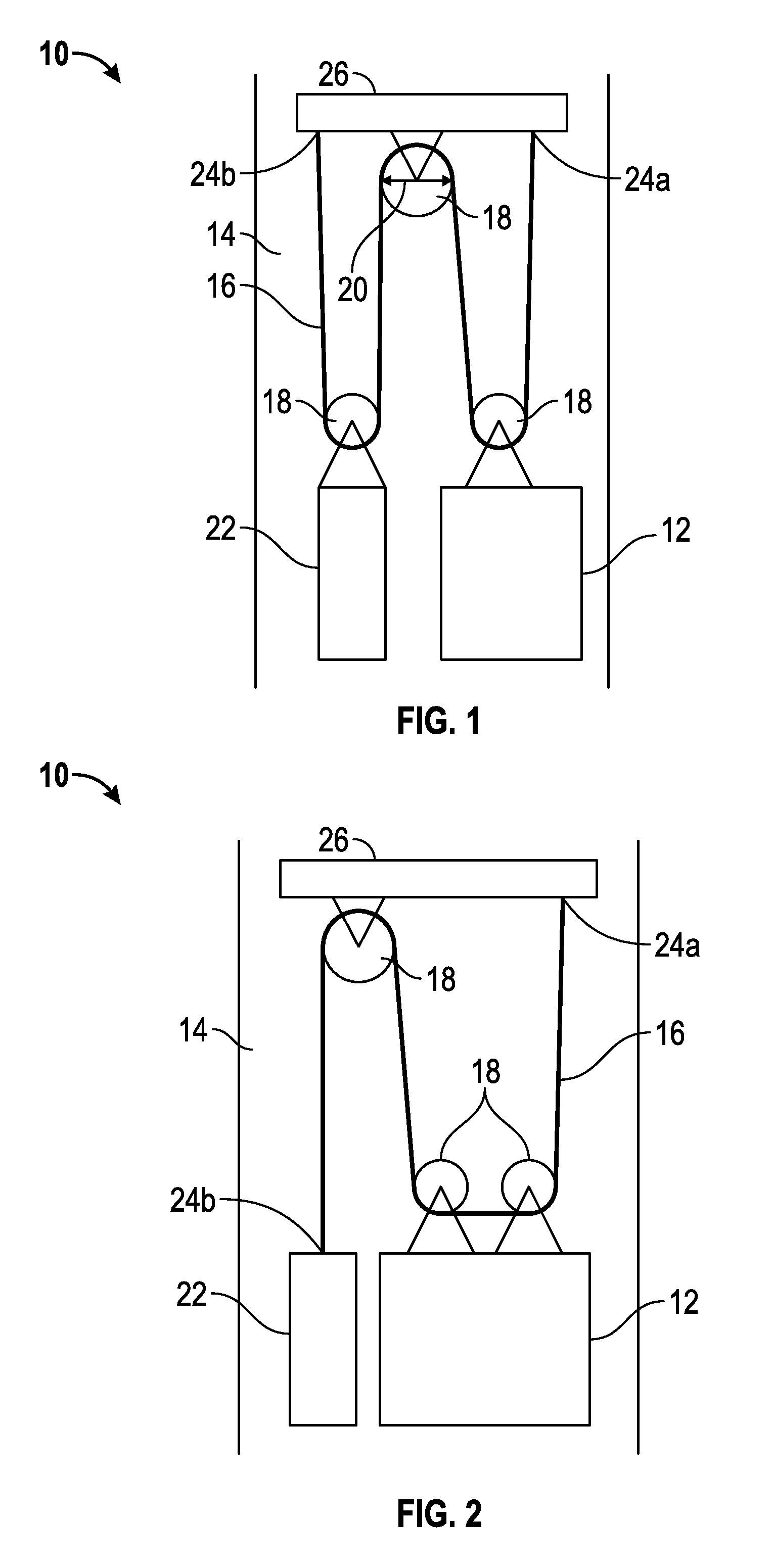

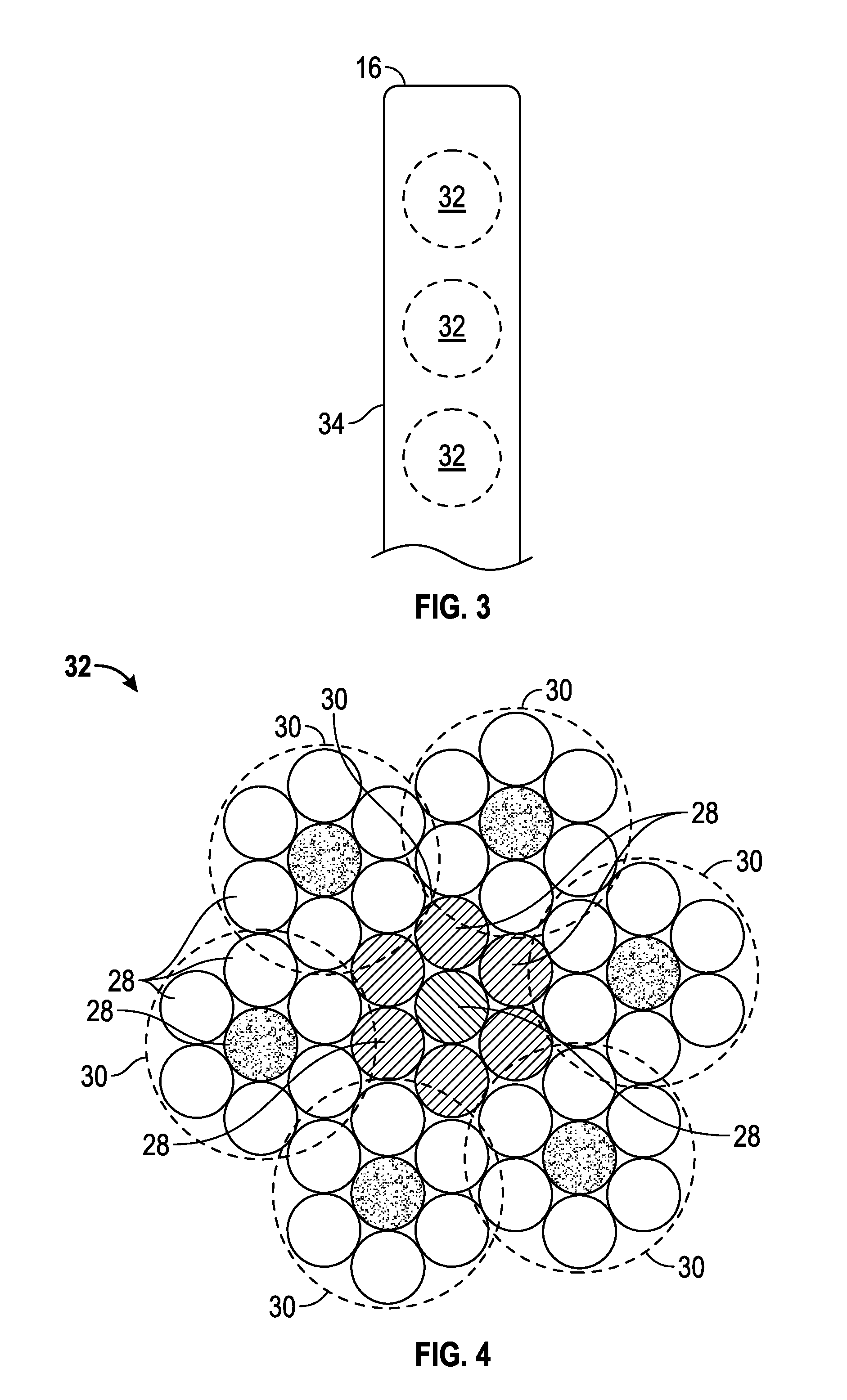

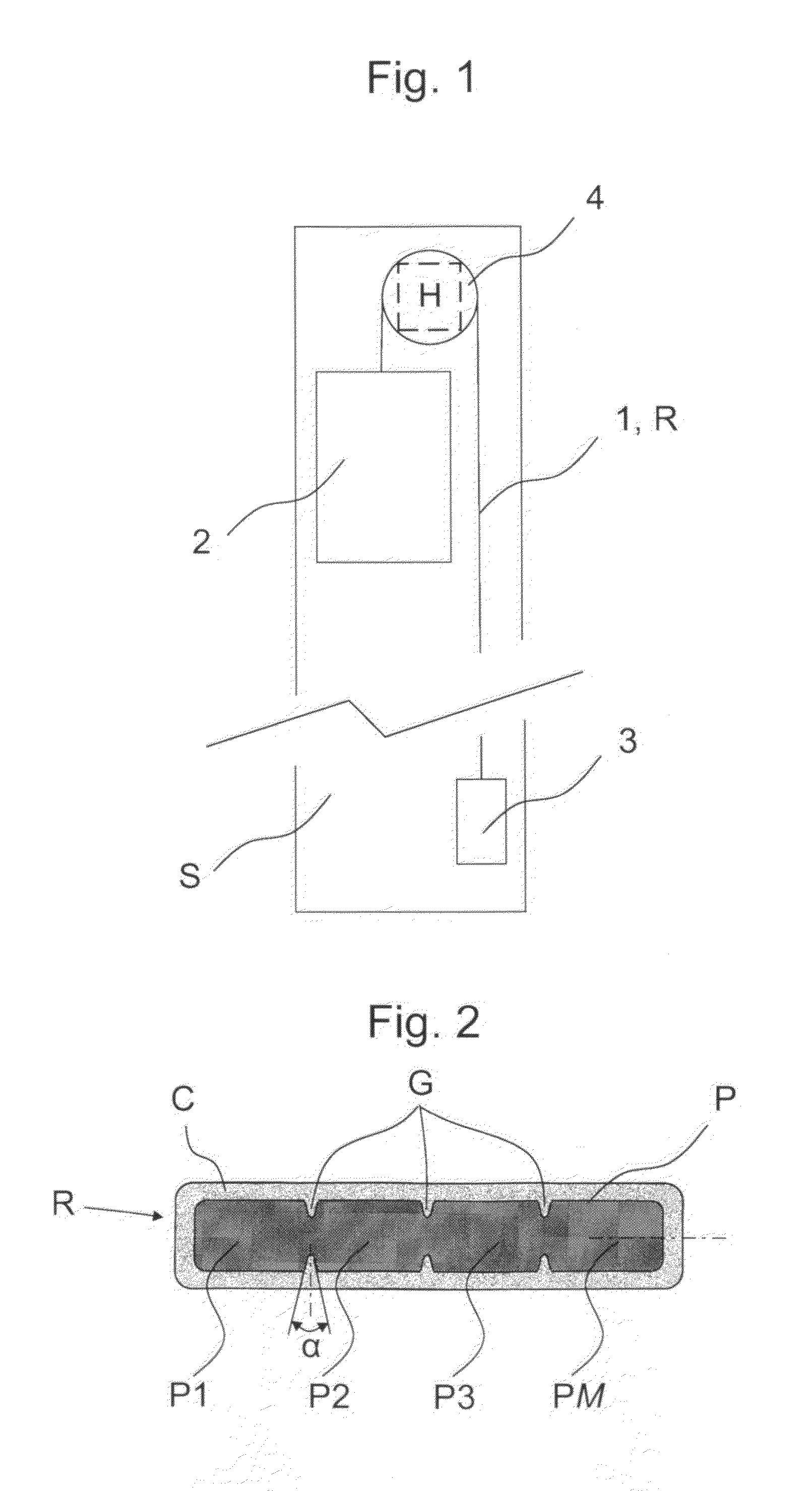

Elevator load bearing assembly having a detectable element that is indicative of local strain

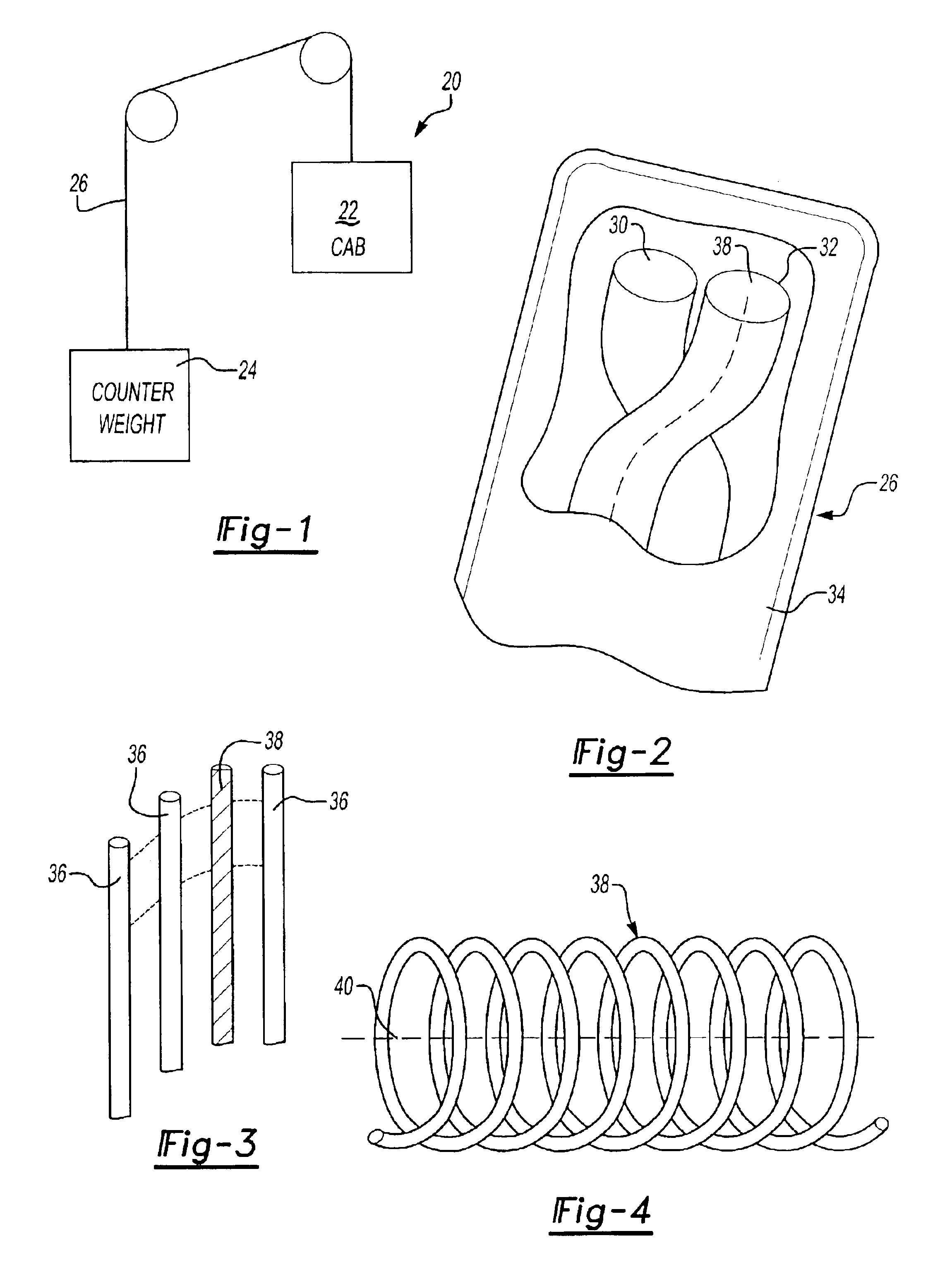

A load bearing member, such as a polymer cord reinforced belt, includes at least one element of a different material having a characteristic that distinguishes it from the polymer fibers that make up the strands of the cord. The element of second material has a configuration that is repeated along the length of the load bearing member. The configuration of the second material element provides a readily detectible indication of localized strain on the load bearing member. As the load bearing member is strained over time, the configuration of the second material element is also altered. Analyzing the configuration of the second material element along the length of the load bearing member provides information regarding the condition of the belt.

Owner:OTIS ELEVATOR CO

Measurement of large strains in ropes using plastic optical fibers

InactiveUS6999641B2Minimal intrusionPrevent slippingControlOptical rangefindersTime domainMeasuring instrument

A method for the direct measurement of large strains in ropes in situ using a plastic optical fiber, for example, perfluorocarbon or polymethyl methacrylate and Optical Time-Domain Reflectometer or other light time-of-flight measurement instrumentation. Protective sheaths and guides are incorporated to protect the plastic optical fiber. In one embodiment, a small rope is braided around the plastic optical fiber to impose lateral compressive forces to restrain the plastic optical fiber from slipping and thus experience the same strain as the rope. Methods are described for making reflective interfaces along the length of the plastic optical fiber and to provide the capability to measure strain within discrete segments of the rope. Interpretation of the data allows one to calculate the accumulated strain at any point in time and to determine if the rope has experienced local damage.

Owner:WILLIAMS JERRY GENE +2

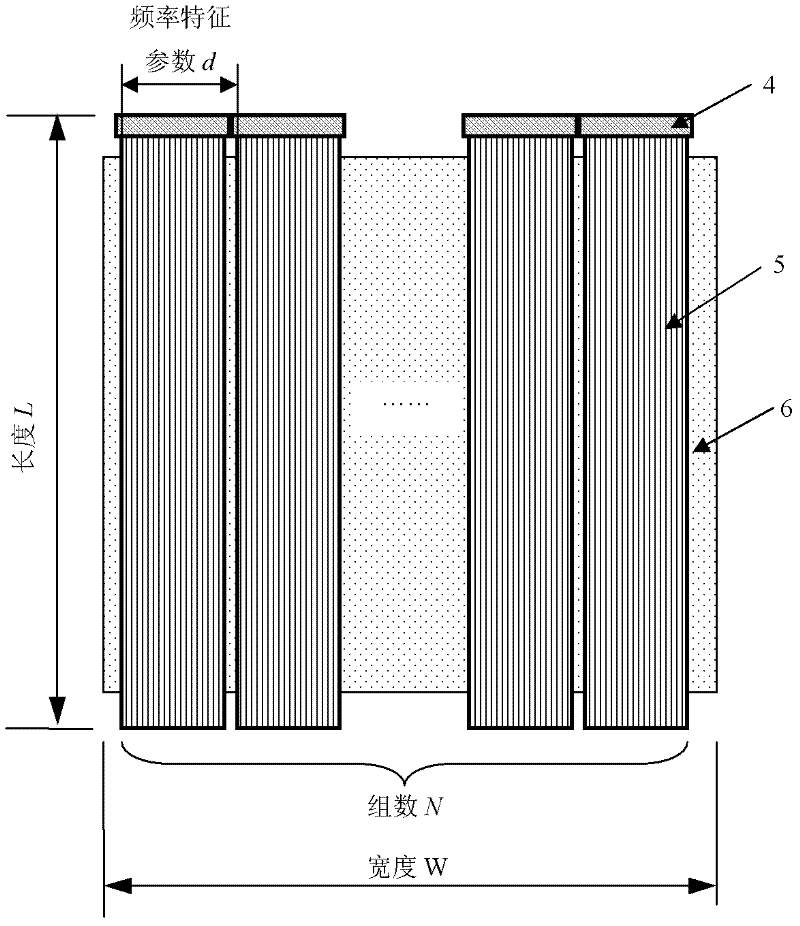

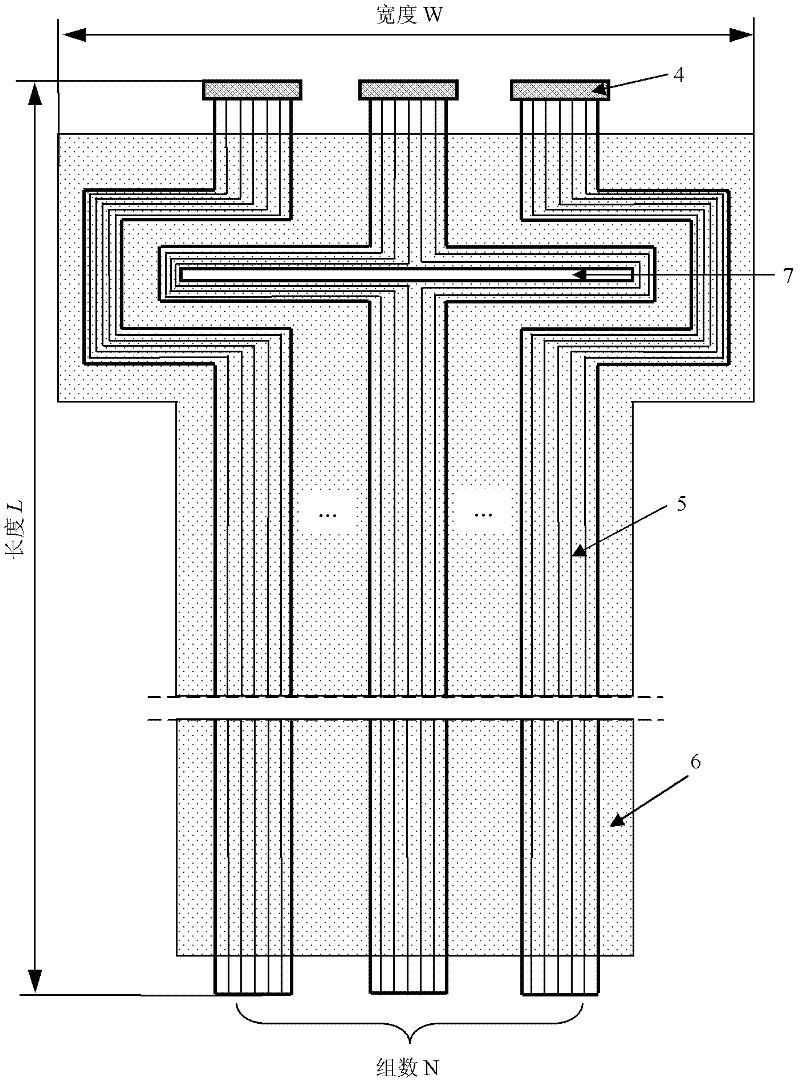

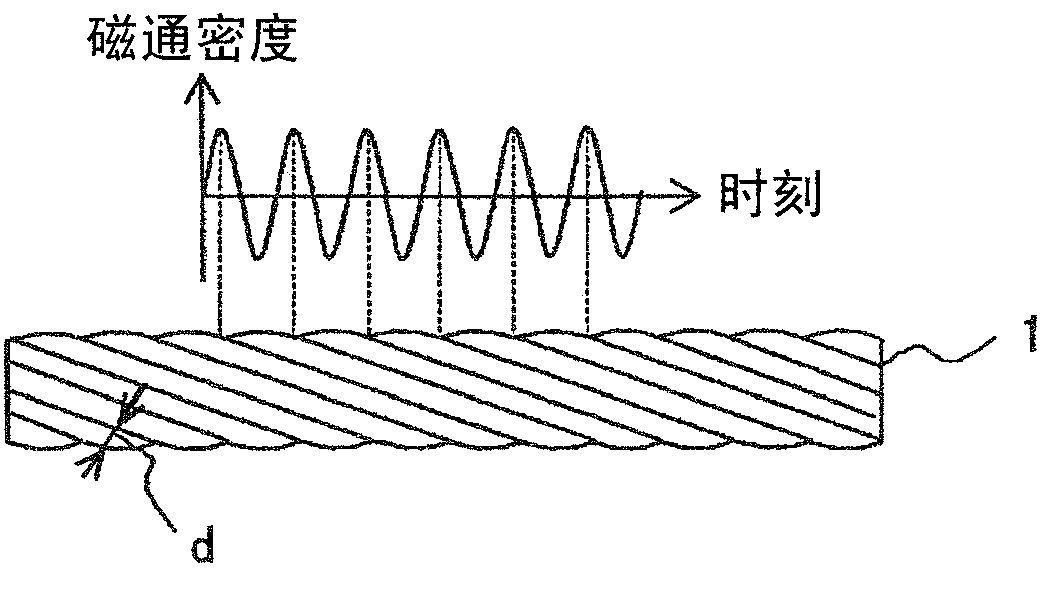

Flexible magnetostriction and magnetoelastic integrated sensor for detecting stress and defect of wire rope

ActiveCN102435357ALight structureEasy to disassembleControlForce measurement by measuring magnetic property varationEngineeringUltrasonic guided wave

The invention discloses a flexible magnetostriction and magnetoelastic integrated sensor for detecting stress and defect of a wire rope. The integrated sensor comprises an inner flexible printing coil and an outer flexible printing coil, wherein the structure of the flexible printing coil can be curled and attached to the surface of the wire rope to form a single-layer or multi-layer solenoid coil which is locked by a connector and then mounted on the detected wire rope; and after the locked state is released, the solenoid coil is removed from the surface of the wire rope. The integrated sensor can work as a magnetostriction sensor and excite a longitudinal modal ultrasonic guide wave in the wire rope to perform long-distance defect detection of the wire rope or to measure the average stress of the wire rope in a certain distance based on the acoustoelastic effect of the ultrasonic guide wave; and the integrated sensor also can work as a magnetoelastic sensor and calculate the stress value of a section of the wire rope based on the magnetoelastic effect by measuring the magnetic conductivity of the material of the wire rope, or scan along the length direction of the wire rope to obtain the change of the magnetic conductivity of the material of the wire rope along the length direction and reflect the size and position of the defect.

Owner:BEIJING UNIV OF TECH

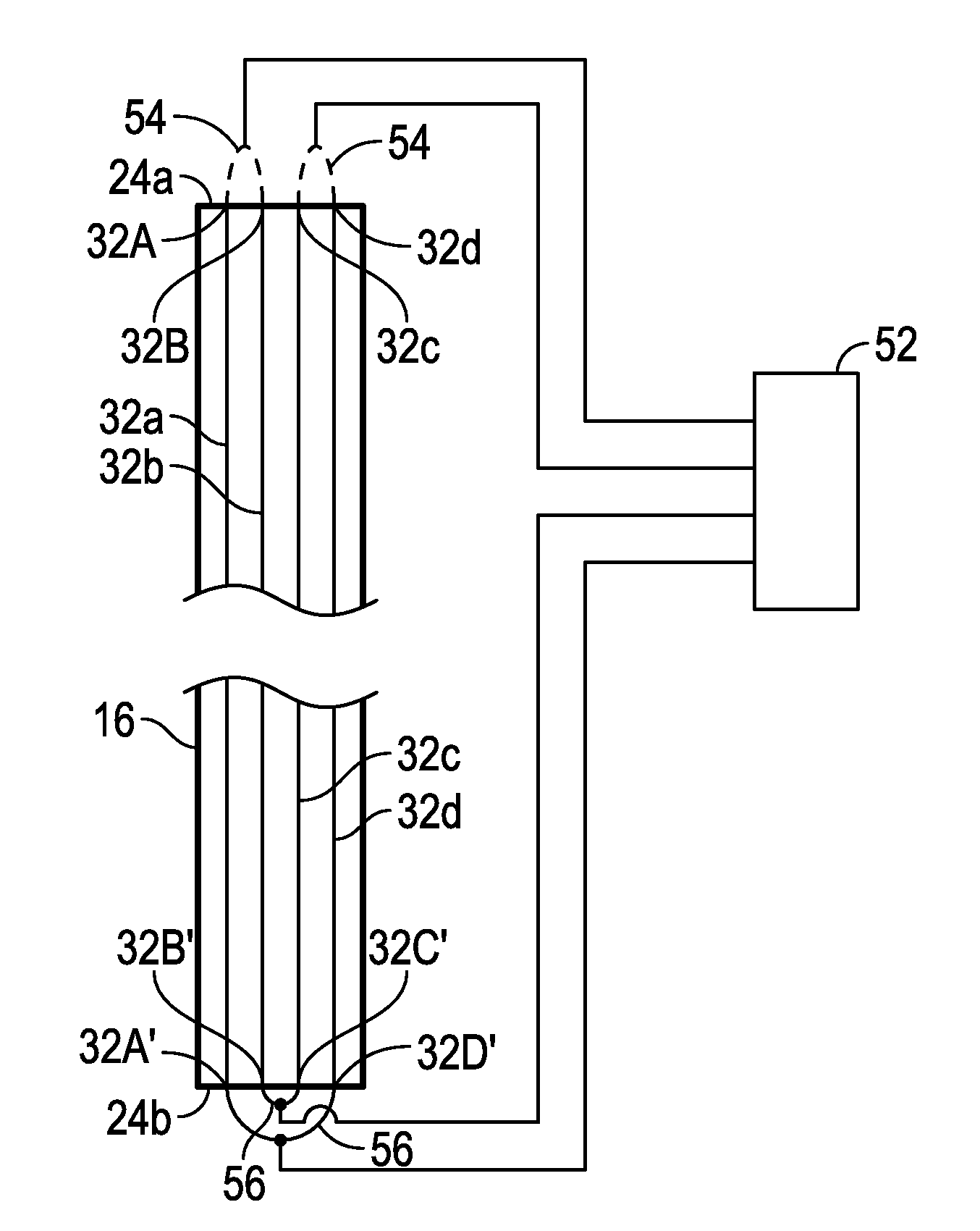

Elevator cord health monitoring

ActiveUS20160002006A1Suppress ambient noiseImprove signal-to-noise ratioControlTesting dielectric strengthEnvironmental noiseBridge circuit

A method of fault detection of a belt or rope includes interconnecting a plurality of cords of the belt or rope, the cords including a plurality of wires, to form a bridge circuit. A fault detection bridge circuit is subjected to a voltage excitation and outputs a voltage which is indicative of the belt or rope damage but remaining insensitive to other environmental noises.

Owner:OTIS ELEVATOR CO

Electrical cable with temperature sensing means and method of manufacture

An electrical cable having a holding member arranged longitudinally along the cable for an optic fiber, which can be used for temperature sensing and / or communications. The holding member can replace one or more strands of the cable, be placed inside an interstice of the cable, be placed in between various layers of the cable, or placed in the jacket of the cable. The cable can be produced through the addition of a planetary strander device to a wire assembly apparatus.

Owner:SOUTHWIRE CO LLC

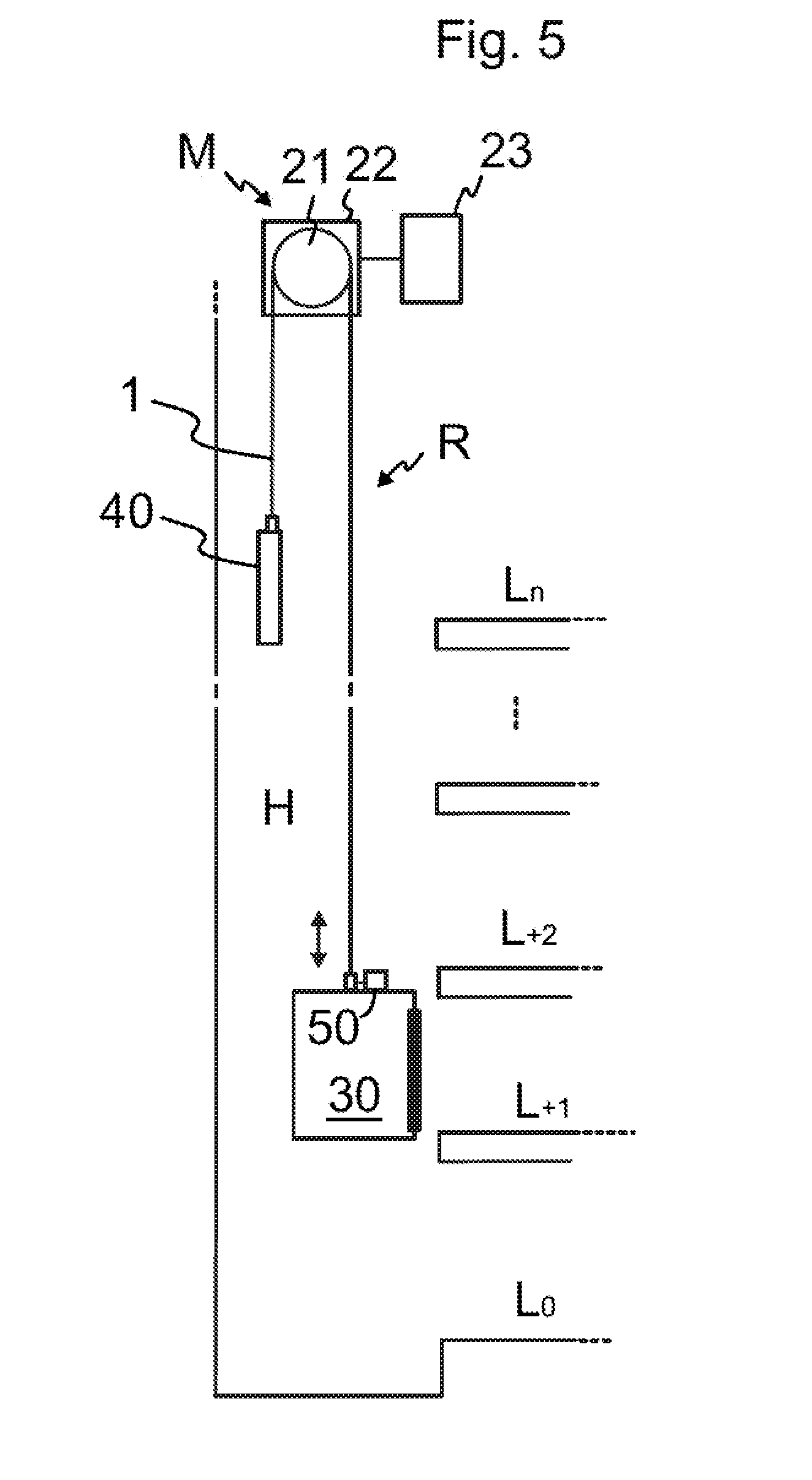

Rope for an elevator, elevator and method

ActiveUS20150191332A1Transportation safetyImprove staminaControlSynthetic resin layered productsFiberBiomedical engineering

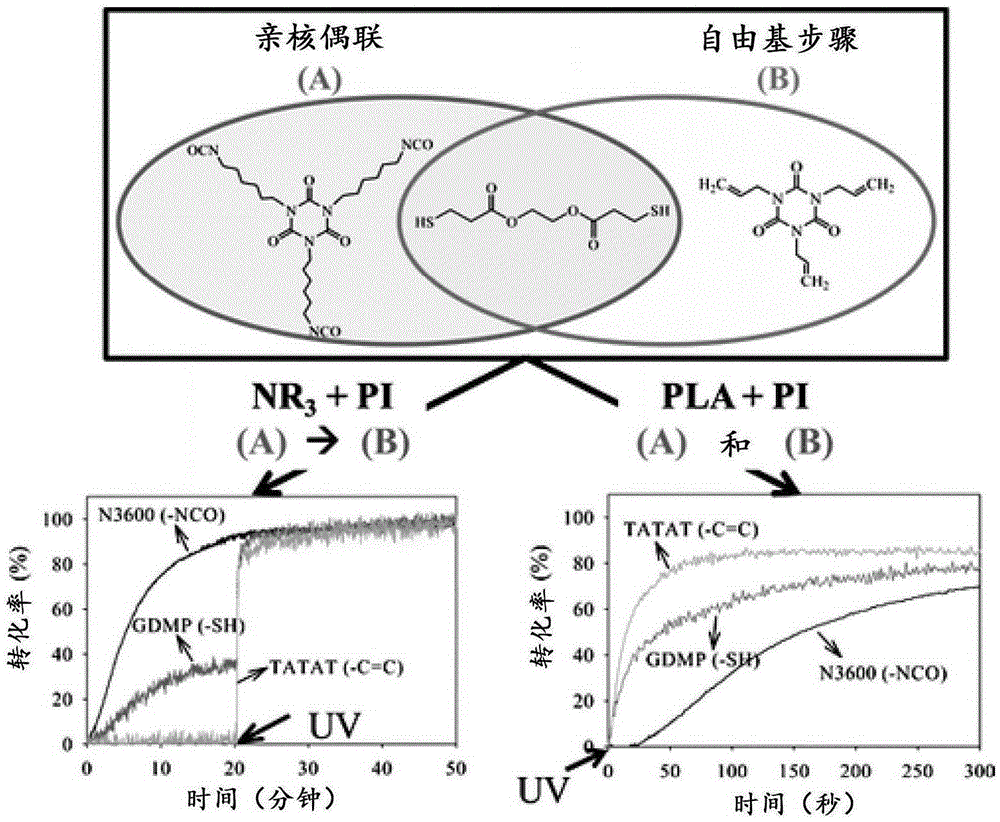

A rope for a hoisting device, in particular for an elevator, includes at least one continuous load bearing member extending in longitudinal direction of the rope throughout the length of the rope, the load bearing member being made of composite material including reinforcing fibers embedded in polymer matrix. The composite material includes capsules embedded in the polymer matrix, the capsules storing monomer substance in fluid form. An elevator includes a rope of the aforementioned kind and a method for condition monitoring of a rope of an elevator.

Owner:KONE CORP

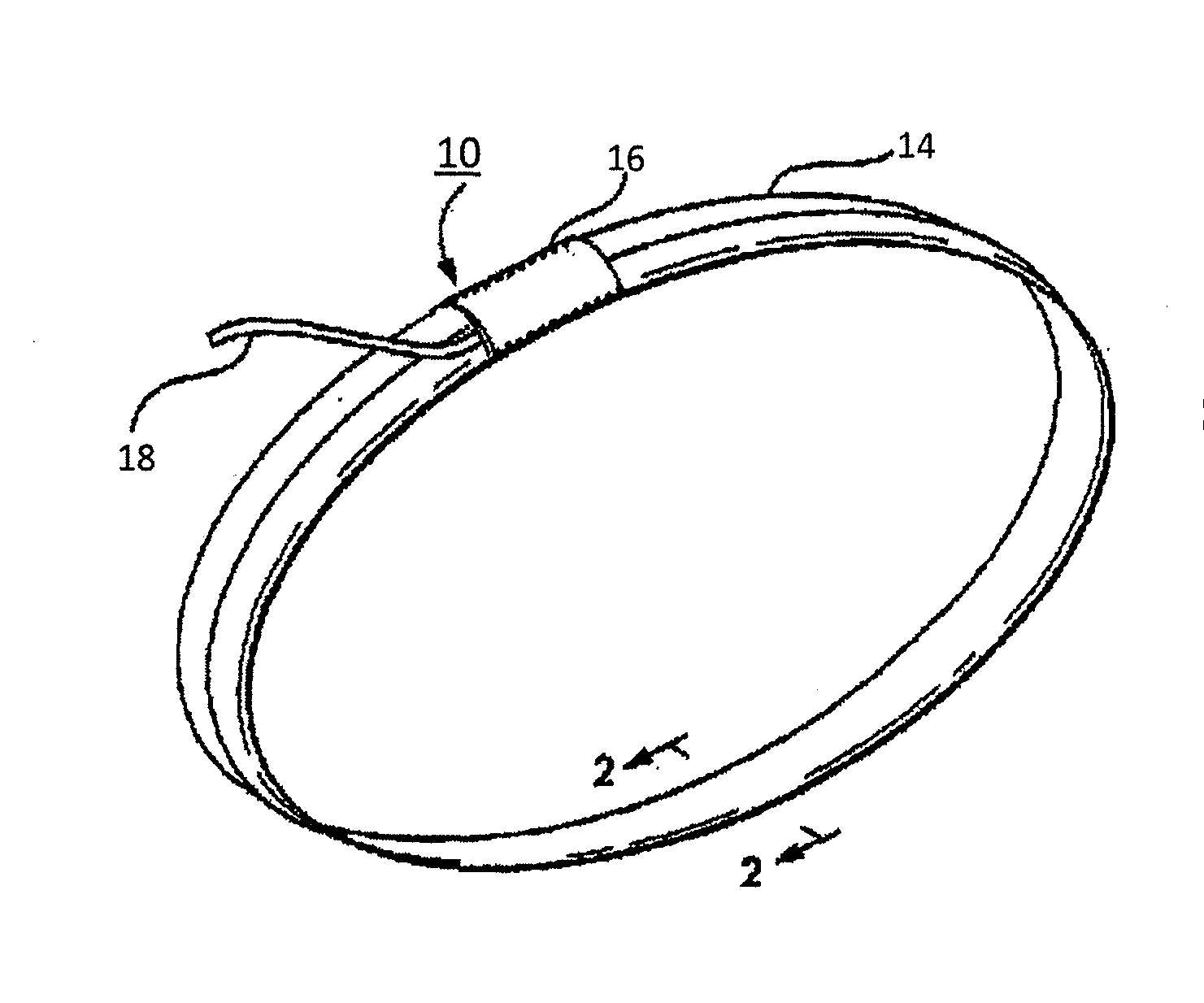

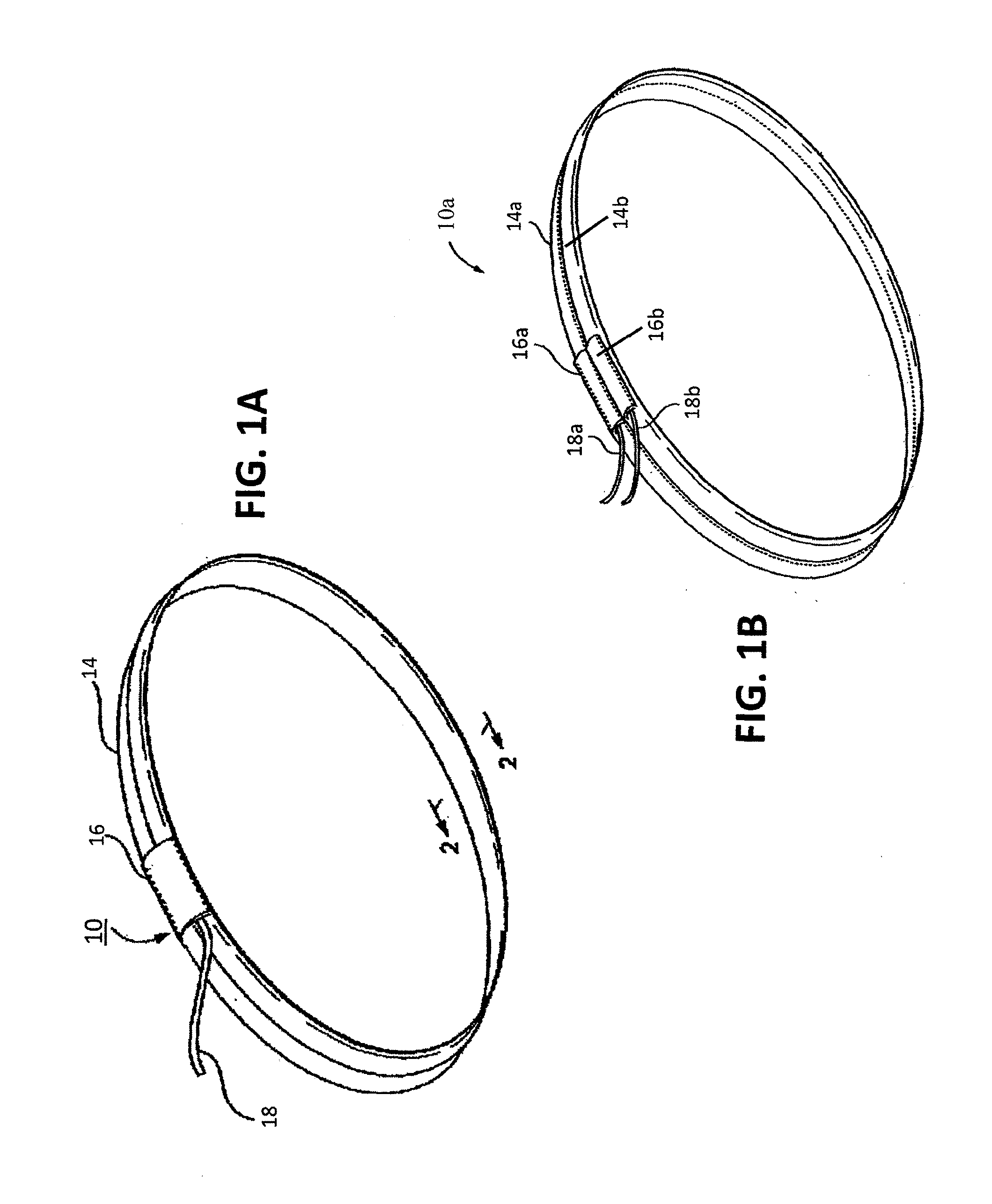

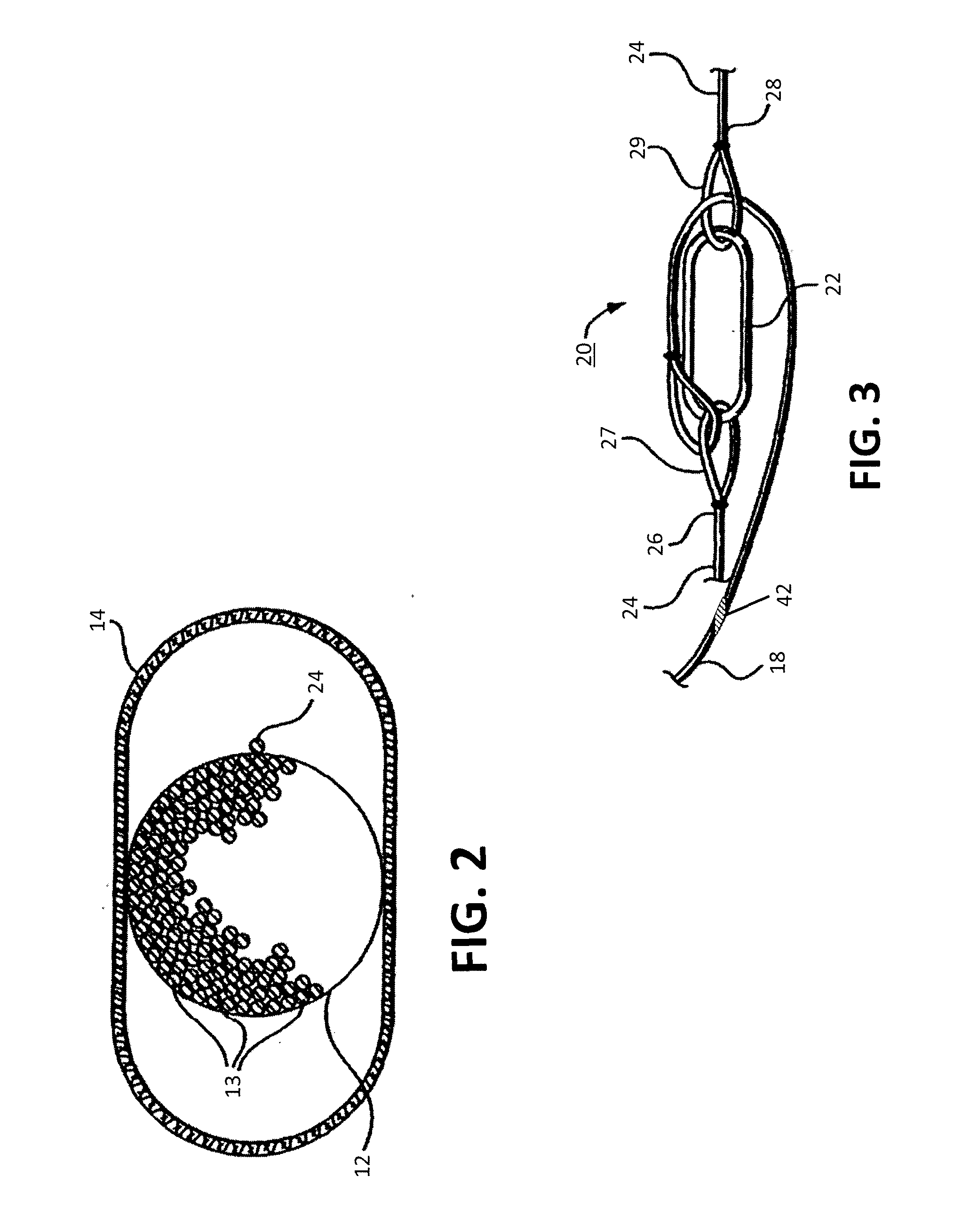

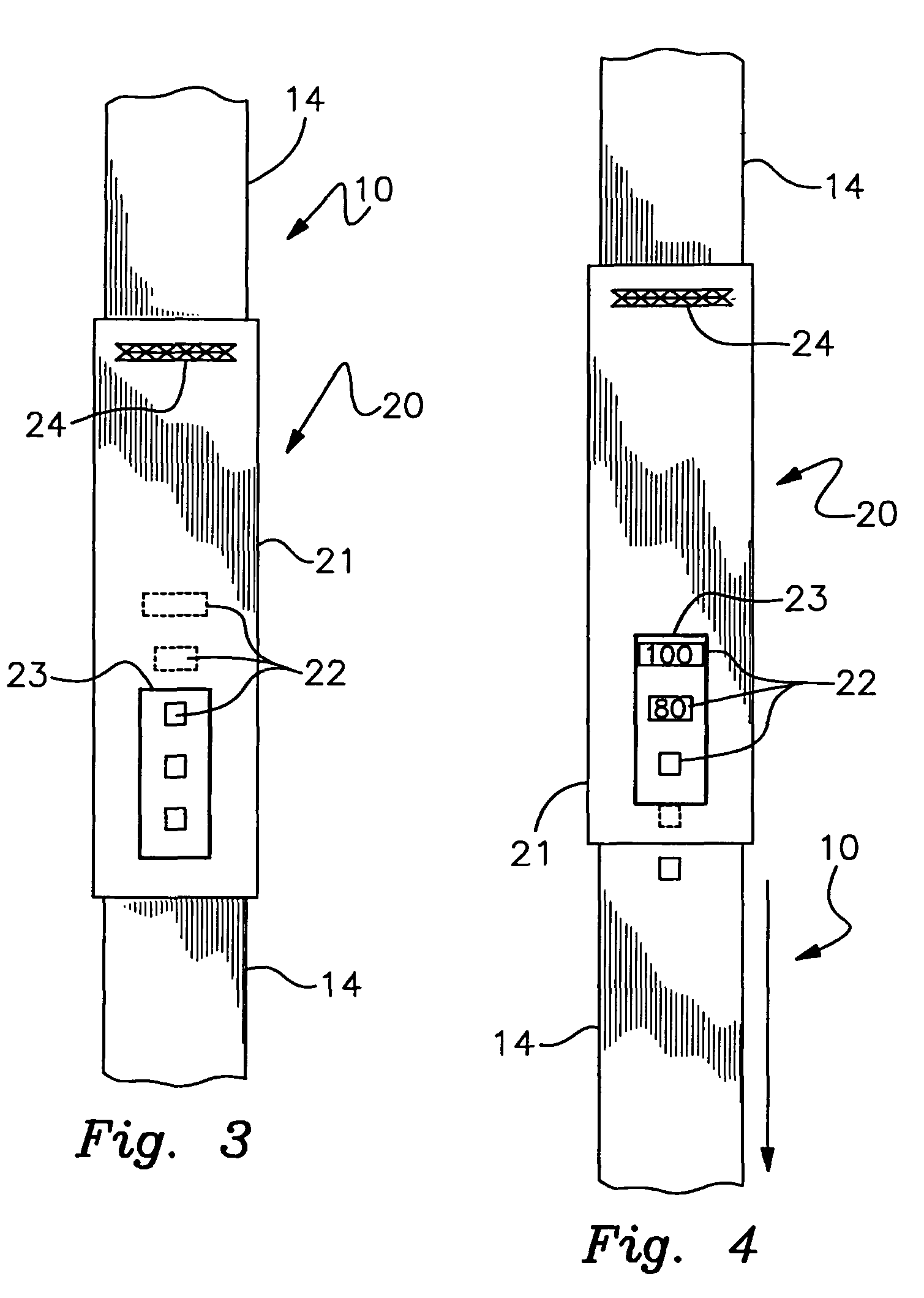

Roundslings with radio frequency identification pre-failure warning indicators

Roundslings with radio frequency identification pre-failure warning indicators comprise radio frequency identification tags, radio frequency identification tag sensors, and radio frequency signal receivers that inform a user of a pre-failure condition with the roundsling. The radio frequency tags may be affixed to one or more of an indicator yarn, a strand of the roundsling core, a dedicated strand of a pre-failure indicator assembly, or a ring of the pre-failure indicator assembly. The radio frequency tags may be active or passive, and active radio frequency tags may comprise a shield that block a signal transmitted from the tag.

Owner:SLINGMAX TECH LLC

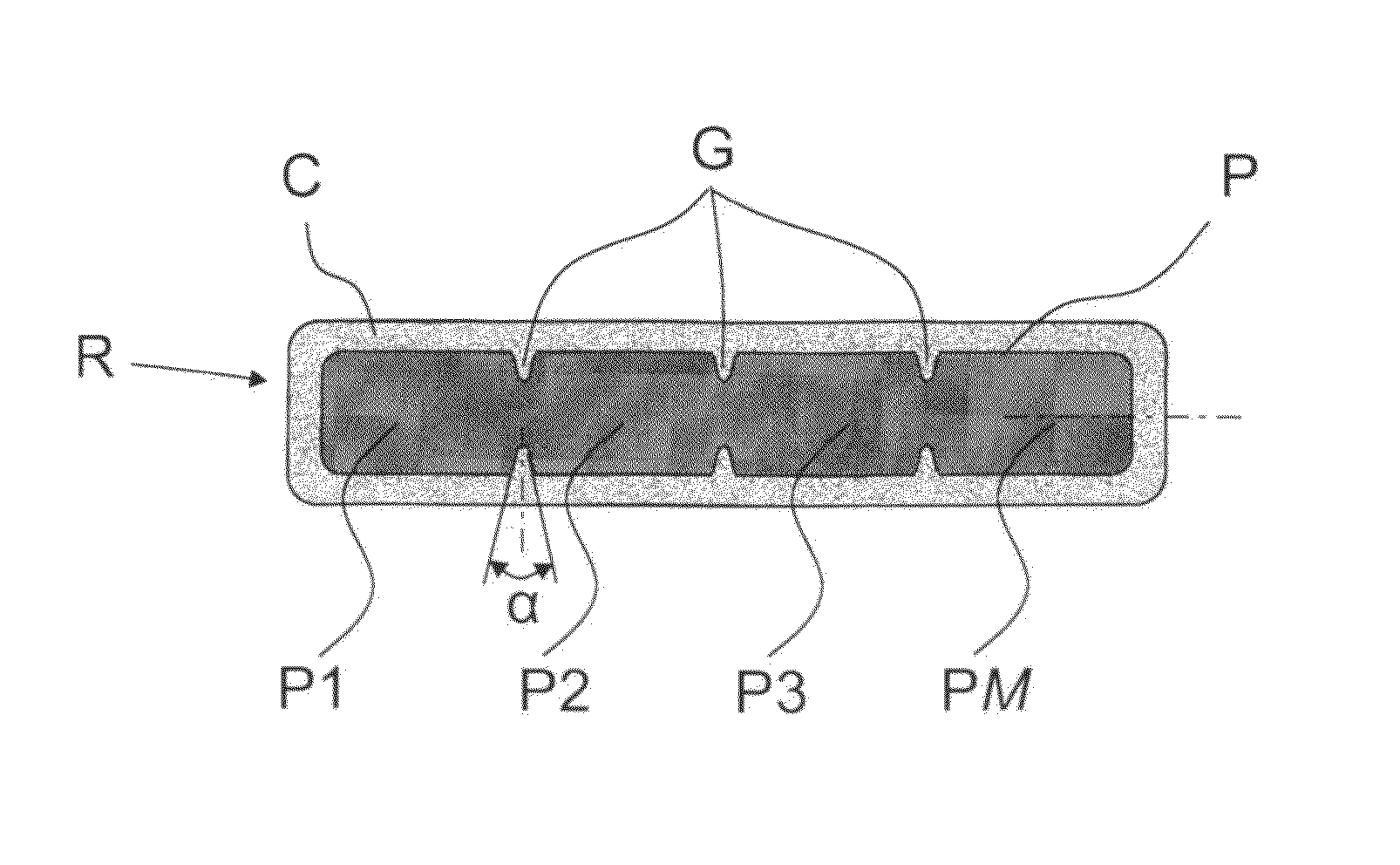

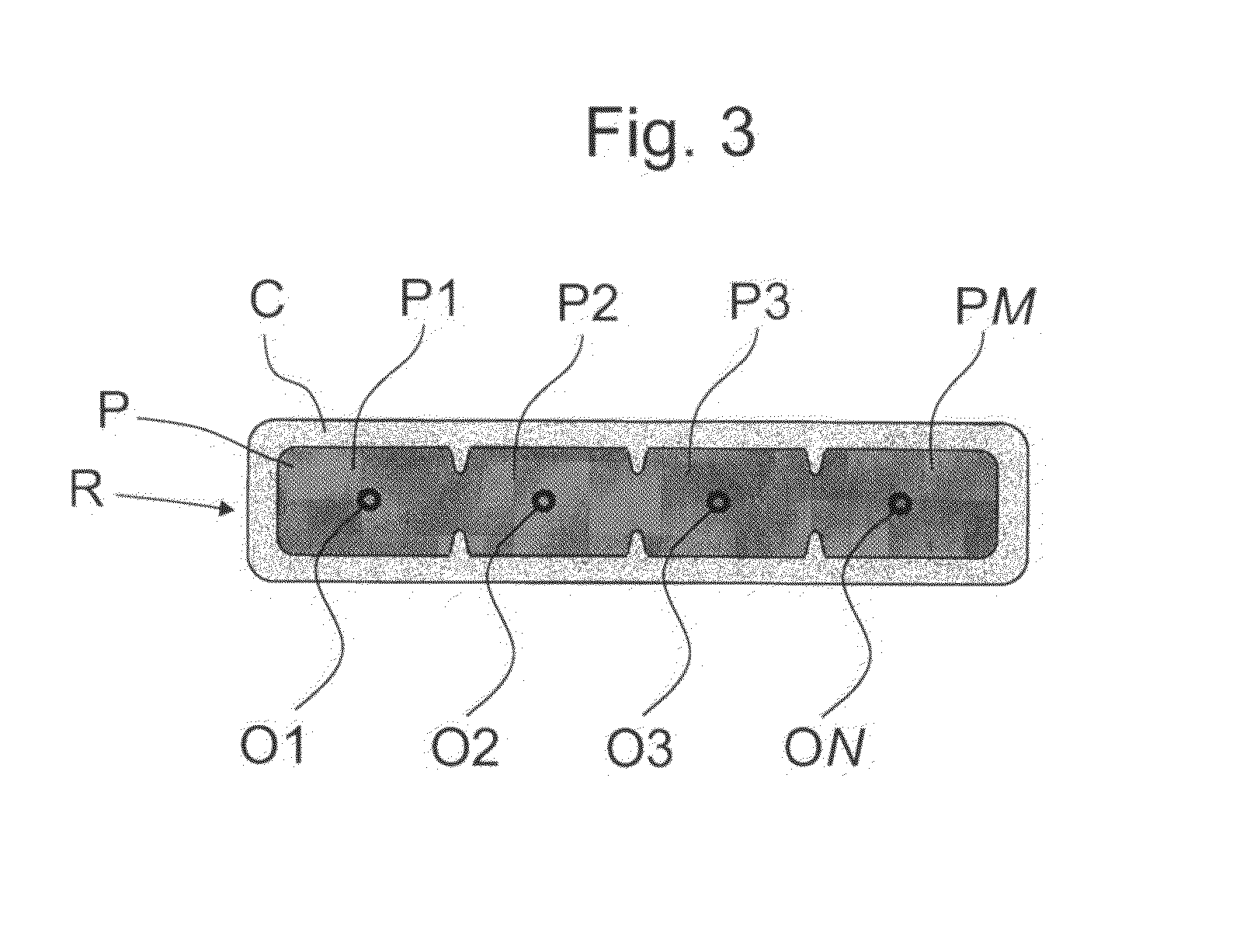

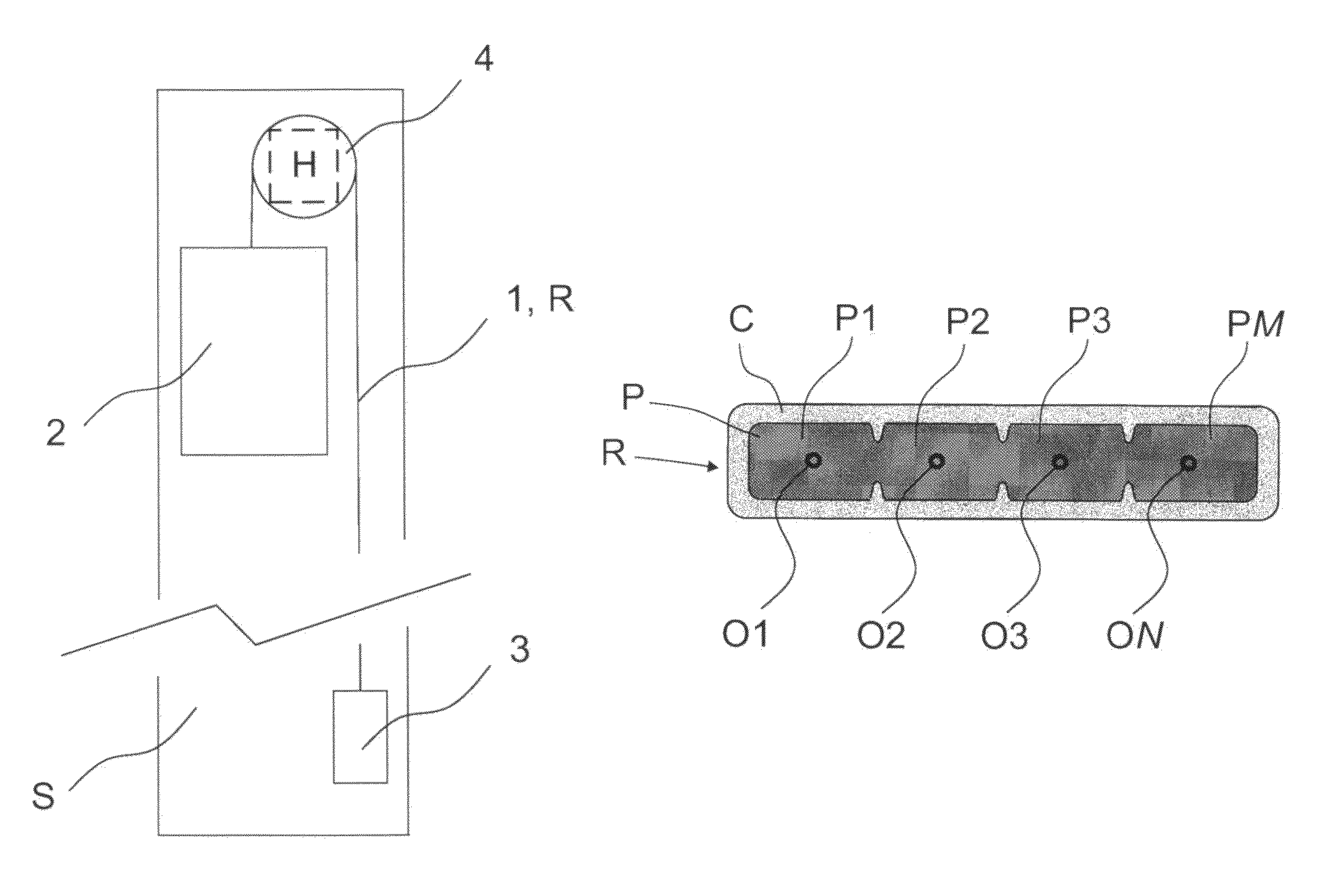

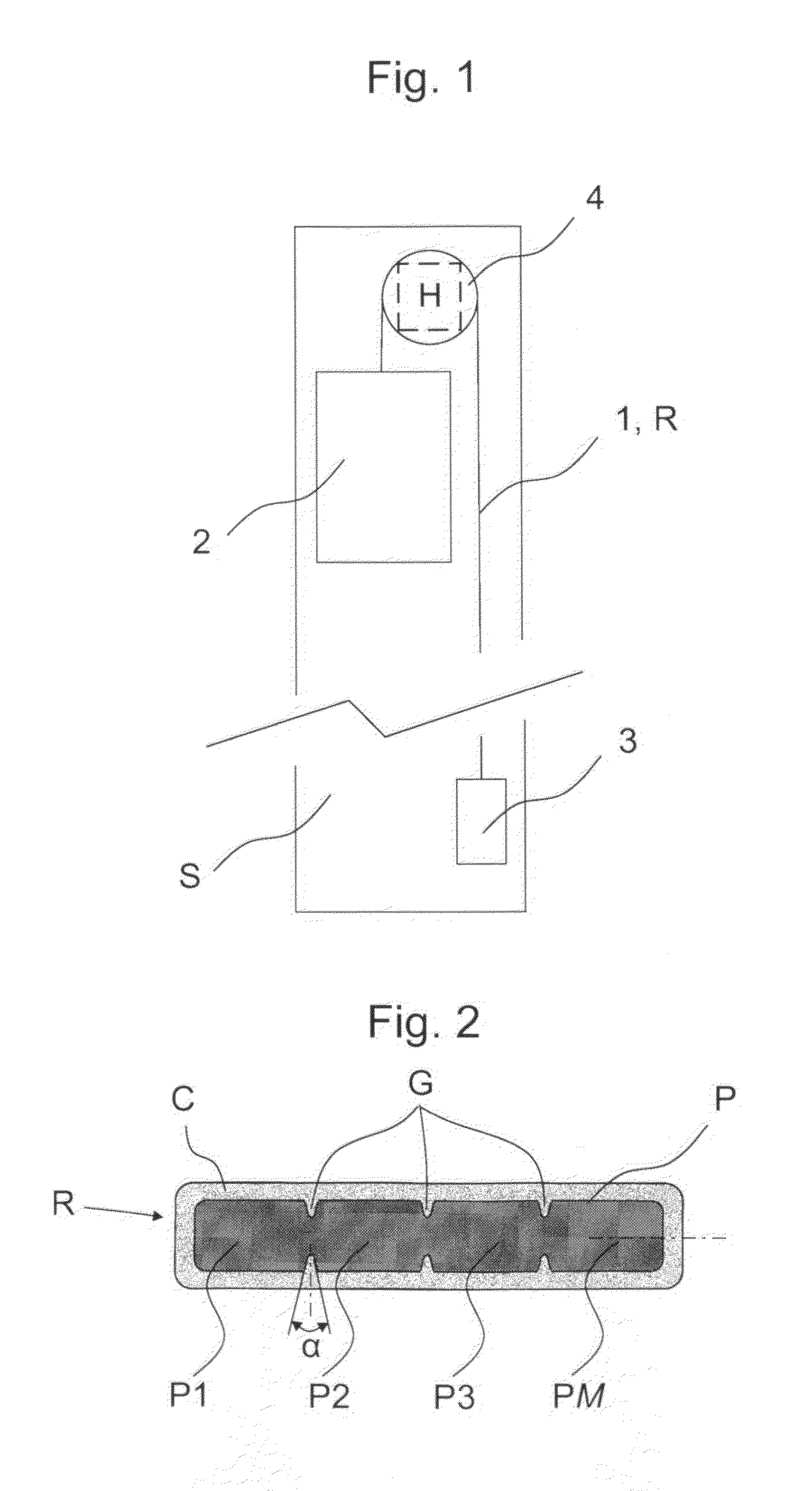

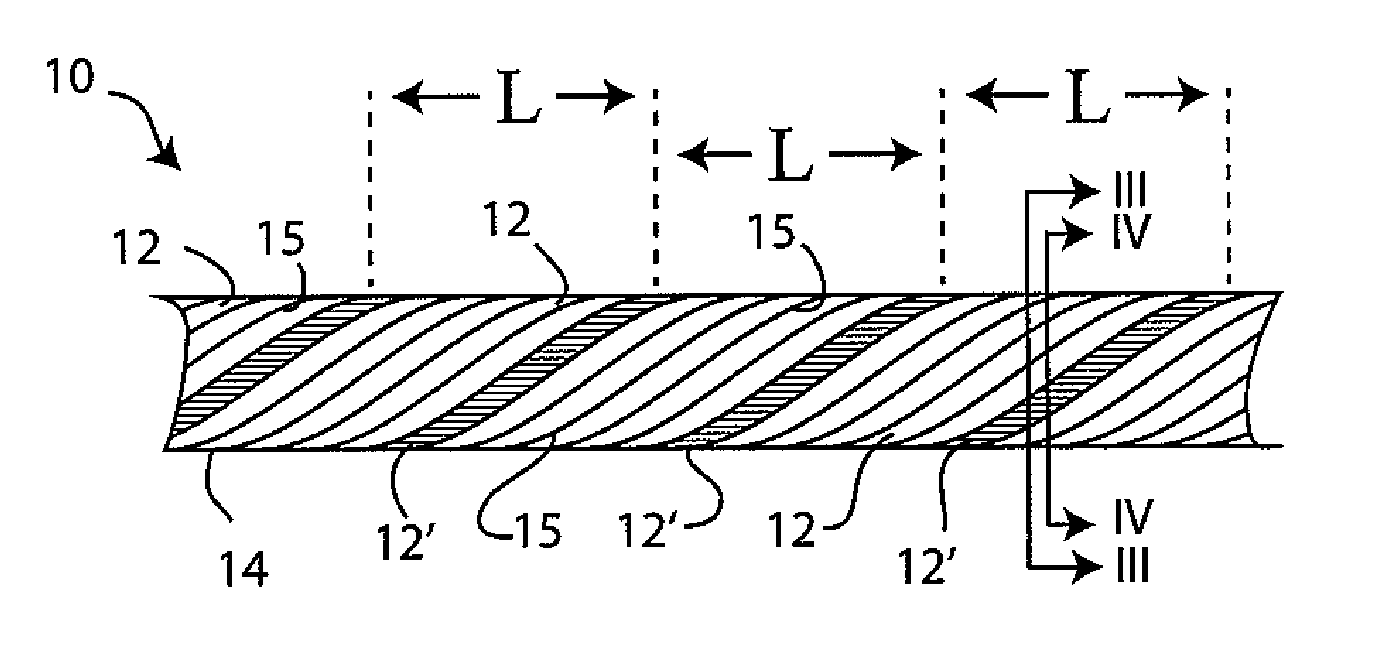

Rope of a lifting device, an elevator and a method for manufacturing the rope

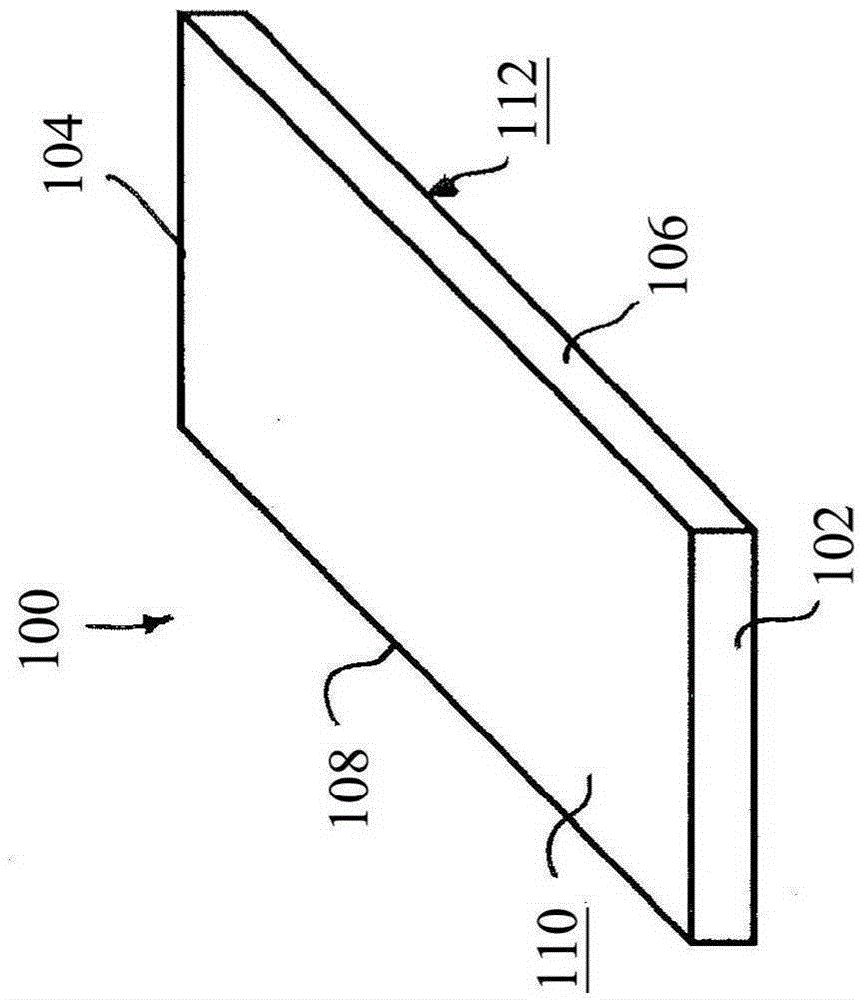

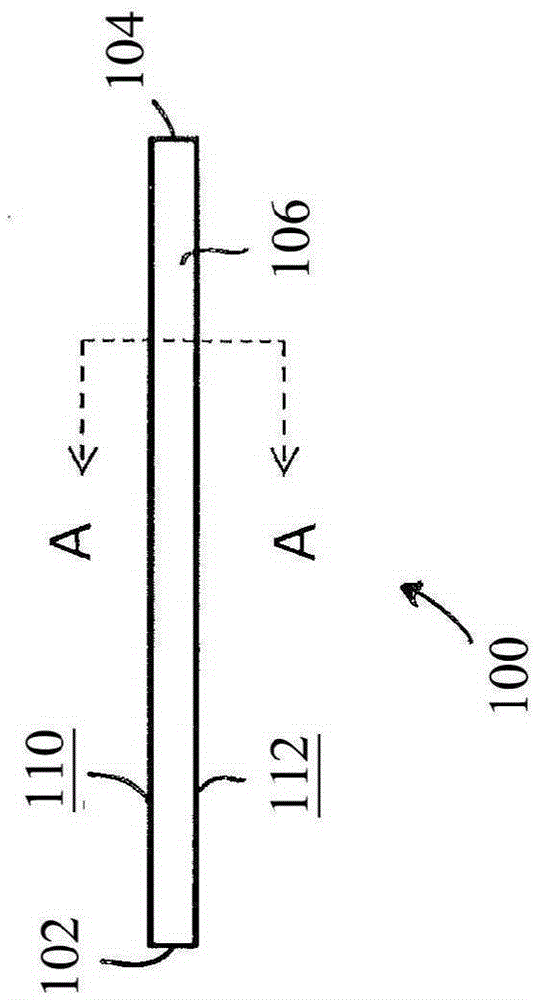

ActiveUS20130206516A1Drawback can be obviatedControlRopes and cables for vehicles/pulleyGlass fiberCarbon fibers

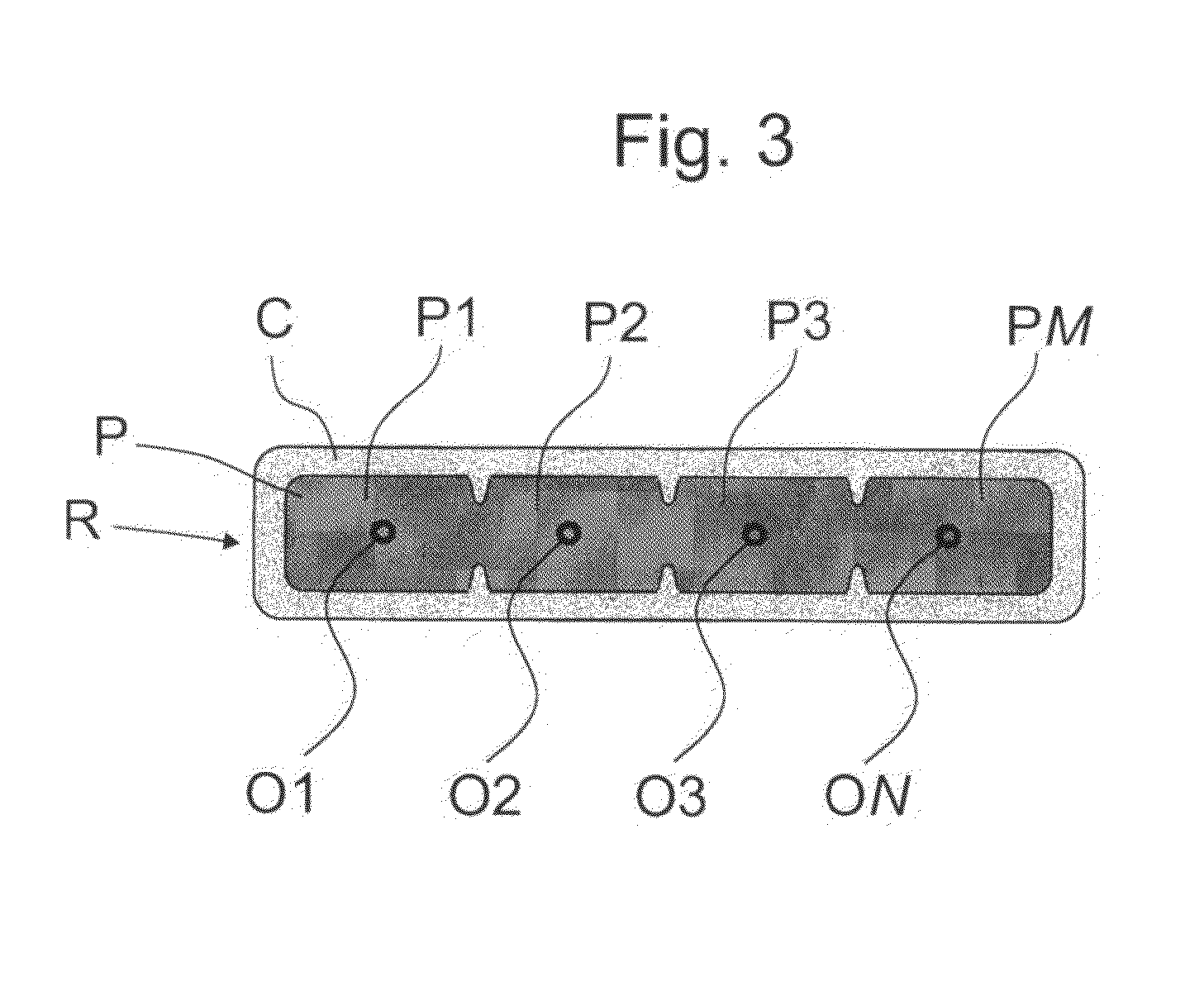

A rope of a lifting device, more particularly of a passenger transport elevator and / or freight transport elevator, an elevator, and a method for manufacturing the rope are disclosed. The rope includes an unbroken load-bearing part, the profile of which is essentially of rectangular shape, and the width of the cross-section is greater than the thickness and which load-bearing part comprises glass fiber reinforcements and / or aramid fiber reinforcements and / or carbon fiber reinforcements and / or polybenzoxazole fiber reinforcements and / or polyethylene fiber reinforcements and / or nylon fiber reinforcements in a polymer matrix material. The long sides of the cross-section of the load-bearing part include one or more grooves symmetrically or asymmetrically in the longitudinal direction of the rope, which grooves divide the load-bearing part into smaller parts.

Owner:KONE CORP

Rope of an elevator and a method for manufacturing the rope

ActiveUS9126805B2Drawback can be obviatedControlRopes and cables for vehicles/pulleyGlass fiberCarbon fibers

A rope of a lifting device, more particularly of a passenger transport elevator and / or freight transport elevator, an elevator, and a method for manufacturing the rope are disclosed. The rope includes an unbroken load-bearing part, the profile of which is essentially of rectangular shape, and the width of the cross-section is greater than the thickness and which load-bearing part comprises glass fiber reinforcements and / or aramid fiber reinforcements and / or carbon fiber reinforcements and / or polybenzoxazole fiber reinforcements and / or polyethylene fiber reinforcements and / or nylon fiber reinforcements in a polymer matrix material. The long sides of the cross-section of the load-bearing part include one or more grooves symmetrically or asymmetrically in the longitudinal direction of the rope, which grooves divide the load-bearing part into smaller parts.

Owner:KONE CORP

Electric cable with strain sensor and monitoring system and method for detecting strain in at least one electric cable

ActiveCN102460606AControlForce measurement by measuring optical property variationFiberTensile strain

Owner:PRYSMIAN SPA

Electric cable with strain sensor and monitoring system and method for detecting strain in at least one electric cable

ActiveUS8953915B2Low costAvoid permanent damageControlForce measurement by measuring optical property variationElectrical conductorMonitoring system

An electric cable includes a strain sensor longitudinally extending along the cable and including a strain optical fiber arranged within a bending neutral region surrounding and including a bending neutral longitudinal axis of the electric cable, and at least two longitudinal structural elements, at least one of the at least two longitudinal structural elements being a core including an electrical conductor, wherein the strain sensor is embedded in a strain-transferring filler mechanically coupling at least one of the at least two longitudinal structural elements with the strain sensor. With the disclosed cable construction, the strain experienced by the at least one of the at least two longitudinal structural elements is transferred to the strain sensor at least in a strained condition. In the preferred embodiments, the electric cable is a heavy-duty cable.

Owner:PRYSMIAN SPA

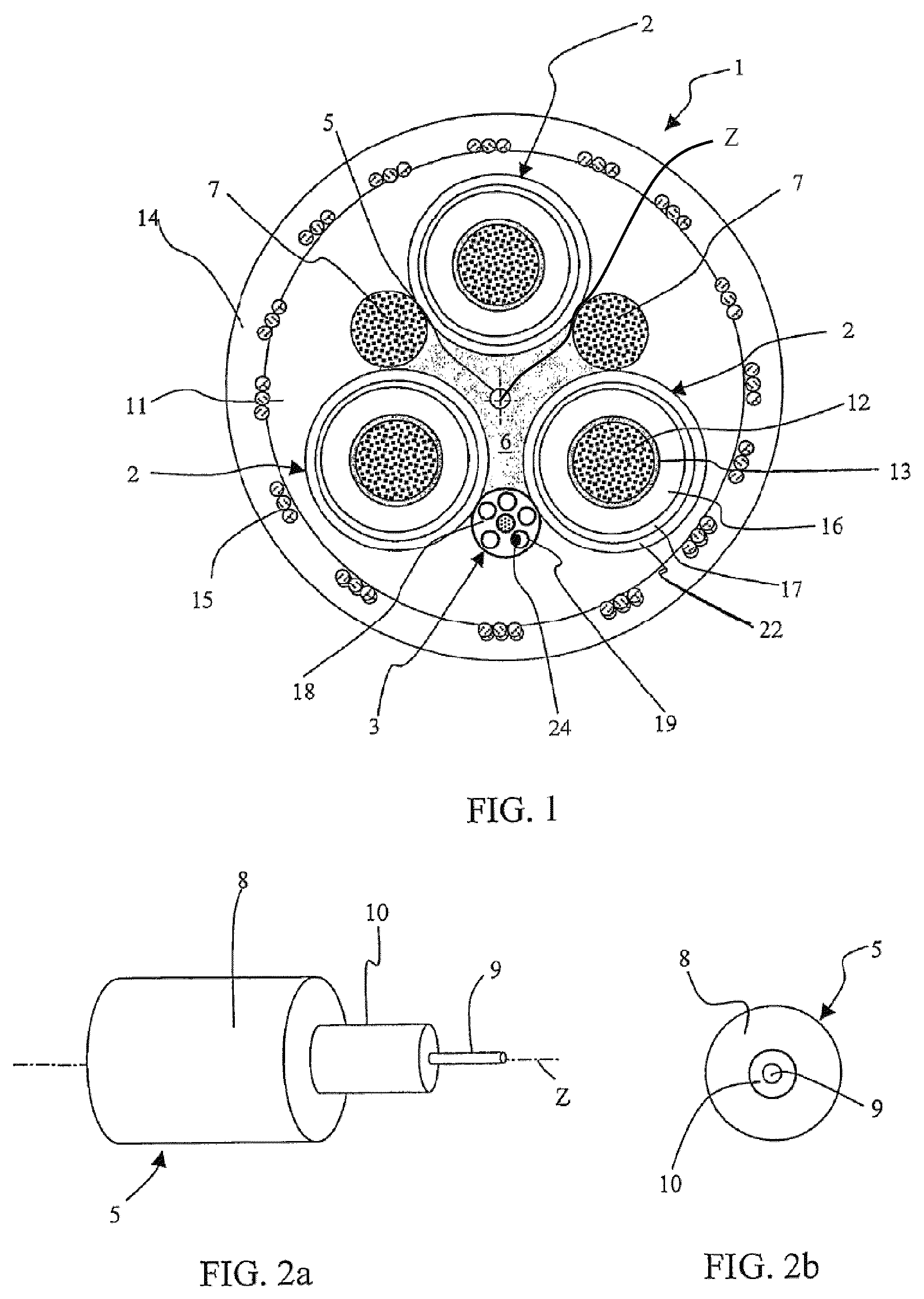

Bridge Intelligent Cable System with Built-In Fiber Grating Sensor

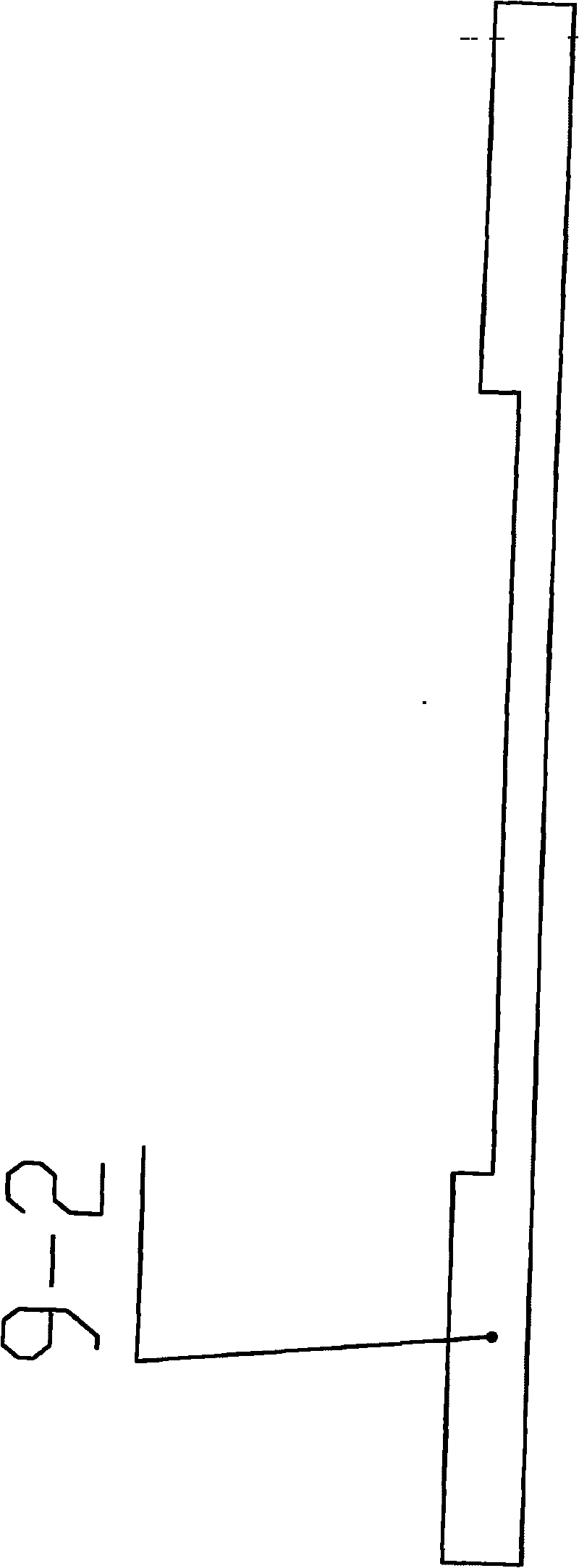

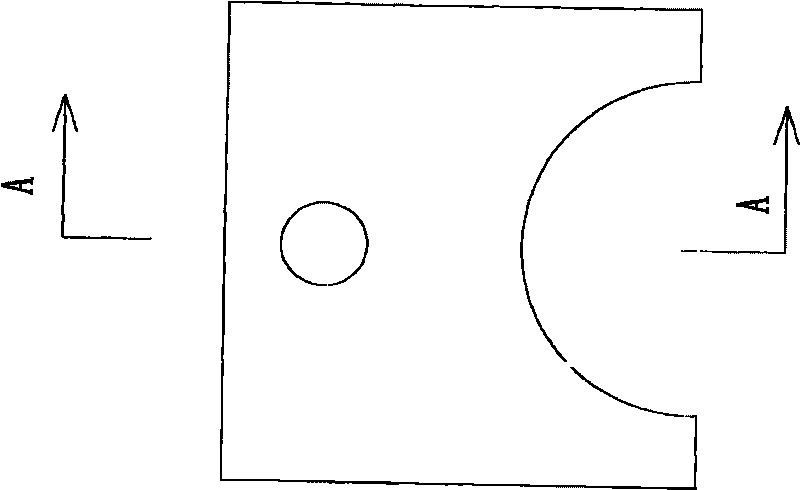

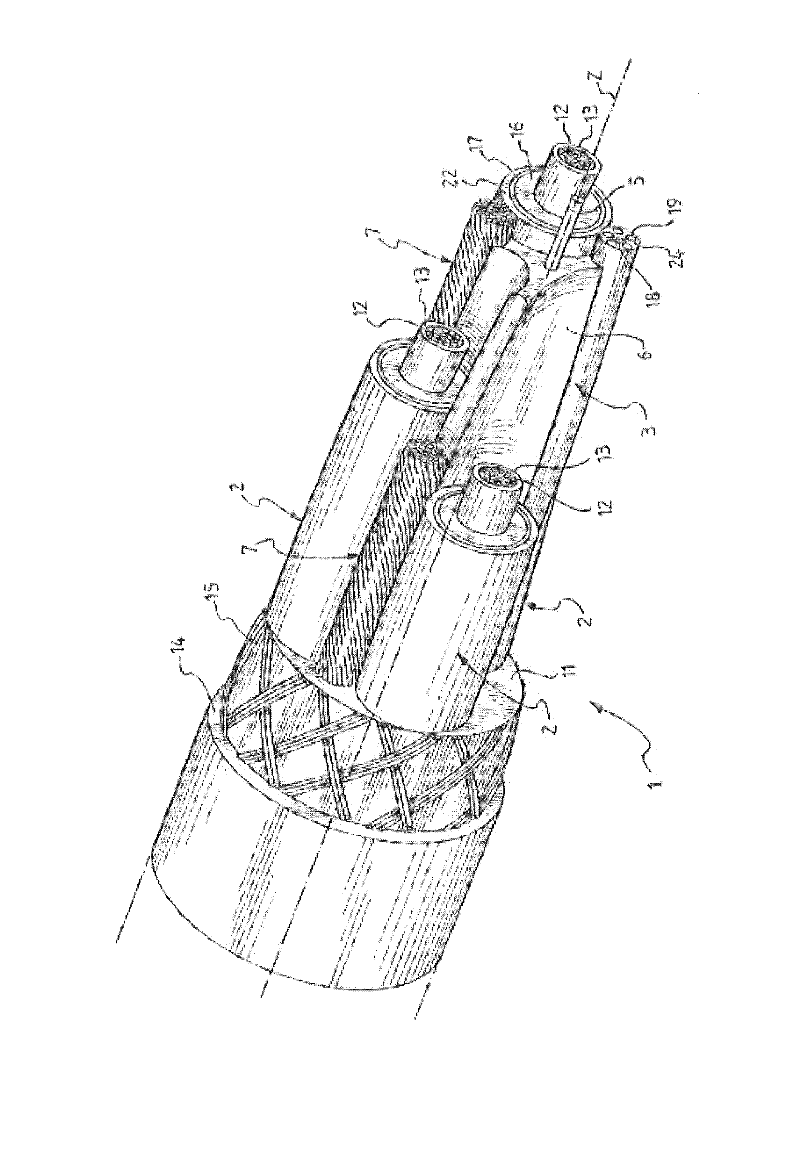

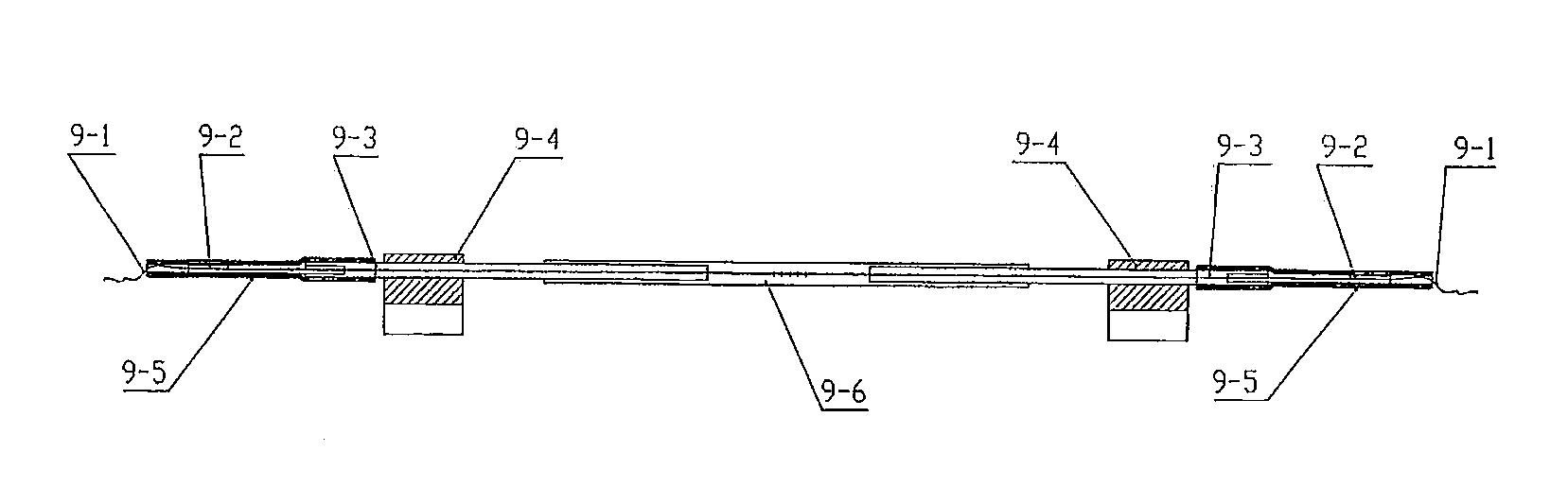

ActiveUS20110243185A1Improving bridge safetyImprove survival rateThermometer detailsControlFiberGrating

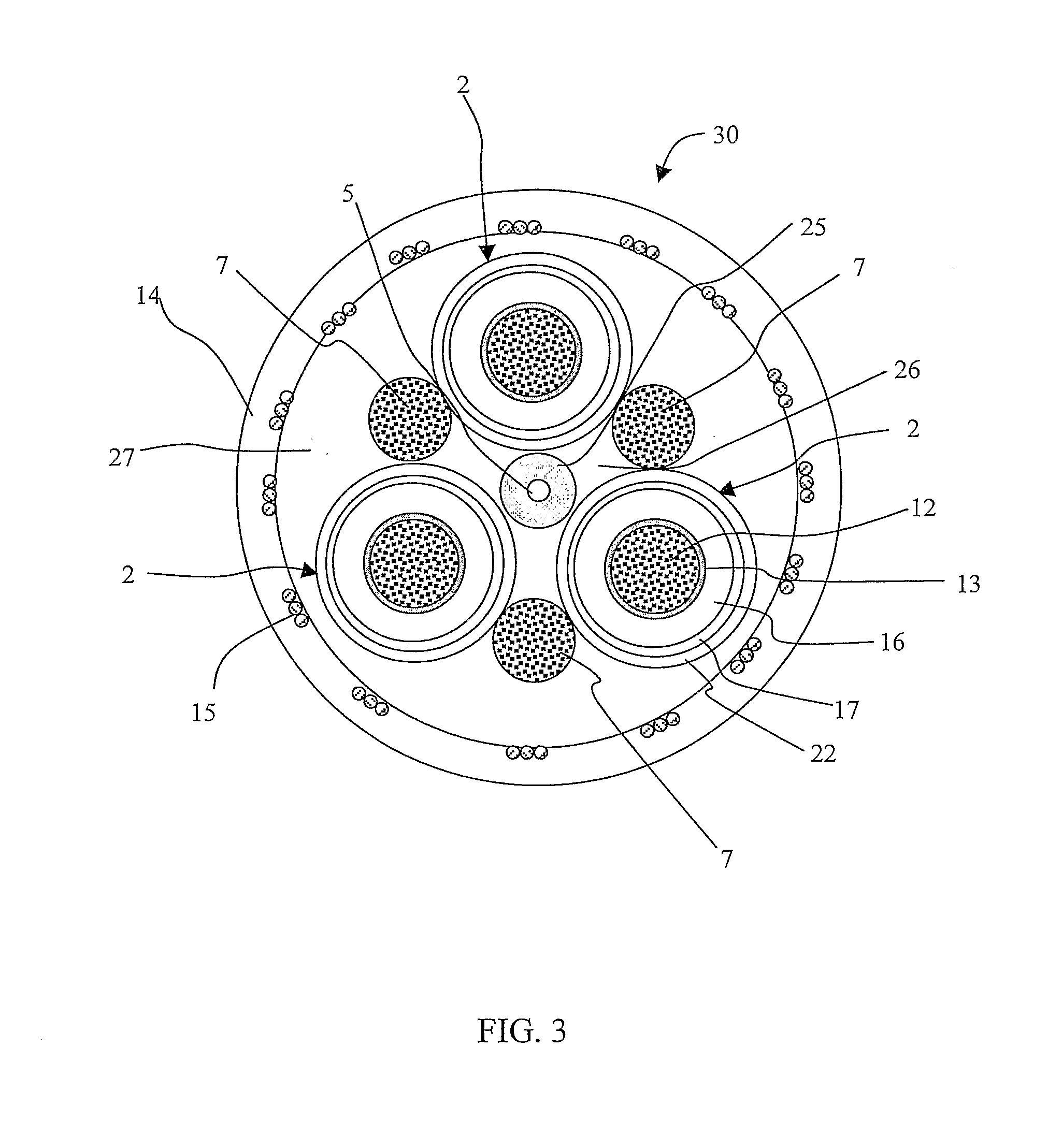

A bridge intelligent cable system with a built-in fiber grating sensor is provided, which is applied in a cable bearing structure such as a cable-stayed bridge, a suspension bridge, and an arch bridge. The system includes an anchor cup (1), a wire dividing plate (5), a connecting cylinder (4), a fiber grating sensor, and a cable body (11), in which the fiber grating sensor includes a fiber grating strain sensor (9) and a fiber grating temperature sensor (10), tail fibers of the fiber grating strain sensor (9) and the fiber grating temperature sensor (10) are led out, the packaged fiber grating strain sensor (9) is fixedly connected to an outer-layer steel wire (3) of the connecting cylinder (4), the packaged fiber grating temperature sensor (10) is suspended on the steel wire (3) of the connecting cylinder (4), holes (5-1) are punched in the wire dividing plate (5), and a preserved steel pipe (7) is buried in advance in the connecting cylinder (4) and the anchor cup (1). The system improves survival rates of the fiber grating sensor and the fibers in cable manufacturing and application processes, ensures reliability of the embedding technology of the fiber grating sensor, and effectively leads a fiber grating signal out of the cable body without distortion.

Owner:FASTEN HONGSHENG GRP CO LTD

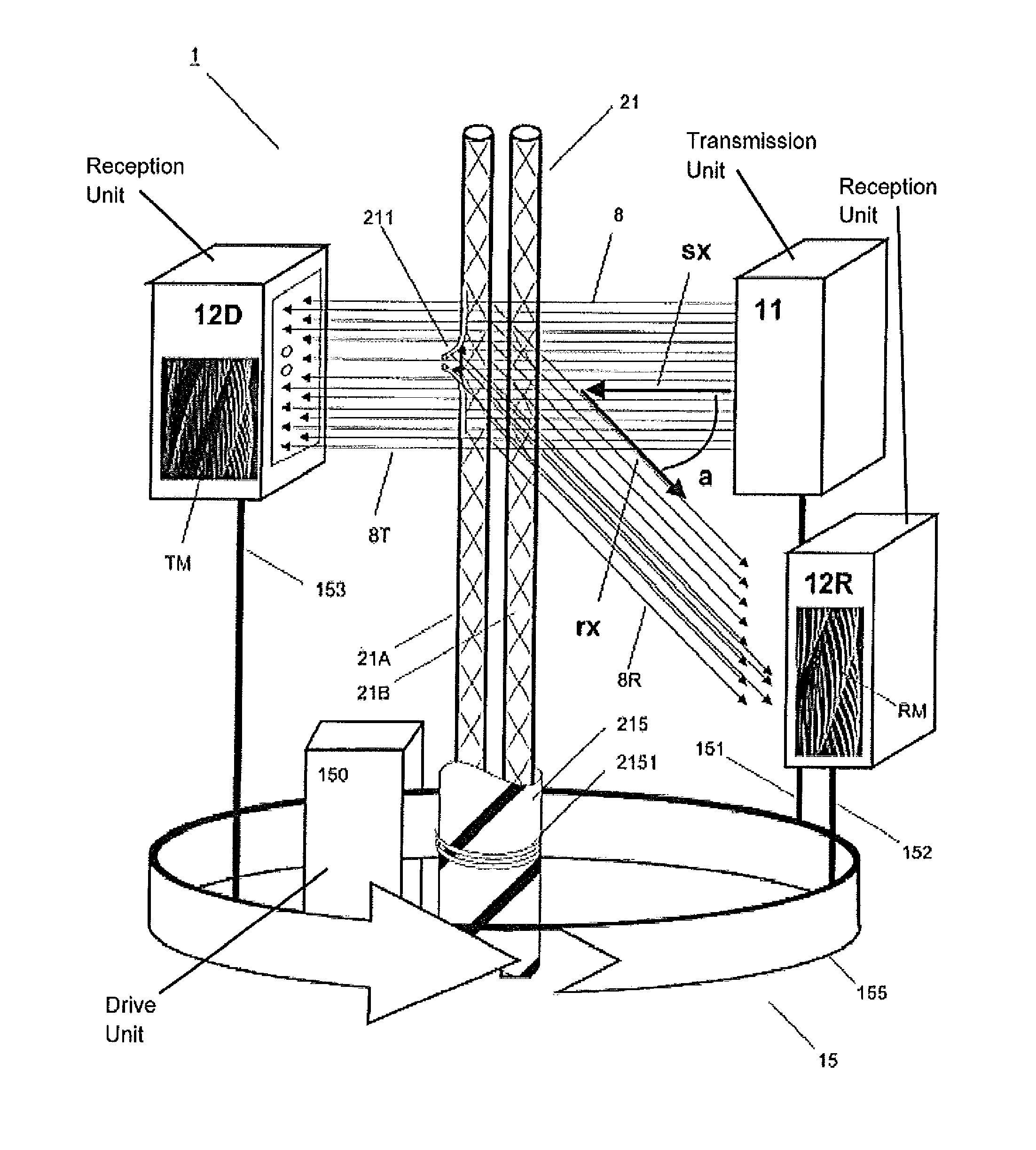

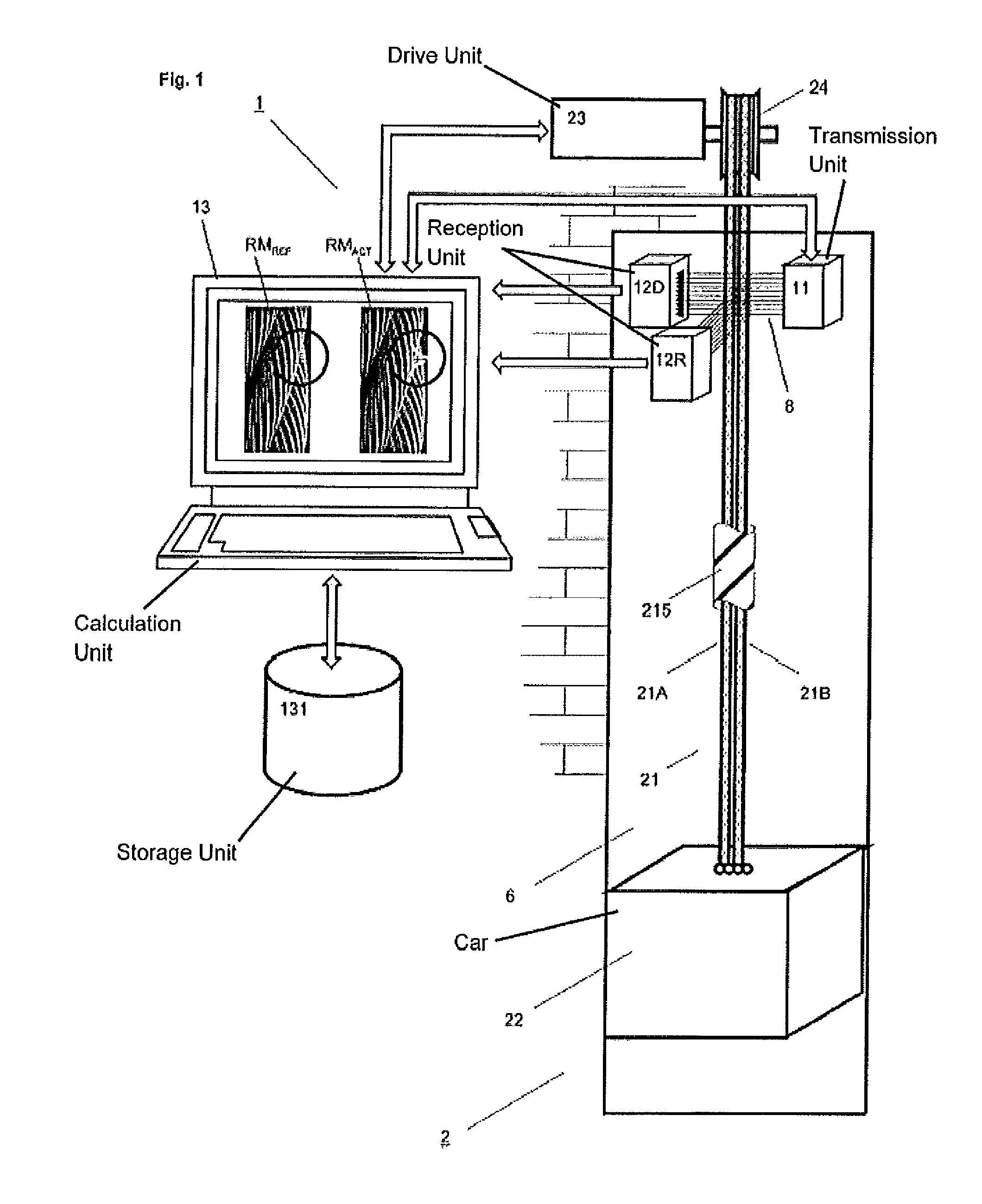

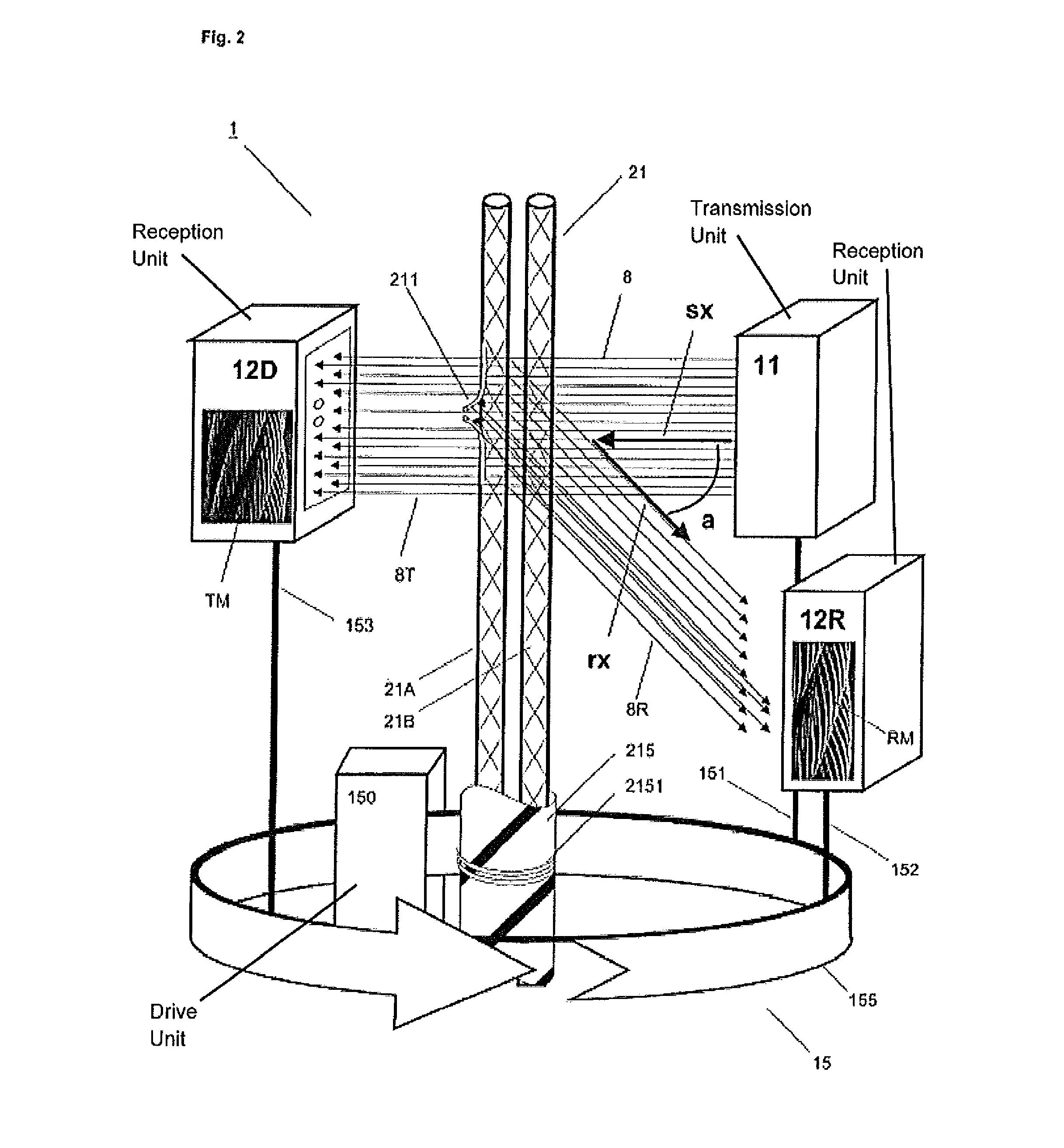

Nondestructive testing of a carrier element of an elevator installation

InactiveUS20130126737A1Simple and cost-effective designQuality improvementControlMaterial analysis by optical meansTest fixtureHandling system

A testing device includes a receiving unit for electromagnetic signals arranged on a carrier element to be tested to generate test data from received electromagnetic radiation. The test data are evaluated in a processing system in order to determine a deviation of the test data from a nominal state of the carrier element. The testing device is used to test a carrier element of an elevator installation on which the elevator car is suspended.

Owner:INVENTIO AG

Monitoring method and system for detecting the torsion along a cable provided with identification tags

A method for monitoring the torsion of a cable includes the steps of: providing a cable having an outer surface and extending along a longitudinal direction, the cable being provided with at least one identification tag, preferably an RFID tag, arranged in a tag angular position in a cross-sectional plane taken transverse to the longitudinal direction, the at least one tag storing a tag identification code and being capable of transmitting a tag electromagnetic signal; interrogating the at least one identification tag to receive the tag electromagnetic signal, and detecting the tag electromagnetic signal, wherein the step of detecting the tag electromagnetic signal includes the step of reading the tag identification code and determining the tag angular position of the at least one identification tag. A torsion monitoring system of a cable includes at least one identification tag.

Owner:PRYSMIAN SPA

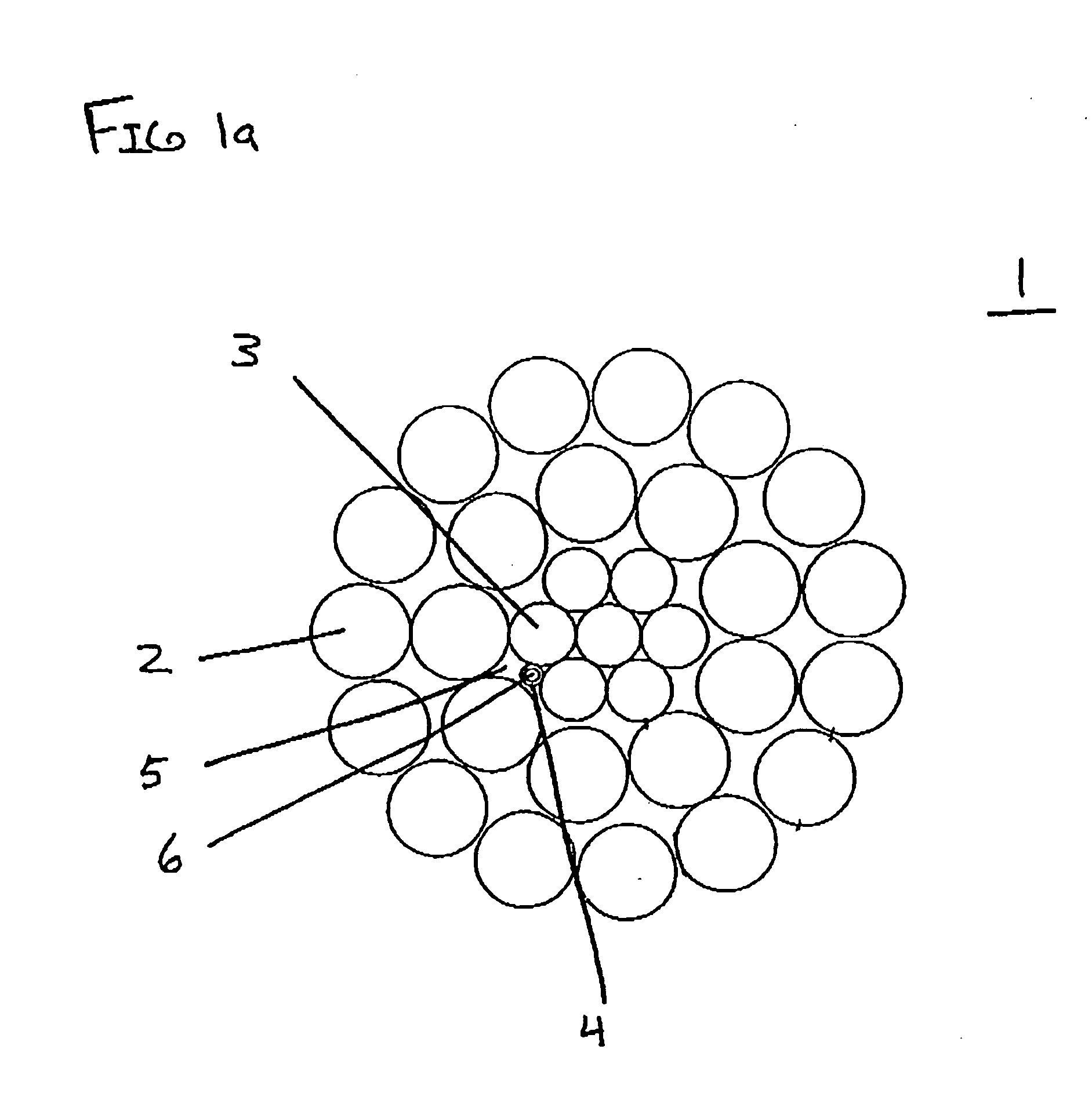

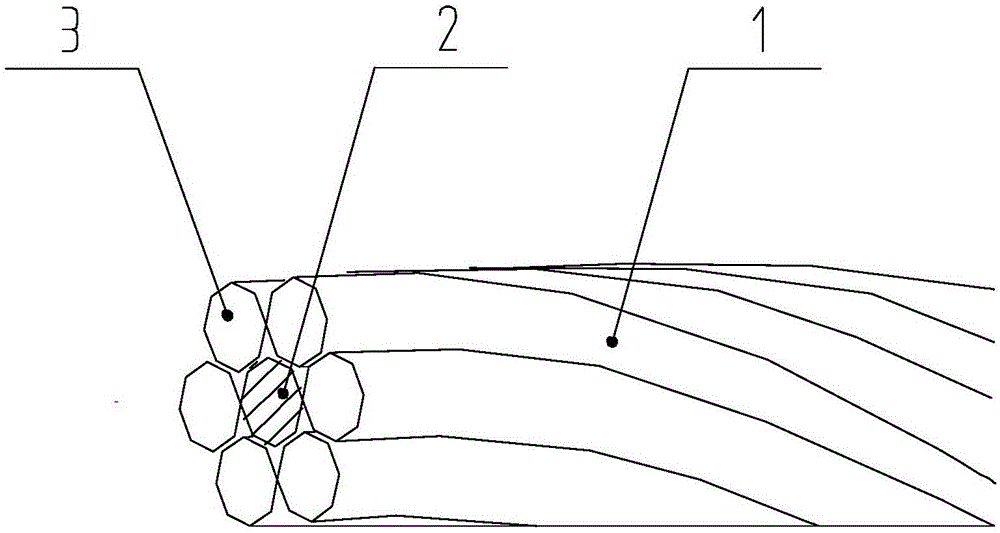

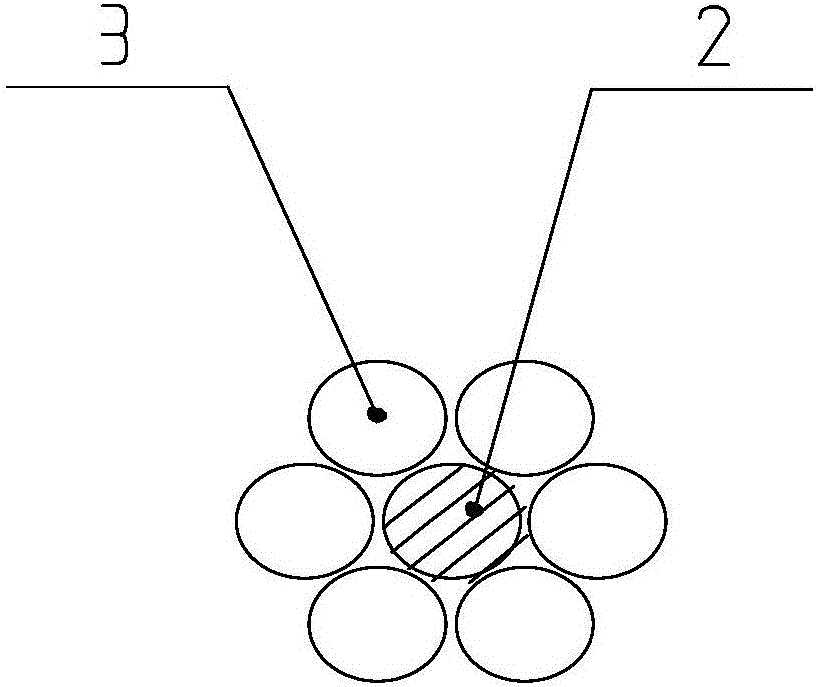

Fiber bragg grating intelligent steel strand and manufacturing method thereof

InactiveCN106400556AGuaranteed adhesionAvoid situations of practical strainControlForce measurement by measuring optical property variationFiberGrating

The invention provides a fiber bragg grating intelligent steel strand. The fiber bragg grating intelligent steel strand comprises a center wire and side wires, wherein the center wire and the side wires are twisted; at least one groove is formed in the center wire, optical fiber is placed in the grooves, and at least one grating is carved in the optical fiber. The invention further provides a manufacturing method of the fiber bragg grating intelligent steel strand. The technical problem that the laying process survival rate is low and monitoring range is narrow when stress conditions of the steel strand is monitored by an existing fiber bragg grating are solved.

Owner:朱万旭 +1

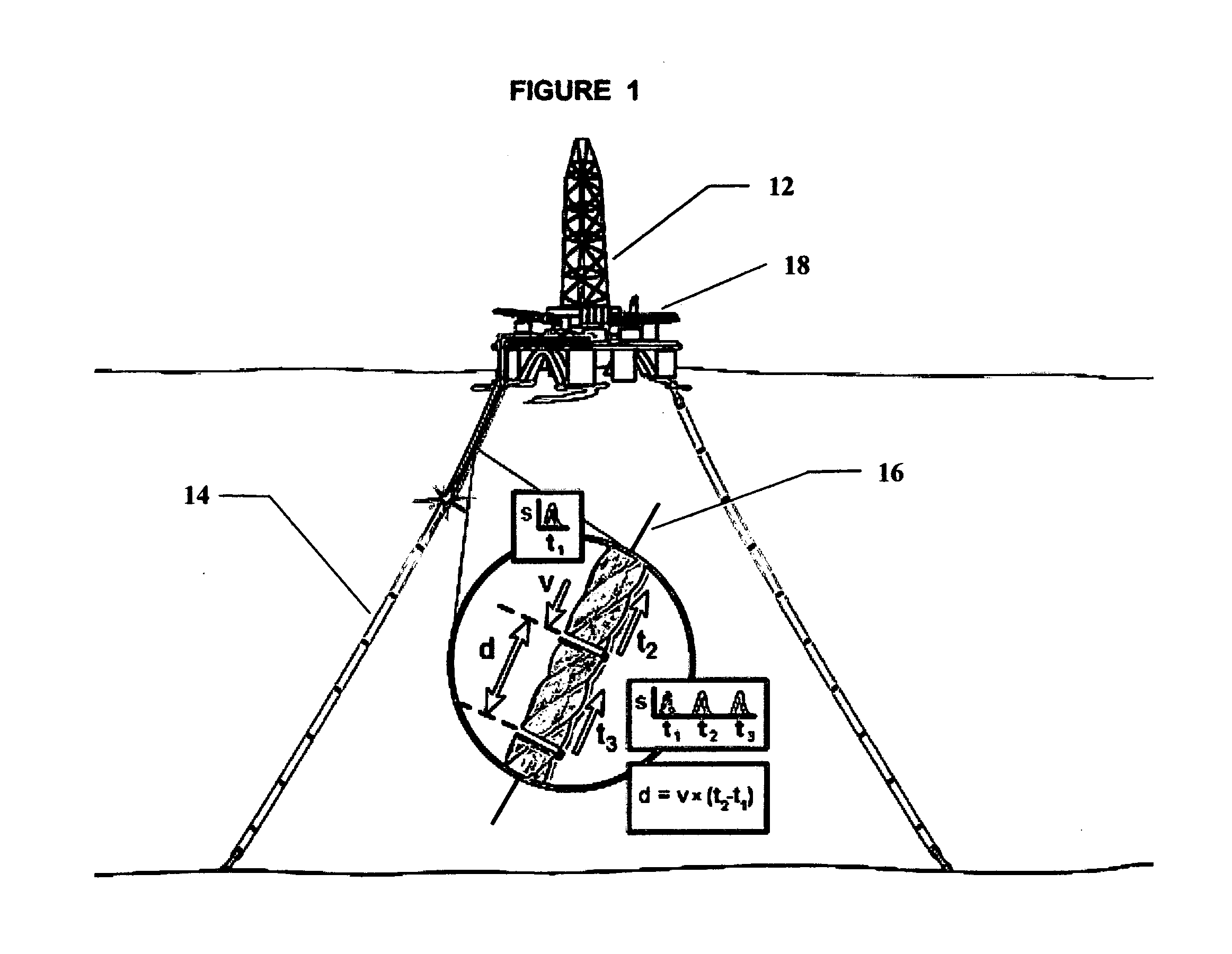

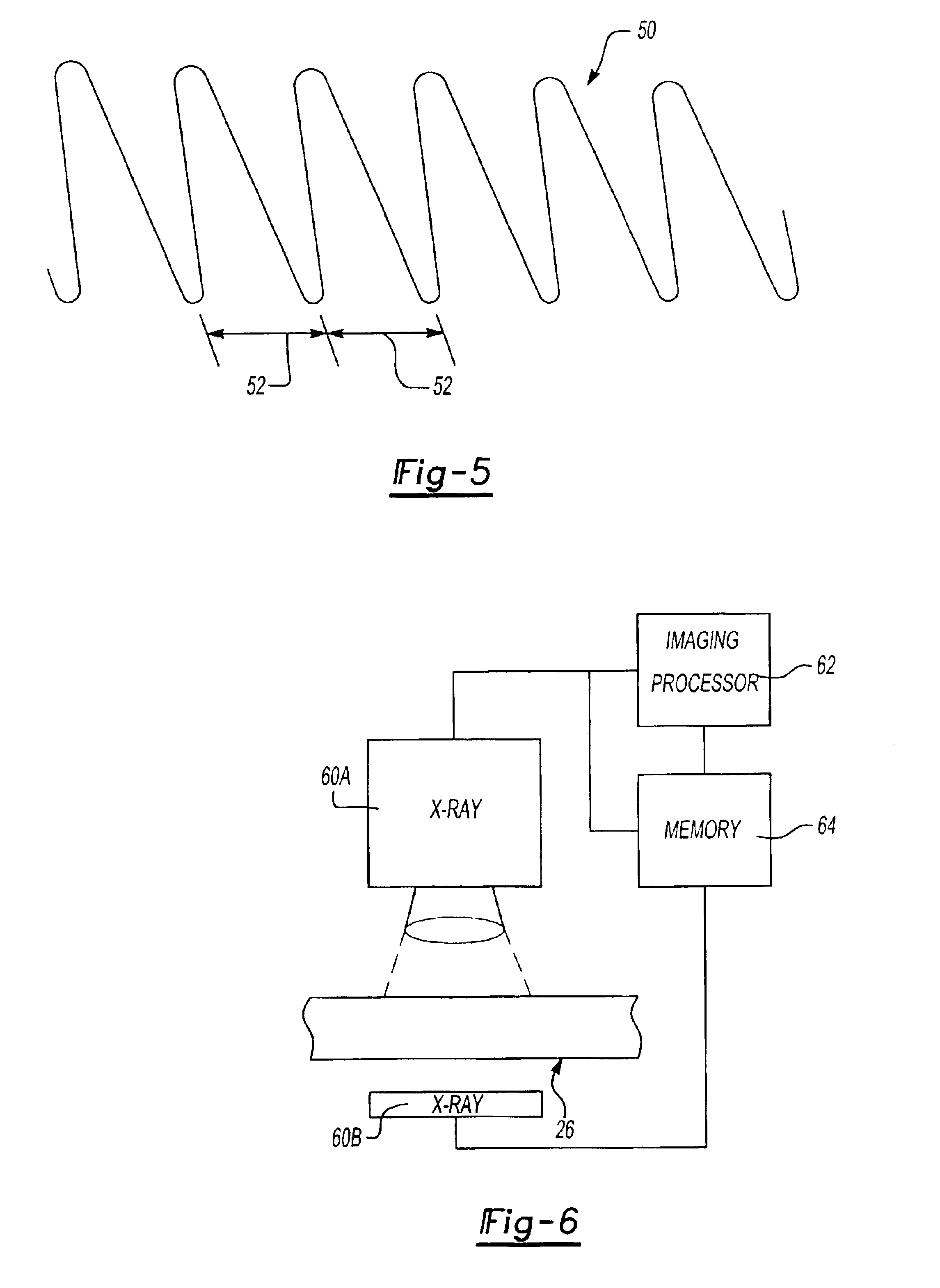

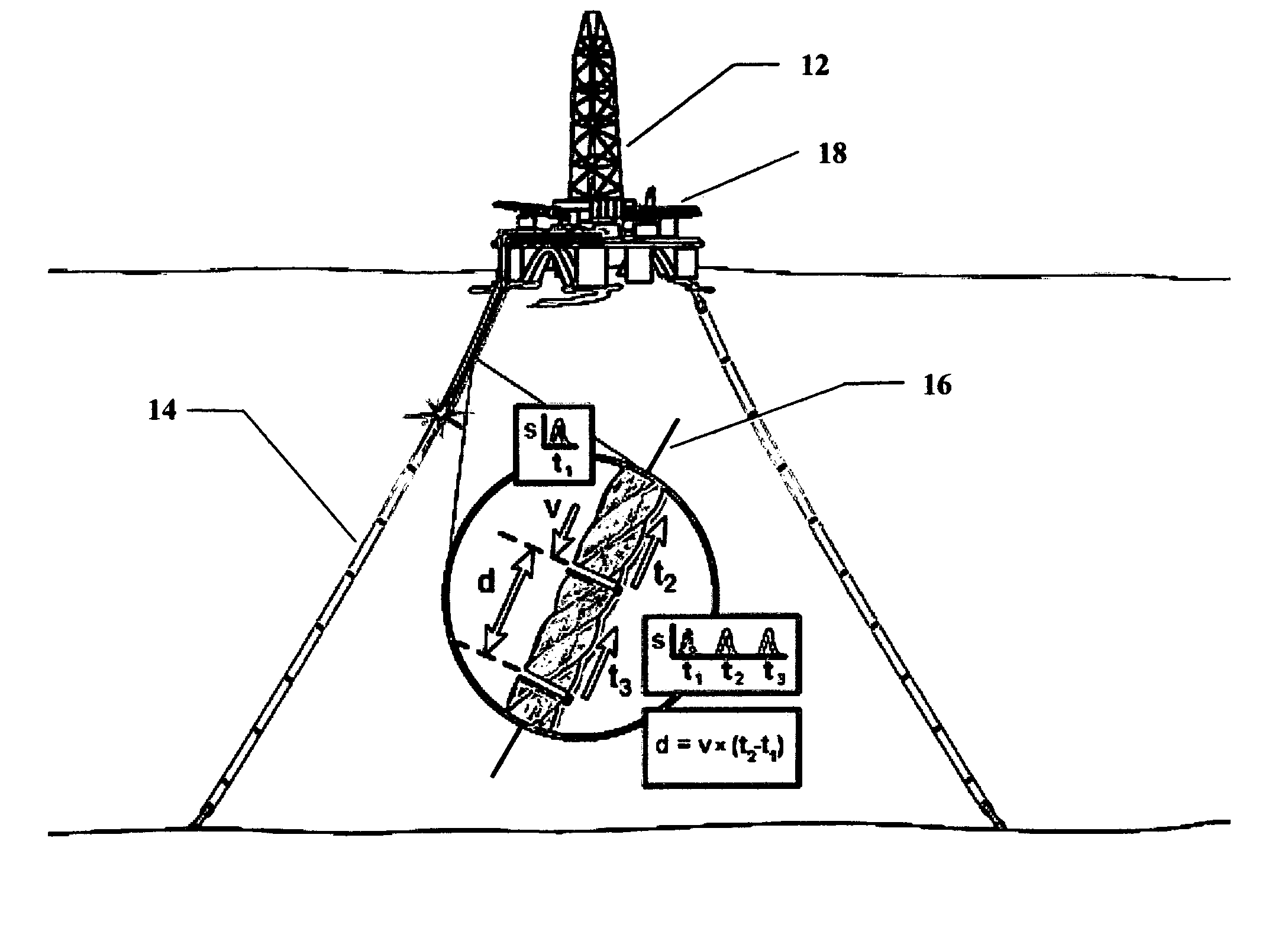

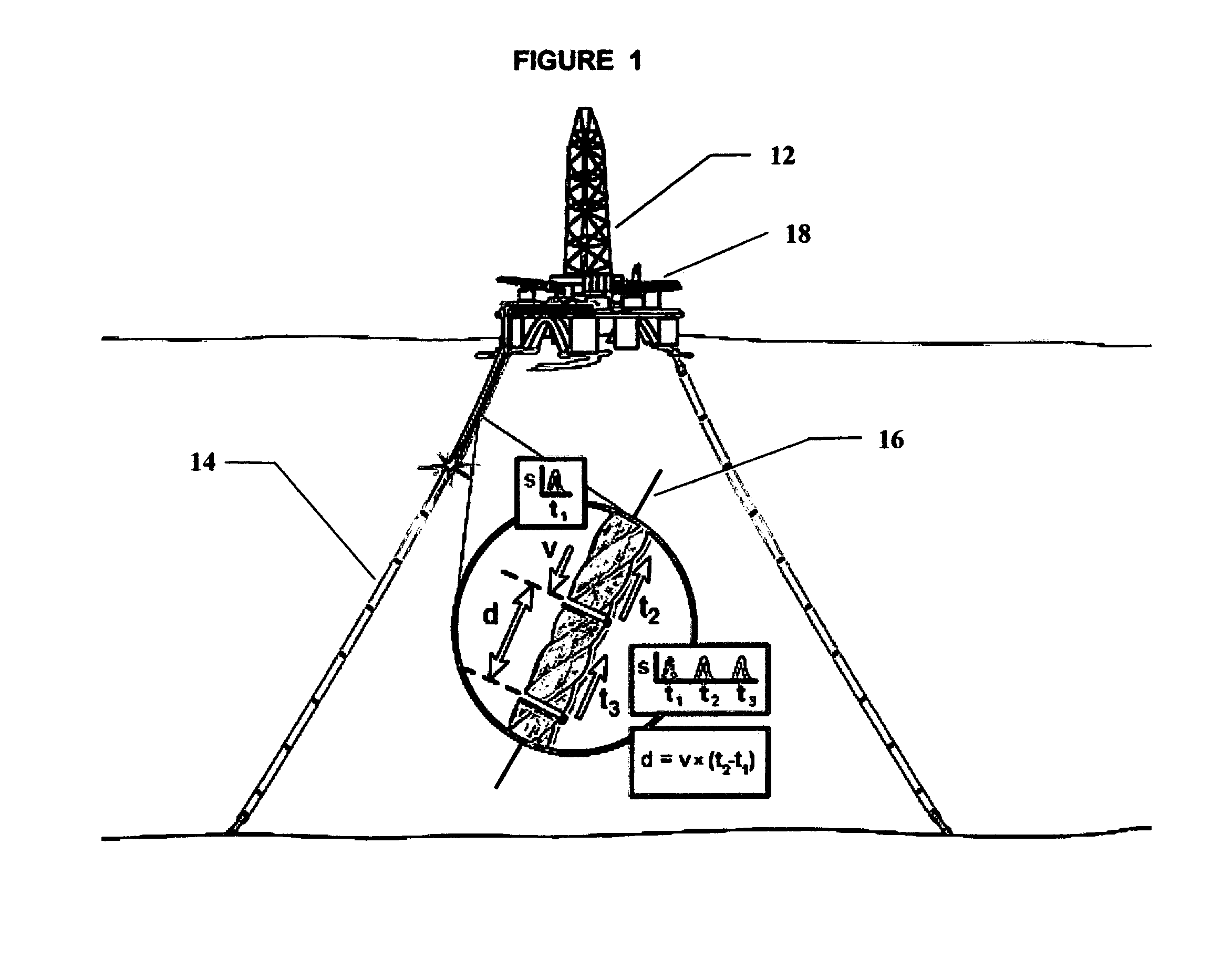

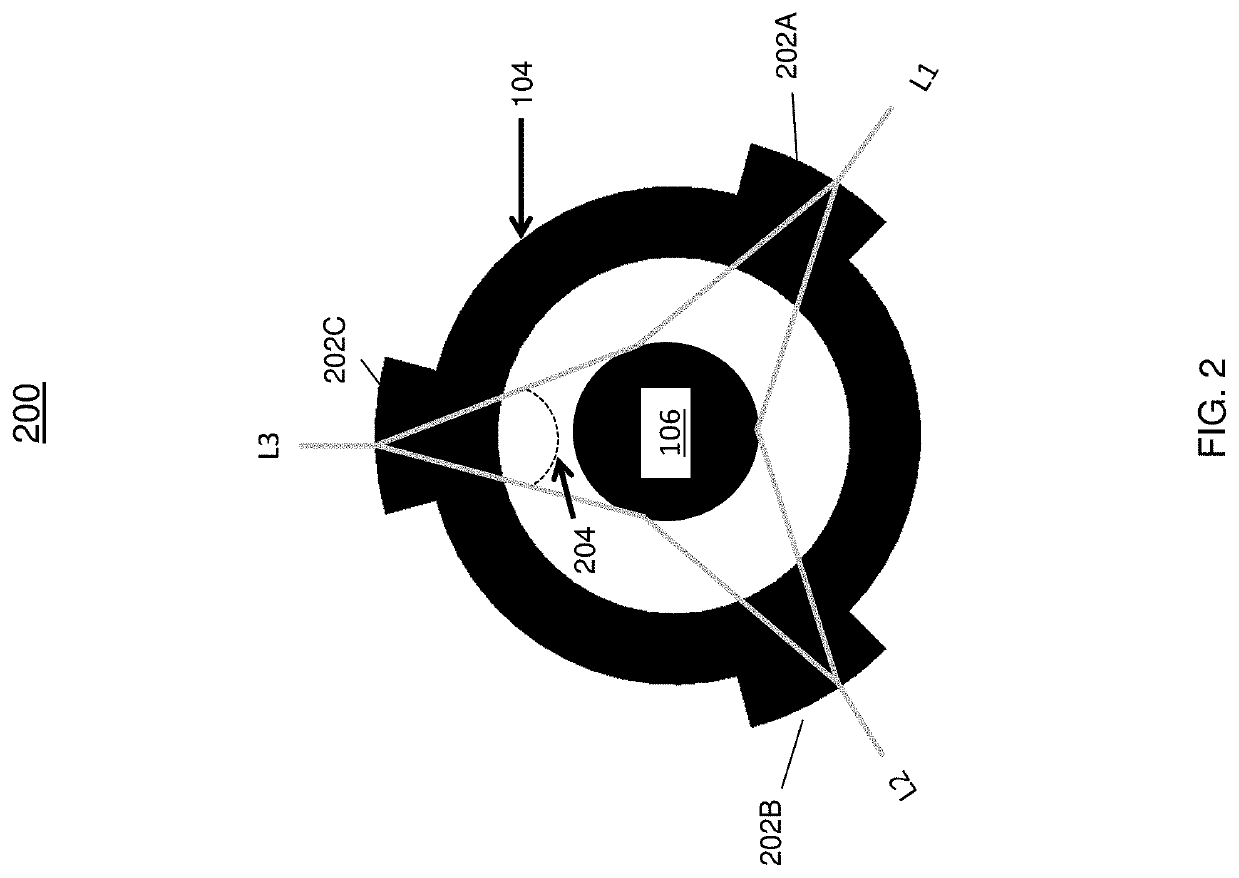

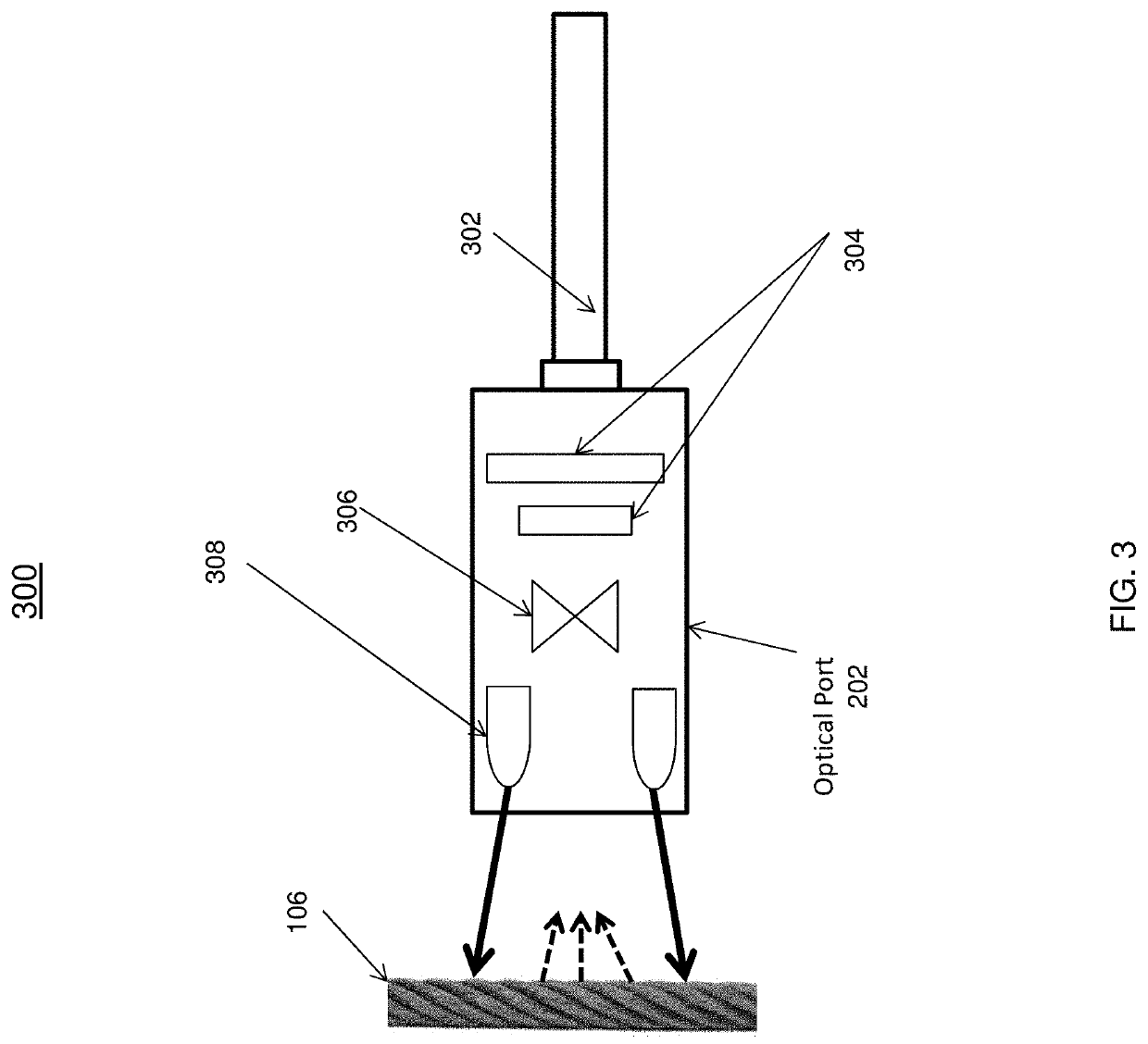

Measurement of Lay Length of Wire Rope

ActiveUS20150285767A1Restricts lateral movementControlMagnetic field measurement using flux-gate principleMagnetic fluxWire rope

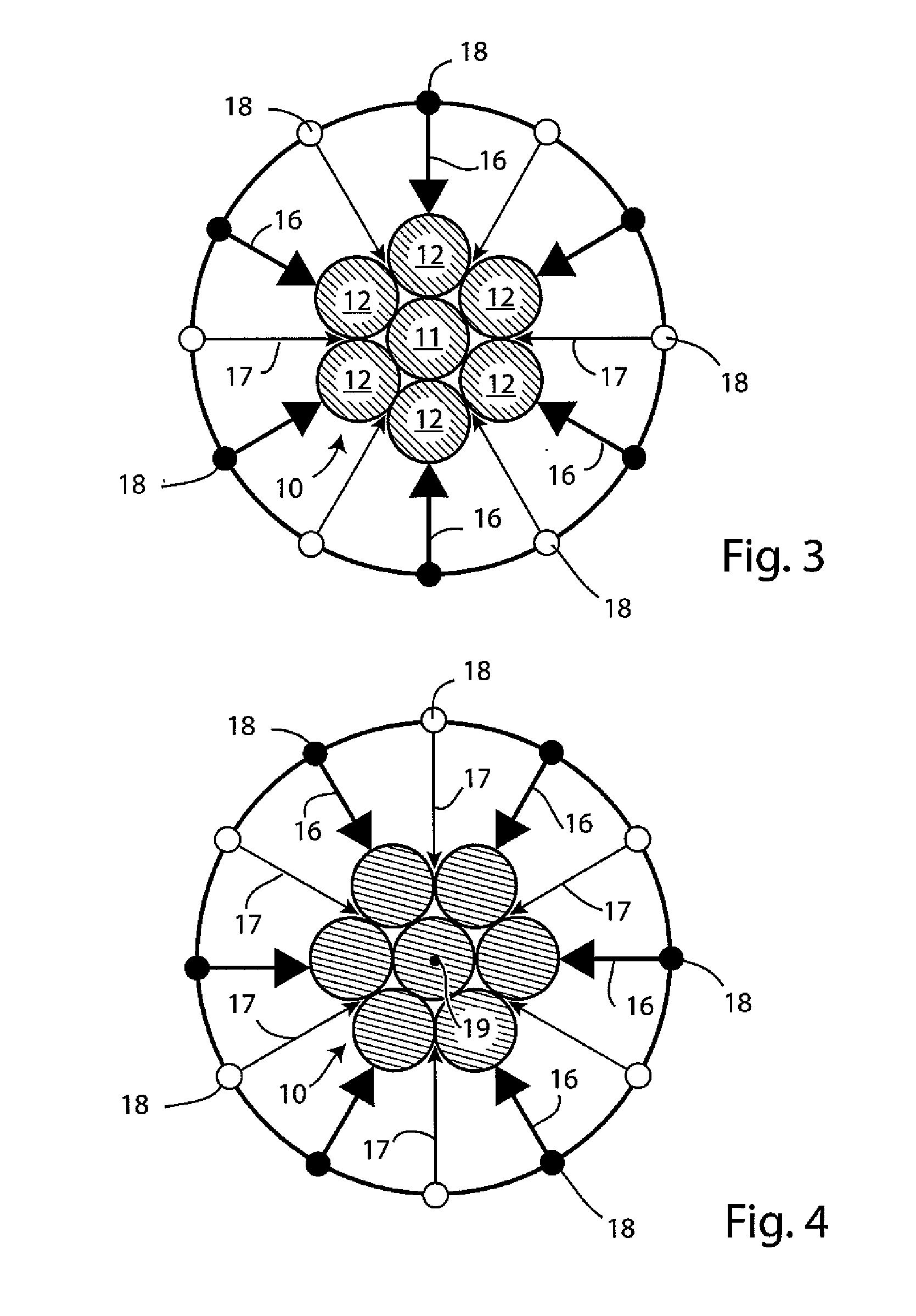

The invention relates to a method and apparatus for measuring lay length of a wire rope having a number or external strands to form a rope having spiral grooves in the surface between the strands. A magnetic flux circuit is generated, part of which is formed within a region of the advancing wire rope. Variations of magnetic field around the region of the rope or variations of magnetic flux entering or leaving the rope are sensed by at least two sensors arranged around the rope. Signals from the sensors are subtractively combined to eliminate variations due to off-axis movements of the rope, and the combined signals reveal an oscillating pattern due to the undulating surface of the rope. Linking the oscillating pattern to distance along the rope reveals the lay length, which corresponds to a number of oscillations which is the same as the number of strands at the surface.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

Lifting sling with excessive elongation warning indicator

Owner:MUELLER DEWAYNE

Monitoring method and system for detecting the torsion along a cable provided with identification tags

ActiveUS20120182130A1Short lifeEffective periodic maintenanceControlTransmission systemsMonitoring systemEngineering

A method for monitoring the torsion of a cable includes the steps of: providing a cable having an outer surface and extending along a longitudinal direction, the cable being provided with at least one identification tag, preferably an RFID tag, arranged in a tag angular position in a cross-sectional plane taken transverse to the longitudinal direction, the at least one tag storing a tag identification code and being capable of transmitting a tag electromagnetic signal; interrogating the at least one identification tag to receive the tag electromagnetic signal, and detecting the tag electromagnetic signal, wherein the step of detecting the tag electromagnetic signal includes the step of reading the tag identification code and determining the tag angular position of the at least one identification tag. A torsion monitoring system of a cable includes at least one identification tag.

Owner:PRYSMIAN SPA

Elevator suspension and transmission strip

A suspension and transmission device for use with an elevator system comprises one or more strips that provide load carrying, transmission or traction, and load carrying redundancy or safety functions for the elevator system. In one version, a single strip comprised of polymer and composite materials provides these functions. In another version, multiple strips comprised of polymer and composite materials provide these functions. In another version, a strip comprises a hollow interior portion. In another version, one or more strips incorporate materials that can be detected when using the strip to monitor the condition of the one or more strips.

Owner:TK ELEVATOR INNOVATION & OPERATIONS GMBH

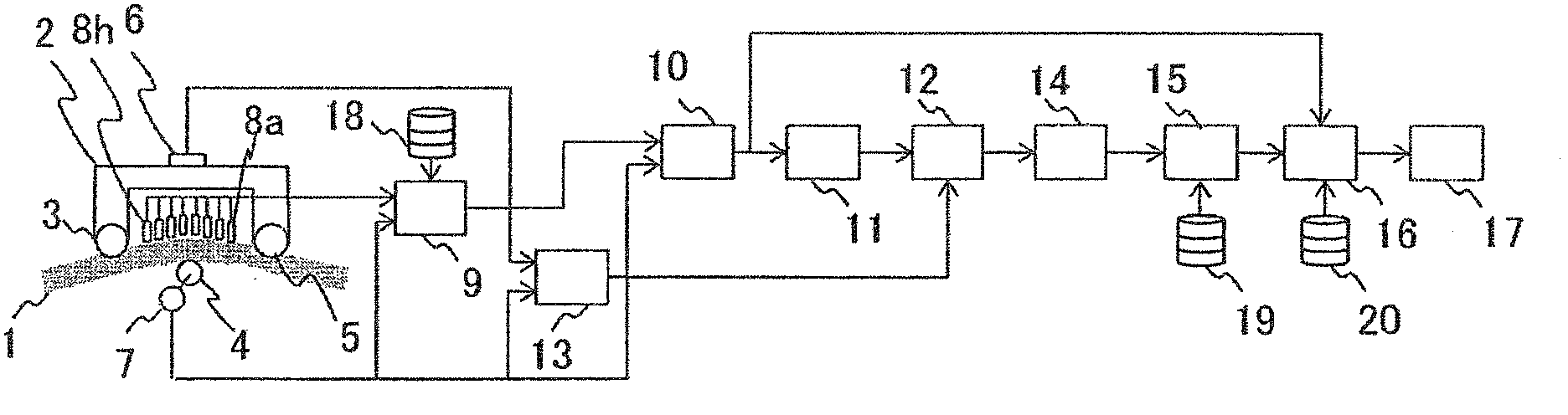

Inspection equipment for wire rope

An inspection equipment to detect twist of a wire rope with high precision by taking influences of change in the rope pitch due to the relative movement between the rope and the inspection equipment and tension of the rope into consideration, a magnetization device (2) magnetizes a wire rope (1) in a longitudinal direction thereof, the wire rope being produced by twisting steel wire bundles; magnetic detectors (8a-8h) disposed near the wire rope detect magnetic flux leakage from the wire rope, an arithmetic unit calculates (9,10,11) a rope pitch using a relative velocity between the wire rope and the inspection equipment from an encoder (7) and the magnetic flux leakage and corrects (12) elongation of the rope due to the tension measured by a tension measurement unit (6,13) based on the calculated pitch to thereby calculate (14,15) twist of the rope, and supplies results of the calculation to determine acceptability or inacceptability of the rope (16,17).

Owner:HITACHI LTD +1

Electric cable with bending sensor and monitoring system and method for detecting bending in at least one electric cable

ActiveUS9032809B2Low costGood mechanical resistanceControlForce measurement by measuring optical property variationNon symmetricMonitoring system

A method for monitoring at least the bending strain of at least one electric cable provided with at least one peripheral mechanically non-symmetric strength member is provided.

Owner:PRYSMIAN SPA

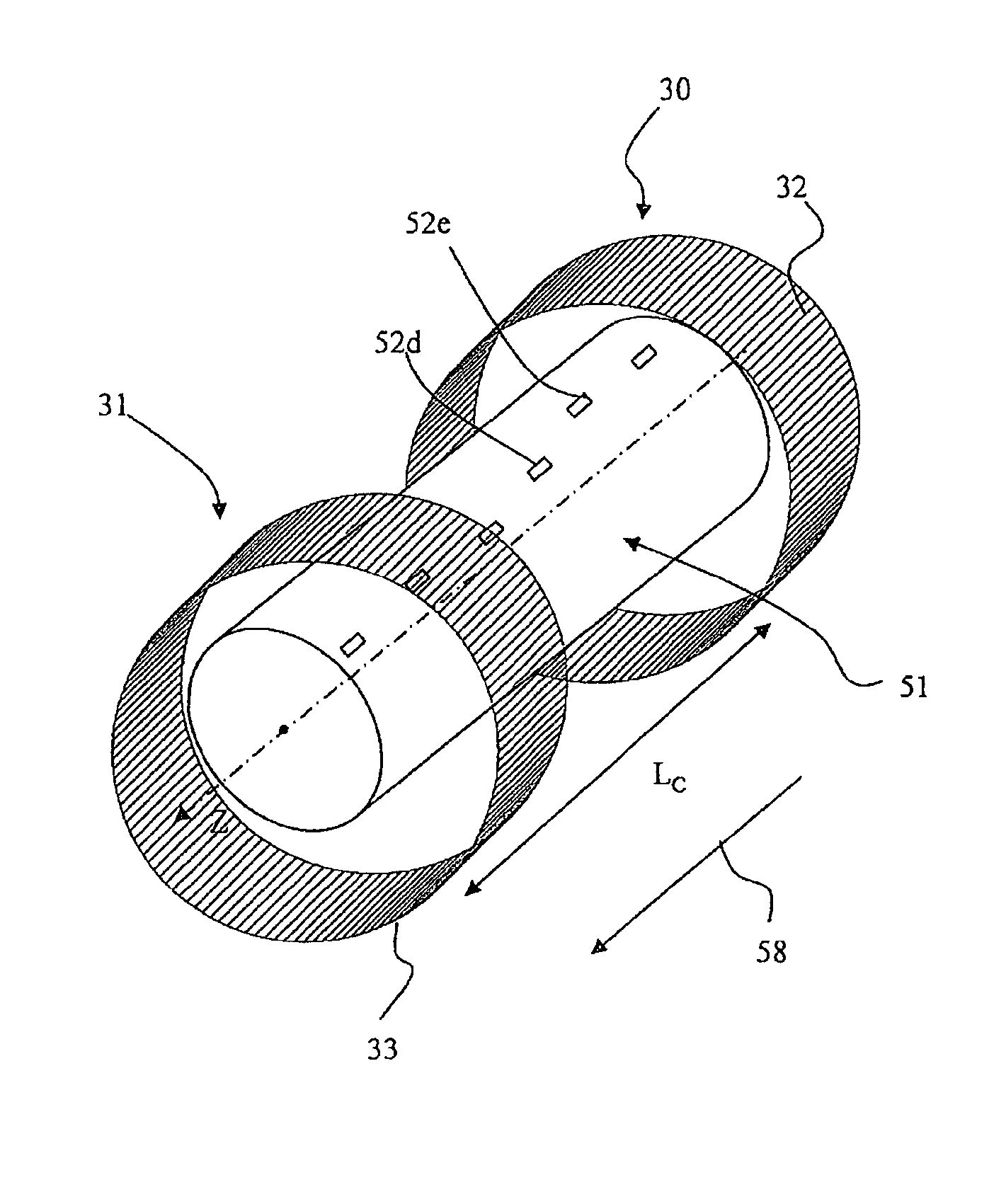

Cable and method for monitoring a cable

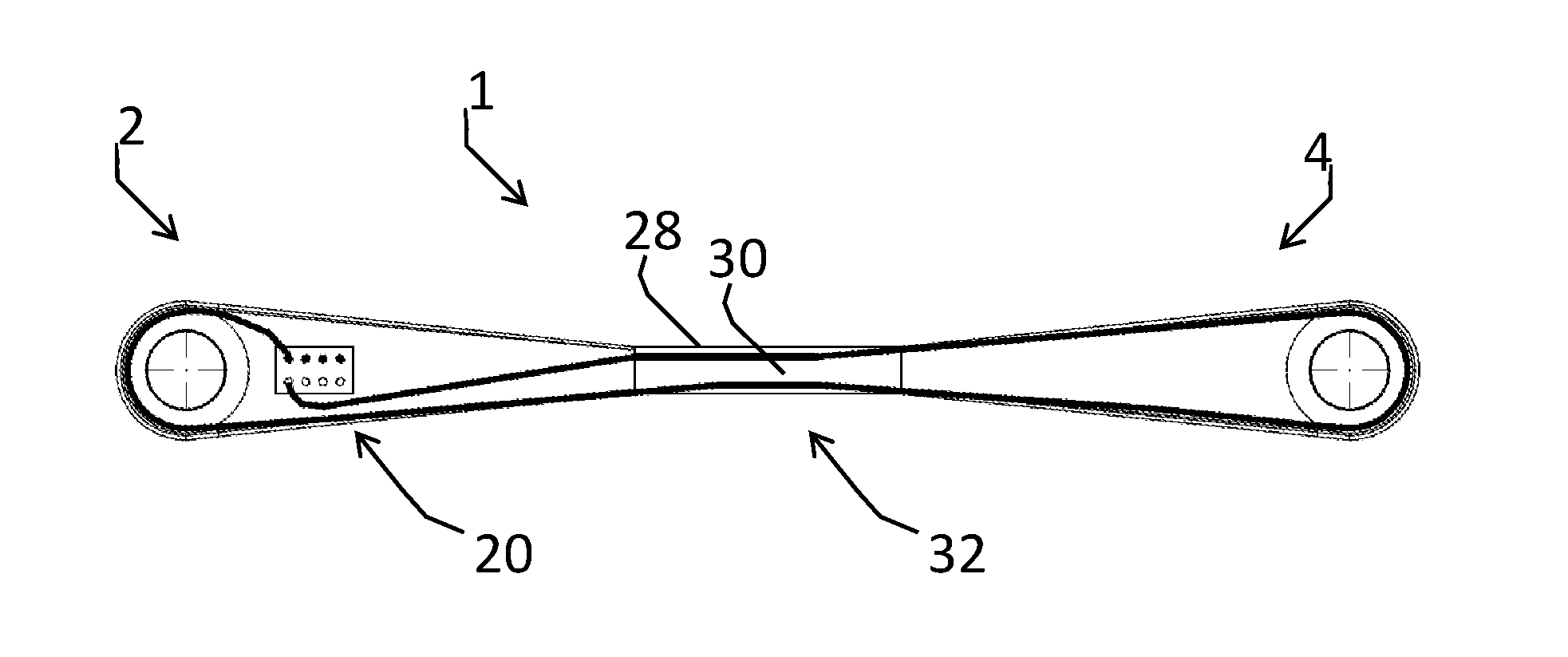

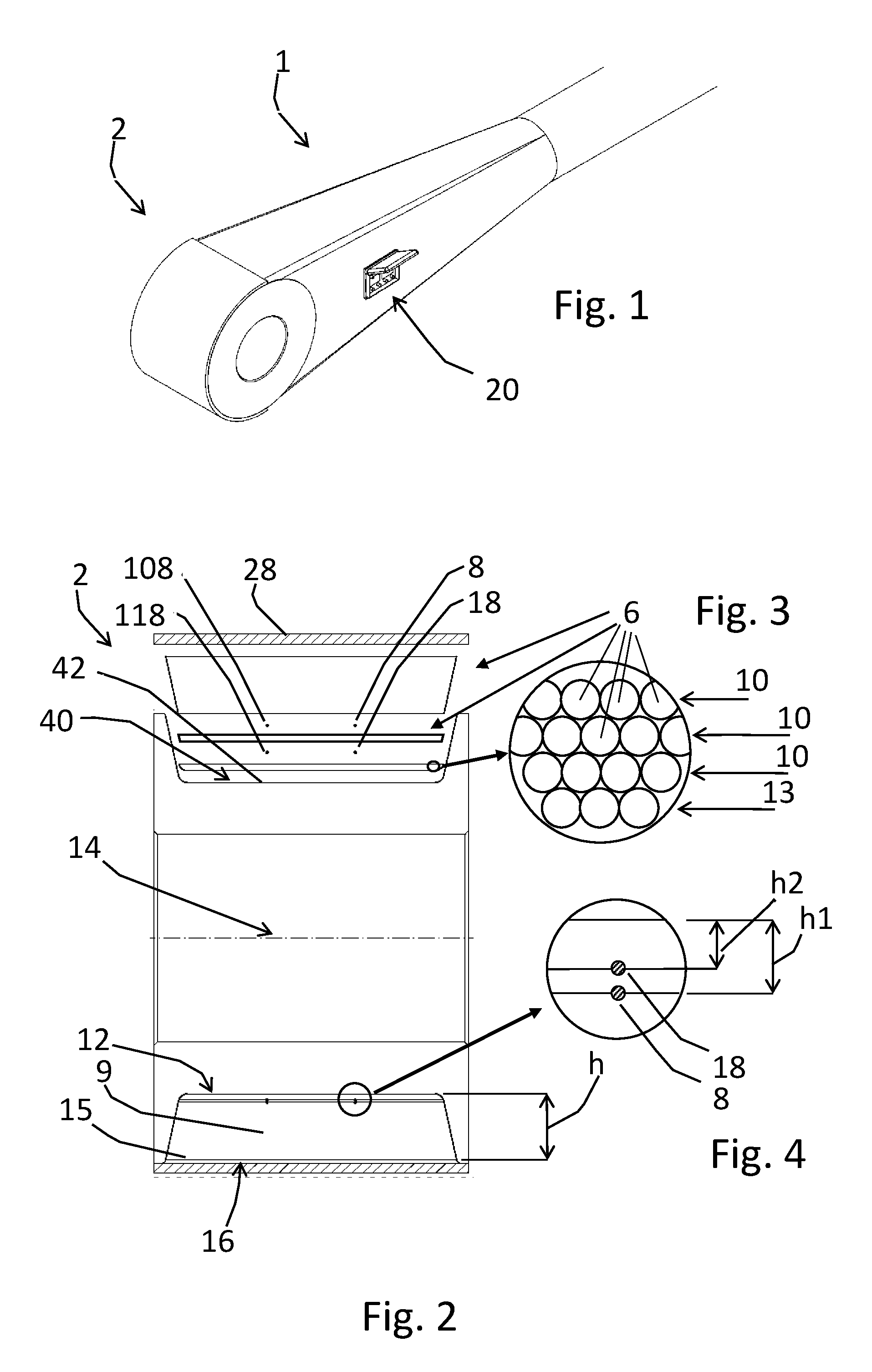

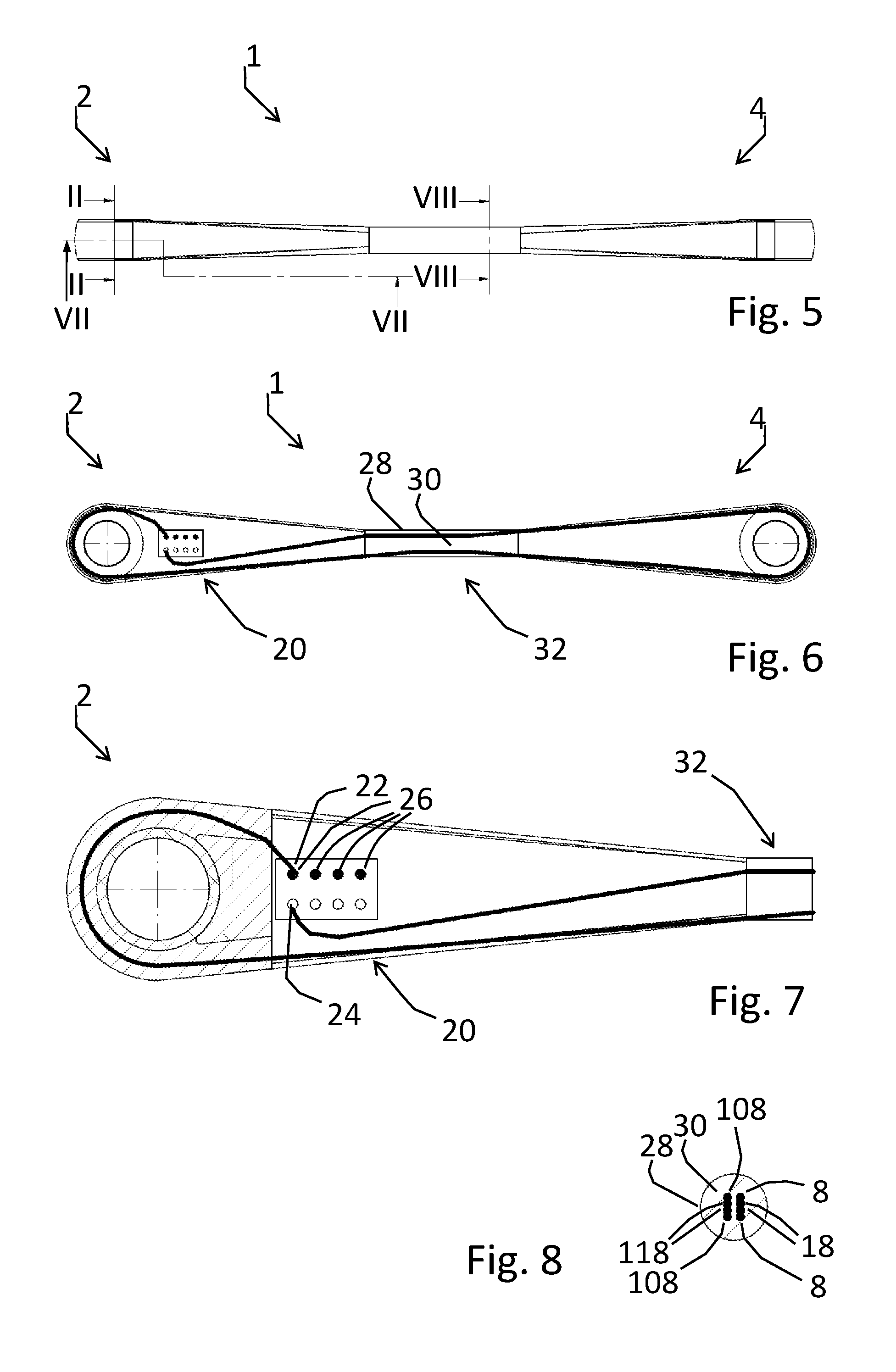

ActiveUS20170037570A1Improve mechanical propertiesShort production timeGlass optical fibreControlFiberElectrical and Electronics engineering

A cable 1 comprises a first thimble 2 and a second thimble 4, at least one yarn 6, and at least a first conductive fibre 8 for monitoring the cable 1. The yarn 6 extends from the first thimble 2 to the second thimble 4, turns around the second thimble 4, extends from the second thimble 4 to the first thimble 2, and turns around the first thimble 2. Each thimble holds a stack 9 of layers 10 of turns of the yarn 6. The first conductive fibre 8 is designed to signal the wear of the yarn 6 by breaking after a predetermined portion of the turns of the yarn 6 breaks. The first conductive fibre 8 is positioned at the first thimble 2 between the turns of the yarn 6 at less than 50% of the stack height h.

Owner:CABIN AIR GRP

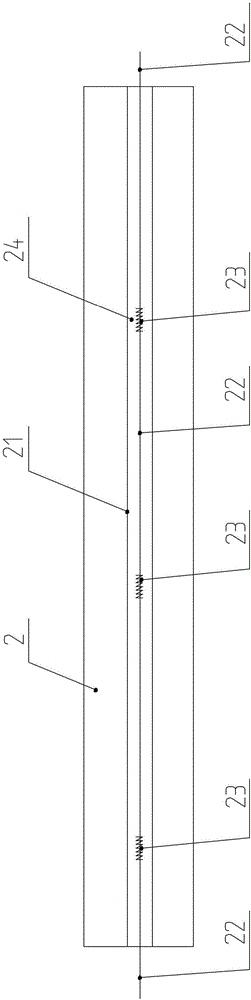

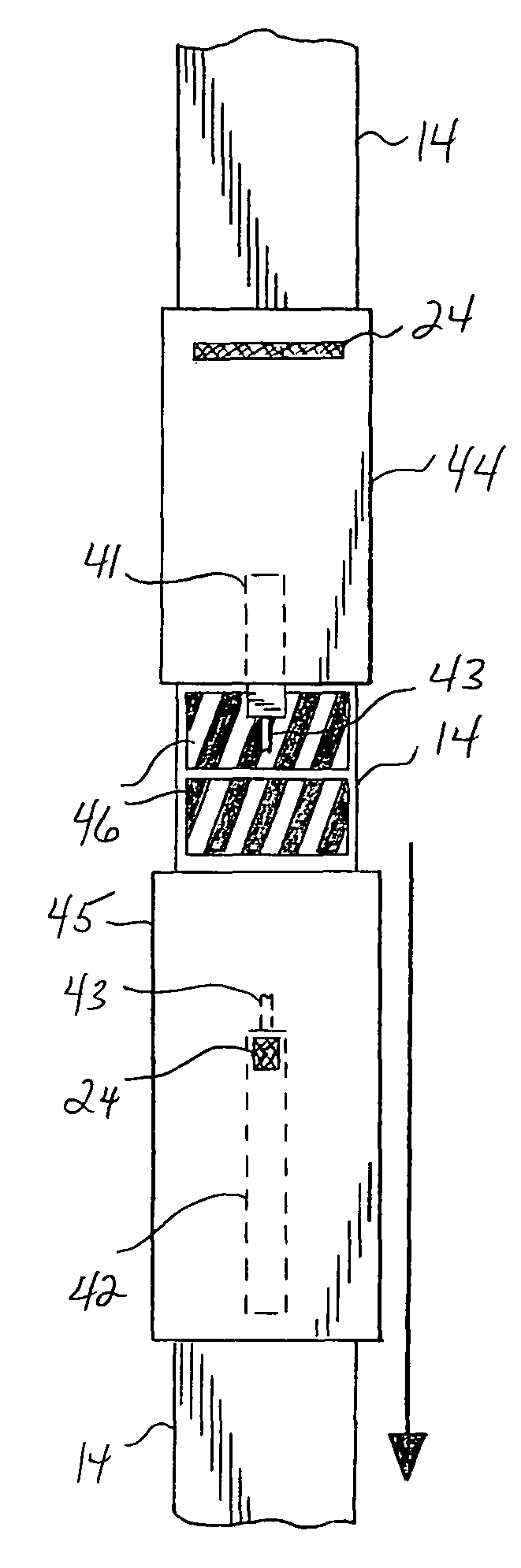

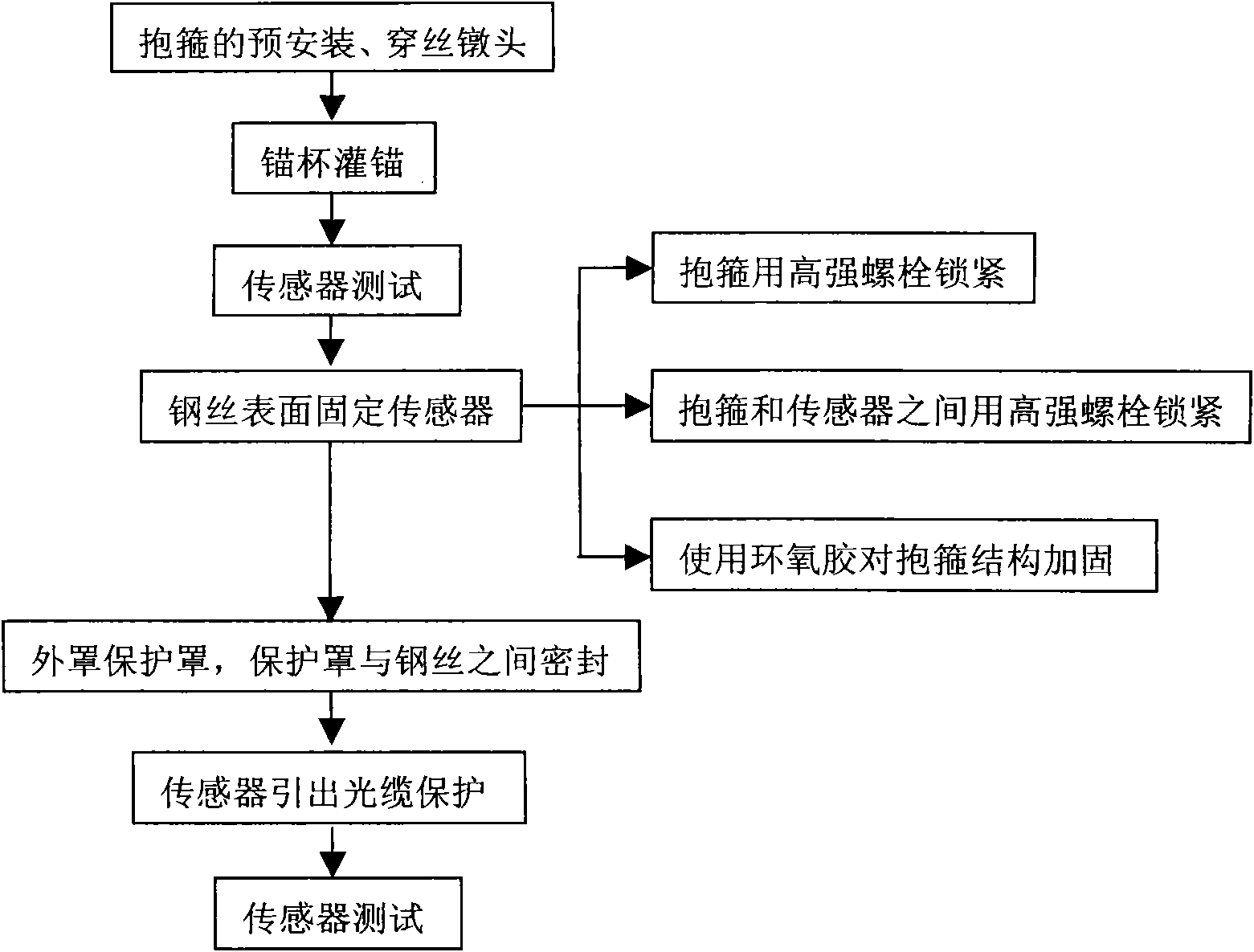

Method for assembling cable built-in fiber bragg grating strain transducer

ActiveCN101787676AGuaranteed reliabilityGuaranteed long-term stabilityControlBridge structural detailsFiberGrating

The invention relates to a method for assembling a cable built-in fiber bragg grating strain transducer. The method comprises the following technical processes of: sleeving a hoop onto a peripheral steel wire of a cable connecting cylinder place to be assembled with the fiber bragg grating strain transducer before working procedures of feeding and heading the cable to complete preassembly of the hoop; fixing the fiber bragg grating strain transducer on the surface of the peripheral steel wire of the cable connecting cylinder place with the hoop in the area of a cable connecting cylinder after finishing the working procedure of anchoring the cable; adding a transducer protection cover to protect the fiber bragg grating strain transducer fixed on the surface of the peripheral steel wire of the cable connecting cylinder place after fixing the fiber bragg grating strain transducer, and sealing gaps among the transducer protection cover and the peripheral steel wire of the cable connecting cylinder place; and penetrating a tail cable of the fiber bragg grating strain transducer into a reserved steel tube channel arranged in the cable connecting cylinder and a socket, and protecting the joint of the tail cable and the reserved steel tube with a heat-shrinkable bush in a hot shrinkage way. The method effectively ensures reliability and long-term stability of intelligent cabling operation.

Owner:法尔胜集团有限公司 +1

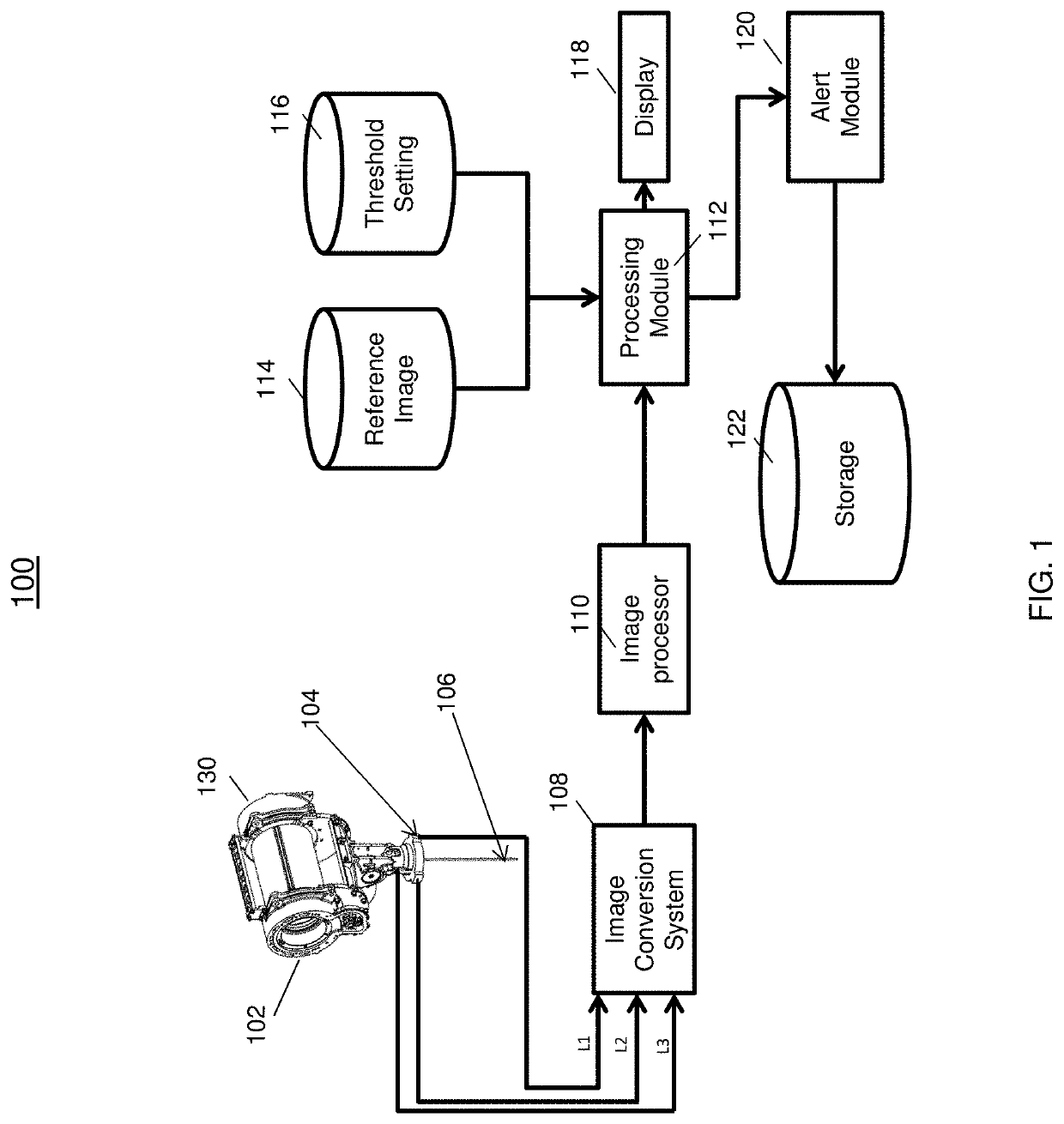

Automated defect detection for wire rope using image processing techniques

PendingUS20200118259A1Efficiently monitor healthImage enhancementControlImaging processingData translation

Provided are embodiments for performing automated defect detection for a flexible member using image processing. The techniques include monitoring, by one or more sensors, a flexible member to obtain sensor data, converting the sensor data from the one or more sensors to image data, and receiving reference image data to compare to the image data. The techniques also include determining a defect based on the comparison and threshold setting information for the flexible member, and transmitting a notification based on the defect.

Owner:THE BF GOODRICH CO

Popular searches

Photoelectric discharge tubes Using optical means Coupling light guides Photometry using electric radiation detectors Optical apparatus testing Fibre with gratings Communication cables Thermometers using physical/chemical changes Fibre mechanical structures Power cables including optical transmission elements

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com