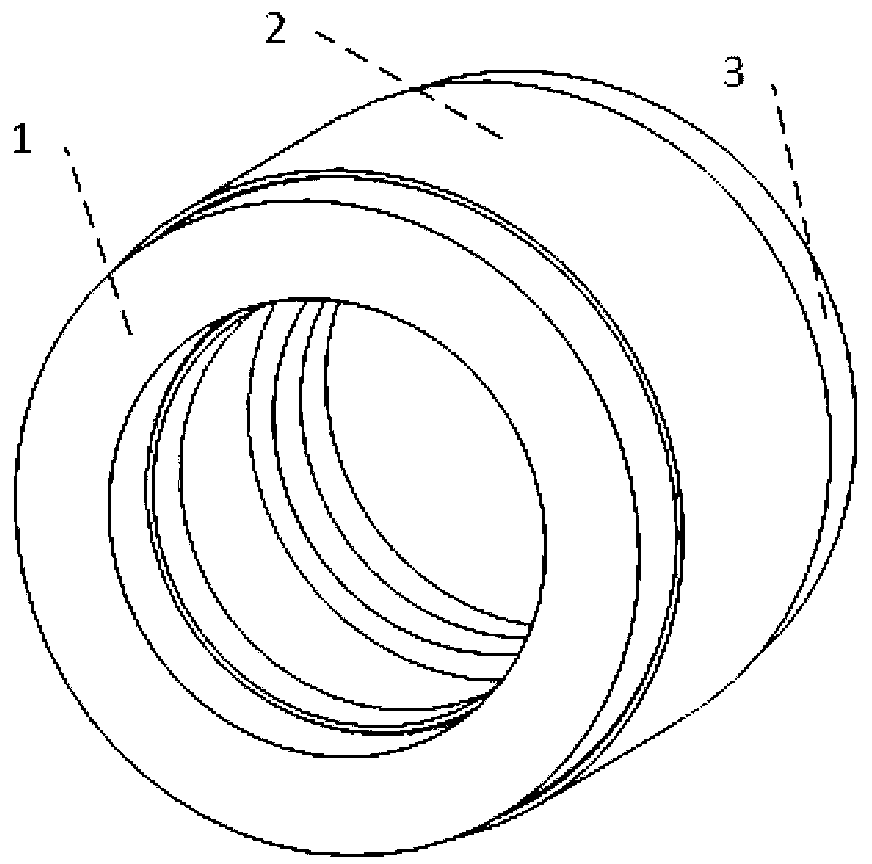

On-line magnetic flux leakage detection probe for steel wire rope

A technology of magnetic flux leakage detection and steel wire rope, applied in the direction of material magnetic variables, etc., can solve the problems of large size and weight, unfavorable automatic detection action, and destructive interaction, etc., and achieve the effect of small size, light weight and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

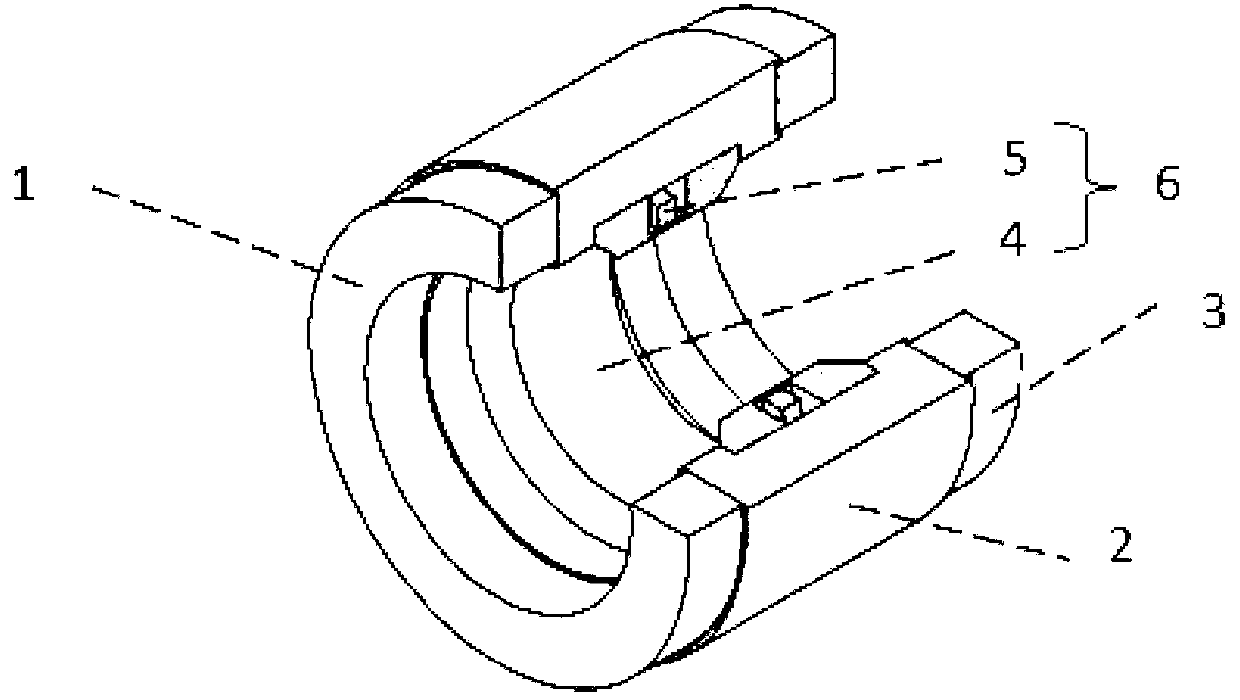

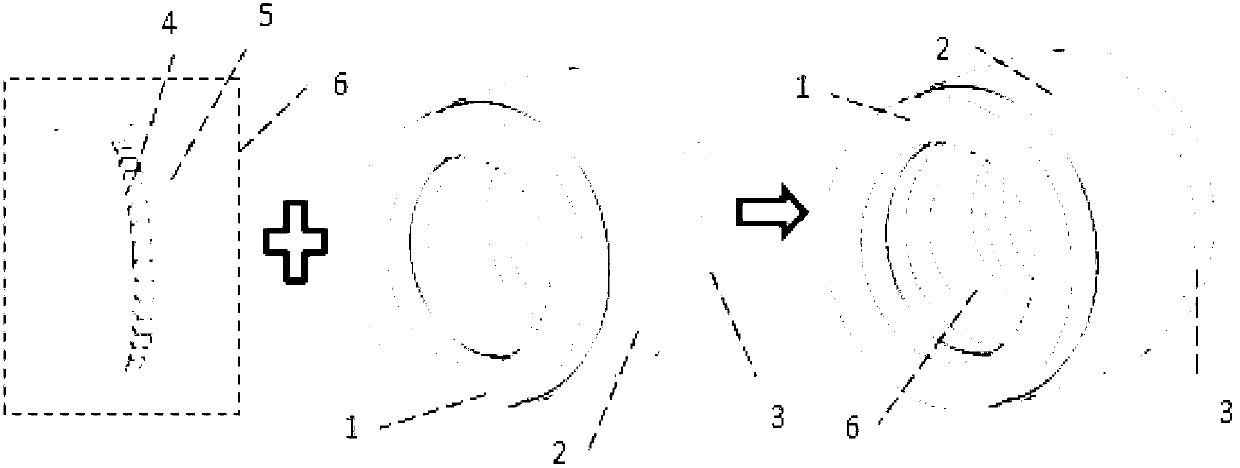

[0021] The principle of the invention is to realize the floating tracking of the probe by "releasing" the degree of freedom of the probe and through the cooperation of the cylinder, the guide rail and the magnetizer. The device of the present invention is an open-loop structure with "openings". It does not need to pass through the ring sleeve from the end to the component to be detected, but can directly "snap" the ring sleeve to the component to be detected, and can especially realize the completion of no end or two ends. Floating tracking of head anchorage and other components during vibration.

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com