Inspection equipment for wire rope

A technology for inspection devices and steel wire ropes, applied in transportation and packaging, textiles and papermaking, and manipulating parts, etc., can solve problems such as changes, confusing measurement results, and difficult applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

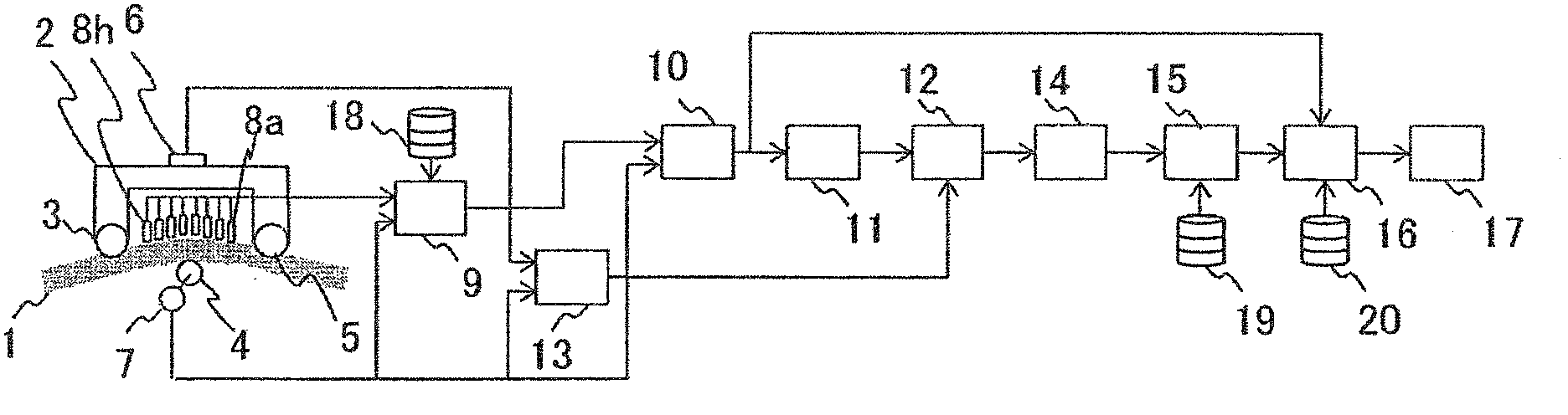

[0054] figure 1 It is a block diagram showing the basic configuration of the inspection device for the wire rope 1 according to the first embodiment of the present invention.

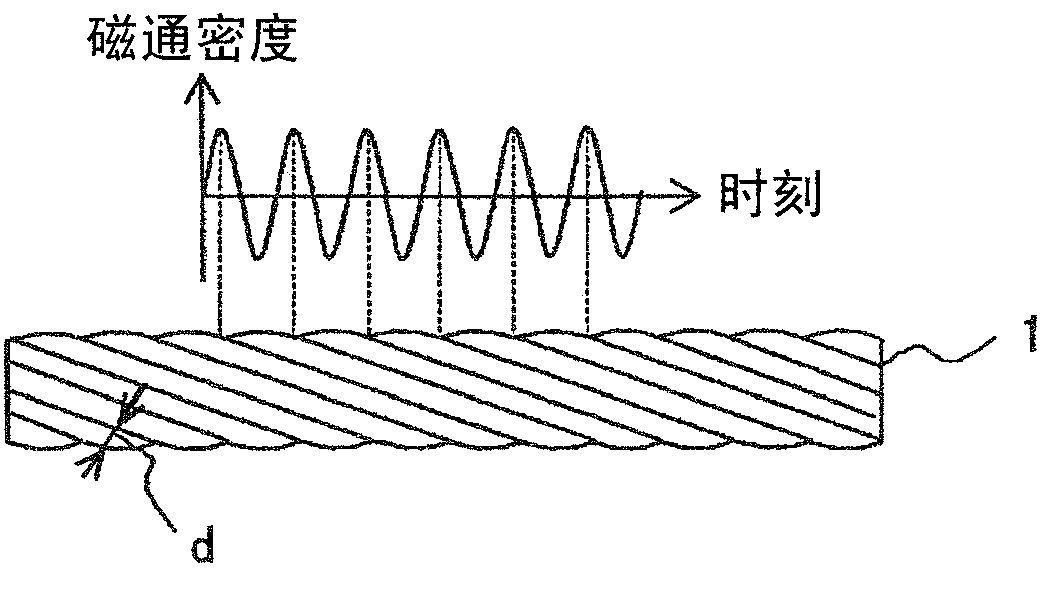

[0055] The inspection device for the steel wire rope 1 according to Embodiment 1 includes: a magnetizer 2 as a magnetization unit for magnetizing the steel wire rope 1 formed by twisting a bundle of a plurality of steel wires in the longitudinal direction; and a plurality of magnetic sensors as a magnetic detection unit. 8a to 8h, which are equipped close to the wire rope 1 and detect the leakage magnetic flux in the wire rope 1 magnetized by the magnetizer 2; , and the leakage flux detected by the magnetic sensors 8a-8h to calculate the rope pitch, and correct the elongation of the steel wire rope 1 based on the tension according to the calculated rope pitch, and on this basis, calculate the torsion of the steel wire rope 1.

[0056] Specifically, the inspection device uses a magnetizer 2 to magnetize...

Embodiment 2

[0079] Figure 8 It is a block diagram showing the basic configuration of the inspection device for the wire rope 1 according to the second embodiment of the present invention. The inspection device involved in embodiment 2 is in figure 1 On the basis of the inspection device related to the illustrated embodiment 1, instead of using the torsion amount converter 15 based on the initial torsion rate of the wire rope 1 stored in the storage device 19, the torsion rate from the filter 14 (measured Twist rate) is changed to the twist amount of each pitch, and the twist rate from the filter 14 (measured twist rate ) is changed as the function of the amount of twist for each pitch, and other parts are common to those of Embodiment 1. That is, the inspection device according to the second embodiment differs from the case of the first embodiment in the calculation method of the twist amount of the twist amount converter 15 .

Embodiment 3

[0081] The inspection device for the steel wire rope 1 according to Embodiment 3 of the present invention is figure 1 The application of the inspection device involved in the shown embodiment 1 Figure 8 The structure of the inspection device related to the shown embodiment 2 uses figure 1 In the illustrated configuration, the output of the storage device 18 is connected to the twist converter 15 . According to the above configuration, the inspection device according to the third embodiment can arbitrarily switch between the initial twist rate of the wire rope 1 using the storage device 19 and the use of the storage device 18 when calculating the twist amount by the twist amount converter 15 . The processing mode in the case of the design value of the twist pitch of the wire rope 1 is used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com