Patents

Literature

863 results about "Magnetic flux leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic flux leakage (TFI or Transverse Field Inspection technology) is a magnetic method of nondestructive testing that is used to detect corrosion and pitting in steel structures, most commonly pipelines and storage tanks. The basic principle is that a powerful magnet is used to magnetize the steel. At areas where there is corrosion or missing metal, the magnetic field "leaks" from the steel. In an MFL (or Magnetic Flux Leakage) tool, a magnetic detector is placed between the poles of the magnet to detect the leakage field. Analysts interpret the chart recording of the leakage field to identify damaged areas and to estimate the depth of metal loss.

ID-OD discrimination sensor concept for a magnetic flux leakage inspection tool

ActiveUS6847207B1Successfully detectMagnetic property measurementsPipe elementsSignal processing circuitsElectrical polarity

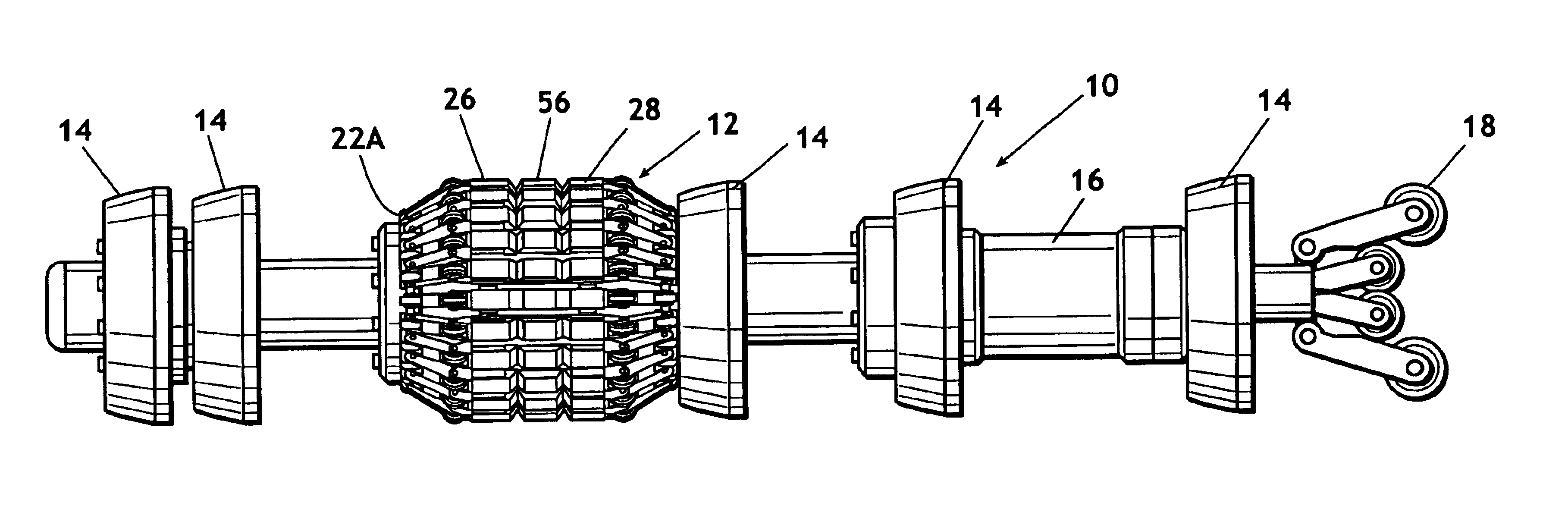

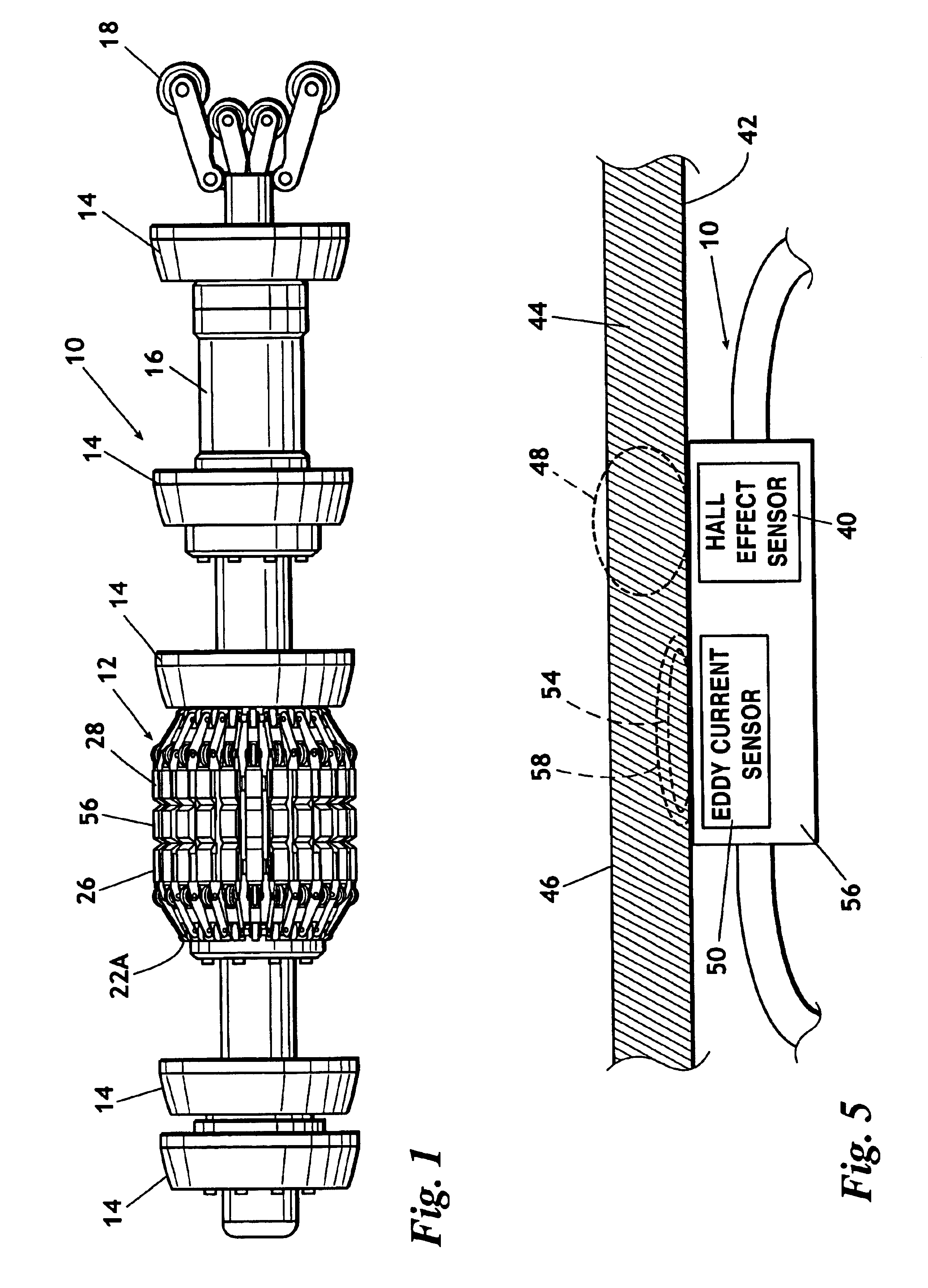

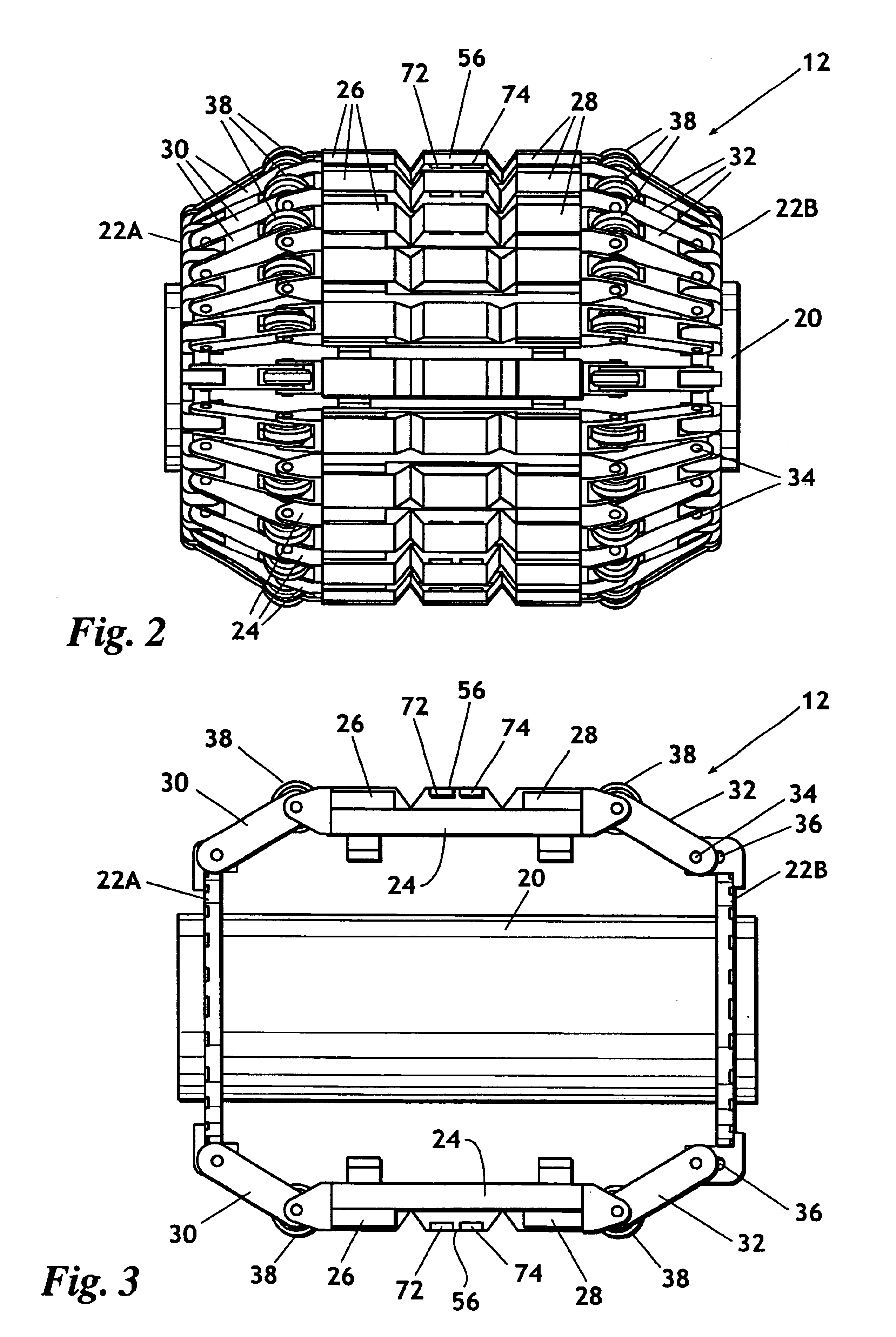

An instrument pig and method of operation thereof for determining the characteristics of a ferromagnetic pipeline through which it passes, including a pig body, first and second coaxial circumferential, spaced apart magnets of opposed polarities supported to the pig body and providing substantially complete magnetic saturation of an area of the pipeline between the magnets, first instruments between the magnets and arranged to generate signals that are responsive to flux leakage servicing to provide first information as to anomalies in the pipeline interior and / or exterior surfaces, second instruments supported by the pig body between said magnets and arranged to generate signals that are responsive to eddy currents induced in the pipeline interior surface servicing to provide second information as to anomalies in the pipeline interior surface, signal processing circuitry combining the first and second signals and wherein the second instruments are energized only in response to signals generated by said signal processing circuitry.

Owner:TDW DELAWARE INC

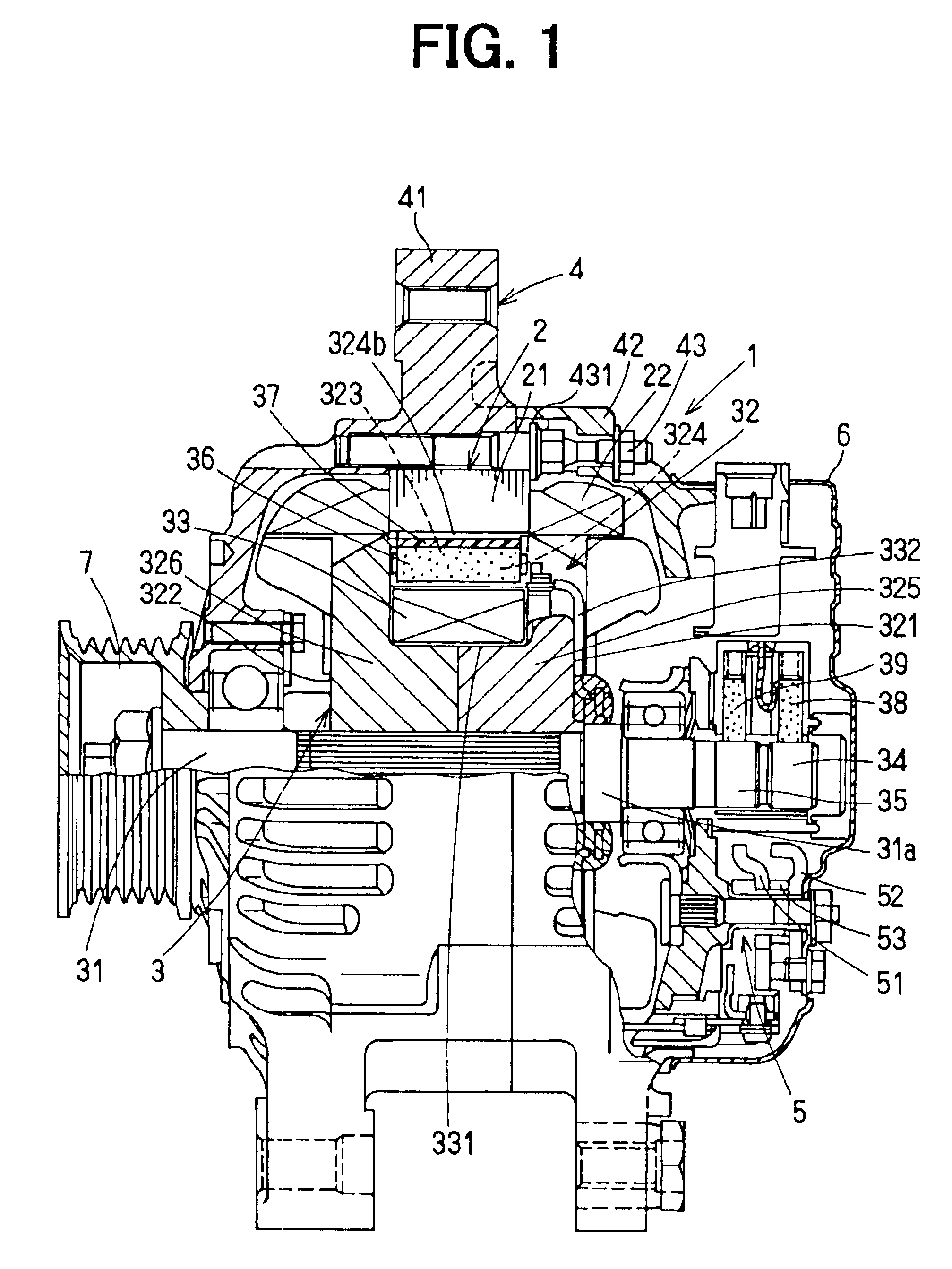

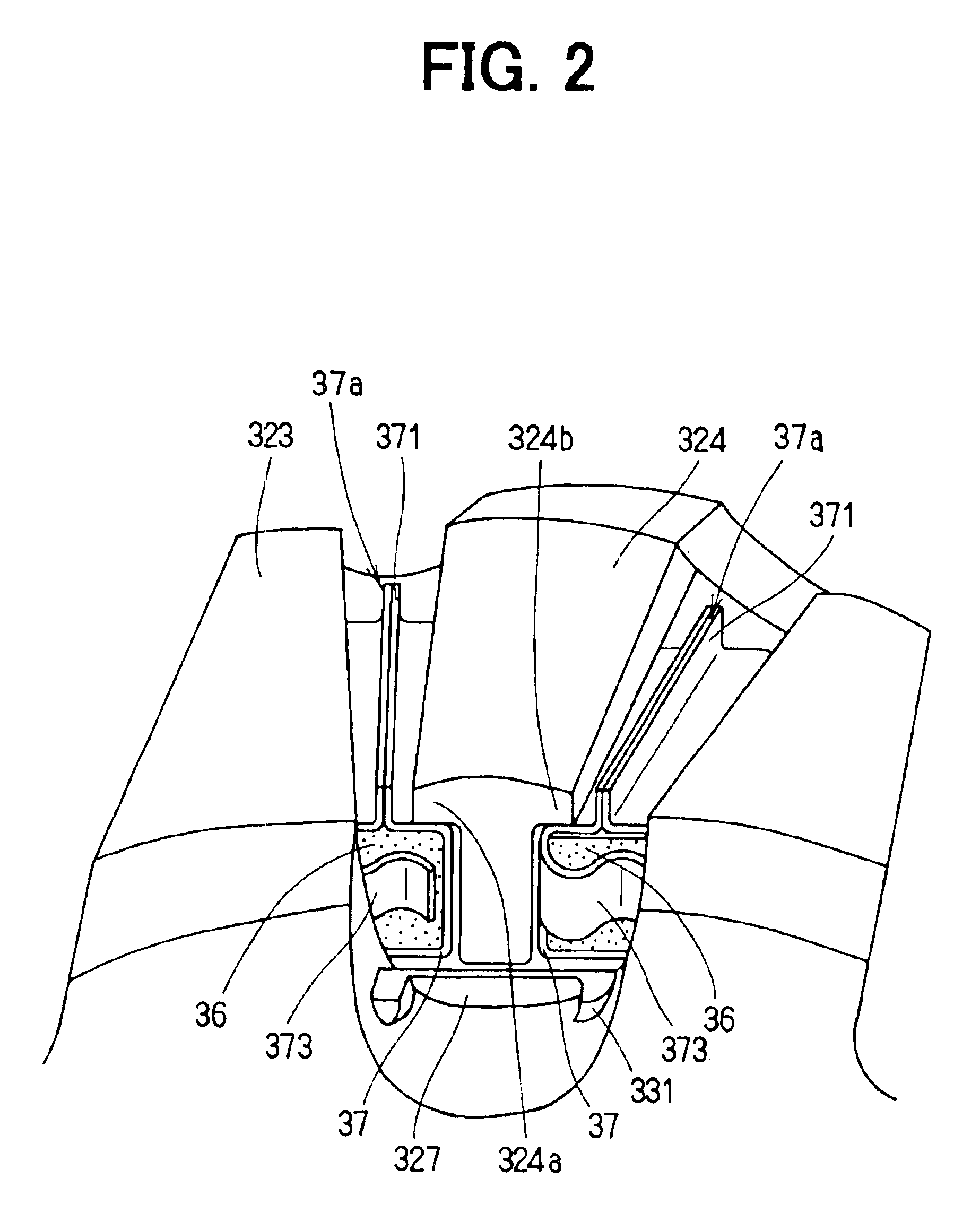

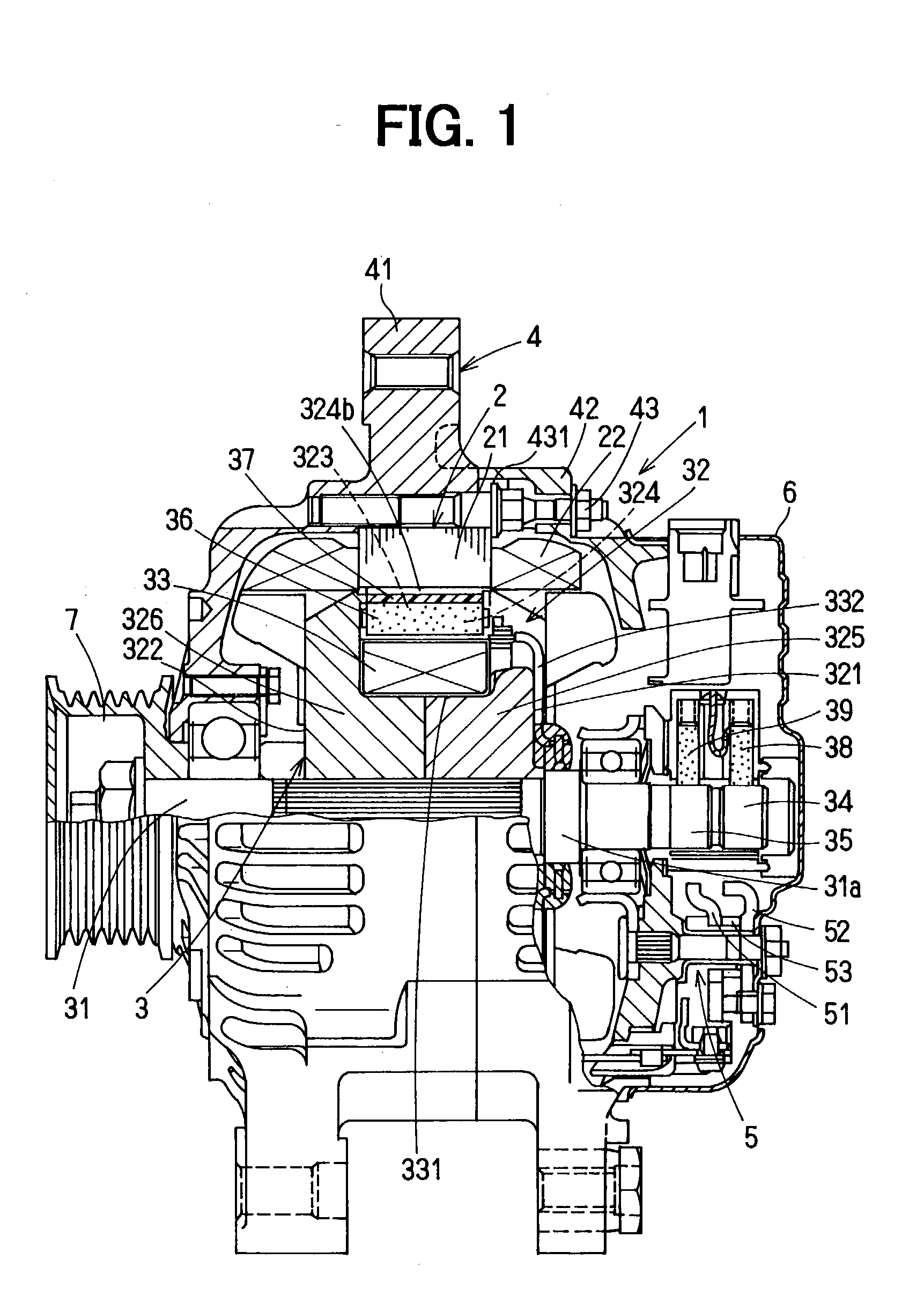

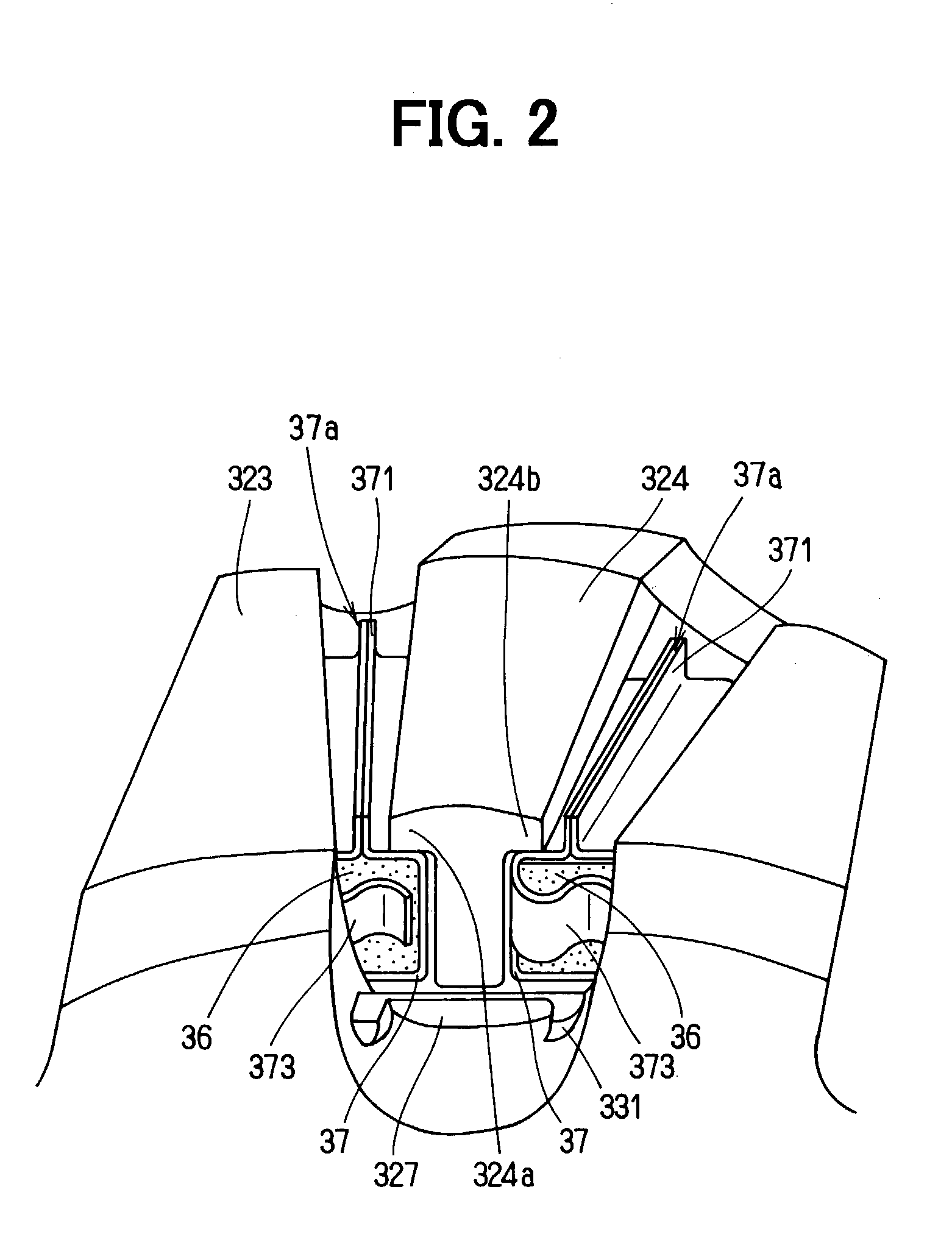

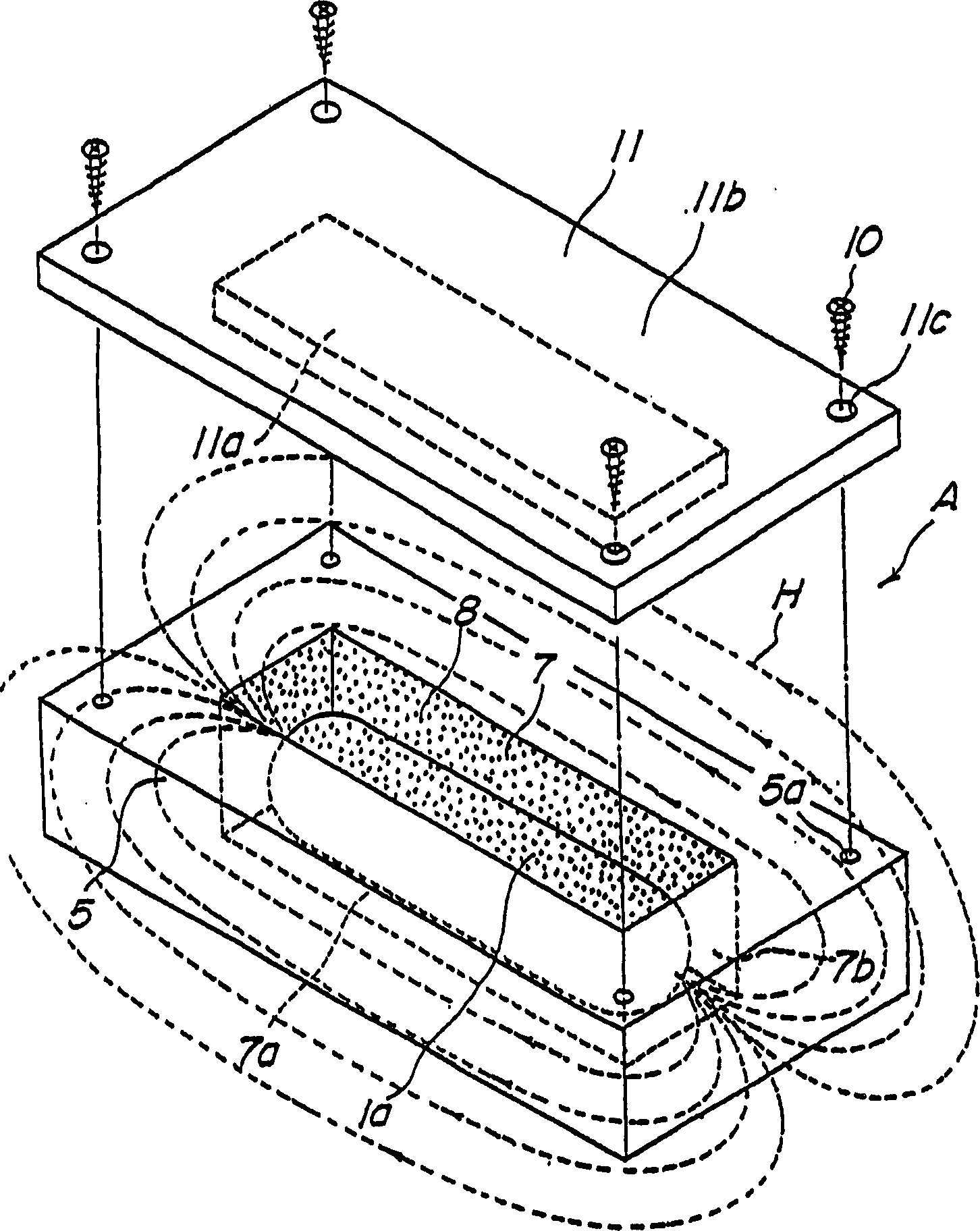

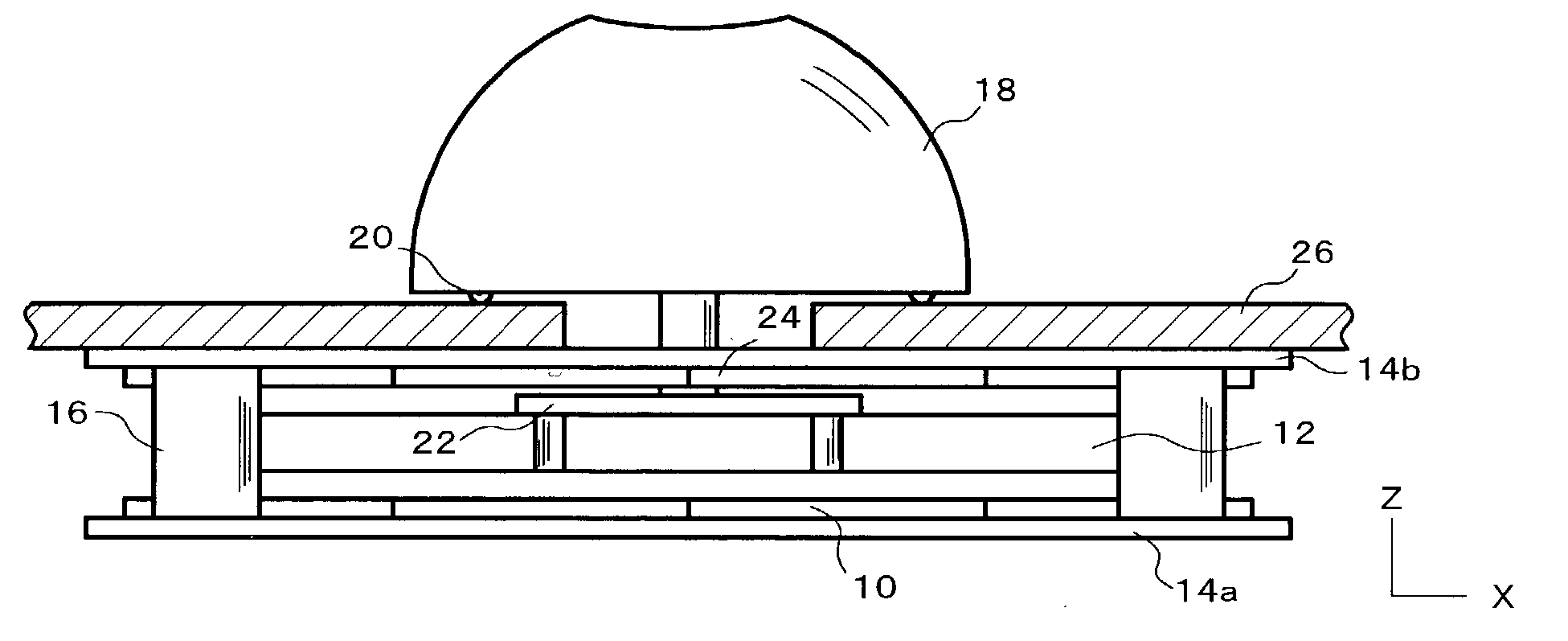

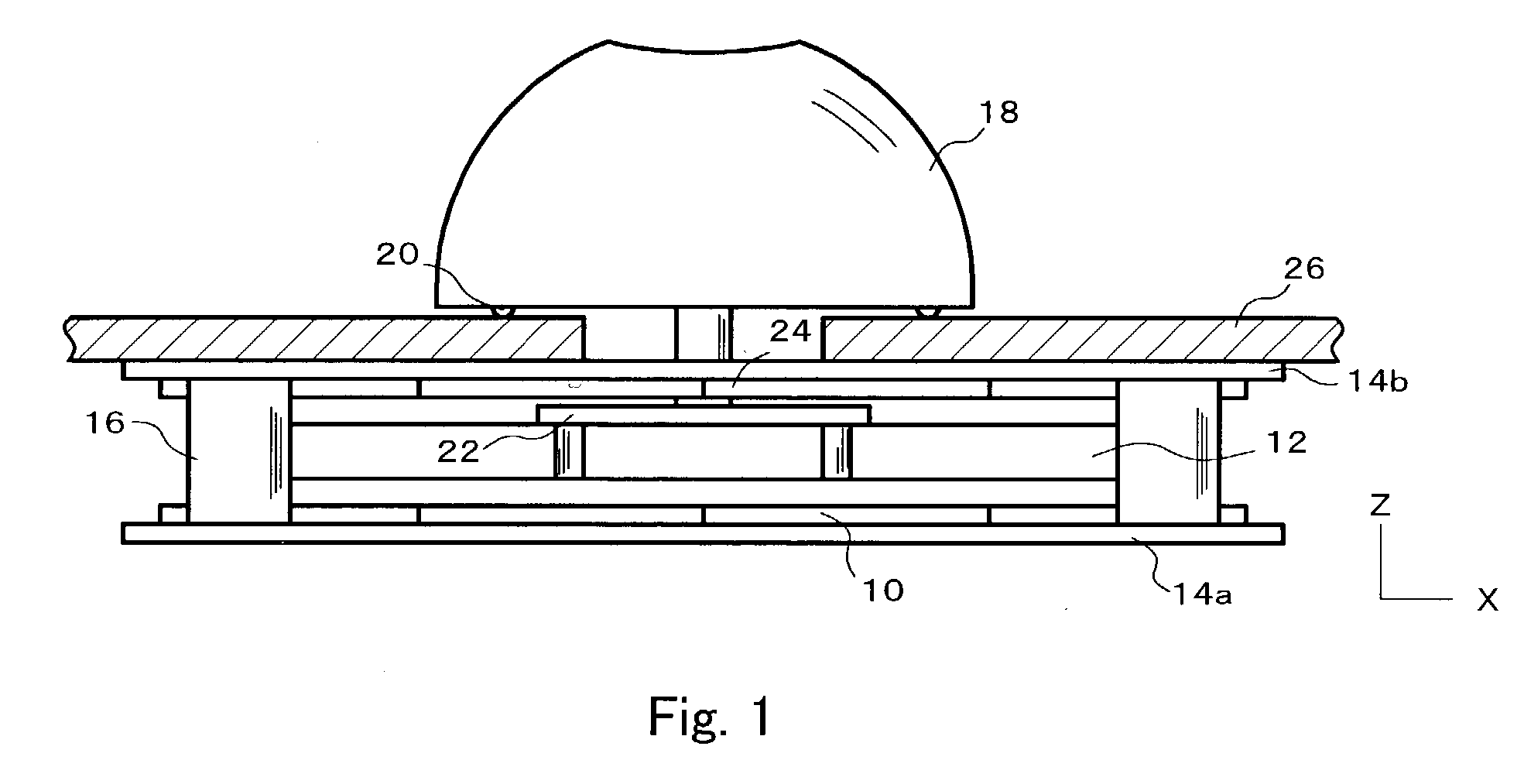

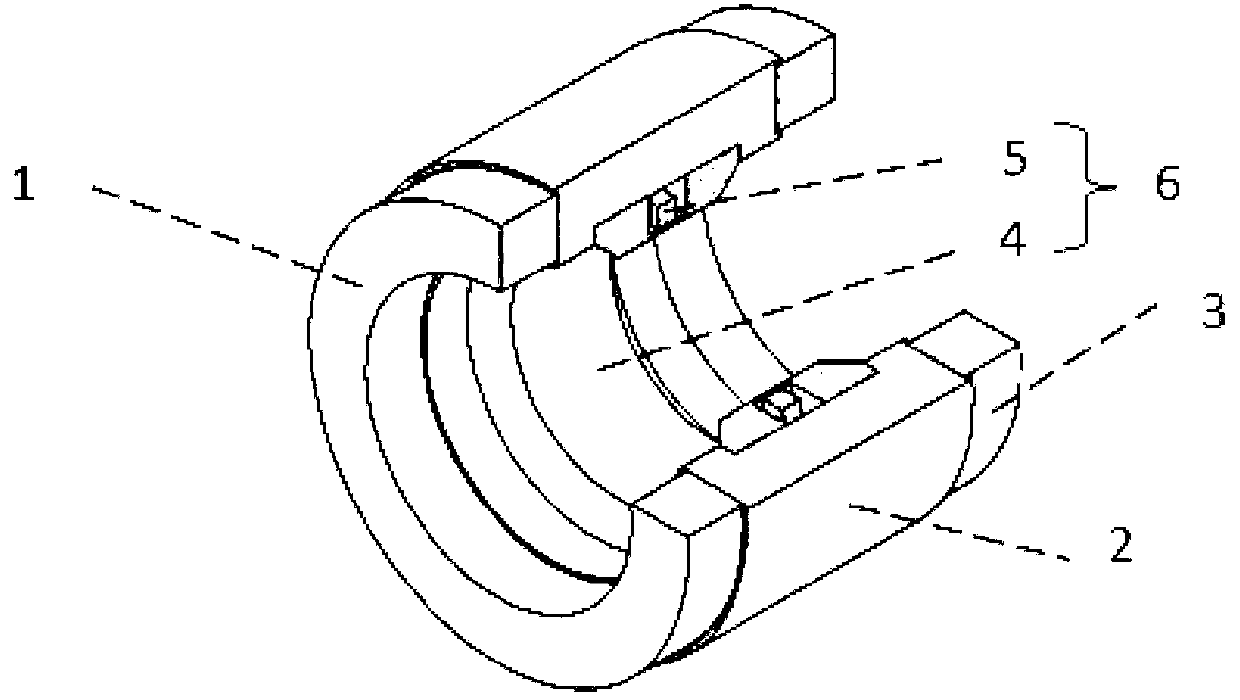

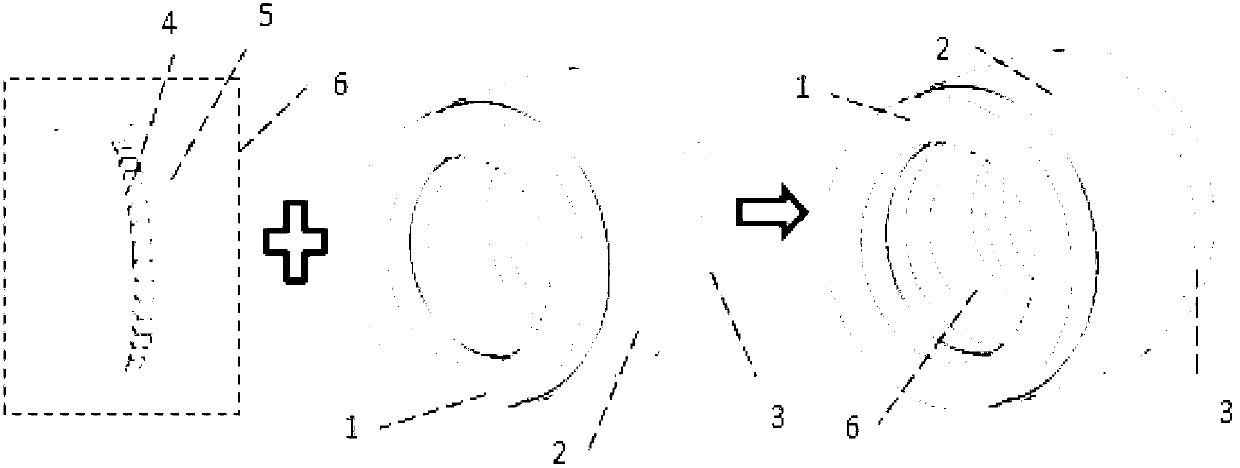

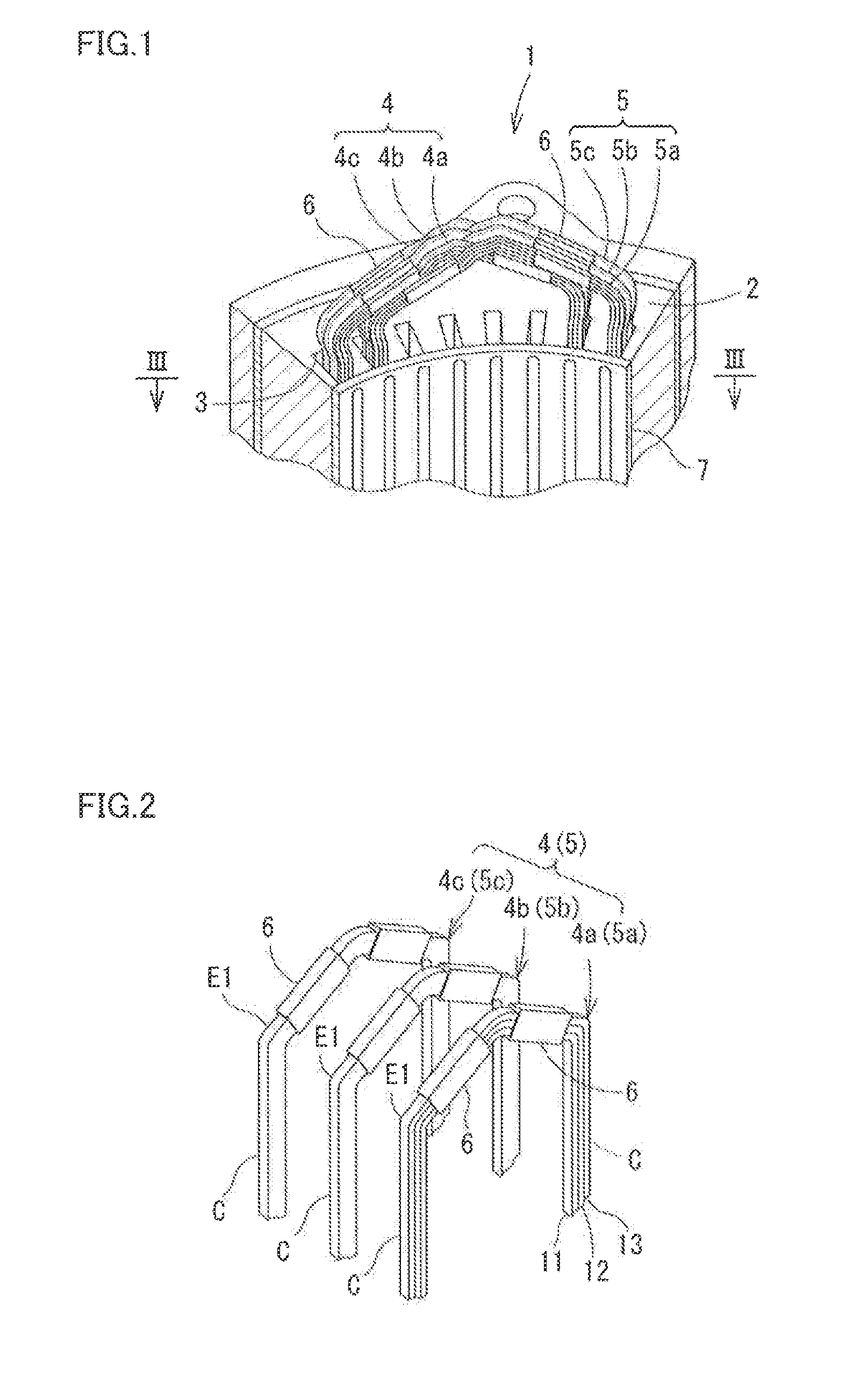

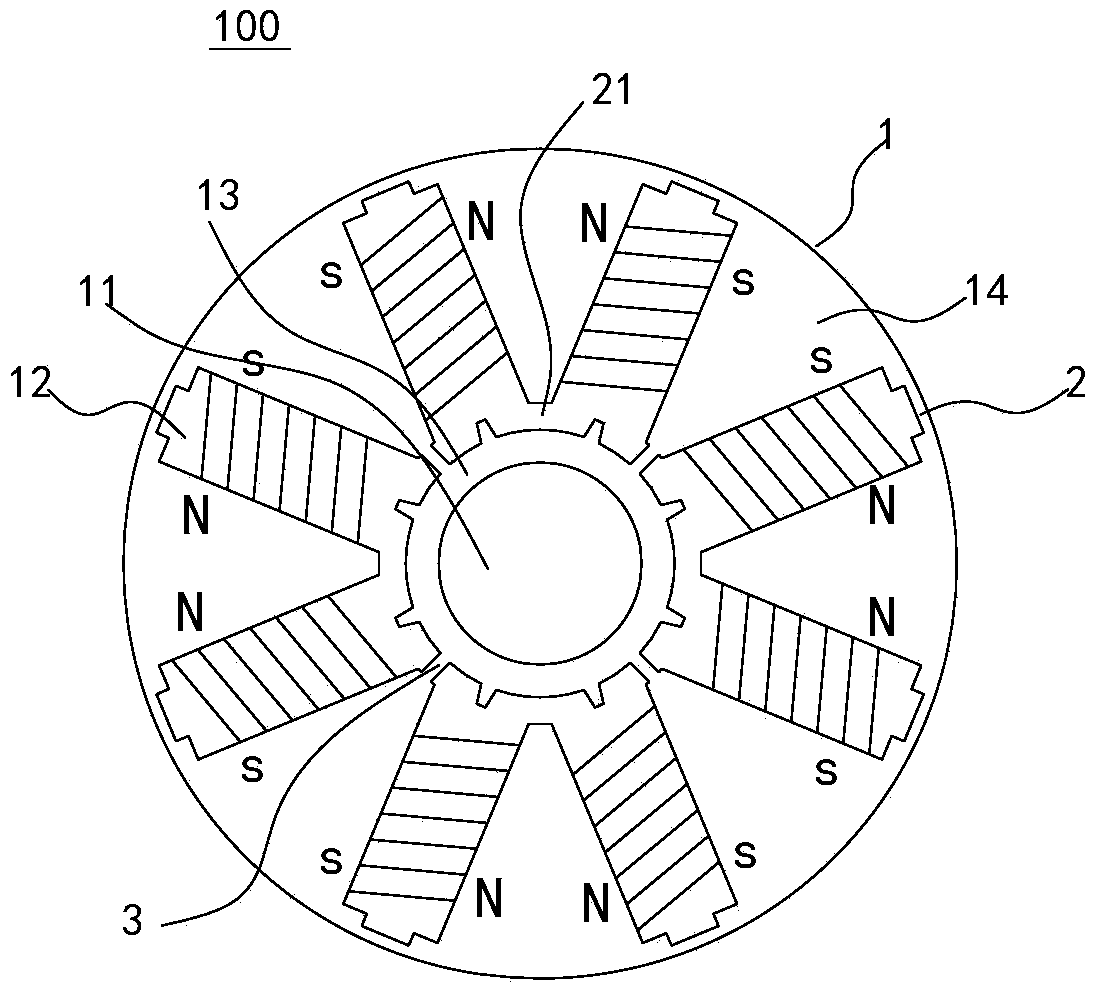

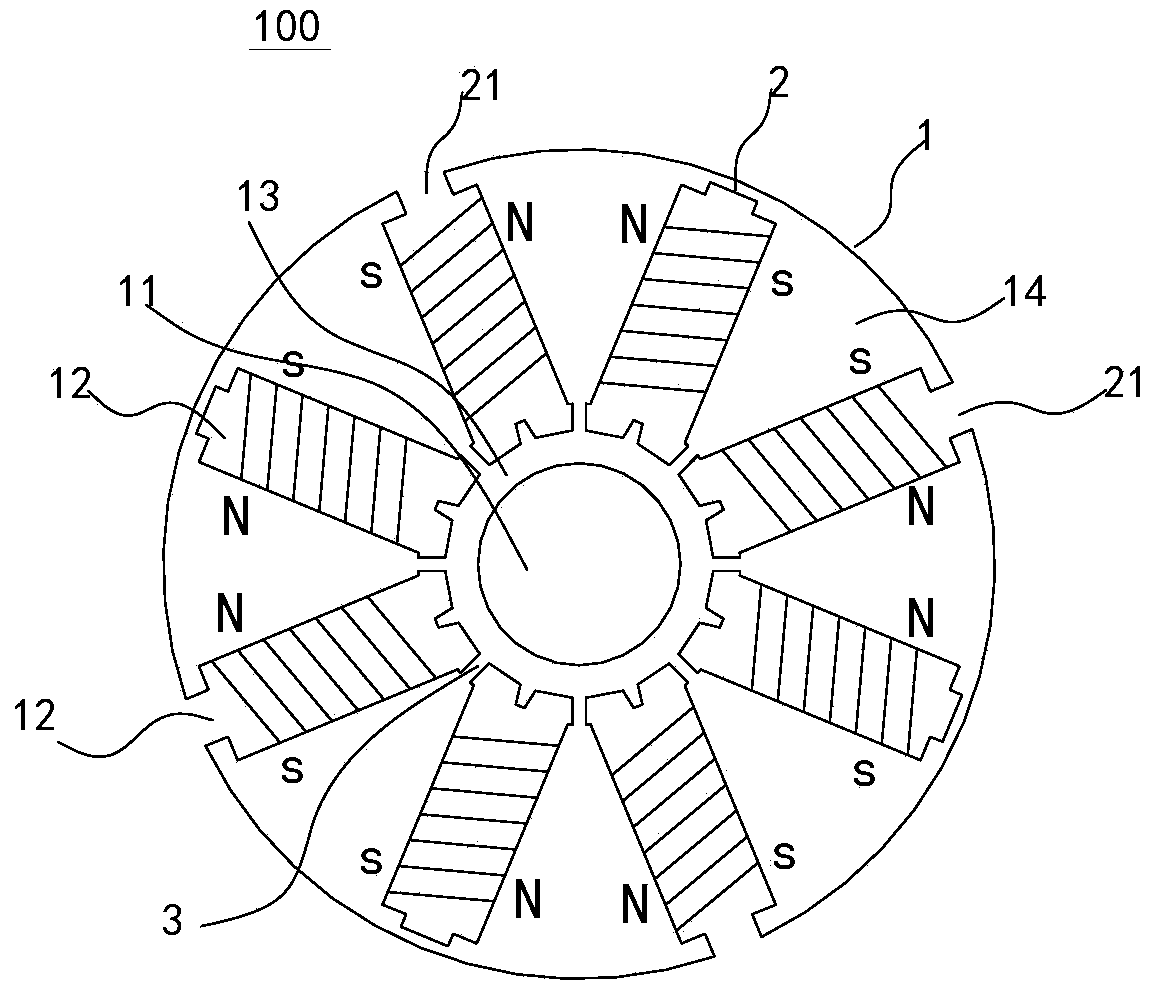

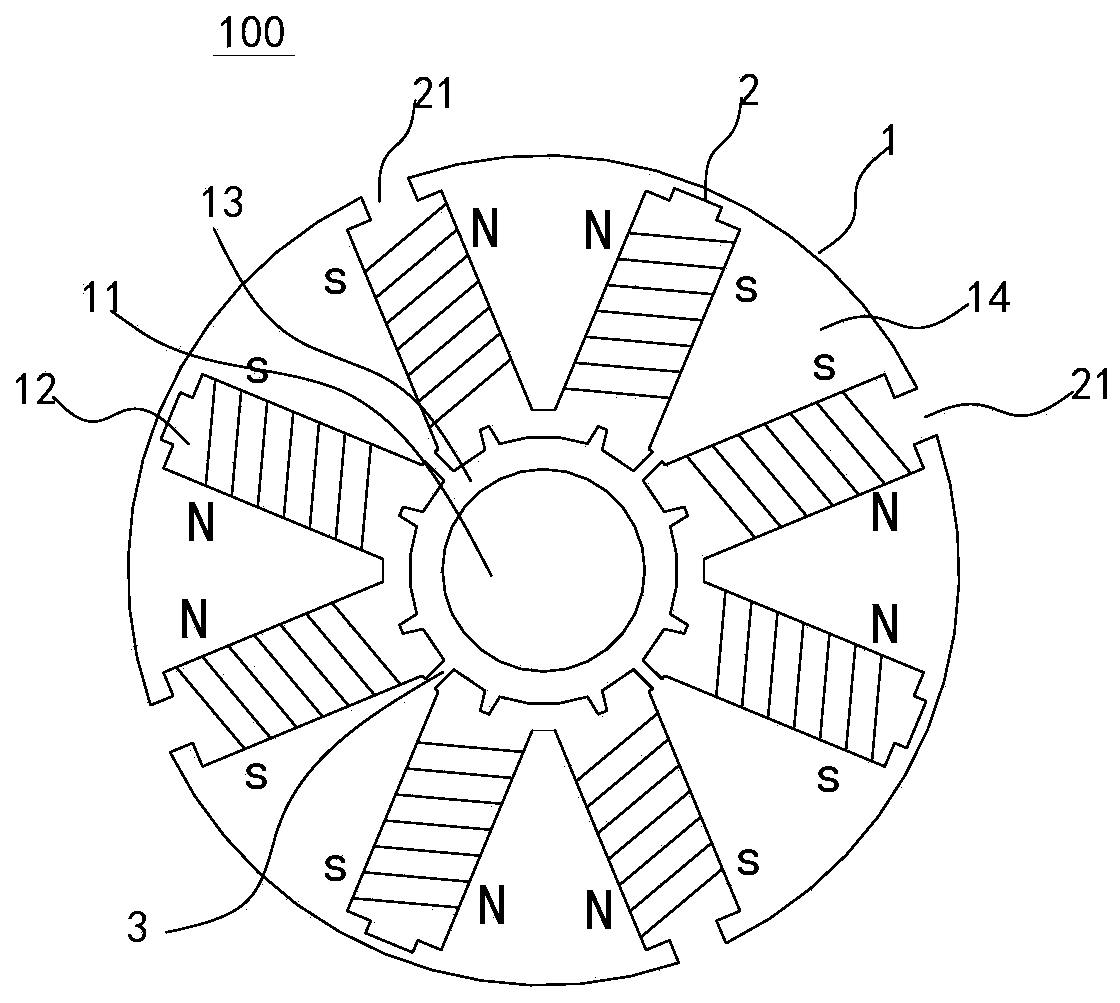

Rotating electric machine

InactiveUS6853112B2Improve rigidityIncrease radial thicknessSynchronous generatorsMagnetic circuit rotating partsElectric machineMagnetic poles

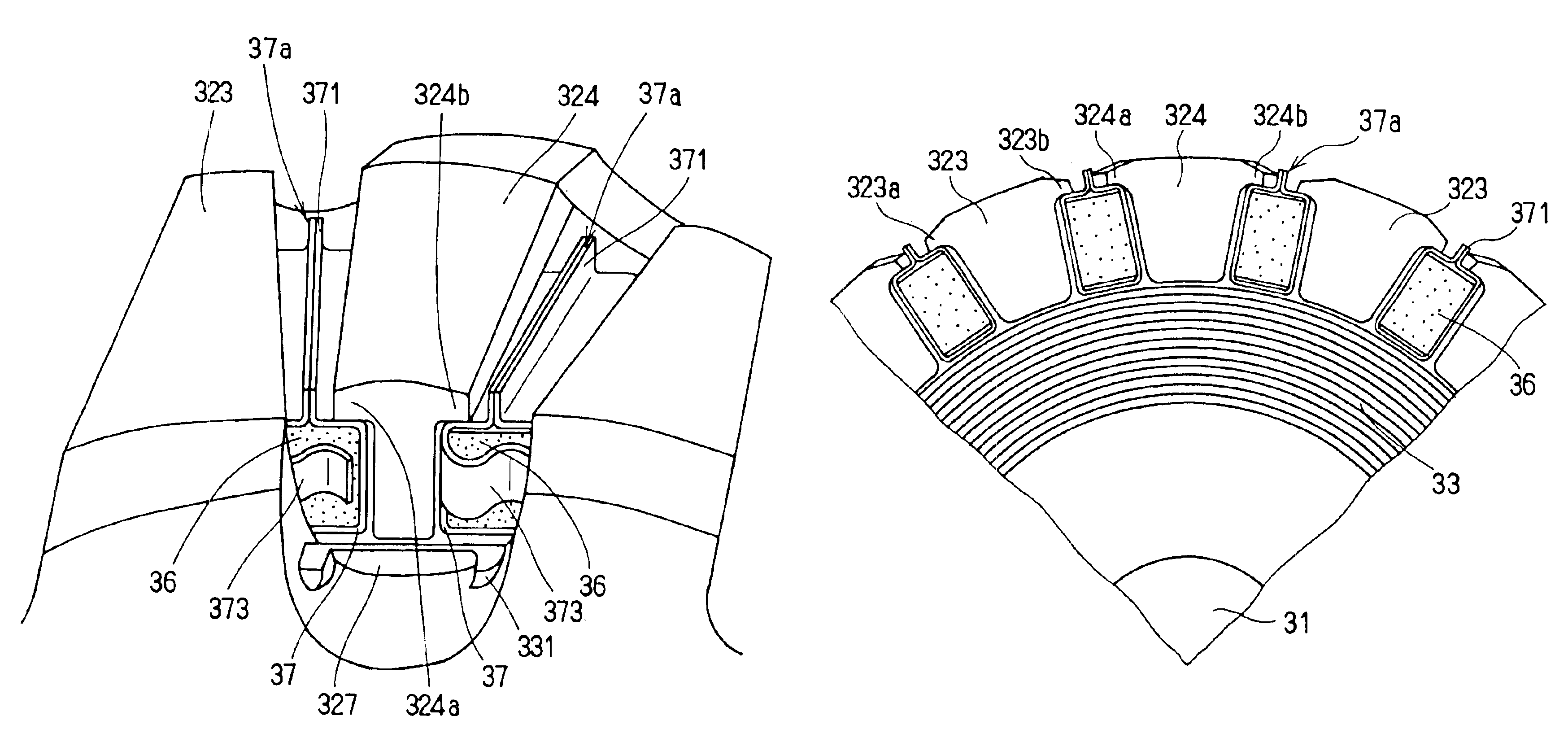

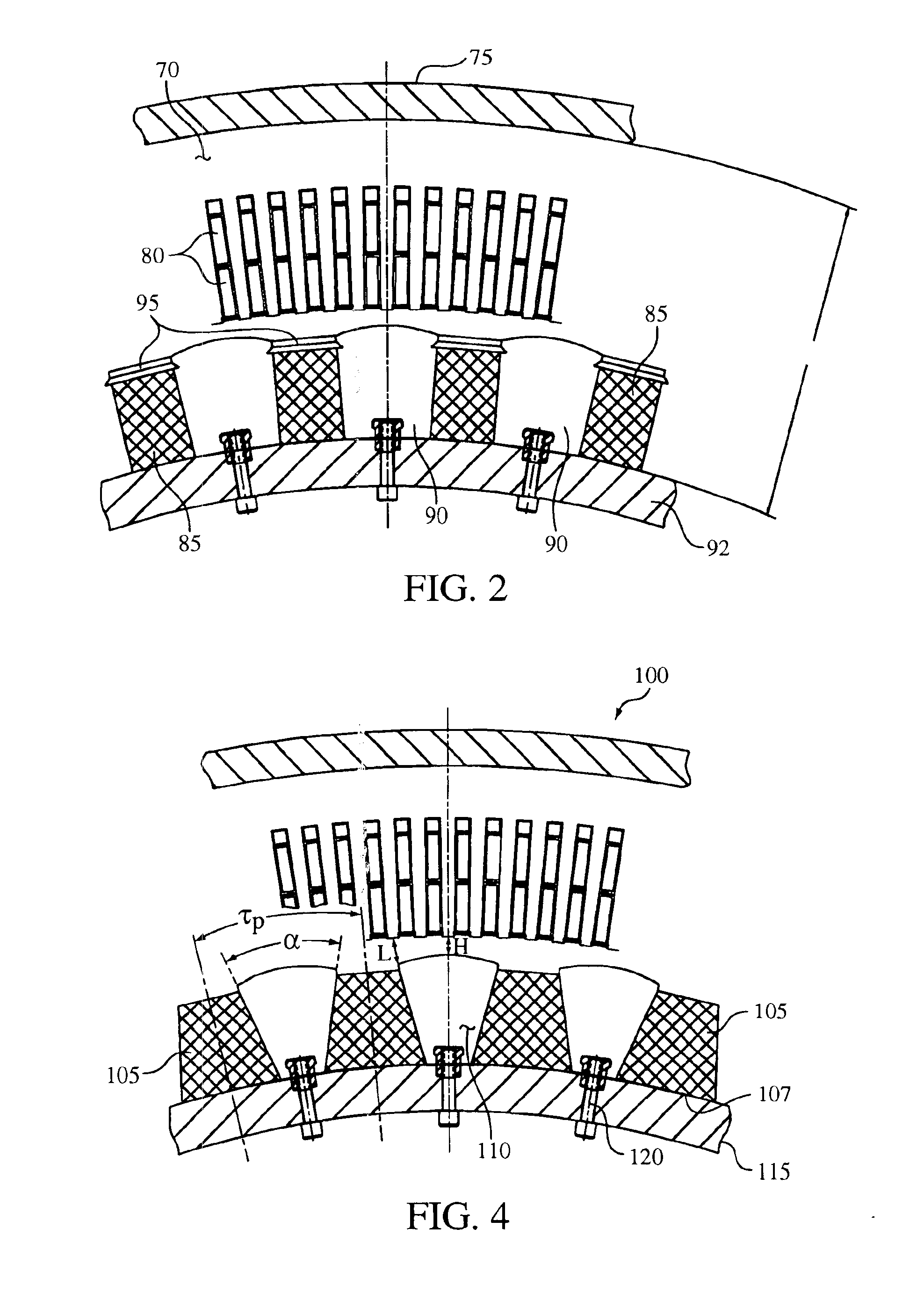

A rotating electric machine for a vehicle includes magnet holders for holding permanent magnets. The magnet holder is fitted between adjacent two claw-like magnetic poles of pole cores, and plural permanent magnets are provided to be magnetized for reducing magnetic-flux leakage between the magnetic poles. The magnet holder includes a radial outer surface, and a protrusion that protrudes from the radial outer surface to a radial outside around a center in a circumferential direction. Therefore, a thickness of the radial outside surface of the magnet holder increases, and its rigidity can be increased. Accordingly, it can prevent the radial outside surface of the magnet holder from being deformed due to centrifugal force, and it can prevent the magnet holder from being damaged.

Owner:DENSO CORP

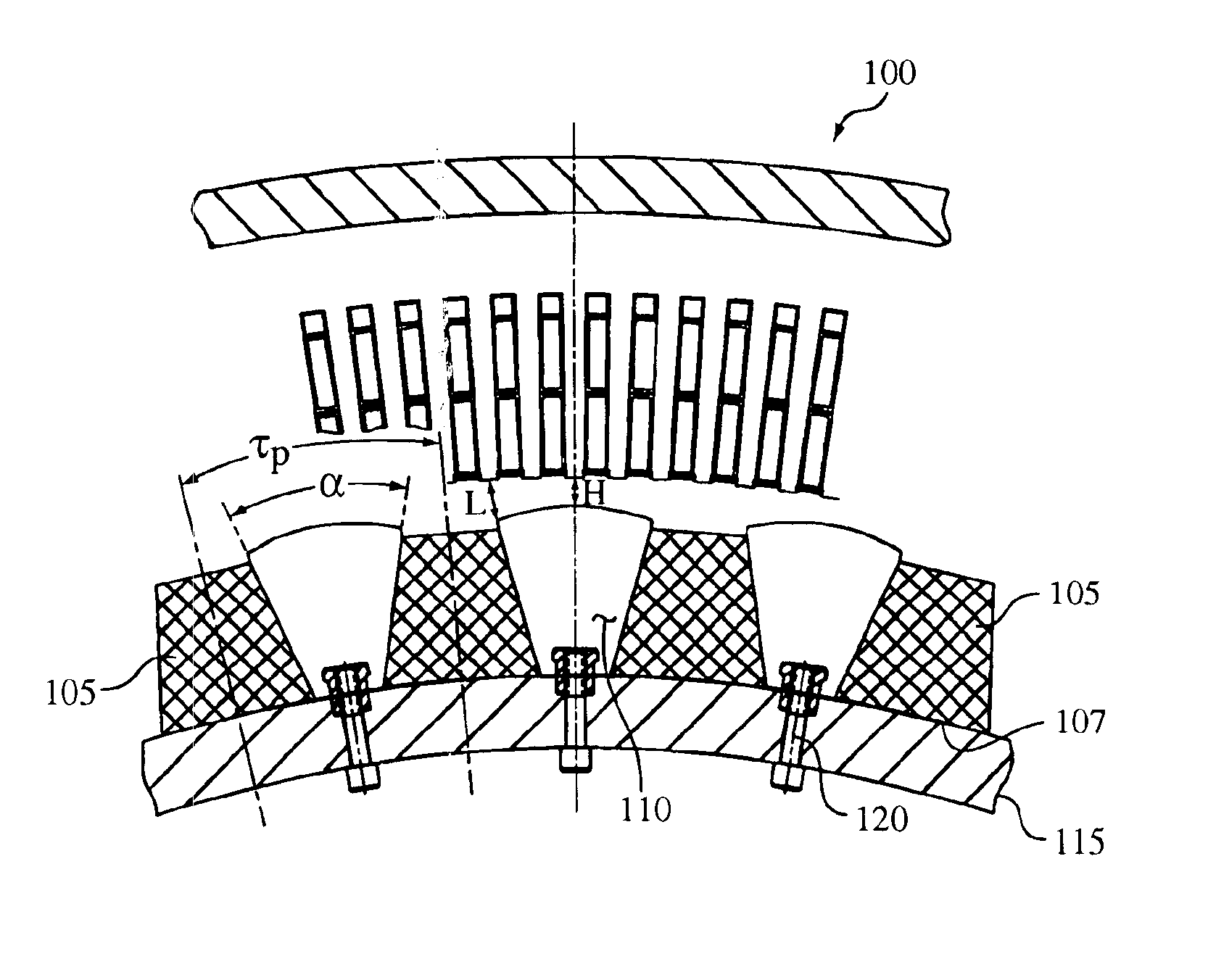

Trapezoidal shaped magnet flux intensifier motor pole arrangement for improved motor torque density

InactiveUS6879075B2Increase torqueImprove power characteristicsSynchronous generatorsWindingsPermanent magnet synchronous machineElectric machine

A permanent magnet synchronous machine with improved torque and power characteristics. A circumferential-oriented rotor assembly is provided with alternating permanent magnets and magnetic pole pieces. In order to reduce the amount of leakage flux in the rotor and increase the effective length of the permanent magnet, a trapezoidal or otherwise tapered permanent magnet structure is used. By alternating trapezoidal permanent magnet, and magnetic pole pieces, a higher intensity magnetic field is created in the air gap utilizing the same radial space in the motor without altering the weight or volume of the motor compared to conventional machines.

Owner:CURTISS WRIGHT ELECTRO MECHANICAL

Magnetic field detection device

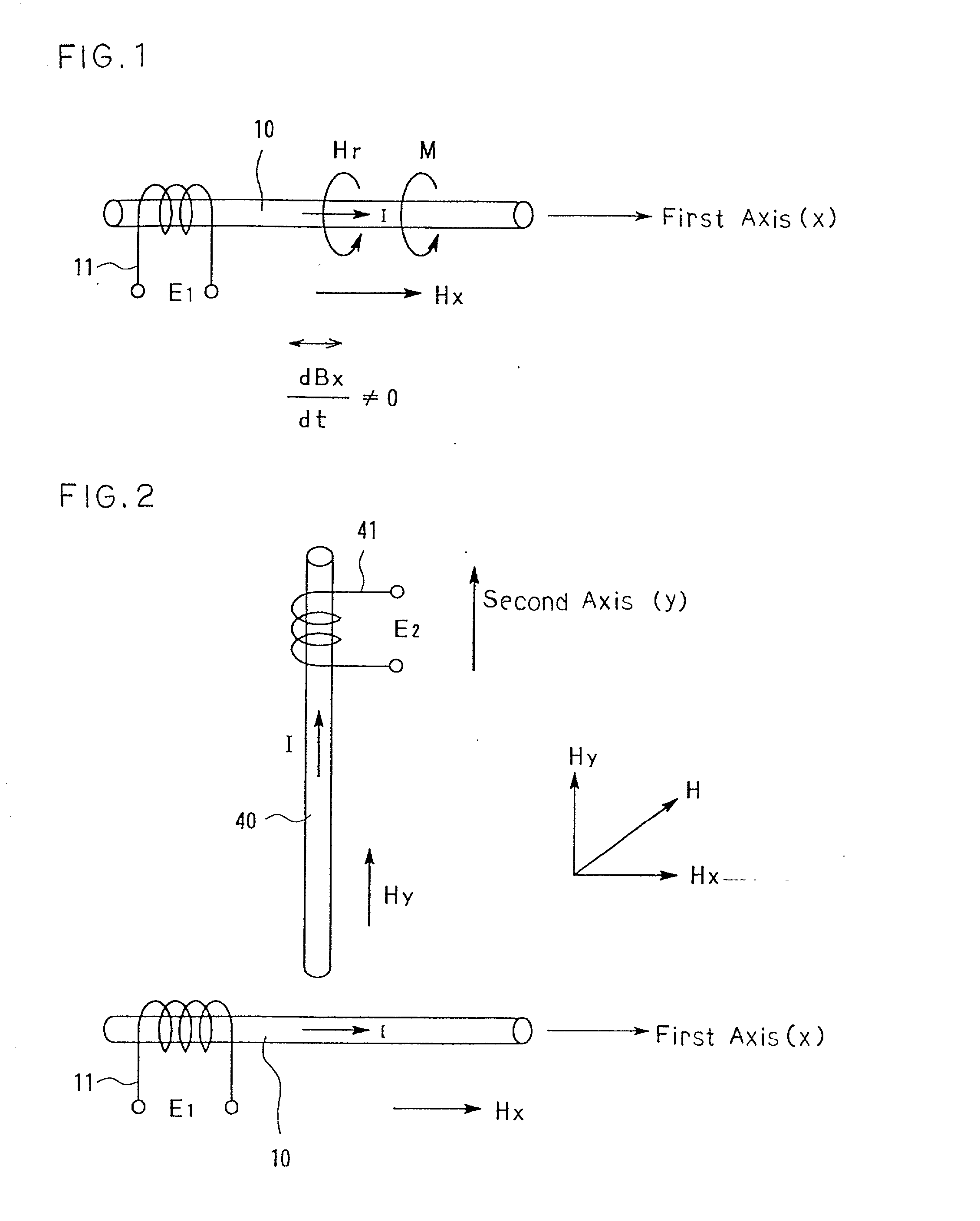

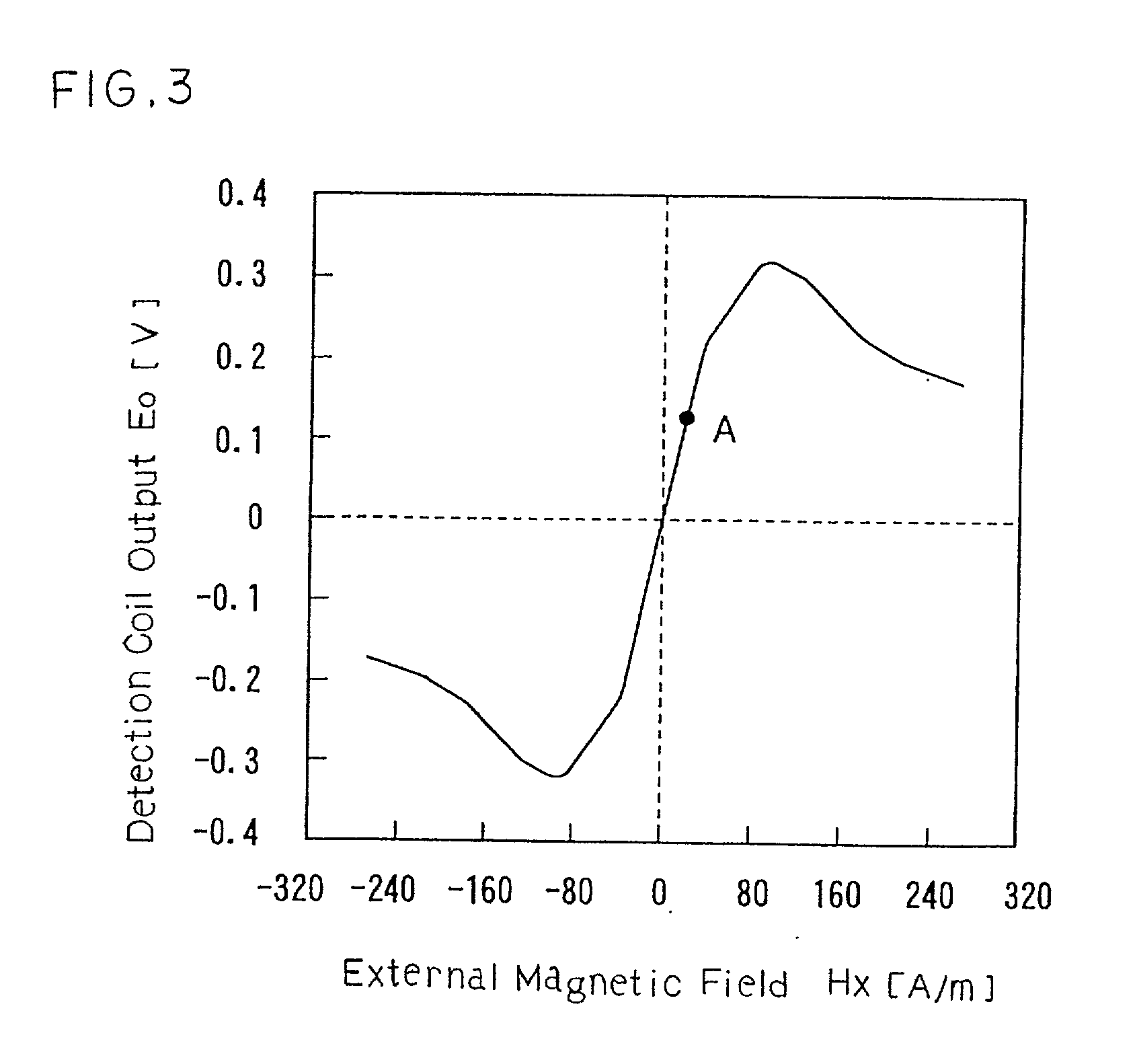

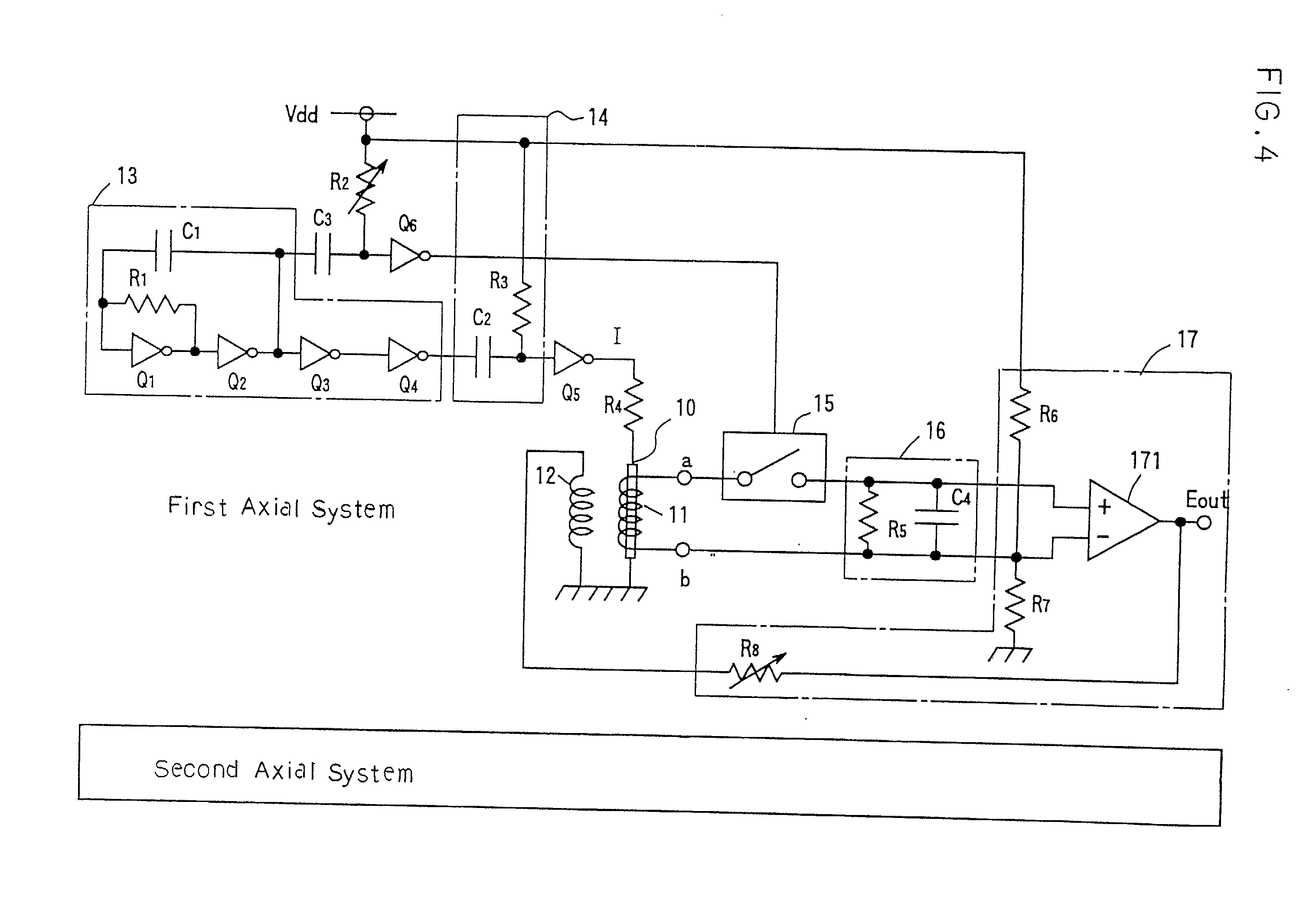

InactiveUS20010030537A1Electrical testingMagnitude/direction of magnetic fieldsNegative feedbackMagnetic flux

A magnetic field detection device that detects two components of an external magnetic field. The device uses the magneto-impedance effect in ferromagnetic amorphous wire. A detection coil wrapped around the amorphous wire detects the magnetic flux change of the amorphous wire, which is proportional to the external magnetic field. The sensitivity of the device is increased due to circuitry that extracts the initial output pulse. It is also increased with the use of negative feedback and with the comparison of differential outputs. The two sets of detection elements are placed orthogonally for greatest sensitivity. Resin molding is employed for easy handling. This detection device can be used as part of a compass.

Owner:JAPAN SCI & TECH 33 3 0 0

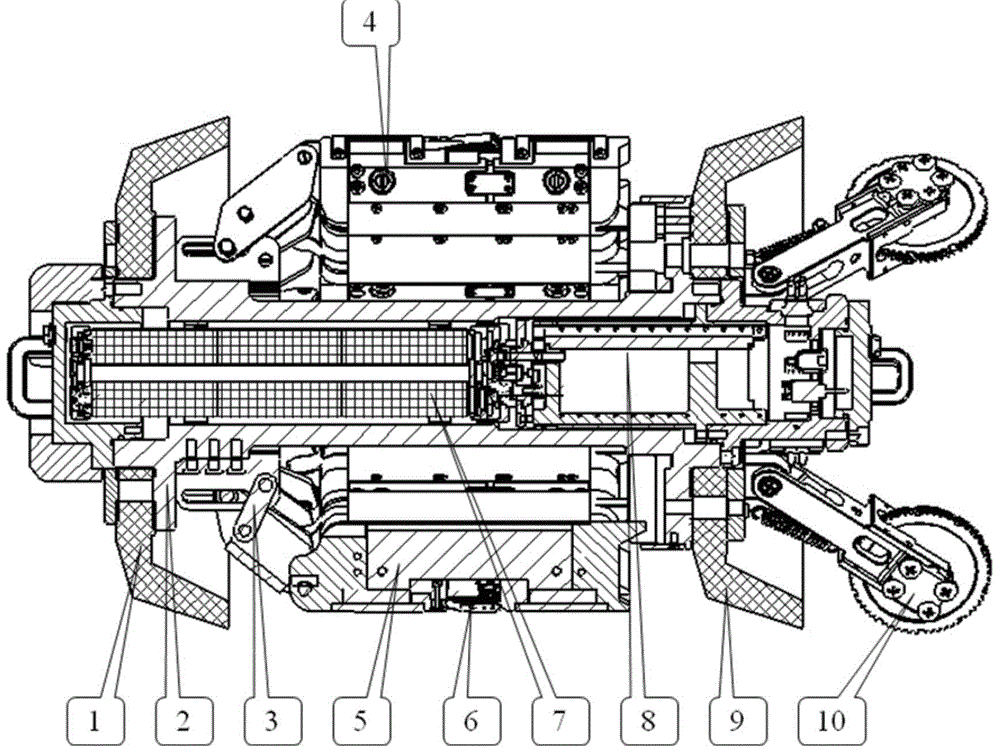

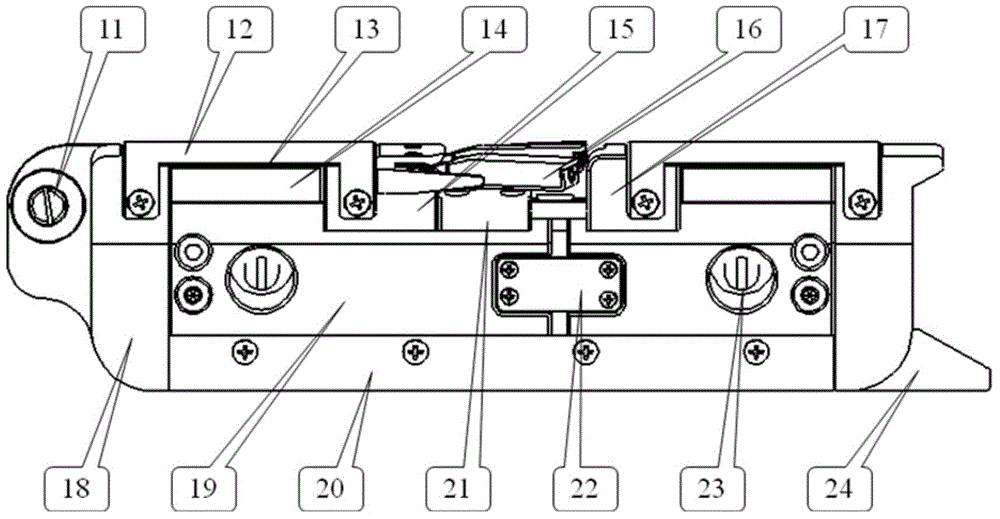

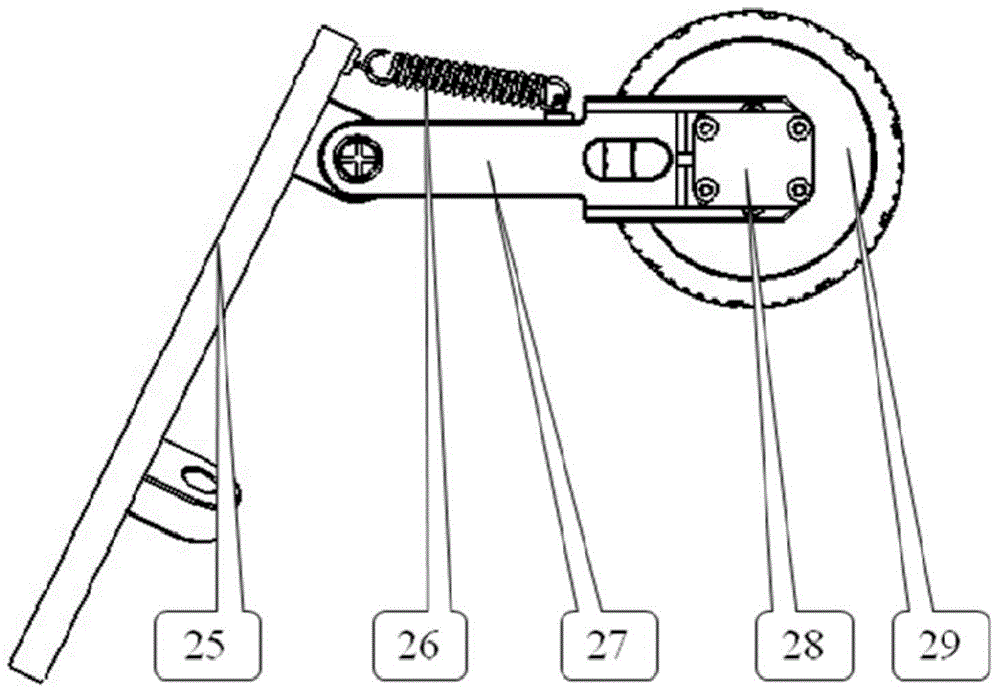

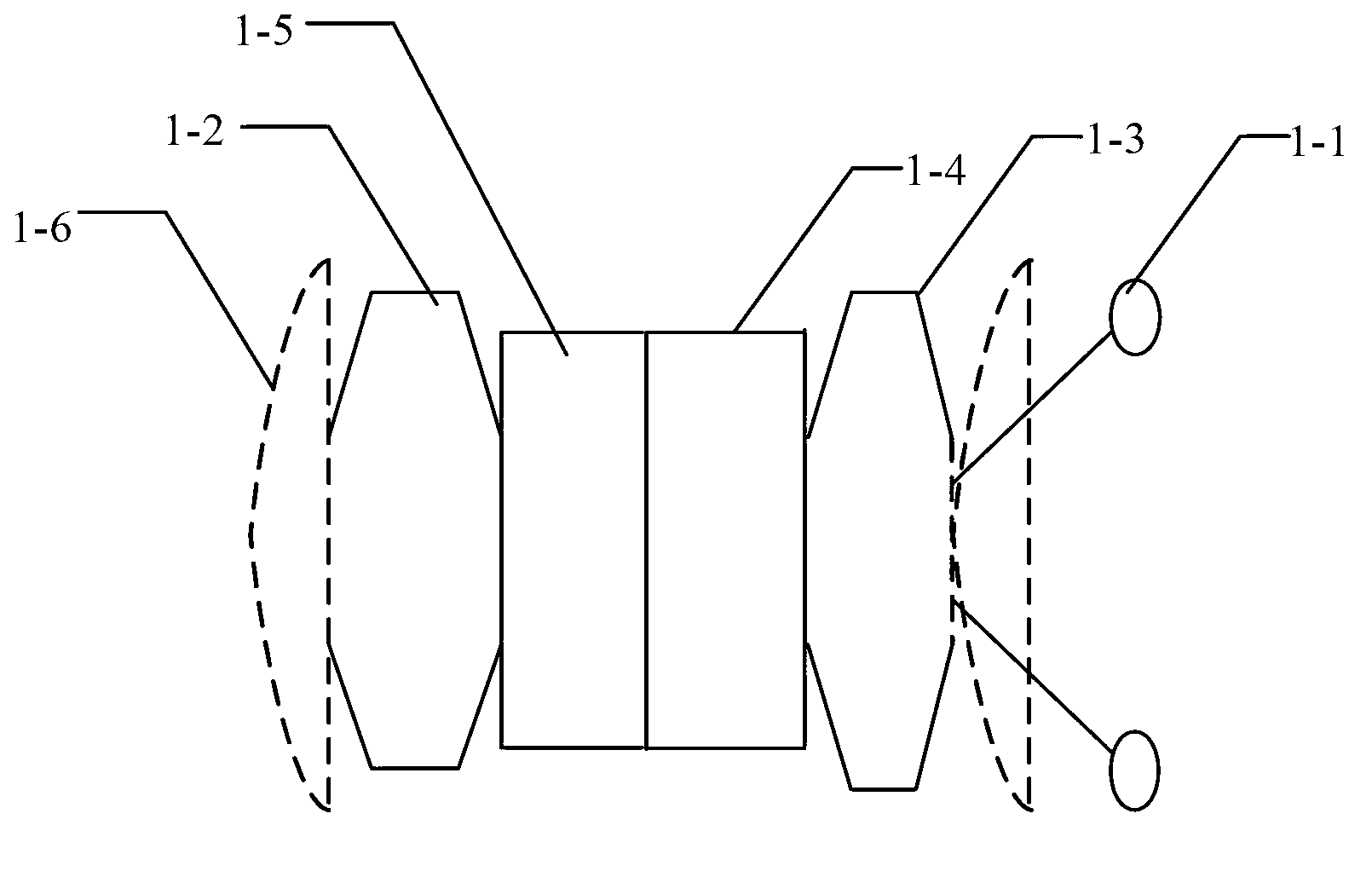

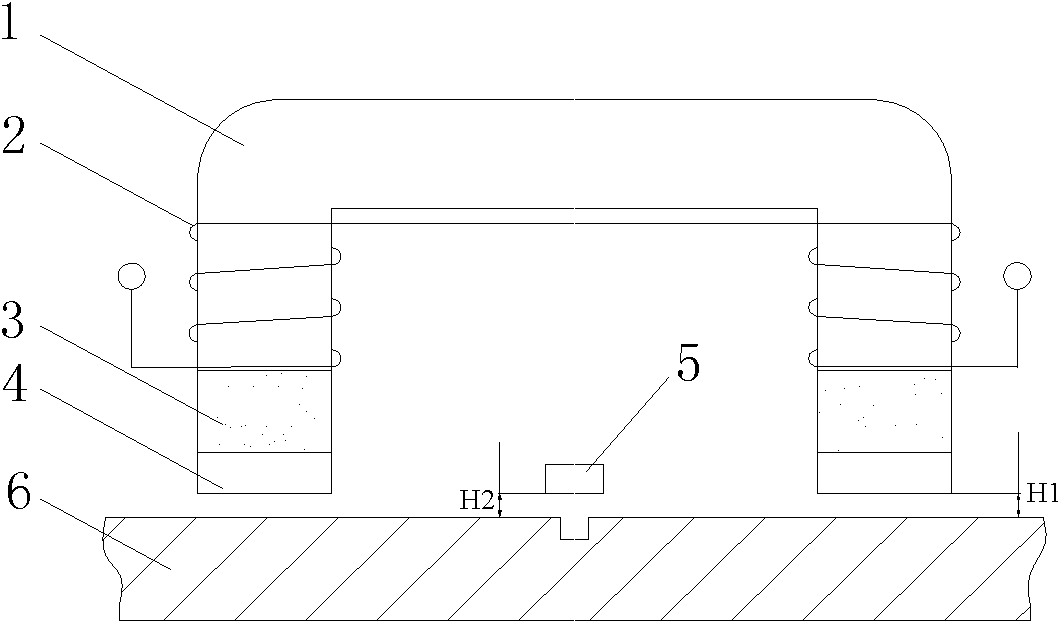

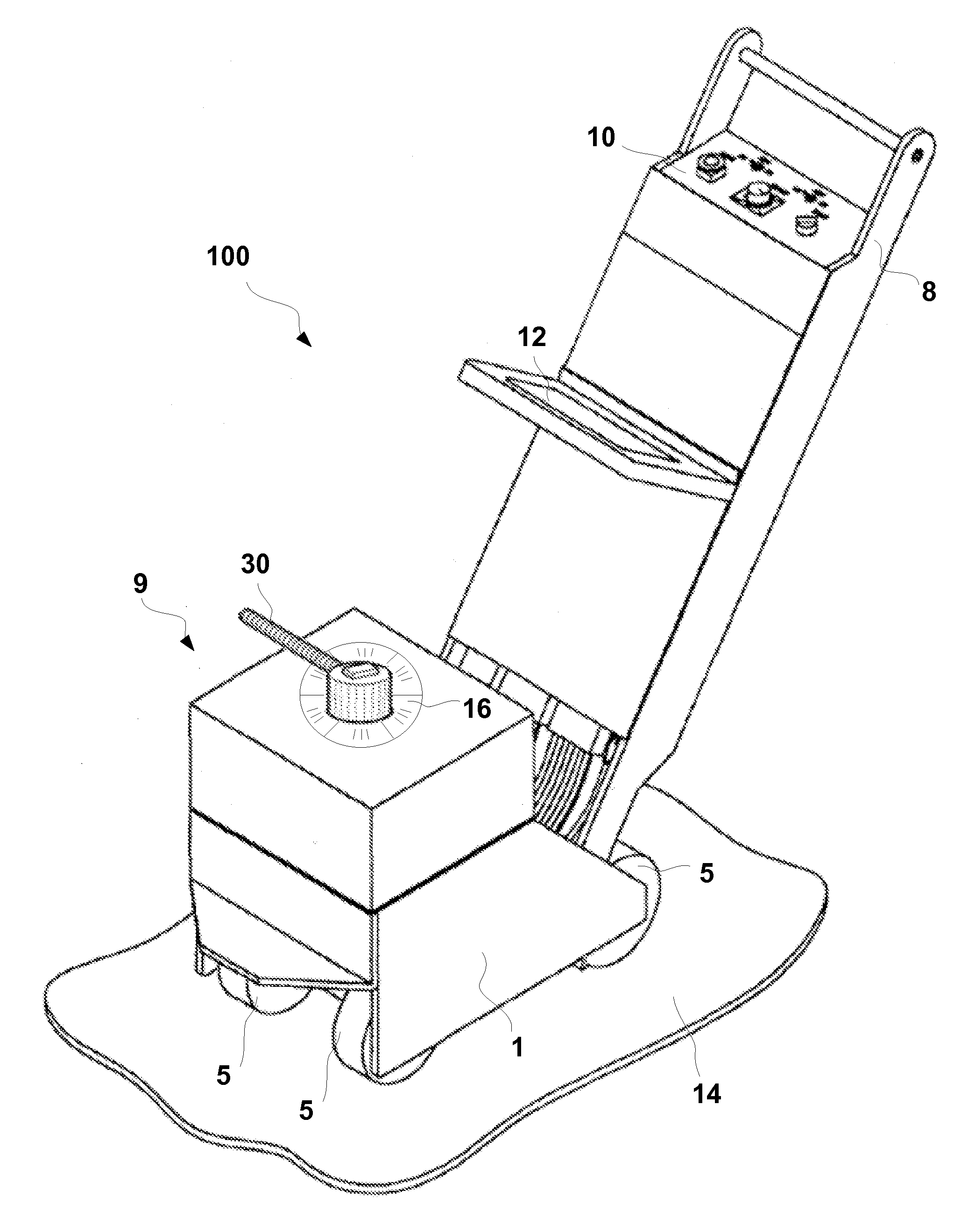

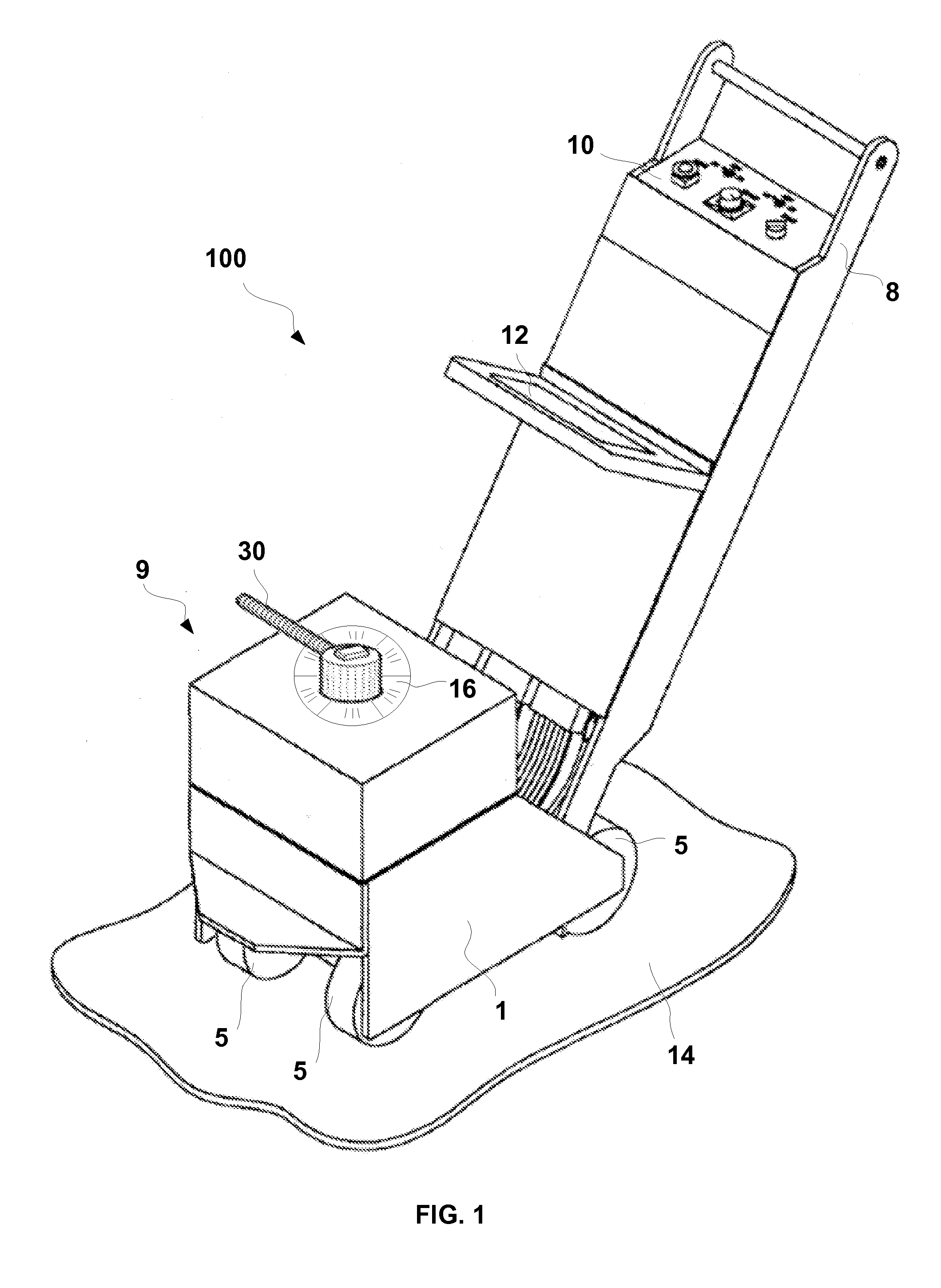

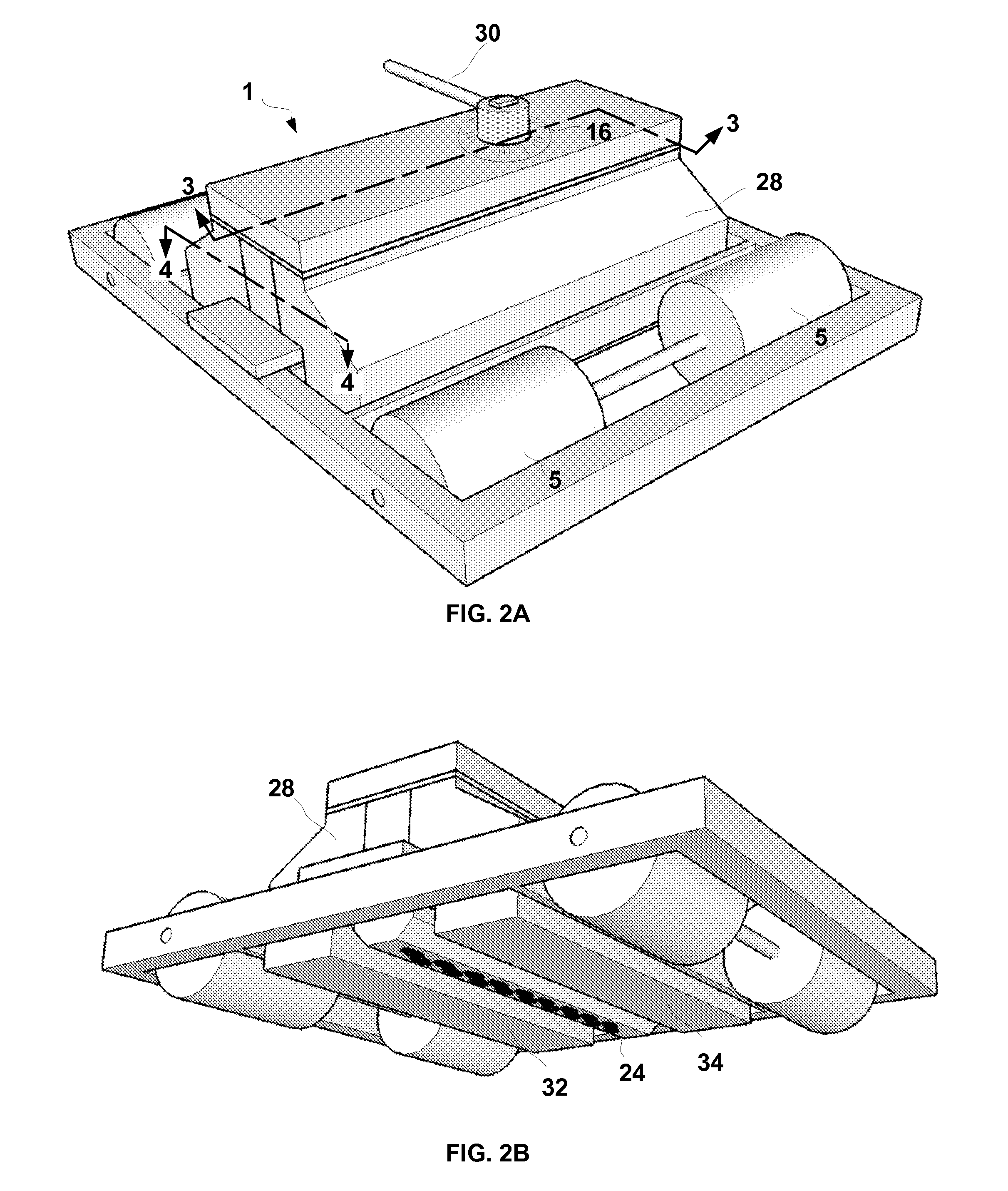

High-precision inner detecting device for seabed oil and gas pipeline flaws

A high-precision inner detecting device for seabed oil and gas pipeline flaws is characterized in that an anti-collision head and a front power packing cup are connected to the front end of a body support shaft, the rear of the front power packing cup is connected with a floating magnetization detecting block through a hinge mechanism, and a lateral jacking spring is disposed on each of the front side and the rear side of the floating magnetization detecting block to form a floating magnetization circuit and a magnetic flux leakage detecting block unit. A finger probe is disposed on the floating magnetization detecting block. A guide groove and a limit ring are arranged at the rear end of the body support shaft. A rear power packing cup is disposed at the rear of the guide groove. The front packing cup and the rear packing cup jointly form a power drive system. A battery pack unit and an electronic recorder are respectively disposed at the front and the rear of a seal cabin in the body support shaft in an opposite insertion manner. A detector odometer wheel unit is mounted at the tail of the body support shaft. By the floating magnetization detecting structure, online inner detection of oil and gas pipeline flaws under complex working conditions can be well achieved.

Owner:TSINGHUA UNIV

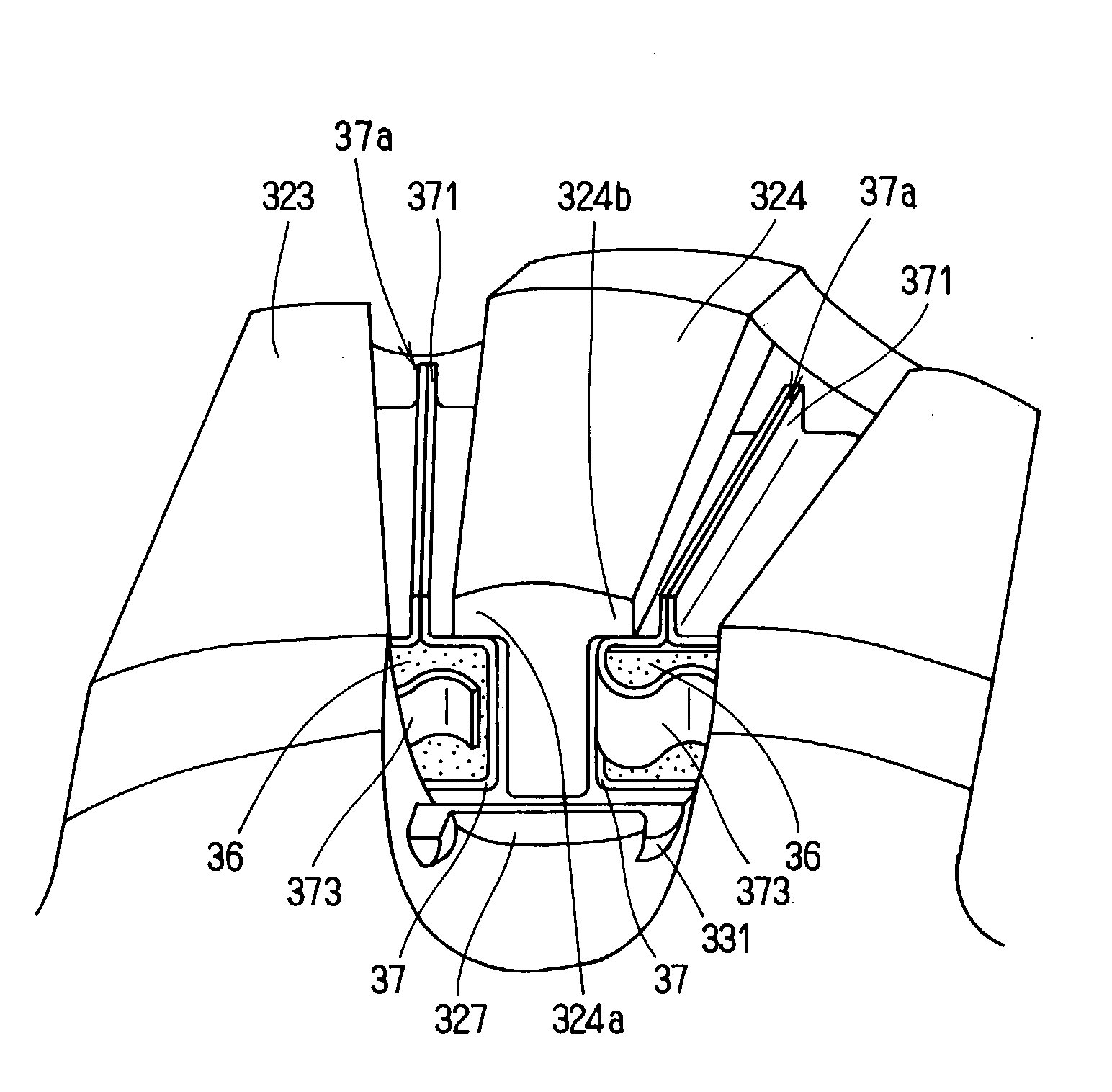

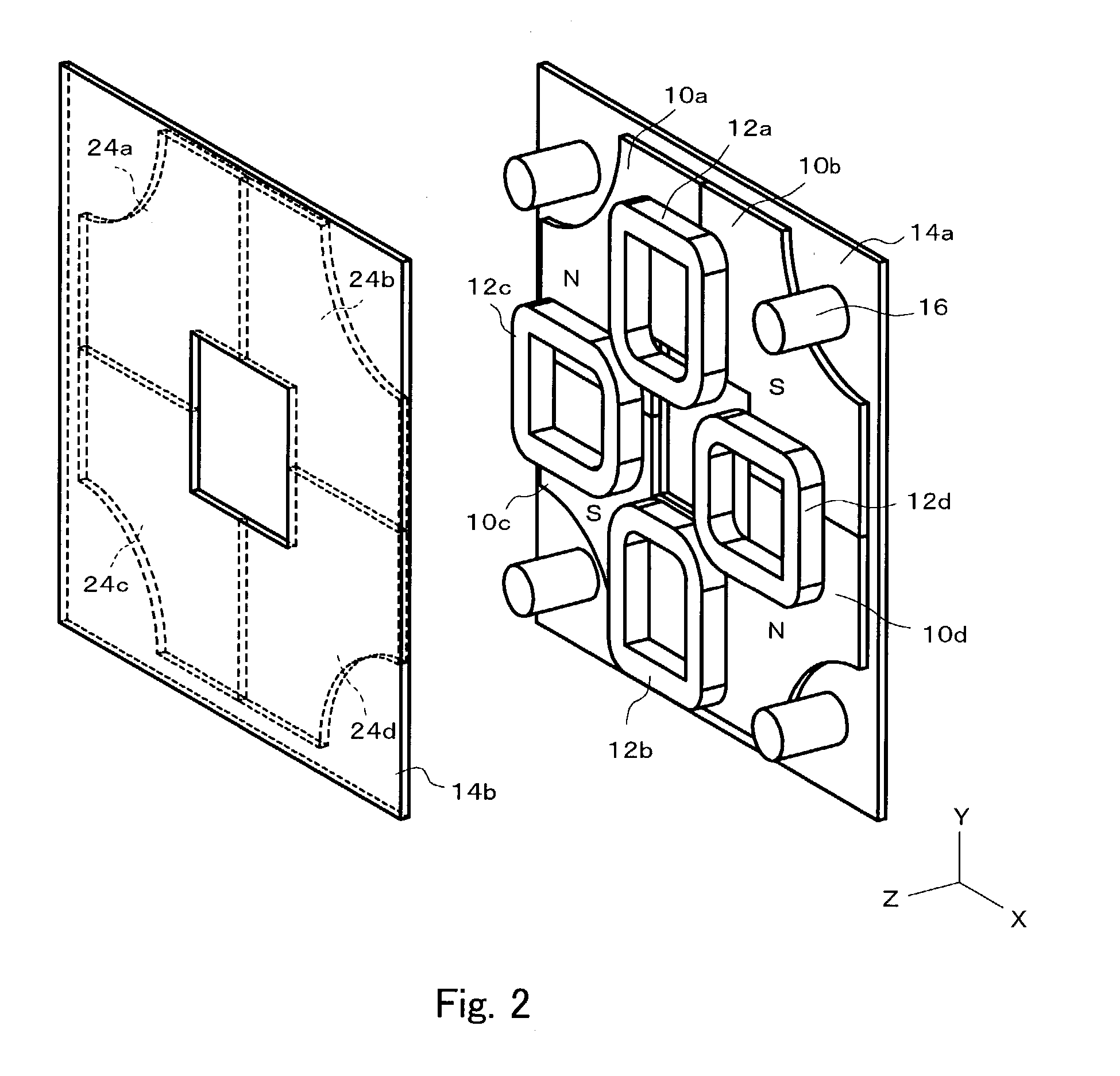

Rotating electric machine

InactiveUS20040032183A1Increase radial thicknessImprove rigiditySynchronous generatorsSynchronous machine detailsElectric machineMagnetic poles

A rotating electric machine for a vehicle includes magnet holders for holding permanent magnets. The magnet holder is fitted between adjacent two claw-like magnetic poles of pole cores, and plural permanent magnets are provided to be magnetized for reducing magnetic-flux leakage between the magnetic poles. The magnet holder includes a radial outer surface, and a protrusion that protrudes from the radial outer surface to a radial outside around a center in a circumferential direction. Therefore, a thickness of the radial outside surface of the magnet holder increases, and its rigidity can be increased. Accordingly, it can prevent the radial outside surface of the magnet holder from being deformed due to centrifugal force, and it can prevent the magnet holder from being damaged.

Owner:DENSO CORP

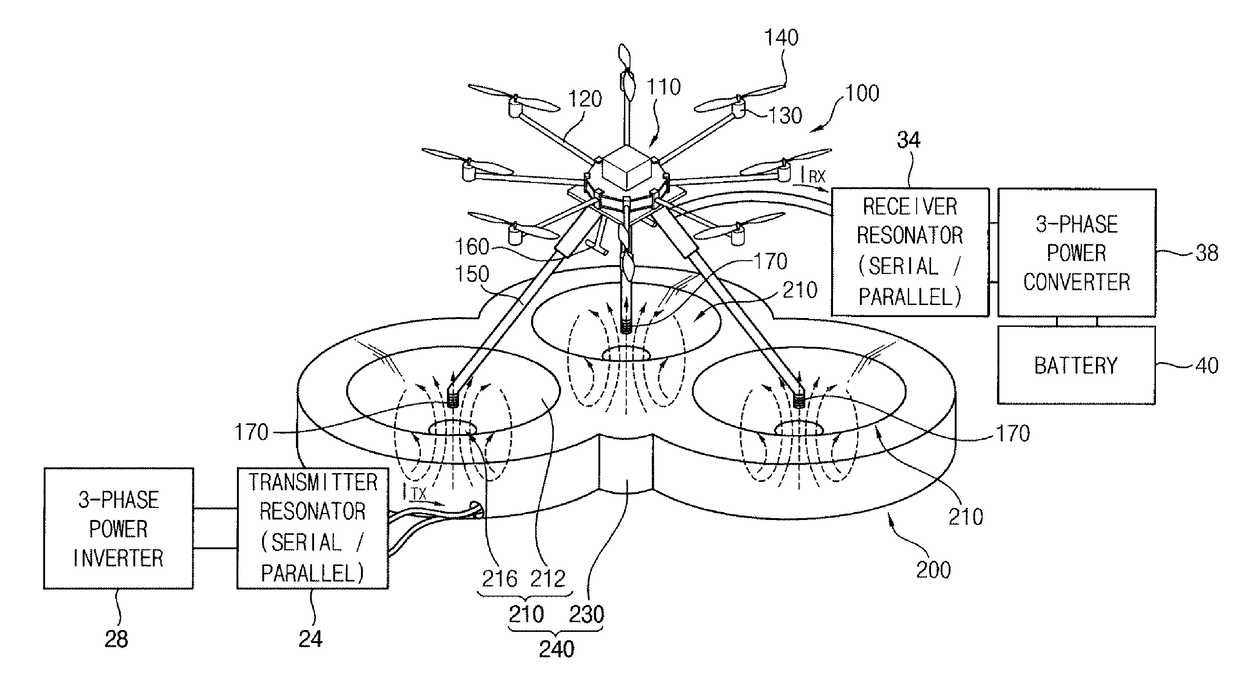

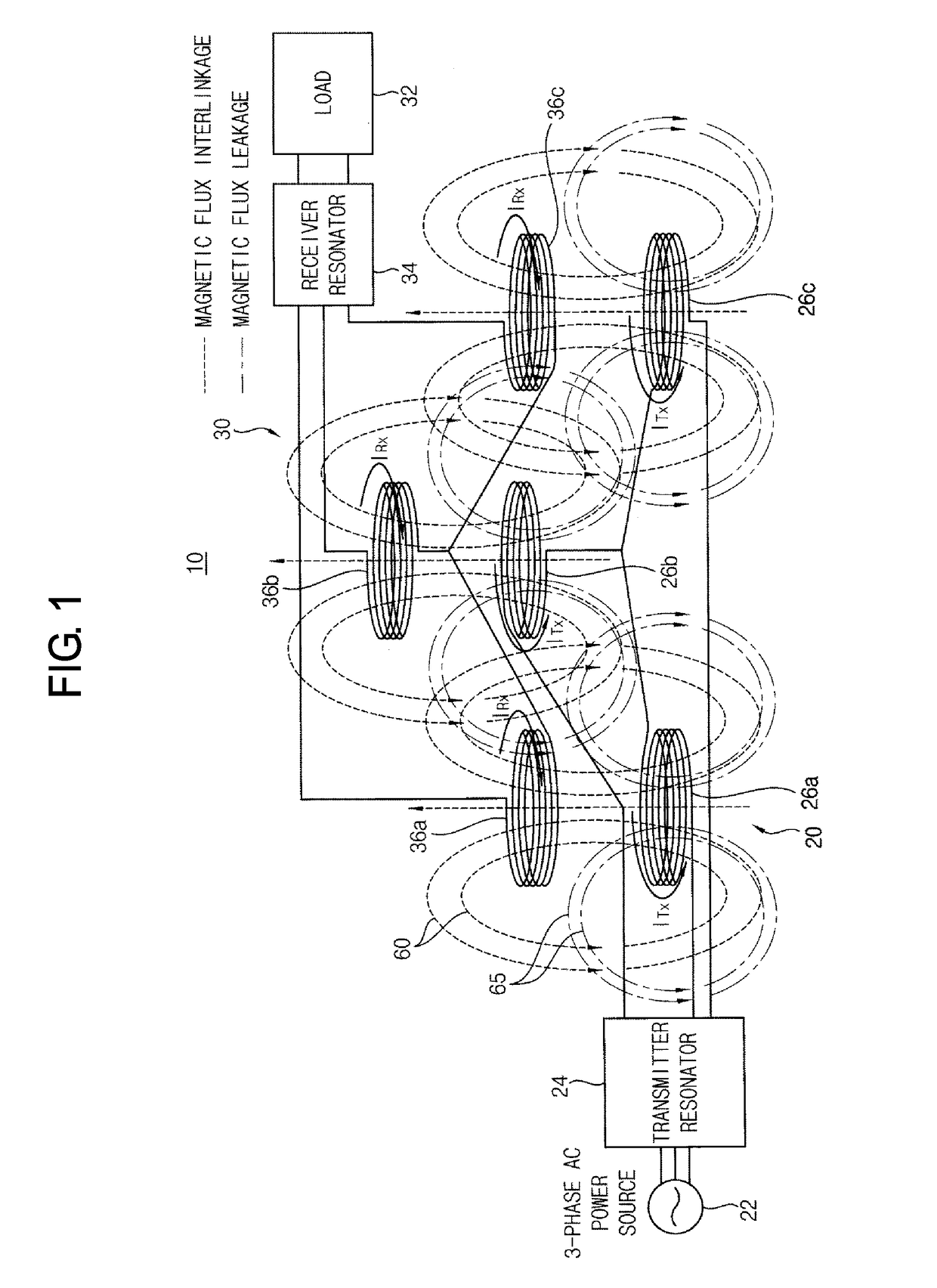

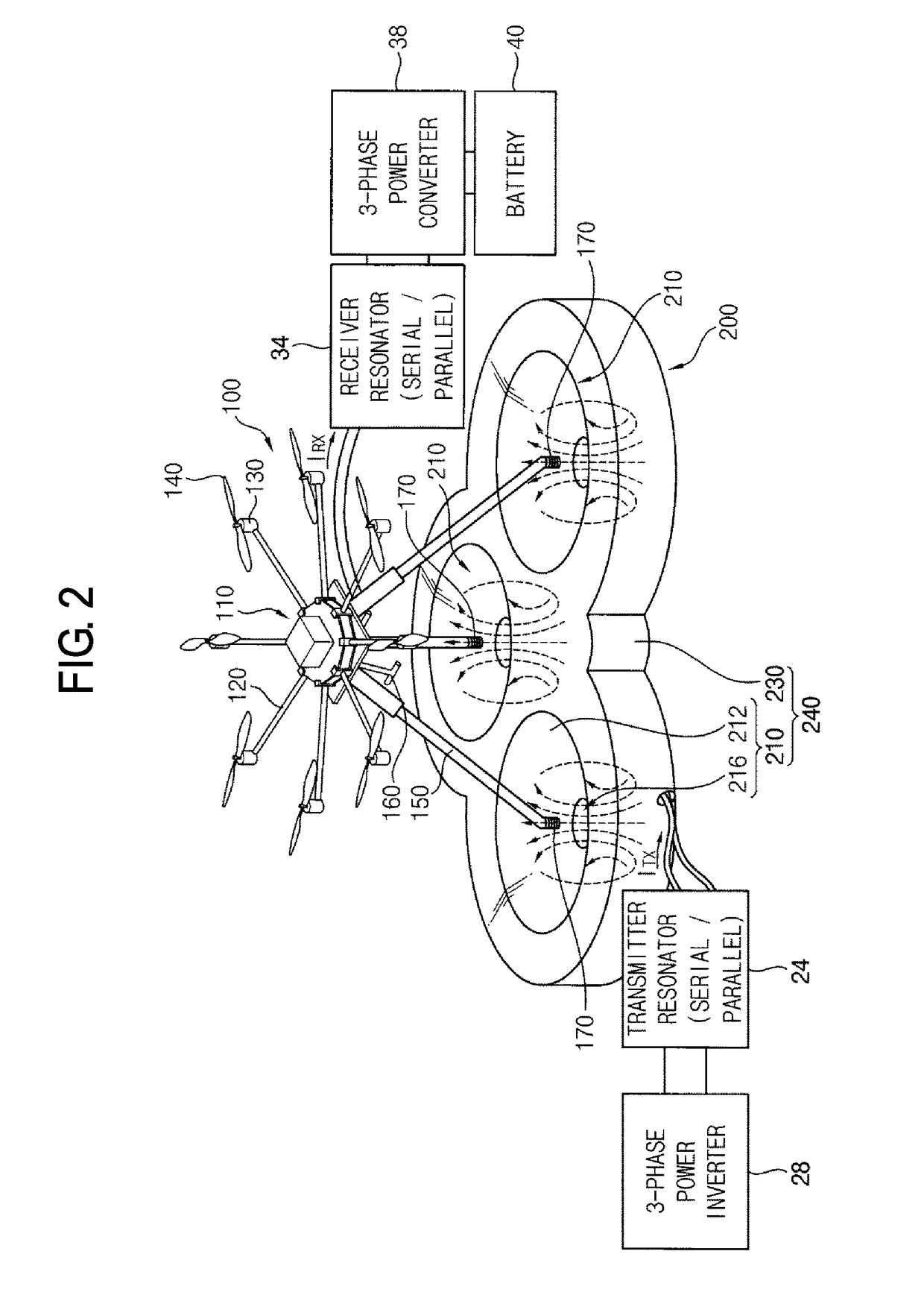

Three-Phase Wireless Power Transfer System And Three-Phase Wireless Chargeable Unmanned Aerial Vehicle System Based On The Same

ActiveUS20180056794A1Reduce magnetic field strengthReduce EMI noiseCharging stationsUnmanned aerial vehiclesElectric power transmissionDc current

Disclosed are a three-phase wireless power transfer (WPT) system and three-phase wireless rechargeable unmanned aerial vehicle (UAV) system based on the same. Three power receiving coils, including resonators, are installed at the ends of three landing leg of the UAV. A three-phase power converter installed in the UAV receives the three-phase AC induction current induced in three power receiving coils, including resonators, converting the three-phase AC induction current into a DC current to be charged in a battery. A three-phase power wireless charging apparatus wirelessly transfers three-phase power from three power transmitting coils to the three power receiving coils of the UAV when the three landing legs land on three coil seating units provided on a charging platform. A magnetic flux leakage shielding coil may be provided to prevent magnetic flux leakage from approaching the UAV. The power transfer efficiency is excellent, and electromagnetic interference can be also reduced.

Owner:KOREA ADVANCED INST OF SCI & TECH

Device and method for detecting defects of inner and outer walls of pipeline based on three-axis magnetic flux leakage and eddy current

ActiveCN102798660ASave electricityImprove detection qualityMaterial magnetic variablesNon destructiveElectricity

The invention relates to a device and a method for detecting defects of inner and outer walls of a pipeline based on three-axis magnetic flux leakage and eddy current, and belongs to the technical field of non-destructive testing. The device comprises a magnetic flux leakage detector, a data processing and storing device, a power supply, at least three odometer wheels and an eddy current detector, wherein the eddy current detector consists of an eddy current sensor and is a device used for detecting the defects on inner and outer surfaces of the pipeline. According to the device provided by the invention, a magnetic flux leakage detection method and an eddy current detection method are combined by using different characteristics of the magnetic flux leakage detection method and the eddy current detection method, so that the function of distinguishing the defect of the inner wall from the defects of the outer wall is realized; and in addition, the method provided by the invention is favorable in detection quality and simple in operation and can be widely applied to non-destructive detection of oil transmission pipelines in the industrial fields of petroleum, petrifaction and the like.

Owner:NORTHEASTERN UNIV

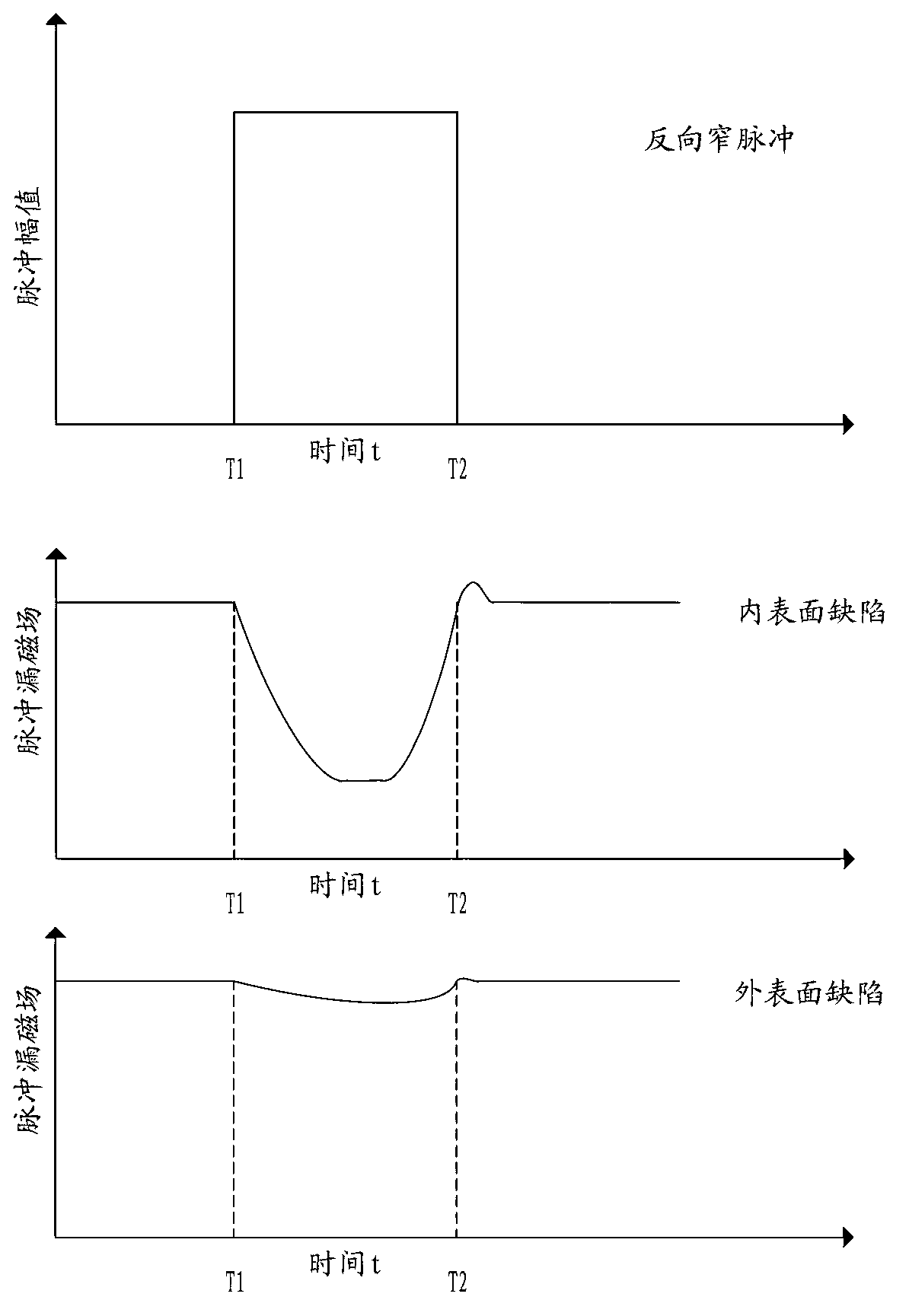

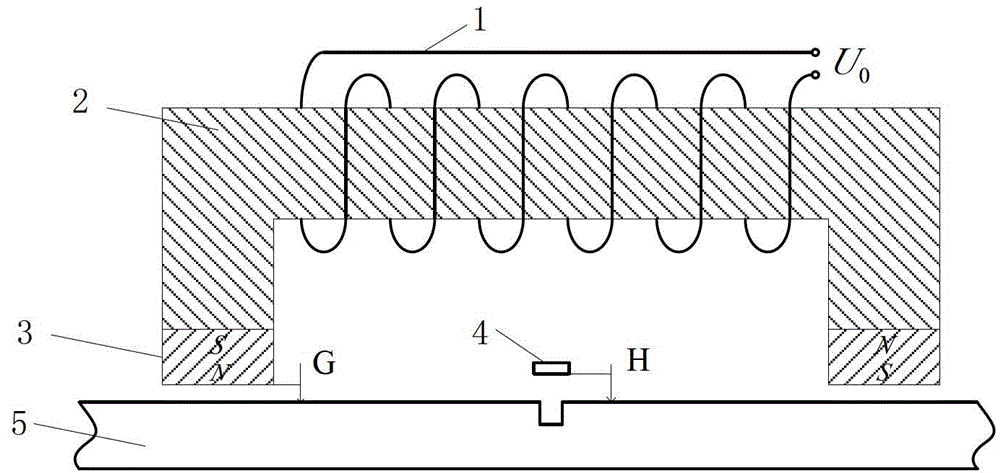

Permanent magnetic and alternating current direct current composite magnetic flux leakage detecting method

InactiveCN102590328AImprove signal-to-noise ratioHigh measurement accuracyMaterial magnetic variablesMagnetizationTime-sharing

A permanent magnetic and alternating current direct current composite magnetic flux leakage detecting method relates to a magnetic flux leakage detecting method of a pipeline. A magnetizer is composed of a U-shaped magnetic core and a permanent magnet, and an exciting coil is wound around the U-shaped magnetic core. By giving different excitation to the exciting coil, the exciting coil and the permanent magnetic generate composite direct current magnetic field and alternating magnetization field in time-sharing mode. During measurement, the direct current magnetic field magnetizes a ferromagnet to be detected to a deep saturation state, a detected leakage magnetic field signal B1 is compared with a set threshold lambda 1, and whether defects exist in the ferromagnet to be detected is judged; if the defects exist, the alternating magnetization field magnetizes a component to be detected, and an alternating current frequency component B2 of leakage magnetic field strength is compared with a set threshold lambda 2 so as to judge if the defects exist on the inner surface or the outer surface. The method effectively overcomes the defects in the prior art that the defects of the inner surface and the outer surface can not be identified efficiently and accurately and has the advantages of being simple in principle, convenient to operate, free of coupling agent, non-contact in measurement and the like.

Owner:XIAMEN UNIV

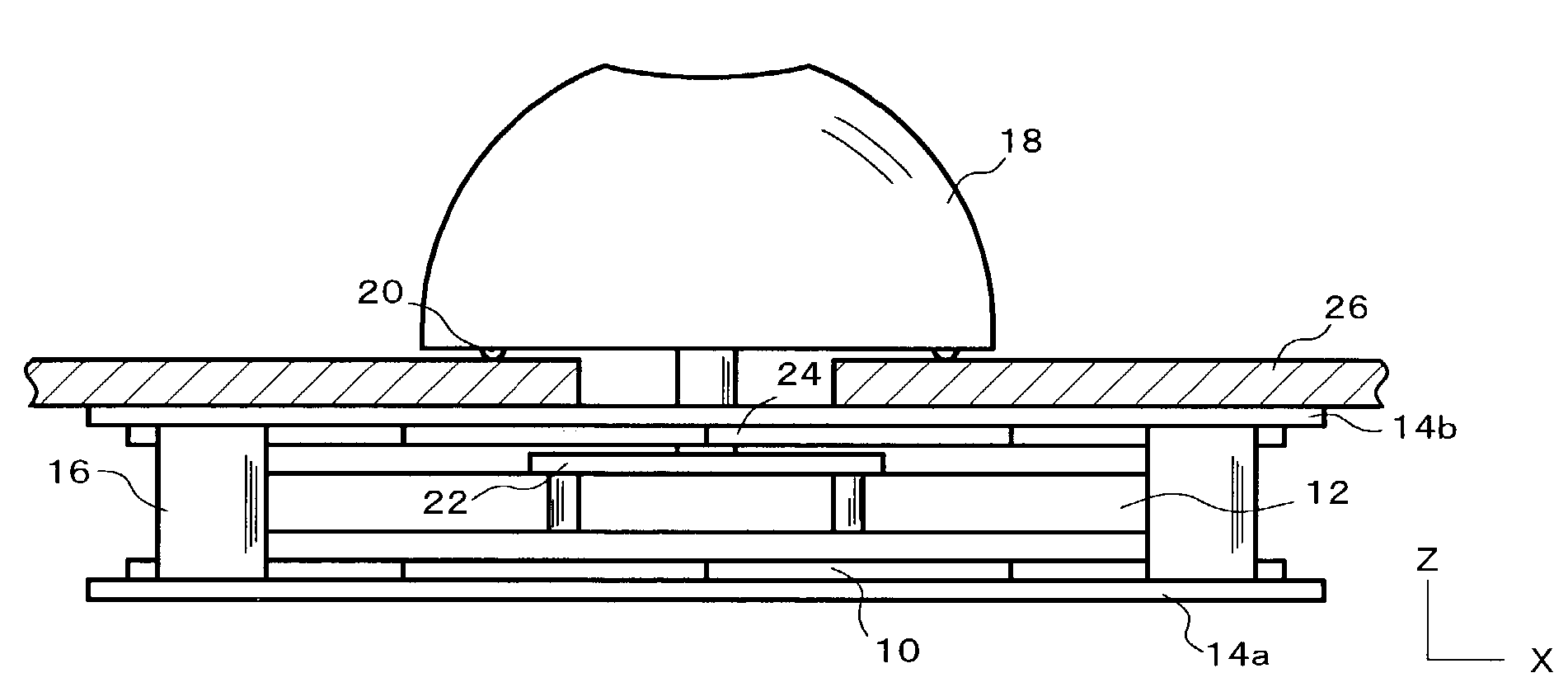

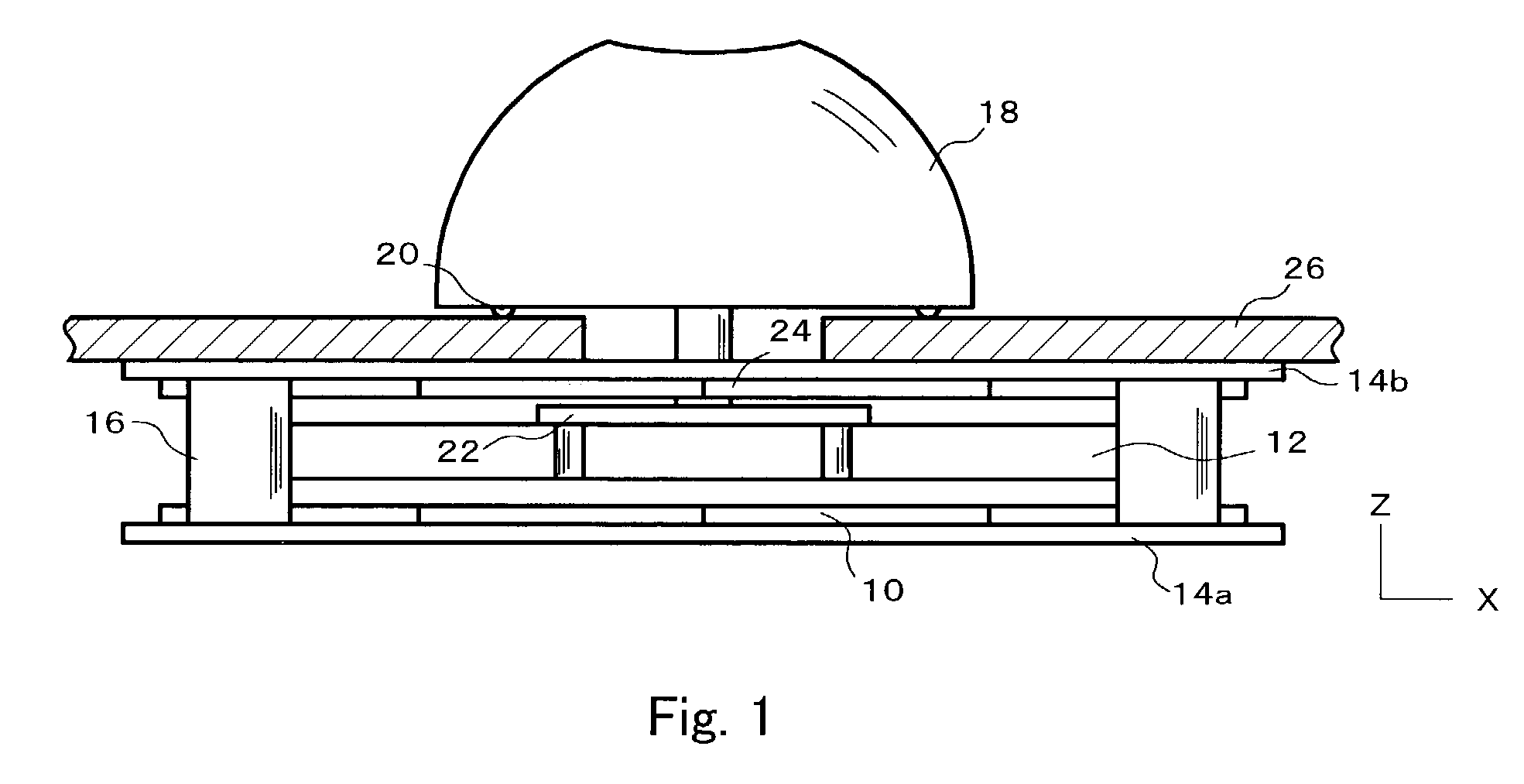

Magnetic actuator with reduced magnetic flux leakage and haptic sense presenting device

InactiveUS7336006B2Reduce magnetic field leakageKeep sizeInput/output for user-computer interactionManual control with multiple controlled membersEngineeringActuator

Owner:FUJIFILM BUSINESS INNOVATION CORP

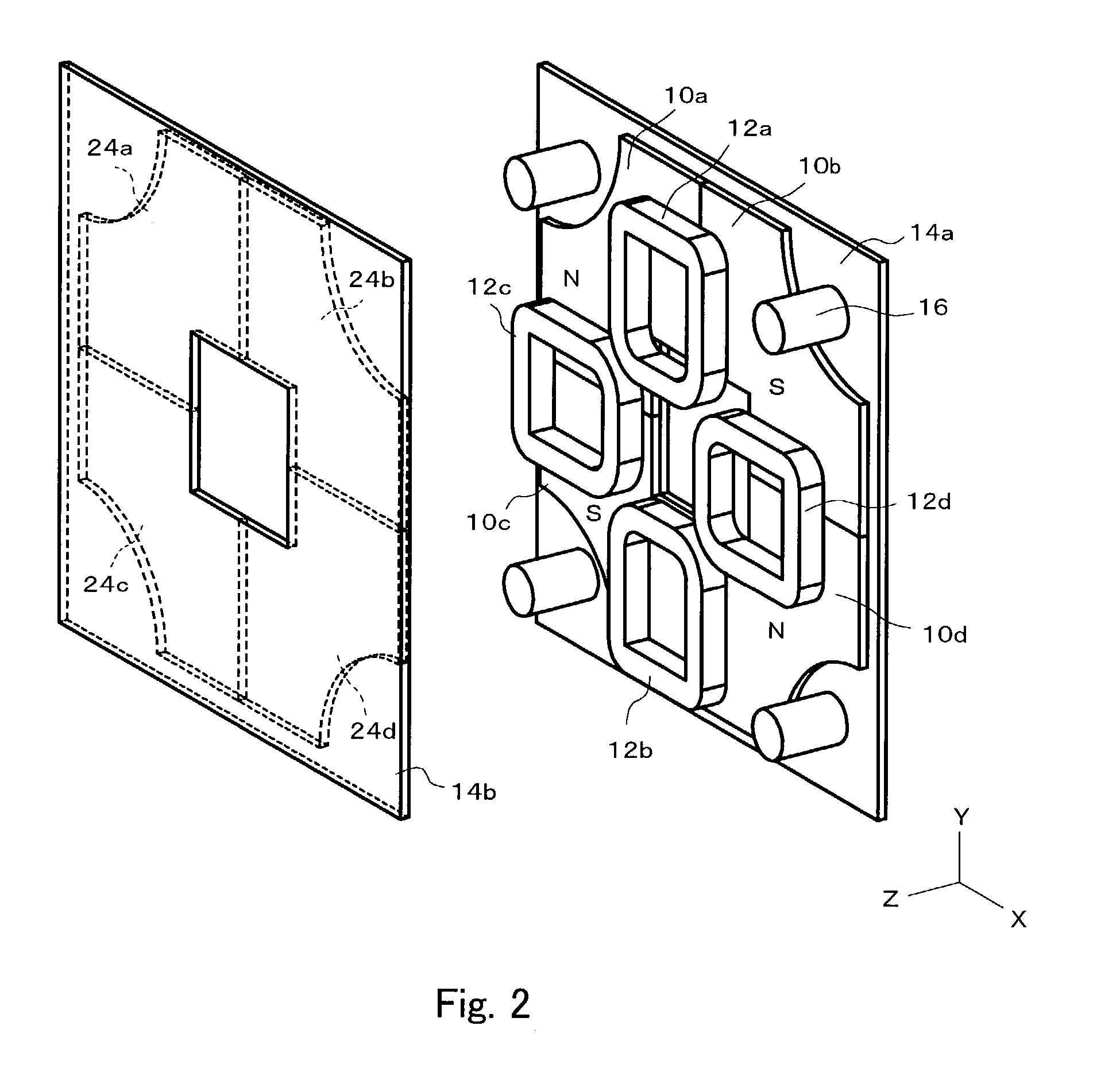

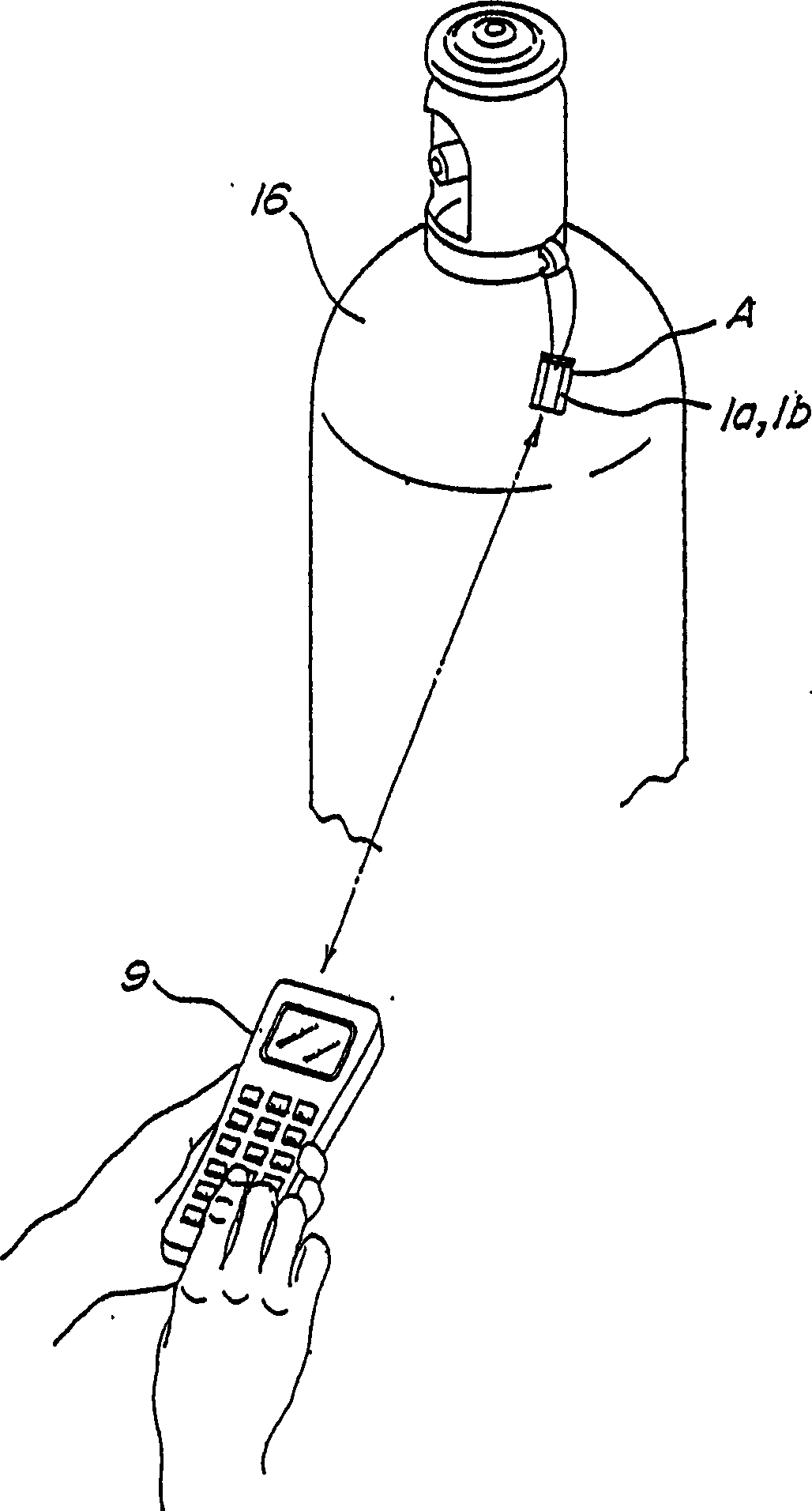

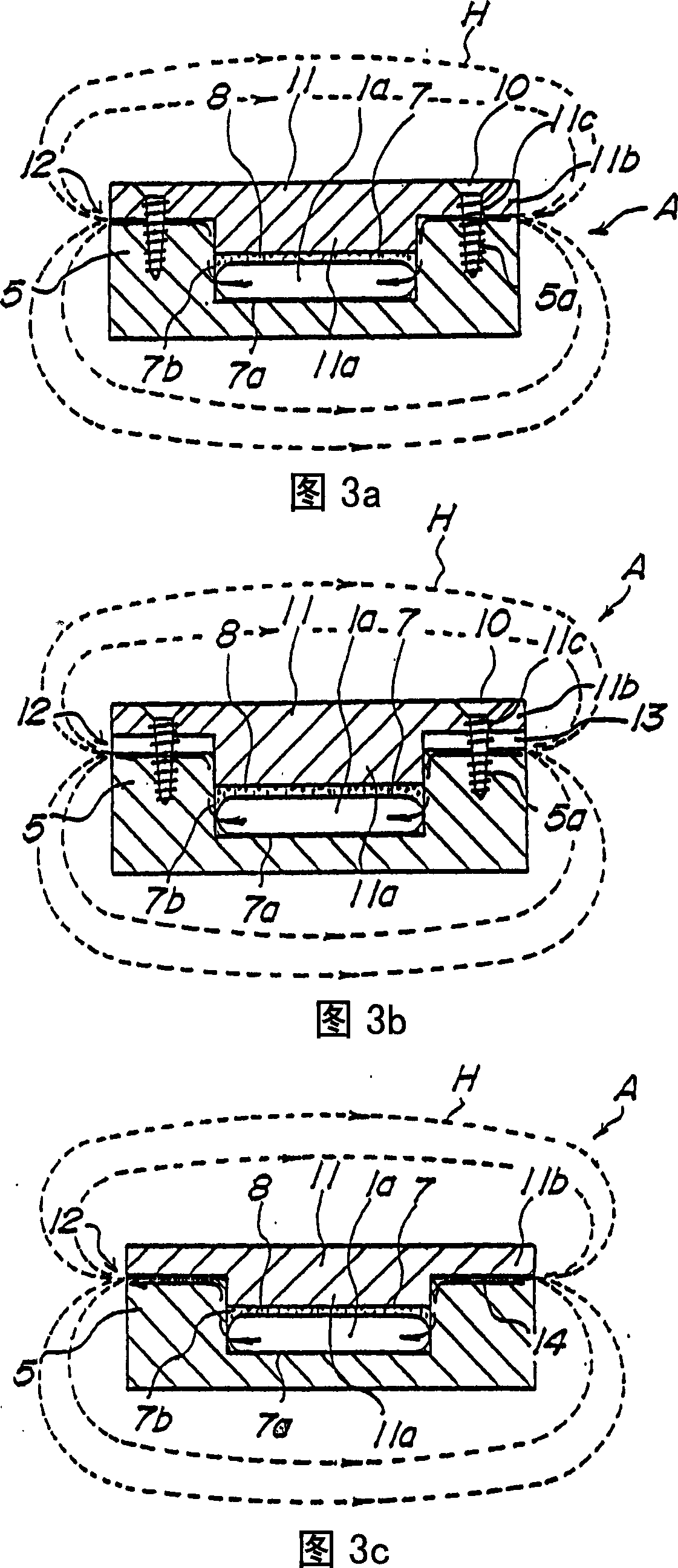

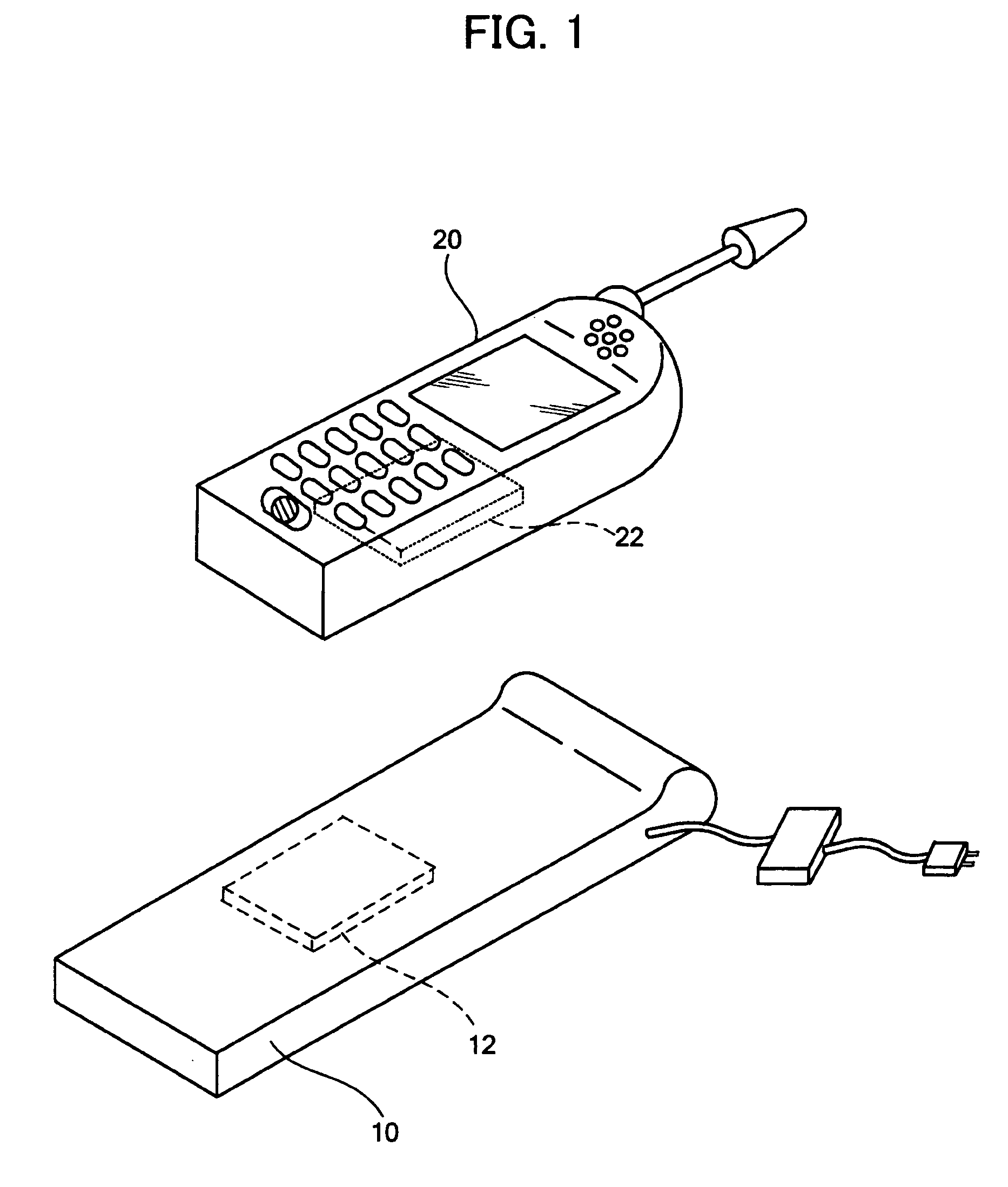

RFID tag housing structure, RFID tag installation structure and RFID tag communication method

InactiveCN1443340AAntenna supports/mountingsCasings/cabinets/drawers detailsConductive materialsRadio frequency

A first object of the present invention is to provide a new installation structure of RFID tags which can effectively protect the RFID tags from external pressure or impact and communicate with the outside during storage, transportation and use. The second object of the present invention is to provide a new mounting structure of an RFID tag even though the RFID tag is mounted on a conductive part such as a metal part and its surface is generally made of metal having excellent strength and durability The protective part cover is also able to communicate with the outside. A third object of the present invention is to provide a communication method using an RFID tag surrounded by a conductive member usually made of metal. Even if the RFID tag is housed in a container generally made of a conductive material such as metal having a large mechanical strength, if a magnetic flux leakage path 12 consisting only of, for example, a gap is formed in this container A, the RFID tag can leak magnetic flux. Communicates with external read / write terminal 9 as a medium.

Owner:HANEX CO LTD

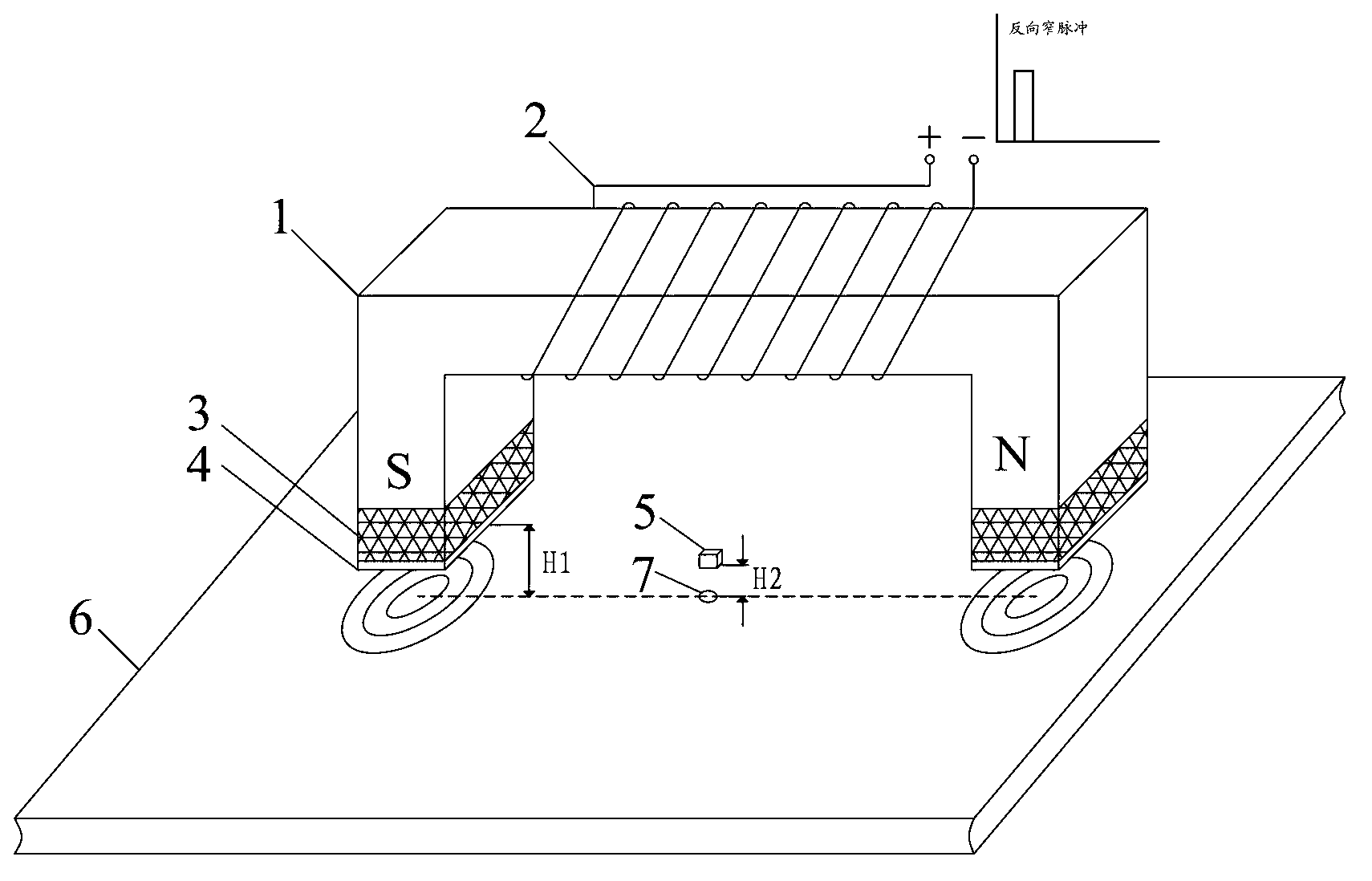

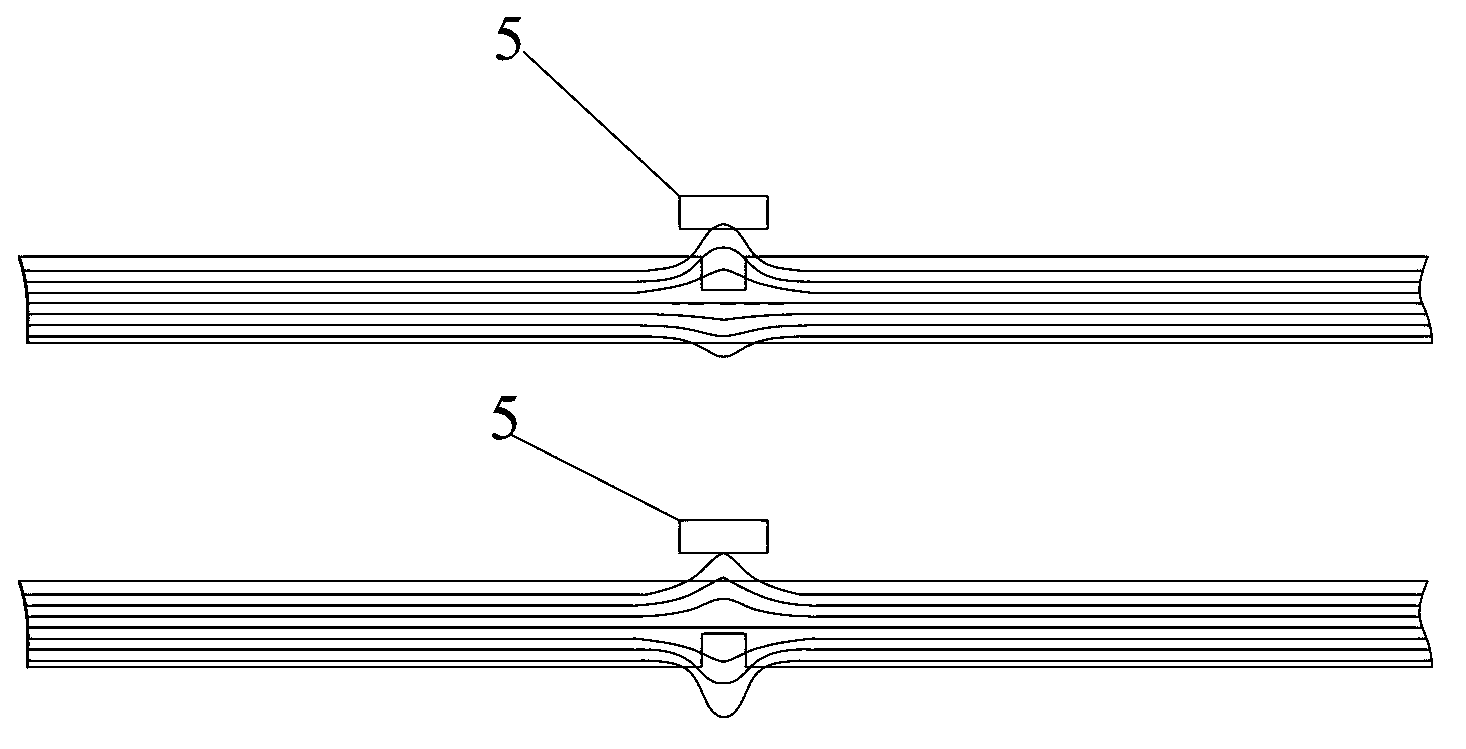

Permanent magnet and pulsed eddy current composite magnetic flux leakage detection method

InactiveCN103175891ASimple hardware structureSimple processing capacityMaterial magnetic variablesHardware structureMagnetization

The invention relates to a permanent-magnet and pulsed-eddy-current composite magnetic flux leakage detection method. With the method provided by the invention, defects on inner and outer surfaces can be effectively identified. The method belongs to the field of nondestructive test. With the effect of a permanent magnet, a ferromagnetic material requiring detection is magnetization into a local saturation state; if a detected magnetic flux leakage signal is larger than a preset intensity threshold B1, the ferromagnetic material has a defect; a reverse narrow pulse signal is applied to a excitation coil, such that the excitation coil generates a pulsed magnetic field, and pulsed eddy current is formed on the inner surface of the ferromagnetic material below two poles of a U-shaped magnetic yoke; at the time, if a detected leakage field intensity pulsation value is larger than a preset pulsation threshold B2, the defect is positioned on the inner surface of the ferromagnetic material; otherwise, the defect is positioned on the outer surface of the ferromagnetic material. The method provided by the invention has the advantages of simple hardware structure, low energy consumption, and convenient and fast signal processing.

Owner:XIAMEN UNIV

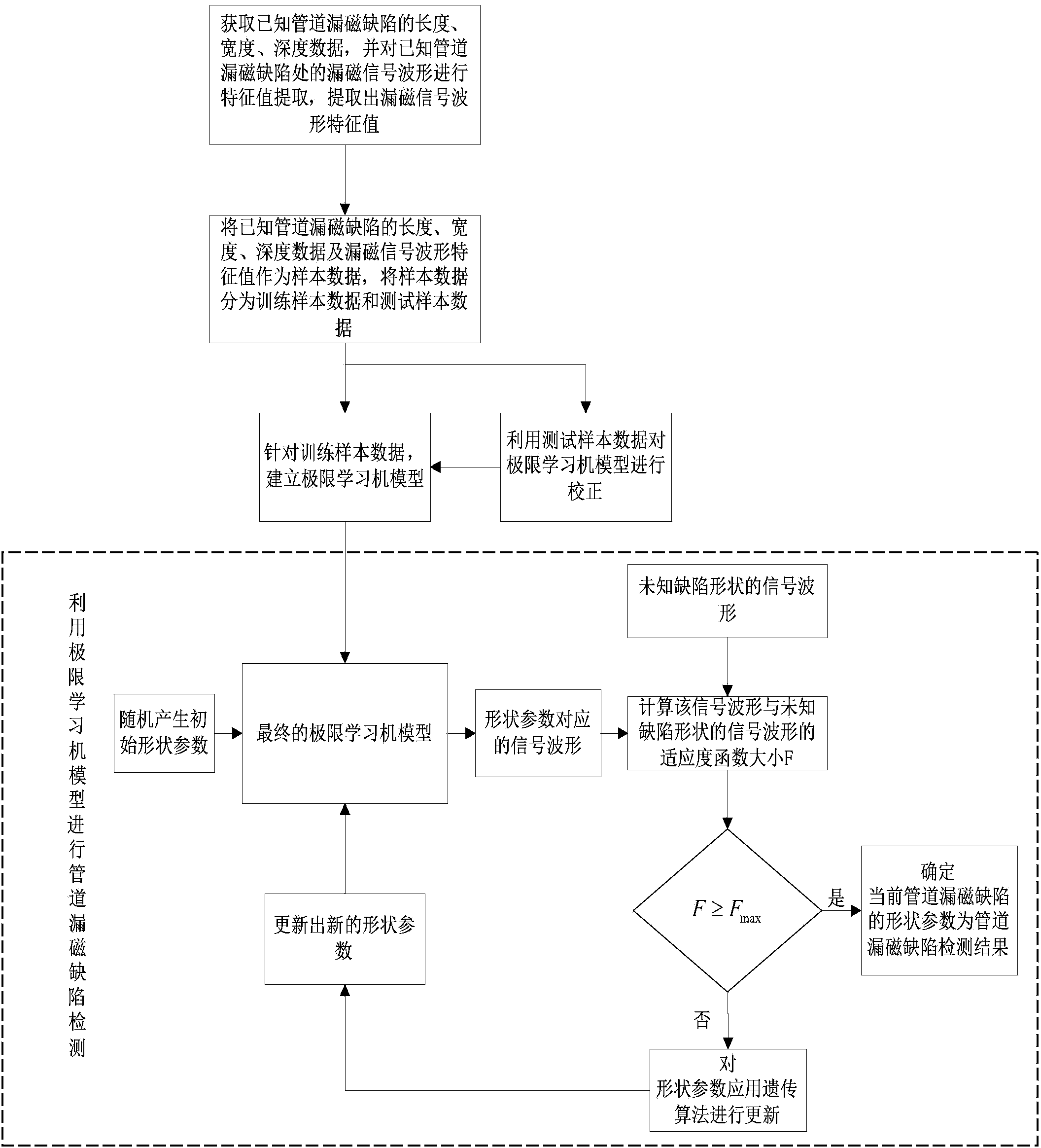

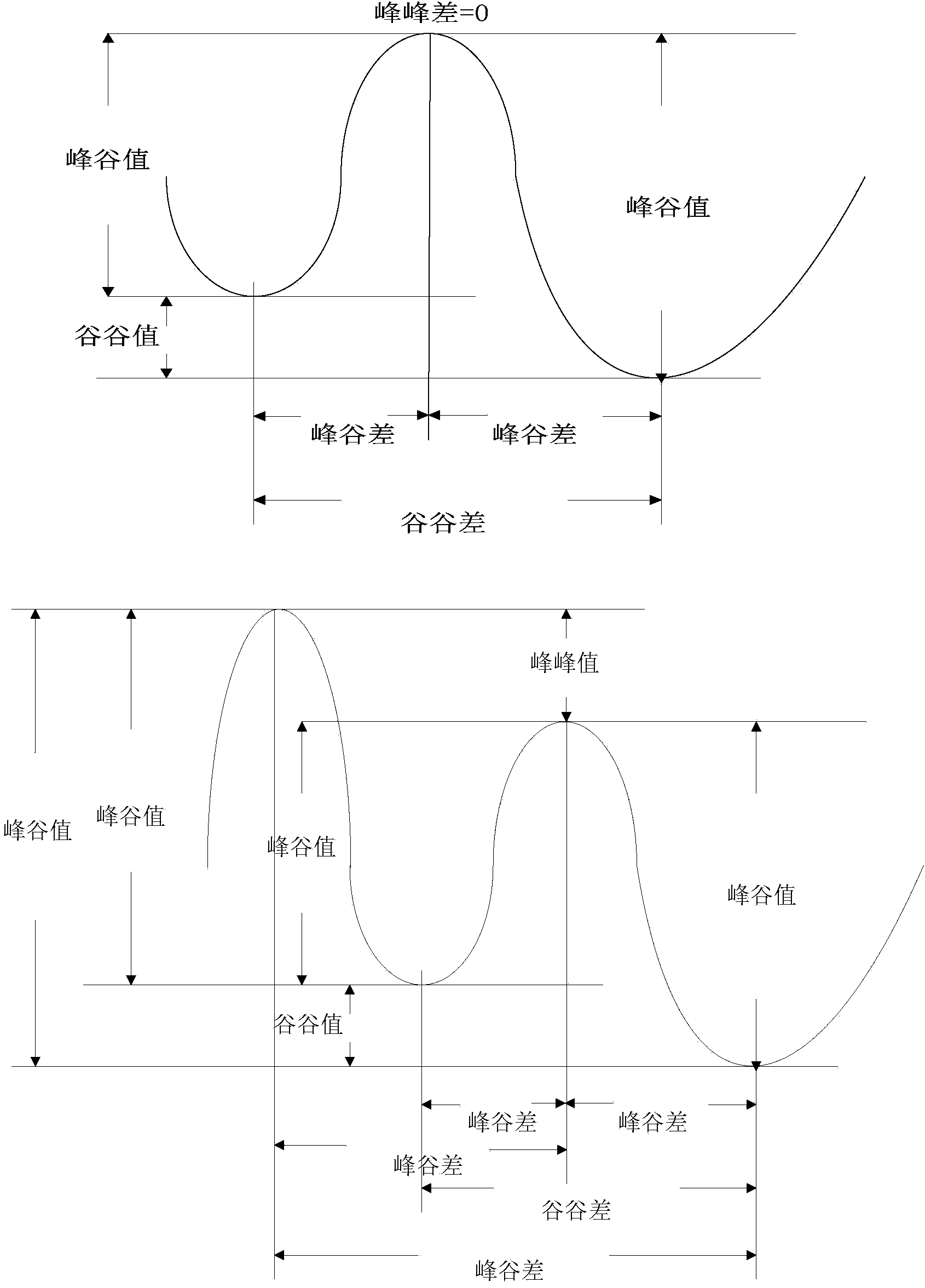

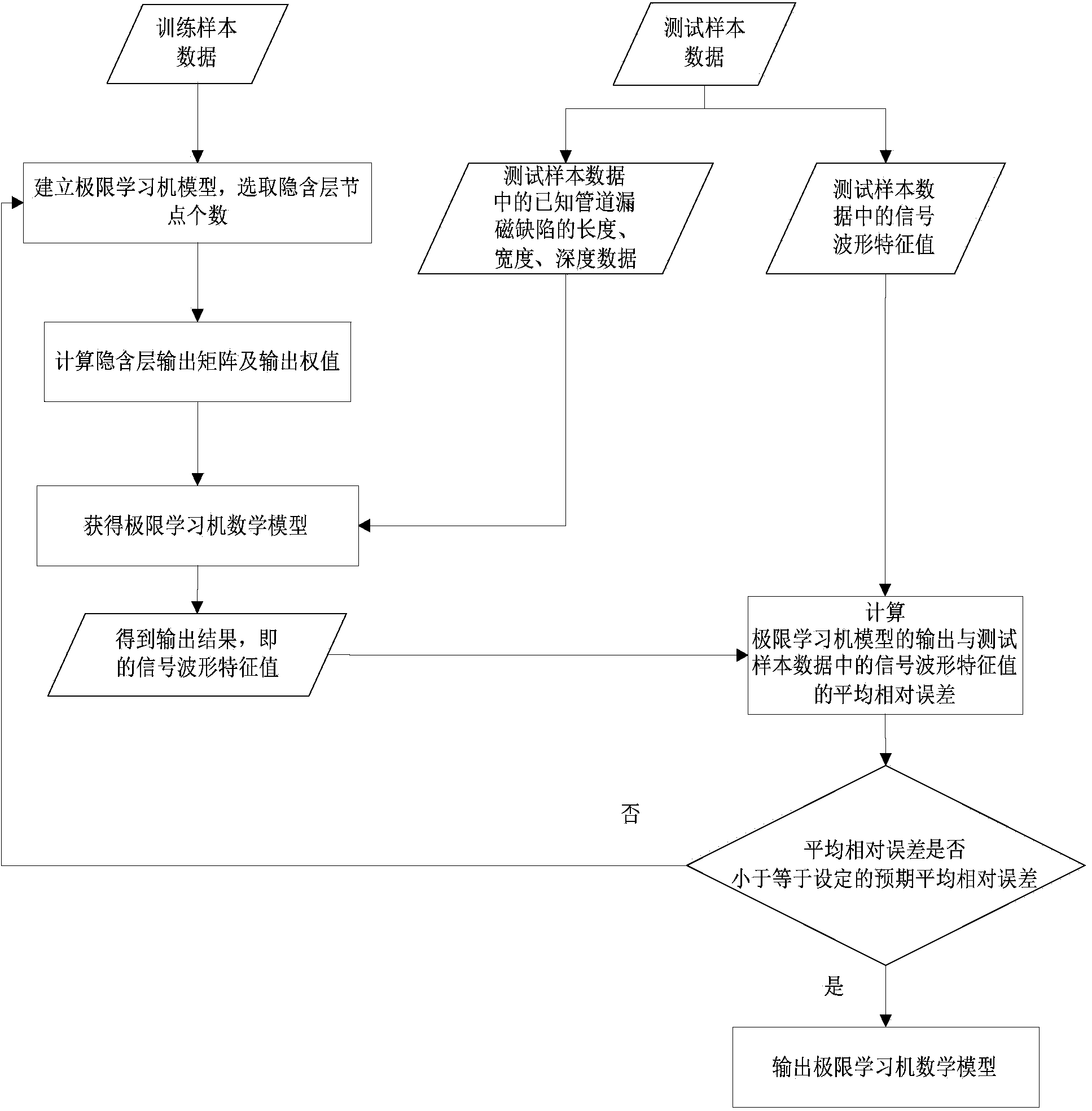

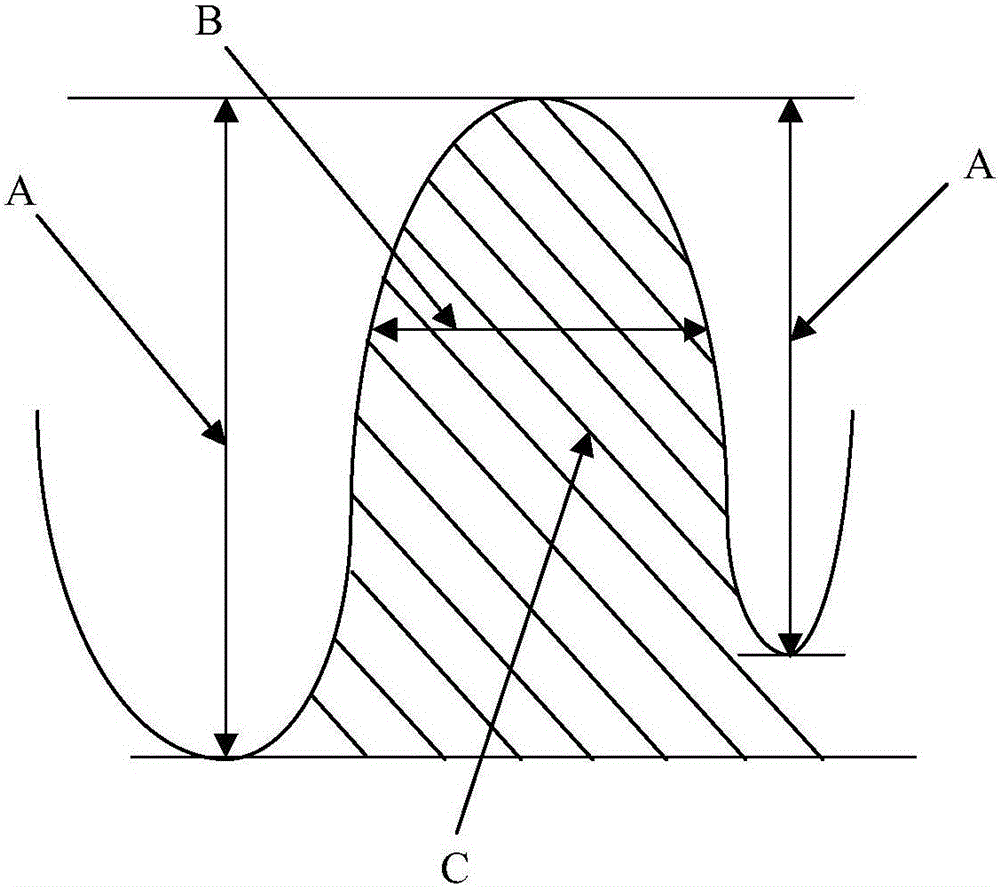

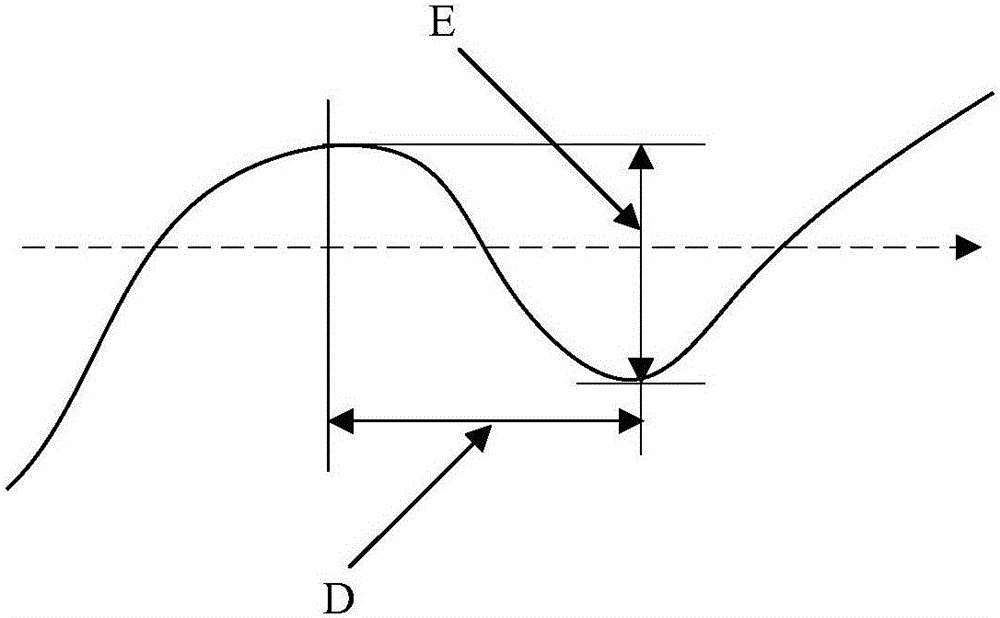

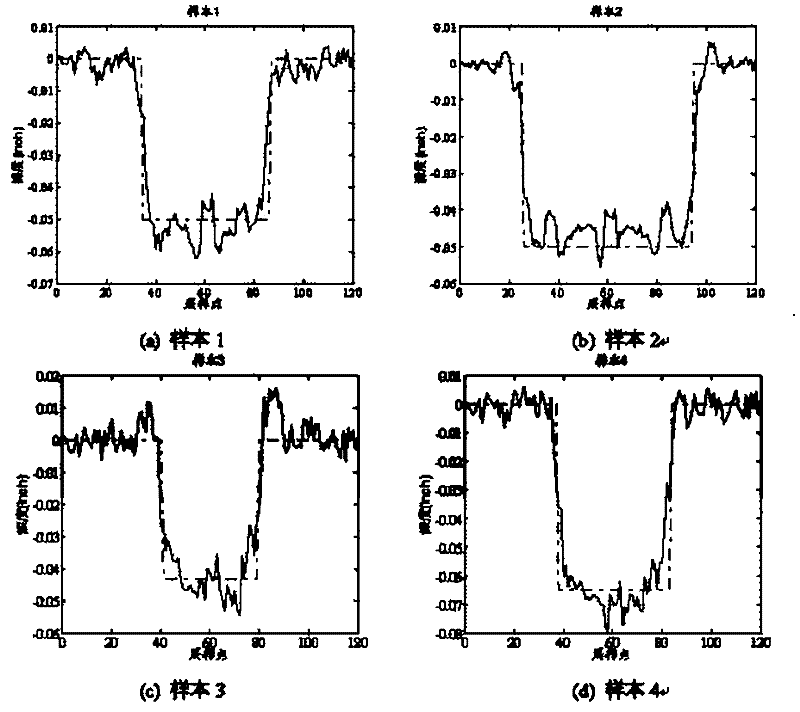

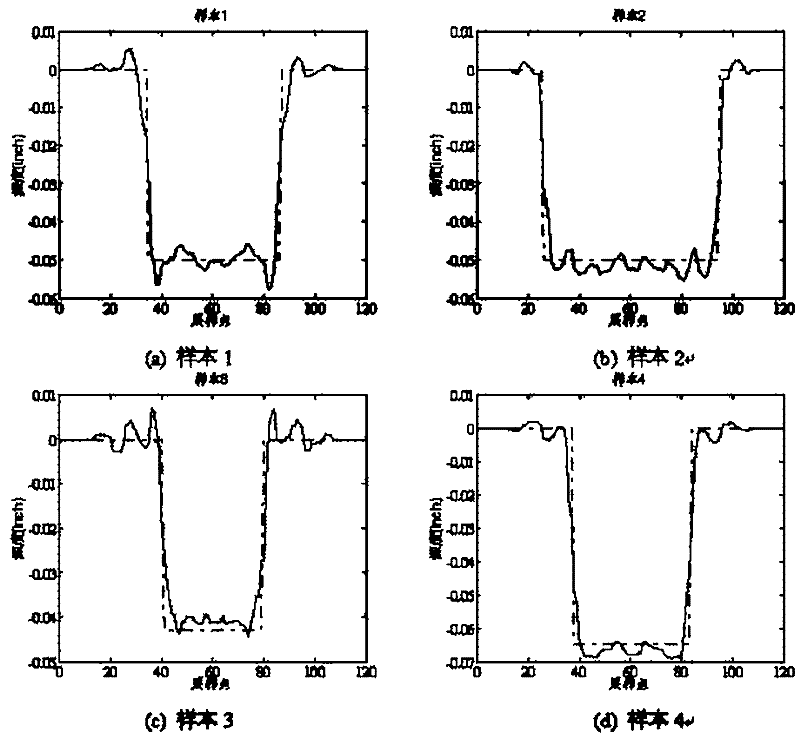

Extreme learning machine-based pipeline magnetic flux leakage defect detection method

ActiveCN104034794AFast learningPrevent leakageMaterial magnetic variablesHidden layerLearning machine

The invention relates to an extreme learning machine-based pipeline magnetic flux leakage defect detection method. The method comprises the following steps: establishing an extreme learning machine model according to data of the length, the width and the depth of a known pipeline magnetic flux leakage defect and a magnetic flux leakage signal waveform characteristic value; training the data of the length, the width and the depth of the known pipeline magnetic flux leakage defect in sample data, wherein the data is taken as the input of the model; selecting the number of nodes of a hidden layer by a cut-and-trial method; and calculating an output matrix and an output weight value of the hidden layer, wherein the magnetic flux leakage signal waveform characteristic value is taken as the output of the model; when a pipeline suffers from magnetic flux leakage, acquiring the waveform of a magnetic flux leakage signal of an unknown magnetic flux leakage shape, and performing pipeline magnetic flux leakage defect detection by the extreme learning machine model. According to the method, the pipeline defect shape is subjected to intelligent inversion by the extreme learning machine model; the method has the advantages of high learning speed, high generalization performance and the like; the shape of the defect can be constructed quickly and accurately by virtue of the waveform of the detected defect, so that the severity of the defect is learnt, a pipeline risk can be foreknown, and the leakage of the pipeline is prevented.

Owner:NORTHEASTERN UNIV

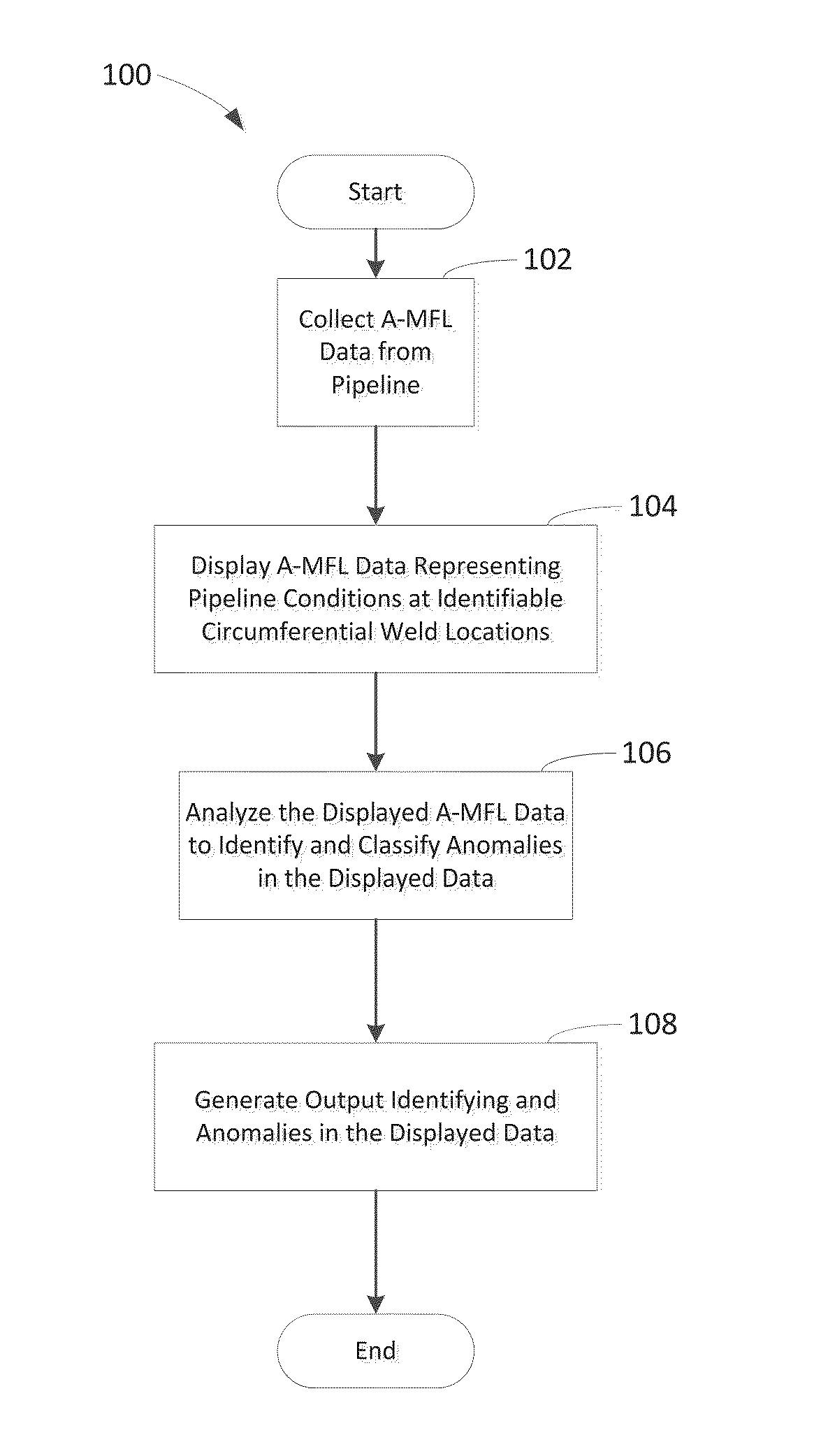

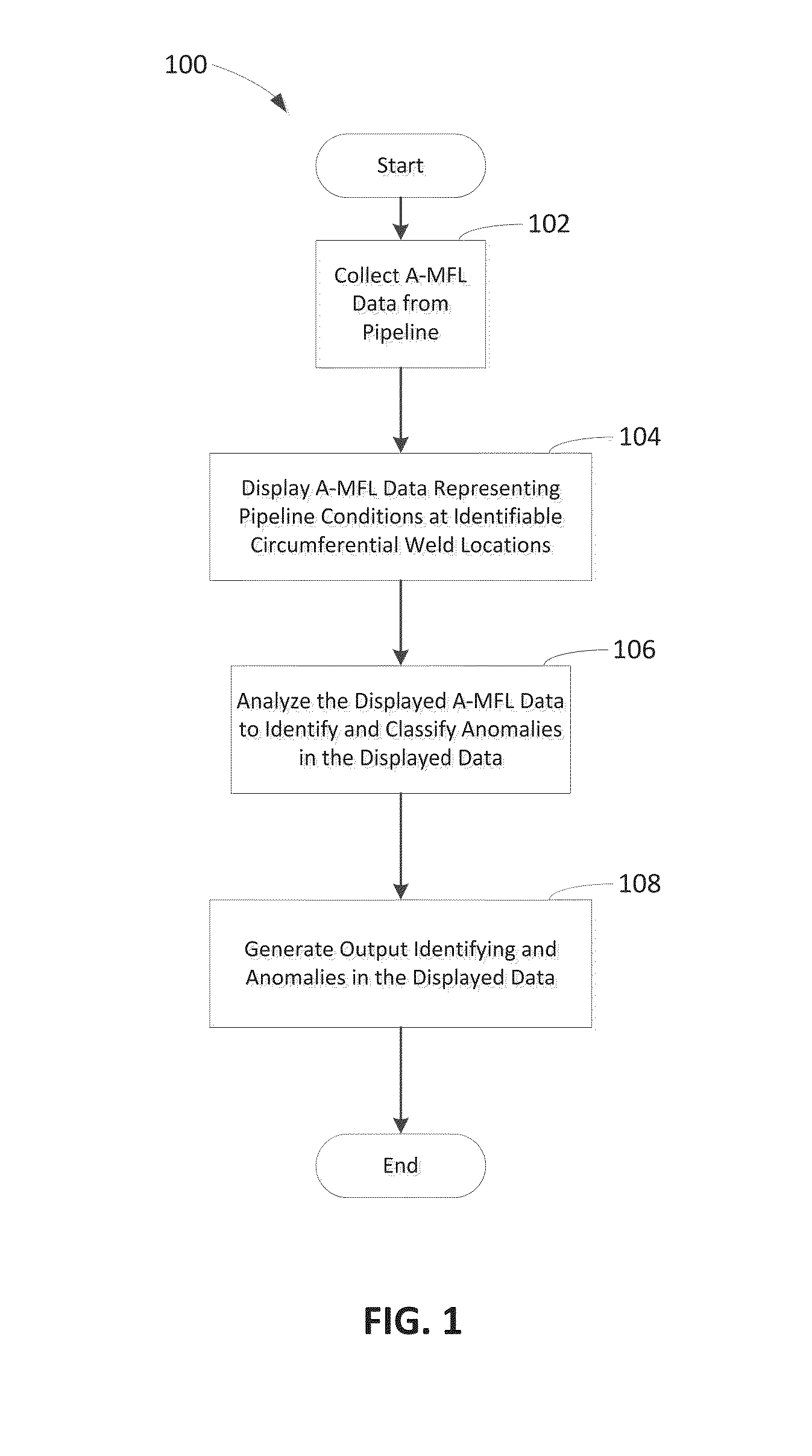

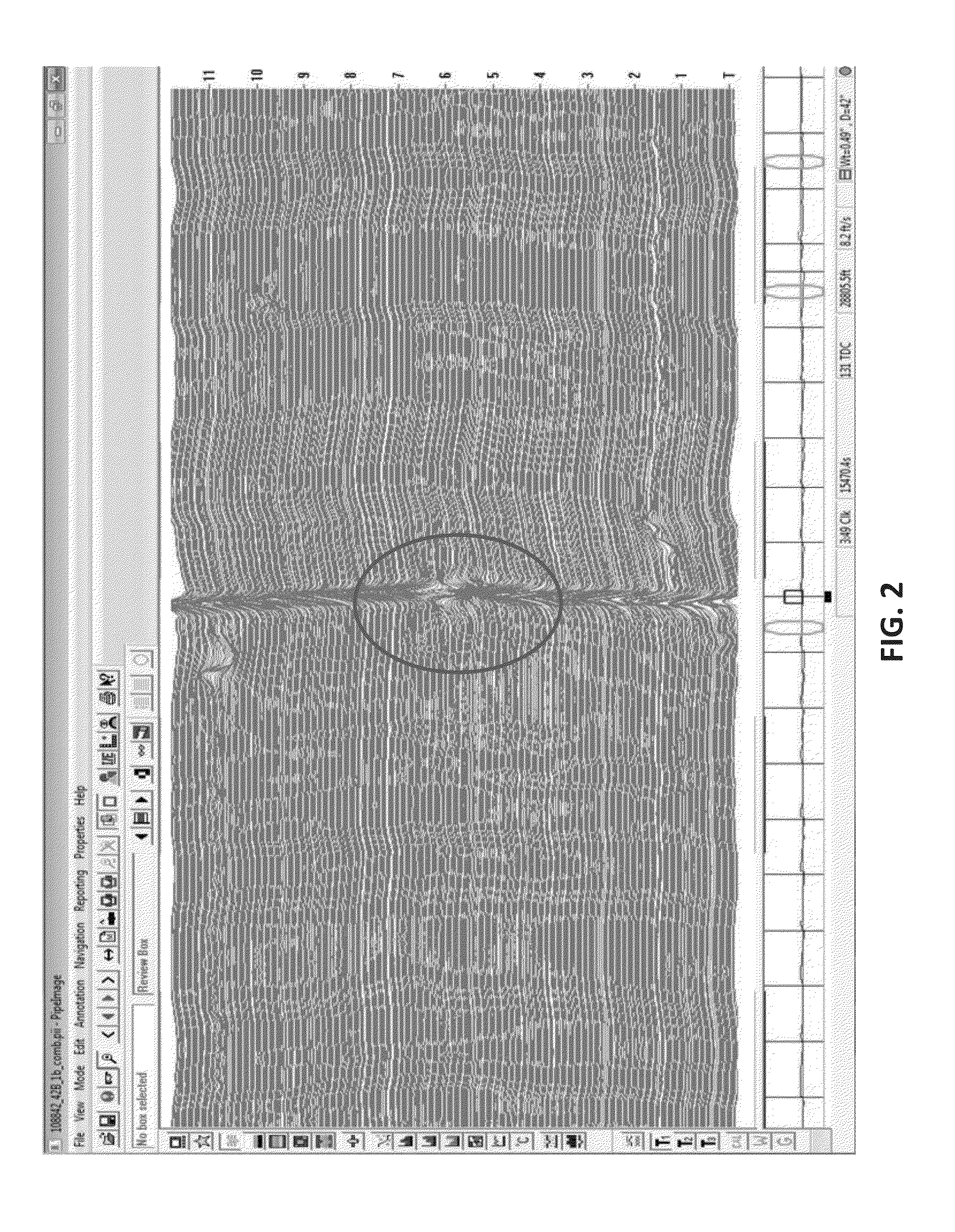

Method, machine, and computer medium having computer program to detect and evaluate structural anomalies in circumferentially welded pipelines

Embodiments of the present invention provide methods, machines, and a computer medium or media having computer programs to determine presence anomalies in circumferential welds of one or more pipelines transporting fluids associated with energy therethrough. Wave form analysis or pattern recognition in pipeline data such as magnetic flux leakage data is employed. A screening process, for example, does not affect or change how survey data is recorded such as in survey tools; only how it is analyzed after the survey data is completed. Embodiments of the machines, methods, and computer medium having computer programs can be used to screen for anomalies potentially threatening the structural integrity of the one or more pipelines so that site excavation can occur for confirmation and validation of the output results.

Owner:KINDER MORGAN

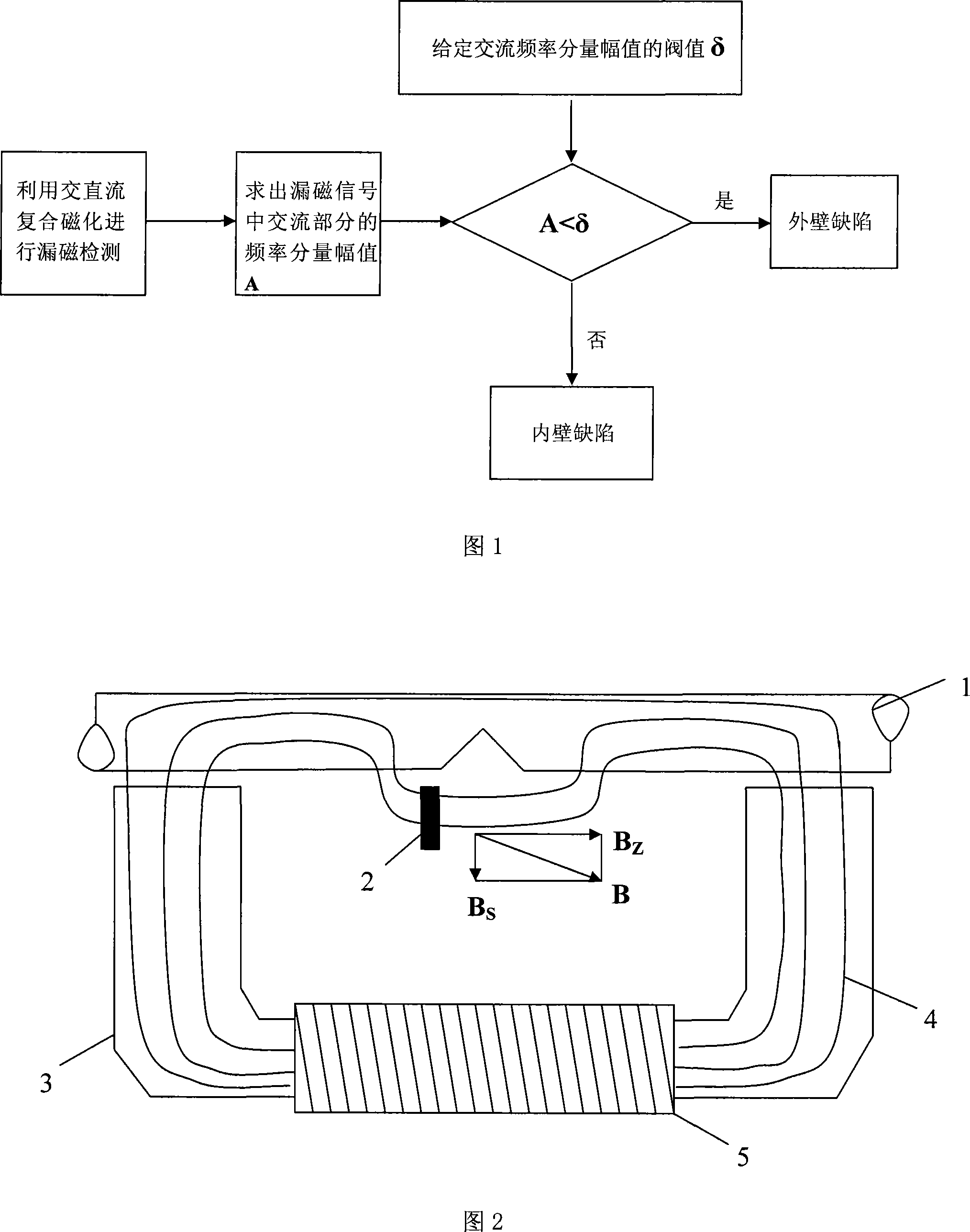

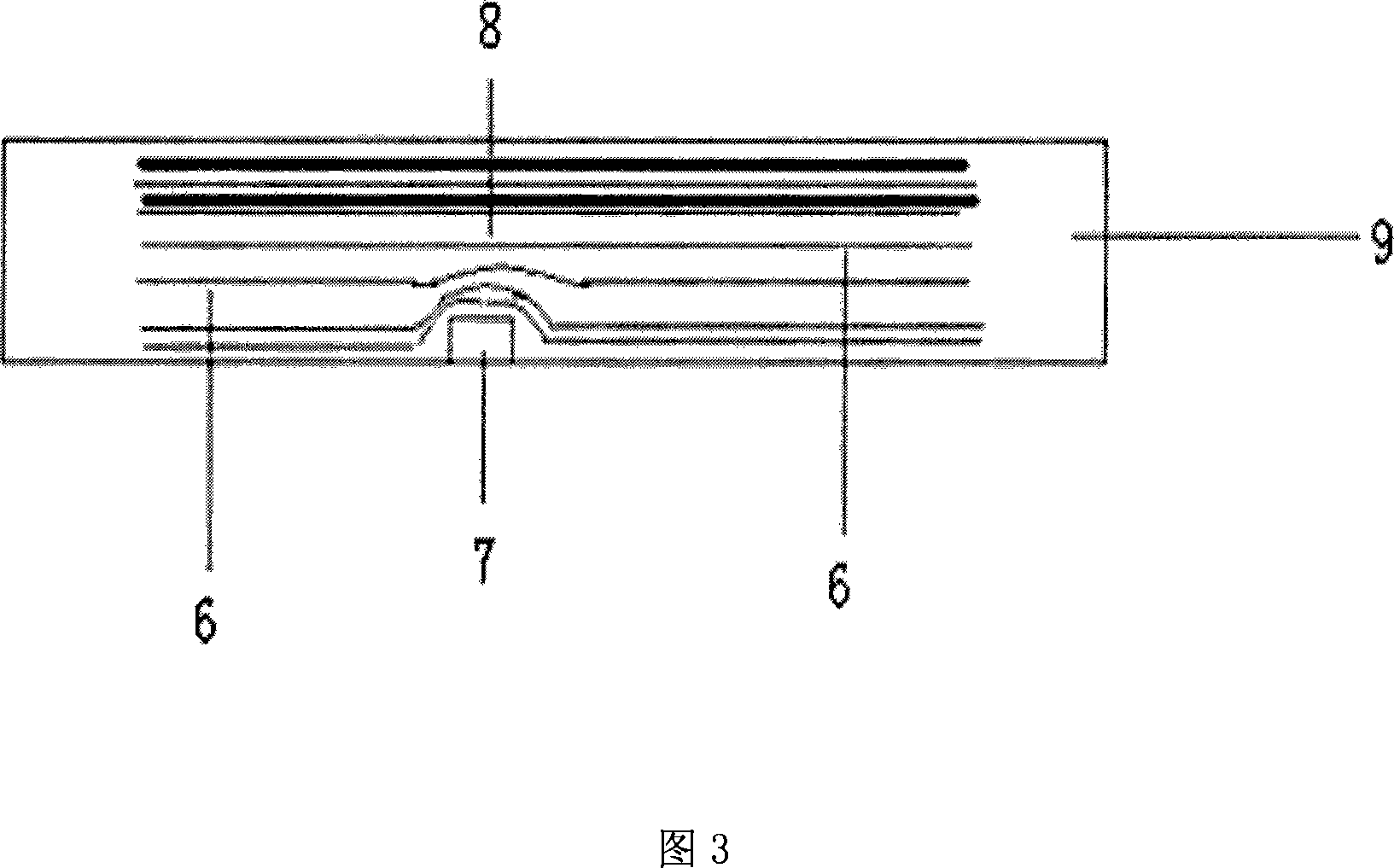

AC and DC composite magnetisation based leakage detection recognition method for inside and outside wall defect

A method for recognizing defects on inner and outer walls by magnetic flux leakage detection based on AC / DC combined magnetization is used for determining whether a defect is present on inner or outer wall of a material to be detected, which belongs to nondestructive detection field. The method is characterized in that the method comprises three basic steps of: (1) subjecting the material to magnetic flux leakage detection by AC / DC combined magnetization; (2) subjecting the magnetic flux leakage signals detected by a sensor to spectral analysis to obtain the magnitude of the frequency component of an AC magnetic flux leakage signal of a defect portion; and (3) setting the threshold of an AC frequency component and comparing the AC frequency component of the magnetic flux leakage signal with the threshold to determine whether the defect is present on the inner wall or on the outer wall of the material. The invention can conveniently determine the defect position and simultaneously execute inner / outer wall recognition by one-step magnetic flux leakage detection, thus facilitating the development of defect quantization after magnetic flux leakage detection.

Owner:TSINGHUA UNIV

Magnetic flux leakage inspection device

InactiveUS20110234212A1High strengthStrength of magnetic field can be easilyMagnetsMagnetic property measurementsUltimate tensile strengthMagnetic flux leakage

Disclosed are a method and an improvement to the existing conventional magnetic flux leakage inspection device that employ some fixed magnets that are fixed inside the magnet yoke and some movably adjustable magnets, allowing their dipole orientation to be adjusted between 0° and 180° relative to that of the fixed magnets. A lever and gear set connected to the adjustable magnets can be operated to achieve desired level of magnetic strength of the device, including turning off the whole magnetic field, by causing the fields of the fixed and adjustable magnets to cancel each other. The disclosed adjustable yoke can also be used in other NDT / NDI applications where providing an adjustable magnetic strength is desirable.

Owner:OLYMPUS NDT

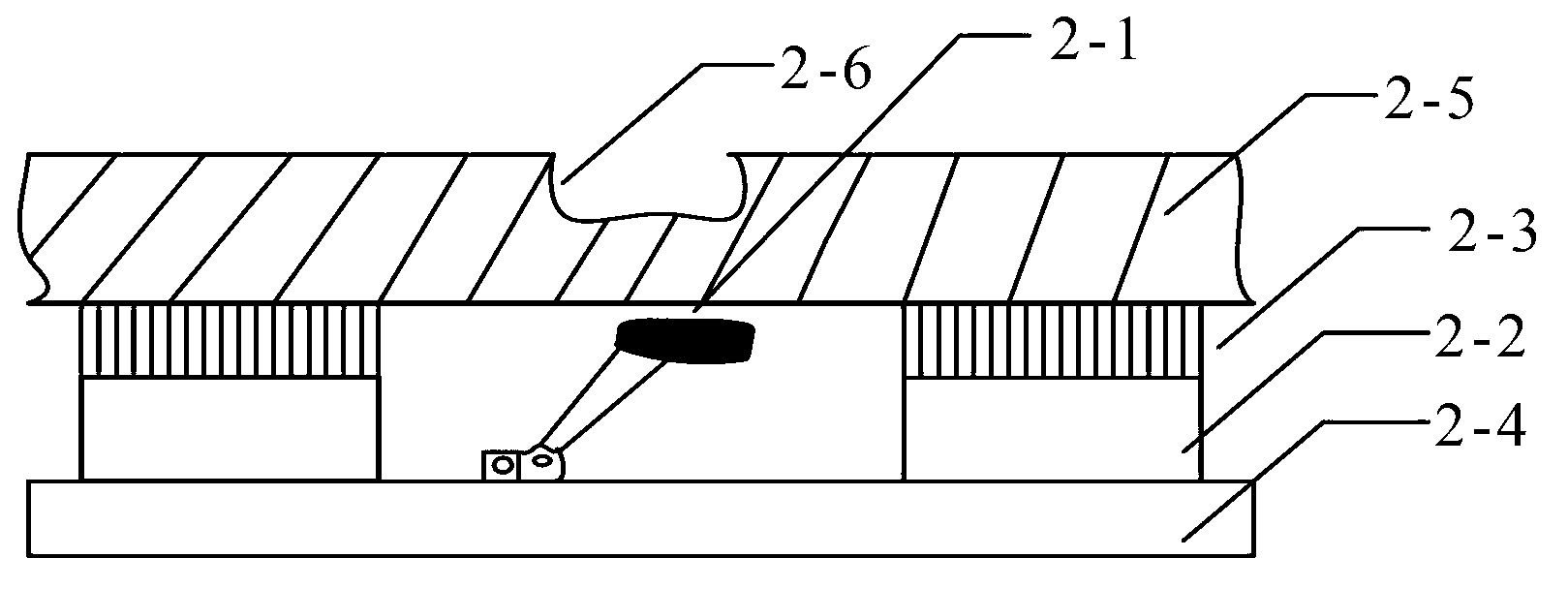

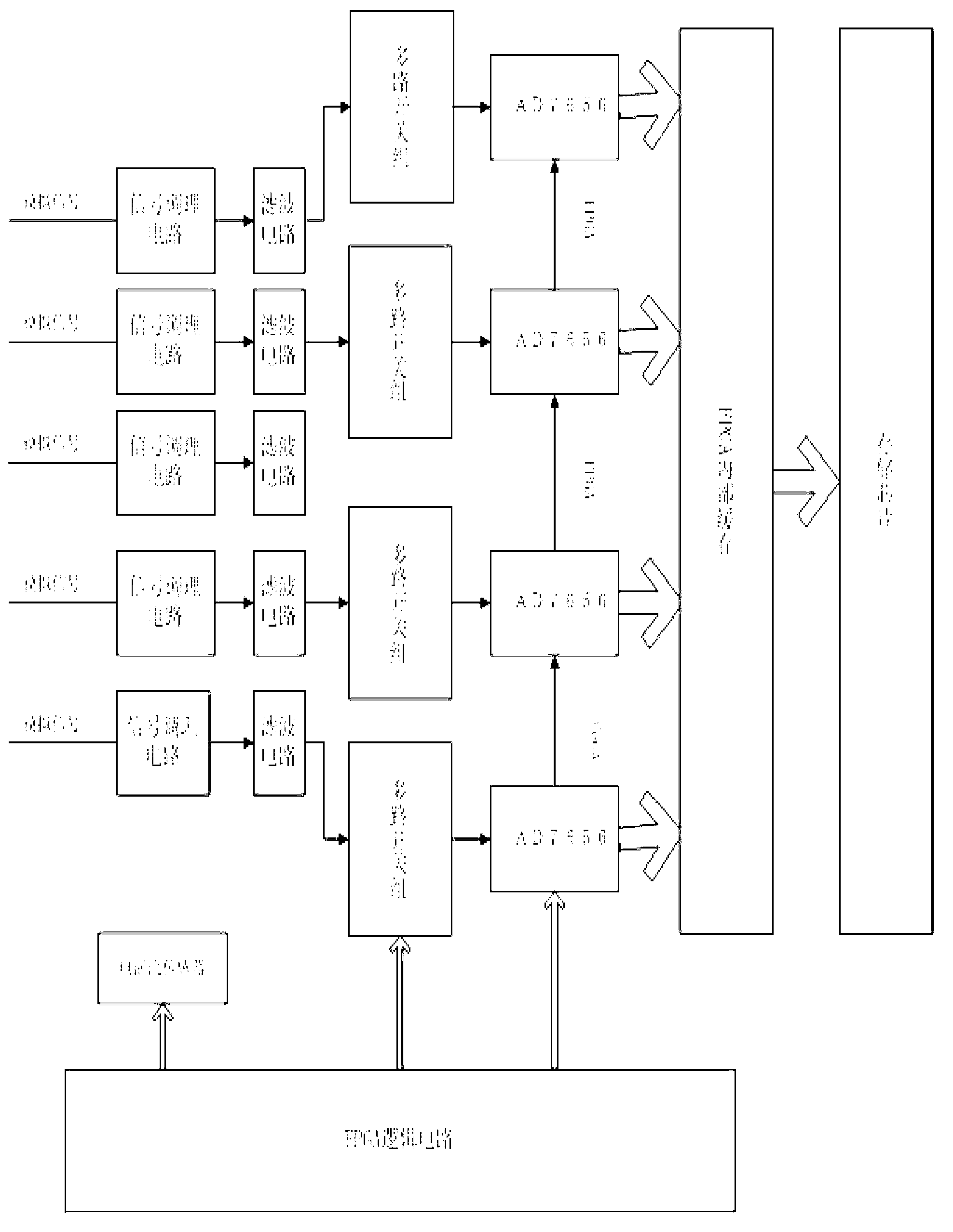

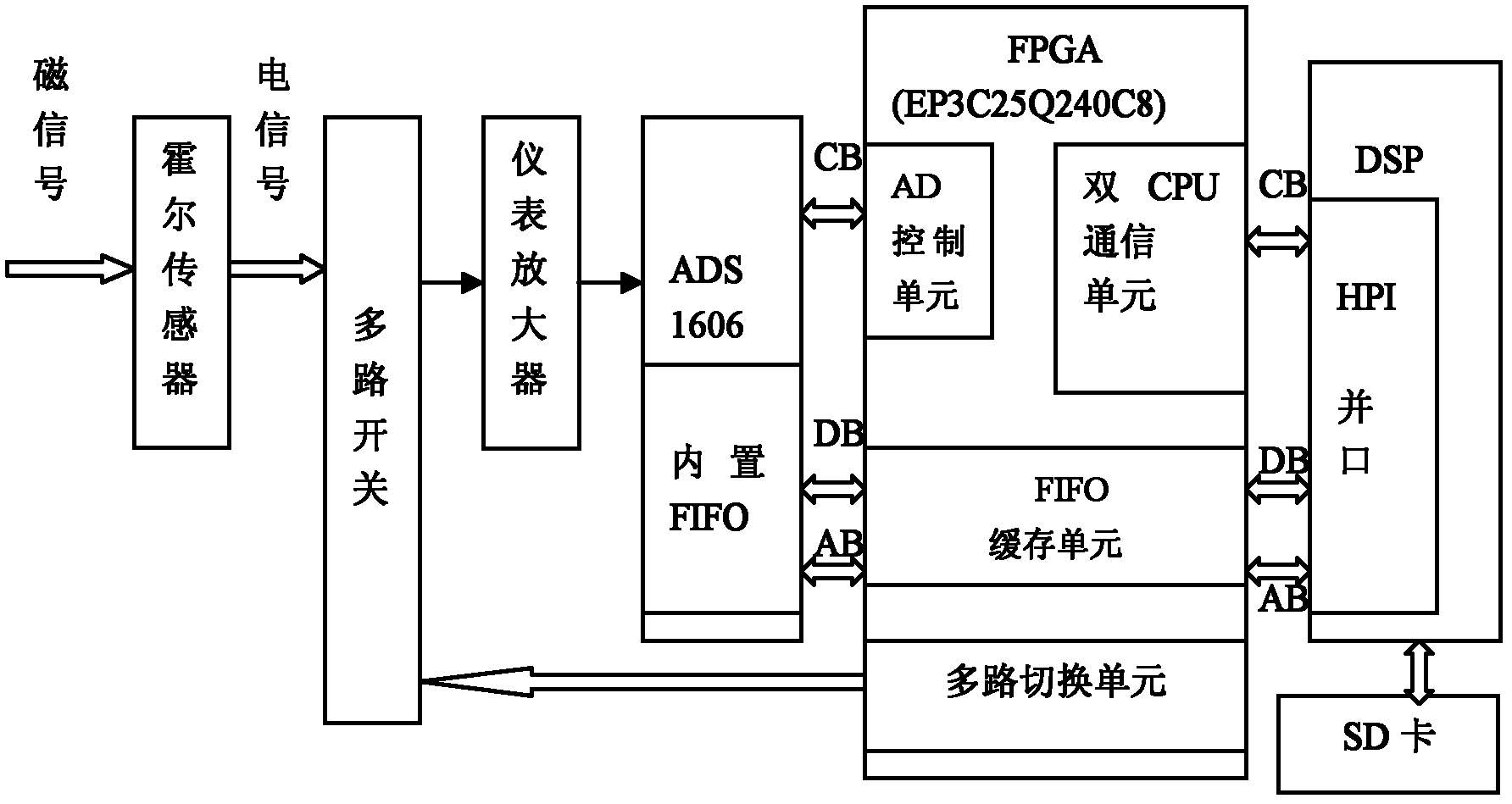

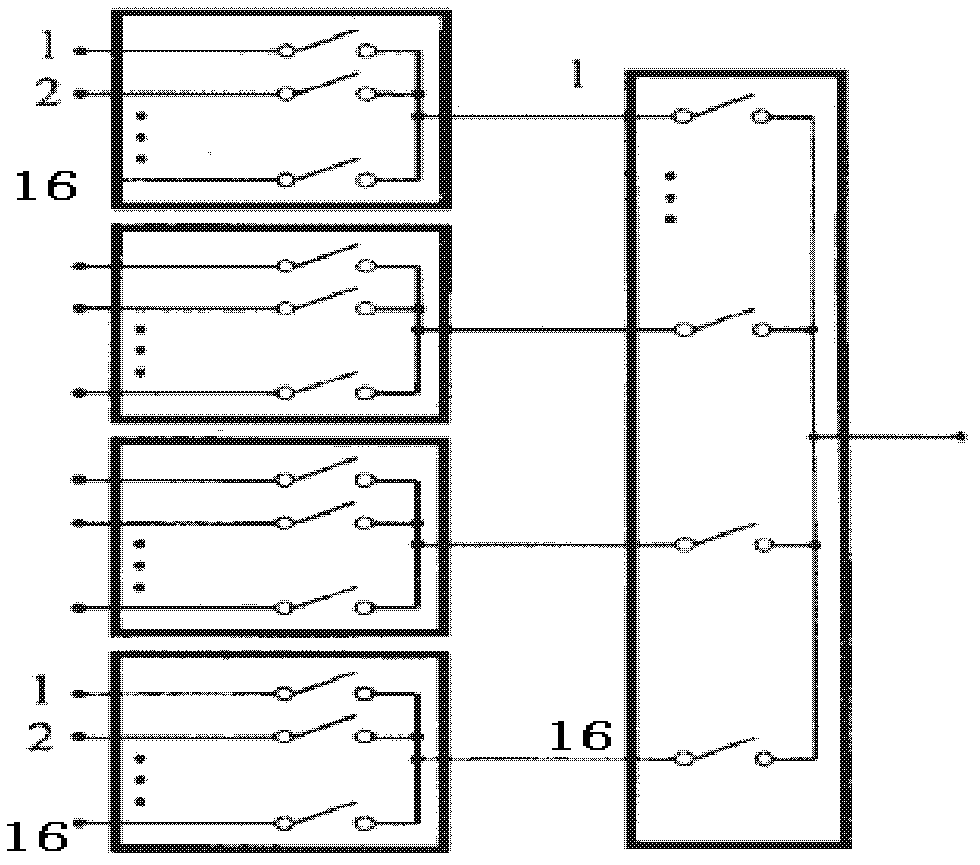

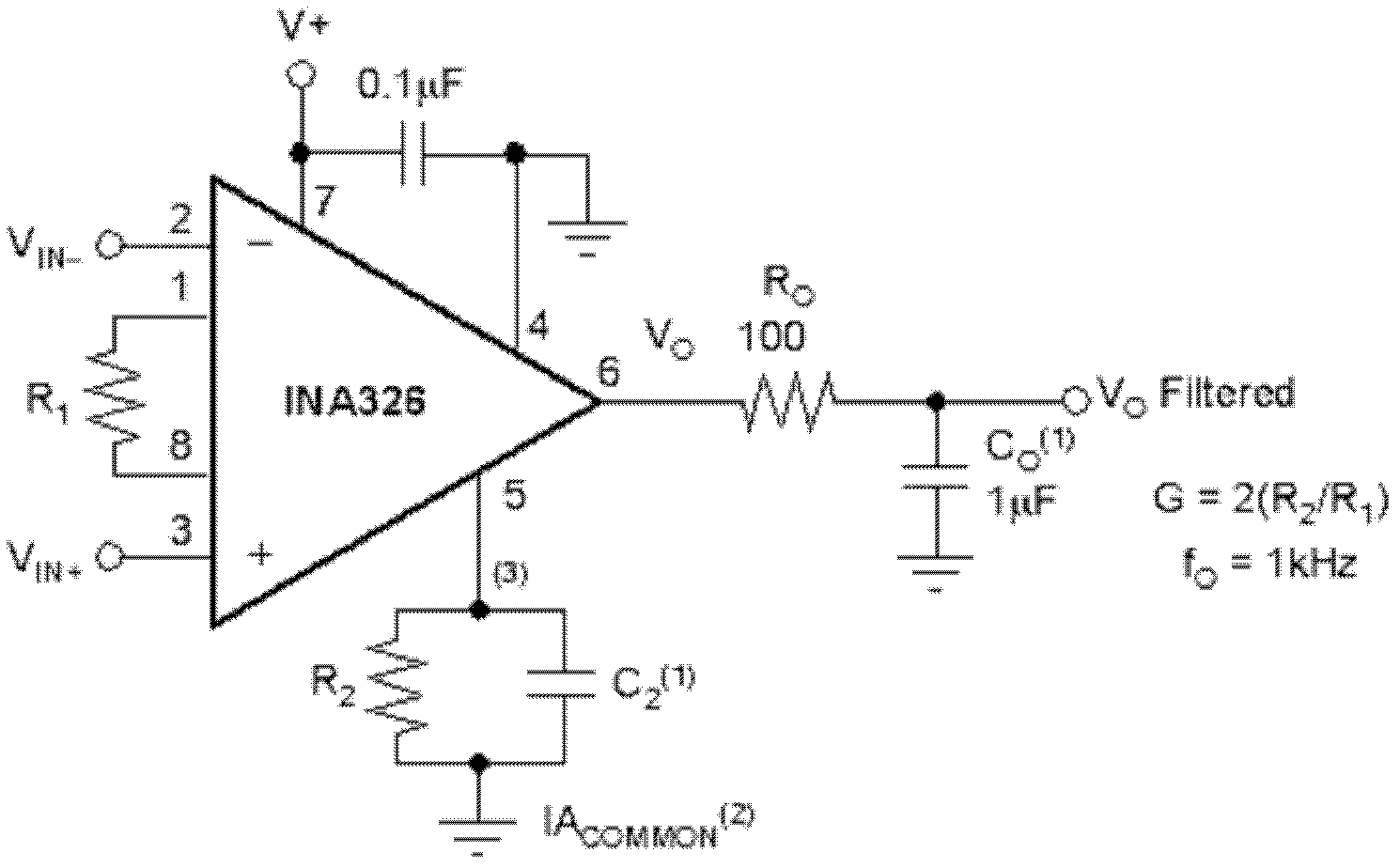

Multi-channel data acquisition device for submarine pipeline magnetic flux leakage internal detector

ActiveCN102495132AReduce distractionsFlexible modificationMaterial magnetic variablesOcean bottomData acquisition

The invention discloses a multi-channel data acquisition device for a submarine pipeline magnetic flux leakage internal detector. The multi-channel data acquisition device comprises a hall sensor, a multi-path switch, an instrument amplifier, an analog-to-digital (AD) conversion module, a field programmable gate array (FPGA), a digital signal processor (DSP) and a secure digital memory (SD) card, wherein the multi-path switch has a two-stage series structure; the multi-channel data acquisition device is provided with heat insulation cotton so as to adapt to a specific high-temperature and high-corrosion environment of a submarine pipeline; the hall sensor converts the magnetic induction density into voltage; the voltage is switched by the multi-path switch, so that a signal is transmitted to the instrument amplifier; the instrument amplifier amplifies a weak signal; the AD conversion module sets sampling for eight times through software, performs analog-to-digital conversion, and transmits a digital value to the FPGA after the conversion; and the DSP receives FPGA cached data, digitally filters and compresses the cached data, and finally stores the data into the SD card. Due to a dual central processing unit (CPU) structure consisting of the FPGA and the DSP, a large amount of data can be stored and processed; the device has the characteristics of high speed, multiple channels, high resolution and the like; furthermore, pipeline transportation safety is guaranteed; and early maintenance is facilitated.

Owner:NORTHEASTERN UNIV

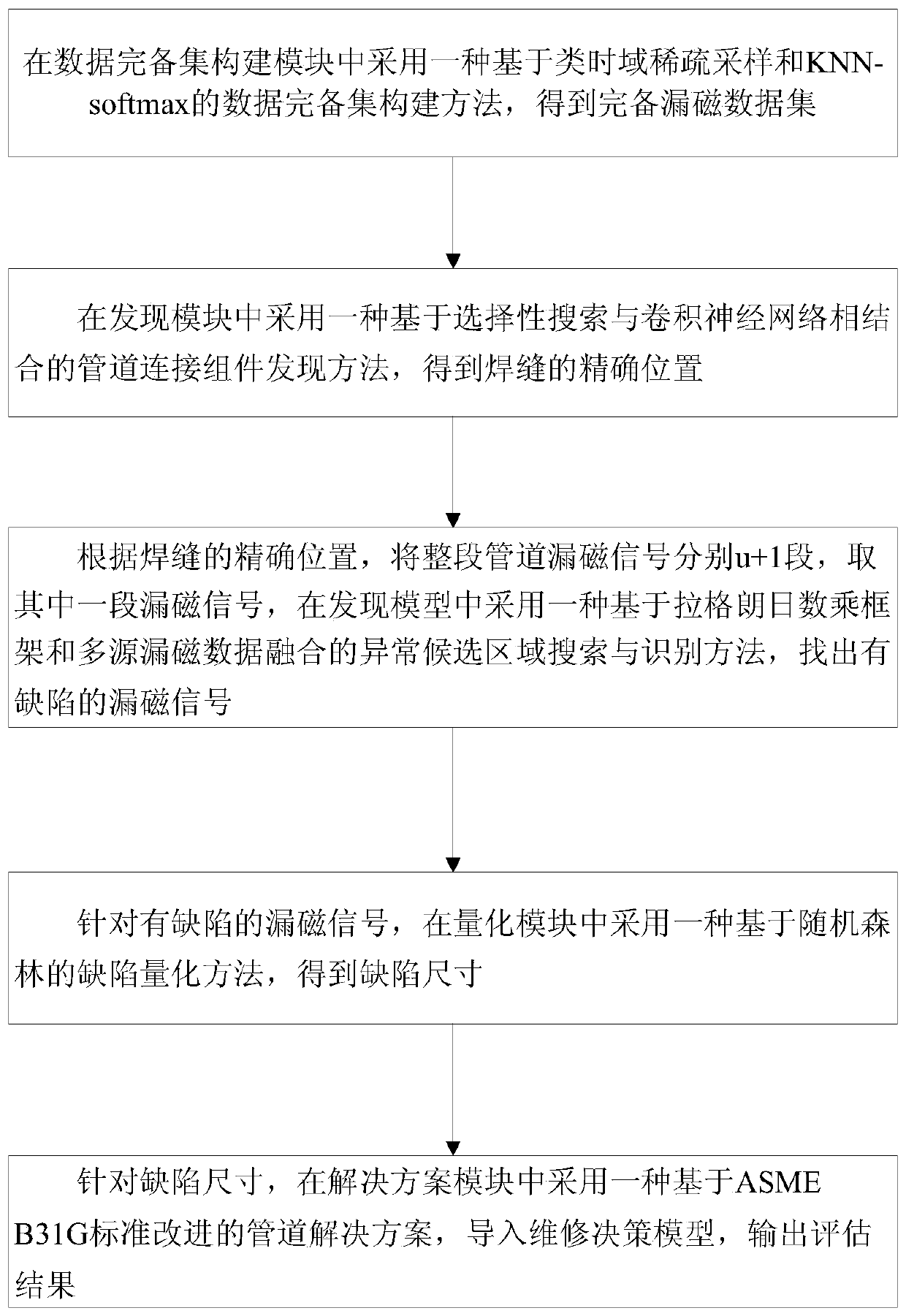

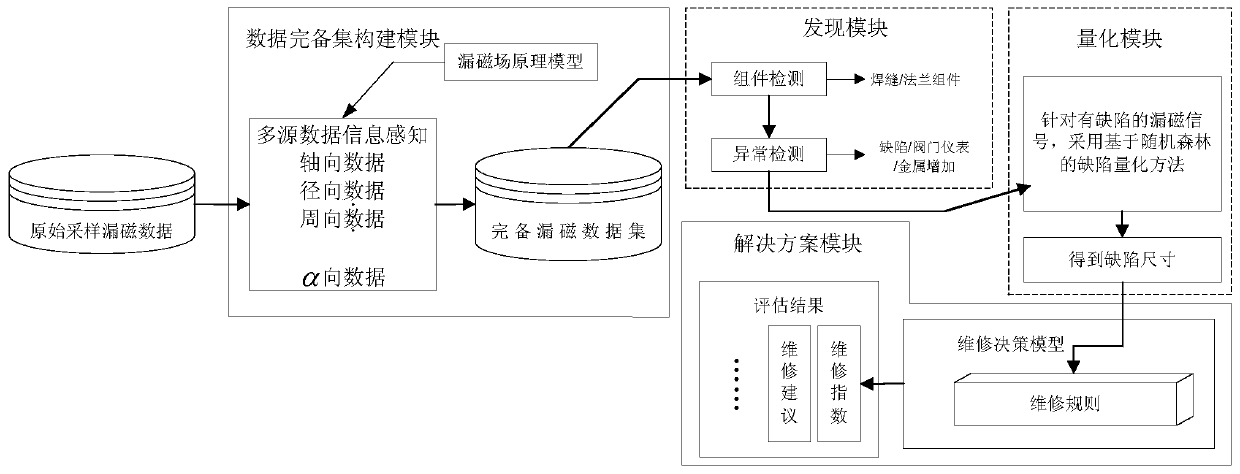

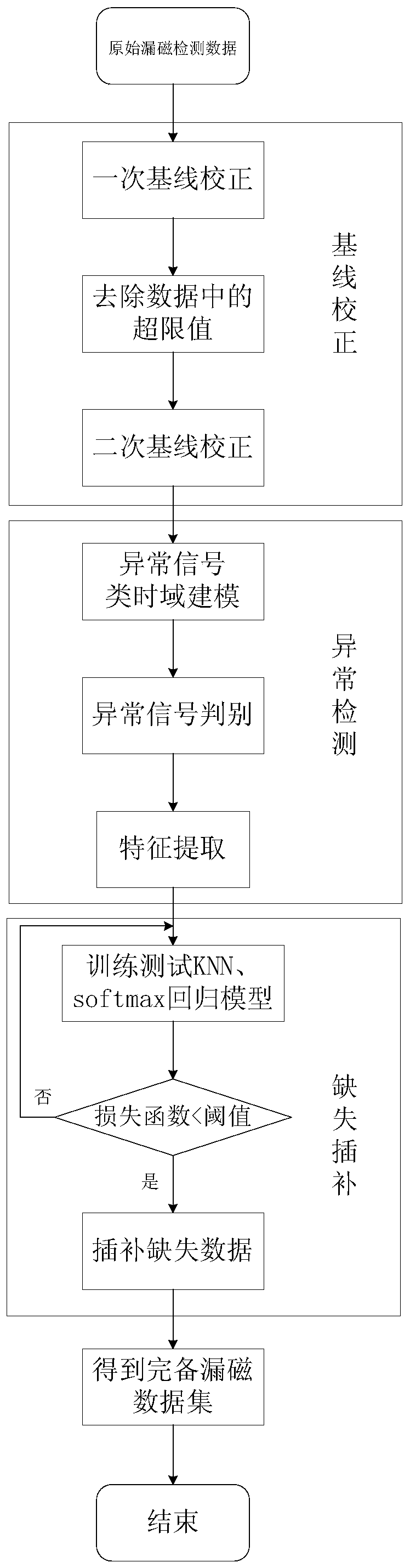

Intelligent analysis system and method for magnetic flux leakage detection data in pipeline

ActiveCN109783906AImprove accuracyImprove anti-interference abilityPipeline systemsNeural architecturesTime domainData set

The invention provides an intelligent analysis system and method for magnetic flux leakage detection data in a pipeline. The process comprises the following steps: adopting time domain-based sparse sampling and KNN-softmax data complete set construction module, obtaining a complete magnetic flux leakage data set; a pipeline connection assembly discovery method based on combination of selective search and a convolutional neural network is adopted in the discovery module to obtain the accurate position of the weld joint; adopting an abnormal candidate region searching and identifying method based on a Lagrangian multiplication frame and multi-source magnetic flux leakage data fusion in the discovery model to find out defective magnetic flux leakage signals; Adopting a defect quantification method based on a random forest in a quantification module to obtain a defect size; a pipeline solution improved based on the ASME B31G standard is adopted in the solution module, and an evaluation result is output. An analysis method is provided from the overall perspective, and pretreatment, connection assembly detection and abnormity detection, defect size inversion and final maintenance decision are achieved.

Owner:NORTHEASTERN UNIV

Magnetic actuator with reduced magnetic flux leakage and haptic sense presenting device

InactiveUS20040059245A1Input/output for user-computer interactionMechanical apparatusMagnetic polesActuator

A magnetic actuator, comprising a magnet, mutually opposite magnetic poles thereof being arranged opposing each other, and a coil, at least one portion thereof being inserted between the corresponding magnetic poles, wherein a driving force for the coil is generated by applying an electric current to the coil in a magnetic field generated by the magnet.

Owner:FUJIFILM BUSINESS INNOVATION CORP

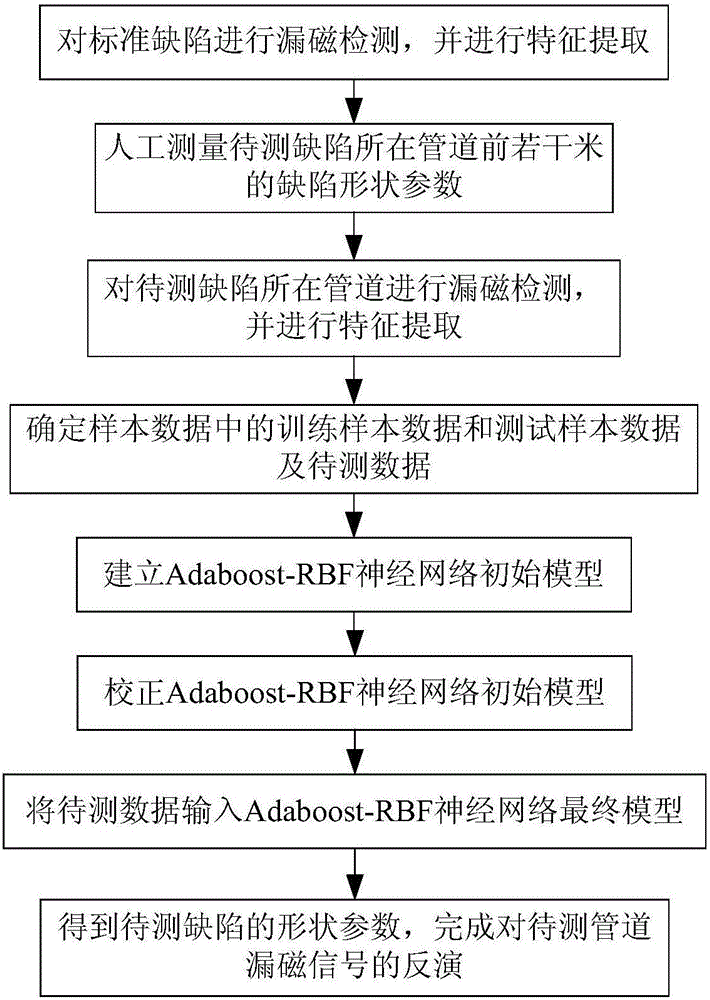

Pipeline defect magnetic flux leakage inversion method based on Adaboost-RBF synergy

InactiveCN106018545APrevent leakageGuaranteed generalization abilityBiological neural network modelsMaterial magnetic variablesFeature extractionAdaBoost

The invention provides a pipeline defect magnetic flux leakage inversion method based on Adaboost-RBF synergy, relating to the technical field of magnetic flux leakage detection of pipelines. The method comprises the following steps: carrying out magnetic flux leakage detection on standard defects, and carrying out feature extraction; measuring defect shape parameters of front several meters of a pipeline on which to-be-tested defects are located; carrying out the magnetic flux leakage detection on the pipeline on which to-be-tested defects are located, and carrying out feature extraction; determining sample data and to-be-tested data; establishing an Adaboost-RBF neural network initial model; correcting the Adaboost-RBF neural network initial model; and inputting the to-be-tested data into the final model, so as to obtain the shape parameters of the to-be-tested defects, thereby finishing the inversion. By inverting the pipeline defects by virtue of an Adaboost-RBF neural network model, the rapid defect shape reconstitution can be realized, the learning speed is high, the precision is high, the generalization performance is good, and the severity of the defects can be judged, so that the pipeline leakage is prevented, and the loss is avoided.

Owner:NORTHEASTERN UNIV +1

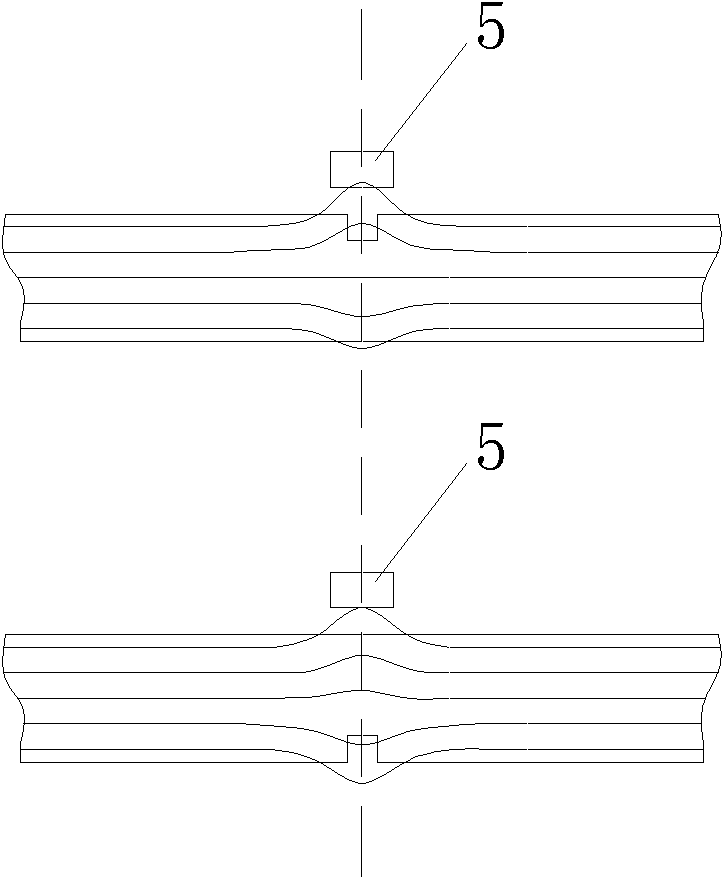

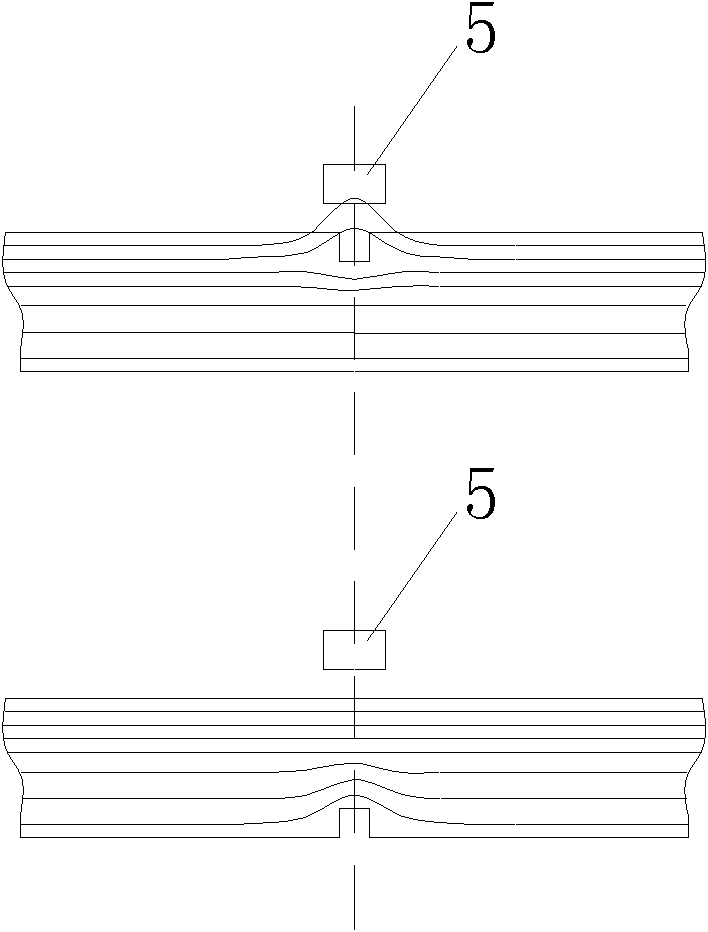

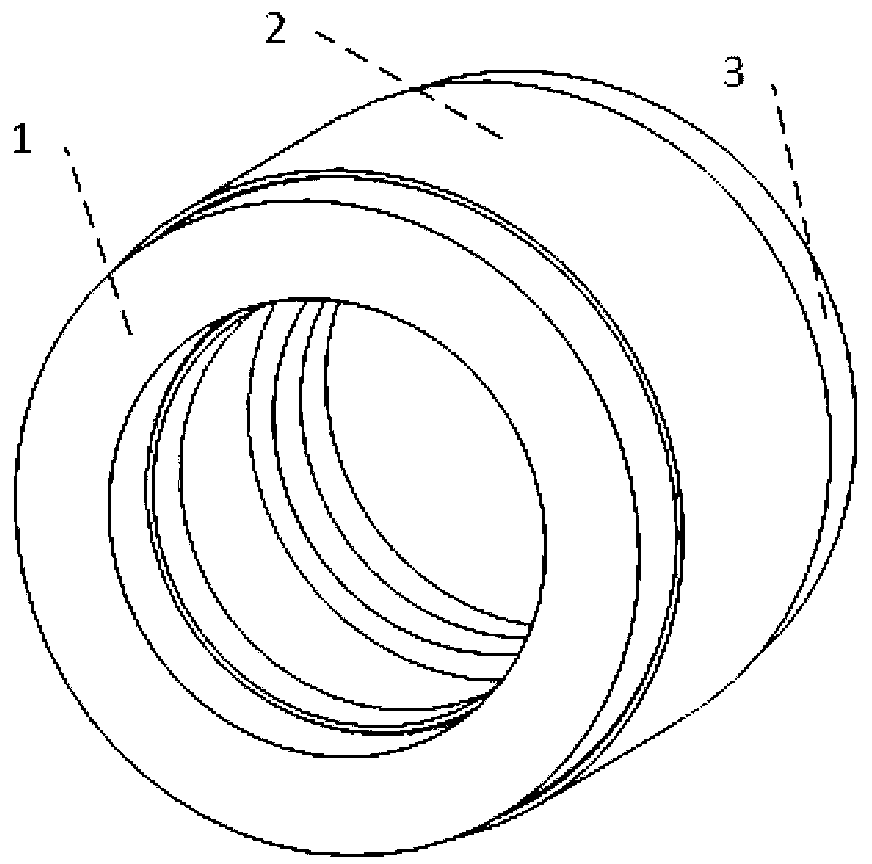

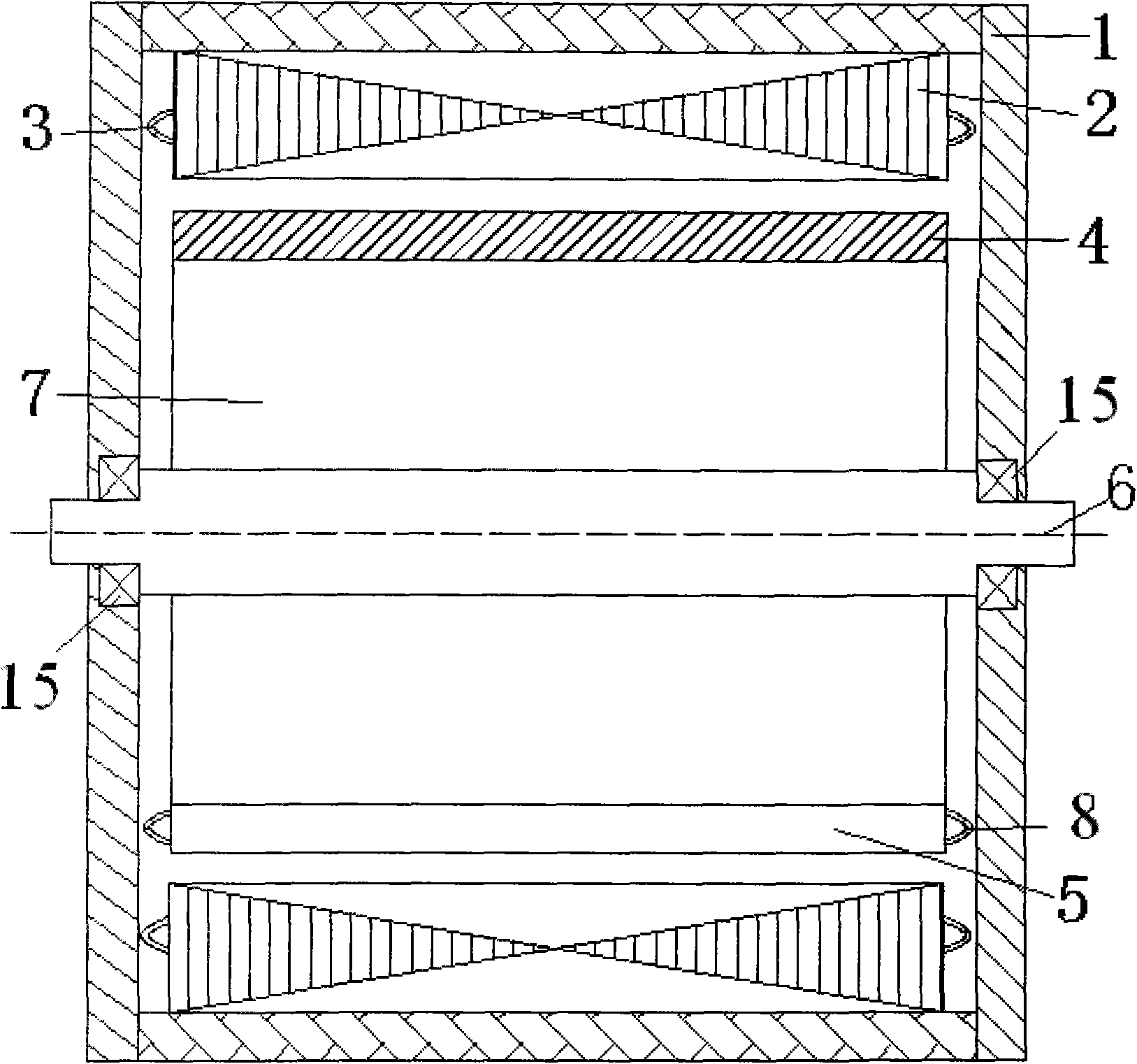

On-line magnetic flux leakage detection probe for steel wire rope

The invention belongs to nondestructive detection technology for magnetic flux leakage of a steel wire rope, relates to an on-line magnetic flux leakage detection probe for the steel wire rope. The on-line magnetic flux leakage detection probe comprises an open-close magnetic flux leakage detection assembly and a floating track mechanism. The floating track mechanism comprises a pedestal, a change-over base, a first linear guide rail, an installation plate, and air cylinder and a second linear guide rail. The magnetic flux leakage detection assembly realizes real-time tracking for the postures of the steel wire rope through the floating track mechanism. The floating track mechanism can realize cohesion detection and opening restoration for the steel wire rope. The detection probe provided by the invention integrates the functions of magnetization and signal output, has the advantages of small size, light weight, strong universality, low cost and the like, and can be suitable for some to-be-detected components with large swing amplitude and fast speed change. The probe is in a split structure but can form a through type probe during a work process, has the effect close to that of through type solenoid coil magnetization, and particularly can realize the nondestructive detection requirements of components such as end-free or two-end anchorages and the like under the conditions of high speed and large swing.

Owner:HUAZHONG UNIV OF SCI & TECH

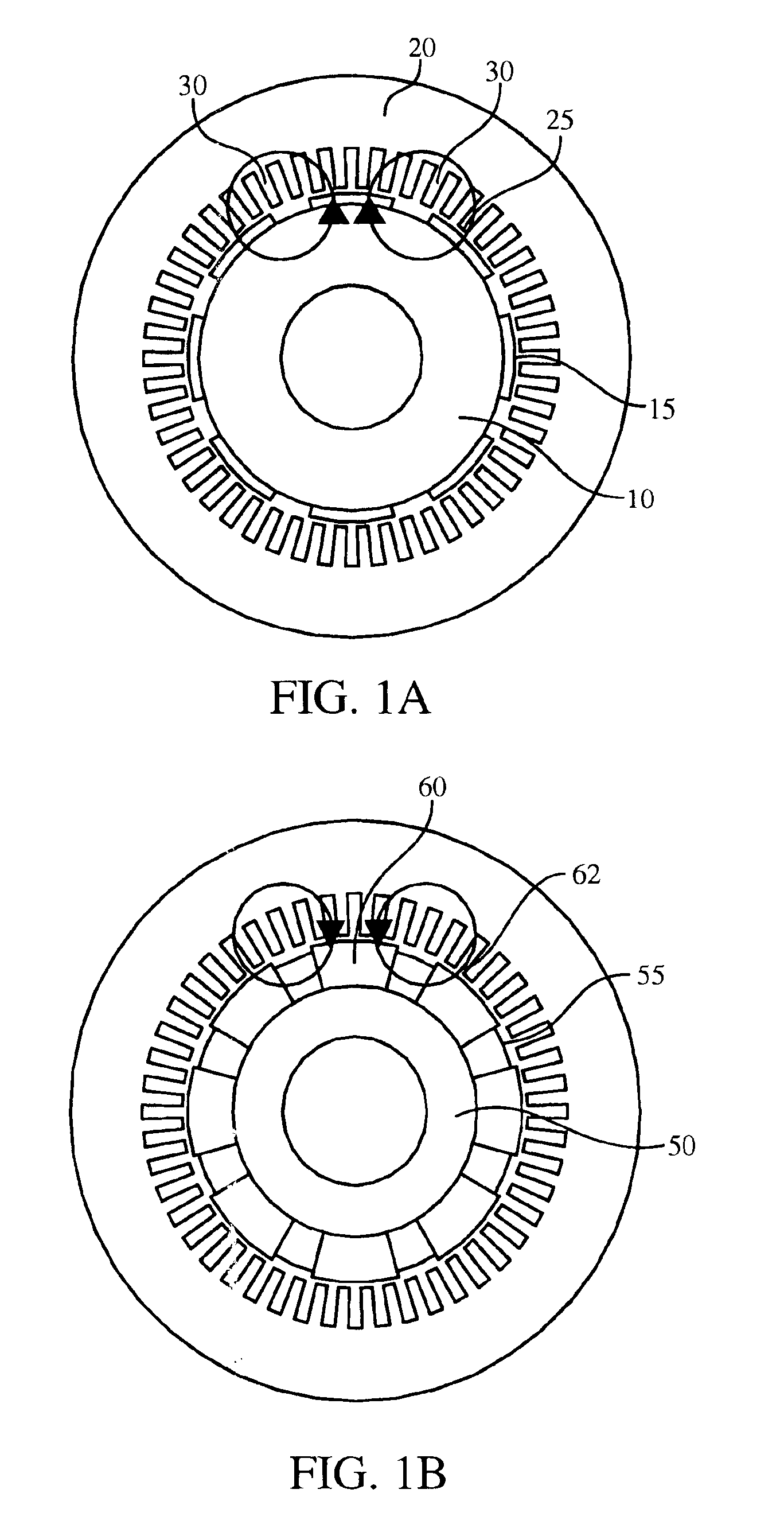

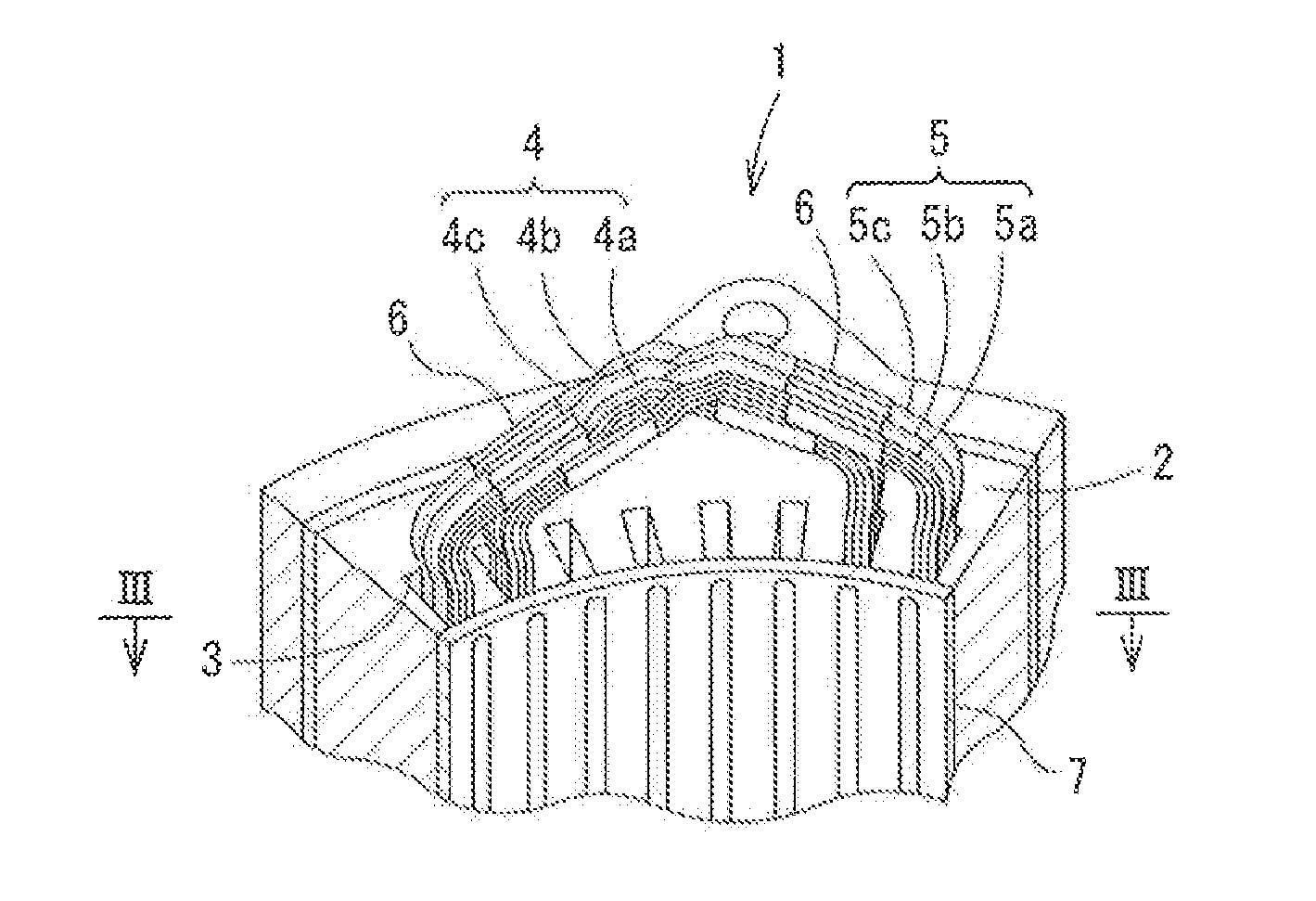

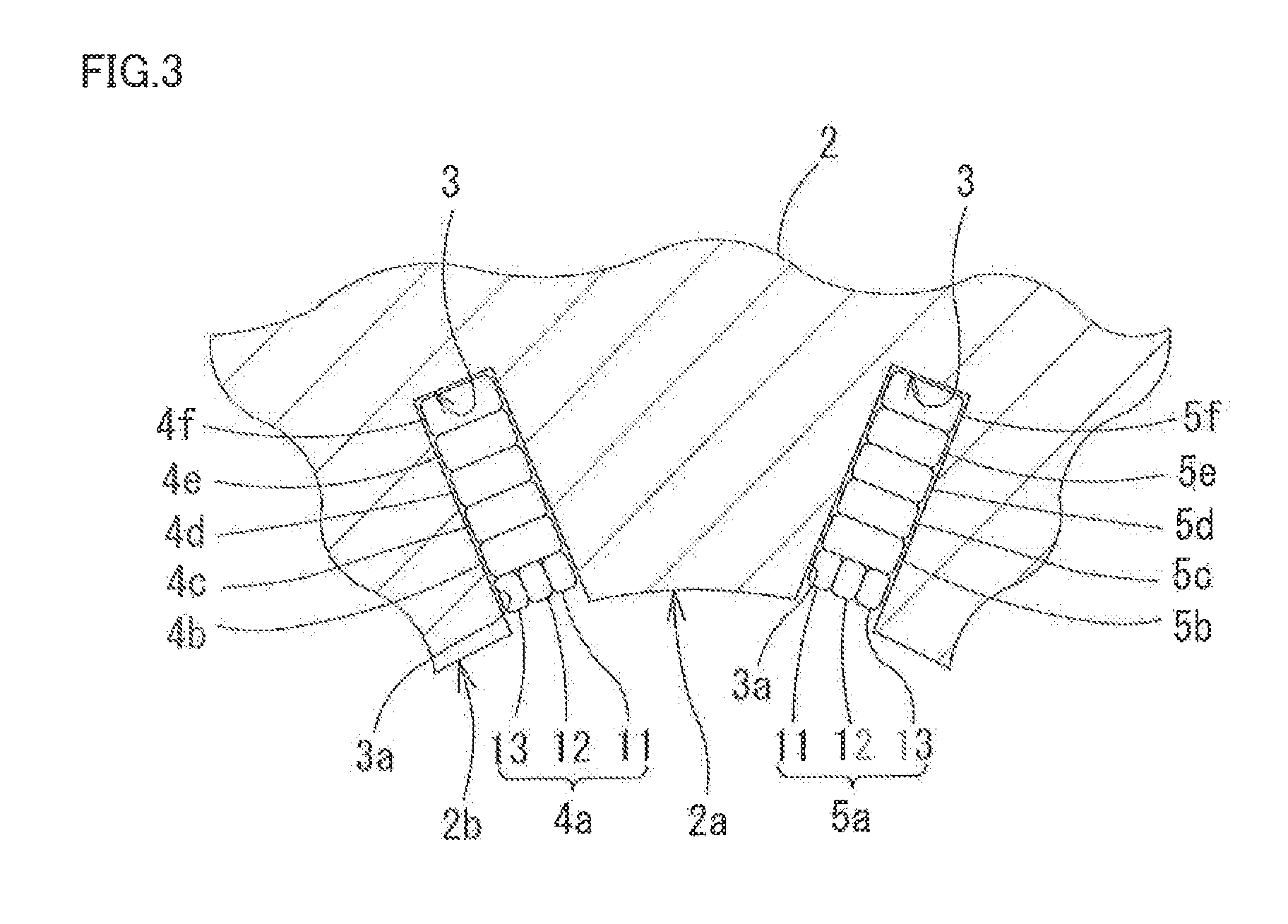

Segment coil, method of manufacturing segment coil, wire rod for segment coil, and stator

InactiveUS20140300239A1Effective preventionEffective prevention of eddy current and magnetic flux leakageWindings insulation shape/form/constructionSynchronous machinesWire rodElectric machine

A segment coil capable of achieving effective prevention of magnetic flux leakage or eddy current and enhancing efficiency of a motor is provided. Segment coils in stator of a rotating electric machine including an annular core and rectangular wire coils in a plurality of layers, which are attached on an innermost circumferential side in a direction of radius of a slot formed in an inner circumferential portion of the annular core and are opposed to a rotor, are each constituted of a plurality of divided wires as divided in a circumferential direction of the annular core. The plurality of divided wires are integrally joined in coil end portions extending from the slot.

Owner:TOYOTA JIDOSHA KK

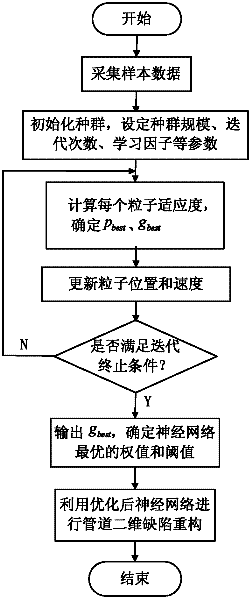

Method for reproducing two-dimensional defect of petroleum pipeline PSO-BP (Particle Swarm Optimization-Back-Propagation) neural network

InactiveCN102364501AAchieve exact reproductionSolve the shortcomings of easy to fall into local minimumNeural learning methodsComputational physicsParticle swarm algorithm

The invention aims at providing a method for reproducing a two-dimensional defect of a petroleum pipeline PSO-BP (Particle Swarm Optimization-Back-Propagation) neural network. Actually measured pipeline magnetic flux leakage data and pipeline defect data are used as experimental data of defect reconfiguration. The method comprises the steps of: with a magnetic flux leakage signal as input and a defect outline as outlet, setting a particle initial parameter, randomly initializing an initial position and an initial speed of each particle, calculating a particle fitness function numerical value , determining a past best value pbest of each particle and a global best value gbest of the whole particle swarm, updating the position and the speed of each particle, judging whether reaching the maximum iteration time or preset precision, if meeting the weight and the threshold of outputting a neutral network; and otherwise, re-comparing. The neutral network after the weight and the threshold are optimized by using a particle swarm algorithm is used for reproducing the two-dimensional defect of the pipeline and also reproducing a defect outline of the pipeline. According to the invention, the defect that the BP algorithm is easy to fall into a local minimum value can be effectively solved, and the convergence precision is improved, thus the defect of the pipeline is accurately reproduced.

Owner:HARBIN ENG UNIV

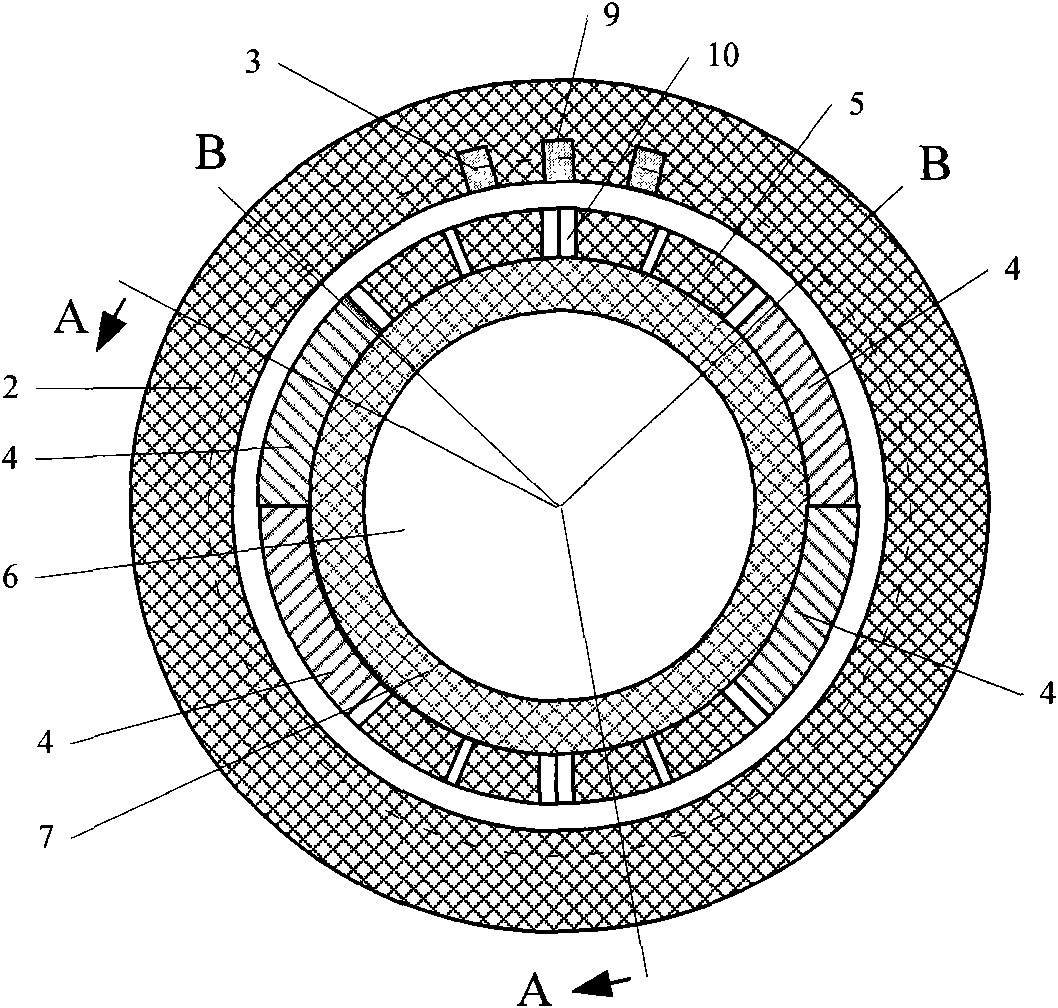

Rotor punching sheet, rotor core with same and motor

ActiveCN103973003AImprove performanceReduce Flux LeakageMagnetic circuit rotating partsPunchingElectrical polarity

The invention discloses a rotor punching sheet, a rotor core with the same and a motor. The rotor punching sheet comprises a body. The body is provided with an inner hole, a plurality of installation grooves and an annular area surrounding the inner hole, wherein the installation grooves are distributed in the circumferential direction of the body, a pole part is defined between every two adjacent installation grooves, an outer magnetic bridge is defined between the outer end of each installation groove and the peripheral edge of the body, an inner magnetic bridge is defined among the every two adjacent installation grooves, the inner ends of the pole parts of the adjacent installation grooves and the annular area, at least one inner magnetic bridge and / or at least one outer magnetic bridge are / is disconnected, and the number of the disconnected inner magnetic bridges and the number of the disconnected outer magnetic bridges are both less than the number of poles of a rotor. According to the rotor punching sheet, magnetic flux leakage caused by the fact that rotating shafts assembled in the pole parts and the rotating shaft in the inner hole are directly communicated or caused by the fact that poles of different polarities are communicated is reduced as much as possible, and performance of the rotor is improved. Additionally, the rotor can be directly molded without injection molding conducted or other connecting parts adopted and is convenient and easy to manufacture.

Owner:ANHUI WELLING AUTO PARTS CO LTD +1

Integral processing method for refabrication of waste oil tube

InactiveCN101947714AIncrease the number ofQuantity increase can be repairedNumerical controlAbrasive blasting

The invention relates to an integral processing method for refabrication of a waste oil tube, which comprises the steps of: pretreating: selecting a waste oil tube with wall thickness of above 3mm, dismantling a coupling, detecting magnetic flux leakage, cutting threads, removing oil and scales, aligning, blasting sand, and separating by lengths; lining ceramics: filling melted iron subjected to combustion synthesis into a plough groove and a corrosion groove which are eccentrically worn on the inner wall of the oil tube under the action of centrifugal force in a high-speed rotating centrifuge, metallurgically combining with the inner wall of the oil tube, and melting with a transition iron layer under a ceramic layer into a whole; and processing threads: processing threads at a tube discharging end by using a numerical control lathe and a precise carding tool, coating thread grease, and installing the coupling. A new waste-judging standard is made on the basis of the judging standard of the waste oil tube in an oil field, which greatly reduces the waste quantity of the oil tubes, and increases the quantity of repairable oil tubes. The service life of the repaired waste oil tubes is above 5 times longer than that of the original new oil tube, thus the operation cost of the oil field is greatly lowered.

Owner:杨永利

Defect detecting system for steel wire rope

InactiveCN102879460AReduce in quantityReduce assembly requirementsMaterial magnetic variablesMeasurement pointEngineering

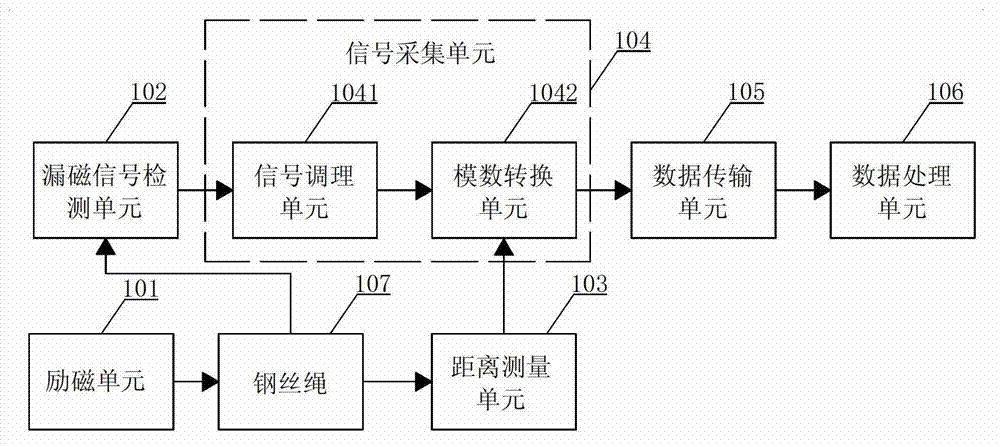

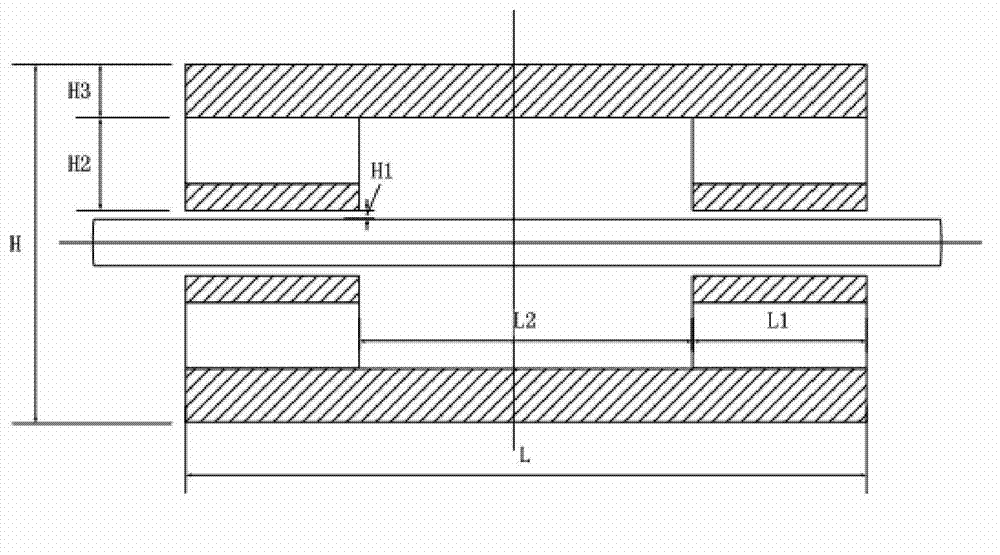

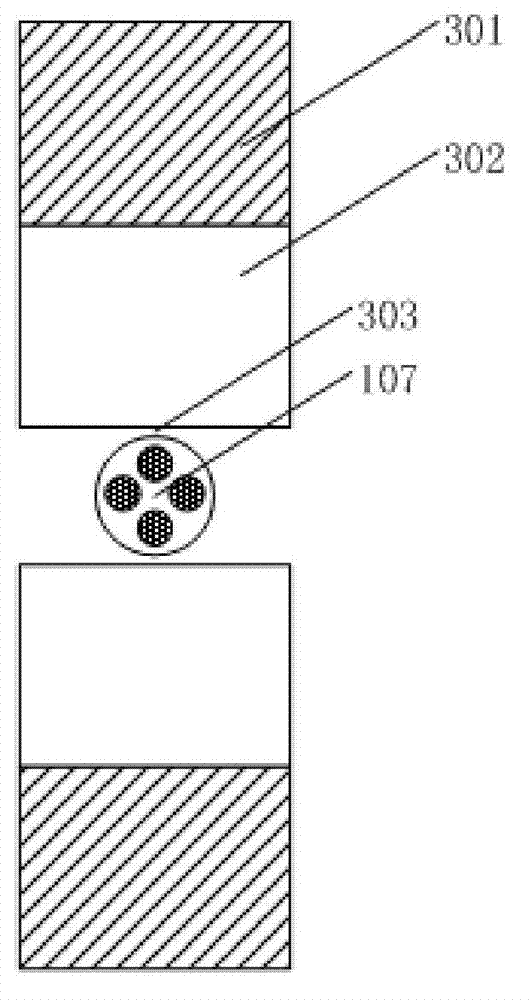

The invention discloses a defect detecting system for a steel wire rope. Twist numbers of magneto-dependent sensors are uniformly arranged along the radial direction of the steel wire rope and in a position at the middle part of an excitation unit close to the surface of the steel wire rope with a certain distance; and then, magnetic flux leakage signals detected by the various magneto-dependent sensors are combined into one path to be output to a signal acquisition unit through a certain weight. The signal acquisition unit converts the combined magnetic flux leakage signal into a figure signal, and a data transmission unit transmits the figure signal to a data processing unit. The data processing unit obtains a difference signal by subtracting the figure signal and figure signals of N measuring points before the measuring point, and judges whether wire fracture exists in the steel wire rope or not according to the difference signal. Compared with the conventional defect detecting system for the steel wire rope, the defect detecting system for the steel wire rope, disclosed by the invention, efficiently reduces a strand wave signal, enables detection and quantization of broken wires to be more convenient, rapid and accurate, and moreover, can realize defect positioning for the steel wire rope, quantitative analysis and report generation of the detection result, and meets the requirement of modern safety production.

Owner:SHENXI MACHINERY

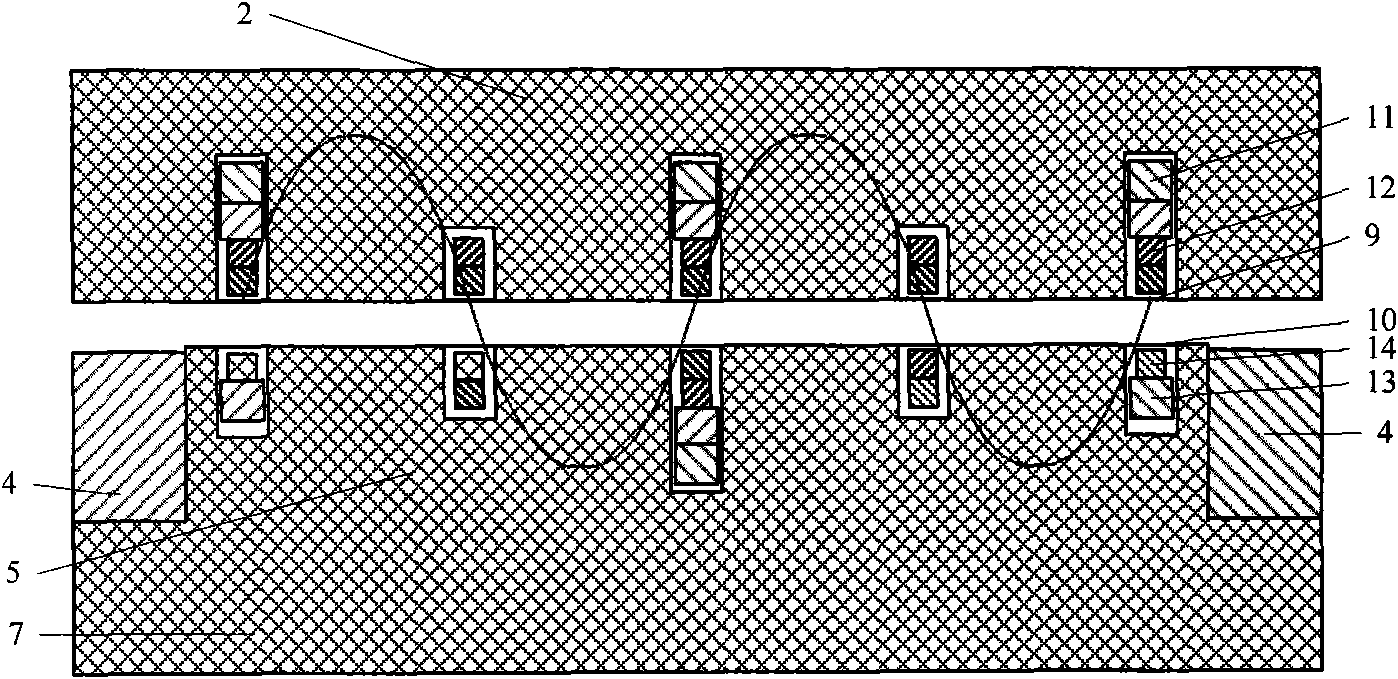

Mixed excitation magnetoelectric machine adopting harmonic excitation

ActiveCN101651394ASimple structureImprove reliabilityWindingsMagnetic circuit rotating partsRotor magnetsHarmonic

The invention discloses a mixed excitation magnetoelectric machine adopting harmonic excitation, comprising a machine shell (1), a stator core (2), a stator winding (3), a permanent magnet pole (4), aferromagnetic pole (5), a rotating shaft (6), a rotor core (7) and a rotor winding (8), wherein, a rotor magnet pole is composed of the permanent magnet pole (4) and the ferromagnetic pole (5) whichis provided with the rotor winding (8); the rotor winding (8) consists of a harmonic winding (14) and an excitation winding (13); the stator winding (3) comprises a main winding (11) and a harmonic excitation winding (12), and is distributed in a stator groove; the pole distance of the main winding and the pole distance of the rotor excitation winding are identical; the pole distance of the harmonic excitation winding and the pole distance of the rotor harmonic winding are identical; the harmonic excitation winding is connected with an excitation controller; when the motor runs, the current inthe harmonic excitation winding can be controlled to achieve the functions of adjusting magnetic field and voltage. Compared with the prior art, the invention has no electric brush, collecting electric ring, additional air gap, axial magnetic circuit, has simple structure, little magnetic-flux leakage, less excitation loss, high efficiency of the motor and strong ability of adjusting the main magnetic field.

Owner:浙江清岭科技有限公司

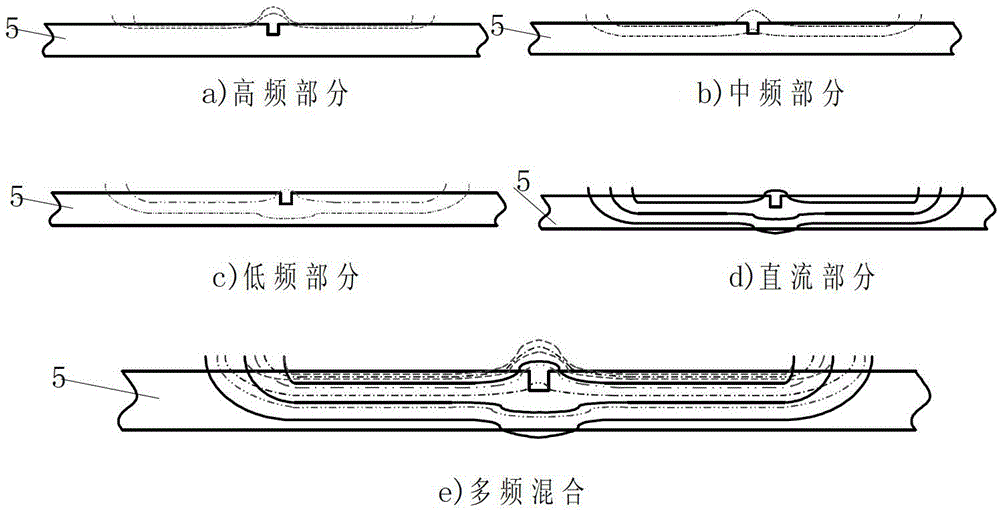

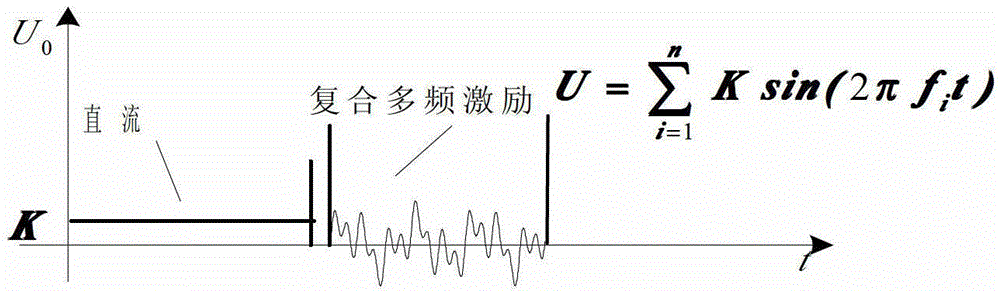

Sub-saturated time-division and multi-frequency magnetic flux leakage testing method

InactiveCN103149272ASimple probeEasy to operateMaterial magnetic variablesMagnetizationAlternating current

The invention discloses a sub-saturated time-division and multi-frequency magnetic flux leakage testing method. At an early stage, a permanent magnet and direct-current excitation are used for realizing saturated magnetization of a steel plate to be detected; general examination on defects is realized by a magnetic flux leakage signal and positions of the defects are determined; then, a plurality of sine alternative-current excitations with different frequencies are used for replacing the direct-current excitation and carrying out alternating magnetization on the steel plate to be detected; and magnetic flux leakage scanning cloud pictures with different depths are finished by adopting a skin depth difference of the excitations with the different frequencies in an alternating magnetic field. According to the method disclosed by the invention, the disadvantages that the judging effect of the defect depth is not ideal and the accuracy is not high in the existing magnetic flux leakage testing technology are overcome; the method has the advantages of simple probe, convenience in operation and high detection precision on various defects; and the method can be used for detecting steel plates of a pipeline, a storage tank and the like, and has a wide market prospect.

Owner:XIAMEN UNIV

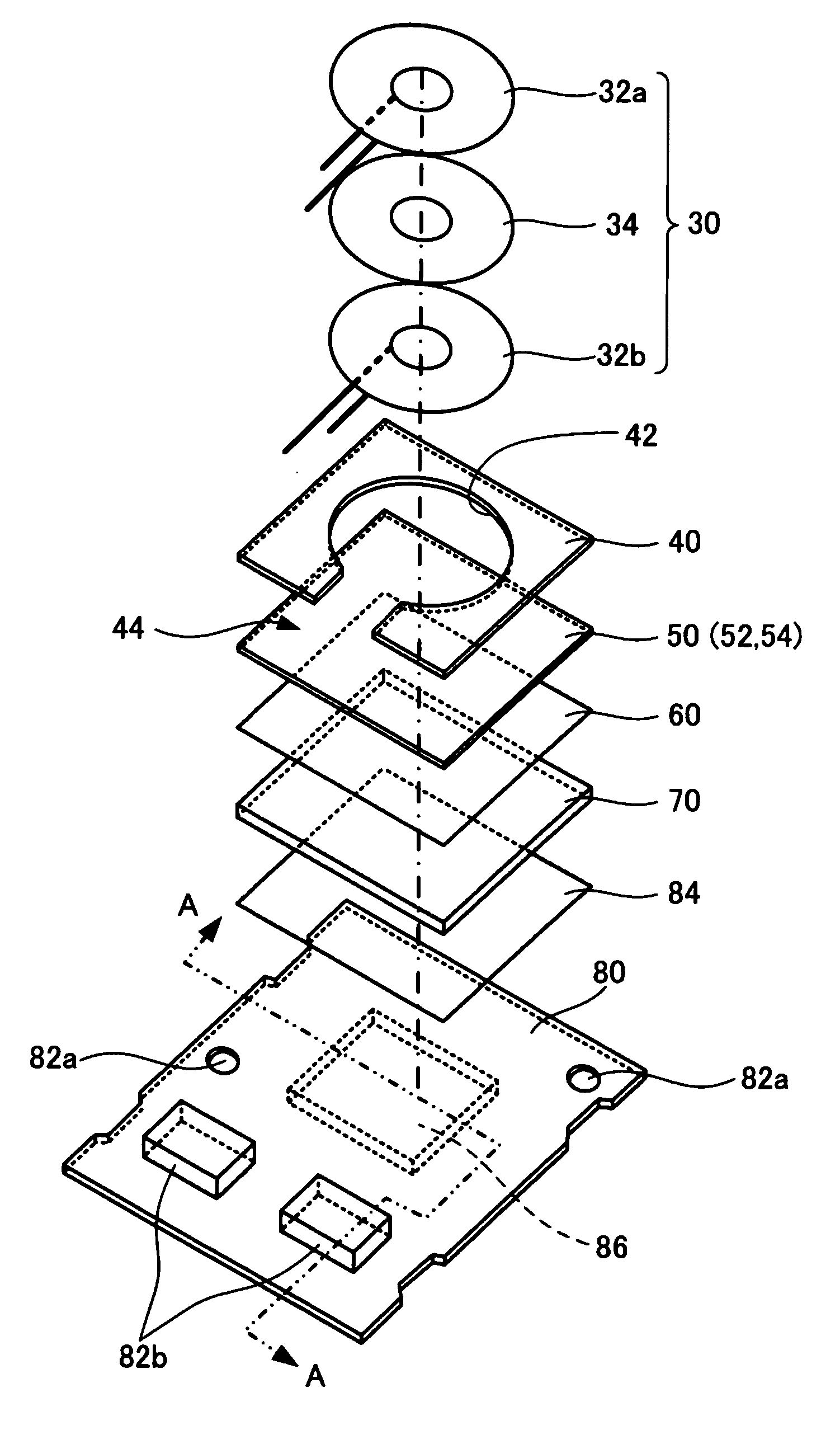

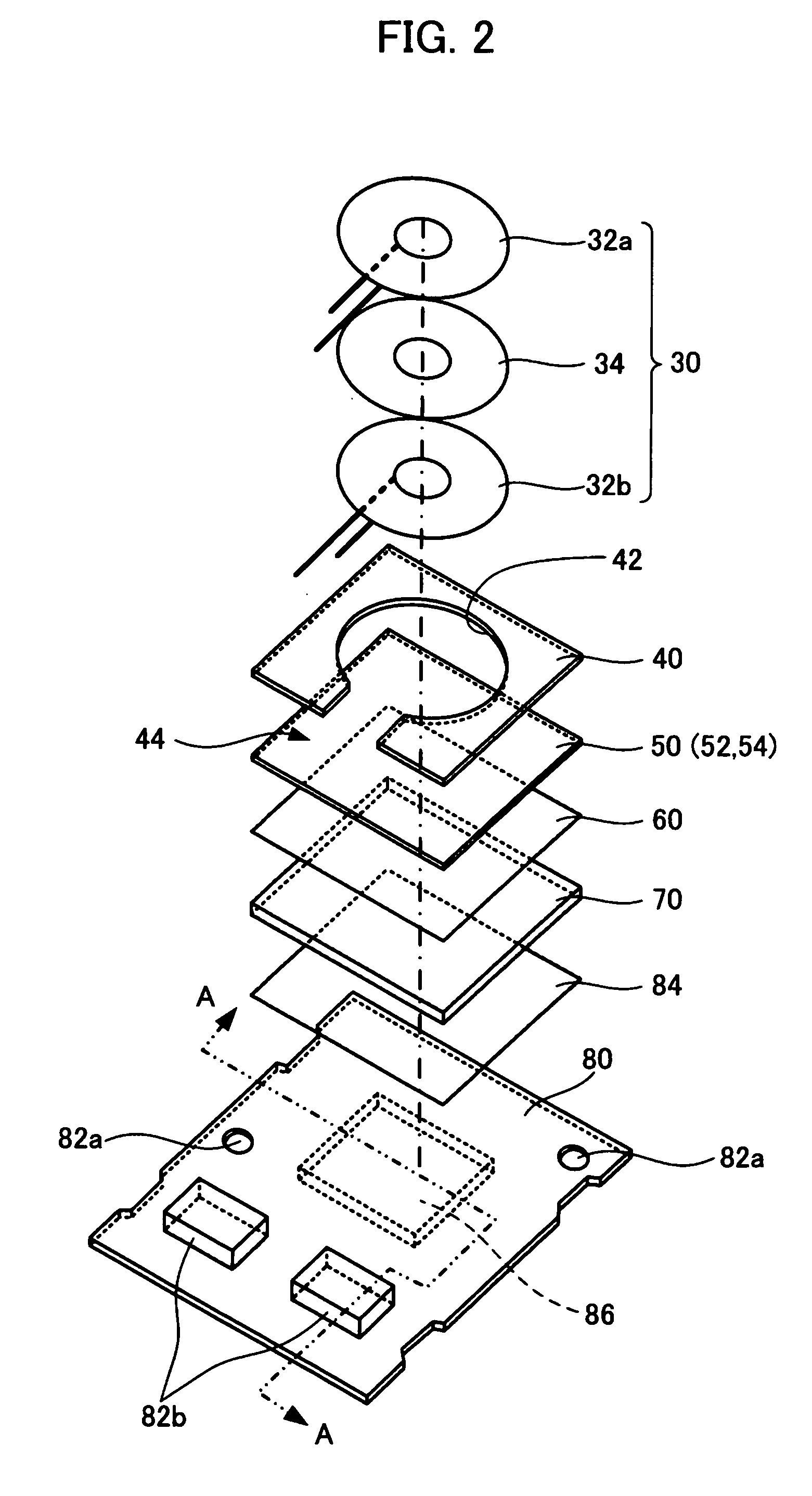

Coil unit, method of manufacturing the same, and electronic instrument

ActiveUS20080197956A1Transformers/reacts mounting/support/suspensionTransformers/inductances coolingEngineeringMagnetic flux

A coil unit includes a planar coil, a magnetic member that is provided under the planar coil, a magnetic flux leakage prevention member that is provided under the magnetic member, and a heat sink that is provided under the magnetic flux leakage prevention member. The magnetic flux leakage prevention member is electrically insulated from the heat sink. The magnetic flux leakage prevention member is insulated from the heat sink using a double-sided adhesive tape, for example. Since the heat sink dissipates heat generated from the planar coil and is electrically insulated from the magnetic flux leakage prevention member, the heat sink does not function as a member which receives a magnetic flux.

Owner:138 EAST LCD ADVANCEMENTS LTD

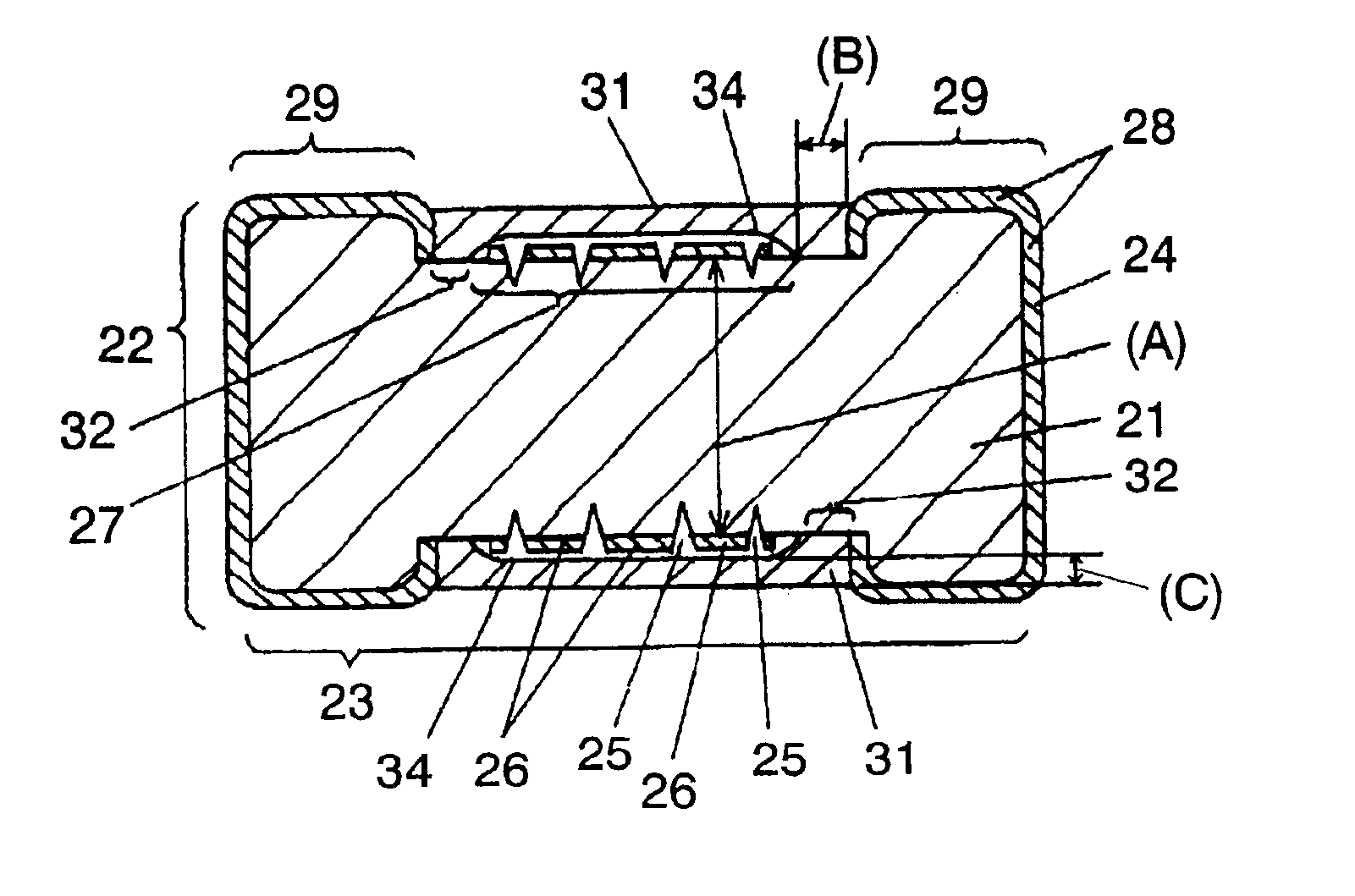

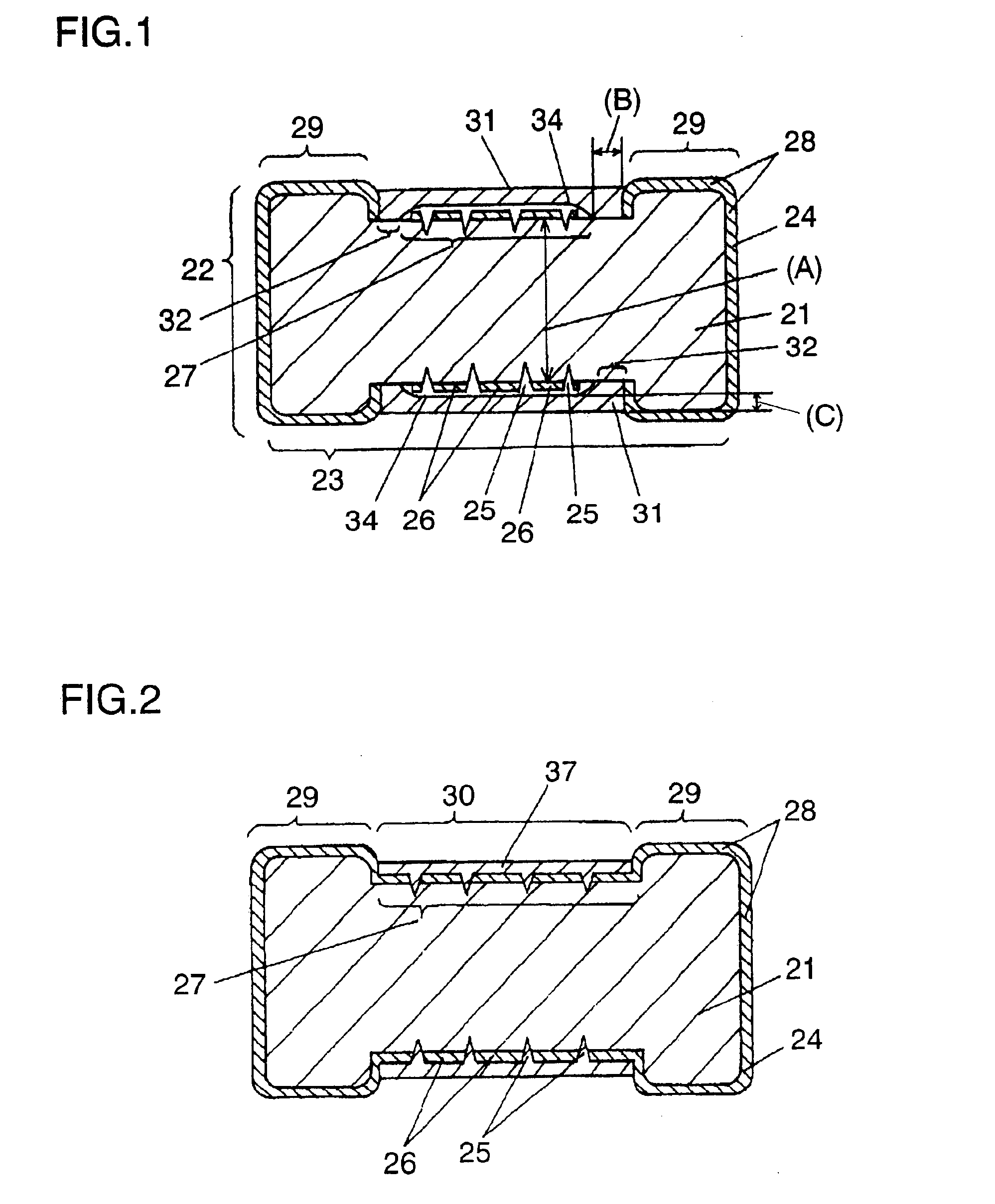

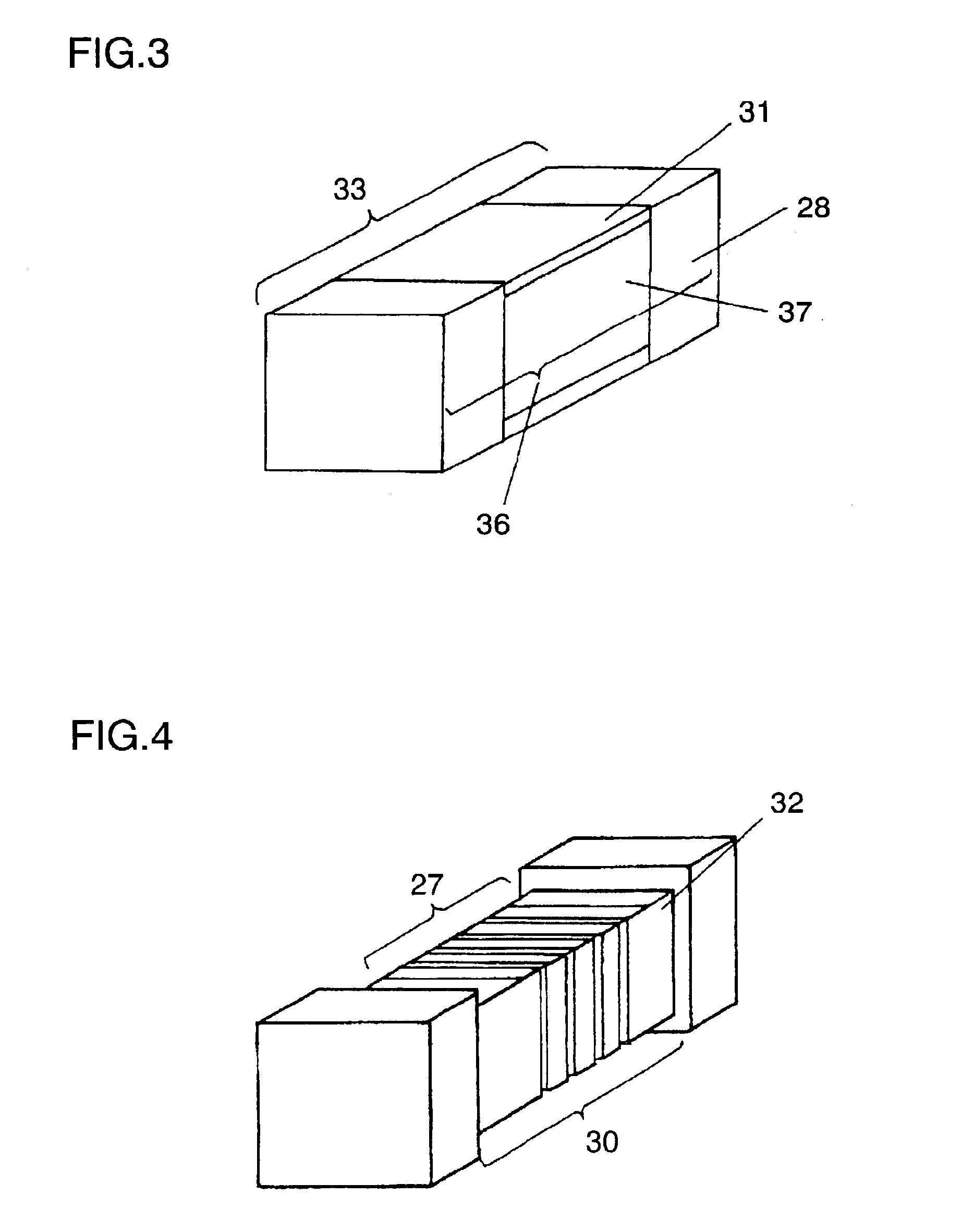

Inductance component and method of manufacturing the same

InactiveUS6864774B2Increase inductanceUndesirable magnetic effectTransformers/inductances casingsCoils manufactureMagnetic effectElectrical conductor

An inductance component comprising a column-shaped magnetic material substrate 21, conductor layer 24 covering ends and a peripheral surface of the substrate, coil portion 27 having groove portion 25 and wire conductor portion 26 formed in the conductor layer covering the peripheral surface, electrode portions 28 including the conductor layer covering the ends of the substrate, and magnetic material portion 31 made of sintered magnetic material on the coil portion, wherein the conductor layer has a melting point higher than a sintering temperature of the sintered magnetic material. The manufacturing process comprises forming a substrate, forming a conductor layer, forming a coil portion, forming electrode portions at ends of the substrate, and forming a magnetic material portion of sintered magnetic material on the coil portion. The present invention provides an inductance component with high inductance, low magnetic flux leakage, and less undesirable magnetic effects on adjacent components.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com